Dual platform switching system for mask aligner silicon slice platform using conveyer structure

A technology of switching system and silicon wafer stage, which is applied in the field of semiconductor manufacturing equipment, can solve the problems of insufficient utilization of system space, high precision of rail docking, etc., and achieve the effects of shortening working time, small size and improving exposure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

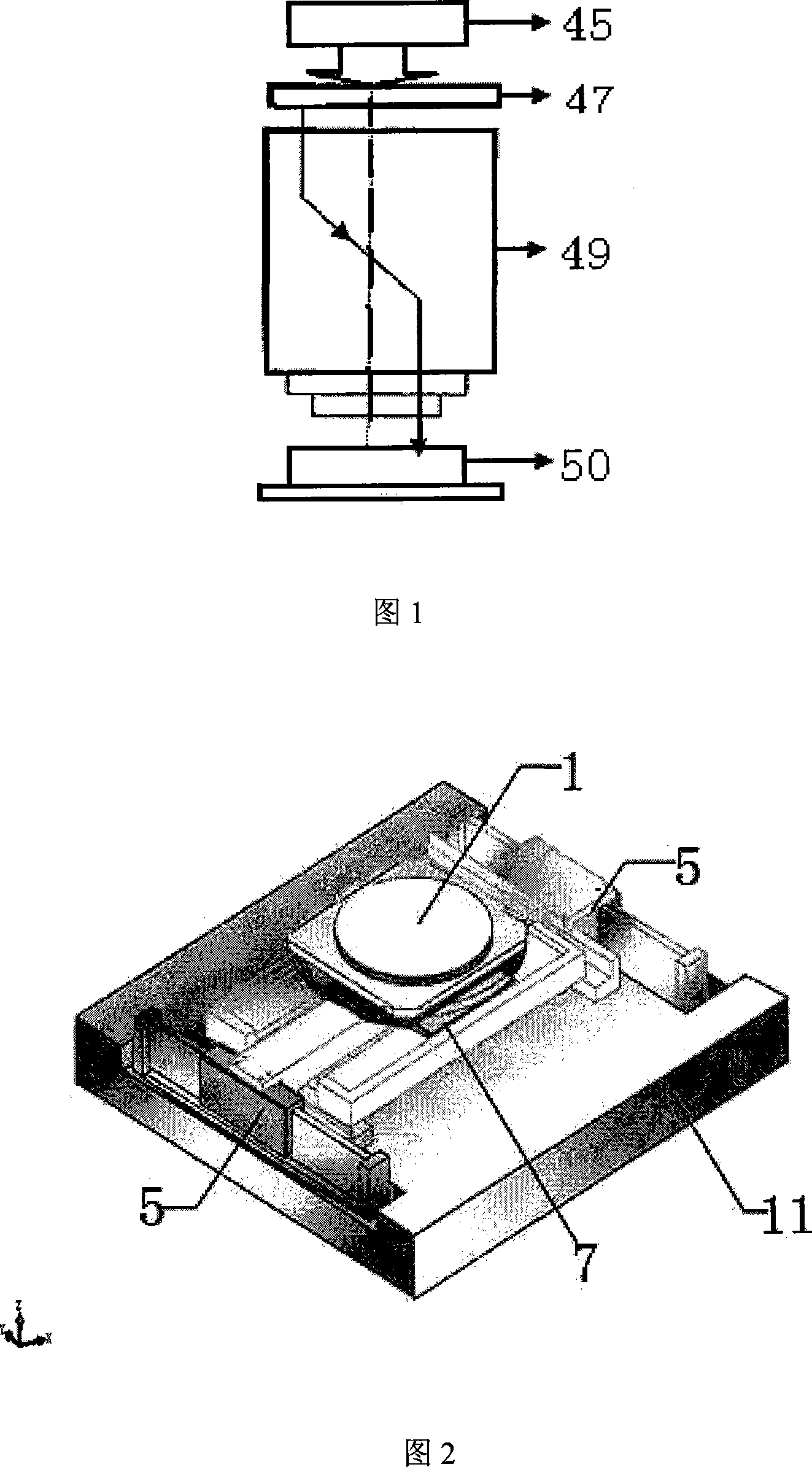

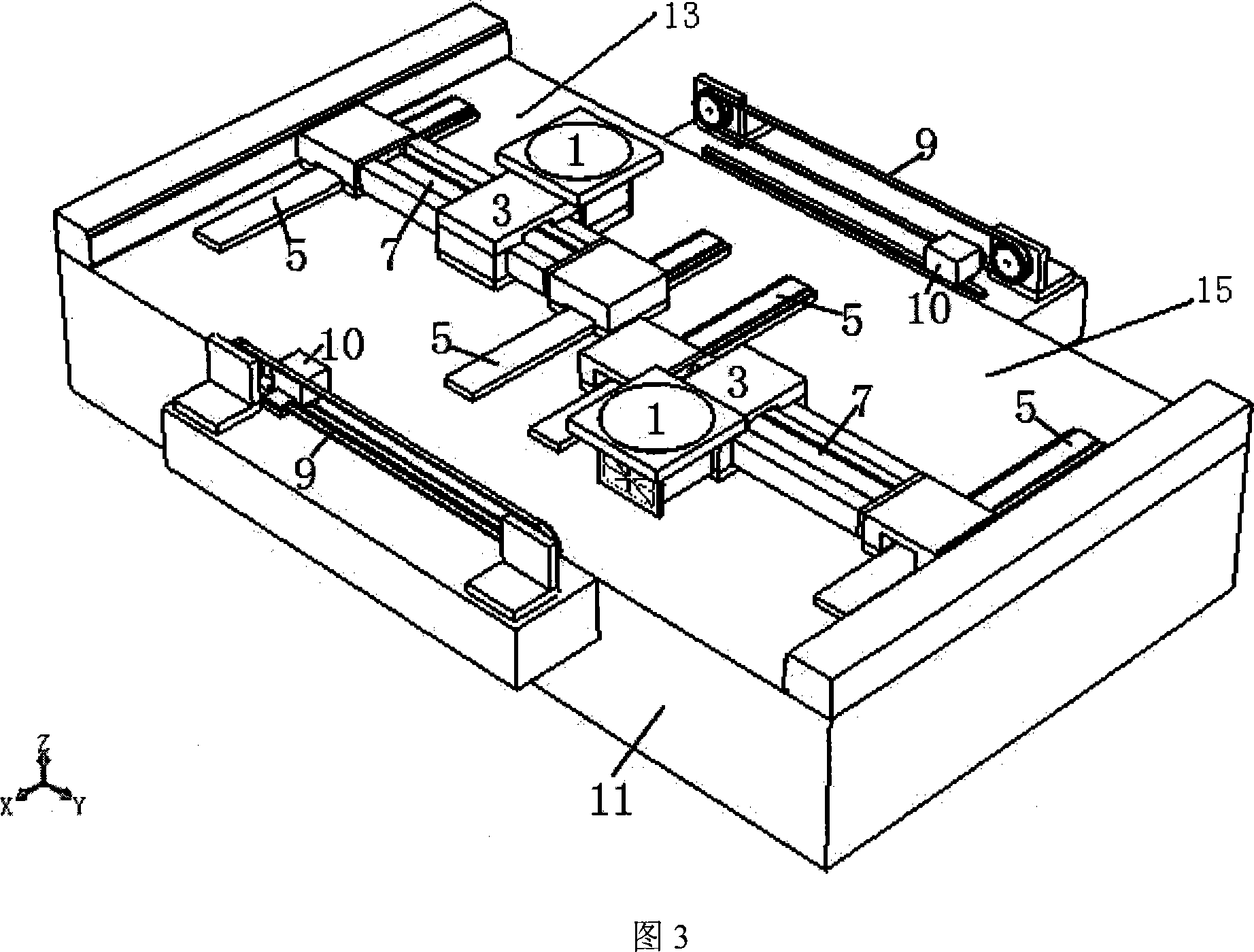

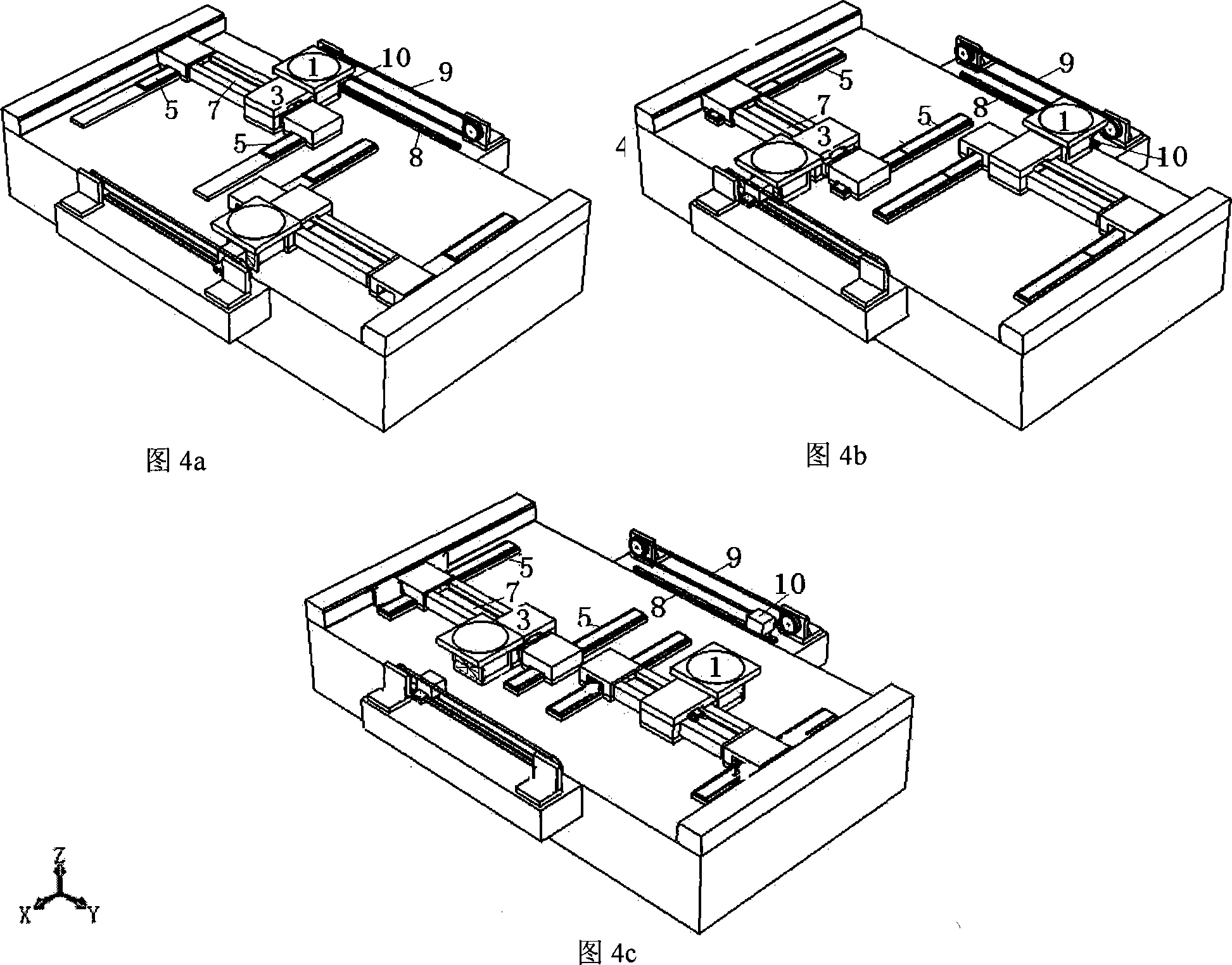

[0019] As shown in Fig. 2, the wafer stage of a traditional lithography machine has only one wafer motion positioning system in the lithography machine, that is, only one wafer stage. Preparations such as leveling, focusing, and alignment must be done on the exposure wafer stage, and these tasks take a long time, especially for alignment, which requires extremely high-precision low-speed scanning (typical alignment scanning The speed is 1mm / s), so it takes a long time. In order to improve the exposure efficiency of the photolithography machine, a dual-stage exchange system for the silicon wafer stage of the photolithography machine using a conveyor belt structure according to the present invention transfers the exposure preparation work such as leveling, focusing, and alignment to the preprocessing station On the wafer stage of the exposure station, and independently at the same time as the wafer stage of the exposure station, thus greatly shortening the working time of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com