Patents

Literature

127 results about "European standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emission standard for industrial environments; EN 62061 /IEC 62061 Safety of machinery: Functional safety of electrical, electronic and programmable electronic control systems; Moreover, there are a lot of ISO and IEC standards that were accepted as "European Standard" (headlined as EN ISO xxxxx) and are valid in the European Economic Region.

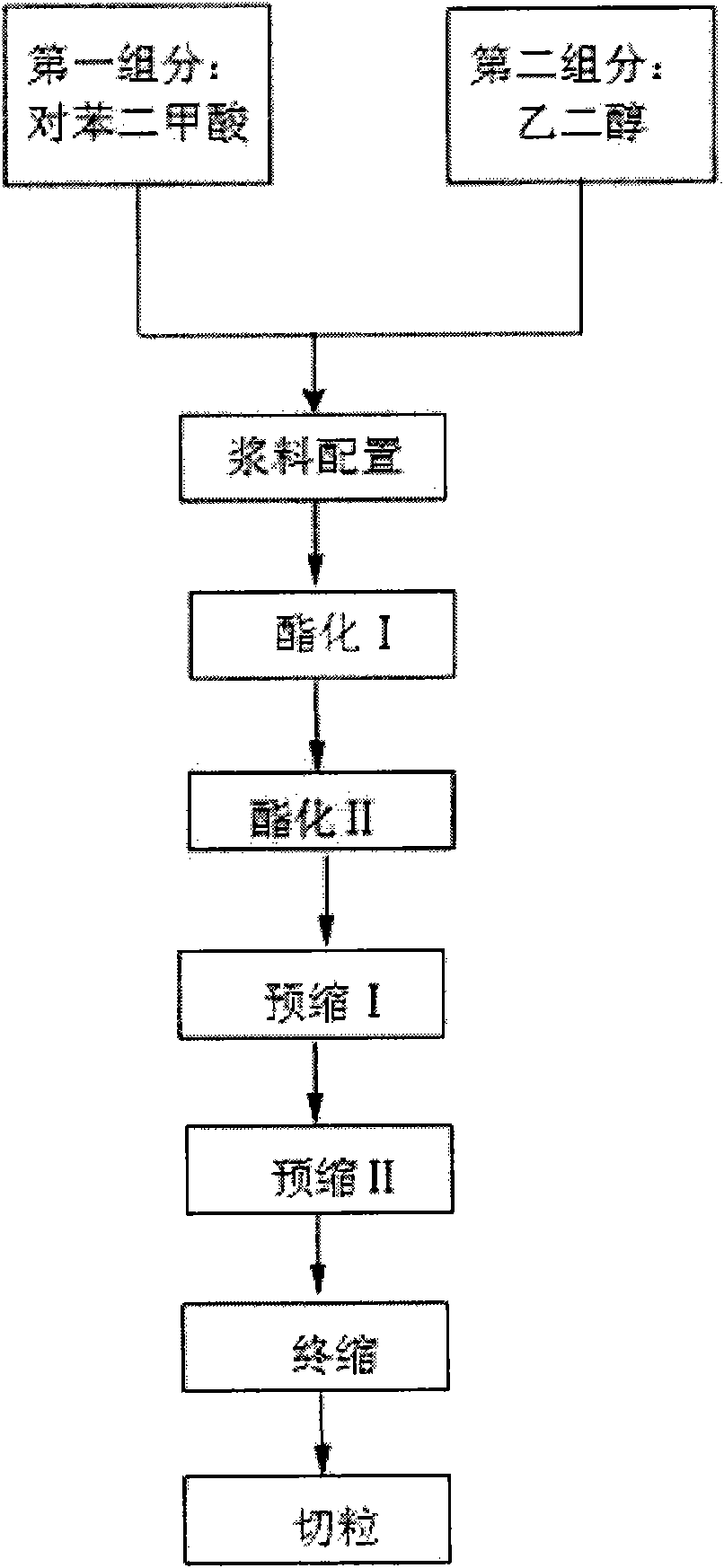

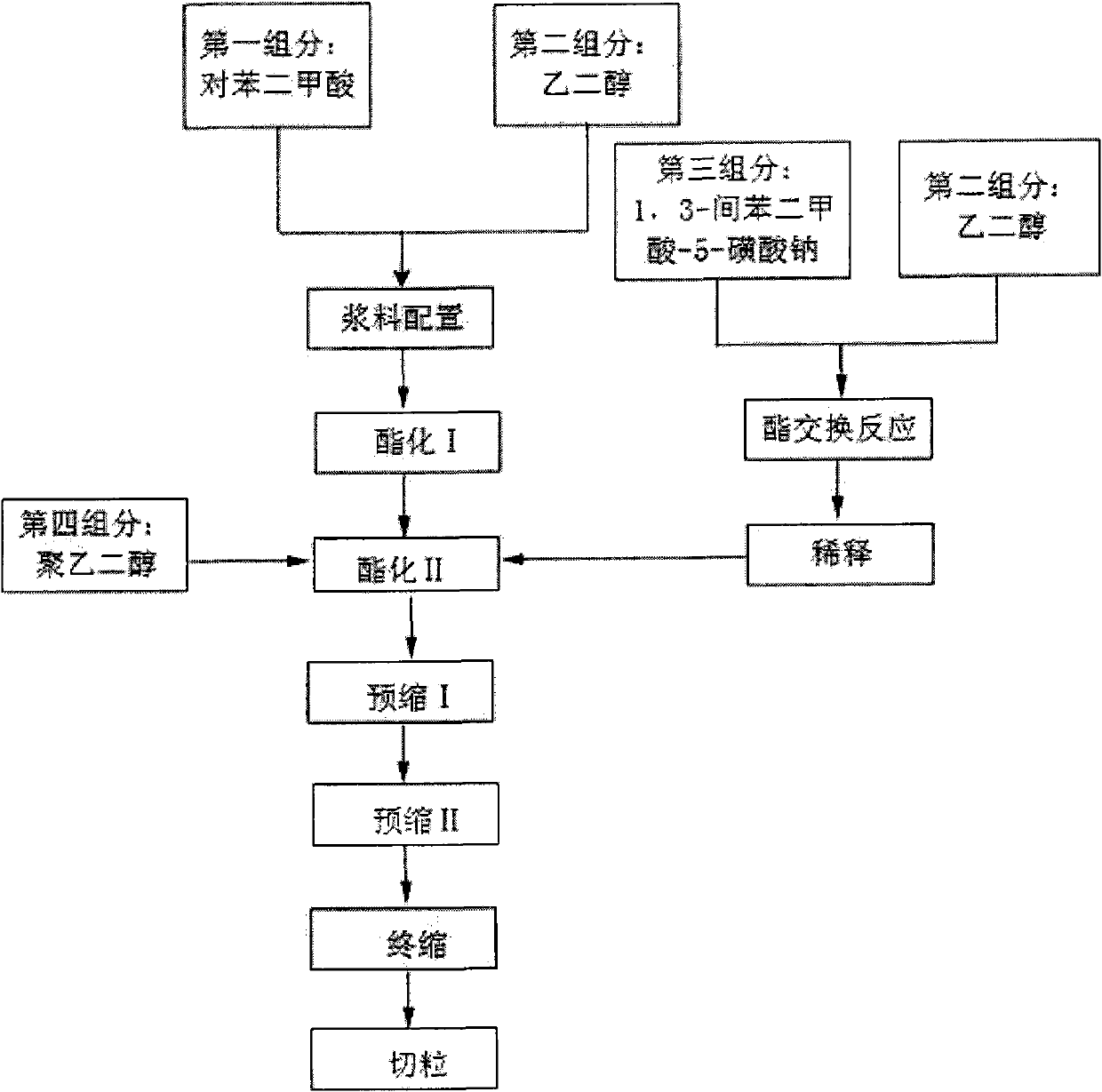

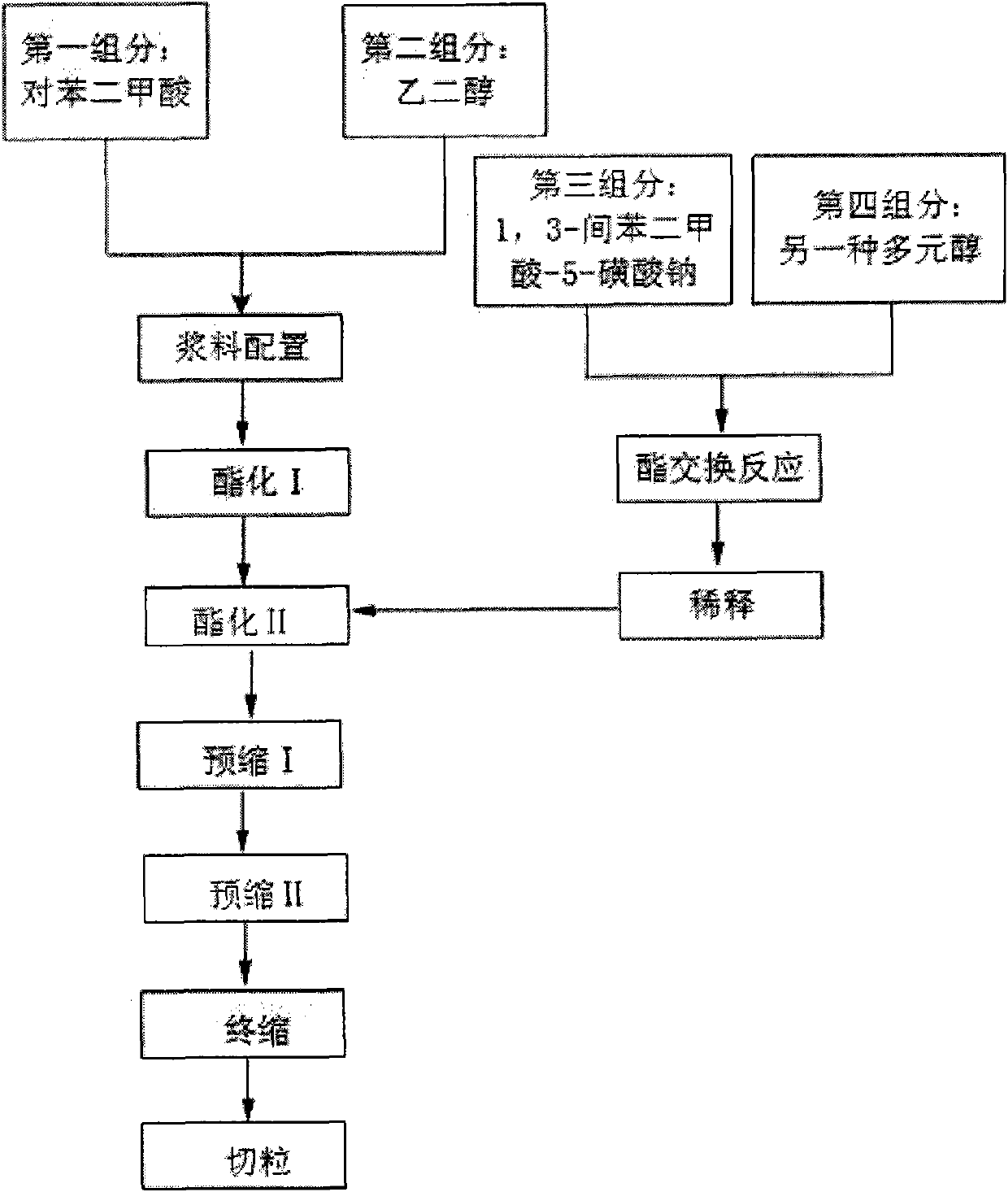

Preparation method of polyol copolyester

InactiveCN102086261AIncrease the chances of participating in a responseAchieve mass ratioDyeing processSlurryPhotochemistry

The invention discloses a preparation method of polyol copolyester. The preparation method comprises the following steps of carrying out slurry preparation, esterifying I, esterifying II, pre-condensing I, pre-condensing II, final condensing and pelletizing on terephthalic acid and glycol. The preparation method also comprises: carrying out ester exchange reaction on 1,3-isophthalic acid-5-sodium sulfonate and another polyol; diluting with the glycol, and then performing the esterifying II. In the preparation method, 1,3-isophthalic acid-5-sodium sulfonate and another polyol react in advance, thereby increasing the reaction probability of another polyol and ensuring that another poyol can reach the required mole ratio in a finished product. The preparation method is mainly applied to production of dye modified polyester by using various dihydric alcohols at normal temperature and normal pressure. The modified polyester is dyed by mainly using anode pigment, the used dye chromatograph is more than that of common polyester, dye-uptake rate can reach above 99%, colour fastness reaches 4-5 grade of European standard, and the color is more flamboyance and beautiful. When filament yarns are subjected to spinning, full-package rate is up to 95%-100%.

Owner:SHANGHAI DEFULUN CHEM FIBER

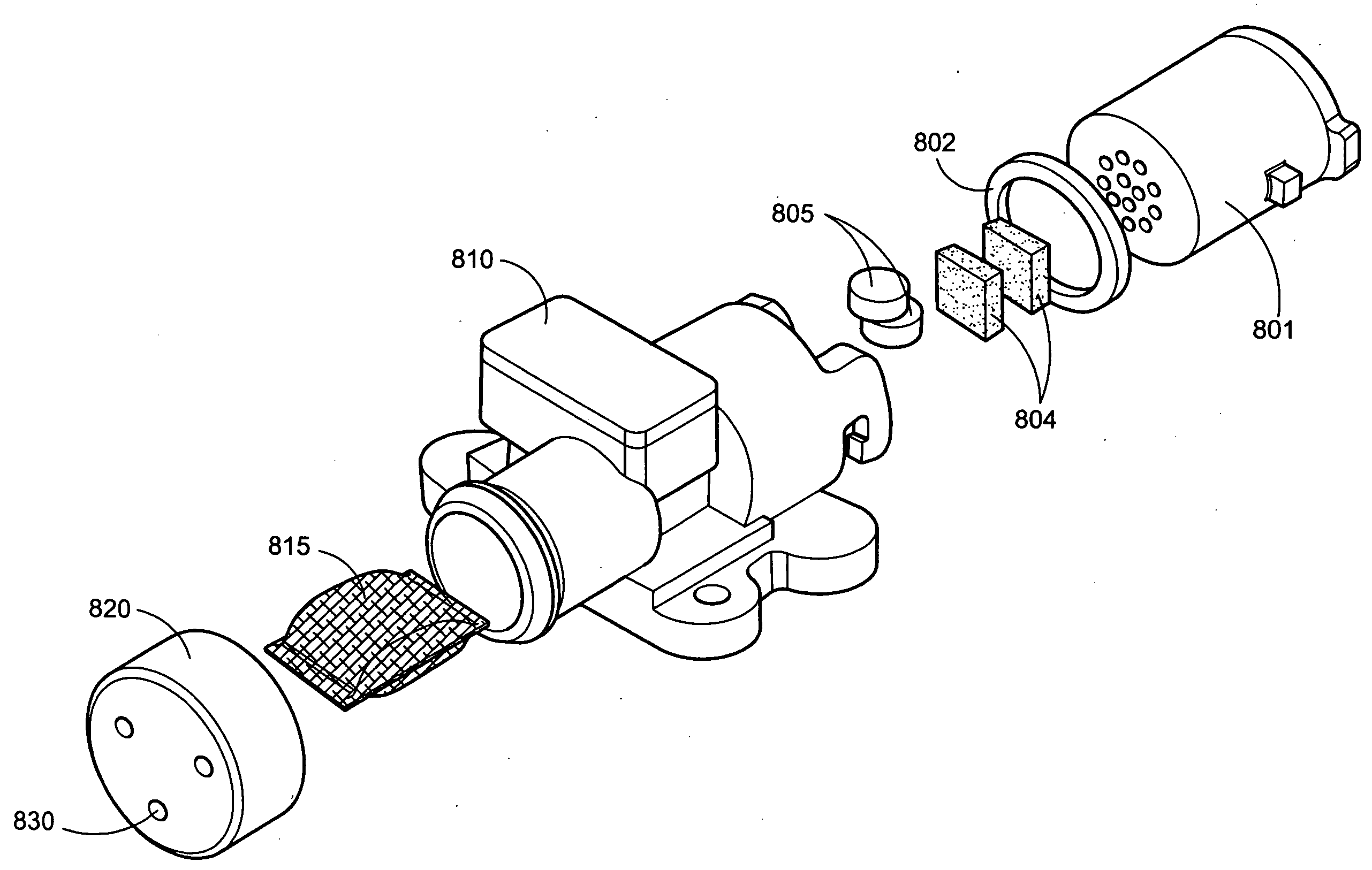

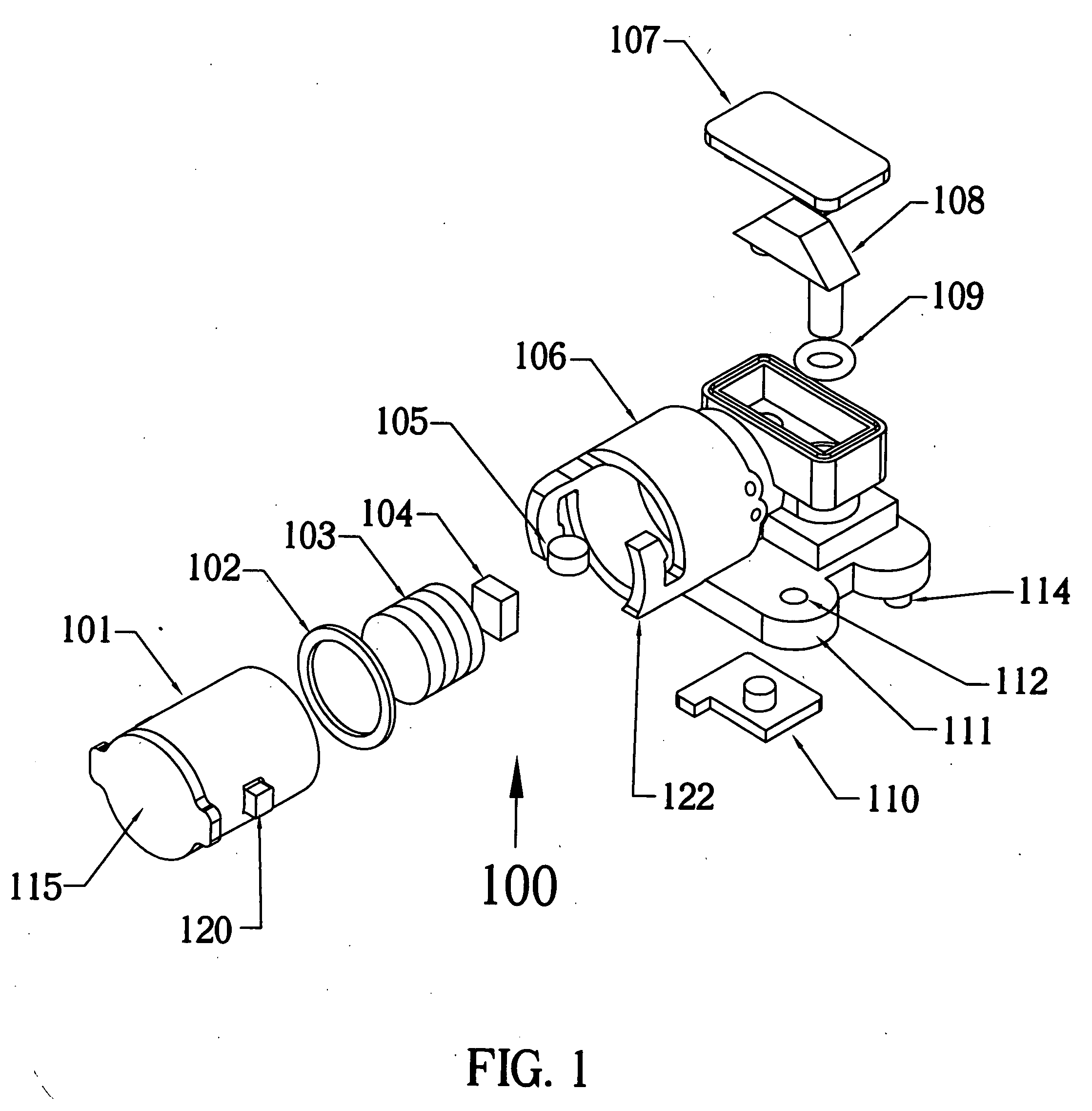

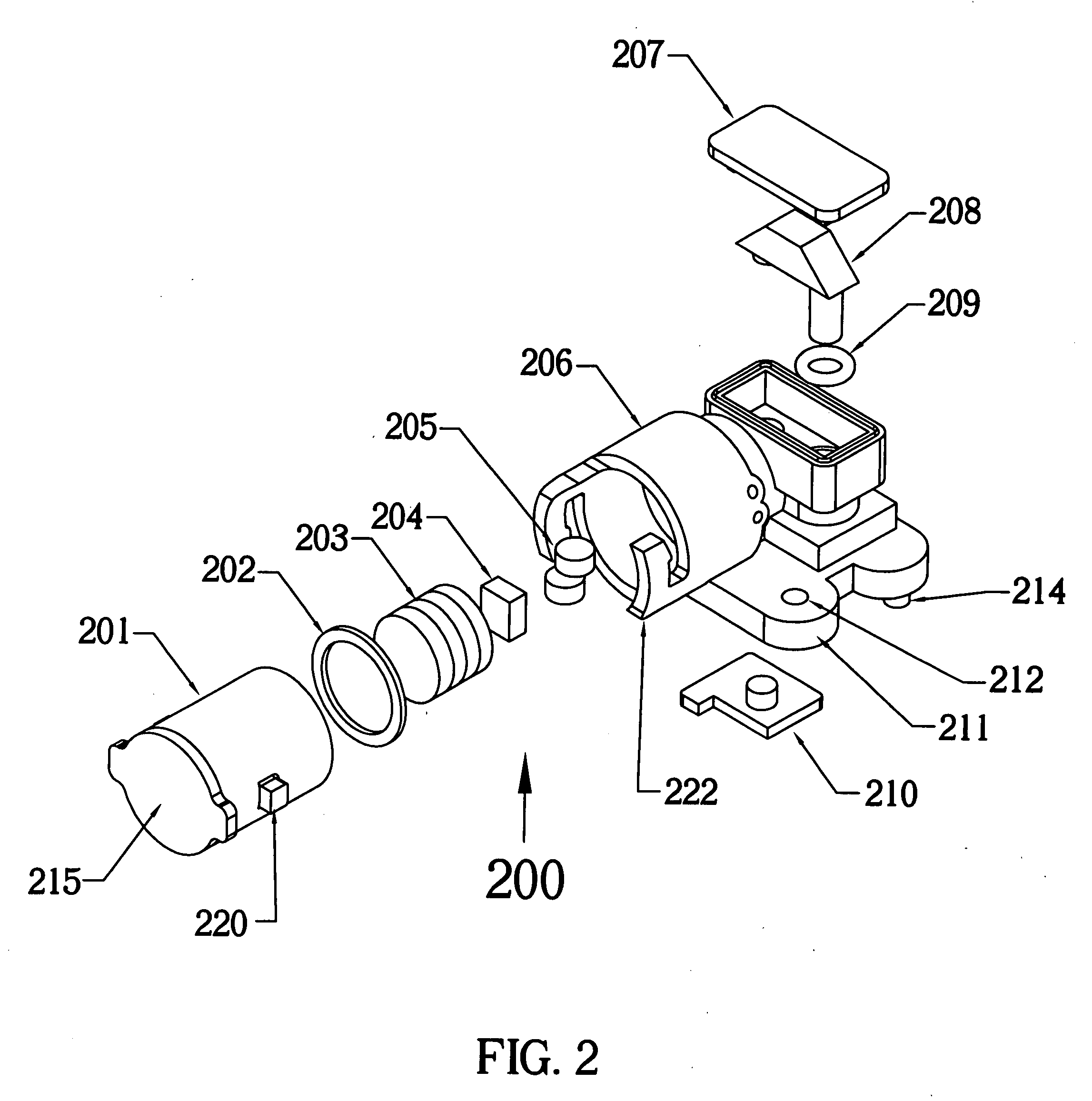

Carbon monoxide (CO) microsir sensor system

InactiveUS20080173817A1Different in diameterDifferent in structureRadiation pyrometryAnalysis using chemical indicatorsDual sensorReservoir system

The present invention provides very small low cost apparatus and method for determining the concentration and / or hazard from a target gas by means of optically monitoring one or more sensors that responds to carbon monoxide. The apparatus comprises a photon source optically coupled to the sensor and the photon intensity passing through the sensor is quantified by one or more photodiode(s) in a system, so that the photon flux is a function of at least one sensor's response to the target gas, e.g., transmits light through the sensor to the photodiode. The photocurrent from the photodiode is converted to a sensor reading value proportional to the optical characteristics of the sensors and is loaded into a microprocessor or other logic circuit. In the microprocessor, the sensor readings may be differentiated to determine the rate of change of the sensor readings and the total photons absorbed value may be used to calculated the CO concentration.There are a number of methods to compute the CO hazard and these is subject of another patent to be filed. In addition, a preferred method to meet the BSI and European CO Standards is described using two sensor systems with two different sensors each having different sensitivity within one housing. The single housing dual sensor uses one LED and two photodiodes. The novel two sensors method to meet the European (BSI) CO standard is similar to the method developed to meet the Japanese standard.The major advantages of MICROSIR over SIR are: 1. Lower cost (estimates saving of US$1.25 per sensor, 2. Better controlled gas path therefore more accurate and more precision, 3. Better getter system therefore longer life (as shown by ammonia accelerated age tests), and 4. Better RESERVOIR SYSTEM THEREFORE BETTER humidity CONTROL AT BOTH LOW AND HIGH (as shown by sensor response curves).5. The MICROSIR Edgeview is faster and meets the Japanese standard for CO and the European Standard for CO enhanced smoke, 6. More easily automated as the board of alarms use surface mount and MICROSIR is a surface mount part that attaches over surface mounted optics after the soldering, 7. small size, and 8. approved UL recognized component.The MICROSIR device can also be used to detect the CO, which may be combined with temperature and smoke in a very small package. The detection of one or more indicators such as smoke and CO; increases the sensitivity of the other indicators. Combining signals produces an improved fire detector comprising a CO sensor and a smoke sensor in one unit. The smoke detection sensor may be either ionization or photoelectric either or both may be combined with the CO sensor to provide earlier warning to fire and reduce false alarms.

Owner:THE QUANTUM GROUP

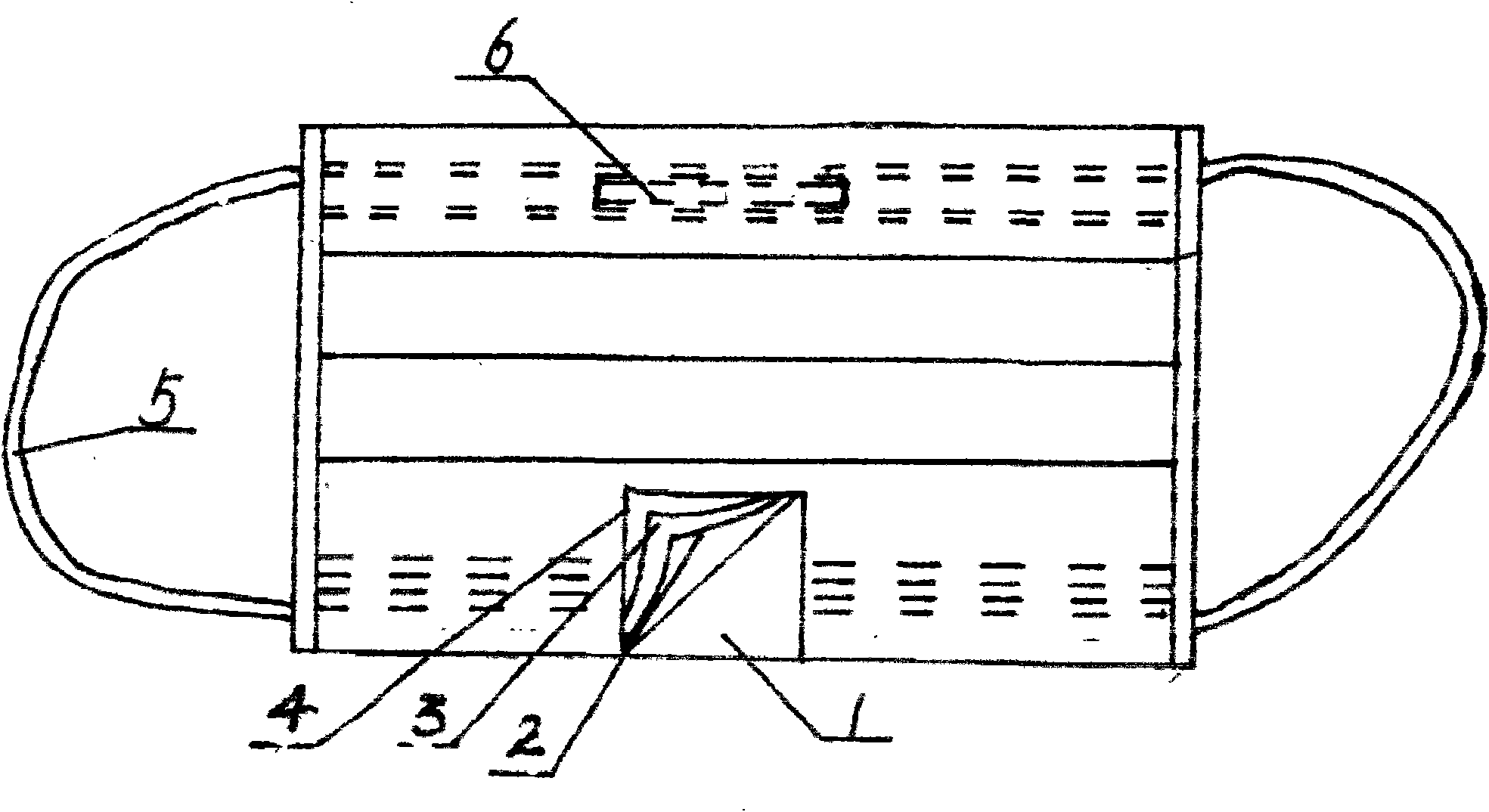

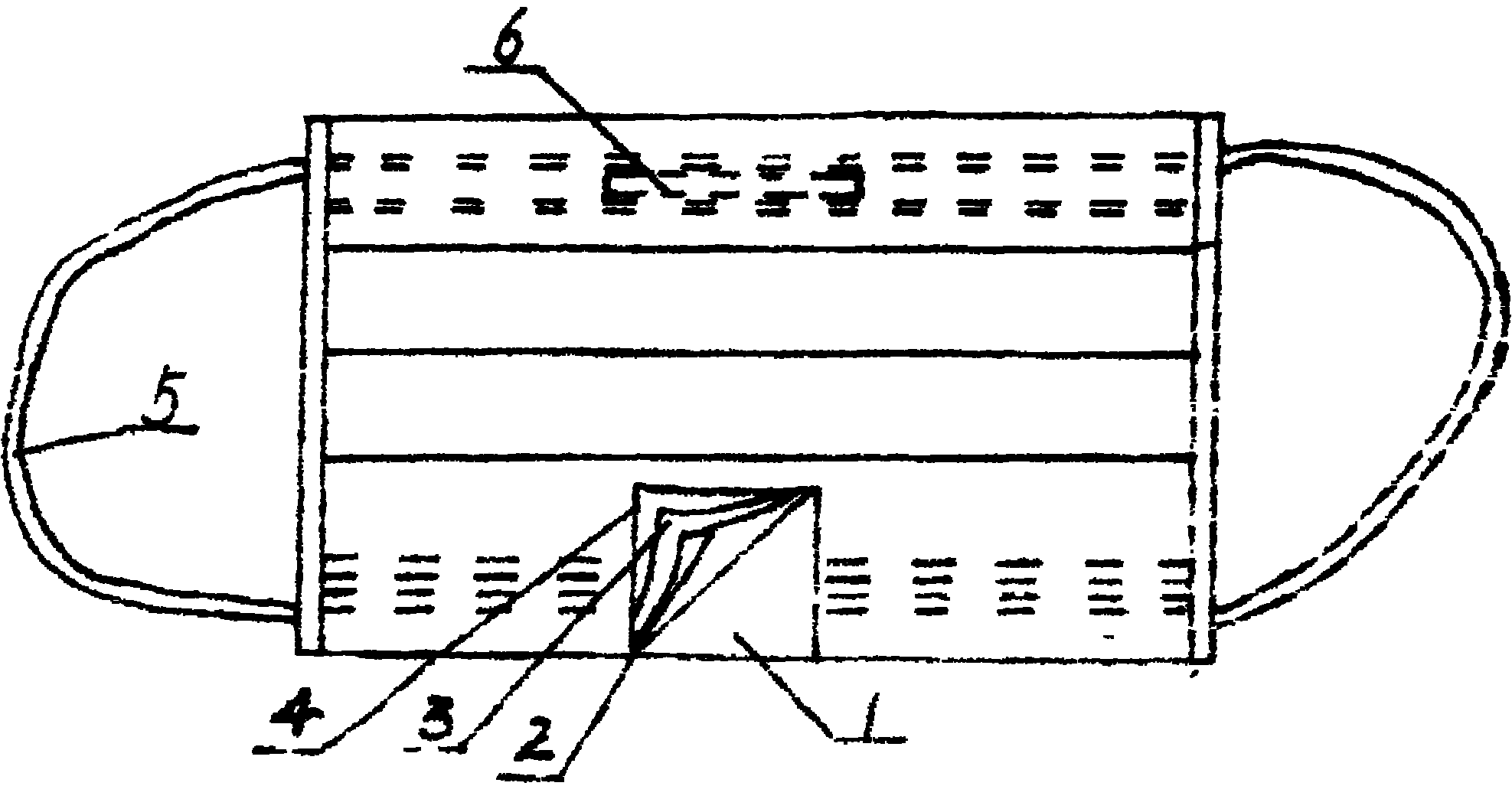

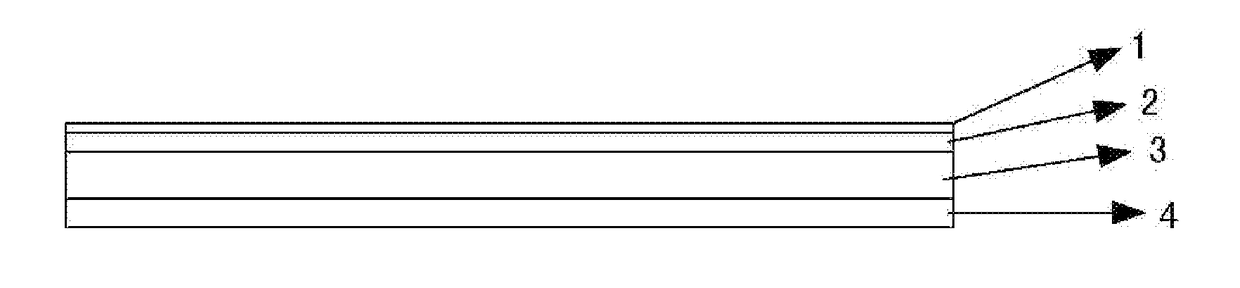

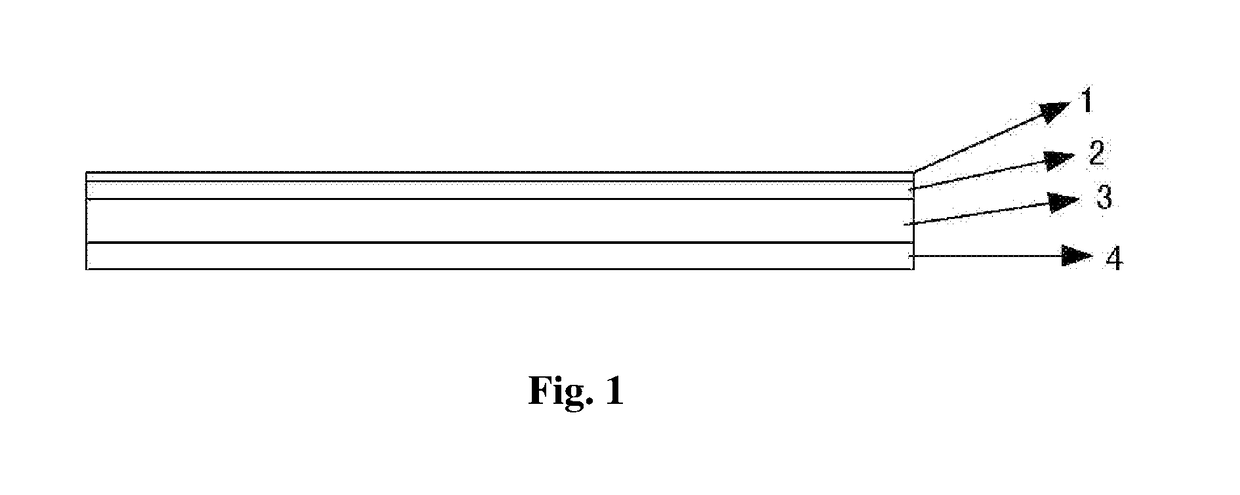

N95 type negative ion mask

The invention discloses an N95 type negative ion mask which is a layered matter comprising four layers of materials, wherein the first layer is a receiving layer, the second layer is an adsorbing layer, the third layer is a filtering layer and the fourth layer is a nursing layer; the first layer is the outward layer when the mask is used; the layers are sequentially stacked together; and an ultrasonic mask special device is adopted for processing, then the N95 type negative ion mask in various required shapes can be produced, the N95 type negative ion mask is a special mask for the public for prevention and control of a variety of epidemic situations and is characterized in that the N95 type negative ion mask not only conforms to the functions of masks made of American N95 standard filtering material and European standard masks, but also has the function of killing various bacteria and viruses, and can prevent the viruses from entering into the oral cavity and the nasal cavity, provide better air negative ions for the respiratory tract and prevent the occurrence of various diseases of the respiratory tract, and the N95 type negative ion mask additionally has the characteristics of excellent air permeability, comfort, appropriate product cost and the like.

Owner:胡敬军

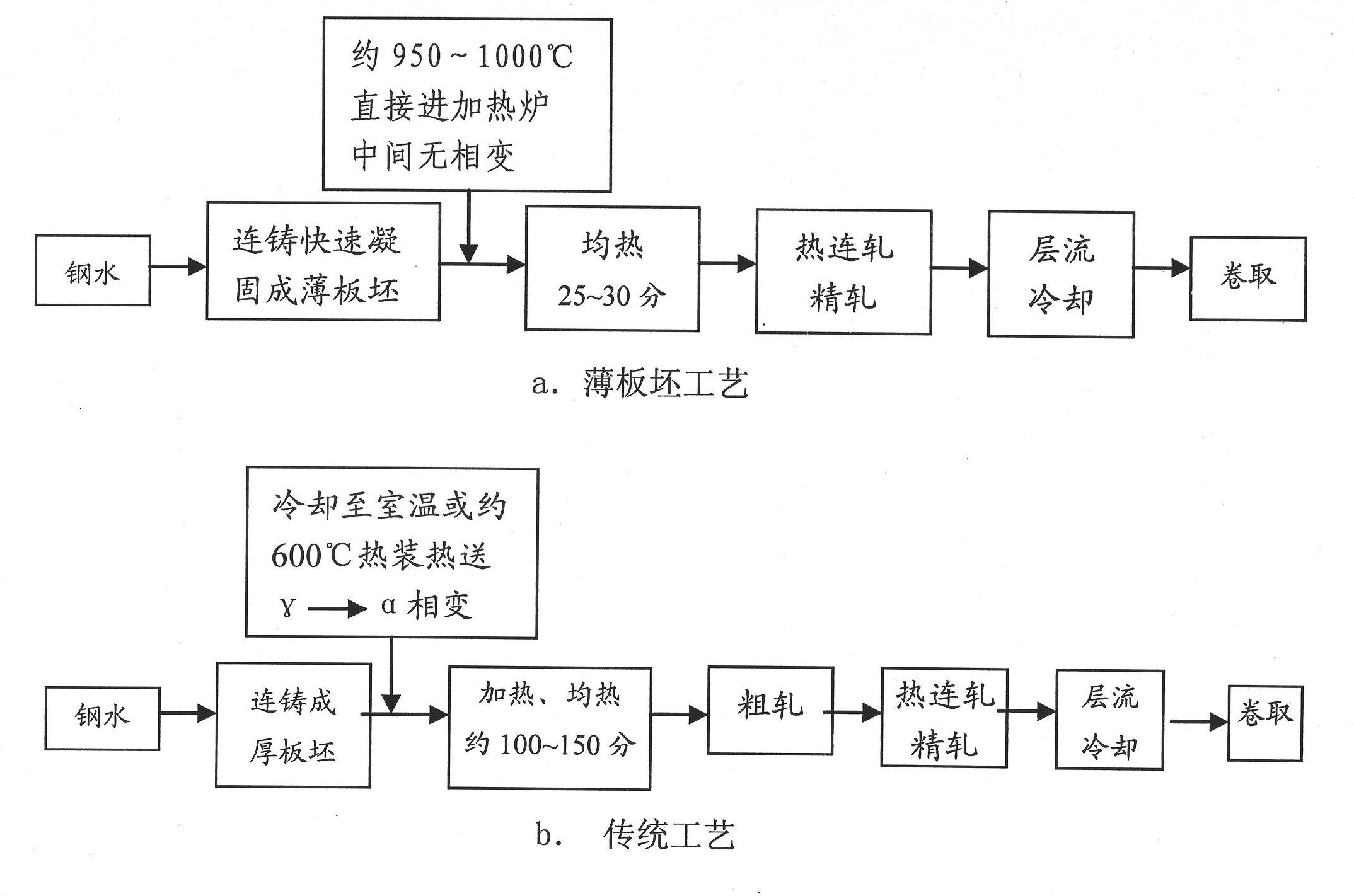

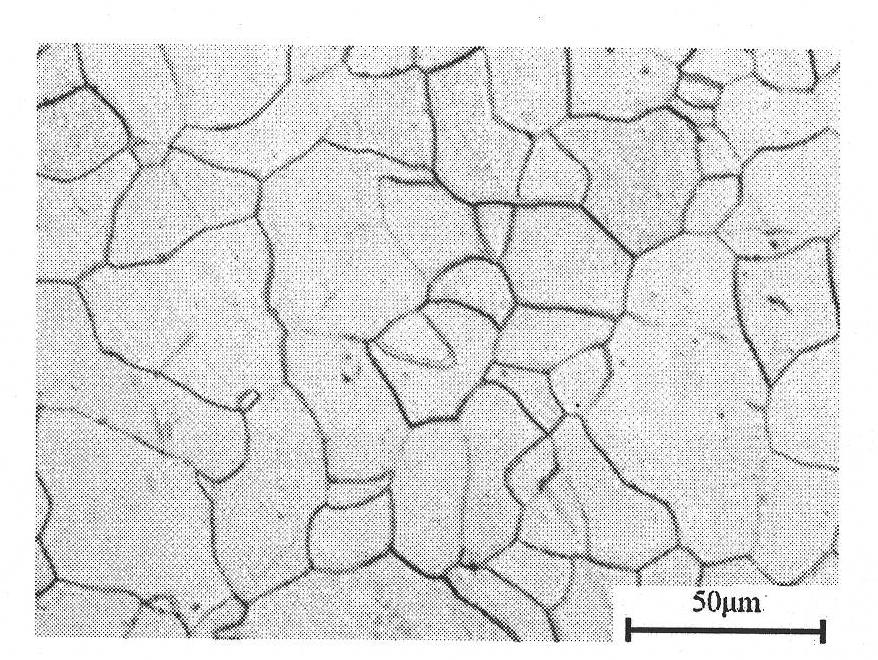

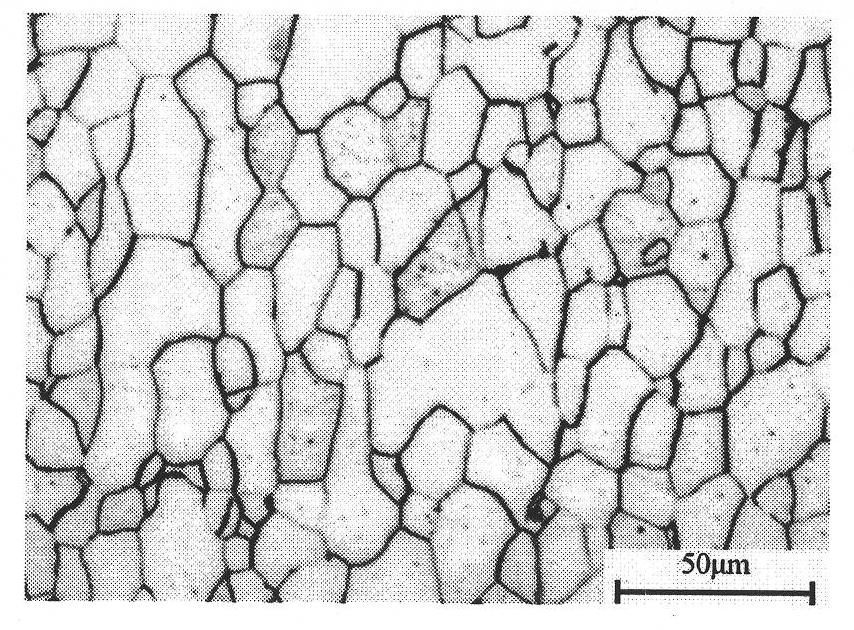

Method for producing extra-deep drawing cold-rolled steel plate based on ASP process

InactiveCN101941021AReduce manufacturing costMeet needsRoll mill control devicesWork treatment devicesProduction lineAcid washing

The invention discloses a method for producing an extra-deep drawing cold-rolled steel plate based on a sheet billet continuous casting and rolling process in ASP, and belongs to the technical field of rolled steel. After molten steel meeting the component requirement is obtained by adopting molten iron pretreatment, a converter, LF and RH, a hot-rolled substrate is produced by the sheet billet continuous casting and rolling process in the ASP, and the hot-rolled substrate is subjected to acid washing, cold rolling, cover annealing and leveling processes to obtain the extra-deep drawing cold-rolled steel plate. Compared with the prior art, the performance of the produced extra-deep drawing cold-rolled steel plate meets the European standard EN10130-2006, meanwhile, the production cost is reduced, energy is saved and consumption is reduced. The method broadens the variety range of products produced by a sheet billet continuous casting and rolling production line in the ASP, can meet the increasing requirements of the industries of automobiles, home appliances, buildings, transports, light industry and the like for plates, and improves the product competitiveness of enterprises.

Owner:SHANDONG IRON & STEEL CO LTD +1

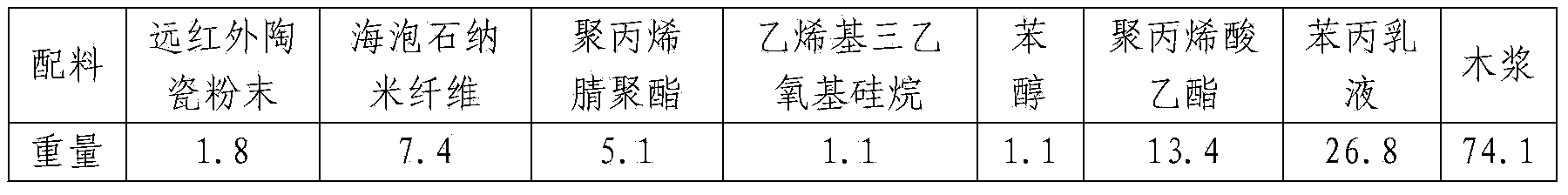

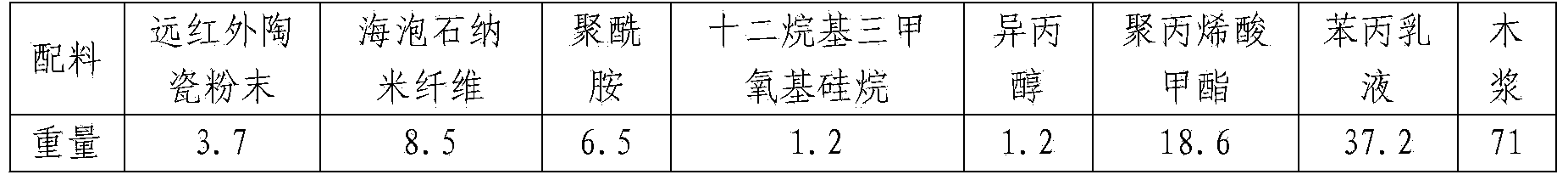

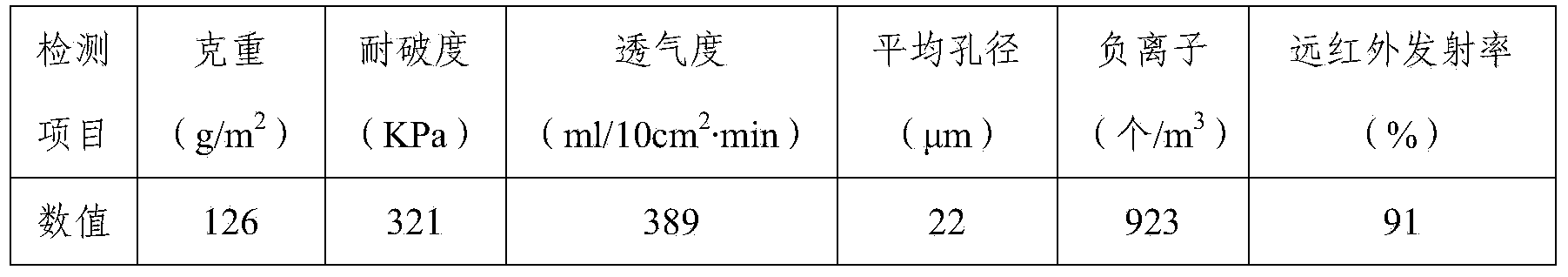

Filter paper coating material for auto filters and preparation method thereof

ActiveCN103774492ASimple processHigh filtration precisionCoatings with pigmentsWater-repelling agents additionEmission standardFar infrared

The invention relates to a filter paper coating material for auto filters, and the filter paper coating material for auto filters is prepared from the following components in parts by weight: 1-6 parts of far infrared ceramic powder, 2-20 parts of sepiolite nano fiber, 4-10 parts of synthetic fiber, 0.8-2 parts of silane coupling agent, 0.8-2 parts of diluent, 9-20 parts of sizing agent, 20-40 parts of styrene-acrylic emulsion and 60-96 parts of wood pulp. According to the coating material provided by the invention, the manufactured air, fuel and oil filters have remarkable comprehensive functions, the motor vehicle exhaust emission is decreased by 13-40%, the dynamic performance is improved by 5-15%, the fuel can be saved by 2-7% and the emission standard is up to the European standard IV.

Owner:北京联飞翔科技股份有限公司

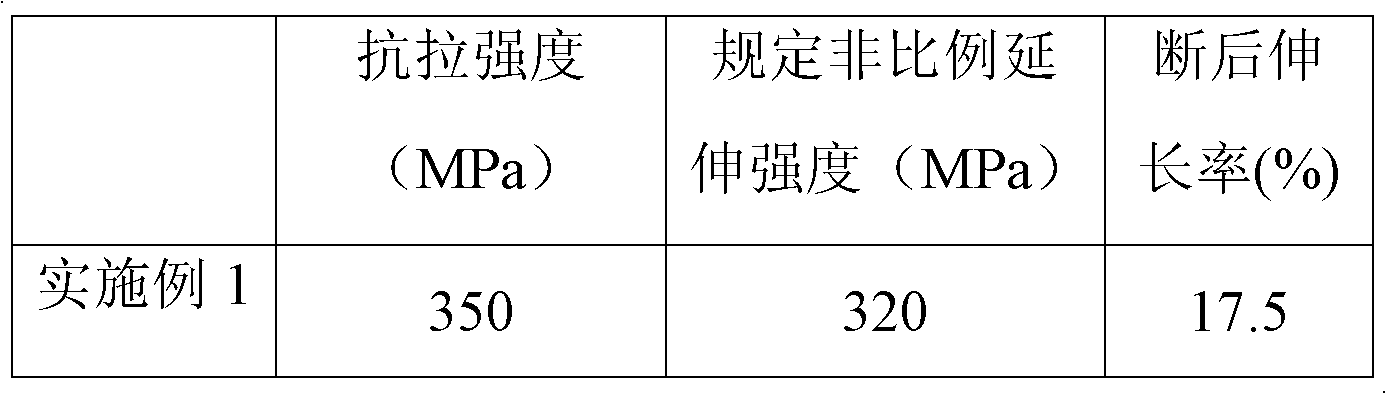

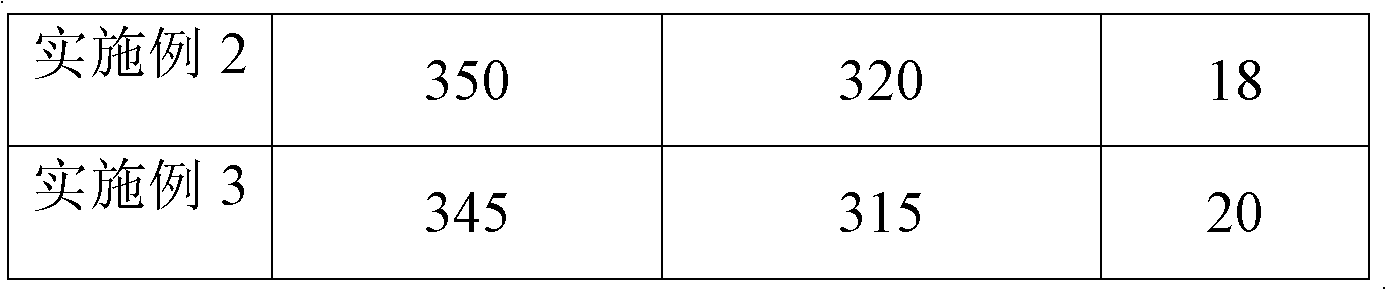

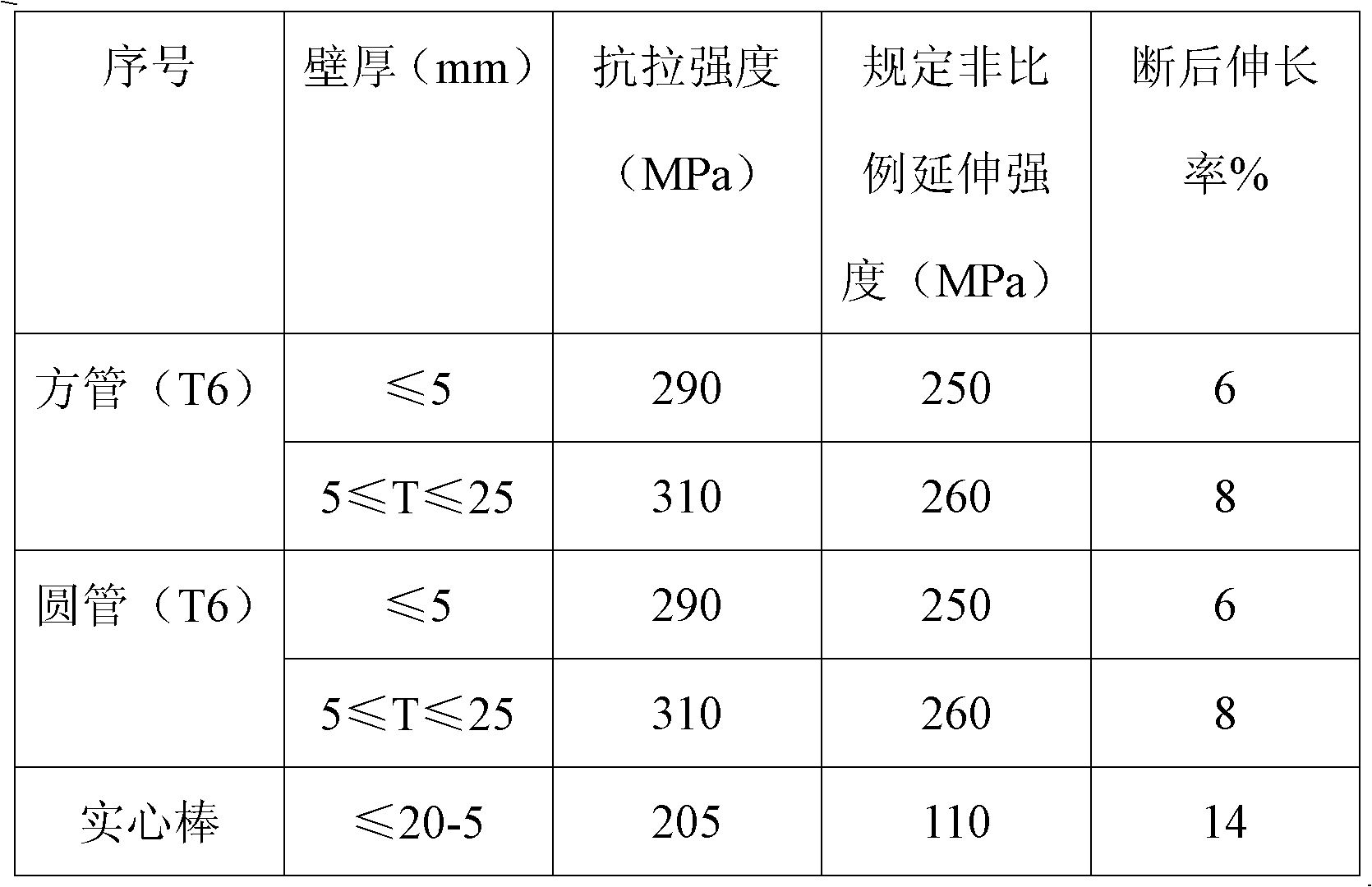

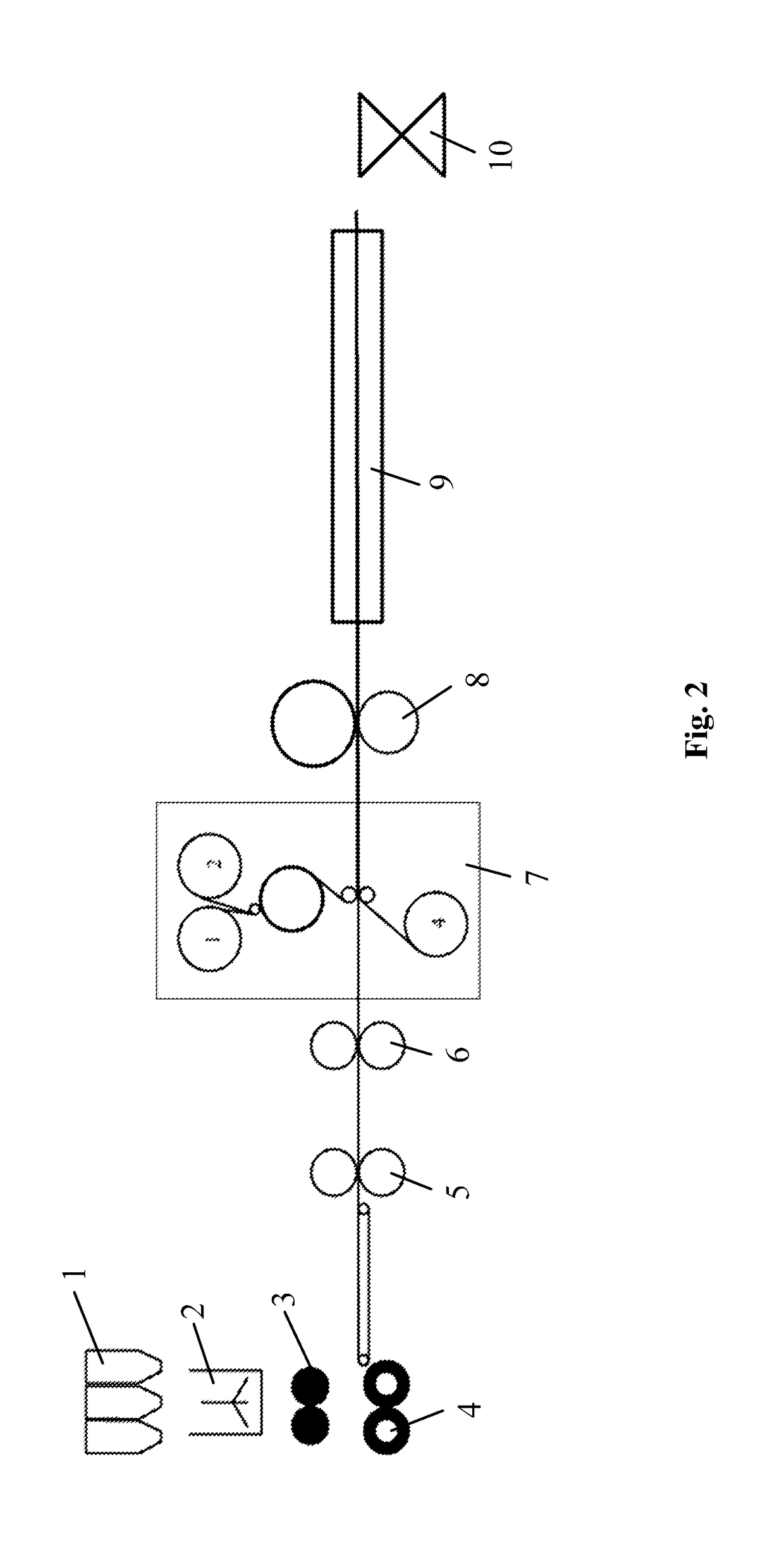

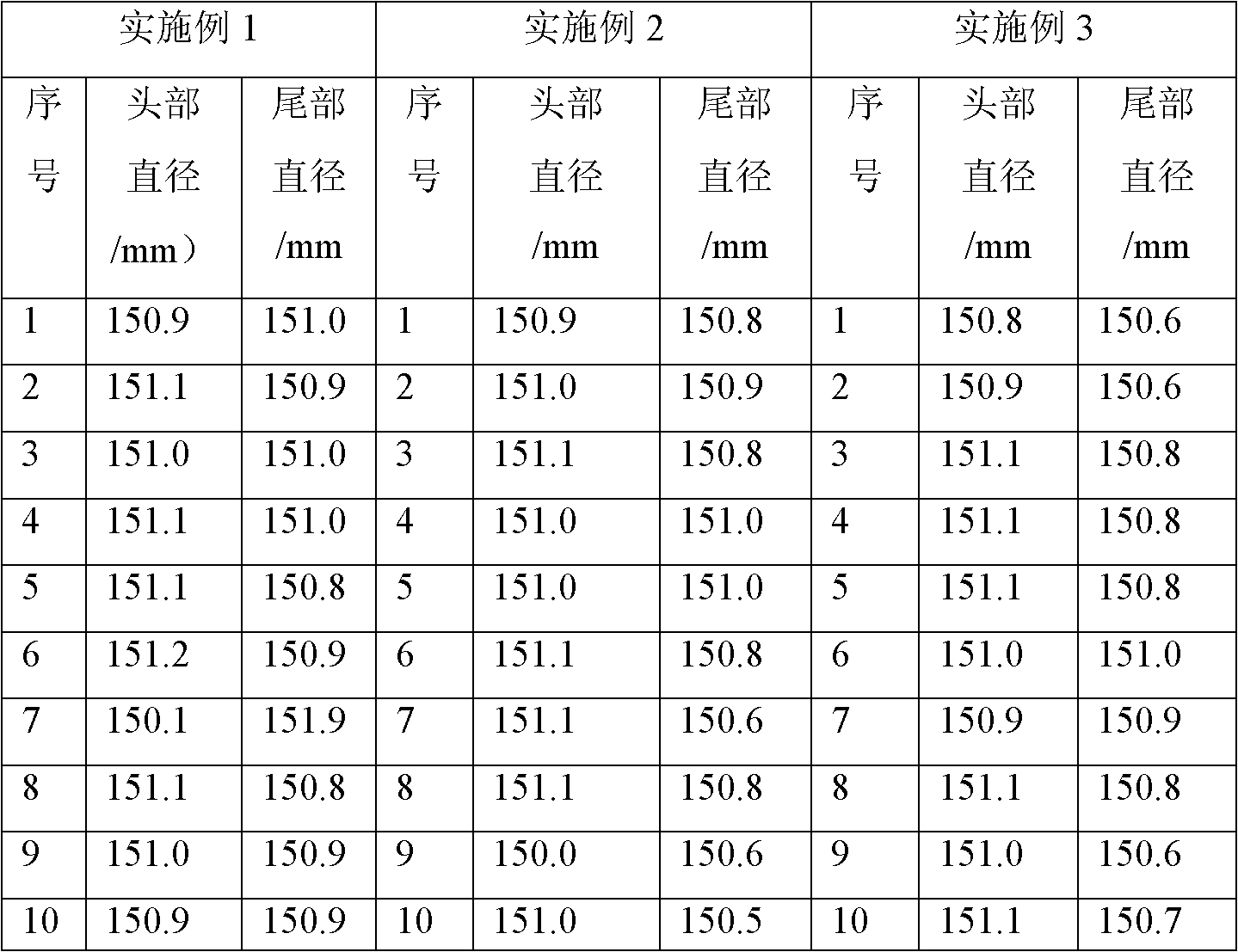

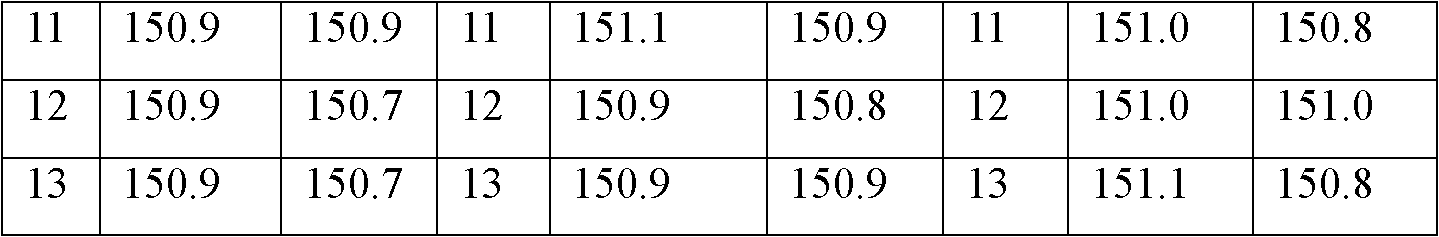

Extrusion and heat treatment method for high speed railway locator aluminum material

The present invention discloses an extrusion and heat treatment method for a high speed railway locator aluminum material. The method comprises the following steps: preheating an aluminum rod to a temperature of 450-540 DEG C, preheating a mold to a temperature of 460-510 DEG C, preheating an ingot holding cylinder to a temperature of 400-450 DEG C, and then carrying out extrusion; carrying out online quenching on the profile after extrusion material discharging, wherein a temperature of the aluminum material after online quenching is 25-70 DEG C; naturally cooling to a temperature of 10-40 DEG C; standing for 100-160 h at a temperature of 10-40 DEG C; placing the obtained material into an aging furnace to carrying out artificial aging, wherein an aging temperature is 175-185 DEG C, and a thermal insulation time is 4-5 h; and cooling to a temperature of 10-40 DEG C after discharging out of the furnace. The high speed railway locator aluminum material produced according to the extrusion and heat treatment method has high mechanical properties, wherein tensile strength of the product is 3-31% higher than the European standard, yield strength of the product is 8-36% higher than the national standard, and elongation of the product is 28-100% higher than the national standard.

Owner:FOSHAN GOLDEN SOURCE ALUMINUM PROD

Method for producing a molded sheet metal part from an as-rolled, non-hardenable aluminum alloy

Method for producing an open molded sheet metal part from a non-hardenable aluminum alloy that has the following steps:a) a sheet is prepared that is made of a non-hardenable aluminum alloy, the temper of which is H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36 or H38 according to European Standard EN 515:1993 and that in addition to aluminum includes at least magnesium and where necessary manganese;b) the aluminum is heated at least locally to a temperature between 200° C. and 350° C. within a period of 1 to 60 seconds;c) the heated sheet is placed in a cold forming die of a forming press and the sheet is formed, creating a molded sheet metal part.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Production process of water-permeable, air-permeable, oil-proof and wear-resistant gloves

ActiveCN105520238AEasy to operateGood oil resistanceGarment special featuresGlovesWear resistantProcess engineering

The invention relates to a production process of water-permeable, air-permeable, oil-proof and wear-resistant gloves. The production process comprises such steps as covering gloves on a mold, preheating the gloves, immersing the gloves in a coagulating agent, immersing the gloves in gum, conducting surface treatment, drying, soaking, drying and vacuumizing, de-molding and the like. The process disclosed by the invention is simple to operate, and the manufactured glove product, on the basis of satisfying air permeability and water permeability, can achieve an excellent waterproof effect; and in a test conforming to European standard EN388, the wear-resistant performance of the gloves manufactured by the process far exceeds 4th level and achieves the level of 30000 turns, so that the wear-resistant performance of the product is greatly improved.

Owner:HUIHONG NANTONG SAFETY PRODS

Preparation of timber adhesive

ActiveCN101497772AMeet the use requirementsReduce viscosityProtein adhesivesAldehyde/ketone condensation polymer adhesivesCelluloseAdhesive

The invention discloses a preparation method of wood adhesive which is prepared by 10-70 portions of modified soybean flour solution and 90-130 portions of phenol formaldehyde adhesive (E1 level in market). The preparation method comprises the following steps: preparing 20-30 percent of solution by more than 100 mu of defatted soybean flour condensate, adjusting the pH value to be 4.5-5.5; respectively adding 0.1-0.5 percent of cellulose and 0.01-0.5 percent of pectase; hydrolyzing the solution added with the cellulose and the pectase for 30-120 minutes at the temperature of 48-52 DEG C; adjusting the pH value to be 7.0-10; hydrolyzing the solution added with the cellulose and the pectase for 30-120 minutes by 0.01-0.5 percent of neutral or alkali protease; adjusting the pH value to be 7.5-10.5, and mixing the solution added with the cellulose and the pectase with metlbond according to the proportion of 10-70 portions so as to obtain the wood adhesive. The release amount of formaldehyde achieves the E0 level of European standard. The wood adhesive has lower viscocity which can achieve less than 30s by mixing with the low-viscocity phenolic resin, thereby meeting the use requirements of spraying and coating.

Owner:山东万得福生物科技有限公司

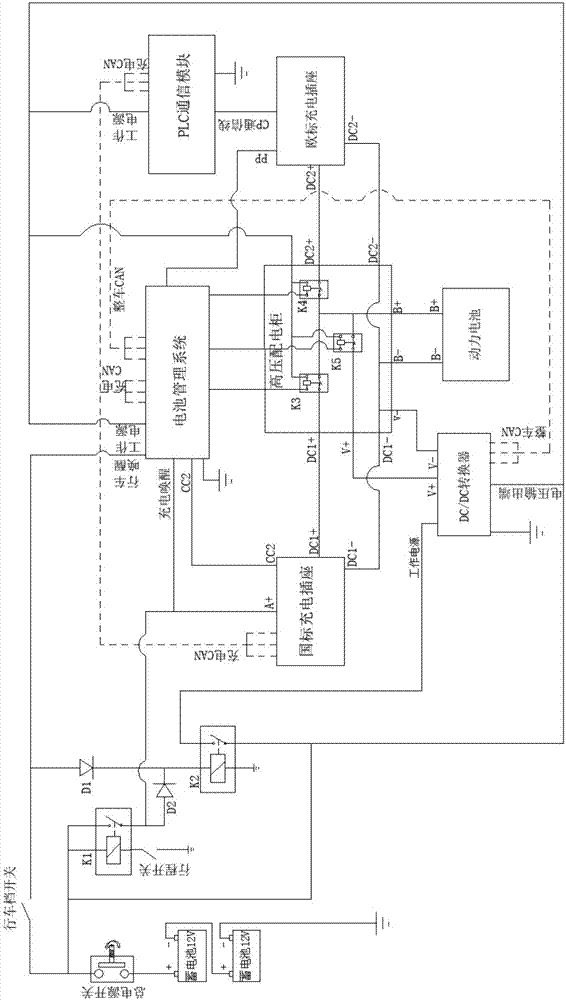

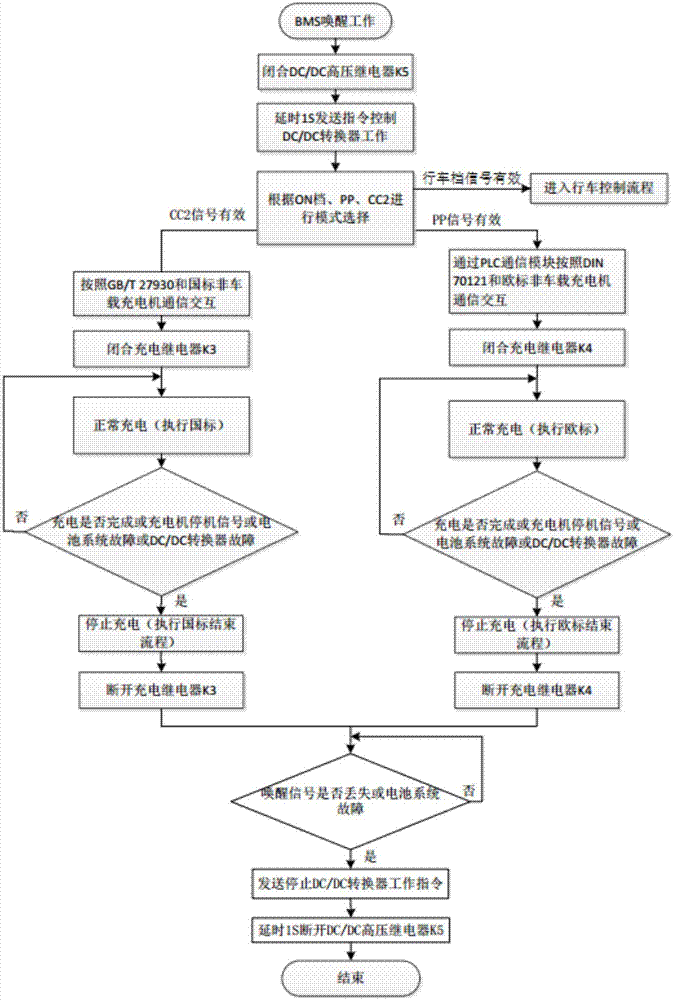

Combined charging system for electric vehicle and control method of combined charging system for electric vehicle

ActiveCN107336632AGuaranteed volumeCharging supportCharging stationsCharging managementElectrical batteryEngineering

The invention discloses a combined charging system for an electric vehicle. The combined charging system comprises a battery management system a high-voltage distribution cabinet, a DC / DC converter, a power battery, a national standard charging socket, an European standard charging circuit and a lead acid battery power source formed by connecting two 12 V storage batteries in series. The battery management system is provided with a running wakeup terminal and a charging wakeup terminal. The national standard charging socket is provided with a wakeup line and a national standard connecting signal line. The wakeup line is electrically connected with the charging wakeup terminal. The national standard connecting signal line is connected with the battery management system. The European standard charging circuit comprises a stroke switch, a low-pressure replay, a PLC communication module and a European standard charging socket. The battery management system is electrically connected with the DC / DC converter, the PLC communication module and the national standard charging socket through a CAN bus. The combined charging system for the electric vehicle is convenient to use and good in charging effect.

Owner:XIAMEN GOLDEN DRAGON BUS

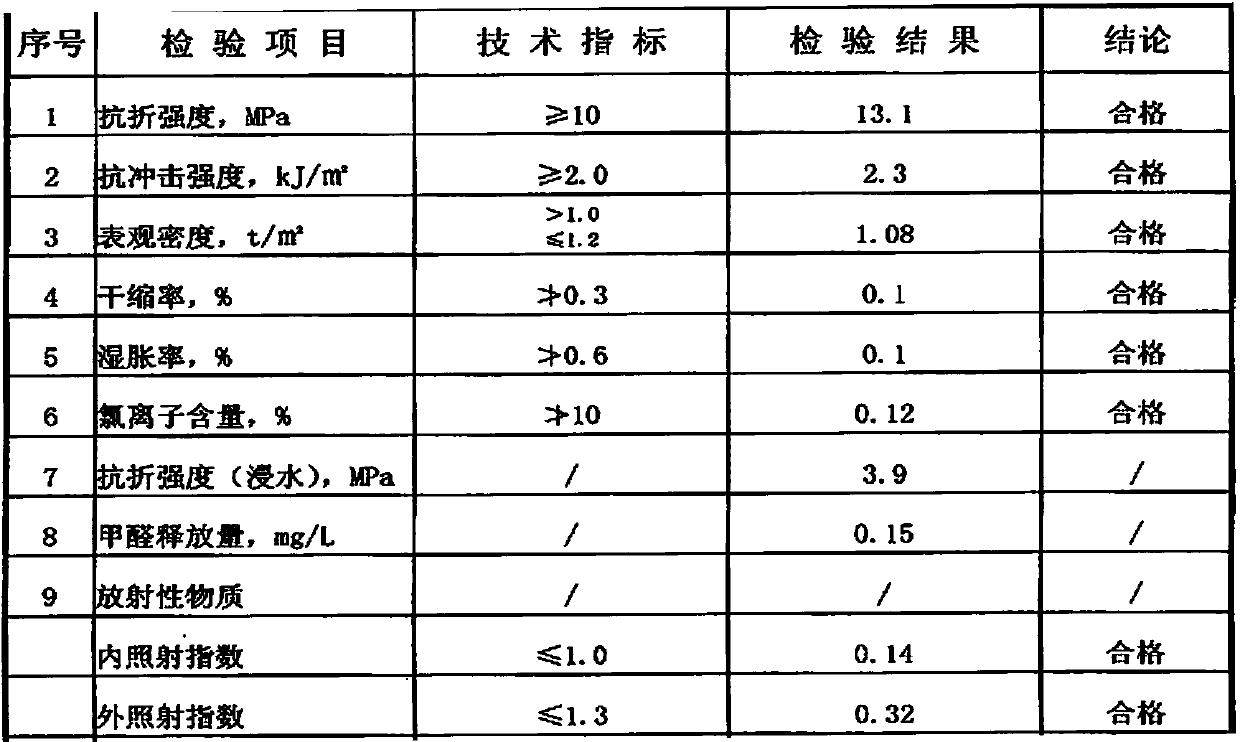

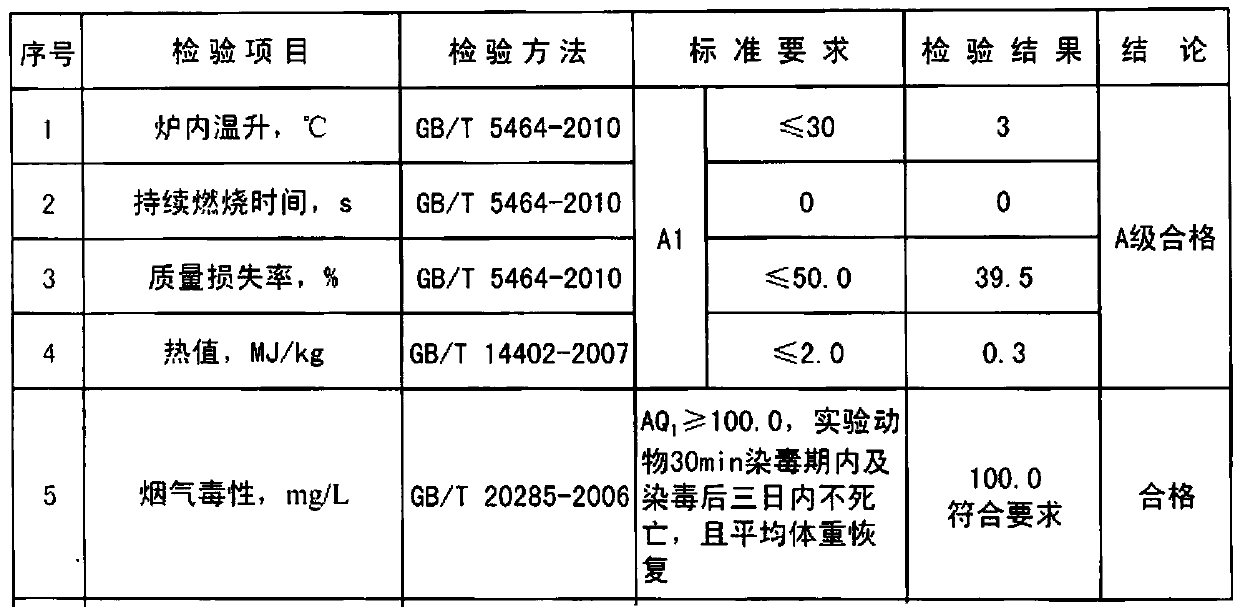

Magnesium crystal fireproof and flame-retardant plate and preparation method thereof

The invention discloses a magnesium crystal fireproof and flame-retardant plate. The magnesium crystal fireproof and flame-retardant plate comprises the following components in parts by weight: 18 to23 parts of magnesium oxide, 10 to 12 parts of magnesium sulfate, 40 to 45 parts of sawdust, 5 to 6 parts of alumina, 2 to 2.5 parts of copper sulfate, 8 to 10 parts of bentonite, 1 to 2 parts of organosilicon, 3 to 4 parts of calcium stearate, 3.5 to 4.5 parts of a modifying agent, 10 to 12 parts of water, 2 to 3 parts of polyvinyl alcohol, 1 to 2 parts of polypropylene fiber and 4 to 5 parts ofsilane based powder. The flame-retardant plate provided by the invention has a formaldehyde emission amount lower than the formaldehyde emission amount in European standard, has multiple performancesof preventing fire, water and moisture, and solves the problem that a conventional plate can not combines fireproof, waterproof and moisture-proof performances or has poor effects of preventing fire,water and moisture.

Owner:重庆市镁晶防火材料有限公司

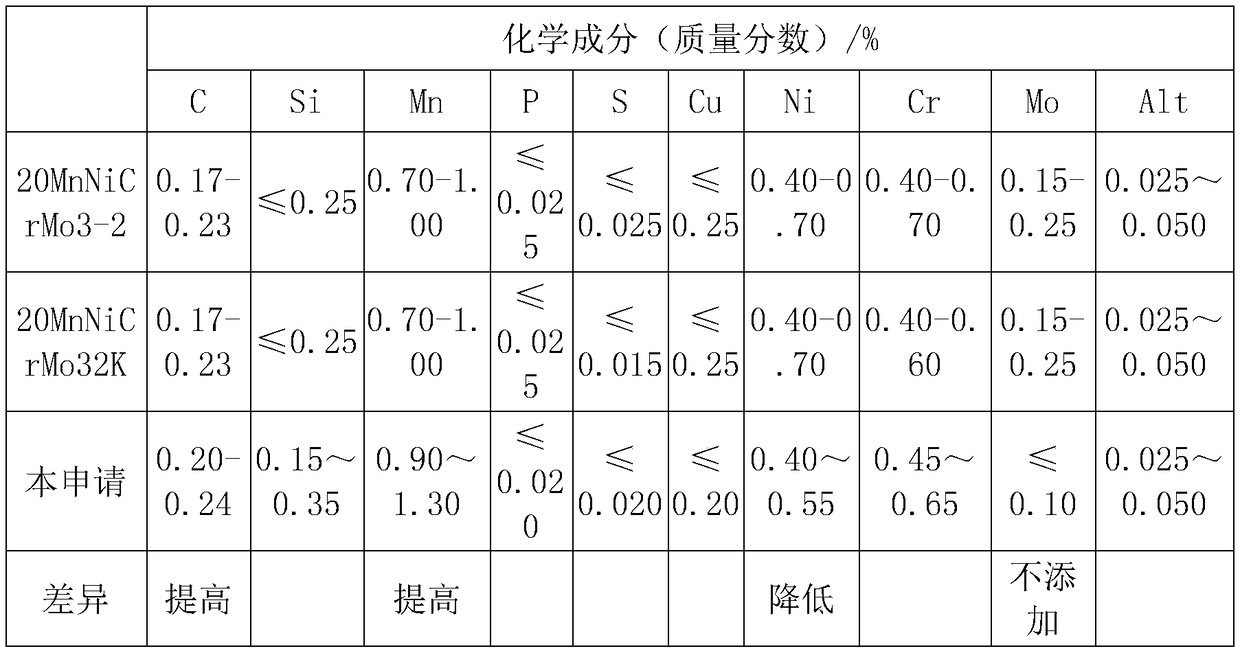

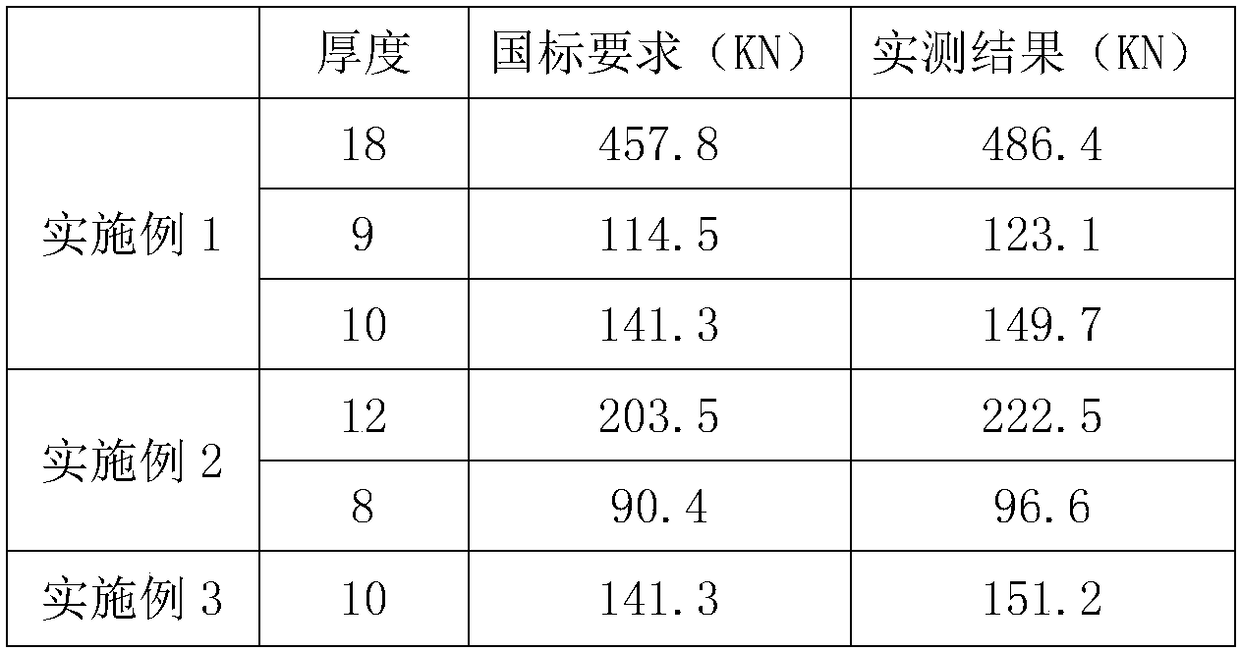

Grade-90 chain steel

The invention relates to grade-90 chain steel. The grade-90 chain steel is prepared from the following chemical components by weight percent: 0.20 to 0.24 percent of C, 0.15 to 0.35 percent of Si, 0.90 to 1.30 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, less than or equal to 0.20 percent of Cu, 0.40 to 0.55 percent of Ni, 0.45 to 0.65 percentof Cr, less than or equal to 0.10 percent of Mo, 0.025 to 0.050 percent of Alt, and the balance of Fe and unavoidable impurities. Compared with the brand number corresponding to the national standardand European standard, the grade-90 chain steel disclosed by the invention ahs the following advantages: (1) the contents of C and Mn are increased, the cost is slightly increased, and the strength and hardness of the material are greatly improved; (2) the content of Ni is reduced, no Mo element is added, and the cost is greatly reduced; and (3) by reasonably optimizing the alloy elements, on thepremise of ensuring the qualification of breaking strength of the material, the welding performance of the material is also considered, and the cost of raw materials are greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

Fire-resistant cellulose-bitumen roofing sheet and method of manufacturing

InactiveUS20130186033A1Low thermal conductivityLow densityRoof covering using slabs/sheetsLiquid surface applicatorsCellulose fiberGraphite

Bitumen-impregnated cellulose fiber sheets include on one of their main surfaces, an adhesive primer layer, and, deposited on this adhesive primer layer, a fireproof coating including expandable graphite. In a preferred embodiment of the invention, the expandable graphite has a trigger temperature lower than 300° C. and the layer of expandable graphite corresponds to a dry matter basis weight of 80 to 140 g / m2. The sheets have a fire resistance fulfilling in particular the European Standard EN 13 501-5. They are mainly intended to be used as covering material, and in particular, as roof covering material.

Owner:ONDULINE SA

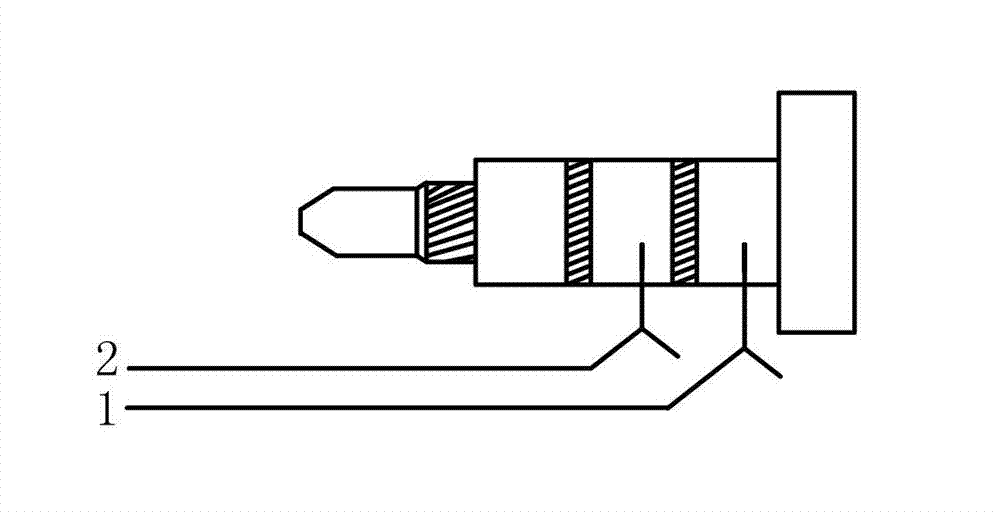

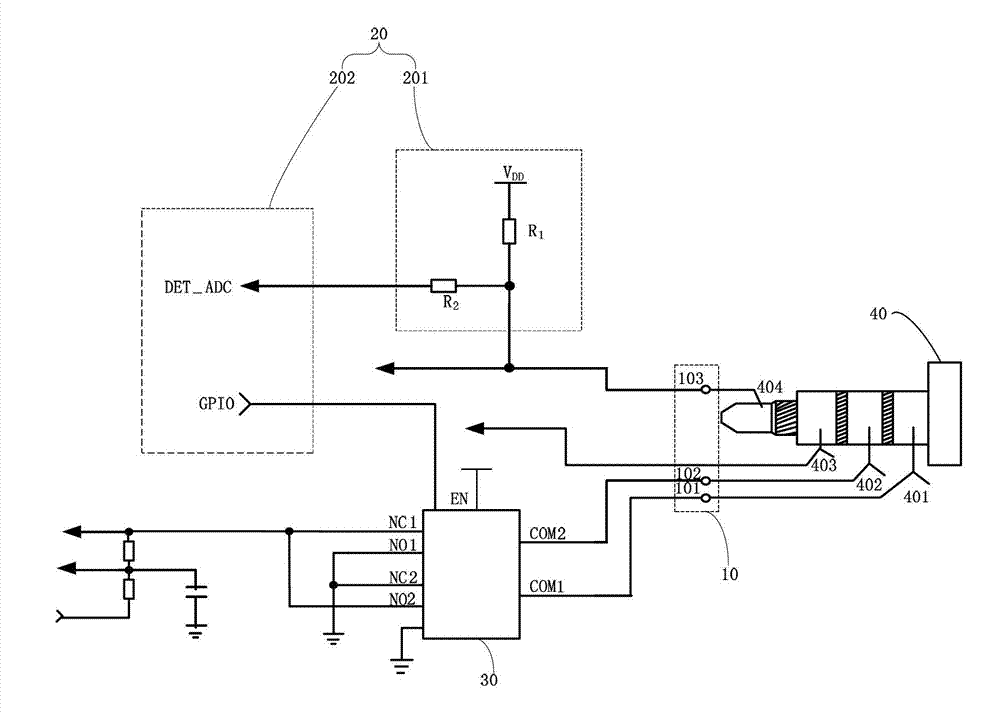

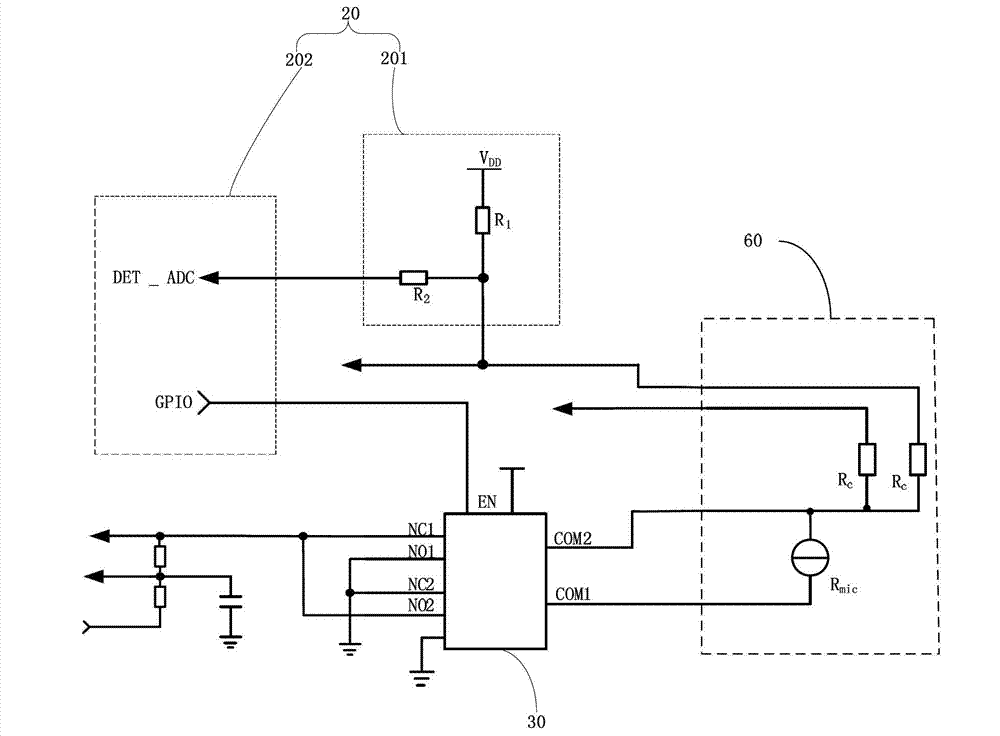

Earphone interface circuit and mobile communication device

The invention discloses an earphone interface circuit, which comprises an earphone jack and an identification module. The earphone jack comprises a first metal contact part, a second metal contact part and a third metal contact part. The third metal contact part is connected with an European standard earphone plug which is plugged into the earphone jack or one of a left-channel signal output end and a right-channel signal output end of an American-standard earphone plug; and the identification module is connected with the third metal contact part, and the earphone plug which is plugged into the earphone jack is judged to be the European-standard earphone plug or the American-standard earphone plug according to a voltage value of the third metal contact part. The invention also discloses a mobile communication device. Through the earphone interface circuit and the mobile communication device, the European-standard earphone and the American-standard earphone can be identified.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Rigid polyvinyl chloride floor tile and process for producing the same

InactiveUS20180171644A1Increase resistanceGood lookingLamination ancillary operationsSynthetic resin layered productsPolyvinyl chlorideHardness

The present invention provides a rigid polyvinyl chloride floor tile comprising, in order from top to bottom, a protective layer, a decorative layer, a support layer and a balance layer, wherein the rigid polyvinyl chloride floor tile has a thermal dimensional shrinkage of 0-0.15% as determined in accordance with European Standard EN434, and a Shore-D hardness of 60°-90°. The present invention also provides a process for preparing the rigid polyvinyl chloride floor tile.

Owner:Minghe Technology (Tangshan) Co Ltd

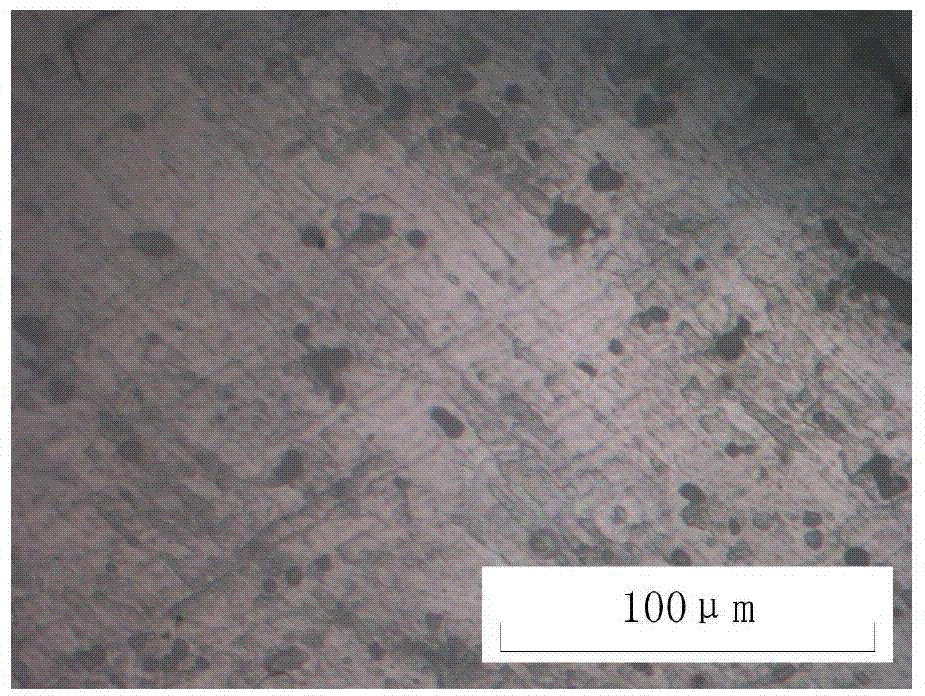

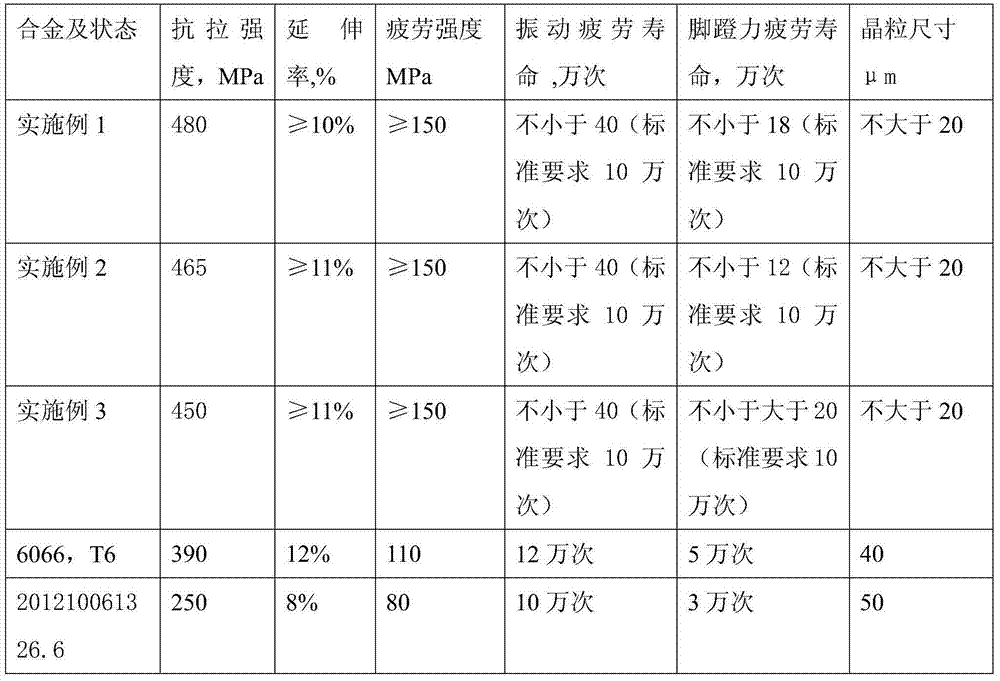

Aluminum alloy for bicycle frame tube and preparation method thereof

The invention discloses an aluminum alloy for a bicycle frame tube and a preparation method thereof, wherein the aluminum alloy aims at solving the technical problems that the intensity of the existing aluminum alloy which is used for manufacturing the bicycle frame tube is not good or the welding process property is not good or the safe reliability is not good. The aluminum alloy comprises the following components according to weight percentage 0.8-1.6% of Mg, 0.8-1.8% of Si, 0.7-1.2% of Cu, 0.6-1.4% of Mn, 0.10-0.30% of Cr, 0.1-0.6% of Er, 0.08-0.20% of Zr, and the balance Al and inevitable impurities. The aluminum alloy provided by the invention have the beneficial effects that the intensity of the aluminum alloy is good, the plasticity is good, the light weight of a bicycle is realized, the intensity of the bicycle frame tube which is made of the aluminum alloy is greater than 450MPa, and the extending ratio can be kept to be more than 10%; the welding property and the extrusion property are excellent, the welding requirements on the extrusion moulding of the bicycle frame tube and a frame are met, and the aluminum alloy can smoothly pass the European standard safety test.

Owner:TIANJIN GOLDEN WHEEL BICYCLE GRP +1

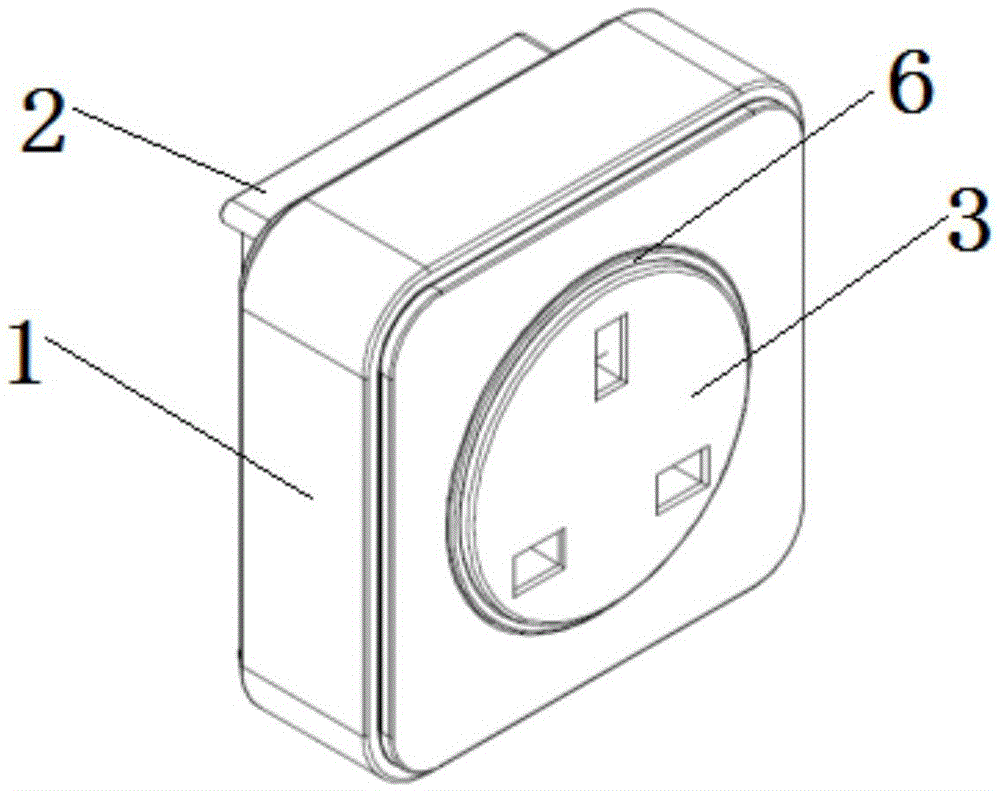

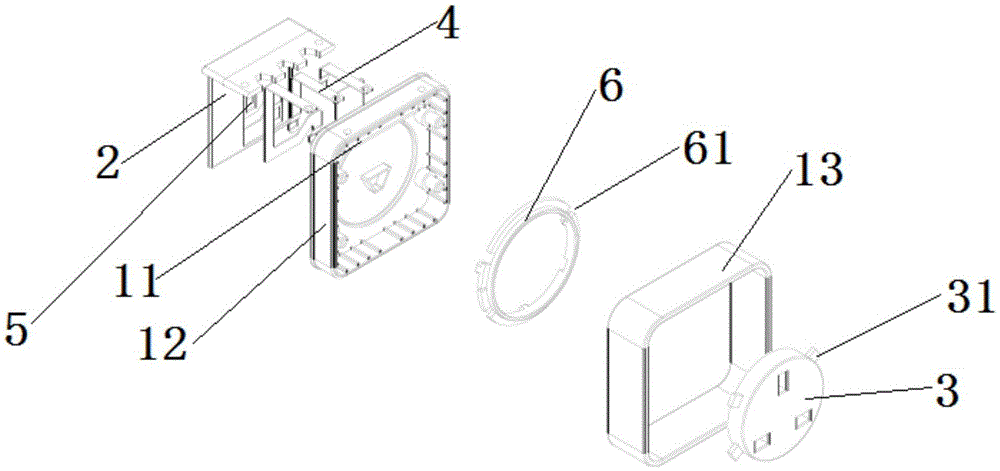

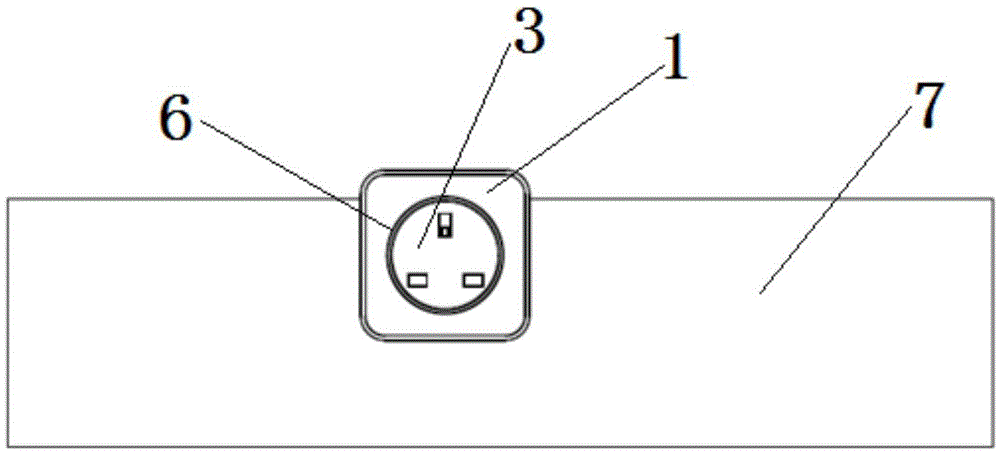

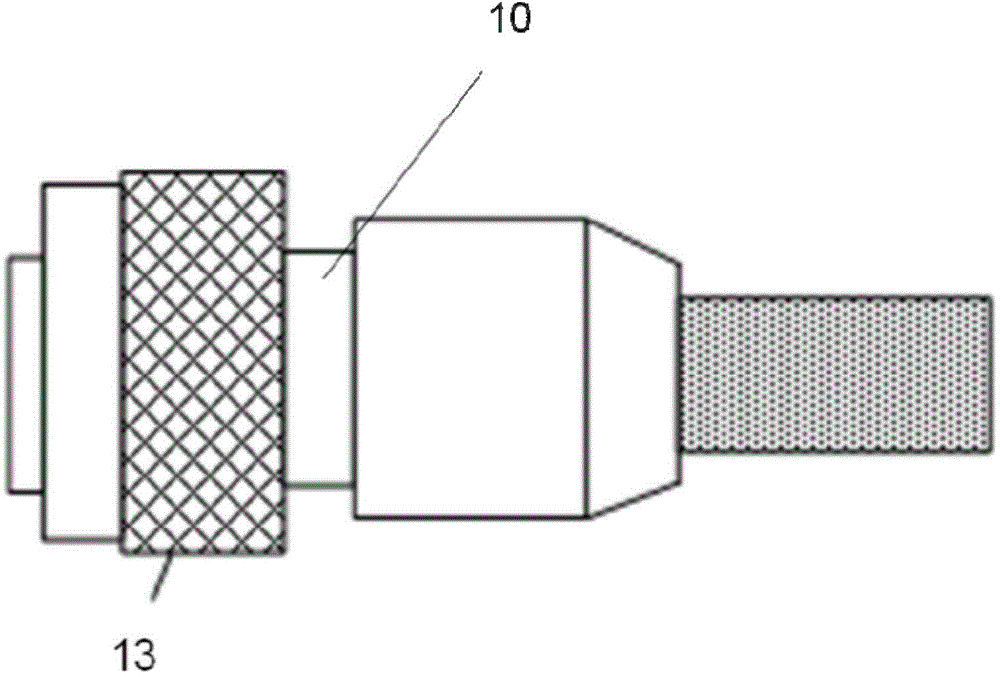

Hanging plate socket

InactiveCN105428858AConductiveFunctionalCoupling contact membersClamped/spring connectionsEngineeringNational standard

The invention relates to a hanging plate socket. The hanging plate socket comprises a shell and a hanging plate, wherein a socket core connected with a plug is arranged on at least one side surface of the shell; the hanging plate is hung on the outer side of the shell; a connecting conductive plate is arranged in the shell; one end of the connecting conductive plate is connected with the socket core and the other end of the connecting conductive plate is communicated with the hanging plate; an indicator light is arranged on the shell and is connected with the connecting conductive plate; and when the hanging plate is communicated with a power supply, the indicator light is turned on. Compared with the prior art, the hanging plate socket provided by the invention has the function of indicating conducting or not; and the safety of the socket is improved. In addition, in the form of the socket core, on one hand, production, disassembly and composition are facilitated; and on the other hand, the socket core can be separately replaced. Furthermore, a national standard jack or a British standard jack or an American standard jack or an European standard jack or a south African standard jack or an Australian standard jack can be selected as the jack on the socket core provided by the invention, so that the compatibility of the socket is improved; and the application range is wide.

Owner:SHANUTEC (SHANGHAI) CO LTD

Environment friendly flame-retardant carpet latex and preparation technique

InactiveCN101497797AEliminate secondary pollutionImprove flame retardant performanceFloor carpetsGreen environmentEuropean standard

The invention relates to environment-friendly fire resistant carpet latex with fire resistant function and a preparation process thereof. The fire resistant carpet latex comprises 26-36 percent of carboxylic styrene butadiene latex by weight, 7-11 percent of calcium carbonate by weight, 5-7 percent of ammonium polyphosphate by weight, 12-18 percent of trihydrate alumina, and 30-40 percent of water. The fire resistant carpet latex has better fire resistant effect, can radically eliminate the secondary pollution generated by burning the carpet when being applied to the carpet, and smoothly satisfies the requirements of the ship environment-friendly fire resistant product in the International Maritime Organization, the green environment-friendly performance test of Green Label Plus of the CRI in America, the requirement more than Cfl level of the public fire resistant product in the national force standard GB20286-2006, and the requirement more than Cfl level of the building fire-fighting product classification of the European standard EN13501-1.

Owner:ZHEJIANG ARTISTIC CARPETAB MFG

Charging connecting device of electric vehicle

InactiveCN104701701AEnsure structural stabilityAvoid leakage accidentsCoupling device connectionsVehicle connectorsEngineeringNational standard

The invention provides a charging connecting device of an electric vehicle. The device comprises a vehicle plug, a charging pile plug, a first adapter and a second adapter; the vehicle plug comprises a first AC power contact, a first medium line contact, a first protecting grounding contact, a first charging confirmation contact and a first control confirmation contact; the charging pile plug comprises a second AC power contact, a second medium line contact, a second protection grounding contact, a second charging confirmation contact and a second control configuration contact; the first adapter is connected with the vehicle plug through a first cable; the second adapter is connected with the charging pile plug through a second cable; the first adapter and the second adapter are equipped with a third contact and a fourth contact which are arranged in the same position and adapted to each other by the structure; in addition, the contacts with the same function in the vehicle plug and the charging pile plug can be correspondingly connected. With the adoption of the device, the problem that the electric vehicle produced according to the European standard and US standard cannot be charged through charging pile produced according to national standard in the prior art can be solved.

Owner:STATE GRID CORP OF CHINA +1

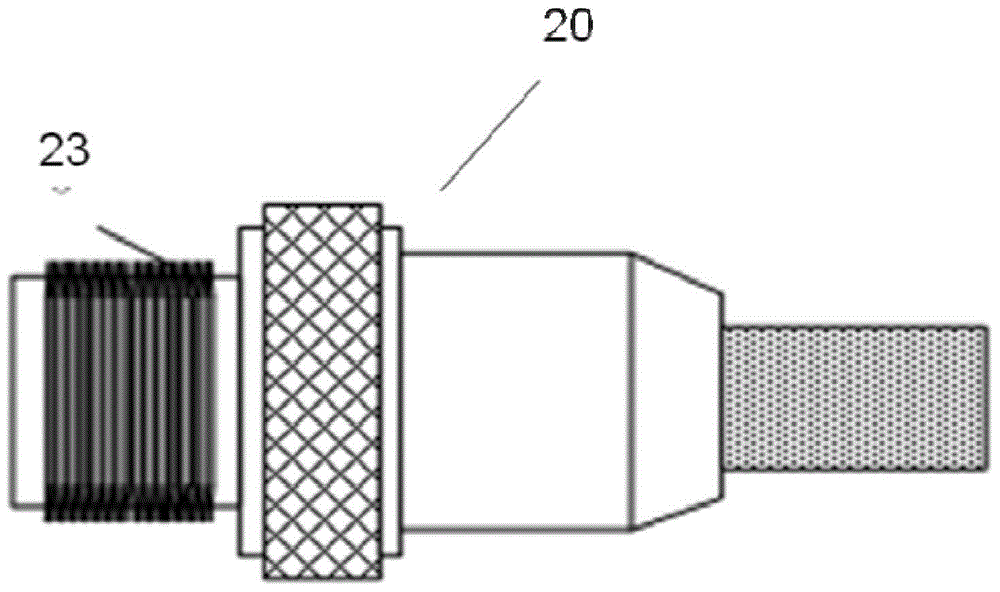

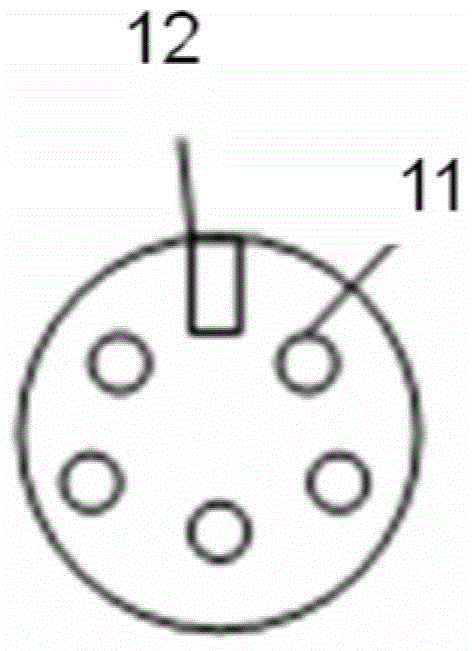

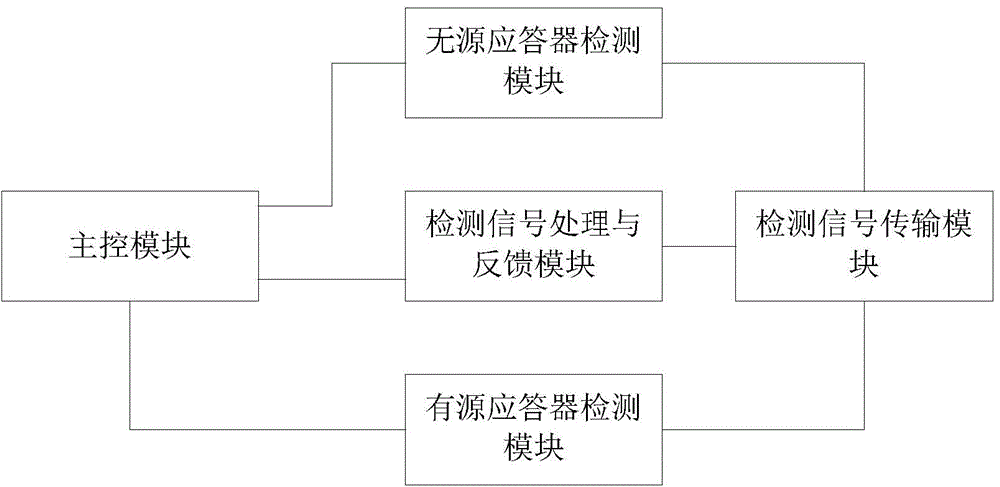

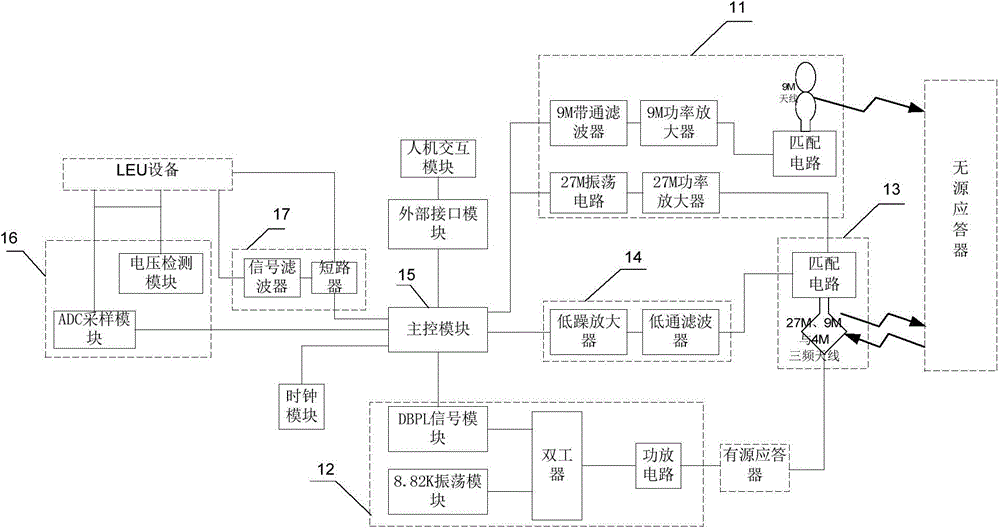

Automatic detection device of transponder

ActiveCN104702349ARealize detectionEnsure driving safetyTransmission monitoringComputer moduleEngineering

The invention discloses an automatic detection device of a transponder. A master control module is used for controlling a passive transponder detection module to detect the strength of an uplink signal of a passive transponder, the frequency and phase of an uplink link signal and a message read-write status; the automatic detection device can further simulate LEU (Lineside Electronic Unit) equipment, and detect the operating status of an active transponder through an active transponder detection module so as to judge whether the active transponder and the passive transponder are in good conditions, therefore the traffic safety can be effectively guaranteed; in addition, the automatic detection device can simulate the active transponder to generate a rail passing signal to detect the responding status of the LEU equipment; meanwhile, according to the technical scheme, the detection of large-capacity transponders can be realized, and the detection of an existing European standard transponders can be compatible.

Owner:CHINA RAILWAYS CORPORATION +2

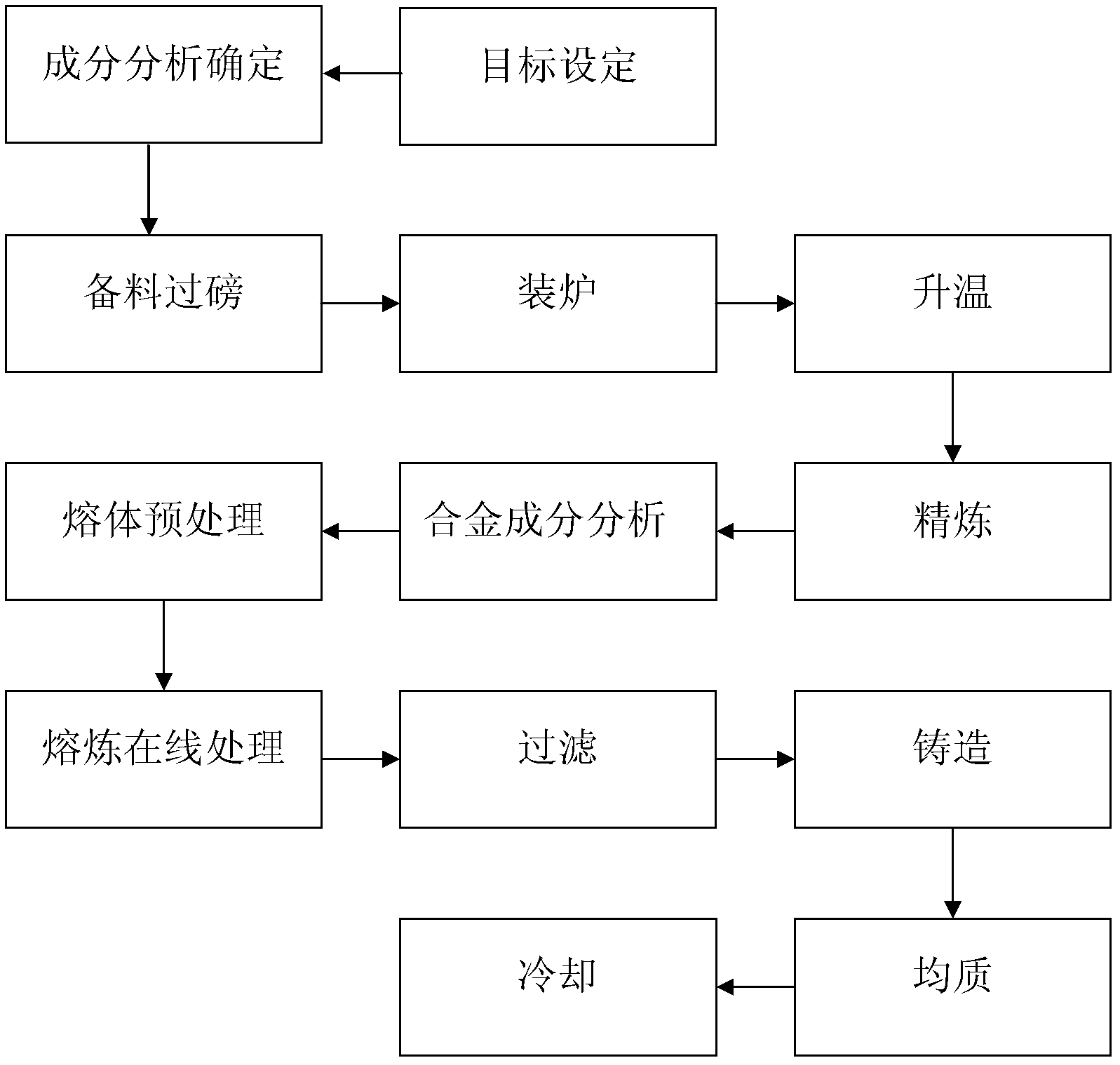

Aluminum alloy, preparation method and applications thereof

The present invention discloses an aluminum alloy, which comprises the following components, by mass, 0.8-1.0% of Si, 0.75-0.95% of Mg, 0.01-0.09% of Cu, 0.45-0.85% of Mn, 0.10-0.24% of Cr, less than 0.25% of Fe, less than 0.15% of other impurities, and the balance of Al. A preparation method for the aluminum alloy comprises: adding raw materials to a furnace, and carrying out heating melting; adding a smelting co-solvent to carry out refinement; carrying out a pretreatment on the obtained melt; carrying out a smelting online treatment; filtering; casting; carrying out homogenization; and cooling to obtain the aluminum alloy. The high speed railway aluminum material produced by adopting the aluminum alloy has the following characteristics that: a tensile strength is 3-30% higher than the European standard, a yield strength is 8-36% higher than the national standard, elongation is 2-100% higher than the national standard, fatigue resistance can be more than 500 thousand times, and the aluminum material is suitable for high speed railway locators.

Owner:FOSHAN GOLDEN SOURCE ALUMINUM PROD

Production method of high-strength marine aluminum alloy cylinder profiles

The invention relates to a production method of high-strength marine aluminum alloy cylinder profiles. The production method comprises aluminum alloy ingot casting; high-strength aluminum alloy cylinder profile extrusion and online quenching; high-strength aluminum alloy cylinder profile tension extension and aging treatment; high-strength aluminum alloy cylinder profile sampling and inspection; high-strength aluminum alloy cylinder profile test and packaging. According to the production method of the high-strength marine aluminum alloy cylinder profiles, the high-strength aluminum alloy cylinder profiles are produced through the online quenching and accordingly various performance indicators of the products meet the European standard requirements, the labor productivity is improved, the cost is saved, the order requirements of users are met, the localization production of the high-strength marine aluminum alloy cylinder profiles is achieved, and the import is replaced.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

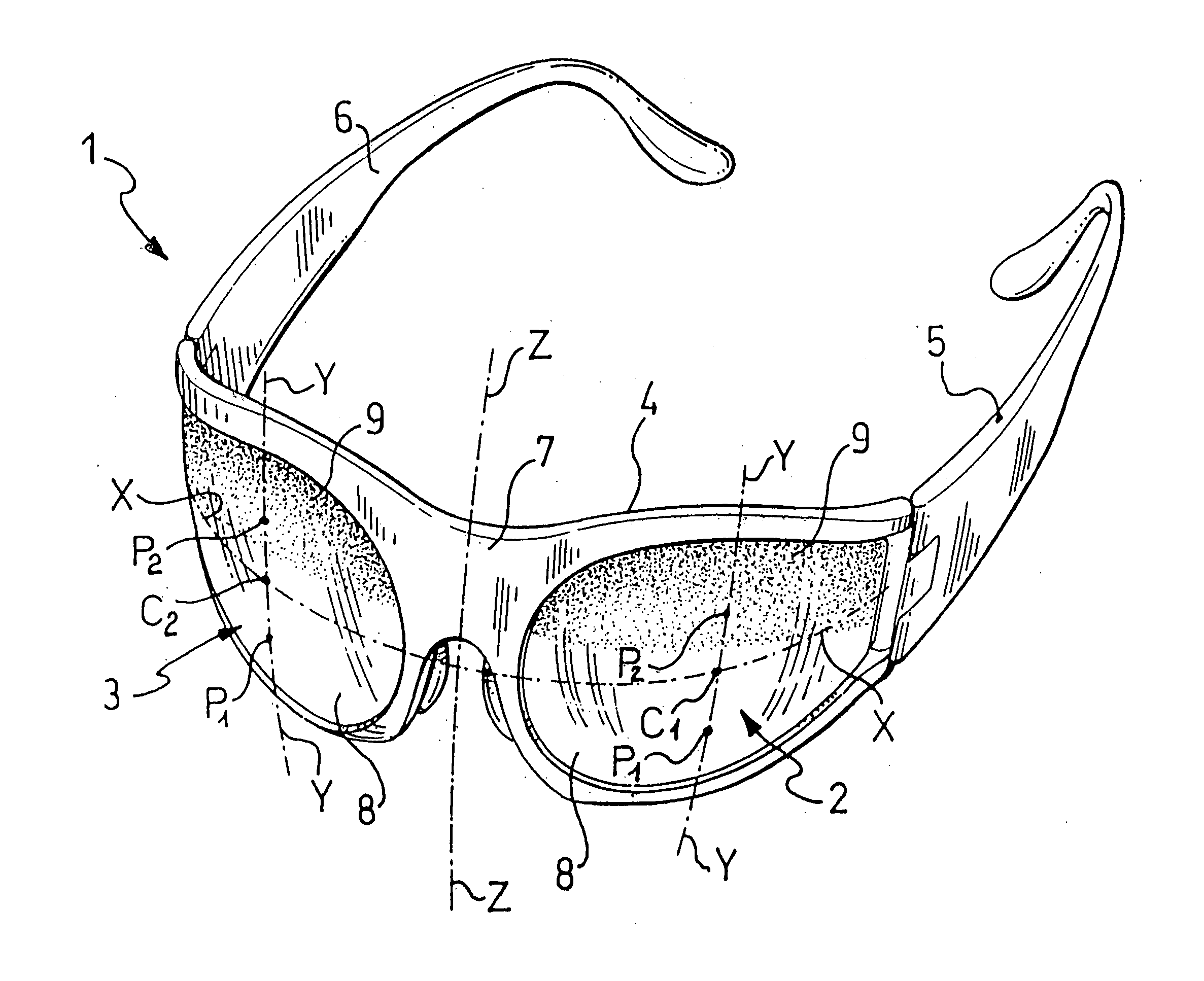

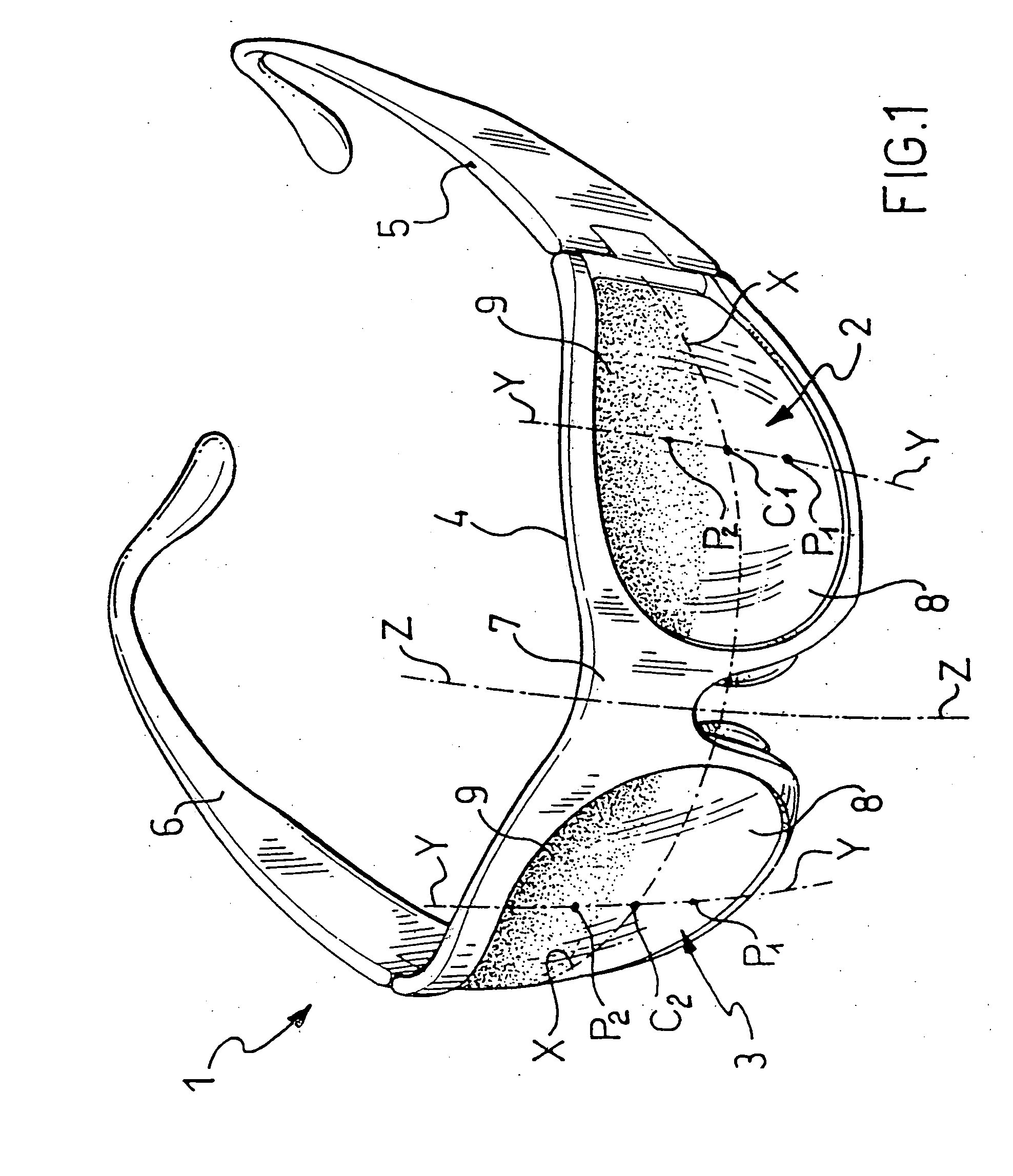

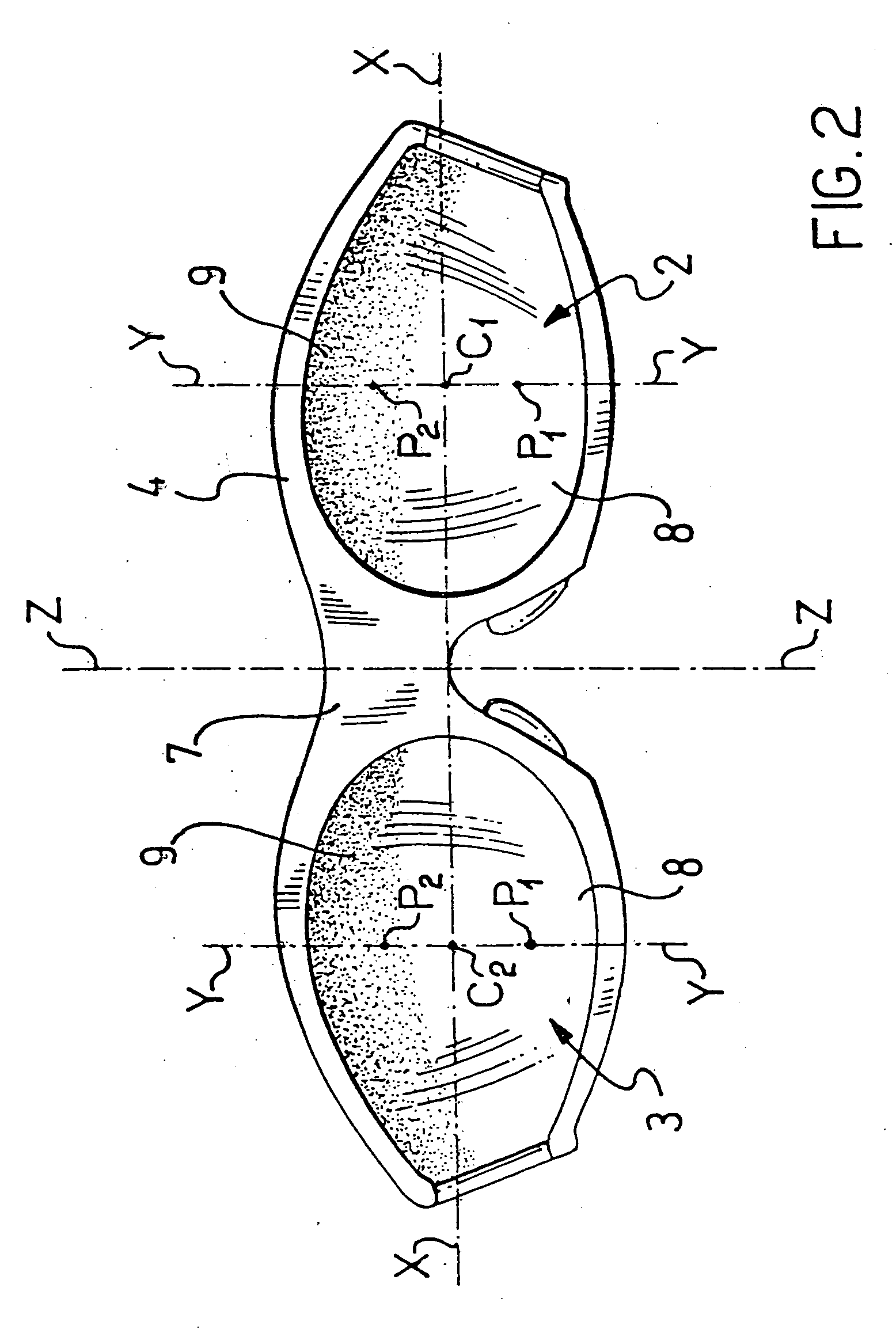

Polarized optical element having differentiated transmittance properties for use in eye-protecting devices

InactiveUS20070008485A1Reduce eye fatigueEffective reduction of the visual discomfortOptical partsOptical transmittanceMiddle line

A polarized optical element is disclosed comprising an upper portion and a lower portion defined at opposite parts with respect to a median line passing through the geometric center of the optical element, wherein: a) in the upper portion and at a distance of at least 10 mm from the median line the factor of luminous transmittance is between 3% and 20%; b) in the lower portion and at a distance of at least 10 mm from the median line the factor of luminous transmittance is between 15% and 65%; c) the ratio of the luminous transmittance measured in the lower portion at a distance of at least 10 mm below the median line and the luminous transmittance measured in the upper portion at a distance of at least 10 mm above the median line is not lower than 1.5; d) the colors of the upper and lower portions of the optical element are such that: d1) the absolute value of the difference between the value of the colorimetric coordinate a* of the upper portion measured at a point located 10 mm above the median line and the value of the colorimetric coordinate a* of the lower portion measured at a point located 10 mm below the median line is comprised between 0 and 60, d2) the absolute value of the difference between the value of the colorimetric coordinate b* of the upper portion measured at a point located 10 mm above the median line and the value of the colorimetric coordinate b* of the lower portion measured at a point located 10 mm below the median line is comprised between 0 and 60, e) the degree of polarization of the optical element is uniform both along a vertical and along a horizontal direction and is equal to at least 45% as measured according to European Standard EN 1836.

Owner:INTERCAST EURO

Methanol diesel oil for automobile

InactiveCN101368115AEasy to stratifySolve technical problems such as poor cold start at low temperatureLiquid carbonaceous fuelsEthyl acetateOleic Acid Triglyceride

The invention discloses methanol-diesel for vehicle. According to volume portion, the composition formulation comprises 20 to 65 portions of diesel oil, 30 to 70 portions of methanol, 0.5 to 1.5 portions of oleic acid, 0.5 to 2.0 portions of ethyl acetate, 0.5 to 1.0 portions of diphenyl carbonate, 0.5 to 1.5 portions of petroleum ether, 0.3 to 0.7 portions of cyclopentyl ferrocen, 0.2 to 0.8 portions of nitric acid iso-octyl, 0.5 to 2.0 portions of normal butyl alcohol and 0.5 to 1.5 isobutyl alcohol. The formulation is suitable for the normal diesel oil of any label, the technical problems that the methanol-diesel is easy to be delaminated and the low temperature cool start is imperfect are solved, and the source of the required raw materials and auxiliary materials is wide and the price is low; the cetane value of the formulated methanol-diesel for vehicle can reach 57, the flash point can reach 88 DEG C, and the exhaust emission is accorded with the requirements of the 3# European standard; the using of the methanol-diesel for vehicle has important social significance and economic value for energy conservation and environmental protection.

Owner:SHANGHAI SHUNTIAN CHEMISTERY TECH

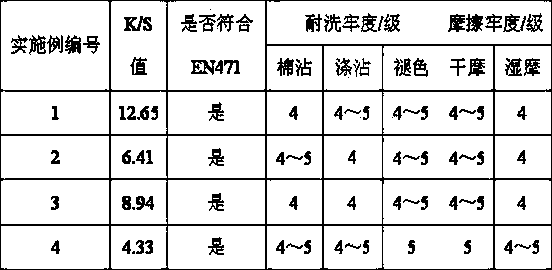

Preparation method of fluorescent yellow polyester-cotton fabric

InactiveCN104018370ALower dyeing temperatureReduce manufacturing costDyeing processPolyesterFluorescence

The invention discloses a preparation method of a fluorescent yellow polyester-cotton fabric. A carrier of reducing a polyester dyeing temperature is added in dyeing bath of disperse fluorescent yellow 10GN and active fluorescent yellow FL of the polyester-cotton fabric, so that the dyeing temperature of the polyester disperse fluorescent yellow 10GN is reduced, and most hydrolysis of reactive dyes under a high-temperature condition is prevented; and a dyeing method of fixing the active fluorescent yellow FL on cottons after dyeing the disperse fluorescent yellow 10GN on polyesters is adopted, so that all quality indexes of the dyed polyester-cotton fabric are accordant with that of the dyed fabric of a two-bath two-step method. The fluorescent dyeing is performed for the polyester-cotton fabric by adopting a one-bath one-step dyeing process, so that the production cost is reduced, and the quality of the obtained product is accordant with that of the two-bath two-step method, and satisfies the requirements of European standards EN471.

Owner:HENAN INST OF ENG

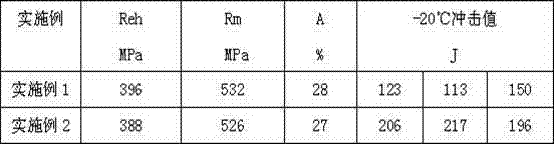

Export S355J2 titanium-added steel plate and production method thereof

The invention provides an export S355J2 titanium-added steel plate and a production method thereof. The export S355J2 titanium-added steel plate contains the following chemical ingredients by wt%: not more than 0.16% of C, 0.25-0.45% of Si, 1.0-1.4% of Mn, not more than 0.02% of P, not more than 0.004% of S, 0.05-0.06% of Ti, not more than 0.40 of CEV, and the balance of ion and inevitable impurities. Total heating time of continuous casting billet heating is not less than 9min / cm, the highest heating temperature is 1220 DEG C, soaking temperature is not more than 1200 DEG C, and soaking zone in-furnace time is more than 90min; the first stage start rolling temperature is not more than 1140 DEG C, and total reduction rate is more than 60%; the second stage start rolling temperature is 950 DEG C, finial rolling temperature is less than 900 DEG C, and deformation rate is controlled to 50%-60%; stacking temperature is not less than 400 DEG C, and stacking time is not less than 16h. The production technology provided by the invention has short technological process, and is low in production cost, suitable for large-batch production and beneficial for increasing export volume; product ingredients and product performance of the steel plate completely meet the requirements of European standard EN10020, Reh of the steel plate is up to 386MPa, Rm of the steel plate is up to 522MPa, A value of the steel plate is 28%, and average impact value of the steel plate at -20 DEG C is up to 172J.

Owner:ANGANG STEEL CO LTD

European-standard R320Cr steel rail and producing method thereof

The invention discloses a European-standard R320Cr steel rail. The steel rail is prepared from the following ingredients by weight percent: 0.73 to 0.78% of C, 0.75 to 0.85% of Si, 0.95 to 1.05% of Mn, 0.90 to 0.95% of Cr, smaller than or equal to 0.020% of P, smaller than or equal to 0.025% of S and smaller than or equal to 0.004% of Al. The invention further discloses a producing method of the European-standard R320Cr steel rail. The European-standard R320Cr steel rail producing method disclosed by the invention improves a steel rail producing efficiency and reduces energy consumption and production cost; the obtained European-standard R320Cr steel rail has good straightness, small residual stress and high quality; abrasion resistance is improved, service life is prolonged, rail transportation safety is improved, and a requirement of railway speed increasing development is favorable for being met.

Owner:BAOTOU IRON & STEEL GRP

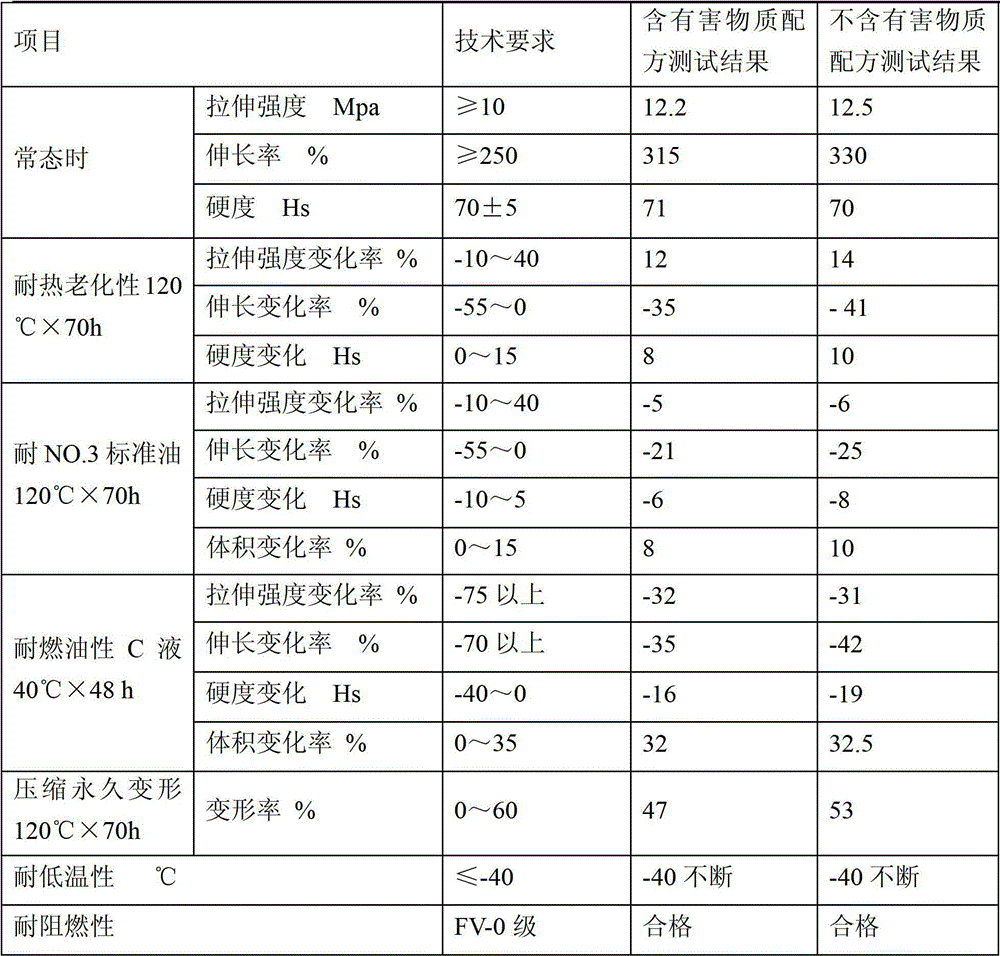

Environment-friendly flame-retardant type epichlorohydrin-rubber pipe formula

The invention relates to a formula of an environment-friendly flame-retardant type epichlorohydrin-rubber pipe, which comprises the following components in parts by weight: 30-70 parts of epichlorohydrin rubber C, 30-70 parts of epichlorohydrin rubber H, 1-8 parts of age inhibitor RD, 0.5-7.5 parts of age inhibitor MB, 1-7 parts of acid-absorbing agent DHT-4A, 2-10 parts of calcium oxide, 3-9 parts of diantimony trioxide, 7-13 parts of decabromodiphenyl ethane, 5-12 parts of lead-free vulcanizing agent H2, 35-55 parts of fast-extruding carbon black N550 and 1-9 parts of ATBC (Acetyl Tributyl Citrate). The environment-friendly flame-retardant type epichlorohydrin-rubber pipe also comprises 1-7.5 parts of anti-roll-bonding agent SPR 66. The environment-friendly flame-retardant type epichlorohydrin-rubber pipe can achieve the effect of flame retardance and simultaneously has the effect of environmental protection, and environment-friendly requirements in many aspects are met. Moreover, the requirements of European standards are met by the formula, and requirements on the required performances of products are achieved.

Owner:TIANJIN BINHAI NEW DISTRICT DAGANG TIANLI RUBBER HOSE

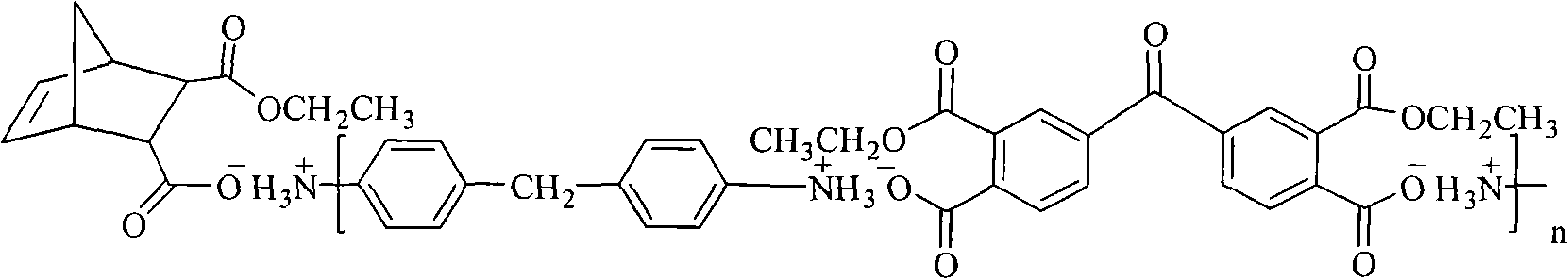

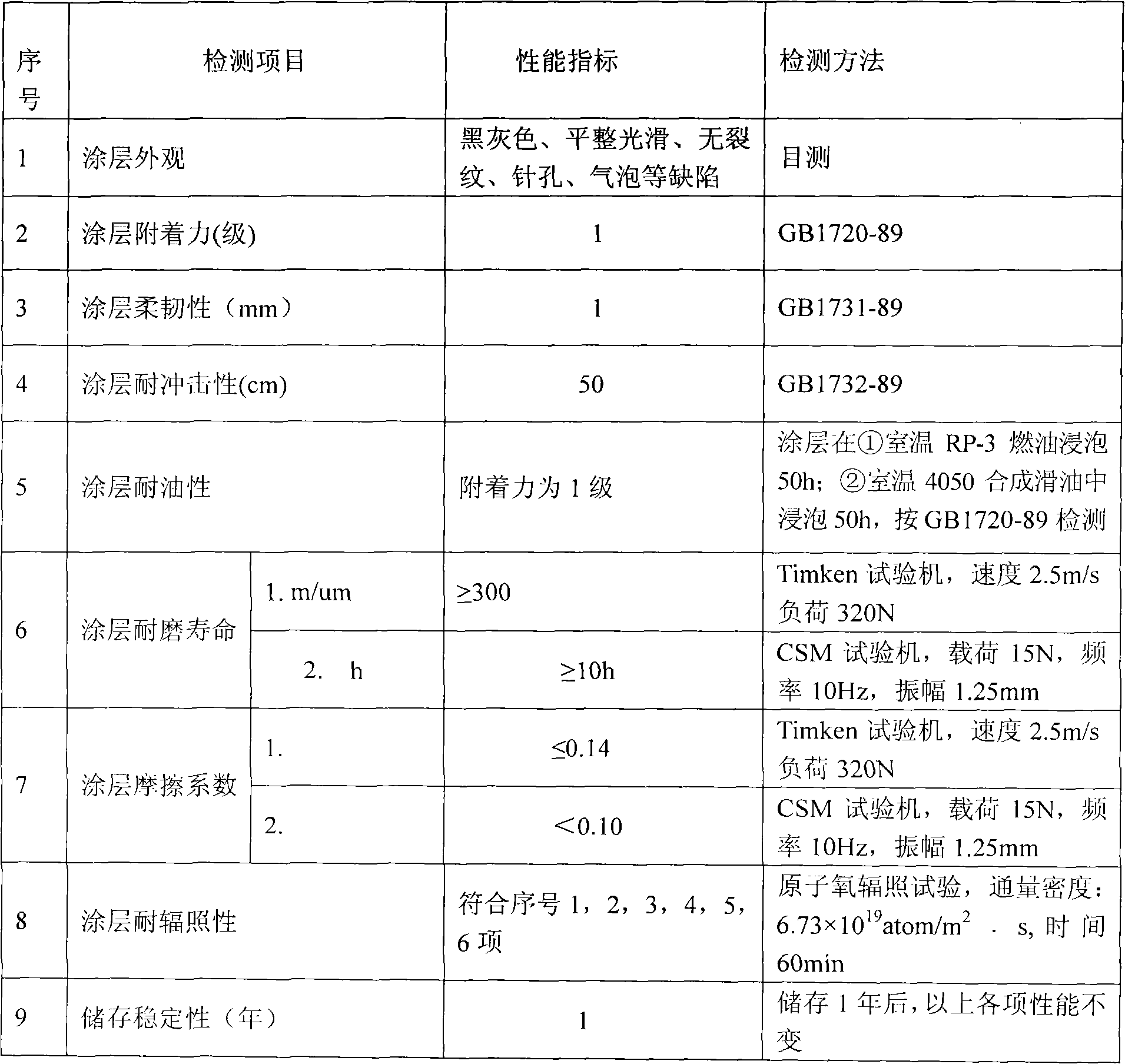

Lubricating coating with low friction and long service life

The invention discloses a lubricating coating with low friction and a long service life. The coating comprises, by mass: 15-25% of PMR (polymerizable monomeric reactant) type thermosetting polyimide resin, 3-8% of molybdenum disulfide powder, 0.5-4% of graphite powder, 0.1-0.5% of nanometer lanthanum trifluoride, and the balance mixed solvent. In the invention, the lubricating coating with low friction and a long service life is free of lead oxide, cadmium oxide, antimony trioxide and other metallic compounds forbidden by European standards. A paintcoat prepared with the coating of the invention can have high hardness, oil resistance and anti-irradiation property, low friction coefficient and long wearing life, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

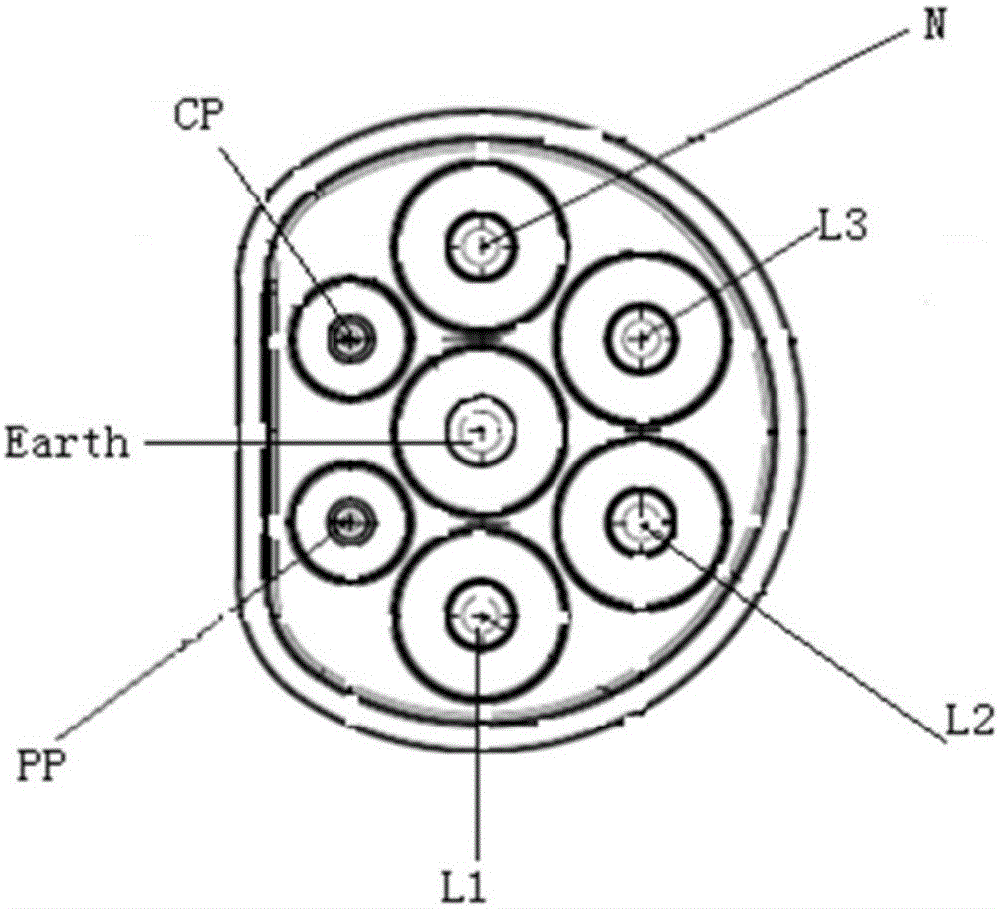

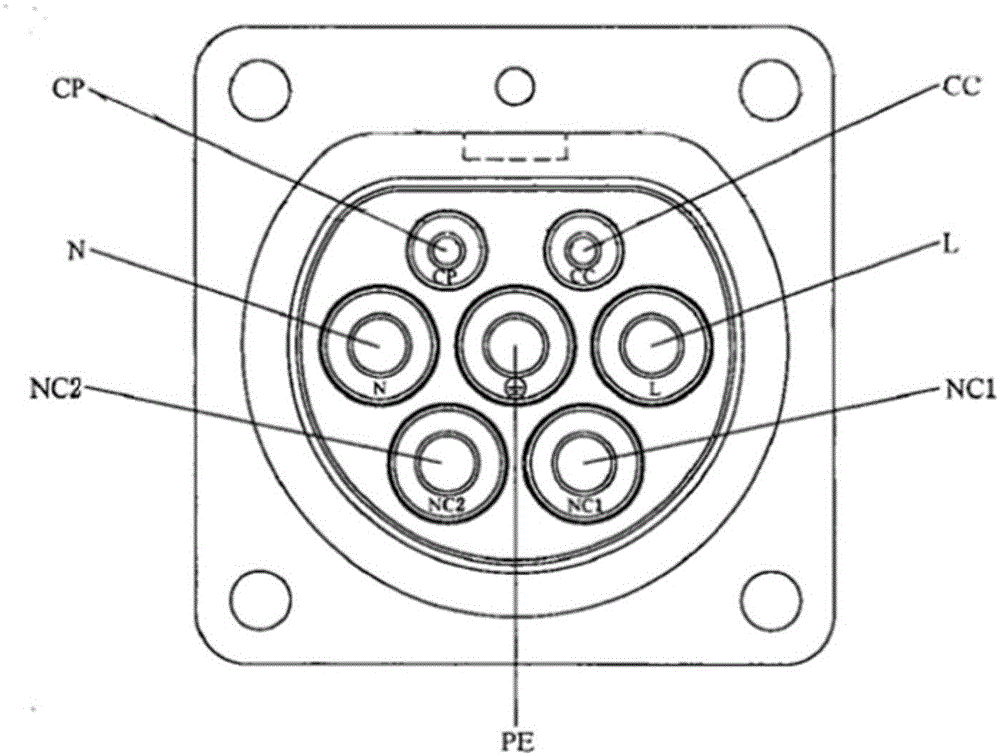

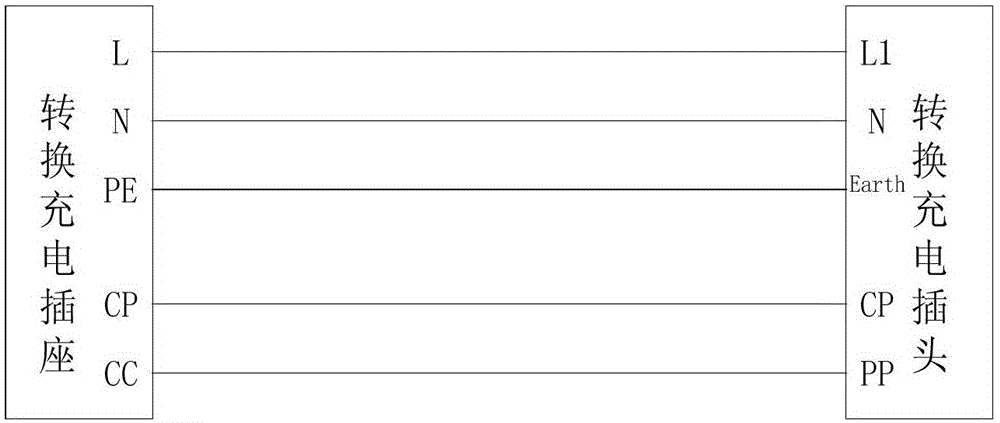

Converter for converting national-standard automobile charging interface into European-standard automobile charging interface

InactiveCN105140744AEasy to chargeEasy to operateCoupling device connectionsCharge controlNational standard

The invention provides a converter for converting a national-standard automobile charging interface into a European-standard automobile charging interface. The converter comprises a converting charging socket and a converting charging plug. The converting charging socket is connected with a national-standard charging plug, and comprises a live wire jack, a zero line jack, a grounding jack, a charging control jack and a gun head detection jack. The converting charging plug is connected with a European-standard electrical automobile charging socket, and comprises a live wire jack, a zero line jack, a grounding jack, a charging control jack and a gun head detection jack. The live wire jack, the zero line jack, the grounding jack, the charging control jack and the gun head detection jack of the converting charging plug are connected with the live wire jack, the zero line jack, the grounding jack, the charging control jack and the gun head detection jack respectively in one-to-one correspondence. European-standard automobile can use a national-standard charging pile for charging via the converter, and operation is convenient.

Owner:上海ABB联桩新能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com