Patents

Literature

107results about How to "No extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

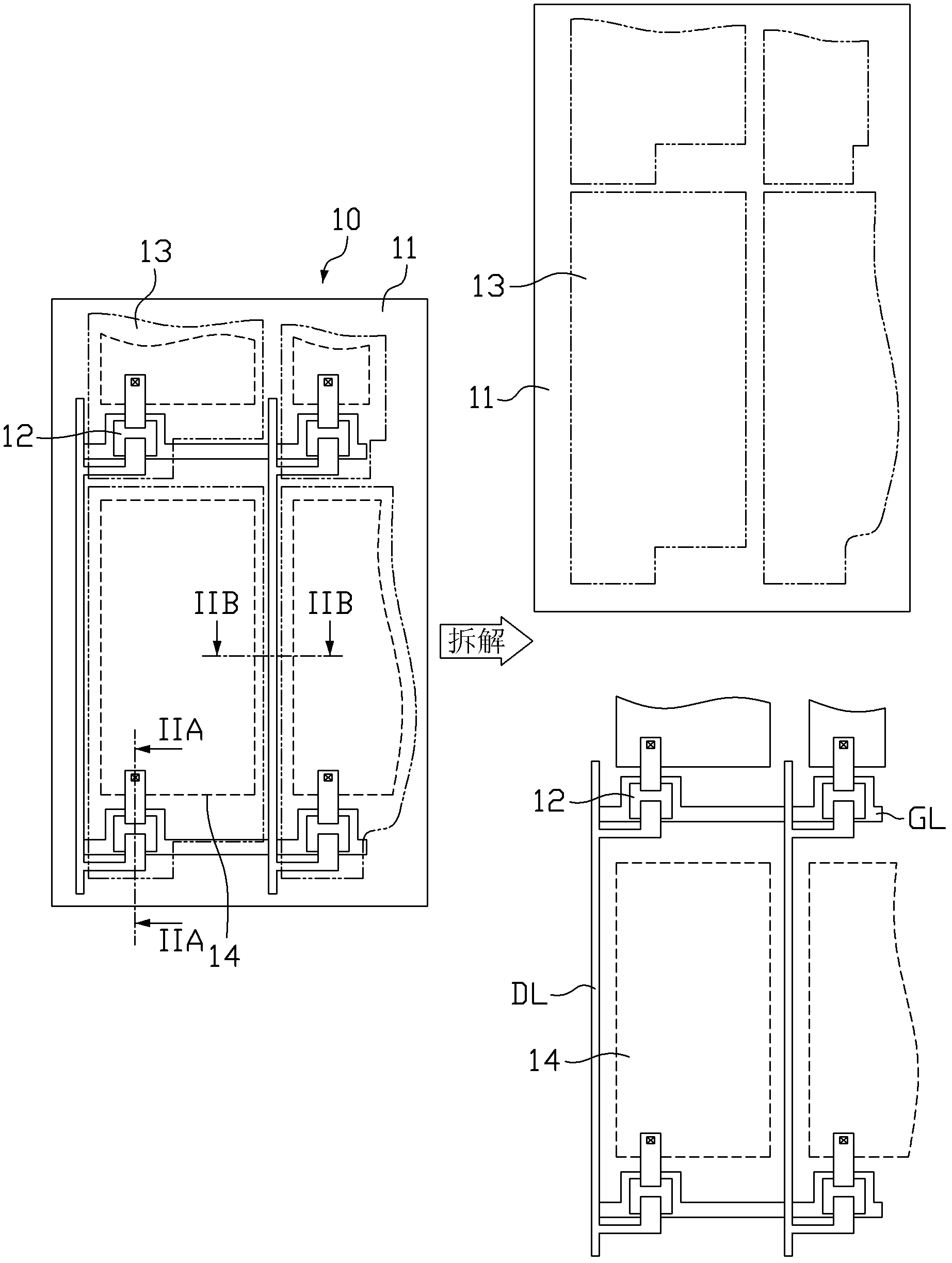

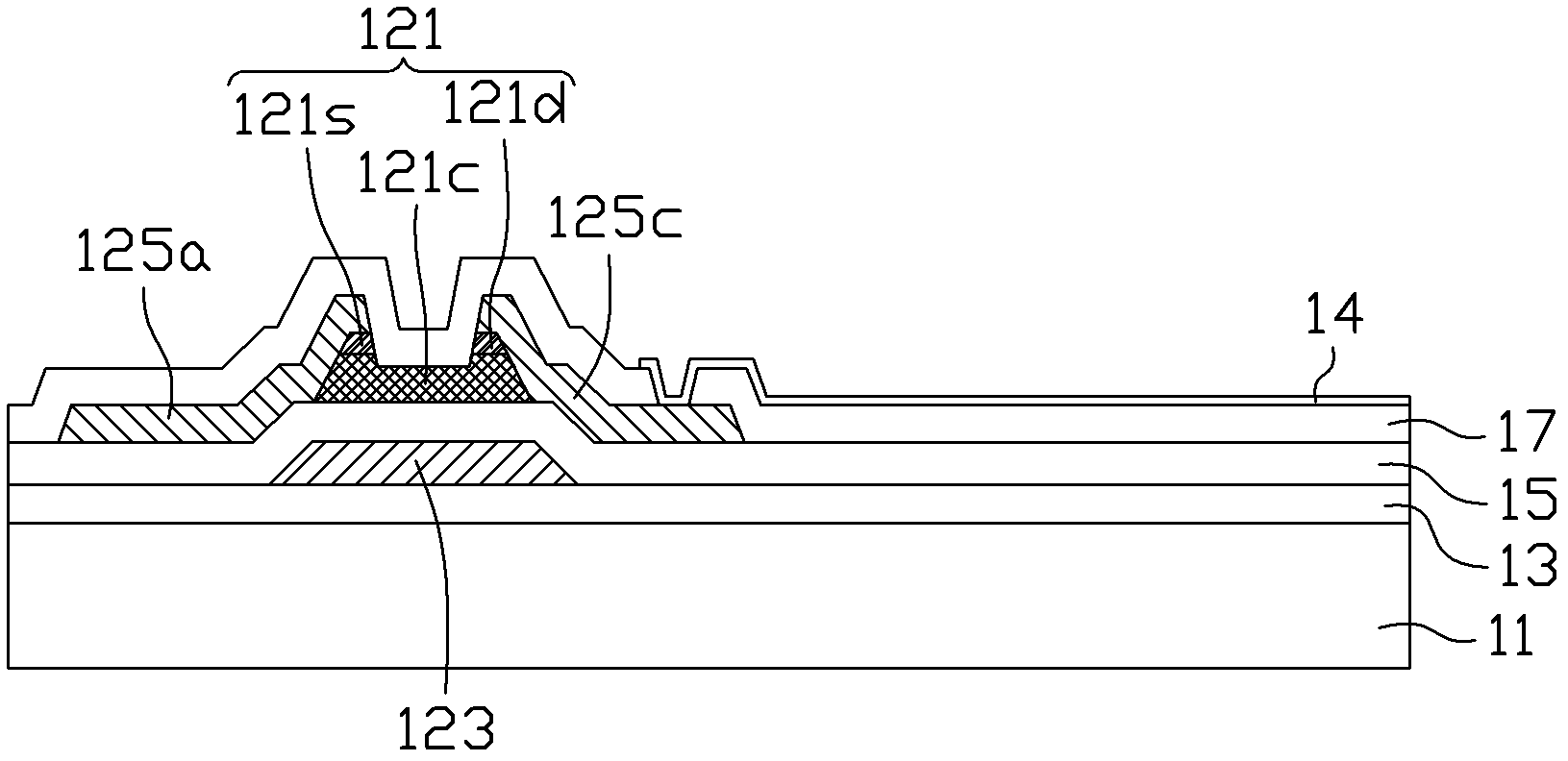

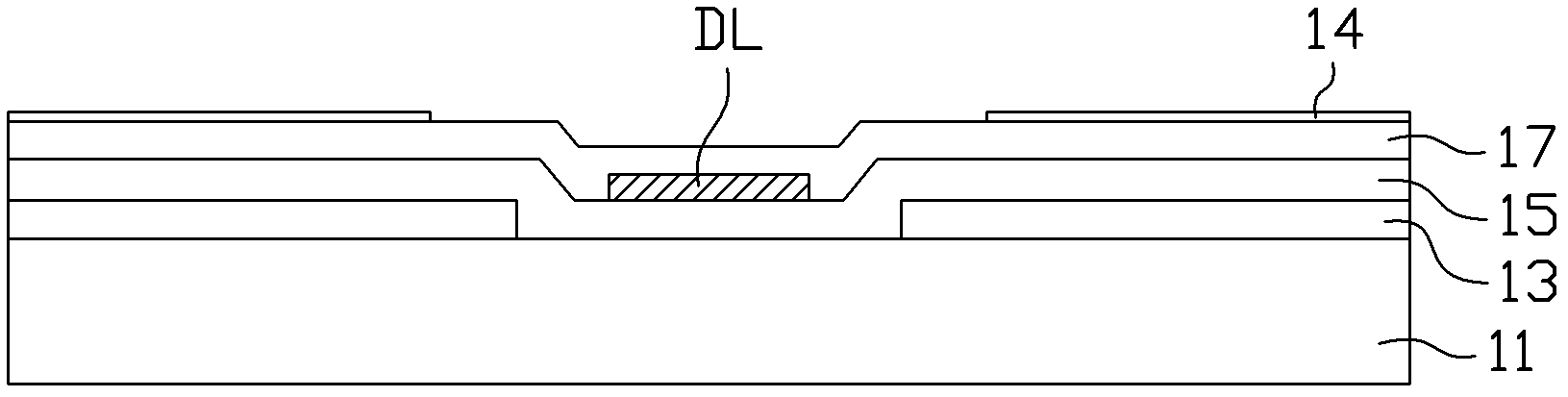

Flexible display

ActiveCN102496684ALong bending lifeNo collisionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlexible display

The present invention relates to a flexible display which comprises a back plate, a front plate and a display function layer which is clamped between the back plate and the front plate. The display function layer is distributed with a plurality of data lines and gate lines, and a plurality of pixel units are formed in a rectangle region which is enclosed by intersection of two adjacent data lines and two adjacent gate lines. Each of the pixel units comprises a pixel electrode and a common electrode. According to the invention, the back plate of the flexible display is a flexible substrate; the flexible display is provided with a plurality of rigid layer blocks which are arranged with intervals, and each rigid layer block is at least corresponding to a position area where a pixel unit locates in the display function layer of the flexible display. According to the flexible display, gap between rigid layer blocks ensures that mutual collision and extrusion between electronic devices in adjacent blocks do not occur in a bending process, so a service life of flexible display can be prolonged.

Owner:KUSN INFOVISION OPTOELECTRONICS

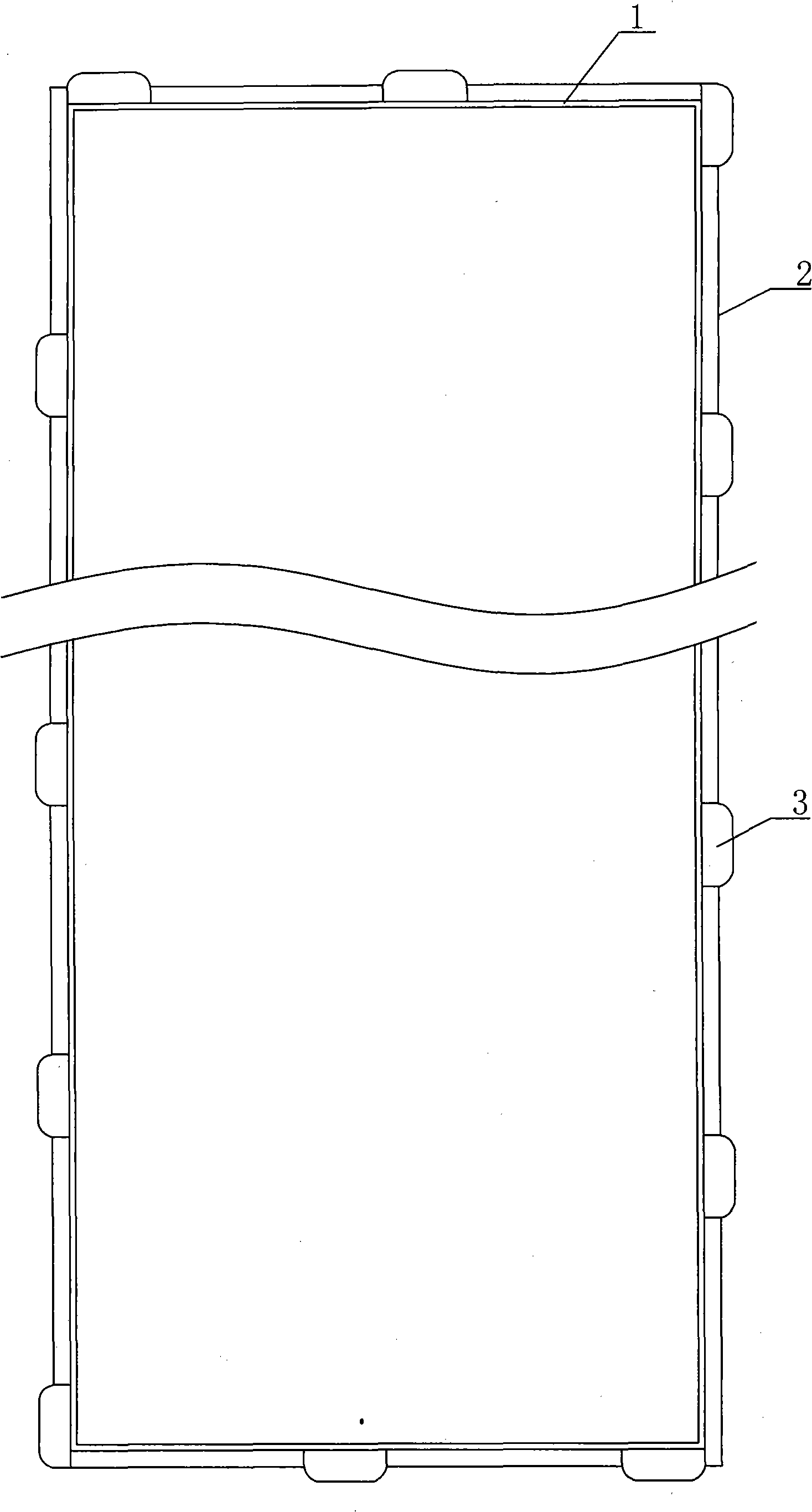

Floor plastic rubber lock catch convenient for connecting and positioning

The invention relates to the improvement of mortice structure of wood floor and fiber glued floor, and the improvement of assembly method of wood floor and fiber glued floor, in particular to floor plastic fastener which is convenient for connecting and positioning. The improvement of the invention includes that plastic frame is arranged at the periphery of wood floor or fiber glued floor; the lower part of the external side of the plastic frame is respectively provided with a step guide which is capable of drawing back; the step guides are respectively and evenly provided with a plastic slide block, the external side of which extends out of the guide surface, and the plastic slide block, the external side of which extends out of the guide surface, matches with the step guide surface corresponding to the frame of the assembly floor; while assembling, the plastic slide block sliding along guide surface causes the plastic slide block and the plastic slide block to match with each other and to be located. The mortice structure of the invention changes the fastener structure and assembly method of the existing floor, causing no squeezing of the surface decoration layer of floor edge and no edge collapsing of the decoration layer while assembling, being able to adjust the size of the clearance between floors; the fastener of the floor need not differentiate with left and right, and thus free assembly in any end can be done while disassembling, which is convenient for production and assembly; in addition, the plastic fastener has high intensity, saves material and has low cost.

Owner:罗生权

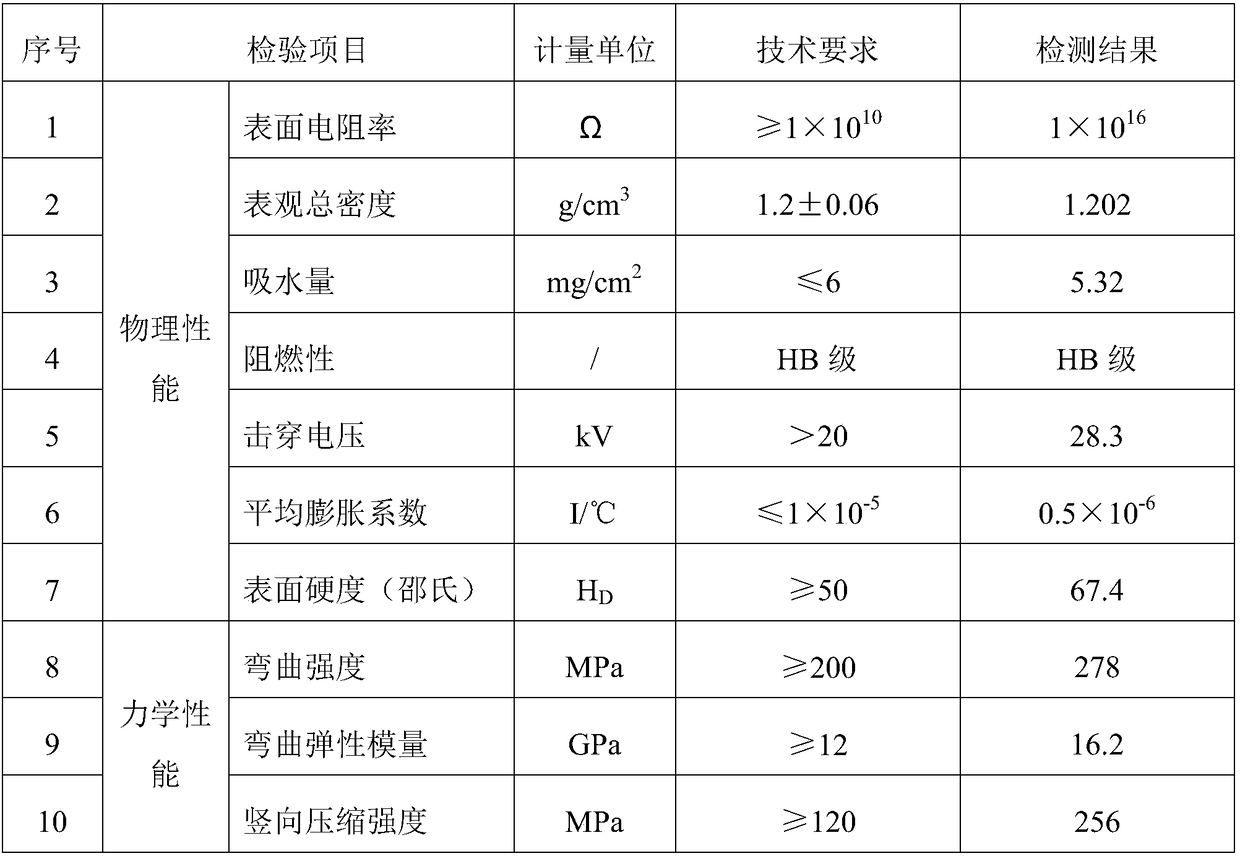

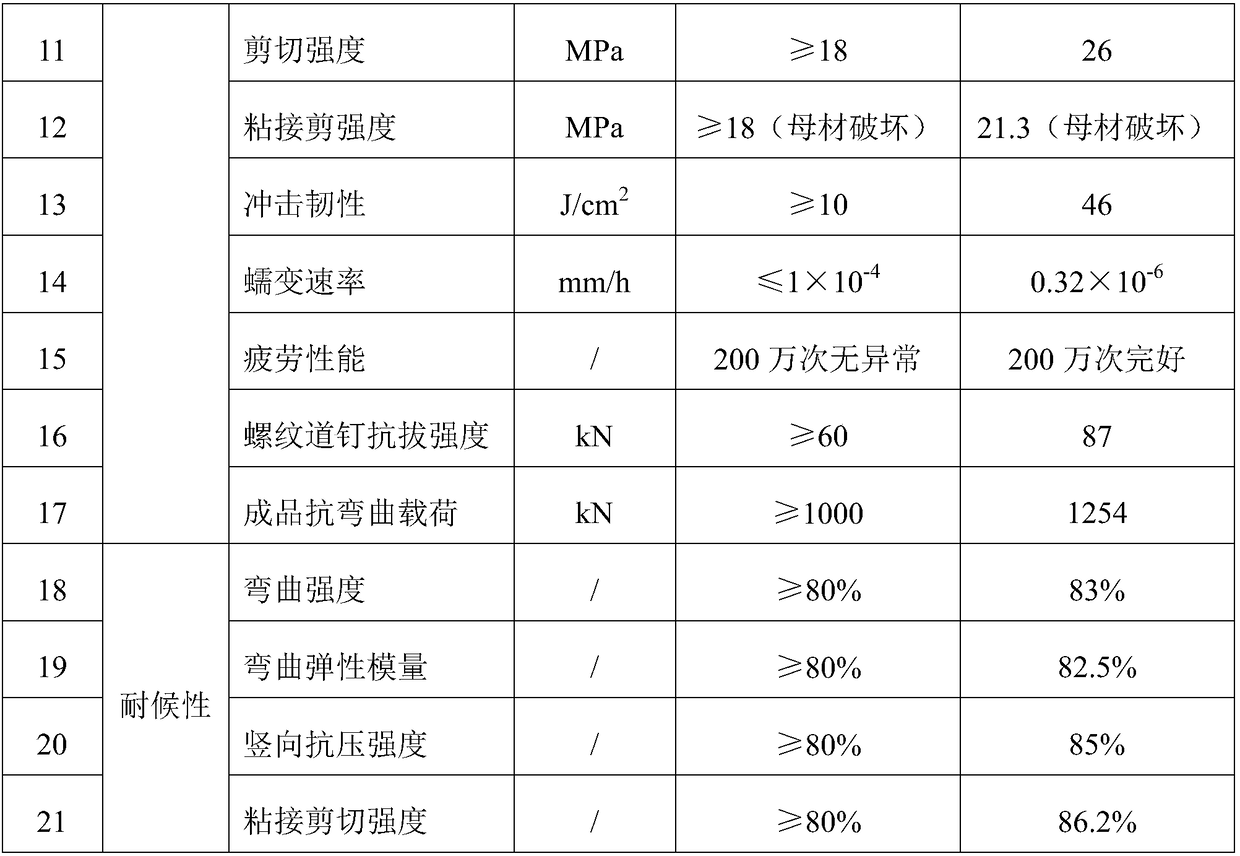

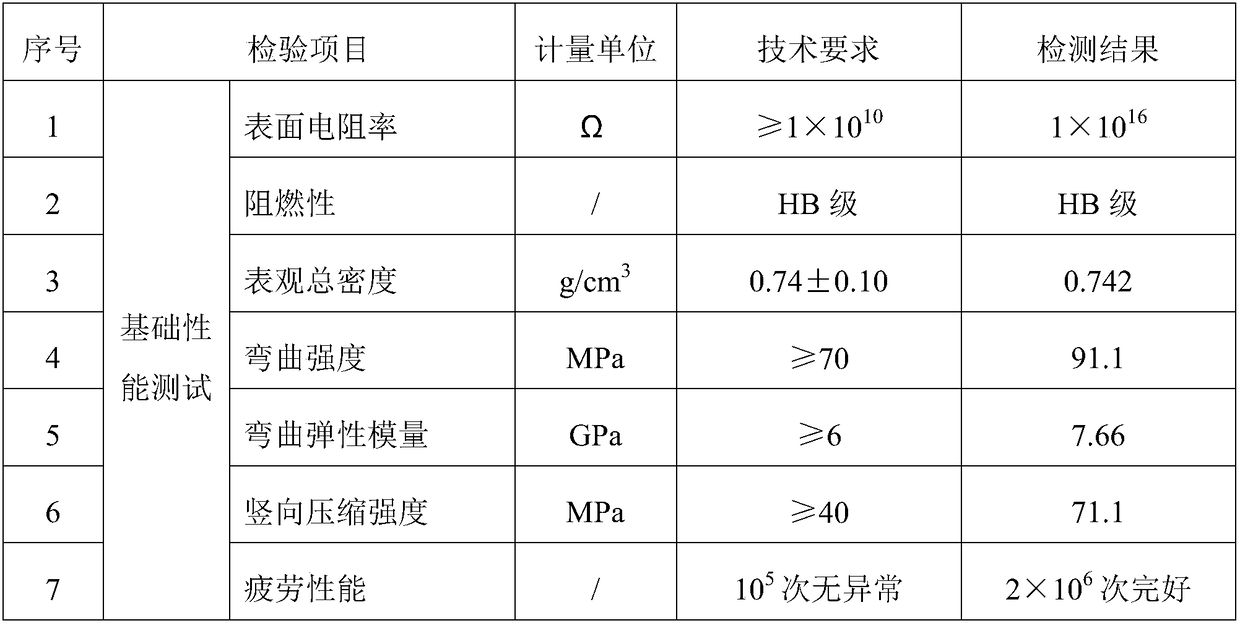

Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

The invention discloses a fiber-reinforced polyurethane foamed and synthesized sleeper and a preparation method thereof. The sleeper comprises a body formed by polyurethane resin in a one-time lamination manner, wherein multiple layers of composite felts with a transverse reinforcing effect are transversely arranged in the body, and a fiber yarn layer with a longitudinal reinforcing effect penetrates into the polyurethane resin between two adjacent composite felts; the fiber yarn layer and the composite felts account for 65%-75% of the total weight of the sleeper; the polyurethane resin accounts for 25%-35% of the total weight of the sleeper, and the density of the sleeper is 0.6g / cm<3>-1.6g / cm<3>; and the sleeper is prepared through combination of a double-steel belt laminating machine and a multilayer synchronous glue injection primary formation. According to the fiber-reinforced polyurethane foamed and synthesized sleeper, gum dipping is relatively adequate and uniform, so that thetransverse strength of the sleeper is enhanced, and the cracking phenomenon of a product during punching and indenting can be avoided; and the production process is simple, the equipment input is reduced, the production cost is lowered, and the production efficiency is improved.

Owner:铁科腾跃科技有限公司

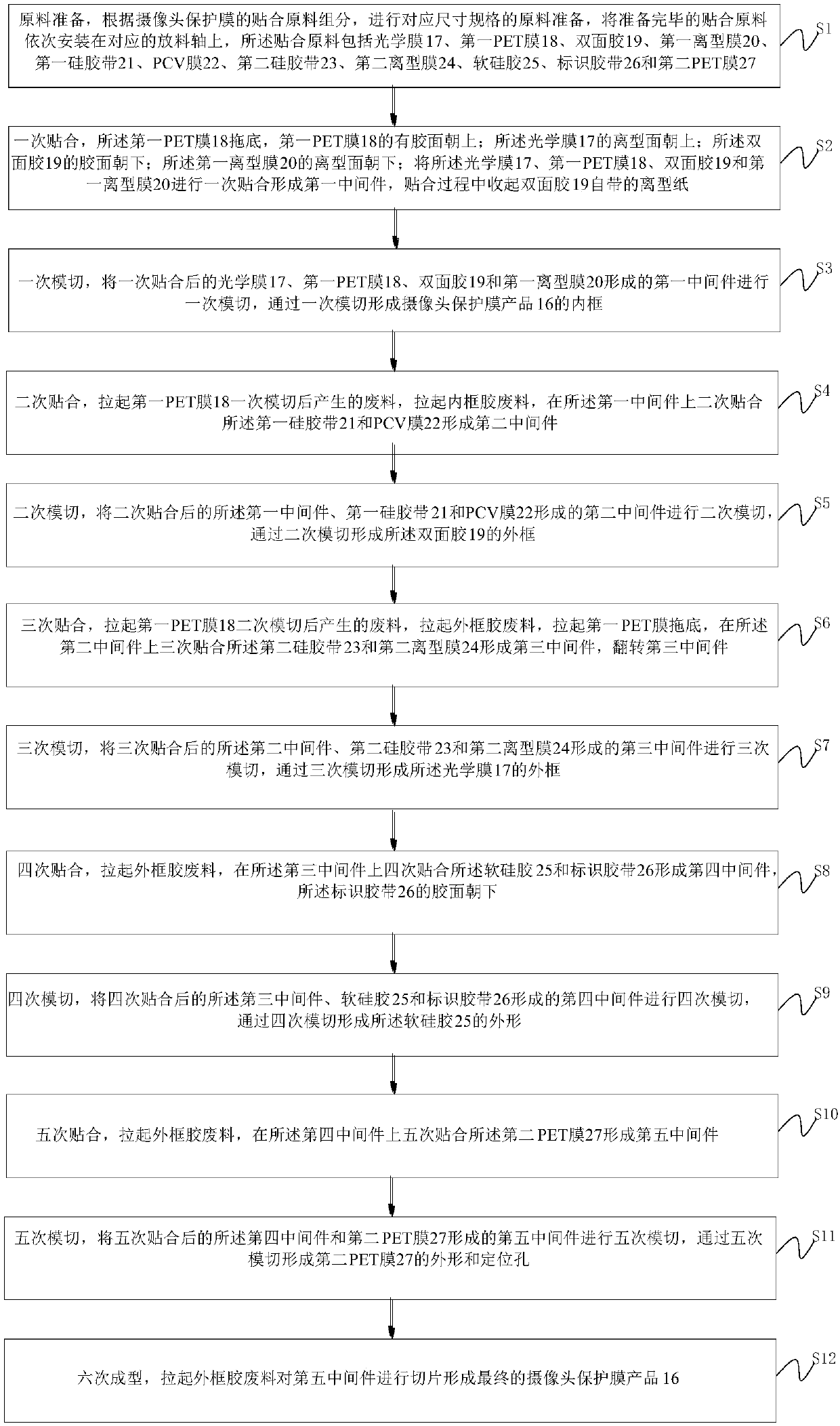

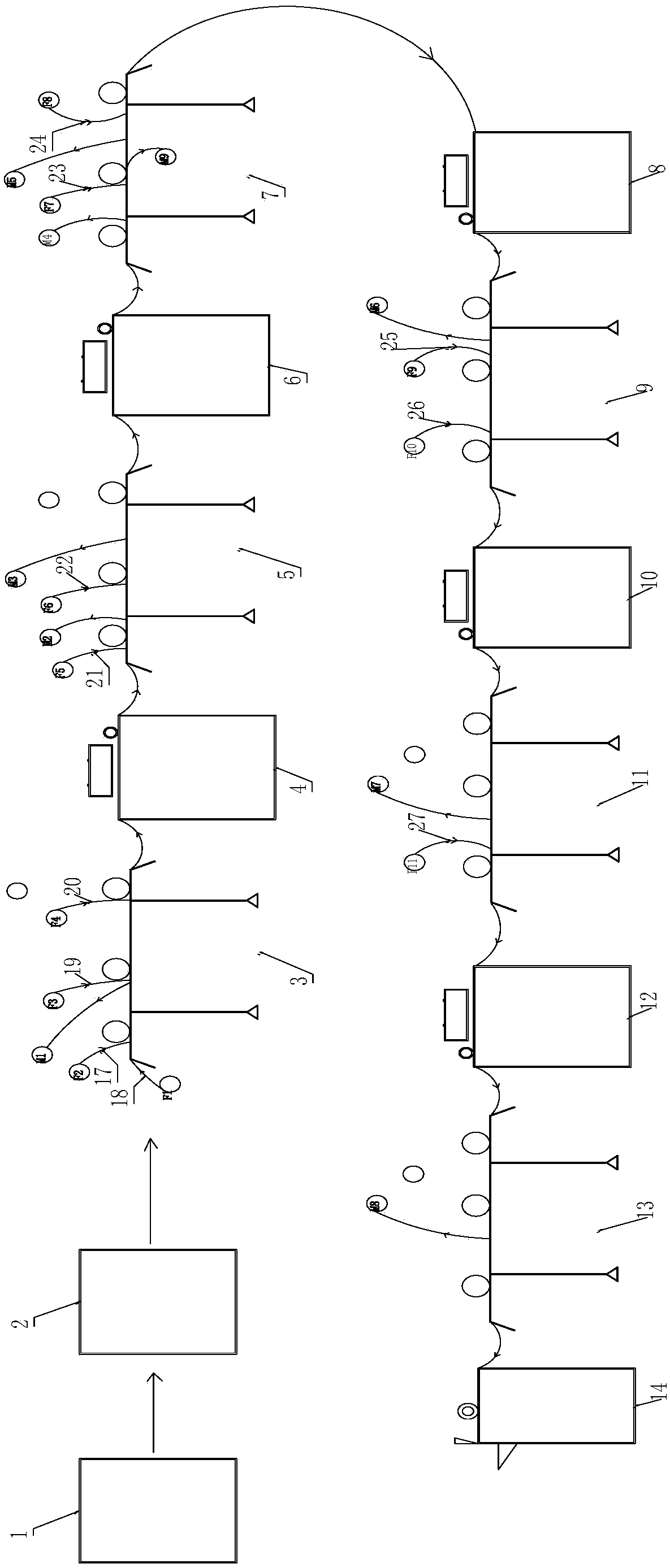

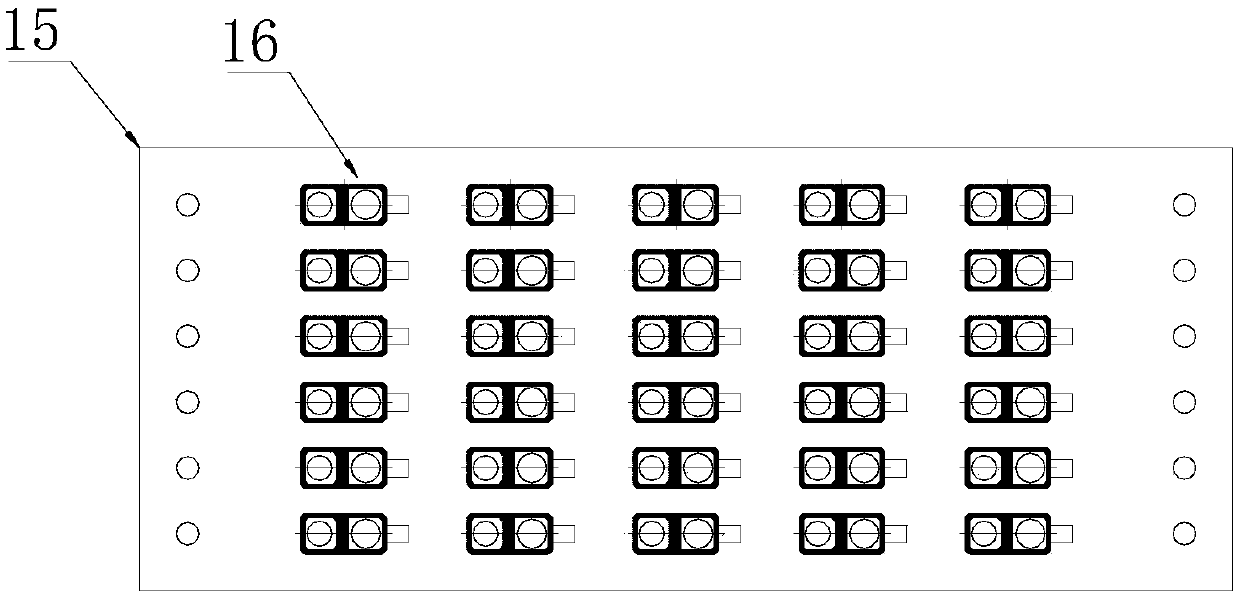

Camera protection membrane, die cutting production process and device

ActiveCN109677089ANo deformationNo extrusionLamination ancillary operationsSynthetic resin layered productsPolyethylene terephthalateEngineering

The invention discloses a camera protection membrane, a die cutting production process and a device. The die cutting production process comprises the following steps: preparing raw materials accordingto pasting raw material components of the camera protection membrane, and sequentially mounting the prepared pasting raw materials on corresponding placing shafts, wherein a first PET (Polyethylene Terephthalate) membrane is used at the bottom, the side with an adhesive, of the first PET membrane faces upwards, the release surface of an optical membrane faces upwards, the adhesive side of a double-side adhesive faces downwards, and the release surface of a first release membrane faces downwards; carrying out primary pasting to form a first middle part, and withdrawing release paper of a double-side adhesive tape in the pasting process; carrying out primary die cutting after primary pasting, and forming an inner frame of a camera protection membrane product through primary die cutting; carrying out secondary pasting, secondary die cutting, third pasting, third die cutting, fourth pasting, fourth die cutting, fifth pasting, fifth die cutting and sixth molding in sequence, pulling up anouter frame rubber waste material, and slicing a fifth middle part, thereby finally forming a membrane carrier with a plurality of membrane products arranged in sequence. A manual combination procedure is avoided, assembling steps are reduced, the labor can be saved, and the pass percent can be increased.

Owner:山东昶正智能科技有限公司

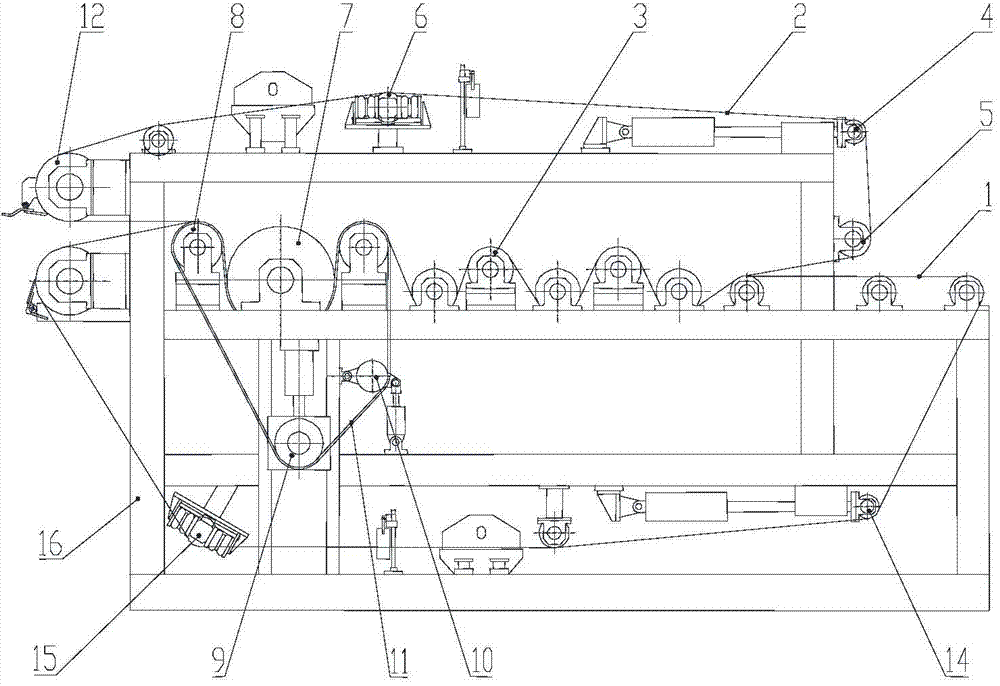

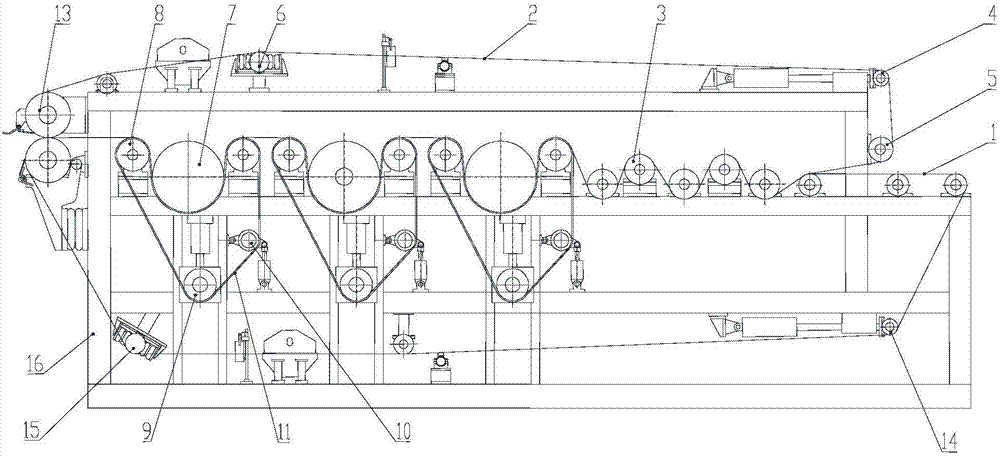

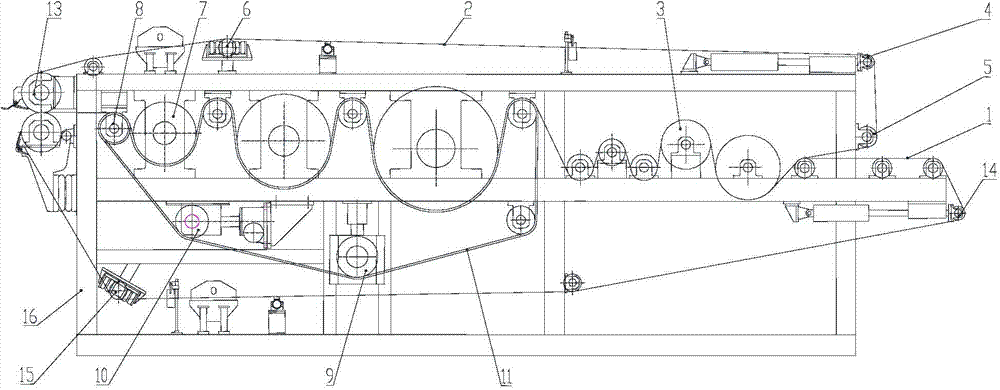

Cascade pressurization belt type pressure filter

InactiveCN103785217APrevent crushingImprove dehydration effectMoving filtering element filtersSludgeEngineering

The invention discloses a cascade pressurization belt type pressure filter which comprises an upper filtering belt, a lower filtering belt, filtering belt pressing rollers, an upper filtering belt tension roller, an upper filtering belt adjustment roller, a lower filtering belt tension roller, a lower filtering belt adjustment roller, a metal mesh belt, metal mesh belt pressing rollers, metal mesh belt redirection rollers, a metal mesh belt tension roller and a metal mesh belt offset adjustment roller. The pressure filter can firstly perform pressure filtering through low filtering pressure and then perform the pressure filtering through high filtering pressure and finally perform the pressure filtering through higher filtering pressure; by adopting the method for gradually increasing the filtering pressure, the advanced dewatering on sludge is realized.

Owner:光大清洁技术股份有限公司

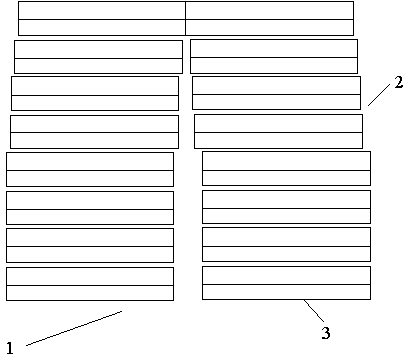

Method for maintaining turf under high temperature and a large stack of mow

InactiveCN103548507AAbsorption will not be a problemNo extrusionAgriculture tools and machinesHarvested fruit hanging devicesStructural engineeringHigh heat

The invention discloses a method for maintaining turf under high temperature and a large stack of mow. The method is applied to processes of turf transferring and stacking and comprises the following steps of (1) splitting the turf: splitting the planted turf into the dimension of 30X30cm and preserving mud with the thickness of 1.5-2cm to be adhered to the bottom of the turf; (2) transferring and loading: sequentially stacking the turf up in a carriage, enabling pieces of the turf to contact with each other, and enabling only half of the area between the upper layer of the turf and the lower layer of the turf to be overlapped; (3) stacking for storage: unloading the turf from a transfer trolley, and stacking the turf to the position near the ground to be paved, wherein a plurality of small stacks of turf are adjacent to each other to form the large stack of mow; each of small stacks of turf is formed by stacking a plurality of pieces of turf in layers; the upper piece of turf and the lower piece of turf are completely overlapped; the plurality of small stacks of turf are independent to each other; the upper end of the plurality of small stacks of turf draws close towards the inside in a concentrated mode. By means of the method for maintaining the turf under high temperature, the loss is less, less water evaporates, and the survival rate is high.

Owner:FLOWER KING ECO ENG CO LTD

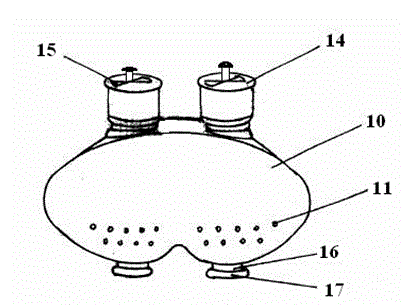

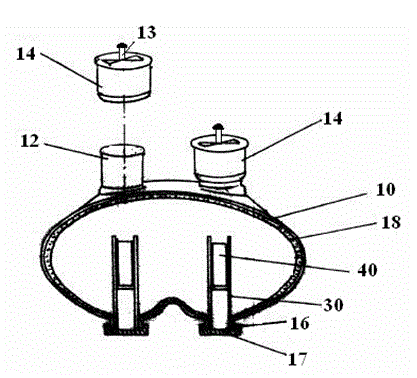

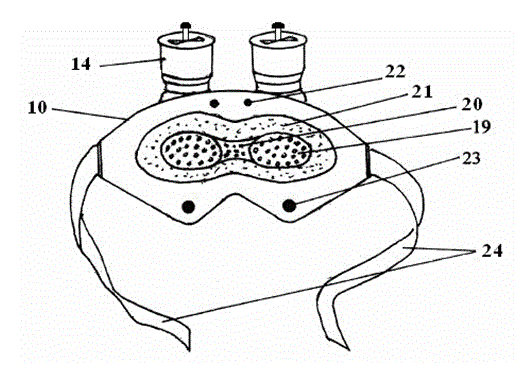

Ophthalmic therapy device

ActiveCN104856799AOvercome the defects of high temperature deformationPromote combustionDevices for heating/cooling reflex pointsElectrotherapyNasal bridgeOPHTHALMOLOGICALS

The invention discloses an ophthalmic therapy device. The ophthalmic therapy device comprises a periscope shell, wherein a plurality of convection holes are formed in the shell; an eyelet cushion is arranged on the open end at the reverse side of the shell, and porous lenses communicated with the inner part of the shell are arranged on left and right parts of the eyelet cushion; a nose bridge cushion is arranged between left and right porous lenses, left and right smoke discharging columns are arranged at the upper end of the shell, smoke discharging holes are formed in the tops of the left and right smoke discharging columns, smoke discharging caps are sleeved on the left and right smoke discharging columns, left and right ash outlets are formed at the lower end of the shell, ash receiving slots are formed in the shell, and moxibustion cone fixing tables for placing moxibustion cones are erected in the left and right ash receiving slots. The ophthalmic therapy device has a certain effect to relief and treat ophthalmic diseases such as amblyopia, shortsightedness, hyperopia and strabismus in young children and senior cataracts.

Owner:连云港市一明医疗科技有限公司

Flexible seal and self-adaption recycling device for immersed photoetching machine

InactiveCN101634811AReduce entrainmentReduce exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

The invention discloses a flexible seal and self-adaption recycling device for an immersed photoetching machine. The device is placed between a projecting lens group and a silicon wafer, comprises an injected liquid recycling component and a following disk piece and is used for restraining the boundary of an immersed liquid flow field. When liquid generates impact on the following disk piece due to the high-speed motion of the silicon wafer, the following disk piece can generate a certain offset along the direction of motion, thereby relieving the pressure of the boundary of the flow field and increasing the quantity of recycling openings to accelerate recycling; conversely, when the high-speed motion of the silicon wafer leads the pressure at one side of the flow field to be reduced, the flexible seal disk piece at the side can generate a certain offset along the direction of motion to carry out pressure compensation and reduce the quantity of the recycling openings and the liquid recycling amount at the same side. The self-adaption recycling of the liquid can be realized by adaptively the contact quantity of the recycling openings and the flow field, the recycling efficiency is effectively improved, and the vibration and the noise brought by recycling are reduced.

Owner:ZHEJIANG UNIV

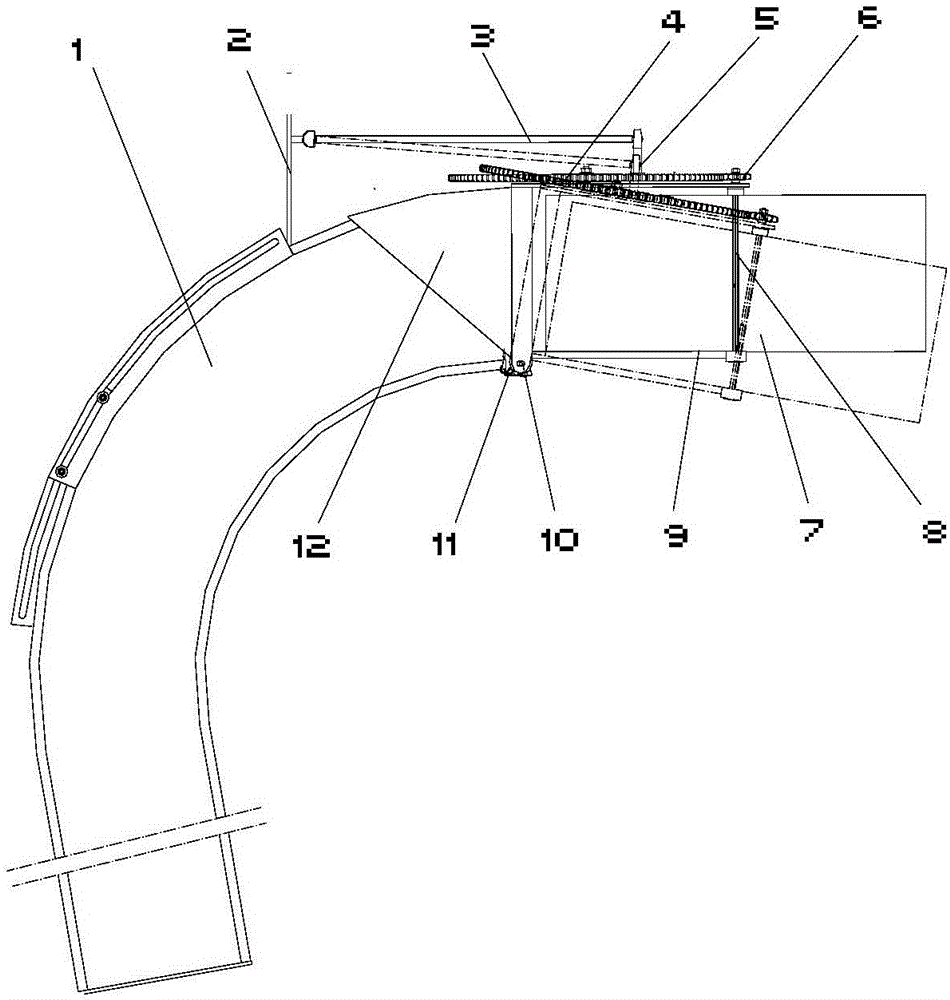

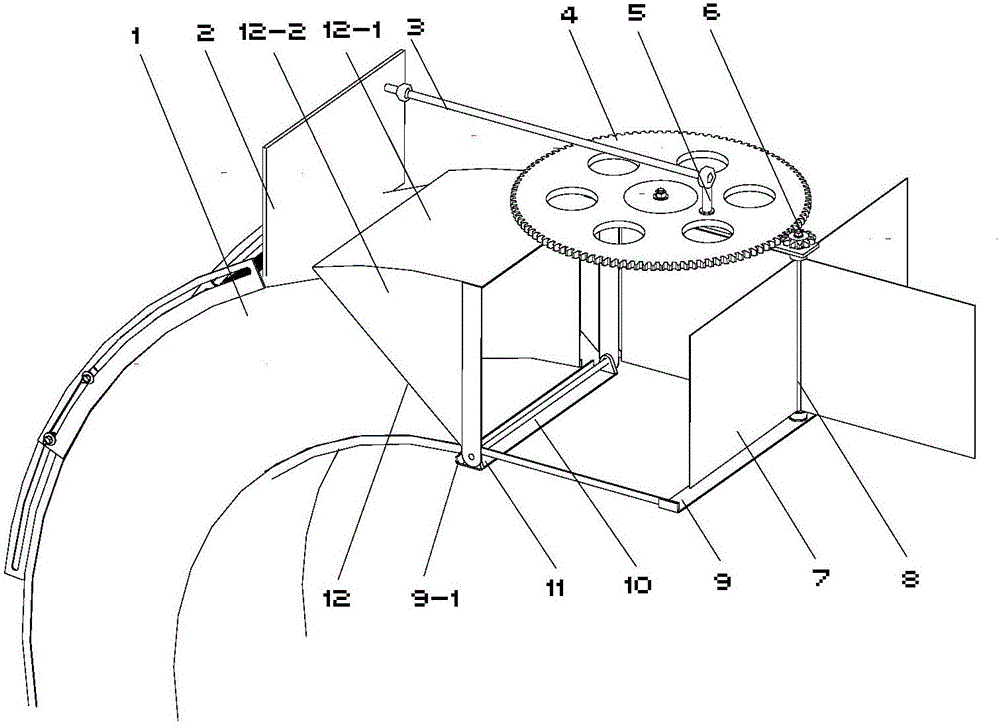

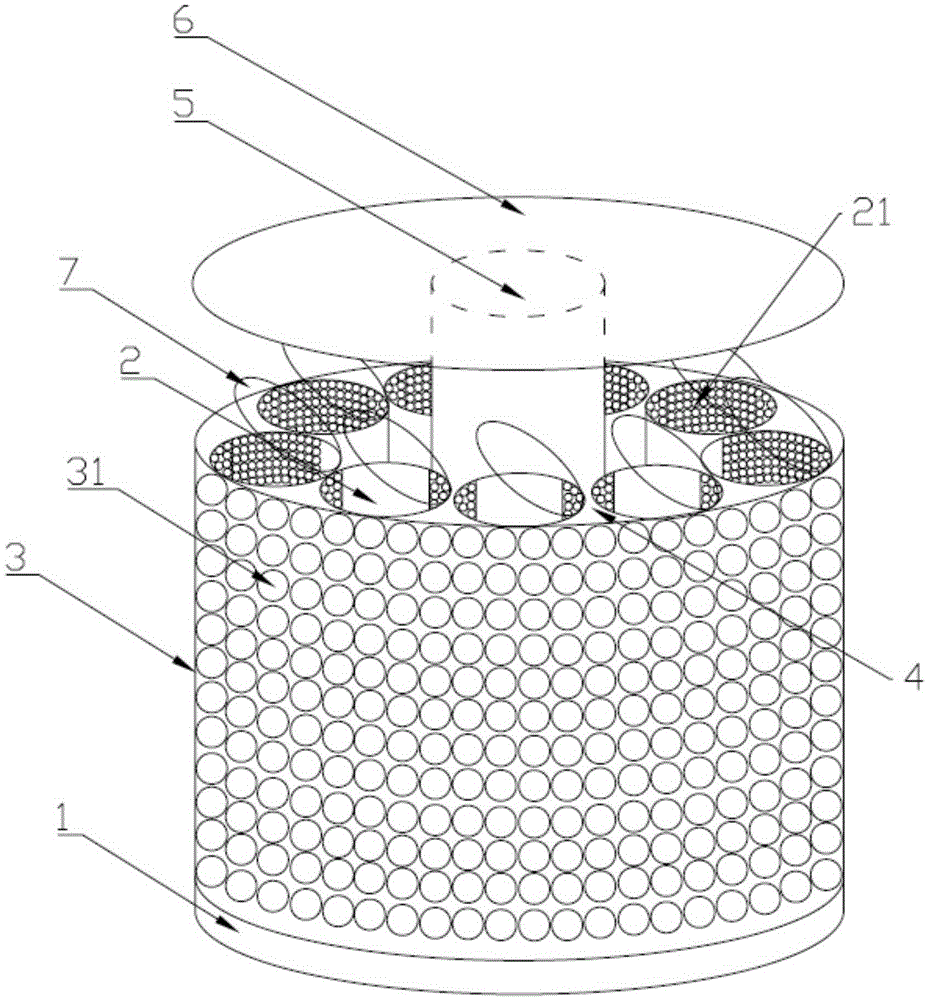

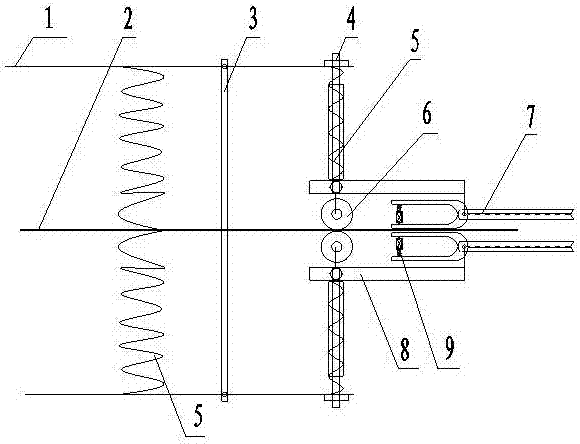

Particle material uniform paving apparatus for pneumatic conveying

A particle material uniform paving apparatus for pneumatic conveying, belongs to the material conveying mechanical technical field. The apparatus comprises a horizontal installation bearer, an installation bearer support and a horizontal articulated shaft vertical to the outlet air-flow direction; a hinge edge that supports a rectangular bottom frame of the framework is hinged on the articulated shaft; a vertical blade rotating shaft is equipped with at one corner of the opposite edge of the hinge edge of the rectangle frame; the blade rotating shaft extends out of the blades distributed circumferential uniformly in radial direction; a coaxial pinion is installed on the top of the blade rotating shaft; the pinion and a bull gear hinged at one side of the support framework are engaged; the bull gear is hinged to one end of a connecting rod through a connecting rod bearer with a ball hinge; and the other end of the connecting rod is hinged to a sidewall plate fixed on the end pipeline through a spherical hinge head. The pneumatic is used directly as the power and no additional power facility is needed, therefore the structure is simple; vertical and transversal combination can be realized instead of shattering the material in a single direction; the bunker volume can be fully utilized; no extruding effect is applied to the material; and damage to the material is avoided.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

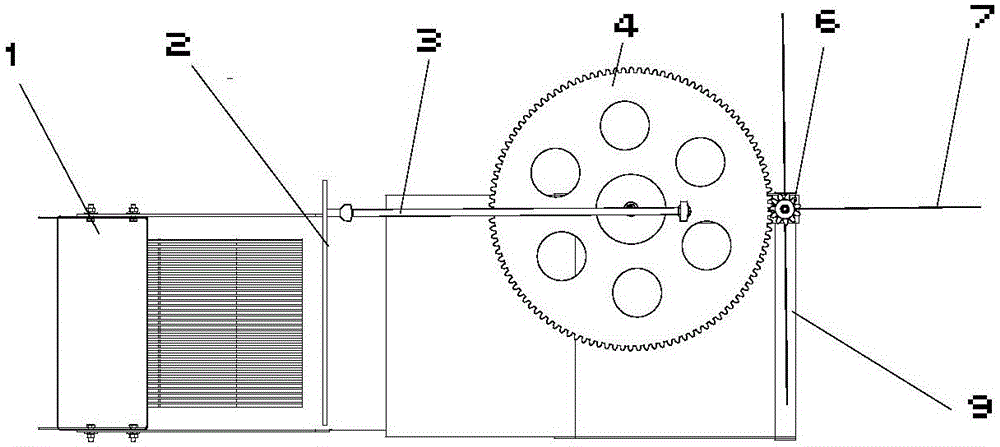

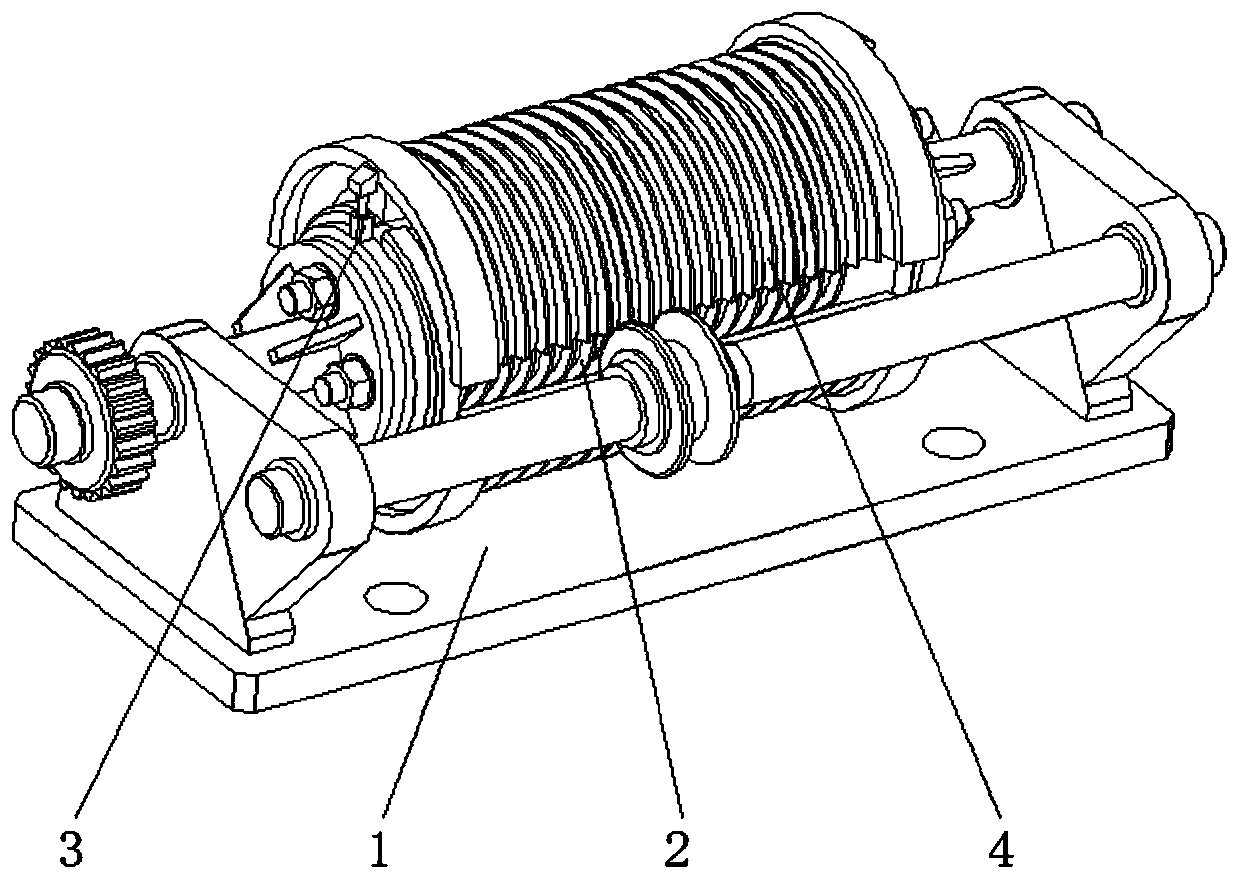

Winch traction wheel disc used for marine ship

ActiveCN110937537AFacilitates single-layer distributionGuaranteed connection strengthWinding mechanismsTraction cordWinch

The invention relates to the winch traction equipment technology field and discloses a winch traction wheel disc used for a marine ship. An installation base is included. Middle portions of two sidesof an inner cavity of the installation base are fixedly connected with two ends of an inner traction disc, the two ends of the inner traction disc movably sleeve a conversion mechanism, and an upper end and a lower end of the conversion mechanism are fixedly connected with an upper side and a lower side of one end of an outer traction disc wrapping a periphery of the inner traction disc. By usingthe winch traction wheel disc used for the marine ship, the inner traction disc and the outer traction disc are arranged so that a wound and dragged rope can be conveniently distributed in a single layer. Compared with an existing winch wheel disc, by using the winch traction wheel disc of the invention, when the rope is used for winding and pulling an object, the ropes on each layer cannot be extruded and scraped; then, a rust-proof coating on a surface of the traction rope can be effectively protected, a corrosion phenomenon caused by seawater corrosion is avoided, connection strength of thetraction rope is ensured and safety is high; and meanwhile a service life of the traction rope is prolonged.

Owner:SHANGHAI SAJIE MASCH EQUIP CO LTD

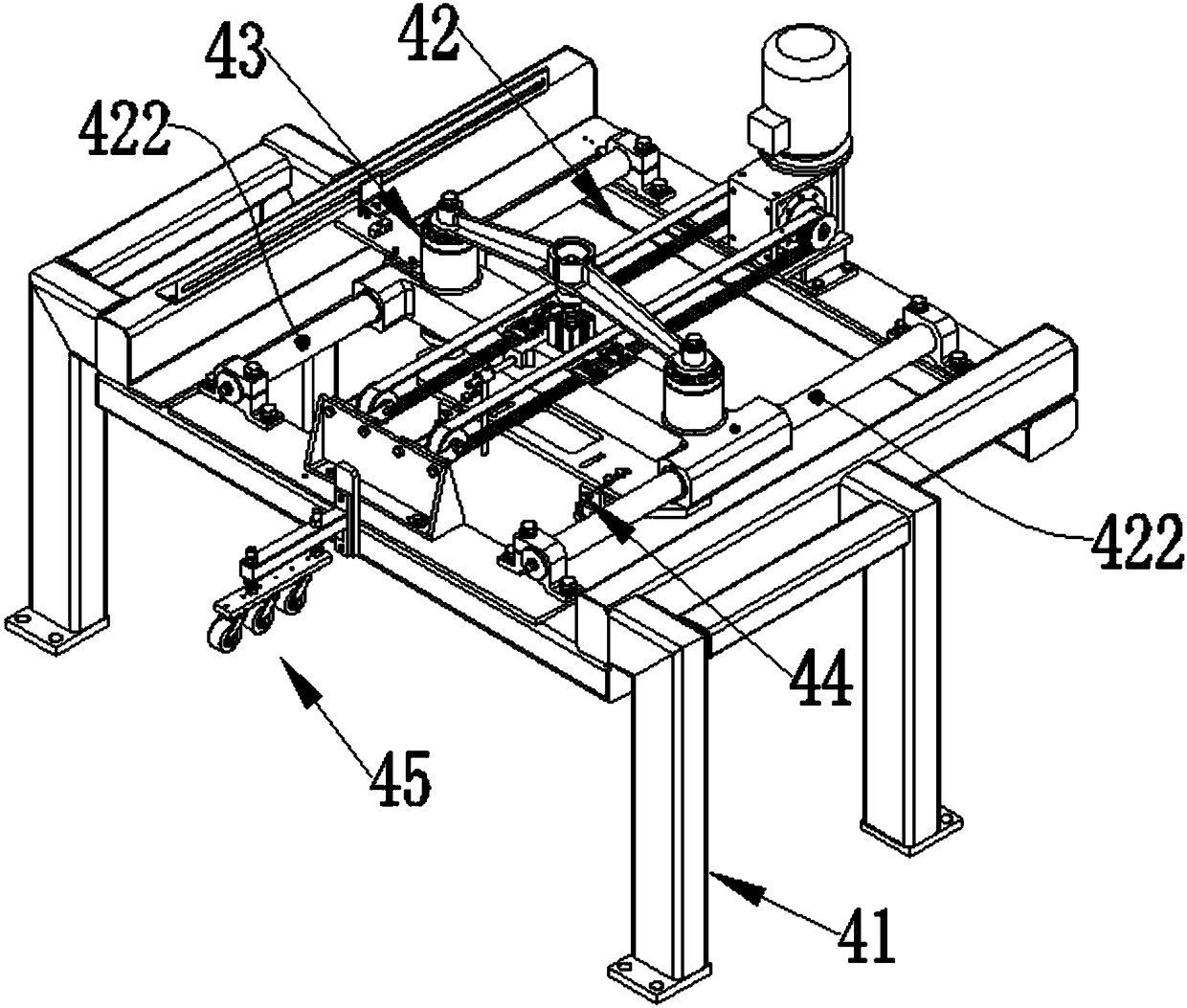

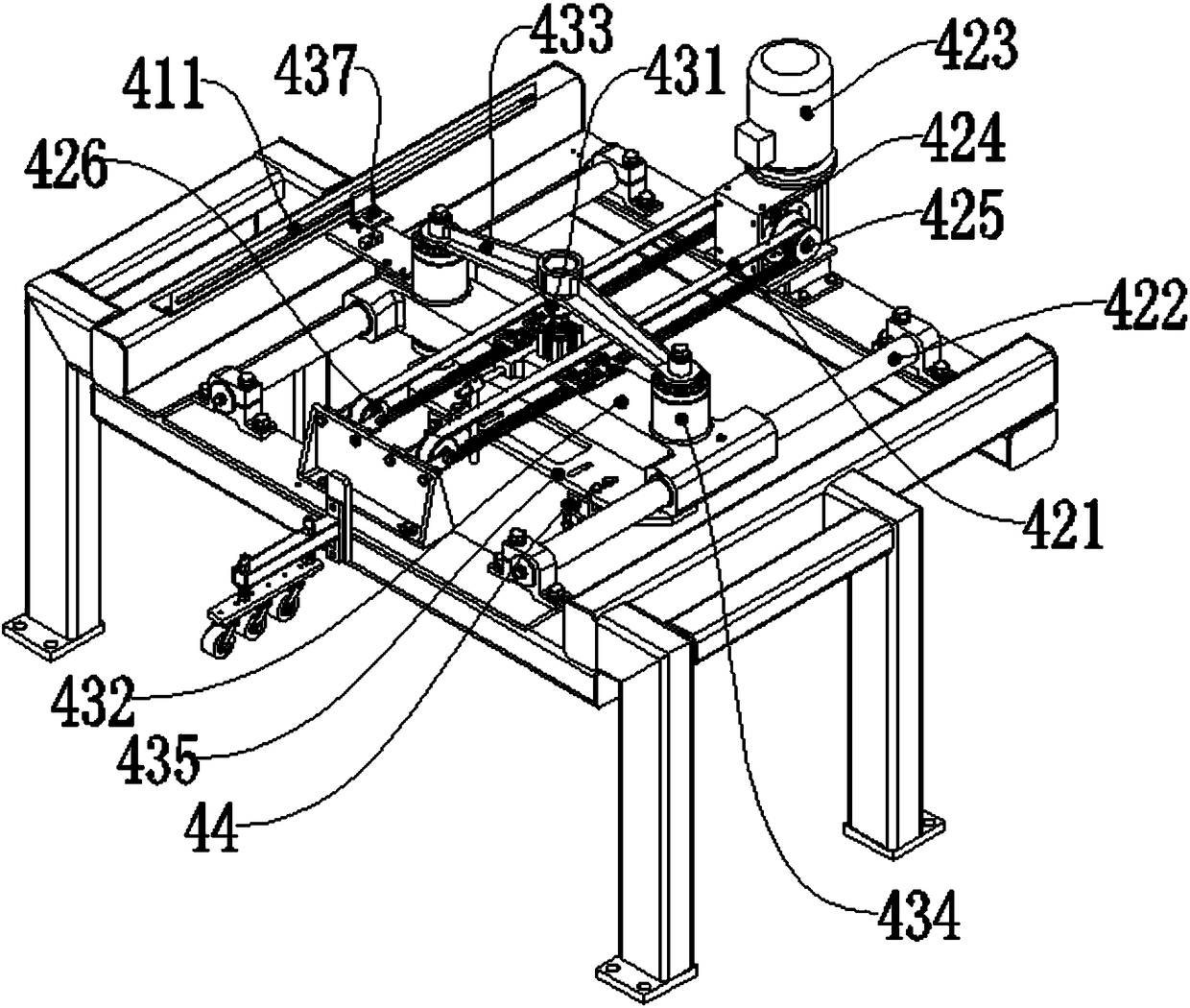

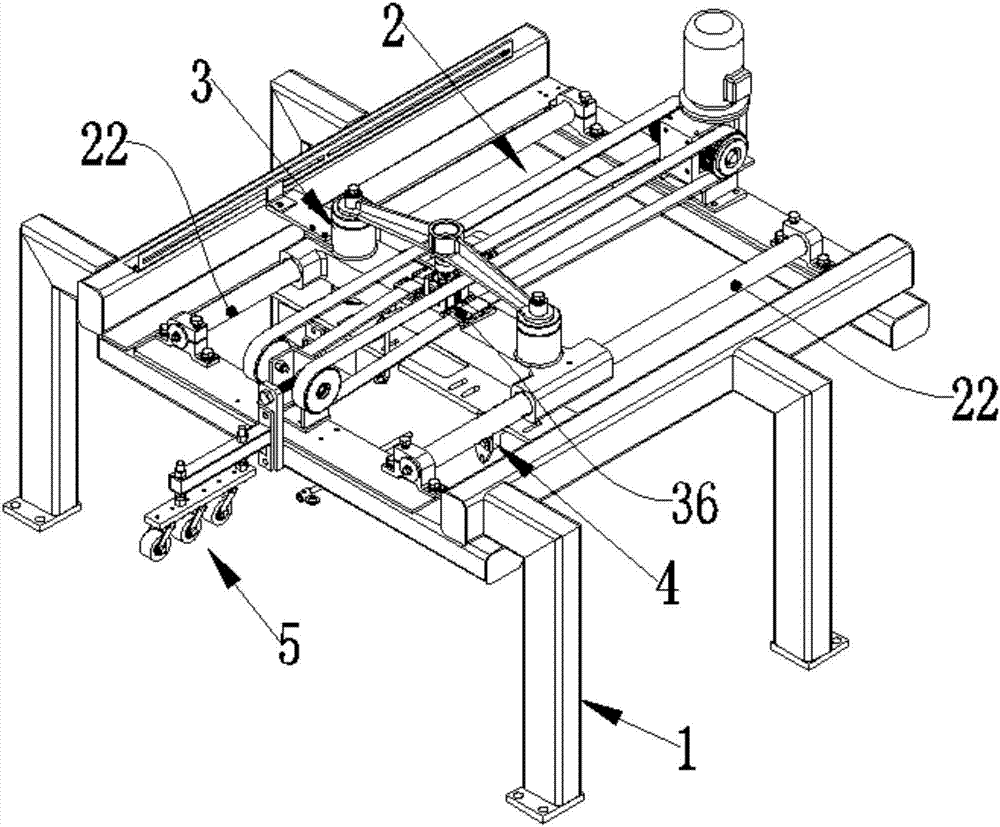

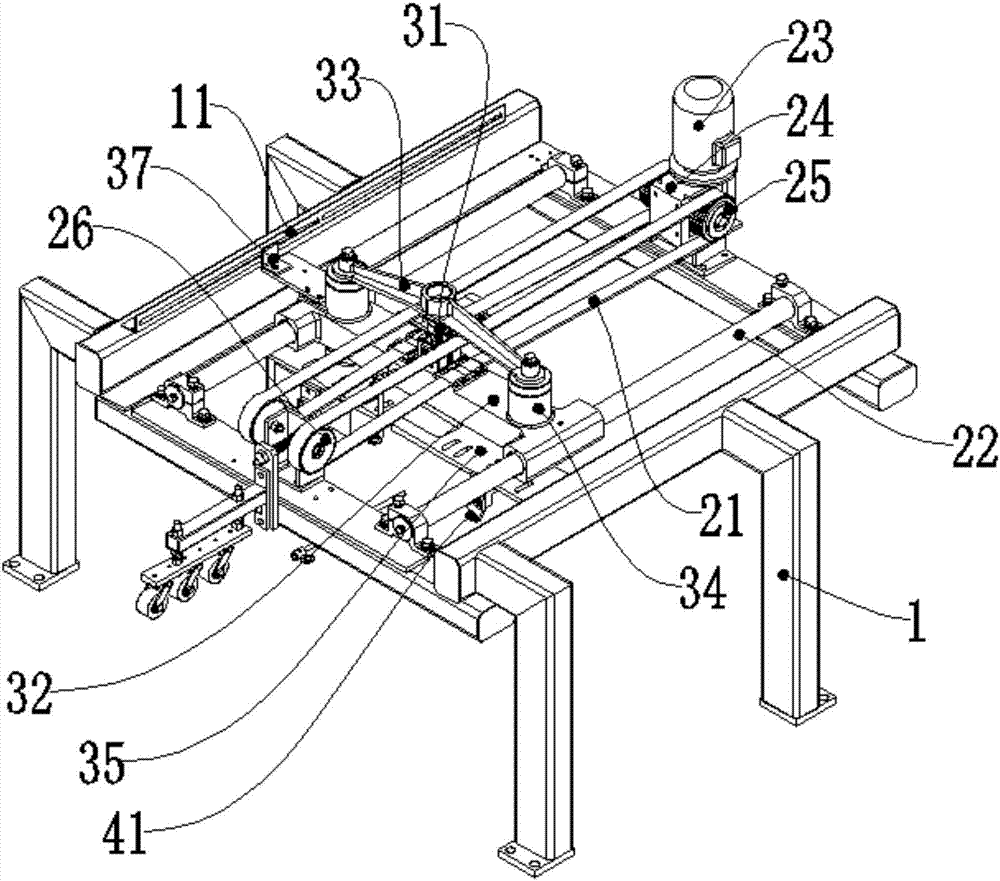

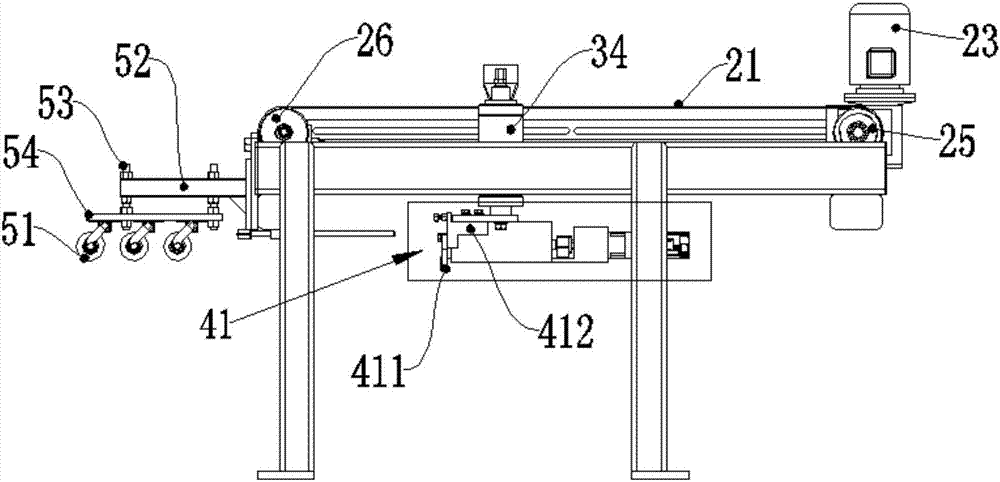

Ceramic trimming machine with high-precision correction function

InactiveCN109422086AReduce diagonal errorNo extrusionCeramic shaping apparatusConveyor partsBrickTransmission belt

The invention discloses a ceramic trimming machine with a high-precision correction function. The ceramic trimming machine comprises a base, a feeding conveyor belt and at least two trimming devices,and further comprises a correction device; a tile pushing sliding base is driven by a sliding transmission belt to slide horizontally; and a tile pushing lifting module drives a correction block mounting plate to move up and down. The ceramic trimming machine with the high-precision correction function corrects tiles before the trimming process, thus, the diagonal error of the tiles is reduced, the cutting precision is improved, and the effect that the produced tiles after trimming are square is ensured; and the tiles of different specifications can be corrected, that is, when the tiles of different specifications are conveyed by the feeding conveyor belt at a time, the mounting position of a correction block unit does not need to be adjusted, and the production flexibility and adaptability are high.

Owner:刘长江

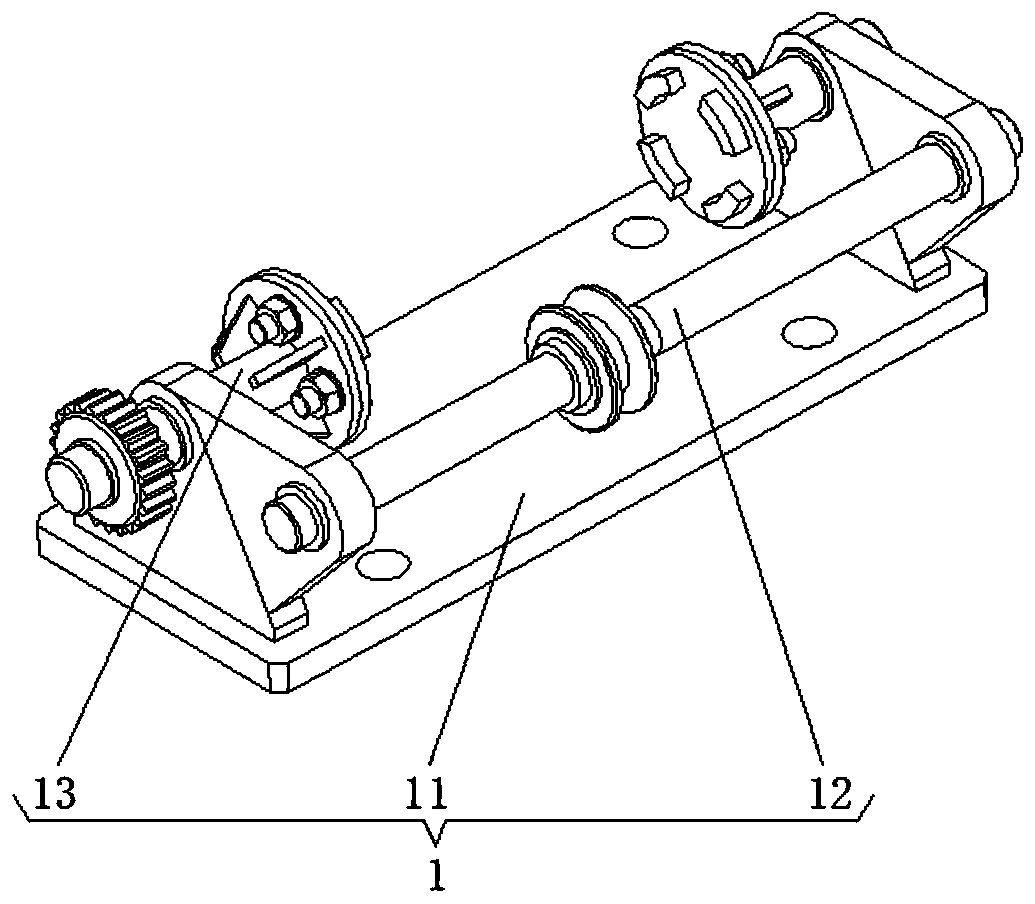

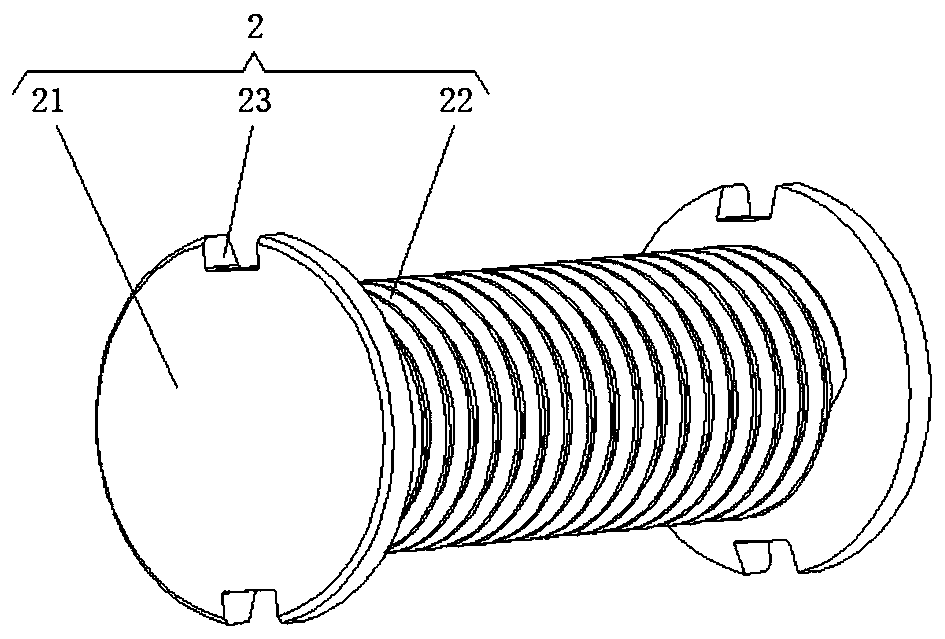

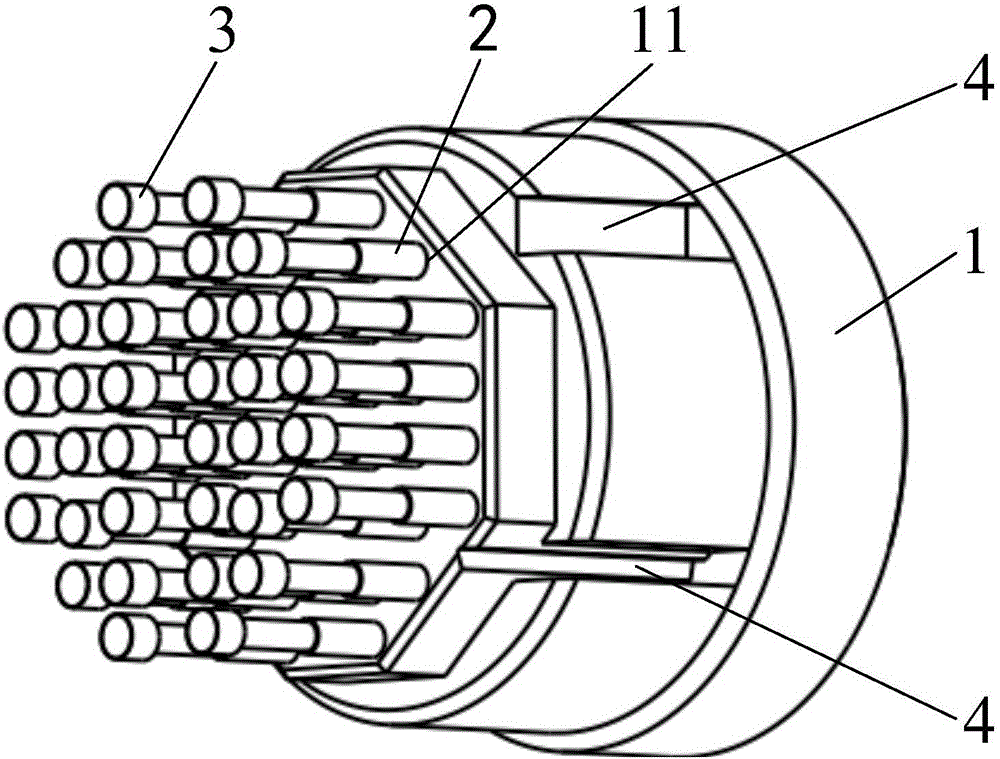

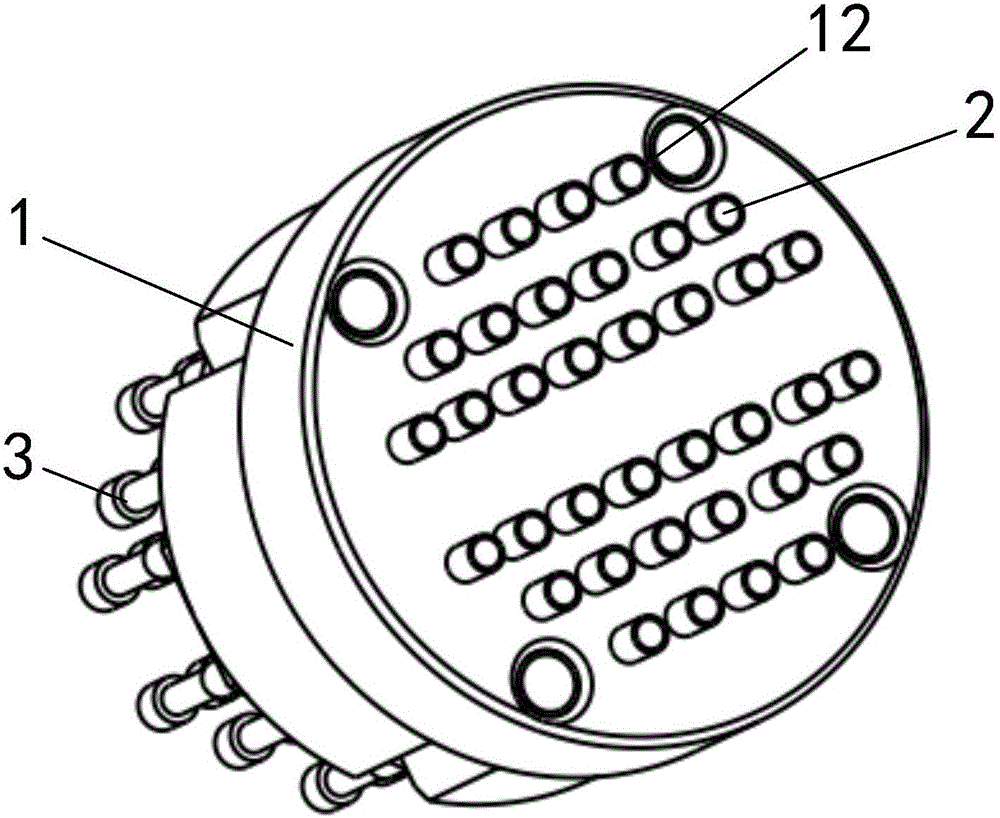

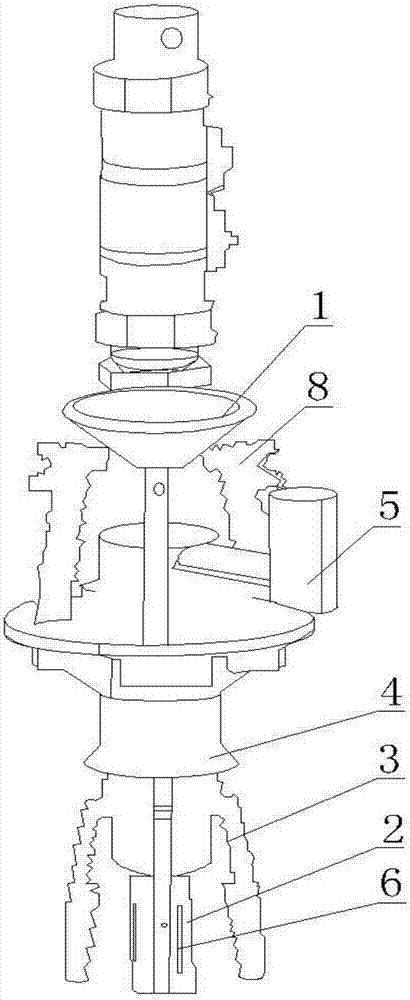

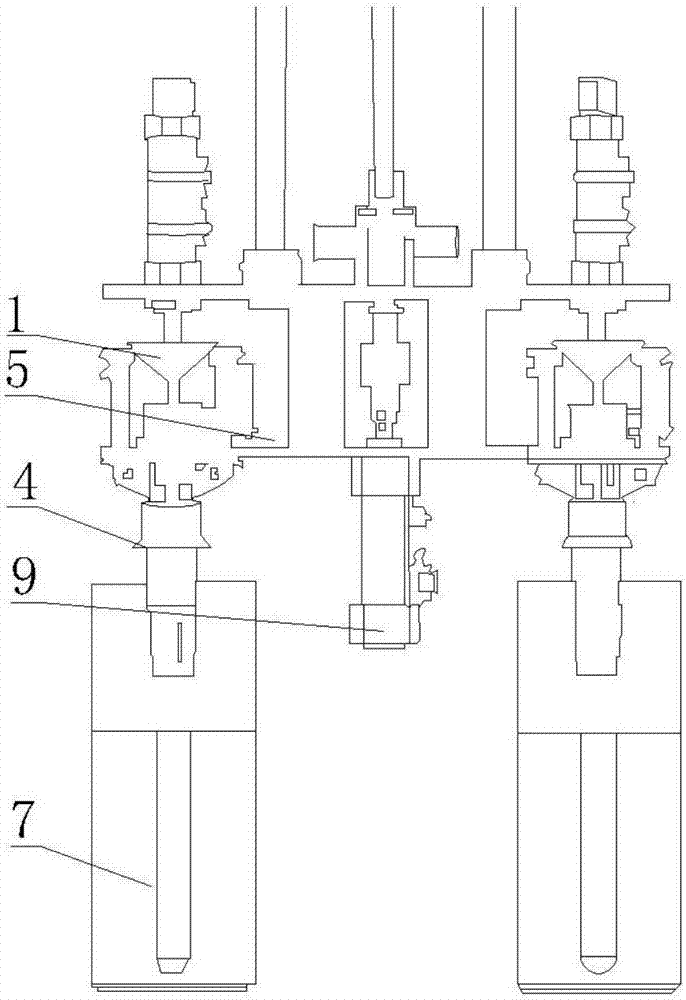

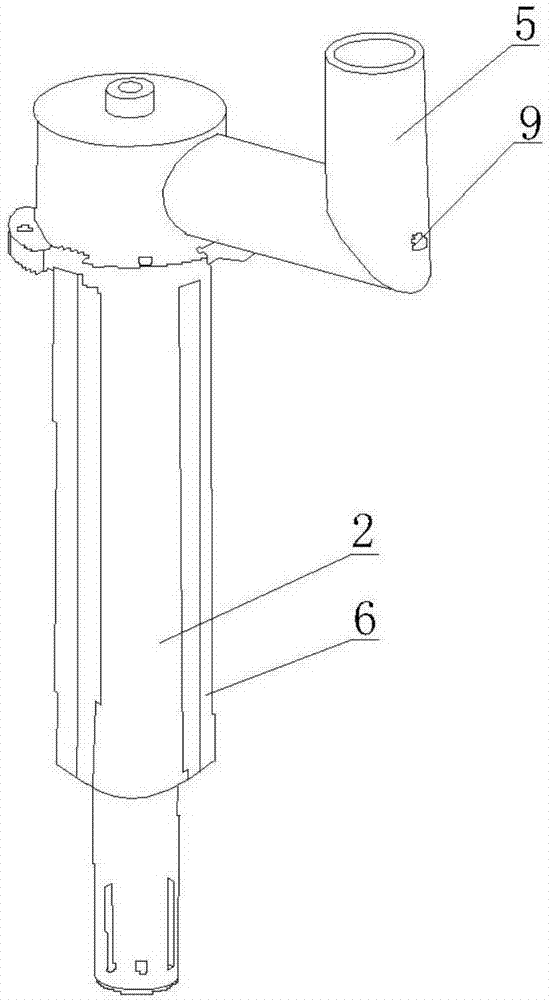

Connection plug-in for automatic transmission end of line test bench

ActiveCN105826739AActive connectionExtend your lifeMachine gearing/transmission testingIncorrect coupling preventionAutomatic transmissionTest bench

The invention discloses a connection plug-in for an automatic transmission end of line test bench, which comprises a plug-in seat (1). The plug-in seat (1) is provided with a plurality of mounting through holes (11); each mounting through hole (11) is internally provided with a terminal mounting casing (2); one end of the terminal mounting casing (2) is fixedly connected with a connection wire, and an elastic terminal (3) is inserted in the other end; the plug-in seat (1) is also provided with a limiting groove (4); and the limiting groove (4) is matched with a stiffened plate inside a to-be-tested automatic transmission harness plug-in. the purpose of quick connection can be realized, terminal connection reliability and influences on the transmission harness terminal by pressure in the case of pressing can both be considered, and better durability is realized.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

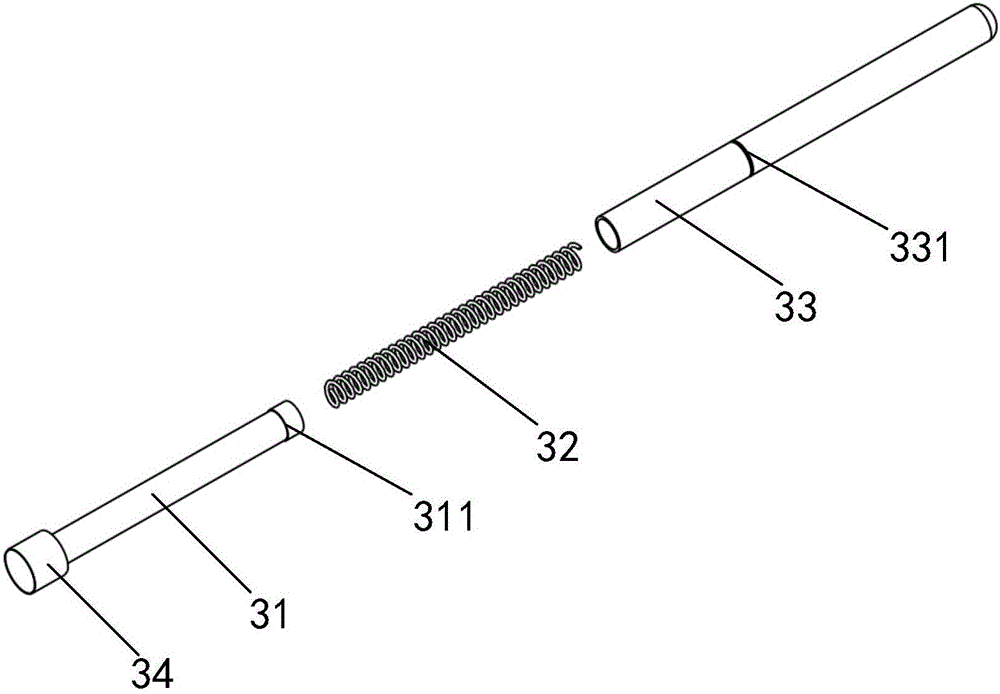

Roller sliding block human assistance non-contact type mechanical hand electric apricot picker

InactiveCN106856832AWith floating profiling functionNo extrusionPicking devicesReciprocating motionContact type

The invention provides a roller sliding block human assistance non-contact type mechanical hand electric apricot picker which comprises a handle, a supporting rod, a spring, a picker body and a collection bag. The spring, the supporting rod and the picker body are fixedly installed on the handle. The supporting rod is installed on the handle and hinged to the handle. The picker body is composed of rollers, stretchable rods, springs and shear knives, wherein each spring is a compressed spring, one end of each stretchable rod is linked to the roller, the other end of the stretchable rod penetrates through the spring and a through hole formed in the handle and is linked to the handle, one end of a connecting rod is fixed to the stretchable rod through a bolt, the other end of the connecting rod is linked to a linkage plate on a motor through a bolt, a blade of each shear knife is in the shape of a plurality of concave small circular arcs, a U-shaped groove is formed in the external circle face of the roller, the handle is operated through human assistance, a power switch is turned on, the motor rotates to drive the shear knife to reciprocate, the roller rotates on an apricot branch, the shear knife cuts off carpopodium of apricot fruits, and the apricot fruits fall into the collection bag.

Owner:ZIBO VOCATIONAL INST

Organic sulphur hydrogenation catalyst and preparation method thereof

ActiveCN104607197AEnhance synergyImprove dispersionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonLarge aperture

The invention provides an organic sulfur hydrogenation catalyst and a preparation method thereof. The catalyst adopts a special aperture passage structure that activated carbon with large particle diameter is arranged inside a carrier, activated carbon with small particle diameter is arranged on the surface of the carrier, after roasting, a plurality of slight aperture passages can be formed on the surface of the carrier, aperture passages with larger apertures are formed inside the carrier, the slight apertures on the surface of the carrier and the apertures with larger apertures are communicated with one another, the special aperture passage structure facilitates the load of active components, and the conversion rate of the catalyst provided by the invention to the carboxide sulfur can reach 99.8 percent. Moreover, during the preparation process of the carrier, a metal additive is added, the control of the aperture passage structure and the pore size distribution of the carrier is facilitated, the synergistic effect of all active components is improved, further the dispersibility of the active component is increased, and the catalytic activity of the catalyst is improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

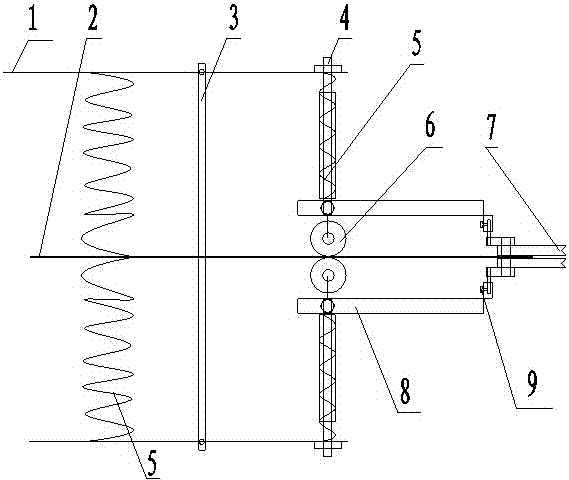

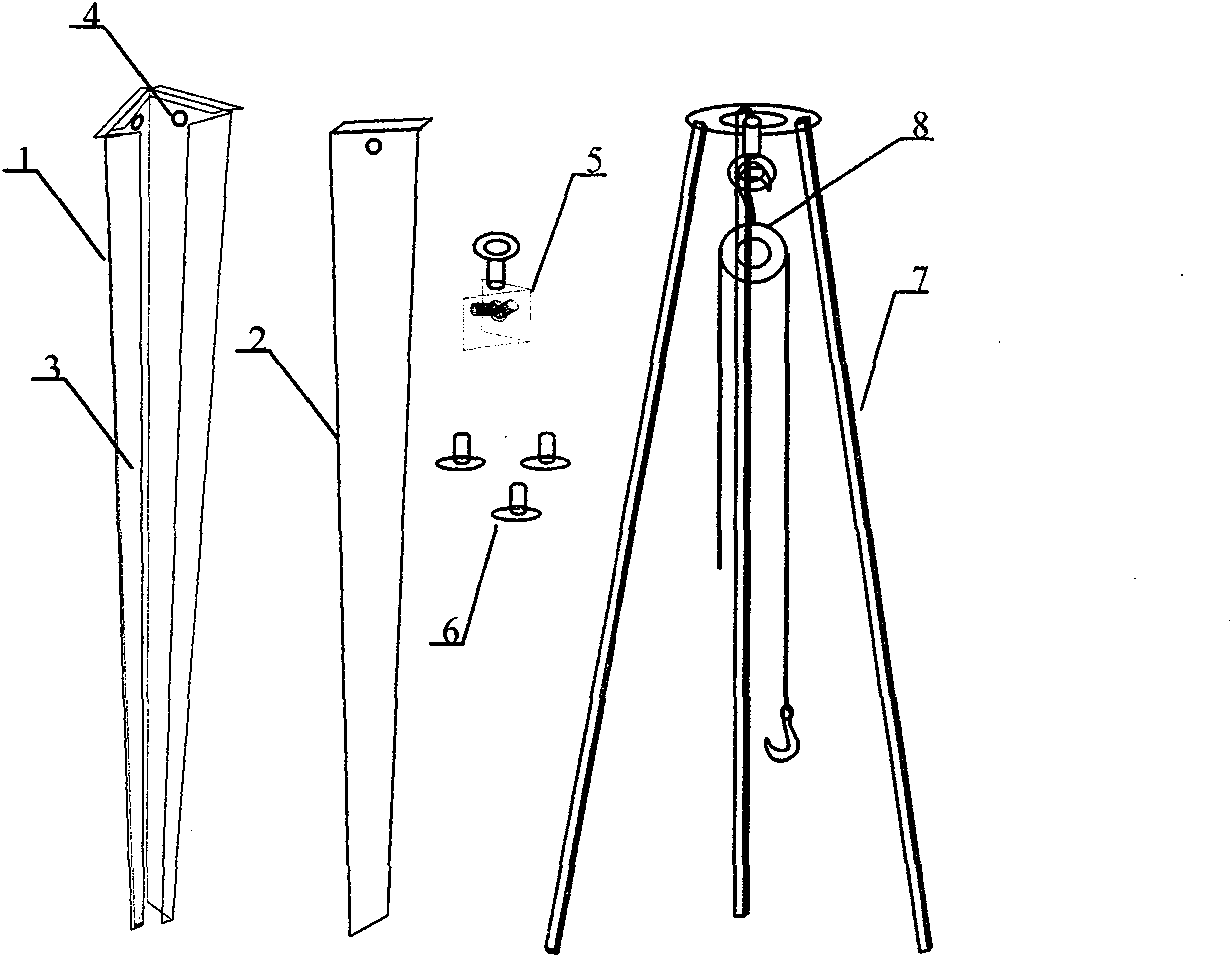

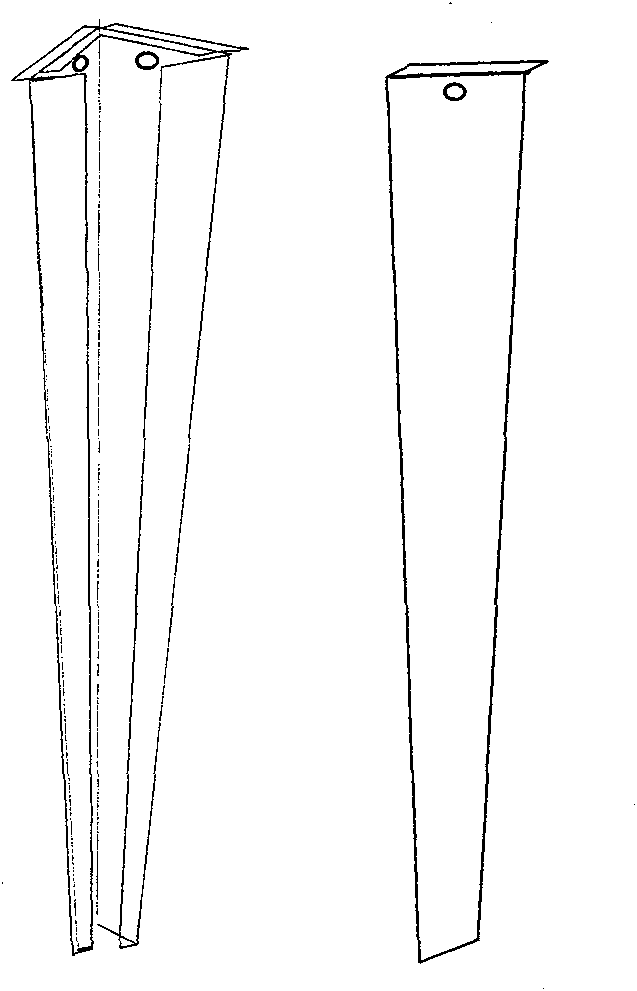

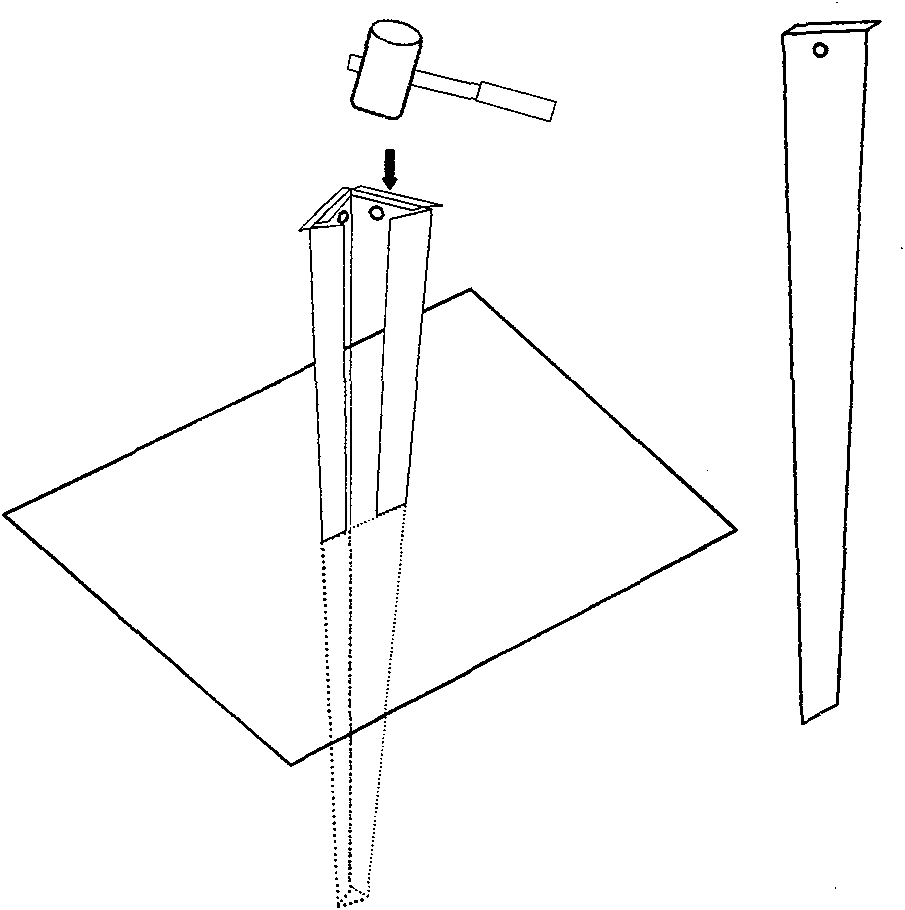

Deep layer section soil sampler and sampling method thereof

InactiveCN101598637ANot easily deformedEasy to separateWithdrawing sample devicesRight triangleEngineering

The invention relates to a deep layer section soil sampler and sampling method thereof, belonging to the ecologic study field of soil science, environmental science, and the like. The invention comprises an inverted triangular pyramidal main sampler, a seal sheet, a fixer and a tripod, the transversal surface of the main sampler is an equilateral right-angled triangle, a longitudinal opening is arranged along the bevel edge of the main sampler, the sealing strip fits the longitudinal opening, the upper end of the main sampler and the upper end of the sealing strip are respectively provided with an extension piece, the two adjacent right-angle sides of the main sampler are respectively provided with a connecting round hole, the sidewall of the sealing strip is provided with a connecting hole corresponding with the connecting round hole; the fixer is arranged in the interior of the upper part of the main sampler and is respectively connected with the main sampler and the sealing strip by a strengthened screw; the upper end of the fixer is provided with a round ring; and the lower end of the tripod is connected with an engineering pulley and the end part of the engineering pulley is connected with a hook. The invention has the characteristics that disturbance on soil is small, a mass of soil samples can be obtained, soil samples can be collected quantitatively in constant height, and soil is easy to separate from the sampling device.

Owner:HOHAI UNIV

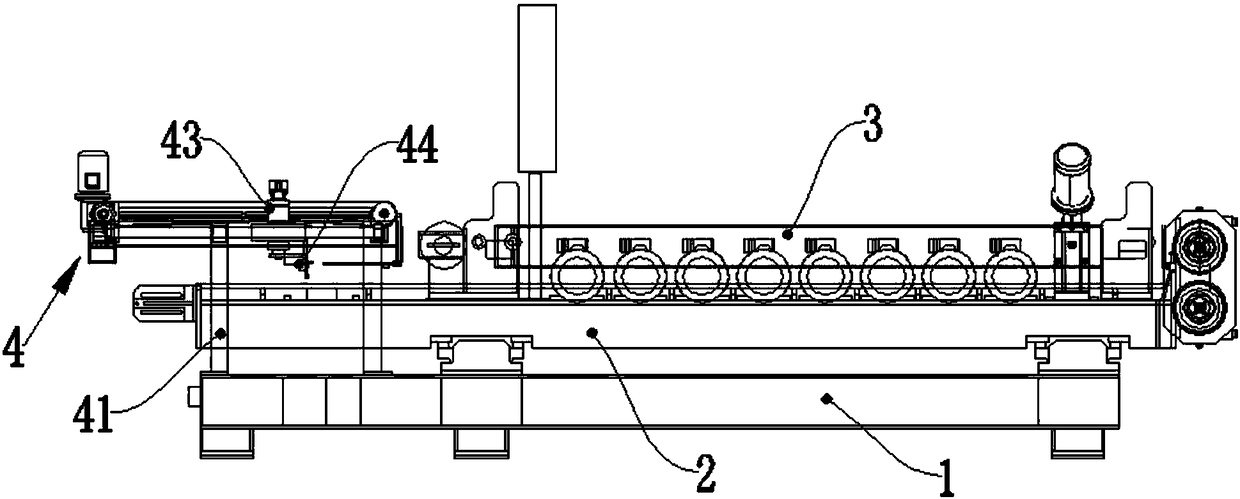

Full-automatic numerically-controlled chamfering production line and control method thereof

InactiveCN102765026AAchieve seamless connectionQuick chamferEdge grinding machinesProduction lineControl system

The invention relates to a full-automatic numerically-controlled chamfering production line and a control method thereof. The full-automatic numerically-controlled chamfering production line is provided with a first assembly line, a second assembly line and a production line control system, both the first assembly line and the second assembly line are double-speed assembly lines, the first assembly line is provided with a first arrival switch for detecting whether a material plate arrives at a switching position or not, the second assembly line is provided with a numerically-controlled chamfering and edging machine, the numerically-controlled chamfering and edging machine is provided with at least two chamfering and edging working units controlled by a numerical control system, the second assembly line is further provided with a second arrival switch for detecting whether an edge of the material plate is chamfered in place or not, and the production line control system controls the first assembly line to run in an acceleration manner according to a trigger signal of the first arrival switch, and controls the second assembly line to run in an acceleration manner, so that the material plate is forwardly conveyed to the second arrival switch. Four corners of the material plate can be quickly and automatically chamfered without squeezing, and the full-automatic numerically-controlled chamfering production line is high in work efficiency and is operated in an unattended manner.

Owner:常州东基数控机械有限公司

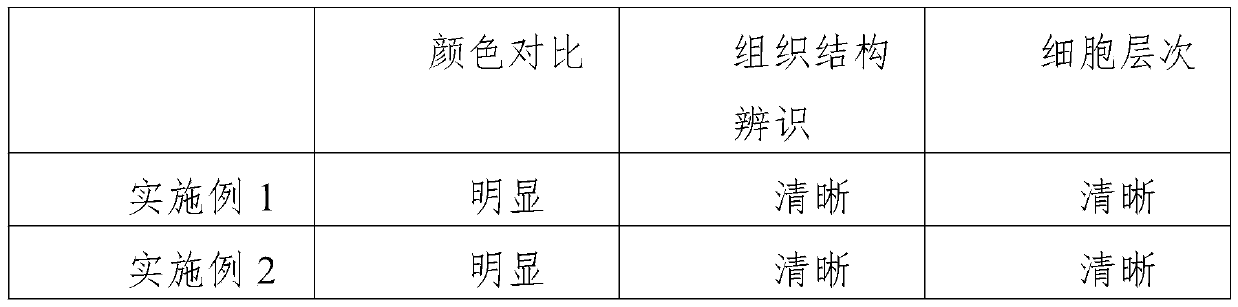

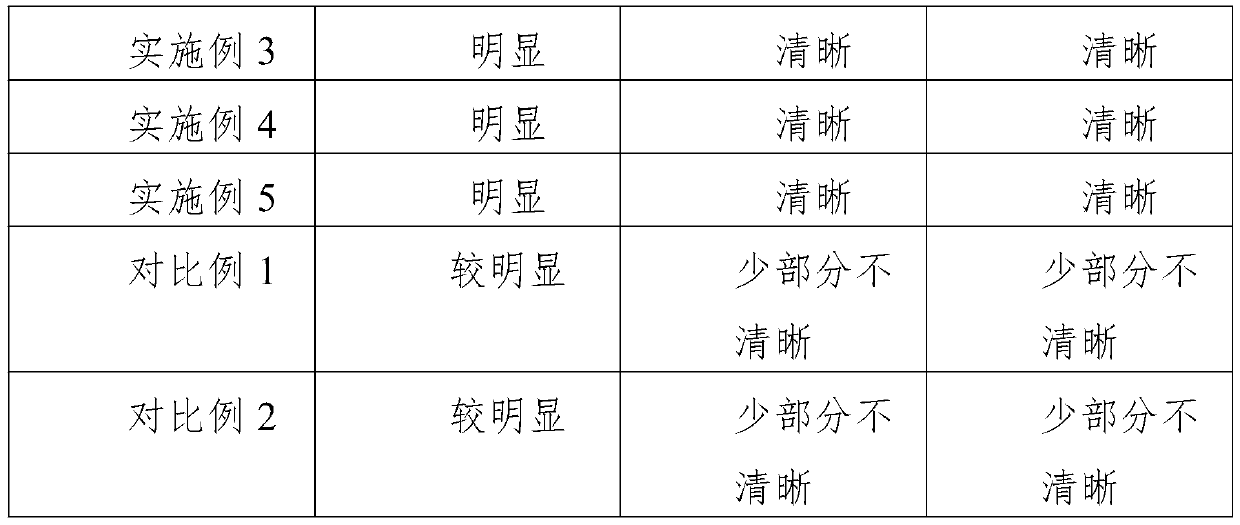

Histopathological tissue sample treatment method

PendingCN110887719AEffective preservationEasy to fixPreparing sample for investigationStainingEthylic acid

The invention provides a histopathological tissue sample treatment method, which comprises the following steps: (1) fixing: fixing an in-vitro tissue sample by adopting a fixing agent I and a fixing agent II in sequence during fixing; (2) washing; (3) dehydrating; (4) transparency treatment; (5) wax dipping and embedding; and (6) slicing and dyeing: carrying out dewaxing, treating dewaxed slices with a hematoxylin pre-dyeing solution for 2-3 minutes, and then, treating the dewaxed slices with a hematoxylin dyeing solution for 5-10 minutes, wherein the hematoxylin dyeing assistant solution comprises the following components: hematoxylin, aluminum sulfate, potassium permanganate, citric acid, nonylphenol polyoxyethylene ether and water, and the hematoxylin dyeing solution comprises the following components: hematoxylin, aluminum potassium sulfate dodecahydrate, potassium permanganate, acetic acid, nonylphenol polyoxyethylene ether, glycerol, absolute ethyl alcohol and water. The treatment method disclosed by the invention is easy to operate, high in tissue sample section integrity, good in dyeing effect, obvious in dyeing, clear in comparison and clear in cell hierarchy.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

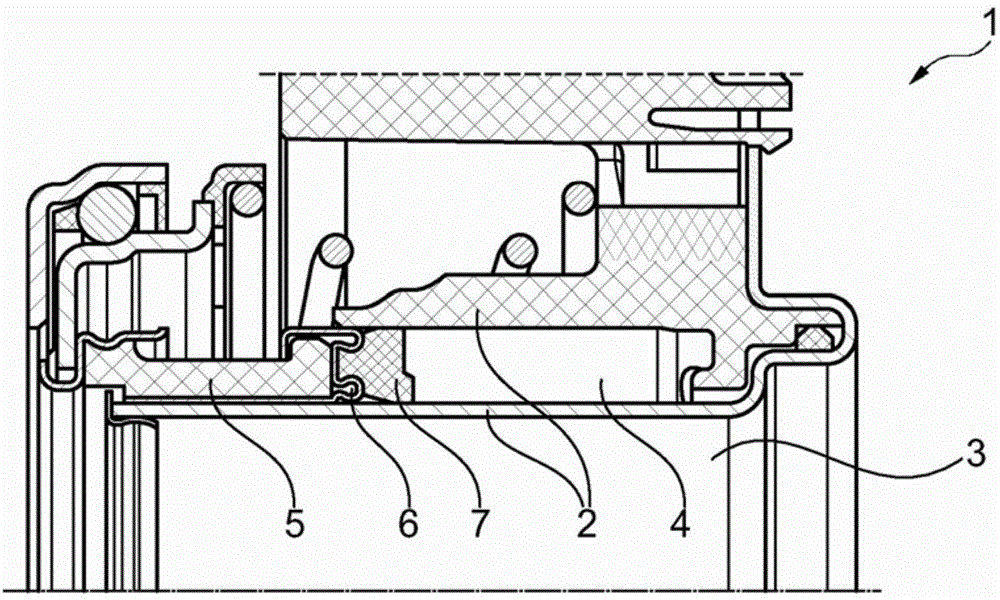

Dewatering frame of cheese water extractor

InactiveCN105239300AThoroughly dehydratedPrevent disengagementLiquid/gas/vapor removalTextile treatment carriersYarnPulp and paper industry

The invention creates and provides a dewatering frame of a cheese water extractor. The dewatering frame comprises a bottom plate and yarn containing grooves. A surrounding edge is fixedly arranged in the circumferential direction of the bottom plate. A plurality of first water spin-drying holes are evenly formed in the surrounding edge. The yarn containing grooves are evenly and fixedly formed in the bottom plate. The yarn containing grooves are connected through connecting pieces, and the yarn containing grooves are connected with the surrounding edge through connecting pieces. The connecting pieces are connected with the top of the surrounding edge. The connecting pieces are connected with the tops of the yarn containing grooves. Second water spin-drying holes are evenly formed in the side walls of the yarn containing grooves. A rotating shaft is fixed to the bottom plate. A cover plate is arranged on the top of the rotating shaft. The cover plate is located above the yarn containing grooves. The height of the surrounding edge is matched with that of the yarn containing grooves. The dewatering frame is simple in structure, convenient to use, thorough in cheese dewatering and free of squeezing phenomena.

Owner:TIANJIN BAOXIN LINE IND CO LTD

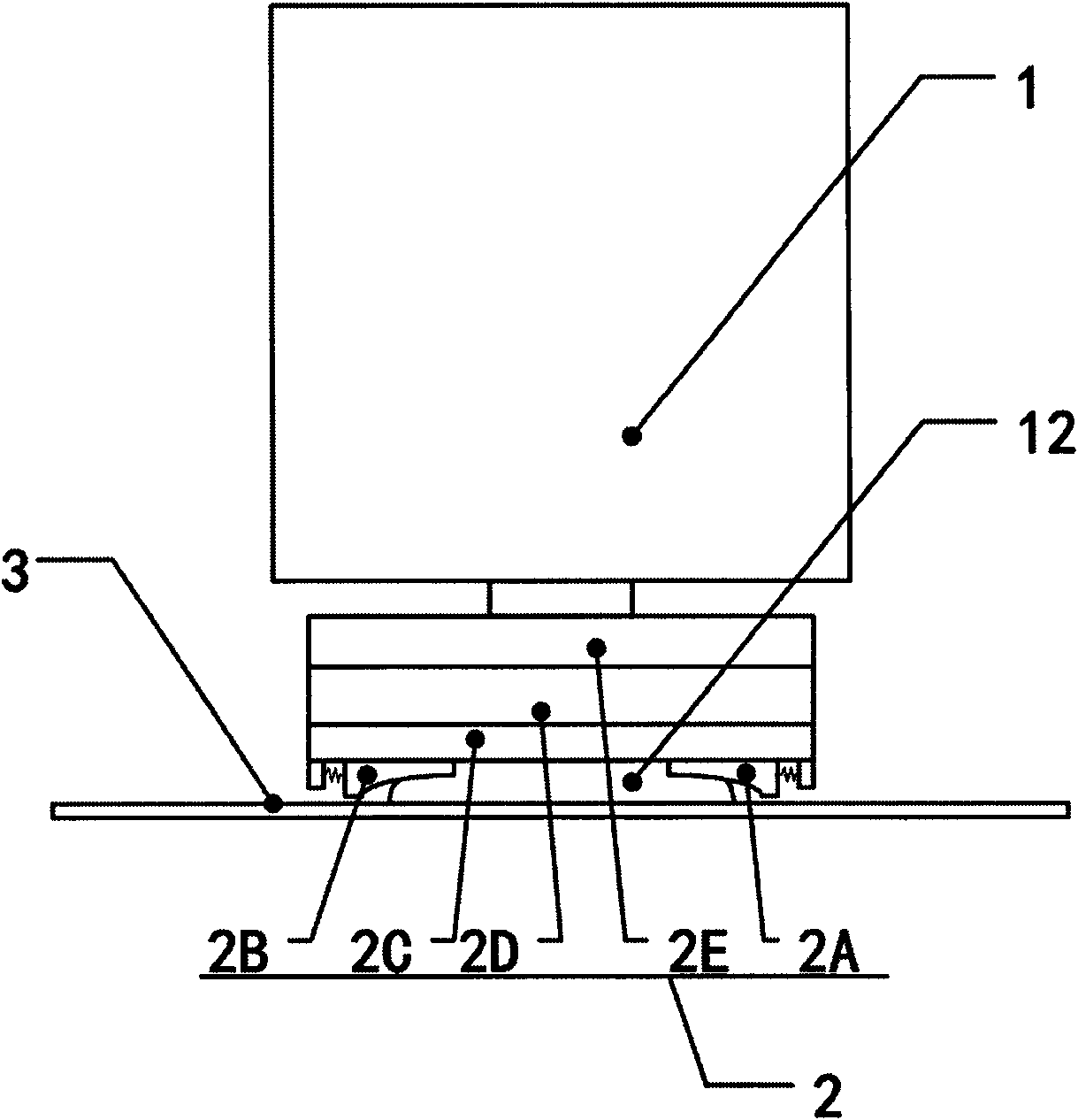

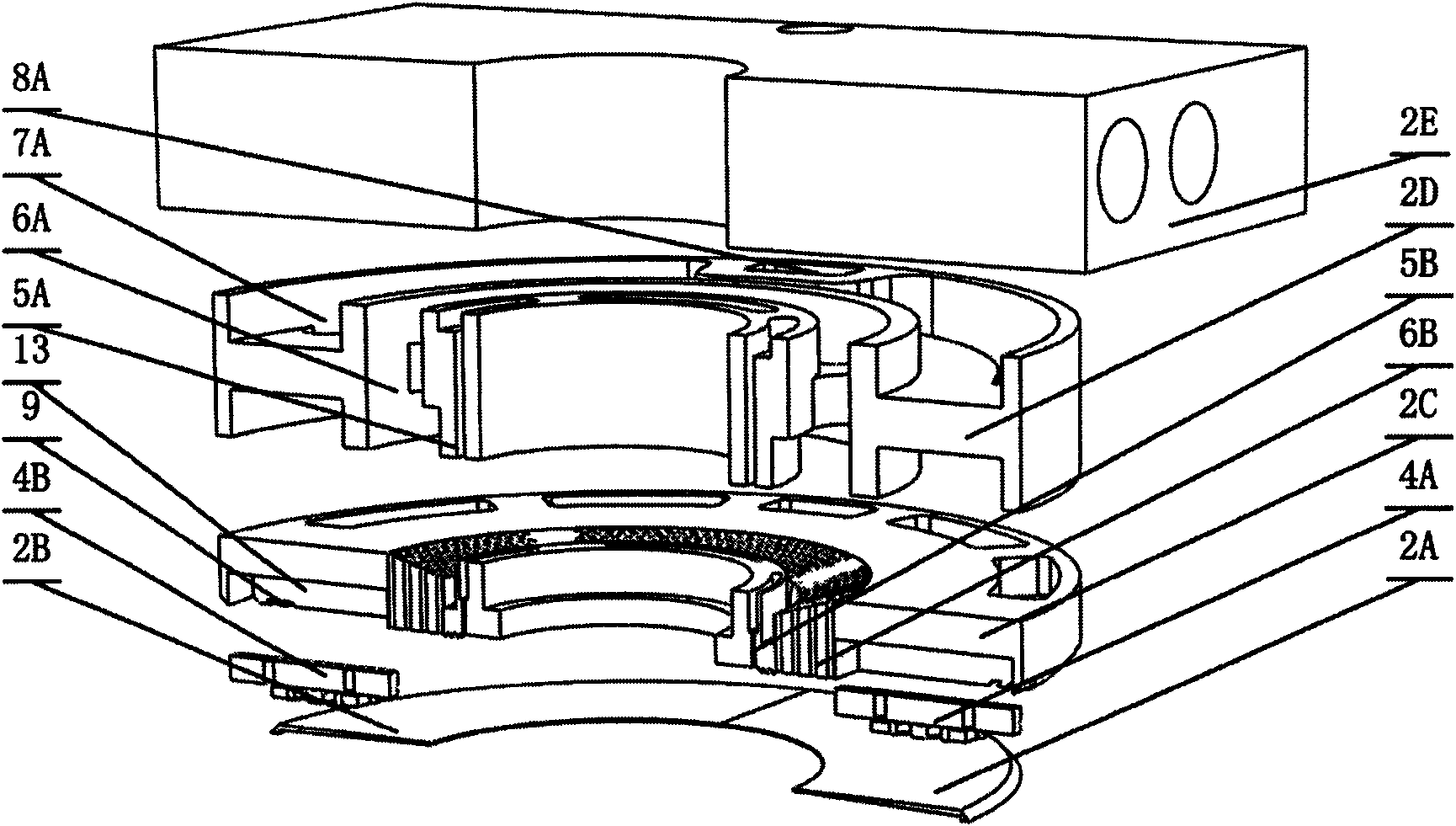

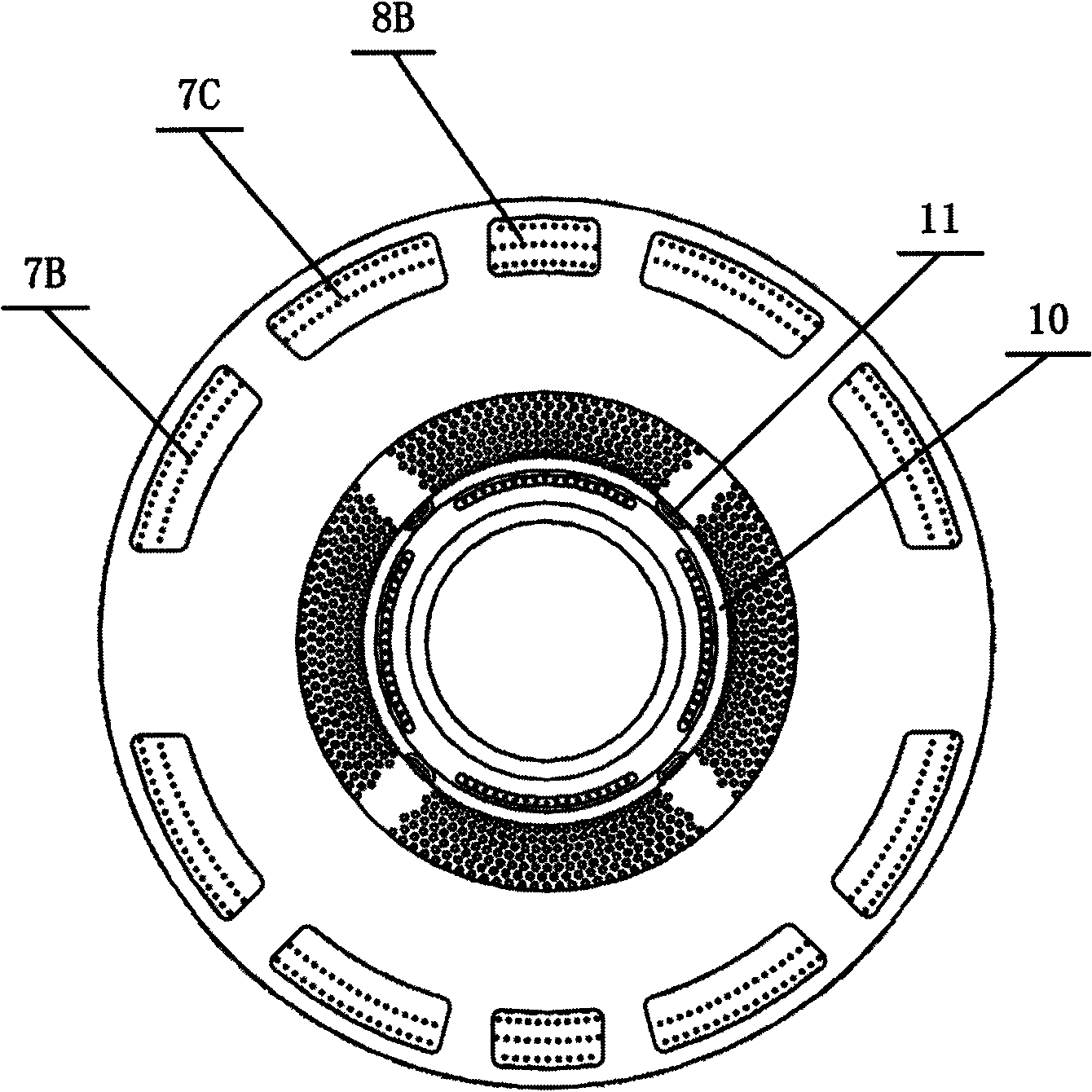

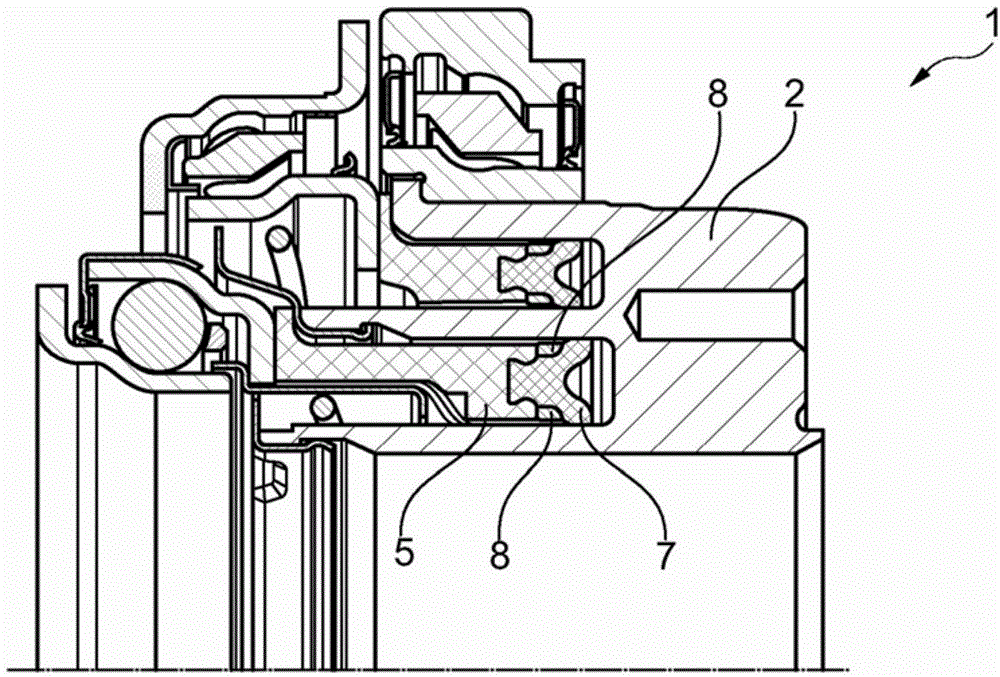

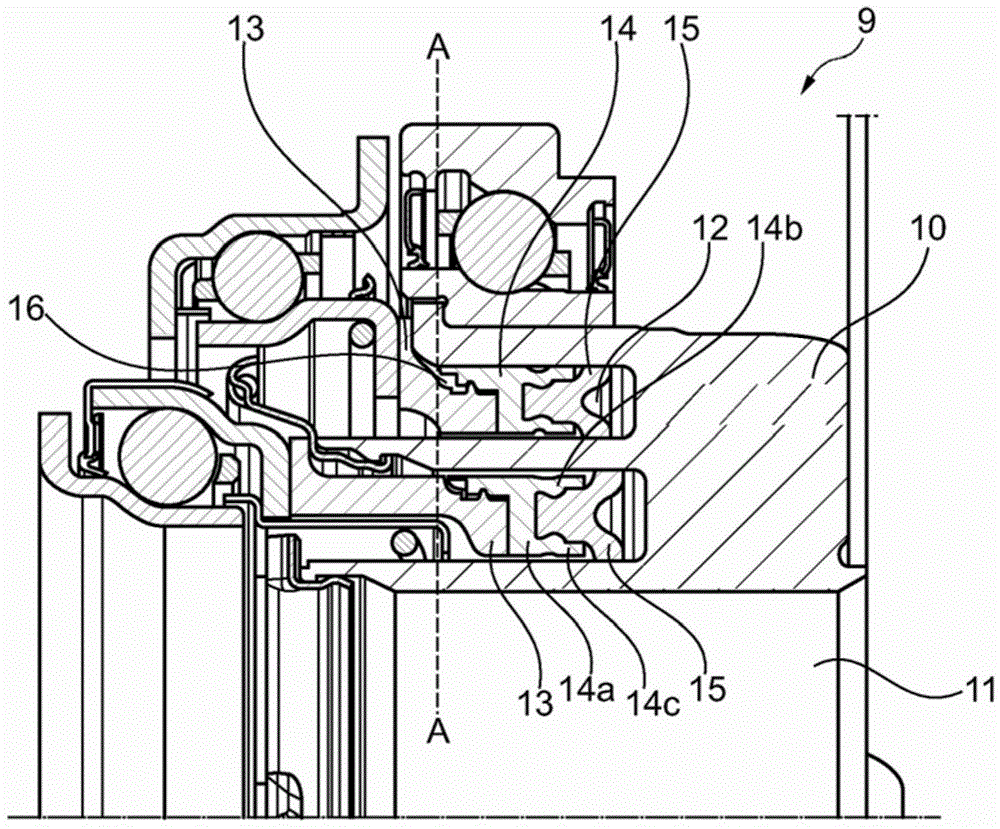

Piston-cylinder arrangement, in particular for a clutch actuation system in a motor vehicle

ActiveCN104603488AGuaranteed self-lockingEasy to installFluid actuated clutchesCouplingsMobile vehicleMotorized vehicle

Disclosed is a piston-cylinder arrangement, in particular for a clutch actuation system in a motor vehicle, comprising a housing (10) that is concentrically arranged around a shaft (11), and an annular pressure chamber (1) inside which a piston (13) is movably mounted. A sealing ring support (14) on which a seal (15) is arranged is connected to the piston. In a piston-cylinder arrangement which is less expensive to produce and nevertheless reliably prevents gap extrusion of the seal between the housing and the sealing ring support, the piston is connected without play to the sealing ring support.

Owner:SCHAEFFLER TECH AG & CO KG

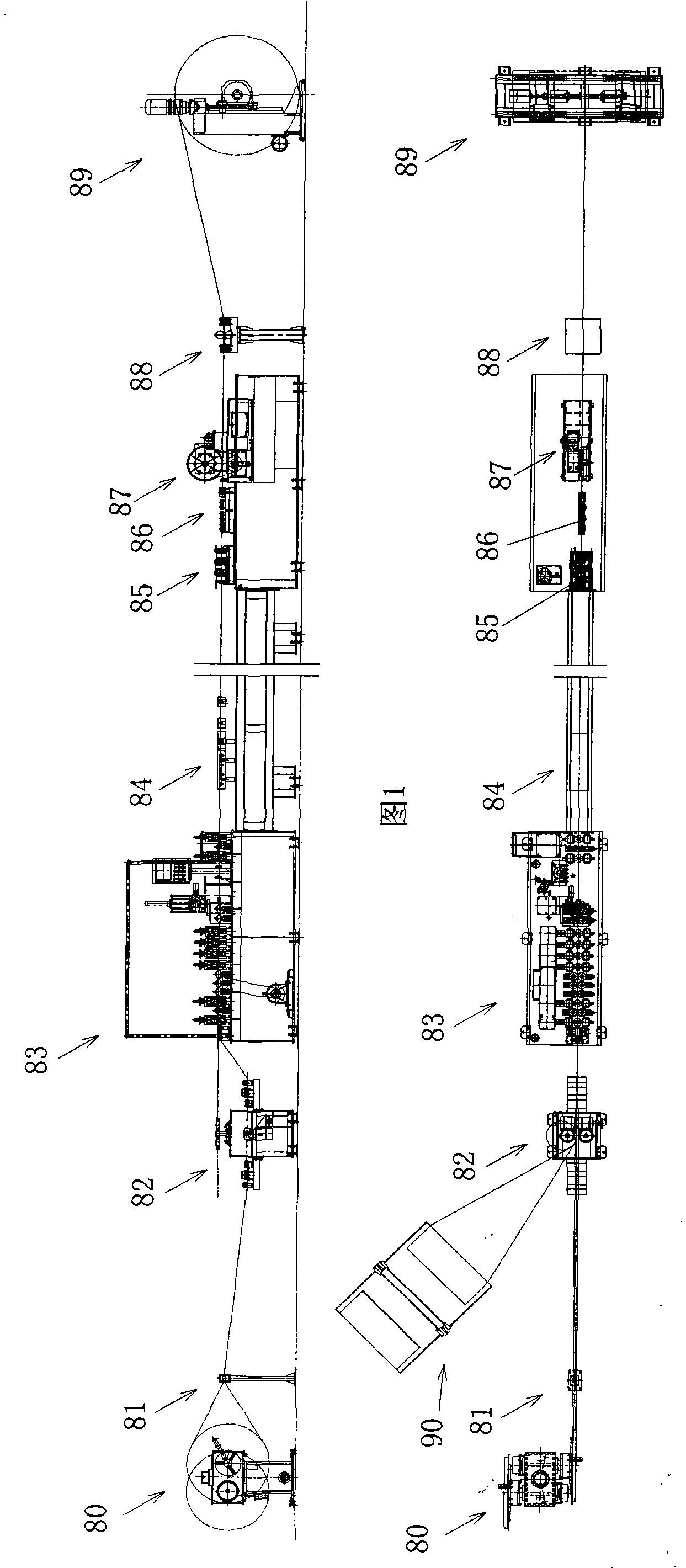

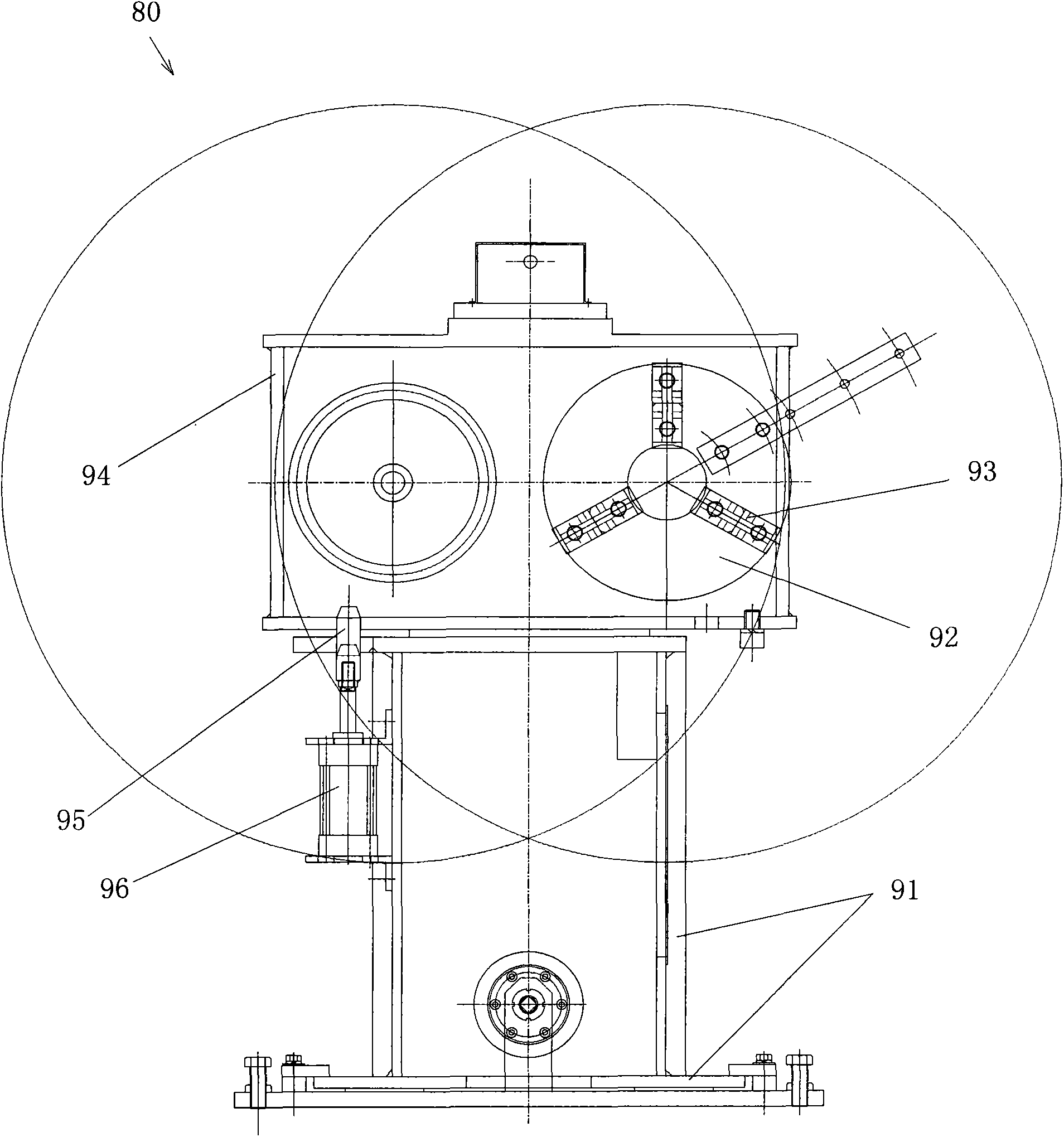

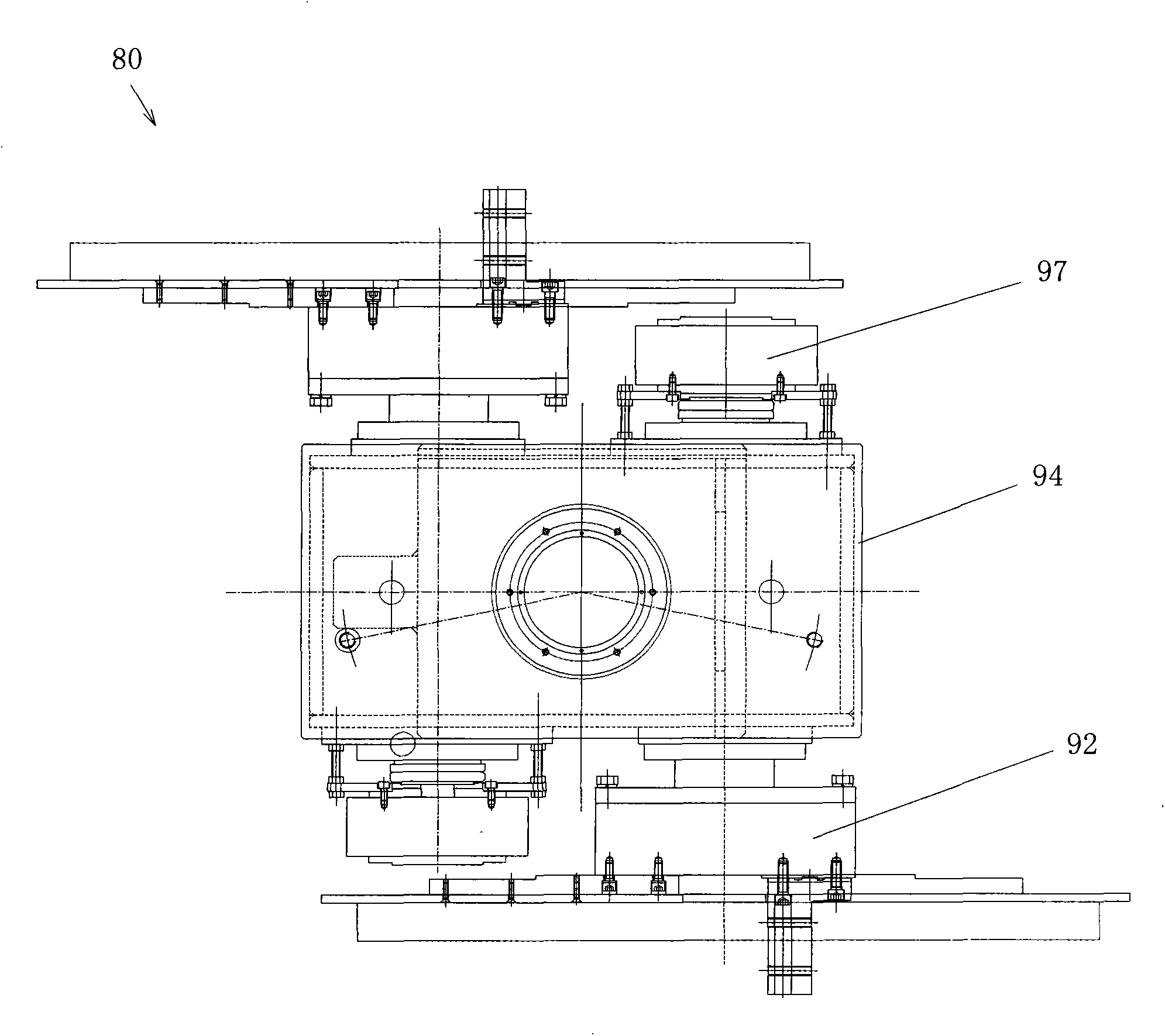

Consecutive wrapping welding drawing production line for railway subgrade through ground wires

A consecutive wrapping welding drawing production line for railway subgrade through ground wires sequentially comprises a belt releasing machine, a copper belt edge grinding washing machine, a consecutive wrapping welding device, a cooling tank, a drawing die seat device, a tractor, a wire-rewinding machine and a core wire pay-off machine. The production line is good in effect of washing copper belts, ensures that the upper face, the lower face and two side faces wrapping a front copper belt are processed and washed, and improves wrapping welding quality and the appearance quality of products. Due to the fact that a cooling component is arranged in a drawing oil cavity, reduction of the viscosity of drawing oil is effectively prevented, drawing quality is remarkably improved, the requirements of the quality of present railway subgrade through ground wires are met, production consecutiveness is good, and the failure rate in middle links is reduced. A line arranging roller is arranged on the tractor, so that wire rods wound on traction wheels can be arrayed evenly, and extrusion phenomena do not exist. Consequently, the final quality of products is further ensured.

Owner:王玉凯

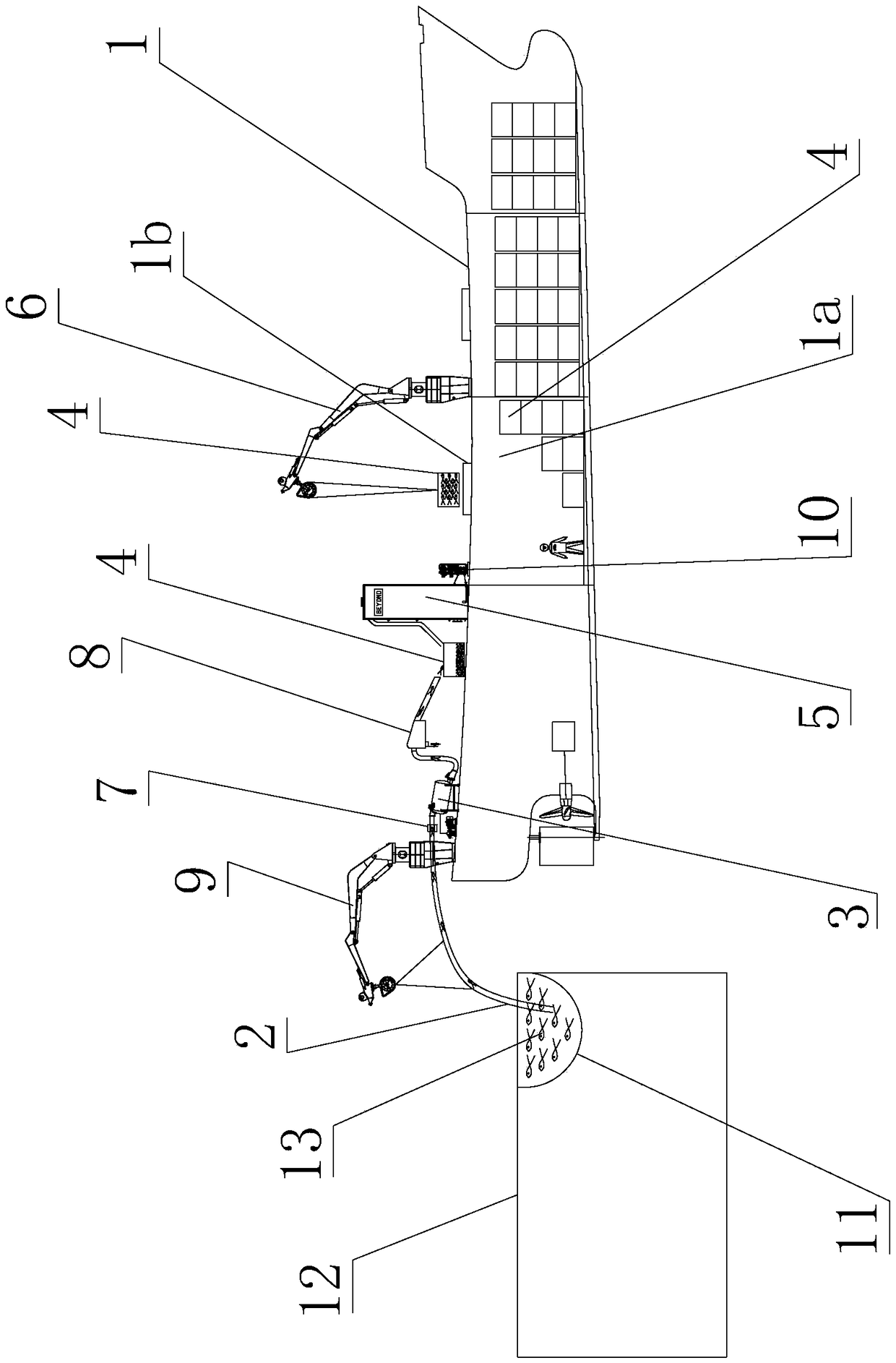

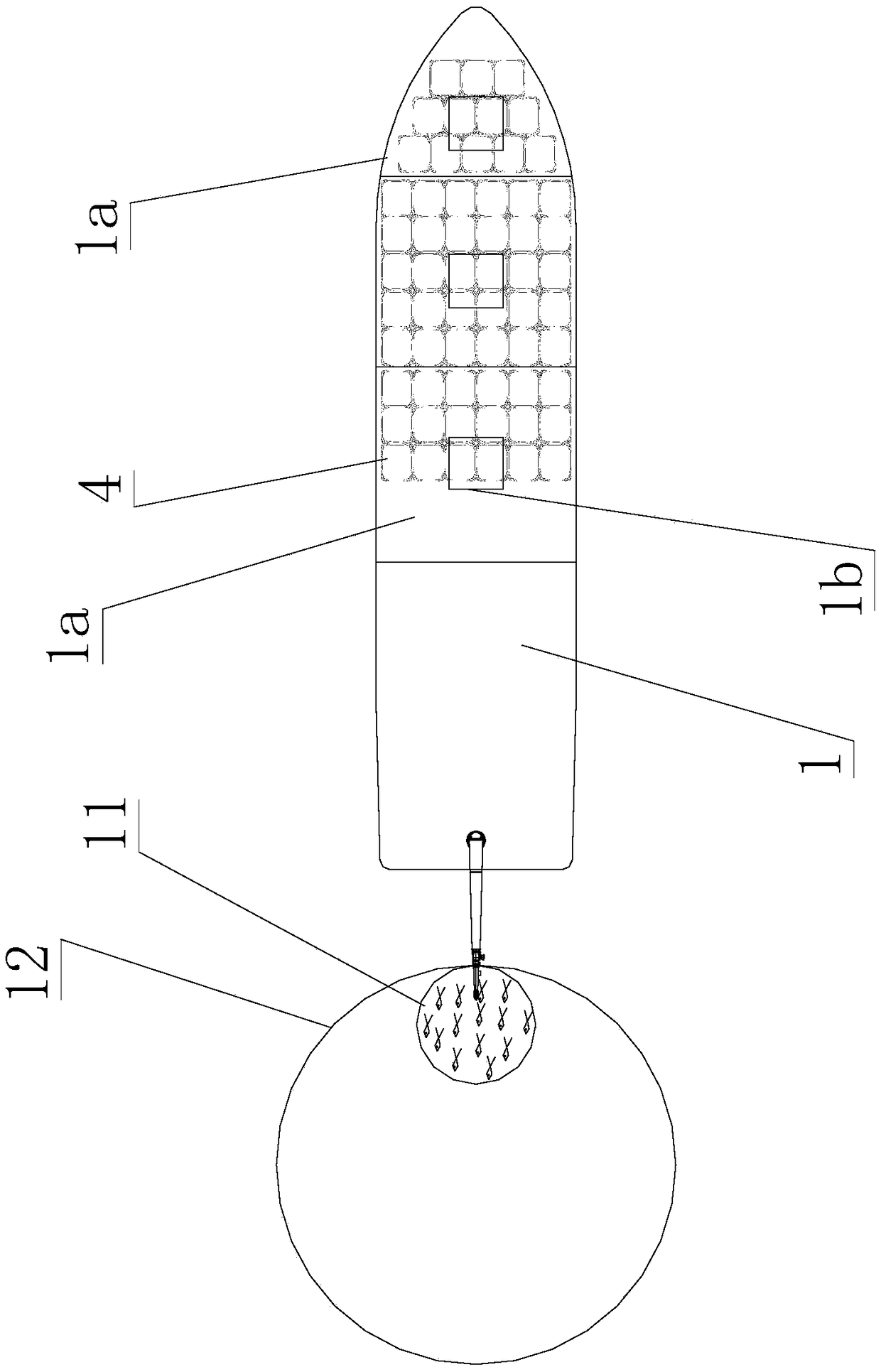

Fish-catch collecting operation boat for aquaculture

InactiveCN109278946AGood fresh-keeping effectHigh degree of automationFishing vesselsFishingEngineeringAutomation

The invention provides a fish-catch collecting operation boat for aquaculture, and belongs to the technical field of boats. The technical problem that freshness of fish-catch is hard to guarantee by an existing fish-catch collecting operation boat is solved. The fish-catch collecting operation boat comprises a fish sucking pipe, a vacuum fish sucking tank and an insulation box. The vacuum fish sucking tank is arranged on the fish sucking pipe, the outer end of the fish sucking pipe can extend out of the operation boat, and the inner end of the fish sucking pipe can be connected with the insulation box. The operation boat further comprises an ice slurry storage bucket which communicates with the insulation box. According to the fish-catch collecting operation boat, ice slurry and fish-catchare mixed to achieve the good freshness keeping effect, and the fish-catch collecting operation boat is high in operation automation degree and can reduce manual operation and greatly improve work efficiency.

Owner:碧阳广远(广州)海洋工程技术有限公司

Automatic tile correction device

ActiveCN106965333AReduce corner errorNo extrusionWorking accessoriesStone-like material working toolsBrickTransmission belt

The invention discloses an automatic tile correction device. The automatic tile correction device comprises a tile pushing rack, a synchronous sliding unit, a tile pushing movable unit and a correction block unit. A sliding transmission belt drives a tile pushing sliding base to horizontally slide. A tile pushing lifting module drives a correction block installation plate to ascend or descend. A correction drive motor drives a first correction block to move horizontally. The automatic tile correction device is used for correcting tiles before a trimming working procedure is conducted, and therefore the diagonal errors of the tiles are reduced, the cutting precision is improved, and it is guaranteed that four sides of the tiles subjected to trimming are square; the tiles are pushed from the back sides, fine adjustment correction is achieved, no extrusion effect exists for the tiles, and the tiles are not damaged easily; and the automatic tile correction device can correct the tiles in different specifications, it is not need to adjust the installation positions of the correction block unit, and the production flexibility and adaptation are high.

Owner:GUANGDONG SINID TECH

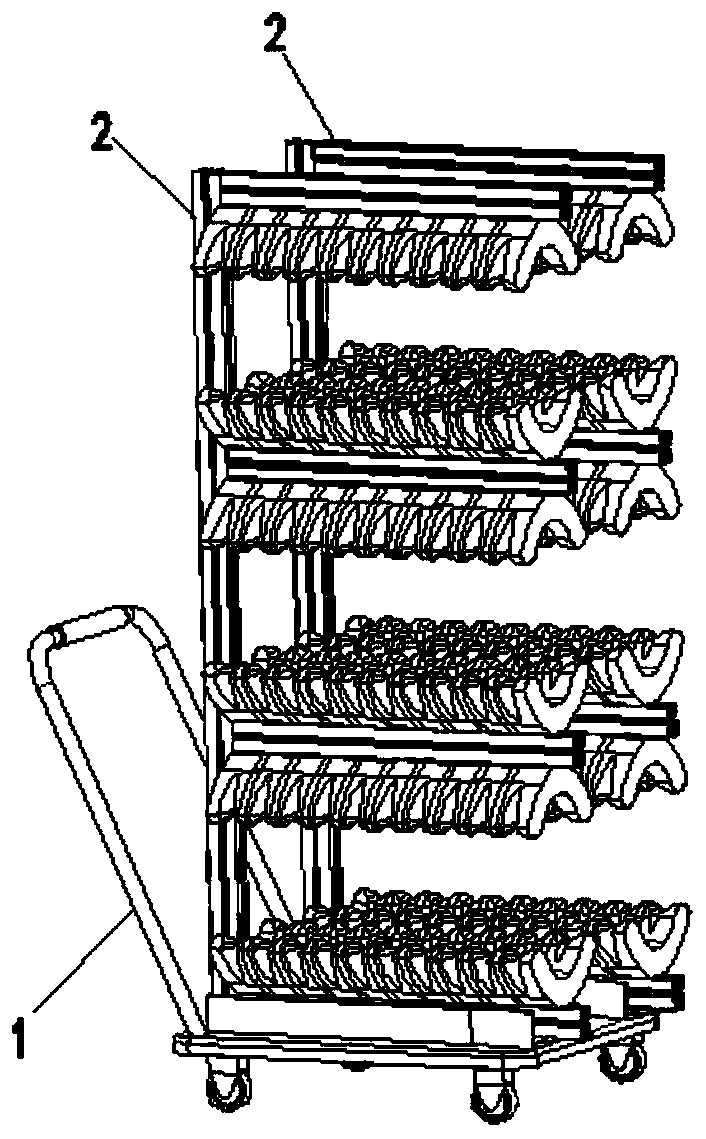

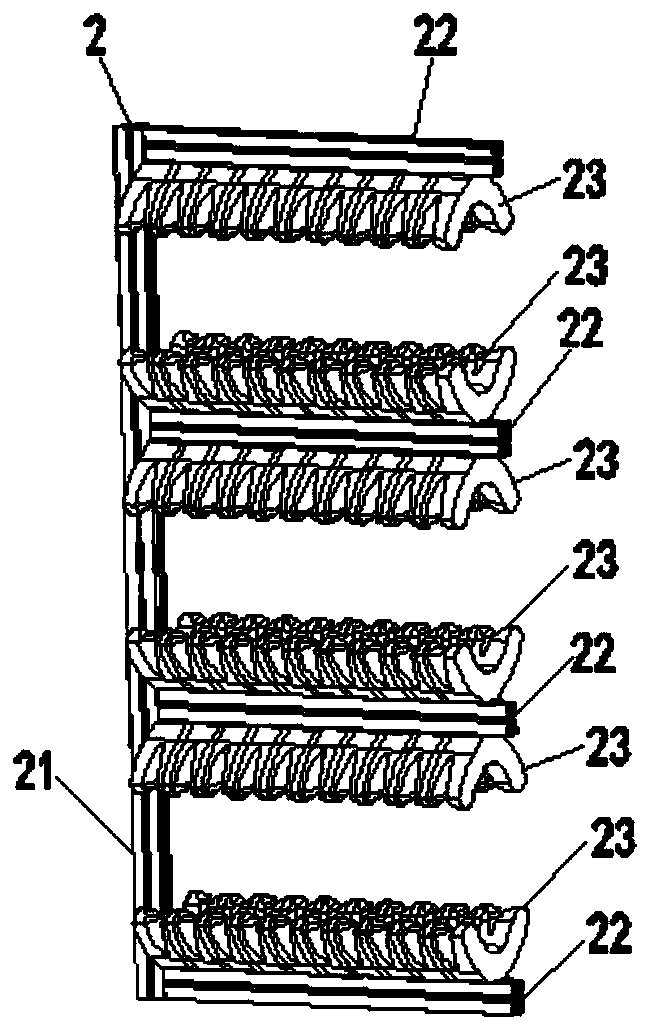

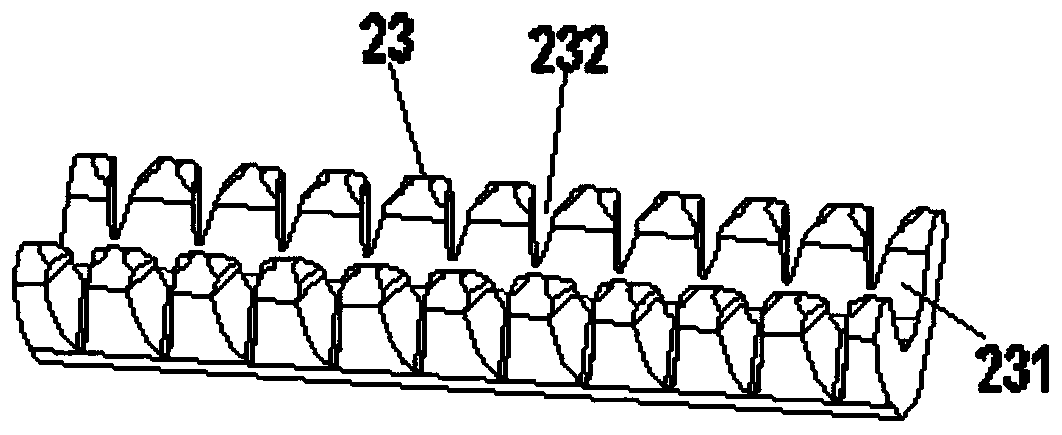

Transport vehicle for transporting aviation pipe

The invention provides a transport vehicle for transporting an aviation pipe. The transport vehicle comprises a movable vehicle body and a goods shelf arranged on the vehicle body, wherein the goods shelf is provided with fixing grooves used for fixing aviation pipes. Due to the fact that the fixing grooves used for fixing the aviation pipes are arranged on the goods shelf, the aviation pipes areplaced on the fixing grooves correspondingly, and the positions are fixed so that squeezing and collision cannot occur among the aviation pipes, and the situation that paint layers of metal surfaces of the aviation pipes fall off due to random stacking of the aviation pipes is avoided; and each aviation pipe has a fixed position, and random stacking is avoided so that workers can conveniently andquickly find the aviation pipe with a specified specification, and the working intensity of the workers is reduced.

Owner:四川铭航兰德科技有限公司 +1

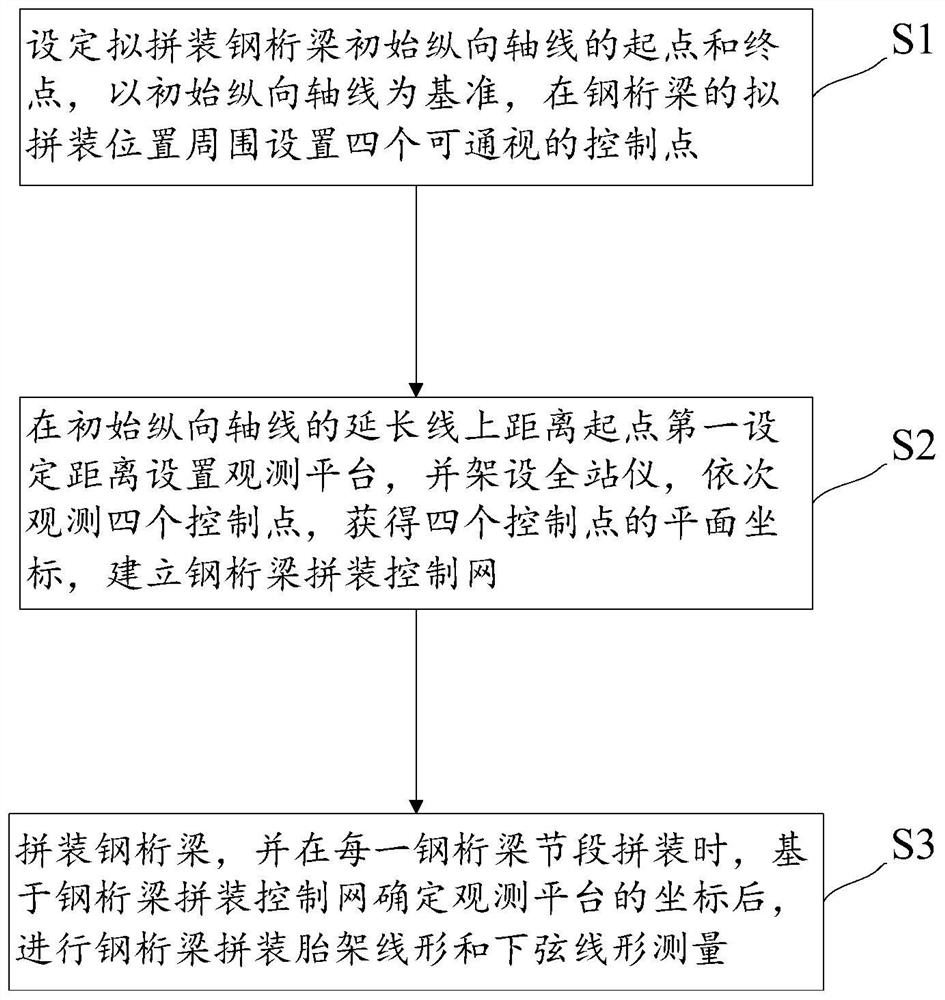

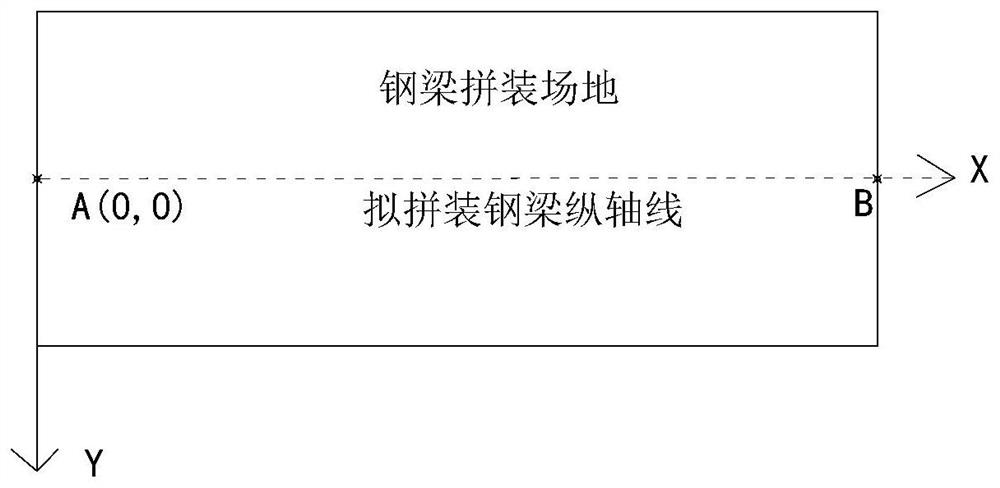

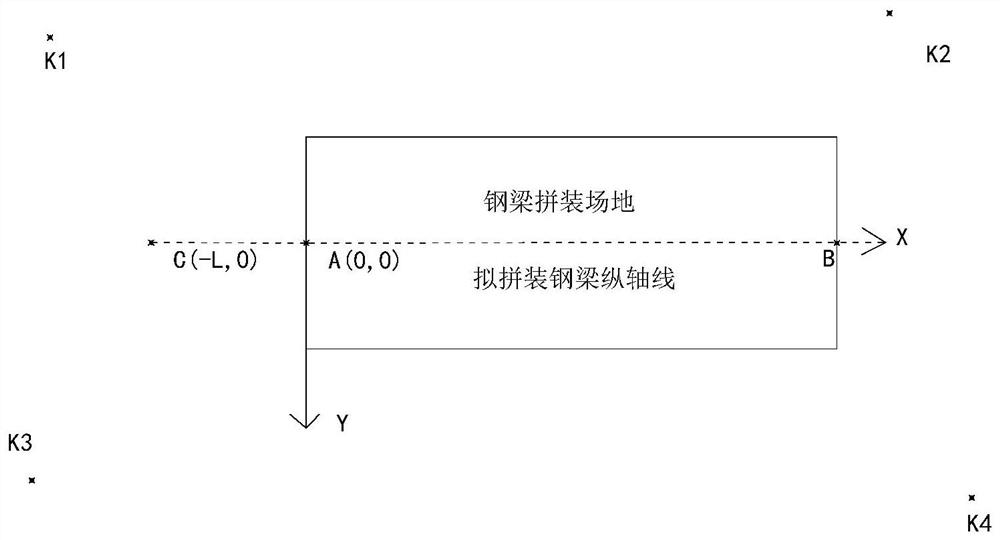

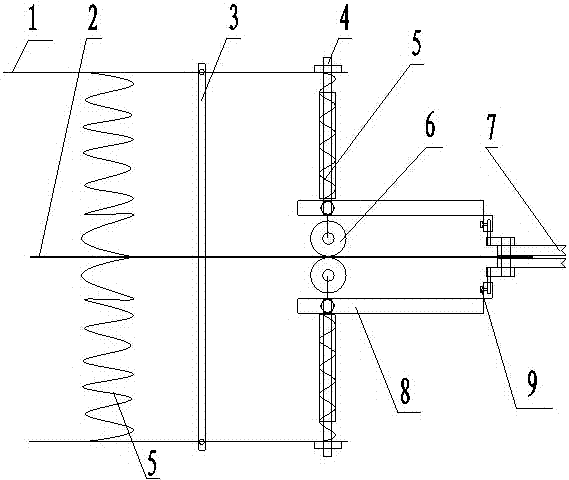

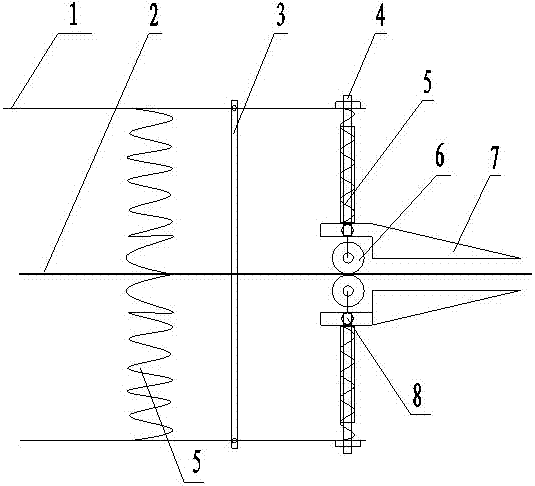

Steel truss girder assembly linear control method

ActiveCN112900266AAvoid mistakesNo extrusionSurveying instrumentsBridge erection/assemblyLinear controlArchitectural engineering

The invention relates to the technical field of engineering construction auxiliary equipment, in particular to a steel truss girder assembly linear control method which comprises the following steps: setting a starting point and an ending point of an initial longitudinal axis of a steel truss girder to be assembled, and setting four intervisible control points around a position to be assembled of the steel truss girder by taking the initial longitudinal axis as a reference; arranging an observation platform on the extension line of the initial longitudinal axis at a first set distance from the starting point, erecting a total station, observing the four control points in sequence, obtaining plane coordinates of the four control points, and establishing a steel truss girder assembly control network; and assembling the steel truss girder, and when each steel truss girder section is assembled, determining the coordinate of the observation platform based on the steel truss girder assembling control net, and then carrying out steel truss girder assembling jig frame linear measurement and lower chord linear measurement. The problems that geological sedimentation or foundation extrusion causes displacement of the observation platform, and assembly linear control is affected can be effectively solved.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP +1

Electric cherry picker with roller-slide-block manually-assisted non-contact mechanical hand

InactiveCN106973638AReduce volumeReduce weightPicking devicesReciprocating motionArchitectural engineering

The invention provides an electric cherry picker with a roller-slide-block manually-assisted non-contact mechanical hand. The picker comprises a handle, a support rod, a spring, a picking device and a collecting bag, wherein the spring, the support rod and the picking device are fixedly arranged on the handle; the support rod is hinged to the handle; the picking device is composed of a roller, a telescopic rod, a cutter and a spring which is a compression spring; one end of the telescopic rod is connected with the roller, and the other end of the telescopic rod penetrates through the spring and a through hole formed in the handle and is connected with the handle; one end of a connecting rod is fixed on the telescopic rod through a bolt, and the other end of the connecting rod is connected with a connecting plate of a motor through a bolt; the cutting edge of the cutter is provided with a plurality of concave small circular arcs; the outer circle surface of the roller is provided with a U-shaped groove. The handle is manually operated to turn on a power switch, accordingly the motor rotates and drives the cutter to reciprocate, the roller rotates on a cherry branch, the cutter cuts off cherry stalks, and the cherries fall into the collecting bag.

Owner:ZIBO VOCATIONAL INST

Roller type reducing branch artificial assistance blueberry picking device

The invention provides a roller type reducing branch artificial assistance blueberry picking device which comprises a handle, a supporting rod, a spring, a picker and a collection bag. The spring, the supporting rod and the picker are fixedly installed on the handle. The supporting rod is installed on the handle and hinged to the handle. The picker is composed of a roller, a stretchable rod, a spring and a cutter. The spring is a compression spring, one end of the stretchable rod is in linkage with the roller, the other end of the stretchable rod penetrates through through holes formed in the spring and the handle and is in linkage with the handle, the cutter is in linkage with the stretchable rod through a bolt, the point of the cutter is in a U shape, the bolt is loosened, the cutter is rotated, an included angle formed between the cutter and the outer surface of a blueberry branch is 0-30 degrees, a U-shaped groove is formed in the external circle of the roller, force in the forward direction is exerted to the handle, the roller rotates on the blueberry branch, the cutter is driven to move, the cutter cuts off stems of blueberries, and the blueberries fall into the collection bag to be recycled.

Owner:ZIBO VOCATIONAL INST

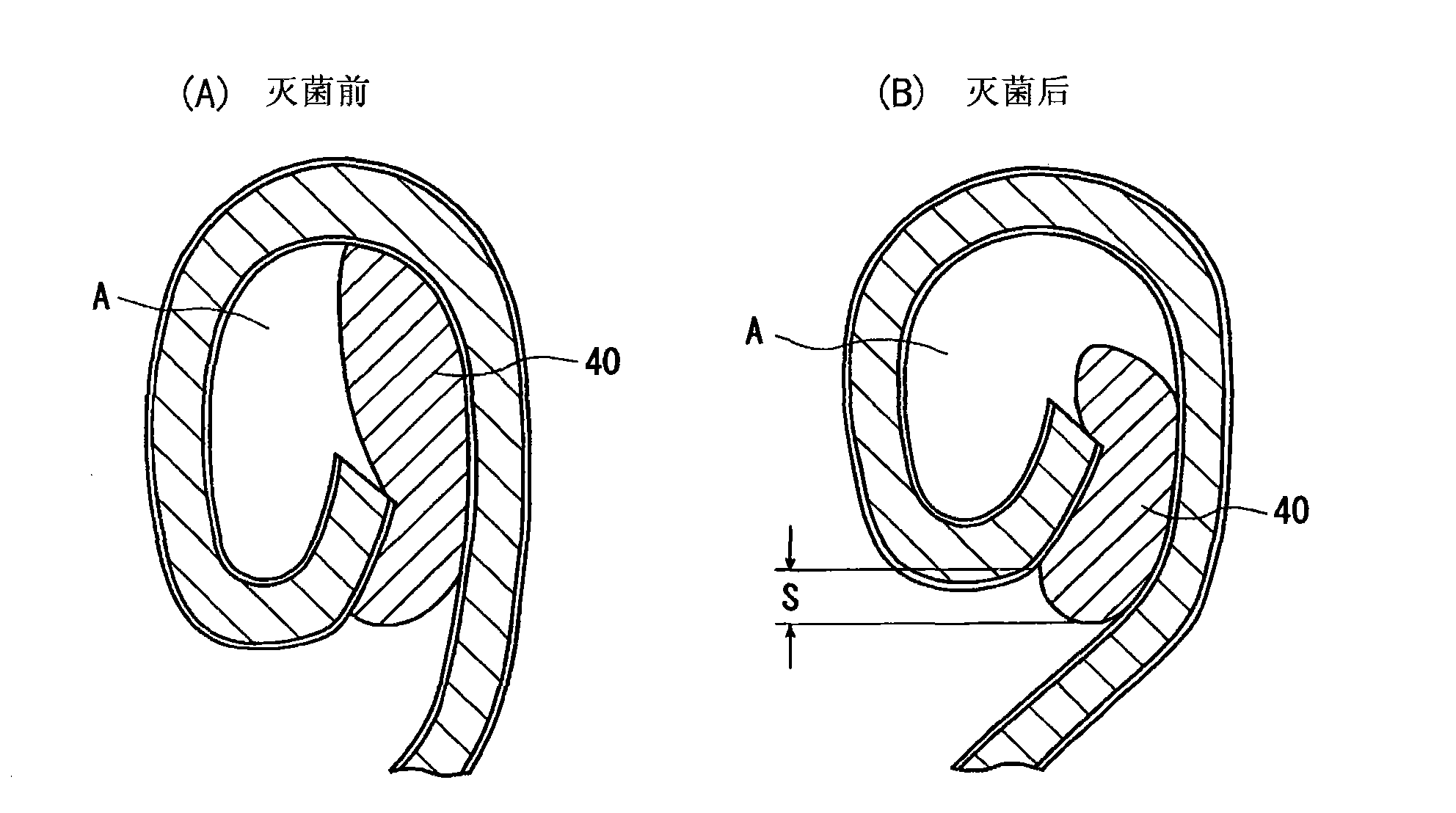

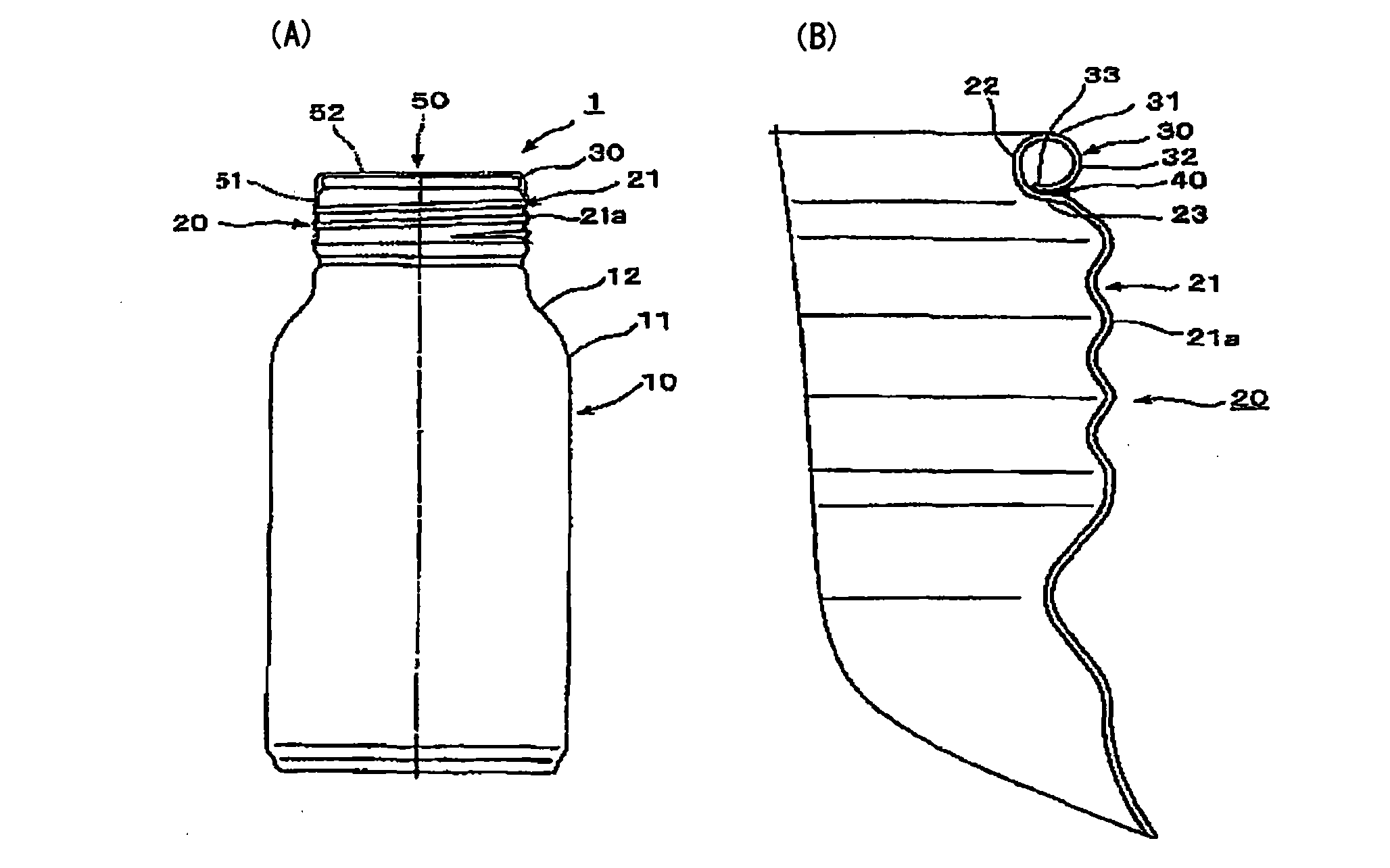

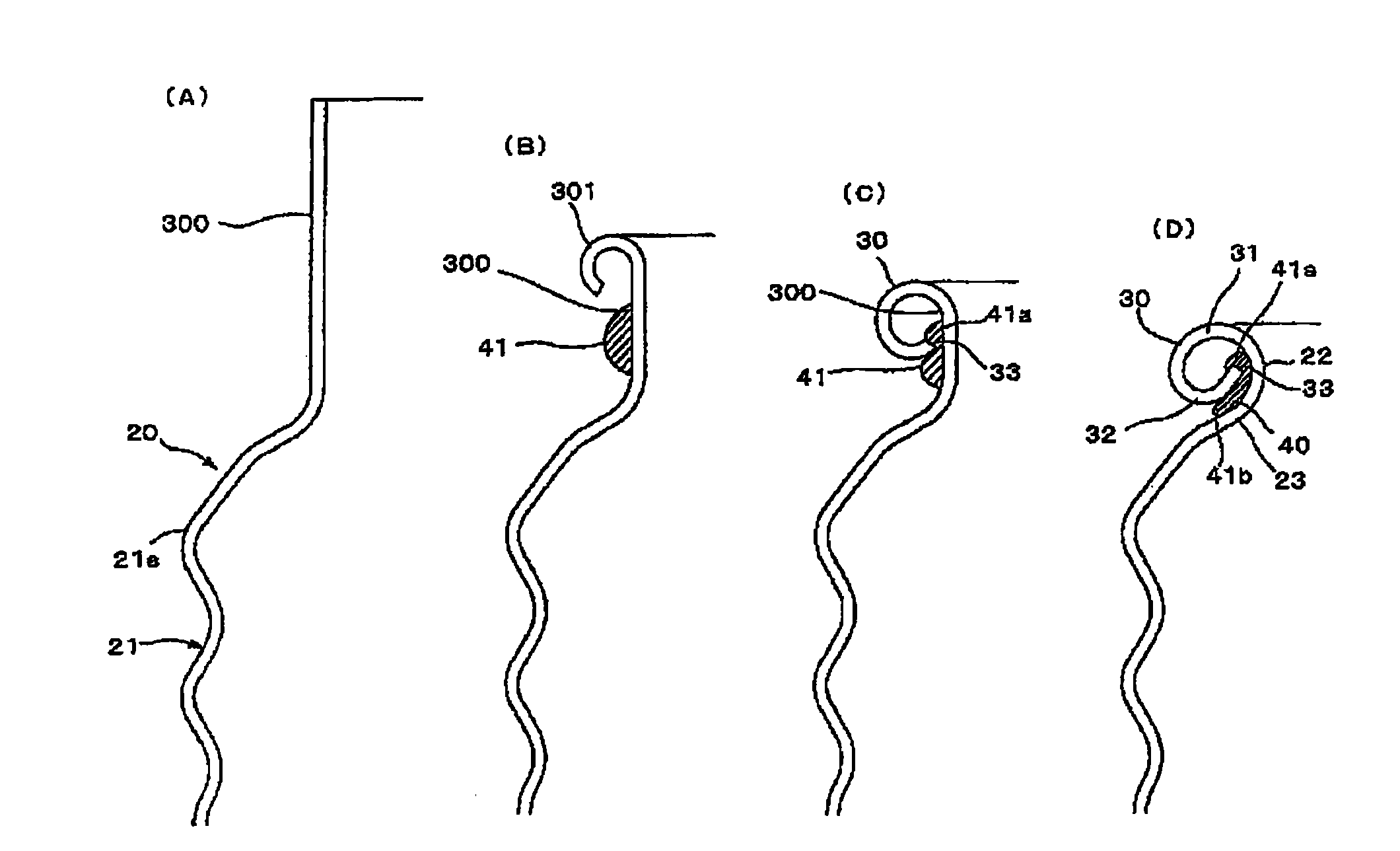

Hotmelt composition for metal can and metal can utilizing the same

InactiveCN101528840AImprove heat resistanceImprove sealingCoverings/external coatingsAdhesivesWaxPolyolefin

The invention provides a hot-melt composition comprising a thermoplastic elastomer, a tackifier, a wax and a polyolefin resin, the wax having a softening point (R & B system) of 140 to 160 DEG C. The hot-melt composition can be easily applied to the mouth-neck portion of a metal can and can be excellently produced. Even when placed under a high-temperature condition, the sealing material that is formed exhibits excellent heat resistance maintaining the sealing.

Owner:TOYO SEIKAN KAISHA LTD

Full-automatic tying and ring-sleeving device and operation method for same

InactiveCN107396756AFor subsequent cappingAvoid cloggingCultivating equipmentsMushroom cultivationEngineeringAutomatic testing

The invention discloses a full-automatic beam mouth collar device and its operation method, which include a centering adsorption tube, a first jaw, a first cylinder, and a second cylinder, and the upper periphery of the centering adsorption tube is provided with a first jaw and a The first cylinder, the first cylinder brings the mouth of the material bag into the gap opened by the first jaw; the upper end of the centering adsorption tube and the position where the first jaw is located is provided with a second jaw and a lower pressing block 1. The second air cylinder, the lower pressing block is connected with the centering adsorption pipe, and the second air cylinder drives the lower pressing block to move to control the closing of the second clamping jaw. Set the first cylinder, the second cylinder, the centering adsorption tube, the lower pressing block, the first jaw, the second jaw, the centering adsorption tube absorbs the bag mouth, and the first cylinder drives the bag mouth into the first clamp In the gap between the claws, the bag mouth is tightly adsorbed on the centering adsorption tube. After the collar is closed, the first jaw opens and expands the inside of the bag mouth; the second cylinder drives the second jaw to move, pressing down on the unfolded bag mouth to turn over the bag , which is convenient for subsequent capping.

Owner:四川哈贝智能科技有限公司

Roller electromagnetic-push-and-pull size-changed manual-assisted electric branch mulberry picker

The invention provides a roller electromagnetic-push-and-pull size-changed manual-assisted electric branch mulberry picker. The roller electromagnetic-push-and-pull size-changed manual-assisted electric branch mulberry picker comprises handles, a supporting rod, a spring, a picking device and a collecting bag, wherein the spring, the supporting rod and the picking device are fixedly mounted on the handles, the supporting rod is mounted on the handles and is hinged to the handles, the picking device consists of rollers, telescopic rods, springs and shear knives, the springs are compression springs, one end of each telescopic rod is connected with one corresponding roller, the other end of each telescopic rod penetrates through one corresponding spring and a through hole formed in one corresponding handle and is connected with the corresponding handle, one end of each connecting rod is fixed on one corresponding telescopic rod through a bolt, the other end of each connecting rod penetrates through an axial hole formed in one corresponding shear knife, cutting edges of the shear knives are serrate, and U-shaped grooves are formed in outer circle faces of the rollers; and the handles are manually assisted, a power switch is turned on, electromagnetic push-and-pull devices drive the shear knives to reciprocate, the rollers rotate on mulberry branches, fruit stems of mulberries are cut off by the shear knives, and the mulberries fall into the collecting bag.

Owner:ZIBO VOCATIONAL INST

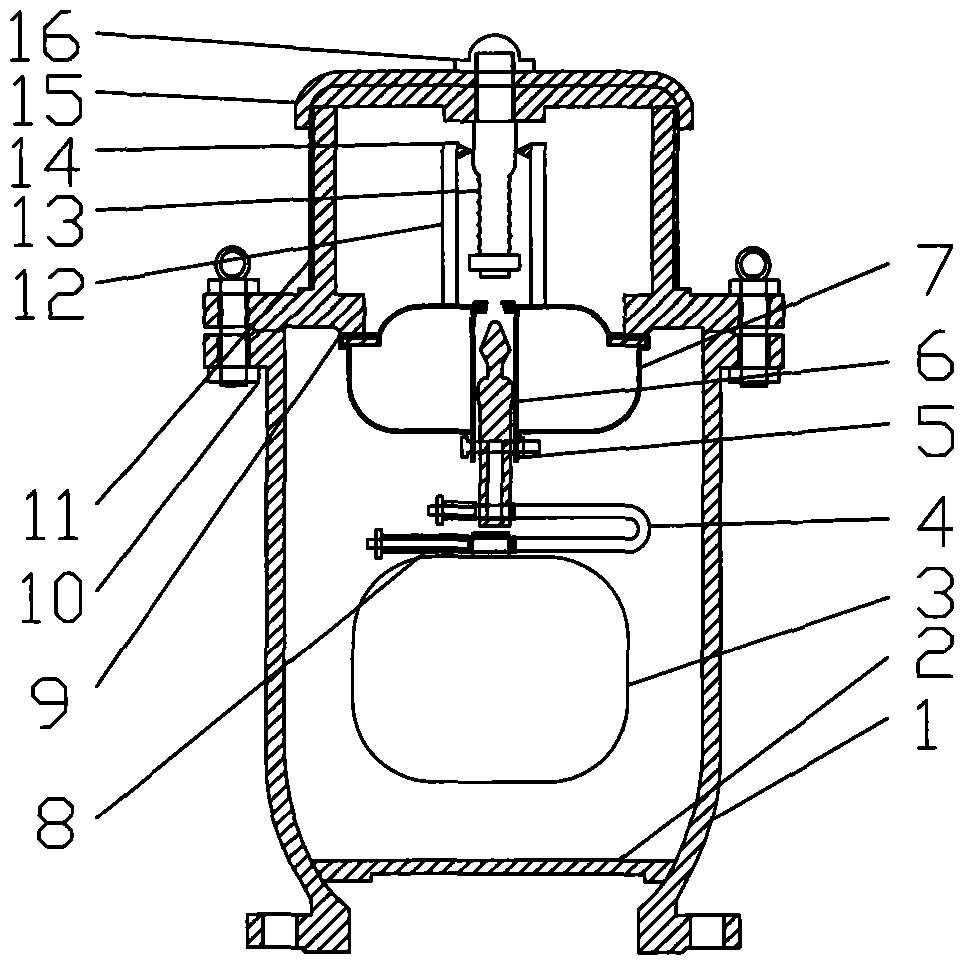

Resultant high pressure relief air exhaust/supply valve

InactiveCN102808988ASmall form factorNeat appearanceOperating means/releasing devices for valvesLift valveExhaust valvePeak value

The invention belongs to the technical field of water pipeline valves, and particularly relates to a resultant high pressure relief air exhaust / supply valve, which is characterized in that the split parts of the compound exhaust valve are compressed into a main body to form a whole, so as to solve the problems that the outline dimension is large, the appearance is irregular, and the making is complex; a big floating ball is combined with U-shaped connecting piece, and further solve the problems that the air exhaust is slow as a small exhaust port is over-small and the gravity force of the small floating ball can't pull open the sealed surface of the small exhaust port for air exhaust when the pressure reaches the peak value; the force produced by the big floating ball and connecting piece can amount to 4 to 45kg, the air exhaust area of the small exhaust port can amount to 13 to 200mm2; and by adopting the plane sealing of a ball head plane sealing element to replace the ball sealing, the problems that as the contact area of the ball sealing is small and the squeezing force is big, the ball is easily clamped, and the sealed surface is sometimes pulled broken during the falling process of the ball. The valve is used for air exhaust or air supply of the water pipeline, and is mainly characterized by completing exhaust of the high-pressure air in the long complex pipeline with big diameter and high drop, thereby bringing safety guarantee for the operation of the pipeline.

Owner:杨鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com