Aluminum alloy, preparation method and applications thereof

A technology of aluminum alloy and silicon aluminum alloy, which is applied in the field of alloy materials, can solve the problem that the mechanical properties of 6082 aluminum alloy cannot meet the requirements of high-speed rail positioners and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

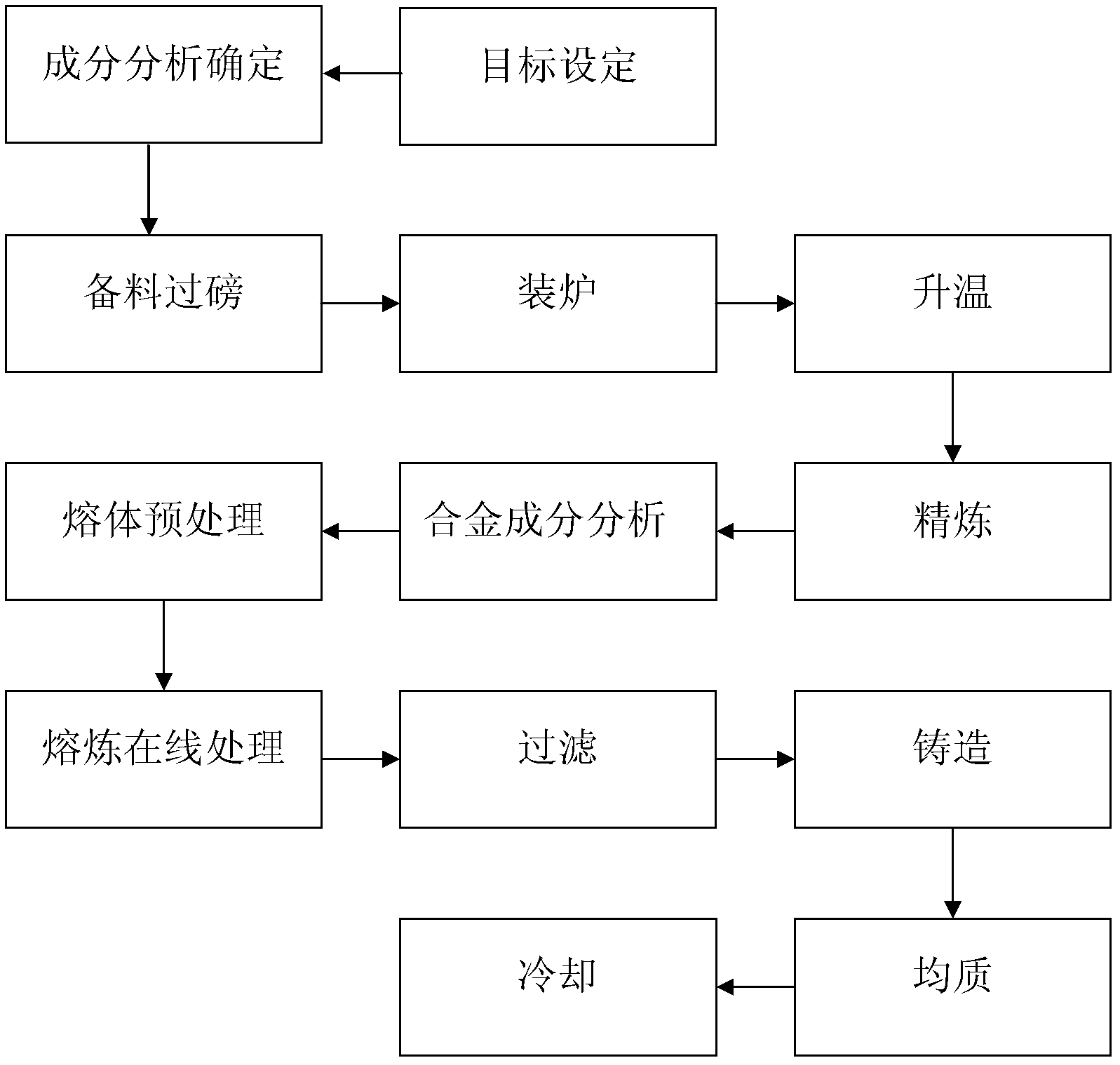

Method used

Image

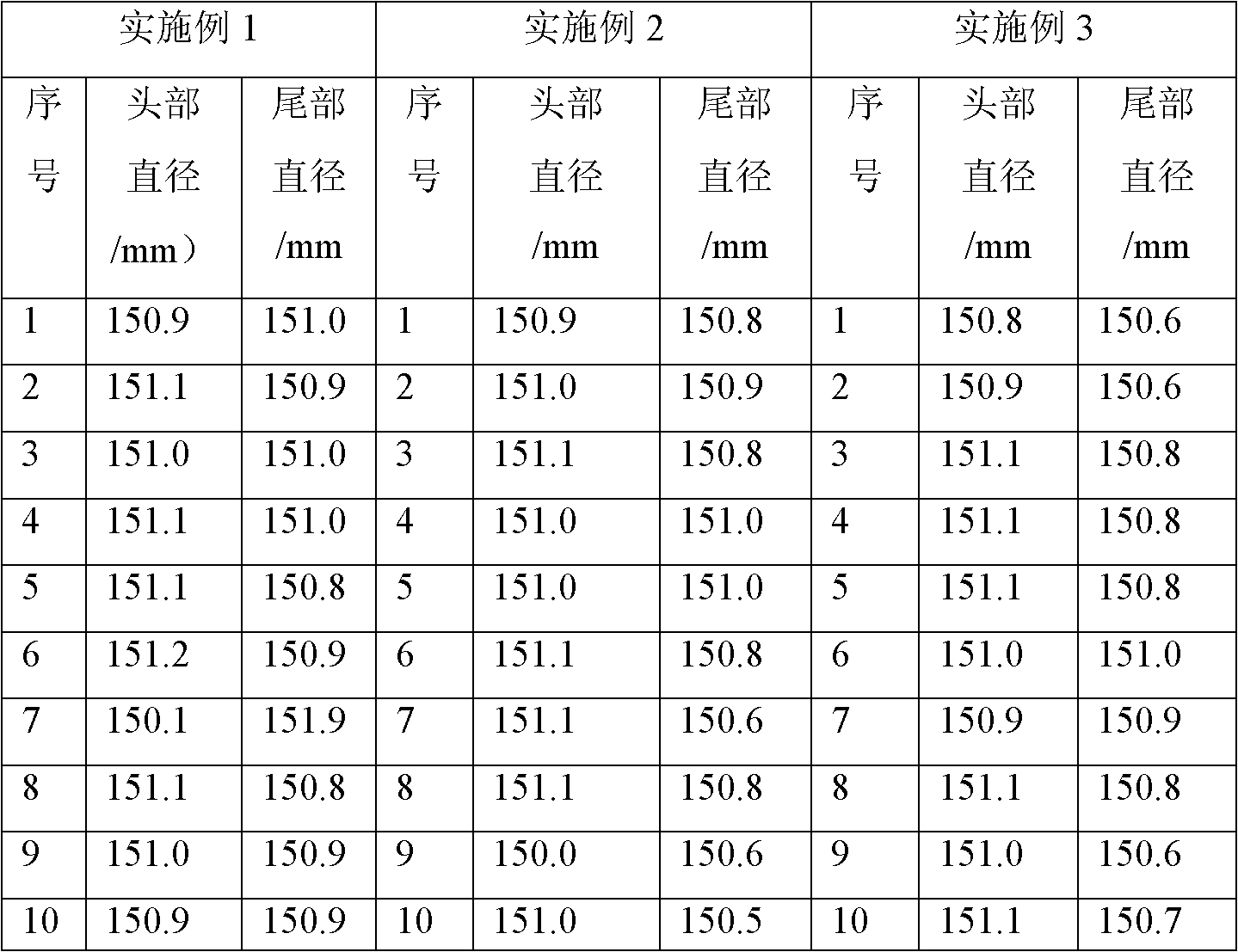

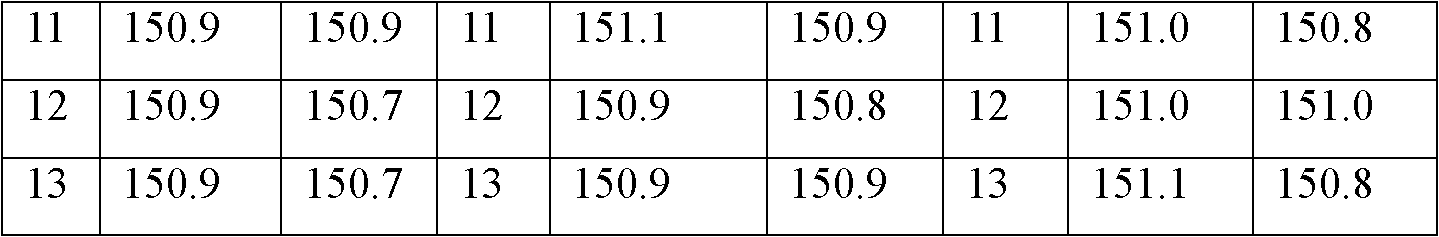

Examples

Embodiment 1

[0025] raw material

[0026] Aluminum ingots: Al99.7 aluminum ingots are used, and the mass percentage of Al in the aluminum ingots is more than 99.70%, which meets the standard GB / T1196-2008 "Aluminum Ingots for Remelting";

[0027] Magnesium ingots: Magnesium ingots with the brand Mg-2 are used, and the mass percentage of magnesium in the magnesium ingots meets the standard GB / T3499-2003 "Primary Magnesium Ingots";

[0028] Aluminum-silicon alloy: AlSi12 aluminum-silicon alloy is used, and the mass percentage of silicon in the aluminum-silicon alloy is 12±1%, which meets the standard YS / T282-2000 "Aluminum Master Alloy Ingot";

[0029] Mn additive: use brand 75# manganese agent, the mass percentage of manganese in the manganese agent is 75%, which meets the standard YS / T492-2005 "Aluminum and Aluminum Alloy Component Additives";

[0030] Cr additive: use 75# chromium agent, the mass percentage of chromium in the chromium agent is 75%, which meets the standard YS / T492-2005 "...

Embodiment 2

[0050] (1) Target setting: According to the requirements of aluminum materials for high-speed railways, set the target: the tensile strength is 3-30% higher than the European standard, the yield strength is 8-36% higher than the national standard, and the elongation is higher than the national standard 2-100%;

[0051] (2) Component analysis and determination: according to the set target, carry out component analysis, and finally determine the mass percentage of each component, see Table 1;

[0052] (3) Prepare the material and weigh: the amount of raw materials (the same as in Example 1) is as follows: the mass ratio of the aluminum in the aluminum ingot to the silicon in the aluminum-silicon alloy is 70:1; the addition of the Mn additive is the total amount of the aluminum ingot and the silicon-aluminum alloy 0.75% by weight; the addition of Cr additive is 0.27% of the total weight of aluminum ingot and silicon-aluminum alloy; the addition of magnesium ingot is 0.85% of the ...

Embodiment 3

[0064] (1) Target setting: According to the requirements of aluminum materials for high-speed railways, set the target: the tensile strength is 3-30% higher than the European standard, the yield strength is 8-36% higher than the national standard, and the elongation is higher than the national standard 2-100%;

[0065] (2) Component analysis and determination: according to the set target, carry out component analysis, and finally determine the mass percentage of each component, see Table 1;

[0066] (3) Prepare the material and weigh: the raw material (model is the same as in Example 1) consumption is as follows: the mass ratio of the aluminum in the aluminum ingot and the silicon in the aluminum-silicon alloy is 80: 1; 0.82% of the weight; the addition of Cr additive is 0.33% of the total weight of aluminum ingot and silicon-aluminum alloy; the addition of magnesium ingot is 0.95% of the total weight of aluminum ingot and silicon-aluminum alloy; the addition of electrolytic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com