Crawler crane with lateral reinforcement structure

A technology of crawler crane and strengthening structure, which is applied to cranes, ships, cargo handling equipment and other directions, can solve the problems of complex design, high processing cost, high material consumption, etc., and achieves low manufacturing cost, convenient transportation and less material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

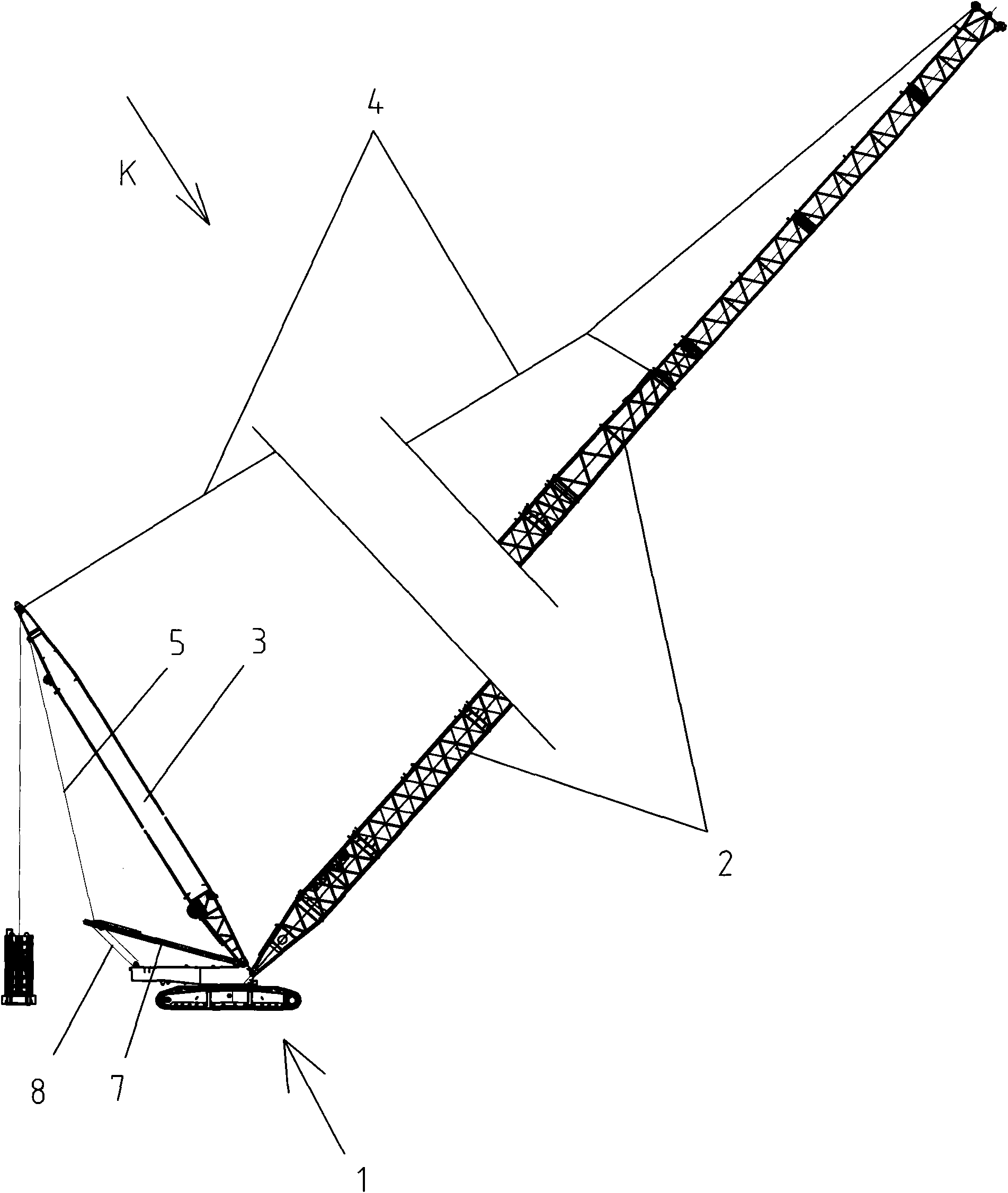

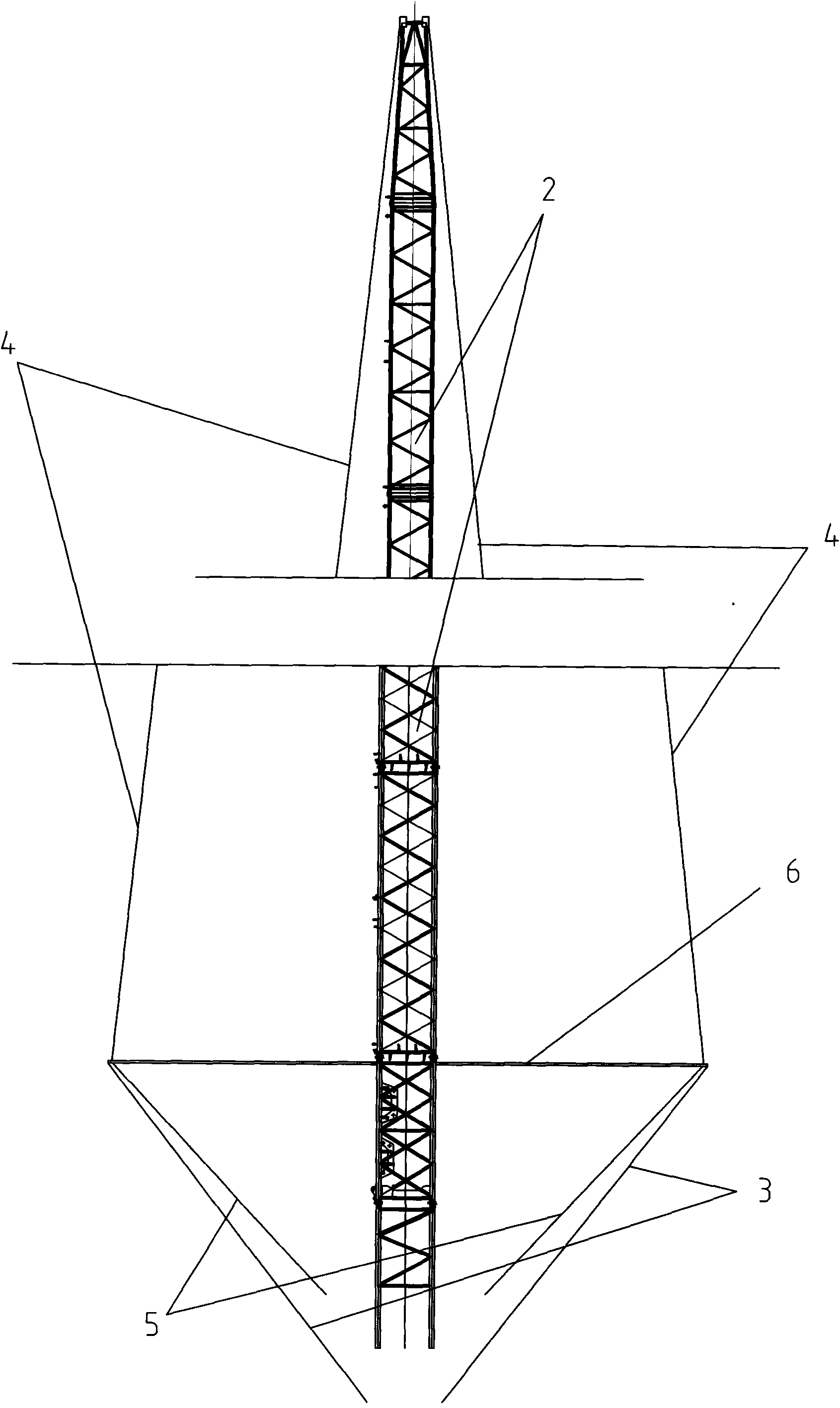

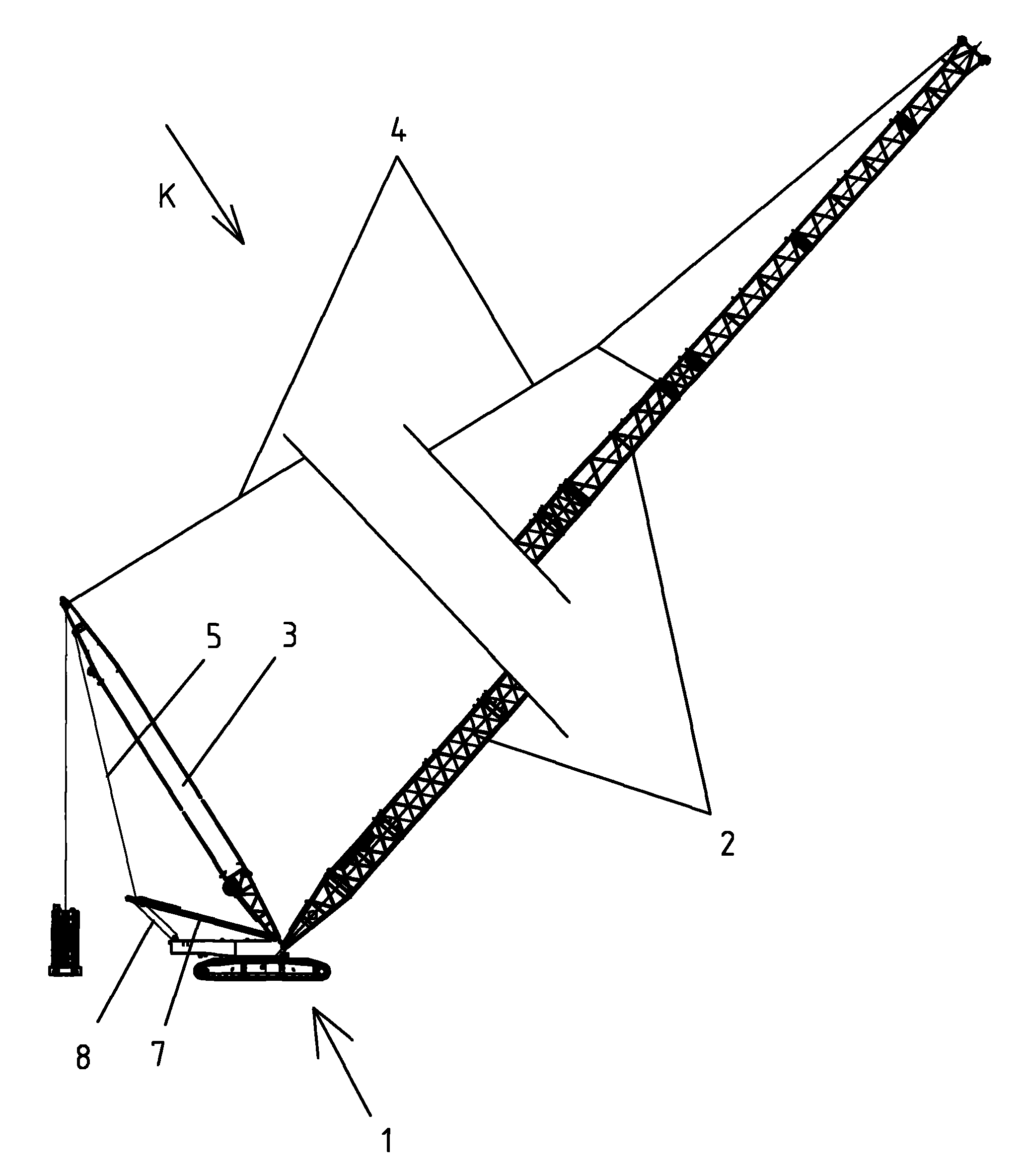

[0010] Such as figure 1 , 2 Shown: 1 is the crane body, the crane body 1 is connected with the bottom rotating shaft of the jib 2, the super-lifting mast 3, and the mast 7, and the front end is connected by a pin shaft between the top of the jib 2 and the top of the super-lifting mast 3. The stay cable 4 is connected with the back stay cable 5 through the pin shaft between the top of the superlift mast 3 and the top of the mast 7, and the main luffing rope 8 is connected between the top of the mast 7 and the crane body 1. The above-mentioned superlift mast 3, mast 7, front stay cable 4, and back stay cable 5 are two groups, and are symmetrically arranged left and right with respect to the central plane of the crane body 1 and the jib 2. The bottom ends of the two super-lifting masts 3 are located at the center of rotation of the crane body 1 and the root of the jib 2, and the upper parts of the super-lifting masts 3 are respectively inclined to both sides to form a symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com