Patents

Literature

593 results about "Motion accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition. In a motion application, accuracy is the ability of a motor to achieve an exact rotational position. Precision is the ability of a motor to consistently repeat the desired motion. Applications such as medical analyzers require precision and accuracy in microns as samples are handled and pass through various stages of the workflow.

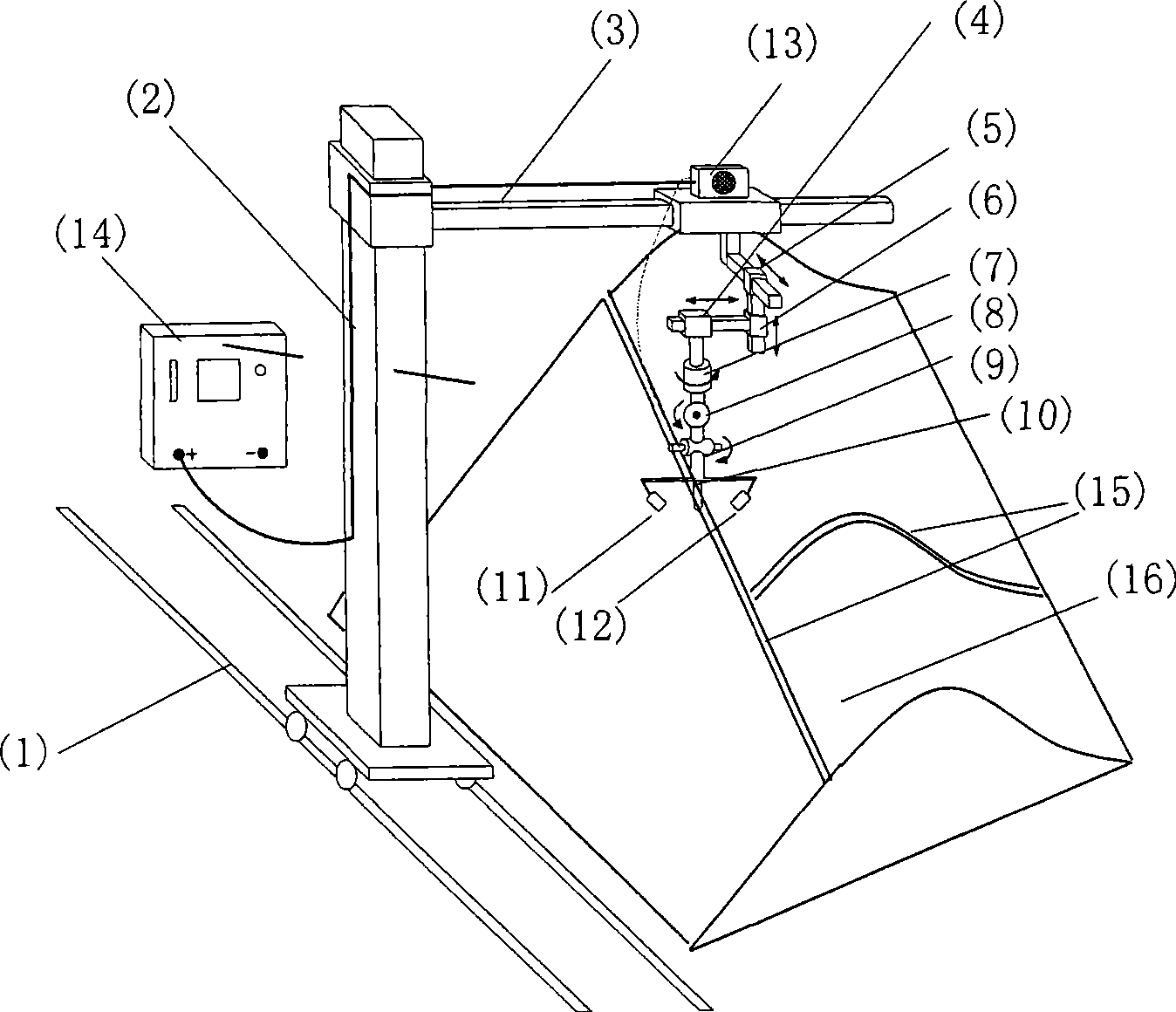

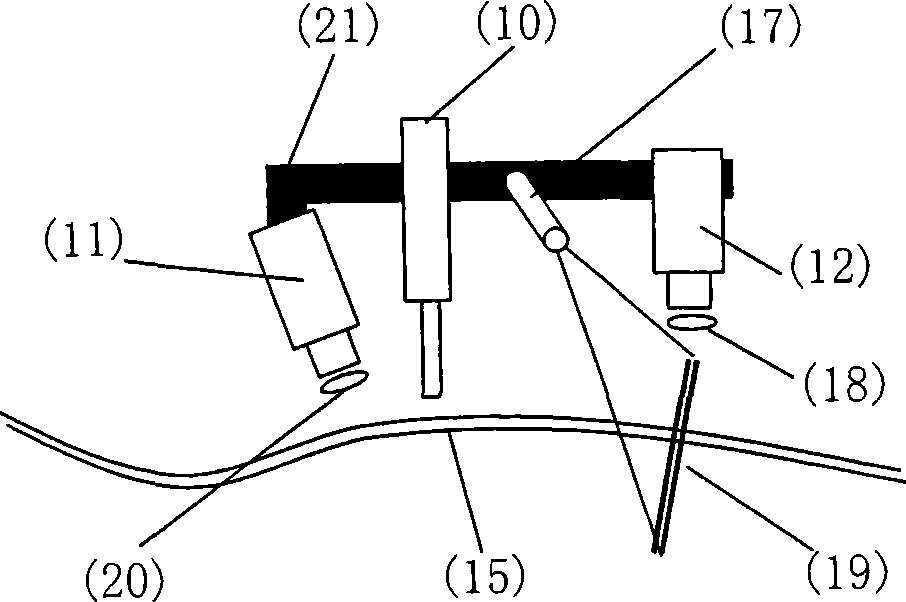

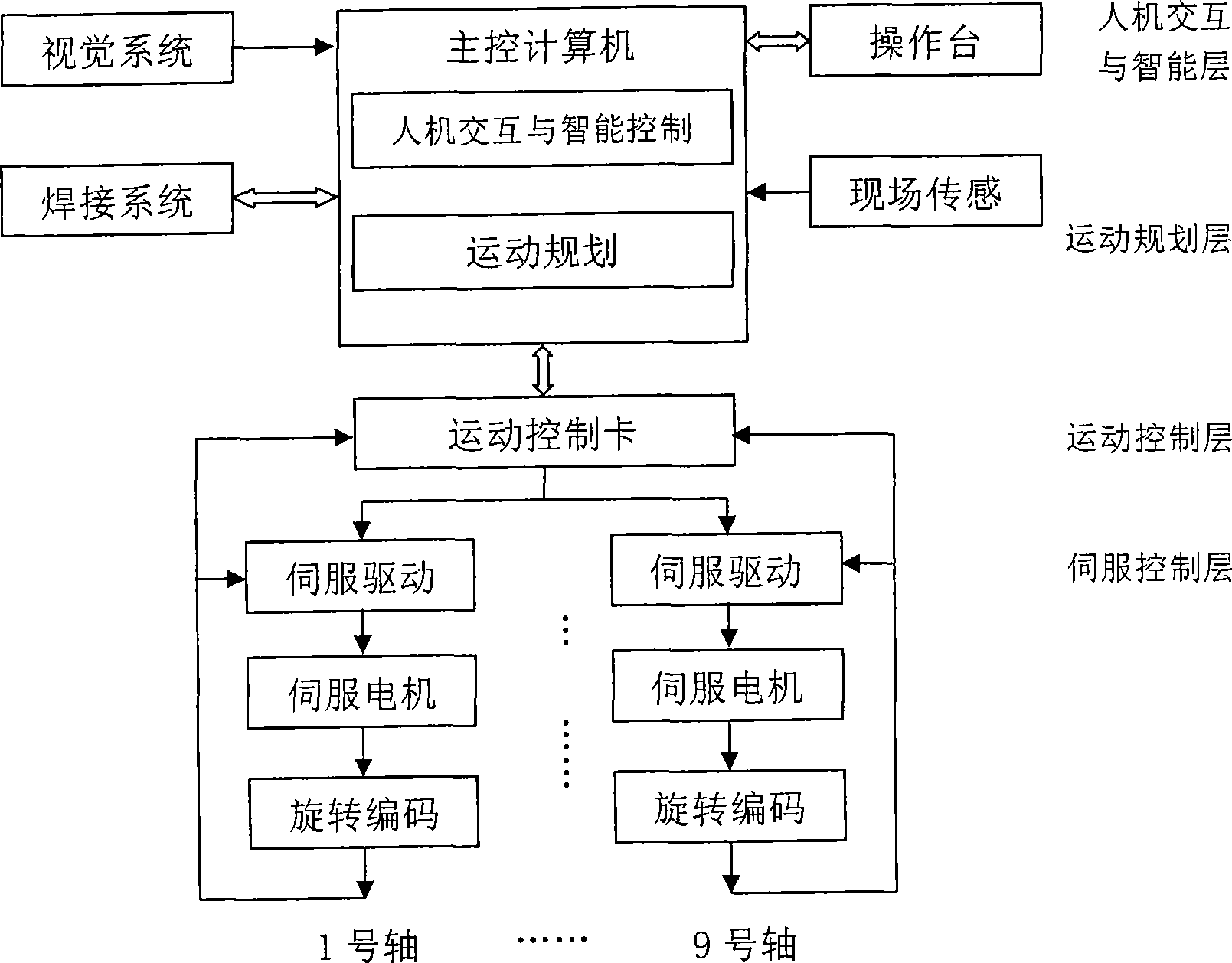

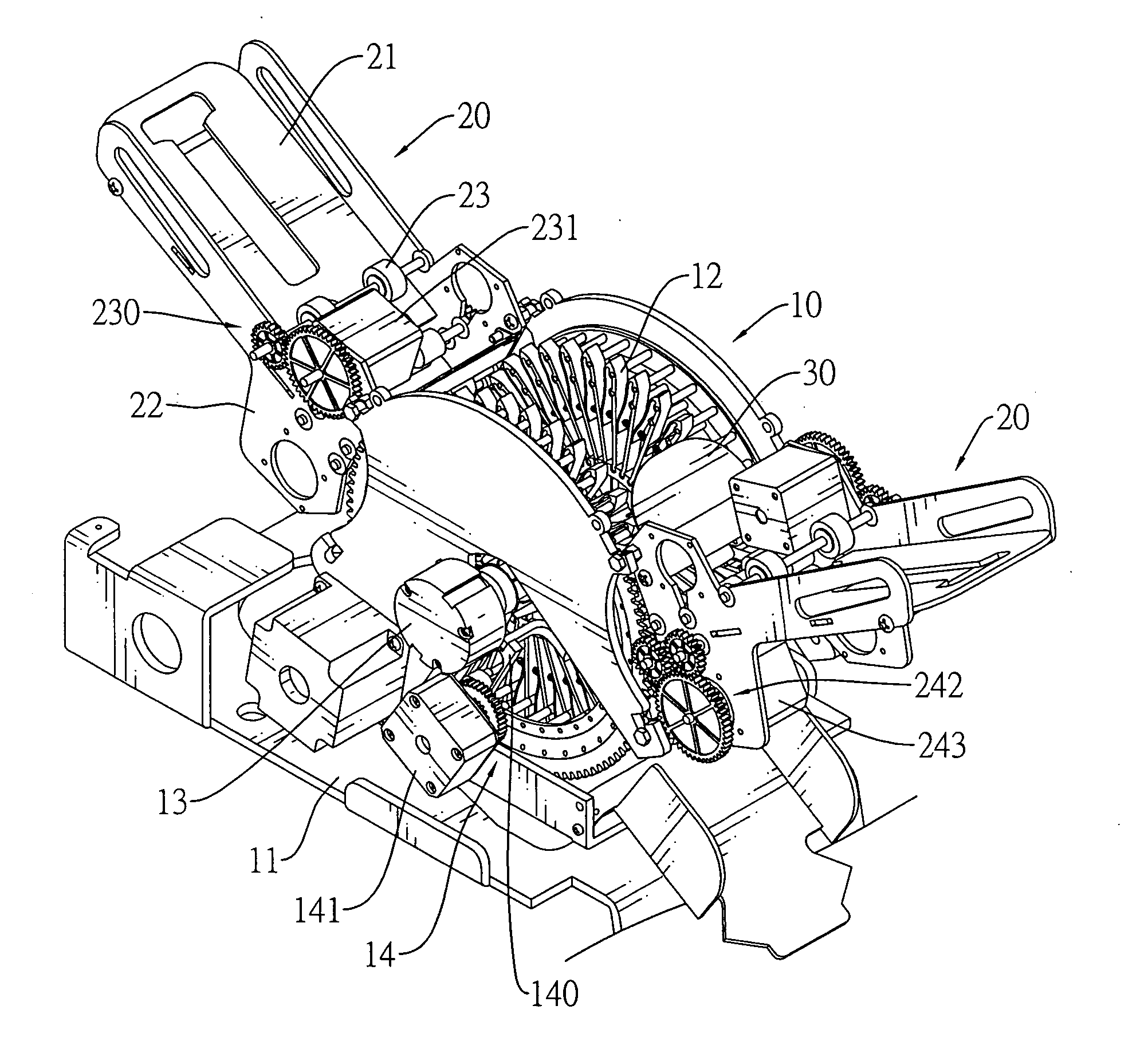

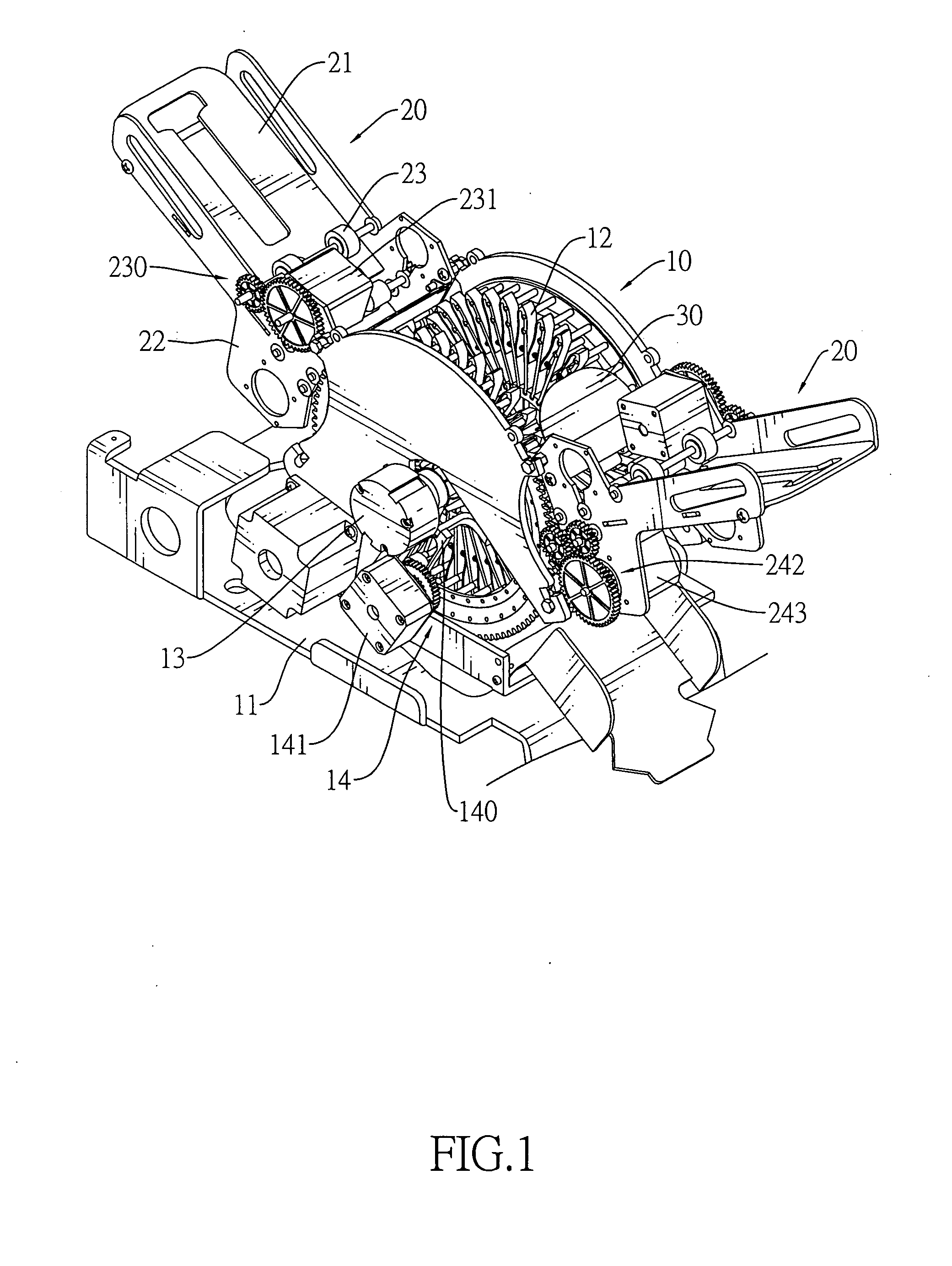

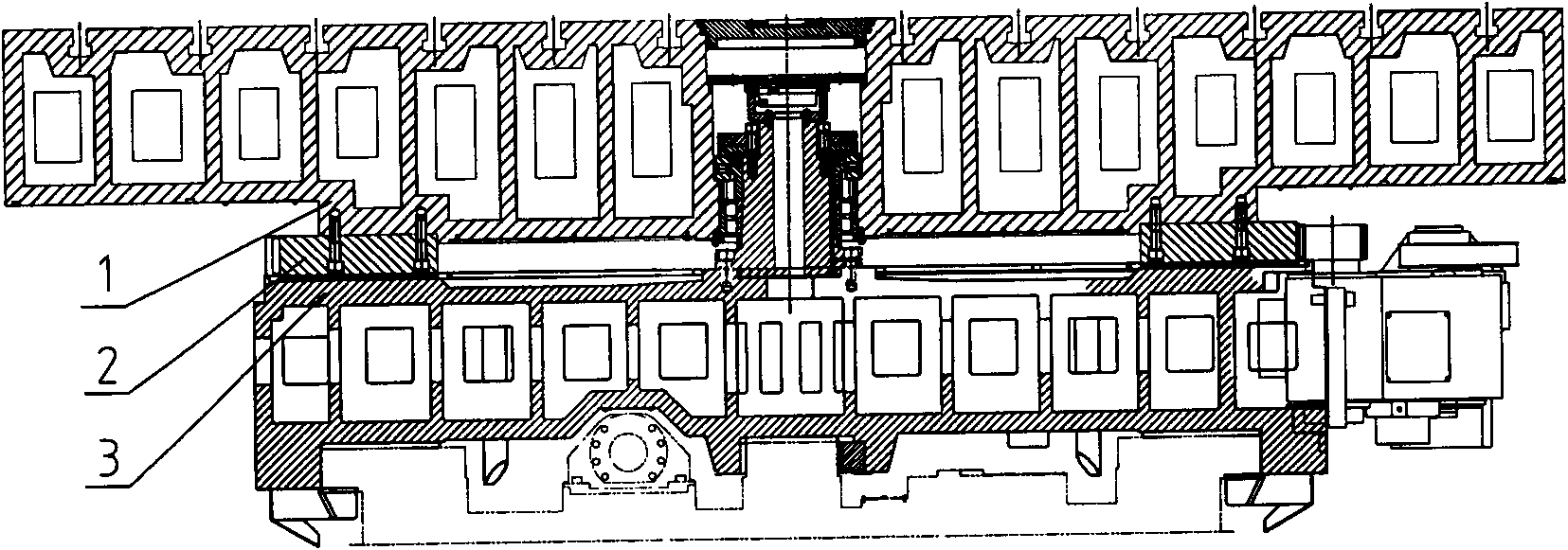

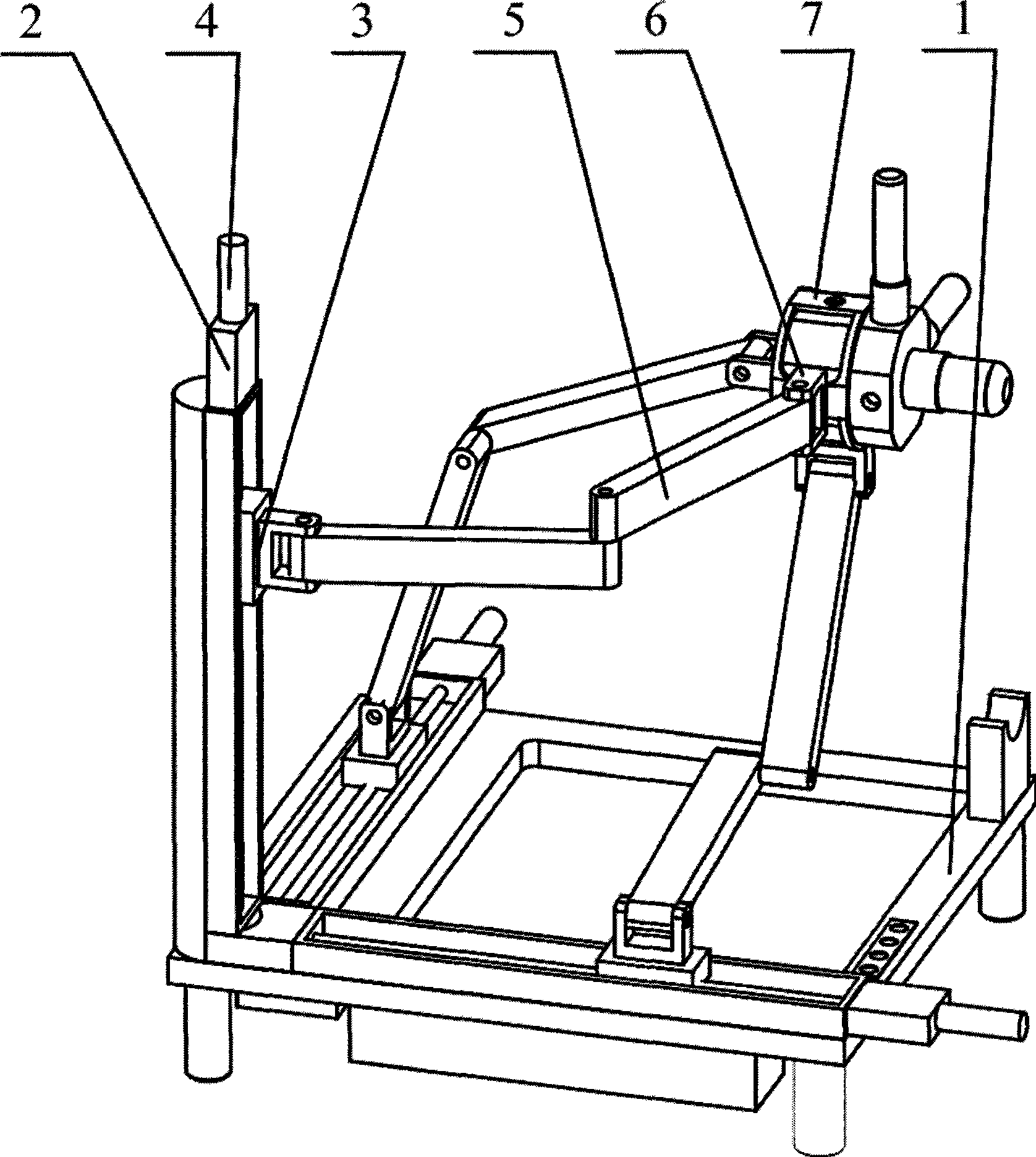

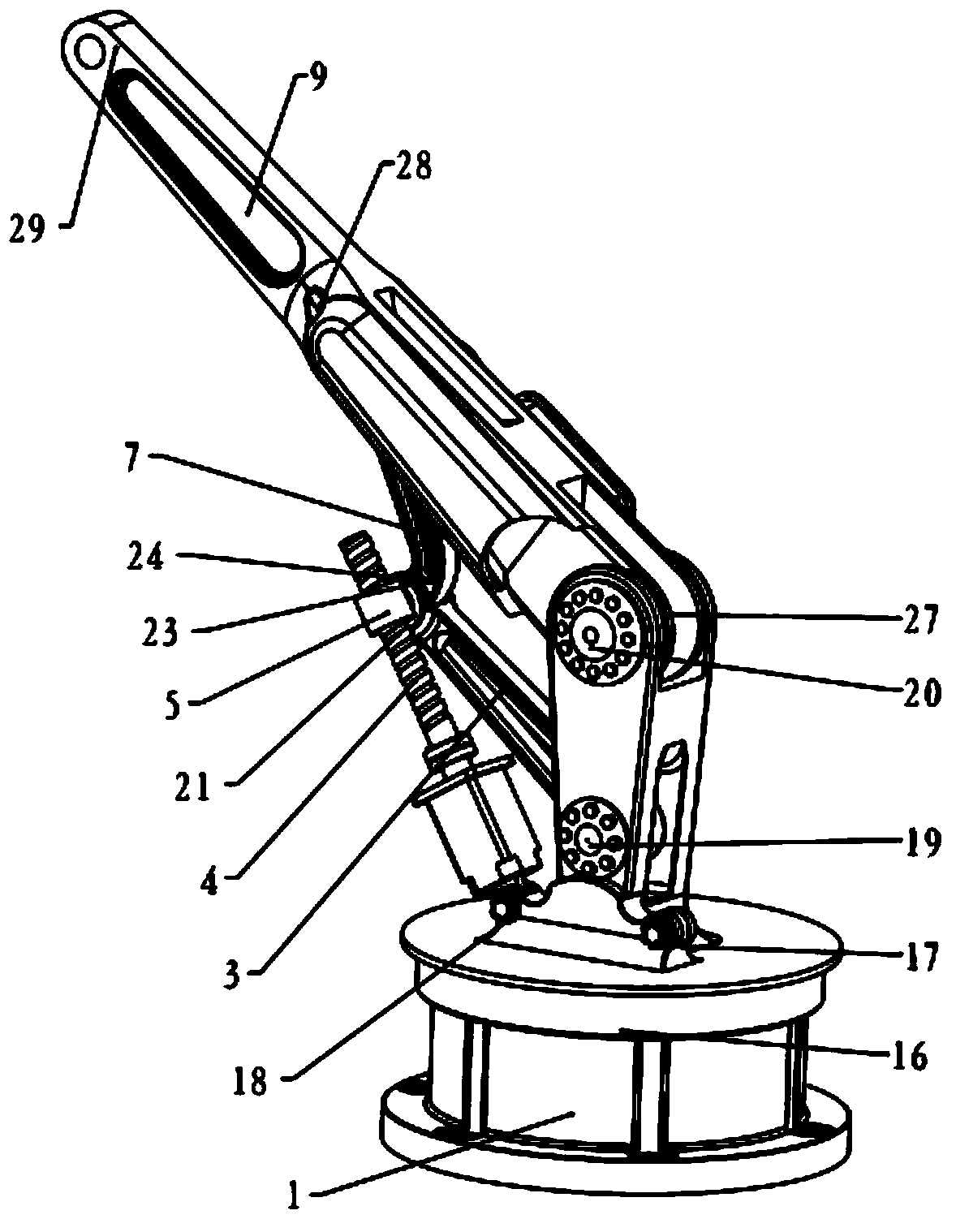

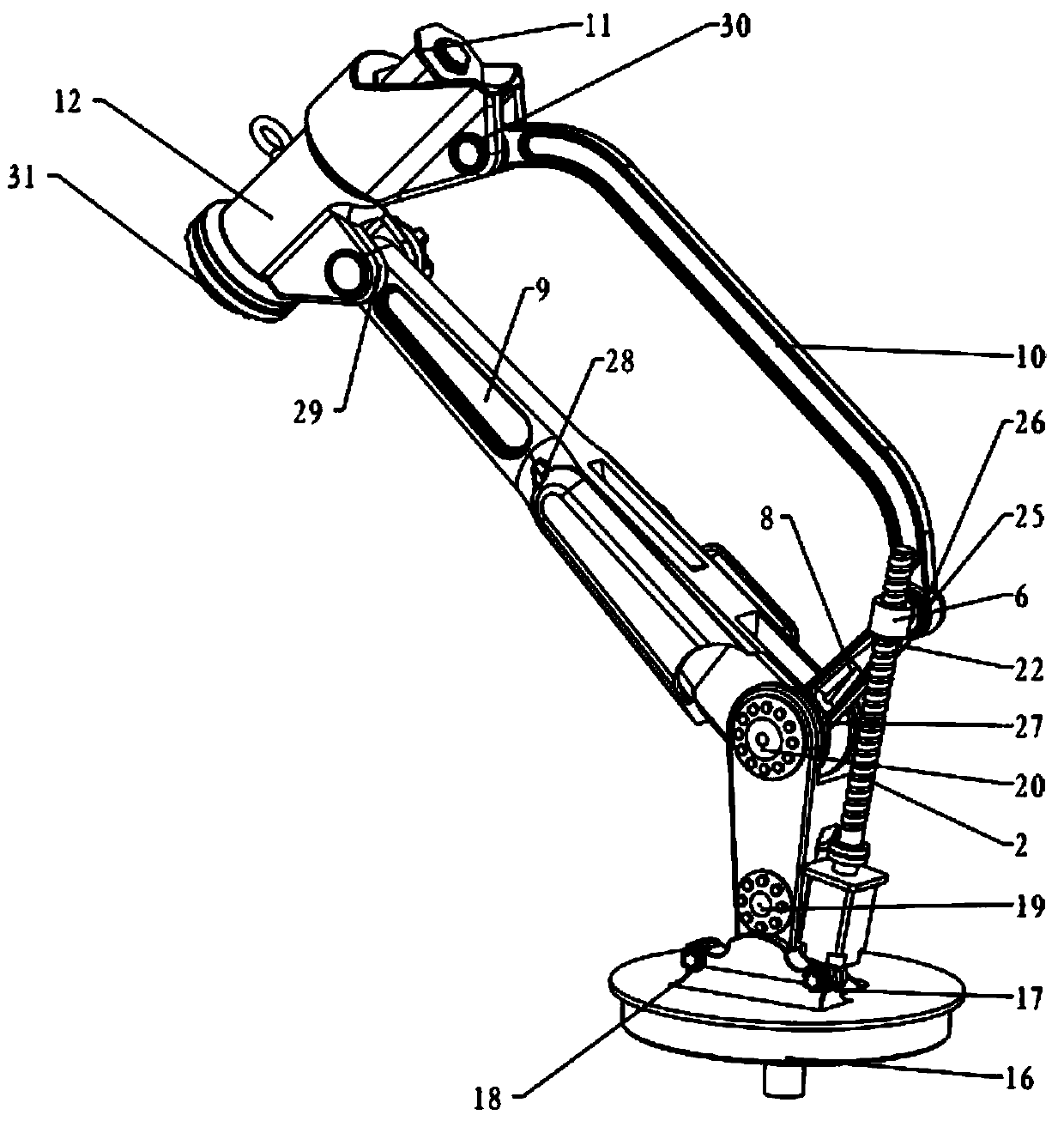

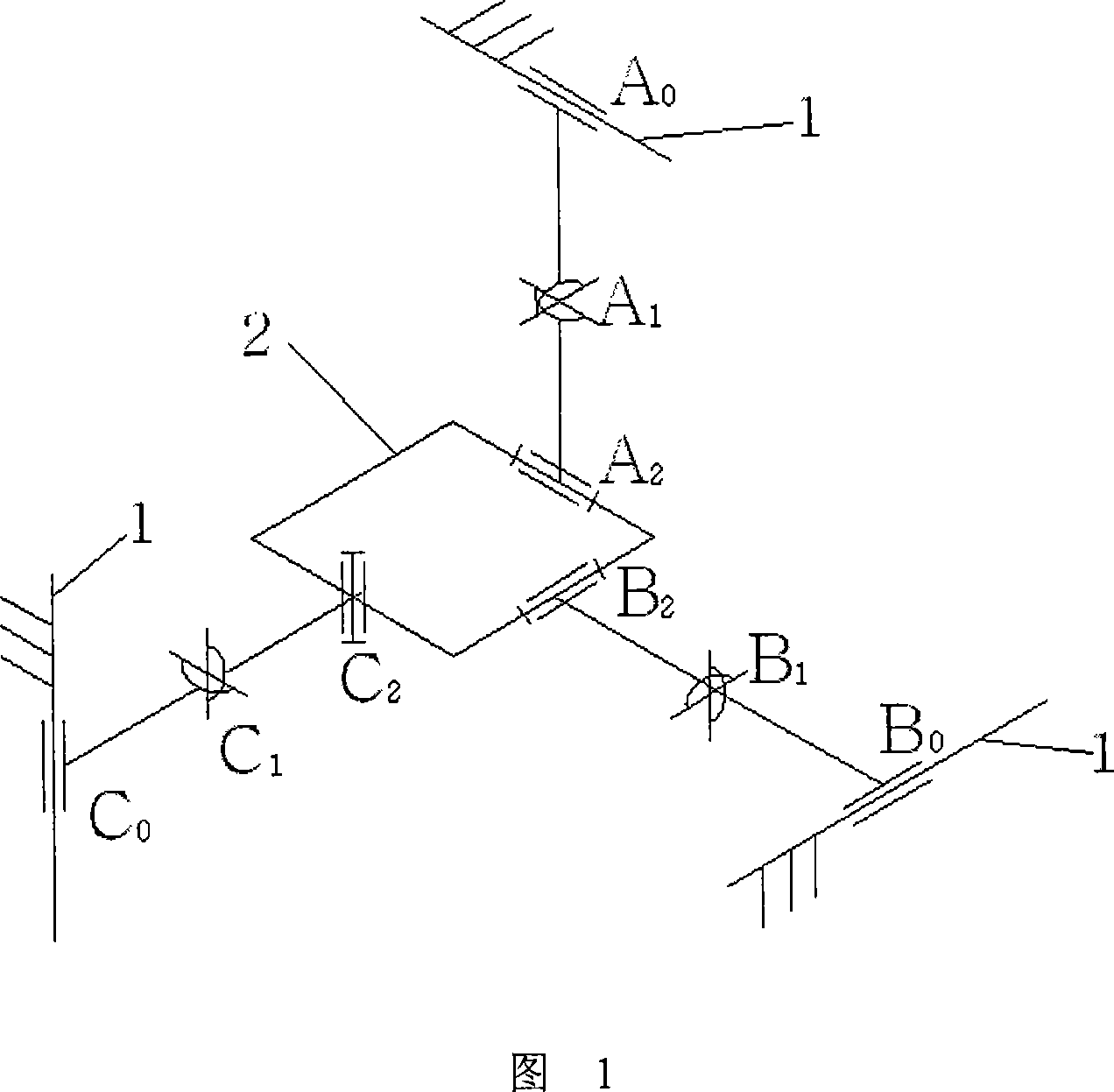

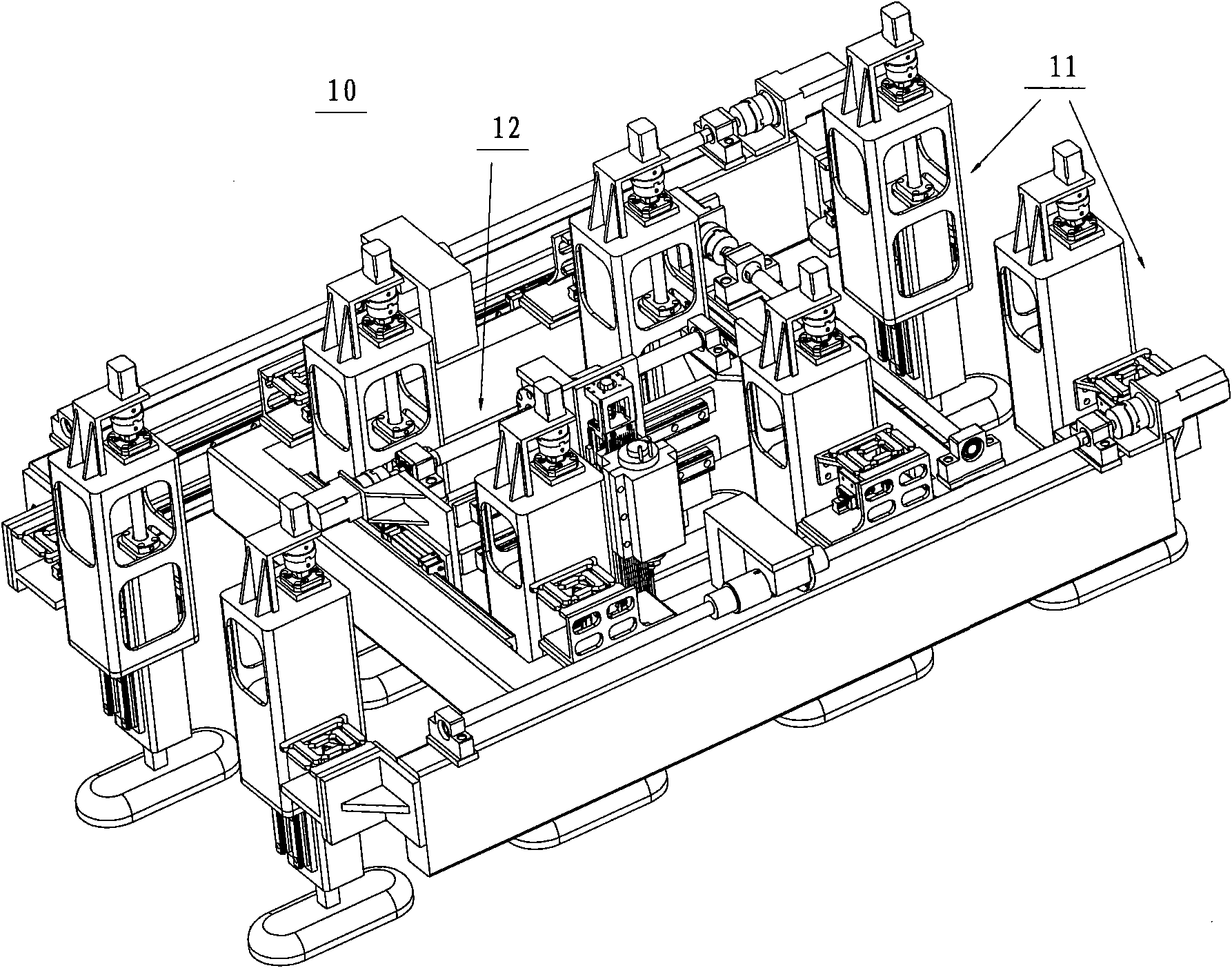

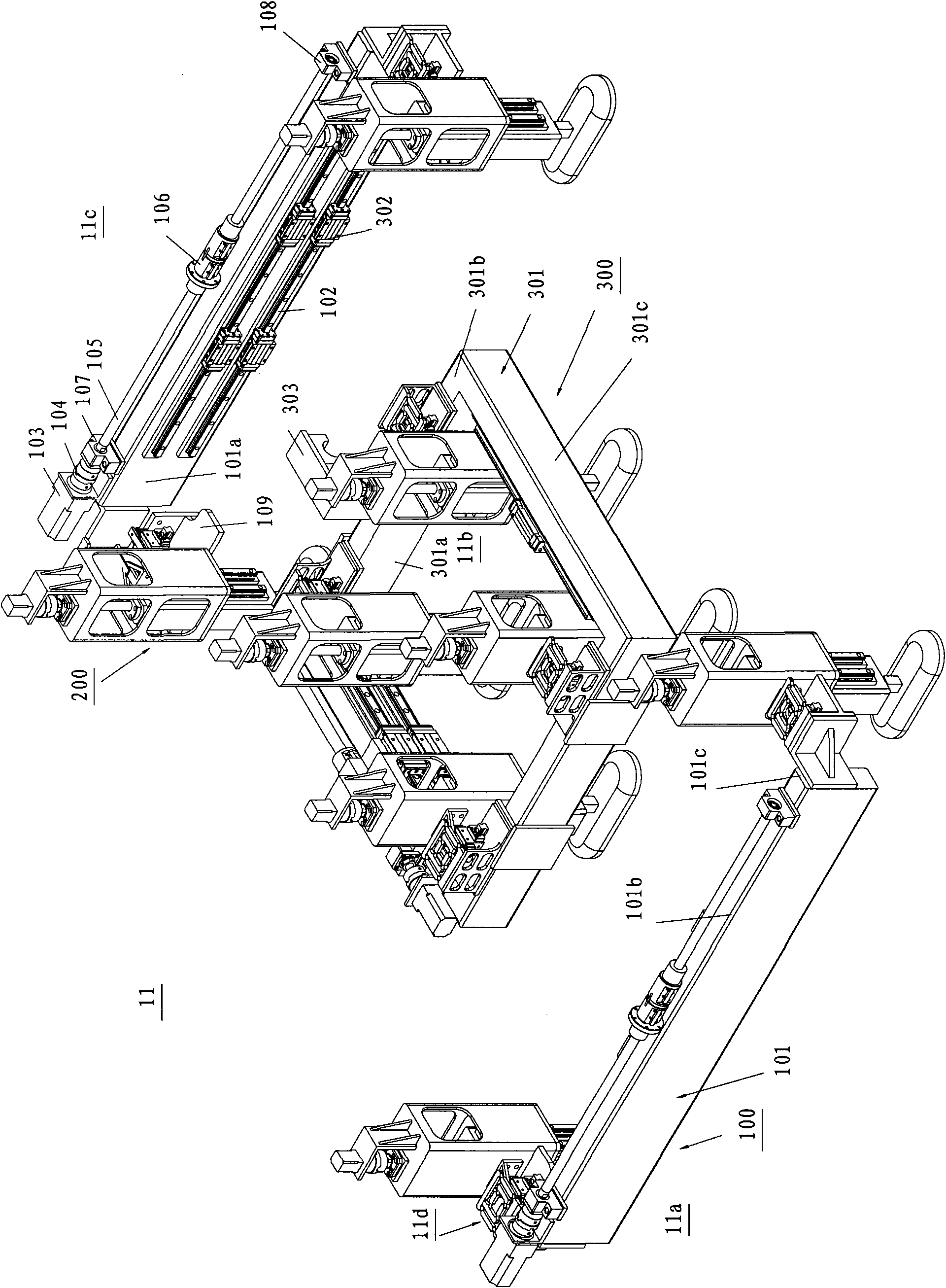

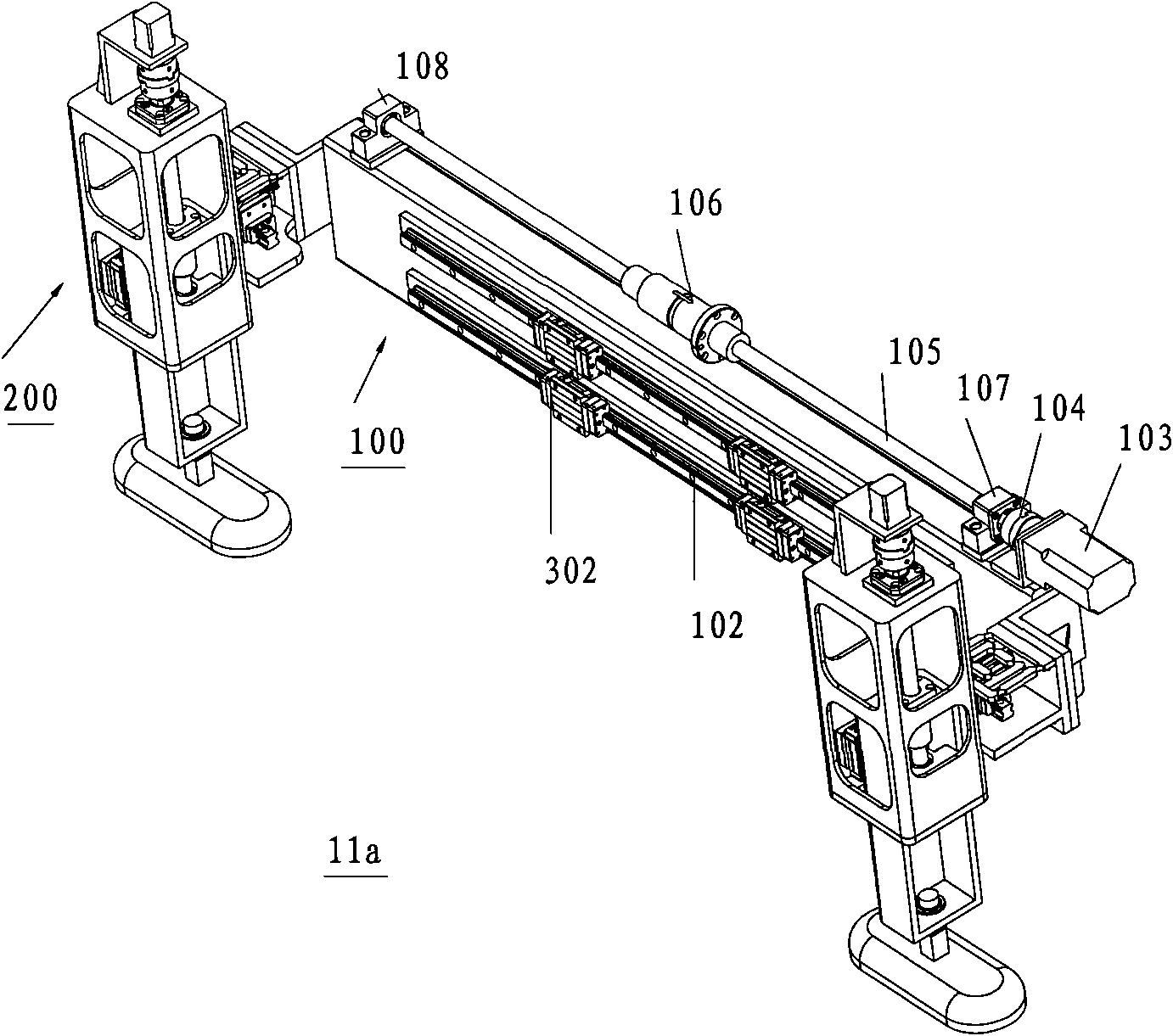

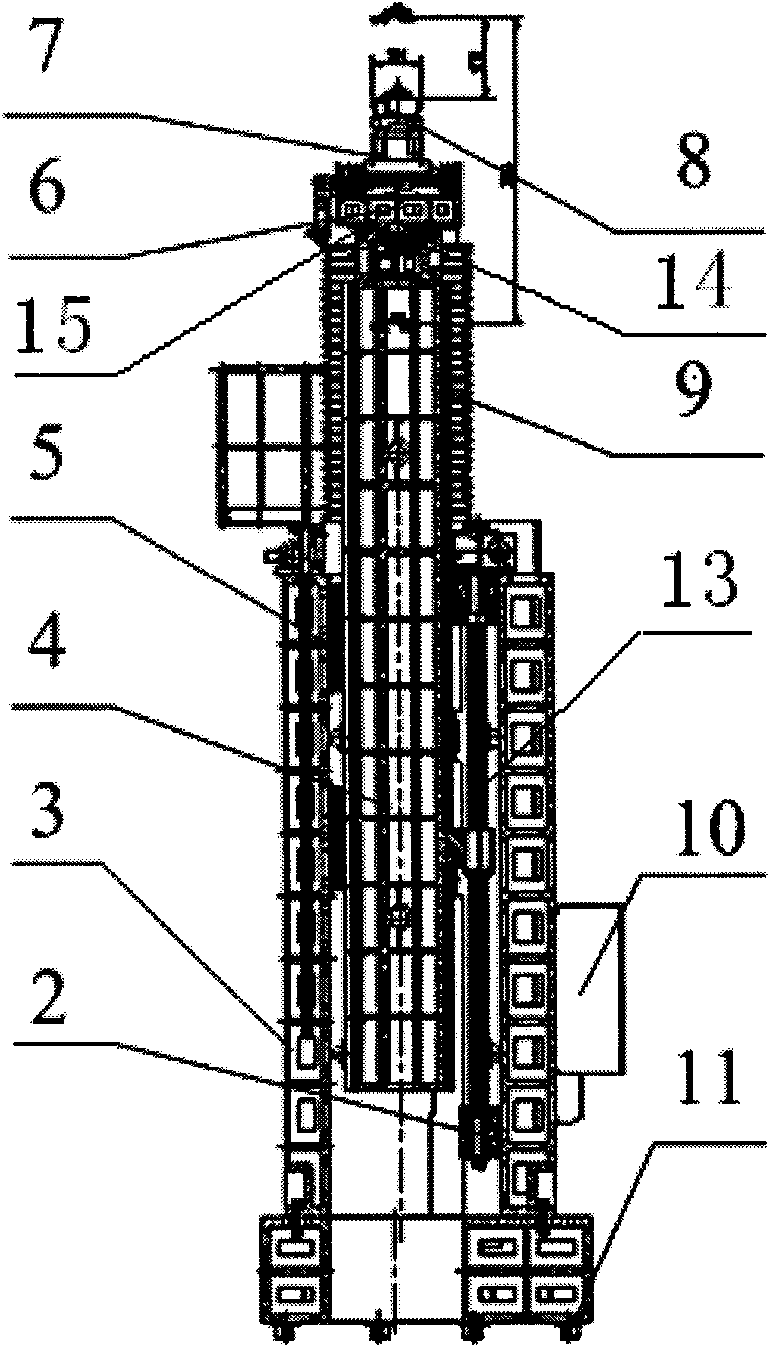

Intelligent robot welding device using large-scale workpiece

InactiveCN101456182AWith visual functionSimple motion controlProgramme-controlled manipulatorArc welding apparatusRotational axisRotational degrees of freedom

The invention discloses a large-sized workpiece welded intelligent robot device, relates to robot technology, in particular to the robot device based on visual control technology. The device consists of a robot body, a sensing system, a robot controller and a welding auxiliary mechanism. The welded robot is provided with nine moving shafts, including three macrographic moving translational moving shafts, three microscopic moving translational moving shafts and three rotating shafts. The robot body comprises a robot frame and a robot head which is arranged on a transverse arm of the robot frame, and the robot frame consists of the three macrographic moving translational moving shafts, namely a horizontal lead rail, an upright post and the transverse arm. The robot head consists of the three microscopic moving translational moving shafts, the three rotating shafts and a welding gun. The robot frame provides the large-scale three-dimensional movement of the robot; the precision of macrographic moving movement is compensated by the microscopic moving mechanisms of the robot head which also provides rotating freedom of motion. The robot device can meet the movement requirements of large scale and precise positioning for the welding operation of large-sized workpieces. Through the visual sensing technology and intelligent visual controlling technology, the device can improve the automatic welding quality and efficiency of the welded robot.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

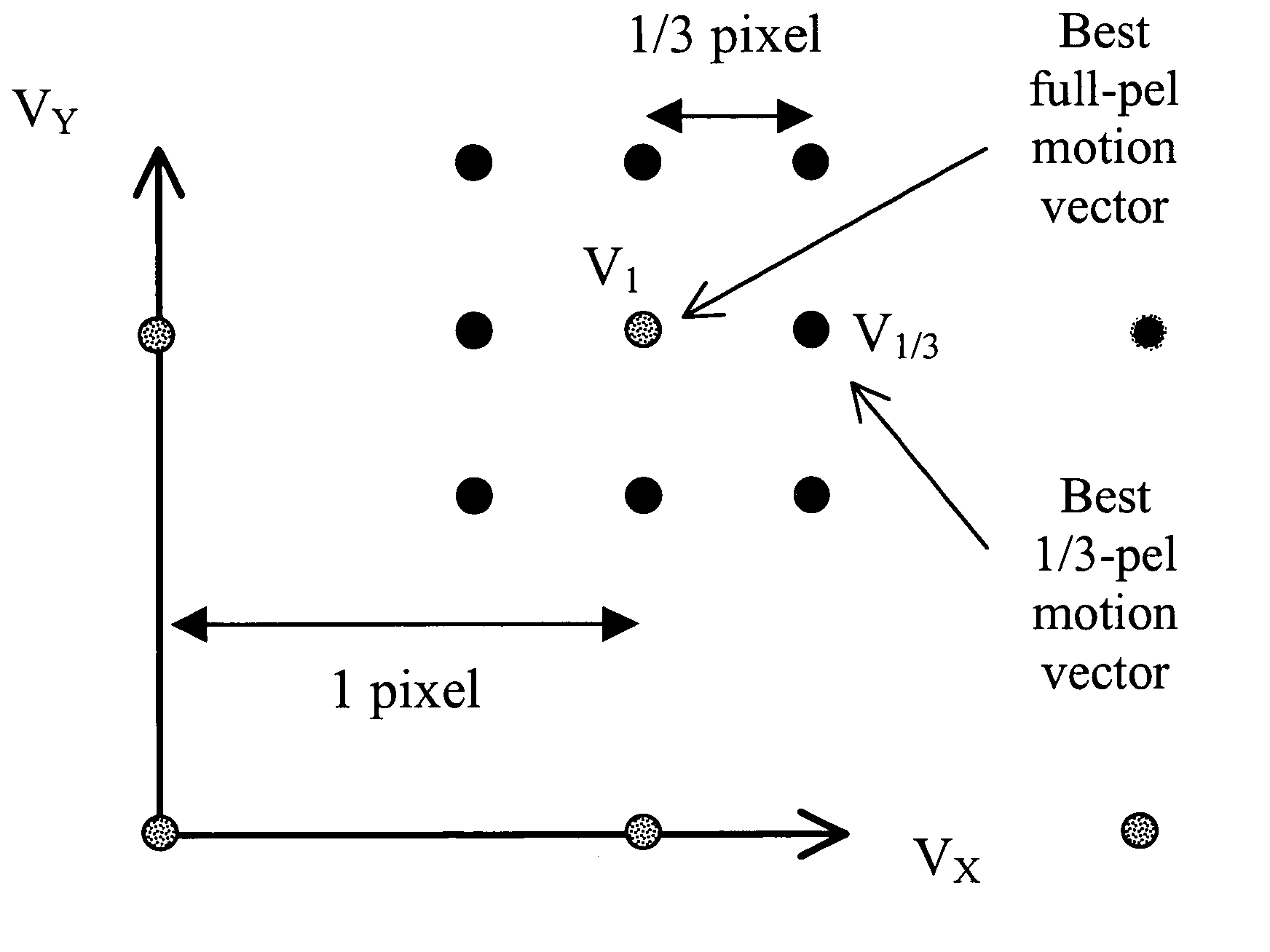

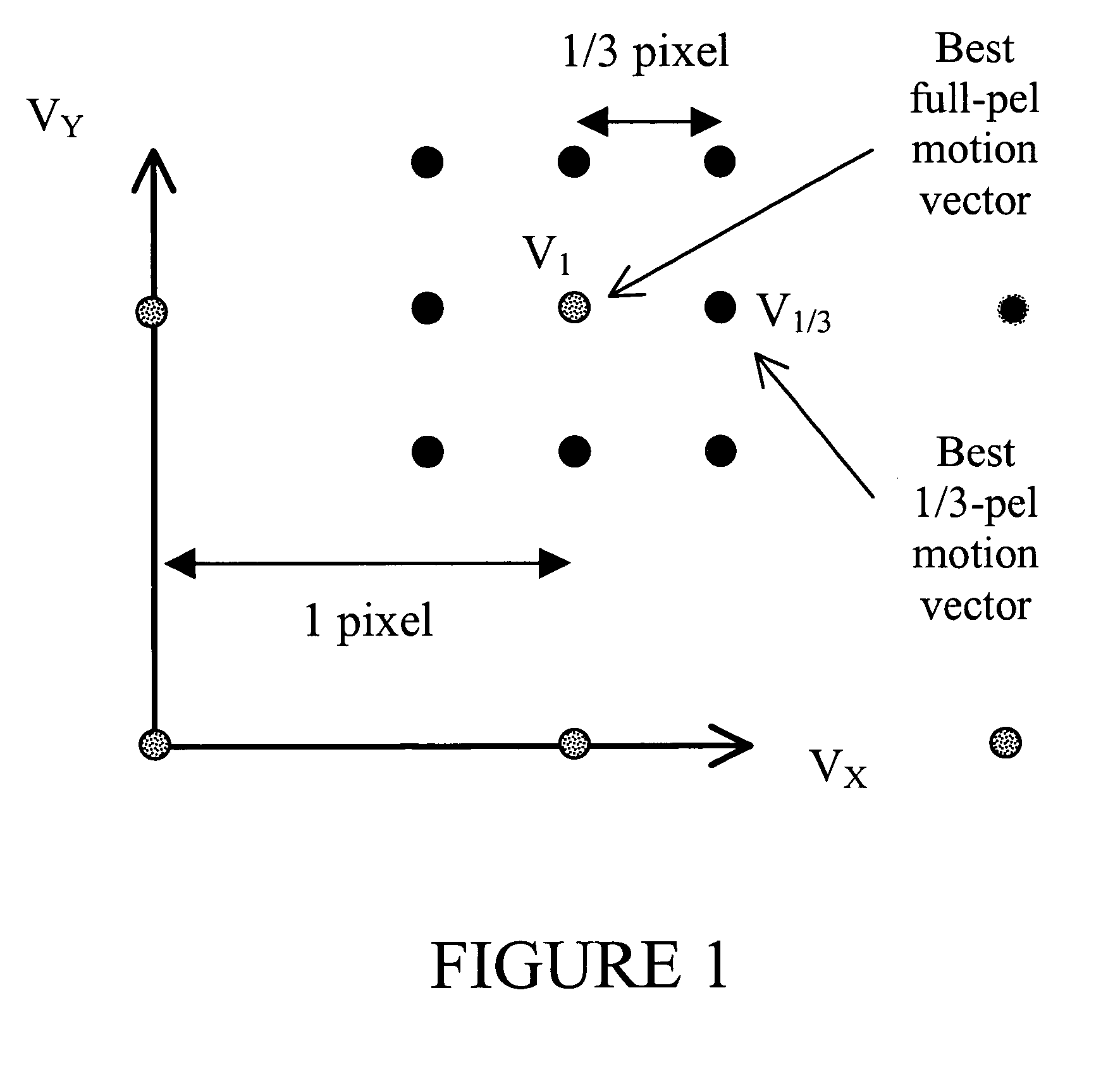

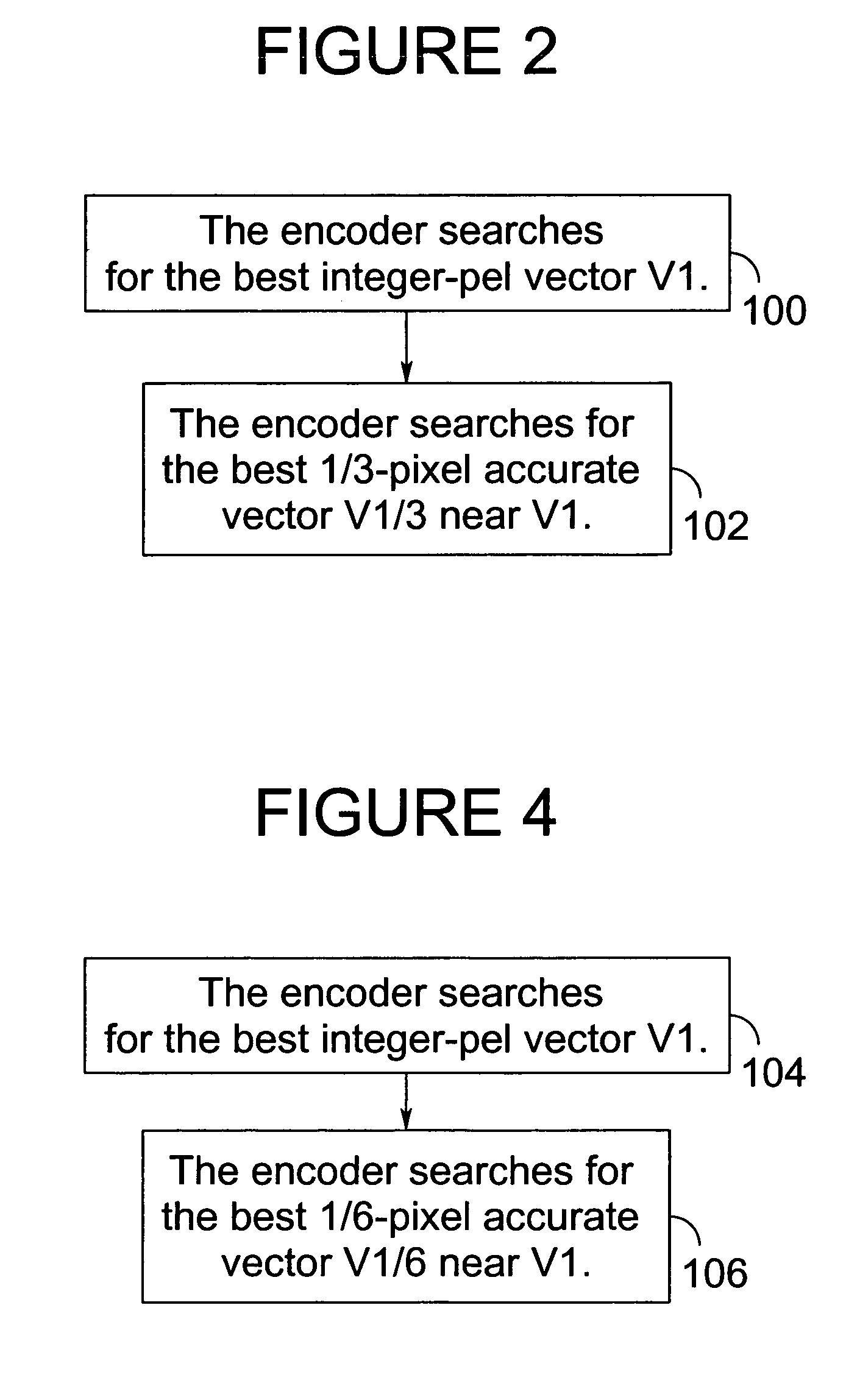

Methods for motion estimation with adaptive motion accuracy

InactiveUS6968008B1Reduce computational complexitySignificant compression gainPicture reproducers using cathode ray tubesCode conversionComputation complexityMotion vector

Methods for motion estimation with adaptive motion accuracy of the present invention include several techniques for computing motion vectors of high pixel accuracy with a minor increase in computation. One technique uses fast-search strategies in sub-pixel space that smartly searches for the best motion vectors. An alternate technique estimates high-accurate motion vectors using different interpolation filters at different stages in order to reduce computational complexity. Yet another technique uses rate-distortion criteria that adapts according to the different motion accuracies to determine both the best motion vectors and the best motion accuracies. Still another technique uses a VLC table that is interpreted differently at different coding units, according to the associated motion vector accuracy.

Owner:SHARP KK

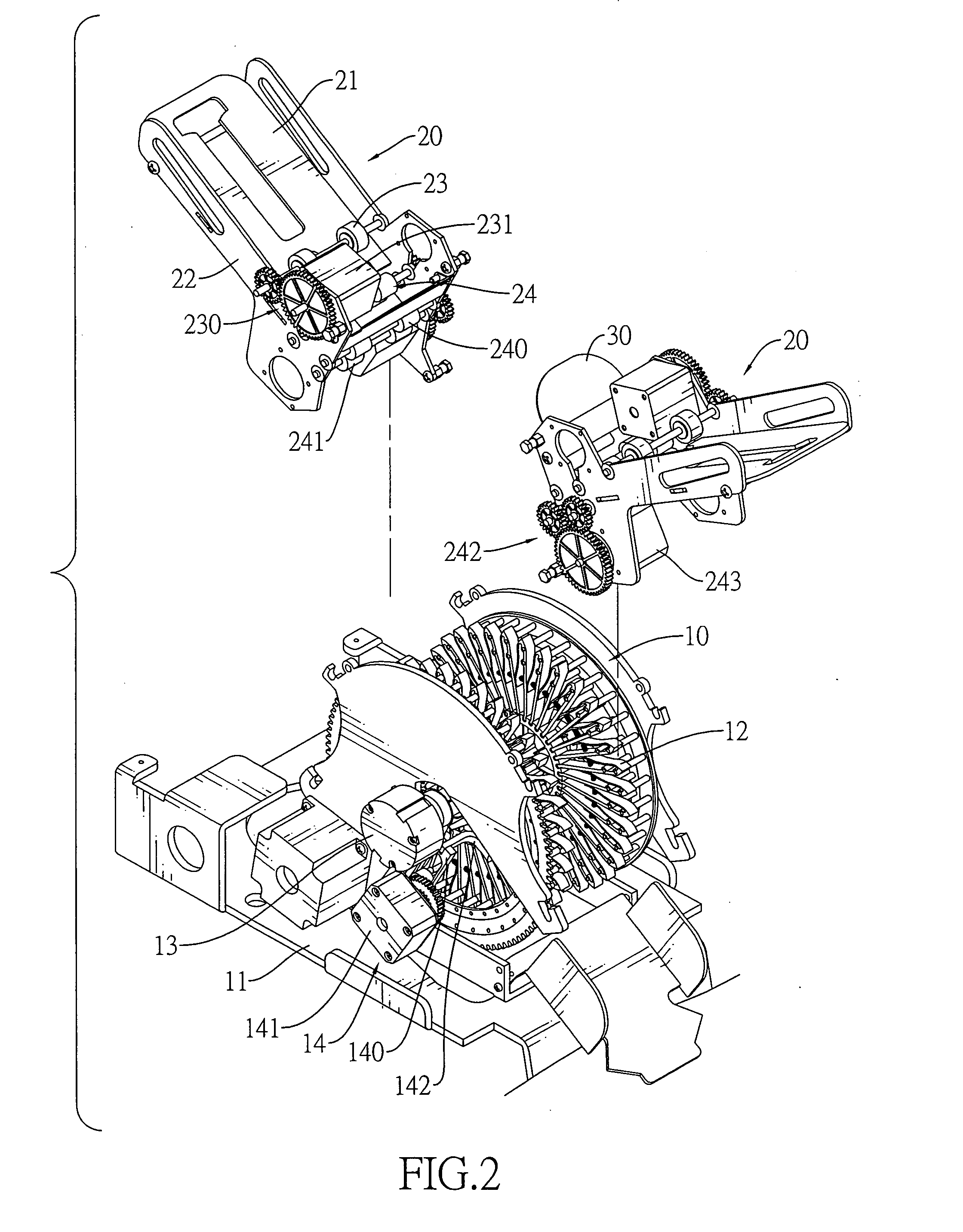

Multiple-inlet shuffling machine

The multiple-inlet shuffling machine has a shuffler and at least two card inputs. The shuffler has a base, a shuffling wheel mounted rotatably on the base and has multiple card slots formed radially around which, and a controller having at least one random number generator (RNG) that generates at least one random number. The card inputs are mounted oppositely on the base of the shuffler adjacent to the shuffling wheel and are controlled by the at least one random number generator (RNG) of the controller to randomly place cards into a same wheel further raising a randomness of the cards. relative to a number of compartments to number of cards ratio. Furthermore, operations are made via gears, so the multiple-inlet shuffling machine has improved precision of movement.

Owner:TAIWAN FULGENT ENTERPRISE

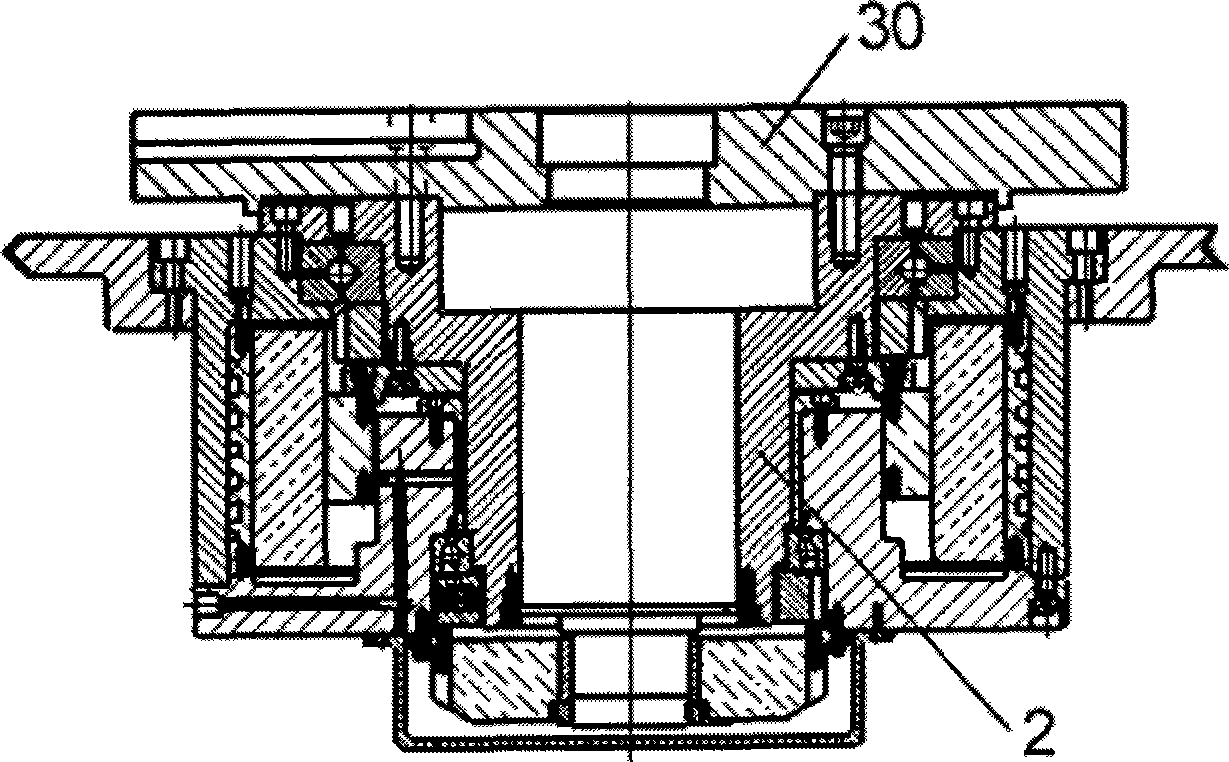

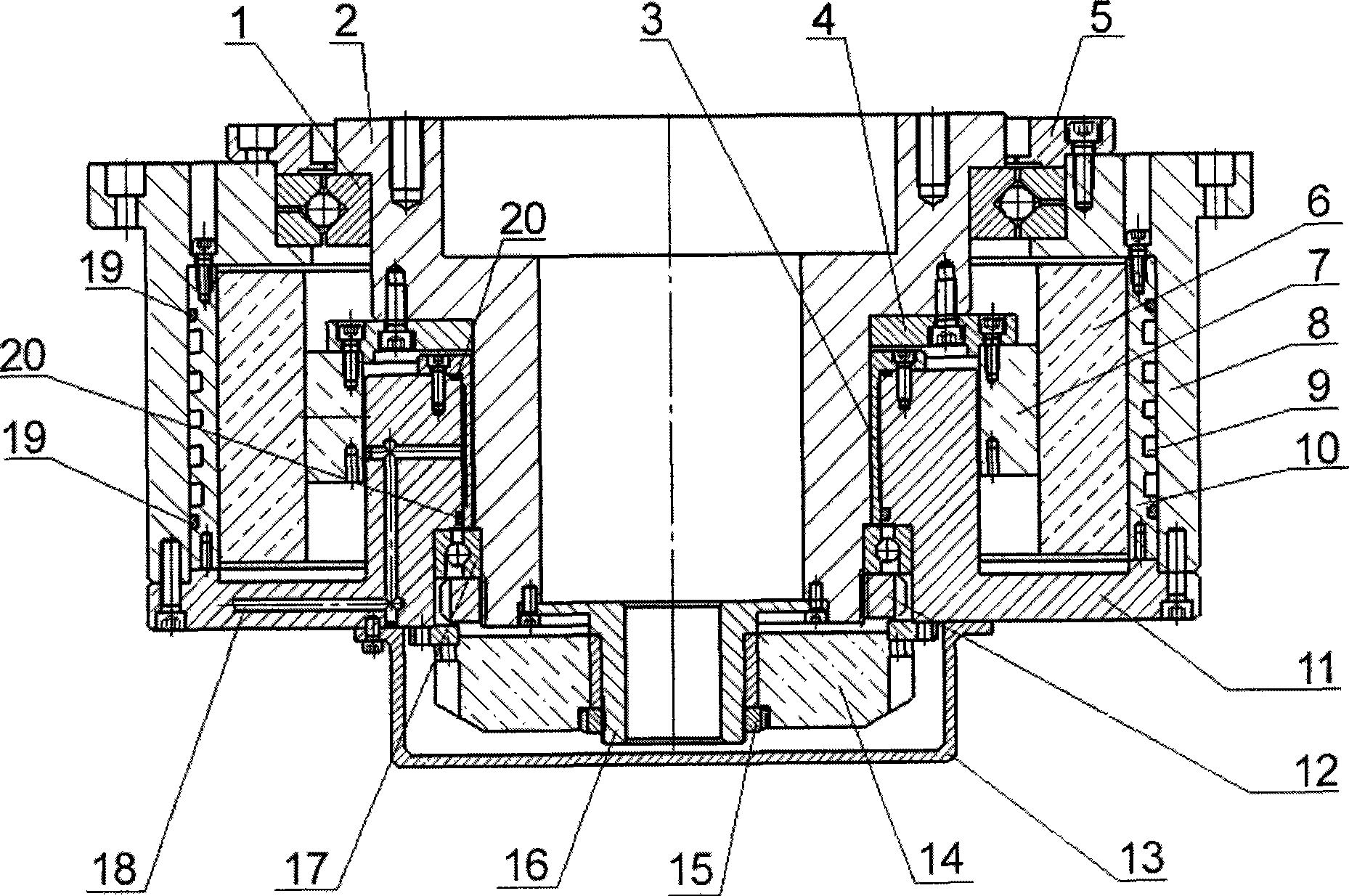

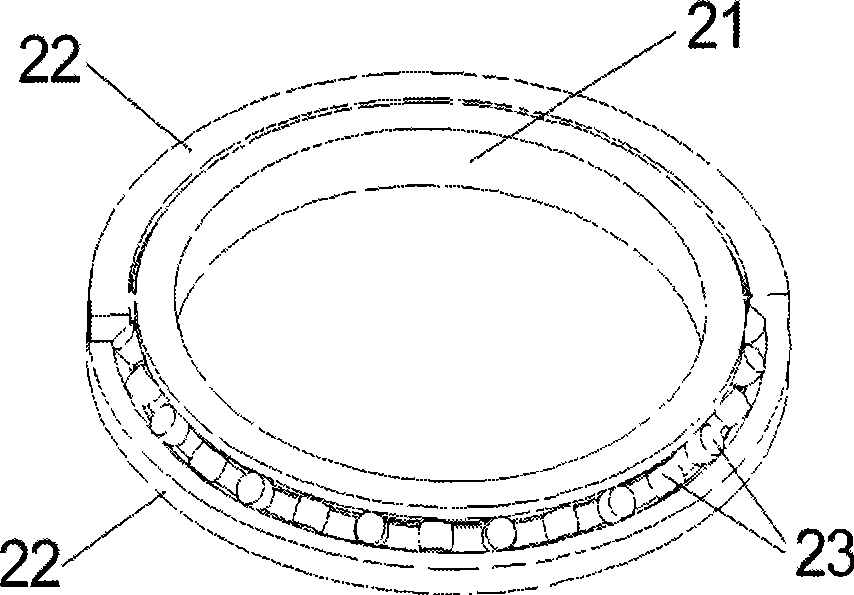

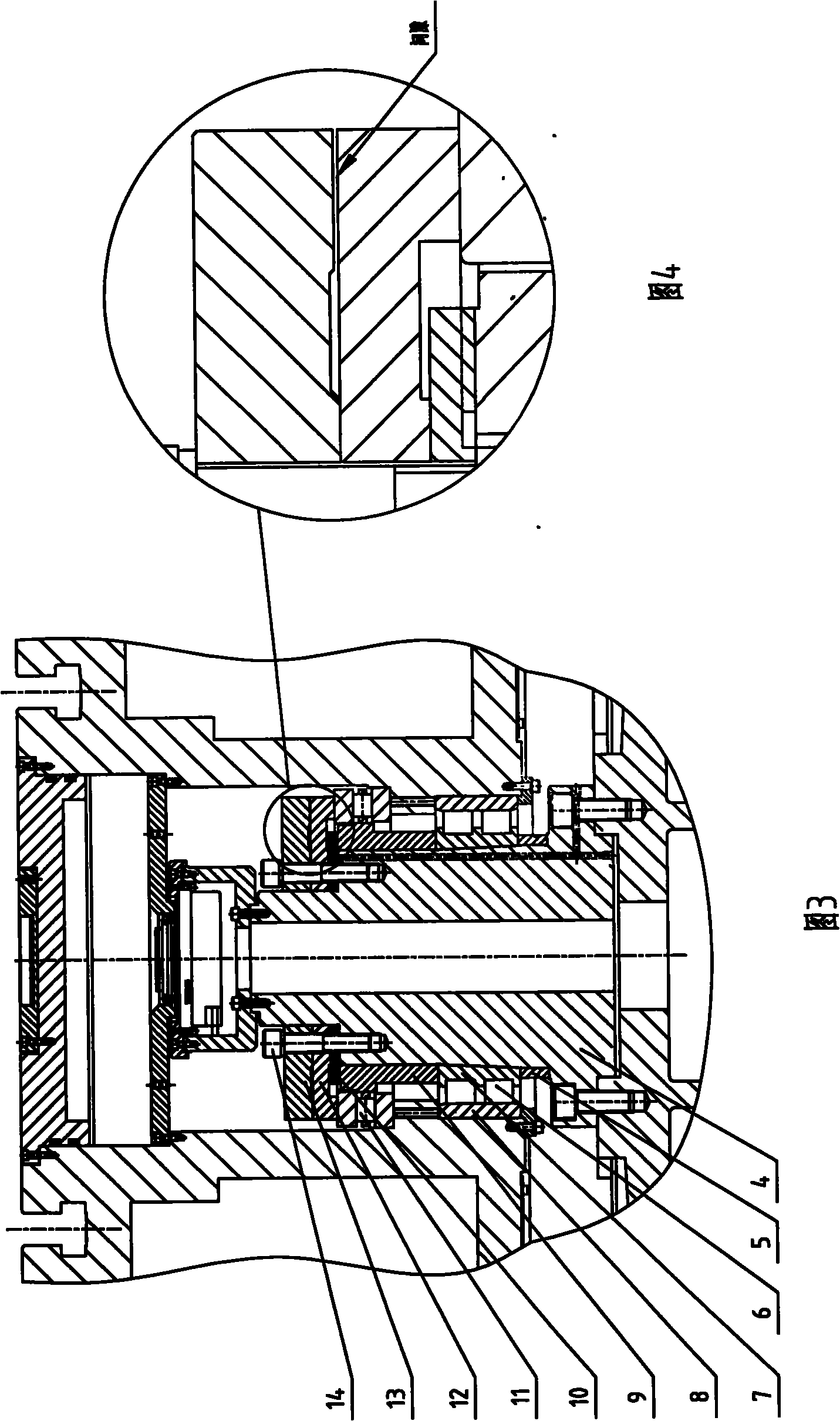

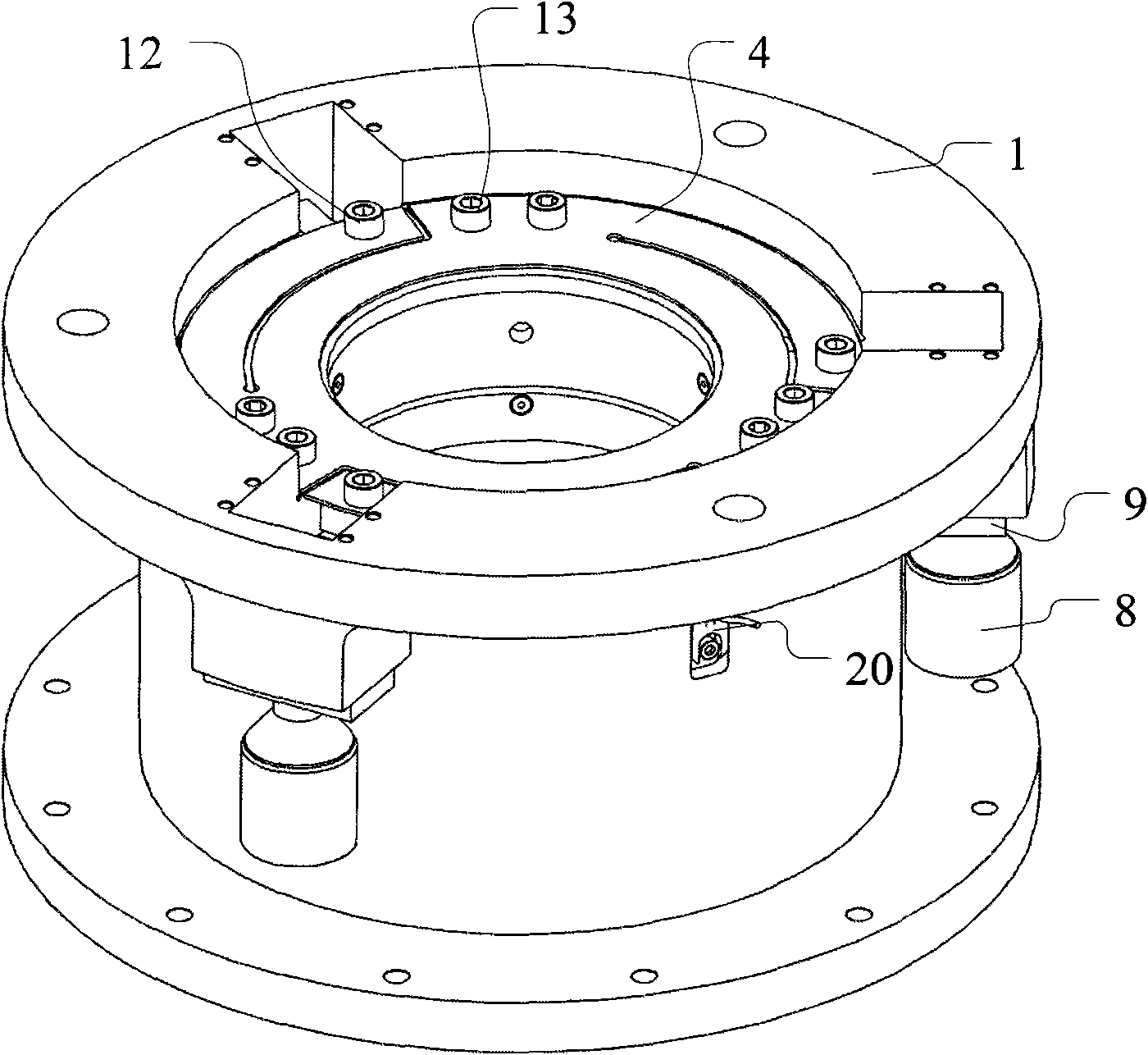

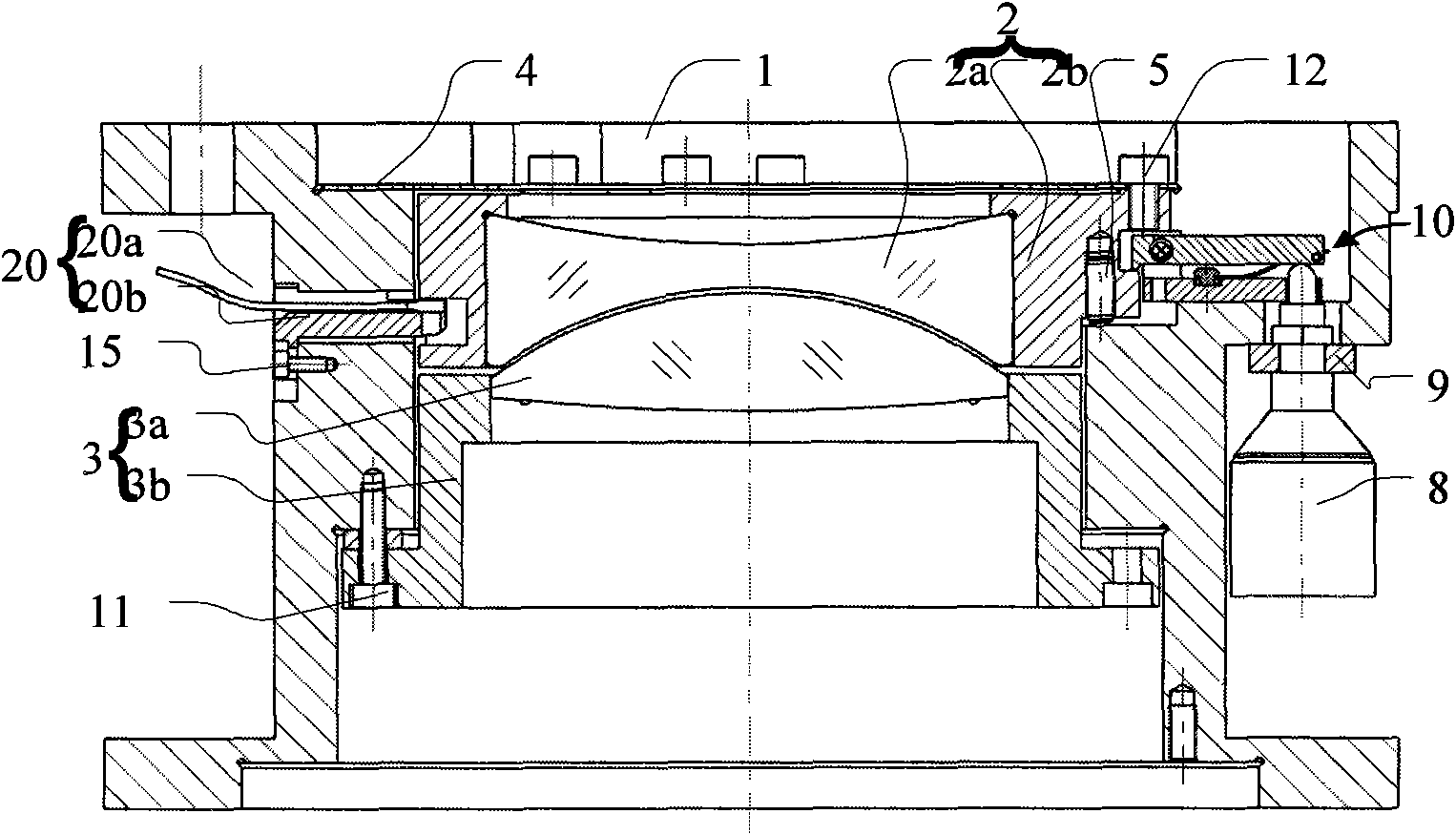

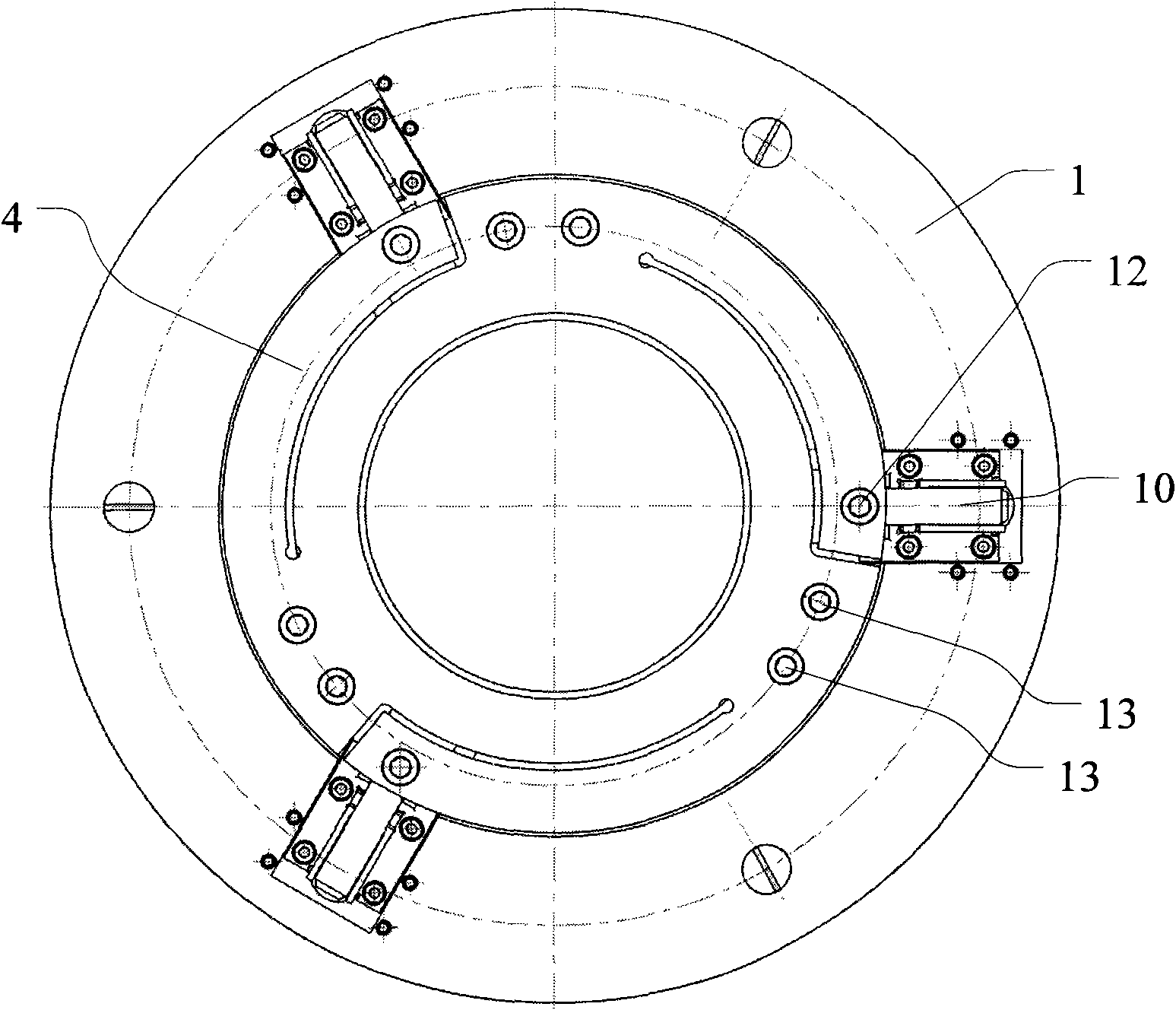

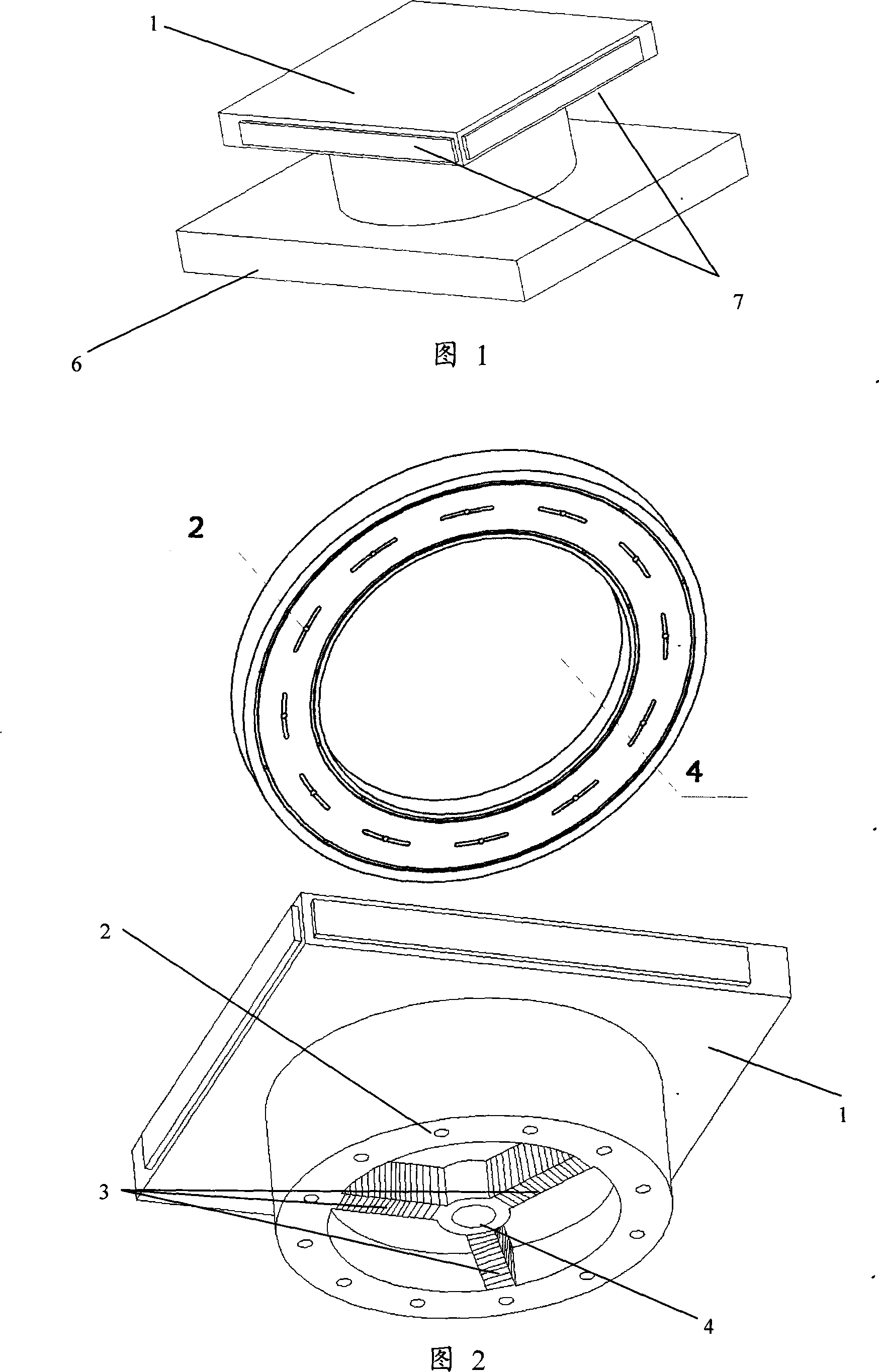

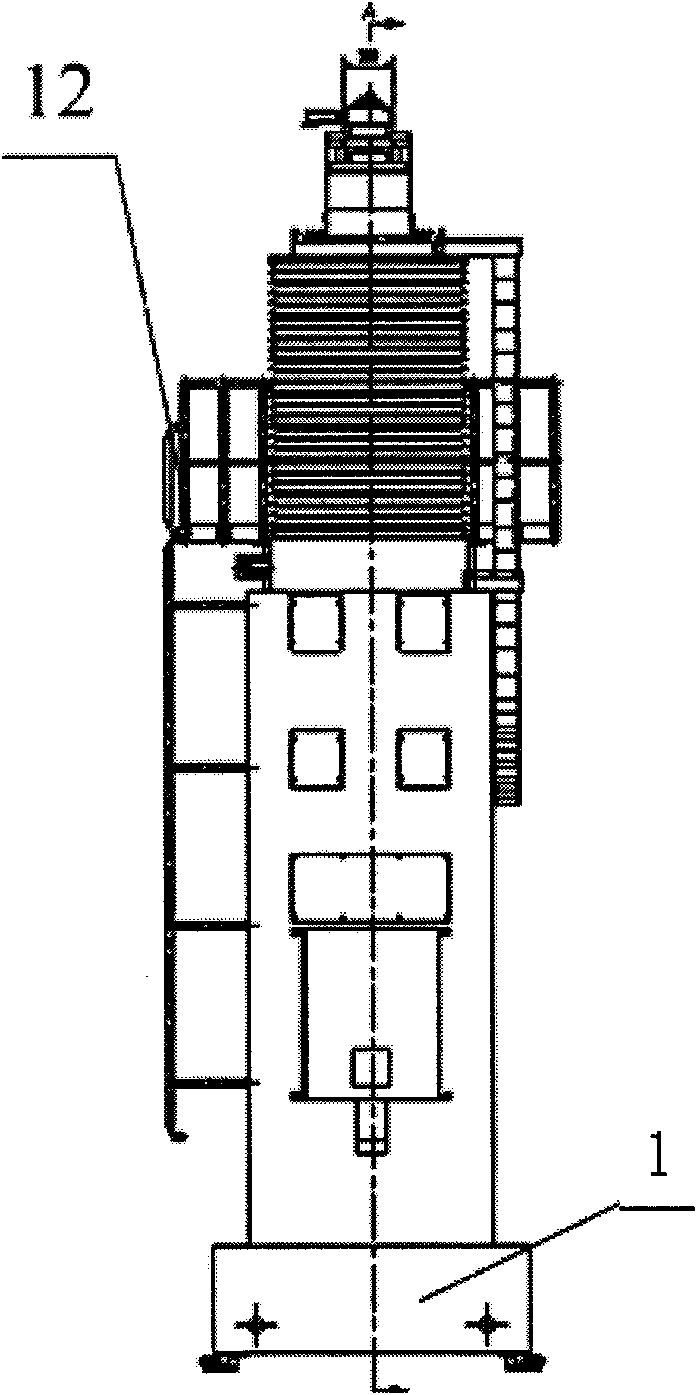

Direct driving type accurate turn plate

InactiveCN101480778ANo wearGood precision continuityRoller bearingsLarge fixed membersTorque motorDigital control

The invention discloses a direct driving type precise rotating table which comprises a working table (30) and a torque motor, wherein the torque motor comprises a motor shell (8), a main shaft (2), a stator (6) and a rotor (7), the motor shell (8) is fixedly connected with the stator (6) to form a static part, the main shaft (2) is fixedly connected with the rotor (7) to form a rotating part, and the working table (30) is directly and fixedly connected with the main shaft (2) of the torque motor. Furthermore, a circular arc crossing roller bearing (1) is arranged between the motor shell (8) and the main shaft (2) and comprises an inner ring (21), two outer rings (22) and a plurality of circular arc rollers (23) arranged among of the inner ring (21) and the outer rings (22), and the circular arc rollers (23) are sequentially crossed in an angle of 90 DEG. The invention has high radial and axial load capacity, good rigidity and high motion precision and stability, and can meet the integrated requirements of serving as a high-precision digital control rotating table.

Owner:三六零安全科技股份有限公司 +2

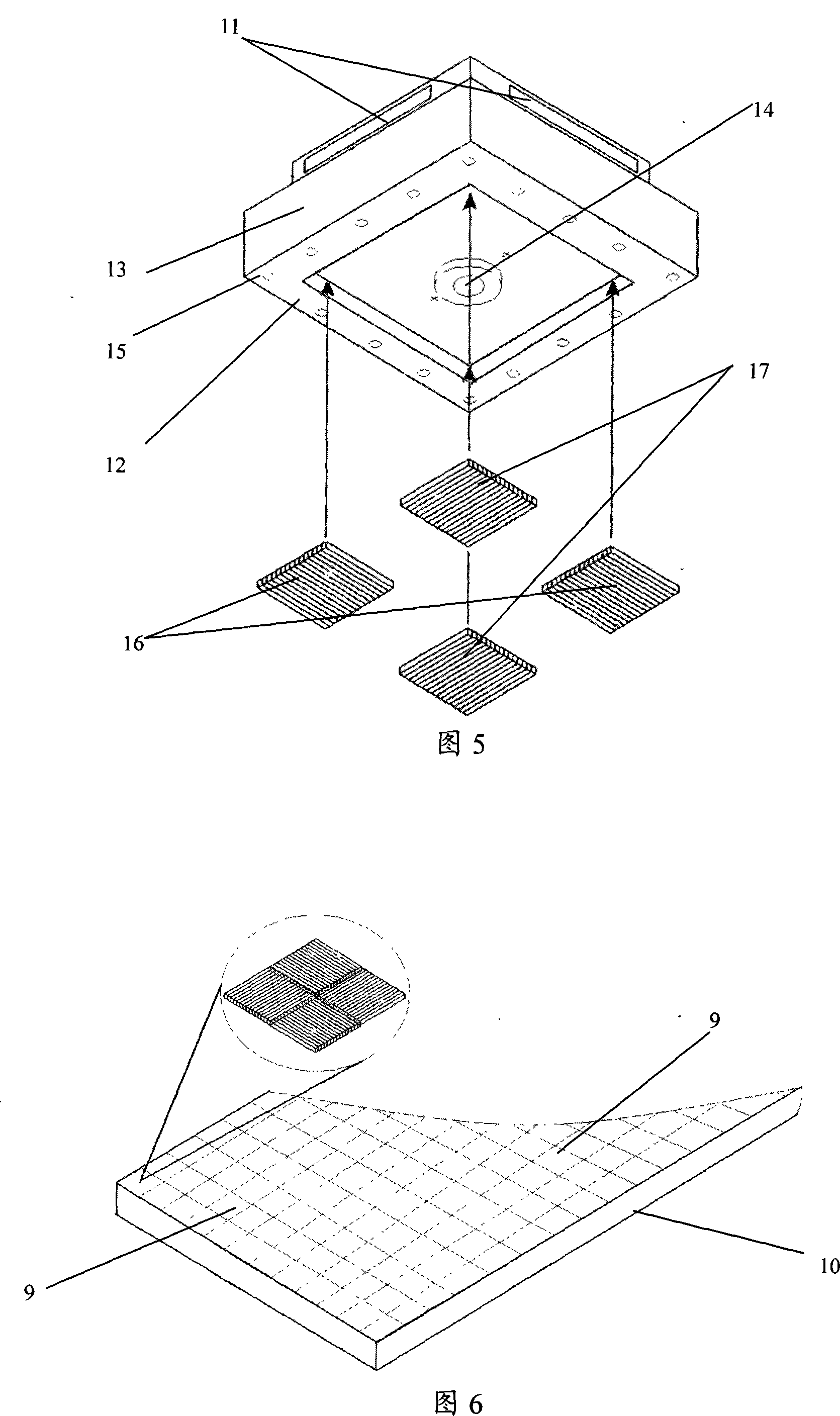

Hydraulic vibration active isolation platform

InactiveCN102141110ASix degrees of freedom of movementQuick responseNon-rotating vibration suppressionStands/trestlesThree degrees of freedomOptical observation

The invention discloses a hydraulic vibration active isolation platform which comprises an upper platform, a lower platform, a two-degree-of-freedom hook joint, a three-degree-of-freedom hook joint and a hydraulic active actuating rod. According to the invention, since the two-degree-of-freedom hook joint and the three-degree-of-freedom hook joint are designed by adopting a pre-tightening anti-backlash technology, the hinge gap is eliminated and the motion accuracy of the hydraulic vibration active isolation platform is much higher. Based on the isolation platform, an active isolation platform with six-degree-of-freedom large-range vibration isolation capability is provided for the application field of vehicle mounted or onboard optical observation and laser aiming and other technologies, so that the disadvantage that the low-frequency large amplitude vibration is hardly isolated by the traditional isolation platform is overcome.

Owner:BEIHANG UNIV

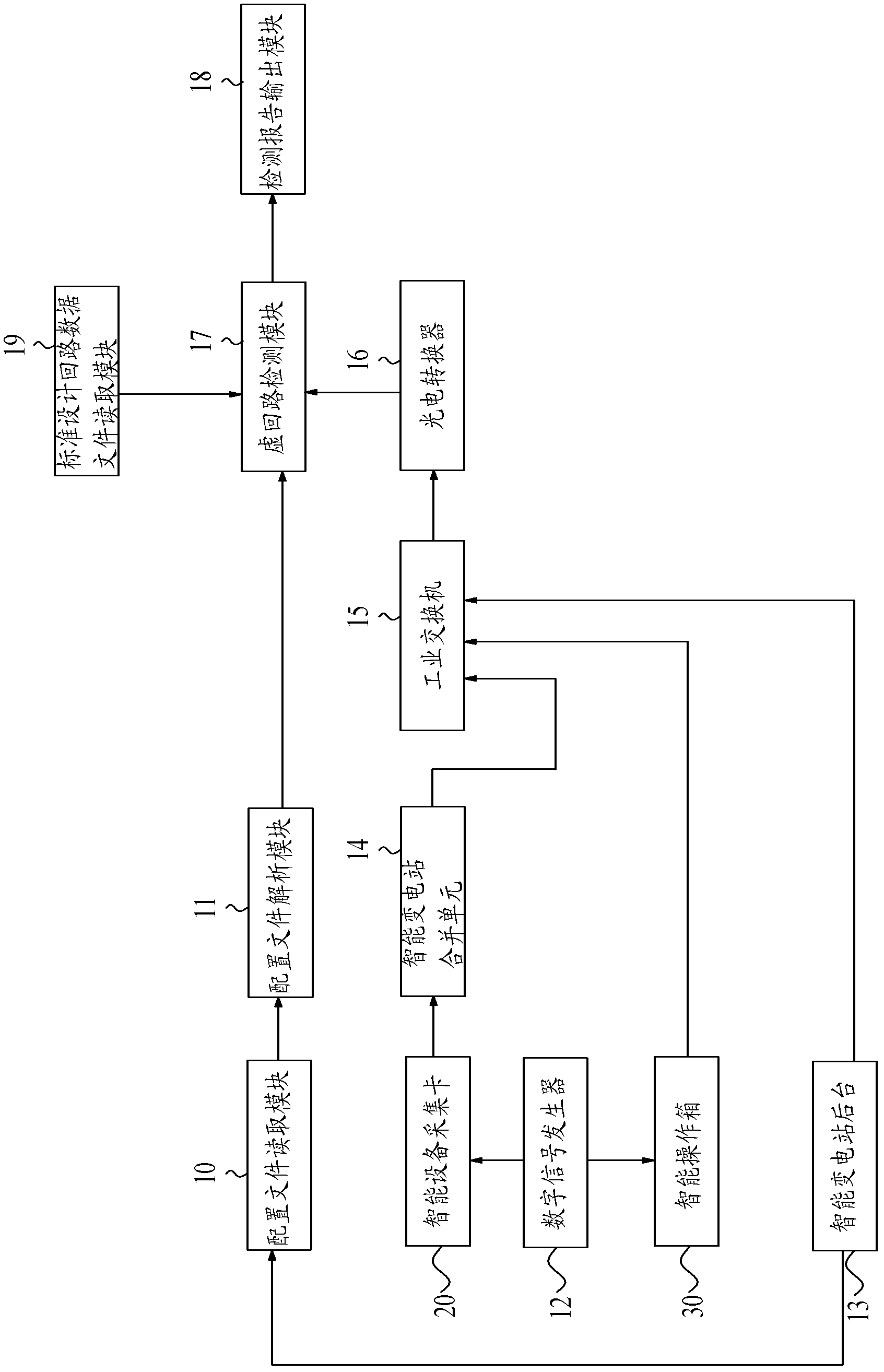

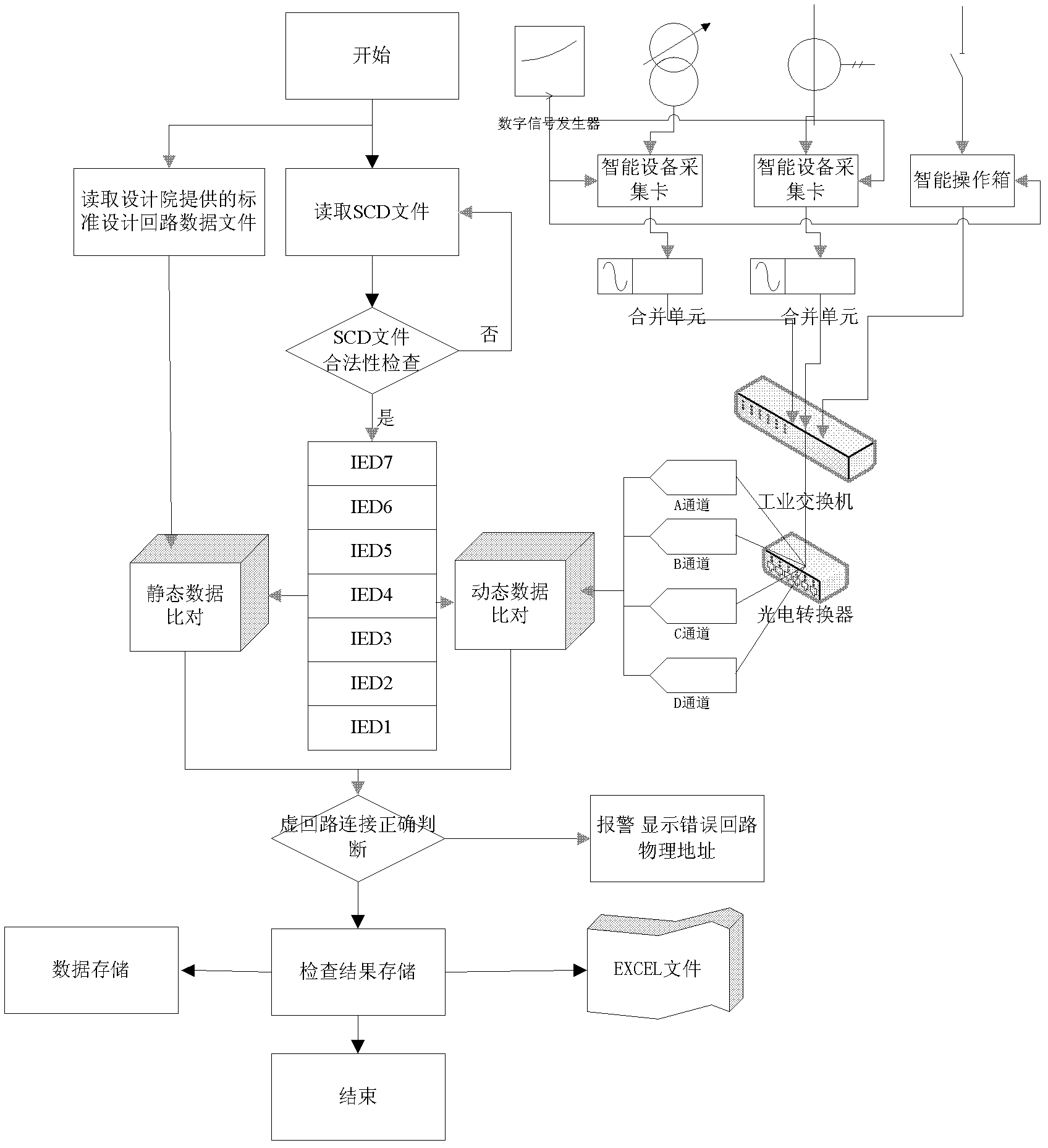

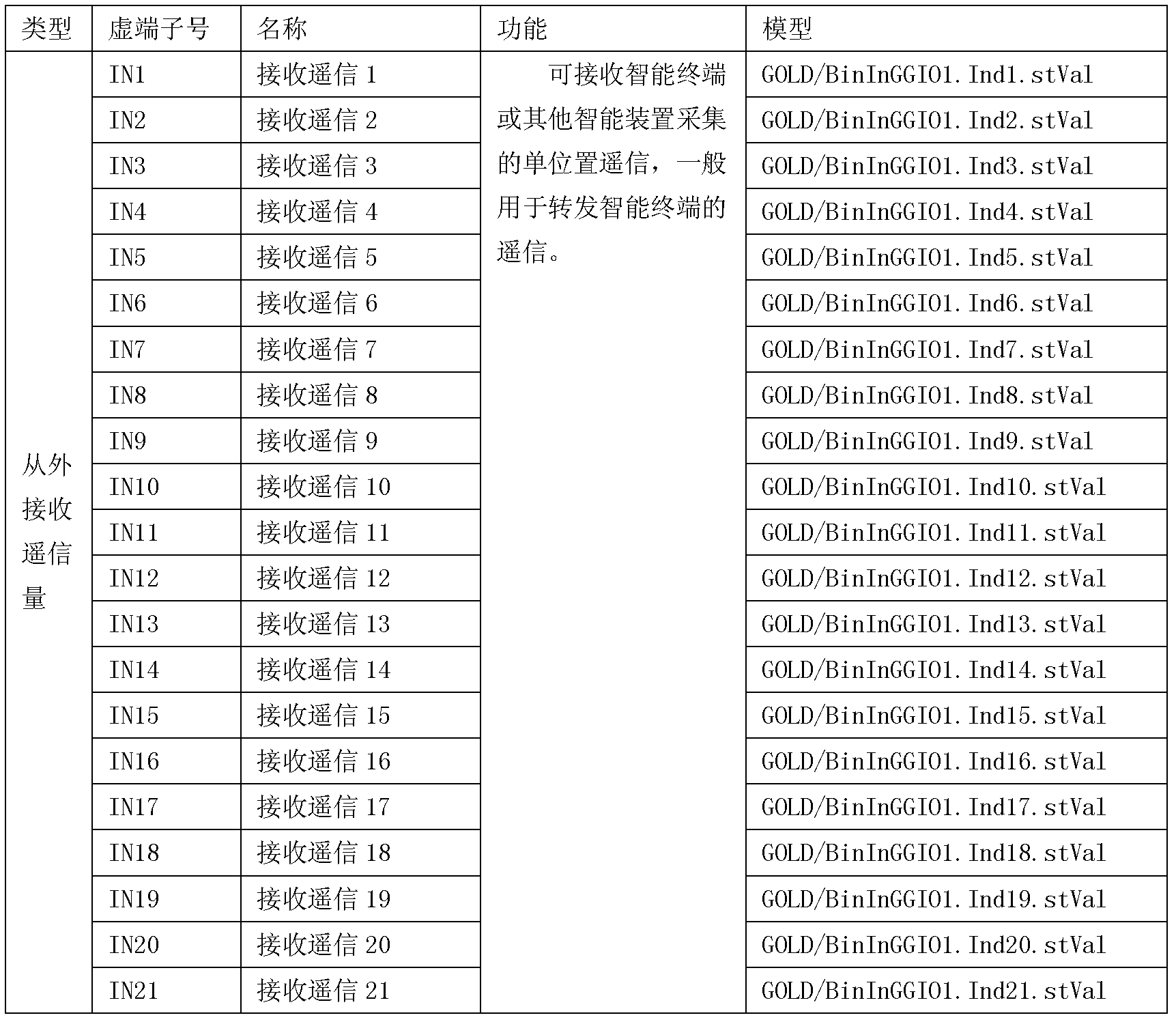

Device and method for detecting secondary virtual loop of intelligent transformer substation

ActiveCN102879662ACheck the connection performance of the secondary circuitGuaranteed accuracyElectrical testingResistors adjusted by auxillary driving meansSmart substationTransformer

The invention discloses a device for detecting a secondary virtual loop of an intelligent transformer substation. The input end of a configuration file reading module is connected with the output end of a background of the intelligent transformer substation; the input end of a configuration file analysis module is connected with the output end of the configuration file reading module; a digital signal generator is respectively connected with an intelligent equipment acquisition card and an intelligent operating box; the output end of the intelligent equipment acquisition card is sequentially connected with an intelligent transformer substation combination unit and an industrial switch; the output end of the intelligent operating box is connected with the industrial switch; the output end of the industrial switch is connected with the input end of a photoelectric converter; and the output end of the photoelectric converter is connected with the input end of a virtual loop detection module. The invention also provides a method for detecting the secondary virtual loop of the intelligent transformer substation. The invention has the advantages that the secondary loop connection performance of the whole transformer substation can be comprehensively detected, the motion accuracy of the secondary equipment of the transformer substation is ensured, technical basis is provided for checking, reforming and improvement of a transformer substation automatic system and the secondary equipment, and the safety production and steady operation of a power grid are facilitated.

Owner:STATE GRID CORP OF CHINA +1

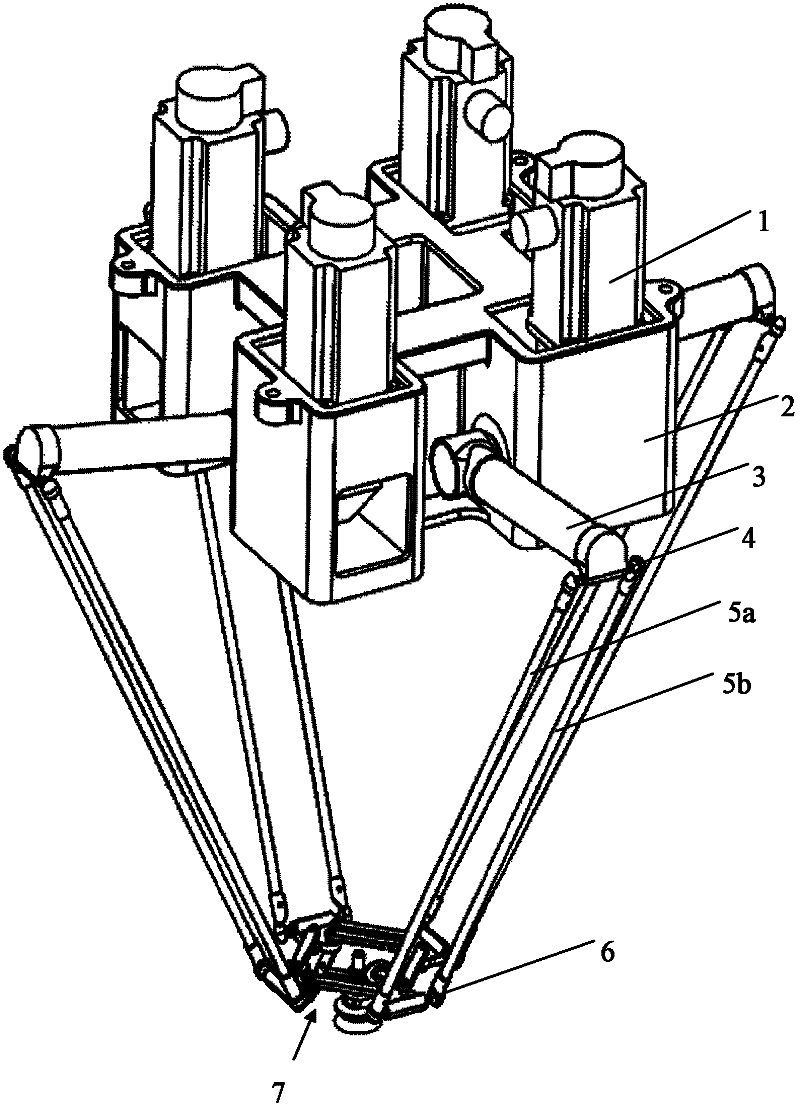

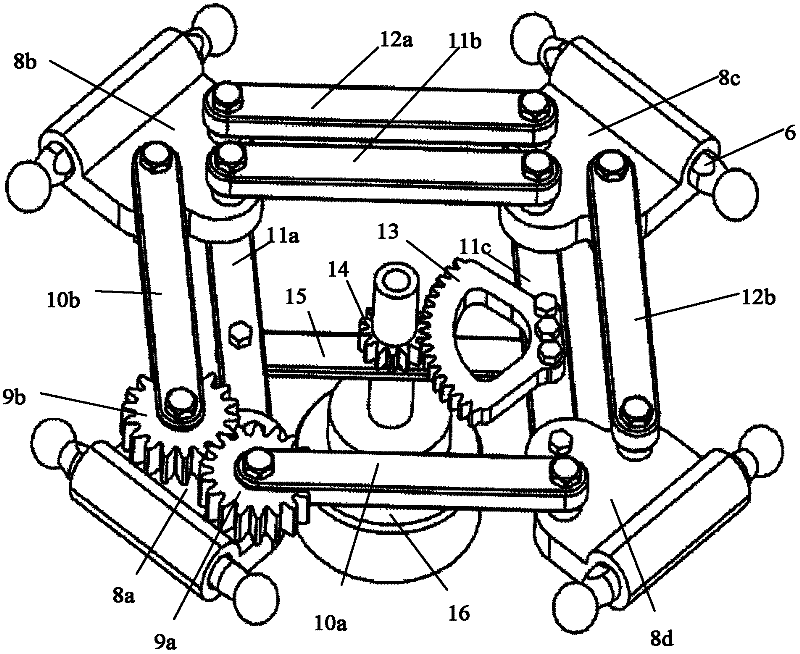

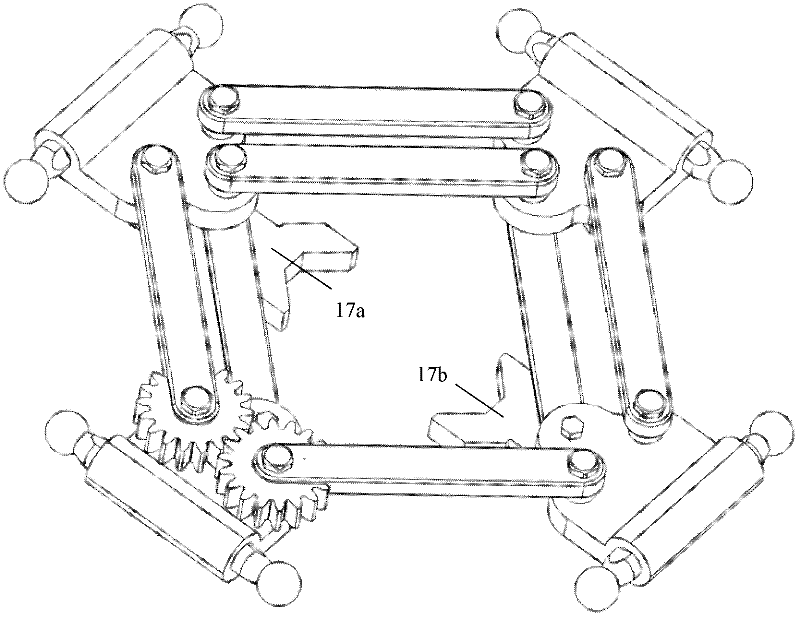

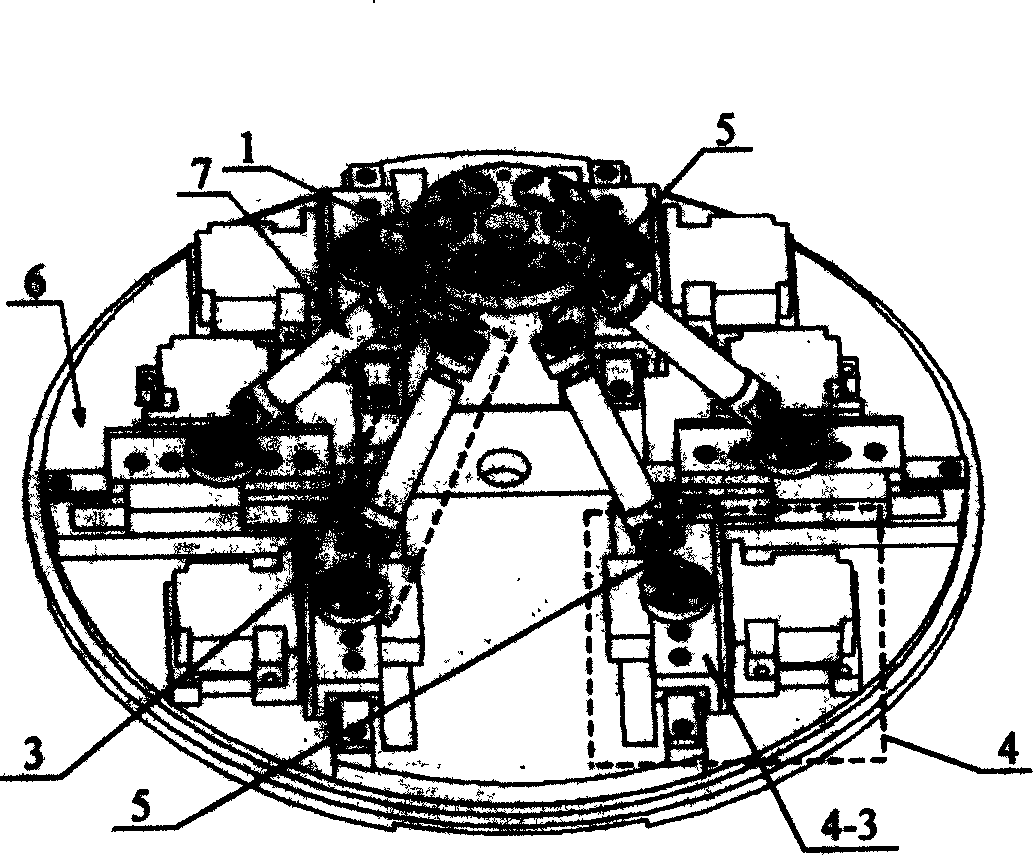

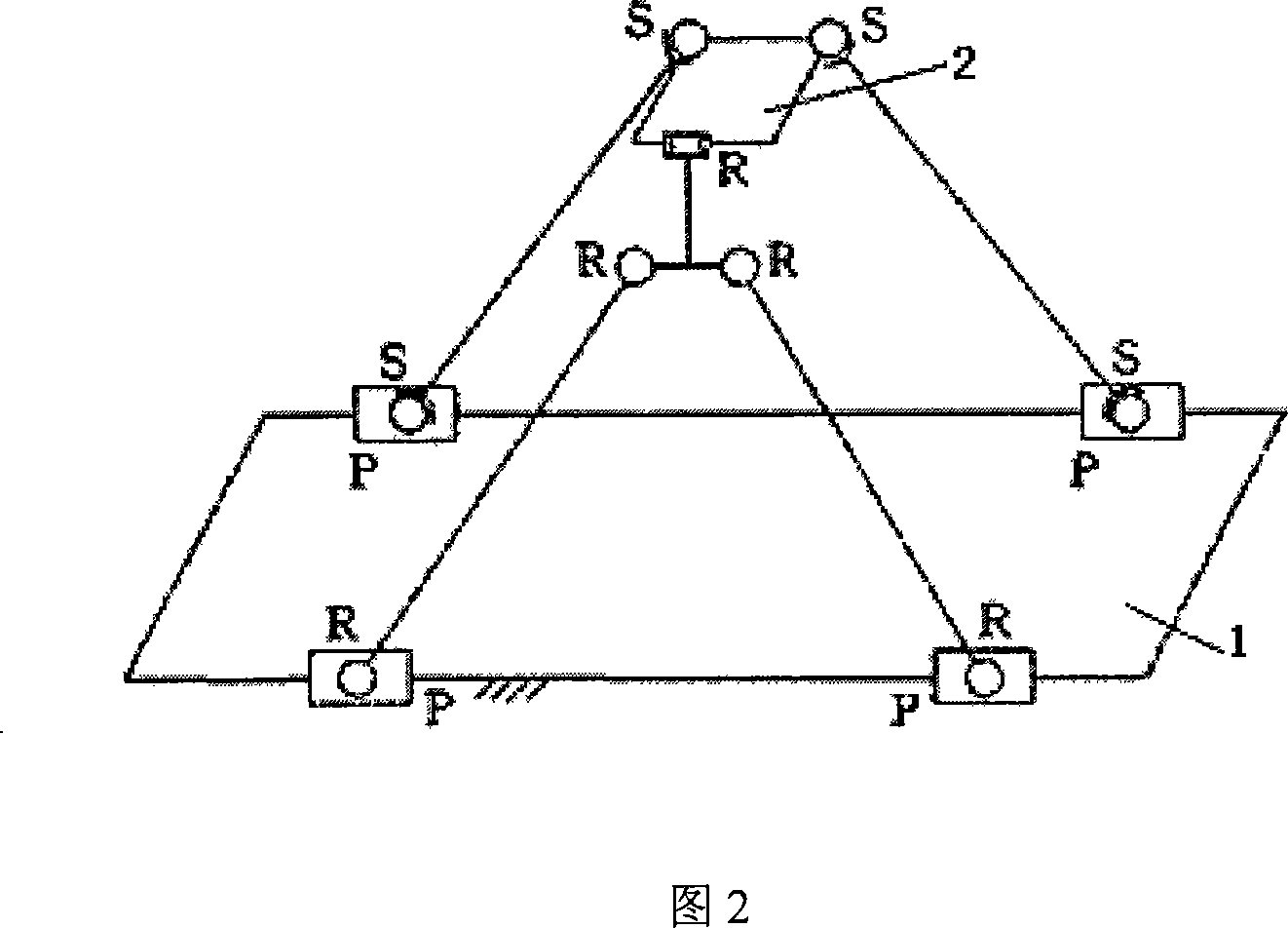

Parallel mechanism capable of realizing four-degree-of-freedom movement

ActiveCN102229141AFlexible structureFlexible movementProgramme-controlled manipulatorDiagonalMagnification

The invention discloses a parallel mechanism capable of realizing four-degree-of-freedom movement. The mechanism is characterized in that a subangle mechanism or the combination of the subangle mechanism and a parallelogram structure is adopted for a moving platform, thus the moving platform is of a rhombus structure, the relative positions of virtual central points of the structure are not changed, and only the deformation movement of relative extension and compression along the diagonal direction can be performed. The mechanism provided by the invention has the advantages of flexible movement, uniform stress, high movement accuracy; the relative movement is converted into rotation movement of an actuator through an angular magnification mechanism, moving pairs are not used in the mechanism, the defects such as nonuniform stress, great friction, short service life and the like are avoided, the integral structure has good rigidity and stability, high-speed movement can be realized easily, and requirements of complex grabbing operations are satisfied; and the mechanism has high reorganization, multiple configurations can be realized, and the clamping and rotation operations can be implemented, thus multiple choices are provided for practical applications.

Owner:WUHU IROBSYS ROBOT CO LTD

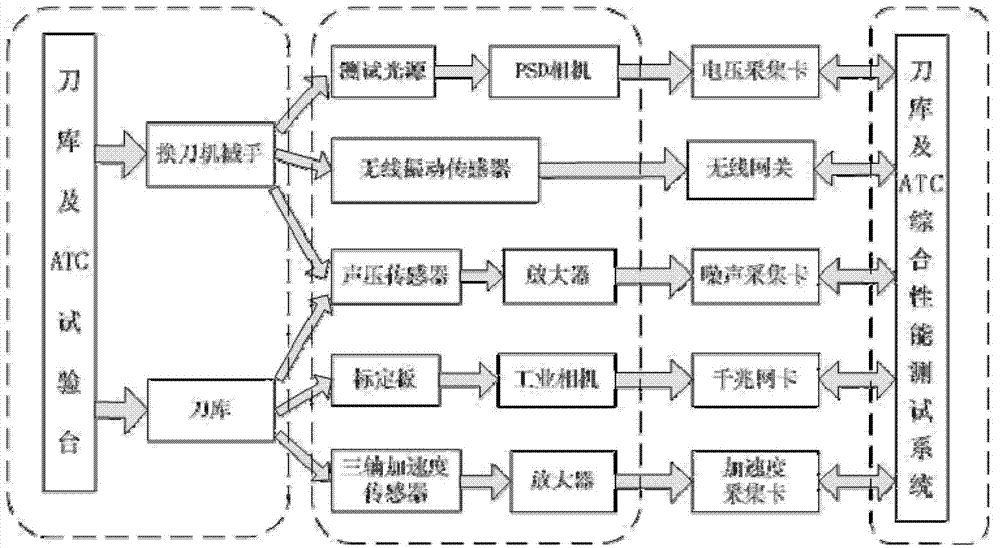

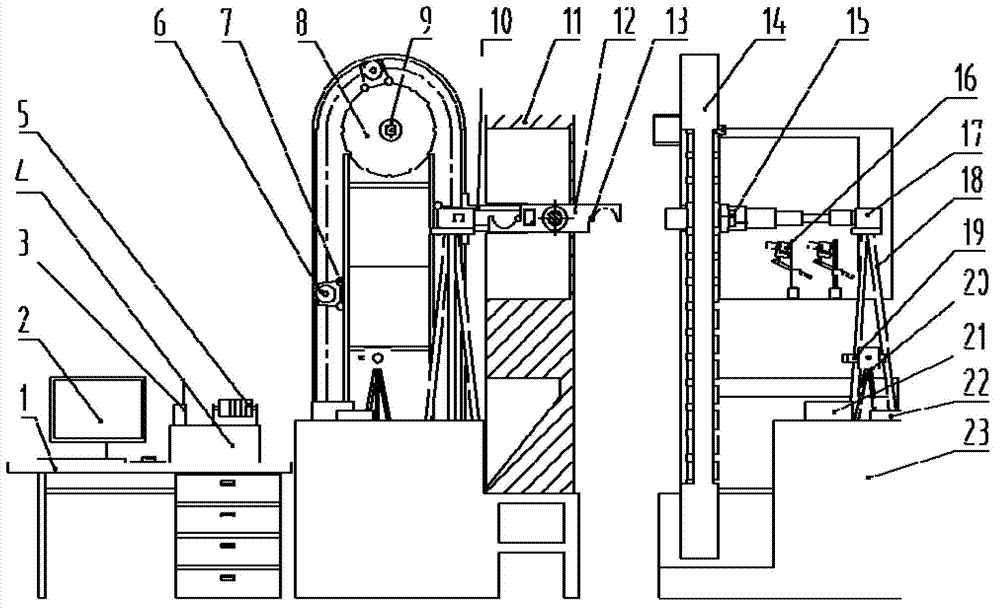

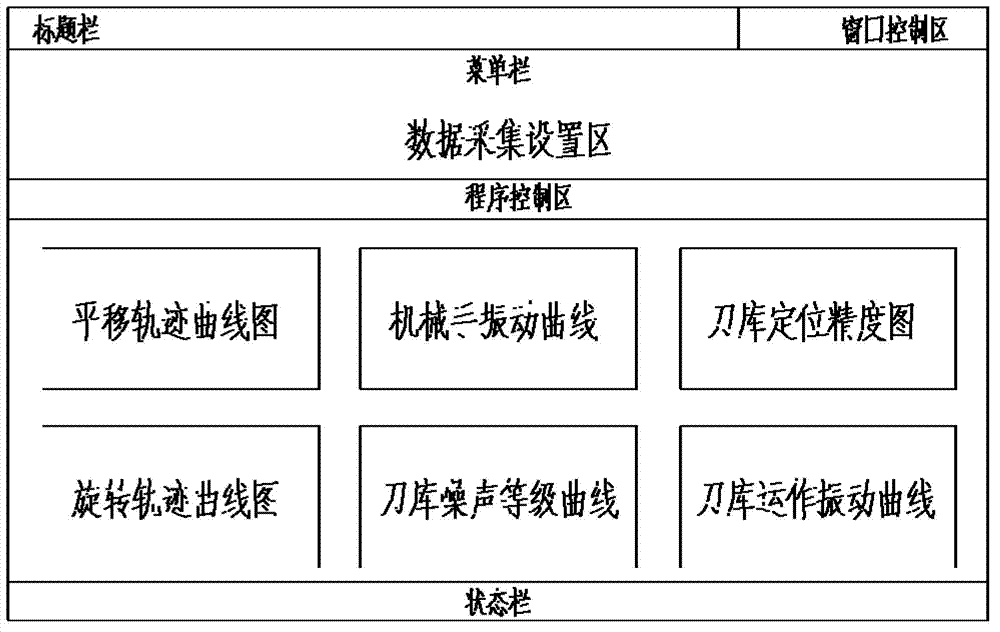

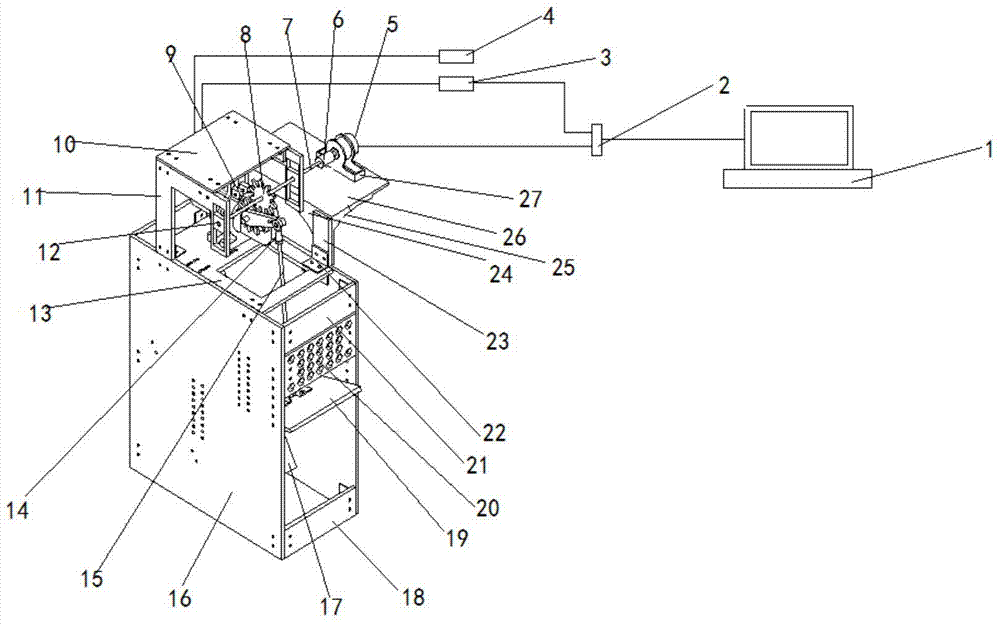

Tool magazine and automatic tool changer comprehensive performance detecting system

ActiveCN102785126AImprove interactivityAvoid windingAutomatic control devicesMeasurement/indication equipmentsRobotic armIntegrated electronics

The invention relates to a tool magazine and automatic tool changer comprehensive performance detecting system, which adopts a three-shaft acceleration sensor, a wireless vibration sensor, an industrial camera, a PSD (position sensory device) camera and a sound pressure sensor as detecting elements for detecting the comprehensive performance of a large-sized tool magazine and an automatic tool changer thereof. An IEPE (integrated electronics piezo electric) analog quantity collection card, a wireless gateway, an image collection card and an analog voltage collection card are adopted as a data collection or a signal transmission device to detect performances of the large-sized tool magazine and the automatic tool changer on the five aspects such as vibration of the tool magazine, vibration of a mechanical arm, positioning error of the tool magazine, the tool changing movement precision of a mechanical hand and the working noise of the entire machine and to transmit collected signals to an industrial personal computer. LabVIEW is adopted as a tool to design processing software special for analyzing and calculating data and for analyzing, operating and storing the acquired experimental data. The tool magazine and automatic tool changer comprehensive performance detecting system has the advantages of strong portability, wide measurement range, high measurement precision, low requirement on the professional technical level of an operator and the like and has strong practical application value.

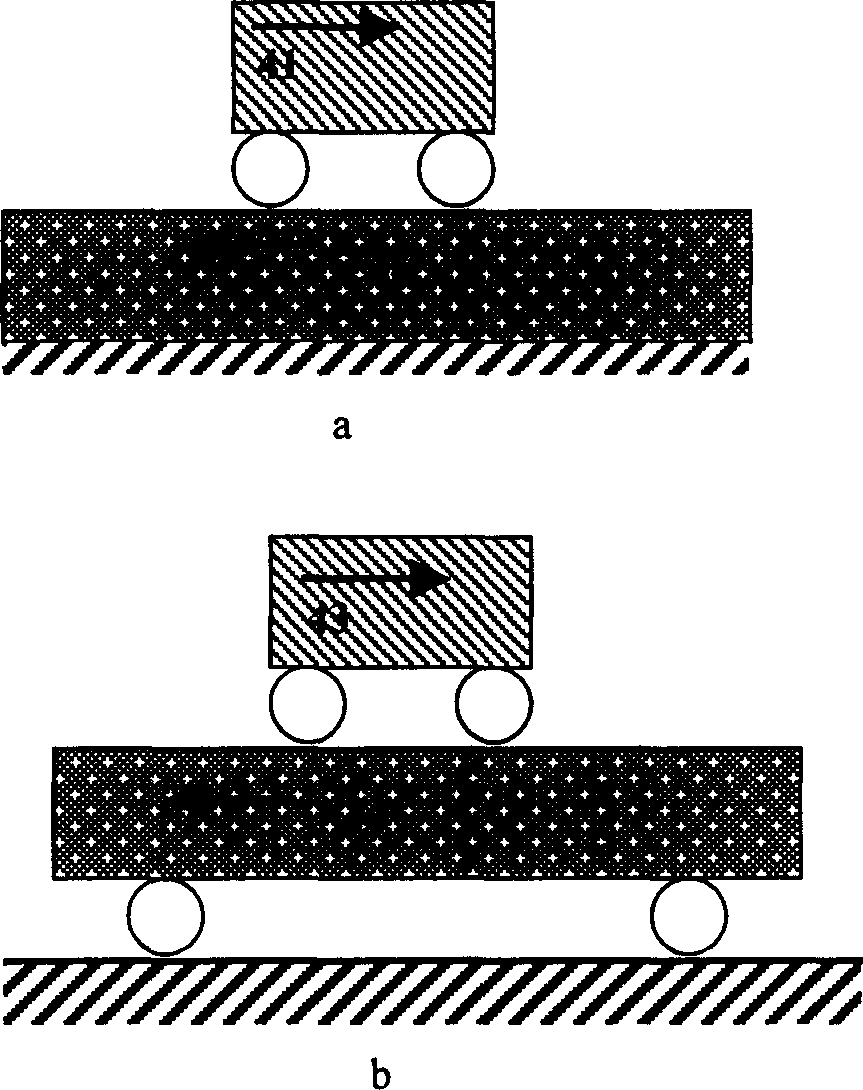

Ultra-precise silicon wafer positioning system with balance weight damping apparatus

ActiveCN1595299ALimited rotational freedomReduce positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusMomentumThree degrees of freedom

It is ultra-fine silicon pad position system with balance damping apparatus, which uses conservation of momentum principle and put the silicon pad supporting apparatus and its guide apparatus on a balance block with X, Y freedom degree supported by a float axis. When the silicon supporting apparatus moves along one direction, the balance block moves oppositely and eliminates the vibration caused by move reaction. The system also has a momentum wheel system used to eliminate the vibration caused by the momentum distance non-conservation in the moving surface of the silicon pad supporting apparatus. The whole system is supported by three air elastic spring and absorbs the remaining vibration of rest three freedom degrees and further improves the moving accuracy of the silicon pad position system.

Owner:TSINGHUA UNIV +1

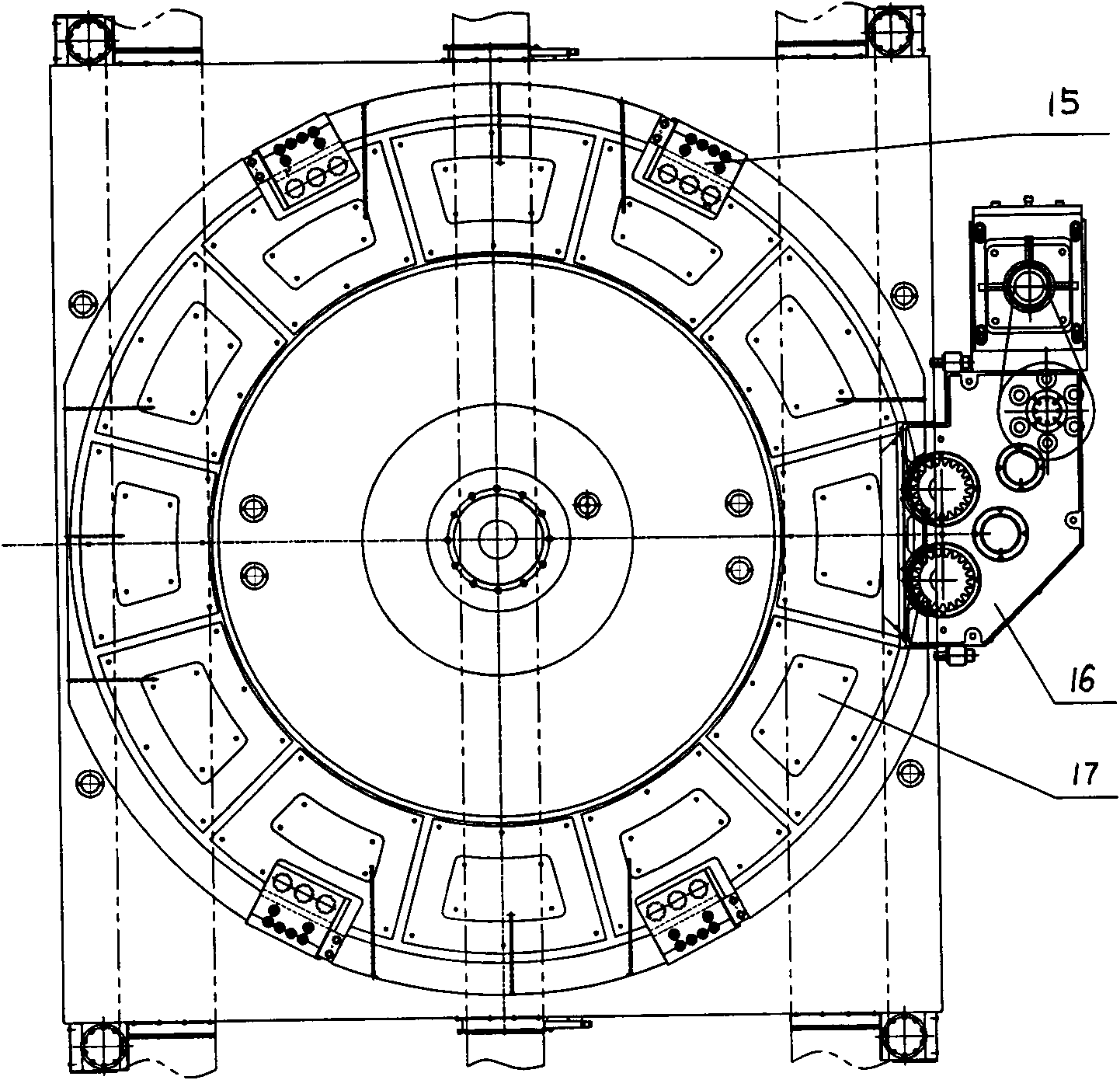

Open-type static pressure rotating table for controlling floating degree and manufacturing method thereof

ActiveCN102039527AImprove motion smoothnessHigh movement precisionLarge fixed membersBearingsThrust bearingHydrostatic pressure

The invention relates to an open-type static pressure rotating table for controlling floating degree and a manufacturing method thereof. The open-type static pressure rotating table is characterized in that: a column on the lower part of a rotary table body and the inner hole of a large gear ring forms clearance fit by a coaxial basic hole system; the large gear ring and the table are arranged ona slide carriage, and the bottom surface of the large gear ring with high planeness and roughness and a static pressure oil chamber on the upper surface of the slide carriage form a hydrostatic pressure guide rail pair; an additional axial thrust bearing structure arranged on a centering structure provides preloads for hydrostatic pressure guide rails of the table; and the bottom surface of the large gear ring is assembled and ground correctly according to design requirements till plane precision, and the upper surface of the static pressure oil chamber on the slide carriage is scraped by facing-up simultaneously to ensure the fit accuracy of the upper and lower hydrostatic pressure guide rails. In the open-type static pressure rotating table, the thrust bearing structure is adopted on the basis of a common centering shaft structure, so the initial preloads of the hydrostatic pressure guide rail pair are controlled effectively and the floating degree of the open-type static pressure rotary table is controlled effectively, the rigidity of an oil film is increased, and the motion stability, motion accuracy and unbalance load-resistant capacity of the open-type static pressure rotarytable are improved.

Owner:沈阳机床中捷友谊厂有限公司

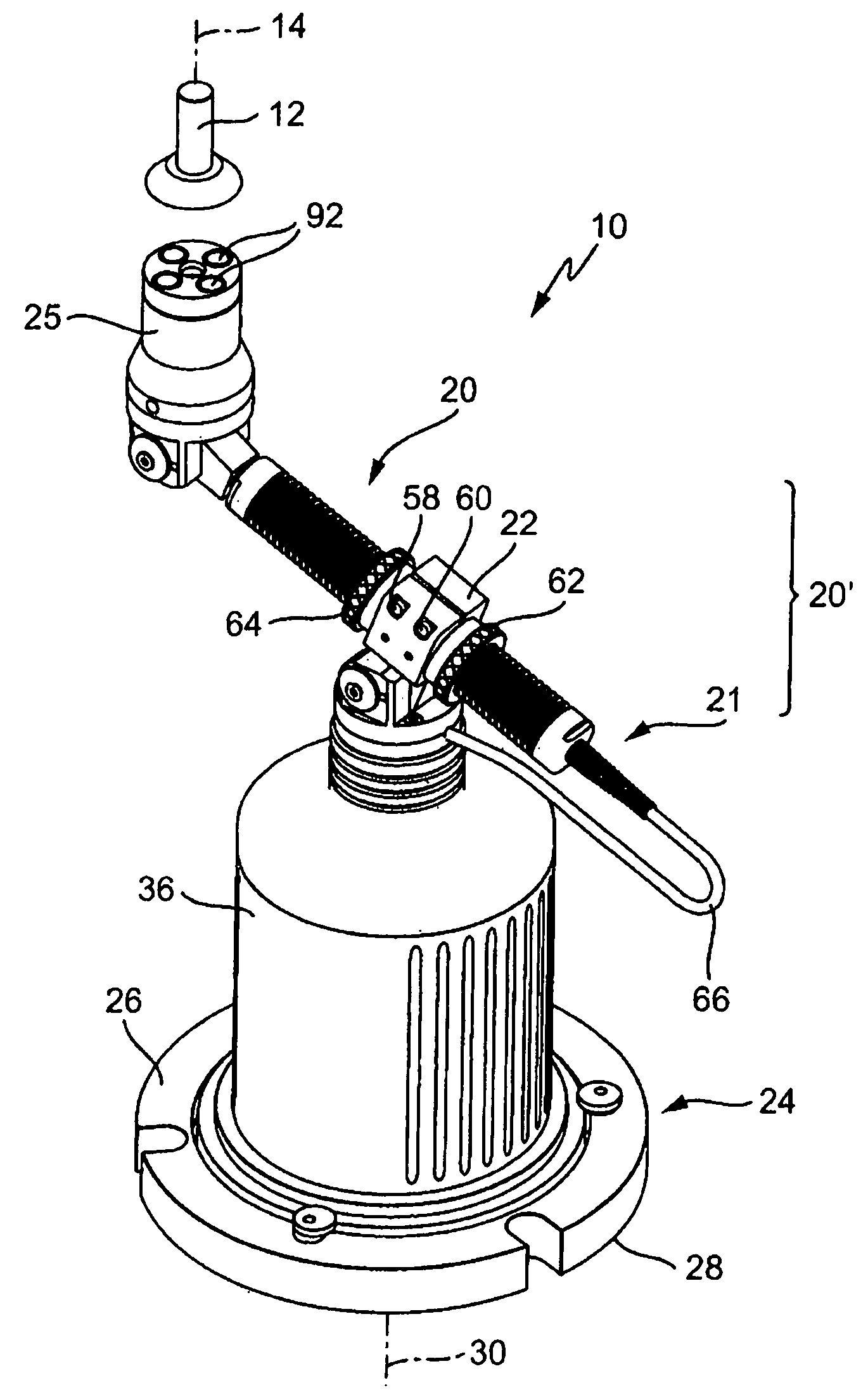

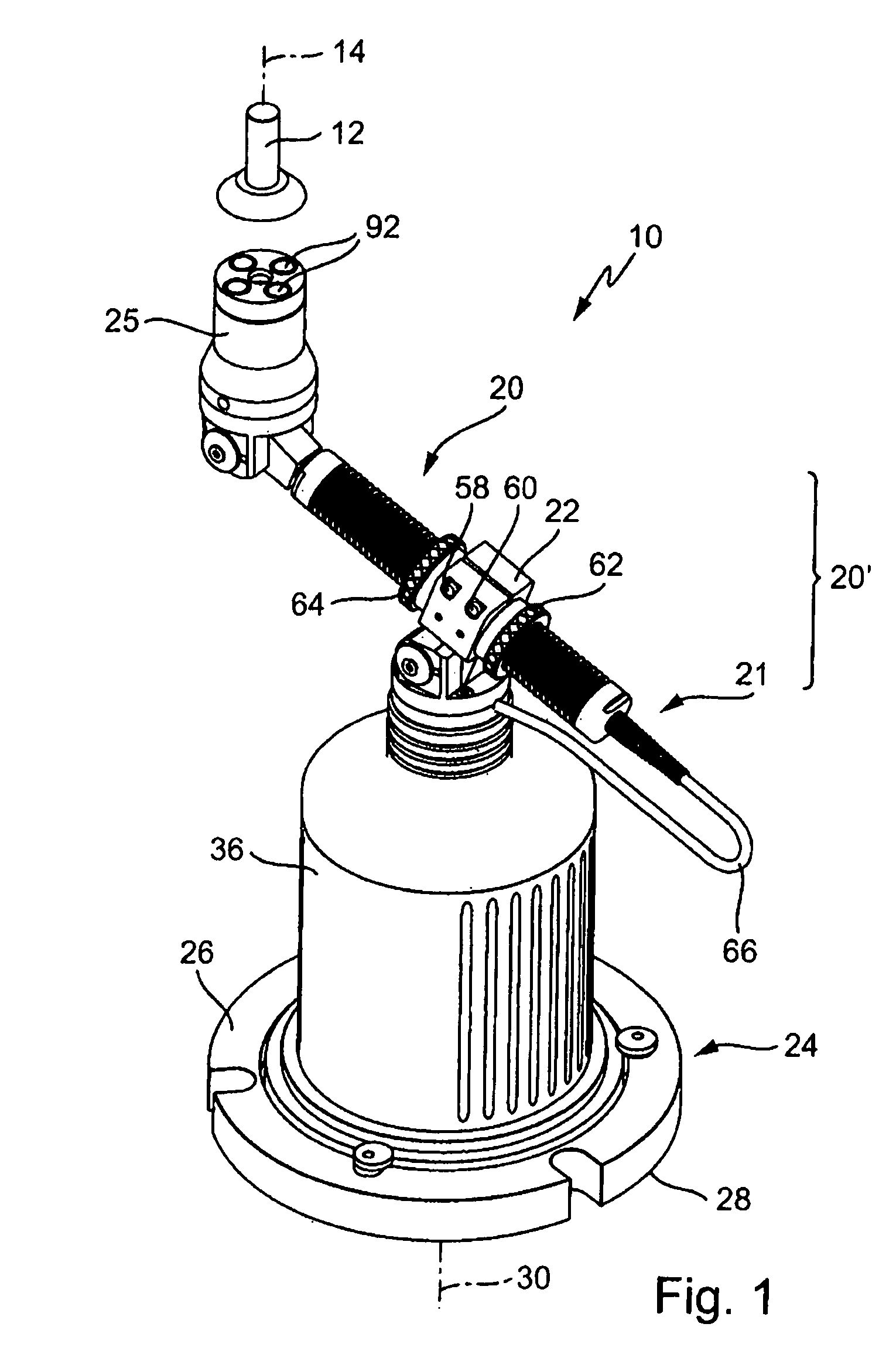

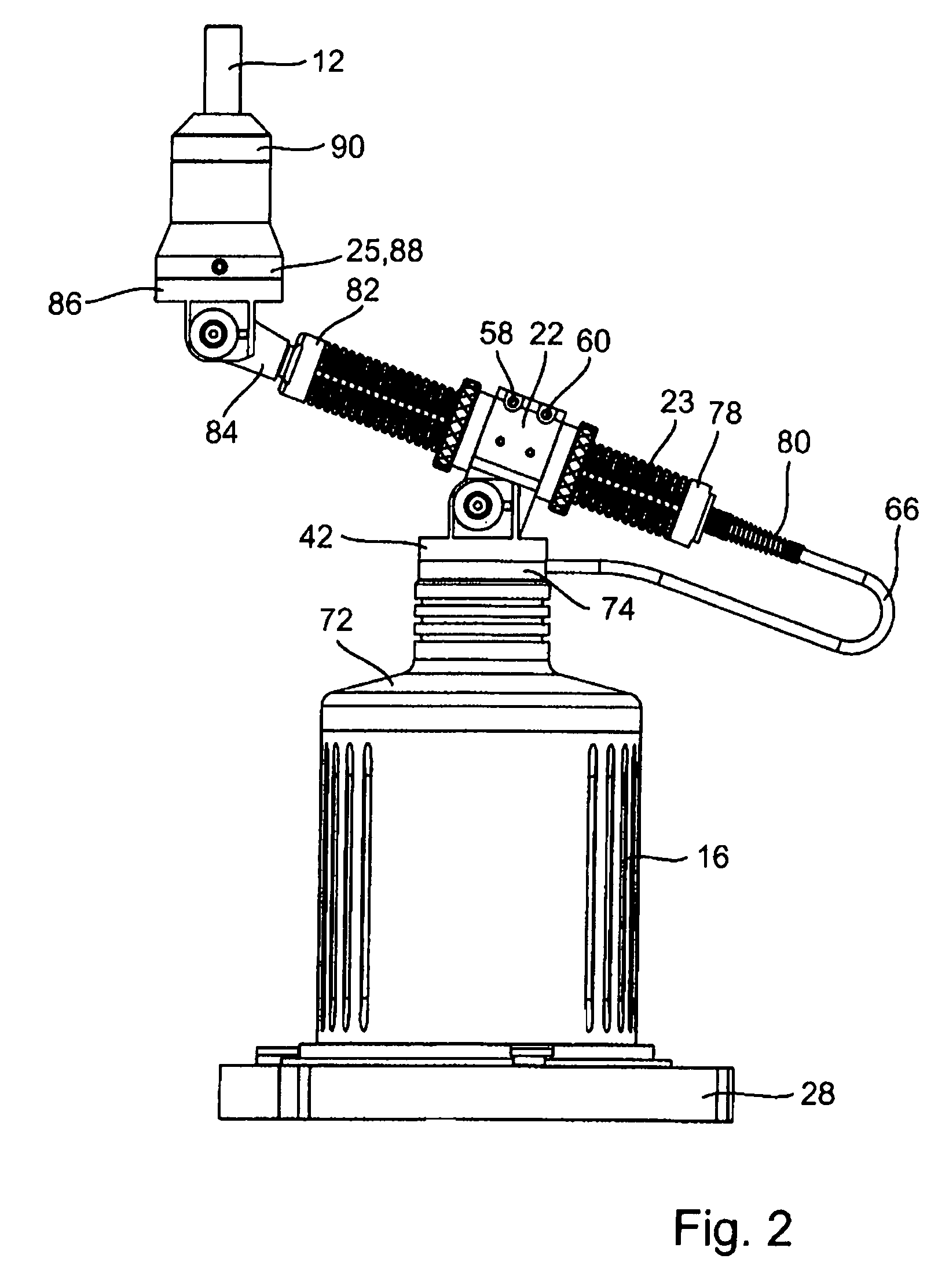

Device for examining the precision of a circular path which is to be executed by a working spindle

ActiveUS7296955B2Sure easyEasy to adjustProgramme controlProgramme-controlled manipulatorEngineeringMachine tool

The invention concerns a device for examining the precision of motion of a working spindle of an NC-controlled machine tool along a circular path for producing circular cylindrical surfaces on workpieces, comprising a first device part which can be coaxially mounted to the working spindle, a second device part which can be positioned on a machine table, which receives a workpiece to be processed, coaxially to the axis of a circular cylindrical surface to be produced on the workpiece, an electronic measuring value sensor which extends radially with respect to the axes of working spindle and circular cylindrical surface and is hinged to both device parts, and a shaft encoder which is rotatably disposed in the second device part coaxial relative to the axis of the circular cylindrical surface to be produced to determine the angular position of the measuring value sensor, wherein the measuring value sensor is held on one of the two device parts such that it can be adjusted and fixed transversely to the axes of the working spindle and the circular cylindrical surface.

Owner:DREIER TECH GMBH

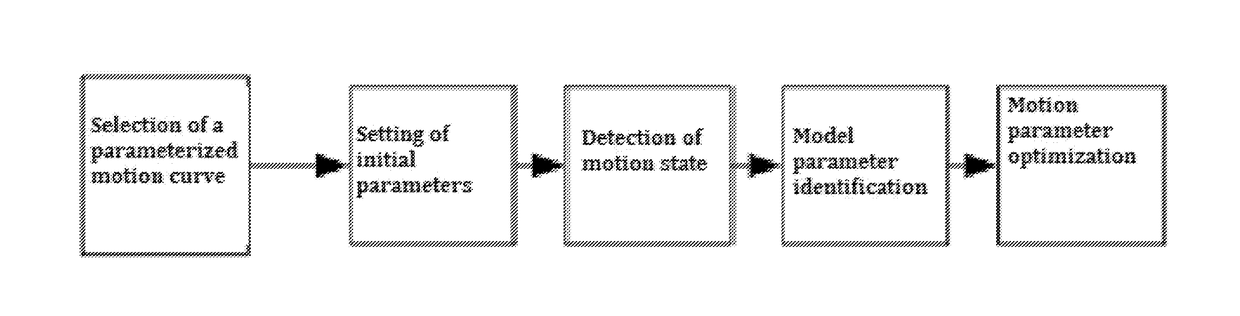

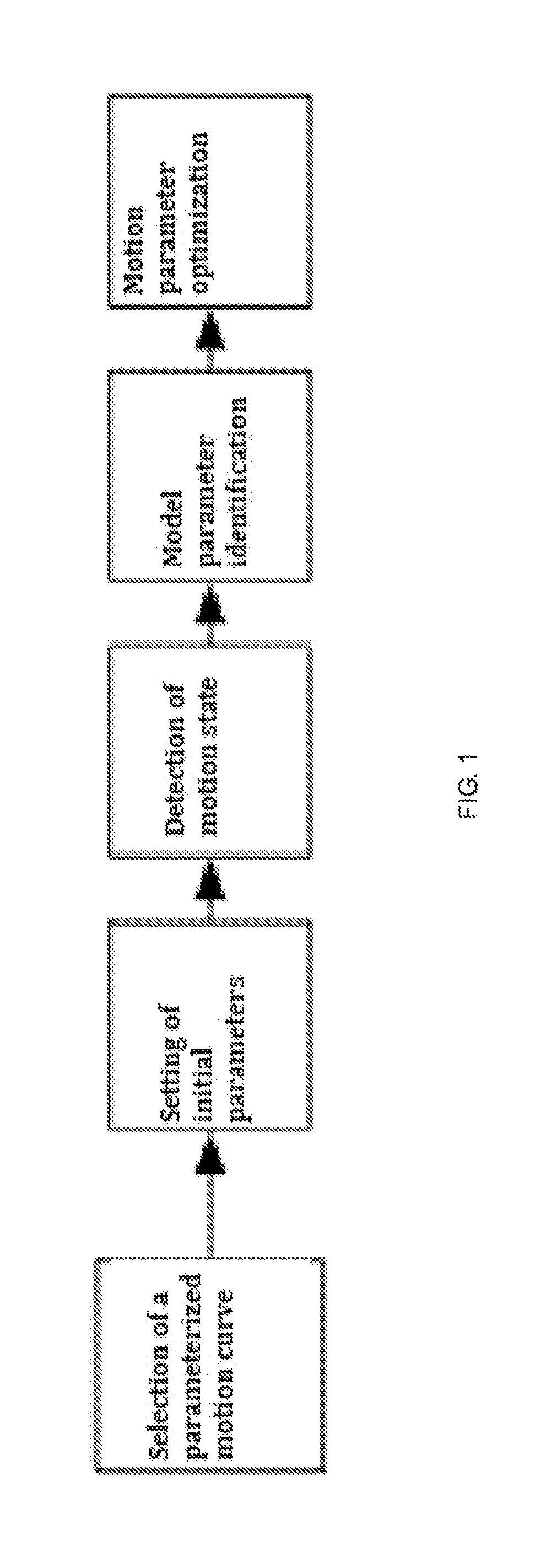

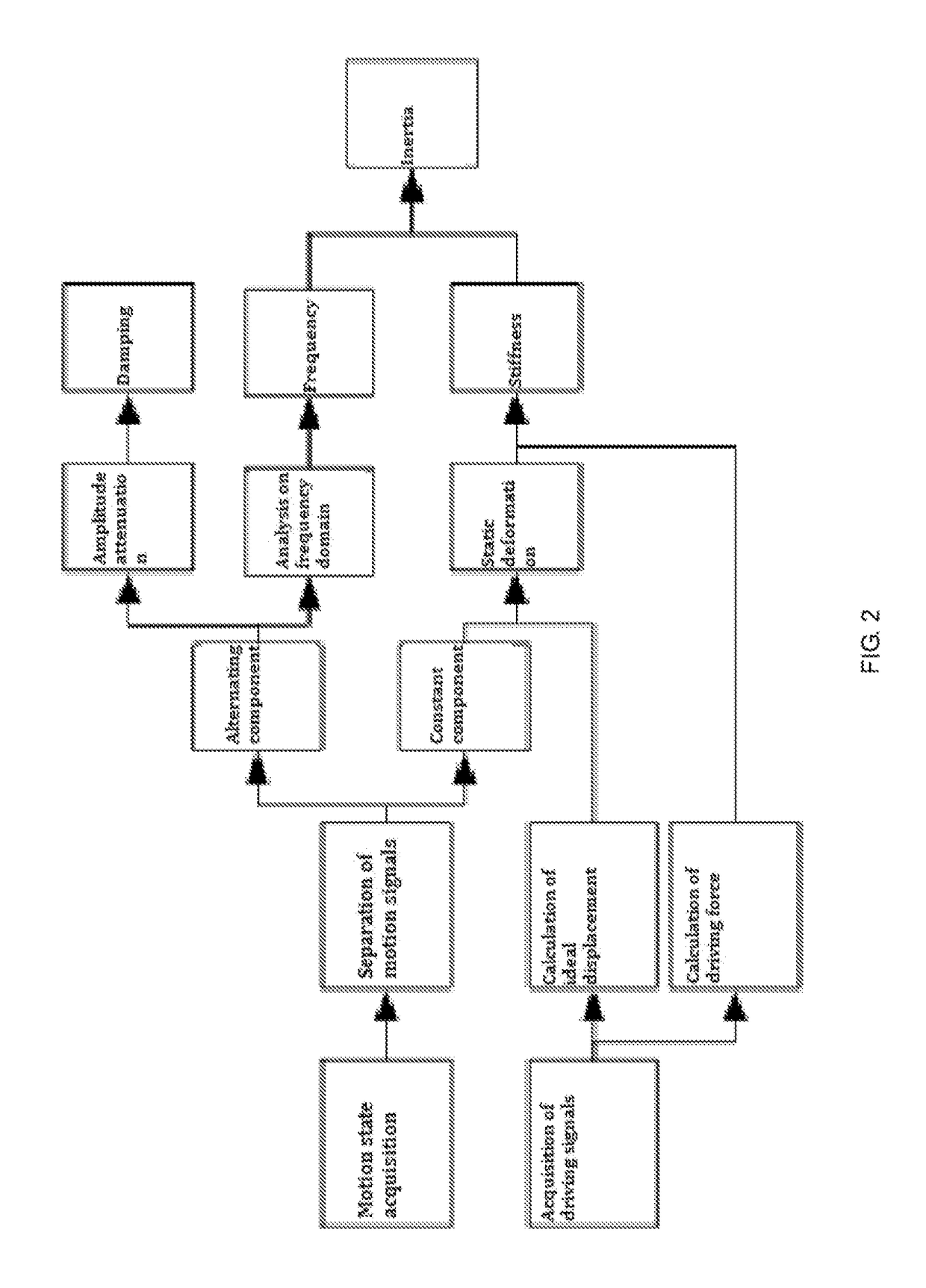

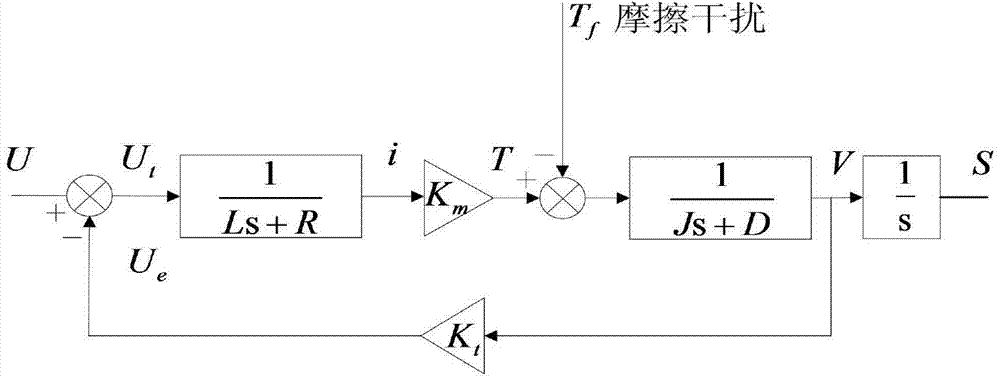

High-speed platform motion parameter self-tuning method based on model identification and equivalent simplification

InactiveUS20170124249A1Avoid defectsEasy accessGeometric CADDesign optimisation/simulationReduced modelSimulation

A high-speed platform motion parameter self-tuning method based on model identification and equivalent simplification is provided, comprising: establishing a test of a motion state of a high-speed platform, identifying model parameters, and optimizing motion parameters of an equivalent simplified model; selecting any motion function from a pre-set parameterized curve, setting initial parameters, and driving the high-speed platform to move under the action of a controller and an actuator; collecting dynamic response information of the platform, calculating dynamic characteristic information of the platform such as stiffness, frequency, damping and the like; establishing a dynamic response equivalent simplified model by using the acquired dynamic characteristic information, and performing the optimization constrained by meeting motion precision and targeting at shorter execution time for the motion parameters in the selected parameterized motion function to obtain the optimum parameters. The method of the present invention gives consideration to the dynamic characteristic requirement of the platform and the comprehensive requirement of the parameter identification and optimization on the industrial site, facilitates the implementation of an algorithm in a motion control card, and is suitable for rapidly acquiring the optimum motion parameters of the actual high-speed platform on site.

Owner:GUANGDONG UNIV OF TECH

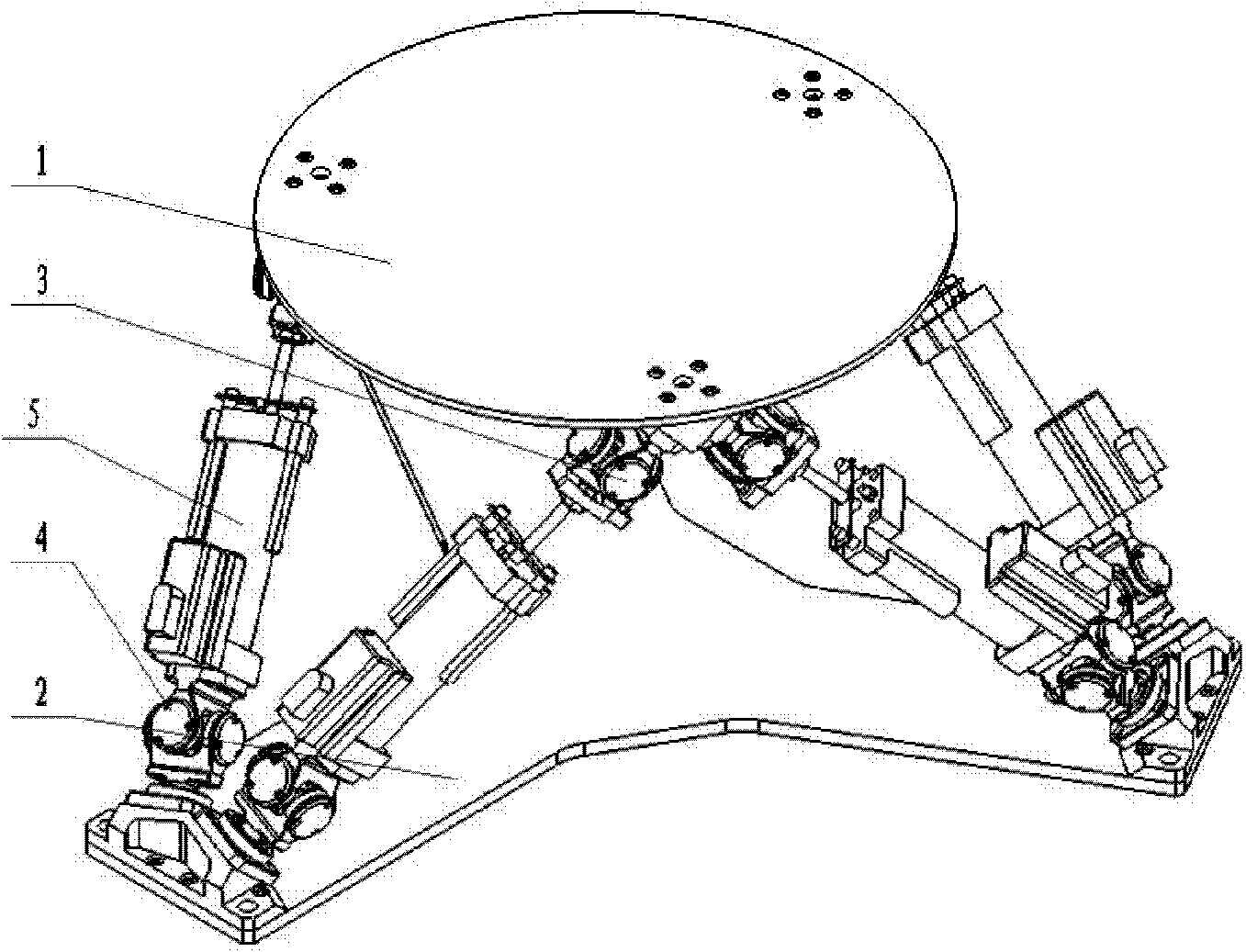

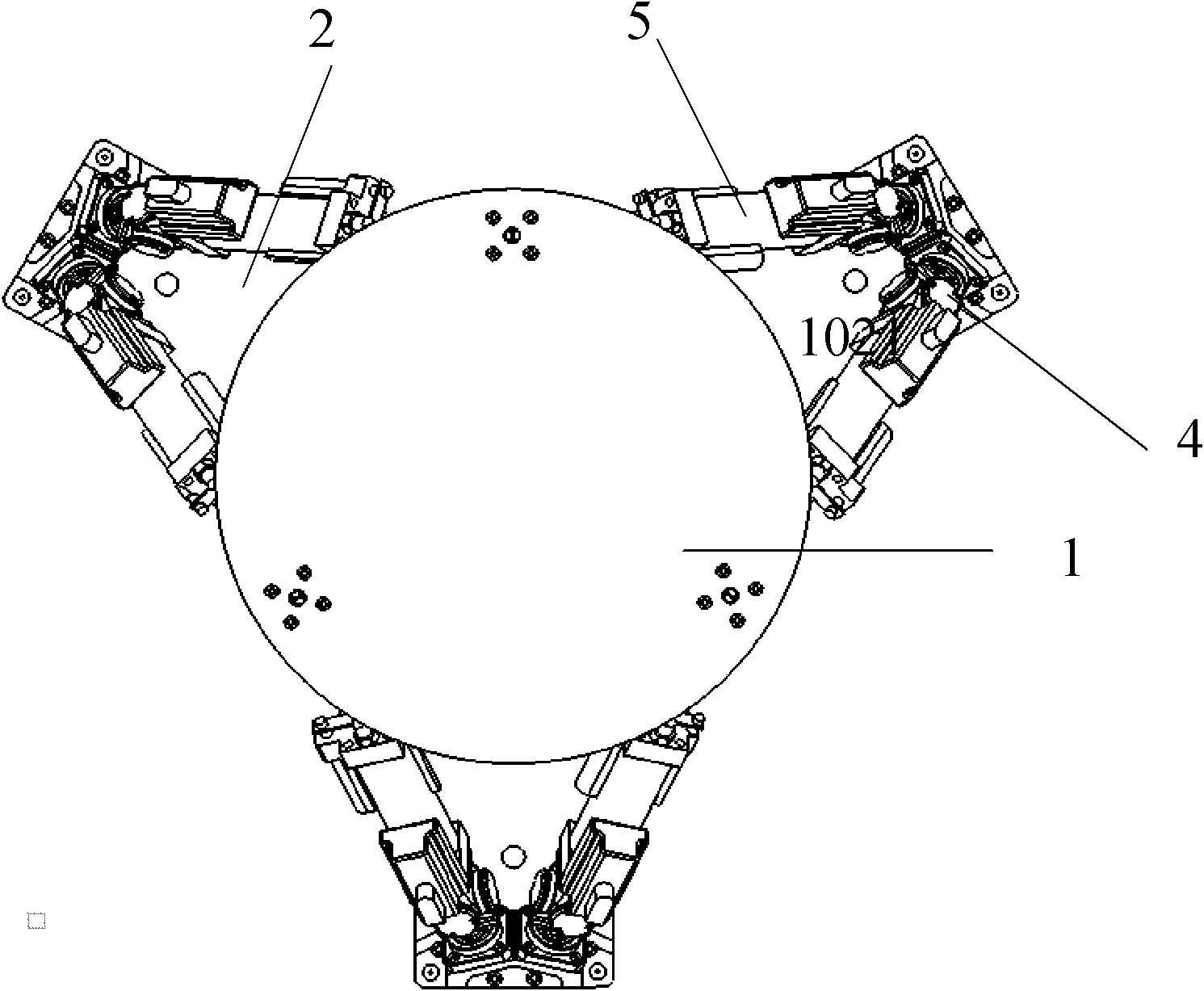

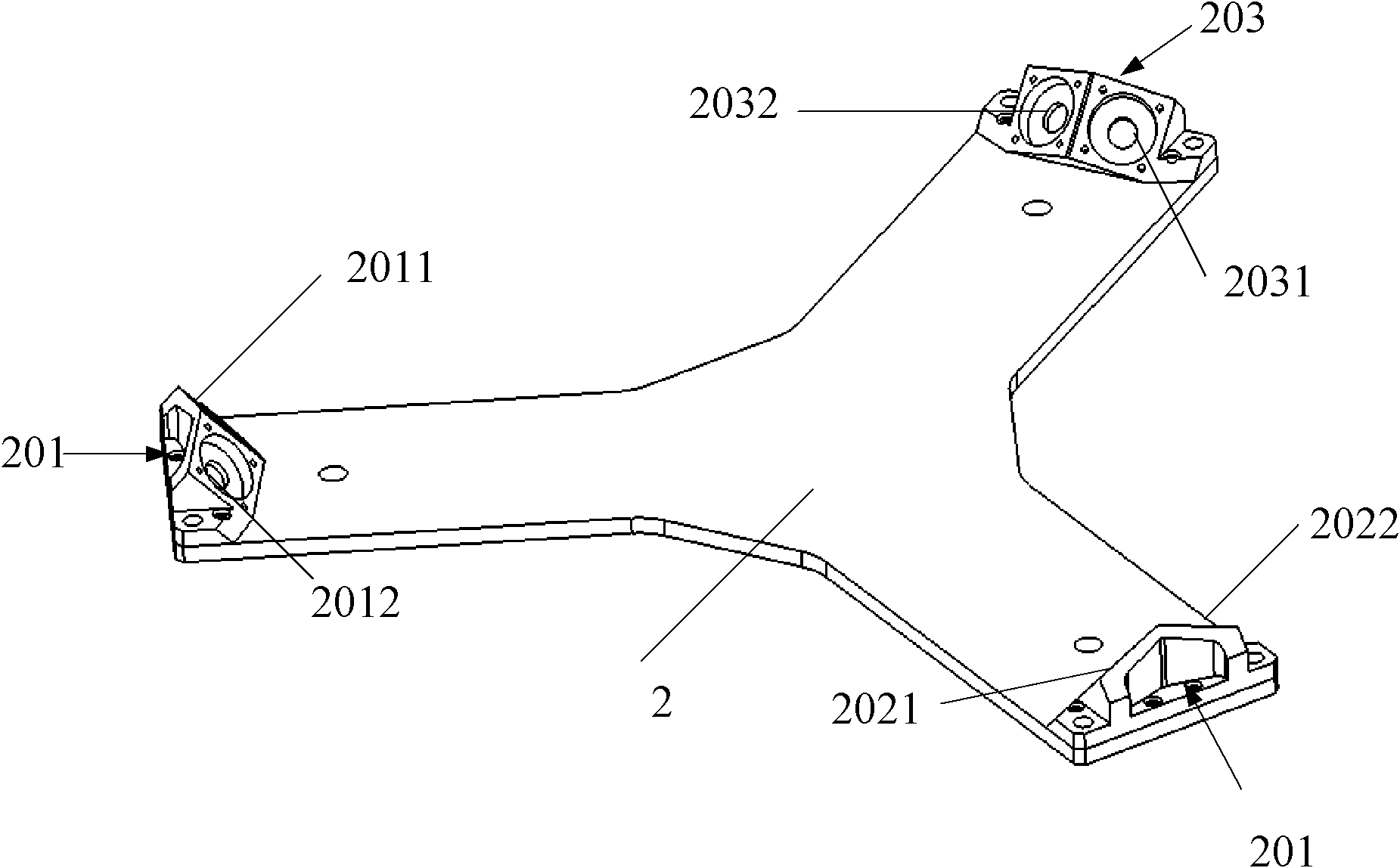

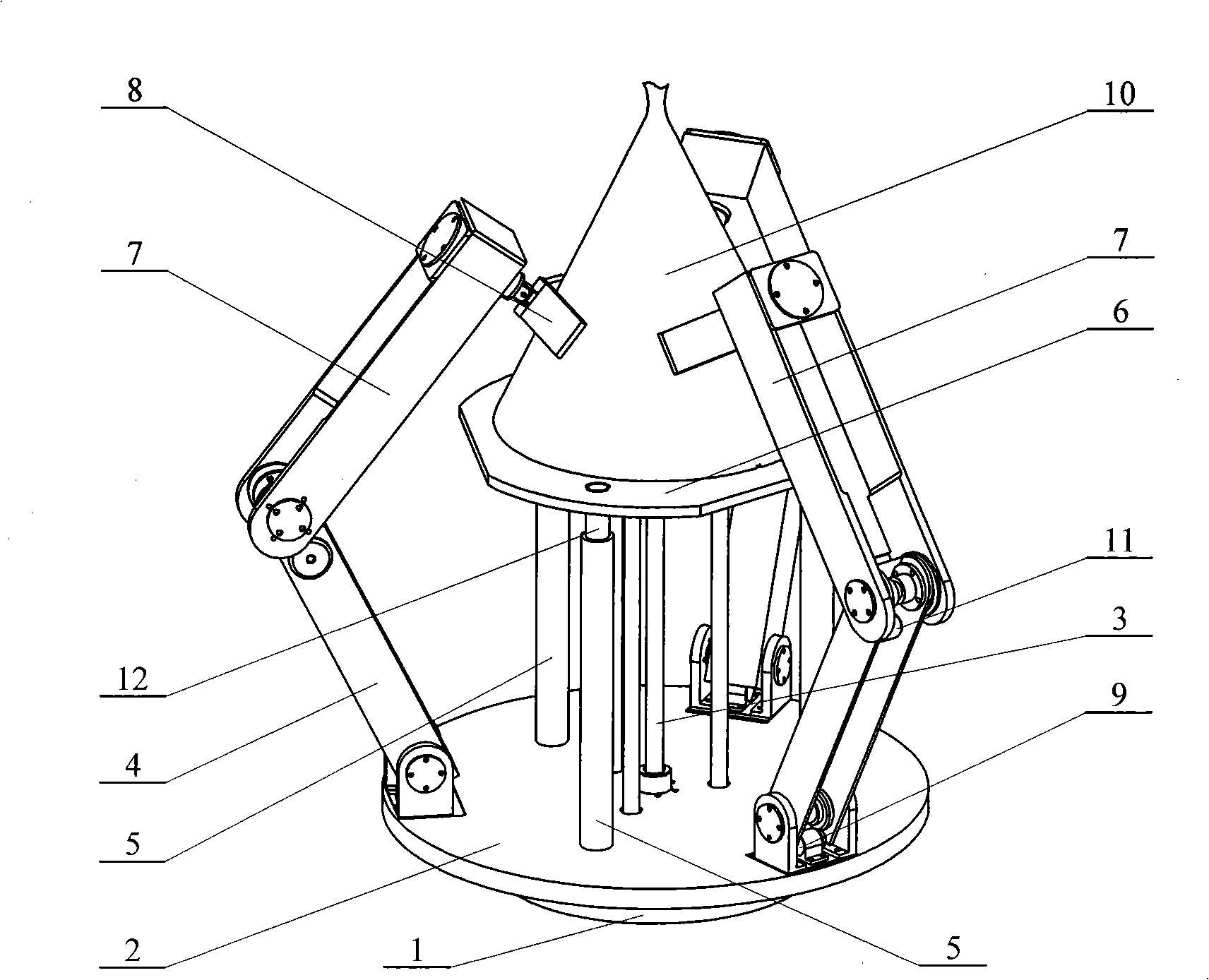

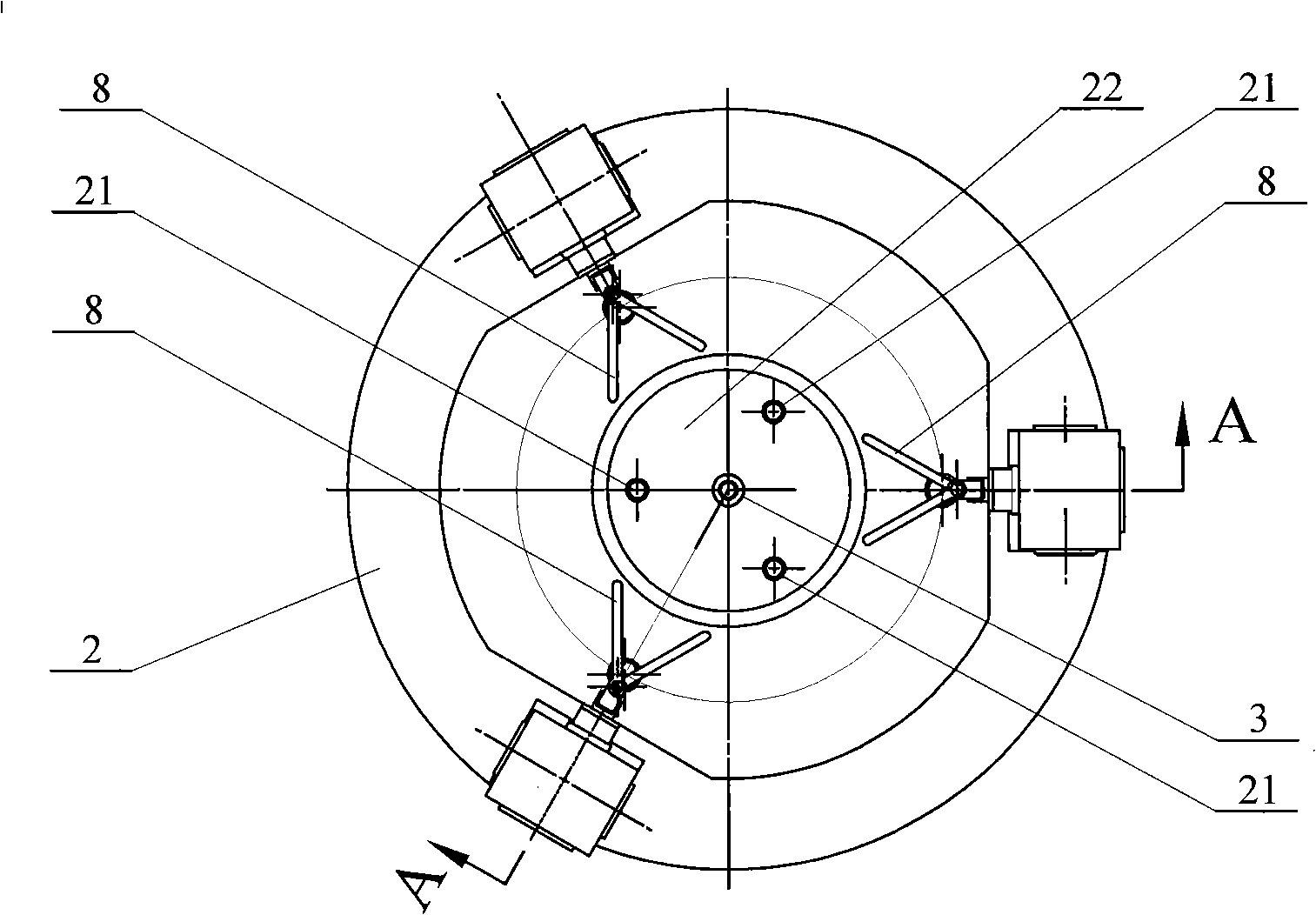

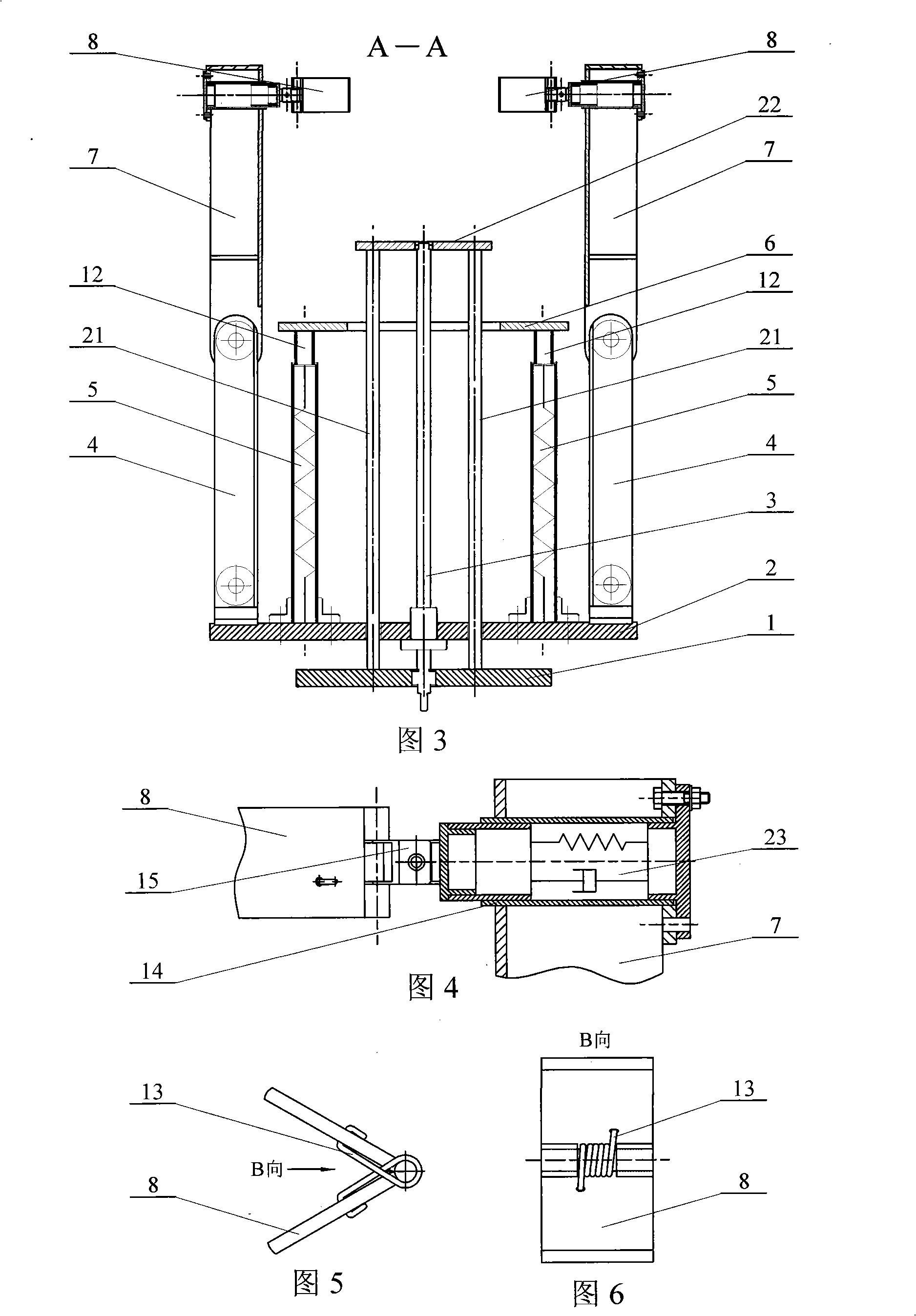

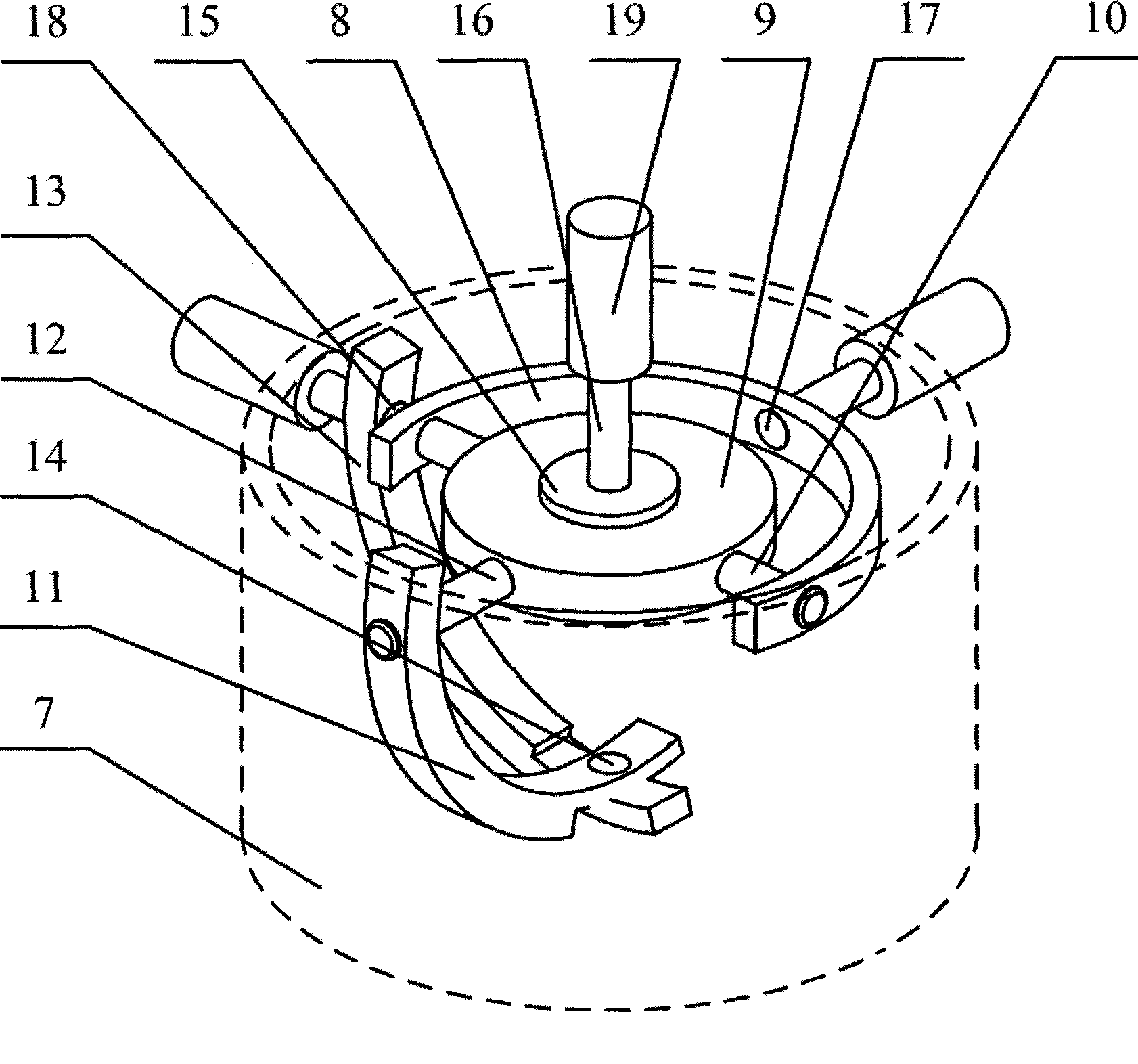

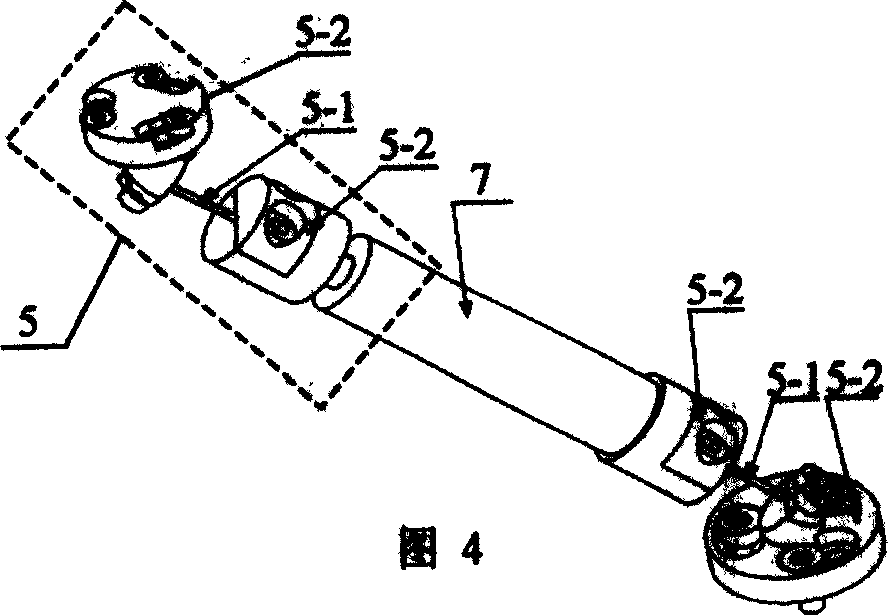

Three-arm type noncooperative target docking mechanism

ActiveCN101323377ALow motion precision requirementsImprove docking success rateCosmonautic component separationFlight vehicleActuator

The invention discloses a three-arm type non-cooperative target docking mechanism, relating to a satellite docking mechanism. The invention aims at solving the problems that the docking success rate of the existing satellite docking mechanism is comparatively low and the requirement on motion precision is extremely high. The three large mechanical arms of the invention are arranged on the periphery of a supporting platform at a 120 degree angle, one end of the large arm of the mechanical arm is articulated with the supporting platform, the other end thereof is articulated with one end of the small arm of the mechanical arm, and the other end of the small arm of the mechanical arm is connected with an end effector; the lower end of each bumper post is fixedly connected with the upper end of the supporting platform, the free end of each dashpot plunger is fixedly connected with the lower end of a target docking platform. In the invention, when the docking mechanism reaches a preset position, the three mechanical arms and the target docking platform form a closed region to encase a jet pipe, therefore, the jet pipe is placed in an inescapable space, and a target aircraft is clamped and fixed by the underdraught of the three mechanical arms and the upthrust of the target docking platform.

Owner:HARBIN INST OF TECH

Sliding block type structure decoupling six-dimension force feedback device

InactiveCN101439514AAchieving Motion DecouplingSimple structureProgramme-controlled manipulatorThree degrees of freedomEngineering

The invention discloses a decoupling 6D force feedback device of a sliding block type structure. The device is composed of a fixed base, a three-degree-of-freedom parallel mobile unit, and a three-degree-of-freedom parallel-serial rotation unit, wherein, the three-degree-of-freedom parallel mobile unit comprises three mutually orthogonal branches, each of the branches is guided to a sliding block by a column guide rail driven by a mobile drive motor, a double-link end is articulated with the sliding block, and the other end is connected with a rotation base by a U-shaped block, the three-degree-of-freedom parallel-serial rotation unit are driven by three rotary drive motors, the rotation base is respectively connected with a first arc rod and a third arc rod by a support hinge A and a support hinge B, the first arc rod is connected with a transfer platform by a long shaft, a second arc rod is connected with the transfer platform by a mid-length shaft, the third arc rod is connected with the second arc rod by a short shaft, and the transfer platform is in serial connection with a moving platform. The device can achieve unconditional decoupling with six degrees of freedom, and has the advantages of simple structure, easy control, high movement accuracy, lower cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Movable optical element adjusting and positioning device

ActiveCN101609193AFrictionlessNo lubricationPhotomechanical exposure apparatusMicrolithography exposure apparatusHysteresisOptical axis

A movable optical element adjusting and positioning device relates to a photoetching apparatus. A movable lens set in the device is fixed on a main lens cone by a laminated spring plate and can move along an optical axis or carry out horizontal inclination adjustment under the action of a driving motor. The driving of the driving motor adopts a long handle of a level mechanism in a driving mechanism of a gapless flexible bearing, and a short handle thereof drives the movable lens set to move along the optical axis. The adjusting and positioning device achieves an axial movement accuracy which can be lower than 0.5 microns and a horizontal adjustment accuracy which can reach 0.5mrad. The adjusting and positioning device has compact structure, stable operation, no friction or lubrication, low hysteresis and good repeatability, and the movement stroke of the movable lens set can reach 0.2 mm and the linearity is good.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

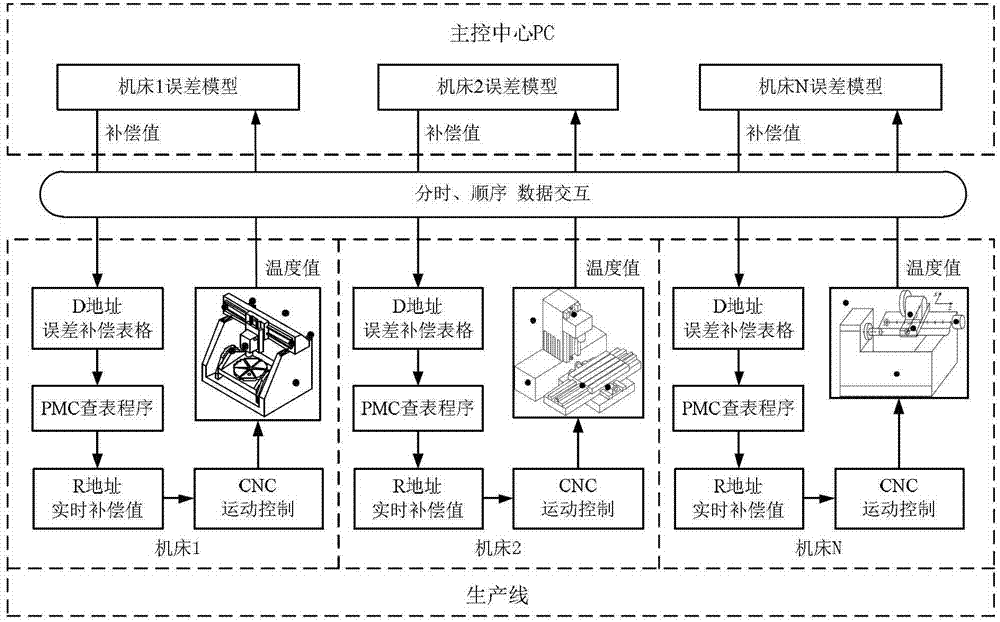

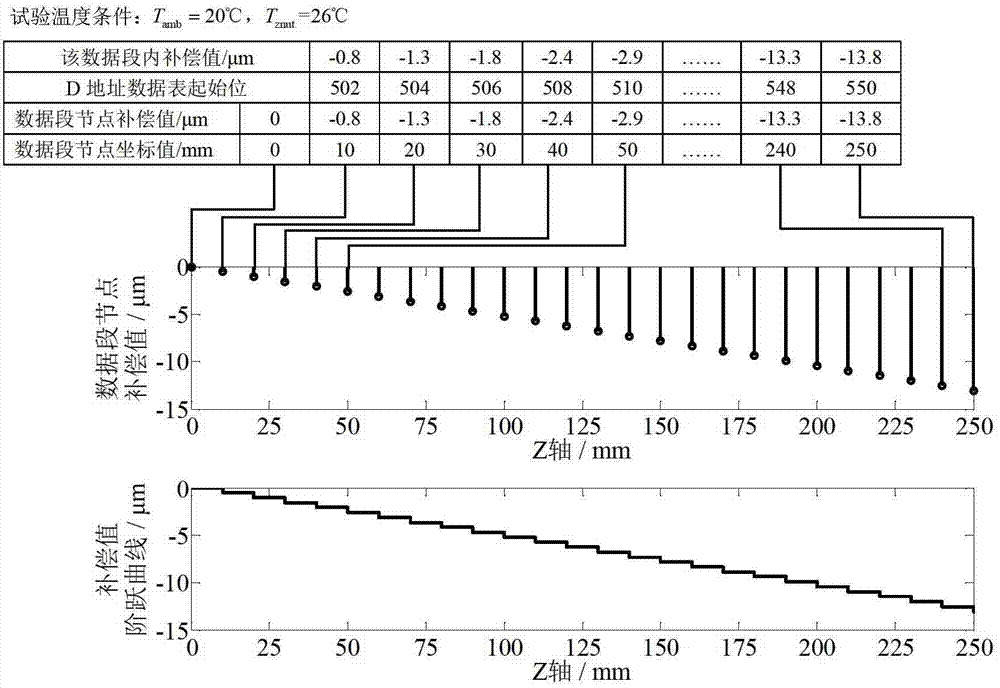

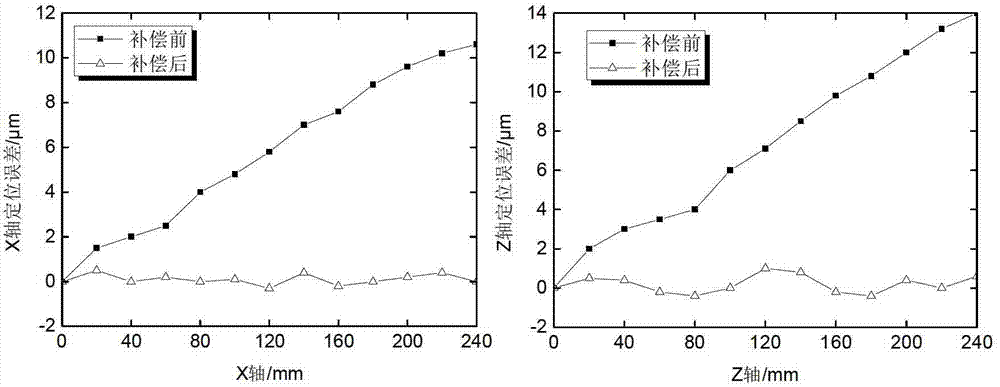

Network cluster-control-based numerical control machine tool error real-time compensation system and compensation method

ActiveCN103048968AImplementation statusLow costComputer controlSimulator controlNumerical controlData acquisition

The invention discloses a network cluster-control-based numerical control machine tool error real-time compensation system and a network cluster-control-based numerical control machine tool error real-time compensation method. The compensation system comprises a hardware part and a software part built in hardware, wherein the hardware part comprises a master control center personal computer (PC), a router, a built-in Ethernet port or a personal computer memory card international association (PCMCIA) Ethernet card, a temperature sensor and a temperature data acquisition card; and the software part comprises a temperature acquisition module, an error modeling and calculating module, a cluster-control compensation module and a machine tool state network monitoring module. By the compensation system and the compensation method, error real-time compensation and working state information monitoring can be performed on a plurality of numerical control machine tools on a production line at the same time; the movement precision of the numerical control machine tools is improved in batches; and therefore, the compensation efficiency and the final machining precision are greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

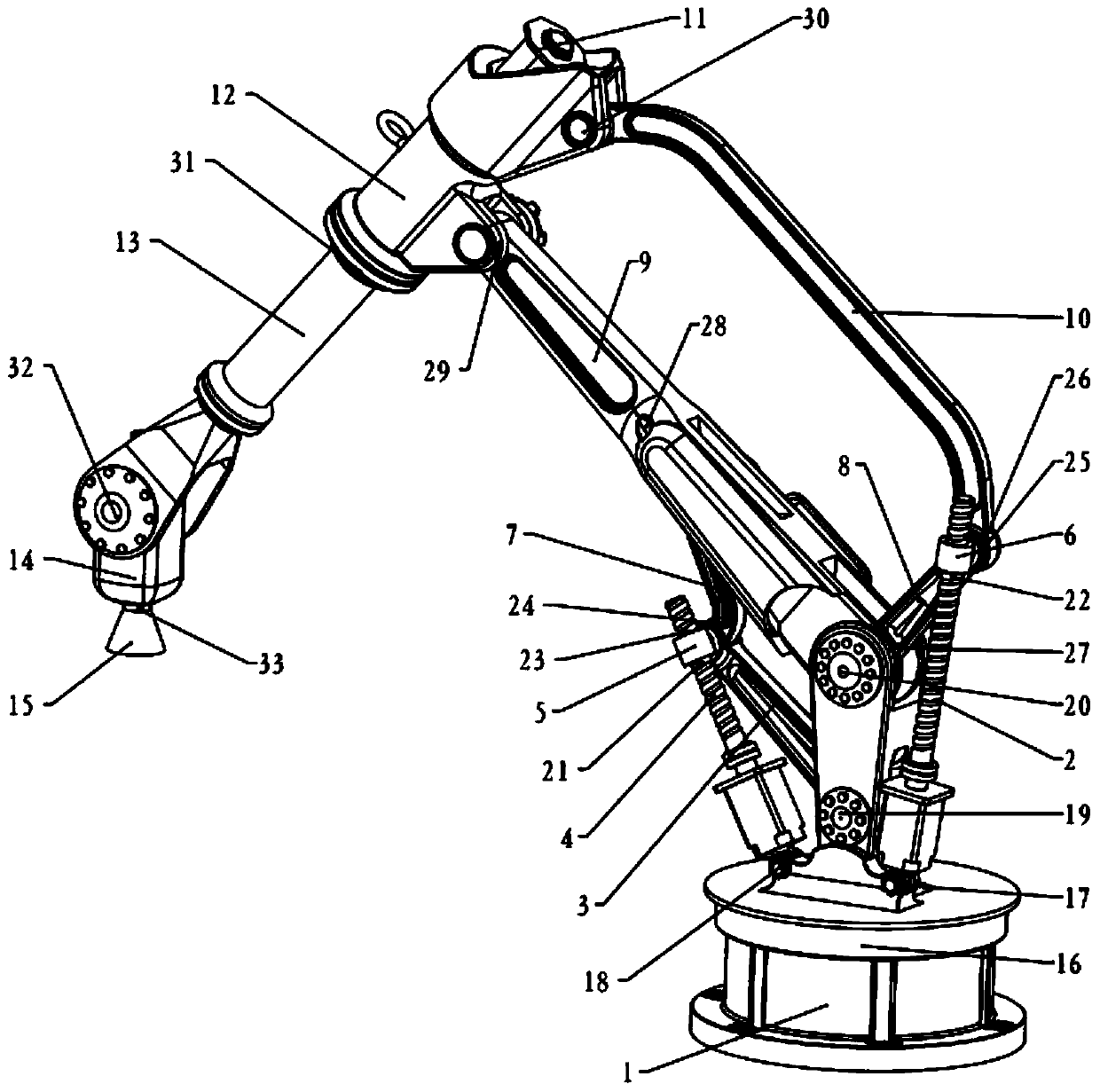

Six-freedom-degree industrial robot with ball screw pair transmission

InactiveCN103737577ARealize two-dimensional translationRealize three-degree-of-freedom attitude adjustmentProgramme-controlled manipulatorBall screw driveDrive motor

The invention relates to a six-freedom-degree industrial robot with ball screw pair transmission. Waist whole circle rotating is achieved through a waist swing mechanism, a shoulder swing mechanism and an elbow swing mechanism form a two-freedom-degree parallel mechanism to achieve two-dimensional horizontal moving, and ball screws are driven by motors arranged on a swing platform respectively. Three mutual-orthometric rotating shafts connected through a front arm rotating mechanism, a wrist swing mechanism and a tool clamping base swing mechanism are driven independently by three motors respectively, and three-freedom-degree gesture adjusting of an executing tail end tool is achieved. The advantage of the large working space of a serial mechanism is kept, ball screw transmission is used, the rigidness of the mechanism is guaranteed, the positions of the driving motors are lowered, good dynamic characteristics are obtained, bearing capacity is large, high-speed or superspeed operation can be easily achieved, and the six-freedom-degree industrial robot has the advantages that side gaps do not exist, rigidness is high, micro-motion feeding can be conveniently achieved, accumulated errors are small, motion accuracy is high, positive and athwart kinematics solving is convenient, and control is convenient.

Owner:GUANGXI UNIV

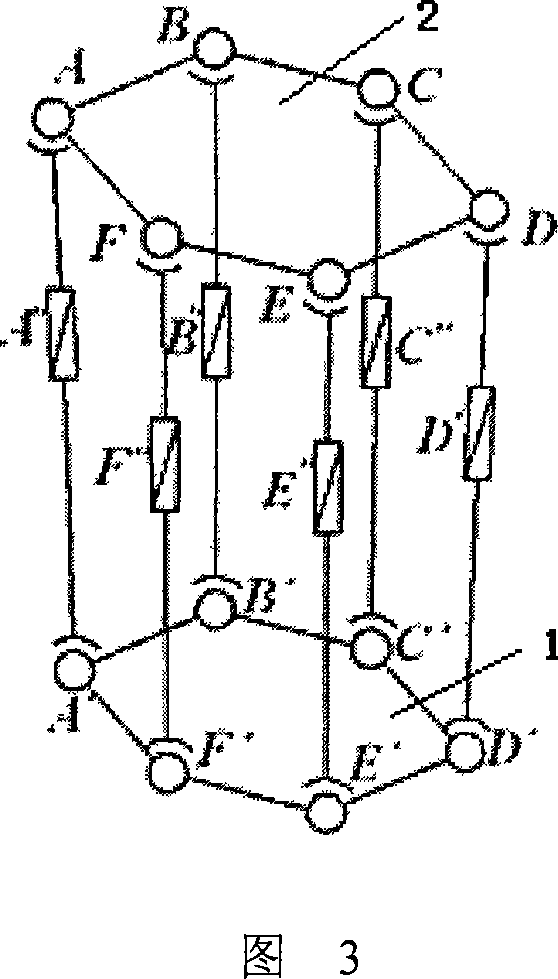

High precision flexible parallel robot with six degreed of freedom and large travel

InactiveCN1562579AEliminate gapsClose contactProgramme-controlled manipulatorImage resolutionRange of motion

Owner:HARBIN INST OF TECH

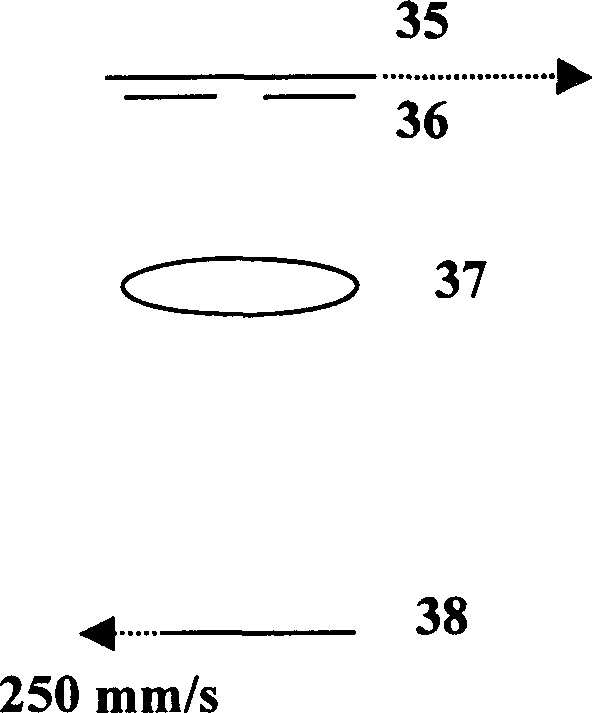

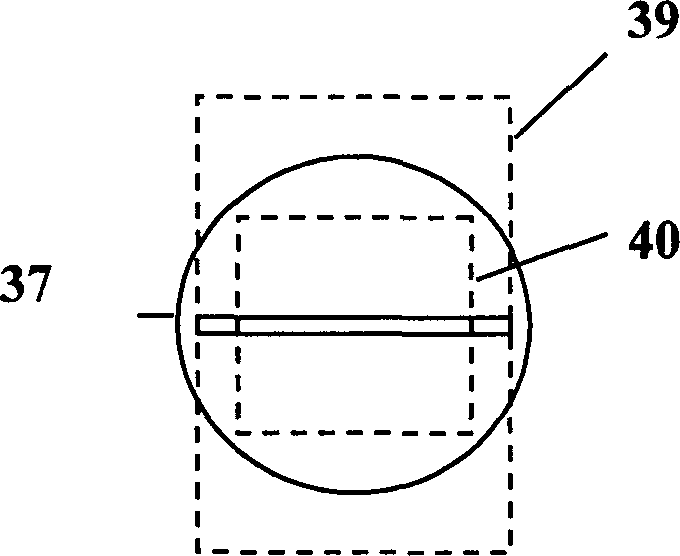

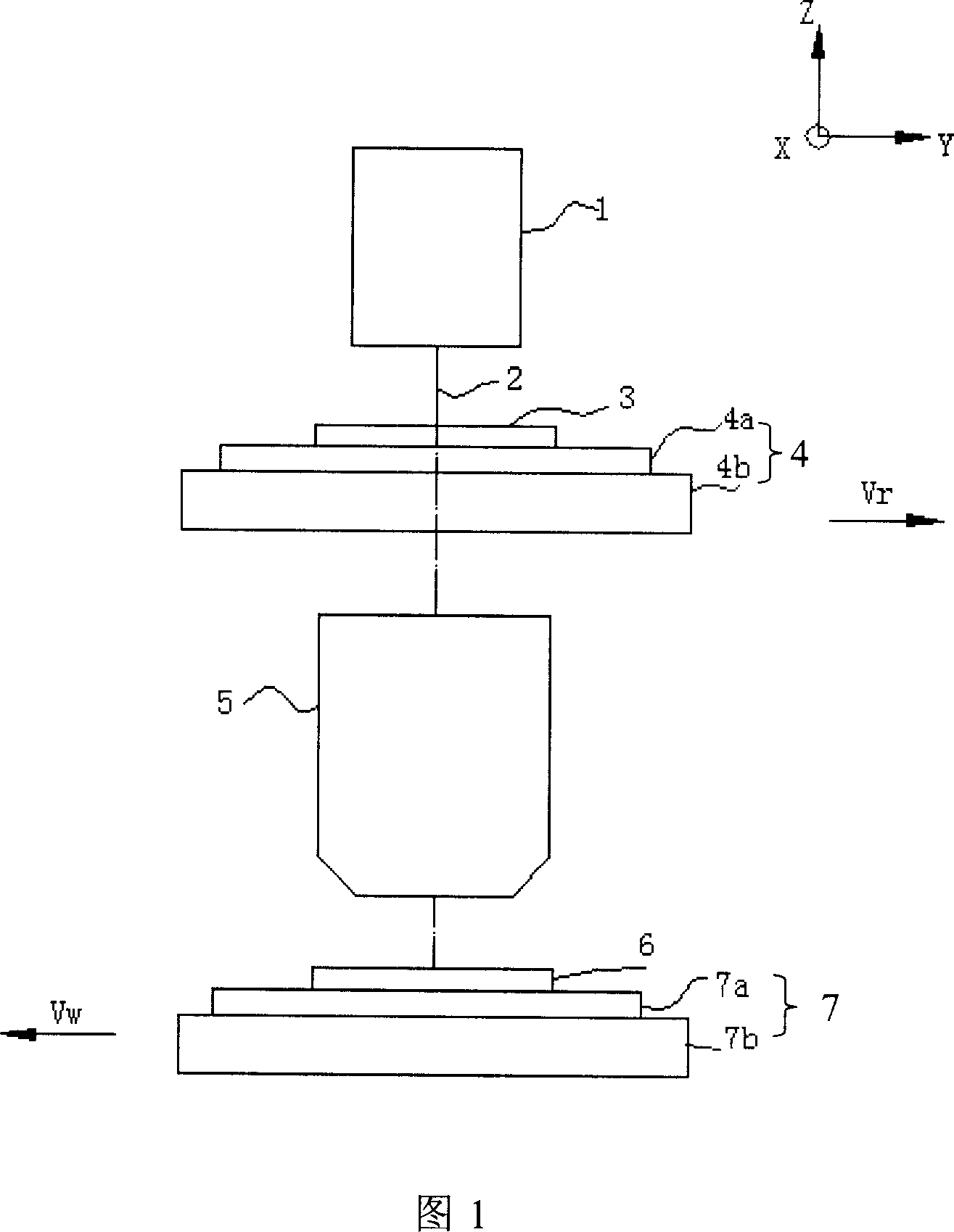

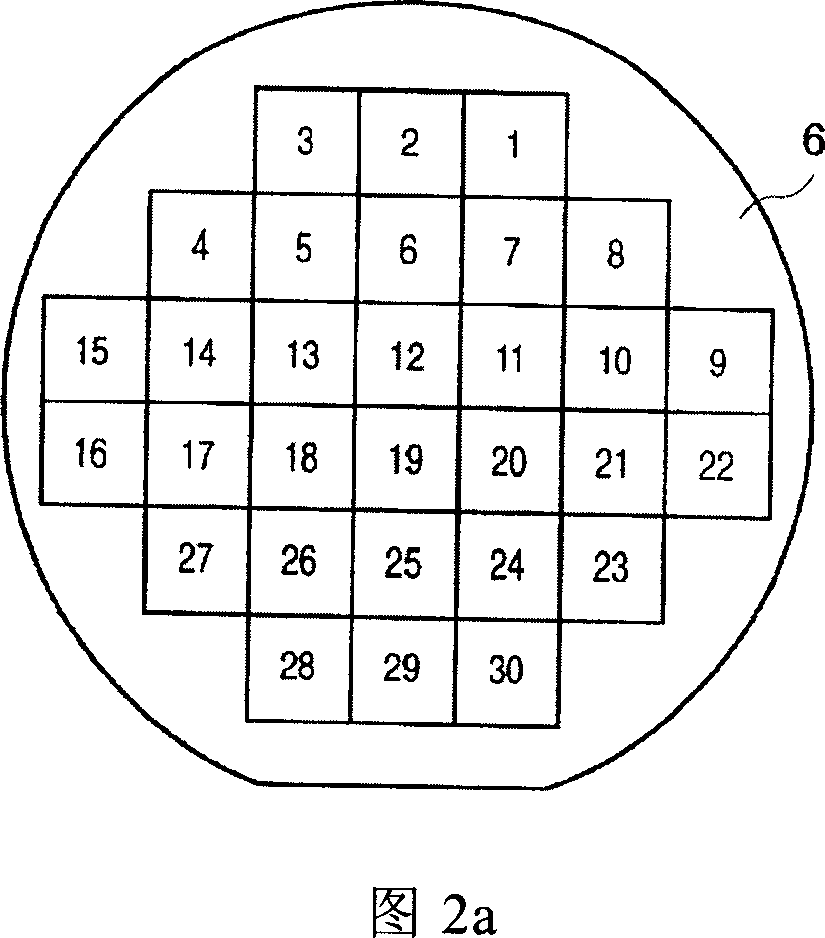

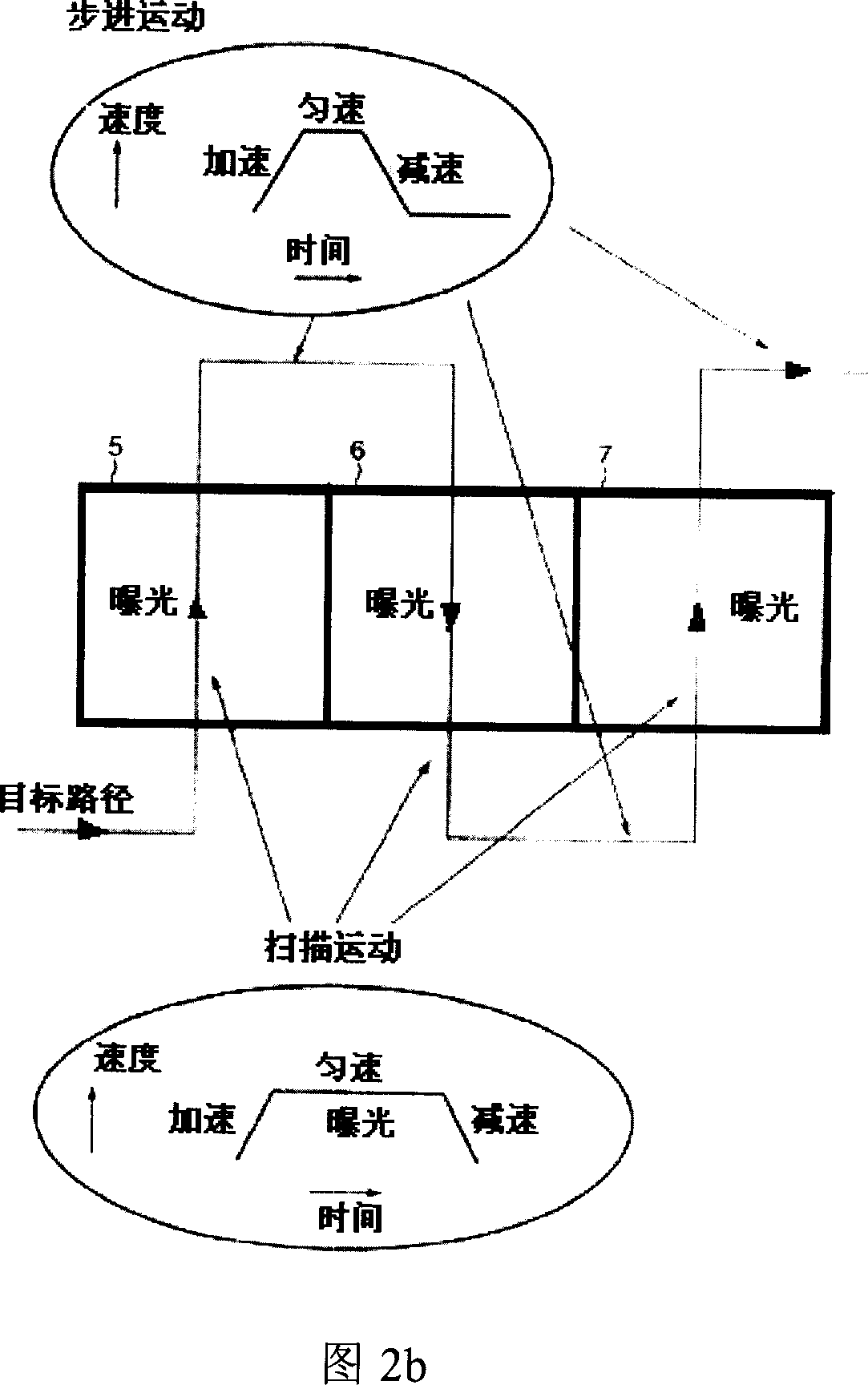

Wafer platform mask platform synchronous control system of step-scan photoetching machine

InactiveCN1967386ARun fastIncrease flexibilityPhotomechanical exposure apparatusControl using feedbackSynchronous controlControl system

A step-and-scan optical engraver wafer station mask station control system, its characteristics are: it comprises the main control module [13], the wafer station control module [12], the masking station control module [10] and the synchronization control module [11]. The invention uses the synchronous control with disturbance controller to reduce the effect of the movement precision and stability of disturbance to the wafer station and masking station, and it introduces the synchronization control compensation device to reduce the synchronization error, and finally improve the optical engraver accuracy. The invention can not only realize step-and-scan movement required during the scanning exposure process, but also improve the machinery precision and stability. The invention is applicable to optical scan projection optical engraver, and extreme ultraviolet scanning exposure machine, and the synchronous control of other micro-processing equipment.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

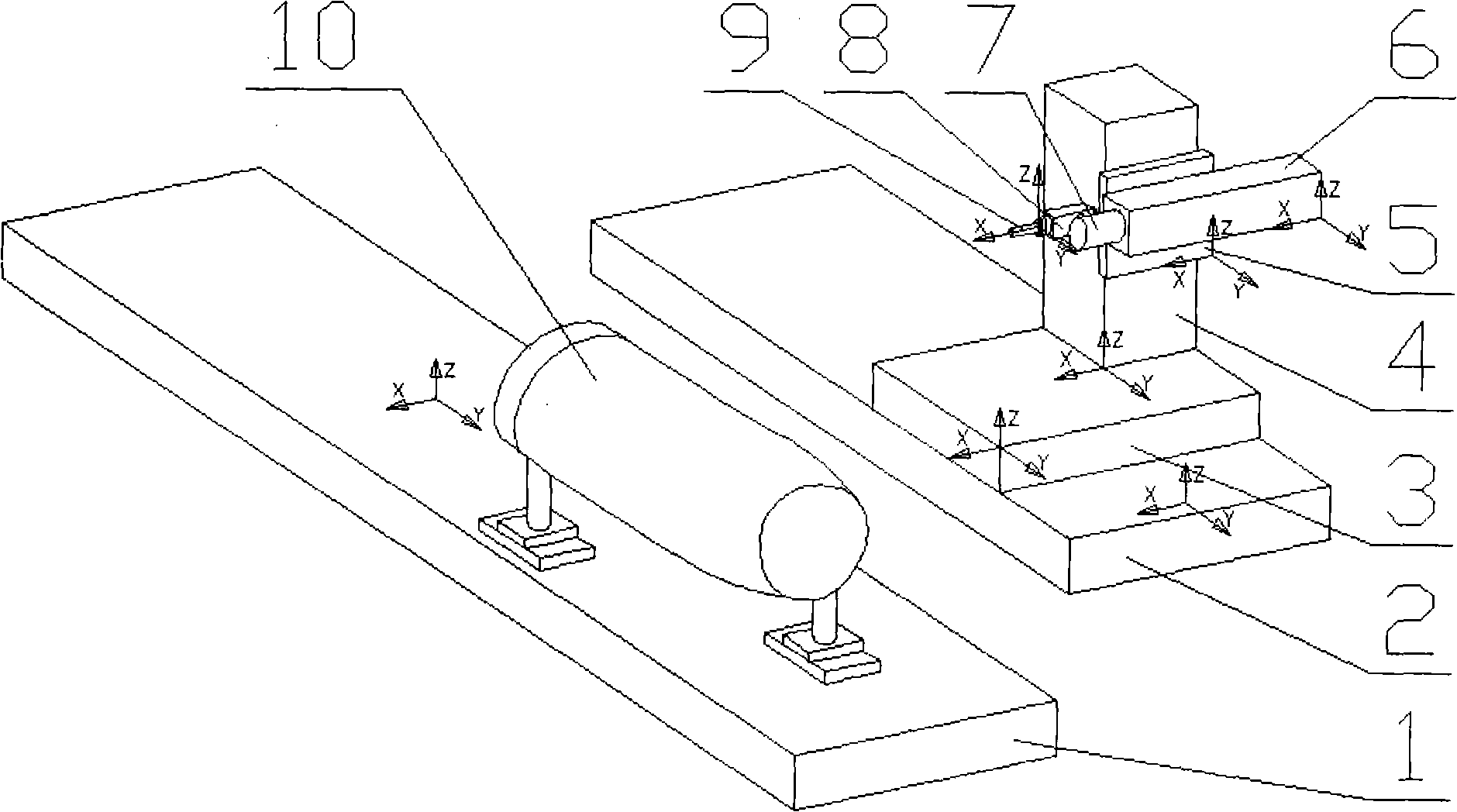

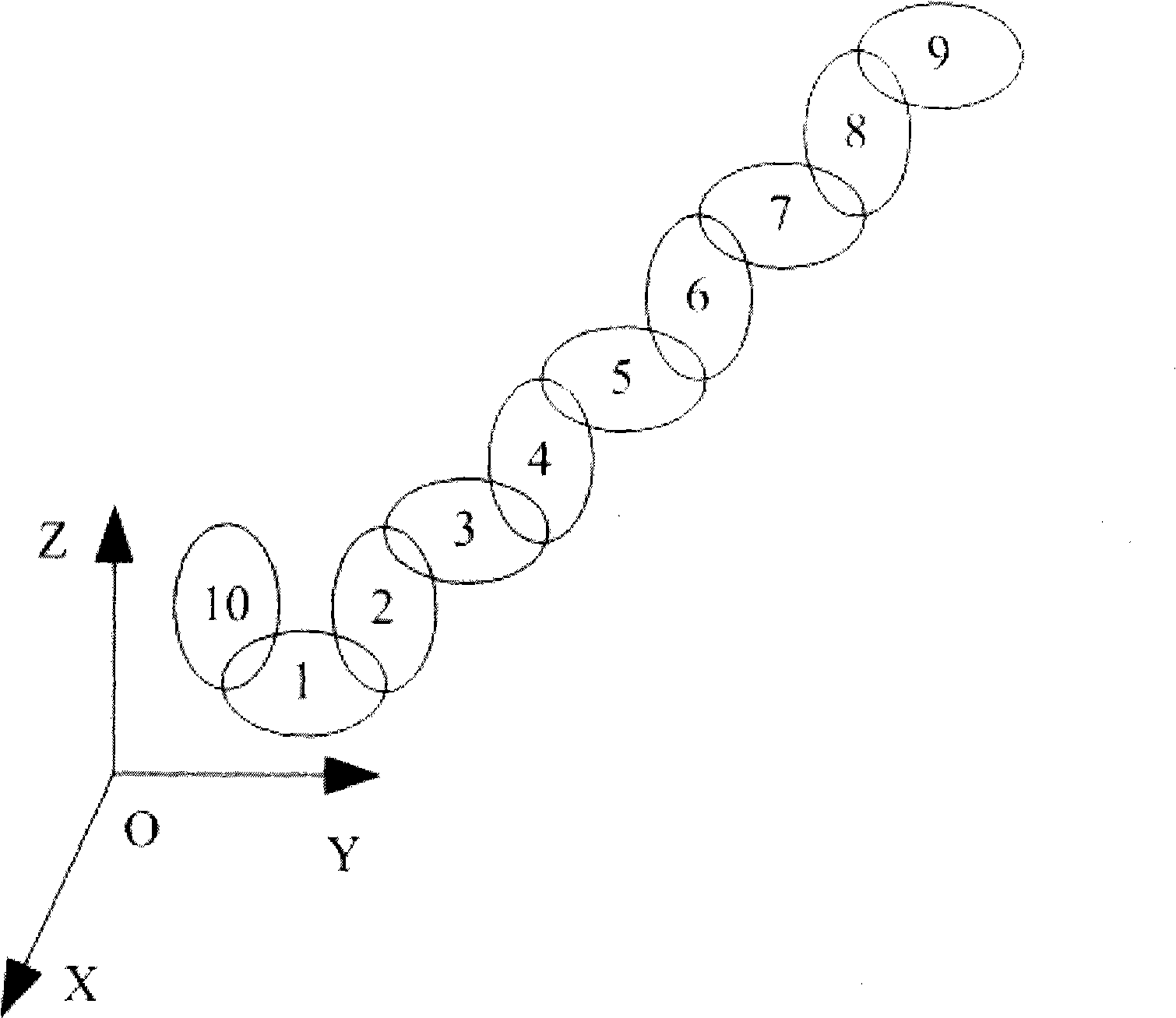

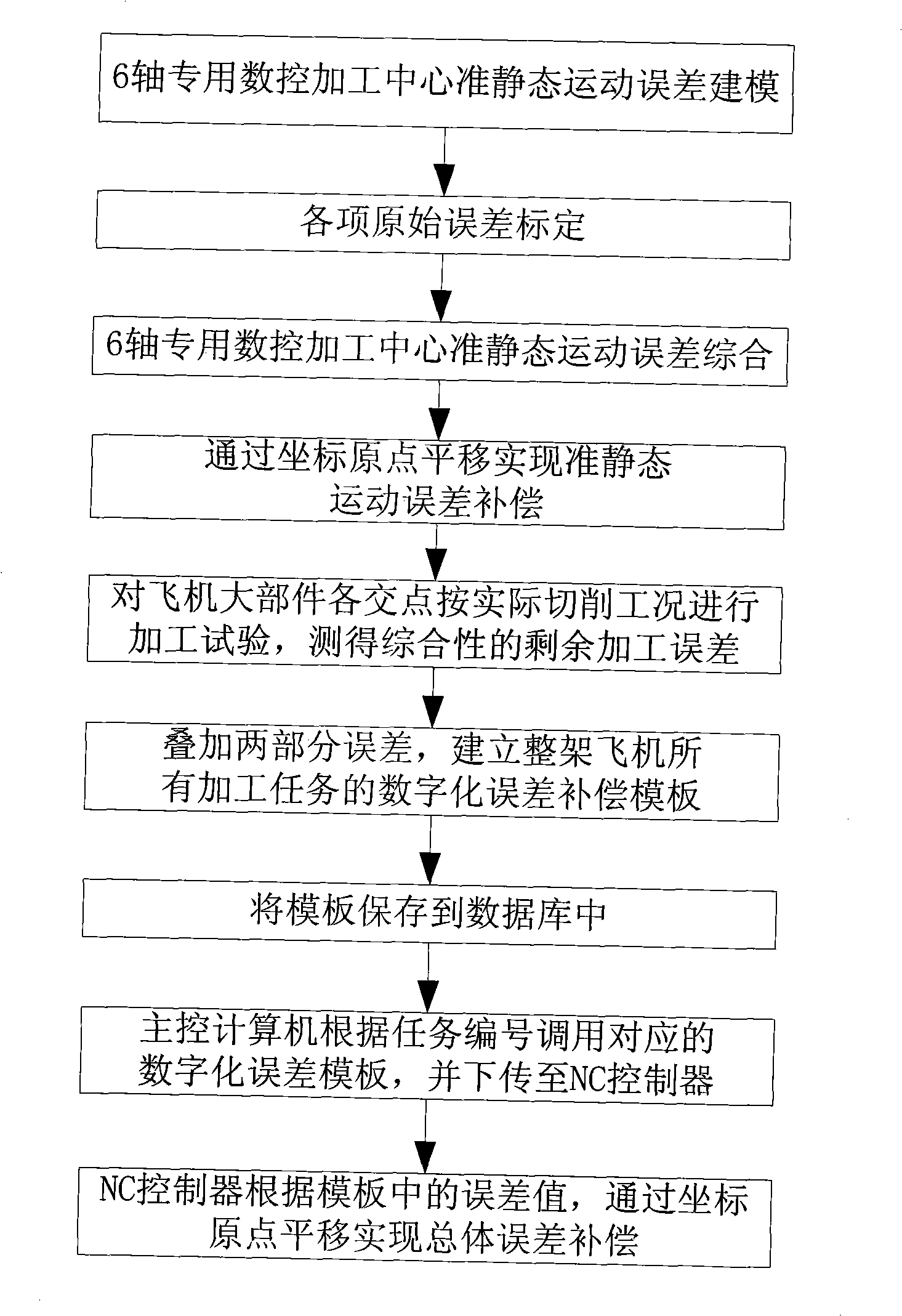

Method for implementing numerical control finish machining for large component of aeroplane based on digitalization error compensation template

InactiveCN101493683AReduced absolute motion precision requirementsReduce control requirementsProgramme controlComputer controlNumerical controlStatics

The invention discloses a method which realizes numerical control finish machining of intersection of large parts of the airplane on the basis of a digital error compensation template, comprising the steps as follows: firstly, a quasi static movement error model thereof is built, all the original errors are measured and obtained, and then a compensation of the quasi static movement error is realized; all machining tasks are carried out under a practical working condition; the comprehensive machining error residual after the first compensation is measured; and the total error compensation value is obtained comprehensively and a corresponding digital error compensation template is built. The machining precision of the intersection of a plurality of airplane wings of the same type is ensured by the repeated movement precision of a machining center. The method has the advantages that the precise numerical control machining center can be adopted to realize the precise machining of the intersection of the large parts of the airplane, the real-time performance is high, the numerical control program and the software and hardware of the machining center are not required to be changed, the advantages of the high precision of the repeated movement of the numerical control machining center is sufficiently played, and the control requirement on the workshop environmental temperature is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

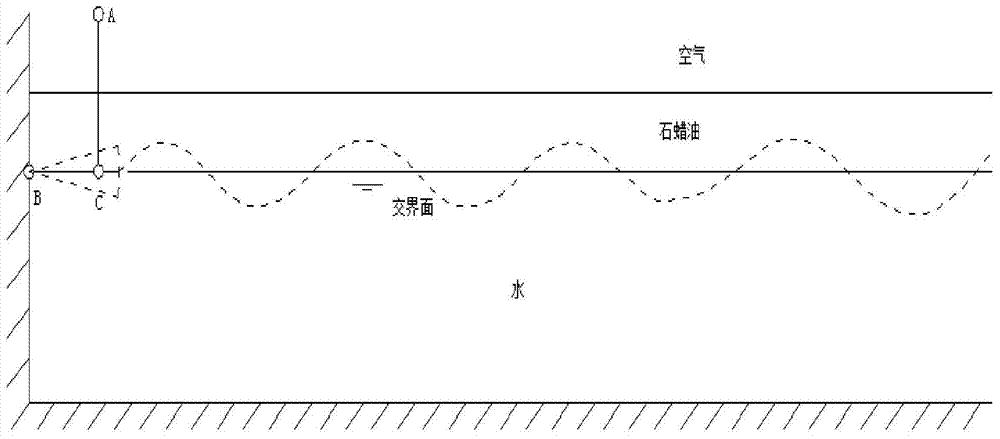

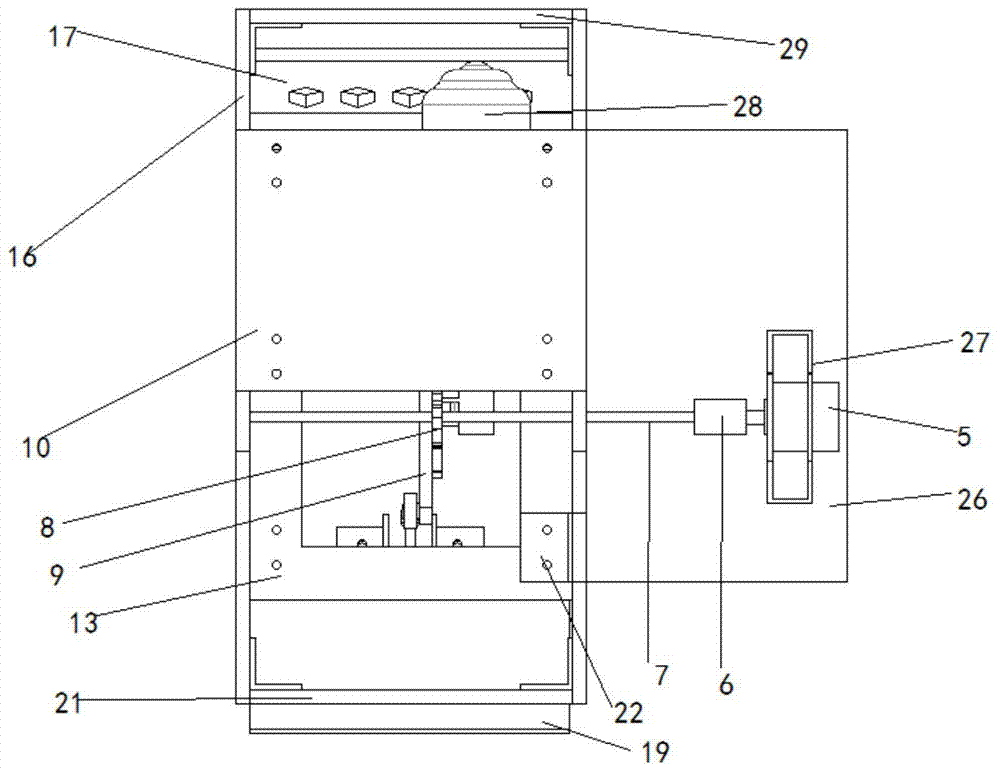

Horizontal swing plate type internal wave generation device

InactiveCN103575500AControl exercise frequencyRealize measurementHydrodynamic testingHydraulic modelsElectric machineControl signal

The invention aims to provide a horizontal swing plate type internal wave generation device. The horizontal swing plate type internal wave generation device comprises a wave generation mechanism, a control and measurement system and a machine base. The wave generation mechanism is a horizontal swing plate type wave generation mechanism. A swing plate is placed at the junction of two layers of flowing liquid levels, is driven by a crank and rocker mechanism and can do reciprocating wave generation motion up and down at the junction of the two layers of flowing liquid levels to generate periodical internal waves. The control and measurement system provides control signals for the wave generation mechanism and feeds back the motion frequency of a motor. The wave generation mechanism and the measurement system are supported by the machine base to make the whole device integrated, and the machine base also has the wave absorbing function. Due to the adoption of the horizontal swing plate type internal wave generation device, complex wave generation motion can be carried out at the junction of the two layers of flowing liquid levels by the swing plate to generate the periodical internal waves without generating surface waves at the same time when ocean internal waves are truly simulated, and interference of surface waves in original experiments is completely eliminated. The device is simple in structure, convenient to operate, high in motion precision and low in energy consumption and has good application and market value.

Owner:HARBIN ENG UNIV

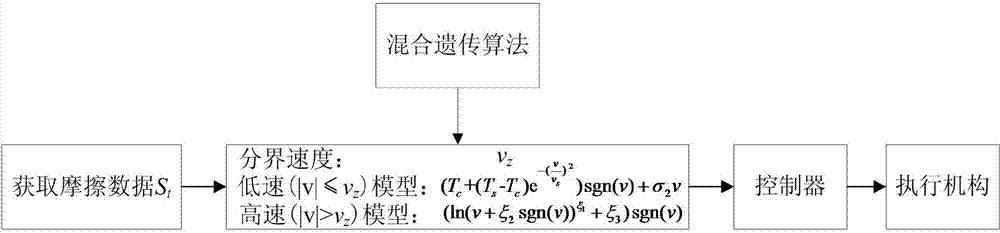

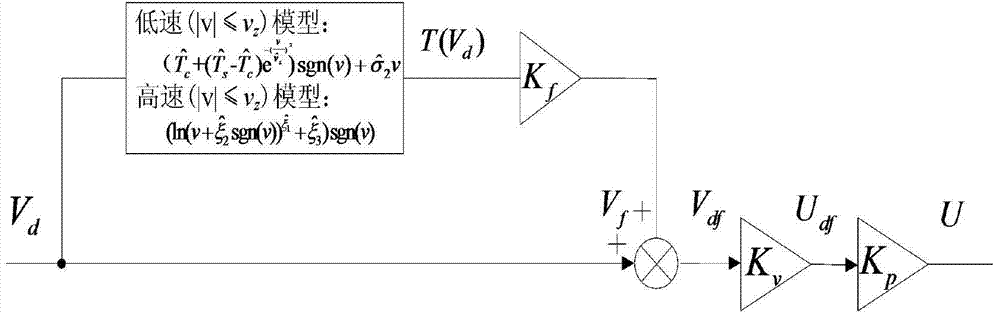

Method for friction compensation of ball screw feeding system

ActiveCN103926875AHigh compensation accuracyReduced friction rateProgramme controlComputer controlFriction torqueLow speed

The invention discloses a method for friction compensation of a ball screw feeding system. On the basis that the actual friction phenomenon of the system is analyzed, segmented models of friction torque in speed sections are provided, friction in the low-speed section is modeled through a Steck Berry model, and friction in the high-speed section is modeled through a logarithmic model. Unknown parameters of the friction models are recognized through a hybrid genetic algorithm, the friction compensation amount at the real-time speed is estimated based on the recognized friction models, and friction compensation of the system is achieved in a compensation amount feedforward mode. Through the segmented friction model, friction in the ball screw feeding system is accurately described, the parameters of the friction models are accurately recognized through the designed hybrid genetic algorithm, motion accuracy of the ball screw feeding system is improved based on the feedforward compensation mode of the friction models, and the method can be widely applied to various systems which comprise ball screw feeding mechanisms.

Owner:SOUTHEAST UNIV

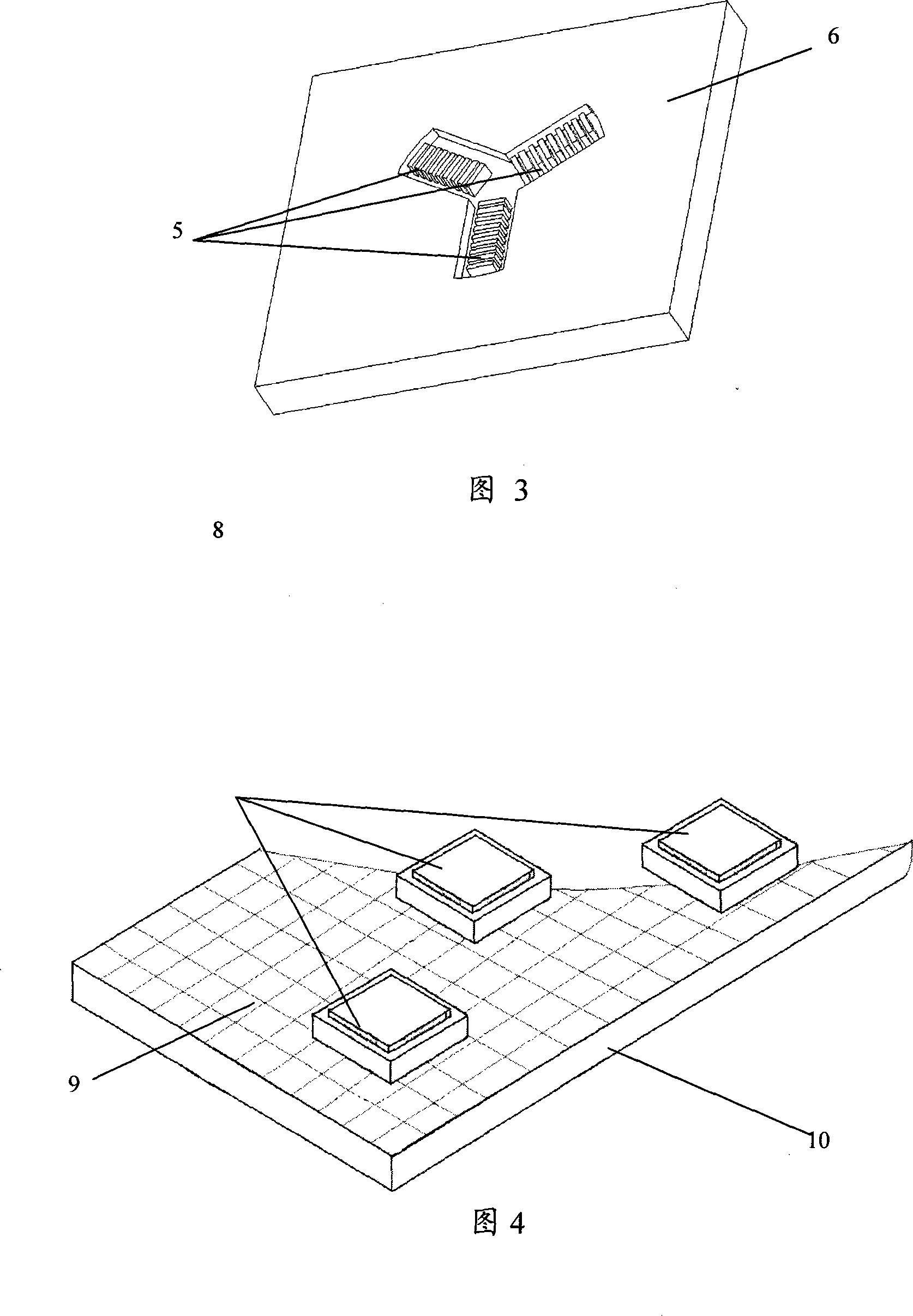

Air-float magnetic controlled precision movement platform

InactiveCN101158815ASuspension stabilityQuick responseSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMicrometerMotion accuracy

The present invention discloses an air-floating magnetic-control precision motion platform, which comprises a mover platform, a stator platform, a mover thrusting coil, a stator magnet permanent iron array and an x-y directional reflection mirror. The x-y directional reflection mirror is positioned at two sides of the top of the mover platform. The bottom edge of the mover platform is provided with an air-floating hole. The center of the mover platform is provided with a vacuum cavity. The mover thrusting coil is positioned at the inner side of the bottom of the mover platform. The stator magnet permanent iron array is fixed on the stator platform. The entire mover platform floats above the stator platform. The way of the arrangement of the mover thrusting coil is matched with that of the stator magnet permanent iron array. By adopting the air-floating magnetic-control precision motion platform of the present invention, fretting precision and positioning precision of micrometer / nanometer can be realized by the single mover air-floating magnetic-control precision motion platform while the precision motion of multi-working station and large stroke can be realized by a plurality of the mover air-floating magnetic-control precision motion platforms. As the mover platform floats above the stator platform, the mechanical friction between the platforms and the problem of the motion precision of the platform caused by the friction are avoided, and meanwhile a mover coil can be cooled.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

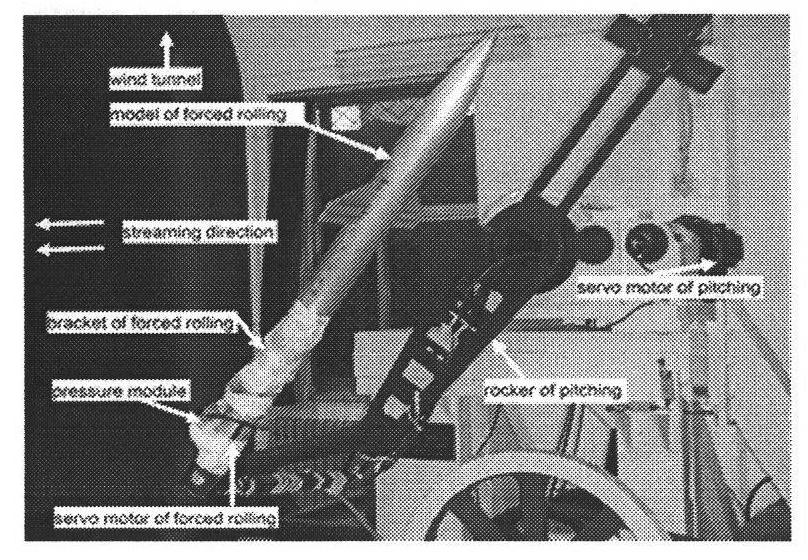

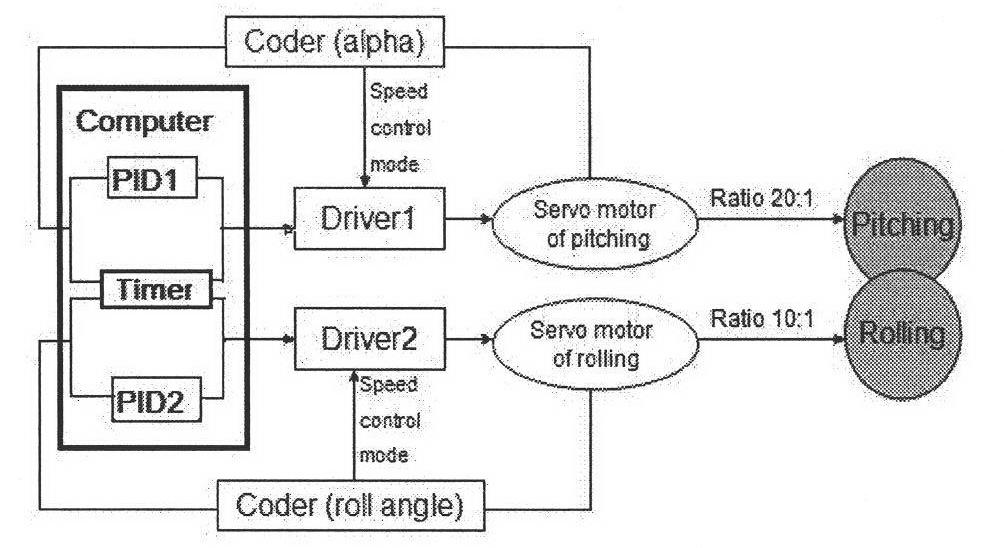

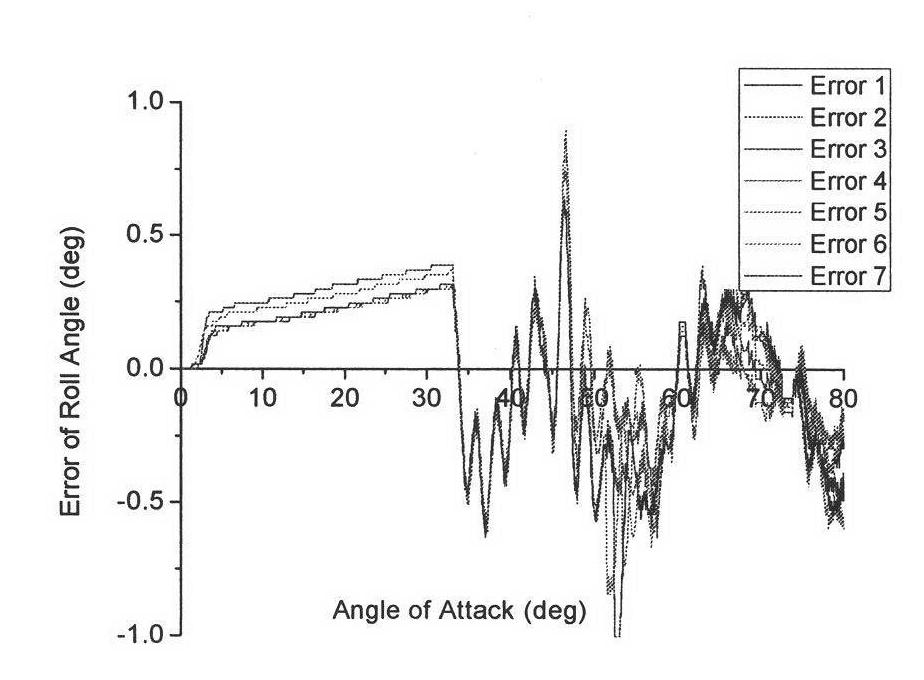

Method and device for jointly and synchronously measuring velocity/pressure during pitching/rolling movement of model

The invention relates to an experiment method for jointly and synchronously measuring model motion track, object plane pressure and space velocity field during pitching-rolling two-degree-of-freedom dynamic simulation motion control process. A pitching motion mechanism and a model support rod are simultaneously driven through an industrial personal computer to respectively drive the model to make pitching and rolling motion along preset tracks. When the model moves to a position requiring data acquisition, the industrial personal computer sends an instruction to pressure measuring equipment and PIV (Particle Image Velocimetry) equipment at multiple points, and the actual motion position, the object plane pressure and the space velocity field of the model are collected synchronously. Experiment results show that two-degree-of-freedom coupled simulation motion has high precision under the control of PID (Proportion Integration Differentiation) closed loop feedback, and the error of synchronous measurement can be reduced by transmitting an external trigger signal of synchronous measurement according to a partitioning method. The joint and synchronous experiment technology provides an effective research means for the analysis of the large angle-of-attack unsteady flow mechanism.

Owner:BEIHANG UNIV

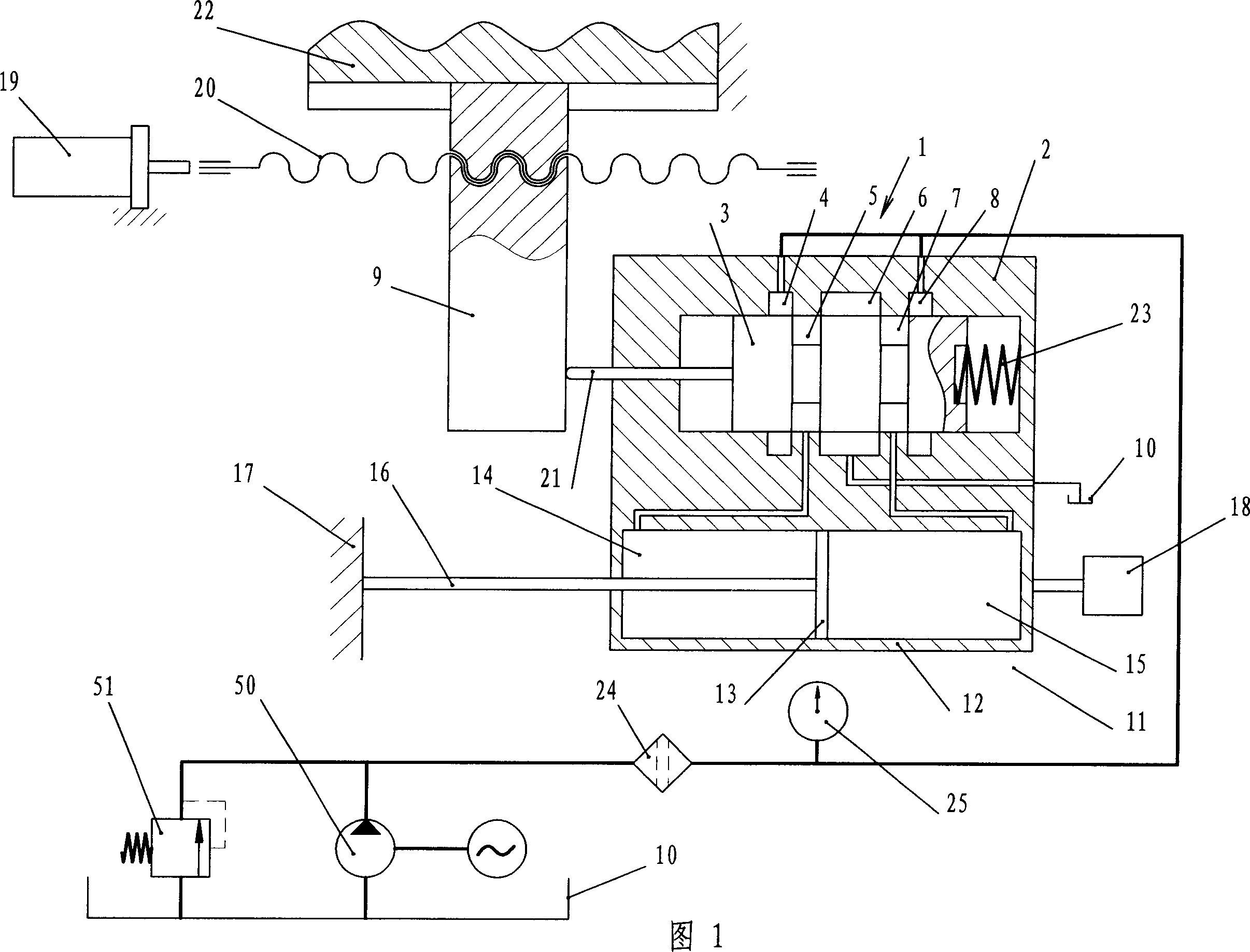

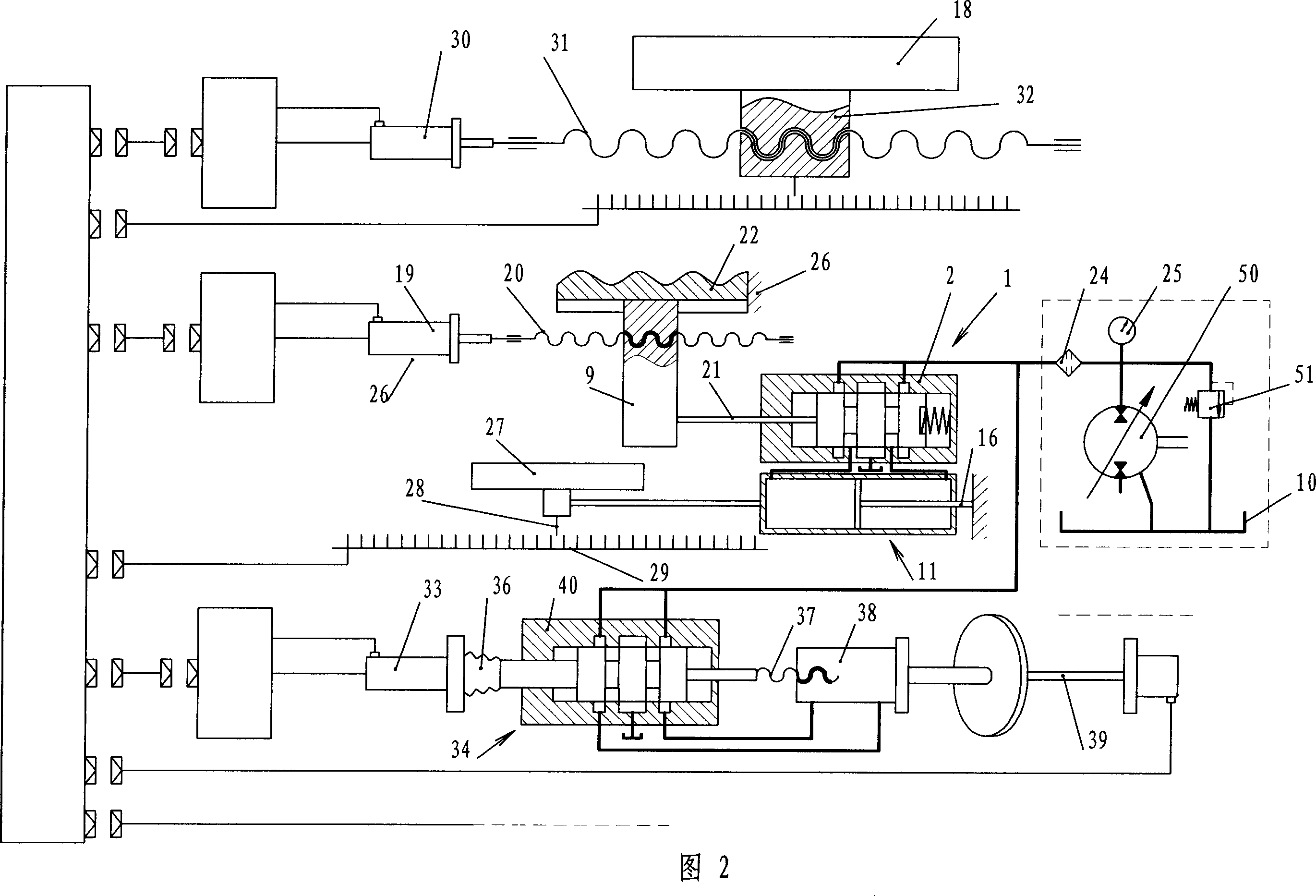

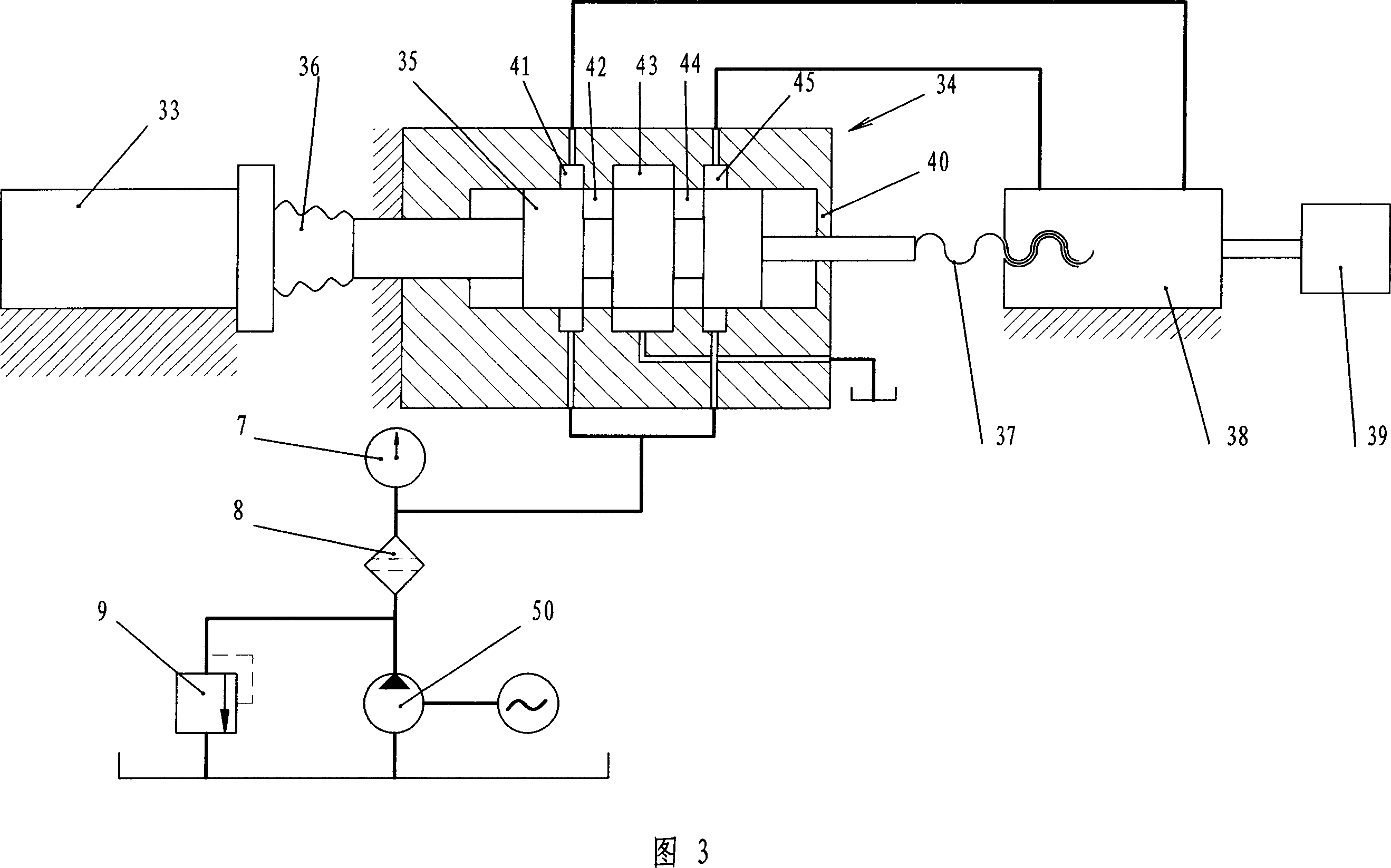

Electrohydraulic servo oil cylinder and numerical control machine tool using same

InactiveCN101008413AServo follow-up motion with high precisionHigh precisionOperating means/releasing devices for valvesServomotor componentsHydraulic cylinderControl system

The invention relates to an electro-hydraulic servo cylinder, comprising a four-edge sliding valve whose base is mounted with a valve element moving left and right. The valve base is fixed on the cylinder whose piston rod is fixed with the frame; the cylinder is connected with the load. The left driving chamber via tube is communicated with the left working chamber, while the right driving chamber via tube is communicated with the right working chamber; one end of valve element is engaged with the dial block mounted on the straight motion output element of straight motion output device. The digit-control machine with said electro-hydraulic servo cylinder comprises a first axle servo driving system, a second axle servo driving system, a third axle servo driving system and a digit-control system, wherein, the second driving system comprises a straight load axle. The invention has high accuracy, quick steering speed, and stable property, which combines the digit control technique with the electro-hydraulic servo motion, with high accuracy in large power.

Owner:路文忠

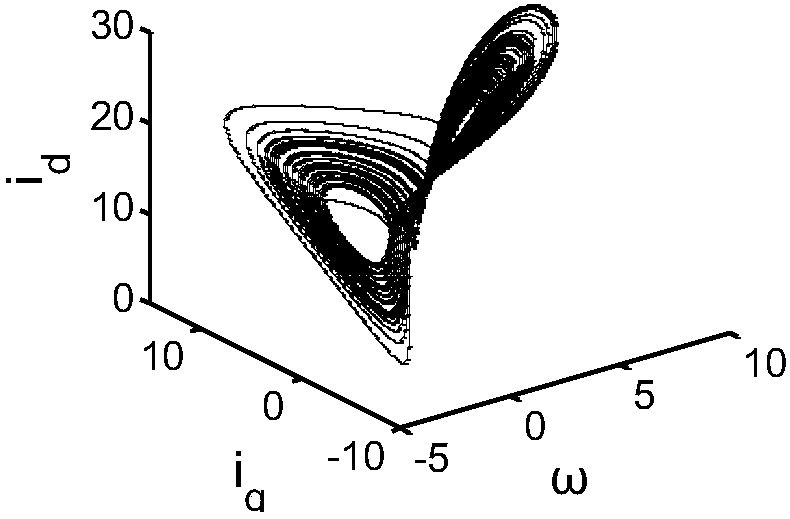

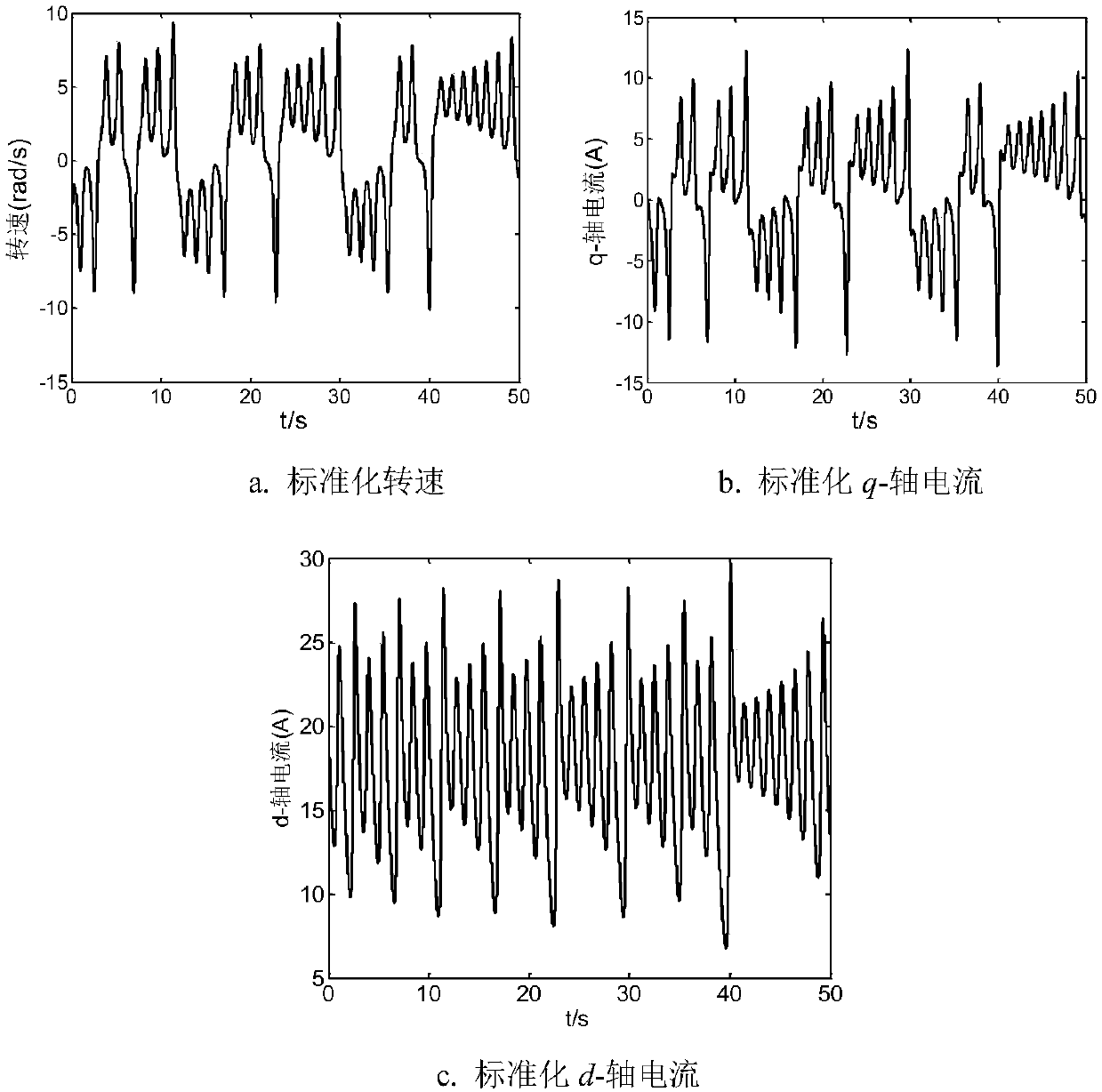

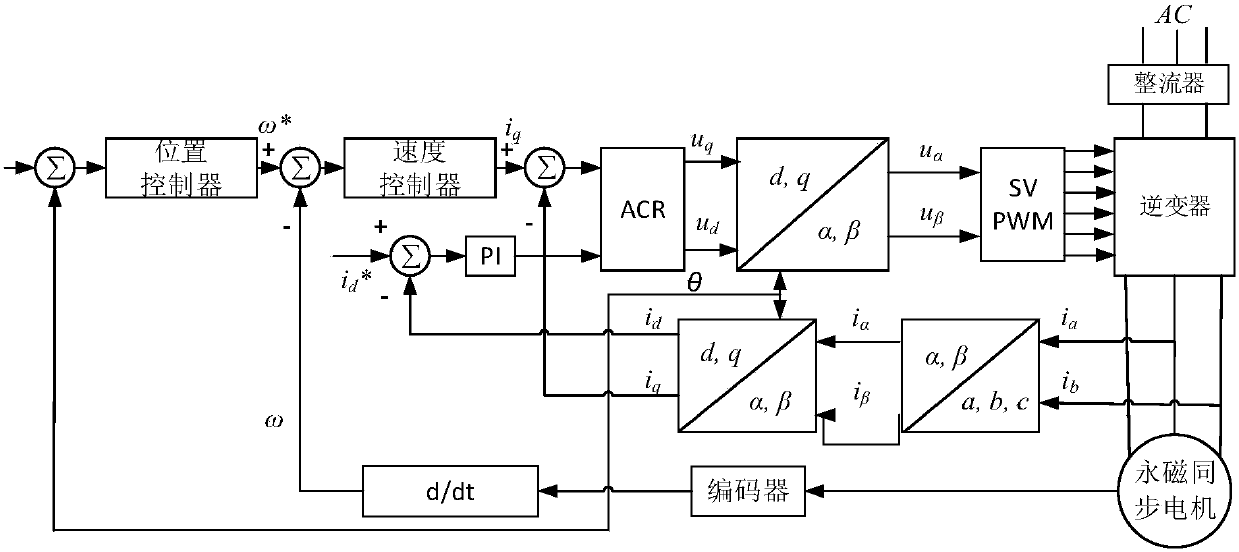

Permanent magnet synchronous motor adaptive sliding mode control method based on dynamic surface

ActiveCN108390606AReduce design difficultyReduced need for precise measurementsAC motor controlElectric motor controlBacksteppingTime lag

The present invention discloses a permanent magnet synchronous motor adaptive sliding mode control method based on a dynamic surface. The method comprises the following steps of: establishing a permanent magnet synchronous motor standardization model with time varying and time lag; applying a single-weight RBF neural network with an approaching function for processing unknown disturbance and unknown system dynamics into the design of a controller; and performing design of an adaptive sliding mode controller in a backstepping frame, wherein a first-order low pass filter is introduced to processthe problem of 'differential item explosion' in a traditional backstepping control, a rapid terminal sliding mode is employed to further improve the tracking precision and obtain better performances,and an adaptive sliding mode control method is employed in a condition of merging of the rapid terminal sliding mode surface, the first-order low pass filter and the RBF neural network. The method reduces the requirements of system accurate modeling and parameter accurate measurement, simplifies the controller design, overcomes the influences of external disturbance, chaos vibration and time varying and time delay on the system and improves the system operation stability and motion precision.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Parallel device multiple-dimensional vibration platform

InactiveCN101055221AHigh movement precisionArbitrary waveform outputVibration testingEngineeringMulti dimensional

A multi-dimensional parallel mechanism vibrating table which relates to middle, small type mechanical vibration measuring field includes a multi-freedom parallel mechanism composed of 3~6 branch chains, a moving platform and a static platform, each branch chain can select one or several motion pairs from revolute pair, shifting pair, column pair, sphere pair or helix pair which are connected by connecting bars therebetween, axes configuration between the motion pairs can be coincident, parallel, upright, intersected or coplane, one end of each branch chain is connected with the moving platform, while another is connected with the static platform. The invention is capable of outputting arbitrary waveform with simple structure, low costs, great firmness, high motion precision and convenience for control.

Owner:JIANGSU UNIV

Walking and positioning device for walking and positioning on workpiece

The invention discloses a walking and positioning device for walking and positioning on a workpiece. The device comprises a walking mechanism, a positioning mechanism, an actuator and a central processing unit, wherein the walking mechanism comprises a first walking unit, a second walking unit and a driving unit; the positioning mechanism comprises a positioning unit for positioning in a first direction and a positioning unit for positioning in a second direction, wherein the first direction is vertical to the second direction; the positioning unit for positioning in the first direction comprises a guide plate, a driving assembly which is arranged on the guide plate in the first direction, and a guide rail in the first direction; the positioning unit for positioning in the second direction comprises a driving assembly which is arranged in the second direction of the second walking unit, and a guide rail in the second direction; the actuator is arranged on the positioning unit for positioning in the first direction; and the central processing unit is used for controlling the mechanisms. The walking and positioning device can meet higher requirements on motion accuracy and positioning accuracy so as to guarantee automatic assembly quality, also can reduce the requirements on the conventional tools as much as possible, and avoids changing the conventional tools.

Owner:COMAC +1

Three-coordinate positioner with large stroke, high rigidity and high precision

InactiveCN101850512AGuaranteed stabilityIncrease stiffnessAssembly machinesWork holdersControl systemEngineering

The invention discloses a three-coordinate positioner with large stroke, high rigidity and high precision. A main pillar and an auxiliary pillar are arranged on a base; a main pillar is provided with a Z-axis transmission unit; a Z-axis telescopic column is connected with the main pillar by the Z-axis transmission unit; the Z-axis telescopic column is connected with the auxiliary pillar by a roller sliding block; the Z-axis telescopic column is provided with an X longitudinal sliding plate and a Y transversal sliding plate; the X longitudinal sliding plate is provided with an X-axis transmission unit; the Y transversal sliding plate is provided with a Y-axis transmission unit; the Y transversal sliding plate is fixed with a bulb clamping device or vacuum adsorption equipment; a process bulb is arranged in the bulb clamping device; the positioner is controlled by a control system; and the main pillar and the auxiliary pillar are provided with lift working tables. The invention can make movement in three directions of X, Y and Z, can realize linkage control and has high movement precision and accurate positioning; the positioner has big safety working stroke and high rigidity; the Z direction is provided with a displacement and force sensor positioner, and thereby, the three-coordinate positioner has stable and reliable support. The three-coordinate positioner is the basic unit for the digital posture adjustment of aircraft components.

Owner:ZHEJIANG UNIV +1

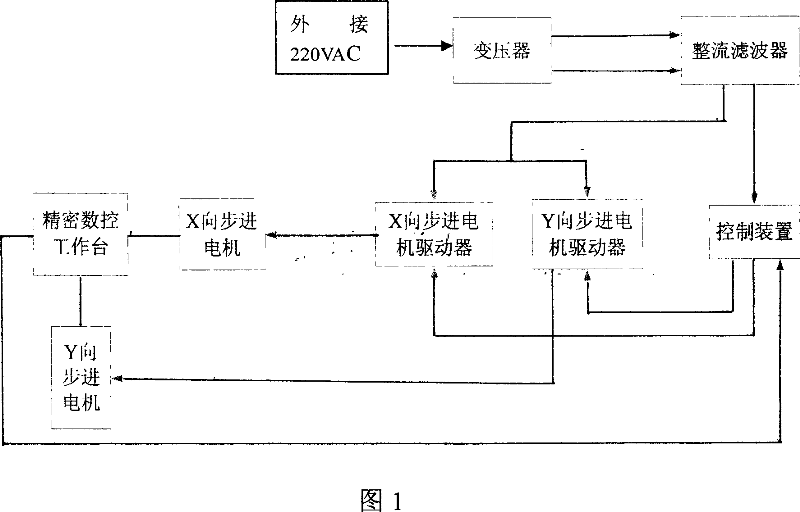

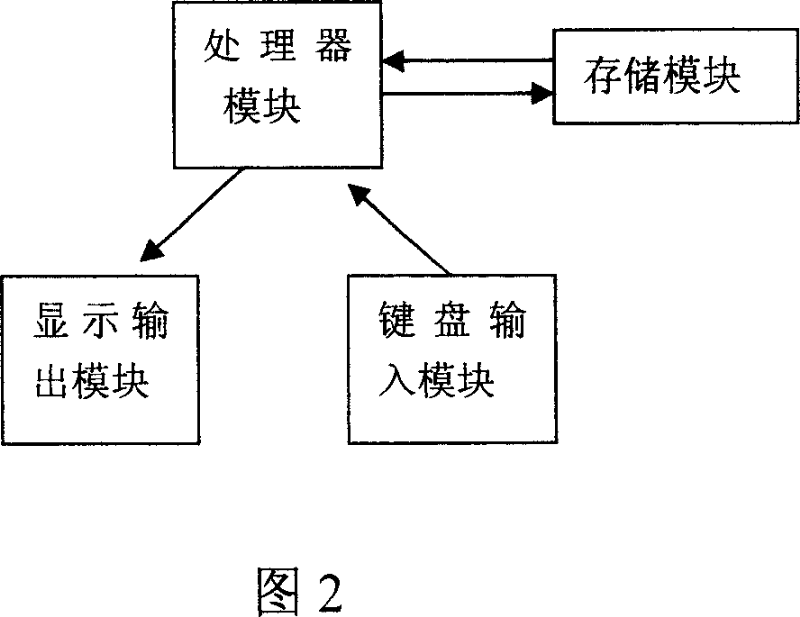

Phantom model sport platform and method for sport simulating

InactiveCN101036596ASimple structureEasy maintenanceSurgical instrument detailsDiagnostic recording/measuringNumerical controlMotor drive

The invention discloses a phantom motion platform and a method for processing the motion simulation, wherein the phantom motion platform includes a telemechamic apparatus, a step motor driver and a control device. The telemechamic apparatus is a precise numerical control table matching with two step motors. The step motors are respectively connected with the step motor driver, while the step motor driver and the precise numerical control table are connected with the control device. The method to process the motion simulation is: the parameters of the motion trace, the amplitude and the rotate speed etc are set in advance, and the control device computes the required frequency and sends to the drivers, so the control step motor drives the precise numerical control table to move. The invention has simple structure, high kinematic accuracy, which can process the straight line, the diamond and ellipse motion having different frequency and amplitude, and systematacially simulate the motion of the human body apparatus, and provides effective means for the clinical diagnosis, quality assurance and the quality control.

Owner:SHANDONG TUMOR HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com