Ring forging of rotary support ring for wind power equipment and method for manufacturing same

A technology for slewing bearings and wind power equipment, which is applied to wind power generator components, wind power generation, mechanical equipment, etc. It can solve the problems of simple and rough heat treatment process, unstable product quality, etc., and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiments.

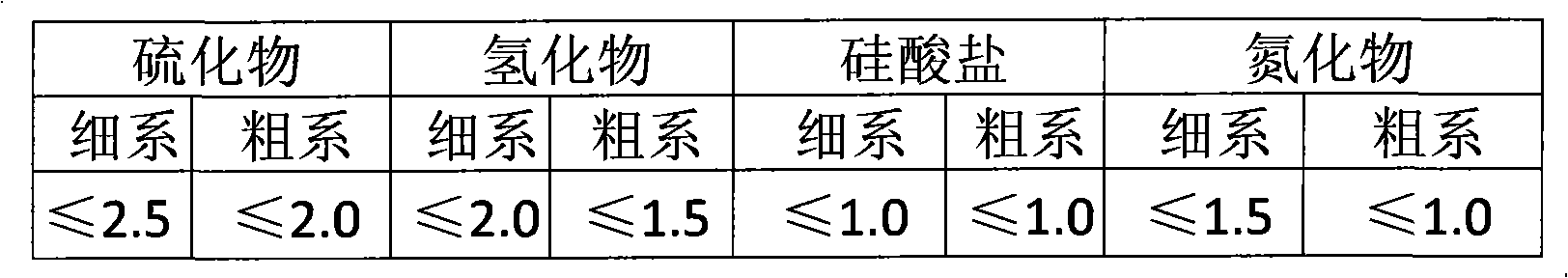

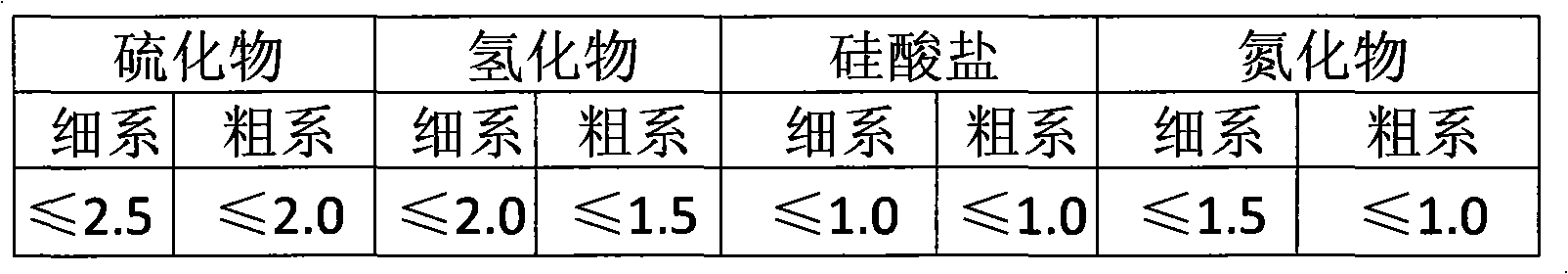

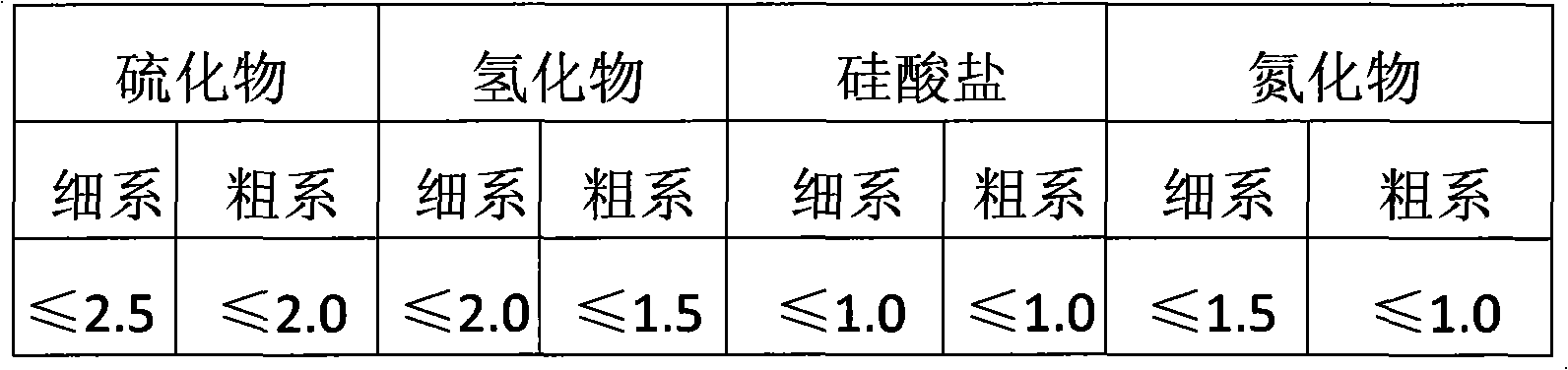

[0011] The weight composition of each chemical element contained in the slewing support ring forging for wind power equipment is as follows: C: 0.41-0.45%, Si: 0.17-0.37%, Mn: 0.60-0.80%, P: ≤0.025%, S: ≤0.025%, Cr: 1.0~1.20%, Ni: ≤0.30%, Mo: 0.15~0.25%, Cu: ≤0.25%, Al: 0.01~0.04%, the balance is Fe; and hydrogen and oxygen elements The content meets the following requirements: [O]: ≤20ppm, [H]: ≤2.0ppm. The above-mentioned slewing support ring ring forging can be obtained by electric converter, refining outside the furnace, and vacuum degassing to obtain continuous casting billet steel.

[0012] The manufacturing method of the slewing support ring ring forging for wind power equipment according to the present invention comprises the following process steps:

[0013] 1. Take the billet steel made of the above components—such as φ390, φ450, φ500, or φ600 continuous casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com