Permanent magnet synchronous motor adaptive sliding mode control method based on dynamic surface

A permanent magnet synchronous motor, adaptive sliding mode technology, used in motor generator control, motor control, AC motor control and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below in conjunction with accompanying drawing.

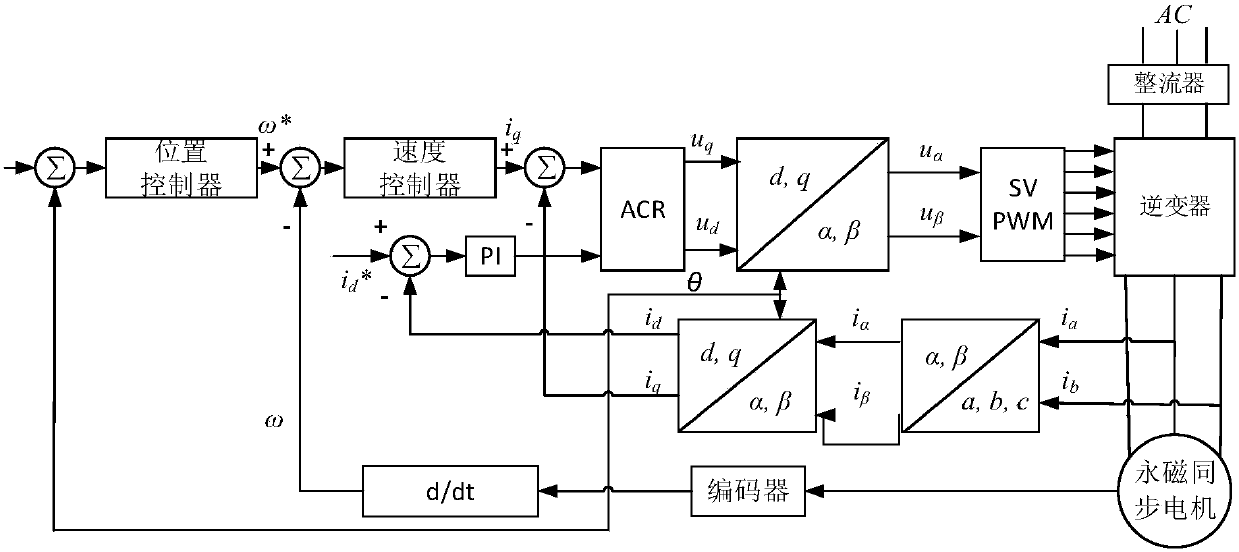

[0090] Control method provided by the invention comprises the steps:

[0091] Step 1. Establish a standardized model of permanent magnet synchronous motor;

[0092] The mathematical model of permanent magnet synchronous motor can be written as

[0093]

[0094] in Indicates the d-axis current (A), Indicates the q-axis current (A), Indicates the speed (rad / s), Indicates time(s), Indicates the d-axis voltage (V), Indicates the q-axis voltage (V), Indicates load torque (Nm), R indicates stator coil resistance (Ω), L d Indicates the d-axis winding inductance (H), L q Indicates the q-axis winding inductance (H), ψ r Indicates permanent magnet flux (Wb), B indicates viscous damping coefficient (N / rad / s), J indicates inertia pole moment (kgm 2 ), n p Indicates the number of pole pairs.

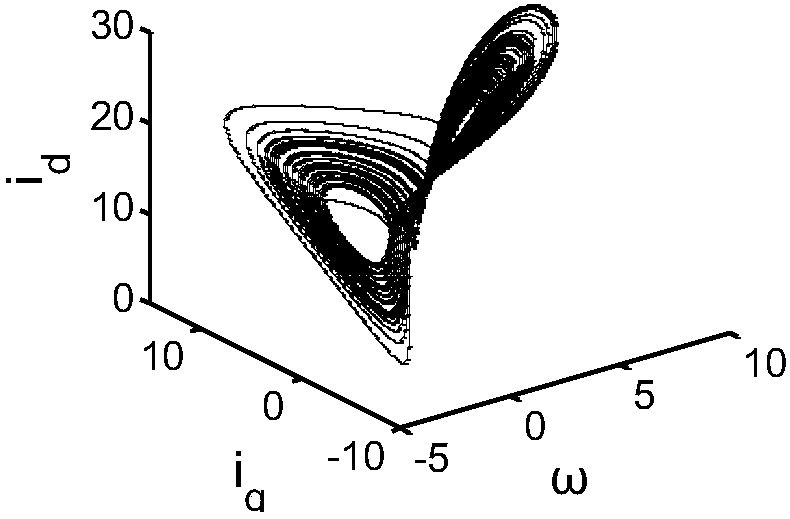

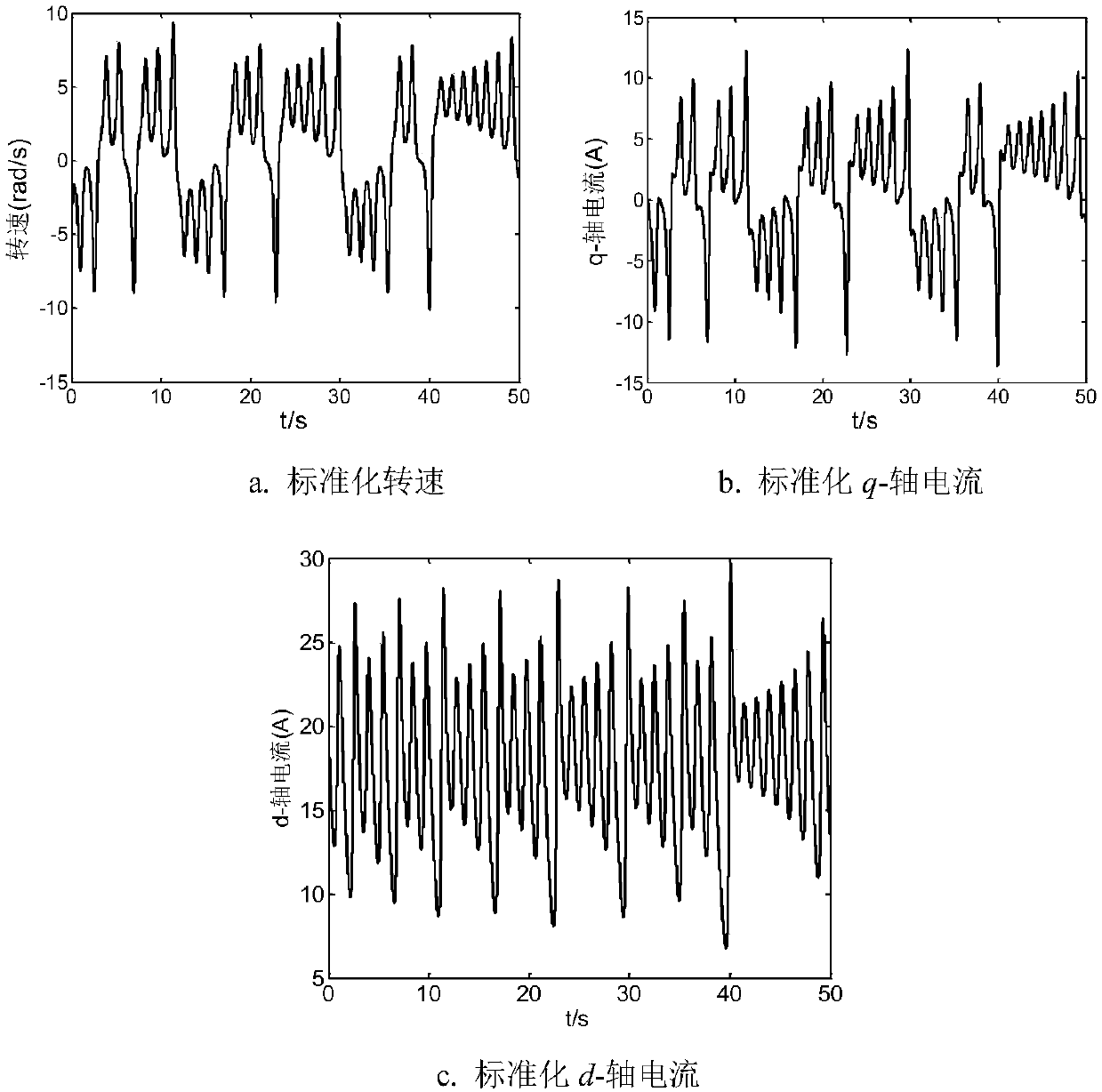

[0095] By solving the permanent magnet synchronous motor control proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com