Method for producing RE510L steel of thin specification based on ESP sheet billet continuous coasting and rolling procedure

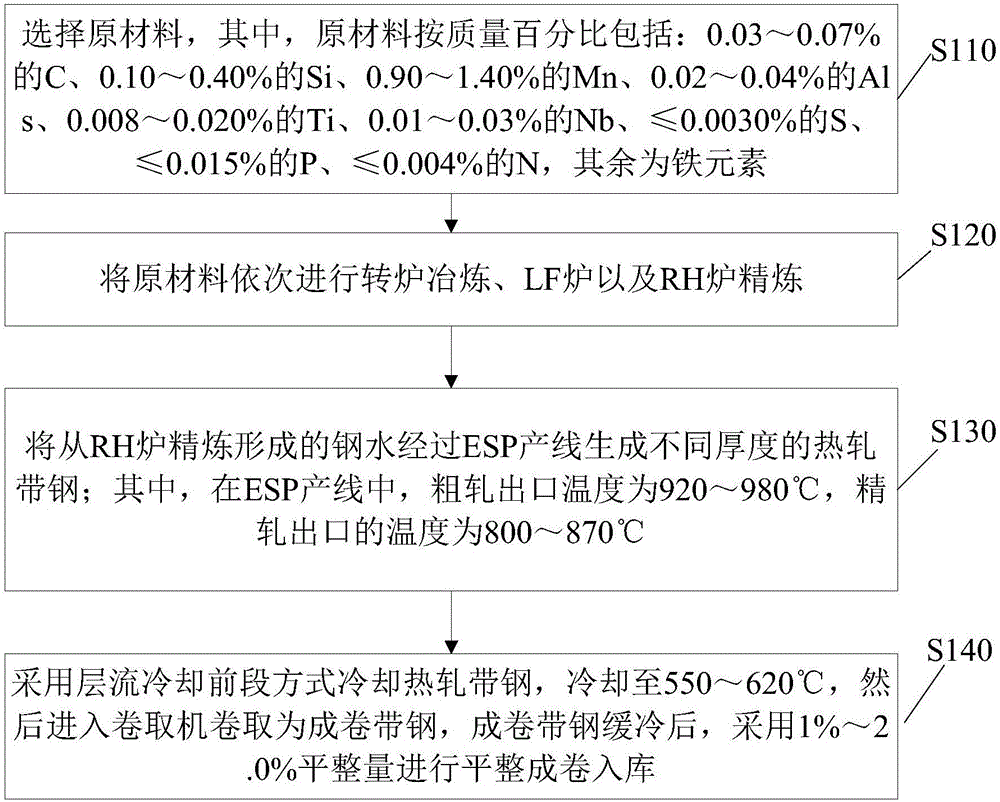

A thin-slab continuous casting and thin-gauge technology, which is applied in the direction of metal rolling, can solve the problems of high cost and high energy consumption of hot rolling, and achieve the effects of reduced rolling passes, stable performance, and small dimensional tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In the embodiment, the process of producing RE510L steel by the all-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → RH → ESP continuous casting and rolling → laminar cooling → coiling → slow Cold → smooth → finished product.

[0046] In this embodiment, raw materials such as molten iron and steel scrap are sequentially subjected to converter smelting, LF refining, and RH refining, and the composition of molten steel is controlled as C: 0.035Wt%; Si: 0.15Wt%; Mn: 1.05Wt%; Als: 0.032Wt%; Nb: 0.012 Wt%; Ti: 0.013Wt%; S: 0.0020Wt%; P: 0.012Wt%; N: 0.0032Wt%. The balance is Fe.

[0047] The molten steel refined by LF and RH goes through continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling and tempering of ESP production line to produce hot-rolled steel strips of different thicknesses.

[0048] In the continuous casting process, the superheat of the tundi...

Embodiment 2

[0058] In the embodiment, the process of producing RE510L steel by the all-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → RH → ESP continuous casting and rolling → laminar cooling → coiling → slow Cold → smooth → finished product.

[0059] In this embodiment, raw materials such as molten iron and steel scrap are sequentially subjected to converter smelting, LF refining, and RH refining, and the composition of molten steel is controlled as C: 0.038Wt%; Si: 0.18Wt%; Mn: 1.08Wt%; Als: 0.030Wt%; Nb: 0.018 Wt%; Ti: 0.013Wt%; S: 0.0020Wt%; P: 0.012Wt%; N: 0.0035Wt%, the balance being Fe.

[0060] The molten steel refined by LF and RH goes through continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling and tempering of ESP production line to produce hot-rolled steel strips of different thicknesses.

[0061] In the continuous casting process, the superheat of the tun...

Embodiment 3

[0070] In the embodiment, the process of producing RE510L steel by the all-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → RH → ESP continuous casting and rolling → laminar cooling → coiling → slow Cold → smooth → finished product.

[0071] In this embodiment, raw materials such as molten iron and steel scrap are sequentially subjected to converter smelting, LF refining, and RH refining, and the composition of molten steel is controlled as C: 0.040Wt%; Si: 0.20Wt%; Mn: 1.10Wt%; Als: 0.032Wt%; Nb: 0.020 Wt%; Ti: 0.013Wt%; S: 0.0025Wt%; P: 0.012Wt%; N: 0.0033Wt%. The balance is Fe.

[0072] The molten steel refined by LF and RH goes through continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling and tempering of ESP production line to produce hot-rolled steel strips of different thicknesses.

[0073] In the continuous casting process, the superheat of the tundi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com