Special hanger with guide cover wheel hub and turning and hanging method

A technology of covering wheels and spreaders, which is applied in the fields of special spreaders, flip hoisting, and special spreaders for hubs, can solve problems such as complex shapes, and achieve the effects of low manufacturing cost, high efficiency, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments.

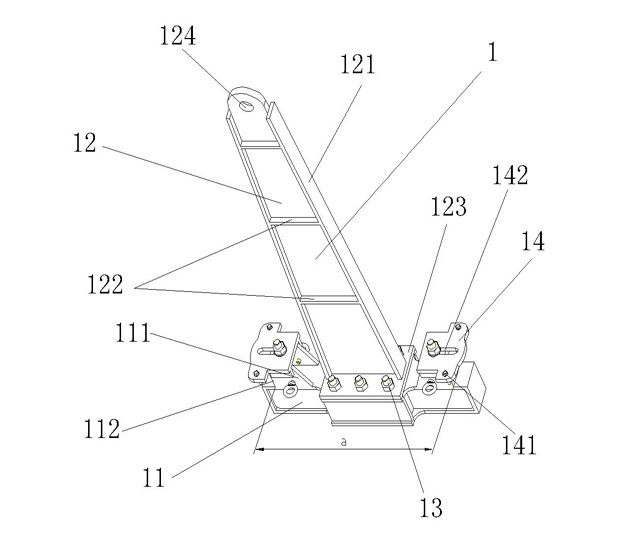

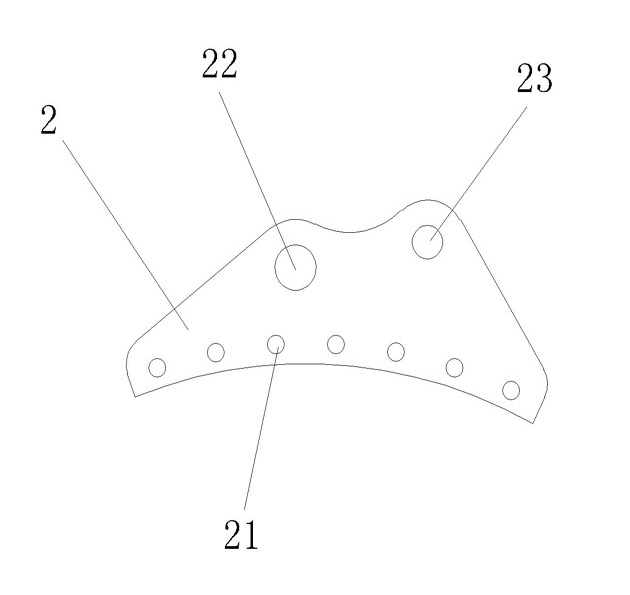

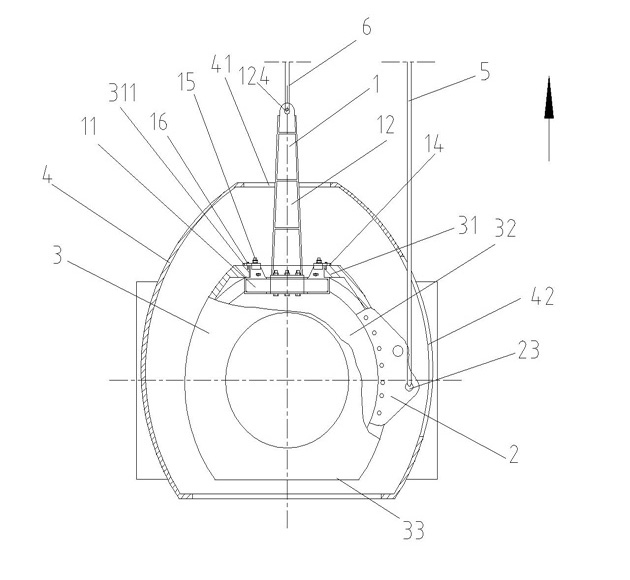

[0028] like figure 1 As shown, the special sling equipped with the hub of the shroud of the present invention includes a T-shaped sling 1 and two double-hole lifting lug plates 2. The T-shaped sling includes a beam 11 and a vertical beam 12. The beam 11 of this embodiment The vertical beams 12 are all frame-shaped welded steel structural parts, and the horizontal beams 11 and the vertical beams 12 can also be cast steel parts. Since the beam 11 has to bear the overall weight of 17-18 tons with the hub 3 of the shroud installed, a frame-shaped welded steel structure with high strength is used. The vertical beam 12 is a welded steel structure with webs 121 on both sides, several rib plates 122 in the middle, and a bottom plate 123 at the bottom. The upper end of the vertical beam 12 is provided with a hoisting hole 124. Six fastening bolts and nuts 13 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com