Direct driving type accurate turn plate

A direct drive, precise technology, applied in the direction of large fixed members, roller bearings, electromechanical devices, etc., can solve the problems affecting the performance of the torque motor, affecting the stiffness of the torque motor, affecting the performance of the encoder, etc., to achieve easy processing and assembly, overcome Effects of vibration, good precision continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

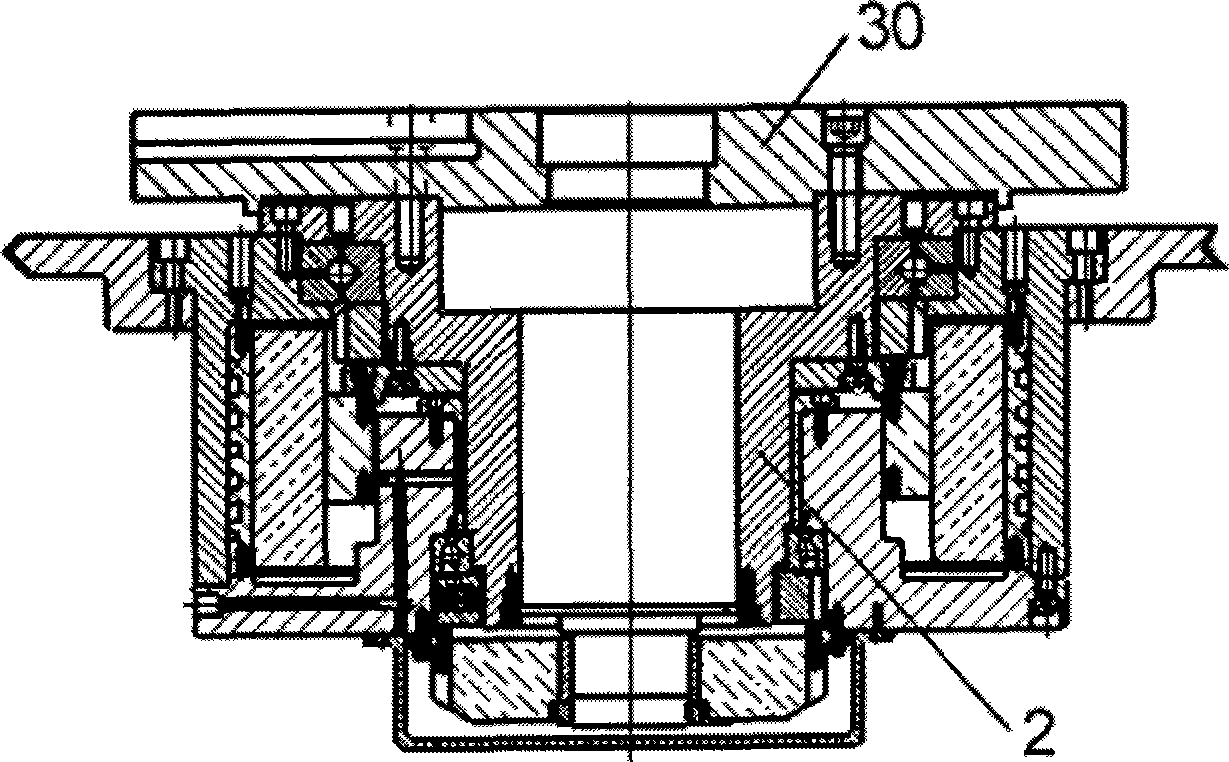

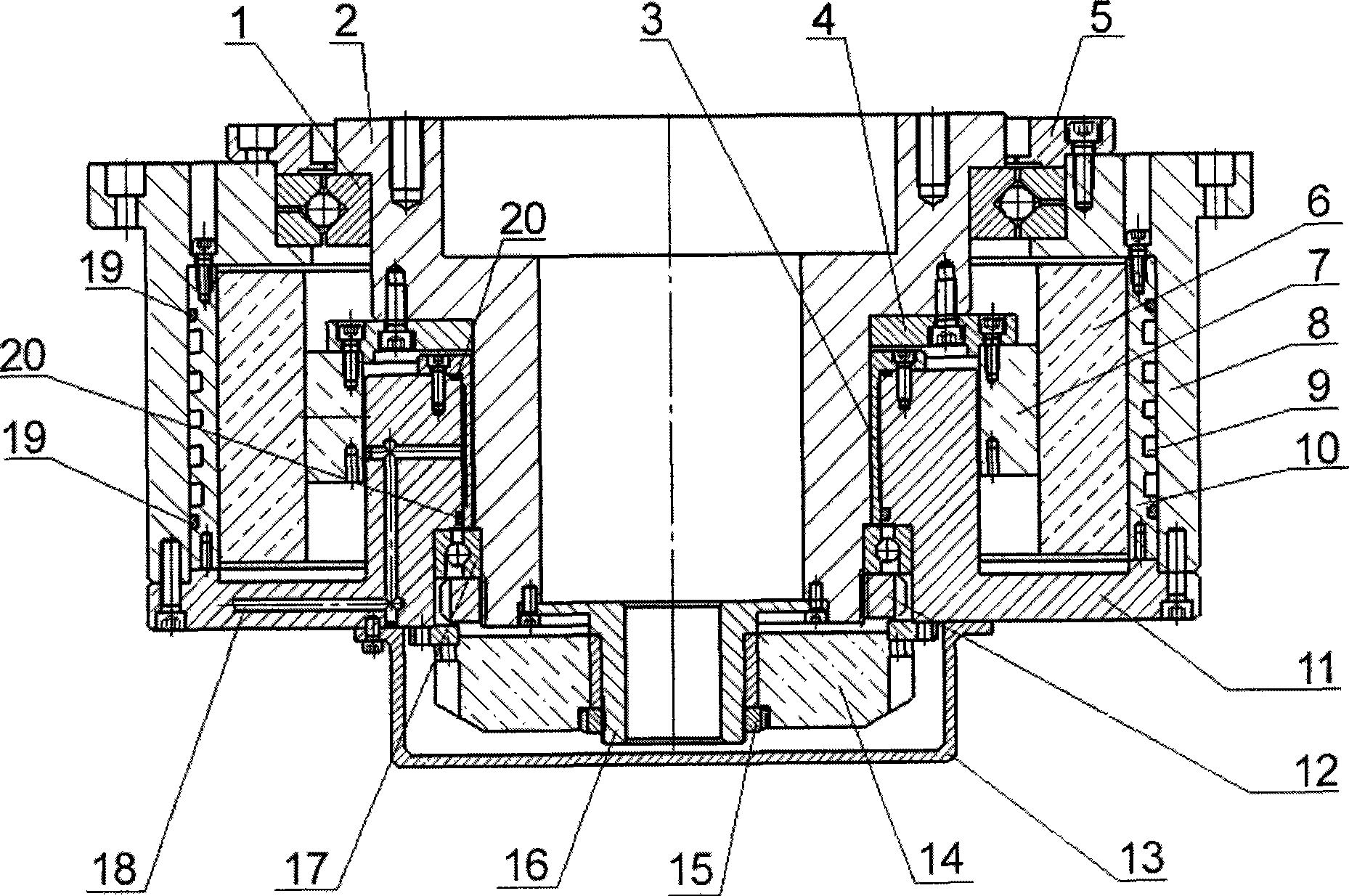

[0032] Example: such as figure 1 As shown, a direct-drive precision turntable includes a workbench 30 and a torque motor. Such as figure 2 As shown, the torque motor includes a motor housing 8, a bearing sleeve 11, a water ring 10, a stator 6, a brake disc 3, an encoder 14, a motor cover 13, a main shaft 2, a rotor 7, and a hollow shaft 16. The workbench 30 is fixedly connected directly with the main shaft 2 of the torque motor.

[0033] Such as figure 2 As shown, the motor housing 8 is fixedly connected to the stator 6 to form a stationary part, and the main shaft 2 is fixedly connected to the rotor 7 to form a rotating part. A hollow shaft 16 is fixed at the end of the main shaft 2, and an encoder 14 is connected to the hollow shaft 16. The bearing sleeve 11 is fixedly connected with the motor housing 8 .

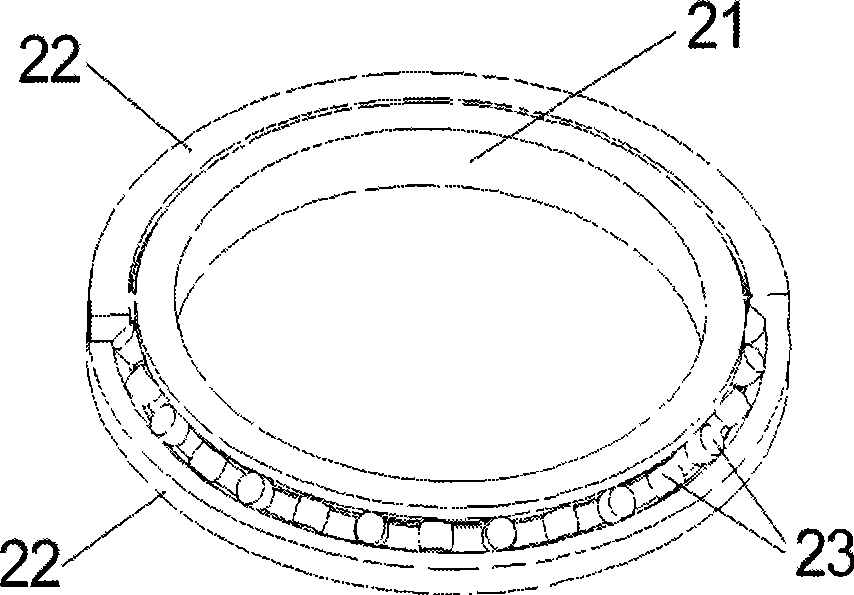

[0034] An arc crossed roller bearing 1 is arranged between the motor housing 8 and the main shaft 2 . Such as image 3 As shown, the arc crossed roller bearing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com