Device for generating oil-containing water with micro air bubble

A technology for generating devices and micro-bubbles, which is applied in the directions of dissolution, liquid separation, chemical instruments and methods, etc., and can solve the problems of increasing the difficulty and limited treatment effect of the follow-up process of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

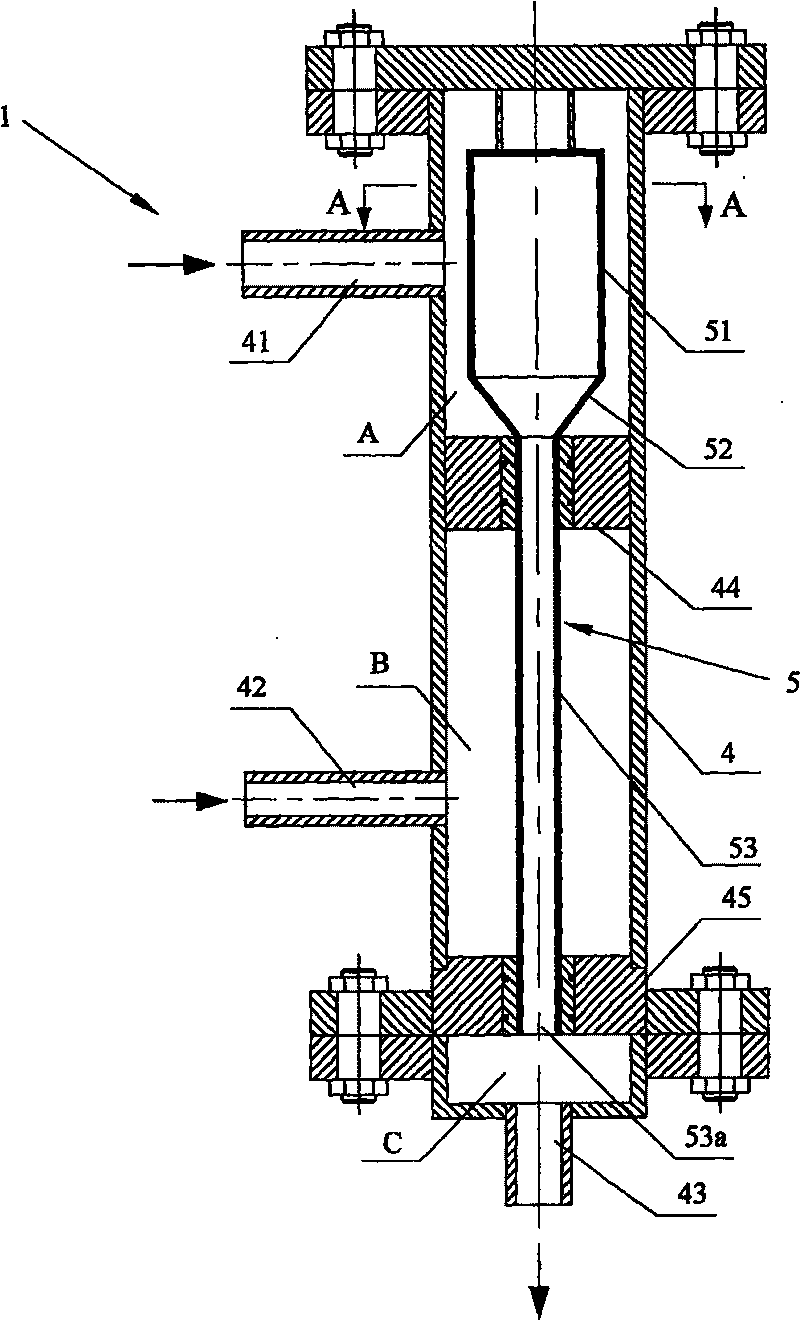

[0037] Such as Figure 1 to Figure 6 As shown, the generating device for oily water with fine bubbles is a combined device composed of a gas filter 2, a dissolved air water generator 1 and a large bubble remover 3 connected in sequence;

[0038] Among them, such as figure 1 Shown, described dissolved air water generator 1 comprises:

[0039] A top-sealed cylindrical container 4 has a water inlet 41 on its upper side wall, an air inlet 42 on the lower side wall, and a water outlet 43 on the bottom. The position between the gas ports 42 is provided with a first partition sealing plate 44, and the position below the air inlet 42 in the columnar container 4 is provided with a second partition sealing plate 45. The first and second partition sealing plates 44, 45 The inner cavity of the columnar container 4 is sequentially divided into a first liquid inlet chamber A, an air inlet chamber B, and a first liquid outlet chamber C from top to bottom;

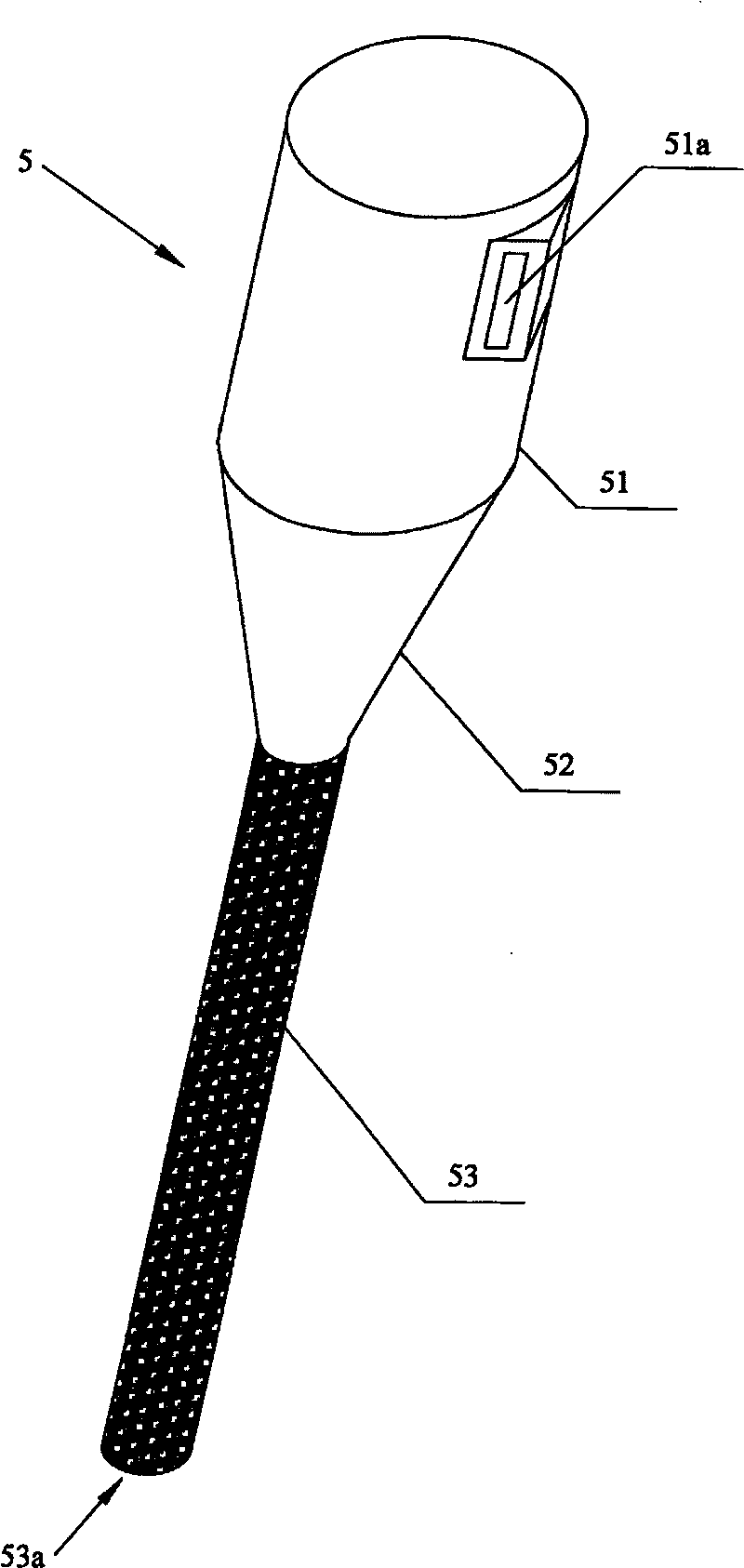

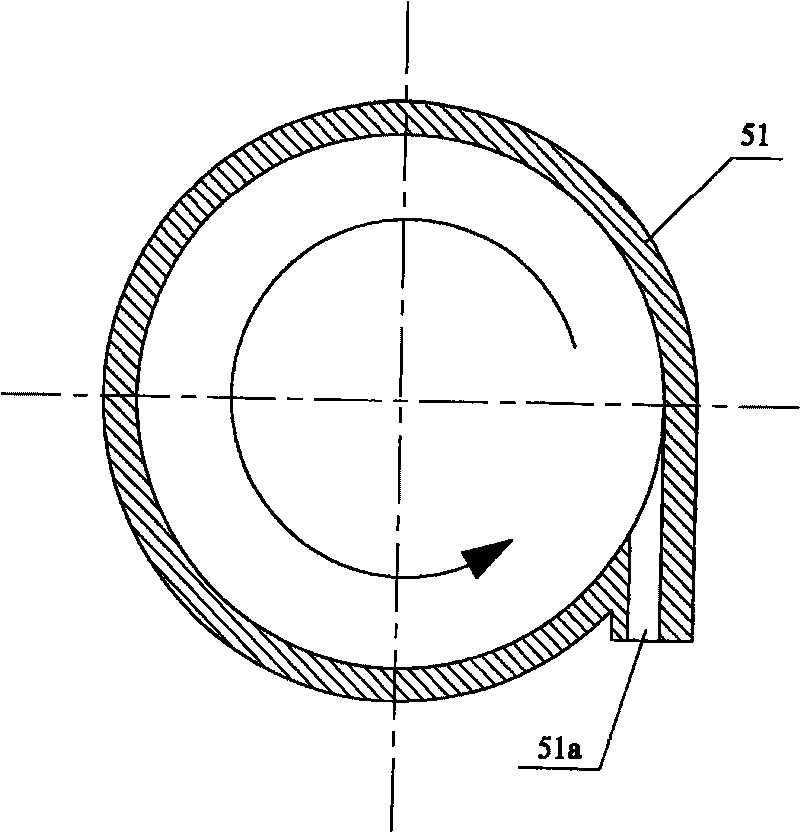

[0040] A top-sealed swirl-type ...

Embodiment 2

[0053] Such as Figure 7 , Figure 8 , Figure 9 As shown, it is Embodiment 2 of the present invention. The difference between this Embodiment 2 and Embodiment 1 is: in the dissolved air water generator 1, how many are evenly distributed in the manner of central symmetry in the columnar container 4? A described swirl-type dissolved air water generating tube 5, in the described large bubble remover 3, a plurality of the swirl-type gas-liquid are evenly distributed in the columnar housing 6 in a center-symmetric manner Separation tube 7, its distribution mode can also refer to Figure 8 , to apply to the treatment of large flow oily water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com