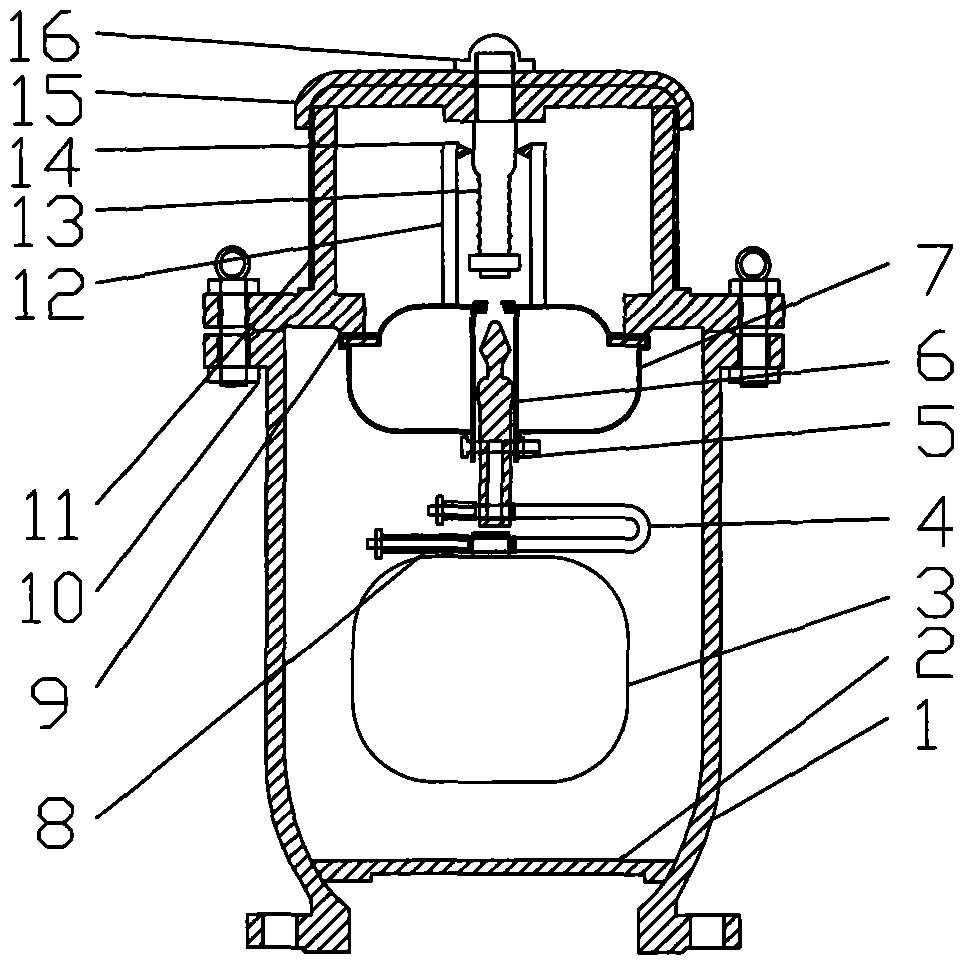

Resultant high pressure relief air exhaust/supply valve

A technology of air supply valve and high pressure, which is applied in the direction of valve lift, valve details, valve device, etc., which can solve the problems of slow exhaust and no exhaust, and achieve the effects of tight sealing, reasonable structure and simplified production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] like figure 2As shown in the embodiment of high-pressure and small exhaust of Heli high-pressure exhaust and replenishment valve, when the large exhaust port is closed and the pressurized gas in the pipeline enters the valve body, the buoyancy of the large floating ball disappears and gravity is generated. At this time, the arrow-type dome seal that blocks the small exhaust port is subjected to two forces, one is the pipeline pressure pushing it up, and the other is the gravity of the large floating ball and the U-shaped connector that pulls it down. Since the resultant force pulling it down is greater than the pressure of the pipe pushing it up, the arrowhead dome seal is forced to pull away from the small vent, allowing high-pressure gas to exit the valve.

Embodiment 2

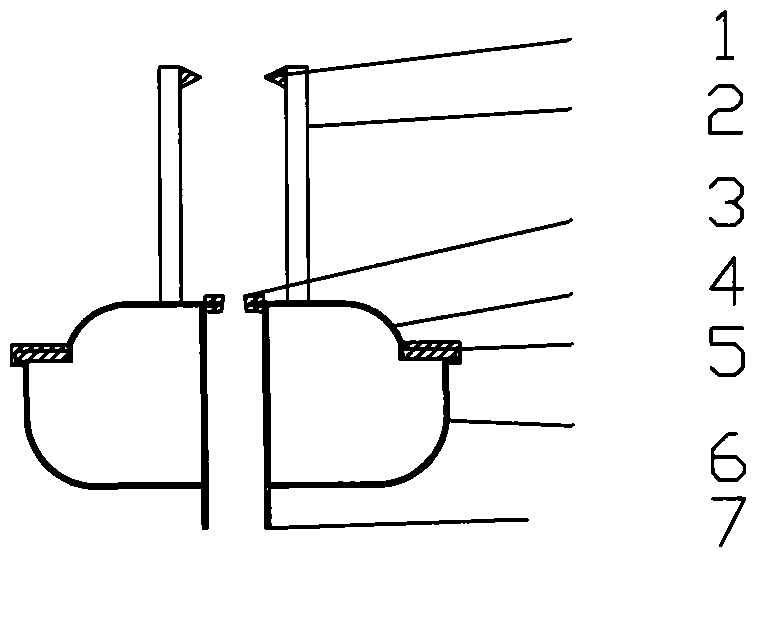

[0034] like image 3 As shown in the example, the Heli type high-pressure exhaust and supplementary air valve is implemented in large quantities. When the pipeline is filled with water for the first time, the gas in the pipeline first hits the energy dissipation plate, and then flows to the inner wall of the valve and enters the valve. Because the energy dissipation plate flows over one side Large area, small flow area on one side, large flow area, large gas flow, small flow area, small gas flow, so the gas will move the large floating ball and ball head flat seal from the side with large flow area Blow to the side with small flow area to generate oblique tension. At the same time, the pointed sliding ring forms an angle with the large thread at the lower part of the guide shaft and bites together to prevent the ball-type flat seal from moving upwards, achieving the anti-back effect and making the pipeline A large amount of gas is discharged smoothly.

Embodiment 3

[0036] Figure 4 It is a schematic diagram of the static state of the combined high-pressure discharge and air supply valve for gas injection. When the pipeline stops water supply, the ball-type flat seal after the large exhaust port is blocked, under the influence of gravity of itself, the large floating ball and the U-shaped connector. Under the action, the large exhaust port is smoothly opened and the gas is injected inward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com