Patents

Literature

122results about How to "Small dimensional tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

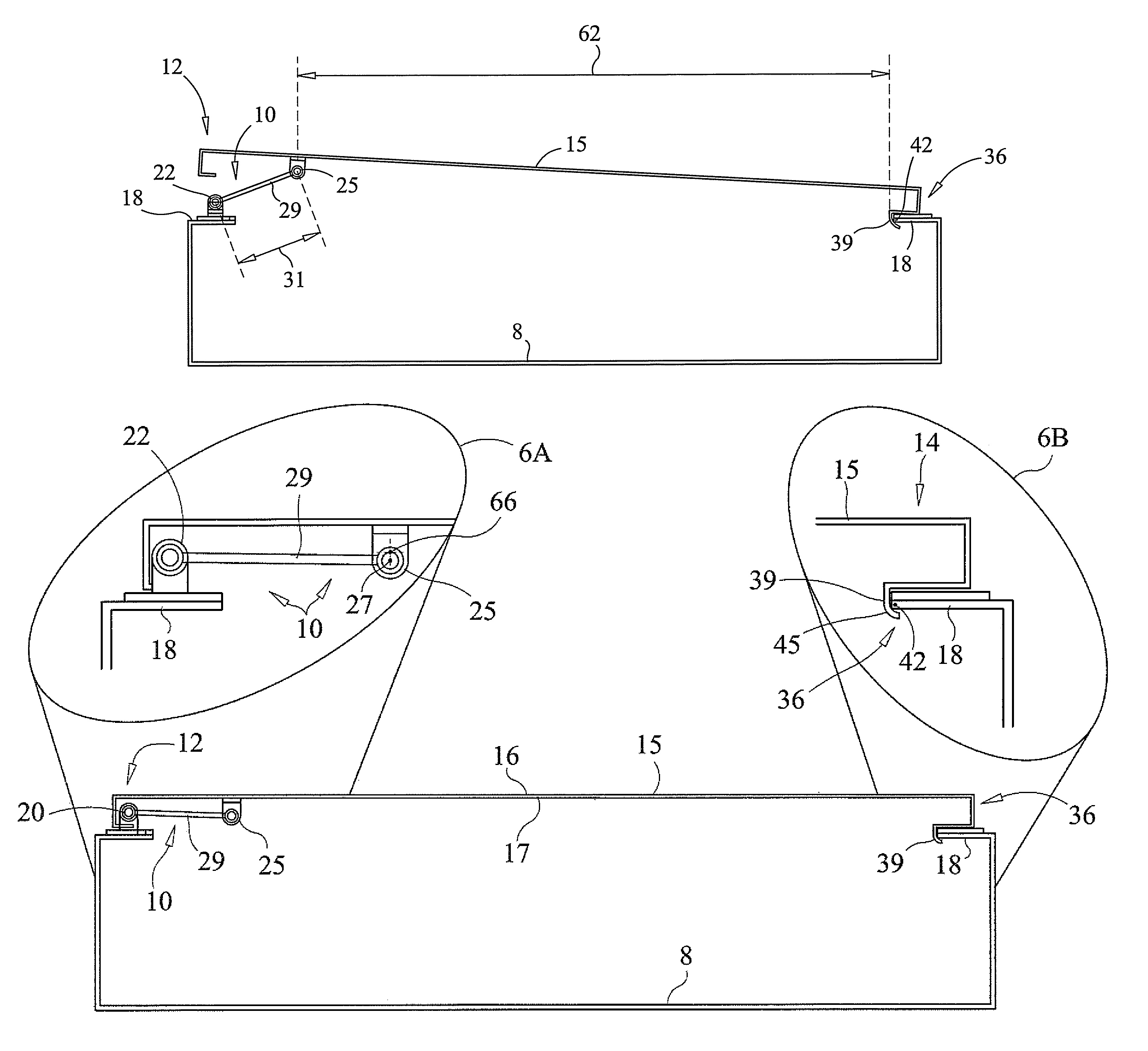

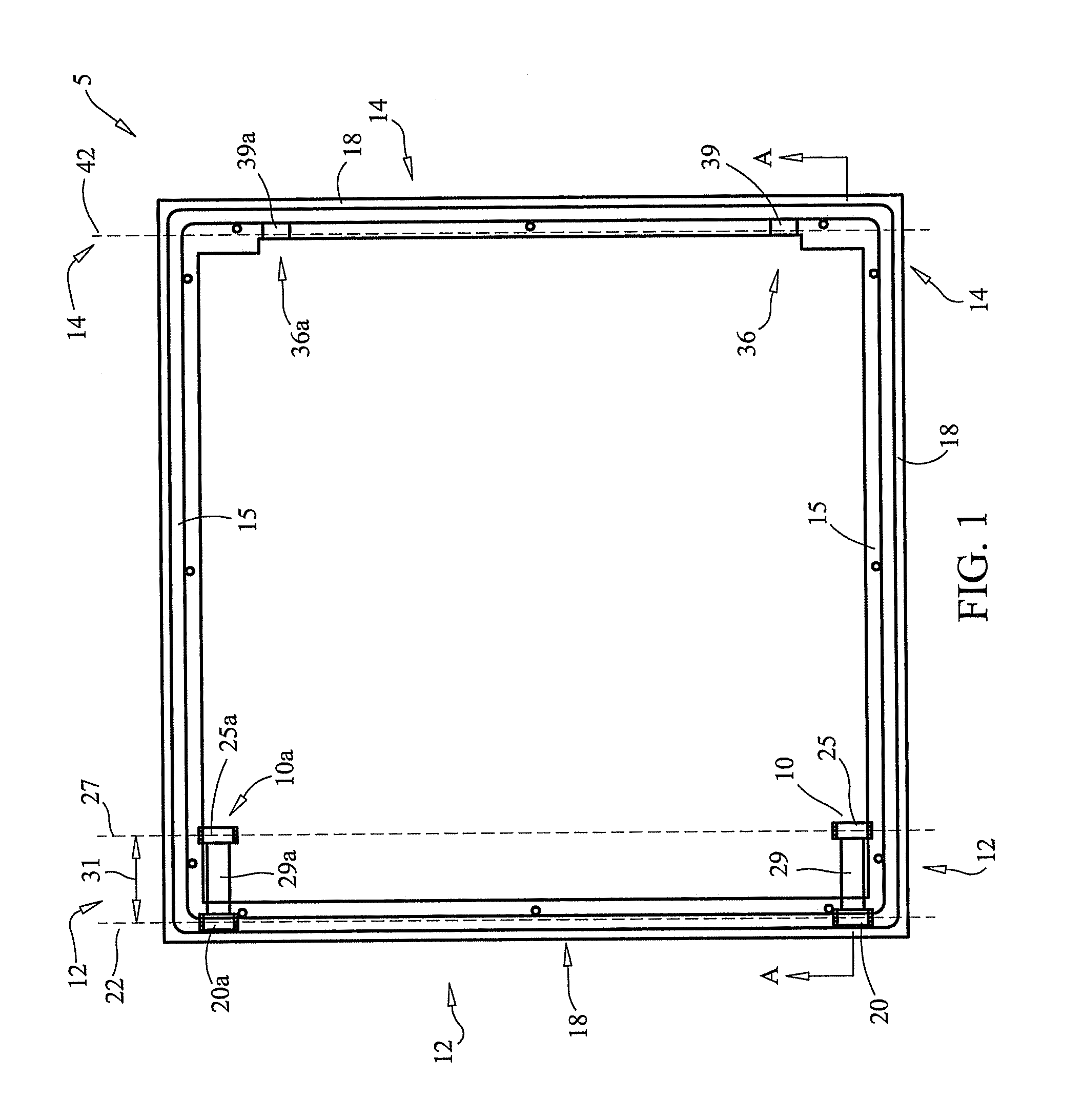

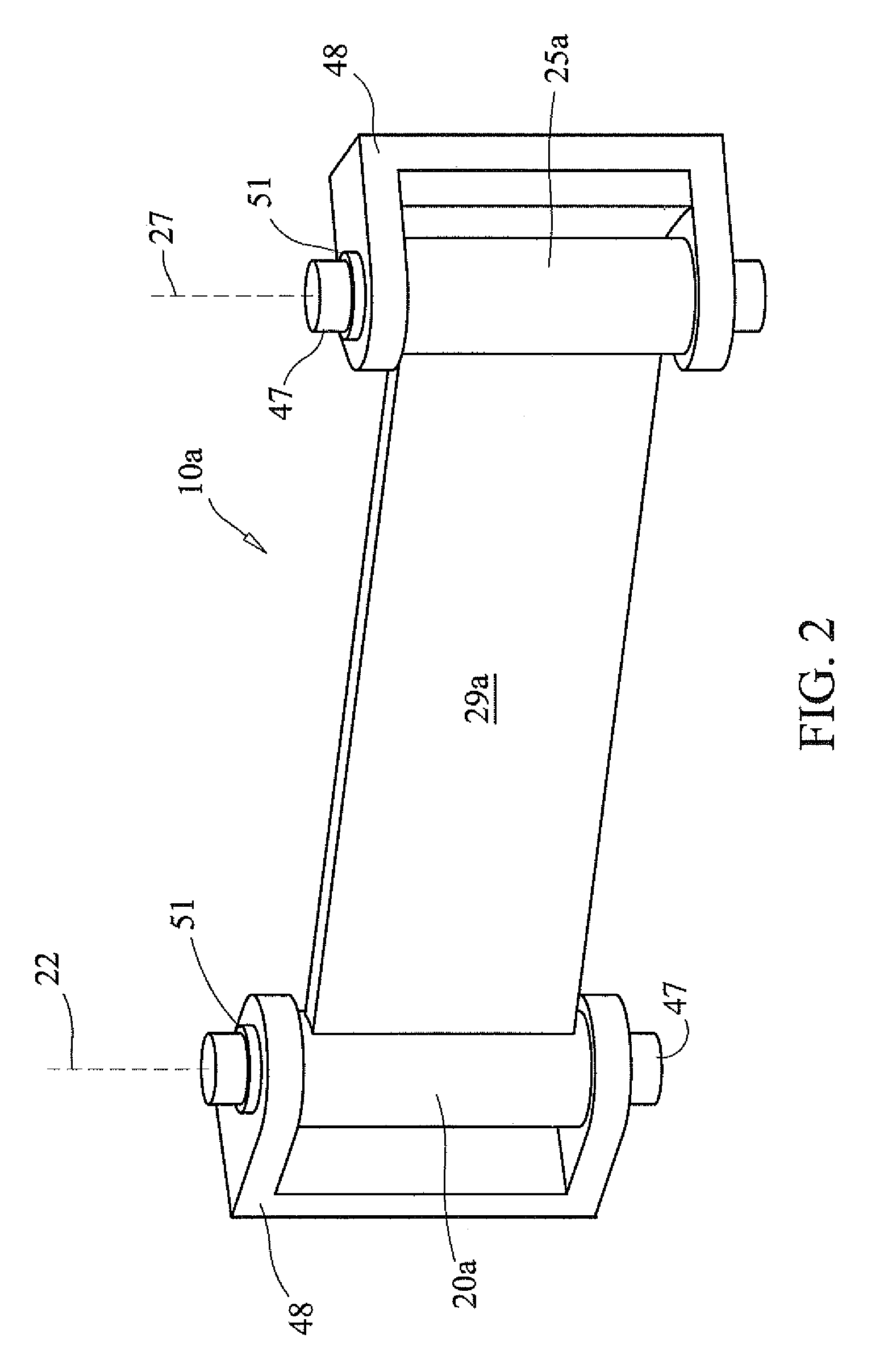

Self-locking door assembly

InactiveUS7735261B2Improve clearancePrevents rattling and shakingSubstation/switching arrangement detailsWing fastenersEngineeringSelf locking

A preferred embodiment of a self-locking door assembly includes a door whose hinged-side connects to one side of a door frame by at least one hinge having two pivot joints. One of the pivot joints is mounted to the door frame and the other is mounted to the inside of the door. The free end of the door carries a latch member which engages an underside of the opposite side of the door frame when the door is partially or fully closed. After the latch engages the frame, forcing the hinged side of the door closed causes the hinge to toggle, holding the door closed under force and takes up play in the pivot joints and / or latch. For security, the pivot joints and latch are concealed when the door assembly is closed.

Owner:STRIKE INDS

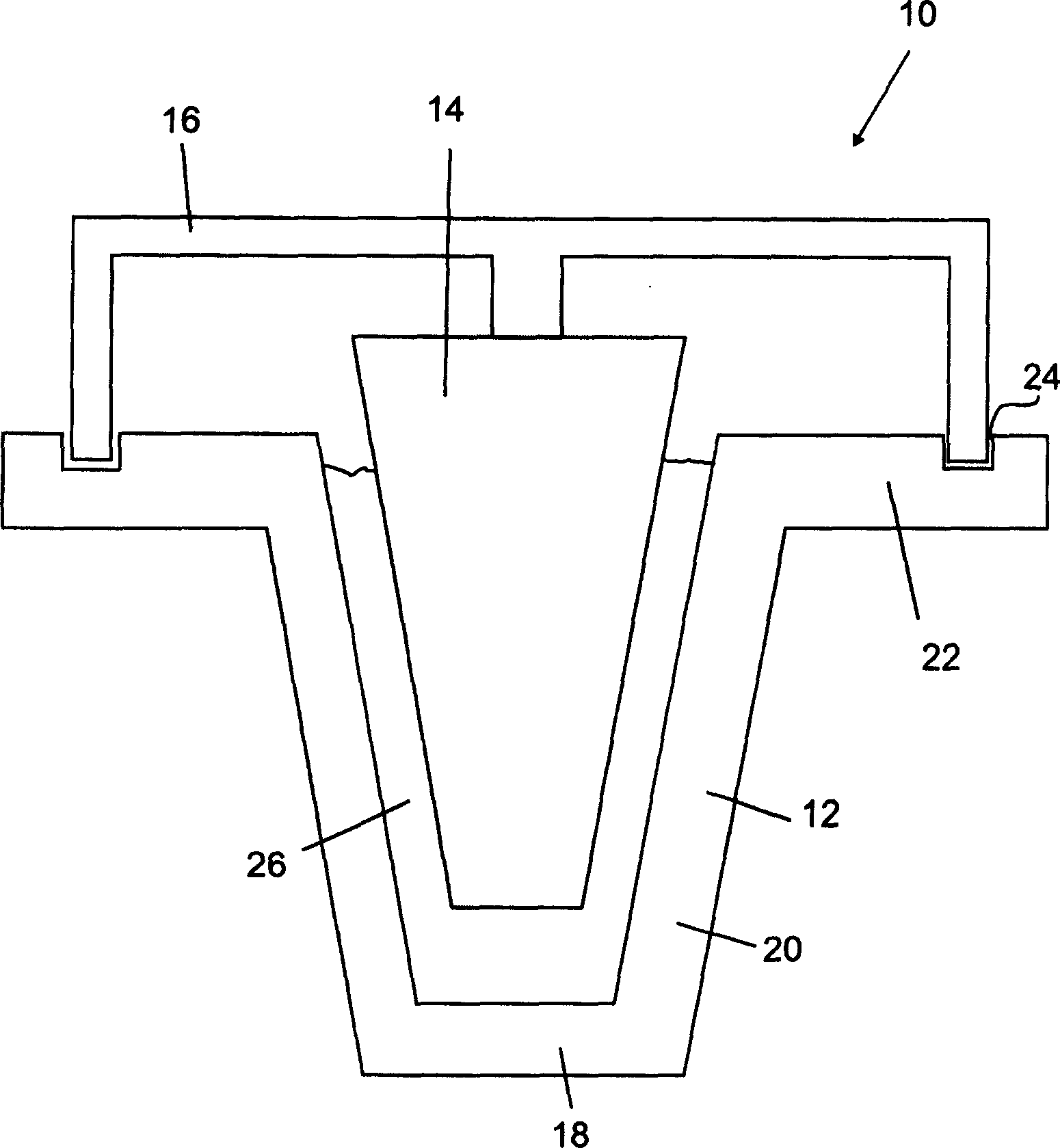

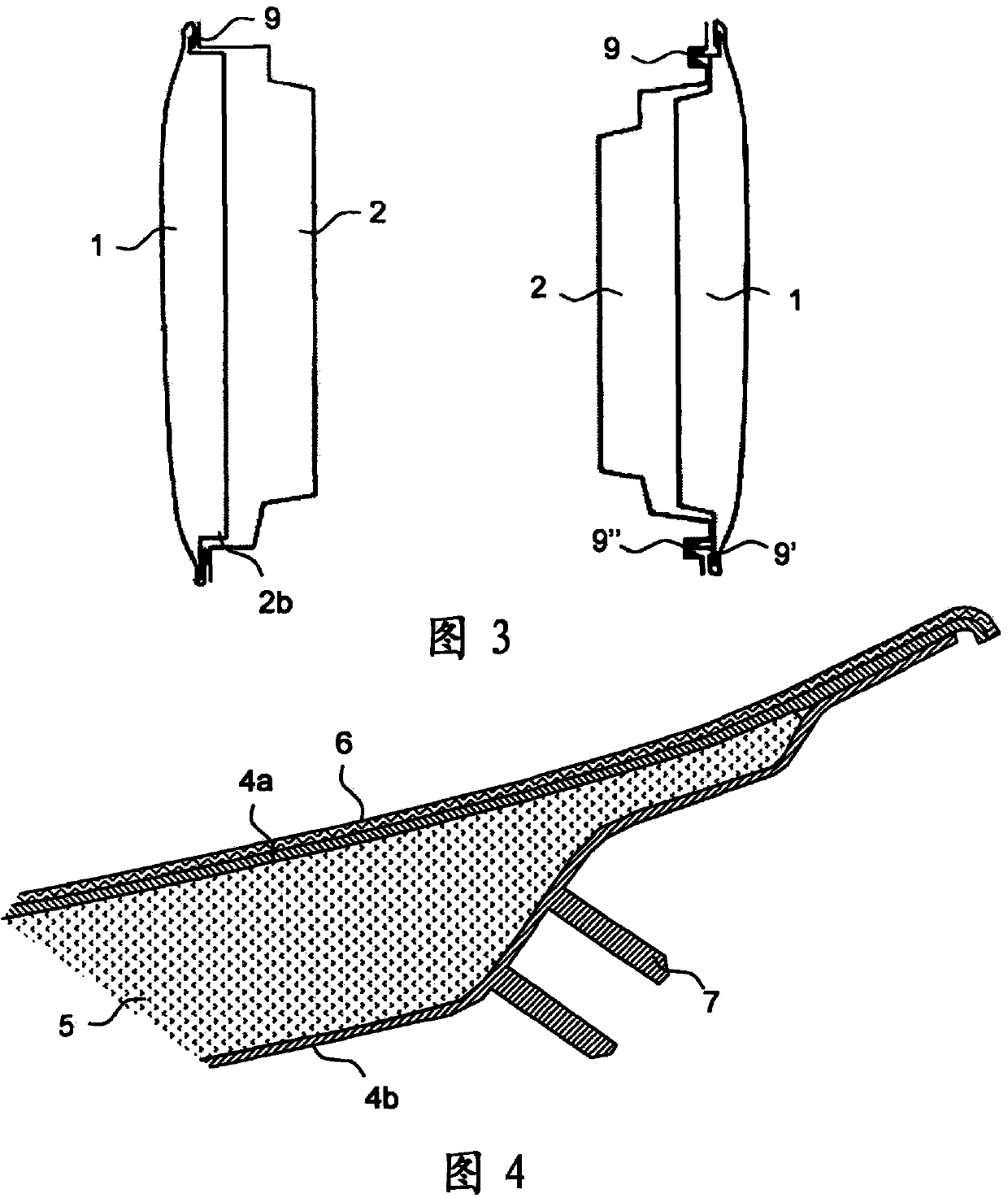

Herbst bremer goldschlaegerei

InactiveCN1789204ASimple and cheap to manufactureSmall dimensional toleranceMaterial nanotechnologyCeramic shaping apparatusCrucibleAlloy

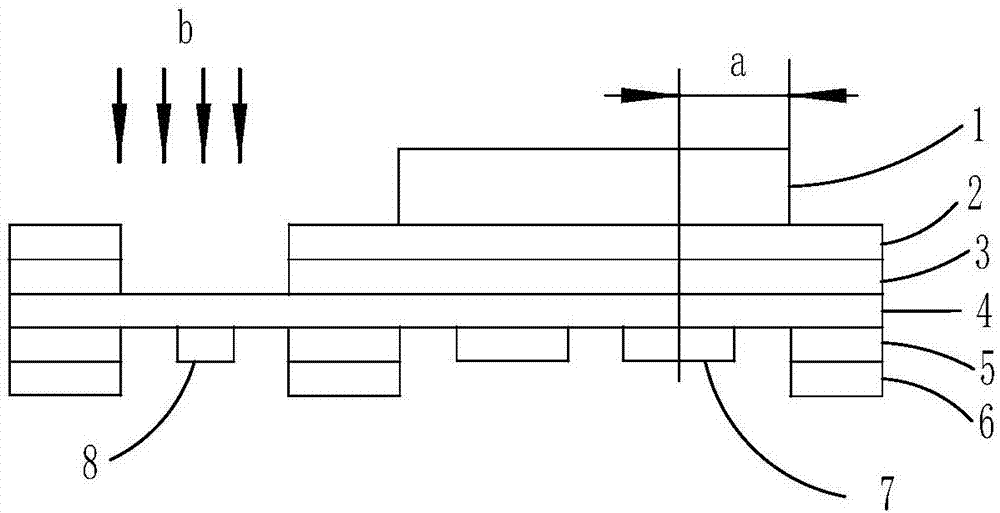

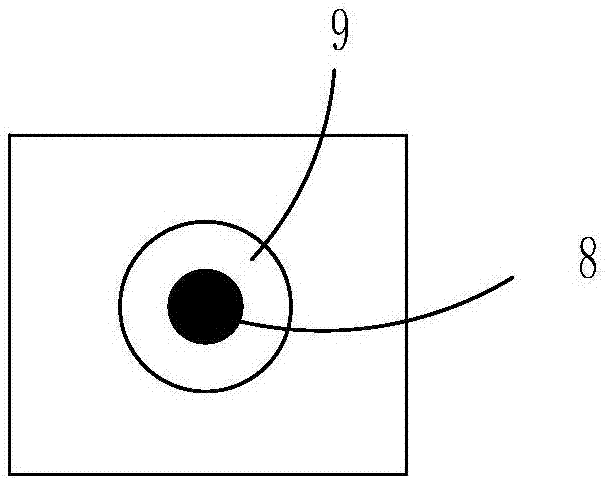

The invention relates to a method for preparing a ceramic crucible. The following steps are proposed: providing a curable slurry; providing a casting mold (10) for a ceramic crucible, pouring the slurry into the casting mold, allowing the slurry to solidify in the mold by: (a) freezing and / or (b ) changing the pH value of the slurry to obtain a preformed body, and heat-treating the preformed body to obtain a ceramic crucible. The present invention also relates to a ceramic crucible prepared by said method and a complete set of equipment for preparing said ceramic crucible, comprising: a casting mold for a ceramic crucible, preferably a metal mold; a sol, preferably SiO2 water containing nano-ceramic particle components Sols; ceramic particles comprising particulate ceramic components; optionally metal powders consisting of metals and / or alloys and / or intermetallic compounds; optionally one or more other additives and optionally organic or inorganic binders . The invention also relates to a device for carrying out the method.

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

Piston rod of damper and preparation method of piston rod

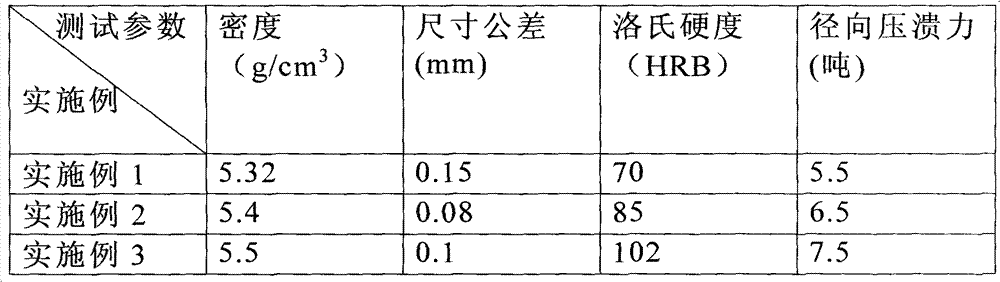

ActiveCN102921941ALow costHigh product densitySpringsShock absorbersPowder metallurgyManganese sulfide

The invention provides a piston rod of a damper, belonging to the field of automobile accessories and solving the problem of low density of the conventional piston rod of the damper. The piston rod of the damper comprises the following components in parts by weight: 55-70 parts of reducing iron powder, 0.5-0.7 part of electrolytic copper powder, 0.06-0.1 part of colloidal graphite, 0.25-0.35 part of lubricant and 0.25-0.35 part of manganese sulfide. The invention also provides a preparation method of the piston rod of the damper. By means of rationally selecting ingredients for preparing the piston rod of the damper and utilizing a powder metallurgy method, the cost can be reduced, the product density can be improved, the dimensional tolerance of a product can be reduced, and the hardness of the product can be improved. Further, the dimensional tolerance of the product is reduced by using shaping, and the product density is further improved through water atomization steam treatment, so that the product density of the piston rod of the damper can reach 5.32-5.5 g / cm<3>.

Owner:宁波拓发汽车零部件有限公司

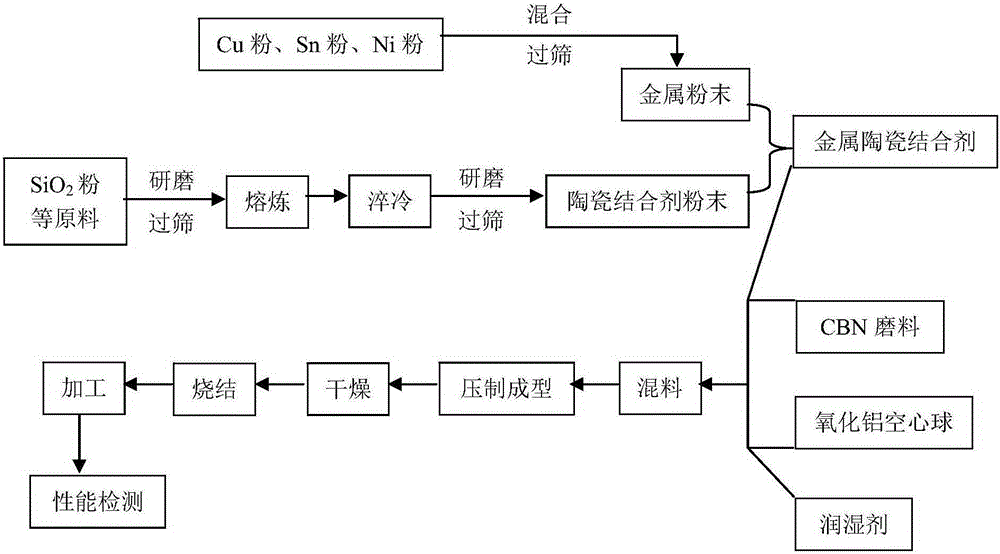

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

Technology for producing aluminum alloy section bar for ships

ActiveCN103589922AExcellent physical and chemical propertiesSmall dimensional toleranceAluminium alloyExtrusion

The invention discloses a technology for producing an aluminum alloy section bar for ships. The technology orderly comprises component optimization, pouring blank-making, extrusion molding, quenching, stretching straightening and aging treatment. The optimal aluminum alloy comprises, by mass, 0.27-0.37% of Si, 0.16-0.20% of Fe, 0.02-0.04% of Cu, 0.22-0.33% of Mn, 1.35-1.65% of Mg, 0.04-0.06% of Cr, 0.09-0.11% of Zn, 0.09-0.11% of Ti and the balance Al. In the extrusion molding, an extrusion rate is in a range of 1.3-2.2m / min, a bar casting temperature is in a range of 515-545 DEG C, a mold temperature is in a range of 450+ / -15 DEG C and an extrusion cylinder temperature is in a range of 460+ / -15 DEG C. The aluminum alloy section bar obtained by the technology has excellent physical and chemical performances, small dimensional tolerance and high product surface quality.

Owner:CHINA ZHONGWANG

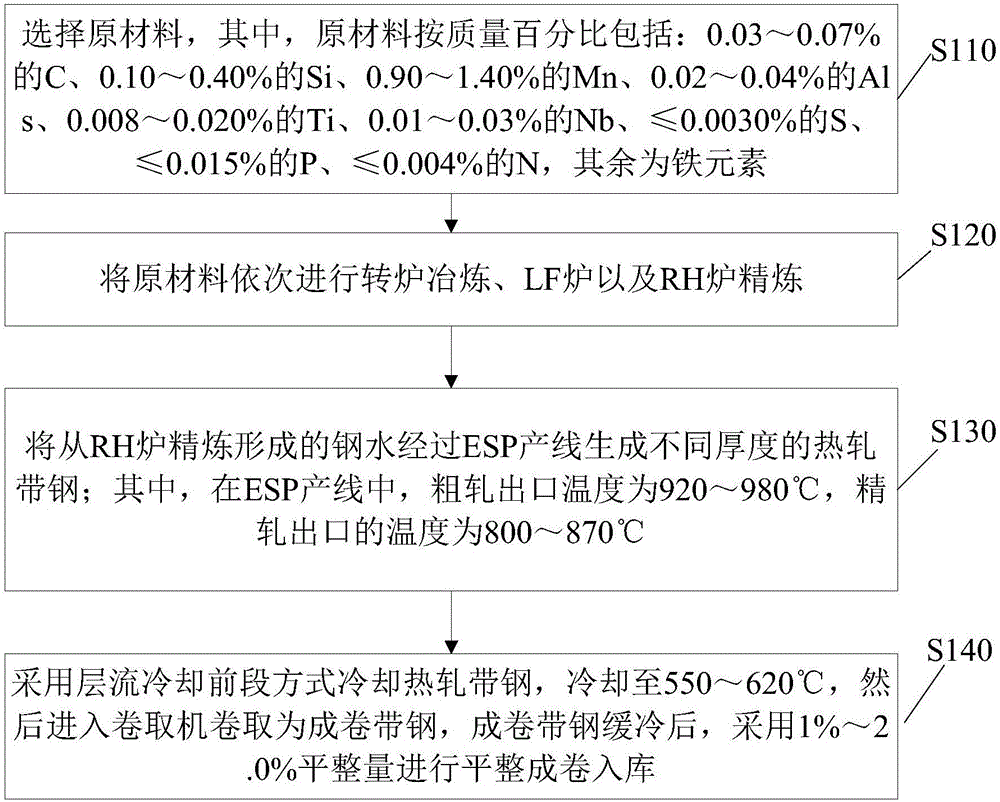

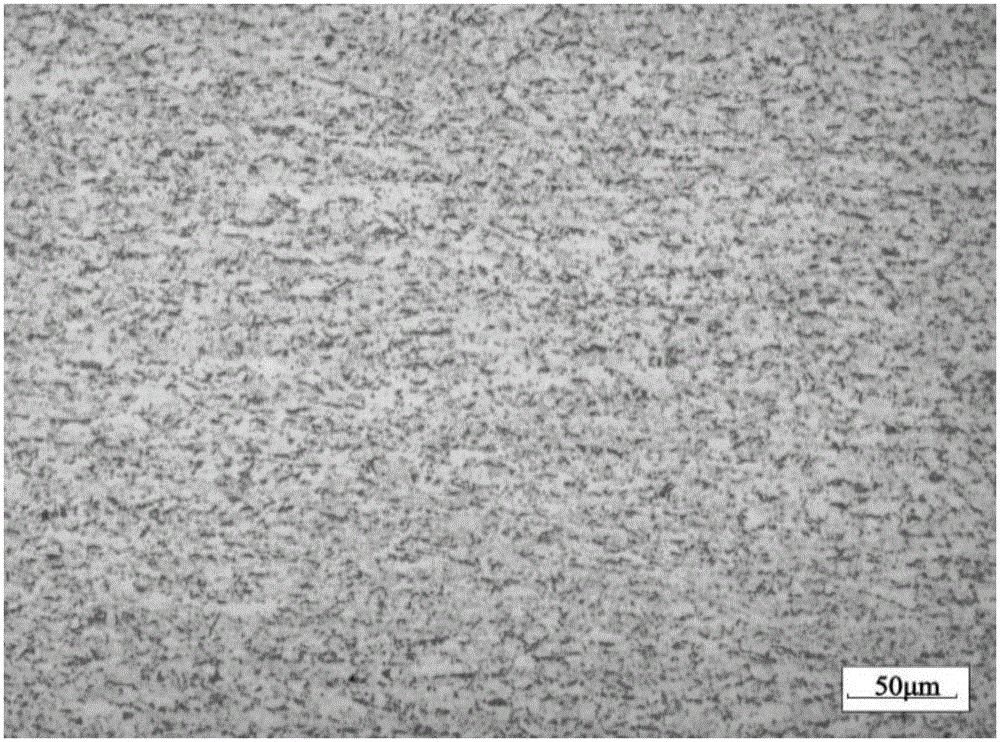

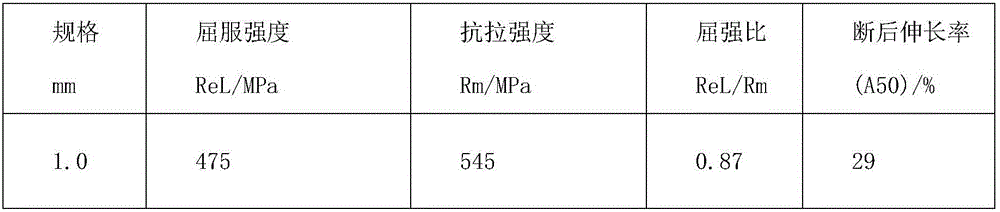

Method for producing RE510L steel of thin specification based on ESP sheet billet continuous coasting and rolling procedure

ActiveCN106834887ASolve the costSolve the problem of energy consumptionMetal rolling arrangementsProduction lineStrip steel

The invention provides a method for producing RE510L steel of a thin specification based on an ESP sheet billet continuous coasting and rolling procedure. The method includes the steps that raw materials are selected, and the raw materials comprise, in percentage by mass, 0.03-0.07% of C, 0.10-0.40% of Si, 0.90-1.40% of Mn, 0.02-0.04% of Als, 0.008-0.020% of Ti, 0.01-0.03% of Nb, less than or equal to 0.0030% of S, less than or equal to 0.015% of P, less than or equal to 0.004% of N and the balance Fe elements; the raw materials are subjected to converter smelting and LF furnace and RH furnace refining; molten steel formed through RH furnace refining generates hot rolling strip steel of different thicknesses through an ESP production line; in the ESP production line, the rough rolling outlet temperature is 920-980 DEG C, the finish rolling outlet temperature is 800-870 DEG C; the hot rolling strip steel is cooled in a front segment laminar flow cooling manner, and the hot rolling strip steel is cooled to 550-620 DEG C and then enters a recoiling machine to be coiled into coiled strip steel; and after the coiled strip steel is cooled, leveling, coiling and entering warehouse are performed by adopting the leveling quantity of 1-2.0%. By means of the method, problems that traditional hot rolling is high in cost, energy consumption is large and the like are solved.

Owner:RIZHAO STEEL HLDG GROUP

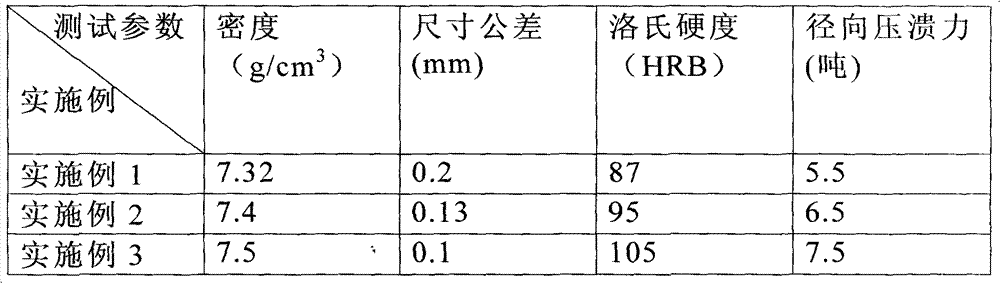

Damper compression valve and preparation method thereof

The invention provides a damper compression valve, belongs to the field of automobile parts, and is used for solving the problem that the existing damper compression valve is low in density. The damper compression valve provided by the invention comprises the following components in parts by weight: 50-80 parts of reduced iron powder, 7.5-10 parts of electrolytic copper powder, 0.2-0.5 part of colloidal graphite, 0.25-0.35 part of lubricant and 0.25-0.35 part of manganese sulfide. The invention also provides a preparation method of the damper compression valve. Through rationally selecting the ingredients for preparing the damper compression valve and utilizing a powder metallurgy method, the cost is reduced, the density of a product is improved, the size tolerance of the product is lessened, and the hardness of the product is improved. Furthermore, the size tolerance of the product is further lessened through reshaping; and the density of the product is further improved through water atomizing steam treatment, and the density of the damper compression valve can reach up to 7.32-7.5g / cm<3>.

Owner:宁波拓发汽车零部件有限公司

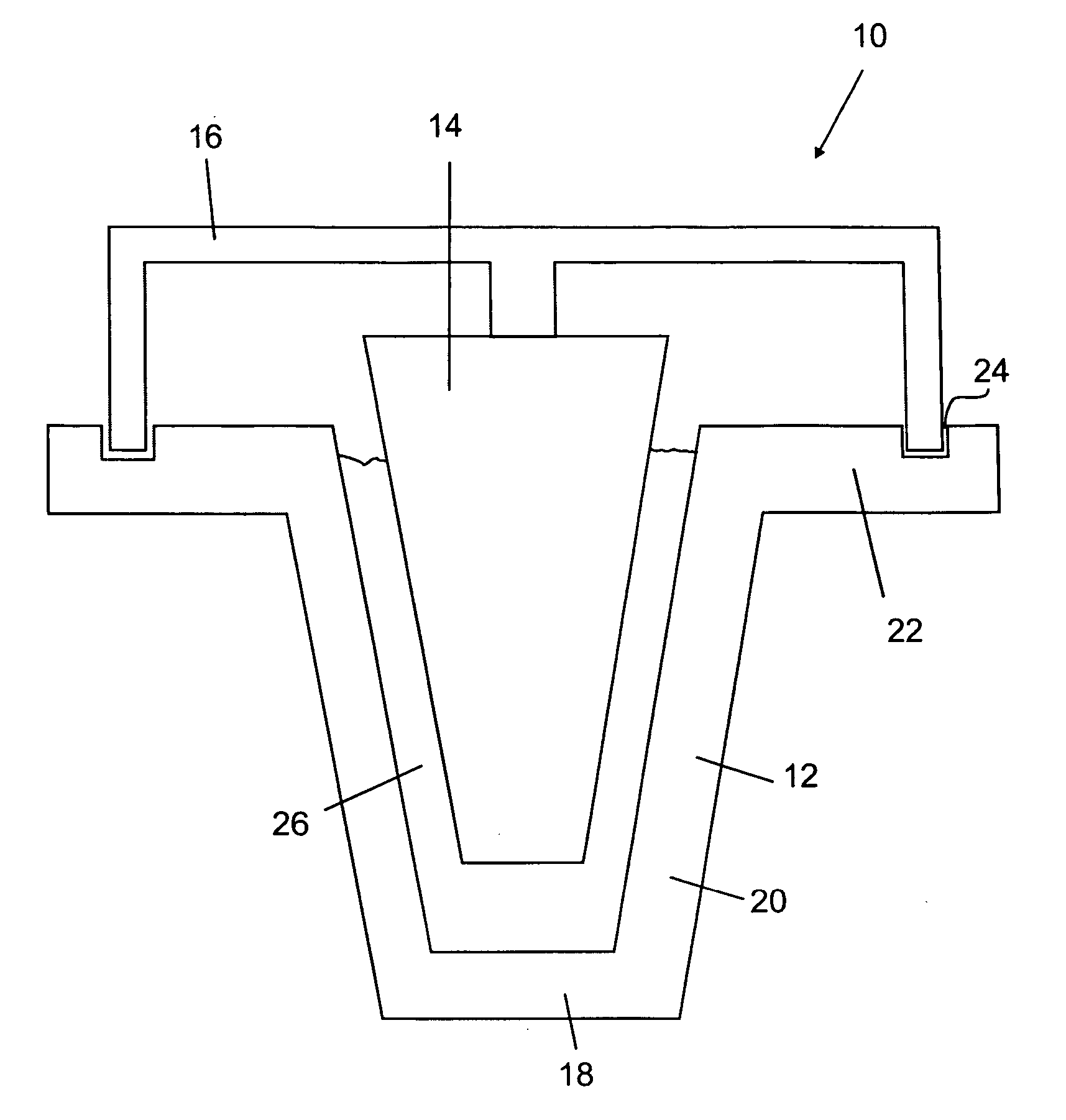

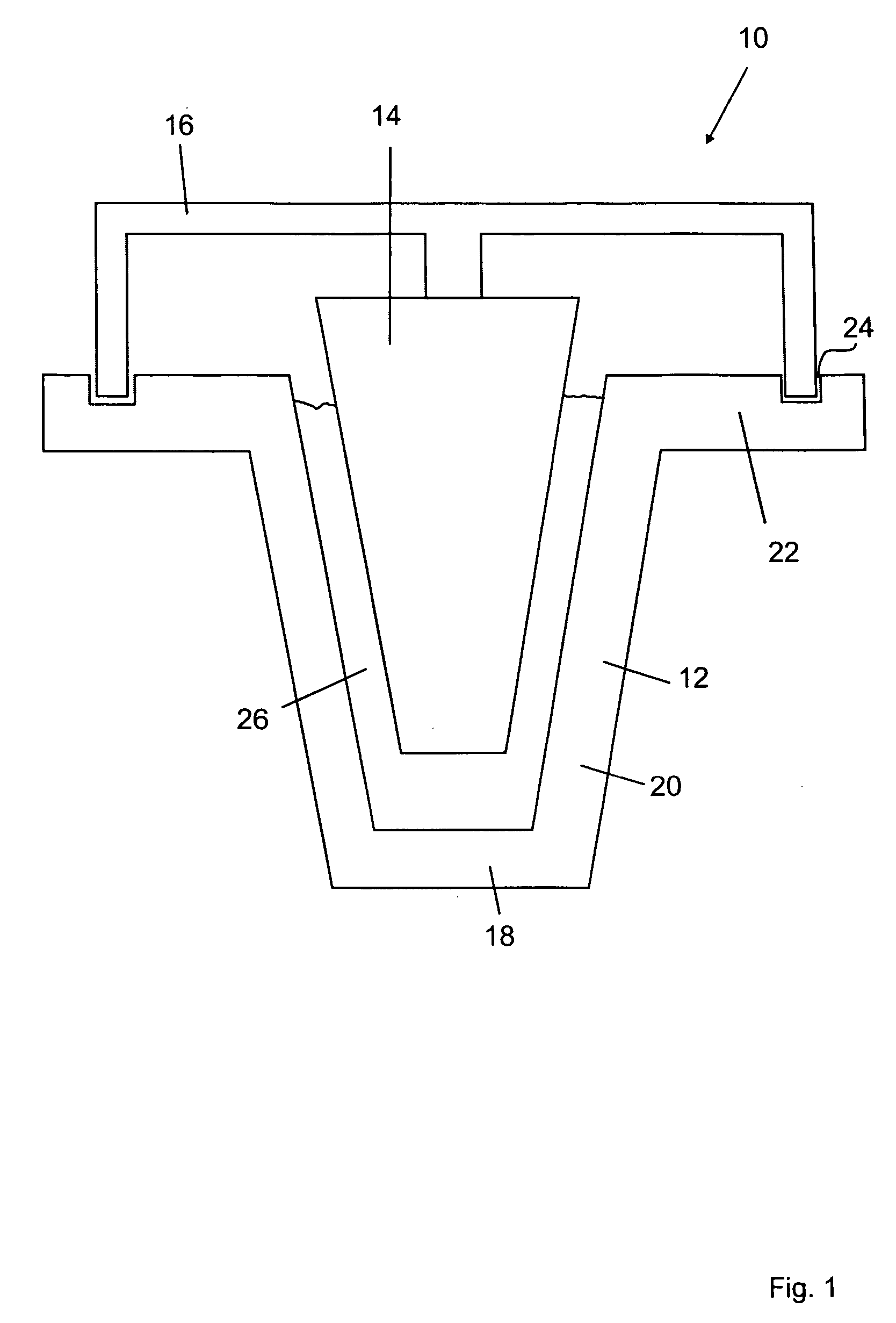

Method for producing a ceramic crucible

InactiveUS20060138716A1Cost-effectiveSmall dimensional toleranceMaterial nanotechnologyAnalysis using chemical indicatorsCrucibleNanoparticle

The invention relates to a method for producing a ceramic crucible. The following steps are proposed: providing a solidifiable slip, providing a casting mould (10) for the ceramic crucible, pouring the slip into the casting mould, solidifying the slip in the casting mould by (a) freezing and / or (b) changing its pH value, such that a preform is obtained, and heat-treating the preform, such that a ceramic crucible is obtained. The invention additionally relates to a ceramic crucible producible using such a method and a kit for producing such a ceramic crucible, having: (a) a casting mould, preferably a metal mould, for a ceramic crucible, (b) a sol, preferably an aqueous SiO2 sol, comprising a ceramic nanoparticle fraction, (c) ceramic particles comprising a microceramic fraction, (d) optionally a metal powder consisting essentially of metals and / or alloys and / or intermetallic compounds, (e) optionally one or more further additives and optionally organic or inorganic binders. Finally, the invention relates to an apparatus for performing the stated method.

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

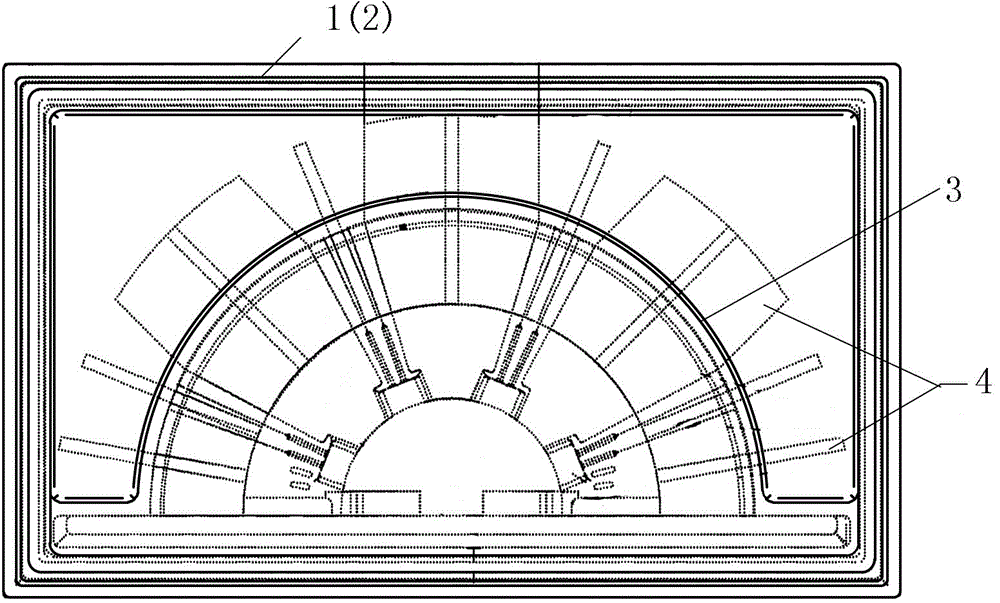

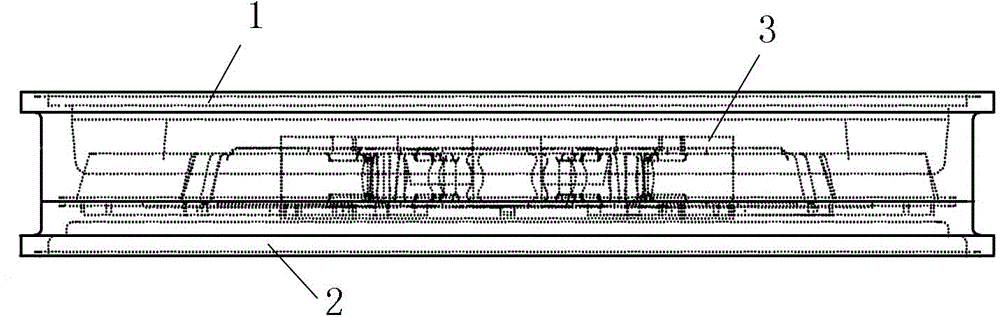

Lost foam casting die and method for braking disc

InactiveCN104889327ASmall dimensional toleranceSmall surface finishFoundry mouldsFoundry coresHardnessLost-foam casting

The invention relates to a lost foam casting die and method for a braking disc and belongs to the technical field of lost foam casting and aims to solve the technical problem of short service life. According to the lost foam casting die and method for the braking disc, lost foam casting is adopted, the hardness of a friction surface of the braking disc is uniform and the service life is long. According to the technical scheme, the lost foam casting die comprises an upper die, a lower die and a semi-circular casting lost foam pattern, wherein cavities are formed in inner surfaces of the upper die and the lower die, a casting cavity is formed between the upper die and the lower die after the upper die and the lower die are buckled, the semi-circular casting lost foam pattern is arranged in the casting cavity, multiple movable blocks are arranged in the semi-circular casting lost foam pattern, and sprue gates are formed in tops of the upper die and the lower die. The lost foam casting die and method for the braking disc are widely used for casting of the braking disc.

Owner:山西威龙铁路机车制动配件制造有限公司

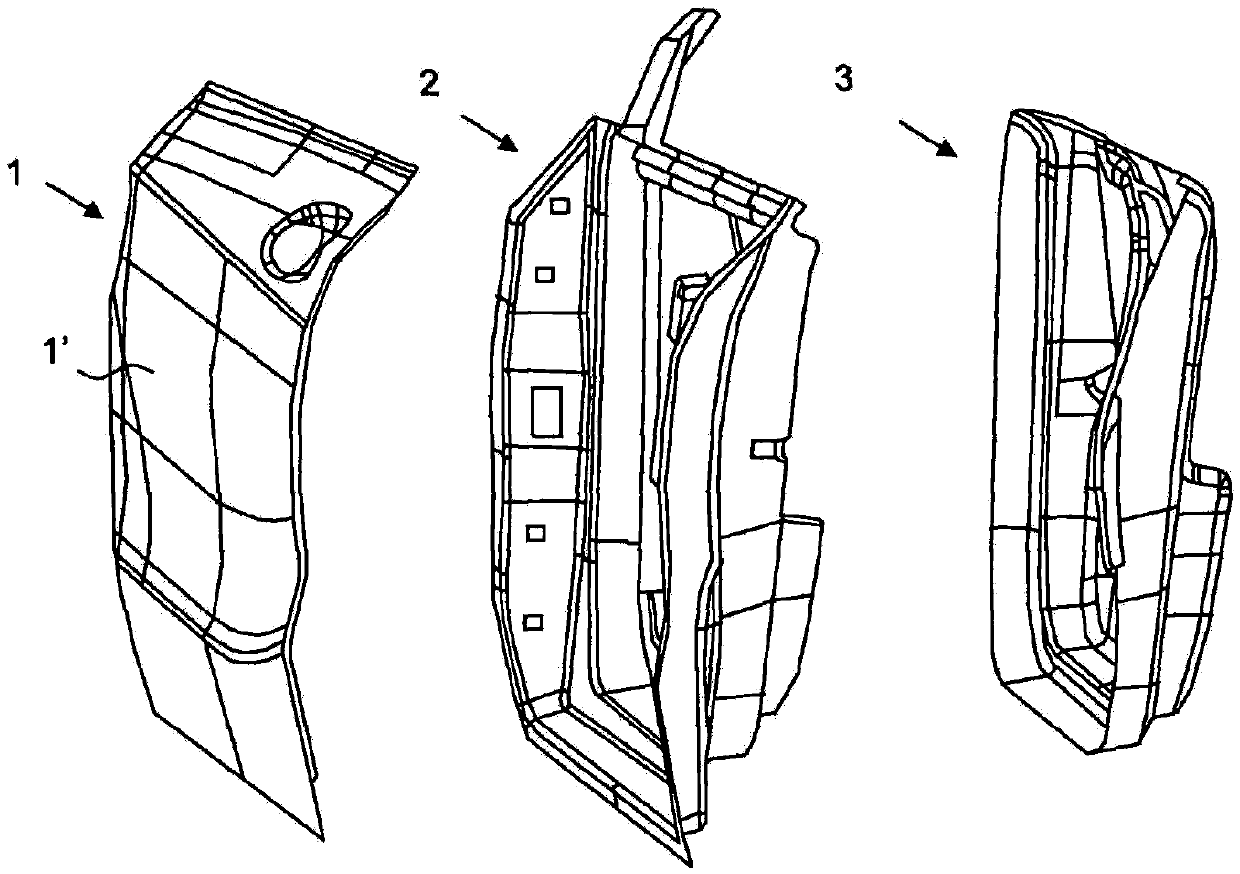

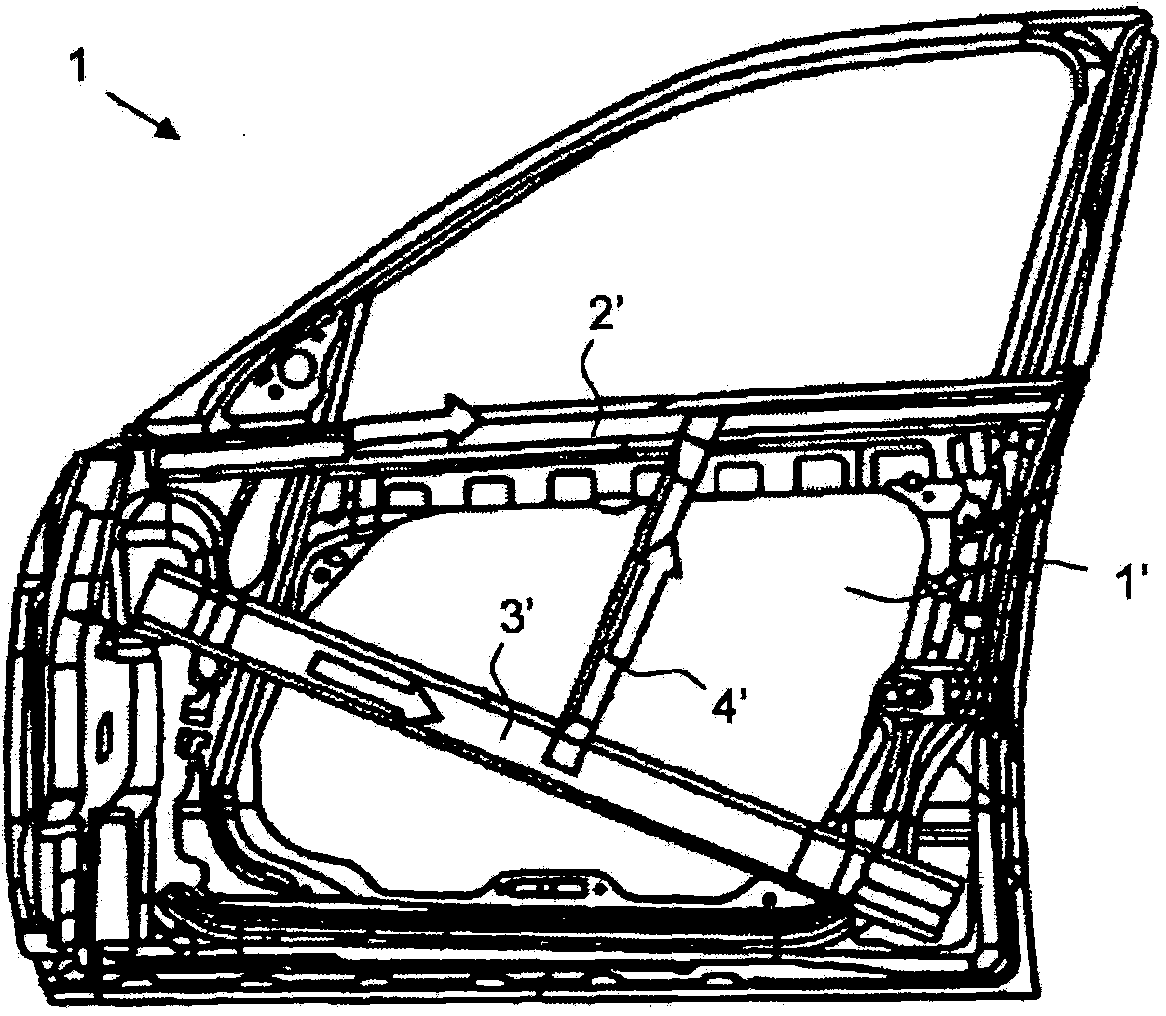

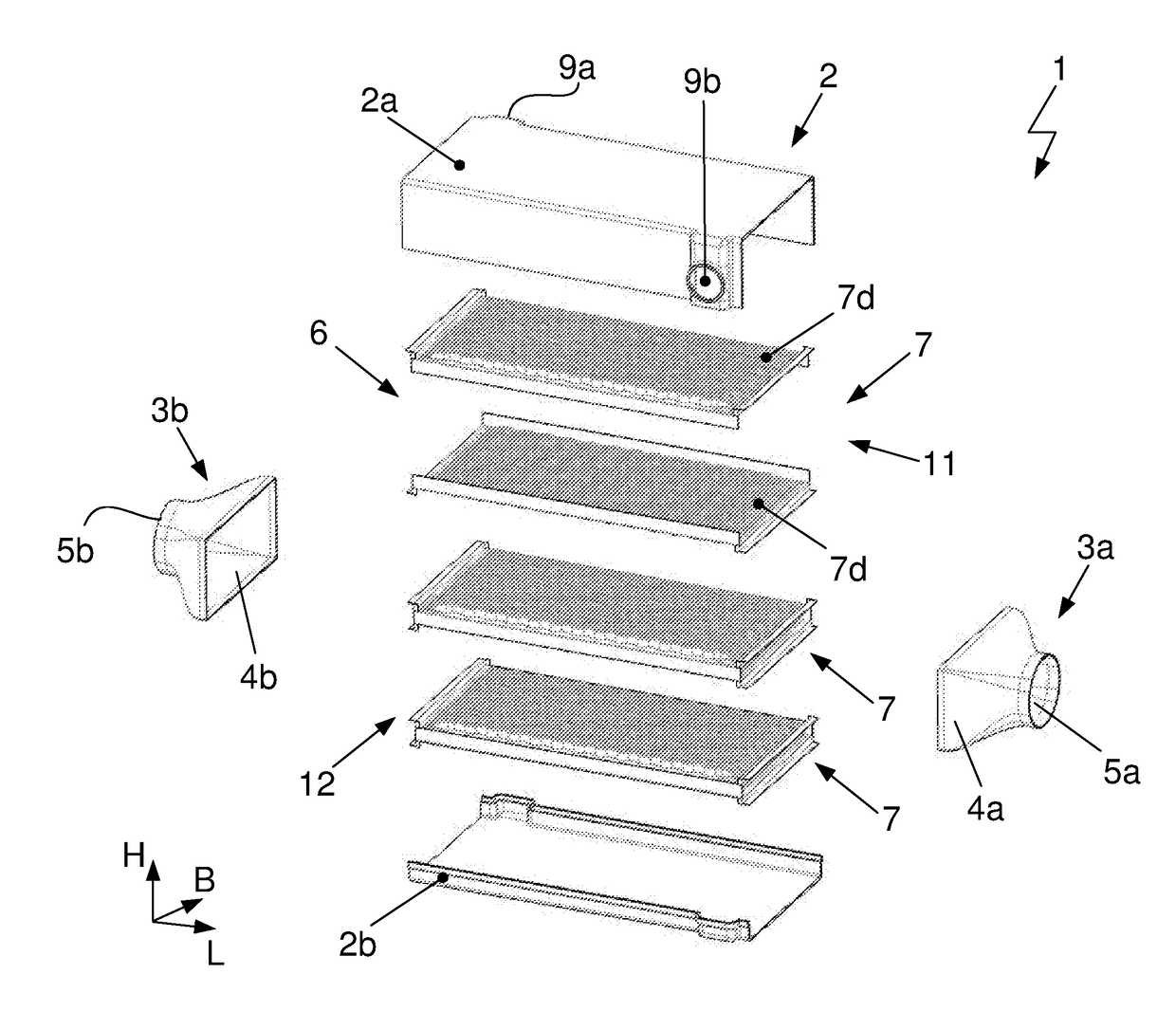

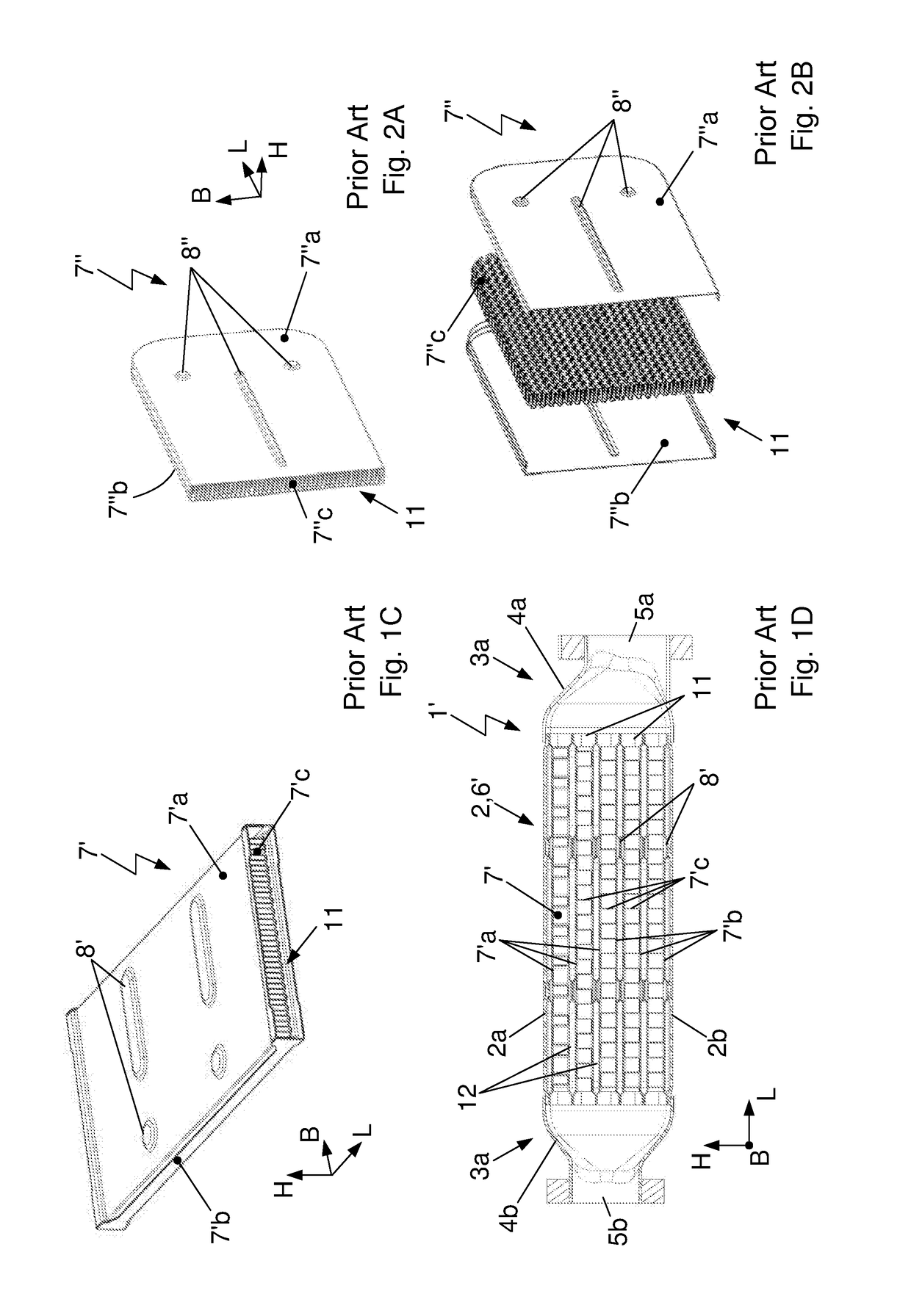

Exterior module with an exterior panelling for a modularly constructed housing component and the modularly constructed housing component itself, and method for producing the exterior module

InactiveCN103635336ALow investment costReduce manufacturing costDoorsSuperstructuresStructural engineeringMechanical engineering

The present invention relates to an exterior module (1) of a motor vehicle having an exterior panelling (1') for a modularly constructed housing component. The exterior module (1) has a multi-layer construction which comprises an inner surface layer (4b) and an outer surface layer (4a) with an exterior skin (6) arranged thereon, which exterior skin (6) forms the exterior panelling (1'). Here, at least the inner surface layer (4b) is a thermoplastic FVK surface layer (4b) which has stiffening elements (7, 10, 11) on the side pointing away from the outer surface layer (4a). Also disclosed are a modularly constructed housing component which comprises the exterior module (1) and an interior module (2), and a method for producing the exterior module (1).

Owner:DAIMLER AG

Production process for C-shaped channel steel

InactiveCN102328191ASmall dimensional toleranceSmall straightnessMetal rolling arrangementsUltimate tensile strengthLinearity

The invention discloses a production process for C-shaped channel steel. The production process comprises the following steps of: hot-rolling the section of a blank body material into an unfolded shape of the section of the C-shaped channel steel; correcting the size through cold rolling; cold-bending the section of the material into a shape which is the same as the section of the finished C-shaped channel steel; and improving the size precision of the product by cold-drawing and straightening and thus producing the finished C-shaped channel steel. The C-shaped channel steel processed by using the method has the advantages that: the size tolerance is small, the linearity is low and the torsion degree is small; and under the matching of a bolt, the C-shaped channel steel is high in tensilestrength, tensile yield strength, fatigue resistance and the like.

Owner:无锡市佳之华轨道交通科技有限公司

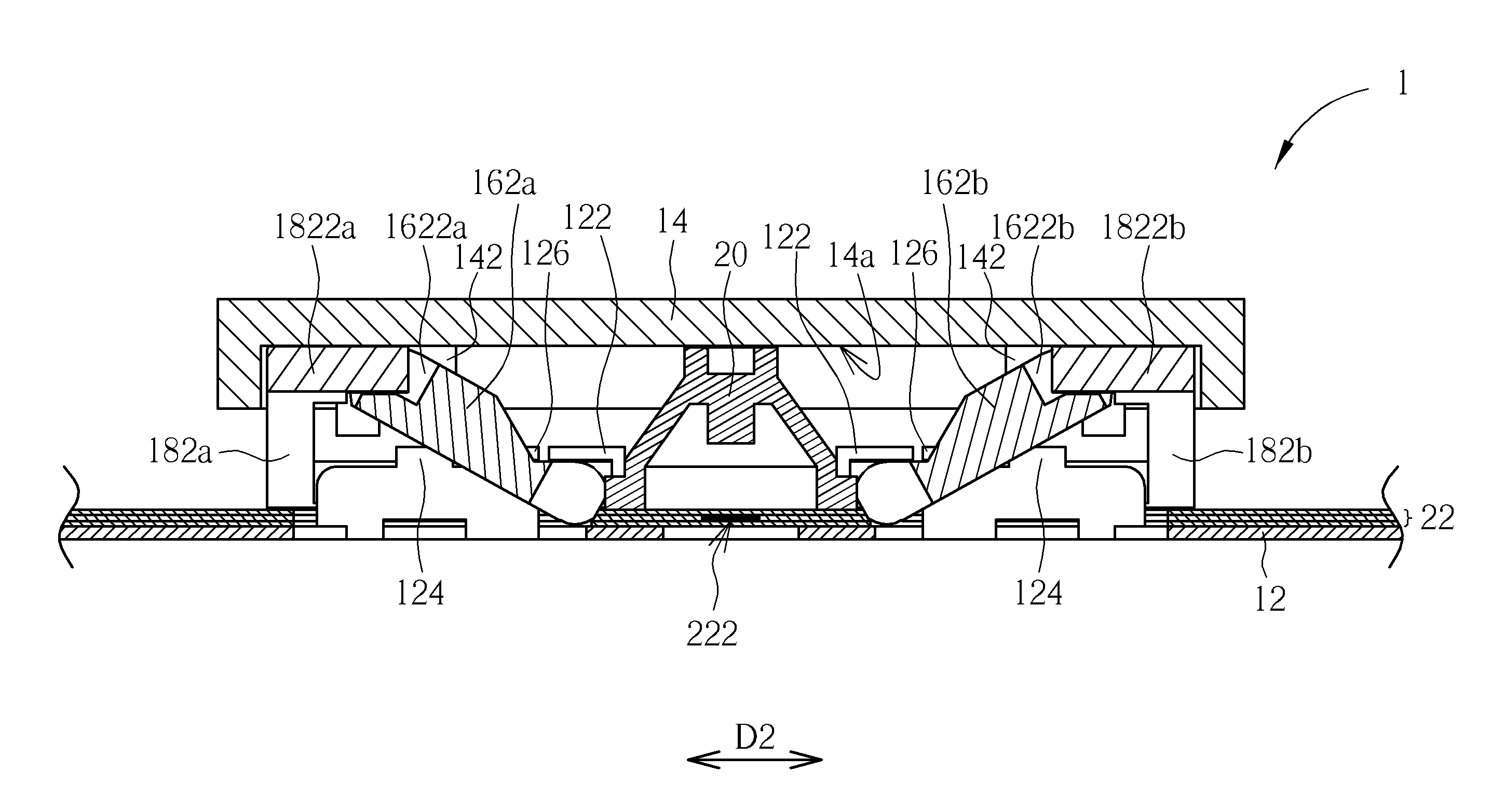

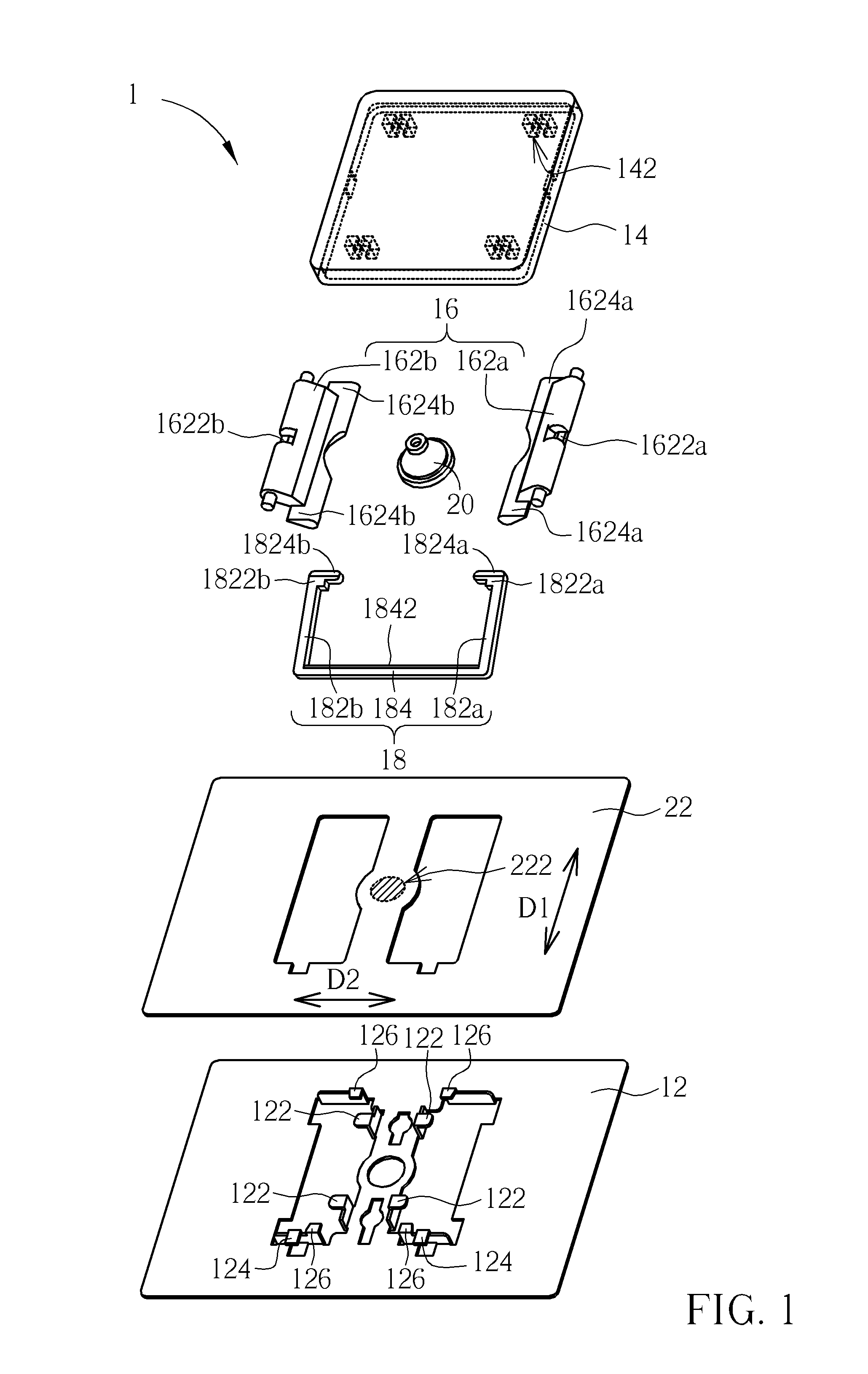

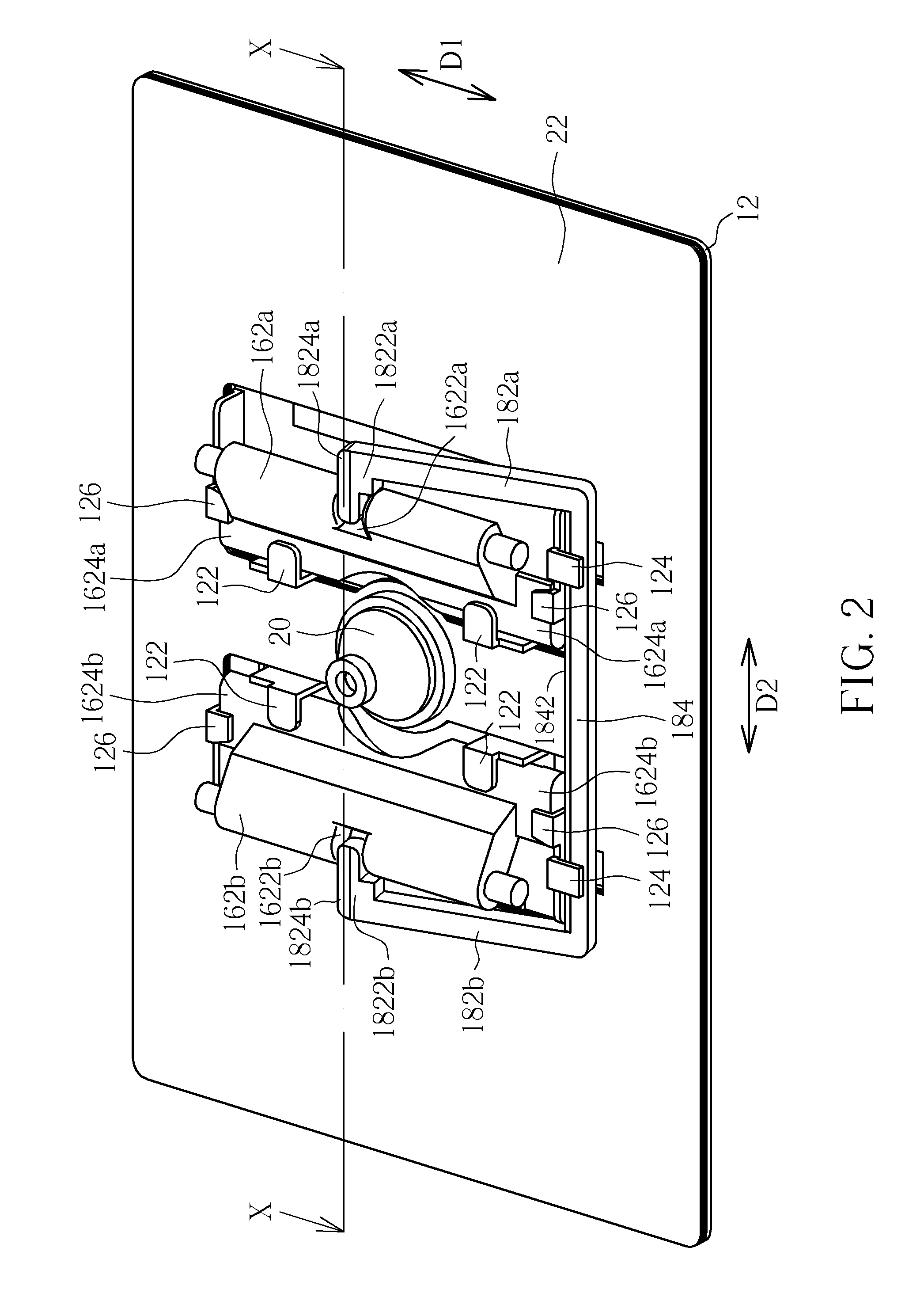

Keyswitch structure and balance link thereof

ActiveUS20140174900A1Easy to moveLifting range is limitedContact operating partsKey-laykey mechanismBackplaneMechanical engineering

A keyswitch structure includes a base plate, a keycap, a lift mechanism, and a balance link. The lift mechanism connects between the keycap and the base plate such that the keycap can move up and down relative to the base plate. The balance link is formed substantially in a U-shaped profile. The middle portion thereof is rotatably disposed on the base plate; the two ends thereof are respectively formed in an L-shaped profile and rotatably inserted into two slot structures on the keycap or the lift mechanism or both. Compared with a conventional balance link formed in an n-shaped profile connecting a keycap and a base plate, the invention provides more diverse structural connections, conducive to structural miniaturization. Furthermore, a support of the lift mechanism includes a protrusion capable of being blocked by a limitation structure disposed on the base plate for controlling the rotation angle of the support.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Omni-directional metallic-coating polyolefin conductive foam and preparation method thereof

ActiveCN102963096AEffective shieldingImprove conductivitySynthetic resin layered productsPolyolefinOmni directional

The invention relates to electro-magnetic interference (EMI) protection omni-directional metallic-coating polyolefin conductive foam and a preparation method thereof. The preparation method comprises the following steps of: preparing conductive master batches, preparing flame retardant master batches, preparing foamed master batches, extruding sheets, carrying out radiation crosslinking on the sheets, foaming the sheets, bonding conductive non-woven fabrics, punching the foam and electroplating the foam. The conductive foam provides effective EMI shielding, has the advantages of high conductivity, ultra-thin type, light weight, corrosion resistance, attractive appearance and the like, is easy to shape; the surface of the conductive foam can conduct electricity, and the whole material is conducted from top to bottom; and the conductive foam has omni-directional electrical conductivity, and has the thickness of 0.10-0.50mm. The conductive foam disclosed by the invention is widely applied to electronic products such as a personal digital assistant (PDA) palm computer, a liquid crystal display (LCD), a mobile phone, a digital television, a notebook computer and a digital camera.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

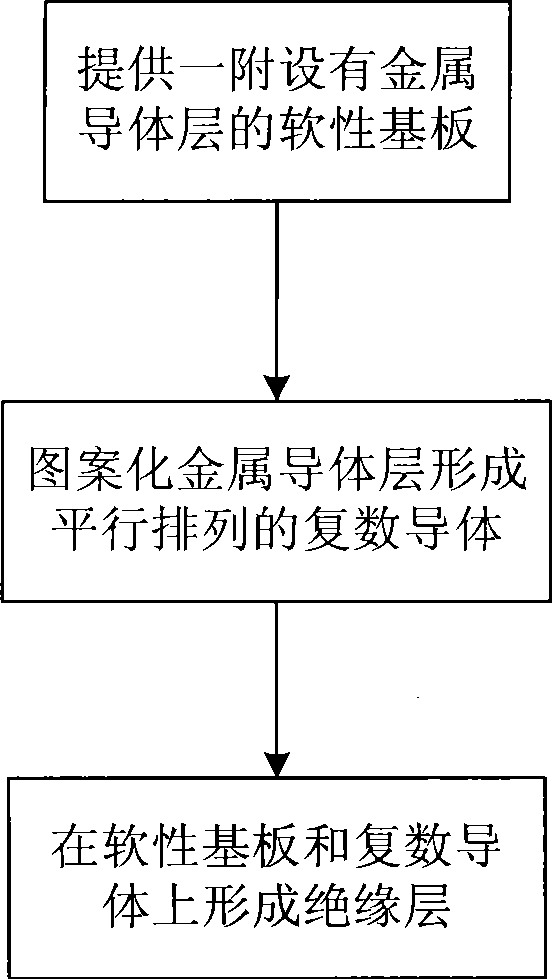

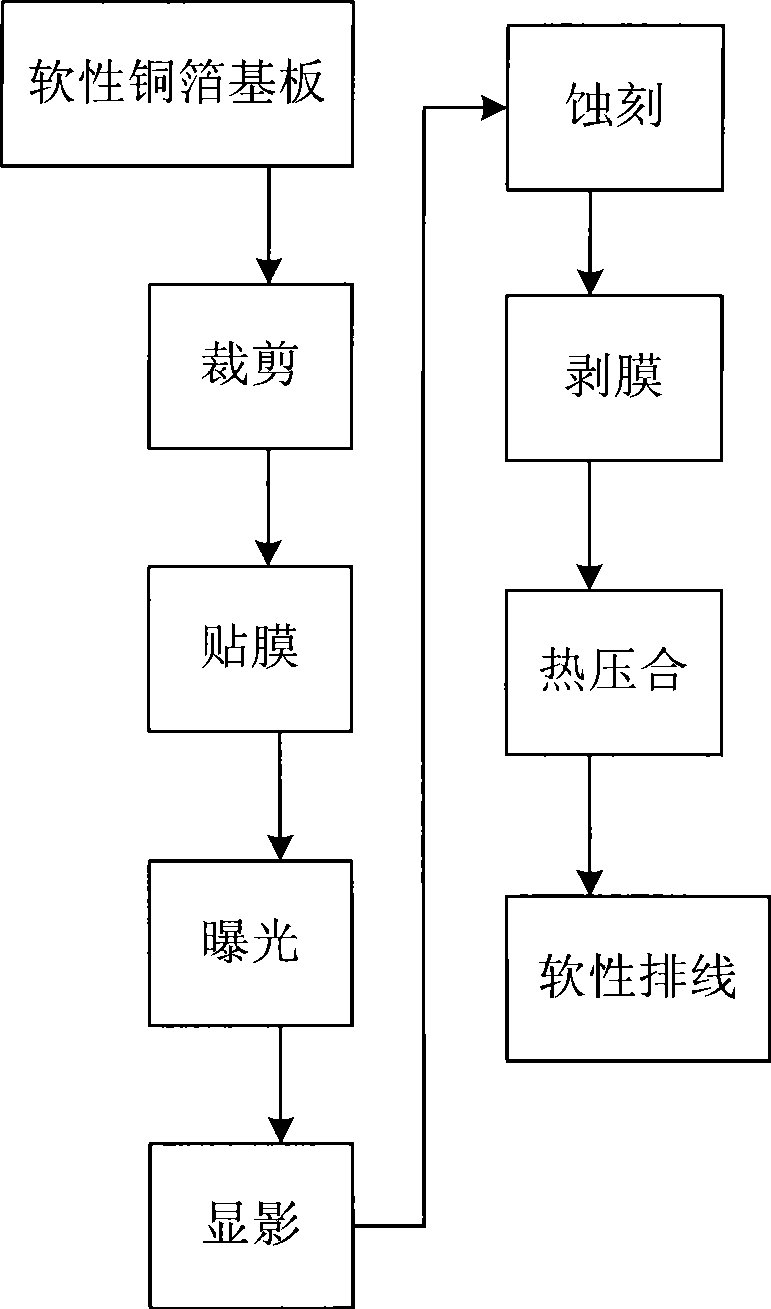

Manufacturing method for flexible bus

InactiveCN101393788APrecise control of pitch sizeSmall dimensional toleranceFlat/ribbon cablesElectrical connection printed elementsElectrical conductorEngineering

Owner:DACHANG ELECTRONICS TECH SUZHOU CO LTD +1

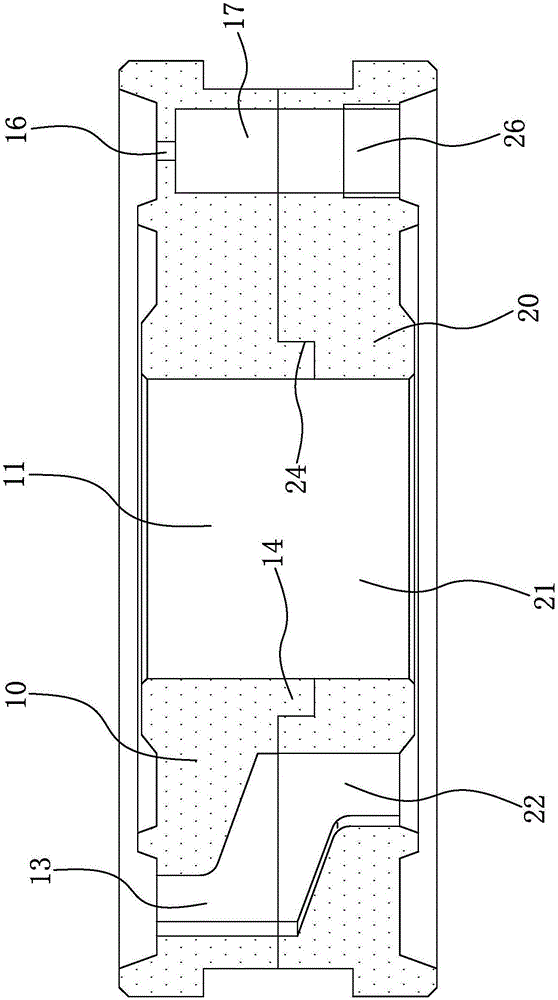

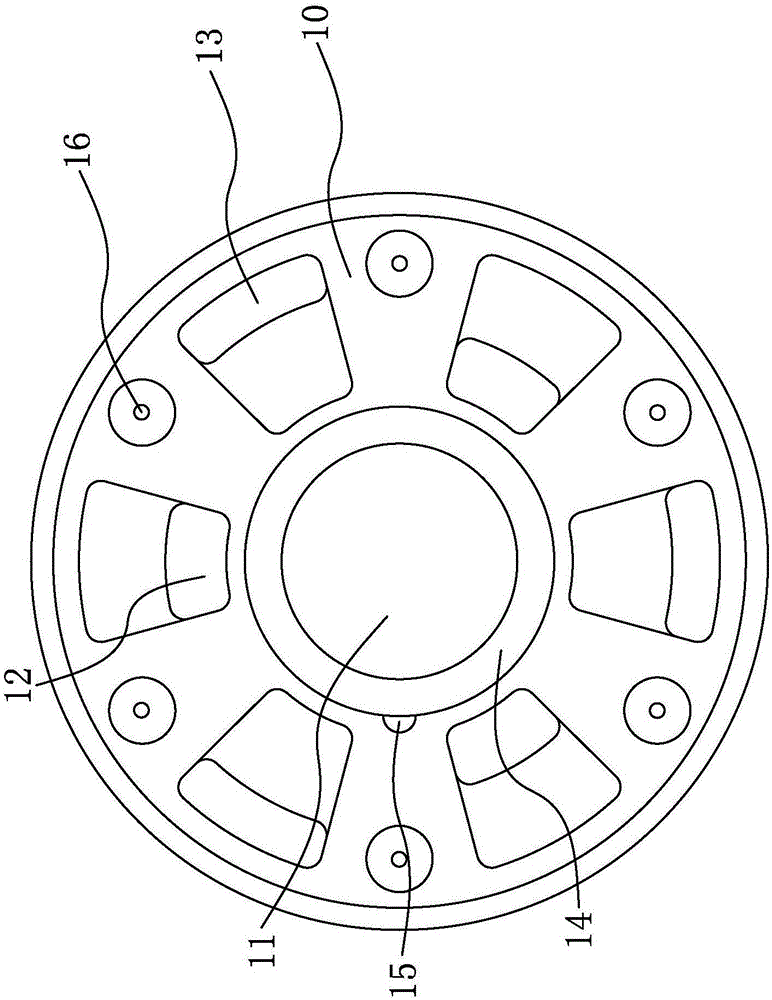

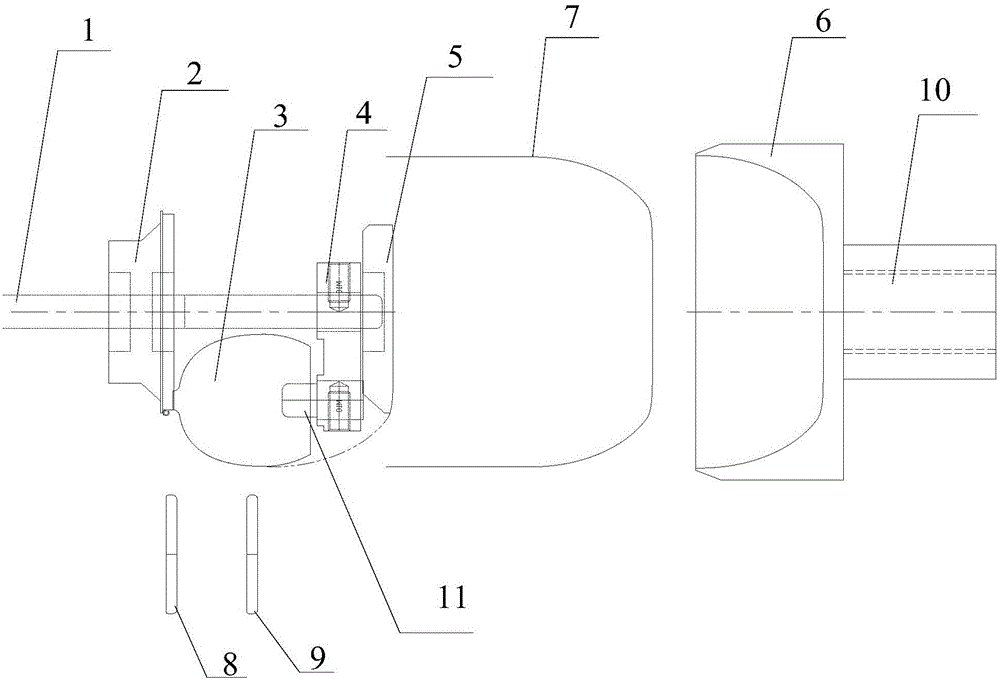

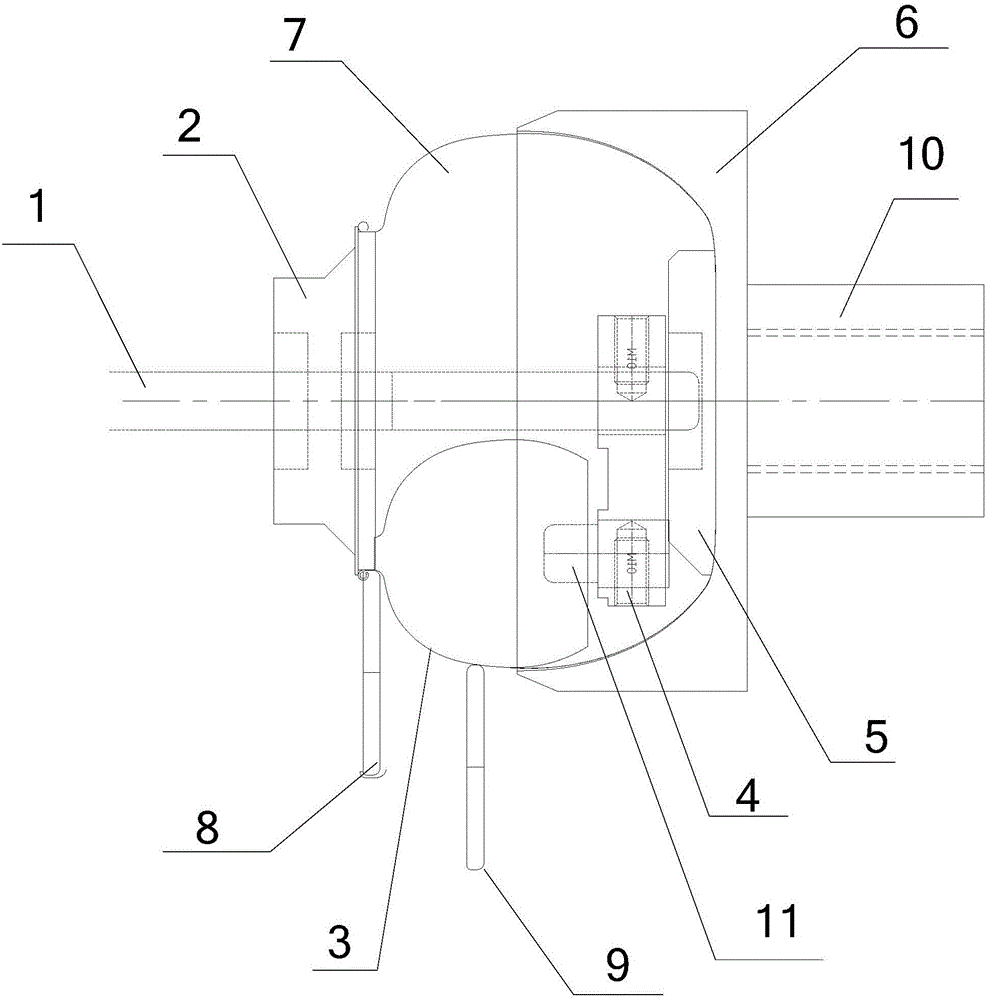

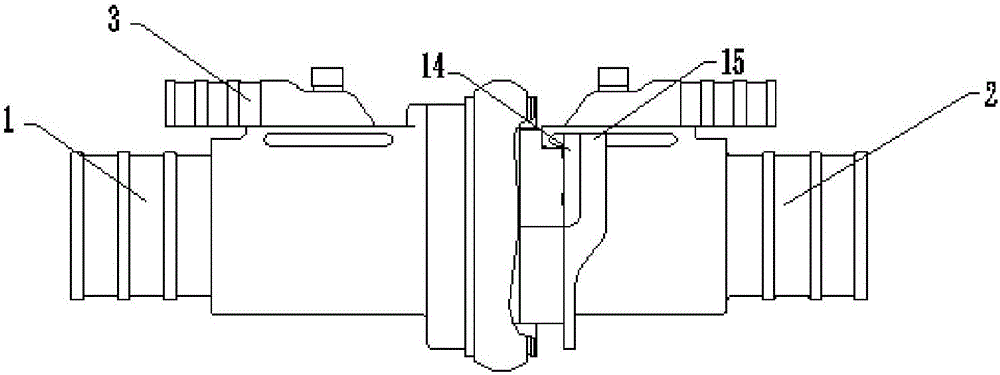

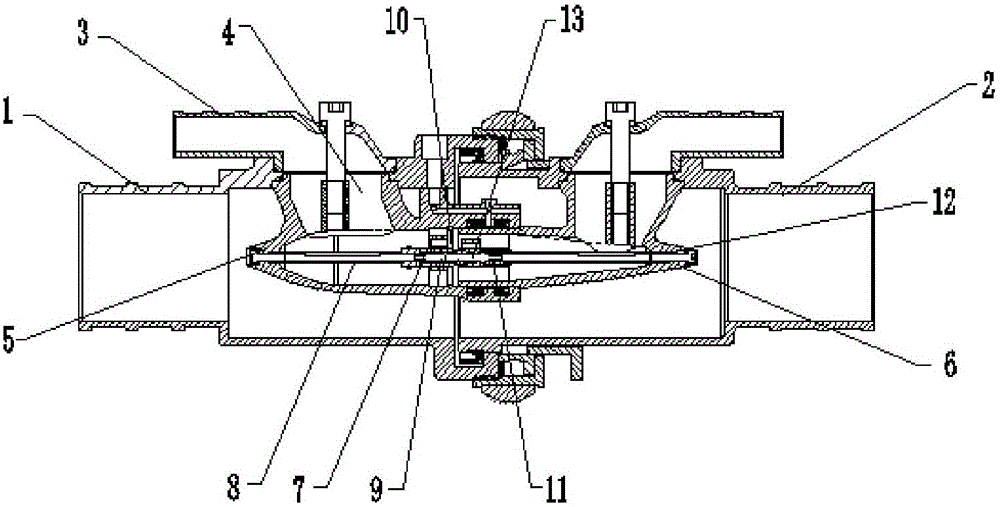

Piston valve for motor car damper

The invention provides a piston valve for a motor car damper, and belongs to the technical field of dampers. The piston valve comprises an upper valve body and a lower valve body connected with the upper valve body. An upper mounting hole is formed in the middle of the upper valve body. Three first inwards-bent holes are formed in the upper valve body. Three first outwards-bent holes are formed in the periphery of the upper valve body. A lower mounting hole is formed in the middle of the lower valve body. Three second inwards-bent holes are formed in the lower valve body. Second outwards-bent holes are evenly formed in the periphery of the lower valve body. The first inwards-bent holes communicate with the second inwards-bent holes. The first outwards-bent holes communicate with the second outwards-bent holes. The piston valve for the motor car damper is made from powder metallurgical sintered steel. The powder metallurgical sintered steel is mainly composed of 0.3-0.6% of C, 1.5-3.9% of Cu and the balance Fe. The powder metallurgical sintered steel adopts iron-based powder alloy as a basal body, and is obtained through infiltration treatment with a copper infiltration agent. By adopting the structure, the inclined load of the damper is faster, the response is rapider, the damping effect is good, and the service life is long.

Owner:NINGBO RUIFENG AUTO PARTS

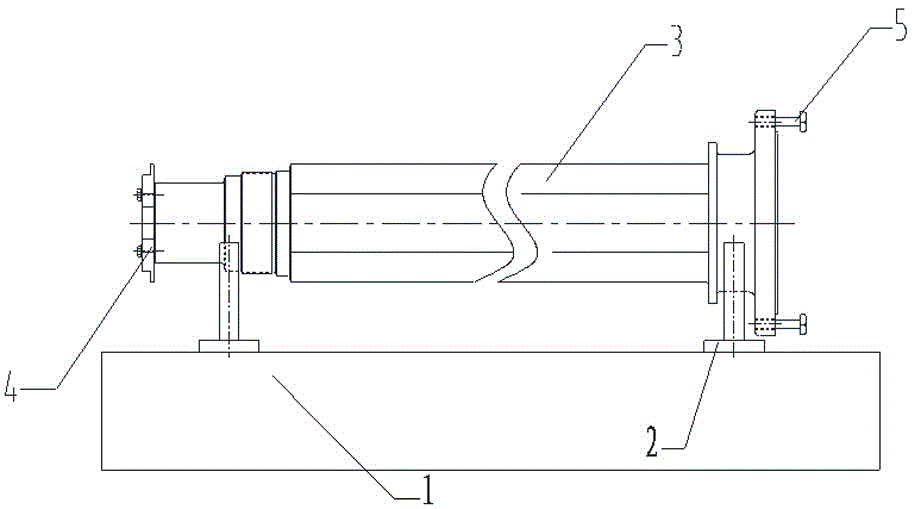

Spin-forming mould for kettle body of sliver kettle

InactiveCN105057461AReduce consumptionIncrease production capacityShaping toolsMaterial consumptionEngineering

The invention provides a spin-forming mould for a kettle body of a sliver kettle. The spin-forming mould comprises a mould rack, a kettle body internal supporting module arranged on the mould rack, a kettle body external forming module and a kettle body closing-in and rolling module, wherein the kettle body is arranged between the kettle body internal supporting module and the kettle body external forming module; and in a rotary process of the kettle body, the kettle body closing-in and rolling module can apply pressure to the kettle body, so that the kettle body completes closing-in. According to the spin-forming mould for the kettle body of the sliver kettle, the material consumption is reduced, the labor amount of an operator is reduced and the manufacturing cost can be effectively saved, and a manufactured product is light, uniform in thickness and high in yield.

Owner:宜兴瑞鑫贵金属艺术品有限公司

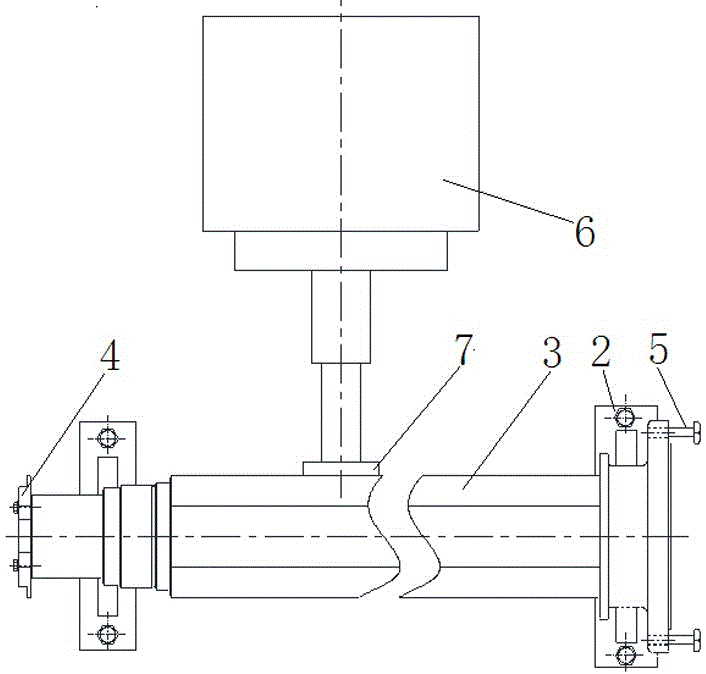

Method for machining high-precision hexagonal shaft through ordinary numerical control boring machine

ActiveCN105773087APrecisely control the rotation anglePrecise processingNumerical controlMilling cutter

The invention relates to a method for machining a high-precision hexagonal shaft through an ordinary numerical control boring machine. A worktable is arranged in the machining range of the ordinary numerical control boring machine; two V-shaped bases are fixed on the worktable; round parts on two ends of a workpiece are separately arranged on the two V-shaped bases, and the levelness and perpendicularity of the workpiece are detected; a hexagonal aligning template is fixed on the end surface of one end of the workpiece; the hexagonal aligning template is a regular hexagon plate; the symmetry center of the hexagonal aligning template is located on the axis of the workpiece; whether the corresponding edge lines of the hexagonal aligning template rotate to be perpendicular or not is detected; the workpiece is tightly pressed after the corresponding edge lines of the hexagonal aligning template rotate to be perpendicular; corresponding surfaces of the workpiece are machined by the ordinary numerical control boring machine through a milling cutter; and firstly a pair of parallel surfaces are machined, and then the other surfaces are sequentially machined. By adopting the method, the rotation angle of the workpiece can be precisely controlled; the machining is precise; the operation is simple; and the cost is low.

Owner:HUAXIN EQUIP MFG

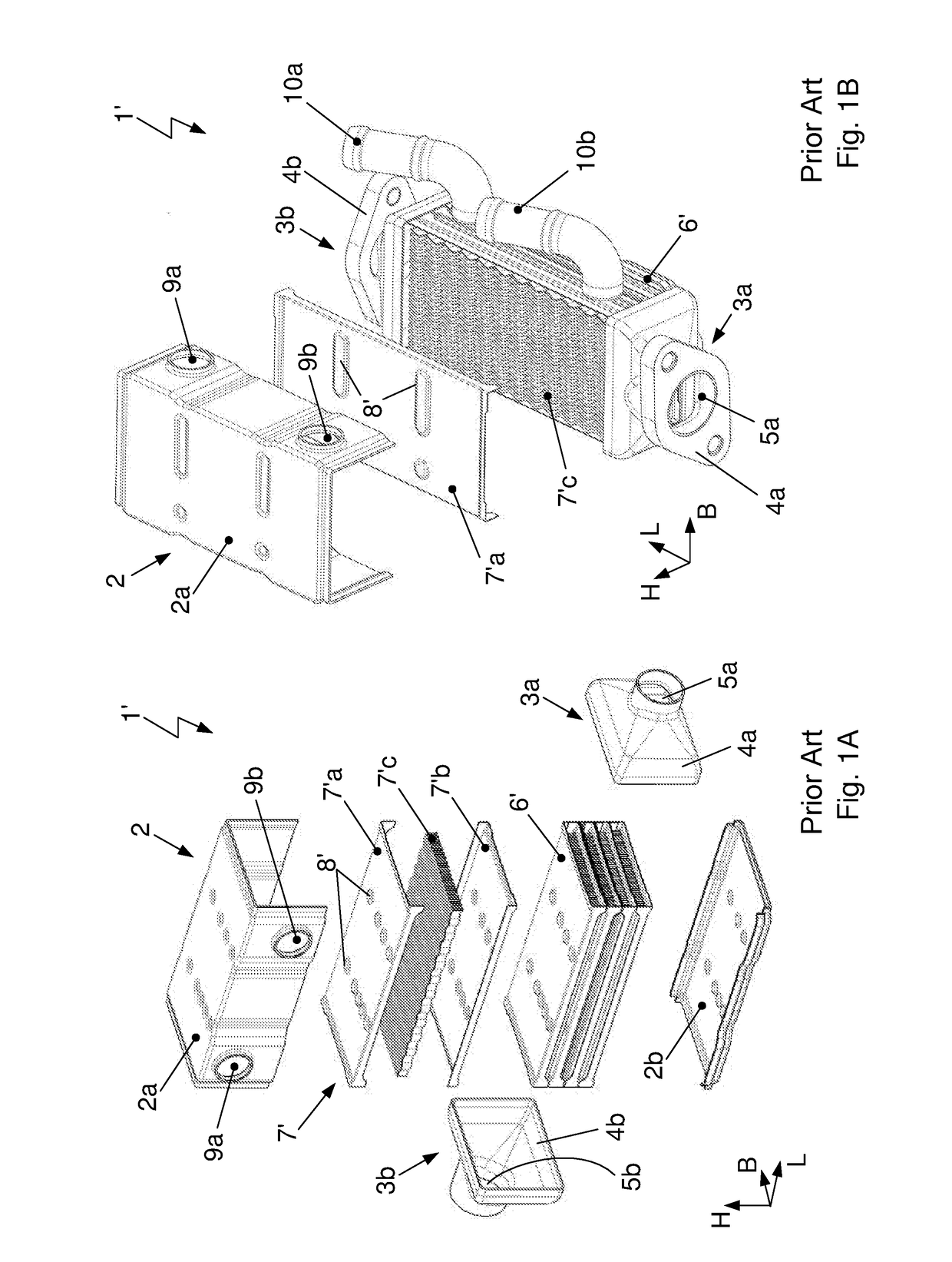

Fin - shaped - plate (FSP) egr cooler

InactiveUS20170152816A1Firmly connectedImprove accuracyExhaust apparatusExhaust gas recirculationCoolant flowEngineering

A heat exchanger includes a heat exchanger housing with an exhaust gas inlet adapter and an exhaust gas outlet adapter, which encloses and bounds off a flow space for a coolant. The heat exchanger is furthermore configured with platelike heat exchanger elements arranged in parallel with each other and forming exhaust gas flow ducts, through which exhaust gas flows and around which liquid coolant flows. A heat exchanger element comprises two wall elements, which are joined together on opposite side surfaces and are configured with ribs on both surfaces. The ribs are arranged on an inner side and within the exhaust gas flow duct and on an outer side of the heat exchanger element. Adjacent heat exchanger elements arranged with outer sides facing each other are joined together at end faces abutting each other, forming a coolant flow duct having the ribs disposed therein.

Owner:HANON SYST

Manufacturing method of 6A02T651 aluminum alloy seam pipe for air separators

The invention belongs to the technical field of aluminum alloy materials for air separators, in particular to a manufacturing method of a 6A02T651 aluminum alloy seam pipe for a low-temperature oxygen / nitrogen air separator, more particularly to a manufacturing method of a 6A02T651 (phi 411*30) aluminum alloy seam pipe. According to the manufacturing method, online quenching production of an ultralarge-diameter and large-wall-thickness seam pipe material for an air separator is realized; under the condition that the standard requirements are met, the labor productivity is raised, the cost is reduced and the ordering requirements of users are met.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

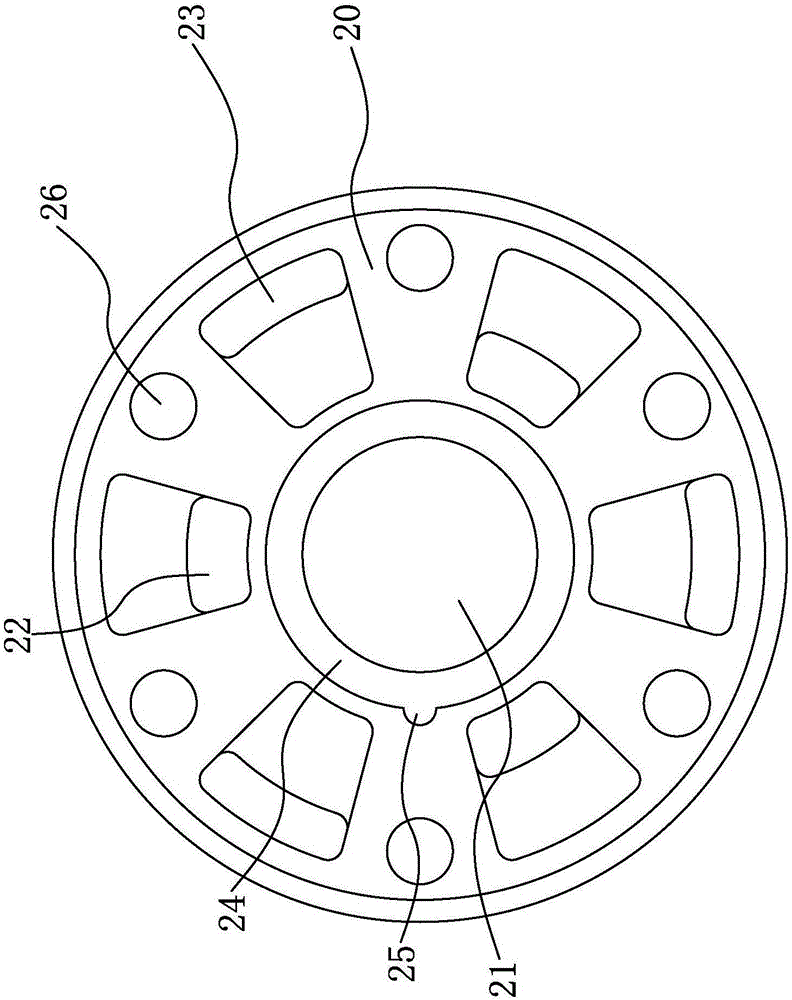

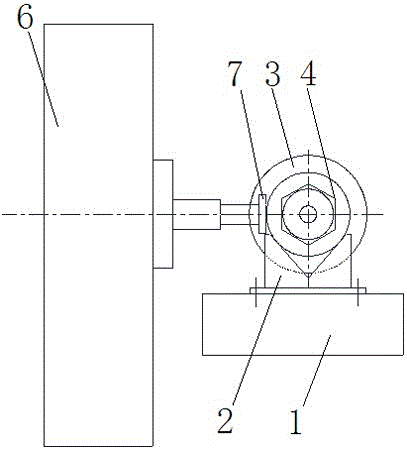

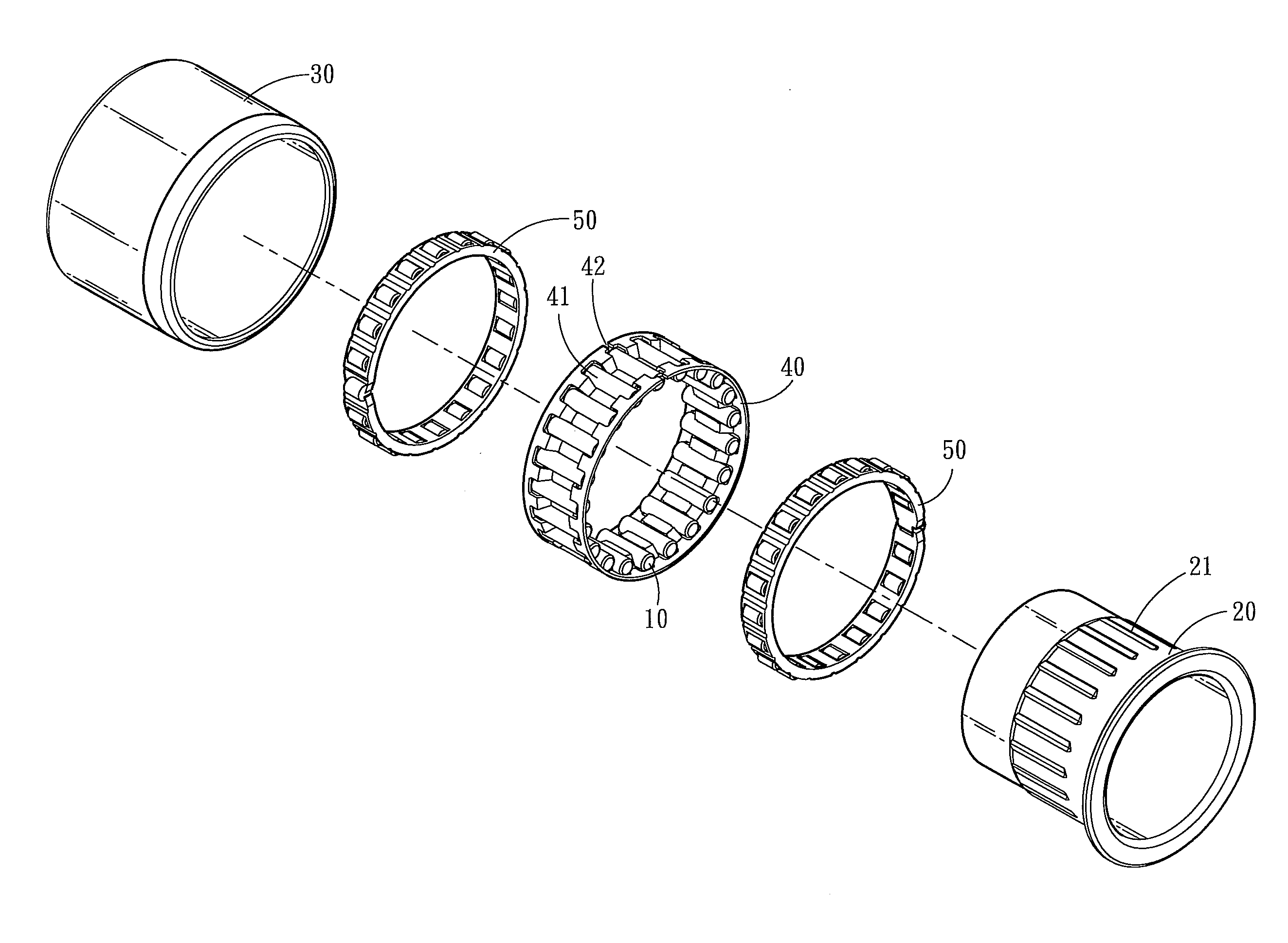

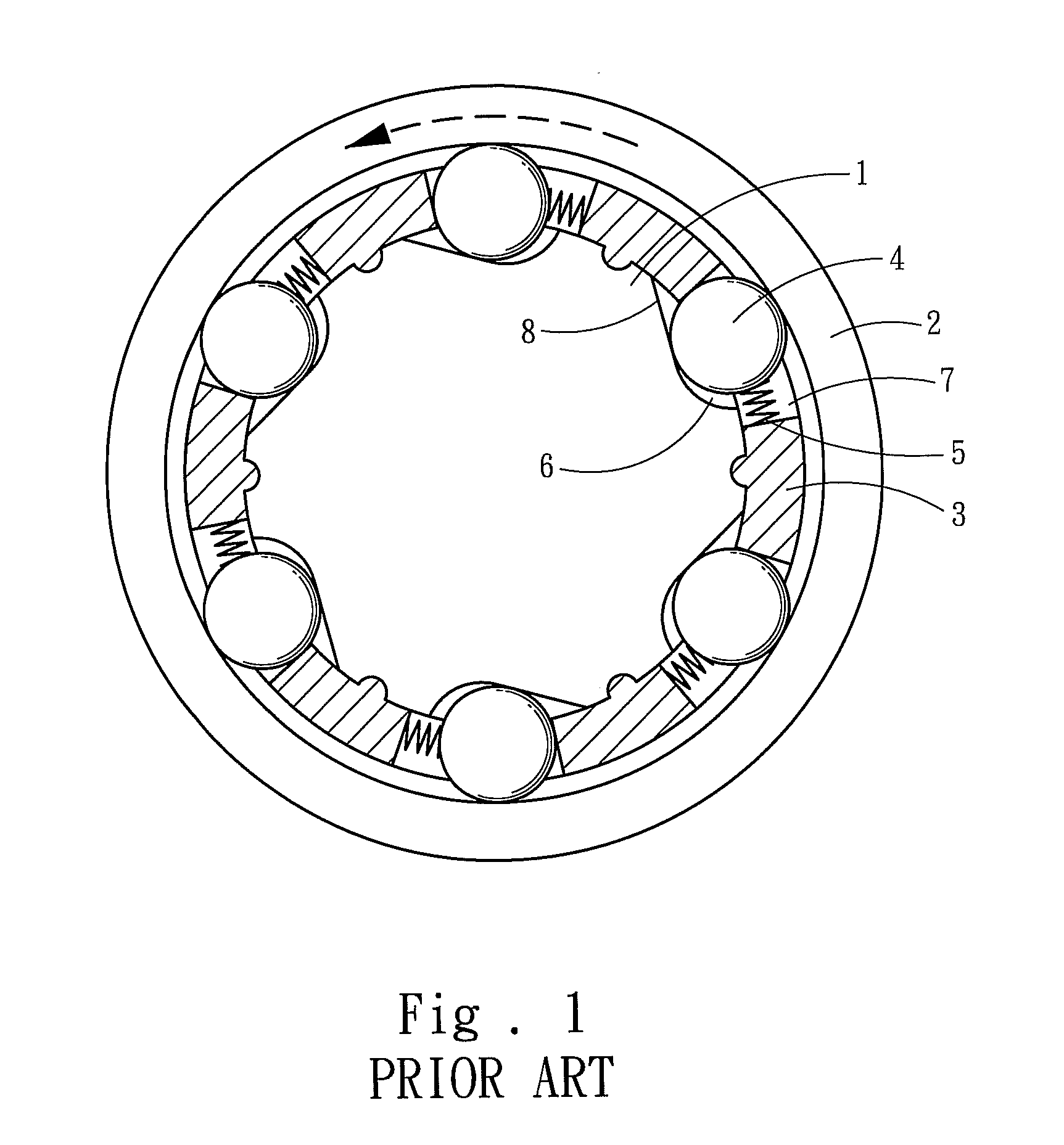

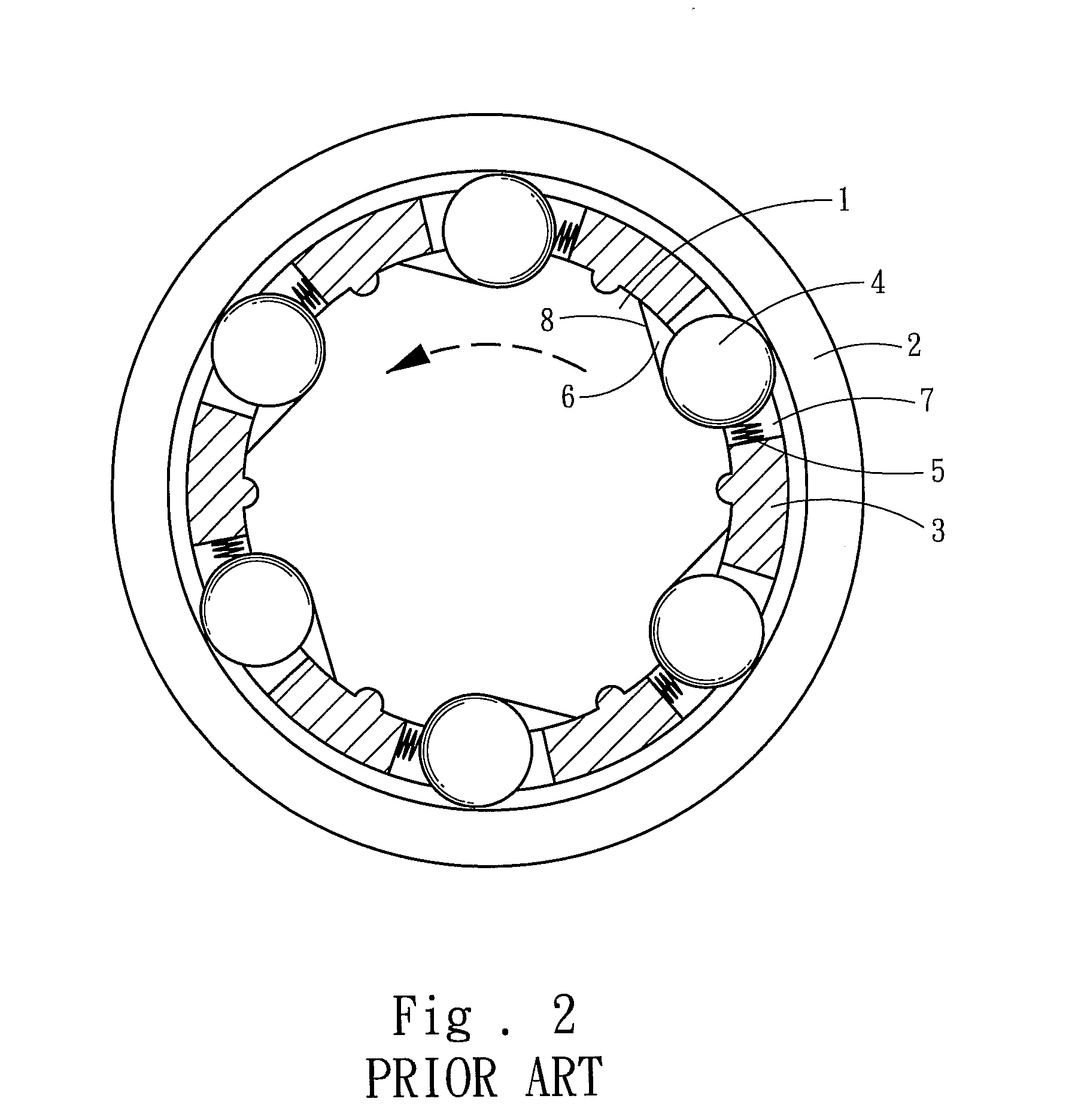

One-way clutch

InactiveUS20130092493A1Torsional force is increasedIncrease forceMechanical actuated clutchesAutomatic clutchesEngineeringShaft collar

A one-way clutch includes multiple rollers, a first collar and a second collar that are coupled together to form relative rotation between them, and a circular holding frame. The first collar has multiple cavities each having an inclined bottom surface. The circular holding frame has multiple slots corresponding to the rollers and exposing the cavities. The second collar is rotated to drive the circular holding frame rotating through friction force so that each roller is pushed to contact a higher portion of the inclined bottom surface and also the second collar drives the first collar rotating via pushing of the rollers. When rotational speed of the first collar is greater than that of the second collar, each roller enters a lower portion of the inclined bottom surface and separates from the second collar without transmitting torsional force between the second collar and first collar.

Owner:NEEDLE ROLLER BEARING

Flexible circuit board reinforcing method and flexible circuit board

ActiveCN107278023ASmall dimensional tolerancePhenomena that reduce dimensional tolerancesCircuit bendability/stretchabilityLaminating printed circuit boardsFlexible circuitsEngineering

The invention, which belongs to the technical field of the flexible circuit board manufacturing, provides a flexible circuit board reinforcing method and a flexible circuit board. The method comprises: four mark points are arranged at a welding plate of a flexible circuit board and a plane where a component is located and an annular copper-free area is formed around each mark point; the four mark points and the annular copper-free area are printed with white ink; and the four mark points are identified and selected for positioning by using an automatic reinforcing machine to carry out pasting reinforcement. According to the method provided by the invention, the mark points and the welding plate are located at the same plane, so that positioning becomes accurate; and during the dual-side manufacturing process of the flexible circuit board, a phenomenon that the tolerance of the welding plate and the reinforced edge is reduced by staggering of two copper layers can be avoided, so that the pasting reinforcement precision is improved.

Owner:SHENZHEN KINWONG ELECTRONICS

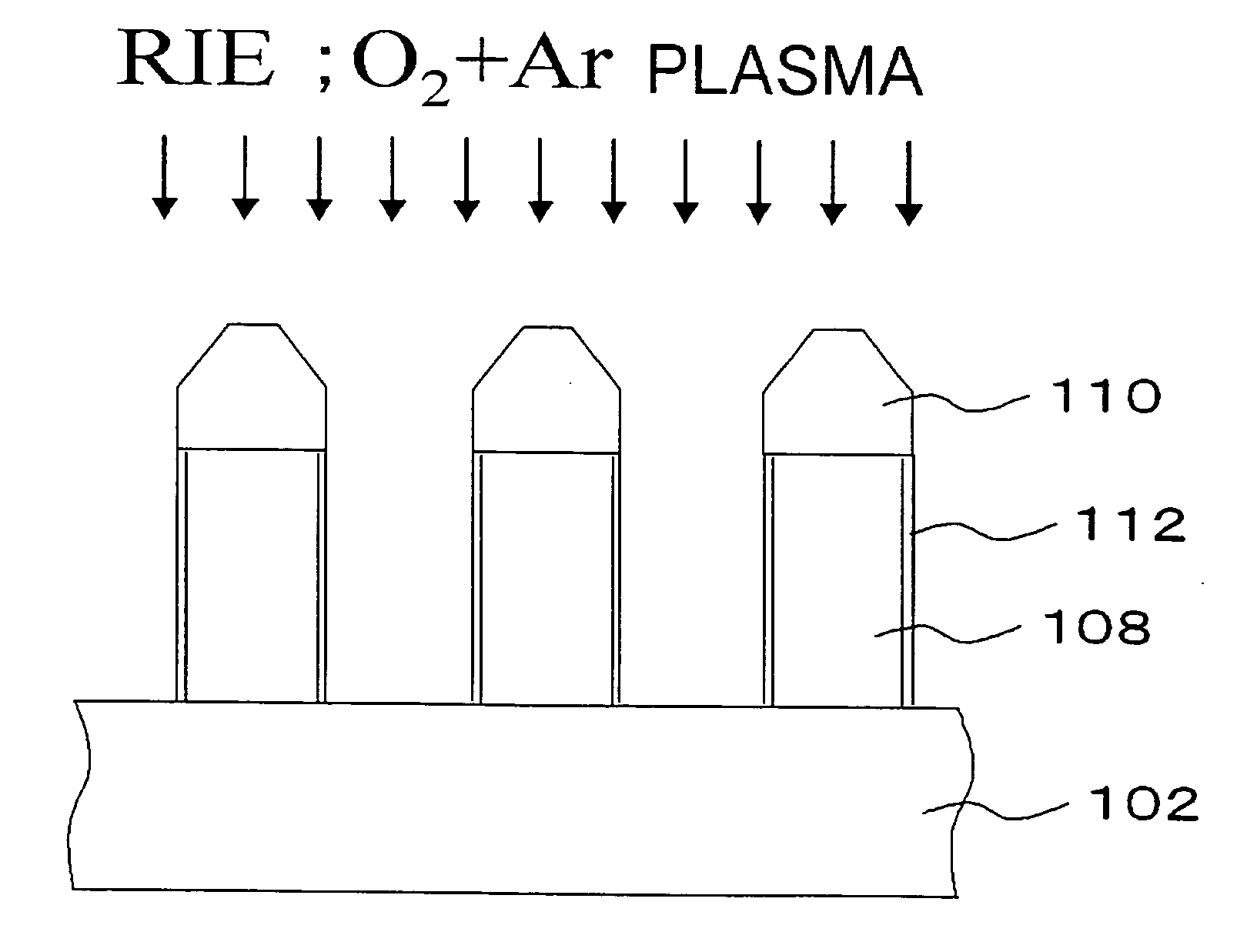

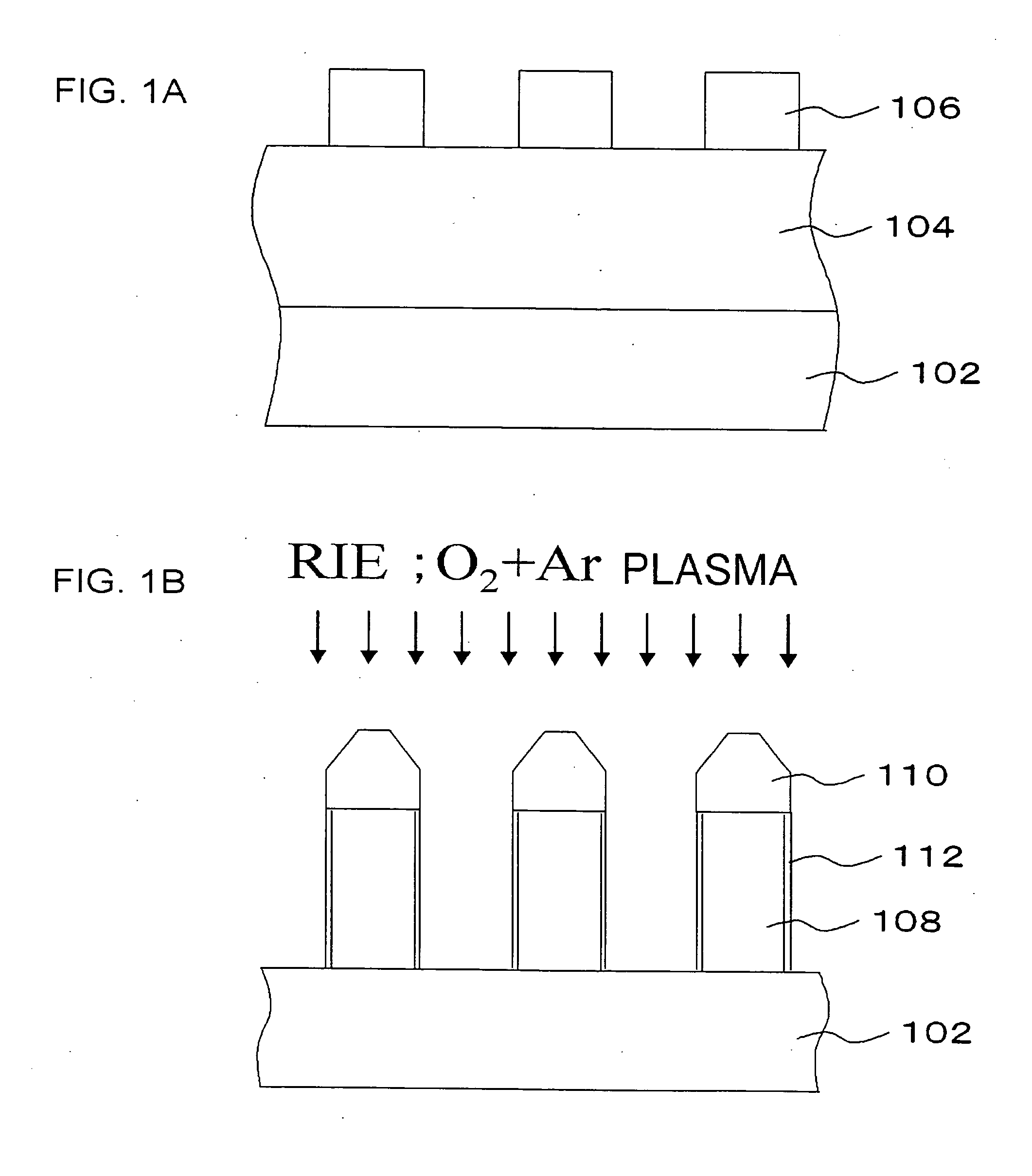

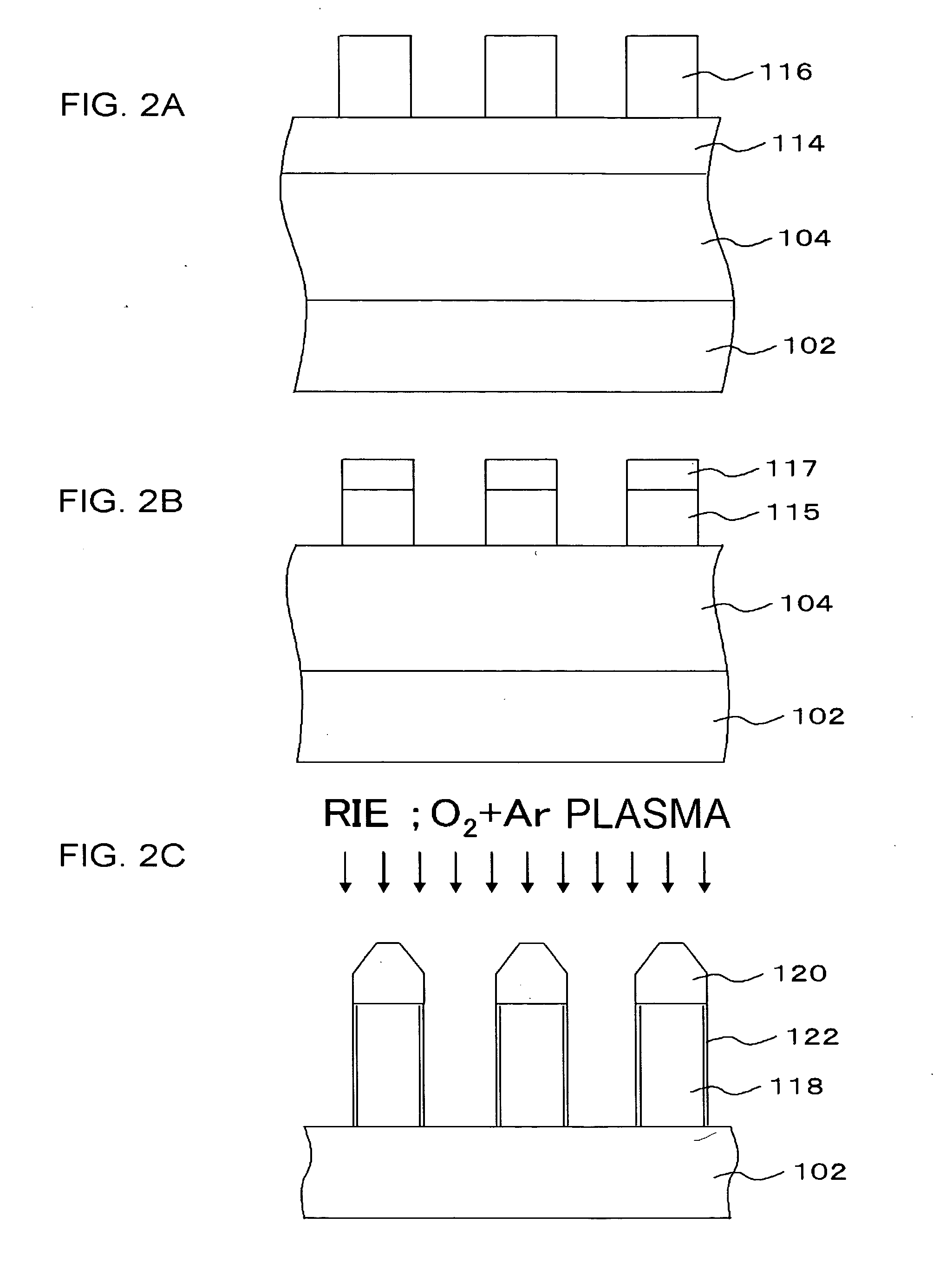

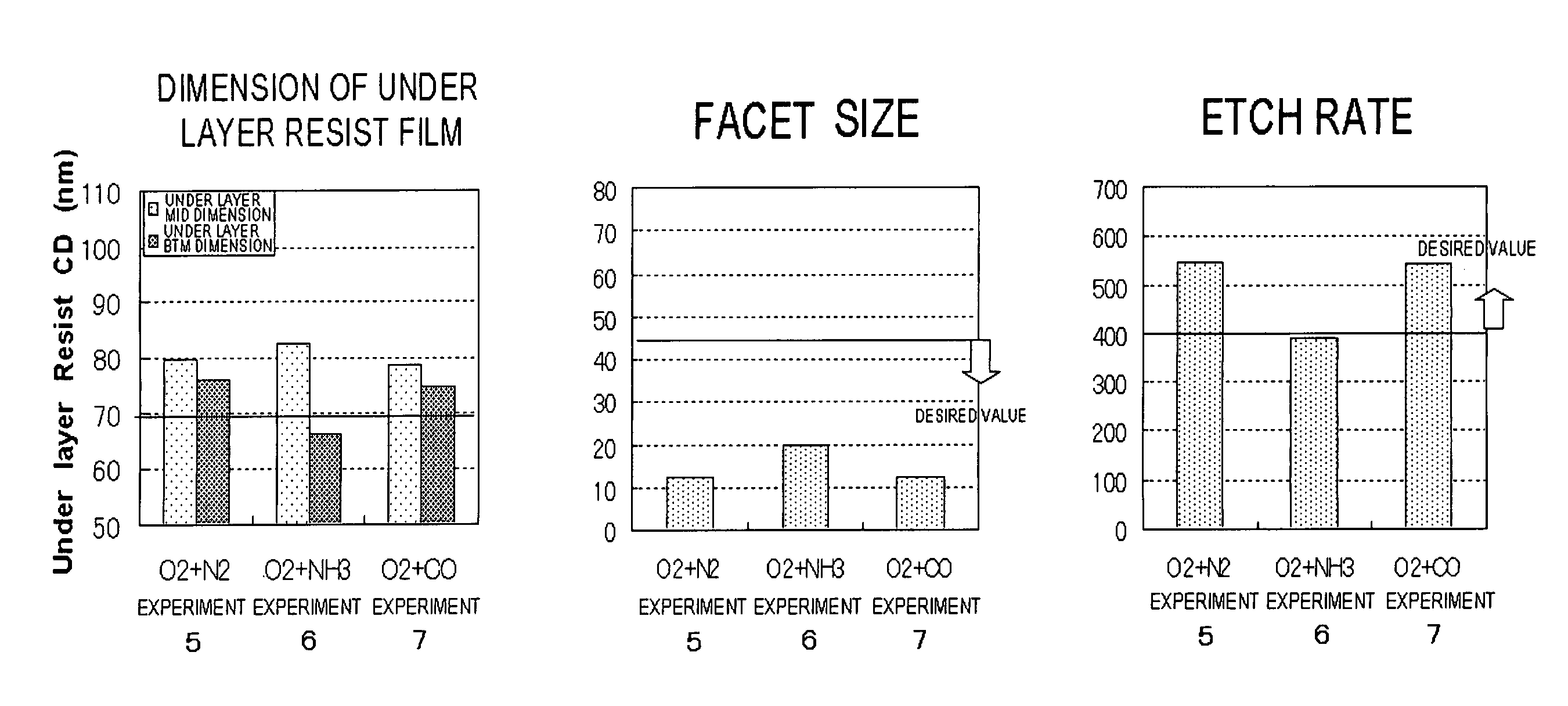

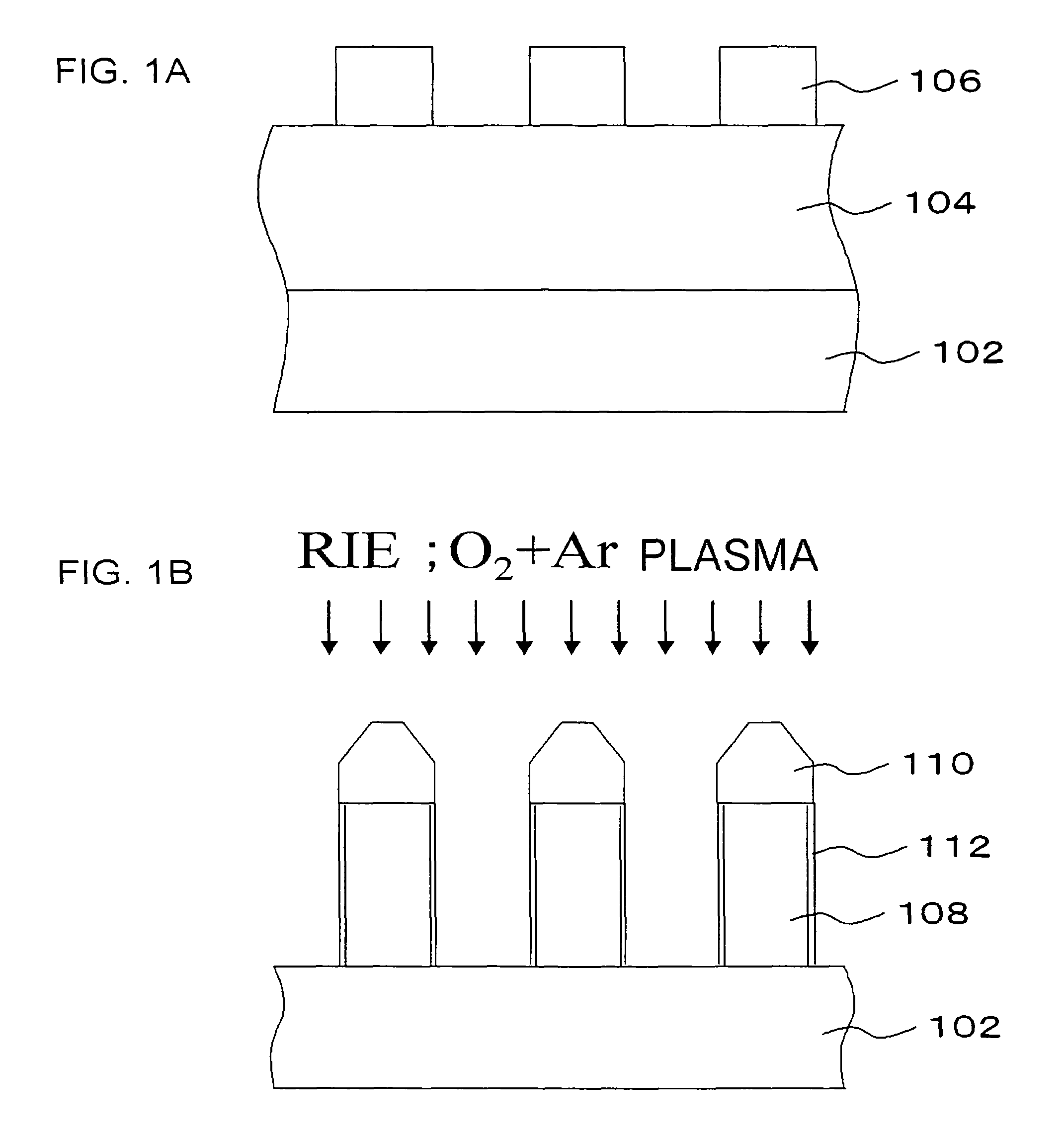

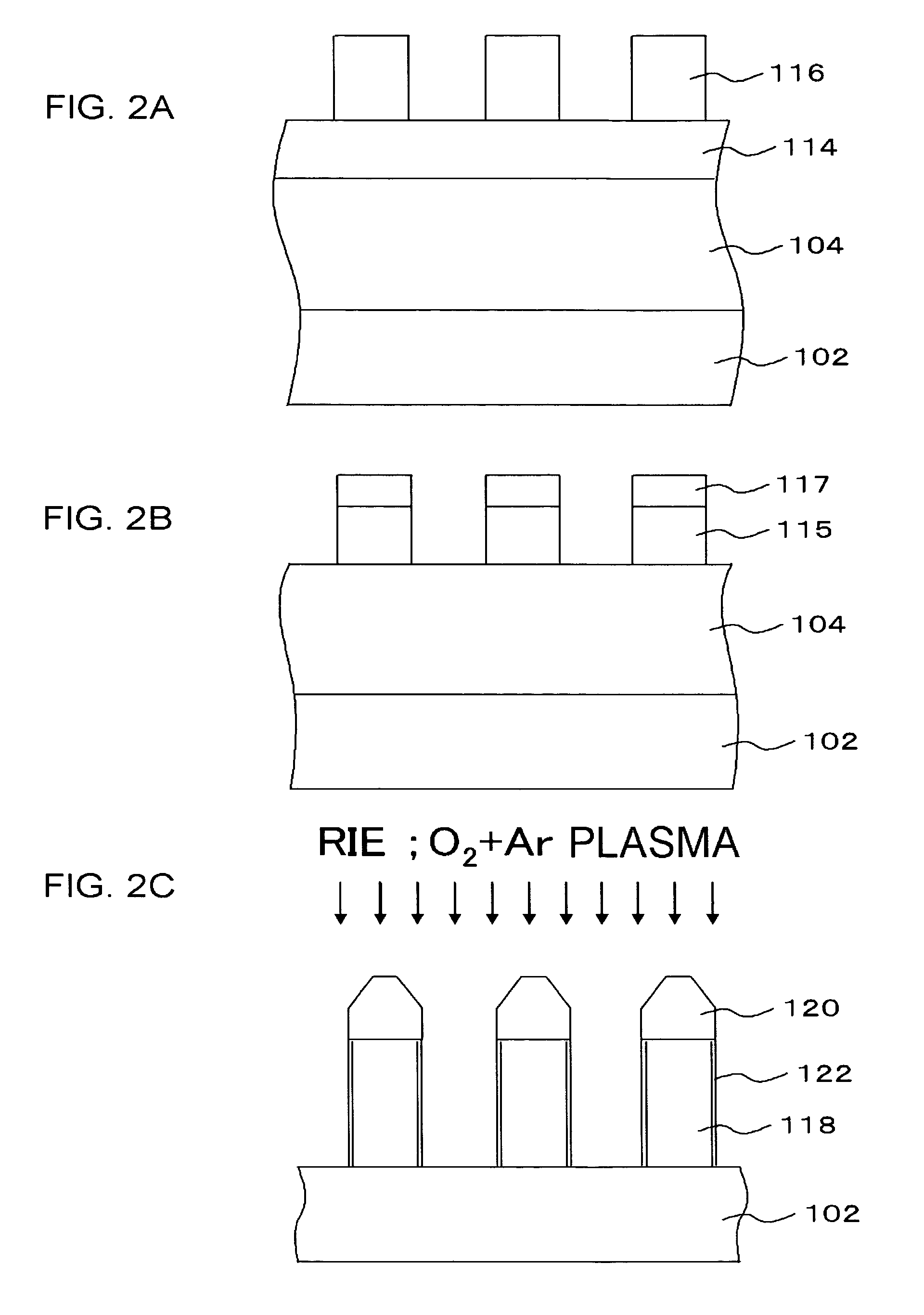

Method of patterning multiple-layered resist film and method of manufacturing semiconductor device

InactiveUS20070141764A1Improve reliabilityImprove production yieldDecorative surface effectsSemiconductor/solid-state device manufacturingResistDevice material

A method of patterning a multiple-layered resist film and a method of manufacturing a semiconductor device, which can provide an improved reliability of the semiconductor devices and a reduced operation time for an etch process, are provided. A method of patterning a multiple-layered resist film according to the present invention include: forming a lower layer resist film 104 on a semiconductor substrate; forming a silicon-containing upper layer resist film on the lower layer resist film 104; patterning the silicon-containing upper layer resist film into a predetermined geometry; and performing dry etching process for removing the lower layer resist film 104 through a mask of the patterned silicon-containing upper layer resist film 106 employing an etching gas containing oxygen (O2) gas and argon (Ar) gas at a pressure within a range of from 0.075 mTorr to 50 mTorr both inclusive.

Owner:RENESAS ELECTRONICS CORP

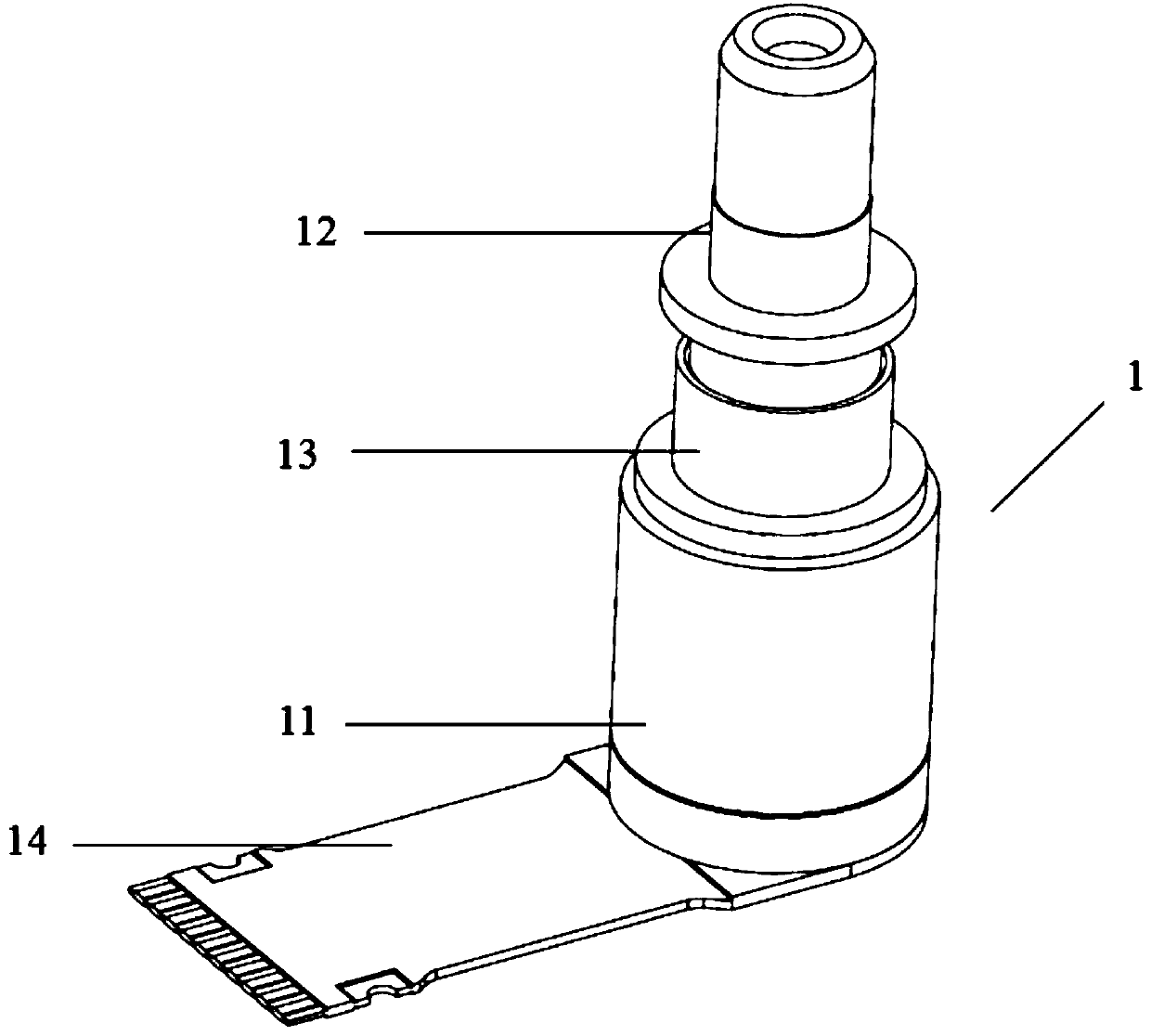

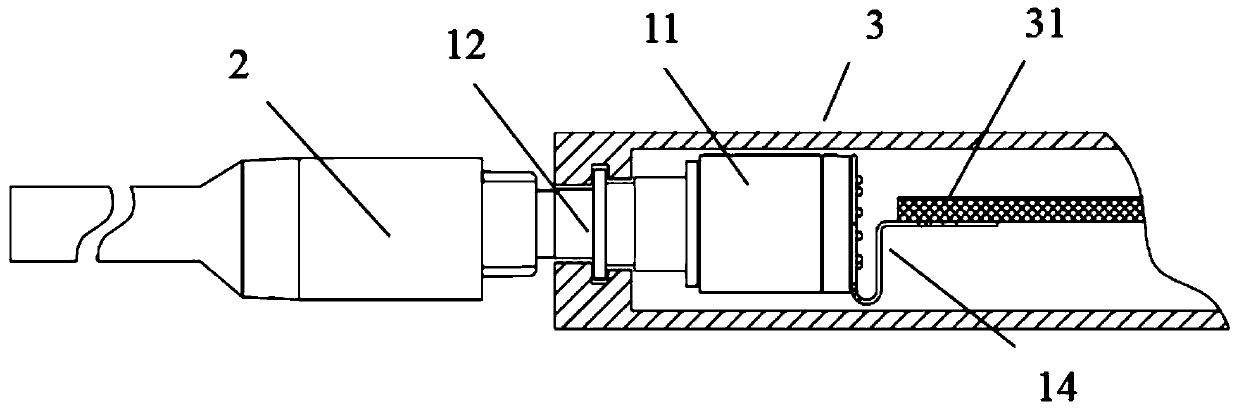

Optical signal transmitting device

PendingCN111293582AIncrease bandwidth usageAvoid long tracesLaser detailsSemiconductor lasersParasitic capacitanceEngineering

The invention discloses an optical signal transmitting device in the field of laser diodes. The optical signal transmitting device comprises a driving chip assembly, a laser TEC assembly and a housing, wherein the driving chip assembly and the laser TEC assembly are packaged in the housing; and a laser heat sink substrate in the laser TEC assembly comprises a first part used for installing a laserdiode chip and a second part used for installing a prism, wherein the first part is provided with a plating layer used for installing a semiconductor laser LD, and the laser heat sink substrate is further provided with a positioning structure used for positioning the prism. The device has the following beneficial effects: long wiring between the driving chip and the semiconductor laser is avoided, and the parasitic inductance and parasitic capacitance caused by long wiring are reduced, so that the problem that the parasitic inductance, parasitic capacitance, impedance mismatching and the likeinfluence the quality of high-frequency signals is solved, the use bandwidth of the optical signal transmitting device is improved, and the optical signal transmitting device is more suitable for high-speed light communication equipment.

Owner:成都英思嘉半导体技术有限公司

Method of patterning multiple-layered resist film and method of manufacturing semiconductor device

InactiveUS7754543B2Keep for a long timeEtch rate reductionDecorative surface effectsSemiconductor/solid-state device manufacturingResistEngineering

A method of patterning a multiple-layered resist film and a method of manufacturing a semiconductor device, which can provide an improved reliability of the semiconductor devices and a reduced operation time for an etch process, are provided. A method of patterning a multiple-layered resist film according to the present invention include: forming a lower layer resist film 104 on a semiconductor substrate; forming a silicon-containing upper layer resist film on the lower layer resist film 104; patterning the silicon-containing upper layer resist film into a predetermined geometry; and performing dry etching process for removing the lower layer resist film 104 through a mask of the patterned silicon-containing upper layer resist film 106 employing an etching gas containing oxygen (O2) gas and argon (Ar) gas at a pressure within a range of from 0.075 mTorr to 50 mTorr both inclusive.

Owner:RENESAS ELECTRONICS CORP

High-magnetism high-mechanical-strength bonded neodymium iron boron (NdFeB) permanent magnet and preparation method thereof

InactiveCN102938283AImprove magnetismHigh mechanical strengthPermanent magnetsInorganic material magnetismEpoxyMaterials science

The invention relates to a high-magnetism high-mechanical-strength bonded neodymium iron boron (NdFeB) permanent magnet and a preparation method thereof and belongs to the technical field of magnets. The high-magnetism high-mechanical-strength bonded NdFeB permanent magnet comprises NdFeB magnetic powders, a thermosetting resin, a curing agent and a lubricating agent, and the magnetic powders comprise metallocene macromolecule ferromagnetic powders and stainless steel powders. The preparation method includes firstly, evenly mixing the thermosetting resin, the curing agent and acetone; secondly, evenly mixing the NdFeB magnetic powders, the metallocene macromolecule ferromagnetic powders and the stainless steel powders; thirdly, adding a mixture obtained from the step two to a mixture obtained from the step one and evenly mixing the two mixtures; fourthly, performing drying and screening, adding the lubricating agent, and evenly mixing the mixtures to obtain a magnetic powder mixture; fifthly, using a compression molding machine to press the mixtures into a magnet green body; and sixthly, curing the magnet green body at the temperature of 175-200 DEG C to obtain the magnet. The magnet has the advantages of being convenient to prepare, high in magnetic property and mechanical strength, small in dimensional tolerance, convenient to subsequently barrel and grind and low in transportation and assembly loss of finished products.

Owner:TIANJIN NIBBOH MAGNETS

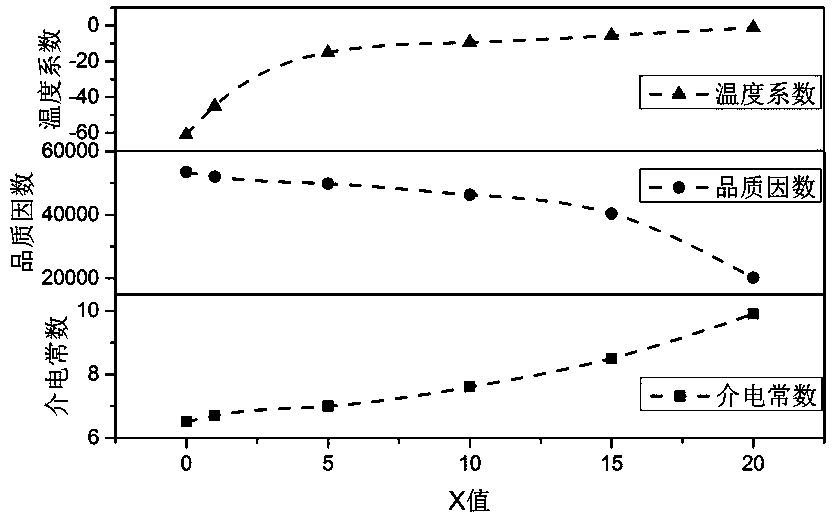

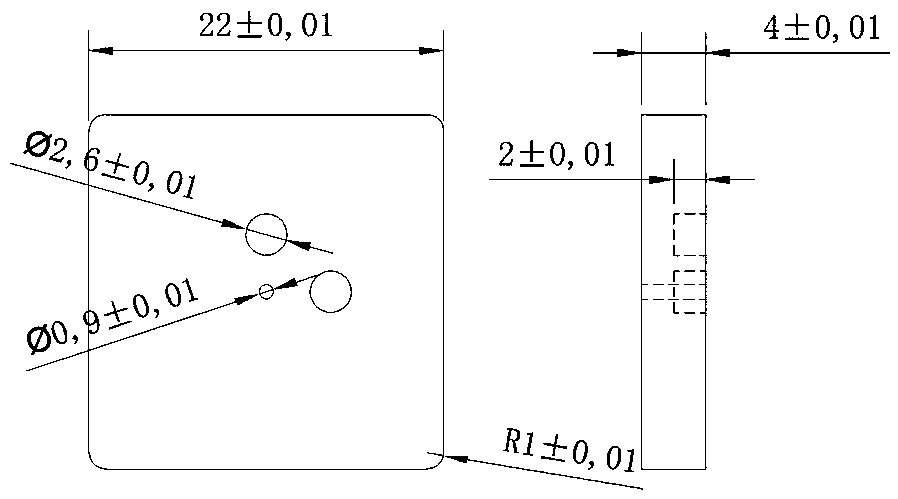

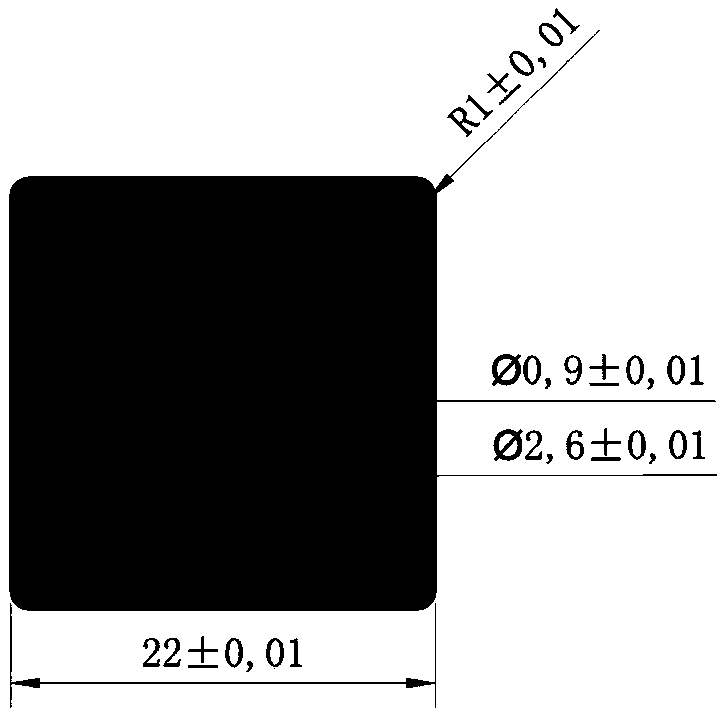

Microwave dielectric ceramic material, microwave dielectric ceramic antenna and preparation method thereof

InactiveCN111377722AGood precisionGood repeatabilityRadiating elements structural formsDielectricMicrowave

The invention relates to a microwave dielectric ceramic material, a microwave dielectric ceramic antenna and a preparation method of the microwave dielectric ceramic antenna. The chemical compositionof the microwave dielectric ceramic material is xTiO2-(1-x)Zn2SiO4, wherein x is greater than or equal to 1.0 wt% and less than or equal to 20.0 wt%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

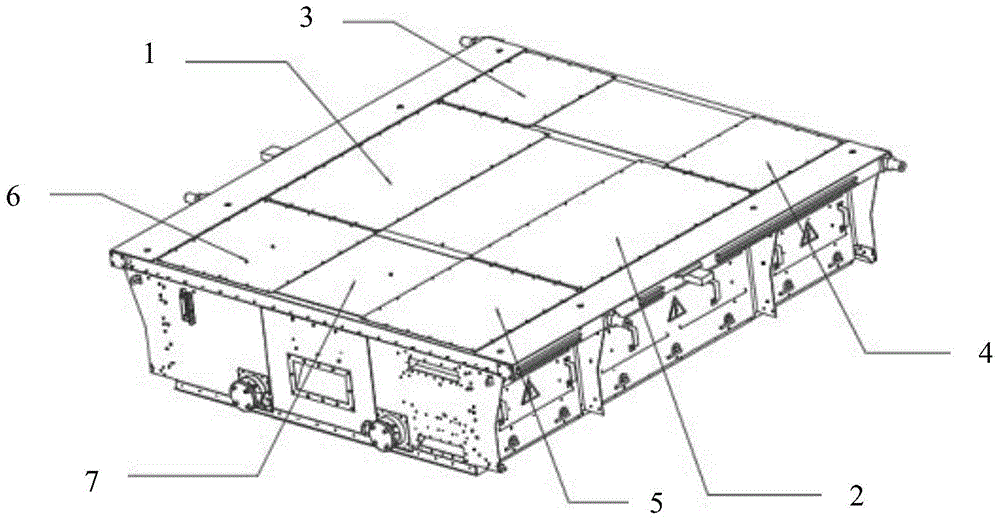

Traction converter device box and vehicle

InactiveCN104967283AAvoid deformationSmall dimensional toleranceElectrical apparatus casings/cabinets/drawersPower conversion systemsCapacitanceEngineering

The invention provides a traction converter device box and a vehicle. The traction converter device box comprises a first power module platform, a second power module platform, a control platform, a contactor platform, a resistor platform, a capacitor platform, a center pipeline platform, wherein each platform is integrated with at least one component; the first power module platform is connected with the control platform and the capacitor platform; the second power module platform is connected with the resistor platform and the contactor platform; and the first power module platform, the second power module platform, the control platform, the contactor platform, the resistor platform and the capacitor platform are connected with the center pipeline platform. Therefore, the box is not easy to deform after being assembled and combined; the dimensional tolerance is small; assembly work efficiency is improved; and the box is convenient to assemble, disassemble and maintain.

Owner:CRRC YONGJI ELECTRIC CO LTD

Fire hose coupling connector

ActiveCN105953004APrecise blind matingSmall dimensional toleranceFire rescueHose connectionsButt jointEngineering

The invention relates to a fire hose coupling connector. The fire hose coupling connector comprises a female joint and a male joint, wherein the female joint is movably connected to the male joint through a thread; air joints are arranged on the tops of the female joint and the male joint, and one ends of the air joints are connected to inner tubes; the inner tubes are arranged in inner cavities of the female joint and the male joint; a first inner connector and a second inner connector are arranged in the inner cavities of the female joint and the male joint, respectively, and are arranged at the bottoms of the inner tubes; the inner cavity of the first inner connector is connected to a first optical fiber rod through a first fixed part; one end of the first optical fiber rod is connected to a first optical fiber magnetic head; an optical fiber inner joint wraps the outer wall of the first optical fiber magnetic head; the inner cavity of the second inner connector is connected to a second optical fiber rod through a second fixed part; and one end of the second optical fiber rod is connected to a second optical fiber magnetic head; and two ceramic inserted cores can be precisely butt-jointed with each other through the optical fiber inner connector, and accurate blind insertion of a fire-fighting connector in actual use can be guaranteed.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

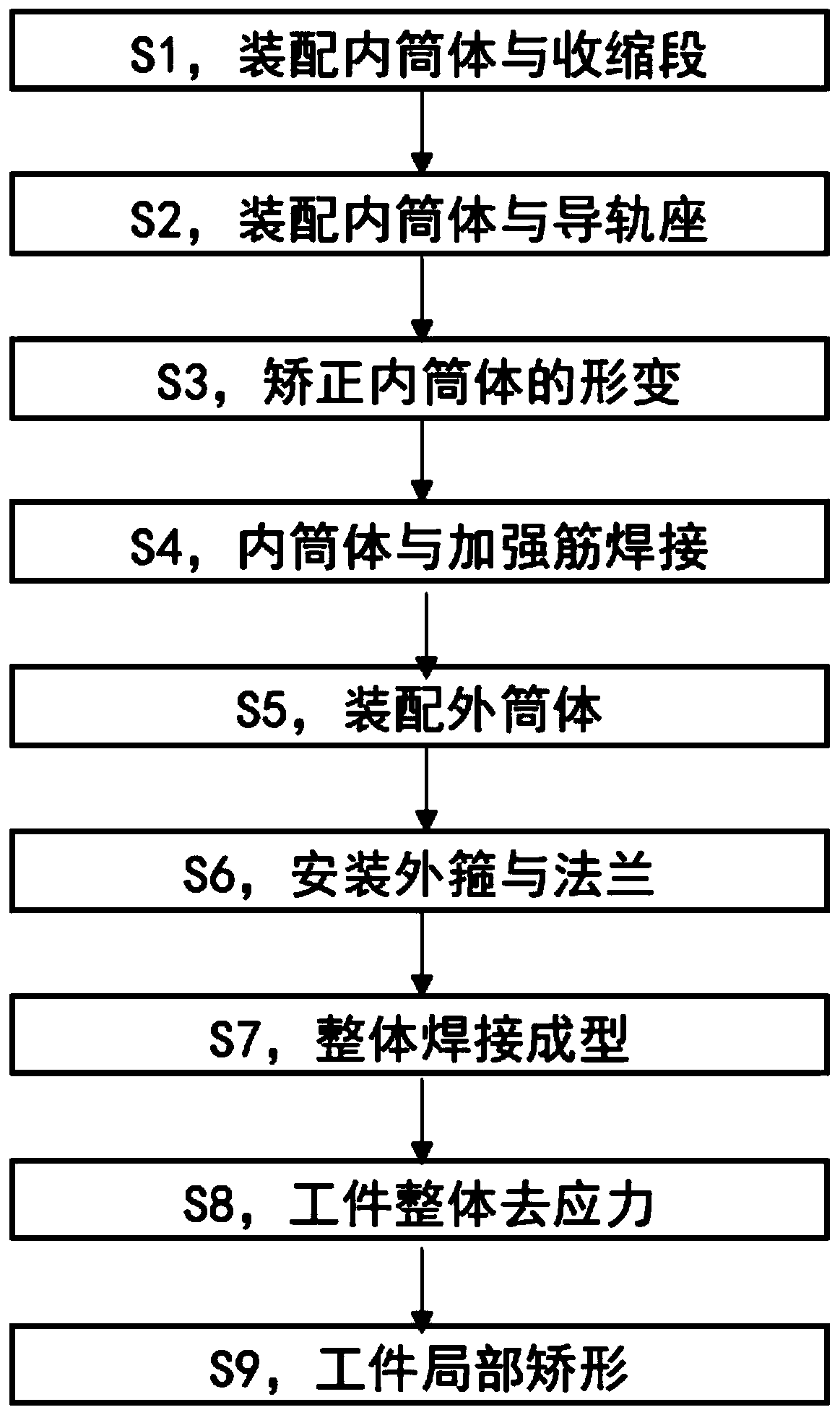

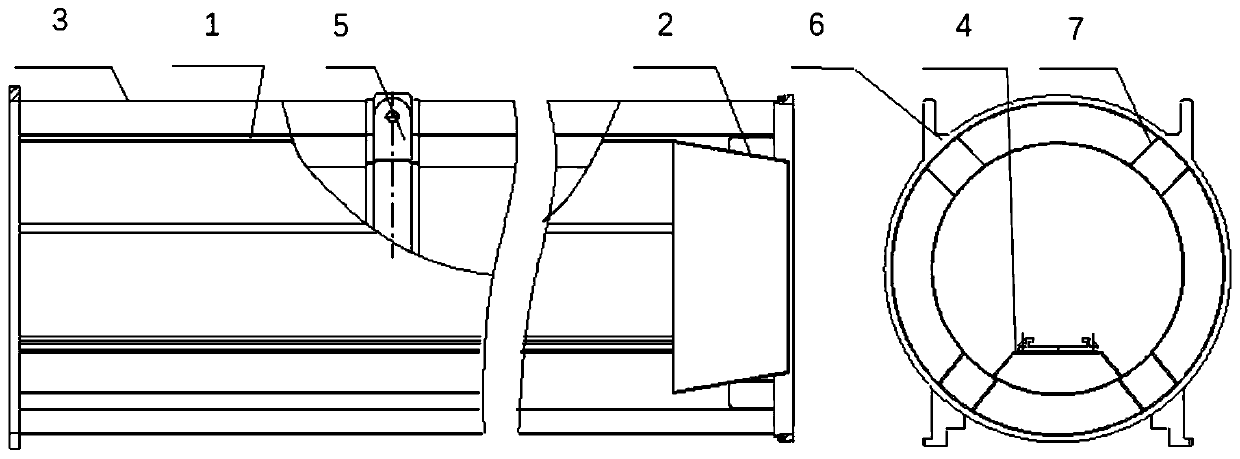

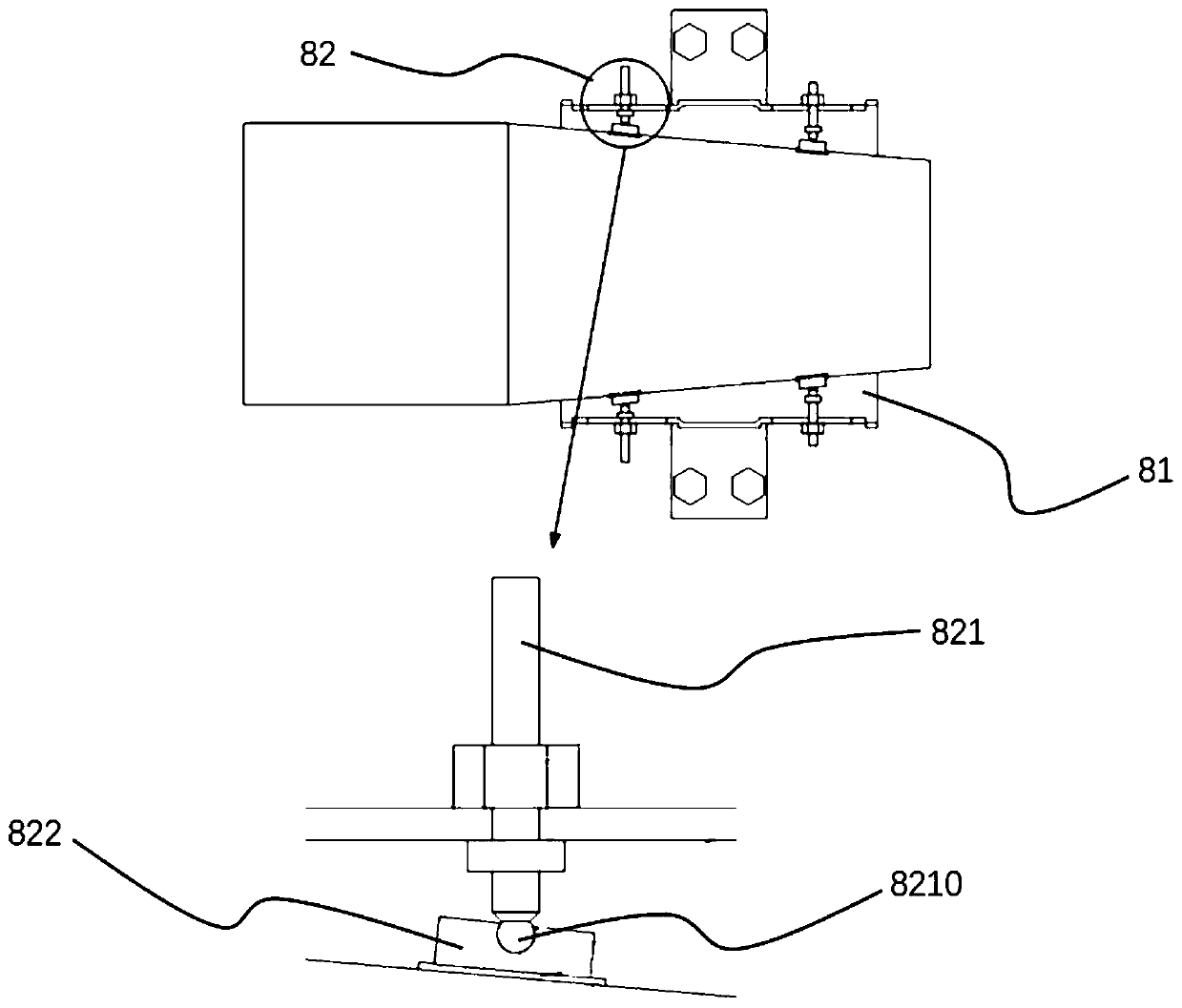

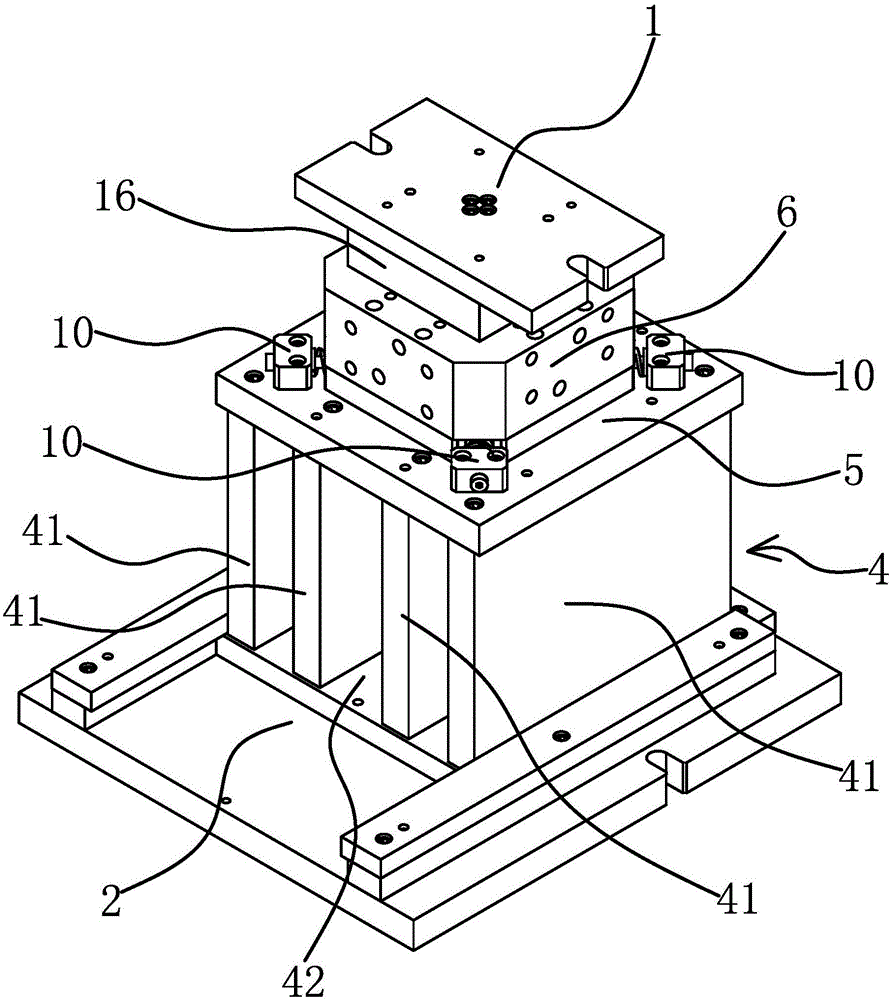

Concentric launch canister body welding method

ActiveCN110653511AHigh-precision control of welding deformationReduce welding linksWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a concentric launch canister body welding method in the field of welding deformation control. The concentric launch canister body welding method comprises the steps of: (S1) assembly of an inner cylinder and a shrinkage section; (S2) assembly of the inner cylinder and a guide rail base; (S3) correction of the deformation of the inner cylinder; (S4) welding of the inner cylinder and a reinforcing rib; (S5) assembly of an outer cylinder; (S6) installation of an outer hoop and a flange; (S7) overall welding molding; (S8) overall destressing of workpieces; and (S9) local shape correction of the workpieces. Multiple tools are matched for use in overall welding process of concentric launch canister bodies, so that the spot welding positioning can be performed to each part of the concentric launch canister bodies beforehand, the welding links in the process are reduced to the greatest extent, the technical effect of nearly once overall molding is achieved, and the concentric launch canister body welding deformation can be controlled with high precision; and the inner cylinder and the guide rail base need no machining after welding to greatly reduce the productioncost.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

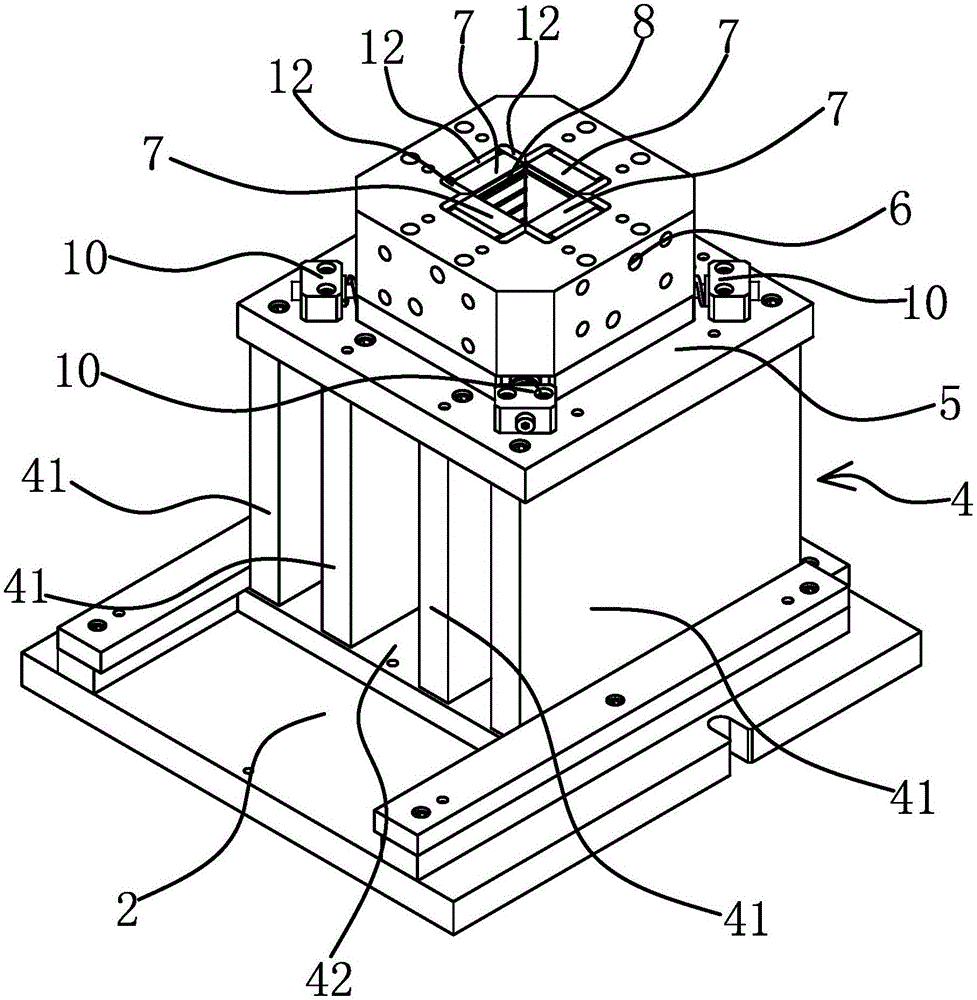

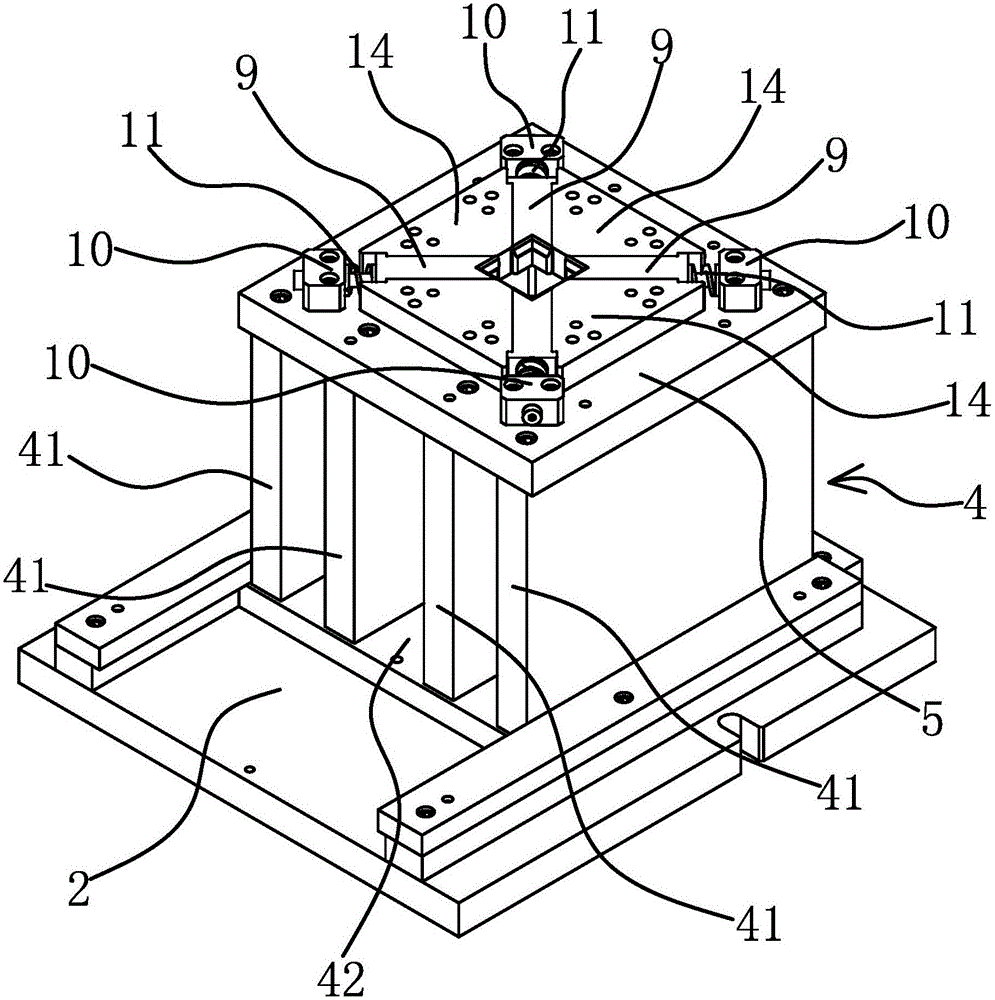

Shaping die for square pipe

ActiveCN105081097ASmall dimensional toleranceUniform surface thicknessShaping toolsEngineeringDimensional precision

The invention provides a shaping die for a square pipe and belongs to the technical field of dies. By the adoption of the shaping die for the square pipe, the problem that the dimensional precision of an existing square pipe is low is solved. A core bar is fixed to a female die installation plate of the shaping die for the square pipe. A supporting frame is arranged on the male die installation plate. An installation platen is fixed to the supporting frame. A shaping shell is fixed to the installation platen. A square receding through hole is formed in the shaping shell. The core bar can be inserted into the square receding through hole. Installation grooves communicated with the square receding through hole are formed in the shaping shell and located in the four circumferential inner walls of the square receding through hole respectively. A shaping block is arranged in each installation groove. A plurality of pin rollers which are perpendicular to the core bar are arranged in each shaping block in the insertion direction of the core bar. Four pressing wedge blocks are further arranged between the installation platen and the shaping shell. One end of each pressing wedge block is in a V shape and located at one corner of the square receding through hole. By rolling the inner surface and the outer surface of the square pipe repeatedly, the dimensional tolerance of the square pipe is made smaller, and the surface thickness of the square pipe is made more uniform.

Owner:松渤电器(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com