Flexible back plate for flexible display

A flexible display and backplane technology, applied in the direction of instruments, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as poor function, white turbidity, circuit damage, etc. The effect of changing and prolonging the bending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

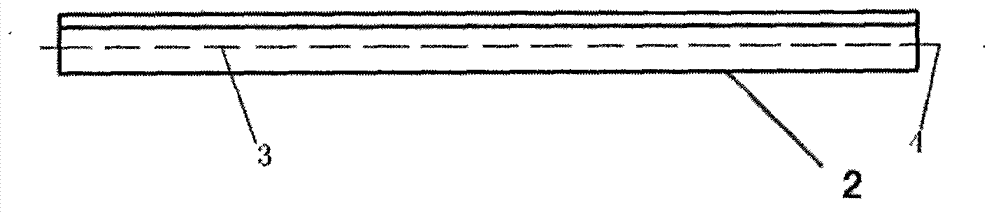

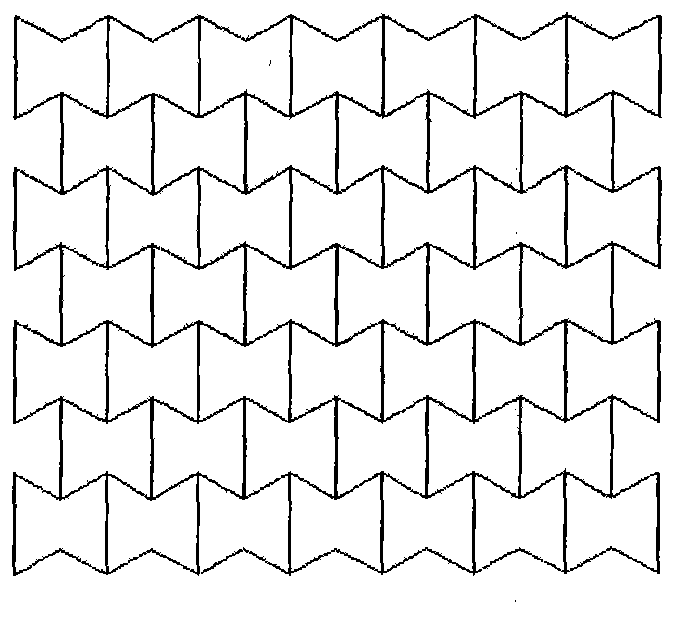

[0027] Such as figure 1 As shown, a flexible backplane for a flexible display includes a structural layer 2 and a laying layer 3. The structural layer adopts a negative Poisson’s ratio honeycomb structure, and the laying layer is evenly tiled in the central plane of the structural layer. The structural layer adopts a shape memory It is made of polymer or its composite material, and the laying layer is made of carbon fiber and its composite material, silicon carbide fiber and its composite material, copper wire, nickel wire or carbon-based nano-paper material, and the laying layer is provided with two electrode leads 4 ;Such as figure 2 As shown, when the two electrodes are energized, the laying layer generates heat, the structural layer is heated to reach the glass transition temperature of the structural layer material, and an external force is applied to the honeycomb structure to achieve the purpose of deforming the honeycomb. After the heating is stopped, the shape of the...

Embodiment 2

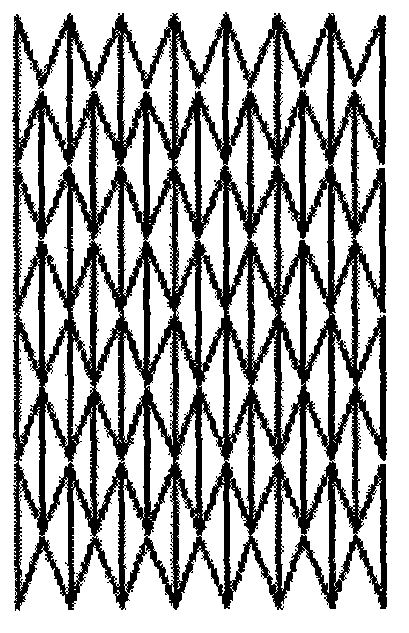

[0029] Such as Figure 4-5 As shown, the present embodiment is like embodiment 1, and the negative Poisson's ratio honeycomb structure adopts a chiral honeycomb structure with a negative Poisson's ratio effect, including a plurality of rigid blocks 5 and their connected ligaments 1 evenly spaced from each other. The change depends on the bending of the connecting ligament 1. Each rigid layer block corresponds to the area where the pixel unit in the display function layer of the flexible display is located. The gap between each rigid block can ensure that the flexible display does not bend during the bending process. Collision and extrusion between electronic devices in adjacent blocks occur, so as to ensure that the flexible display can still be displayed normally after being bent many times. And a highly elastic rubber ring can be set on the periphery of the structure layer to protect the structure and users. Furthermore, the honeycomb structure of the flexible display backp...

Embodiment 3

[0031] Such as Figure 6 As shown, the difference between this embodiment and Example 2 is that the structural layer 2 is a triligamentous foreschiral honeycomb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com