Pole piece and battery

A technology of pole pieces and tabs, which is applied in the field of pole pieces and batteries using the pole pieces, can solve the problems of low battery safety, too thick batteries, poor charge and discharge rate performance, etc., and achieve good safety and great practicality Significance, improvement of safety and effect of charge and discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

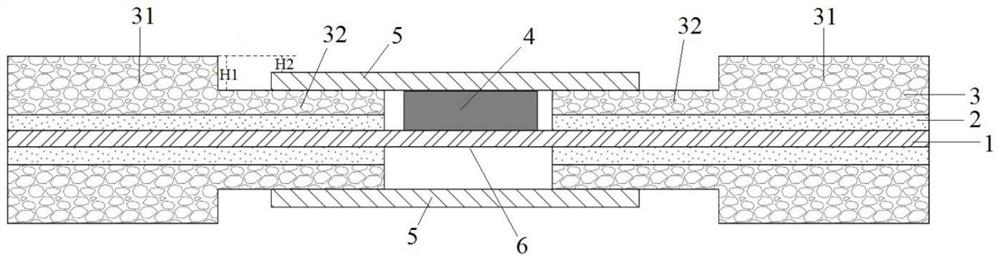

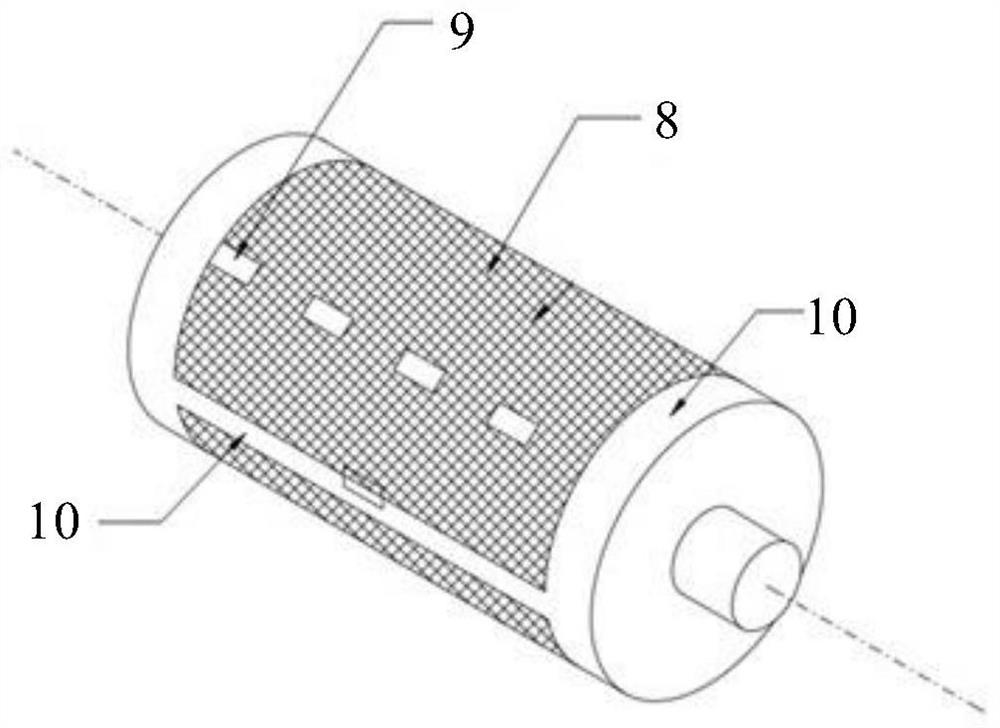

[0037] The pole piece of the present invention can be prepared according to conventional methods in the field such as the coating method. For example, in one embodiment, the preparation method can specifically include: after coating the primer layer 2 on the surface of the current collector 1, and then coating the primer layer 2 The surface is coated with an active material layer 3, and then after removing the undercoat layer and the active material layer at the preset tab position, welding the tab on the current collector at the preset tab position, and according to the width and thickness of the preset recessed area and other parameters to remove the functional layer in the preset recessed area to form a recessed area 32 to obtain a pole piece; wherein, the gravure coating method is used to coat the primer layer, such as image 3 As shown, the gravure roll used in the gravure coating method is provided with a reserved tab position 9, and the preset tab position on the current...

Embodiment 1

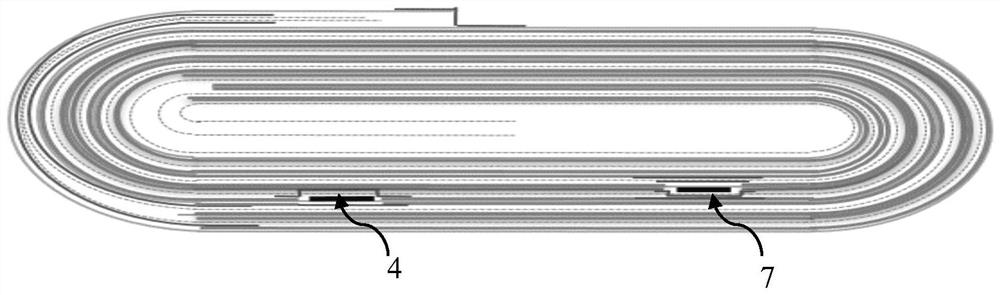

[0053] The positive electrode sheet of this embodiment includes a positive electrode current collector and a positive electrode functional layer coated on both surfaces of the positive electrode current collector. One surface of the positive electrode current collector is provided with a positive electrode ear (the positive electrode ear is located in the middle of the positive electrode sheet), and the positive electrode on this surface The functional layer is composed of a normal area away from the positive tab and a recessed area close to the positive tab, the thickness of the recessed area is smaller than that of the normal area; the other surface of the positive current collector is provided with an uncoated area corresponding to the position of the positive tab The positive electrode functional layer on the other surface is the same as the positive electrode functional layer on the surface provided with positive tabs (composed of the above-mentioned normal area and the rec...

Embodiment 2

[0060] The difference between this example and Example 1 is that the thickness of the undercoat layer is 7 μm, the thickness of the positive electrode active material layer in the depressed area is 50 μm, and the depth of the depressed area is 60 μm, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com