Method for correcting elasticity modulus and stress-strain curve in metal material compression test

A compressive elastic modulus and strain curve technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of wrong compressive elastic modulus and too large difference between the nominal values of compressive elastic modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Preferred embodiments of the present invention are described in detail below in conjunction with accompanying drawing:

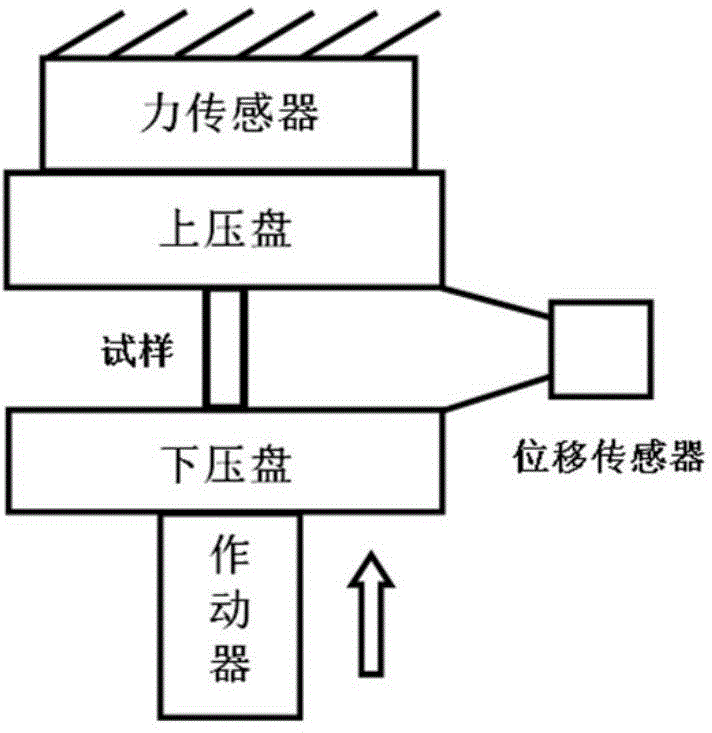

[0071] (1) Place the sample between the upper and lower pressure plates, and install a displacement sensor between the upper and lower pressure plates to measure the displacement between the upper and lower pressure plates as the compression deformation of the sample, such as figure 1 shown. This test method can ensure that the measured deformation is the compression deformation of the sample, and because the displacement sensor is located on the side of the upper and lower pressure plates, it will not be crushed by the pressure plate due to the accidental sudden break of the sample, which is relatively safe.

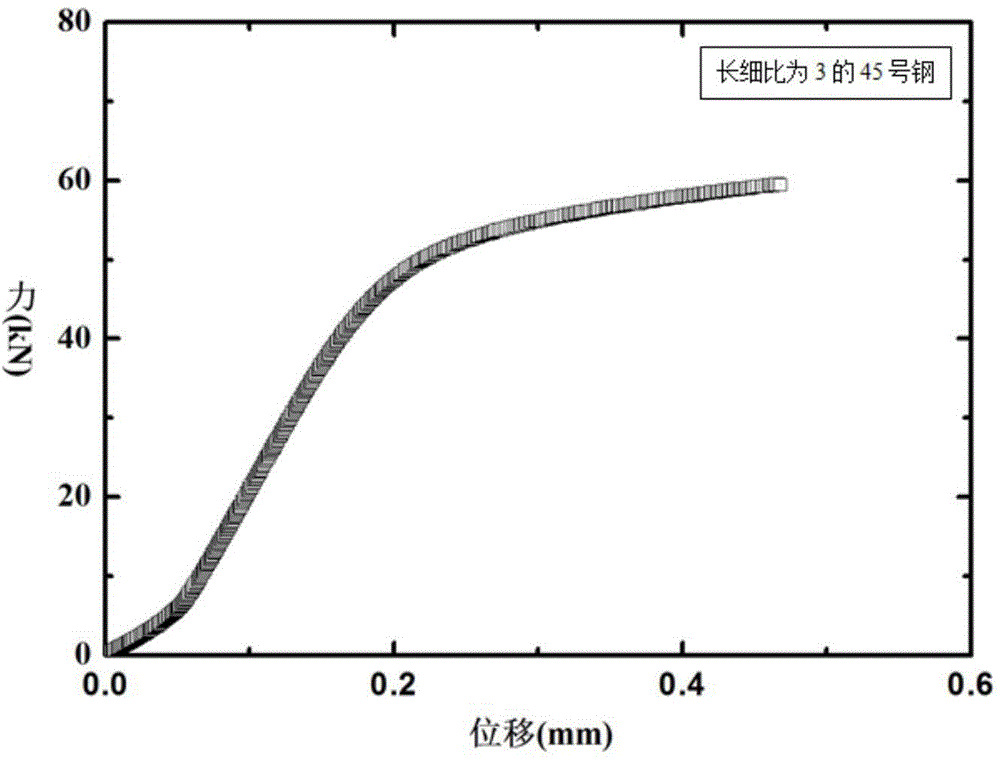

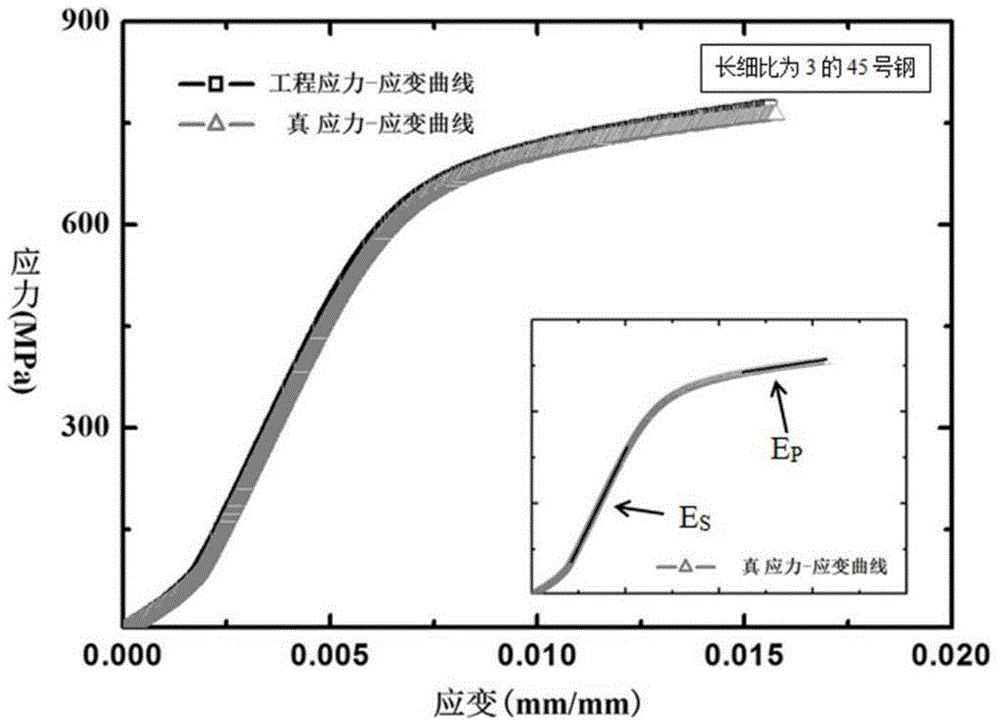

[0072] The sample used here is No. 45 steel with an aspect ratio of 3, a diameter of 10 mm, and a height of 30 mm. The displacement sensor used here is a strain gauge displacement sensor. Non-contact displacement sensors such as laser or vid...

Embodiment 2

[0090] The sample used here is 304 steel with an aspect ratio of 2, a diameter of 10mm, and a height of 20mm. The steps are the same as in Example 1, but in step (5), change formula (3) to formula (4), and the correction process is the same as the correction process of β of the sample whose slenderness ratio is 3 in the specification. For comparison of stress-strain curves before and after correction, see Figure 5 .

[0091] β = 0.26 m = 0.26 E P E S - - - ( 4 )

[0092] In this embodiment, the modulus of the 304 steel national standard size sample with a slenderness ratio of 2 is 78.1 GPa measured by the compression test, which is very different from the nominal value of 188.6 GPa (error 58.6%).

[0093] After being corrected by the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive modulus of elasticity | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com