Nitrate molten salt heat transferring and reserving medium and preparation method and application thereof

A heat storage medium and molten salt technology, applied in the field of nitric acid molten salt heat transfer heat storage medium and its preparation, heat transfer and heat storage medium field, can solve the problem of increased corrosiveness, high environmental atmosphere requirements, and increased corrosiveness of molten salt. and cost, to achieve the effect of good thermal stability and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a nitric acid molten salt heat transfer heat storage medium, comprising the following steps:

[0037] Mix 33.4% potassium nitrate, 11.44% sodium nitrate, and 55.16% calcium nitrate and stir evenly, heat statically (without stirring) until the solids are completely melted, then keep warm for 10 minutes, and then cool naturally to 20°C to obtain molten nitric acid Salt heat transfer and heat storage medium; the percentages mentioned are the percentages of each component in the total mass of raw materials of the nitric acid molten salt heat transfer and heat storage medium.

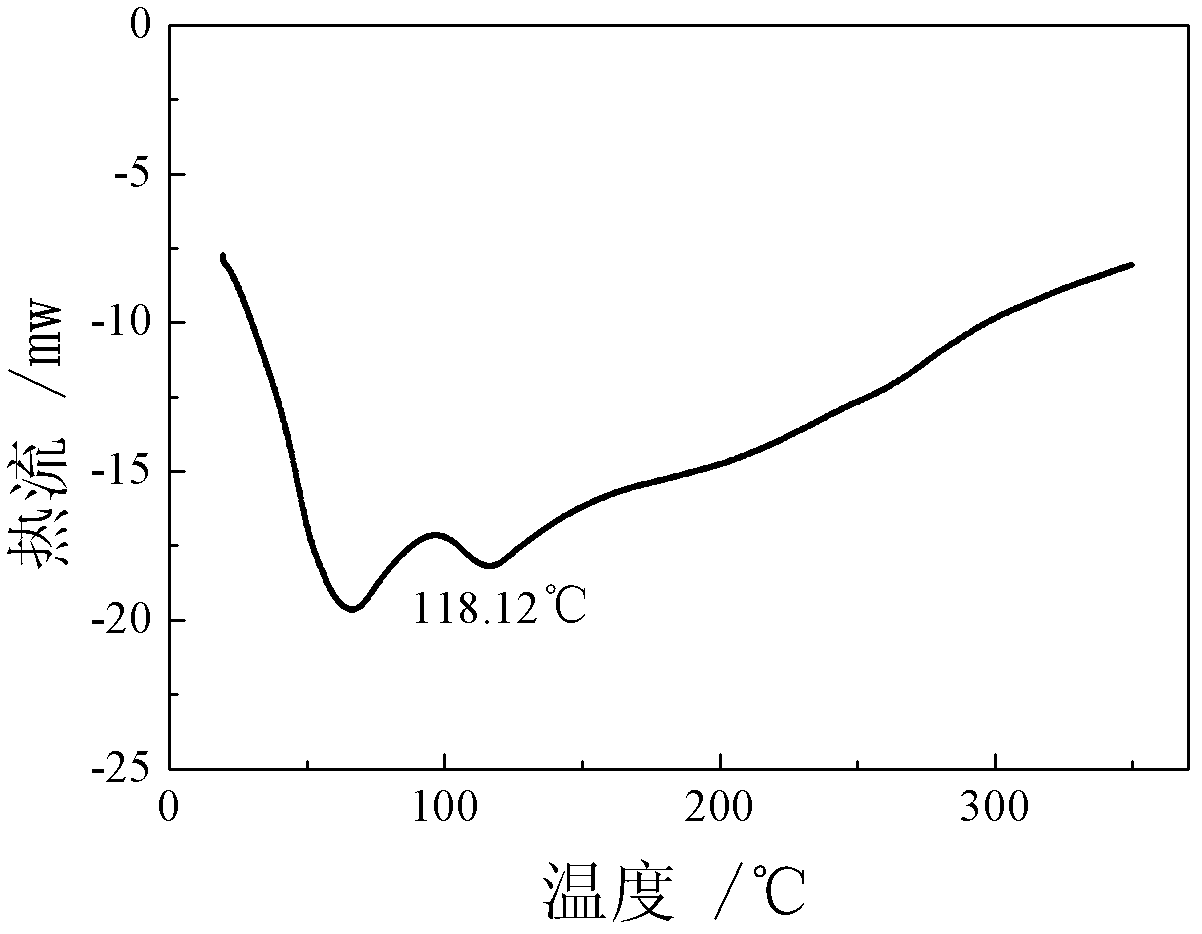

[0038] The melting point test was carried out on the heat transfer and heat storage medium of the nitric acid molten salt prepared in this embodiment. The test is carried out with a common differential scanner (DSC). The DSC curve obtained from the test is as follows figure 1 shown. The test results showed that the melting point of the molten salt was 118.12°C.

Embodiment 2

[0040] A method for preparing a nitric acid molten salt heat transfer heat storage medium, comprising the following steps:

[0041] Mix and stir 29.97% potassium nitrate, 20.53% sodium nitrate, and 49.5% calcium nitrate evenly, statically heat until the solids are completely melted, then keep warm for 20 minutes, and then cool naturally to 25°C to obtain the molten salt heat transfer storage Heat medium; the percentages mentioned are the percentages of each component in the total mass of the raw materials of the nitric acid molten salt heat transfer heat storage medium.

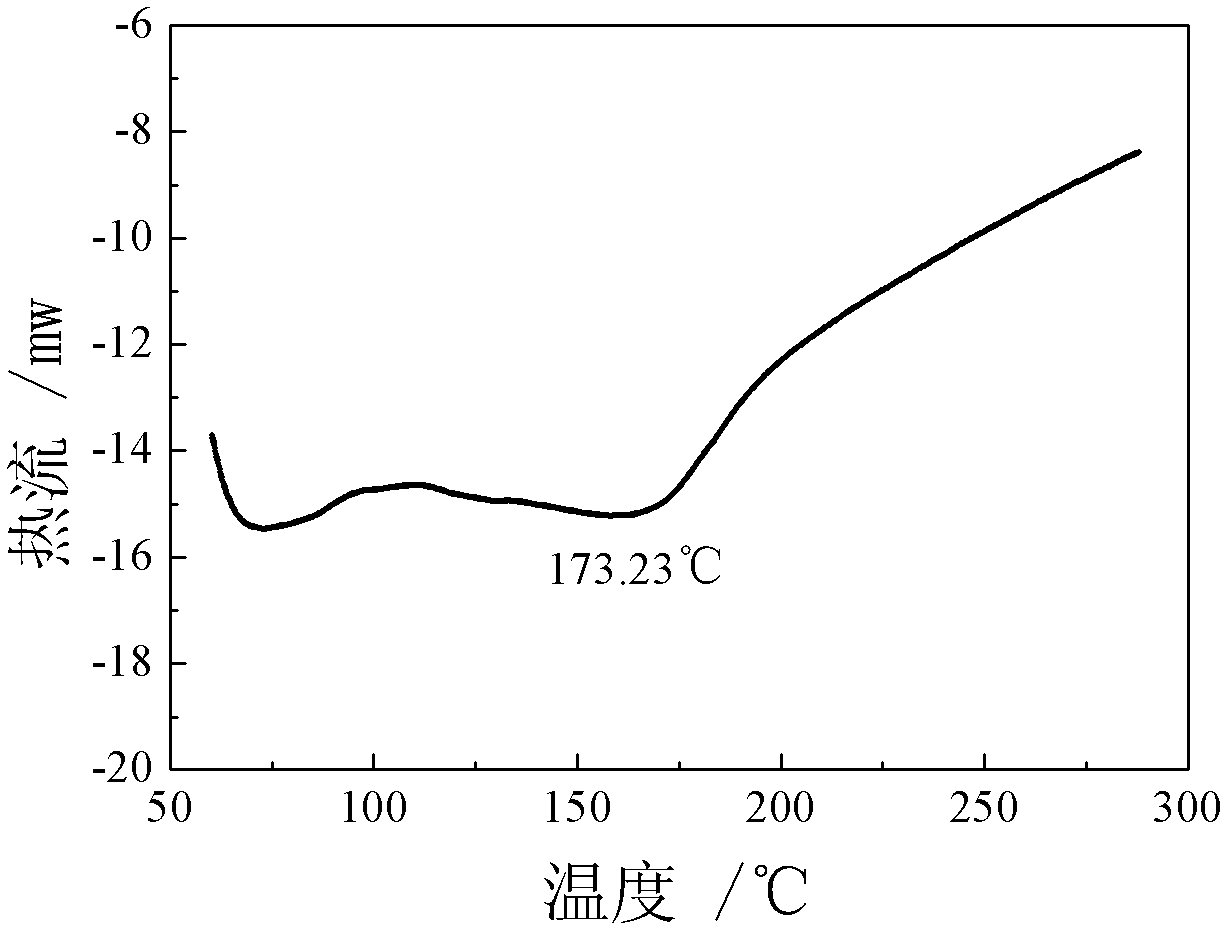

[0042] The melting point of the nitrate molten salt heat transfer and heat storage medium prepared in this embodiment was tested. Test method is the same as embodiment 1. The results showed that the melting point of the molten salt was increased from 118.12°C to 173.23°C compared with Example 1.

Embodiment 3

[0044] A method for preparing a nitric acid molten salt heat transfer heat storage medium, comprising the following steps:

[0045] Mix 22.79% of potassium nitrate, 11.89% of sodium nitrate, and 65.32% of calcium nitrate and stir evenly, statically heat until the solids are completely melted, then keep warm for 30 minutes, and then naturally cool to 30°C to obtain the molten salt heat transfer storage Heat medium; the stated percentages are the percentages of each component in the total mass of the raw materials of the nitric acid molten salt heat transfer heat storage medium.

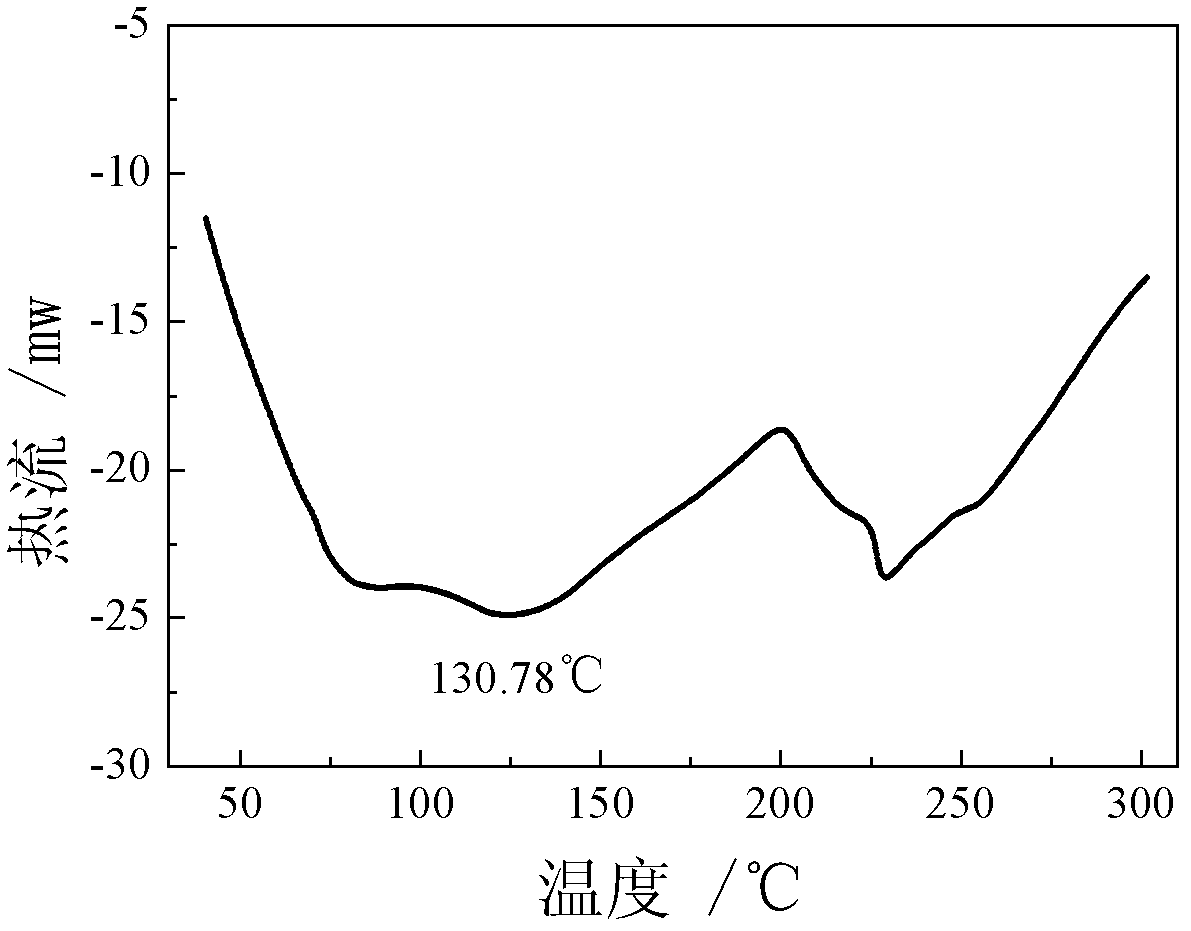

[0046] The melting point of the nitrate molten salt heat transfer and heat storage medium prepared in this embodiment was tested. Test method is the same as embodiment 1. The test results show that the melting point of the molten salt is 130.78°C, which is lower than that of Example 2.

[0047] The thermal stability of the molten salt medium prepared in Example 1 was tested: firstly, the molten salt sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com