Preparation method of high-rate fast-rapid graphite

A high-magnification, graphite technology, applied in the direction of graphite, chemical instruments and methods, structural parts, etc., can solve the problems of poor fast charge and discharge performance, long diffusion path of lithium ions, and increased processing costs, and achieve excellent comprehensive performance and preparation methods Simple and feasible, the effect of stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

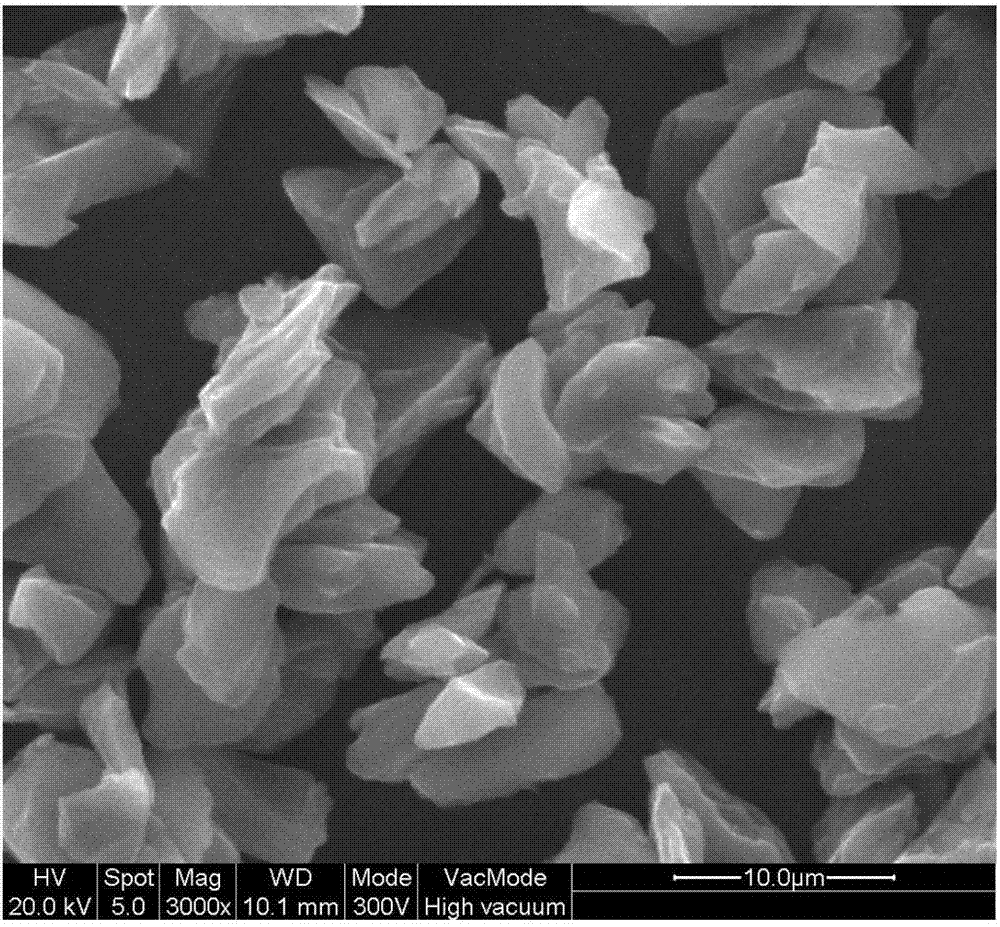

Image

Examples

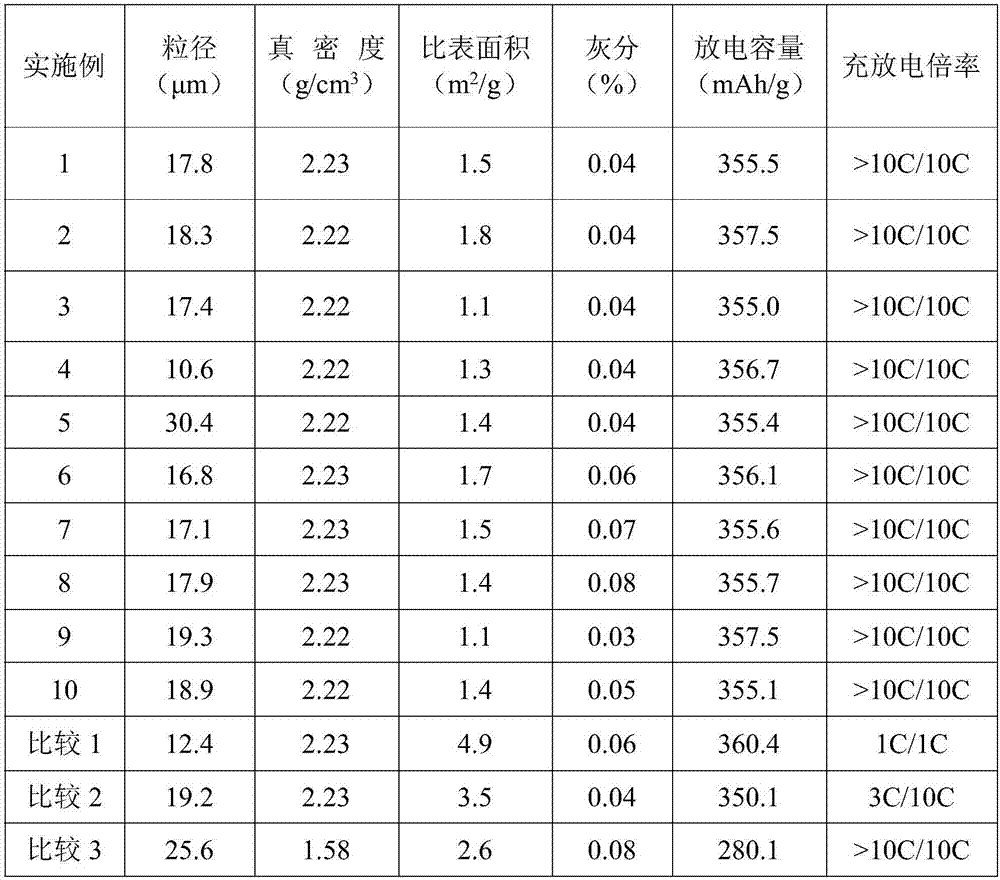

Embodiment 1

[0032] 1. Crushing and shaping processing of petroleum coke raw materials, the particle size D50 is controlled at 5-10 μm;

[0033] 2. Mixing the pulverized petroleum coke raw material with petroleum tar as a modifier with a mass ratio of 90:10;

[0034] 3. Under the protection of inert gas, conduct graphitization high temperature treatment at 3000°C for 48 hours;

[0035] 4. Mix the graphitized high-temperature-treated mixture with petroleum pitch as a binder; the amount of petroleum pitch added is 20% of the quality of the petroleum coke raw material;

[0036] 5. Under the protection of inert gas, conduct low-temperature heat treatment at 600°C for 18 hours, and then cool to room temperature;

[0037] 6. Carry out carbonization heat treatment at 1300°C for 30 hours under the protection of inert gas;

[0038] 7. Mixing and screening to produce high-rate fast-charging graphite with a half-battery capacity of 355.5mAh / g and a charge-discharge rate of >10C / 10C.

Embodiment 2

[0040] 1. Crushing and shaping processing of petroleum coke raw materials, the particle size D50 is controlled at 5-10 μm;

[0041] 2. Mix petroleum coke raw materials and coal tar as a modifier in a mass ratio of 70:30;

[0042] 3. Under the protection of inert gas, conduct graphitization high-temperature treatment at 3200°C for 24 hours;

[0043] 4. Mix in petroleum asphalt as a binder, and the amount of petroleum asphalt added is 30% of the quality of petroleum coke raw materials;

[0044] 5. Under the protection of inert gas, conduct low-temperature heat treatment at 800°C for 10 hours, and cool to room temperature;

[0045] 6. Carry out carbonization heat treatment at 2000°C for 10 hours under the protection of inert gas;

[0046] 7. Mixing and screening to produce high-rate fast-charging graphite with a half-battery capacity of 357.5mAh / g and a charge-discharge rate of >10C / 10C.

Embodiment 3

[0048] 1. Crushing and reshaping the pitch coke raw material, the particle size D50 is controlled at 5-10 μm;

[0049] 2. Mix pitch coke raw material and coal tar as a modifier in a mass ratio of 50:50;

[0050] 3. Under the protection of inert gas, conduct graphitization high temperature treatment at 2800°C for 36 hours;

[0051] 4. Mix in coal tar pitch as a binder, and the amount of coal tar pitch added is 10% of the mass of the pitch coke raw material;

[0052] 5. Under the protection of inert gas, conduct low-temperature heat treatment at 300°C for 20 hours, and cool to room temperature;

[0053] 6. Carry out carbonization heat treatment at 800°C for 50 hours under the protection of inert gas;

[0054] 7. Mixing and screening to produce high-rate fast-charging graphite with a half-battery capacity of 355.0mAh / g and a charge-discharge rate of >10C / 10C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com