Patents

Literature

2575results about How to "Small form factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

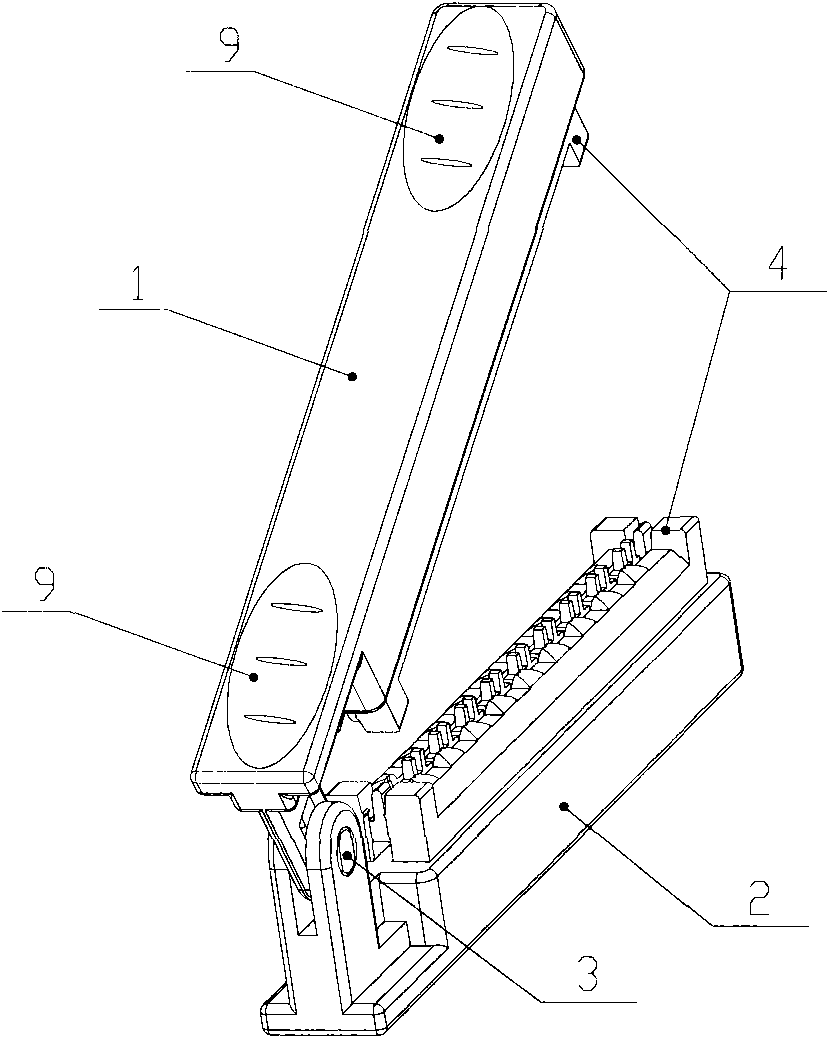

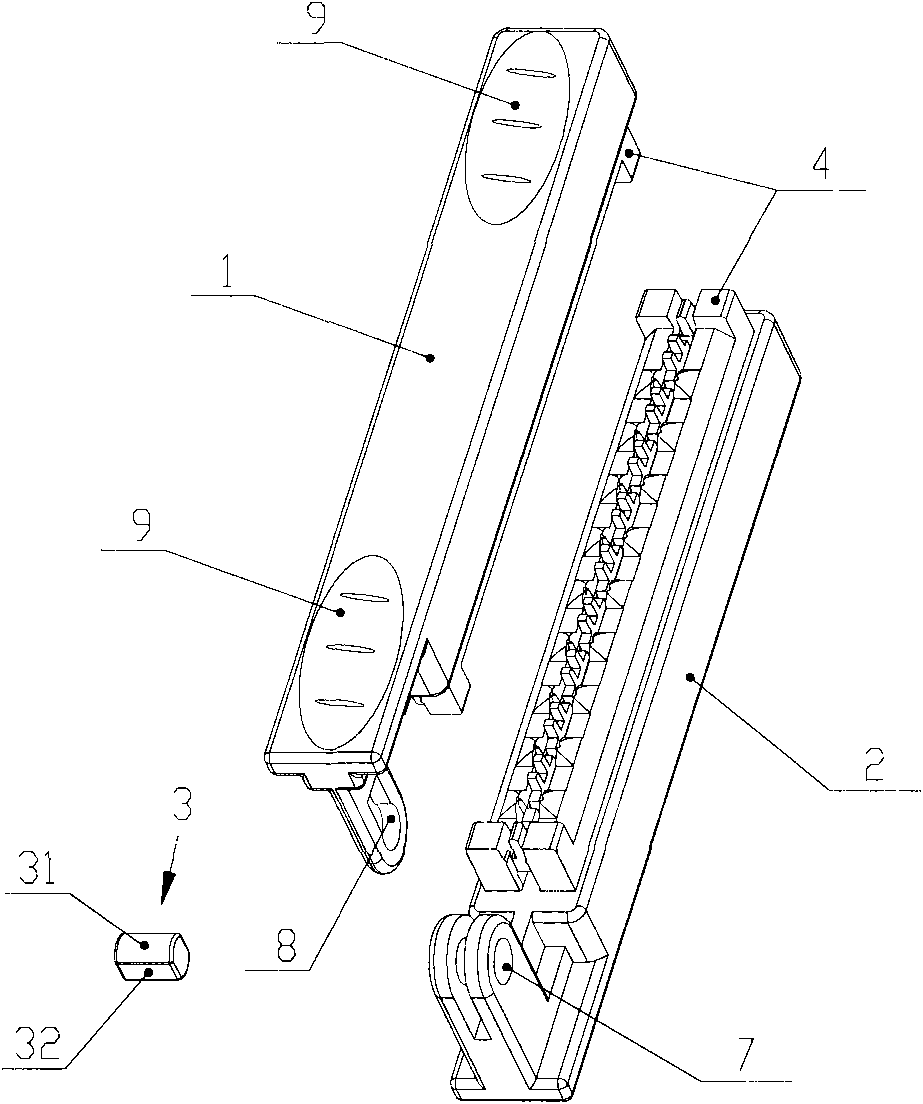

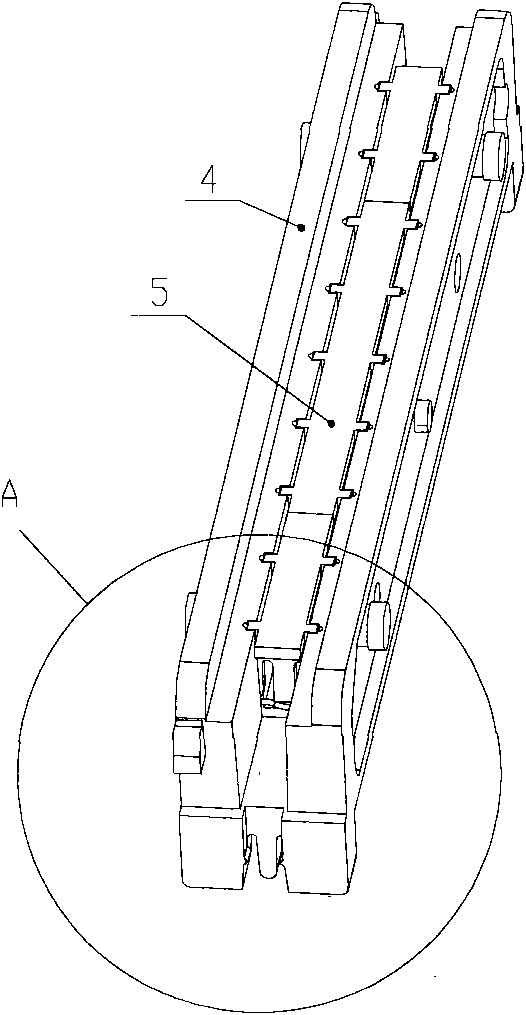

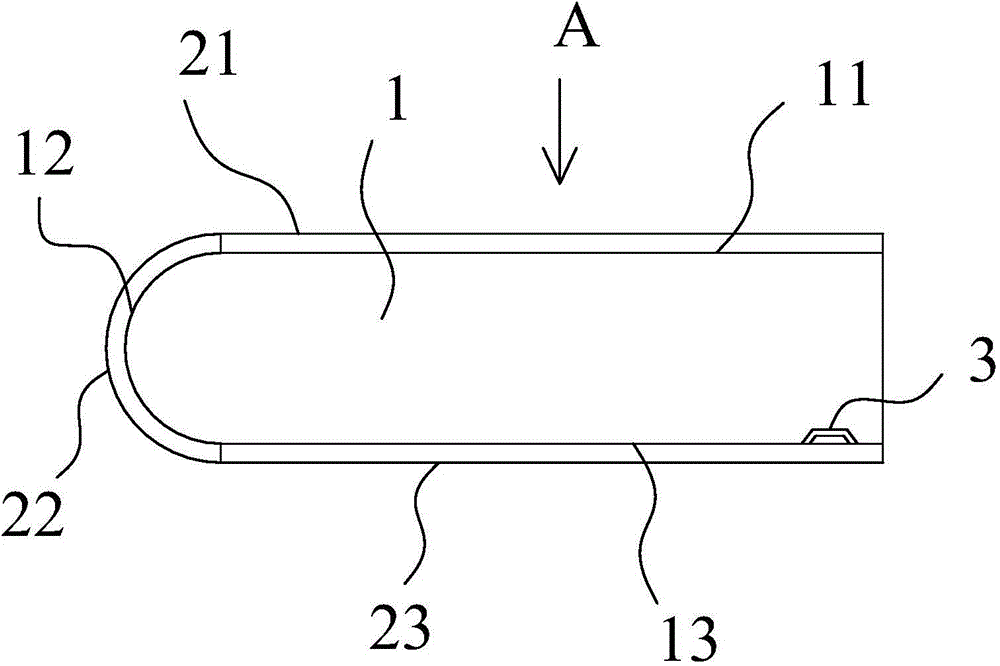

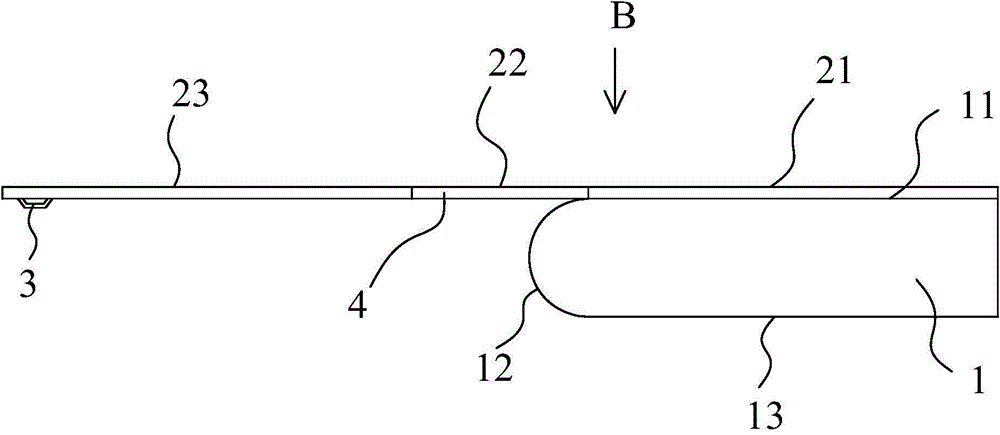

Automatic purse-string device

The invention provides an automatic purse-string device, which comprises an upper shell and a lower shell, and nail warehouse components arranged inside of the shells, wherein the nail warehouse components comprise a nail warehouse, a nail pushing piece and a nail arranged in the nail warehouse. When in an initial state, one end of the upper shell and one end of the lower shell are in pivot connection and are arranged in an angle; and when in the process of working, the upper shell rotates relative to the lower shell, and the upper shell and the lower shell move relative to make the nail pushing piece push the nail out of the nail warehouse after the upper shell is parallel to the lower shell. The automatic purse-string device has the main advantages that the device is compact in appearance, can be packaged and sold serving as an attachment of other surgical instruments, saves material cost, can reduce the economic burden of a patient, and can satisfy the use in a smaller surgical space, thereby enlarging use range and providing a doctor with convenience.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

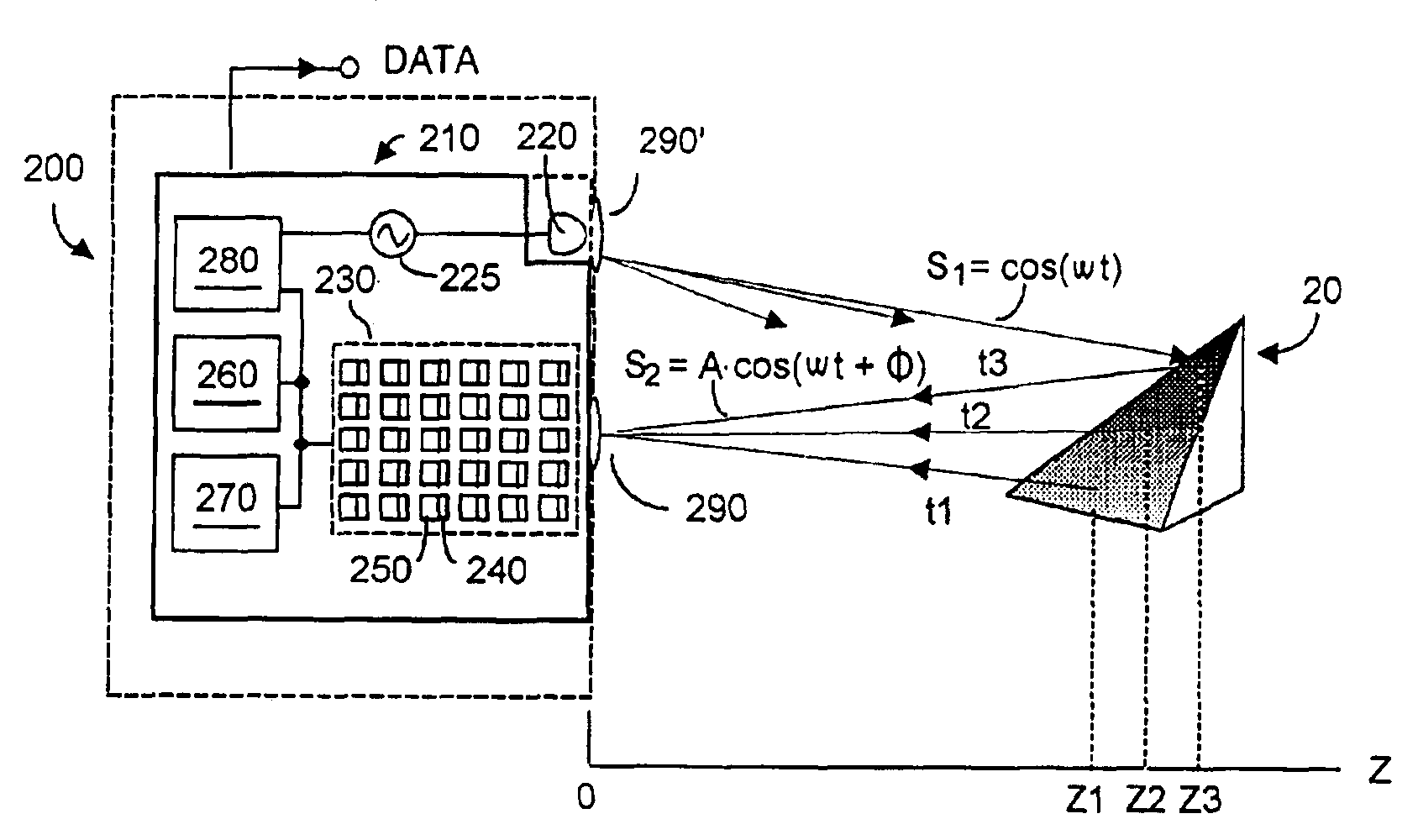

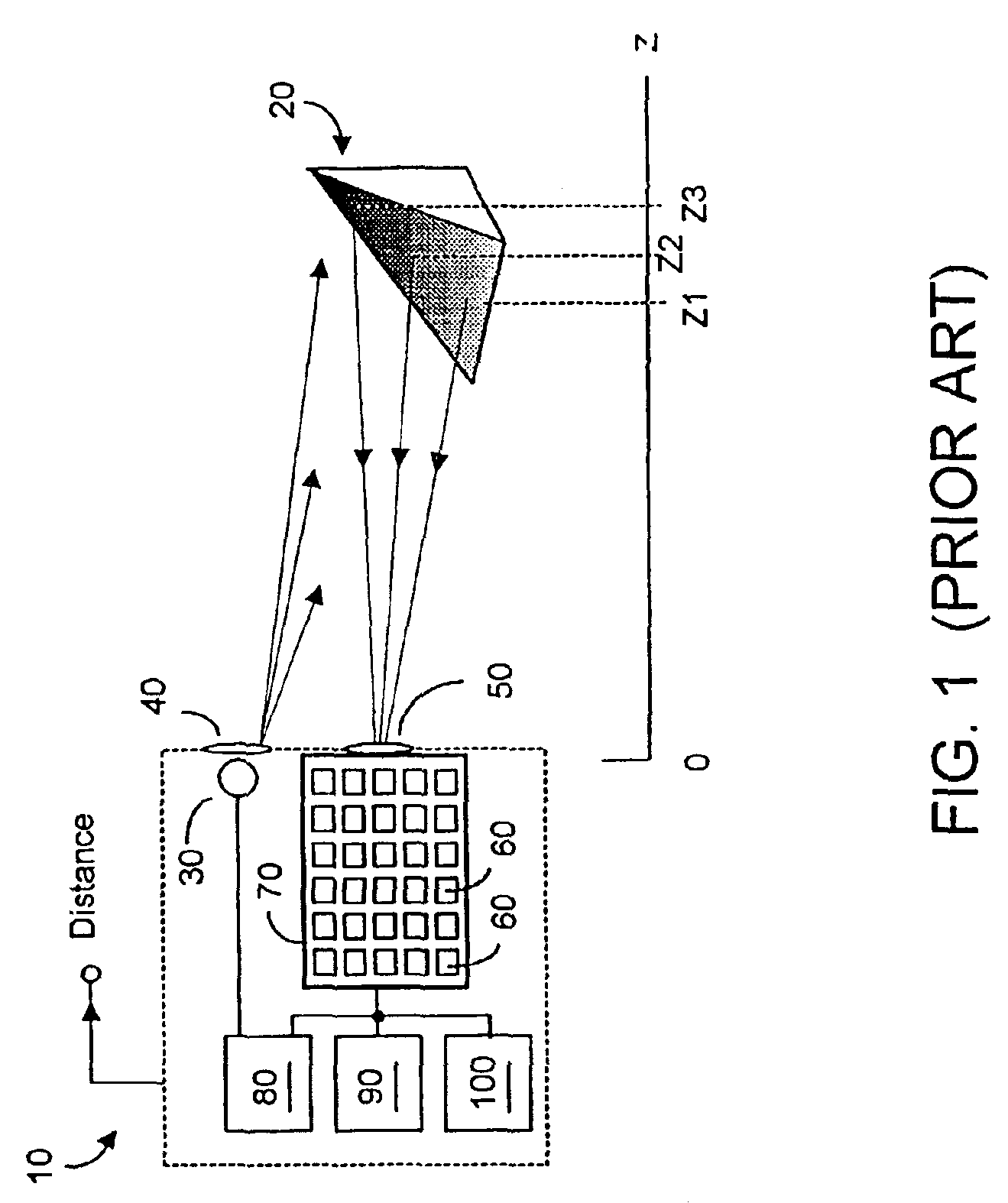

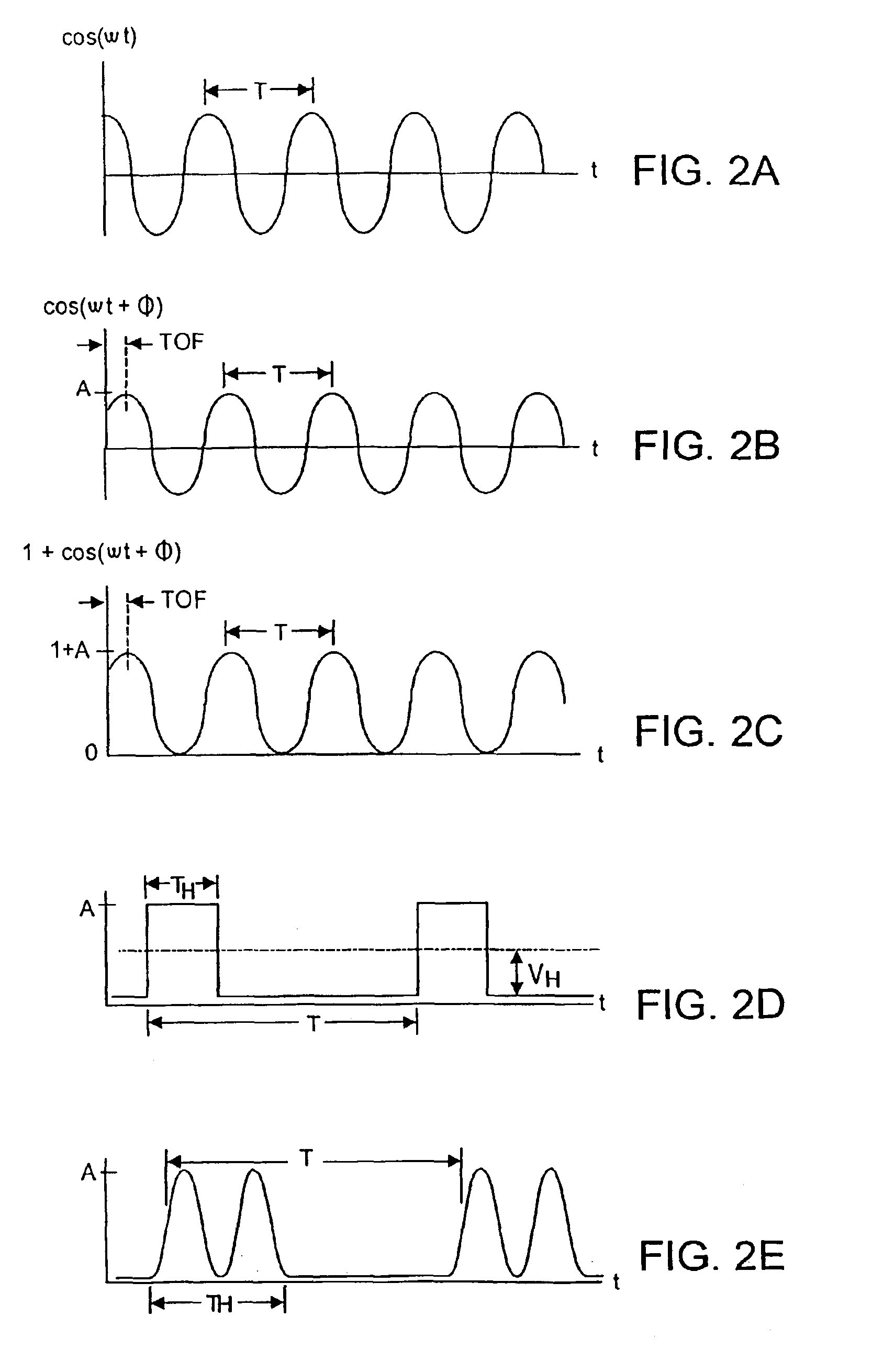

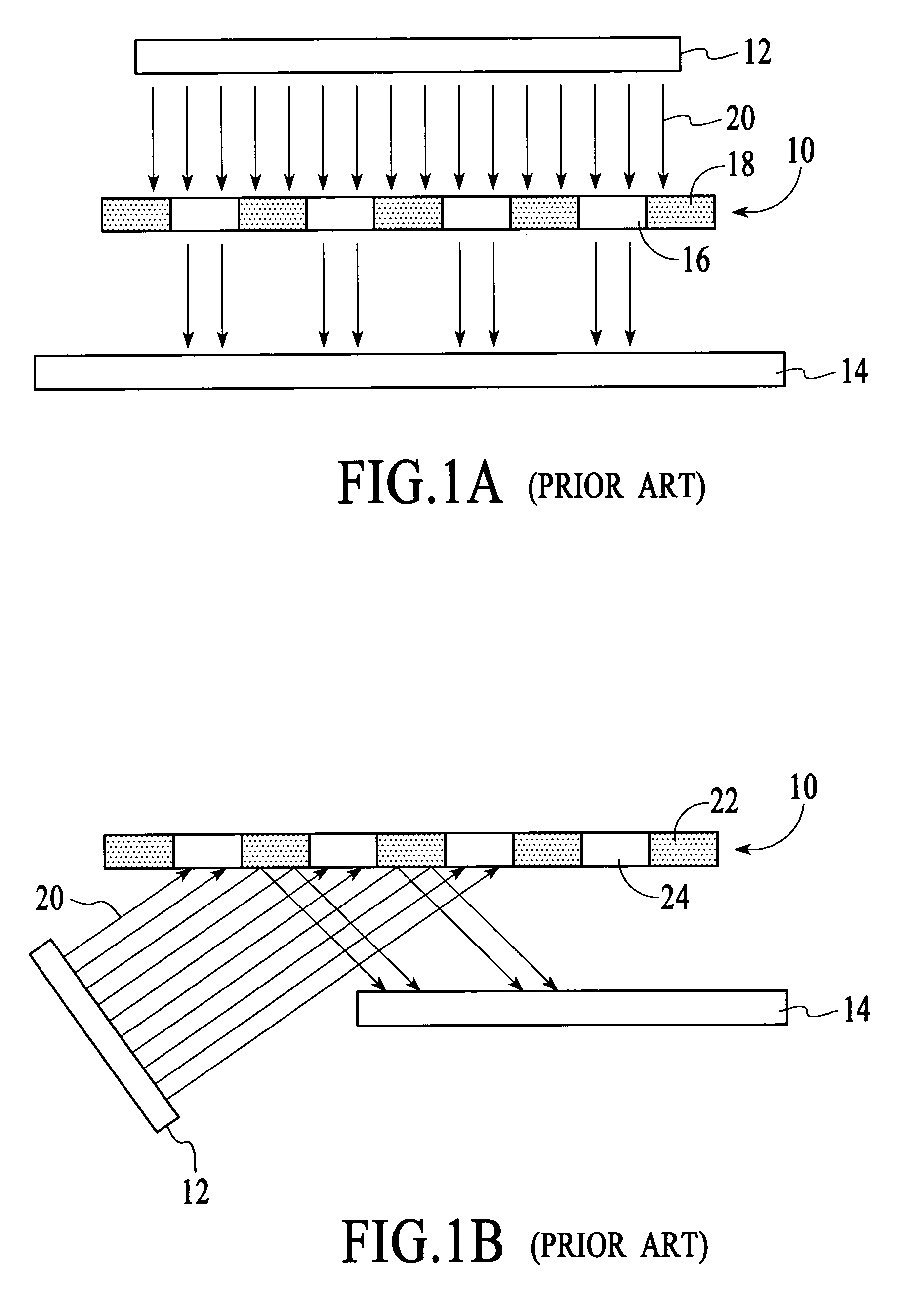

Methods and devices for charge management for three-dimensional sensing

InactiveUS6906793B2Minimal overheadEffective coloringTelevision system detailsOptical rangefindersCMOSHigh frequency modulation

Structures and methods for three-dimensional image sensing using high frequency modulation includes CMOS-implementable sensor structures using differential charge transfer, including such sensors enabling rapid horizontal and slower vertical dimension local charge collection. Wavelength response of such sensors can be altered dynamically by varying gate potentials. Methods for producing such sensor structures on conventional CMOS fabrication facilities include use of “rich” instructions to command the fabrication process to optimize image sensor rather than digital or analog ICs. One detector structure has closely spaced-apart, elongated finger-like structures that rapidly collect charge in the spaced-apart direction and then move collected charge less rapidly in the elongated direction. Detector response is substantially independent of the collection rate in the elongated direction.

Owner:MICROSOFT TECH LICENSING LLC

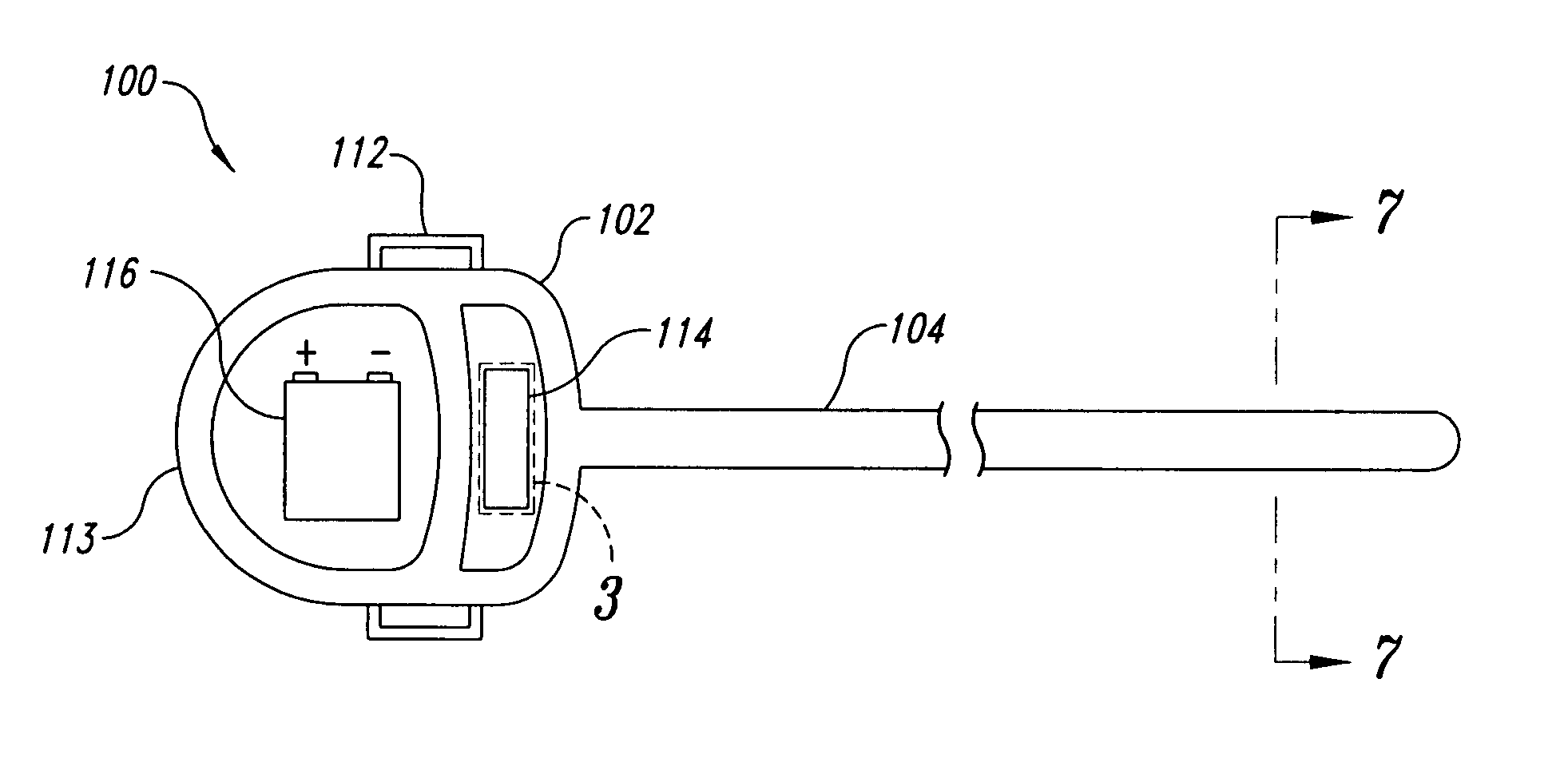

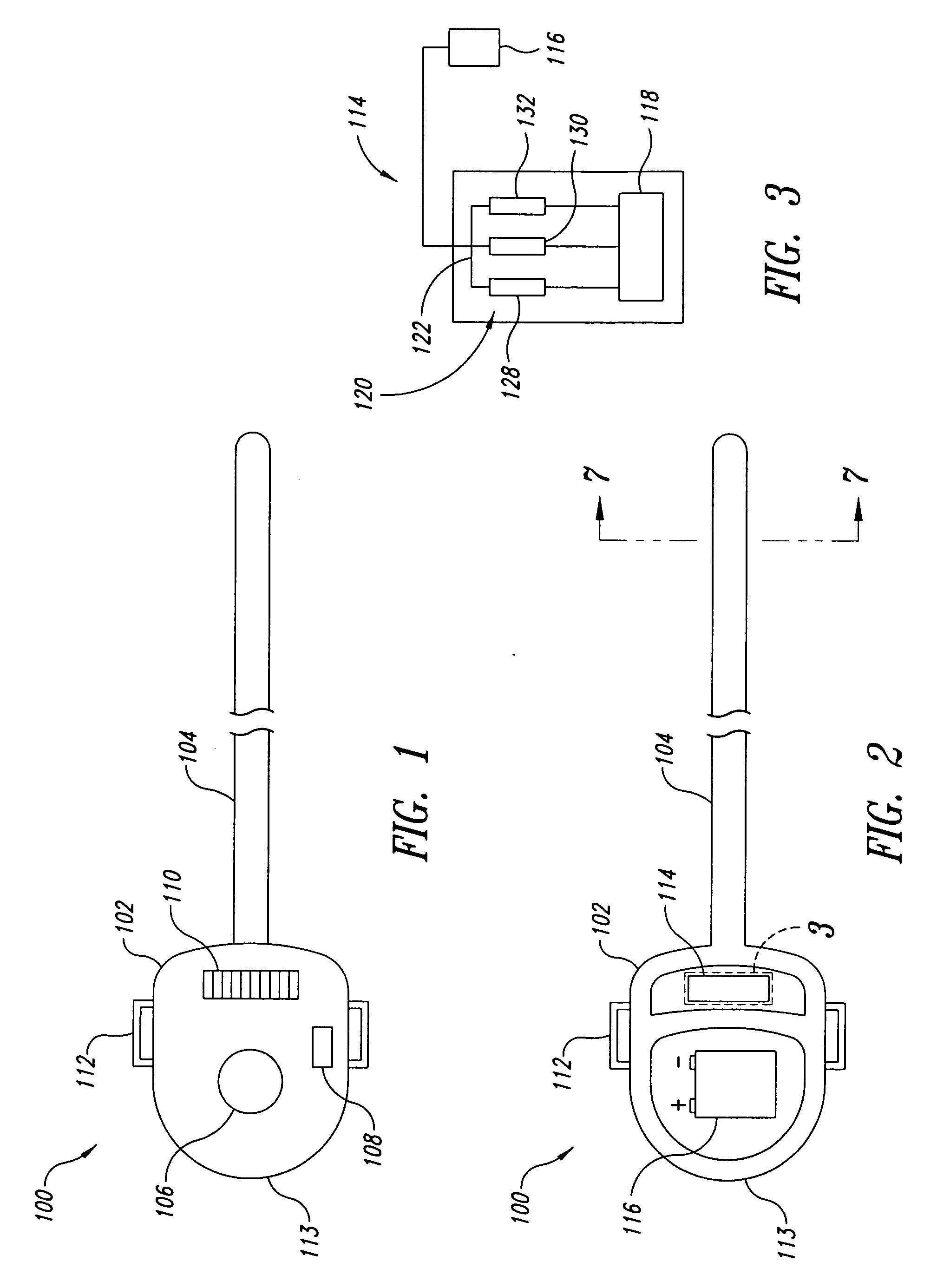

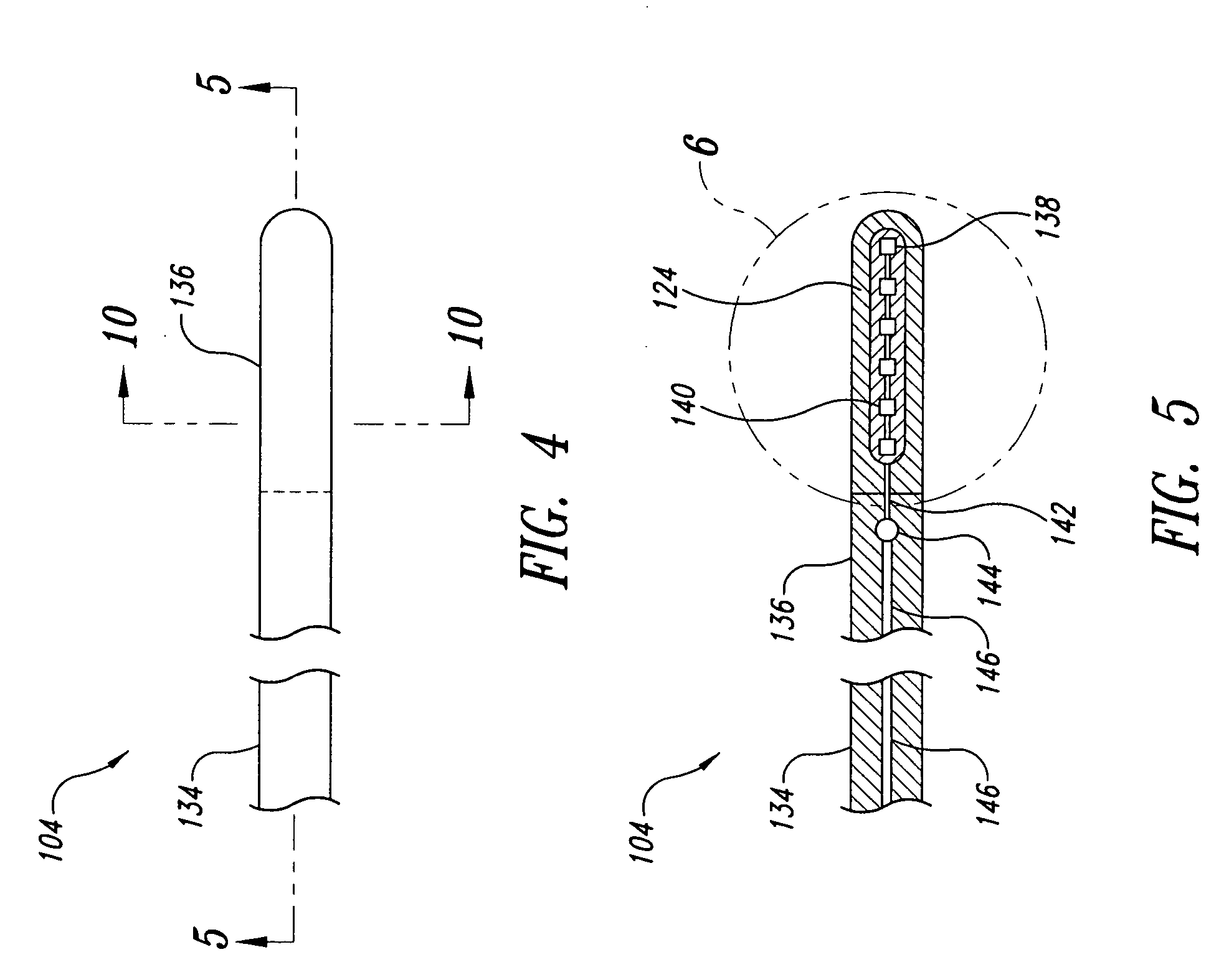

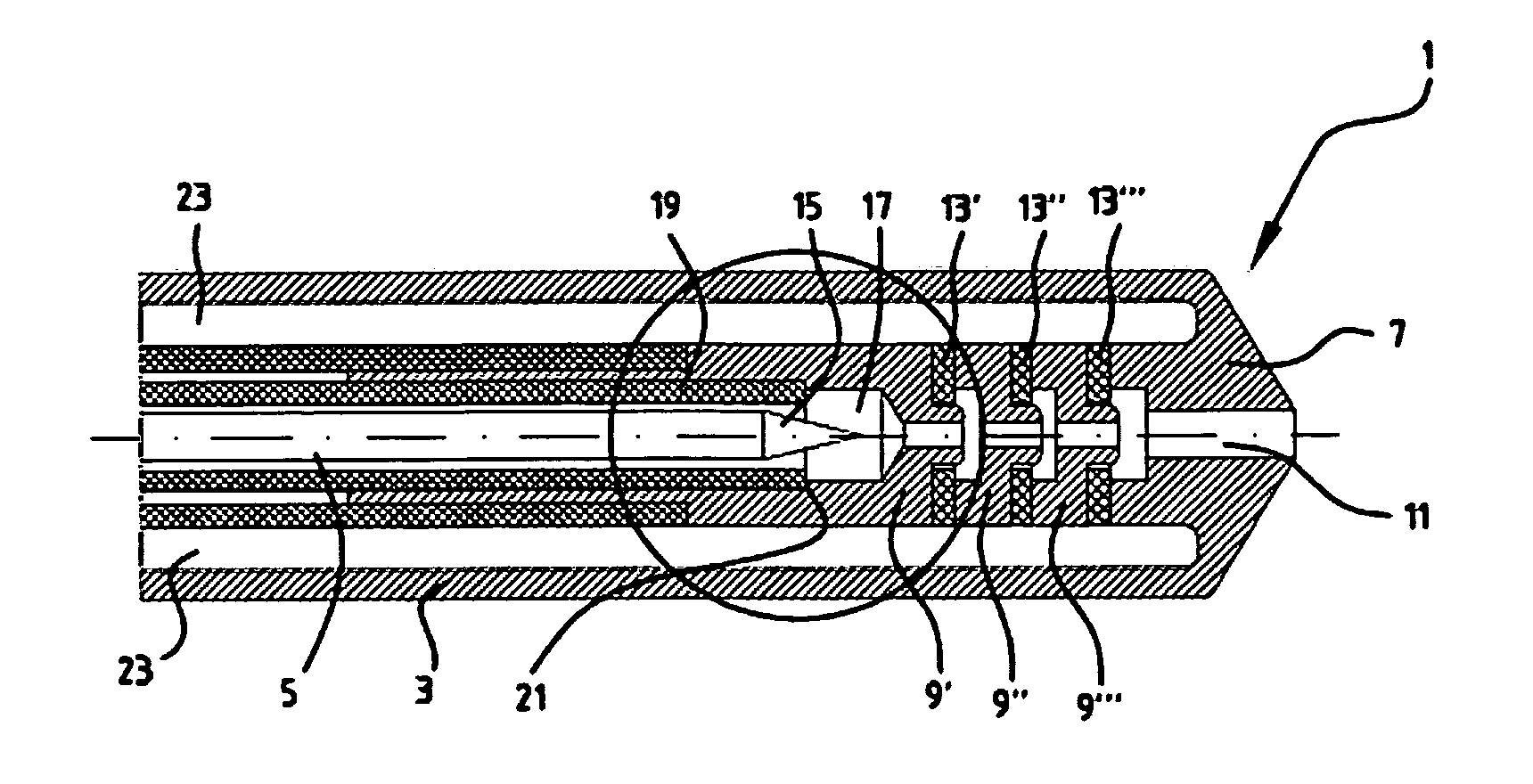

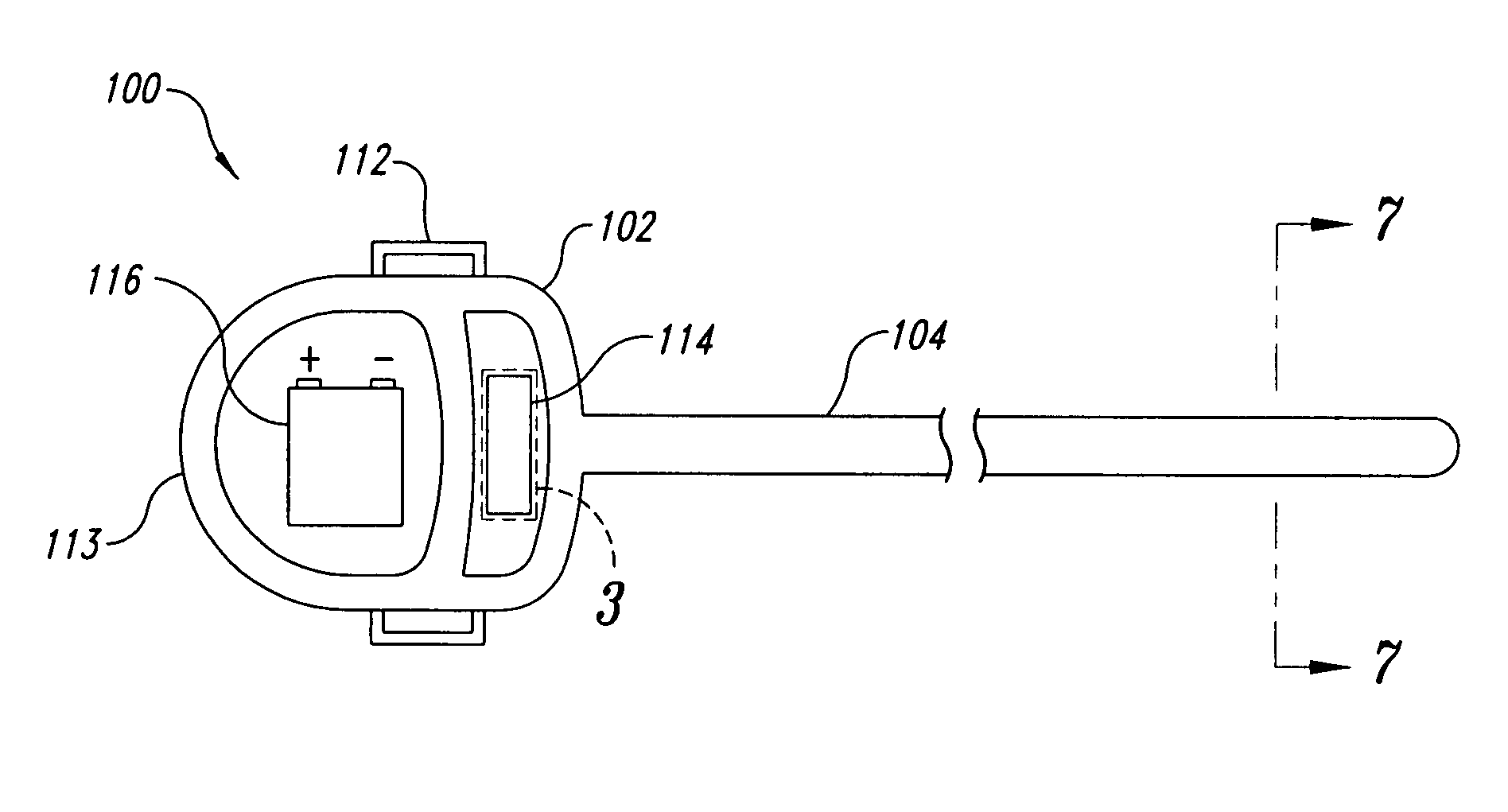

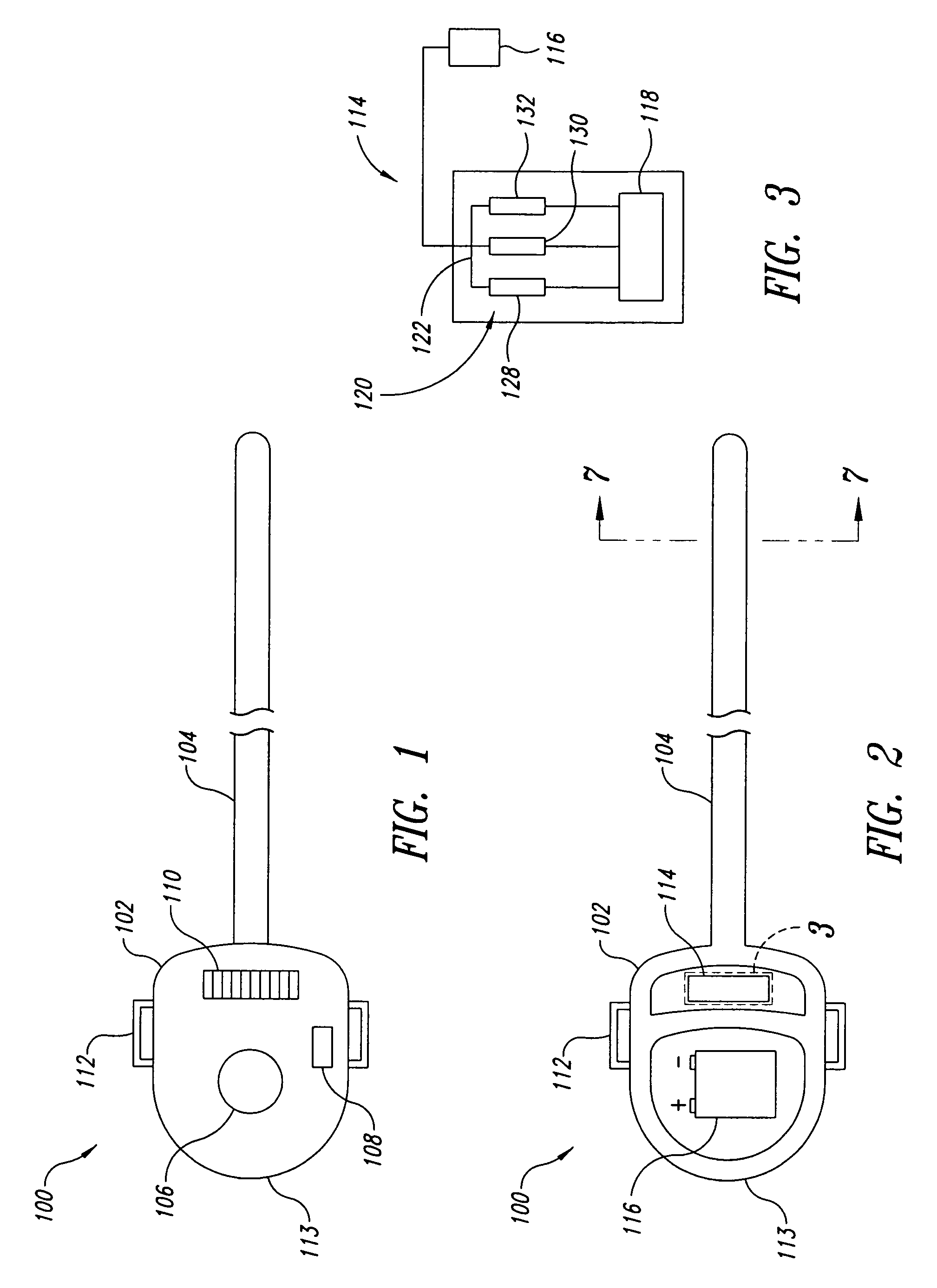

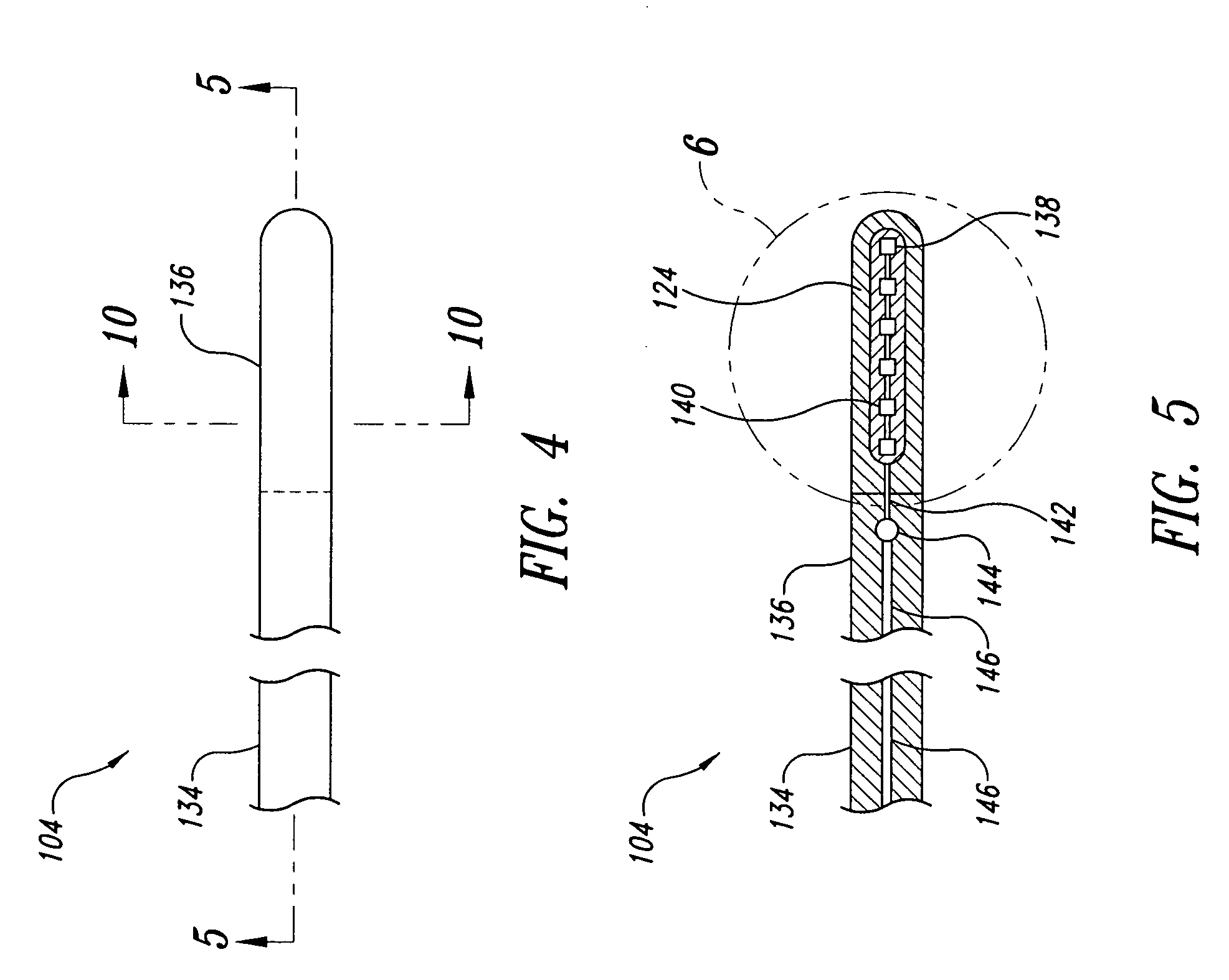

Light transmission system for photoreactive therapy

ActiveUS20070260295A1Minimizes tissue traumaConvenient treatmentSurgical furnitureEndoscopesMedicineCombined use

A light transmission system to provide photodynamic treatment to a patient includes a single use integrated control module and catheter assembly having a plurality of light emitting diodes (LEDs) to transmit light toward target cells within a patient. The integrated light catheter and control module are used in combination with a light activated drug. Selected operating parameters may be programmed into the control module, or it may be wirelessly programmable in situ prior to use to allow user flexibility to tailor treatment for a particular patient or condition. Among the features that prevent reuse are that the control module lacks access to recharge the power source, and it may include a deactivation module that destroys circuitry or software when triggered. To prevent patient interference when in use, the control module may also be configured to selectively deactivate.

Owner:LIGHT SCI ONCOLOGY

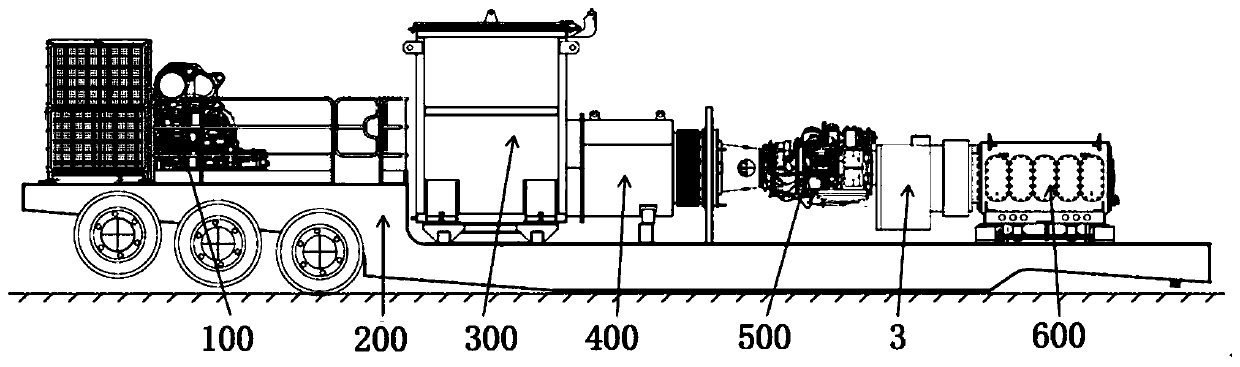

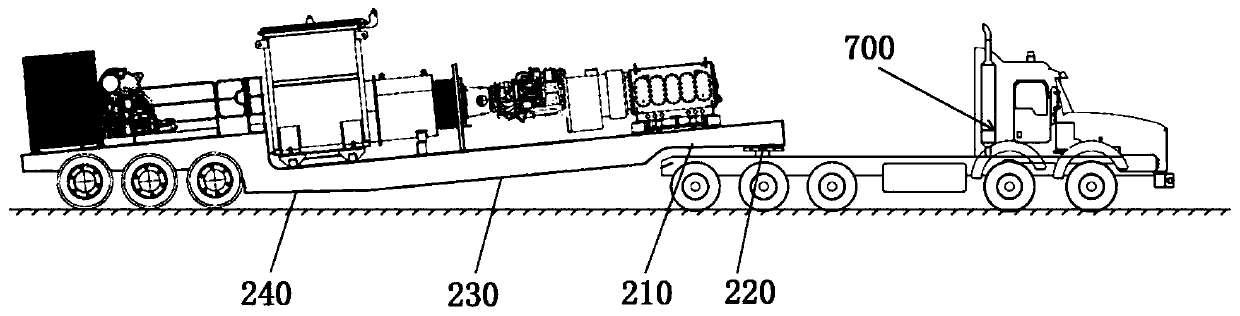

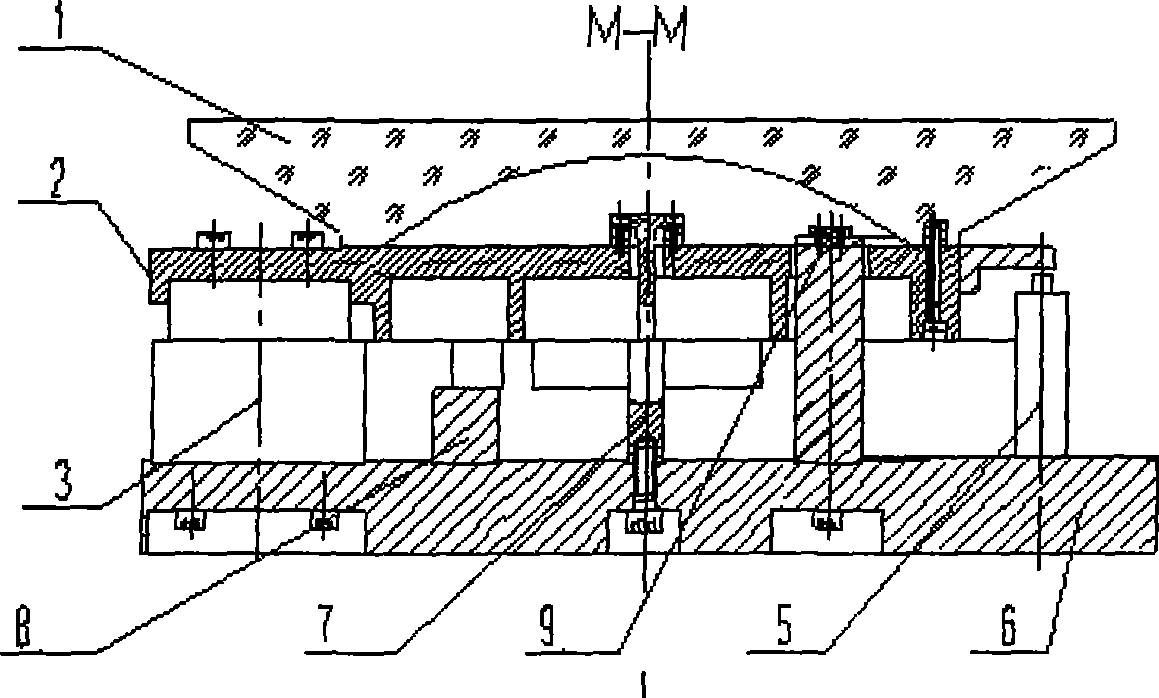

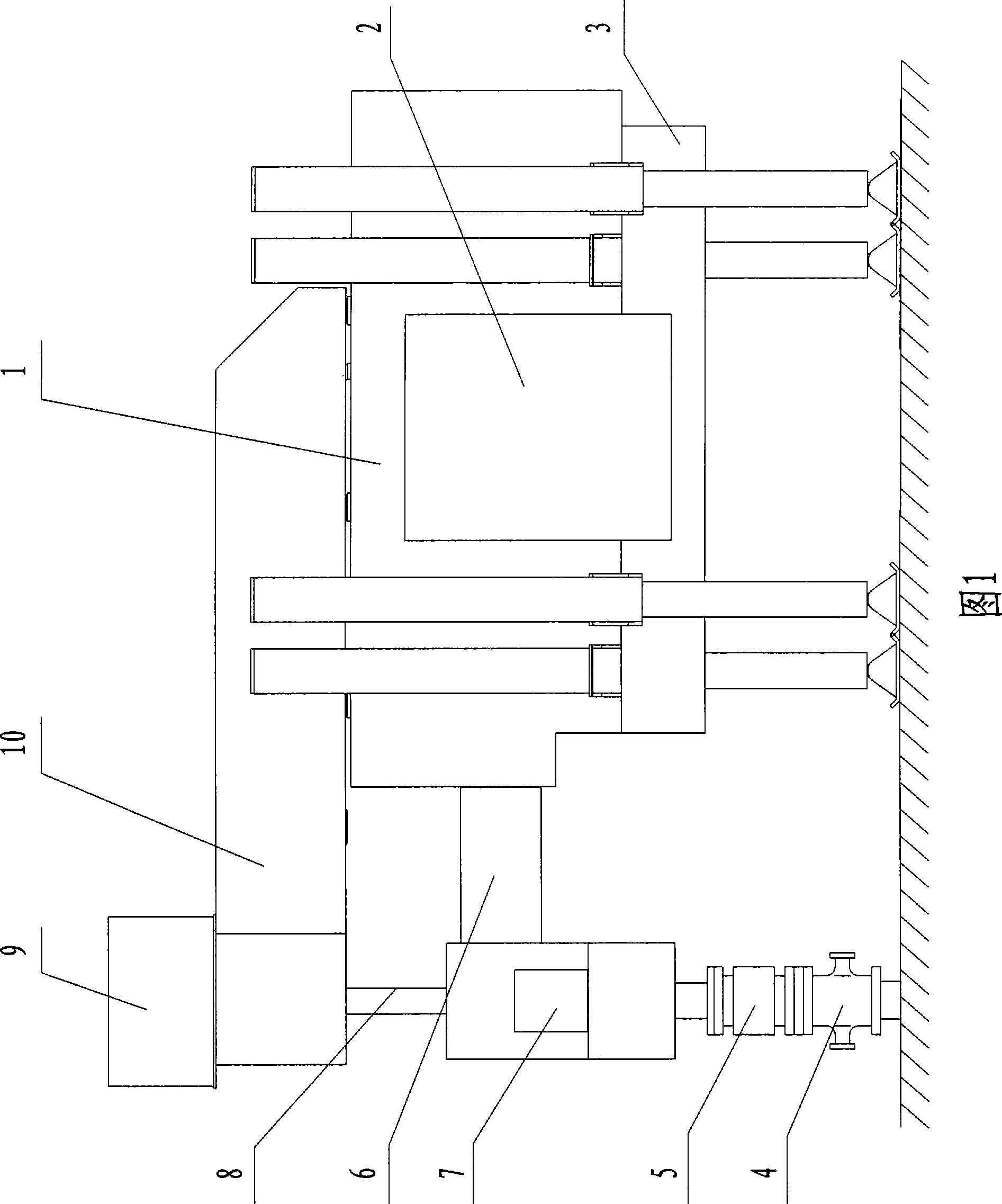

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

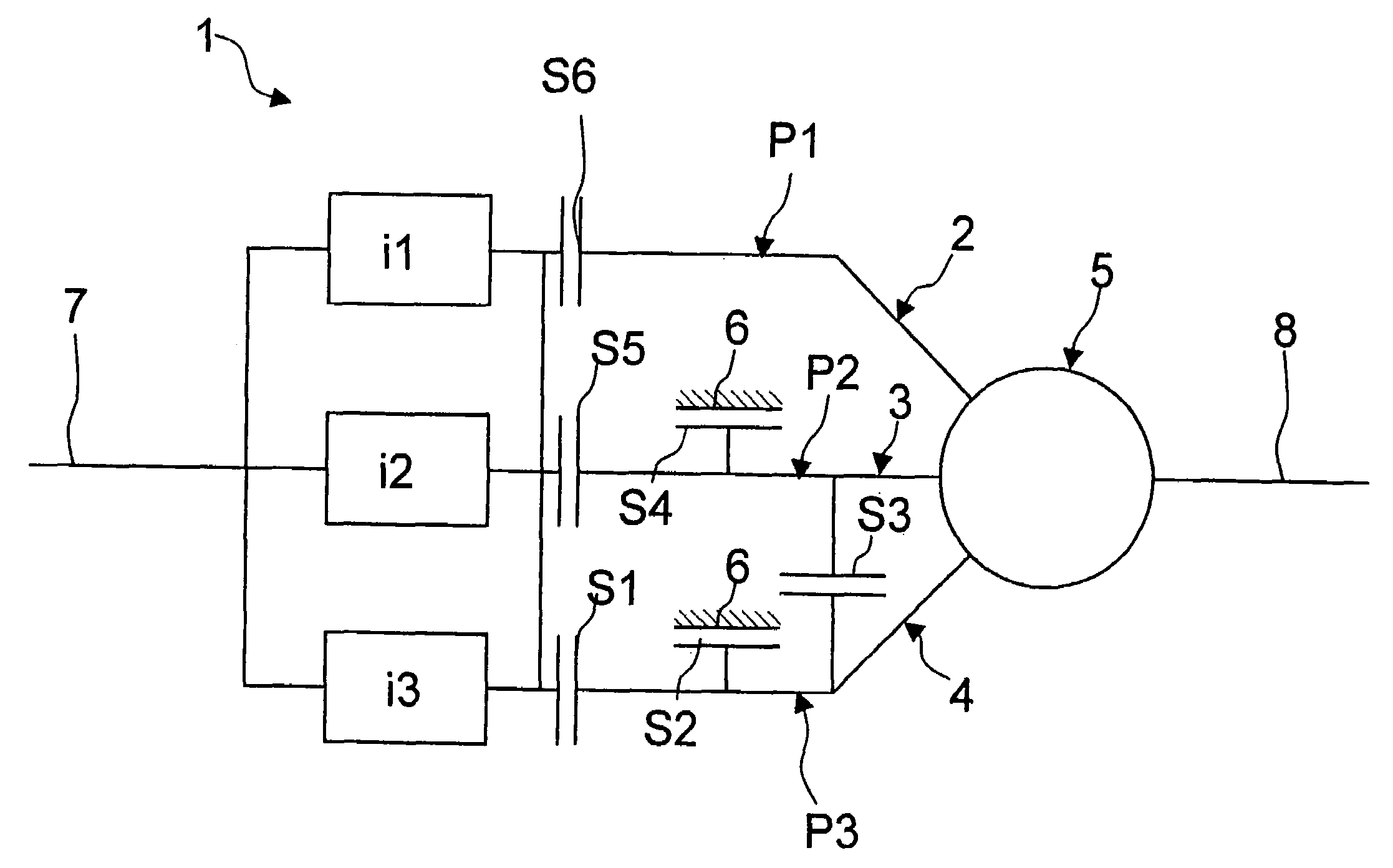

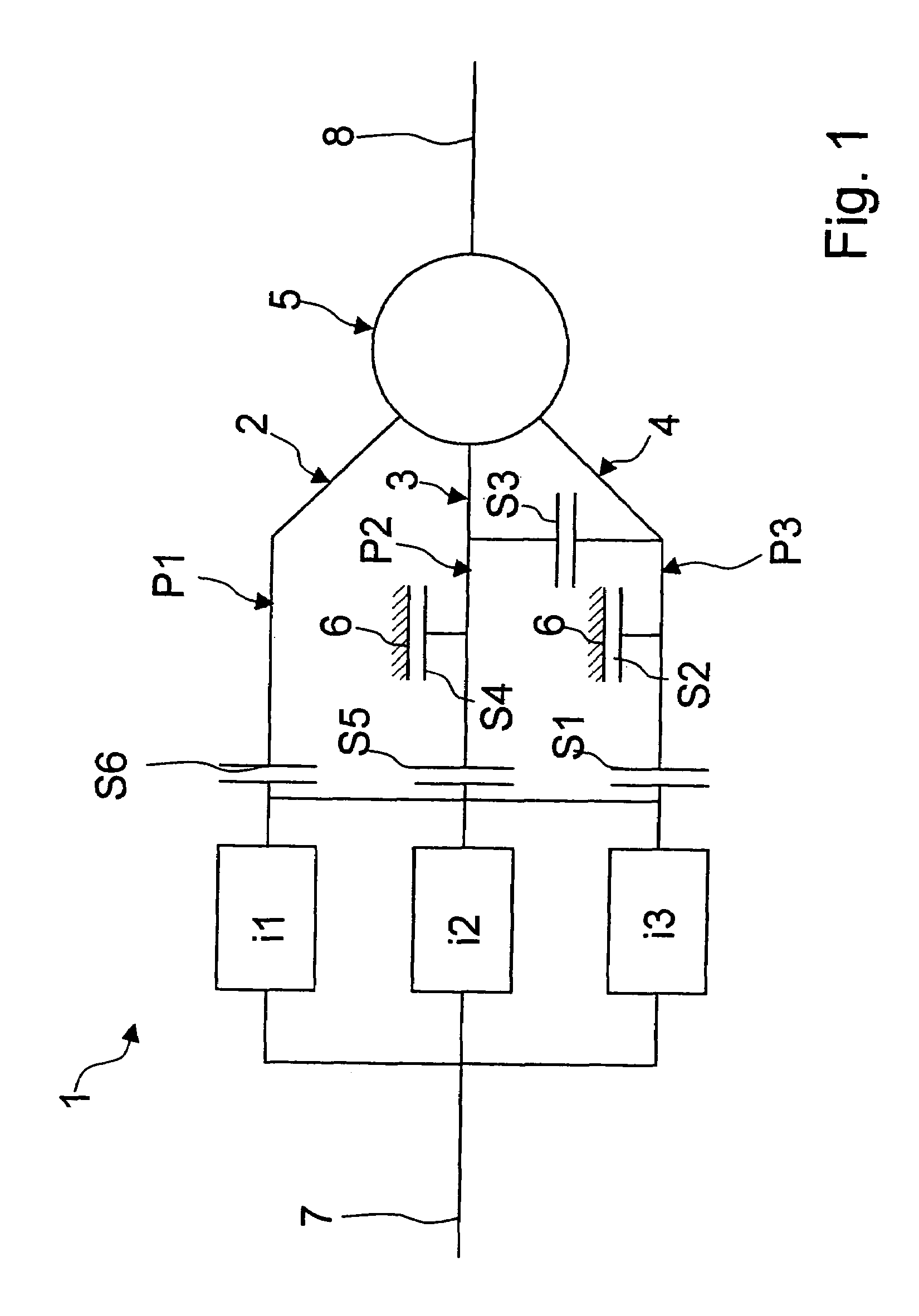

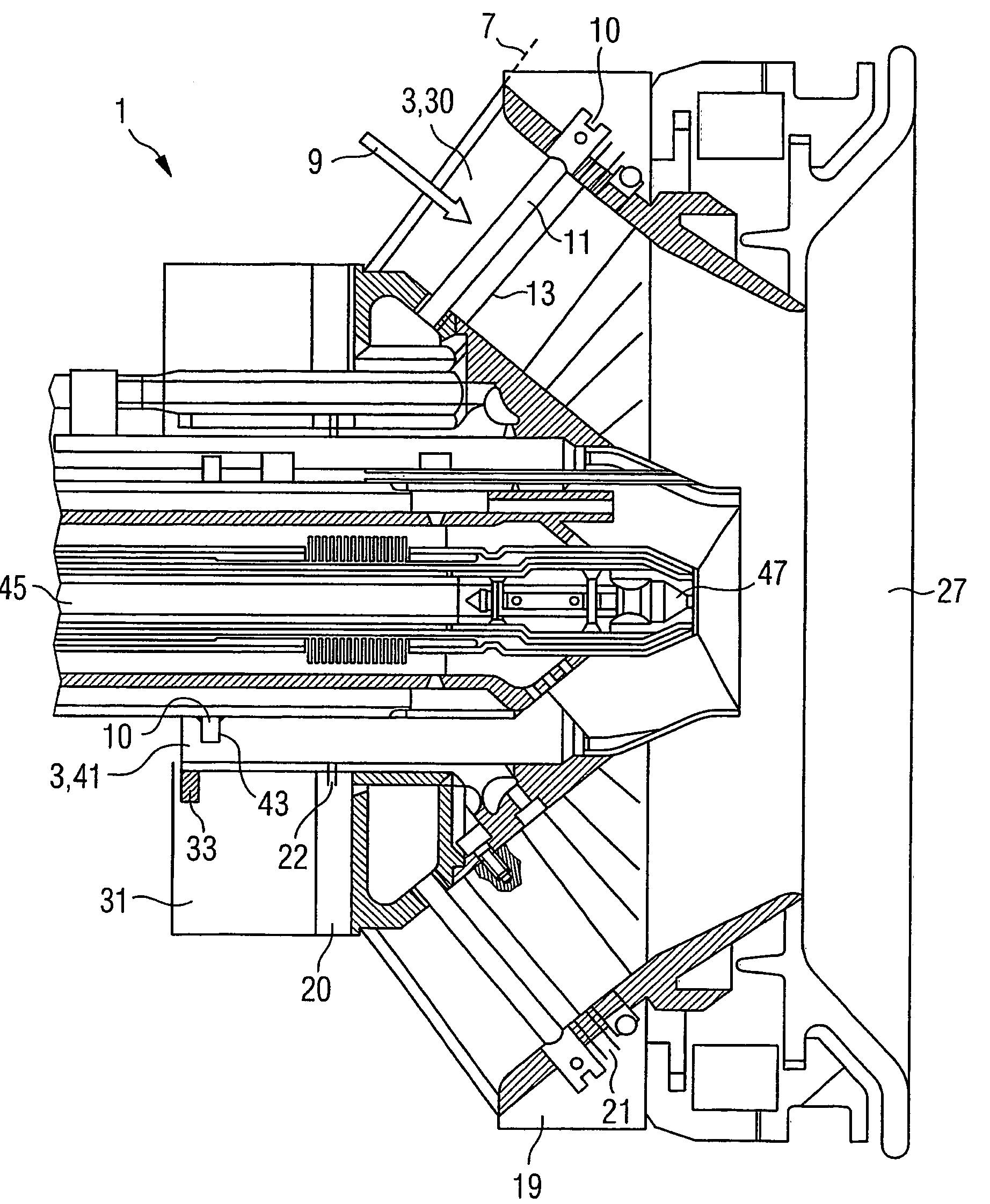

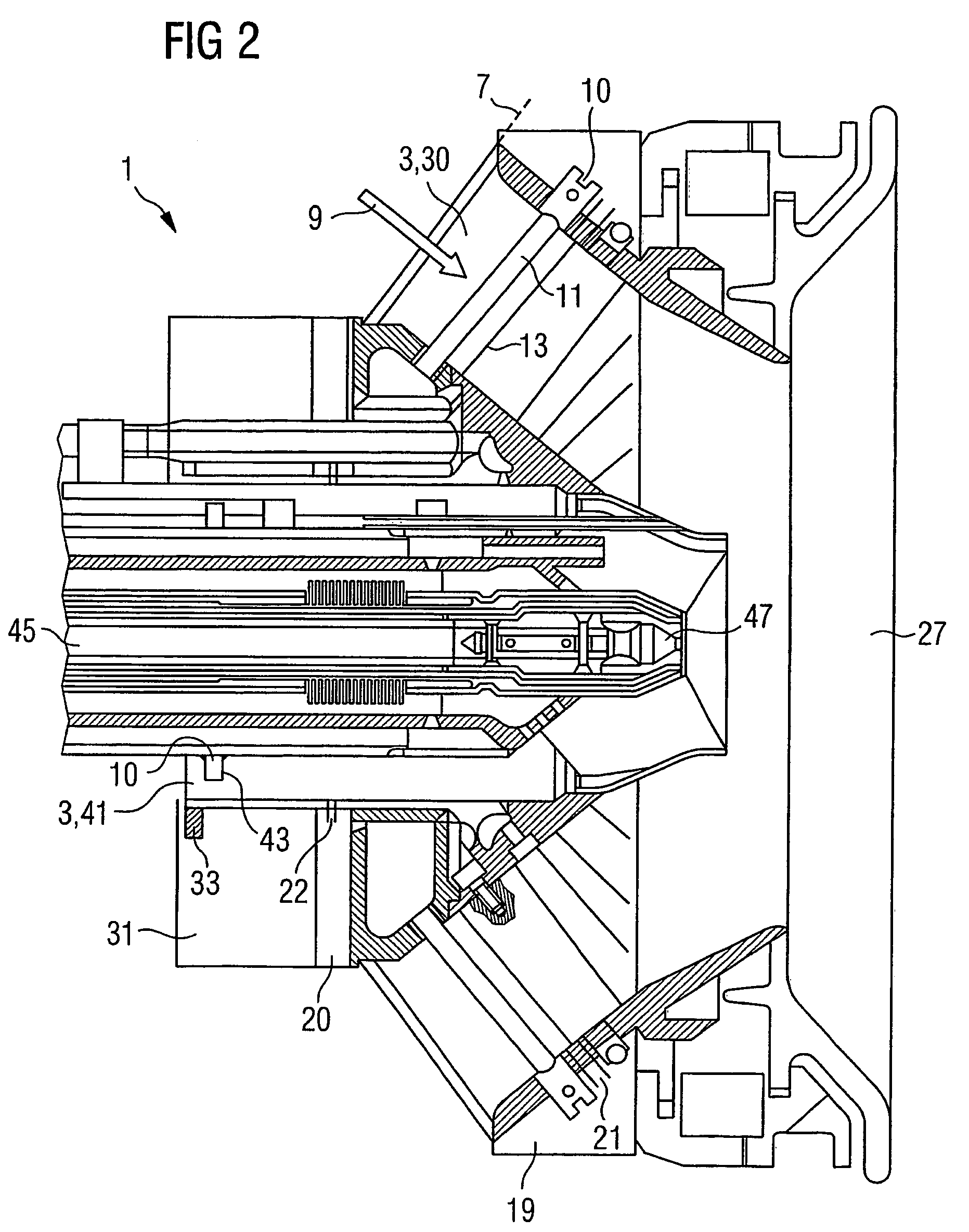

Transmission, in particular an automated power-branched multi-speed gearing

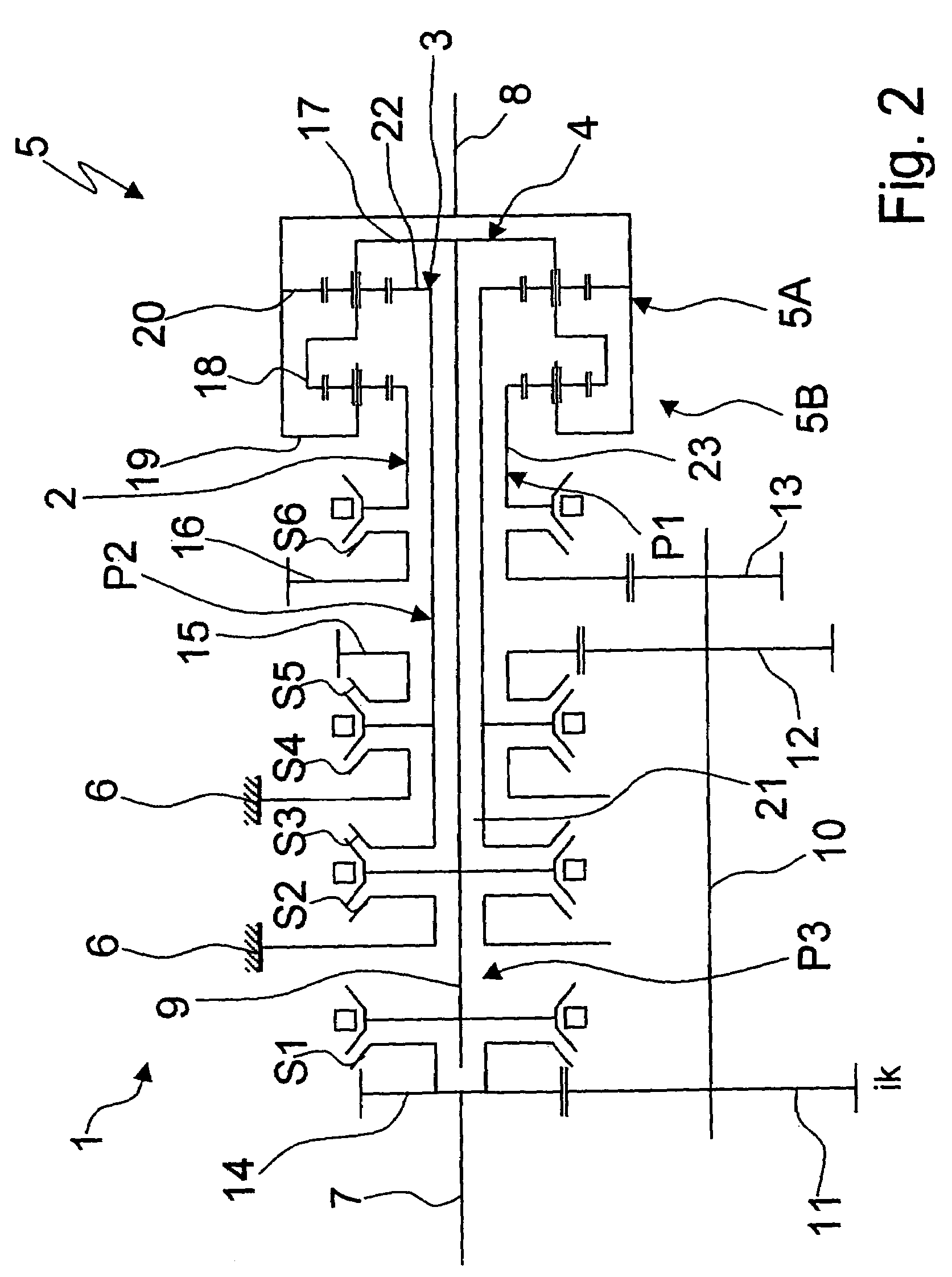

InactiveUS20060223666A1Shifted easily and pleasantlySmall outer dimensionToothed gearingsTransmission elementsPower flowGear wheel

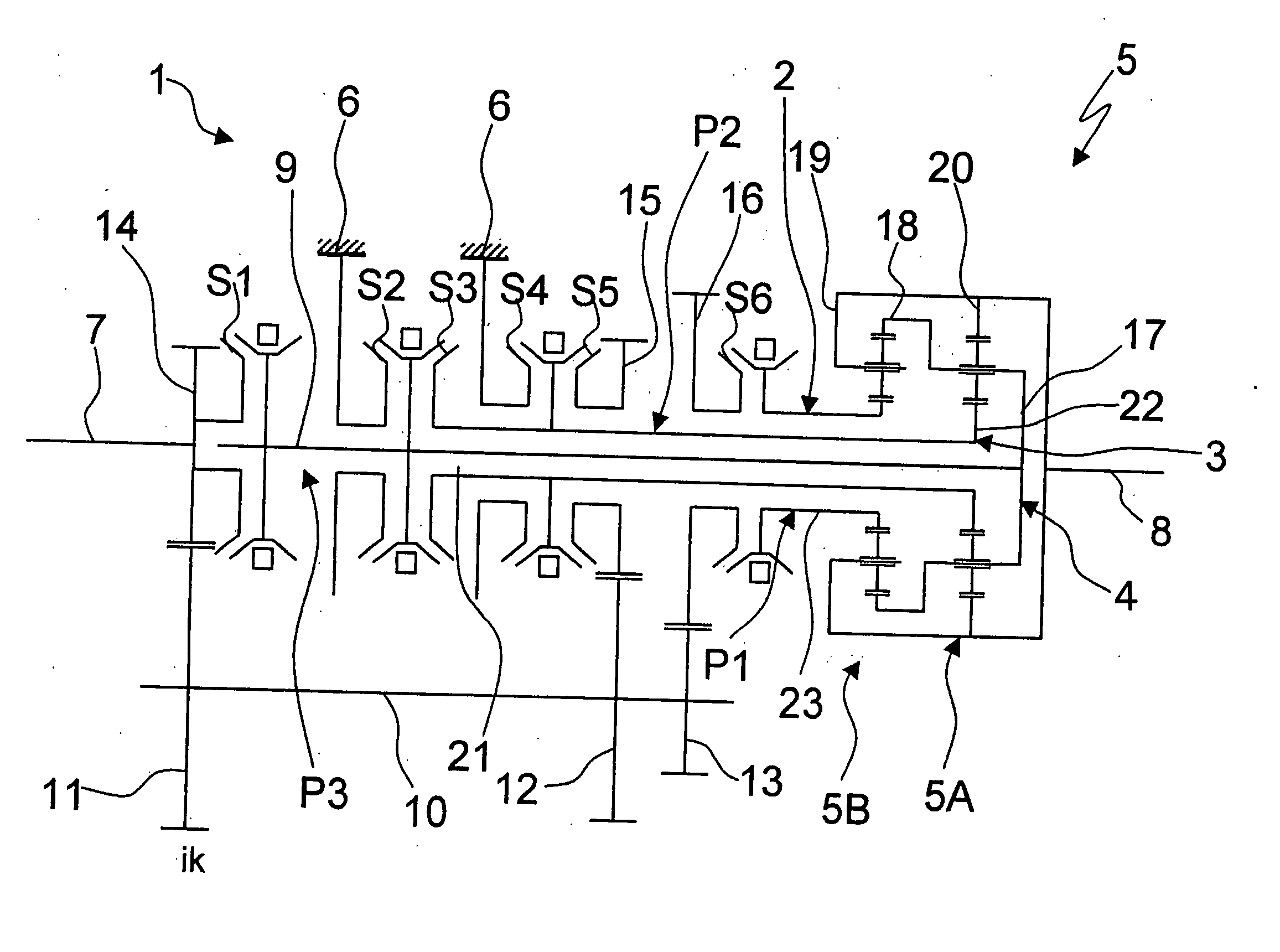

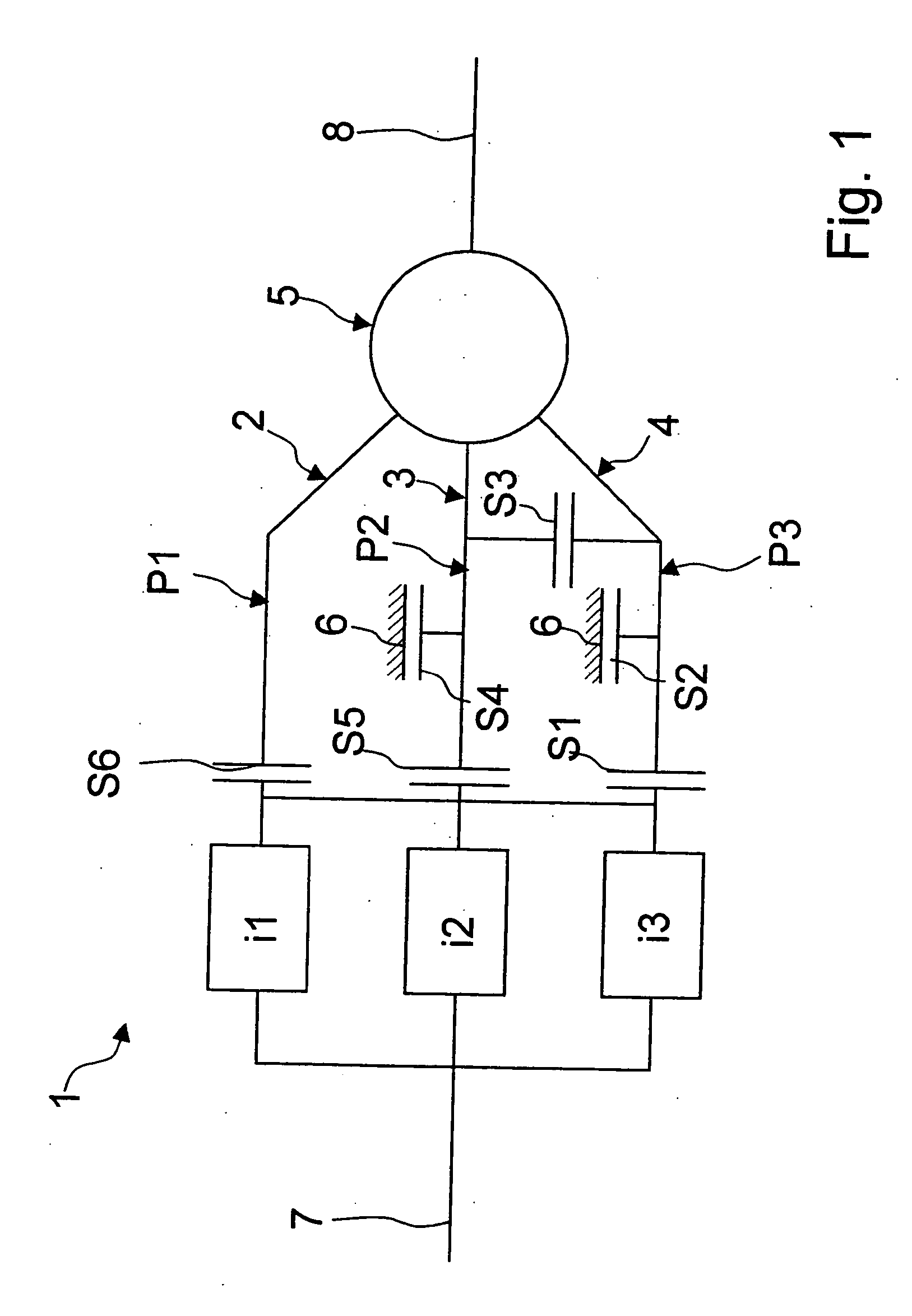

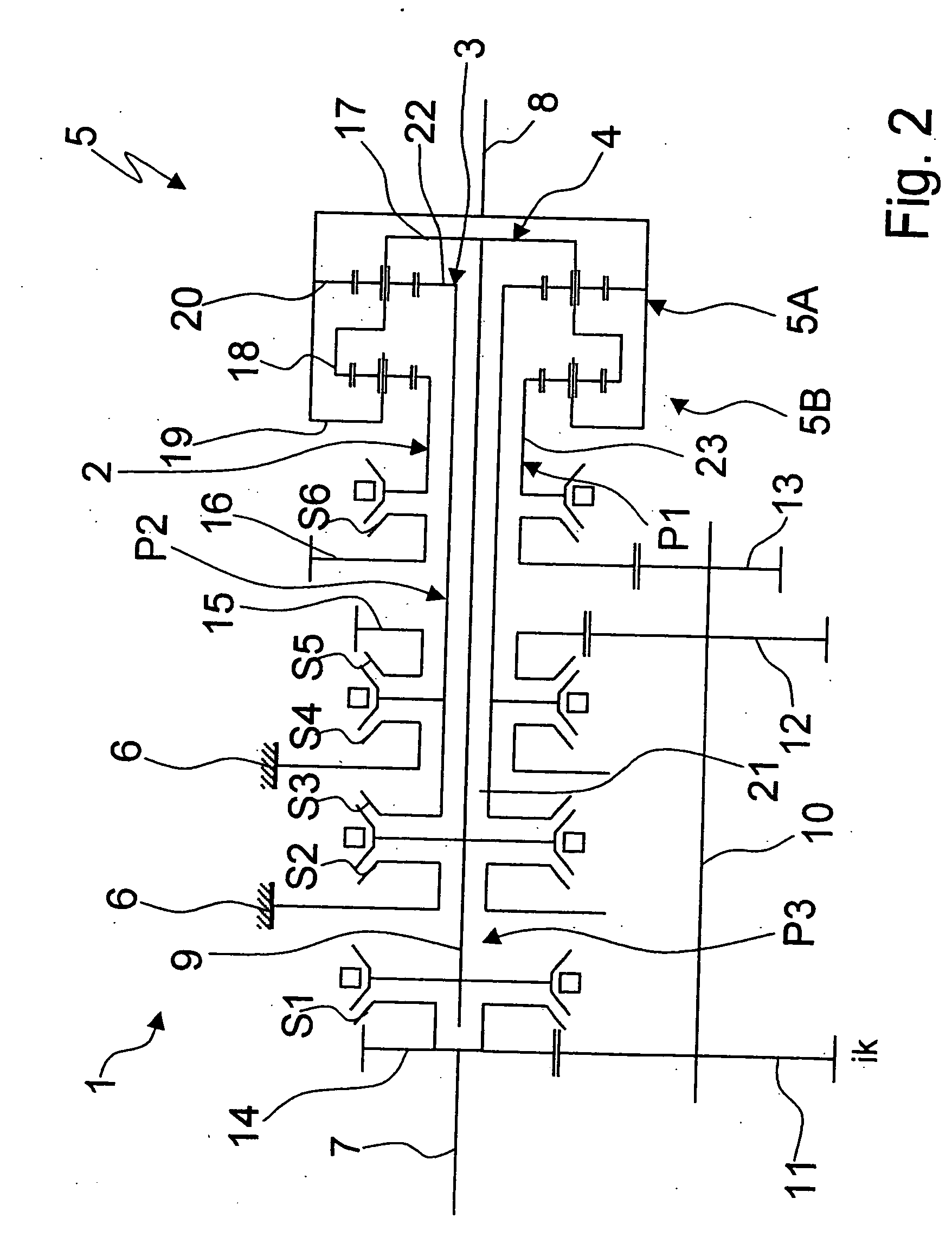

A transmission (1) is proposed, especially an automated power-split multi-speed transmission, comprises at least three power branches (P1, P2, P3), which are each connected to a shaft (2, 3, 4) of a downstream planetary gearset (5) and are configured with at least one partial transmission ratio (i1, i2, i3). Each power branch (P1, P2, P3) comprises a control element (S1, S5, S6) for connecting the power branches (P1, P2, P3) to a power flow of the transmission (1) at a partial transmission ratio (i1, i2, i3). At least one of the shafts (3, 4) of the planetary gearset (5) interacts with an additional control element (S2, S4), via which the shaft (3, 4) can be supported in relation to a housing (6). An additional control element (S3) is arranged between two shafts (3, 4) of the planetary gearset (5) which, in its closed state, blocks the planetary gearset (5).

Owner:ZF FRIEDRICHSHAFEN AG

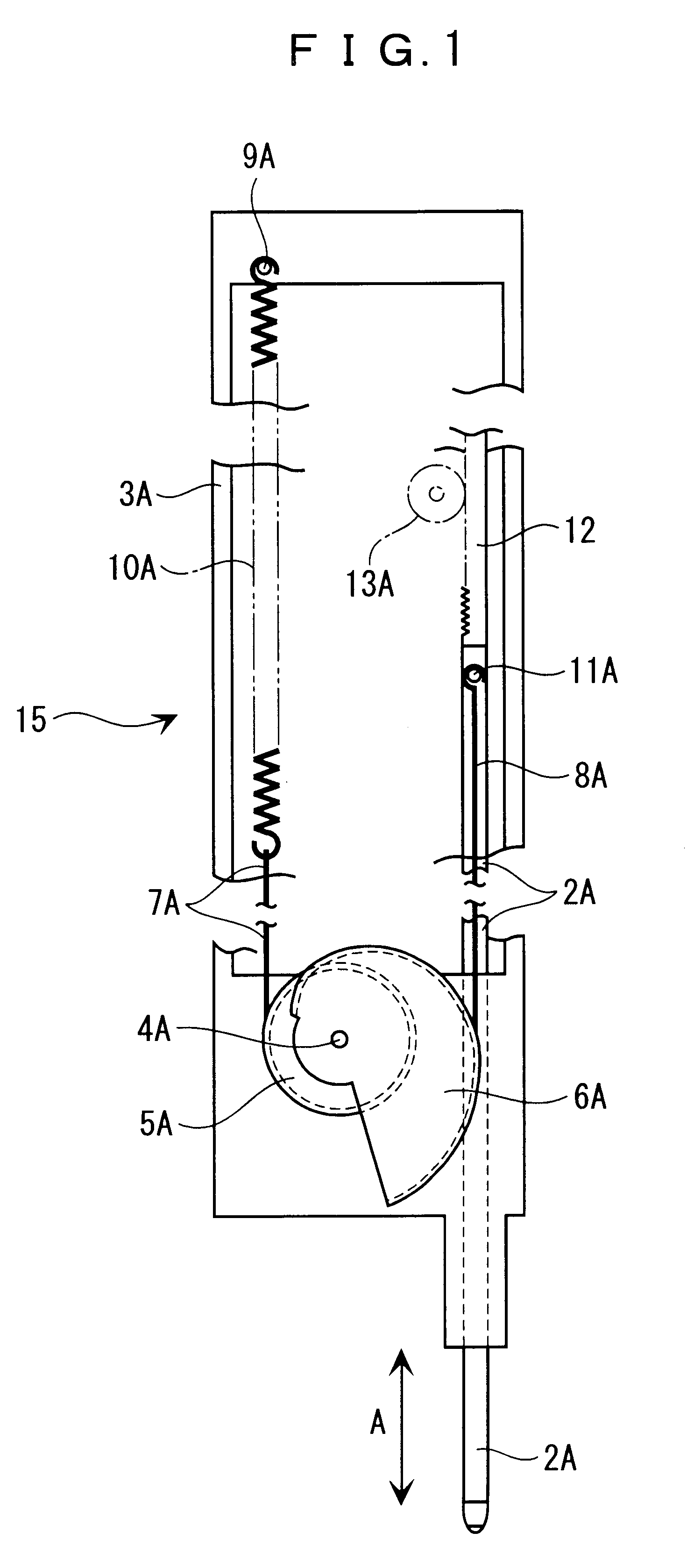

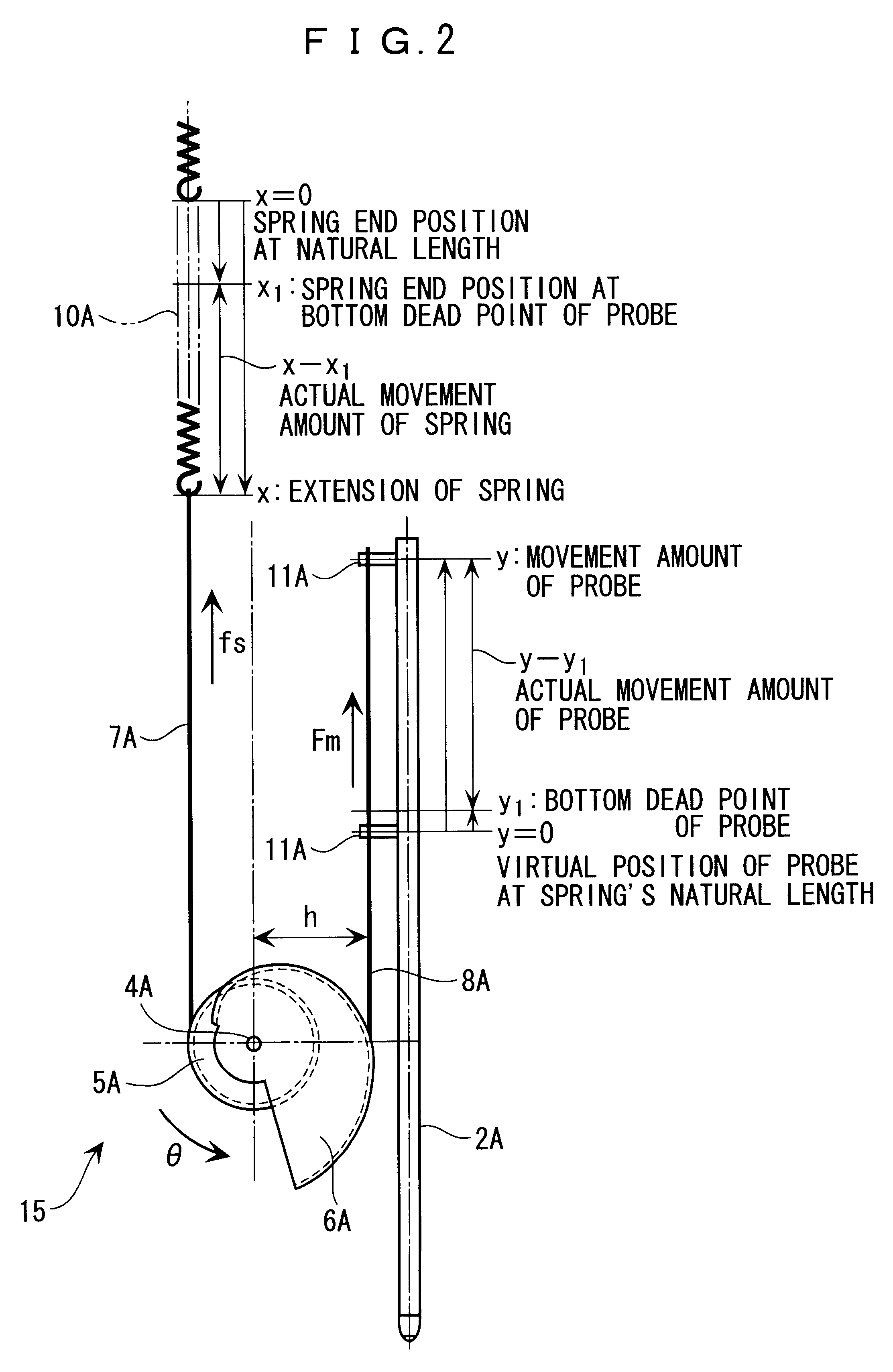

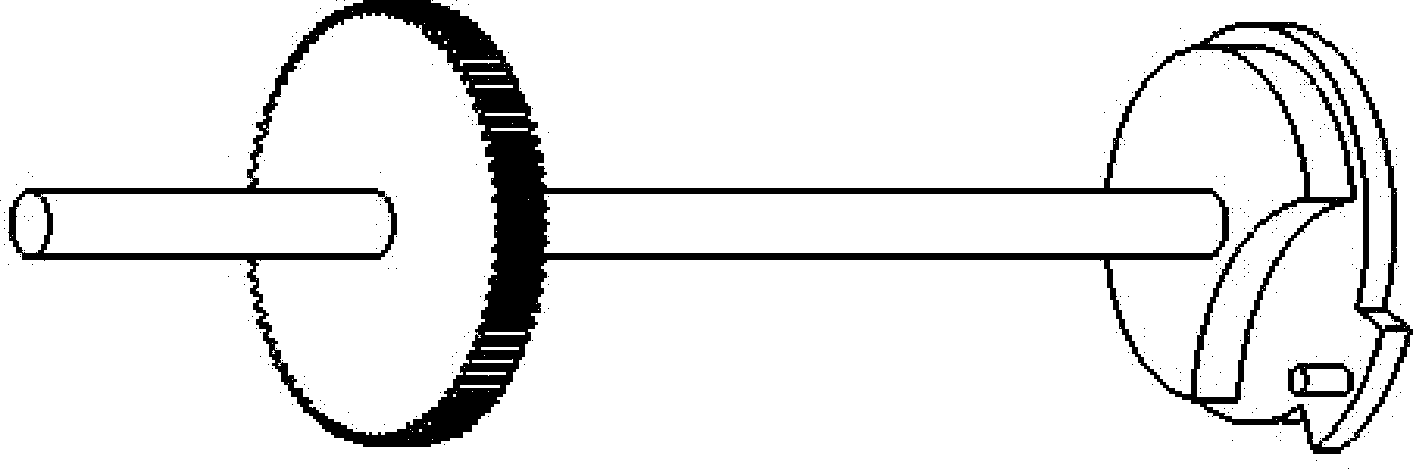

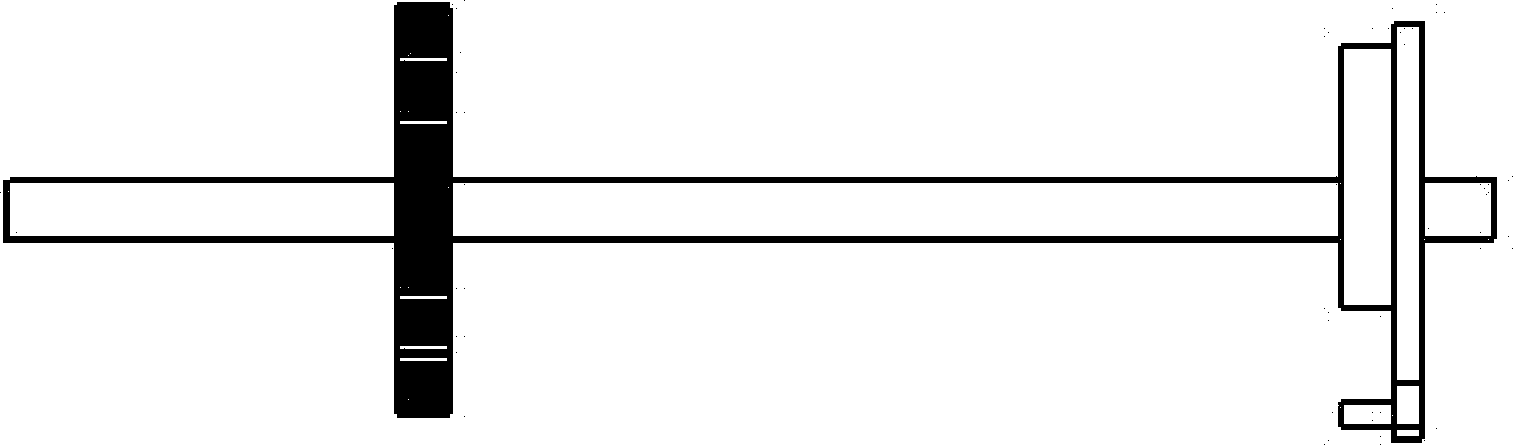

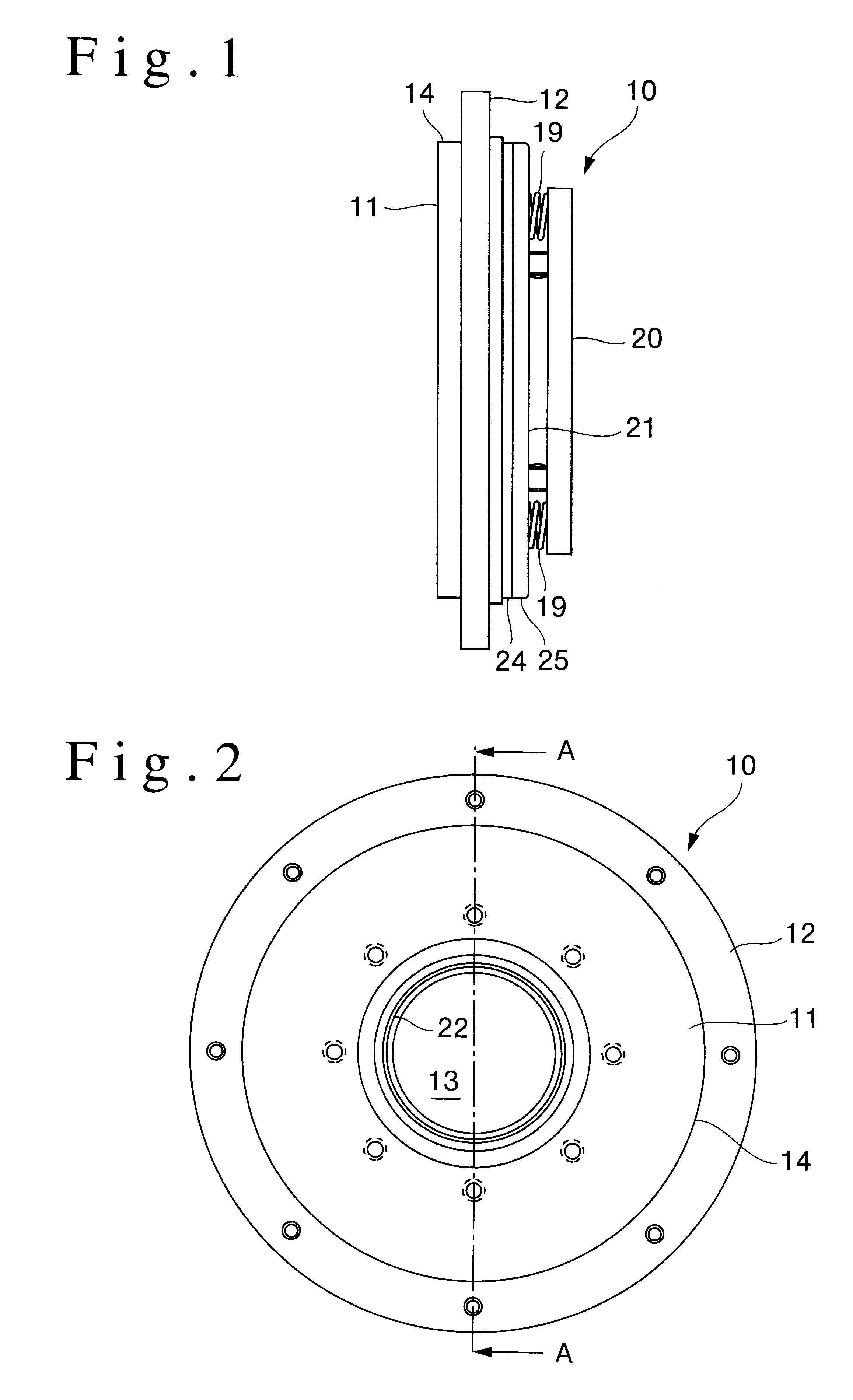

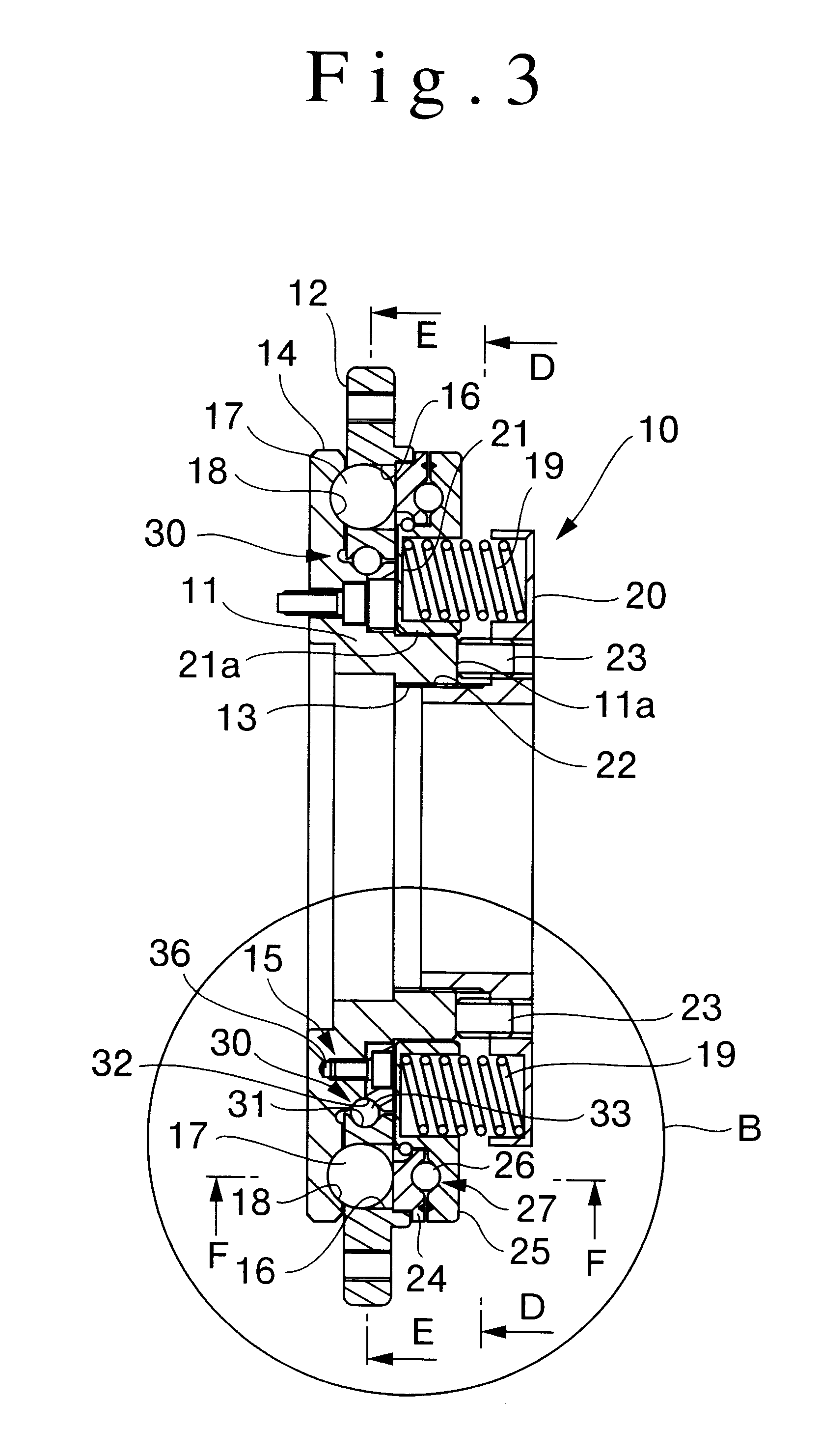

Constant pressure mechanism of probe

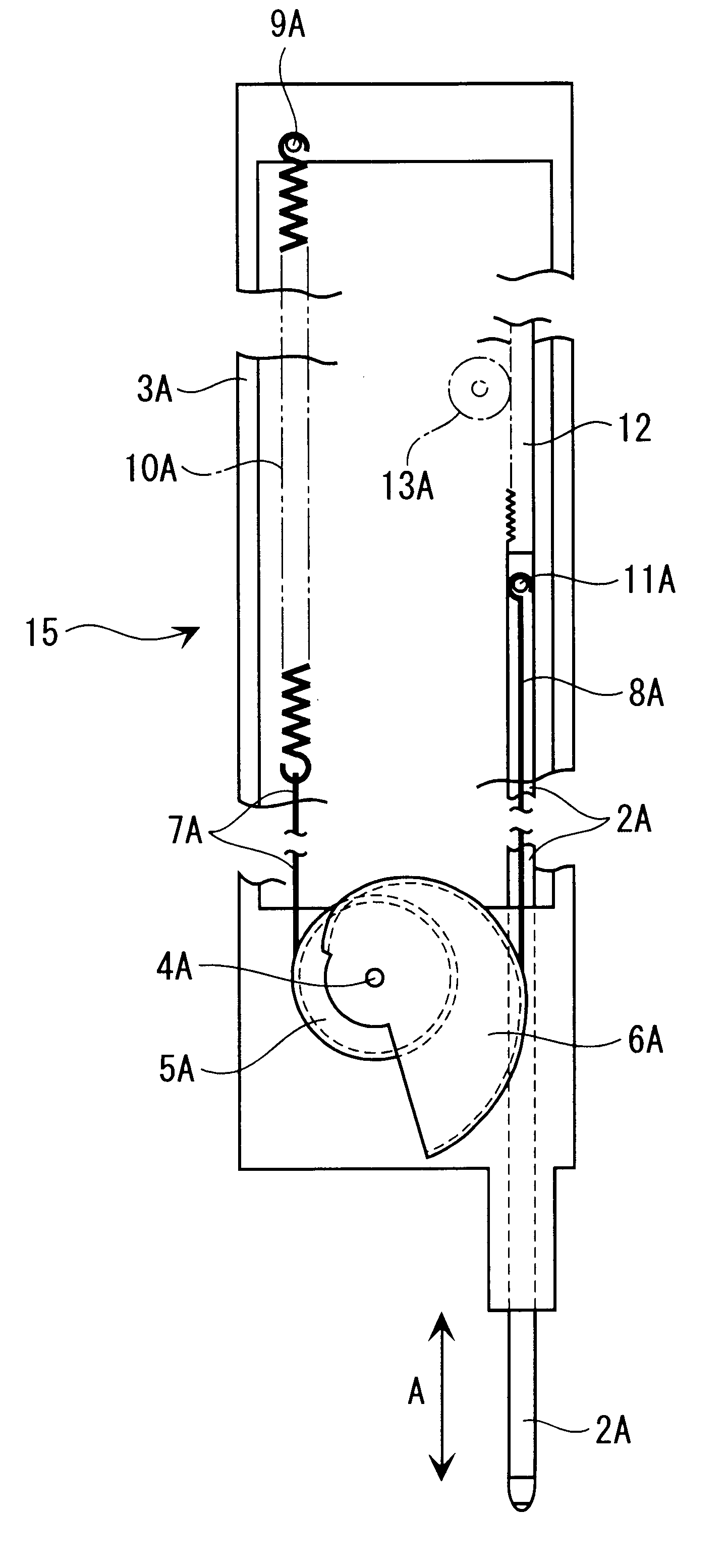

InactiveUS6434851B1Small form factorLight weightMechanical counters/curvatures measurementsStands/trestlesEngineeringPulley

A constant pressure mechanism of a probe for urging the probe in a predetermined direction by virtue of elastic force of a spring is provided. The mechanism comprises a circular pulley rotatably supported around a central axis by an instrument stationary portion, a rotation force urging mechanism for urging the pulley in the predetermined direction, and a first wire adjoining the pulley to the probe. The rotation force urging mechanism comprises a spiral pulley coaxial with and capable of combined rotation with the circular pulley, and a second wire connecting the spiral pulley to the spring. The other end of the spring is connected to the instrument stationary portion. Strict contact pressure of the probe is maintained throughout its motion.

Owner:MITUTOYO CORP

Transmission, in particular an automated power-branched multi-speed gearing

InactiveUS7288044B2Shifted easily and pleasantlyLarge possible number of gear stepGearingTransmission elementsPower flowGear wheel

A transmission (1) is proposed, especially an automated power-split multi-speed transmission, comprises at least three power branches (P1, P2, P3), which are each connected to a shaft (2, 3, 4) of a downstream planetary gearset (5) and are configured with at least one partial transmission ratio (i1, i2, i3). Each power branch (P1, P2, P3) comprises a control element (S1, S5, S6) for connecting the power branches (P1, P2, P3) to a power flow of the transmission (1) at a partial transmission ratio (i1, i2, i3). At least one of the shafts (3, 4) of the planetary gearset (5) interacts with an additional control element (S2, S4), via which the shaft (3, 4) can be supported in relation to a housing (6). An additional control element (S3) is arranged between two shafts (3, 4) of the planetary gearset (5) which, in its closed state, blocks the planetary gearset (5).

Owner:ZF FRIEDRICHSHAFEN AG

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

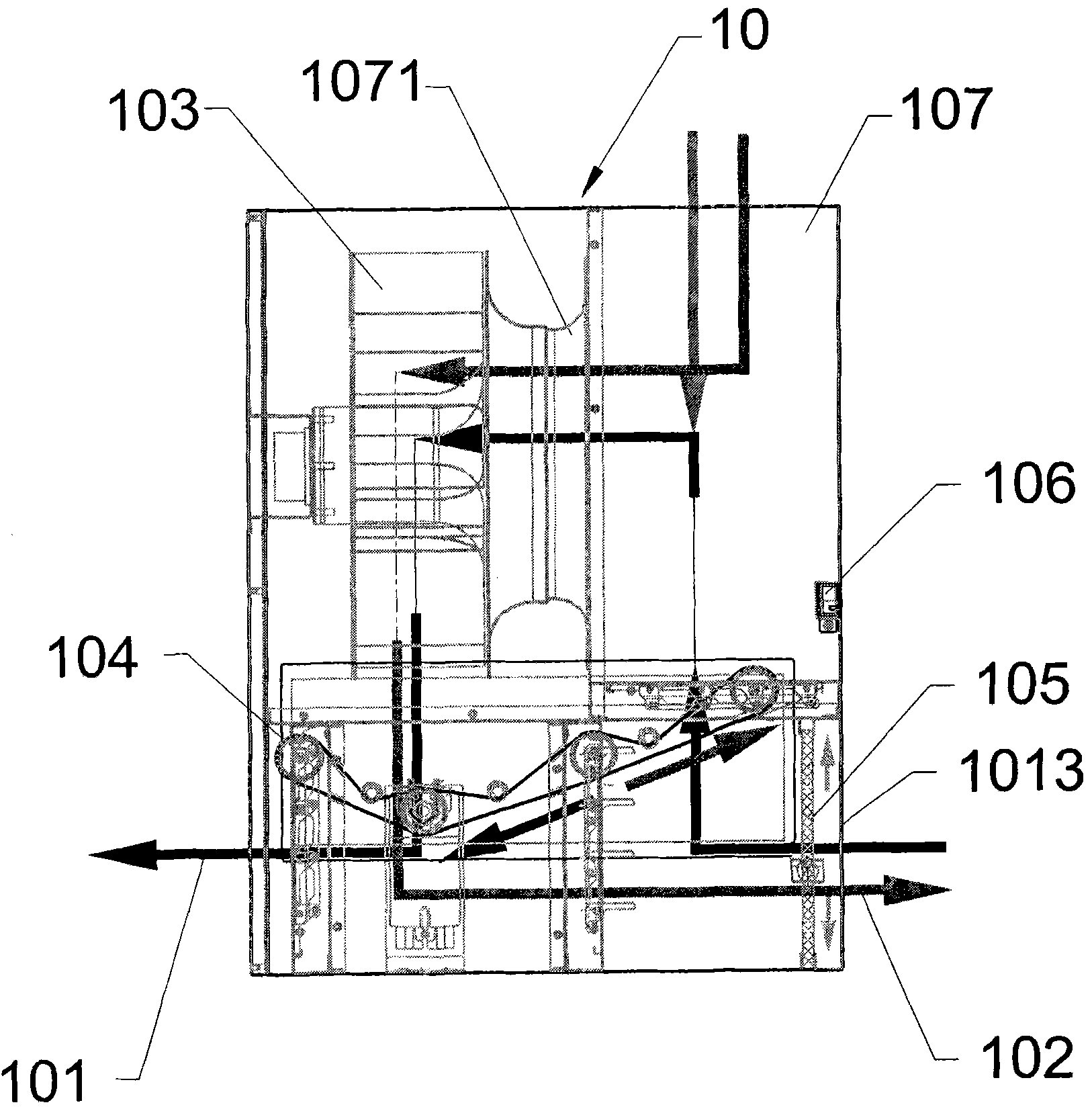

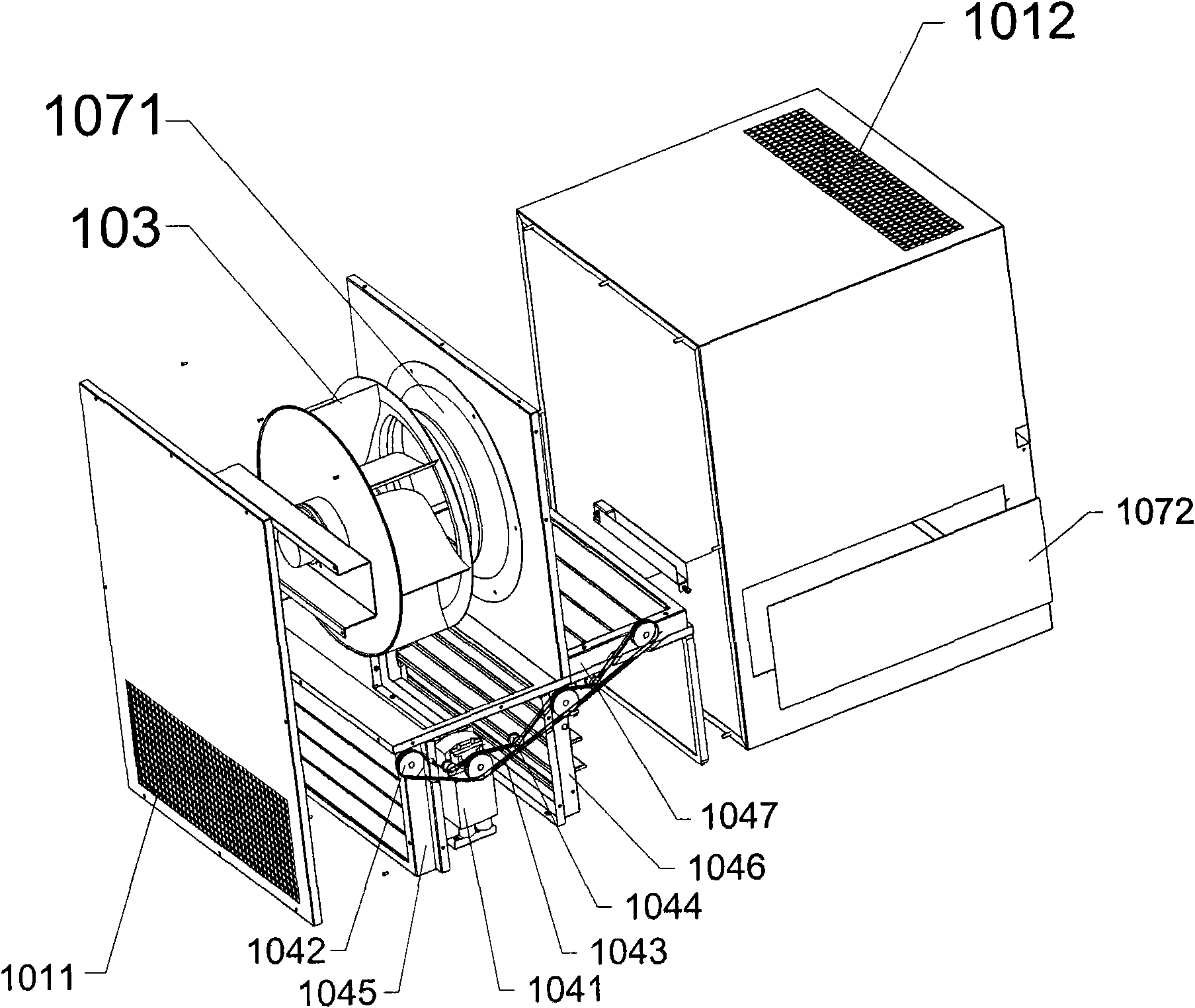

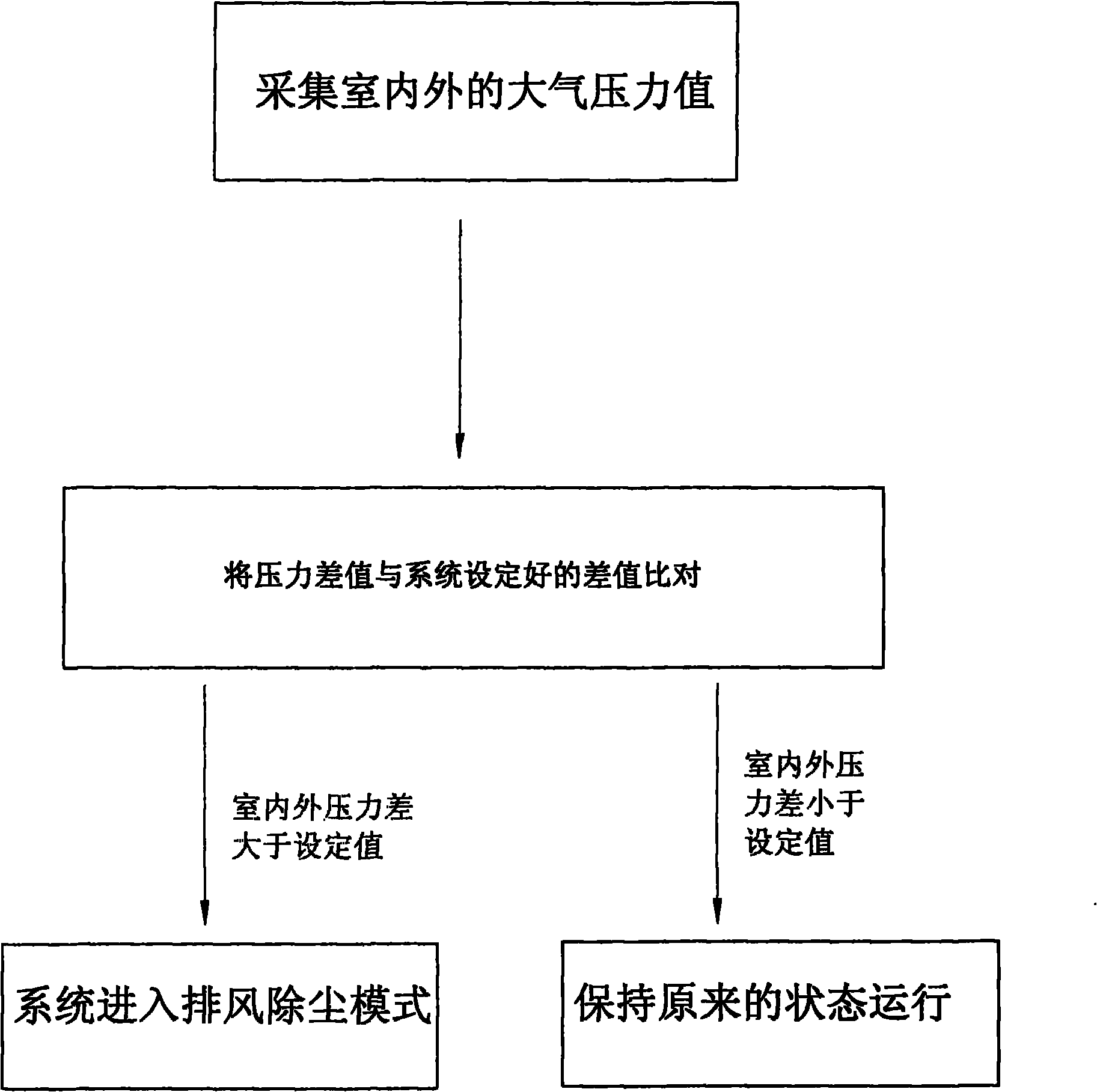

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

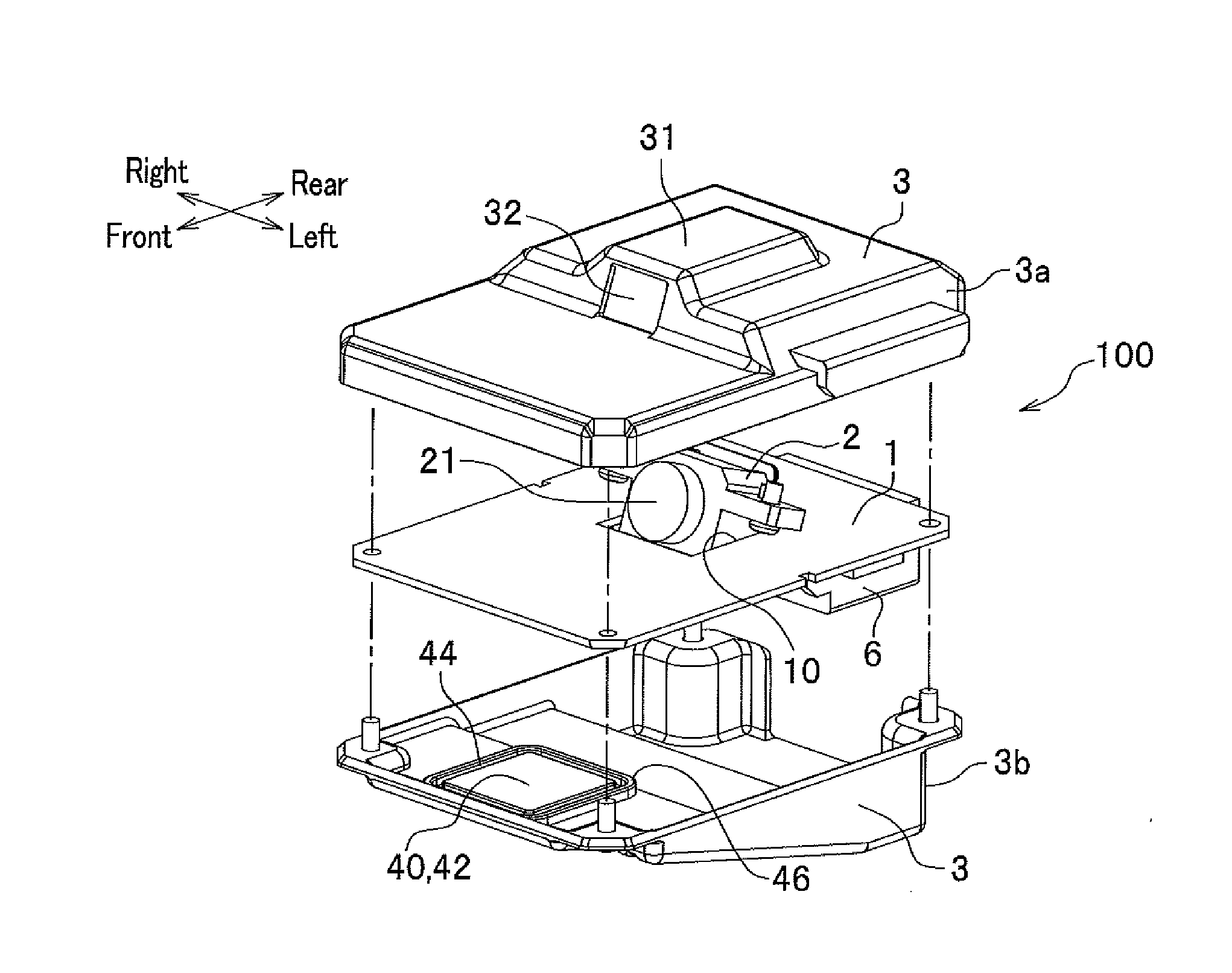

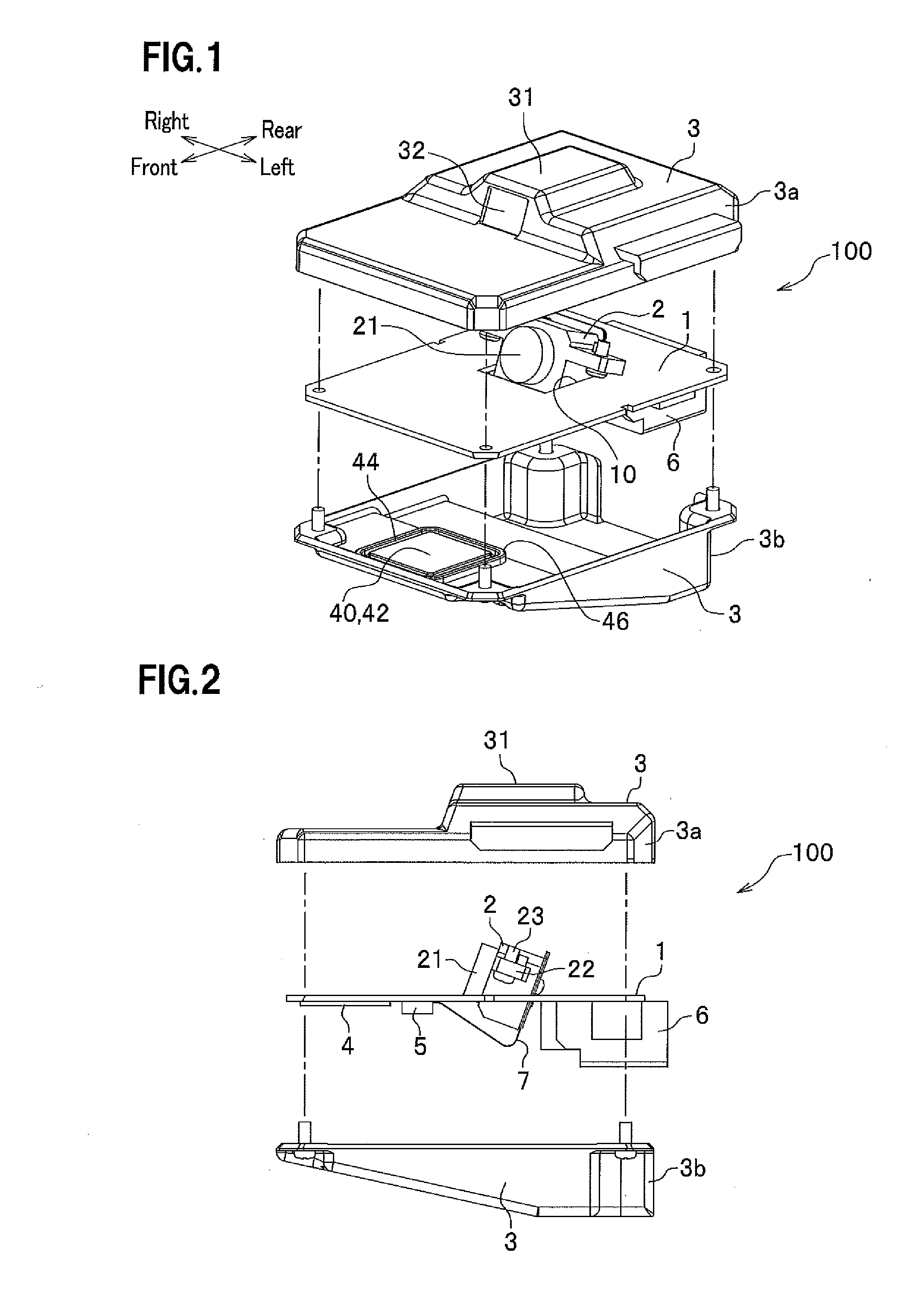

In-vehicle camera

InactiveUS20150042874A1Small sizeSmall thicknessTelevision system detailsColor television detailsComputer graphics (images)In vehicle

Owner:NIDEC ELESYS

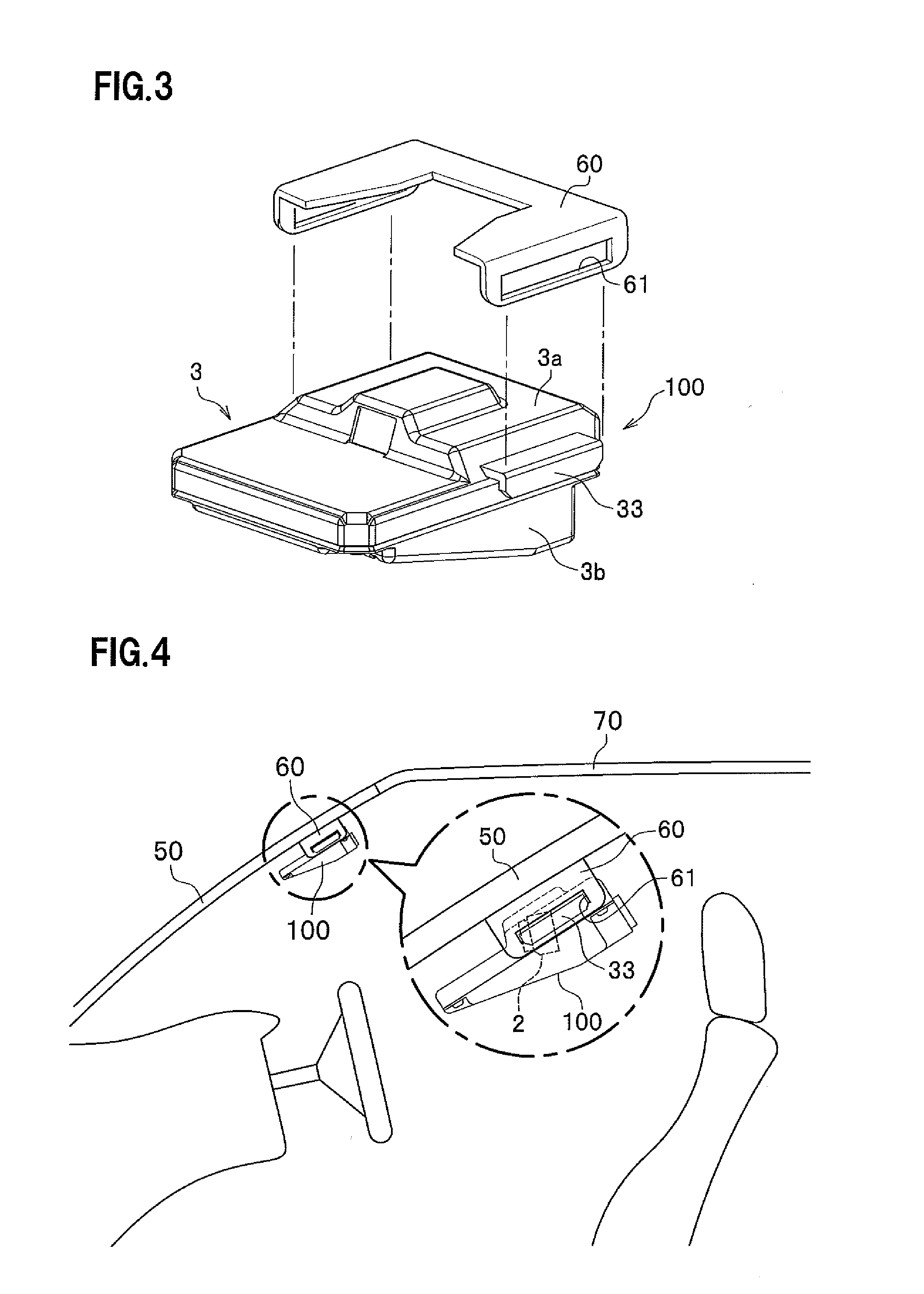

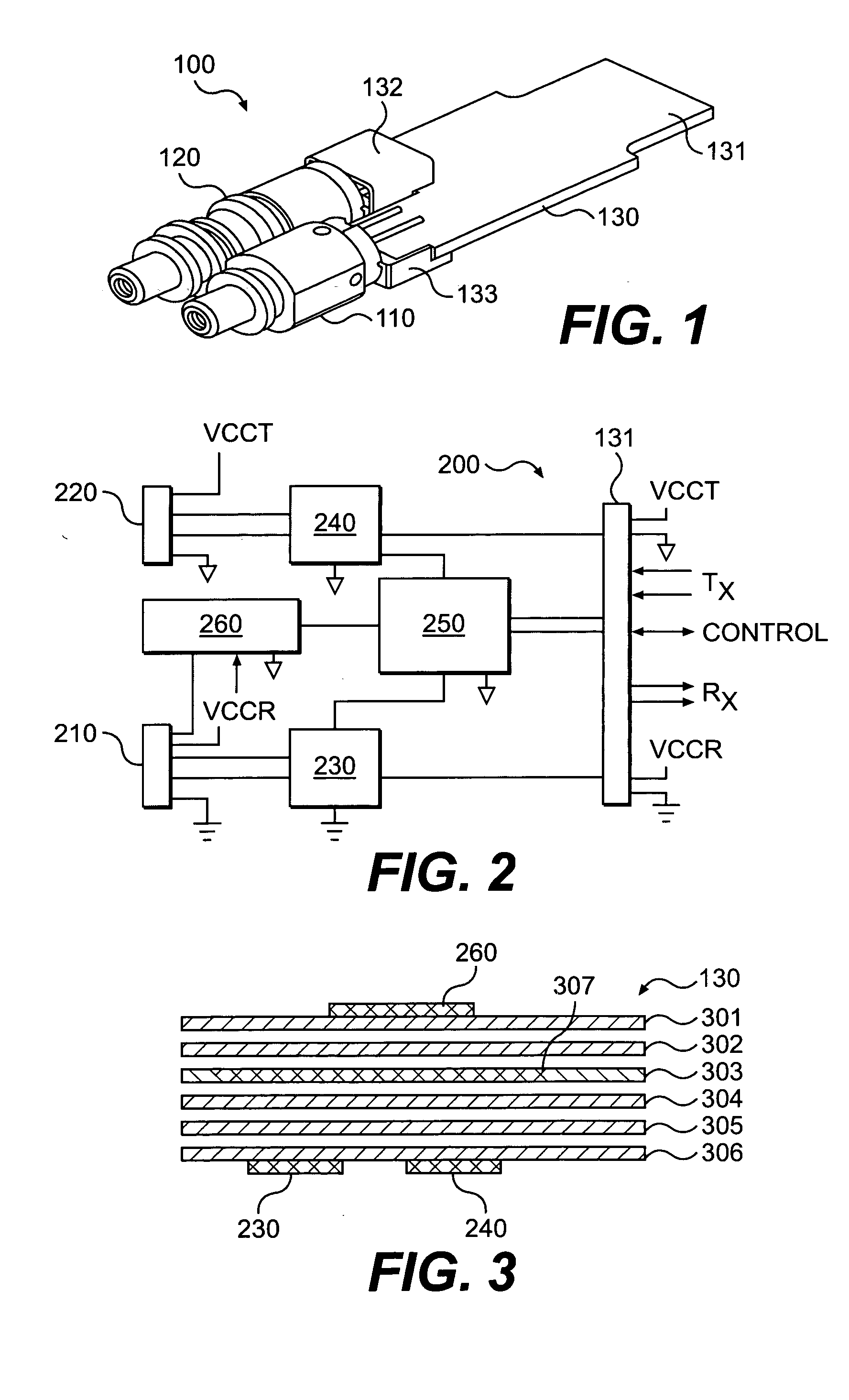

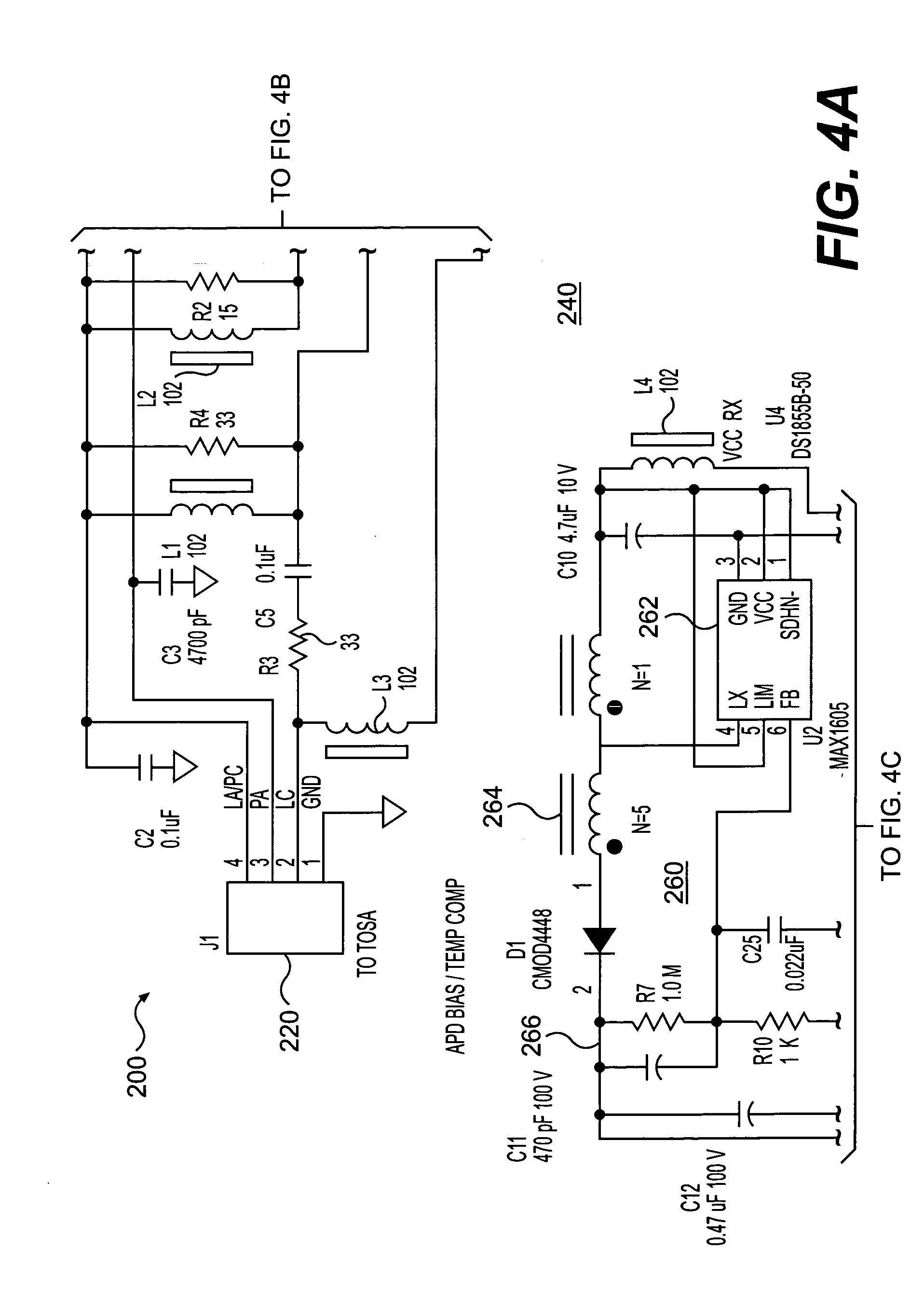

Electronic interface for long reach optical transceiver

ActiveUS20050175350A1Small form factorSmall sizeCross-talk/noise/interference reductionPrinted circuit aspectsGround planeTransceiver

A low form-factor transceiver system appropriate for long-reach optical communications is presented. In accordance with the present invention, an electronic interface to a receiver optical sub assembly (ROSA) and a transmitter optical sub assembly (TOSA) is arranged on a multi-layer board to electrically isolate the transmitter and receiver portions from a high-voltage power supply, which is utilized to provide bias voltages to optical detectors in the ROSA. In some embodiments of the invention, the high-voltage power supply is arranged on a top layer while the transmitter and receiver are arranged on a bottom layer in a split-ground arrangement. Layers between the top layer and the bottom layer include at least one ground plane and provide vias for electrical connections.

Owner:LUMENTUM FIBER OPTICS INC

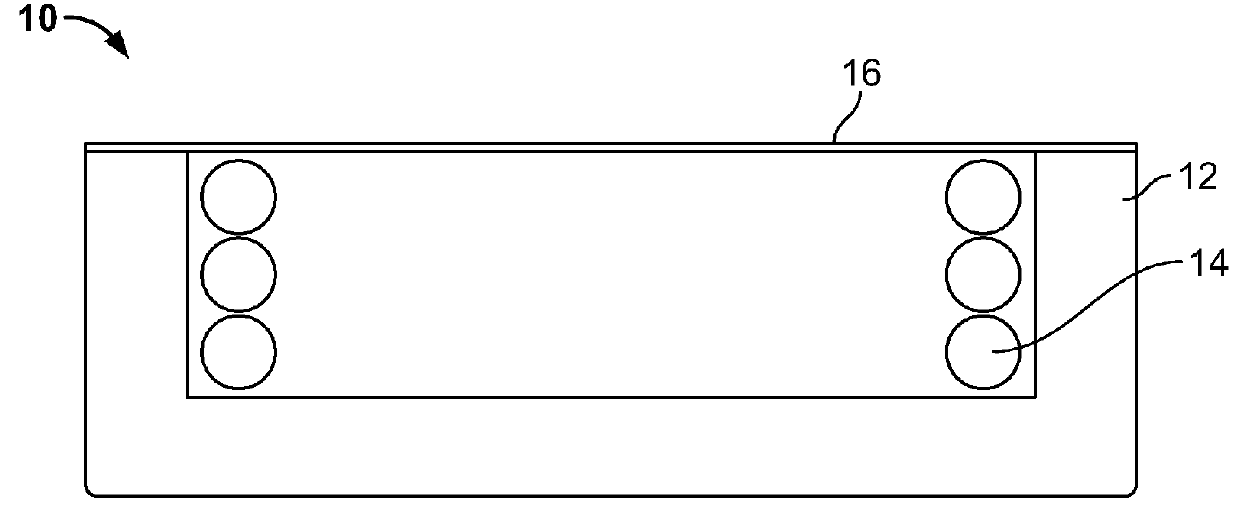

Pressure sensing implant

ActiveUS20160029956A1Small form factorOptimal rf quality factorMagnetic/electric field screeningPrinted circuit aspectsSecondary layerBiomedical engineering

A wireless circuit includes a housing having at least one opening, and sensor connected to the housing at the opening. The sensor includes a first layer having a first dimension and a second layer having a second dimension shorter than the first dimension. The second layer may be positioned entirely within the housing and a surface of said first layer may be exposed to an exterior of the housing.

Owner:ENDOTRONIX

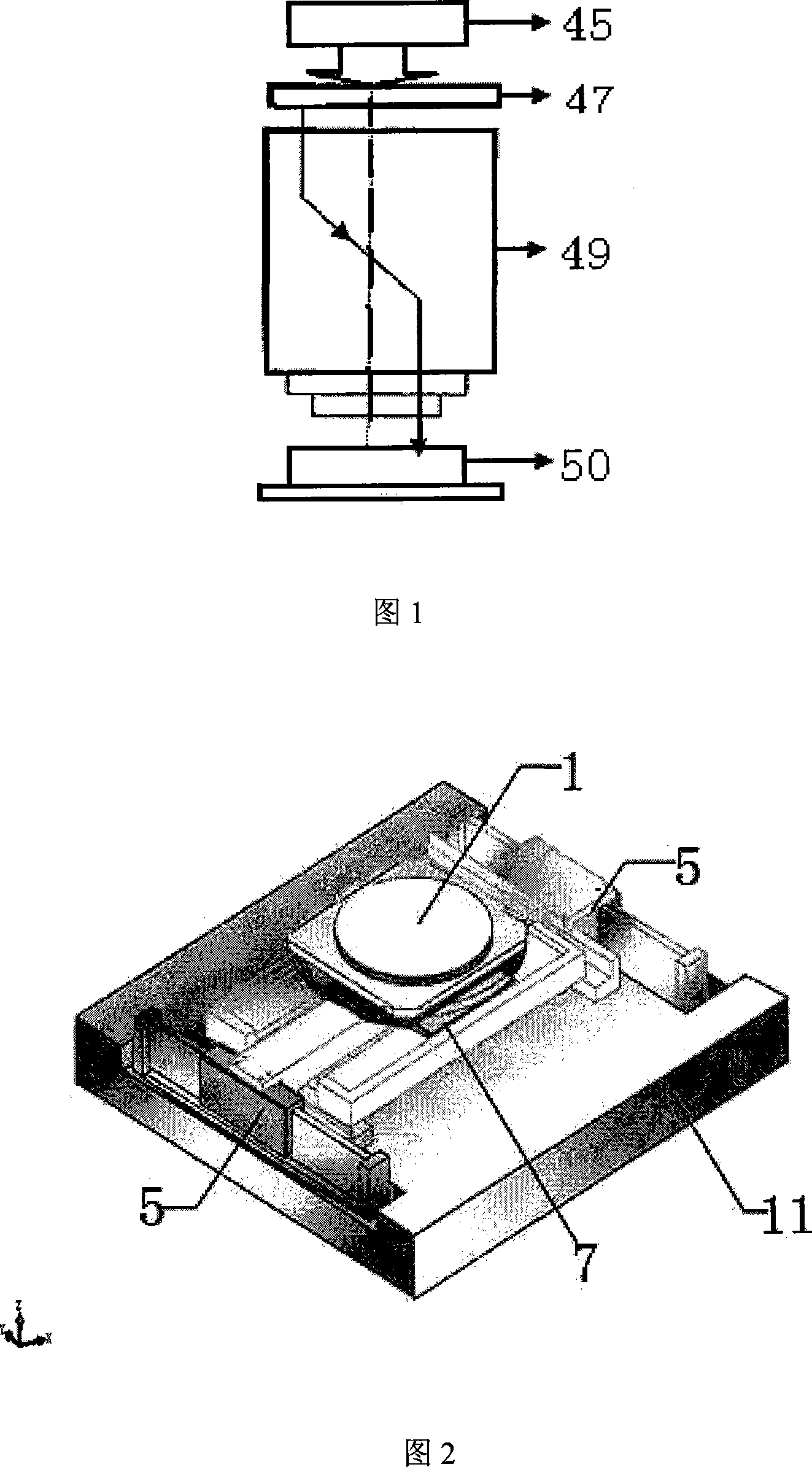

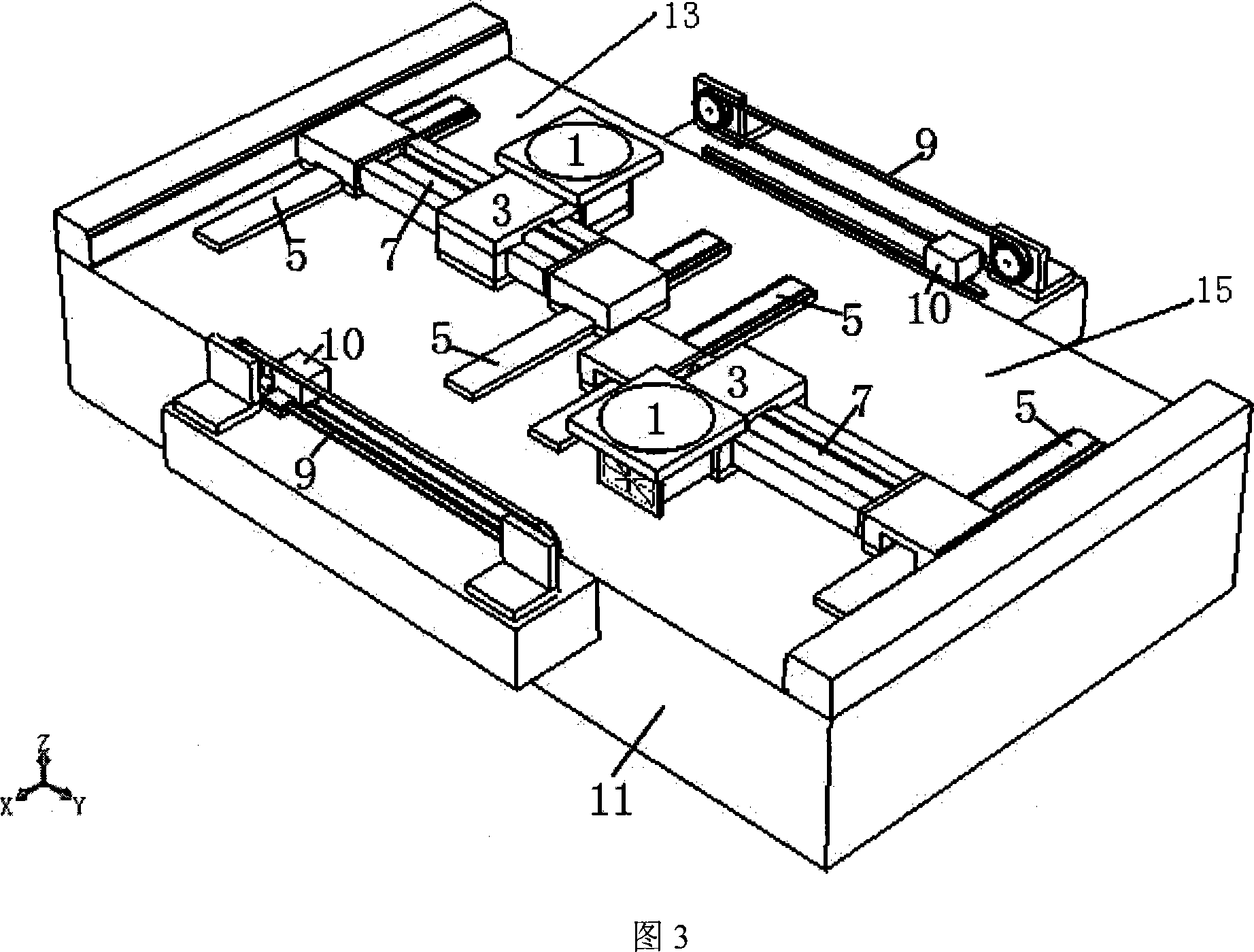

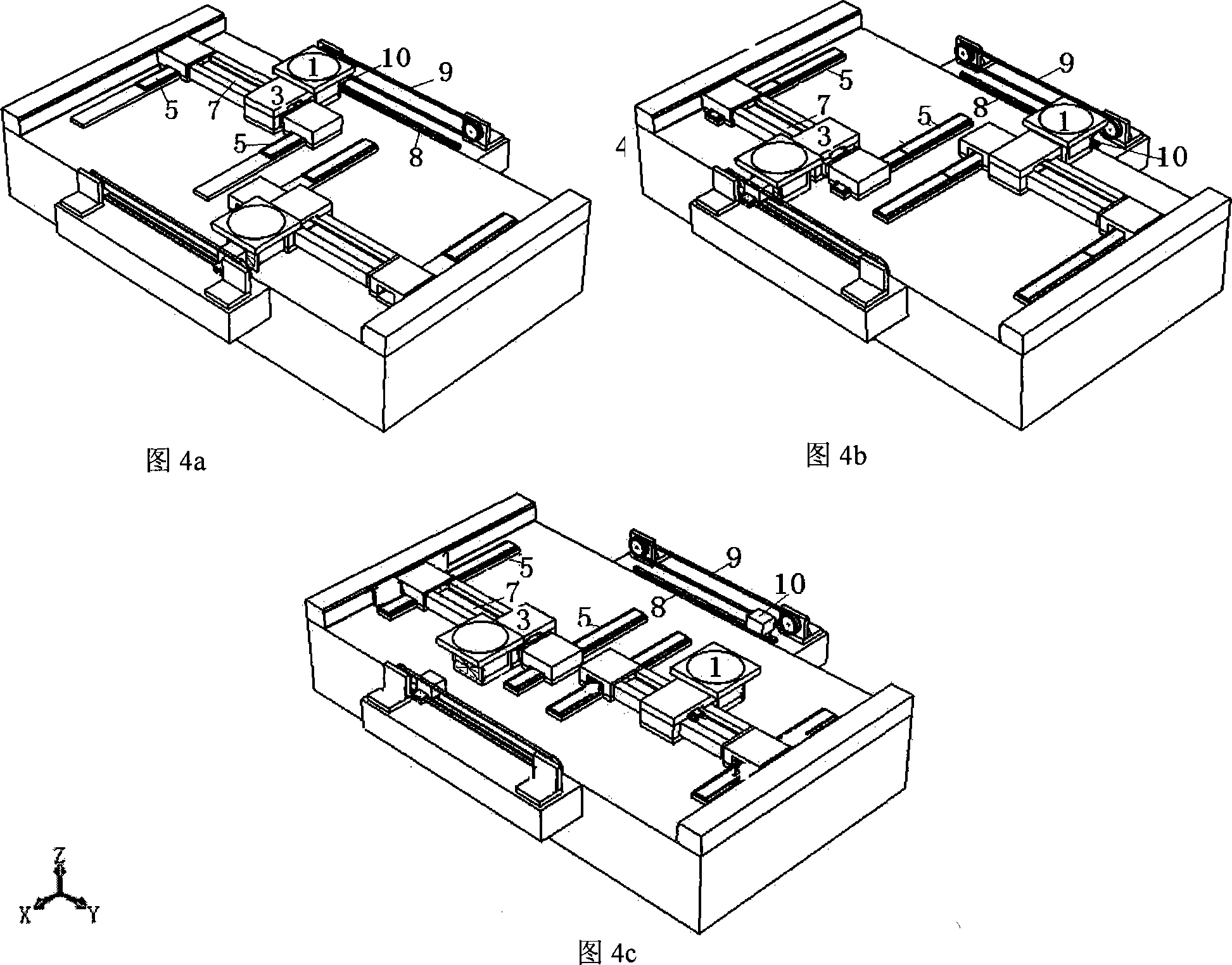

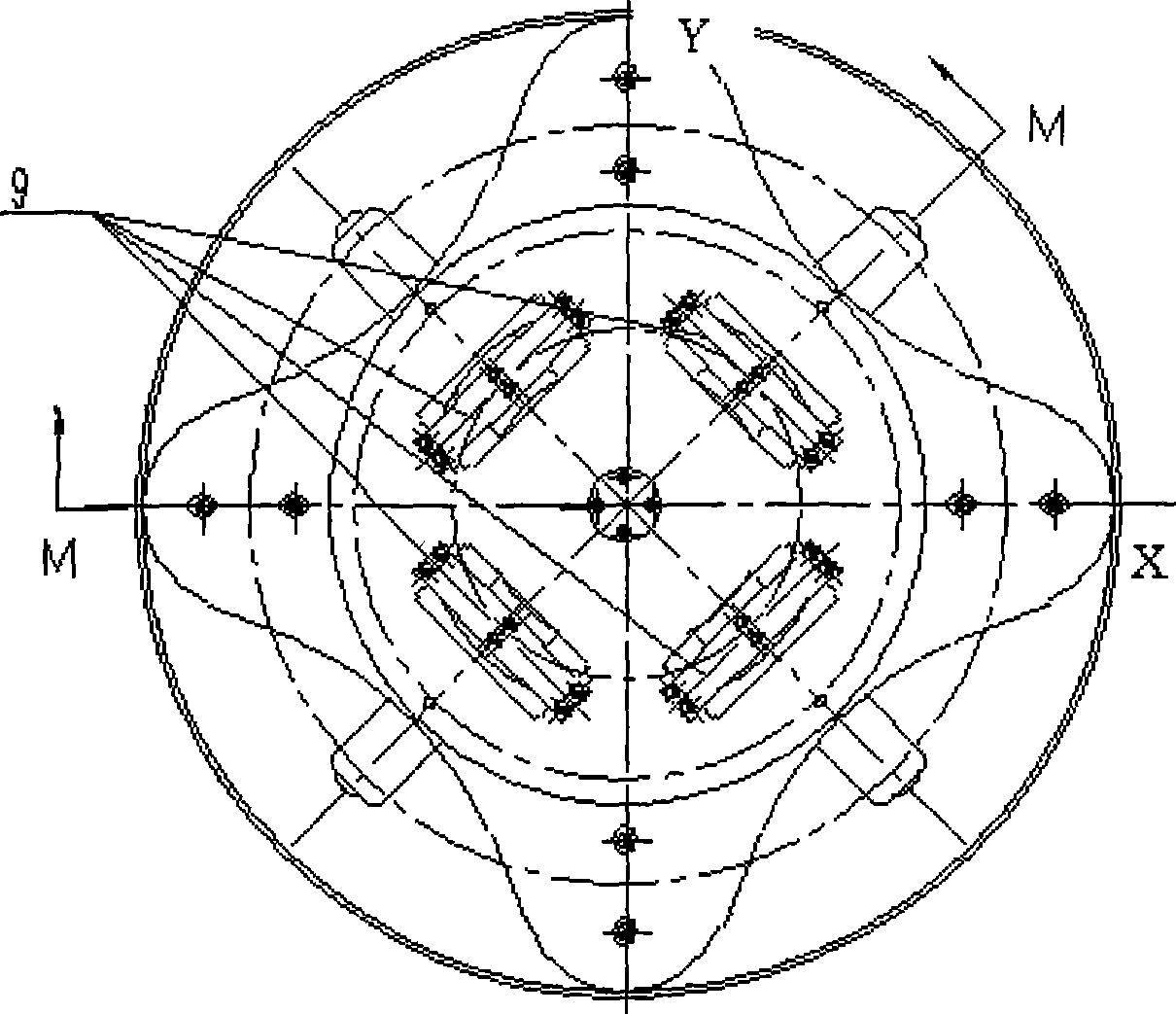

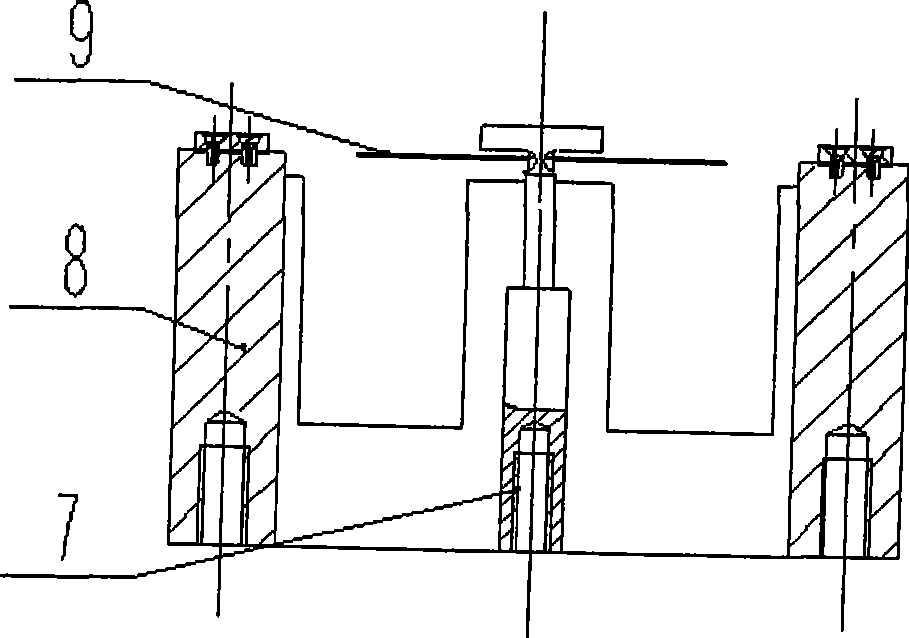

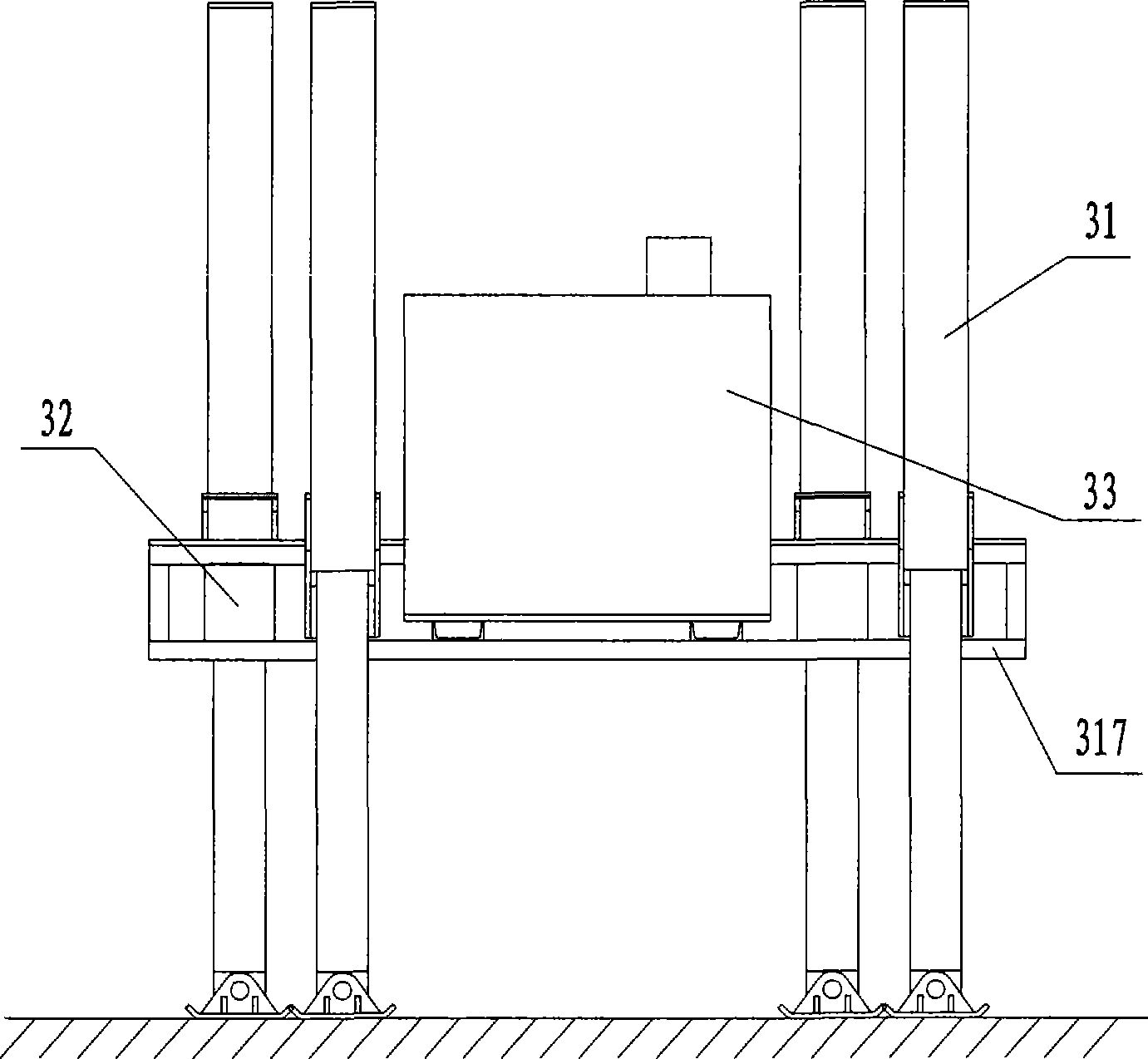

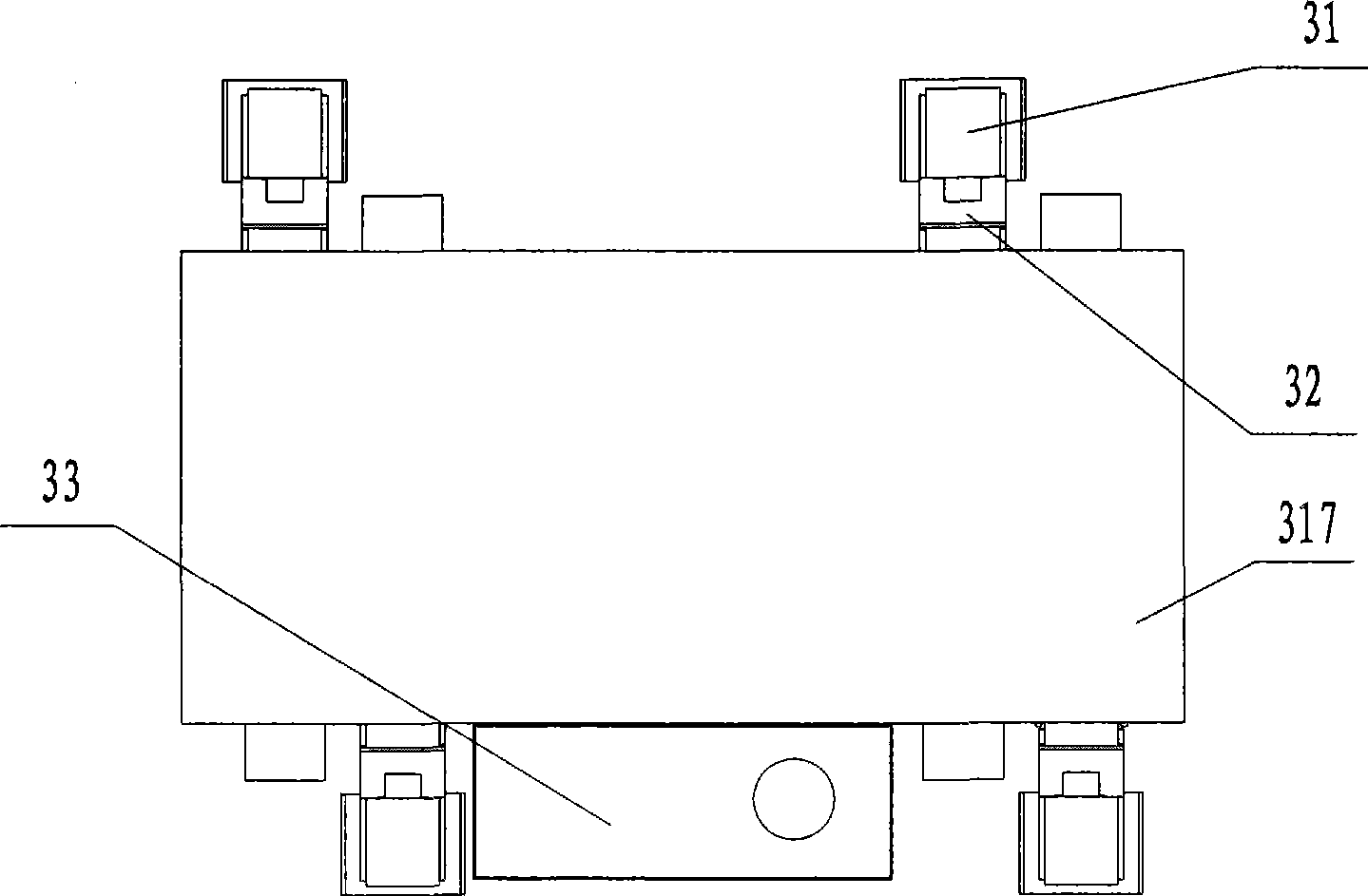

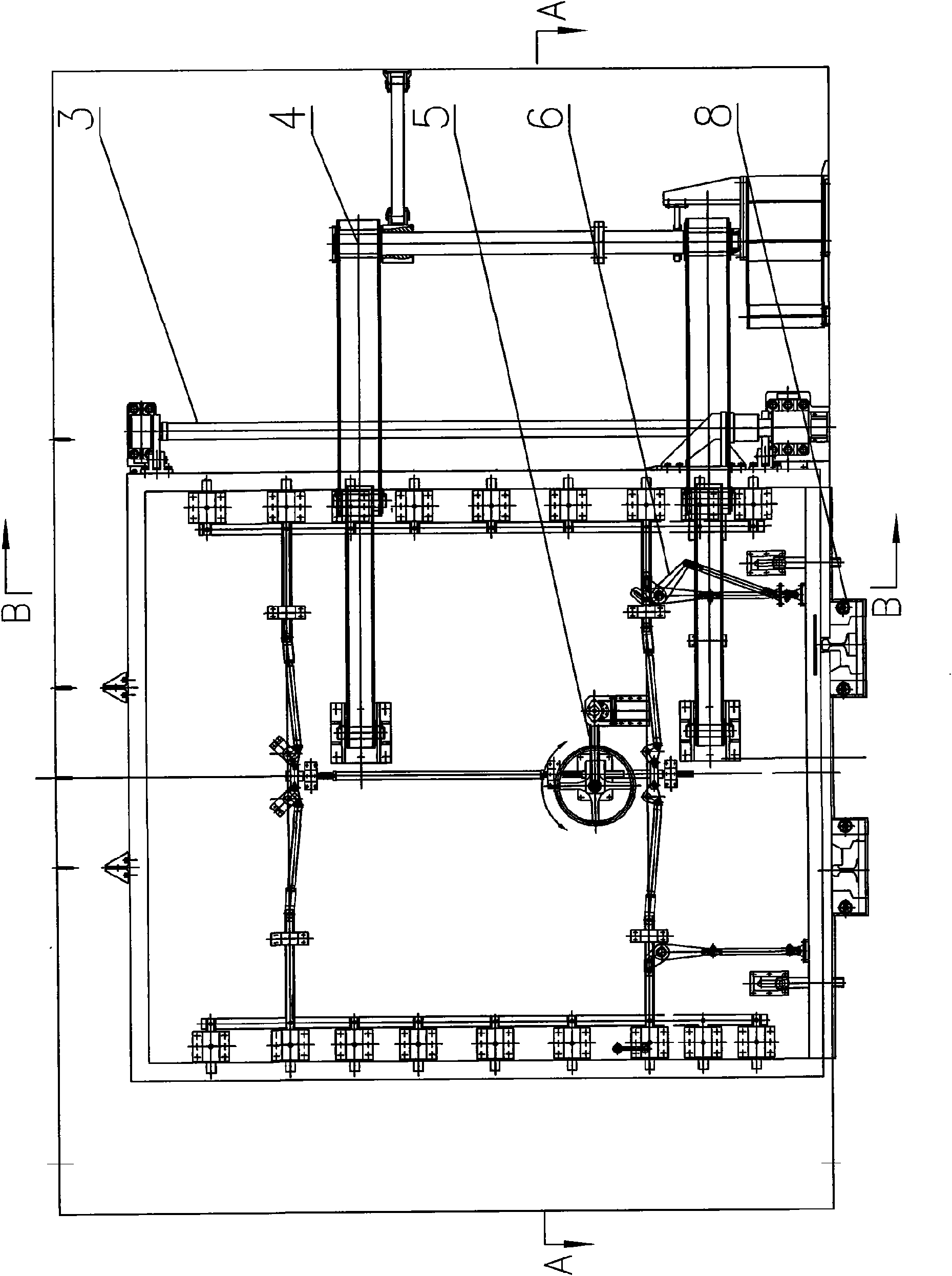

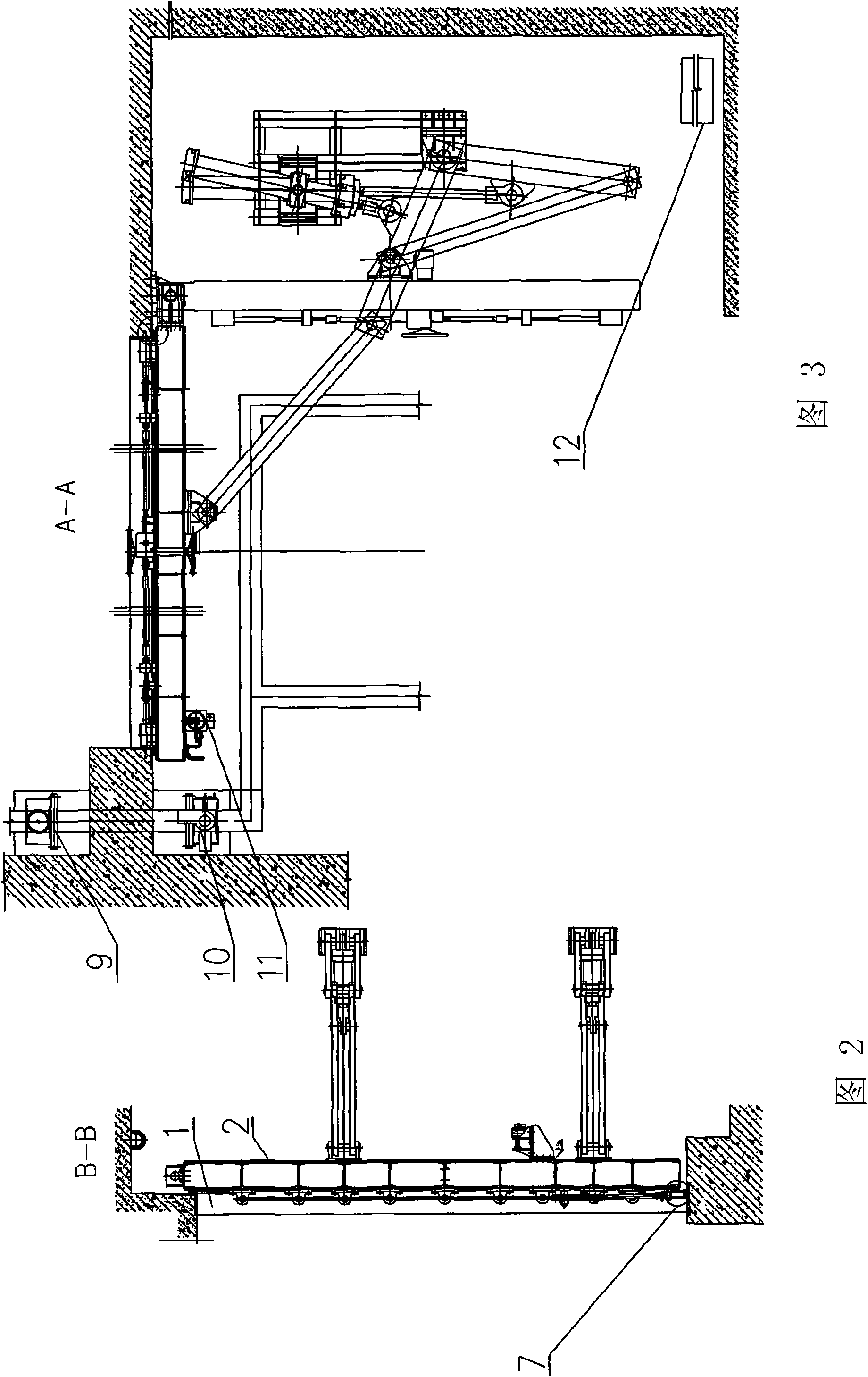

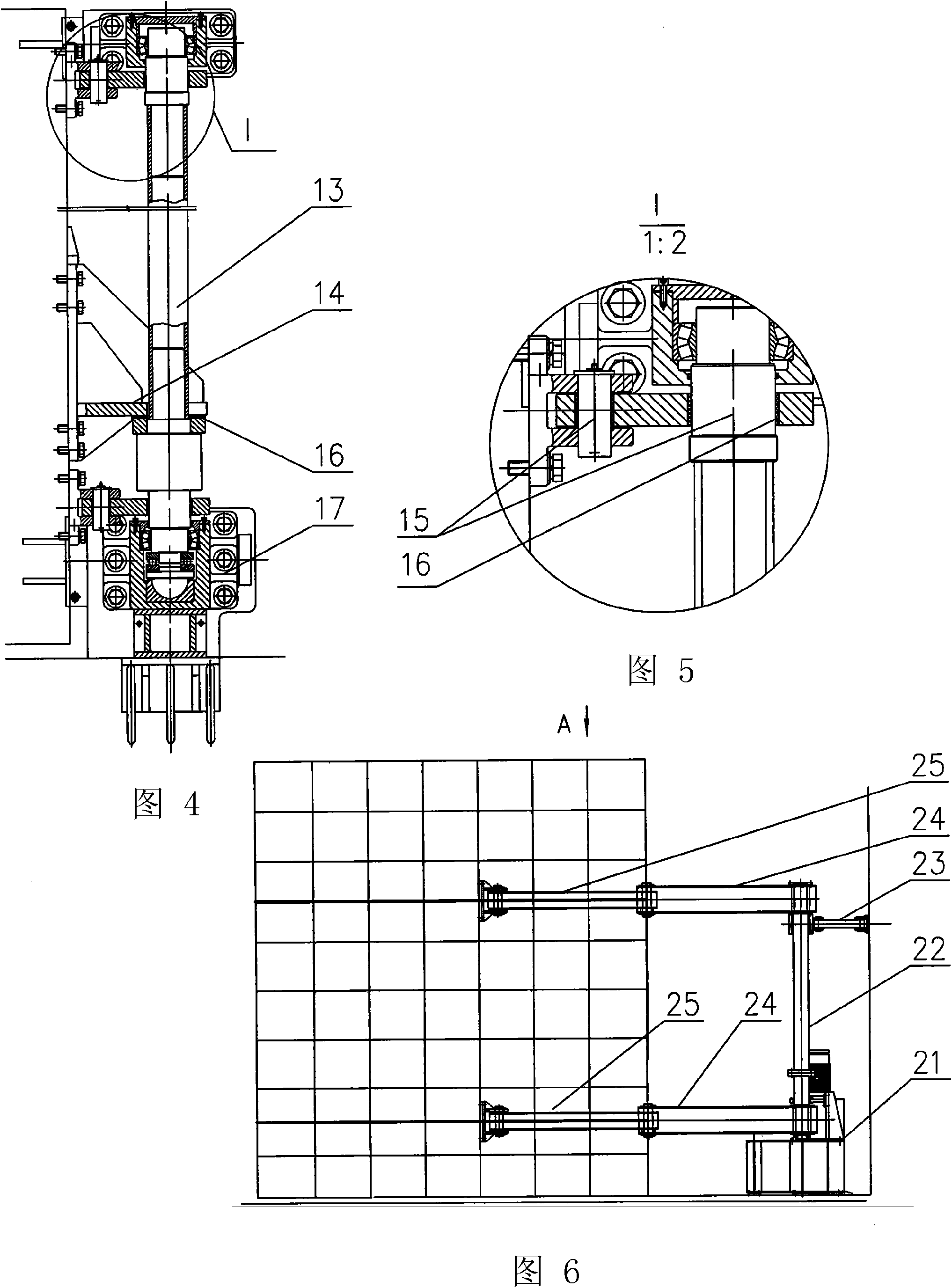

Dual platform switching system for mask aligner silicon slice platform using conveyer structure

InactiveCN101201555ASave time at workAvoiding problems with precision dockingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringSilicon chip

The invention provides a double-platform exchanging system for a photoetching machine silicon chip platform with a conveyor belt and belongs to the technical field of the manufacturing equipment of a semiconductor. The invention comprises a silicon chip platform operated on a pretreatment station and a silicon chip platform operated on an exposure station; the pretreatment station and the exposure station are respectively provided with a H-typed driving unit and the H-typed driving unit consists of X-directional straight line motors on the two sides and a Y-directional straight line motor, both of which are used for driving the silicon chip platform to move along X direction and Y direction on the pretreatment station and the exposure station; the two sides of a base station are respectively provided with a conveyor belt in the system and a butt slide block is fixed on and connected with the lateral side of the conveyor belt; with the conveyor belt and the butt slide block, the transition of the silicon chip platform 1 from the pretreatment station to the exposure station can be realized. As the invention adopts the conveyor belt structure, the invention effectively avoids the problem of accurate abut joint of the guide rail of the patent ZL03156436.4 double-platform exchanging system and has the characteristics of simple operation and small size of outline, etc.

Owner:TSINGHUA UNIV

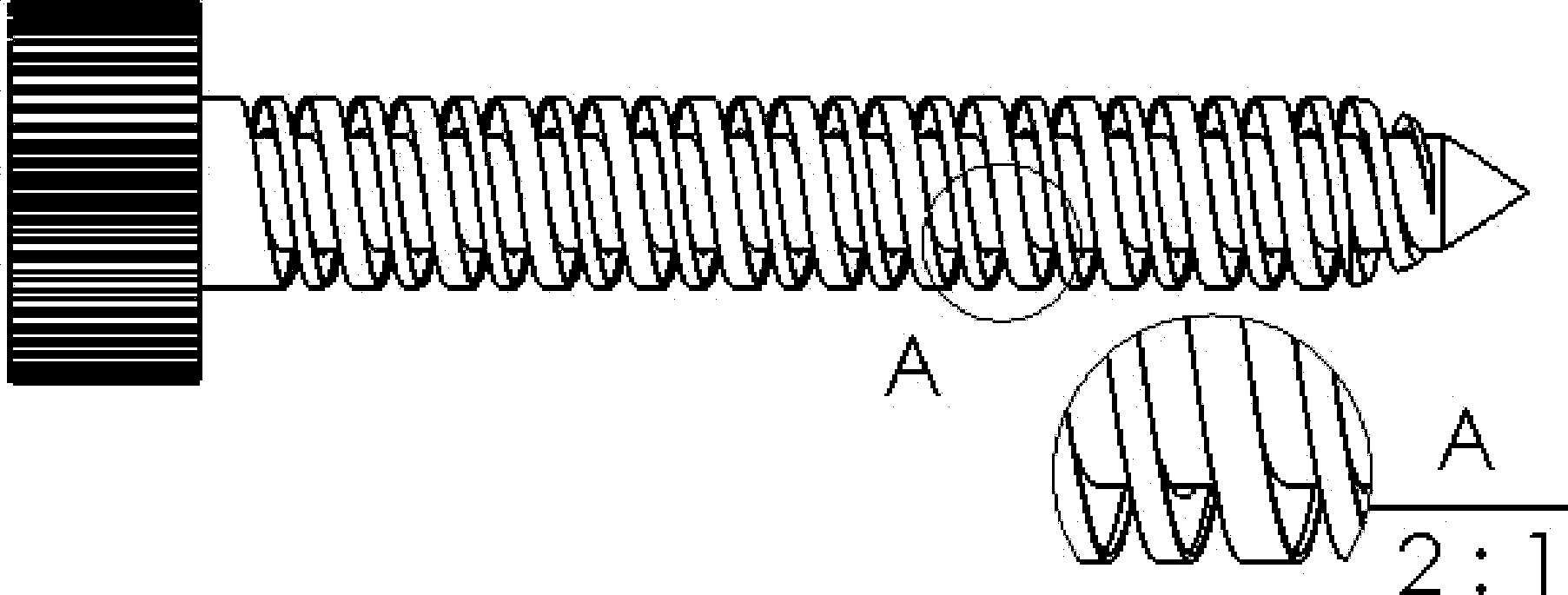

Mechanical soil-sampling device

ActiveCN102661875AEasy to sampleSampling is convenient and effectiveWithdrawing sample devicesEngineeringDrill

The invention discloses a mechanical soil-sampling device. The mechanical soil-sampling device comprises motors, a soil-sampling drill, a soil collection disc and a fixing box. A spiral inner groove is arranged at a lower end of the soil-sampling drill; outer edges of the spiral inner groove are provided with extended small flanges; the bottom end of the soil-sampling drill is processed into a cone-shaped drill head; an upper end of the soil-sampling drill is provided with a driven spur gear; the driven spur gear and a driving spur gear cooperate with each other thereby moving; the driving spur gear is installed on a main shaft of a first decelerator; the first decelerator is connected to an output shaft of a first motor; the main shaft of the first decelerator is fixedly connected to the upper end of the soil-sampling drill; the soil-sampling drill vertically and rotatingly move to pass through one of soil collection chambers; a baffle is installed in the fixing box and is located above the soil collection disc; and an end of the baffle extends into the spiral inner groove of the soil-sampling drill. The mechanical soil-sampling device has the advantages of convenient use, reliable running, simple structure, high efficiency and good applicability.

Owner:ZHEJIANG UNIV OF TECH

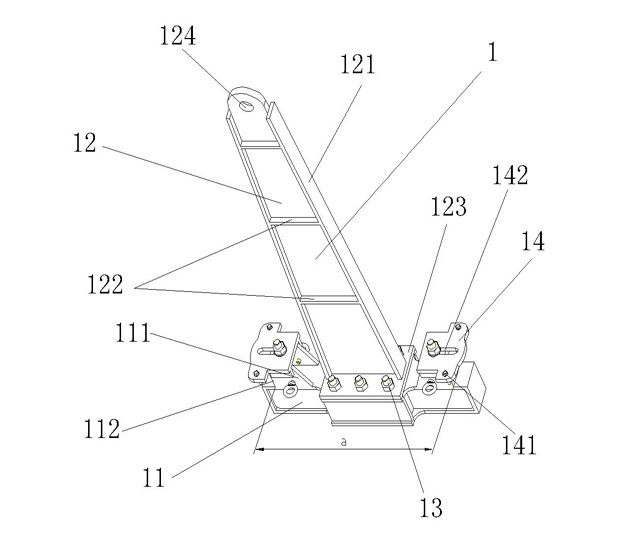

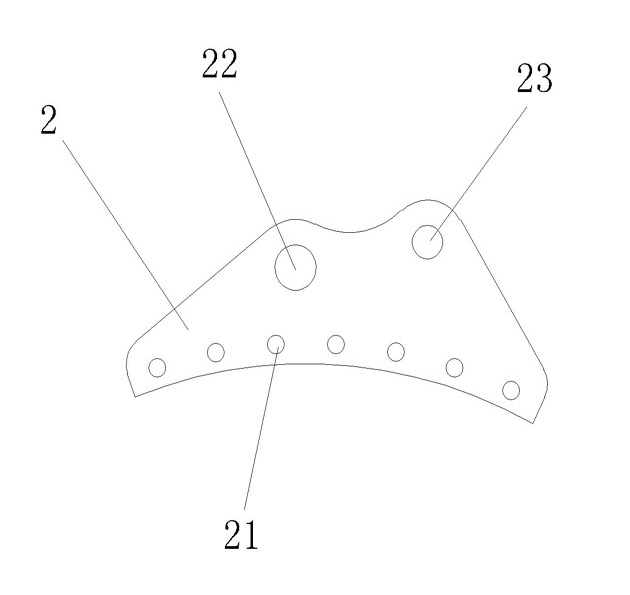

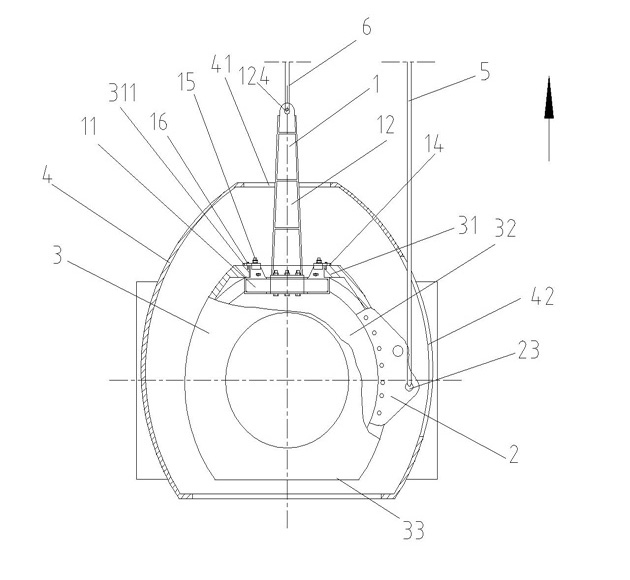

Bidimensional large-diameter fast control reflection mirror

A two-dimensional large caliber fast control reflection mirror is suitable for various optical systems to drive and stabilize the light beam. The problem to be solved is that, the requirement of the reflection mirror caliber larger than 250 mm is satisfied driven by a straight-line drive device, the inclination angle range and the resonance frequency of the fast control reflection mirror can be effectively improved and increased. The invention compares four blocks of distributed spring sheets to the central spherical hinge to implement the flexible rotation around the dual shafts of the reflection mirror and rigid fastening of the rest freedom degrees; the light weighting of the rotating body and the minimum of the rotational inertia around the shaft can be implemented by improving the reflection mirror fixing mode, uniting the rotating centers of the dual shafts and the gravity centers of the rotating body and light weighting design of the supporting frame and the reflection mirror; the compact whole structure and the small appearance size can be implemented by reasonable arrangements of the straight-line drive device and the micro-displacement position sensor.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

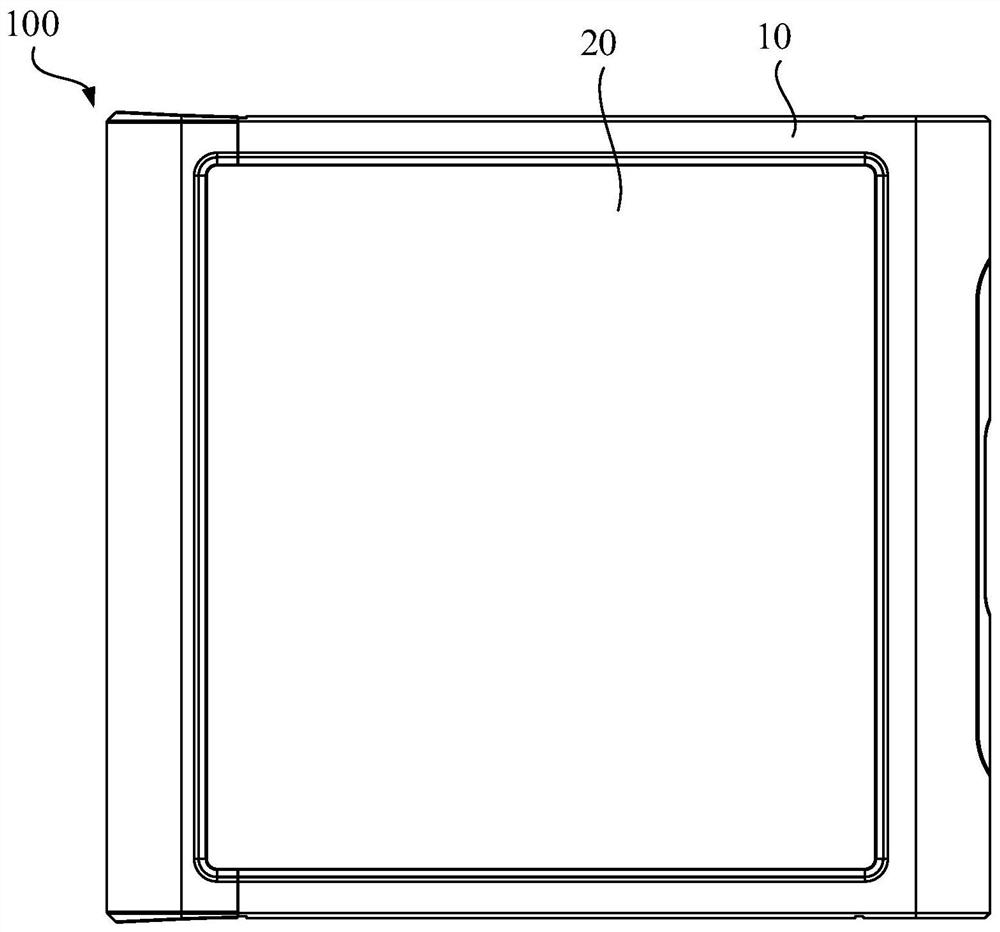

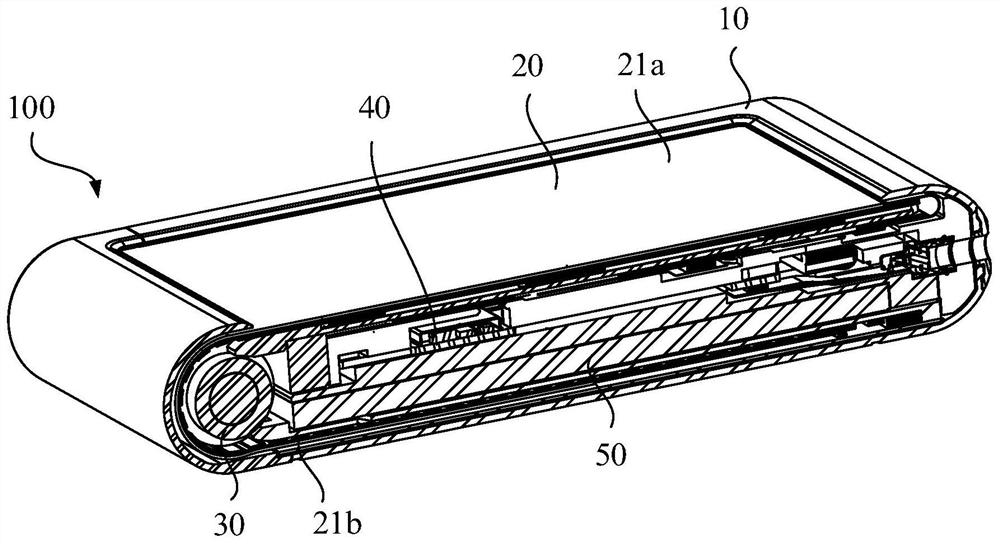

Electronic equipment

ActiveCN111968503AIncrease the display areaSmall form factorDigital data processing detailsCasings with display/control unitsStructural engineeringMechanical engineering

The invention relates to electronic equipment. The electronic equipment comprises a shell assembly, a tensioning assembly and a flexible screen module. The shell assembly comprises a first shell and asecond shell connected to the first shell, the first shell is provided with a first supporting face, the second shell is provided with a second supporting face, and the first supporting face is flushwith the second supporting face. The tensioning assembly is connected to the shell assembly, the flexible screen module comprises a fixed end and a free end which are oppositely arranged, the fixed end is connected with the first shell, the first supporting face supports the fixed end, the free end bypasses the end, away from the first shell, of the second shell and stretches into the shell assembly, and the free end is connected to the tensioning assembly. The first shell can move relative to the second shell so that at least part of the flexible screen module can be unfolded on the second supporting face or retracted into the shell assembly. The electronic equipment has good portability and use experience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

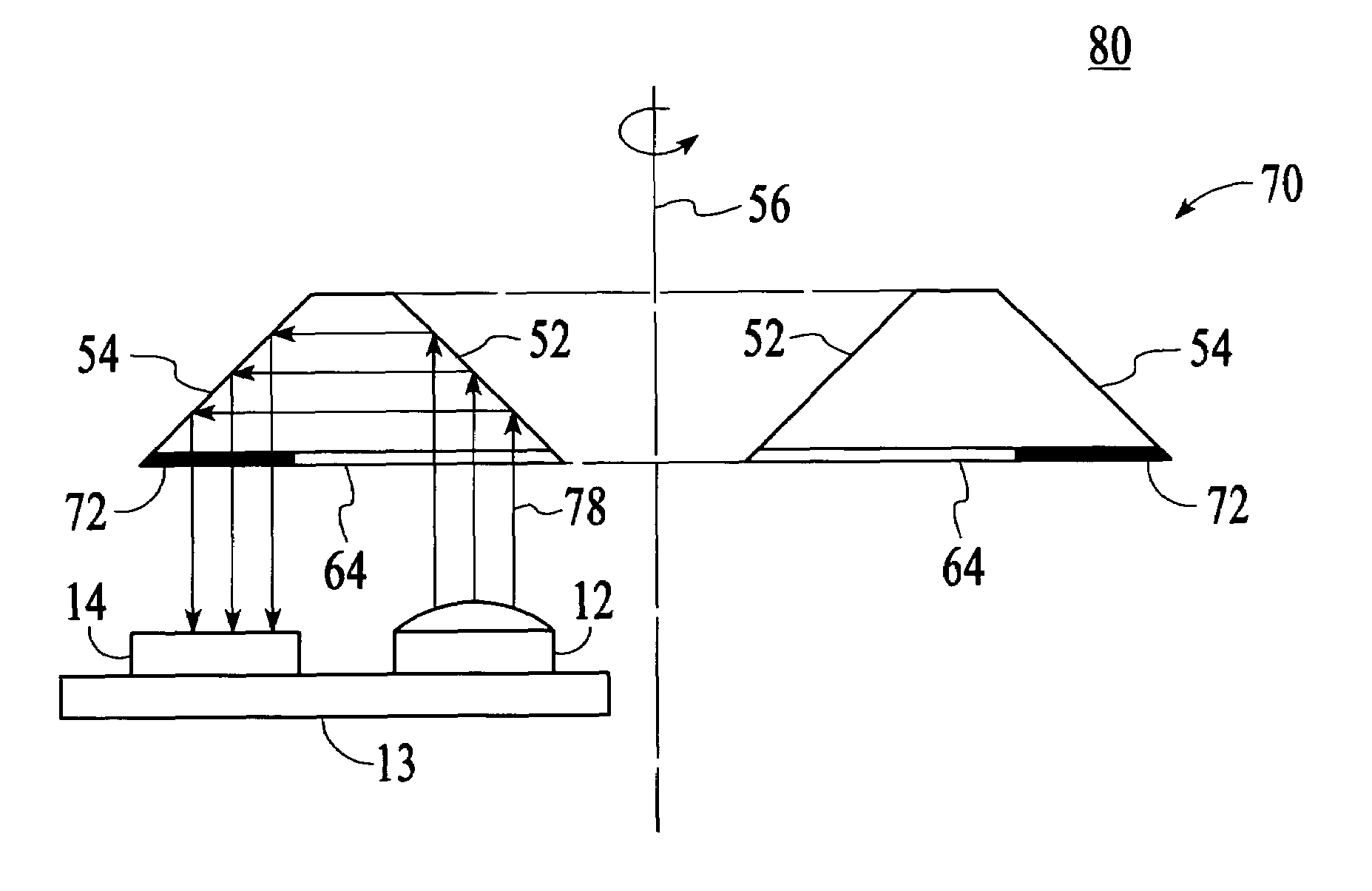

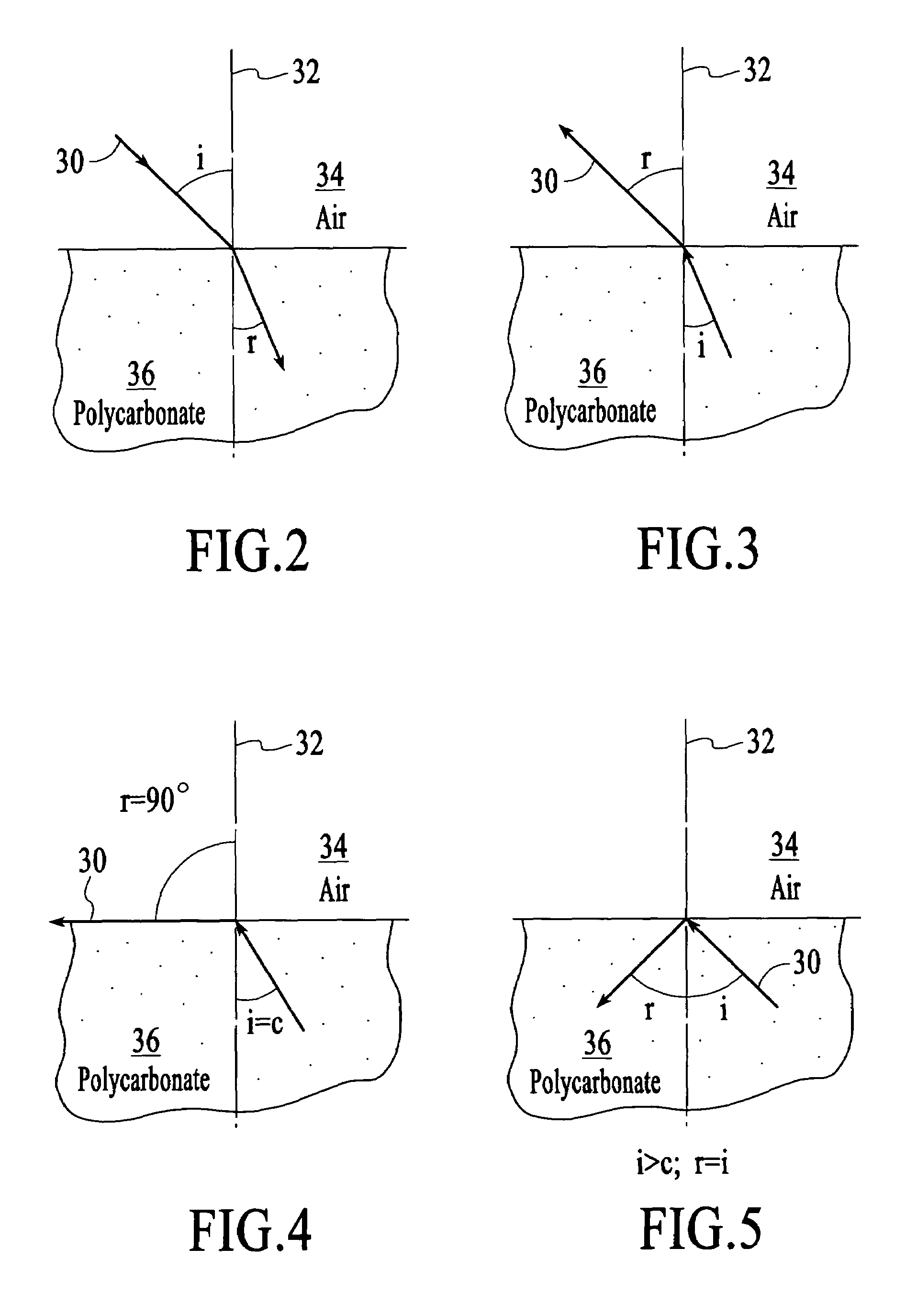

Optical encoding that utilizes total internal reflection

ActiveUS7145127B2Sharp contrastSmall form factorElectric signal transmission systemsBeam/ray focussing/reflecting arrangementsTotal internal reflectionPhotovoltaic detectors

A coding element such as a codewheel includes first and second surfaces that are configured with respect to each other and with respect to a light beam such that the light beam is reflected at the two surfaces using the optical phenomenon of total internal reflection. The coding element also includes a coding pattern that is aligned in an optical path of the light beam after the light beam has reflected off of both of the surfaces. A coding element with surfaces that reflect a light beam as a result of total internal reflection can be utilized in an encoding system that operates in transmission while the light source and the photodetector array are located on the same side of the coding element.

Owner:AVAGO TECH INT SALES PTE LTD

Foldable mobile terminal

The invention discloses a foldable mobile terminal which comprises a mobile terminal body and a display screen. The display screen is a flexible screen, the outer surface of the mobile terminal body comprises a front surface, a curved surface and a rear surface which are connected sequentially, the flexible screen comprises a front surface screen, a curved surface screen and a rear surface screen which are sequentially connected and integrally formed, the front surface screen is fitted and fixedly connected on the front surface, the rear surface screen is provided with a fixed part, and a memory alloy frame is arranged at each of the upper end and the lower end of the curved surface screen. When the fixed part is fixed on the rear surface, the curved surface screen is fitted on the curved surface, and the rear surface screen is fitted on the rear surface; when the fixed part breaks away from the rear surface, the curved surface screen and the rear surface screen breaks away from the curved surface and the rear surface respectively under action of the memory alloy frame, and the flexible screen extends to form a plane. The foldable mobile terminal has the advantages of small appearance size and convenience in carrying and storing.

Owner:SHANGHAI CHUANGGONG COMM TECH

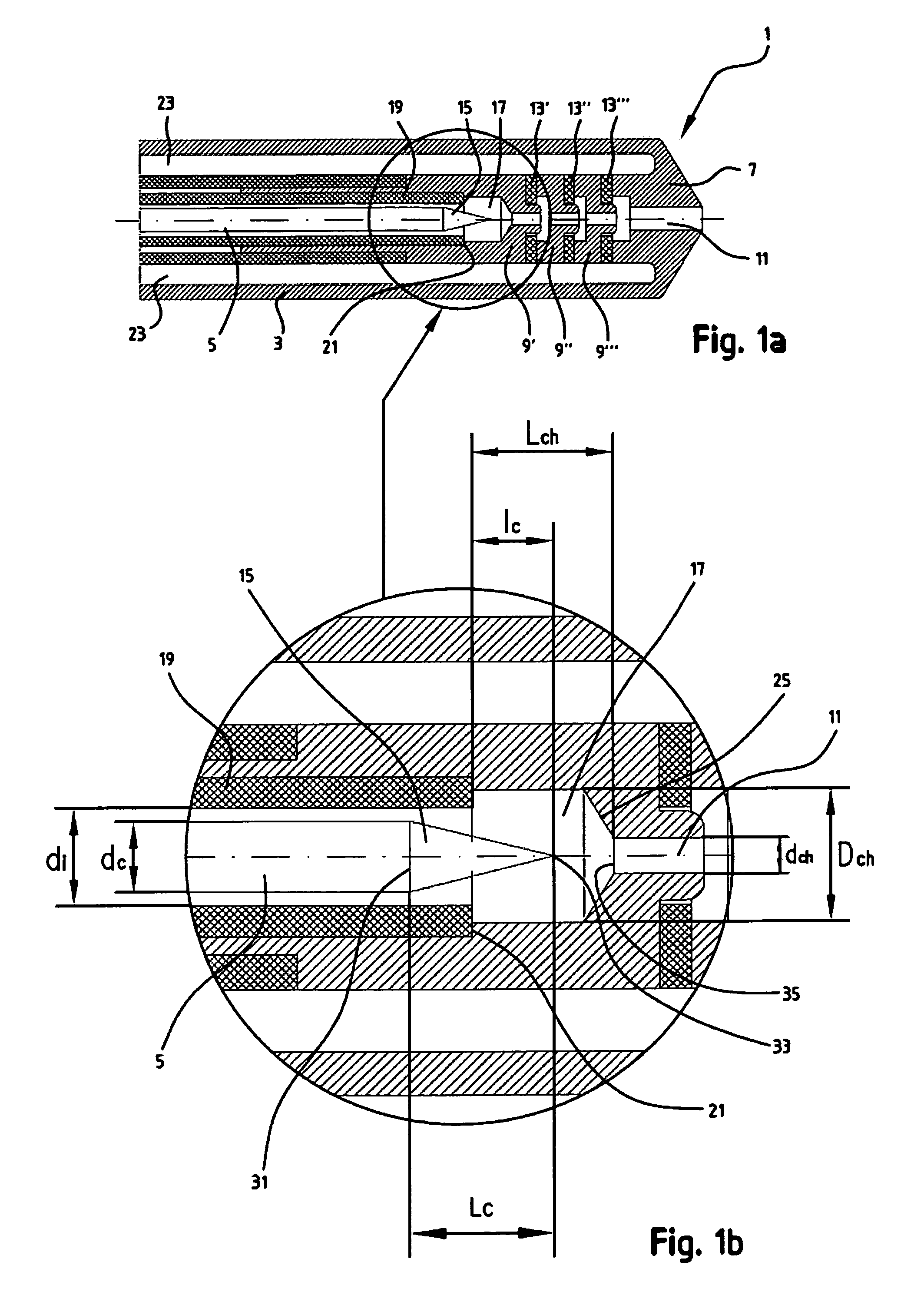

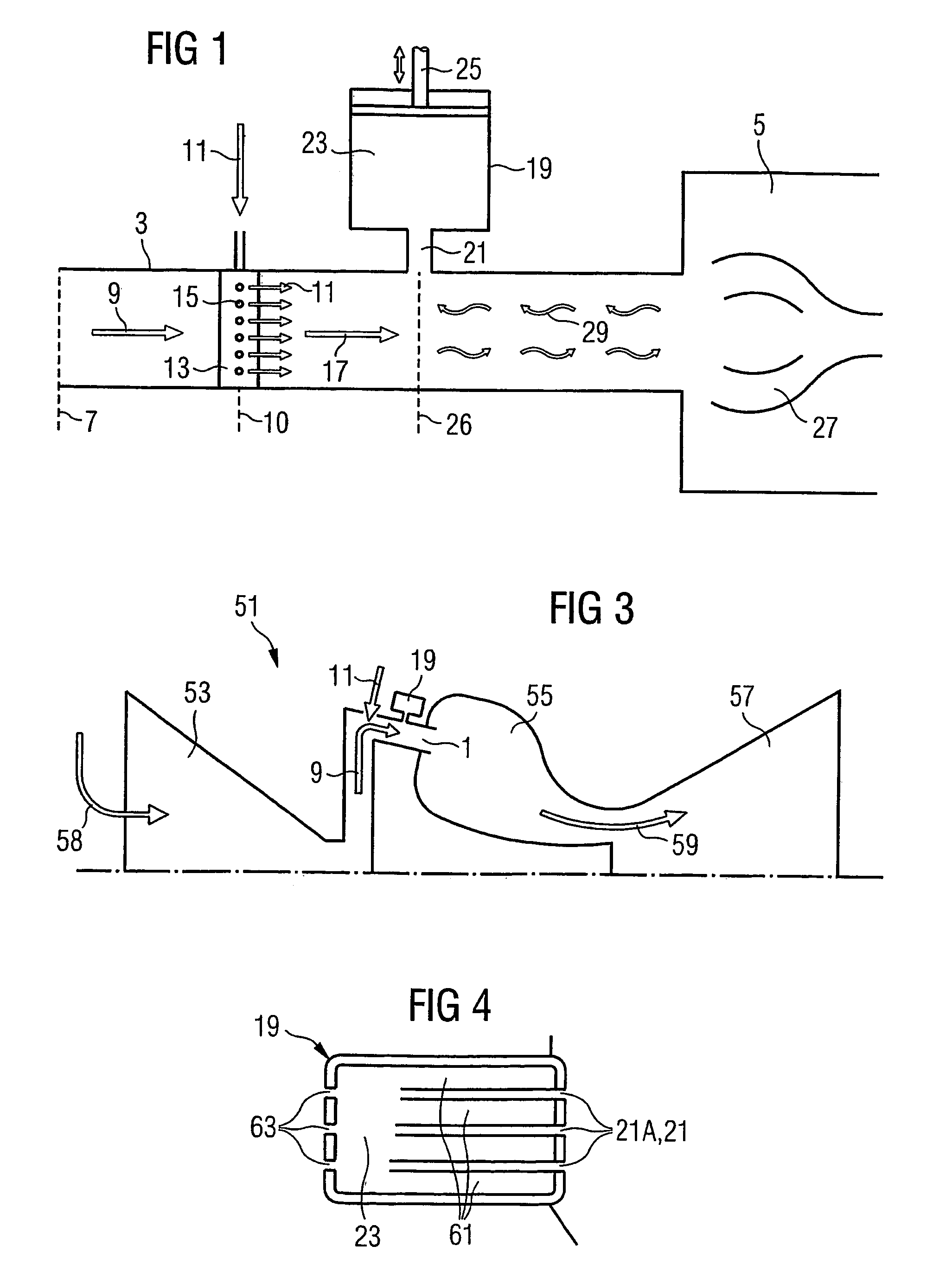

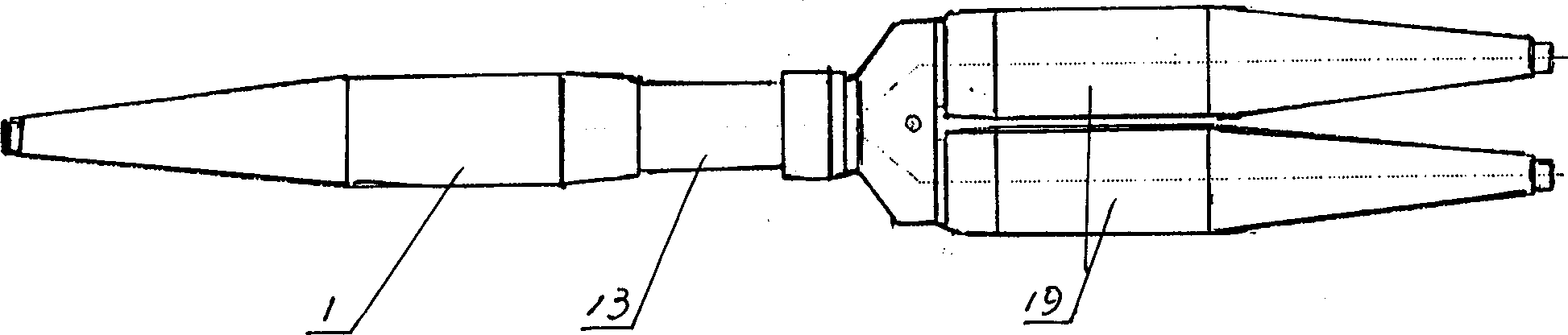

Plasma-generating device, plasma surgical device and use of plasma surgical device

ActiveUS20070021747A1Long operating timeSmall form factorSurgical instruments for heatingPlasma techniquePlasma channelSurgical device

The present invention relates to a plasma-generating device, comprising an anode, a cathode and a plasma channel which in its longitudinal direction extends at least partly between said cathode and said anode. The end of the cathode which is directed to the anode has a cathode tip tapering towards the anode, a part of said cathode tip extending over a partial length of a plasma chamber connected to the plasma channel. The plasma chamber has a cross-sectional surface, transversely to the longitudinal direction of the plasma channel, which exceeds the cross-sectional surface, transversely to the longitudinal direction of the plasma channel, of an opening, positioned closest to the cathode, of the plasma channel. The invention also concerns a plasma surgical device and use of such a plasma surgical device.

Owner:PLASMA SURGICAL INVESTMENTS

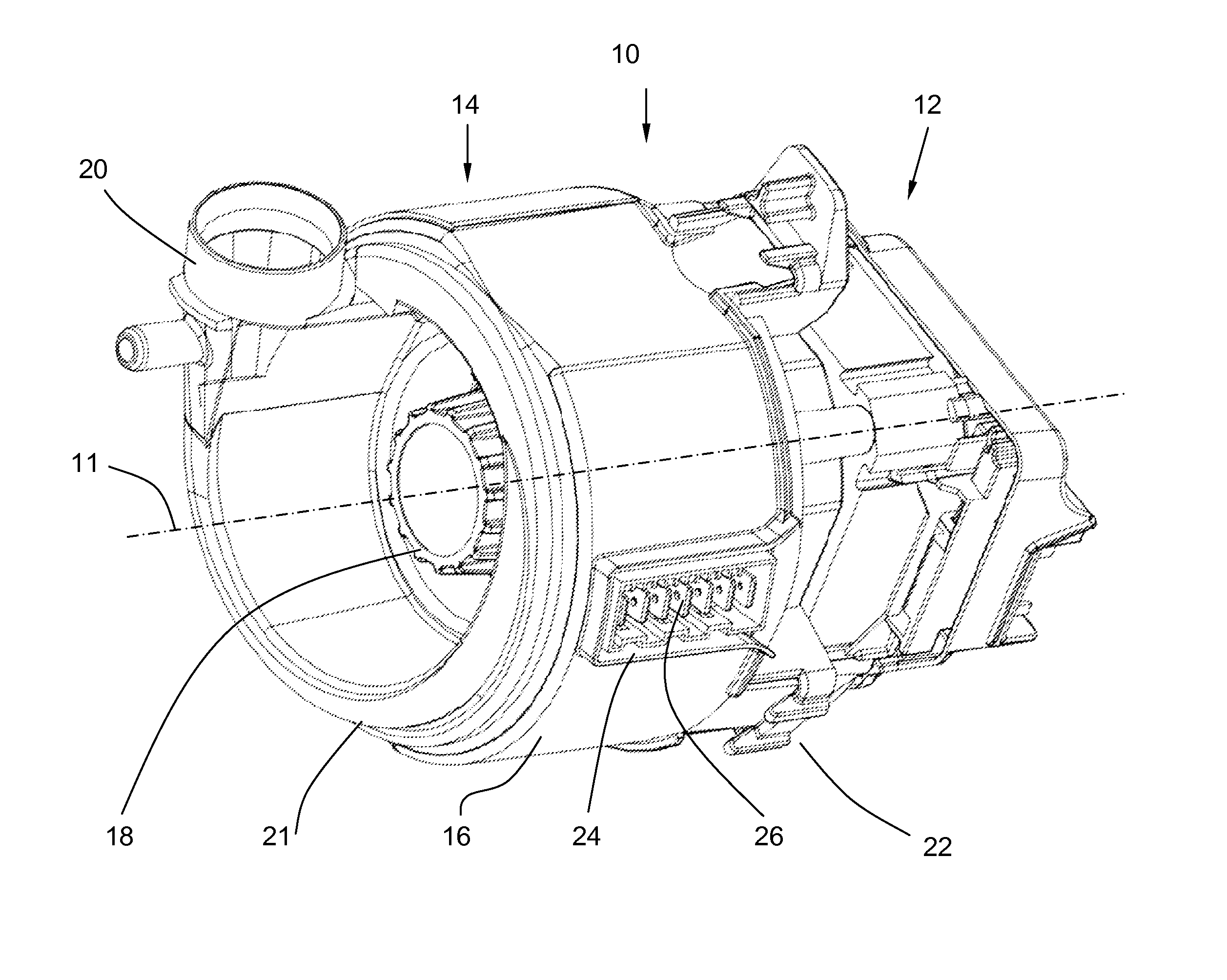

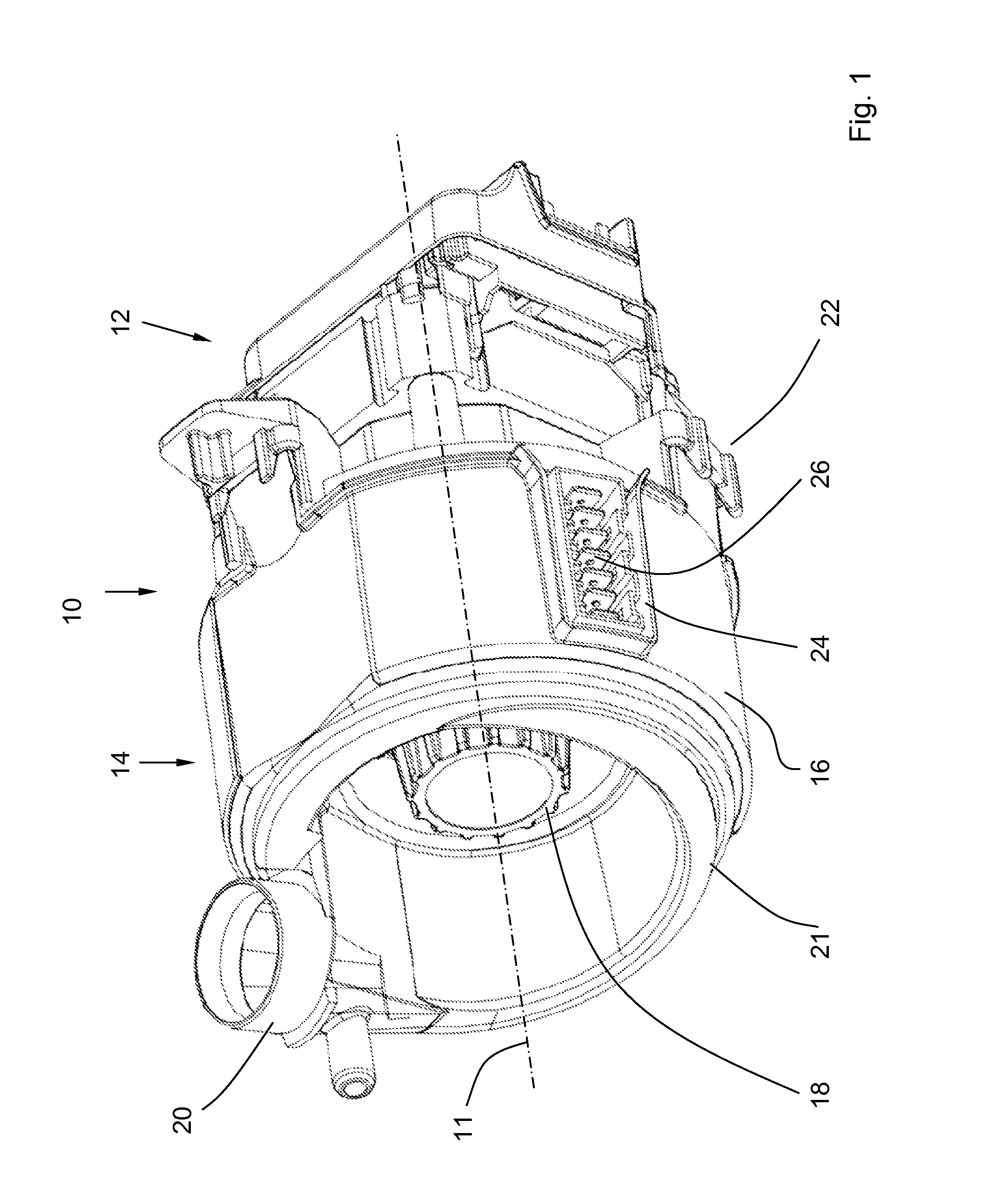

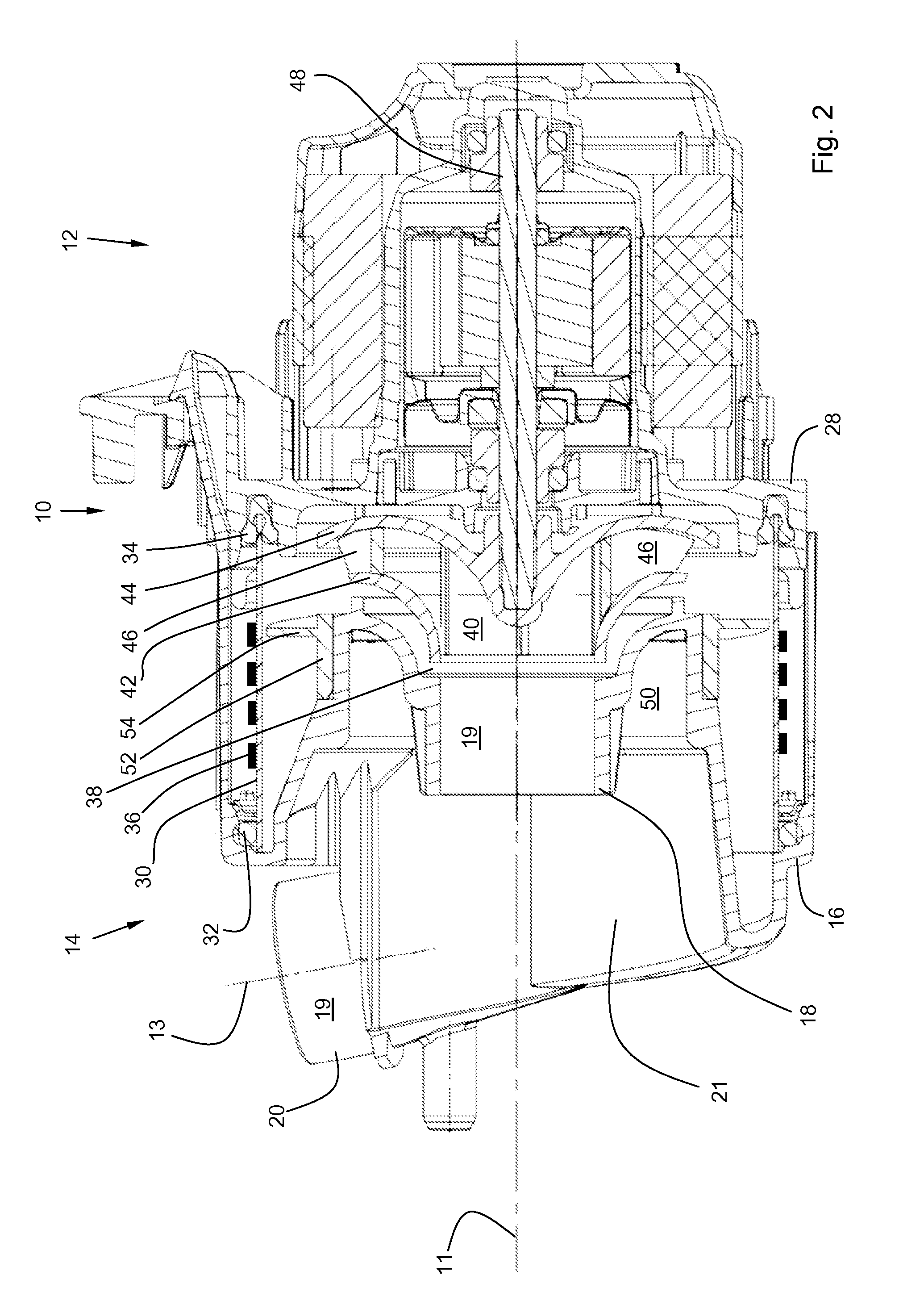

Pump having a heating device

ActiveUS8245718B2Improve reliabilitySmall form factorPump componentsReaction enginesImpellerDevice form

A pump, particularly for dishwashers, is provided and includes a housing made of a housing bottom, a housing cover, and a heating device disposed in between the bottom and cover for heating a washing fluid. The heating device forms a ring-shaped side wall of the housing. An impeller is arranged in the housing, an intake connection is arranged axially in the housing cover relative to the axis of rotation of the impeller, and a pressure connection is arranged in the housing cover.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

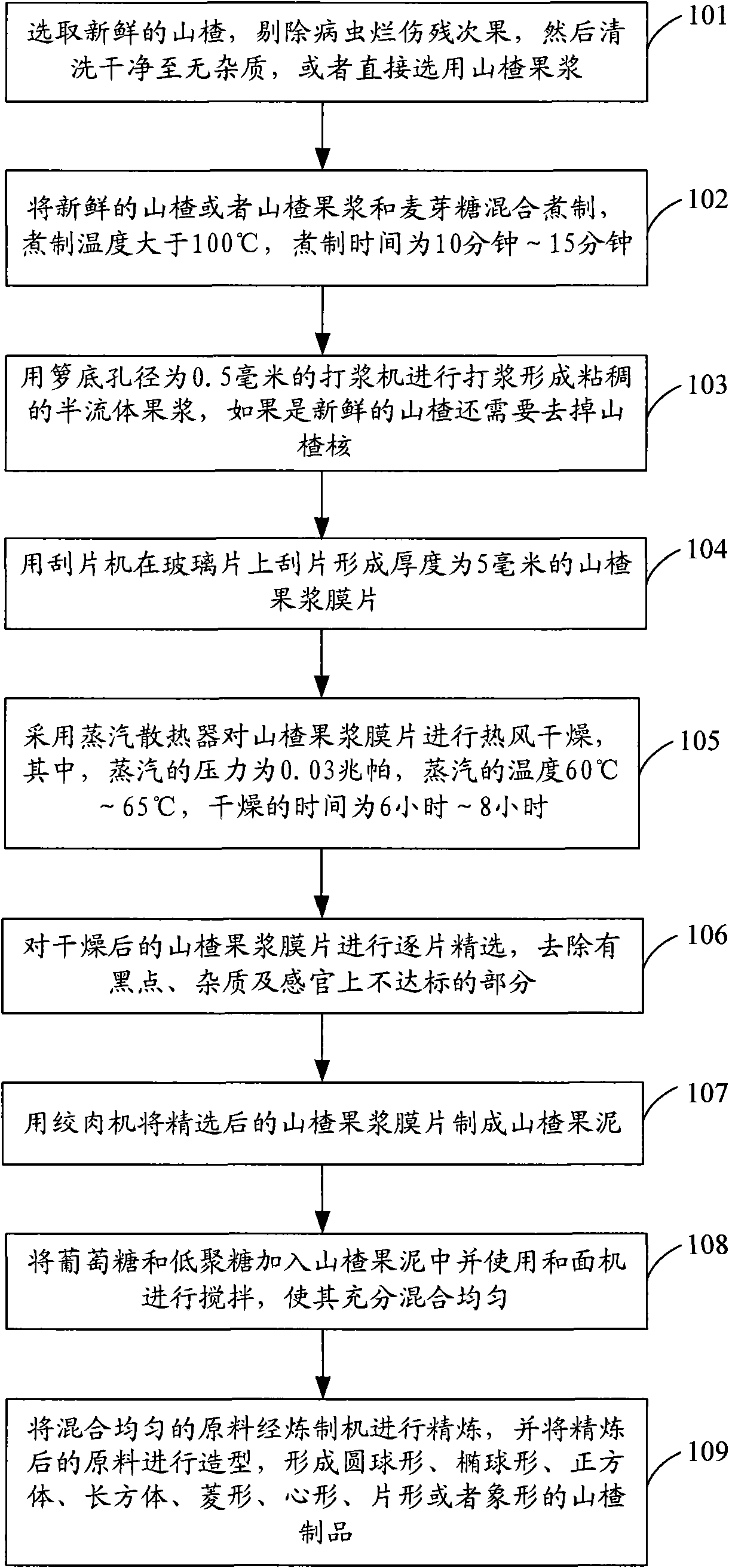

Haw product and producing method thereof

The invention relates to a haw product and a producing method thereof. The haw product includes haw, sugar component and water, the sugar component includes maltose, glucose and oligose. The haw product is diversified in flavours, healthy, suitable for old and young, thoroughly disinfected in materials, secure and sanitary, and has long shelf life, small size, convenient carrying and storing, thereby not only enriching the nutrition but also reducing the cost; has pleasant sweetness and sourness, suppleness in the mouth feel, and machine packing on the whole line, thereby not only being sanitary but also reducing the cost and increasing the efficiency.

Owner:姜云天 +1

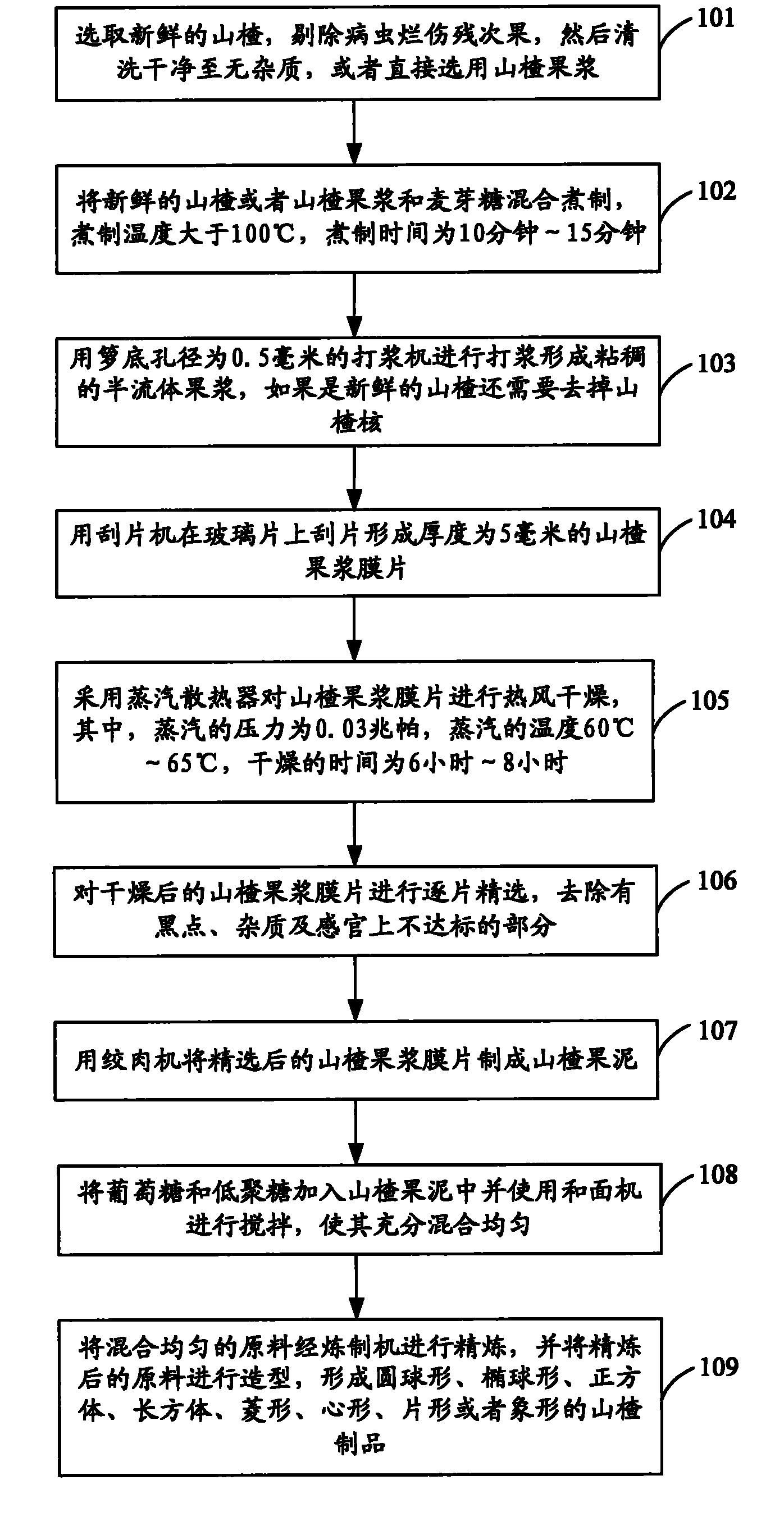

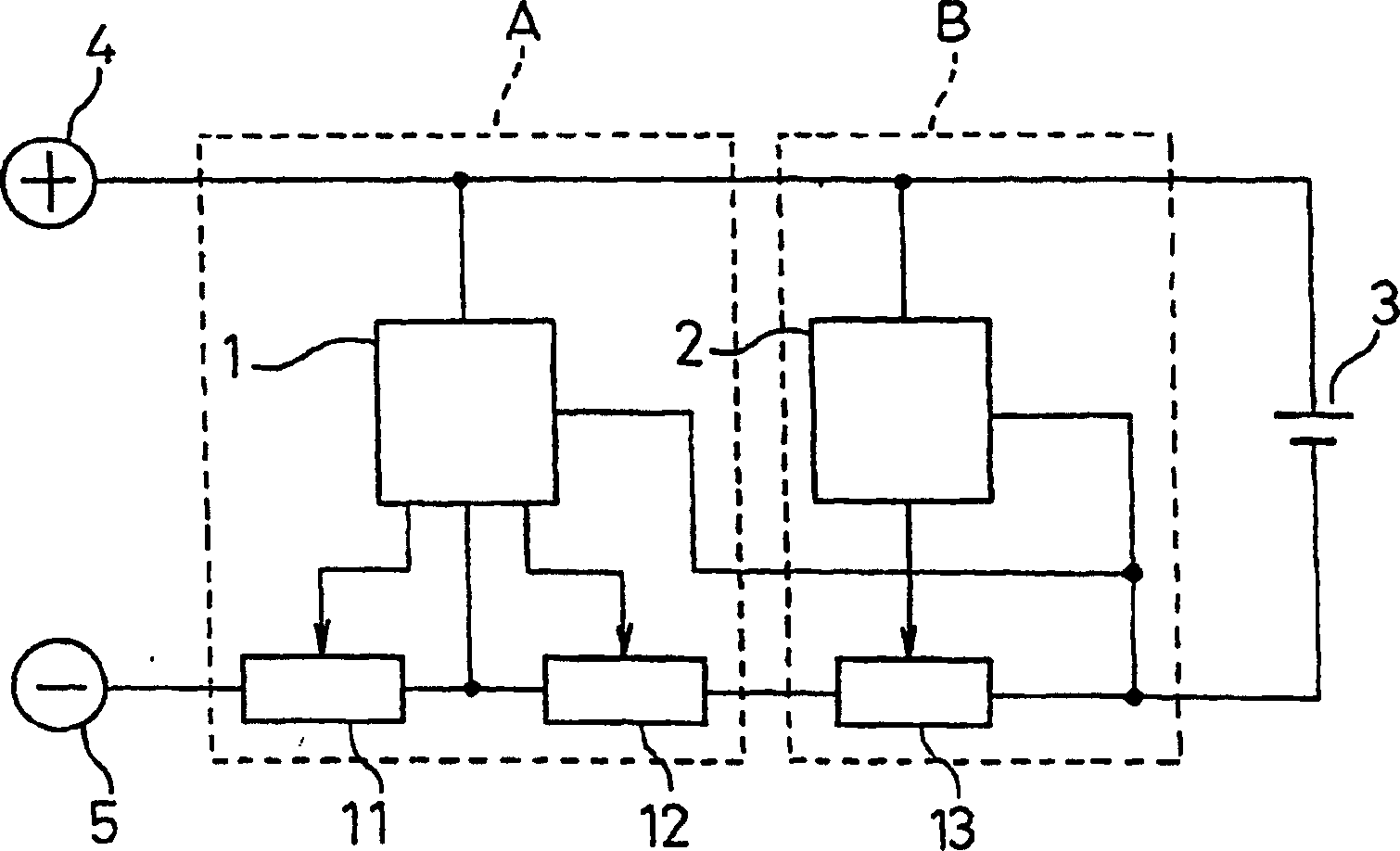

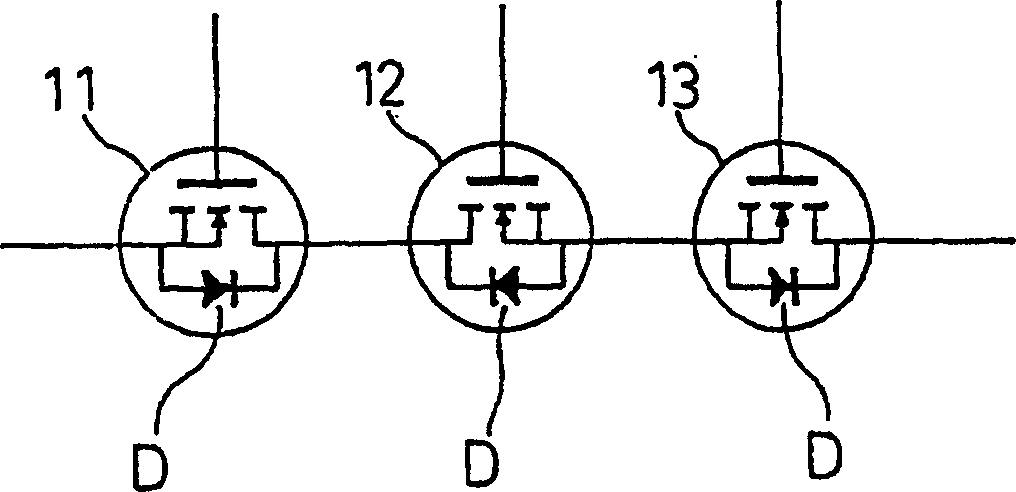

Protective circuit and unit for secondary battery

InactiveCN1291518CFirmly connectedSmall form factorPrimary cell maintainance/servicingSecondary cells charging/dischargingEngineeringDischarge current

A protective circuit for protecting a rechargeable battery from battery breakdown caused by prolonged overcharging, and a protective element incorporated in this circuit are provided. A main protective circuit (A) is equipped with main control means (1) for shutting off a first FET (11) or a second FET (12) when any of overcharging, overdischarging, or excessive discharge current is detected. A sub-protective circuit (B) is equipped with sub-control means (2) for shutting off a third FET (13) when the anti-overcharging function of the main control means (1) is not operating properly.

Owner:PANASONIC CORP

Oil field well workover operation machine

InactiveCN101429847AFlexible layoutEasy to install/removeDrilling rodsDrilling casingsControl systemOil field

The invention relates to an oil field operation device, in particular to an oil field workover treatment machine. The machine body is arranged on a hydraulic load-bearing traveling gear and is interlocked with the hydraulic load-bearing traveling gear. Hydraulic tongs connected with a telescopic bracket on the machine body can be extended out and retracted with the telescopic bracket. A clip seat is positioned below the hydraulic tongs and is arranged on a well head. An elevator which is suspended onto the machine body can reciprocate up and down. A faucet is positioned above the machine body and the clip seat; a pipe throwing device is arranged on the faucet and the machine body; and a clip unlocking device and a clip locking device corresponding to the elevator are arranged on the clip seat and the pipe throwing device respectively. A righting mechanism and a valve mechanism are further arranged on the faucet. A control cabinet is arranged on the machine body; and the clip seat, the hydraulic tongs, the elevator and the pipe throwing device are connected with a control system in the control cabinet respectively. The oil field workover treatment machine can be assembled and disassembled conveniently and rapidly, thereby not only facilitating transportation, but also changing the positions to meet the requirements of different work. Simultaneously the machine can be laid freely at a well field according to the practical conditions.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU +1

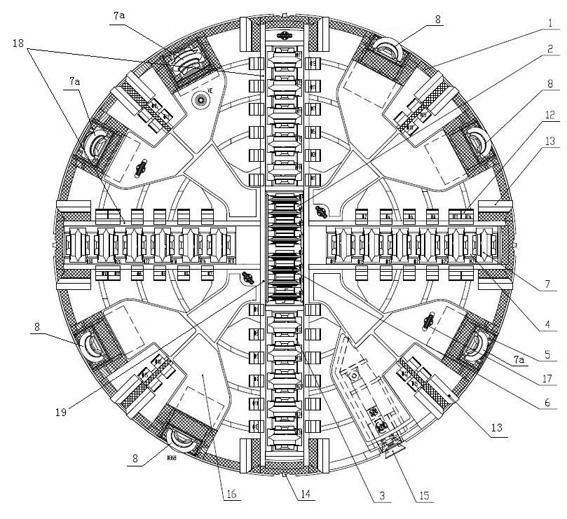

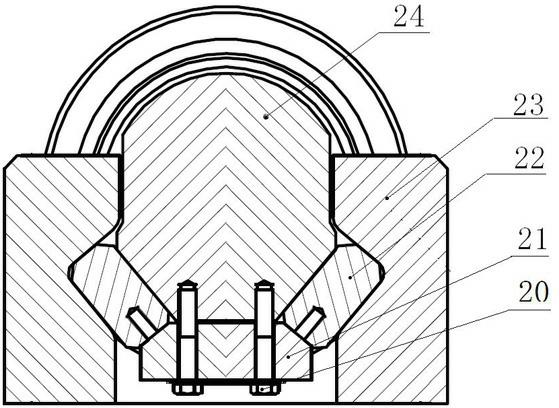

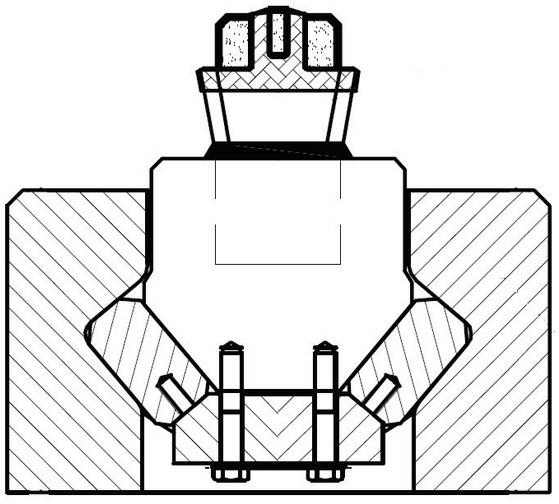

Shield cutter for composite ground

The invention discloses a shield cutter for a composite ground, which comprises a cutter head with a box body structure, wherein a hobbing cutter is arranged on the front face of the cutter head and comprises a plurality of single-blade standard hobbing cutters, a plurality of single-blade central hobbing cutters, a plurality of single-blade standard hobbing cutters and a plurality of single-blade eccentric hobbing cutters; the single-blade standard hobbing cutters are arranged on a cross cutter beam; the single-blade central hobbing cutters are arranged on a transverse I-shaped cutter beam positioned in the central area of the cross cutter beam; the single-blade standard hobbing cutters and the single-blade eccentric hobbing cutters are arranged in an edge area of the cross cutter beam; cutting knives are symmetrically arranged along the two sides of the cross cutter beam in the form of a concentric circle; edge scraping knives are arranged on the two sides of the cross cutter beam and at the middle positions of every two cutter beams of the cross cutter beam, on the edge of the front face of the cutter head; a plurality of radius retaining knives are arranged at the periphery ofthe cutter head; and an over cutter extended from the periphery is arranged in a box body of the cutter head. When the shield cutter is compared with the prior art, the boundary dimension of a cutterholder is reduced, the aperture opening ratio of the cutter is increased, the slag flowability is improved, and the wear resisting property of the whole cutter is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Hydraulic vertically rotary airtight flood and preventive partition door in metro running

ActiveCN101666242AOvercome the disadvantage of being thickMeet strength requirementsGasproof doorsMining devicesMonitoring systemEngineering

An airtight flood and preventive partition door used for civil defense in metro running mainly comprises a door leaf, a door frame, a hinge, a hydraulic drive device, a manual and electric locking device, a manual gate valve, a manual and electric gate valve, a support locking device, a monitoring device and the like. A hydraulic drive system drives the door leaf to open and close. The manual andelectric locking device can open and close the locks manually and electrically. The gate valve is used for sealing a drainage ditch passing by the partition door. The support locking device is used for supporting and safely locking the door leaf. A monitoring system is used for monitoring the water level and state of each component and controlling action of each component. The partition door simultaneously satisfies the requirements of civil defense and flood standards, is suitable for the characteristics of the metro running structure, occupies little space, has low overall cost, is characterized in that all the components can be used manually and electrically, can be monitored remotely and opened and closed easily and quickly, and has higher application value.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA +1

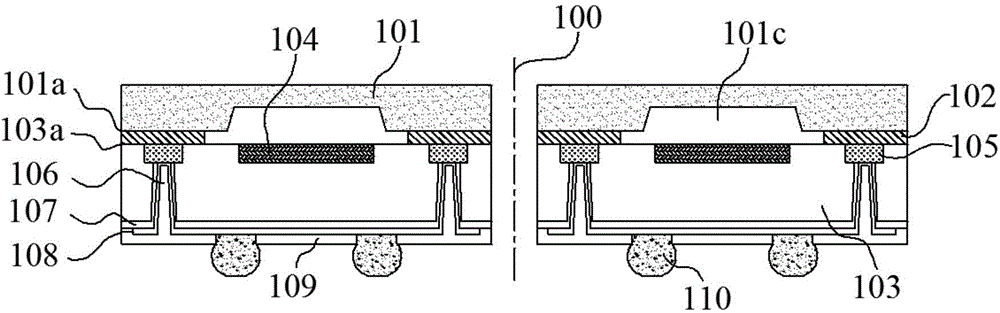

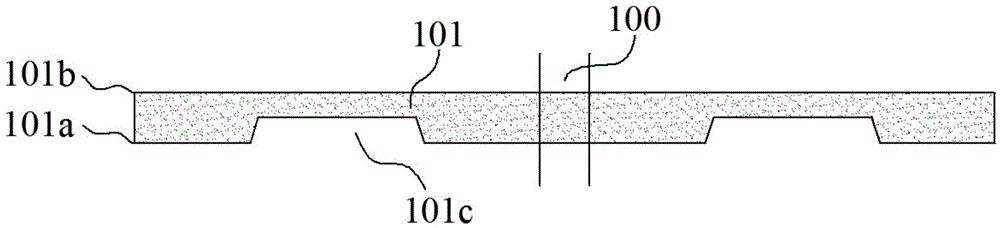

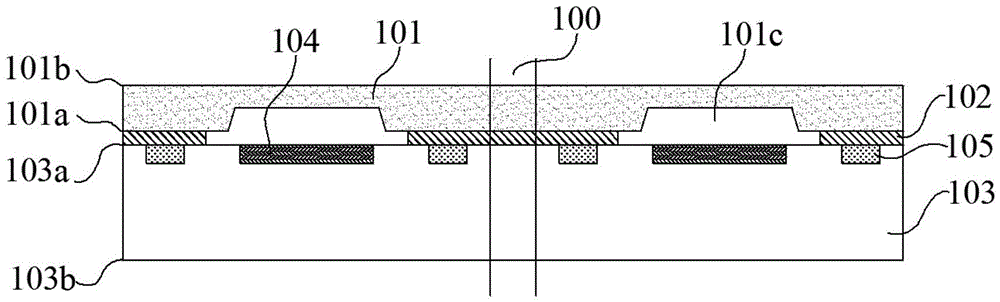

Semiconductor packaging method of wafer level silicon-based through hole

InactiveCN104392958AImprove yieldReduce stress levelsSolid-state devicesSemiconductor/solid-state device manufacturingStress levelSolder ball

The invention discloses a semiconductor packaging method of wafer level silicon-based through hole, belonging to the field of semiconductor packaging. The packaging method substantially comprises the following steps: 1, making a cavity structure on a cover plate; 2, bonding the front surface of the cover plate with the front surface of a wafer through a bonding machine; 3, grinding the rear surface of the wafer by a grinder, and implementing a stress plasma etching on the rear surface of the wafer; 4, removing all silicon belonging to a scribe line region starting from the rear surface of the wafer; 5, etching the rear surface of the wafer in order to form silicon through holes, and exposing a bonding pad; 6, making passivation layers, metal layers and solder mask layers sequentially in the rear surface of the wafer and the silicon through holes, so as to compose a redistributed circuit layer, thereby conducting the solder pad to a designated solder ball position on the rear surface of the wafer; 7, making solder balls and cutting along the scribe line. By the implementation of the semiconductor packaging method of wafer level silicon-based through hole, the yield rate of wafer cutting technique is increased, the stress level in package structure is reduced, and the boundary dimension of the package structure is decreased.

Owner:BEIJING UNIV OF TECH

Special hanger with guide cover wheel hub and turning and hanging method

InactiveCN101966965ASmall form factorSimple structureWind energy generationLoad-engaging elementsEngineeringMechanical engineering

Owner:JIANGSU WENDE NEW ENERGY

Light transmission system for photoreactive therapy

ActiveUS8057464B2Reduce user costsMinimizes tissue traumaSurgical furnitureEndoscopesMedicineLight activated

Owner:LIGHT SCI ONCOLOGY

Burner, method for operating a burner and gas turbine

InactiveUS7320222B2Avoid it happening againReduce rateContinuous combustion chamberGas turbine plantsCombustorHelmholtz resonator

This invention relates to a burner, especially a gas turbine burner, wherein a Helmholtz resonator downstream of a fuel inlet position in directly linked with a burner channel. In this manner, combustion oscillations do not arrive at the fuel inlet position, thereby reducing acoustic disturbances and air ration deviations which are the main cause for the formation of combined oscillations. The invention also relates to a method for operating a burner and a gas turbine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

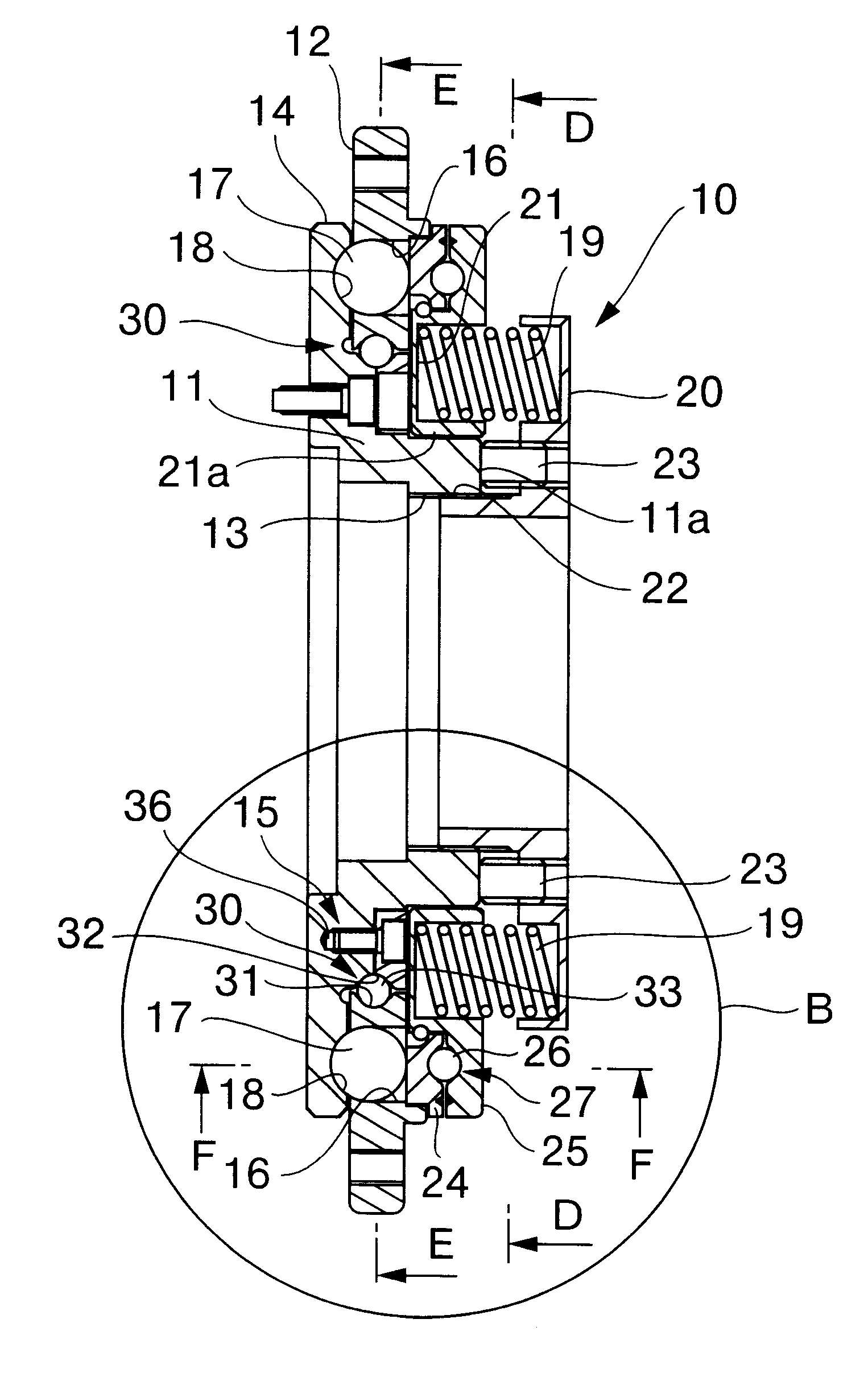

Torque limiter

InactiveUS6206784B1Small and more compact dimensionReduce in quantitySlip couplingBearing componentsCompact dimensionBall bearing

A torque limiting device capable of transferring torque within a power train, and also capable of disengaging the torque transfer connection when the torque level exceeds a specific point. A specific ball bearing joint is formed where a radial boss mates with the inner circumference of a flange. The ball bearing joint consists of an outer radial groove formed on the aforesaid inner circumference, an inner radial groove formed on the boss and facing the outer groove, and ball bearings inserted between the two radial grooves. Each radial groove is formed to a V-shape cross section having a radius of curvature smaller than that of the ball bearings, thus providing ball bearing support at two points within each groove, and four points of bearing support in total. Rotation of the torque output part is thus supported adequately in both the radial and axial thrust directions by a single ball bearing structure which allows the torque limiter to be made to compact dimensions.

Owner:SANKYO SEISAKUSHO

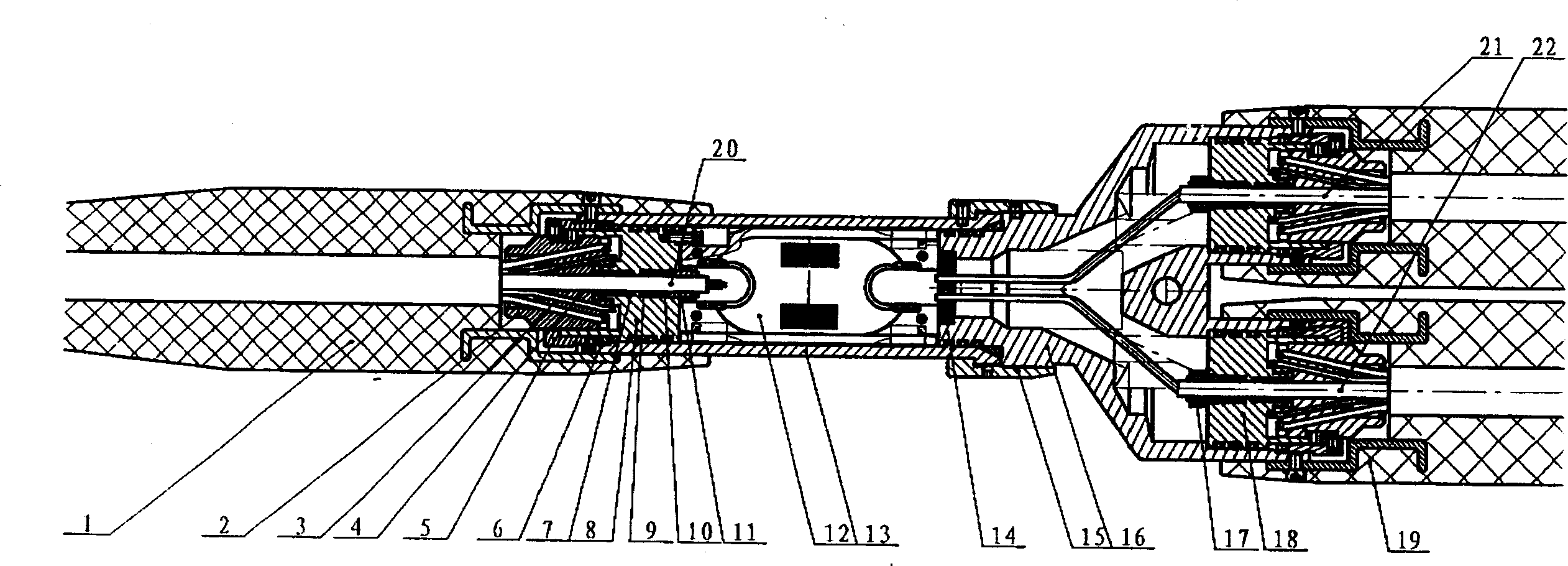

Seabed optical cable branch joint box and connection process thereof

ActiveCN1790078AAvoid excessive bendingSmall form factorOptical fibre/cable installationCoupling light guidesCommunications systemEngineering

The invention discloses a submarine optical branch connector box and connecting technology, which comprises the following parts: main cable bending limiter, external pyramid, middle pyramid, conical axle, bearing nut, pushing sleeve, O-shaped coil liner, sealing seat body, support ring, compression ring, locking axle, tray, sealing cylinder, branch line case, branch seat bearing nut, branch seat, locking nut, branch sealing seat and branch binding limiter, wherein the main cable bending limiter, bearing nut, pushing sleeve, sealing component, branch seat bearing nut and sealing seat pierce the main cable end sequently; branch one and two cables pierce the branch binding limiter, bearing nut, pushing sleeve and sealing component.

Owner:ZHONGTIAN TECH MARINE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com