Gasification system and gasification method for pulverized coal and blending combustion combustible materials

A gasification system, pulverized coal technology, applied in the field of coal chemical industry, can solve problems such as inability to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

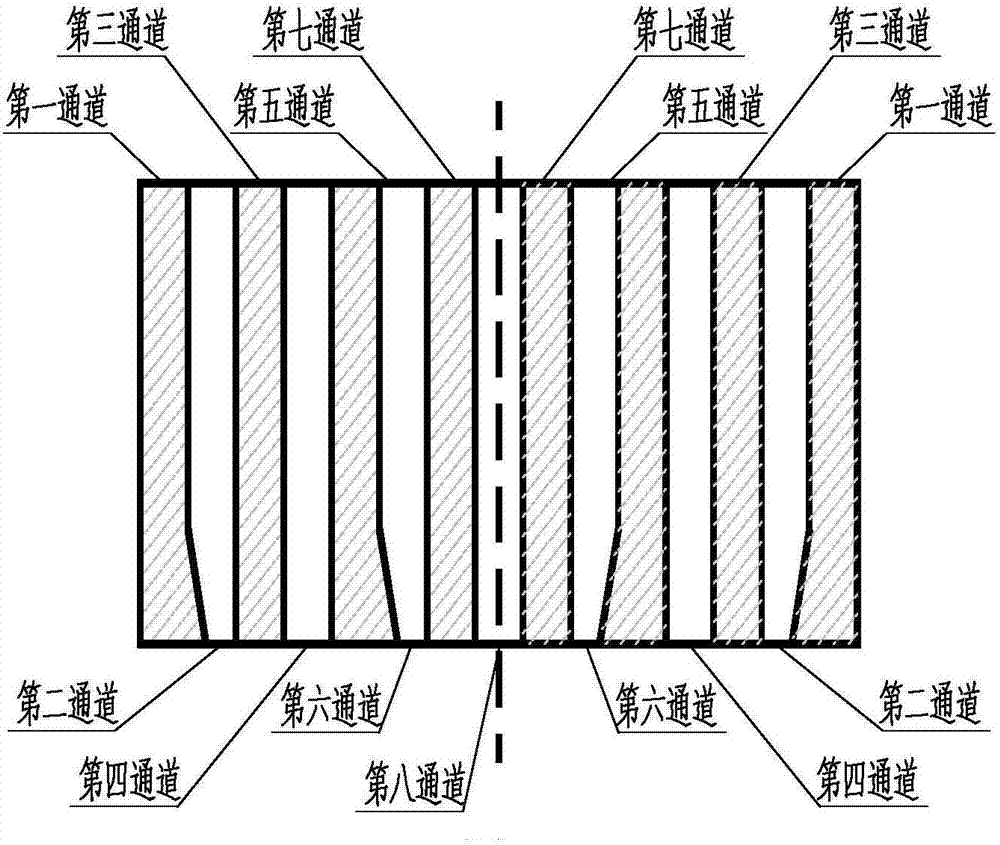

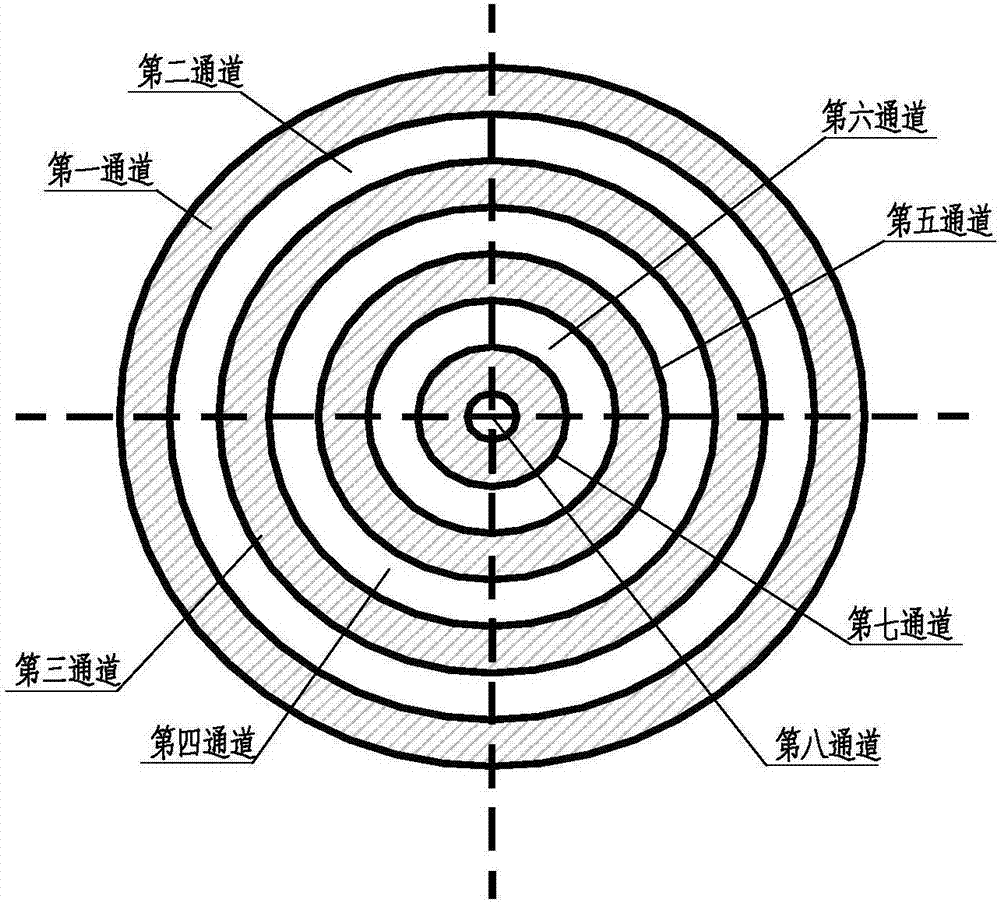

[0036] This embodiment provides a gasification system for pulverized coal mixed with combustibles. The system includes a feed system, a multi-channel gasification burner and a pulverized coal gasification furnace, wherein the multi-channel gasification burner has a concentric arrangement There are eight channels, from outside to inside, they are the first channel, the second channel, the third channel, the fourth channel, the fifth channel, the sixth channel, the seventh channel, and the eighth channel.

[0037] Wherein, the first channel, the third channel, the fifth channel and the seventh channel are burner cooling water channels; the fourth channel is the main oxygen channel; the sixth channel is the central oxygen channel; the second channel is pulverized coal channel, the eighth channel is petroleum coke channel or coke channel.

[0038] The pulverized coal passage and the combustible combustible passage are in a spiral structure to ensure that the pulverized coal and pe...

Embodiment 2

[0046] The pulverized coal mixed combustion combustible gasification system provided by the invention includes a feed system, a novel multi-channel gasification burner and a high-pressure pulverized coal gasification furnace.

[0047] Wherein, in this embodiment, the combustible substance blended is petroleum coke.

[0048] In the present embodiment, the coal quality parameter of pulverized coal is as follows:

[0049] Table 1 Pulverized coal quality data

[0050]

[0051]

[0052] The data for petroleum coke are as follows:

[0053] Table 2 Characteristic parameters of petroleum coke

[0054]

[0055] The feeding system of the present invention includes a pulverized coal pipeline, a petroleum coke pipeline, a main oxygen pipeline, a central oxygen pipeline, two superheated steam pipelines and a burner cooling water pipeline.

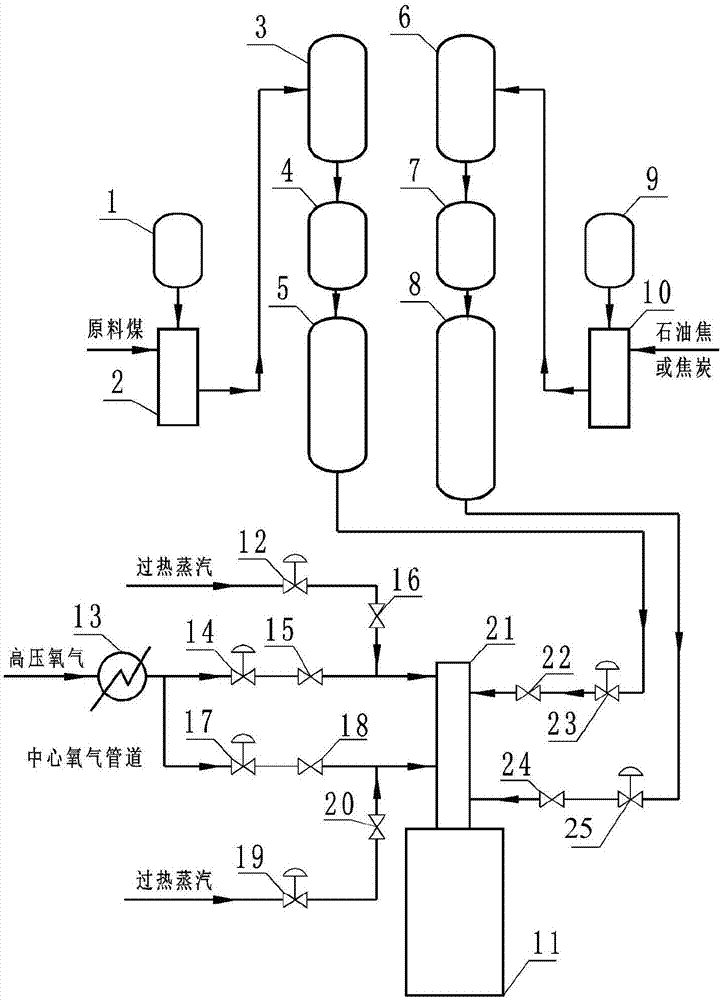

[0056] For the process flow of the feed, see figure 1 shown.

[0057] The raw coal is transported to the raw coal storage bin 1 through a...

Embodiment 3

[0074] The pulverized coal mixed combustion combustible gasification system provided by the invention includes a feed system, a novel multi-channel gasification burner and a high-pressure pulverized coal gasification furnace.

[0075] Wherein, in this embodiment, the combustibles blended are coke.

[0076] The feeding system of the present invention includes pulverized coal pipeline, coke pipeline, main oxygen pipeline, central oxygen pipeline, two superheated steam pipelines and burner cooling water pipeline.

[0077] For the process flow of the feed, see figure 1 shown.

[0078] The raw coal is transported to the raw coal storage bin 1 through a belt, and the pulverized coal from the raw coal storage bin 1 is fed into the coal mill 2 and ground into powder until the particle size is ≤90 μm, accounting for 90%. The pulverized coal is sent to the normal pressure pulverized coal storage tank 3 through the pipeline, and the pulverized coal in the normal pressure pulverized coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com