Patents

Literature

158results about How to "Save design cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic greenhouse solar energy distribution method based on crop growth mode and device thereof

InactiveCN103163904AHigh simulationSave time and costPV power plantsControl using feedbackMathematical modelElectrical battery

A photovoltaic greenhouse solar energy distribution method based on a crop growth mode includes: firstly, building an illumination need model based on green house crops, a photovoltaic cell equivalent mathematical model and a luminous environment mathematical model of crop canopies, building a multi-parameter, multivariable and nonlinearity coupling pair time differential equation, achieving utilizing an optimization algorithm to design, regulate and control a photovoltaic greenhouse cell array under conditions of different illumination intensity, different illumination angles and different temperatures by solving the differential equation, and achieving solar energy reasonable distribution of photovoltaic cell maximum electric energy production under a condition which satisfies greenhouse crop growth conditions. The invention provides a device used for achieving the photovoltaic greenhouse solar energy distribution method based on the crop growth mode. The invention provides the photovoltaic greenhouse solar energy distribution method based on the crop growth mode and the device of the photovoltaic greenhouse solar energy distribution method based on the crop growth mode, and the photovoltaic greenhouse solar energy distribution method based on the crop growth mode is capable of effectively achieving greenhouse photovoltaic power generation and effective regulation and control of crop growth and energy.

Owner:浙江海宁经编产业园区开发有限公司

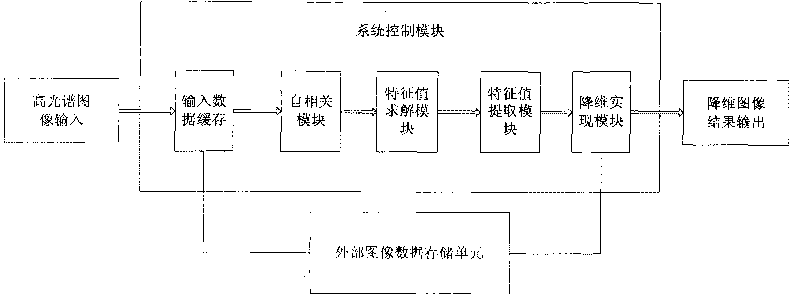

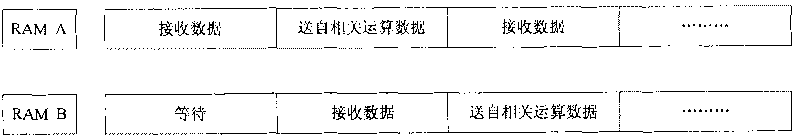

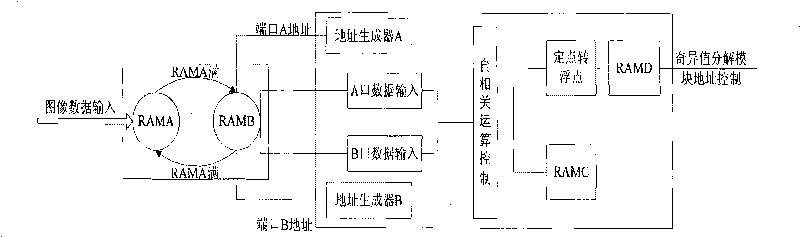

High-spectrum image dimensionality reduction chip

InactiveCN101763445AShort development cycleSave design costSpecial data processing applicationsImaging processingDimensionality reduction

The invention provides a high-spectrum image dimensionality reduction chip, which belongs to the field of image processing. The chip mainly completes the real-time dimensionality reduction processing on a large amount of high-spectrum image data. The chip is completed by adopting the VHDL speech, and is realized through being based on an in-site programmable gate array. The system chip manly comprises five parts: a system control module, a self correlation module, a feature value solving module, a feature value extracting module and a dimensionality reduction realization module. The invention can complete the real-time dimensionality reduction processing of the high-spectrum image data, and has the advantages of short development period, low design cost and low development risk.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

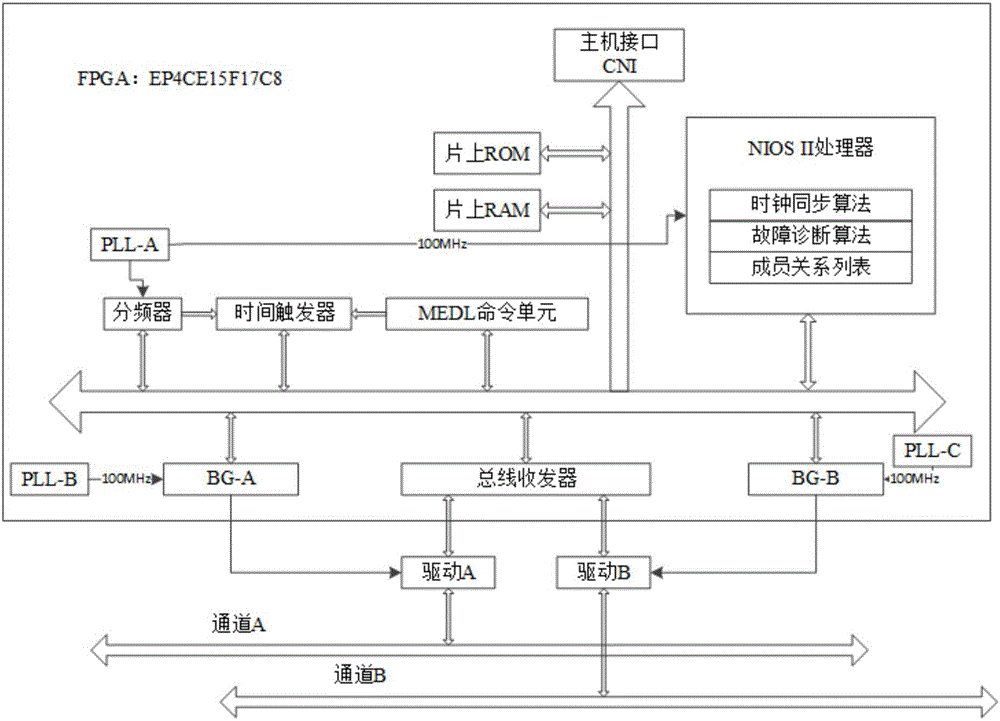

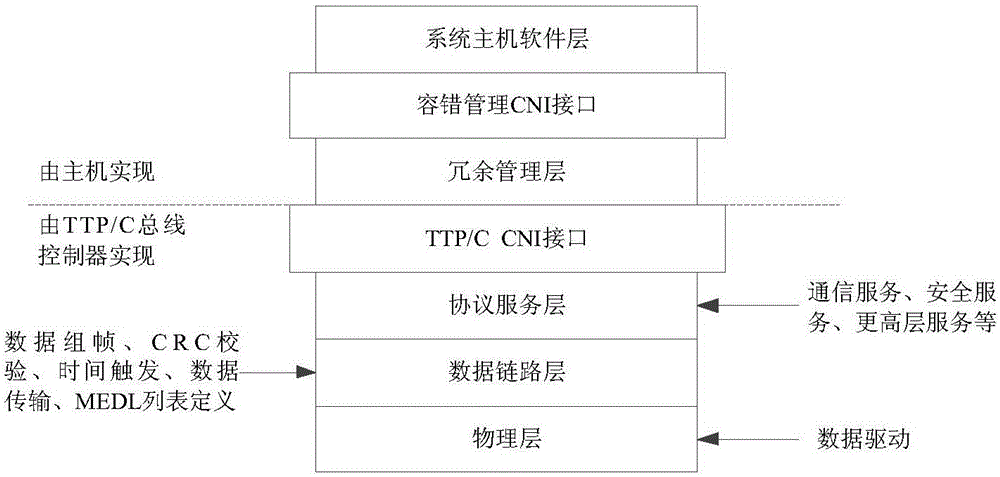

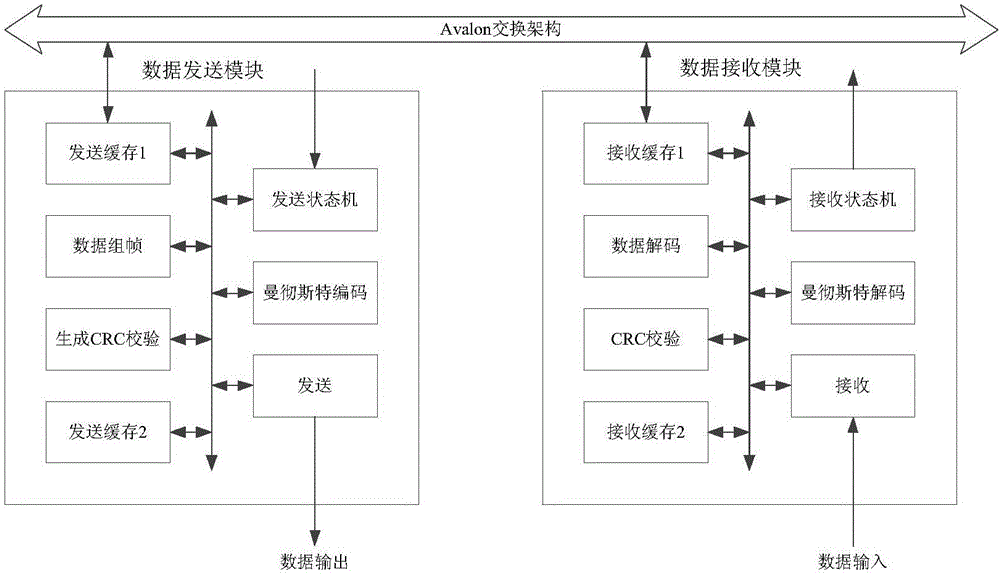

Design method of DCS controlled TTP/C bus controller catering to aeroengine

The invention discloses a design method of DCS controlled TTP / C bus controller catering to aeroengine. Considering the performance demands of the DCS system of aeroengines, the design method of TTP / C bus controller comprises the steps of general design of the TTP / C bus controller, data link layer design of the TTP / C bus controller, protocol service layer design of the TTP / C bus controller, communication network interface design of the TTP / C bus controller, and the state machine of the TTP / C bus controller. The controller designed by the method on the basis of field bus programmable gate array has the advantage of being light in weight, being low in cost, being simple in maintenance. At the same time the transmission bandwidth is high, the error tolerance is strong, and the bus use rate is high, thus satisfying the demands of the DCS system of aeroengine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

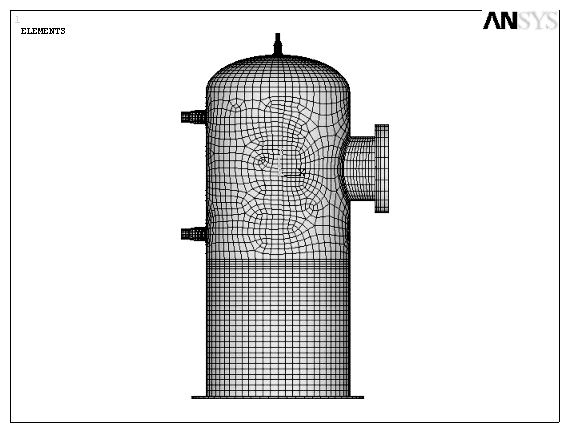

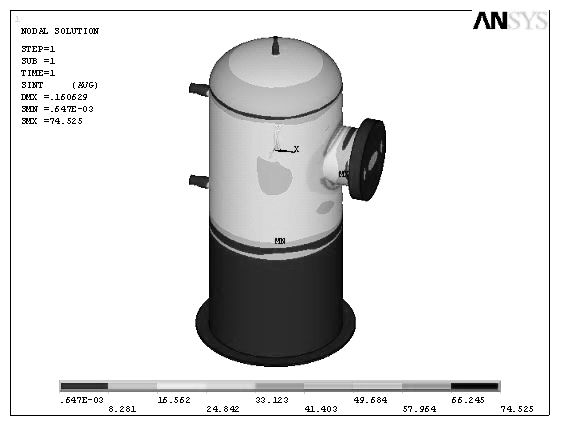

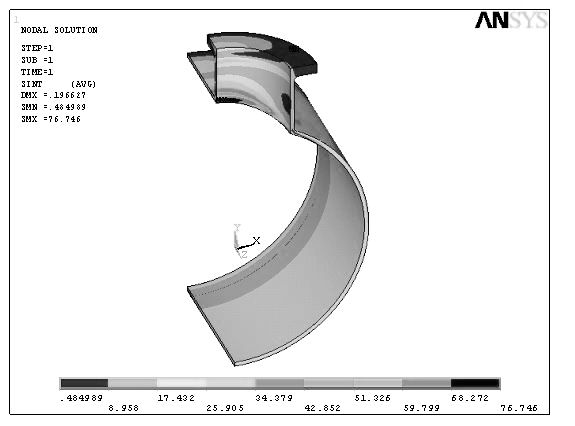

Method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software

ActiveCN102184289AShorten design timeSave design costSpecial data processing applicationsElement modelDesign specification

The invention discloses a method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software, belonging to the technical field of analysis and design methods for first-class nuclear reactors. The method comprises the following steps: firstly, after carrying out routine design according to a design specification, thus obtaining a design drawing; establishing a geometric model and a finite element model by using a simulation device in an ANSYS; carrying out analysis and calculation on all nuclear parts; extracting a stress analysis result; and carrying out strength assessment according to the specifications stipulated in subsections NB and NF of section III of ASME (American society of mechanical engineers), then obtaining a detailed design report. Compared with the prior art, the method disclosed by the invention summarizes and improves a method for carrying out analysis and design on first-class nuclear reactors through using ANSYS software; compared with an analytical method and a test method, by using the method disclosed by the invention, the design time is greatly shortened, the design expense is reduced, the analysis efficiency is greatly improved, and the analysis cost is reduced; and in the process of analysis, an entity is adopted for modeling a hexahedron unit, thereby improving the calculation accuracy.

Owner:大连船舶重工集团装备制造有限公司

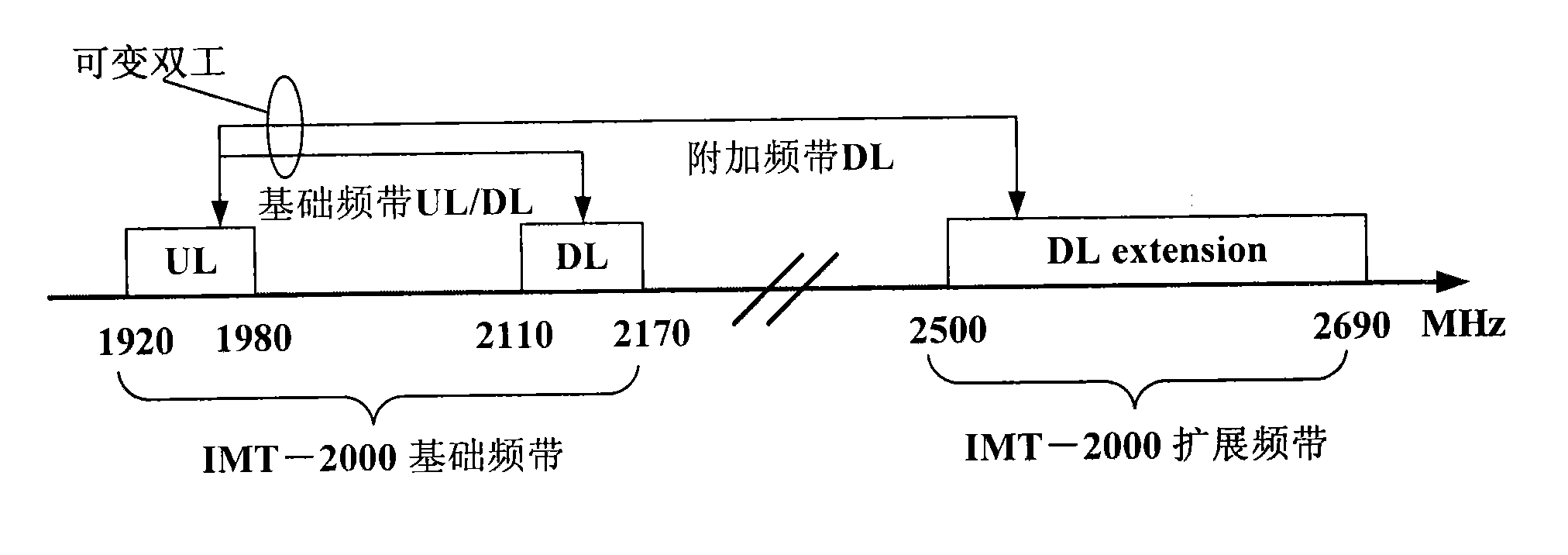

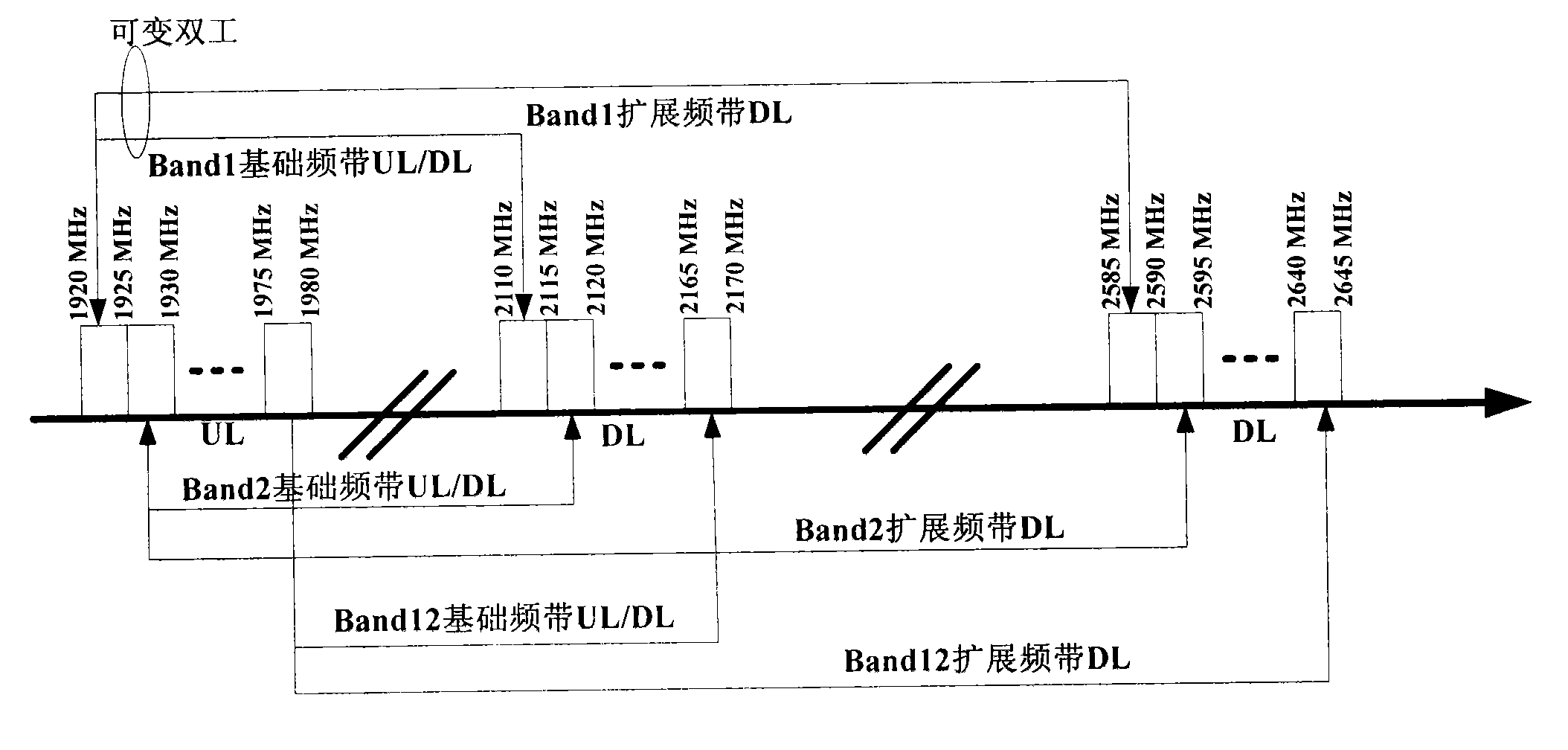

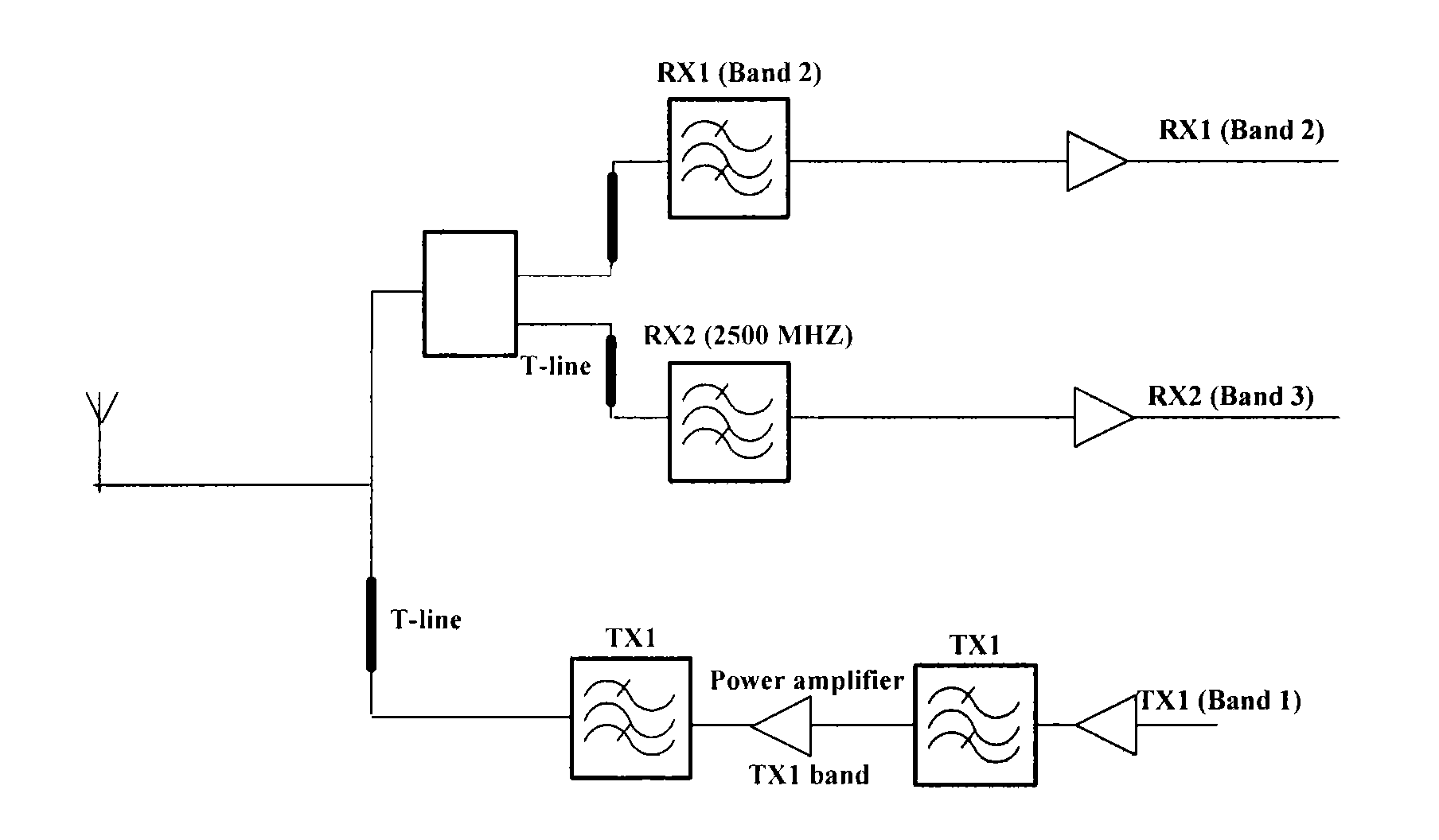

Asymmetric frequency division duplex transceiving system and transceiving method

InactiveCN102075209ARealize asymmetric transmissionMeet asymmetric business needsDuplex signal operationTransceiverEngineering

The invention discloses an asymmetric frequency division duplex transceiving system and an asymmetric frequency division duplex transceiving method. The system comprises a single band transmitter band1 and a double band receiver, wherein the double band receiver comprises a first frequency receiver band2 and a second frequency receiver band3; the first frequency receiver band2 is normally communicated with the single band transmitter band1, the switching of the second frequency receiver band3 is controlled by a baseband, and control information is acquired from the first frequency receiver band2; and when downlink signals transmitted by a base station contain the signals of the second frequency receiver band3, the first frequency receiver band2 transmits information to user equipment (UE), and the second frequency receiver band3 is switched on when the UE acquires the information. By the system and the method, asymmetric transmission can be realized. Meanwhile, by adopting a broadband radio-frequency down-conversion scheme, the system and the method have the advantage that power consumption is low compared with a scheme raised by a 3rd generation partnership project (3GPP). By using a block diagram of the invention for designing an integrated circuit chip, optimized design of chip area and power consumption of a transceiver can be realized.

Owner:SHANGHAI RES CENT FOR WIRELESS COMM

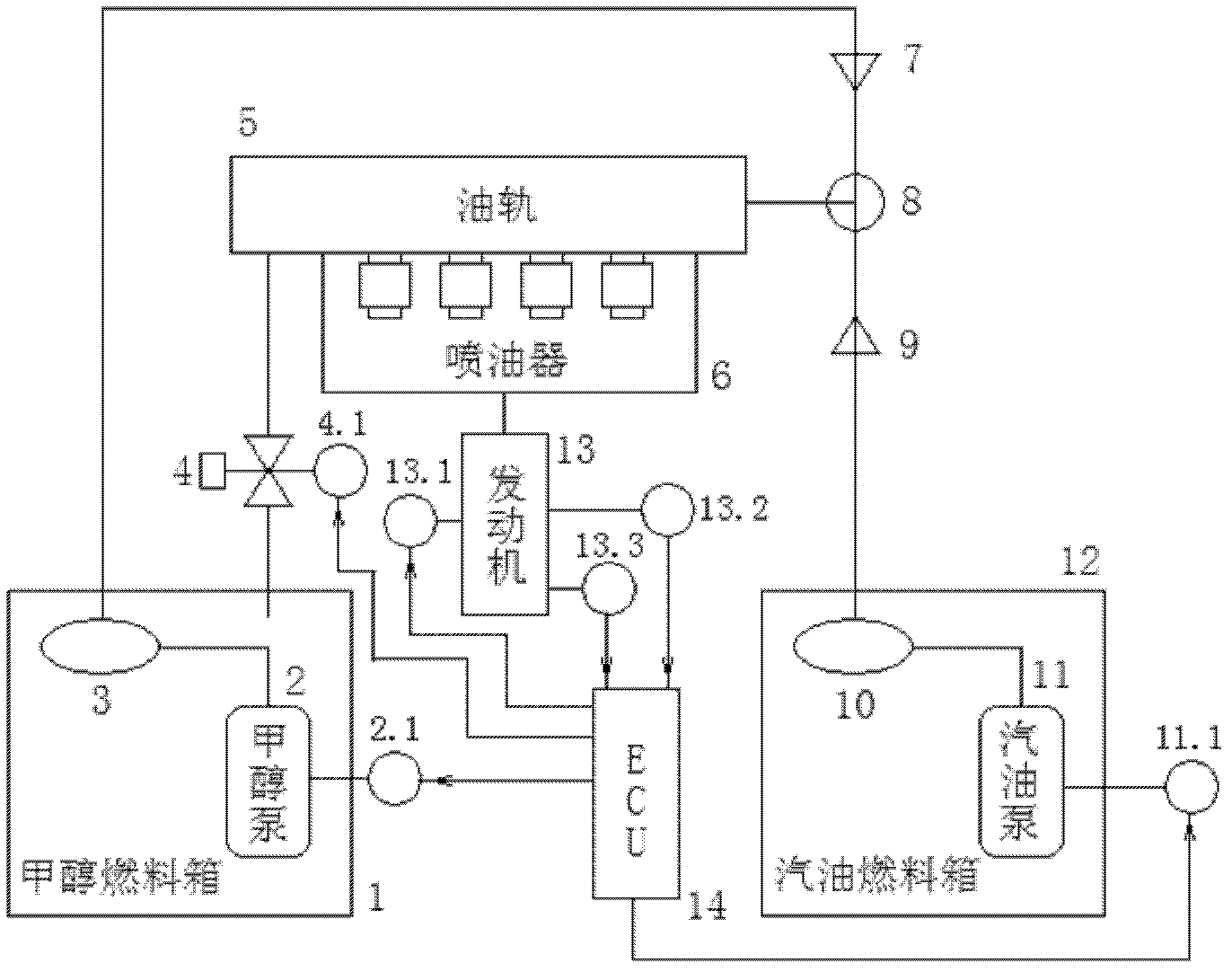

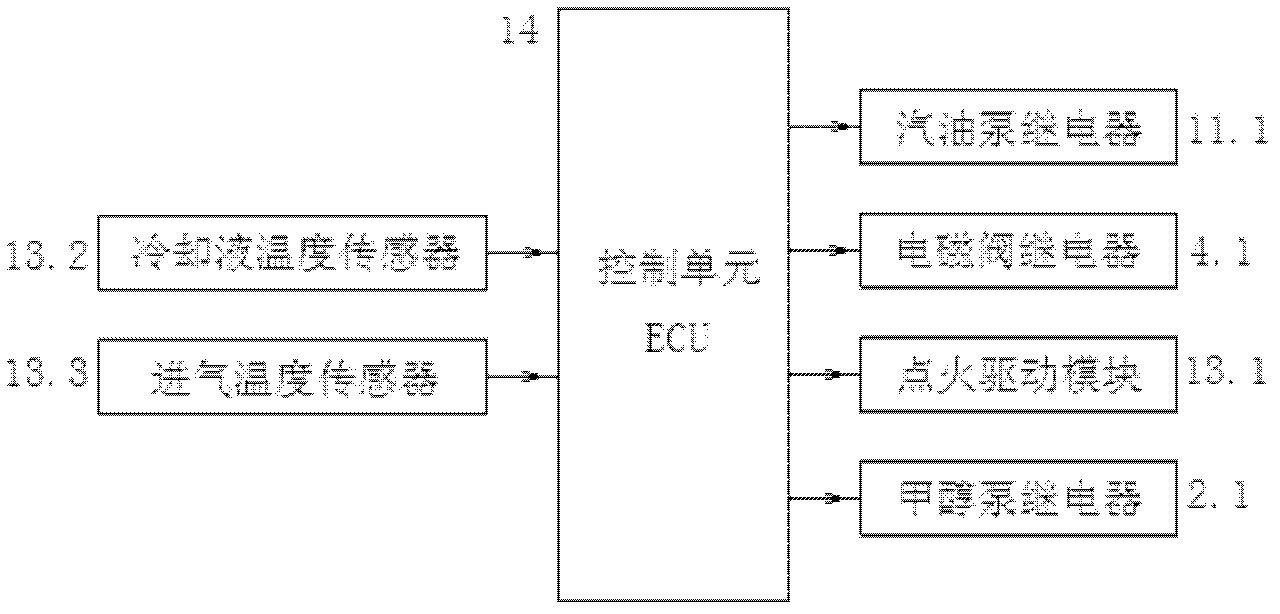

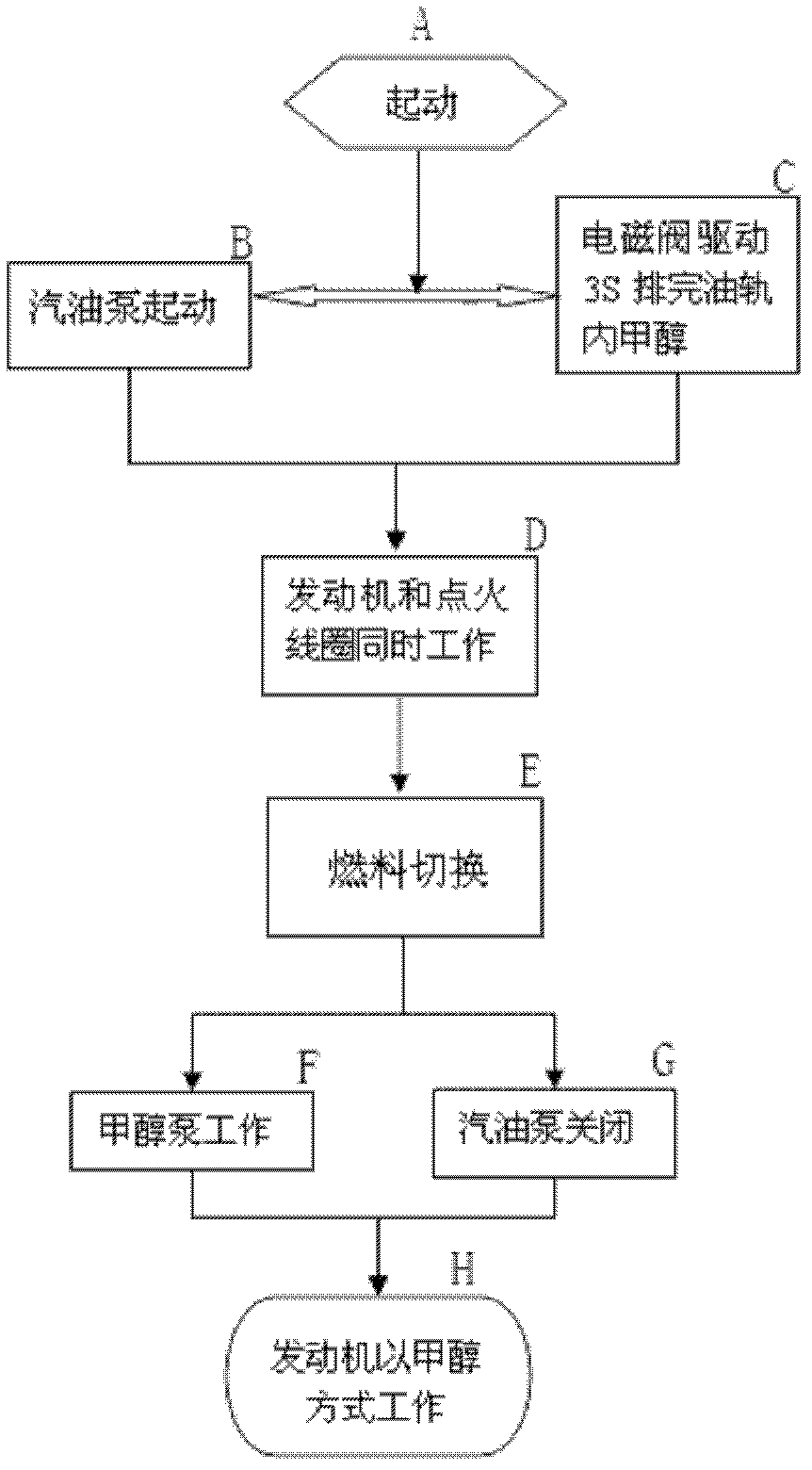

Automobile dual-fuel supply system based on single fuel rail and single fuel injector set

ActiveCN102588124AImprove control efficiencyFlexible and convenient controlEngine controllersMachines/enginesMethanol fuelGasoline fuel

The invention discloses an automobile dual-fuel supply system based on a single fuel rail and a single fuel injector set, which relates to automobile fuel supply systems. The system is structurally characterized in that a gasoline fuel tank, a gasoline pump, a gasoline pressure adjustor, a gasoline one-way valve, a three-way valve, a fuel rail, a fuel injector and an engine are sequentially connected to form a gasoline fuel supply unit, a methanol fuel tank, a methanol pump, a methanol pressure adjustor, a methanol one-way valve, a three-way valve, the oil rail, the fuel injector and the engine are sequentially connected to form a methanol fuel supply unit, and an electronic control unit is respectively connected with two sensors and four executive parts to realize control and switching from the gasoline fuel supply unit to the methanol fuel supply unit. By means of the automobile dual-fuel supply system, high power performance, fuel economy, environment-friendliness in discharge and safety and reliability in control can be obtained.

Owner:武汉菱电汽车电控系统股份有限公司

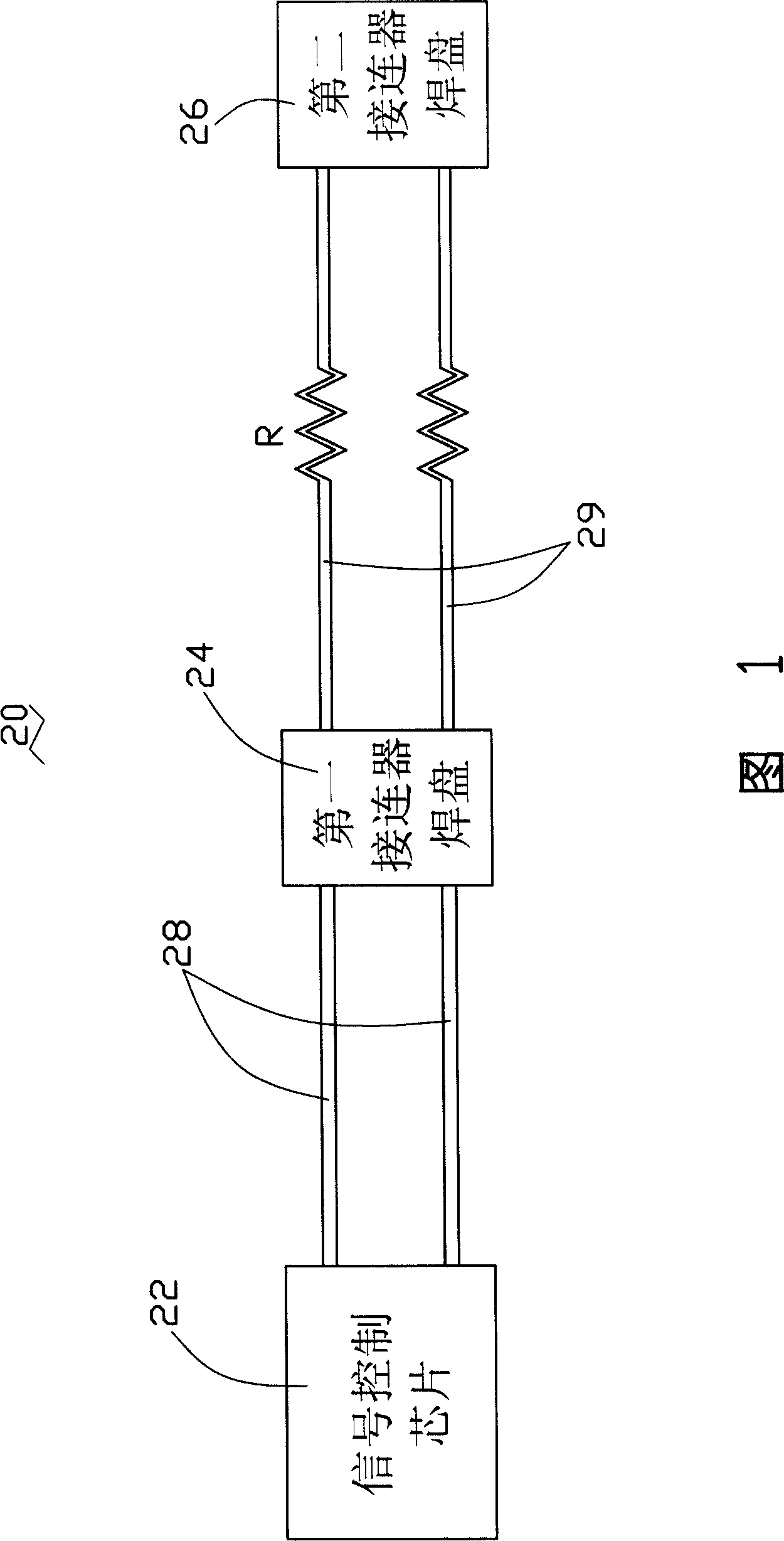

High speed differential signal transmission structure

InactiveCN101136003ASave design costMeet needsPrinted circuit aspectsElectric digital data processingEngineeringMotherboard

The invention comprises: a signal control chip, a first connector bonding pad, several first transmission lines, a second bonding pad and several second transmission lines. Said first connector is connected to said signal control chip via said first transmission line; said second connector bonding pad is connected to the first transmission line via the second transmission line; on each second transmission line there is a switch. By the invention, two different connectors can be selectively installed on a motherboard by controlling the switch.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

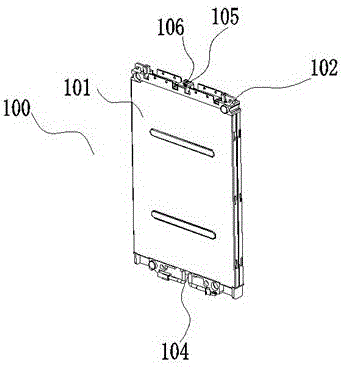

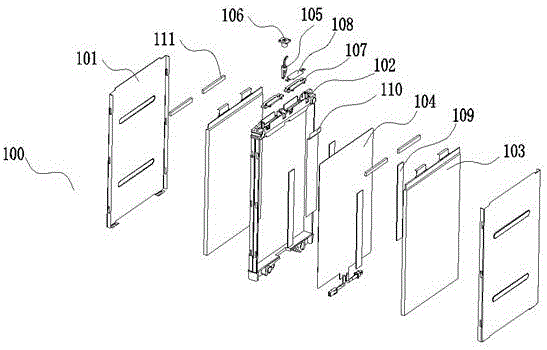

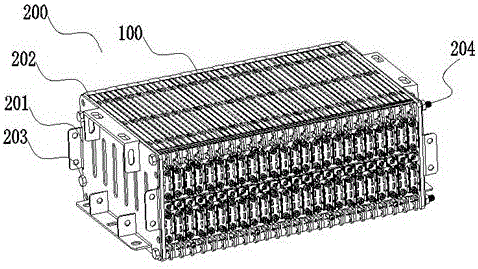

New energy power batter

PendingCN106356587AExquisite structureEasy to installFinal product manufactureCurrent conducting connectionsAluminiumGraphite

The invention discloses a new energy power battery. The new energy power battery comprises a battery box upper cover, a power battery module and a battery box lower casing, wherein the power battery module comprises an electric core bracket, more than two electric cores and an aluminum casing clamp plate; the electric cores are arranged in the electric core bracket, and the two outermost sides of each electric core are tightly attached to the aluminum casing clamp plate. The new energy power battery is characterized in that Lvte cotton is adhered to one surface of each electric core, and a silica gel sheet is adhered onto an electrode lug of each electric core; after the two electric cores are adhered with the Lvte cottons and the silicon rubber sheets, a heat conduction graphite sheet is adhered onto the surface, adhering with the Lvte cotton, of one electric core, a heating plate is arranged between the two electric cores, and the two side surfaces of the heating plate are respectively adhered with the Lvte cotton surfaces; a temperature sensor is connected with the heat conduction graphite sheet; a water cooling system is arranged at the exterior of the battery box lower casing, and a connecting structure of positive and negative electrode lugs of each electric core adopts laser welding or riveting type. The new energy power battery has the advantage that the water cooling heat radiating and heating functions are simultaneously realized.

Owner:JIANGXI DIBIKE

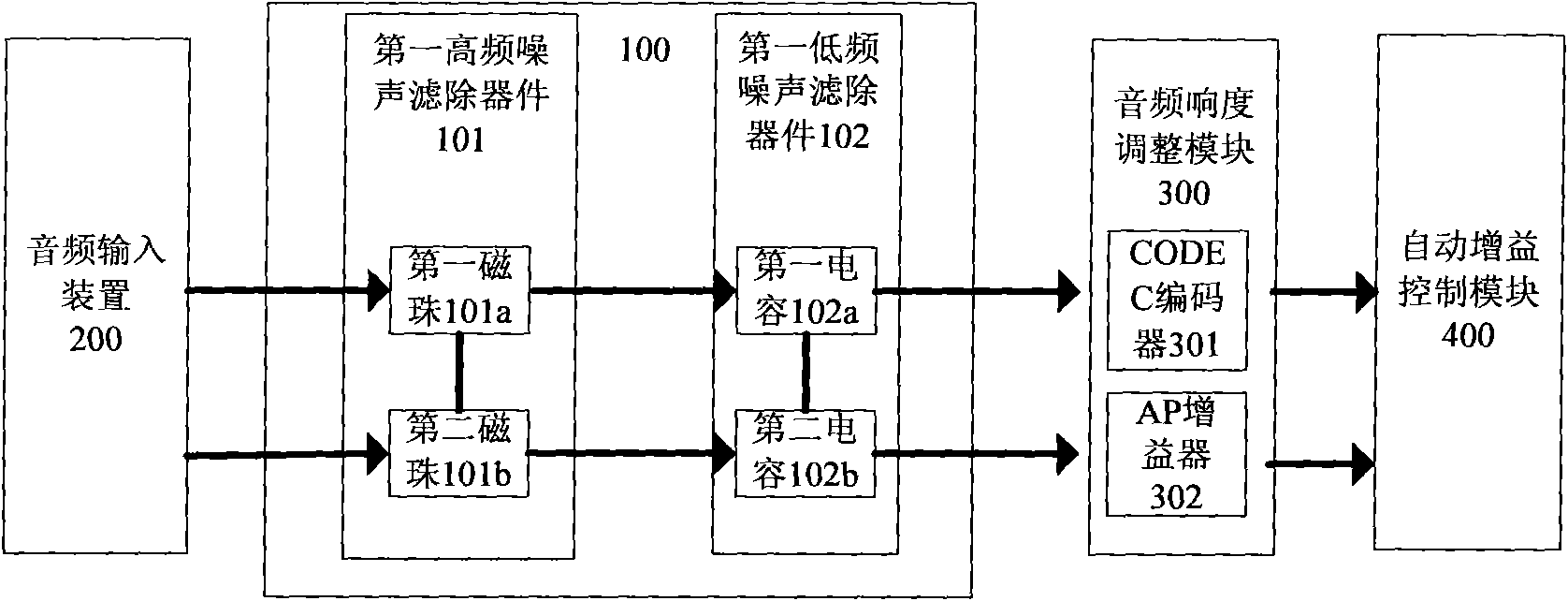

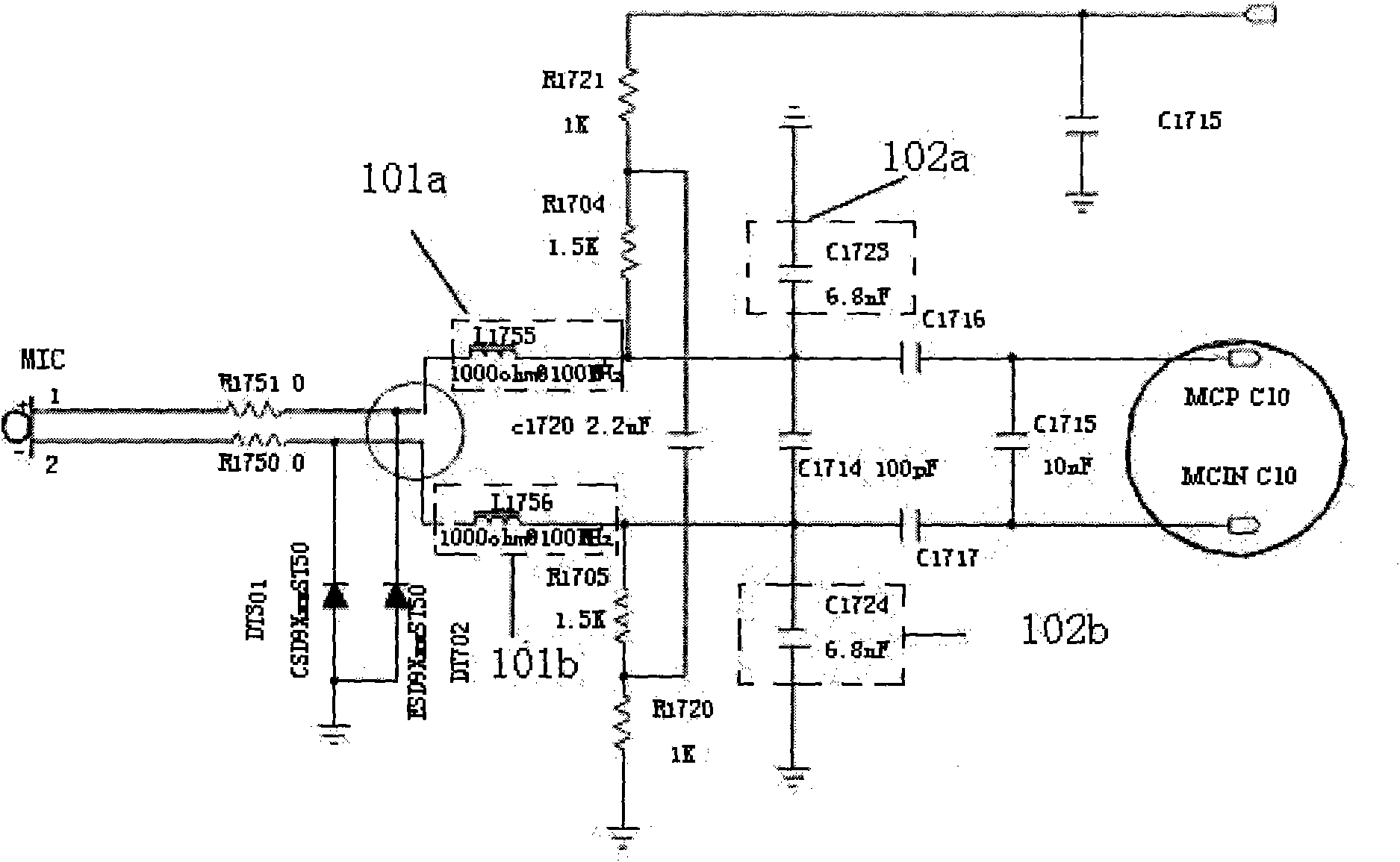

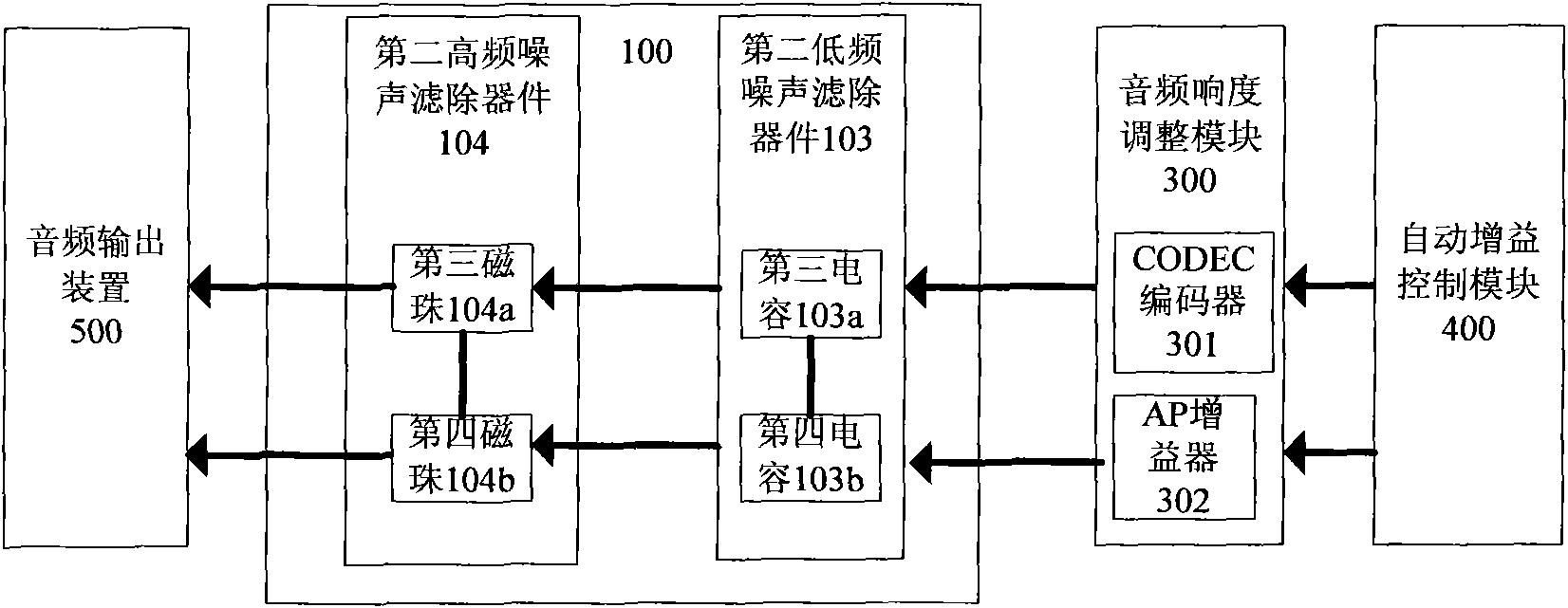

Audio processing device and method of electronic equipment

ActiveCN102136273AImproved ability to suppress audio breakout interferenceSuppress noiseGain controlSpeech analysisCapacitanceNoise energy

The invention provides an audio processing device of electronic equipment, comprising a high-frequency noise filtering device and a low-frequency noise filtering device, wherein the high-frequency noise filtering device comprises a first magnetic bead and a second magnetic bead; the low-frequency noise filtering device comprises a first capacitor and a second capacitor for filtering the low-frequency noise of an audio signal. The invention also provides an audio processing method of electronic equipment, comprising the following steps: receiving an audio input signal by the audio input deviceof the electronic equipment; consuming and adsorbing noise energy in the audio signal by the high-frequency noise filtering device so as to filter the high-frequency noise of the audio signal; and filtering the low-frequency noise of the audio signal by the low-frequency noise filtering device. According to the method and the device for inhibiting audio breakthrough interference, the capability of the electronic product on inhibiting audio breakthrough interference can be obviously improved. According to the method and the device, the function of inhibiting noise is realized by the magnetic beads and the capacitors, and the product design cost is saved.

Owner:BYD CO LTD

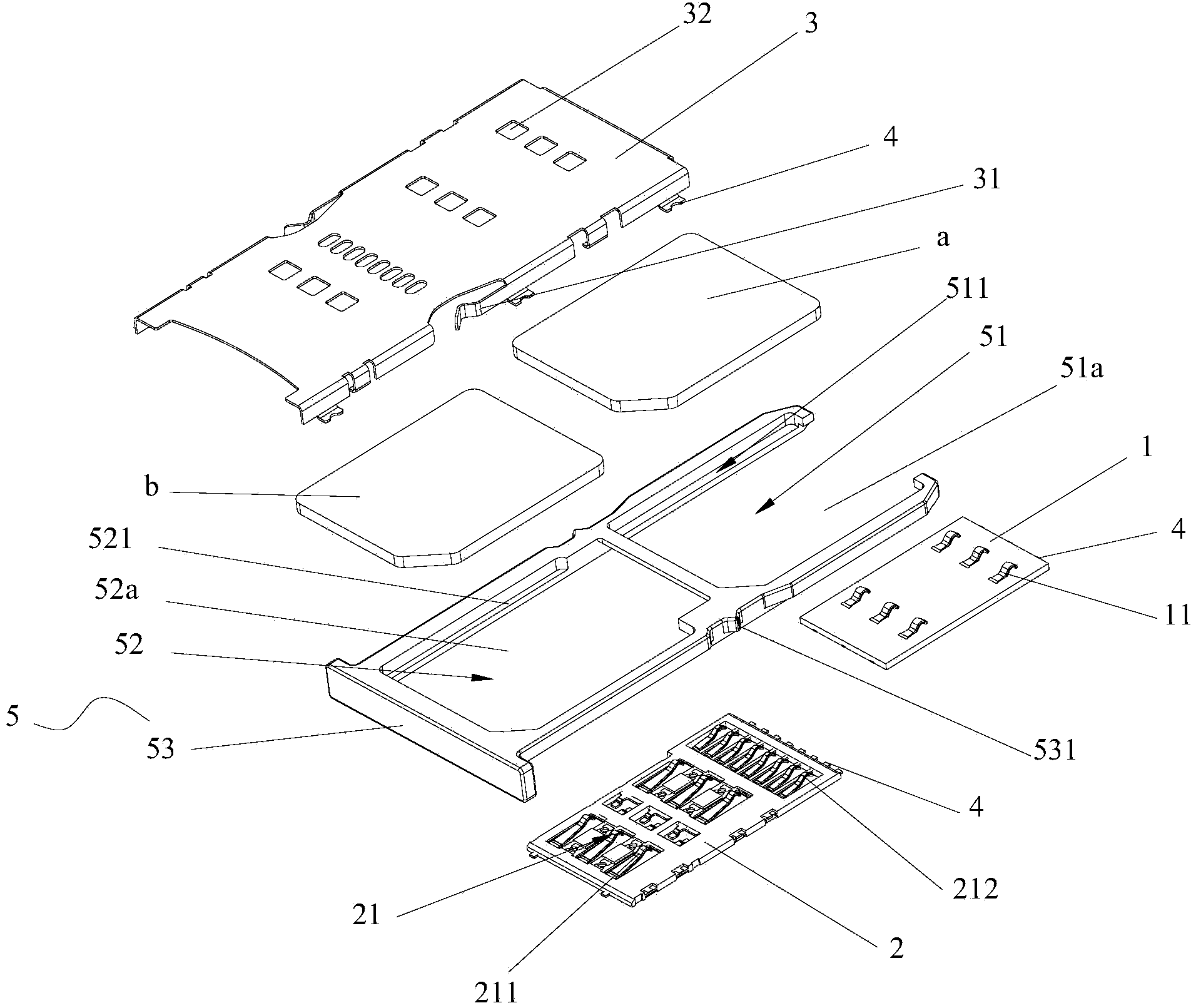

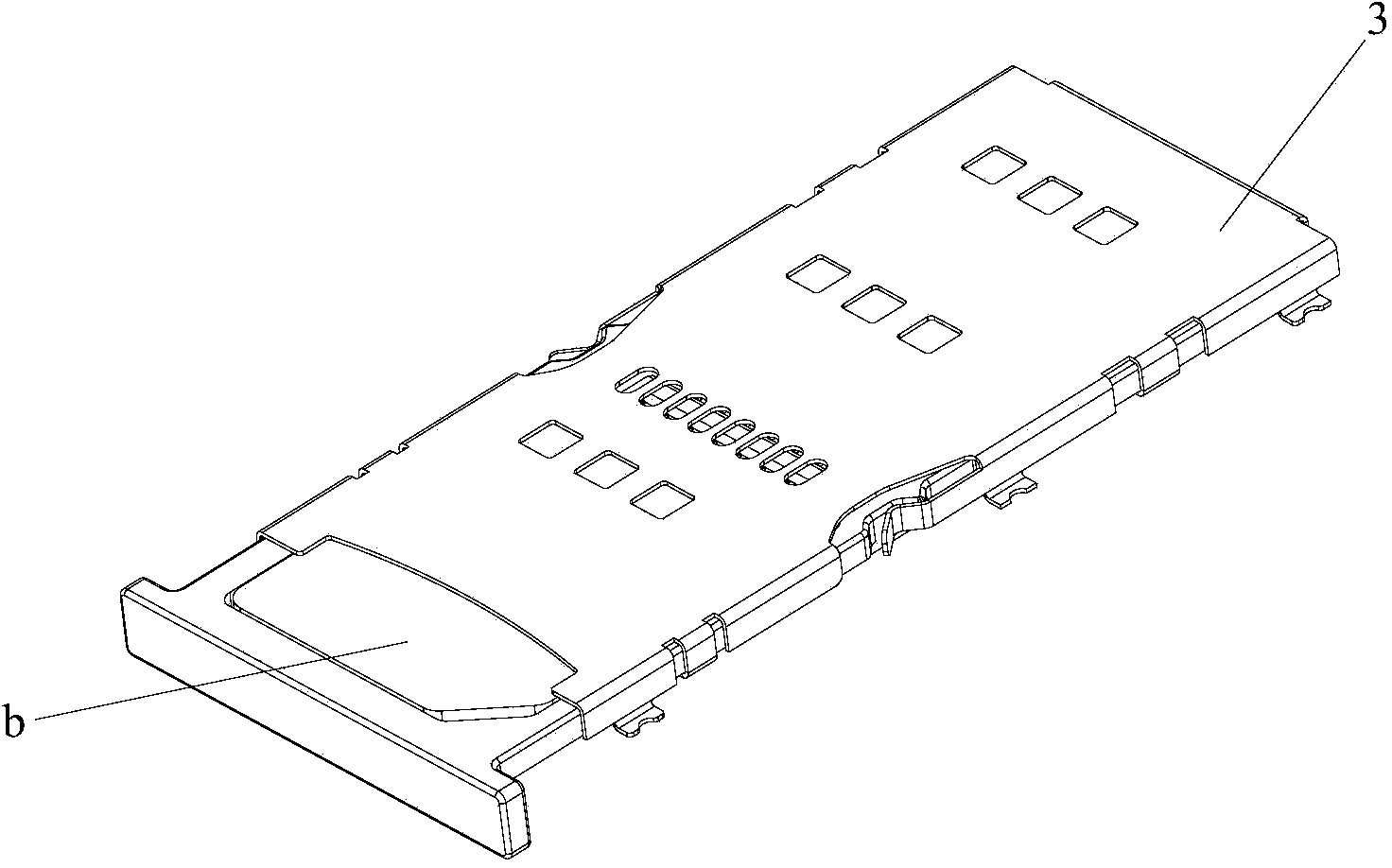

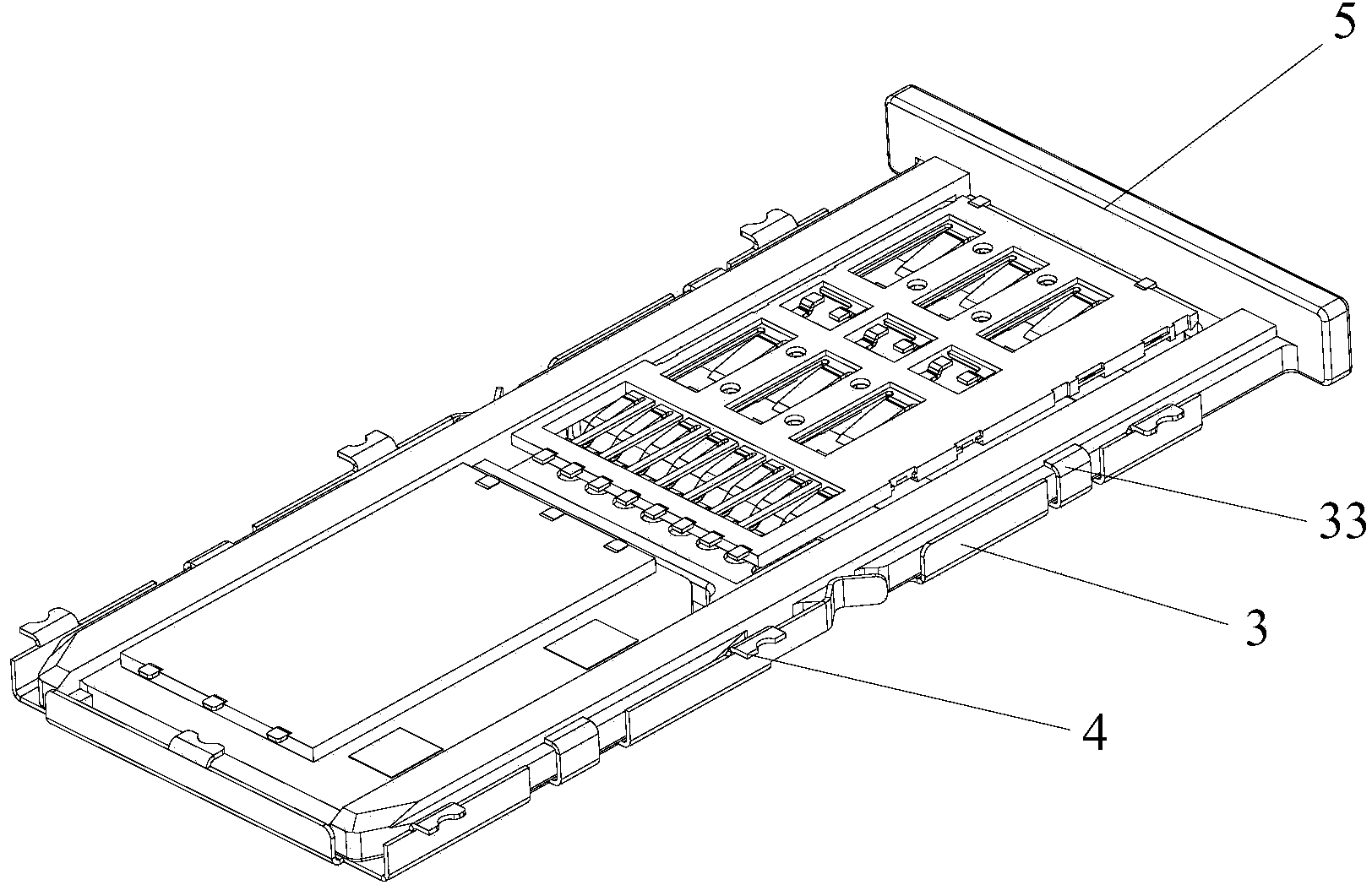

Combined card connector and cell phone

InactiveCN103730744ASave design costSave manufacturing costCoupling contact membersTelephone set constructionsEngineeringMotherboard

The invention is applied to the field of cell phones and provides a combined card connector. The combined card connector comprises a first card base, a second card base, a metal clamping cover and a clamping support, wherein the first card base and the second card base are arranged in an abreast mode, the metal clamping cover is arranged on the first clamping base and the second clamping base, the clamping support is provided with a first card arranging position and a second card arranging position to be respectively used for supporting a first card and a second card, and an inner cavity enabling the clamping support to slide in a drawer mode in the inner cavity is formed by enclosing the metal clamping cover and the two clamping bases. The combined card connector is provided with the clamping support provided with the first card arranging position and the second card arranging position, the combined card connector is provided with the first card base in electric contact with the card and the second card base, wherein the second card base is suitable for different cards and respectively in contact communication with the cards, and the inner cavity enabling the clamping support to slide in a drawer mode is formed by enclosing the metal clamping cover and the two clamping bases, so that when it is necessary to change a Micro-SIM card scheme into a Micro-SIM card+Micro-SD card scheme, a user only needs to replace the clamping support and the double cards on the clamping support without changing the whole card connector and a circuit main board of the cell phone, and cell phone design and manufacturing cost further can be saved.

Owner:SHENZHEN LINKCONN ELECTRONICS

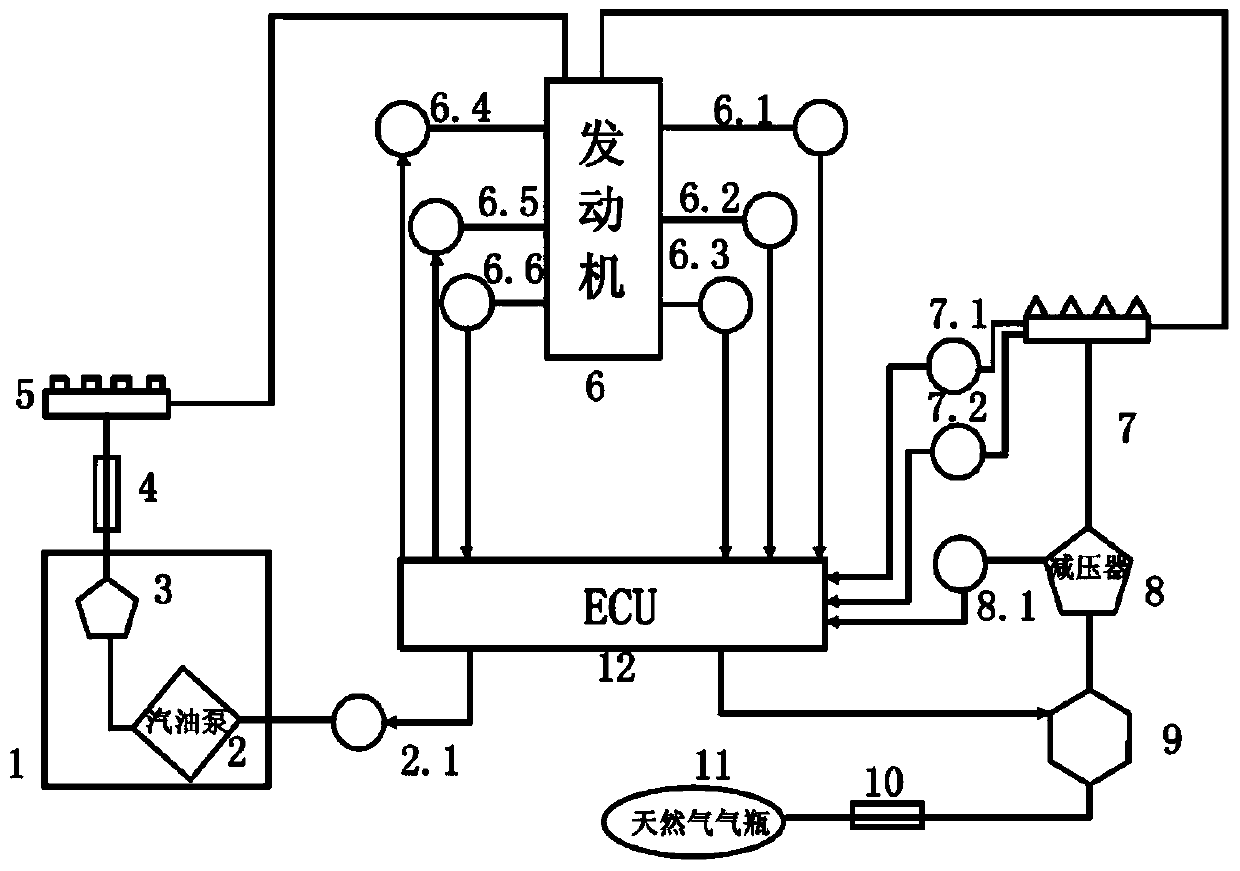

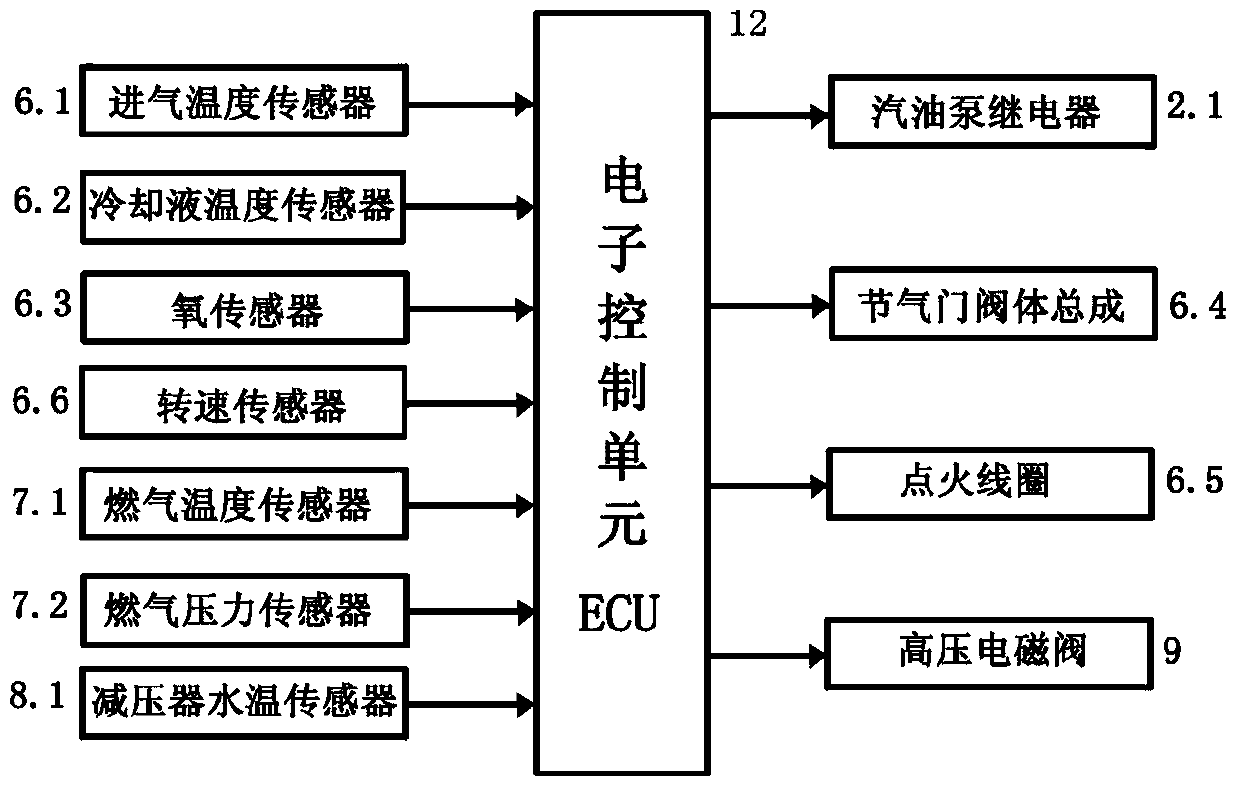

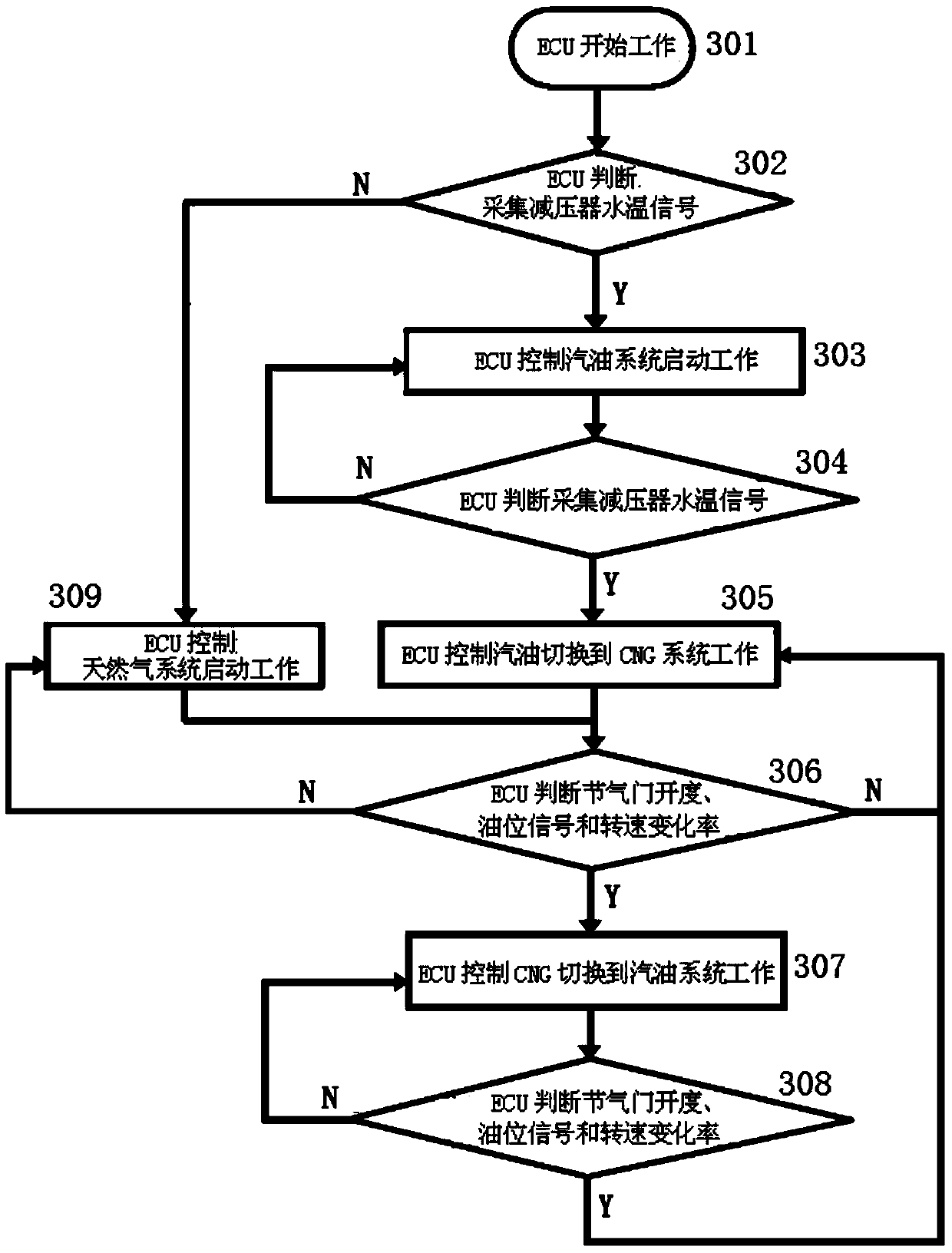

Automotive CNG and gasoline double-fuel supply system based on simultaneous control by single ECU

InactiveCN103628989ASave design costLow costInternal combustion piston enginesEngine controllersGasoline fuelSolenoid valve

Owner:武汉菱电汽车电控系统股份有限公司

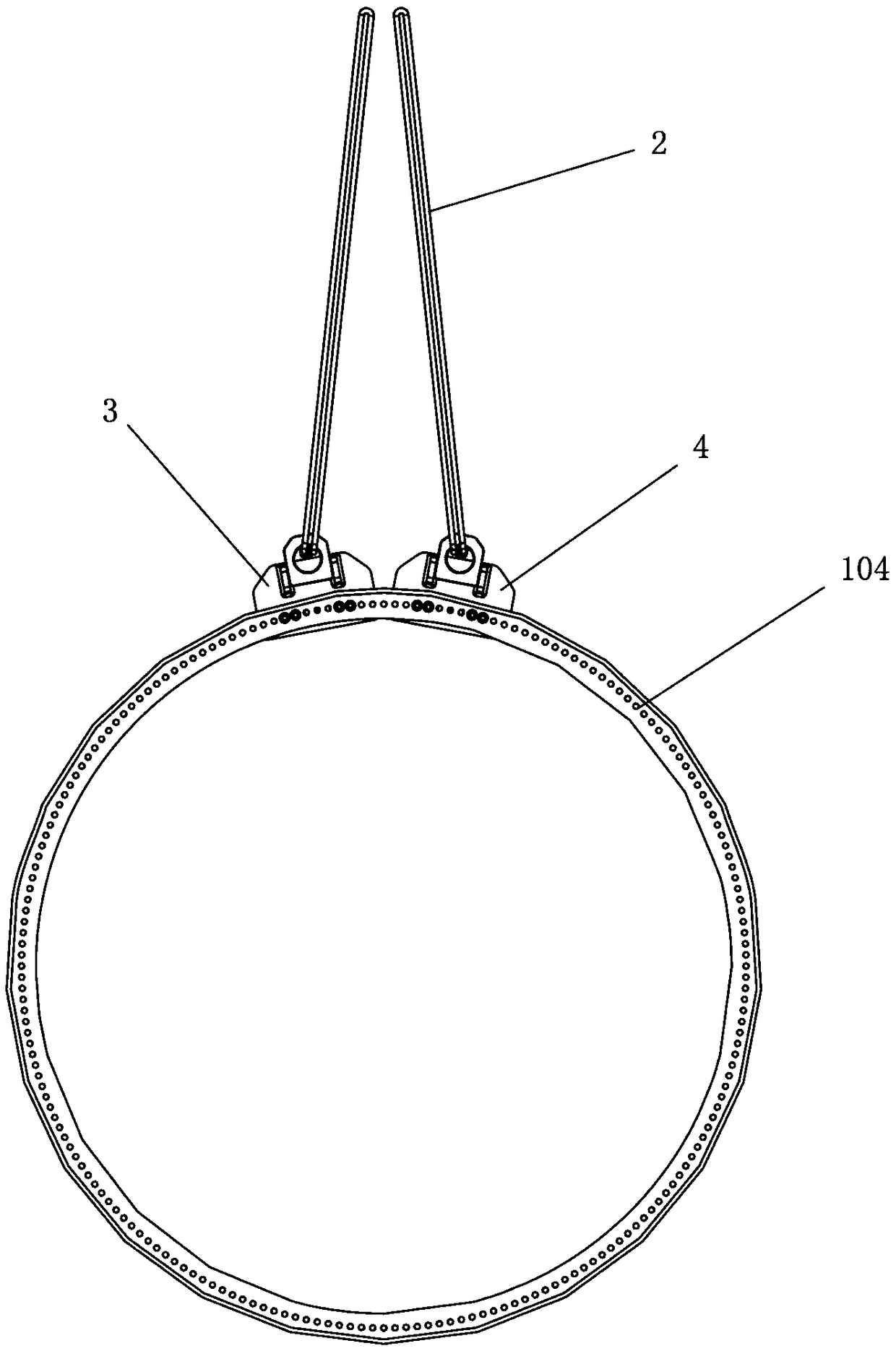

Welding process of large-diameter annular part

ActiveCN104191095AReduce welding shrinkageReduced clamping man-hoursElectron beam welding apparatusUltimate tensile strengthVacuum chamber

The invention discloses a welding process of a large-diameter annular part. The welding process particularly comprises the following steps that (1) cleaning is carried out before welding; (2) primary positioning connection is carried out on the part to be welded through a manual padding argon arc welding tack-weld method; (3) the end, with a flange edge, of the part to be welded is fixed to a disk; (4) densification tack-welding is carried out on the connecting position of the part through vacuum electron beams; (5) sealing welding is carried out on the intervals of densification tack-welding in the step (4) through vacuum electron beams; (6) the part is taken out of a vacuum chamber, excess weld metal of a manual argon arc welding point is ground through a hand blower gun; (7) welding is carried out through vacuum electron beams. Through the welding process, the welding shrinkage amount of the part is largely reduced, the design and manufacturing expenses caused by a vacuum electron beam welding clamp in a traditional welding process are saved, and therefore the welding and machining cost is reduced. Meanwhile, the clamping work time of the part is saved, the labor intensity is relieved for a worker, and the production efficiency of the part is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

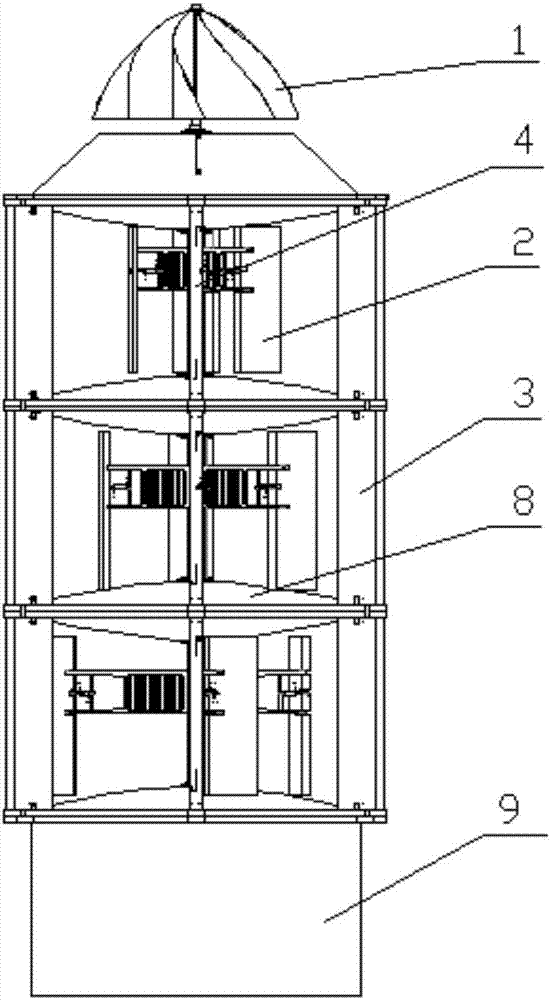

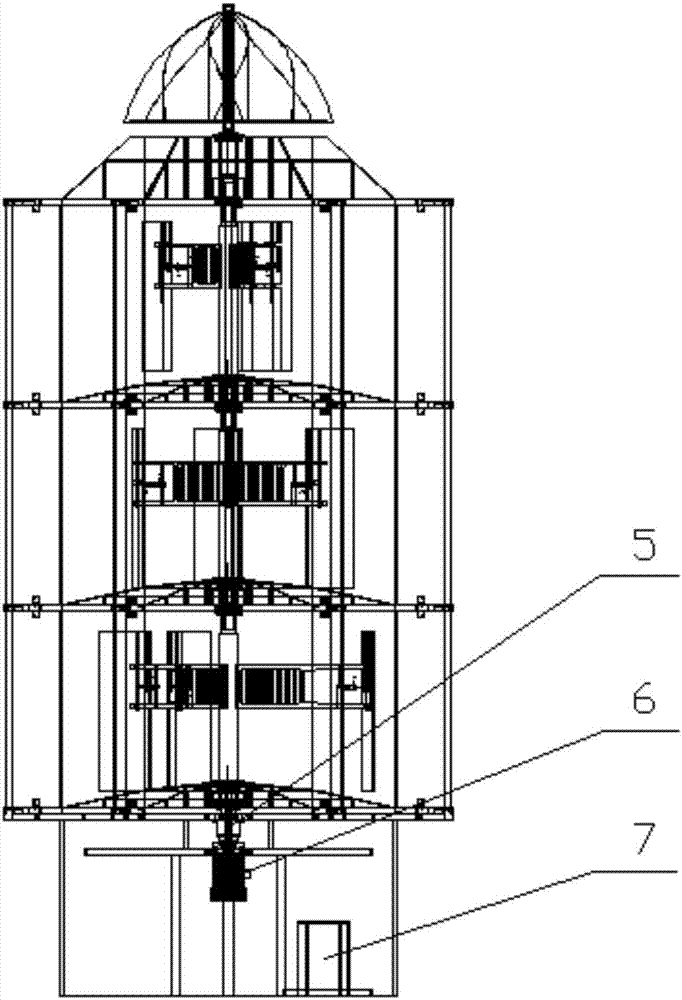

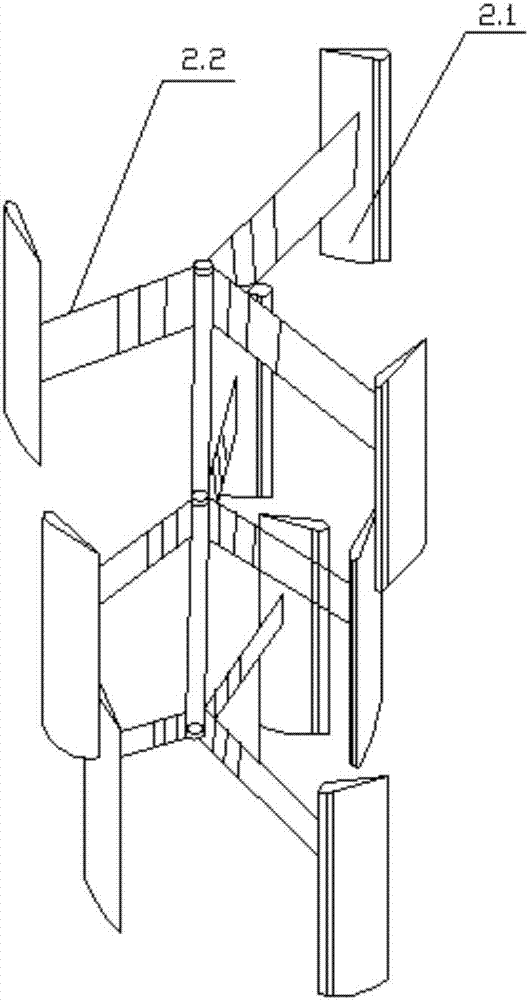

Modular frame type high-efficiency vertical axis wind turbine

ActiveCN107061151ASave design costSave installation costsMachines/enginesWind motor with perpendicular air flowImpellerEngineering

The invention relates to a modular frame type high-efficiency vertical axis wind turbine. The modular frame type high-efficiency vertical axis wind turbine comprises a wind wheel spindle, a step-up gear box, a permanent magnet synchronous generator, a wind power control cabinet and a peripheral foundation, and is characterized by further comprising a resistance type wind wheel, a force lifting type wind wheel, wind direction flow guide plates and transverse supporting structures; the resistance type wind wheel is mounted on the top of the wind turbine, and the lower part of the resistance type wind wheel is connected with the wind wheel spindle; the force lifting type wind wheel has a three-layer stacked impeller structure, a corresponding section of the wind wheel spindle is arranged in the center of each layer of the force lifting type wind wheel, each layer comprises a plurality of blades, each blade is connected with the corresponding section of the wind wheel spindle through a wind wheel support, and the different sections of the wind wheel spindle are flexibly connected through shaft sleeves; all the blades on the three layers are arranged in a staggered manner, projections of all the blades on the horizontal plane are distributed in a circular area, and the number of the blades in each layer is an odd number; and each wind wheel support comprises a rectangular frame, and one end of each rectangular frame is connected with the wind wheel spindle.

Owner:HEBEI UNIV OF TECH

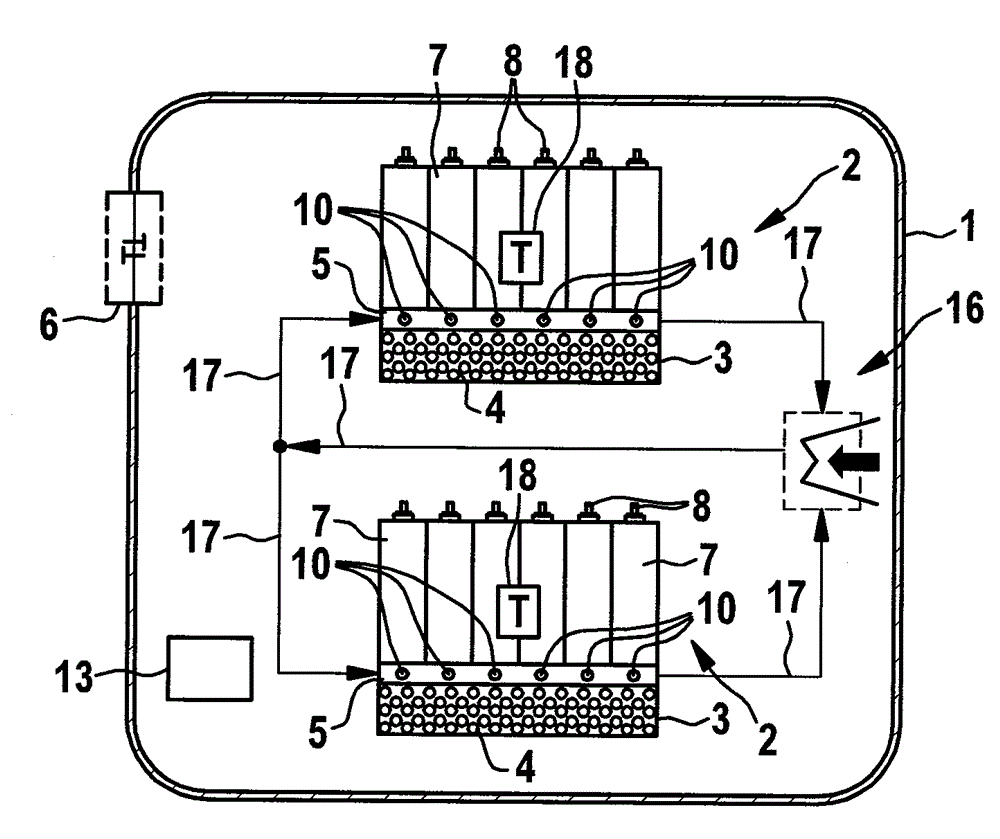

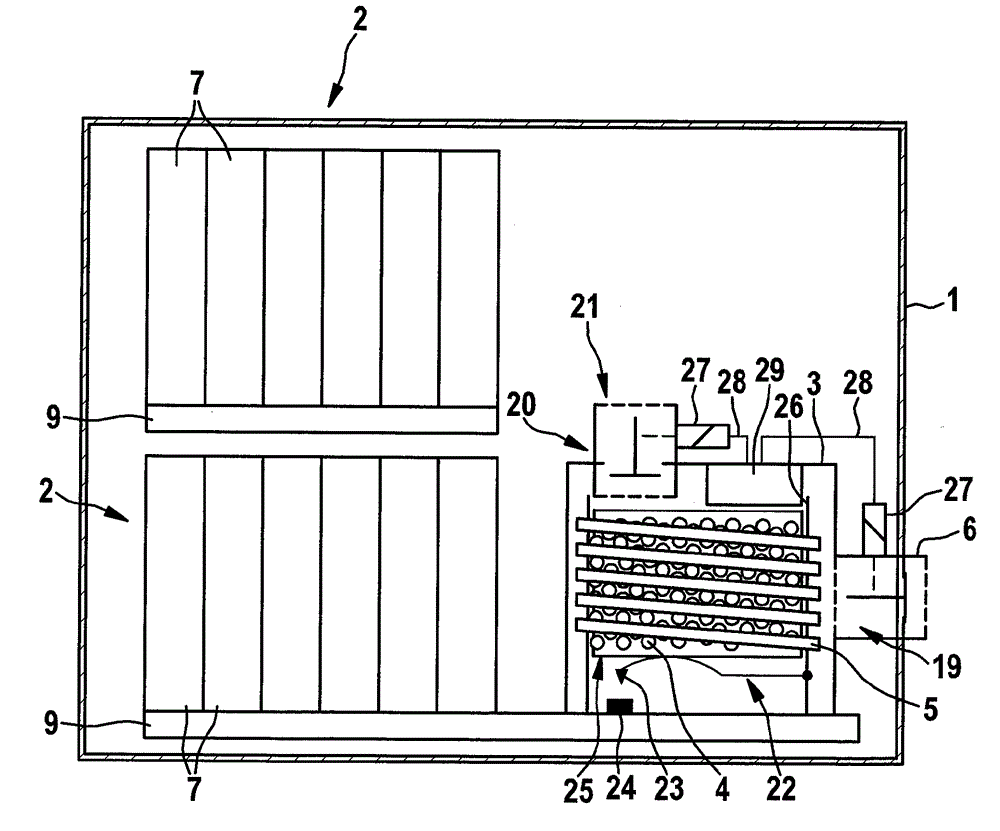

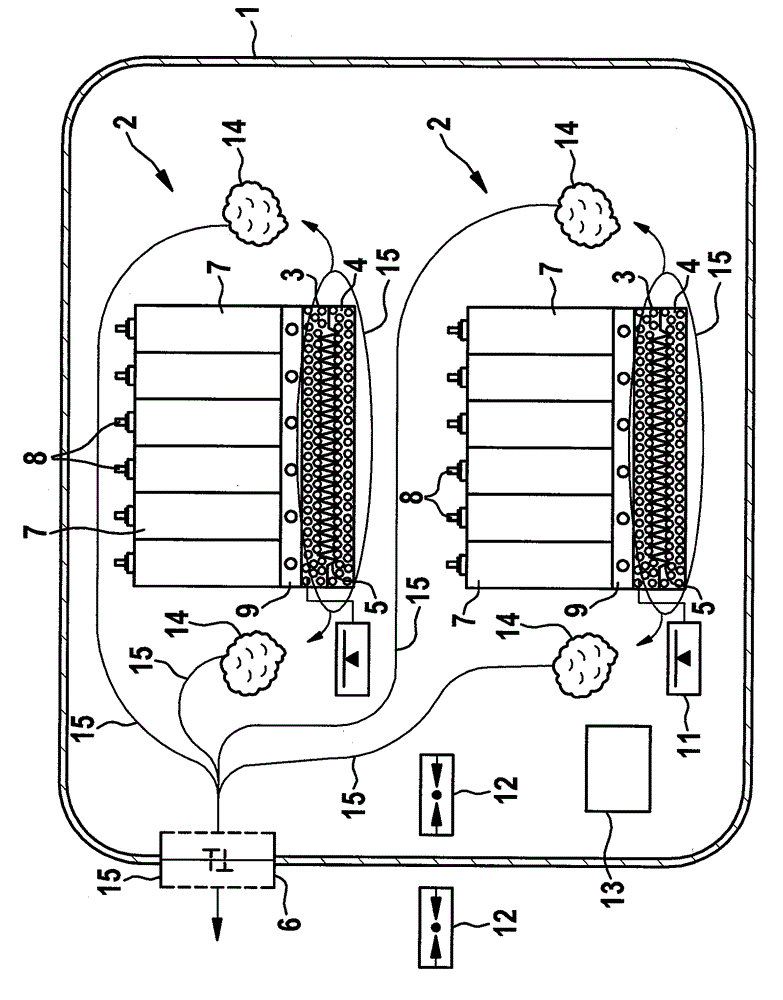

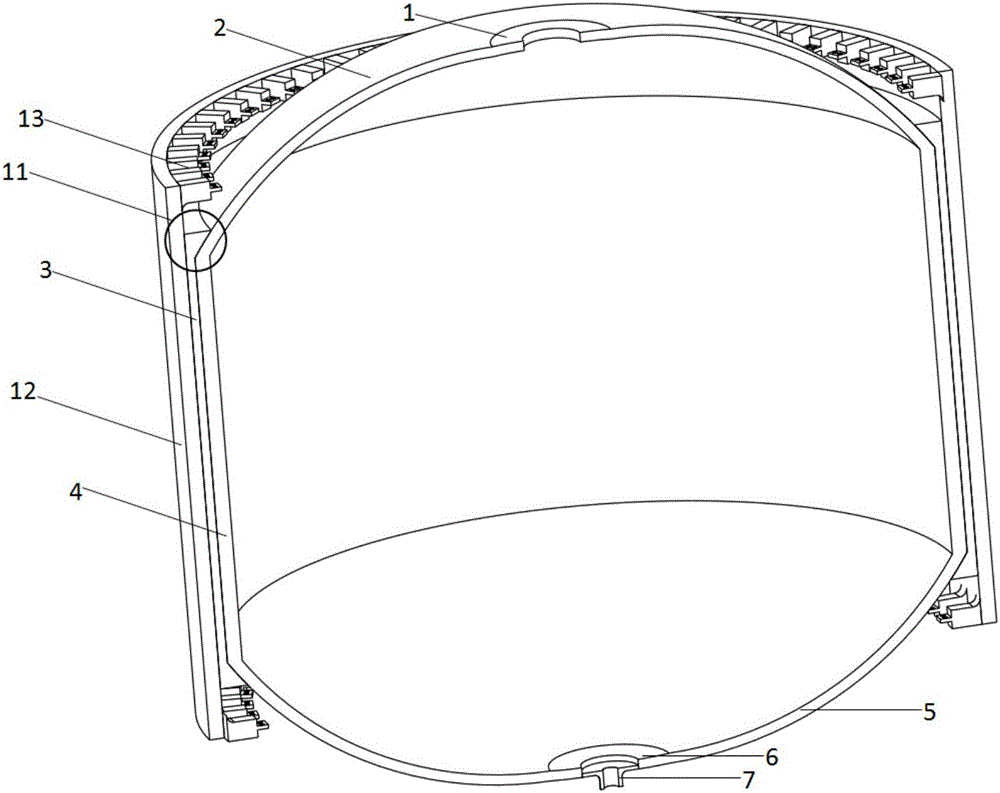

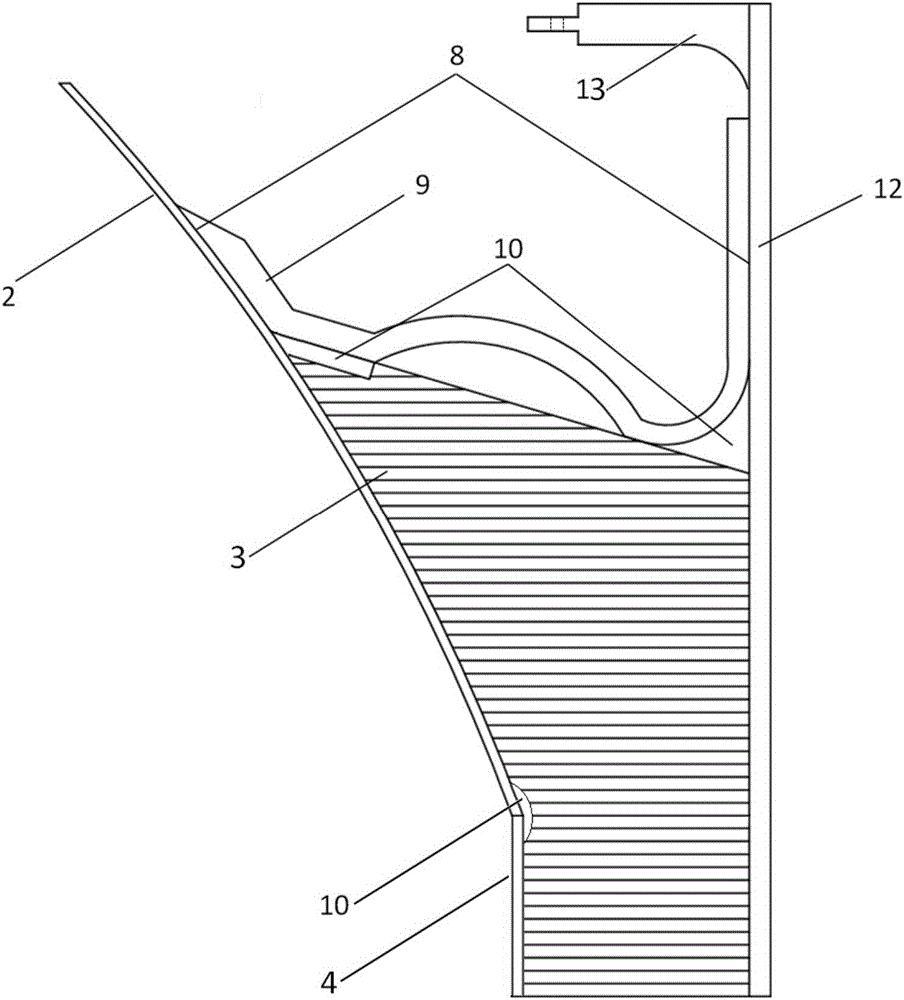

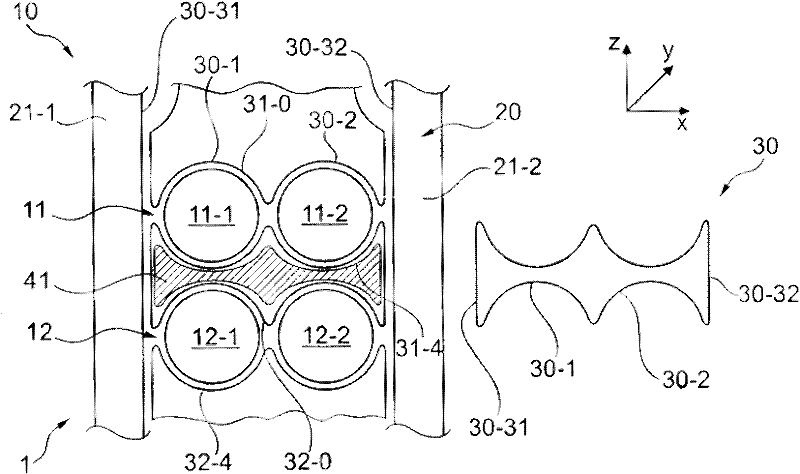

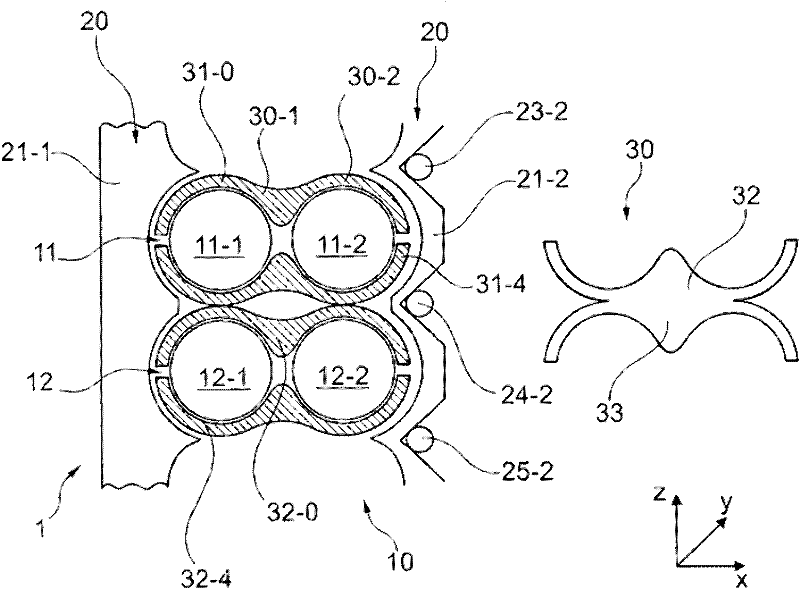

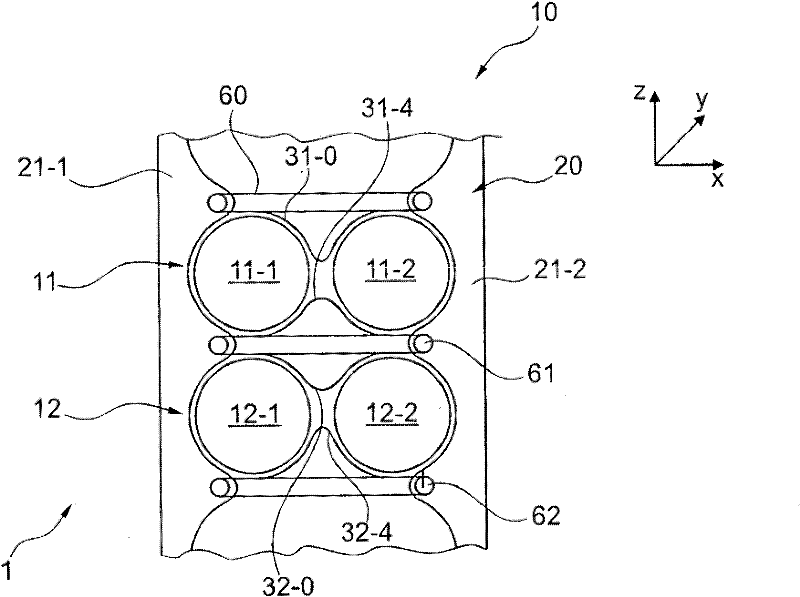

Housing used for at least a battery module or battery system, and battery pack with a housing surrounding battery system

InactiveCN104795514AAchieve inflowAvoid enteringGas treatmentSmall-sized cells cases/jacketsEngineeringBattery system

The invention relates to a housing (1) used for at least a battery module (2) or a battery system. The housing comprises at least a drying unit (3) which is arranged in the housing (1). The drying unit is provided with a drying medium (4) which absorbs moisture. The housing also comprises at least a thermoregulation unit (5) used to regenerate the drying medium (4), and at least a control device (13). The control device is configured to control regeneration of the drying medium (4). The housing (1) comprises at least a valve (6). The valve has a fist state and a second state. The valve (6) basically closes the housing (1) in the first state in an airtight manner, and in the second state, the valve (6) can realize that moisture emitted in regeneration of the drying medium (4) discharges from the housing (1). In addition, the invention relates to a battery pack, which has the battery system and the housing (1) surrounding the battery system.

Owner:ROBERT BOSCH GMBH

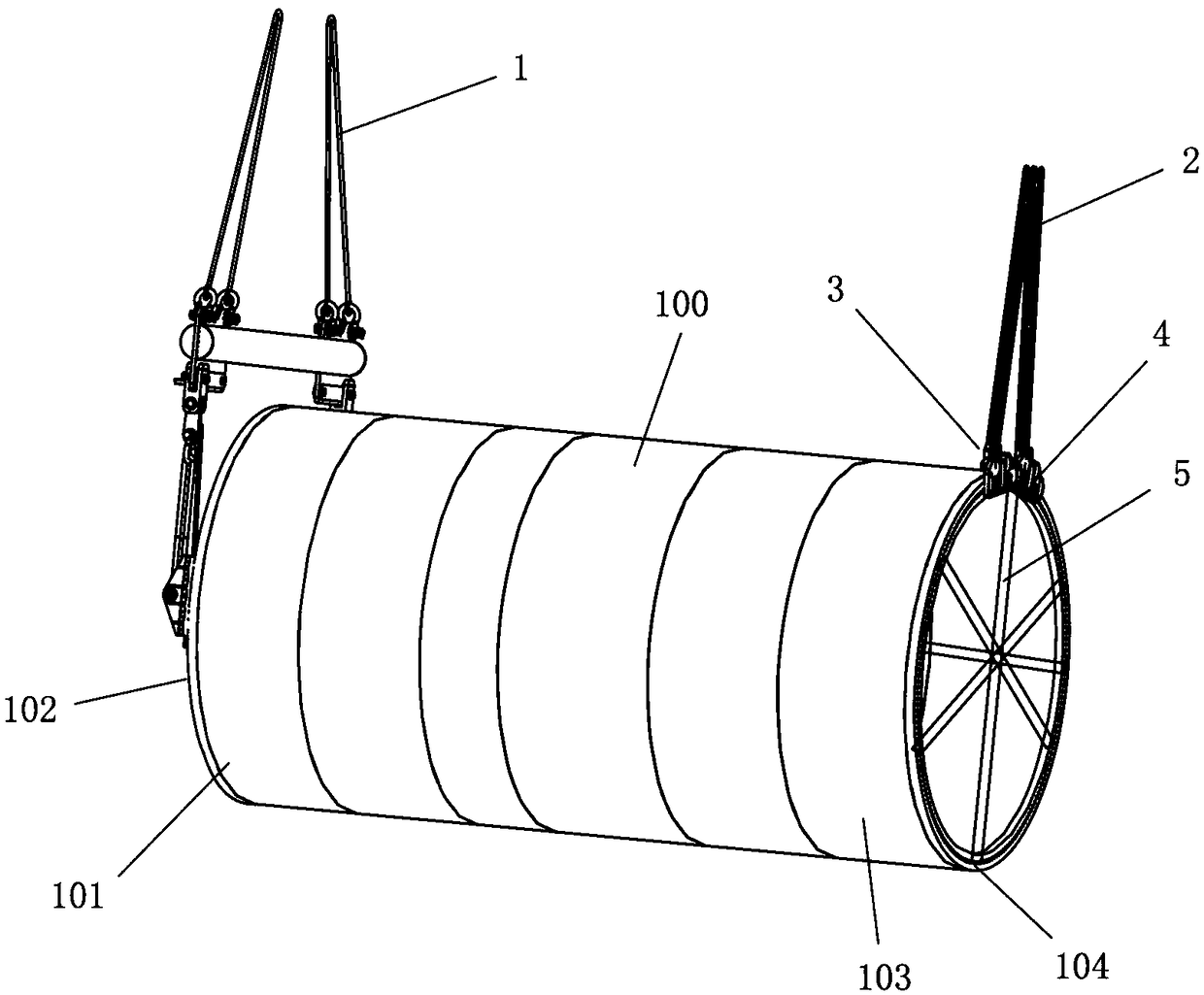

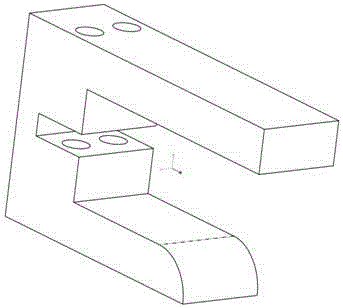

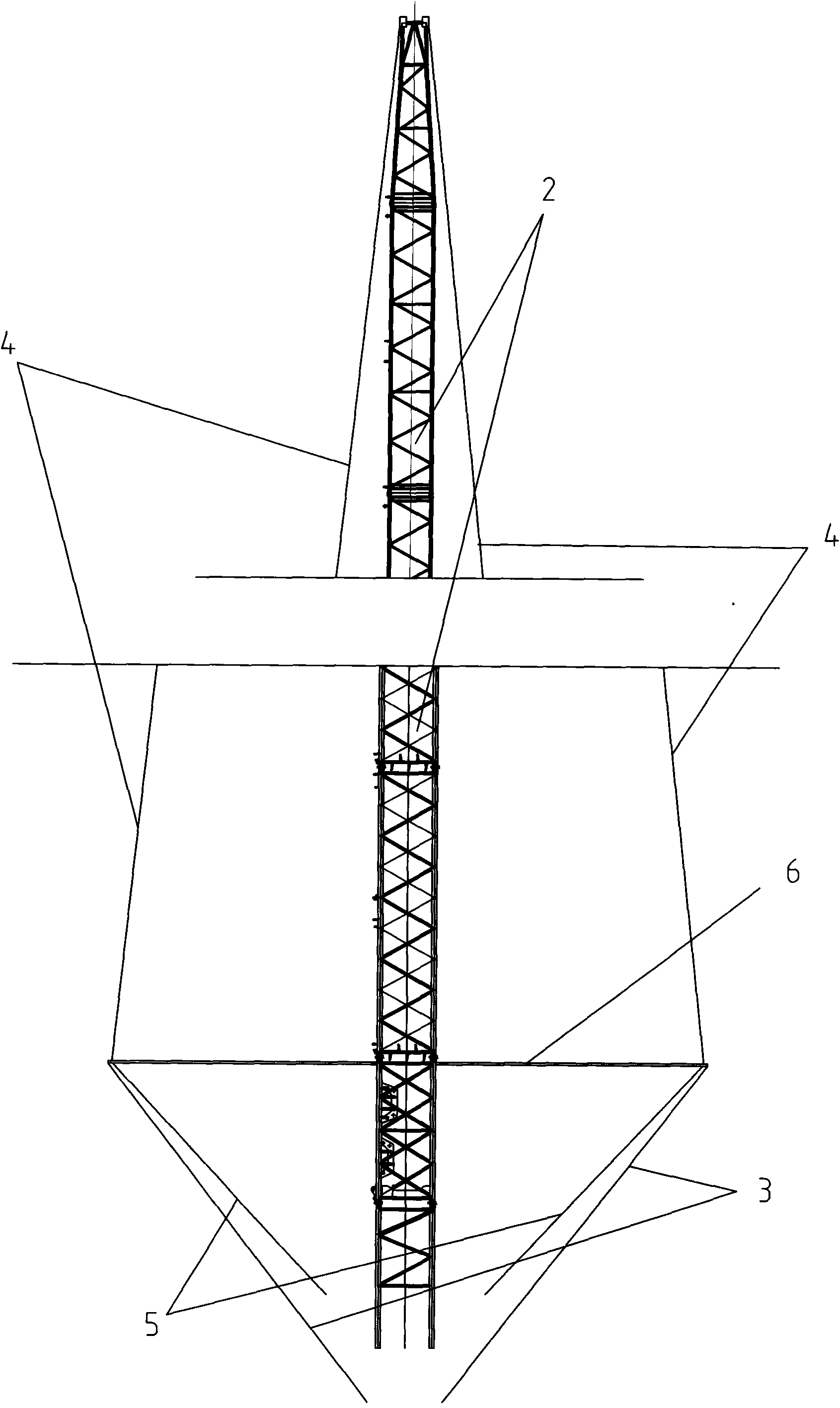

Tower drum overturning device and tower rack mounting system

The invention provides a tower drum overturning device and a tower rack mounting system. The tower drum overturning device is used for overturning a tower drum from a horizontal state to a vertical state, and comprises a tower drum overturning supporting seat; the tower drum overturning supporting seat comprises a first overturning supporting seat and a second overturning supporting seat; each ofthe first overturning supporting seat and the second overturning supporting seat comprises a fixed support and a rotary support; each rotary support comprises a rotary arm and a supporting portion; each rotary arm is rotatably connected with the corresponding fixed support; and a supporting portion is formed on each rotary arm in the radial direction and is used for fixedly supporting a first endof a tower drum. The tower rack mounting system comprises the tower drum overturning device. The tower drum can be overturned from the horizontal state to the vertical state, and deformation of a lower flange of the tower drum in an overturning process is relieved.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

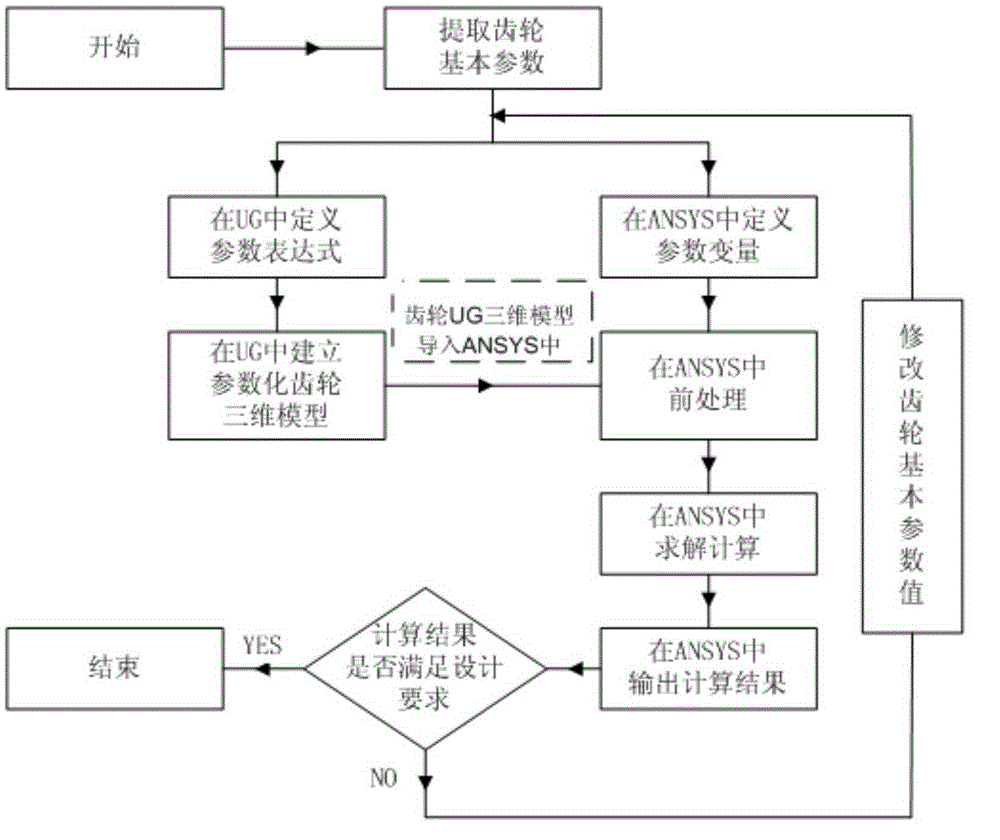

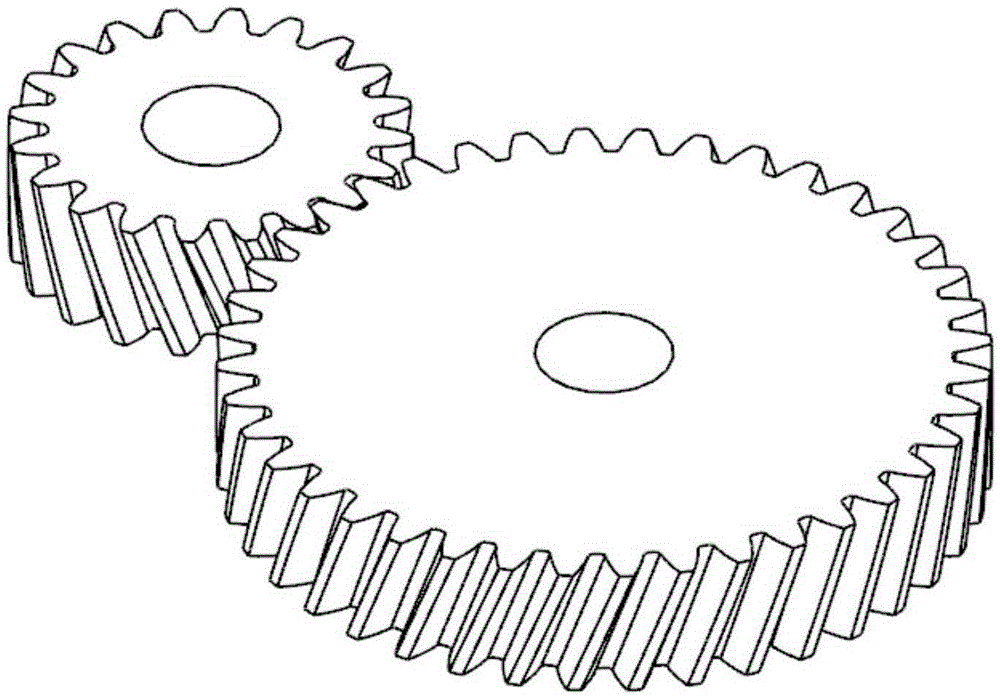

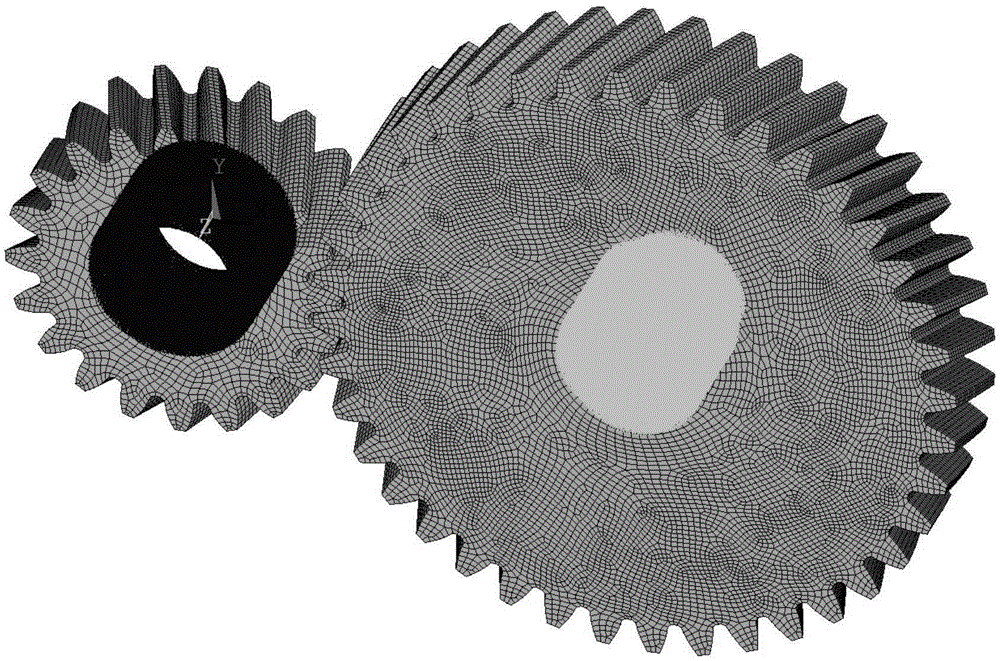

Involute cylindrical spiral gear mechanism parameterization analysis method

InactiveCN105302991AReduce workloadShorten design timeSpecial data processing applicationsGear geometryElement model

The invention discloses an involute cylindrical spiral gear mechanism parameterization analysis method and relates to the technical field of gear drive design and analysis. The method is characterized by comprising the following steps that 1, parameters are extracted, wherein all the parameters influencing work of an involute cylindrical spiral gear mechanism are analyzed comprehensively, integrated and classified, gear geometry parameters, material characteristic parameters, load features and finite element model parameters are extracted according to the classes, and the parameters are compiled according to a list form; 2, a parameterized gear three-dimensional model is set up in UG software; 3, preprocessing is carried out in ANSYS software; 4, solving and calculating are carried out in the ANSYS software, wherein the ANSYS software enters a solving module for assigning an analysis type to be static analysis, total solving time is set to be one, the number of solving steps is set to be 100, a PCG is adopted as a solver, and after solving is completed, the ANSYS software quits the solving module; 5, the calculation result is analyzed to judge whether new analysis and calculation need to be carried out or not after the parameters are modified.

Owner:天津市鑫达物业管理有限公司

Carrier rocket composite storage tank provided with honeycomb sandwich walls and machining method thereof

ActiveCN106542123AIncreased shear strengthImprove sealingCosmonautic vehiclesCosmonautic propulsion system apparatusHoneycombRocket

The invention provides a carrier rocket composite storage tank provided with honeycomb sandwich walls. The carrier rocket composite storage tank comprises a front bottom cover, a front end socket, a tank cylinder section inner wall, a tank cylinder section outer wall, a back end socket, a back bottom cover and a back bottom pool shell. The front bottom cover is connected with the front end socket. The back end socket is connected with the back bottom cover. The front end socket and the back end socket are fixed to the upper end and the lower end of the tank cylinder section correspondingly through adhesive layers. The back bottom cover is in bolt connection with the back bottom pool shell. The carrier rocket composite storage tank is characterized in that the tank cylinder section outer wall is connected with the front end socket, the back end socket and the tank cylinder section inner wall in a honeycomb manner. The invention further discloses a machining method of the carrier rocket composite storage tank provided with the honeycomb sandwich walls. According to the machining method of the carrier rocket composite storage tank provided with the honeycomb sandwich walls, the integral forming technology comprising filament winding forming, filament placement forming and cementing co-curing is adopted. According to the carrier rocket composite storage tank provided with the honeycomb sandwich walls, because the honeycomb sandwich structure is additionally arranged at the connection portions between the storage tank end socket section, the tank cylinder section inner wall and the tank cylinder section outer wall, so that the shearing strength of the carrier rocket composite storage tank provided with the honeycomb sandwich walls is improved, and the overall axle load bearing capacity of the storage tank structure is improved; and the carrier rocket composite storage tank provided with the honeycomb sandwich walls is manufactured through the forming technology comprising winding, placement and cementing co-curing, and the effects of improving the seal performance, resisting seepage, lowering the structure assembly complexity, improving the production efficiency and the like are achieved.

Owner:DALIAN UNIV OF TECH

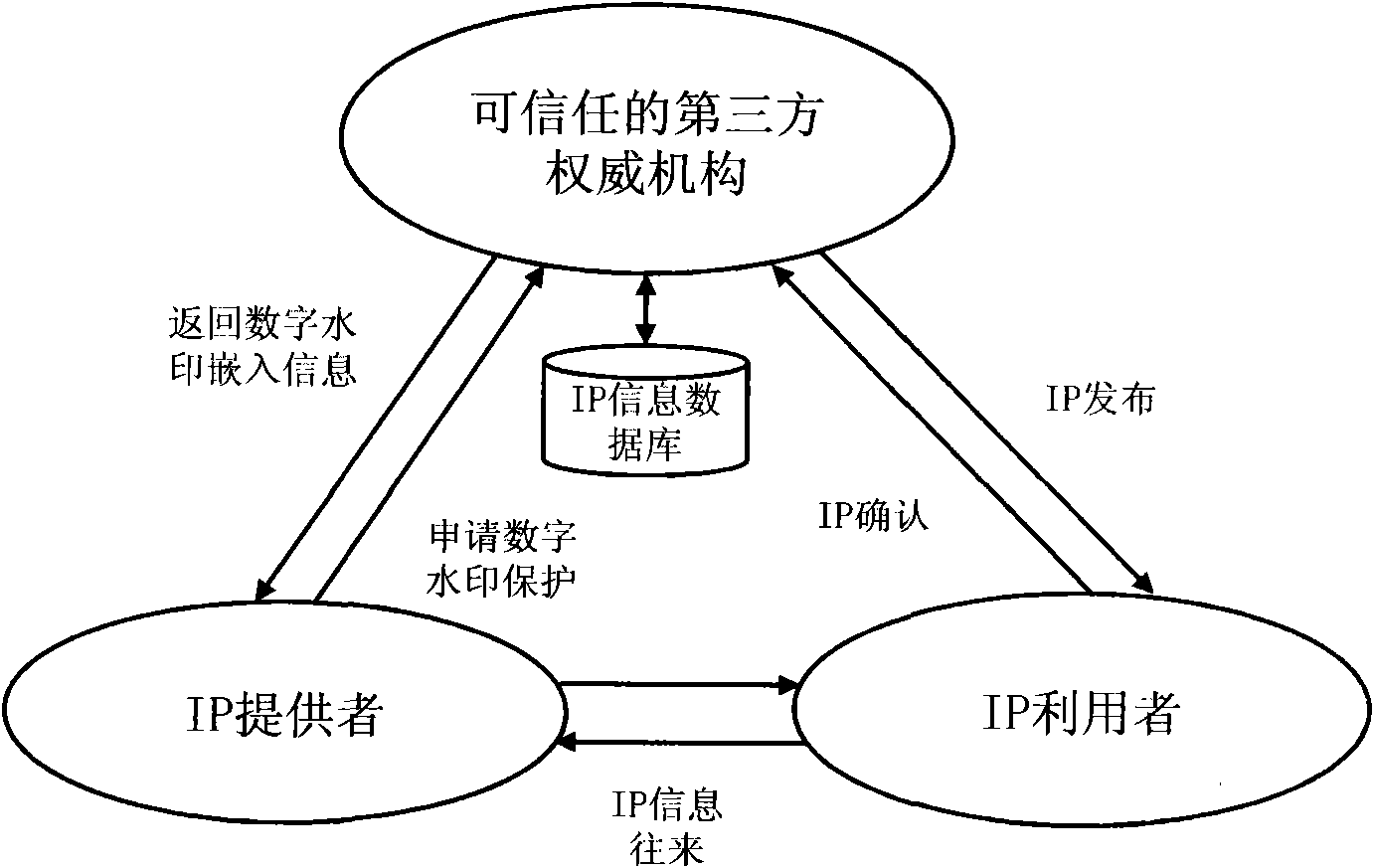

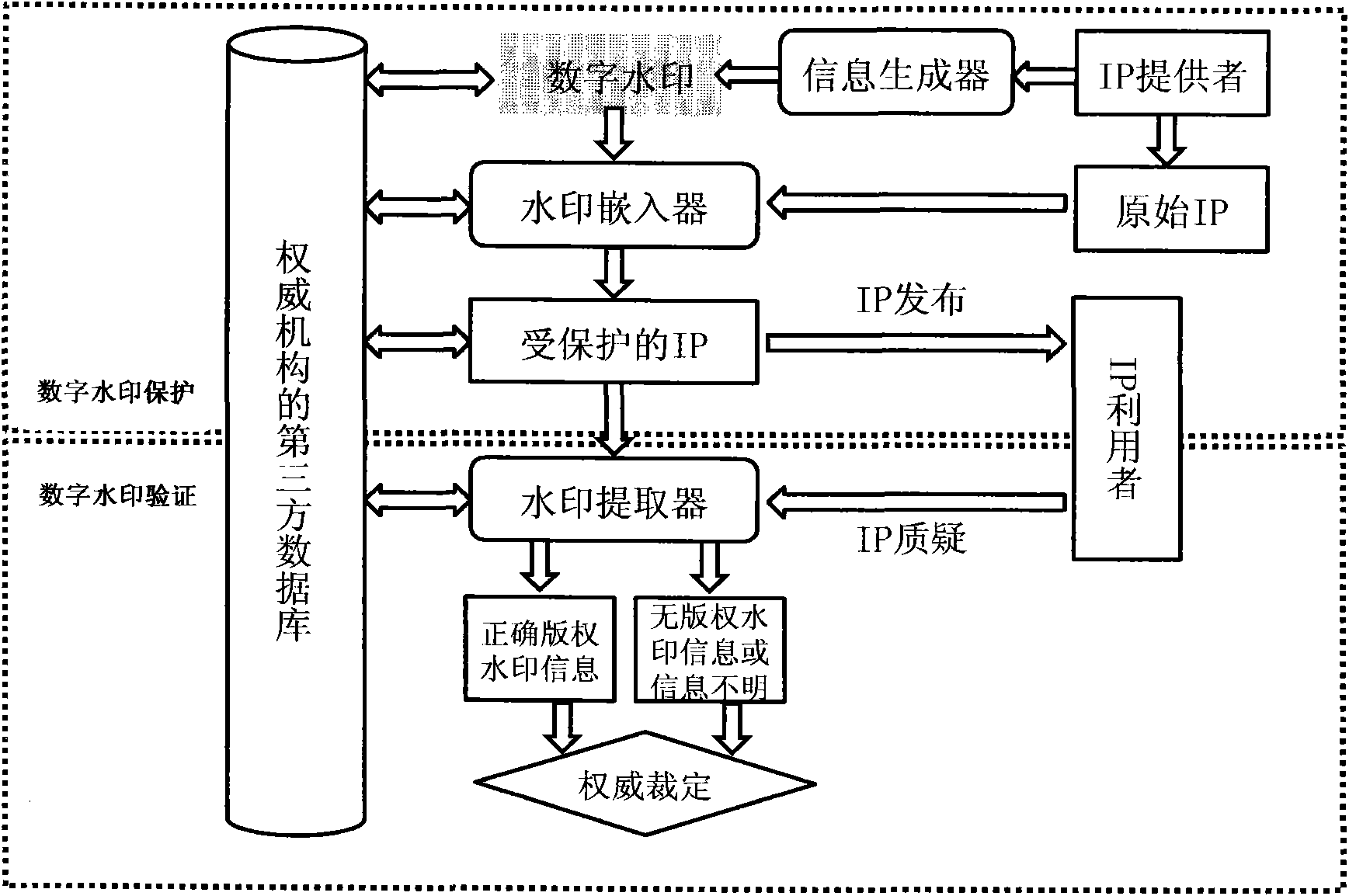

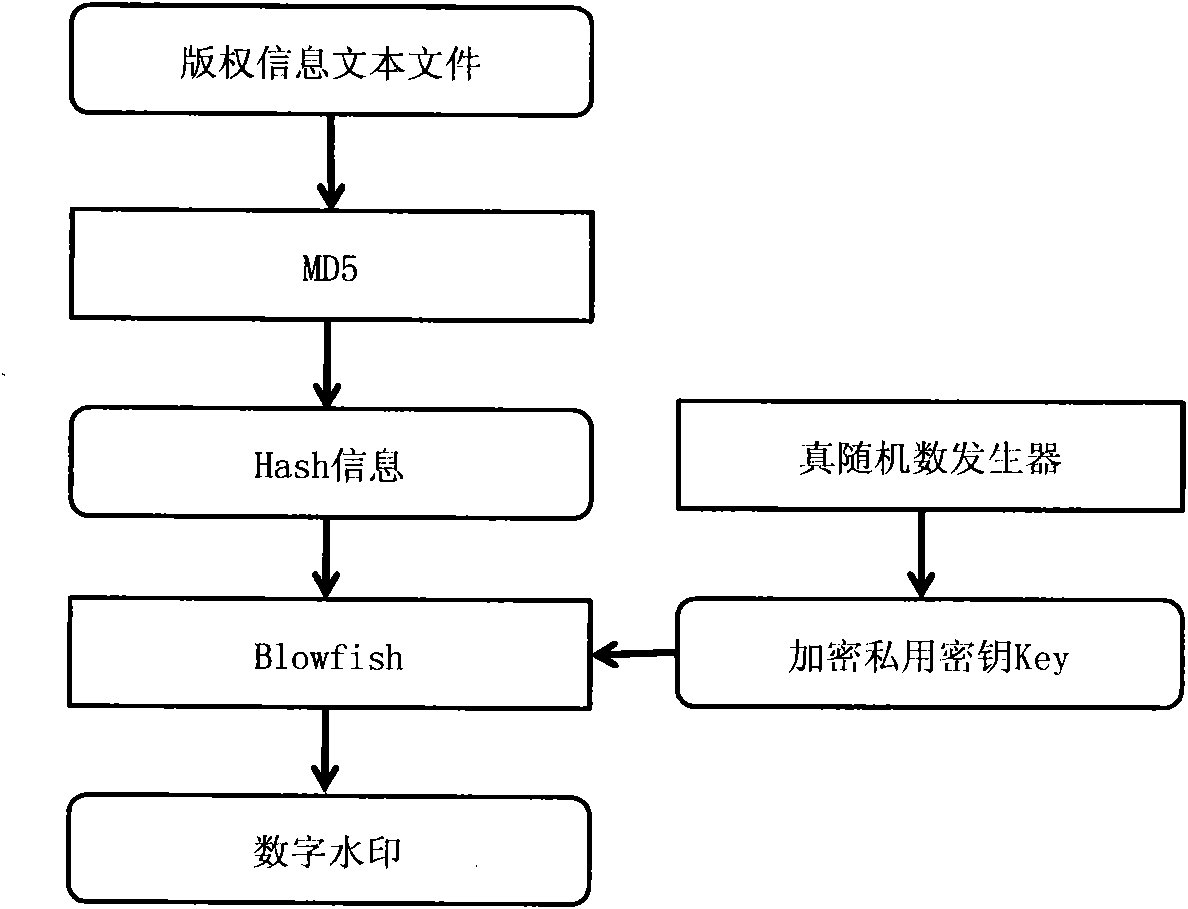

Digital watermarking method

InactiveCN101882297AWith transparencyImprove universalityImage data processing detailsSpecial data processing applicationsRelevant informationData file

The invention provides a digital watermarking method, which protects and checks an IP copyright by means of a digital watermarking technology and has the characteristics of high efficiency, low design cost, low overhead and high feasibility, etc. The technical scheme comprises a watermarking embedding part and a watermarking checking part. The watermarking embedding part comprises the following steps of: encrypting copyright information to generate digital watermarking; selecting a wire net which accords with a carrier for adding a digital watermarking condition in an IP domain territory; changing partial wiring trend of the wire net according to a set constraint condition; passively generating digital watermarking piece information according to the change of the topological structure of a constitutional diagram of the wire net and ambient nodes; normally embedding the piece information into the IP and generating a watermarking secret key after mapping the piece information on the digital watermarking; and outputting a domain territory data file with the digital watermarking information after all digital watermarking information are embedded into the IP. The watermarking checking part comprises the following steps of: extracting correlative information of the IP from a digital watermarking system database; watermarking the secret key and the original IP domain territory data; extracting the wire net from the original IP domain territory data according to the watermarking secret key information; watermarking the wire net with the same method of watermarking embedding; extracting the digital watermarking piece information if structure of the wire net is as the same as that of corresponding wire net in the IP to be checked; synthesizing all digital watermarking piece information to extract the whole digital watermarking information; comparing with the original digital watermarking stored in the database to check the IP and generate an IP copyright checking report.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

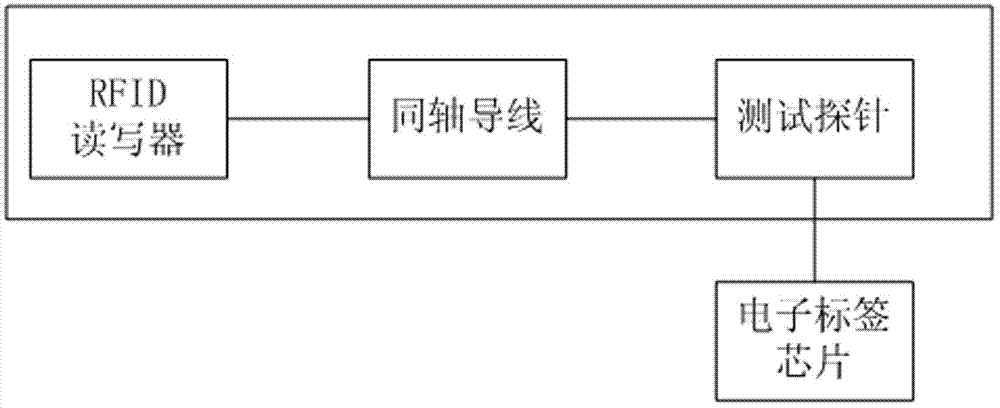

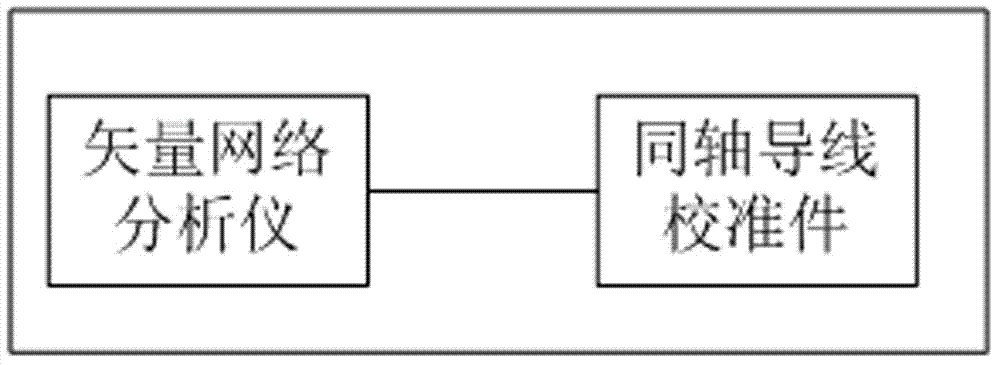

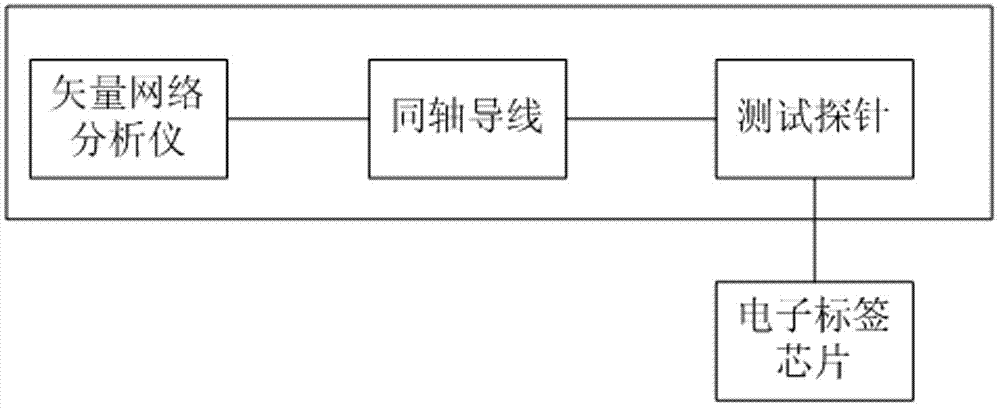

Measuring method and system of electronic tag matching impedance

ActiveCN103091556ASimplifies Antenna DesignSave design timeResistance/reactance/impedenceAntenna designEngineering

The invention relates to a measuring method and a system of electronic tag matching impedance. The measuring method of the electronic tag matching impedance comprises the steps of connecting a reader-writer, a coaxial wire, a test probe and an electric tag chip in sequence, finding out the minimum output power P0 that the reader-writer can support the electric tag chip to work, connecting a vector network analyzer, the calibrated coaxial wire, the corrected test probe and the electric tag chip in sequence, setting output power of the vector network analyzer to be the P0, obtaining a fourth echo reflected value through measurement, processing the fourth echo reflected value, and obtaining the matching impedance of the electric tag chip. According to the measuring method and the system of the electronic tag matching impedance, a resistance value of the electric tag chip in a sensitivity limit can be obtained, and therefore the antenna design of an electric tag is simplified, design time and cost are saved, and design precision is improved.

Owner:NATIONZ TECH INC

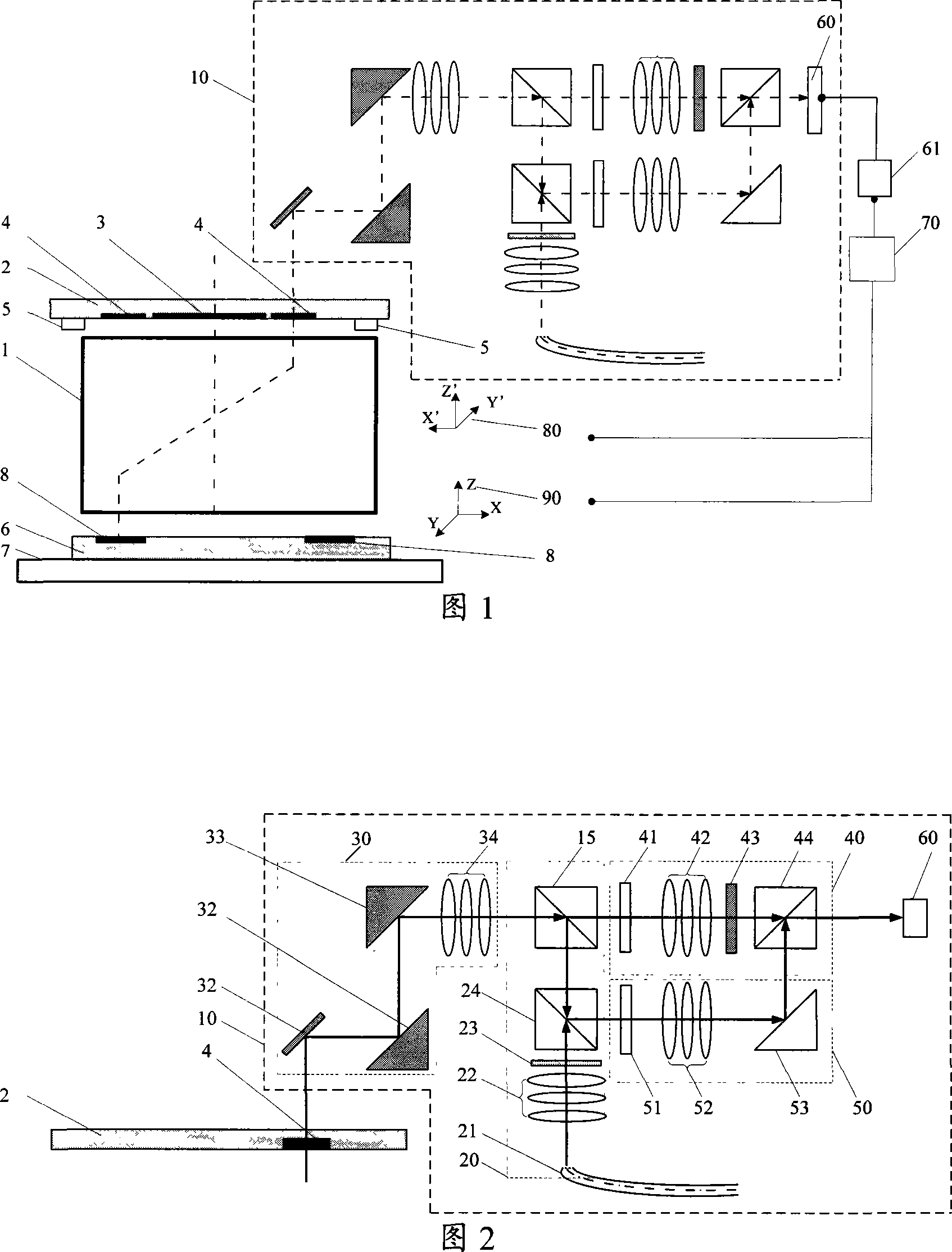

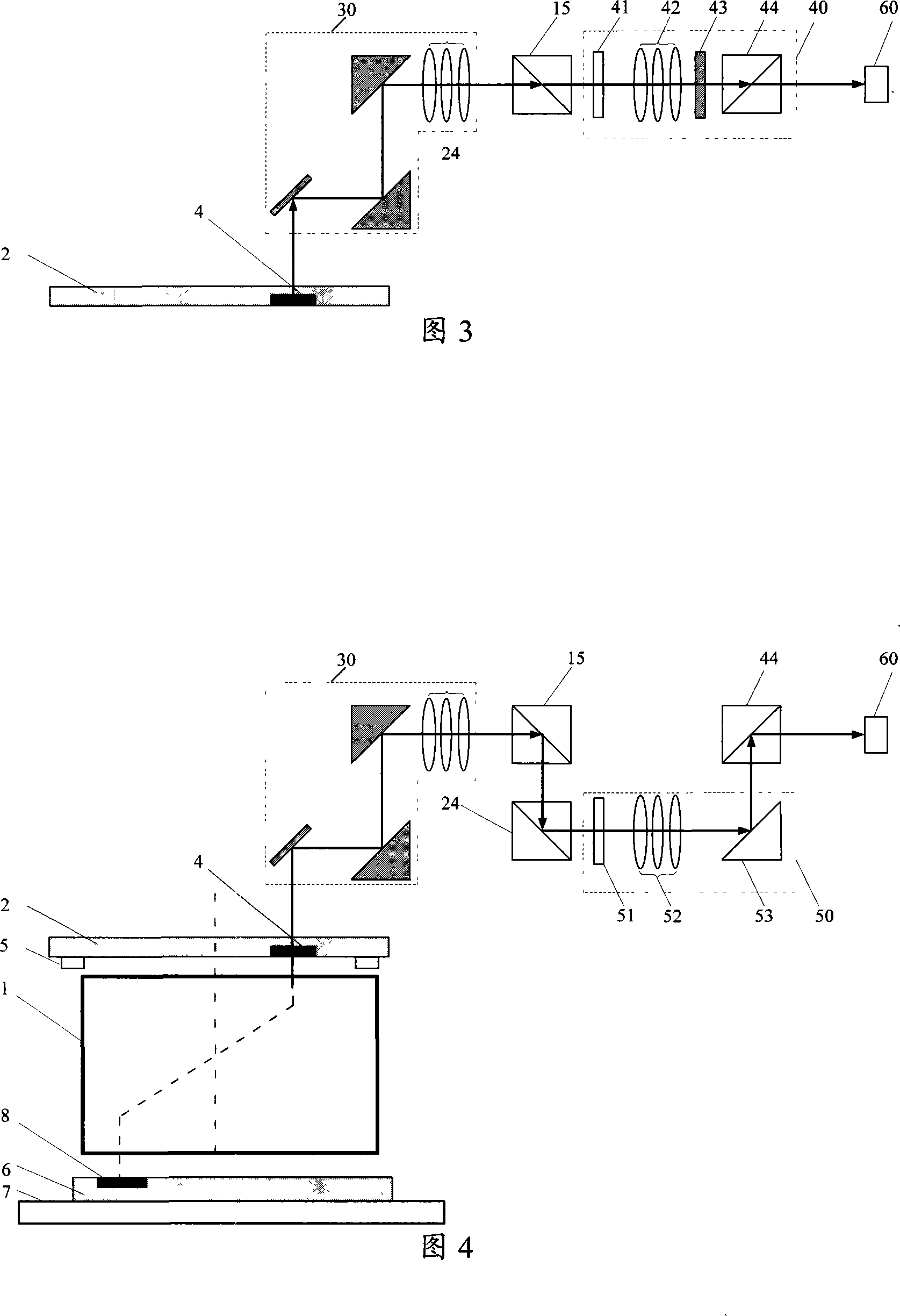

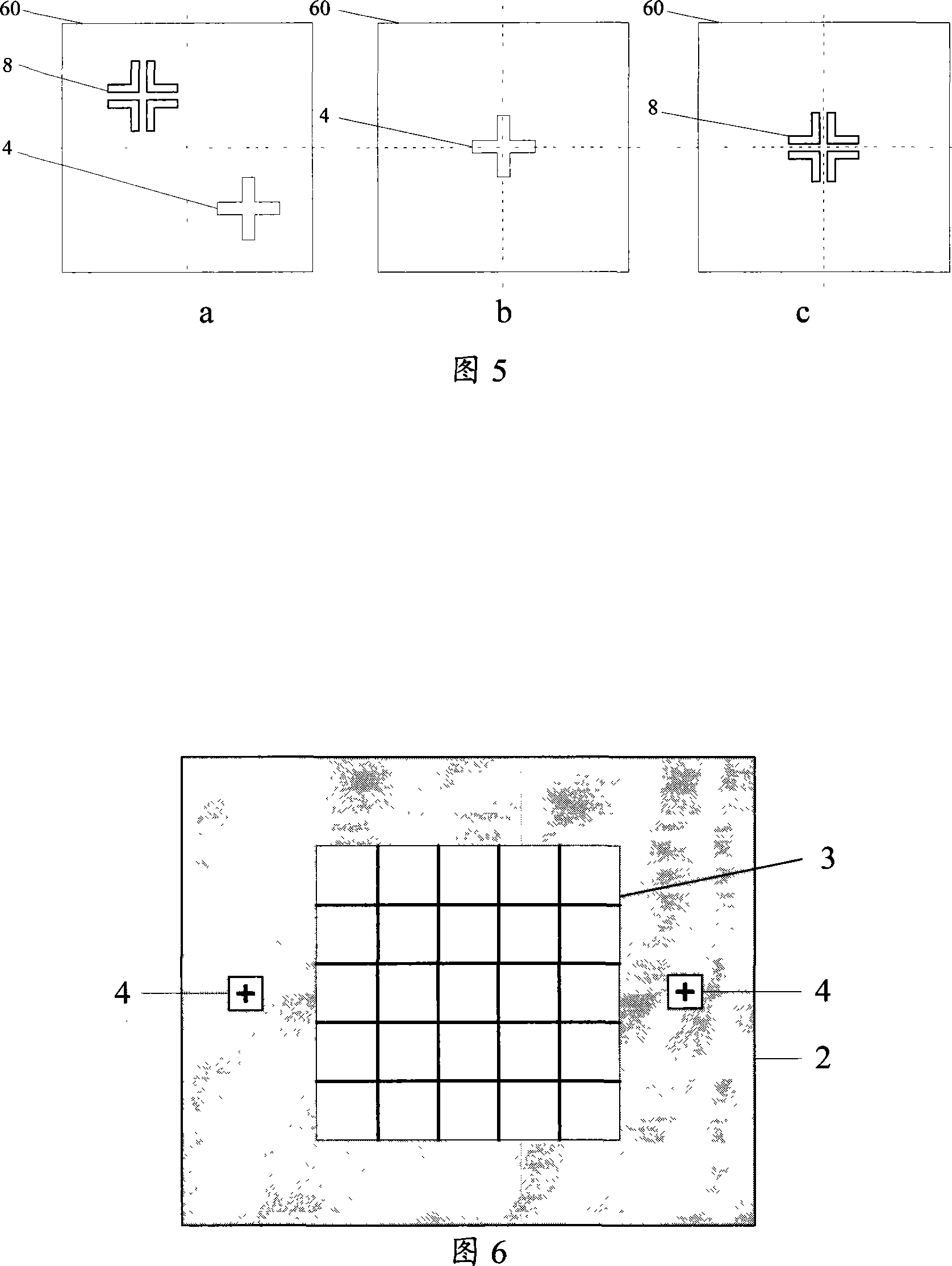

Time sharing alignment apparatus and alignment method

ActiveCN101158816AReduce manufacturing costReduce system complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotovoltaic detectorsPhotodetector

The present invention discloses a time-sharing alignment device and an alignment method for using the device. A mask marker imaging optical system and an exposure object marker imaging optical system are simultaneously optimized in optical structural designing, the imaging of the mask marker and the exposure marker can be carried out through different optical channels of the optical structure, and the condition of simultaneous imaging of the mask marker and the exposure marker on the surface of a photodetector is avoided by the sequential control of opening and closing of a mechanical shutter of the mask marker imaging optical system and the exposure object marker imaging optical system in view of time. The present invention reduces the designing difficulty, manufacturing cost and complex degree of the optical projection system in an exposure device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

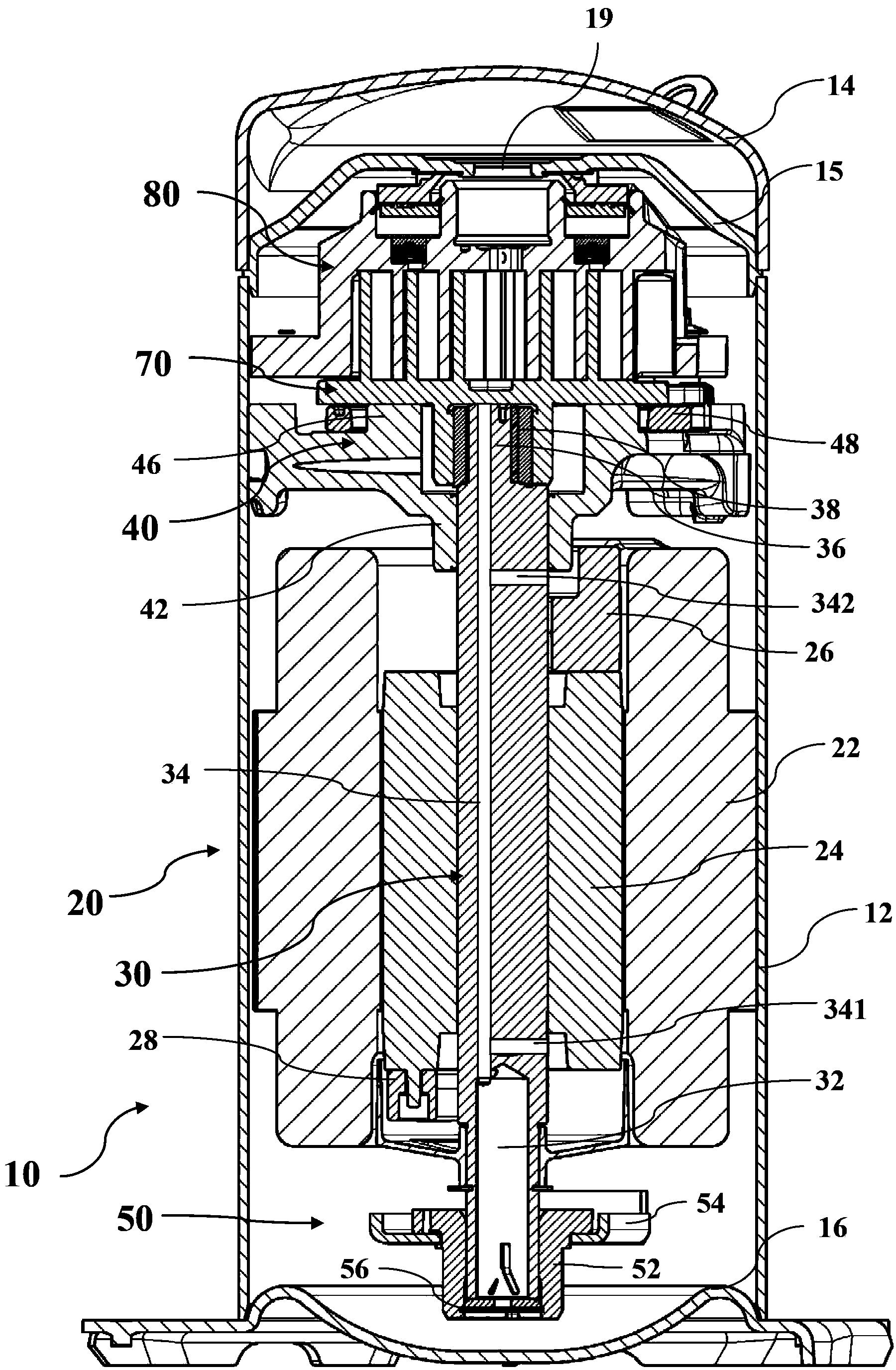

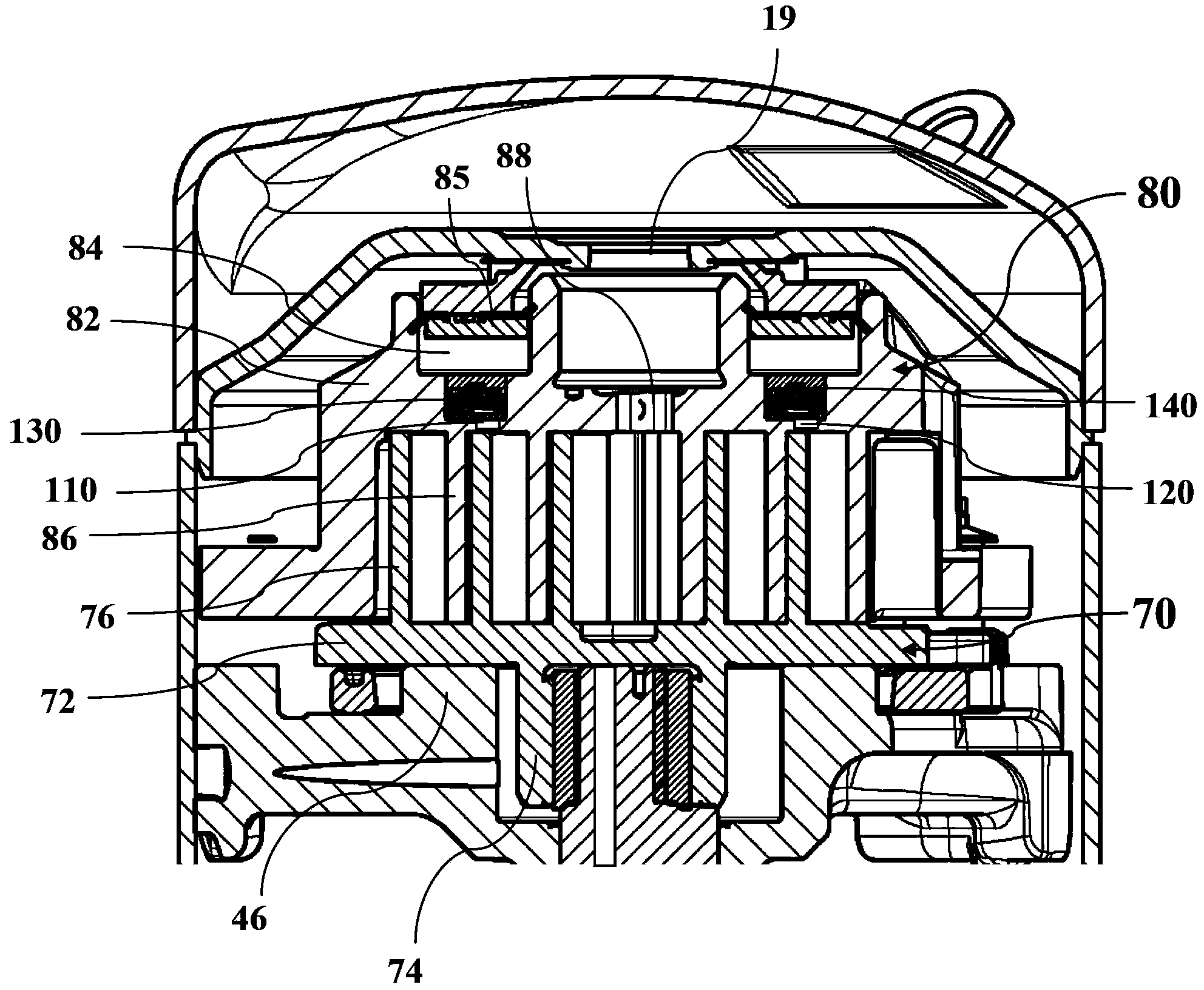

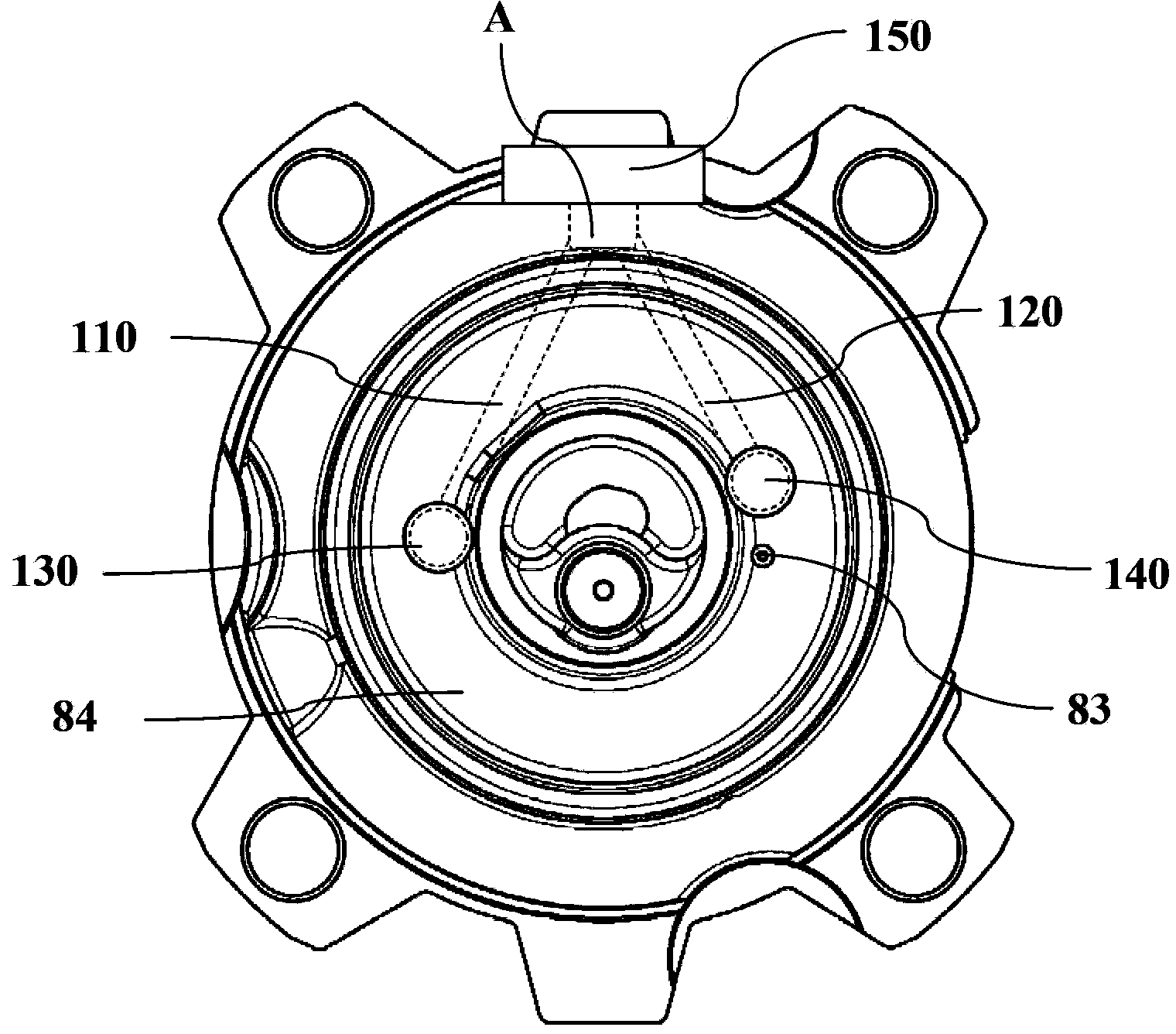

Compressor

ActiveCN103573619ASave design costSave manufacturing costRotary piston pumpsRotary piston liquid enginesControl valvesDischarge pressure

A disclosed compressor (10) comprises: a shell (12) in which an inspiratory pressure zone and an exhaust pressure zone are defined, and a compression mechanism arranged in the shell; and the compression mechanism comprises: a first vortex part (80) comprising a first end plate (82) and a first vortex blade (86), a second vortex part (70) comprising a second end plate (72) and a second vortex blade (76), a first communication channel (110) which is arranged between a first compression chamber (C1) and the inspiratory pressure zone and selectively provides fluid communication, and a first control valve (150). When the first control valve closes the first communication channel, the compressor works with full capacity, and when the first valve opens the first communication channel, the compressor works with reduced capacity. The compressor provided by the invention helps to realize capacity adjusting of compressors by employing a relatively simple manner.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

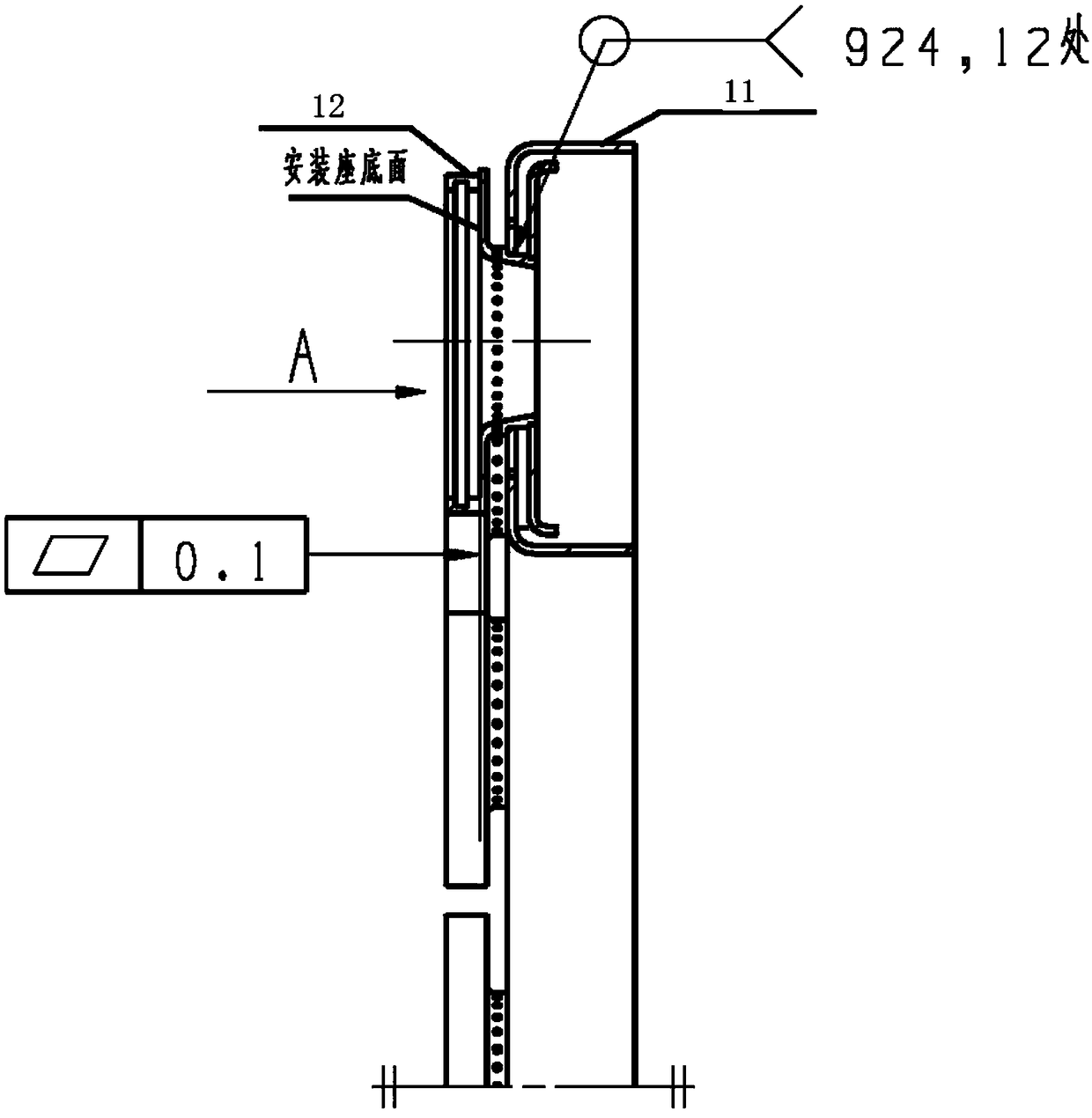

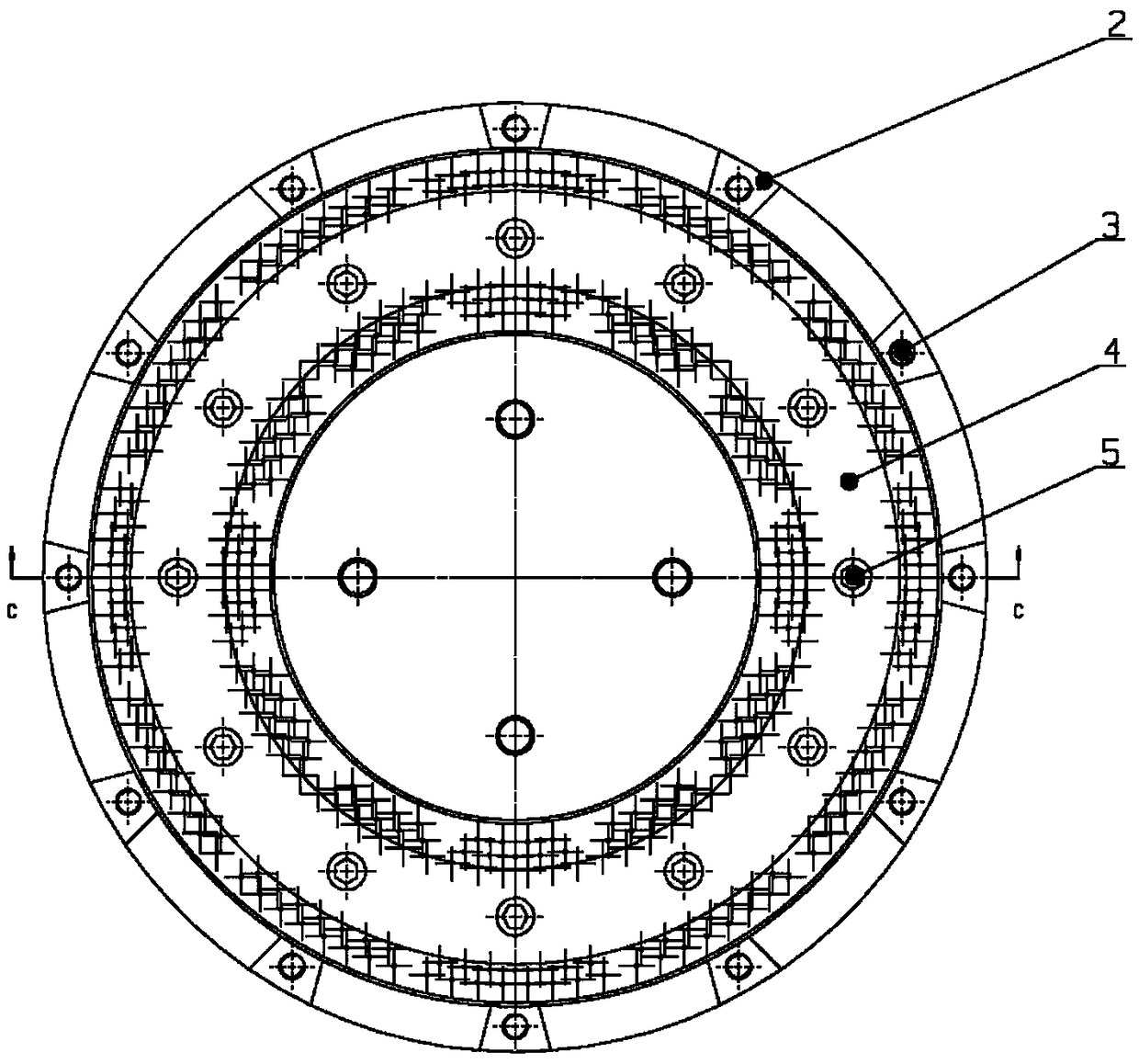

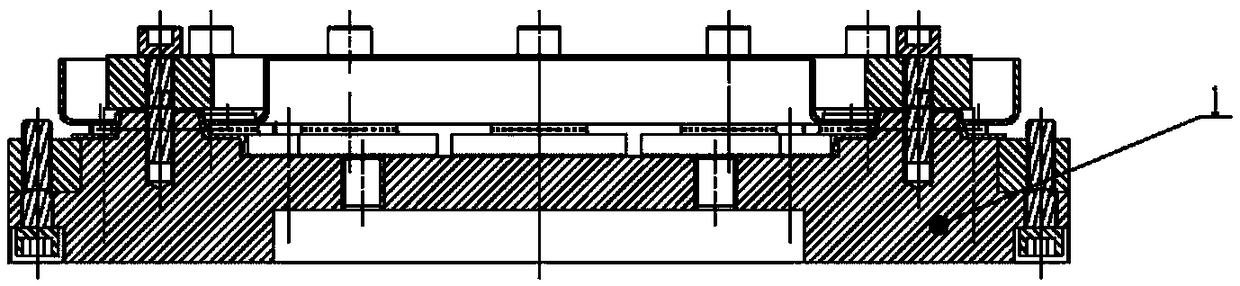

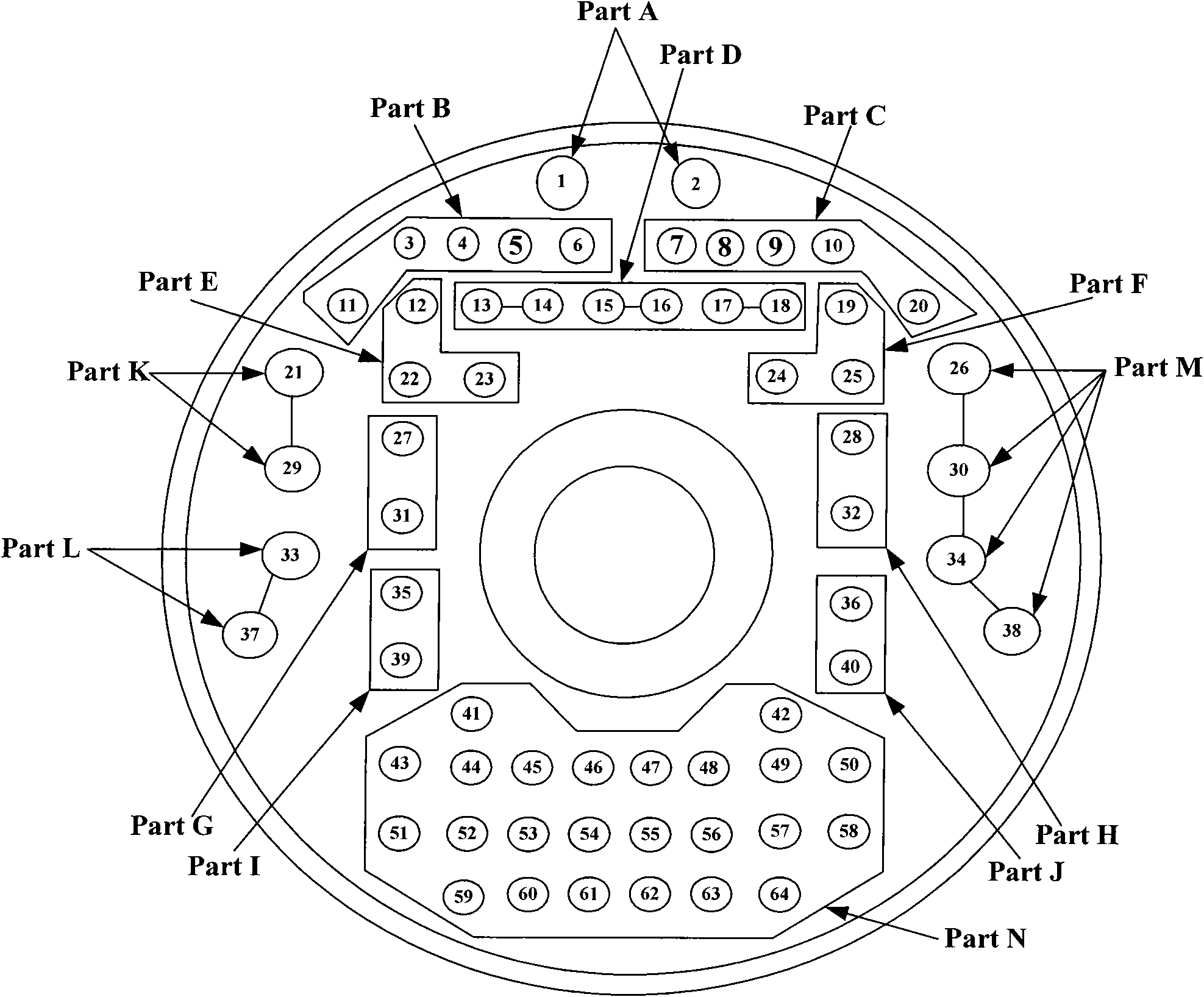

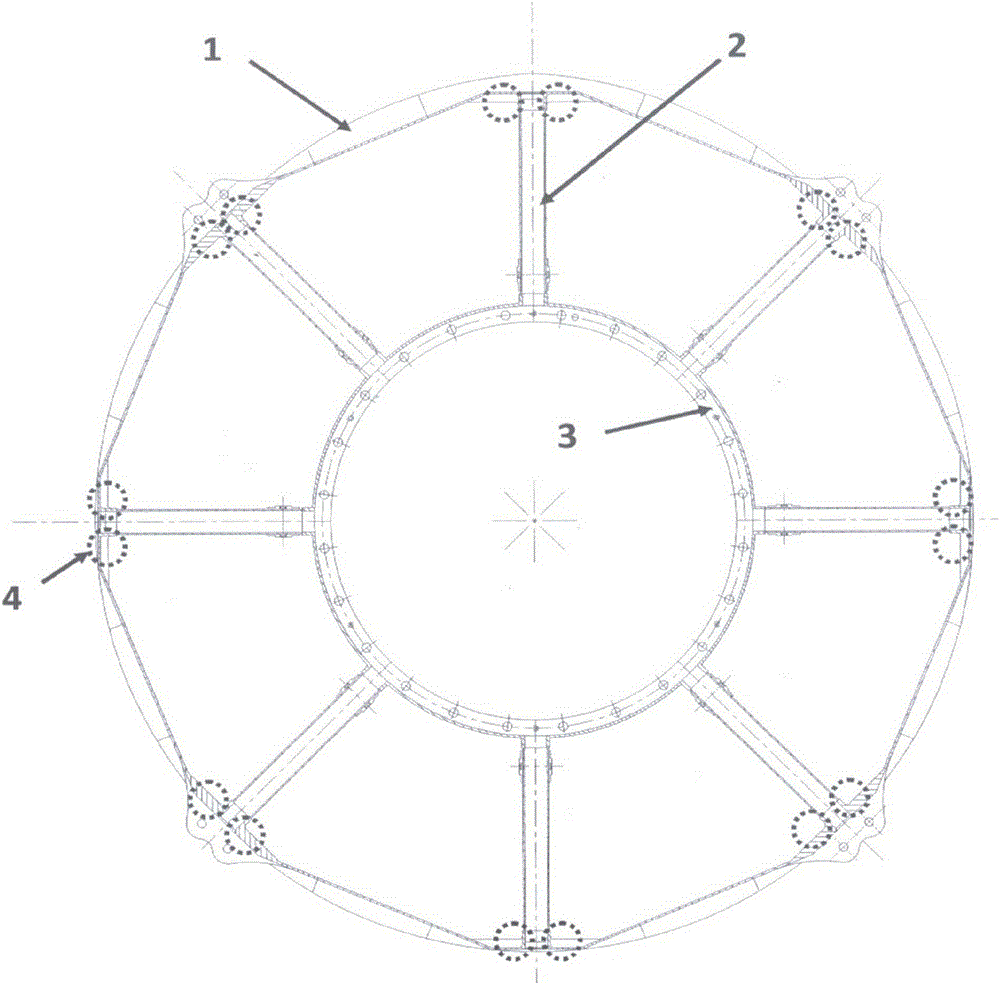

Vacuum brazing fixture and method for flame tube head assembly

ActiveCN109365947ASave design costControl deformationWelding/cutting auxillary devicesAuxillary welding devicesCylinder headEngineering

The invention discloses a vacuum brazing fixture and method for a flame cylinder head assembly. The the clamp comprises a clamp body (1), a positioning block (2), a positioning bolt (3), a pressure plate (4) and a compression bolt ( 5). After using the clamp clamping ring (11) and the swirler mount (12), the polishing, assembling parts, positioning weld, and vacuum brazing are operated in turn tobraze. By means of the fixture and the method, the flatness of the part of 0.1 mm can be ensured, the milling process of the parts can be omitted, the positioning welding tool of the parts can be saved, the labor intensity of the workers can be reduced, the machining cost of the parts can be reduced, and the production efficiency of the parts can be improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

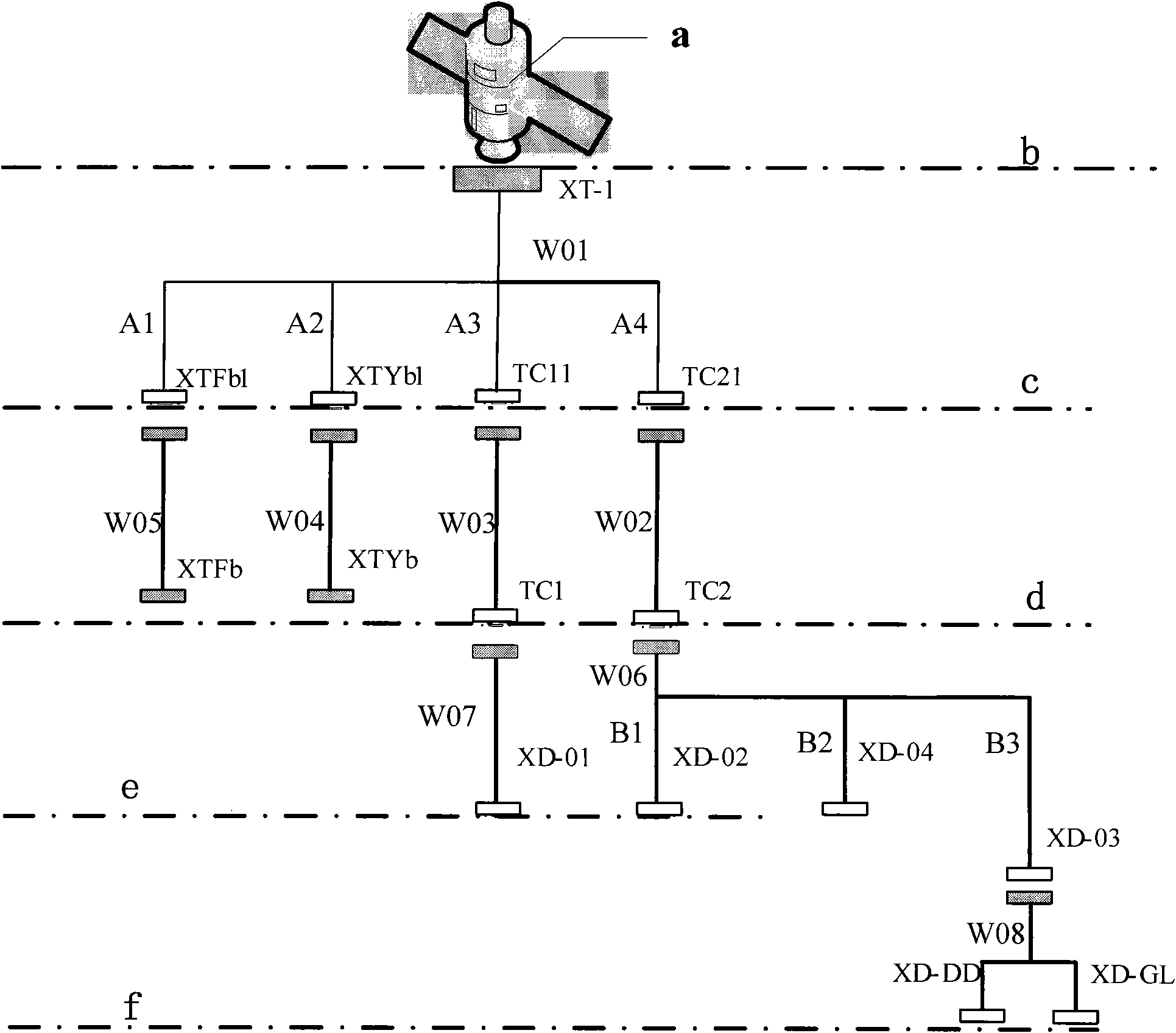

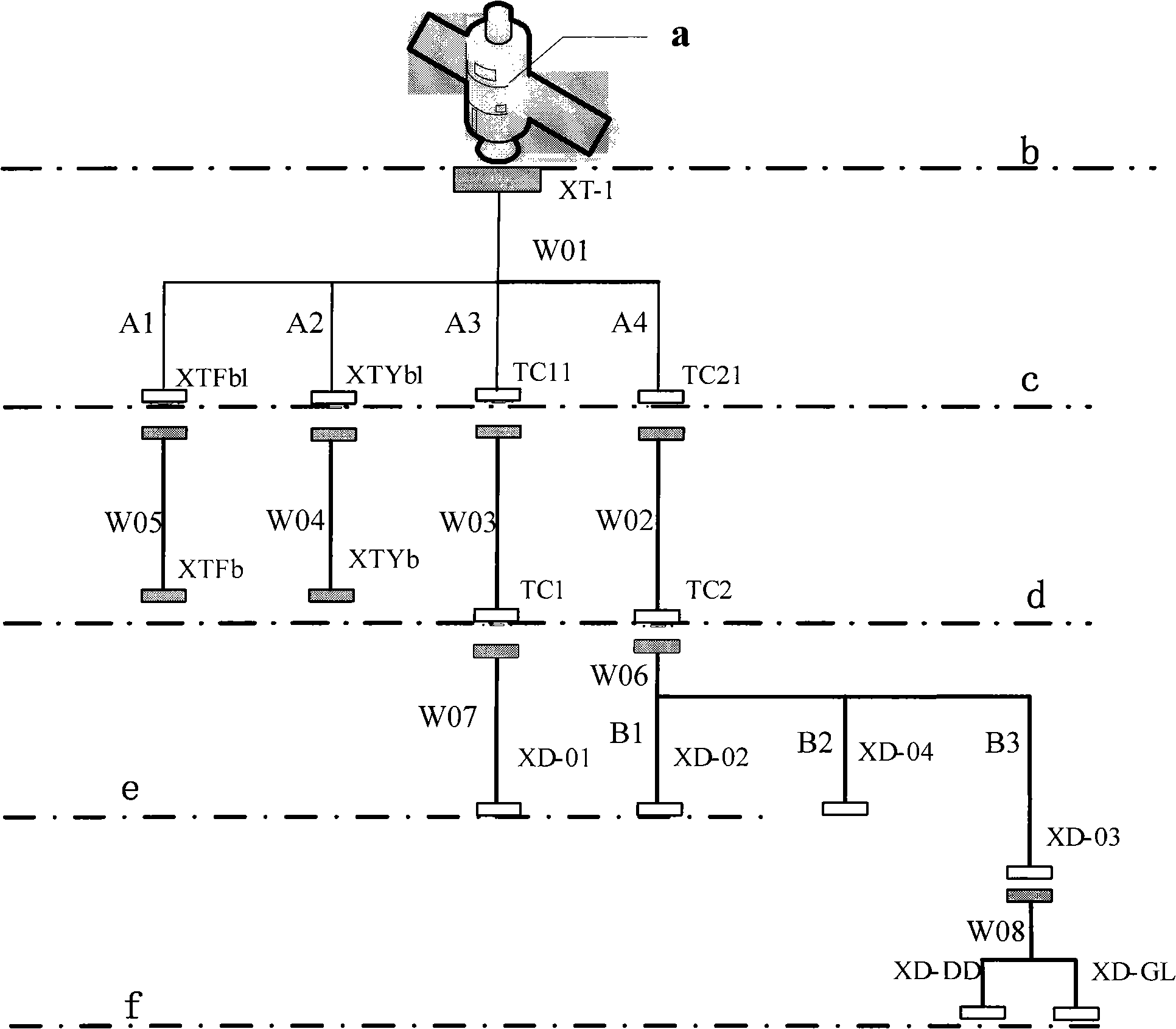

Microsatellite unplugged cable network

ActiveCN101938076ASave structural resourcesSolve problemsCoupling device connectionsArtificial satellitesElectricityMultiplexing

The invention relates to a microsatellite unplugged cable network, which solves the problem that the design of a star catalogue plug is difficult due to structural characteristics of the microsatellite of small volume, body-mounted solar cell array and the like. In the prior art, in order to preserve the star catalogue plug, only a star catalogue plug interface is arranged on the body-mounted solar cell array, which necessarily damages the integral structure of the satellite body-mounted solar cell array. In order to meet the task requirement of the microsatellite and overcome the defects in the prior art, the microsatellite unplugged cable network integrates the satellite star catalogue and the microsatellite unplugged cable, maintains satellite power supply of the traditional unplugged cable, a satellite task test computer interface and controlled quantity, state quantity and analog quantity contacts of a wired station, reasonably utilizes limited pin resources of the unplugged cable, and successfully integrates the traditional star catalogue plug and star catalogue cable into the unplugged cable network according to the electromagnetic compatibility of strong and weak current and pin multiplexing of an electric connector.

Owner:AEROSPACE DONGFANGHONG SATELLITE

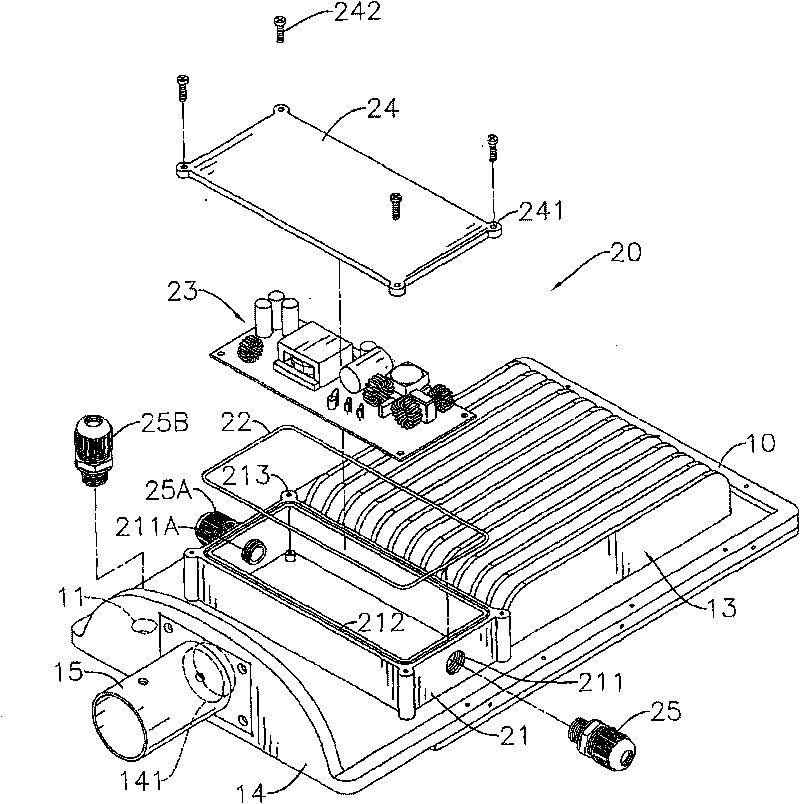

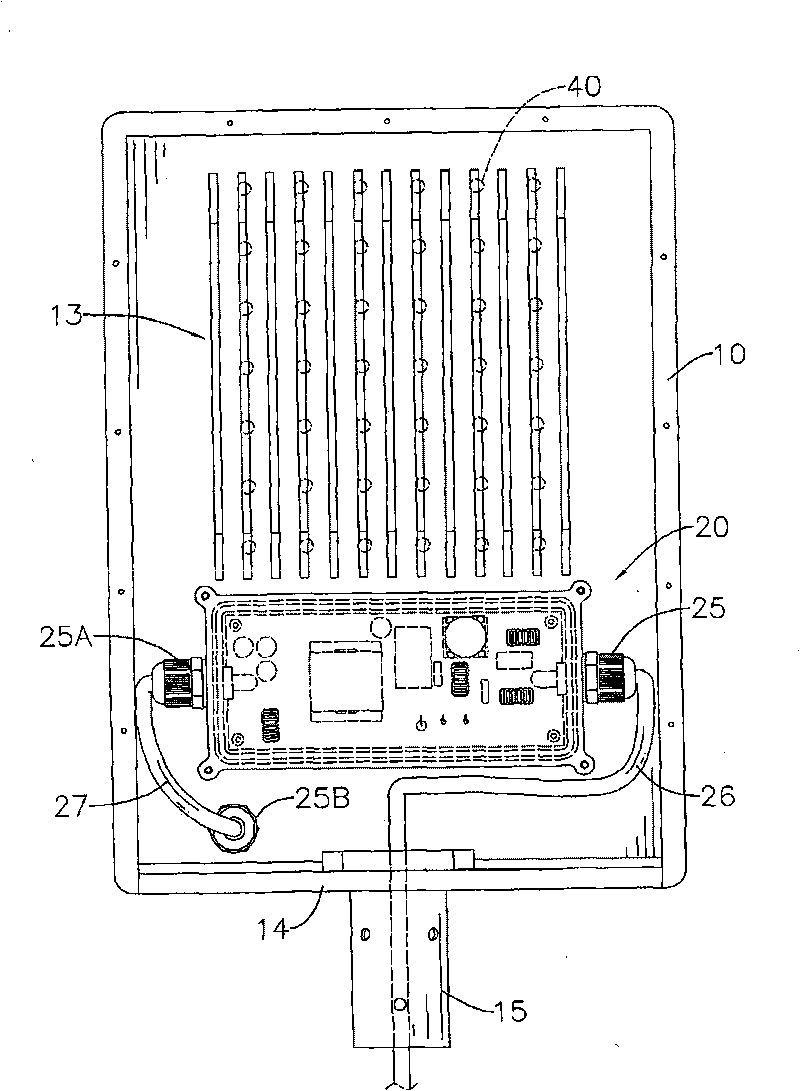

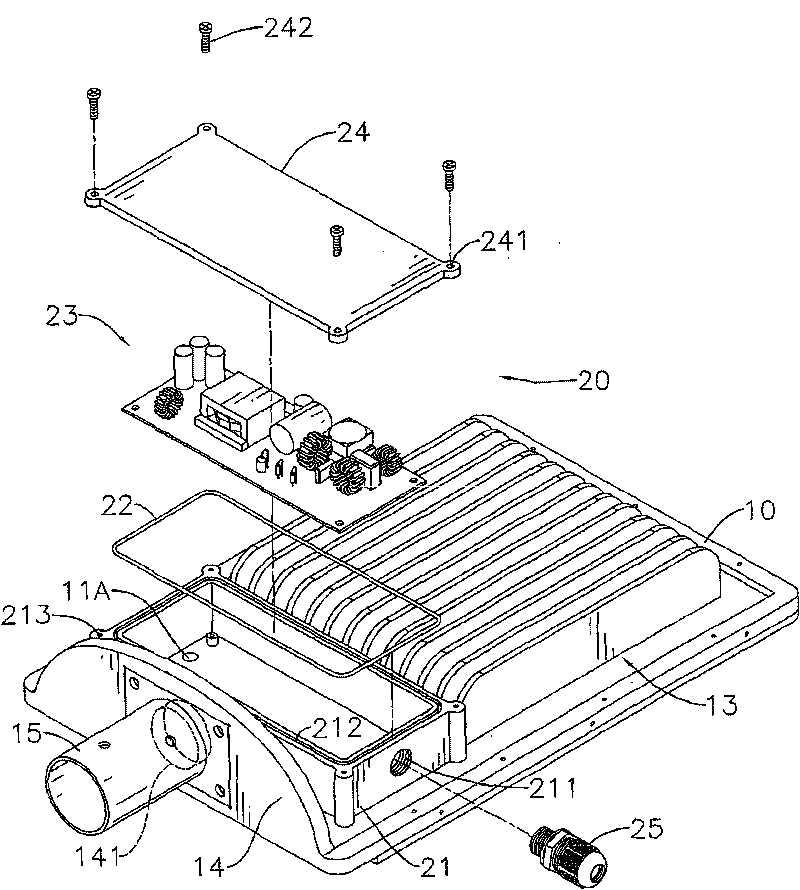

Power supplier assembling structure of lighting device

InactiveCN101749662ASave design costSave manufacturing costPoint-like light sourceElectric circuit arrangementsComputer moduleAlternating current

The invention discloses a power supplier assembling structure of lighting device, which comprises a substrate and a power supplier. The power supplier converters a current into a DC power, which comprises a shell integrally formed on the substrate. A water-proof joint is arranged on the shell; a through hole is formed inside the shell on the substrate through penetrating; an AC cable and a DC cable are respectively connected with the power supplier; wherein one end of the AC cable is connected with an AC power source; while the other end of the AC cable is connected with the power supplier by arranging the water-proof joint through penetration; one end of the DC cable is connected with the power module and the other end penetrates the through hole and is arranged at the other side of the substrate; the structure can save the processing cost as well as the cost for die designing and manufacturing.

Owner:ACBEL POLYTECH INC

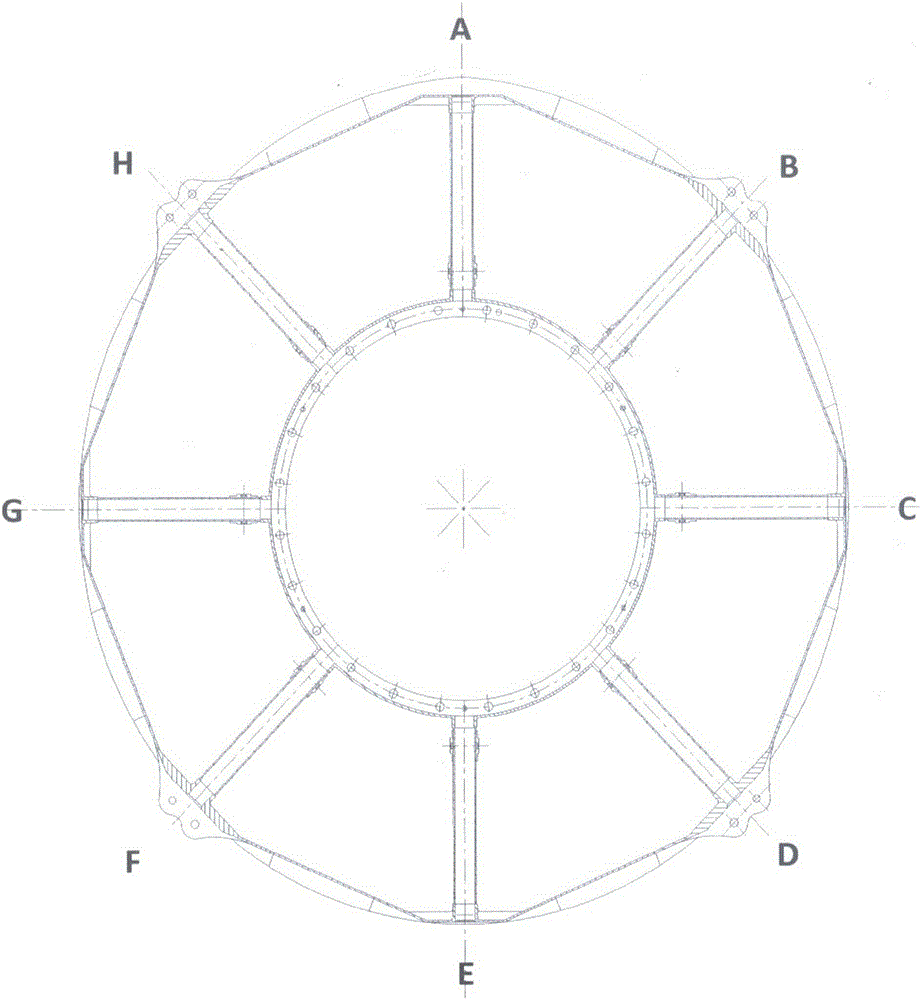

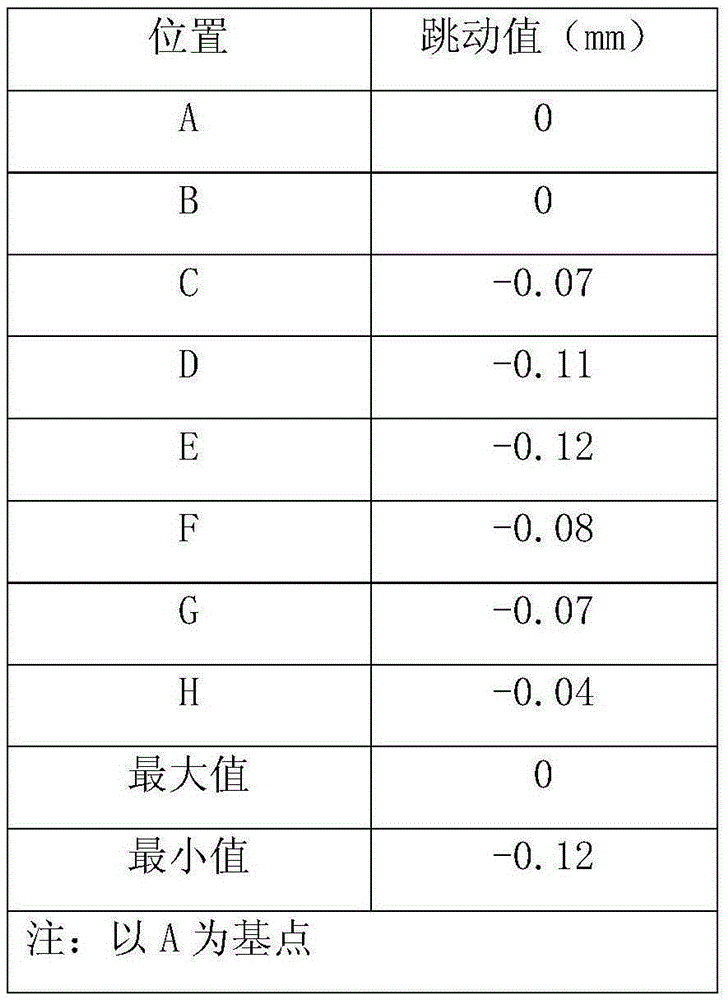

Method for shape correction of high-temperature alloy thin-wall aeroengine casing part through electric arc heating

ActiveCN105290162AThe process is simpleEasy to operateShaping toolsMetal working apparatusThin walledElectric arc

The invention provides a method for shape correction of a high-temperature alloy thin-wall aeroengine casing part through electric arc heating, and belongs to the technical field of welding. The method comprises the first step of carrying out size measurement before shape correction, selecting the outer ends of all supporting tubes as measurement points and then carrying out marking, and measuring the jump values of all measurement points on an inner ring; the second step of determining the sequence of shape correction, carrying out heating shape correction on the minimum jump value point firstly and then carrying out heating shape correction on two points adjacent to the minimum jump value point, and carrying out shape correction in priority on the point, with the smaller jump value, of the two points; the third step of carrying out electric arc heating shape correction, and carrying out electric arc heating on reinforcing ribs on the two sides of each measurement point sequentially according to the sequence of shape correction; the fourth step of carrying out accurate measurement after shape correction, measuring the jump values of all the measurement points of the inner ring to obtain a radial jump value, and executing the fifth step if the radial jump value meets the design requirement, otherwise, executing the second step; and the fifth step of carrying out stress relief heat treatment, measuring the jump values of all the measurement points on the inner ring after heat treatment to obtain a radial jump value, and ending shape correction if the radial jump value meets the design requirement, otherwise, executing the second step.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

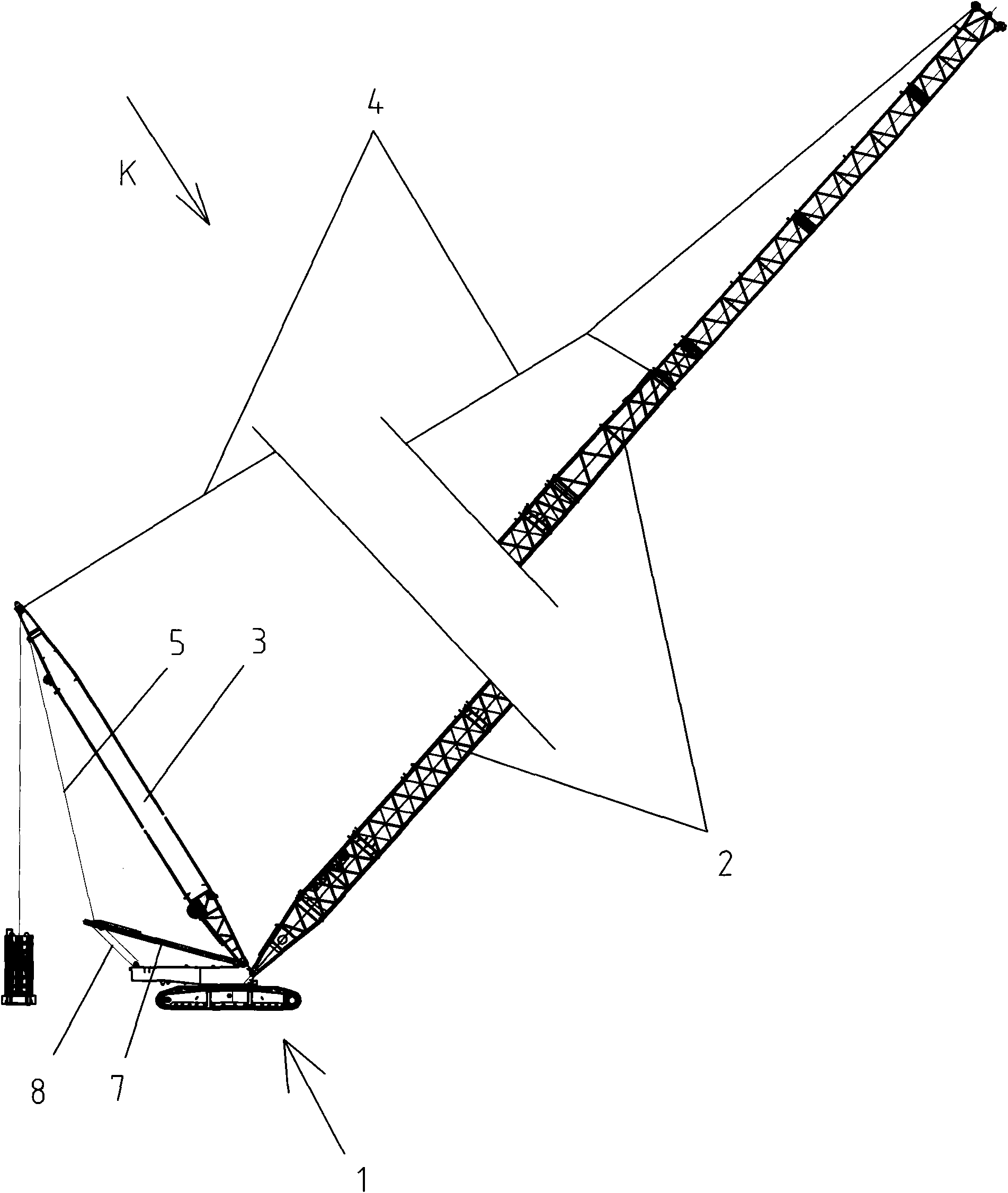

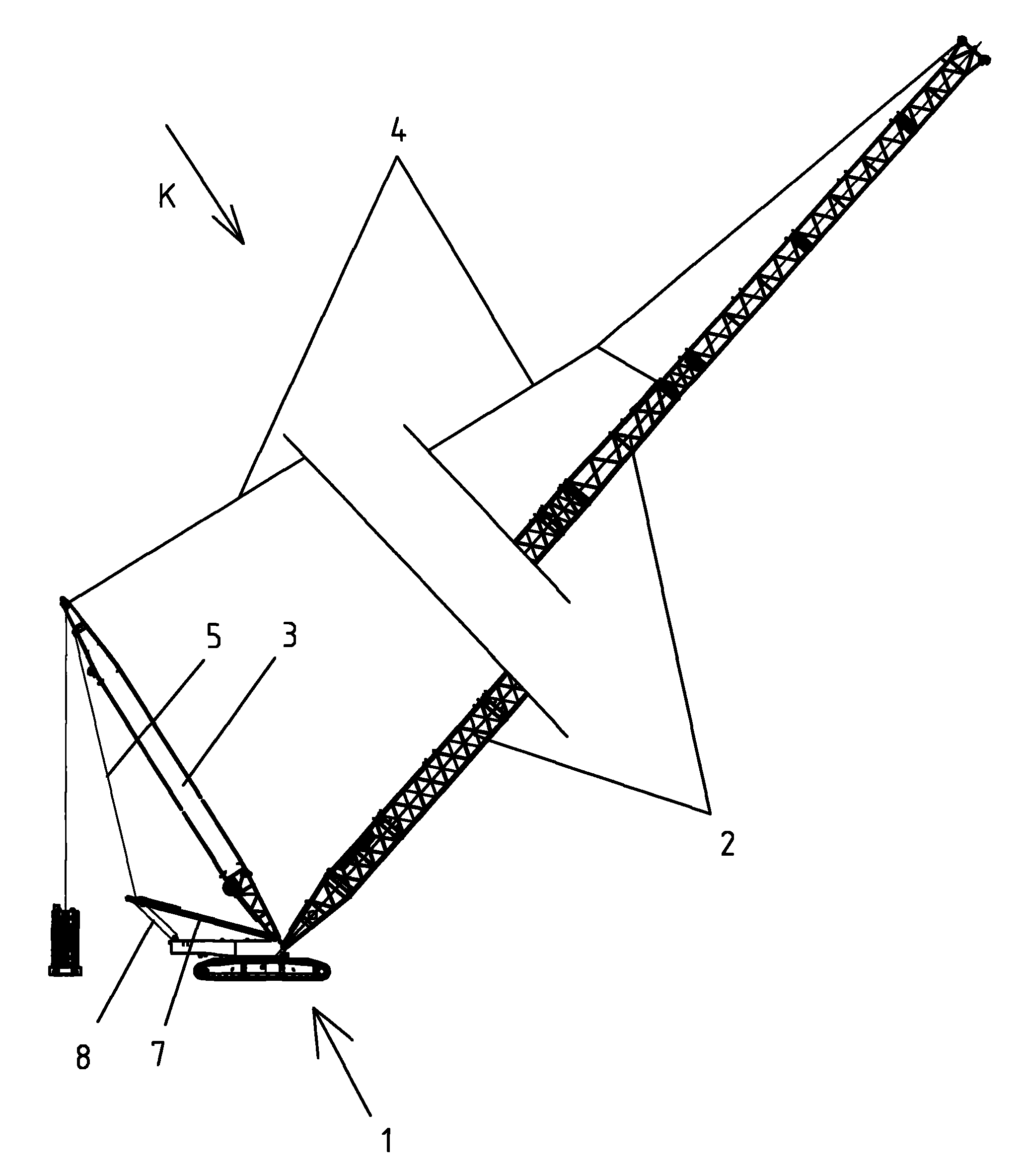

Crawler crane with lateral reinforcement structure

InactiveCN101811646AReduce dosageImprove lateral stabilityCargo handling apparatusPassenger handling apparatusMaterial consumptionEngineering

The invention relates to a crawler crane with a lateral reinforcement structure. The crawler crane comprises a crane body, an arm frame connected with a rotating shaft of the crane body, super-lifting masts and masts, wherein front bracing wires are connected between the top end of the arm frame and the top ends of the super-lifting masts, back bracing wires are connected between the top ends of the super-lifting masts and the top ends of the masts, main derricking ropes are connected between the top ends of the masts and the crane body, the super-lifting masts, the masts, the front bracing wires and the back bracing wires are respectively arranged in two groups and arranged symmetrically relative to the central plane of the crane body and the arm frame; and a cross beam is connected between the super-lifting masts in each group, a support beam is connected between the top ends of the masts in each group, and the main derricking ropes are connected on the support beams. The crawler crane can simplify the structure of the whole machine while reinforcing the lateral stability and has the advantages of low material consumption, light weight of equipment, convenient transportation, low design cost and low manufacturing cost.

Owner:DALIAN YILIY CONSTR MACHINERY +1

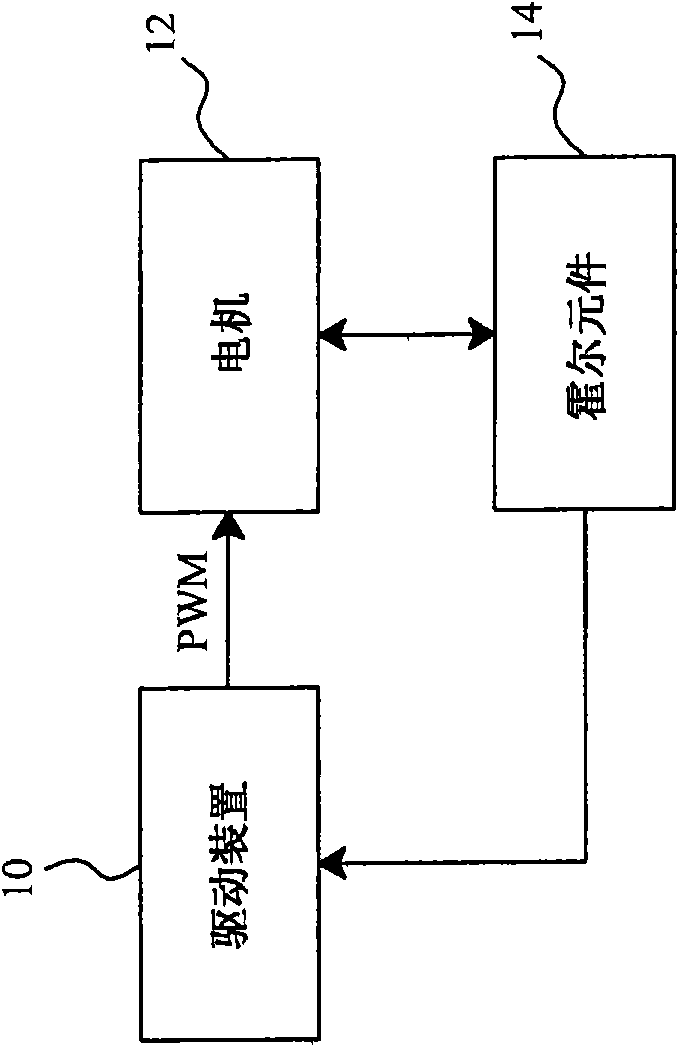

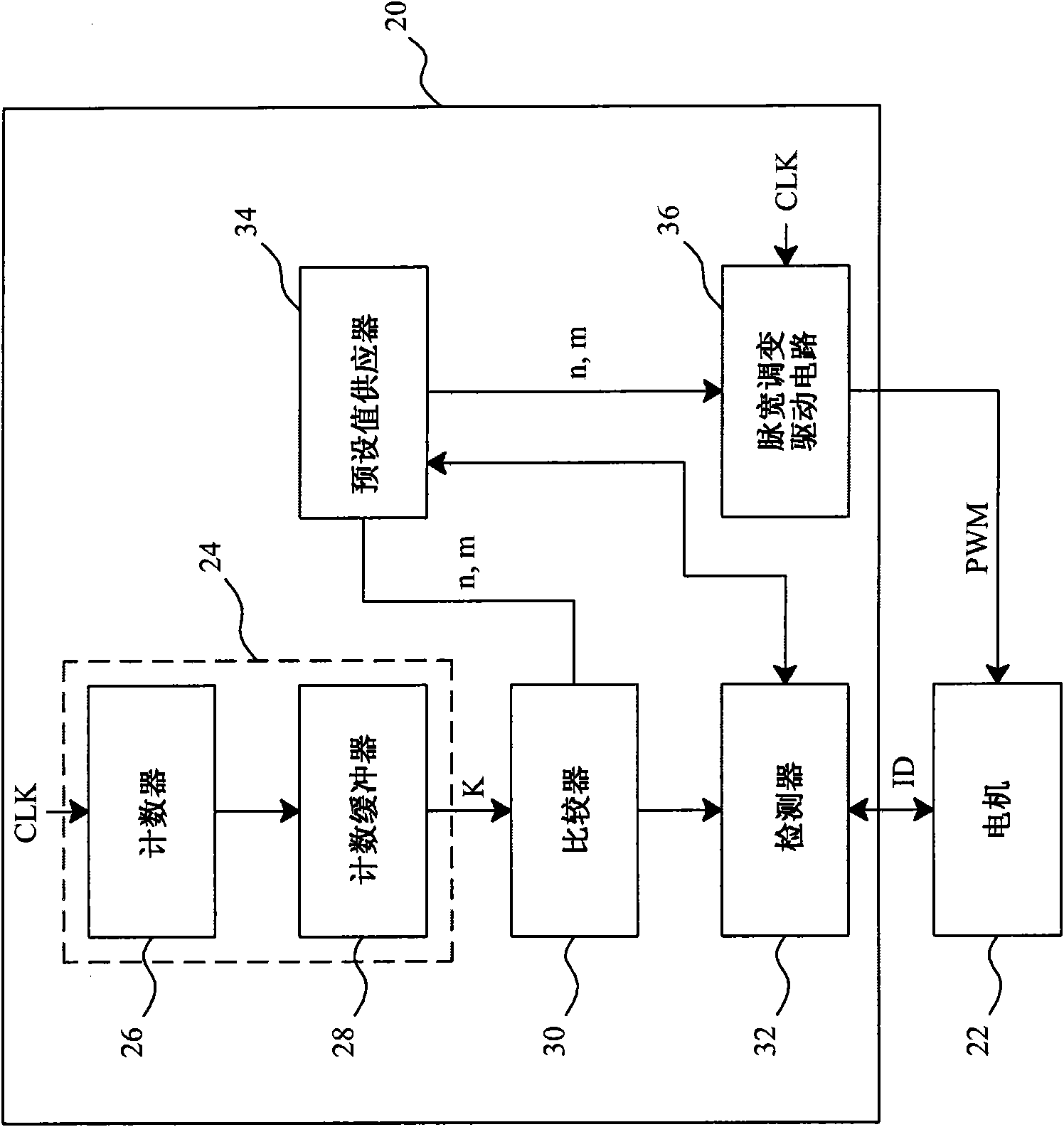

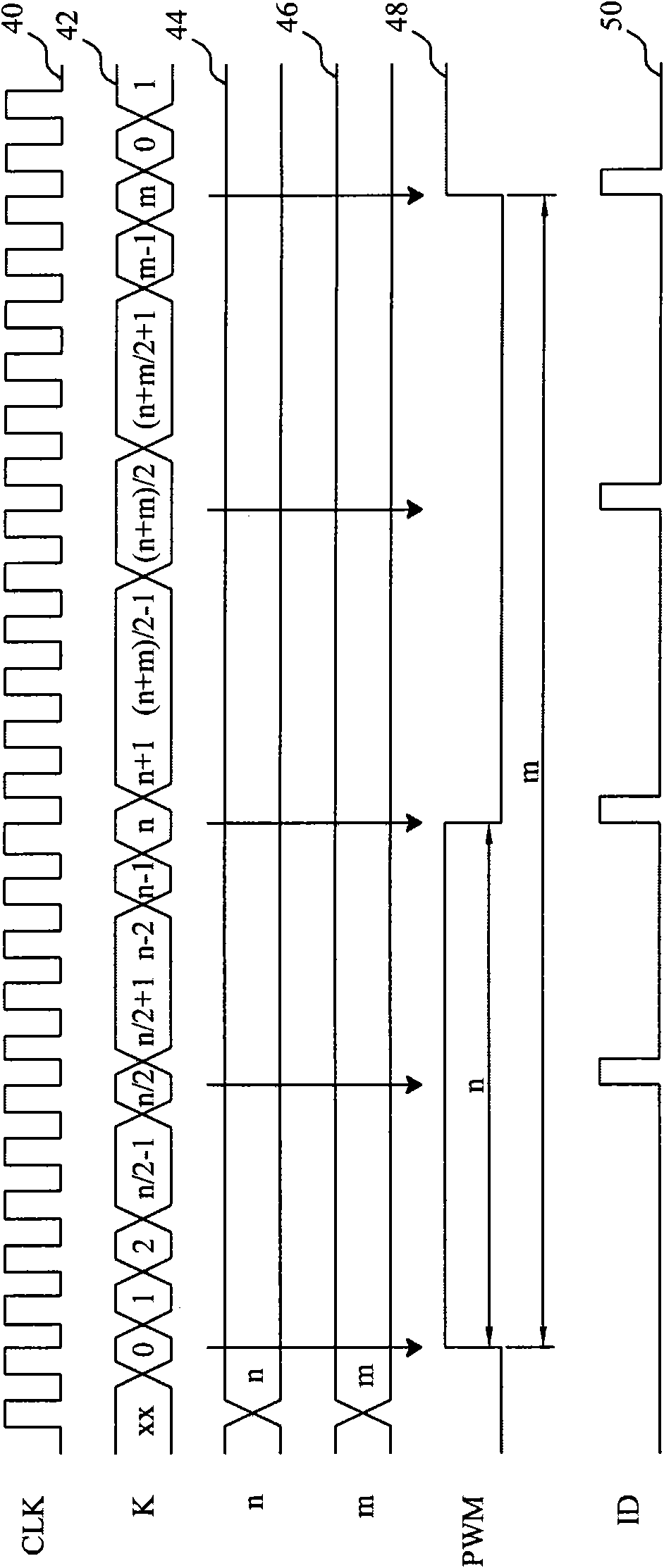

Driving device and method

InactiveCN101610064AReduce complexityShorten detection timeElectric motor controlEnergy industryActive detectionRapid response

The invention provides a driving device and a method. The driving device comprises a pulse width modulation drive circuit, a detector, a counting circuit and a comparator, wherein the pulse width modulation drive circuit generates a pulse width modulation signal according to a preset value to drive a driven device; the detector is used for detecting the status of the driven device; when the status of the driven device is abnormal, the preset value is regulated; the counting circuit is used for counting a counting value generated by a clock; the comparator is used for comparing the counting value and a target value changed along with the preset value; and when the counting value reaches the target value, the detector is triggered. Because the driving device is combined with a detecting function and is in active detection, the reaction can be more quickly carried out, and the design cost and the time also can be reduced, thereby the work efficiency is increased.

Owner:ELAN MICROELECTRONICS CORPORATION

Thermally Optimized Automotive Power Supply

ActiveCN102272975AUniform temperature distributionSave design costLi-accumulatorsPropulsion by batteries/cellsHeat conductingElectrical battery

A voltage supply apparatus for a motor vehicle, especially a passenger car, truck or a motorcycle, includes a storage cell arrangement having one or more electrochemical storage cells and / or double layer capacitors that are mounted on top of each other. The storage cell arrangement is releasably connected in a form-fitting way to a heat-conducting cooling device that removes heat from the storage cells and / or double layer capacitors such that at least some of the storage cells and / or double layer capacitors of a respective storage cell group can each be thermally connected with the heat-conducting cooling device.

Owner:BAYERISCHE MOTOREN WERKE AG

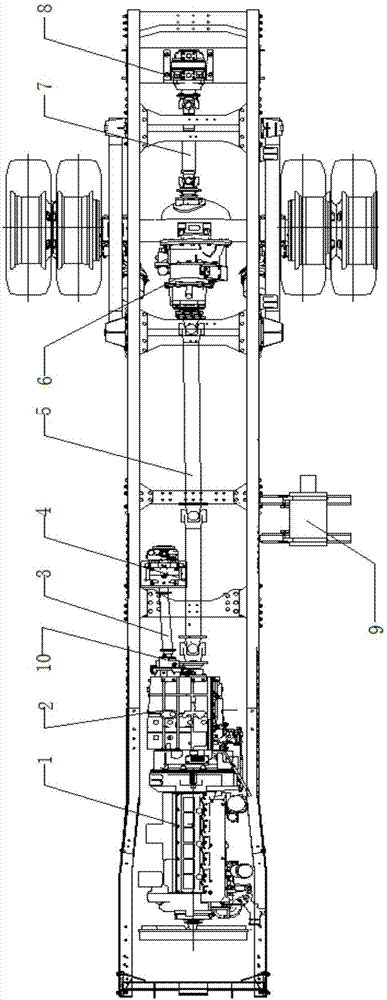

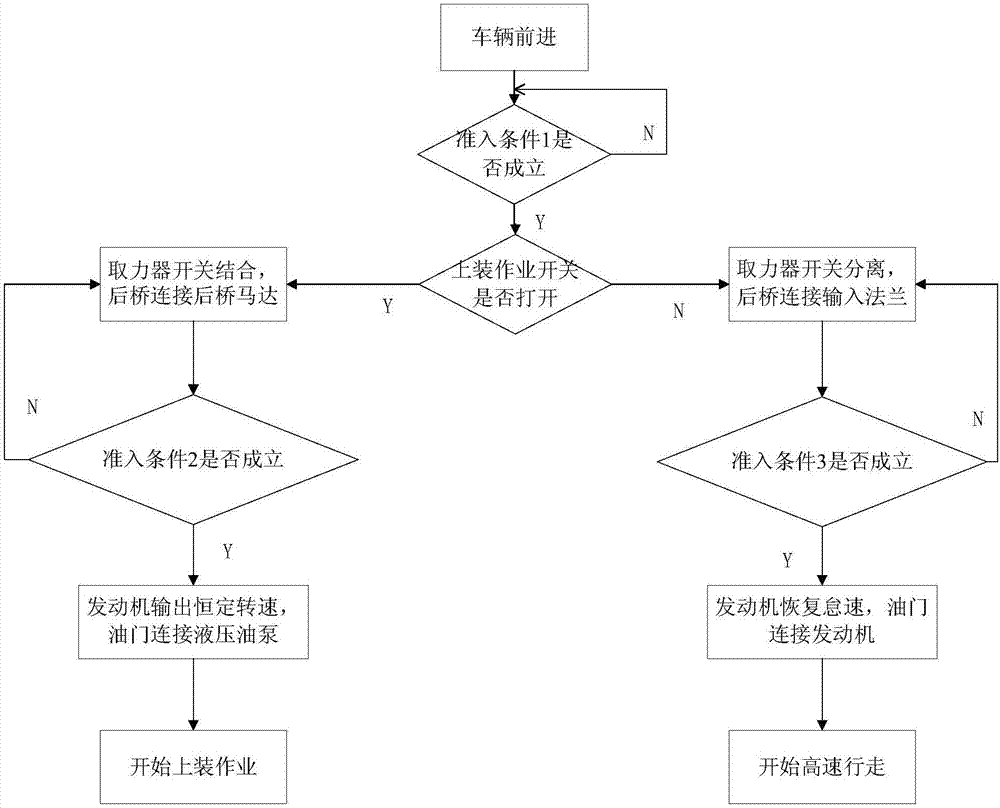

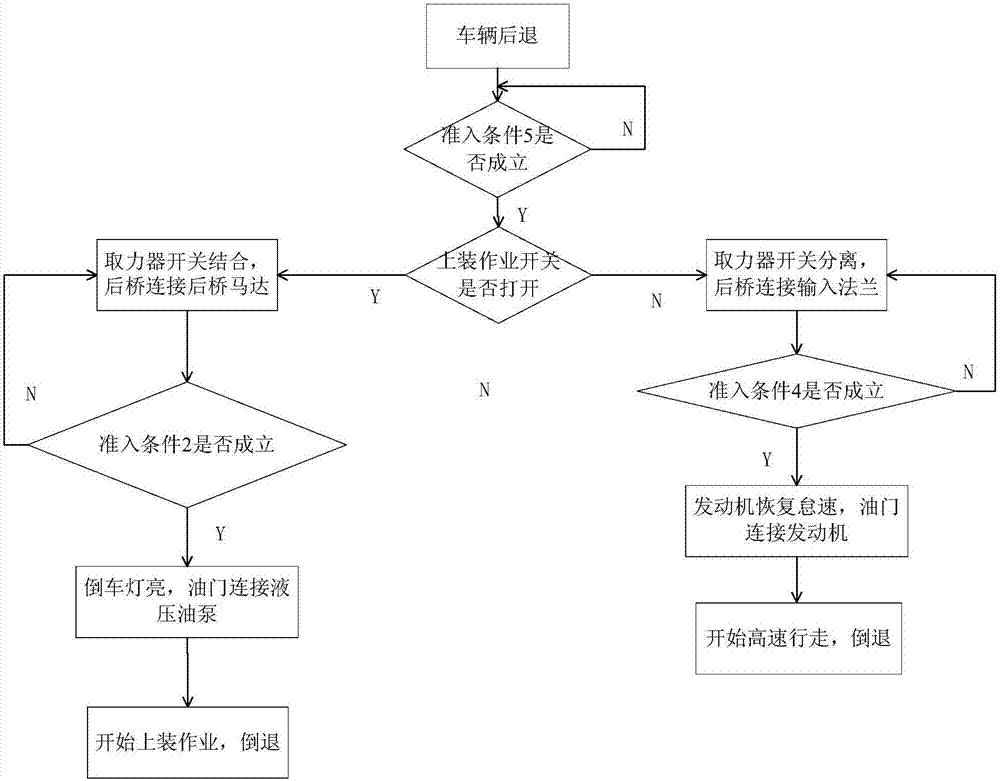

Special vehicle chassis and vehicle controlling method of hybrid power transmission system

ActiveCN107160999AFulfil requirementsMeet the low speed of the working conditionHybrid vehiclesAuxillary drivesDrivetrainControl system

The invention discloses a special vehicle chassis and a vehicle controlling method of a hybrid power transmission system. The special vehicle chassis of the hybrid power transmission system comprises a conventional running system, a loading operating system and a controlling system. The output end of the controlling system is connected with the input end of the conventional running system and the input end of the loading operating system, and the input end of the controlling system is connected with a selective switch. The conventional running system and the loading operating system are both powered by an engine. Compared with the prior art, the special vehicle chassis and the vehicle controlling method of the hybrid power transmission system meet the high-speed operating requirement of normal running of a vehicle, and low vehicle speed and infinitely variable speed requirements under the loading operation, operation is simple during switching, burden of a driver is reduced, and the price is reasonable.

Owner:SINO TRUK JINAN POWER

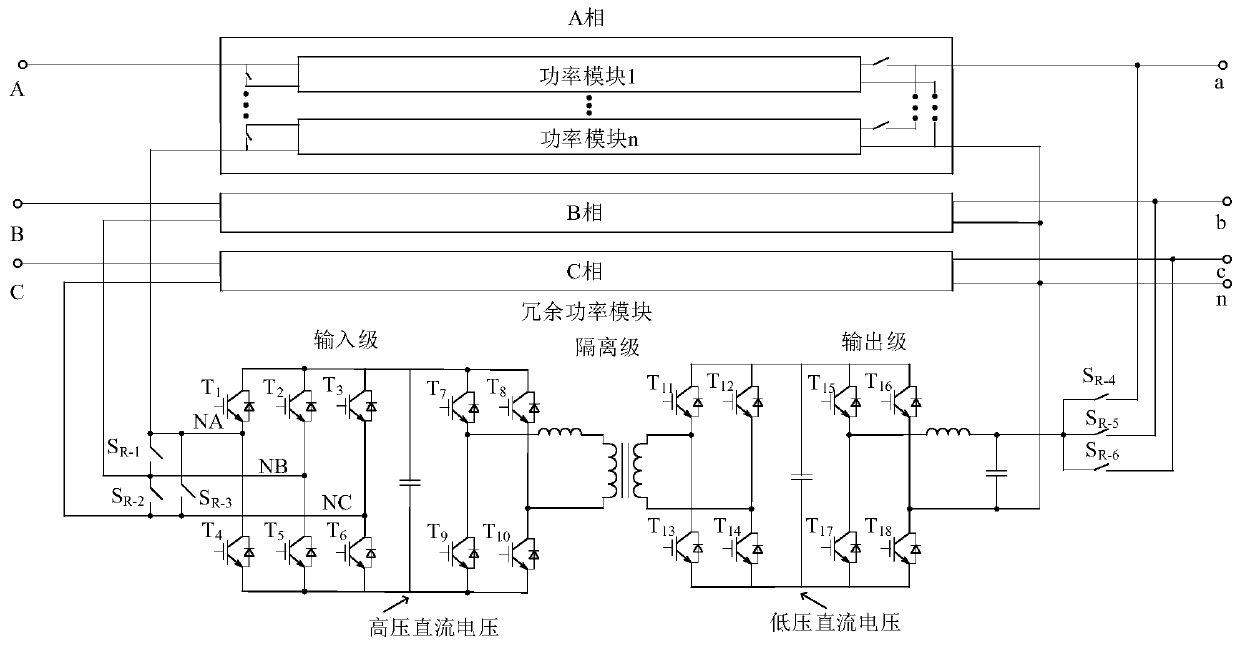

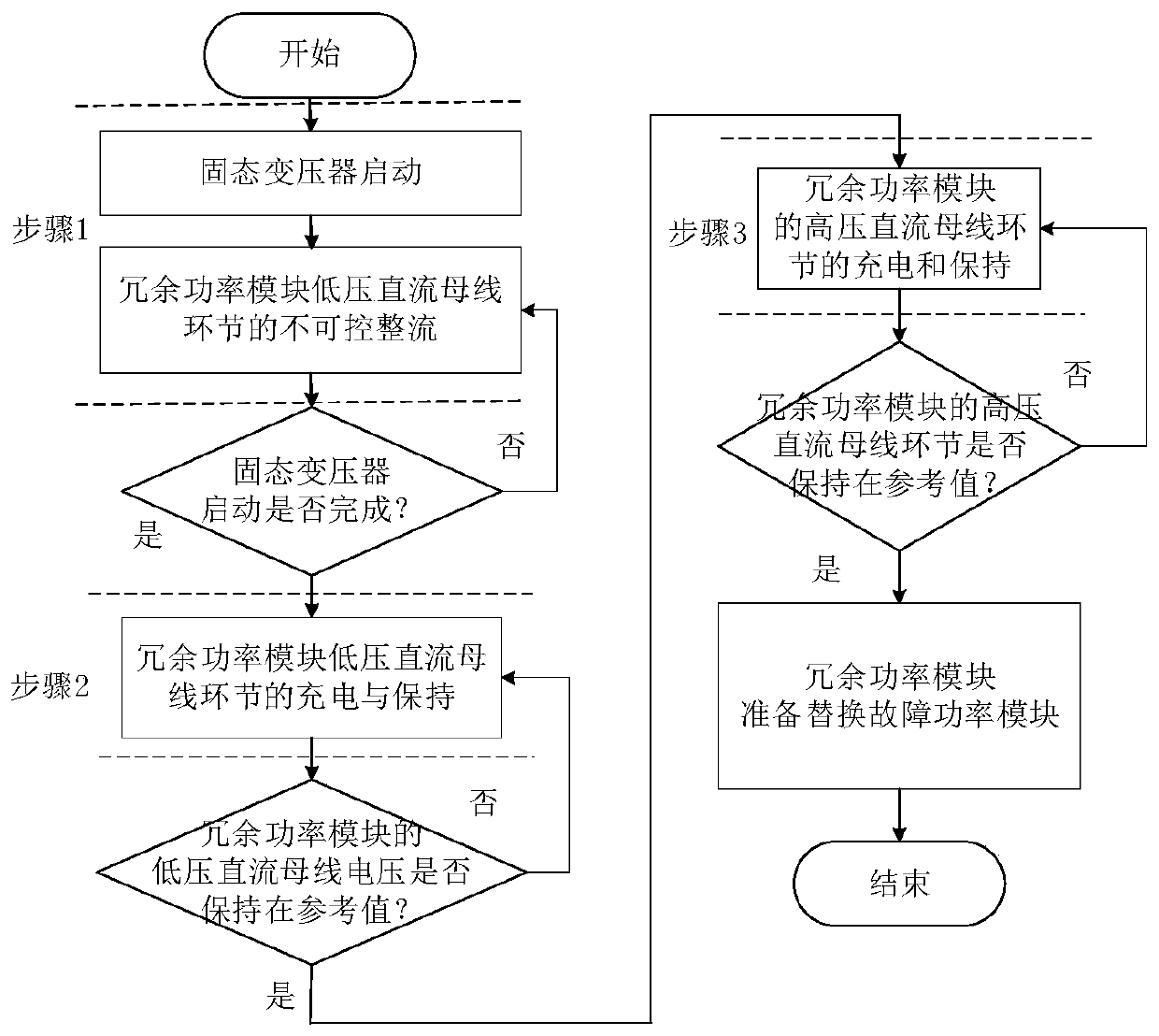

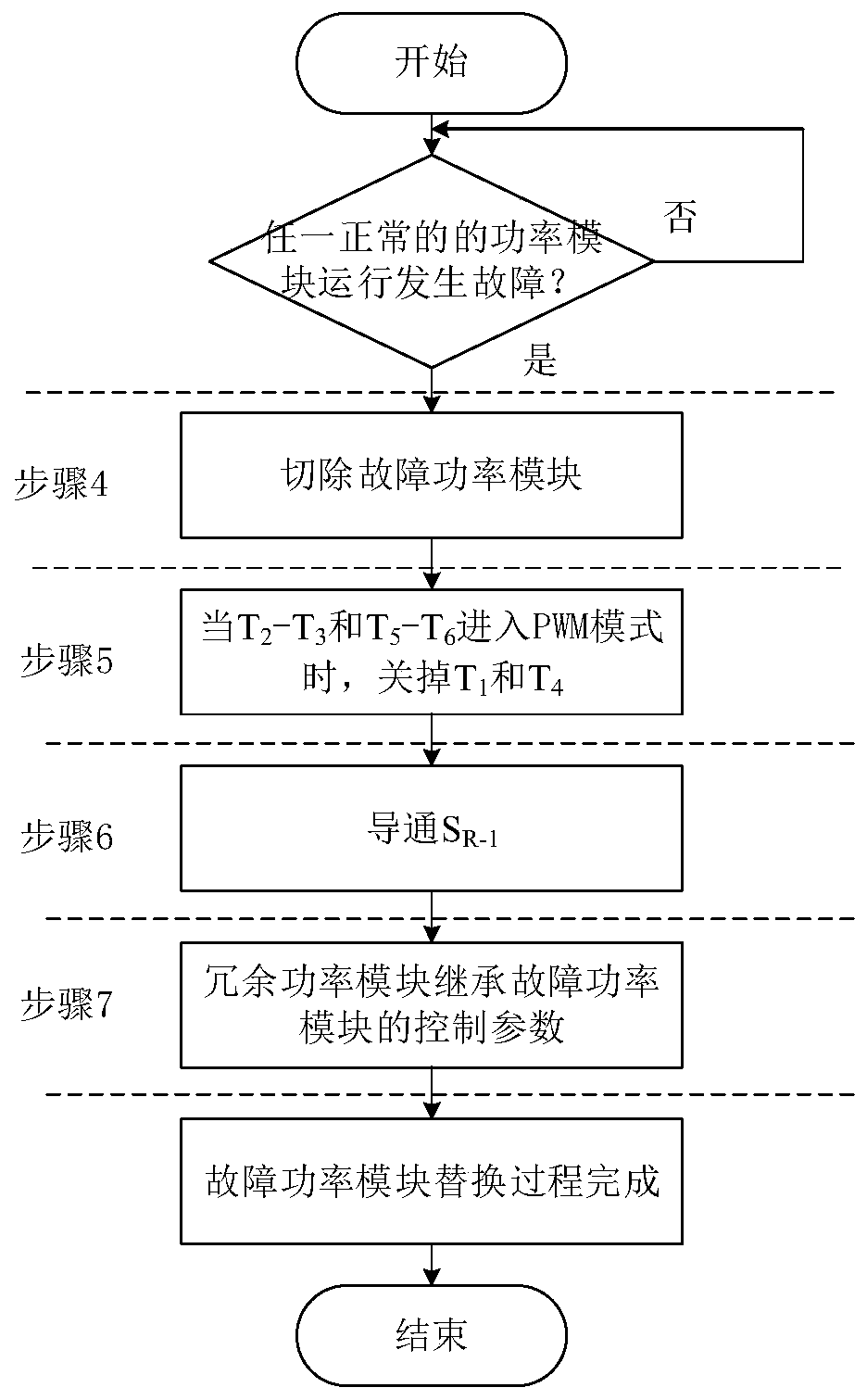

Redundant control system and method applied to three-phase solid-state transformer

InactiveCN109802571AShort transition timeSave design costDc-dc conversionElectric variable regulationControl systemLow voltage

The invention relates to a redundant control system and method applied to a three-phase solid state transformer. According to the technical schemes of the invention, the redundant control system applied to the three-phase solid state transformer is characterized in that the system comprises a plurality of power modules in an A phase, a B phase and a C phase and one redundant power module; the input stages of the plurality of power modules are connected in series, and the output stages of the plurality of power modules are connected in parallel; and the A phase, the B phase and the C phase share one redundant power module; and the redundant power module is divided into three parts, namely, an input stage, an isolation stage and an output stage, wherein the input stage of the redundant powermodule is connected with three high-voltage half-controlled bypass switches SR_1-SR_3, the output stage of the redundant power module is connected with three low-voltage full-control switches SR_4-SR_6, the input stage is a rectifying unit composed of 6 switching tubes, and the output stage is an inverter unit composed of 4 switching tubes. With the redundant control system and method applied tothe three-phase solid state transformer of the invention adopted, the number of the applied redundant power modules is decreased, transition time for replacing a faulty power module is shortened, andthe operational reliability of the system is effectively improved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com