Self-suction CEMS multi-point flue gas sampling device and control method

A flue gas sampling and self-priming technology, applied in sampling devices, sampling, measuring devices, etc., can solve problems such as air preheater blockage, flue gas turbulence, and difficulty in controlling denitrification and ammonia injection of thermal power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the features and advantages of this patent more obvious and easy to understand, the following specific examples are given together with the accompanying drawings and described in detail as follows:

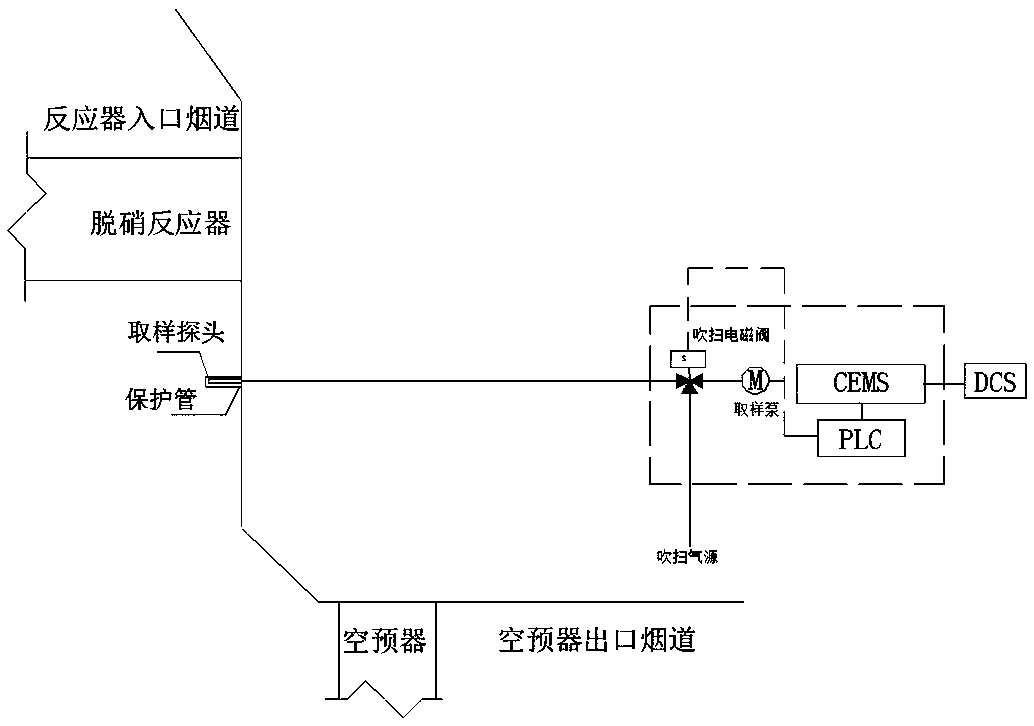

[0030] Such as figure 1 As shown, in the existing CEMS flue gas sampling devices produced by major CEMS equipment manufacturers, the depth of the sampling pipe inserted into the flue is less than 2m, and the flue gas extraction relies on the sampling pump to provide power extraction.

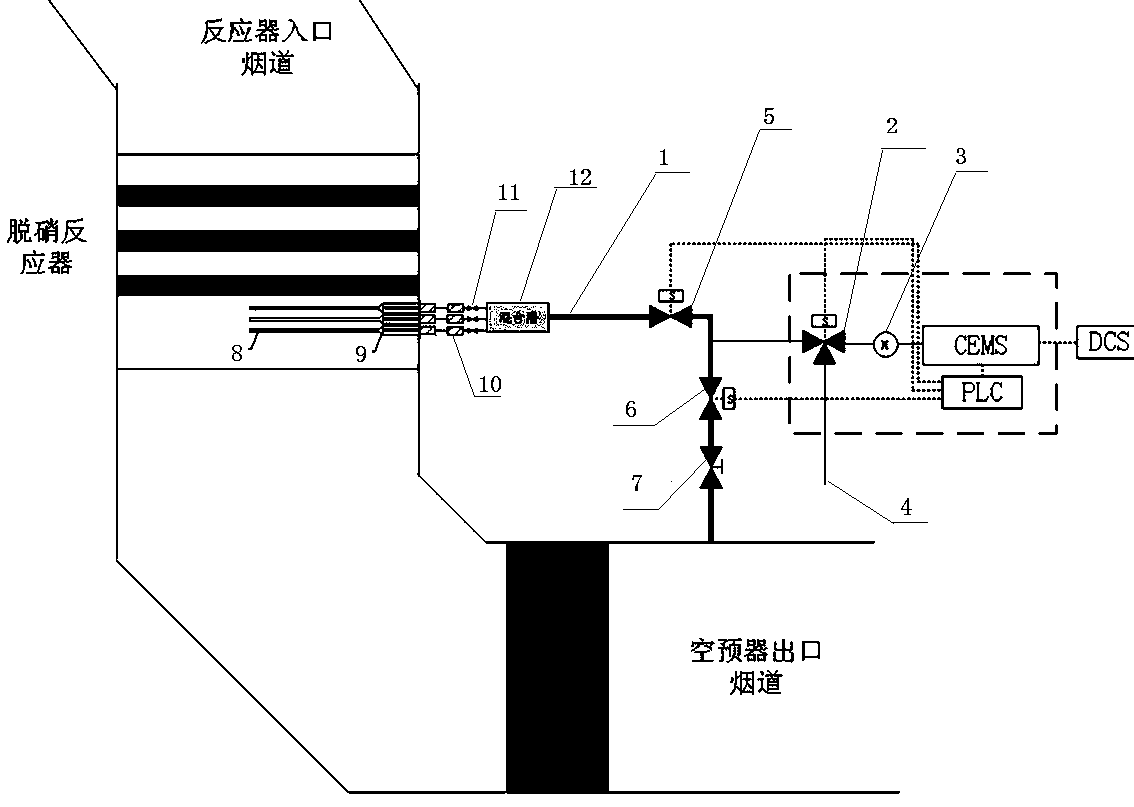

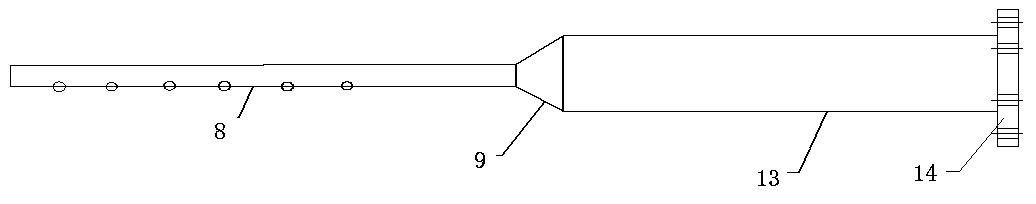

[0031] Such as figure 2 , image 3 As shown, in the solution provided in this embodiment, in order to overcome the problems of long sampling time and measurement lag, the sampling pipe 1 is connected to the outlet flue of the air preheater, and the pressure ratio of the outlet flue of the air compressor to the outlet flue of the denitrification reactor is used. The channel pressure is 1-2KPa lower, and the pressure difference is much larger than the pressure head of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com