Patents

Literature

93results about How to "Eliminate strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

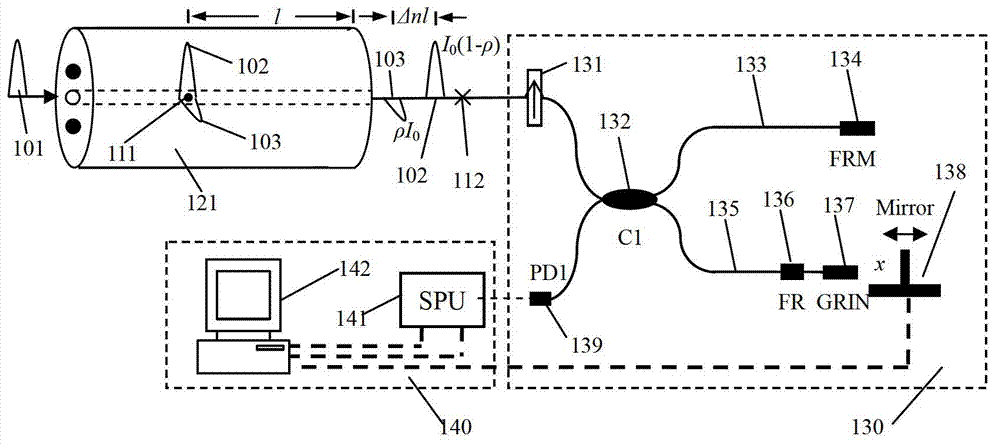

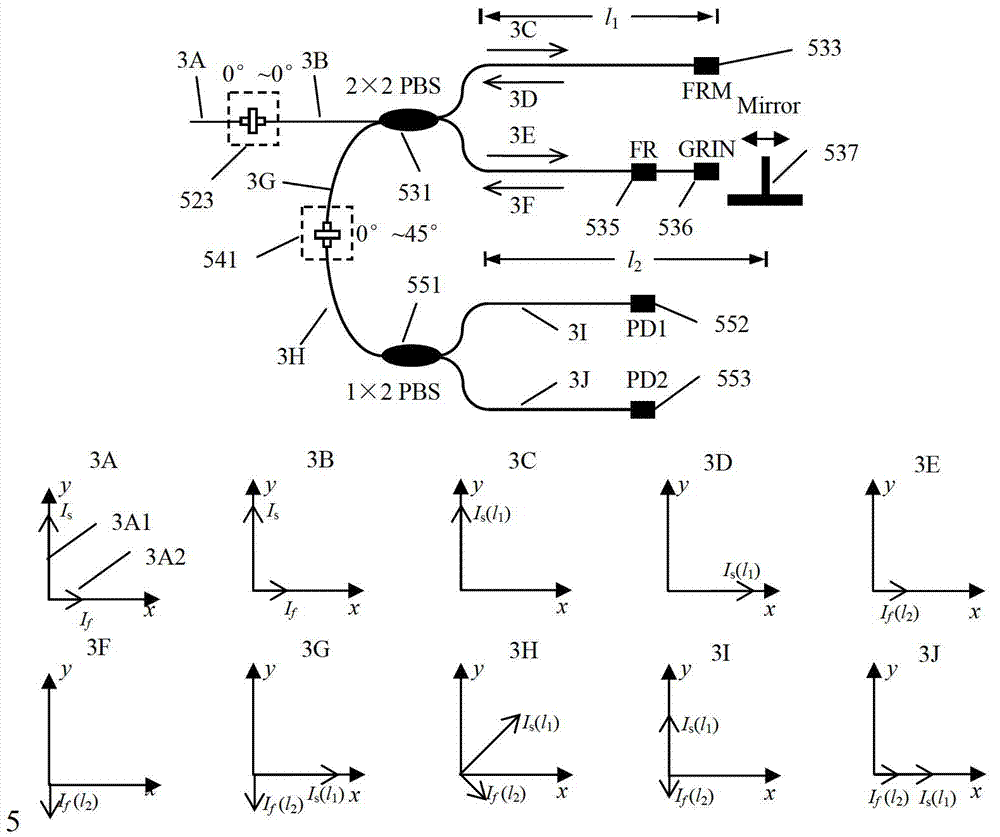

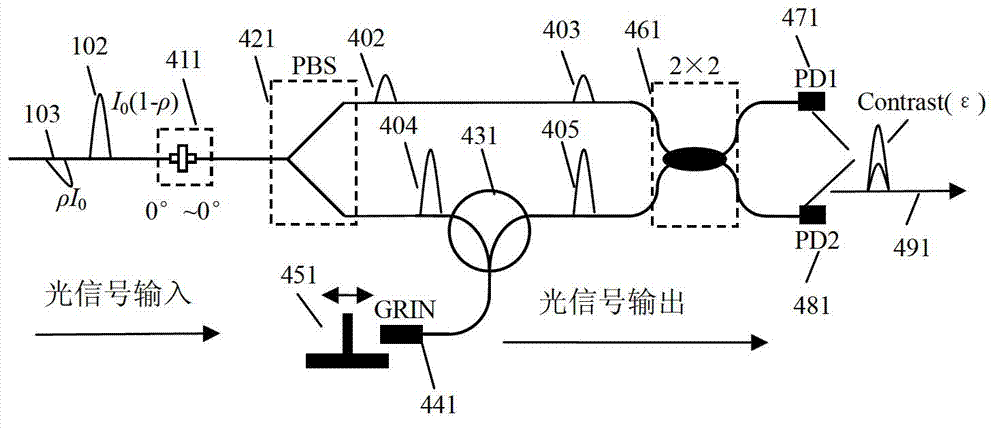

All-fiber testing device for testing polarization crosstalk of optical device

ActiveCN102928198AImprove stabilityEliminate back lightTesting optical propertiesBeam splittingPolarizer

The invention provides an all-fiber testing device for testing the polarization crosstalk of an optical device. The all-fiber testing device comprises a wide-spectrum light source (501), a polarizer (511), a to-be-tested polarizing device (522), an optical path correlator (530), a difference detector (550) and a photoelectric signal conversion and signal recording device (560), wherein the wide-spectrum light source (501) is connected with the to-be-tested optical fiber device (522) through the polarizer (511) and a first rotary connector (521) and is connected with the optical path correlator (530) with a polarization beam splitting Michelson structure through a second rotary connector (523); and the optical path correlator (530) is connected with the polarization difference detector (550) through a third rotary connector (541) and is connected with an interference signal detecting and processing device (560). The all-fiber testing device has the advantages of small size, high measurement accuracy, high temperature and vibration stability and the like, so that the all-fiber testing device is widely applied to high-accuracy measurement and analysis of the polarization performance of the optical device.

Owner:HARBIN ENG UNIV

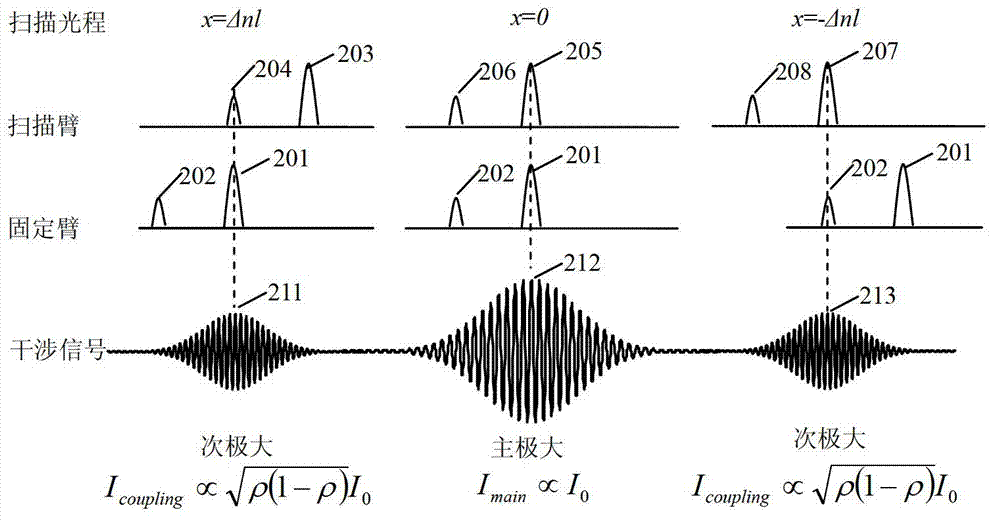

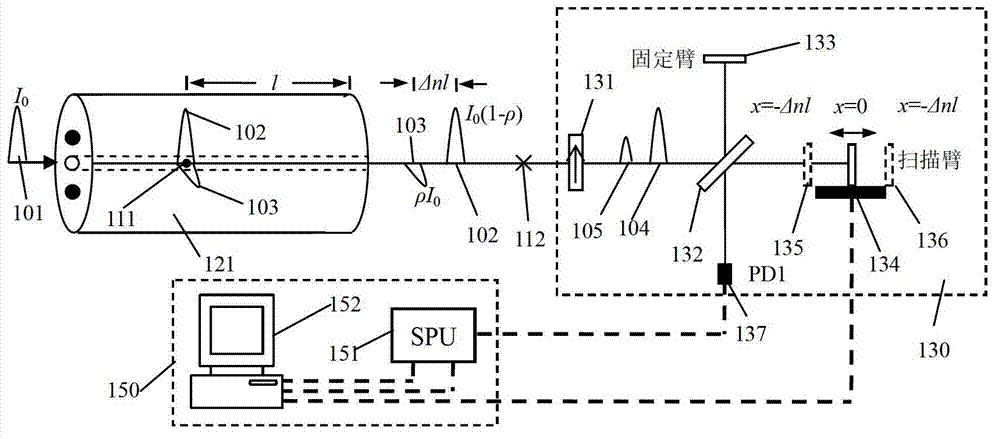

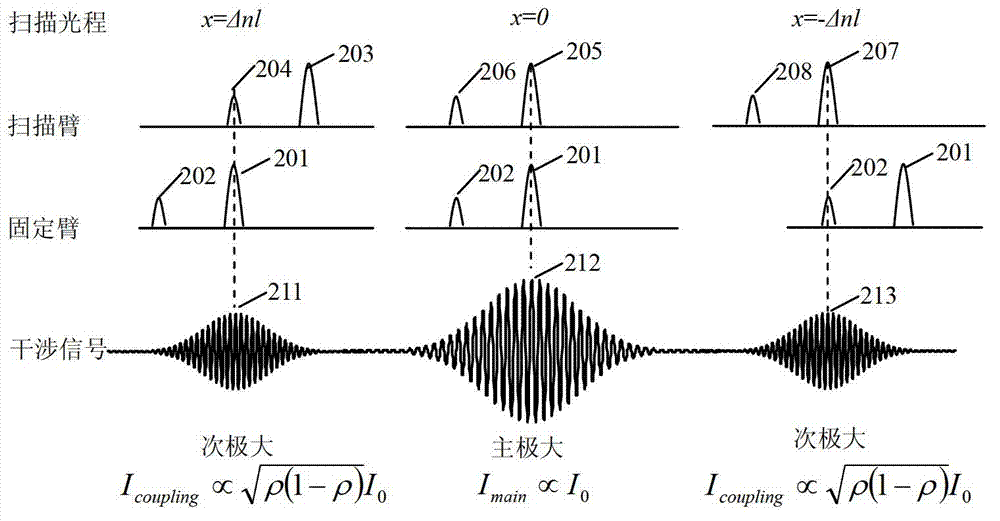

Device and method for improving polarization crosstalk measurement performance of optical device

ActiveCN102928199AFunction increaseIncrease signal amplitudeTesting optical propertiesCrosstalk measurementPolarizer

The invention provides a device and a method for improving polarization crosstalk measurement performance of an optical device. The device comprises a wide spectrum light source (301), a polarizer (311), a polarization device to be tested (632), an optical path correlator (640) and a polarization crosstalk detection and signal recording device (150), wherein the wide spectrum light source (301) is connected with the optical device to be tested (632) by the polarizer (311) and a first rotation connector (631) and then is connected with the optical path correlator (640) by a second rotation connector (633). By the device and the method, noise amplitude can be greatly suppressed, the sensitivity of polarization crosstalk measurement is improved, the dynamic range of polarization crosstalk measurement is expanded, and the device and the method are widely used for high-precision measurement and analysis on polarization performance of the optical device.

Owner:HARBIN ENG UNIV

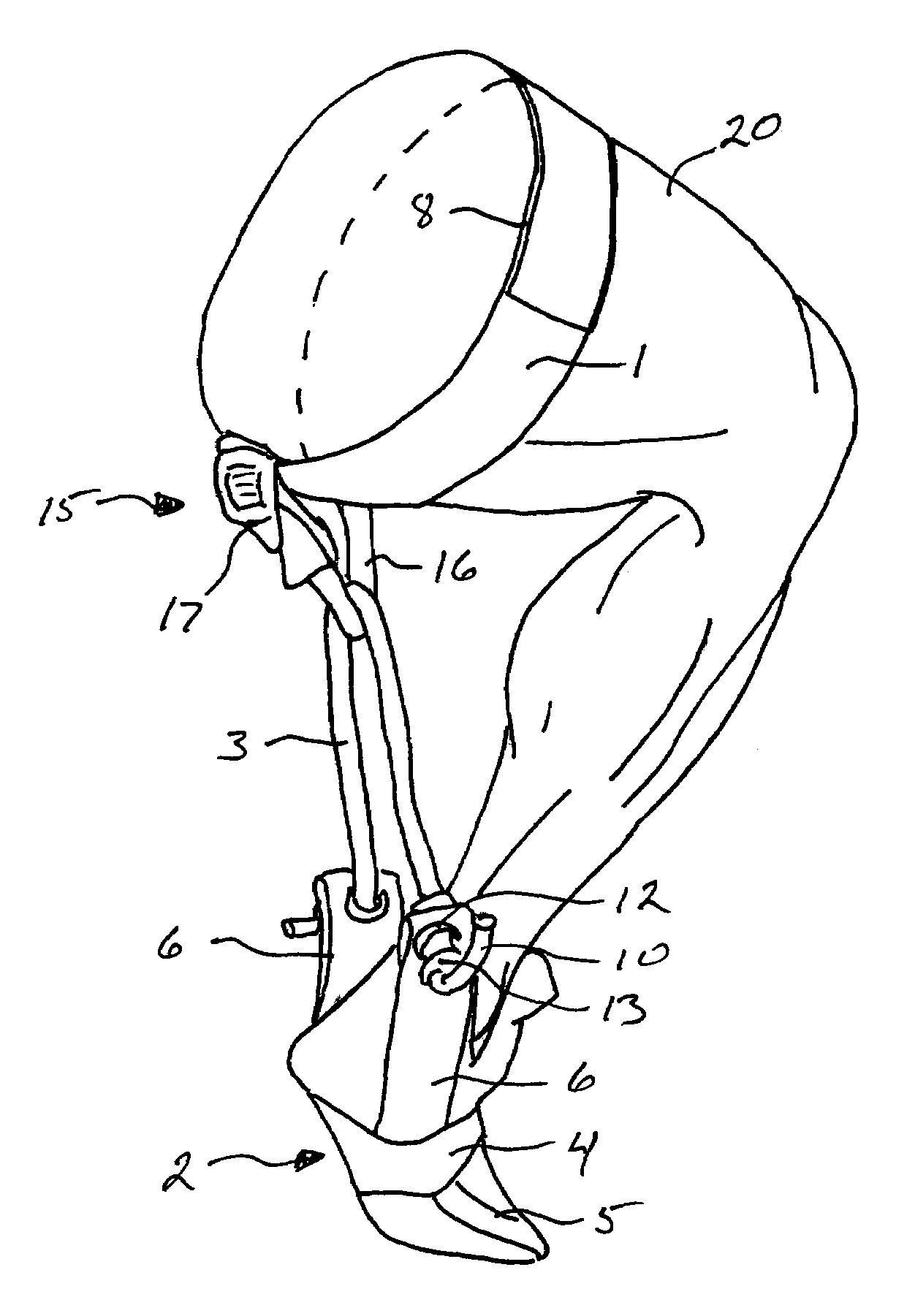

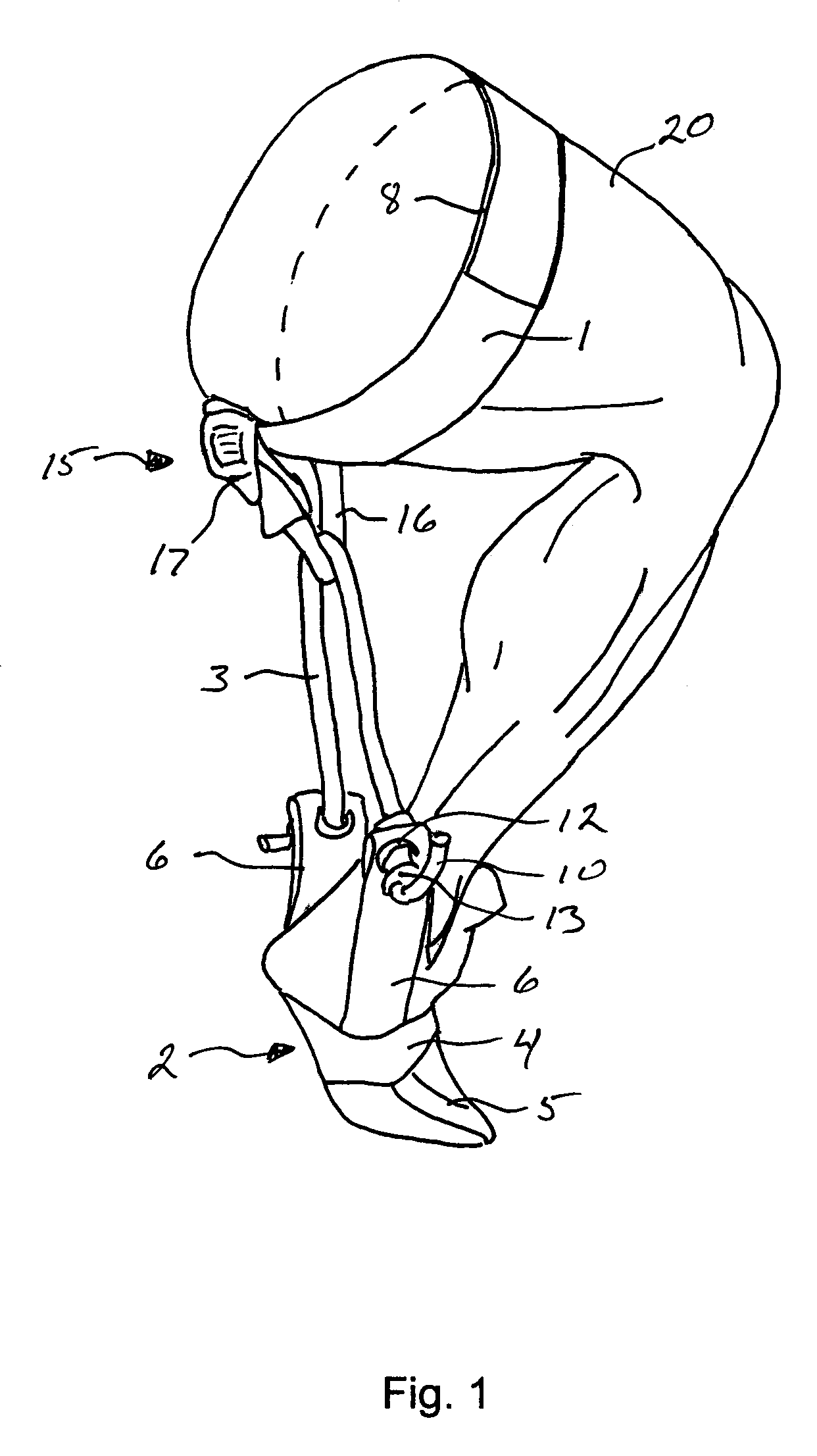

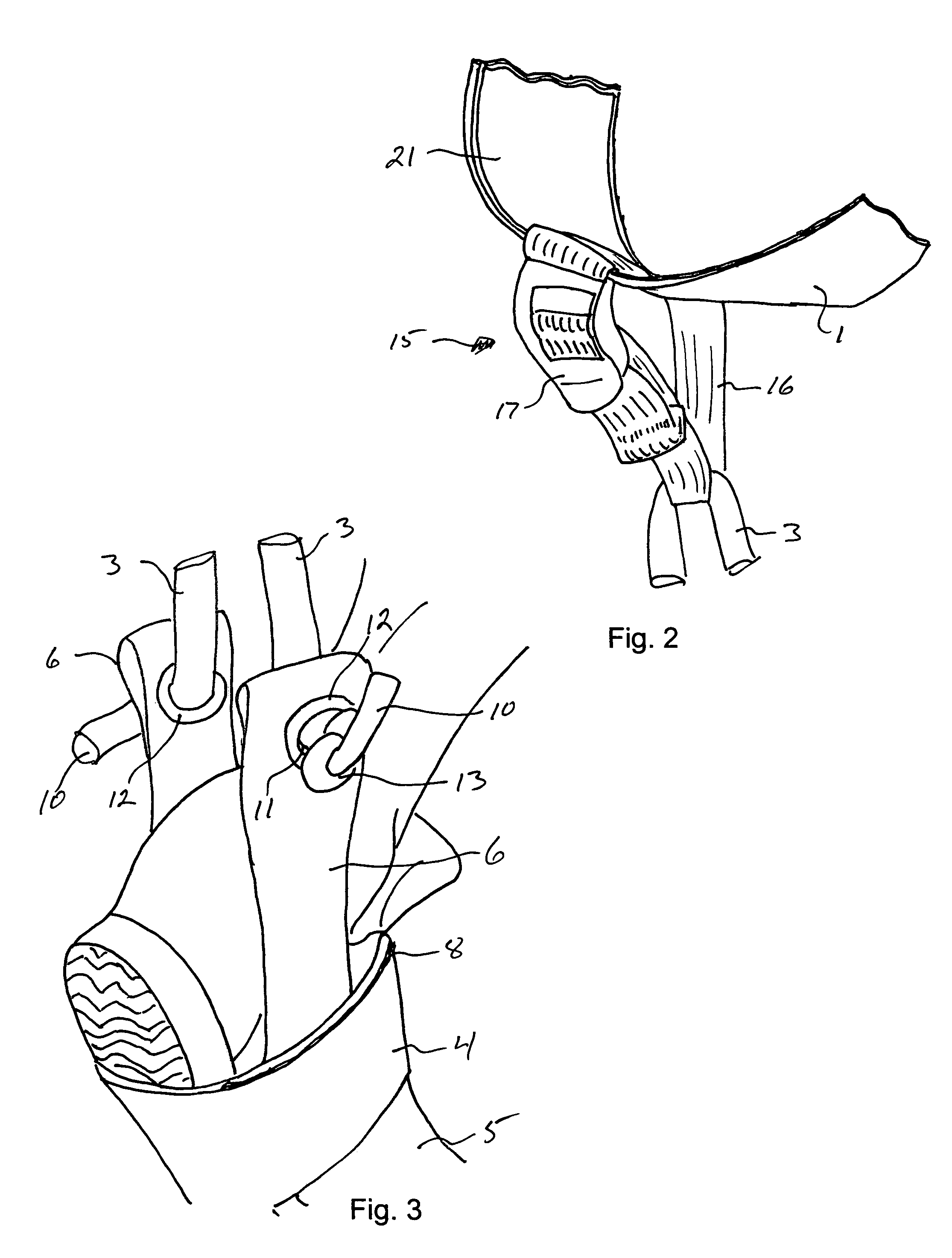

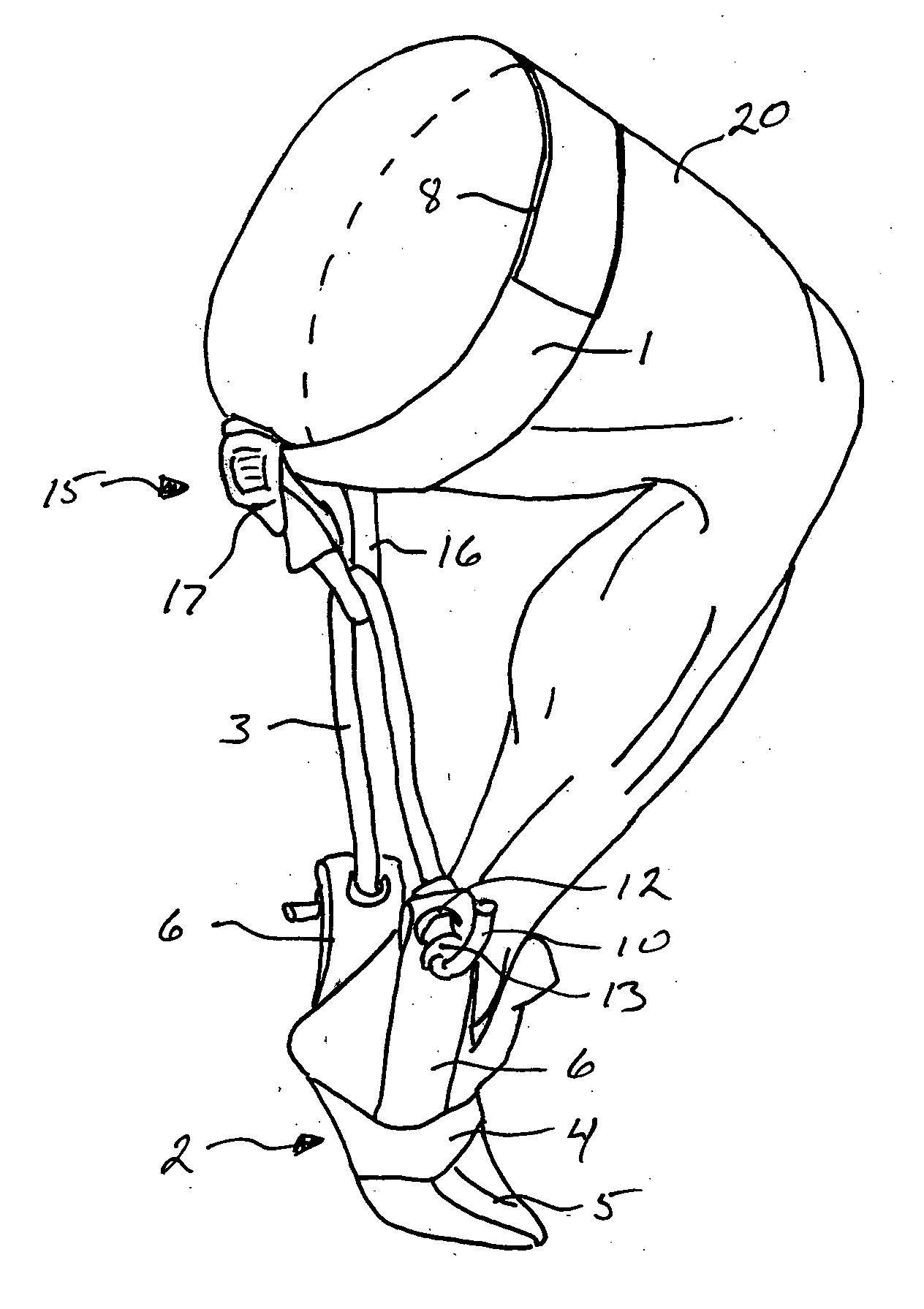

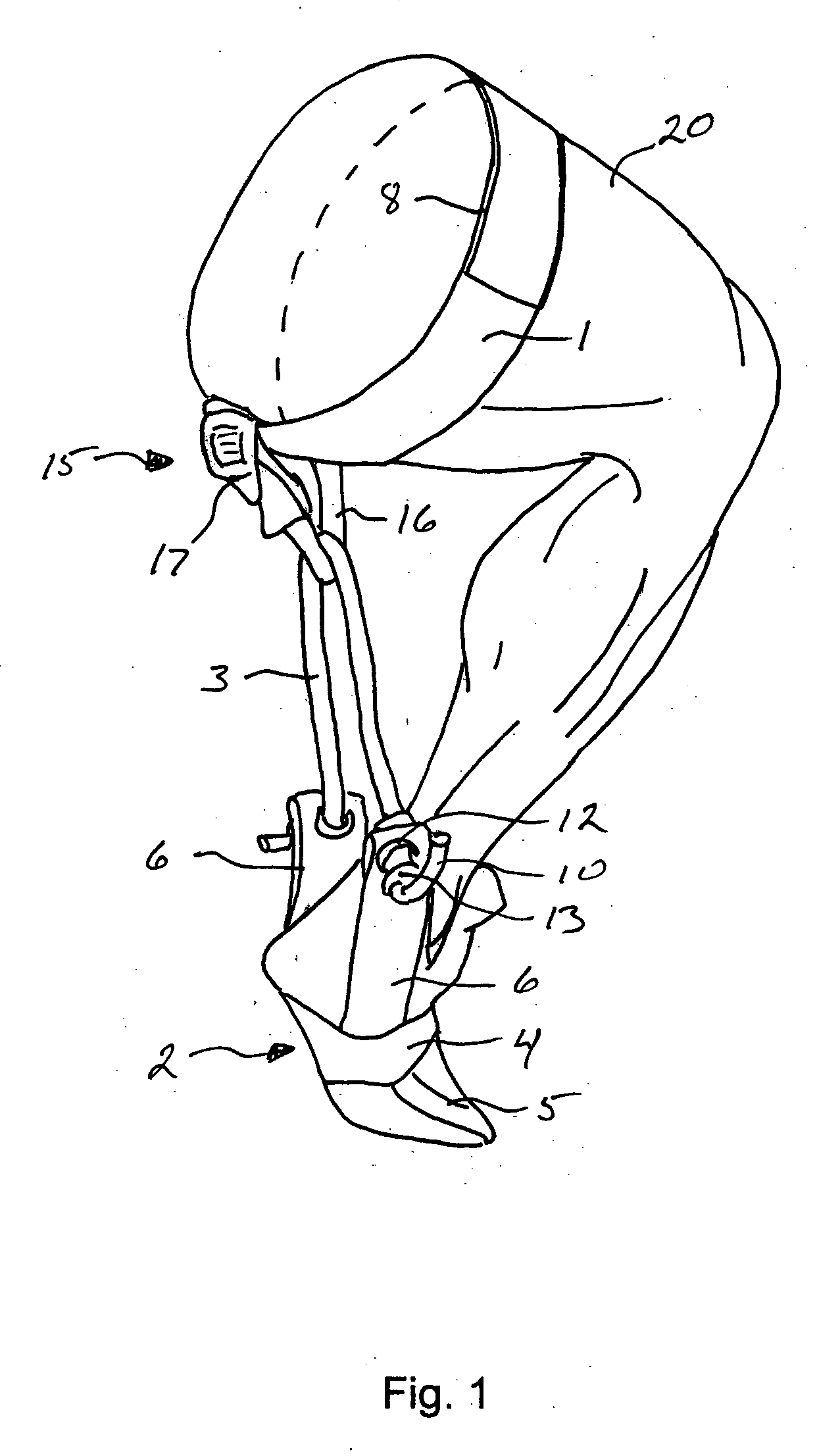

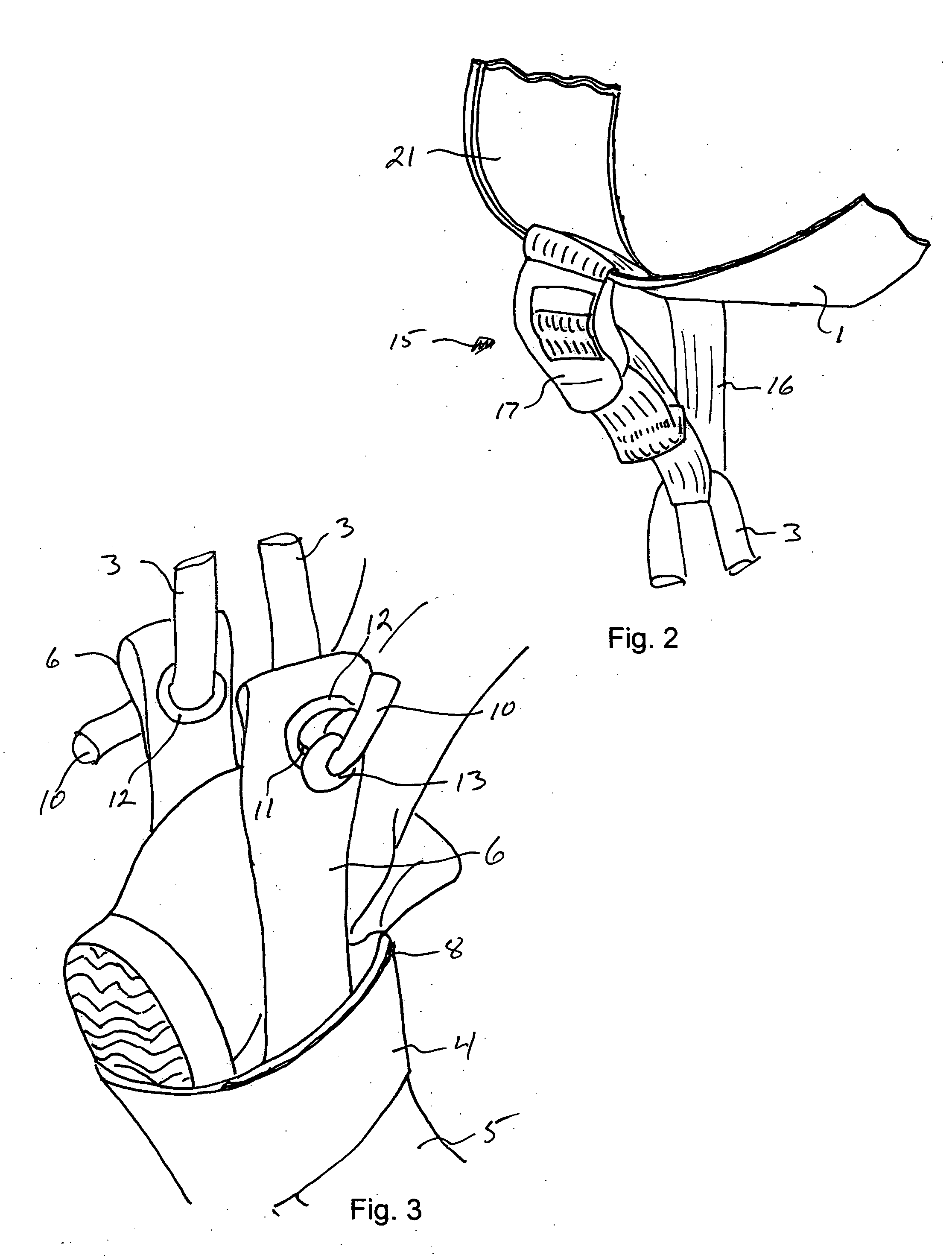

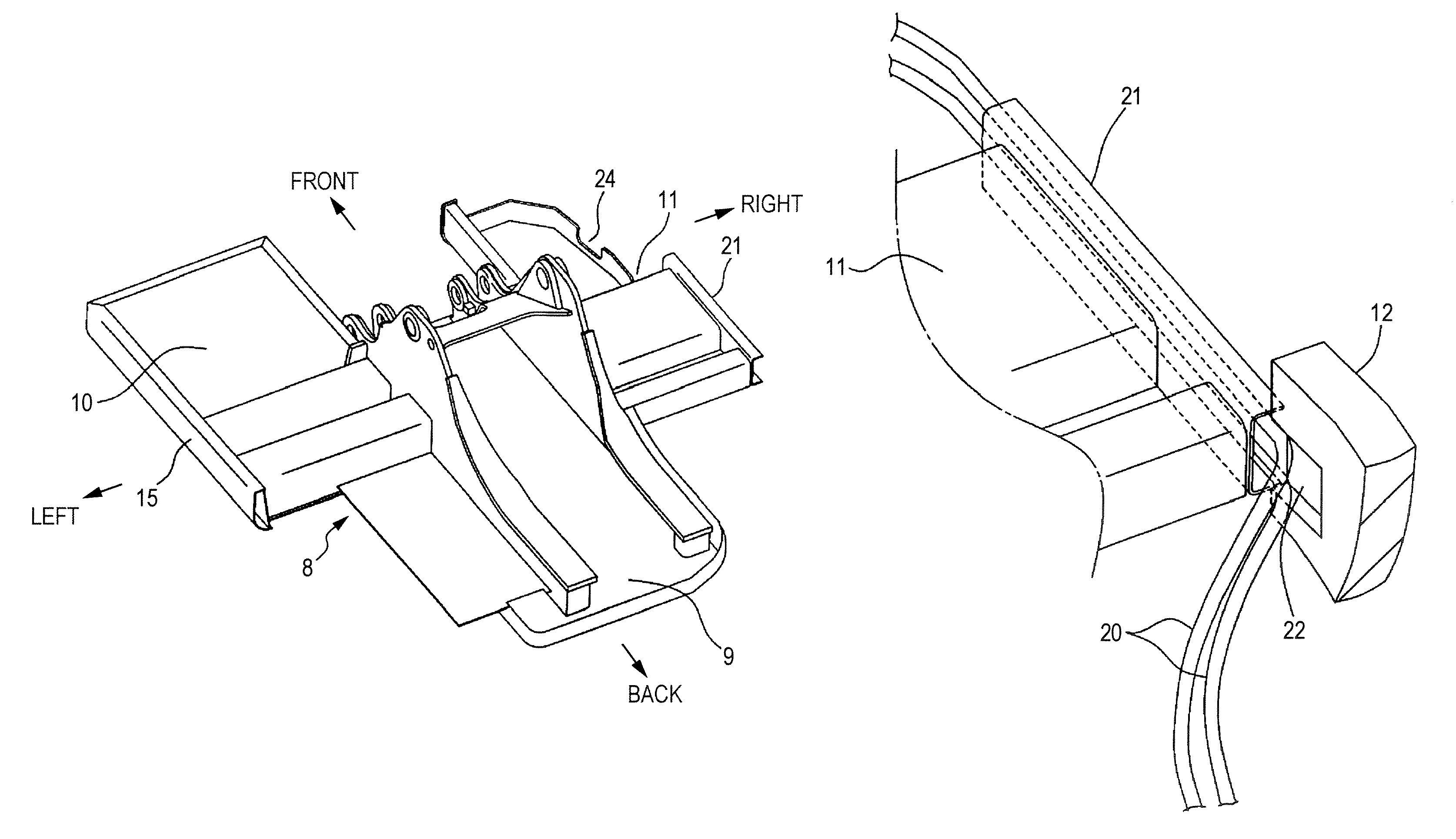

Runner training and exercise device

InactiveUS7261679B2Easy can be wornEliminate strengthResilient force resistorsJumping apparatusUpper thighEngineering

The present invention is directed to an exercise and training device for runners and provides a means to train them to stay in the most efficient position for optimum muscle use and to improve speed and lateral quickness. The device comprises an upper thigh strap, a foot stirrup and a length of resilient elastic material adjustably secured therebetween and adjusted to maintain the user's knee at a 90° angle during running.

Owner:SLOAD JASON M

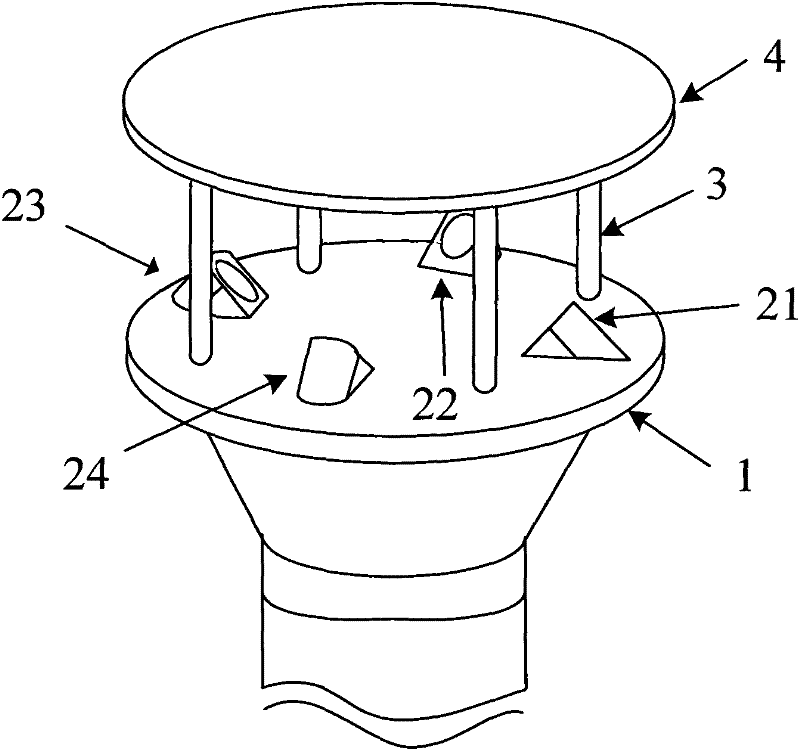

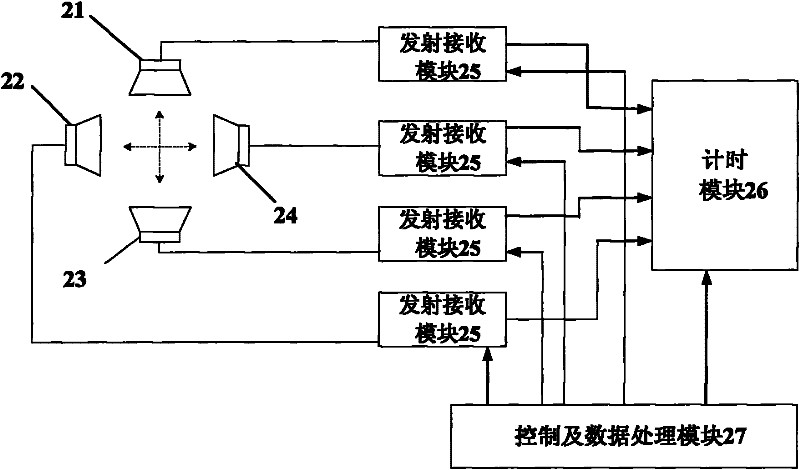

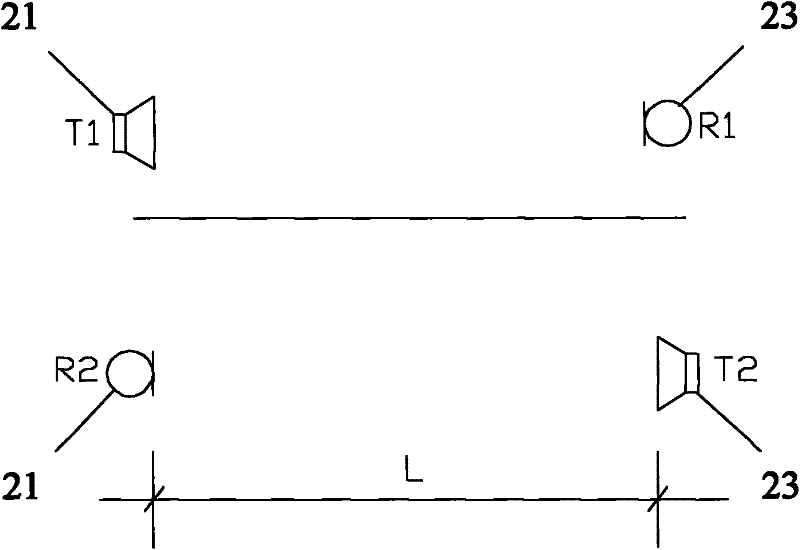

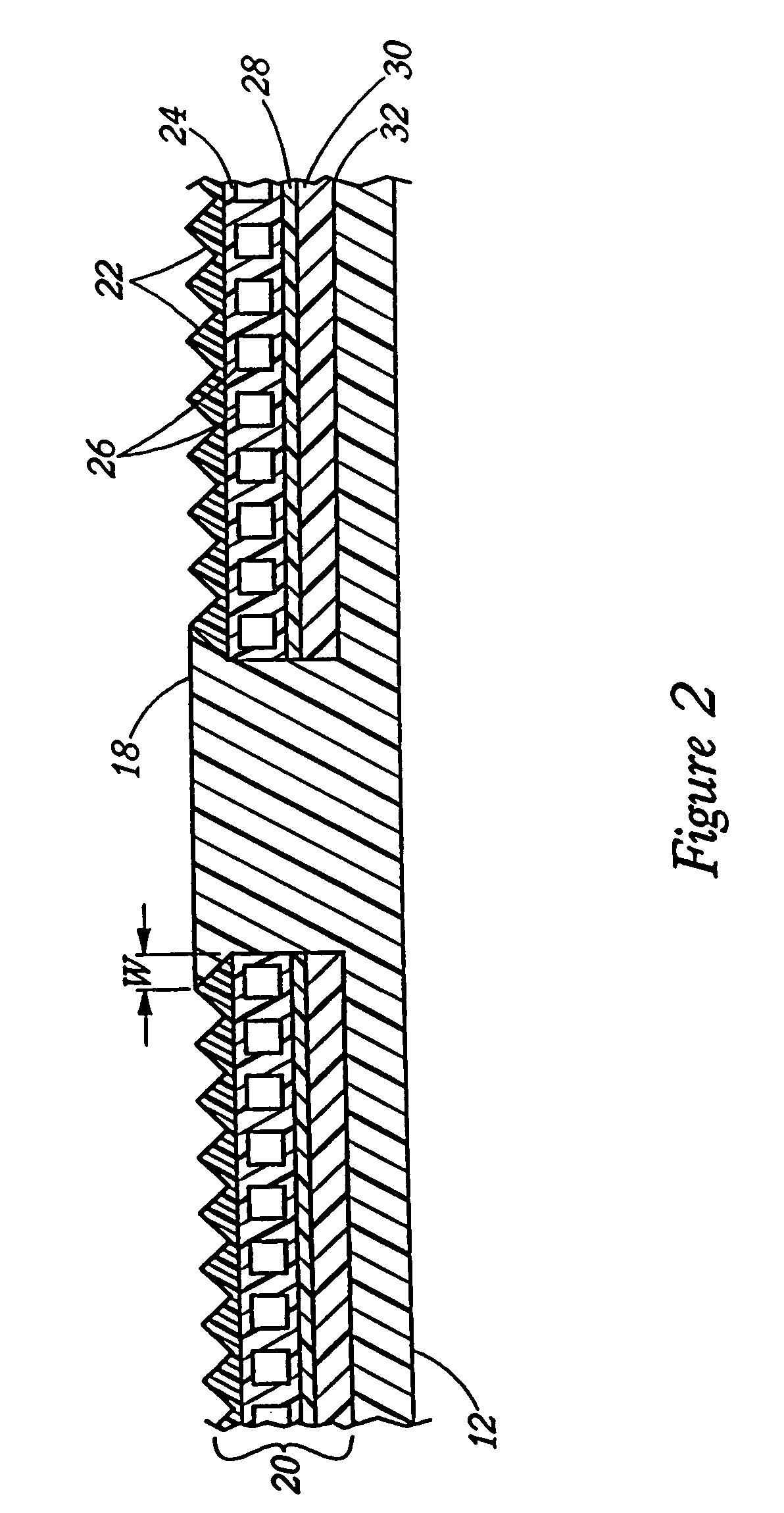

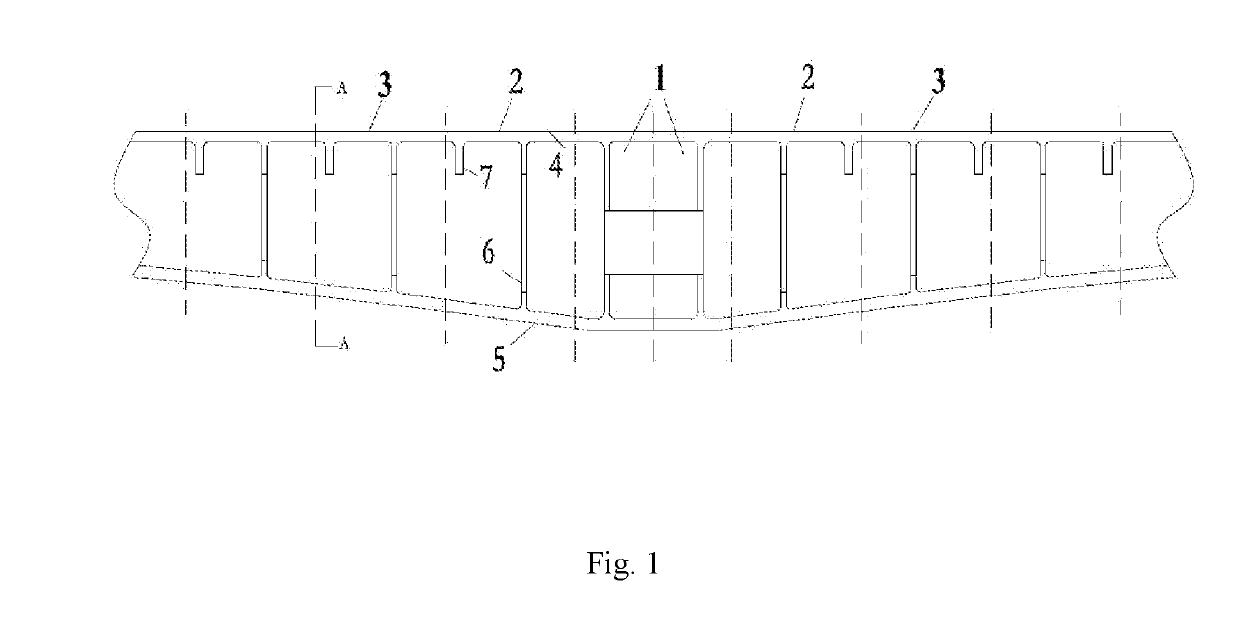

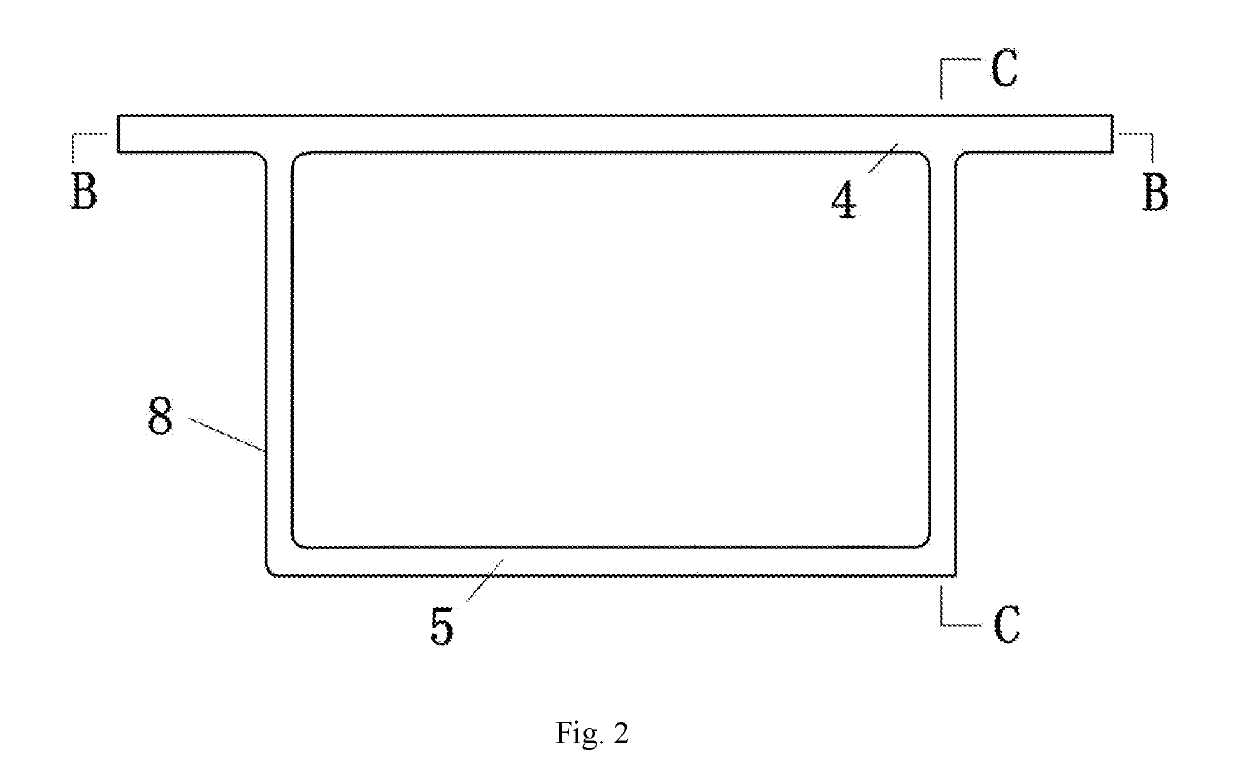

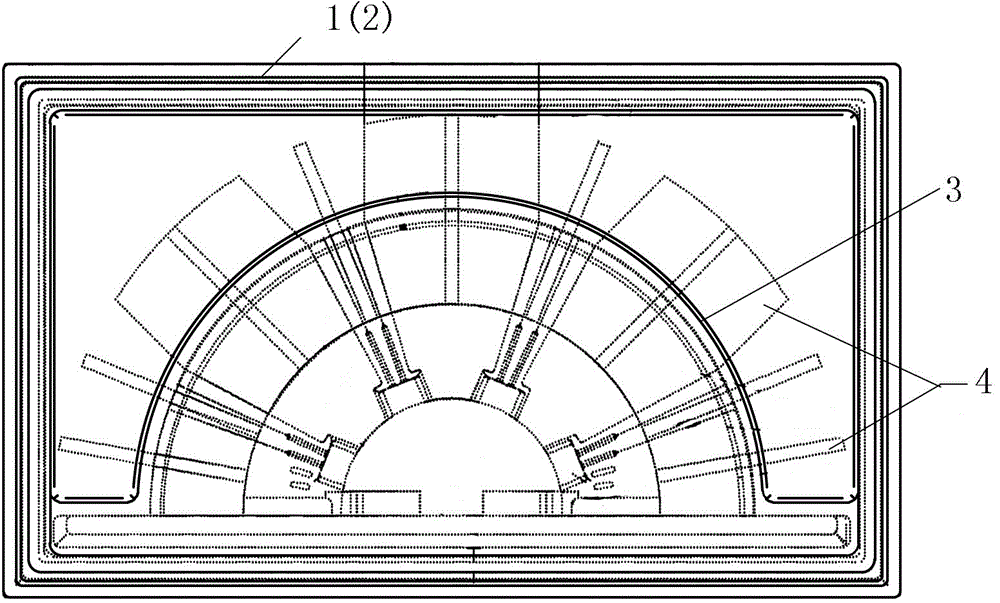

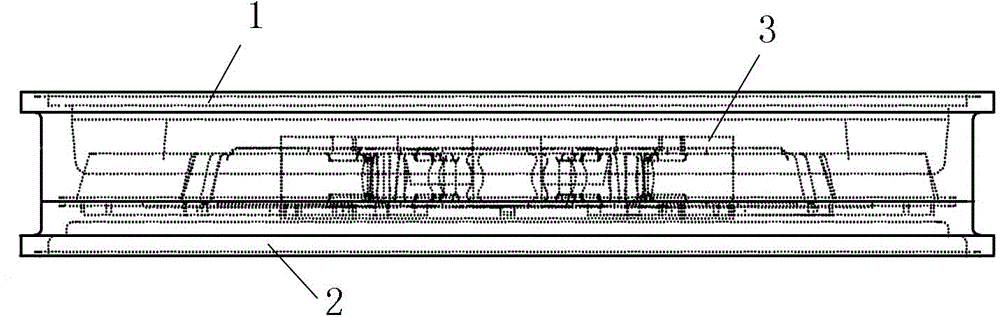

Reflective ultrasonic anemoscope and measuring method thereof

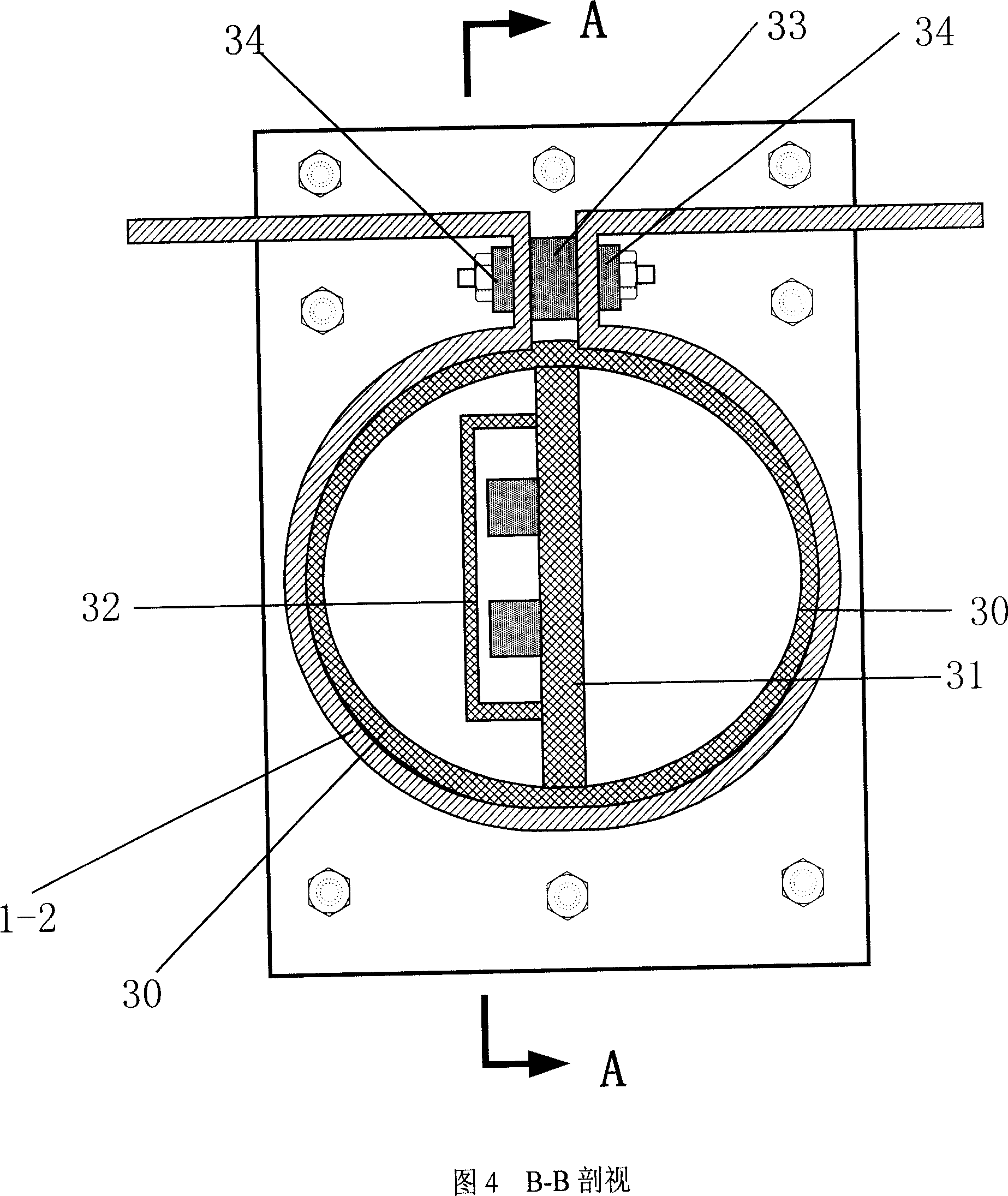

InactiveCN102288781AEliminate immobilityEliminate strengthIndication/recording movementFluid speed measurementUltimate tensile strengthUltrasound probe

The invention discloses a reflective ultrasonic anemoscope and a measuring method thereof. The reflective ultrasonic anemoscope comprises four parts, namely a probe mounting seat (1), ultrasonic probes (21, 22, 23 and 24), a bracket (3) and a reflecting surface (4), wherein the four ultrasonic probes (21, 22, 23 and 24) are fixedly arranged on the probe mounting seat (1), are divided into two groups and are arranged on two orthogonal axes; and various ultrasonic probes (21, 22, 23 and 24) transmit ultrasonic signals in turn, and opposite ultrasonic probes (21, 22, 23 and 24) receive signals reflected by the reflecting surface (4). A wind speed value and a wind direction value are solved by a vector composition method. The reflective ultrasonic anemoscope eliminates influence on measurement due to a difficultly fixed measuring structure and great change of signal intensity along with the wind speed.

Owner:北京东方迪码科技有限公司

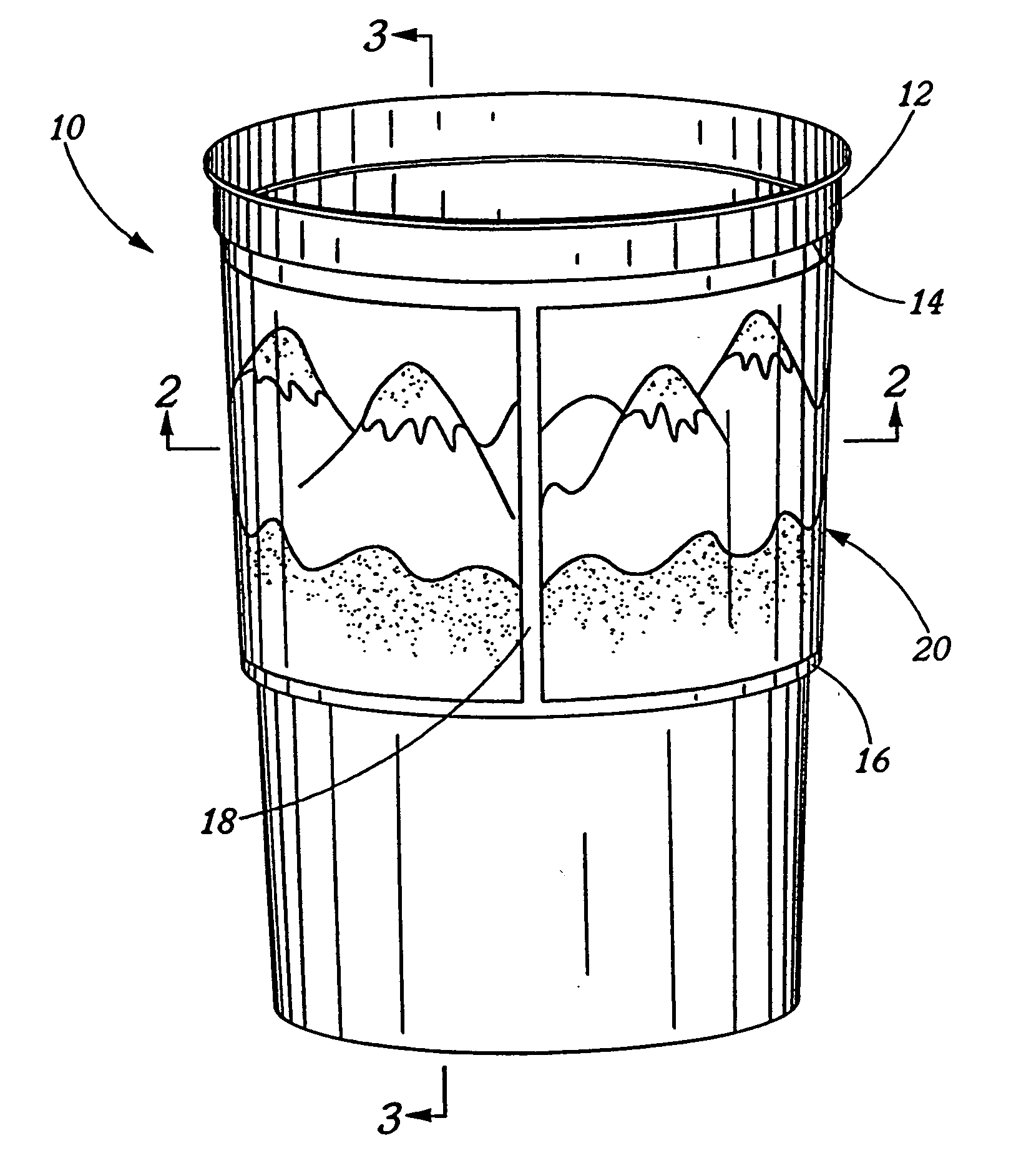

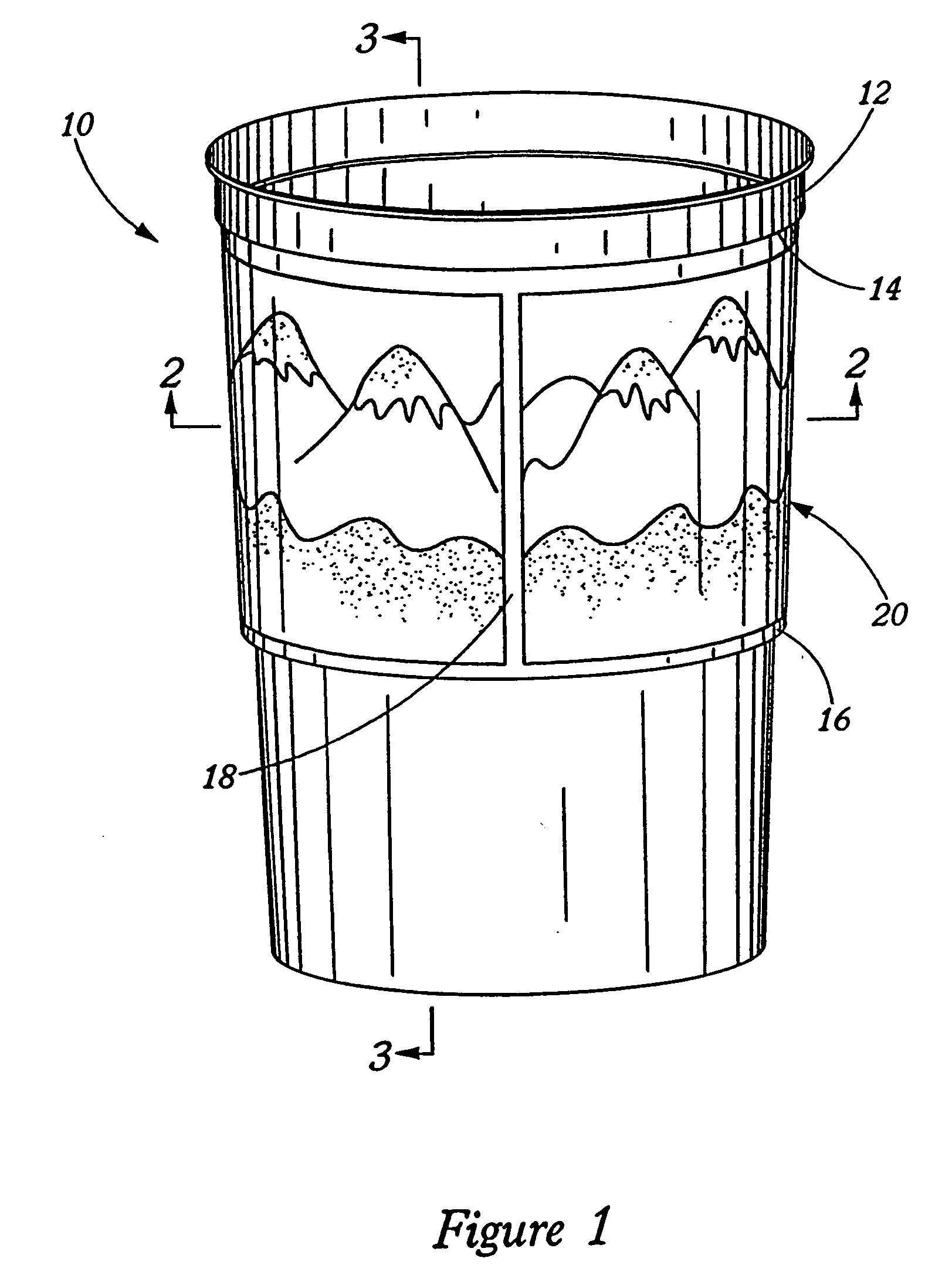

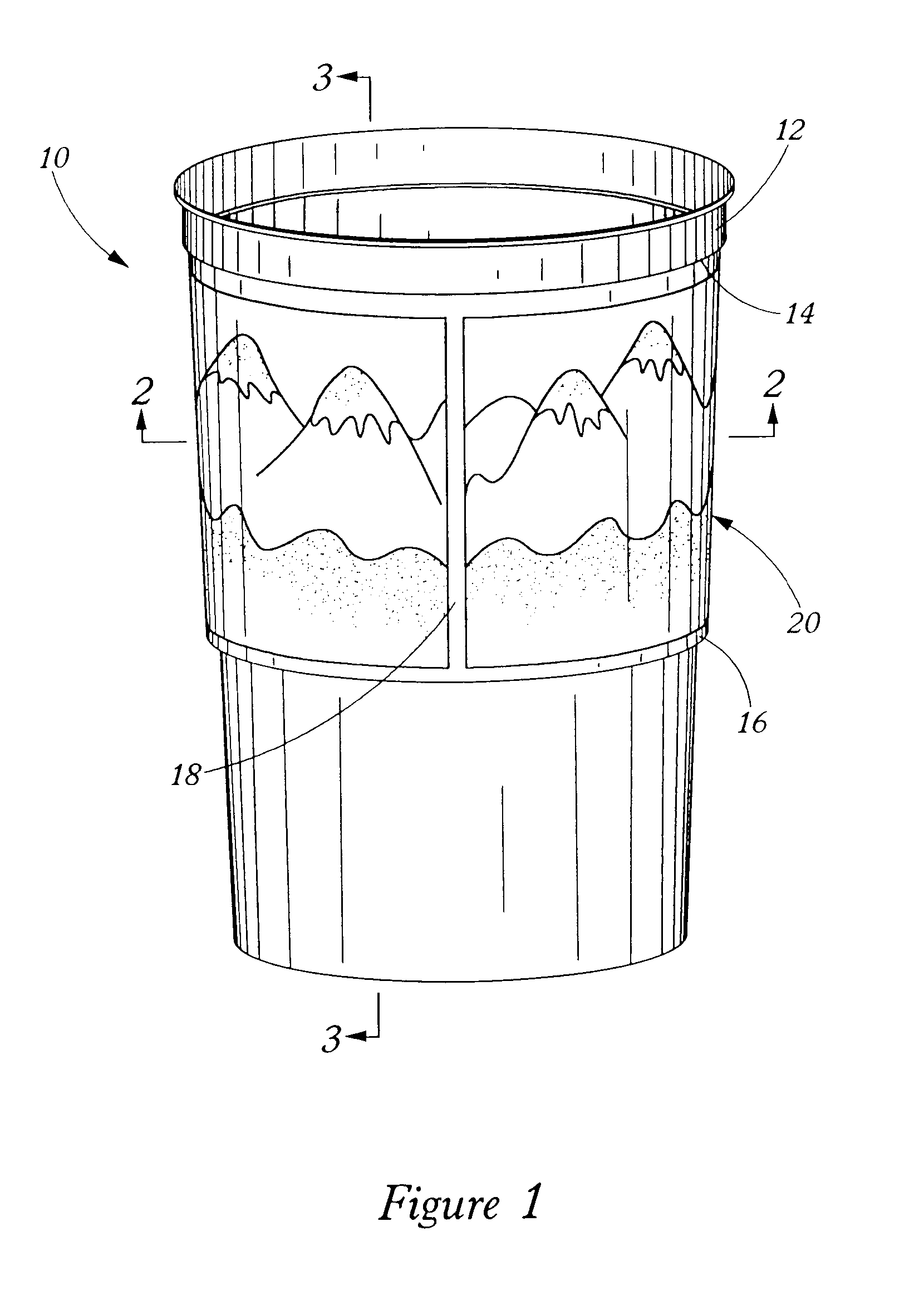

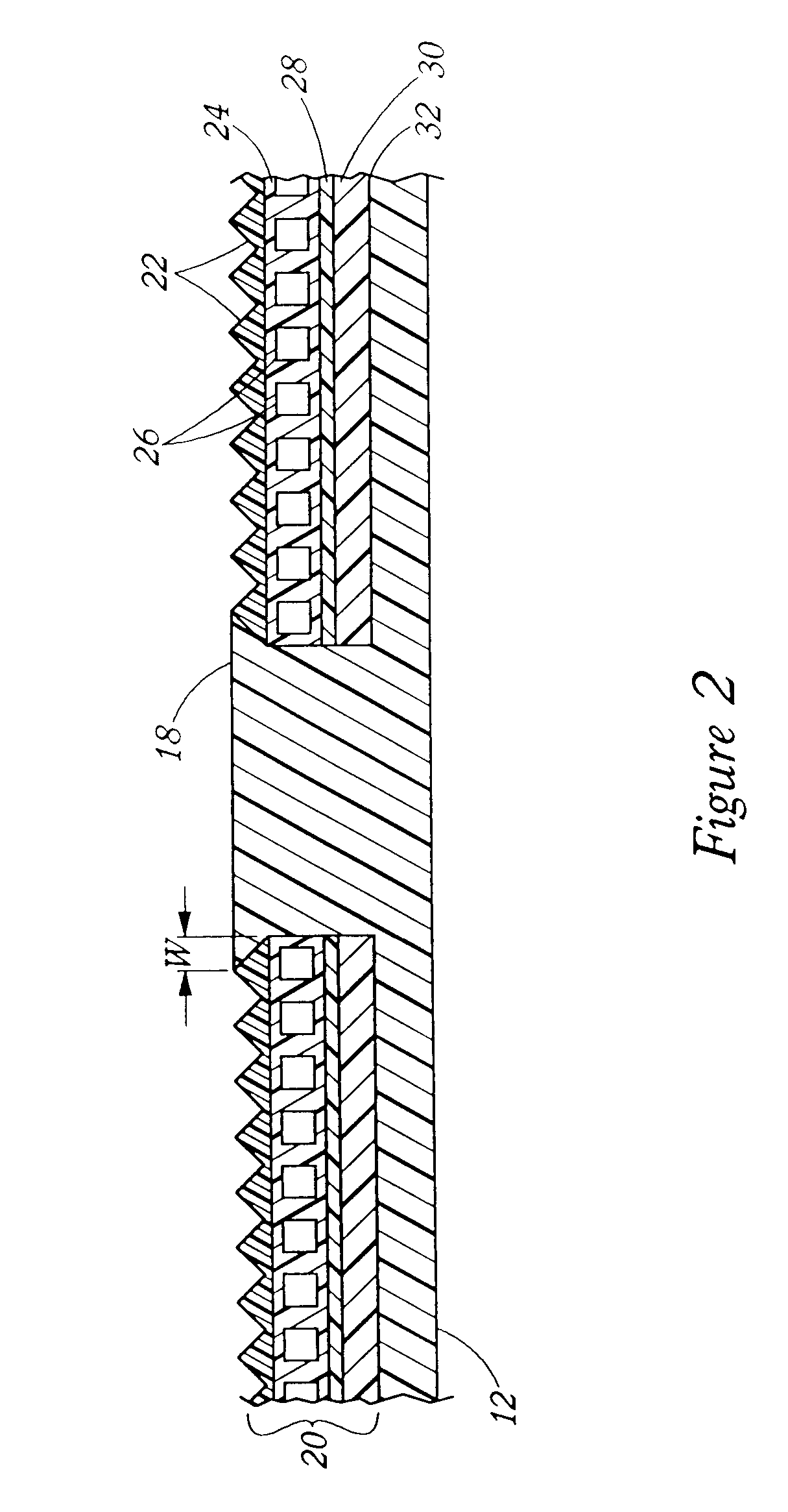

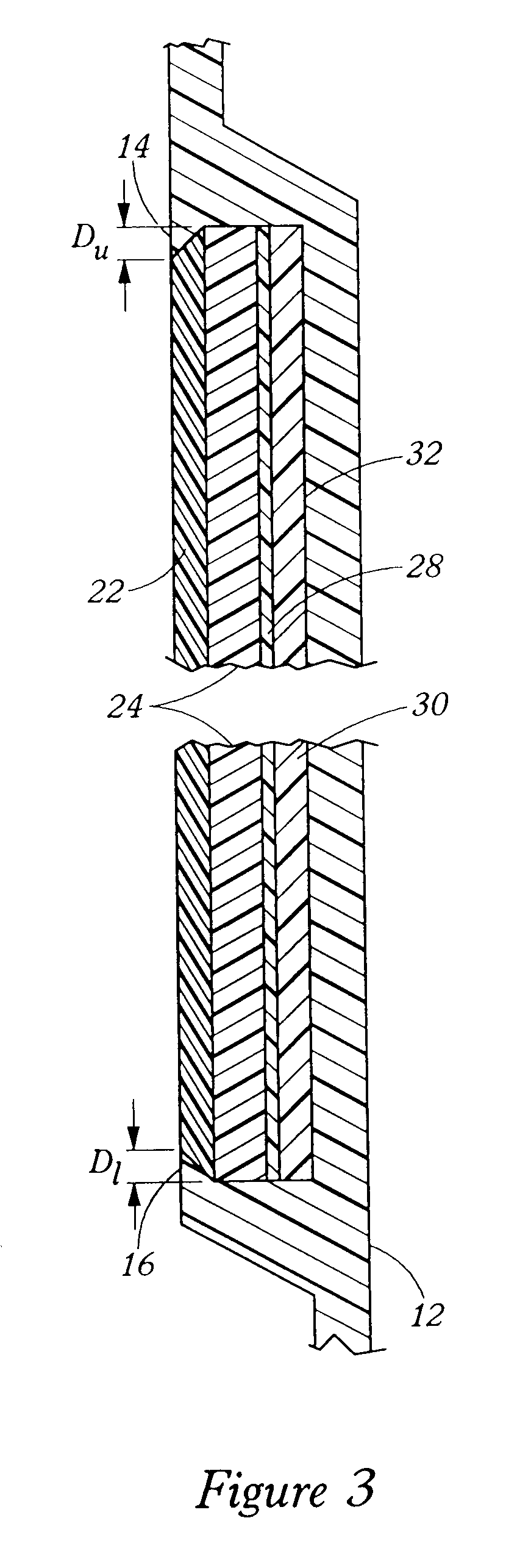

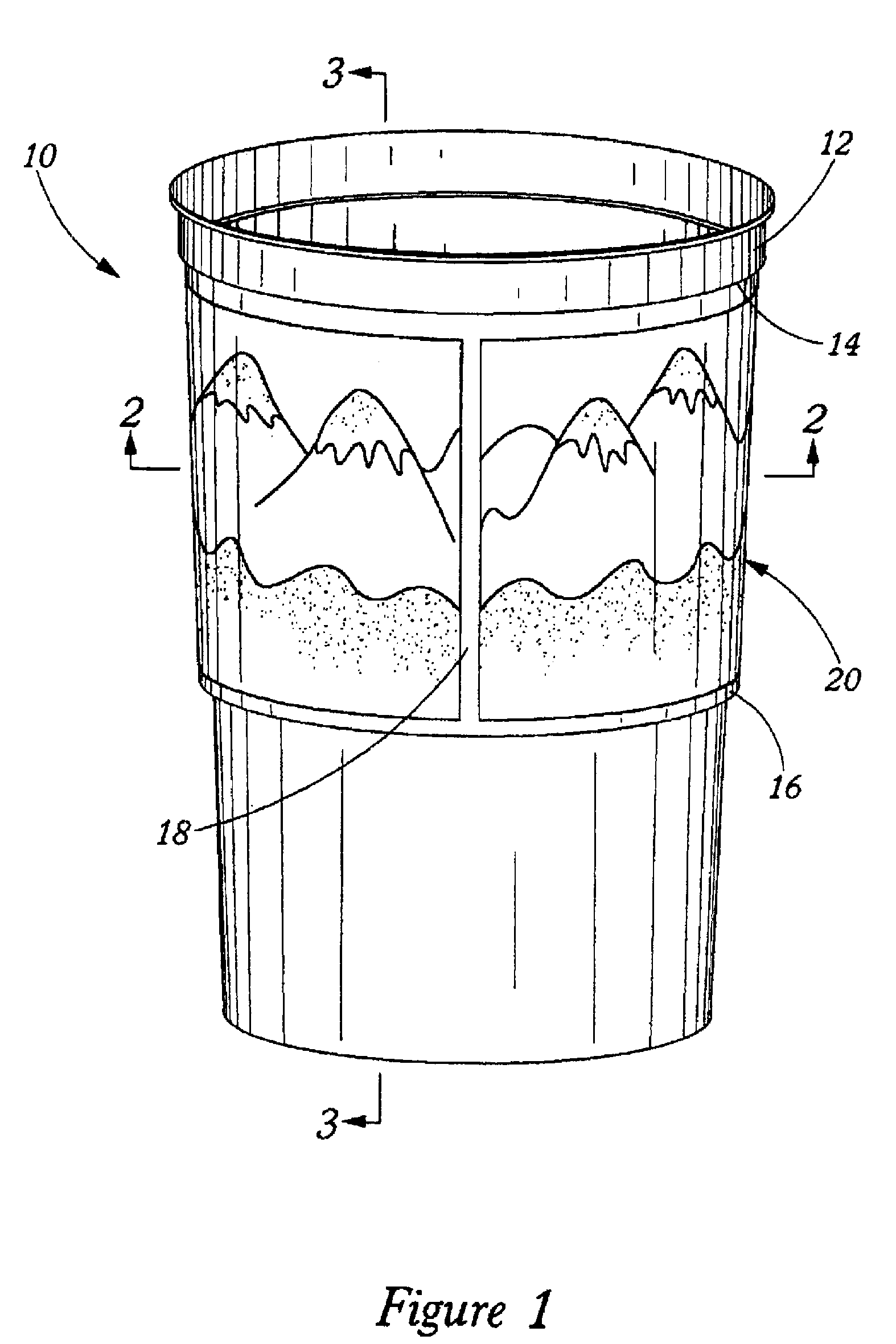

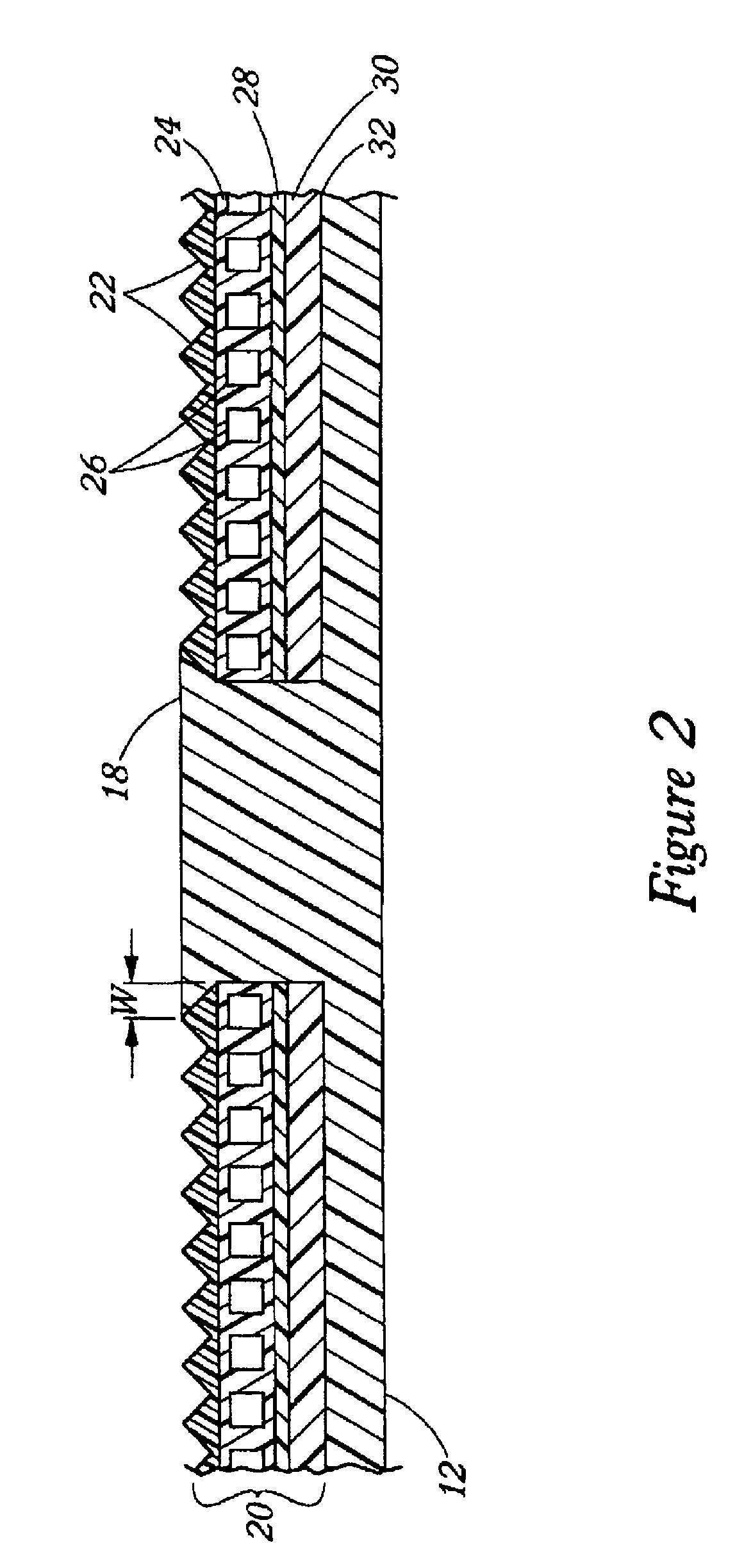

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

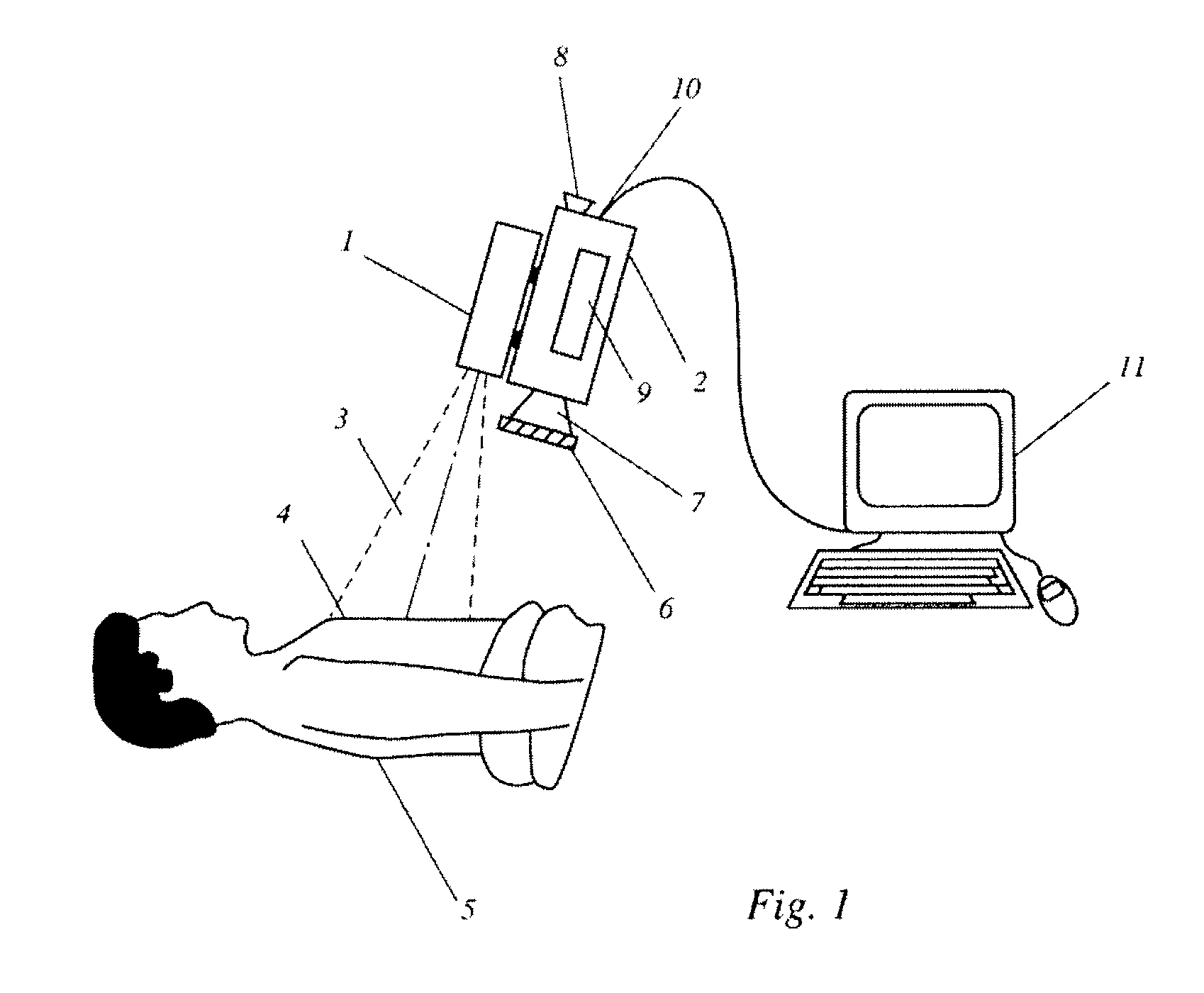

Method for evaluating blush in myocardial tissue

ActiveUS20100305454A1Eliminate strengthAvoid excessive intensityImage enhancementMedical imagingFluorescenceCardiac muscle

Vessel perfusion and myocardial blush are determined by analyzing fluorescence signals obtained in a static region-of-interest (ROI) in a collection of fluorescence images of myocardial tissue. The blush value is determined from the total intensity of the intensity values of image elements located within the smallest contiguous range of image intensity values containing a predefined fraction of a total measured image intensity of all image elements within the ROI. Vessel (arterial) peak intensity is determined from image elements located within the ROI that have the smallest contiguous range of highest measured image intensity values and contain a predefined fraction of a total measured image intensity of all image elements within the ROI. Cardiac function can be established by comparing the time differential between the time of peak intensity in a blood vessel and that in a region of neighboring myocardial tissue both pre and post procedure.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

Friction material of disc brake pad, disc brake pad and preparation technology of disc brake pad

ActiveCN102965078AOvercoming performance deficienciesImprove performanceOther chemical processesFriction liningFiberPotassium

The invention discloses a friction material of a disc brake pad. The friction material comprises the following raw materials in parts by weight: 13-18% of cashew nut shell oil-modified phenolic resin, 9-16% of butyronitrile rubber powder, 3-7% of steel wool fiber, 6-11% of calcium sulfate whisker, 2-5% of potassium feldspar powder, 3-6% of graphite, 2-6% of brown fused alumina, 3-5% of antimony sulfide, 11-16% of baryta powder, 5-9% of chromite powder, 6-11% of heavy calcium carbonate, 2-4% of zircon sand and 3-6% of brass powder. Visibly, in the preparation raw materials, the cashew nut shell oil-modified phenolic resin is adopted for replacing ordinary phenolic resin as an organic carrier of a brake pad material, so that the shortcomings of poor resistance to thermal ablation, high abrasiveness, low anti-impact strength and the like of the ordinary phenolic resin are eliminated, the performance defects of the friction material of the disc brake pad caused by the ordinary phenolic resin can be avoided, and the overall performance of the friction material of the disc brake pad can be further improved.

Owner:SHANDONG GOLD PHOENIX

Collagen fiber solidified tannin adsorptive material and its preparation method and its adsorption and separation of metallic ion

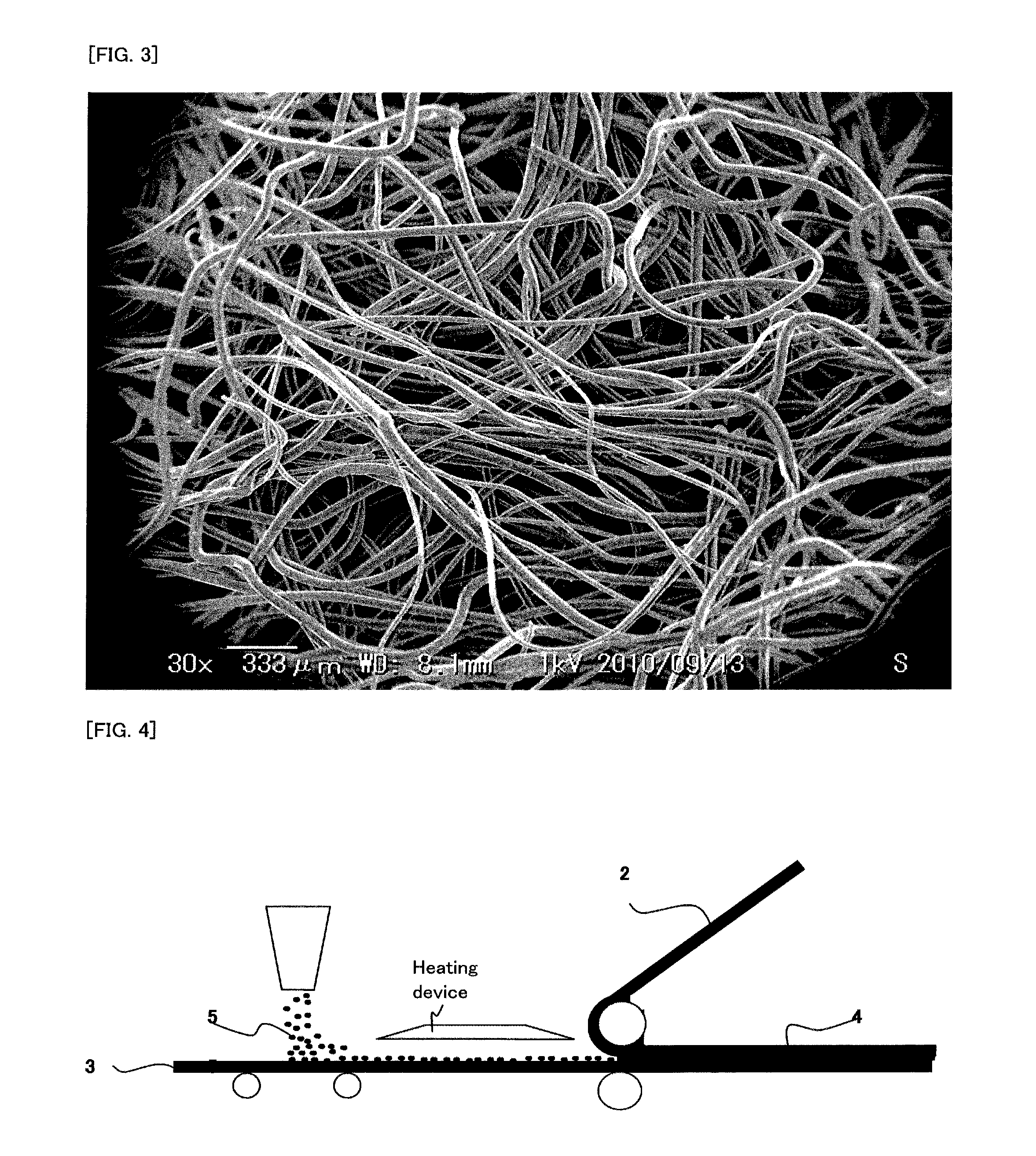

InactiveCN1410157AEliminate solubilityEliminate strengthOther chemical processesWater/sewage treatment by sorptionFiberTannin

An adsorbing collagen fibre-solidified tannin material for adsorbing and separating metallic ions (Pb, Cd, Hg, Cr and Cu) is prepared from animal skin through preparing collagen fibre membrane or granules, adding the said collagen fibres along with the aqueous solution of tannin to a reactor, reacting at 10-45 deg.c for 6-24 hr, laying aside for 12-24 hr, filtering, washing to remove excessive tannin, adding cross-linking agent, reacting at 20-70 deg.c for 2-8 hr, filtering, washing and drying at 60 deg.c for 12-24 hr. It has very high adsorption selectivity.

Owner:SICHUAN UNIV

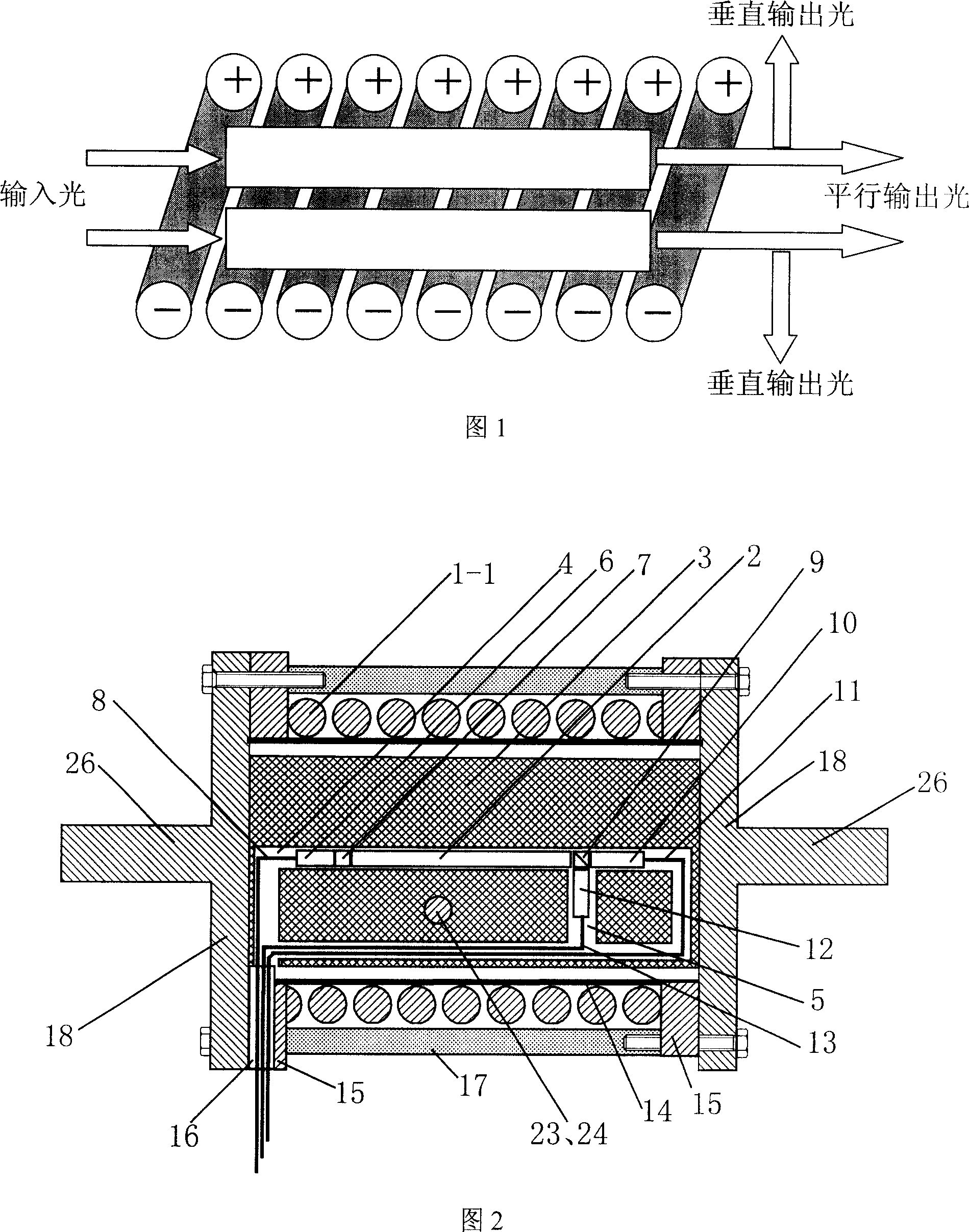

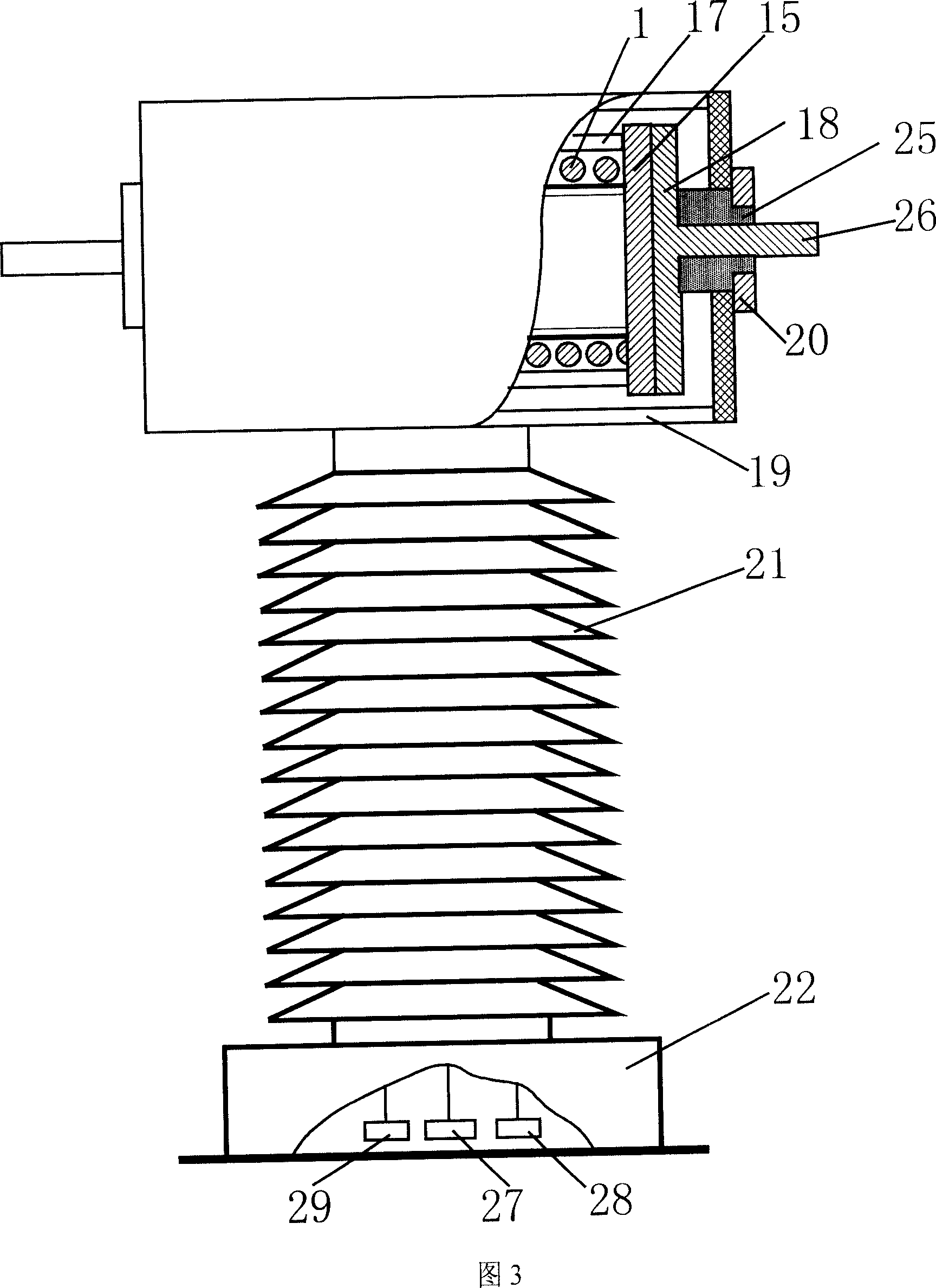

Optical current transformer and method for measuring current with the same

InactiveCN1963539AImprove performanceGuaranteed uptimeCurrent/voltage measurementVoltage/current isolationFiberElectrical conductor

This invention relates to high voltage circuit current measurement optical inductor and its test method, wherein, the sensor head is of bar magnetic materials along line distribution input fiber; the basic path is composed of self focus lens, bias device, optical sensor head, test bias device, parallel output self focus lens and fiber and vertical output focus lens and fiber. The test current passes through ring conductor to establish parallel magnetic field with at least one basic light path. The multiple light paths each sensor head is of same distance separately connected to low voltage two photoelectricity converters to output voltage signal and vertical voltage to compute test current.

Owner:李岩松 +1

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20040157011A1Efficient and economicalHigh qualityEnvelopes/bags making machineryWrappers shrinkageLens materialsPolyester

Abstract of the Disclosure A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:REIL JENNIFER +4

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

Runner training and exercise device

The present invention is directed to an exercise and training device for runners and provides a means to train them to stay in the most efficient position for optimum muscle use and to improve speed and lateral quickness. The device comprises an upper thigh strap, a foot stirrup and a length of resilient elastic material adjustably secured therebetween and adjusted to maintain the user's knee at a 90° angle during running.

Owner:SLOAD JASON M

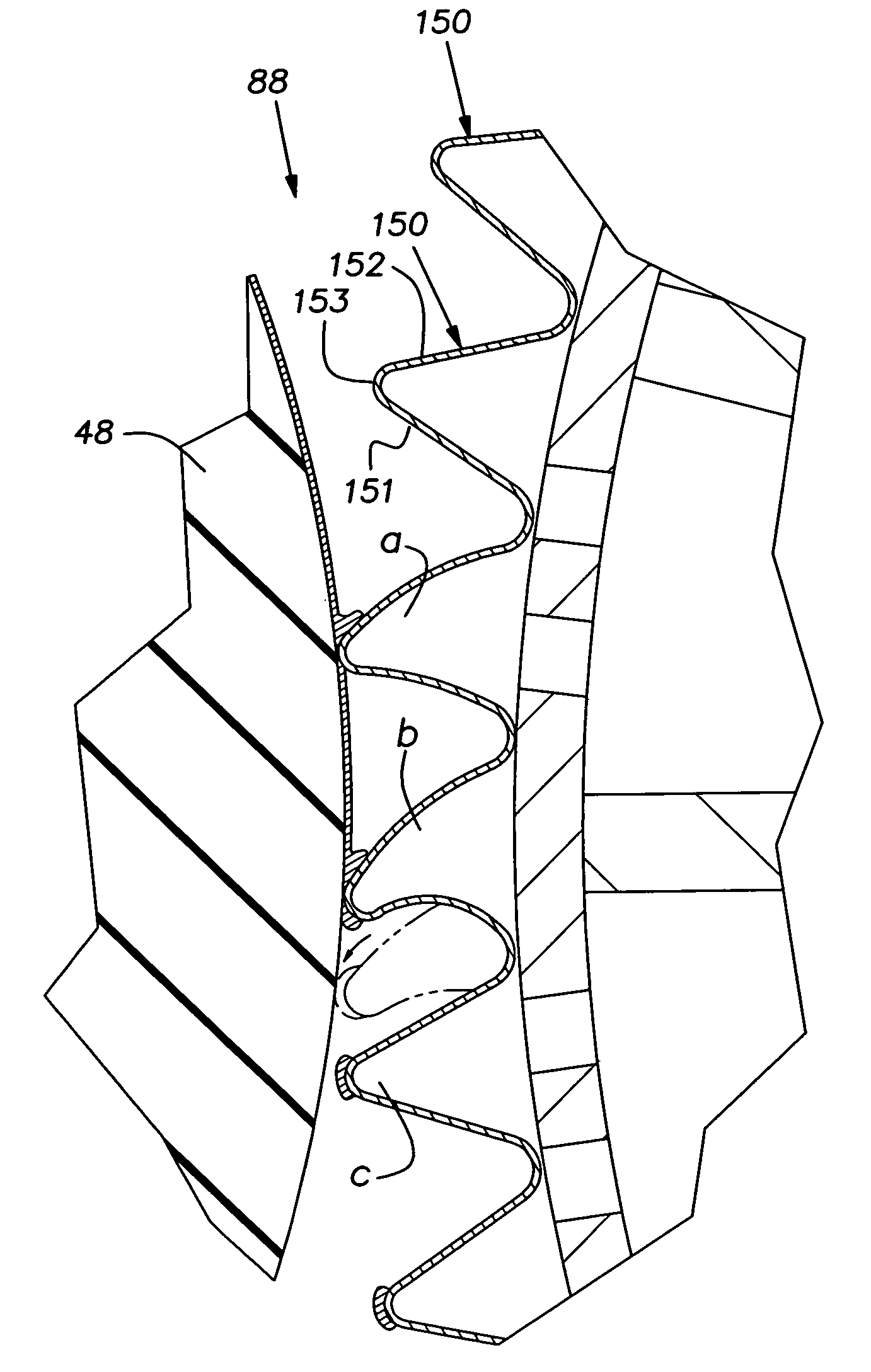

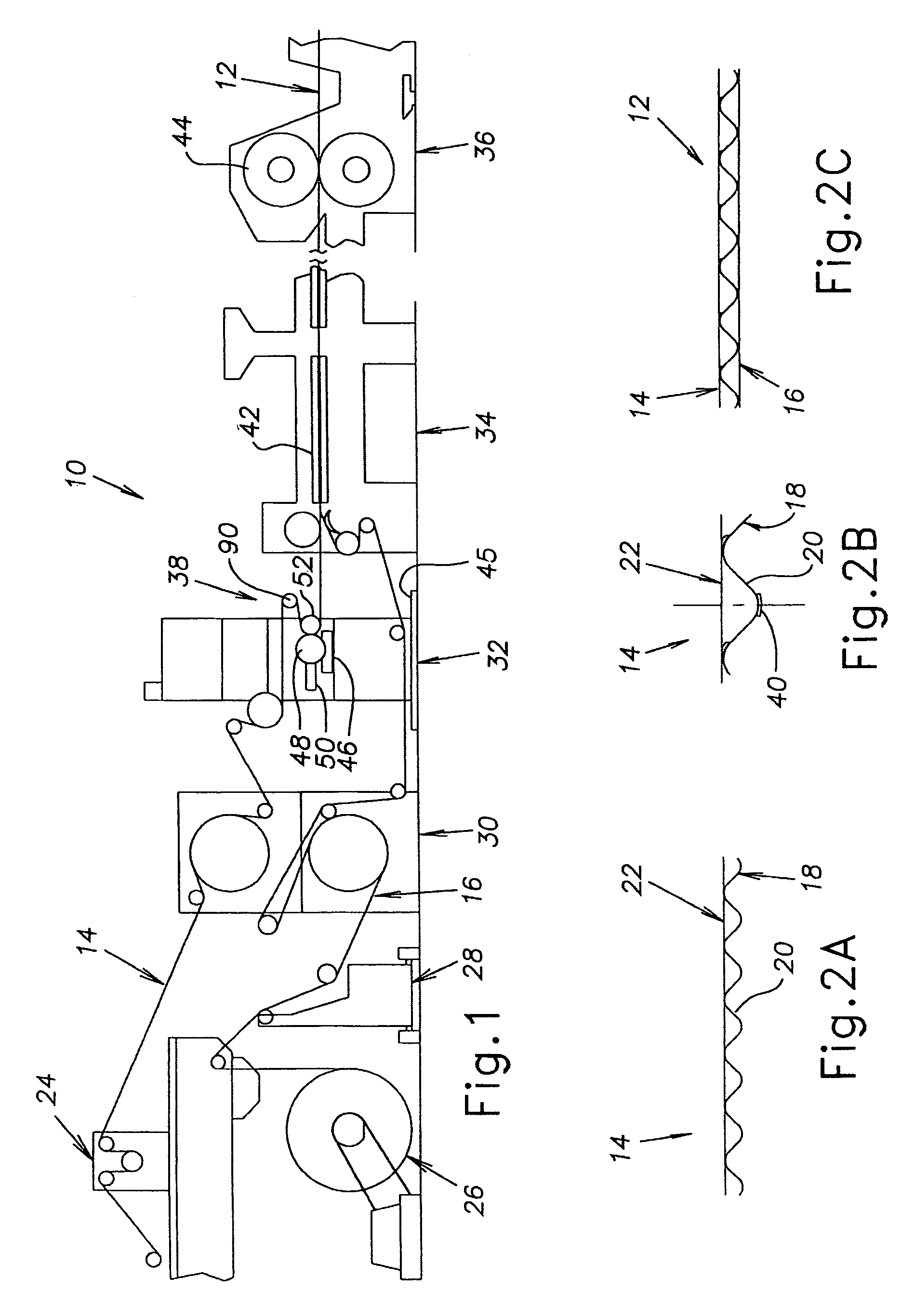

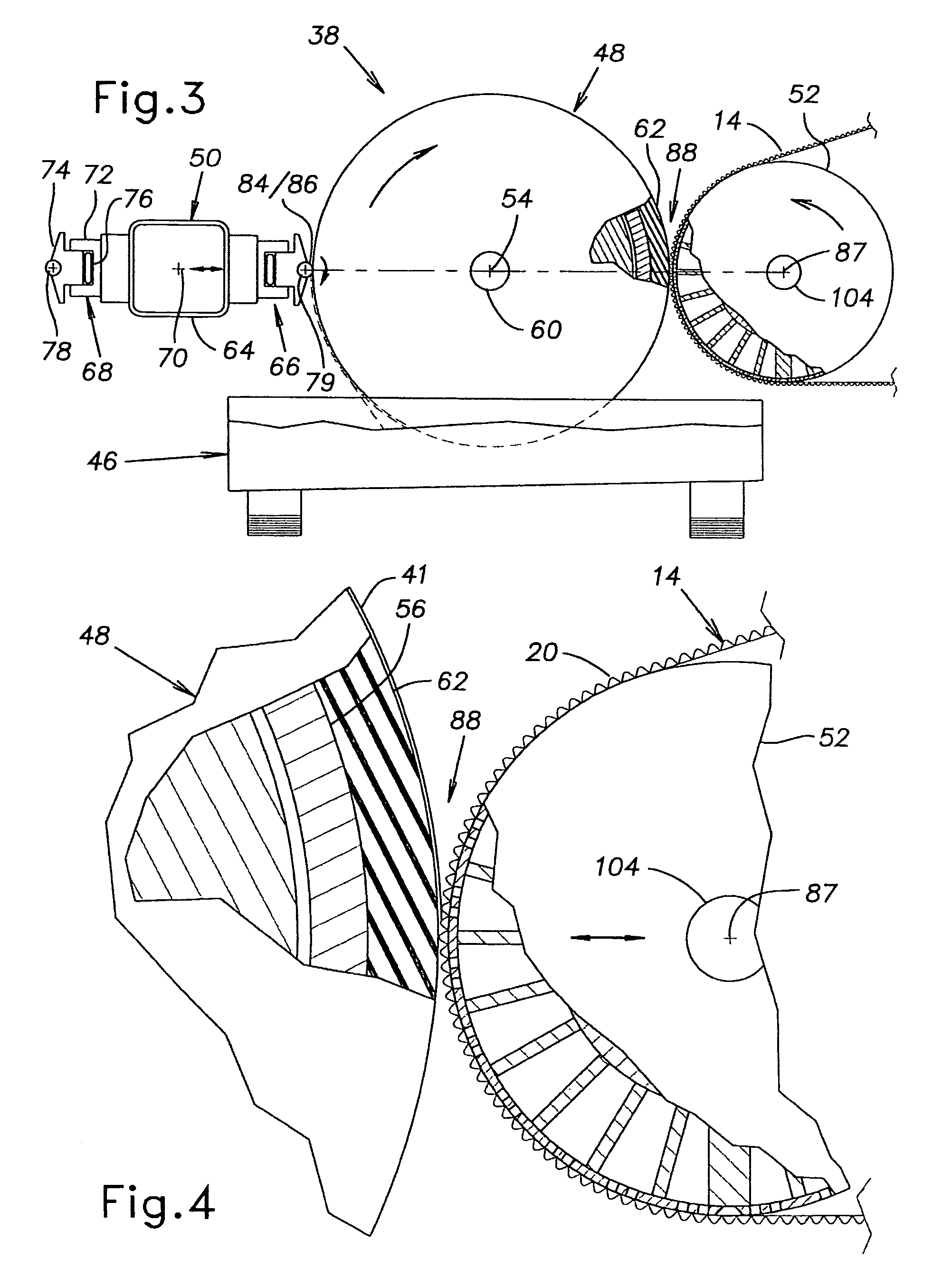

Method for producing corrugated cardboard

ActiveUS7595086B2Uniformly and accurately applyingReduce the amount requiredMechanical working/deformationPretreated surfacesFluteCardboard

A method is provided for applying adhesive to the flutes of a corrugated sheet web. An applicator roll is provided with a uniform thin coating of adhesive by a metering rod. Exposed crests of the flutes are brought into contact with a coating of adhesive that has been applied to a surface of an applicator roll in order to provide a uniform bead of adhesive on the flute crests. The flutes are compressed against the applicator roll surface in a forward direction relative to the direction in which the web is moving adjacent the applicator roll surface. In one embodiment, the applicator roll has a surface linear velocity greater than the speed at which the web is traveling.

Owner:INTPRO LLC

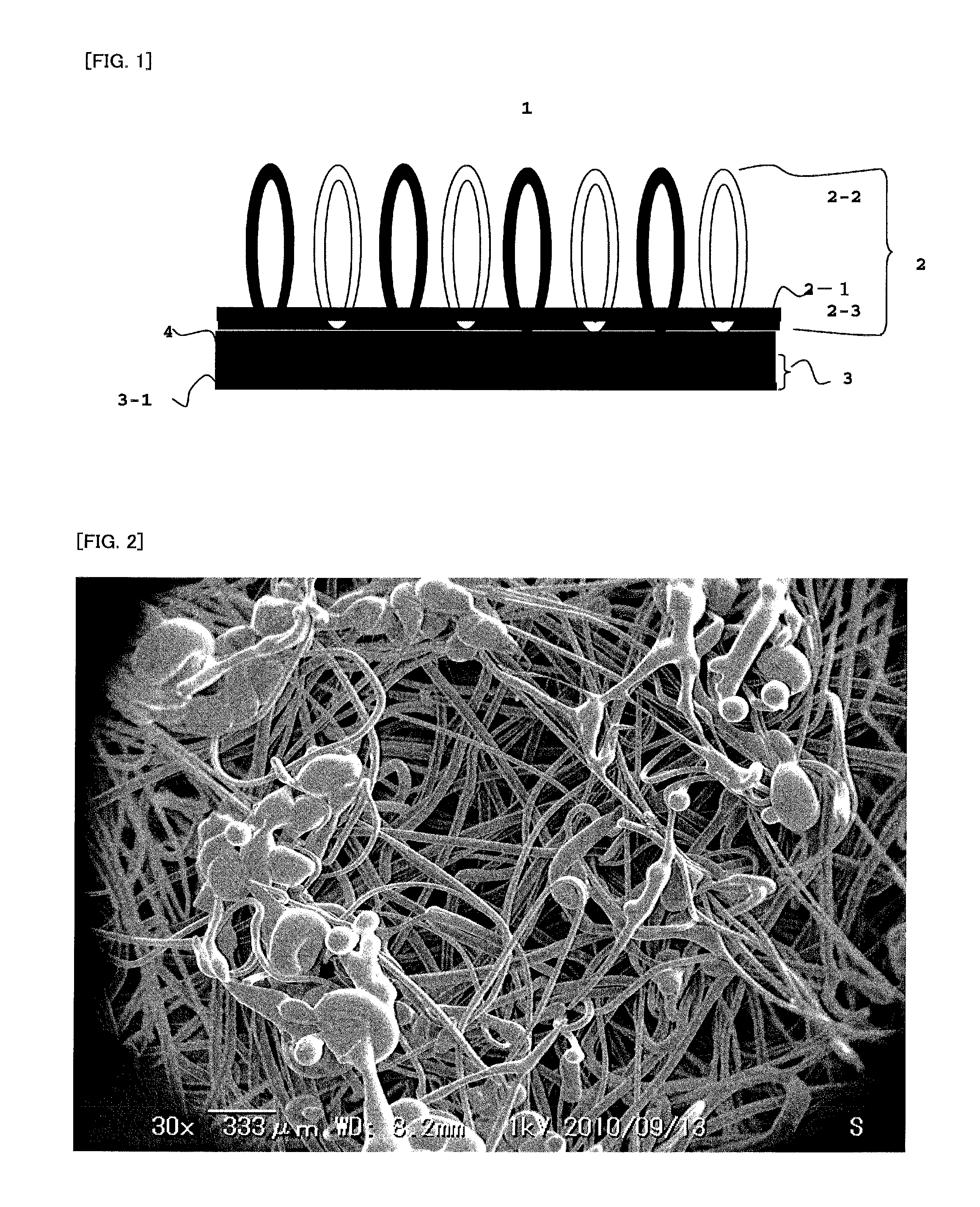

Automobile use mat with a distinguished Anti-slip feature

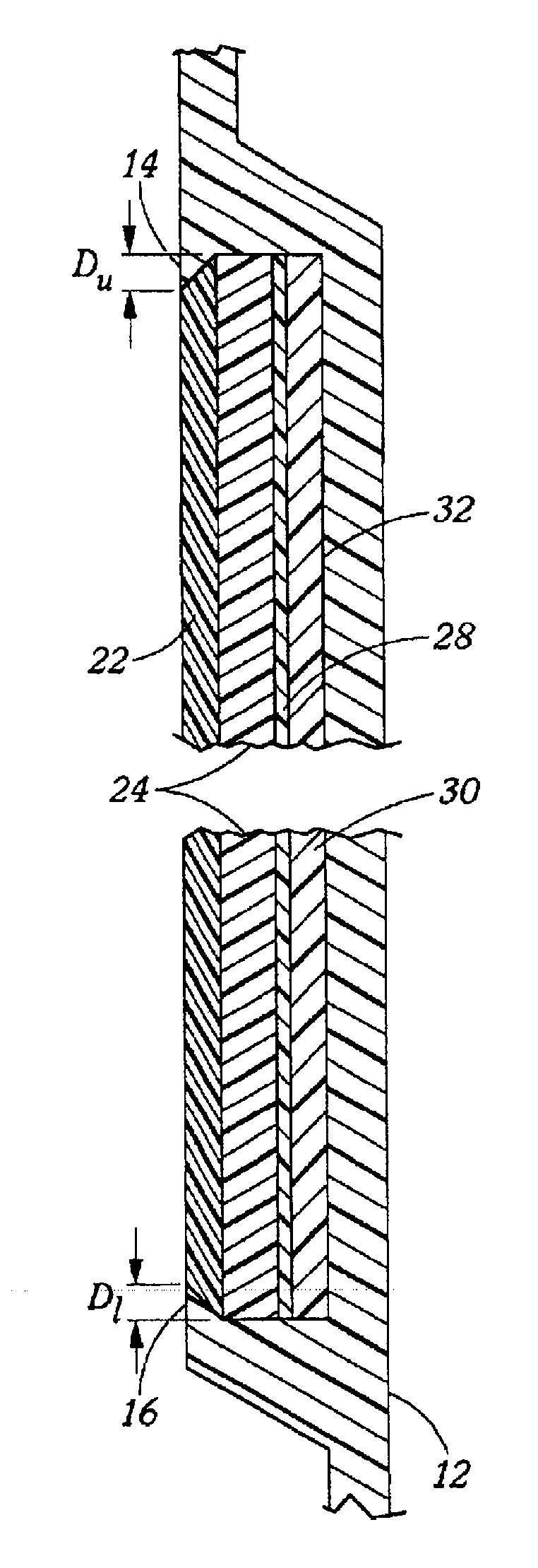

InactiveUS20120121849A1Improve friction resistanceLayer is highLiquid surface applicatorsVehicle arrangementsEngineeringNonwoven fabric

The challenges in this invention is to provide automobile use mat that has distinguished noise absorption and anti-slip features, as well as it being light in weight for a low cost.The inventors, for their exerted investigations in resolving such challenges and as a result, as a replacement to the frequently used conventional mats with mounted resin (bump) emboss configuration, have introduced the nonwoven fabric layer from polypropylene fiber, burned on the lower surface side of the nonwoven fabric layer, deforming the fibers, forming anti-slip layer from melt bonding the fibers together, discovered the possibilities in achieving an automobile use mat that is light weight, permeable, dominant in its anti-slip effect, easy to bend as well as handle, that lead to this invention.

Owner:SUMINOE TEXTILE CO LTD

Methods of manufacturing plastic objects having bonded lenticular lens-sheets

InactiveUS20070132122A1Quality improvementEfficient and economicalOptical articlesContainer/bottle contructionPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

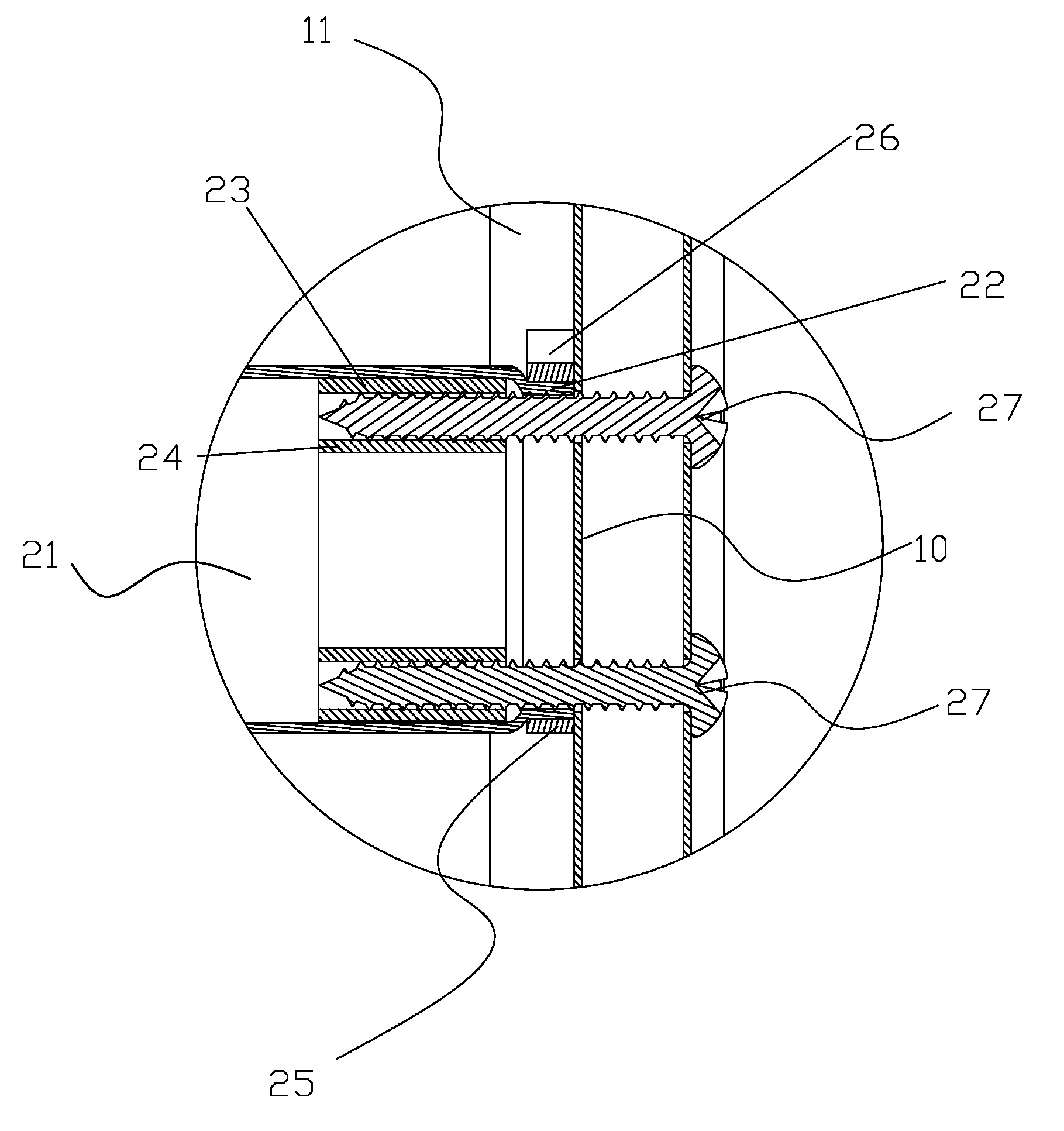

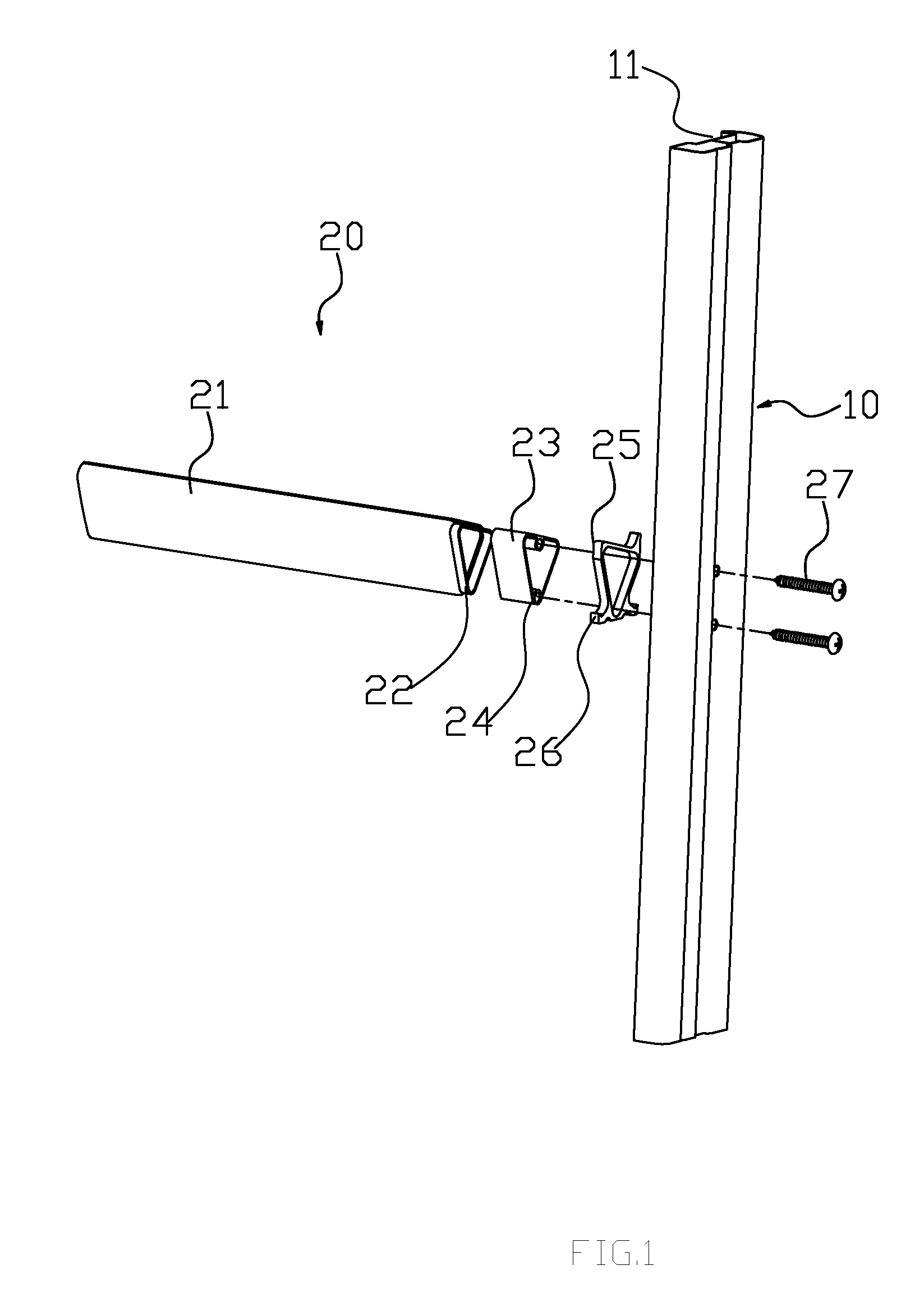

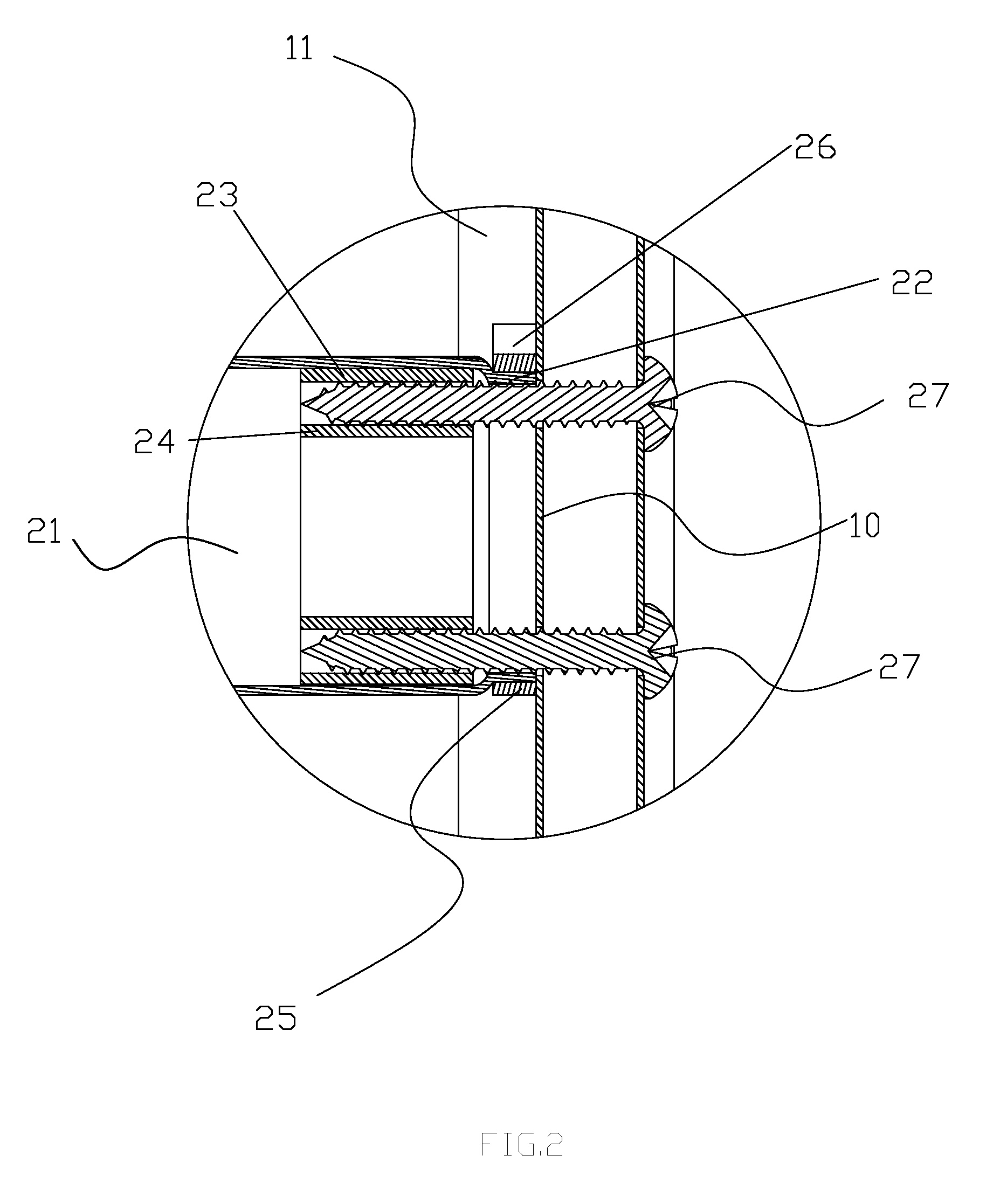

Ladder

A ladder comprises two stiles and at least a step unit mounted between the two stiles. The step unit includes a hollow step, an inner sleeve and an outer sleeve. The inner sleeve is fit into the hollow step, at an end of which a position restriction portion is located to prevent the inner sleeve from moving out, and the outer sleeve is adapted to surround the end of the hollow step. Besides, a fastener is set, the fastening end of which is passed through the stile, the outer sleeve and fastened in the inner sleeve. The present technique solution has a high supporting strength and a high shear resistance.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Copper alloy

InactiveUS20140193293A1Reduce intensityHigh yield strengthConductive materialMetal/alloy conductorsUltimate tensile strengthImpurity

Disclosed is a copper alloy containing 1.0% to 3.6% of Ni, 0.2% to 1.0% of Si, 0.05% to 3.0% of Sn, 0.05% to 3.0% of Zn, with the remainder including copper and inevitable impurities. The copper alloy has an average grain size of 25 pm or less and has a texture having an average area percentage of cube orientation of 20% to 60% and an average total area percentage of brass orientation, S orientation and copper orientation of 20% to 50%. The copper alloy has a KAM value of 0.8 to 3.0 and does not suffer from cracking even when subjected to U-bending. The copper alloy has excellent balance between strengths (particularly yield strength in a direction perpendicular to the rolling direction) and bending workability.

Owner:KOBE STEEL LTD

Environment-friendly oxidation type hydrophobic glucomannan adsorption material and preparation method thereof

InactiveCN101497030ASave oil resourcesAlleviate environmental pollutionOther chemical processesIonChemical industry

The invention relates to an environment friendly oxidation type hydrophobic glucomannan adsorption material and a method for preparing the same, and belongs to the technical field of compositions containing glucomannan materials. The adsorption material comprises the following components in portion by weight: 20 to 100 portions of glucomannan, 50 to 500 portions of 0 to 70 percent glucomannan swelling inhibitor, 5 to 100 portions of alkali, 50 to 500 portions of water, and 1 to 20 portions of oxidizing agent. The preparation method comprises that: the glucomannan is swelled in an alkali mixed solvent of the swelling inhibitor, and subjected to acetyl group removing reaction for 1 to 40 hours at a temperature of between 35 and 90 DEG C; the mixed solution is filtered and washed so as to remove the swelling inhibitor and the excessive alkali, and the obtained product is dried at a temperature of between 50 and 100 DEG C for 8 to 24 hours to obtain the hydrophobic glucomannan; the hydrophobic glucomannan is swelled in water, the pH value is adjusted to be 3 to 12, and then the oxidizing agent is added to hydrophobic glucomannan and reacts for 1 to 24 hours; and the obtained mixed solution is filtered, washed and dried at a temperature of between 50 and 100 DEG C for 8 to 24 hours to obtain the oxidation type hydrophobic glucomannan adsorption material. The material has higher selective adsorption capability on heavy-metal ions and radioactive nuclides, and can be widely applied to the adsorption and separation of the heavy-metal ions and radioactive nuclides generated in mining, mining and metallurgy, chemical industry, electroplating, machinery, nuclear industry, environmental protection and restoration, and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

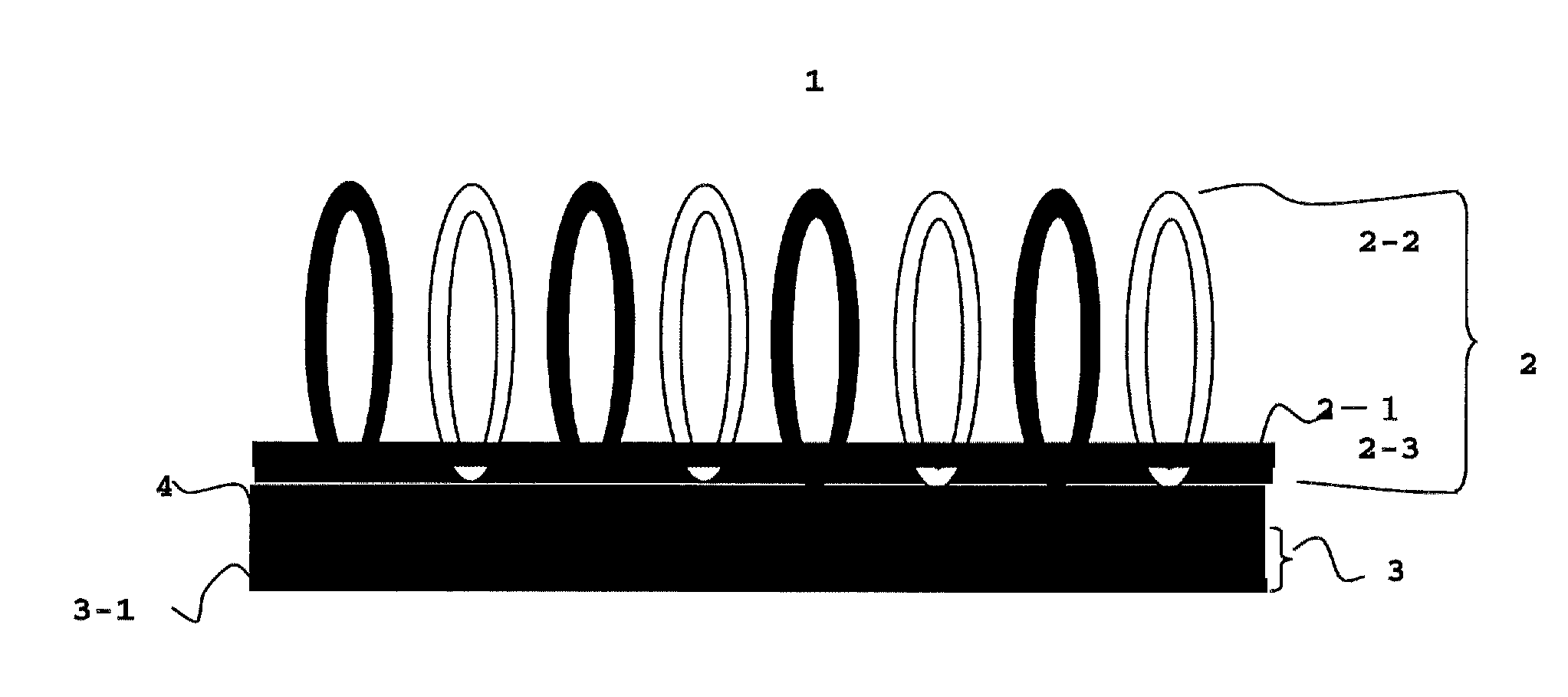

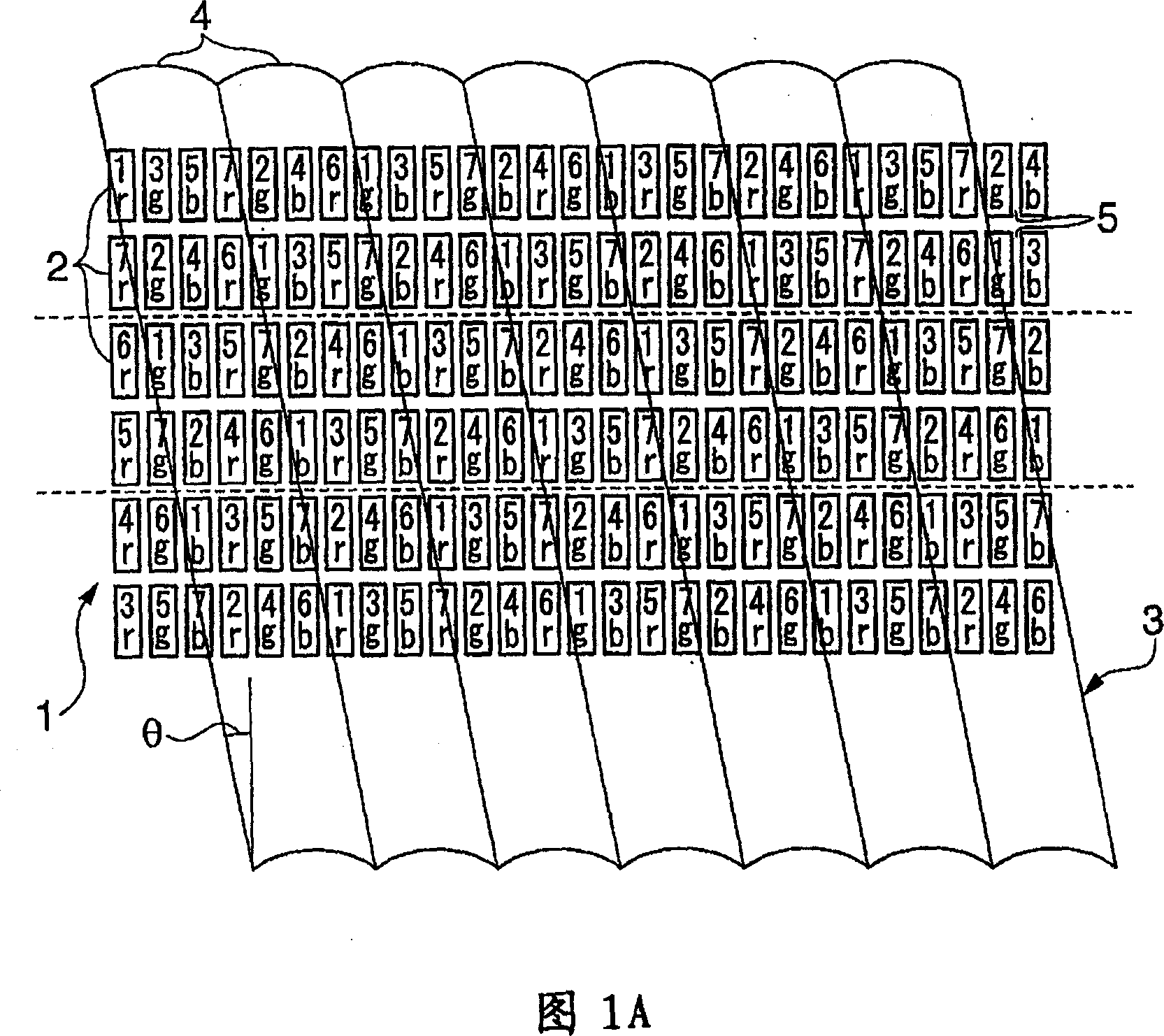

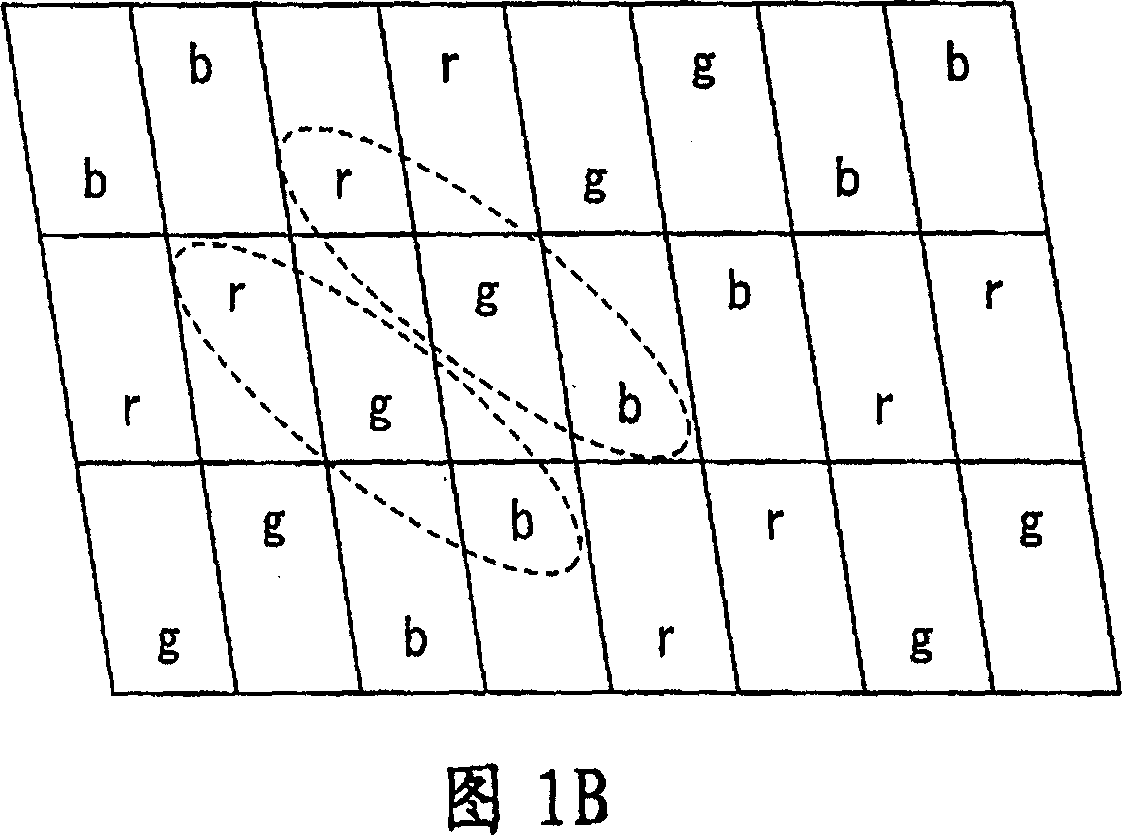

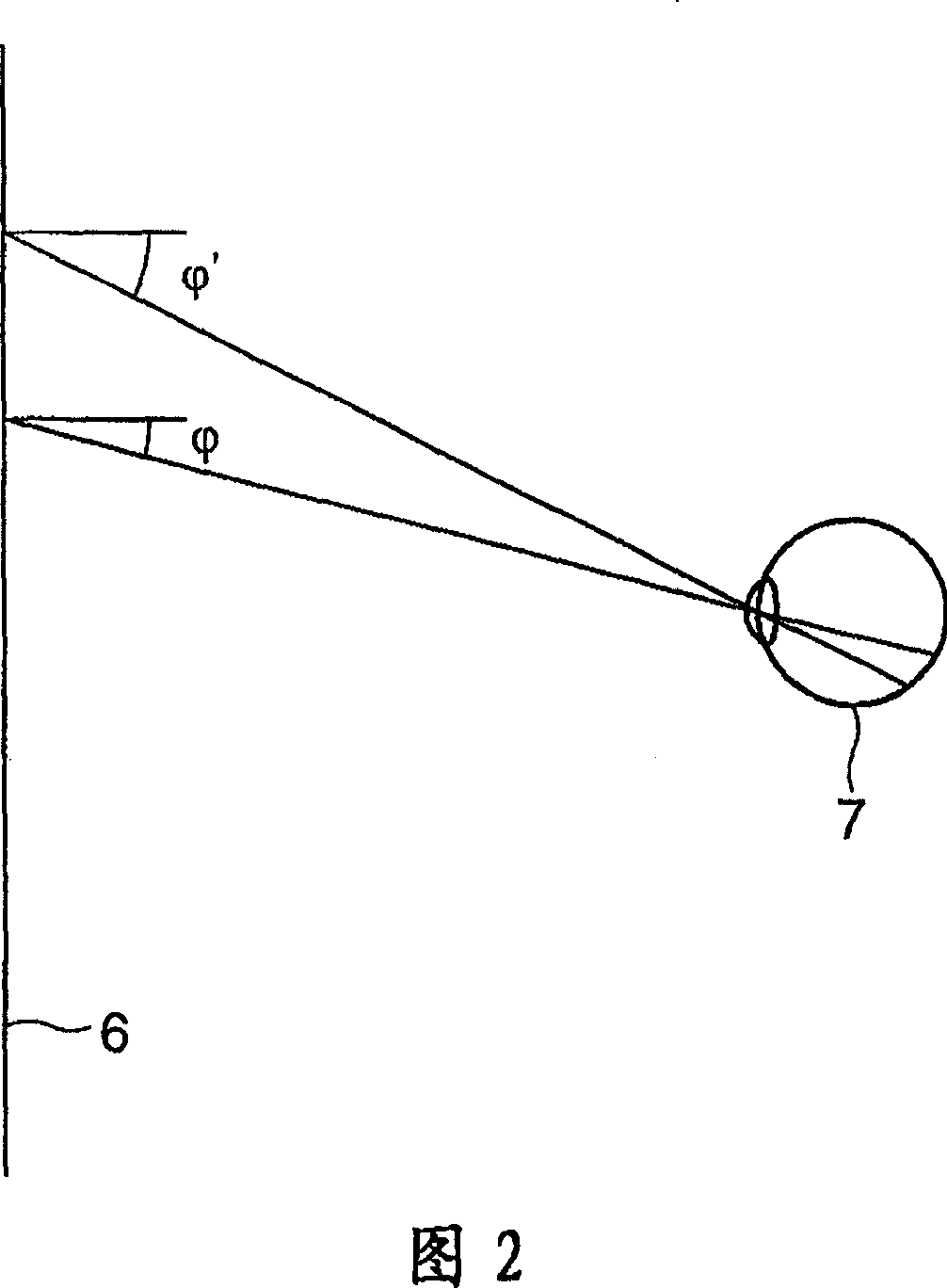

Three-dimensional display

InactiveCN1950744AEliminate strengthProjectorsSteroscopic systemsComputer graphics (images)Cylindrical lens

The invention provides a three-dimensional display capable of eliminating color non-uniformity and intensity non-uniformity on a three-dimensional image. The three-dimensional display comprises: a two-dimensional display, which comprises a plurality of color subpixels arranged in rows extending in a horizontal direction and in columns extending in a vertical direction which is substantially perpendicular to the horizontal direction, the color subpixels of red, green and blue being arranged periodically in the rows and the color subpixels of the same color being arranged in the columns; and a lenticular sheet provided on the two-dimensional display and having a plurality of cylindrical lenses through which the color subpixels are viewed and which extend in parallel with one another, the central axis of each cylindrical lens being inclined at an angle of theta to the column of the two-dimensional display, wherein, when a pitch of the color subpixels in the horizontal direction is px, a pitch of the color subpixels in the vertical direction is py, and a color subpixel group constituting one three-dimensional pixel is constituted by 3M*N number of color subpixels where 3M is the number of color subpixels in each row of one of the cylindrical lenses and N is the number of color subpixels in each column of one of the cylindrical lenses, a relationship, theta = tan -1 (3px / NPy ), is satisfied.

Owner:JAPAN SCI & TECH CORP

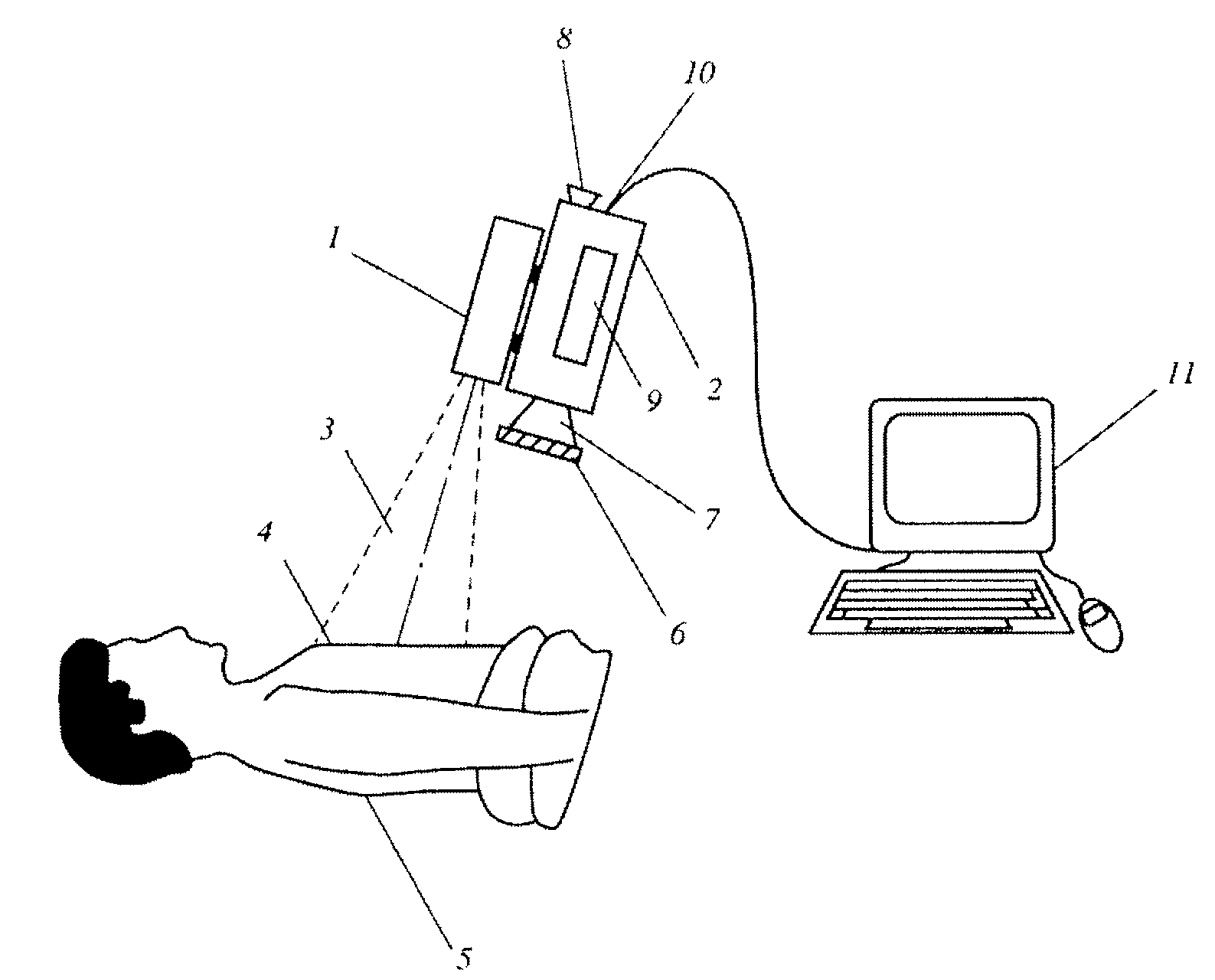

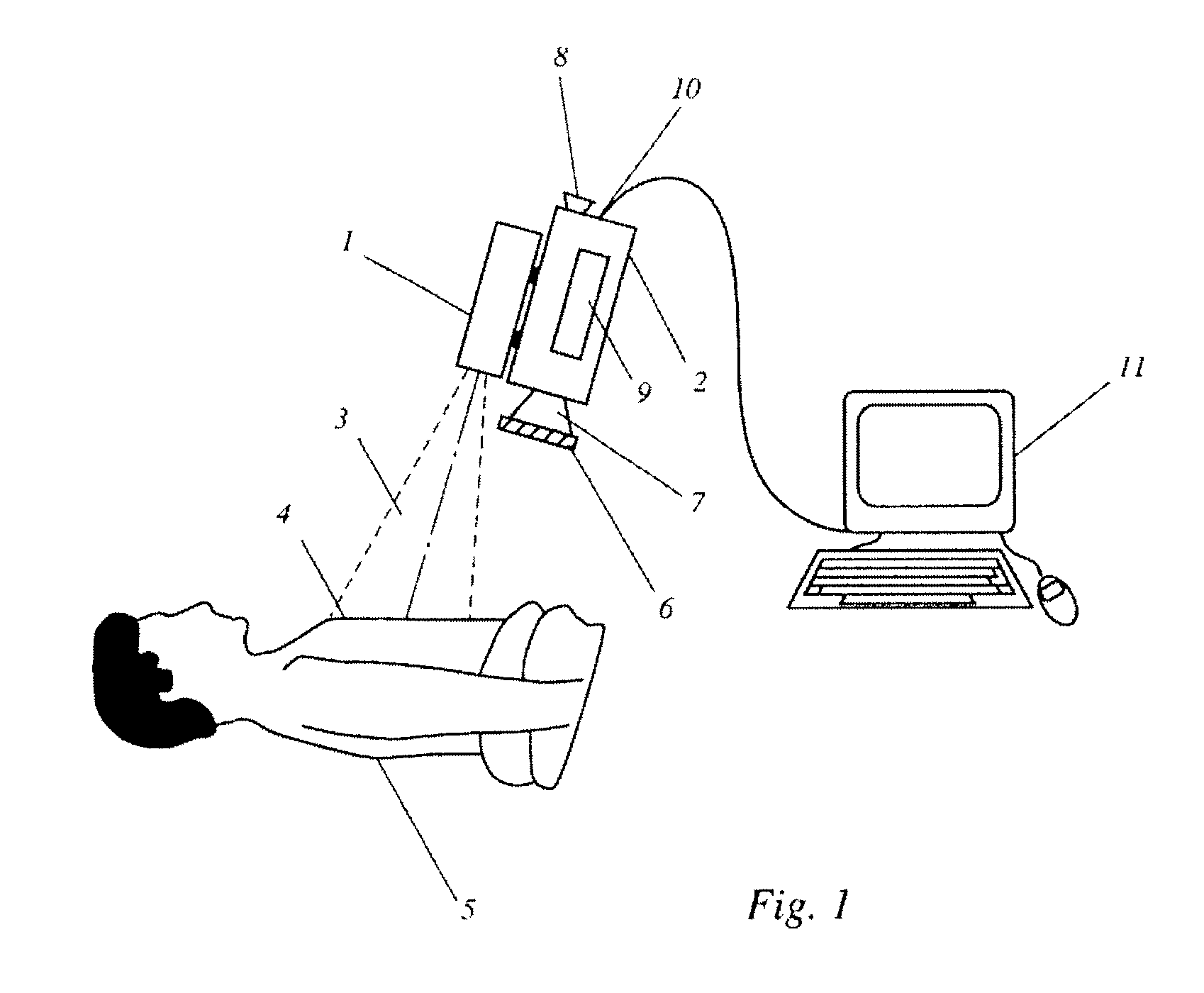

Method for evaluating blush in myocardial tissue

ActiveUS8406860B2Eliminate strengthAvoid excessive intensityImage enhancementMedical imagingFluorescenceCardiac muscle

Vessel perfusion and myocardial blush are determined by analyzing fluorescence signals obtained in a static region-of-interest (ROI) in a collection of fluorescence images of myocardial tissue. The blush value is determined from the total intensity of the intensity values of image elements located within the smallest contiguous range of image intensity values containing a predefined fraction of a total measured image intensity of all image elements within the ROI. Vessel (arterial) peak intensity is determined from image elements located within the ROI that have the smallest contiguous range of highest measured image intensity values and contain a predefined fraction of a total measured image intensity of all image elements within the ROI. Cardiac function can be established by comparing the time differential between the time of peak intensity in a blood vessel and that in a region of neighboring myocardial tissue both pre and post procedure.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

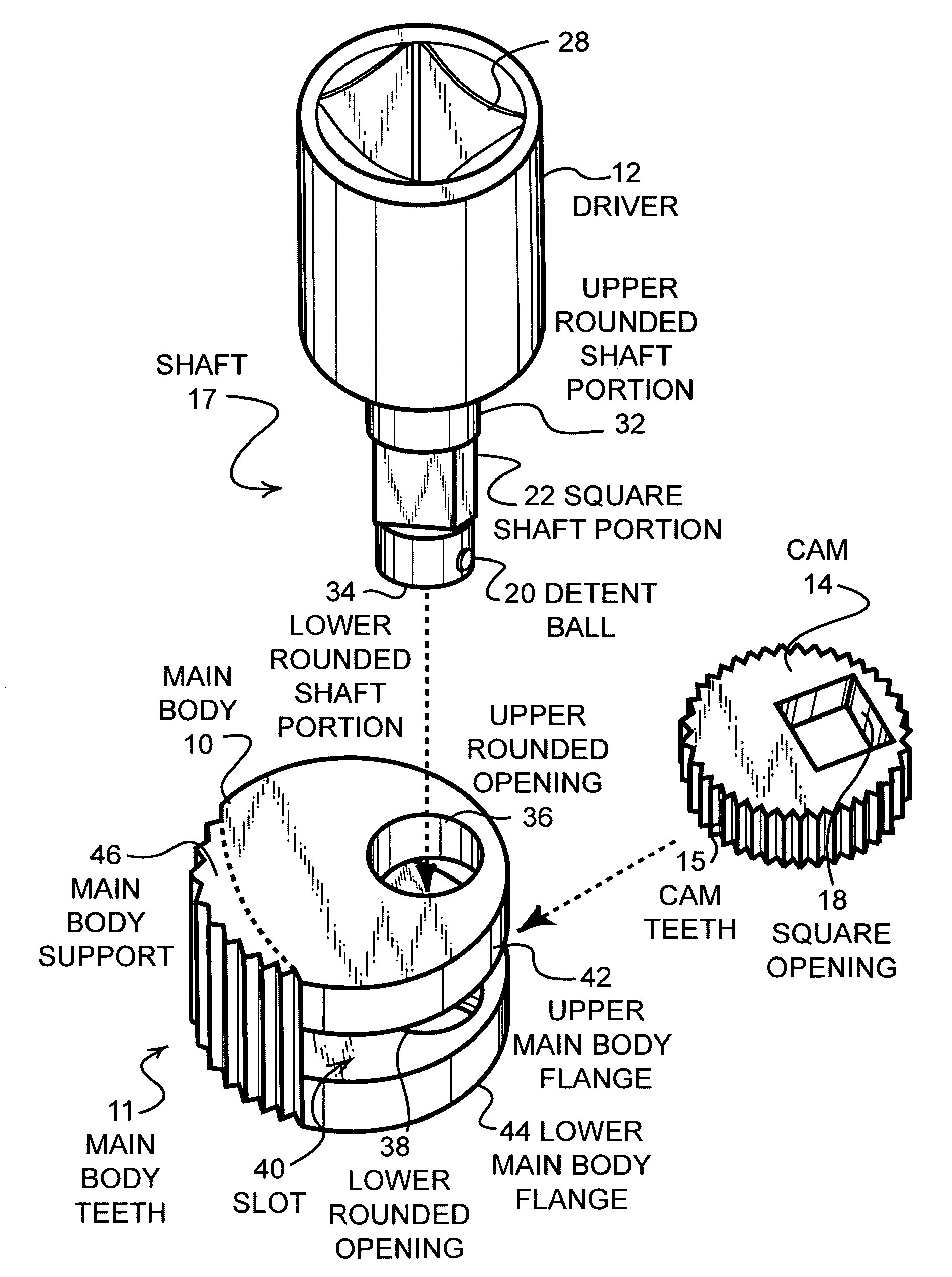

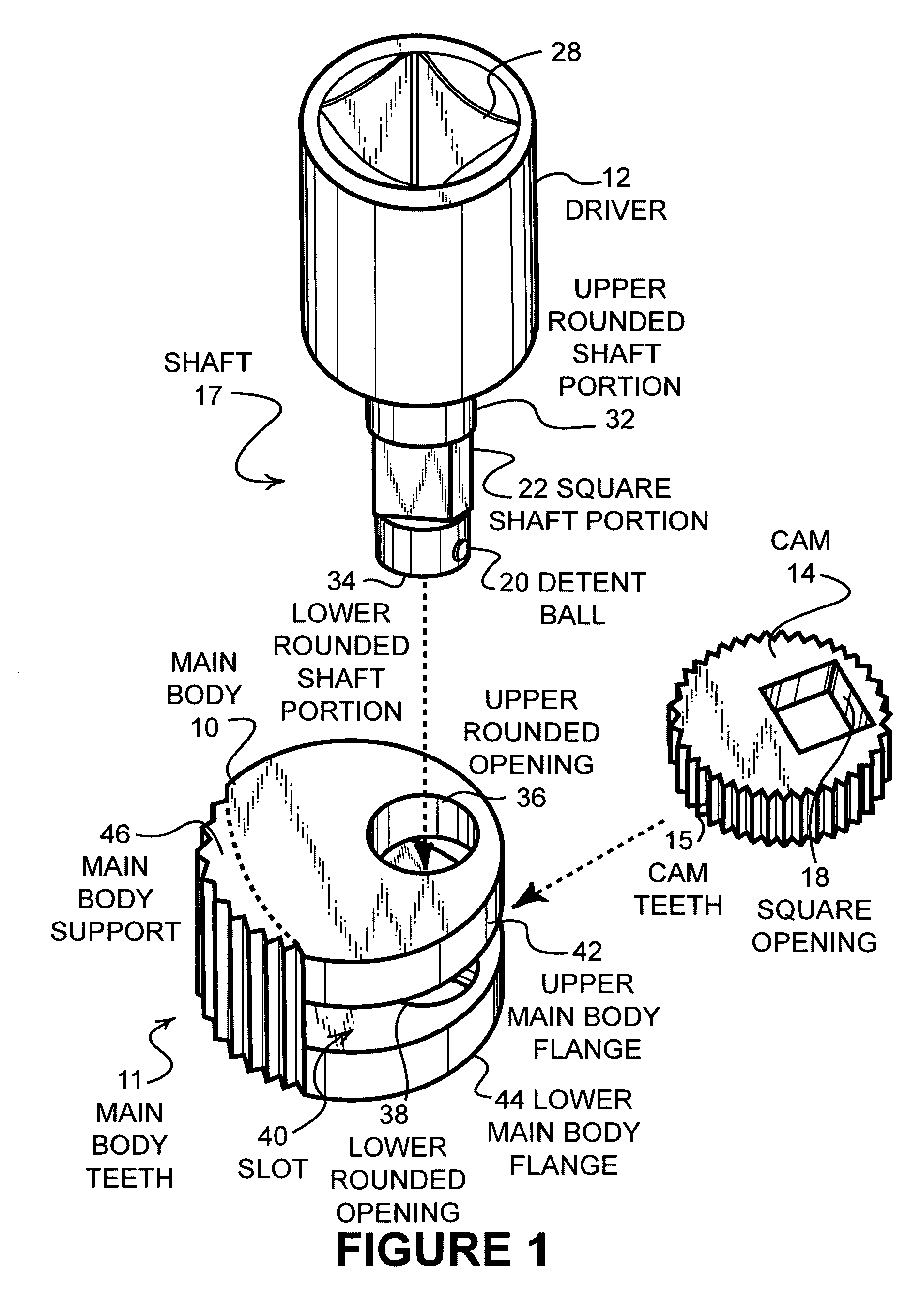

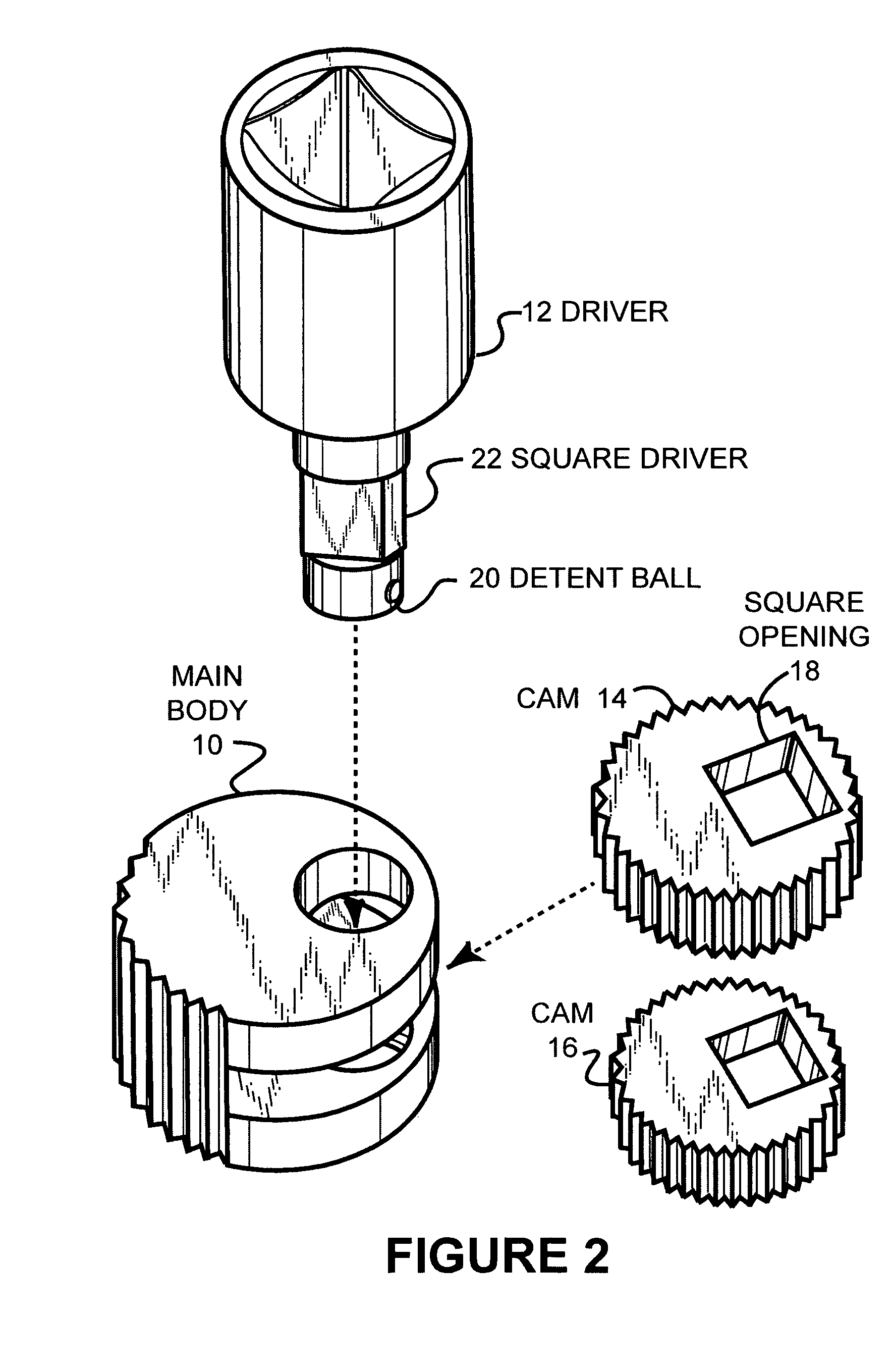

Tool for removing and tightening screw-on drains

ActiveUS7024972B2Simple and inexpensive to manufactureReduced durabilitySpannersWrenchesEngineeringCam

Disclosed is a tool for both removing and tightening screw-on drains that is simple and easy to use, has a simple design and is easy to manufacture. The tool is capable of engaging an inner surface of a drain flange in a manner that is sufficient to transfer enough force to remove screw-on drain flanges and is capable of use with various designs and sizes of screw-on drain flanges. Different size cams and different lever arms used on the cams allow the tool to optimize the radial force to torque ratio for both removal and insertion of screw-on drain flanges. In addition, nubs are used at the bottom of the drain flange to engage arms that typically are used on drain flanges to further add to the resistance that can be provided between the tool and the drain flange and distribute forces in a dynamic, instantaneous and automatic fashion to optimize removal of the drain flange.

Owner:RECTORSEAL LLC

Non-sintering sialon bonded corundum-spinel castable and method for preparing RH (Ruhstahl Hausen) insert tube prefabricated member inner core with same

ActiveCN103880442AImproved thermal shock stabilityImprove high temperature mechanical propertiesMetal powderUltimate tensile strength

The invention discloses a non-sintering sialon bonded corundum-spinel castable and a method for preparing an RH (Ruhstahl Hausen) insert tube prefabricated member inner core with the same. The castable comprises the following raw materials: 50-72% of fused white corundum, 8-21% of spinel, 2-9% of silicon metal powder, 3-11% of 200-mesh fused white corundum, 2-6% of alpha-alumina and 3-7% of rho-alumina; besides, an additive FS60 with weight accounting for 0.04-0.13% of total weight of various raw materials is added. The castable and the method have the beneficial effects that as the castable adopts sialon bonding, impacts of existence of CaO in existing traditional castable cement on the high temperature property and corrosion resistance of the prefabricated member are overcome, thus greatly improving the high temperature strength and thermal shock resistance of the castable; in combination with the 1700 DEG C service conditions of the product, generation of sialon in the service process is achieved, the production cost is effectively reduced, and the service life of the product is prolonged by 30-50%.

Owner:郑州市裕丰耐火材料有限公司

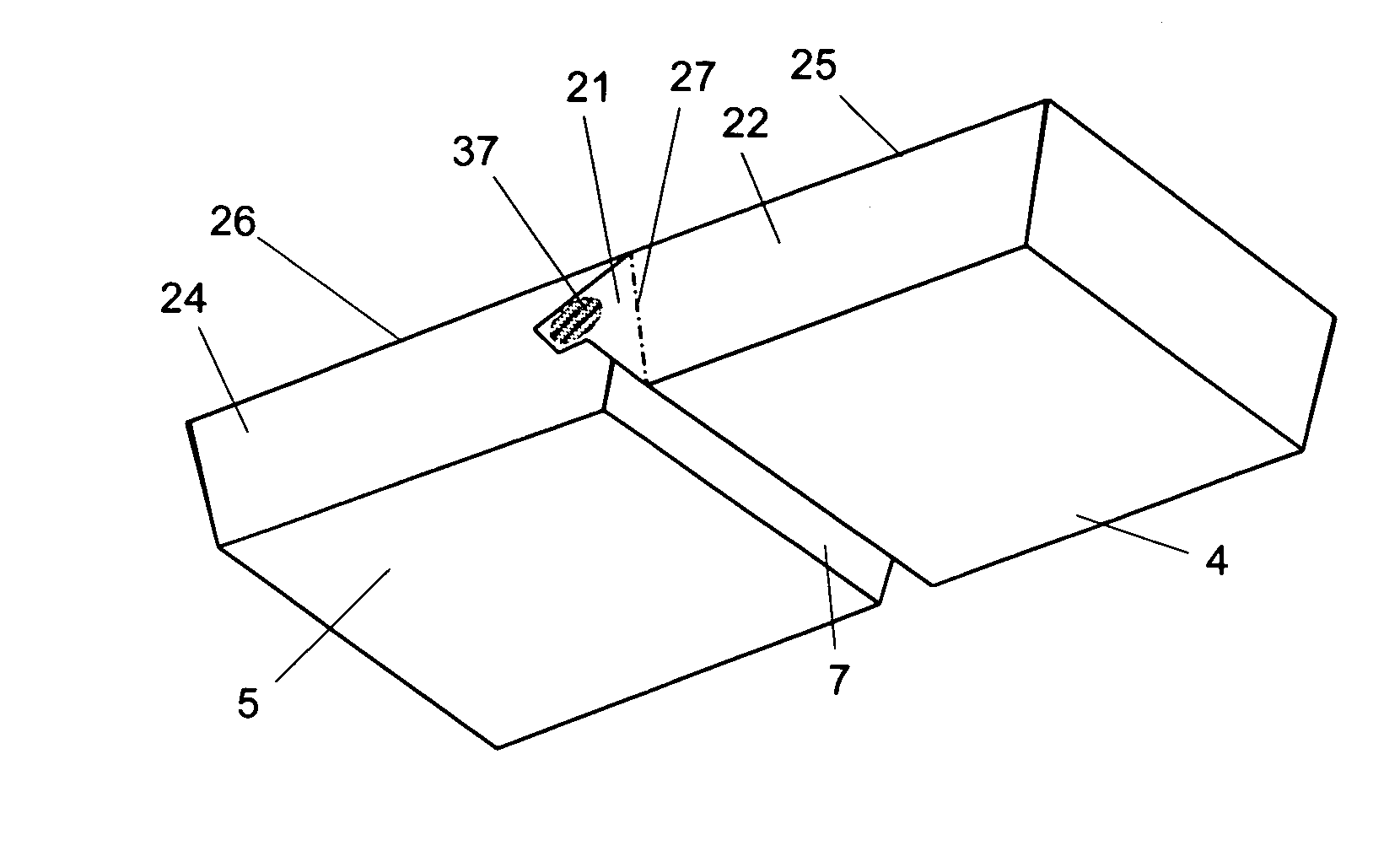

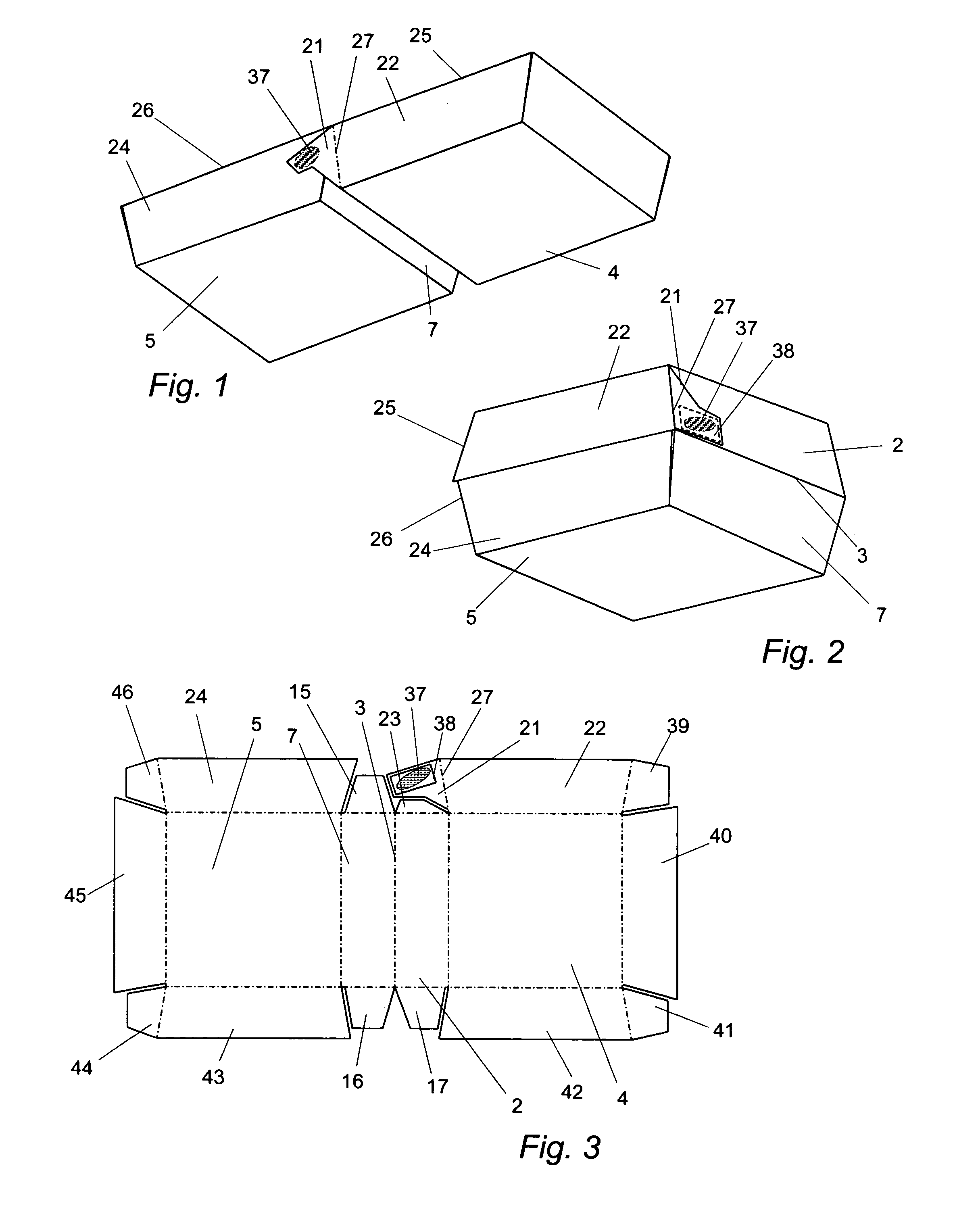

Clamshell container hold open mechanism

ActiveUS8490808B1Maximizes moment arm lengthMinimizing tensileRigid containersEngineeringMechanical engineering

An open clamshell-type food container is prevented from collapsing by means of a securing tab joined to the side wall of one of the container shells, a side wall joined to the other container shell, the two side walls being in alignment, and the securing tab being affixed to the other side wall.

Owner:SNYDER ROBERT GEORGE

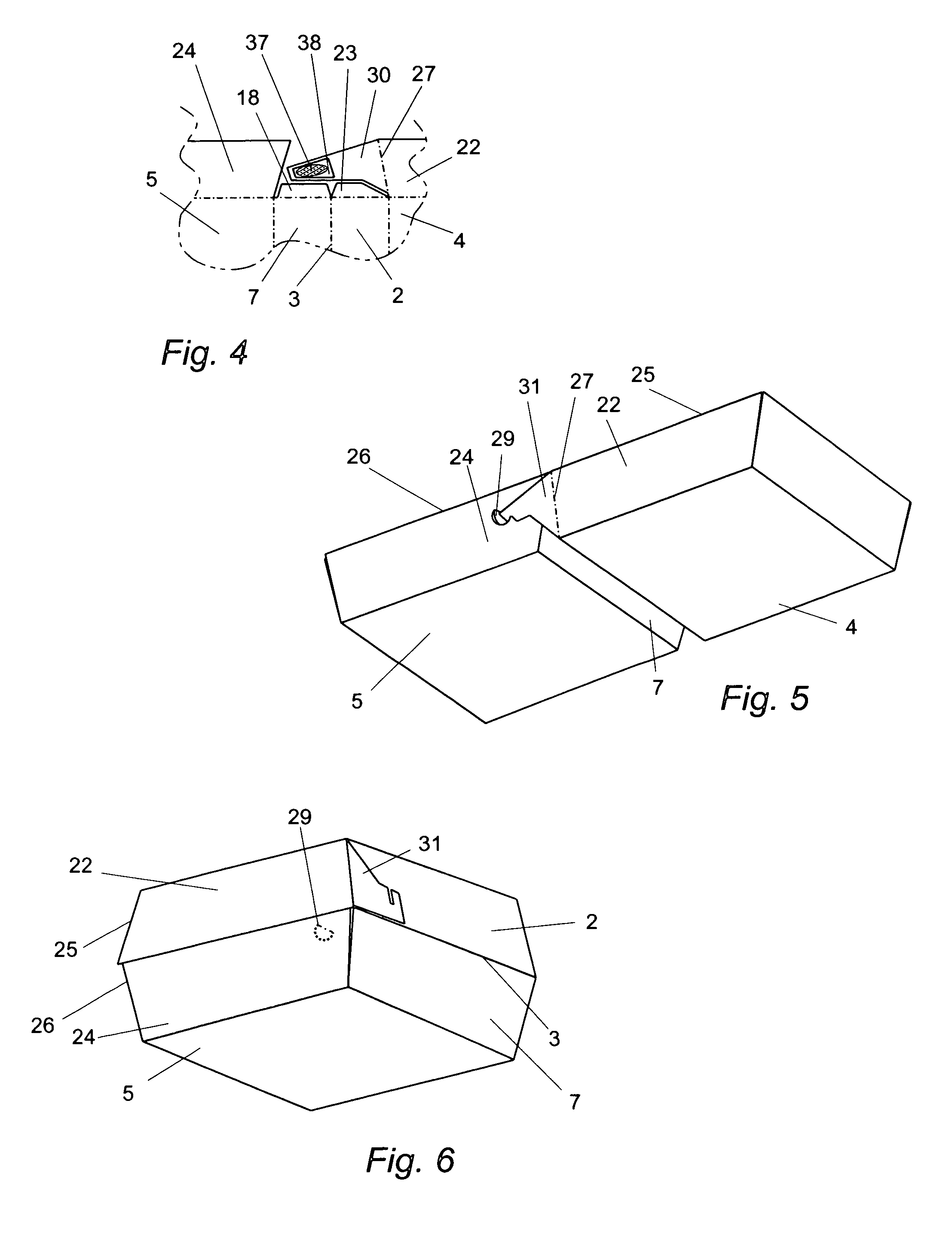

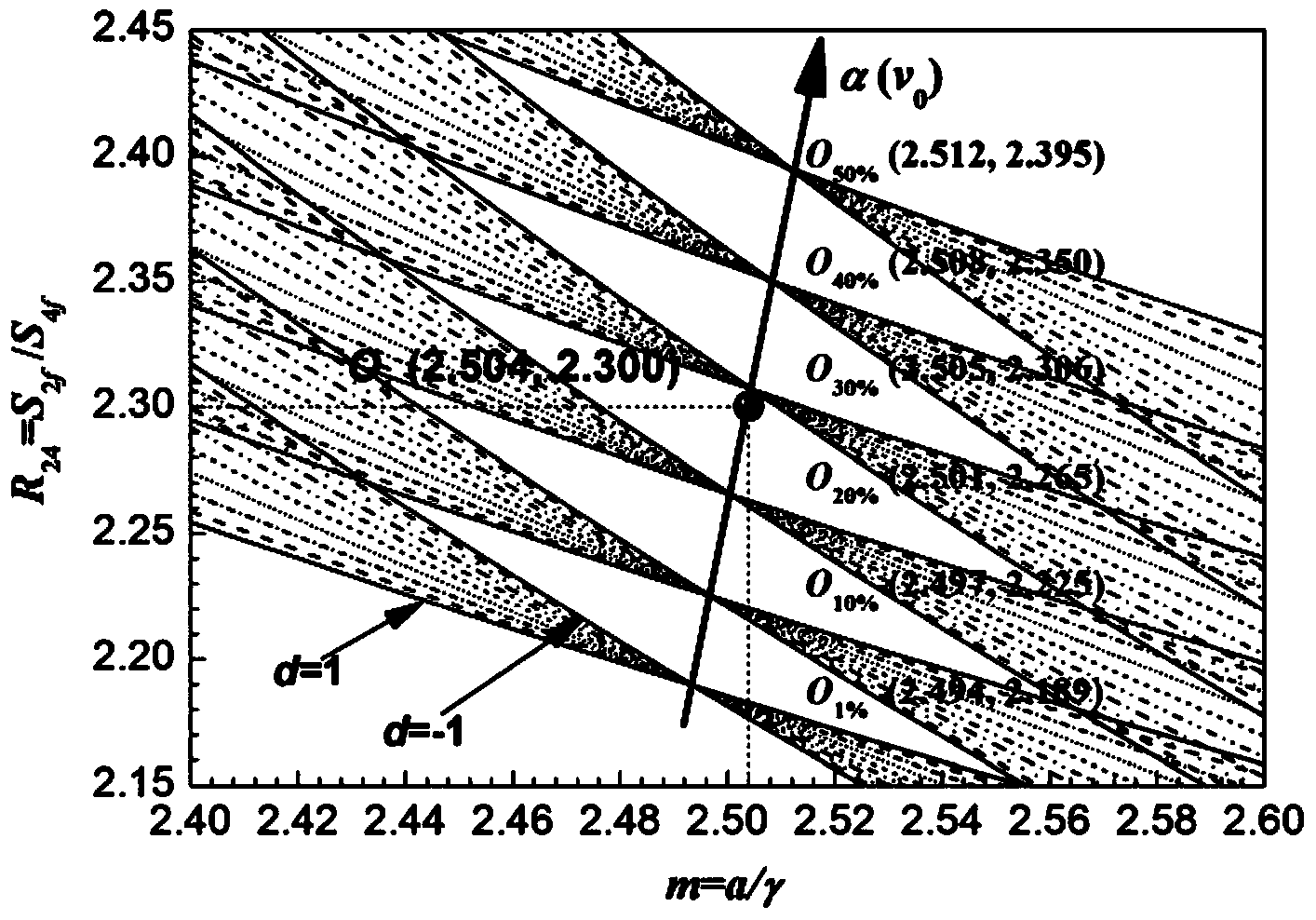

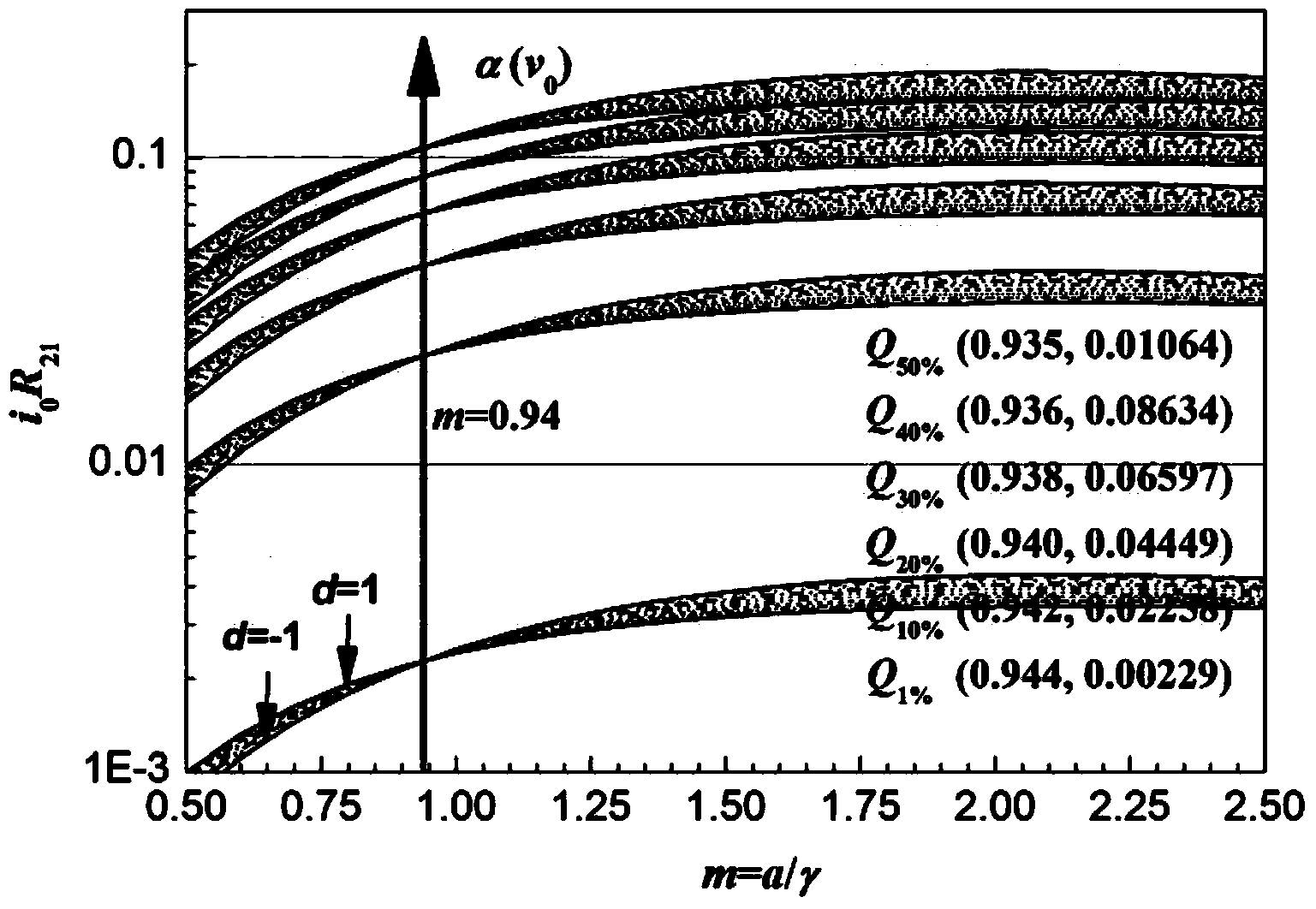

Gas absorptivity online measurement method based on modulation factor

ActiveCN103868884AElimination concentrationEliminate strengthColor/spectral properties measurementsAbsorption rateLine width

The invention discloses a gas absorptivity online measurement method based on a modulation factor, belonging to the technical field of tunable diode laser absorption spectroscopy (TDLAS). The gas absorptivity online measurement method comprises the following steps: firstly, determining the width of an absorption spectral line through a characteristic of a fixed point by using a ratio of a quadratic harmonic wave to a quartic harmonic wave, and figuring out a modulation factor; and then determining a peak absorption rate of the spectrum line according to a ratio of the quadratic harmonic wave to the primary harmonic wave when the modulation coefficient is equal to 0.94. The gas absorptivity online measurement method is simple in principle; the influence of factors such as laser intensity fluctuation and a photoelectric enlargement factor is eliminated, the problem that the absorption rate can not be accurately measured in a wavelength modulation method is effectively solved, and the application range of a TDLAS technology is widened.

Owner:北京新叶科技有限公司

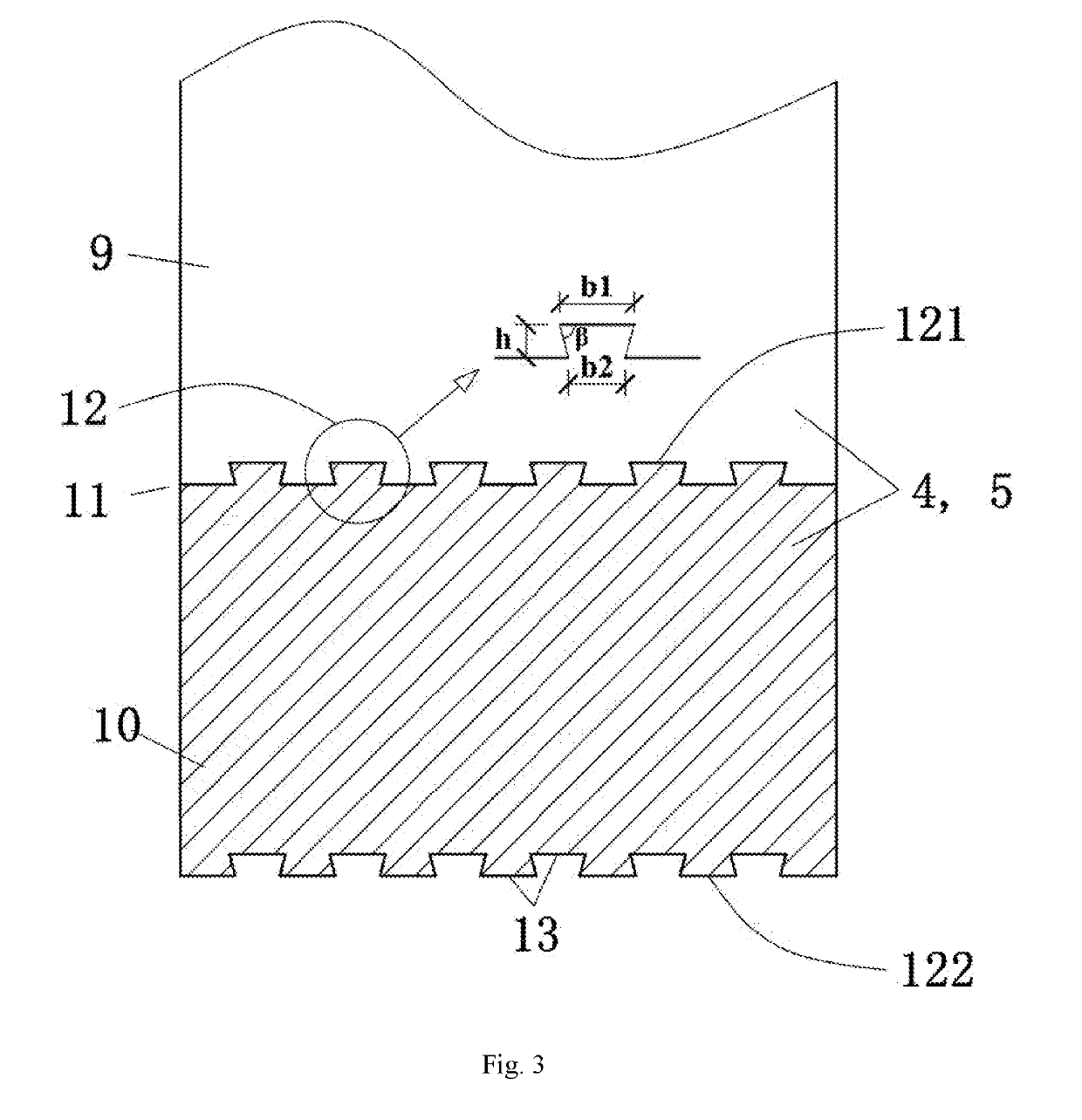

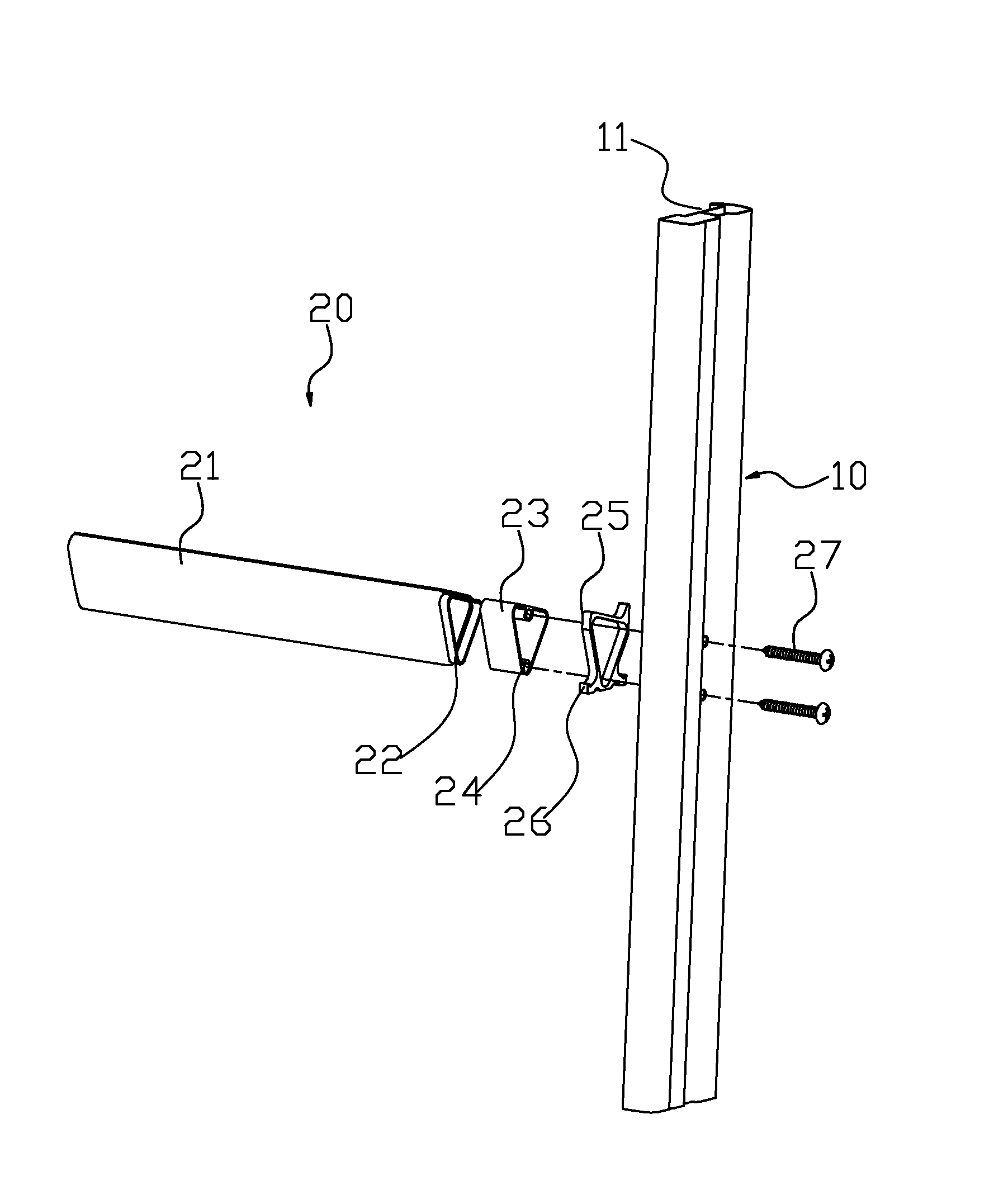

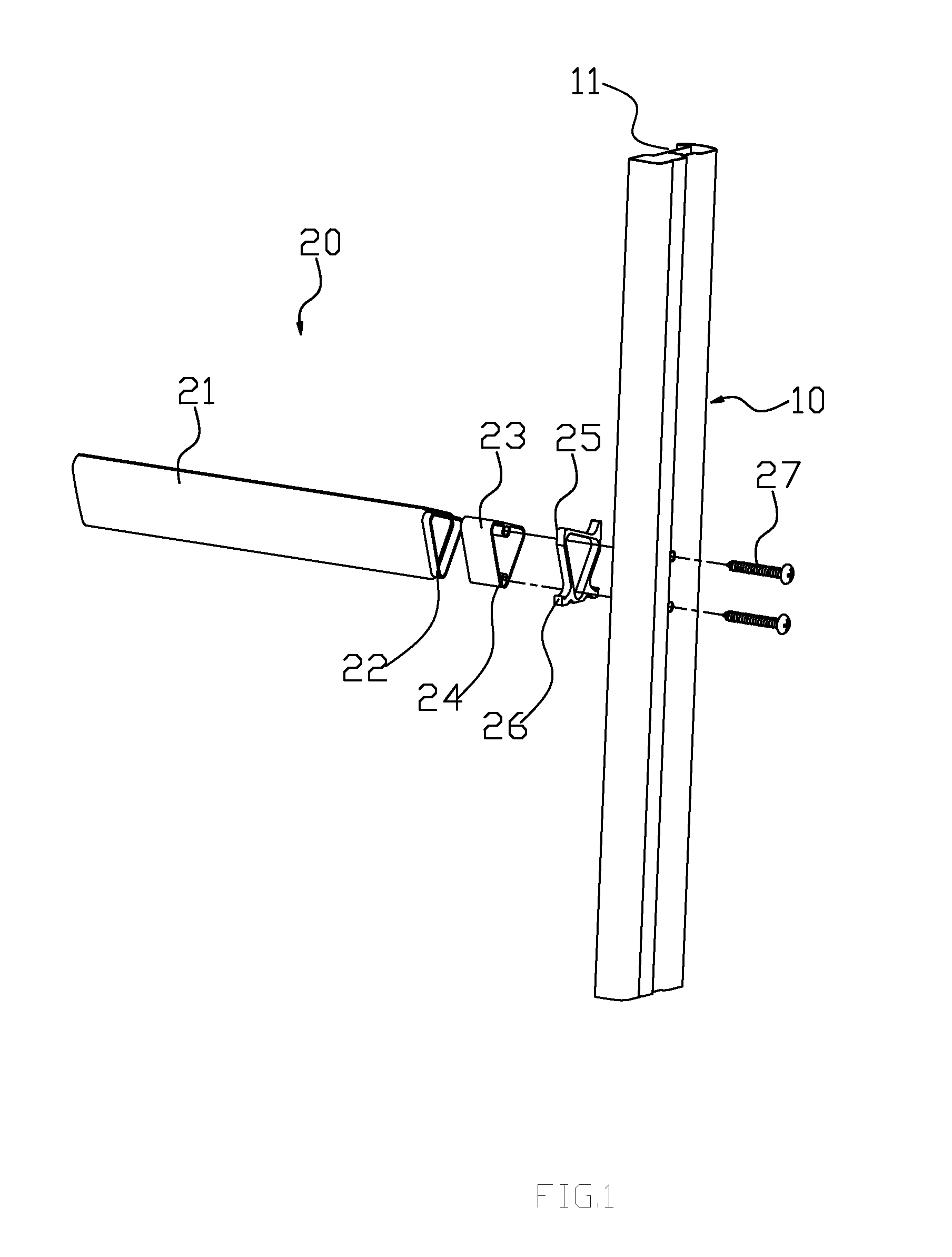

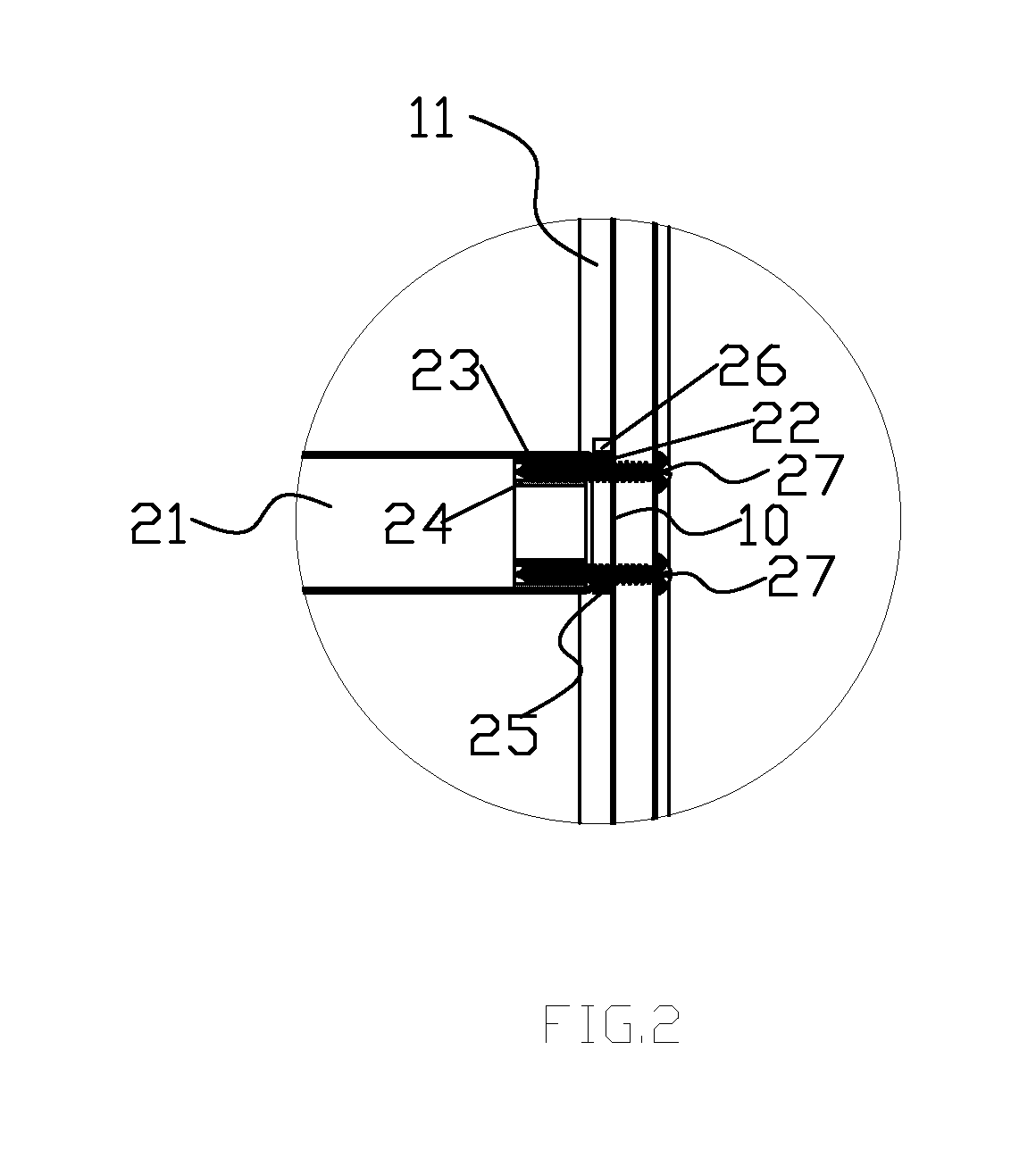

Segmental joint of cast-in-place uhpc beam bridge and construction method thereof

ActiveUS20190309488A1High strengthFacilitate on-site constructionCeramic shaping apparatusBridge structural detailsBridge deckTongue and groove

The present disclosure relates to a segmental joint of cast-in-place UHPC bridge beam, and belongs to the field of bridge structure. The joint comprises a plurality of female joints disposed at an end of a first segment and a plurality of male joints disposed at an end of a second segment, wherein each female joints and the male joints are correspondingly connected to form a tongue-and-groove connection, and each of the male joints is of a structure with big outer part and small inner part. The beam segment joint of the present disclosure not only applies to the joint connection between the segmental cast-in-place UHPC beam segments and the construction of the segmental cast-in-place UHPC beam segment, but also to joint connection of UHPC bridge deck of UHPC-steel composite beam and of full UHPC bridge deck of UHPC composite box girder with corrugated steel webs and to UHPC bridge deck construction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ladder

A ladder comprises two stiles and at least a step unit mounted between the two stiles. The step unit includes a hollow step, an inner sleeve and an outer sleeve. The inner sleeve is fit into the hollow step, at an end of which a position restriction portion is located to prevent the inner sleeve from moving out, and the outer sleeve is adapted to surround the end of the hollow step. Besides, a fastener is set, the fastening end of which is passed through the stile, the outer sleeve and fastened in the inner sleeve. The present technique solution has a high supporting strength and a high shear resistance.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Lost foam casting die and method for braking disc

InactiveCN104889327ASmall dimensional toleranceSmall surface finishFoundry mouldsFoundry coresHardnessLost-foam casting

The invention relates to a lost foam casting die and method for a braking disc and belongs to the technical field of lost foam casting and aims to solve the technical problem of short service life. According to the lost foam casting die and method for the braking disc, lost foam casting is adopted, the hardness of a friction surface of the braking disc is uniform and the service life is long. According to the technical scheme, the lost foam casting die comprises an upper die, a lower die and a semi-circular casting lost foam pattern, wherein cavities are formed in inner surfaces of the upper die and the lower die, a casting cavity is formed between the upper die and the lower die after the upper die and the lower die are buckled, the semi-circular casting lost foam pattern is arranged in the casting cavity, multiple movable blocks are arranged in the semi-circular casting lost foam pattern, and sprue gates are formed in tops of the upper die and the lower die. The lost foam casting die and method for the braking disc are widely used for casting of the braking disc.

Owner:山西威龙铁路机车制动配件制造有限公司

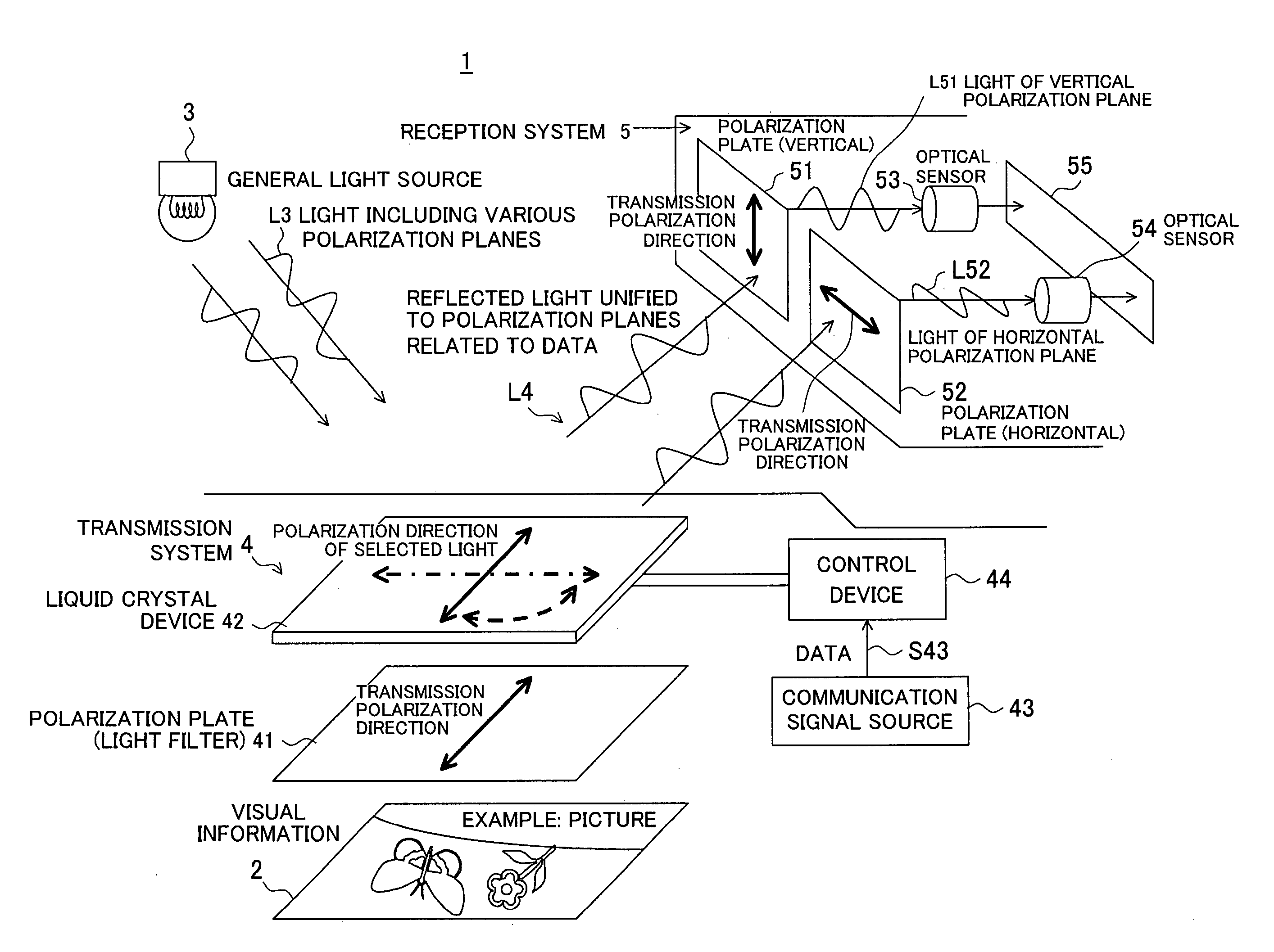

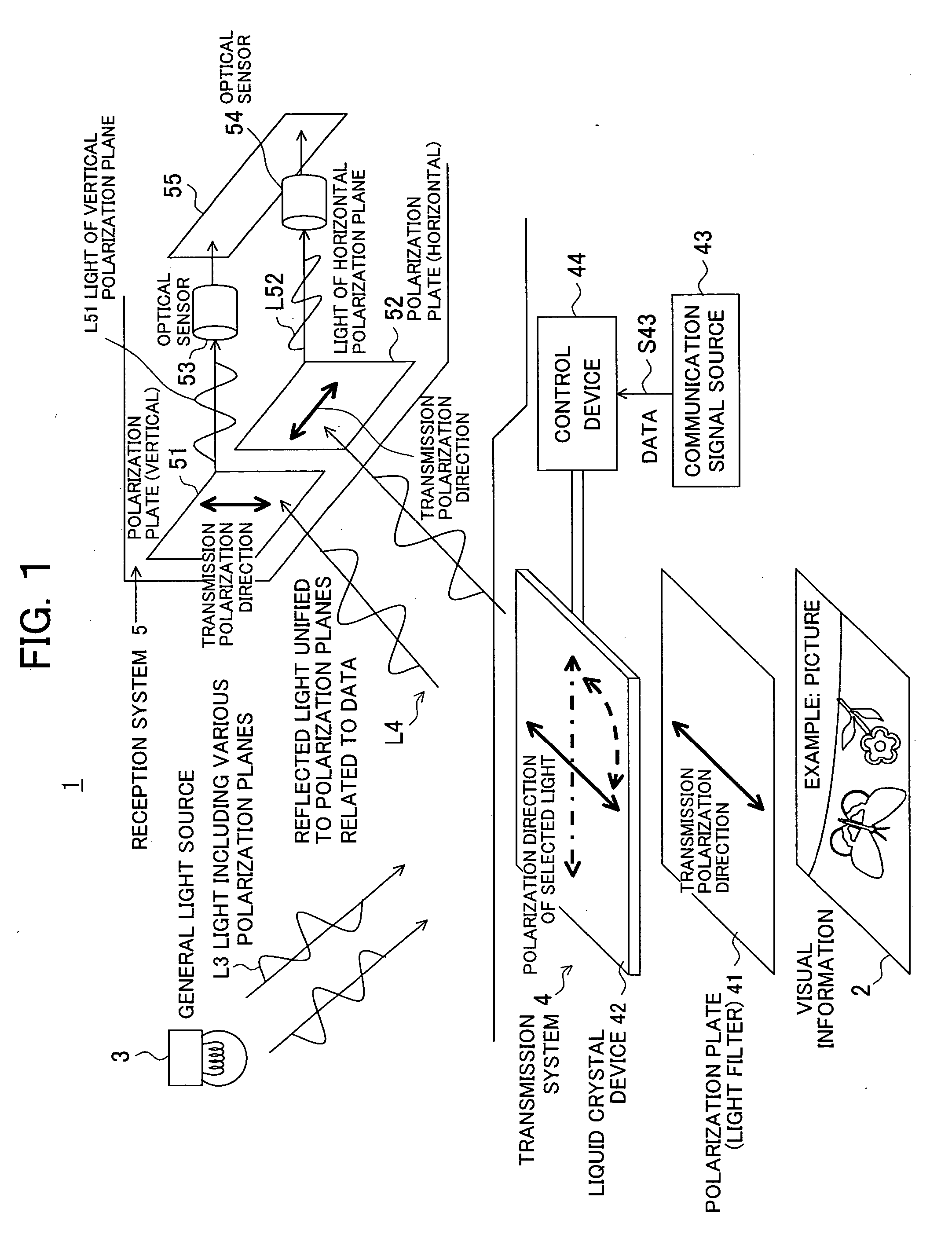

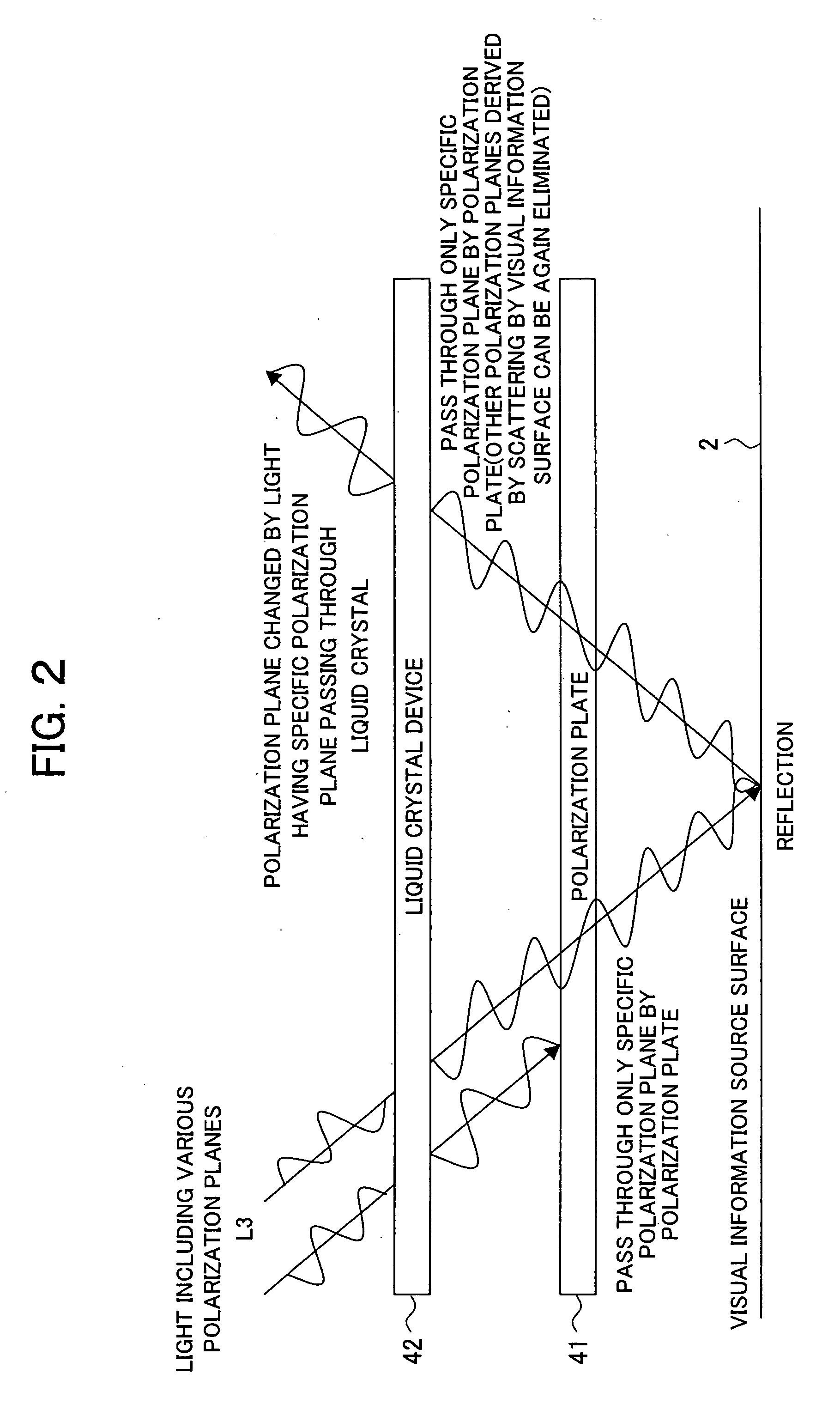

Wireless communication system, wireless transmitting apparatus, and wireless receiving apparatus

InactiveUS20060269293A1Eliminate strengthLine-of-sight transmissionElectromagnetic transmittersOptical wirelessInfrared

A wireless communication system, a wireless transmitting apparatus, and a wireless receiving apparatus which can be applied to all types of light sources and can be applied to a variety of fields, provided with a medium forming an information transmission source, a general light source made of for example a lamp or the sun or another natural light source or artificial light source, a wireless transmitting apparatus for making the polarization of the light from the light source uniform and controlling the polarization plane of an infrared ray, visible ray, UV ray, or other light (modulating the light in polarization) so as to superimpose other information invisible to the human eye on visual information due to general reflected light and transmitting the same as an optical wireless signal, and a wireless receiving apparatus for receiving the optical wireless signal transmitted from the wireless transmitting apparatus and able to determine a change in orientation of the polarization plane of the light as information of the signal.

Owner:KYOCERA CORP

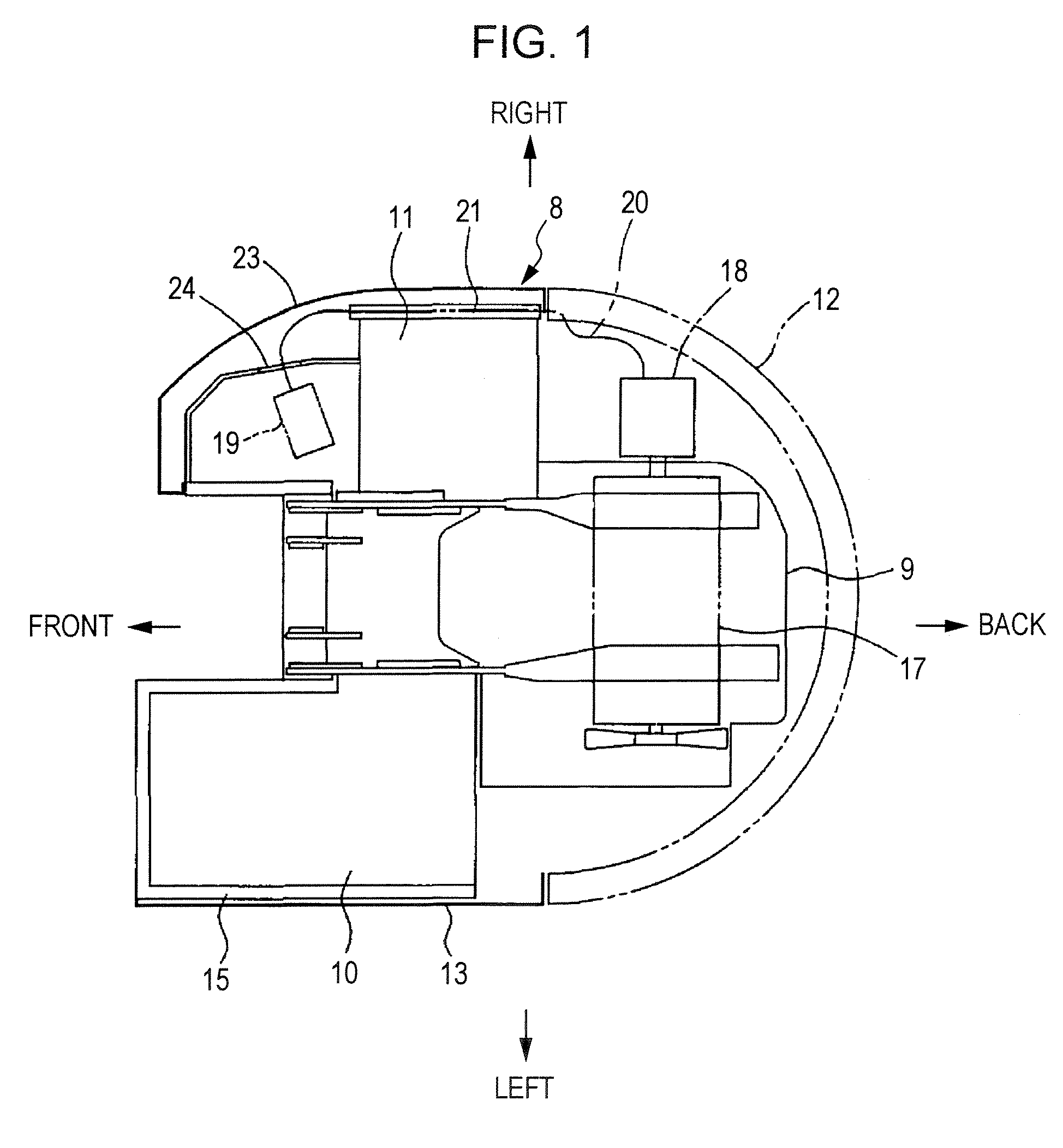

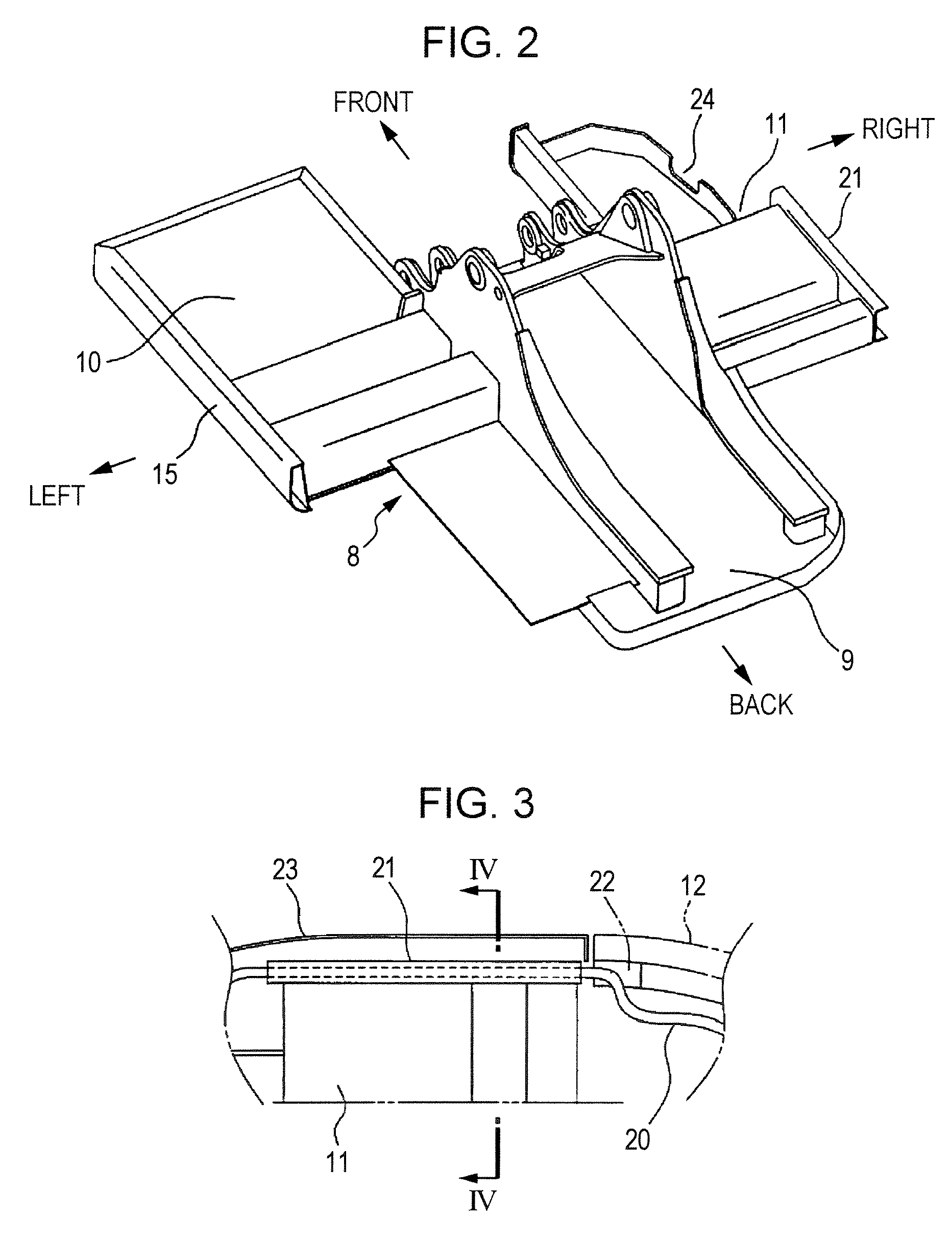

Working machine

ActiveUS7419186B2Eliminate strengthSimplifies pipeworkVehicle seatsVehicle body-frame connectionsHydraulic pumpControl valves

Owner:KOBELCO CONSTR MASCH CO LTD

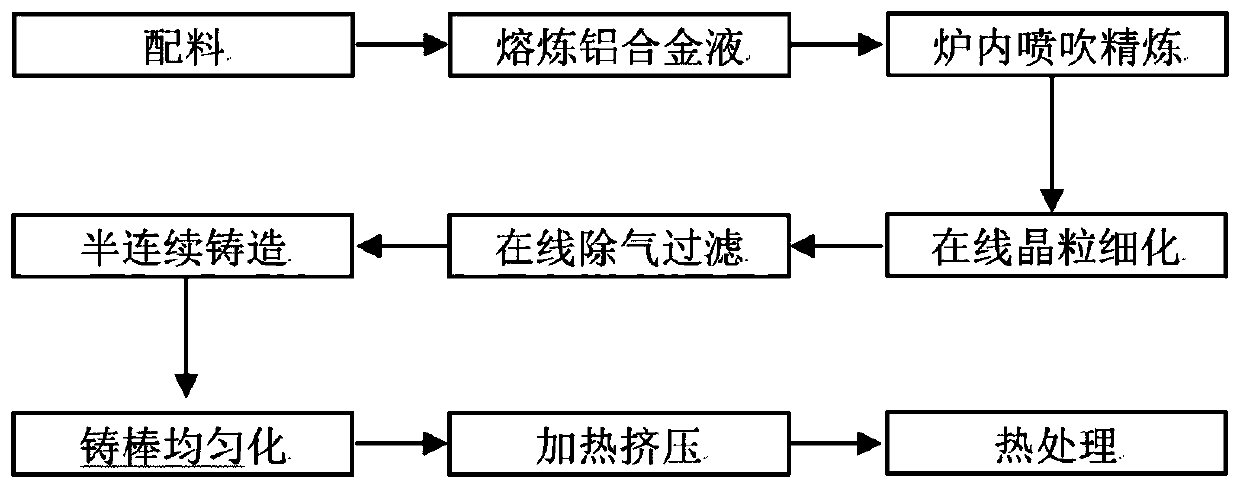

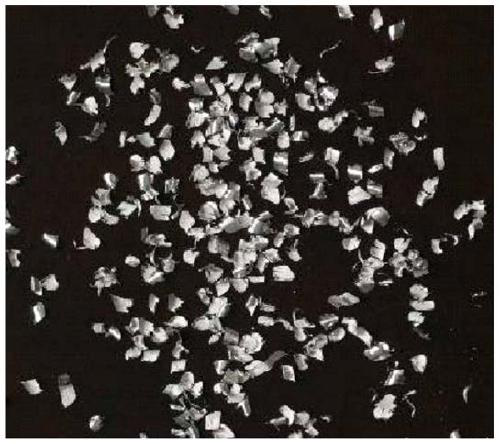

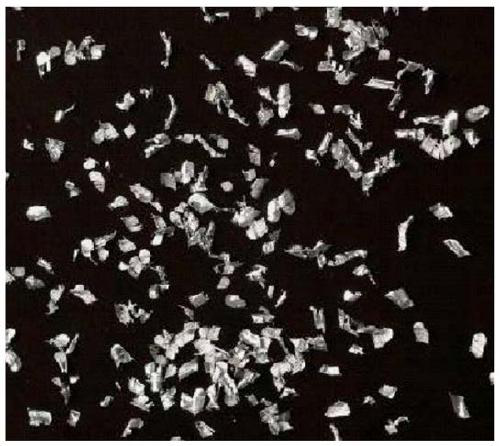

Free-cutting aluminum copper alloy extruded bar and preparation method thereof

ActiveCN110157965AImprove cutting performanceChips are easy to breakSurface finishMechanical property

The invention provides a free-cutting aluminum copper alloy extruded bar and a preparation method thereof. The aluminum copper alloy extruded bar comprises the following components of, in percentage by mass, 3.5%-4.5% of Cu, 0.6%-0.9% of Mg, 0.6%-1.0% of Mn, 0.4%-0.6% of Cr, 0.15%-0.25% of Ce, 0.06%-0.1% of B, 0.01%-0.02% of Ti, 0.0004%-0.0008% of C, 0.8%-1.2% of Sn, 0.3%-0.5% of Bi, less than orequal to 0.2% of Fe, less than or equal to 0.1% of Si, and the balance Al and other impurity elements. The preparation method of the bar sequentially comprises the steps of burdening, smelting an aluminum copper molten alloy, in-furnace blowing and refining treatment and degassing and impurity removing, on-line grain refining, on-line degassing filtering treatment, semi-continuous casting treatment, cast bar homogenizing, heating extruding treatment, on-line quenching and artificial aging treatment. The aluminum copper alloy extruded bar does not contain heavy metal element lead, meets the environment-friendly requirement, and has good mechanical properties and excellent cutting machining performance; cutting chips are easy to break, not prone to adhere to or twine around a cutter, the production efficiency of cutting machining is improved, and the surface smoothness and the size precision of products are improved.

Owner:GUANGDONG XINGFA ALUMINUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com