PLC control system and method for dual power supply and communication of speed regulator hydraulic system

A technology of hydraulic system and control system, which is applied in the dual power supply and communication PLC control system and control field of governor hydraulic system, which can solve the problem of reducing the reliability of PLC control system, HMI cannot update data in time, and PLC system loses control function, etc. problems, to achieve the effect of improving the level of automation technology and production efficiency, realizing power redundancy, and ensuring timely data updates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

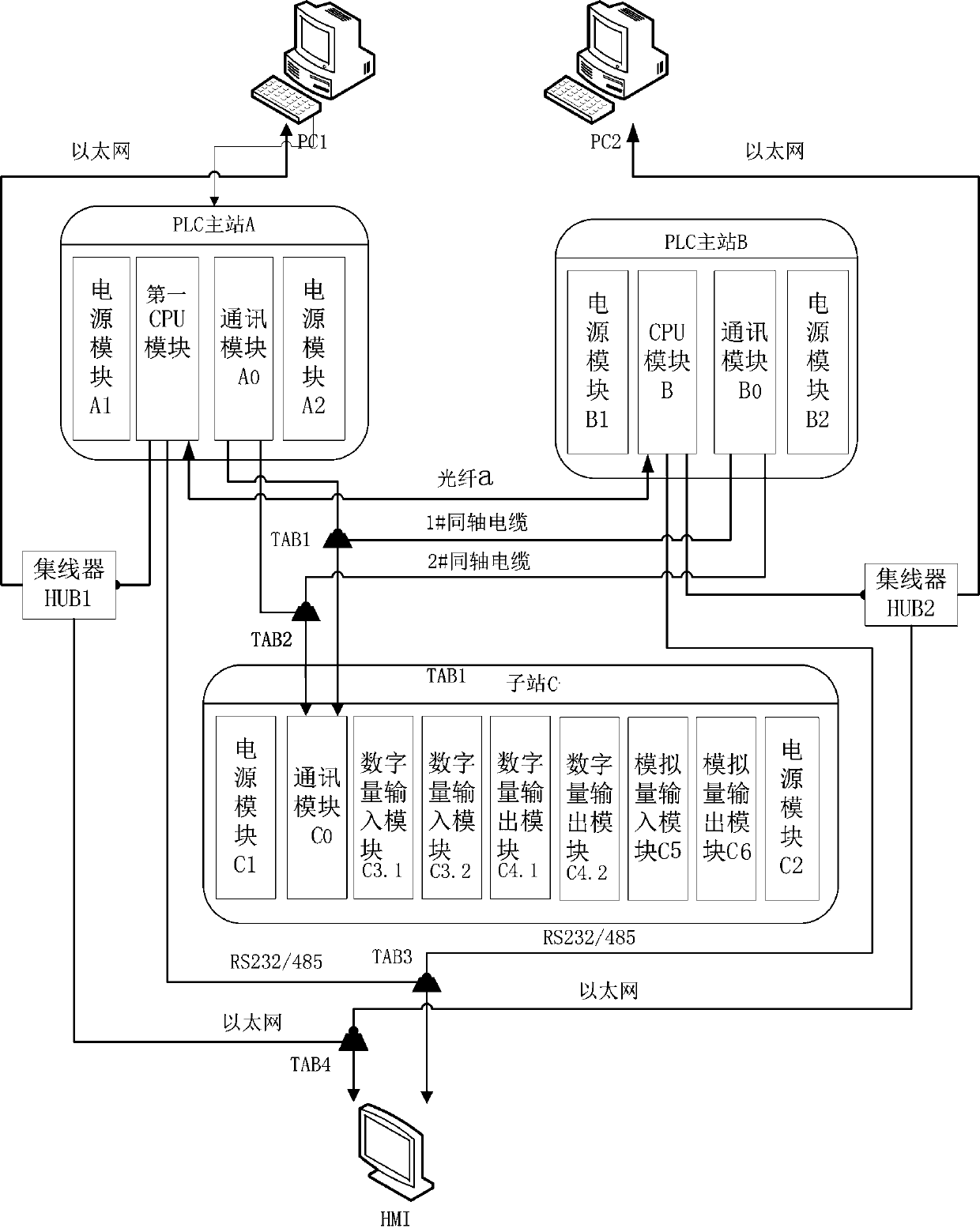

[0047] The first CPU module of PLC master station A and the second CPU module of PLC master station B adopt optical fiber communication to realize the hot standby redundant control of the two CPU controllers, and have the function of hot standby switching; the second CPU module of PLC master station A A communication module A0 and the first communication module B0 of the PLC master station B are connected to the third communication module C0 of the substation C through a dual-channel coaxial cable, so as to share the collected information of all modules of the substation and realize the redundancy of the PLC control system. I control. The specific implementation is as follows:

[0048] The control system of the present invention adopts two sets of PLC control systems, that is, PLC master station A and PLC master station B, and its system structure and hardware configuration are completely the same. PLC master station A is equipped with power module A1, power module A2, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com