Flexible switching system for vehicle welding production line

A welding production line and switching system technology, which is applied to welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of restricting production efficiency, and can not realize the synchronization of loading and welding operations, so as to reduce development risks, The effect of improving speed and ensuring versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

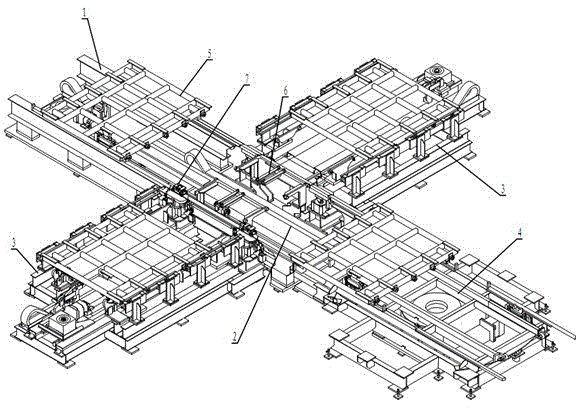

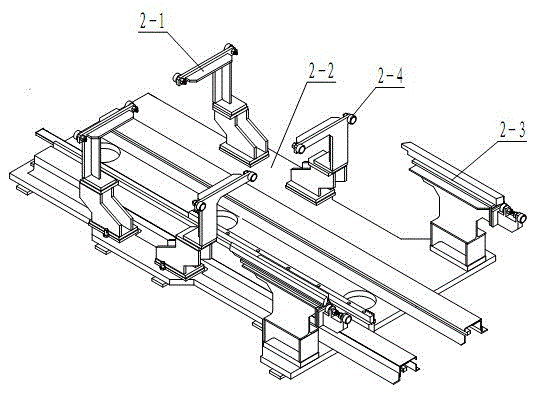

[0028] 1, the present invention includes the upper part mechanism 1, the transition track 2, the storage mechanism 3, the turntable 4, the trolley 5, the steering track switching mechanism 6 and the lifting track switching mechanism 7. The upper part mechanism 1 and the turntable 4 are arranged in At both ends of the transition rail 2, the storage mechanism 3 is arranged on both sides of the transition rail 2, the steering rail switching mechanism 6 is installed at the junction of the storage mechanism 3 and the transition rail 2, and the lifting rail switching mechanism 7 is installed at On the transition track 2, the trolley 5 can move between the loading mechanism 1, the storage mechanism 3 and the turntable 4.

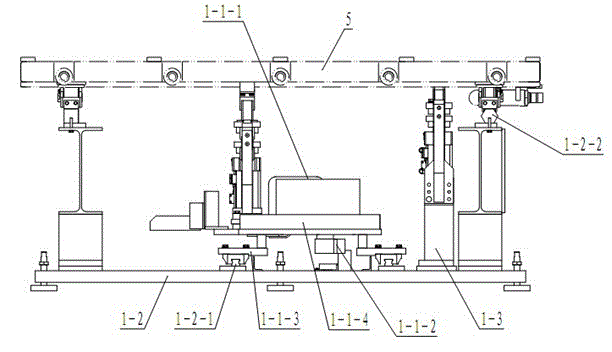

[0029] See figure 1 , figure 2 , image 3 The upper part mechanism 1 of the present invention includes a longitudinal traction device 1-1, an upper part mechanism body 1-2, and an upper part mechanism trolley positioning device 1-3. The longitudinal traction device 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com