Wafer platform mask platform synchronous control system of step-scan photoetching machine

A step-and-scan, synchronous control technology, applied in opto-mechanical equipment, control using feedback, microlithography exposure equipment, etc., can solve the problems of waste, quality decline of finished products, scanning synchronization error exceeding the limit, etc., to achieve fast response speed , reduce synchronization error, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

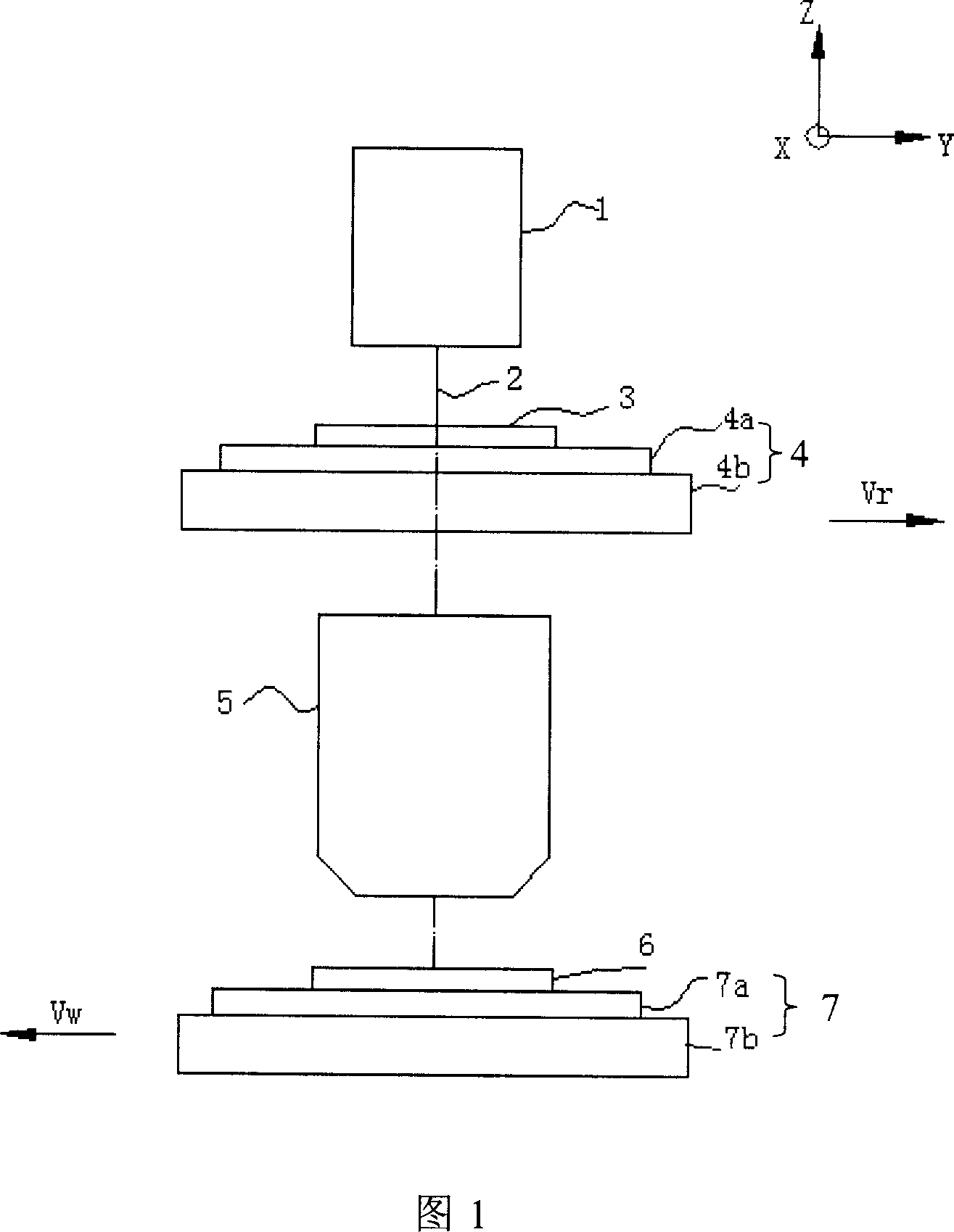

[0034] As shown in FIG. 3 , the wafer stage mask stage synchronization control system of the present invention includes four modules: a main control module 13 , a wafer stage control module 12 , a mask stage control module 10 , and a synchronization control module 11 . The main control module 13 includes a main control CPU card 101, whose function is to send scanning instructions to each module and specify parameters such as scanning synchronization error, scanning speed and acceleration. The wafer stage control module 12 includes: a motion control card 102a, and a position data acquisition card 103a. The former is responsible for adjusting the motion trajectory, speed and acceleration of the wafer stage, and the latter is responsible for collecting the position information of the wafer stage in real time and feeding it back to the motion control card 102a. The mask stage control module 10 includes: a motion control card 102b, and a position data acquisition card 103b. The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com