Patents

Literature

1161 results about "Central plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

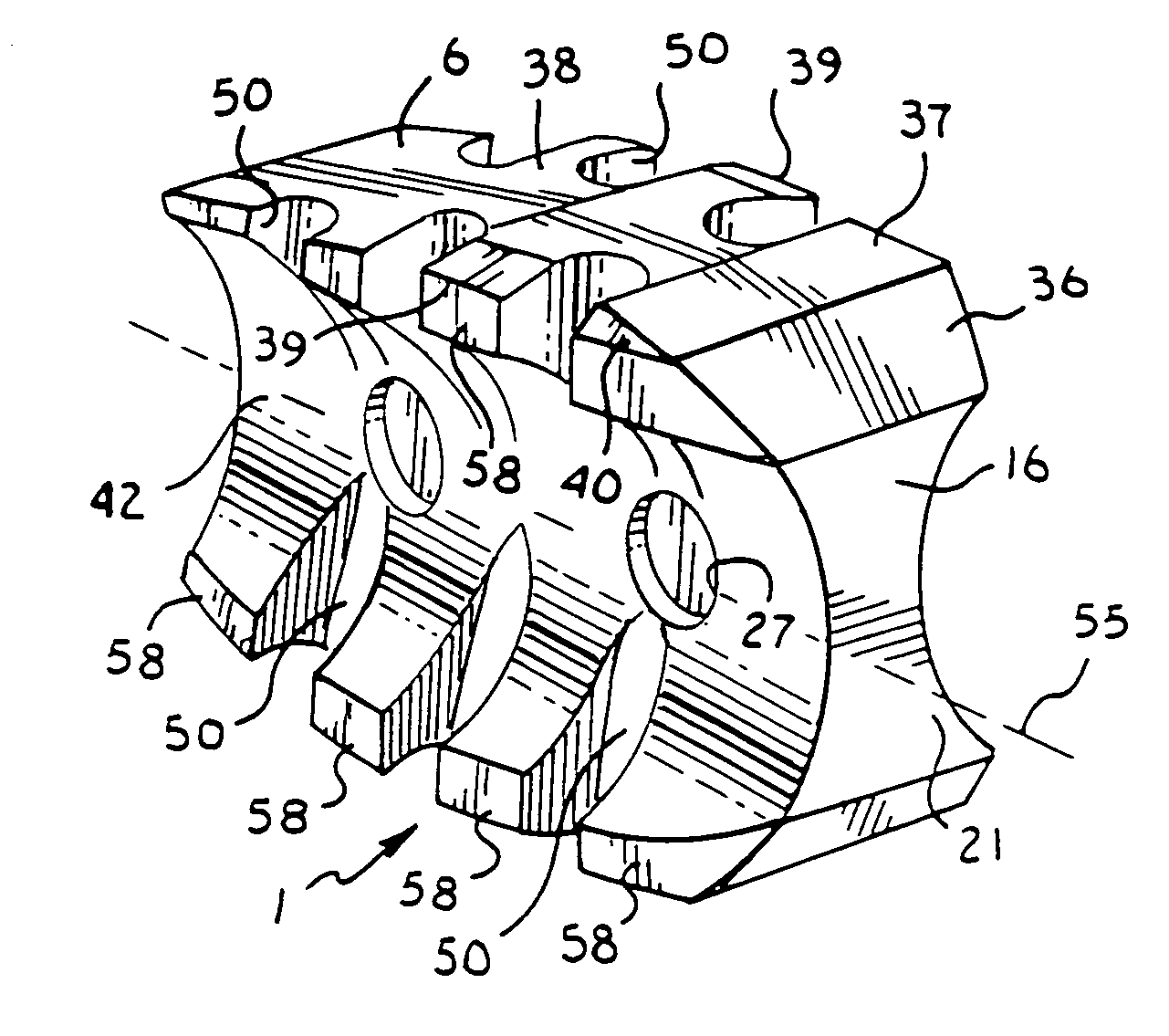

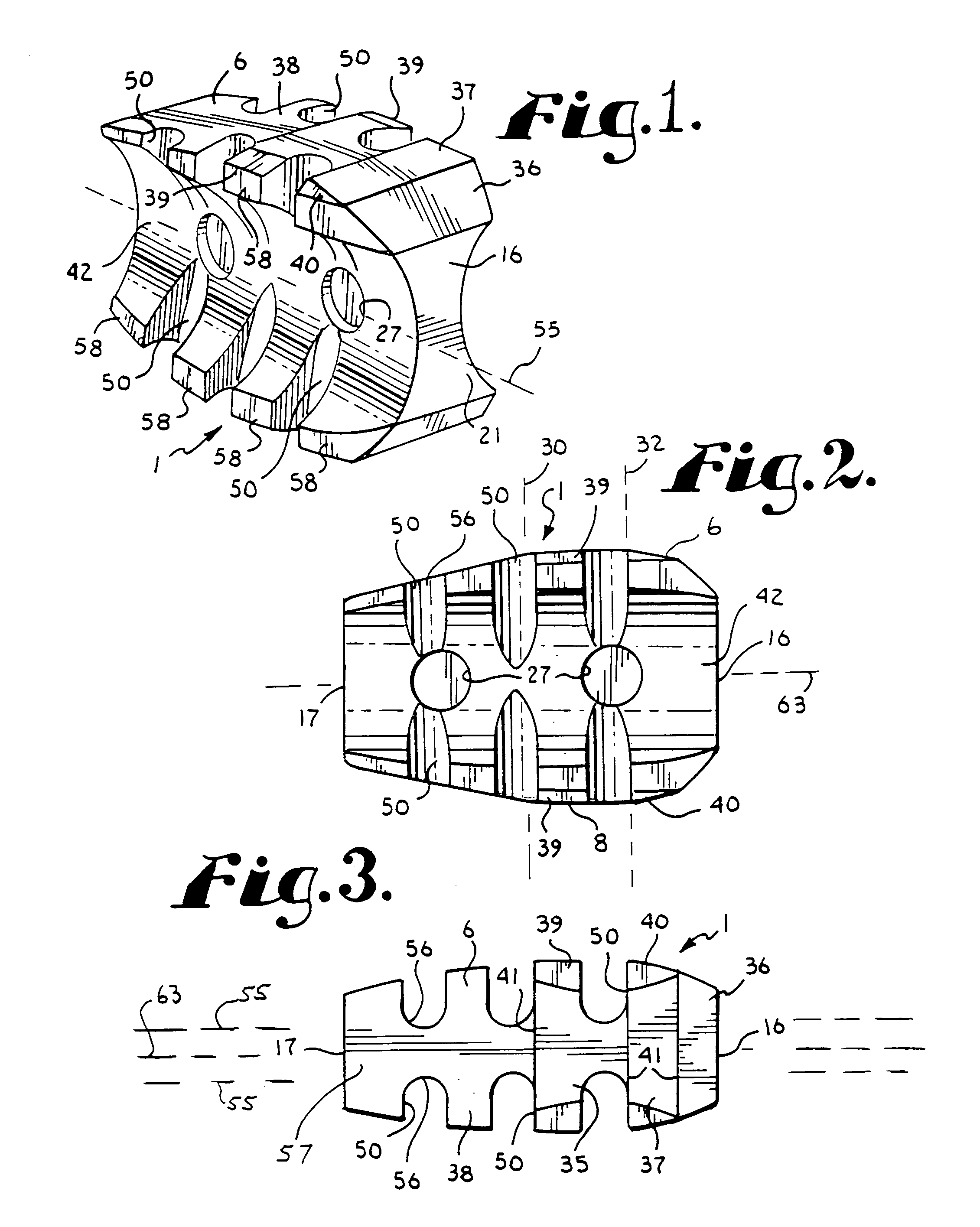

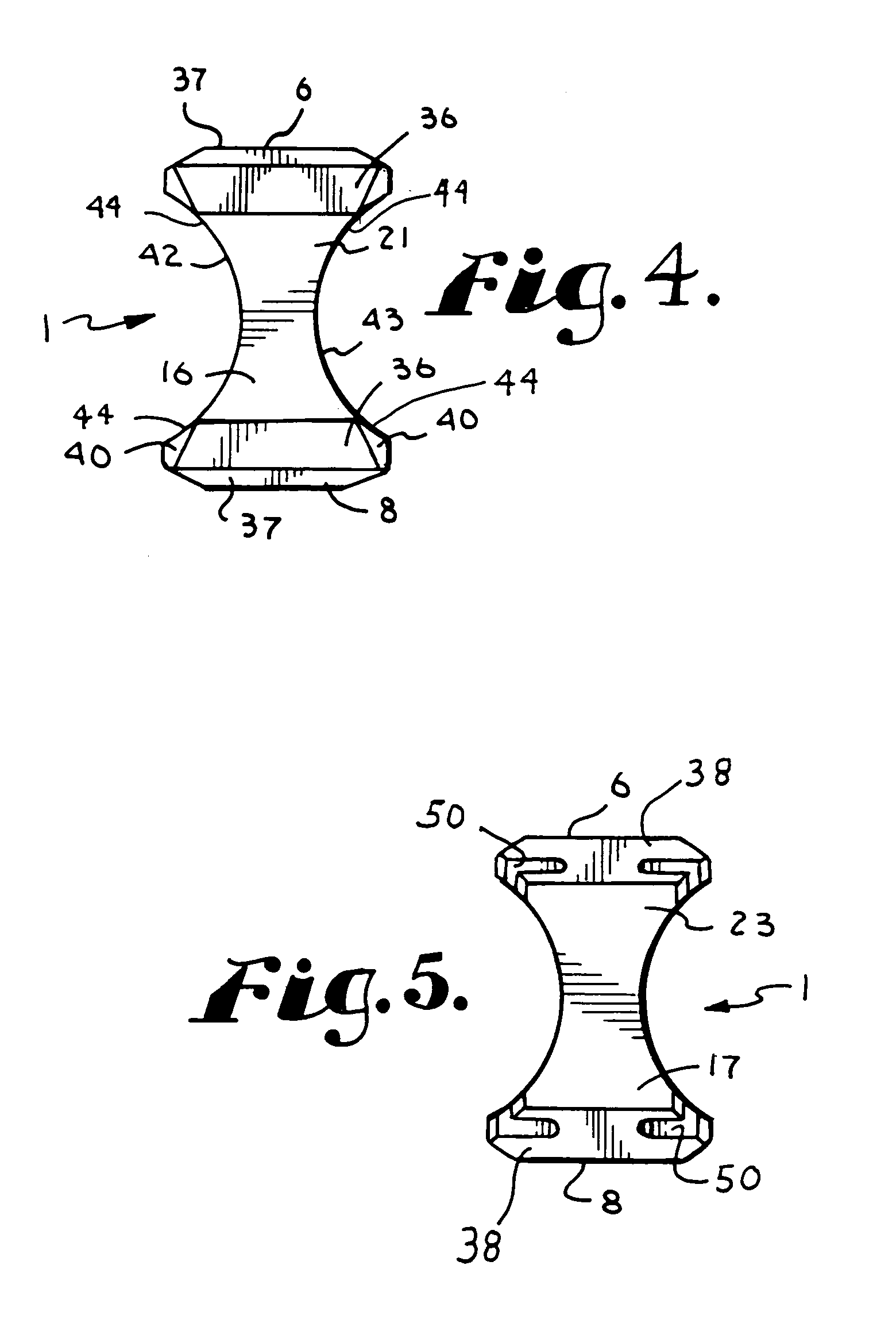

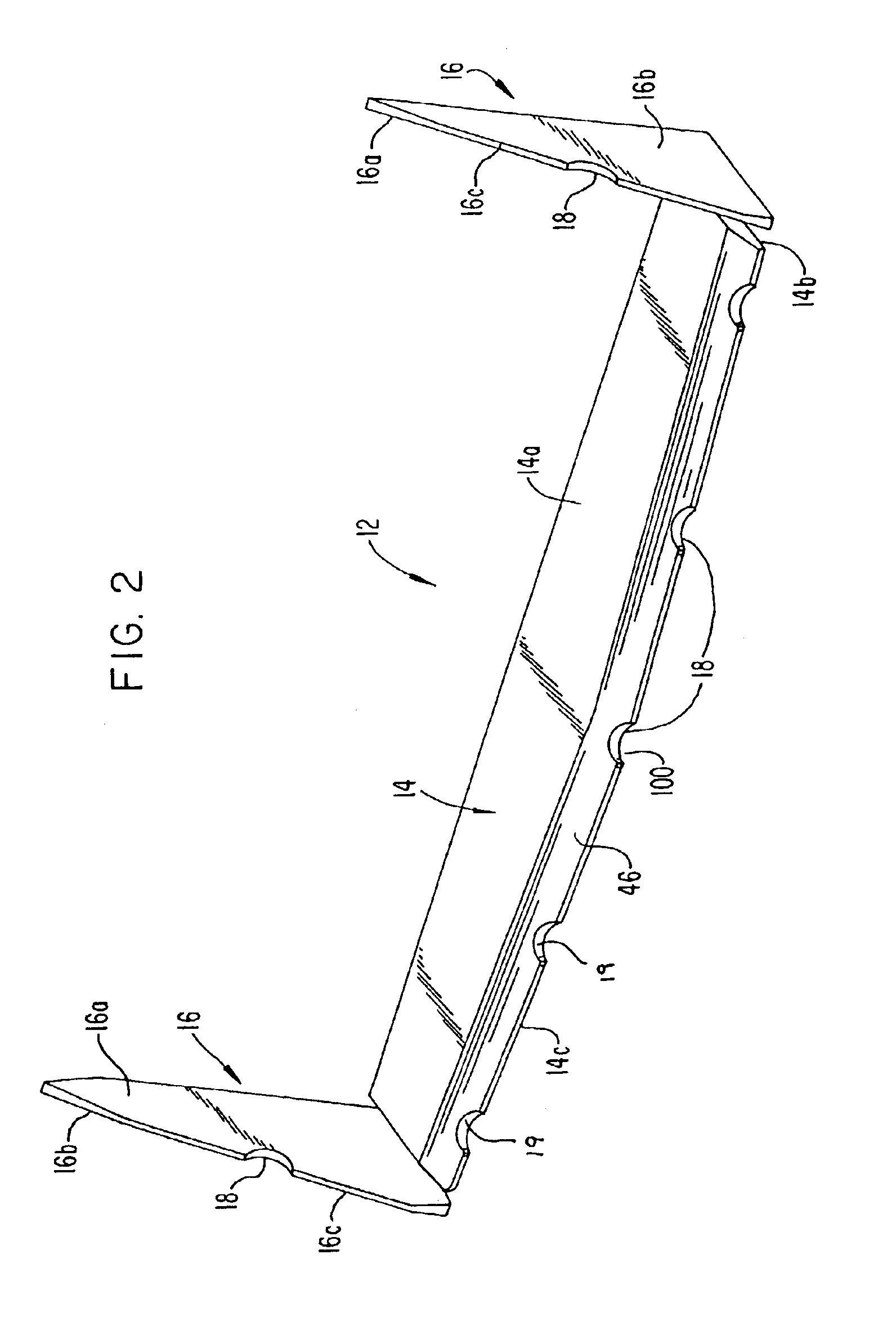

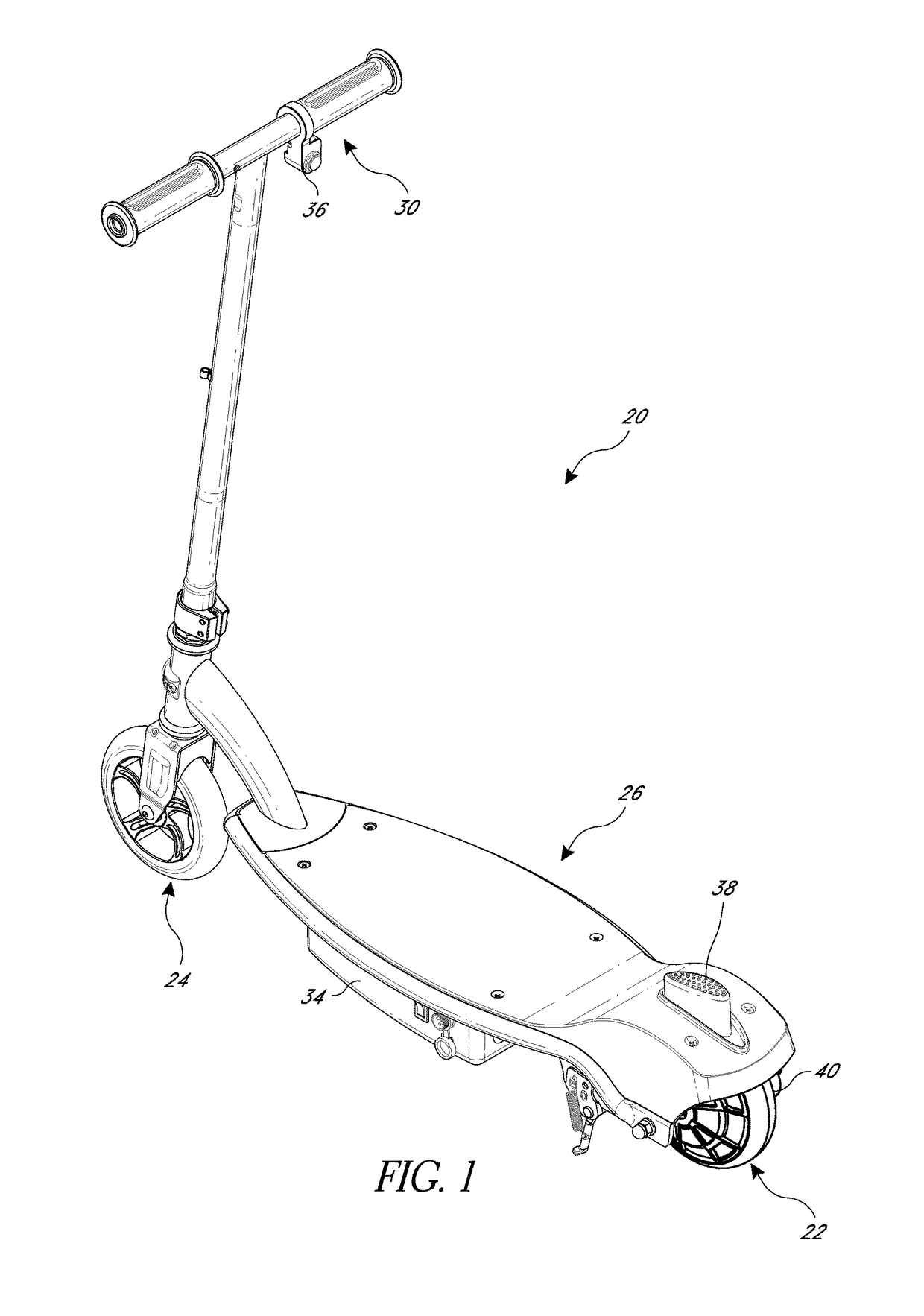

Spinal fusion interbody spacer

ActiveUS6942698B1Minimizing volumeMinimizing weightInternal osteosythesisJoint implantsSpacer deviceBiomedical engineering

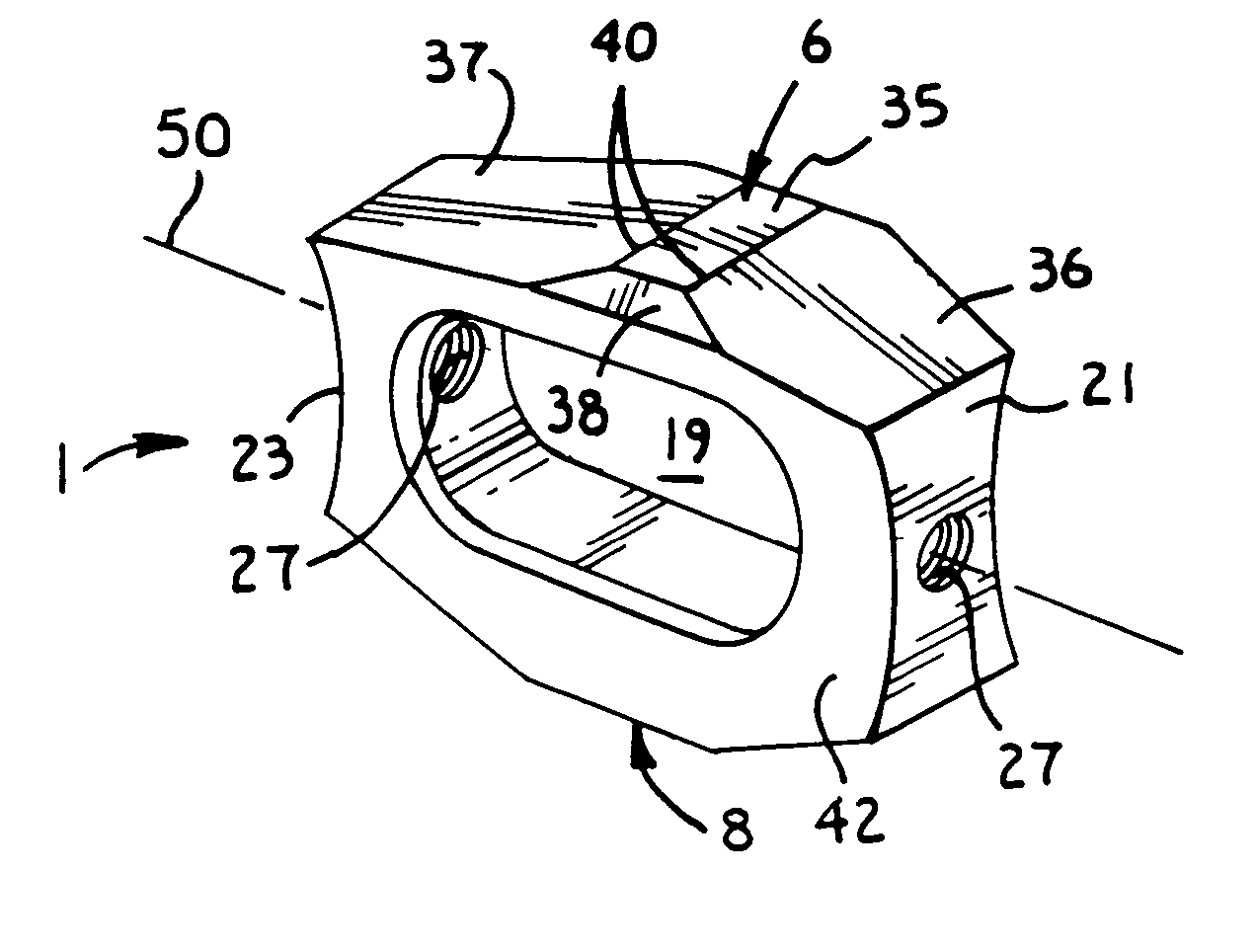

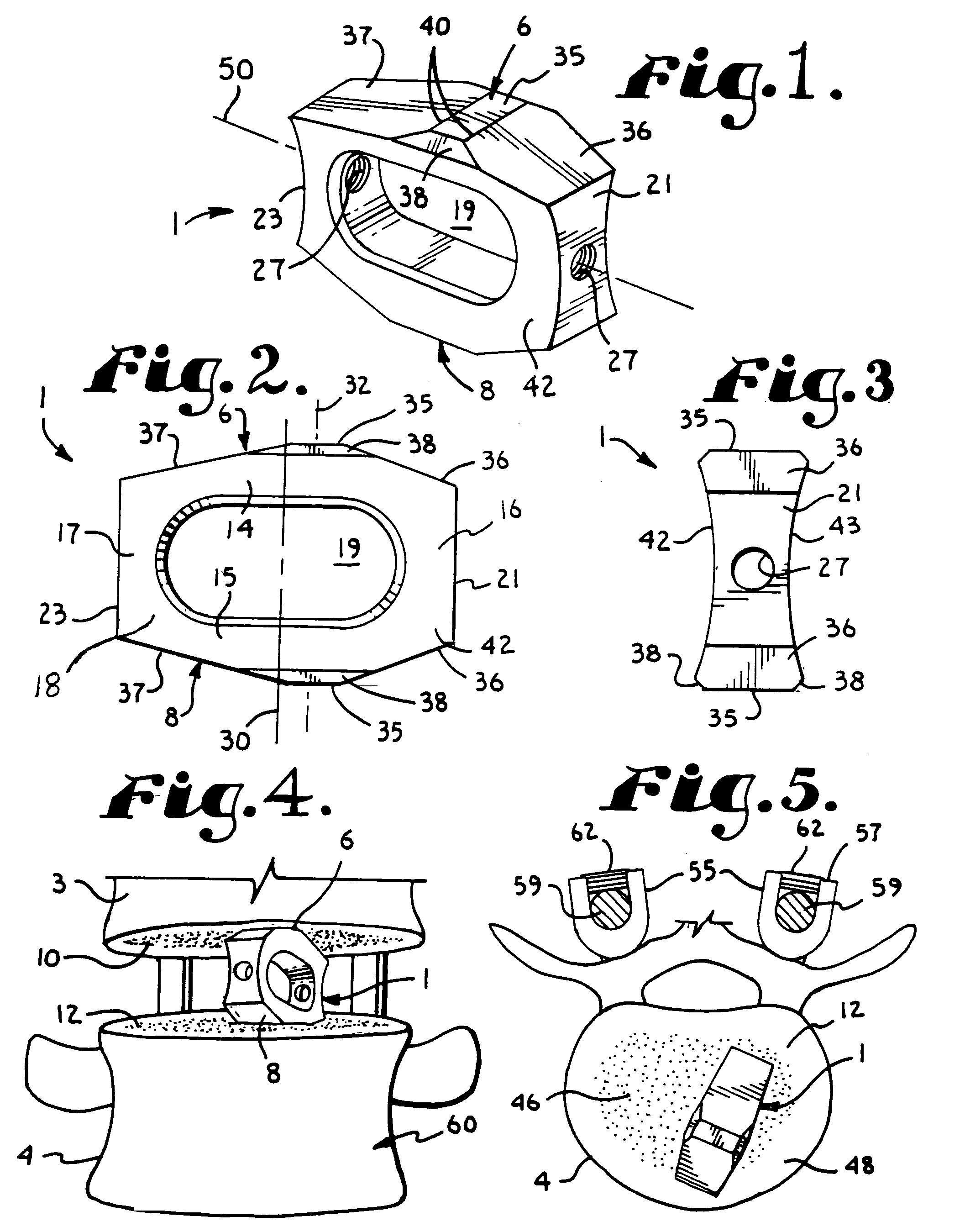

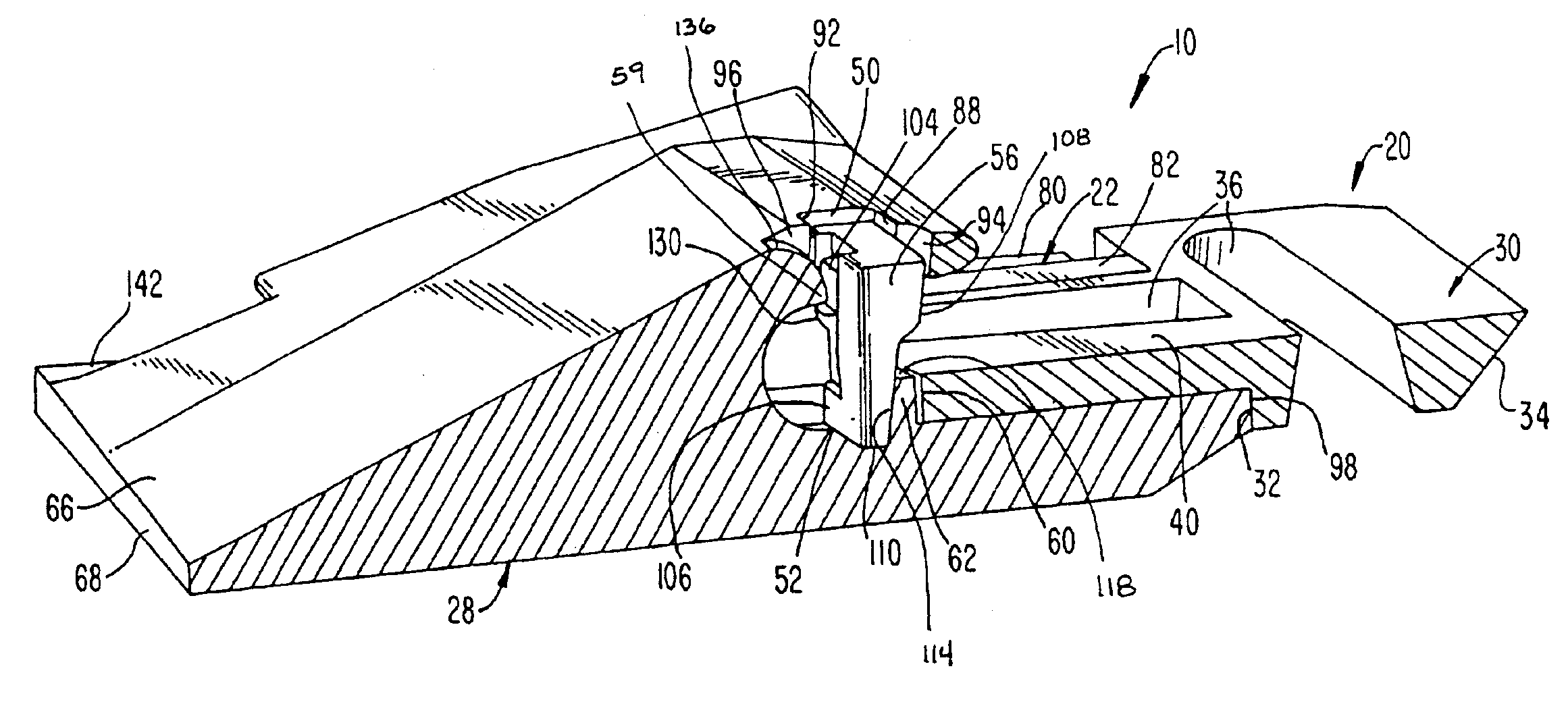

A convex spinal fusion interbody space device includes spaced apart superior and inferior abutment surfaces which are effectively medially convex. The peak of such convexity is displaced anteriorly of a central plane through the device. The spacer device has front to rear lateral concave surfaces and top to bottom lateral side channels that intersect with said convex surfaces. The spacer device has a height which is greater than the width of the device. The spacer device is implanted between a pair of adjacent vertebrae by insertion in a tipped-over orientation and then reoriented to an upright orientation for engagement by facing surfaces of the vertebrae. Fusion promoting bone material is packed between the vertebrae and about the spacer device subsequent to implantation.

Owner:WARSAW ORTHOPEDIC INC

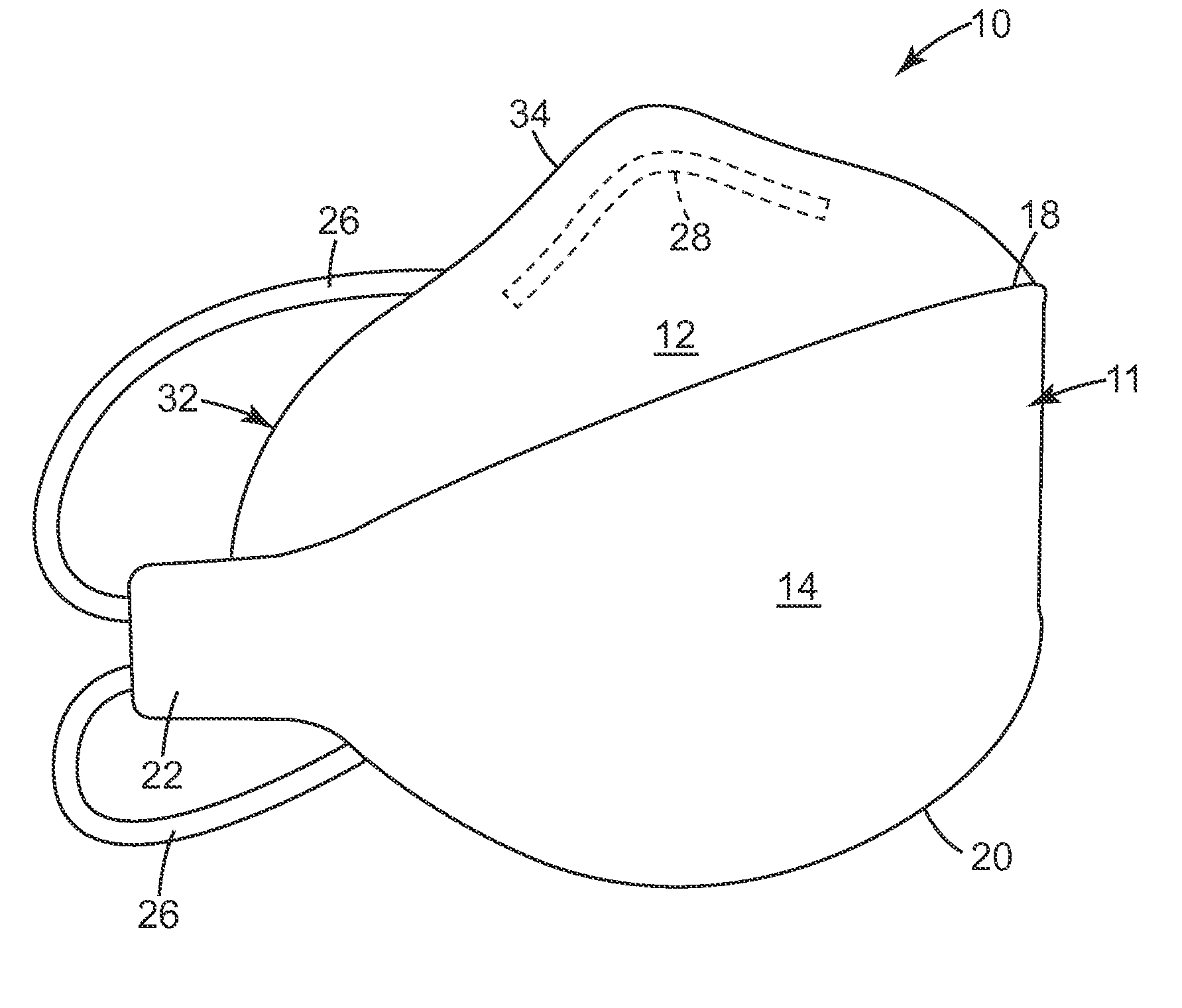

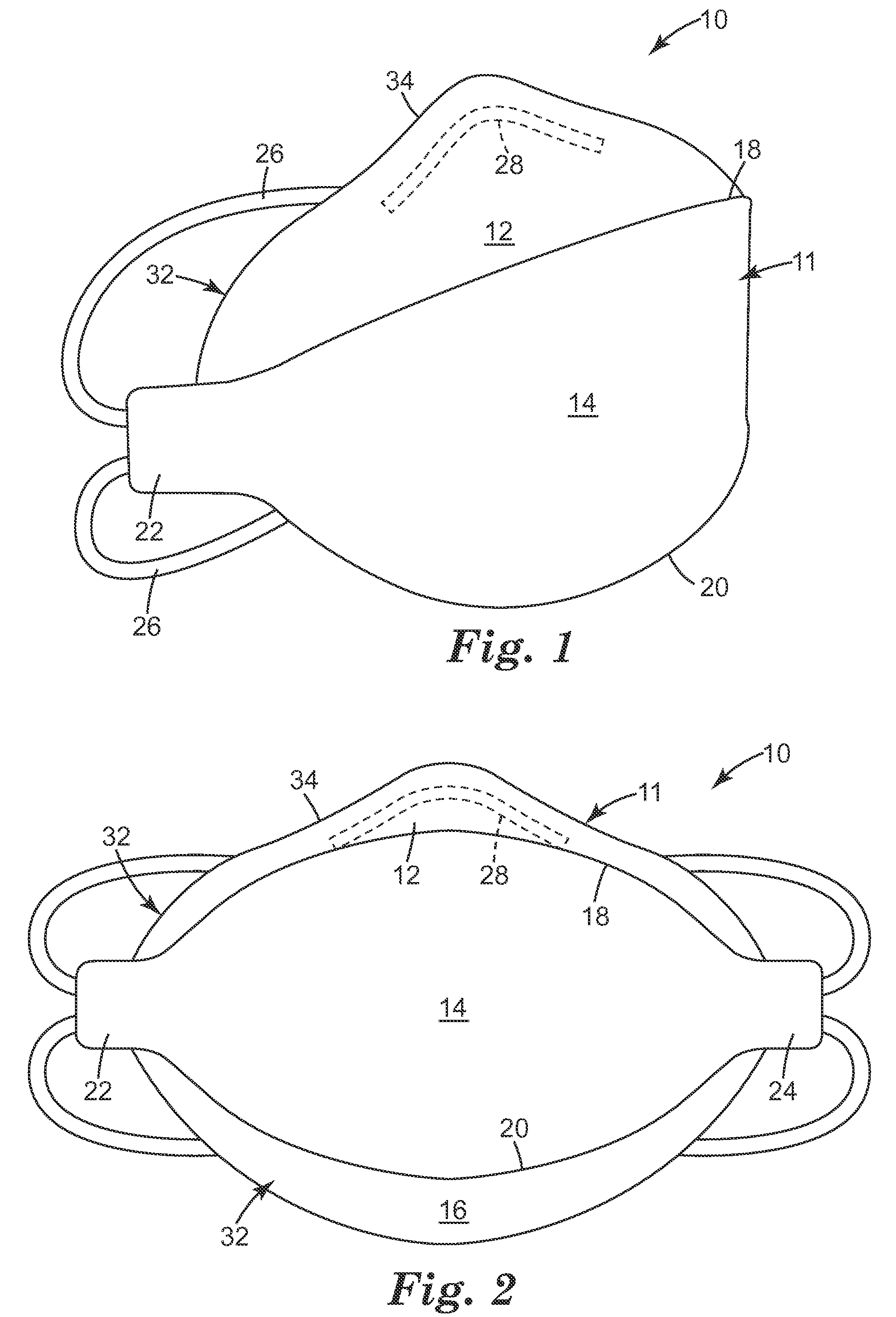

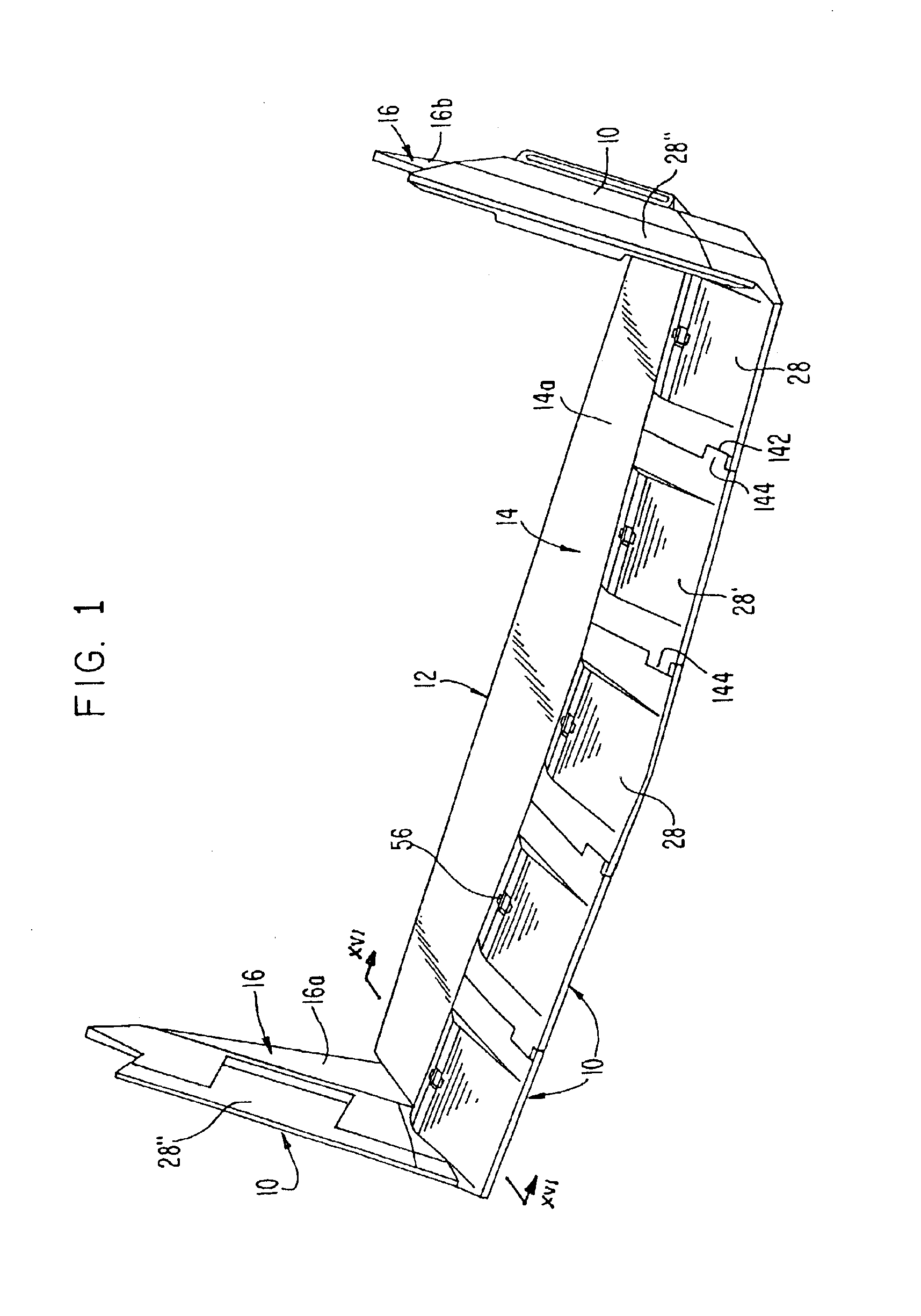

Maintenance-free respirator that has concave portions on opposing sides of mask top section

InactiveUS20080271739A1Improve compatibilityPrevent foggingBreathing filtersBreathing masksRespiratorFilter media

A maintenance-free respirator 10 that includes a mask harness and a mask body 11. The mask body 11 has at least one layer of filter media 56 and has a perimeter 32 that includes an upper segment 34. The upper segment 34 includes first and second concave segments 36, 38 that are located, respectively, on first and second sides of a central plane 40, when viewing the mask body from a top view. A maintenance-free respirator 10 of this configuration is comfortable to wear and can provide a snug fit to a wearer's face, particularly beneath each of the wearer's eyes, while at the same time having an ability to improve compatibility with various protective eyewear.

Owner:3M INNOVATIVE PROPERTIES CO

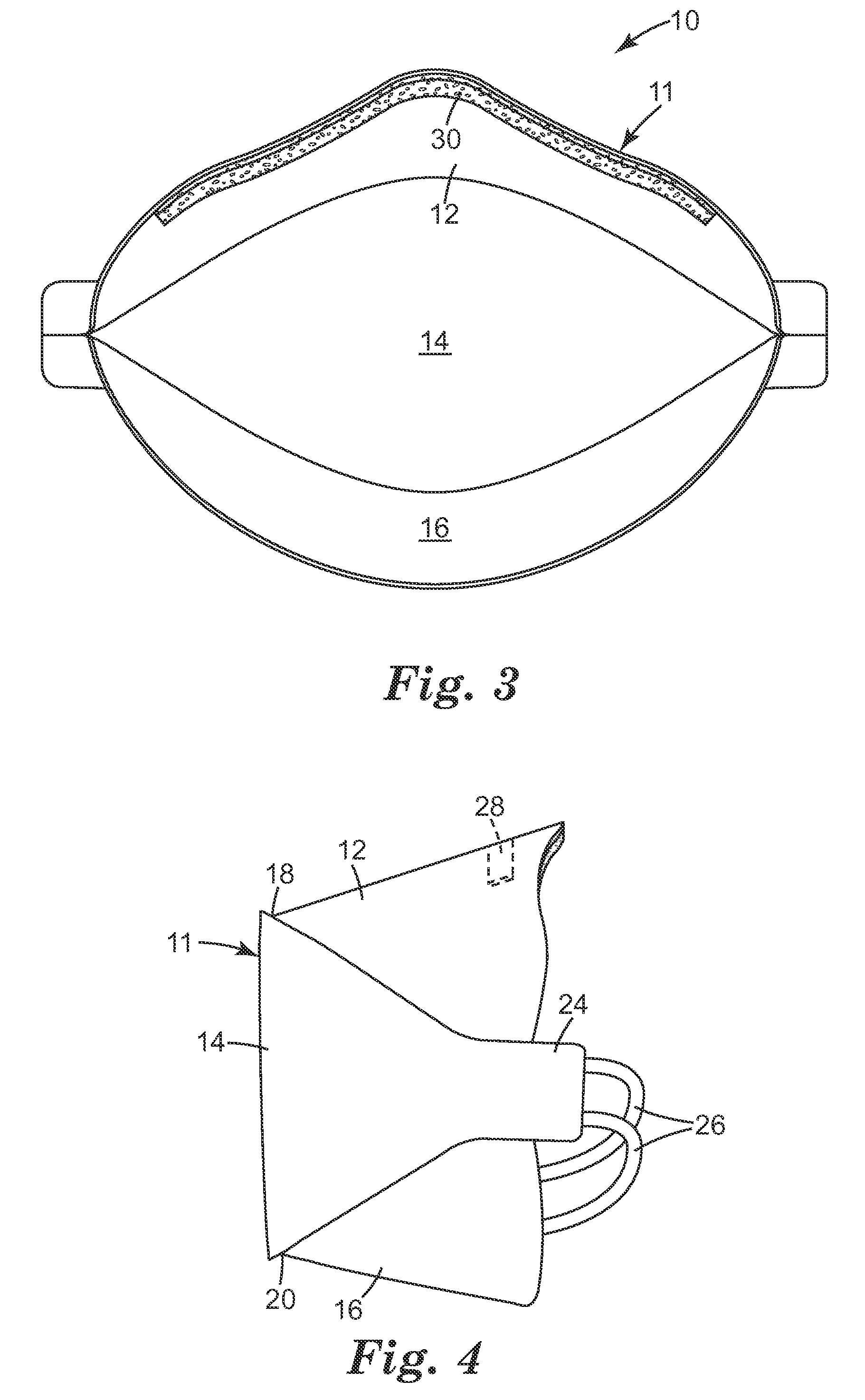

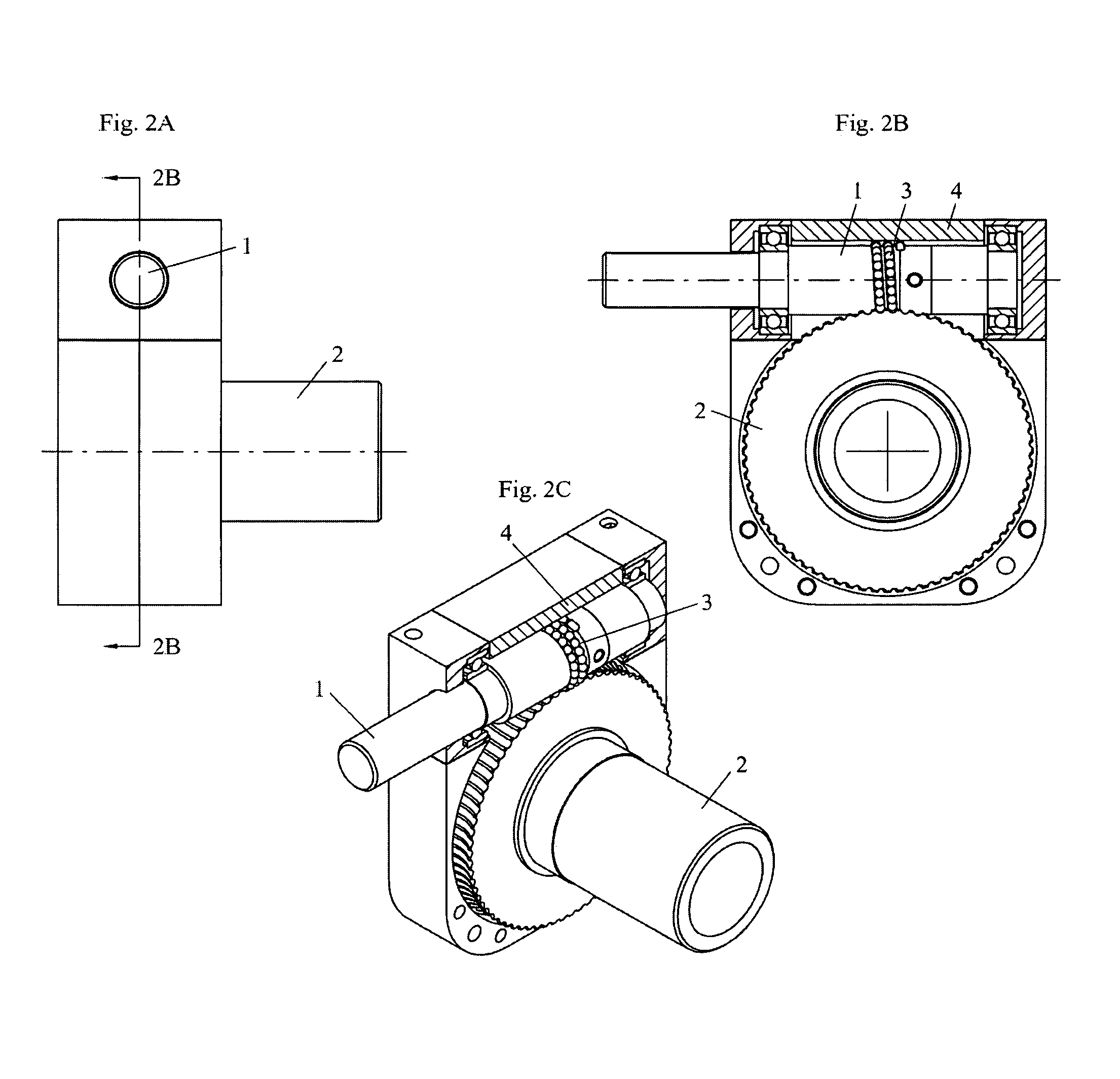

Ball-worm transmission

InactiveUS7051610B2Improve performanceAugments a number of ballsLinear bearingsToothed gearingsGear wheelEngineering

A ball-worm transmission is provided which replaces the sliding friction of the classic worm mechanism with the rolling friction of spherical balls. The ball-worm transmission assembly includes a worm which defines a recirculation path, and a gear coupled to the worm via a plurality of spherical balls. The gear includes a plurality of teeth each having a thickness in a central plane of the gear and a lesser thickness towards both sides of the gear, so that a gap is defined between the teeth is larger towards both sides of the gear than in the central plane of the gear.

Owner:HOLTZ DOUGLAS

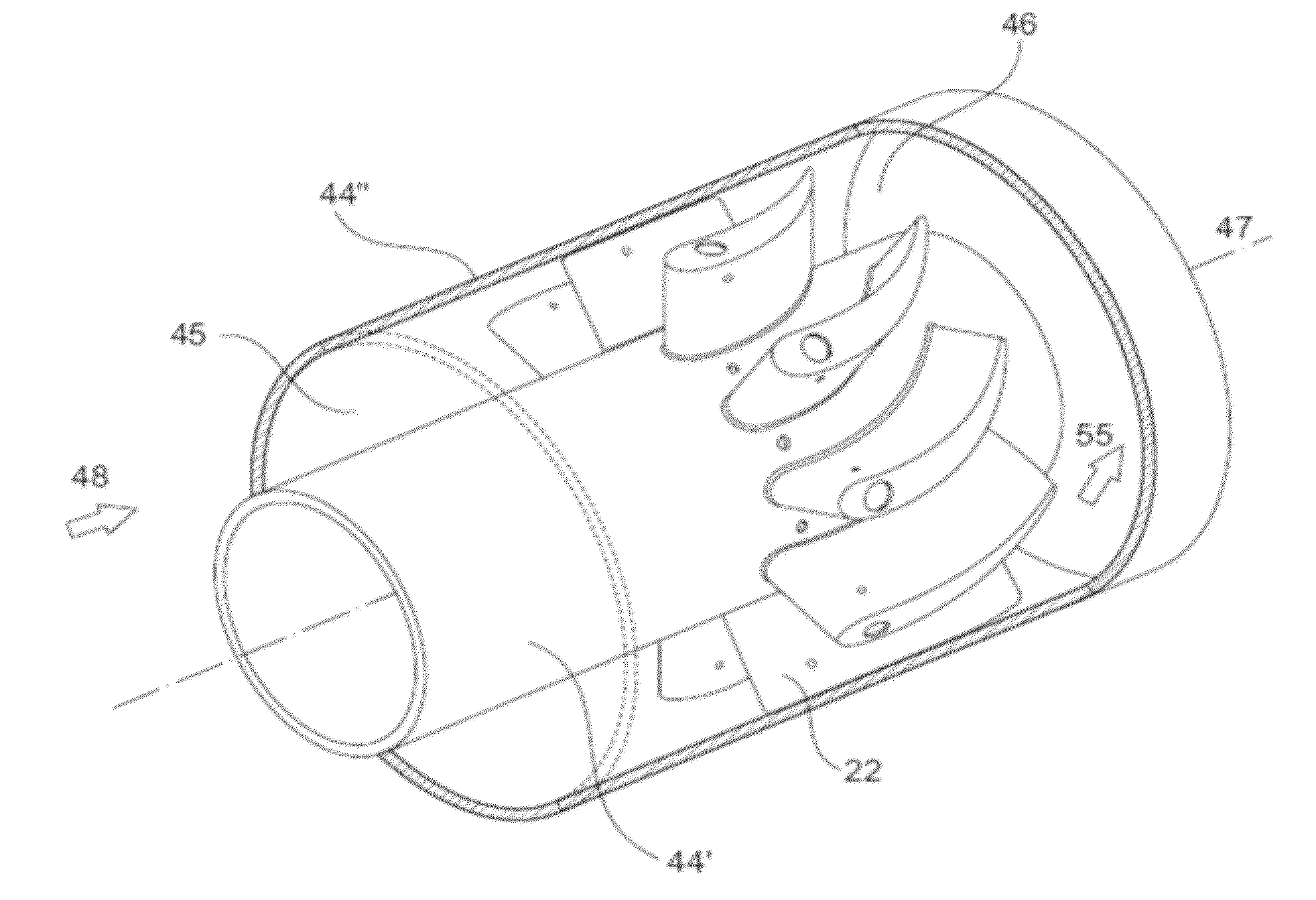

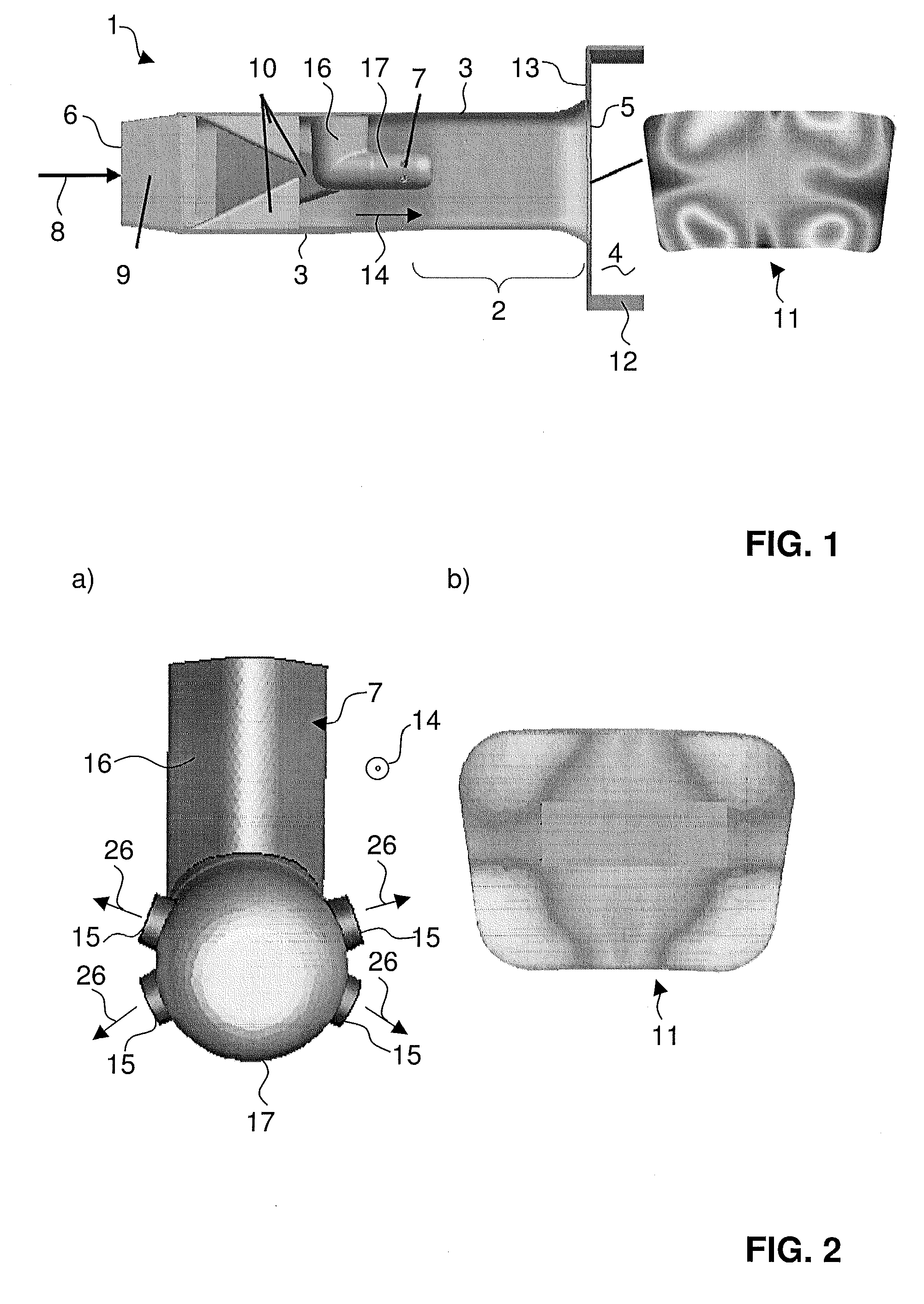

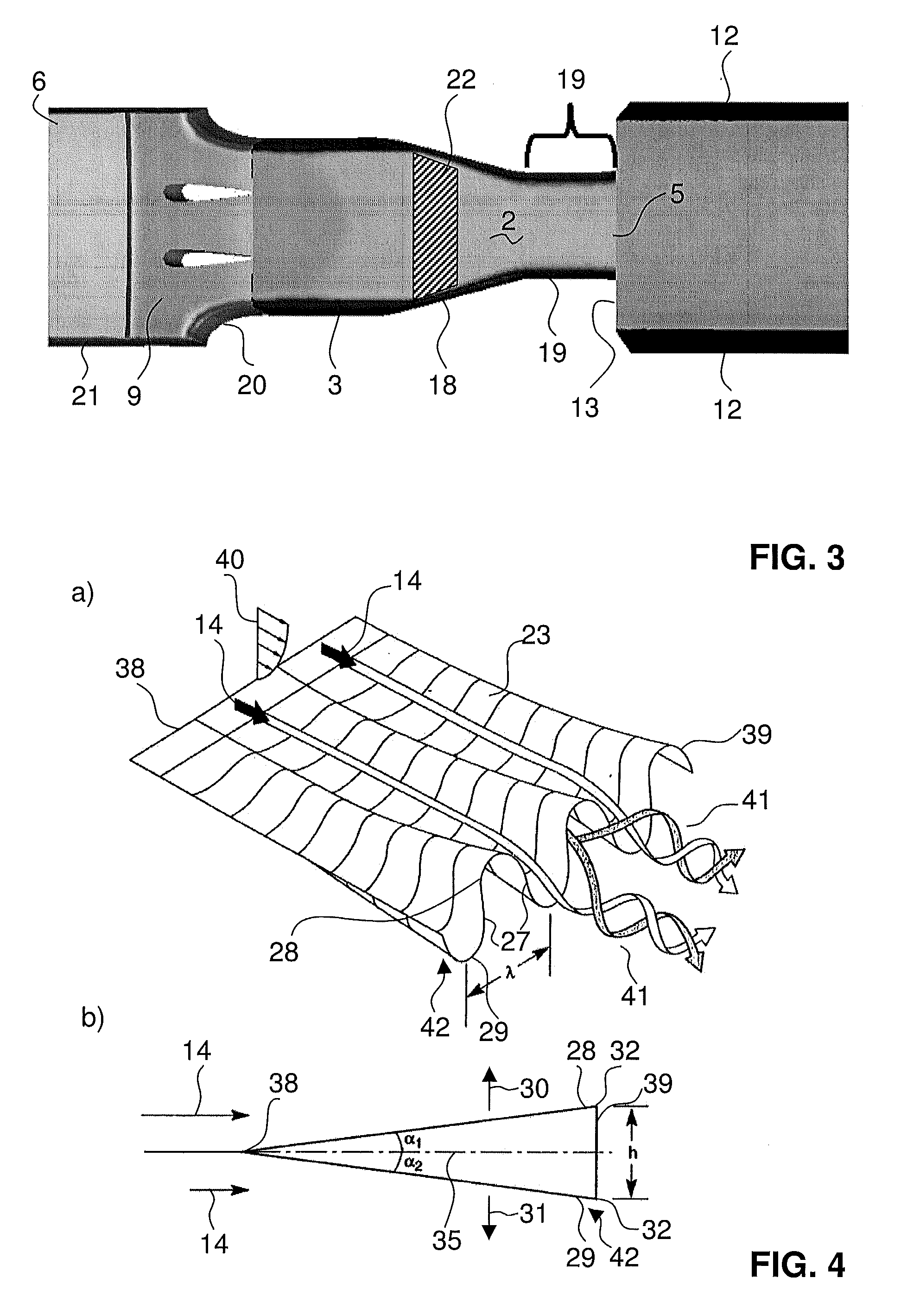

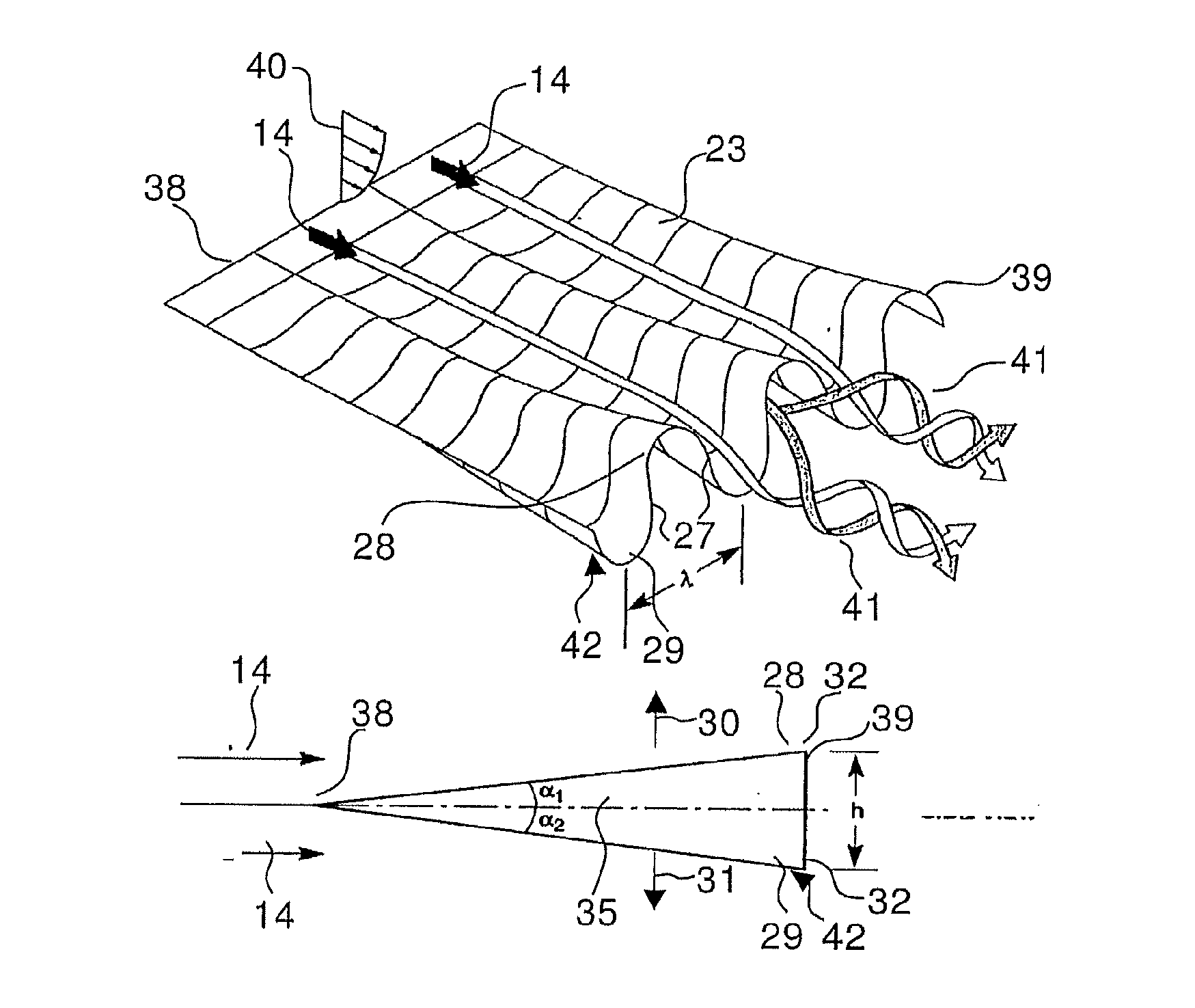

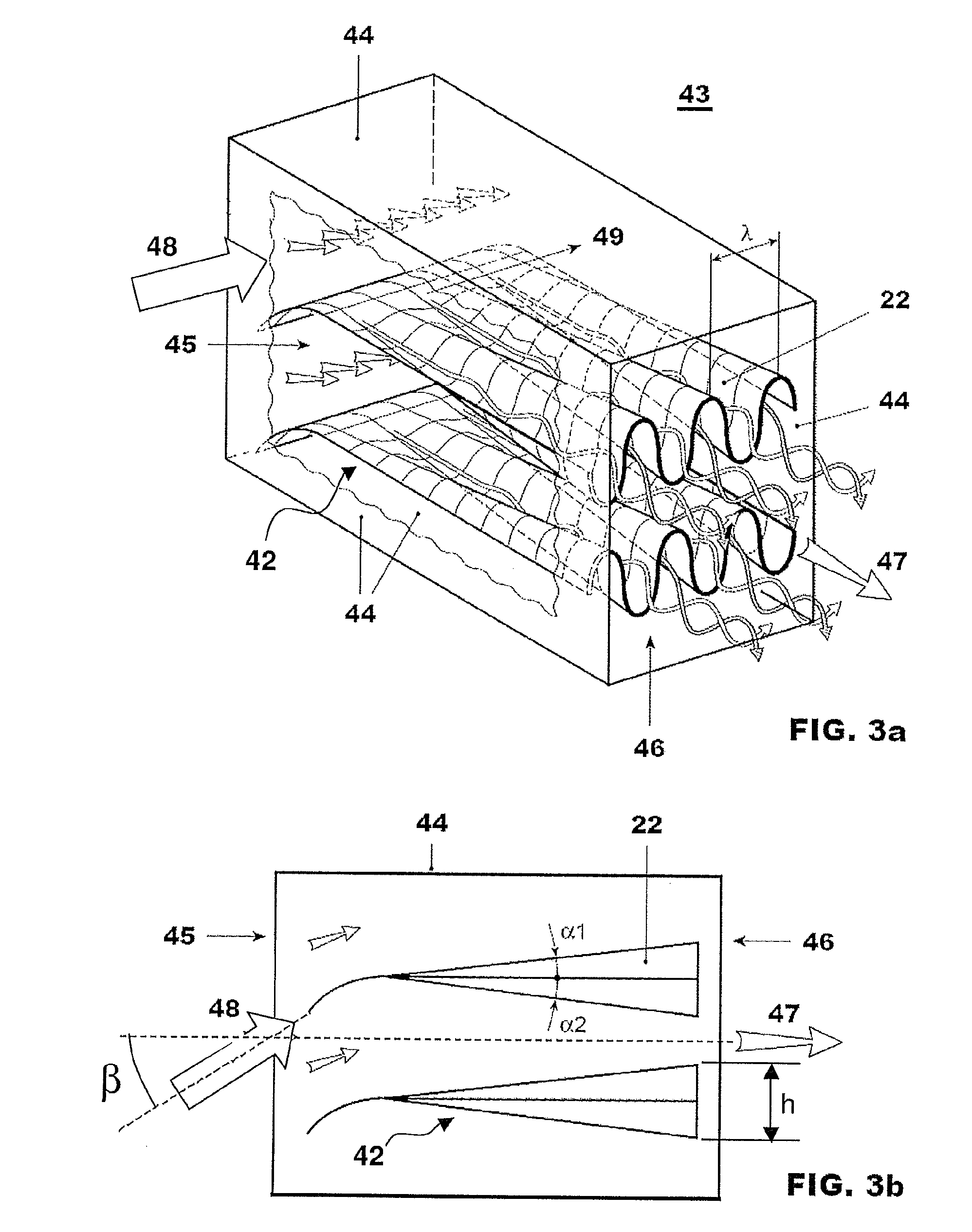

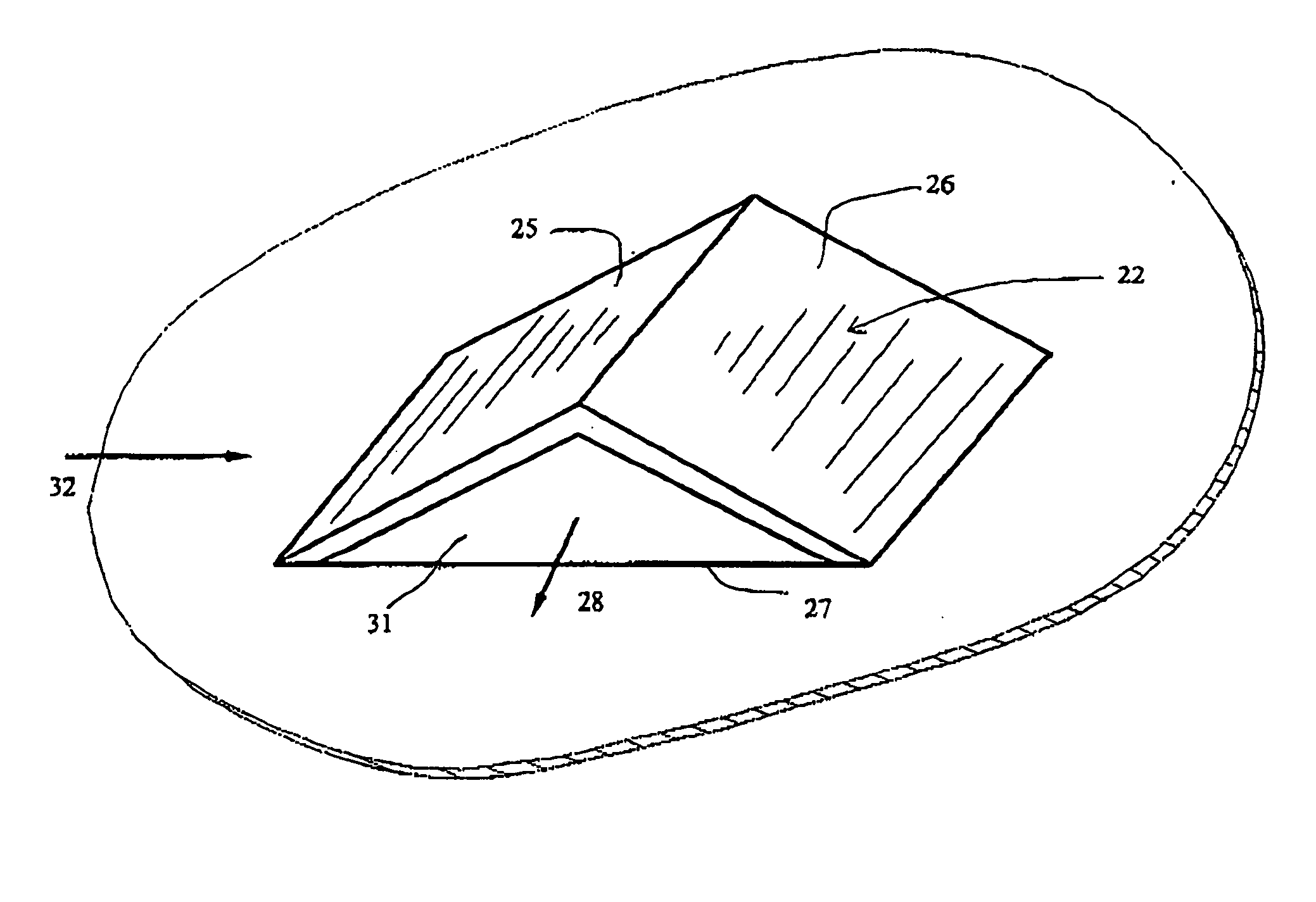

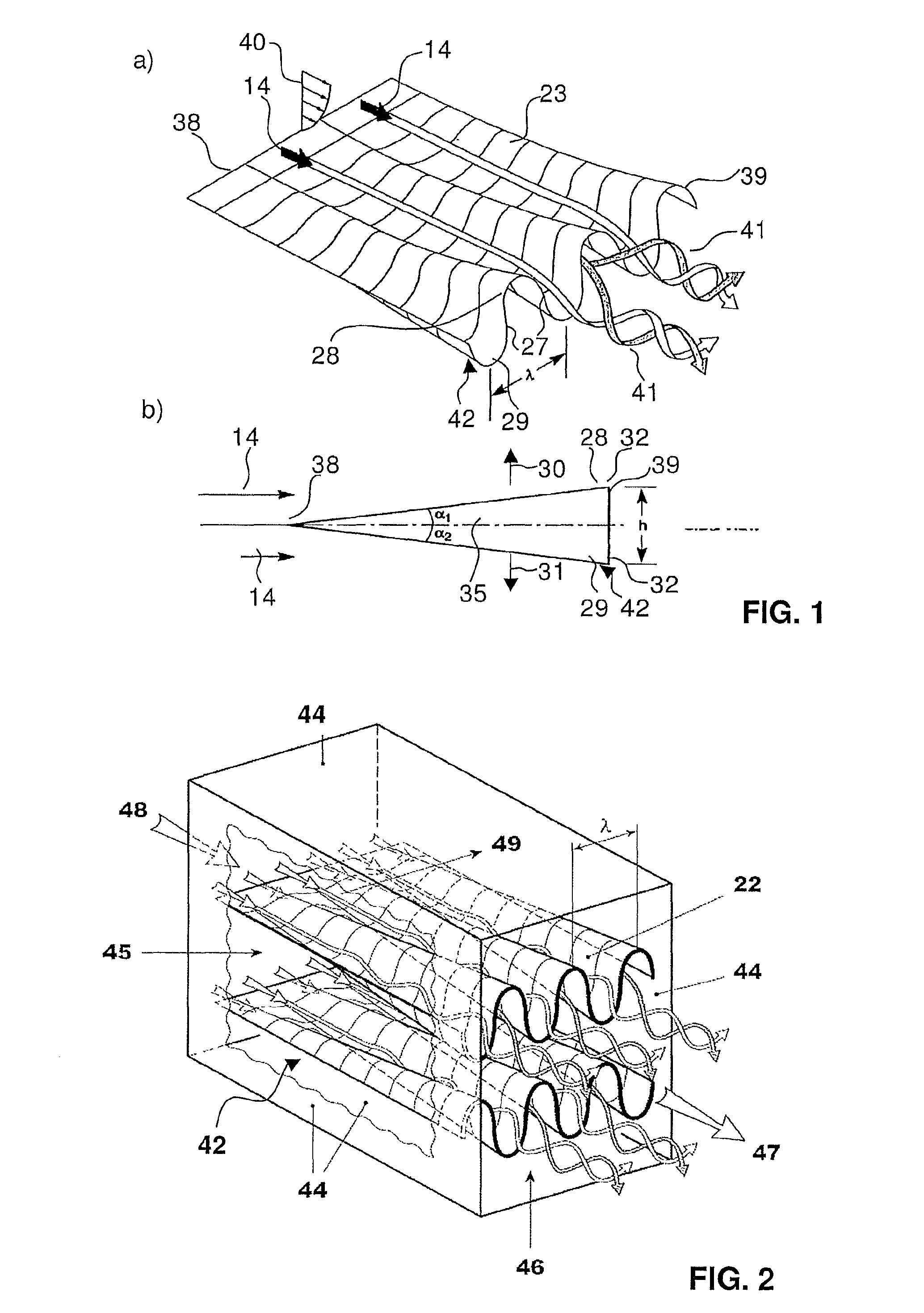

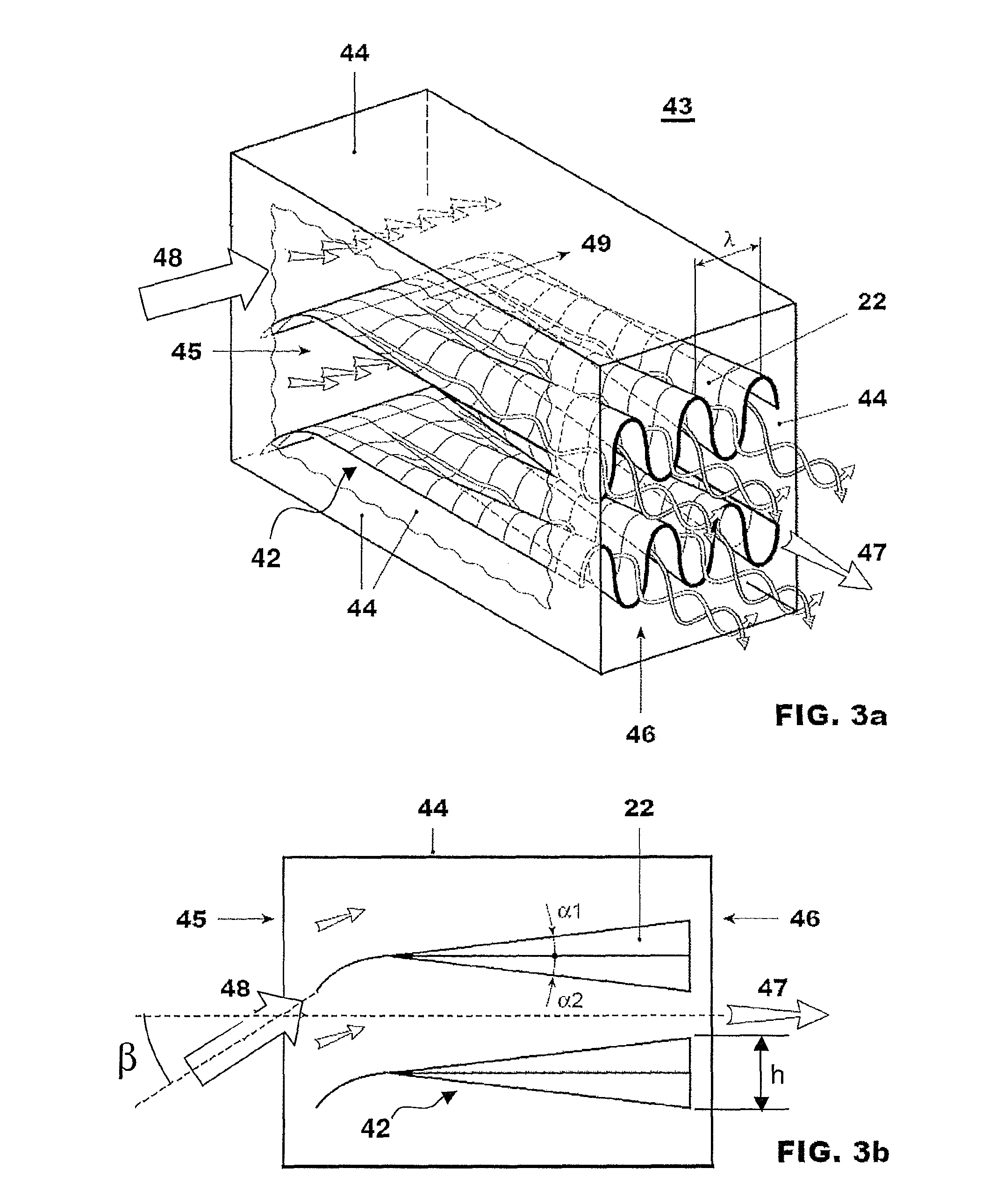

Lobed swirler

A swirler including an annular housing with limiting walls. At least two vanes are arranged in the annular housing including the sidewalls of the swirler. The leading edge area of each vane has a profile, which is oriented parallel to a main flow direction prevailing at the leading edge position, wherein the profiles of the vanes turn from the main flow direction prevailing at the leading edge position to impose a swirl on the flow, and wherein, with reference to a central plane of the vanes the trailing edges are provided with at least two lobes in opposite transverse directions. A burner for a combustion chamber of a gas turbine including such a swirler and at least one nozzle having its outlet orifice at or in a trailing edge of the vane and to a method of operation of such a burner.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Convex spinal fusion interbody spacer

A convex spinal fusion interbody space device includes spaced apart superior and inferior abutment surfaces which are effectively medially convex. The peak of such convexity is displaced anteriorly of a central plane through the device. The spacer device has a height which is greater than the width of the device. The spacer device is implanted between a pair of adjacent vertebrae by insertion in a tipped-over orientation and then reoriented to an upright orientation for engagement by facing surfaces of the vertebrae. Fusion promoting bone material is packed between the vertebrae and about and within the spacer device subsequent to implantation.

Owner:WARSAW ORTHOPEDIC INC

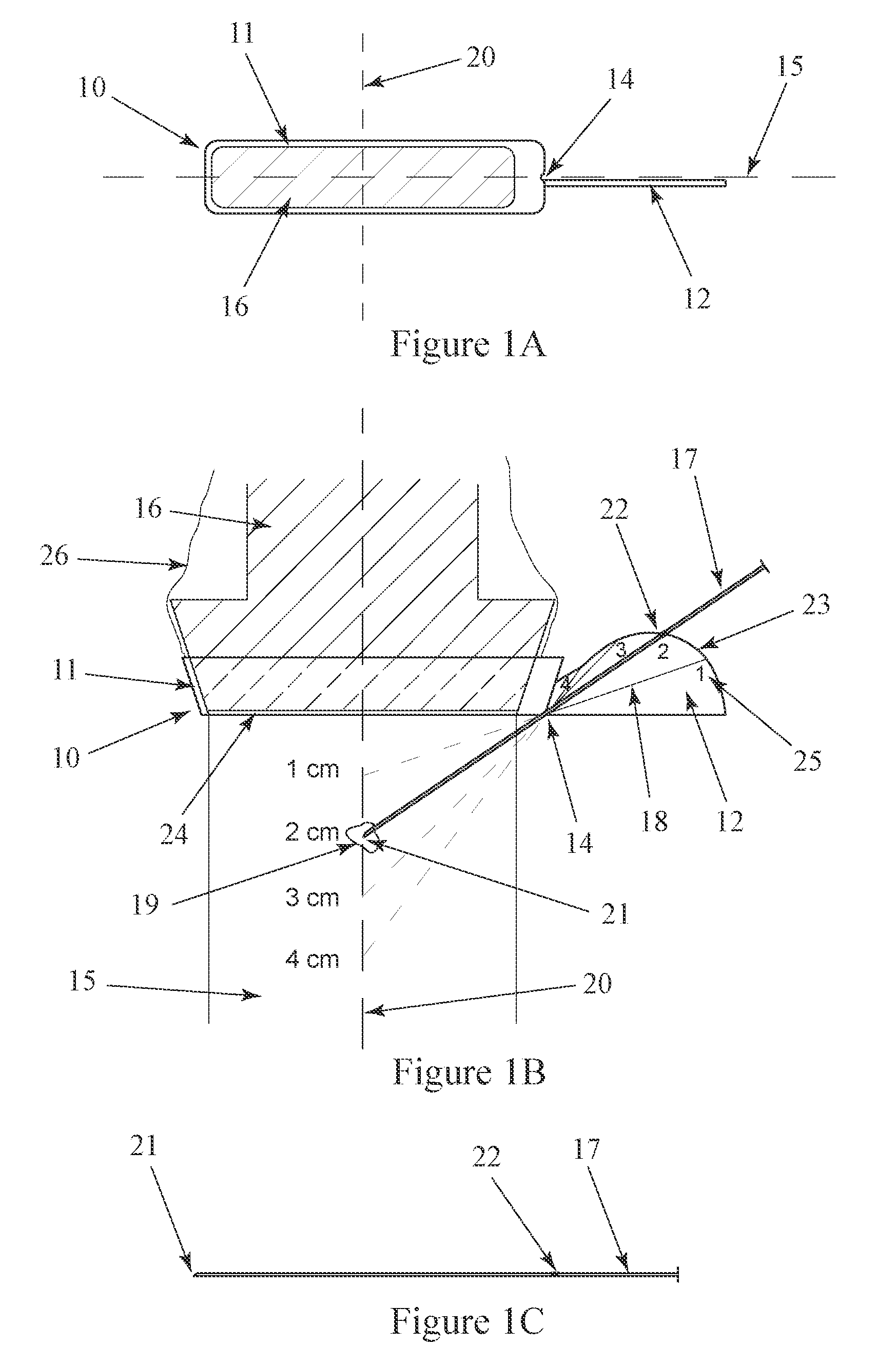

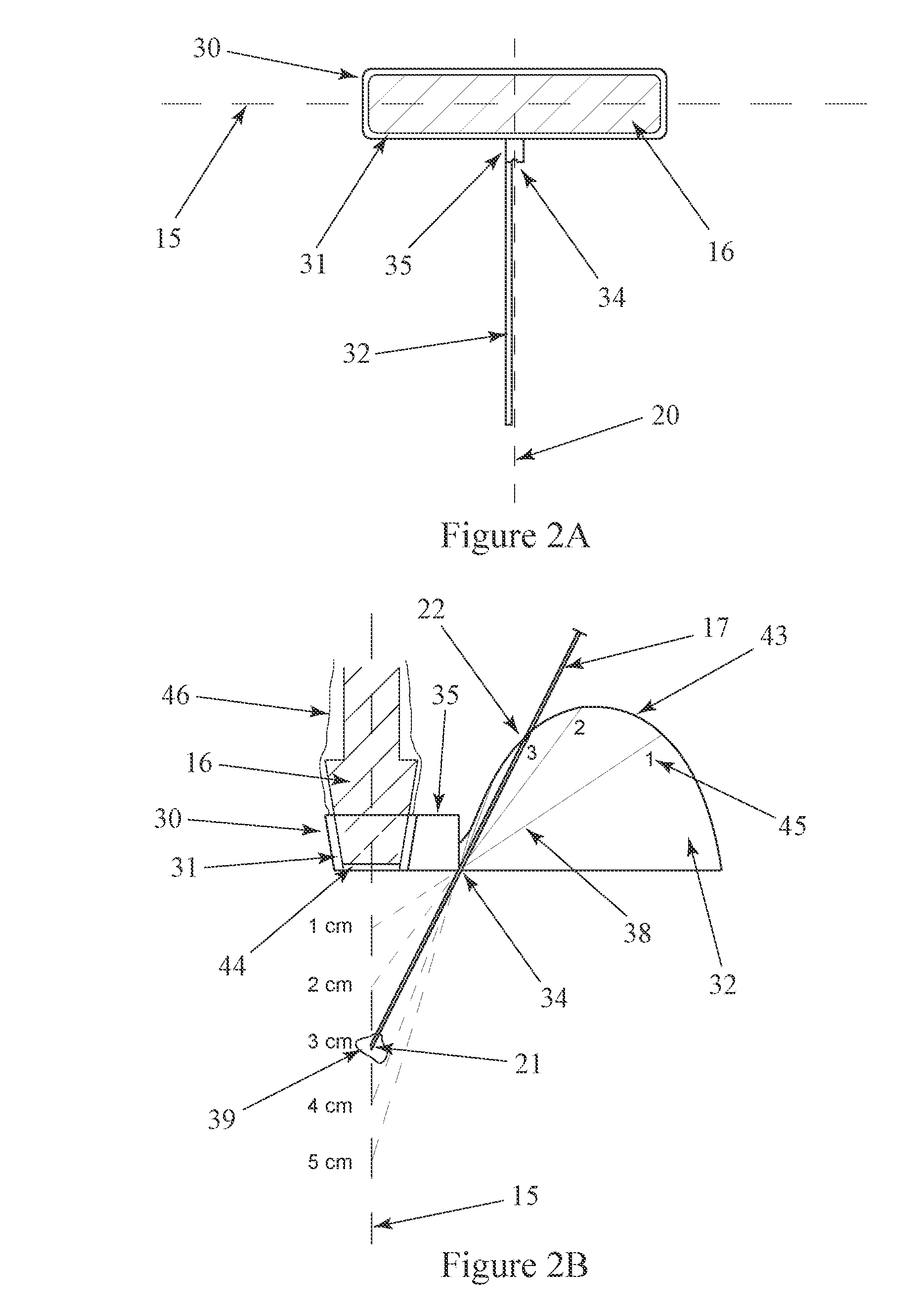

Apparatus for a needle director for an ultrasound transducer probe

InactiveUS20100312121A1Ultrasonic/sonic/infrasonic diagnosticsSurgical needlesProximateUltrasonic sensor

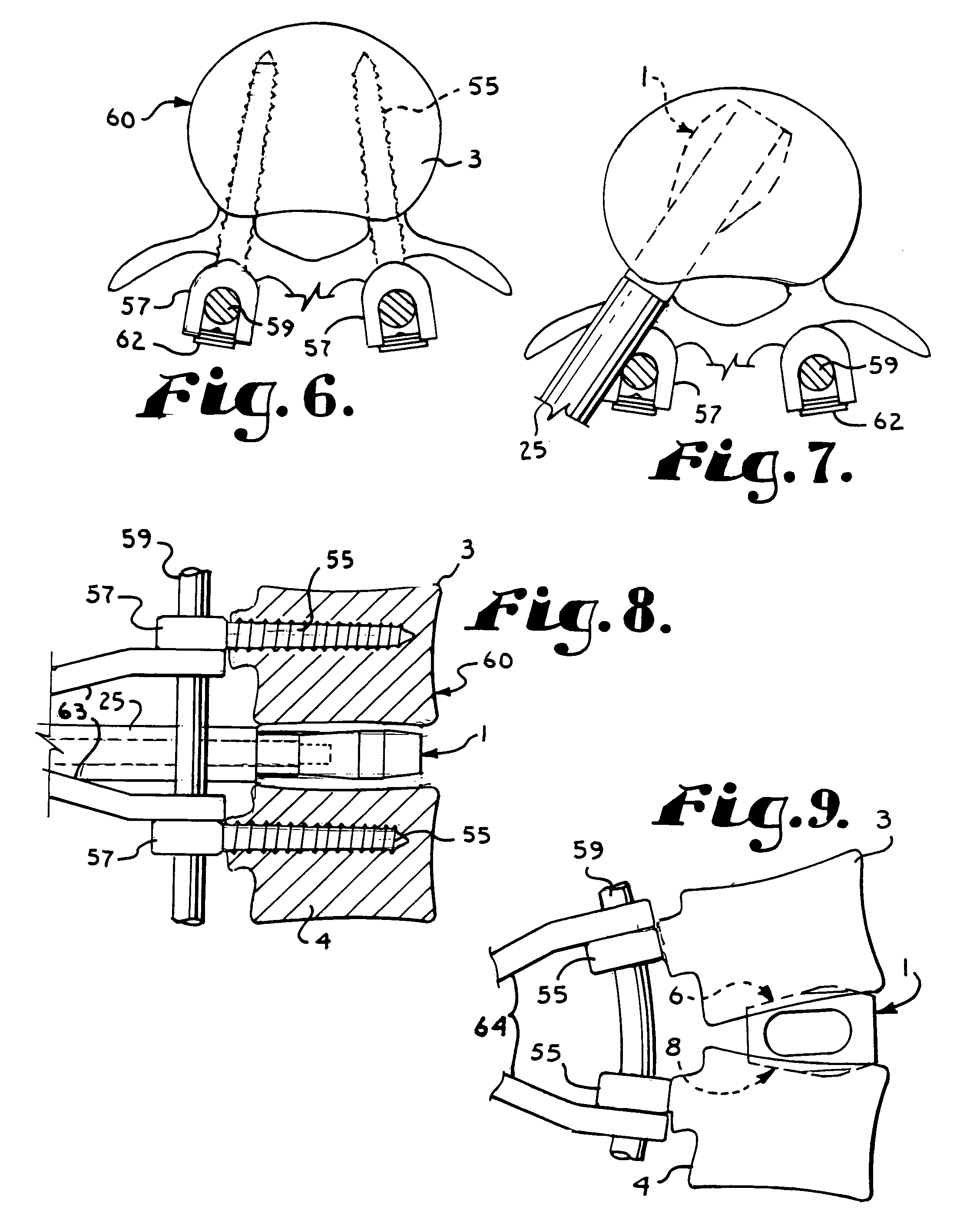

An apparatus for a needle director for an ultrasound transducer probe includes an adapter for joining to the probe. The adapter includes a bottom residing in a first plane perpendicular to a midline of the central plane of the ultrasound transducer probe. A needle insertion site is disposed in the first plane for allowing the needle to pass below the first plane. A plate is disposed in a second plane parallel to and offset from a third plane containing the midline and the needle insertion site. The plate has a flat surface proximate the third plane for guiding an insertion of the needle along the third plane. The flat surface has a plurality of radial lines having indicators of distances along the midline and a curved line intersecting the plurality of radial lines for aligning with a marker on the needle to indicate that a tip of an inserted needle has intersected the midline.

Owner:GUAN ZHONGHUI

Wear assembly for excavator digging edge

InactiveUS7080470B2Stable and mannerIncreased durabilityMechanical machines/dredgersMetal-working hand toolsFront edgeExcavator

Owner:ESCO GRP LLC

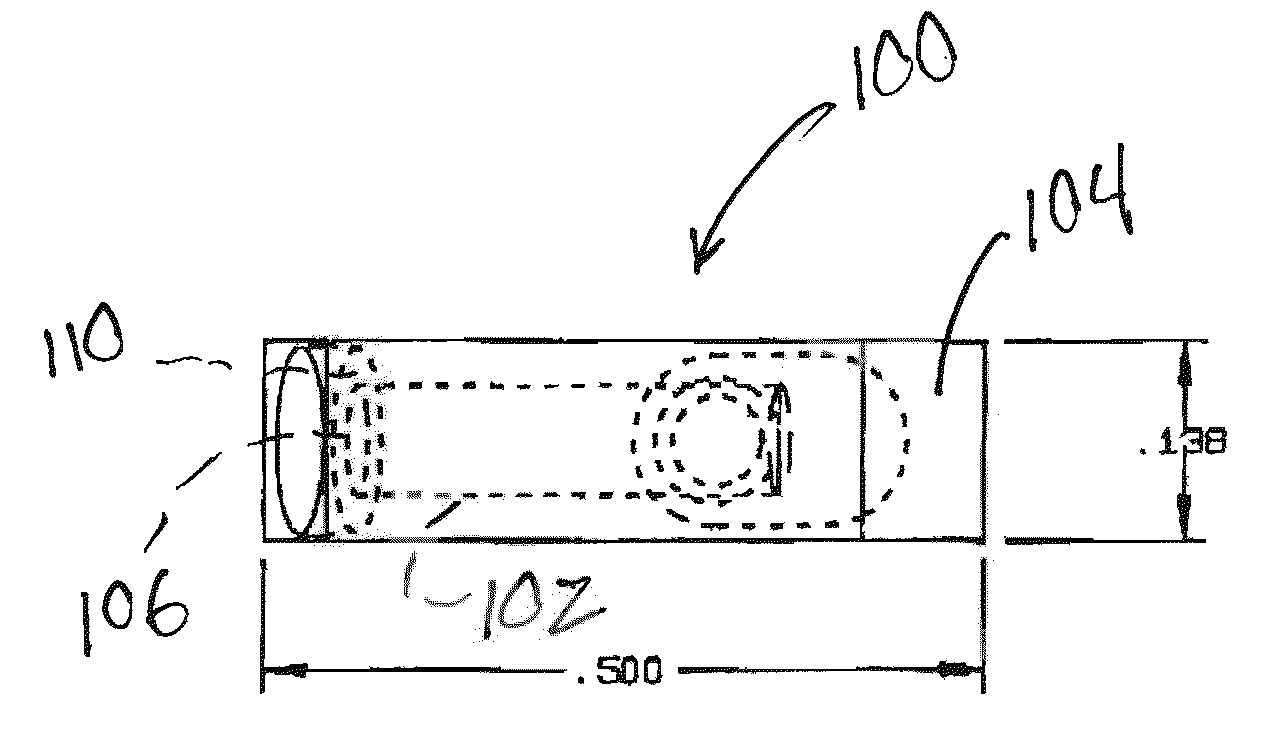

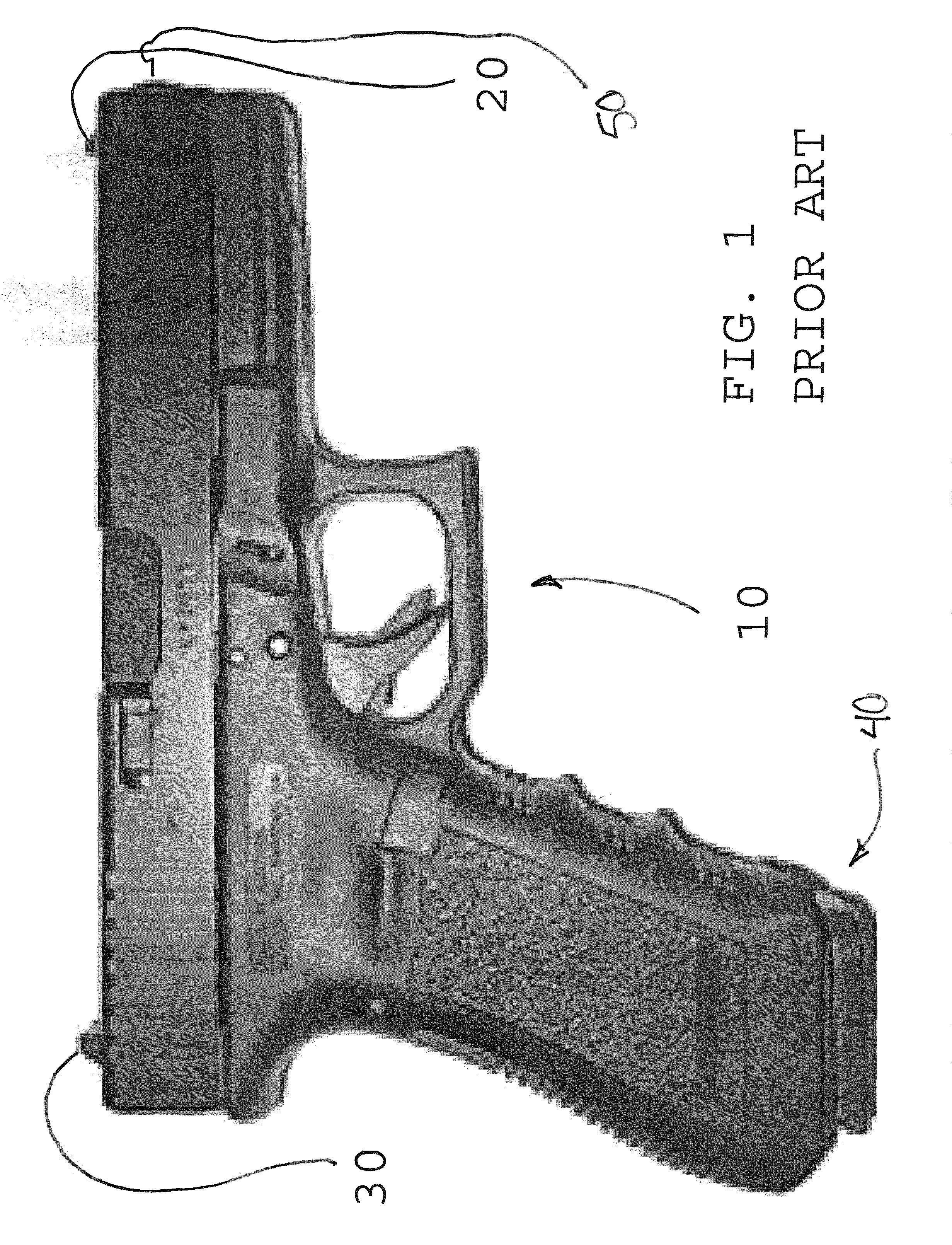

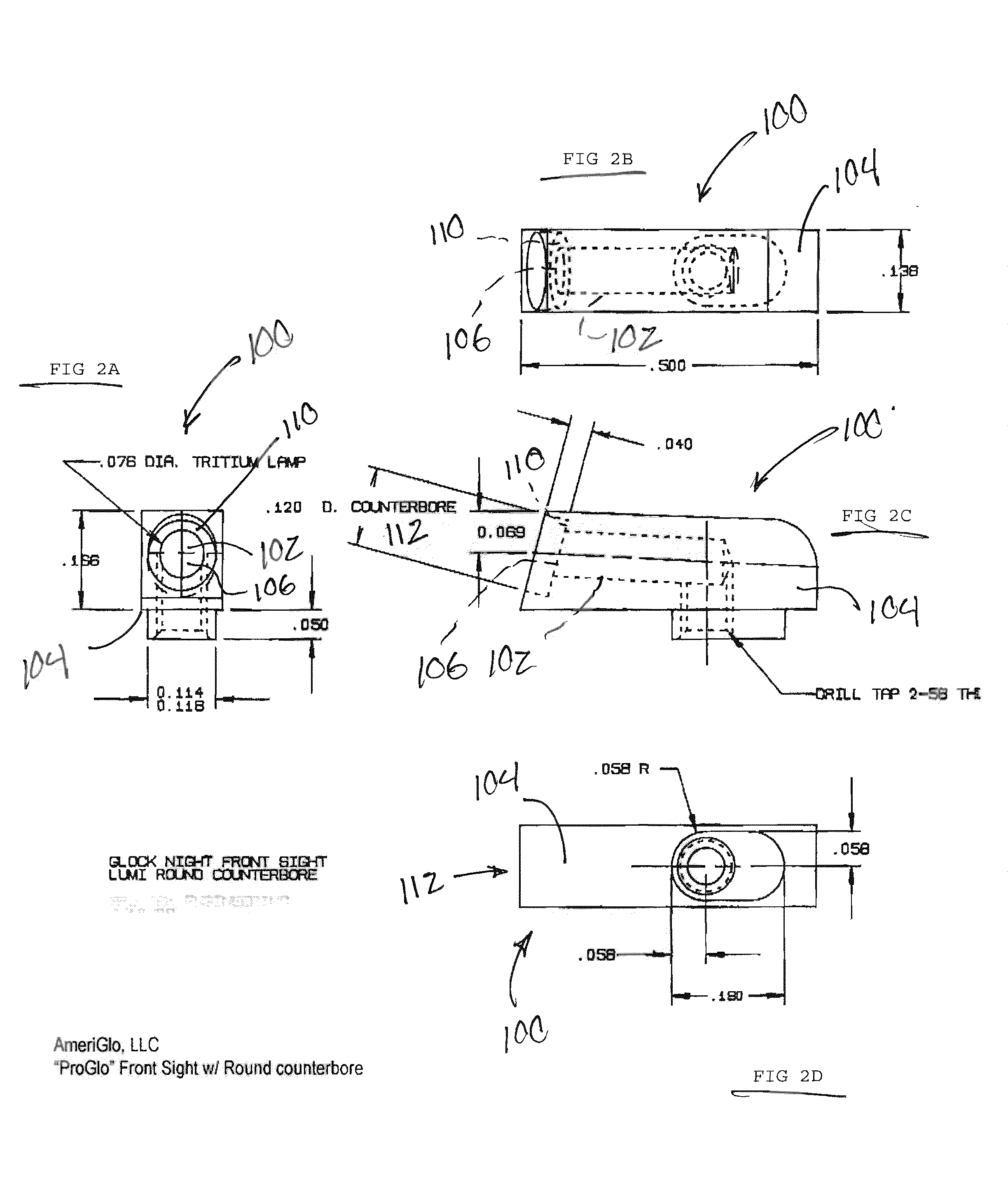

Illuminated Sight for use with Firearms and other instruments

A front sight assembly includes a self powered substantially permanent light source such as tritium source carried within a bore defined in a housing, where the housing preferably defines a structure symmetrically aligned along a central plane, where the bore carrying the light source has a central axis that lies within or parallel to the housing's central plane. The sight assembly housing terminates proximally in a proximal surface that faces the user when mounted on a firearm or other instrument. The sight assembly housing's proximal surface further includes a region surrounding or defining a periphery around the light source which is coated with, laminated with or altered to define a region of photo-luminescence that is substantially concentric with the center of the visible portion of light source.

Owner:CALLIHAN RICK

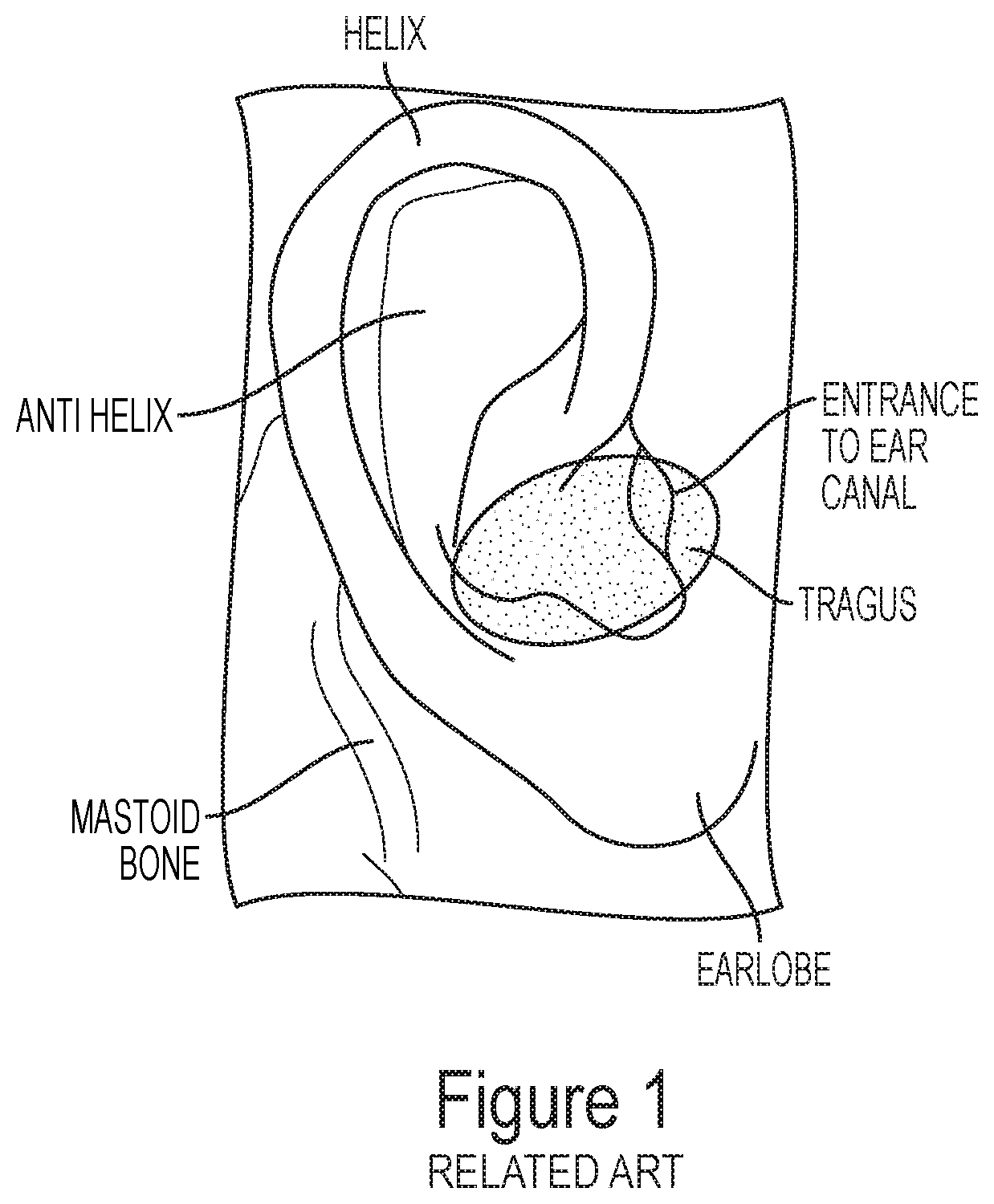

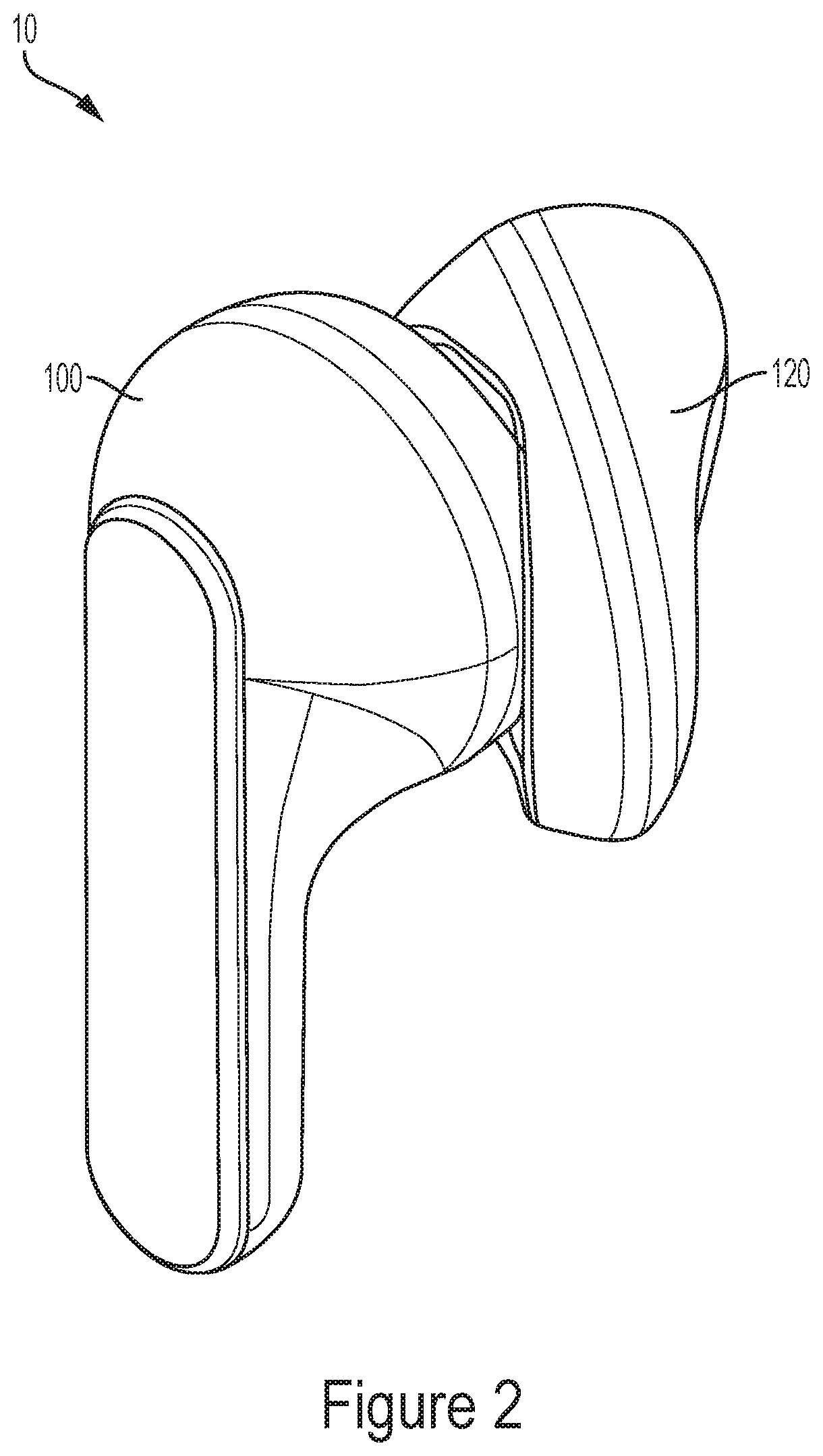

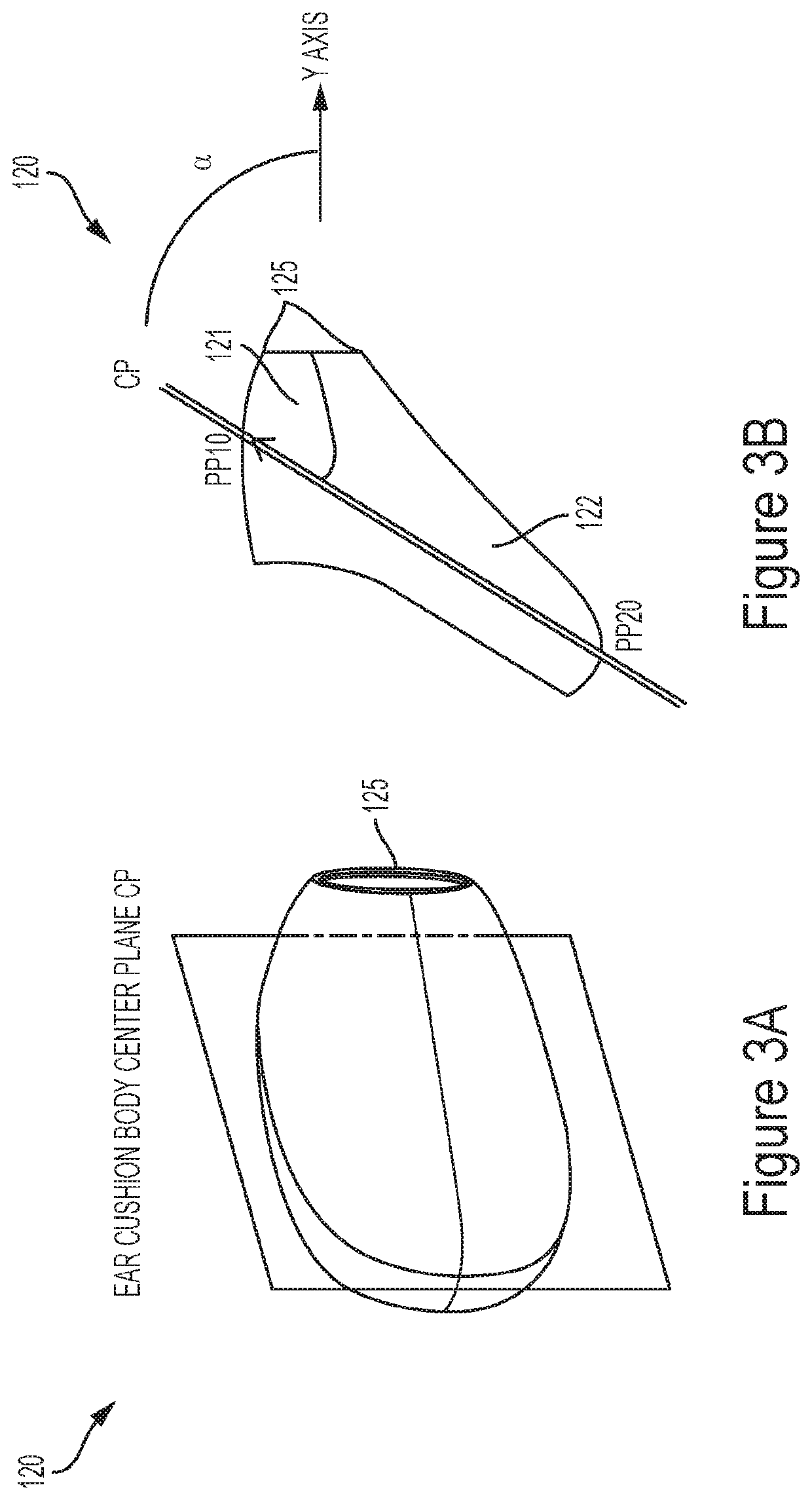

In-ear headphones with an ergonomic cushion and an ergonomic cushion thereof

ActiveUS20200068283A1Improve soundAvoid raising volume levelEar moulds/tips acoustic sealsIntra aural earpiecesEngineeringSound quality

The present invention is directed to a headphone or an earpiece that includes a cushion that advantageously allows for improved comfort, sound quality, and stability in the ear. The cushion includes an inner cavity, an ear-canal aperture and a tip portion, wherein the inner cavity of the cushion accommodates a nozzle portion of a housing within the cavity, and the axis of the inner cavity is substantially parallel to the first axis, and wherein the ear-canal aperture opens toward the ear canal of the user's ear when the headphone or the earpiece is worn by the user. A speaker element is positioned inside the nozzle portion of the housing, and the center of mass of the headphone is shifted close to a center plane of the cushion.

Owner:HEWLETT PACKARD DEV CO LP

Reheat burner injection system

The disclosure relates to a burner for a combustion chamber of a gas turbine, with an injection device for the introduction of at least one gaseous and / or liquid fuel into the burner, wherein the injection device has at least one body which is arranged in the burner with at least one nozzle for introducing the at least one fuel into the burner, the at least one body being configured as a streamlined body which has a streamlined cross-sectional profile and which extends with a longitudinal direction perpendicularly or at an inclination to a main flow direction prevailing in the burner. The at least one nozzle has its outlet orifice at or in a trailing edge of the streamlined body, and with reference to a central plane of the streamlined body, the trailing edge is provided with at least two lobes extending in opposite transverse directions.

Owner:ANSALDO ENERGIA SWITZERLAND AG

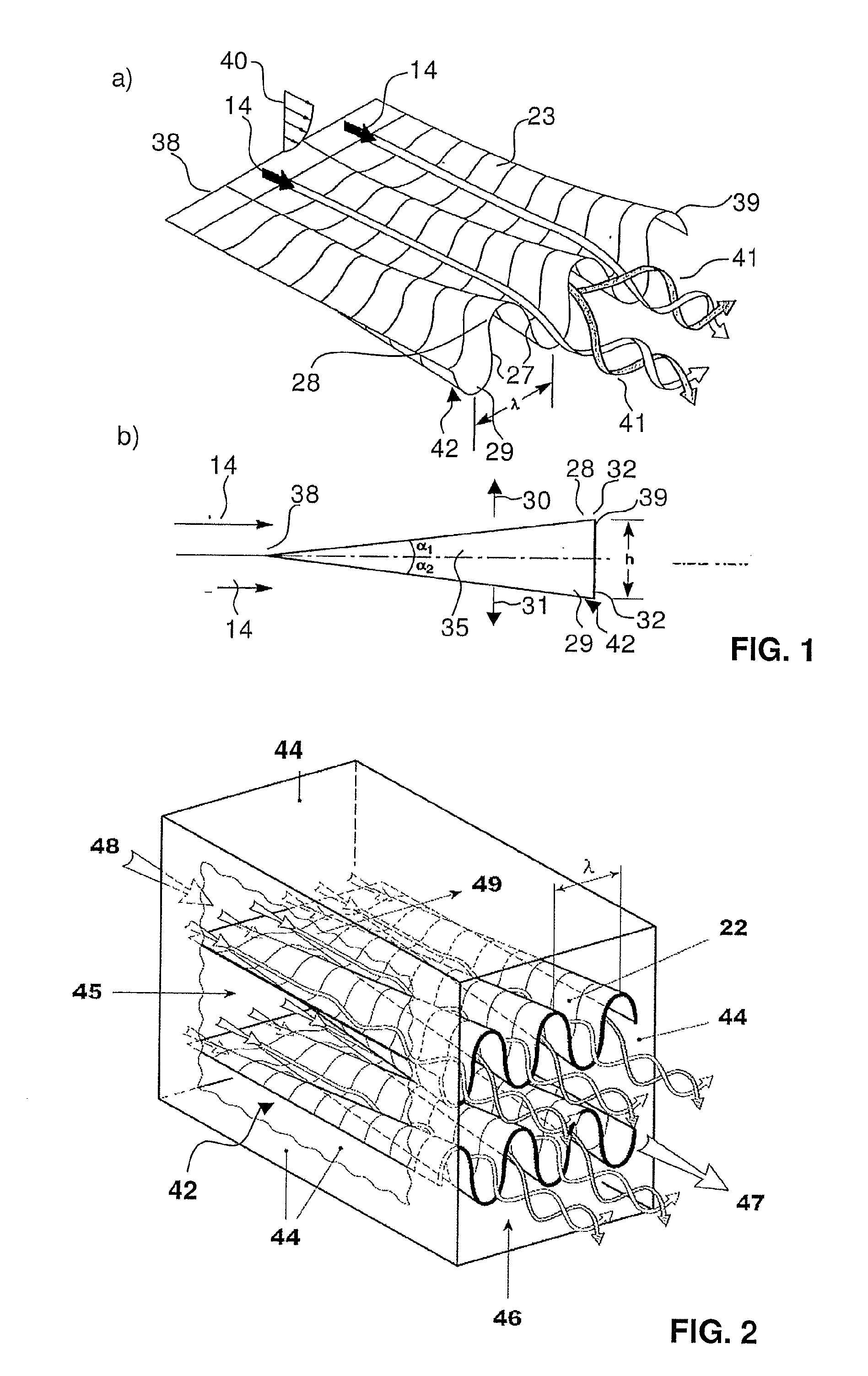

Flow straightener and mixer

A combined flow straightener and mixer is disclosed as well as a burner for a combustion chamber of a gas turbine having such a mixing device. At least two streamlined bodies are arranged in a structure comprising the side walls of the mixer. The leading edge area of each streamlined body has a profile, which is oriented parallel to a main flow direction prevailing at the leading edge position, and with reference to a central plane of the streamlined bodies, the trailing edges are provided with at least two lobes in opposite transverse directions. The periodic deflections forming the lobes from two adjacent streamlined bodies are out of phase.

Owner:ANSALDO ENERGIA SWITZERLAND AG

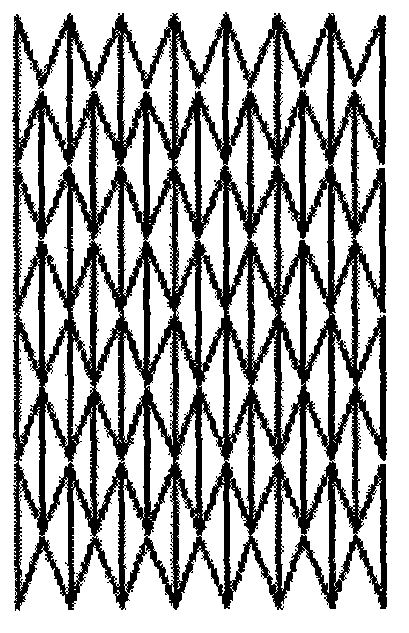

Flexible back plate for flexible display

ActiveCN103177656AGuaranteed display effectDo not collide with each otherSynthetic resin layered productsIdentification meansCentral planeGlass transition

The invention relates to a flexible back plate for a flexible display. The flexible back plate comprises a structure layer and a laying layer, wherein the structure layer is of a honeycomb structure with negative Poisson ratio; the laying layer is evenly laid in the central plane of the structure layer; the structure layer is made of shape memory polymers or composite materials; the laying layer is made of carbon fibers; the laying layer is provided with an leading-out terminal provided with two electrodes; when the two electrodes are electrified, the laying layer generates heat to heat the structure layer to enable the structure layer to reach the glass-transition temperature of the material of the structure layer, and exerts an external force to the honeycomb structure to achieve the purpose of deforming the honeycomb, the shape of the honeycomb can be fixed after the heating is stopped, the size is increased in two directions, in this way, the size of the back plate is increased; when the honeycomb structure is in an unidirectional compression, the size is decreased in a plane, in this way, the size of the back plate is decreased; and the honeycomb structure with negative Poisson ratio has double-curvature characteristic. The flexible back plate has the following characteristics of being bendable, having double curvature, impact resistance and anti-shock performance, being capable of being driven intelligently, and being light and beautiful.

Owner:HARBIN INST OF TECH

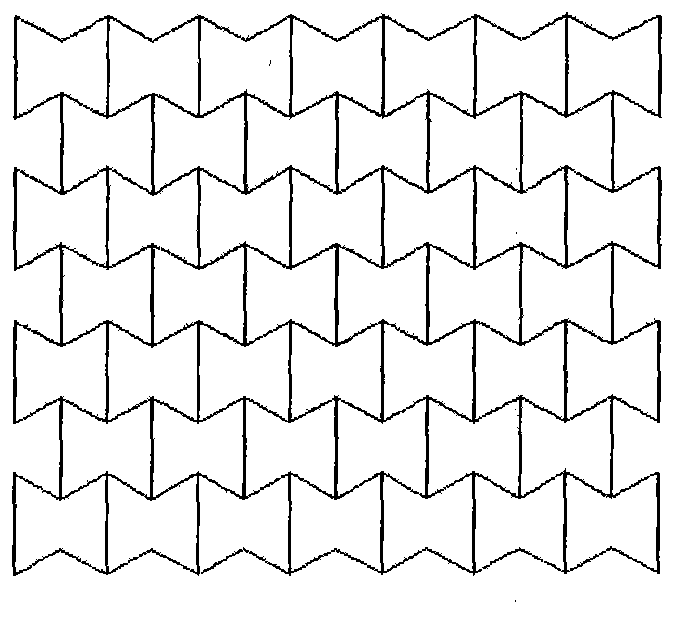

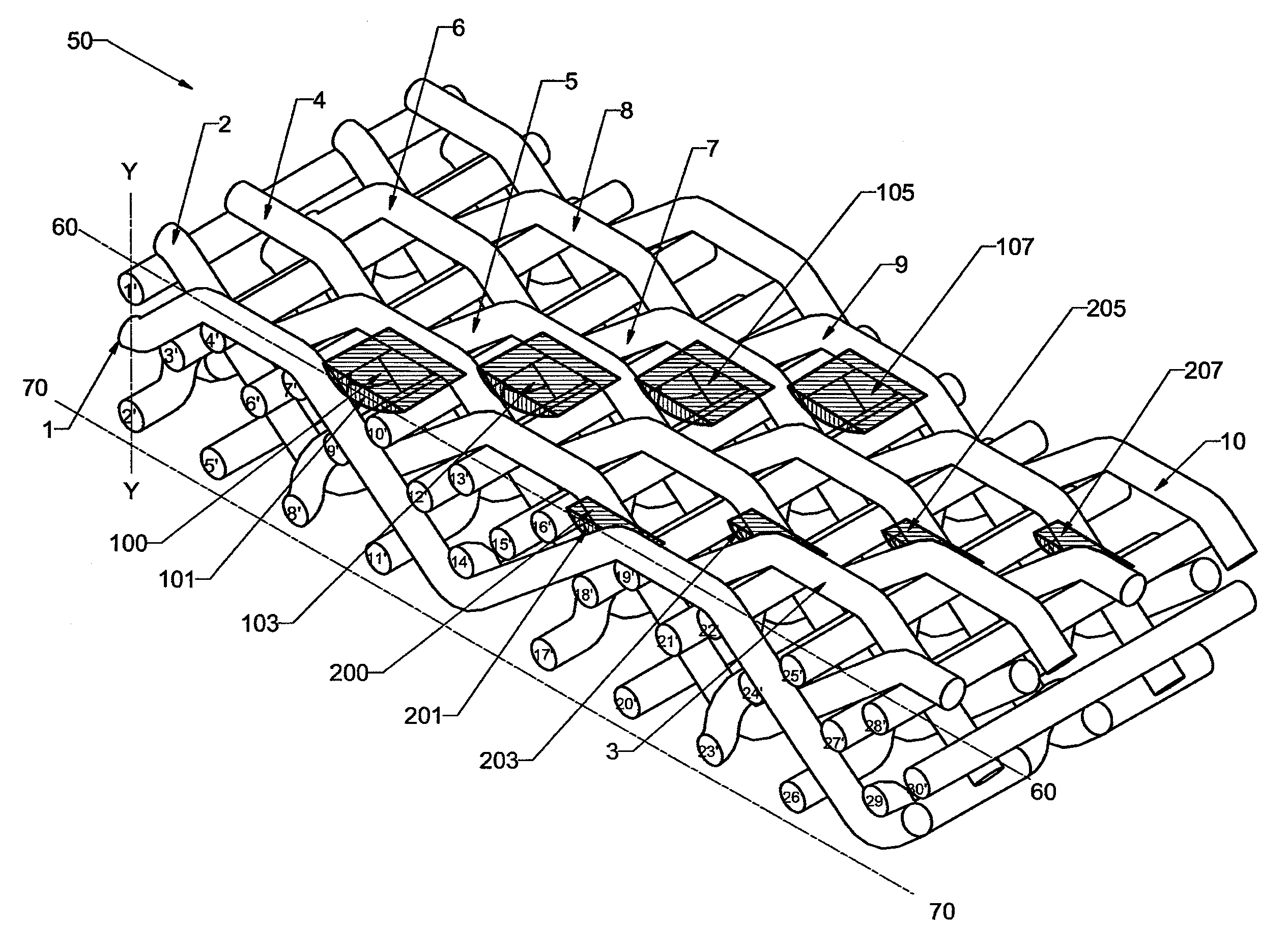

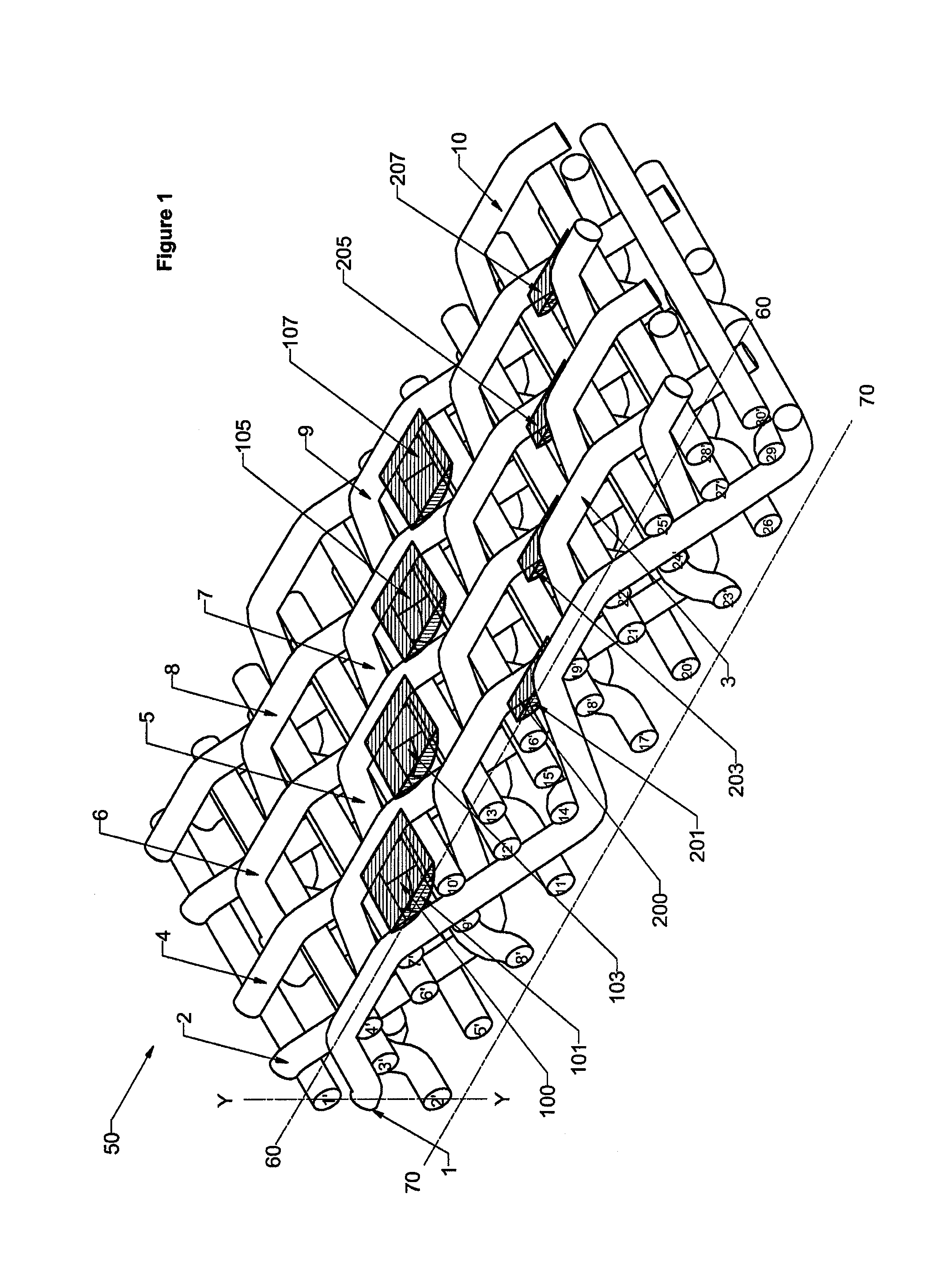

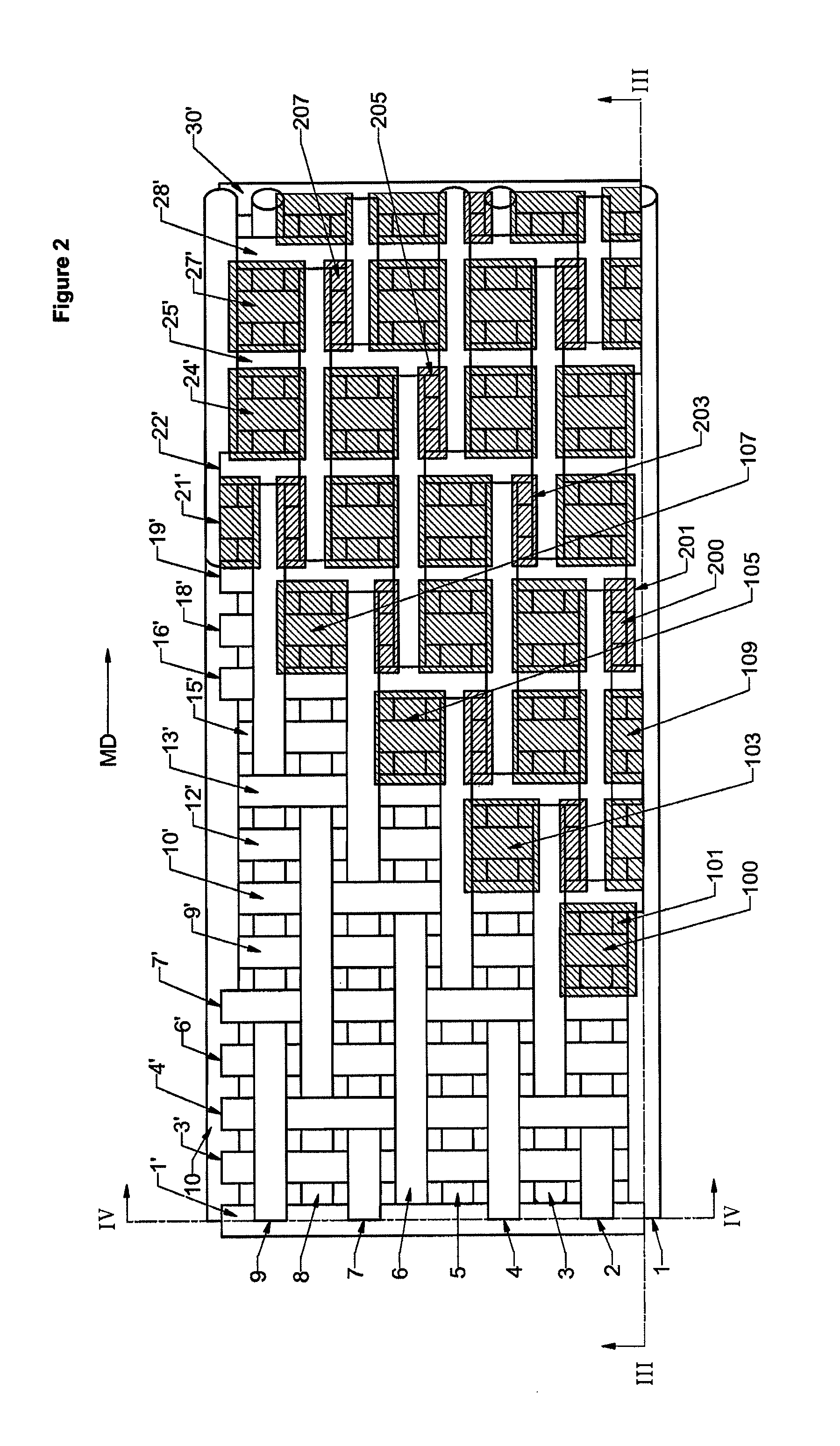

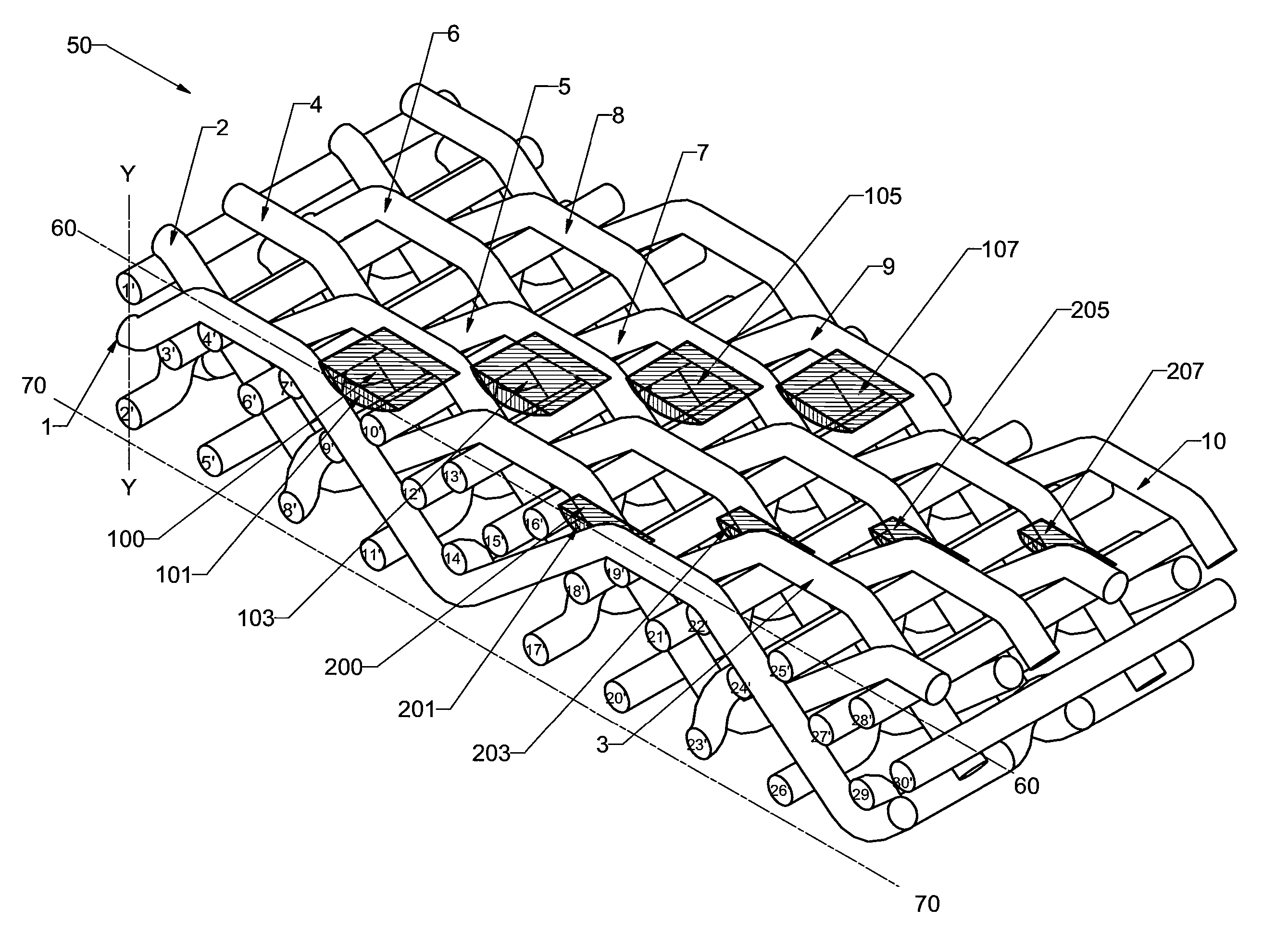

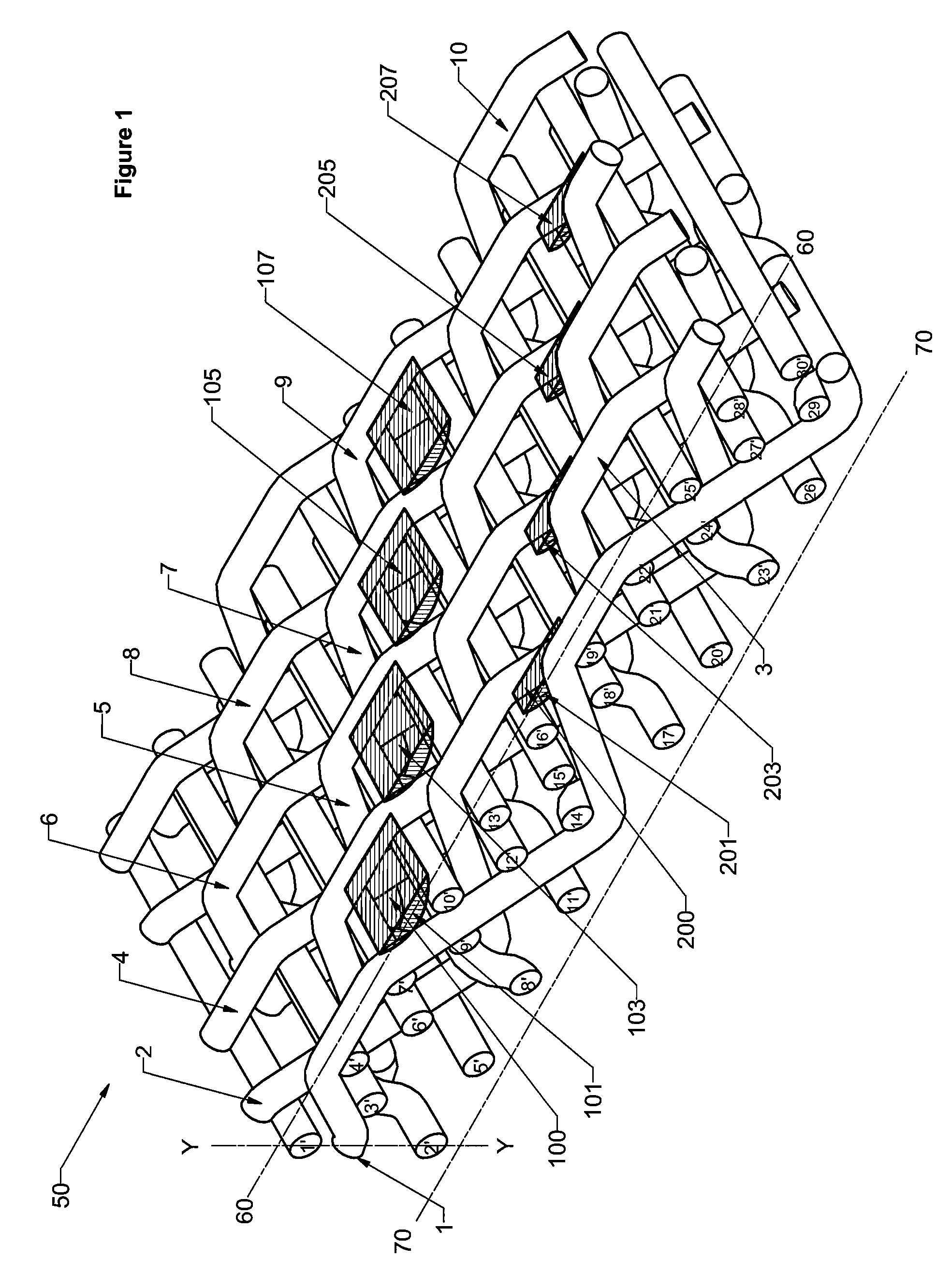

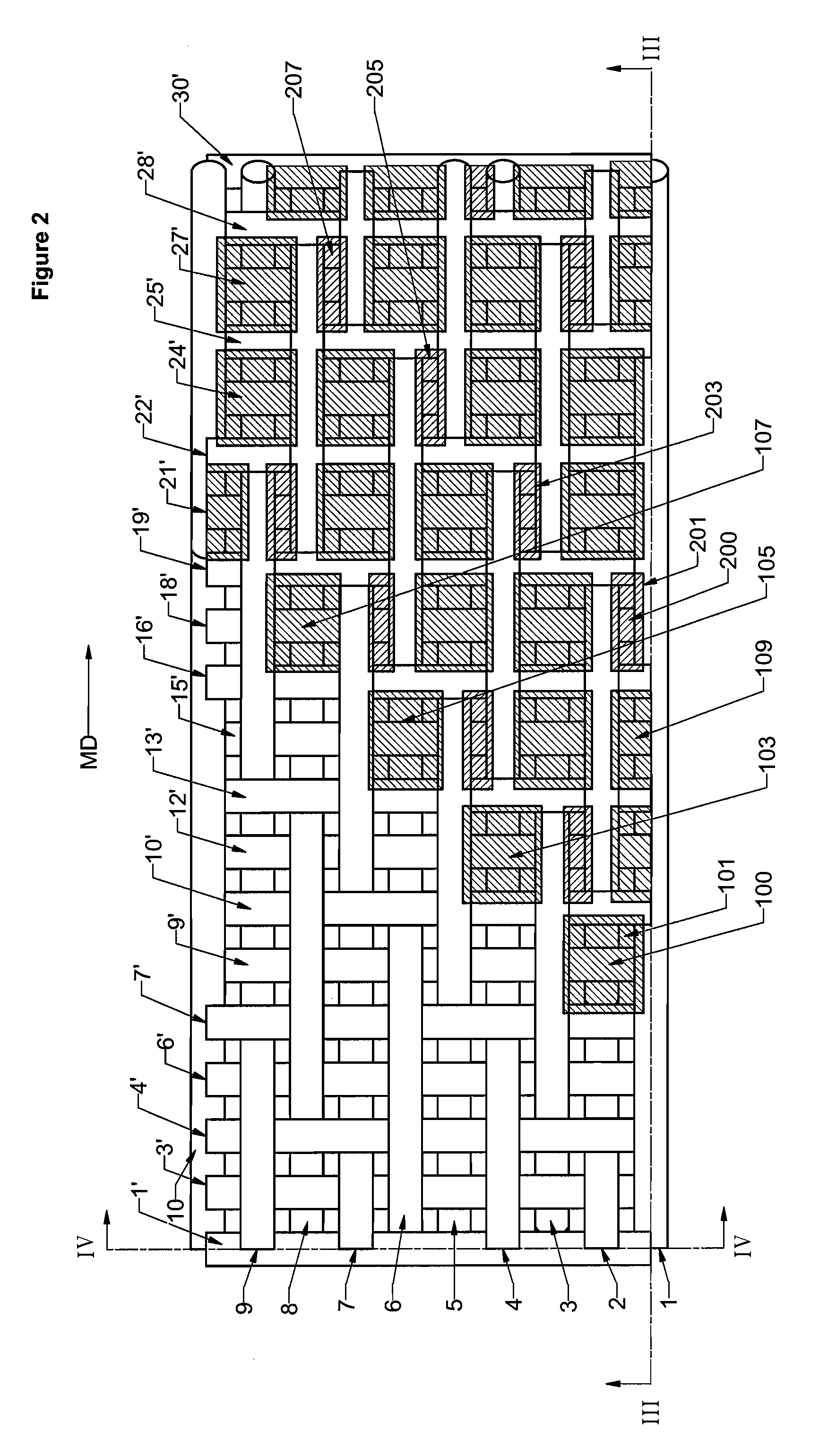

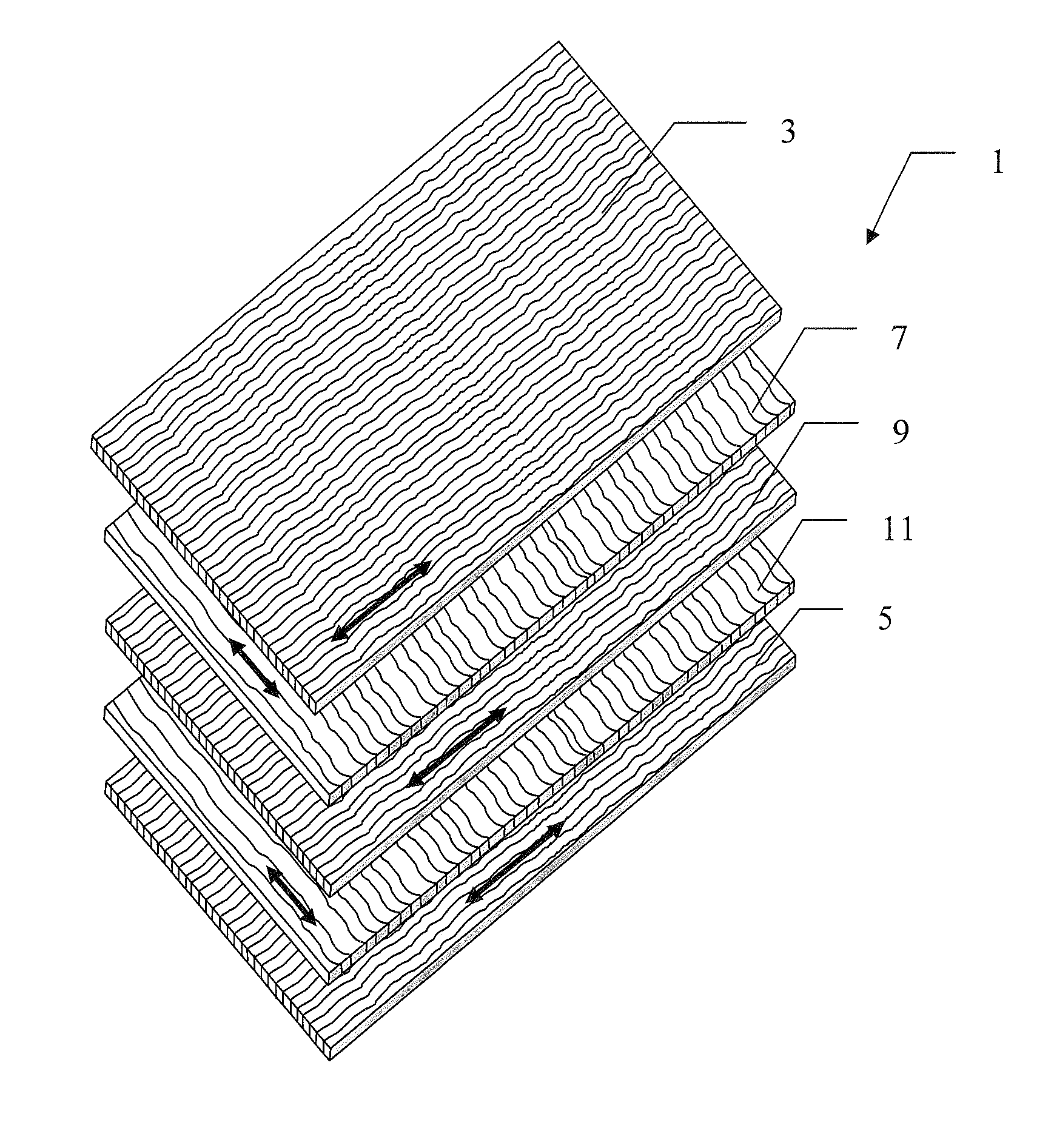

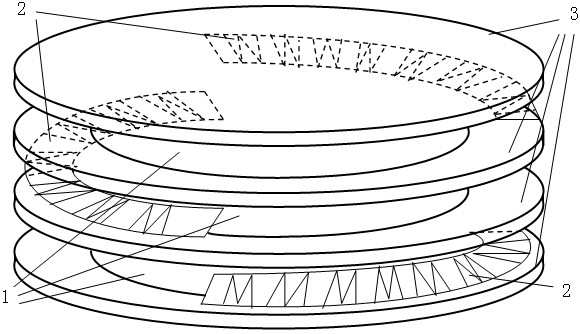

Double layer papermakers fabric with pockets for bulk enhancement

InactiveUS7493923B2Impart surface roughnessSignificant formMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

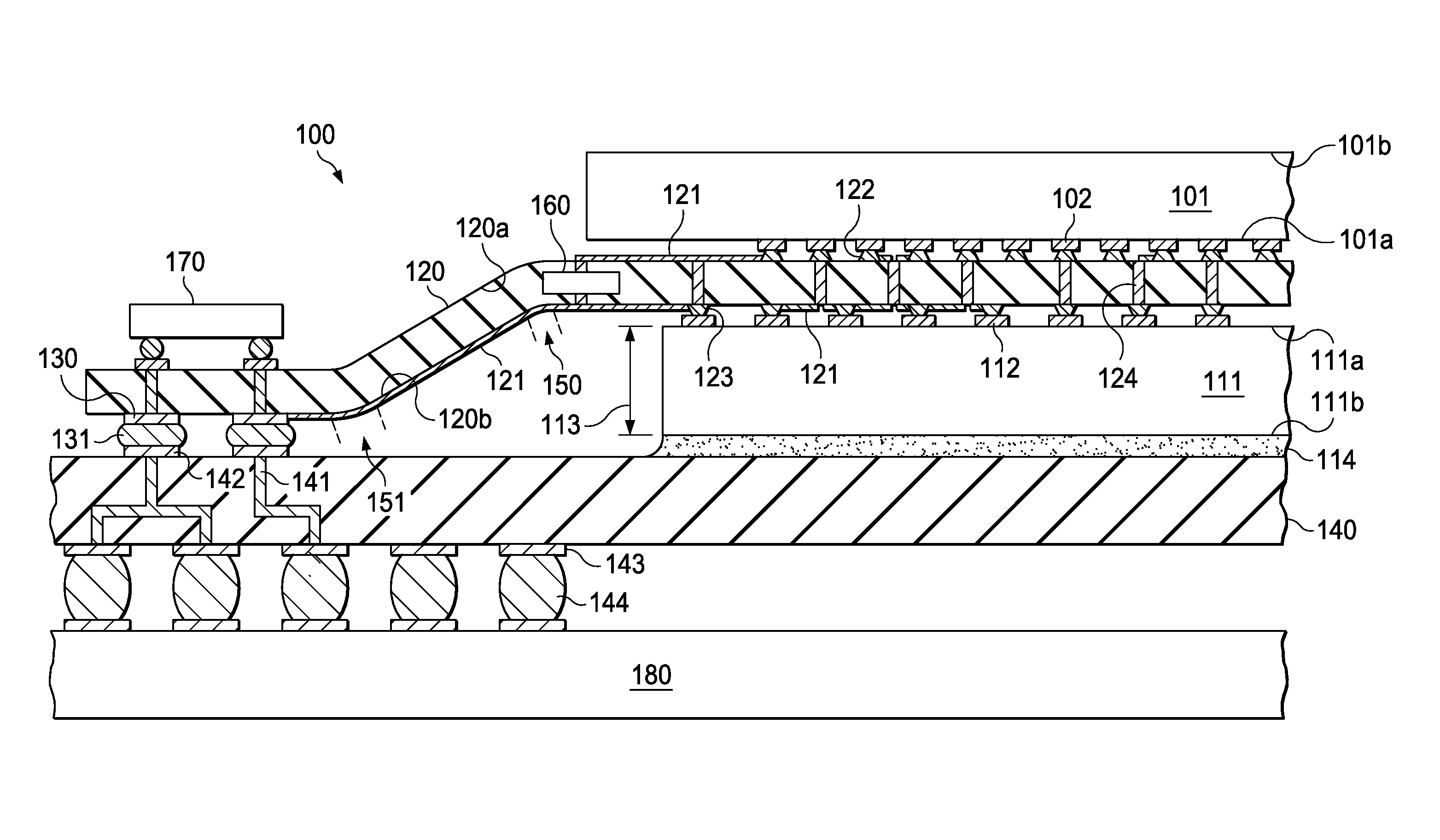

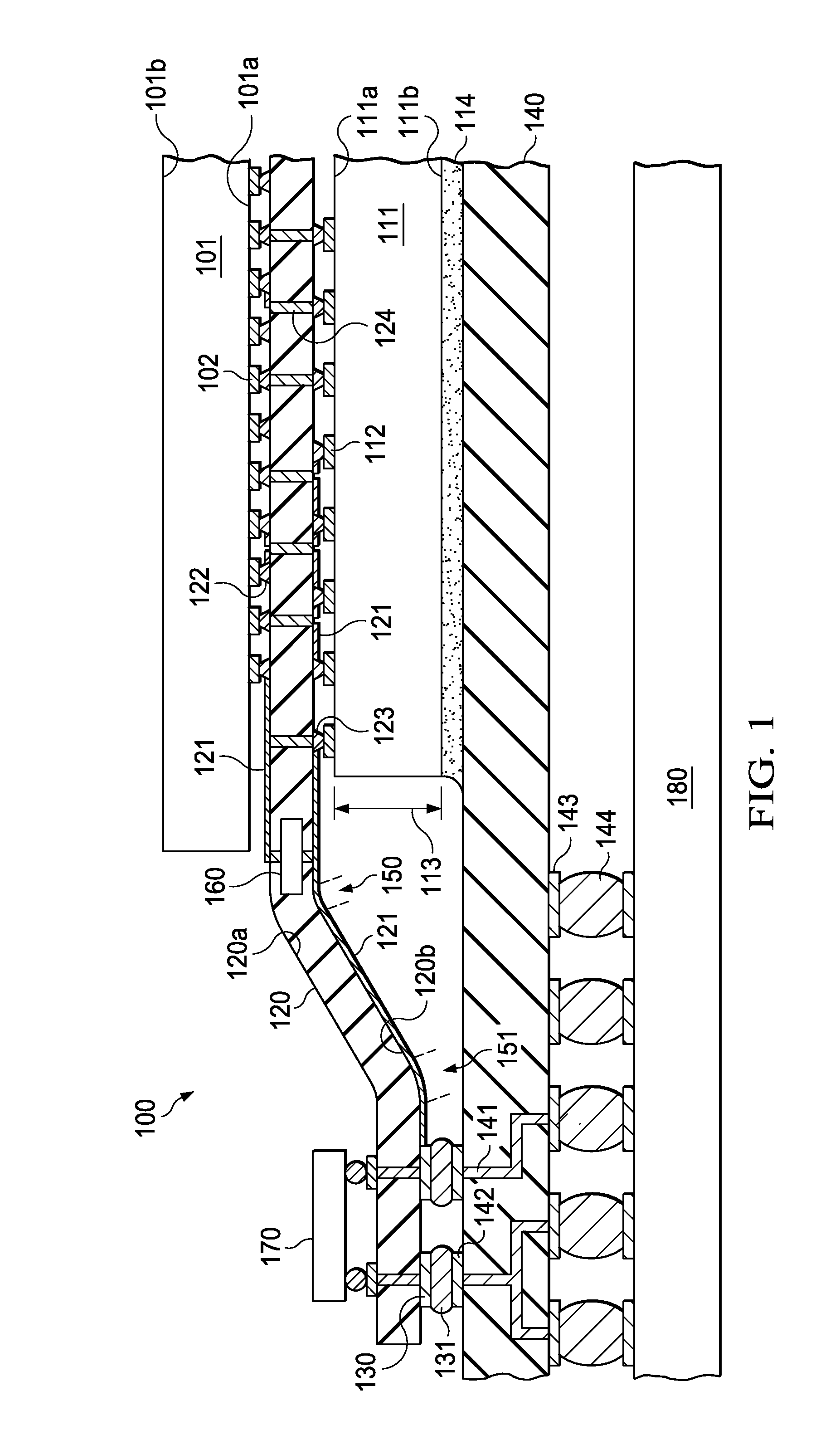

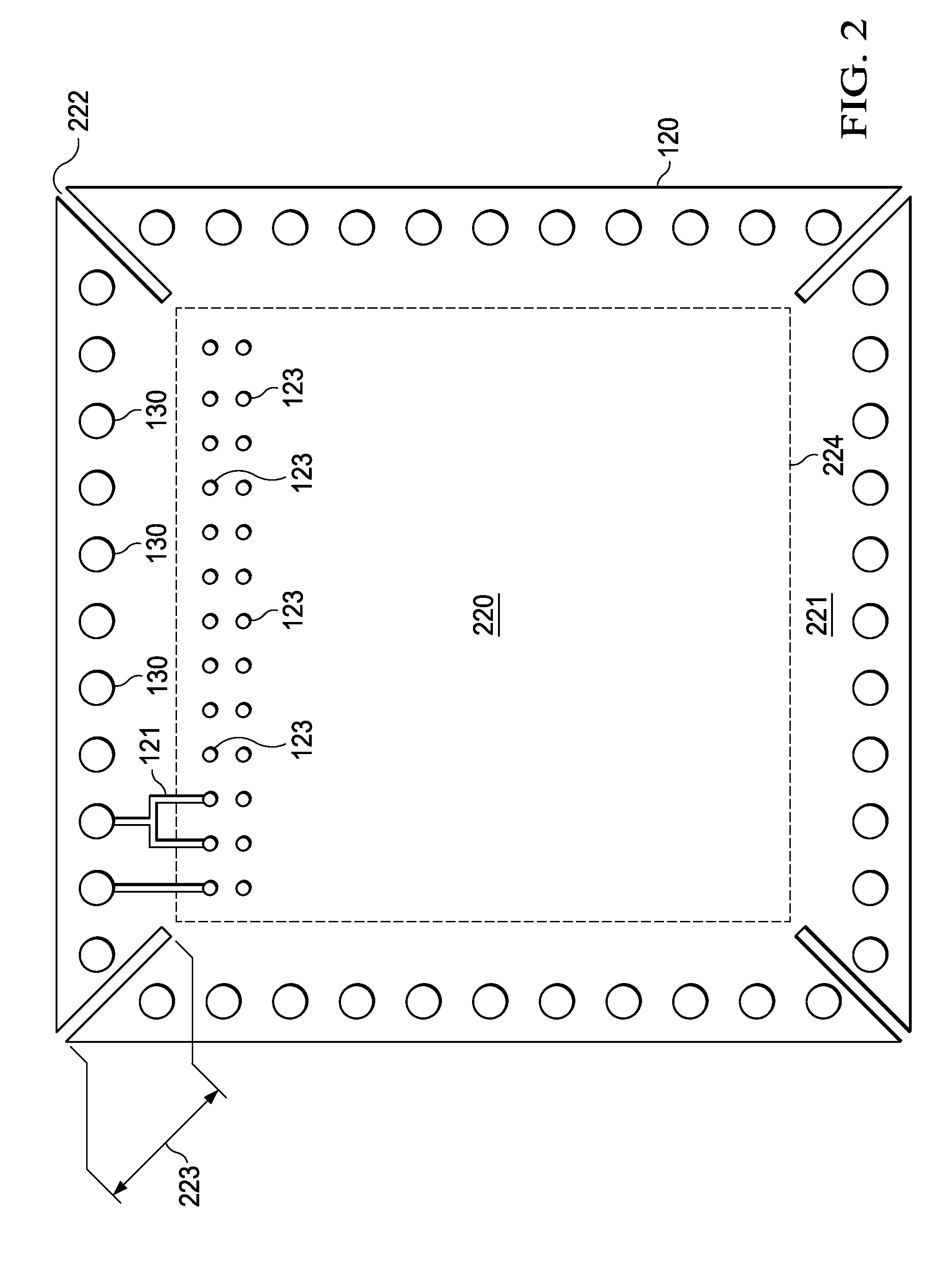

Flexible Interposer for Stacking Semiconductor Chips and Connecting Same to Substrate

ActiveUS20090121346A1Increase the number ofReduce exposureSemiconductor/solid-state device detailsSolid-state devicesAnisotropic conductive filmContact pad

A semiconductor device with a first (101) and a second (111) semiconductor chip assembled on an insulating flexible interposer (120). The interposer, preferably about 25 to 50μm thick, has conductive traces (121), a central planar rectangular area and on each side of the rectangle a wing bent at an angle from the central plane. The central area has metal studs (122, 123) on the top and the bottom surface, which match the terminals of the chips, further conductive vias of a pitch center-to-center about 50 μm or less. The side wings have contact pads (130) with metallic connectors (131) on the bottom surface; the connectors may be solder balls, metal studs, or anisotropic conductive films. The second chip is adhesively attached to a substrate, whereby the interposer faces away from the substrate. The interposer side wings have a convex bending (150) downwardly along the second chip and a concave bending (151) over the substrate; the side wing connectors are attached to the matching substrate sites.

Owner:TEXAS INSTR INC

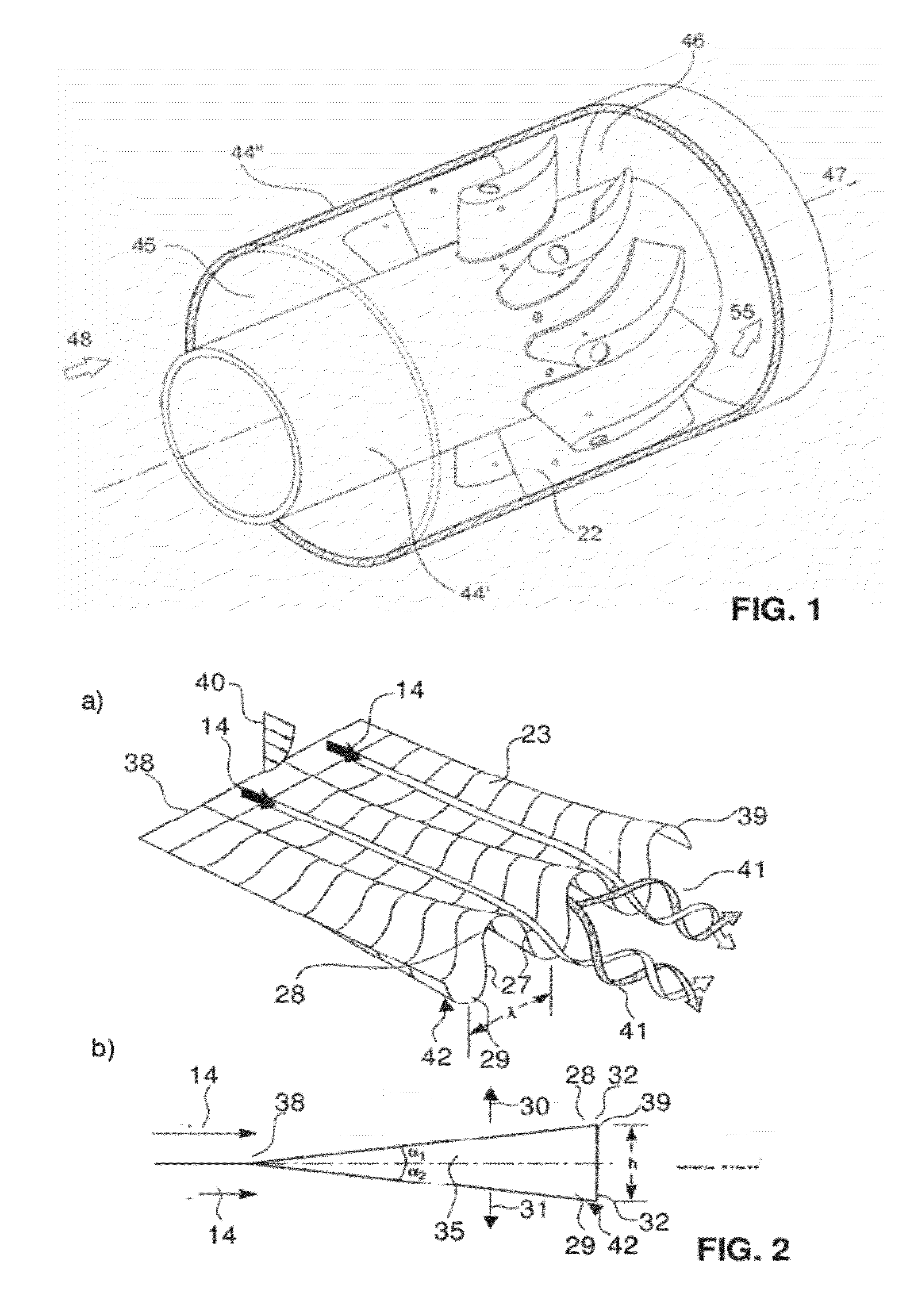

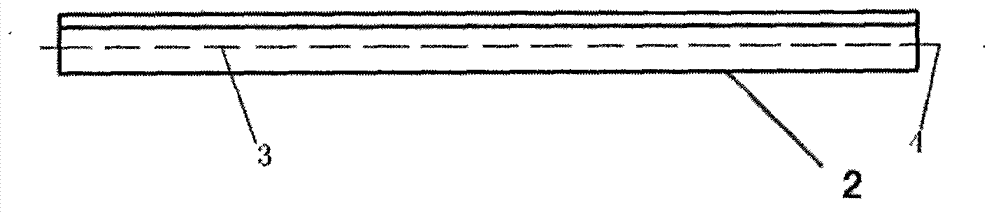

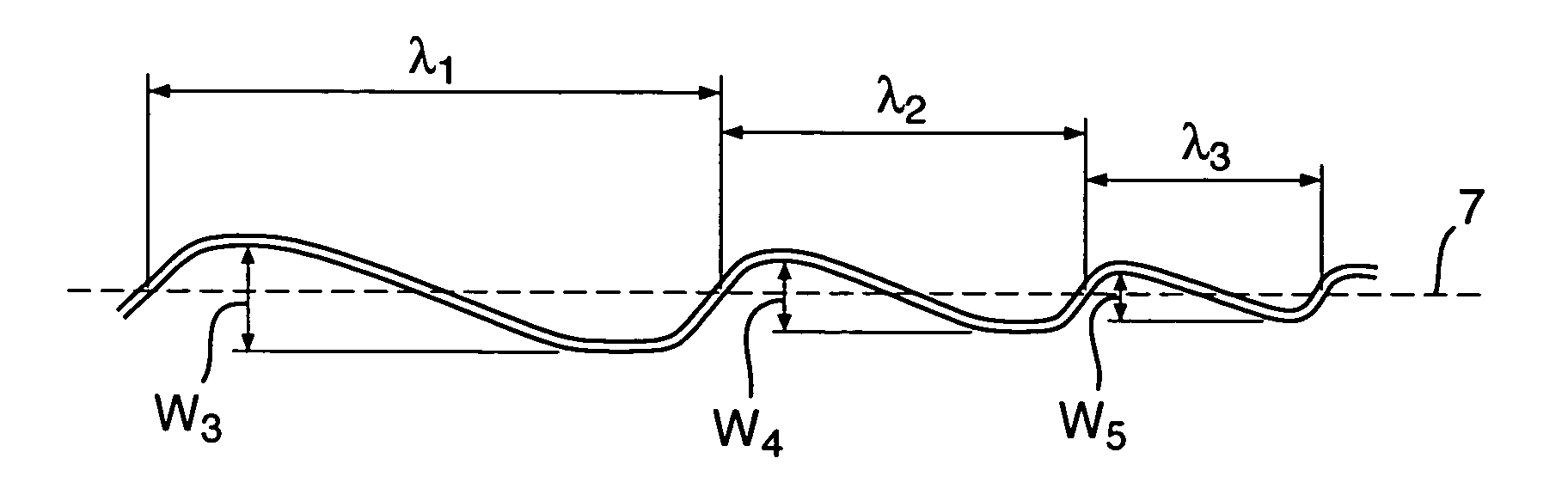

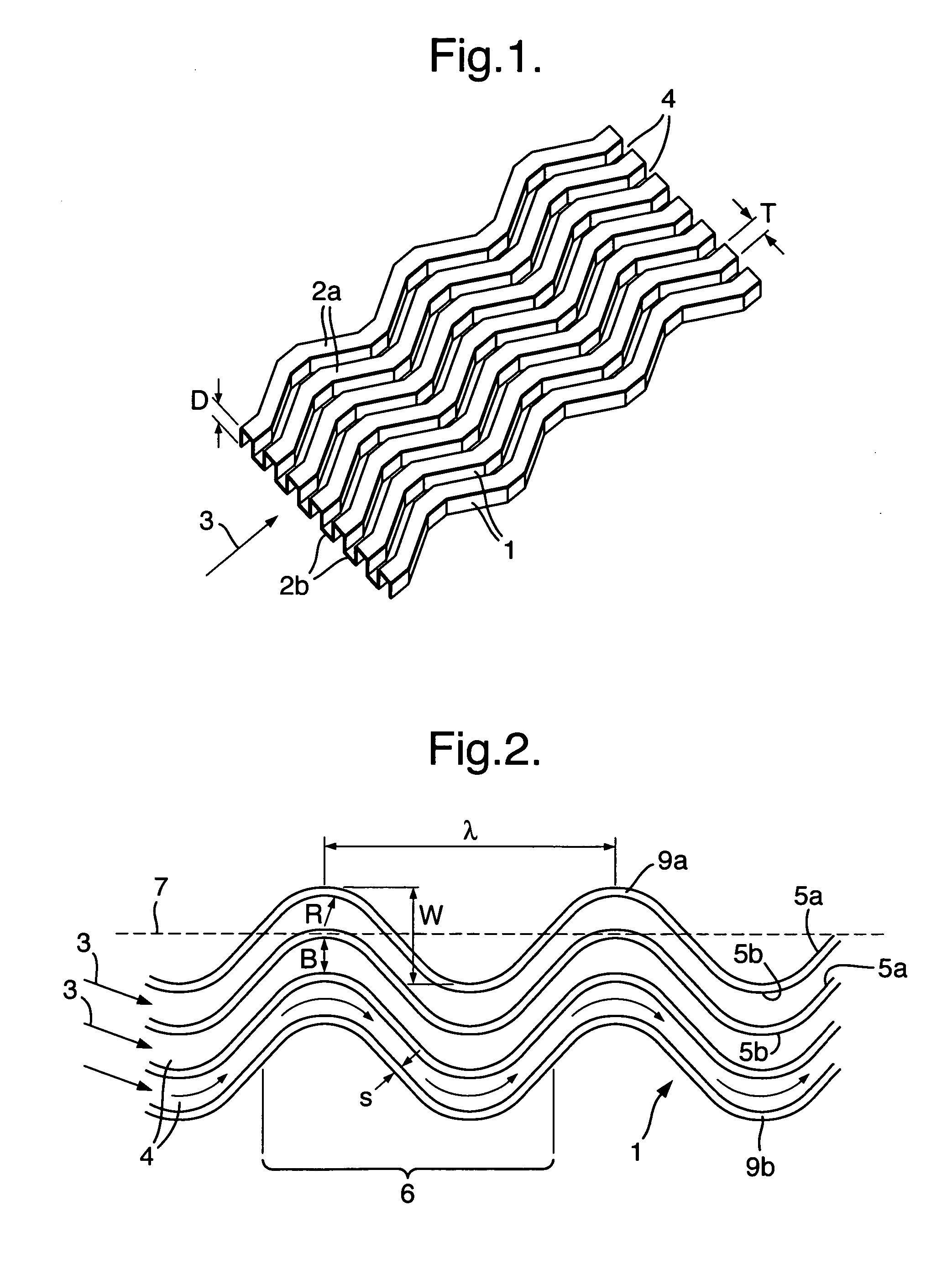

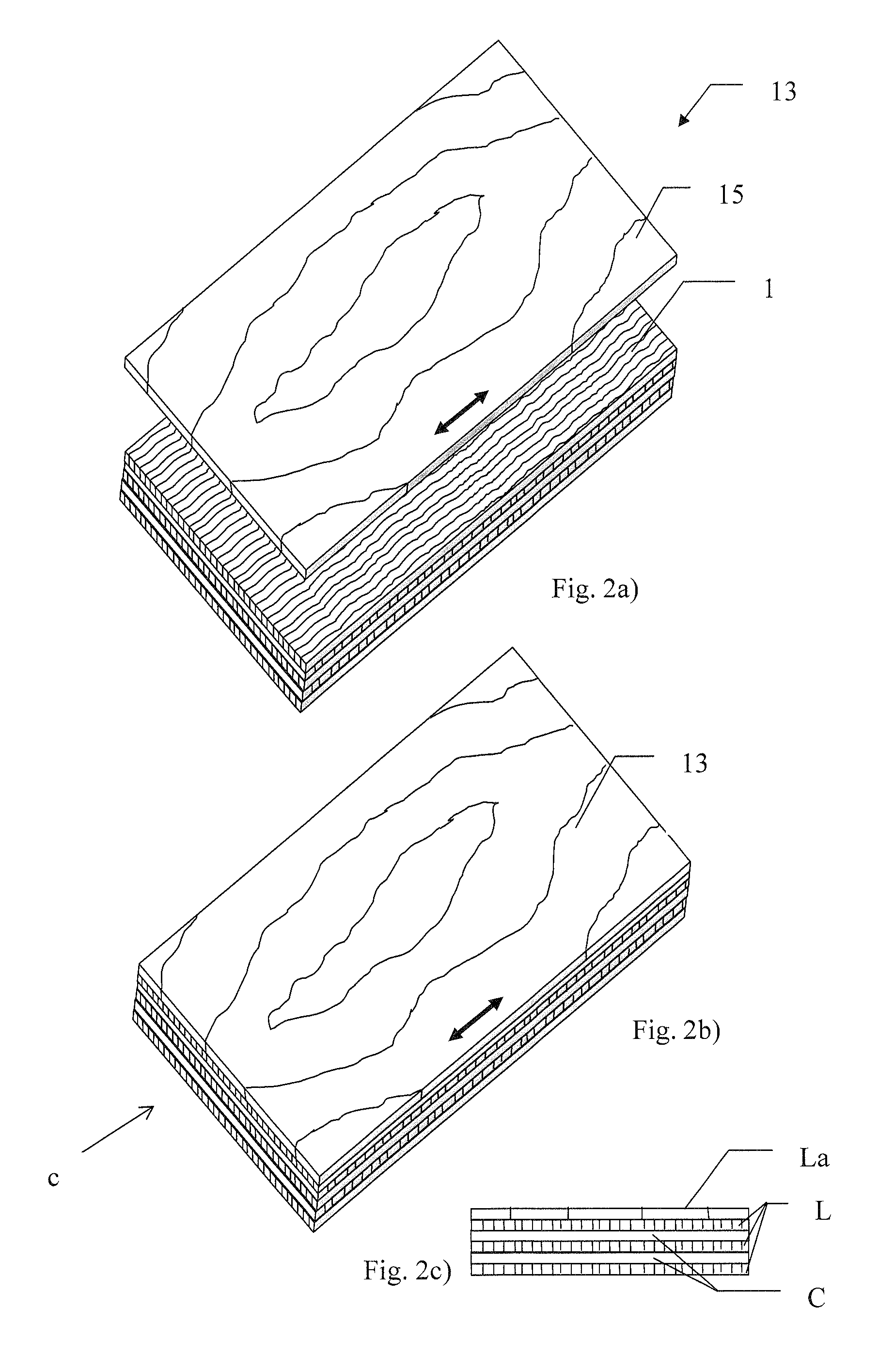

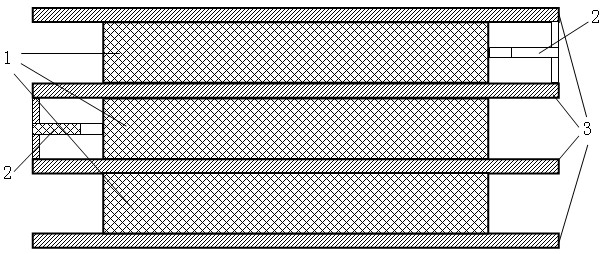

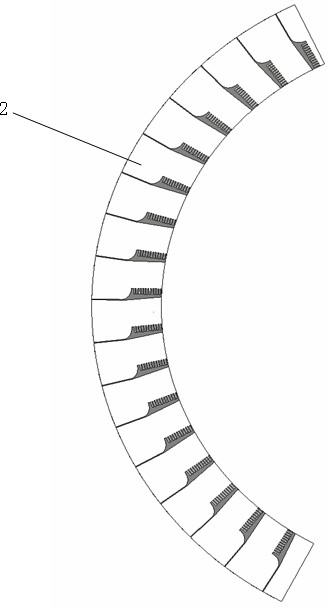

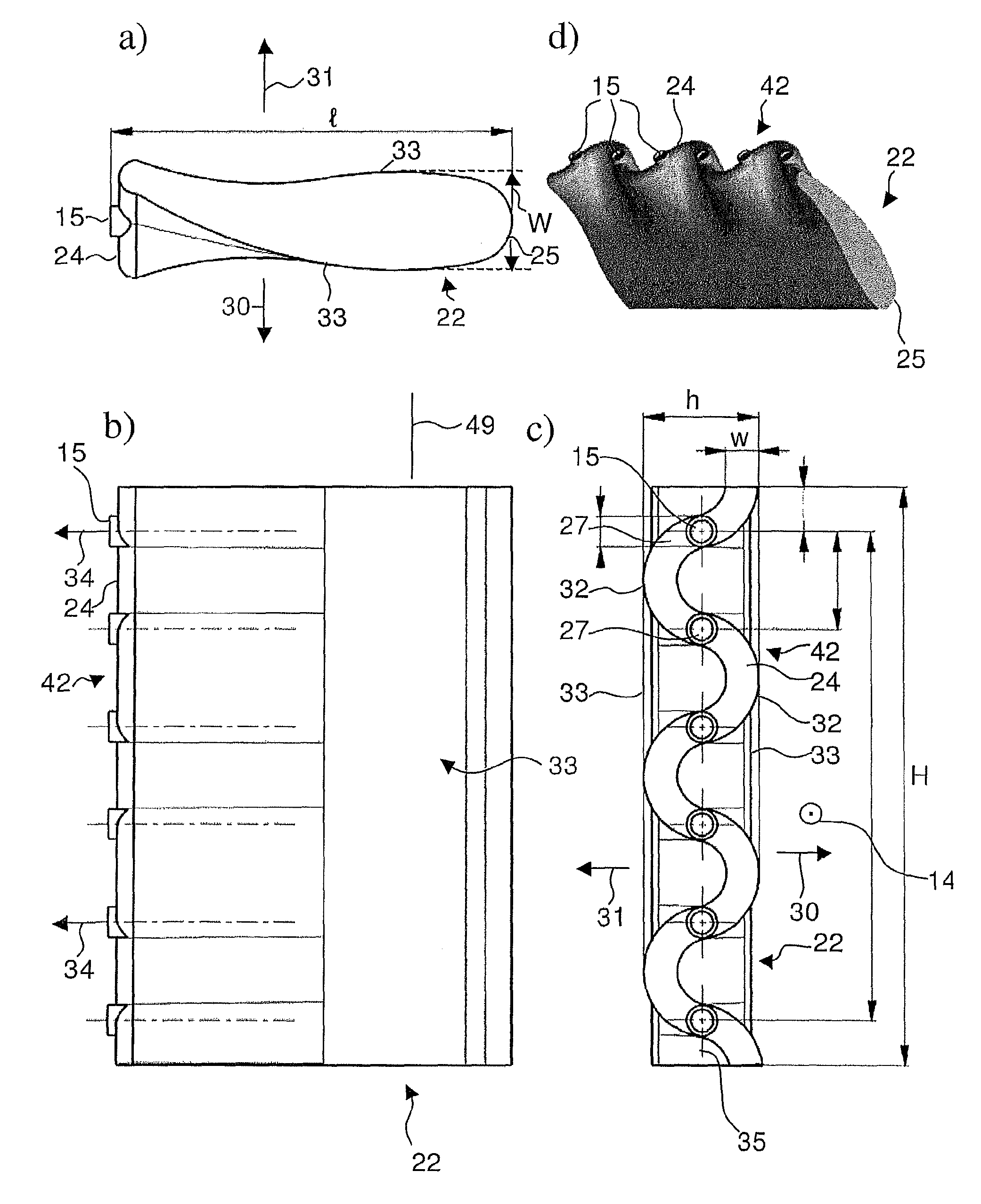

Heat exchange element and heat exchanger produced therewith

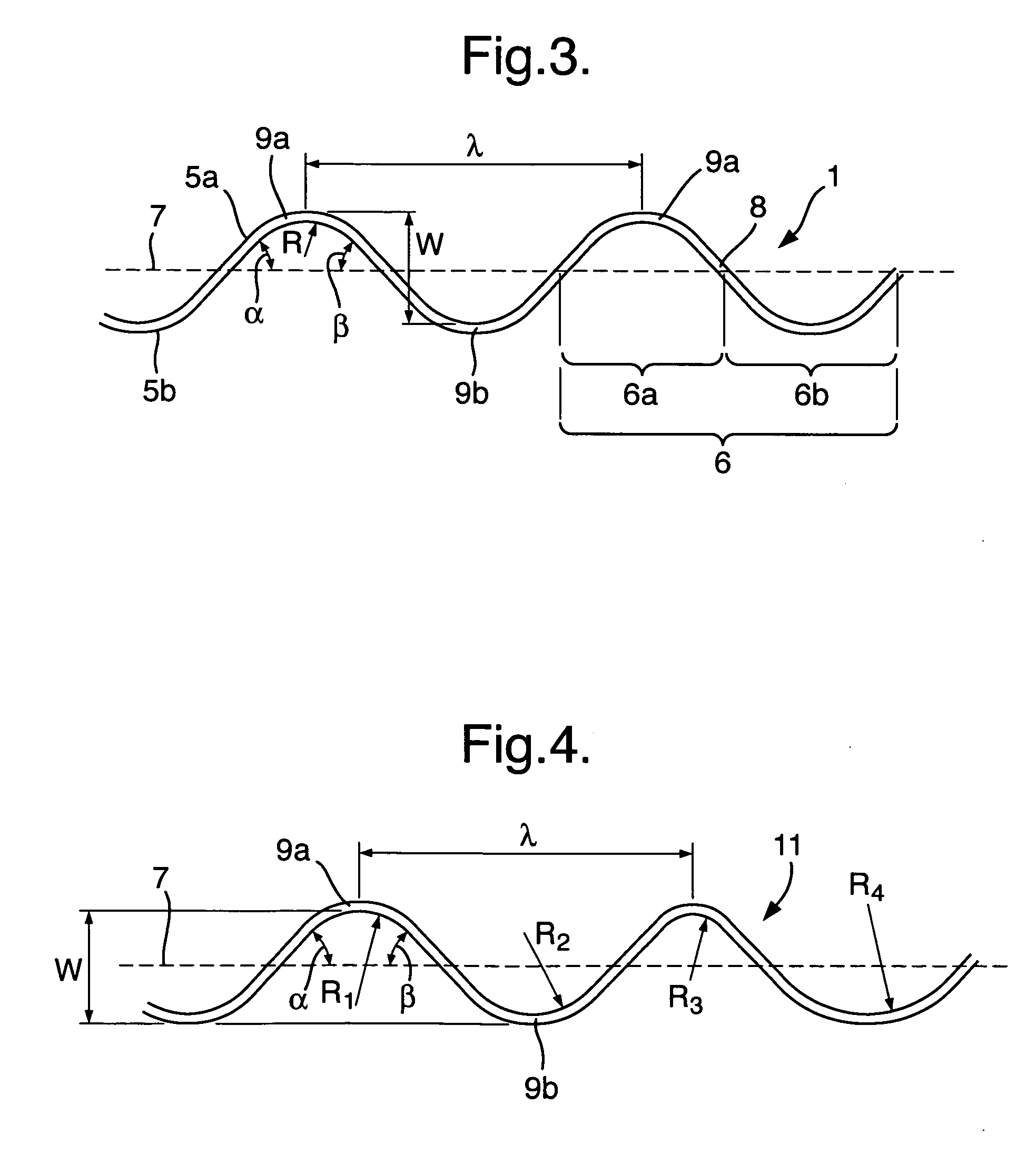

InactiveUS20060289152A1Increase productionReduce total pressure lossStationary conduit assembliesLaminated elementsEngineeringLength wave

A heat exchange element is described having adjacent, heat-transferring, smooth walls (1) which, between each other, delimit flow channels (4) with preselected channel widths (B) for at least one fluid and are provided with undulations (6) which protrude on both sides and transversely relative to imaginary central planes (7), said undulations having preselected wavelengths (λ) as well as apexes (9a, 9b) with radii of curvature (R) and apex spacings (W) measured transversely relative to the central planes (7). According to the invention inequalities 0.1≦B / W≦0.55 and R≧1.2 B apply at least partially to ratios of channel width (B) / apex spacing (W) and channel width (B) / radius of curvature (R) (FIG. 2).

Owner:AUTOKUHLER GMBH & CO KG

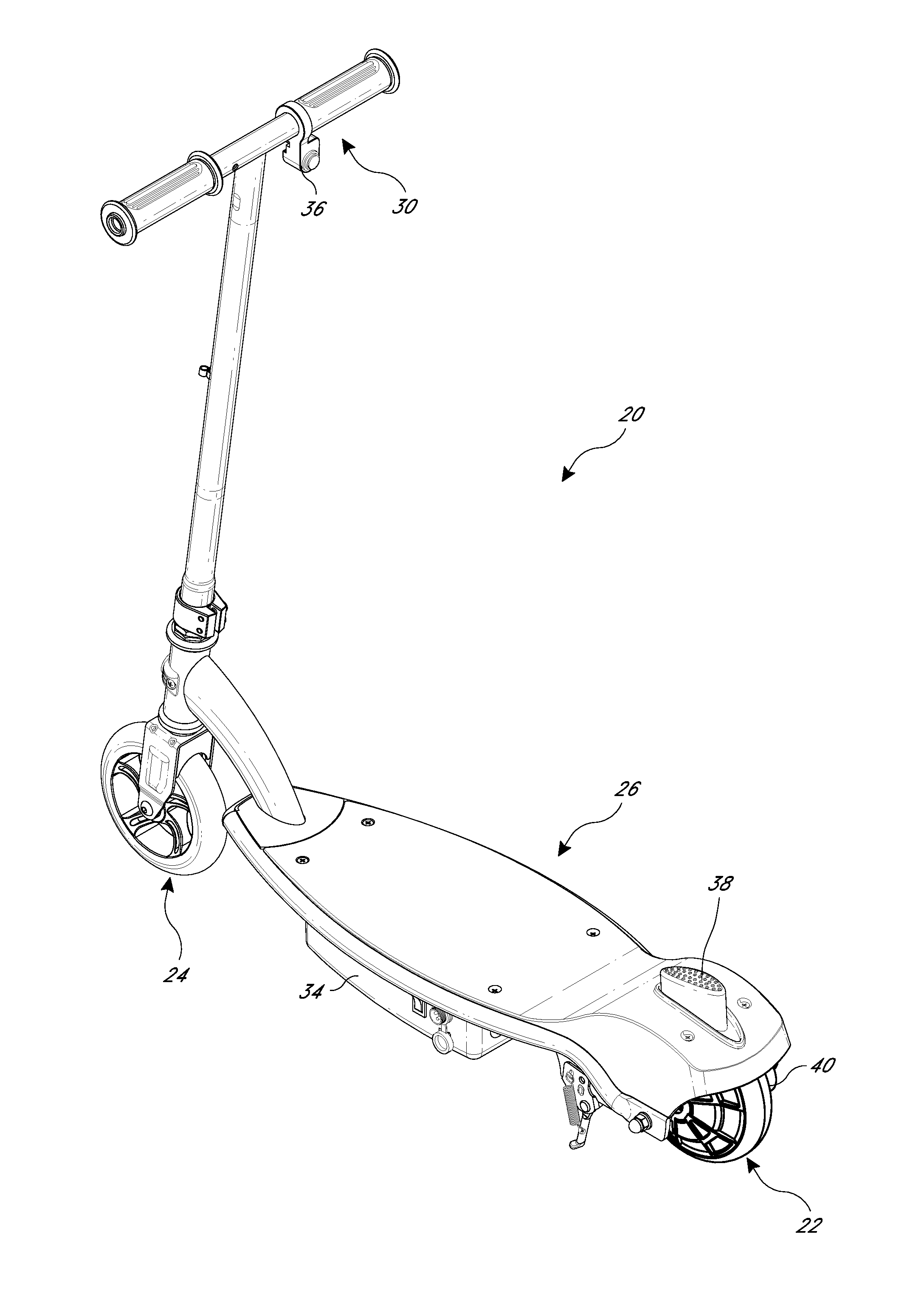

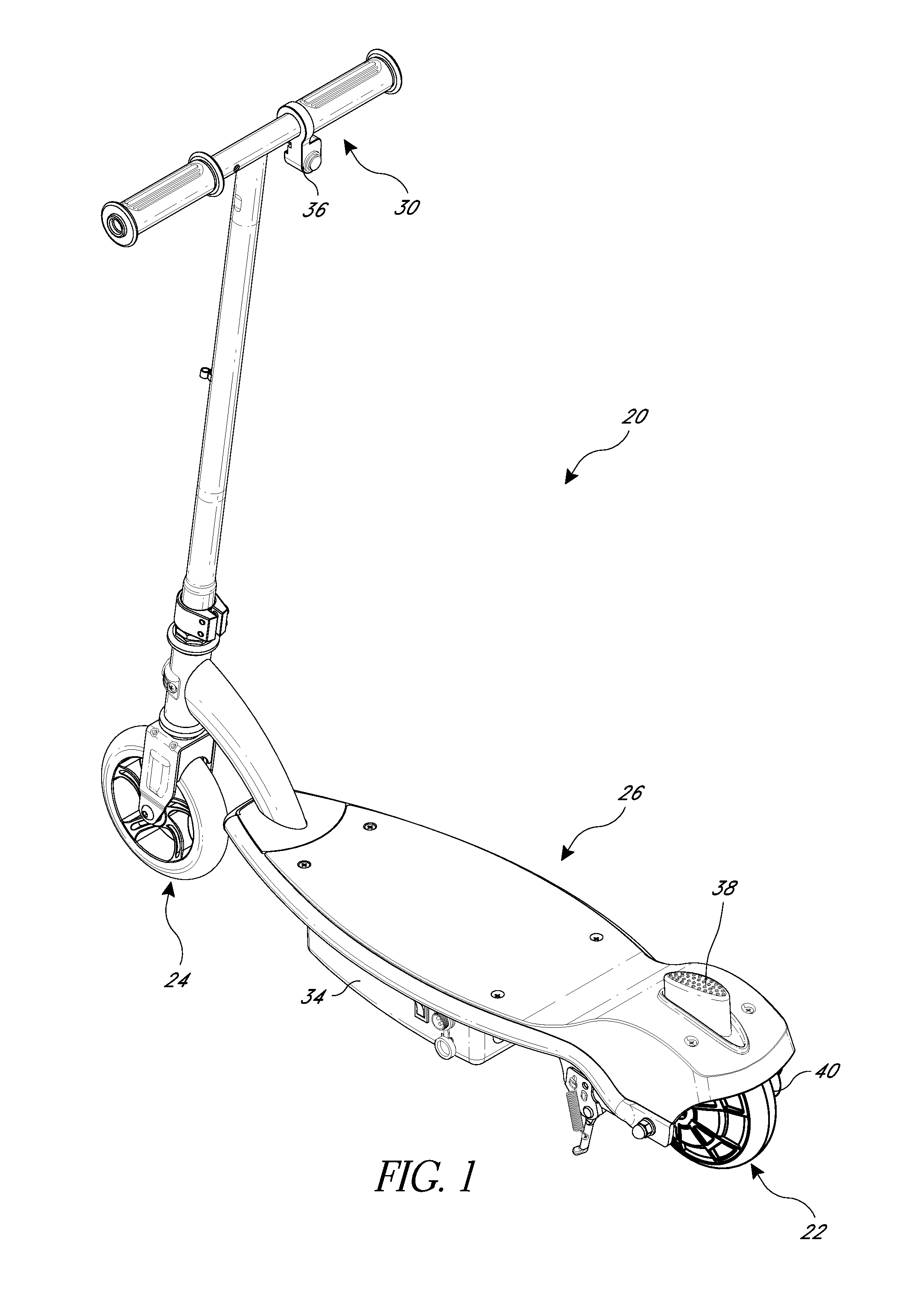

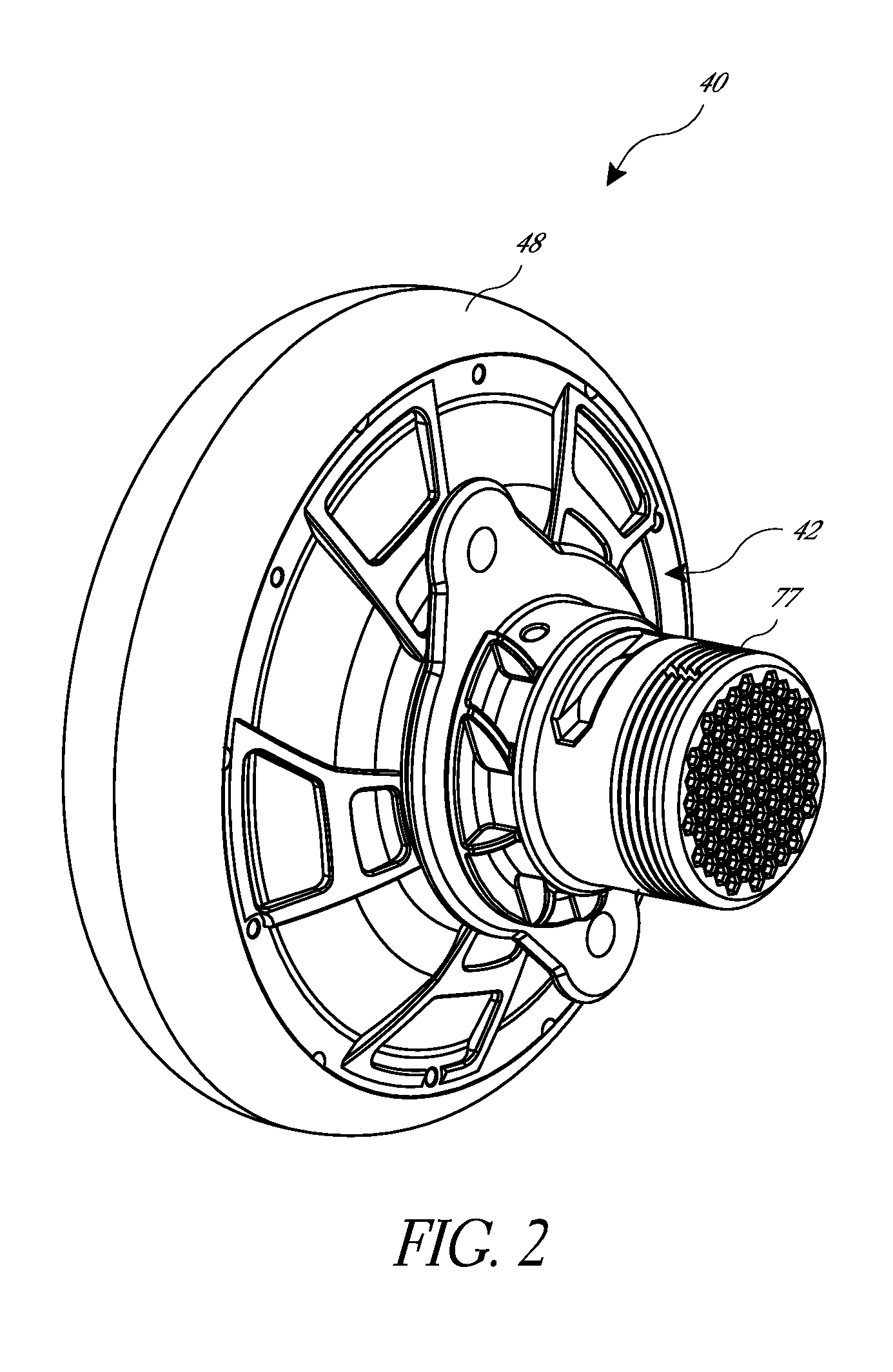

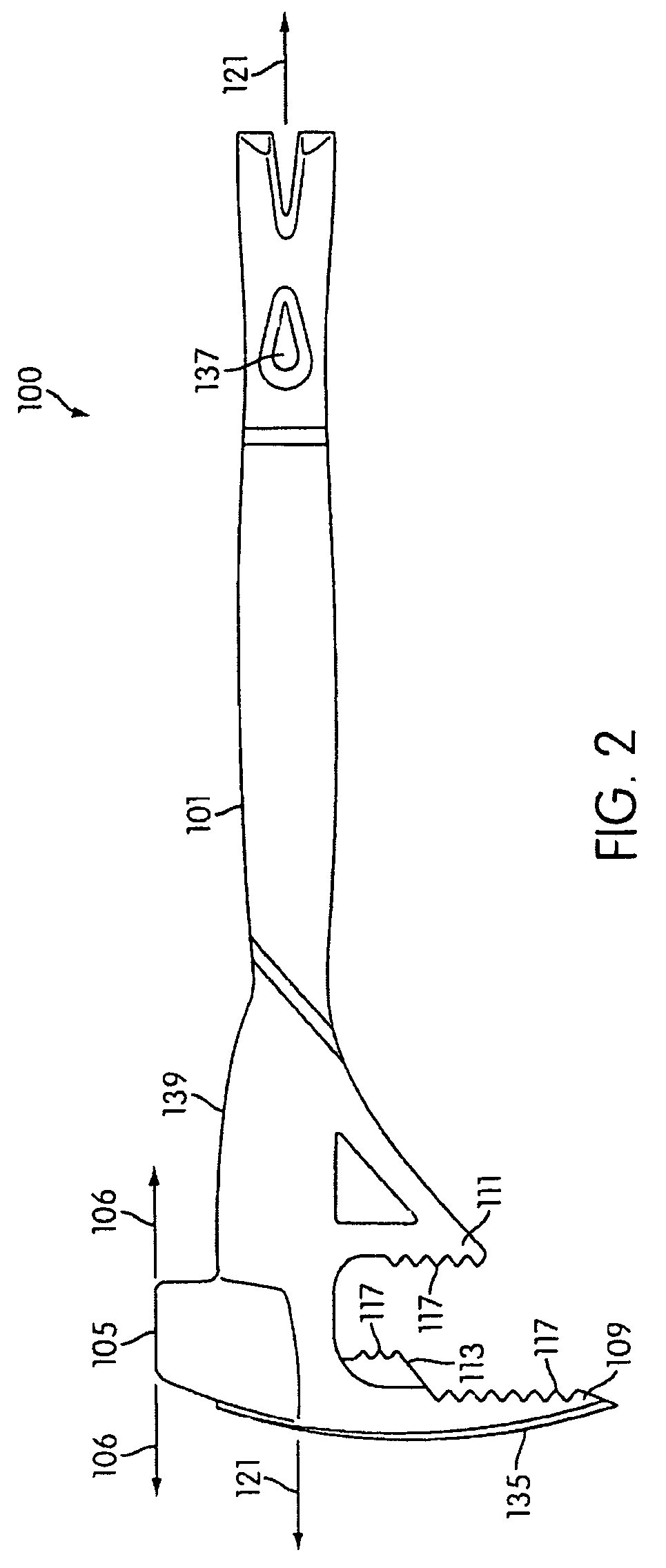

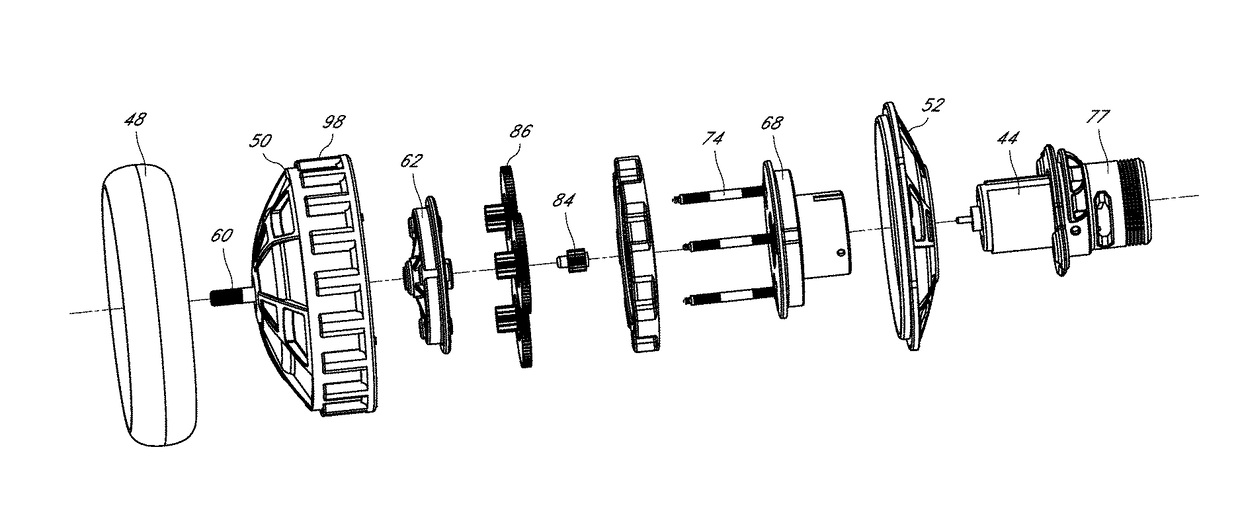

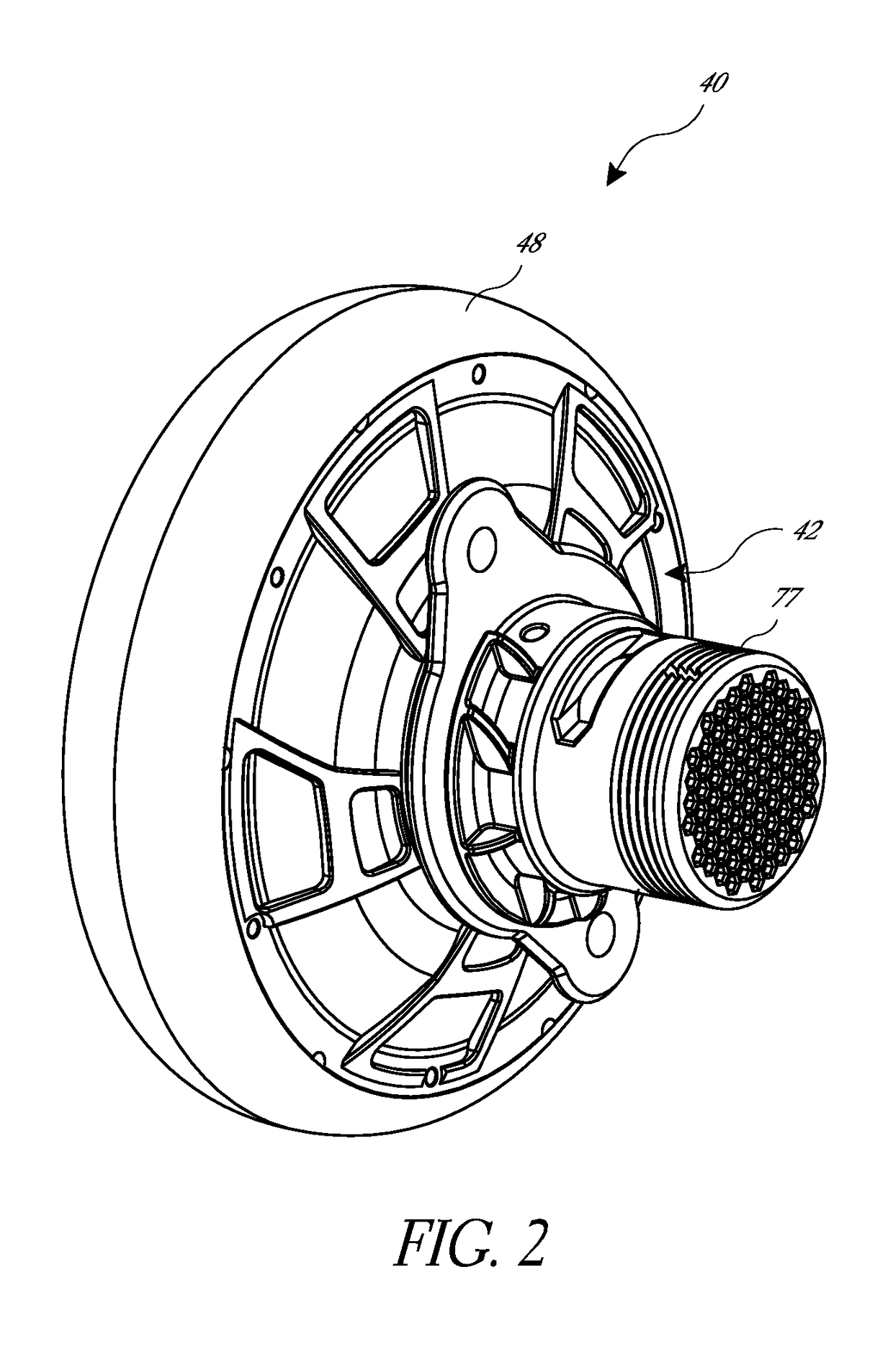

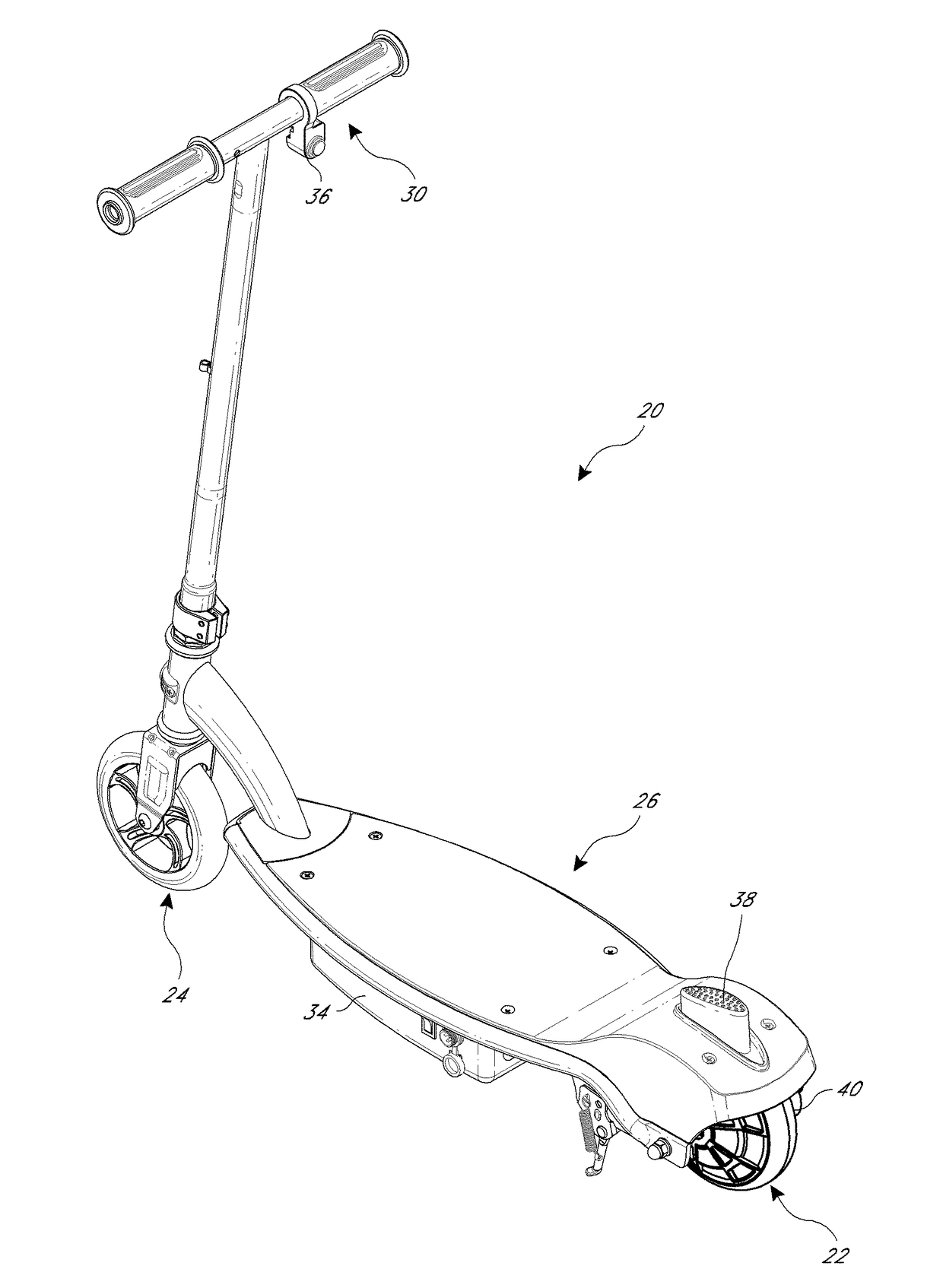

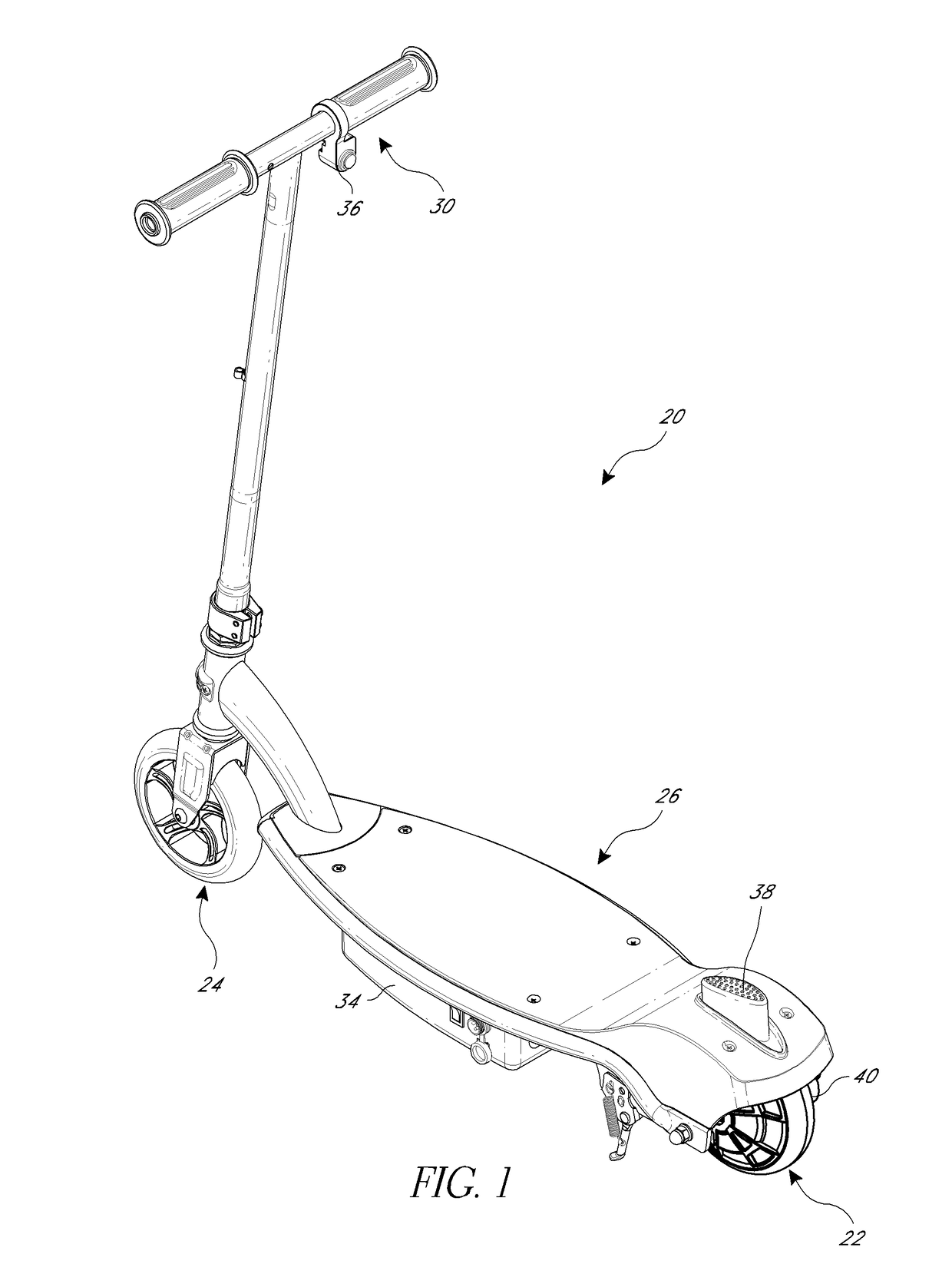

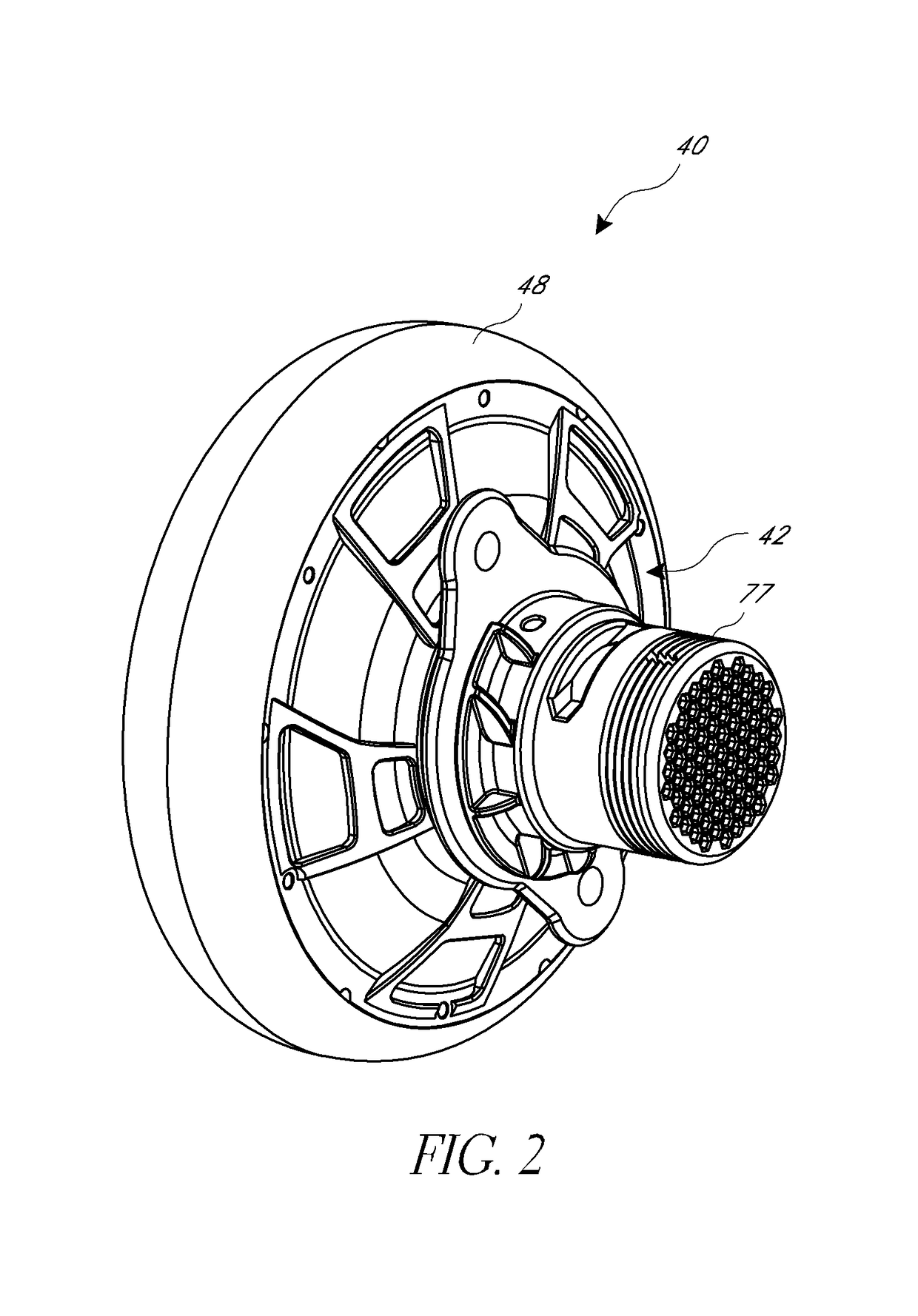

Hub motor arrangement or vehicle with hub motor arrangement

A ride-on vehicle, such as for a child, includes a vehicle body and one or more wheels that support the vehicle body relative to a surface. At least one of the wheels includes a hub motor arrangement that provides a drive torque for propelling the vehicle. The hub motor arrangement includes a housing defining an interior space. An axle or other mounting element(s) define an axis of rotation of the housing. Preferably, the axle or other mounting element(s) do not pass completely through the housing. A motor drives the housing through a transmission. Preferably, the motor is a standard, compact motor that is positioned on the axis of rotation and can be laterally offset from a central plane of the housing. In some embodiments, a traction element is carried directly by the housing.

Owner:RAZOR USA

Double layer papermakers fabric with pockets for bulk enhancement

InactiveUS20070209770A1Reduce penetrationGood sheet formationMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

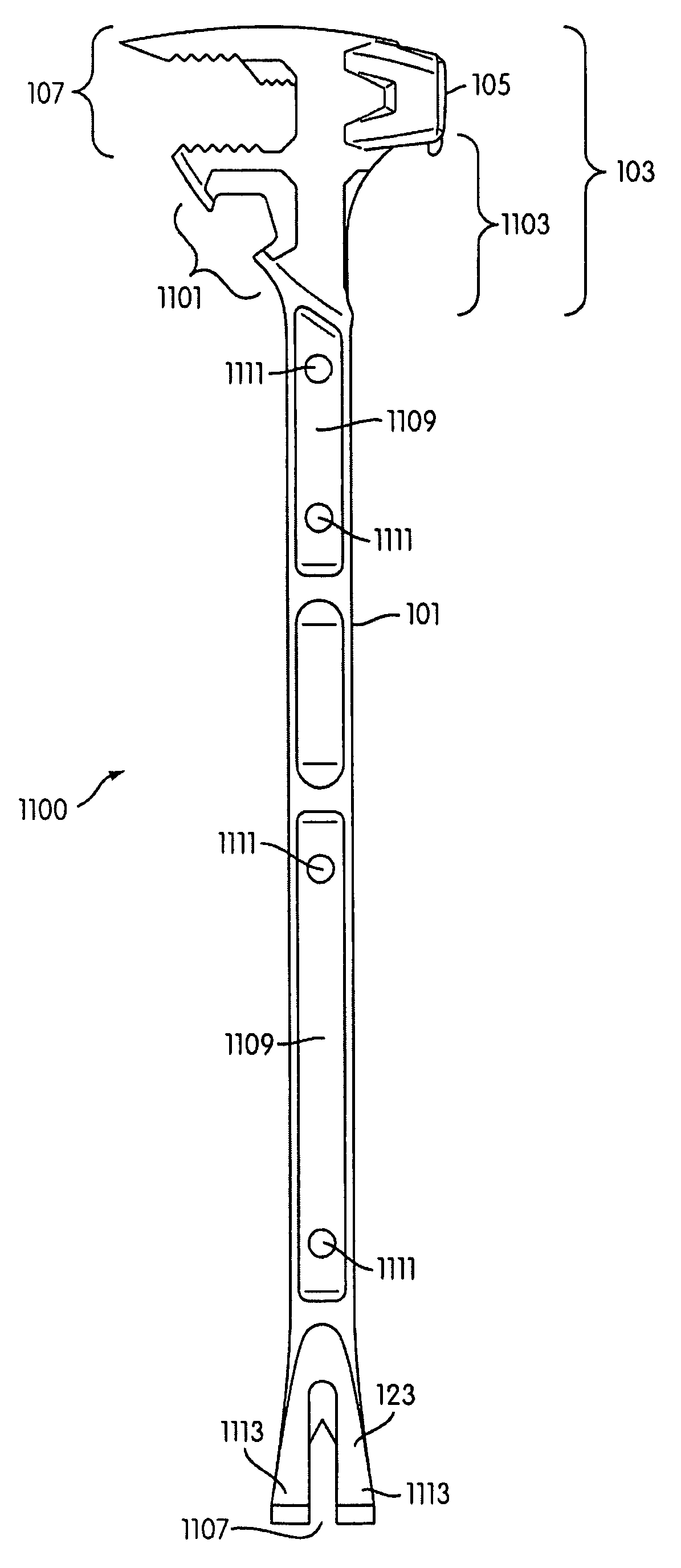

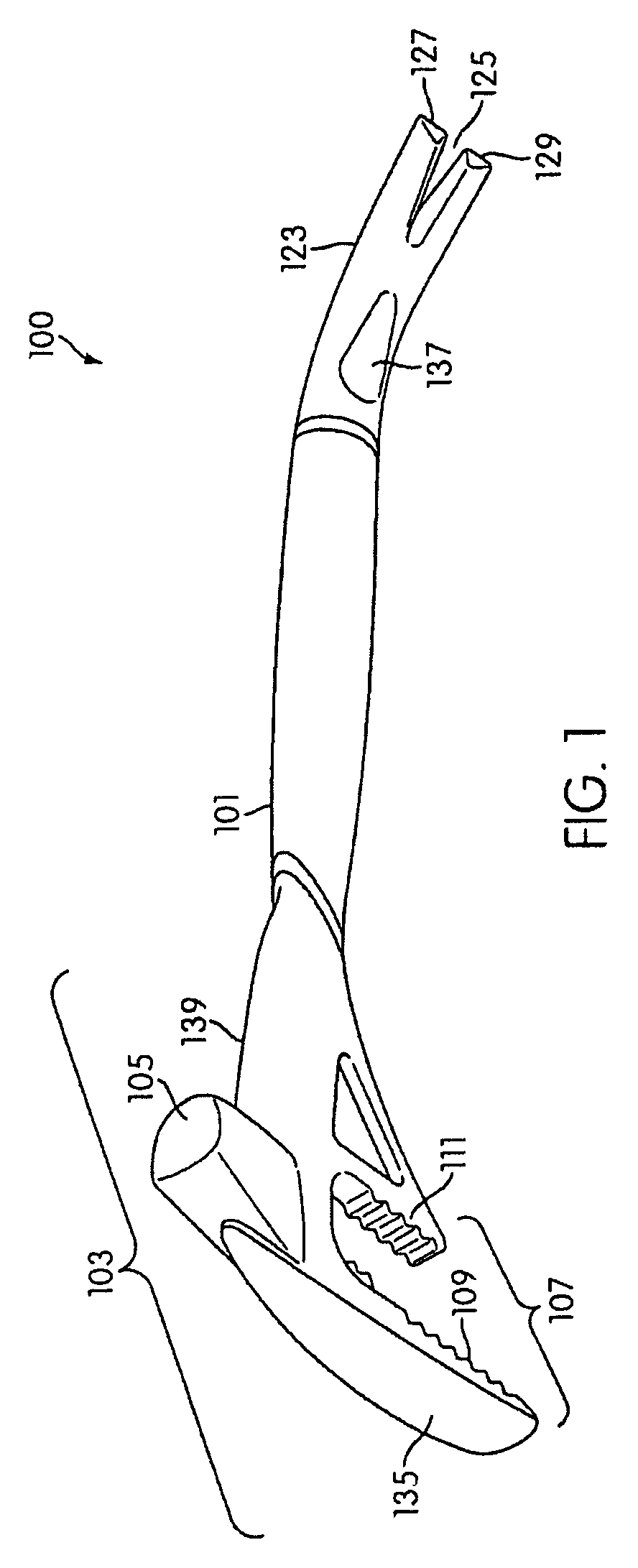

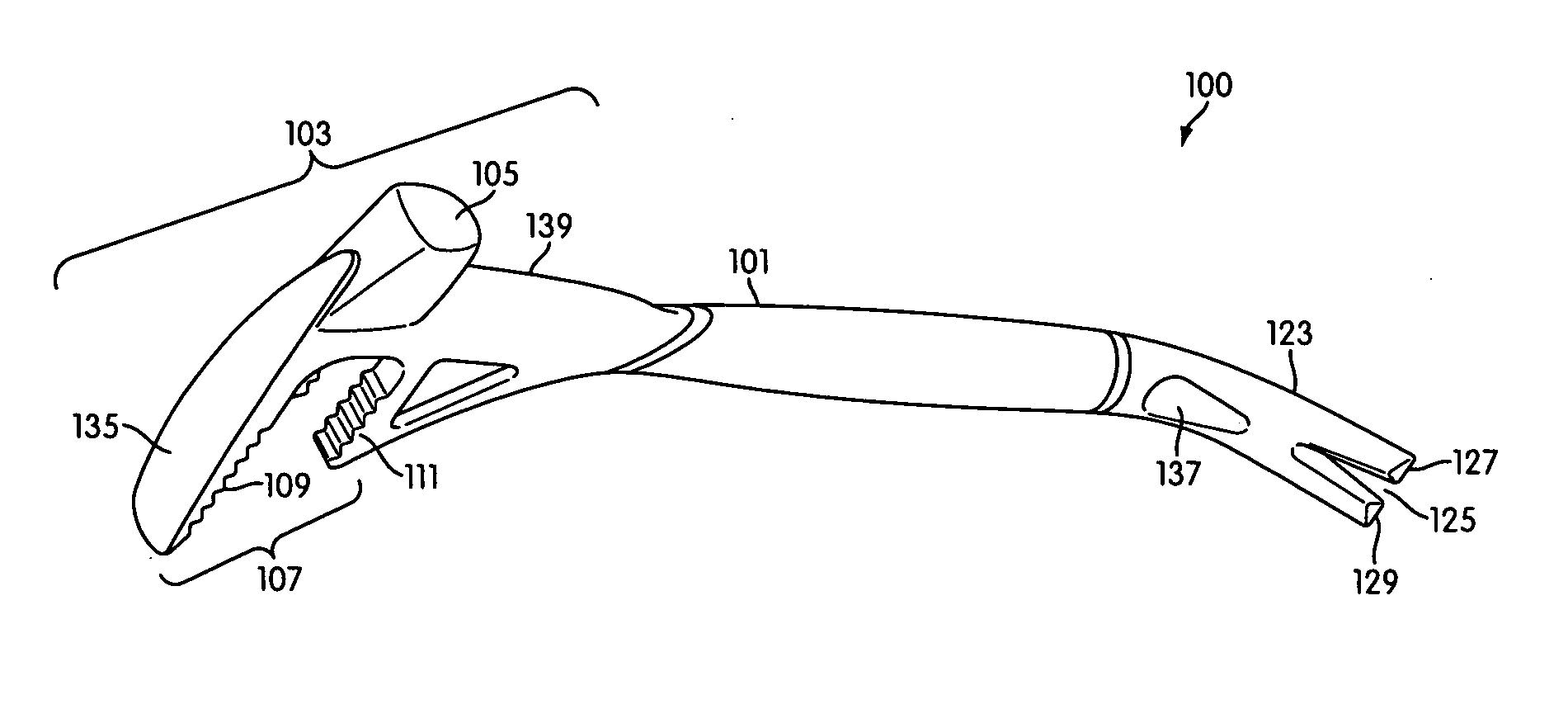

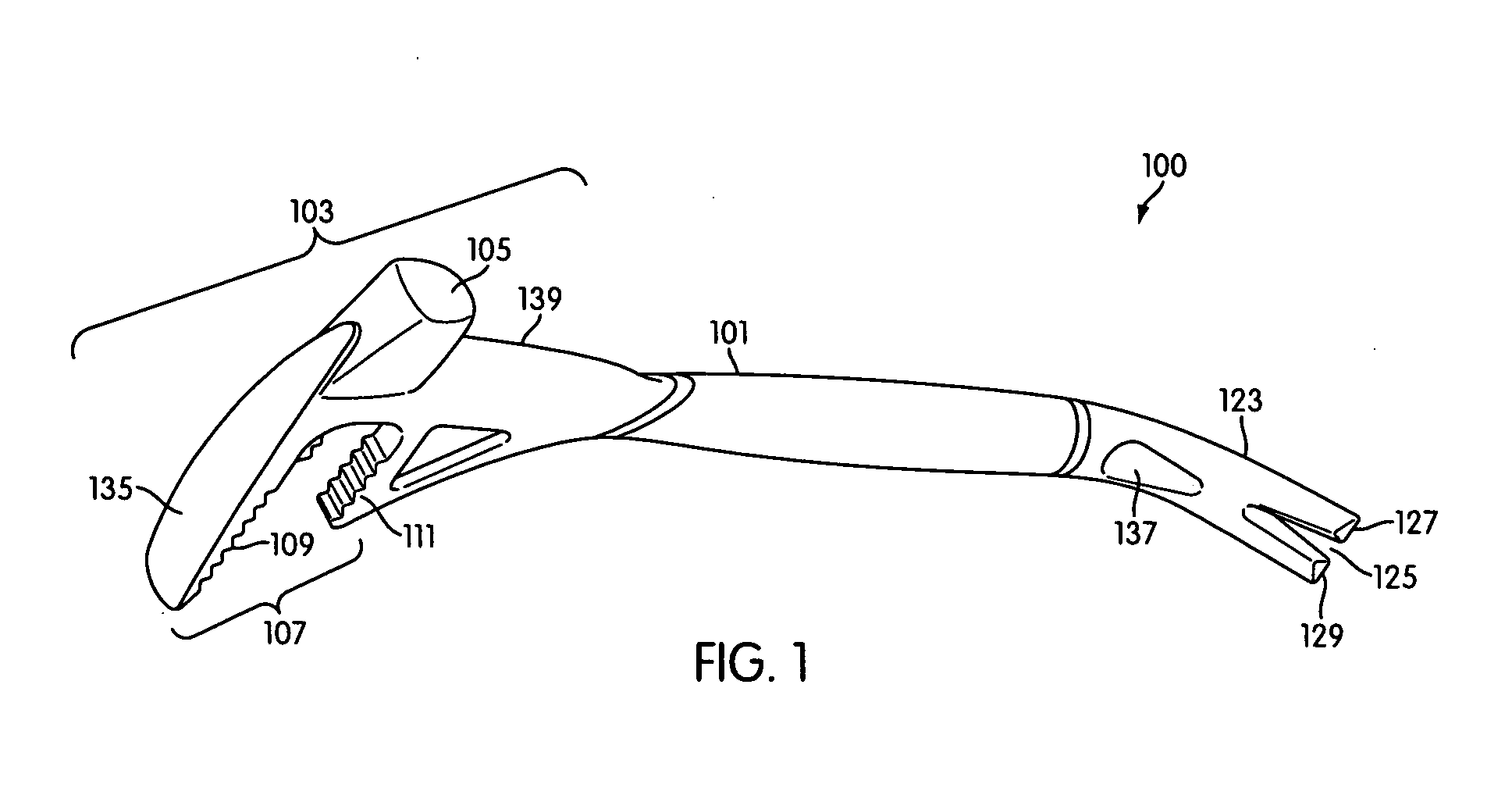

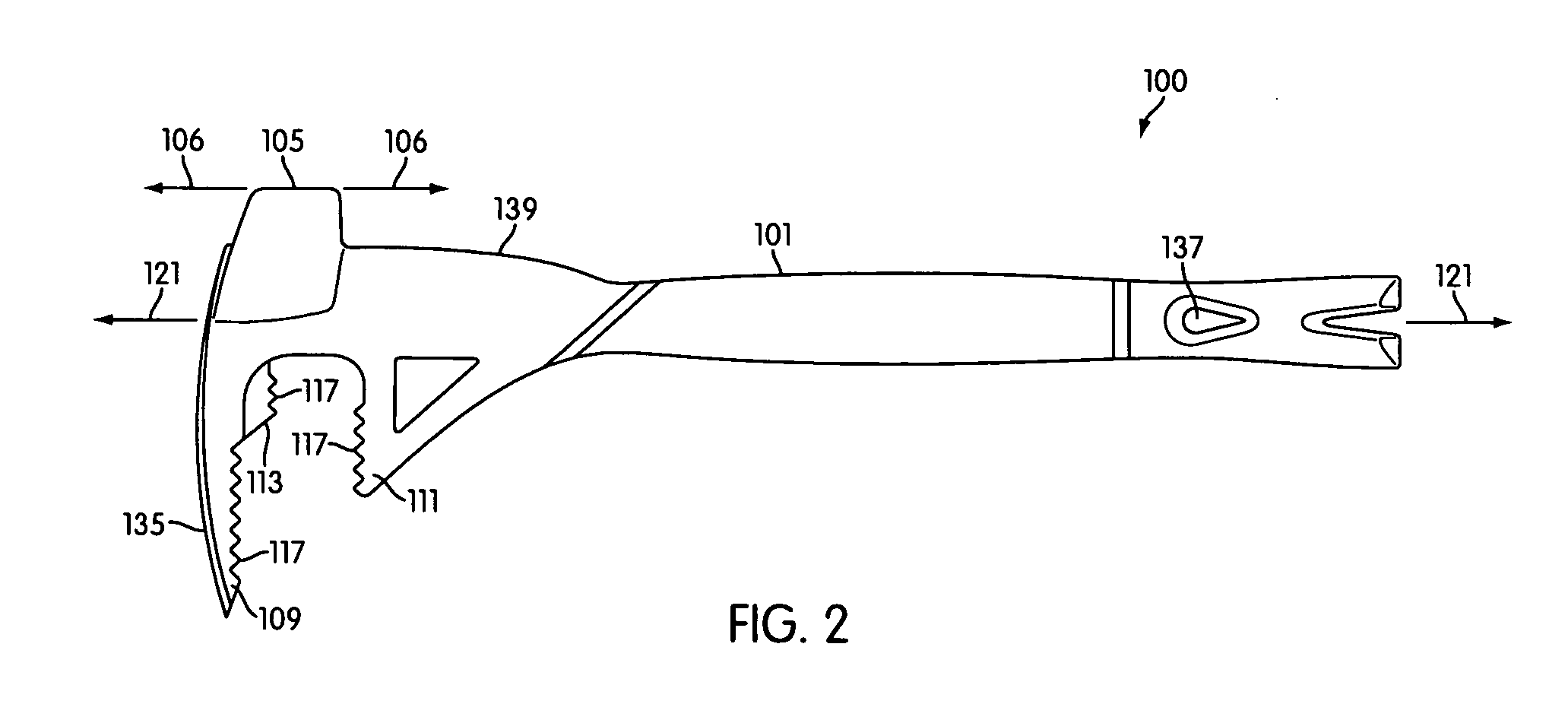

Demolition utility tool

The invention provides a demolition utility tool that can be used in many ways for the demolition of materials and / or for the manipulation of clamps valves, nuts, or other hardware. The tool includes a handle having a head at one end. The head has a longitudinal central plane that bisects the head, a strike contact face, and toothed, stepped grasping jaws that accommodate multiple sizes of material. The demolition tool may include a fixed wrench element and / or a spanner wrench element on the head. The demolition tool may also include a bent end pry bar at a second end of the handle that is offset 90 degrees from the longitudinal central plane of the tool head enabling full range of motion without interfering with other tool functions. The bent end pry bar may include a slot between located between its forked end for manipulating gas shut-off valves.

Owner:STANLEY WORKS THE

Hub motor arrangement or vehicle with hub motor arrangement

A ride-on vehicle, such as for a child, includes a vehicle body and one or more wheels that support the vehicle body relative to a surface. At least one of the wheels includes a hub motor arrangement that provides a drive torque for propelling the vehicle. The hub motor arrangement includes a housing defining an interior space. An axle or other mounting element(s) define an axis of rotation of the housing. Preferably, the axle or other mounting element(s) do not pass completely through the housing. A motor drives the housing through a transmission. Preferably, the motor is a standard, compact motor that is positioned on the axis of rotation and can be laterally offset from a central plane of the housing. In some embodiments, a traction element is carried directly by the housing.

Owner:RAZOR USA

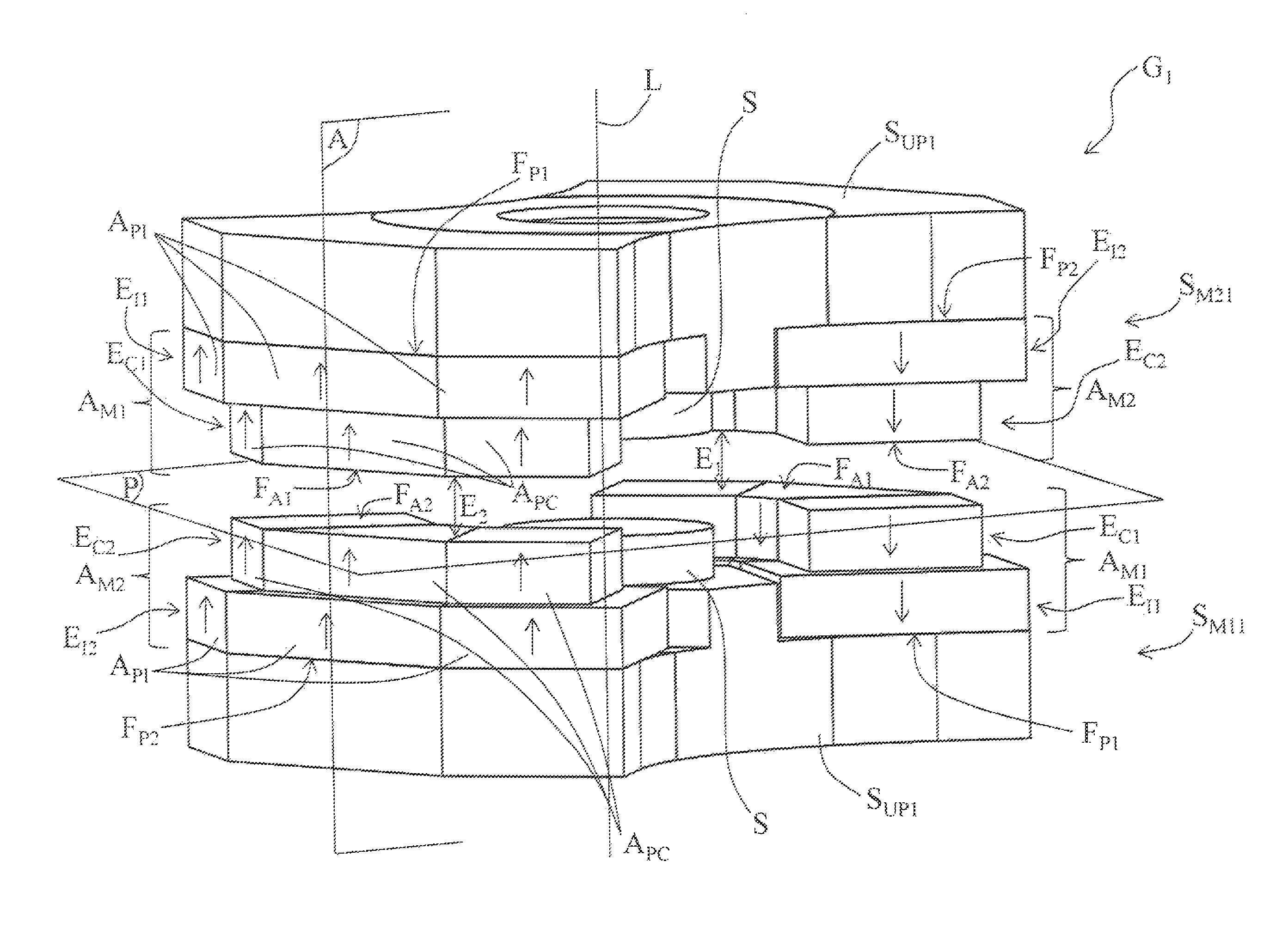

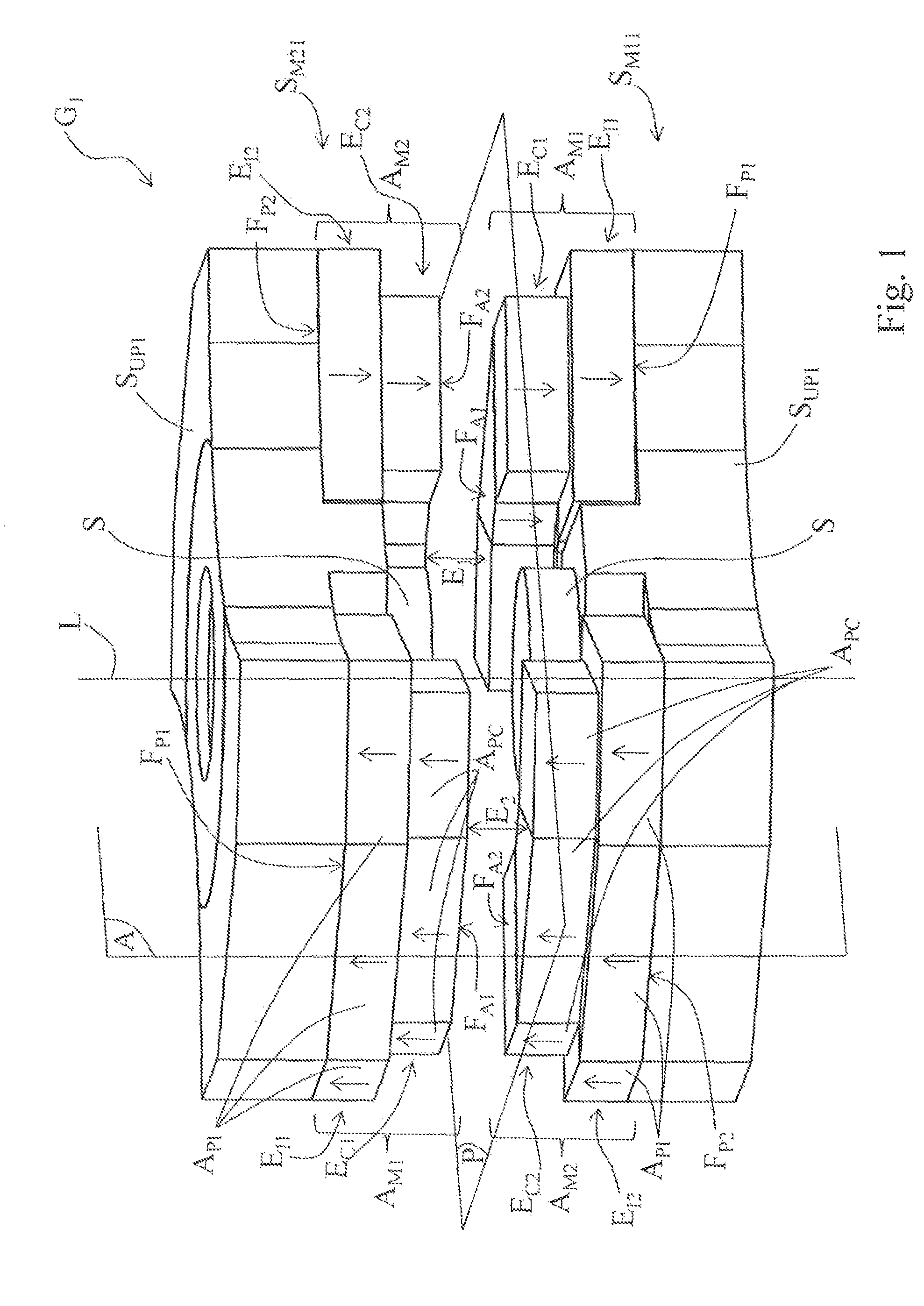

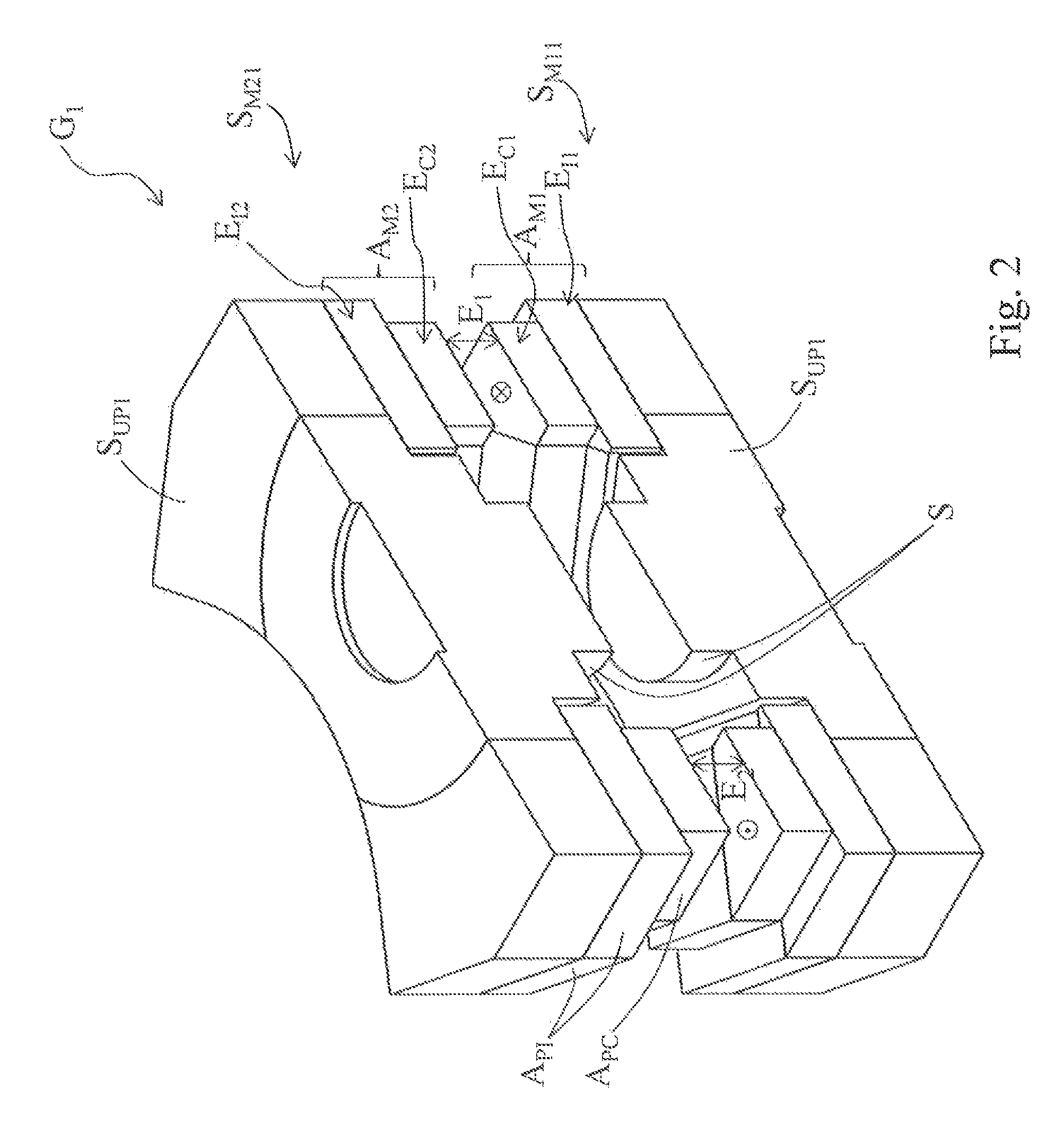

Magnetic field generator for a magnetocaloric thermal device, and magnetocaloric thermal device equipped with such a generator

ActiveUS9548151B2Easy to manufactureSimple geometryEnergy efficient heating/coolingPermanent magnetsEngineeringMagnet

A magnetic field generator (G1) for a magnetocaloric thermal device which comprises first (SM11) and second (SM21) identical magnetizing structures mounted head-to-tail, on either side of a central plane (P) and defining two air gaps (E1, E2). Each magnetizing structure (SMM11, SM12) comprises first (AM1) and second (AM2) magnetizing assemblies, whose induction vectors are oriented in opposite directions, and mounted on a support (SUP1). Each magnetizing assembly (AM1, AM2) has a permanent magnet structure (API, APC) which comprises a passive side (FP1, FP2) and an active side (FA1, FA2), delimiting the air gaps (E1, E2). The induction vectors of the first (AM1, AM19) and the second (AM2, AM29) magnetizing assemblies, form inside the generator, a single circulation loop of a magnetic field through the supports (SUP1) and the air gaps (E1, E2, E3, E4).

Owner:FRANCE BREVETS SAS

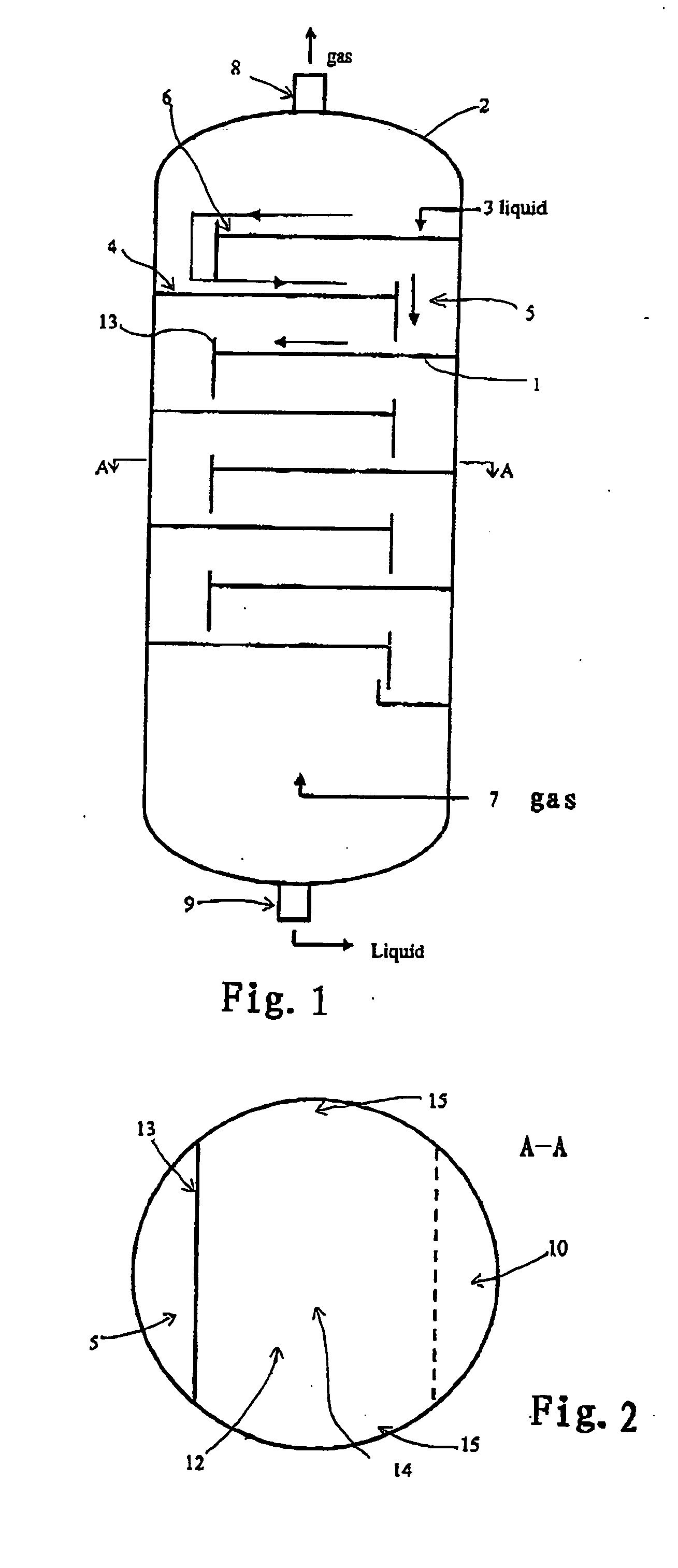

Gas-liquid contact tray with fixed valves for mass transfer

InactiveUS20050280169A1Low liquid entrainmentLow liquid weepingMixing methodsFuel re-atomisation/homogenisationMaterial PerforationVALVE PORT

A gas-liquid contact tray with fixed valves for mass transfer, in which the fixed valve comprising an upstream portion, a midportion and a downstream portion is made by punch from the tray deck so as to form as a deflector, and the upstream portion and the downstream portion are integrated with the tray deck, characterized in that said midportion has a central plane portion and downward inclined margins, and the tray deck is further provided with perforations which are arranged between the fixed valves adjacent in the liquid flow direction. The gas-liquid contact tray with fixed valves for mass transfer according to the present invention has a low liquid entrainment, low liquid weeping, a high mass transfer capacity and good turn-down characteristics.

Owner:CHINA PETROCHEMICAL CORP +1

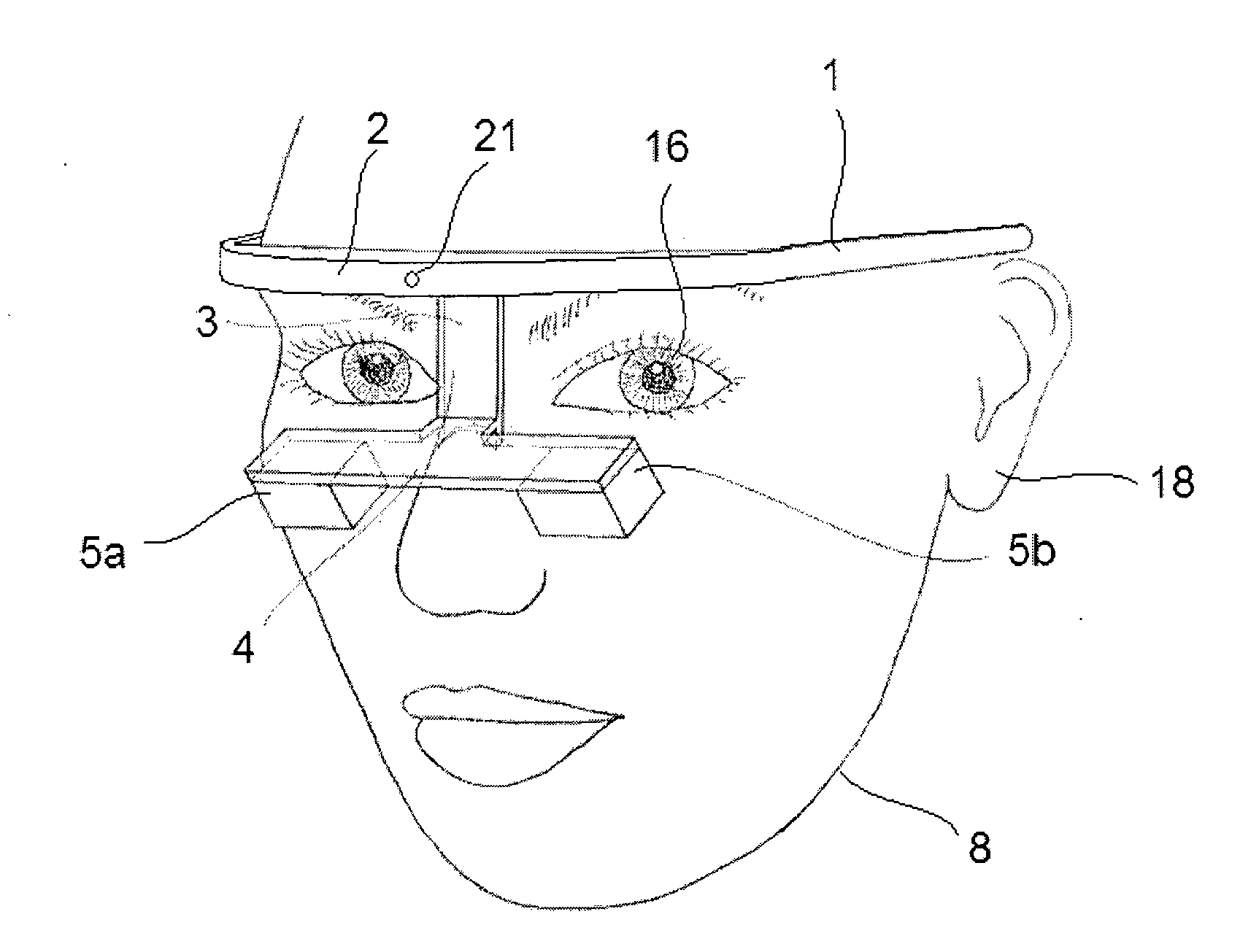

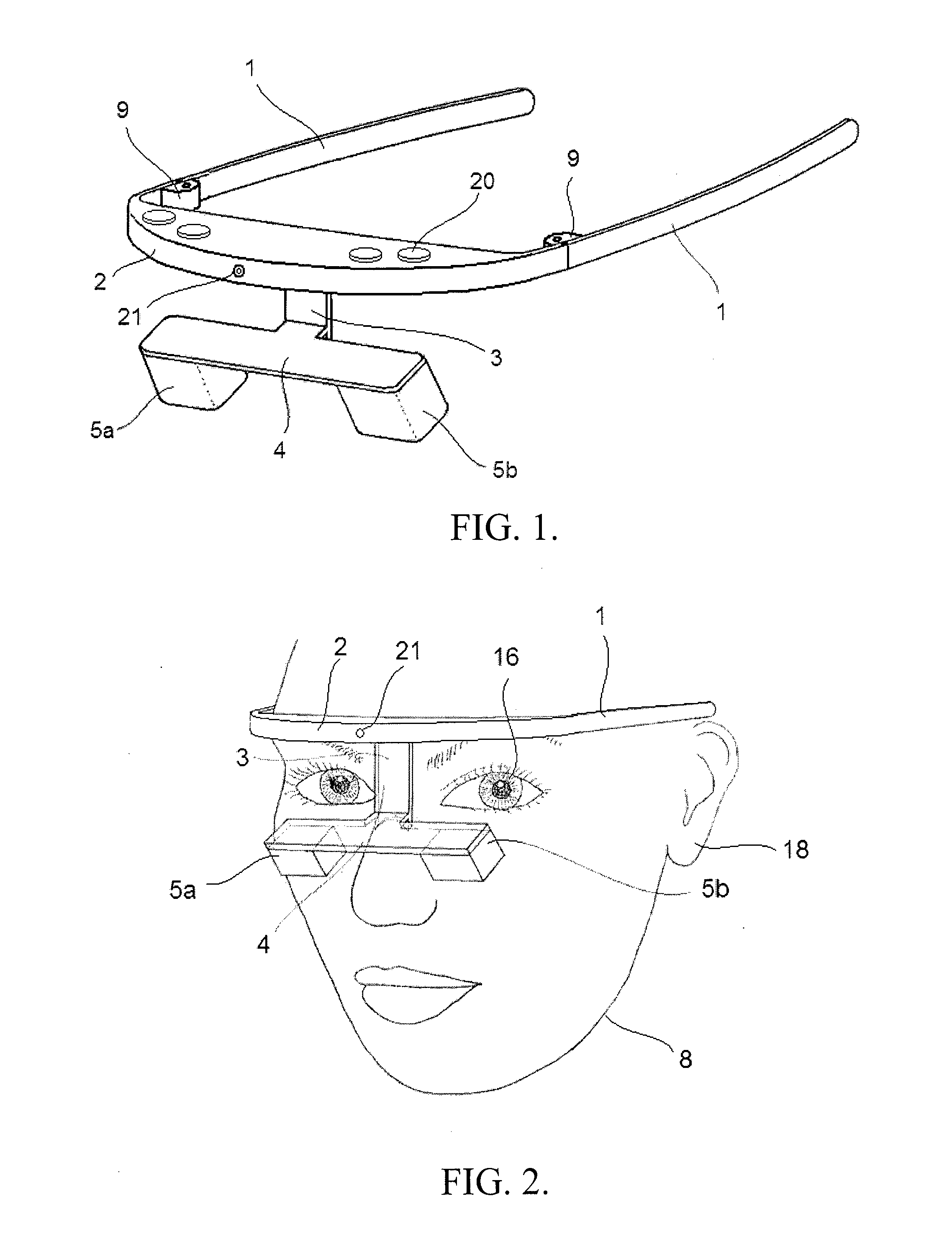

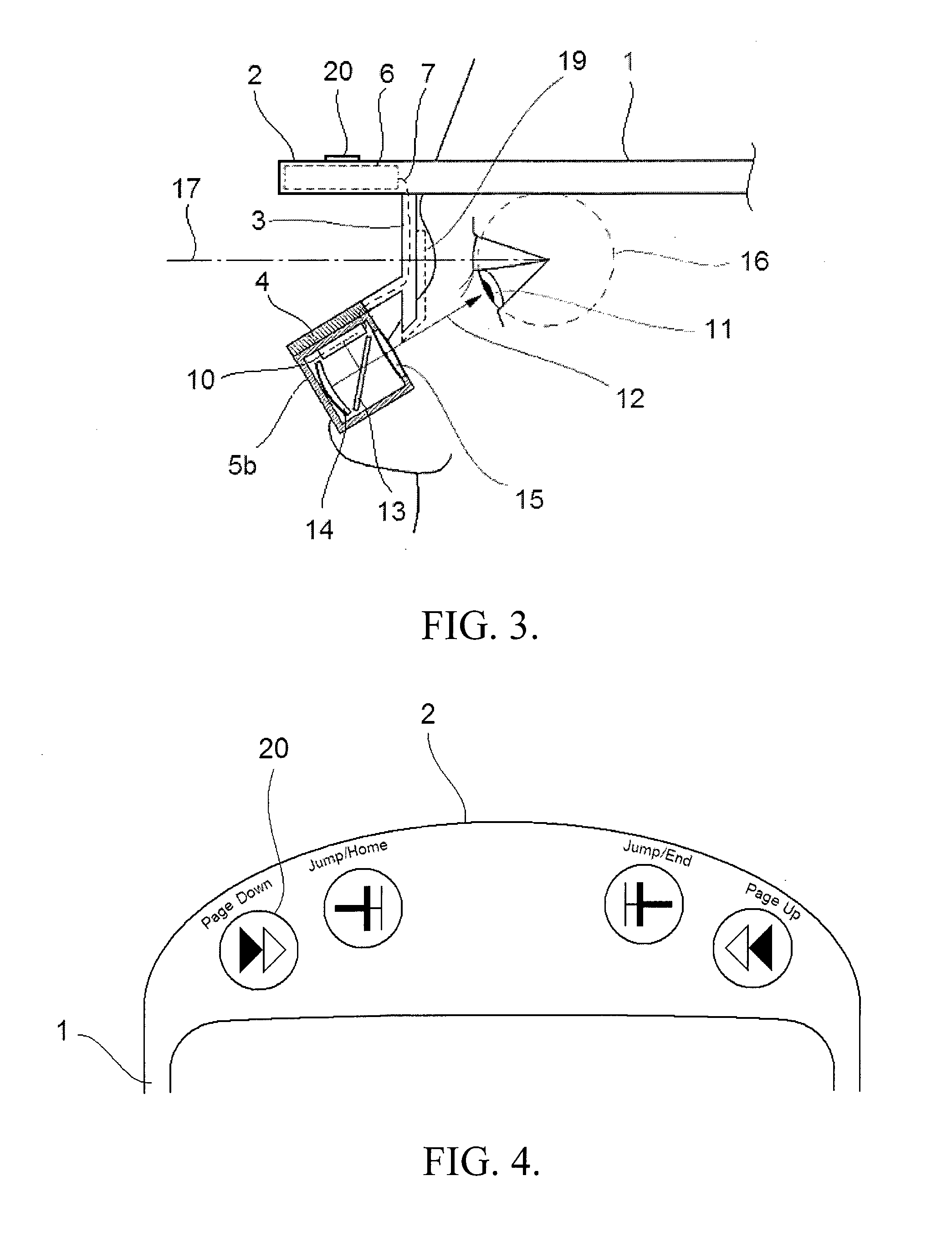

Free-horizon binocular image display device with integrated video signal source

InactiveUS20120280893A1Reduce image generation errorEliminate riskCathode-ray tube indicatorsOptical elementsHorizonDisplay device

A binocular display device comprises a head-mounted supporting frame and two image display blocks arranged below eye level, said blocks comprising a display and a magnifying optical system. The device further comprises a case arranged above eye level, a transversal console arranged below eye level, said consol projecting from the central plane of the head, wherein said blocks are fixed to the end portions of the console, a bridging element adapted to rigidly connect a bottom central part of the case to a central part of the console, said bridging element being arranged between the eyes and extending immediately adjacent the head and leaning, at its lower end, directly or indirectly against the nose ridge. The device further comprises a video signal source arranged in the case, and a plurality of wires extending from the video signal source through the bridging element and the console to the displays.

Owner:SANDOR LORINCZ

Hub motor arrangement or vehicle with hub motor arrangement

A ride-on vehicle, such as for a child, includes a vehicle body and one or more wheels that support the vehicle body relative to a surface. At least one of the wheels includes a hub motor arrangement that provides a drive torque for propelling the vehicle. The hub motor arrangement includes a housing defining an interior space. An axle or other mounting element(s) define an axis of rotation of the housing. Preferably, the axle or other mounting element(s) do not pass completely through the housing. A motor drives the housing through a transmission. Preferably, the motor is a standard, compact motor that is positioned on the axis of rotation and can be laterally offset from a central plane of the housing. In some embodiments, a traction element is carried directly by the housing.

Owner:RAZOR USA

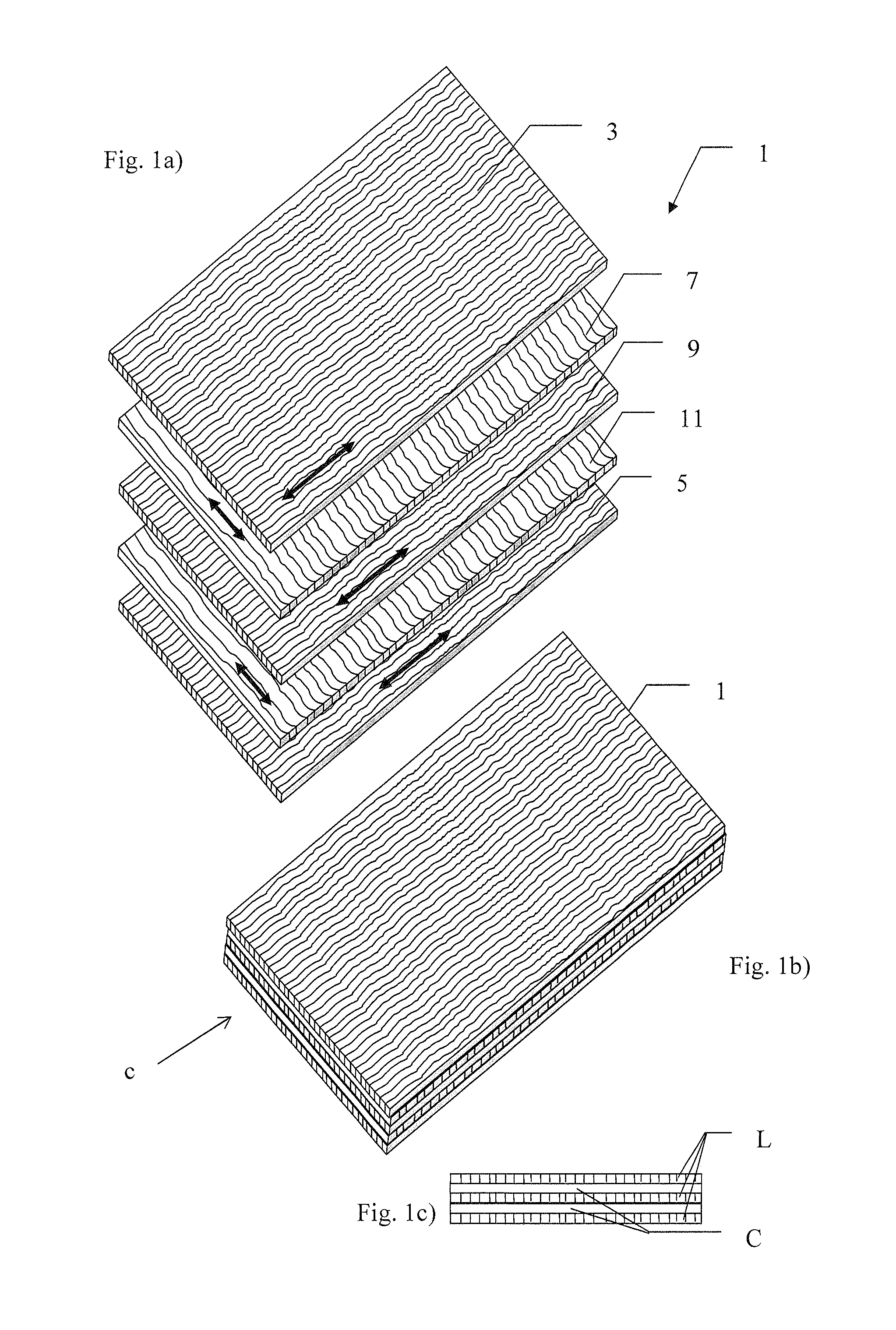

Multi-ply platforms and panels using such a platform

InactiveUS20100326011A1Improve the immunityConstruction materialWood veneer joiningEngineeringRelative humidity

A multi-ply platform suitable for the manufacture of decorative panels and decorative panels incorporating such multi-ply platforms, which has improved resistance to deformation caused by changes in relative humidity and / or temperature of, or around, such decorative panels. This multi-ply platform includes a plurality of plies which are arranged so that the platform is substantially unbalanced around its central plane. The unbalanced platform is achieved by, arranging the plies such that at least two adjacent plies have substantially the same main grain direction and / or that two plies having substantially the same main grain direction are separated only by one or more neutral plies. These unbalanced platforms are intended to be bonded to a further ply to form a substantially balanced decorative panel.

Owner:NORLING HAKAN +1

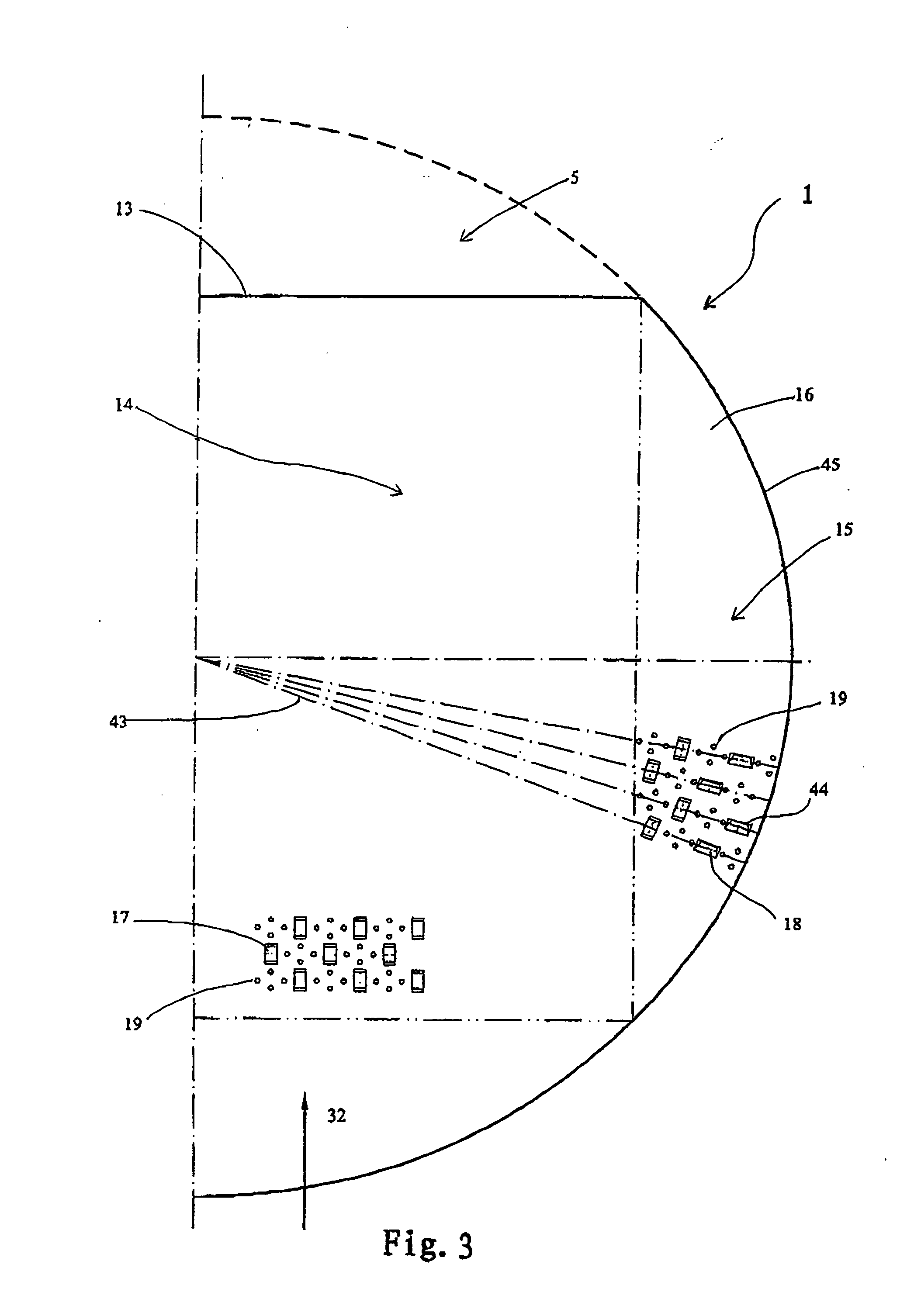

Millimeter-wave 360-DEG omnidirectional-scan dielectric cylinder lens antenna

The invention discloses a millimeter-wave 360-DEG omnidirectional-scan dielectric cylinder lens antenna comprising three dielectric cylinder lenses, three feed source antenna arrays with scan ranges of 120 DEG and four round metal discs. One of the three dielectric cylinder lenses is respectively coaxially arranged among the four round metal discs, one of the three feed source antenna arrays is respectively arranged between the edges of two adjacent round metal discs, the difference between two of the three feed source antenna arrays on a horizontal projection surface is 120 DEG, and a phase central plane of each feed source antenna array is superposed with a focal plane of each dielectric cylinder lens. The invention realizes 360-DEG omnidirectional scan in the horizontal direction; the three dielectric cylinder lens antennas are partitioned by parallel round metal disc-shaped plates, and the scan of each homogeneous dielectric cylinder lens is not interfered by the other two lenses,thus the scanning beam of each layer of cylinder lens antenna is totally consistent; and the millimeter-wave 360-DEG omnidirectional-scan dielectric cylinder lens antenna can be conveniently connected with a printed integrated circuit. The millimeter-wave 360-DEG omnidirectional-scan dielectric cylinder lens antenna is applied to the fields of space flight communication, satellite communication, electronic countermeasure and the like.

Owner:ZHEJIANG UNIV

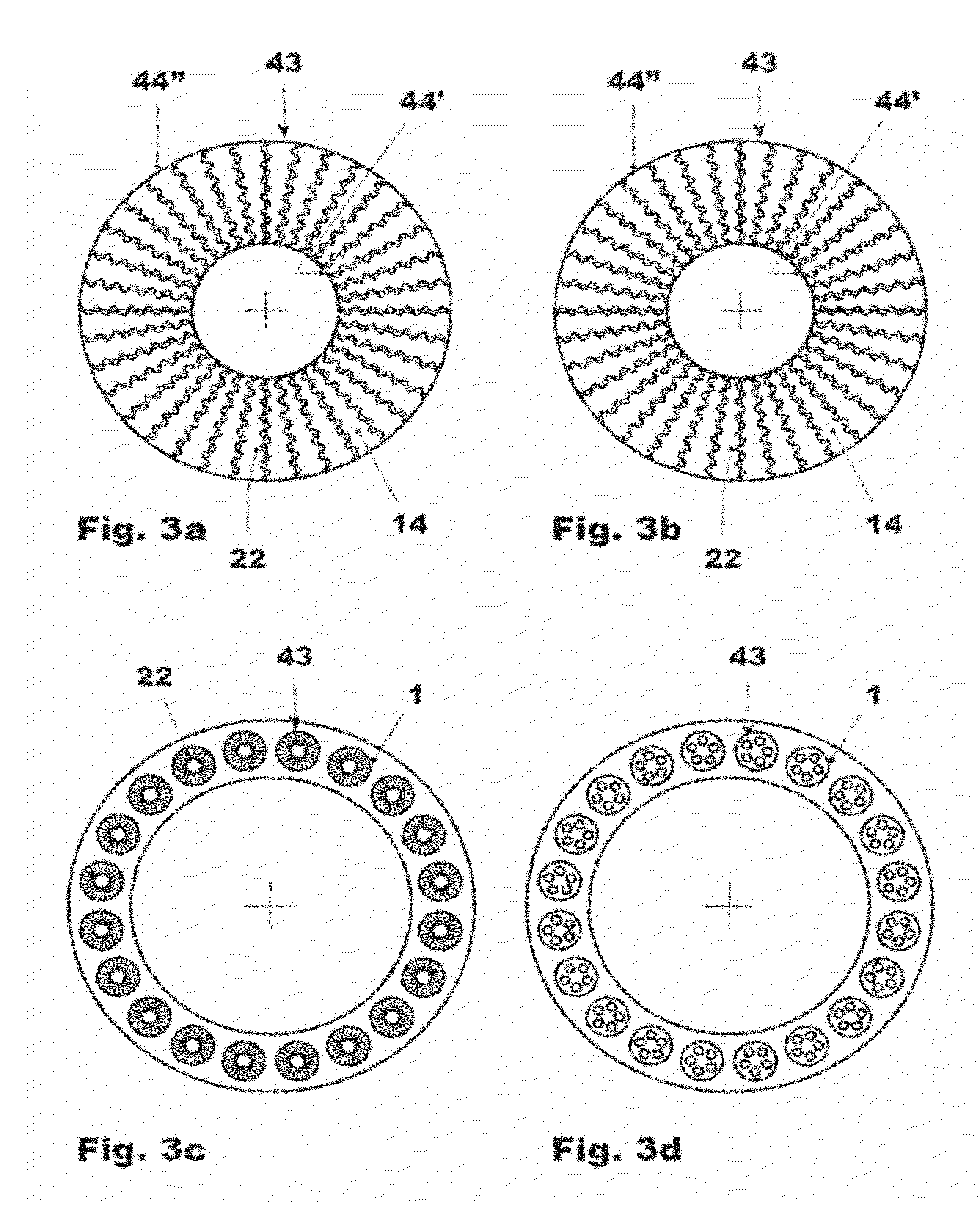

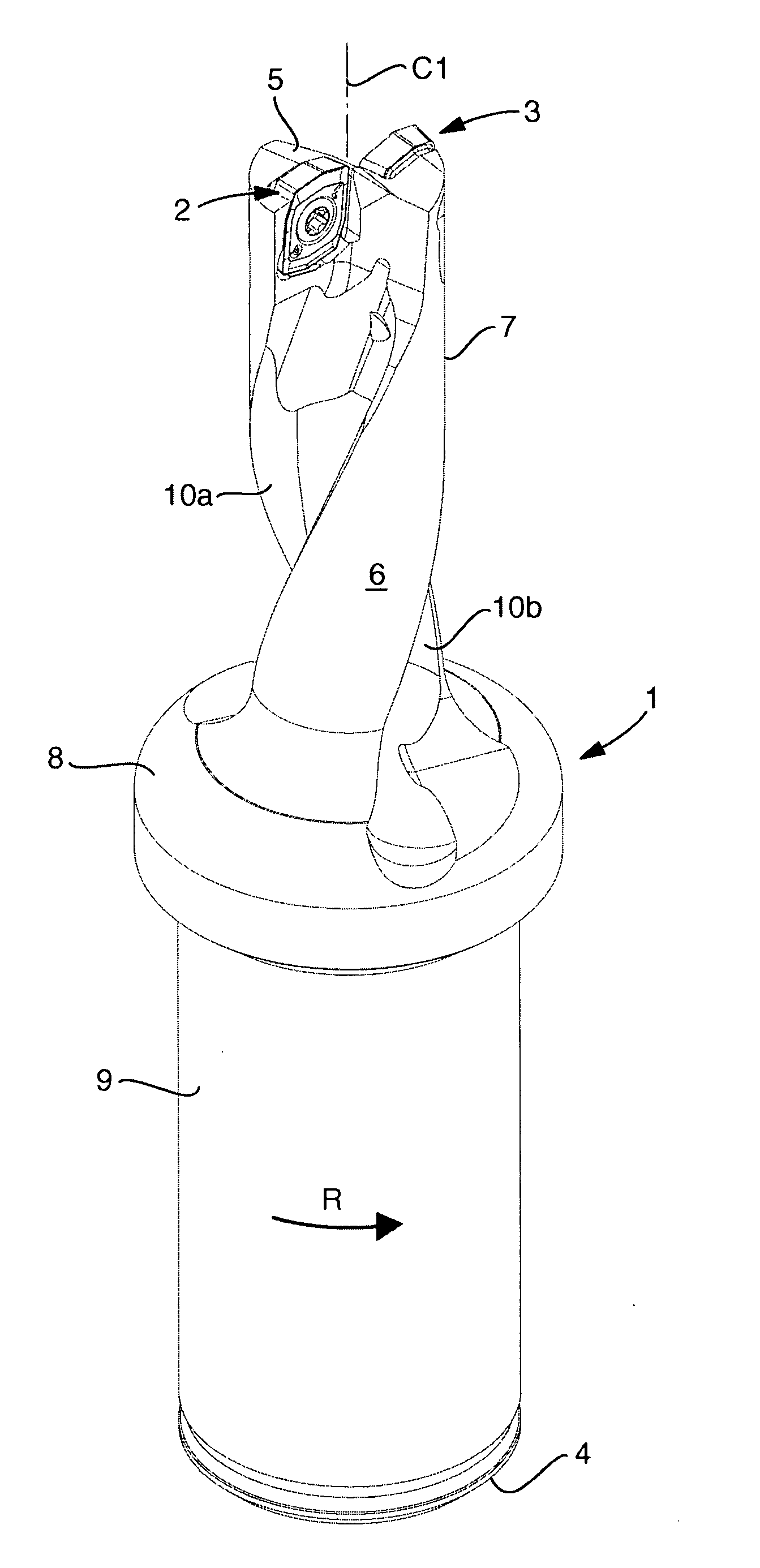

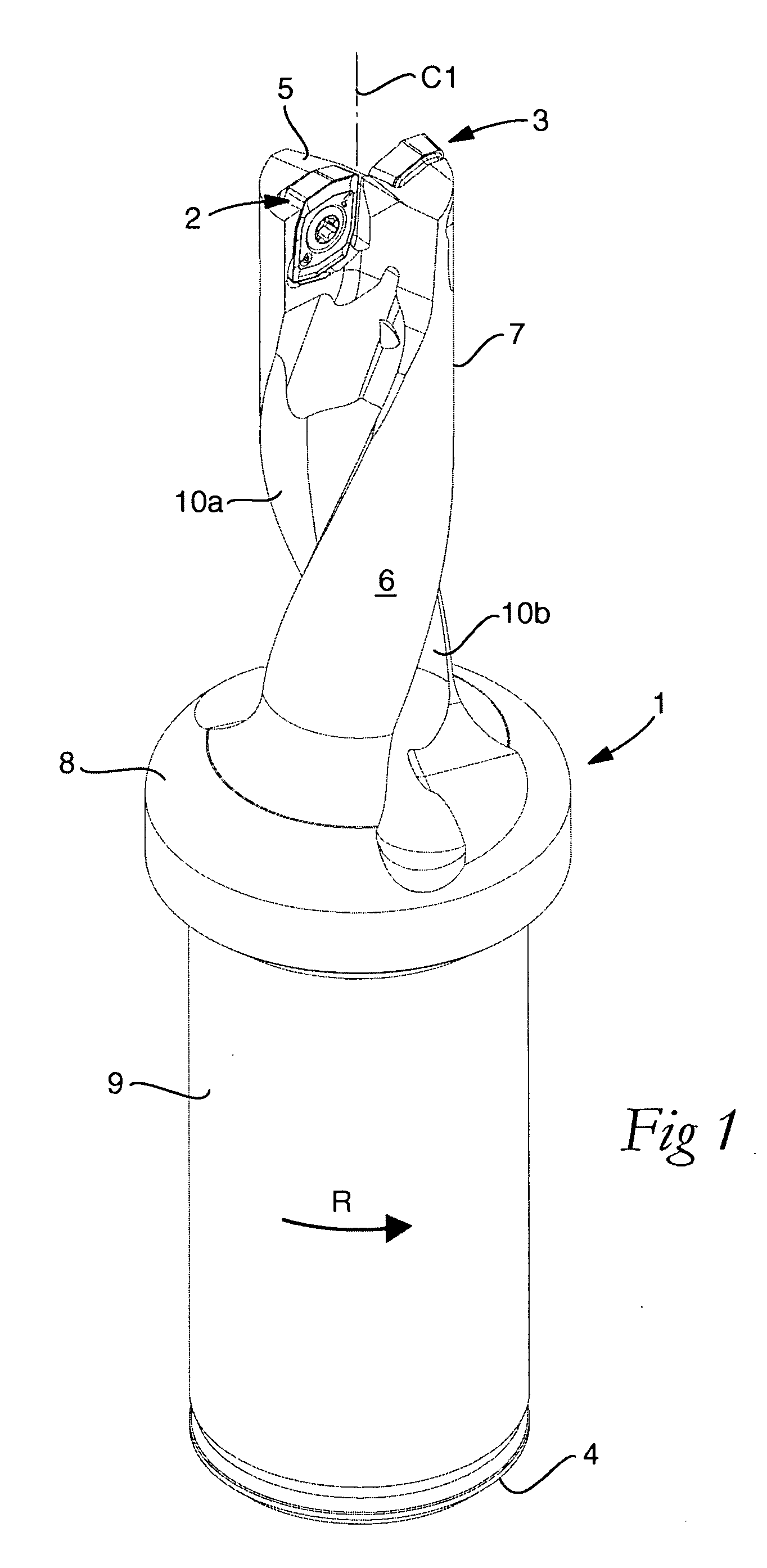

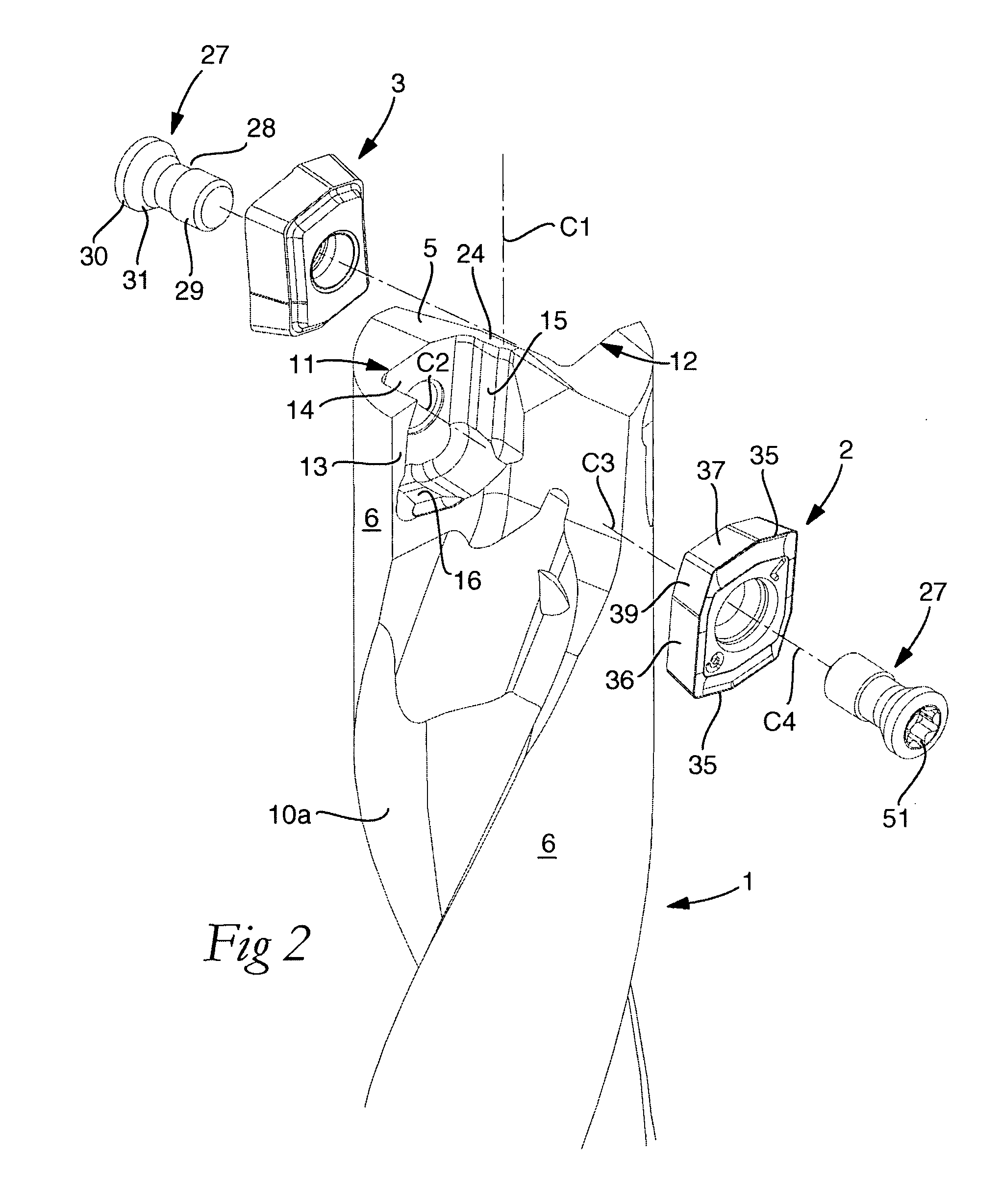

Indexable insert drill and a center insert therefore

ActiveUS20080181737A1Desired strengthDesired widthThread cutting toolsWood turning toolsAcute angleEngineering

A drill for chip removing machining, including a drill body that rotates around a center axis (C1) and has a rear end, and a front end from which there extends rearward an envelope surface in which two chip flutes each having an insert pocket are countersunk, and two replaceable cutting inserts, including a peripheral cutting insert mounted in a peripheral pocket, and a center insert, which is indexable and mounted in a center pocket that opens in the front end of the drill body and is delimited by a bottom surface, a rear end support surface, a side support surface of a partition wall, and an inside of a border adjacent to the envelope surface. The center insert includes an upperside and an underside between which a through hole for a tightening screw extends, and has an elongate basic shape that is mirror-symmetrical in relation to an imaginary, longitudinal central plane (P) with which a center axis (C3) of the hole coincides. One of two opposite, longitudinal side contact surfaces of the cutting insert which run parallel to each other and to the central plane (P), are urged against the side support surface of the center pocket. One of the two opposite end surfaces which are formed adjacent to chip-removing cutting edges at the short ends of the center insert, are urged against the rear end support surface of the center pocket. The side support surface of the center pocket is inclined in relation to the center axis (C1) of the drill body at an acute angle (ε) within the range of 3-8°. At each one of two diagonally opposite corners of the center insert, an intermediate surface is formed between the side contact surface and an end surface. The intermediate surface is shorter than the side contact surface and forms an obtuse angle (α) with the side contact surface. One of the intermediate surfaces is located in an area of a clearance space between the side support surface of the center pocket and the end support surface of the center pocket.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Flow straightener and mixer

Owner:ANSALDO ENERGIA SWITZERLAND AG

Demolition tool

The invention provides a demolition tool that can be used in many ways for the demolition of construction materials or other materials. The demolition tool includes a handle having a head at one end. The head has a longitudinal central plane that bisects the head, a strike contact face, and toothed, stepped grasping jaws that accommodate multiple sizes of lumber or other material. The head may also include a blunt blade edge below the strike contact face for striking and demolishing material. The demolition tool includes a bent end pry bar at a second end of the handle. The bent end pry bar being offset 90 degrees from the longitudinal central plane of the tool head enabling full range of motion without interfering with other tool functions. The demolition tool may comprise a single piece of material and may be softer than tools used to strike it, but harder than materials which it is used to strike.

Owner:STANLEY WORKS THE +1

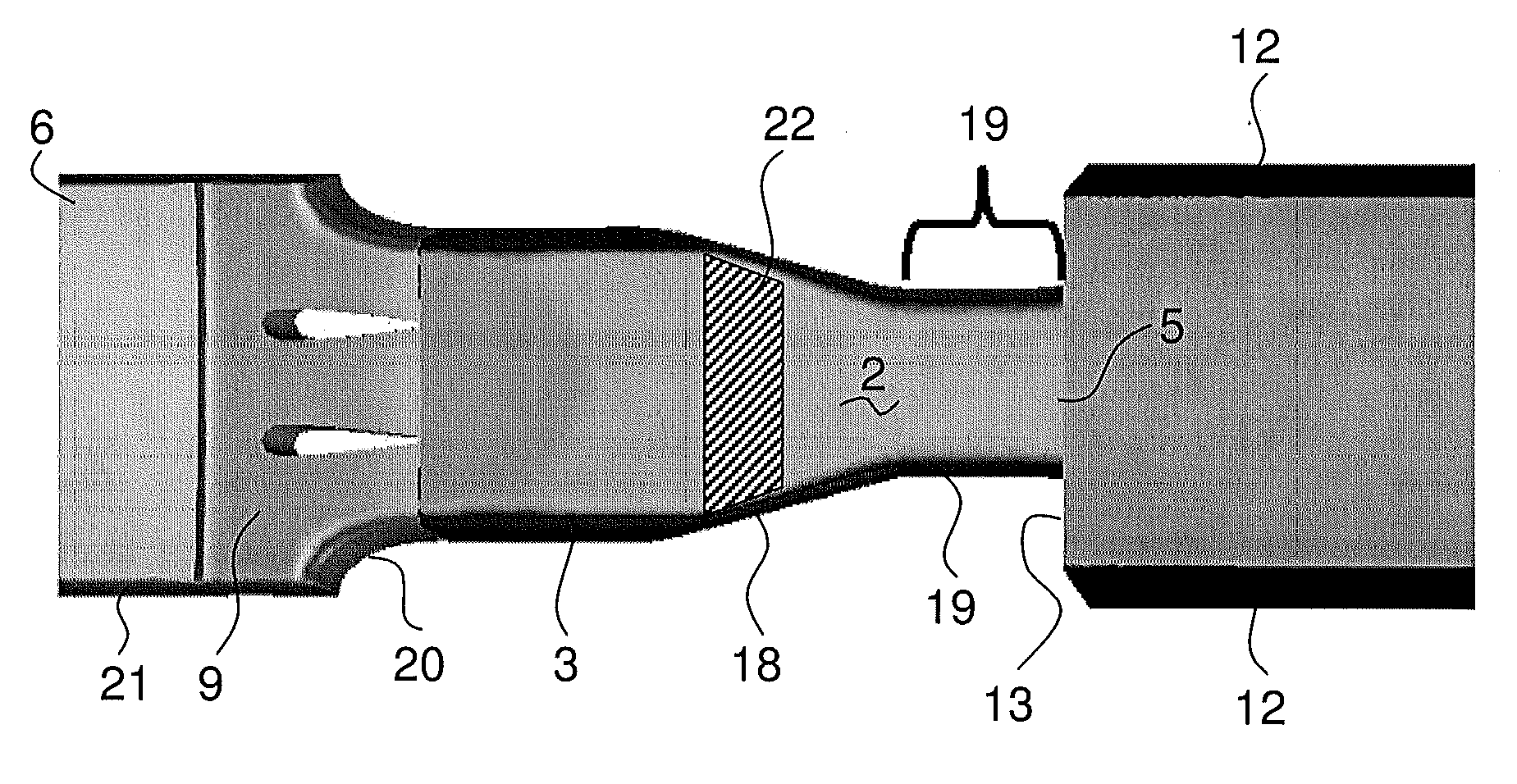

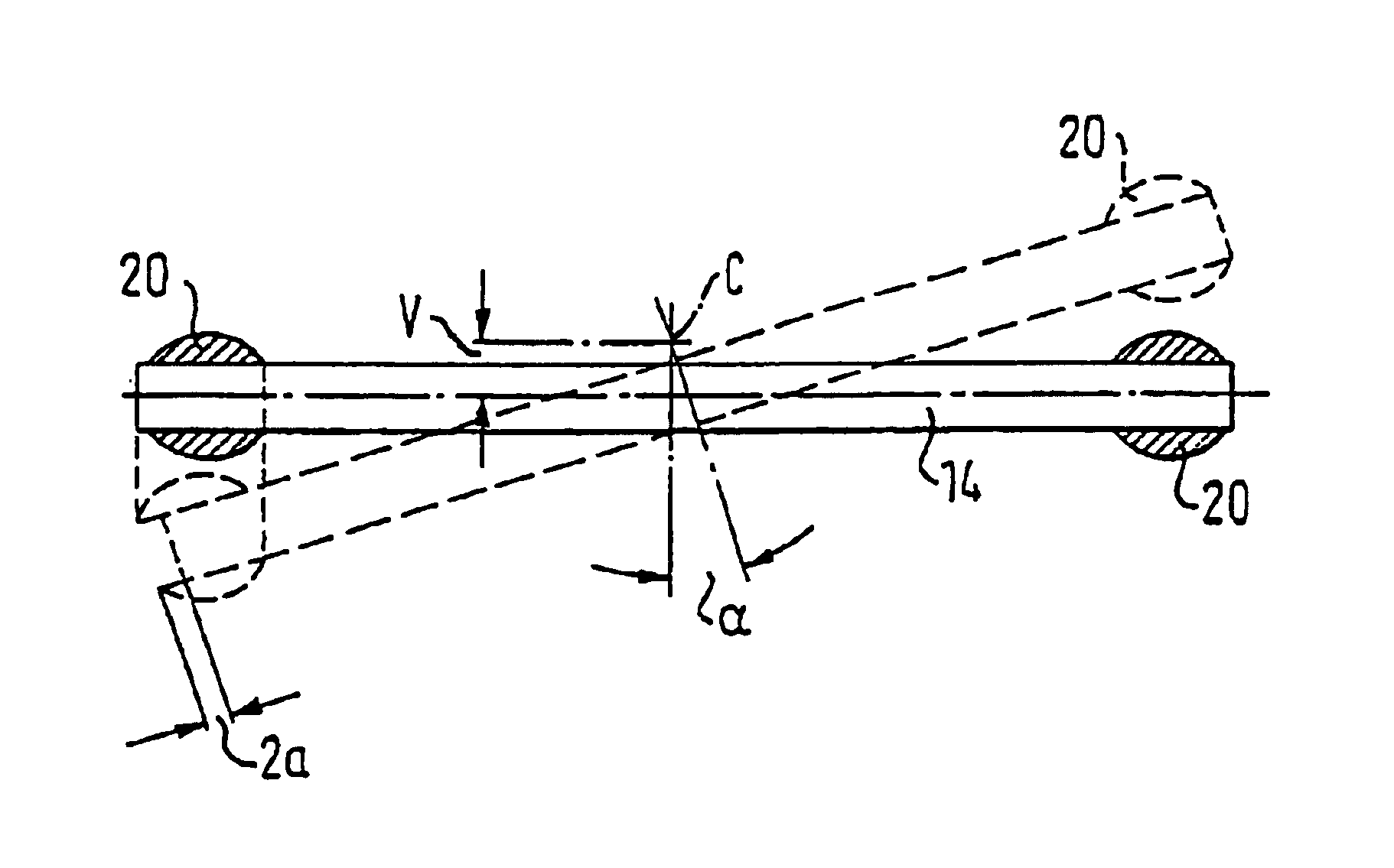

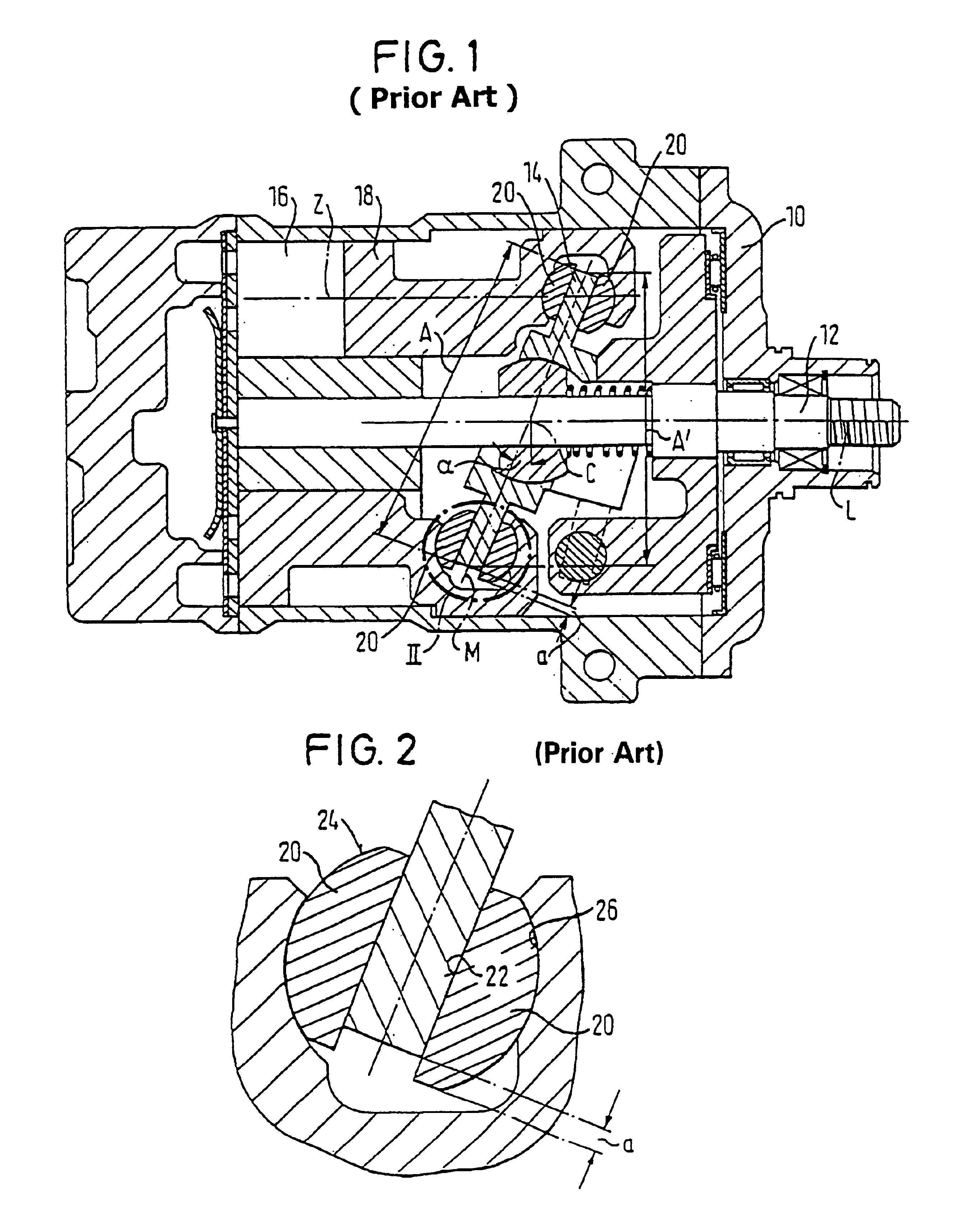

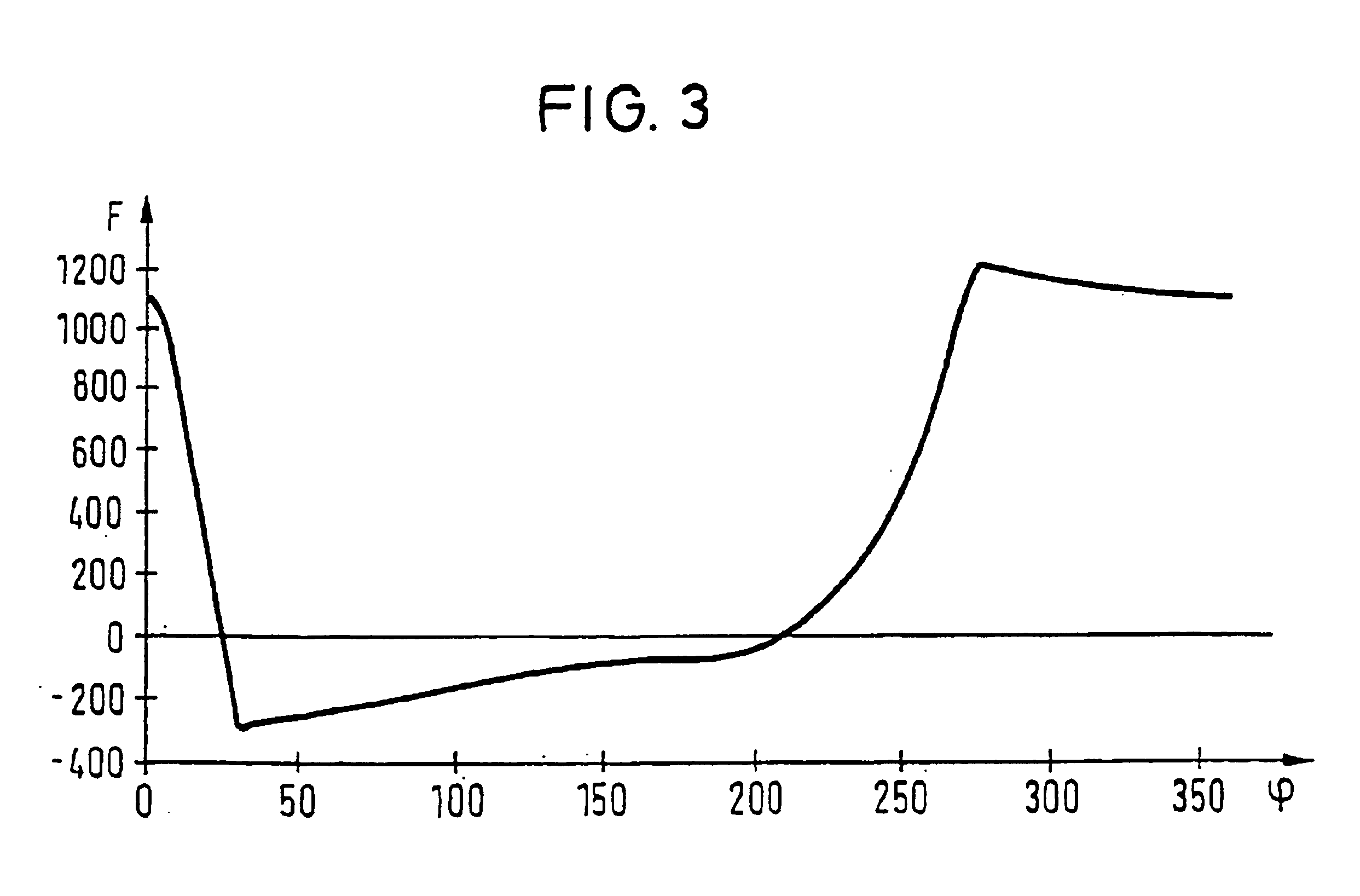

Axial piston displacement compressor

InactiveUS6766726B1Multi-stage pumpsPositive-displacement liquid enginesEffective surfaceDrive shaft

The invention relates to an axial piston displacement compressor, comprising a drive shaft (12), a disc (14) which is mounted on the drive shaft in such a way, that it can be pivoted about a pivotal axis (C) and at least one piston (18) which is provided with sliding blocks (20) that slide on a runway on the disc (14). The invention aims to reduce the maximum effective surface pressure between the disc (14) and the sliding blocks (20). To this end, the pivotal axis (C) of the disc (14) is located eccentrically in relation to the central plane of the disc.

Owner:ZEXEL VALEO COMPRESSOR EUROPE GMBH

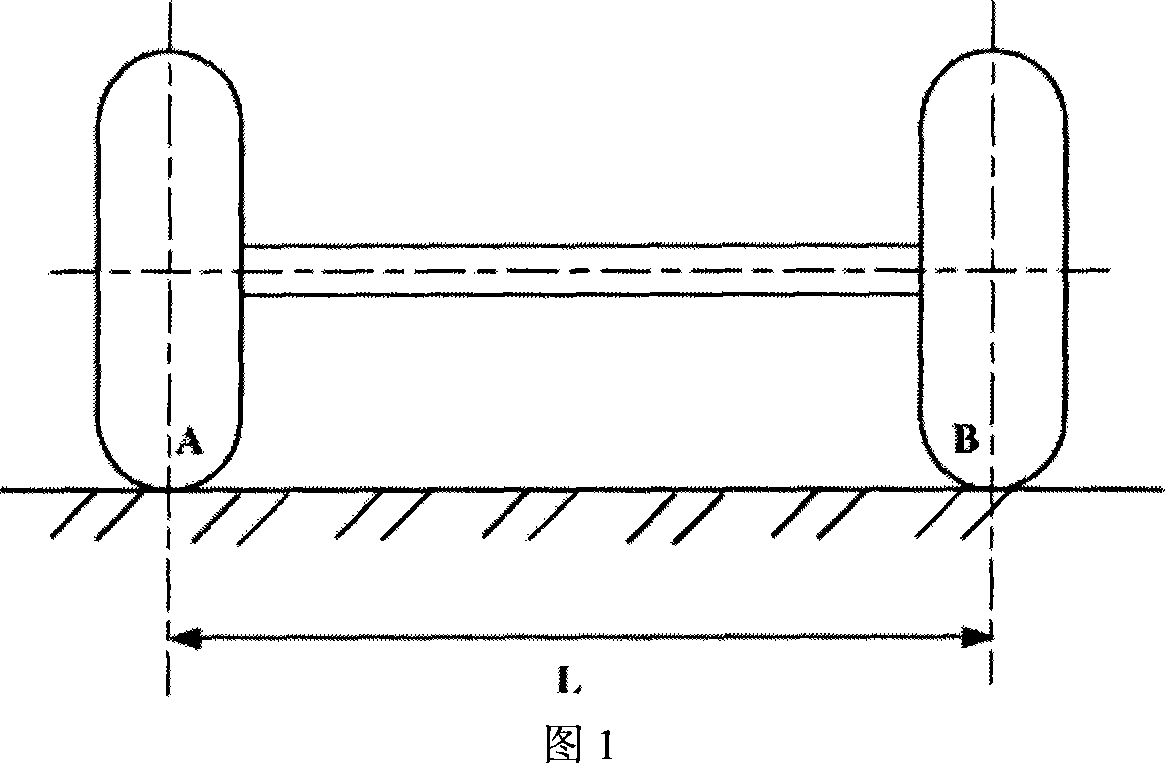

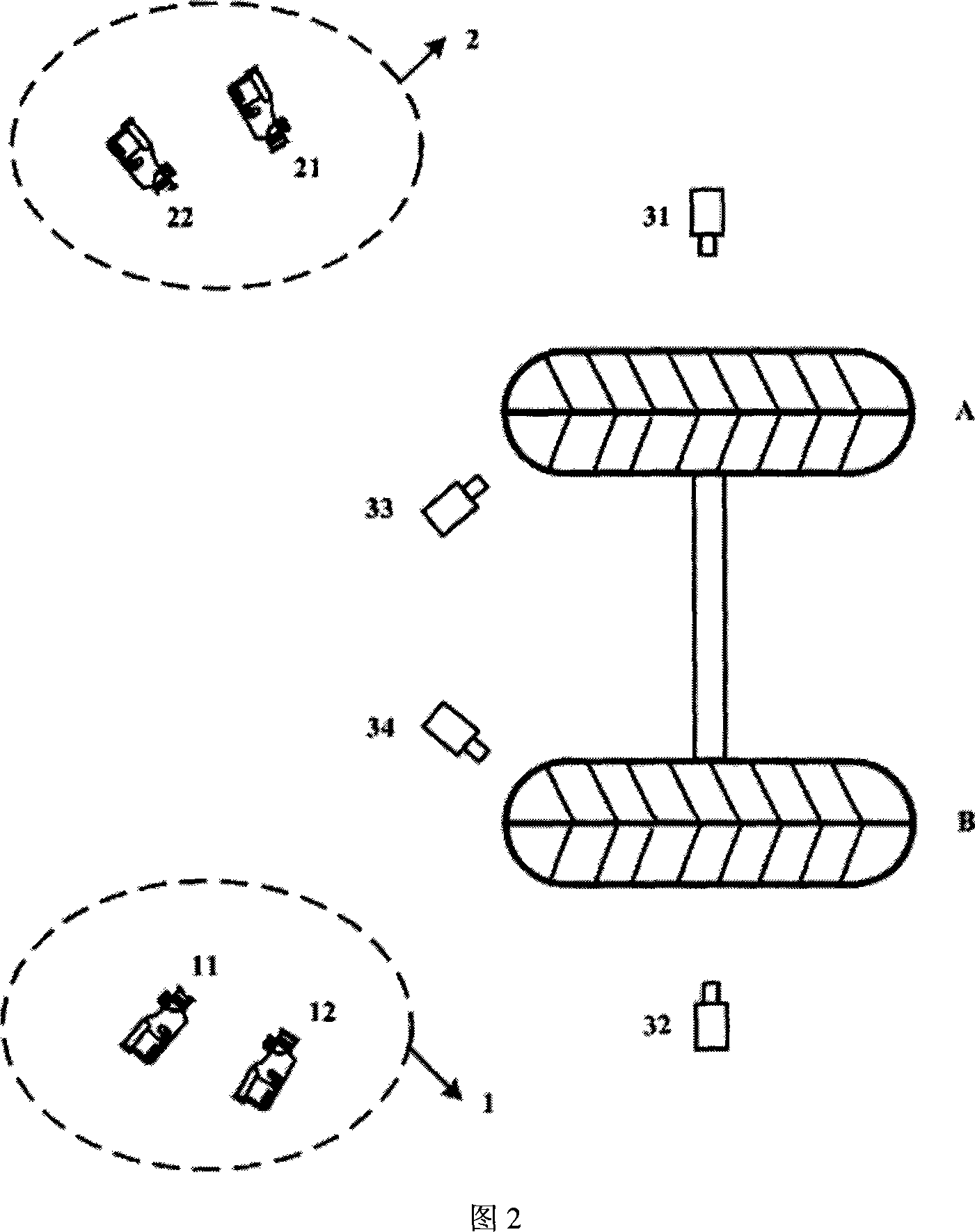

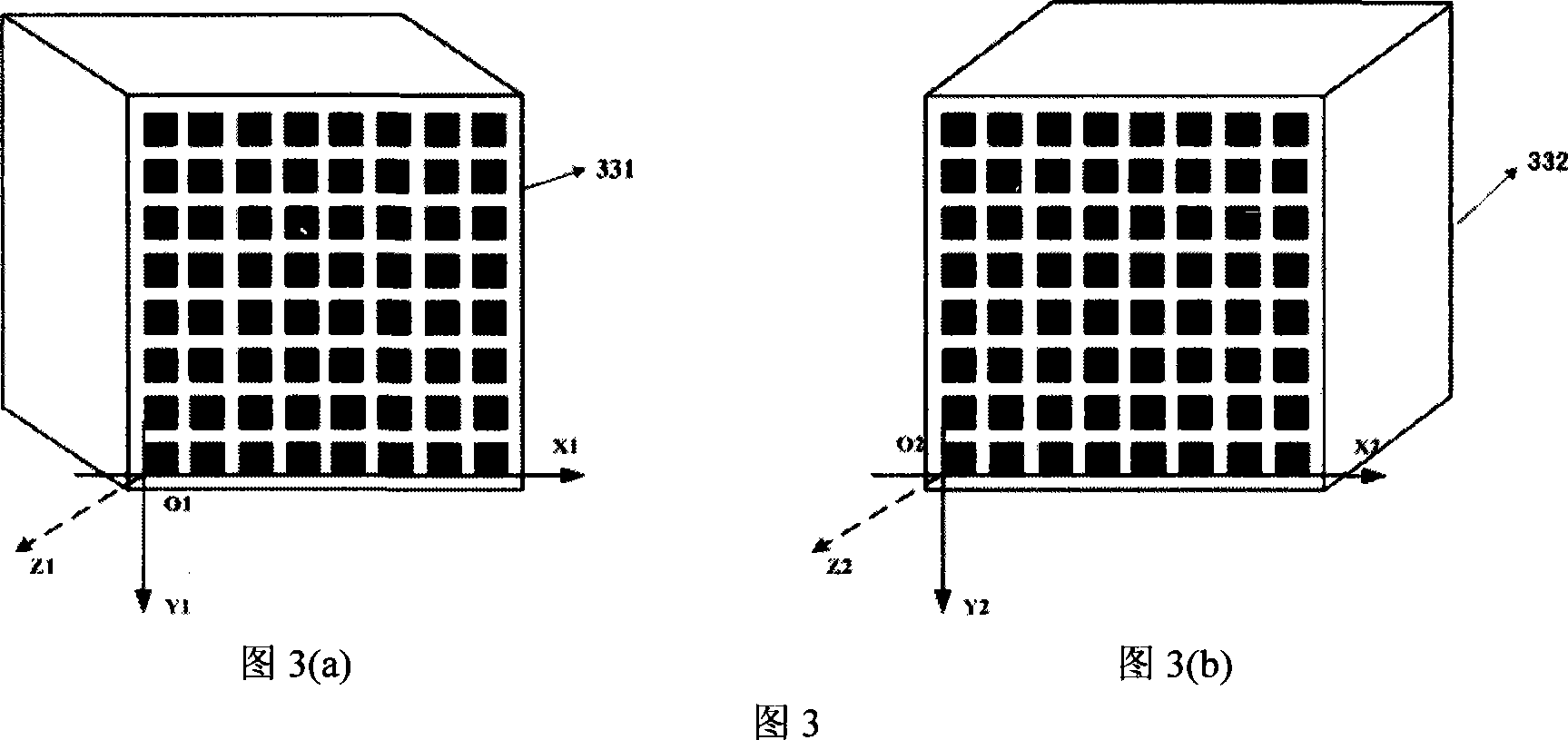

Vehicle tread measurement method based on stereo vision and laser

InactiveCN101059340AHigh precisionExpand field of viewUsing optical meansPicture interpretationVisual perceptionTangential point

The invention provides a wheel distance measuring method based on stereo vision and laser, which uses a stereo vision laser measuring system to obtain relative measuring parameters. The method uses a digit camera to shoot laser pattern projected on the tyre crown, uses image processing method to extract laser pattern target, uses stereo match algorism and three-dimension rebuild algorism to obtain laser pattern stereo point. And the invention projects the laser pattern stereo point on a simulated plane of the laser pattern, uses the projected point to generate a two-dimension curvature, to calculate out an extreme point of the two-dimension curvature, while the extreme point is relative to the tangential point of the tyre crown. And the invention uses one tangential point at inner tyre crown and at least three tangential points at outer tyre crown to simulate a tangential plane to calculate out the central plane of tyre. And the invention calculates out the distance between the cross lines of the central planes of left and right tyres on one shaft and the wheel support plane to obtain the vehicle wheel distance.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com