Patents

Literature

1128 results about "Laminar cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

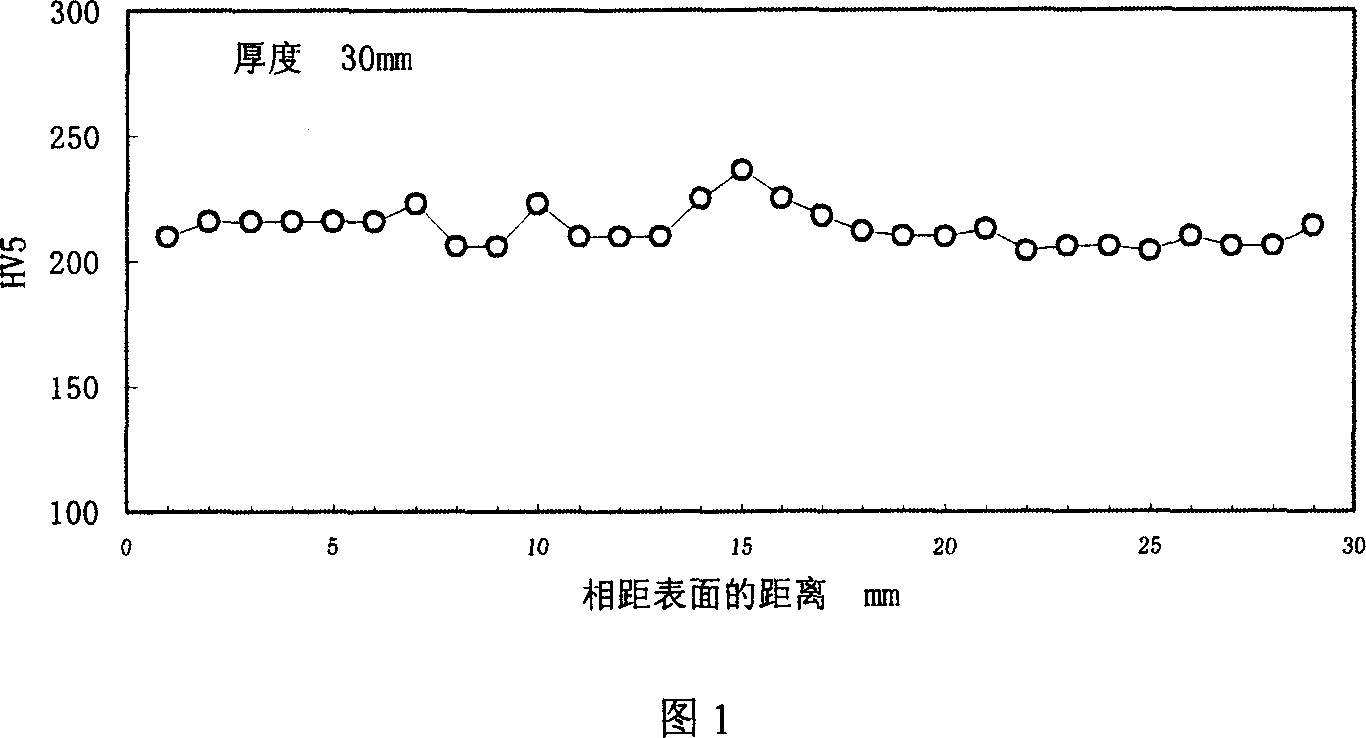

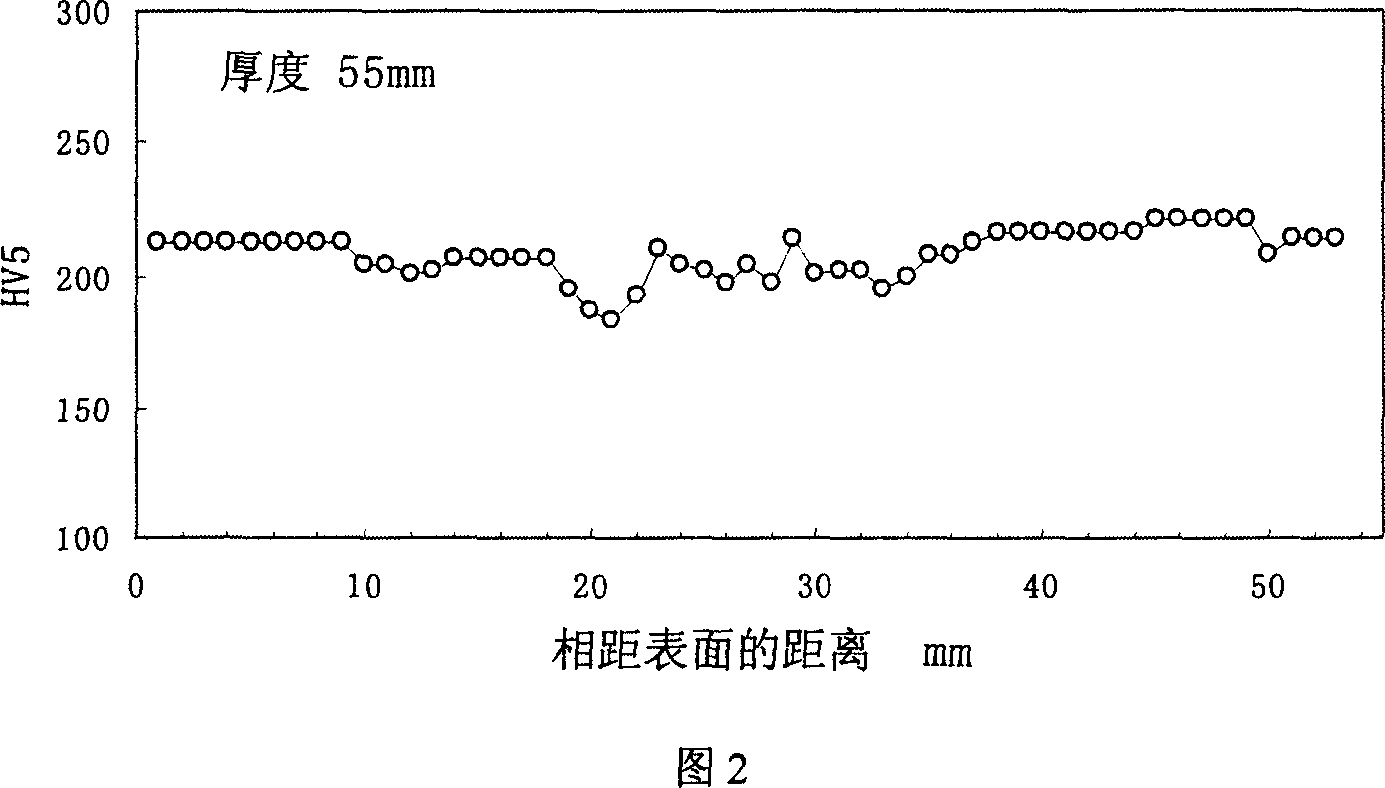

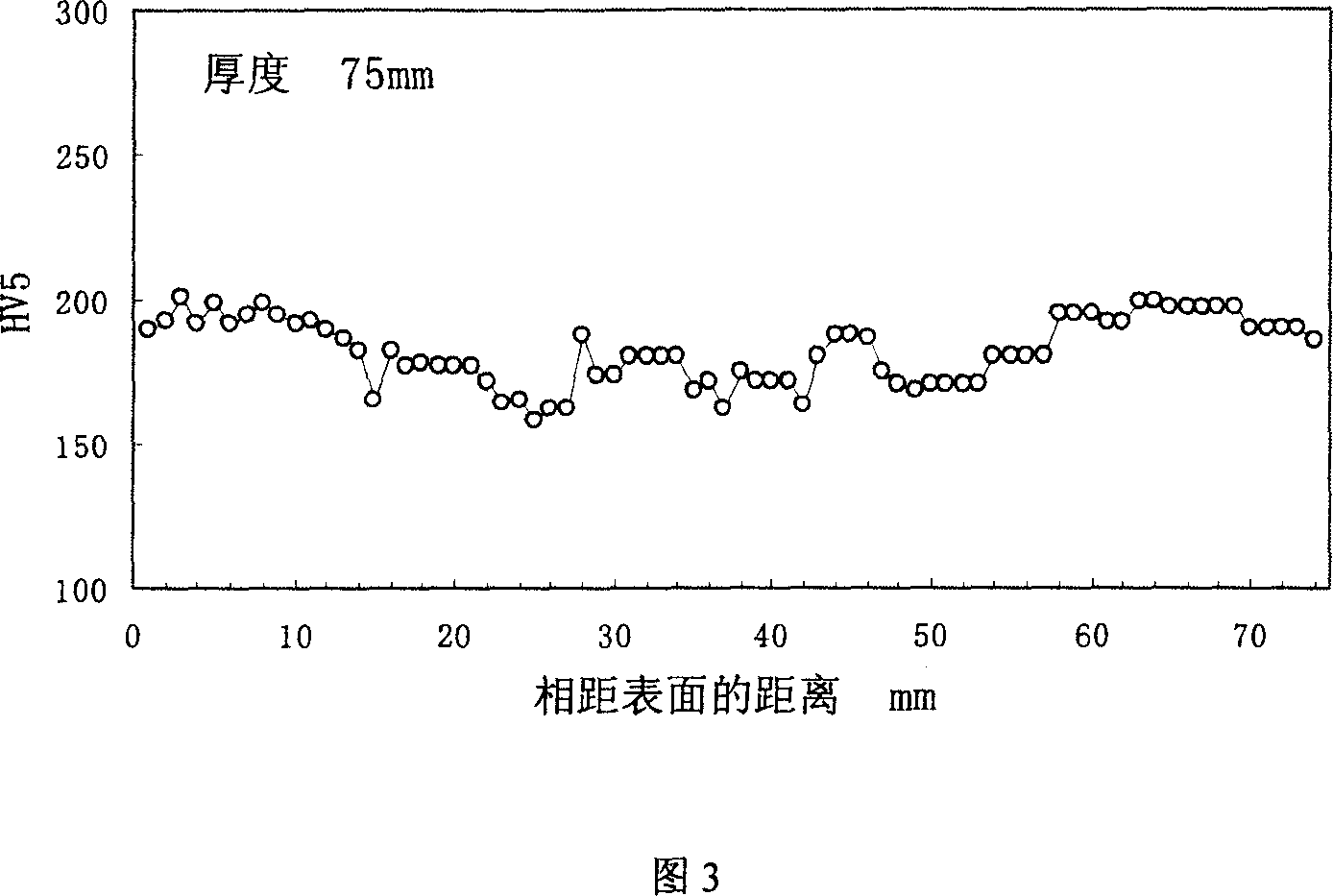

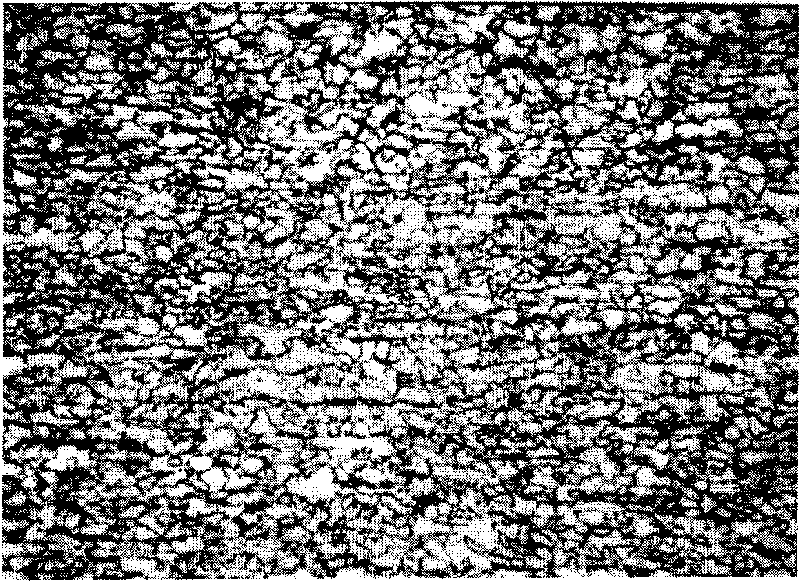

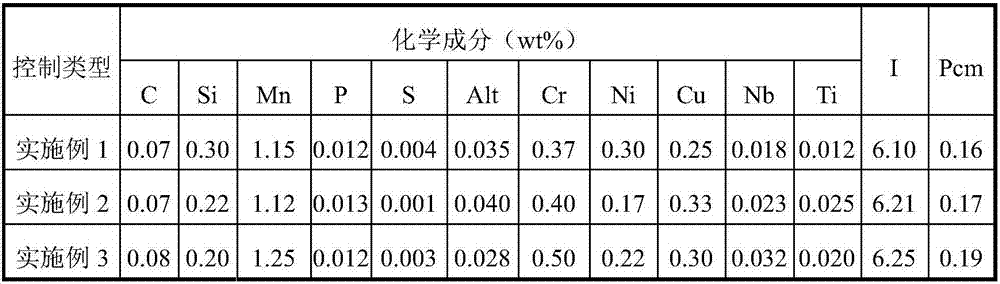

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

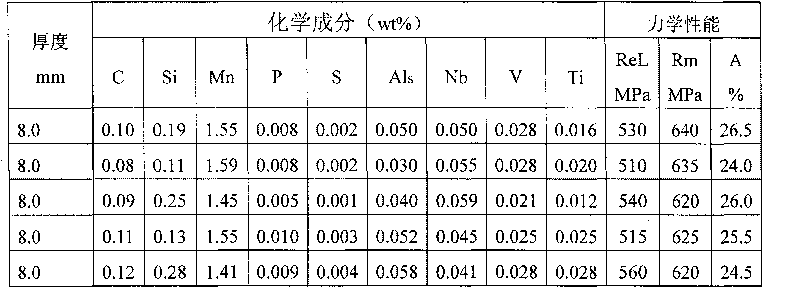

Automobile beam steel with tensile strength of 590MPa and manufacturing method thereof

ActiveCN101701316AHigh strengthImprove toughnessTemperature control deviceHeat treatment process controlChemical compositionLaminar cooling

The invention discloses automobile beam steel with tensile strength of 590MPa and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.07-0.13 C, 0.10-0.30 Si, 1.30-1.60 Mn, at most 0.025 P, at most 0.008 S, 0.015-0.070 Al, 0.025-0.050 Nb, 0.020-0.040 Ti, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the technical steps of molten iron desulfuration, bessemerizing, alloying, vacuum treatment, continuous casting, hot tandem rolling, Laminar cooling, reeling and finishing. Proved by practices, the automobile beam steel has stable chemical compositions and mechanical property as well as good cold forming performance and surface quality and completely meets the requirement for manufacturing novel frame structures of heavy-duty trucks and large vans.

Owner:武汉钢铁有限公司

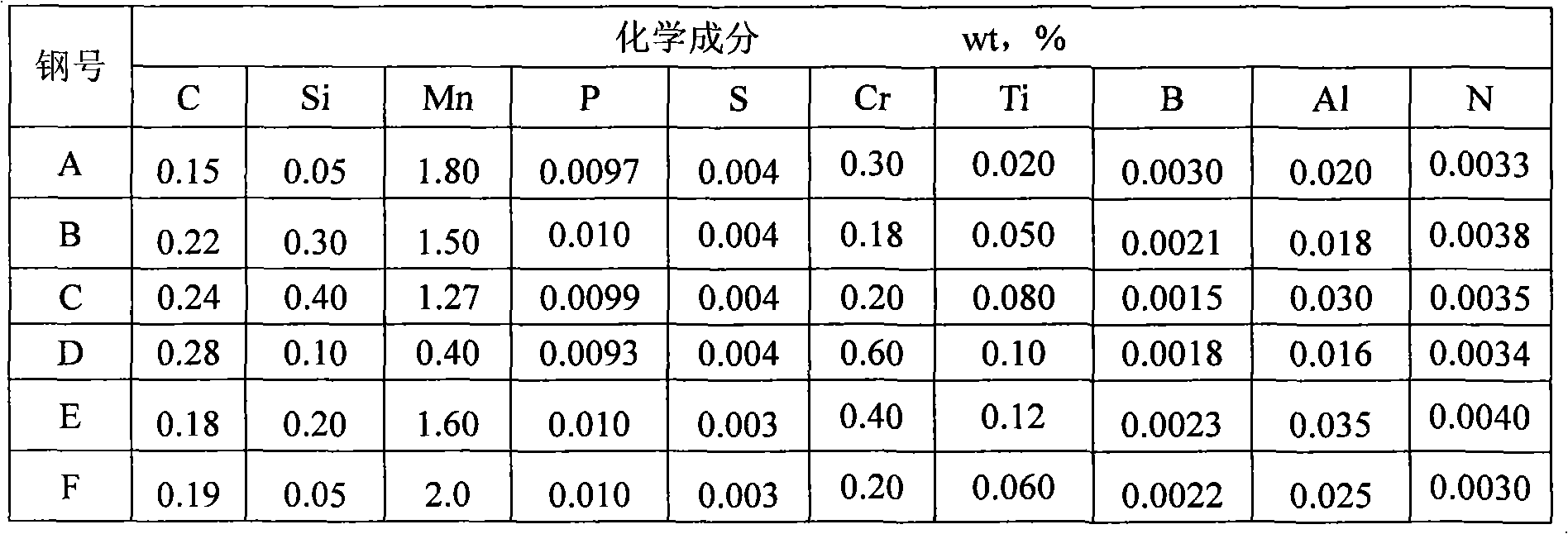

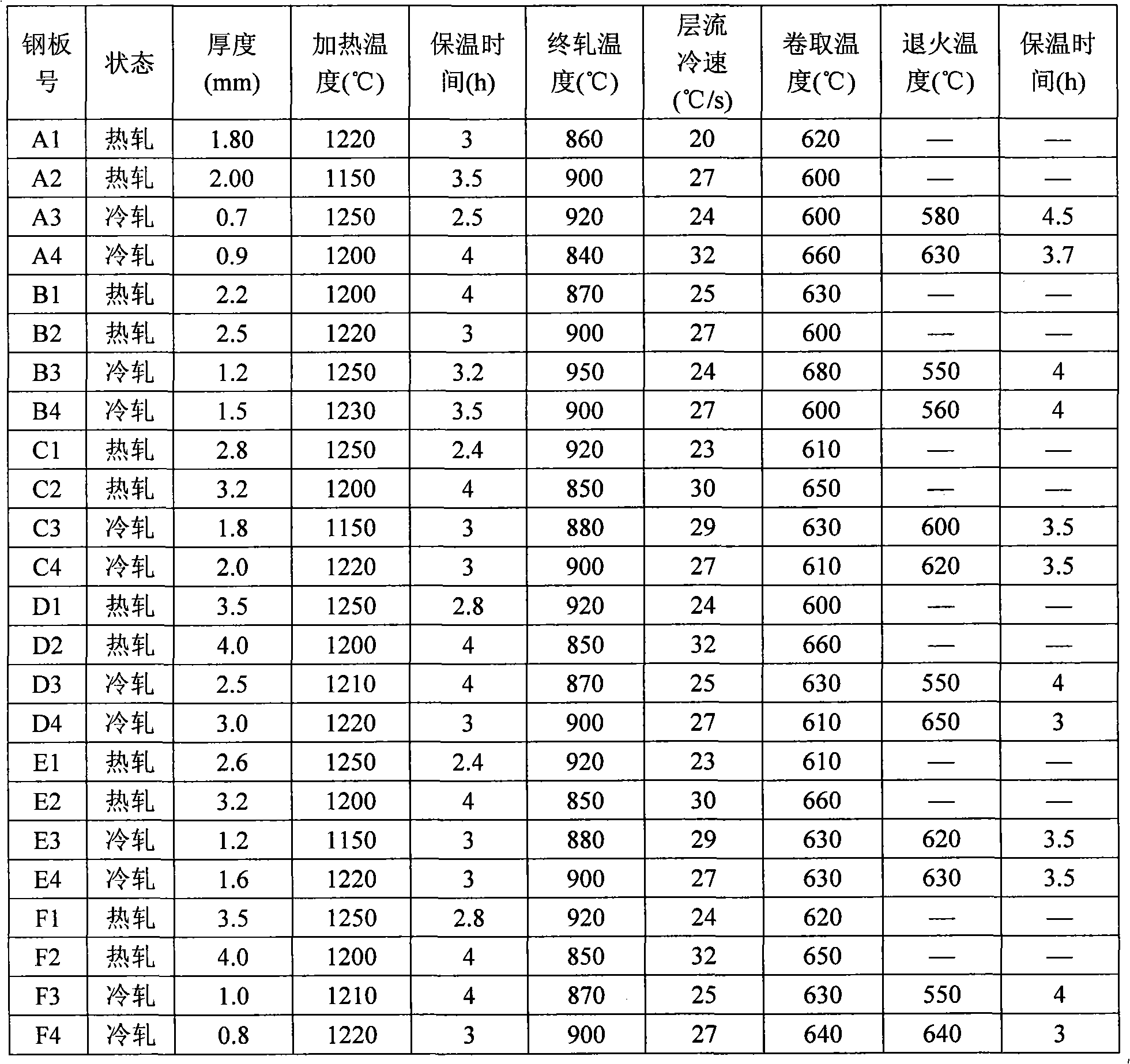

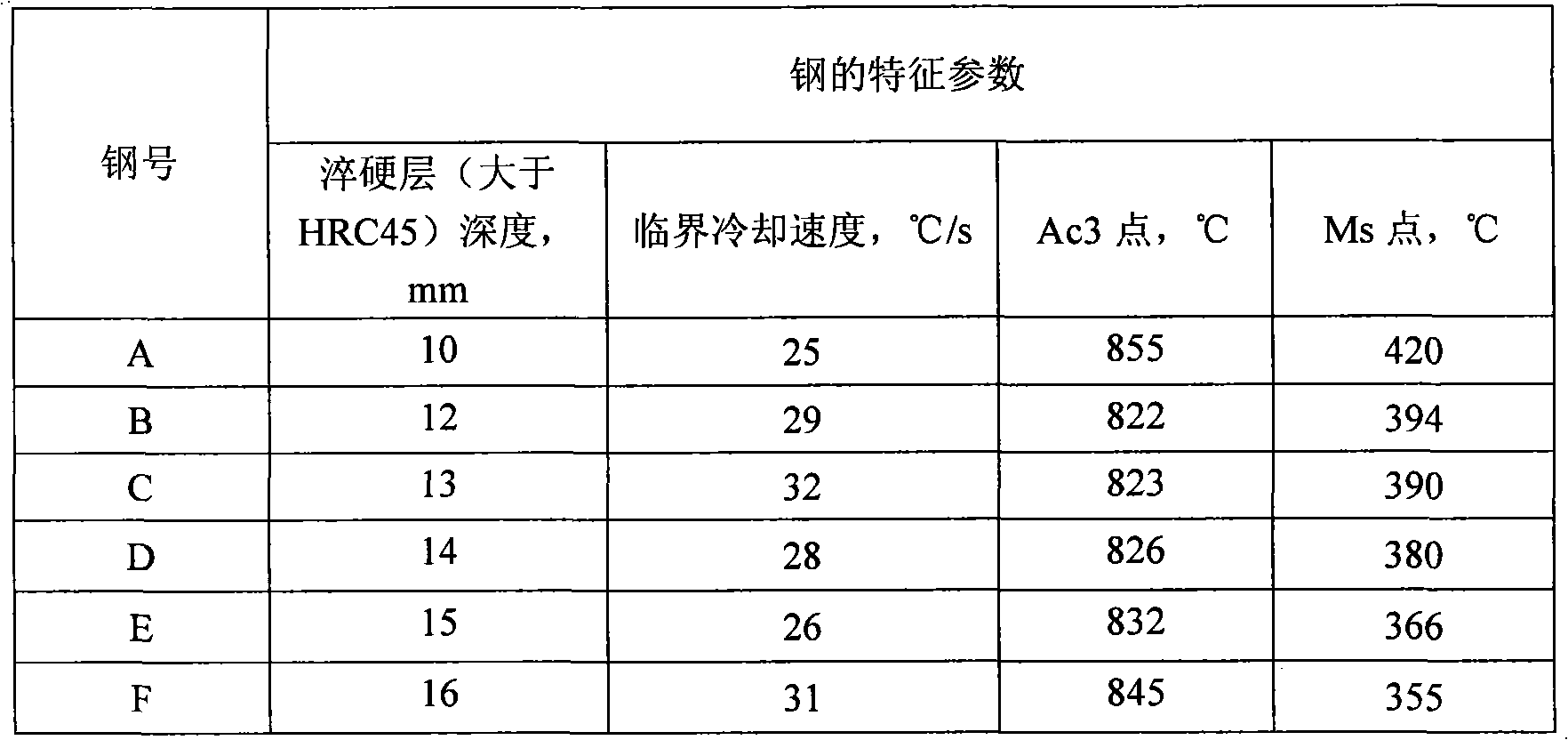

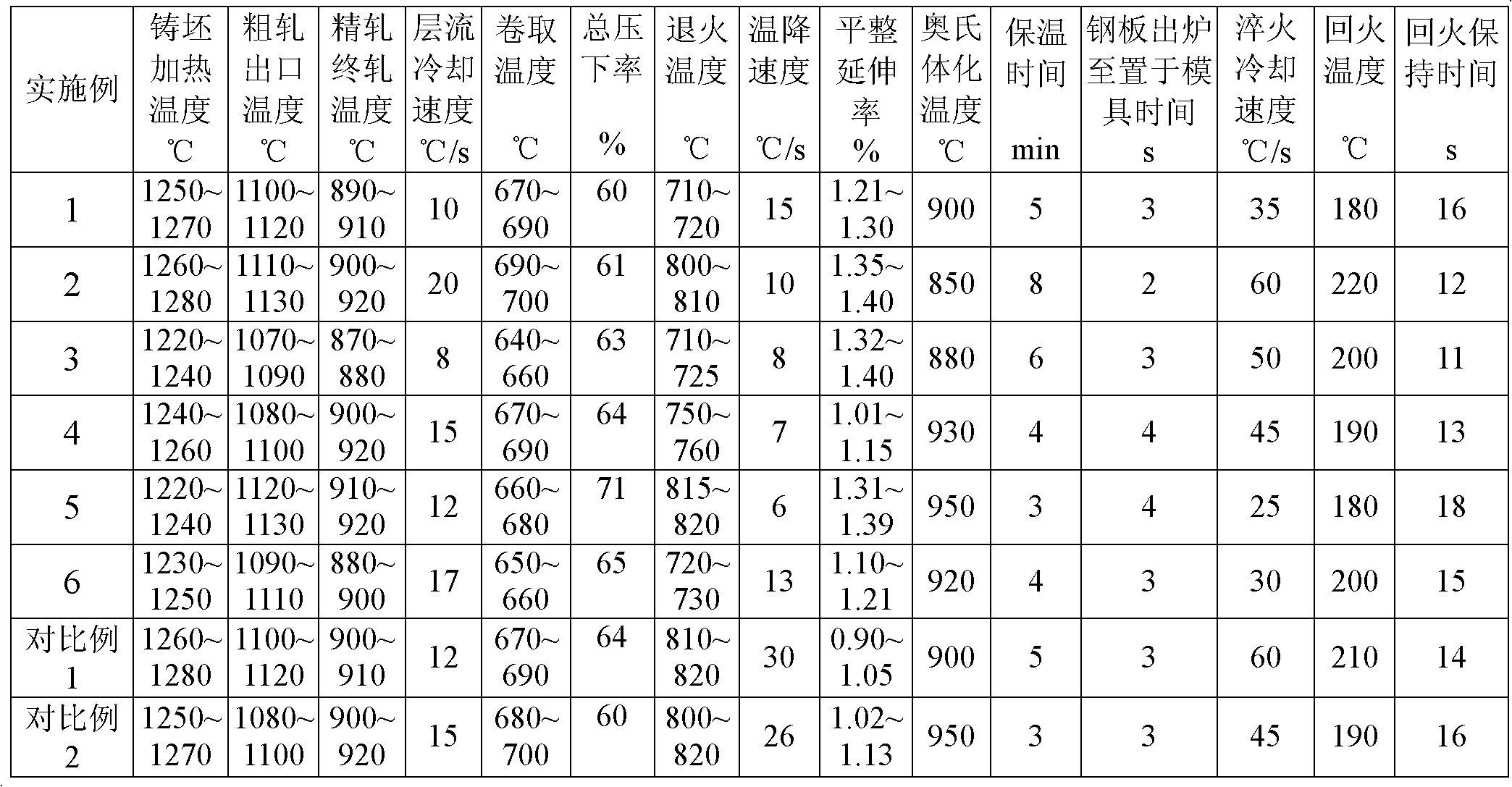

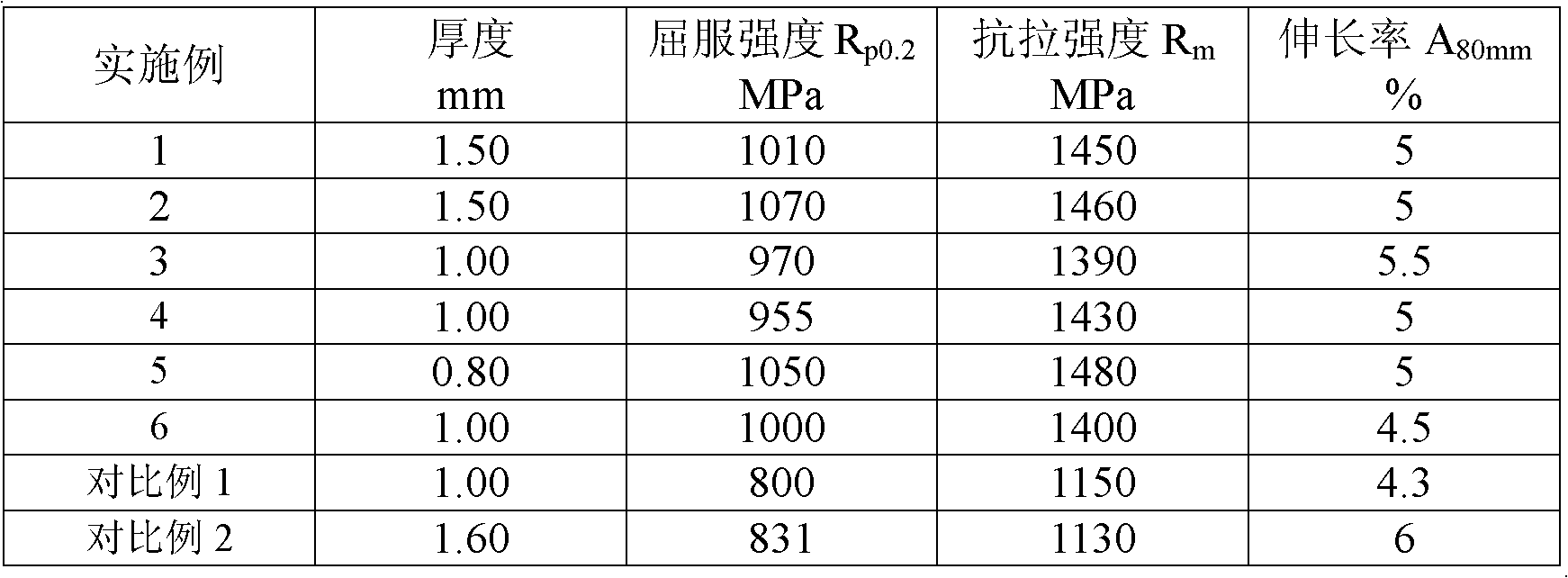

Steel plate for stamping and quenching and manufacturing method thereof

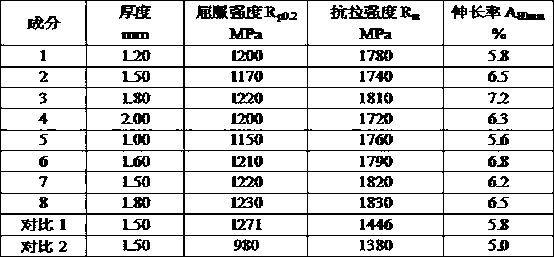

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

Thick steel plate with great line energy and low welding crack sensitivity and its production process

The present invention discloses one kind of thick steel plate with great line energy and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.10 wt%, Si 0.15-0.40 wt%, Mn 1.20-1.60 wt%, P not more than 0.015 wt%, S not more than 0.007 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo 0.15-0.30 wt%, V 0.02-0.06 wt%, Al 0.015-0.045 wt%, Ti 0.010-0.034 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 %. The production process includes pre-treatment of molten iron, smelting in converter, LF furnace plus VD furnace vacuum treatment, two stage controlled rolling, on-line laminar flow cooling, tempering at 600-680 deg.c and other steps. The produced steel plate has no need of quenching and tempering treatment.

Owner:ANGANG STEEL CO LTD

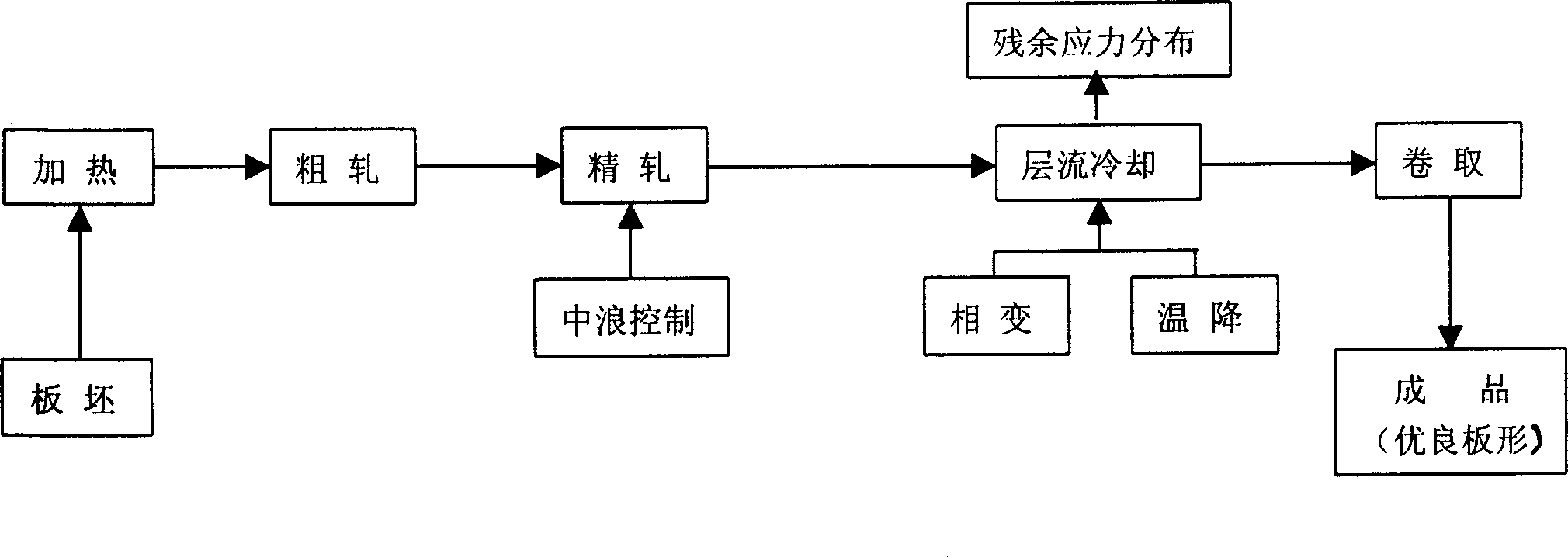

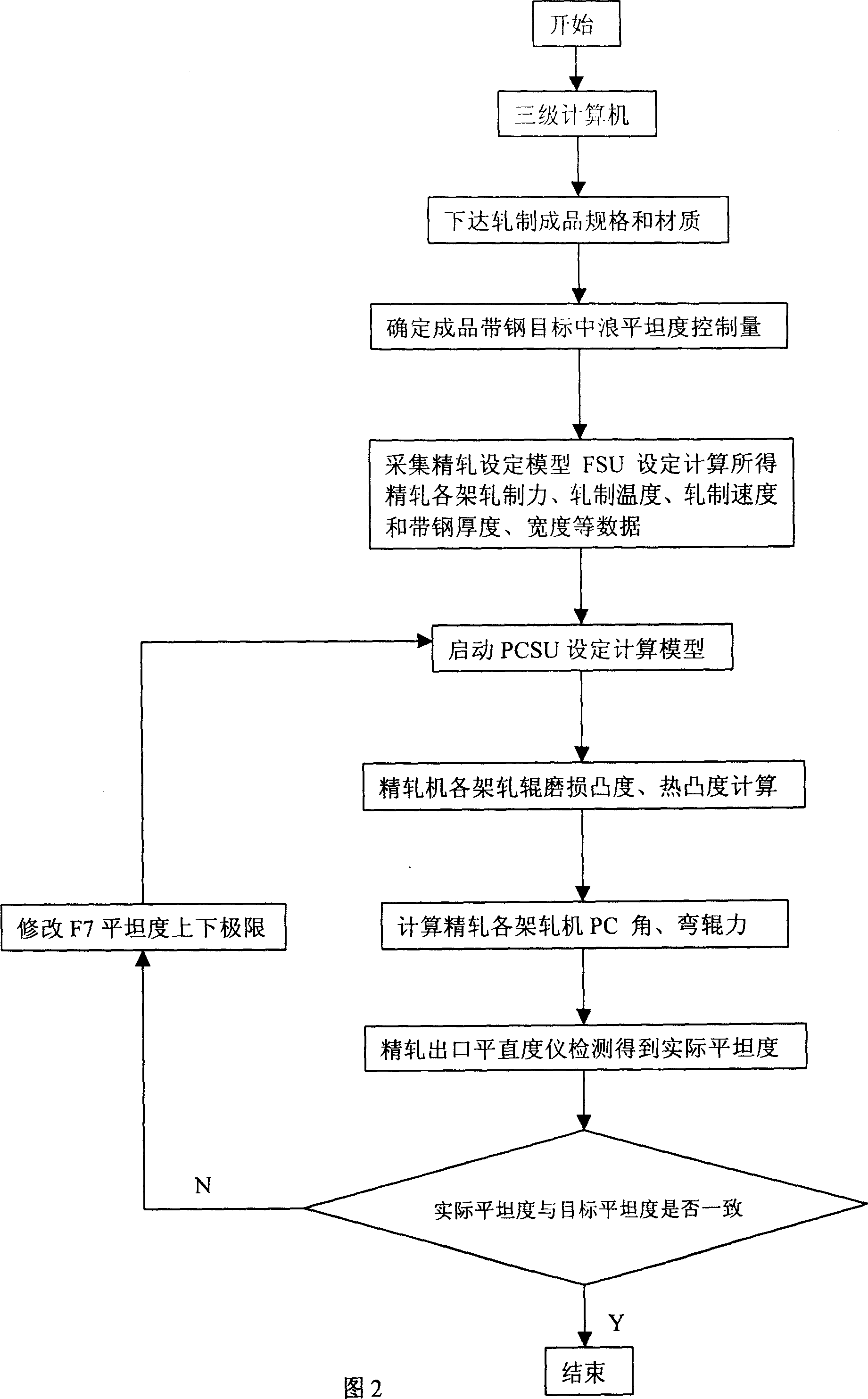

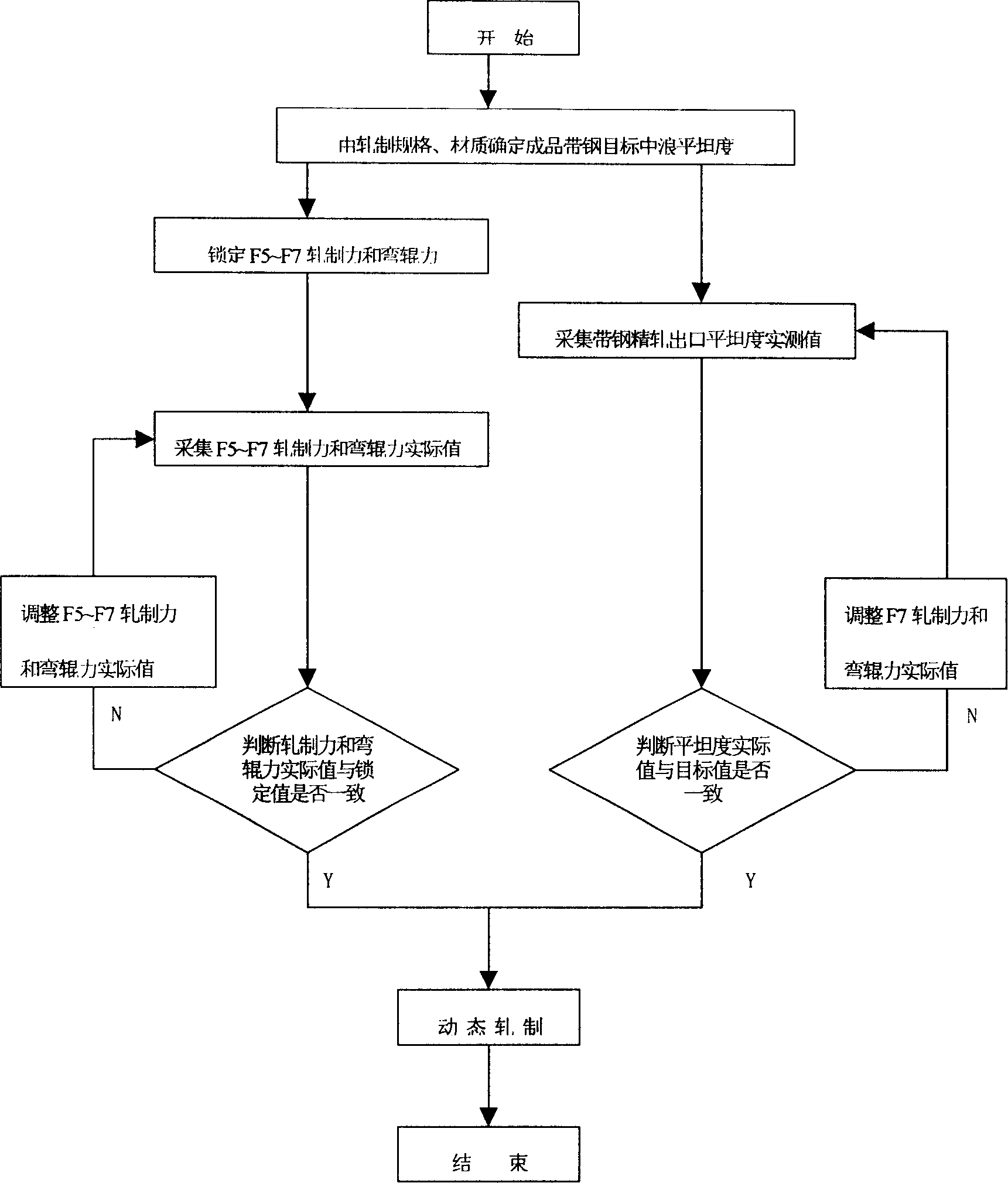

Hot-rolled strip steel moderate sea profile shape controlling method

A method of controlling moderate-sea strip shape of controlling strip steel. The head of strip steel is controlled by moderate-sea PCSU control, that is, PC setting control. The rear of strip steel is controlled by dynamically automatic strip shape moderate-sea control, which is dynamic ASC control. Determining the objective control degree of moderate-sea flatness of strip steel, calculating convexity of finish rolling strip steel, equivalent heat convexity of roller, coefficient of extension and flatness of strip steel. According to kinds, scales of steel, determining factors, constant terms, proportion factors in formulas, making moderate-sea control on flatness of exported finish rolling strip steel. Two-side sea in cooling could be effectively eliminated, which improves the quality ofstrip steel.

Owner:ANGANG STEEL CO LTD

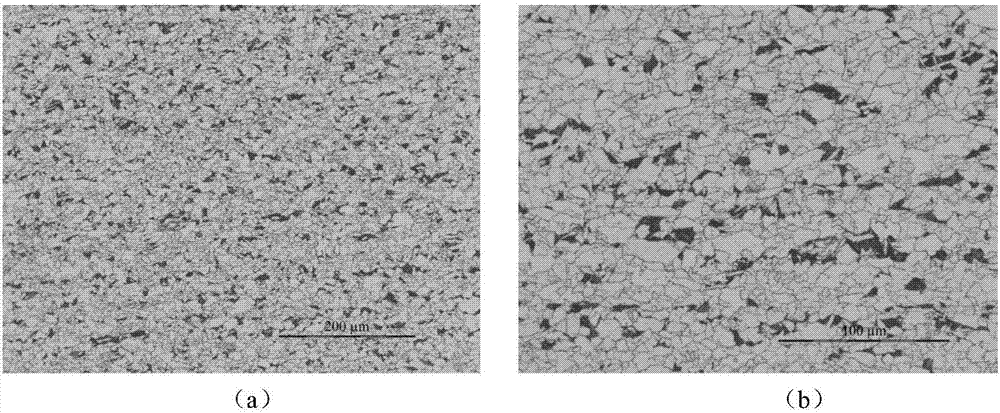

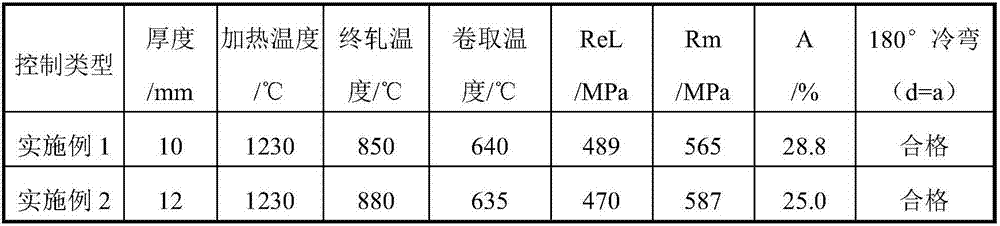

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

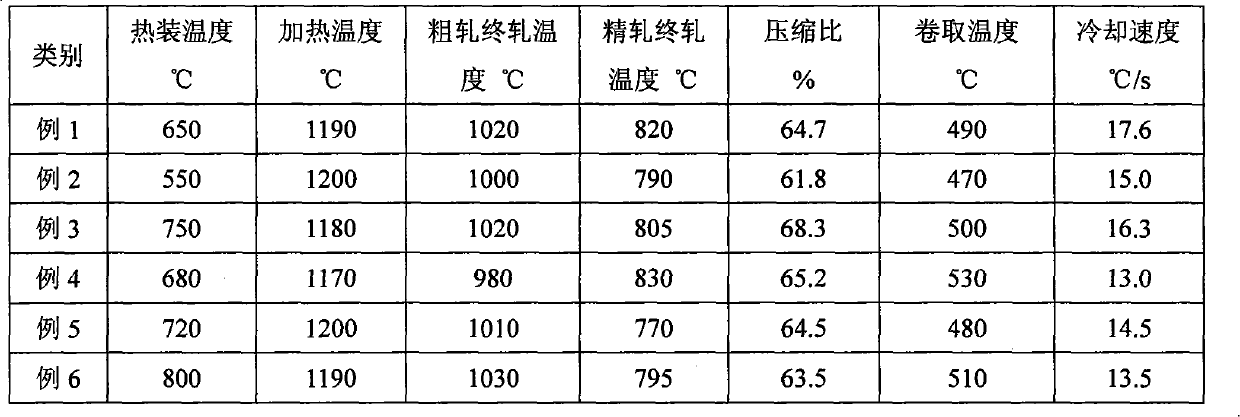

Hot-rolled sheet coils of X80 pipe line steel and manufacturing method thereof

InactiveCN102021497ALow costImprove efficiencyTemperature control deviceManufacturing convertersLaminar coolingService efficiency

The invention discloses hot-rolled sheet coils of X80 pipe line steel and a manufacturing method thereof. The steel comprises the following chemical components by weight percent: 0.02-0.06% of C, 0.05-0.35% of Si, 1.70-1.90% of Mn, not more than 0.015% of P, not more than 0.004% of S, 0.20-0.35% of Cr, 0.06-0.15% of Mo, 0.06-0.11% of Nb, not more than 0.08% of V, not more than 0.20% of Ni, not more than 0.25% of Cu, 0.005-0.025% of Ti, 0.015-0.045% of Als, 0.001-0.004% of Ca, not more than 0.006% of N and the balance Fe and inevitable impurities. The cold cracking susceptivity coefficient Pcm is not more than 0.21%. The manufacturing method is characterized in that the continuous casting slabs are directly subjected to hot charging at 500-850 DEG C and are discharged after being heated to 1150-1250 DEG C, the final rolling temperature of rough rolling is 1030-970 DEG C, the final rolling temperature of finish rolling is 750-850 DEG C, the compression ratio of finish rolling is more than 60% and the sheet coils are rapidly cooled at the speed of 10-25 DEG C / s by way of laminar cooling and are coiled at 450-580 DEG C. In the invention, hot charging rolling is adopted, thus improving the service efficiency of heat, saving energy, shortening the production cycle, improving the production efficiency and greatly lowering the production cost.

Owner:ANGANG STEEL CO LTD

Manufacturing method of HB500 grade low-manganese wear-resistant steel plate

The invention discloses a manufacturing method of a HB500 grade low-manganese wear-resistant steel plate. The manufacturing method comprises the specific steps as follows: continuous casting billets meeting the requirements are selected; the rolling process is conducted: the heating temperature is 1100 to 1200 DEG C, the rolling is conducted at a crystallization region and an austenite non-recrystallization region by adopting austenite, the final rolling temperature is 1000 to 1050 DEG C, and the billets are roughly rolled into intermediate billets of 1.7 to 2.0 times the thickness; the finish rolling starting temperature is 850 to 920 DEG C, a laminar cooling manner is adopted, the final cooling temperature is 600 to 700 DEG C, and the cooling rate is 10 to 20 DEG C / S; the quenching process is conducted: the steel plate heating temperature is 860 to 940 DEG C, the heat preservation time is 10 to 30min, and the billets are cooled to a normal temperature at a cooling speed of 40 DEG C / S; and the tempering process is conducted: the quenching steel plate heating temperature is 150 to 300 DEG C, the billets are loaded to a cooling bed to be air-cooled after the heat of the billets is preserved for 1 to 3 hours, and then the HB500 grade low-manganese wear-resistant steel plate is obtained. The HB500 grade low-manganese wear-resistant steel plate has the advantages of high hardness, high strength and high toughness, and is suitable for being used in bulldozers, loaders, excavators, dump trucks and various mining machines.

Owner:NANJING IRON & STEEL CO LTD +1

Technology of producing Ti micro alloyed high weather resistant steel plate using thin plate blank continuous casting continuous milling process

InactiveCN1785543AGood weather resistanceGood welding performanceMetal rolling arrangementsSheet steelHigh intensity

A conticasting and tandem rolling technology for manufacturing the high-strength and-weatherability Ti-microalloyed steel plate includes such steps as smelting, refining, conticasting, solidifying, heating, hot rolling, laminar flow cooling and coiling. Its advantages are high strength, high shaping performance, high weatherability and high weldability.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

ActiveCN102839321AIncrease the effective Ti contentImprove precipitation strengthening effectCold formedLaminar cooling

An ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level comprises the chemical components by weight: 0.02-007%of C, less than or equal to 0.50% of Si, 0.50-1.40% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.11% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O, or 0.17-0.20% of C, less than or equal to 0.50% of Si, 0.50-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.08% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O. The process comprises melted iron desulfuration, converter blowing, argon blowing, LF furnace refining, continuous casting, rotary descaling, soaking pit soaking, descaling, seven-frame finish rolling, stream cooling and coiling. The ultrathin hot-rolled sheet strip has the advantages that the addition of the alloying element is low, the mechanical property is as follows: the yield strength is more than or equal to 500MPa, the product thickness is less than or equal to 1.4mm, the sheet shape is good, the production flow is short, and excellent cold forming and welding performances are achieved.

Owner:武汉钢铁有限公司

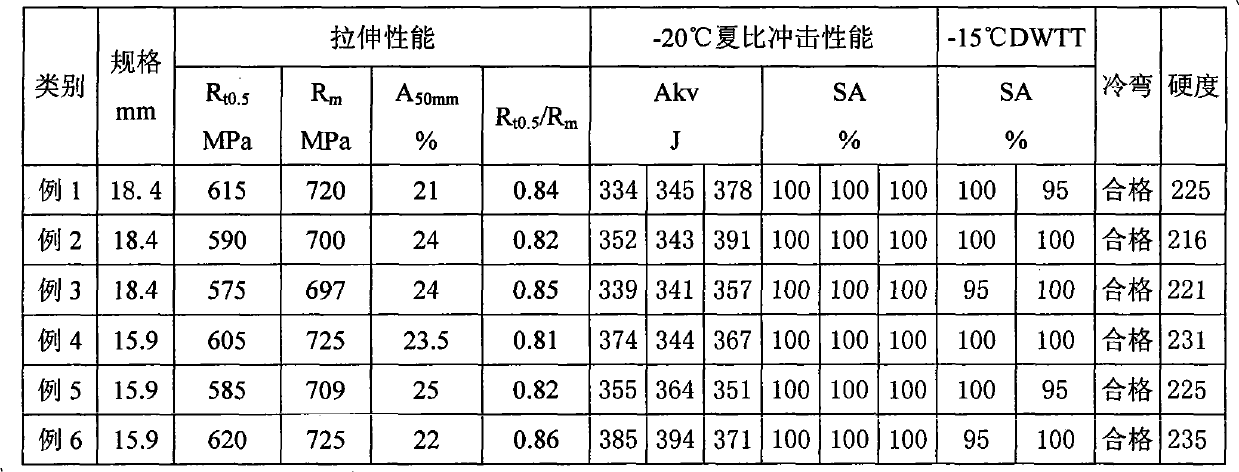

Steel plate with thickness of 80mm and low compression ratio for ocean engineering and manufacturing method thereof

ActiveCN102392192ASuitable for productionWide applicabilityTemperature control deviceFurnace typesLaminar coolingCooling temperature

The invention relates to steel for ocean engineering and a manufacturing method thereof, in particular to a steel plate with a thickness of 80mm and a low compression ratio for ocean engineering and a manufacturing method thereof. The steel plate comprises the chemical components with the weight percentages as follows: 0.12 to 0.16 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.60 percent ofMn, smaller than or equal to 0.010 percent of P, smaller than or equal to 0.003 percent of S, 0.025 to 0.050 percent of Nb, 0.030 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than or equal to 0.20 percent of Cr, 0.10 to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, smaller than or equal to 0.08 percent of Mo, 0.0250 to 0.050 percent of Al, smaller than or equal to 20ppm of O, smaller than or equal to 40ppm of N, smaller than or equal to 3ppm of H, and the remaining amount of Fe and inevitable impurities. A controlled rolling and cooling technology is adopted, the heating temperature before rolling is 1180 DEG C to 1250 DEG C, the rough rolling temperature is 1000 to 1100 DEG C, and the finish rolling starting temperature is 850 to 880 DEG C; laminar cooling is conducted after the rolling, the final cooling temperature is 640 to 680 DEG C, and the cooling rate is 5 to 15 DEG C / s; and normalizing treatment is conducted, the normalizing temperature is 890 to 910 DEG C, the heating rate is 1.4min / mm, and the heat preservation time is 50 to 90min. The obtained steel has the characteristics of high strength, good Z-direction lamellar tearing resistant performance, high plasticity, and the like.

Owner:NANJING IRON & STEEL CO LTD

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

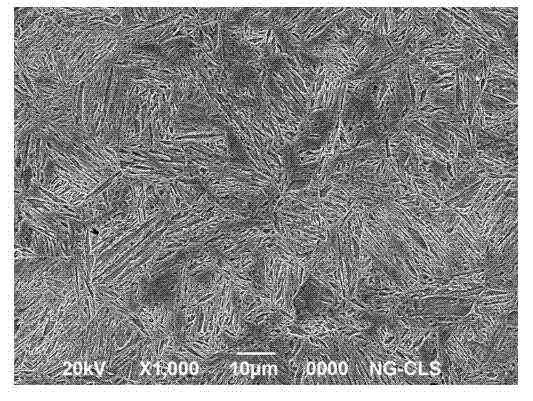

Method for producing low carbon bainite high-strength steel based on sheet bar continuous casting and rolling process flow

ActiveCN101254527ASimple metallurgical compositionImprove toughnessProcess efficiency improvementMetal rolling arrangementsThin slabLaminar cooling

The invention discloses a method for producing high-strength low-carbon bainite steel based on thin slab continuous casting and rolling process. The method includes the following steps: melting by using a rotary furnace or an electric furnace, refining molten steel in an LF furnace after the component analysis, performing the composition adjustment, continuously casting thin slabs, directly heating the thin slabs at the temperature of 950-1100 DEG C in a roller-hearth heating (soaking) furnace at a temperature not less than 1150 DEG C, controlling the tapping temperature of heated thin slabs in a range from 1050 DEG C to1160 DEG C, rolling by using a continuous rolling mill to produce plates, finishing at a temperature of 840-860 DEG C, performing laminar cooling, and coiling with a down coiler at a temperature of 550-600 DEG C to produce the steel coil. The method can produce non-tempered high-strength steel based on thin slab continuous casting and rolling process, and has the advantages of simple metallurgical composition of steel, low cost of alloying production, and stability in high toughness and good forming and welding properties of the steel coil.

Owner:湖南华菱涟源钢铁有限公司 +1

High ductility steel strip for J55 petroleum sleeve and manufacturing method thereof

InactiveCN101210299AImprove toughnessReduce contentManufacturing convertersMetal rolling arrangementsThin slabHigh pressure water

A steel strip for J55 petroleum casing with high strength and high toughness petroleum casing and a manufacture method thereof belong to the field of micro-alloyed steel production technology. The method comprises converter smelting, LF refining, medium-thin slab continuous slab, heating, high-pressure water descaling, hot rolling and laminar cooling, and reeling, wherein the chemical components of steel comprise (wt%) C 0.15 to 0.20, Si 0.15-0.30, Mn 1.00 to 1.45, P not larger than 0.020, S not larger than 0.010, Nb 0.020 to 0.040, Ti 0.015 to 0.040, Al 0.020 to 0.050, and allowance Fe and other in inevitable impurities. A J55 petroleum casing with a yield strength of 420 MPa can be produced by combining Nb and Ti, micro-alloying and reasonable production process, and the product has the advantages of high strength, high toughness and good solderability.

Owner:LAIWU IRON & STEEL GRP

High-strength thin steel plate produced by CSP (cast steel plate) process and preparation method of plate

ActiveCN102965573AImprove wear resistanceMeeting the demands of high-strength steelSheet steelLaminar cooling

The invention discloses a high-strength thin steel plate produced by a CSP (cast steel plate) process and a preparation method of the plate. The high-strength thin steel plate comprises the following components by percent: 0.15-0.25 of C, not larger than 0.10 of Si, 1.00-1.80 of Mn, not larger than 0.020 of P, not larger than 0.010 of S, 0.09-0.20 of Ti, 0.02-0.08 of Als, and not larger than 0.008 of N; and the metallographic structure is a mixture of 20-35% of perlite, 55-75% ferrite and a little of bainite. The preparation method of the high-strength thin steel plate comprises the following steps of smelting and carrying out continuous cast to form blanks; uniformly heating; rolling; carrying out laminar cooling; and reeling. According to the thin steel plate with a hot-rolled structure, disclosed by the invention, the yield strength (ReL) is not less than 700 MPa, the tensile strength (Rm) is not less than 750 MPa, and the wear resistance is good; and according to the preparation method disclosed by the invention, a hot rolling process can replace a cold rolling process, a thin steel plate can replace a thick steel plate, and the prepared high-strength thin steel plate can totally meet requirements of high-strength steel for an engineering structure.

Owner:武汉钢铁有限公司

Thermoforming steel with tensile strength of 1,700MPa level and production method thereof

The invention discloses thermoforming steel with tensile strength of 1,700MPa level, which consists of the following components in percentage by weight: 0.27-0.50% of C, 0.28-0.50% of Si, 1.20-1.60% of Mn, 0.32-0.60% of Cr, 0.025-0.055% of Ti, 0.002-0.005% of B, 0.010-0.06% of Als, less than or equal to 0.012% of P, 0.010-0.035% of Nb or 0.30-0.45% of Mo or less than or equal to 0.50% of the mixture of Nb and Mo, less than or equal to 0.008% of S, less than or equal to 0.005% of N and less than or equal to 0.005% of O. A production method comprises the following steps of: molten iron desulphurization, converter smelting and blank casting; heating of the cast blank; rough rolling; finish rolling; laminar cooling; reeling; acid pickling and cold rolling; annealing; flattening; finishing and shearing; heating in protective atmosphere; moulding; quenching; and low-temperature tempering for later use. According to the thermoforming steel disclosed by the invention, the tensile strength is greater than 1,700MPa, and the yield ratio is not over 0.70; when used for manufacturing structural parts and safety parts of an automobile, the thermoforming steel not only can reduce the body weight of the automobile, but also can realize yield deformation in the case of automobile accidents to absorb energy and impact force; and therefore, the thermoforming steel is not broken immediately, and the safety of a driver and passengers is effectively protected.

Owner:武汉钢铁有限公司

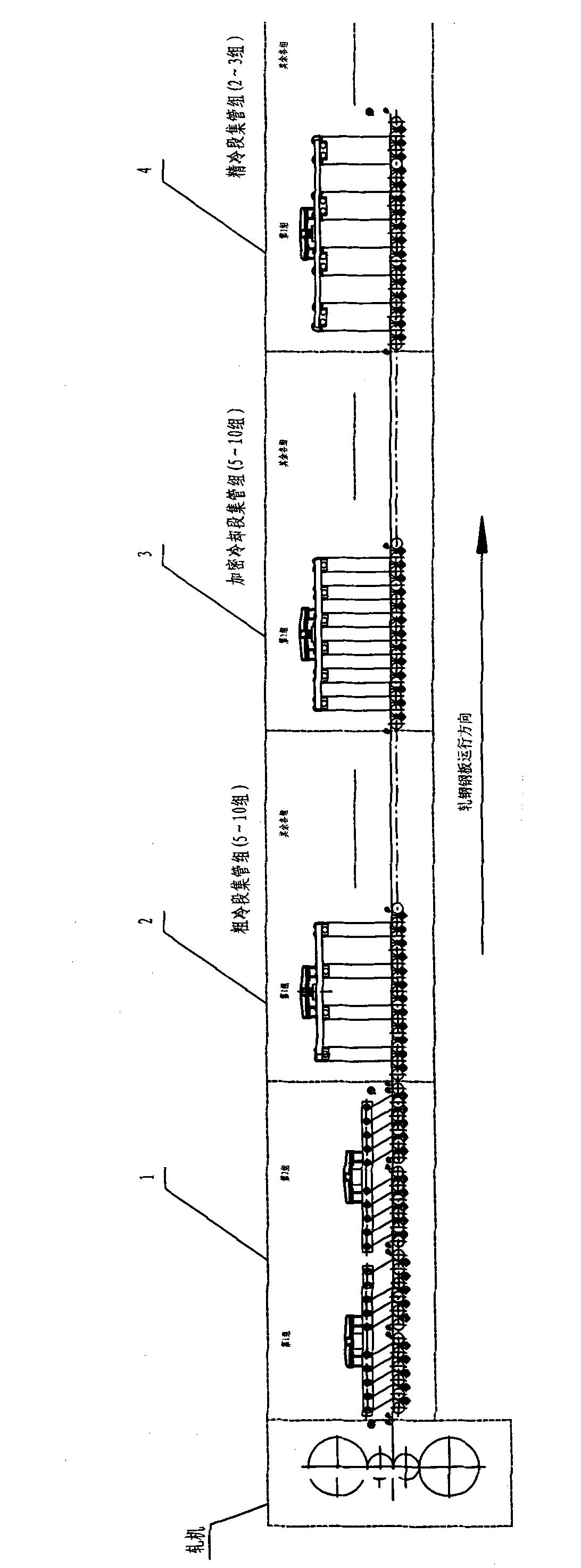

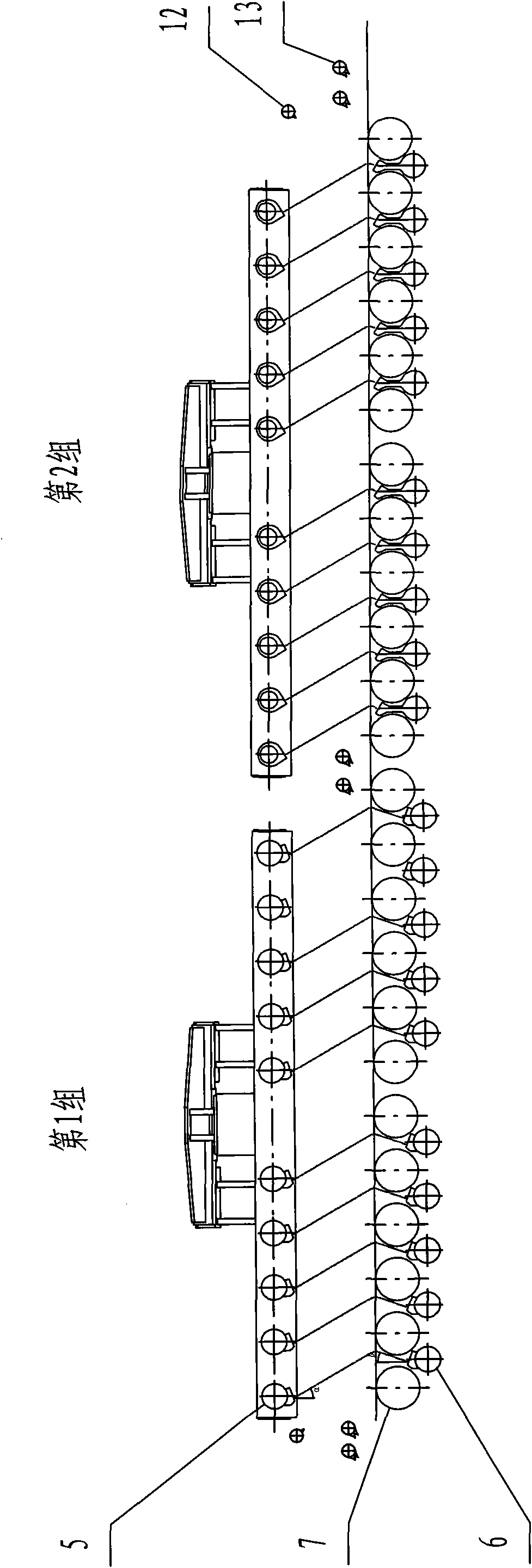

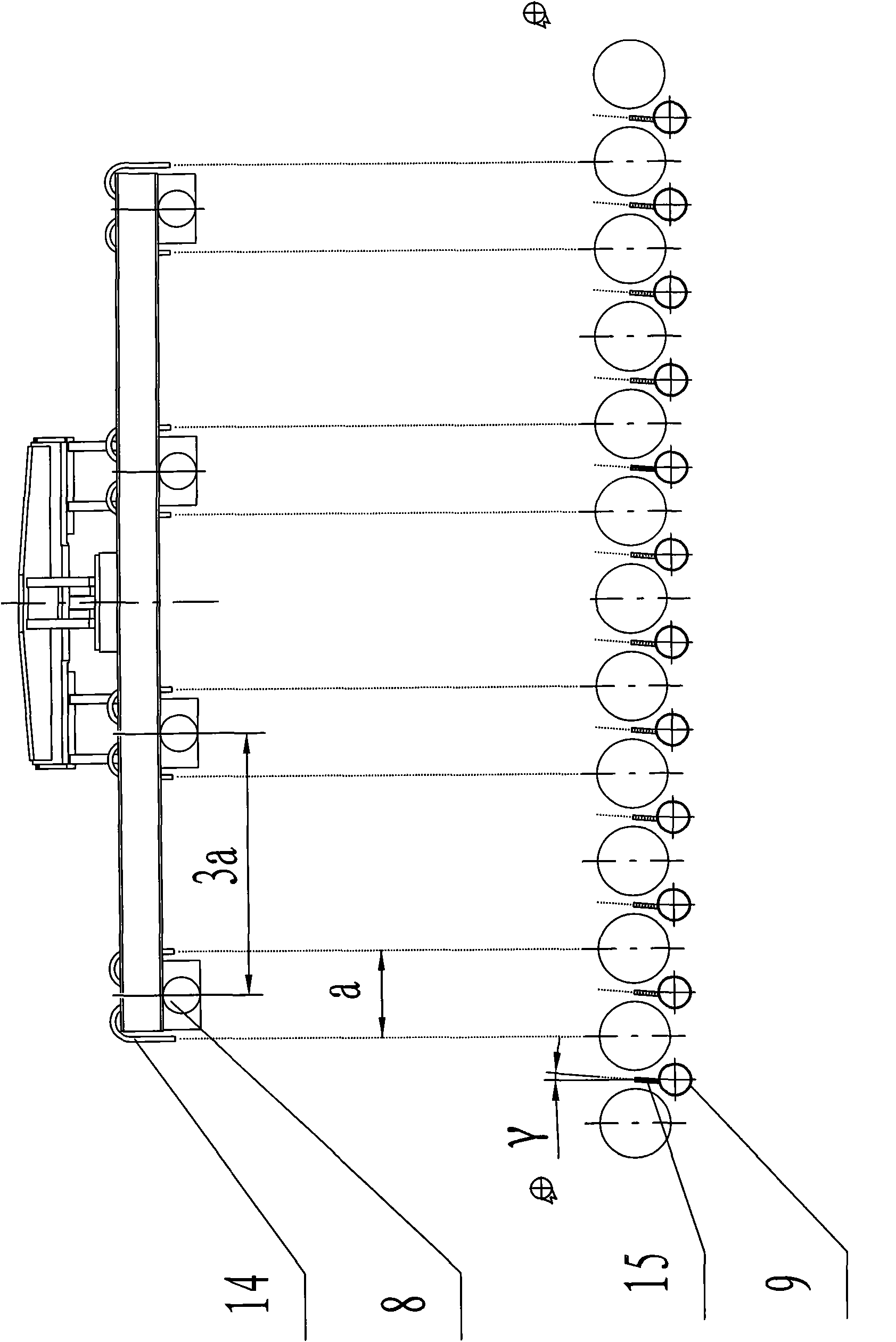

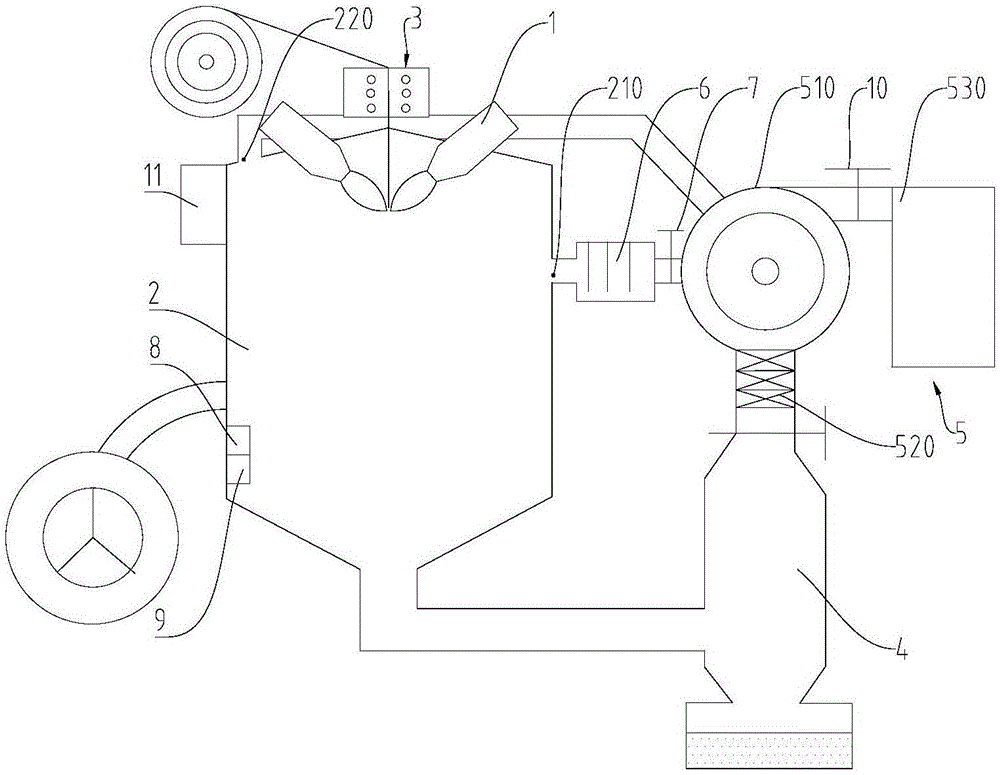

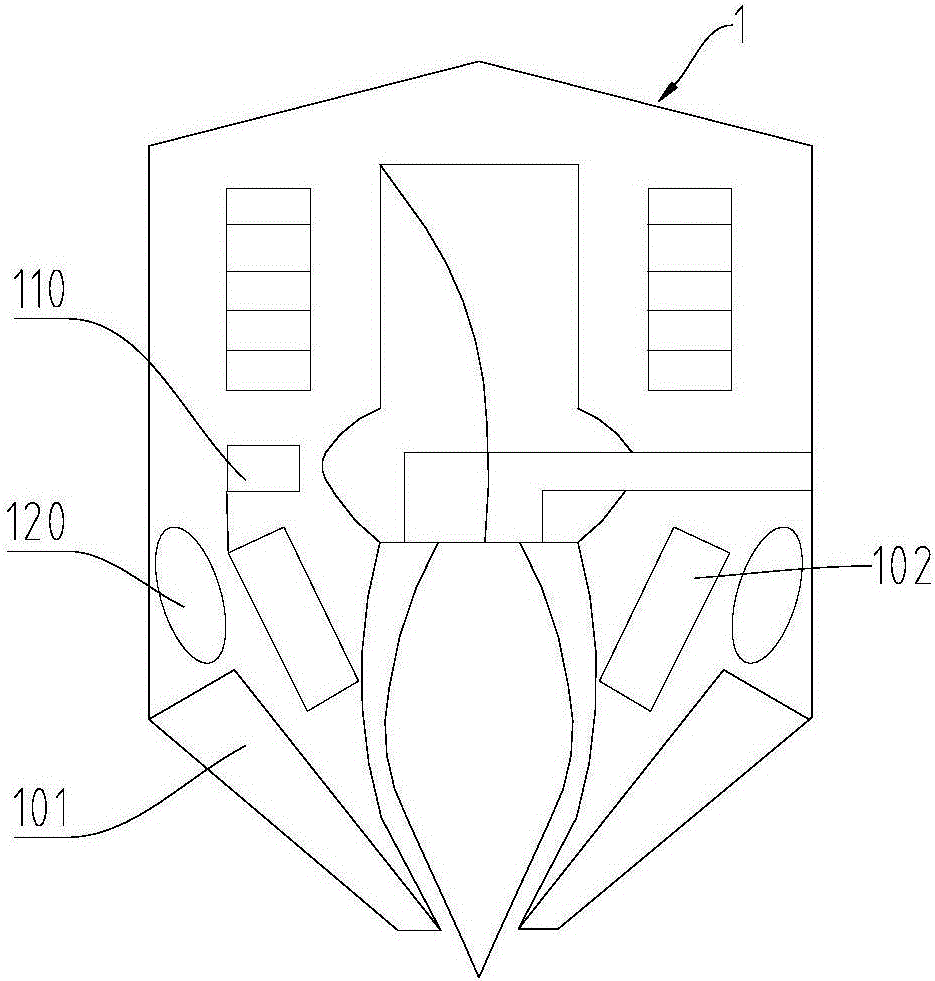

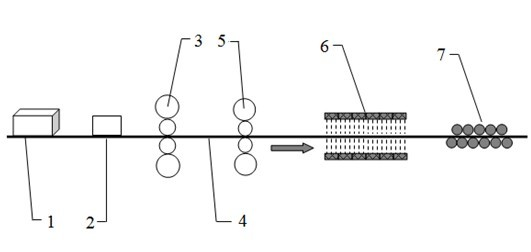

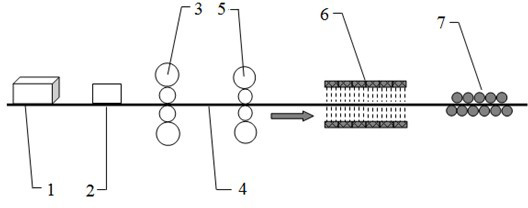

After-rolling cooling system for hot rolled steel strip production line

ActiveCN101890437AReasonable speedReasonable precisionWork treatment devicesMetal rolling arrangementsSprayerVolumetric Mass Density

The invention relates to an after-rolling cooling system for a hot rolled steel strip production line. A cooling device is provided with collecting pipes which have different densities and are arranged on a rolling line along the rolling operation direction of a steel plate sequentially. The after-rolling cooling system is characterized in that: a super fast cooling region and a laminar cooling region are arranged at the back of a rolling mill; the super fast cooling region has a dense pipe flow structure and is provided with two groups; the upper and lower collecting pipes are correspondingly arranged above and below each roller and are connected with high-pressure water pipes; the nozzle of each collecting pipe has an inclined injection-type gap structure; the number of the collecting pipe groups in the roughly cooling section of the laminar cooling region is 5 to 10; the number of the collecting pipe groups in the densely cooling section of the laminar cooling region is 5 to 10; the number of the collecting pipe groups in the finely cooling section of the laminar cooling region is 2 to 3; the lower collecting pipes in the laminar cooling section adopt sprayer nozzles which are formed in the gap of each roller way and are connected with normal-pressure water supply pipelines; sweeping devices are arranged in front of and at the back of each group of collecting pipes of the system; and side blowing devices are arranged on two sides of each roller way and are used for removing residual water on the surface of the steel plate. Cooling intensity is adjusted according to different parameters of products and rolling mills, so the requirement that the steel strip is quickly cooled from a temperature range of 800 to 1,000 DEG C after rolling to a temperature range of 200 to 750 DEG C can be met.

Owner:NORTHEASTERN UNIV +2

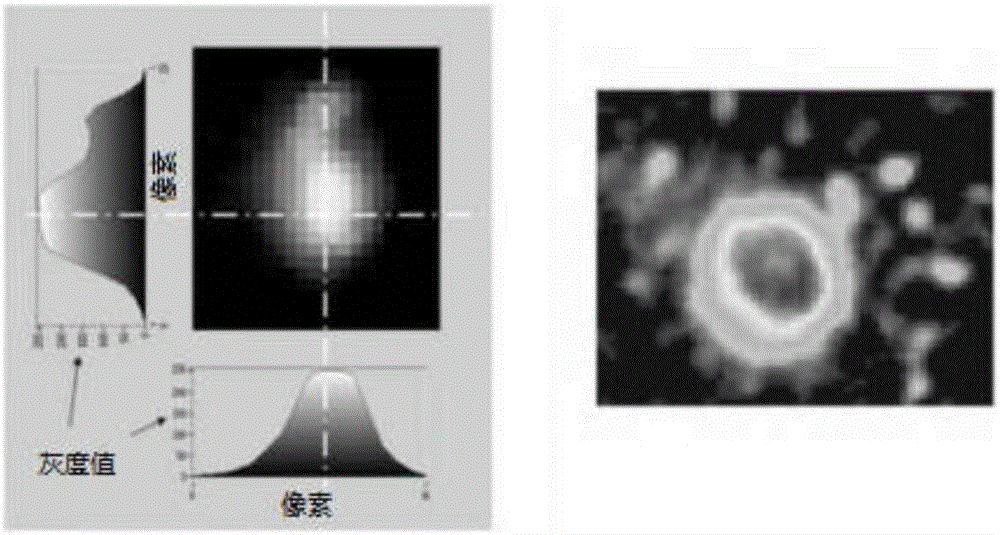

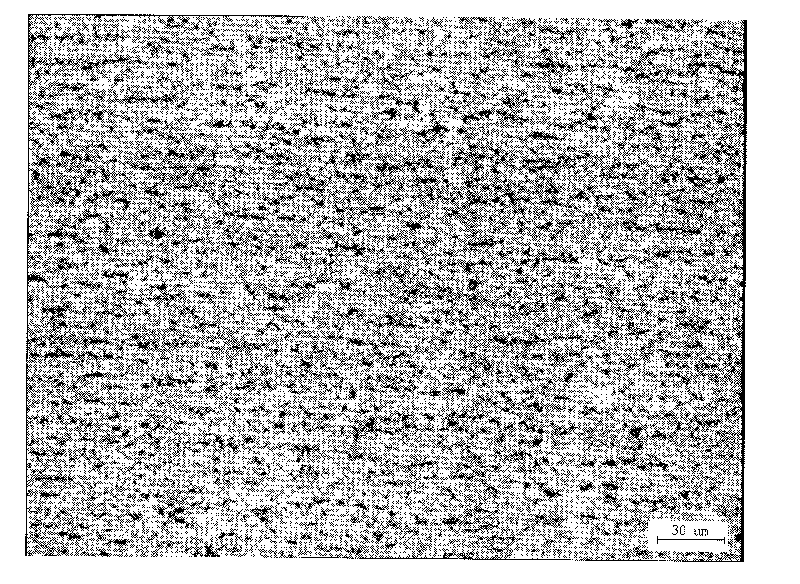

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

Steel for extended automobile crossbeam and mfg, method thereof

This invention relates to a king-sized automobile crossbeam using steal and its manufacturing method, tiny alloy elements of Nb, Ti, V are added in the steal. Their weight percentage is that C 0.07-0.12, ,Si 0.15-0.40, Mn 1.00-1.50,P less than 0.025,S less than 0.015,Nb 0.020-0.050,V 0.025-0.050, Ti 0.010-0.030,and tiny Ca, the rest are iron and other tiny impurities. Board butt is continuous cast, rolling and cooling control technique are used in hot rolling, the butt is heated to 1180-1250 degree centigrade, the temperature is 1020 to 1060 degree centigrade after rough rolling. Then it is finish rolled through blimp, the rolling temperature is maintained at 840 to 880 degree centigrade, the coiled sheet is cooled to 560 to 620 degree centigrade through laminar flow cooling. Because of the multiple unit tiny alloy elements design of the material chemical element, strong strength is got after above process and with good plastic laminar flow, cool formability, so it is specially propitious to king-sized automobile crossbeam making of cladding forming technique.

Owner:宝钢集团上海梅山有限公司

610MPa automobile girder steel and production method thereof

ActiveCN101748329AGood low temperature impact propertiesTemperature control deviceChemical compositionRoll forming

The invention discloses a 610MPa automobile girder steel, and the weight percentage (wt%) of the chemical composition of the steel is as follows: C: 0.08 to 0.12; Si: 0.10 to 0.30; Mn: 1.40 to 1.60; P: less than or equal to 0.010; S: less than or equal to 0.005; Nb: 0.040 to 0.060; V: 0.020 to 0.030; Ti: 0.010 to 0.030; Al: 0.030 to 0.060; Ca: tiny amount; and the rest is iron and residual trace impurities. The invention also discloses a production method for the 610MPa automobile girder steel, which adopts a 2250mm hot rolling line, and a continuously cast slab is heated to 1200 DEG C to 1250 DEG C; after rough rolling, the temperature is 1000 DEG C to 1050 DEG C, the continuously cast slab enters a finishing mill via a heat cover and is rolled, the finish rolling temperature is 820 DEG C to 880 DEG C, and the rolled steel coil is rapidly cooled to 530 DEG C to 580 DEG C by way of laminar cooling, and is then coiled. Since the chemical composition and the production technique are adopted, the tensile strength of an automobile girder is larger than 610MPa, the yield strength is larger than 500MPa, the specific elongation is larger than 20 percent, minus 60 DEG C longitudinal impact energy AKV is larger than 70J, and the automobile girder has excellent cold formability and high fatigue strength. The product is applicable to heavy-duty automobile members such as side members and cross members, which are produced by cold-roll forming and stamping forming techniques.

Owner:MAANSHAN IRON & STEEL CO LTD

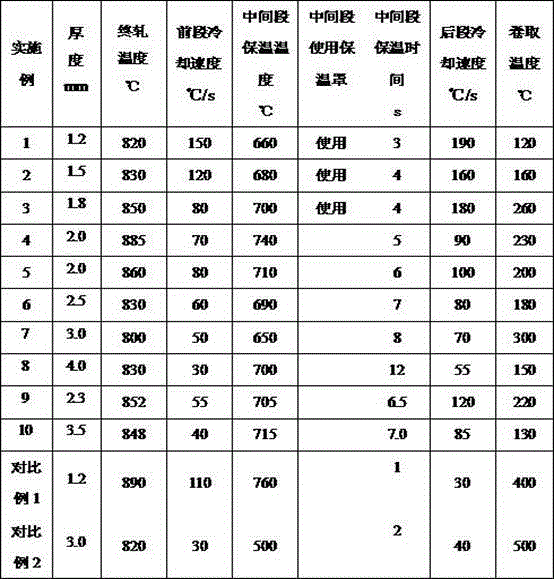

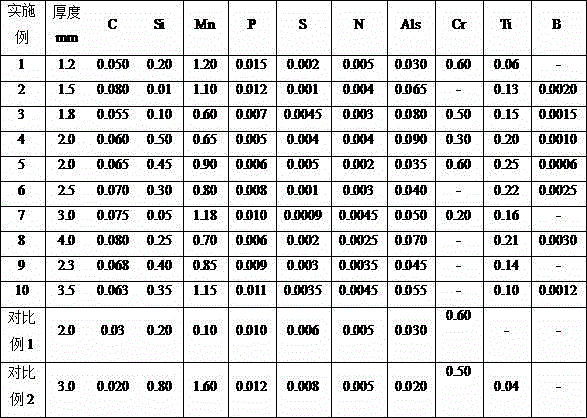

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

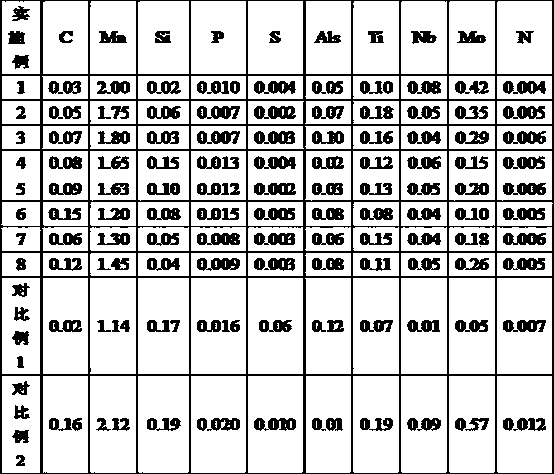

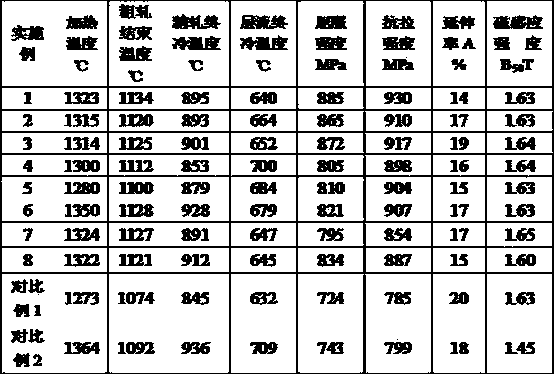

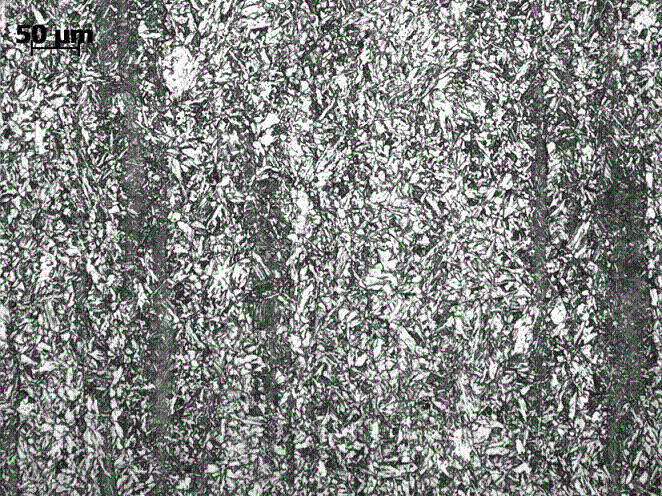

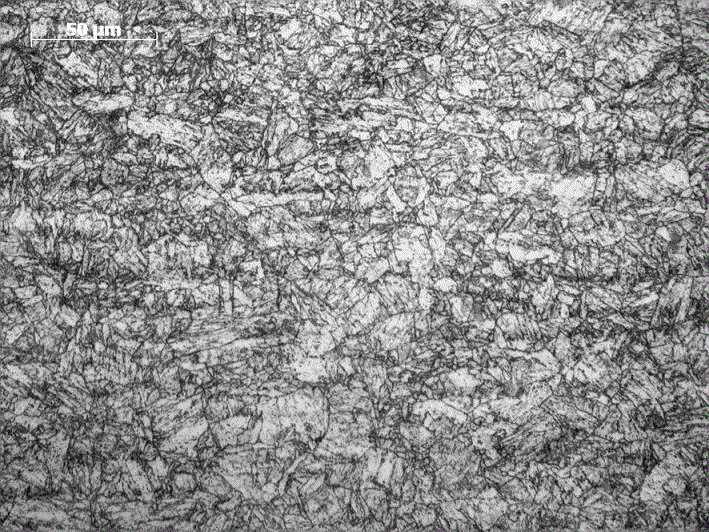

Hot-rolled magnetic yoke steel with yield strength not less than 800Mpa and production method thereof

InactiveCN103451533AMeet the needs of high-strength and high-magnetic-sensitivity steelUltimate tensile strengthContinuous casting

The invention relates to hot-rolled magnetic yoke steel with yield strength not less than 800Mpa. The hot-rolled magnetic yoke steel comprises the following components in percentage by weight: 0.03-0.15% of C, not more than 0.15% of Si, 1.20-2.00% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.08-0.18% of Ti, 0.04-0.08% of Nb, 0.10-0.50% of Mo, 0.02-0.10% of Als and not more than 0.006% of N. The production steps are as follows: smelting and performing continuous casting to form a blank; heating the continuous cast blank; performing rough rolling; performing finish rolling; performing laminar flow cooling; performing conventional winding for later use. As the yield strength is not less than 800MPa, the tensile strength is not less than 850MPa, the elongation rate A is not less than 11%, the magnetic induction performance B50 is not less than 1.50T, the hot-rolled magnetic yoke steel can meet the requirements of high-strength and high-magnetic induction performance steel for rotor magnetic yokes of high-unit capacity ultra-large hydrogenerators.

Owner:武钢集团有限公司

Low-compression ratio hot-rolled 9Ni steel thick plate and manufacturing method thereof

The invention discloses a low-compression ratio hot-rolled 9Ni steel thick plate and a manufacturing method thereof. The low-compression ratio hot-rolled 9Ni steel thick plate comprises, by mass, 0.035-0.075% of C, 0.15-0.25% of Si, 0.50-0.80% of Mn, less than or equal to 0.006% of S, less than or equal to 0.008% of P, 8.9-9.5% of Ni, 0.020-0.045% of Al and the balance Fe and impurities. The manufacturing method comprises the following steps of converter smelting, LF and RH refining, continuous casting of a thick plate blank having the thickness of 150mm, two-stage rolling, rolled workpiece laminar cooling, and heat treatment adopting an out-line quenching and tempering technology. The low-compression ratio hot-rolled 9Ni steel thick plate has simple alloy components and a low cost. Based on a low-compression ratio, the steel thick plate having the thickness above 35mm is rolled and has a good plate shape. After heat treatment, transverse impact energy at a temperature of -196 DEG C is greater than or equal to 160J. The low-compression ratio hot-rolled 9Ni steel thick plate has a good strength-toughness matching degree.

Owner:NANJING IRON & STEEL CO LTD +1

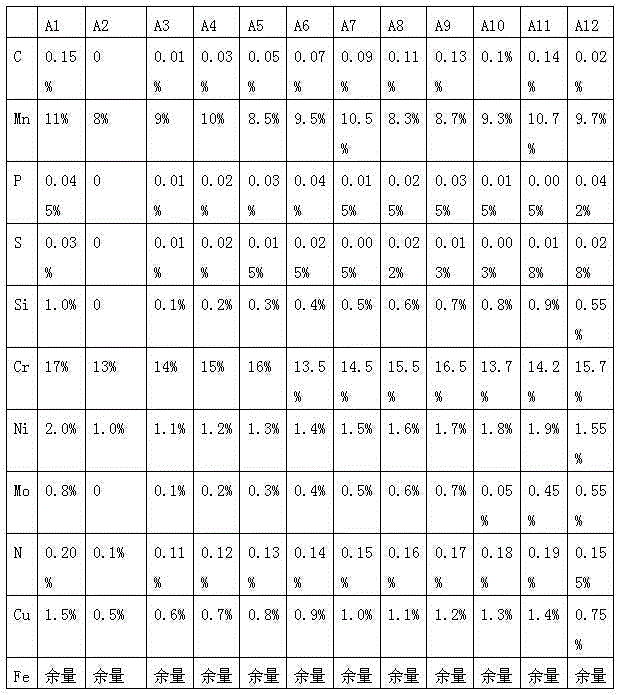

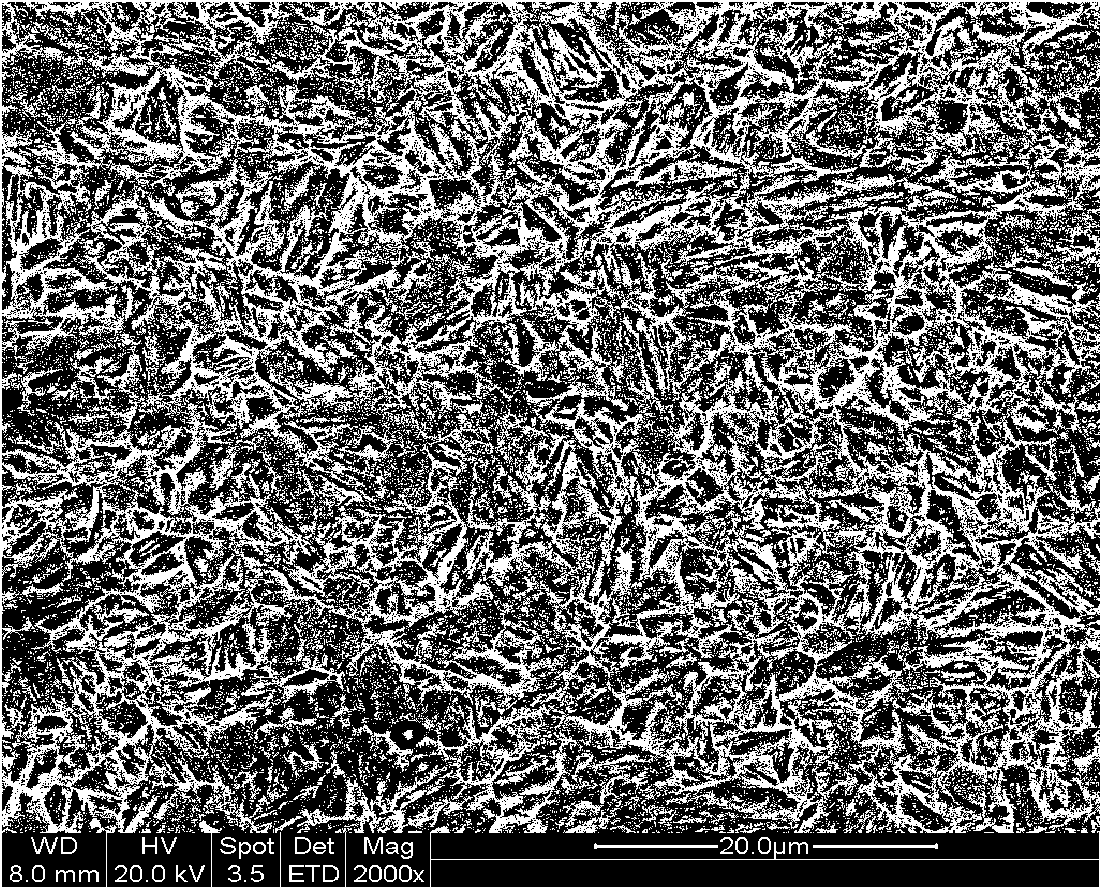

Hot-rolling production method for low-nickel austenitic stainless steel coils

The invention relates to a hot-rolling production method for low-nickel austenitic stainless steel coils, which is specially used for rolling low-nickel austenitic stainless steel coil products with the thicknesses of 2.5-16mm. The technological process comprises grinding, heating, high pressure water dephosphorization, rough rolling, finish rolling, laminar cooling and coiling. The steel coils are made of low-nickel austenitic stainless steel that comprises the following components in percentage by mass: less than or equal to 0.15 percent of C, 8-11 percent of Mn, less than or equal to 0.045 percent of P, less than or equal to 0.03 percent of S, less than or equal to 1.0 percent of Si, 13-17 percent of Cr, 1.0-2.0 percent of Ni, less than or equal to 0.8 percent of Mo, 0.1-0.20 percent of N, 0.5-1.5 percent of Cu and the balance of Fe. The hot-rolling production method can be used for producing low-nickel austenitic stainless steel coils without the defects of edge crack and surface crack, and the yield of the low-nickel austenitic stainless steel coils is increased.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

C-Mn-Ti-Nb series hot-rolled high strength high magnetic induction performance steel and manufacturing method thereof

InactiveCN101016600ARefine the grain sizeHigh yield strengthTemperature control deviceMetal rolling arrangementsHigh intensityContinuous rolling

The invention discloses a preparing method of C-Mn-Ti-Nb system hot-rolled high-intensity and high magnetic property steel in microalloy steel producing domain, which comprises the following steps: a, allocating mass percent of each element as 0.03%-0.15% C, Si<=0.15%, 1.00%-1.80% Mn, P<=0.025%, S<=0.015%, 0.08%-0.18% Ti, 0.02%-0.07% Nb, 0.02%-0.10% Al, N<=0.010% and Fe; desulfurizing with iron melt; b, composite-blowing converter top and bottom; c, blowing argon gas from rear; d, casting to bar plate; e, choosing hot-continuous rolling mill device; heating the bar plate from step d at 1230-1280 deg.c; roughing down with the ending temperature at >=1100 deg.c; planishing with the ending temperature at 850-930 deg.c; cooling with lamellar flow; winding with the temperature at 550-620 deg.c; getting the product.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

15MnNiDR low alloy steel plate for low temperature pressure vessel and production method thereof

ActiveCN102418036ARealize large-scale industrial productionMeet actual needsTemperature control deviceManufacturing convertersLaminar coolingPressure vessel

The invention discloses a 15MnNiDR low alloy steel plate for a low temperature pressure vessel. According to the invention, the 15MnNiDR low alloy steel plate is prepared by smelting and rolling nine alloy elements of Fe, C, Si, Mn, Ni, V, Nb, Ti and Als; through reasonable and strict control of the production processes of KR molten iron pretreatment, converter smelting, LF furnace refining, vacuum degassing treatment, continuous casting, heating, rolling, ACC laminar cooling, normalizing and the like, large scale industrial production of medium and heavy plates used for low temperature pressure vessels is realized, and all the performance of the medium and heavy plates reaches JB / T47030 standard, according with demands for low alloy steel plates in development of the industry of low temperature pressure vessels in China.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Accelerated cooling process method carried out after steel plate normalizing

InactiveCN101831532ACool evenlyRealize different cooling speed controlFurnace typesHeat treatment furnacesLaminar coolingAlloy

The invention belongs to cooling technologies carried out after thermal treatment in steel production, and relates to an accelerated cooling process method carried out after steel plate normalizing. In the specific process method, the normalized steel plate with the thickness of 4-120 mm is heated to 850-950 DEG C in a thermal treatment furnace; and then the steel plate is delivered into an accelerated cooling area to cool by a conveying roller bed, wherein the cooling speed is controlled within 2-20 DEG C / s, and the final cooling temperature is controlled within 400-700 DEG C. The cooling method is the combination of aerial fog cooling and laminar flow cooling or the combination of the aerial fog cooling and spraying cooling, wherein the pressure of the laminar cooling water or the spraying cooling water is 0.10-0.50 MPa, the pressure of the air fog cooling water is 0.10-0.60 MPa, and the pressure of the aerial fog cooling gas is 0.15-0.80 MPa. By adopting the steel plate produced by the accelerated cooling process carried out after the normalizing, the structure is obviously refined, the growth of the particles of the precipitated matters is inhibited, the strength and toughness of the steel plate are enhanced, or the equivalent strength and toughness is realized under the condition of less alloy content.

Owner:UNIV OF SCI & TECH BEIJING

Steel with 1,300MPa-level tensile strength for automobile safety piece and production method thereof

The invention relates to steel with 1,300MPa-level tensile strength for an automobile safety piece and a production method thereof. The steel comprises the following components in percentage by weight: 0.12 to 0.22 percent of C, 0.10 to 0.40 percent of Si, 1.00 to 1.60 percent of Mn, 0.10 to 0.45 percent of Cr, 0.01 to 0.10 percent of Ti, 0.0005 to 0.005 percent of B, 0.01 to 0.06 percent of Als,less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S and less than or equal to 0.008 percent of N. The production method comprises the following steps of: smelting by using a converter; alloying; performing vacuum treatment and component fine turning; continuously casting; heating a casting blank to the temperature of between 1,220 and 1,280 DEG C; performing rough rolling; performing fine rolling; performing laminar flow cooling; reeling; performing acid-washing; performing cold rolling; annealing; smoothing; finishing; cutting; heating and austenitizing under the protective atmosphere of nitrogen; forming a mold; quenching; tempering; and taking a member out for later use. The steel has ultrahigh intensity, meets the requirements of an automobile industry on the intensity and the rigidity of the safety piece of a vehicle body, can be complicatedly deformed without resilience, has high dimensional accuracy of parts and can be industrially produced on common large production equipment.

Owner:武汉钢铁有限公司

Method for producing ocean engineering steel plate with low compression ratio, thick specification and ultrahigh strength

ActiveCN102965592AAvoid the disadvantages of high surface strength and poor toughnessReduce the compression ratioLaminar coolingEngineering

The invention discloses a method for producing an ocean engineering steel plate with a low compression ratio, thick specification and ultrahigh strength, which has a uniform performance in a thickness direction. The method comprises the following steps: carrying out smelting and continuous casting production through a converter, carrying out rolling on a medium-thickness plate coil by using a controlled rolling and controlled cooling process, carrying out laminar cooling at the finish cooling temperature of 650-700 DEG C and the cooling rate of 5-10 DEG C / s after rolling, and finally carrying out normalizing, quenching and tempering thermal treatment. The ocean engineering steel plate with a low compression ratio, thick specification and ultrahigh strength, which has the uniform performance in the thickness direction and is obtained according to the invention is good in performance, and on the basis of meeting the certification requirements of classification societies, such as DNV (Det Norske Veritas), CCS (China Classification Society) and ABS (American Bureau of Shipping), for steel E690, the thickness-specification steel plate is smaller than 15MPa in the thickness direction in terms of thickness difference, is smaller than 20J in terms of the difference of lateral impact average values at the low temperature of minus 40 DEG C, is smaller than 1% in terms of elongation difference, and in addition, has the characteristics of batch production condition, stable production process, strong operability and the like.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com