Three-arm type noncooperative target docking mechanism

A non-cooperative target and docking mechanism technology, applied in the field of satellite docking mechanism, can solve the problems of low docking success rate and extremely high motion precision requirements, and achieve the effect of improved reliability, low motion precision requirements, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

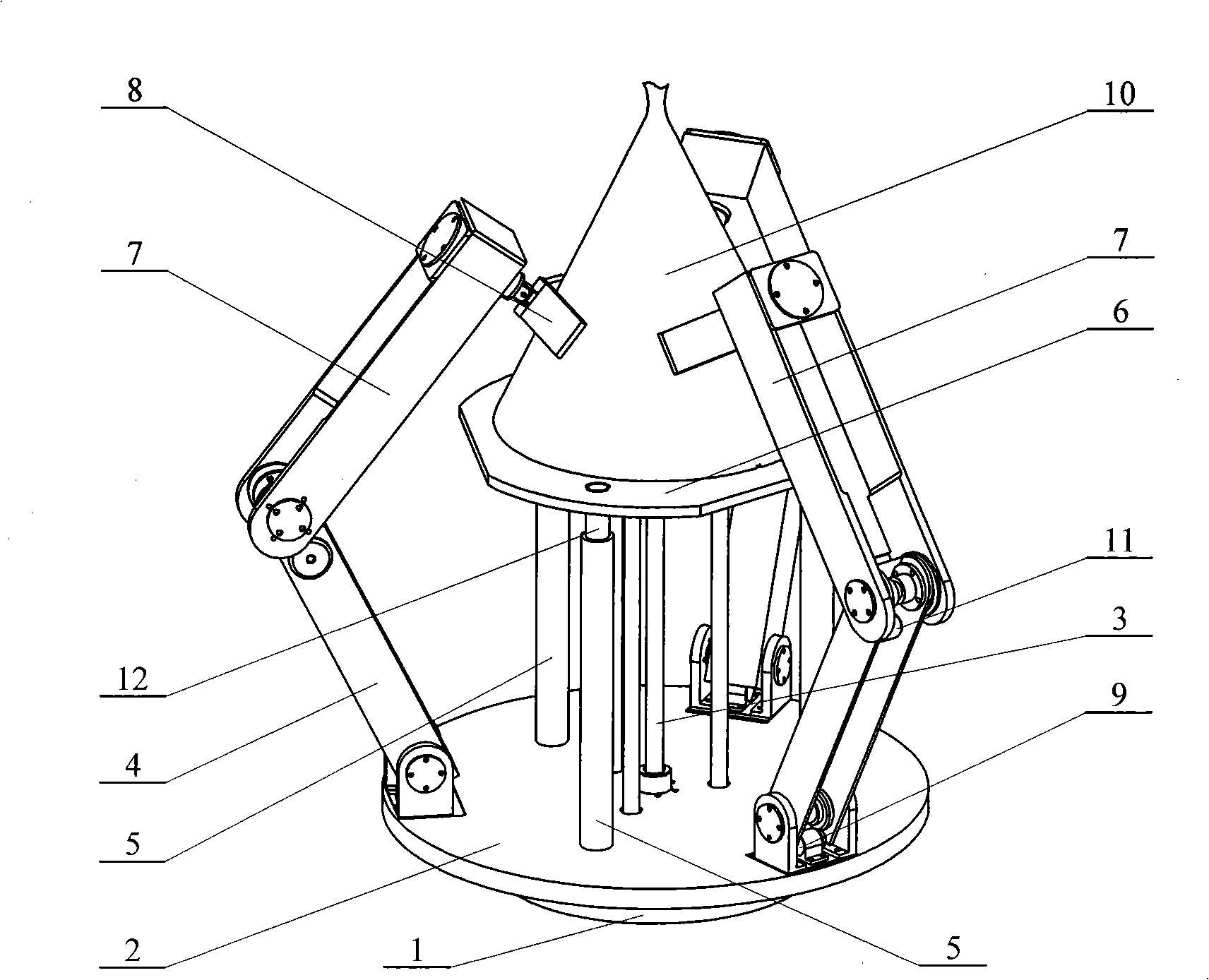

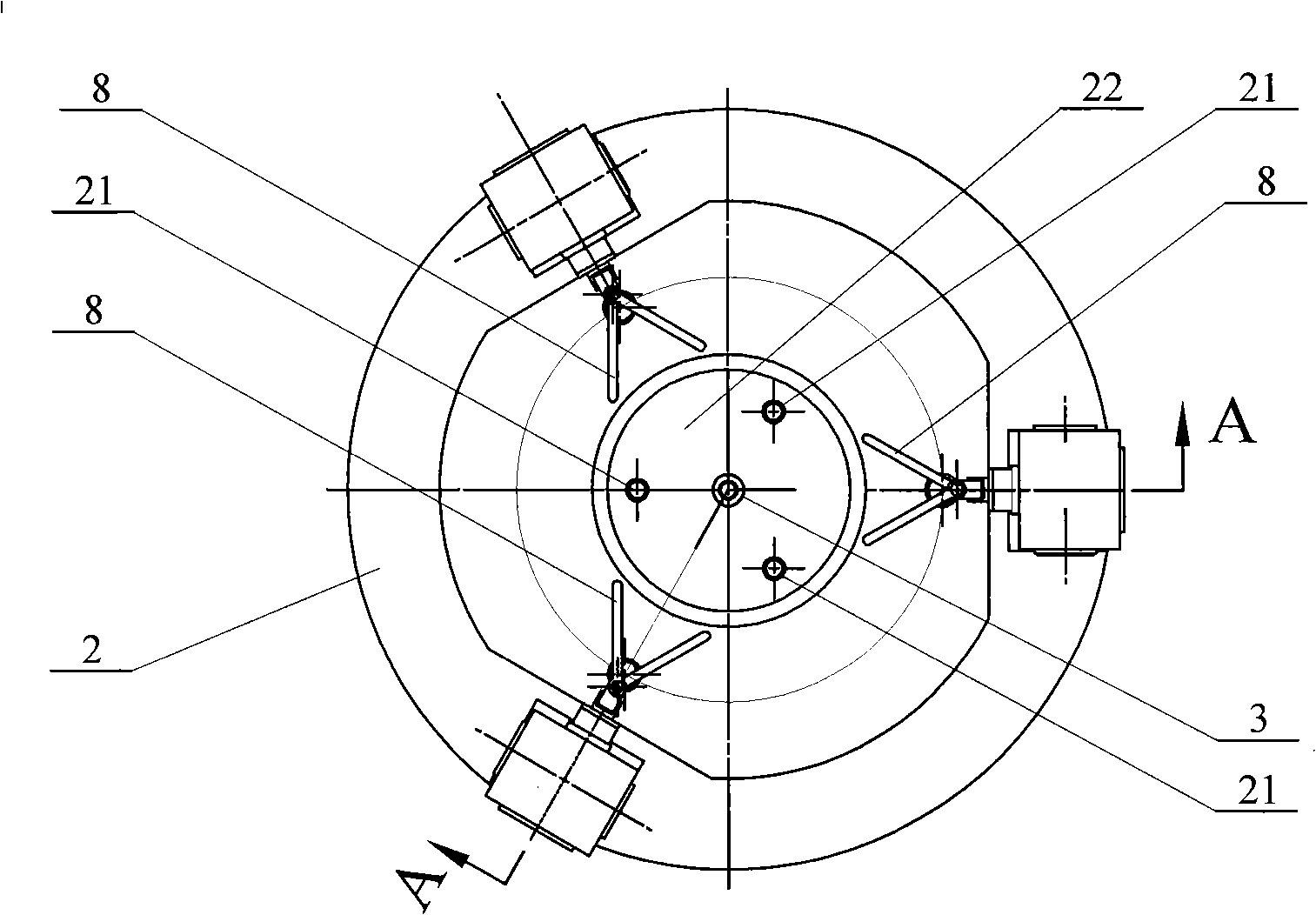

specific Embodiment approach 1

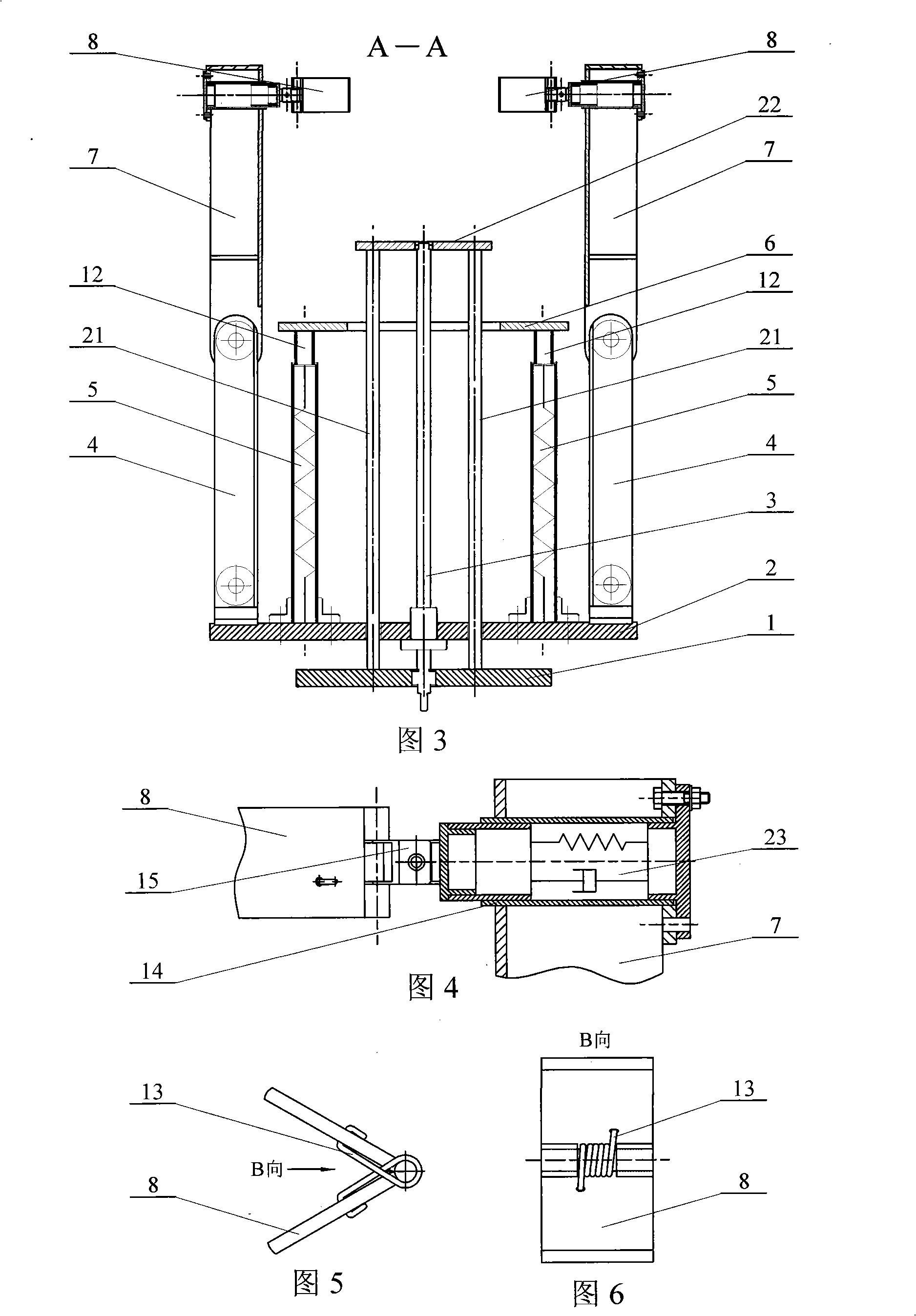

[0006] Specific implementation mode one: (see figure 1 ~ FIG. 6) This embodiment consists of a fixed platform 1, a support platform 2, a screw 3, three mechanical arms 4, three buffer columns 5, a target docking platform 6, three mechanical arms 7, and three ends Actuator, three No. 1 motors 9, three No. 2 motors 11, three buffer pistons 12, three slide rods 21 and a top plate 22. The fixed platform 1 is installed on the tracking satellite or other fixed planes. The fixed platform 1 is set On the lower side of the support platform 2, three mechanical arms 4 are arranged on the periphery of the support platform 2 at an angle of 120°, one end of the mechanical arm 4 is hinged with the support platform 2, and the other end of the mechanical arm 4 is connected to the One end of the small arm 7 of the mechanical arm is hinged, the other end of the small arm 7 of the mechanical arm is connected to the end effector, a No. 1 motor 9 is connected between the large arm 4 of each mechan...

specific Embodiment approach 2

[0007] Specific embodiment two: (referring to Fig. 3~Fig. 6) the end effector of this embodiment comprises hand claw 8, torsion spring 13, buffer bar 14 and Hooke hinge 15, and buffer bar 14 is fixed on the top end of mechanical arm forearm 7, One end of the Hooke hinge 15 is connected with the buffer rod 14, and the other end of the Hooke hinge 15 is connected with the claw 8, and the claw 8 is made up of two plates, and a torsion spring 13 is fixedly connected between the two plates. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0008] Embodiment 3: (see FIG. 3 and FIG. 4 ) The end effector of this embodiment further includes a spring damper 23 , and the spring damper 23 is arranged between the buffer rod 14 and the forearm 7 of the mechanical arm. Other compositions and connections are the same as those in the second embodiment.

[0009] In the present invention, the end effector is composed of the claw 8, the torsion spring 13, the buffer rod 14 and the Hooke hinge 15. Because the small arm 7 of the mechanical arm is constantly moving closer to the nozzle 10 under the drive of the motor 11, after the claw 8 contacts the nozzle 10, and under the action of the contact force, the claw 8 gradually opens, and the two sides of the torsion spring 13 The two ends are respectively fixed on the two plates. As the opening of the claws 8 increases, the torque of the torsion spring 13 also increases. The clamping force makes the nozzle 10 press down on the target docking platform 6, the buffer piston 12 compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com