Device and method for supporting large thin-walled parts

A technology for large thin-walled parts and supporting devices, applied in positioning devices, supports, metal processing machinery parts, etc., can solve problems such as ineffective support of workpieces, deformation, and affecting the processing accuracy of parts, and achieve easy and precise control and difficult control Low, chatter prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

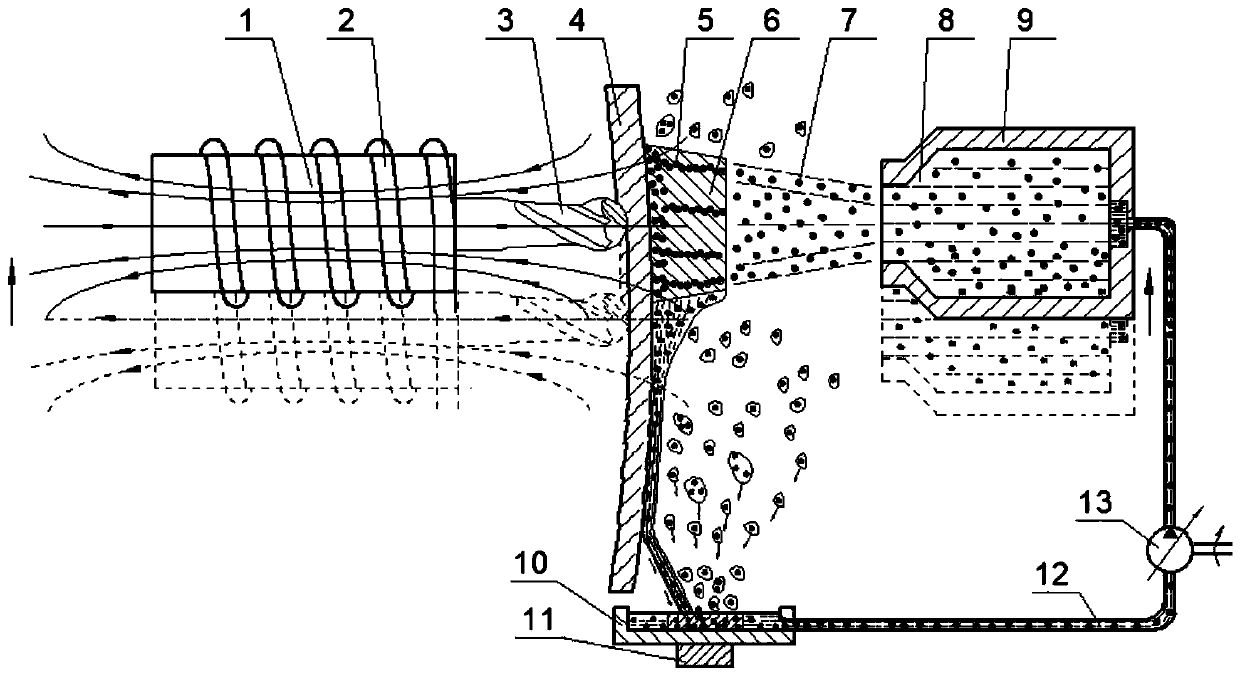

[0023] A supporting device for large thin-walled parts, including a processing device, a supporting device and an auxiliary device for realization. The workpiece 4 is located in the middle of the processing device and the supporting device, and its periphery is clamped in a flexible clamping manner.

[0024] The processing device includes a cutter 3, a coil 2, an iron core 1 and a servo drive device. The cutter moves according to the processing path under the control of the servo drive device, so as to realize the removal of workpiece material. The function of the coil 2 is to precisely control the strength of the magnetic field by changing the magnitude of the current in the coil 2, thereby realizing the control of the magnitude of the supporting force.

[0025] The support device includes nozzle 9 , m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com