Patents

Literature

320 results about "Angle of repose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The angle of repose, or critical angle of repose, of a granular material is the steepest angle of descent or dip relative to the horizontal plane to which a material can be piled without slumping. At this angle, the material on the slope face is on the verge of sliding. The angle of repose can range from 0° to 90°. The morphology of the material affects the angle of repose; smooth, rounded sand grains cannot be piled as steeply as can rough, interlocking sands. The angle of repose can also be affected by additions of solvents. If a small amount of water is able to bridge the gaps between particles, electrostatic attraction of the water to mineral surfaces will increase the angle of repose, and related quantities such as the soil strength.

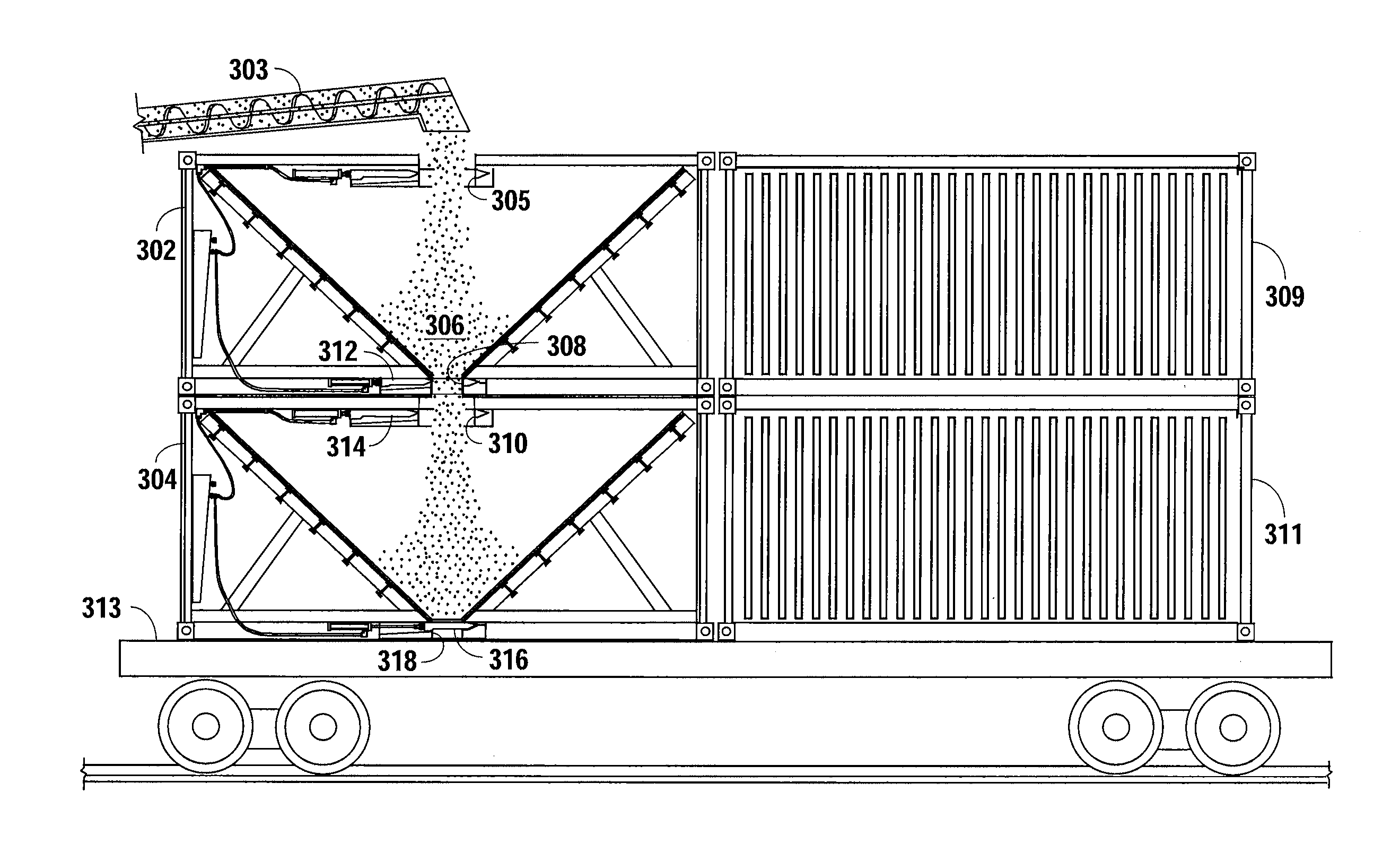

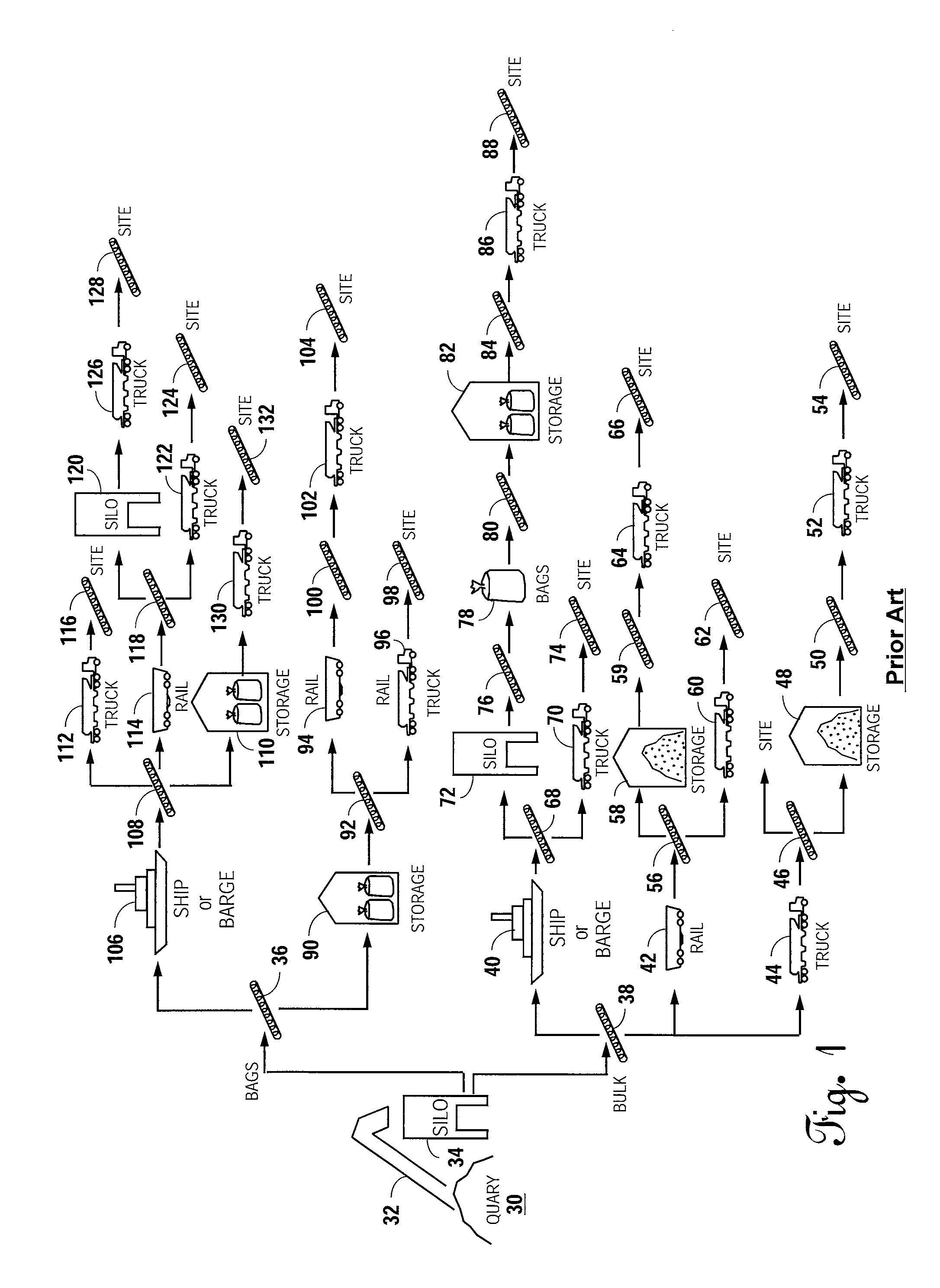

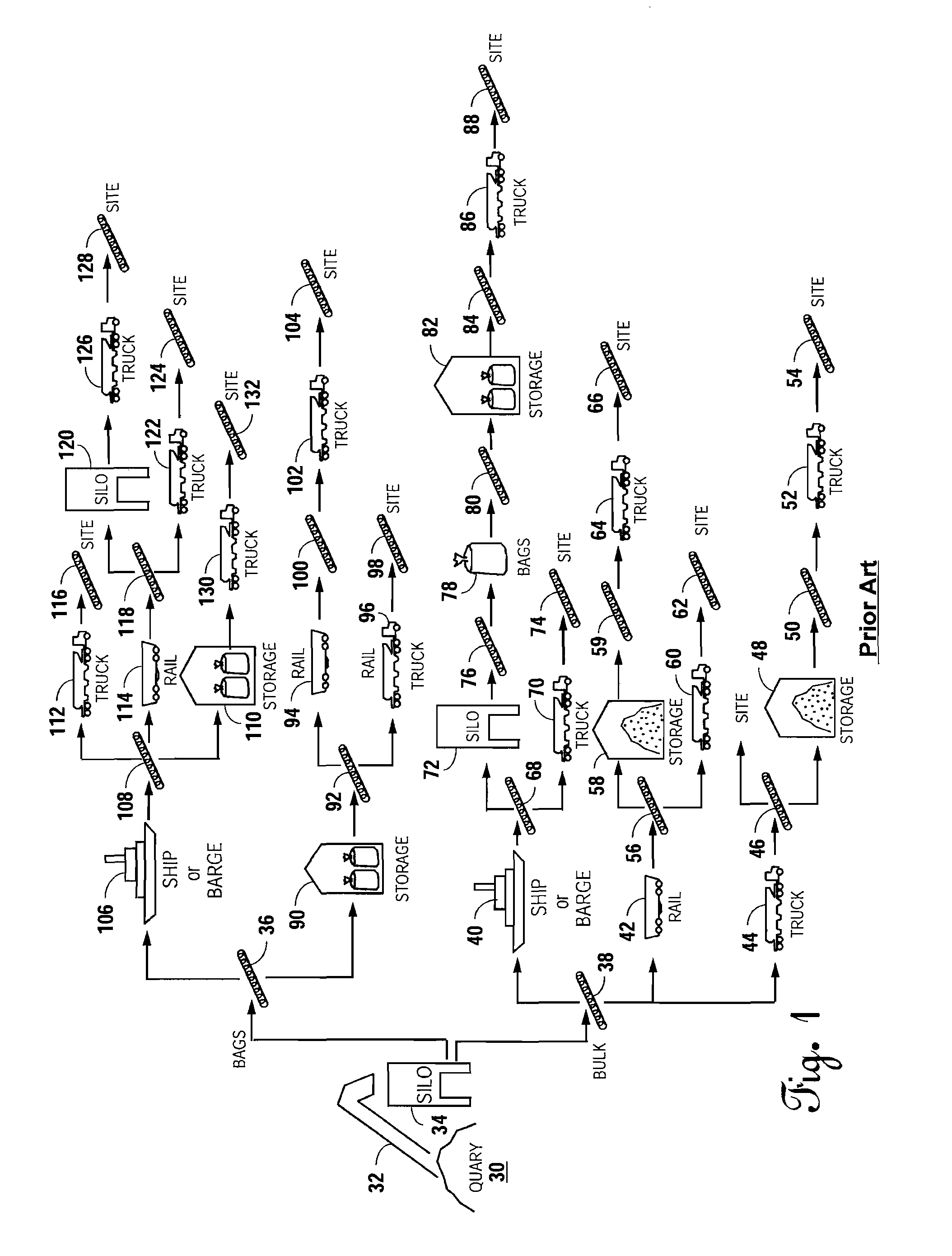

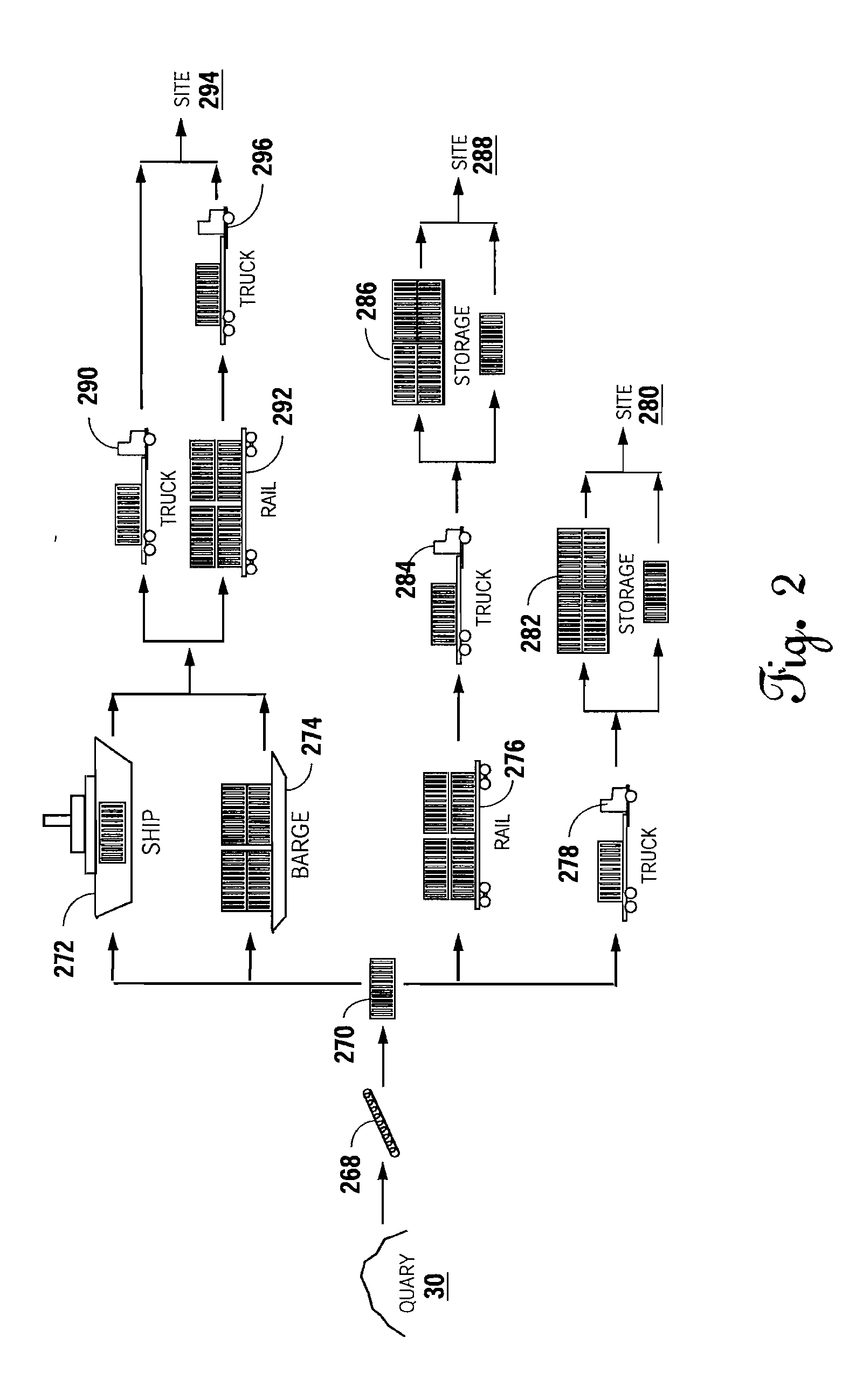

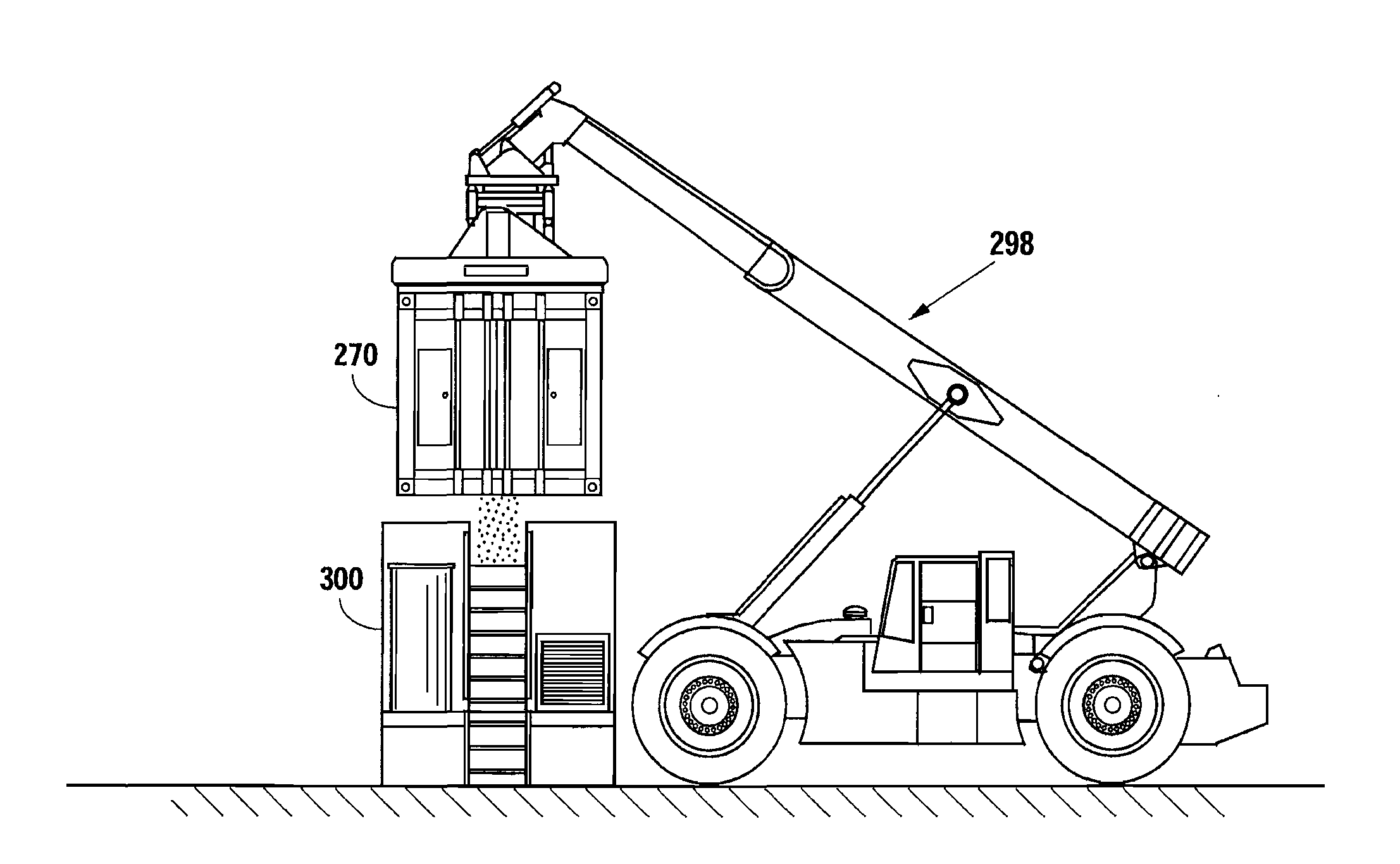

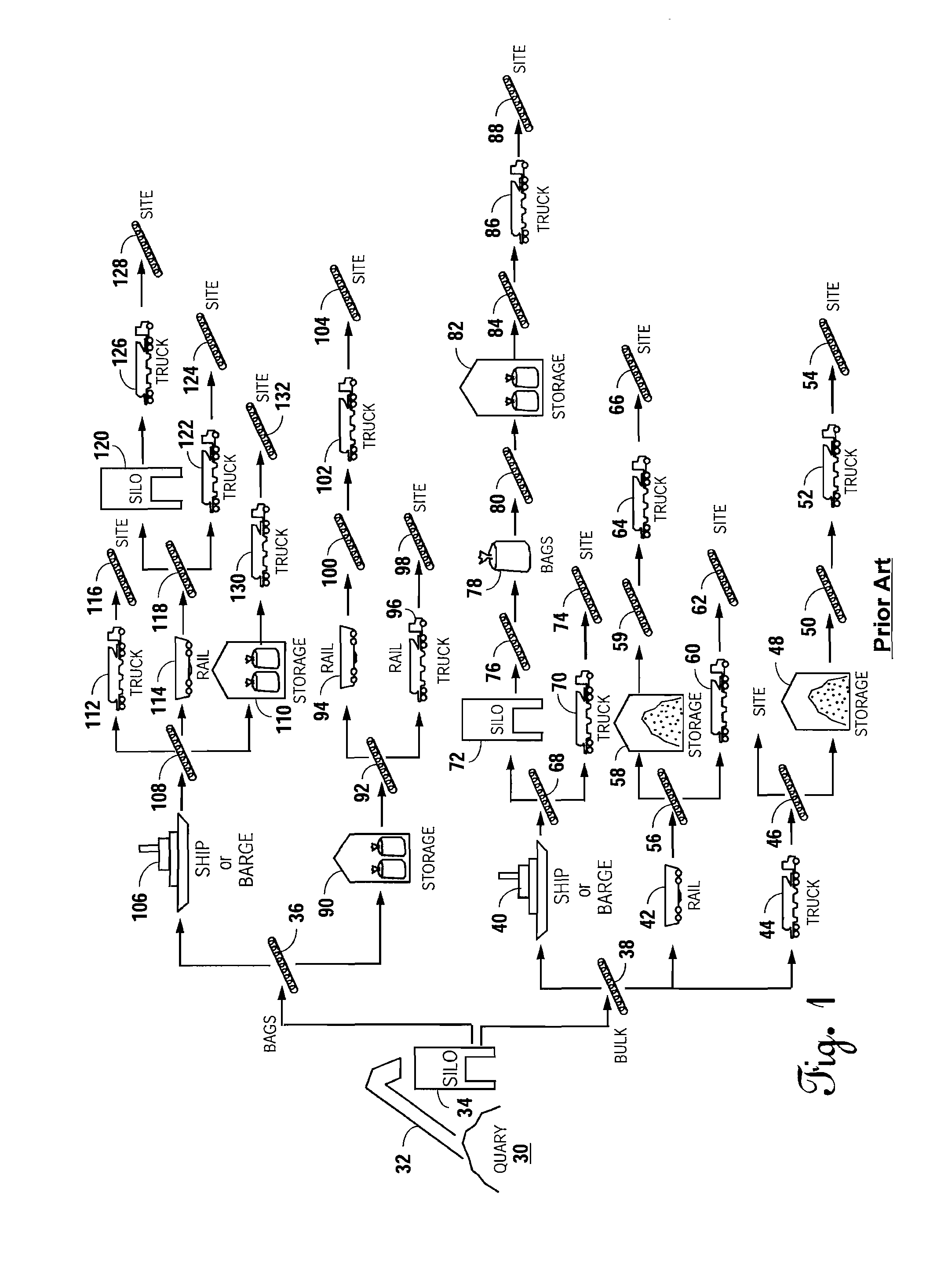

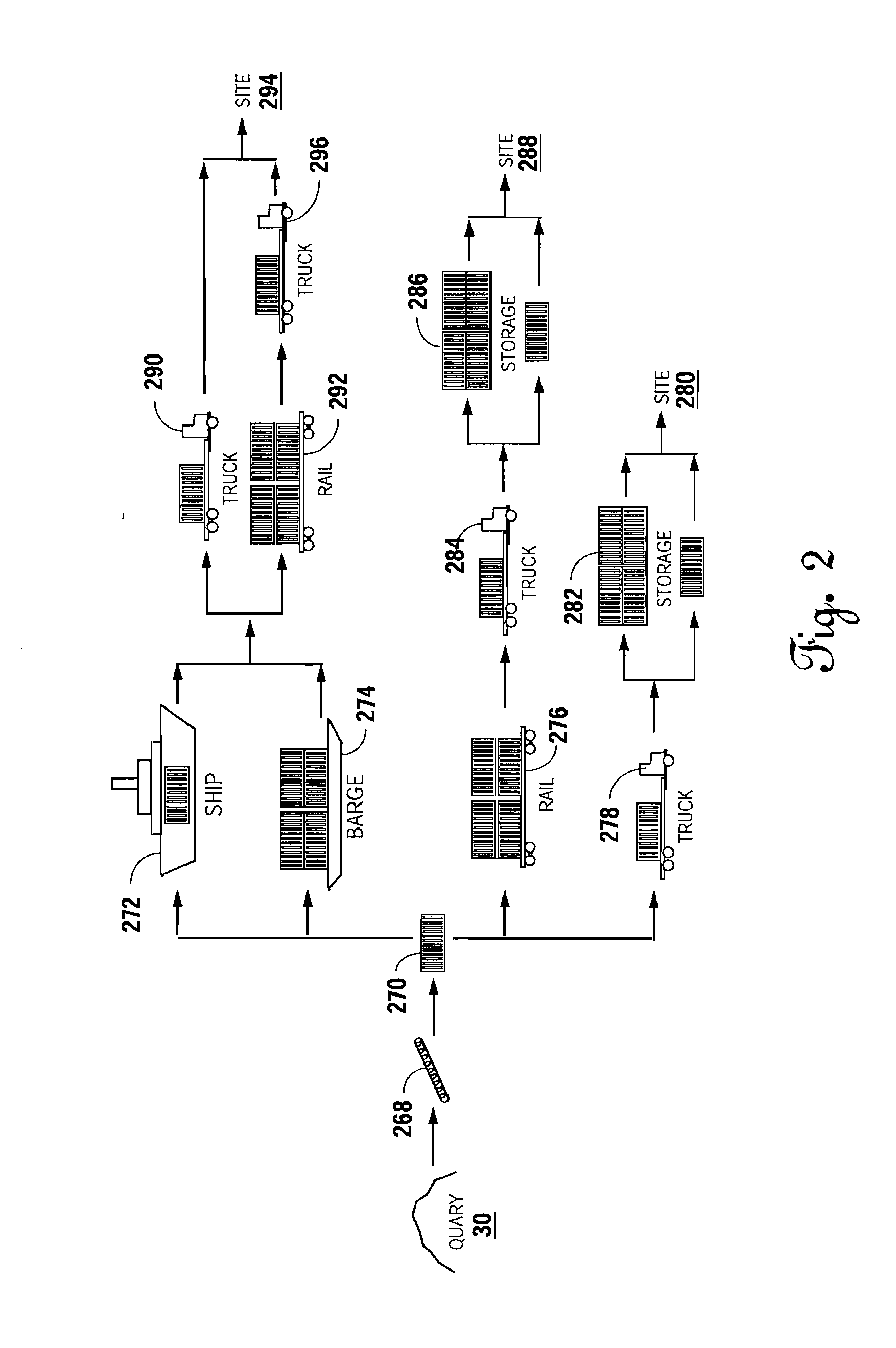

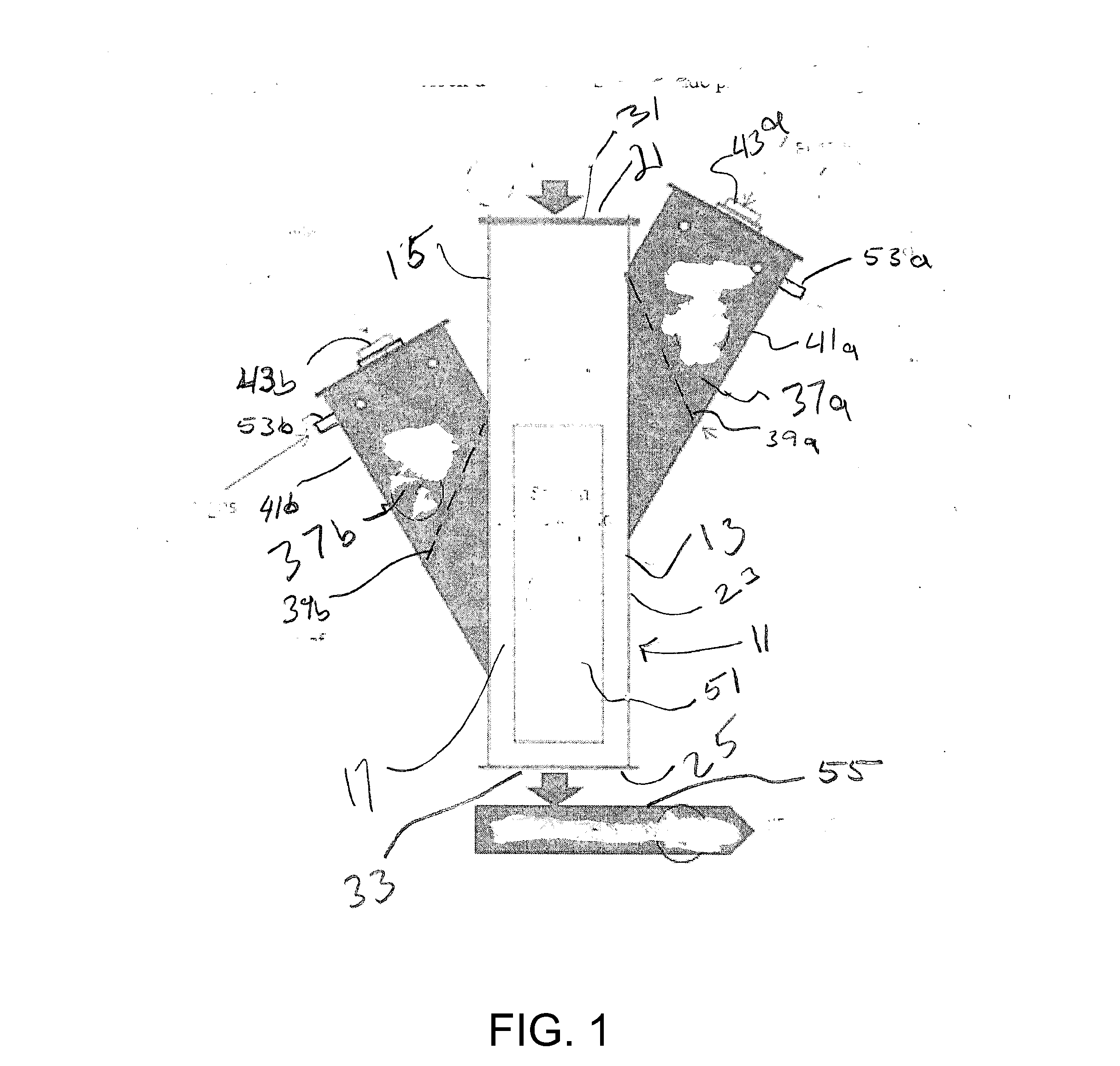

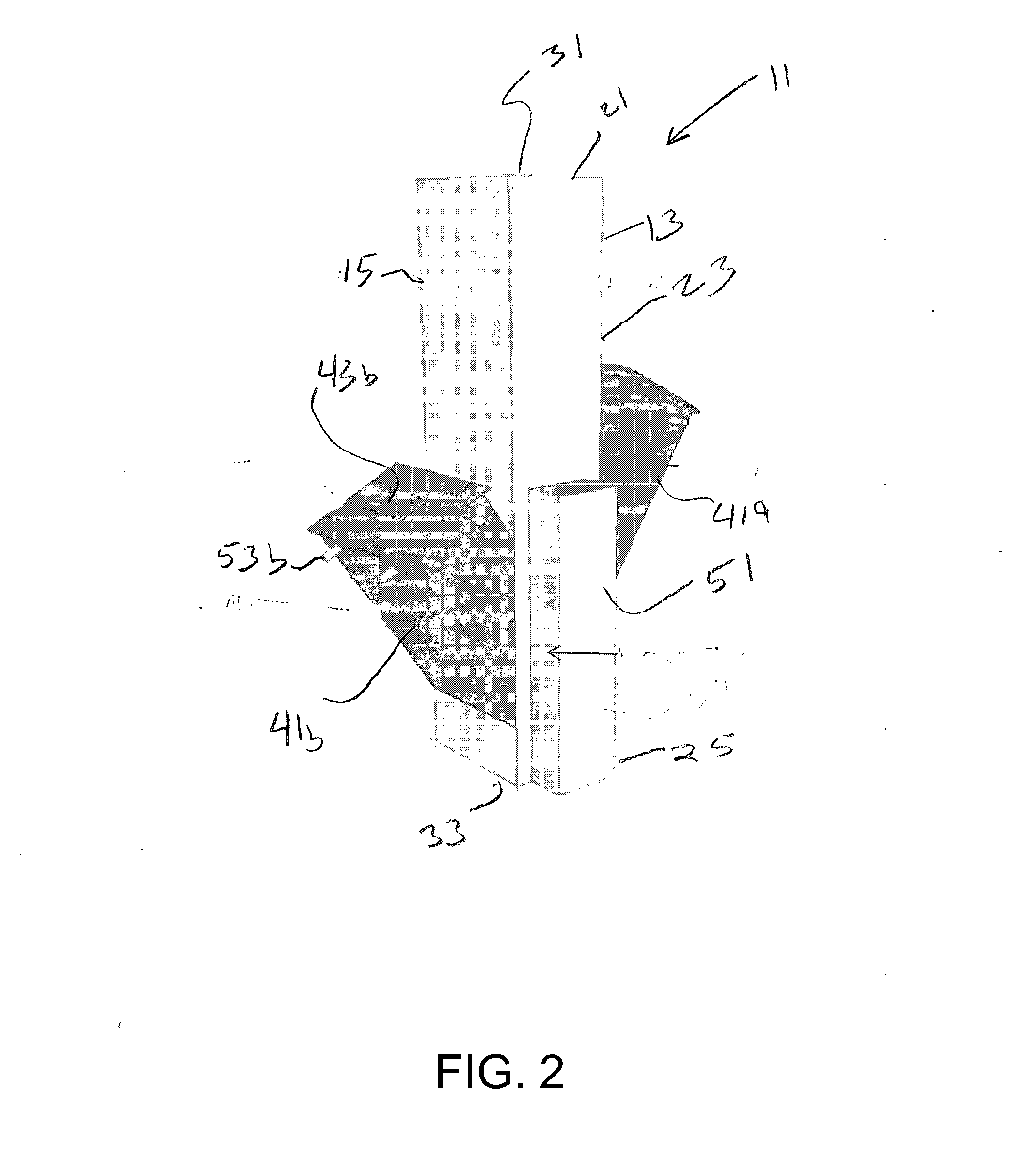

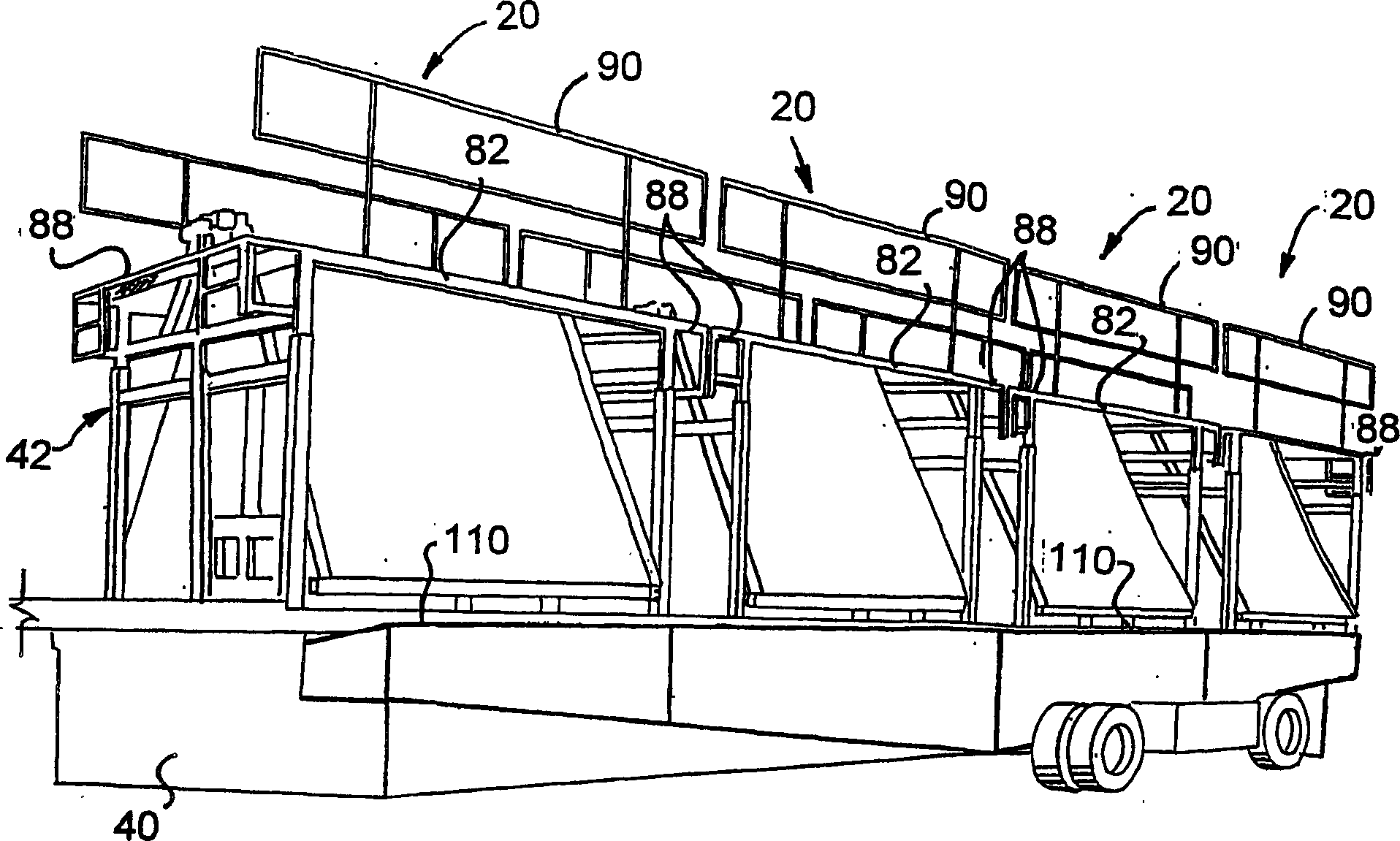

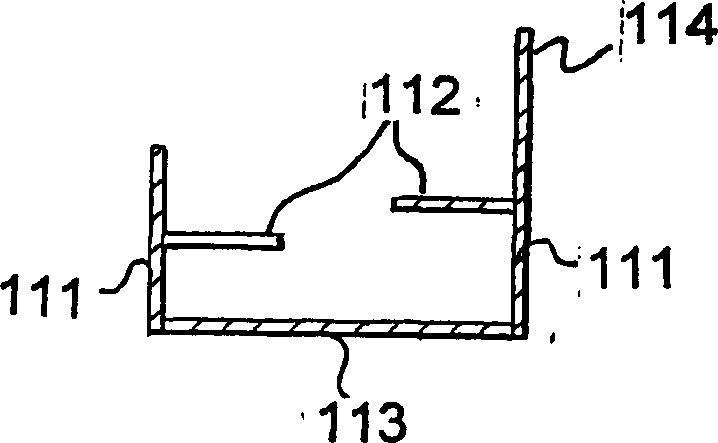

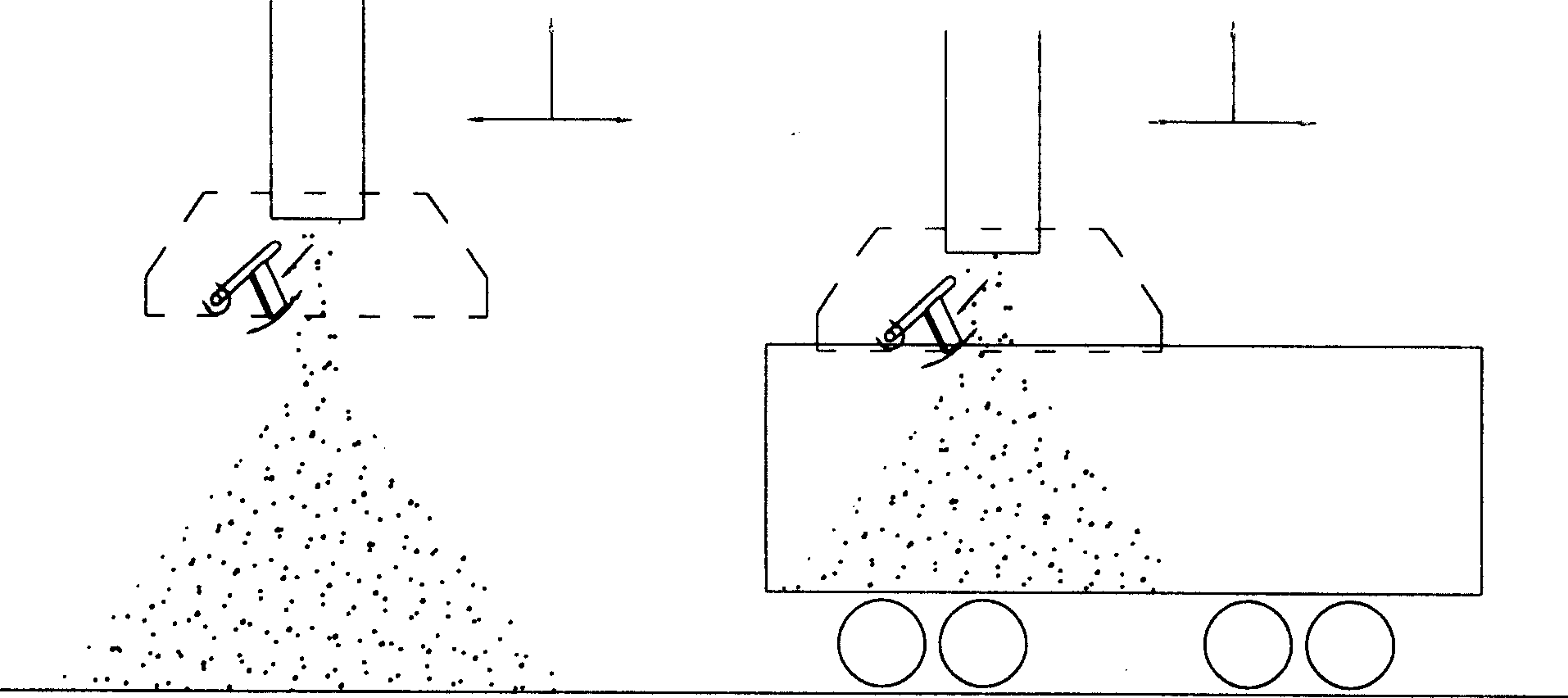

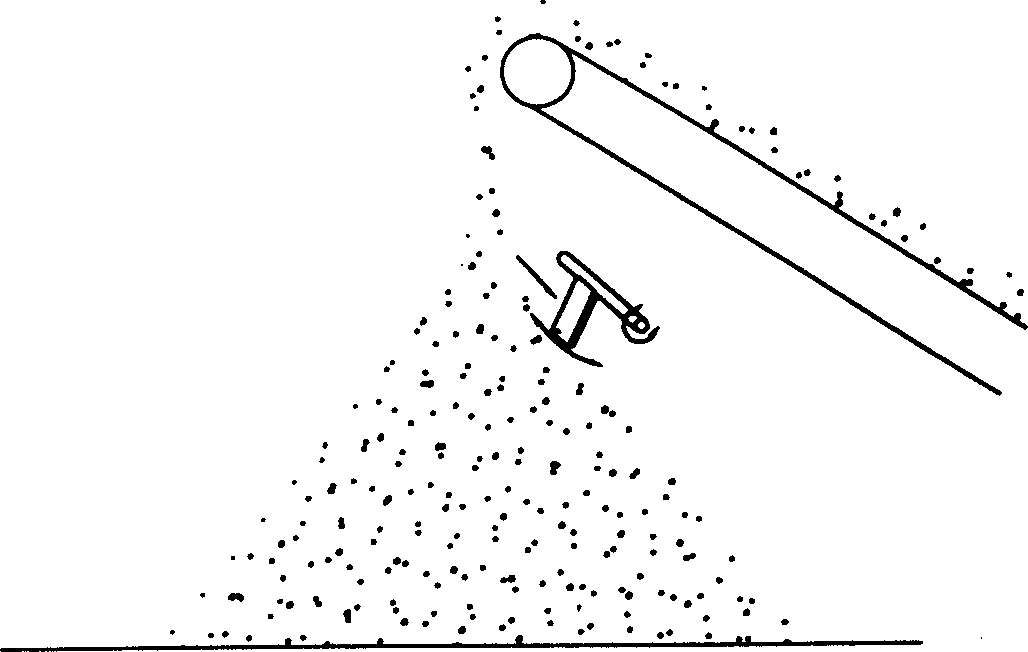

Method and Apparatus for Modifying a Cargo Container to Deliver Sand to a Frac Site

A cargo container is modified to carry a fracing proppant such as sand from a quarry or source to the frac site. Openings are cut in the top and bottom of a cargo container and hydraulically operated sliding doors are placed there under. A hopper module with the walls being inclined to approximately the angle of repose for the proppant is installed inside the cargo container. The hopper module is sealed inside the cargo container so that a proppant enters through the top opening at the quarry and flows out through the bottom opening at the fracing site.

Owner:SANDCAN INC

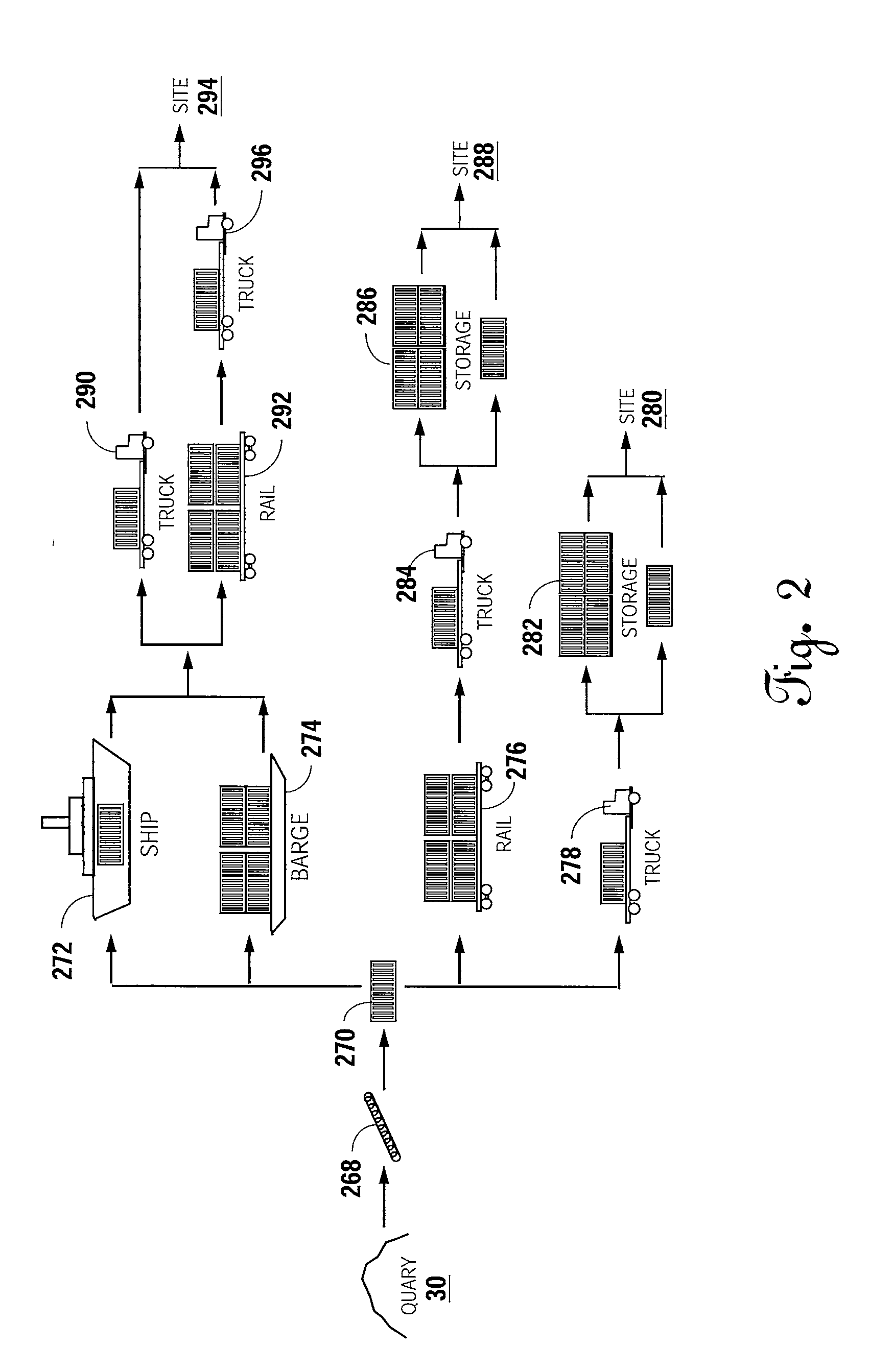

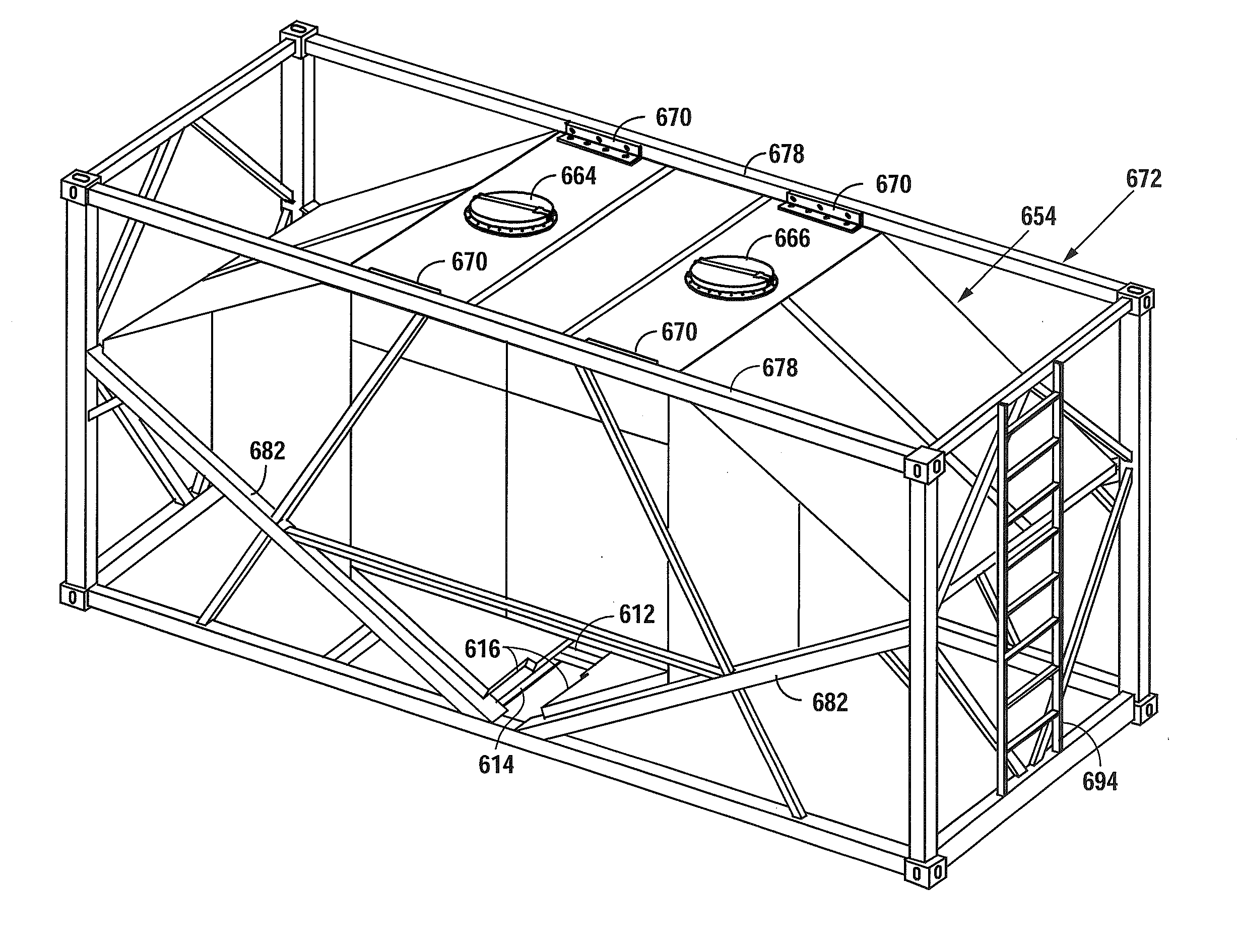

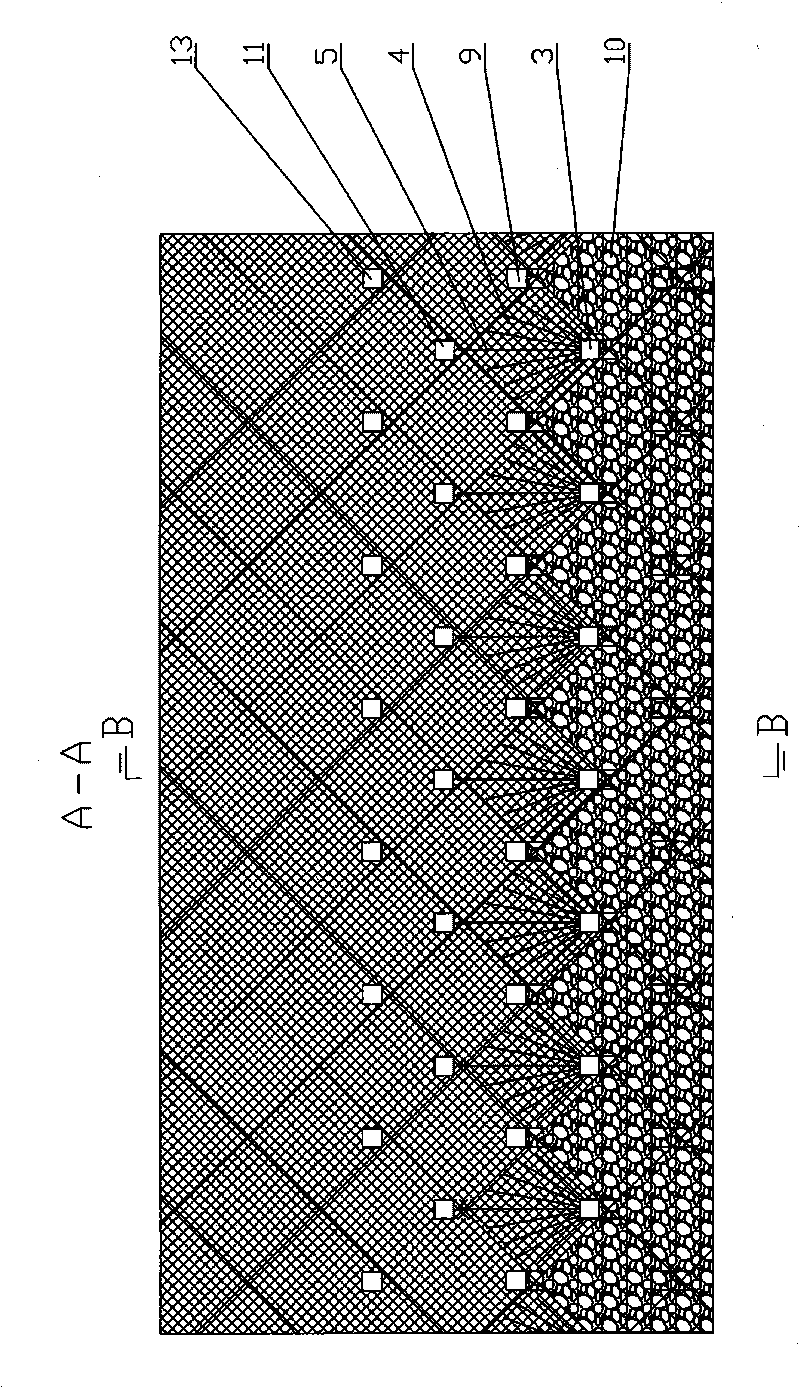

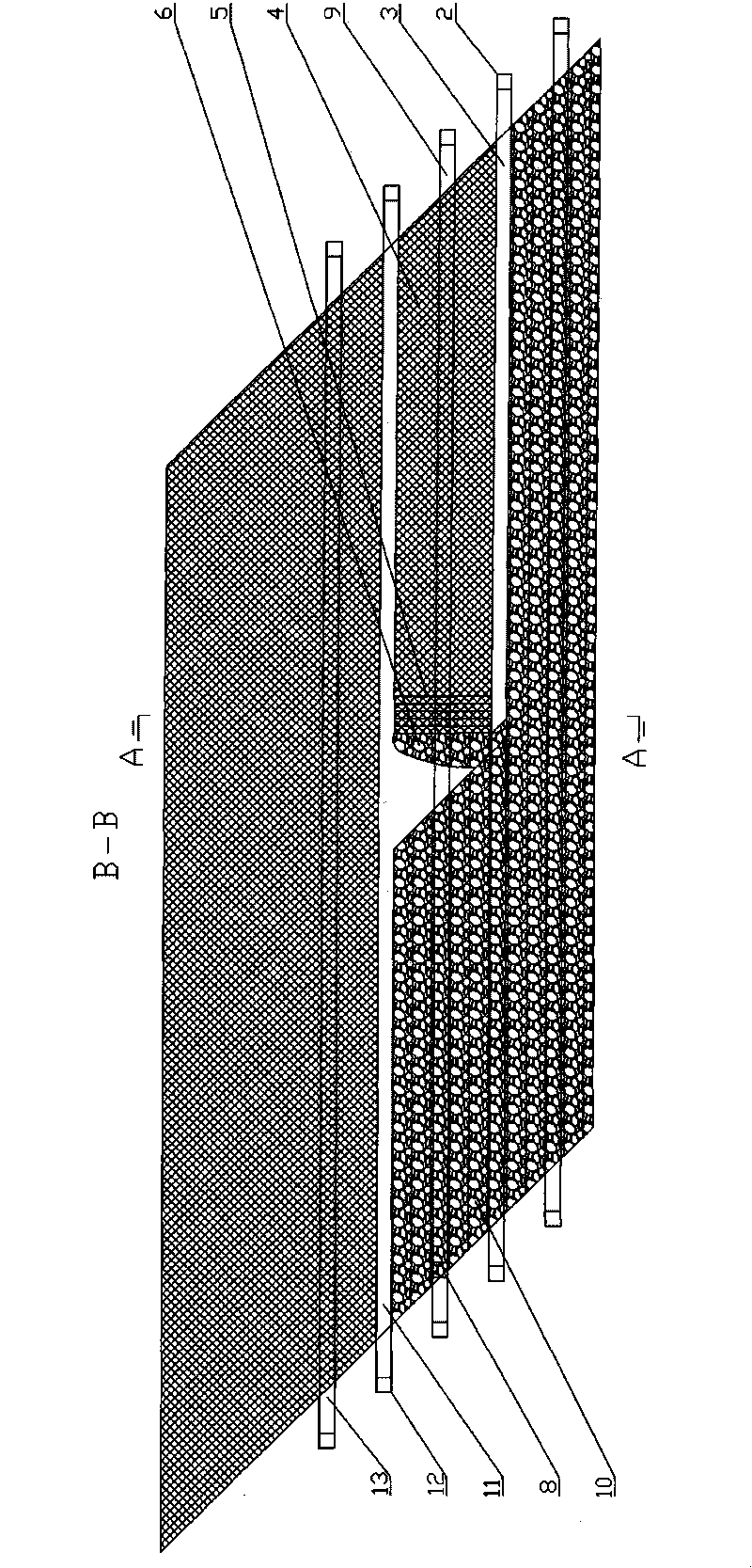

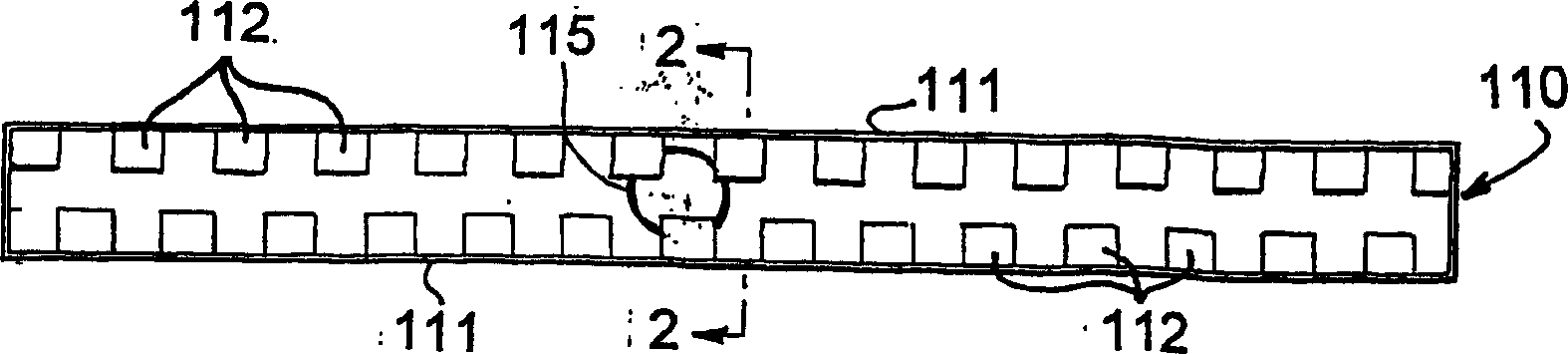

Container to deliver bulk granular material

ActiveUS20140166647A1Prevent leakageLarge containersMetal working apparatusAngle of reposeEngineering

A container is constructed to carry granular material from a quarry or source to the frac site. An open frame the size of a standard cargo container is constructed. An enclosed hopper is formed using flat sheet metal with bolted together perpendicular edges. The hopper is set within, and attached to, the frame. Top hatches provide for loading the hopper, and a lower sliding gate in a bottom opening provides for unloading the hopper. The bottom of the hopper is at an angle slightly above the angle of repose of the granular material carried therein.

Owner:SANDCAN INC +1

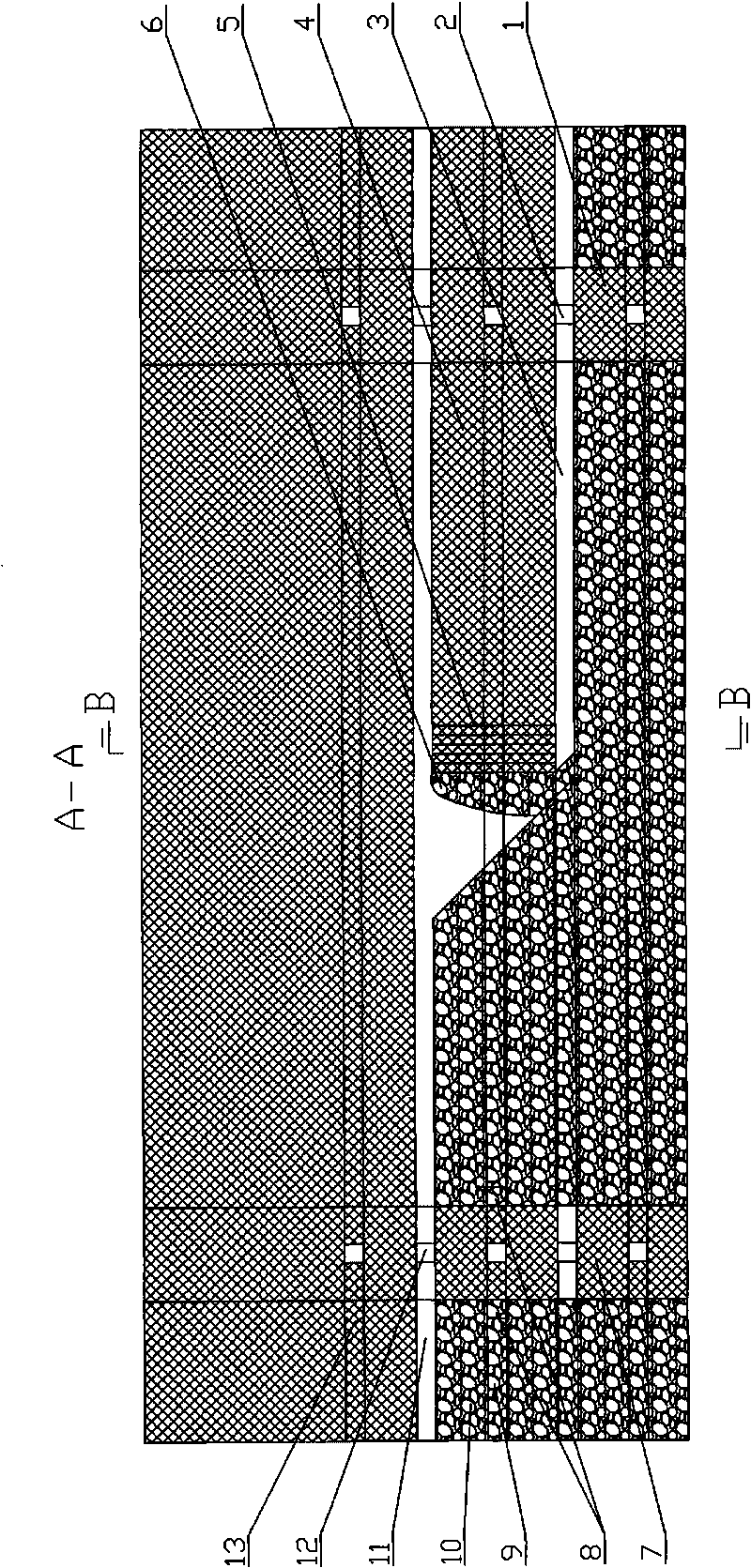

Cargo container to deliver sand to a frac site

A cargo container is constructed to carry a fracing proppant such as sand from a quarry or source to the frac site. An open frame the size of a standard cargo container has an enclosed hopper therein. Upper sliding gate at a top hatch provides for loading the hopper, and a lower sliding gate in a bottom hatch provides for unloading the hopper. The bottom of the hopper is at an angle slightly above the angle of repose of the fracing proppant carried therein.

Owner:SANDCAN INC

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

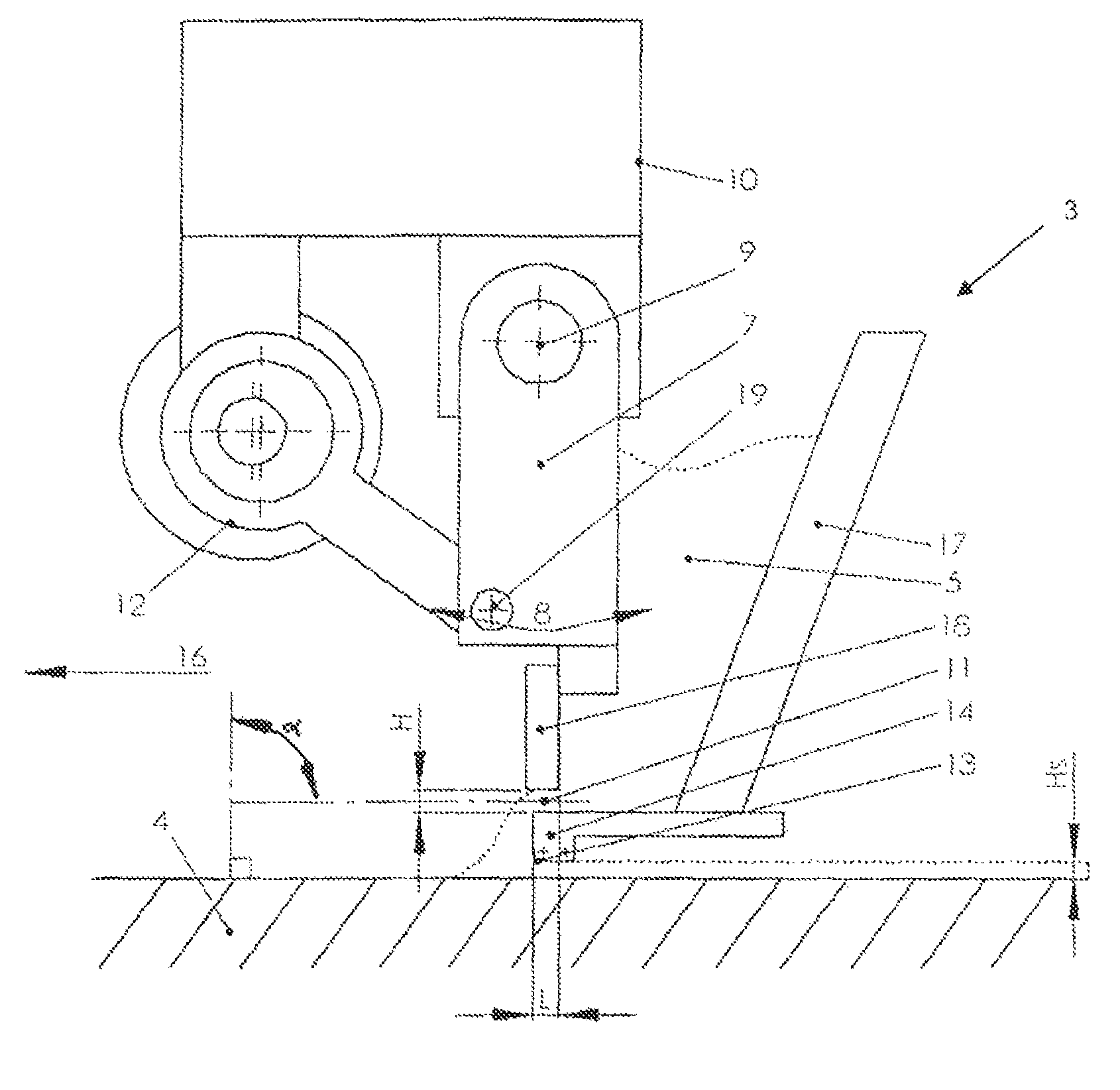

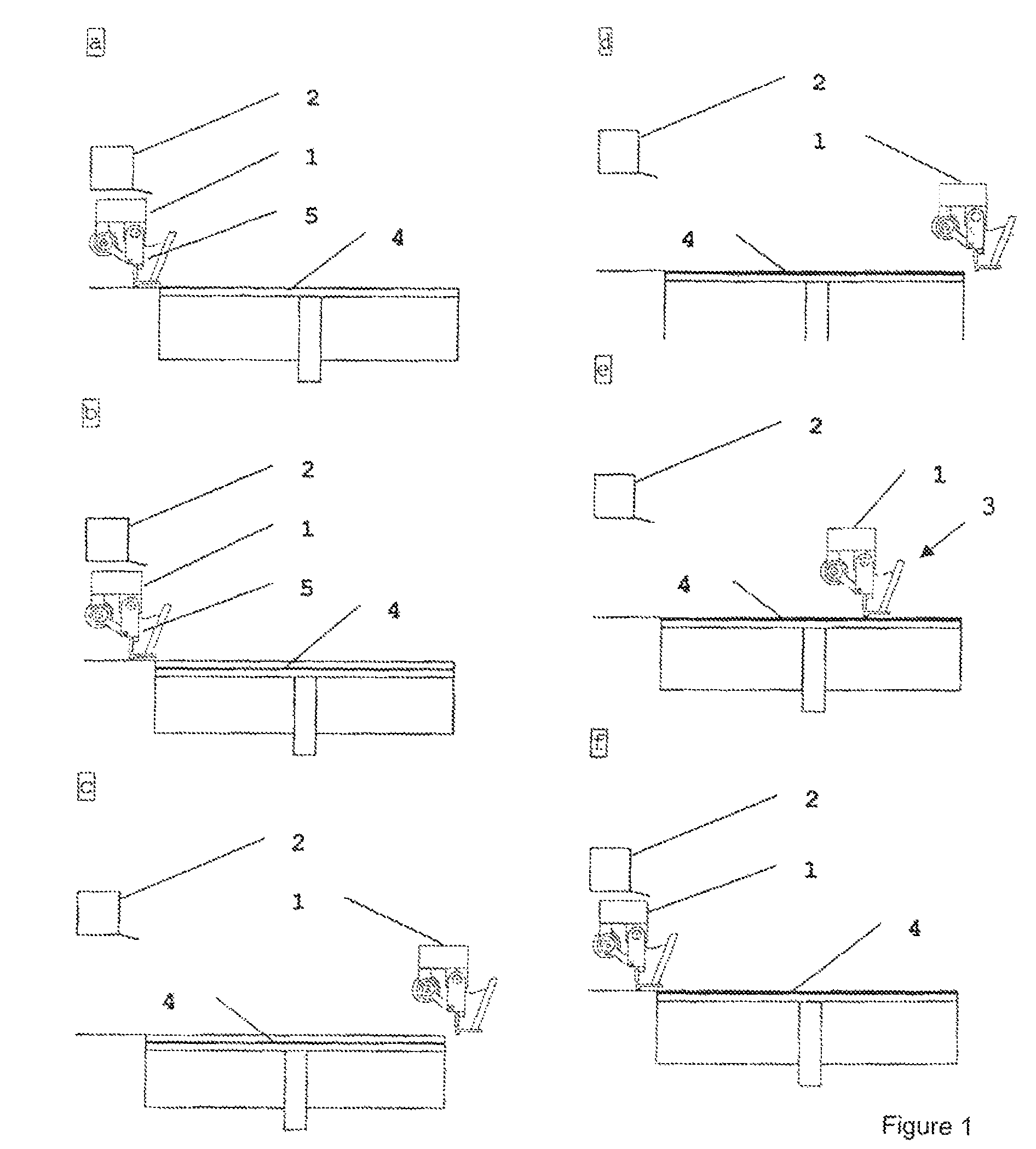

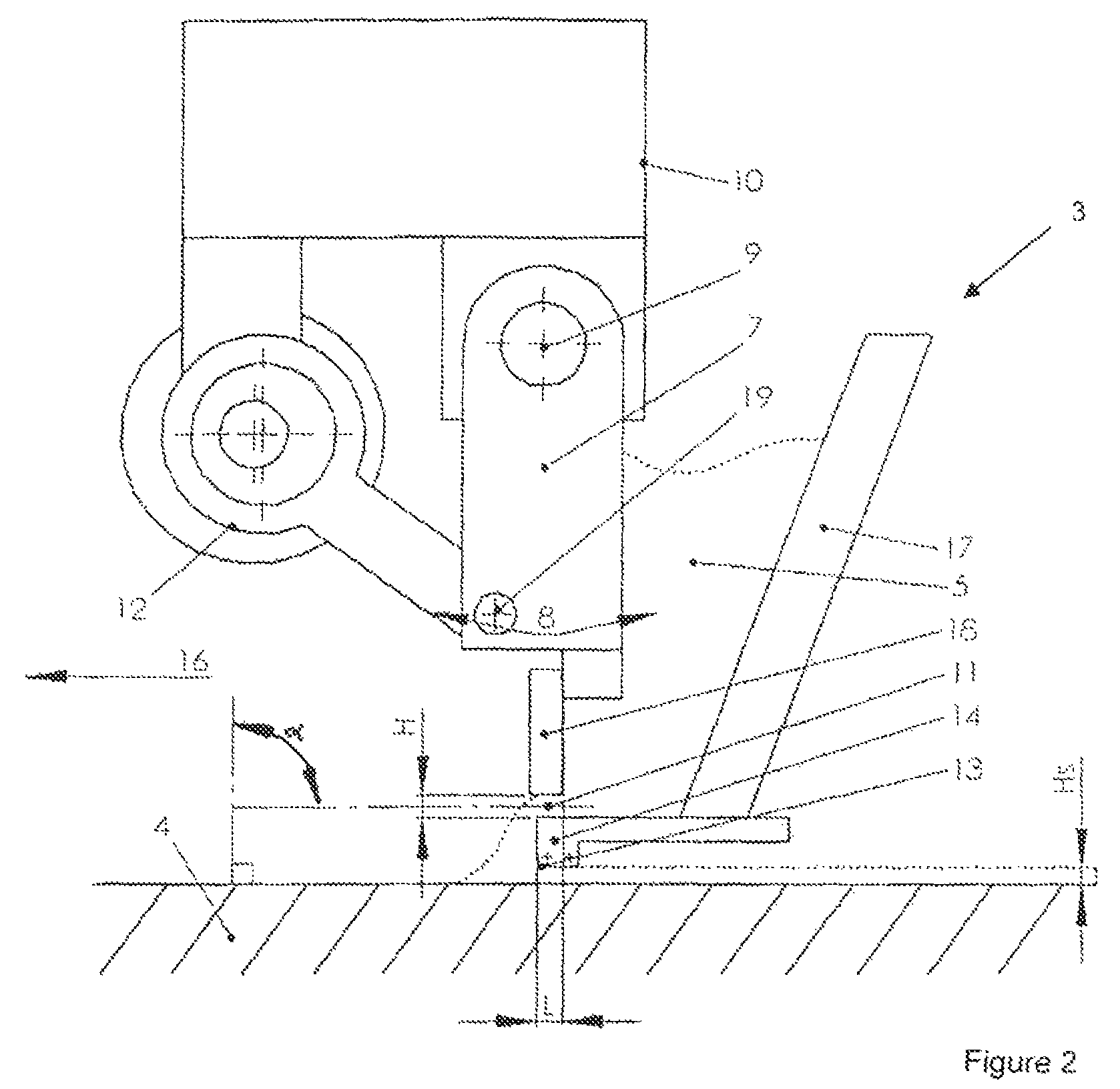

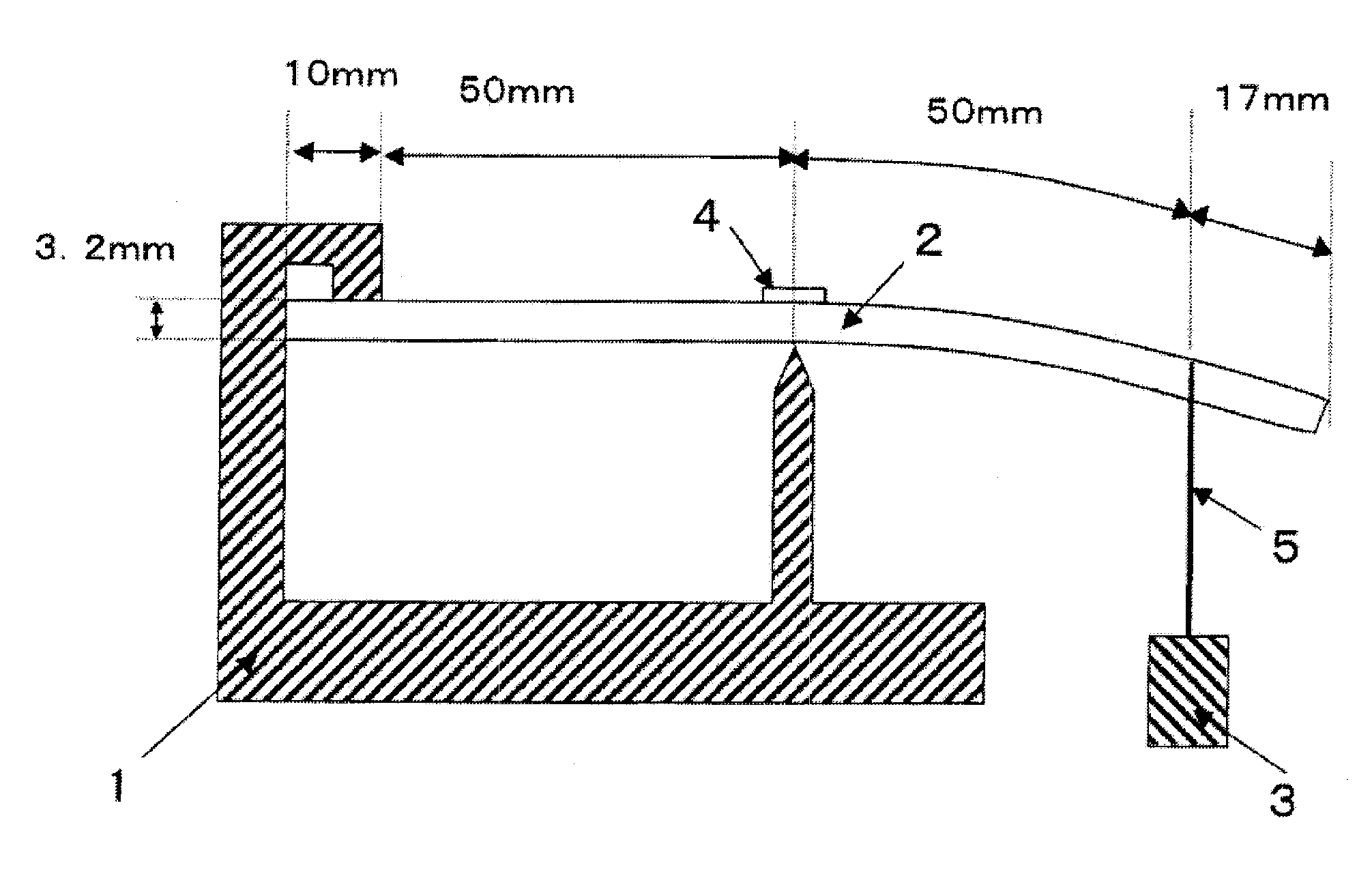

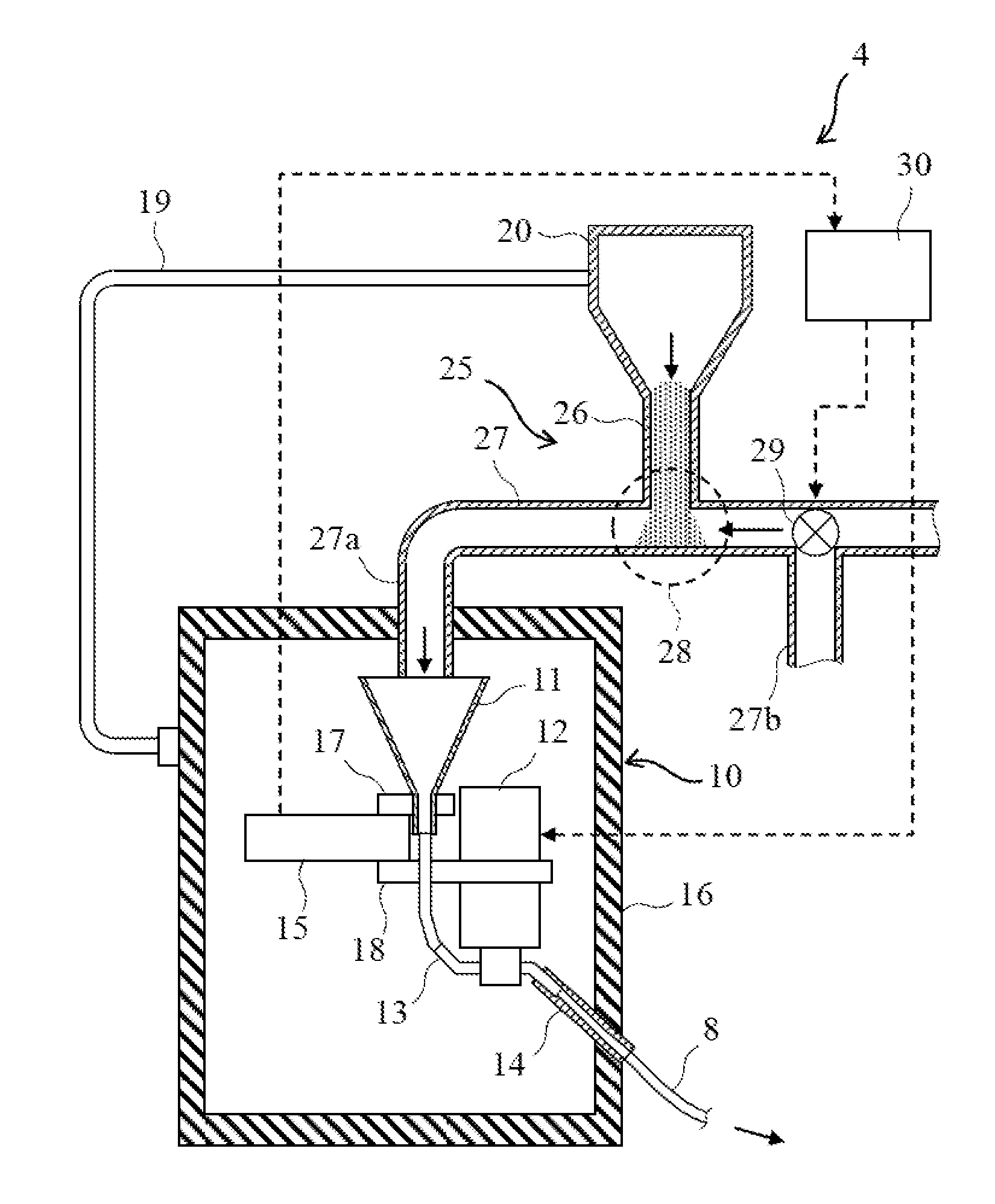

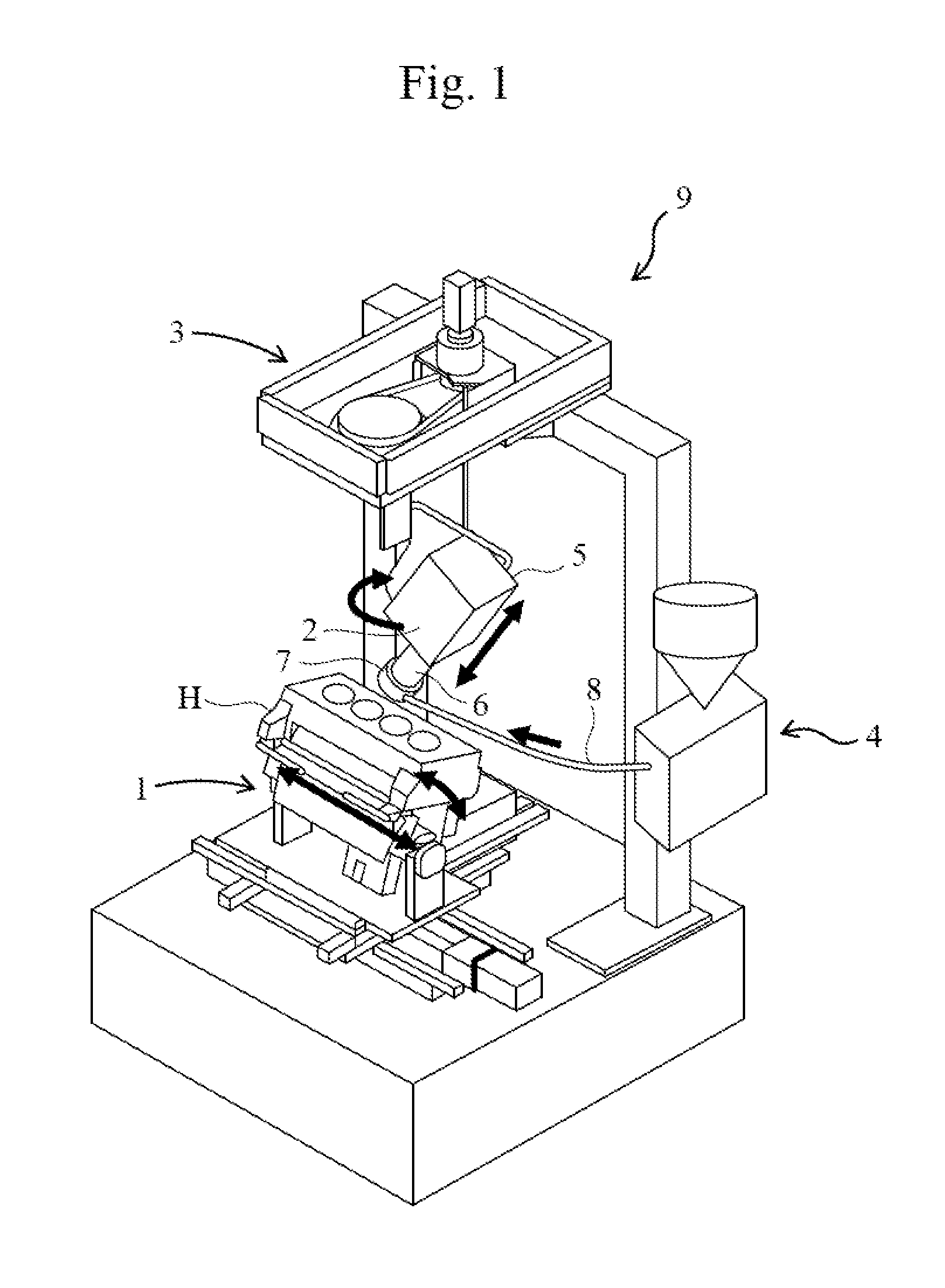

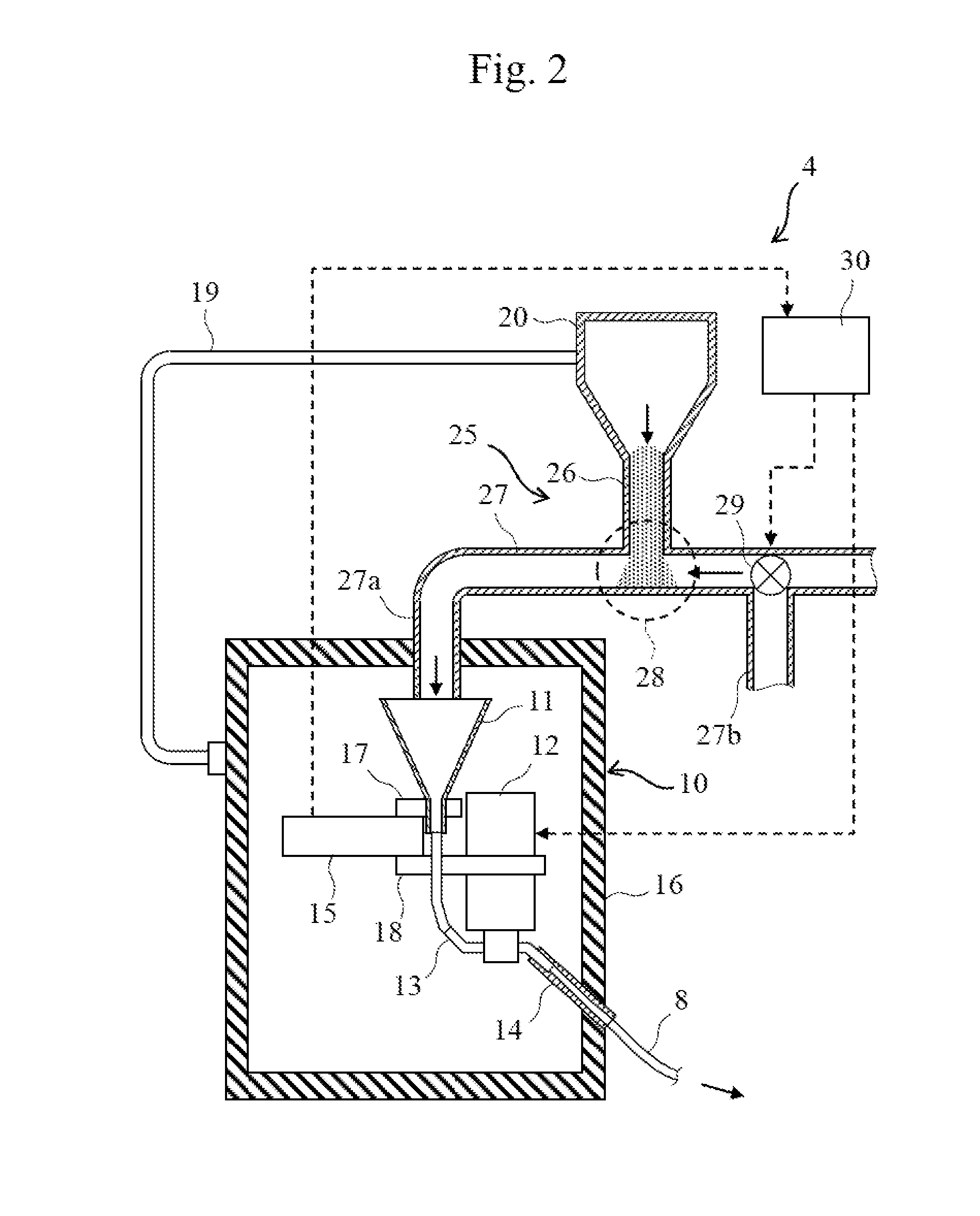

Method and device for applying fluids

ActiveUS8096262B2Avoid emissionsLiquid surface applicatorsAdditive manufacturing apparatusMechanical engineeringAngle of repose

This document describes a process and a device for applying fluids, specifically particle material, on an area to be coated, which is viewed in forward moving direction of the coater, that fluid is applied on the area to be coated and then a leveling element is run over the applied fluid, whereby the fluid is led from a metering system provided with an opening, which oscillates when applying the fluid. The opening shall be designed in such a way that when the metering system is at a standstill this is closed by forming an angle of repose of the fluid.

Owner:VOXELJET AG

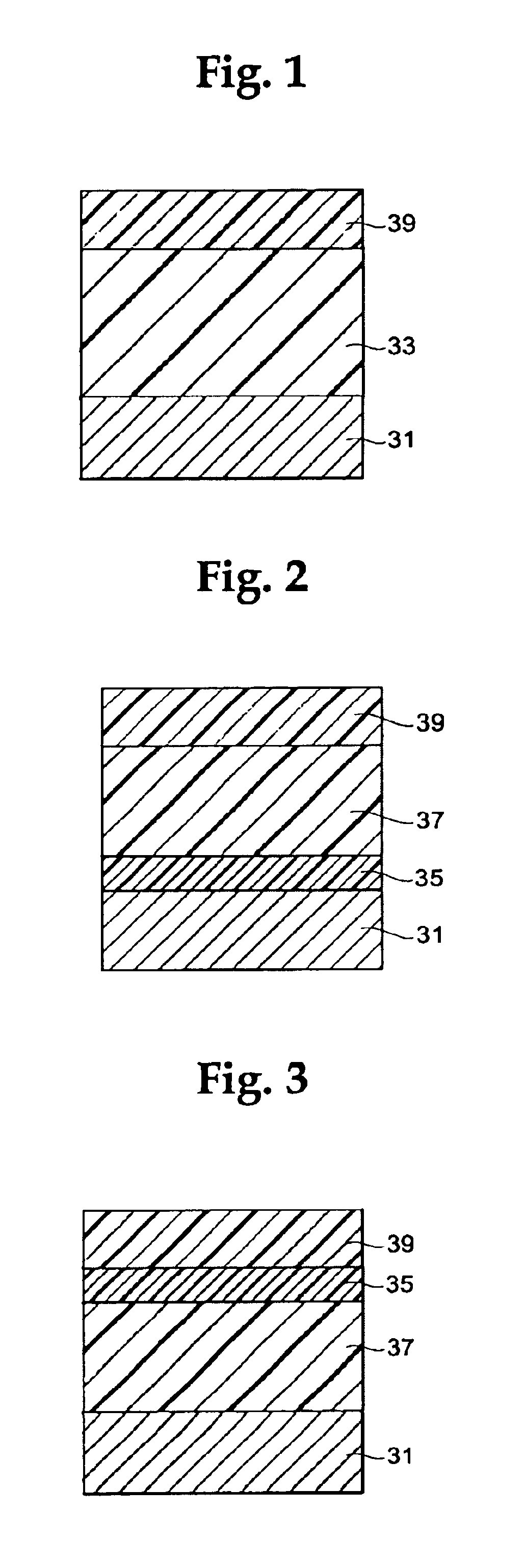

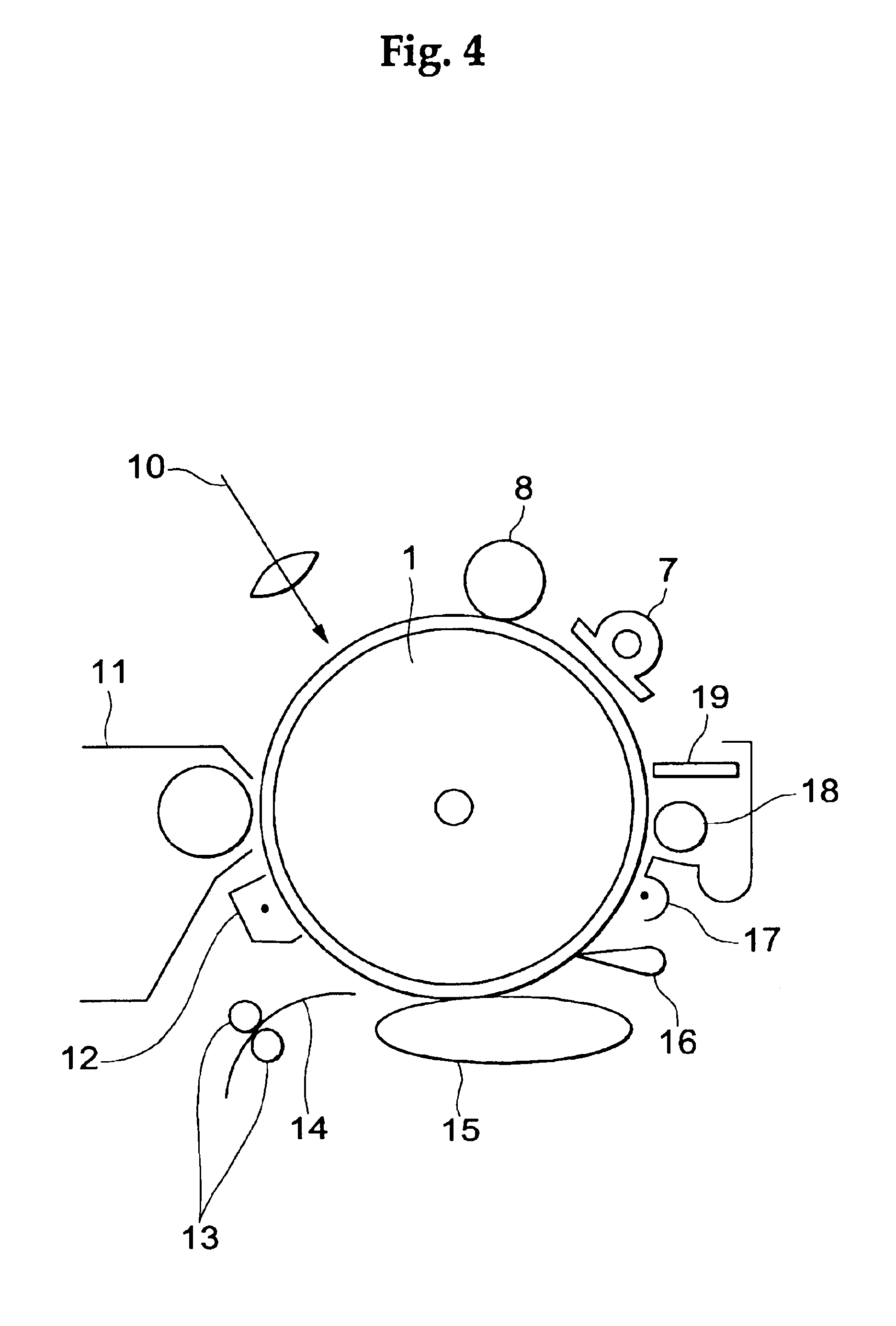

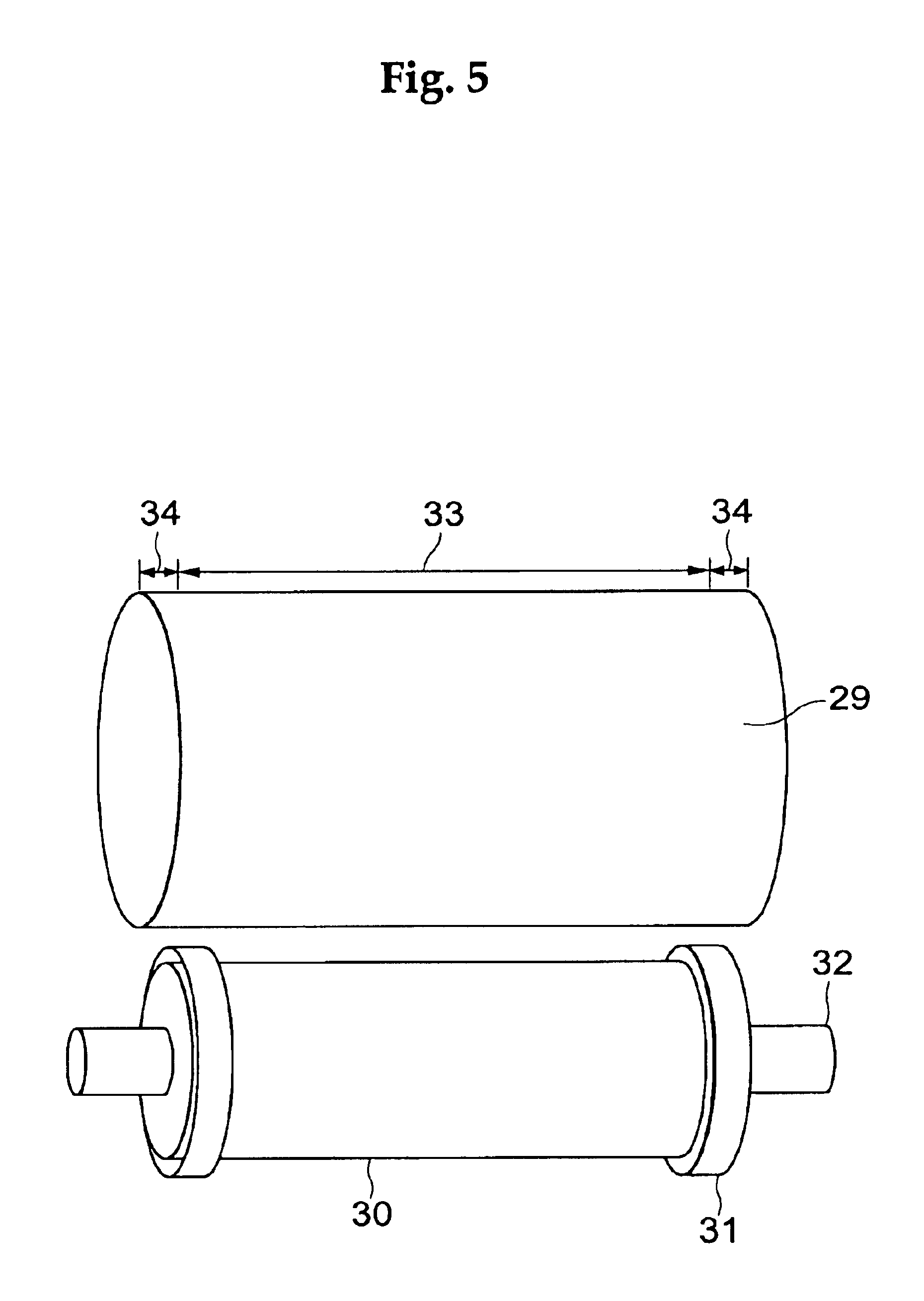

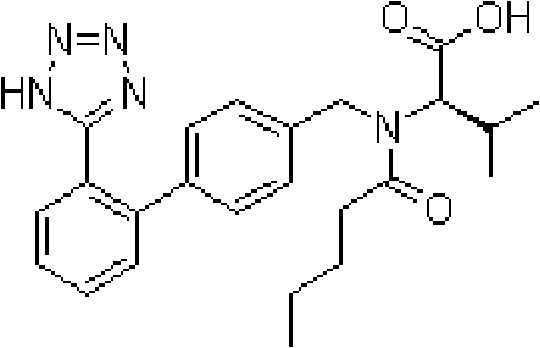

Method for forming electrophotographic image and electrographic device

InactiveUS6902857B2Reduce scrapMinimizationAzo dyesElectrographic process apparatusElectrical conductorEngineering

A method for forming an electrophotographic image and a device for forming an image on a transfer material by the steps for charging, exposing, developing and transferring, and recovering the toner remained untransferred in the step for cleaning by recovering, wherein the toner used in the step for developing has a total surface area ratio Z of additive, which is calculated by Z=(Ht·Wt) / (H·W), satisfies 0.5≦Z≦1.5, the electrophotographic photoconductor used comprises at least a photosensitive layer and a filler-containing protective layer provided on a conductive support in that order, and the angle of repose of the toner to the protective layer surface of the electrophotographic photoconductor is 30° or less.

Owner:RICOH KK

Cellulose powder

InactiveUS7939101B2High hardnessLess destructiveBiocideOrganic active ingredientsMetallurgySpecific volume

Cellulose powder having an especially excellent balance among moldability, fluidity and disintegrating property is provided. Cellulose powder having an average polymerization degree of 150-450, an average L / D (the ratio of the major axis to the minor axis) value of particles of 75 μm or less of 2.0-4.5, an average particle size of 20-250 μm, an apparent specific volume of 4.0-7.0 cm3 / g, an apparent tapping specific volume of 2.4-4.5 cm3 / g, and an angle of repose of 55° or less.

Owner:ASAHI KASEI CHEM CORP

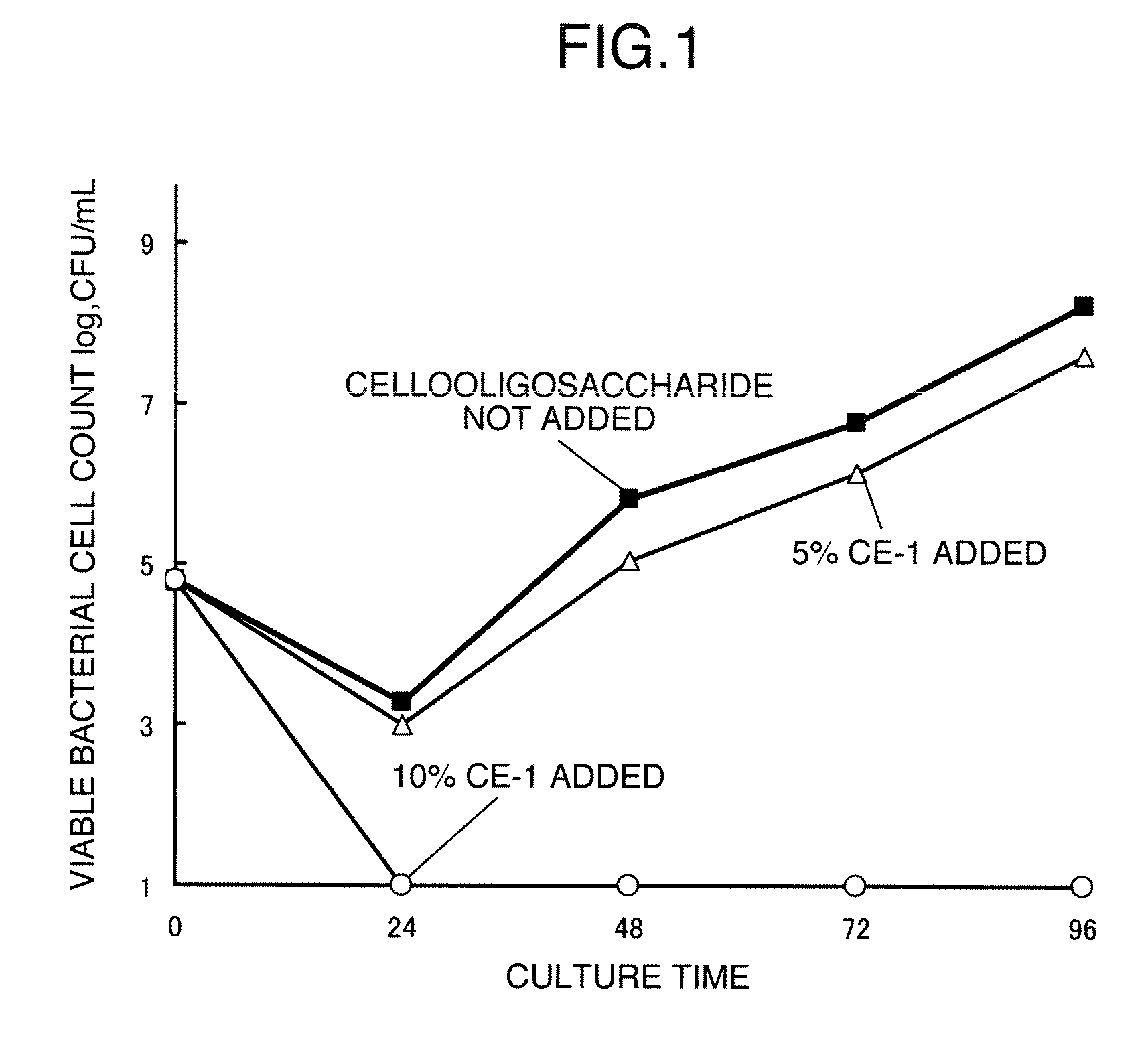

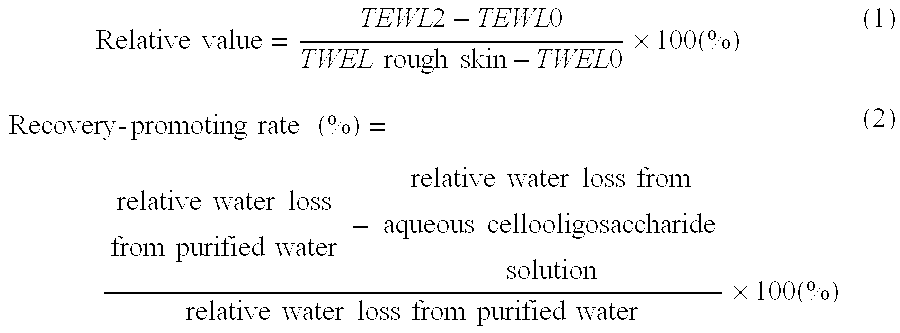

Cellooligosaccharide-Containing Composition

InactiveUS20090232892A1To promote metabolismEnhance skin barrier functionAntibacterial agentsPowder deliveryAdditive ingredientMedicine

Disclosed is a cellooligosaccharide composition comprising, as the main ingredient, at least one cellooligosaccharide selected from the group consisting of cellobiose, cellotriose, cellotetraose, cellopentaose and cellohexaose, which is in the powdery form having an average L / D value of 3.0 or lower, a bulk density of 0.80 g / mL or lower and an angle of repose of 60° or lower.

Owner:ASAHI KASEI CHEM CORP

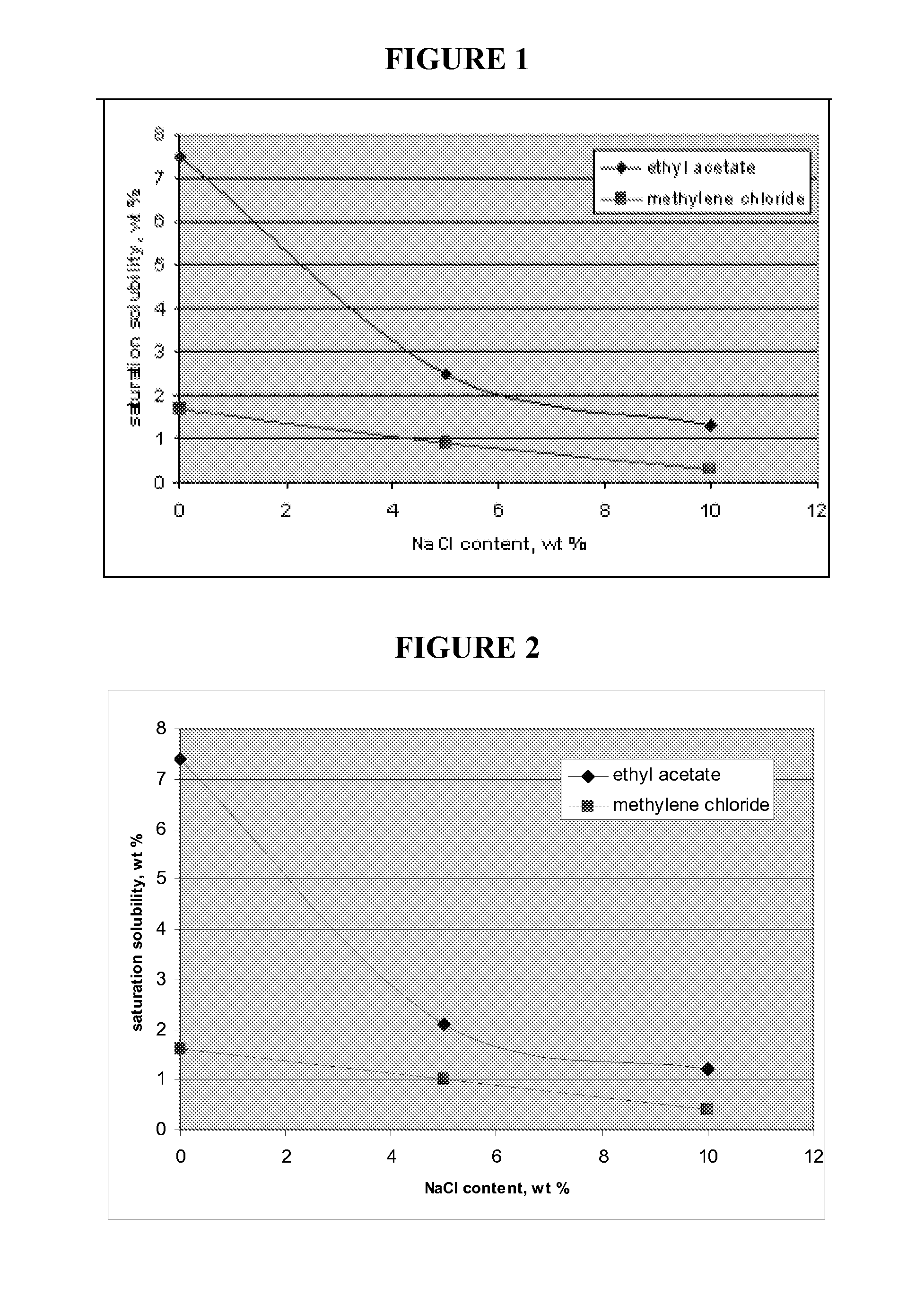

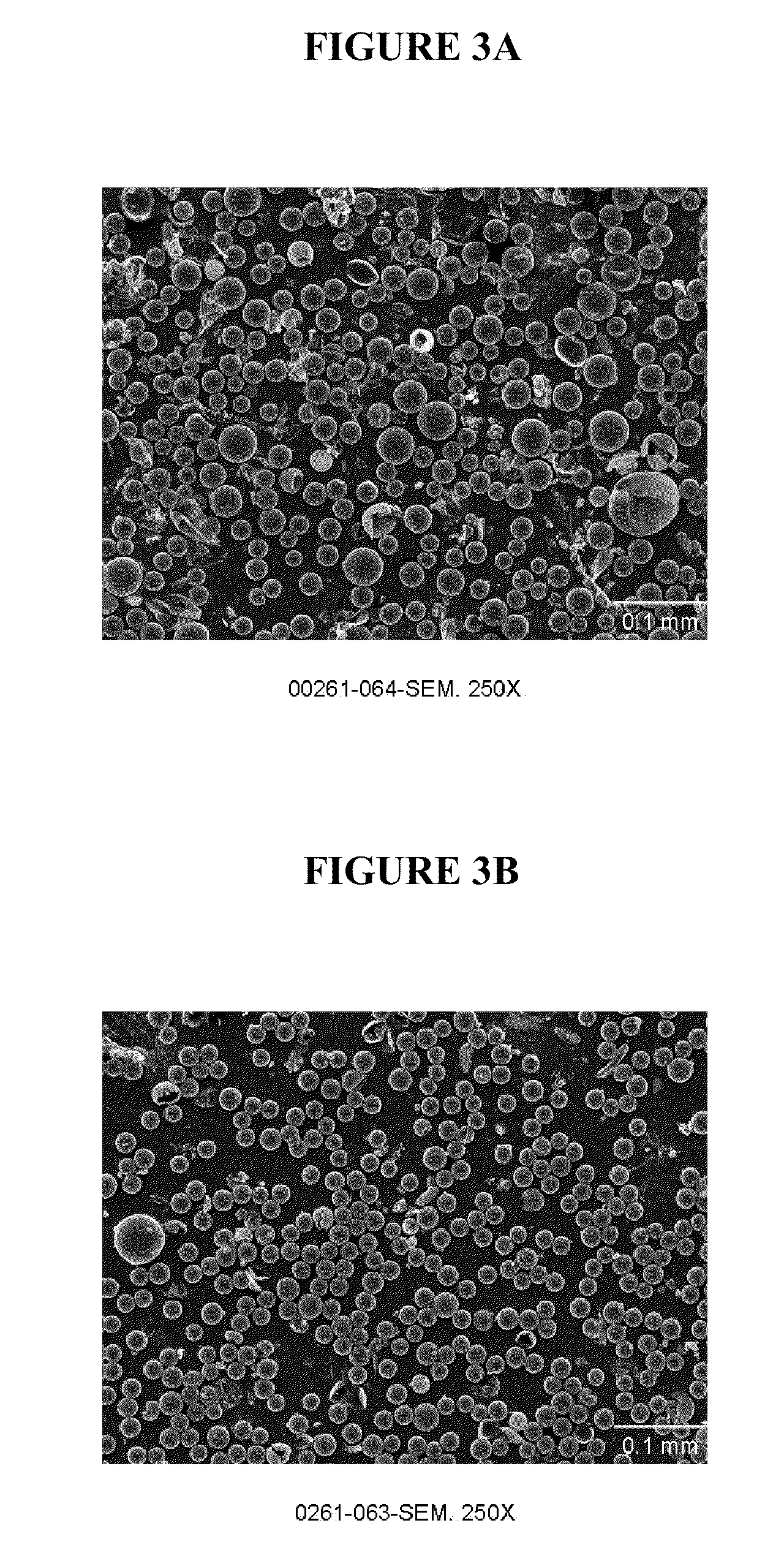

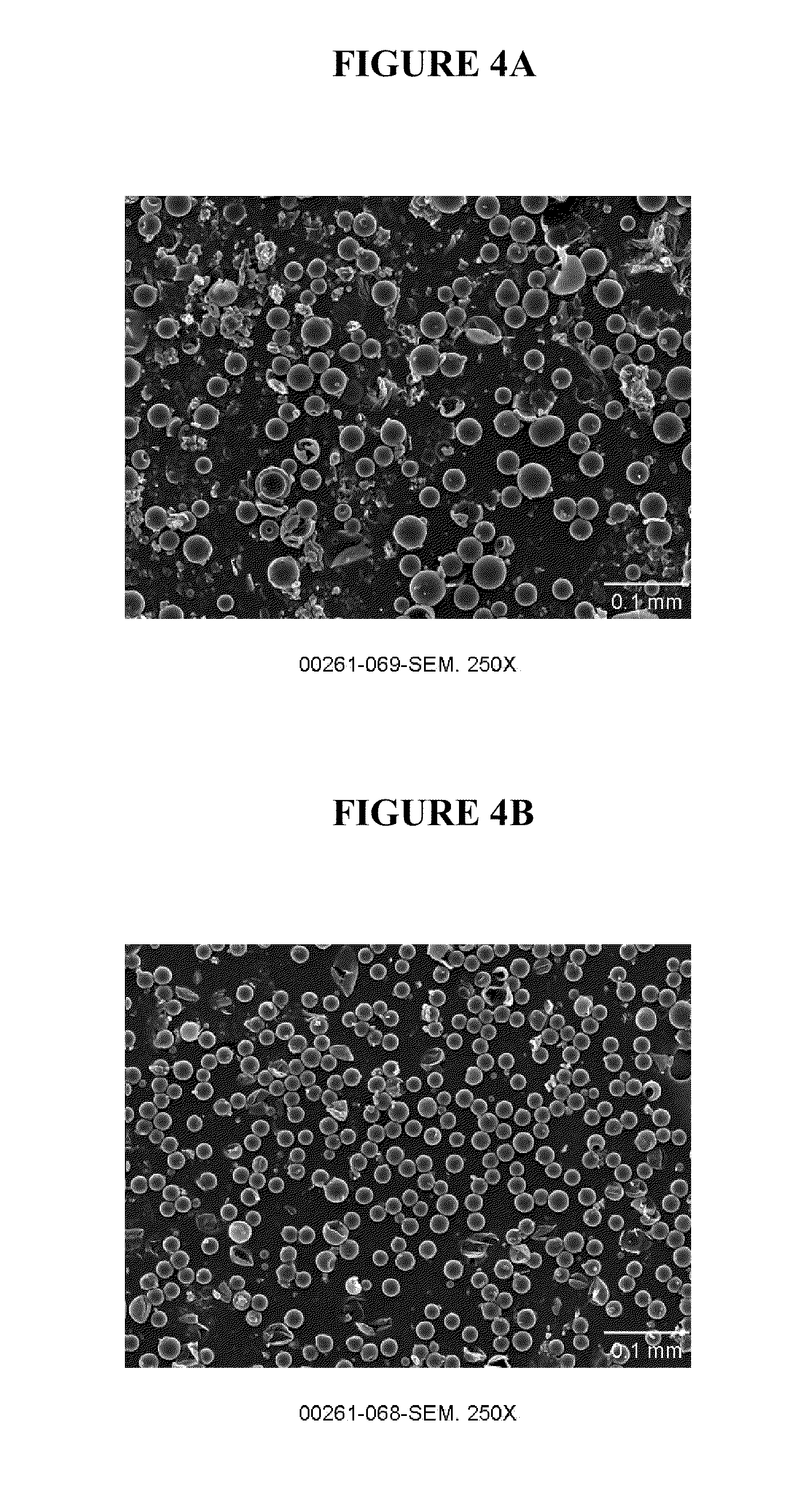

Microencapsulation process with solvent and salt

ActiveUS20100069602A1Safe handlingInexpensive waste disposalGranular deliveryLiposomal deliveryEmulsionMicroparticle

The present disclosure relates to processes for preparing microparticles using an emulsion process where both a solvent and a salt are used in the continuous phase of the emulsion. The present disclosure also relates to micropartices having an angle of repose of ≦35, as measured using a Hele-Shaw cell.

Owner:EVONIK CORP

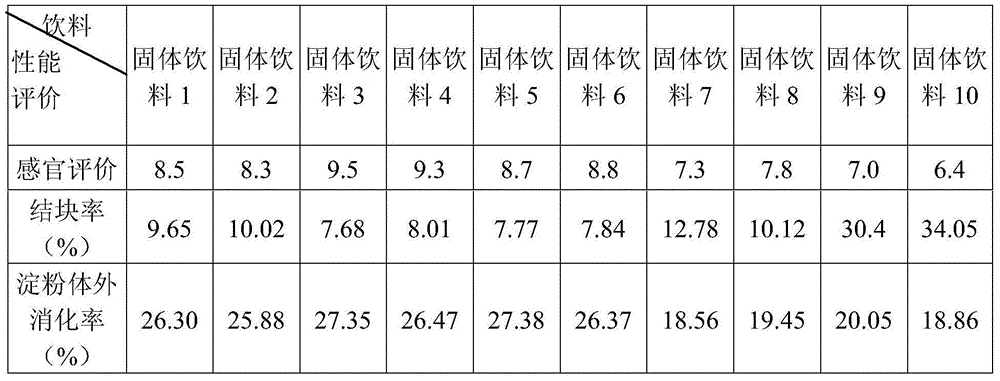

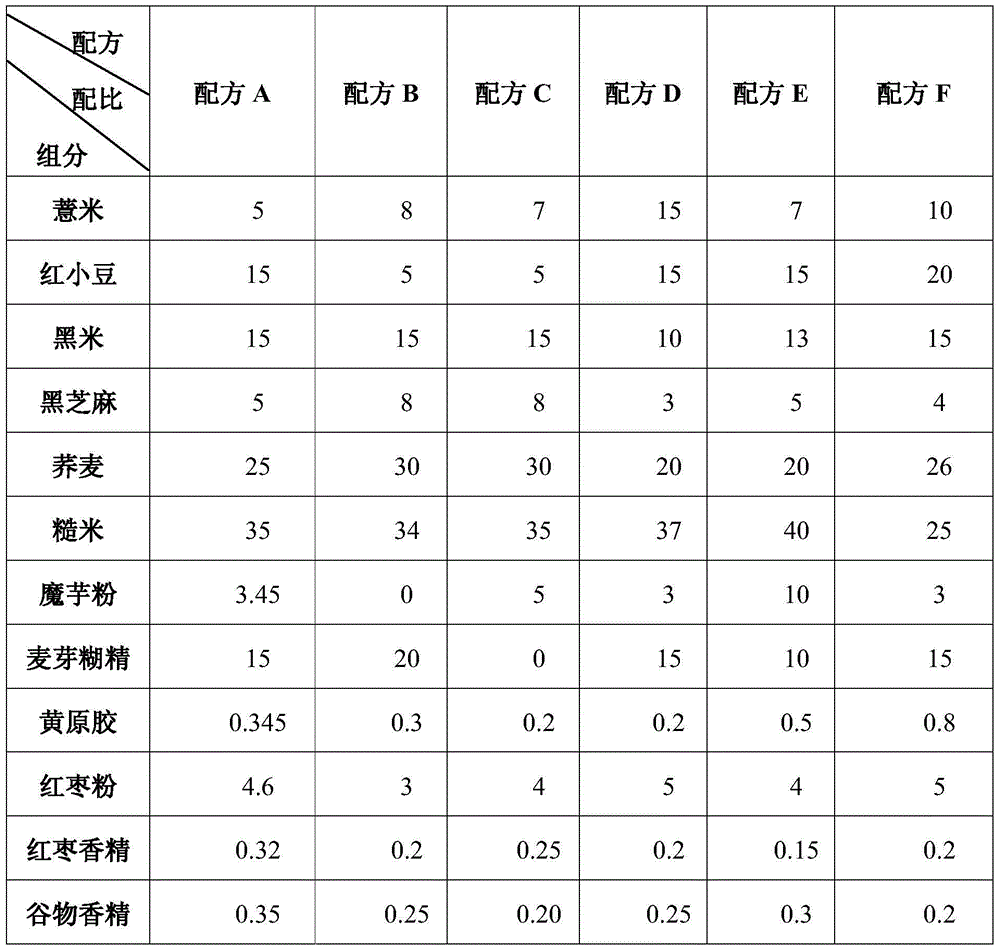

Coarse-cereal solid beverage and preparation method thereof

The invention discloses a coarse-cereal solid beverage and a preparation method thereof. The coarse-cereal solid beverage is prepared from raw materials of coarse cereal powder, maltodextrin, konjaku flour and / or radix puerariae powder, and a stabilizing agent, and the raw materials preferably and further comprise one or more of red jujube powder, a sweetening agent, red jujube essence and grain essence. The preparation method of the coarse-cereal solid beverage disclosed by the invention comprises the step of performing roasting treatment on the coarse cereal powder, the step of performing extruding and puffing, and the step of performing optional boiling granulation, wherein the maltodextrin and other ingredients and components are added together after the step of performing extruding and puffing, or are added in the step of performing optional boiling granulation. The size distribution range of the coarse-cereal solid beverage disclosed by the invention is 80-220 [mu]m, and / or the angle of repose is smaller than 35 degrees. The coarse-cereal solid beverage prepared by the method disclosed by the invention is balanced in nutrition, rich in mouth feel, good in solubility, low in agglomerating rate, good in fluidity and easy to transport and preserve.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

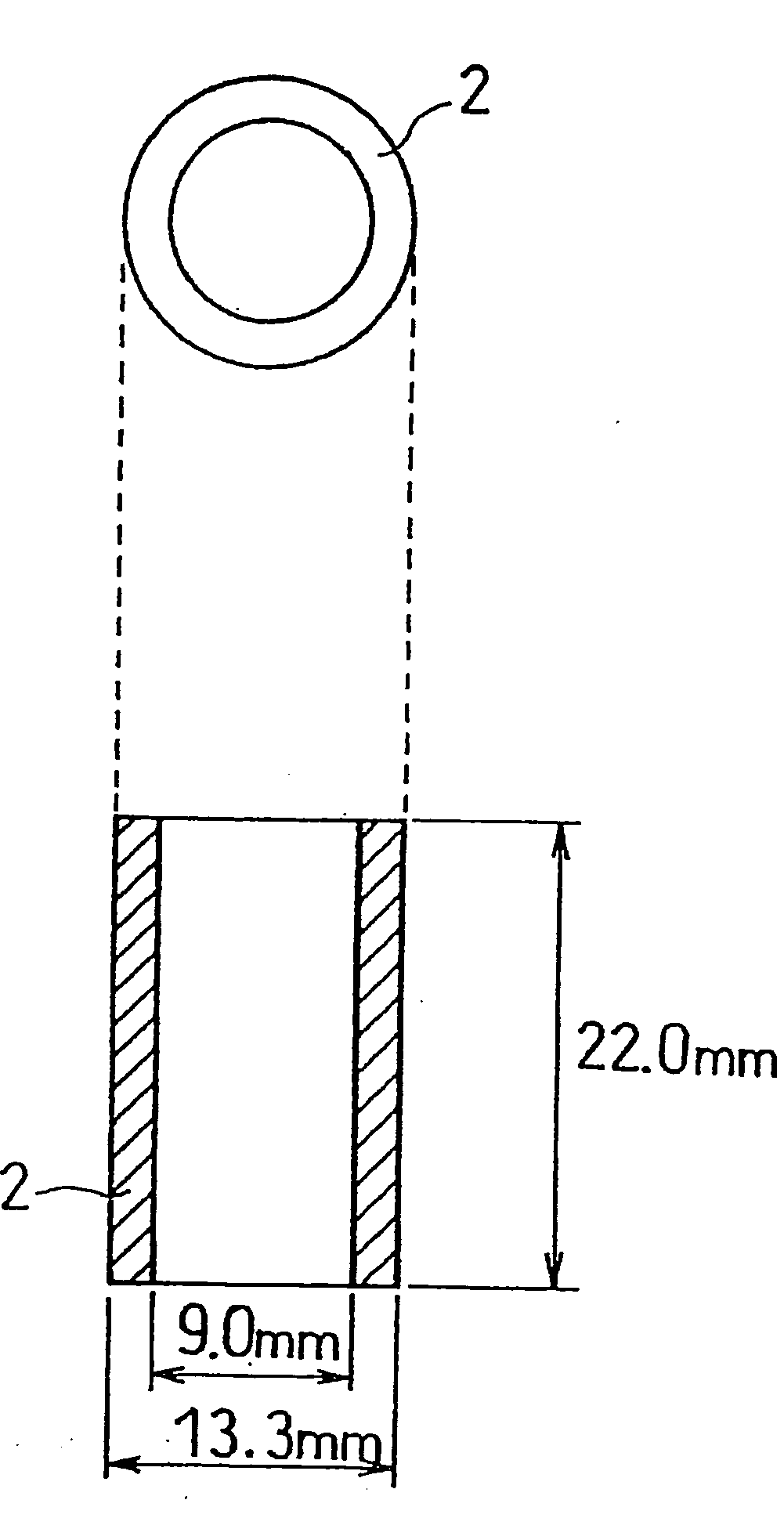

Positive electrode material mixture and alkaline battery using the same

InactiveUS20050031959A1Improve liquiditySmall weight changeGel electrodesNegative electrodesGraphiteMaterials science

In order to provide a positive electrode material mixture for an alkaline battery, the positive electrode material mixtures having small weight variations, a granulated mixture with favorable fluidity is used which comprises graphite and a positive electrode active material containing at least one of manganese dioxide and nickel oxyhydroxide, and has an angle of repose of 20 to 43 degrees.

Owner:PANASONIC CORP

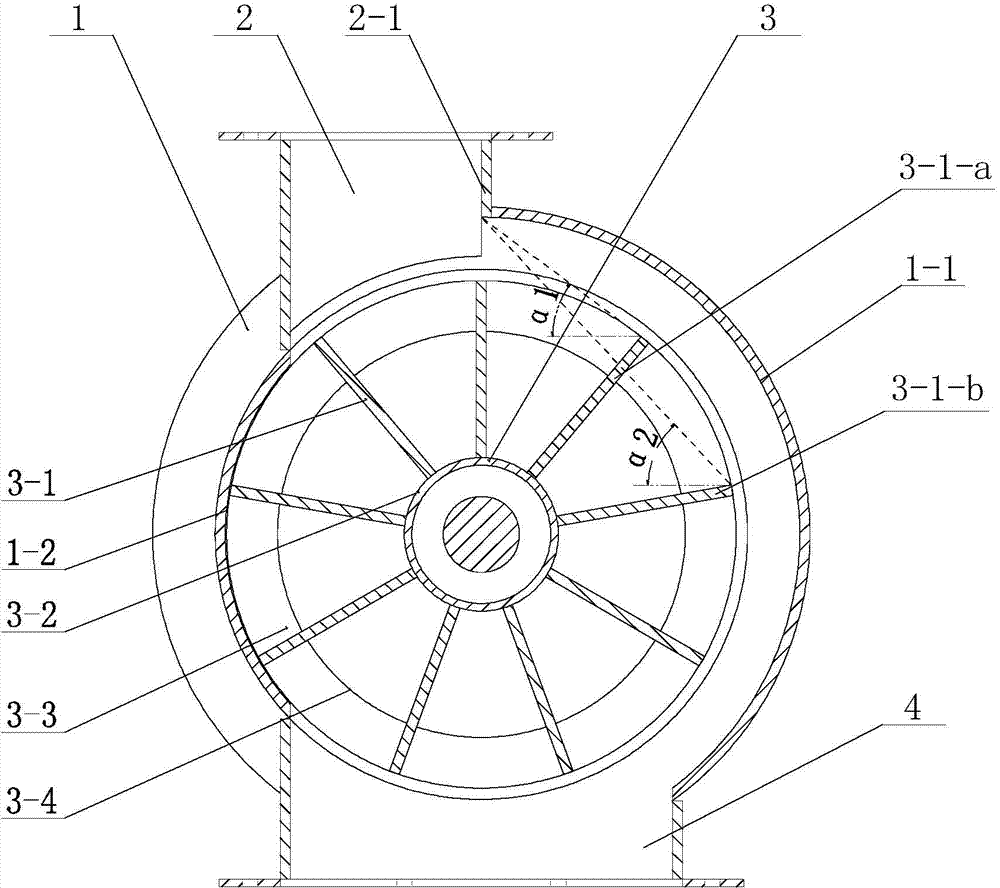

Novel impeller feeder

InactiveCN103896027APrecise control of dischargeEasy to controlRotary conveyorsImpellerMaximum diameter

The invention discloses a novel impeller feeder. The novel impeller feeder comprises a case. A feeding port and a discharge port are formed in the upper portion of the case and the lower portion of the case respectively. An impeller is arranged in the case and comprises a wheel groove bottom with which a rotating shaft is sleeved. A plurality of blades are arranged on the periphery of the wheel groove bottom at intervals in the peripheral direction. N upwardly-inclined blades are arranged in the area, corresponding to the conveying-side inner wall of the case, of the impeller, wherein N is larger than or equal to 2, and the included angle formed between the horizontal plane and the connecting line of the radial edge of at least one of the N blades and the lower end of the conveying-side edge wall of the feeding port is smaller than the angle of repose of materials. The gap between the conveying-side inner wall of the case is 2.5 times larger than the maximum diameter of the materials. The novel impeller feeder is compact in structure, serious abrasion is avoided on the premise that the requirement for full-width feeding is met, blockage caused by the materials can be prevented, control precision can be improved, and the maintenance workload and power consumption of the novel impeller feeder are substantially reduced.

Owner:CHINA UNIV OF MINING & TECH

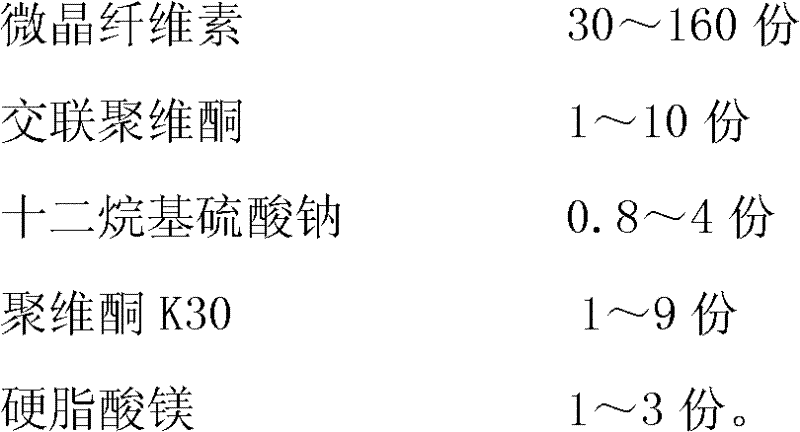

A kind of valsartan capsule and preparation method thereof

The invention relates to valsartan capsules and a preparation method thereof. The valsartan capsules comprise the following components in parts by weight: valsartan 50-200 parts, microcrystalline cellulose 30-160 parts, crosslinked povidone 1-10 parts, sodium dodecyl sulfate 0.8-4 parts, povidone K30 1-9 parts, and magnesium stearate 1-3 parts. The valsartan capsules provided by the invention canbe used for treating mild and moderate primary hypertension. The valsartan capsules have the advantages of reasonable formula, feasible process, stable and reliable quality, and good stability, dissolution and bioavailability. The valsartan capsules are prepared by using a wet granulation process, the addition method of solubilizer sodium dodecyl sulfate is proper, the concentration of the bonding agent is proper, and the granules have angle of repose smaller than 40 degrees, belong to powders with good fluidity and can meet the need of capsule filling. The valsartan capsules have short production process and low production costs, and are easy for industrial production.

Owner:HAINAN JINRUI PHARMA

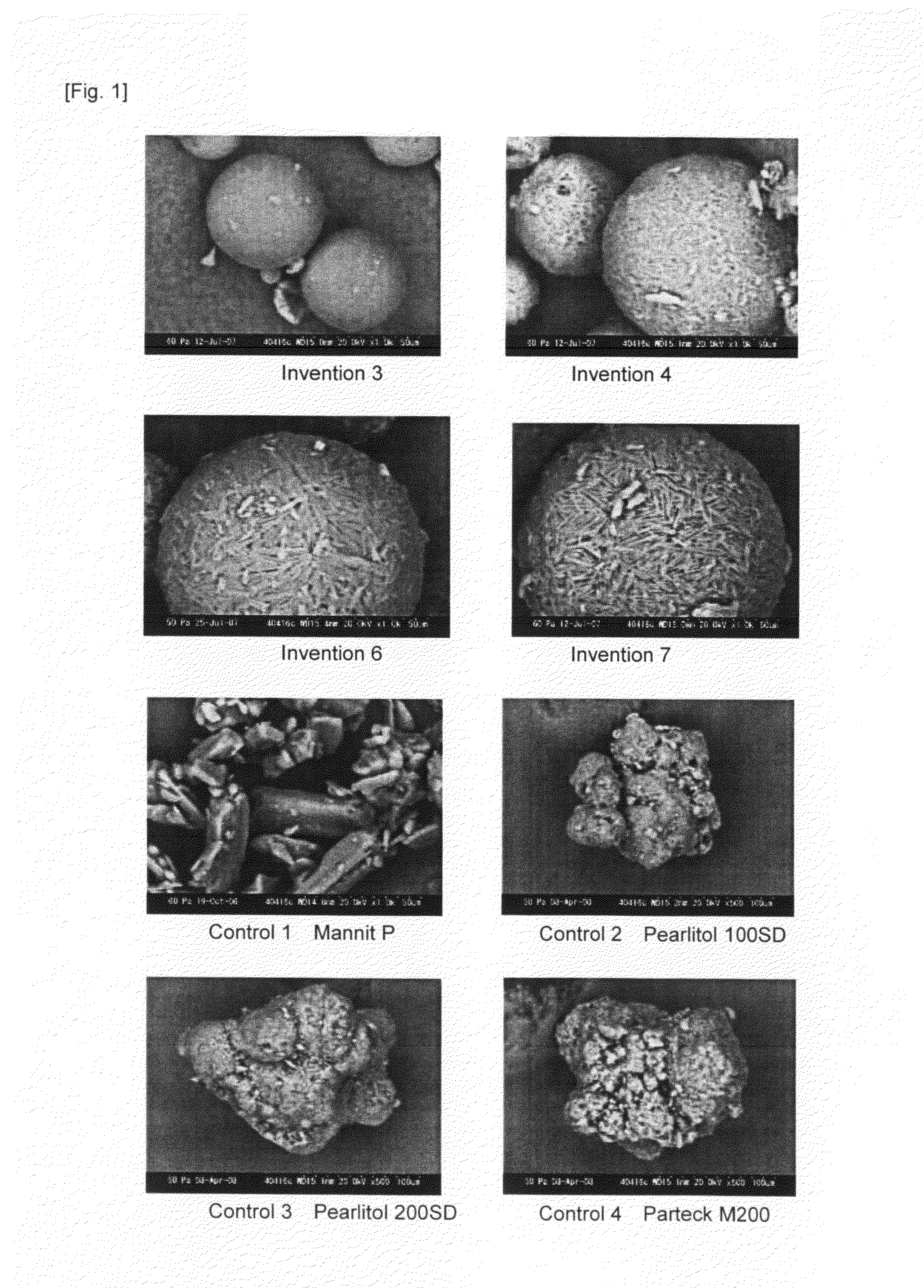

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

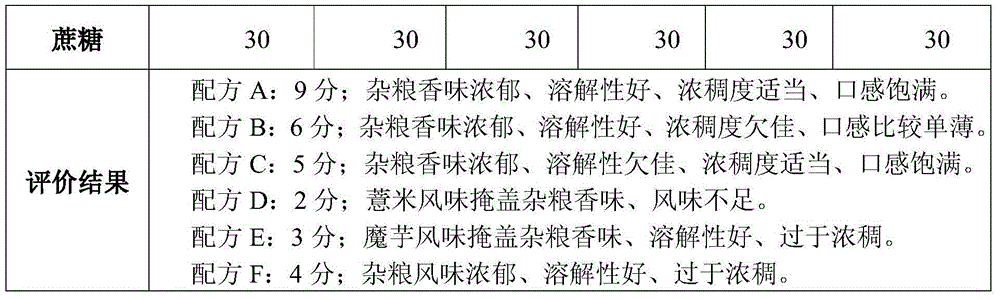

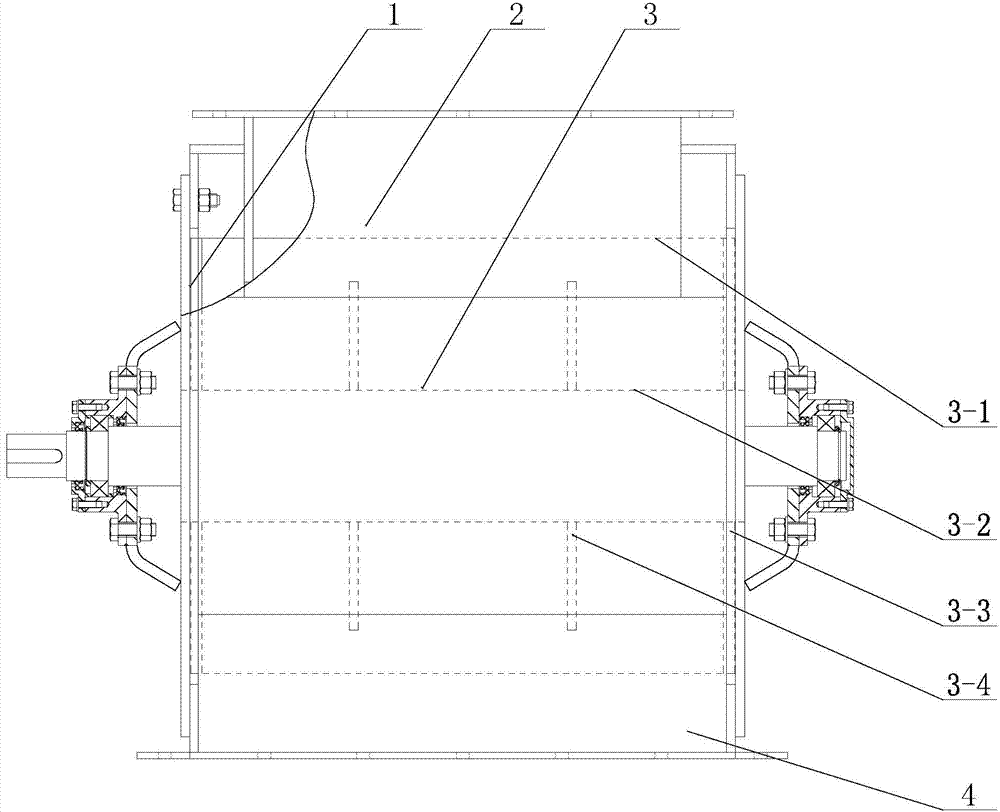

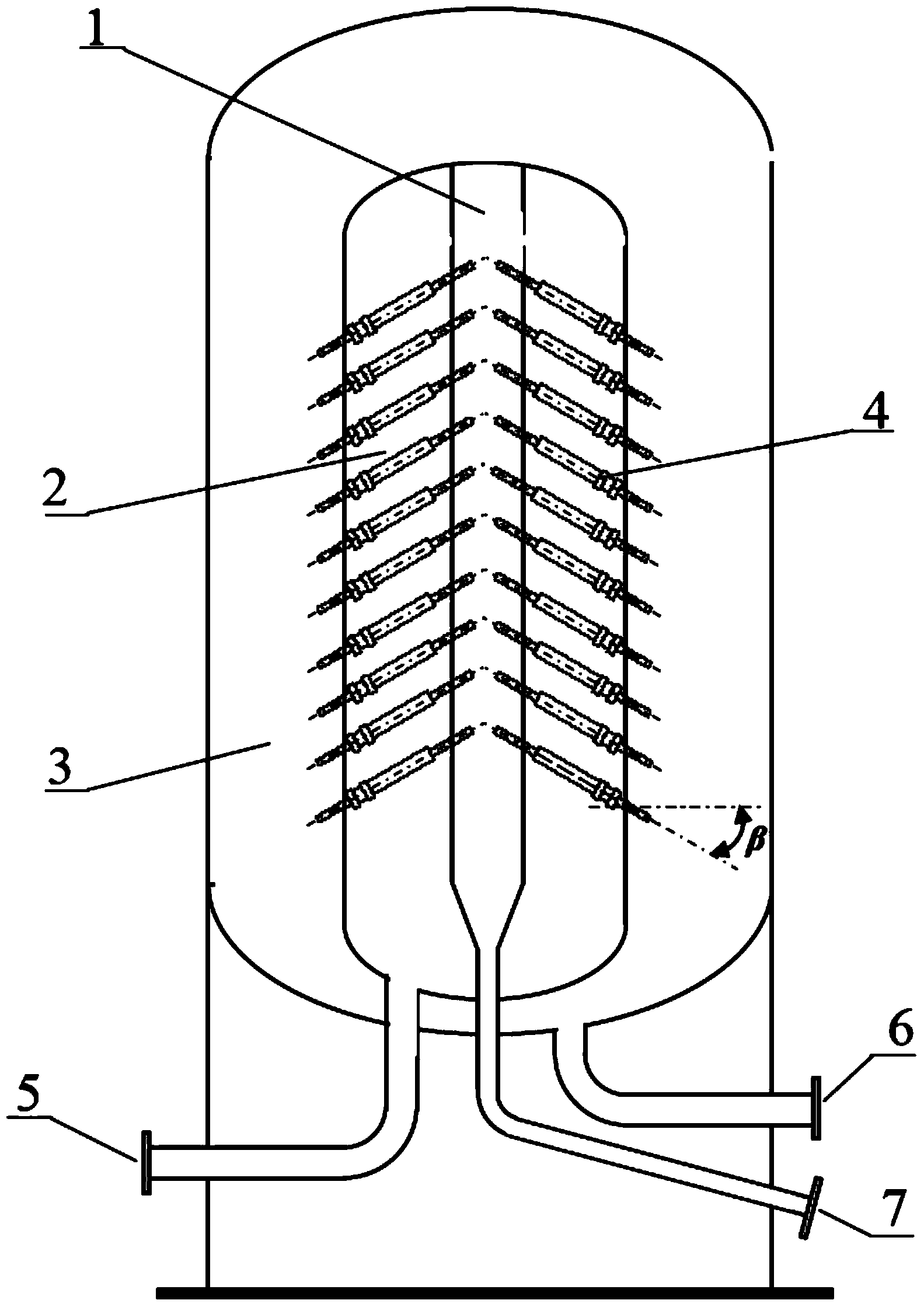

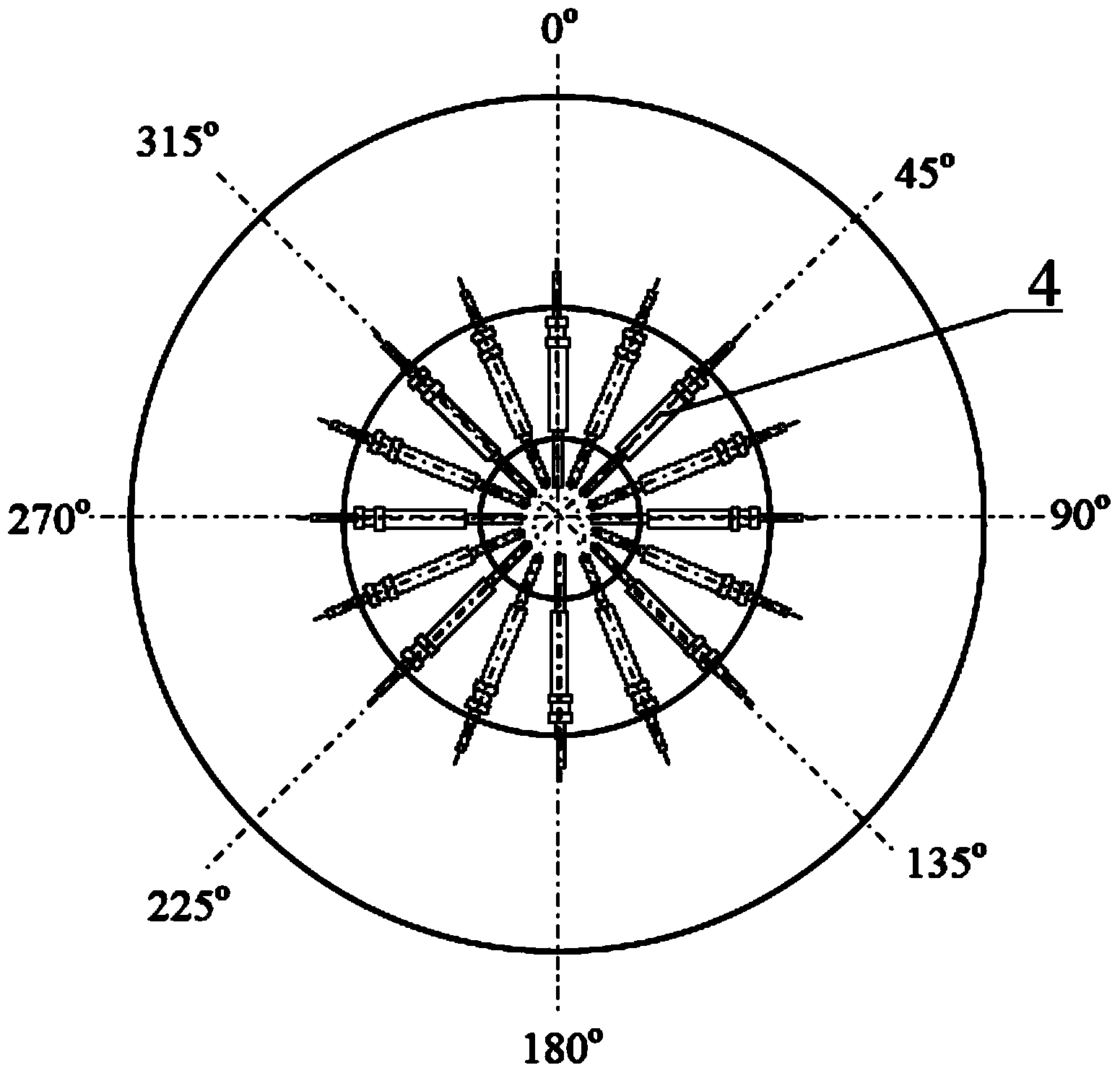

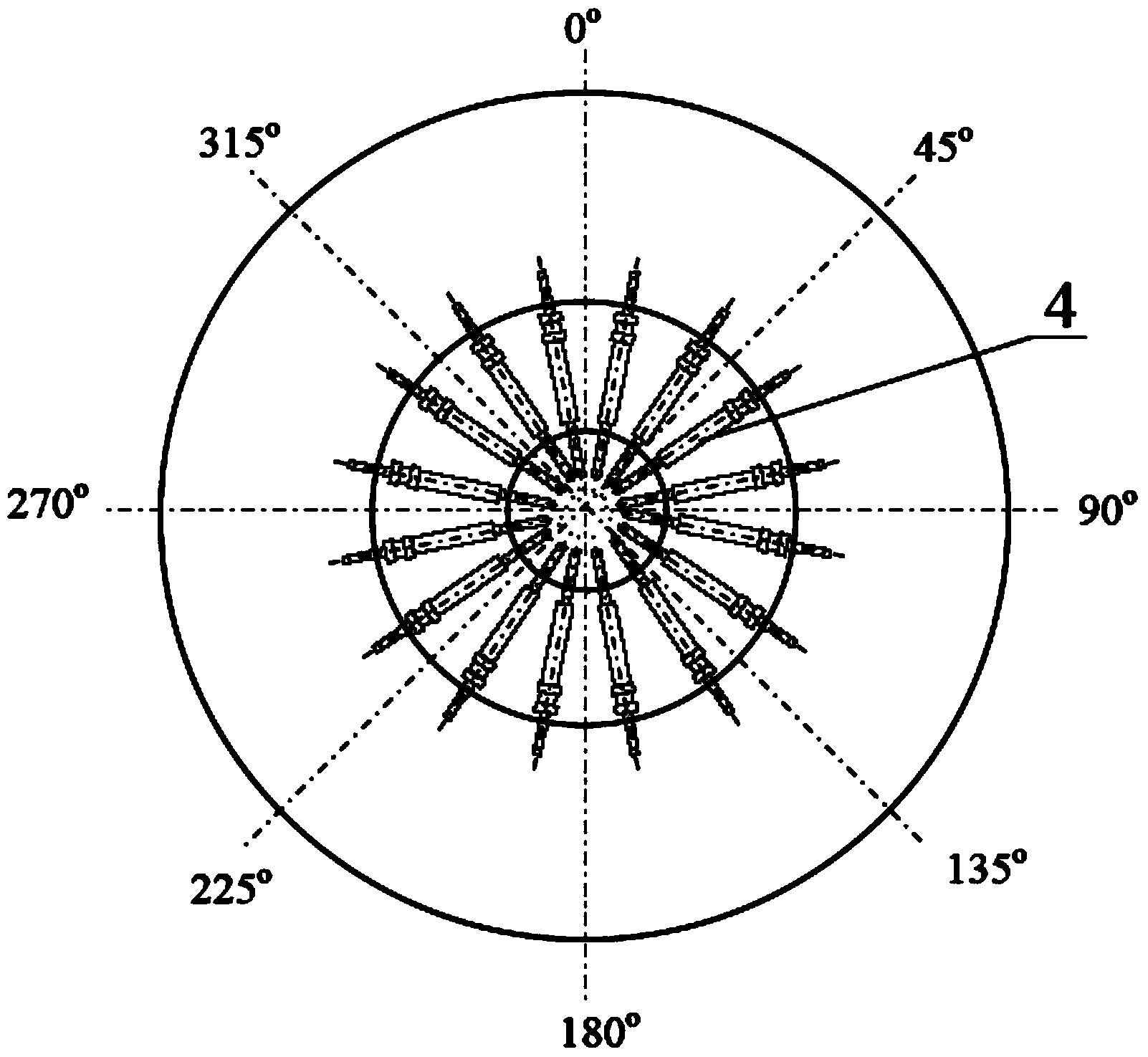

Inverted inclined installation method and device for long-period continuous stable operation of liquid-solid micro cyclone separator

ActiveCN103588260AReduce cloggingGreat operating flexibilityWater/sewage treatment by centrifugal separationCycloneProcess engineering

The invention relates to an inverted inclined installation method and device for long-period continuous stable operation of a liquid-solid micro cyclone separator, and provides the inverted inclined installation method for long-period continuous stable operation of the liquid-solid micro cyclone separator. The method comprises the following steps: liquid-solid micro cyclone core tubes (4) are mounted in a feeding cavity (2) of a three-layer pressure vessel in an inverted and inclined manner, wherein the bottom flow port of each liquid-solid micro cyclone core tube (4) is connected into the bottom flow cavity (1) of the vessel, and the overflow port of each liquid-solid micro cyclone core tube (4) is connected into the overflow cavity (3) of the vessel; the scale height of the bottom flow port of each liquid-solid micro cyclone core tube (4) is higher than the scale height of the overflow port; an sharp included angle beta of the axis of each liquid-solid micro cyclone core tube (4) and the horizontal plane is larger than an accumulation angle of repose of particle materials. The invention also provides the inverted inclined installation device for long-period stable operation of the liquid-solid micro cyclone separator.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

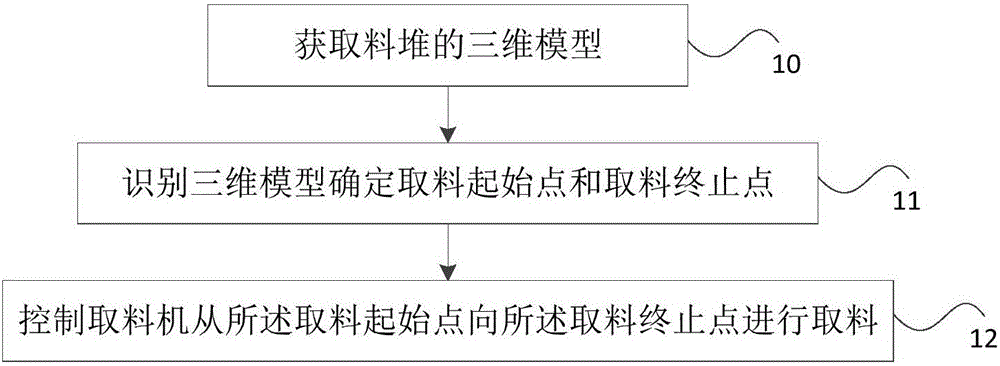

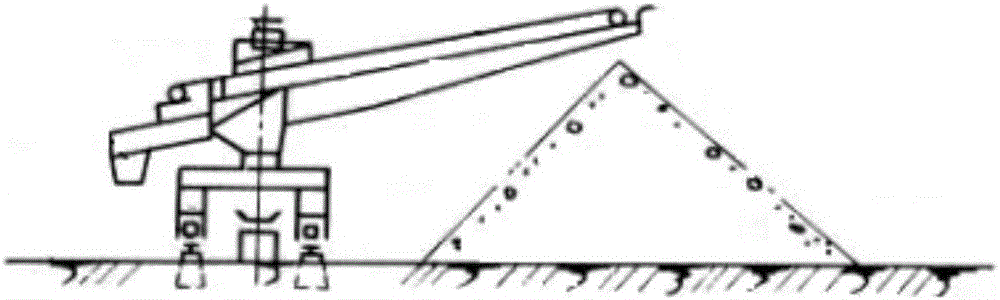

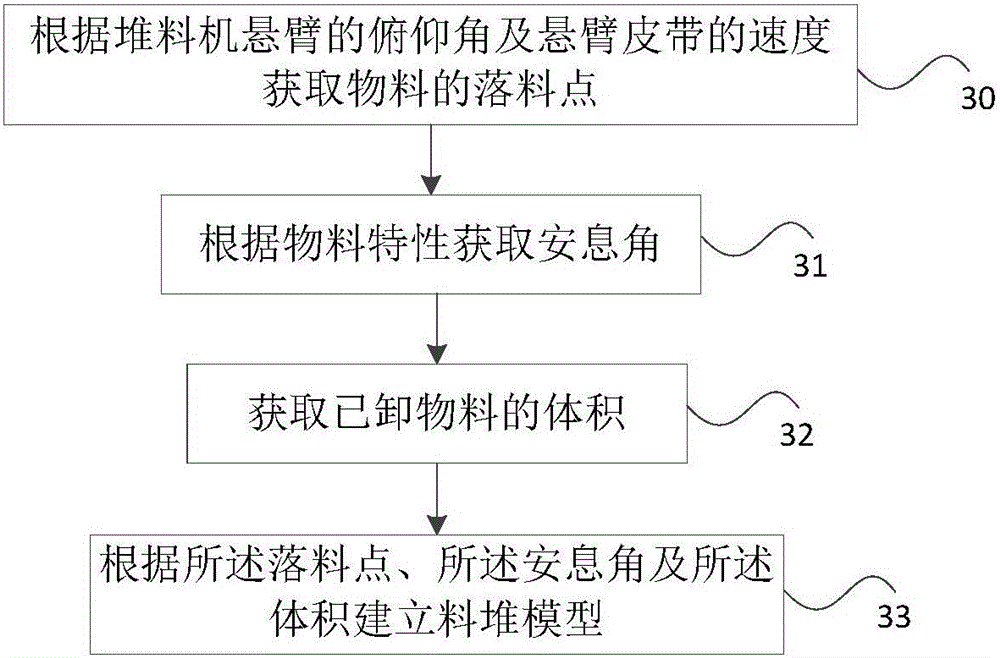

Material pile modeling method and device

ActiveCN106094702AAccurately establishedImprove efficiencyProgramme control in sequence/logic controllersEngineeringCantilever

The invention relates to the field of control engineering and discloses a material pile modeling method and device. The material pile modeling method comprises steps of: acquiring the discharged point of materials according to the angle of pitch of a stacker cantilever and the speed of a cantilever belt; acquiring an angle of repose according to a material characteristic; acquiring the volume of the discharged materials; and establishing a material pile model according to the angle of repose and the volume. The method and device may accurately establish the material pile model, increase efficiency for subsequent material-acquiring engineering, and enhance operating stability.

Owner:CHINA SHENHUA ENERGY CO LTD +1

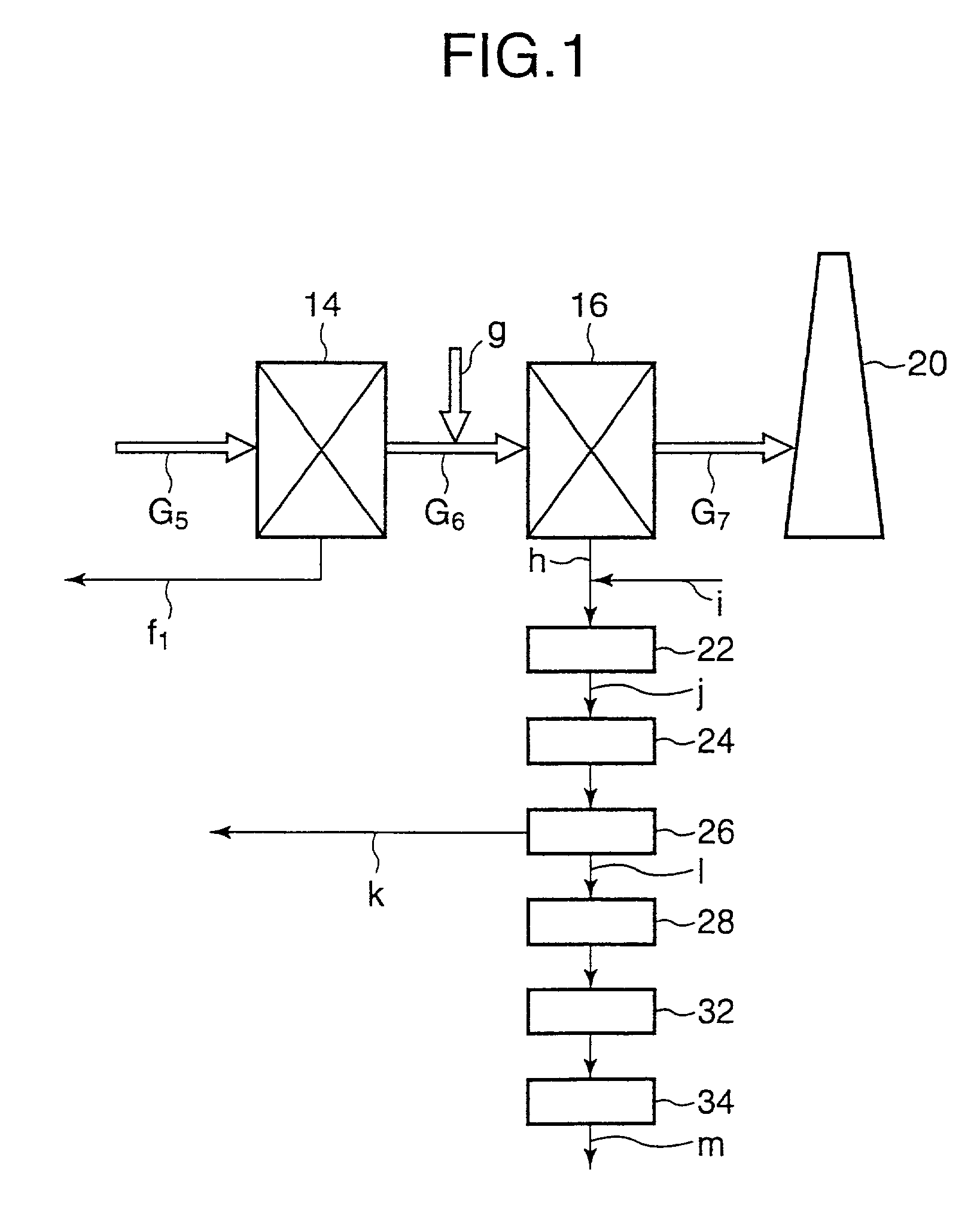

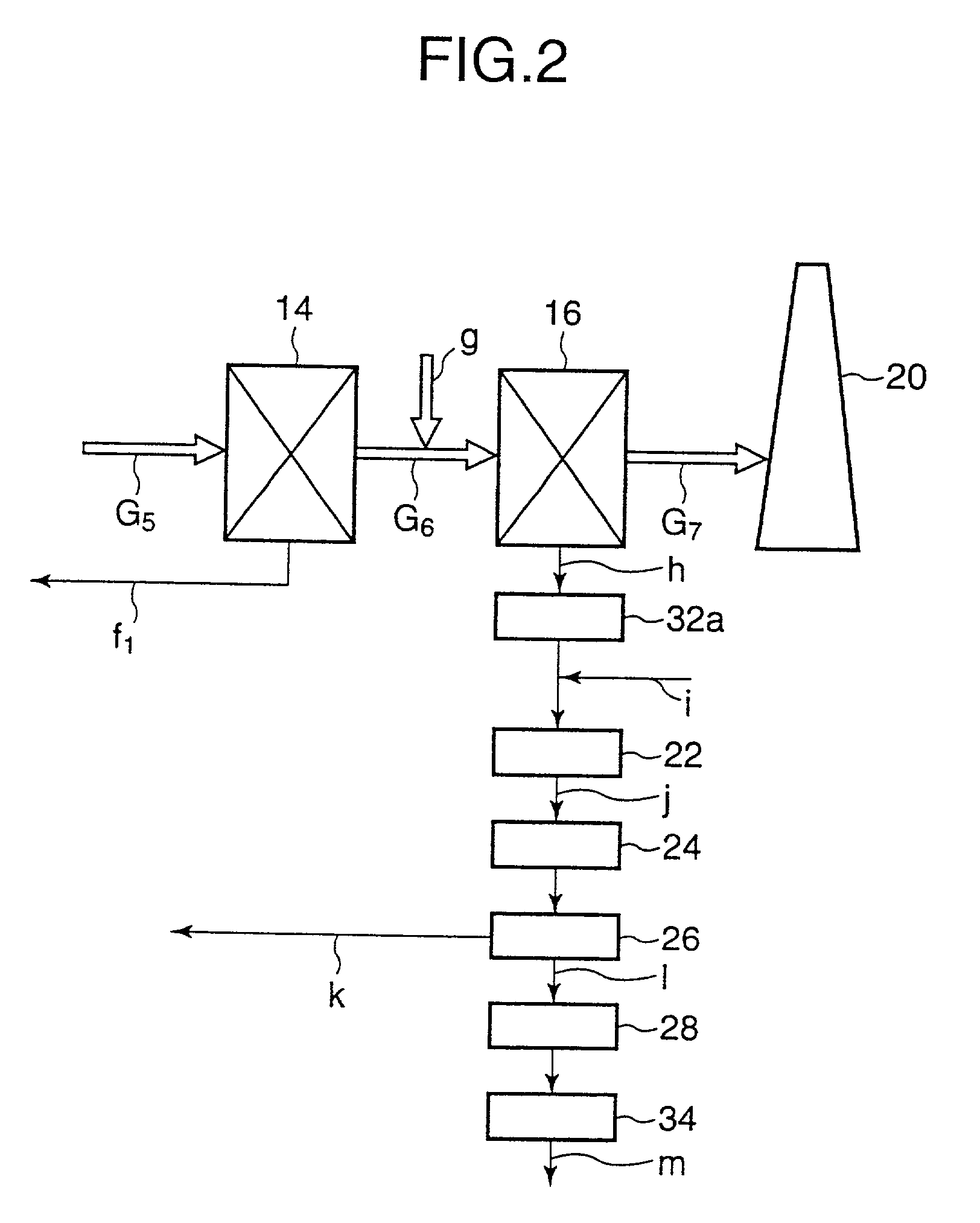

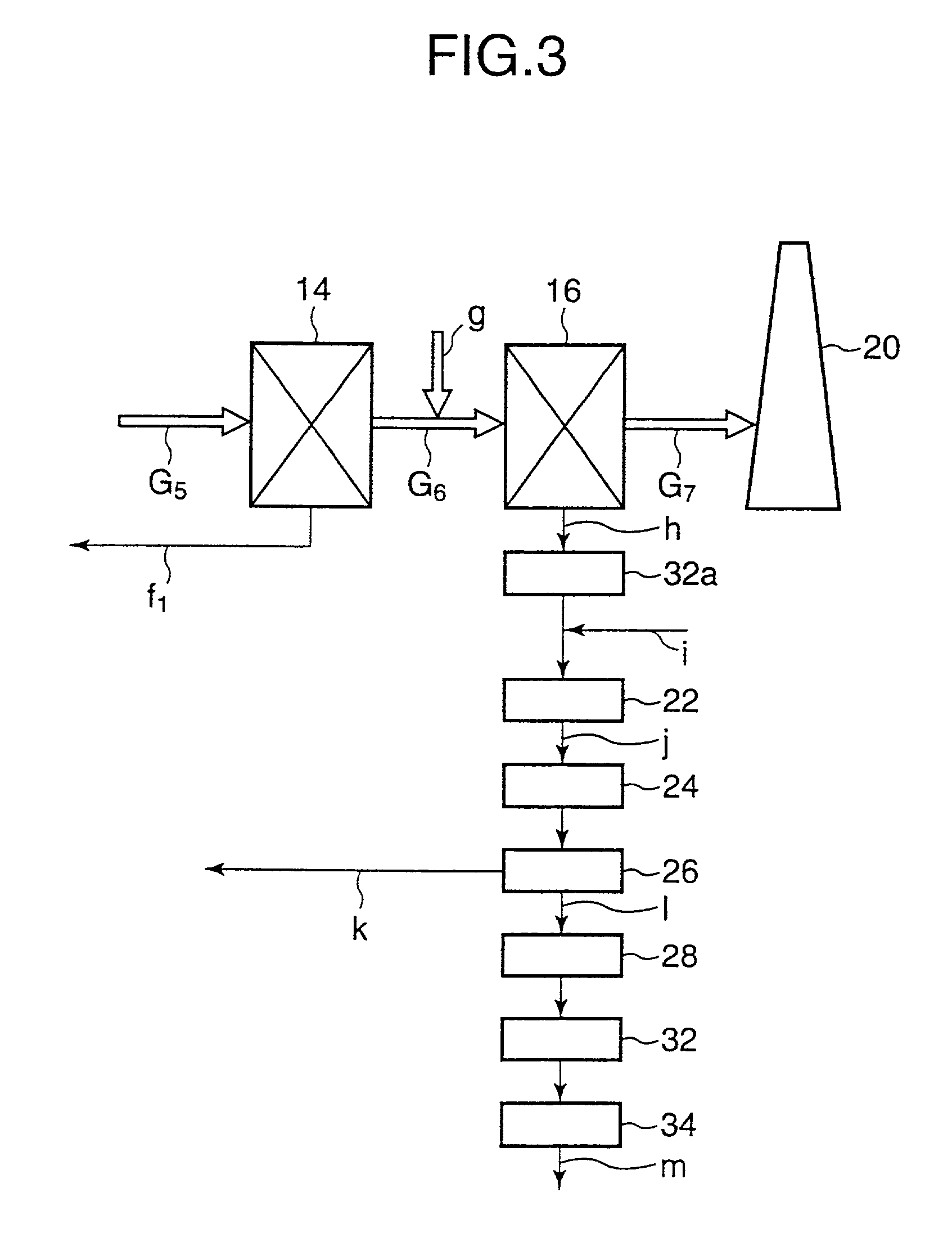

Sodium-based dechlorinating agent and waste treatment equipment

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

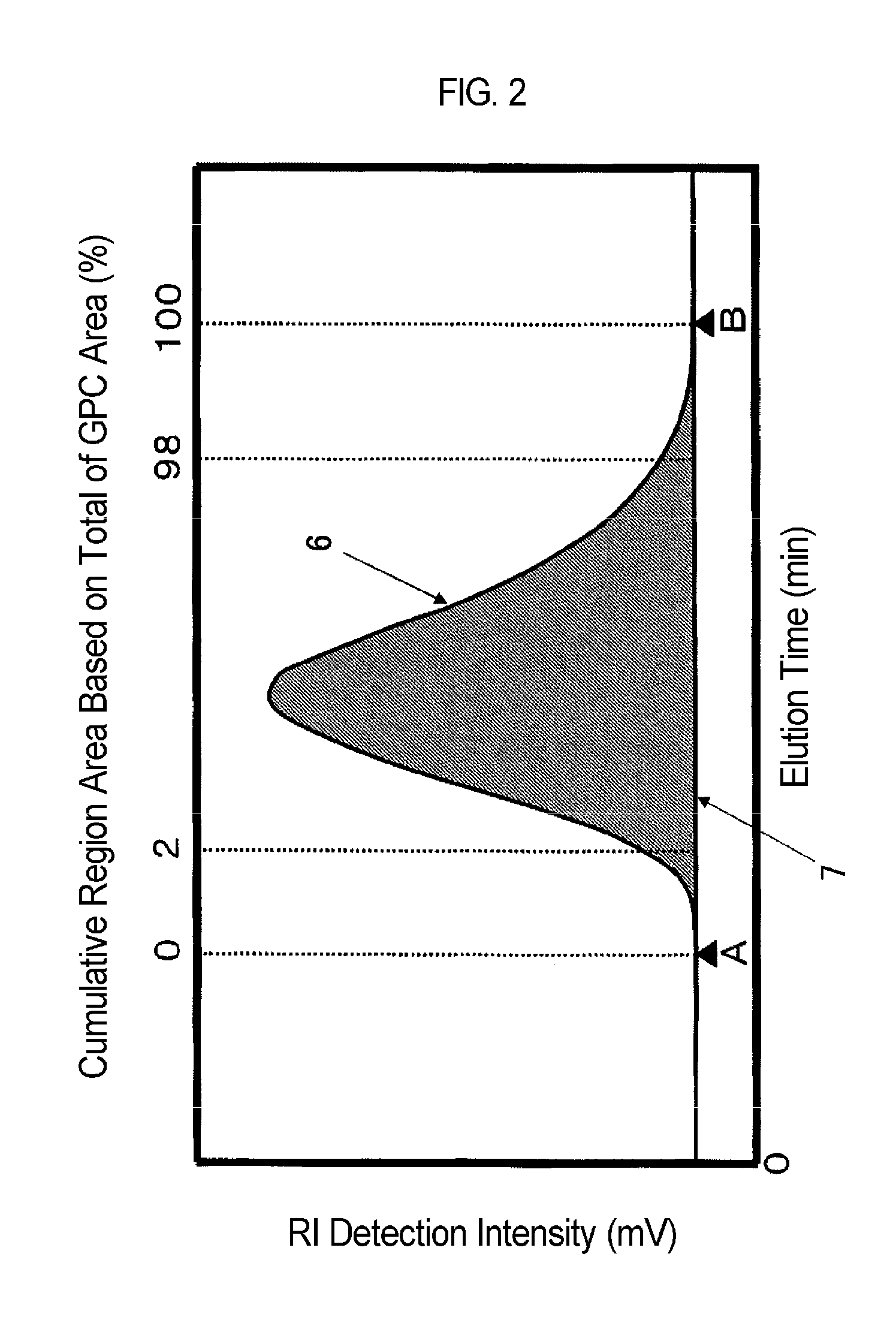

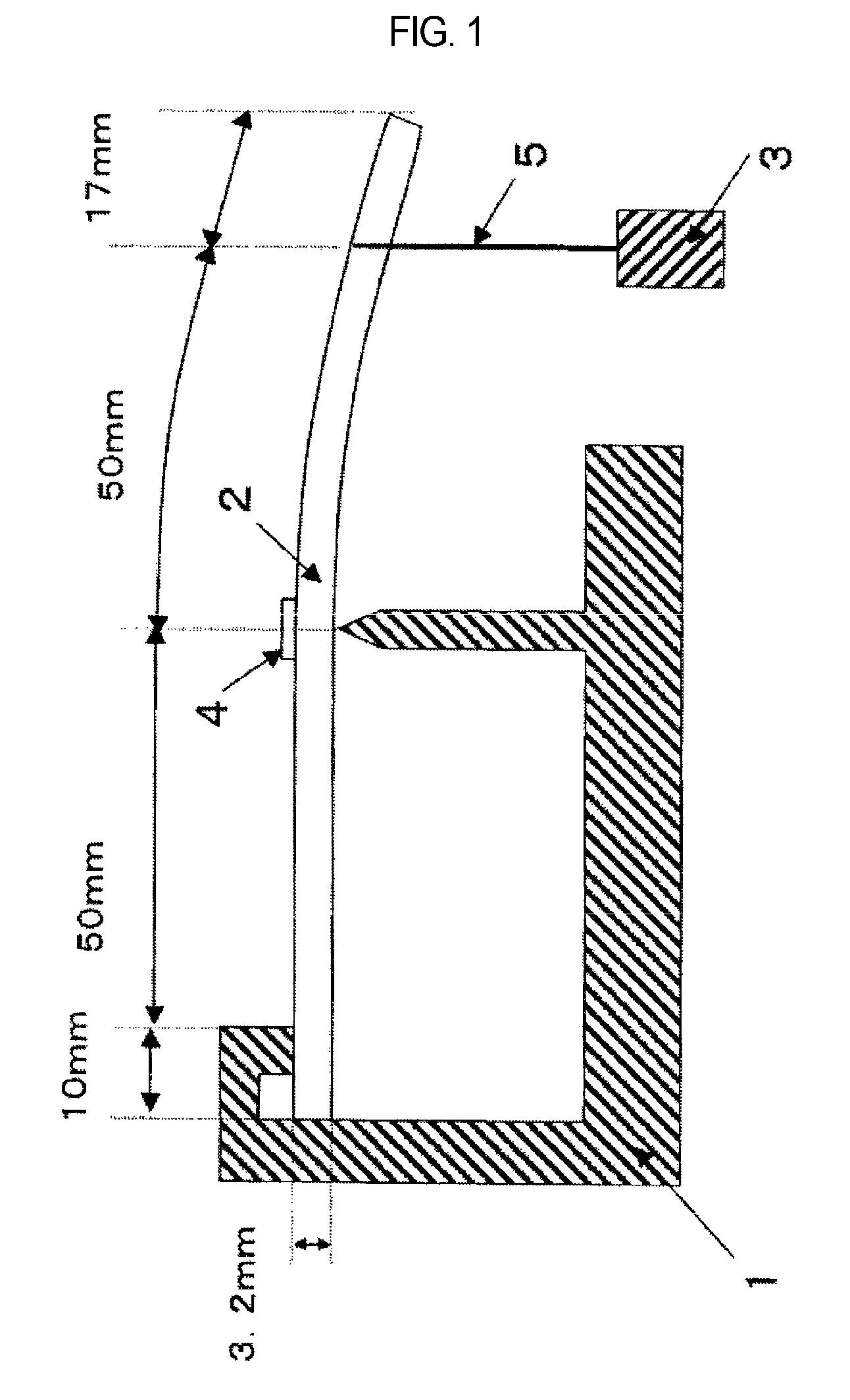

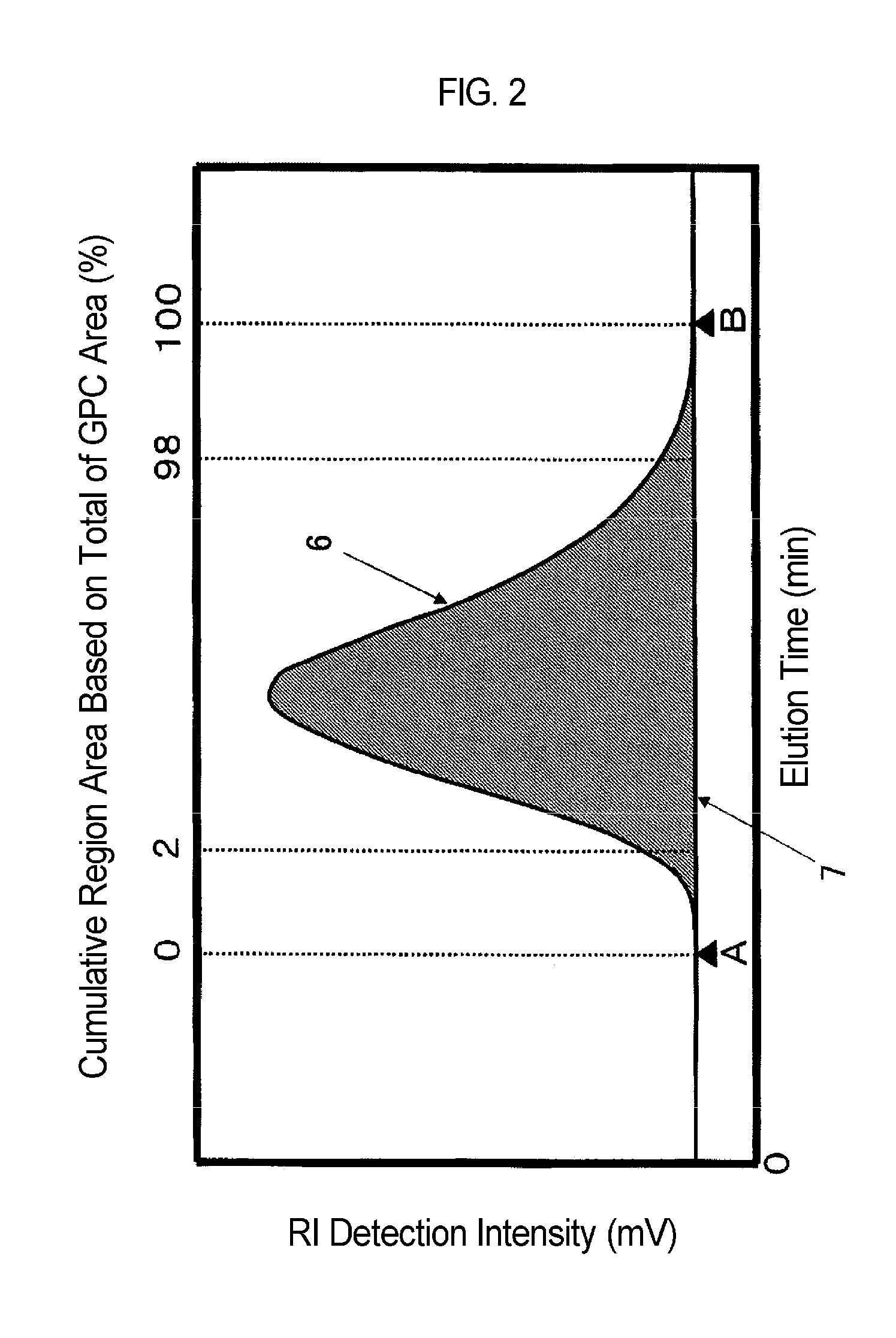

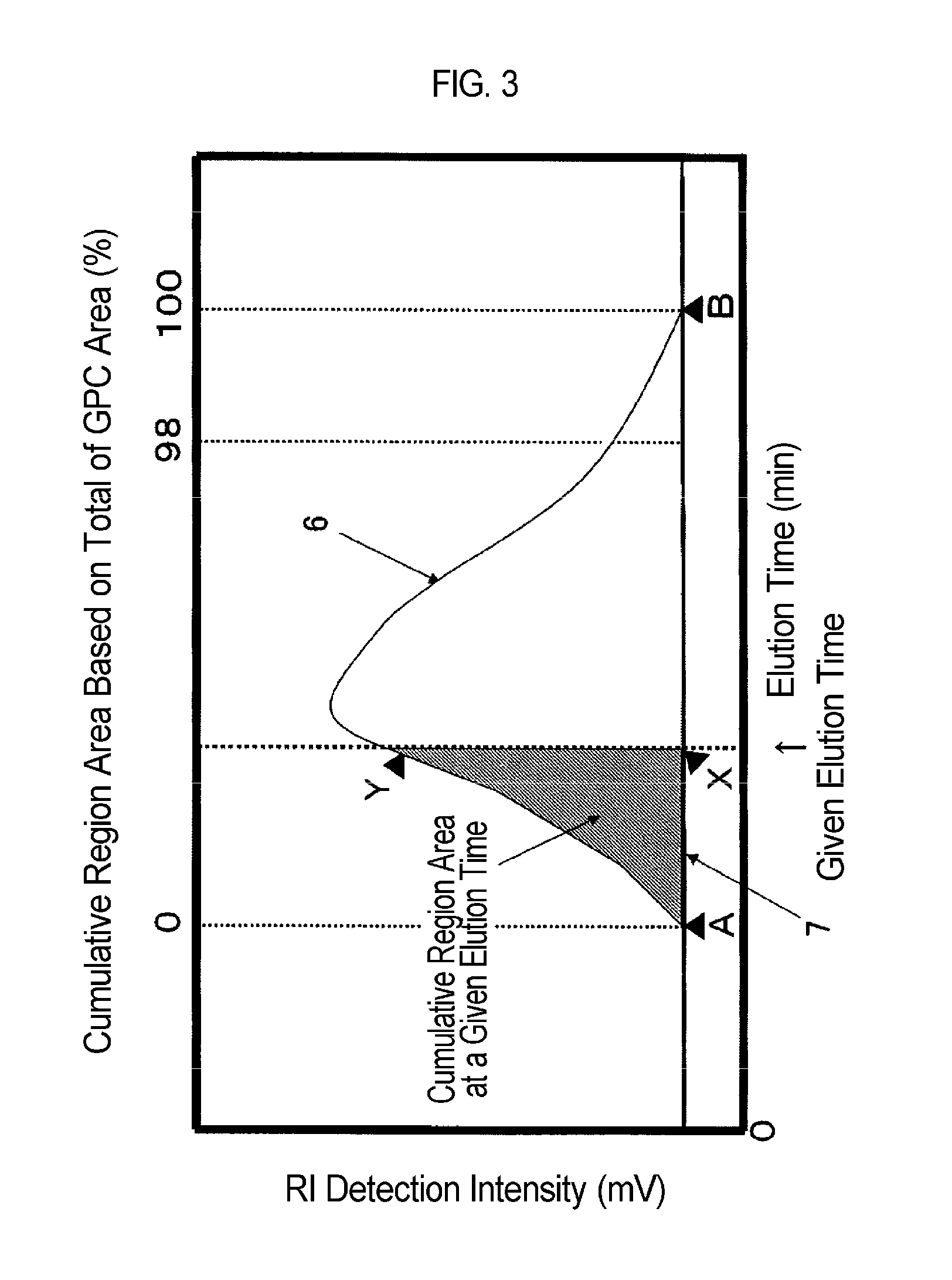

Methacrylic resin, molded article thereof, and method for producing methacrylic resin

ActiveUS20120196127A1Excellent colorless transparencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsMethacrylateElution

A methacrylic resin, including 80 to 99.5% by mass of a methacrylic acid ester monomer unit, and 0.5 to 20% by mass of other vinyl monomer unit which is copolymerizable with at least one of the methacrylic acid ester, wherein the methacrylic resin satisfies the following conditions (I) to (III):(I) having a weight average molecular weight measured by gel permeation chromatography (GPC) of 60,000 to 300,000;(II) having a content of a molecular weight component 1 / 5 or less the peak molecular weight (Mp) obtained from a GPC elution curve, said content being 7 to 40% based on a region area ratio obtained from the GPC elution curve; and(III) having an angle of repose of 20 to 40°.

Owner:ASAHI KASEI CHEM CORP

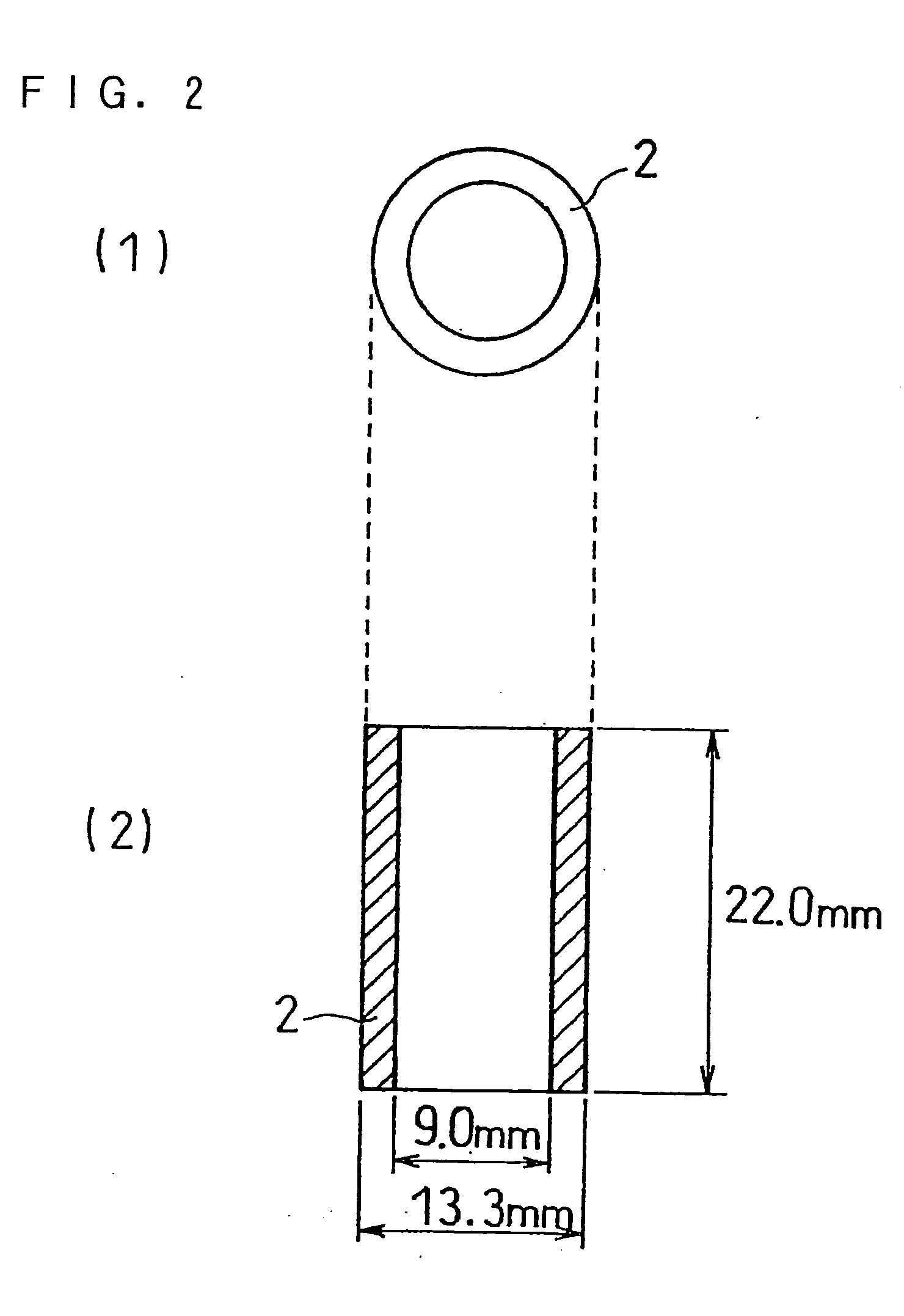

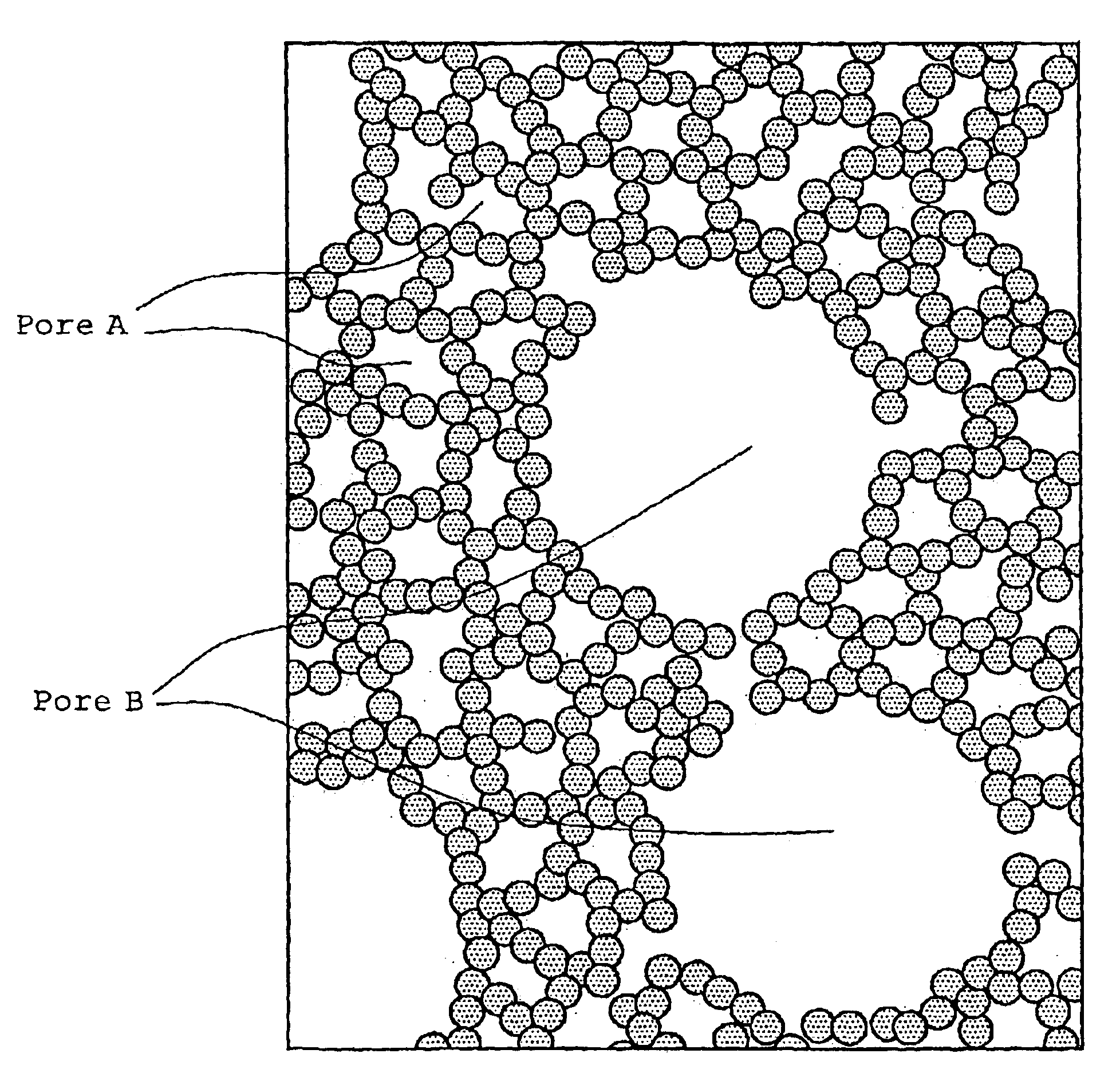

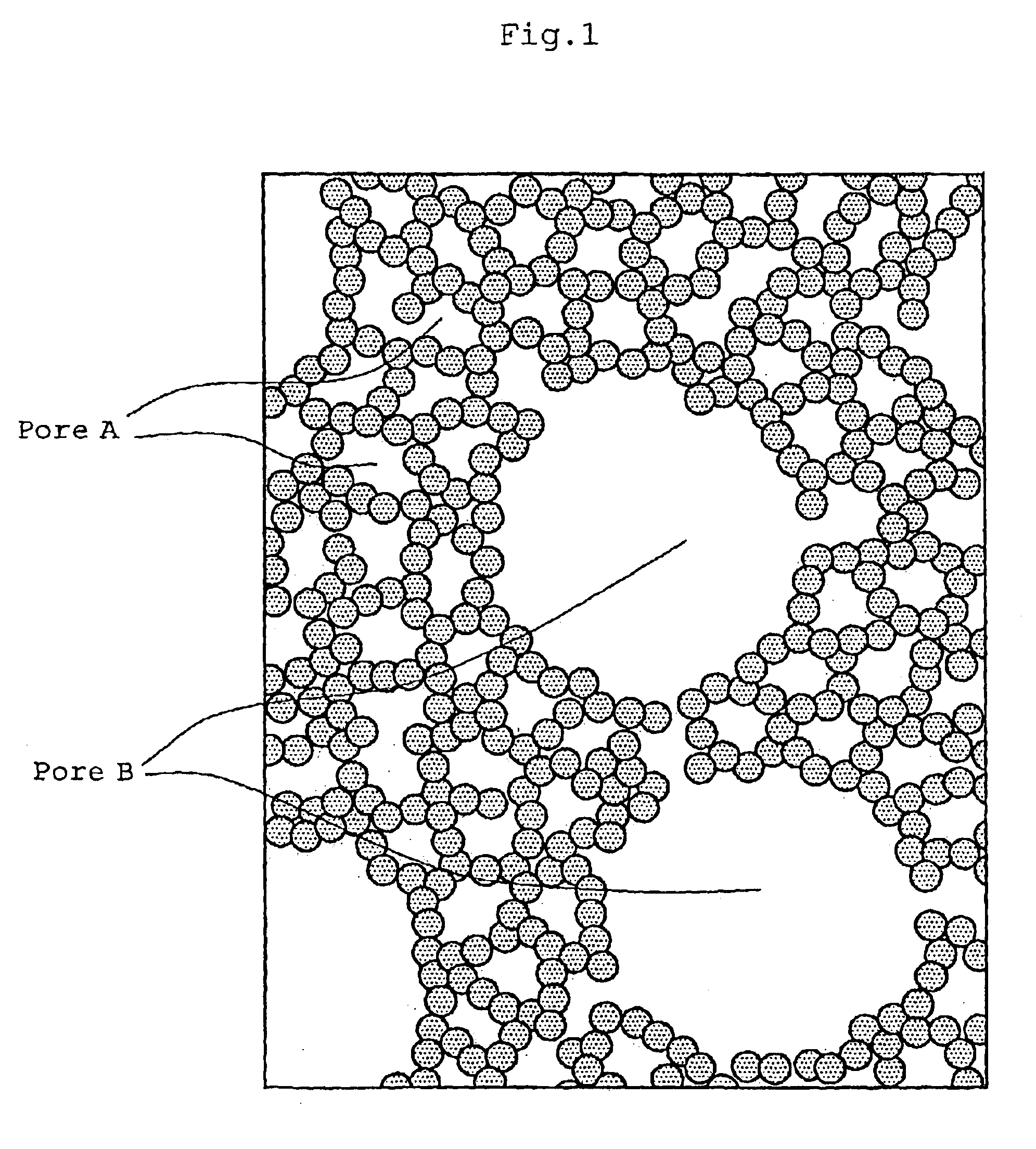

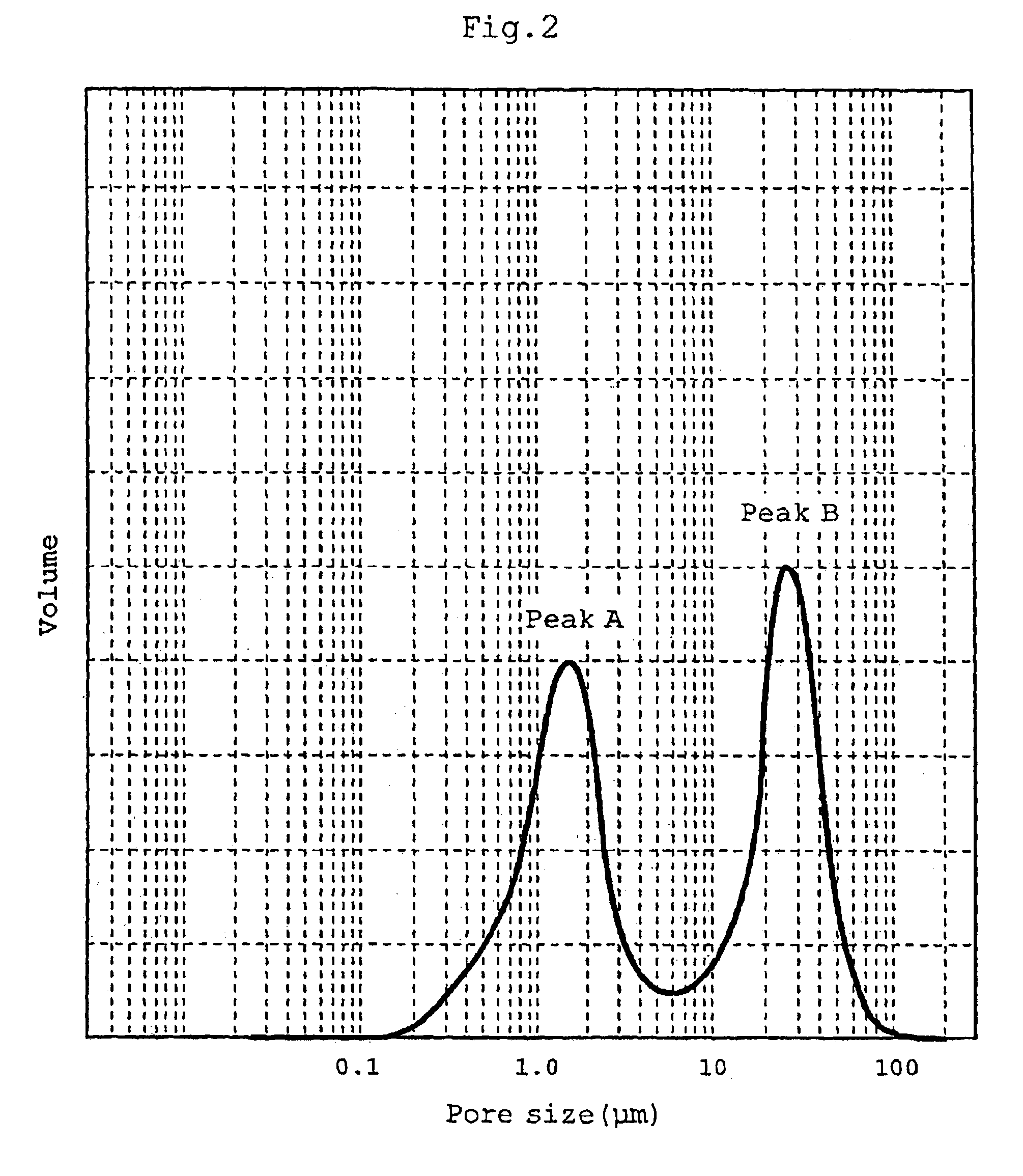

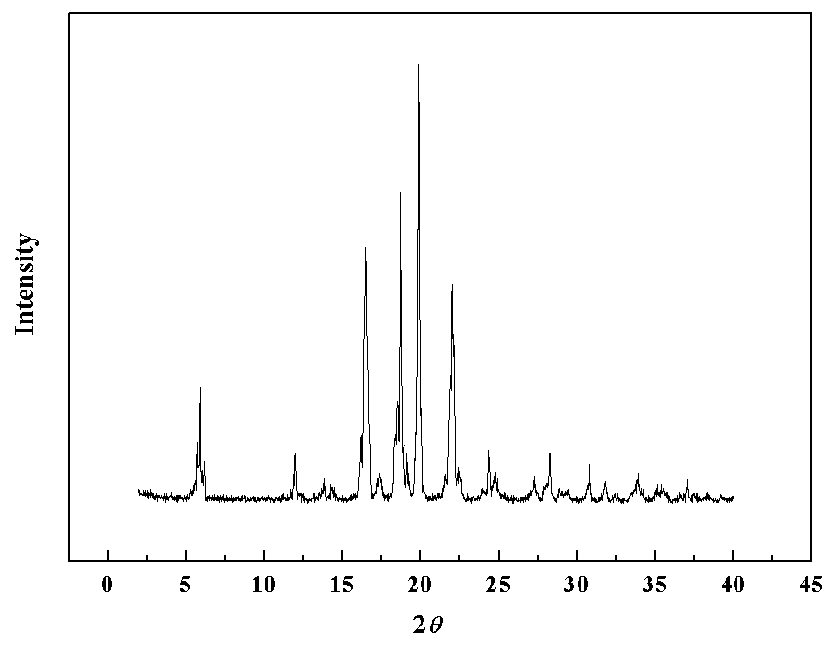

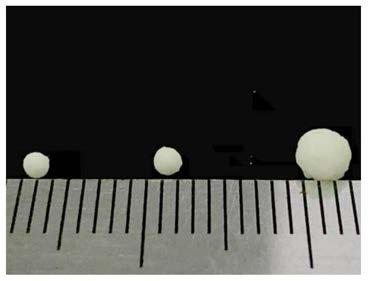

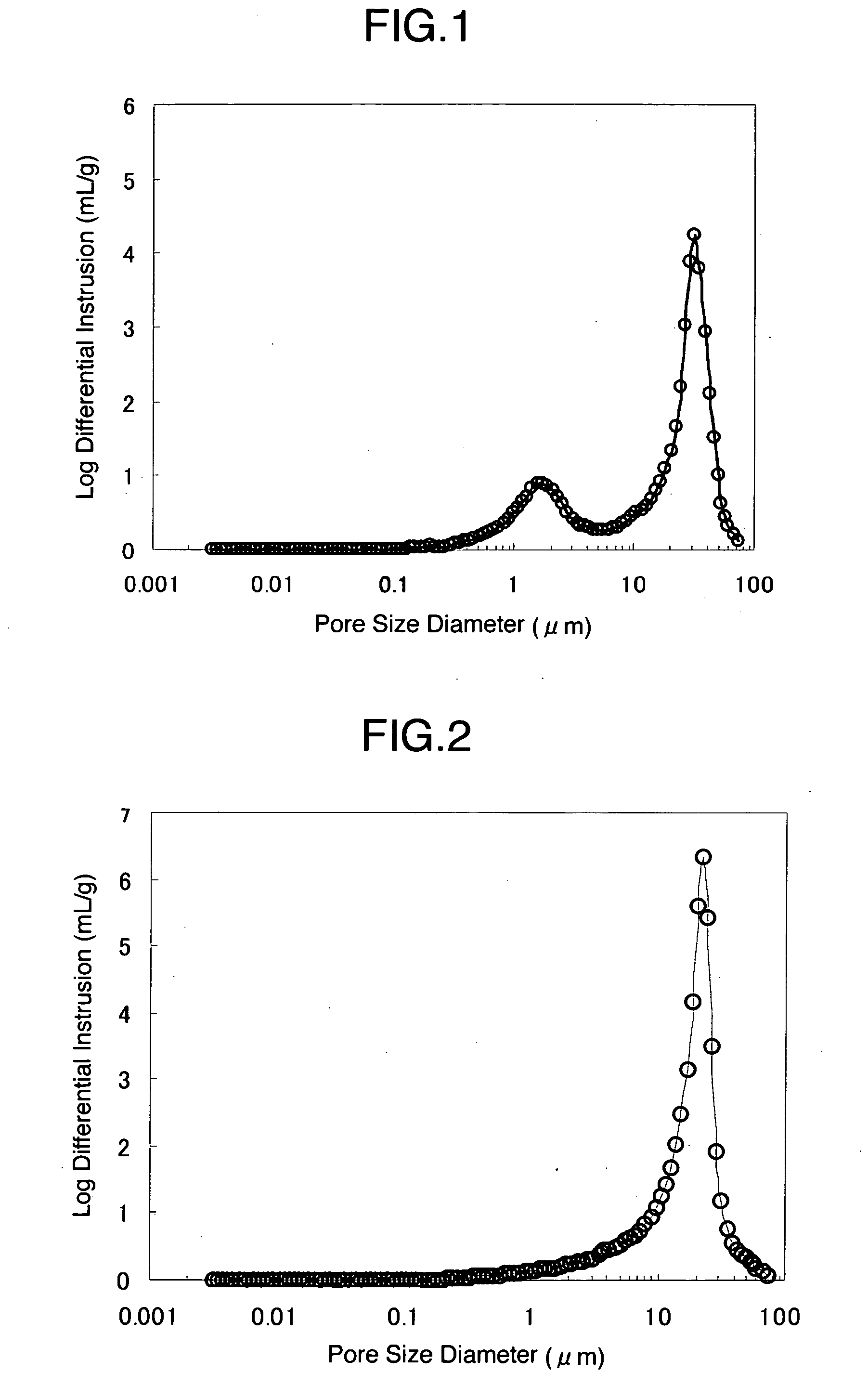

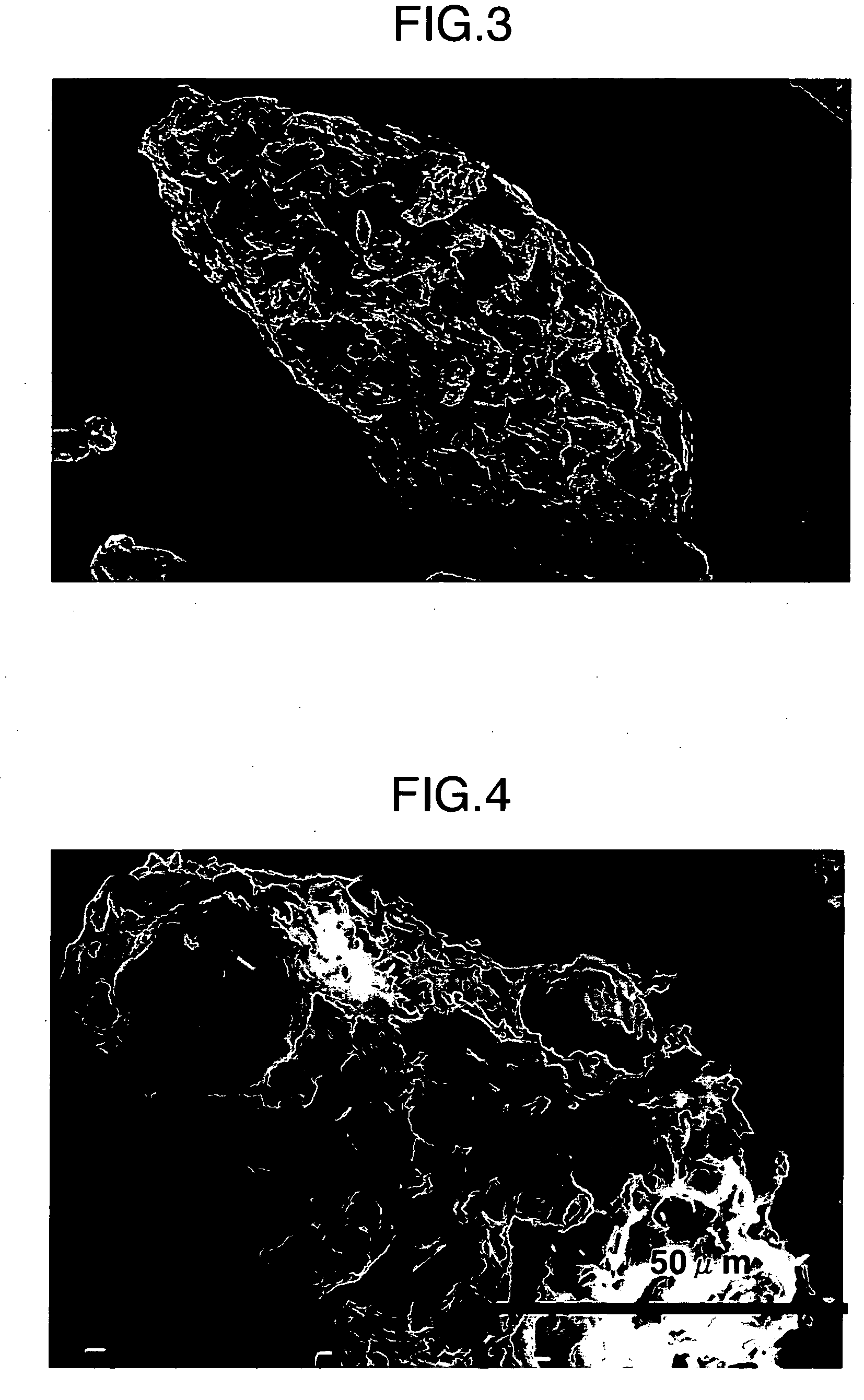

Niobium powder, niobium sintered body and capacitor using the sintered body

InactiveUS6934146B2Improve liquidityStable productionHybrid capacitor electrolytesLiquid electrolytic capacitorsPore distributionNiobium

Owner:SHOWA DENKO KK

Preparation method of ibuprofen spherical crystal

ActiveCN109956860ASimple processImprove efficiencyCarboxylic compound separation/purificationSolventSURFACTANT BLEND

The invention discloses a preparation method of ibuprofen spherical crystal, comprising the following steps: preparing an ibuprofen-water mixed solution with the ibuprofen concentration of 0.01-0.25 g / mL at 75-85 DEG C; continuously stirring until the solution is subjected to liquid-liquid phase separation; abruptly cooling the solution to 1-30 DEG C, and continuously stirring until crystal appears; adding 0.02-0.53 wt% of a surfactant (based on the mass of the ibuprofen-water mixed solution), keeping stirring for 0.5-5 h until crystal is aggregated into spheres; filtering, washing, and dryingto obtain the ibuprofen spherical crystal. The raw material of the crystallization process is single, the solvent only involves water which is green and environmentally-friendly, and the process is simple. The particle diameter of the spherical crystal product can be effectively adjusted by stirring speed, and the average particle size of the product is about 500-1000 microns. The crystal particle is rounded and has high fluidity. The angle of repose is 29-31 degrees, and the tap density is 0.47-0.55 g / cm<3>.

Owner:TIANJIN UNIV

Apparatus and methods for treating solids by electromagnetic radiation

InactiveUS20140352206A1Efficient combustionDegradation of combustionBiofuelsSolid fuelsEngineeringElectromagnetic radiation

Embodiments of the present invention are directed to methods and apparatus for subjecting coarsely divided solid material, such as solid fossil fuels, to microwave radiation using gravity feed through a chamber and protecting irradiating windows by placement outside the angle of repose.

Owner:MICROCOAL INC

Porous cellulose aggregate and formed product composition comprising the same

ActiveUS20070190017A1Excellent in compactibilityExcellent in flowabilityPill deliveryDeodrantsCelluloseMaterials science

A porous cellulose aggregate which has a secondary aggregation structure formed by the aggregation of primary cellulose particles, has a pore volume within a particle of 0.265 cm3 / g to 2.625 cm3 / g, contains I type crystals, has an average particle diameter of more than 30 μm and 250 μm or less, has a specific surface area of 1.3 to 20 cm2 / g, has an angle of repose of 25° or more and less than 44°, and has the property that it collapses in water.

Owner:ASAHI KASEI CHEM CORP

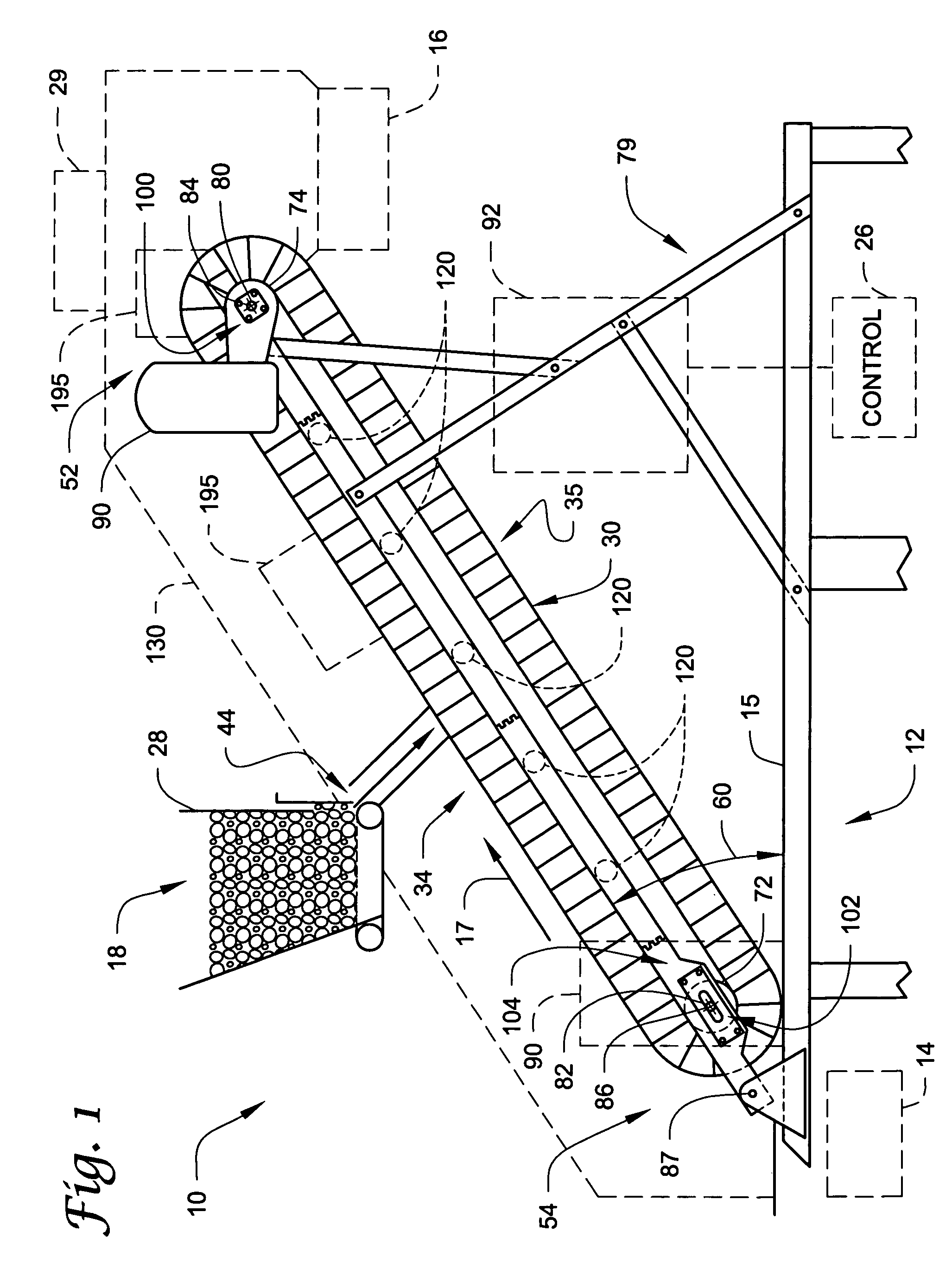

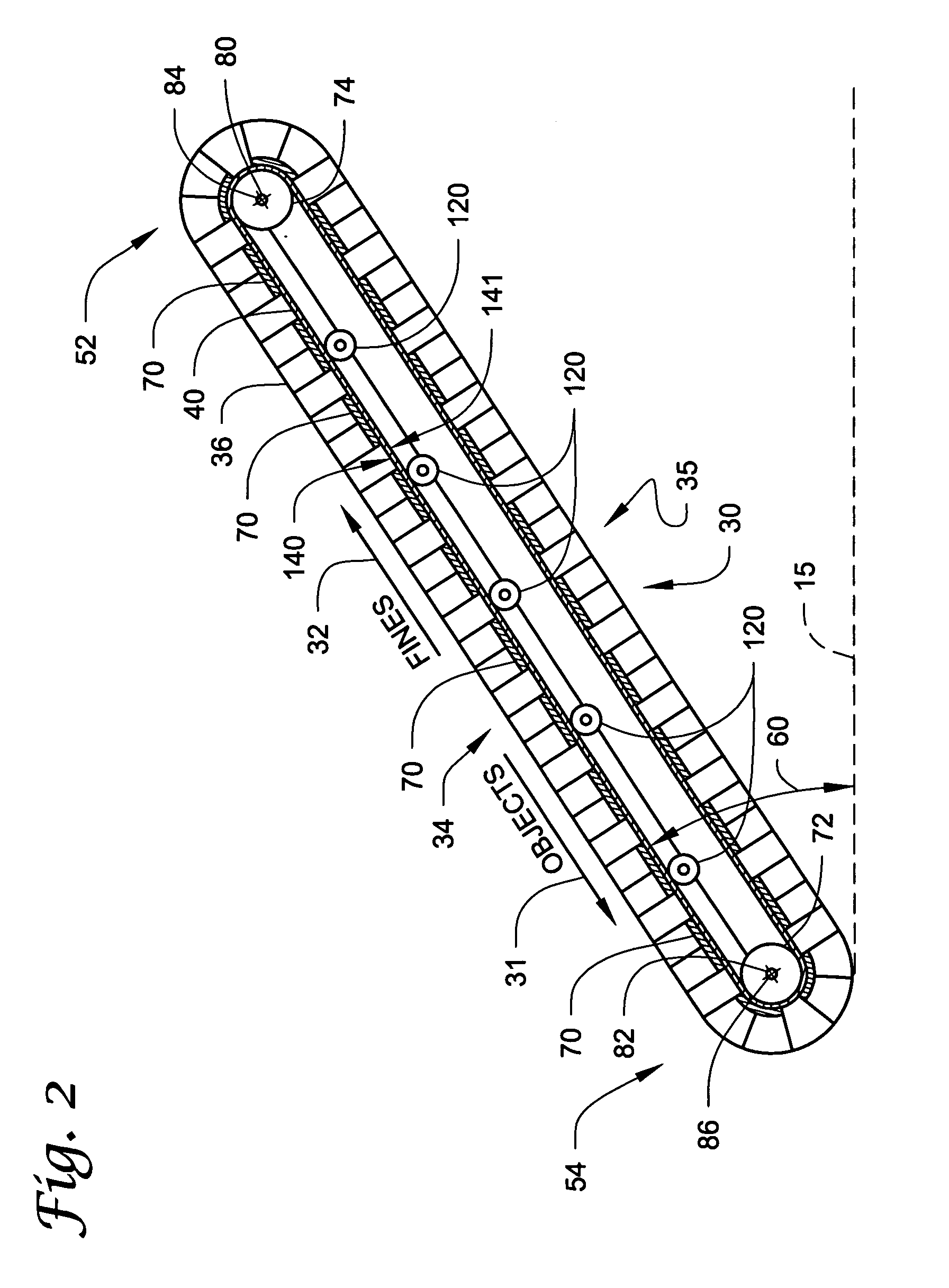

Fines removal apparatus and methods/systems regarding same

Apparatus, methods and systems are used to separate fines from objects of a feed mixture being processed (e.g., iron bearing pellets, chips and dust). For example, at least a portion of an endless belt defining a channel is movable up an incline relative to horizontal (e.g., an incline that is at an angle relative to horizontal that is greater than an angle of repose associated with the objects, but less than an angle of repose associated with the fines being removed). Further, obstruction elements may be used on the endless belt to impede the flow of the fines down the incline.

Owner:RGT UNIV OF MINNESOTA

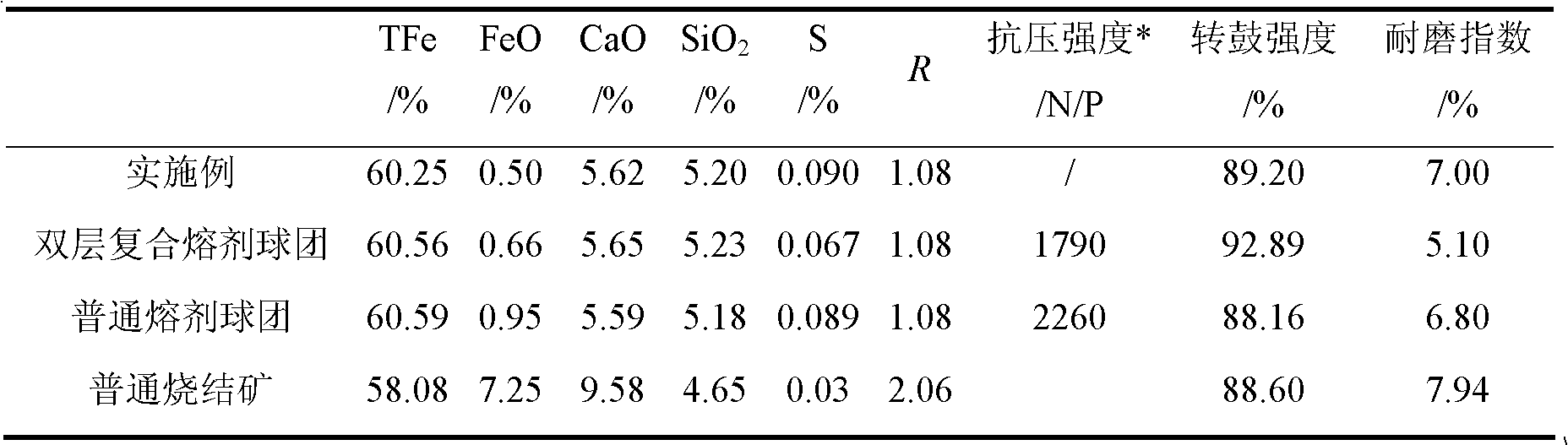

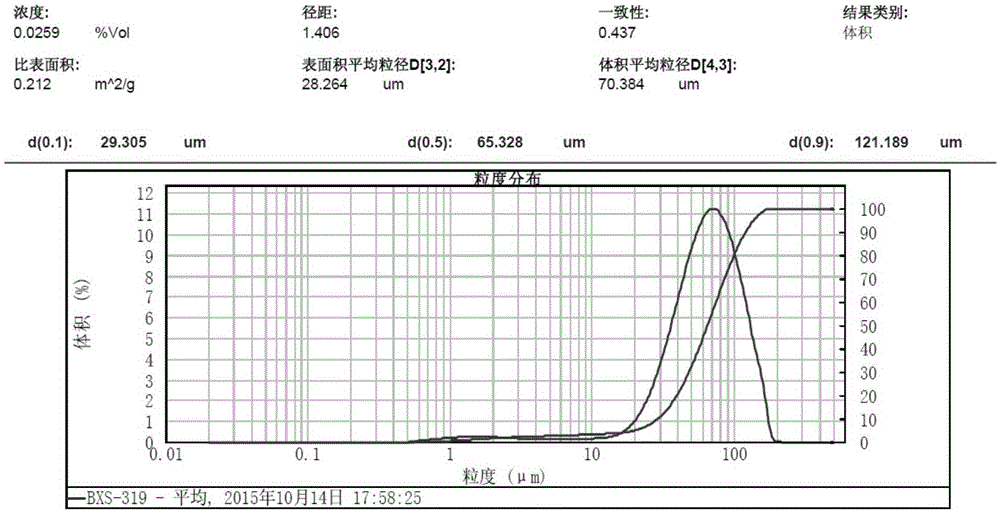

Method for manufacturing crushing pellet sinter

The invention provides a method for manufacturing crushing pellet sinter. The method comprises the following steps: 1) using a secondary pelletizing method: first adding mixed raw materials with alkalinity value of 2-2.2 into a balling machine to make cue balls, and when the diameter of the cue ball reaches 25-30 mm, rolling a prepared raw material with alkali value of 0.8-0.9, so that the finished green-ball has a diameter of 35-40 mm; 2) roasting the finished double-layer green-ball according to a conventional roasting pelletizing process; and 3) crushing the roasted pellets by a crusher, and sieving out a crushing pellet sinter product with particle level higher than 5 mm. The invention has simple production process and reasonable product structure, effectively solves the problem of an ordinary fluxed pellet, such as strict requirements on roasting temperature range and easy adhesion during roasting; and the crushing pellet sinter combines advantages of both pellets and sinter, eliminates phenomenon of abnormal expansion or reduction hysteresis in the reduction of the pellet, and gains increased angle of repose and hardly rolls after crushing, so as to facilitate material distribution of blast furnace.

Owner:ANGANG STEEL CO LTD

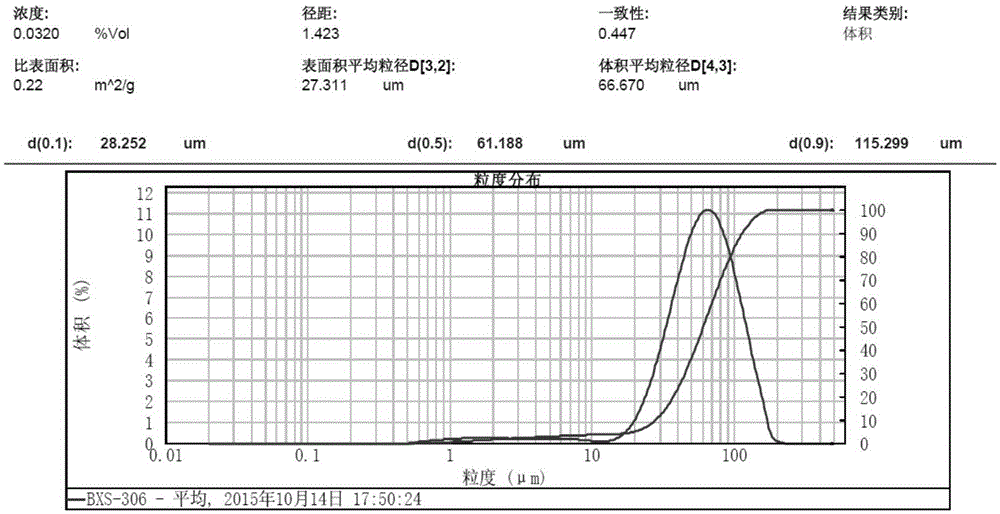

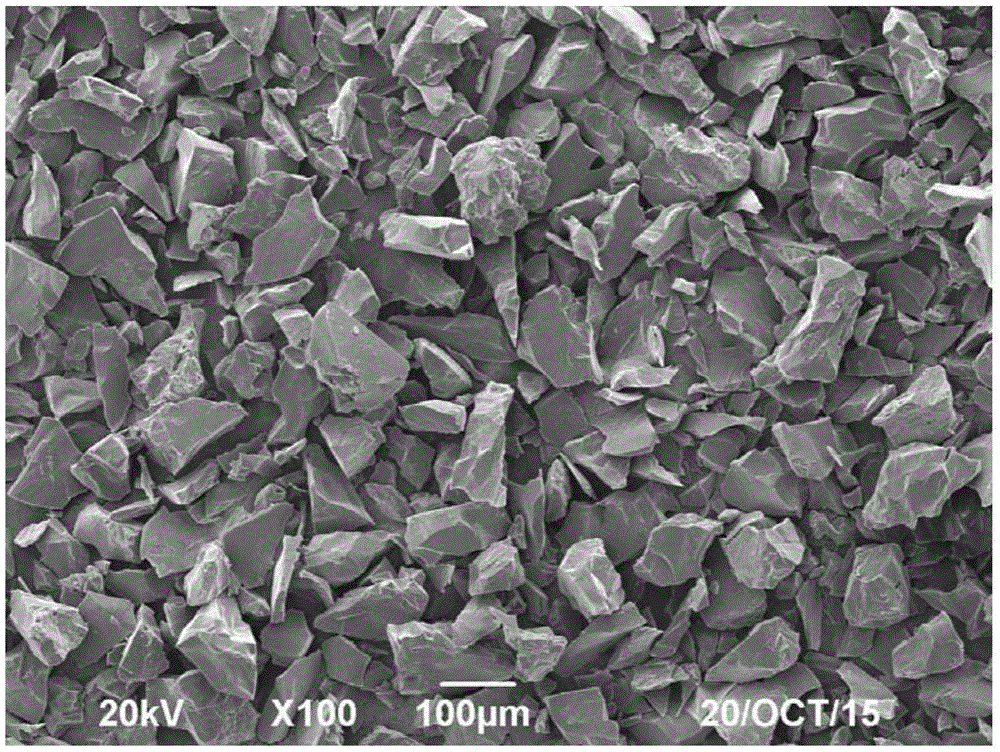

Preparation method of quartz powder used for producing glass

The invention provides a preparation method of quartz powder used for producing glass. The preparation method comprises the steps of selecting quartz ores with silicon dioxide grade not less than 95% and average diameter of 2-5mm after grinding, firstly carrying out color sorting and impurity removal and then carrying out preliminary ball milling, shaping ball milling, flotation impurity removal, optional acid leaching impurity removal and surface modification successively, thus obtaining the quartz powder, wherein in the step of preliminary ball milling, balls with diameters of 15-45mm are adopted to carry out ball milling on the ores, and the balls used for preliminary ball milling are more than two kinds of balls with different diameters; in the step of shaping ball milling, balls with uniform diameters are adopted and the diameters of the balls are between 8mm and 20mm; a grinding aid containing alcoholic hydroxyl is also added in the step of shaping ball milling; and in the step of surface modification, the dried quartz powder is mixed with aerosil with grain size of 800-2000 meshes. The invention also provides a quartz powder preparation method with the characteristics that iron tailings are used instead of the quartz ores, and a magnetic separation process is added. The obtained quartz powder has high bulk density and low angle of repose under the condition that both the grade and chemical elements reach the standards.

Owner:湖南鑫生矿冶废弃物综合利用科技有限公司

Methacrylic resin, molded article thereof, and method for producing methacrylic resin

ActiveUS8617708B2Excellent colorless transparencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsMethacrylateElution

A methacrylic resin, including 80 to 99.5% by mass of a methacrylic acid ester monomer unit, and 0.5 to 20% by mass of other vinyl monomer unit which is copolymerizable with at least one of the methacrylic acid ester, wherein the methacrylic resin satisfies the following conditions (I) to (III):(I) having a weight average molecular weight measured by gel permeation chromatography (GPC) of 60,000 to 300,000;(II) having a content of a molecular weight component 1 / 5 or less the peak molecular weight (Mp) obtained from a GPC elution curve, said content being 7 to 40% based on a region area ratio obtained from the GPC elution curve; and(III) having an angle of repose of 20 to 40°.

Owner:ASAHI KASEI CHEM CORP

Titanium-based powder, and ingot and sintered article thereof

ActiveUS20180021854A1Good fluidityGood shape retention propertyAdditive manufacturing apparatusTransportation and packagingMetallurgyTitanium

Provided are a titanium-based powder excellent in fluidity and shape retention property, and an ingot and a sintered article obtained using the titanium-based powder as a material. The titanium-based powder has an average circularity of 0.815 or more and less than 0.870, a CV value of particle sizes of 22 or more and 30 or less, and an angle of repose of 29 degrees or more and 36 degrees or less.

Owner:TOHO TITANIUM CO LTD

Apparatus and method for high speed dewatering of slurries

InactiveCN1440369AWater treatment parameter controlSludge treatment by de-watering/drying/thickeningPulp and paper industrySlurry

A system and method for dewatering a continuous stream of slurry at high flow rates demonstrates enhanced efficiency, economy and ease of operation. A stream of slurry is subject to continuous or continual measurement of flow rate and pulp density and the measurements are used to control the rate of addition of a flocculating agent to the slurry. The flocculated slurry is delivered to a dewatering unit where it is passed through a diffuser and evenly delivered to a tracking screen for filtering solids from a liquid filtrate. The pulp density of the filtrate may also be measured and used to control addition of a flocculating agent. The tracking screen is adjusted to achieve an angle of repose suited to the particular composition of the filter cake. The diffuser has a base having a horizontal section aspect ratio of from about 1:1 to about 4:1 and continuously changing vertically into an upper portion having a horizontal section with an aspect ratio of from about 40:1 to about 100:1. The ratio of the horizontal sectional areas at the upper portion with respect to the base is from about 1:1 to about 3:1. The dewatering unit of the invention may be adjustably mounted on a transport means for deployment of the high speed dewatering system and method at any convenient location.

Owner:GENESIS FLUID SOLUTIONS

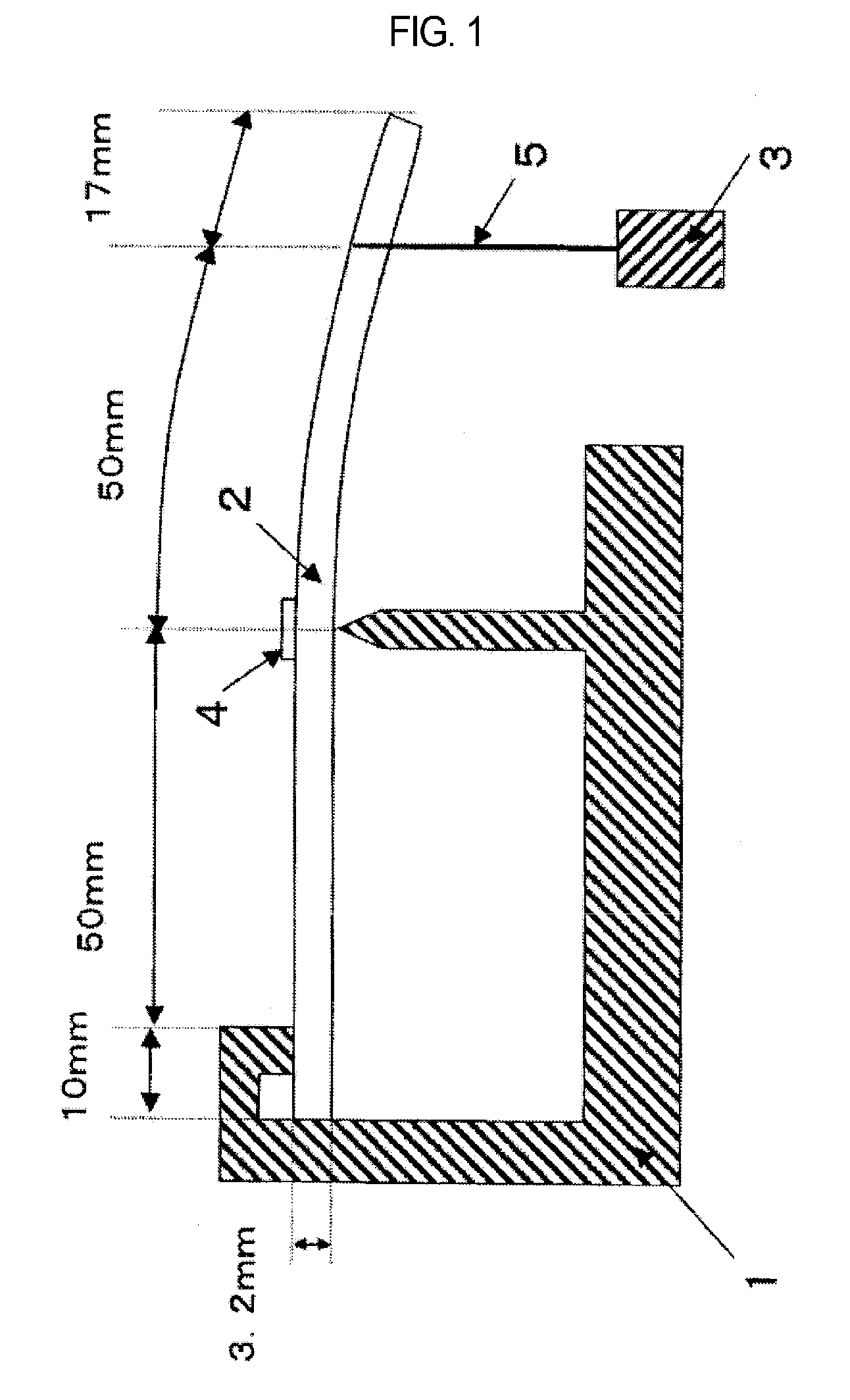

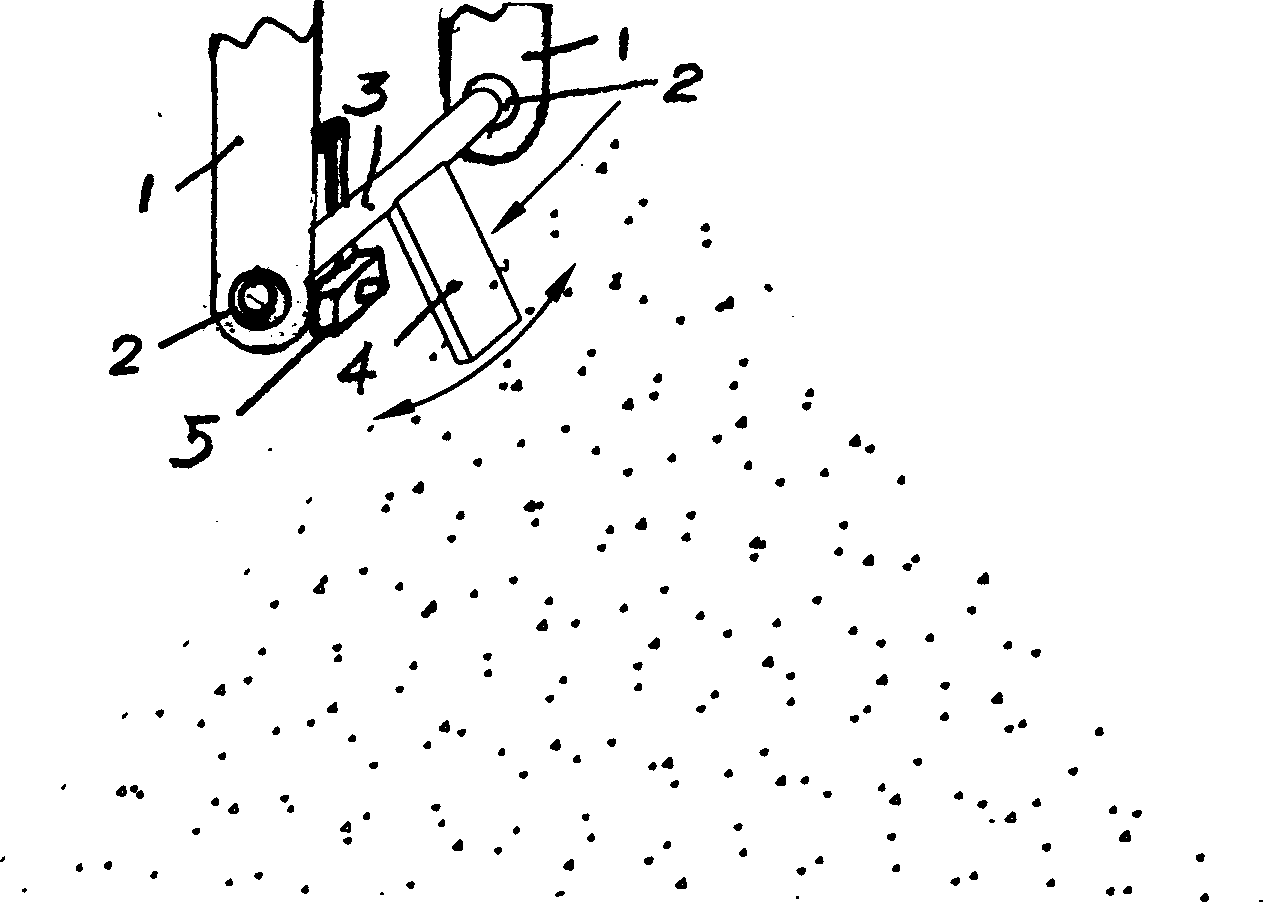

Powder supply device

ActiveUS20150191316A1Simple configurationStable supplyBulk conveyorsLoading/unloadingEngineeringPiping

Provided is a powder supply device that can stably supply powder from a main hopper to a powder supply means including a sub-hopper without requiring component replacement and the like. The powder supply device is provided with: a first piping that guides powder accumulated in a main hopper downward; a second piping that is connected to the first piping at a lower end portion thereof while intersecting with the first piping, and that guides the powder guided by the first piping to a sub-hopper; and a switching valve that pressure-feeds the powder temporarily deposited while forming an angle of repose at an intersecting portion of the first piping and the second piping, to the sub-hopper.

Owner:TOYOTA JIDOSHA KK

Bin level testing method

InactiveCN1490601ASimple structureImprove reliabilityMachines/enginesLubrication indication devicesLocation detectionFree rotation

In the method, an object which can rotate and swing freely is set at position where the material level signal is required. The object is pushed to have a displacement by down wards flowing material when the object is contacted with material which is piled up to the above said position since material at pile top flows down wards along the angle of repose in course of material continuous piling up. The displacement represents signal that the material reaches the position and the displacement is converted to be electrical switching signal by displacement signal detection device set near the object.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com