Novel high speed transport vehicle for bulk cargo

A transport vehicle and high-speed technology, applied in the field of new high-speed bulk cargo transport vehicles, can solve problems affecting driving safety, waste of goods, deformation of side walls, etc., and achieve high transport efficiency and high-speed large-scale marshalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

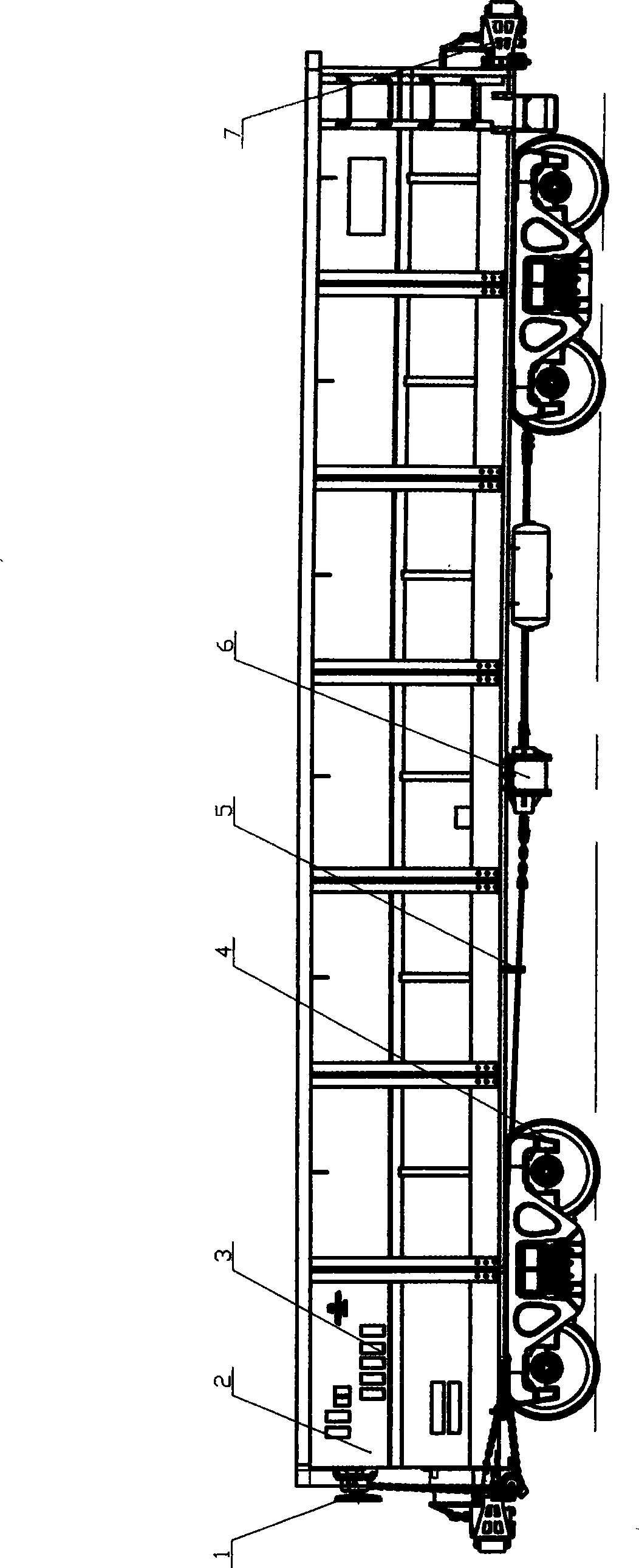

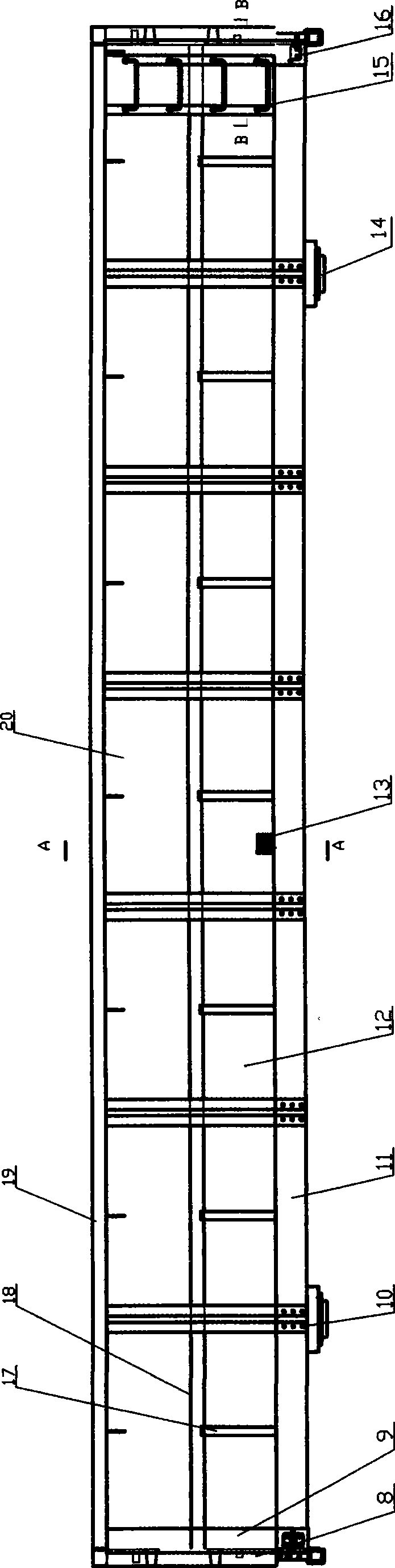

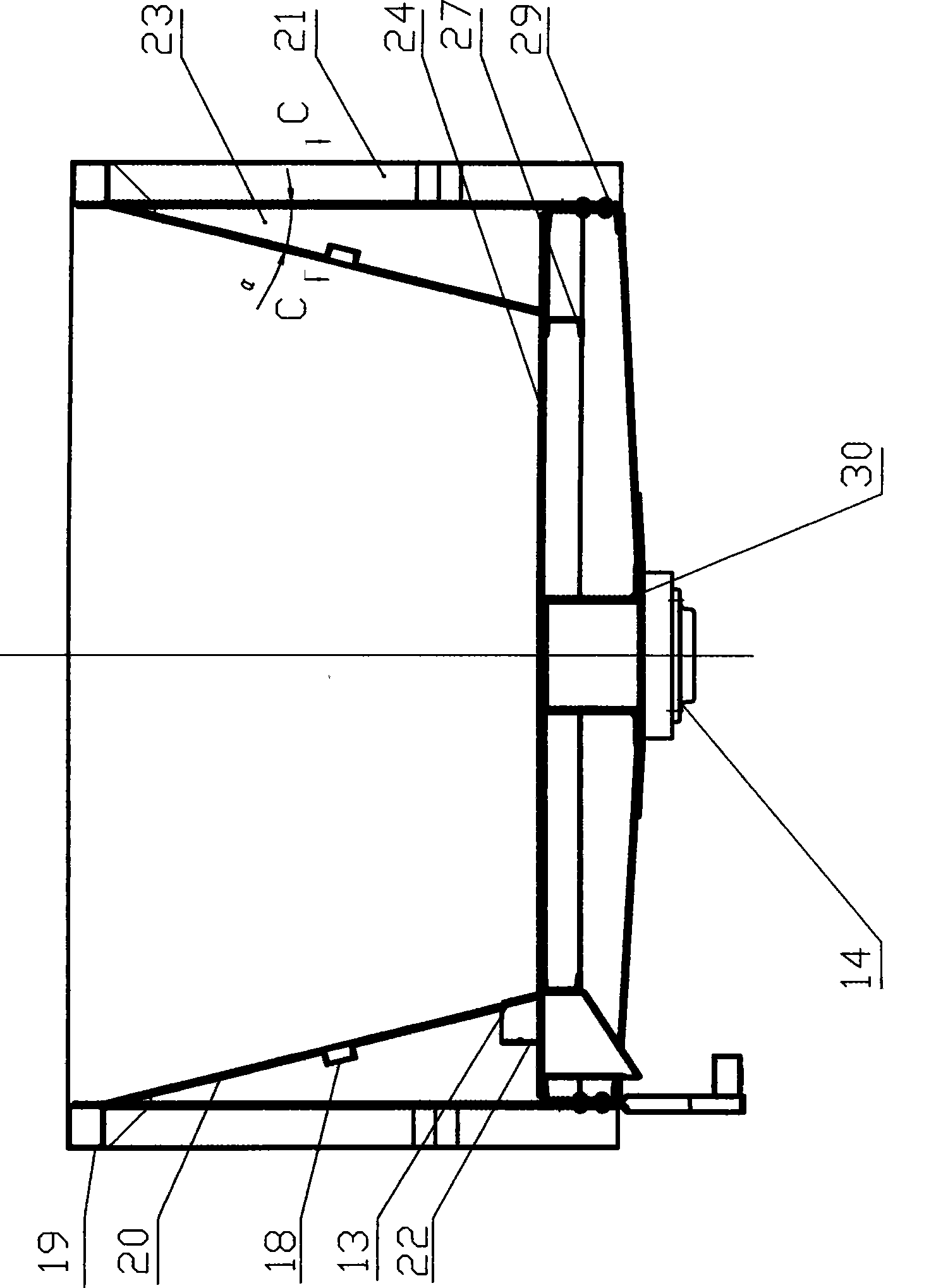

[0013] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. It is mainly composed of car body, underframe, bogie, coupler and braking device. The bogie 4 is a K2 high-speed bogie, and the braking device 6 is a wind brake with a 120 control valve as the main body. The underframe 11 of the vehicle longitudinally consists of symmetrical 310 B-shaped steel middle beams 30, 240 channel steel measuring beams 29 and along beams 27 located between the middle beams and side beams; the underframe 11 horizontally consists of corbel beams 28 and large cross beams 31 It is composed of a small cross beam 32; the upper center plate 14 connected with the bogie is located under the bolster 28; the bottom plate 24 of the vehicle body is laid on the underframe 11.

[0014] The end walls 8 of the car body are vertically arranged at both ends of the underframe 11, and the integral side wall panels 20 are fixed on the underframe 11 and the bottom plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com