A DC power supply system for substation and its control method

A technology of a DC power supply system and a control method, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of shortened service life, waste pollution, and large battery area, and achieve extended service life, excellent performance, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be further described through specific embodiments in conjunction with the accompanying drawings.

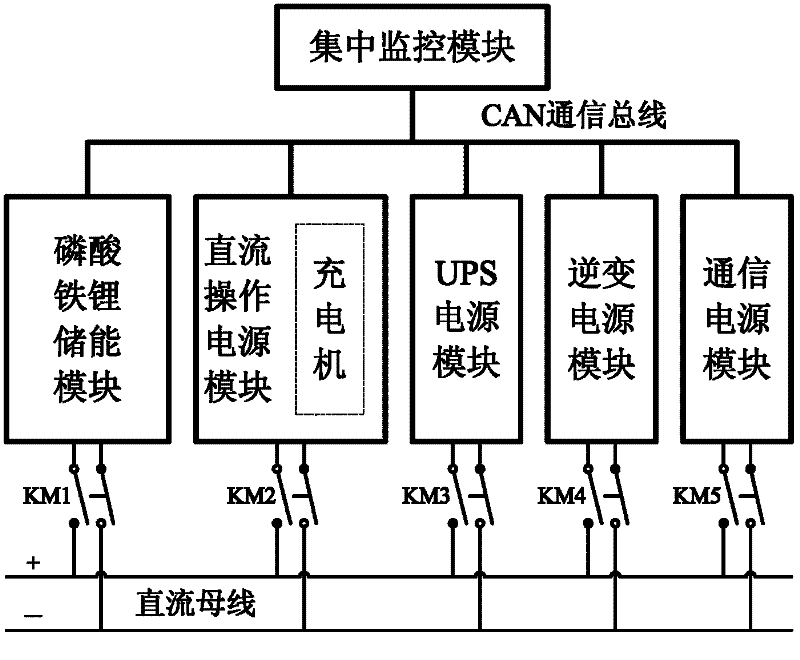

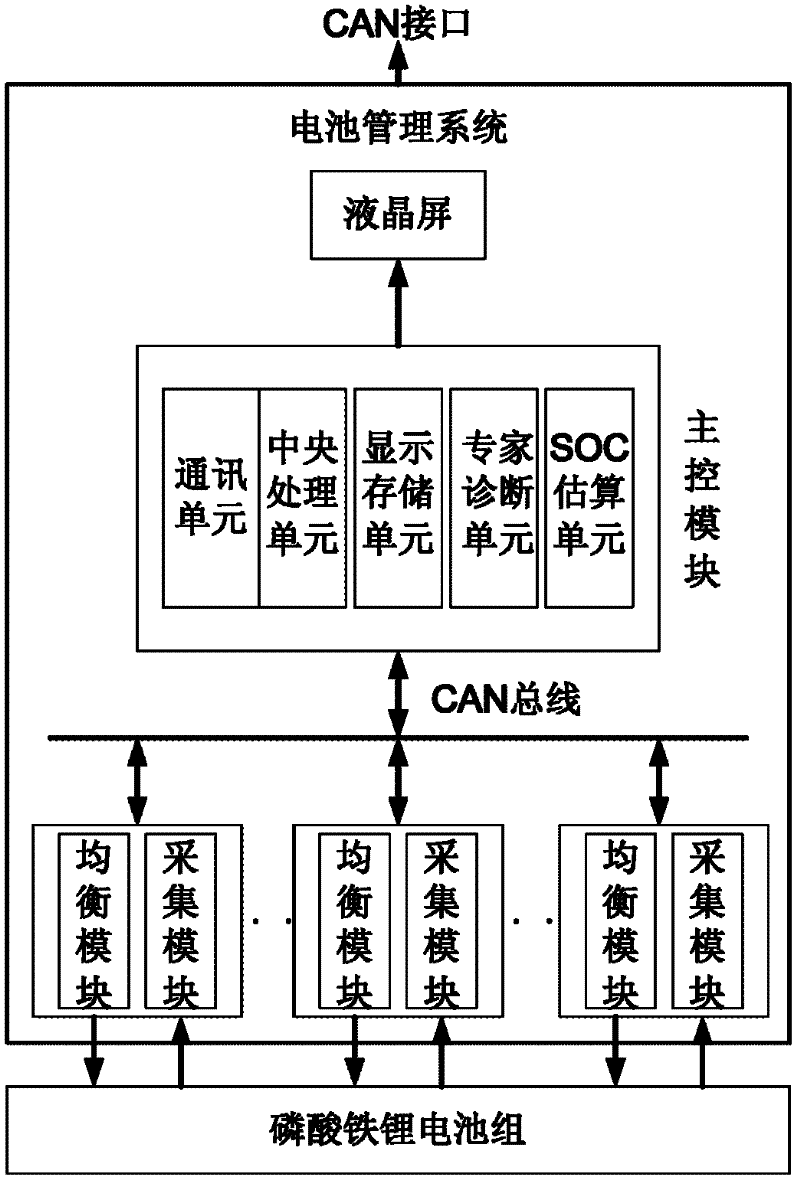

[0032] see figure 1 , in this embodiment, the whole system adopts the idea of centralized management and distributed control. The DC operation power supply module, UPS power supply module, inverter power supply module, communication power supply module and lithium iron phosphate energy storage module are connected to the centralized monitoring system through the CAN bus. on the module. The lithium iron phosphate energy storage module is connected to the DC bus through the first relay switch KM1; each power module is connected to the DC bus through the second to fifth relay switches KM2~KM5, and each power module uses a lithium iron phosphate battery as backup battery.

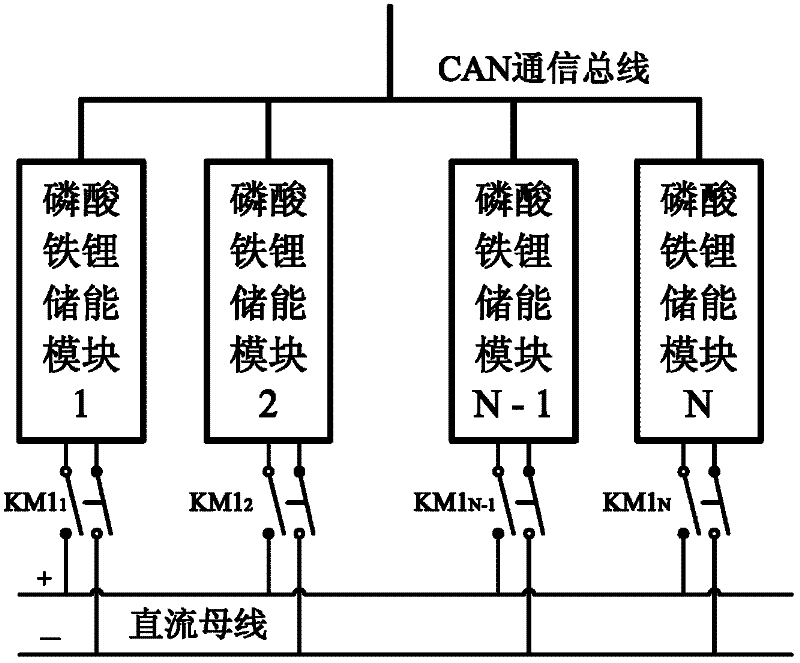

[0033] Each module in the DC power system can realize redundant backup of the system by increasing the number of modules connected in parallel to the DC bus, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com