Patents

Literature

3950 results about "Sodium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium nitrate is the chemical compound with the formula NaNO₃. This alkali metal nitrate salt is also known as Chile saltpeter (large deposits of which were historically mined in Chile) to distinguish it from ordinary saltpeter, potassium nitrate. The mineral form is also known as nitratine, nitratite or soda niter.

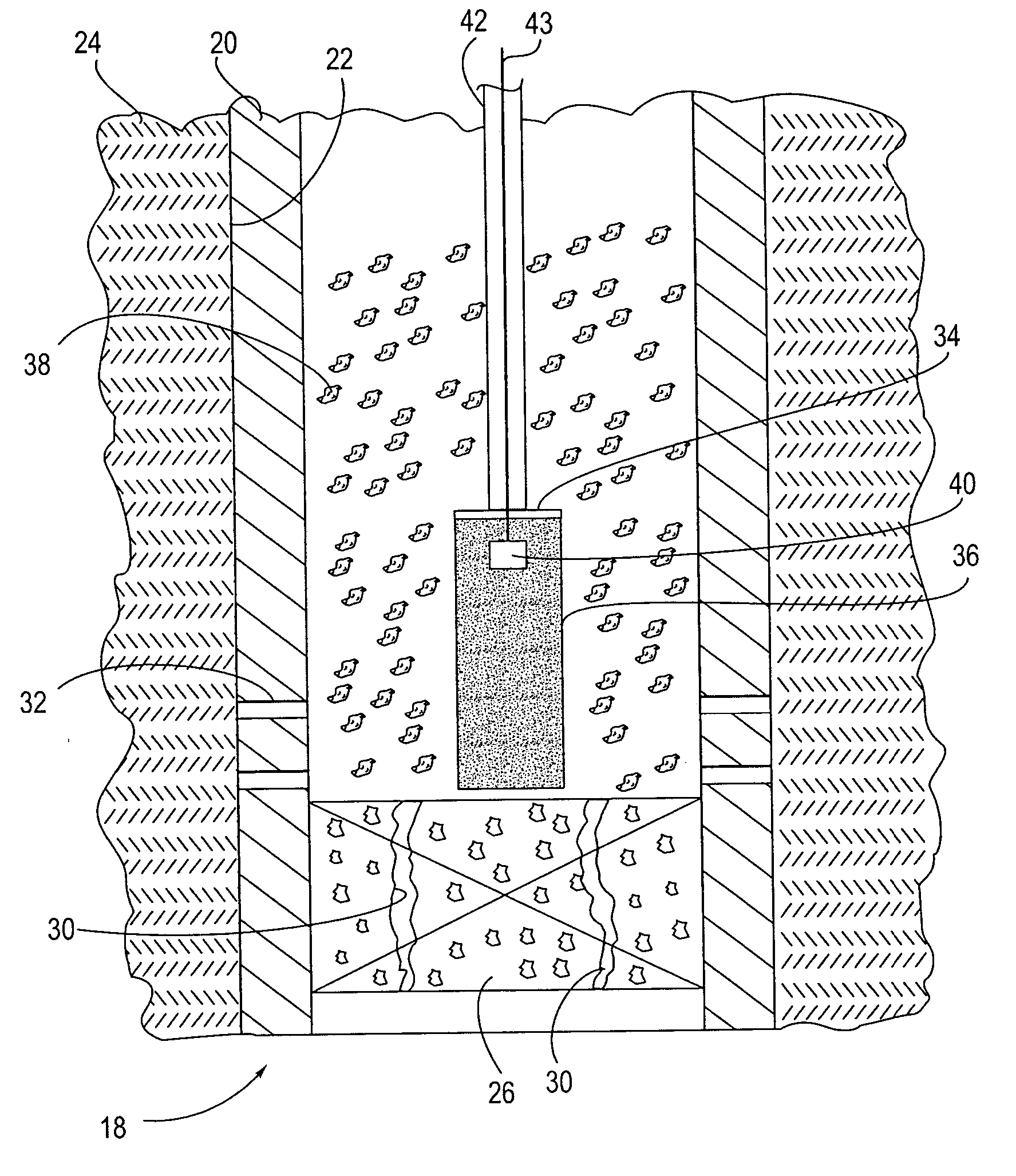

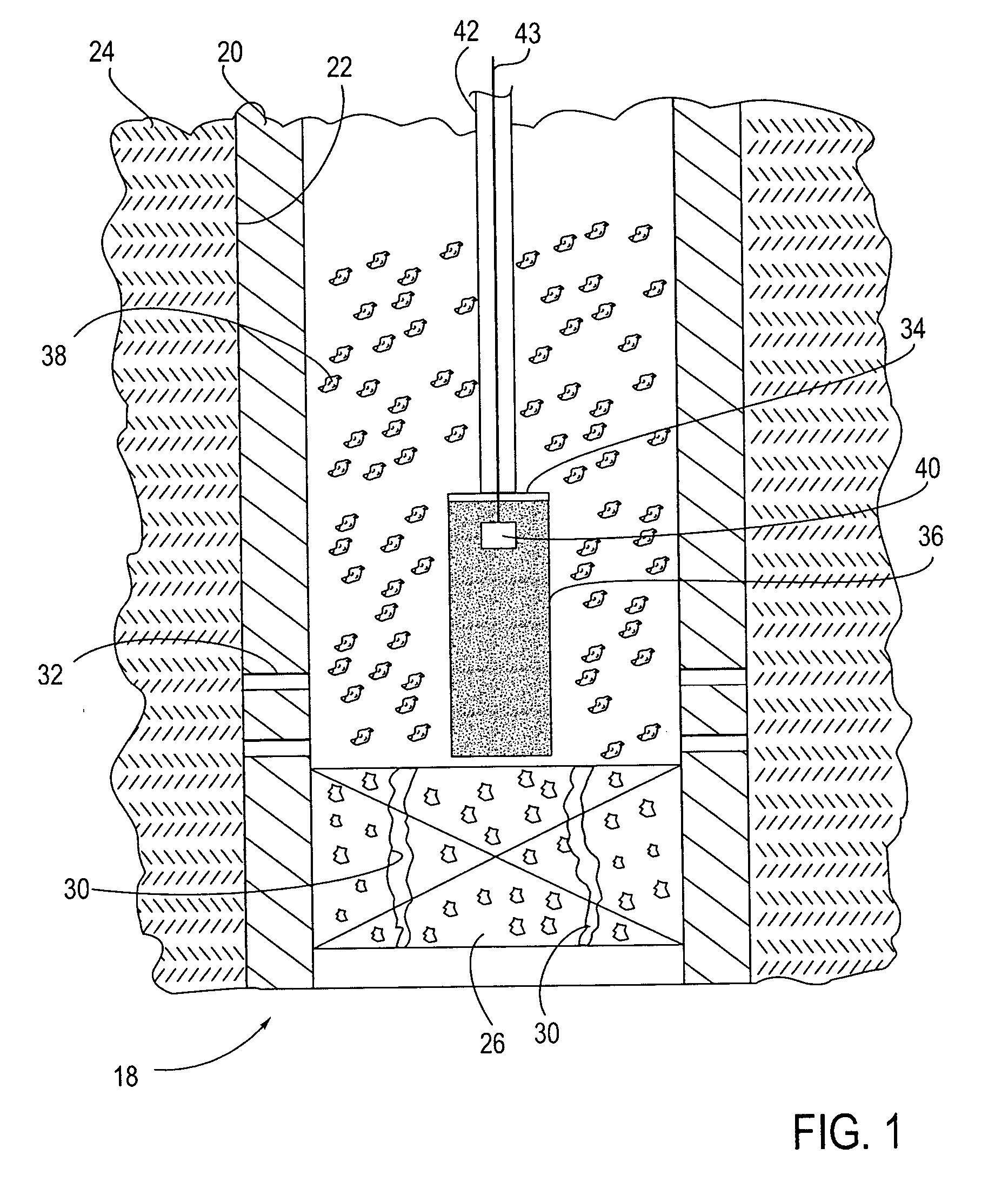

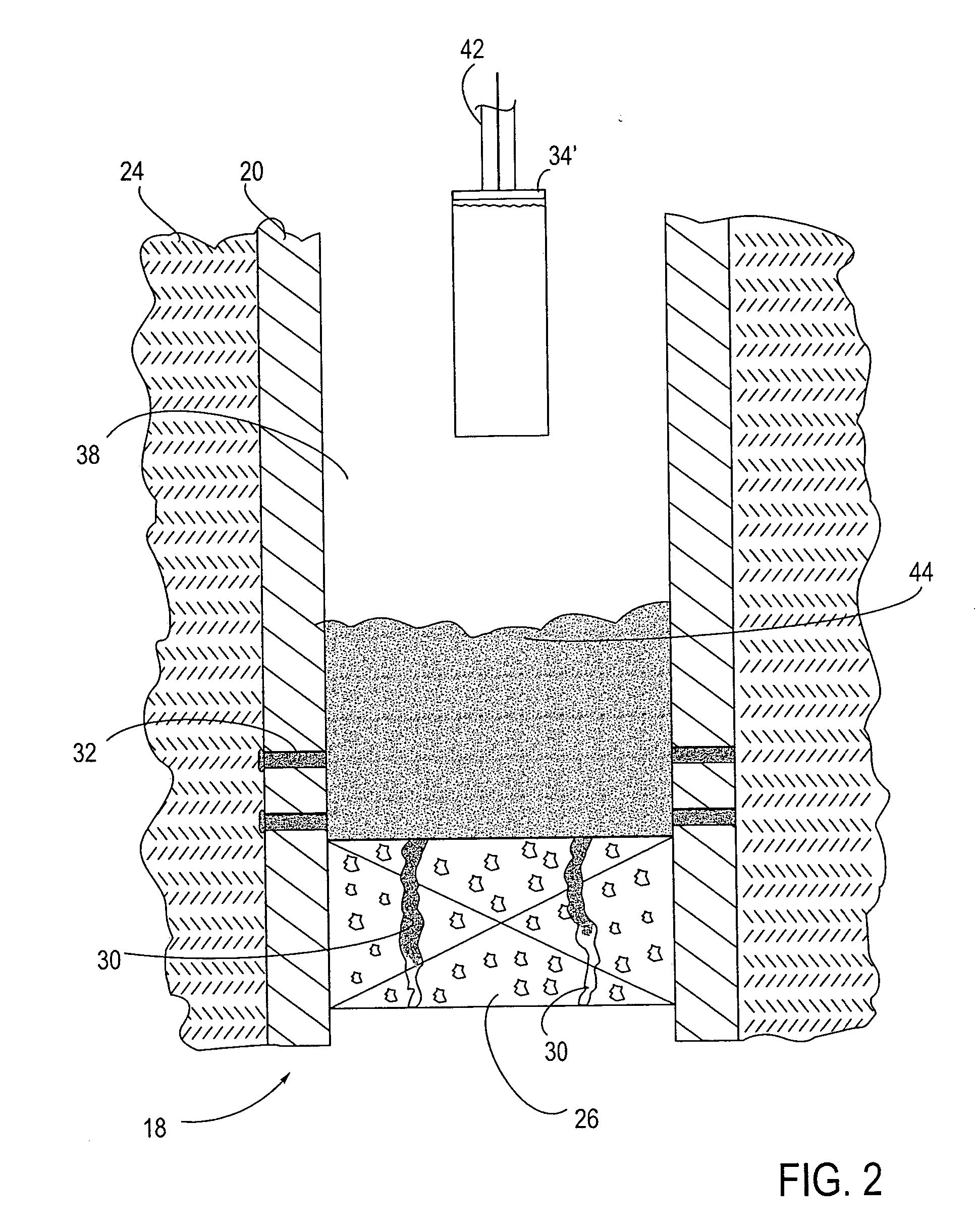

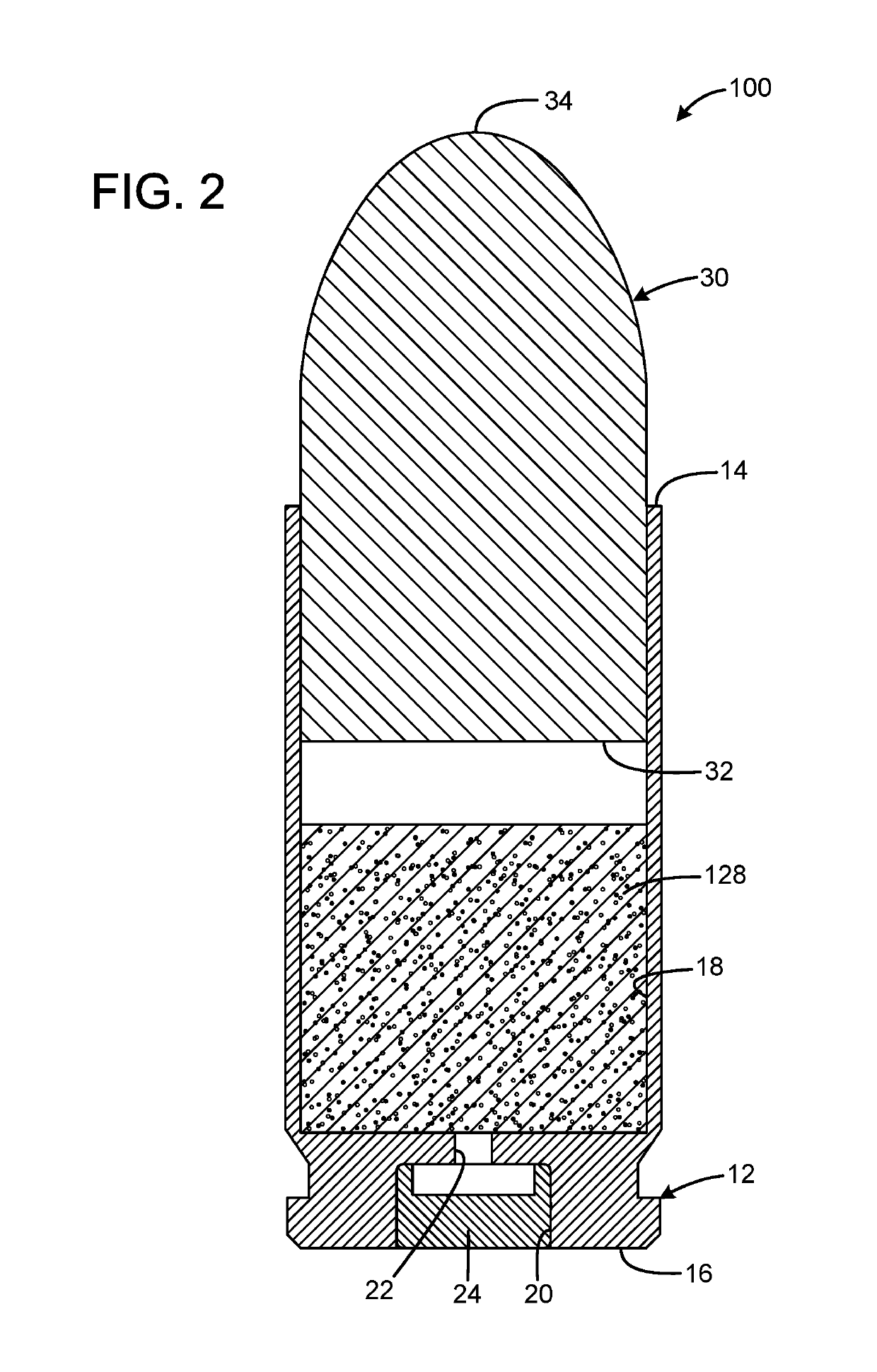

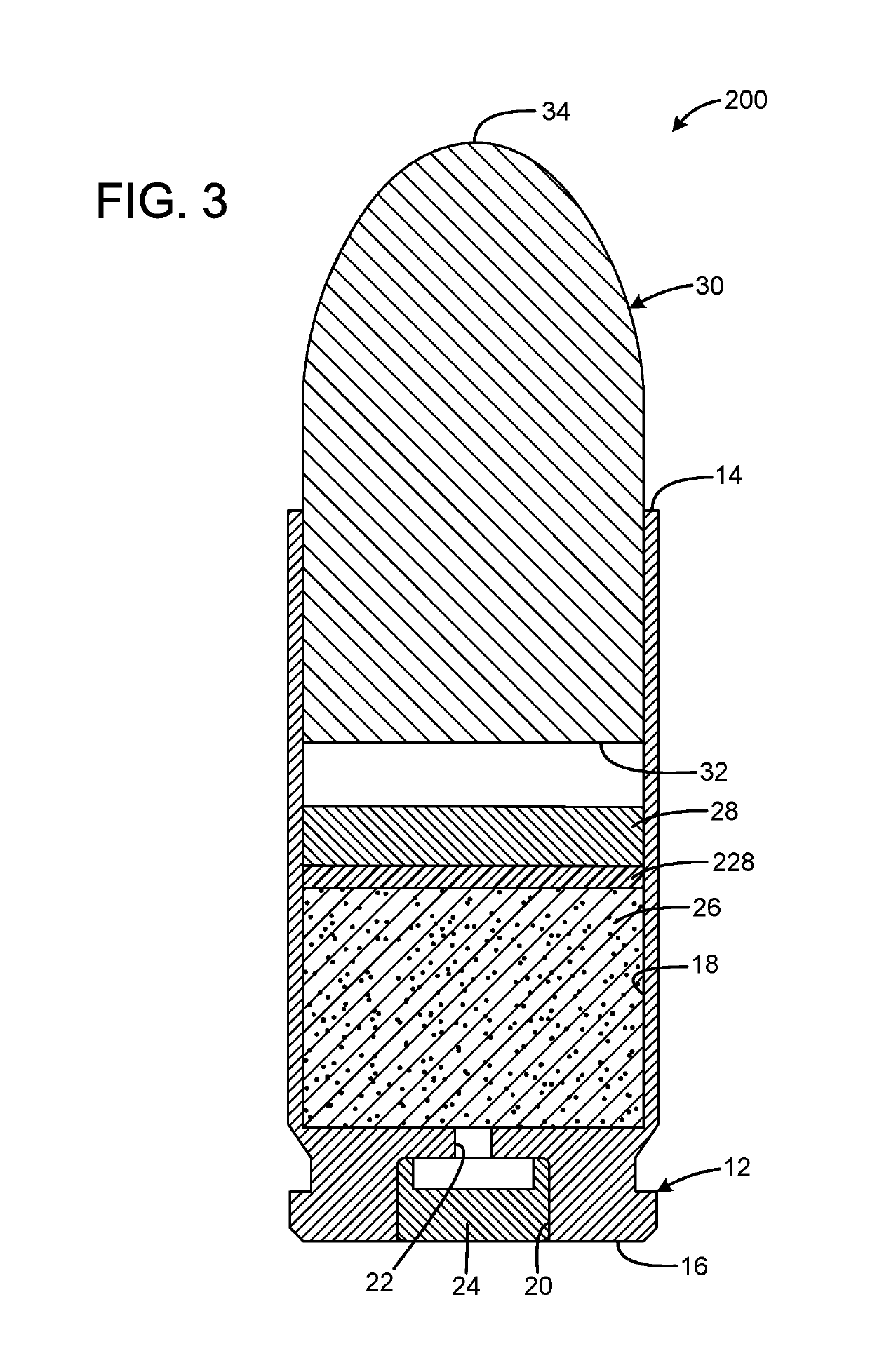

Method and apparatus for repair of wells utilizing meltable repair materials and exothermic reactants as heating agents

A method and apparatus are described for creating a fluid seal in a subterranean well structure having a fluid seal defect. The method comprises introducing a meltable repair material proximate a structure in a subterranean well which has a fluid seal defect or enhanced seal capacity is required or it is desired to temporarily or permanently hydraulically isolate a portion the well or strengthen the structural integrity of well tubulars or tubular hangers. Exothermic reactant materials are located proximate the meltable repair material. The exothermic reactant material is ignited or an exothermic reaction otherwise initiated which supplies heat to and melts the meltable repair material into a molten mass. The molten mass flows and solidifies across the structure and the fluid seal defect to effect a fluid seal in the subterranean well structure or the structural integrity is enhanced. Examples of preferred exothermic reactant materials include thermite, thermate, fusible chemical reactants such as ammonium chloride and sodium nitrate, and oxidizers and accompanying hydrocarbon based fuels. Examples of preferred meltable repair materials include solder or brazing materials and eutectic metals which expand upon cooling and solidifying from a molten state.

Owner:CHEVROU USA INC

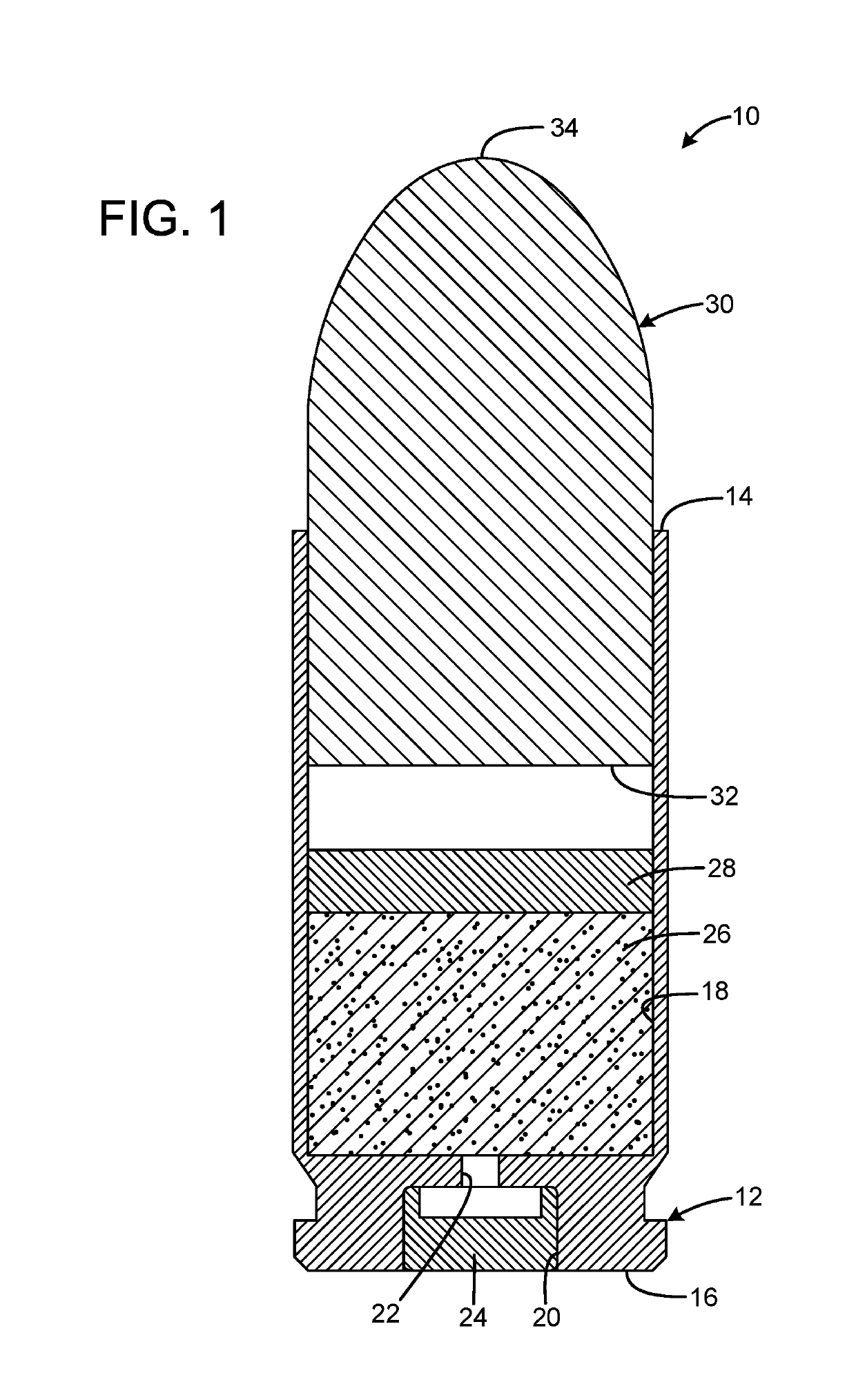

Gas propelled munitions Anti-fouling system

InactiveUS20190106364A1Great contributionShotgun ammunitionNon-explosive/non-thermic compositionsEngineeringCitric acid

A gas propelled munitions anti-fouling system has a case having an open forward mouth end, a rear end, and an interior, the rear end defining a pocket that receives a primer and a passage communicating between the pocket and the interior of the case, a quantity of propellant received within the interior of the case, a quantity of anti-fouling composition received within the interior of the case, and a bullet having a rear portion inserted into the open forward mouth end of the case. The anti-fouling composition may have at least one salt and at least one acid. The acid may be anhydrous. The salt may be sodium chloride or sodium nitrate. The acid may be anhydrous citric acid. The anti-fouling composition may have at least one abrasive. The abrasive may be stannic acid. The anti-fouling composition may be 50% salt by weight and 50% acid by weight.

Owner:ADLER CAPITAL LLC

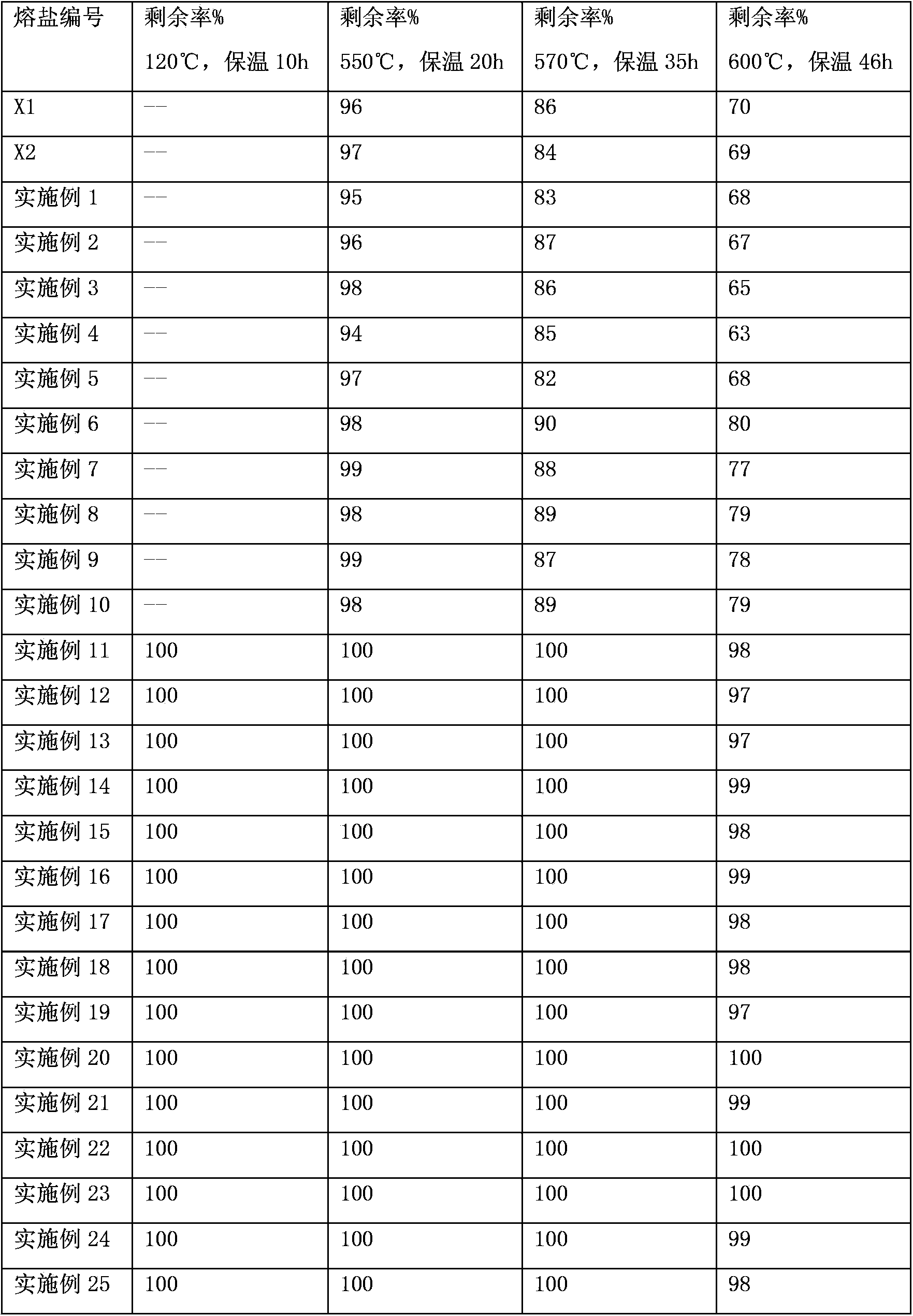

Nitrate molten salt heat transferring and reserving medium and preparation method and application thereof

InactiveCN102533226AWide operating temperature rangeImprove thermal stabilityHeat-exchange elementsDecompositionInstability

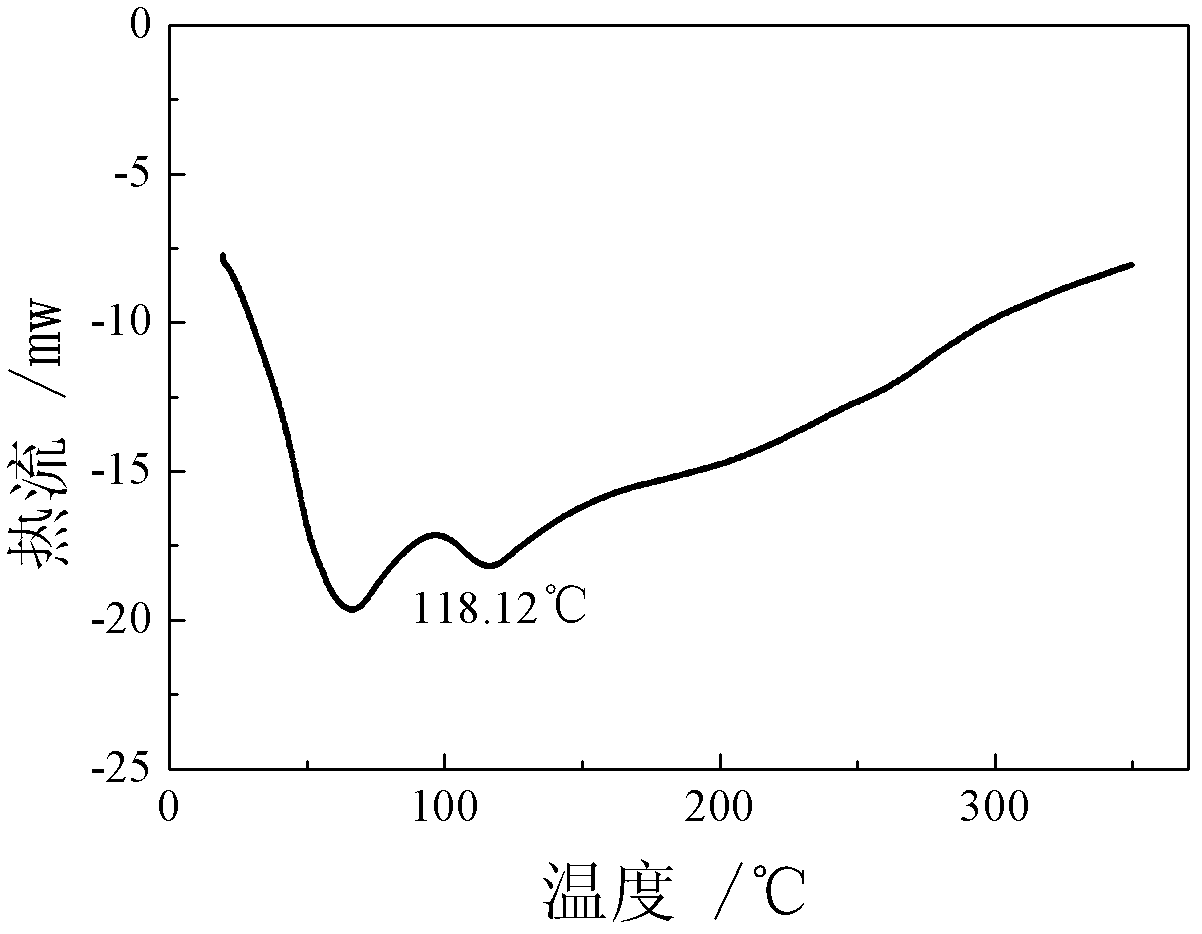

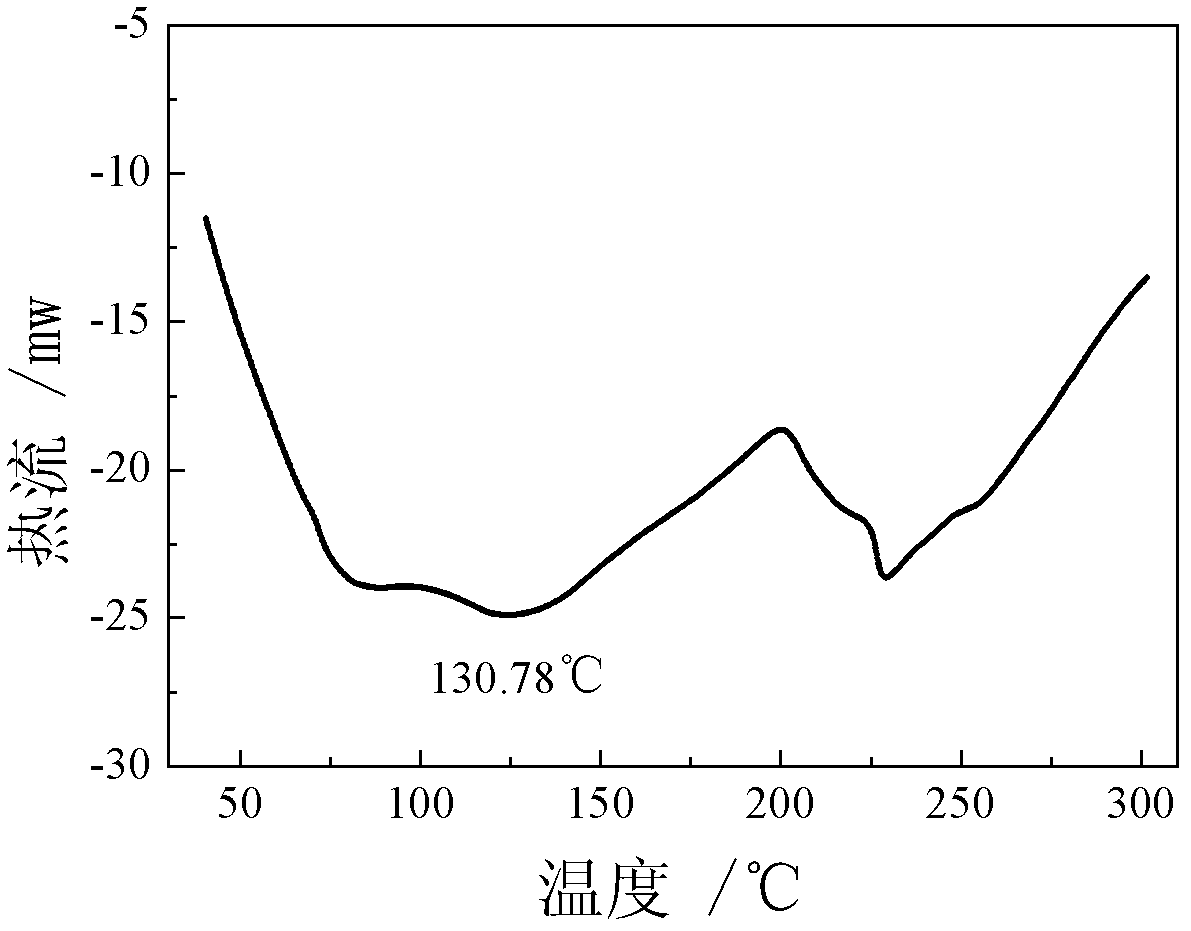

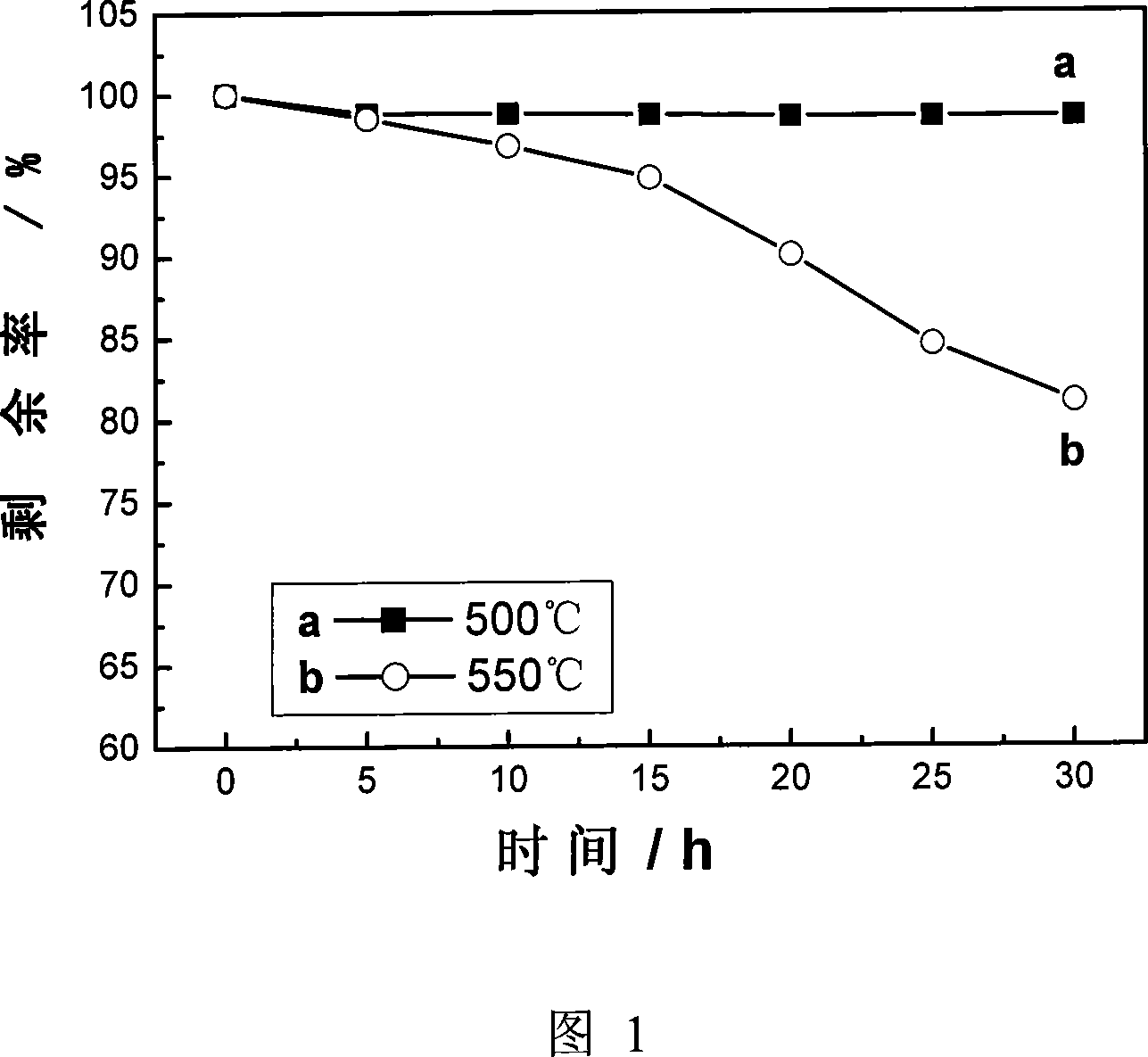

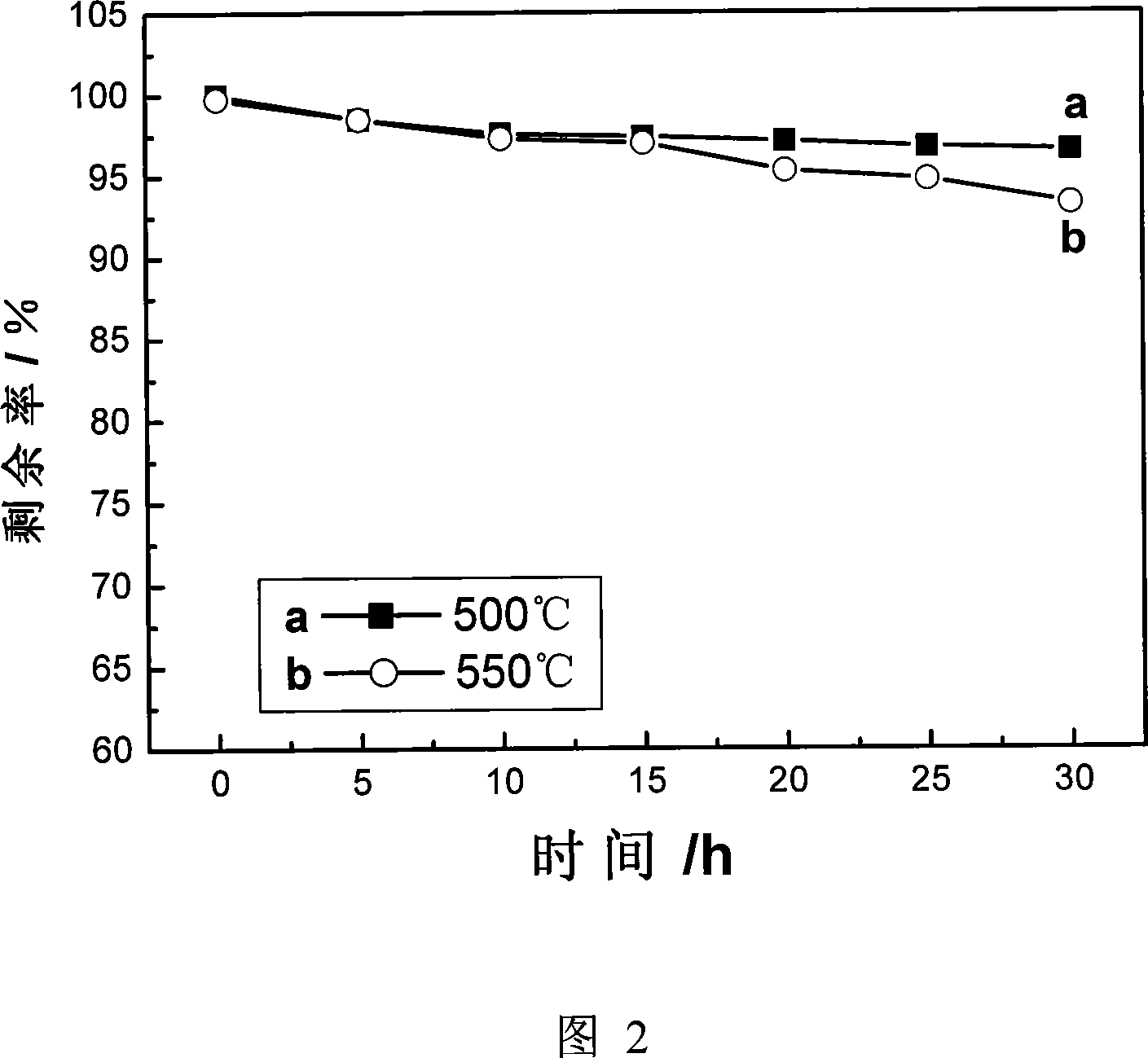

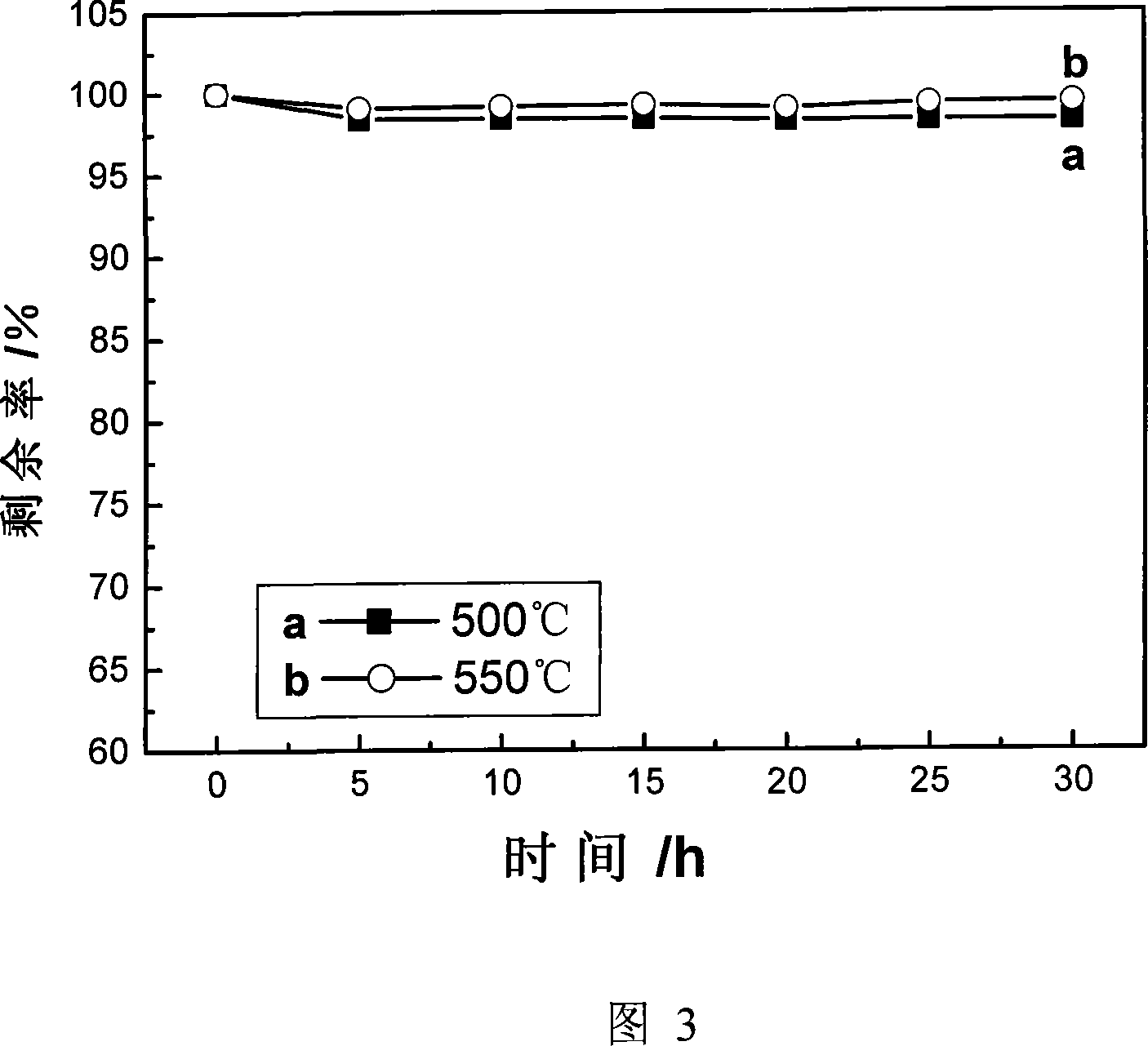

The invention discloses a nitrate molten salt heat transferring and reserving medium and a preparation method and application thereof. The nitrate molten salt heat transferring and reserving medium is prepared with 5 to 40 percent of potassium nitrate, 5 to 25 percent of sodium nitrate, and 10 to 70 percent of calcium nitrate. The melting point of the nitrate molten salt heat transferring and reserving medium can be as low as 120 DEG C, and the upper limit of temperature for use can reach 550 DEG C, the nitrate molten salt heat transferring and reserving medium has a wide temperature scope of application, can work normally at the temperature scope of 180 DEG C to 550 DEG C, and has good thermal stability; the shortcoming of high melting point of binary nitrate molten salt system can be overcome, and the problem of instability caused by easy oxidative decomposition at high temperature of NaNO2 in the Chinese patent 200110027954.1 and ternary nitrate salt system can be solved, and the problems of corrosion and cost increase caused by the existing LiNO3 in the Chinese patent 00111406.9 and the American patent US007588694B1 can also be solved.

Owner:SUN YAT SEN UNIV +1

Fusion tray of thermal transmission and storage medium, and preparation method

InactiveCN101050355AHigh Safe Operating Temperature Upper LimitSafe operating temperature upper limit expandedHeat-exchange elementsHigh energyWorking temperature

This invention discloses a method for preparing molten salt heat-transfer and heat-storage medium, which comprises potassium nitrate, sodium nitrate, sodium nitrite and additives. The additives are cesium nitrate and potassium chloride at a weight ratio of (0.1-0.8):1. The molten salt heat-transfer and heat-storage medium has such advantages as good heat transfer property, wide working temperature range, high heat stability, high upper limit of safe usage temperature, low melting point, high phase-change latent heat, low requirement for system size and energy, and high energy utility.

Owner:SUN YAT SEN UNIV +1

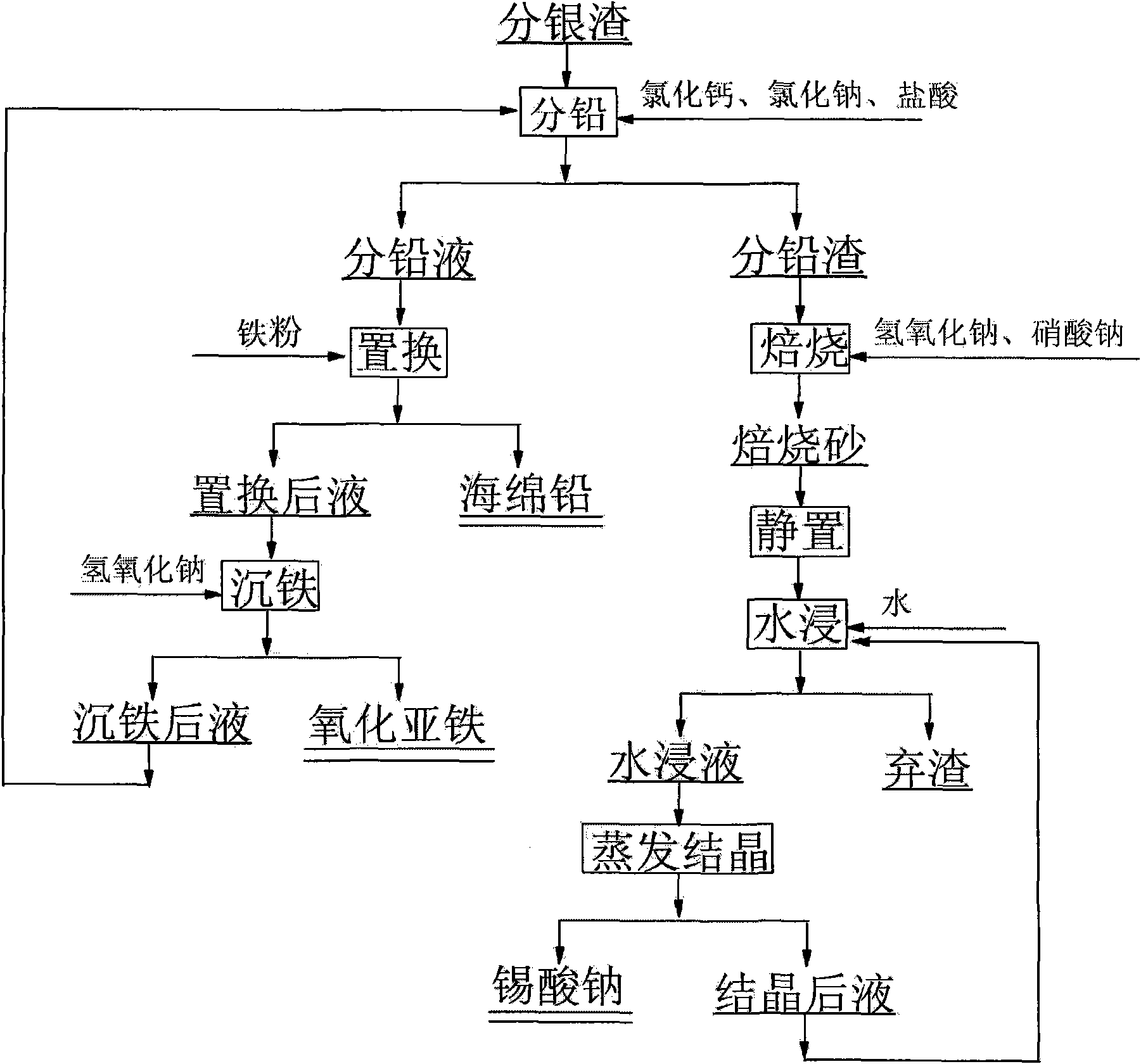

Method for recycling lead-tin in silver separating residue of copper anode slime of circuit board

ActiveCN101555550AReduce generationEmission reductionProcess efficiency improvementIron powderWastewater

The invention discloses a method for recycling lead-tin in silver separating residue of copper anode slime of a circuit board and relates to a method for recycling silver separating residue of copper anode slime of the circuit board by a wetting method. The method comprises the following steps of: stirring silver separating residue, water, hydrochloric acid, calcium chloride and sodium chloride for 0.5 to 2.0h under proper temperature according to requirements, filtering and obtaining lead separating liquid and lead separating residue; carrying out displacement to the lead separating liquid by using excess iron powder, filtering and obtaining spongy lead and displaced liquid; using sodium hydroxide to adjust pH value of the displaced liquid till the precipitate is not generated; and returning lead separating procedure after the iron is precipitated. The lead separating residue, the sodium hydroxide and sodium nitrate are mixed evenly to carry out roasting with the temperature of 350 to 500 DEG C, and then are added with water and filtered, thus obtaining the sodium stannate. Compared with the prior art, due to the adoption of a full-wetting process, the method reduces a large amount of waste gas and dusts in the process of pyrometallurgical treatment; the liquid after the iron is precipitated contains the main compositions of hydrochloric acid and sodium chloride; and the method can return acid pickling procedure, reduce discharge of waste water and lower cost, and is characterized by simple technique, no pollution and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

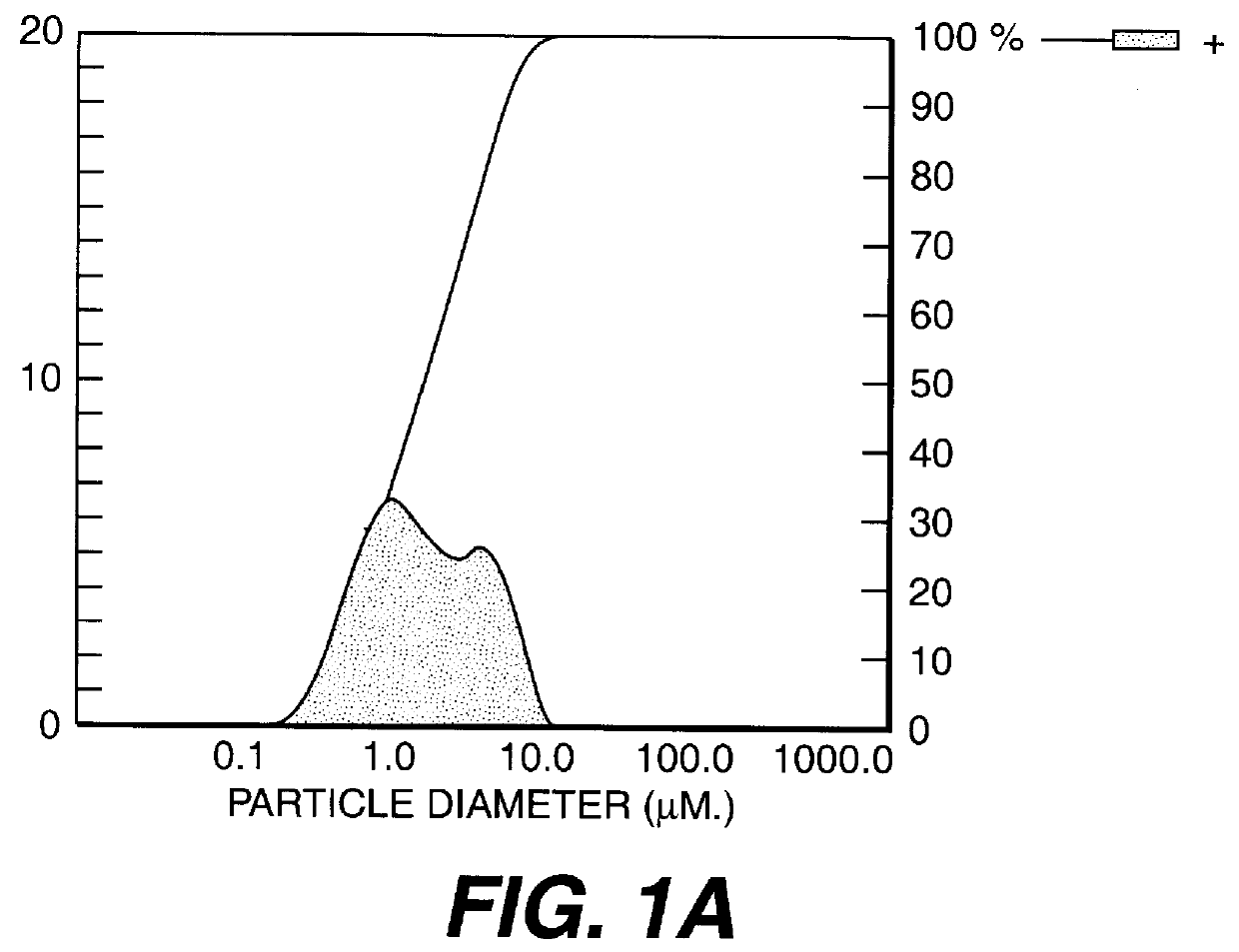

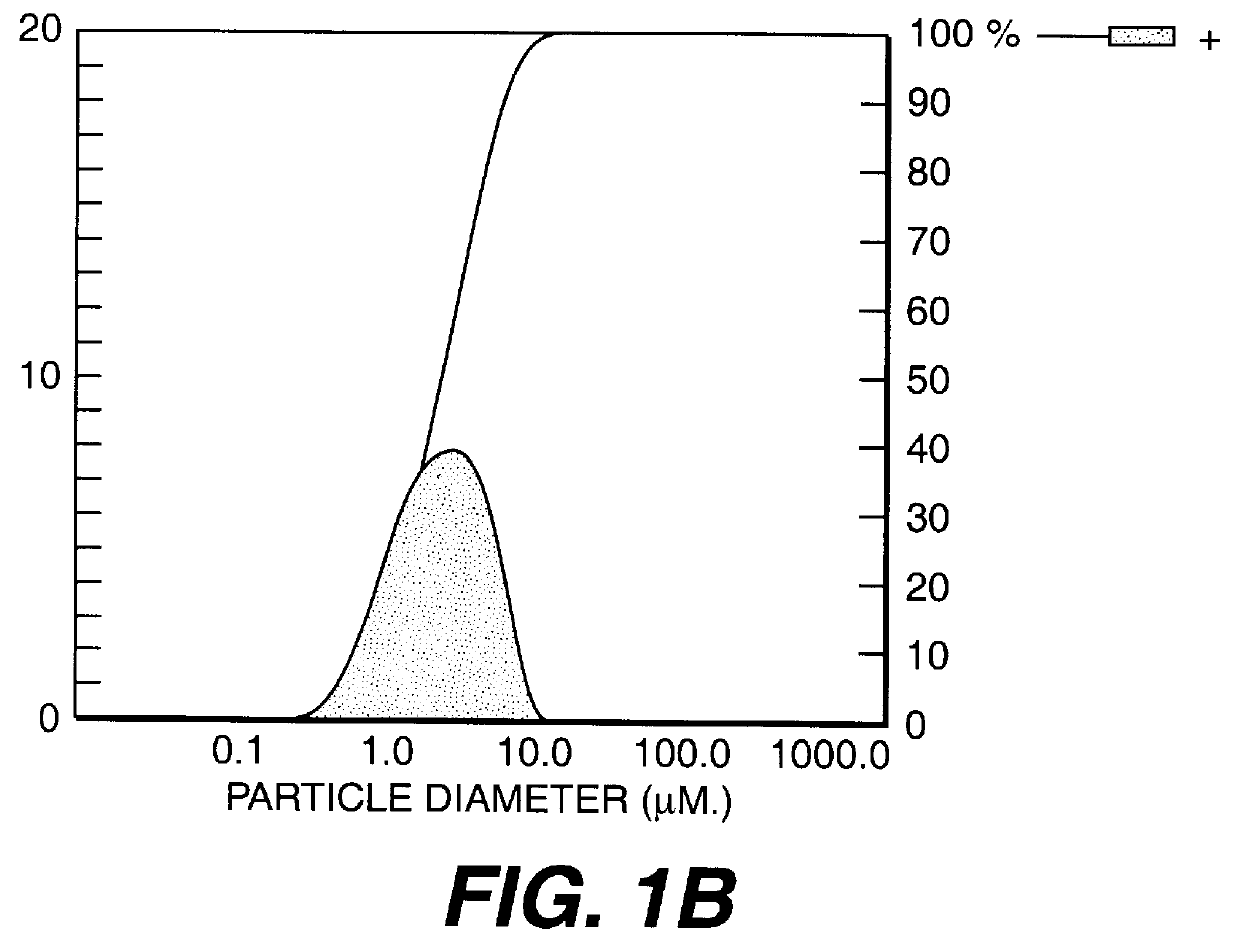

Calcium carbonate precipitation method

InactiveUS6036933ACalcium/strontium/barium carbonatesMagnesium carbonatesNitratePrecipitated calcium carbonate

PCT No. PCT / GB96 / 00488 Sec. 371 Date Oct. 22, 1997 Sec. 102(e) Date Oct. 22, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 26902 PCT Pub. Date Sep. 6, 1996A method for producing precipitated calcium carbonate by reacting an aqueous solution of calcium nitrate [Ca(NO3)2] with an aqueous solution of ammonium carbonate [(NH4)2CO3] and allowing calcium carbonate to precipitate from the resultant mixture containing nitrate [NH4NO3] in the mother liquor, the process being characterized in that: (i) the calcium nitrate [Ca(NO3)2)] solution utilized in the processes is prepared by slaking lime [CaO] in water in the presence of ammonium nitrate [NH4NO3] to form calcium nitrate [Ca(NO3)2] and ammonium hydroxide [NH4OH] in solution, filtering the solution to render it solids free, and heating the filtrate to dissociate the ammonium hydroxide [NH4OH] and to drive ammonia gas [NH3] from the solution; (ii) the ammonium carbonate (NH4)2CO3 solution utilized is prepared by absorbing ammonia gas [NH3] and carbon dioxide gas [CO2] in water, the ammonia gas preferably being derived from the step in (i) above in which the Ca(NO3)2 solution is heated; and (iii) the ammonium nitrate used is derived from the precipitation phase during which calcium carbonate is precipitated from the mother liquor containing ammonium nitrate.

Owner:PRETORIA PORTLAND CEMENT COMPANY +1

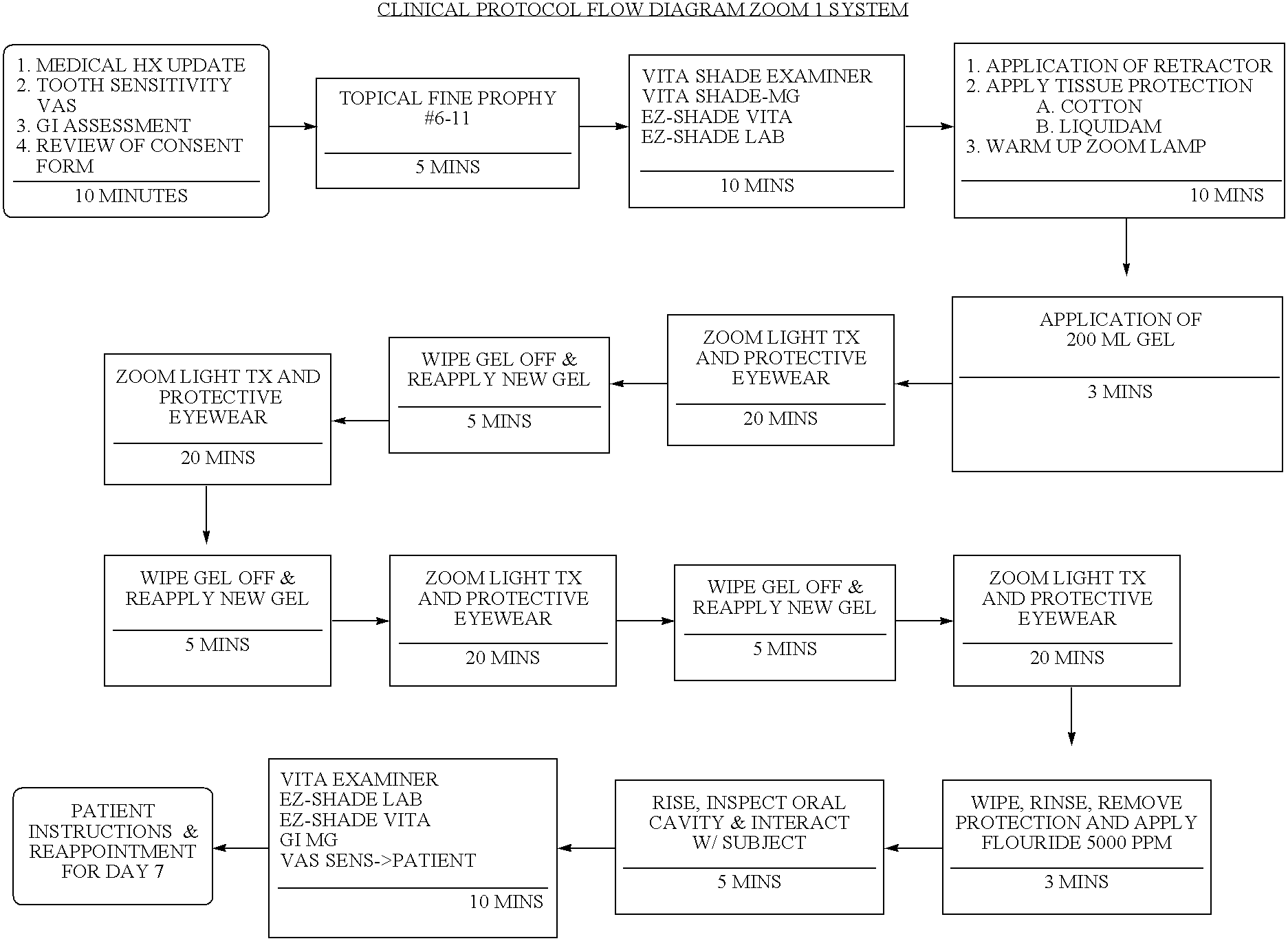

Dental whitening systems

InactiveUS20060099155A1Convenient whiteningFaster effective whiteningCosmetic preparationsToilet preparationsBiological activationTooth whitening

A system and method for tooth whitening are disclosed wherein at least one peroxide-containing gel and at least one transition metal compound-containing gel, particularly at least one lower atomic number transition metal compound, more particularly at least a ferrous compound including gluconate, sulfate, nitrate, acetate or mixtures thereof, are applied to a patient's mouth. Gelling agent is also included. The activation of the peroxide whitens the patient's teeth. The system may be used with or without the application of light. The system further provides an additional gel including a sensitivity reduction compound including potassium nitrate, sodium nitrate or mixtures thereof for possible sensitivity treatment if needed.

Owner:DISCUS DENTAL LLC

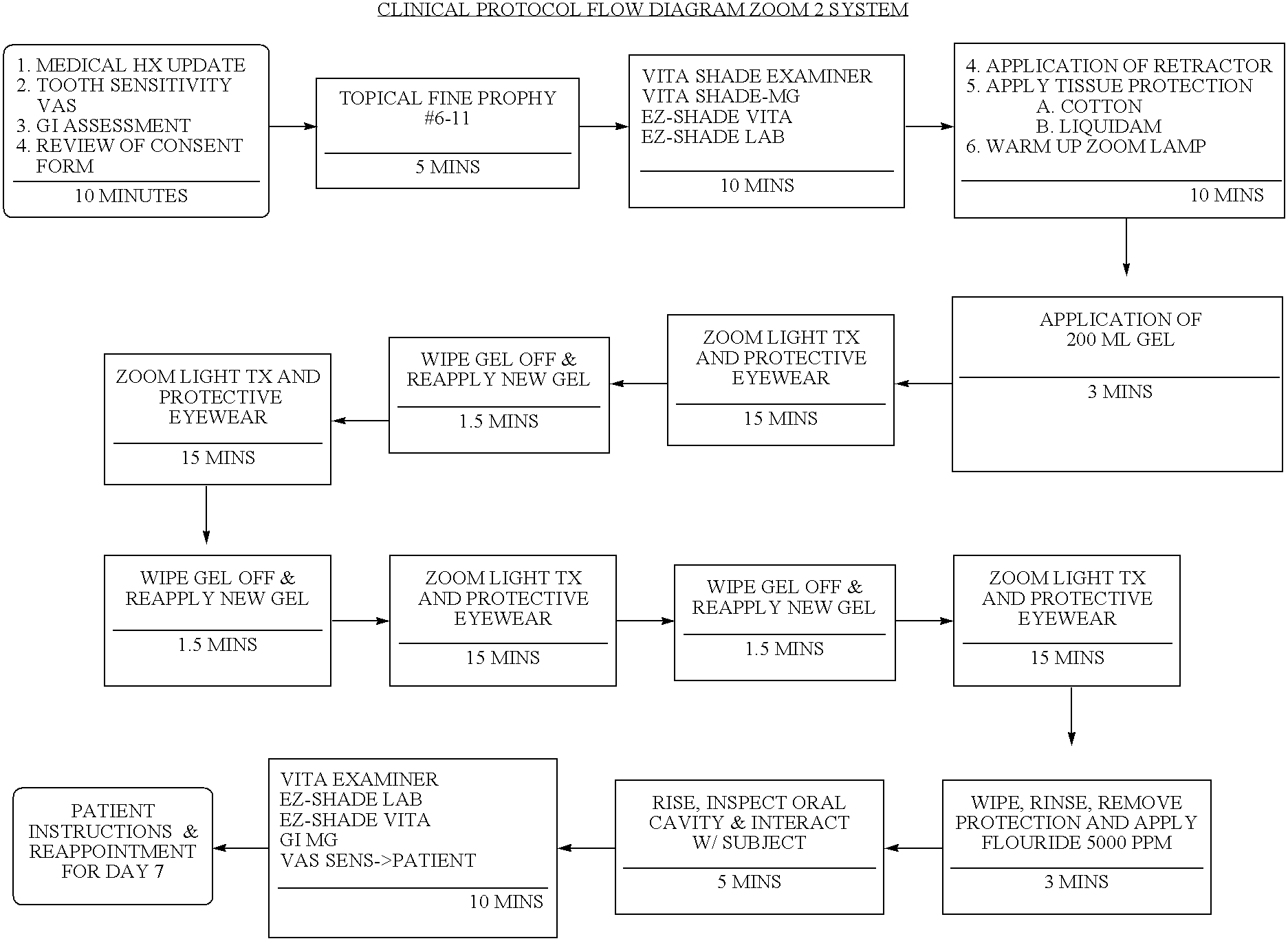

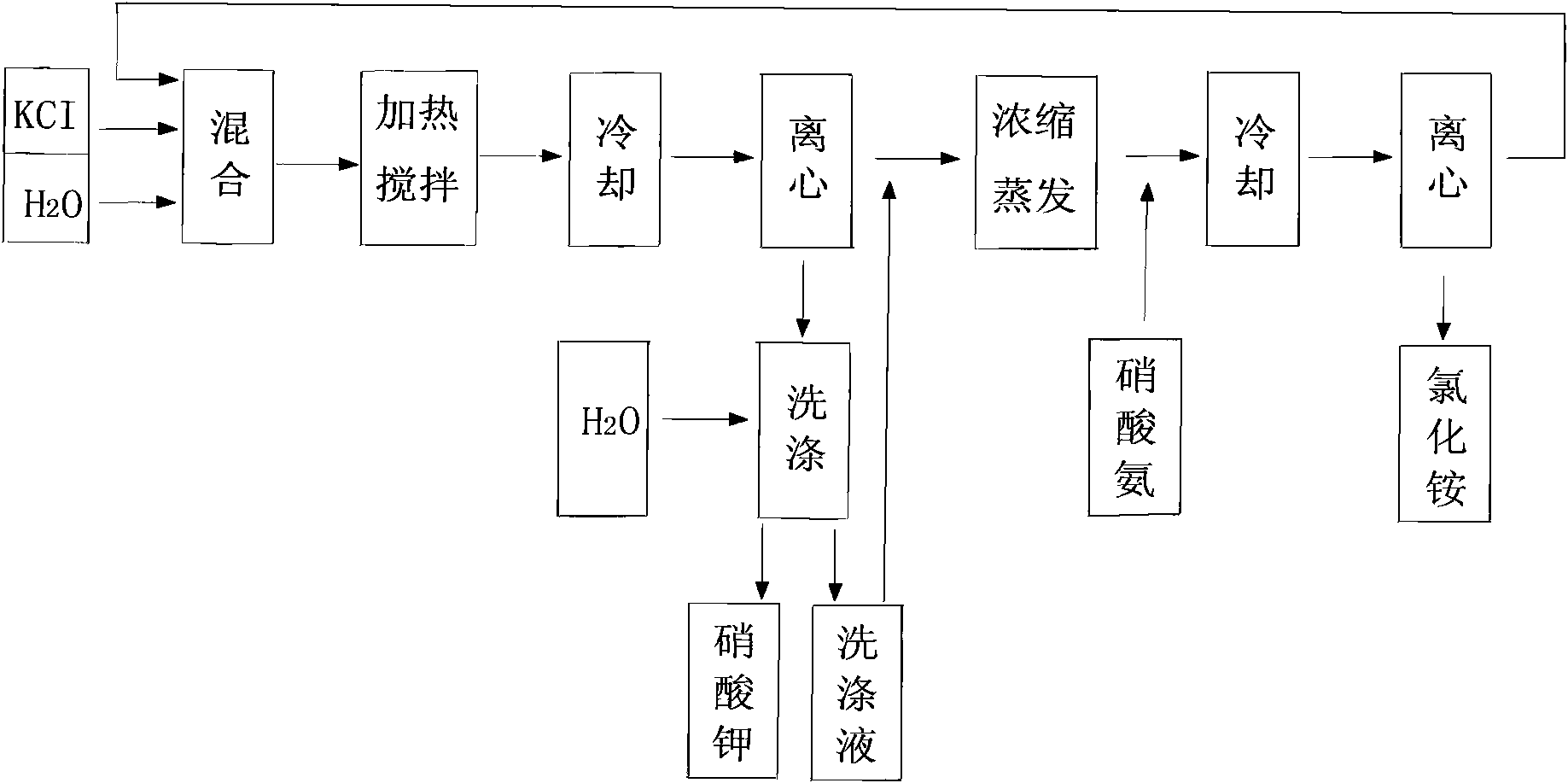

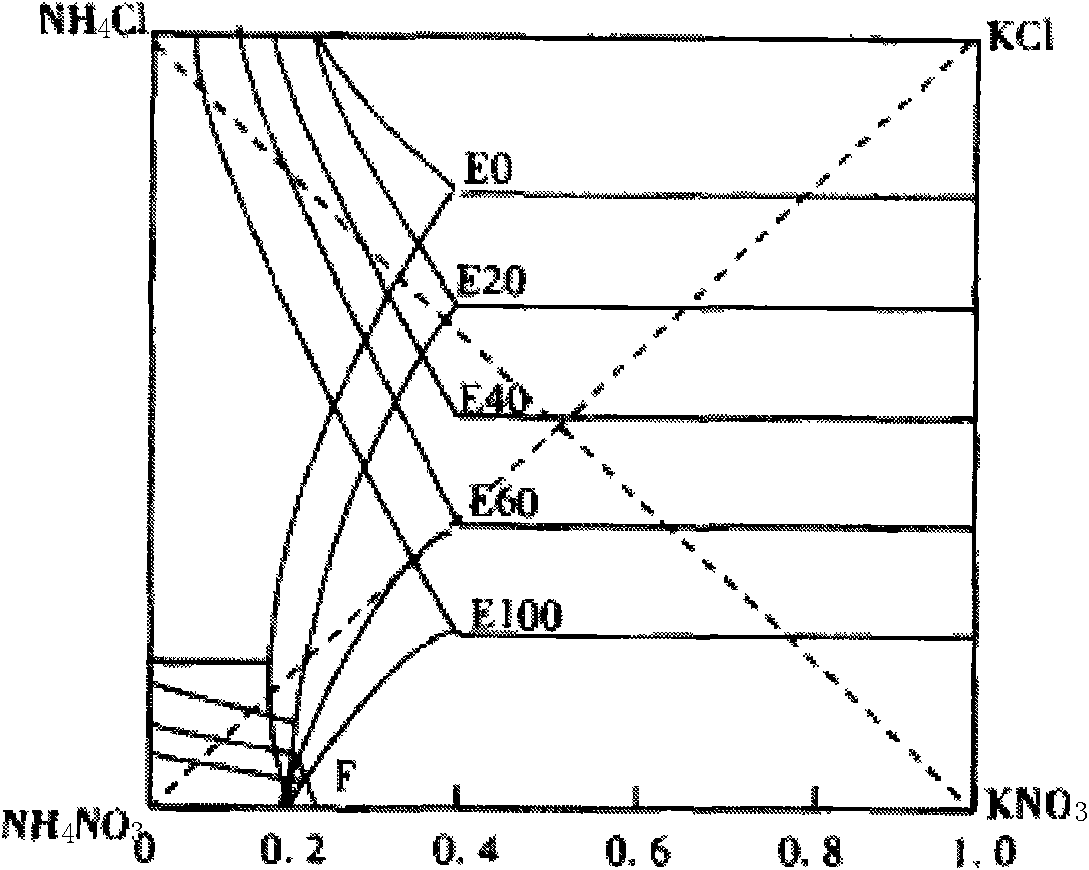

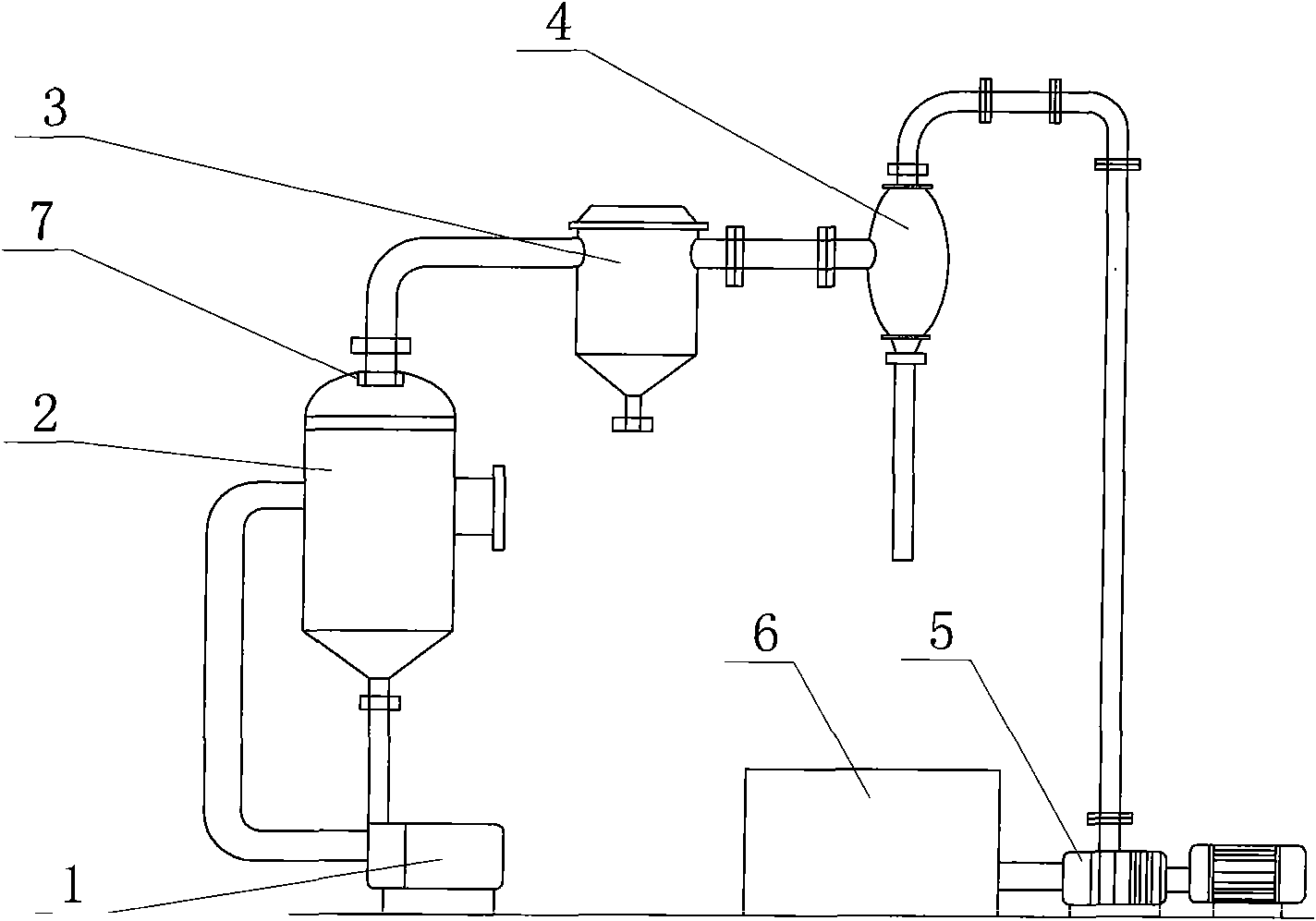

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

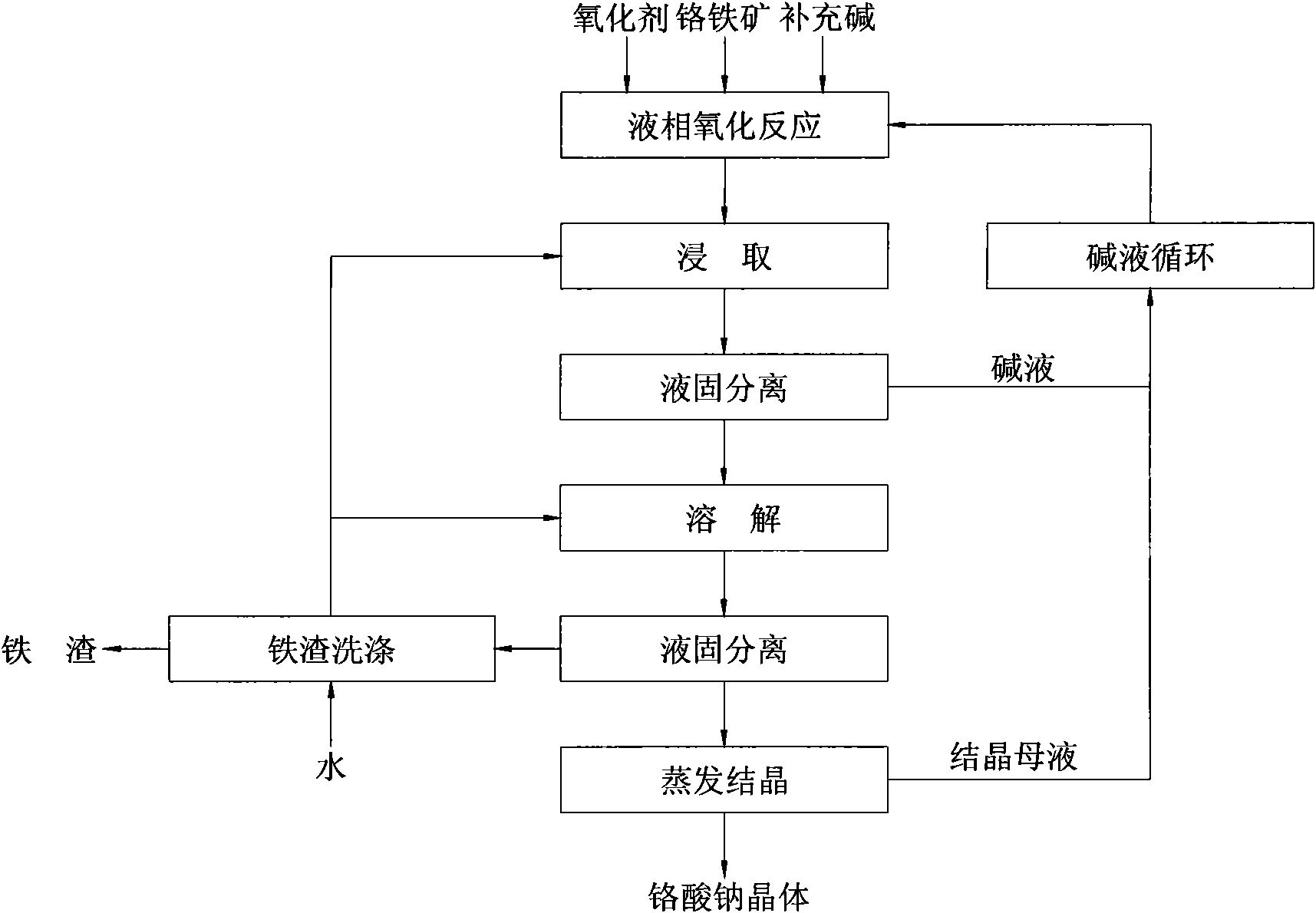

Clean production method for preparing sodium chromate from chromite

InactiveCN101659444AObvious superiorityLow reaction temperatureChromates/bichromatesSlagSodium nitrate

The invention relates to a clean production method for preparing sodium chromate from chromite, which comprises the following steps of: reacting the chromite with an oxidizing gas in a medium of NaOH-NaNO3-H2O, wherein sodium nitrate serves as a catalytic medium and is not consumed in the reaction; obtaining a mixed reaction product of an alkali liquor, the sodium chromate and iron slag after thereaction; leaching the mixed reaction product, performing liquid-solid separation of the alkali liquor and a crystal slag mixture (a mixture of a sodium chromate crystal and the iron slag), dissolvingthe mixture of the iron slag and the sodium chromate crystal, performing liquid-solid separation of the solution of the iron slag and the sodium chromate crystal, performing evaporative crystallization of the sodium chromate solution, rinsing and drying the obtained sodium chromate solution, obtaining qualified sodium chromate products; and circulating the crystallized mother liquor and the alkali liquor together to decompose the chromite. In the method, the chromium conversion ratio is above 99 percent and the chromium content ratio in the slag is less than 0.5 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

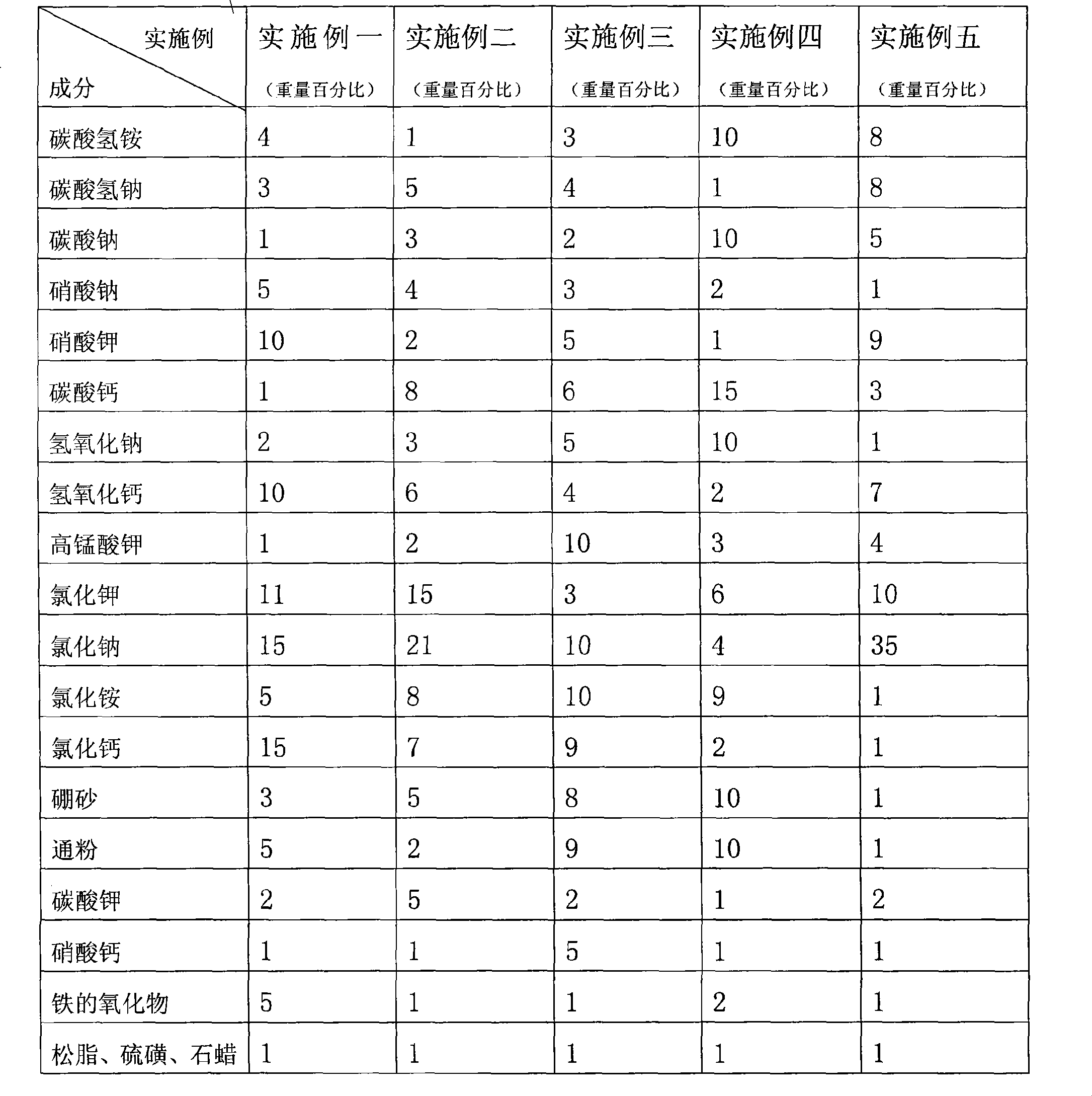

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

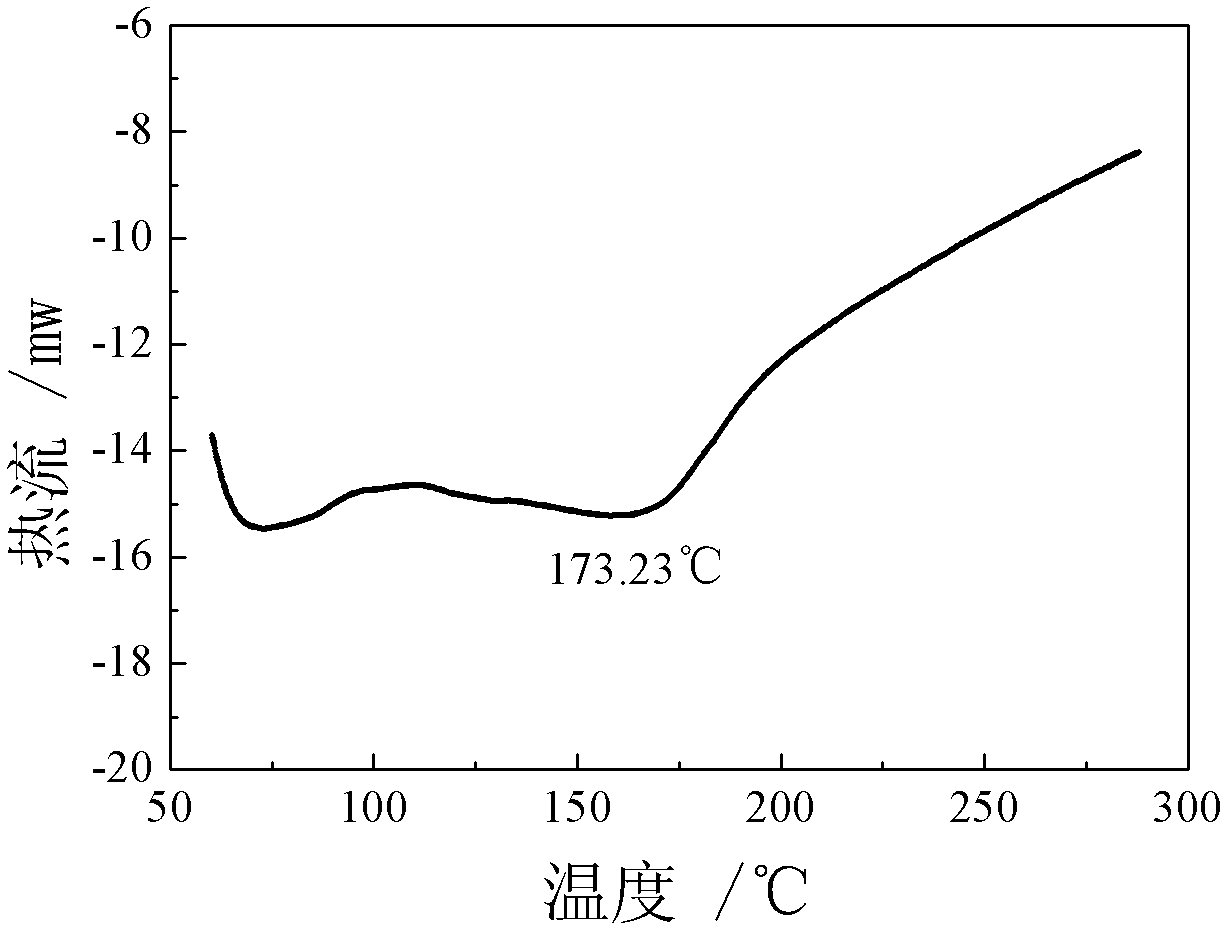

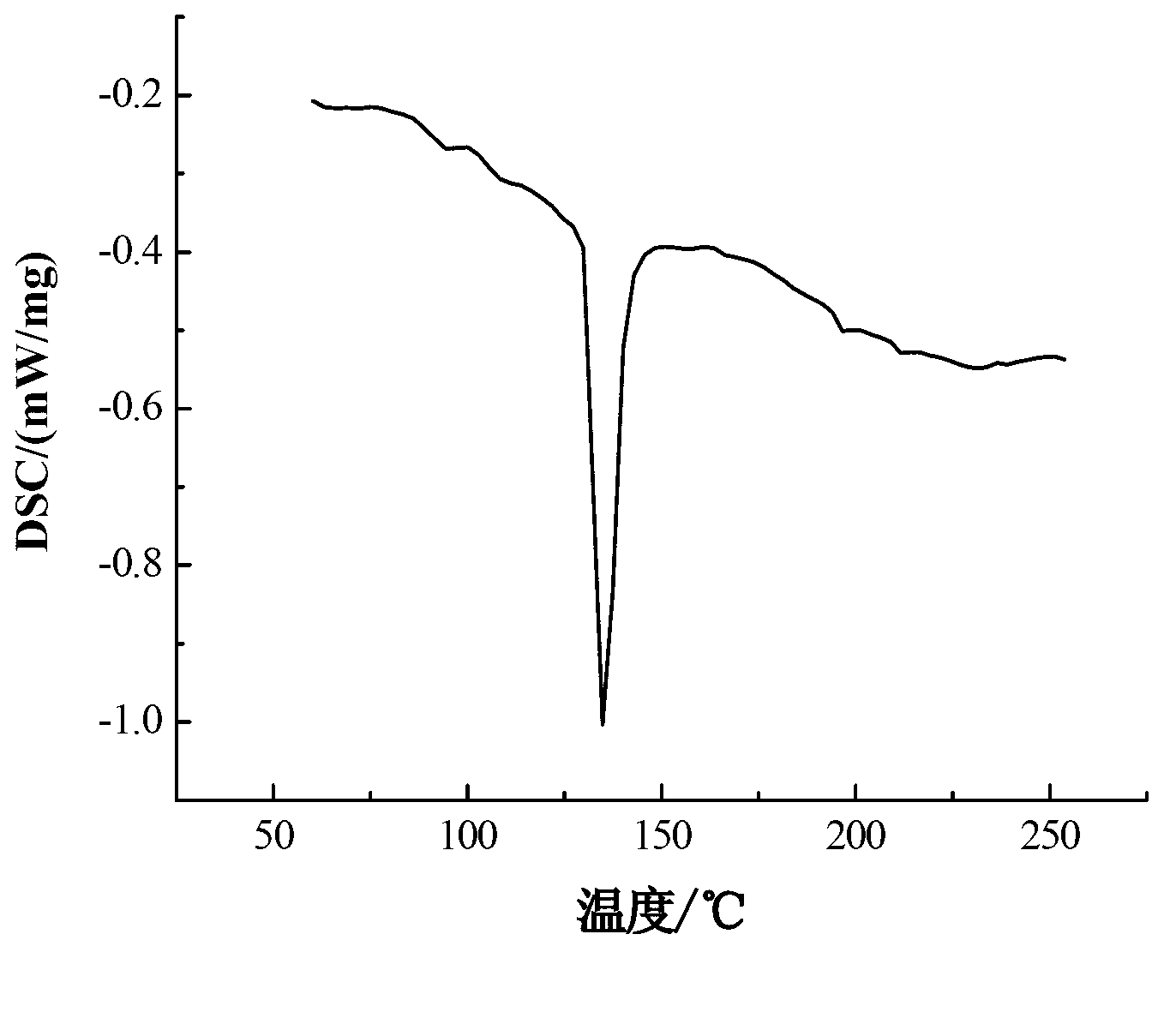

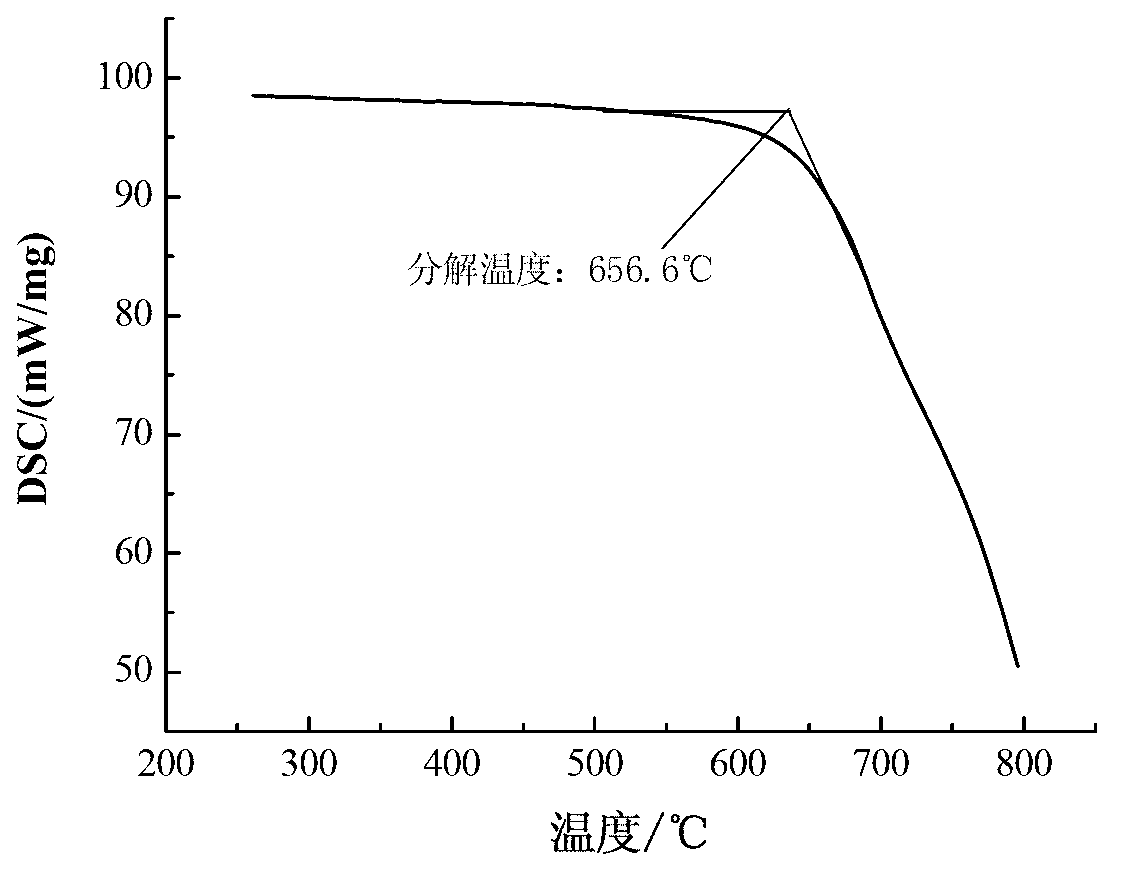

Mixed molten salt as heat transfer and storage medium low in melting point

The invention relates to a formula of a mixed molten salt for medium-high temperature heat transfer and storage, and belongs to the physical heat transfer and energy storage technology in innovative and high technologies. The mixed molten salt comprises components in a ratio as follows: 10wt% of calcium nitrate, 60-70 wt% of potassium nitrate, 10-20 wt% sodium nitrate and 10wt% of sodium nitrite; the melting point of the mixed molten salt is about 130 DEG C, which is reduced by nearly 90 DEG C relative to solar salt and is reduced by about 15 DEG C relative to Hitec salt; and the thermal decomposition temperature thereof reaches above 650 DEG C. Sodium nitrate in the molten salt is changed into lithium nitrate, and the specific component ratio is as follows: 18-20wt% of calcium nitrate, 50-55 wt% of potassium nitrate, 9-10 wt% sodium nitrate and 18-20wt% of sodium lithium nitrate; after the component ratio is changed, the melting point of the mixed molten salt is about 90 DEG C, which is reduced by nearly 130 DEG C relative to the solar salt and is reduced by about 50 DEG C relative to the Hitec salt; and the thermal decomposition temperature thereof reaches above 600 DEG C. 10wt% of sodium carbonate is added continuously, then the melting point is raised to about 110 DEG C, while the decomposition temperature is raised by nearly 20 DEG C.

Owner:河北井矿新能源科技有限公司

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

Aqueous epoxy adhering dried fim lubricant

InactiveCN1450153AReduce pollutionSolution to short lifeLubricant compositionWear resistantCopper oxide

The present invention relates to a water epoxy adhesive dry film lubricant with low-volatile organic compound. Its formula is composed of (by weight portion) 100 portions of epoxy resin, 20-50 portions of solidifying agent, 30-80 portions of one of teflon, molybdenum disulfide and graphite or several kinds of them, 10-40 portions of one of chrome oxide, copper oxide or aluminium oxide, 2-10 portions of attapulgite, 0-30 portions of melamine urea complex, 2-5 portions of sodium dodecanesulfonate, 1-4 portions of sodium nitrate and 100-400 portions of diluting agent (water or water / ethyl alcohol). As compared with existent technology said lubricant can be solidified, and has the characteristics of low pollution and long life, etc. can be used as lubricant wear-resistant coating layer of various slide frictioning components

Owner:上海高分子材料研究开发中心

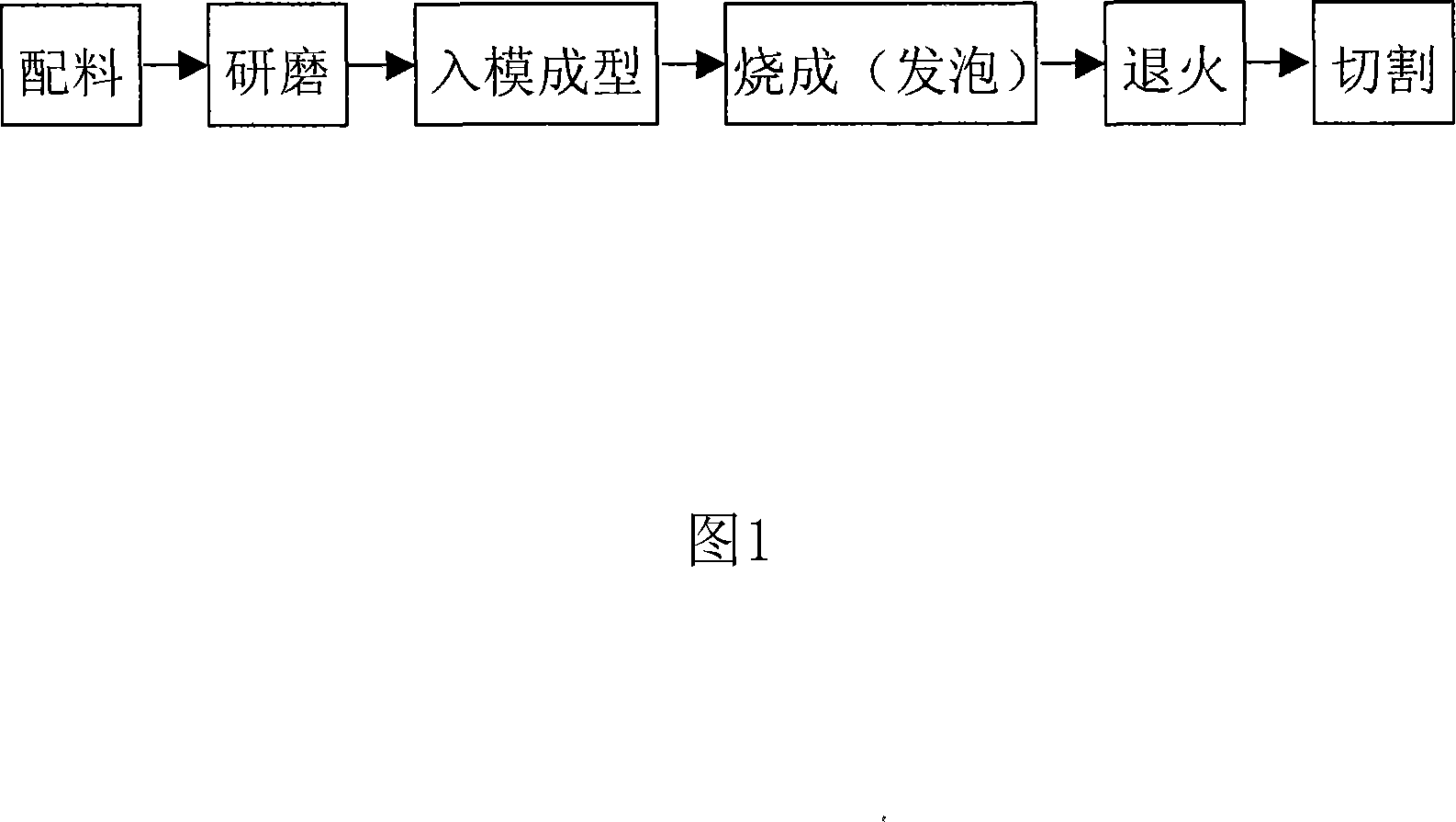

Preparation method of foam glass

The invention discloses a foam glass and a preparation method thereof. The main technique steps are that fly ash and waste glass are mixed and rubbed; the promoters composited by calcium carbonate, potassium nitrate, sodium nitrate, sodium carbonate, lithium carbonate, water glass and fibrin are added; the powder that has been rubbed into mould to mold is put; shaped product is sent to kiln to be dried and fired under high temperature, is annealed and finally cut, after the steps, the foam glass is made. The preparation technique is simple, and the production cost is reduced by choosing fly ash and waste glass instead of pearl rock, pumice, isinglass and other non-mine material, and the technique improves the use of solid wastes and is beneficial to environment protection.

Owner:内蒙古自治区建筑材料工业科学研究设计院

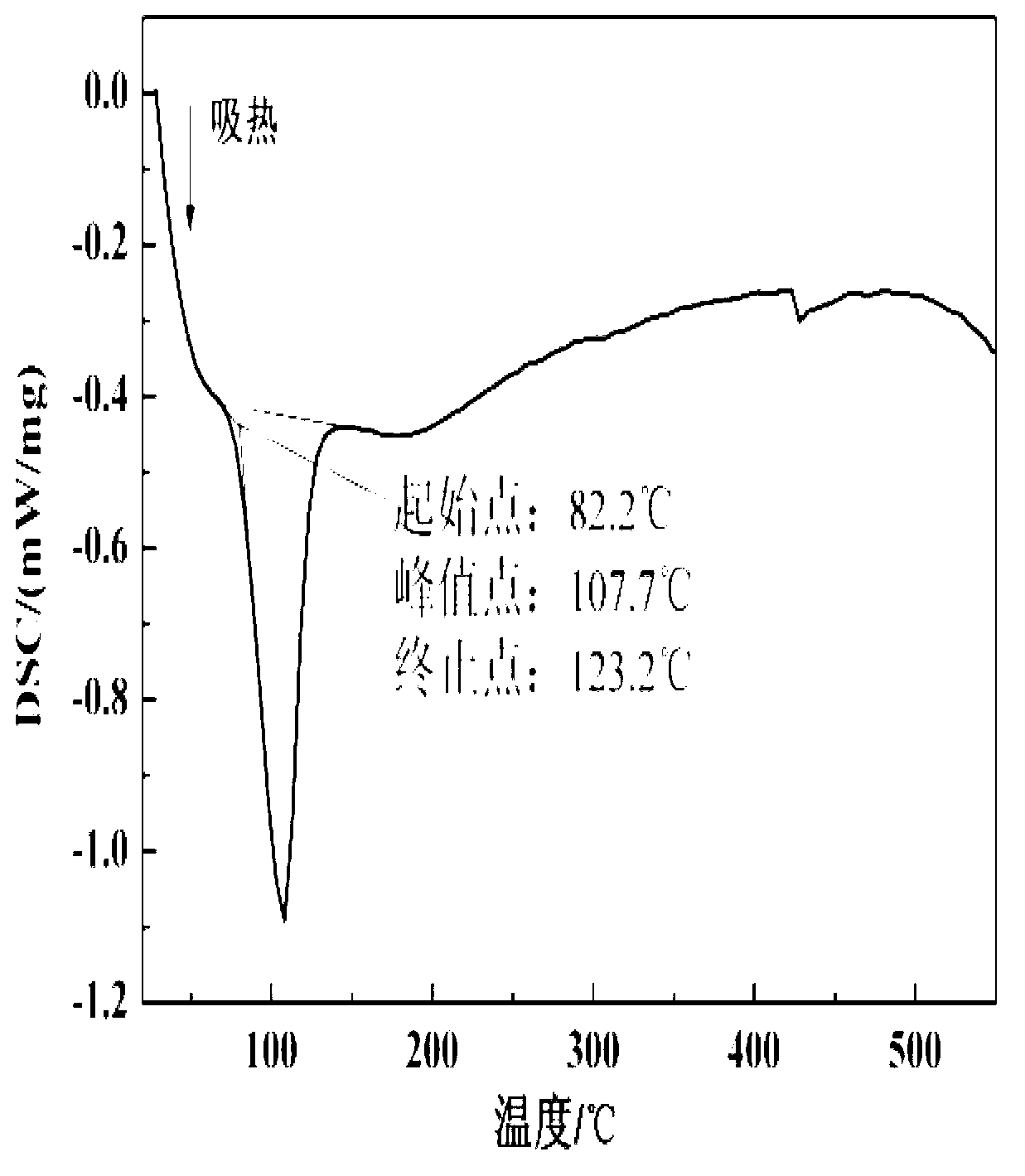

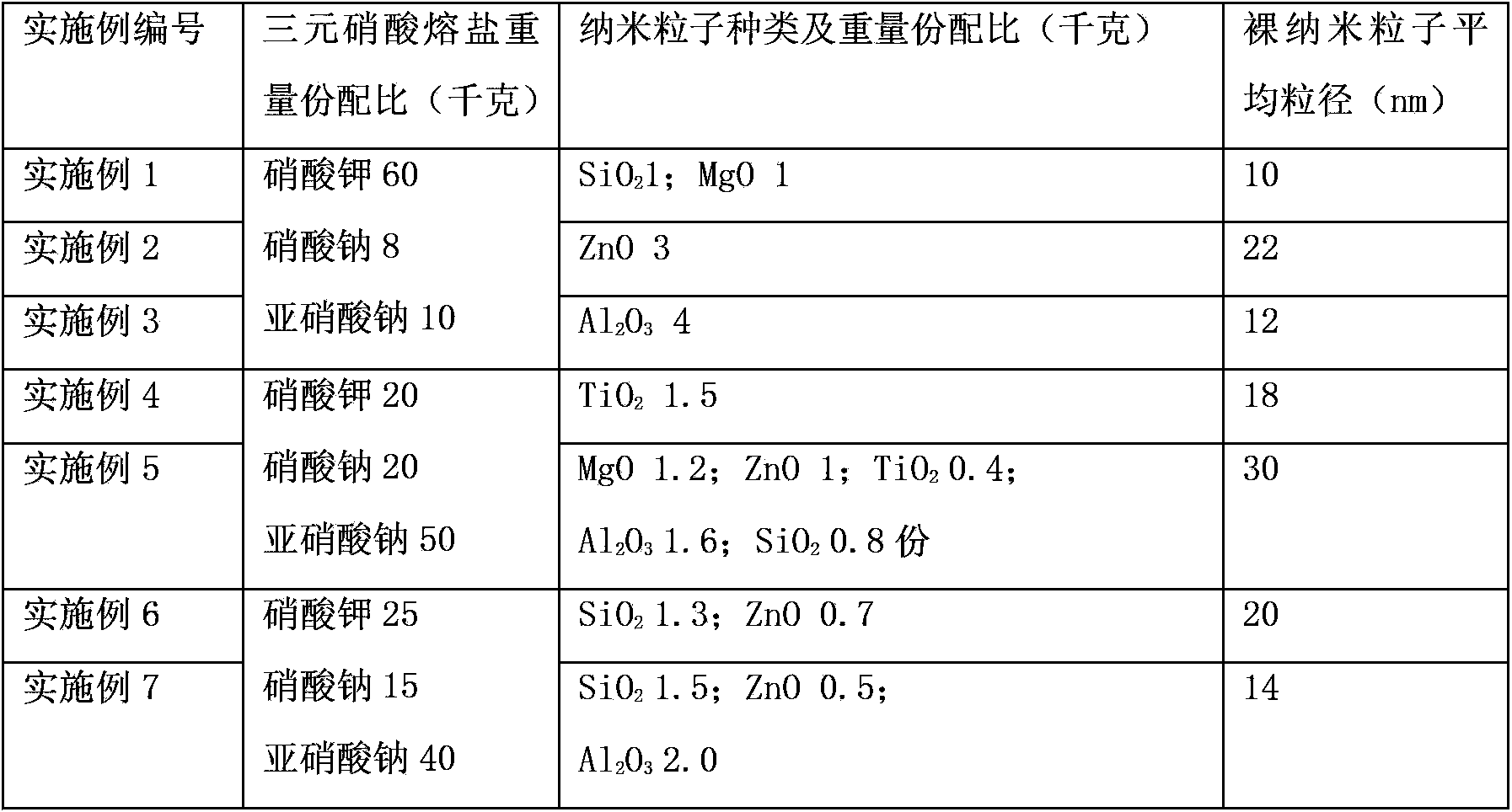

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

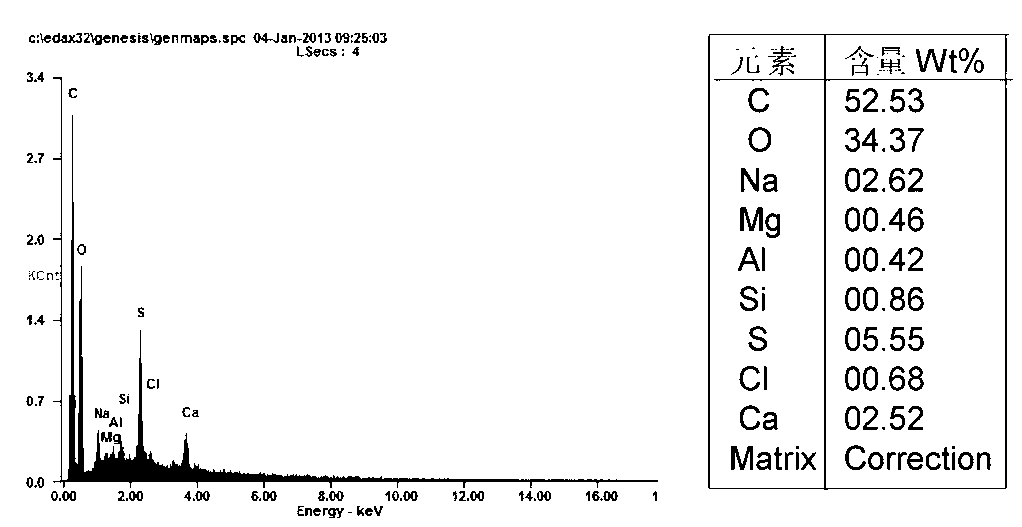

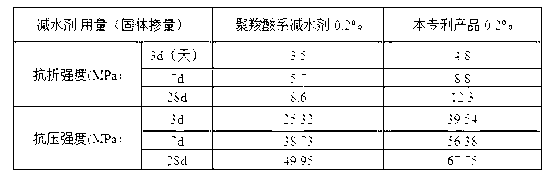

Preparation method of graphene oxide modified polycarboxylic acid type water-reducer

ActiveCN103241983AHigh flexural and compressive strengthRaw materials are easy to getCarbon compoundsCarboxylic acidWater reducer

The invention relates to a preparation method of a graphene oxide modified polycarboxylic acid type water-reducer. A polycarboxylic acid type water-reducer is a novel efficient water-reducer following a naphthalene type water-reducer, a melamine water-reducer and an amino sulfonic acid based water-reducer, but the mechanical property of concrete cannot be obviously improved by adding the polycarboxylic acid type water-reducer. The preparation method comprises the steps of preparing graphene oxide with natural flake graphite, sodium nitrate, concentrated sulfuric acid and potassium permanganate as raw materials; carrying out ultrasonic dispersion on the graphene oxide; and then adding the polycarboxylic acid type water-reducer with a certain proportion to form an intercalation compound of the graphene oxide and the polycarboxylic acid type water-reducer. With the adoption of the modified water-reducer, on the basisthat the existing water-reducing rate is kept, the flexural strength and the compressive strength of a cement-based composite are obviously strengthened, the relevant raw materials are easily obtained, a preparation technology is reasonable, pollution in a preparation process is little, the performance of products is excellent, and the graphene oxide modified polycarboxylic acid type water-reducer is suitable for industrial production.

Owner:广西科达新材料集团有限公司

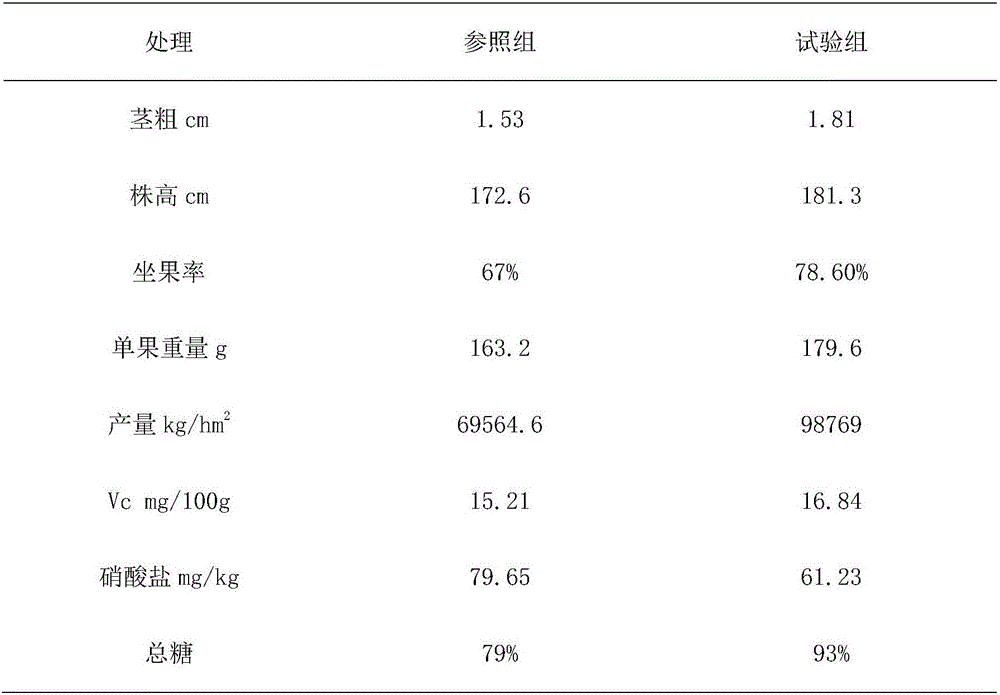

Soilless vegetable culture nutrient solution and preparation method

InactiveCN106699386AImprove stabilityHigh content of effective nutrientsCalcareous fertilisersMagnesium fertilisersAdditive ingredientNutrient solution

The invention relates to the field of nutrient solutions, in particular to a soilless vegetable culture nutrient solution and a preparation method. The soilless vegetable culture nutrient solution is prepared from sodium nitrate, urea phosphate, potassium nitrate, ammonium sulfate, magnesium chloride, Fe-EDTA, boric acid, manganese chloride, zinc sulfate, copper sulfate, sodium molybdate, mixed nitrogen-fixing bacterium solution and a nostoc extracting solution. The nutrient solution is simple and convenient to prepare, comprehensive in nutrient ingredient, high in biological activity and good in homogeneity, can decompose self-toxic materials produced by vegetables, remarkably improve the resistance, yield and the quality of the vegetables.

Owner:GUIZHOU UNIV

Dried salted duck salting seasoning and preparation method of dried salted duck

The invention discloses a dried salted duck salting seasoning and a preparation method of the dried salted duck. The dried salted duck comprises the following components by weight based on 500 parts of a fresh duck: 10 to 15 parts of table salt, 0.1 to 0.3 part of edible sodium nitrate, 0.08 to 0.3 part of cinnamon, 0.02 to 0.1 part of clove, 0.1 to 0.3 part of kaempferiae, 0.06 to 0.2 part of illicium verum, 0.05 to 0.2 part of tsaoko amomum fruit, 0.1 to 0.3 part of radix angelicae, 0.1 to 0.5 part of fennel, 0.1 to 0.4 part of amomum kravanh, 0.1 to 0.5 part of cumin, 0.3 to 0.8 part of liquorice, 0.1 to 0.3 part of pericarpium citri reticulatae, 0.1 to 0.3 part of galangal, 0.02 to 0.08 part of myrcia, 0.03 to 0.06 part of vanilla, 0.2 to 0.7 part of rhizoma zingiberis, 0.5 to 1.5 parts of pickly ash, 4 to 8 parts of white spirit, 8 to 12 parts of white sugar, 0.1 to 0.3 part of chicken essence, and 0.1 to 0.3 part of monosodium glutamate. The preparation method of the dried salted duck comprises the following steps in sequence: slaughtering a live duck, coating seaming salt, soaking, cleaning, sizing, baking, marinating and packaging to obtain the dried salted duck. By adopting the dried salted duck salting seasoning and the preparation method of the dried salted duck, the problems of salty and rank in taste in prior art can be solved, and the dried salted duck prepared by the preparation method is pliable and delicious.

Owner:毛希泽

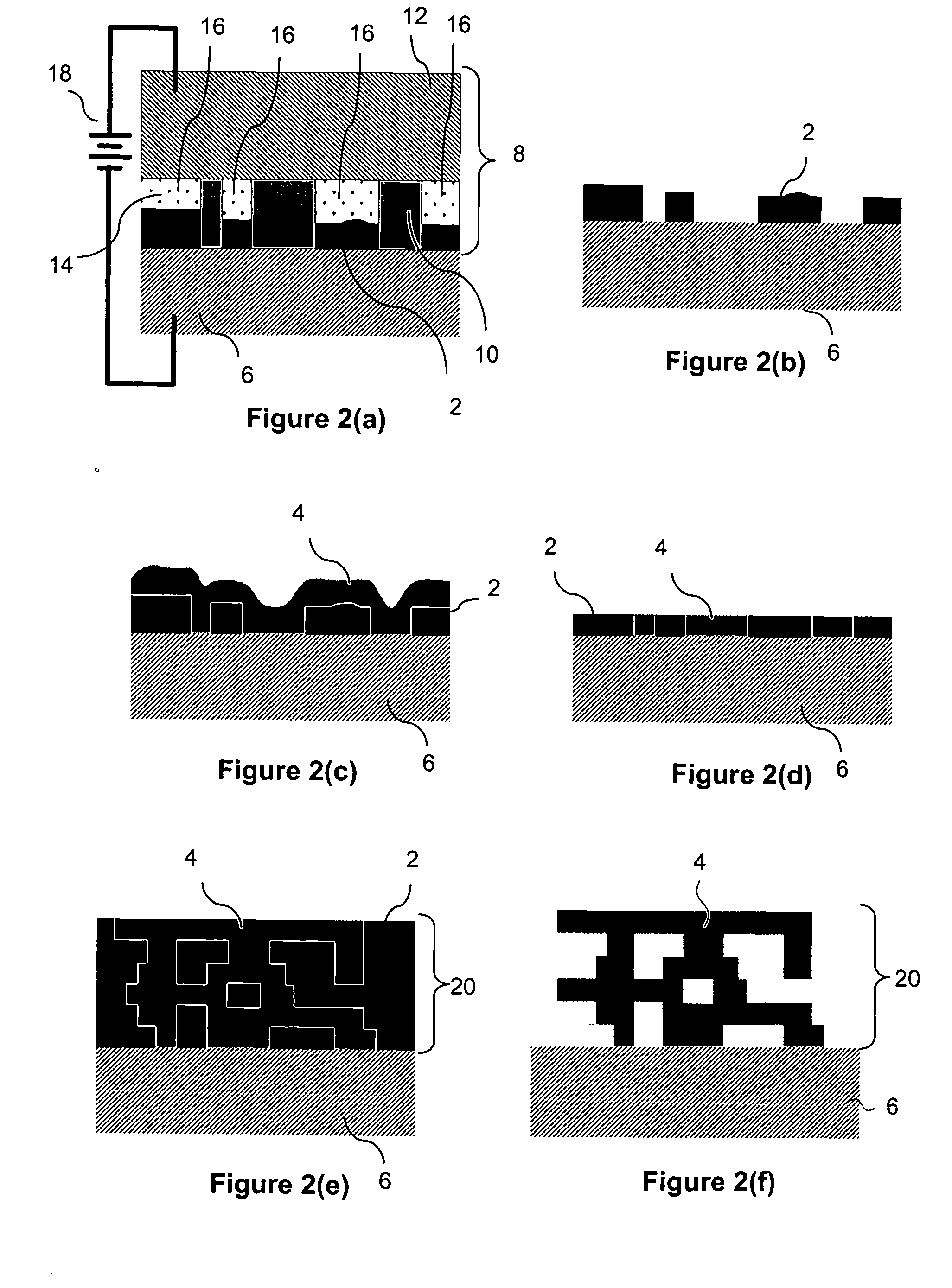

Electrochemical fabrication methods with enhanced post deposition processing

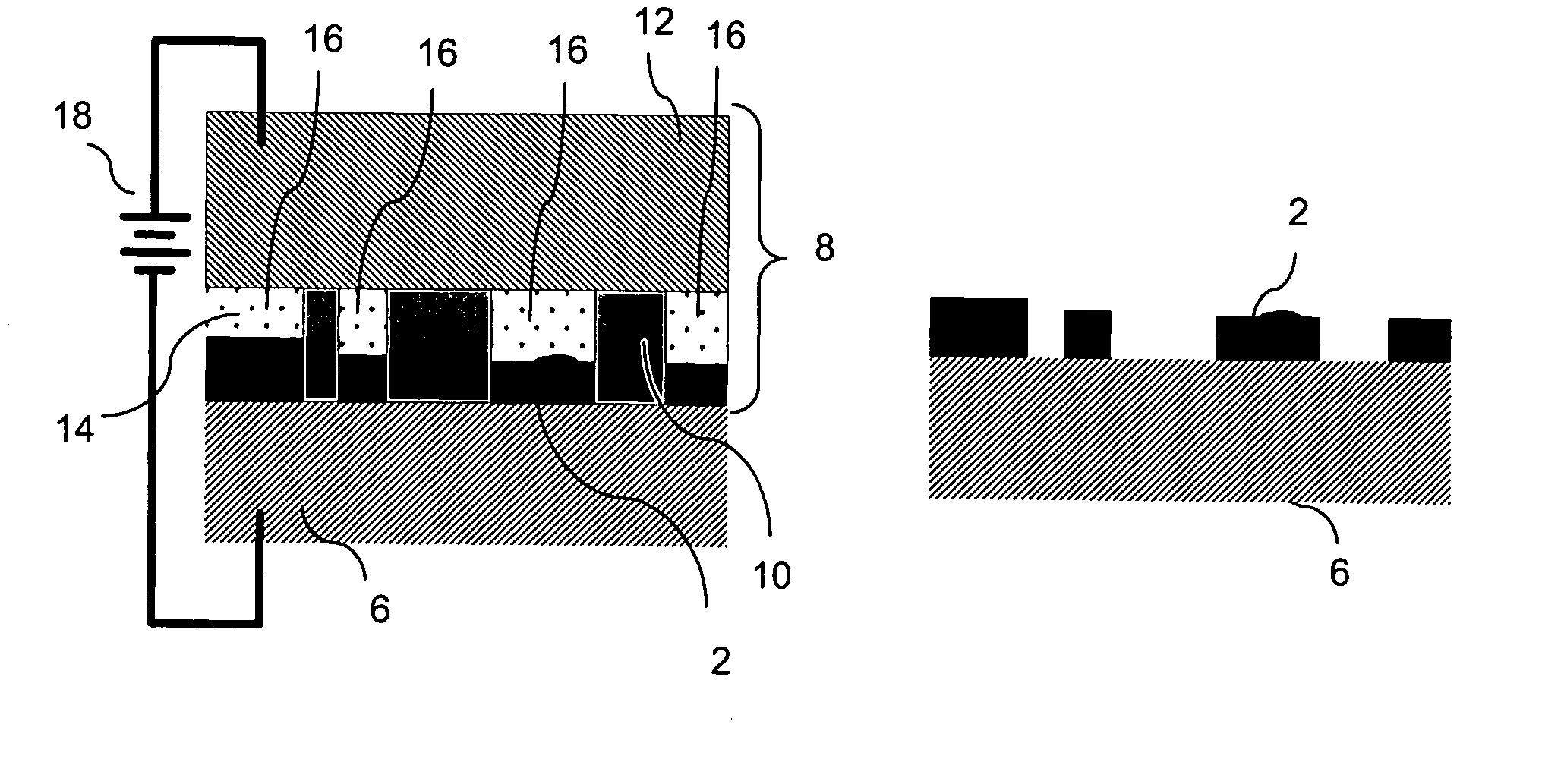

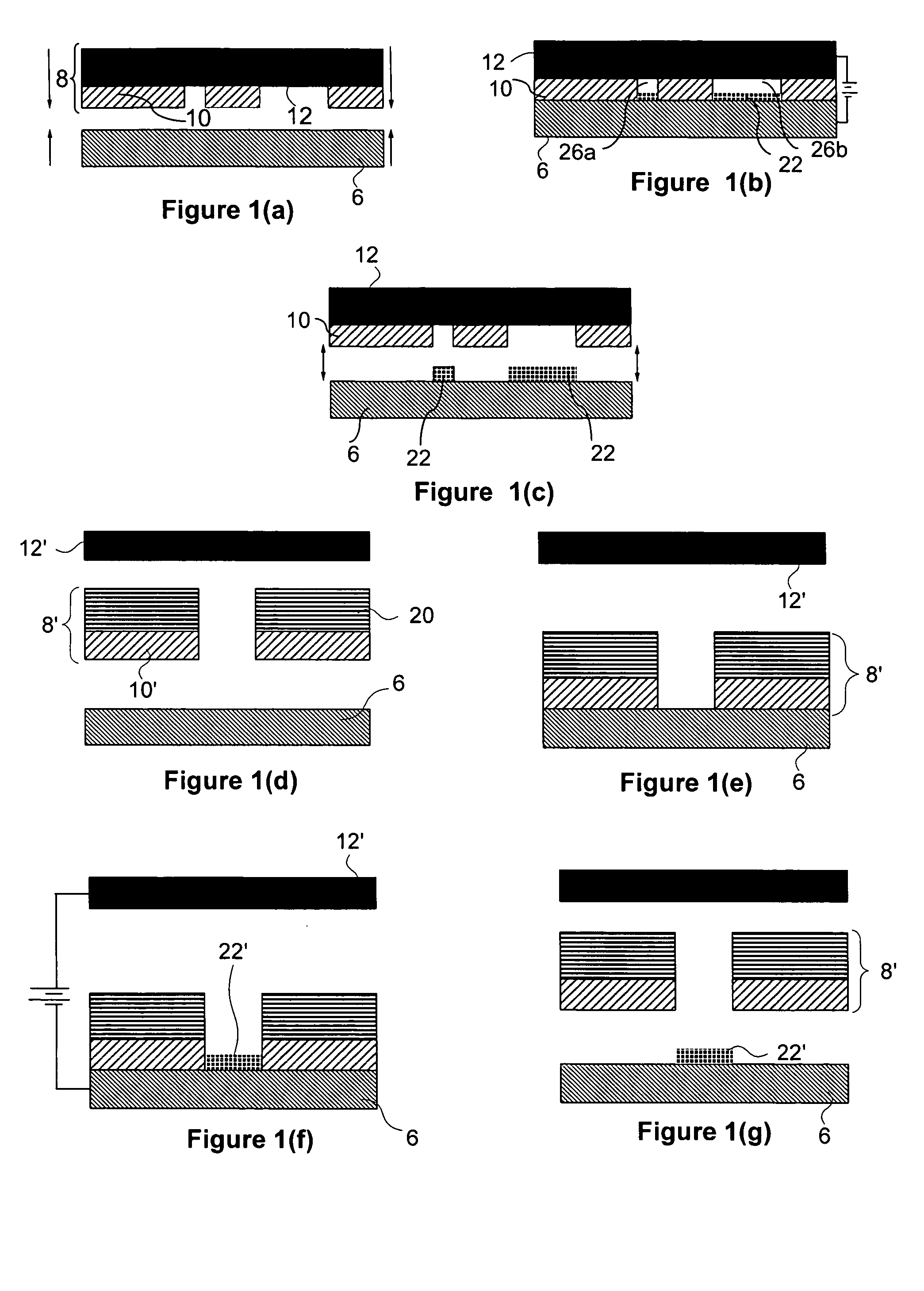

InactiveUS20050029225A1Improved post deposition processingDecorative surface effects3D structure electroformingAlcoholNickel alloy

An electrochemical fabrication process for producing three-dimensional structures from a plurality of adhered layers is provided where each layer comprises at least one structural material (e.g. nickel or nickel alloy) and at least one sacrificial material (e.g. copper) that will be etched away from the structural material after the formation of all layers have been completed. An etchant containing chlorite (e.g. Enthone C-38) is combined with a corrosion inhibitor (e.g. sodium nitrate) to prevent pitting of the structural material during removal of the sacrificial material. A simple process for drying the etched structure without the drying process causing surfaces to stick together includes immersion of the structure in water after etching and then immersion in alcohol and then placing the structure in an oven for drying.

Owner:UNIV OF SOUTHERN CALIFORNIA

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

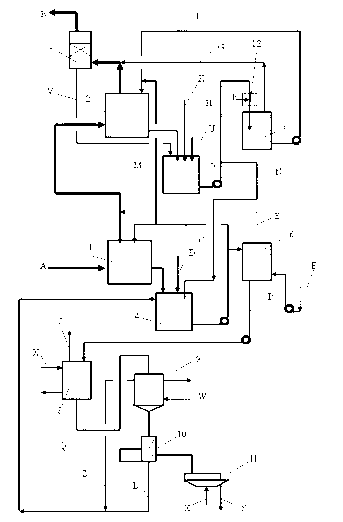

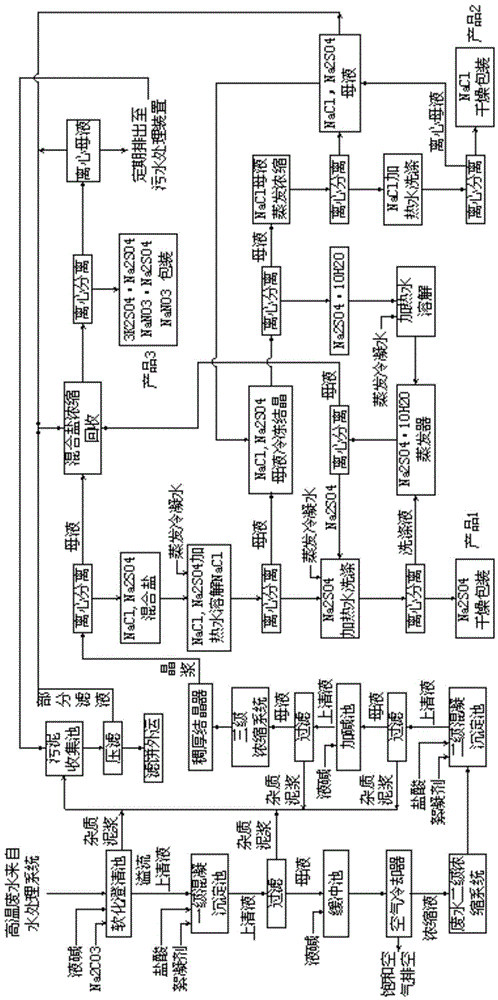

Comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in coal chemical industry

ActiveCN105585194AReduce consumptionReduce evaporative loadChemical industryTreatment involving filtrationHigh concentrationChemical oxygen demand

The invention relates to a comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in the coal chemical industry. After the high-concentration waste saline water is subjected to softening for impurity removal and subjected to coagulation sedimentation to remove COD (chemical oxygen demand), the water is concentrated by 20%-30% through an air cooler; then, the water enters second and third concentration systems and a salt mixture recovery system, and sodium sulfate, sodium chloride and sodium nitrate and potassium sulfate mixed salt are concentrated and separated with a multi-effect negative pressure evaporation method; condensed water is recycled. The purity of separated sodium chloride and the purity of separated sodium sulfate are higher than 99%, and sodium chloride and sodium sulfate can be directly sold. The method has remarkable economic benefits and social benefits, is environment-friendly, comprehensively reaches the standard and can be used for comprehensive treatment and utilization of similar high-concentration saline water in other industries, so that the environment-friendly and energy-saving requirements for full utilization of resources are met.

Owner:和易中诚环保科技有限公司

Carbon fiber reinforced composite material and preparation technology thereof

The invention provides a carbon fiber reinforced composite material and a preparation technology thereof. Carbon fiber braided fabric is pretreated in a composite pretreatment solution with the concentration of 50 to 60 percent, wherein the composite pretreatment solution comprises 5 to 20 percent of oxydol and one or more of the following components: 50 to 70 percent of nitric acid, 30 to 50 percent sodium nitrate, ferric chloride, potassium permanganate, and acidic potassium dichromate; the carbon fiber braided fabric is pre-tightened in a adjustable and controllable stretching mechanism byadopting a compression moulding forming method, and then is fixed on a mould through a positioning device and coated with thermosetting resin powder with a required thickness; according to the performance indexes of the carbon fiber reinforced composite material to be manufactured, the carbon fiber braided fabric and the thermosetting resin powder with the required thickness are laid in a matrix position in the mould lay by lay until to designed layer number and thickness are achieved; and then heating and compression molding are carried. Through the surface treatment to the carbon fiber withthe specially prepared composite solution, the compatibility of carbon fiber and thermoset material is greatly improved, and the adhesion property of the carbon fiber and matrix resin is improved. Through the adoption of compression moulding forming, the forming technology is simple, the production is flexible, the production cycle is short, the equipment investment is small, and the cost is low.

Owner:DANYANG DANJIN AVIATION MATERIAL TECH

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

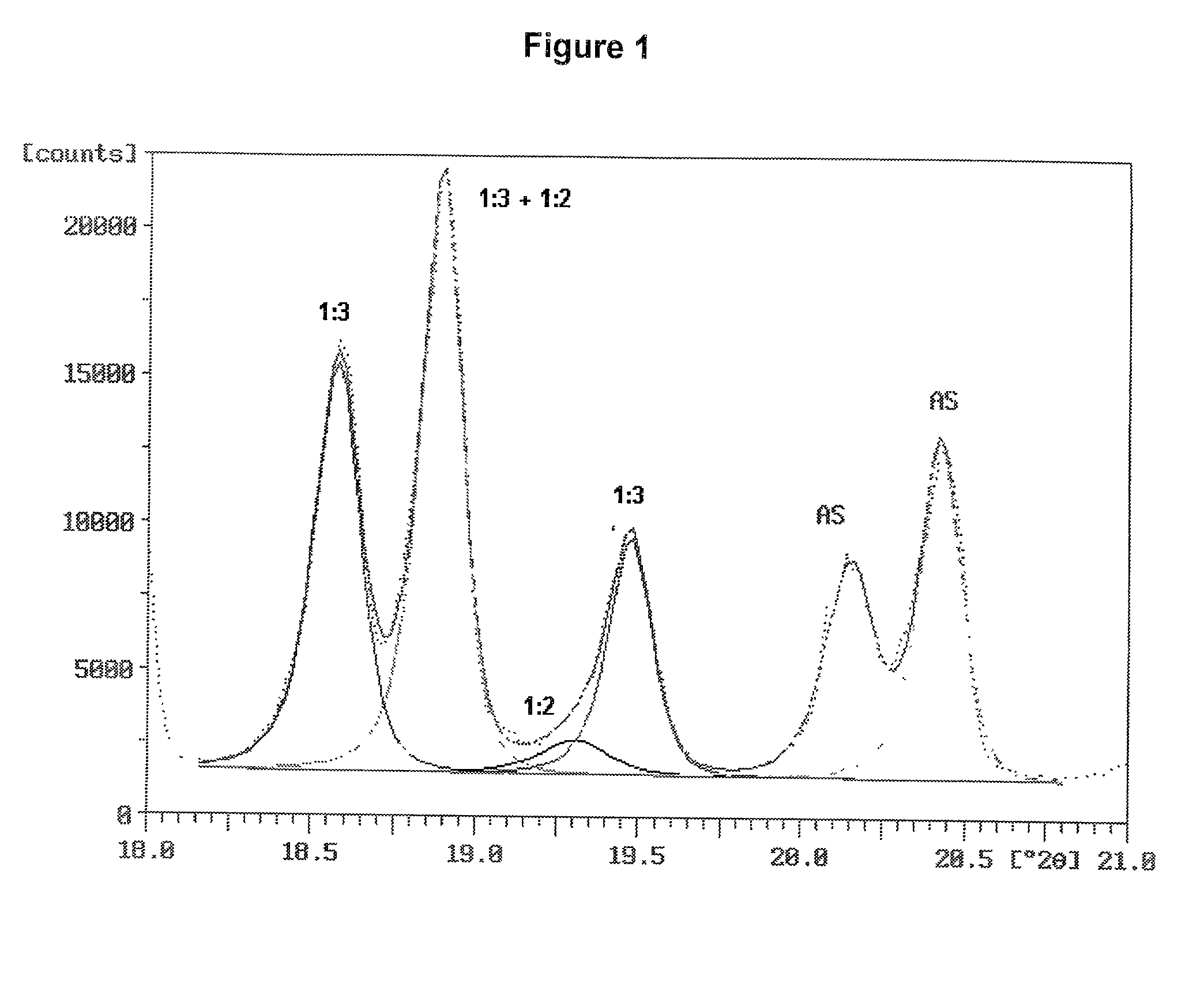

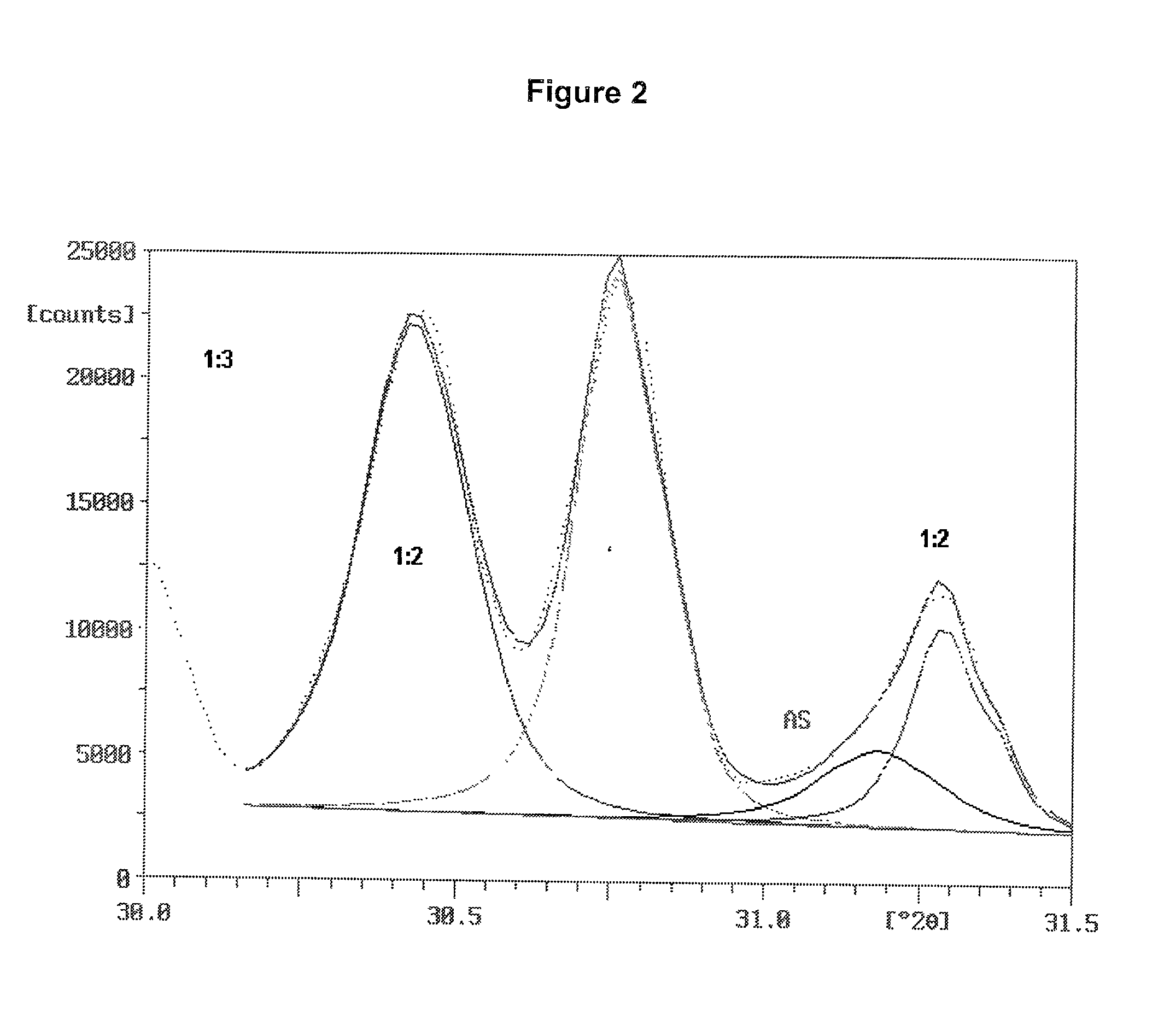

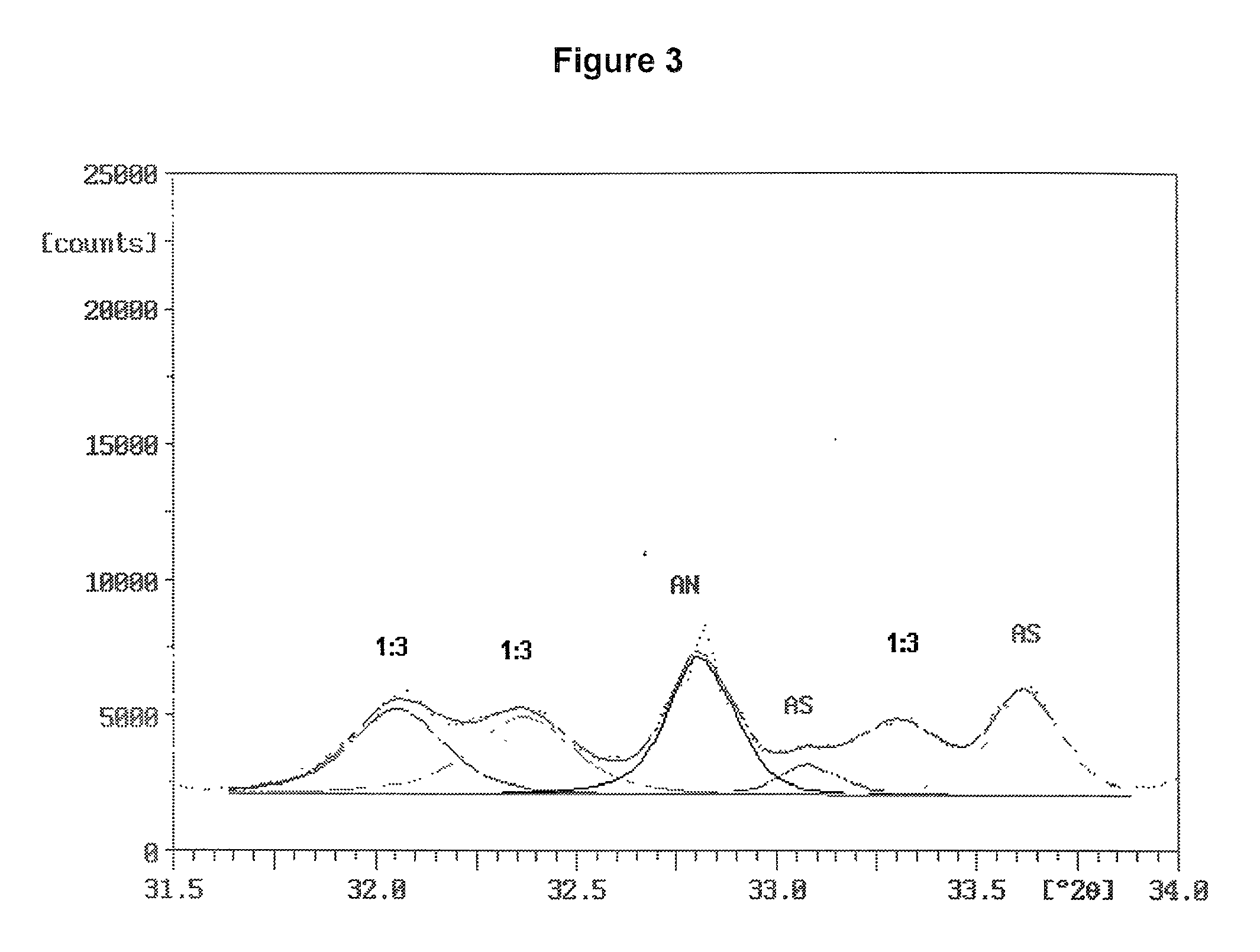

Ammonium sulfate nitrate

Ammonium sulfate nitrate composite materials useful as fertilizers having desirable levels of nitrate ions, superior stability against detonation, higher density, greater resistance to moisture, and a method for their manufacture. The ammonium sulfate nitrate composites have as essential constituents ammonium sulfate and the NH4SO4.2(NH4NO3) double salt with less than 5 wt. % in combined total of the more hazardous NH4SO4.3(NH4NO3) double salt and ammonium nitrate. The composites of the invention are formed by reacting ammonium sulfate with ammonium nitrate in a molar ratio of about 0.9:1 to about 1.1:1 in the presence of a small amount of water in a narrow range of temperatures and then cooling to solidification at a sufficiently rapid rate to prevent macroscopic segregation of the reaction products.

Owner:ADVANSIX RESINS & CHEM LLC

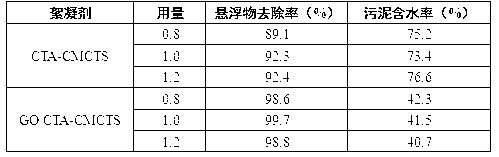

Preparation method of graphene oxide/amphoteric chitosan intercalation composite for sewage treatment

ActiveCN103240063AEnhance sexualityWell formedOther chemical processesWater/sewage treatment by sorptionCarboxyl radicalUltrasound - action

The invention relates to a preparation method of a graphene oxide / amphoteric chitosan intercalation composite for sewage treatment. At present, the dewatering effect of a cationic type polymeric flocculant is limited. The preparation method has the steps of oxidizing graphite by virtue of concentrated sulfuric acid, sodium nitrate and potassium permanganate to prepare graphene oxide; modifying chitosan by virtue of chloroacetic acid and a quaternization reagent to obtain amphoteric chitosan; and then under the action of ultrasonic waves, realizing intercalation compounding of the graphene oxide and the amphoteric chitosan, and carrying out dispersion to obtain a graphene oxide nanometer ion dispersion liquid. According to the preparation method, by virtue of an intercalation method, controllable dispersion of a graphene oxide sheet layer and grains is realized; as being provided with active groups of carboxyl groups, hydroxy groups, quaternary ammonium groups and the like, the surface of the graphene oxide in a dispersed state can adsorb suspended pollutants in wastewater; and the graphene oxide / amphoteric chitosan intercalation composite can be applied to wastewater treatment and has the advantages of little dosage, high efficiency and low water content of sludge, and the preparation method has the characteristics that the preparation technology is unique, equipment is easily botained, and the operation is simple.

Owner:DONGYING DAOYI BIOLOGICAL MEDICINE TECH CO LTD

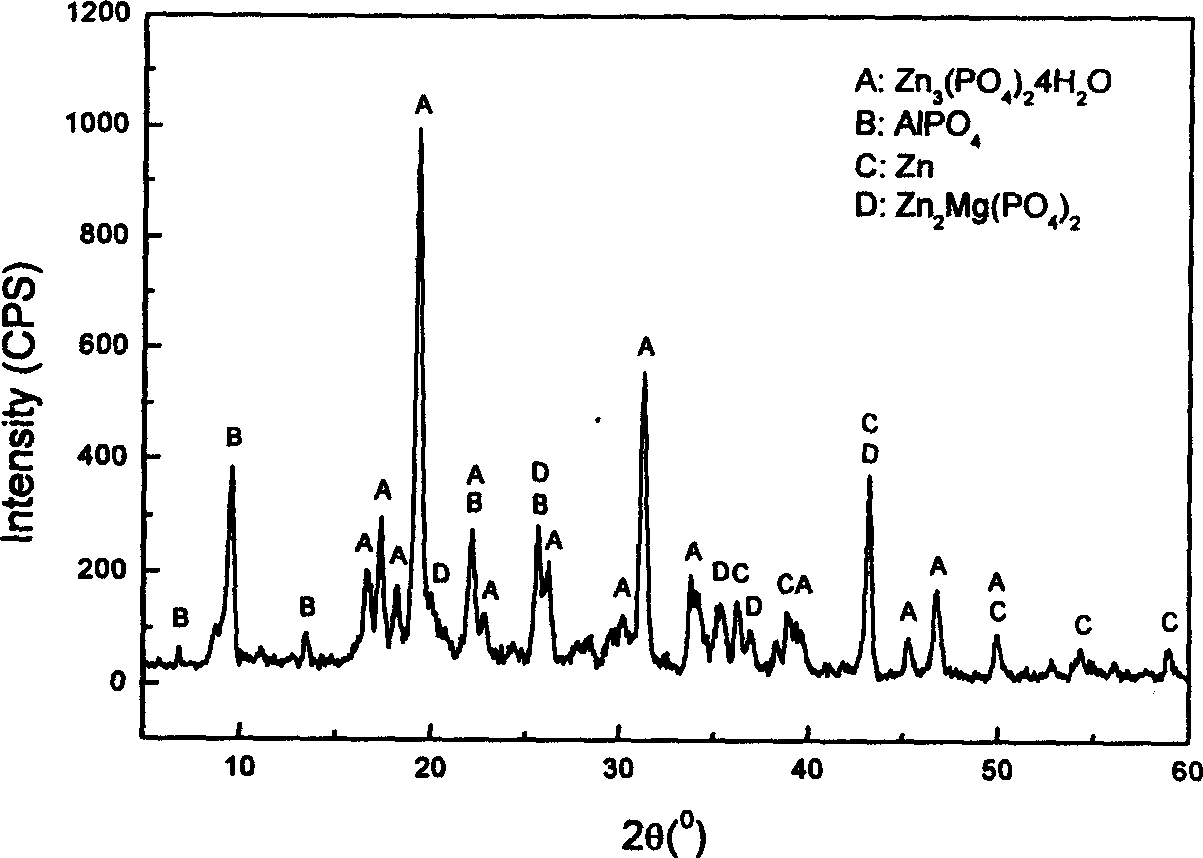

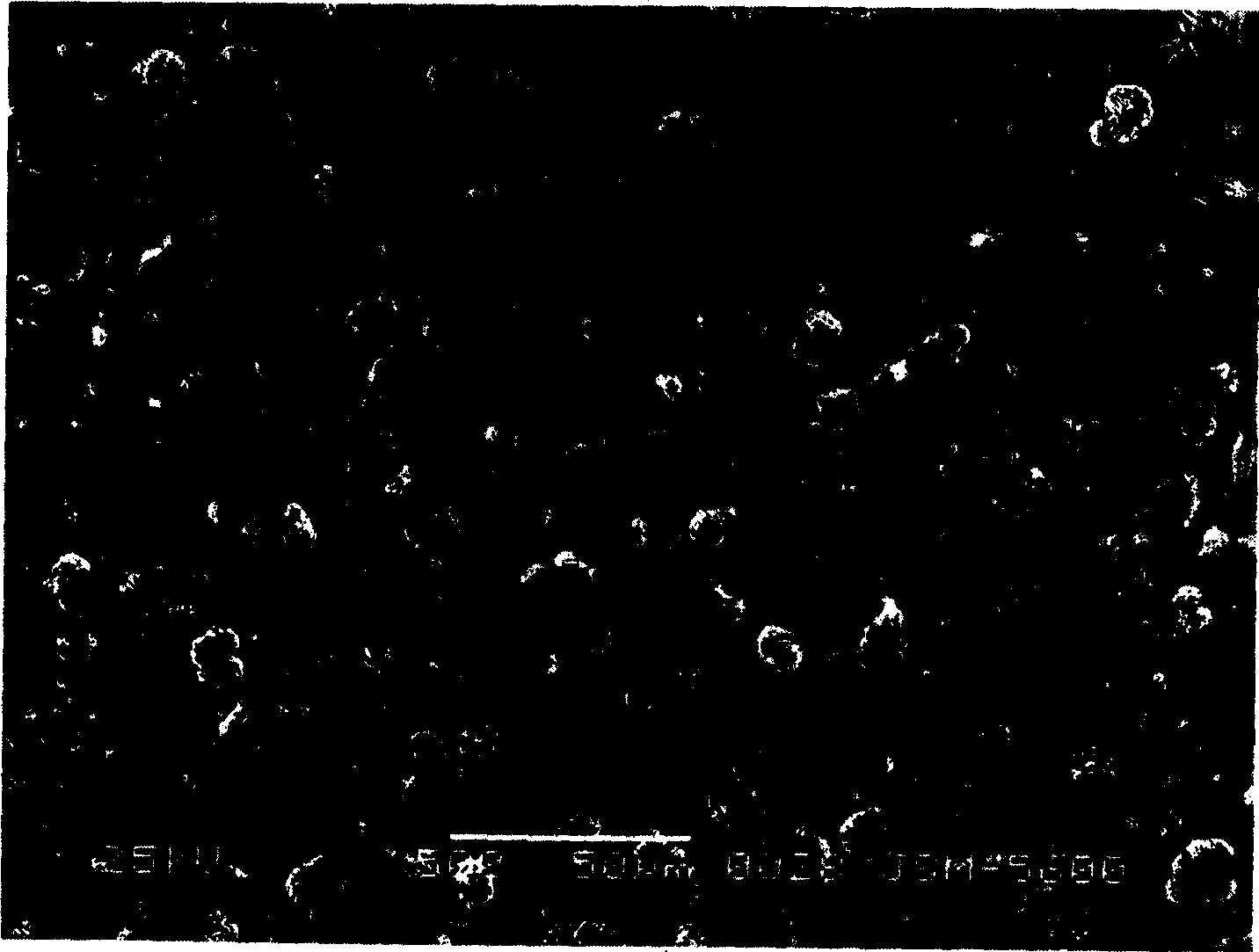

Magnesium alloy phosphorization solution and its phosphorized technology

InactiveCN1598055AProcess stabilityThe process is simple and easy to controlMetallic material coating processesPhosphatePhosphoric acid

Owner:JILIN UNIV

Method for preparing graphene oxide modified composite phase-change microcapsule

ActiveCN107417867AImprove thermal effectGood compatibilityHeat-exchange elementsMicroballoon preparationWater bathsCross-link

The invention discloses a method for preparing graphene oxide modified composite phase-change microcapsules. The method specifically comprises the following steps: preparing a graphene oxide solid from graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and deionized water; mixing the obtained graphene oxide solid with absolute ethyl alcohol and a silane coupling agent, and performing a reaction so as to obtain a double-bond modified functional graphene oxide solid; uniformly mixing the obtained functional graphene oxide solid with a phase-change material, a reaction monomer, a cross-linking agent, a reactive emulsifier and deionized water, and performing ultrasonic dispersion so as to form an oil-in-water type pre-emulsion; and putting the obtained oil-in-water type pre-emulsion into a hot water bath, continuously stirring, further adding an initiator solution, and performing a heat-preservation reaction, thereby obtaining the graphene oxide modified composite phase-change microcapsules. By adopting the method disclosed by the invention, composite phase-change microcapsules which are high in encapsulation efficiency, stable in property, good in heat conductivity, appropriate in phase-change temperature and relatively high in phase-change latent heat enthalpy can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Refining agent for smelting aluminum alloy and preparation method of refining agent

InactiveCN102181757AIncrease surface tensionImprove working environmentPotassium nitrateWorking environment

The invention relates to an aluminum smelting purifying agent, in particular to a refining agent for smelting an aluminum alloy and applied to purification treatment in a smelting furnace in the process of aluminum and aluminum alloy smelting, and a preparation method of the refining agent. The refining agent is prepared from the following raw materials in part by weight: 26 to 34 parts of sodium nitrate (NaNO3), 30 to 40 parts of potassium nitrate (KNO3), 15 to 22 parts of sodium aluminofluoride (Na3AlF6), 4 to 6 parts of calcium fluoride (CaF2), 6 to 12 parts of graphite (C), and 2 to 4 parts of sodium carbonate (Na2CO3). The preparation method of the refining agent comprises the following steps of: putting the raw materials of the sodium nitrate, the potassium nitrate, the sodium aluminofluoride, the calcium fluoride, the graphite and the sodium carbonate into a drying type rotary composite stirrer; stirring the raw materials for 60 to 90 minutes at 150 to 250 DEG C; and finally, preparing a powdery refining agent finished product. The refining agent has strong refining capability, has an obvious function in improving the quality of aluminum industry products, is low in cost and less in used amount, significantly saves the cost, improves the working environment of workers, and causes less environmental pollution.

Owner:湖南德利亨新材料科技股份有限公司

Preparation method of organic-chain-segment-modified graphene oxide

InactiveCN102745672APreparation helpsPromote recombinationCarbon compoundsOrganosolvPotassium manganate

The invention discloses a preparation method of organic-chain-segment-modified graphene oxide. According to the invention, graphite is oxidized under the effects of strong oxidizing agents such as concentrated sulfuric acid, sodium nitrate and potassium permanganate; the oxidized graphite is subjected to ultrasonic dispersion in an organic solvent, such that a graphene oxide dispersion system is prepared; diisocyanate and dihydric alcohol are subjected to a reaction; hydroxyacrylate is used for sealing one end; and an NCO group in the organic chain segment is subjected to a reaction with the prepared graphene oxide, such that the organic-chain-segment-modified graphene oxide is prepared. The organic chain segment contains polymerizable double bonds, such that cross-linking polymerization of the modified graphene oxide and other organic materials can be promoted, and composite materials with special properties can be obtained.

Owner:SHENZHEN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com