Preparation method of quartz powder used for producing glass

A technology of quartz powder and glass, which is applied in the field of preparation of quartz powder for glass production, and can solve the problems of not considering the consistency of powder shape and powder fineness, affecting the glass melting process, powder bulk density and poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

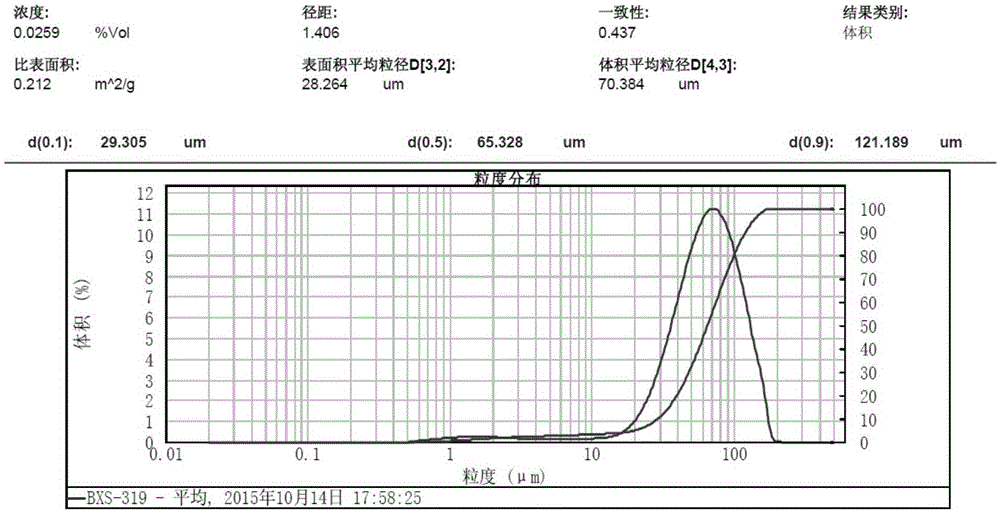

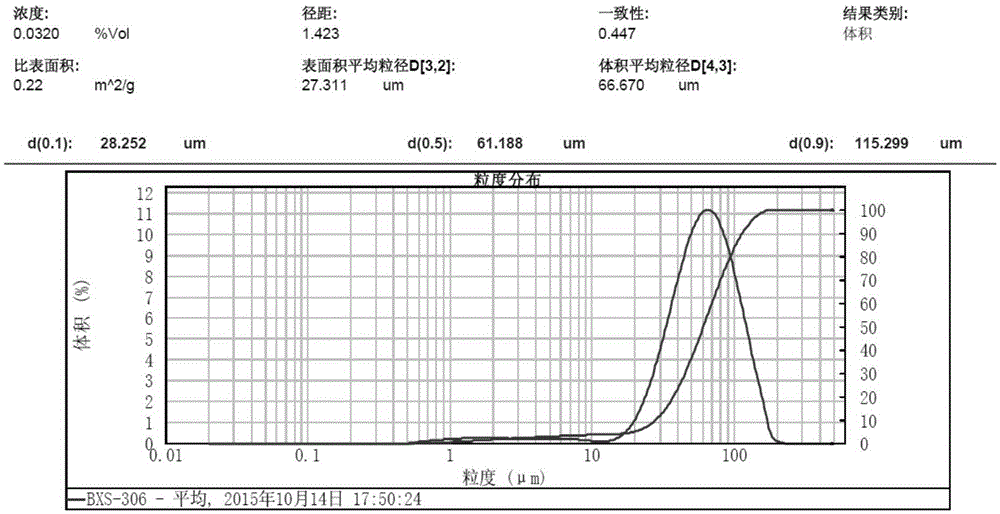

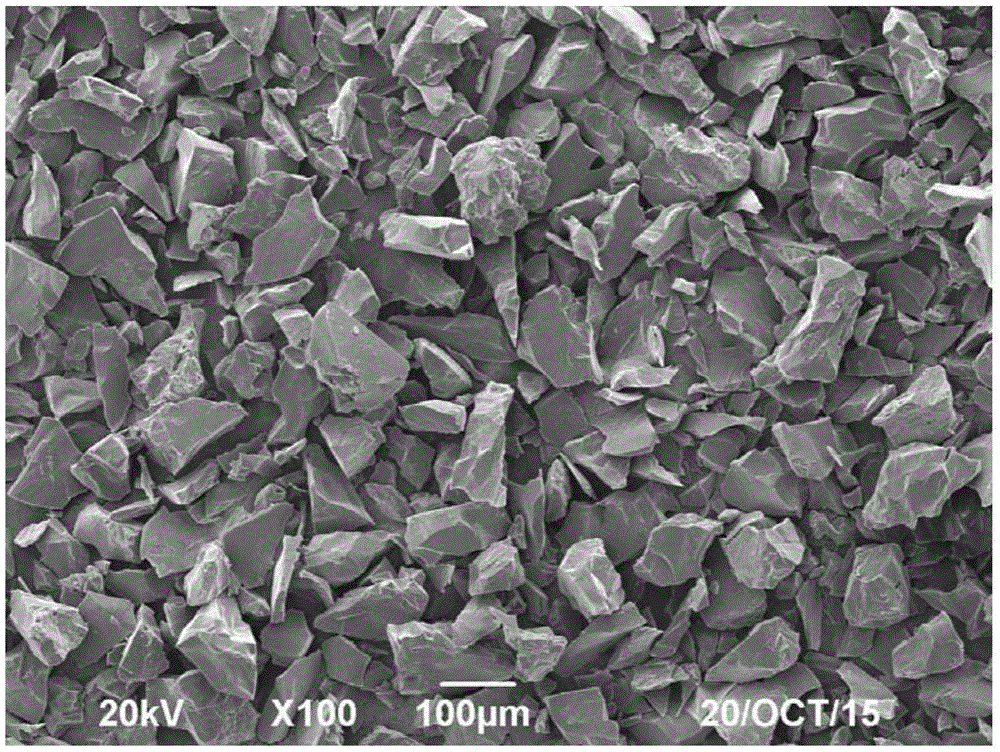

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing target quartz powder from raw quartz ore.

[0030] First select quartz ore with a silica grade greater than 98.5%, (Cr≤0.0005%, Co≤0.0005%, Mn≤0.0005%, Ni≤0.0005%, Pb≤0.005%, Cd≤0.005%, Cu≤0.001%, quartz The content of these elements in the raw ore should be basically satisfied), crush the better quartz ore selected according to this condition to an average particle size of 2-5mm, and select the colored impurities inside through a color sorter to make the silica grade Greater than 99.5%.

[0031] The color sorting finished product enters the ball mill for preliminary wet ball milling. The pulp is mainly composed of quartz powder and water. The ball volume accounts for two-thirds of the ball mill, and the quartz ore for ball milling accounts for one-third of the ball volume. The ball ratio is as follows: 40mm balls account for 20 %, 30mm balls account for 30%, 20mm balls account for 50%, the ball mill concentration is 60-7...

Embodiment 2

[0039] This embodiment provides a method for preparing target quartz powder from iron tailings.

[0040] The raw material is iron tailings, and the silica grade in the iron tailings is greater than 65% (Cr≤0.0005%, Co≤0.0005%, Mn≤0.0005%, Ni≤0.0005%, Pb≤0.005%, Cd≤0.005%, Cu≤ 0.001%, the content of these elements in the raw ore should basically meet the requirements).

[0041] First remove the fine mud in the iron tailings (the fine mud passing through the 400 mesh or 500 mesh sieve has a large amount of impurities, so it is removed first), and the grit enters the ball mill for preliminary ball milling. The ball volume accounts for two-thirds of the ball mill, and the ball milled quartz The ore accounts for one-third of the ball volume, and the ball proportion is as follows: 40mm balls account for 20%, 30mm balls account for 30%, 20mm balls account for 50%, the concentration of the ball mill is 60-70%, and the speed of the ball mill is 60 rpm. The ball mill and the 160-mesh h...

Embodiment 3

[0047] All the other conditions are the same as in Example 1 in this example, but the grinding aid is changed from 0.2wt% triethanolamine to 0.2wt% ethylene glycol. In the present embodiment, the bulk density of the quartz powder before and after shaping ball milling is by 0.95g / cm 3 up to 1.10g / cm 3 , the angle of repose decreased from 37.6 degrees to 36.3 degrees, and the bulk density of the quartz powder before and after surface modification was changed from 1.10g / cm 3 up to 1.18g / cm 3 , the angle of repose is reduced from 36.3 degrees to 35.0 degrees.

[0048] While using other grinding aids such as polymeric polyols, polymeric alcohol amines, triisopropanolamine and diethylene glycol, etc., the results of the bulk density and angle of repose of the obtained quartz powder are equivalent to the results of using ethylene glycol as grinding aids. Illustrate, in the shaping ball milling process of the present invention, use triethanolamine to have best shaping effect as gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com