Salt-separation zero-discharge system for high-salt industrial wastewater

An industrial wastewater, high-salt technology, applied in water/sewage treatment, heating water/sewage treatment, chilled water/sewage treatment, etc., can solve the constraints of high-salt industrial wastewater, high investment and operating costs, chlorine Sodium chloride, sodium sulfate and sodium nitrate are difficult to meet the industrial reuse standards and other problems, so as to achieve the effect of enhancing shock load resistance and reducing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

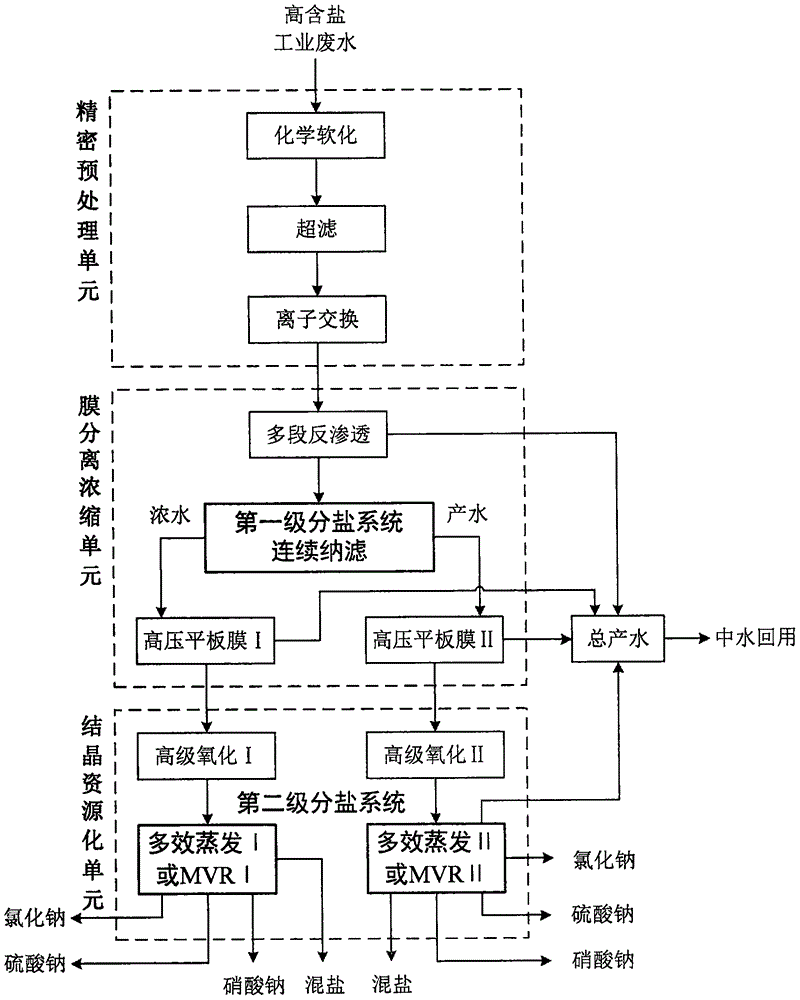

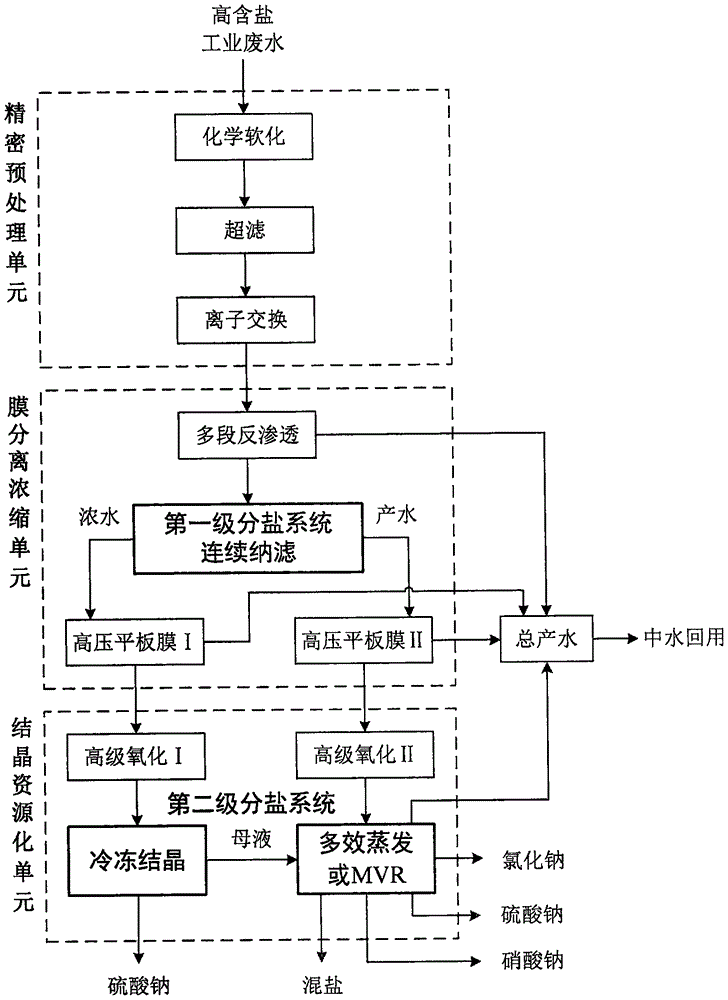

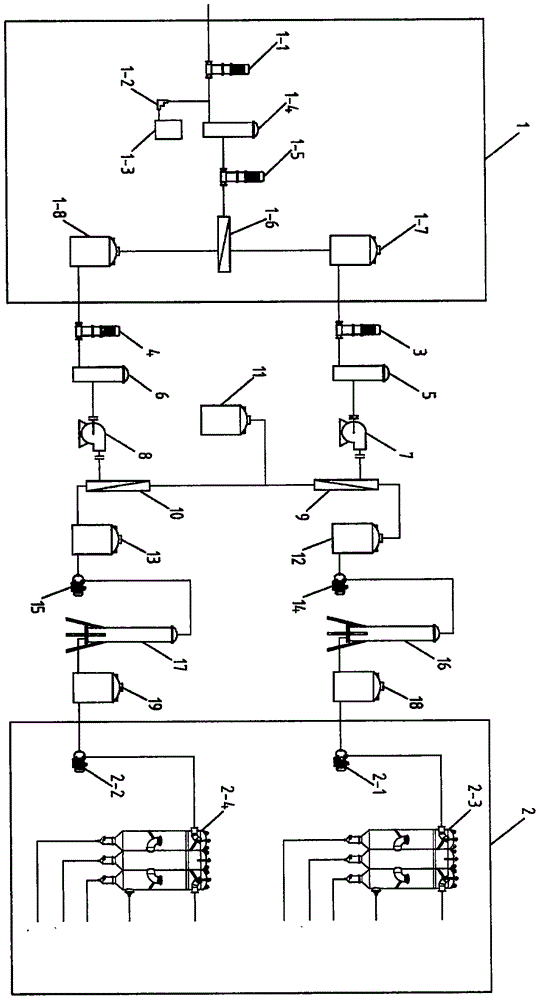

[0031] like figure 1 , 2 , 3 and 4, combined with the high-salt industrial wastewater salt-splitting zero-discharge project of a coal chemical enterprise in an industrial park (treatment capacity 96m 3 / d) As an example, a high-salt industrial wastewater salt separation zero discharge system and its two-stage salt separation treatment process are introduced in detail.

[0032] The average concentration of each pollutant in high-salt industrial wastewater is: COD Cr 120mg / L, total hardness (as CaCO 3 Calculated) is 960mg / L, total alkalinity (as CaCO 3 ) is 200mg / L, silicon dioxide is 50mg / L, total dissolved solids (TDS) is 10200mg / L, among them, the concentration of sodium chloride is 2990mg / L, the concentration of sodium sulfate is 4290mg / L, and the concentration of sodium nitrate is 840mg / L.

[0033] A high-salt industrial wastewater salt separation zero discharge system, which includes: a precision pretreatment unit, a membrane separation and concentration unit, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com