Patents

Literature

90results about How to "Increase charge and discharge rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

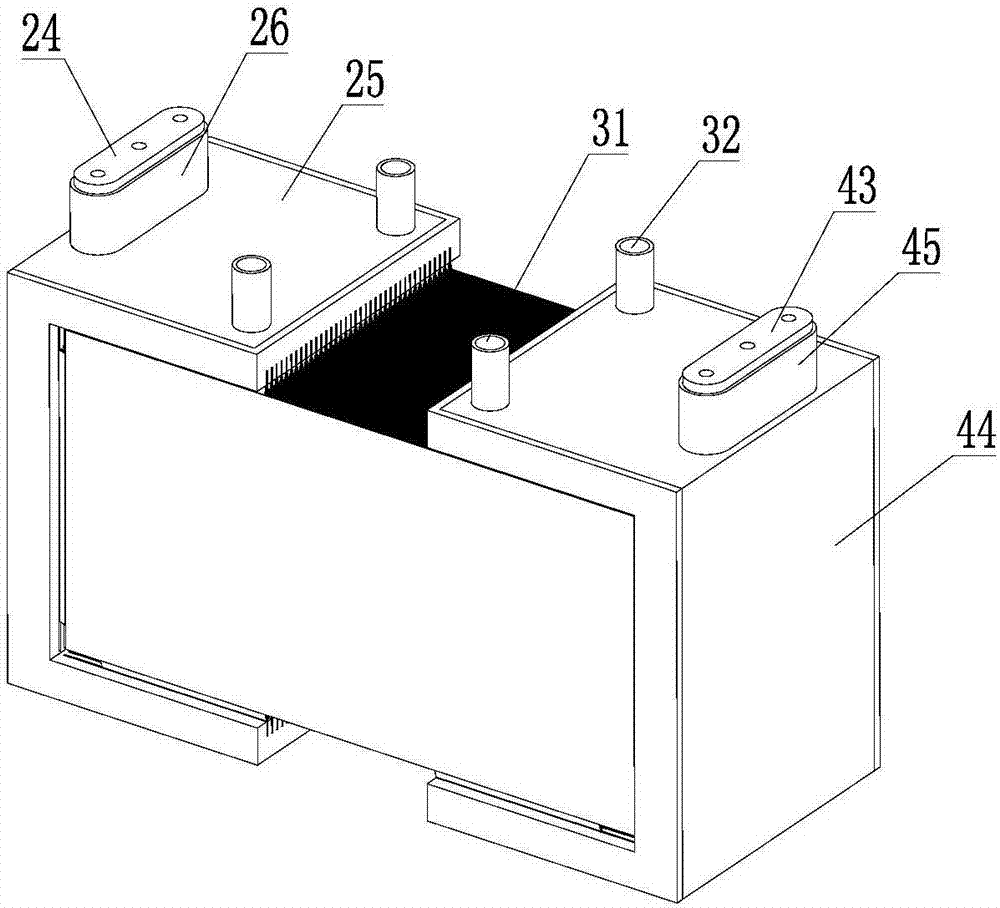

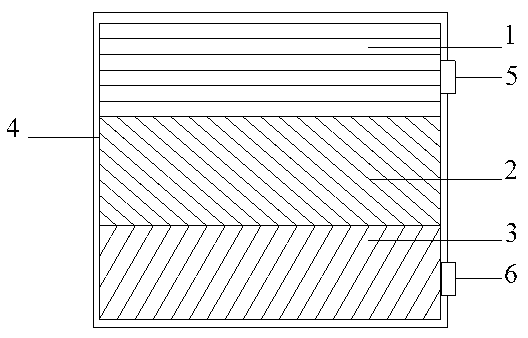

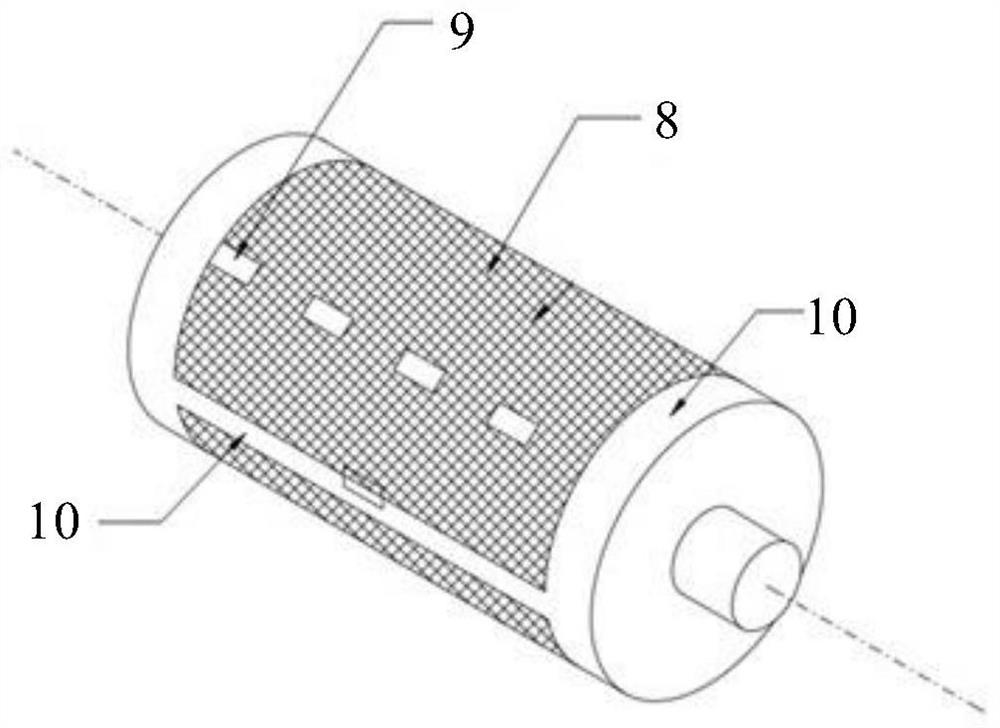

Large-capacity nickel-metal hydride battery

InactiveCN106876651ALow resistivityIncrease charge and discharge rateFinal product manufactureCell temperature controlElectrical conductorHigh rate

The invention discloses a large-capacity nickel-metal hydride battery, comprising a pole plate group, wherein a diaphragm is arranged between the adjacent positive plate and negative plate, three pole ears with C-like distribution are arranged on the pole plates, and the positive plate and the negative plate are oppositely arranged at intervals; one side of the pole plate group is coated with a positive current collector, the outer side of the positive current collector is coated with a positive flow deflector, the positive flow deflector is connected with the positive current collector through a low-melting-point welding layer, a positive pole rod is arranged on the positive flow deflector, the outer side of the positive flow deflector is coated with a positive guard plate, and a positive cooling system is arranged between the positive guard plate and the positive flow deflector; and the negative side structure is the same as the positive side structure. The pole plate adopts the pole ears with C-like distribution, the positive and negative current collectors are connected with the corresponding pole ears, the flow deflector and the current collector are welded together through a low-melting-point silver alloy, the resistivity of a conductor can be reduced, and thus the charge and discharge rate can be increased to a maximum extent; and the positive cooling system and the negative cooling system can cool the temperature rise generated by high-rate charging and discharging of the batteries.

Owner:山东三尺企业管理咨询有限公司

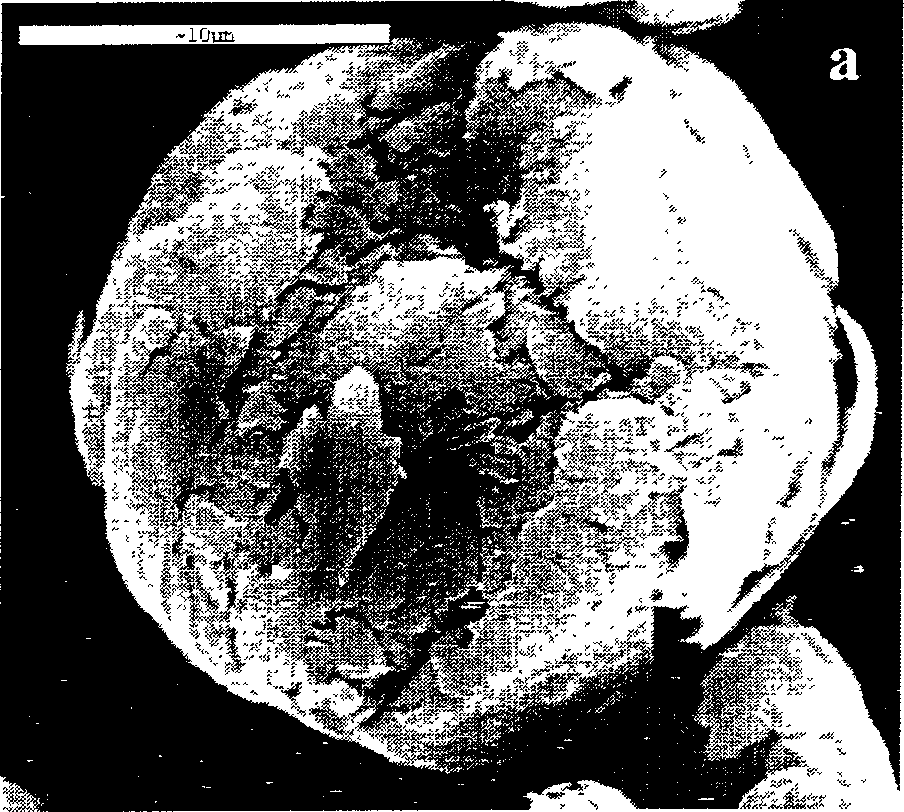

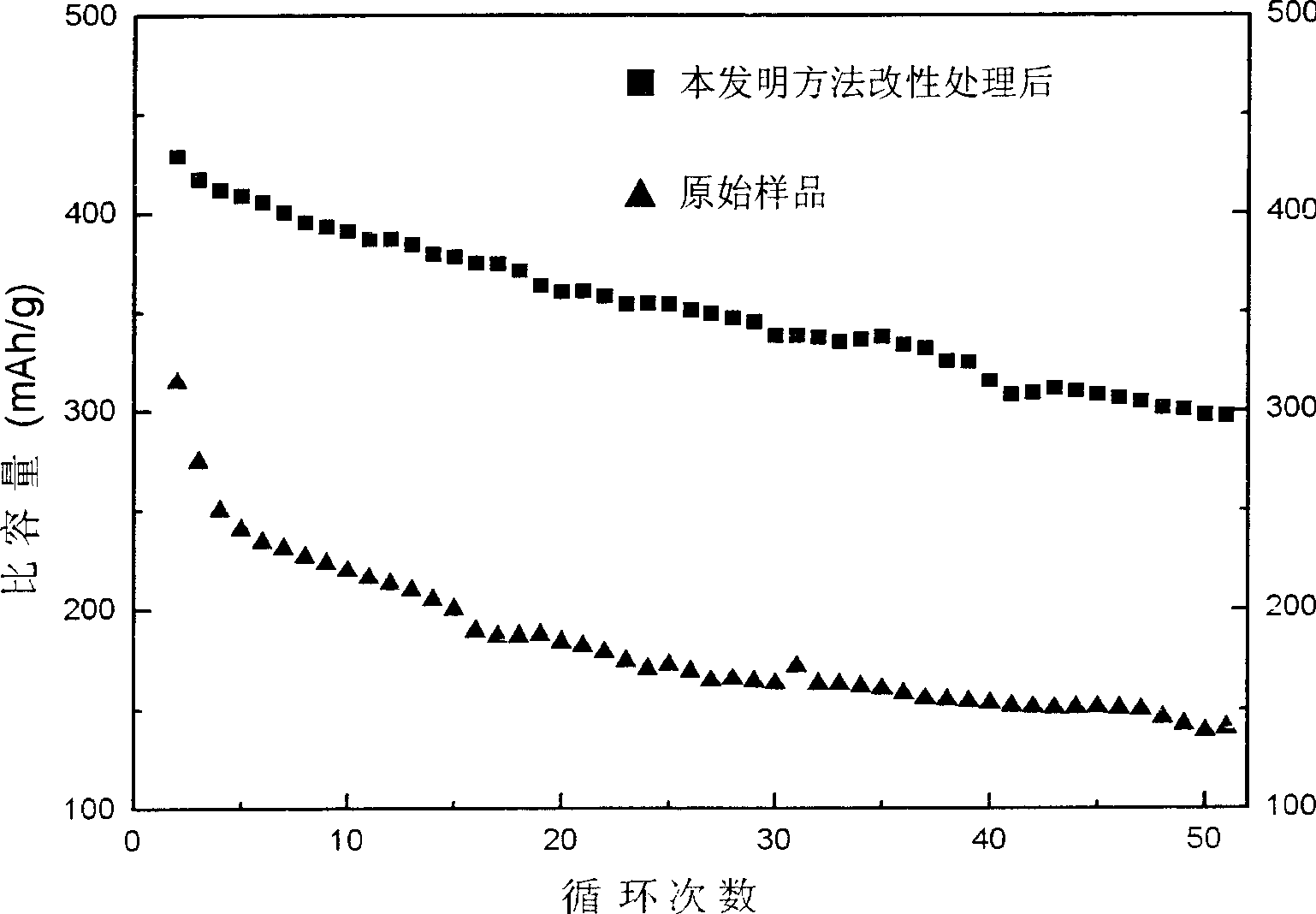

Modified method for lithium ion cell negative electrode material

InactiveCN1812168AGood battery performanceImprove battery performanceElectrode manufacturing processesSecondary cellsModified methodCarbon source

This invention relates to a kind of improving method of lithium ionic cell cathode materials. The cathode materials in need of improving are mixed evenly with catalyst which has 0.1úÑ-10úÑ weight percent of cathode materials. The materials are then put into reaction furnace, which uses hydrocarbon as carbon source. The cathode materials are mixed with buffer gas according to 1í†(0-10) volume ratio. Then the mixture are reacted in reaction furnace at 600-1300íµ for 1-900 minutes. A kind of improved composite cathode materials, at the surface of which in-situ grows nanometer carbon fibrin / carbon tube, are gained. The improved materials have good cell kinetic ability, circulating ability, charge-discharge capacity and consistency with electrolyte.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

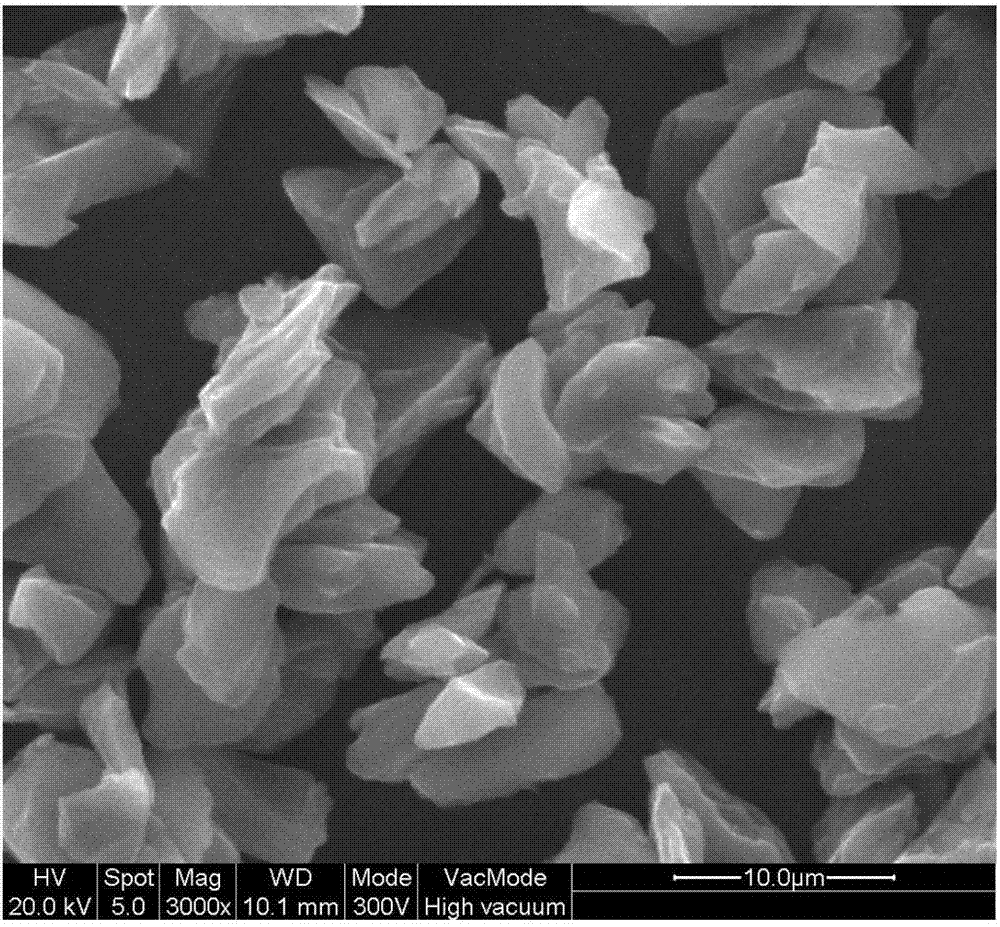

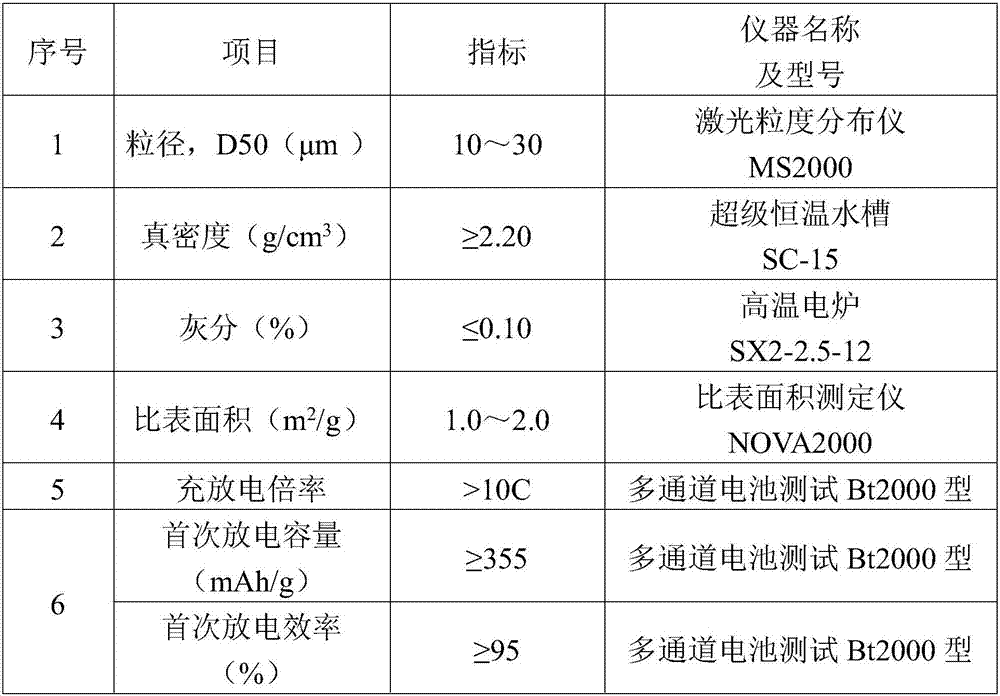

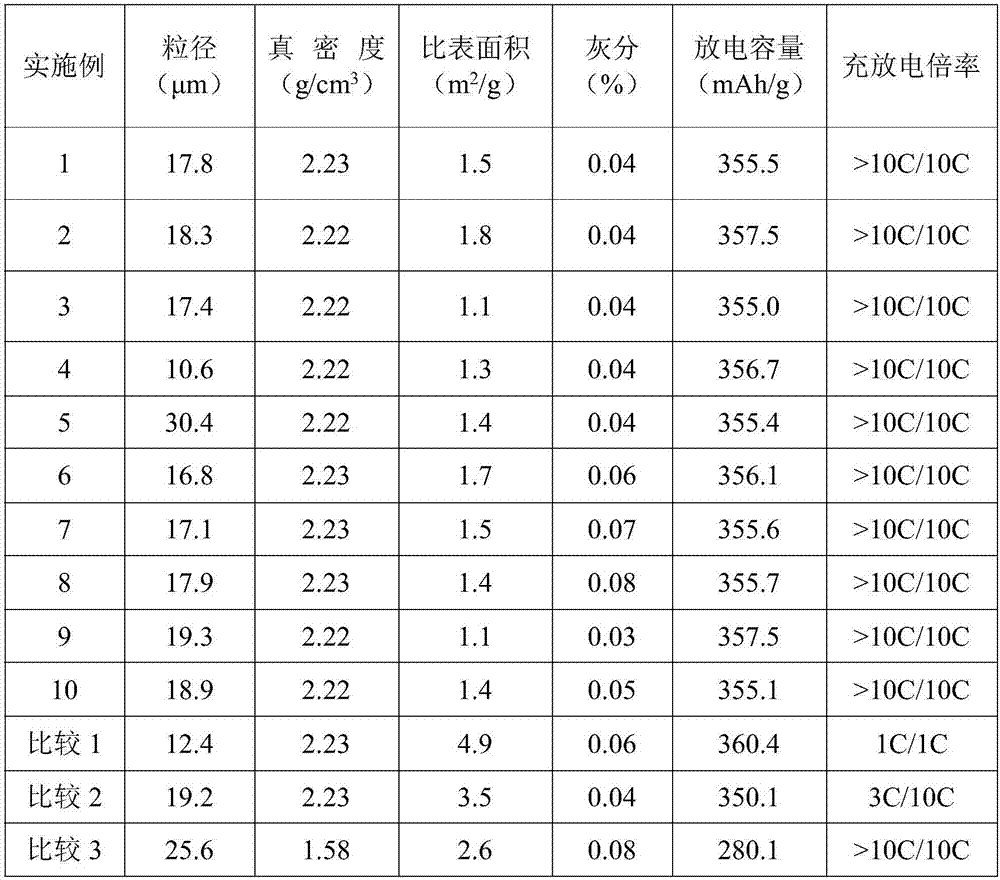

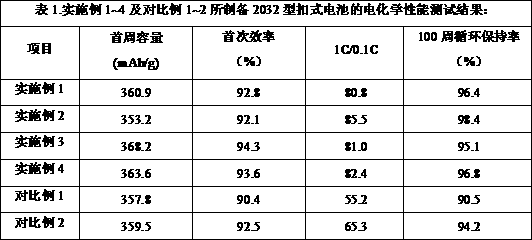

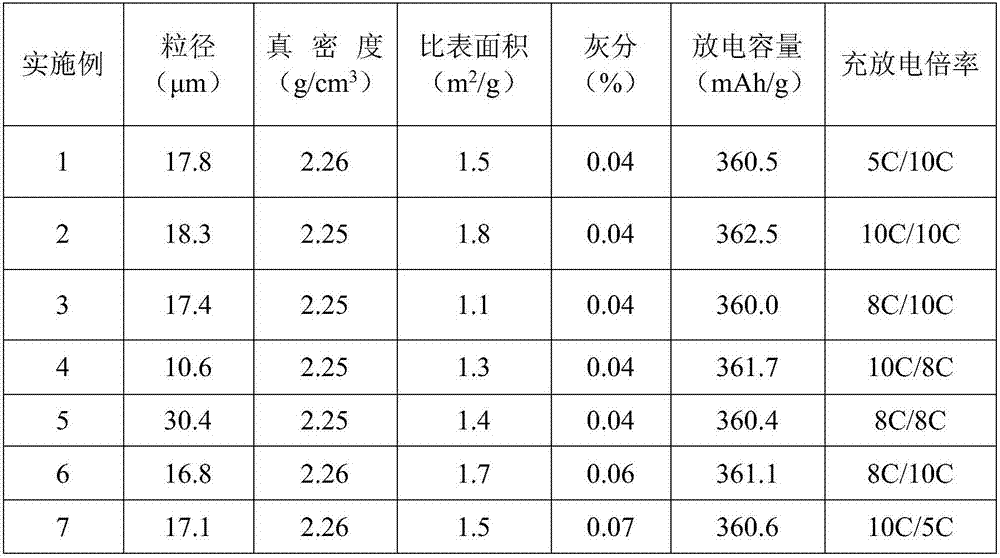

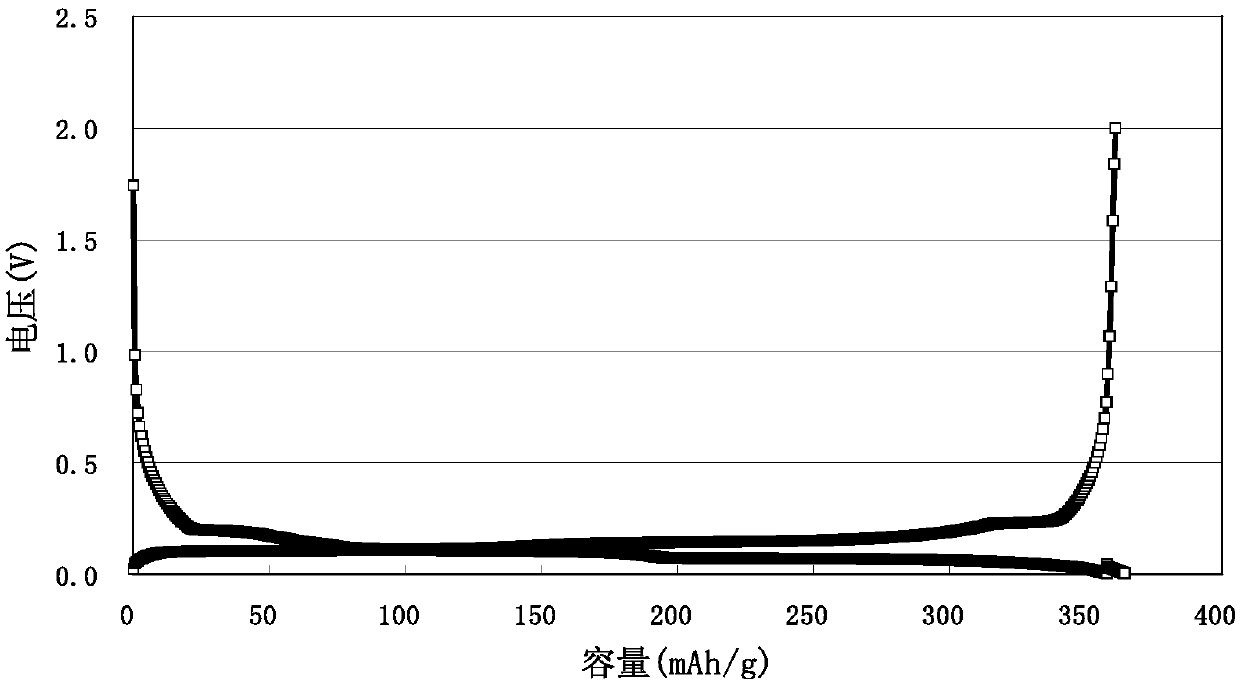

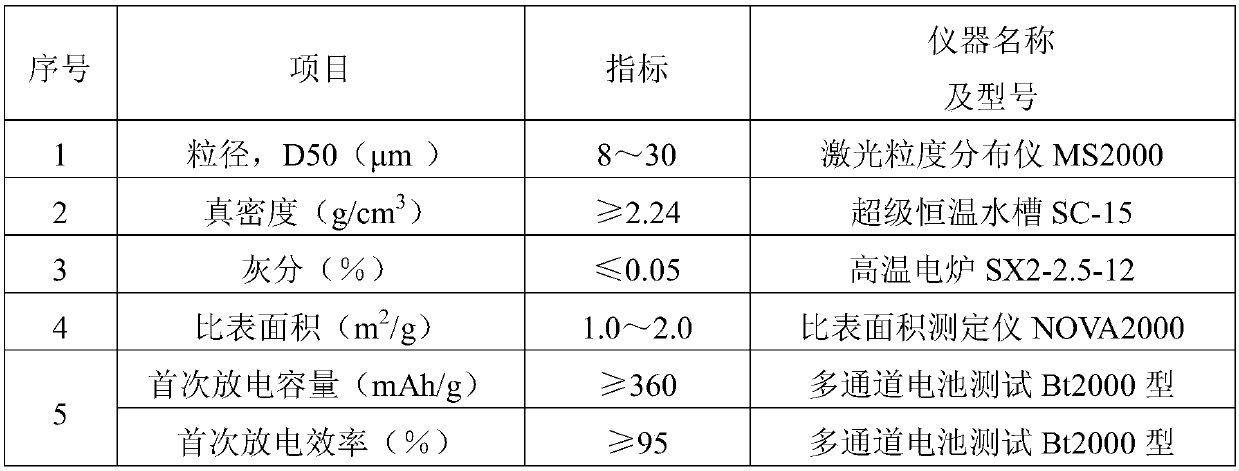

Preparation method of high-rate fast-rapid graphite

PendingCN106981632AHigh retention rateImprove adaptabilityGraphiteCell electrodesHigh rateButton battery

The invention relates to the technical field of a lithium ion secondary battery, in particular to a preparation method of high-rate fast-rapid graphite. The preparation method is characterized by comprising the following steps of (1) smashing and shaping a raw material; (2) mixing; (3) performing graphitization high-temperature processing, in which graphitization high-temperature processing is performed on the mixed material for 24-48 hours at 2,800-3,200 DEG C under protection of inert gas; (4) mixing the materials; (5) performing low-temperature thermal treatment; (6) performing carbonization thermal treatment; and (7) screening the mixed material. compared with the prior art, the preparation method has the advantages that the graphite is high in charge-discharge rate, large in discharge capacity and good in cycle performance, a button cell prepared from the graphite has excellent comprehensive performance and has main following advantages of relatively good large-current charge-discharge performance, good electrochemical performance, good cycle property, relatively high safety, relatively good adaptability to an electrolyte and other additives and stable product characteristic, the charge-discharge rate can reach over 10C, and the preparation method is suitable for industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

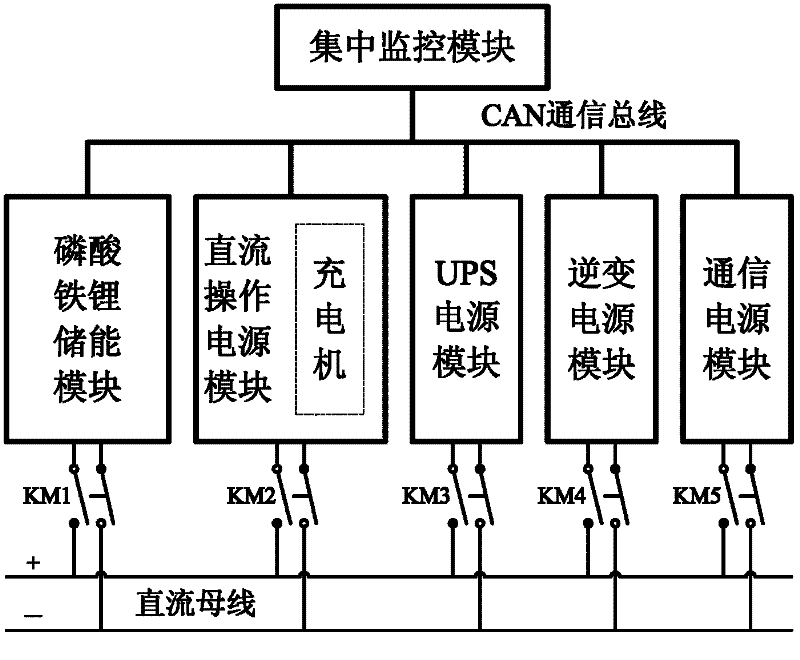

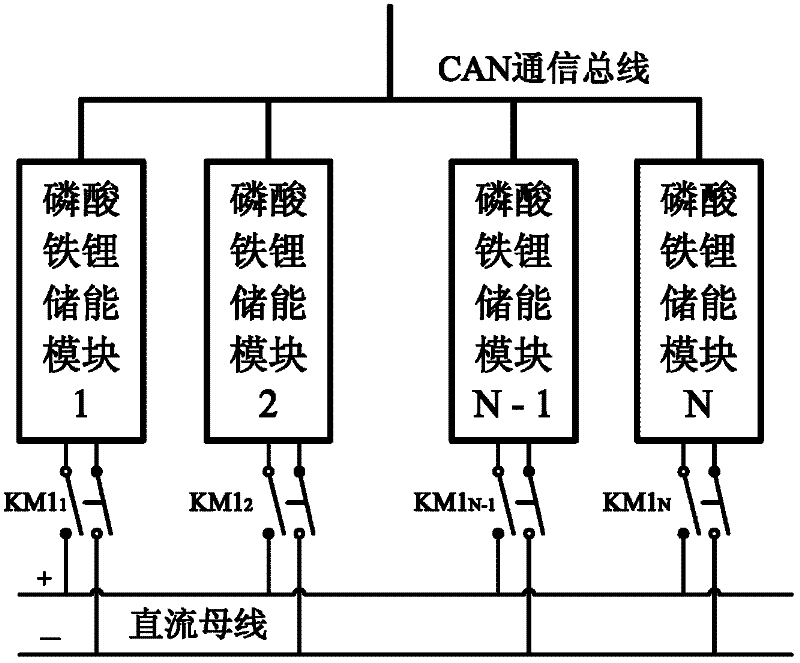

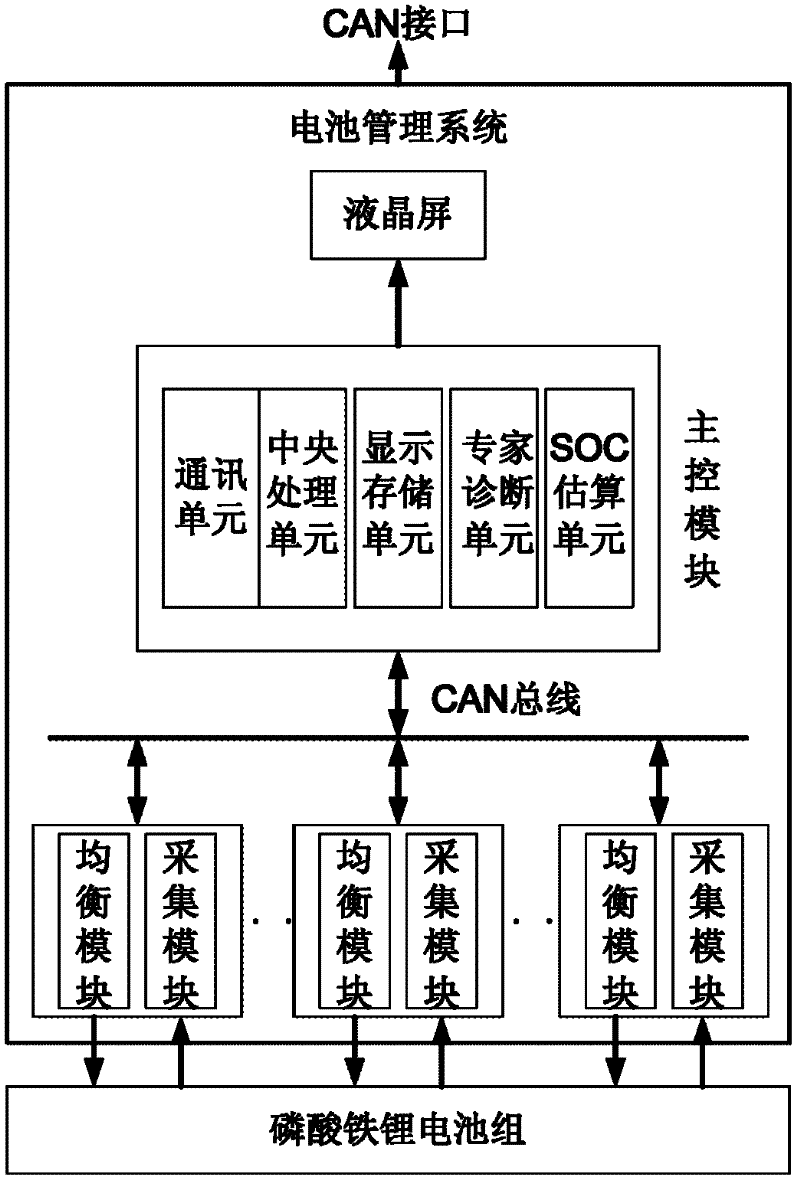

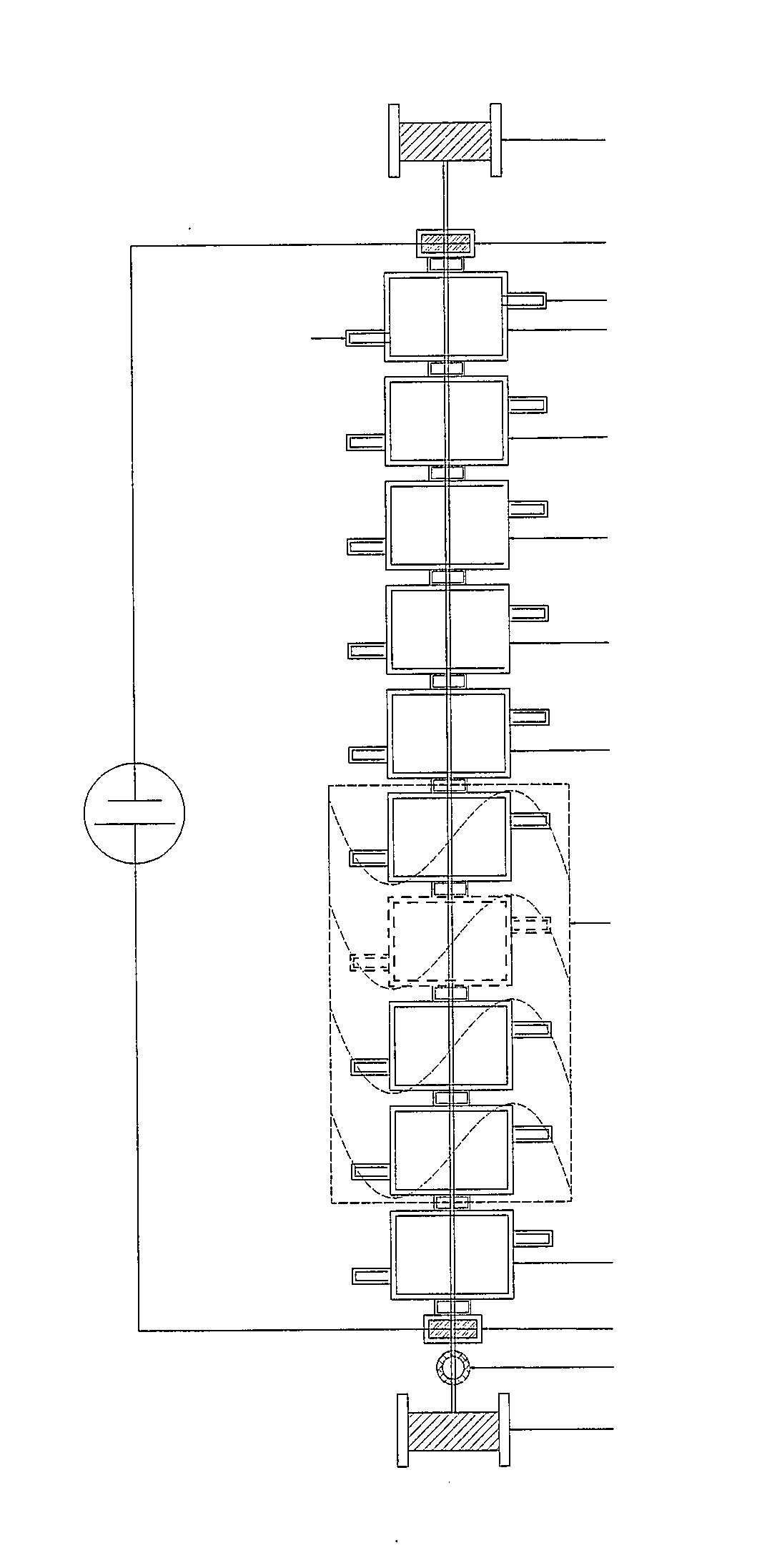

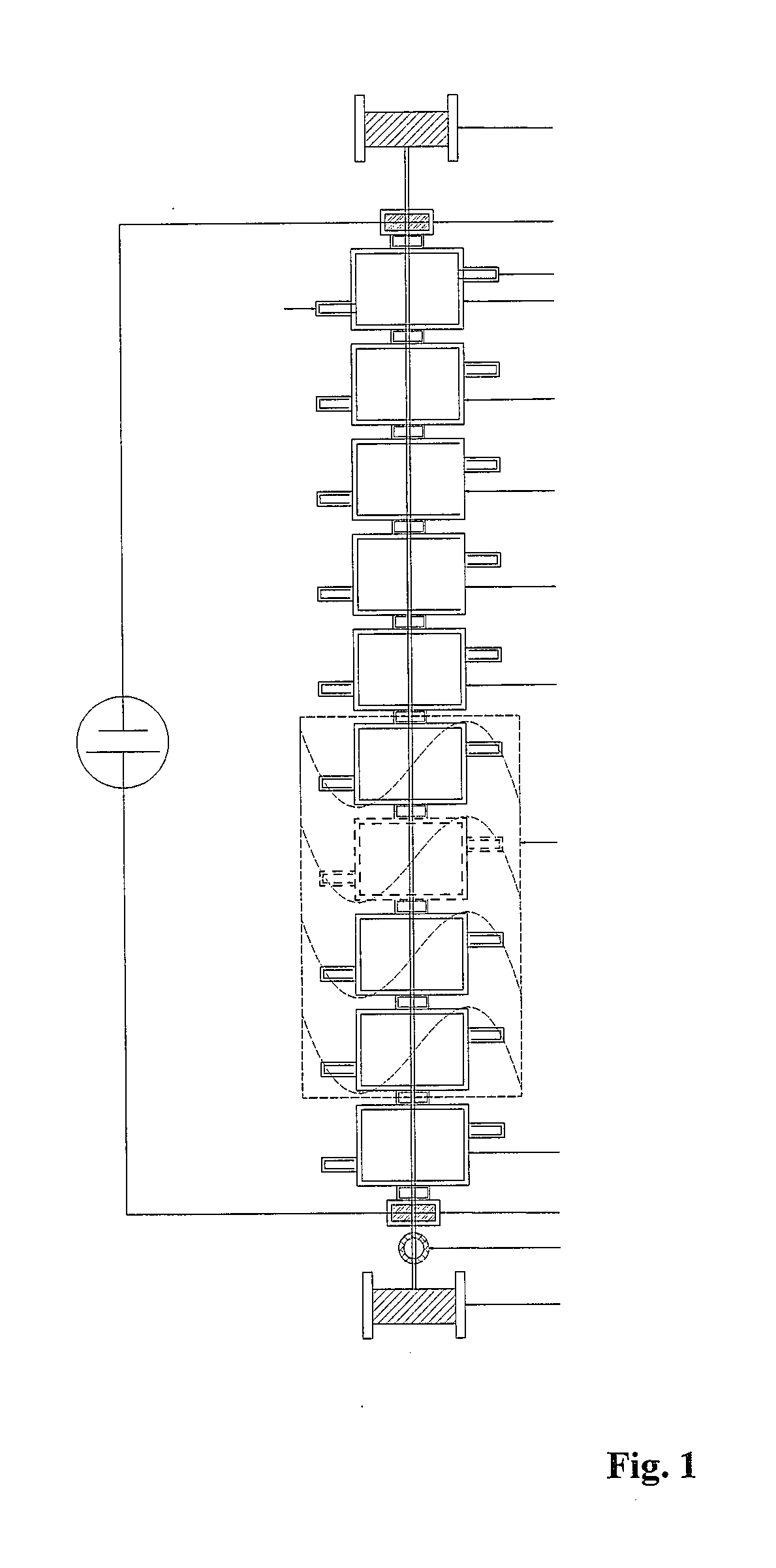

A DC power supply system for substation and its control method

InactiveCN102270878AImprove charge and discharge efficiencyIncrease charge and discharge rateBatteries circuit arrangementsElectric powerArea networkElectrical battery

The invention provides a direct current power supply system for a transformer substation and a control method thereof. The direct current power supply system comprises a centralized monitoring module, a direct current operation power module, an uninterruptible power supply (UPS) power module, an inversion power supply module, a communication power supply module and a lithium iron phosphate energy storage module; each module of the direct current power supply system is connected to a common direct current bus through a relay switch, and redundancy backup of each module is realized in a mode that each module is connected in parallel to the common direct current bus through a multi-submodule; the modules of the direct current power supply system are connected with the centralized monitoring module through a controller area network (CAN) communication bus; the centralized monitoring module collects the running state information of each module and manages the modules of the system uniformly; and a battery is charged or discharged slightly through intelligent coordination control, and on-line automatic maintenance of the battery is realized. The invention has the advantages that: the system has high reliability, high shock load resistance, no maintenance, small floor area, energy conservation and environmental friendliness; and the service life of the battery is prolonged and the performance of the battery is improved by the intelligent coordination control method.

Owner:南瑞(武汉)电气设备与工程能效测评中

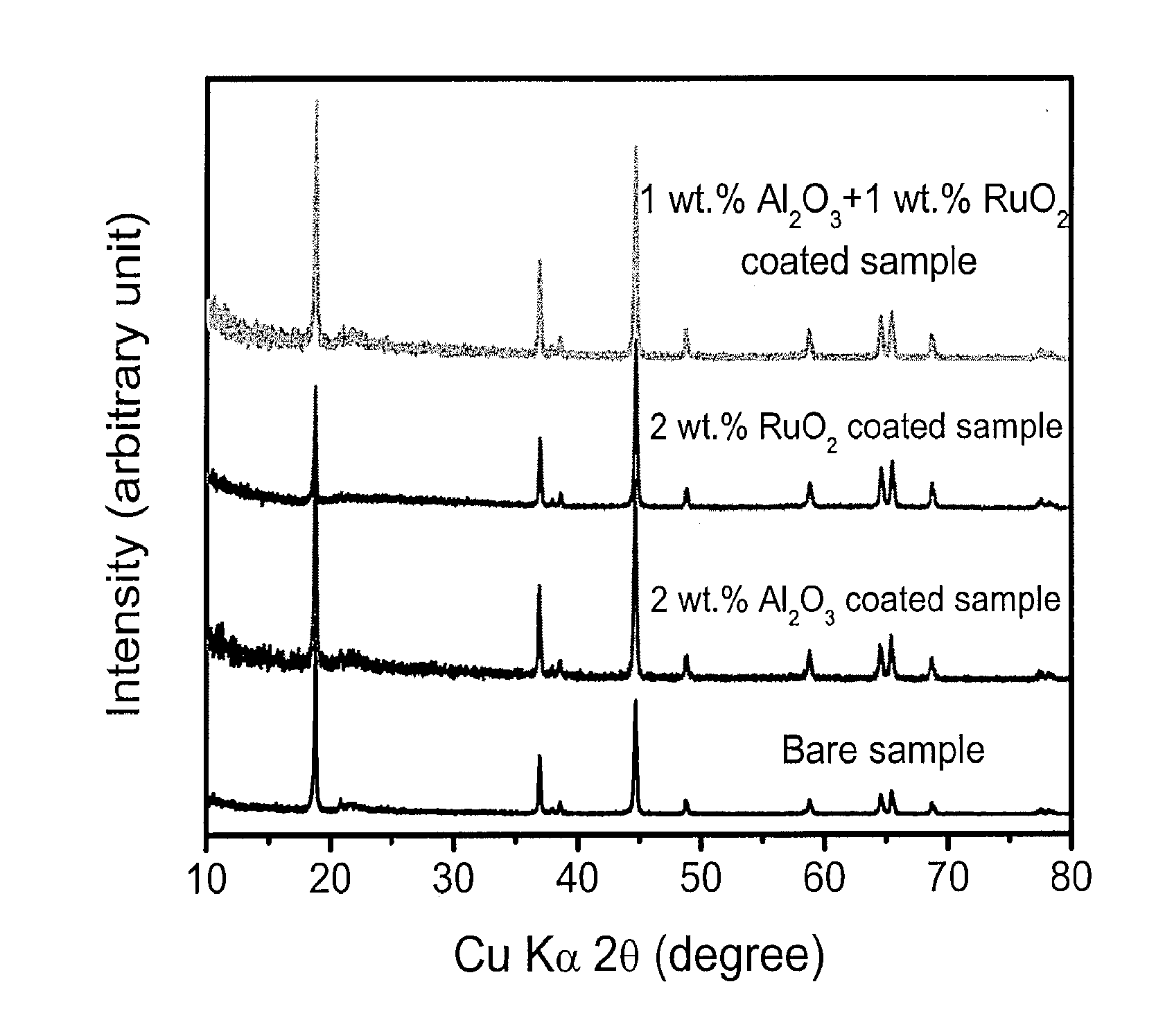

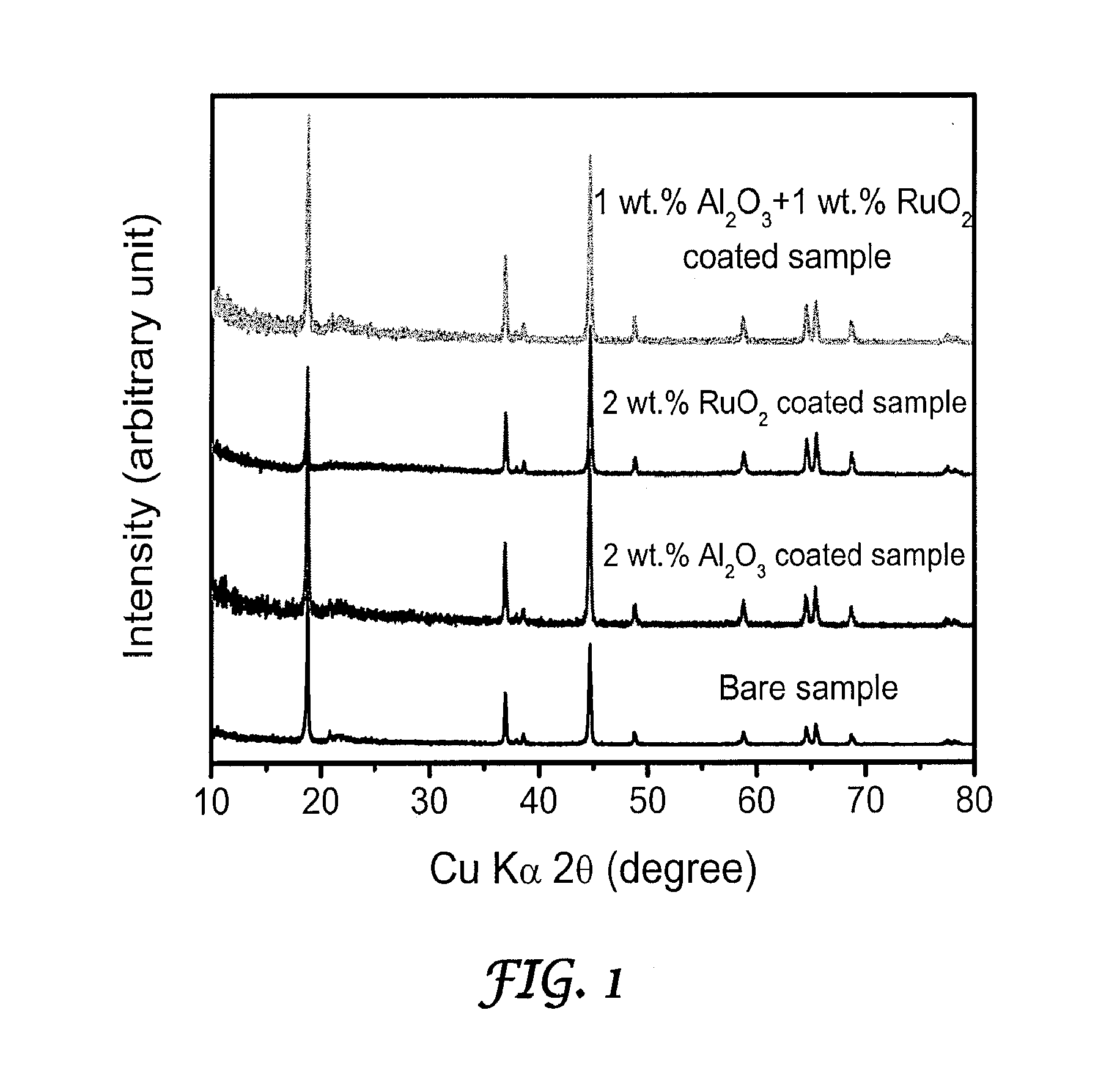

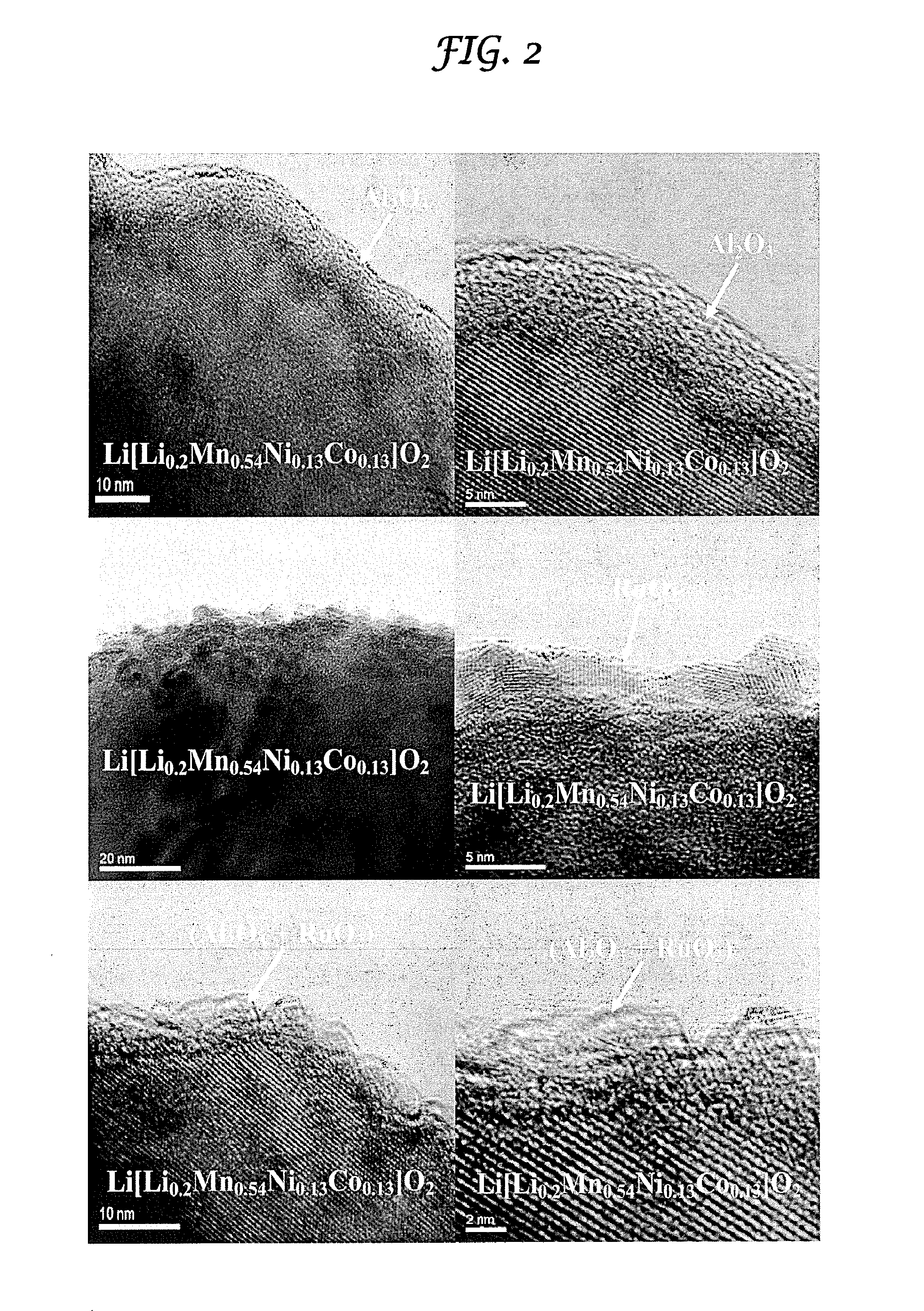

High capacity layered oxide cathods with enhanced rate capability

InactiveUS20130040201A1Inhibitory responseIncrease probabilityNon-aqueous electrolyte accumulator electrodesCapacity lossElectrical conductor

The present invention provides a surface modified cathode and method of making surface modified cathode with high discharge capacity and rate capability having a lithium-excess Li[M1-yLiy]O2 (M=Mn, Co, and Ni or their combinations and 0<y≦0.33) cathode surface with a surface modification comprising lithium-ion coated sample conductor, or an electronic conductor, or a mixed lithium-ion and electronic conductor to suppress the elimination of oxide ion vacancies, reduce the solid-electrolyte interfacial (SEI) layer thickness, reduce the irreversible capacity loss in the first cycle, and enhance the rate capability.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

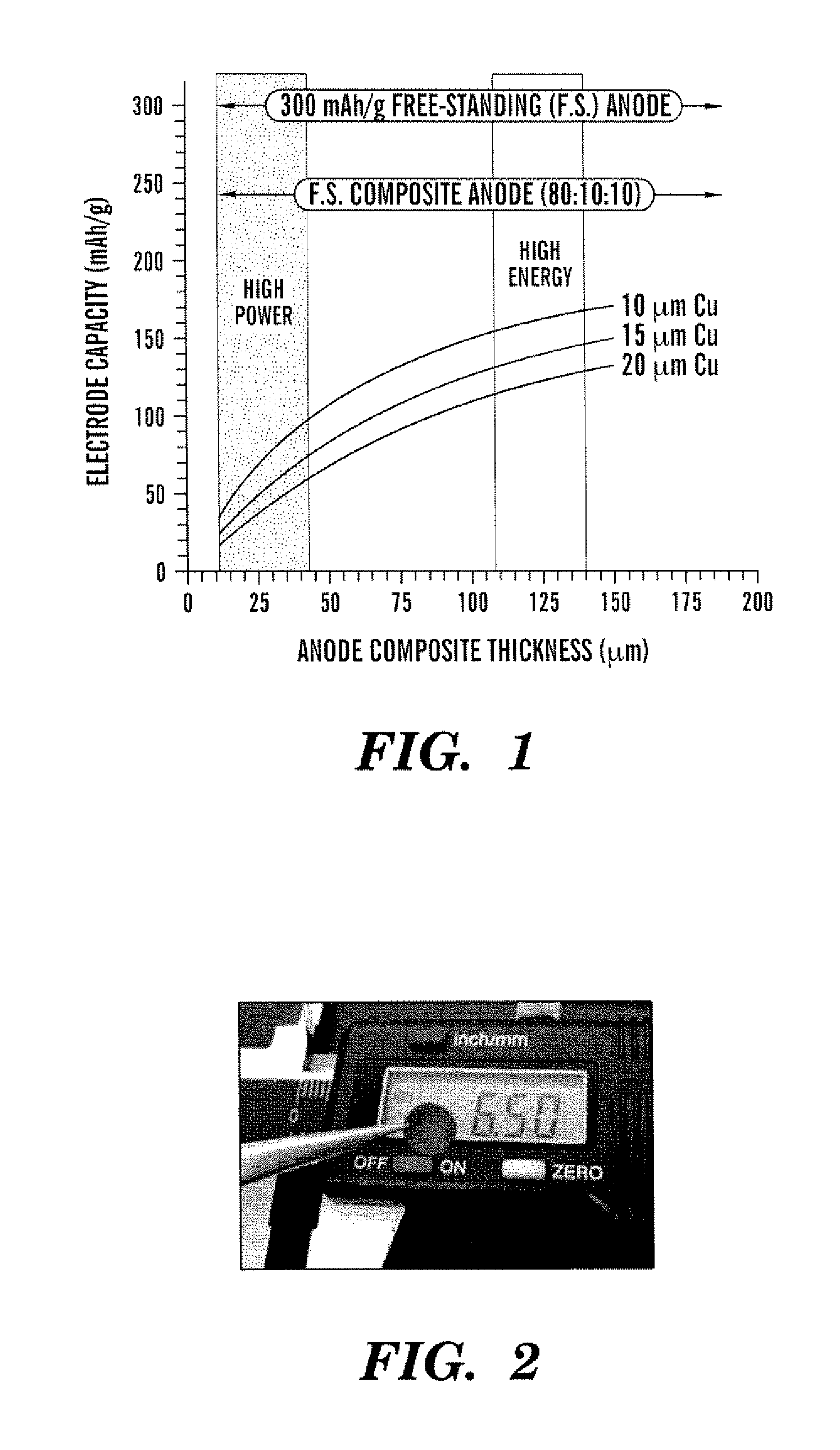

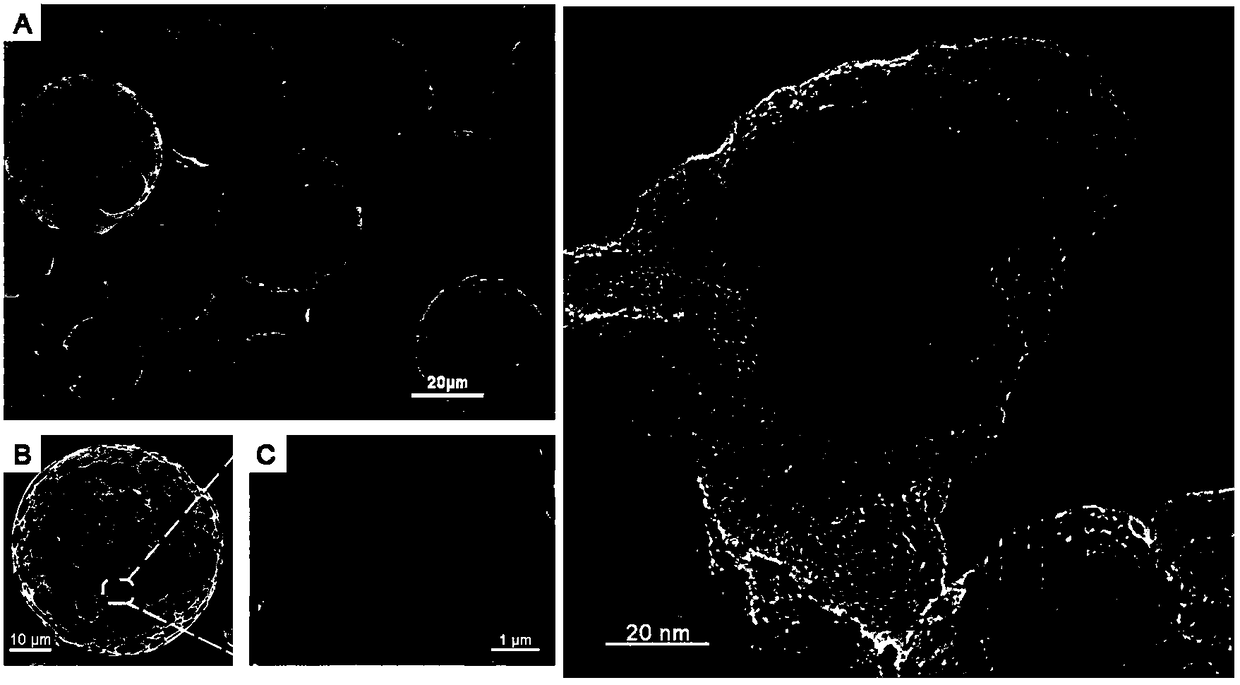

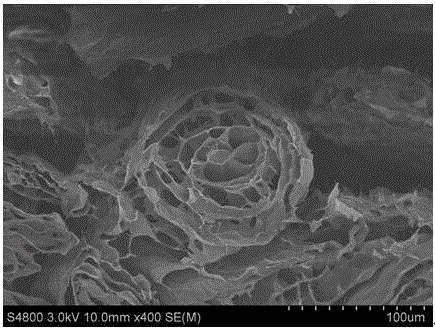

Freestanding carbon nanotube paper, methods of its making, and devices containing the same

ActiveUS20100282496A1Improvement in effective lithium ion capacityEnhancement in lithium ion specific capacityNon-insulated conductorsNanotechOrganic solventFuel cells

The present invention relates to freestanding carbon nanotube paper comprising purified carbon nanotubes, where the purified carbon nanotubes form the freestanding carbon nanotube paper and carbon microparticles embedded in and / or present on a surface of the carbon nanotube paper. The invention also relates to a lithium ion battery, capacitor, supercapacitor, battery / capacitor, and fuel cell containing the freestanding carbon nanotube paper as an electrode. Also disclosed is a method of making a freestanding carbon nanotube paper. This method involves providing purified carbon nanotubes, contacting the purified carbon nanotubes with an organic solvent under conditions effective to form a dispersion comprising the purified carbon nanotubes. The dispersion is formed into a carbon nanotube paper and carbon microparticles are incorporated with the purified carbon nanotubes.

Owner:ROCHESTER INSTITUTE OF TECHNOLOGY

Universal preparation method and application of active site-electrode structure integrated air electrode

InactiveCN108365230AIncrease mass transfer rateFast electron transferCell electrodesActivation methodMicrosphere

The invention relates to a universal preparation method for an active site-electrode structure integrated air electrode. The universal preparation method is characterized in that various polymer microspheres having open internally-communicating hierarchical-pore structures are conjugated with active sites like noble metal groups, transition metal groups, and hetero atom-doped carbon groups in virtue of different treatment methods; the different treatment methods may be one or more selected from the group consisting of a carbon tetrachloride cross-linking method, a concentrated-sulfuric-acid sulfonation method, a carbon dioxide gas activation method, a dopamine coating method, an ammonia gas activation method, a polyaniline coating method, an in-situ precious-metal loading method, an in-situ transition metallide growth method and an in-situ heteroatom doping method. The universal method described in the invention can flexibly conjugate open internally-communicating hierarchical-pore electrode structures containing super-macro pores, macro pores, meso pores and micropores with a plurality of different highly-active catalytic sites by using appropriate methods, so the catalytic performance of the air electrode and the overall performance of a fuel cell and a metal-air battery are improved.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

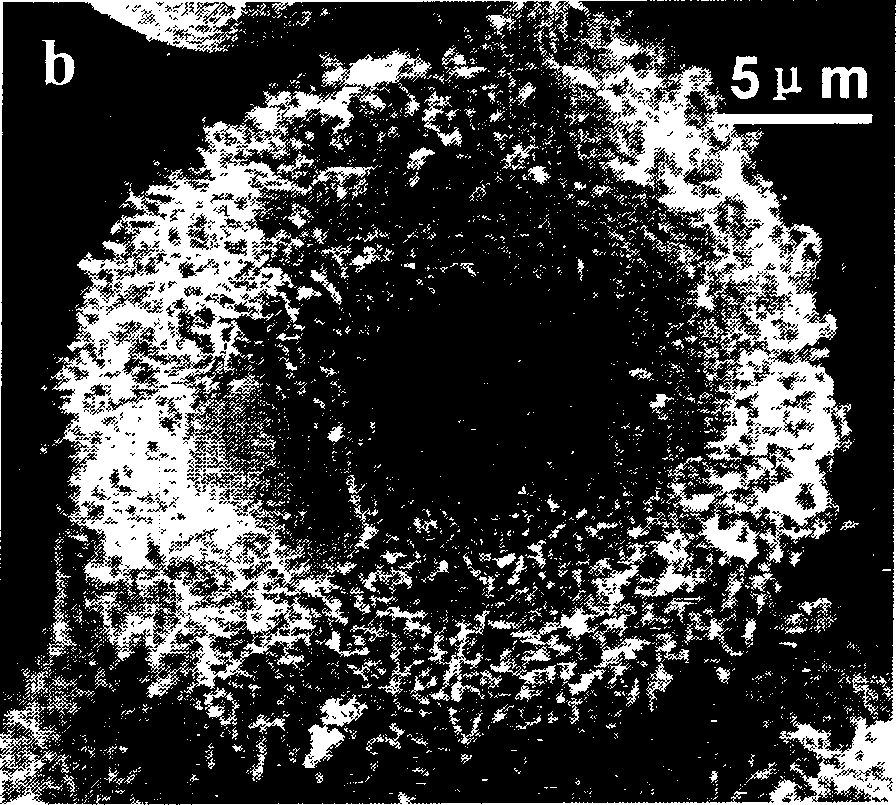

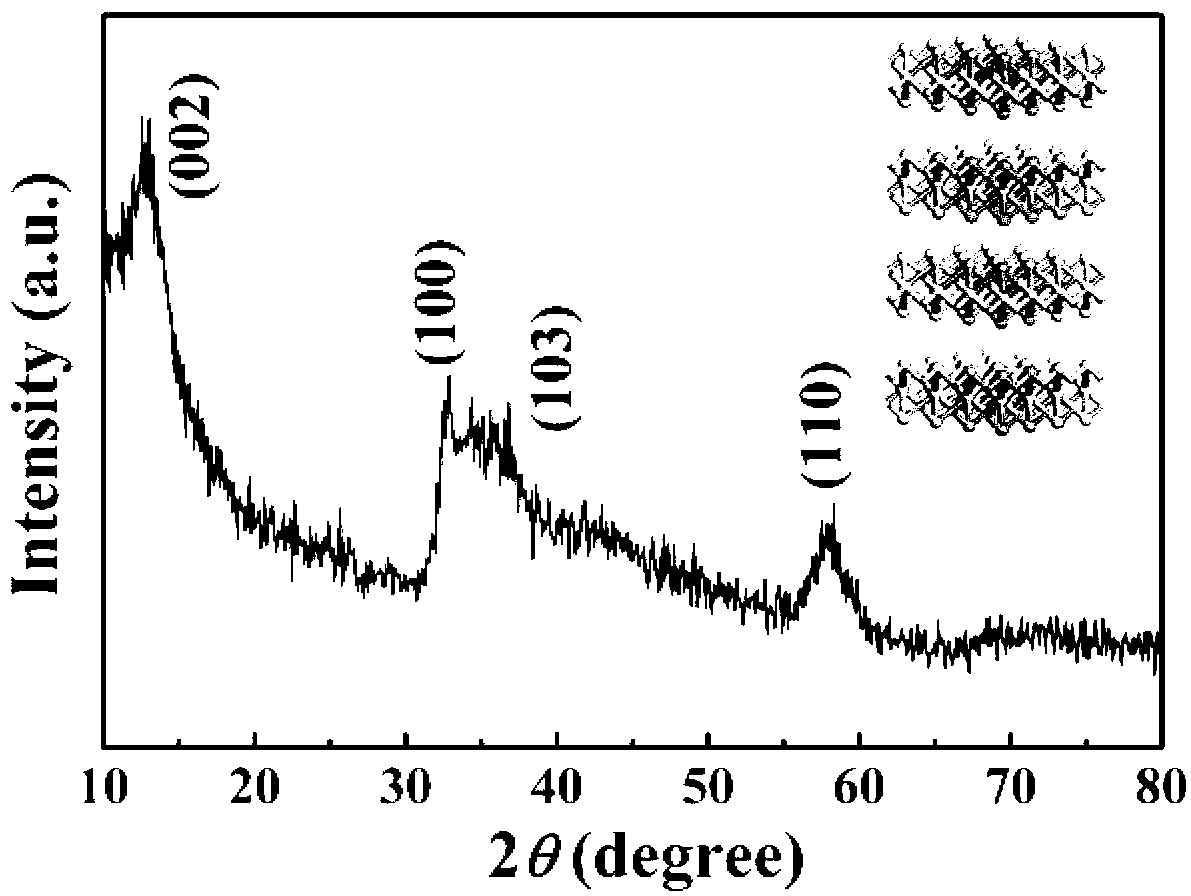

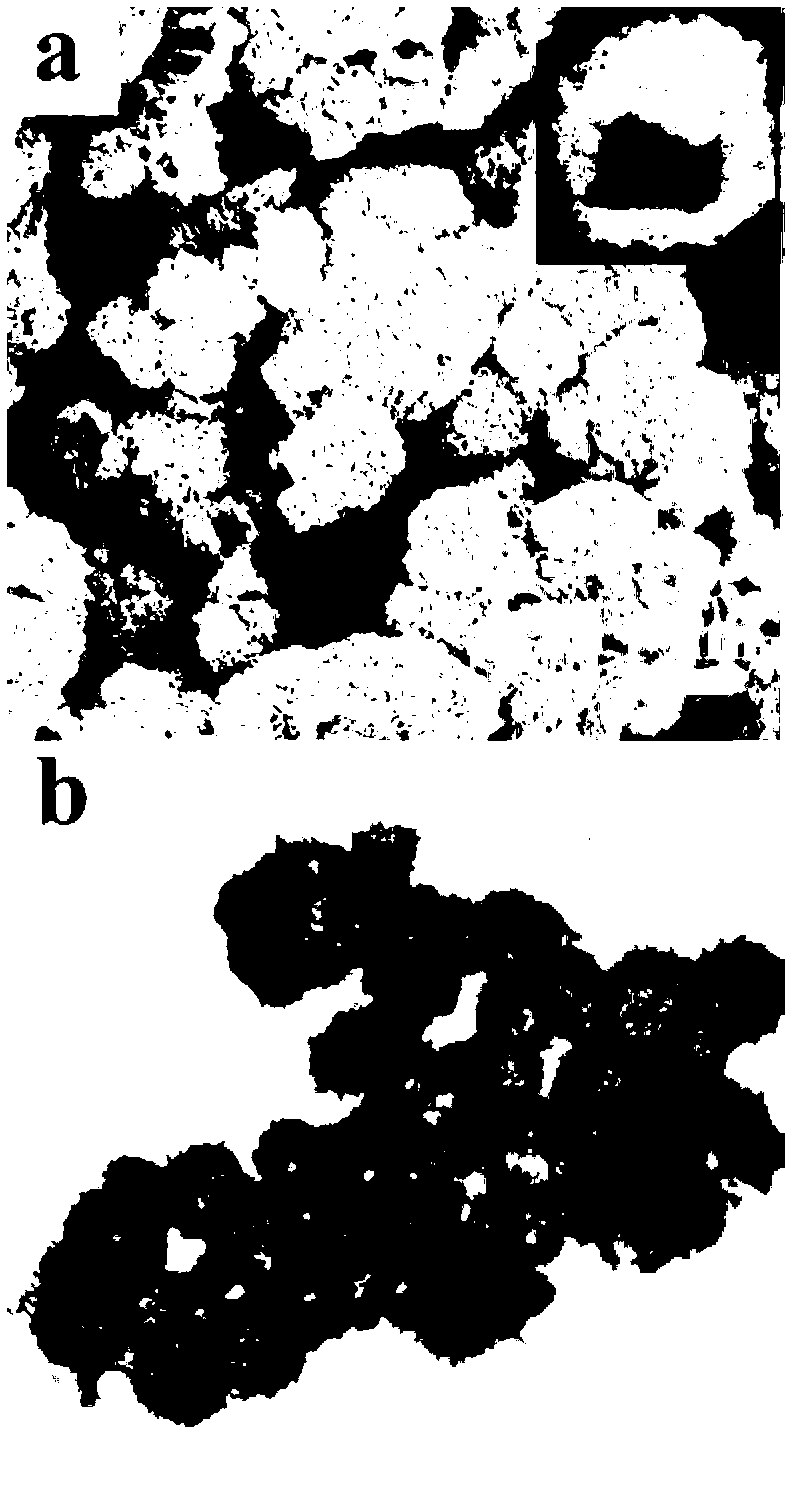

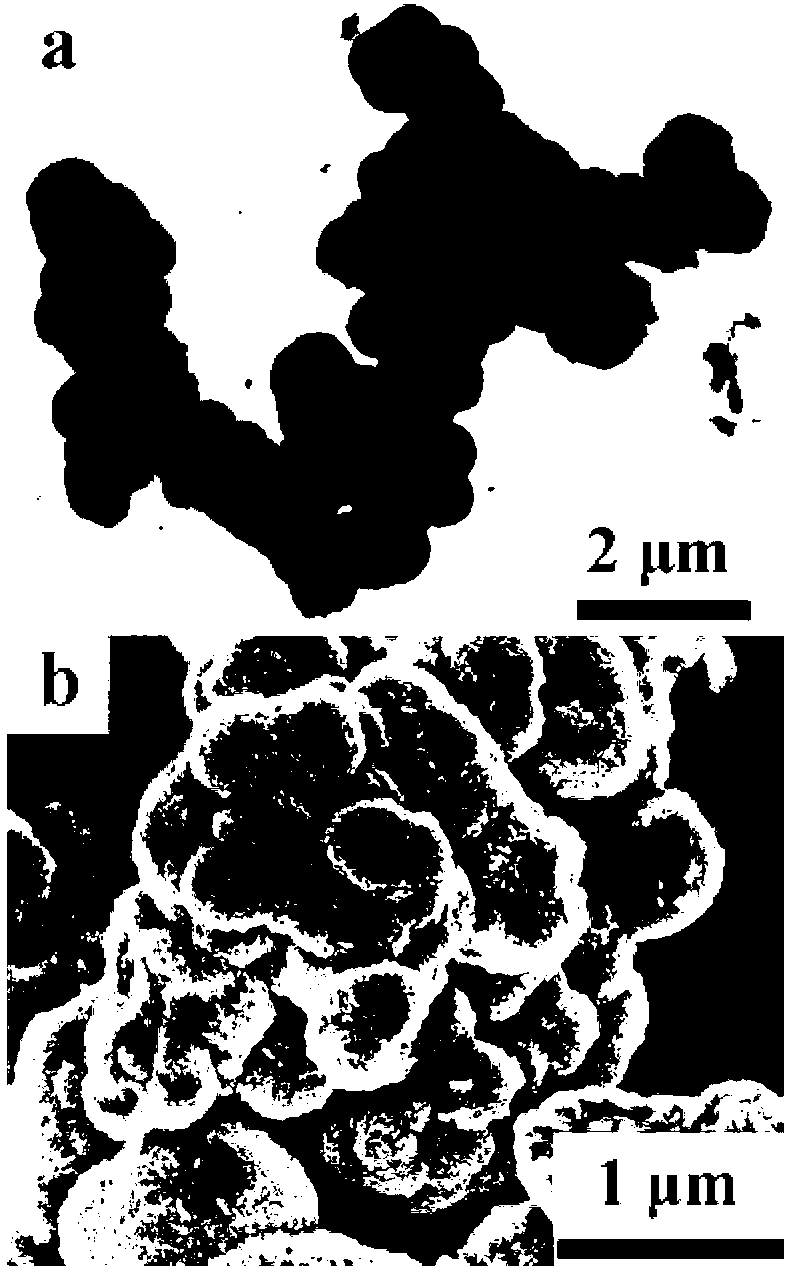

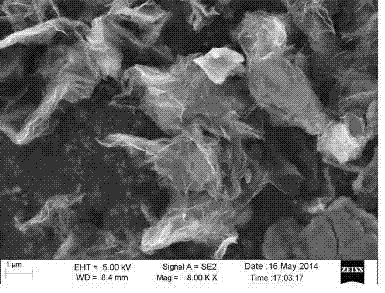

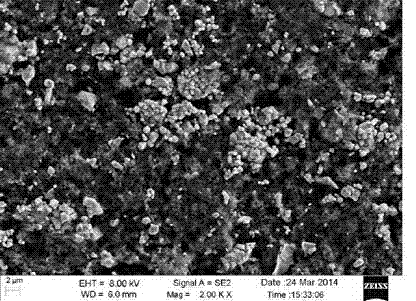

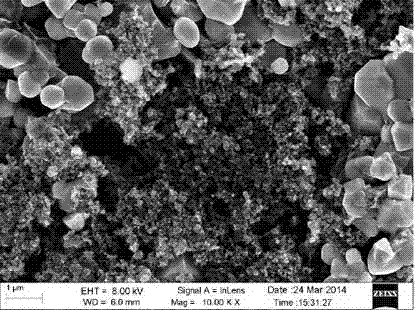

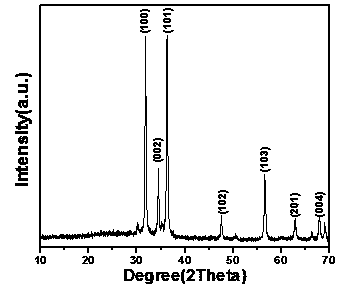

Nano sheet self-assembled MoS2 nano hollow material and preparation and application of MoS2 nano hollow material serving as lithium storage electrode material

InactiveCN102938461AImprove lithium storage performanceGood lookingCell electrodesLithiumPotassium thiocyanate

The invention discloses a nano sheet self-assembled MoS2 nano hollow material and preparation and application of the MoS2 nano hollow material serving as a lithium storage electrode material. The nano sheet self-assembled MoS2 nano hollow material is obtained by mixing raw materials including molybdenum oxide, sodium fluoride and potassium thiocyanate according to the mass ratio of 0.8-0.9:0.5-0.6:1.5-2.9; adding into water-ethanol mixed solvent; placing into a reaction kettle to be sealed; reacting at 140-220 DEG C for 12-30h; and performing washing, separating and drying to obtain products. The method is simple and easy in required condition, cheap and facile in raw materials and controllable in shape and height and easily achieves industrial production. Lithium storage electrodes prepared by adopting the prepared nano sheet self-assembled MoS2 nano hollow material not only have high electro-chemical lithium storage reversible capacity and excellent cycling performance, but also have good rate capability.

Owner:SHANDONG UNIV

Fast charge graphite negative electrode material and preparation method thereof

InactiveCN107601490AIncrease charge and discharge rateImprove cycle performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a fast charge graphite negative electrode material and a preparation method thereof. Through mixing of a graphite precursor and a coating material, low temperature treatment and high temperature graphitization treatment, the fast charge graphite negative electrode material for lithium ion batteries can be obtained. High temperature graphitization treatment enables conversion of the graphite precursor into high capacity graphite, at the same time the coating material converts to a structurally stable amorphous carbon coating layer, thus being conducive to rapid transmission of lithium ions in the material and electrolyte solution interface, significantly enhancing the charge-discharge rate and cycle performance of graphite material, and also ensuring high capacity and high initial coulombic efficiency. The process adopted by the invention is simple and low in energy consumption, and the fast charge graphite negative electrode material is suitable for commercial production and application in lithium ion batteries.

Owner:天津爱敏特电池材料有限公司

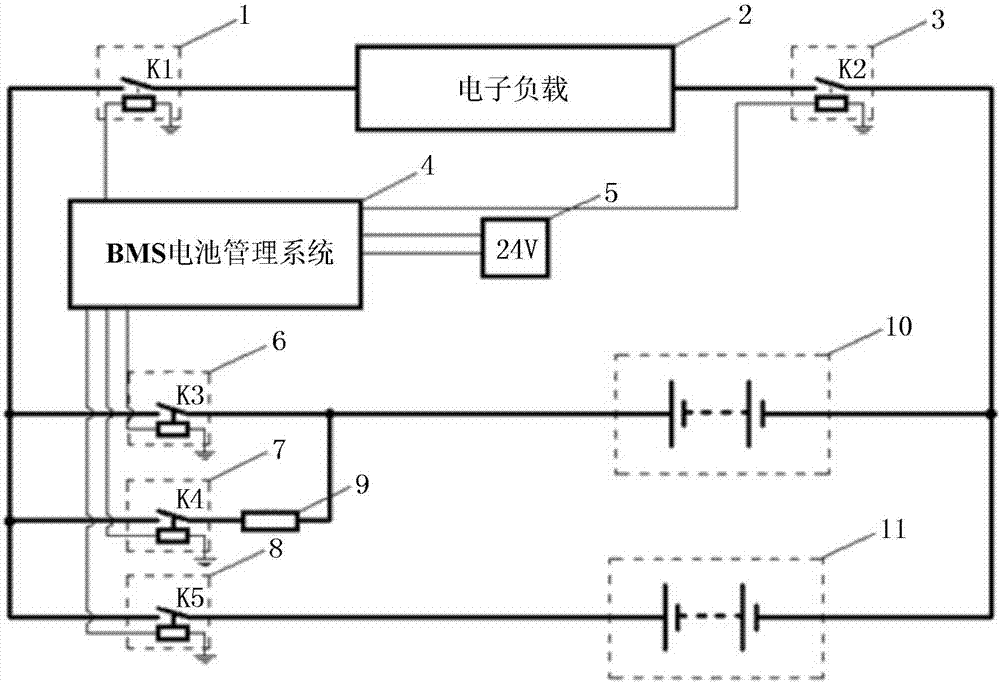

Method for realizing parallel connection of two sets of vehicle-mounted battery systems

ActiveCN107146917AReduce charge and discharge currentReduce damage to high voltage componentsElectric devicesCells structural combinationPower flowRing current

The invention discloses a method for realizing parallel connection of two sets of vehicle-mounted battery systems. A general positive relay and the like are included; the general positive relay, a battery management system, a first parallel relay, a parallel-connection protection relay and a second parallel relay are connected in parallel; the parallel-connection protection relay is connected with a pre-charging resistor in series; the battery management system is connected with a 24V power supply in series; and a first battery system and a second battery system are connected in parallel for supplying power for at least one electronic load. By adoption of the method, the problem existing in improvement of charging and discharging rate when the conditions of energy density, energy requirement and the like are not changed in the power supply system of the existing power automobile is solved; compared with the conventional design, the charging and discharging current can be effectively lowered; damage to a high-voltage device caused by heating due to a high current is effectively reduced, heating in the connecting place of battery modules is lowered, and the long-standing problem existing in module connecting design is relieved; the problem of ring current impact of parallel instantaneous high current in parallel connection use is solved; and the battery system is more reliable, and the service life of electrical devices can be prolonged.

Owner:奇可家居有限公司

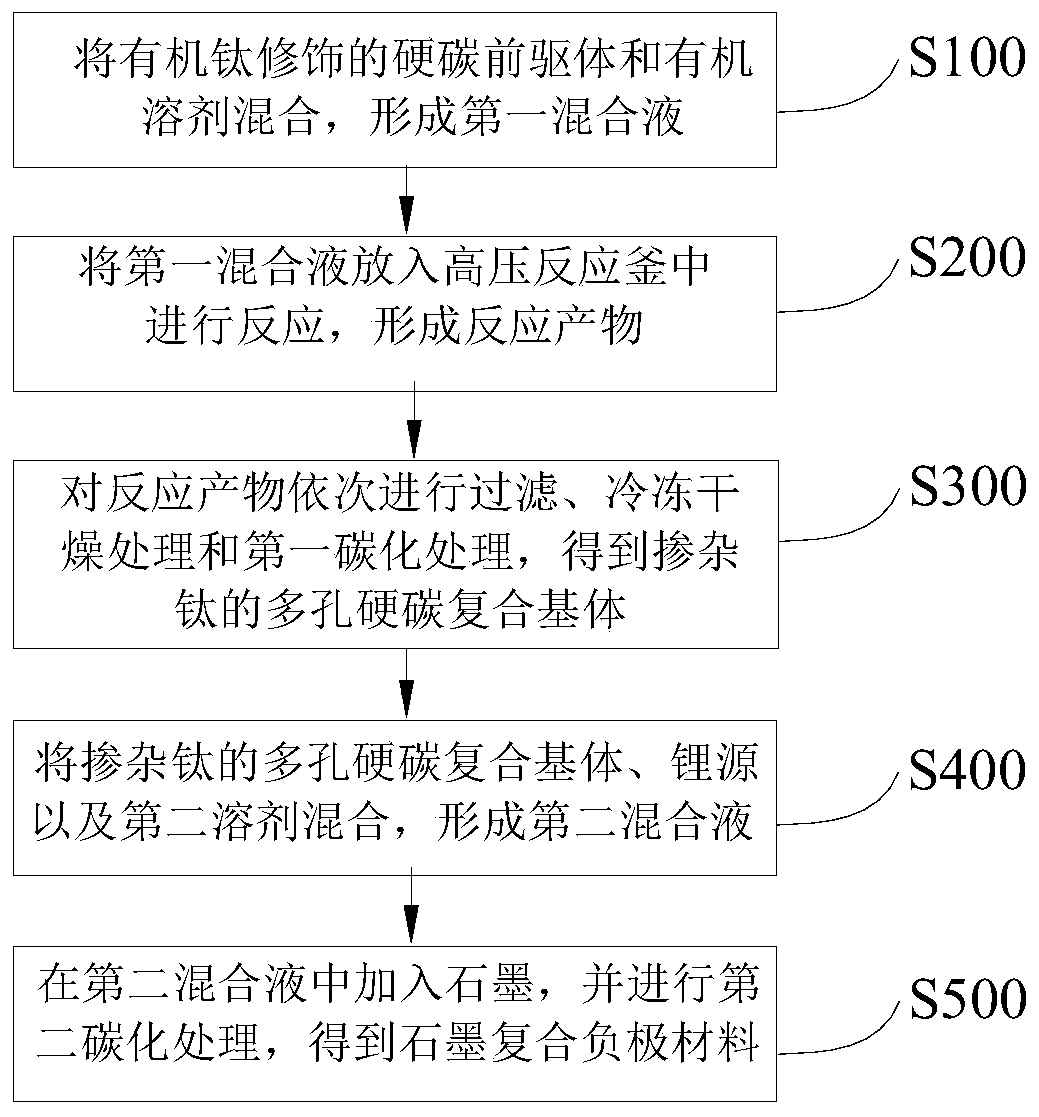

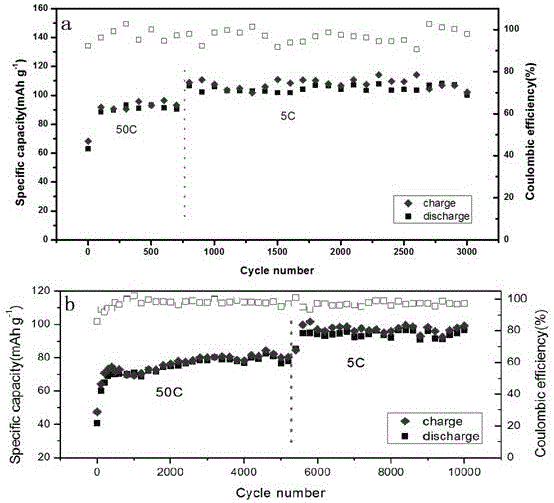

Graphite composite negative electrode material, preparation method thereof and battery

ActiveCN110247054AWide variety of sourcesLow costCell electrodesSecondary cellsLithiumCarbon composites

The invention discloses a graphite composite negative electrode material, a preparation method thereof and a battery. Specifically, the invention provides a graphite composite negative electrode material which comprises a graphite inner core and a coating layer coating the outer side of the graphite inner core. The coating layer comprises a titanium and lithium doped porous hard carbon composite material. Therefore, through the coating layer comprising the titanium and lithium doped porous hard carbon composite material, the lithium ion extraction rate of a negative electrode prepared from the graphite composite negative electrode material in the charging and discharging process can be improved, the rate capability and the cycle performance of the negative electrode are good, and the quick charging performance, the safety performance and the like of a battery using the negative electrode are improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

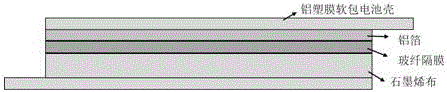

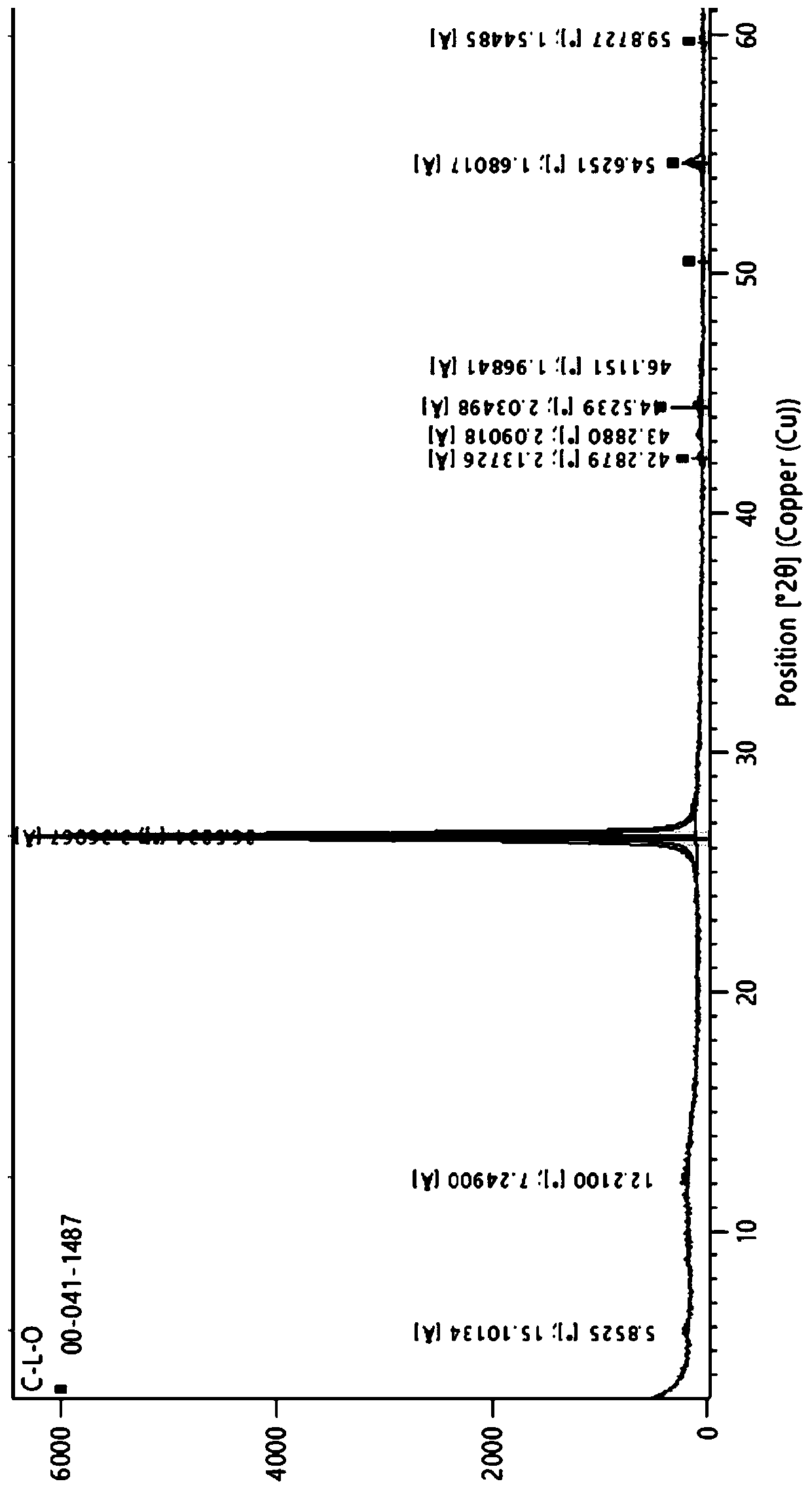

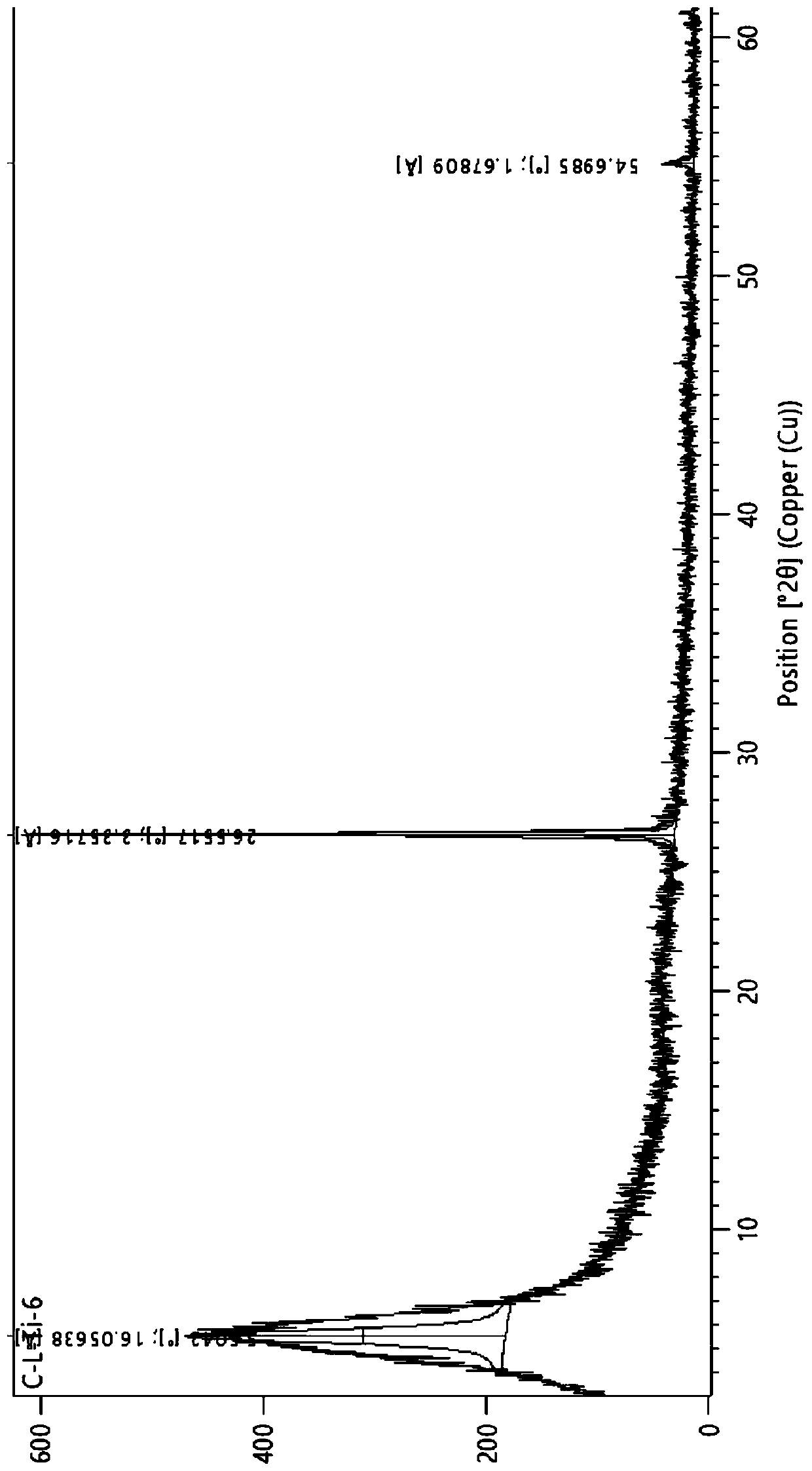

Preparation method for flexible and bendable aluminum ion battery

The invention discloses a preparation method for a flexible and bendable aluminum ion battery. The preparation method comprises the steps of extruding graphene oxide or a graphene oxide inorganic salt mixed solution to rotary inorganic salt solution coagulating bath in spinning equipment with certain diameter; then filtering and collecting short fibers from the coagulating bath by a filtering net, and lapping joint the short fibers into graphene oxide cloth; reducing the obtained graphene oxide cloth in a reduction temperature to obtain graphene cloth; and then assembling the obtained graphene cloth positive electrode material, a diaphragm, a negative electrode, an electrolyte and a battery shell to obtain the aluminum ion battery taking the graphene cloth as the positive electrode material. The flexible and bendable aluminum ion battery is green, environment-friendly and low in cost, and suitable for continuous and controllable large-scale industrial production; under the premise of ensuring relatively high energy density, power density and cycle life of the aluminum ion battery, the flexibility and bendable property of the battery are realized; and the flexible and bendable aluminum ion battery is applicable to the field of high-safety wearable energy storage devices.

Owner:杭州德烯科技集团有限公司

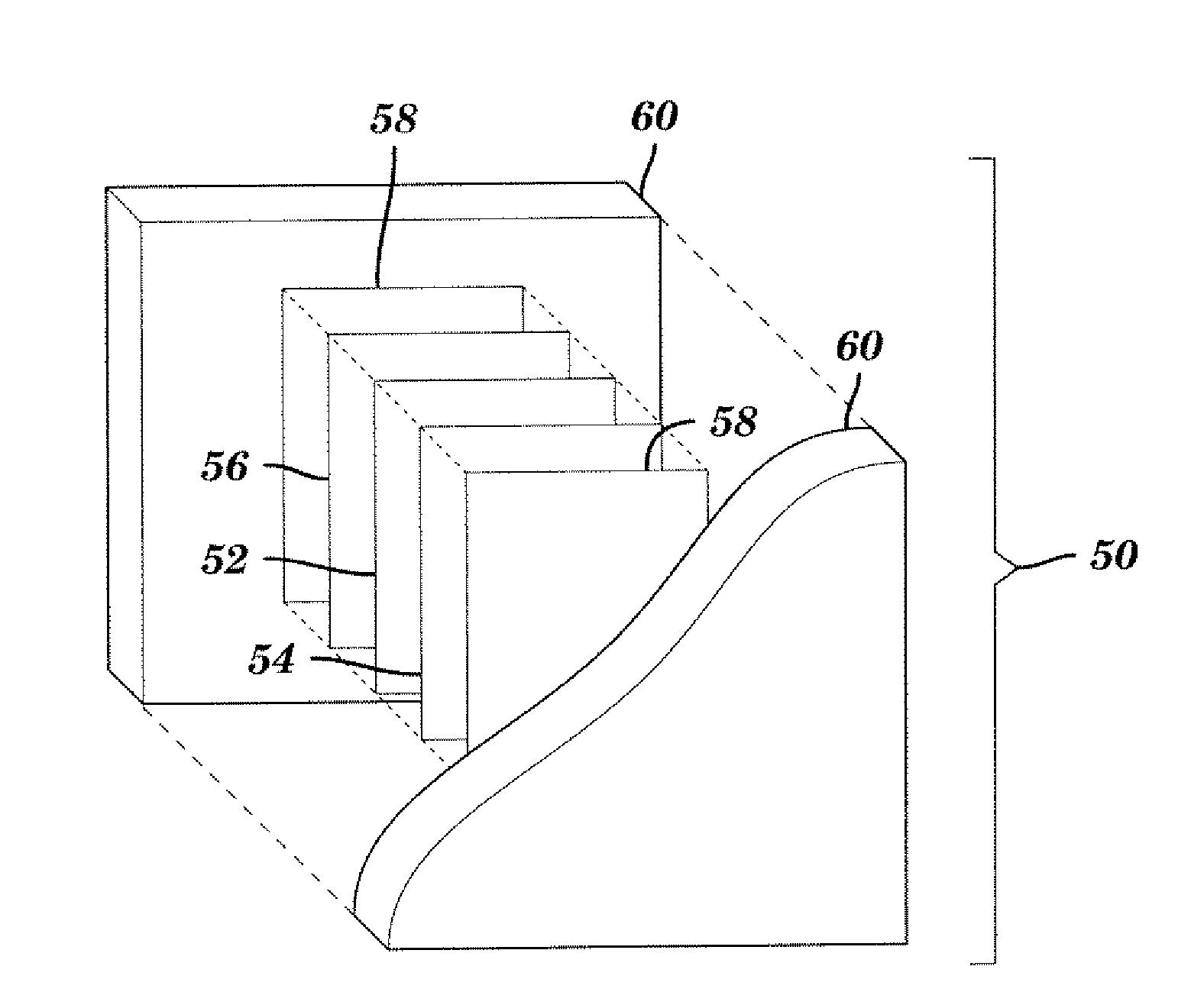

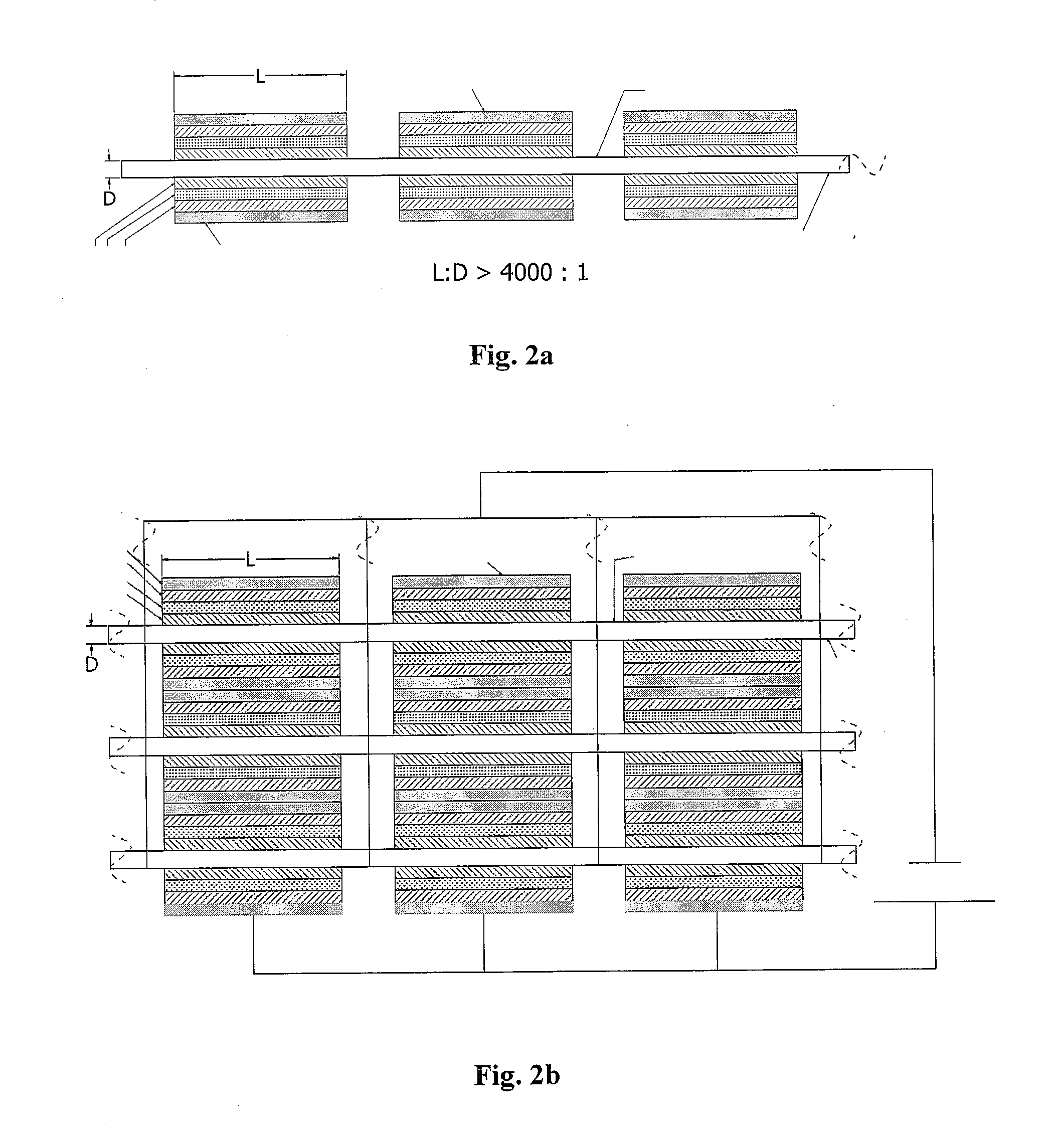

Battery reinforced polymer composite smart structure

InactiveUS20150221974A1High stiffnessHighly structuredPrimary cell to battery groupingFinal product manufactureThermoplasticComposite laminates

A battery having a laminate structure of alternating layers of polymer matrix material and solid-state battery elements is fabricated. Individual solid-state battery elements are created in a deposition apparatus, each battery element having successive solid-state thin films concentrically formed over a conductive wire substrate to define anode, electrolyte and cathode active layers sandwiched between inner and outer current collectors. Inner current collectors are electrically coupled to each other (and likewise the outer current collectors) such that battery elements are connected in a specified series and parallel arrangement. Sets of the individual battery elements are laid upon cloth layers such that outer current collectors of the battery elements physically contact the cloth and the cloth layers are impregnated with selected thermoplastic or thermosetting resin, the impregnated cloth layers and their respective contacting battery elements are stacked to form a composite laminate. The laminate is compacted and cured, and the battery elements of the various layers are coupled to external electrodes. The battery elements double as load components for the laminate structure.

Owner:KALPTREE ENERGY

Lithium battery with total solid ions for conducting power

InactiveCN102800865ASimple structureEasy to produceCell electrodesSecondary cellsElectrical batteryHigh energy

The invention provides a lithium battery with total solid ions for conducting power, effectively solving the problems in the prior art that the energy density and the power density are low and the service life is short. The technical scheme is that the lithium battery comprises a positive electrode, a negative electrode and a housing, wherein the positive electrode and the negative electrode are arranged in the housing; a positive pole connected with the positive electrode and a negative pole connected with the negative electrode are respectively arranged on the housing; the positive electrode is a positive plate comprising of aluminum foil and nanocarbon / sulphate composite material coated thick in 2 to 10 microns on the aluminum coil; and an LiPON solid electrolyte film is arranged between the positive electrode and the negative electrode. The lithium battery has a simple structure, is easy to produce, has a good effect in use, high energy density, high power density, high charging and discharging rate and long service life, and is an innovation based on a power lithium battery and an energy storage battery.

Owner:吴永胜

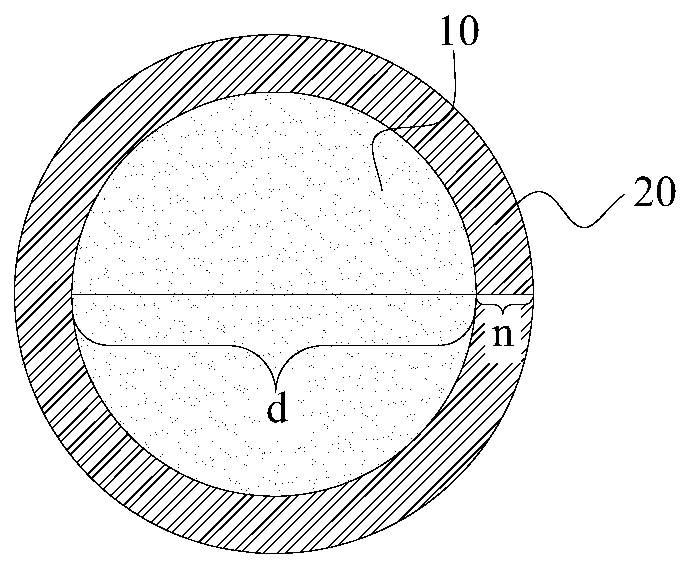

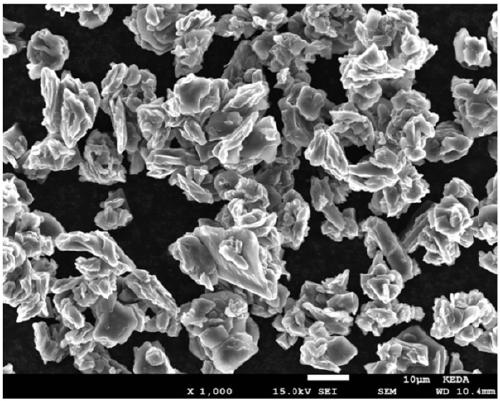

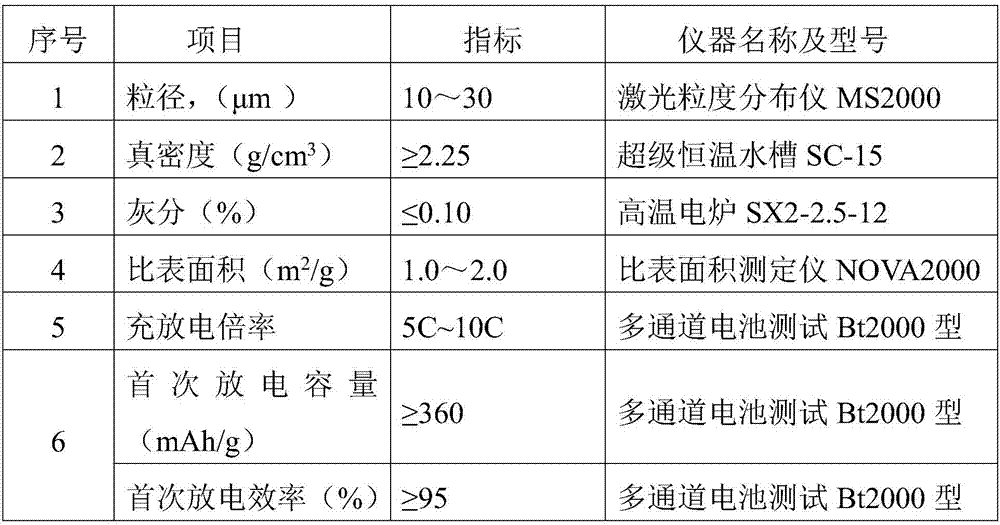

High-rate lithium ion battery graphite cathode material and preparation method thereof

InactiveCN109437184AImprove performanceIncrease charge and discharge rateCarbon compoundsHybrid capacitor electrodesHigh rateSurface oxidation

The invention belongs to the field of lithium ion batteries, and particularly relates to a high-rate lithium ion battery graphite cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) pulverization and shaping of raw materials; (2) graphitization; (3) demagnetization screening; (4) liquid phase coating granulation; (5) surface oxidation treatment. According to the high-rate lithium ion battery graphite cathode material and the preparation method thereof, a liquid phase coating granulation process replaces traditional secondary granulationthrough optimized fine graphite, so as to realize uniform coating of the surface of graphite, reduce the anisotropism of the graphite and shorten the diffusion path of lithium ions; then a micro porestructure is formed on the surface of the graphite through a surface oxidization pore formation process, so that a lithium ion migration channel of a cardinal plane is added to increase the migrationspeed of lithium ions. The charging rate of the graphite obtained by the method is more than 8 C, and the capacity can be maintained at 80 percent or above under the discharging rate more than 30 C.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

Preparation method of high-rate and rapid-charge graphite

PendingCN107146880AHigh retention rateImprove adaptabilityCell electrodesSecondary cellsLithiumHigh rate

The invention relates to the technical field of a lithium ion secondary battery, in particular to a preparation method of high-rate and rapid-charge graphite. The preparation method is characterized by comprising the following steps of (1) smashing and shaping; (2) mixing a modifying agent; (3) performing graphitization high-temperature processing; (4) mixing an adhesive; (5) performing low-temperature thermal treatment; (6) performing carbonization thermal treatment; and (7) screening a mixture. Compared with the prior art, the graphite has the advantages of high charge-discharge rate, large discharge capacity and good cycle performance; and the prepared button cell is excellent in integral performance and mainly has the following advantages that 1, the large-current charge-discharge performance is relatively good; 2, the electrochemical performance is good; 4, the cycle property is good; 5, the safety is relatively good; 6, the adaptability to an electrolyte and other additives is relatively good; and 7, the product property is stable, and the button cell is suitable for industrial production.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

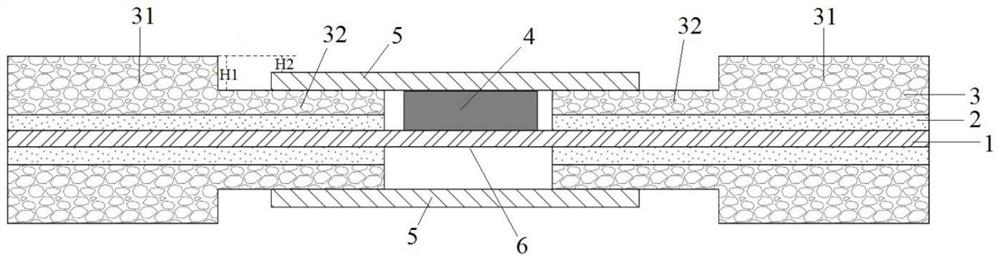

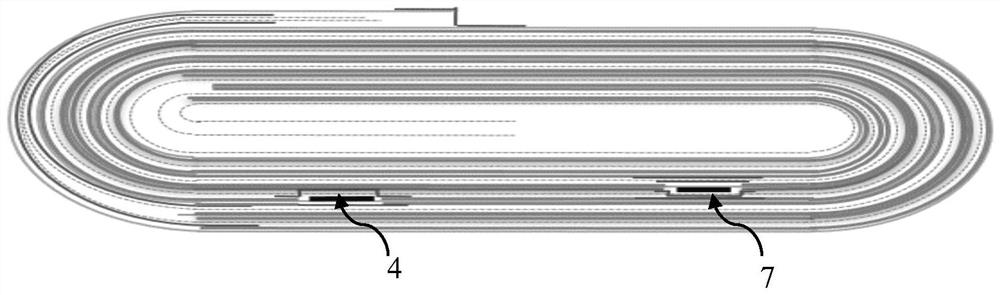

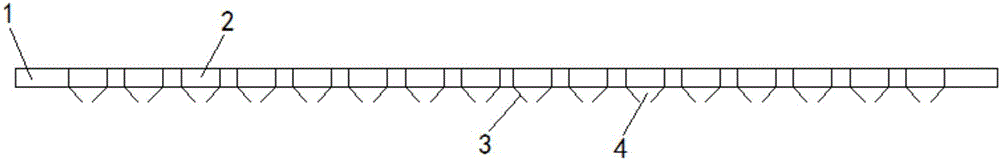

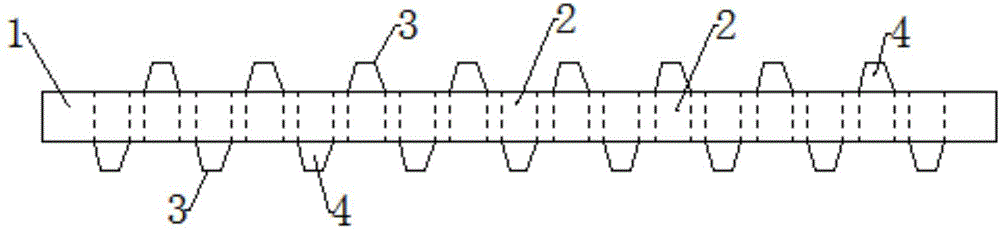

Pole piece and battery

ActiveCN112750978AImprove securityIncrease charge and discharge rateElectrode carriers/collectorsSecondary cellsPole pieceMechanical engineering

The invention provides a pole piece and a battery. The pole piece comprises a current collector and a functional layer located on the first surface of the current collector, wherein the first surface is provided with a tab, the functional layer is composed of a normal region away from the tab and a sunken region close to the tab, and the thickness of the sunken region is smaller than that of the normal region. The pole piece can effectively avoid the problem that the part, close to the tab, of a battery cell is too thick, and improve the safety, the charge-discharge rate and other qualities of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

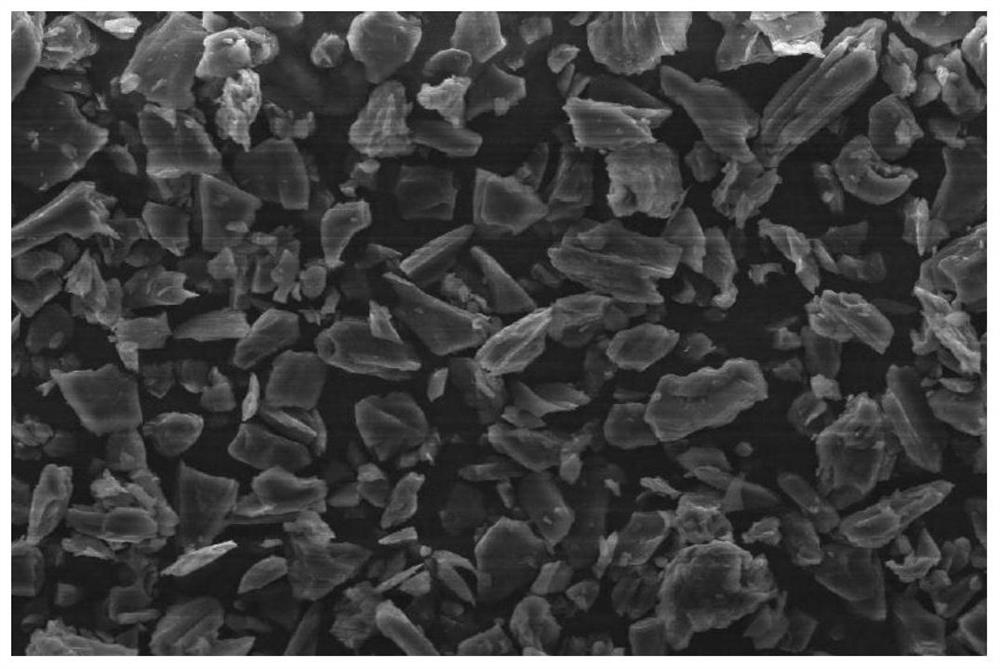

Oxide-graphite interlayer compound, preparation method thereof, electrode and battery

InactiveCN109888241AGood electrical conductivityHigh thermal conductivityCell electrodesSecondary cellsElectrochemistryLithium electrode

The invention discloses an oxide-graphite interlayer compound, a preparation method thereof, an electrode and a battery; the oxide-graphite interlayer compound is an interlayer compound formed by inserting silicon oxide, aluminum oxide or titanium oxide between natural graphite crystalline structure layer pieces. The silicon oxide, aluminum oxide or titanium oxide particles located at the graphitelattice interlayer position have very high electrochemical activity in the charging and discharging process, and the energy density of the electrode can be obviously improved. Through surface activation, a dispersing agent and a binding agent are added and uniformly mixed, the interlayer compound is pressed, formed and dried to obtain an oxide-graphite interlayer compound electrode. The oxide-graphite interlayer compound electrode is suitable for various types of batteries using carbon electrodes. The aluminum ion battery with the carbon electrode used as a cathode, the metal aluminum used asan anode, and aluminum ionic liquid as an electrolyte solution is superior to the lithium ion battery in the aspects of energy density, charging and discharging performance, safety performance and the like. The battery is widely applied to electric appliances such as mobile phones, cameras and the like and power batteries of various vehicles, ships, unmanned aerial vehicles and underwater submerged devices.

Owner:ZHEJIANG UNIV

Pole pieces of lithium battery of aqueous-oily active material electrode and method for producing pole pieces

InactiveCN102403485AReduce manufacturing costImprove the safety of useCell electrodesFinal product manufactureInternal resistanceAdhesive

The invention relates to a lithium battery of an aqueous-oily active material electrode and a method for producing the lithium battery. The lithium battery comprises a cathode piece and an anode piece. The lithium battery is characterized in that: an A-surface coating to which a battery active material is adhered is coated on one surface of the cathode and anode pieces; the A-surface coating comprises the battery active material, an aqueous adhesive and an antioxidant; the aqueous adhesive comprises polytetrafluoroethylene or butylbenzene latex; the weight ratio of the aqueous adhesive to the antioxidant is 100:1.6 to 100:2.0; a B-surface coating to which the battery active material is adhered is coated on the other surface of the cathode and anode pieces; the A-surface coating comprises the battery active material and an oily adhesive; and the oily adhesive is polyvinylidene fluoride. The invention has the advantages that: on the premise of no reduction of the performance (such as the specific capacity and cyclicity of the battery) of the conventional universal technical products, the using safety of aqueous-oily active material battery products is greatly improved; the charge multiplying power and discharge multiplying power of the products are improved; the internal resistance of the battery and the manufacturing cost of the products are reduced; and the social benefit and economic benefit of lithium battery products are further improved.

Owner:江苏中能锂电科技有限公司

Preparation method of high-magnification quick-charging graphite negative electrode material

ActiveCN112289986AImprove defectsImprove the rate of fast charging performanceCell electrodesSecondary cellsGraphitePetroleum coke

The invention discloses a preparation method of a high-magnification quick-charging graphite negative electrode material. The method comprises the following steps: carrying out coarse crushing and fine grinding on one or more of needle coke, petroleum coke and pitch coke, carrying out spheroidizing shaping treatment, mixing with a first carbon source, heating to carry out surface coating, and carrying out high-temperature carbonization; then carrying out high-temperature graphitization treatment to obtain an artificial graphite powder; and mixing the obtained artificial graphite powder with asecond carbon source, heating for surface coating, and carbonizing at a high temperature to obtain the high-magnification quick-charging graphite negative electrode material. The graphite negative electrode material prepared by the invention has the advantages of a high charge-discharge rate, a large discharge gram capacity and good cycle performance, and a battery prepared from the graphite negative electrode material has excellent comprehensive performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Lithium ion cell composite anode material and preparing process thereof

InactiveCN1688051AIncrease capacityImprove cycle stabilityElectrode manufacturing processesLithiumOrganic solvent

This invention relates to a Li ionic battery positive material and its preparation method. Said material contains Li transition metal oxide, carbon nm-tube, black carbon and an adhesive mixed in the quality ratio of 80-90%, 3-10%, 0-8% and 3-10% and mixed to a slurry after dissolved by an organic solvent then to be coated on the Al foil to be rolled and dried in vacuum to get the electrode membrane, which gets the advantages of high capacity, high circulation stability and high charge / discharge multiplying factor.

Owner:TSINGHUA UNIV

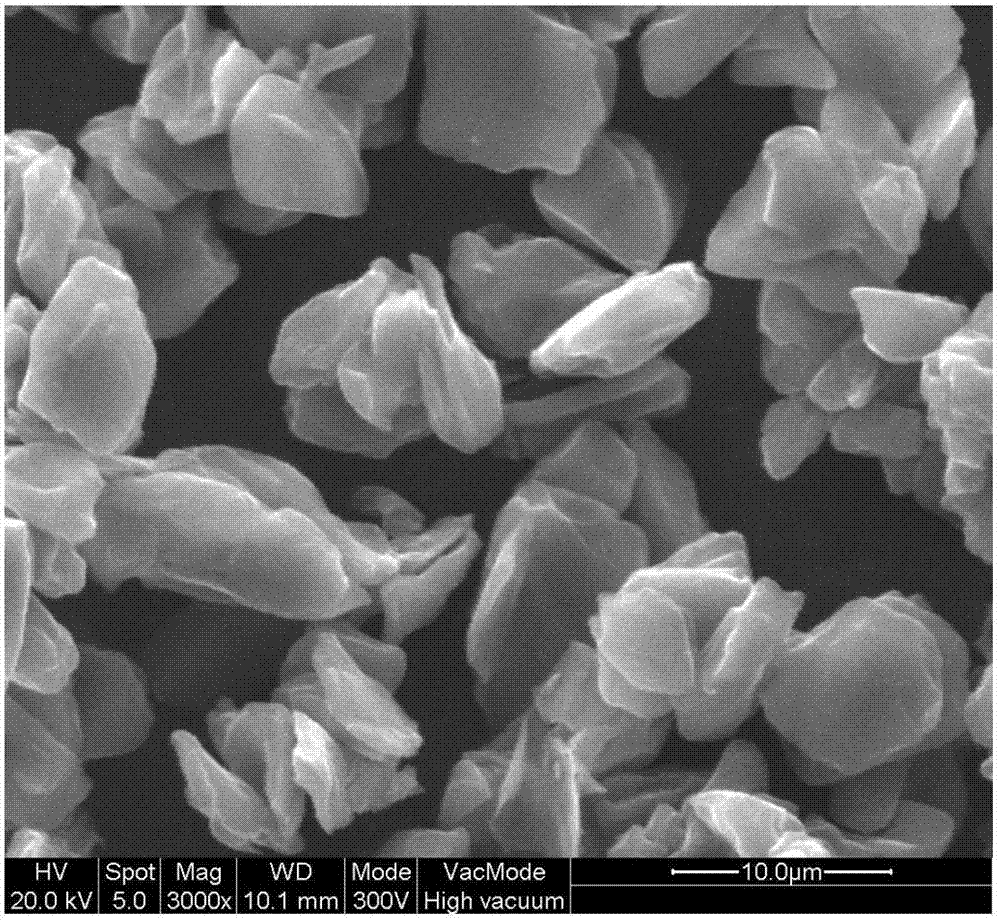

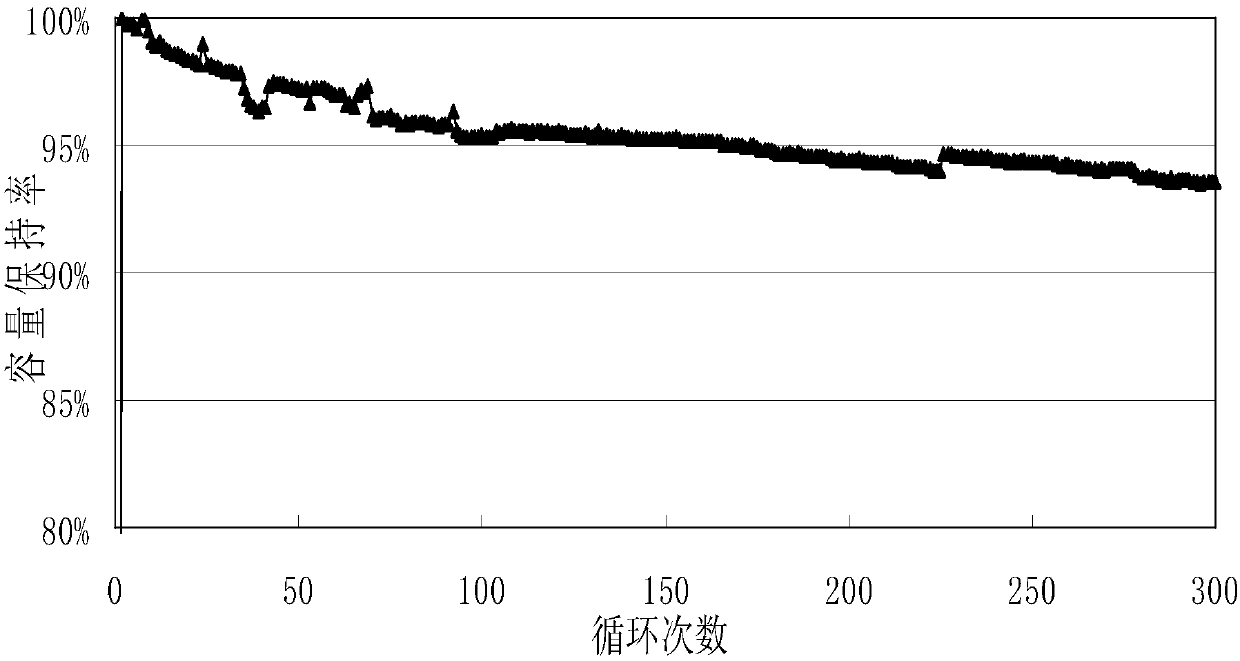

Preparing method of high- capacity intermediate phase coal micro powder

PendingCN106430143AThe preparation method is simple and feasibleIncrease charge and discharge rateCarbon preparation/purificationHot isostatic pressingPetroleum

The invention relates to the technical field of intermediate phase coal micro powder preparation, and particularly relates to a preparing method of high-capacity intermediate phase coal micro powder. The preparing method of the high-capacity intermediate phase coal micro powder is characterized by comprising the first step of smashing and pretreatment, the second step of mixing, the third step of hot isostatic pressure treatment, and the fourth step of catalytic graphitization and high-temperature treatment. An adhesive is one of petroleum asphalt and coal pitch; graphitization catalyst is one or more of carbides or oxides of one or more of silicon, iron, tin and boron. Compared with the prior art, the preparing method of the high-capacity intermediate phase coal micro powder is simple and practicable in preparing method and is applicable to industrial production; the prepared high-capacity intermediate phase coal micro powder has high charge-discharge rate and good cycle performance, and a button cell prepared from the coal micro powder has good overall performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

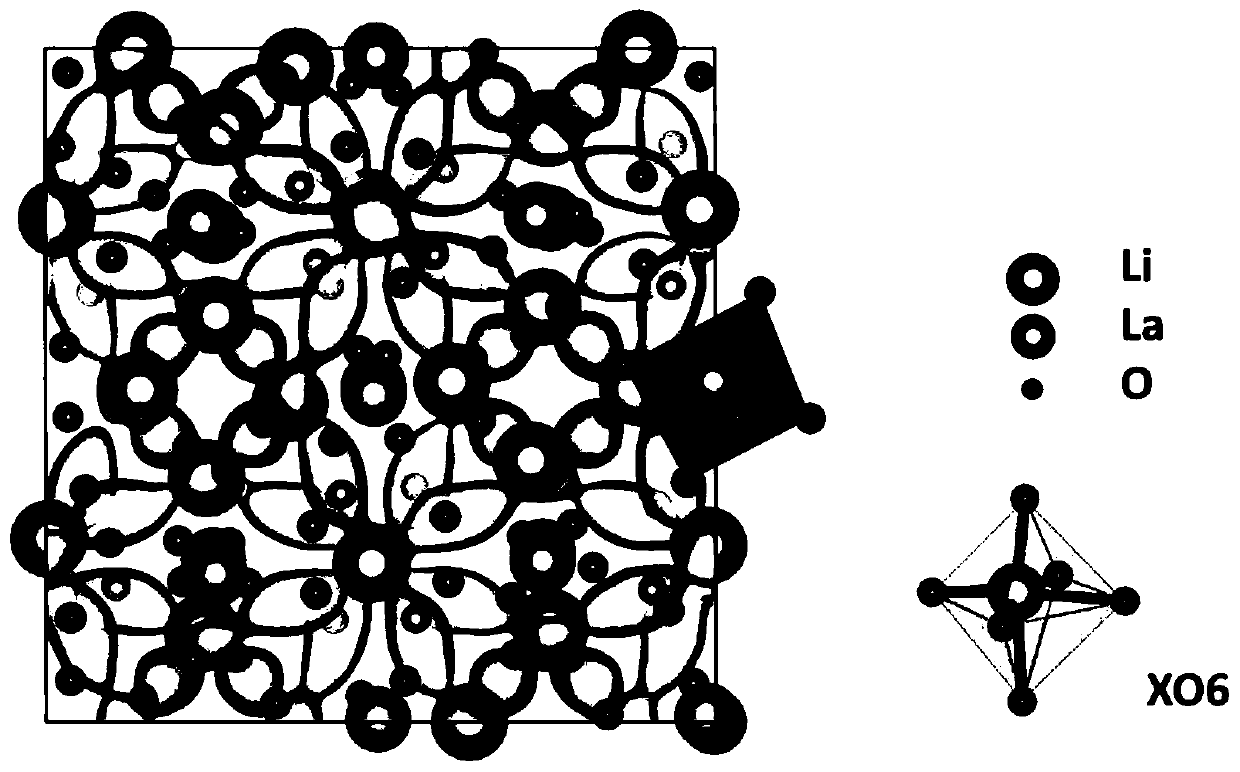

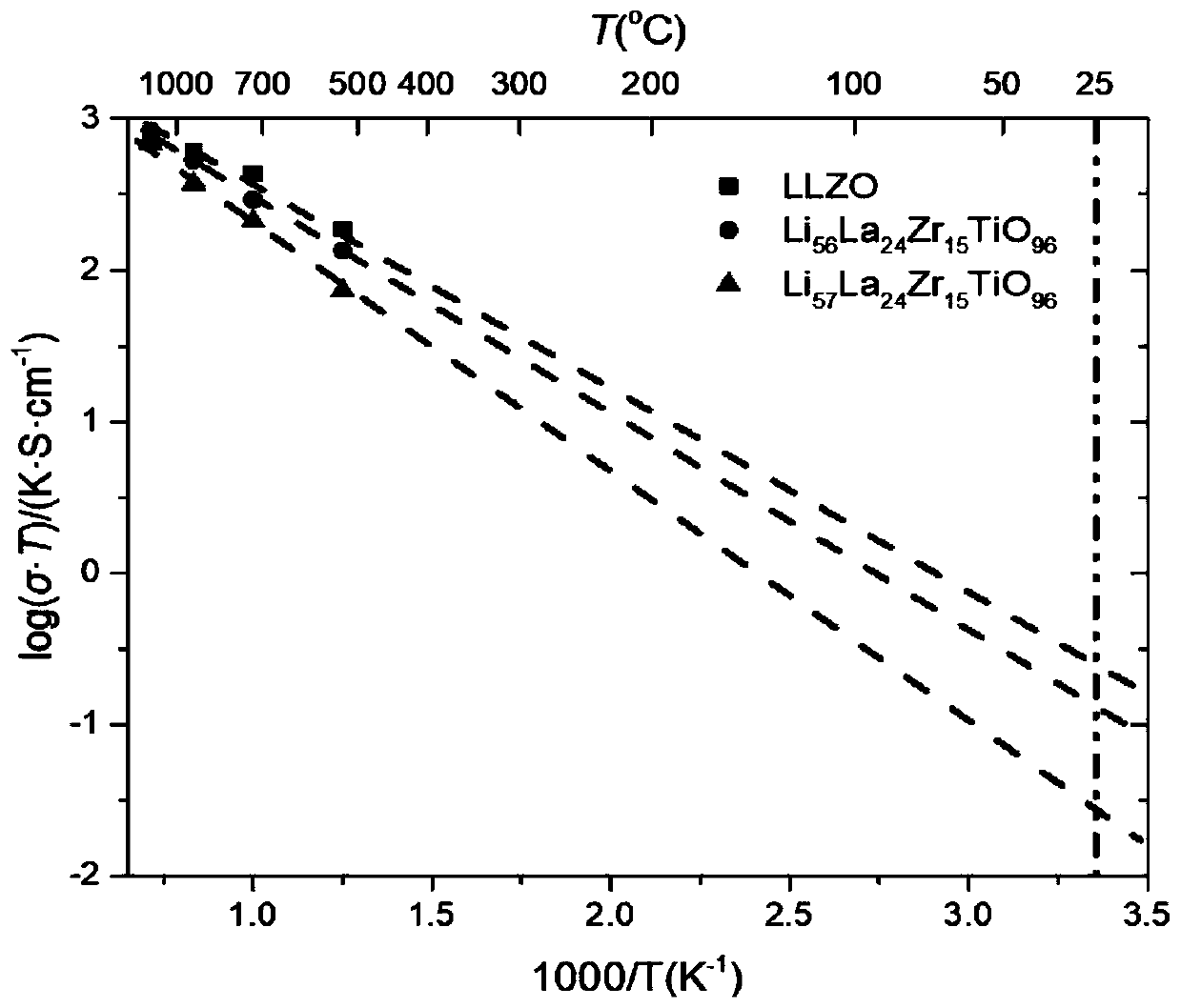

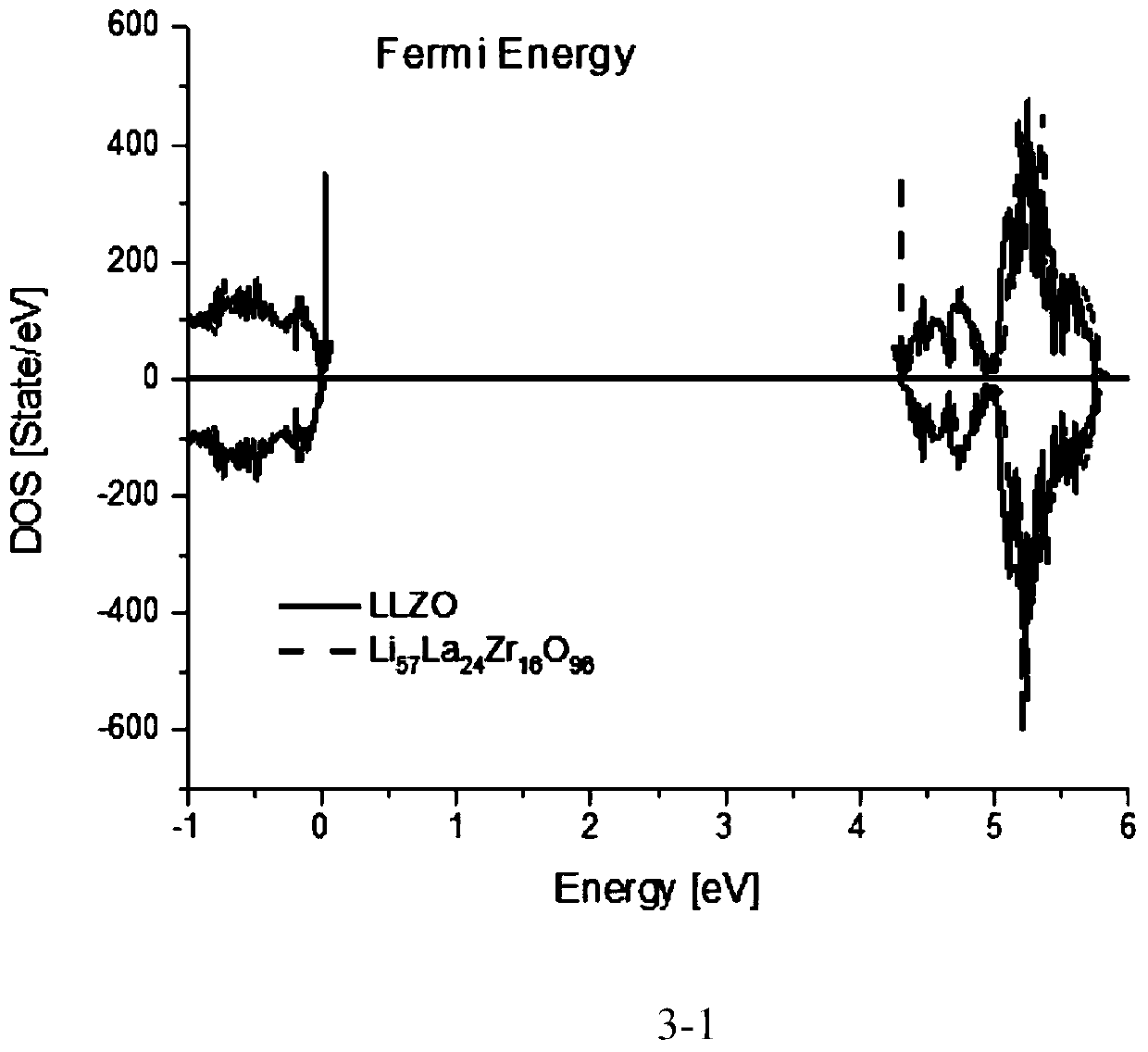

Mixed ion-electron conductor with garnet structure and application thereof in energy storage device

InactiveCN111326787AImprove power densityAdapt to assembly needsHybrid capacitor electrolytesRegenerative fuel cellsMetallic lithiumElectrical conductor

The invention relates to a mixed ion-electron conductor with a garnet structure and application of the mixed ion-electron conductor in an energy storage device. The general formula of the conductor is(LimM)xLa3(Zr<1-a>Xa)2O12, wherein m is greater than 0 and less than or equal to 1, n is greater than or equal to 0 and less than or equal to 0.5, the sum of m and n is less than or equal to 1, and xis greater than or equal to 3 and less than or equal to 7.5; M comprises at least one element selected from H, Na, K, Rb, Mg, Ca, Sr, Ba, Y, La, Ti, Zr, Zn, B, Al, Ga, In, C, Si, Ge, P, S and Se; a is greater than or equal to 0 and less than 1; and X comprises at least one element selected from Ta, Hf, V, Nb, Ta, Cr, Mo, W, Mn, Fe, Co, Ni, Si, Ge, Sn, Pb, As, Sb and Se. The conductor provided bythe invention has high ionic conductivity and electronic conductivity, and can be applied to an electrode / electrolyte interface layer in a battery or a capacitor, a positive electrode layer and a negative electrode layer. The mixed ion-electron conductor can be applied to a lithium ion battery, a rechargeable metal lithium battery, a lithium flow battery and a lithium ion capacitor, and the energystorage devices have wide application.

Owner:BEIJING UNIV OF CHEM TECH

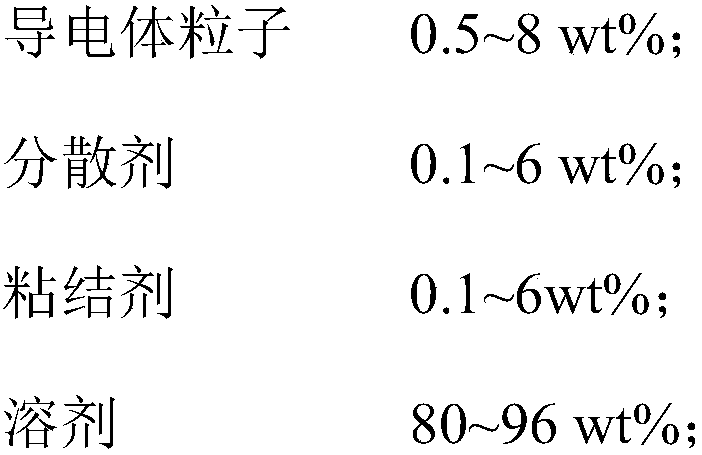

Conductive agent for lithium battery and preparation method thereof

InactiveCN108511760AReduce the dosage ratioReliable long-range conductivityCell electrodesInternal resistanceCarbon nanotube

The invention discloses a conductive agent for a lithium battery and a preparation method thereof. The conductive agent for the lithium battery comprises the following components in percentage by weight: conductor particles, a dispersing agent, a binder and solvent; the conductor particles are carbon particles with carbon nanometer tubes growing on the surfaces. According to the conductive agent provided by the invention, the plurality of carbon nanometer tubes of the conductor particles are firmly connected with a carbon particle, so that the reliable long-range electrical conductivity is provided; the carbon nanometer tubes of the different conductor particles are connected with one another, and contact the active material, so that a conductive network can be constructed for the lithiumbattery; the conductive agent provided by the invention is beneficial to reducing the dosage, lowering internal resistance and temperature rise, and improving charging-discharging multiplying power and cycling performance. According to the conductive agent provided by the invention, the carbon nanometer tubes and the carbon particles form conductive particles of a whole composite structure, so that the steps for preparing the conductive agent only needs one time of dispersing and mixing, and thus the production technology is simplified.

Owner:TRINA SOLAR CO LTD

Preparation method of high-rate natural graphite negative electrode material

InactiveCN107871866AIncrease charge and discharge rateImprove cycle performanceCell electrodesState of artHigh rate

The invention relates to the technical field of a graphite negative electrode material, specifically to a preparation method of a high-rate natural graphite negative electrode material. The method comprises: (1) super fine grinding pretreatment; (2) mixing; (3) heating and kneading; (4) hot isostatic pressing treatment; and (5) catalytic graphitization high-temperature treatment, and then a graphite negative electrode material is prepared. Compared with a method in the prior art, the preparation method is simple and feasible and is suitable for industrial production. The prepared graphite negative electrode material is high in charge and discharge rate and good in cycle performance, and a button cell made from the graphite negative electrode material is excellent in overall performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Preparation method for modified graphene and application of modified graphene to positive materials for lithium batteries

InactiveCN104716322AGood dispersionThe preparation process is non-toxicSecondary cellsPositive electrodesElectric capacityElectric Capacitance

The invention discloses a preparation method of modified graphene and application of the modified graphene to positive materials for lithium batteries. The preparation method for the modified graphene comprises the following steps: preparing a graphene oxide slurry; reducing the graphene oxide slurry at high temperature to prepare graphene; modifying the graphene by a graphene oxidant; modifying the graphene by quaternary ammonium salt; doping the modified graphene into the positive materials for the lithium batteries. The modified graphene prepared by the method has the advantages that the modified graphene is free of agglomeration, excellent in dispersion in solvents, free of toxicity in preparation process, free of pollution to environment and long in service life; through the application of the modified graphene to the positive materials for the lithium batteries, the electric capacity and the charge-discharge rate of the batteries are improved obviously; a small amount of modified graphene is added, so that the cost is reduced.

Owner:山东利特纳米技术有限公司

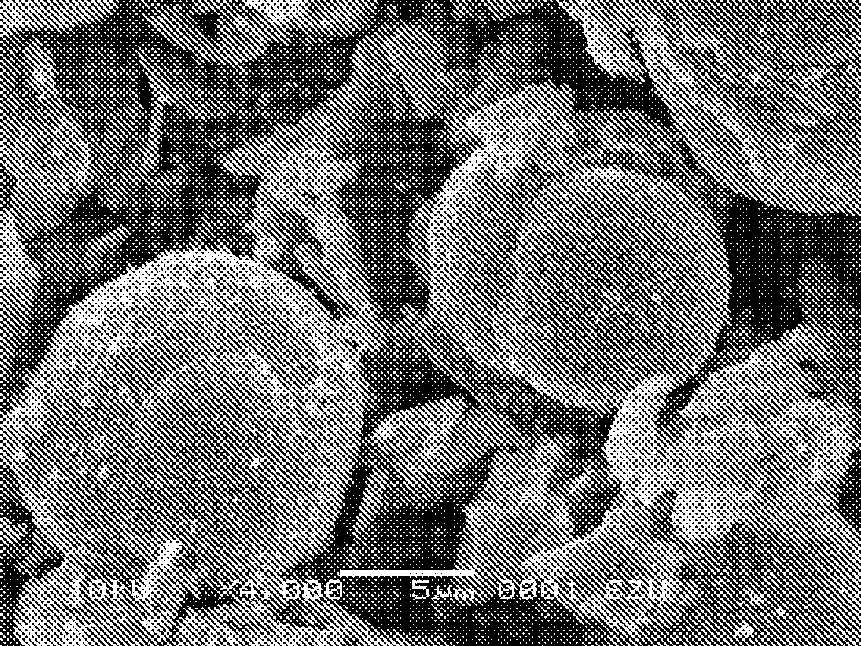

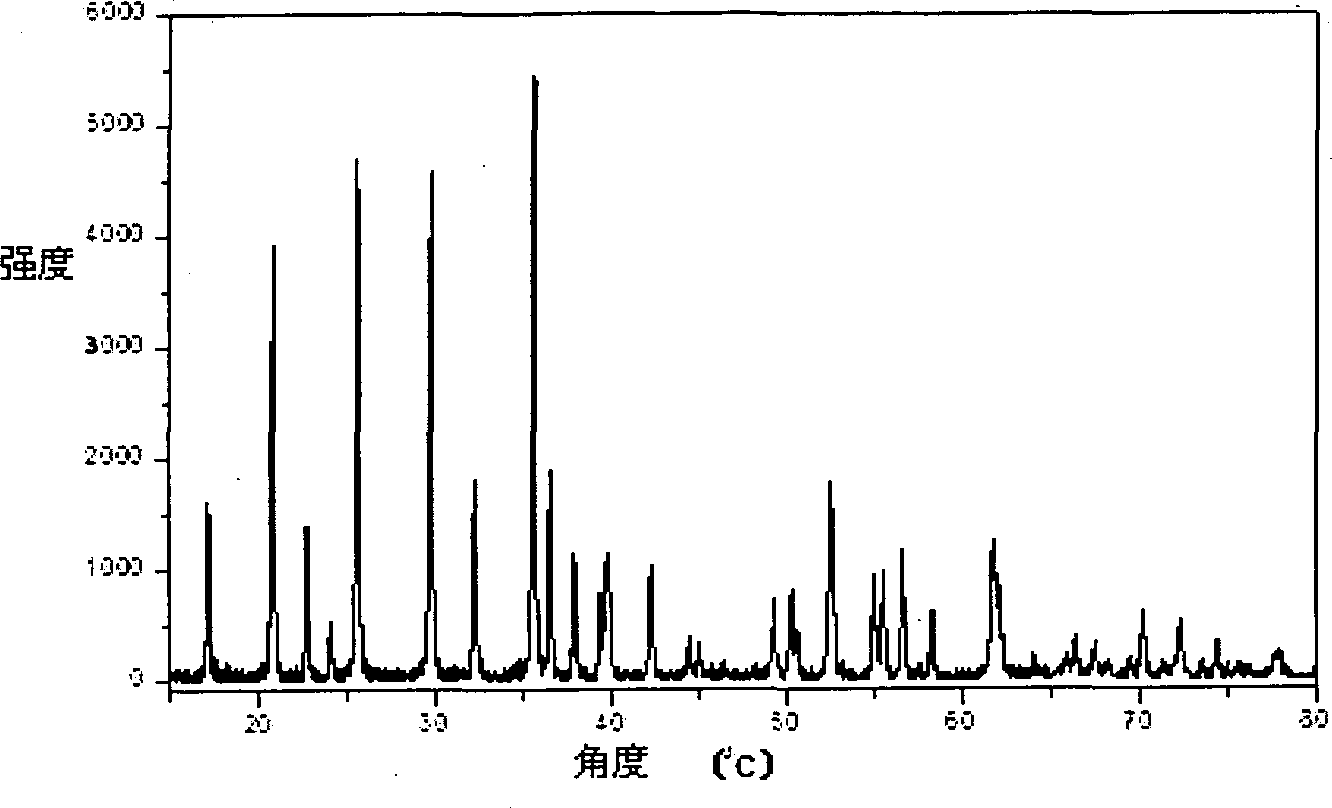

Preparation method of caky-structure nano zinc oxide material

InactiveCN103560238AReduce hole recombination rateIncrease profitMaterial nanotechnologyZinc oxides/hydroxidesElectronic transmissionHexamethylenetetramine

The invention discloses a preparation method of a caky-structure nano zinc oxide material, relating to a preparation method of a zinc oxide material.Zinc nitrate, hexamethylenetetramine, surfactant and the like are all common raw materials. The caky-structure nano zinc oxide material is synthesized by a hydrothermal process. The method comprises the following steps: adding a composite surfactant into a zinc nitrate-hexamethylenetetramine water solution, keeping the temperature at 80-100 DEG C to react for 2-5 hours in a reaction kettle, washing, drying, and carrying out annealing treatment to obtain the caky-structure nano zinc oxide. The method solves the problem that the nanocrystal in the dye-sensitized solar cell (DSSC) has large specific area and can shorten the electronic transmission path, and is beneficial to enhancing the conversion efficiency of the DSSC. The method has the advantages of low production cost, simple preparation process, low requirements for the reactor, mild reaction conditions and no environmental pollution, and can implement large-scale production.

Owner:NANCHANG HANGKONG UNIVERSITY

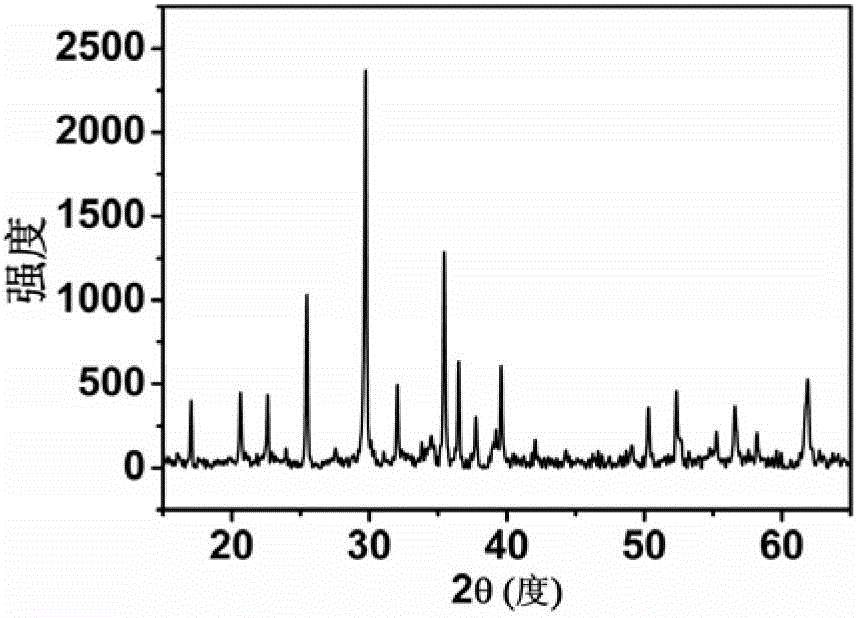

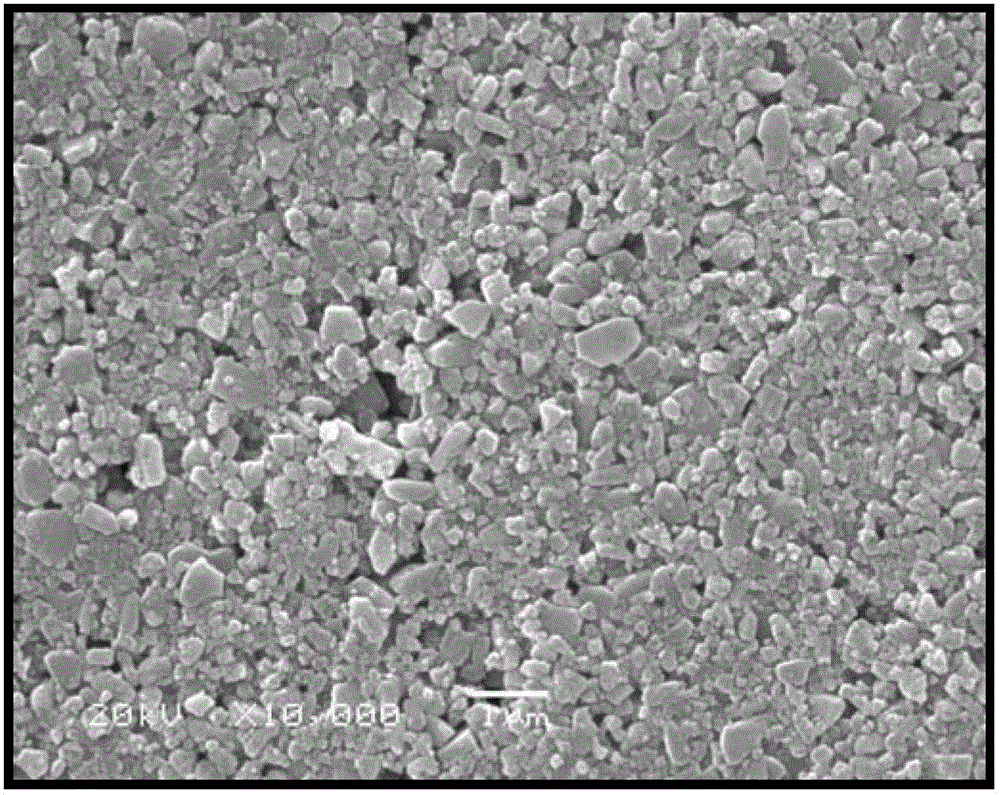

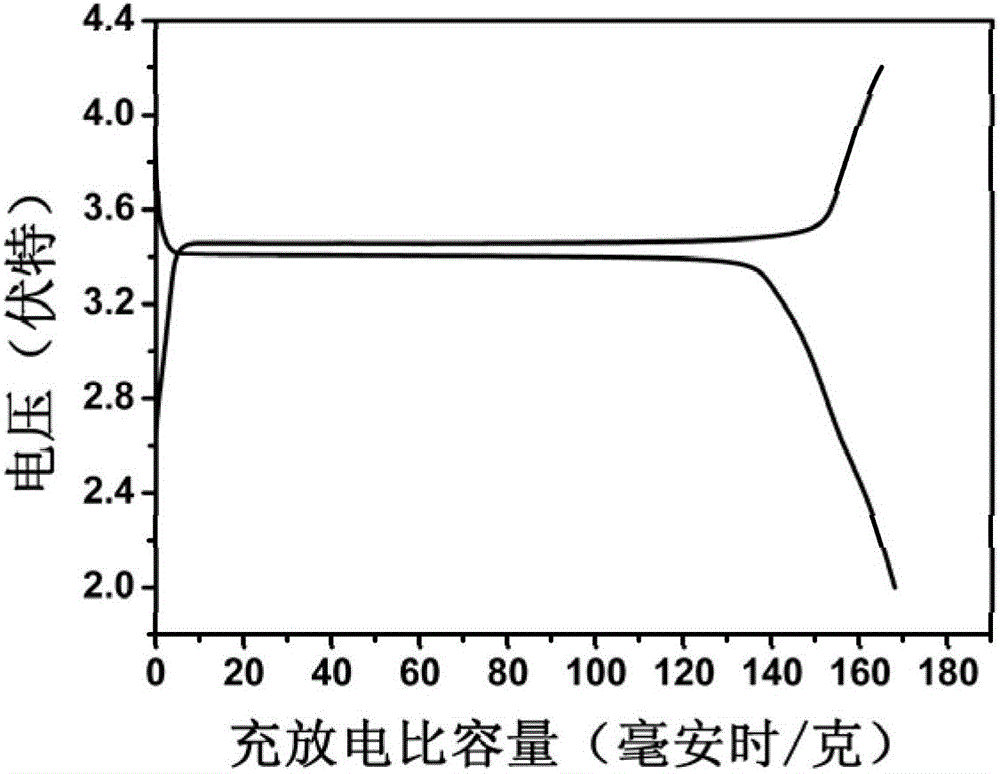

Lithium iron phosphate composite material, production method and use thereof

ActiveCN103003193BImprove conductivityIncrease charge and discharge rateElectrode thermal treatmentLi-accumulatorsHigh rateIron salts

Provided are a lithium iron phosphate composite material, the production method thereof and the use thereof. The lithium iron phosphate composite material has a micro-size particle structure, which contains nano-size grains of lithium iron phosphate and graphene inside, and bears nano-carbon particulates outside. The lithium iron phosphate composite material has the properties of high conductivity, high-rate charge / discharge performance and high tap density. The production method comprises: preparing an iron salt mixed solution according to the mole ratio of P : Fe =1:1; adding the above solution into an organic carbon source aqueous solution, followed by mixing and reacting, so as to obtain nano-iron phosphate covered with organic carbon source; adding the above nano-iron phosphate covered with organic carbon source and a lithium source compound into an aqueous solution of graphene oxide, agitating, mixing, and then spray drying, so as to obtain a precursor of lithium iron phosphate composite material; calcinating said precursor in a reduction atmosphere and cooling naturally, so as to obtain said lithium iron phosphate composite material. The material is used for lithium ion battery or positive electrode material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Preparation method of lithium ion battery positive pole material LiFePO4/C

ActiveCN104037410AExcellent electrochemical performanceImprove the actual energy density and power densityCell electrodesSecondary cellsSolventCarbon source

The invention discloses a preparation method of a lithium ion battery positive pole material LiFePO4 / C. The preparation method comprises the following steps of dissolving or dispersing a ferric salt, a lithium salt and a phosphorus-containing compound in a solvent under the condition of inert gas purging to obtain a reaction precursor, transferring the reaction precursor into a high pressure reactor, carrying out a reaction process for a certain time, carrying out filtration, washing and drying, carrying out mixing with a carbon source, and carrying out calcination treatment to obtain the lithium ion battery positive pole material LiFePO4 / C. The preparation method solves the problem that the traditional preparation method cannot simultaneously realize high crystallization, special morphology and nano-scale particle size. The preparation method can prepare the completely-crystalline flaky nano-scale lithium ion battery positive pole material LiFePO4 / C.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

3D foil material, preparation method and application of positive plate and negative plate containing same

PendingCN106505210AImprove adhesionLarge capacityFinal product manufactureElectrode carriers/collectorsPunchingAdhesive

The invention provides a 3D foil material, a preparation method and an application of a positive plate and a negative plate containing the same. The 3D foil material comprises a base material, wherein multiple first through holes are formed in the middle of the base material; lug bosses are arranged on the peripheries of the first through holes in the base material; the lug bosses and the base material are formed integrally; second through holes are formed in the lug bosses; the side walls of the second through holes are parallel to the side walls of the lug bosses; the second through holes are communicated with the first through holes; the pore diameter, far from the second through hole end, of the first through holes is greater than or equal to that in the connecting place between the first through holes and the second through holes; and the pore diameter in the connecting place between the first through holes and the second through holes is greater than that, far from the first through hole end, of the second through holes. The 3D foil material provided by the invention adopts a mechanical stamping and punching way, so that the foil material is endowed with the three-dimensional structure including the first through holes, the second through holes and the lug bosses; and therefore, the adhesive force between the foil material and slurry can be greatly increased, and dosage of adhesive and an additive in the slurry can be further lowered.

Owner:HUINENG TIANJIN TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com