Patents

Literature

165results about How to "Realize online maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A DC power supply system for substation and its control method

InactiveCN102270878AImprove charge and discharge efficiencyIncrease charge and discharge rateBatteries circuit arrangementsElectric powerArea networkElectrical battery

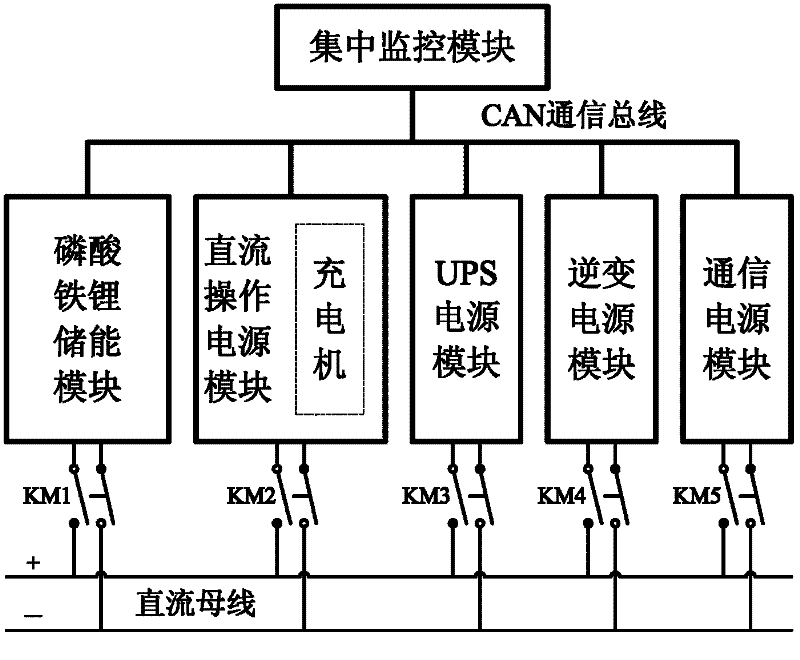

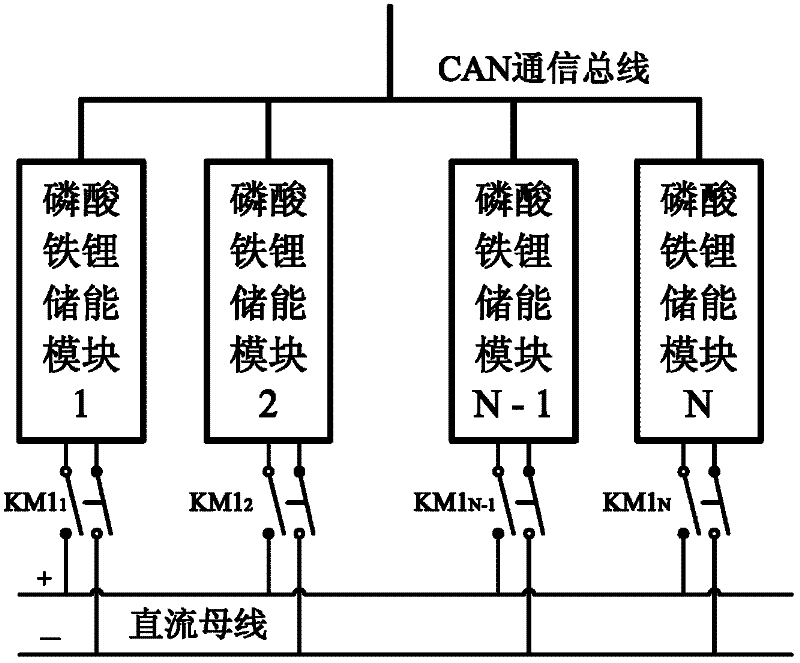

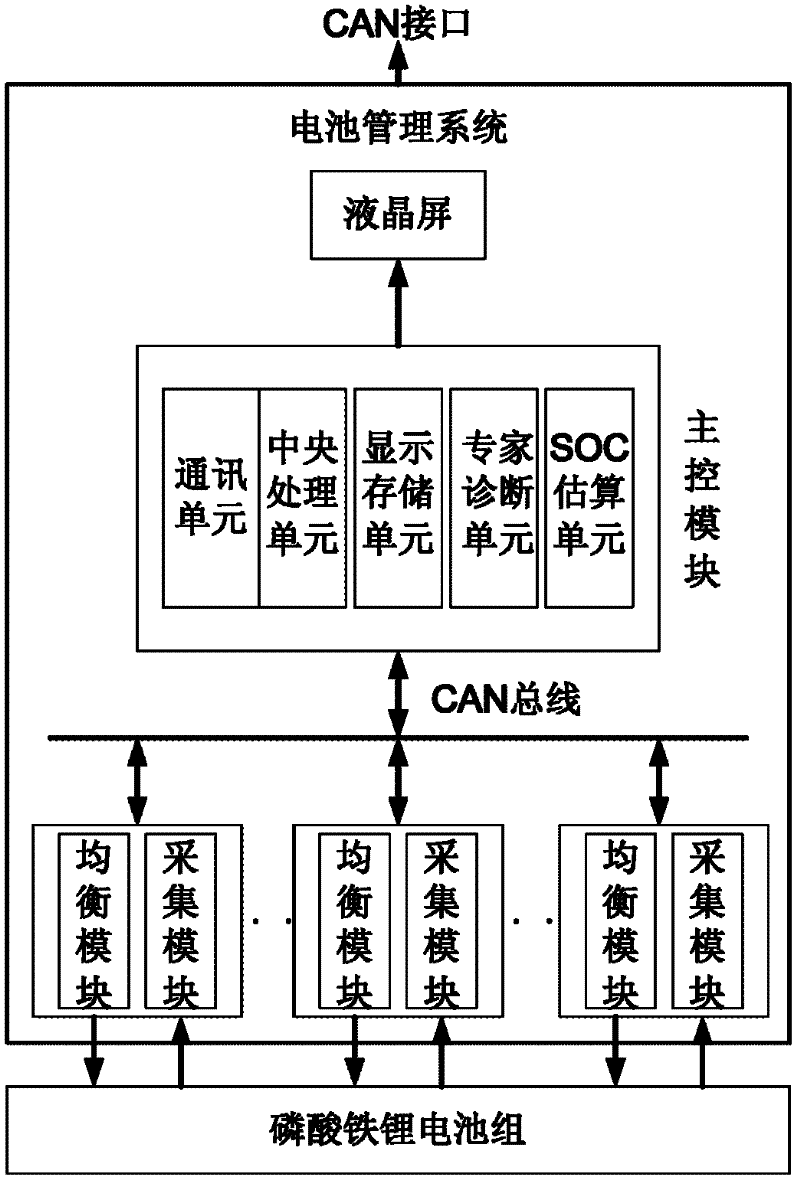

The invention provides a direct current power supply system for a transformer substation and a control method thereof. The direct current power supply system comprises a centralized monitoring module, a direct current operation power module, an uninterruptible power supply (UPS) power module, an inversion power supply module, a communication power supply module and a lithium iron phosphate energy storage module; each module of the direct current power supply system is connected to a common direct current bus through a relay switch, and redundancy backup of each module is realized in a mode that each module is connected in parallel to the common direct current bus through a multi-submodule; the modules of the direct current power supply system are connected with the centralized monitoring module through a controller area network (CAN) communication bus; the centralized monitoring module collects the running state information of each module and manages the modules of the system uniformly; and a battery is charged or discharged slightly through intelligent coordination control, and on-line automatic maintenance of the battery is realized. The invention has the advantages that: the system has high reliability, high shock load resistance, no maintenance, small floor area, energy conservation and environmental friendliness; and the service life of the battery is prolonged and the performance of the battery is improved by the intelligent coordination control method.

Owner:南瑞(武汉)电气设备与工程能效测评中

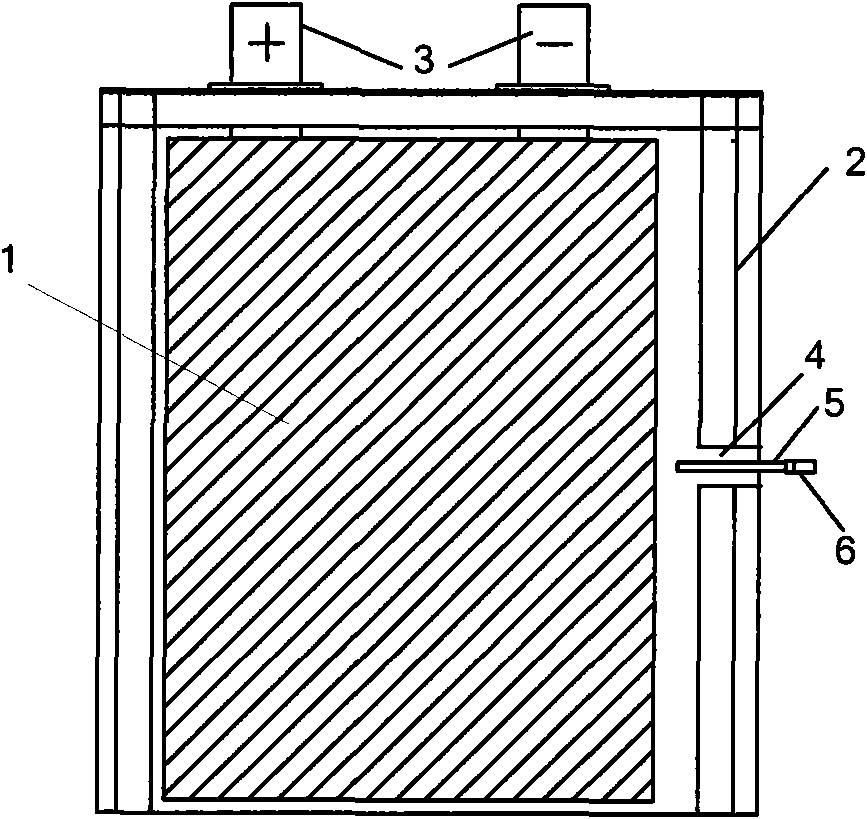

Maintainable lithium ion battery and maintenance method thereof

InactiveCN101552356AEasy maintenanceImprove performanceElectrolyte/reactants regenerationVent arrangementsEngineeringLithium-ion battery

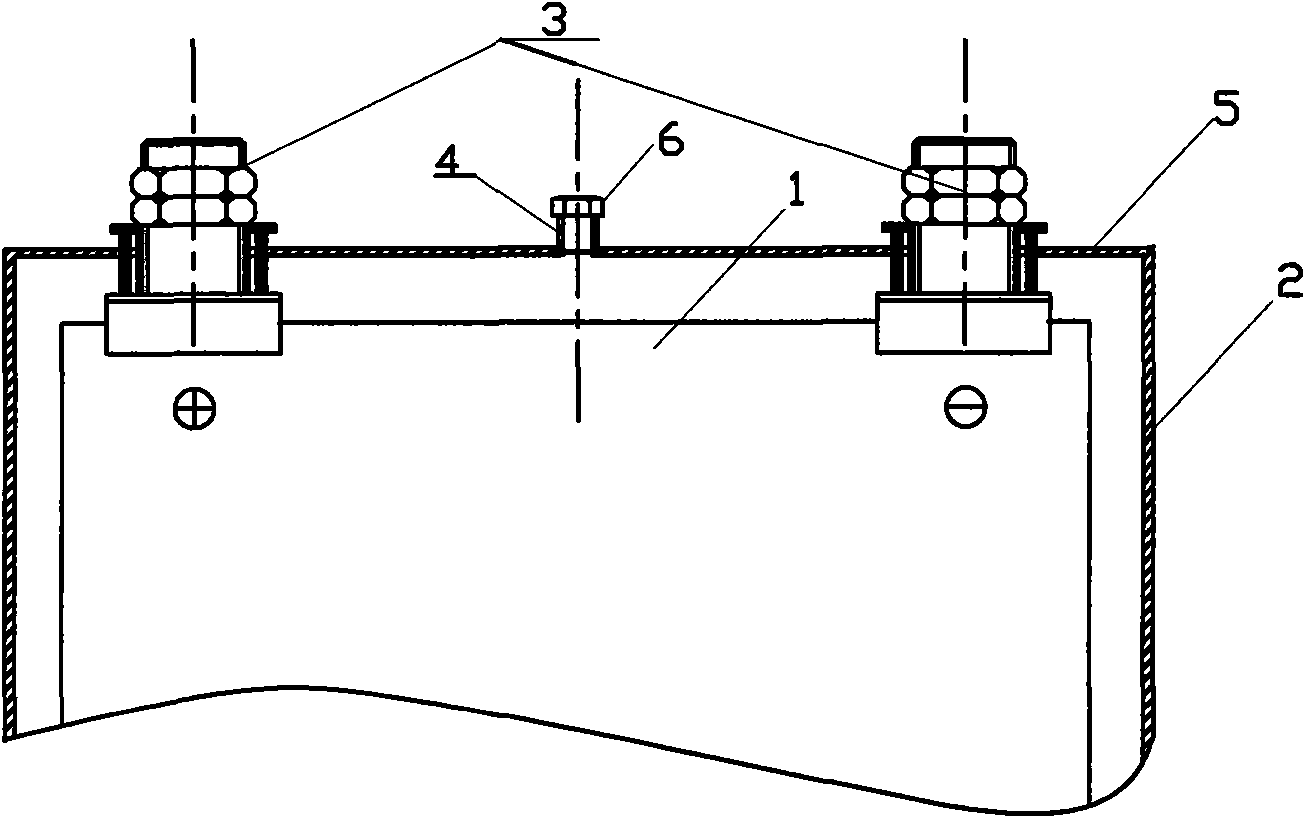

The invention relates to a maintainable lithium ion battery, which comprises a battery cell, a battery shell body, a battery anode post and a battery cathode post. The battery cell is arranged in the battery shell body and the battery anode post and the battery cathode post are arranged on the battery shell body on which at least one channel that is used for communicating the inside of the batter shell body and the outside is arranged. An openable sealing device is arranged at an exit of the channel communicated with the outside. Simultaneously, the invention also provides a maintenance method of the maintainable lithium ion battery, which includes such steps as removing gas in the battery through the channel, adding electrolyte, vacuumization and the like. The invention can effectively improve the performance of the lithium ion battery, thus more effectively utilizing the lithium ion battery and being beneficial to saving cost.

Owner:林道勇 +1

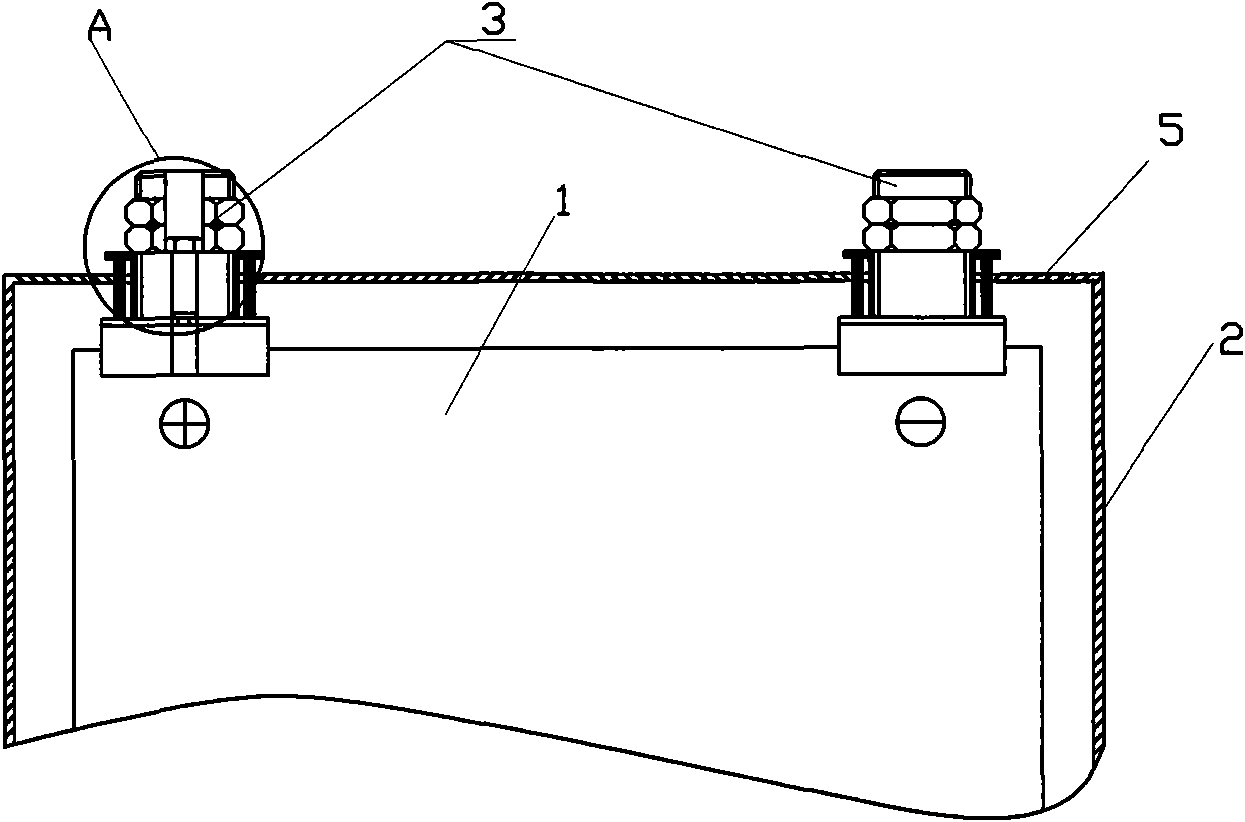

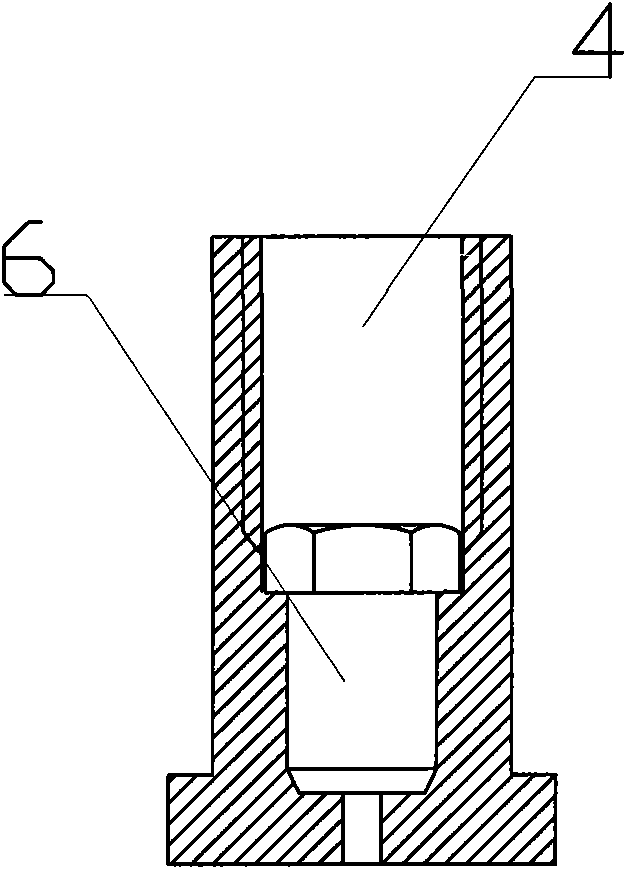

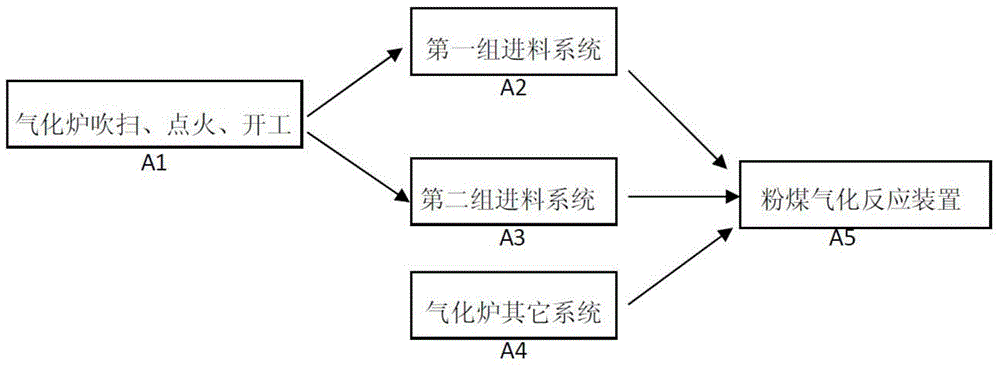

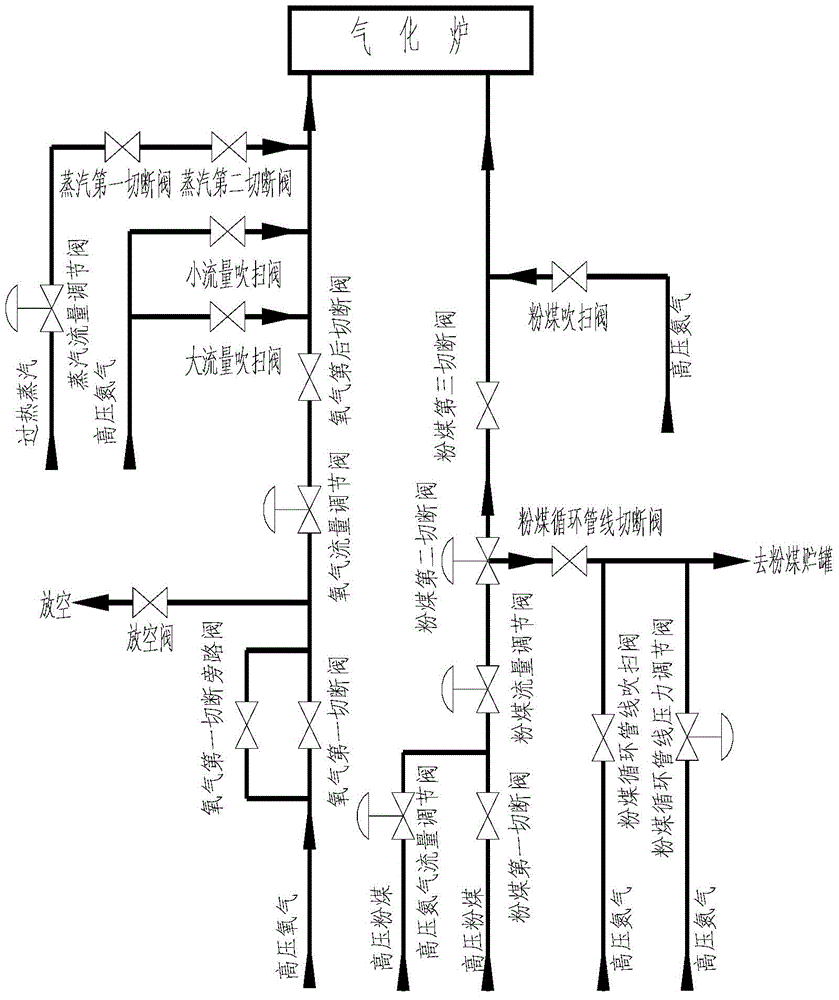

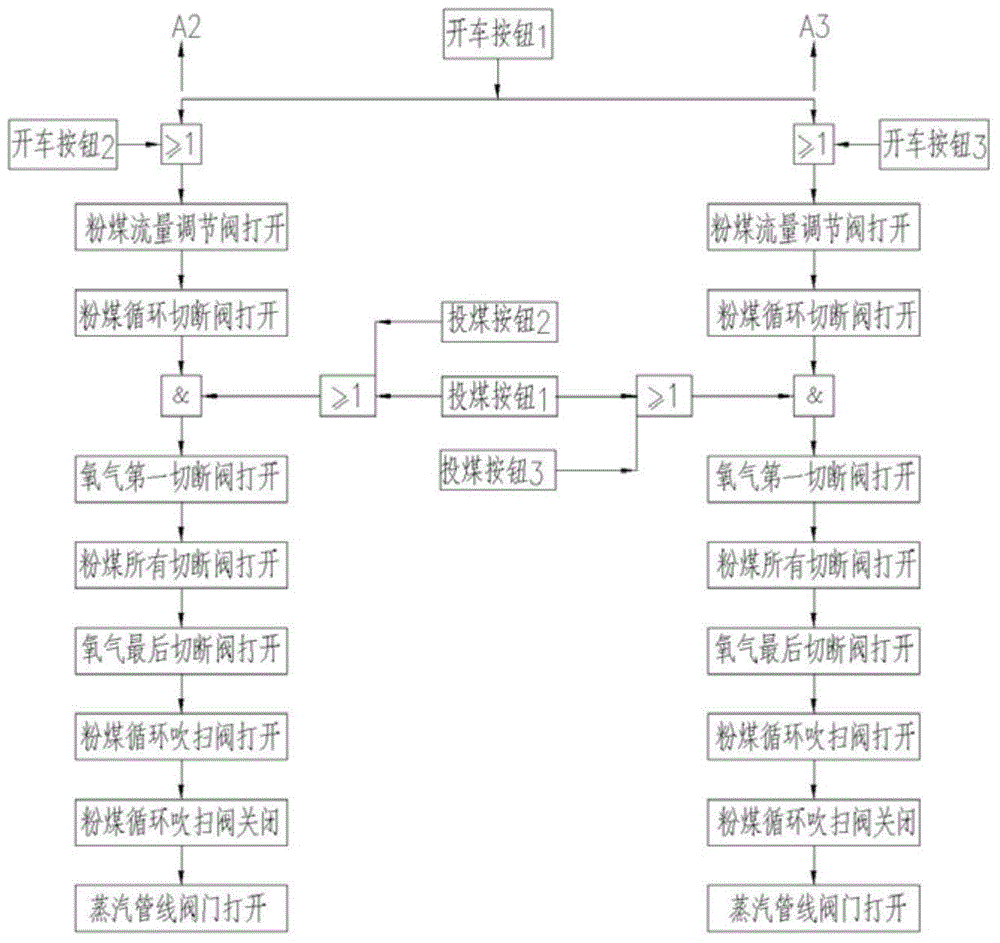

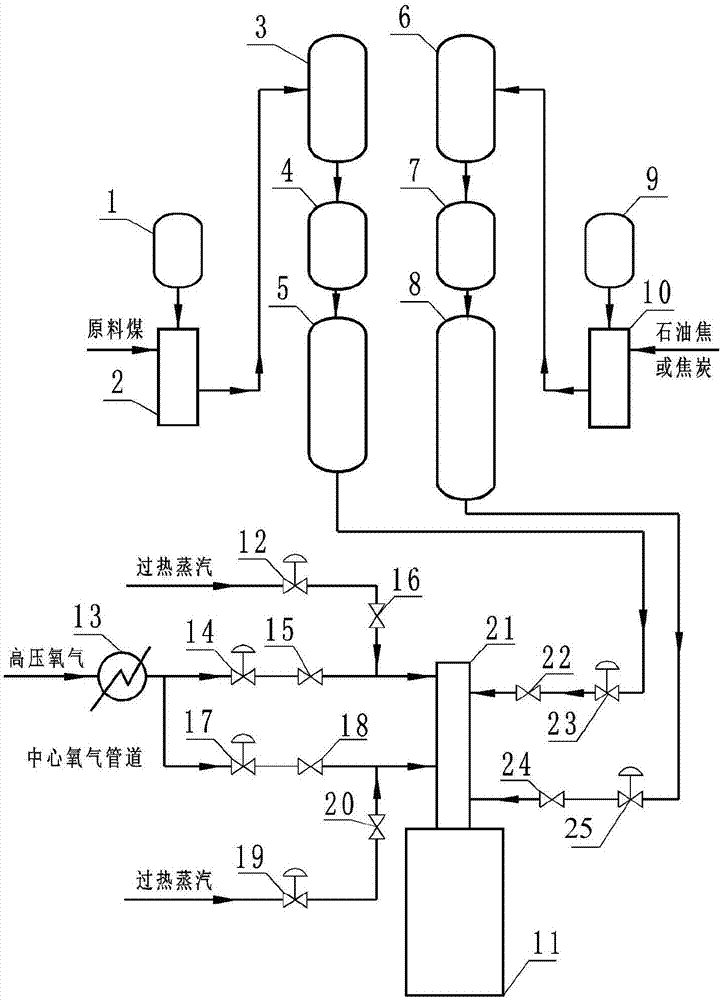

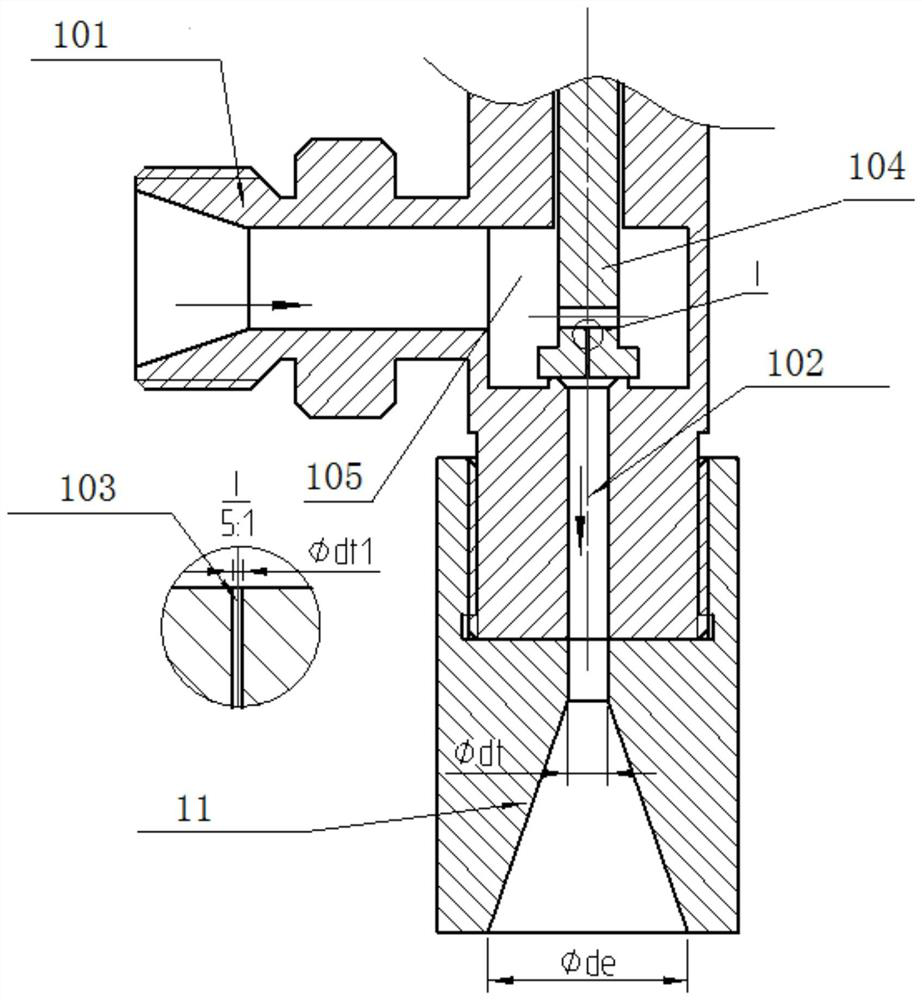

Control method of running of pulverized coal burner of pulverized coal pressurization gasification reaction device

ActiveCN104974798AHigh degree of automationRealize online maintenanceCombined combustion mitigationGranular/pulverulent flues gasificationCoal pipelineProcess engineering

The invention provides a control method of running of a pulverized coal burner of a pulverized coal pressurization gasification reaction device; the control method is used for feeding grouping control of a plurality of oxygen pipelines and a plurality of pulverized coal pipelines of the pulverized coal burner of the pulverized coal pressurization burner gasification reaction device, and comprises starting, running, stopping and purging of the pulverized coal burner. The control method can achieve simultaneous feeding or grouping feeding of the plurality of oxygen pipelines and the plurality of pulverized coal pipelines of the pulverized coal burner, can also achieve simultaneous stopping or grouping stopping of the plurality of oxygen pipelines and the plurality of pulverized coal pipelines of the pulverized coal burner, can achieve on-line maintenance of the oxygen pipelines and the pulverized coal pipelines, and ensures long-period, continuous and stable safe running production of the pulverized coal pressurization gasification device. A gasifier emergency safety system keeps the device running, and allows the device to be safe to start, stop and gasifier purging.

Owner:CHANGZHENG ENG

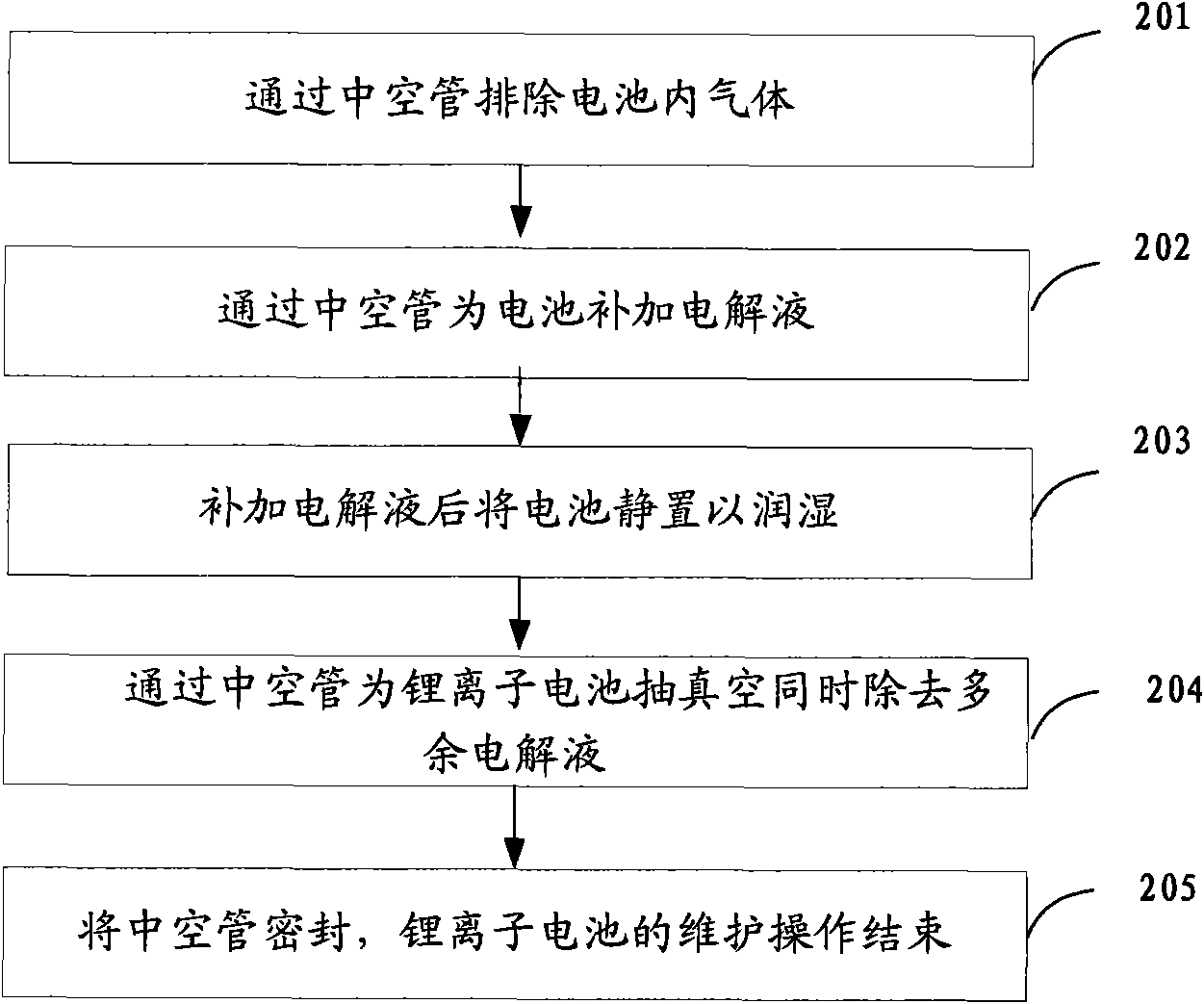

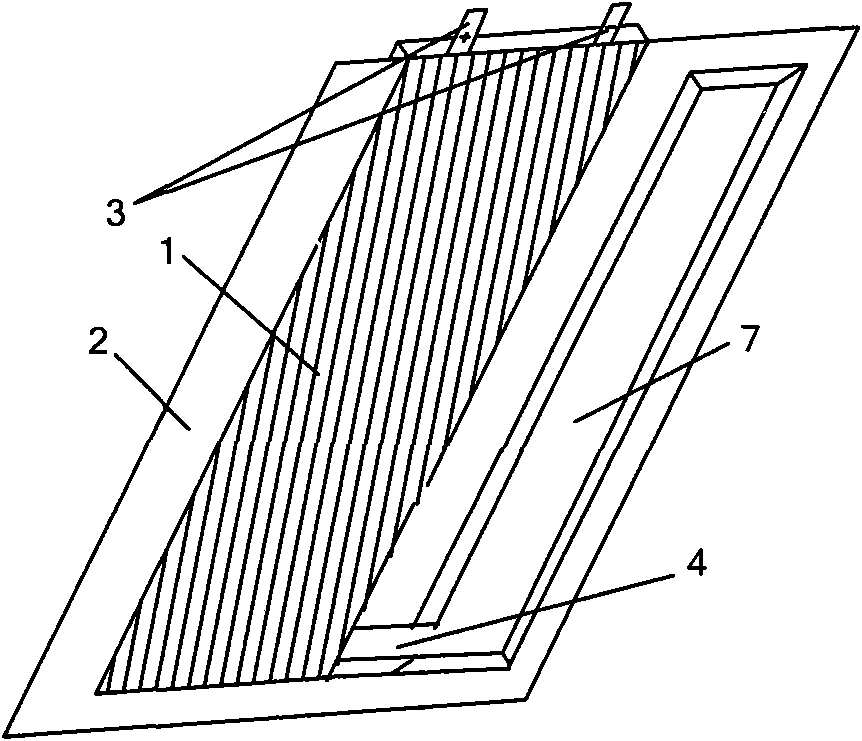

Maintainable lithium-ion battery and maintenance method thereof

InactiveCN101640283AEasy maintenanceEfficient use ofCell component detailsSecondary cells servicing/maintenanceLithium-ion batteryEmbedded system

The invention relates to a maintainable lithium-ion battery and a maintenance method thereof. The maintainable lithium-ion battery comprises a battery cell and a packaging bag, wherein the battery cell is sealed in the packaging bag, a positive and negative connector are left at a side edge of the packaging bag, a channel is also arranged on the lateral side of the packaging bag, and the opening which is positioned at one end of the external side of the packaging bag is sealed in an open manner. The maintenance method of the lithium-ion battery is as follows: discharging the air in the batteryby the channel, adding electrolyte for the battery, vacuuming the battery and the like. The maintainable lithium-ion battery and the maintenance method provided by the invention can effectively improve the performance of lithium-ion batteries and are beneficial for making full use of the lithium-ion battery; in addition, the operation is simple, and the cost is saved.

Owner:林道勇 +1

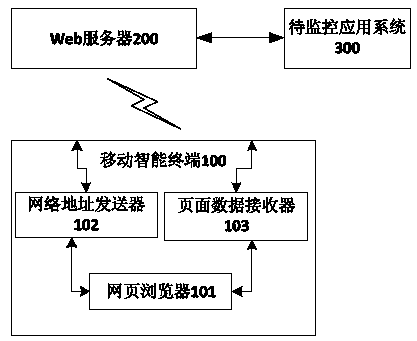

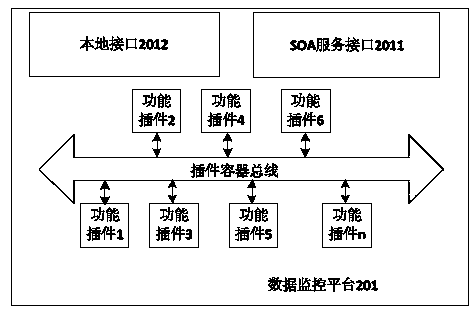

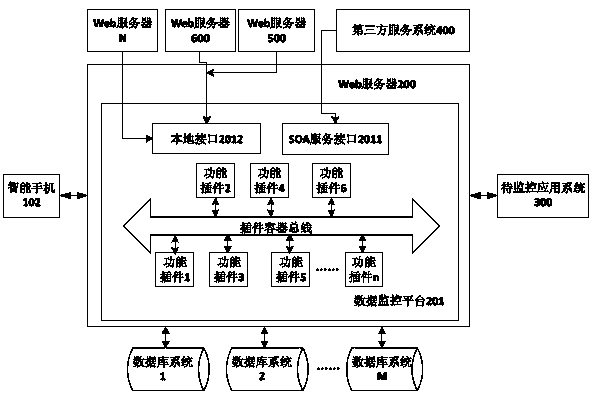

Mobile monitoring system on basis of Web server

The invention discloses a mobile monitoring system on the basis of a Web server, which comprises a mobile intelligent terminal, the Web server and an application system to be monitored, wherein the mobile intelligent terminal is provided with a webpage browser supporting the HTML5 (Hypertext Markup Language) technical specification; and the Web server is on the basis of a system architecture facing a service. The webpage browser carries out data connection with the Web server by the internet according to a user request; the mobile intelligent terminal starts the webpage browser to send out an access request and a control command to the Web server so as to monitor the application system to be monitored; and after the Web server receives the access request, the control command sent out by the mobile intelligent terminal is received in real time, monitoring data of the application system to be monitored is acquired in real time and the monitoring data is fed back to the mobile intelligent terminal. According to the mobile monitoring system on the basis of the Web server, which is provided by the invention, limitation of different operation systems is avoided, online maintenance of the data monitoring system is implemented, and maintenance efficiency and the overall performance of the monitoring system are improved.

Owner:GCI SCI & TECH

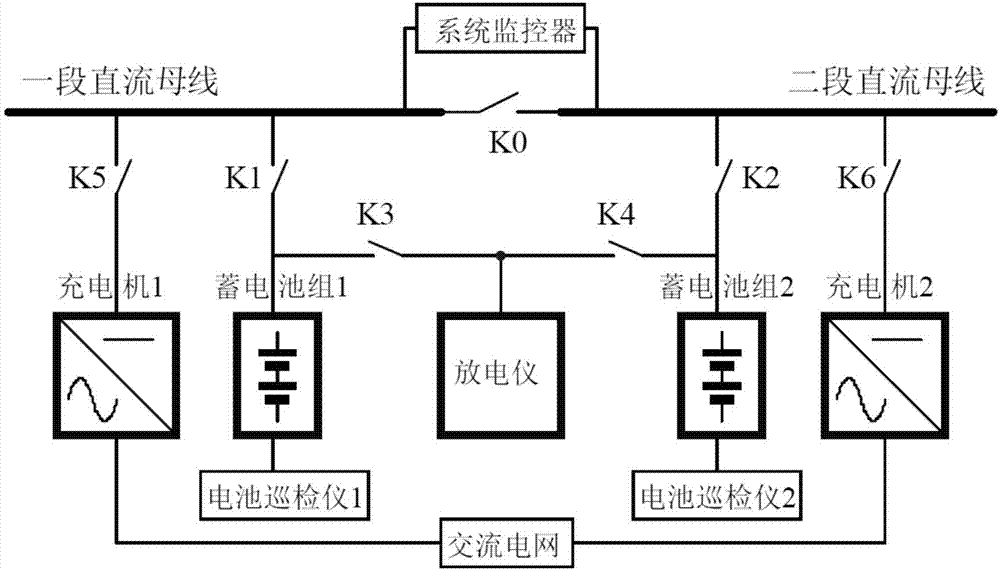

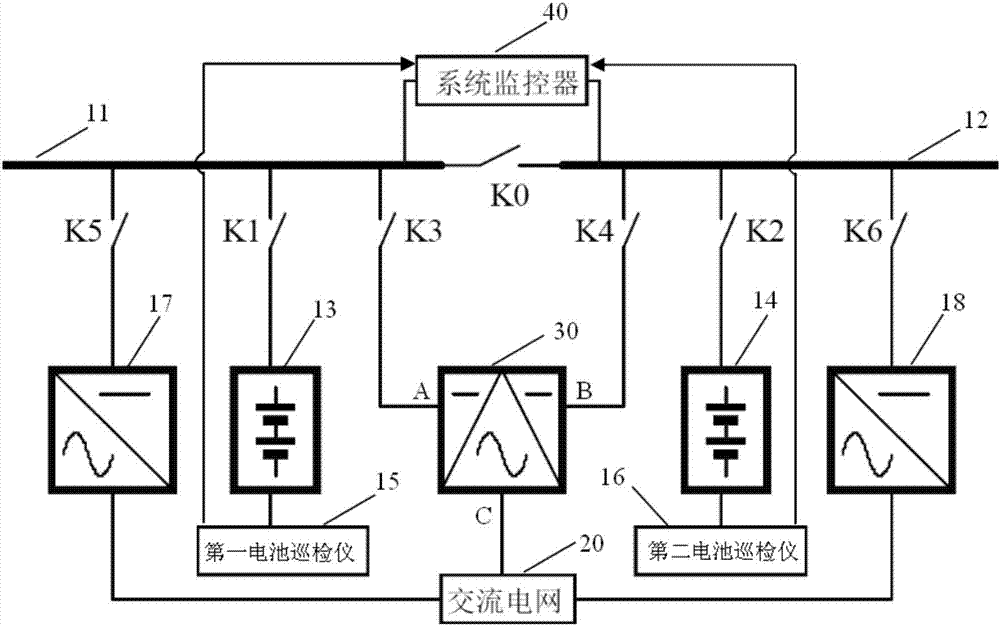

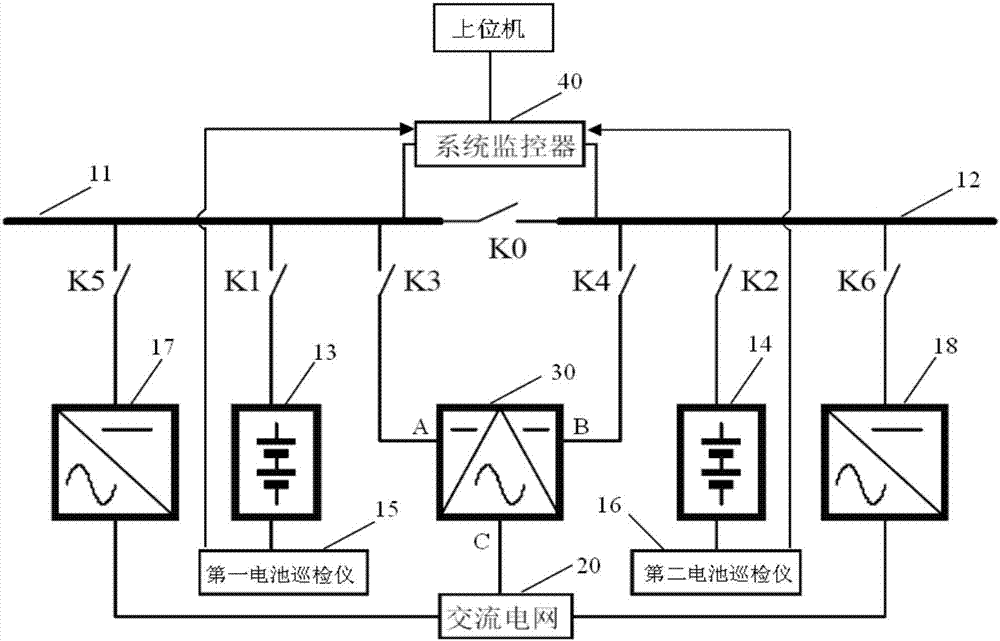

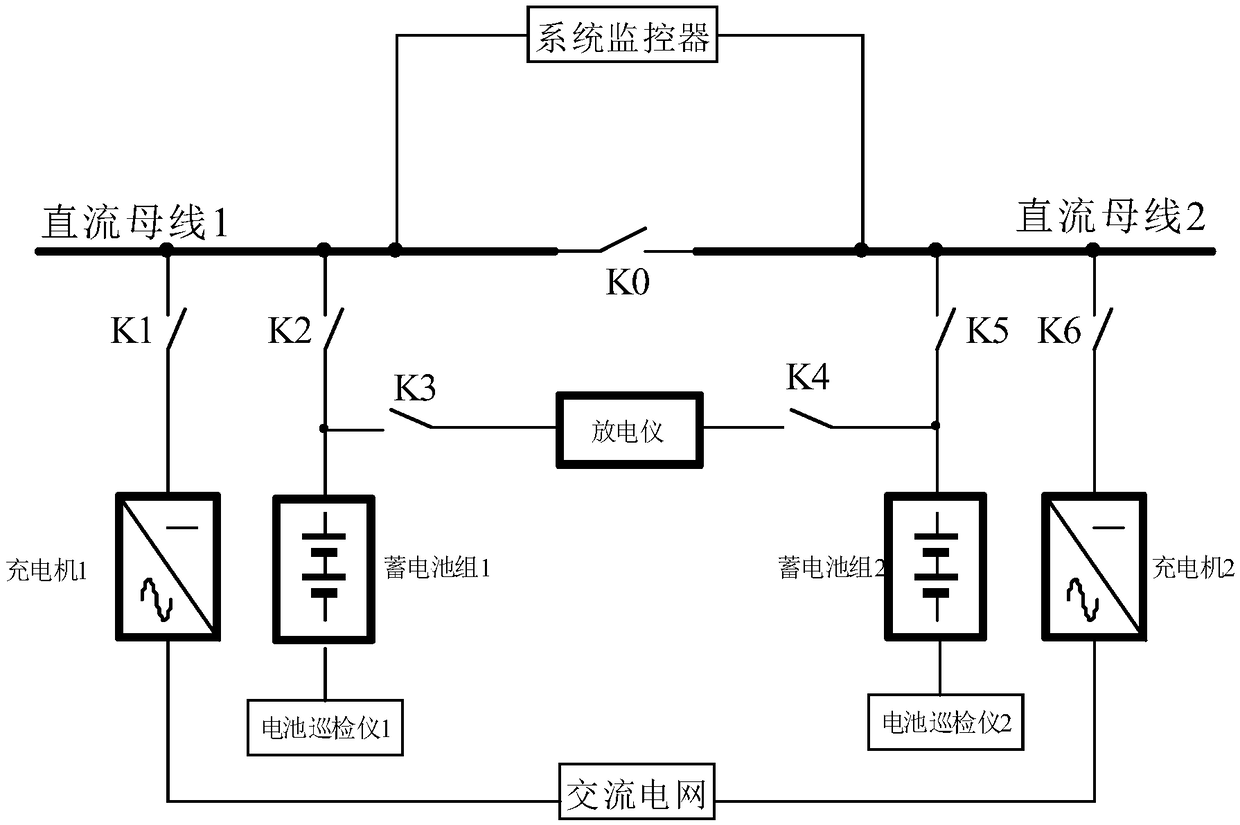

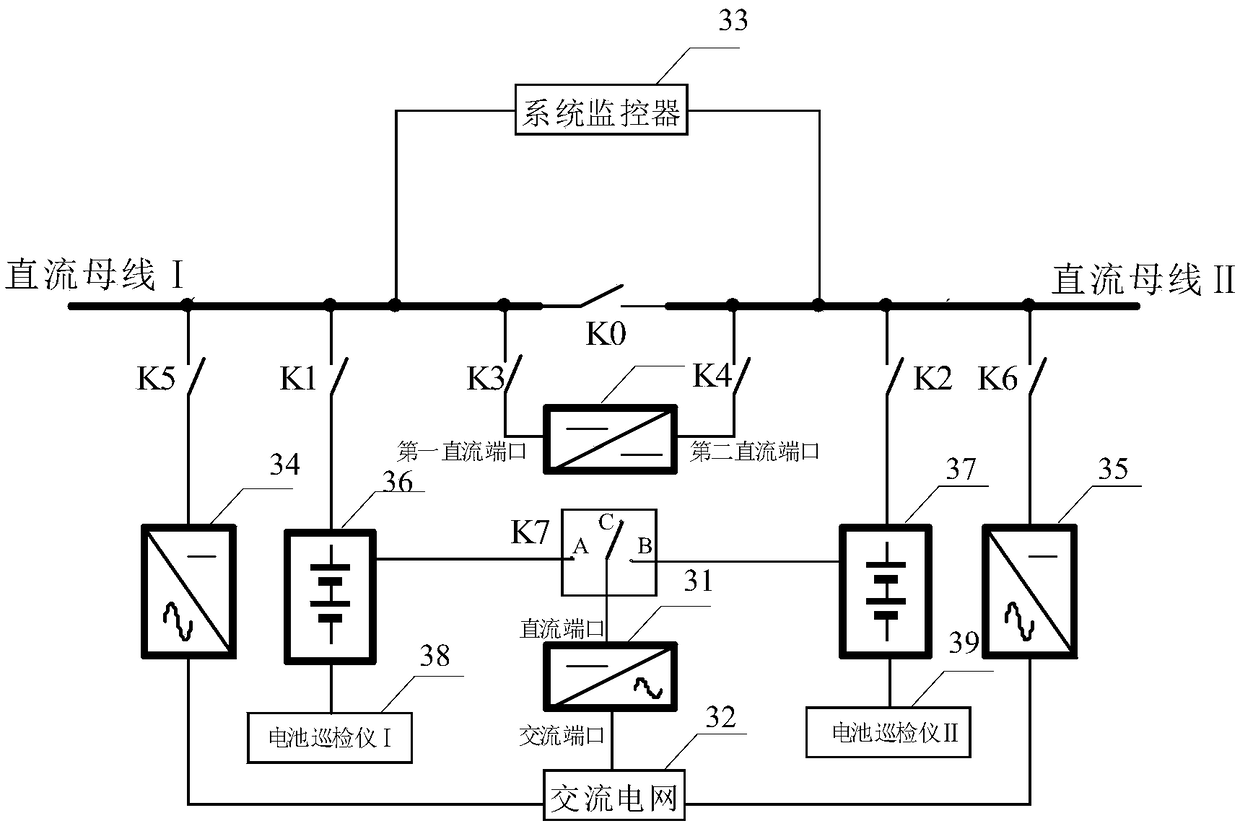

Storage battery online maintenance system based on three-port charging and discharging machine

ActiveCN107196366ARealize online maintenanceImprove reliabilityCharging managementElectric powerAutomotive engineeringSystem monitor

The invention relates to a storage battery online maintenance system based on a three-port charging and discharging machine, which comprises a first battery inspection instrument, a second battery inspection instrument, an alternating current network, the three-port charging and discharging machine and a system monitor, wherein the first battery inspection instrument is connected with a first storage battery pack; the second battery inspection instrument is connected with a second storage battery pack; the alternating current network provides an alternating current for a direct current power supply system; the three-port charging and discharging machine is respectively connected with the first storage battery pack, the second storage battery pack and the alternating current network, provides conditions for online maintenance of the first storage battery pack or the second storage battery pack and outputs discharge capacity of the first storage battery pack or the second storage battery pack to the alternating current network; and when the first storage battery pack or the second storage battery pack meets the online maintenance conditions, the system monitor outputs a maintenance control instruction according to a preset rule to start the three-port charging and discharging machine to carry out online maintenance on the first storage battery pack or the second storage battery pack. According to the scheme, storage batteries can be simply, reliably and automatically maintained on line, and the storage battery online maintenance system is low in cost, flexible and efficient.

Owner:SHENZHEN AUTO ELECTRIC POWER PLANT

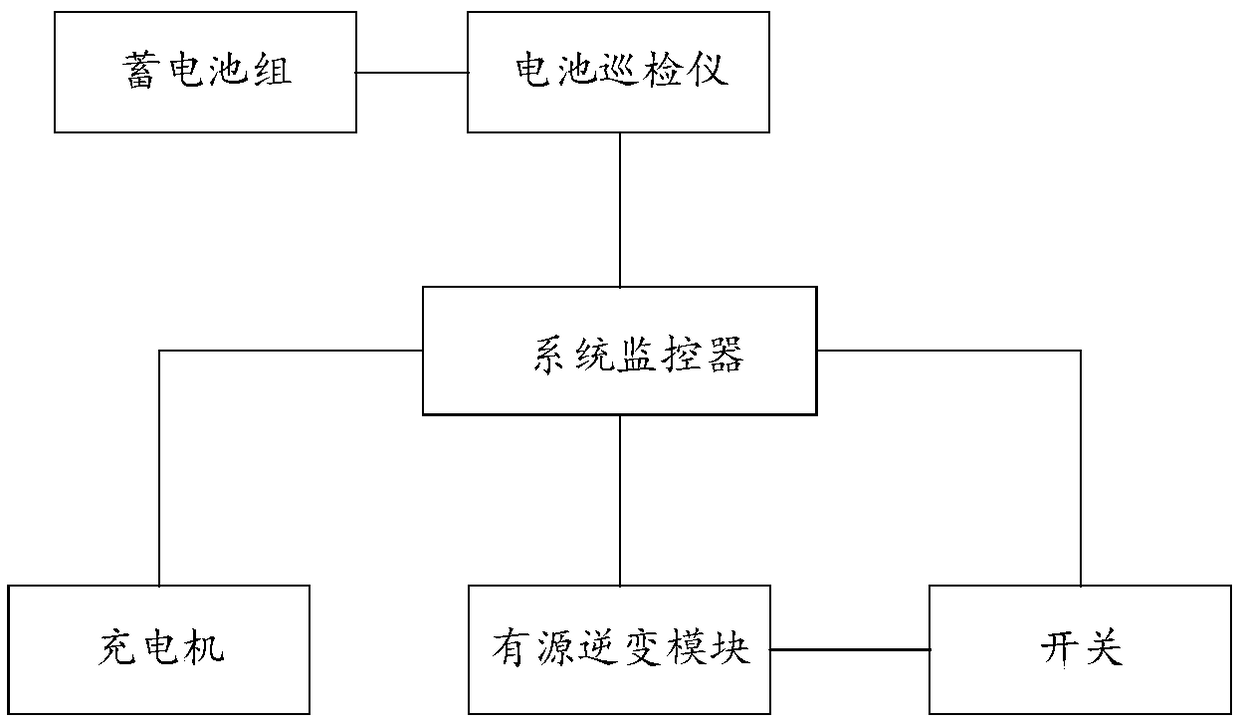

Battery pack online discharge maintenance device and method

InactiveCN108879879ARealize online checking dischargeRealize online maintenanceElectric powerLoad supplying circuitsElectrical batteryTerminal voltage

The invention provides a battery pack online discharge maintenance device and a method, and relates to the technical field of the DC power supply. The device comprises a system monitor, a charger, a battery inspection instrument, a switch and a active inverter module. The switch is connected to the DC port of the active inverter module and the battery pack respectively. The AC port of the active inverter module is connected to an AC network. When the battery pack meets the online discharge maintenance condition, the system monitor issues an instruction to discharge and maintain the battery pack; when receiving the instruction, the charger controls the output voltage to be lower than the terminal voltage of the battery pack, the switch is closed, and the active inverter module is turned onto discharge the battery pack to the AC network and the DC bus. Automatic online maintenance for the battery pack is realized, the cost is greatly reduced. At the same time, the discharge energy whenthe battery is discharged is fed back to the AC network, so that energy conservation and environment protection are achieved.

Owner:GUANGDONG POWER GRID CO LTD +1

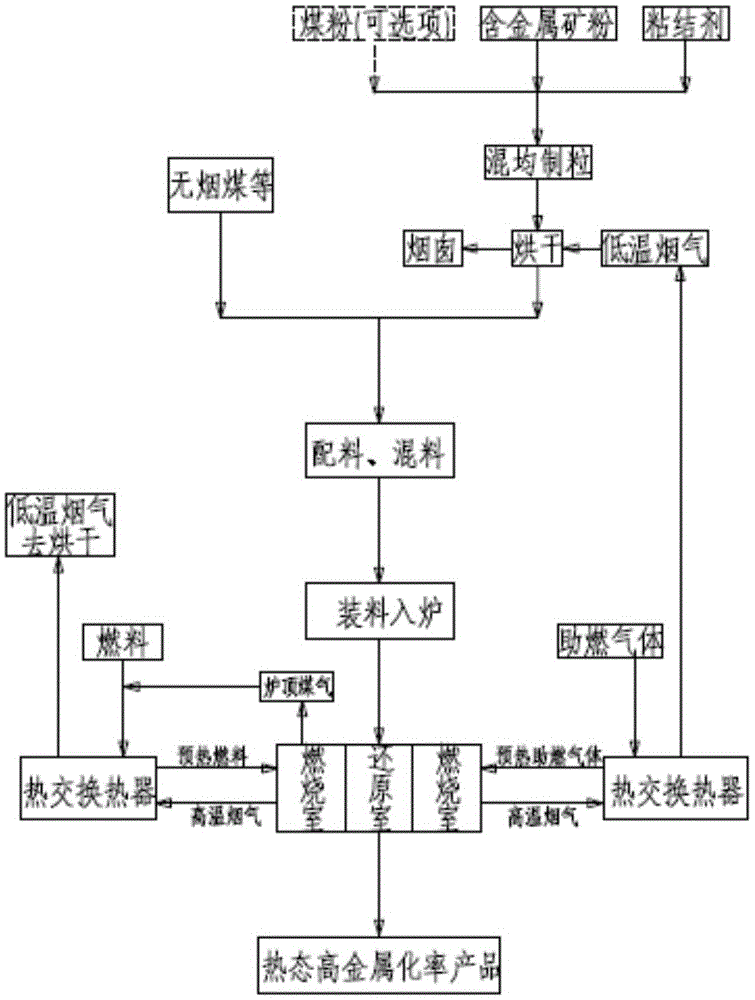

QDF (quiescent direct furnace) direct reduction technology

InactiveCN104630404AAchieve the desired effectReduced strength requirementsFluidised-bed furnacesCombustion chamberProduct gas

The invention relates to a QDF (quiescent direct furnace) direct reduction technology which comprises the following steps: uniformly mixing a metal-containing raw material and reducing agent powder, and putting into each reducing chamber, wherein in a reducing process, the reducing chambers and the reduced material are all kept in a stationary state; uniformly heating the materials in the reducing chambers by use of the heat generated by the combustion of the fuel in a combustion chamber and a combustion-supporting gas so as to perform a reduction reaction between the metal-containing raw material and the reducing agent, wherein each reducing chamber is a narrow long one-section reactor. According to the technology provided by the invention, the reducing chambers and the reduced material are all in a stationary state, the requirement on the strength of the granular raw material is reduced, and the production efficiency of a granulation process is improved; and the reducing time can be prolonged, and the metallization ratio of the reduction product is improved. The reducing chamber is not provided with a preheating area or a cooling area, the temperature is uniform, the atmosphere is uniform and consistent, and the overall quality of the reduction product is improved. The direct reduction technology has remarkable advantages of wide application range of raw materials, uniform temperature field, easy control on reduction process, high product metallization ratio, high yield and the like.

Owner:WISDRI ENG & RES INC LTD

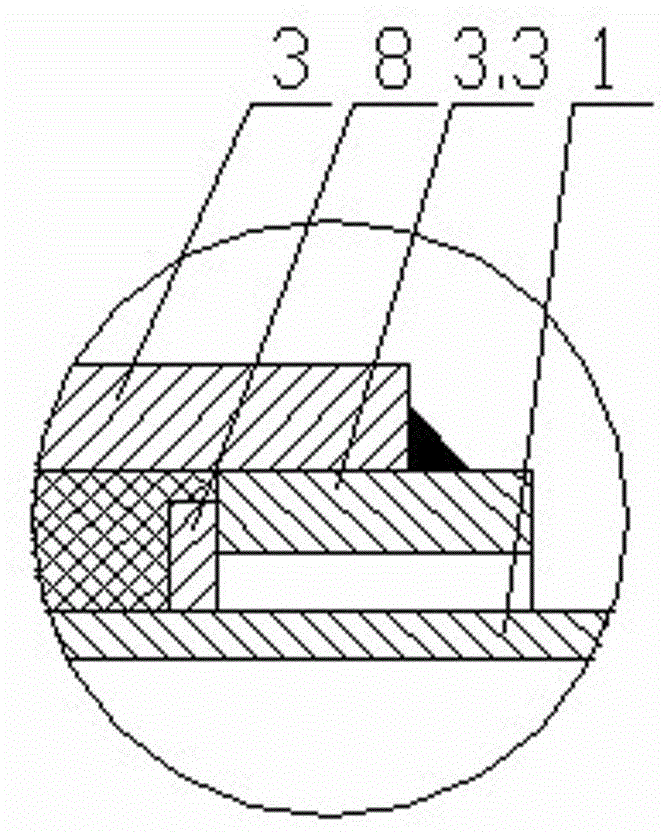

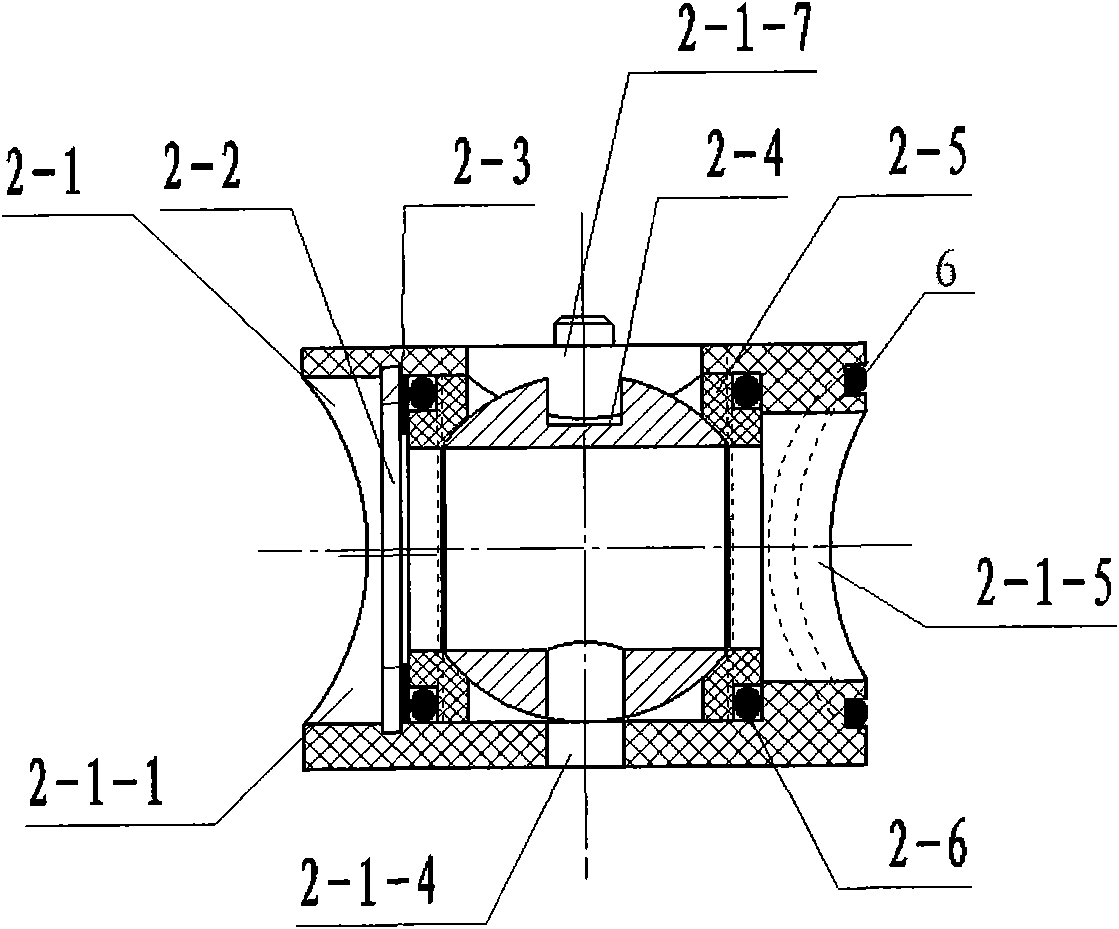

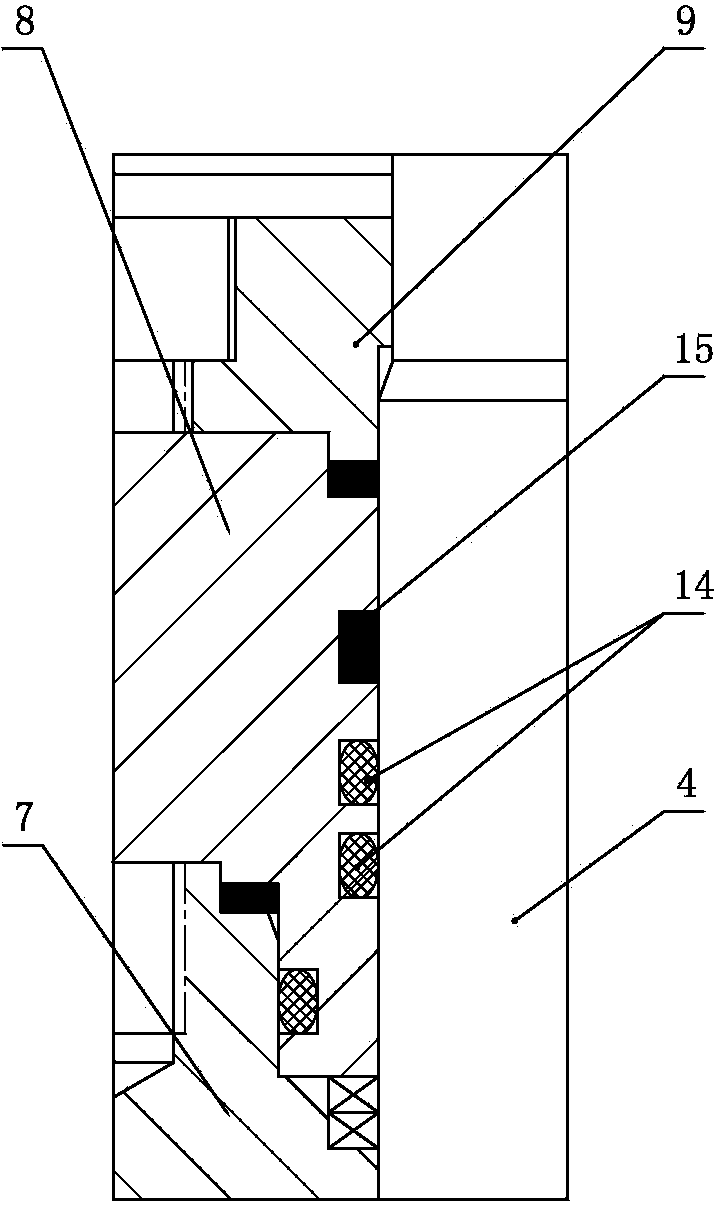

Online maintainable axial flow check valve

ActiveCN106838386ARemarkable resultsRealize online maintenanceCheck valvesValve members for absorbing fluid energyCheck valve

The invention discloses an online maintainable axial flow check valve which is characterized in that a top opening is formed in the top of a valve body, a valve spool component is placed into the valve body from the top opening, a valve cover is arranged at the top opening of the valve body to seal the valve body, a valve spool of the valve spool component is suspended on a valve spool support by a supporting rib, and the valve spool support is fixedly clamped at the top opening of the valve body by the aid of a valve spool fixing clamp ring. The online maintainable axial flow check valve is low in flow resistance and noise, and can realize online maintenance.

Owner:HEFEI GENERAL MACHINERY RES INST

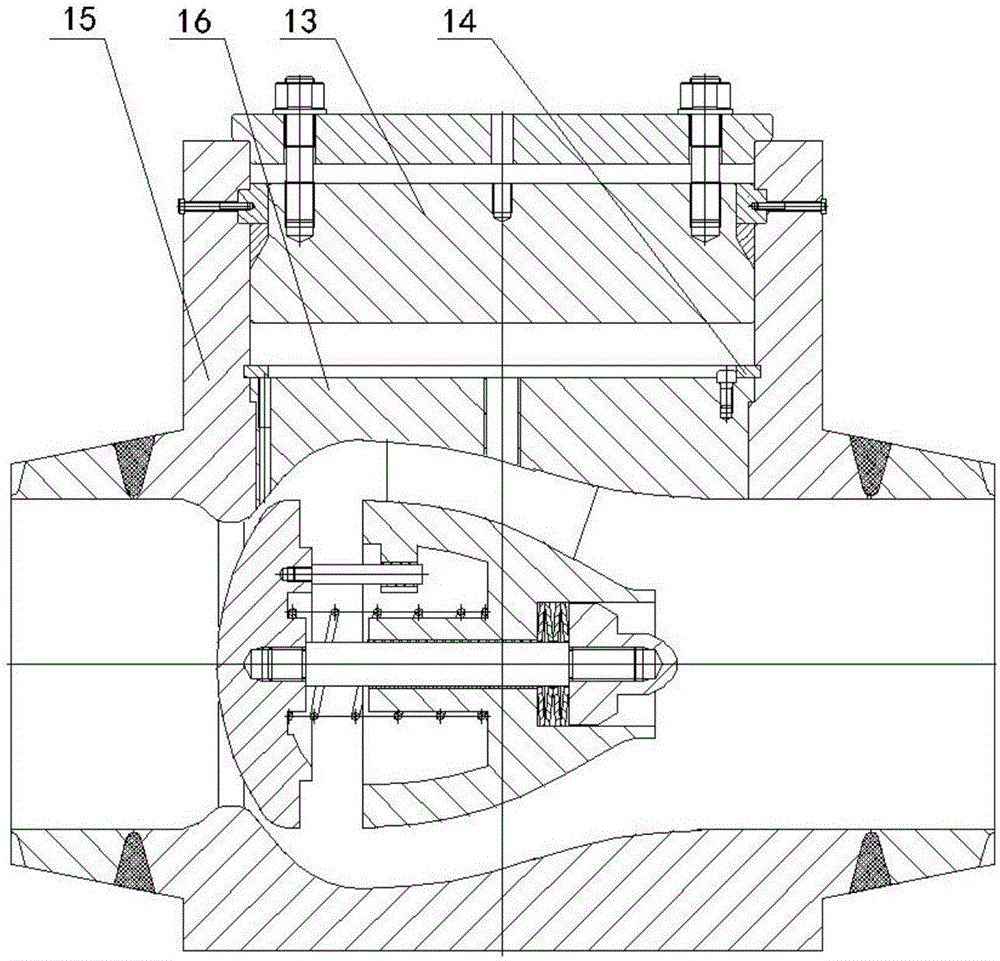

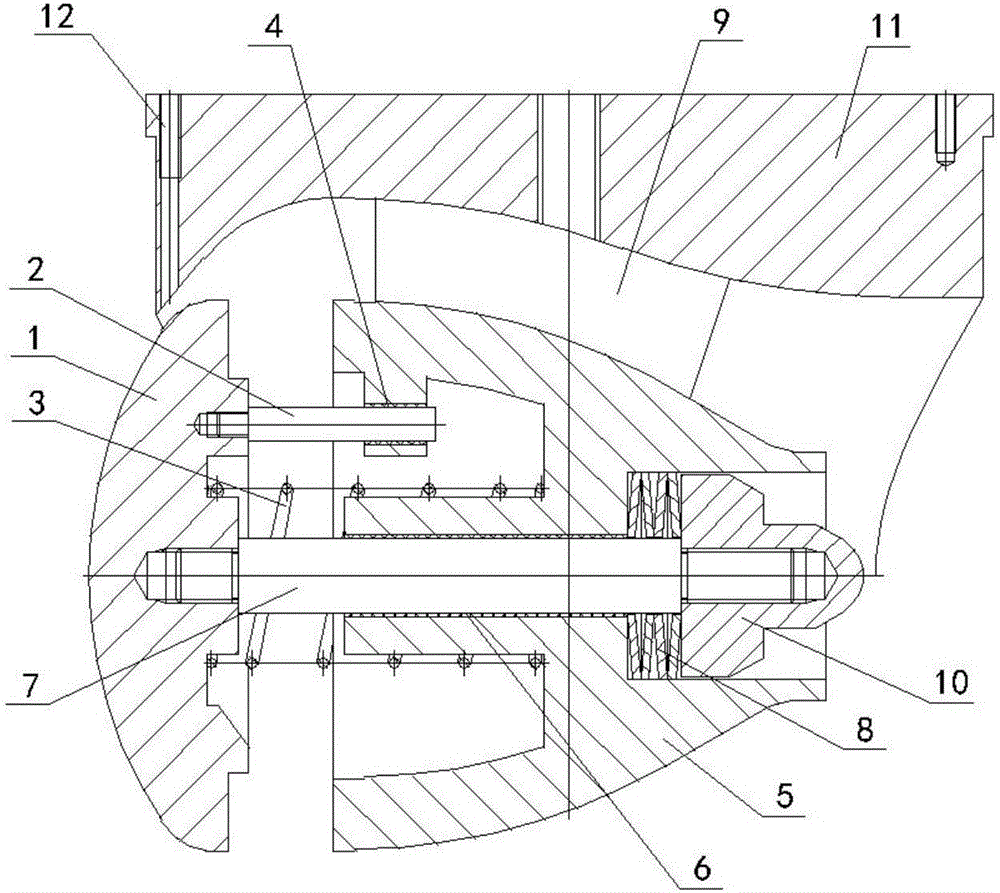

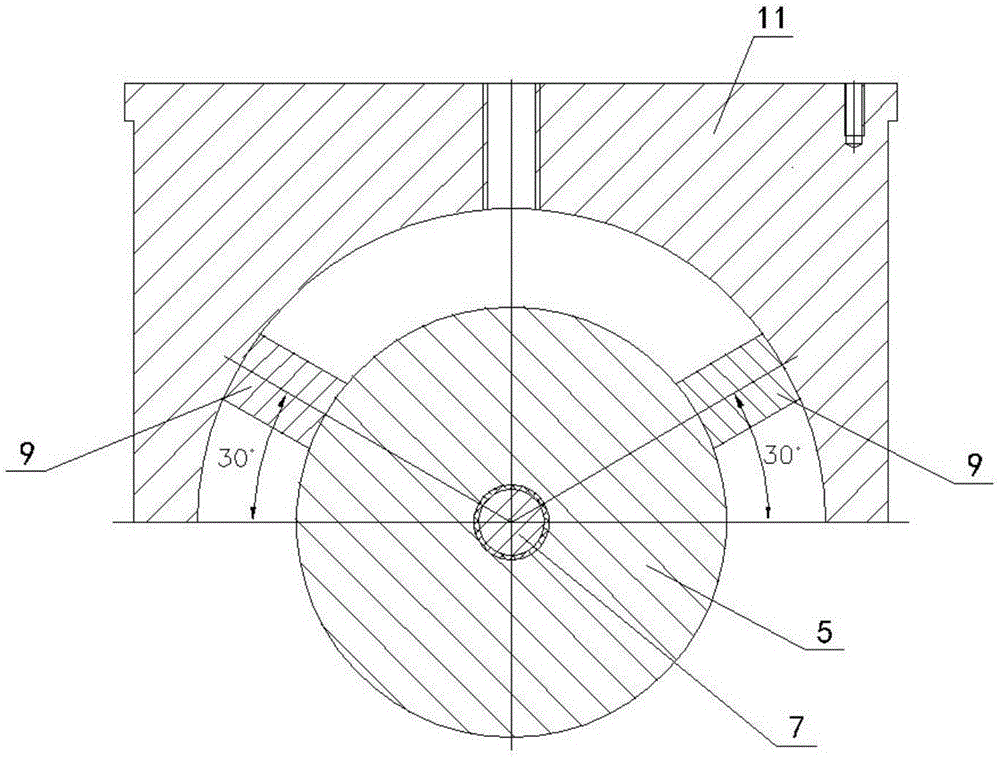

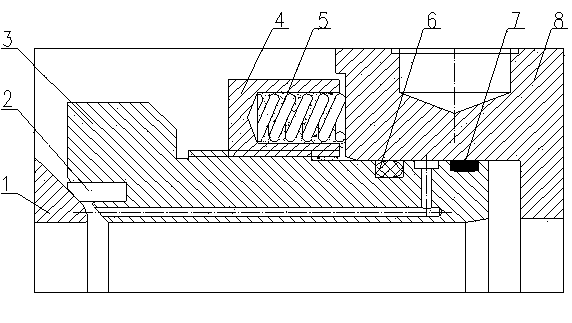

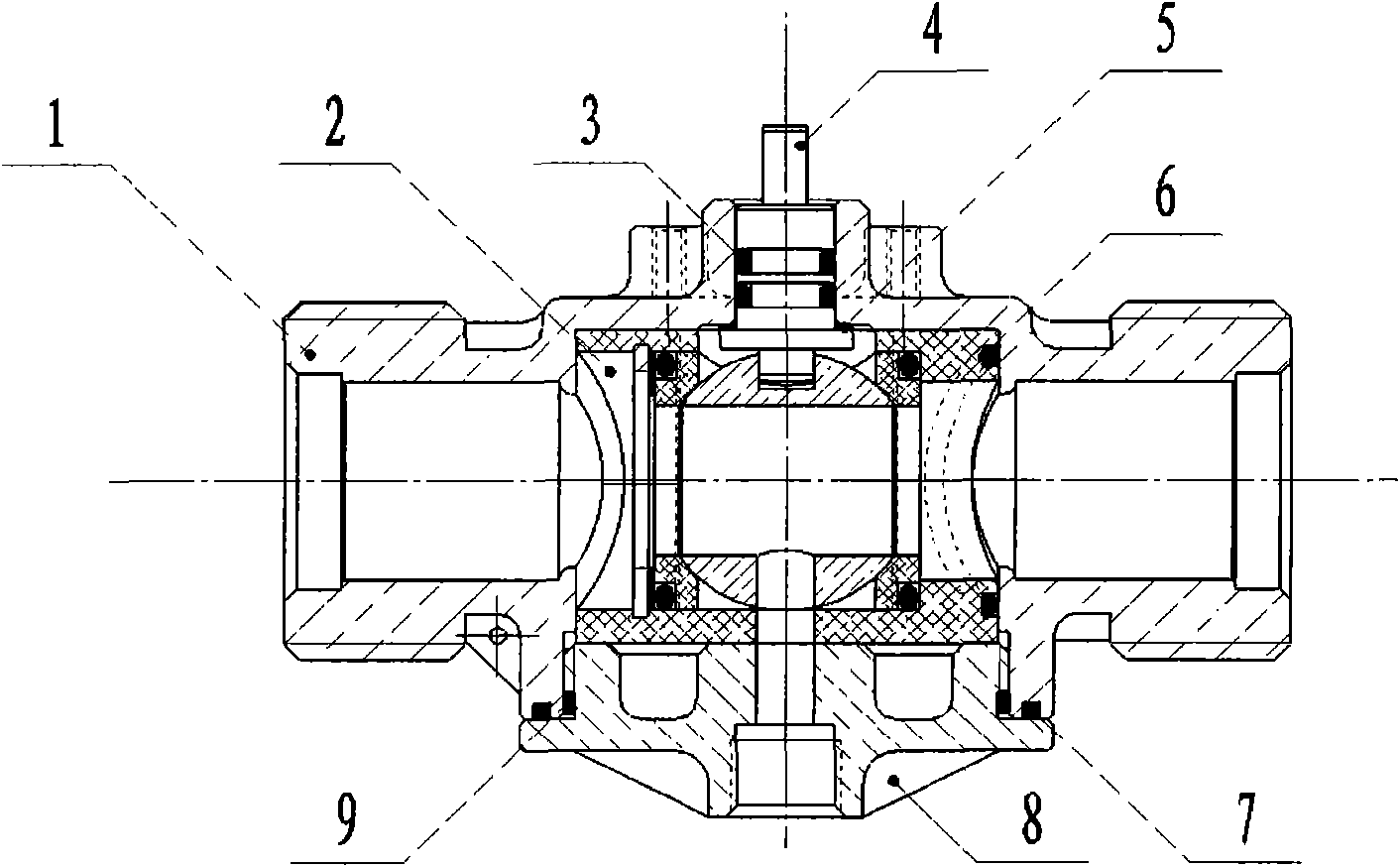

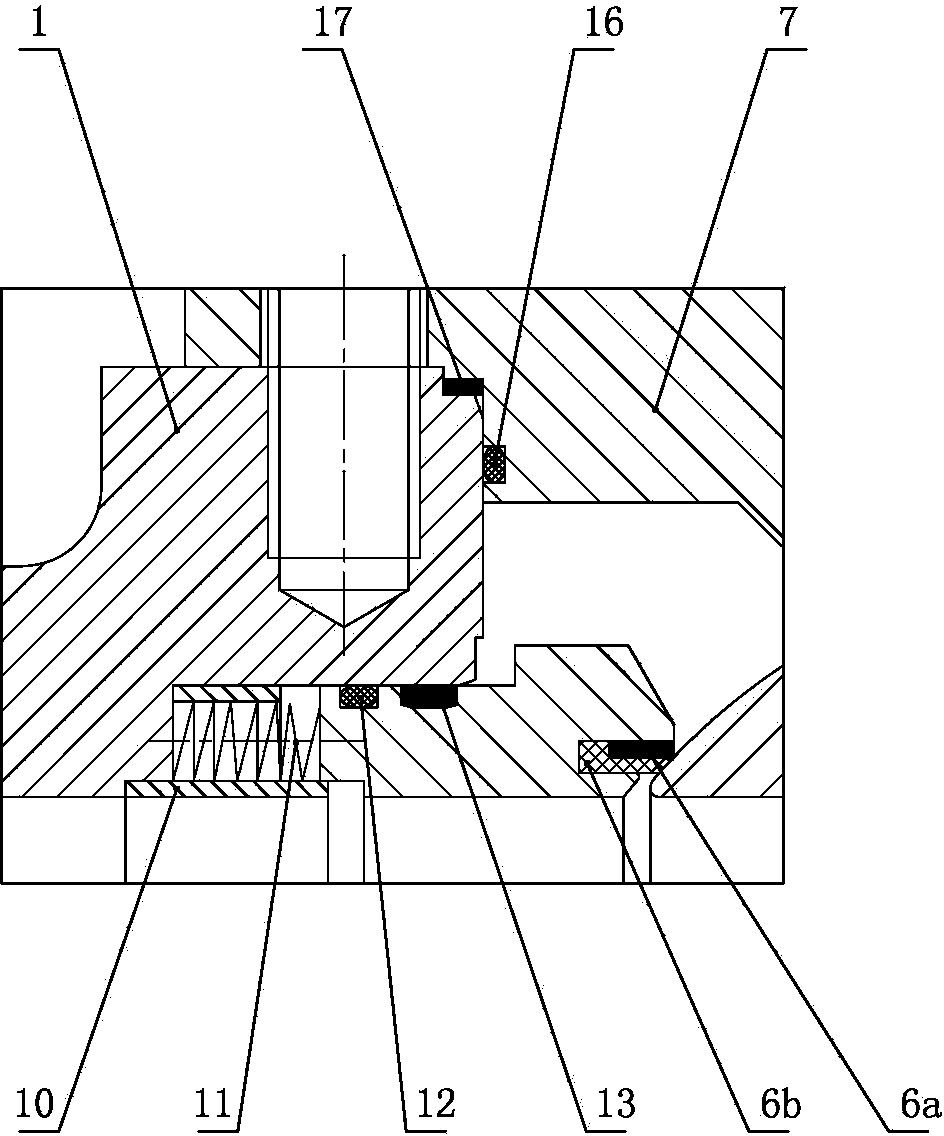

Large-caliber upwardly-installed fixed ball valve

The invention relates to a large-caliber upwardly-installed fixed ball valve. The large-caliber upwardly-installed fixed ball valve comprises a valve ball, a valve seat and a valve body, wherein the valve seat is arranged between the valve ball and the valve body. The large-caliber upwardly-installed fixed ball valve is characterized in that the valve seat comprises a fixing device body and a spring retainer and is of a split structure, a shoulder is arranged on the outer circumference of the fixing device body, outer threads are processed on the outer circumference of the tail portion of the shoulder, inner threads are processed inside the spring retainer, and the fixing device body and the spring retainer are connected though the threads in a matching and screwing mode. The large-caliber upwardly-installed fixed ball valve is simple in structure and low in production cost, the valve seat is of the split structure so that the fixed ball valve can be upwardly installed, then online maintenance of the fixed ball valve can be achieved, the time of work stopping and production stopping is shortened, and the economic loss is reduced.

Owner:KUSN WEISA VALVE

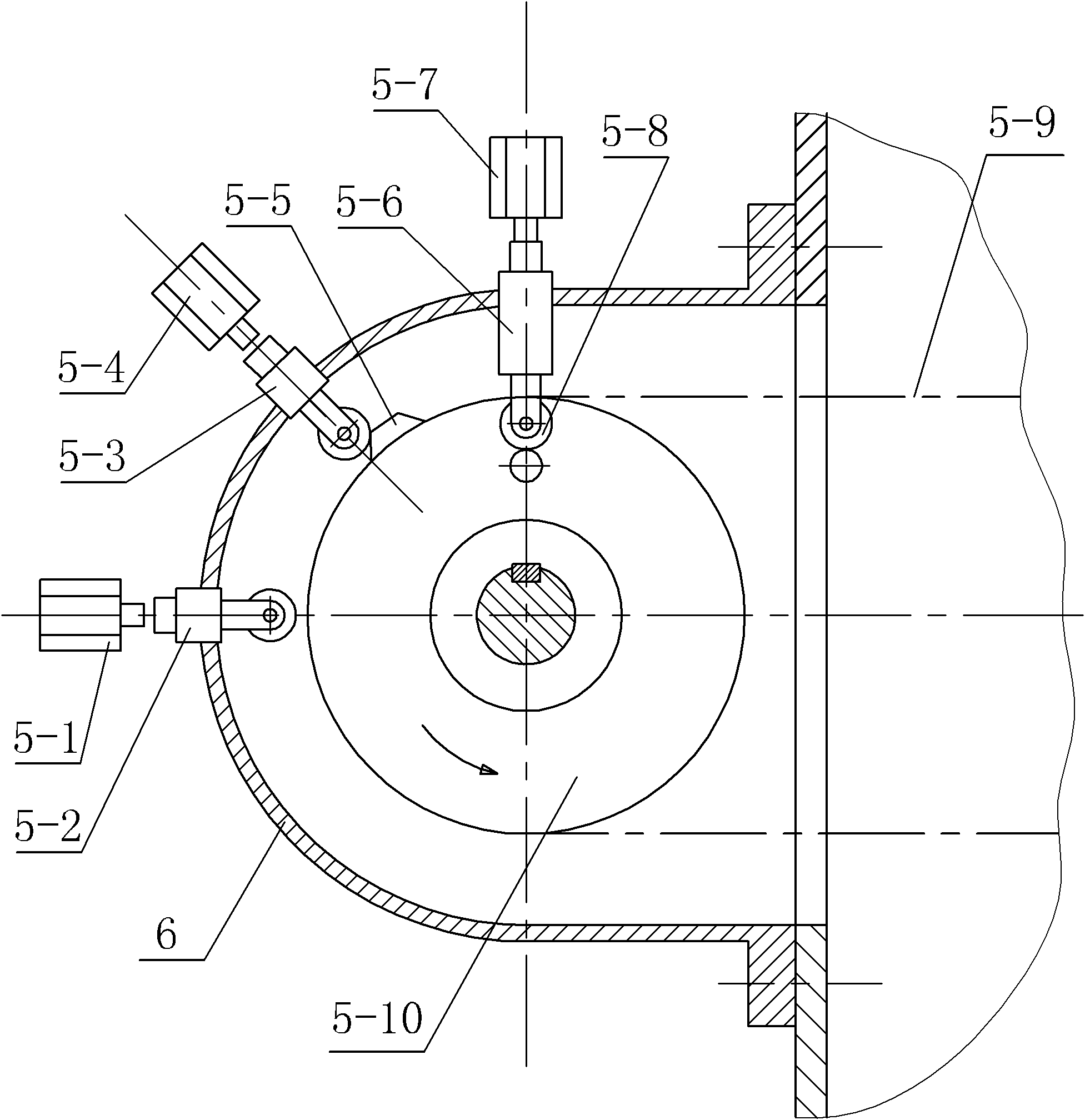

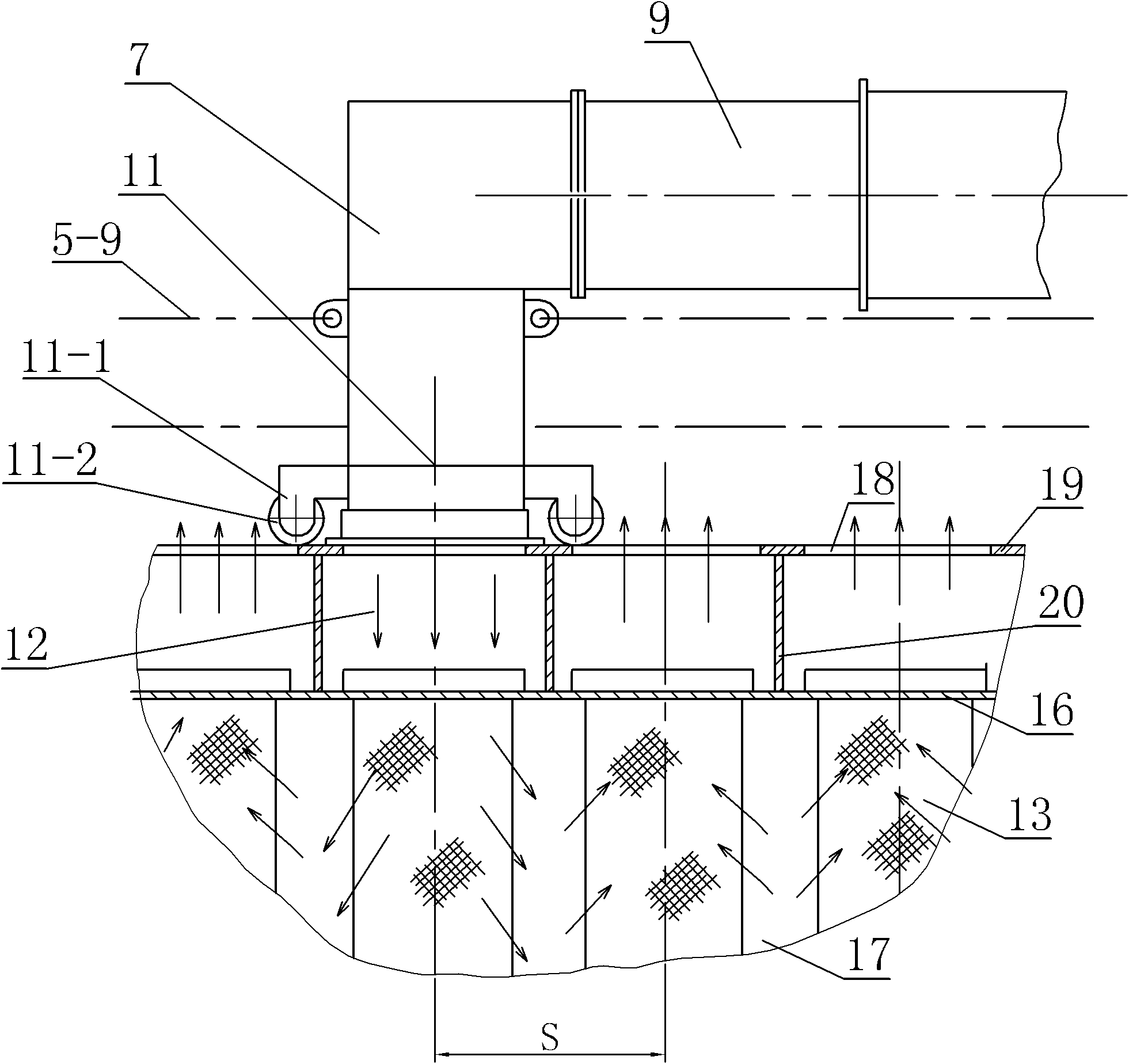

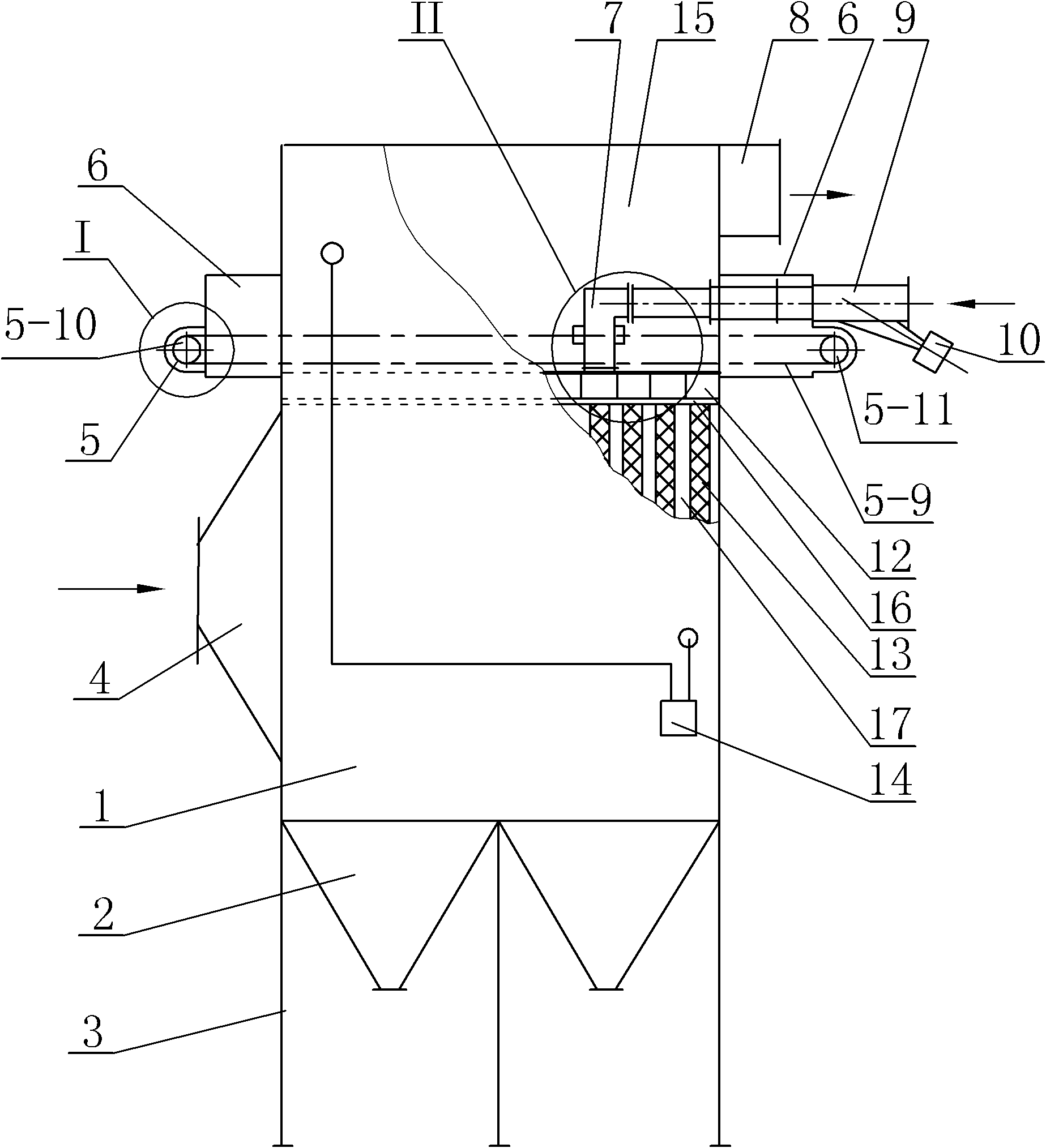

Sub-chamber back blowing bag type dust collector with reciprocating movement back blowing air port

ActiveCN102068864AImprove cleaning abilitySmall running resistanceDispersed particle filtrationChemical industryProcess engineering

The invention discloses a sub-chamber back blowing bag type dust collector with a reciprocating movement back blowing air port, and relates to a bag type dust collector. The bag type dust collector can solve the problems that a deashing mechanism of the conventional bag type dust collector cannot realize port-to-port deashing chamber by chamber, the deashing effect is poor, the structure is complex, faults are easy to occur and the like. The bag type dust collector is technically characterized in that: a sub-chamber back blowing deashing device is arranged in a gas purifying chamber, one end of a telescopic back blowing gas pipe is connected with a deashing gas source for introducing back blowing deashing gas flow, and the other end of the telescopic back blowing gas pipe is connected with the movable back blowing air port; and a transmission mechanism draws the movable back blowing air port and the telescopic back blowing air pipe to reciprocate and move to the outlet of the small gas purifying chamber sequentially for performing port-to-port positioning back blowing deashing chamber by chamber. The sub-chamber back blowing bag type dust collector is mainly applied in dedusting treatment before smoke gas in power stations, metallurgy, chemical industry, mining, cement, grain processing and other industries is discharged.

Owner:彭湃

Duplex pipeline compensator

InactiveCN104132214AComposite structure is simpleComposite structure is reasonablePipeline expansion-compensationAdjustable jointsEngineeringIntegrated design

The invention discloses a duplex pipeline compensator. The duplex pipeline compensator comprises an inner pipe, packing, a shell, a pair of corrugated pipes, amour rings, liner pipes, filling holes, and sliding rings, wherein the amour rings are arranged in outer valleys of the corrugated pipes, the liner pipes are arranged in the pair of corrugated pipes which are coaxially connected in series, and the two ends of the corrugated pipes are connected with inner pipes in a sealed mode, so that the corrugated compensator is formed. The inner walls of the two ends of the shell are respectively provided with a sealing cavity which is composed of an inner shoulder and an outer shoulder, the packing and the sliding rings are embedded in the sealing cavities, and the filing holes are evenly distributed on the outer walls of the two ends of the shell. The shell is arranged on the outer wall of the corrugated compensator in a sleeved mode, the sealing cavities in the two ends of the shell are matched with the outer walls of the inner pipes matched with the shell to form sleeve type compensators, and in this way, the corrugated compensator is protected by the two sleeve type compensators. Due to the integrated design of the duplex independent compensation structure, safety production can be effectively achieved, the frequency of halt maintenance is reduced, and the operating efficiency of a water leading pipeline of a hydropower station is improved.

Owner:江苏百新波纹管有限公司

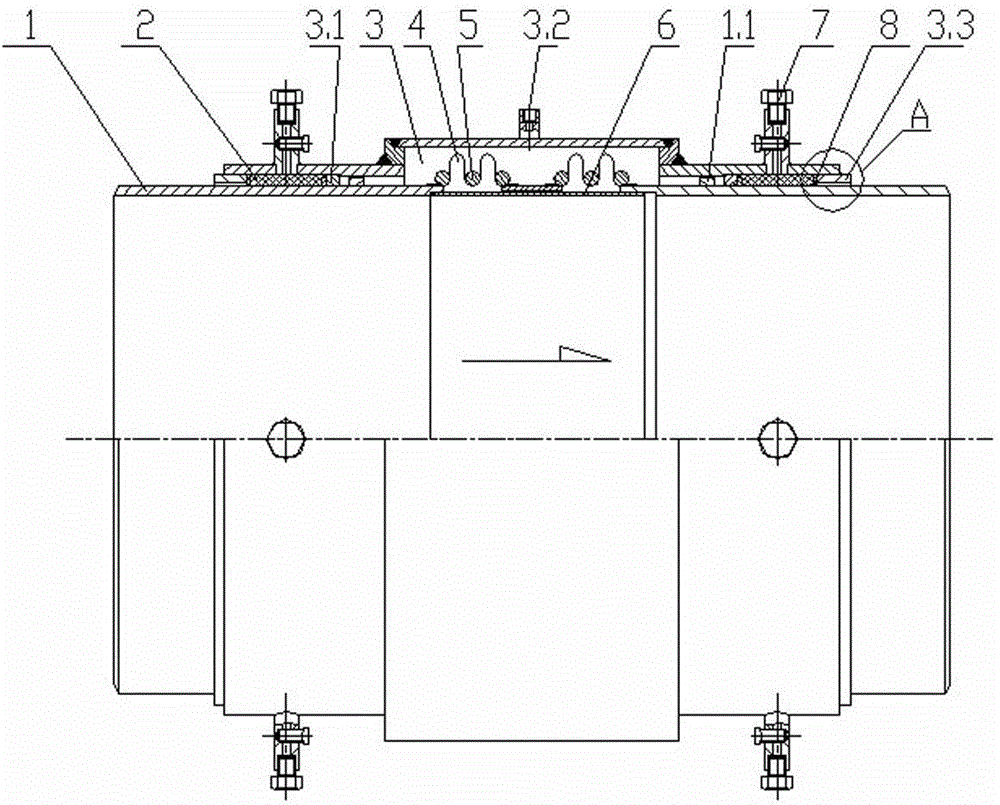

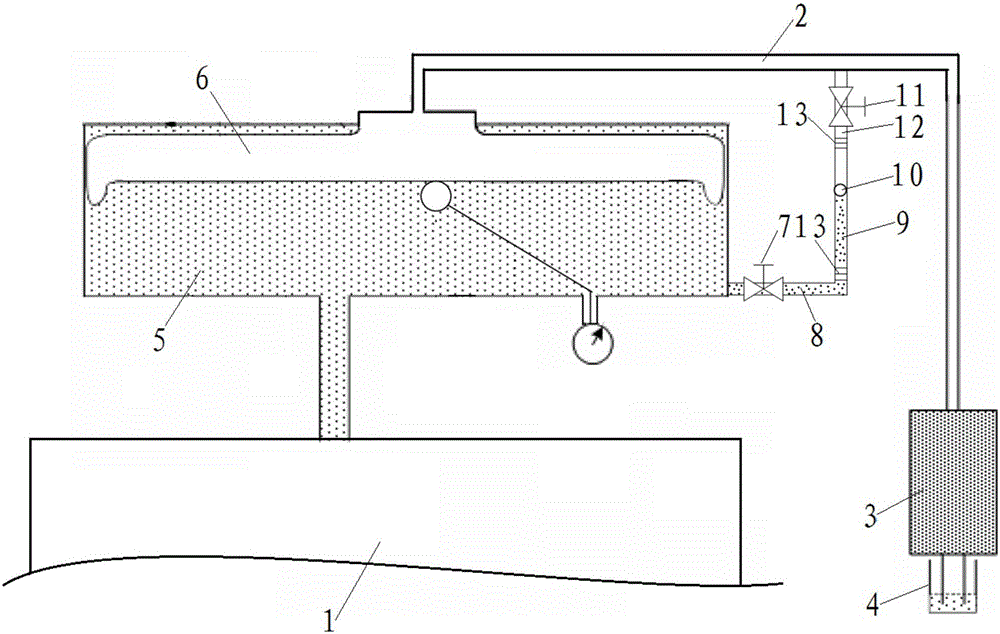

Converter transformer provided with glass tube type oil-level indicator and mounting method of indicator

InactiveCN106409474ASimple structureLow retrofit costTransformers/inductances coolingInductances/transformers/magnets manufactureGlass tubeRespirator

The invention discloses a converter transformer provided with a glass tube type oil-level indicator. The converter transformer comprises a converter transformer body, wherein the top of the converter transformer is communicated with an oil conservator; an air bag is arranged in the oil conservator; the top of the air bag is communicated with one end of an air tube; the other end of the air tube is communicated with one end of a respirator; the other end of the respirator is inserted into a respirator oil cup; the bottom of the converter transformer body is communicated with an oil tube; the oil tube is communicated with a transparent glass tube; a floating ball is arranged in the transparent glass tube; the upper end of the transparent glass tube is communicated with the air tube through an exhaust tube; and a scale line is arranged on the transparent glass tube. A mounting method of the glass tube type oil-level indicator comprises the following steps: emptying the transformer oil in the oil conservator; forming mounting holes in the bottom of the converter transformer body and the air tube respectively; welding the oil tube on one mounting hole, and welding the exhaust tube on the other mounting hole; mounting the transparent glass tube between the oil tube and the exhaust tube, and mounting the floating ball in the transparent glass tube; setting a scale line on the transparent glass tube; opening an oil outlet valve and the exhaust tube. The invention is suitable for the converter transformer.

Owner:STATE GRID CORP OF CHINA +1

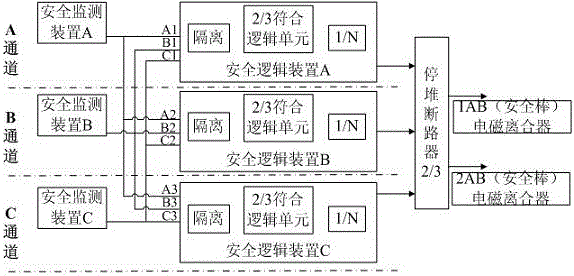

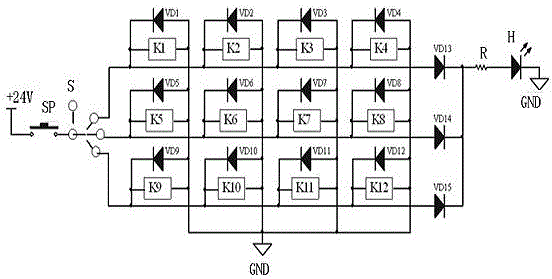

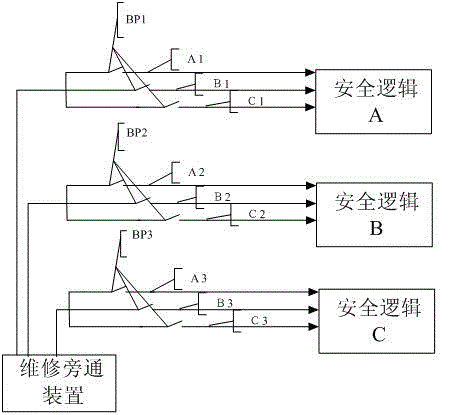

Reactor protection system two-out-of-three conforming maintenance bypass system

ActiveCN105788687AGuaranteed uptimeRealize online maintenancePower plant safety arrangementNuclear energy generationRotary switchControl engineering

The invention discloses a reactor protection system two-out-of-three conforming maintenance bypass system, comprising a reactor protection system and a 2 / 3 conforming logic bypass unit, wherein the 2 / 3 conforming logic bypass unit comprises a rotary switch S which is provided with four gear contactors and also comprises twelve relays which are all normally open relays. Every four relays of the twelve relays are seen as one group; input ends of input circuits of the four relays of the first group are all connected to first gear contactors, input ends of input circuits of the four relays of the second group are all connected to second gear contactors, and input ends of input circuits of the four relays of the third group are all connected to third gear contactors. According to the system, a bypass device is arranged between a safety monitoring device and a safety logic device so that the protection system maintenance bypass function is added. Device on-line maintenance and test can be achieved; non-planned reactor shutdown probability due to device fault is reduced; the performability of reactors is increased; and production efficiency is guaranteed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

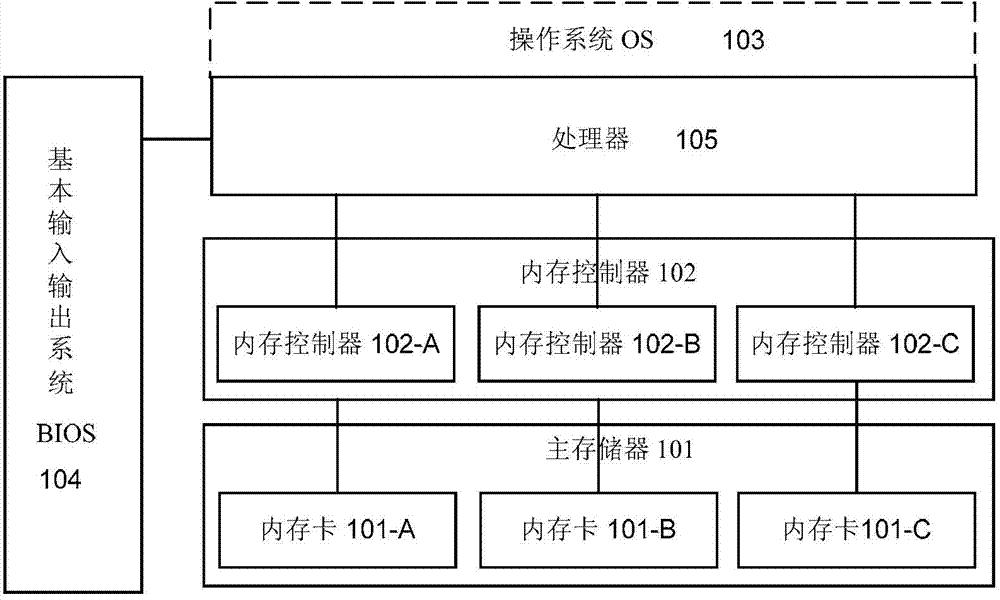

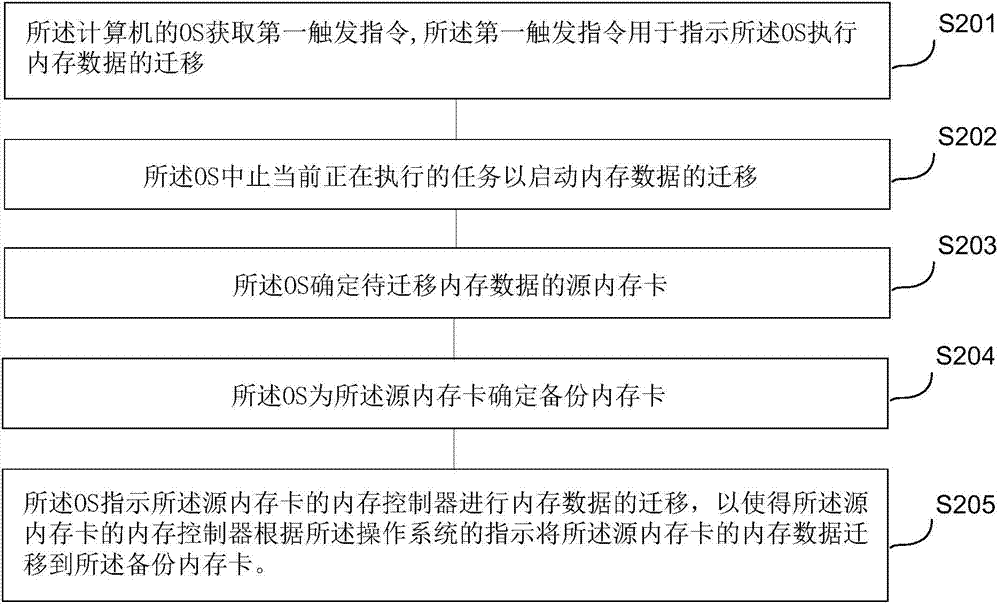

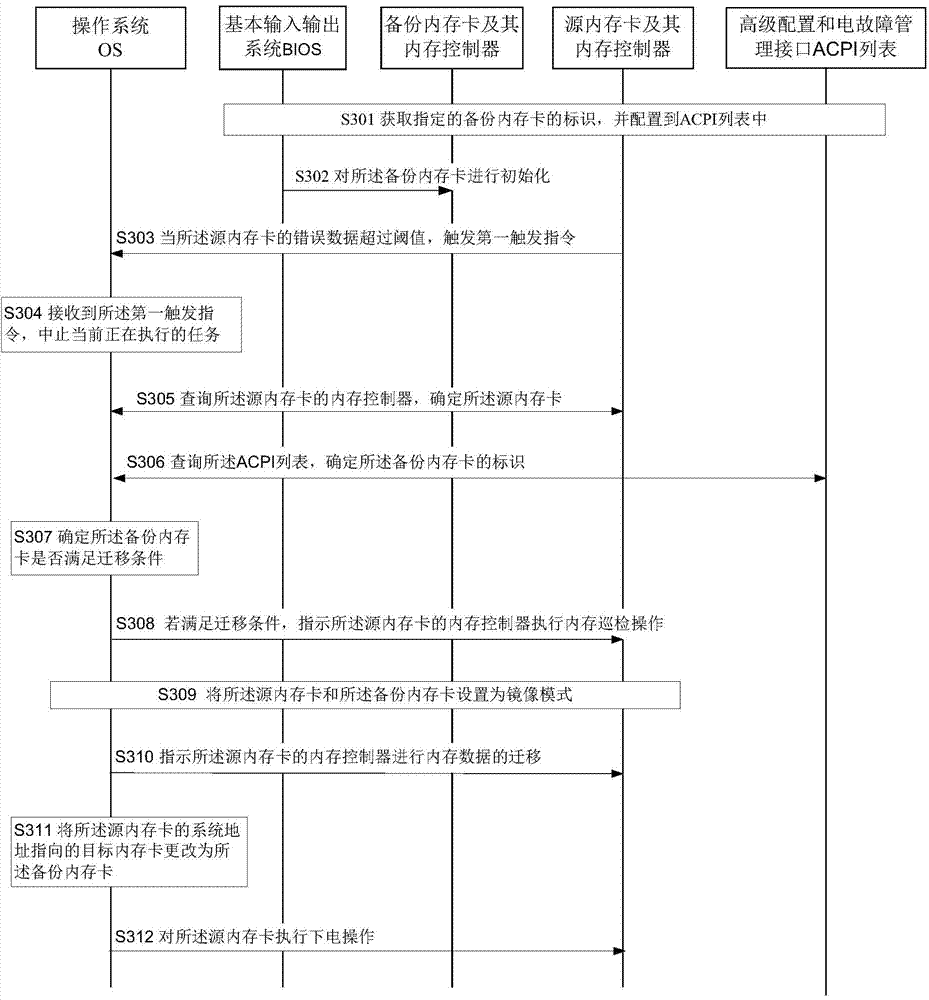

Migration method, computer and device of stored data

ActiveCN103842968ARealize online maintenanceSolve replacementRedundant operation error correctionRedundant hardware error correctionElectricityOperational system

The embodiment of the invention provides a migration method, a computer and a device of stored data, used for migrating the stored data in the computer. An operation system of the computer suspends current executed mission to execute the migration of the stored data after gaining a first trigger command, ensures a source memory card of the stored data to be migrated, ensures a back-up memory card for the source memory card, indicates a memory controller of the source memory card to perform the migration of the stored data to make the memory controller read the stored data in the source memory card according to the indication of the operation system, writing the stored data of the source memory card into the back-up memory card to migrate the stored data in the source memory card when the computer is out of power, thereby realizing online maintenance of the fault stored data and solving the problem that replacement and maintenance of the fault memory card can be performed only when the computer is out of power.

Owner:XFUSION DIGITAL TECH CO LTD

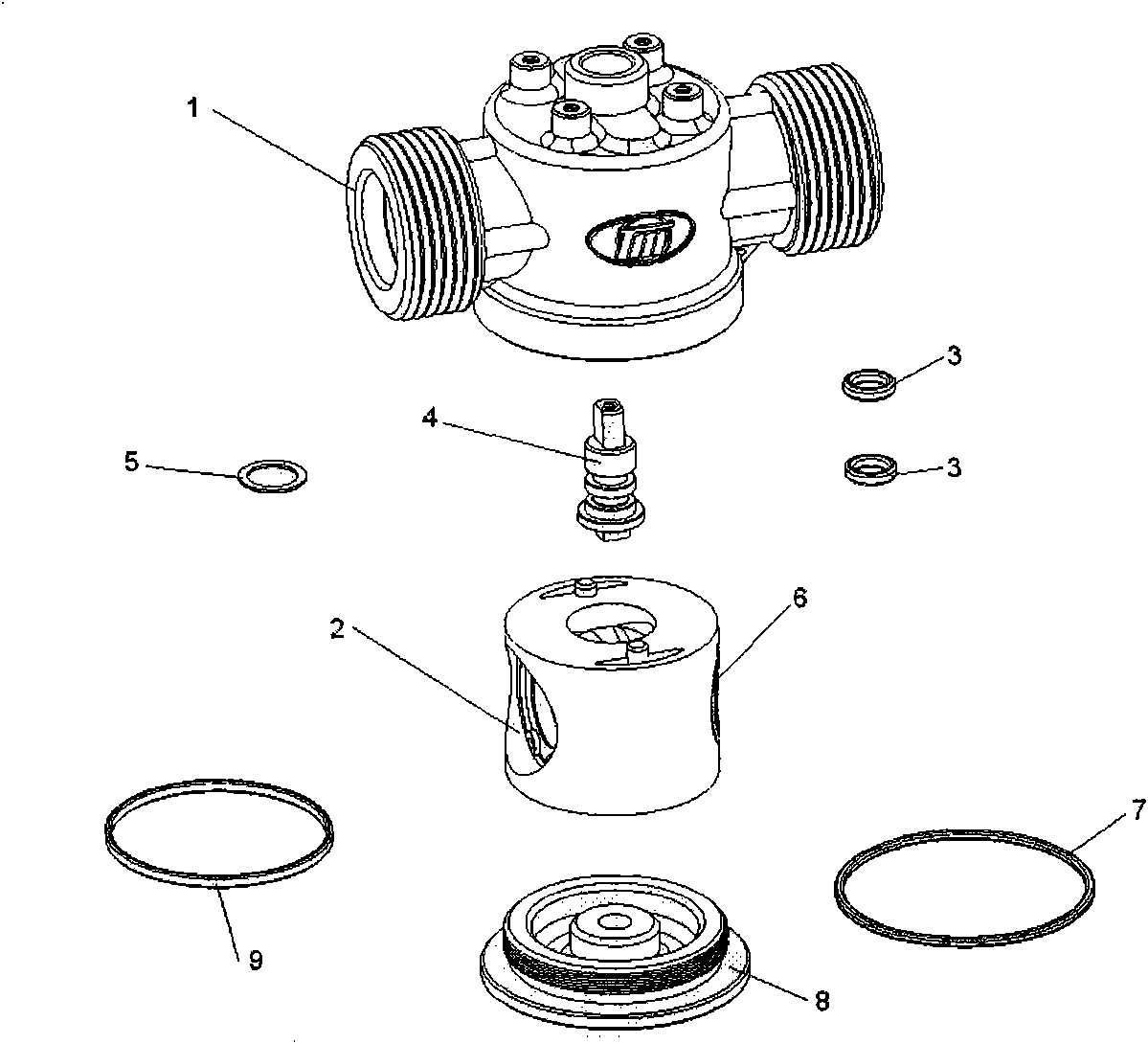

Novel down-mounting ball valve

The invention discloses a novel down-mounting ball valve, which is characterized by consisting of a valve body, a valve core assembly, a rotating shaft sealing ring, a rotating shaft, a polytetrafluoroethylene gasket, a water outlet sealing ring, a lower valve cover end face sealing ring, a lower valve cover and a lower valve cover radial sealing ring. The novel down-mounting ball valve has the advantages that: the novel down-mounting ball valve assembly is arranged into an integrated meter shell of a water meter or a heat meter to realize integration of a flow meter and a control valve of the prepayment water meter and the prepayment heat meter; because of the integral structure, the strength, sealing property, high-temperature resistance and high-pressure resistance of the prepayment water meter and the prepayment heat meter are promoted, and the highest bearing pressure is more than or equal to 4MPa and far higher than the pressure limit of industrial standard high-pressure meter 2.5MPa (common heat meter 1.6MPa); on-line (use site) integral disassembly, maintenance and replacement can be performed; parts such as a speed reducer, a control circuit and the like driven by the ball valve are not involved during maintenance and replacement; and the operation is performed directly from the bottom of the ball valve, and disassembly of other parts is not needed.

Owner:陈沛

Top-mounting fixation ball valve

InactiveCN103982674AImprove work efficiencyReduce economic lossPlug valvesValve housingsLine tubingLeft valve

The invention discloses a top-mounting fixation ball valve. The ball valve comprises valve seats, a valve body, a valve ball, a valve rod and a handle. An inflow channel, an outflow channel and a valve cavity communicating the inflow channel and the outflow channel are formed in the valve body. The valve ball is arranged in the valve cavity and is supported on the valve body through a left valve seat and a right valve seat. The valve body is forged integrally, a valve rod hole for the valve ball to penetrate is formed in the valve body and is covered with a valve bonnet in seal connection with the valve body, a press sleeve flange in seal connection with the valve bonnet is arranged on the valve bonnet, an ejection flange in fixed seal connection with the press sleeve flange is arranged on the press sleeve flange, and the valve rod penetrates the valve bonnet, the press sleeve flange and the ejection flange through the valve rod hole to be in transmission connection with the handle. The valve bonnet, the valve ball and the valve seats are mounted and dismounted through the valve rod hole in the upper portion of the valve body. According to ball valve, pipe stress is not applied, valve body leakage points are reduced, and the medium leakage probability is reduced.

Owner:KUSN WEISA VALVE

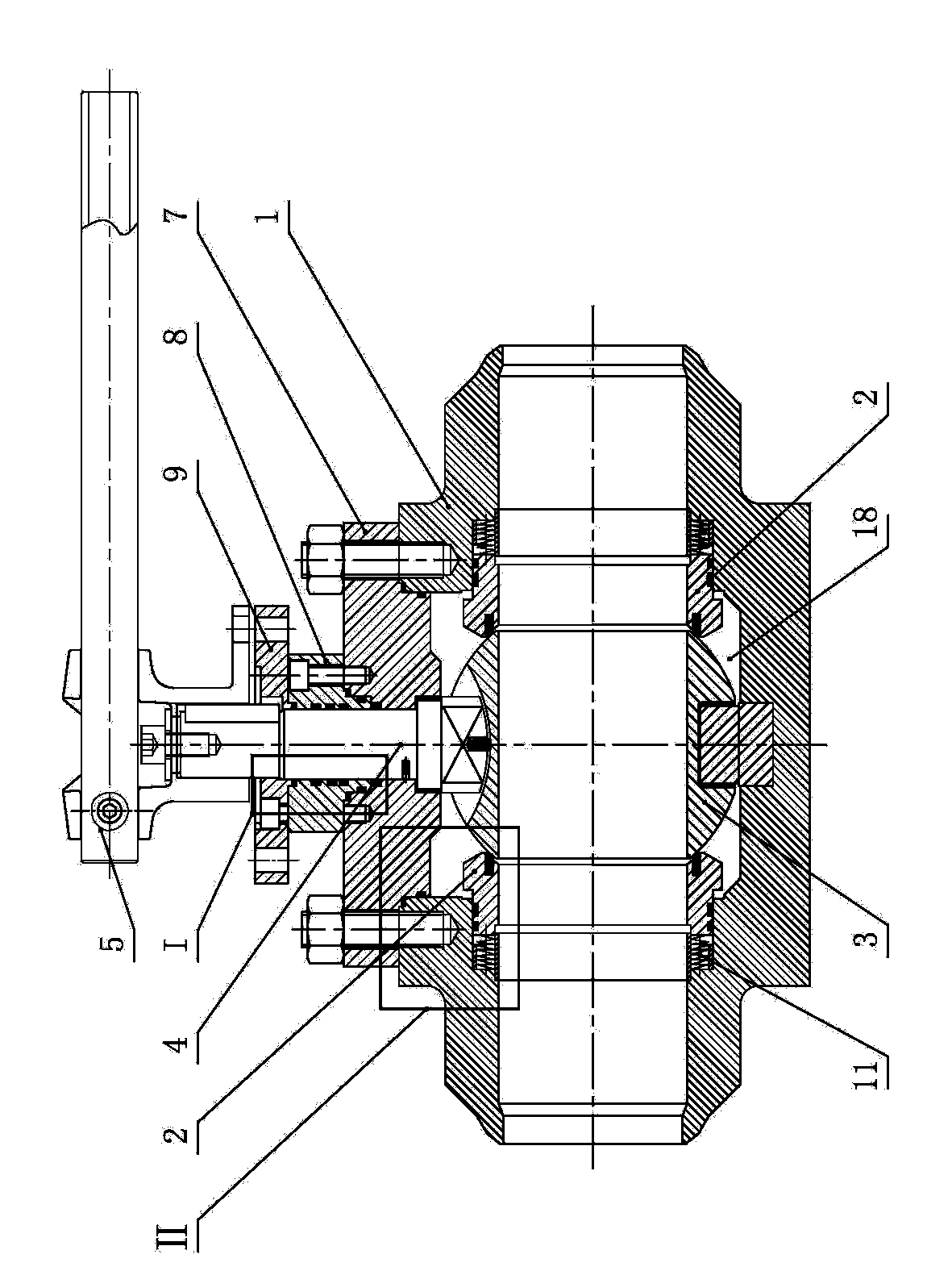

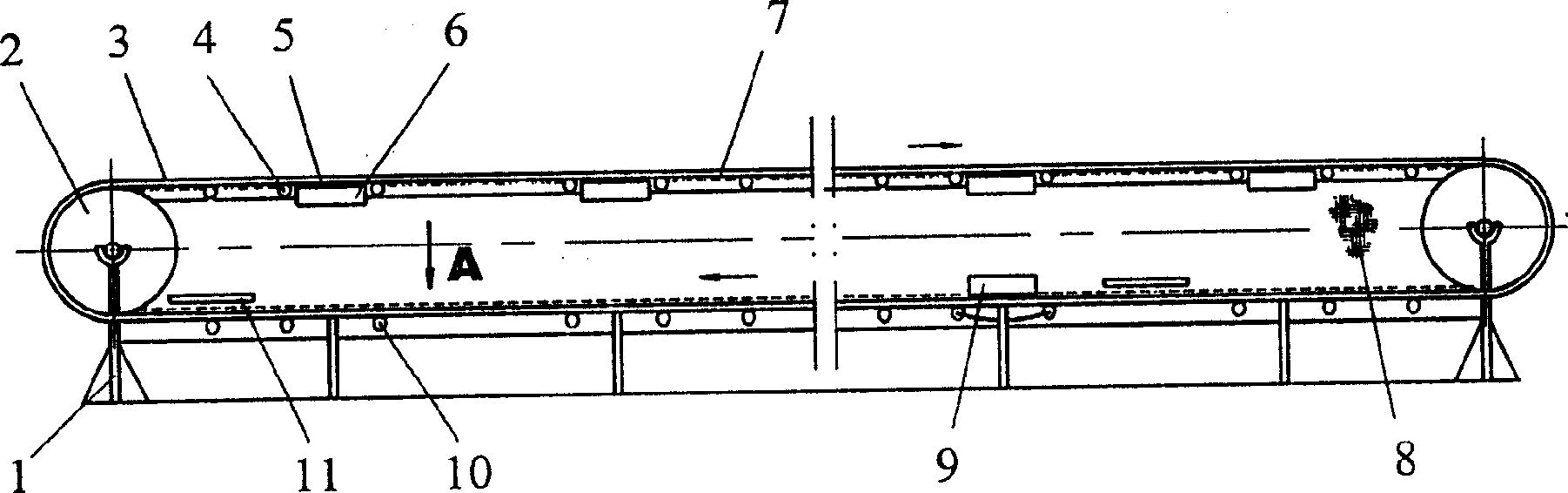

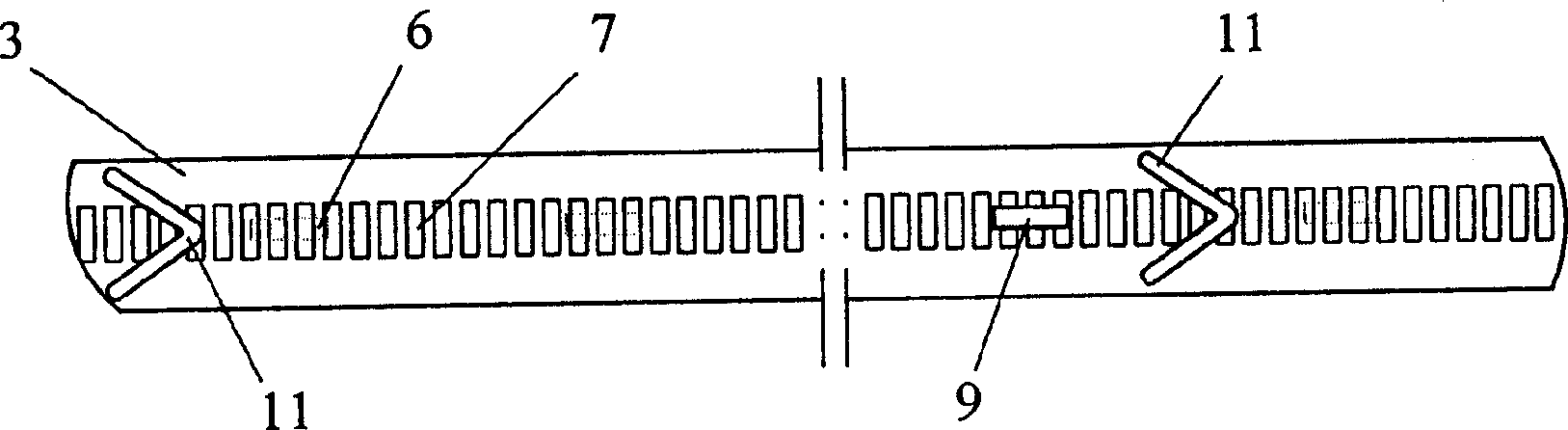

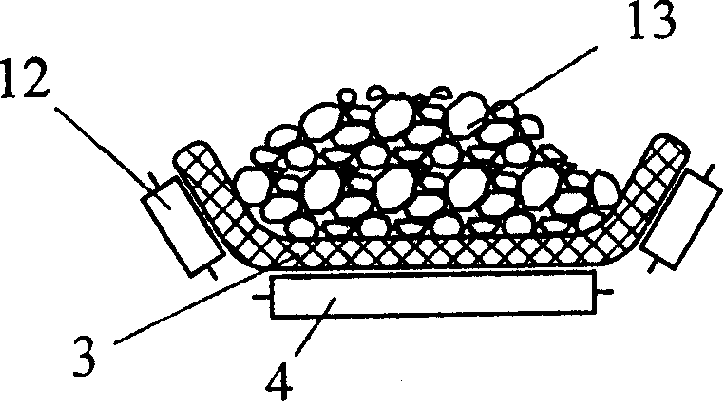

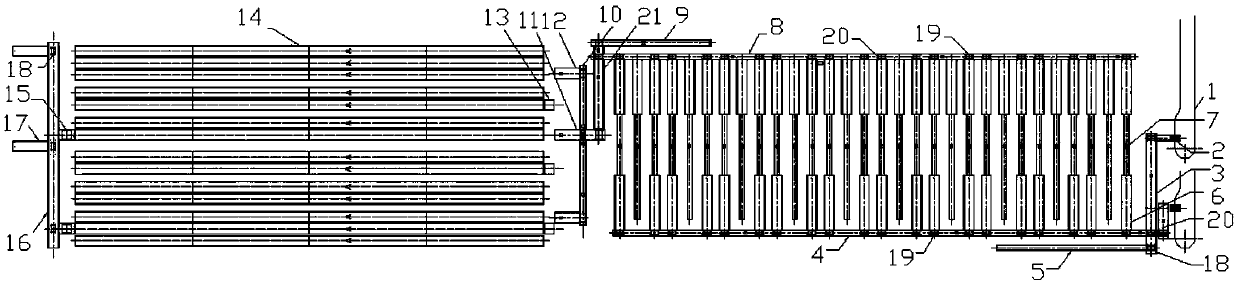

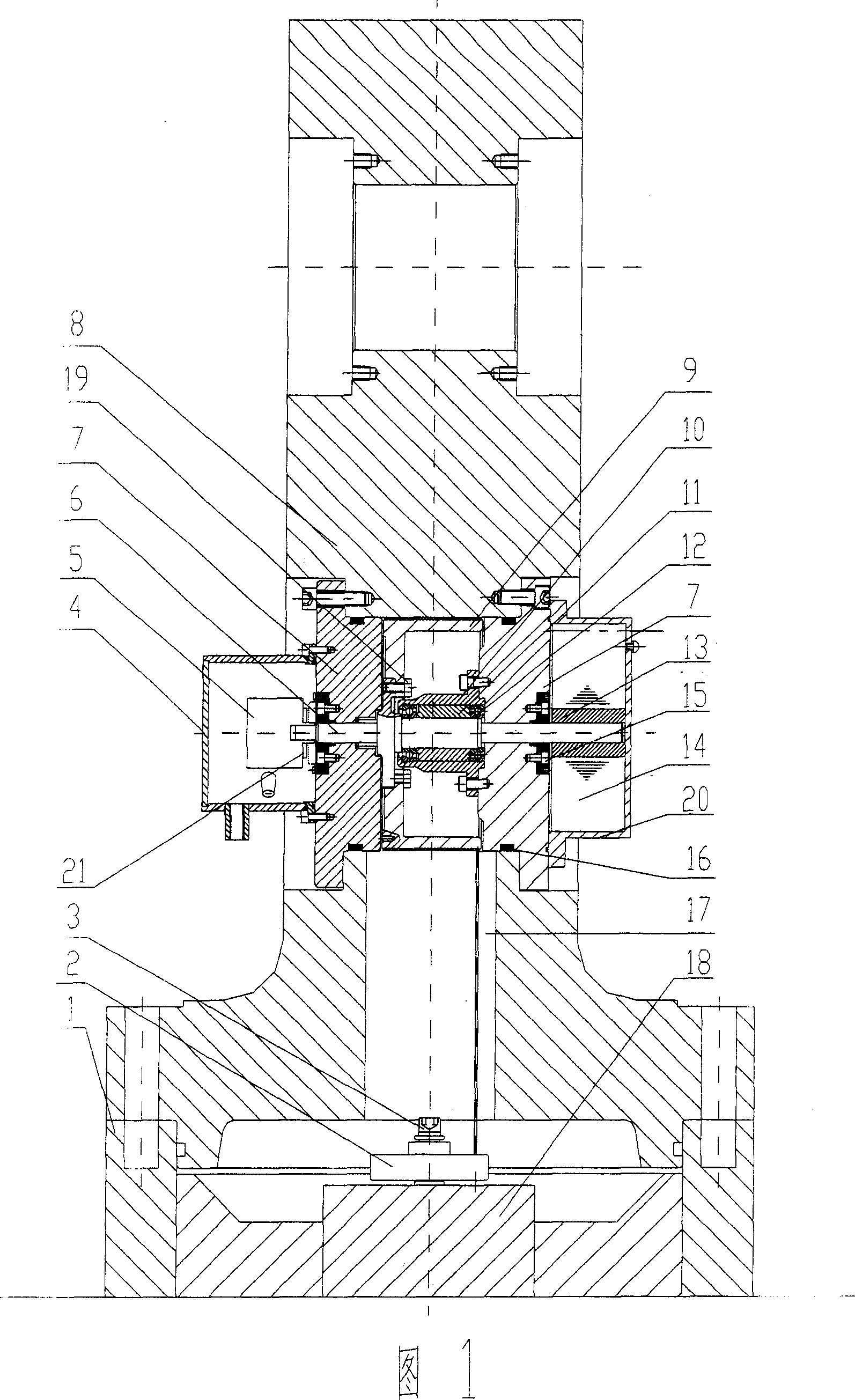

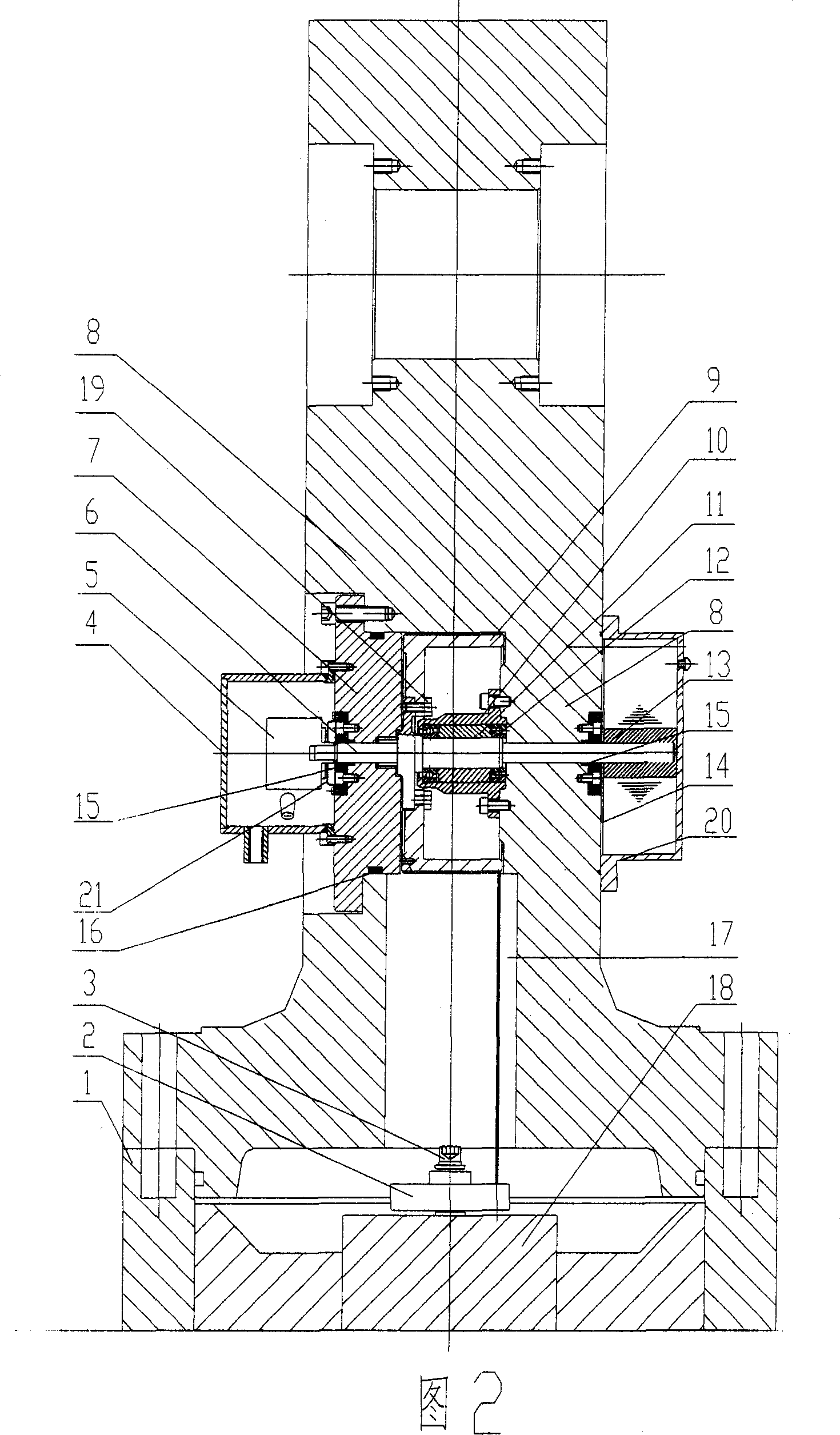

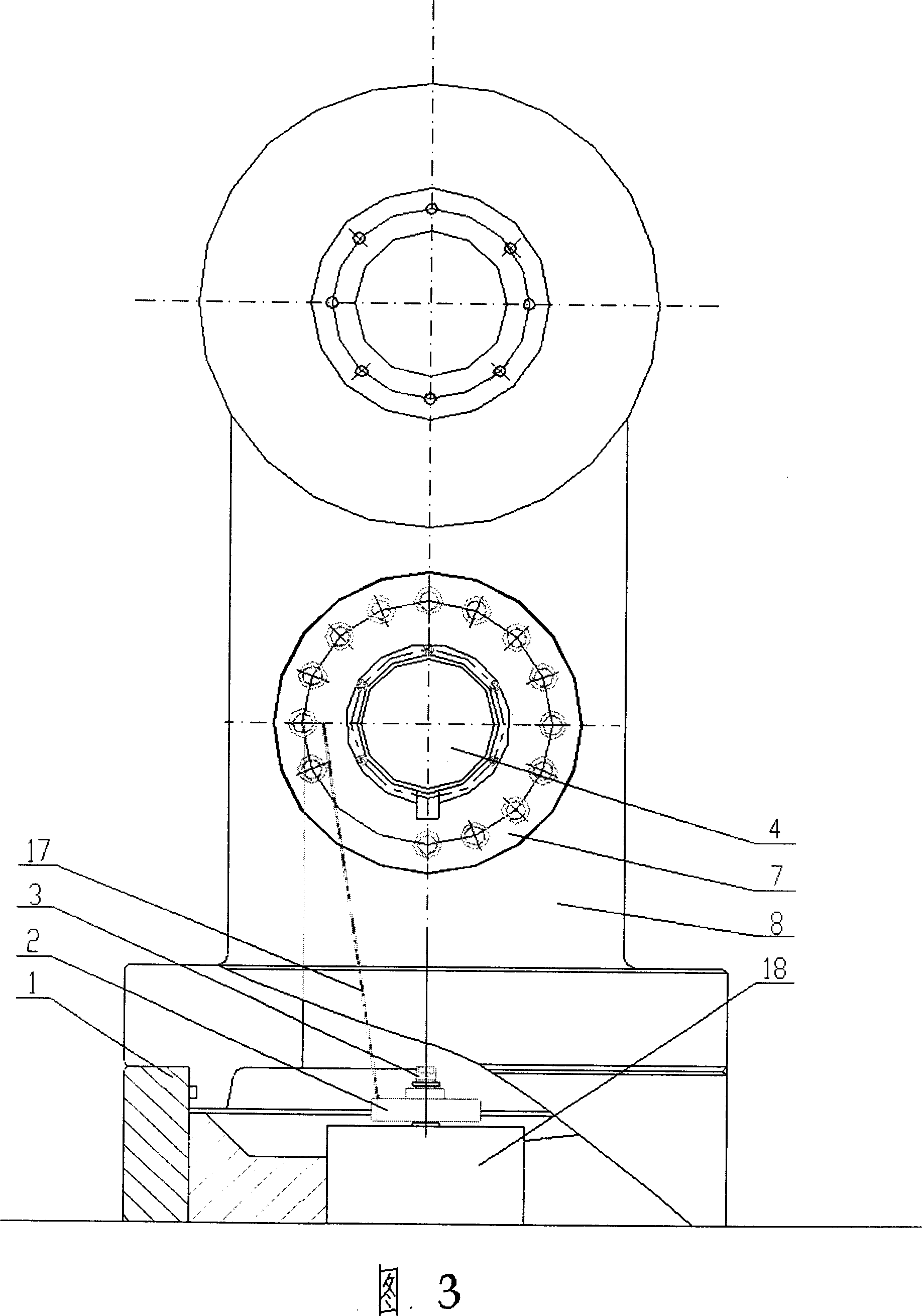

Direct driving type belt conveyer

The invention discloses a material conveying device driven by a linear motor, which comprises a supporting frame (1), drums (2), a conveying belt (3), supporting rollers (4), a linear motor and a controller. It features that the primary windings of the linear motor (6) are arranged along the central line of the conveying belt and are installed on the supporting frame (1) together with the supporting rollers (4). The secondary windings (7) of the linear motor (6), corresponding to the primary windings, are arranged on the inside surface of the annular conveying belt. Secondary plates are transversely arranged along the longitudinal direction of the conveying belt discontinuously in a closed arrangement. The material conveying device effectively reduces the cost and is in favor of automatic monitoring, control, maintenance and management. Meanwhile, the device is uniform in force distribution and stable in operation, which is especially suitable for the long-distance material conveying operation.

Owner:ZHEJIANG UNIV +1

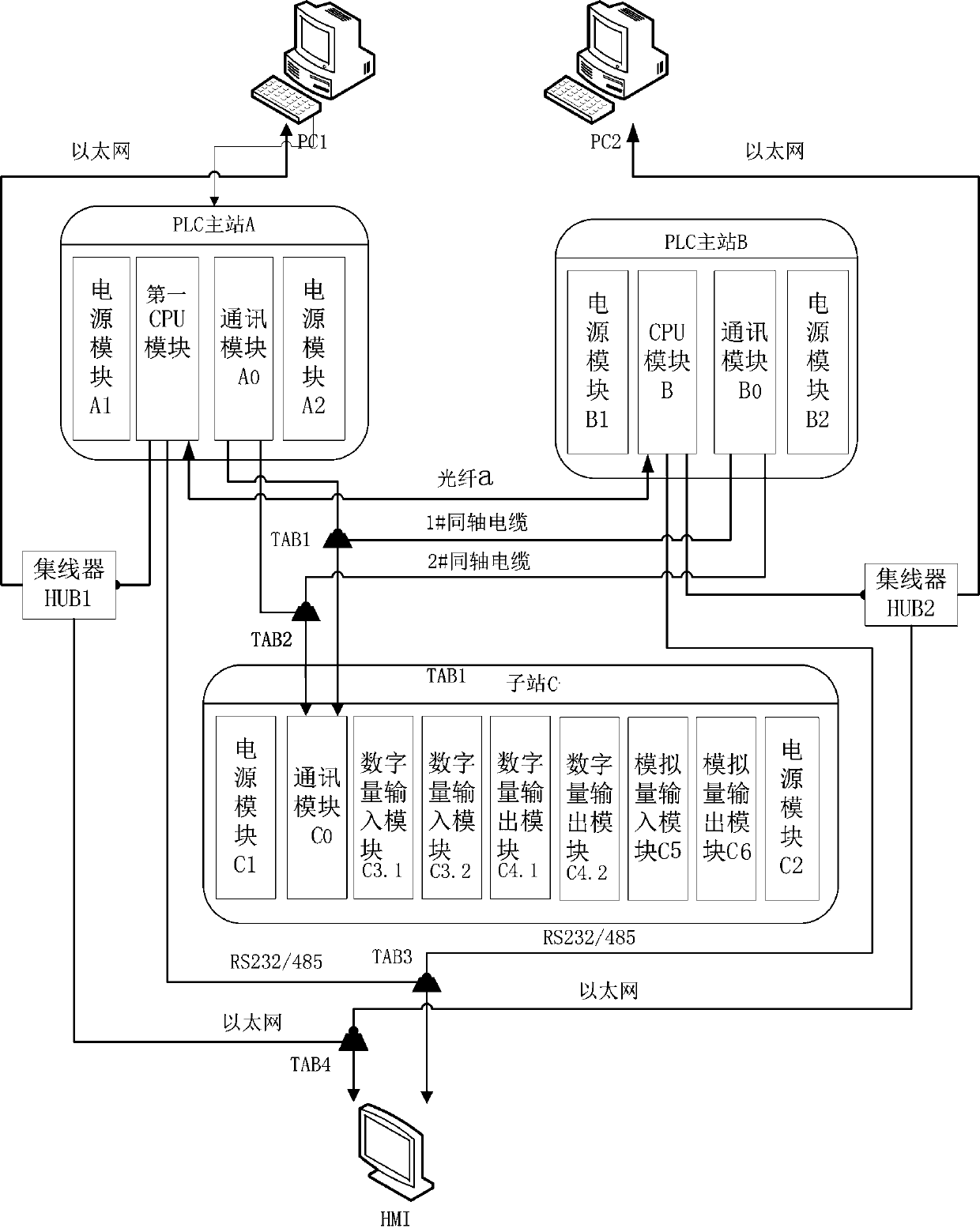

PLC control system and method for dual power supply and communication of speed regulator hydraulic system

PendingCN110955187AEnsure safetyImprove automation technology level and production efficiencyProgramme controlComputer controlSystems engineeringControl system

The invention discloses a PLC control system and method for dual power supply and communication of a speed regulator hydraulic system. The PLC control system comprises a PLC main station A, a PLC mainstation B and a substation C, and the communication module of the substation C is connected and communicated with the communication module of the PLC master station through a double-channel coaxial cable, and uploads data to the CPU module of the master station in real time. And the touch screen HMI is in communication connection with the CPU module of the PLC master station through the concentrator by taking the Ethernet as a transmission medium, so that real-time data exchange between the touch screen HMI and the PLC master station is realized. And redundant communication between the masterstation and the PC is realized. And the PLC main station A and the PLC main station B are in communication connection through an optical fiber. According to the system, dual PLC control of a redundant power supply and communication is adopted, so that the system is not influenced by a local single fault during operation, and online maintenance can be realized; Meanwhile, normal operation of the system is not influenced during offline repair of fault components, so that the purposes of improving the reliability of the system and reducing the failure rate can be achieved.

Owner:CHINA YANGTZE POWER

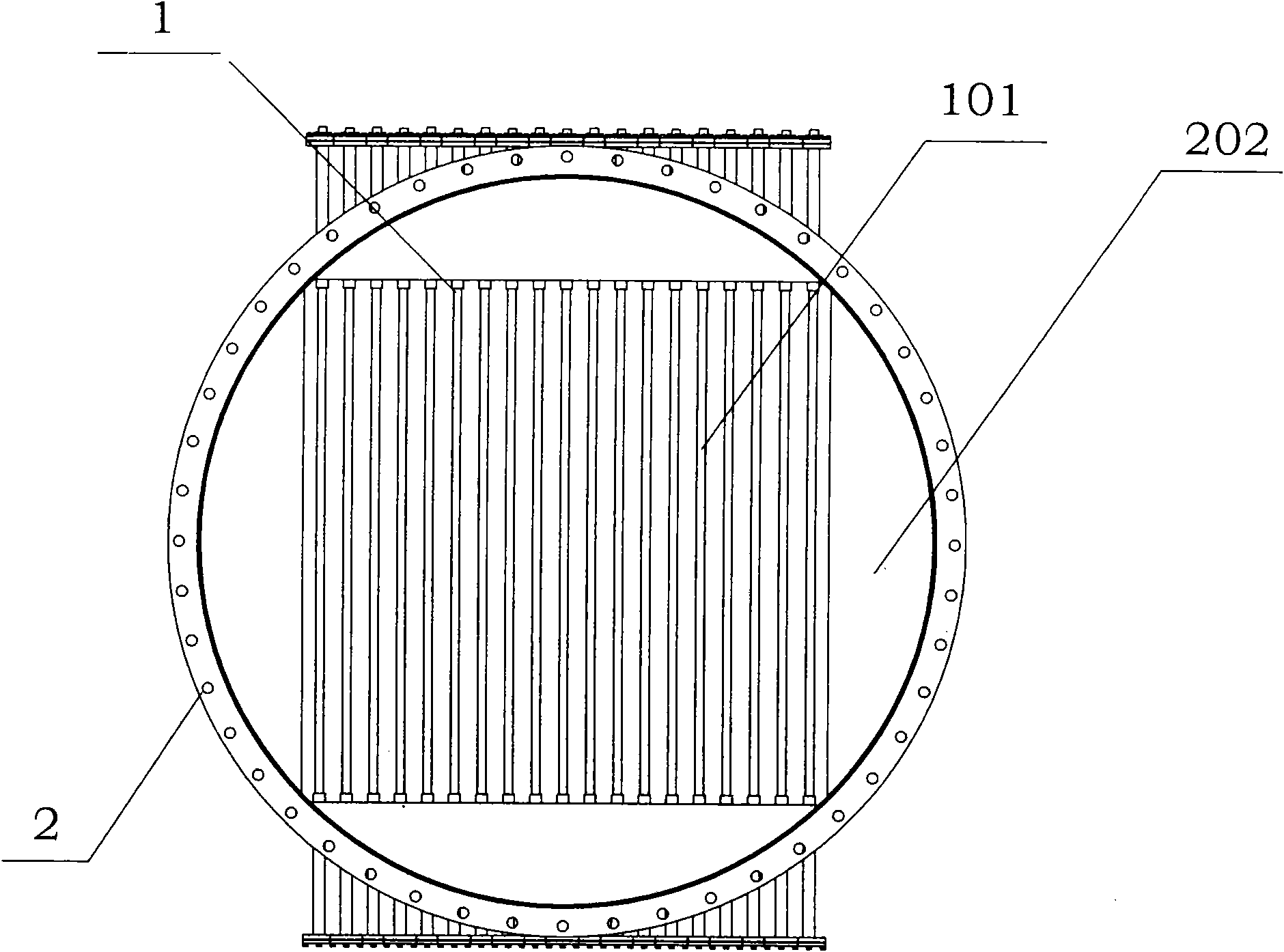

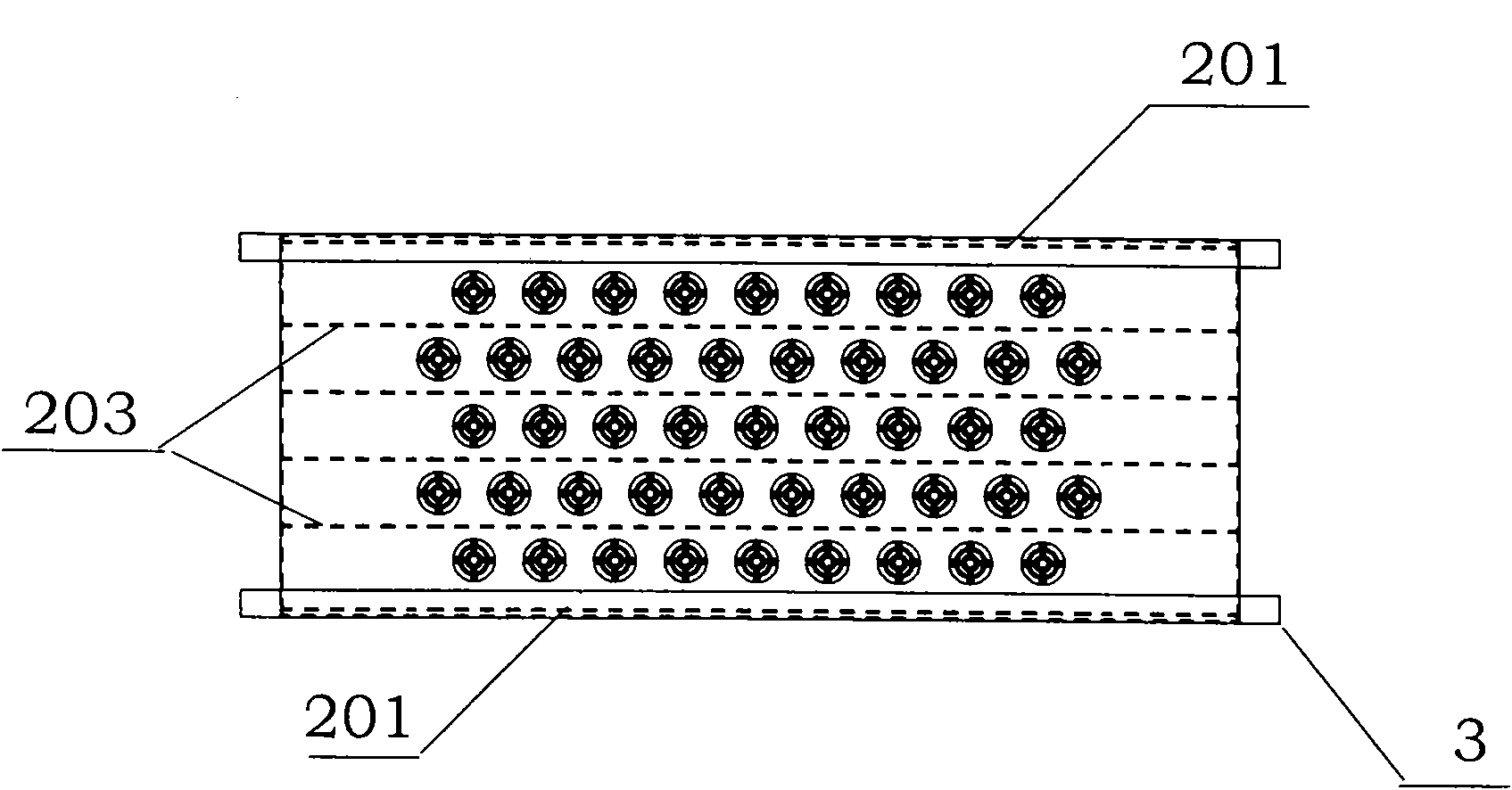

Large-flow ultraviolet fluid sterilizer

ActiveCN101591046AIncrease or decrease the number of installationsChange processing flowWater/sewage treatment by irradiationWater/sewage treatment apparatusUltravioletEngineering

The invention relates to a large-flow ultraviolet fluid sterilizer comprising at least one ultraviolet sterilizing module and an installing and fixing device of the ultraviolet sterilizing module, wherein each ultraviolet sterilizing module at least comprises an ultraviolet lighting tube, a main body of the installing and fixing device is a pipeline which can be passed by sterilized fluid, a plurality of ultraviolet sterilizing module installing holes are arranged on the wall of the pipeline, baffle plates which extend to the center direction of the end surface from the periphery of the end surface are arranged on one or two end surfaces of the installing and fixing device, and water through holes which are passed by the sterilized fluid are arranged on the end surfaces of the baffle plates. The large-flow ultraviolet fluid sterilizer can be widely used for locations which need to sterilize fluid, such as water plants, pharmaceutical factories, food factories, beverage factories, and the like and can be also used for other fluid sterilization systems which need to be sterilized.

Owner:FUJIAN NEWLAND ENTECH CO LTD

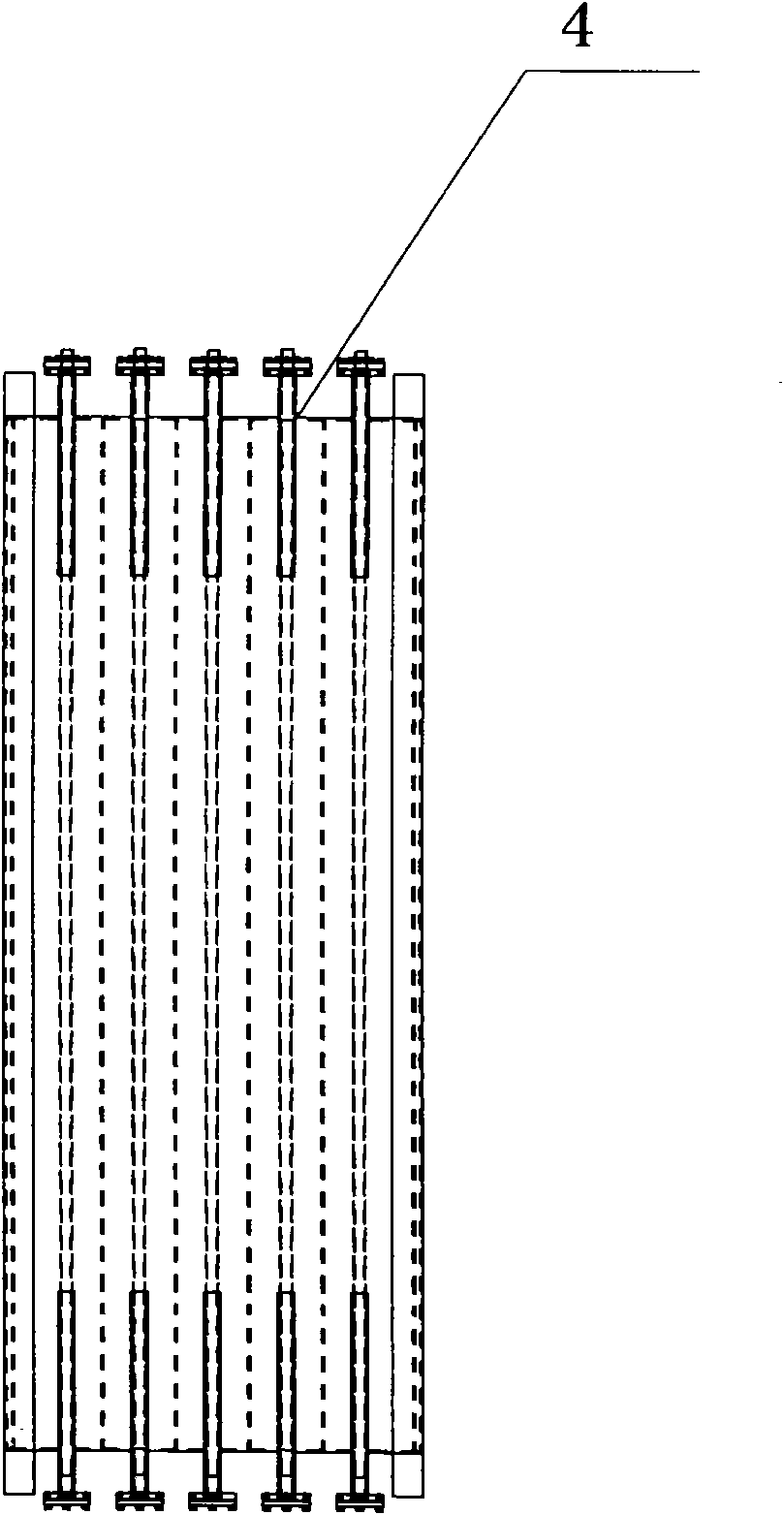

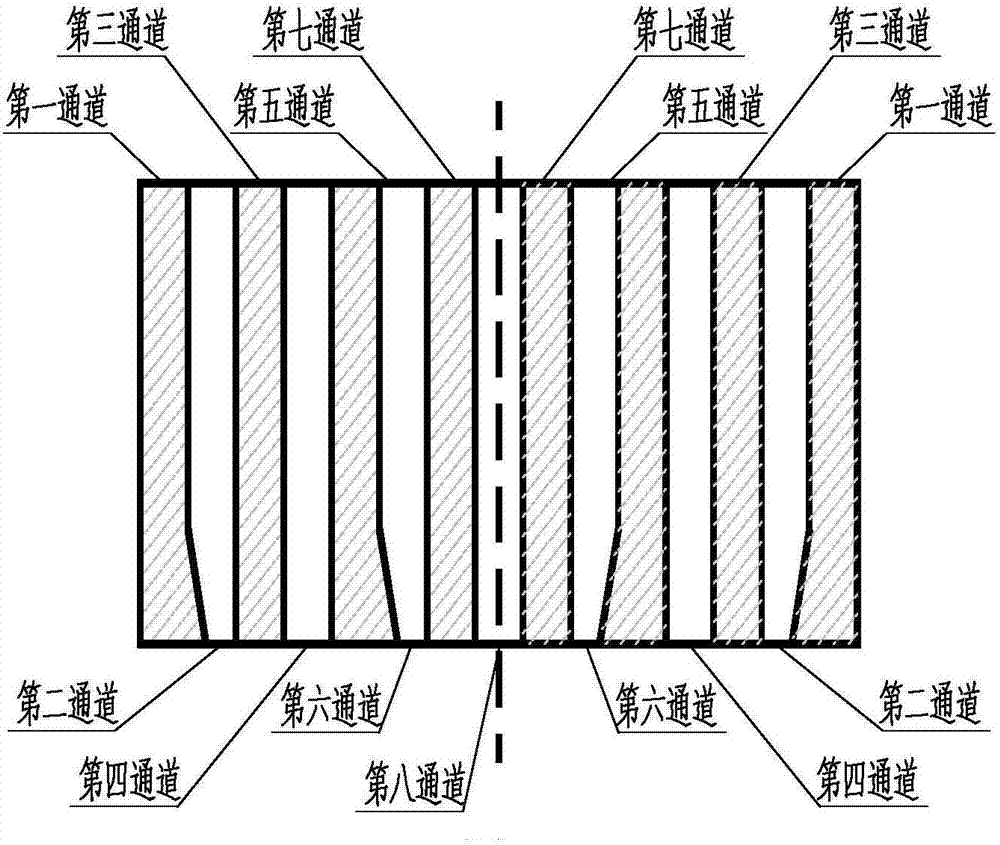

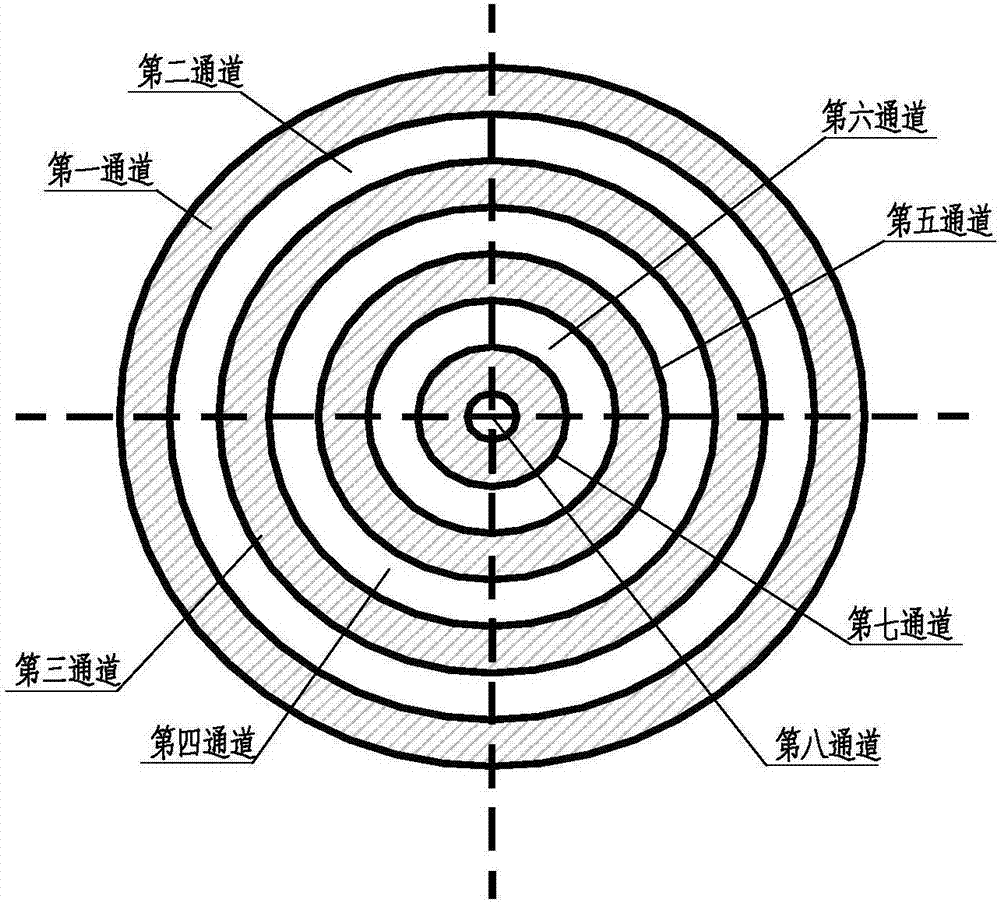

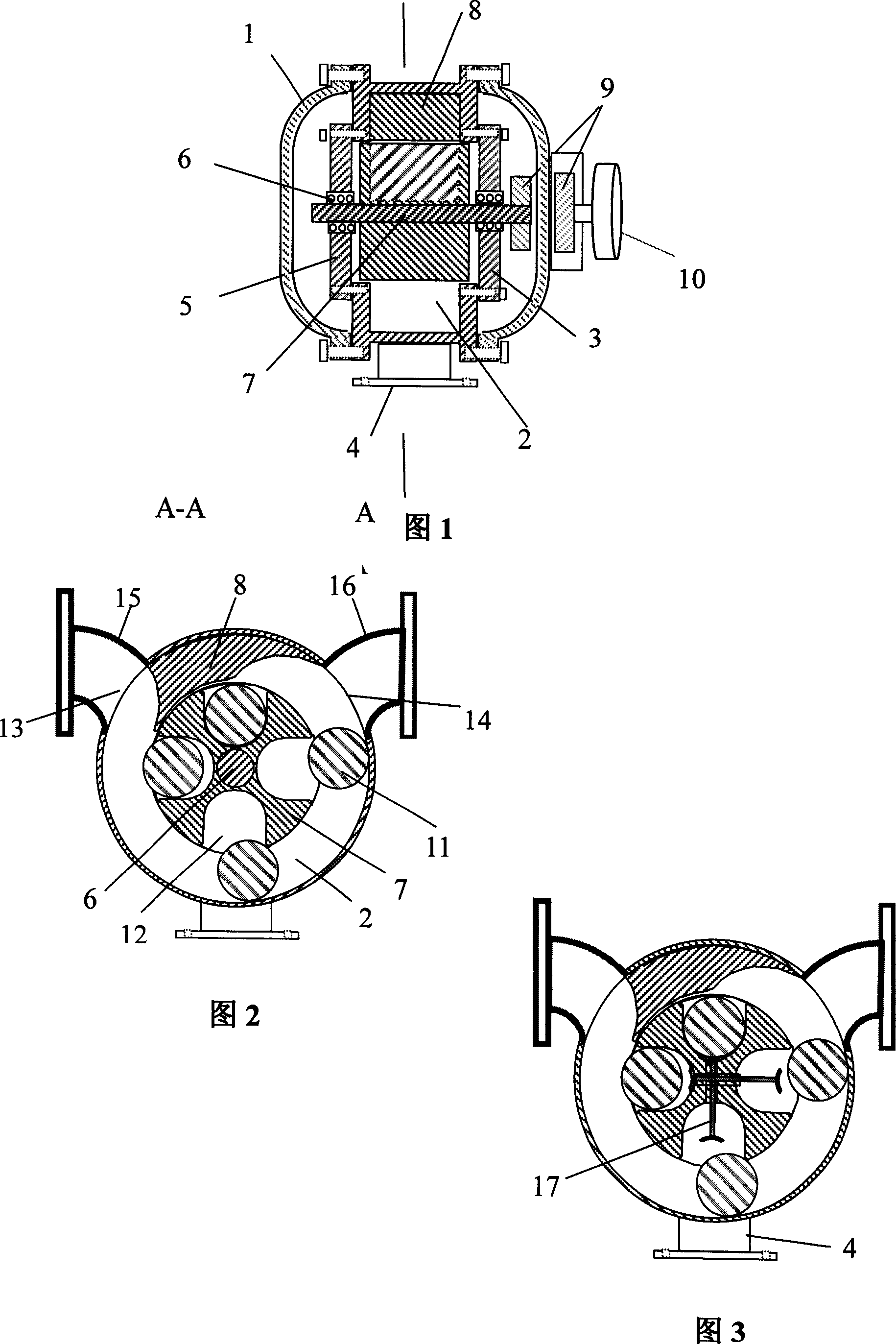

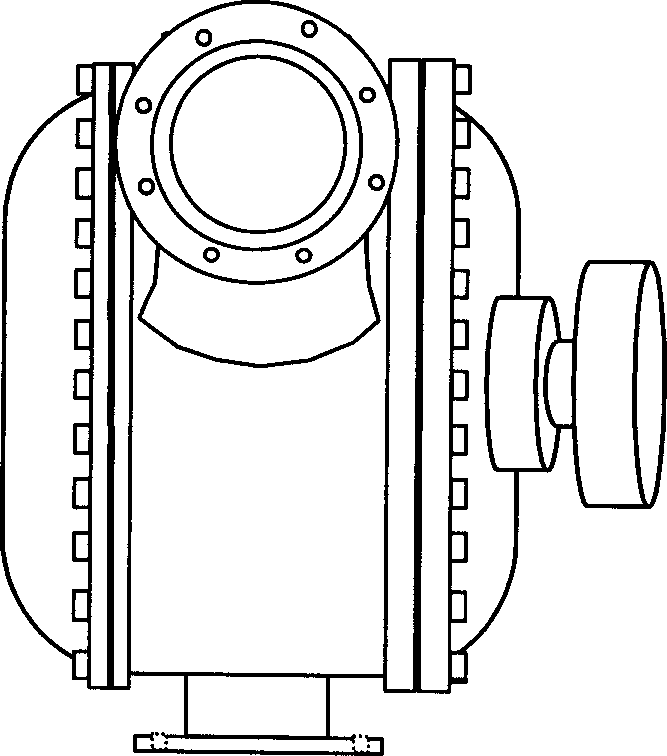

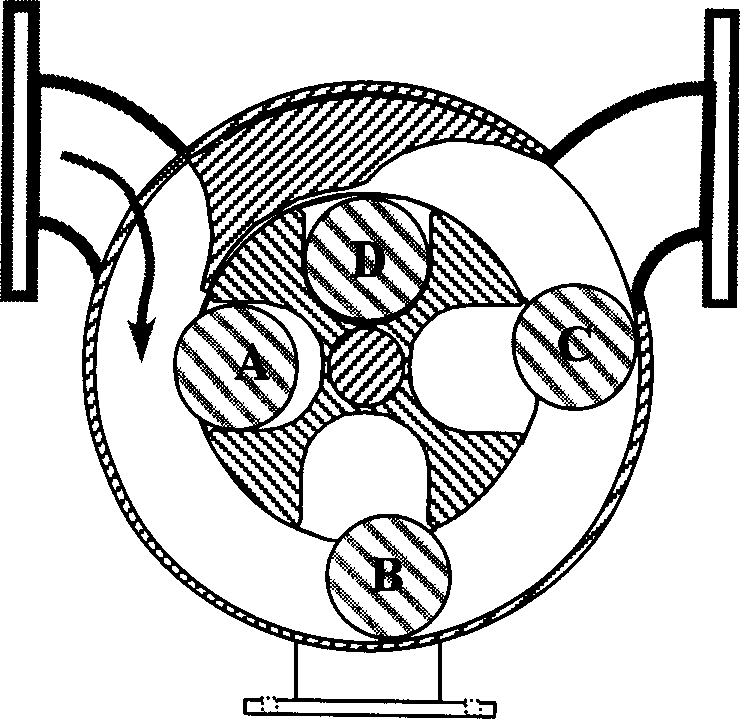

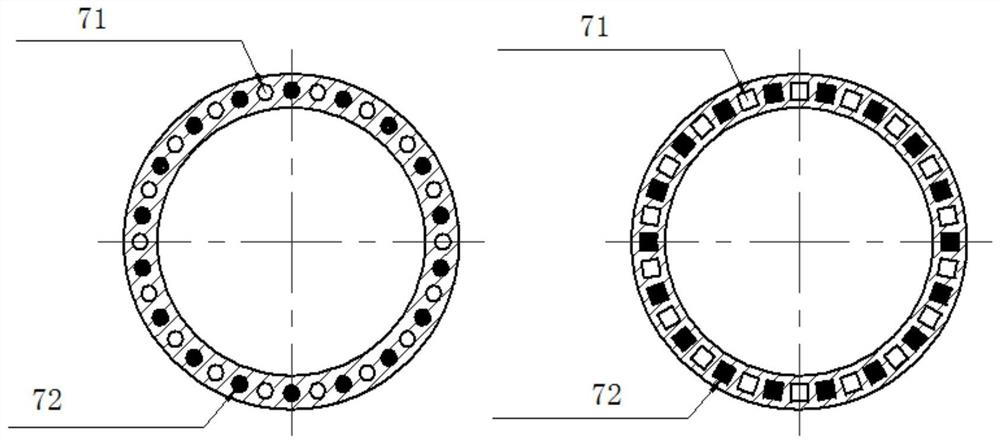

Gasification system and gasification method for pulverized coal and blending combustion combustible materials

PendingCN107118805ARealize large-scaleRealize online maintenanceGasification processes detailsGranular/pulverulent flues gasificationSyngasCombustion

The invention provides a gasification system and a gasification method for pulverized coal and blending combustion combustible materials. The gasification system comprises a feeding system, a multi-channel gasification burner and a pulverized coal gasifier, wherein the multi-channel gasification burner is provided with eight channels which are concentrically arranged; the pulverized coal, the blending combustion combustible materials and oxygen respectively enter respective channels of the multi-channel gasification burner through the feeding system; the ratio of the oxygen to the coal in each layer can be adjusted separately to achieve the effect of controlling the temperature respectively; the carbon conversion rate can be improved, and components of effective gas in syngas can be improved; in addition, the large-scale gasification of the pulverized coal can be realized, and the gasification of low-rank coal and mixed combustion of coal with different characteristics can be realized.

Owner:CHANGZHENG ENG

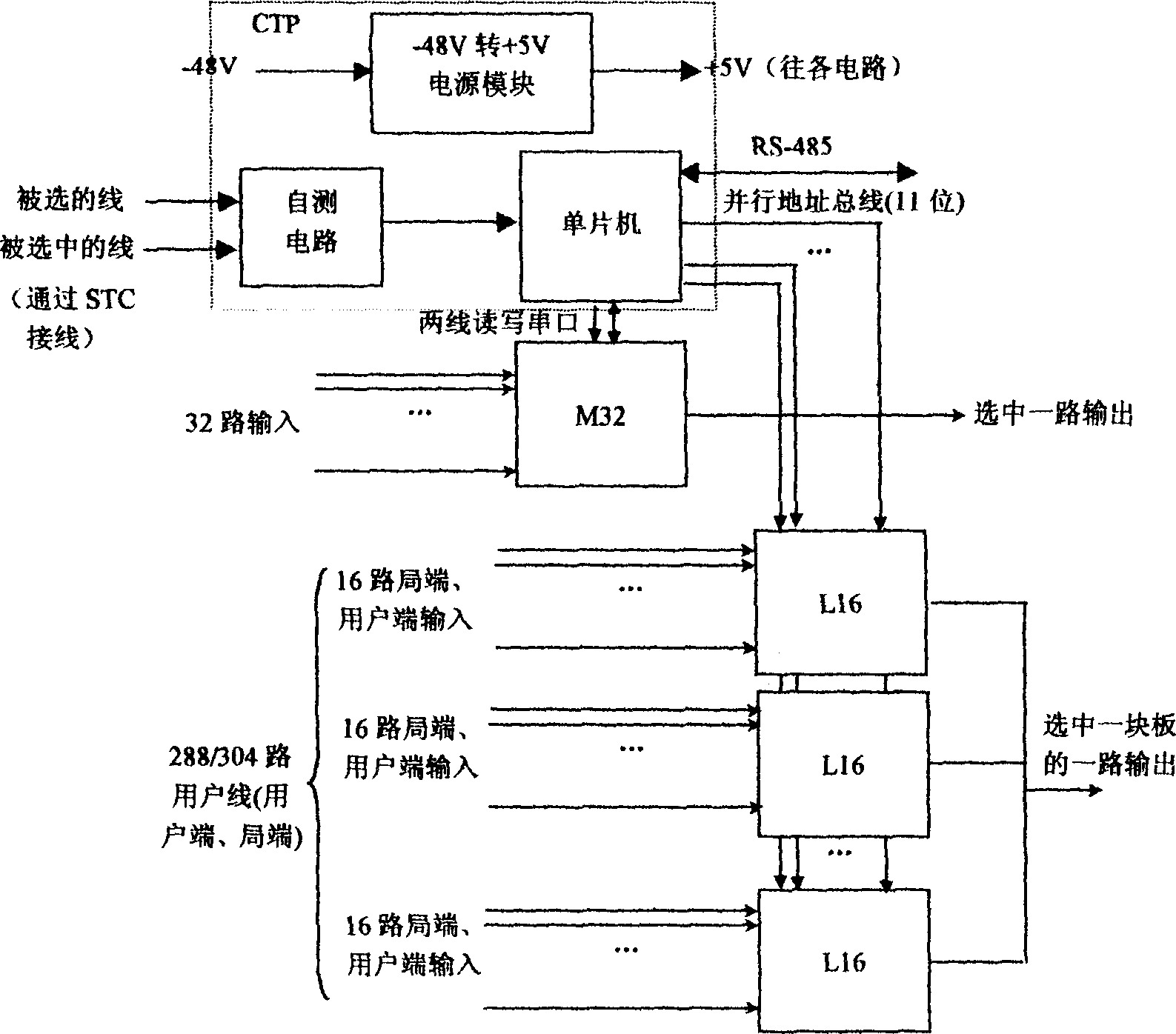

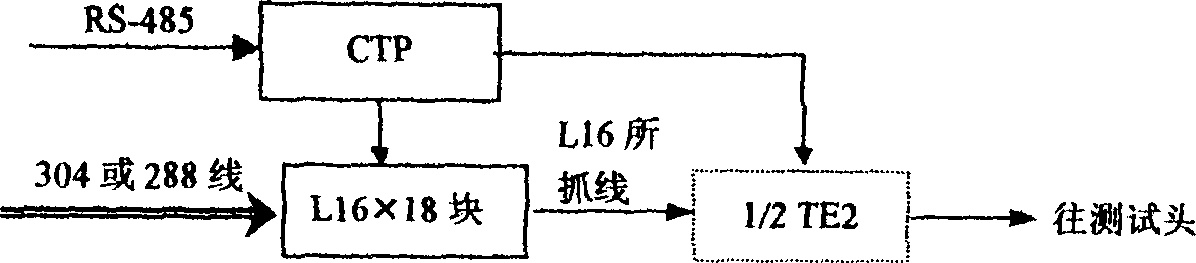

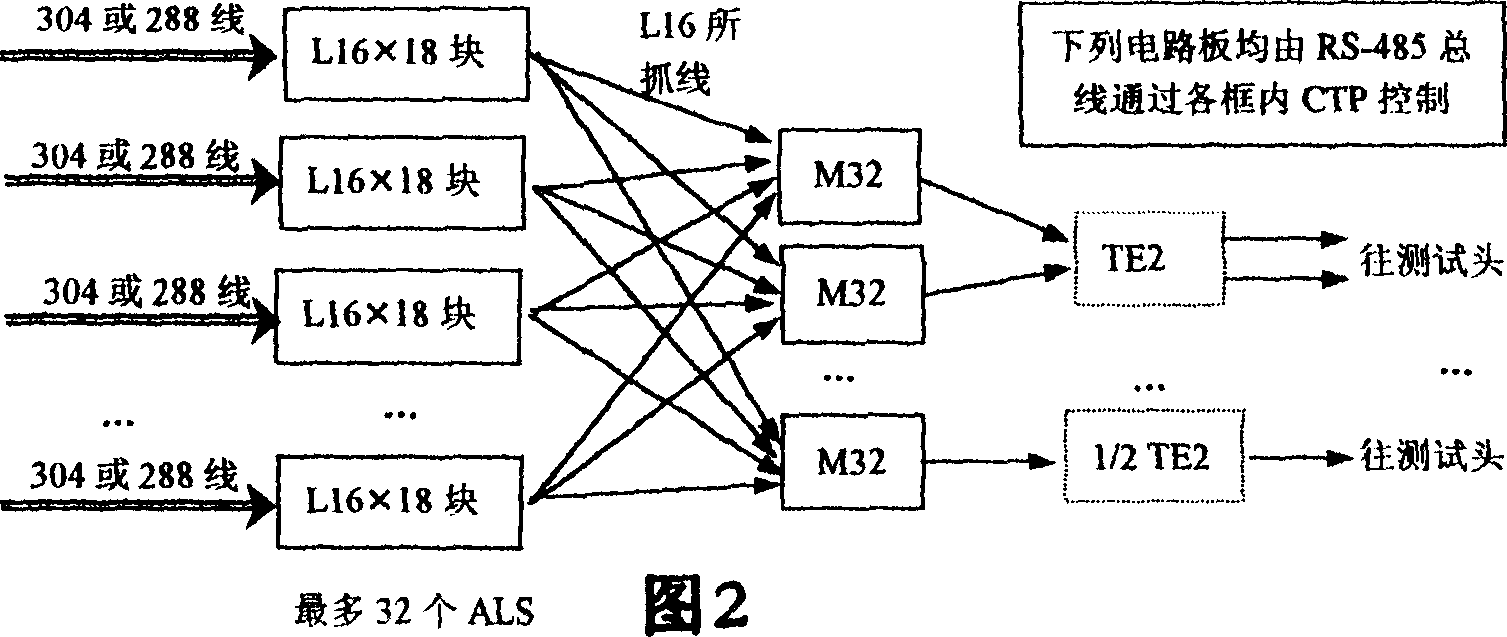

112 testboard gating array

InactiveCN1440180ARealize online maintenanceGuaranteed no interferenceSupervisory/monitoring/testing arrangementsWire frameEngineering

Owner:PCI TECH GRP CO LTD

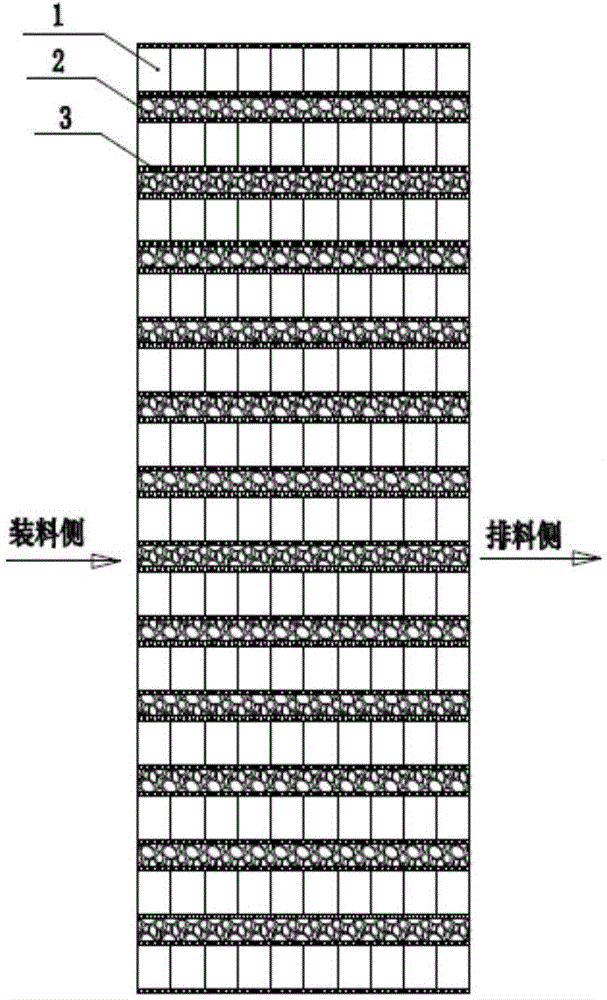

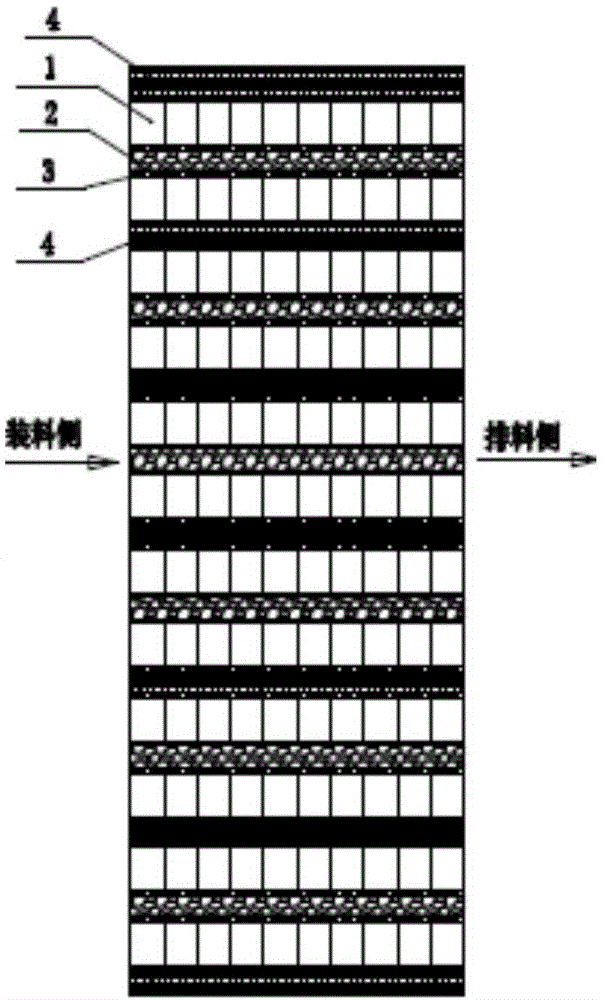

Three-dimensional storing and conveying line for green bodies

ActiveCN105501784AReduce labor intensityRealize automatic deliveryStorage devicesProduct inspectionEngineering

The invention discloses a three-dimensional storing and conveying line for green bodies and belongs to the technical field of sanitary ceramic production equipment. The three-dimensional storing and conveying line is used for conveying, inspecting and storing finished products to be inspected in the production process of sanitary ceramic. According to the technical scheme, the products pass through a suspension line, a lower line transferring machine and a sorting and recognizing line after being formed in a forming shop, reach an inspecting and warehousing line for on-line inspection, then reach a horizontal-moving lifting machine through a delivering confluence line and enter a multi-layer storage line. In the delivery process, the horizontal-moving lifting machine automatically conveys the products in the multi-layer storage line to a multi-layer storage and delivery distribution line, and then the products are conveyed to a multi-layer storage and delivery line. The three-dimensional storing and conveying line is initiative in the production process of the sanitary ceramic, fills in the blank of green body conveying equipment, solves the green body conveying problem existing for a long time, realizes automatic conveying, on-line inspecting and three-dimensional storing of the green bodies from the forming shop to product inspection to multi-layer storage, reduces the occupied area of the products in the storage process, greatly improves the inspection efficiency, and lowers the labor intensity of workers.

Owner:HUIDA SANITARY WARE

Hydraulic cylinder displacement transducer in lifting eye

InactiveCN1963240ASave the shell structureGuaranteed detection accuracyFluid-pressure actuatorsHydraulic cylinderTransducer

The invention relates to a displacement sensing device for measuring the piston strokes within hydraulic cylinders, and it particularly relates to a built-in displacement sensing device of hydraulic cylinders with lifting eyes. The said displacement sensor comprises displacement rotation components for sensors, measuring components for displacement sensors and springs. The displacement sensor components mate with springs to control the movement of the piston, and they also mate with displacement sensor measuring components to measure the displacement strokes of the pistons, with the displacement sensor rotation components connected with pistons. The inventions is meant to solve the technical issues like the those caused by the external displacement sensor, and also the defect of lacking built-in opening checkup devices of those hydraulic cylinders with lifting eyes. With this structure, the invention has high precision of measurement and convenient way for installation and maintenance.

Owner:北京欧特科新技术有限公司

Flowmeter with movable annular rotor

InactiveCN1680788AHigh measurement accuracyGood reliabilityMovable measuring chambersRing typeMechanical engineering

A flowmeter with flexible rotor in ring type consists of main body, liquid inlet and outlet, end covers, central rotation shaft, ring type of metering chamber formed between internal wall of main body and external wall of rotation shaft, multiple rotor containers, multiple flexible rotors, metering space with set volume, liquid inlet - outlet guide in thickness being less than or equal to thickness of said metering chamber. Its design accuracy can be up to plus or minus 0.1 %.

Owner:兰州科庆仪器仪表有限责任公司

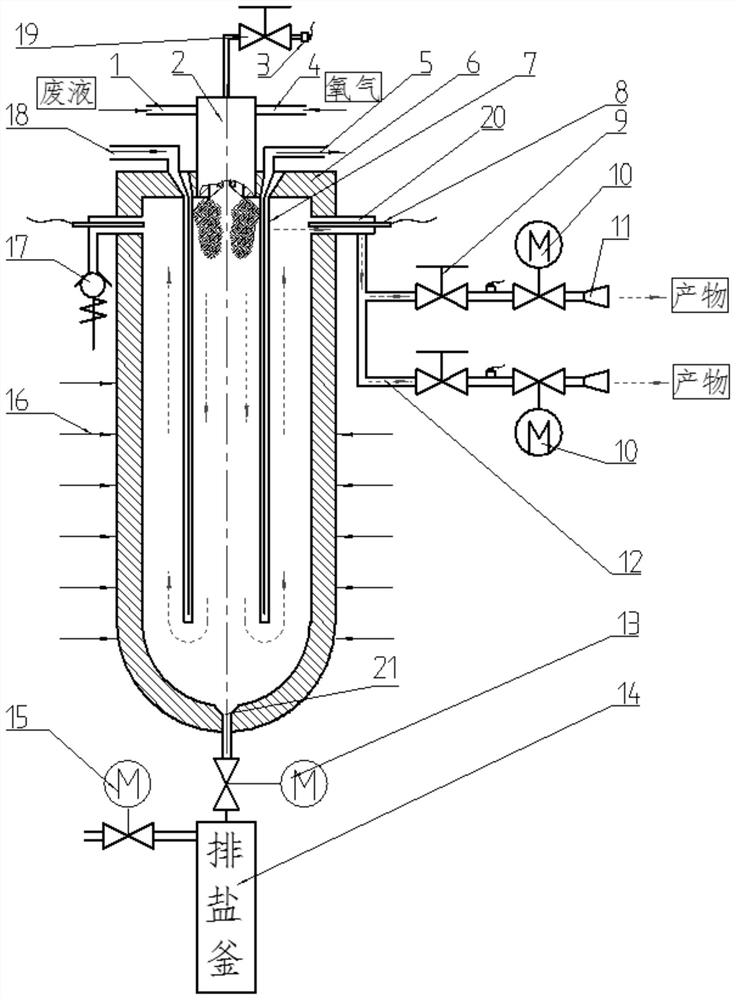

Supercritical water oxidation reaction device and control method

ActiveCN112811567AShorten the timeReduce reaction preparation timeWater treatment parameter controlWater contaminantsSupercritical water oxidationStress sensors

The invention relates to a vertical supercritical water oxidation reaction device and a control method. The device comprises an injector, a vertical reaction kettle, an isolation sleeve with cooling and isolation effects, an external heating device, a salt discharge valve, a salt discharge kettle, a salt discharge kettle vent valve, a stop valve, a discharge spray pipe, a temperature sensor and a pressure sensor. Reactants are atomized and mixed in advance through an injector, and a heat management structure adopts a cold and hot separation mode; the structural layout that a built-in sleeve, a feed port and a discharge port are arranged at the top is utilized; the service life of the blow-off valve is effectively prolonged by using a pressure control mode of small-flow continuous discharge and large-flow intermittent discharge; the use efficiency of the reaction device is improved by adopting a parallel control mode of a plurality of discharge valves and a working mode of a salt discharge kettle and a corresponding control valve thereof; in practical application, long-term unmanned operation and online maintenance and detection under partial fault conditions can be realized, the operation efficiency of the device is greatly improved, and the waste liquid treatment period and cost are effectively reduced.

Owner:贵州航天朝阳科技有限责任公司

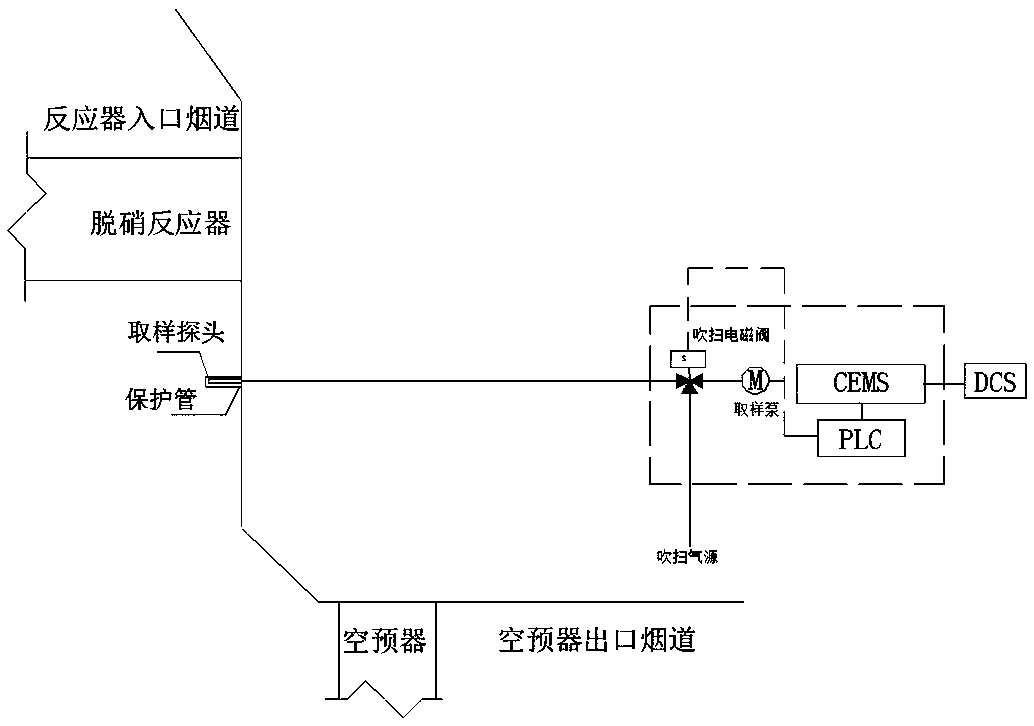

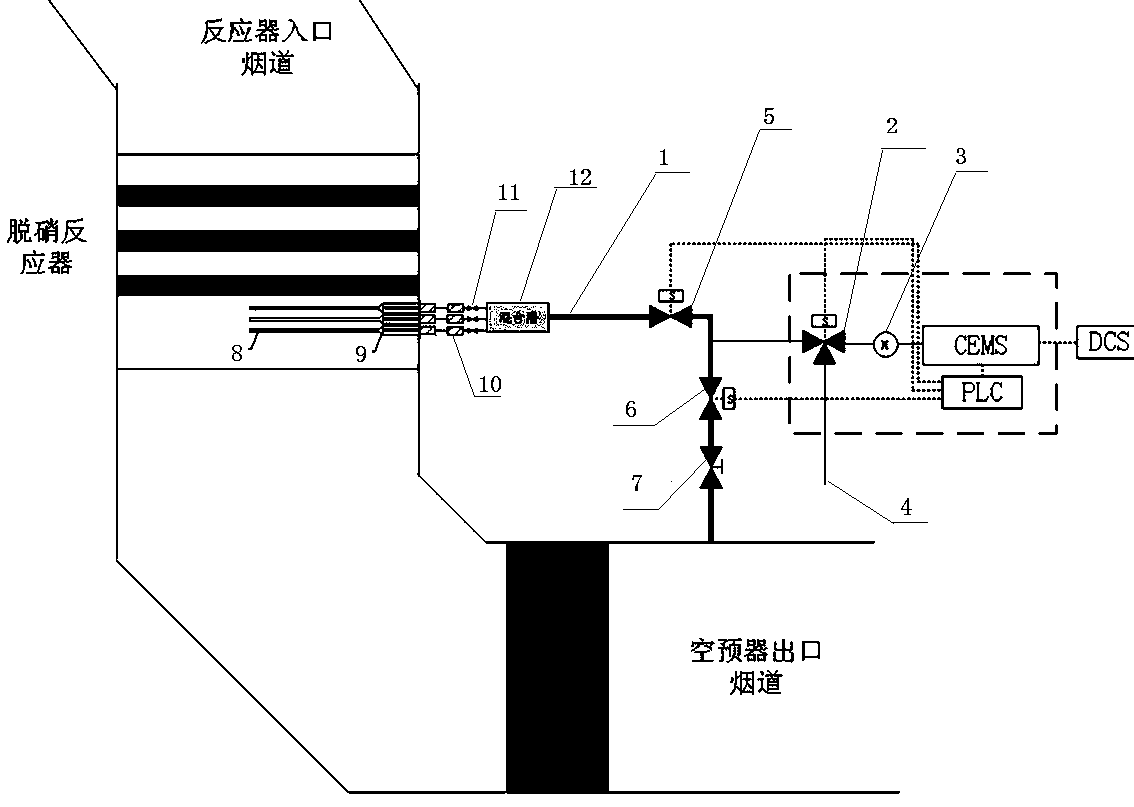

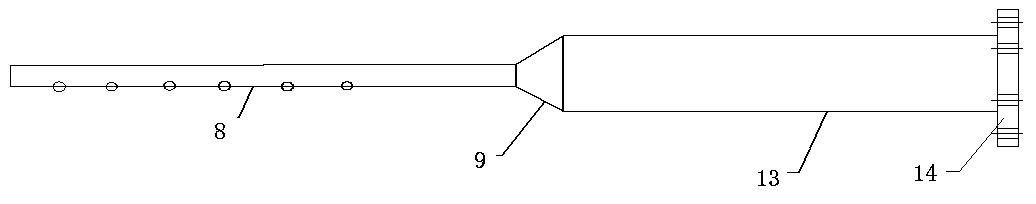

Self-suction CEMS multi-point flue gas sampling device and control method

InactiveCN110887709AAvoid enteringEnter into realizationWithdrawing sample devicesAir preheaterFlue gas

The invention provides a self-suction CEMS multi-point flue gas sampling device and a control method, and aims to overcome the problems of long sampling time and measurement lag. A sampling pipe is connected to the outlet flue of an air preheater. The characteristic that the outlet flue pressure of the air compressor is 1-2KPa lower than the outlet pressure of a denitration reactor is utilized, the pressure difference is far greater than that of the pressure head of a sampling pump and the flue gas can naturally and quickly flow by virtue of the pressure difference so that the quick replacement of the flue gas in the sampling pipe is realized, the sampling lag is eliminated, and the flue gas sampling speed not only depends on the sampling pump, but also depends on the natural circulation of the flue gas by virtue of the flue gas pressure difference between the denitration outlet and the outlet of the air pre-heater. Furthermore, a sampling branch pipe is connected before the pipeline of the sampling pipe passes through the sampling pump of the CEMS, the flue gas is extracted by the sampling pump to enter a CEMS analyzer and experimental verification shows that the sampling time ofthe mode can be shortened by more than 90%.

Owner:HUANENG LUOYUAN POWER GENERATION CO LTD

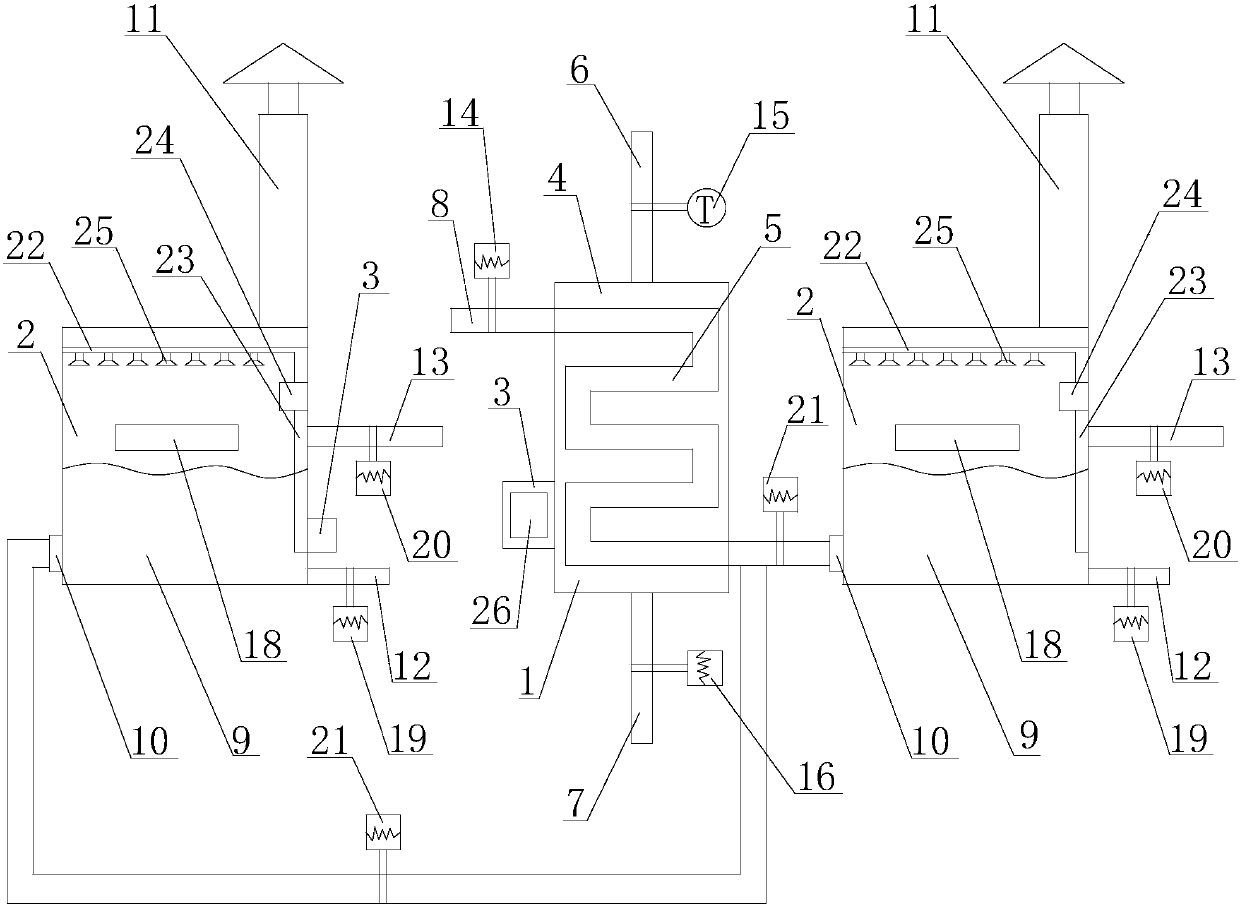

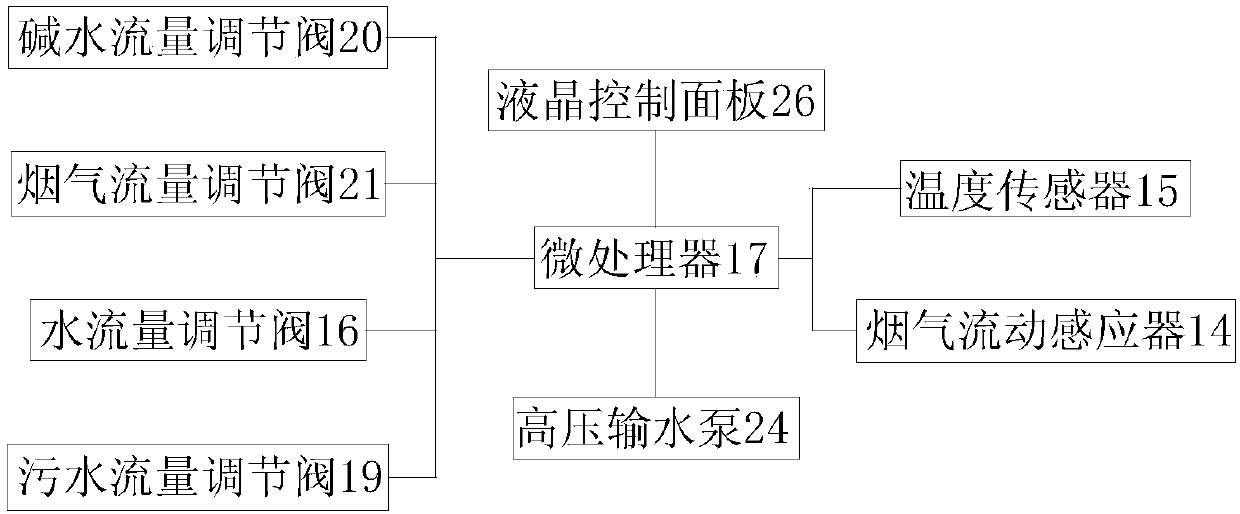

Intelligent flue gas cleaning system capable of achieving online maintenance

InactiveCN107559862AImprove purification efficiencyImprove purification effectIncreasing energy efficiencyCombustion technology mitigationHigh pressure waterHigh pressure

The invention discloses an intelligent flue gas cleaning system capable of achieving online maintenance. The problems that in the prior art, energy resources are wasted, the flue gas cleaning efficiency is low, the flue gas cleaning schedule is delayed after a flue gas cleaning tower breaks down, and the automatic degree is low are solved. The intelligent flue gas cleaning system comprises a heatexchanger, and the flue gas cleaning tower, a control cabinet and a flue gas conveying pipe provided with a flue gas flowing sensor; the heat exchanger comprises a heat exchanger shell, an S-shaped heat exchange pipe, a hot water outlet pipe, a cold water inlet pipe, a temperature sensor and a water flow adjusting valve; the flue gas cleaning tower comprises a flue gas cleaning tower body, a fluegas cleaning alkali water pool, a spraying device and an exhaust window, the cleaning alkali water pool is provided with a flue gas pipe, a pollution discharge water pipe and an alkali water inlet pipe, and the spraying device comprises a spraying pipe, an alkali water conveying pipe, a high pressure water conveying pump and a spraying head; and the control cabinet is provided with a microprocessor and a liquid crystal control panel. The intelligent flue gas cleaning system is simple in structure, energy conservation and environmental protection are achieved, the flue gas cleaning efficiency is high, the cleaning effect is ideal, the flue gas cleaning tower can be maintained online to guarantee the flue gas cleaning schedule, and the automatic degree is high.

Owner:中山市睿丰智能科技有限公司

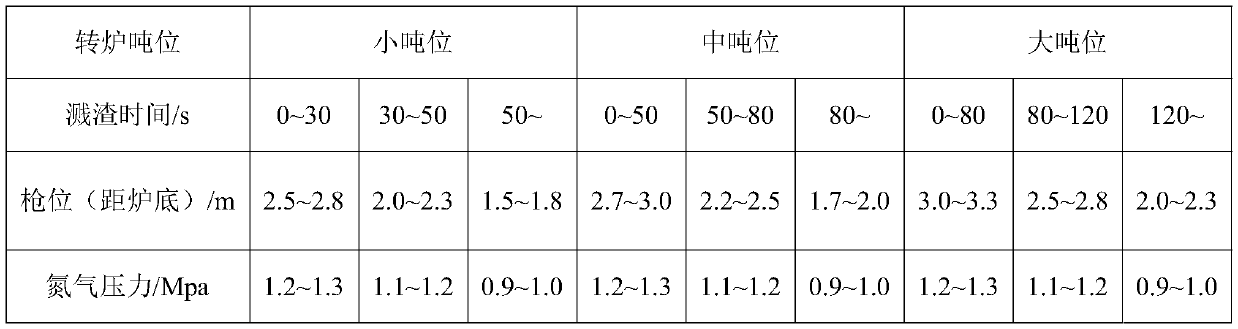

Method for maintaining converter slag surface by using granular steel

InactiveCN111440915AImprove corrosion resistanceReduce maintenance costsManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention relates to a method for maintaining a converter slag surface by using granular steel, and belongs to the technical field of ferrous metallurgy steelmaking. The method comprises the following steps: 1) measuring the height of the bottom of a converter and the distance between the center of a severely eroded part of the slag surface and a converter mouth by one heat in advance; 2) determining the loading position of the granular steel in a scrap steel bucket according to the erosion position of the converter slag surface, and loading all scrap steel into the scrap steel bucket forlater use; (3) conducting slag splashing operation after tapping is completed, and controlling the slag splashing gun position and nitrogen pressure according to certain parameters; (4) confirming that the slag fluidity meets the slag surface maintenance requirement after slag splashing is completed, rocking the converter to the horizontal position and stays for 5 seconds after steel scrap is added into the converter, and then conducting iron mixing operation; and 5) performing normal smelting by lowering the gun after the iron mixing operation is completed. According to the method, the granular steel is flatly laid on the surface of the slag in the loading process and bonded with the slag, the erosion resistance of the slag is improved in the smelting process, erosion to the converter slag surface in the smelting process is relieved, the operation safety of a converter body is improved, and the maintenance cost of the converter body is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

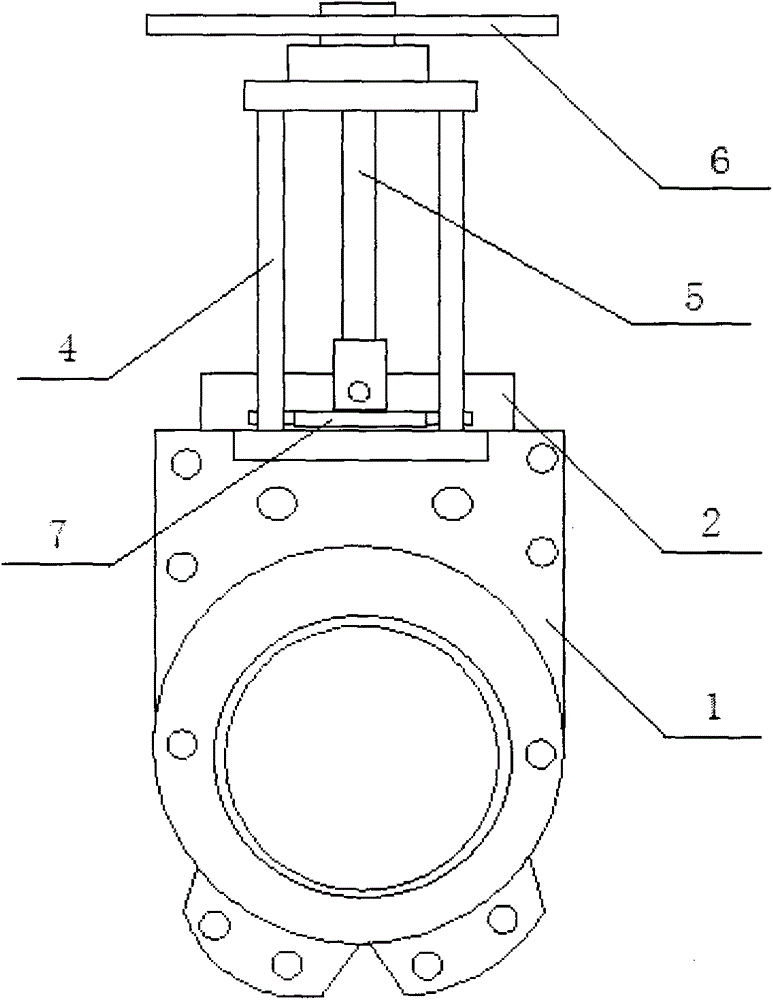

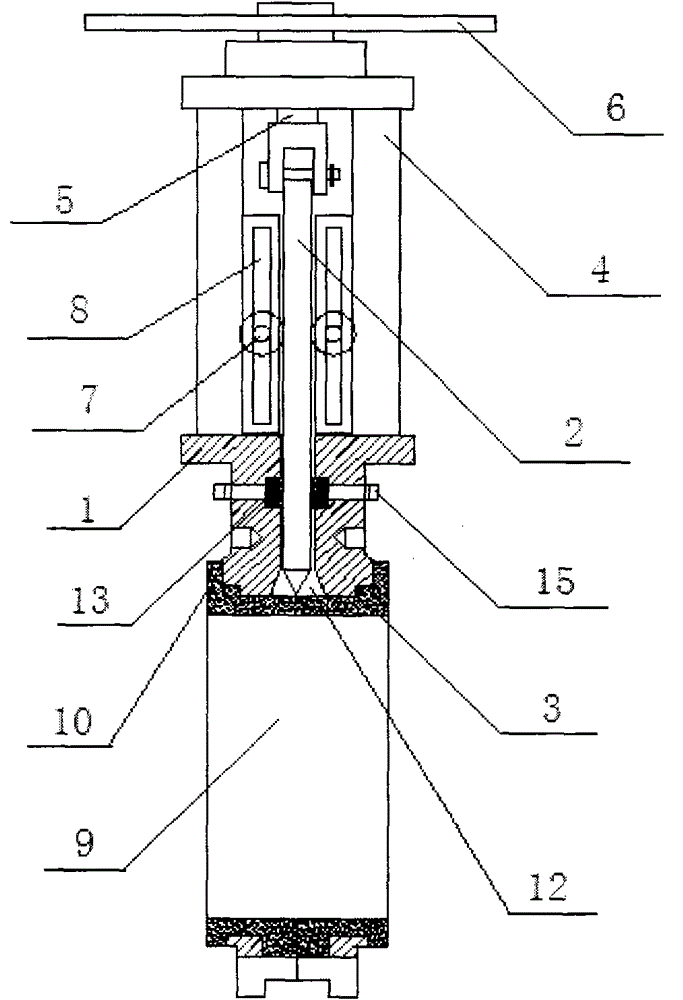

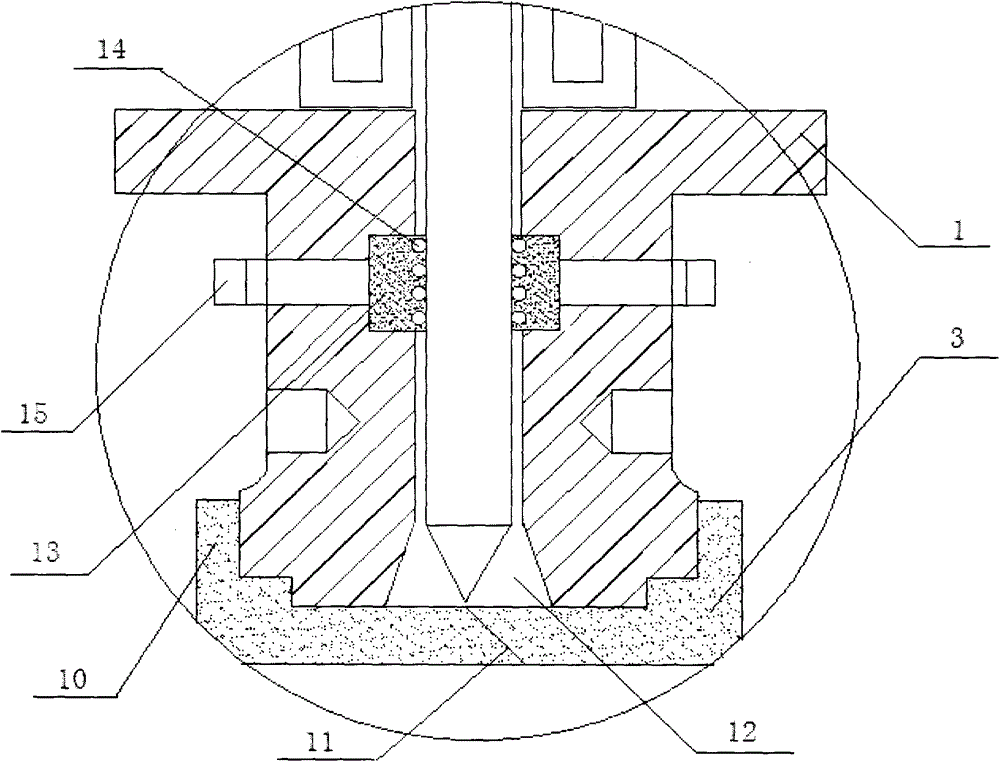

A long-life knife gate valve

The invention discloses a long-life knife gate valve which comprises a valve body, a gate plate and a sealing ring, wherein a support frame, a valve rod, a transmission part and balancing poles are arranged at the upper part of the valve body; sliding chutes are formed in the support frame and located on two edges of the gate plate; two ends of each balancing pole are mounted in the sliding chutes and in rolling contact with the gate plate; the upper part of the inner wall of a valve cavity adopts a step type structure, and the lower part of the inner wall of the valve cavity adopts a platform structure; the sealing ring comprises two independent ring bodies; outer circumferential surfaces of the ring bodies are in interference fit with inner walls of valve cavities of two parts of the valve body to form sealing; an external lug of the sealing ring is located on the outer wall of the valve body; diagonal planes of the two sealing ring bodies at the upper part of the valve cavity are contacted; a V-shaped blade at the lower part of the gate plate is located at the joint of the diagonal planes of the two sealing ring bodies, and a V-shaped groove symmetric to the gate plate is formed in the valve cavity; sealing strips are arranged on the valve body at the upper part of the valve cavity; and cylindrical ribs are arranged on the sealing strips. According to the long-life knife gate valve, the structure design is ingenious, the service life of the gate valve far surpasses that of a conventional gate valve, the use is convenient, and on-line maintenance, overhaul and replacement can be realized.

Owner:HUAIBEI XINXIANG HYDRAULIC ELECTROMECHANICAL COMPLETE EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com