Patents

Literature

85 results about "Hot strip rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

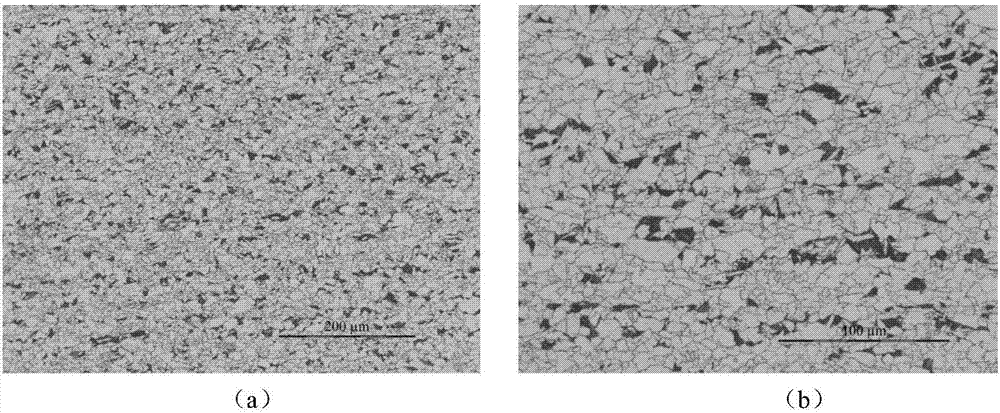

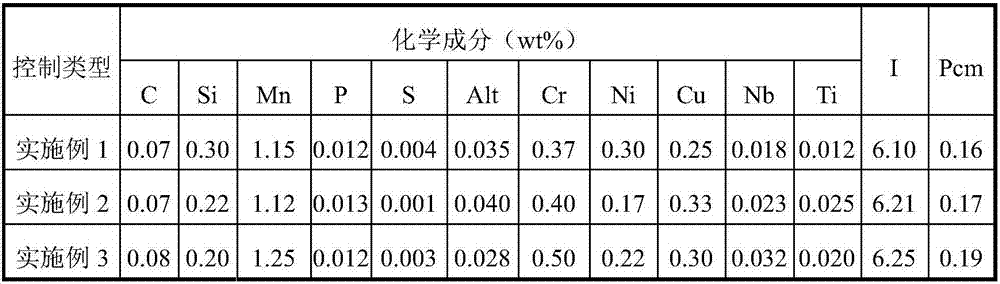

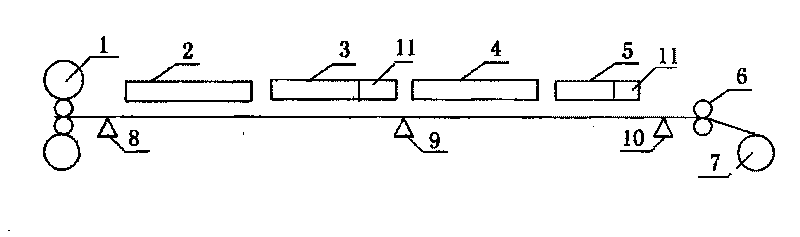

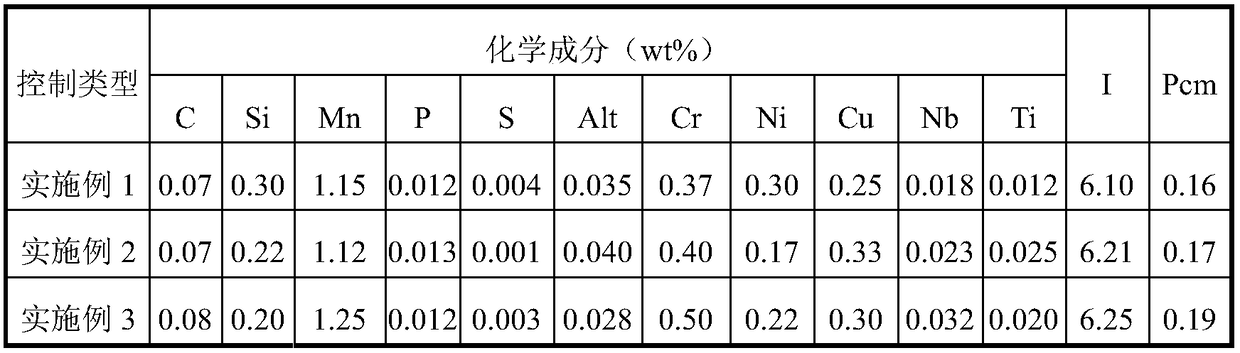

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

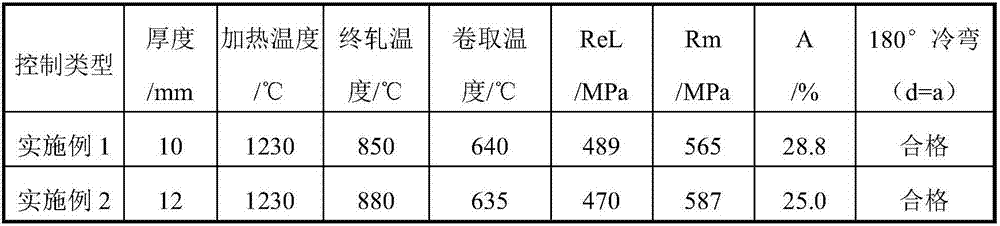

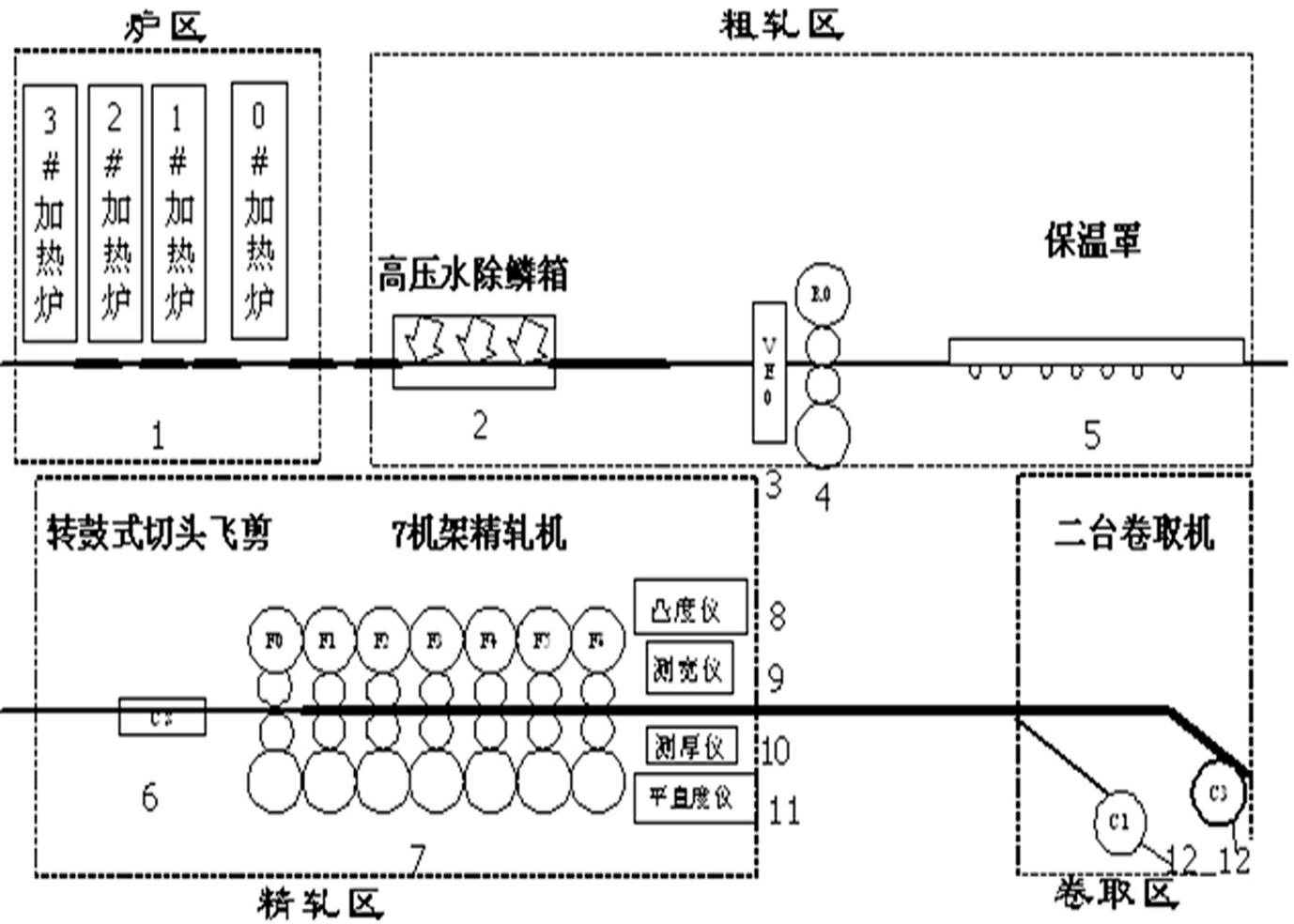

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

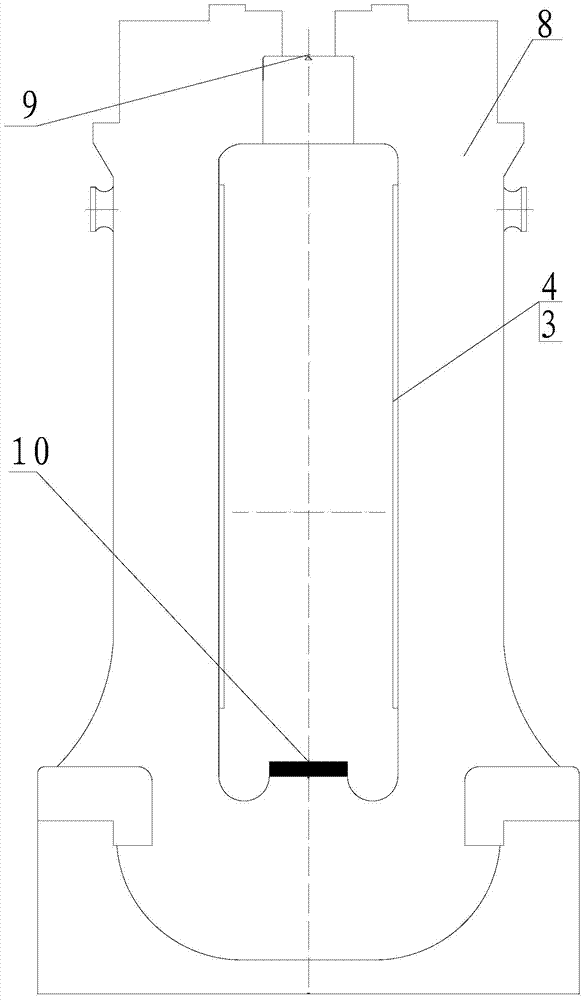

Method for controlling micro-tension of hot strip rolling looper

ActiveCN101661298ALooper moves smoothlyQuality improvementProgramme control in sequence/logic controllersMechanical pressure/force controlAutomatic controlControl system

The invention relates to a method for controlling micro-tension of a hot strip rolling looper, which aims at improving the quality of hot rolled products and the finished product rate of hot rolling.The method is applicable to automatically controlling a finishing rolling hydraulic looper on a hot strip mill, when a strip steel is completely snapped by adjacent two finishing mill stands of the looper, a control system calculates the looper tension torque proportionality coefficient according to the following formula: Kp is equal to (absolute value of (delta Mact multiplied by (1 minus et / T) divided by Mref) multiplied by K1 plus K2 plus 1) multiplied by C, wherein delta Mact is the actual torque variable quantity; Mref is the set torque; K1 is the deviation amplification proportionality coefficient; K2 is the anti-resonance proportionality coefficient; C is a control constant; t is filtering time with the unit being s; T is sampling time with the unit being s; and the control system cuts off the calculation of the micro-tension coefficient of the looper through the tracking calculation of the tail part of the strip steel when the tail part of a front stand of the adjacent stand turns to the small looper at 5 seconds before throwing steel, turns to the constant micro-tension torque calculation and finally determines the final looper position for controlling and setting.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Free cooling method of hot rolling band steel

ActiveCN101745551AIncrease temperatureFreely control the length of the head and tailTemperature control deviceFree coolingTemperature difference

The invention provides a free cooling method of hot rolling band steel, which featured in that temperature testing devices and induction feedback devices are arranged respectively at the fine rolling outlet, the coiling inlet and the laminar flow cooling roller way acting as the middle portion of the cooling device; the temperature of the laminar flow cooling water in the three sections are adjusted and controlled after the coiling temperature difference of the head and tail of the band steel and the middle portion of the band steel is tested and fed back. Therefore, the method of the invention can not only control the head and tail temperature of the band steel freely, but also control the length of the head and tail of the band steel freely.

Owner:BAOSHAN IRON & STEEL CO LTD

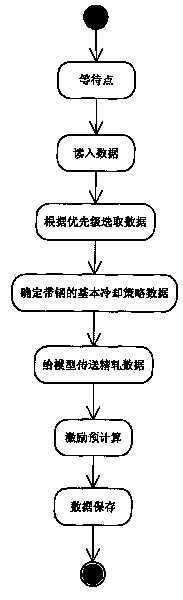

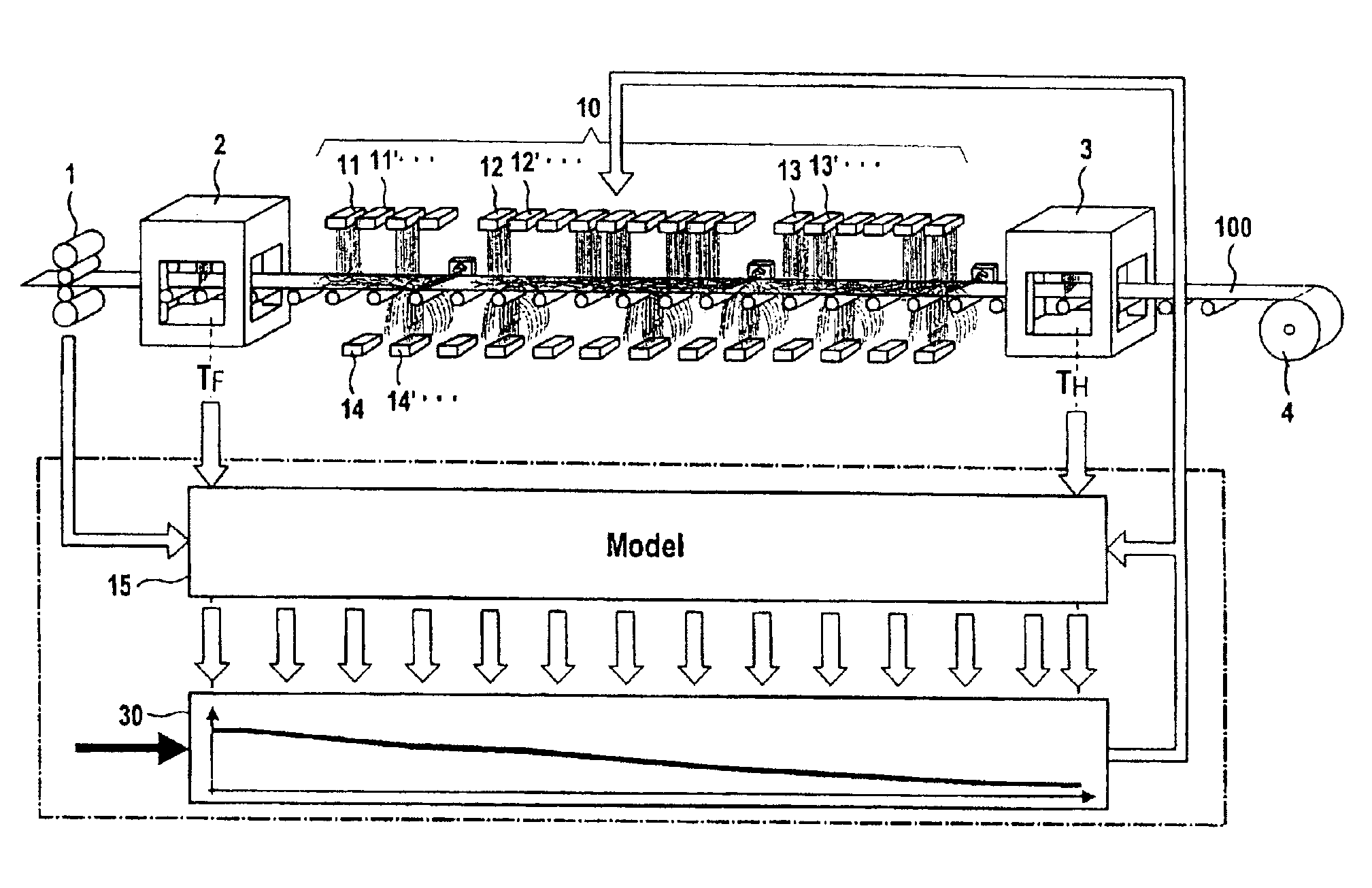

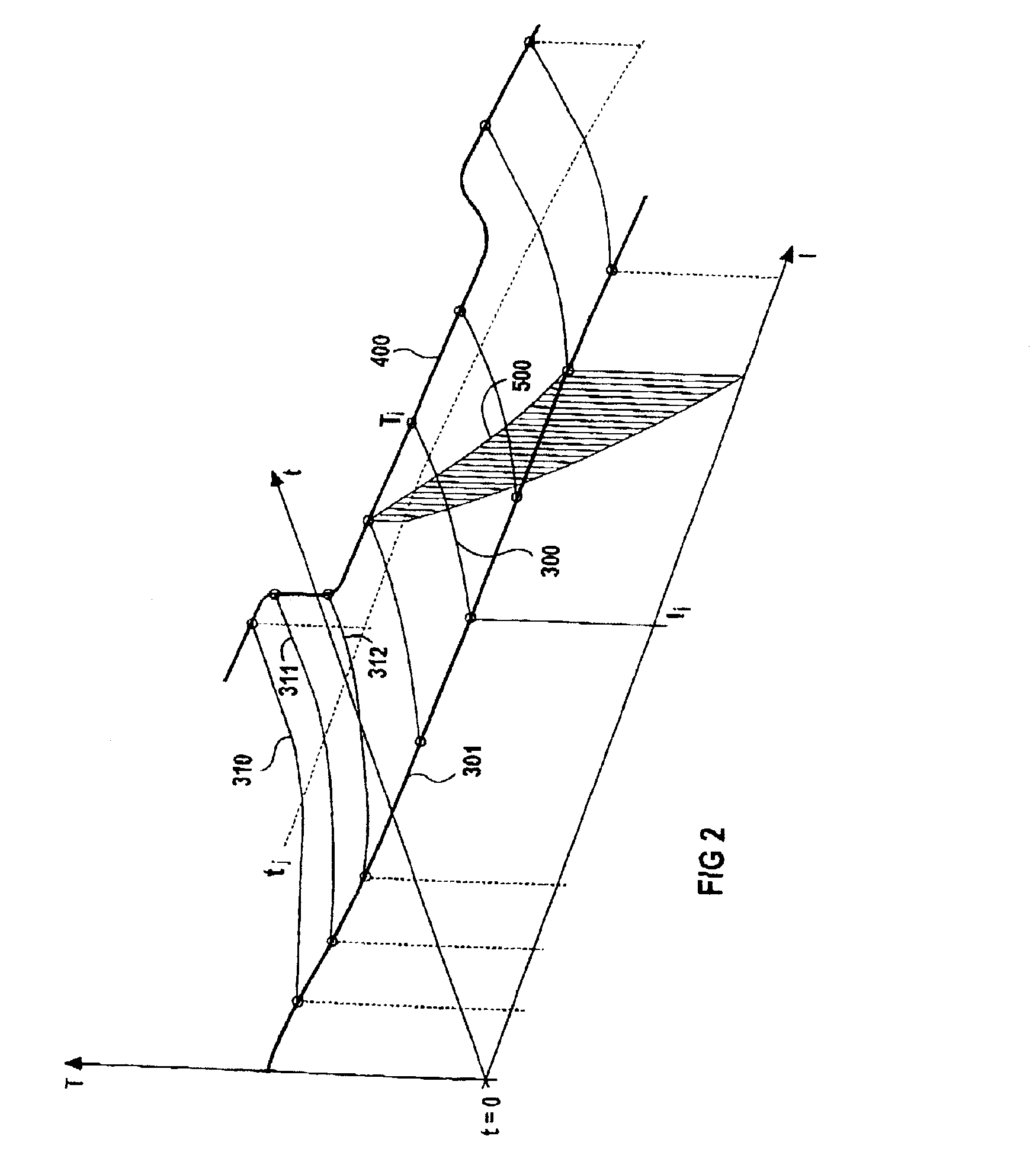

Method for controlling and/or regulating the cooling stretch of a hot strip rolling mill for rolling metal strip, and corresponding device

A method and device for the automation of a cooling section in a hot strip rolling mill, wherein an individual course of cooling over time for each strip point of the metal strip is specified and whereby the cooling specifications can be determined from the desired properties of the steel, independent of variable process value.

Owner:PRIMETALS TECH GERMANY

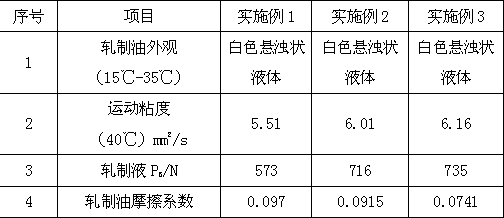

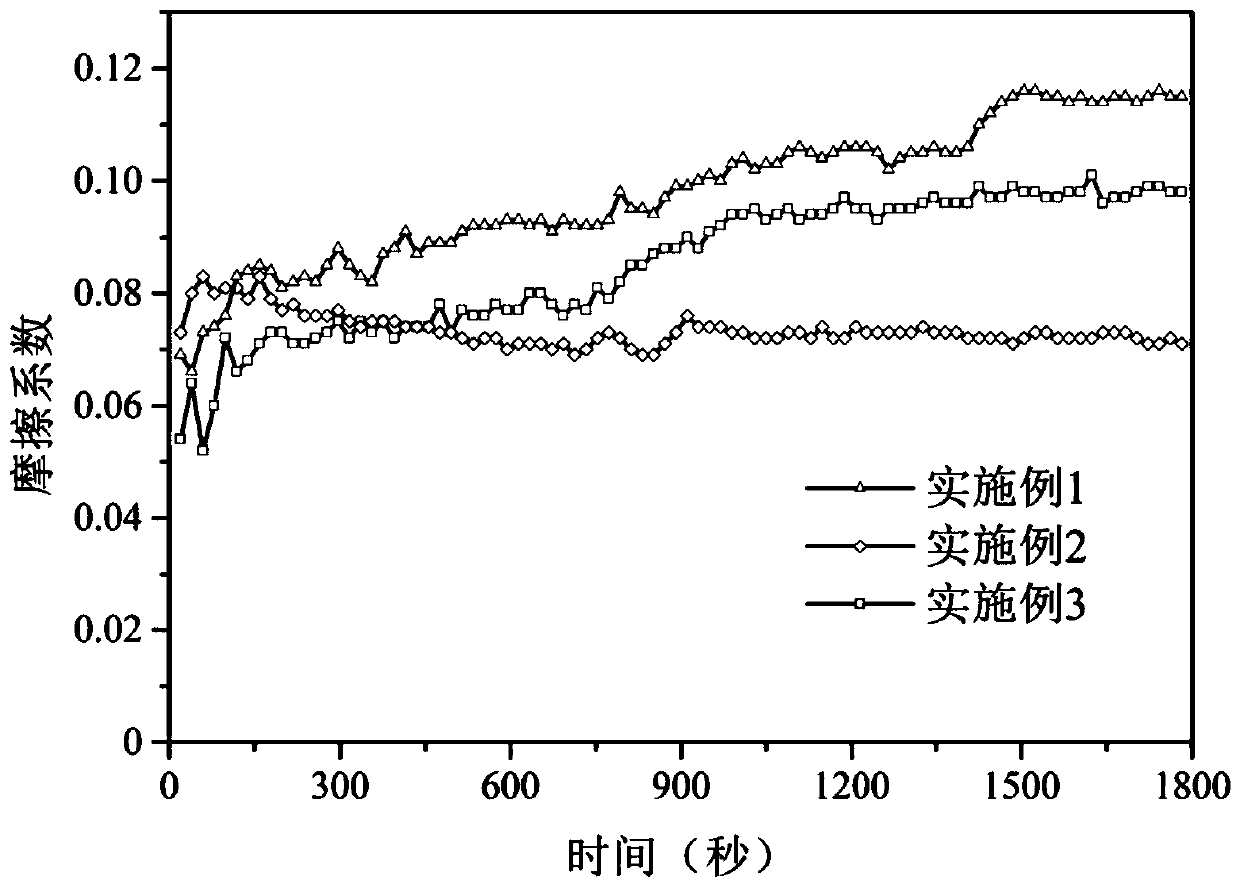

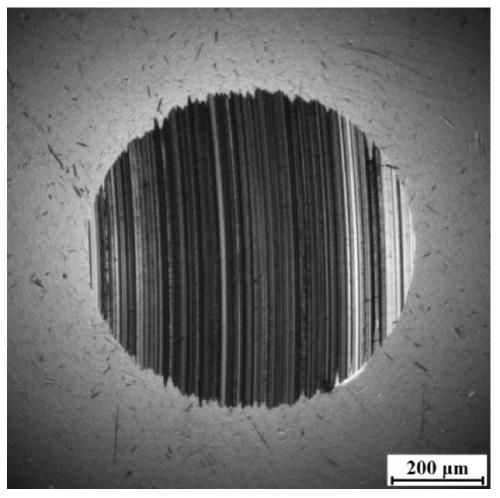

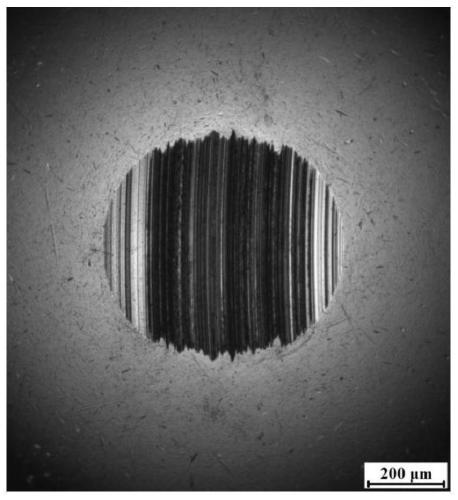

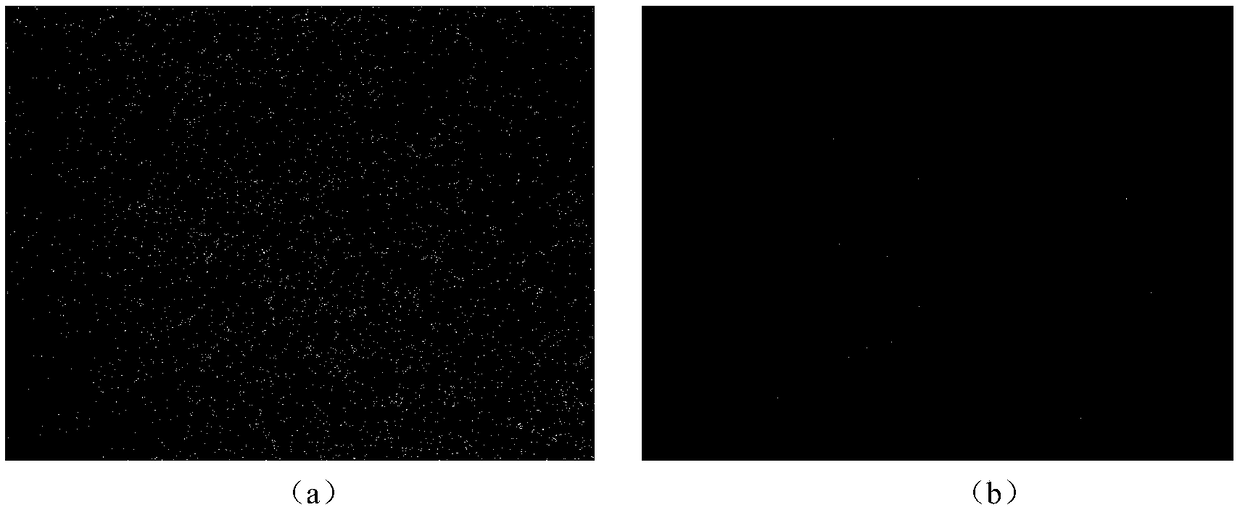

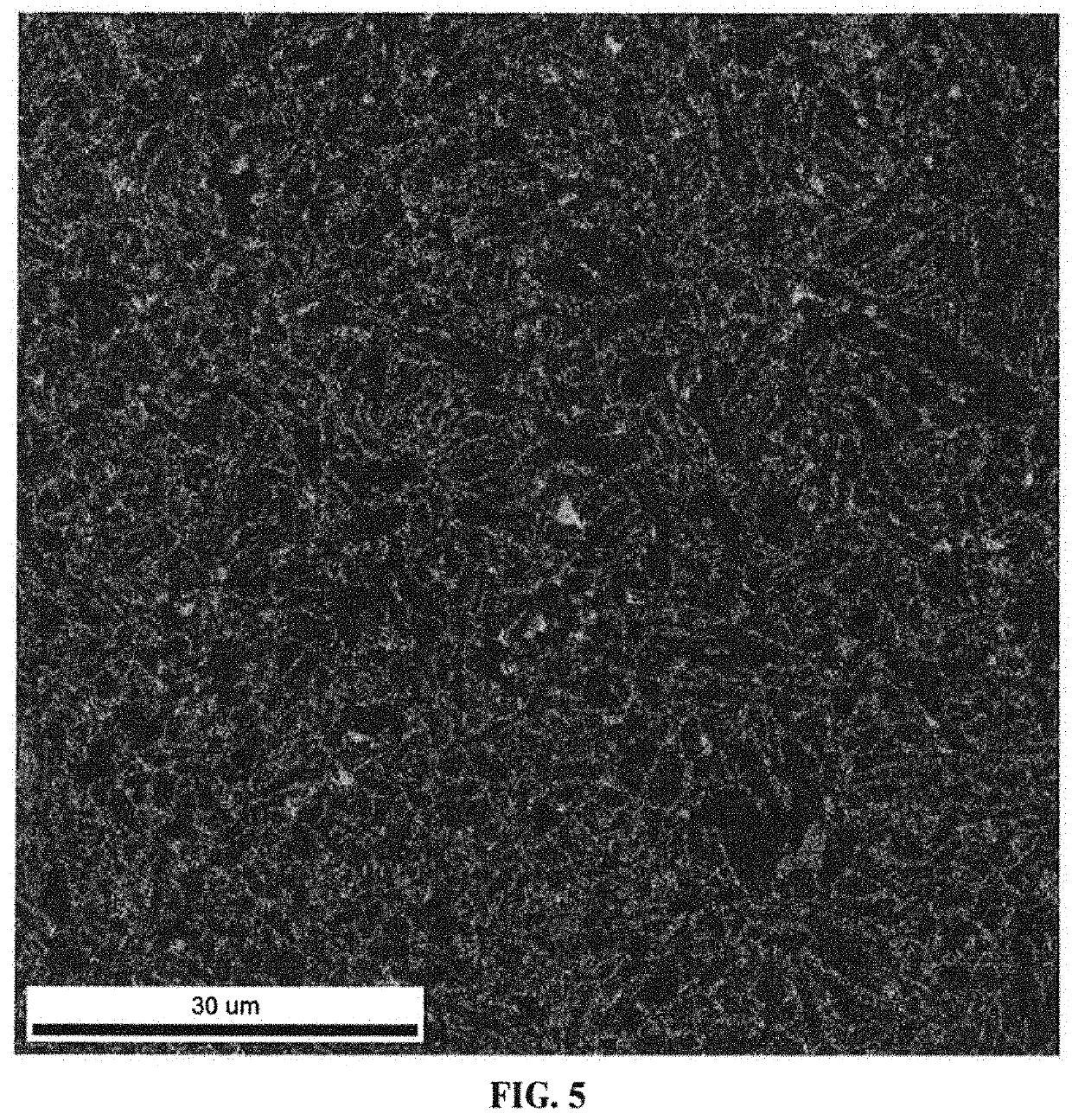

Water-based hot rolling liquid containing nano TiO2 and preparation method thereof

ActiveCN103013642AImprove surface qualityLong anti-corrosion periodLubricant compositionSodium phosphatesGlycerol

The invention belongs to the technical field of lubricant, relates to a water-based hot rolling liquid containing nano TiO2 and a preparation method thereof and is used for the lubrication of steel plates and strips in the hot rolling process. The preparation method is characterized by selecting nano TiO2 having excellent corrosion inhibition and rust prevention performance as extreme pressure agent and using sodium hexametaphosphate and sodium dodecyl benzene sulfonate as dispersant, and comprises the following steps: sequentially adding deionized water, the sodium hexametaphosphate, the sodium dodecyl benzene sulfonate, triethanolamine, isothiazolinone, glycerol and benzotriazole; putting in a reaction kettle having a rotation rate of 80-120 r / min, and stirring while heating; when the temperature reaches 60 DEG C, adding the nano titanium dioxide, keeping the temperature, and continuously stirring for 30 minutes; and then, stopping heating, and further stirring until the temperature reaches room temperature, thus obtaining a white turbid liquid which is the required water-based rolling liquid. By using the water-based rolling liquid, the pollution caused by the traditional hot rolling oil can be reduced; the slow-release rust prevention performance of rolled steel products can be obviously improved; and the rolled steel products have favorable surface quality and long anti-corrosion period.

Owner:UNIV OF SCI & TECH BEIJING

Thin container plate and production method thereof

ActiveCN102337470ALow costStable mechanical propertiesTemperature control deviceFurnace typesChemical IngredientsHot strip rolling

The invention relates to a thin container plate and a production method thereof. The thin container plate comprises the following chemical ingredients in percentage by weight: 0.07-0.11% of C, 0.40-0.55% of Si, 0.30-0.45% of Mn, 0.08-0.12% of P, less than or equal to 0.006% of S, 0.26-0.35% of Cu, 0.35-0.55% of Cr, less than or equal to 0.09% of N and the balance of Fe and inevitable impurities. With the production method for the thin container plate, low-cost thin container plates of which the thickness is at most 1.6mm can be stably produced on a large scale on a traditional hot strip rolling production line which is not provided with a coil box. The production method has the advantages of high rolling yield rate and low alloy cost which is lowered than the traditional container plate alloy cost by ** yuan / ton.

Owner:SHOUGANG CORPORATION

Method for preparing nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization

ActiveCN111117746AMeet friendly requestEasy to save energyLubricant compositionSodium acetateSODIUM METAPHOSPHATE

A method for preparing a nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization belongs to the technical field of lubrication. The method comprises the following steps: auto-polymerizing dopamine to form polydopamine, modifying the surface of a molybdenum disulfide nanosheet with the polydopamine to obtain a polydopamine-modified molybdenum disulfide nanosheet; then adding aluminum chloride hexahydrate, polyethylene glycol 200 and sodium acetate, centrifuging the obtained obtained solution, and washing and drying the obtained material to obtain nano-MoS2-Al2O3 composite powder; and finally, dispersing the prepared composite nano-powder into deionized water, and adding glycerol, triethanolamine, sodium hexametaphosphate, sodium dodecyl benzene sulfonate, water-based borate and a trace amount of a defoaming agent to obtain the required composite rolling lubricant. The composite lubricating oil is simple in preparation process, good in reproducibility, low in cost, high in efficiency and beneficial to batch production, can replace traditional rolling lubricating oil severely polluting the environment to a certain extent, is used for technological lubricationin the plate and strip steel hot rolling process, and promotes energy conservation, emission reduction and environment-friendly production in the plate and strip steel rolling process.

Owner:UNIV OF SCI & TECH BEIJING

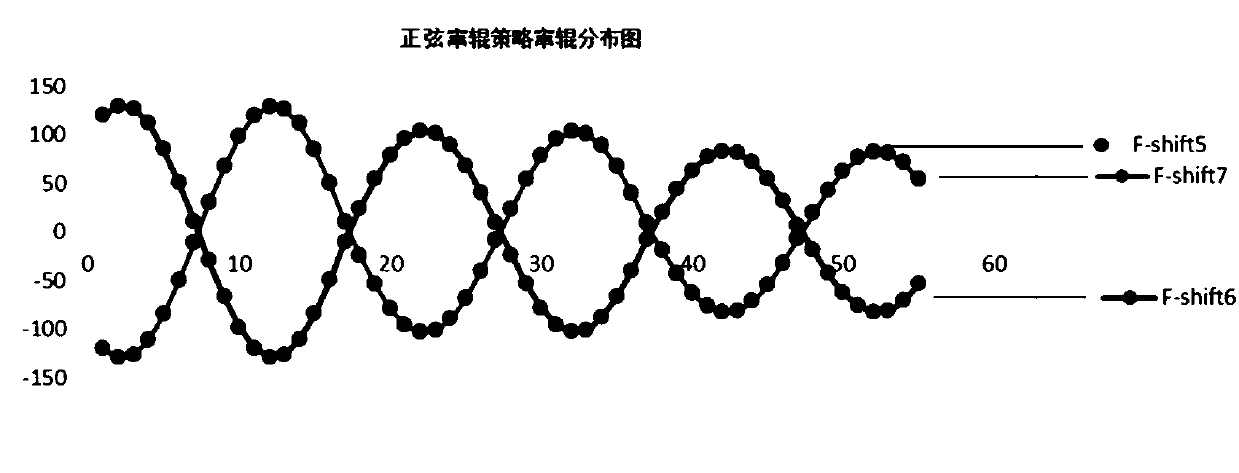

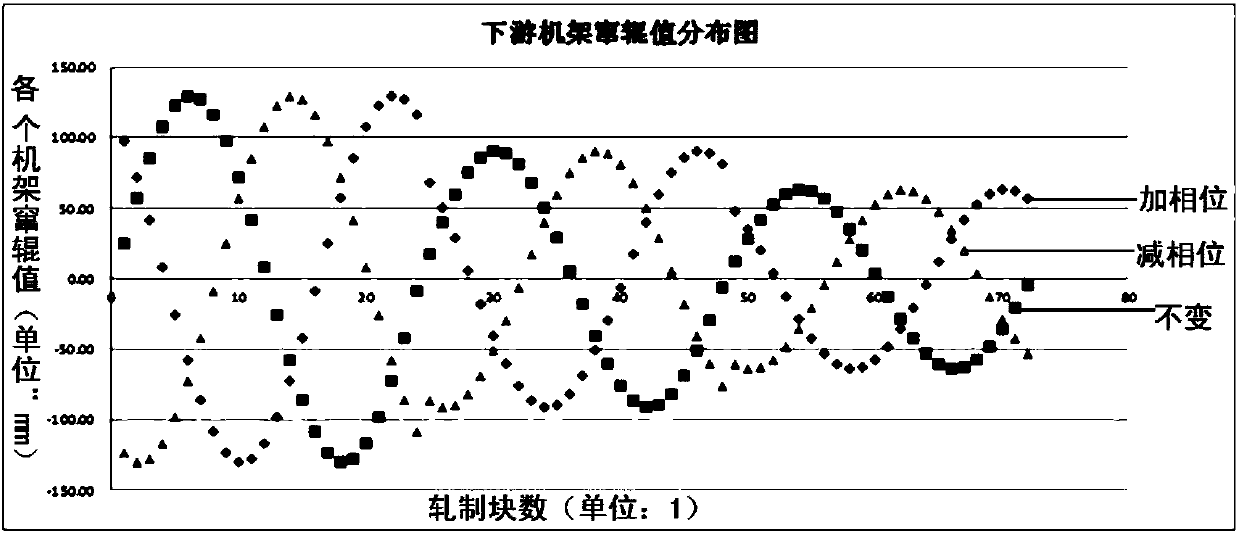

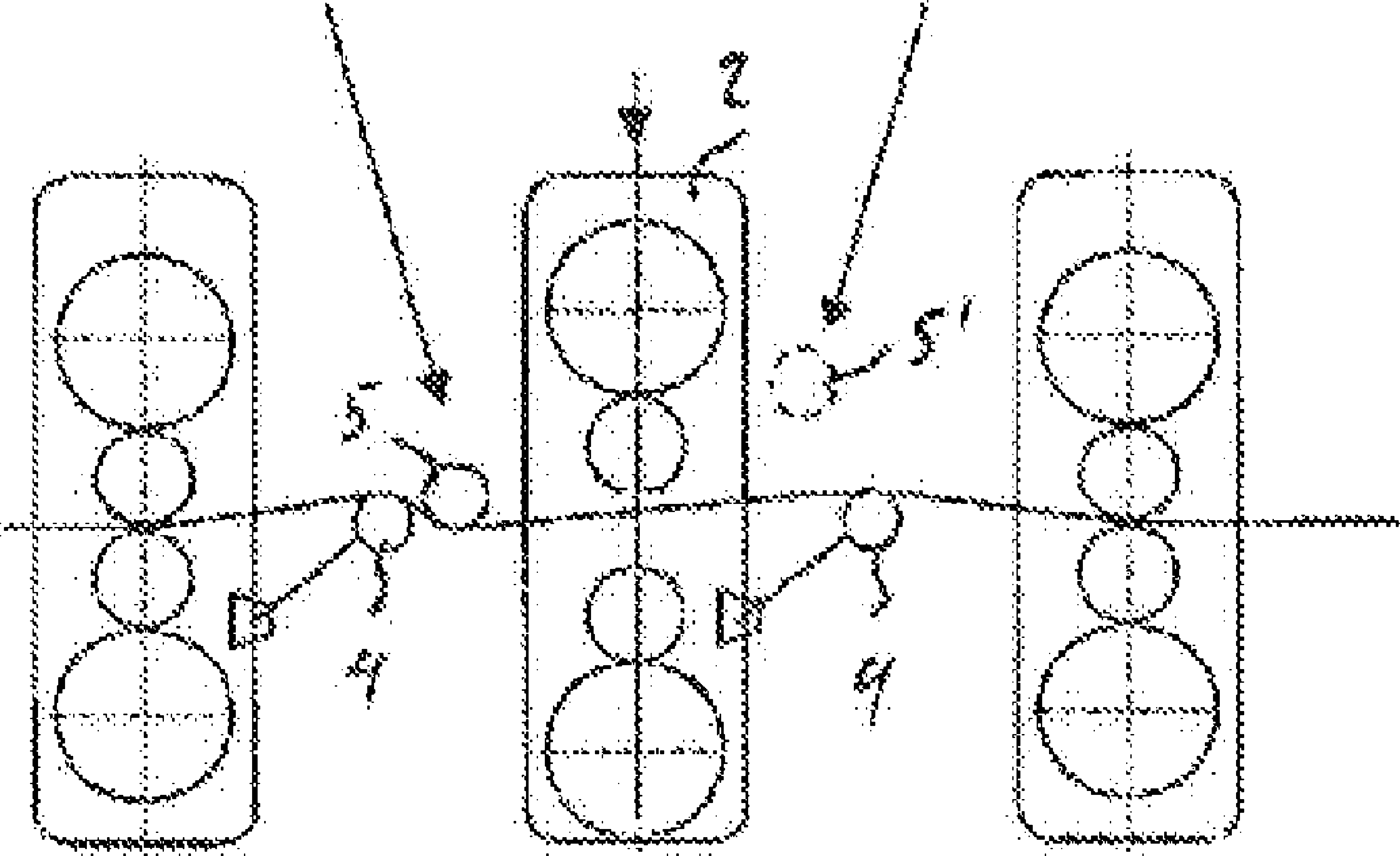

Asynchronous roller alternating control method for hot continuous rolling downstream rack working rollers

ActiveCN107824617AAvoid simultaneous roll shifting to roll shifting zero positionAvoider roll shifting limit positionMetal rolling arrangementsProfile control deviceStrip steelEngineering

The invention relates to an asynchronous roller alternating control method for band steel hot rolling downstream rack working rollers. After a rolled piece is rolled, upper and lower working rollers horizontally move at the same distance in an opposite direction, then a next rolled piece is rolled, and the upper and lower working rollers periodically alternate to and fro between forward and reverse maximum roller alternating stroke positions in a band steel rolling production process, so that phasic positive and negative deviation is respectively performed on previous three downstream racks onthe basis of the same roller alternating function, and asynchronous roller alternation is formed on the three racks. According to the roller alternating control method, on one hand, the control ability on wedge and deviation is increased through asynchronous phasic adjustment, and on the other hand, the bad influence caused by multi-rack roller alternating zero-position superposition in the wholeroller alternating cycle can be avoided, so that the control stability of all strip-shape indices is increased, and the rolling kilometer is extended.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for repairing plate of hot strip rolling mill online

The invention provides a method for repairing a plate of a hot strip rolling mill online. The method comprises the steps of 1, dismounting and removing; 2, detecting abrasion loss according to a fixed reference; 3, repairing the damaged plate surface; 4, repairing failed bolt holes in the plate surface online through a positioning die plate and a drilling machine; 5, mounting an upper sliding plate and a lower sliding plate, and finally detecting the size. The method has the advantages that the dimensional tolerance and the geometric tolerance of the plate surface and the bolt hole can be ensured by the online repair technology method; the combining strength and stability of a welding machine and the plate can be improved; the efficiency is increased by online repairing, and the repairing time can be also reduced.

Owner:SHANDONG IRON & STEEL CO LTD

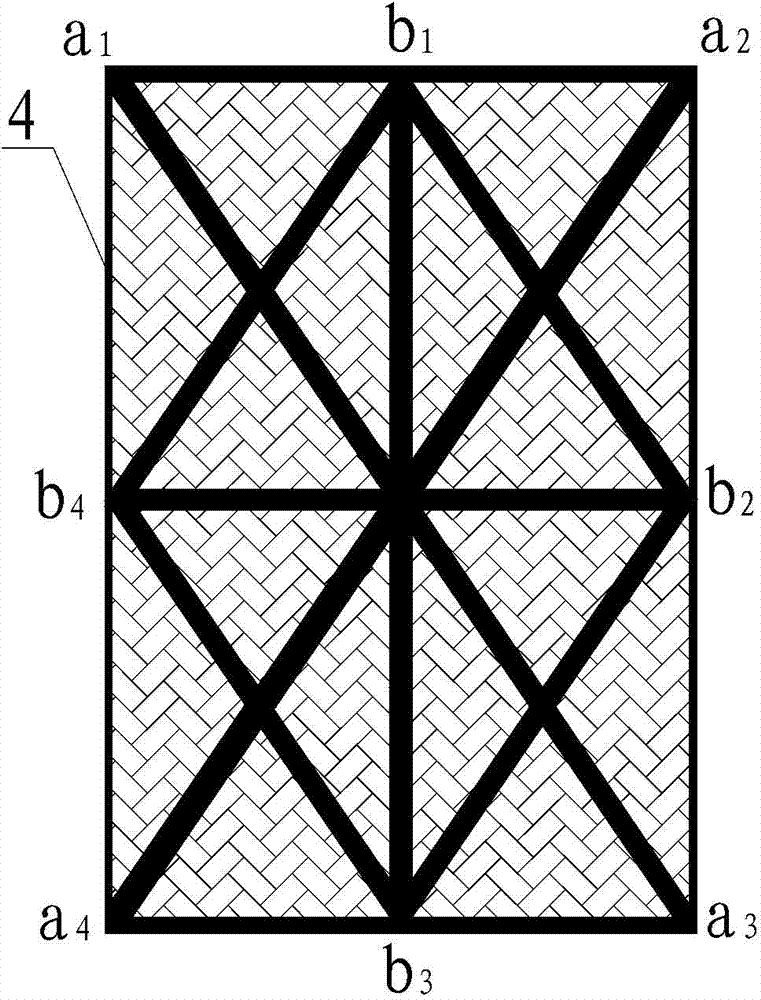

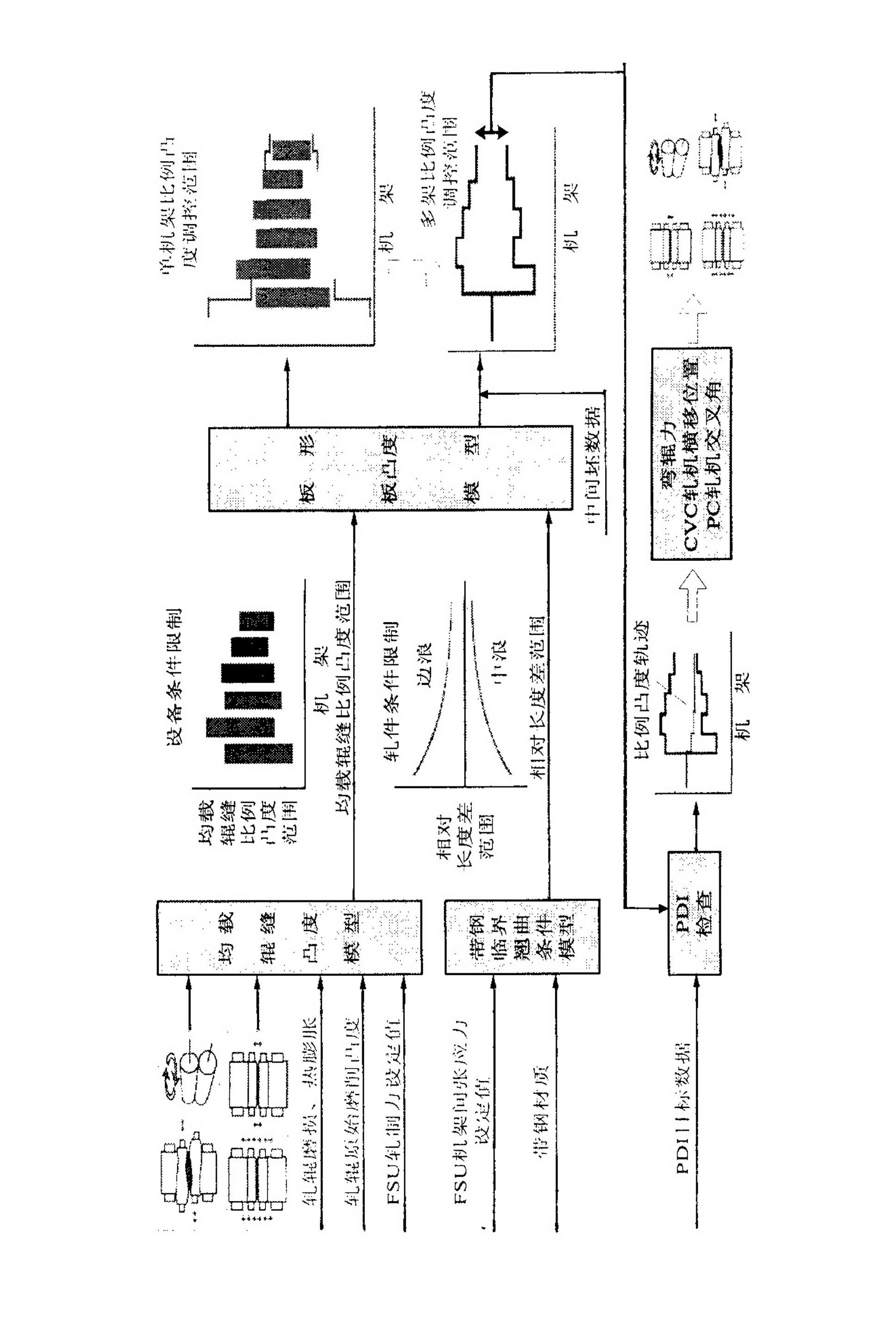

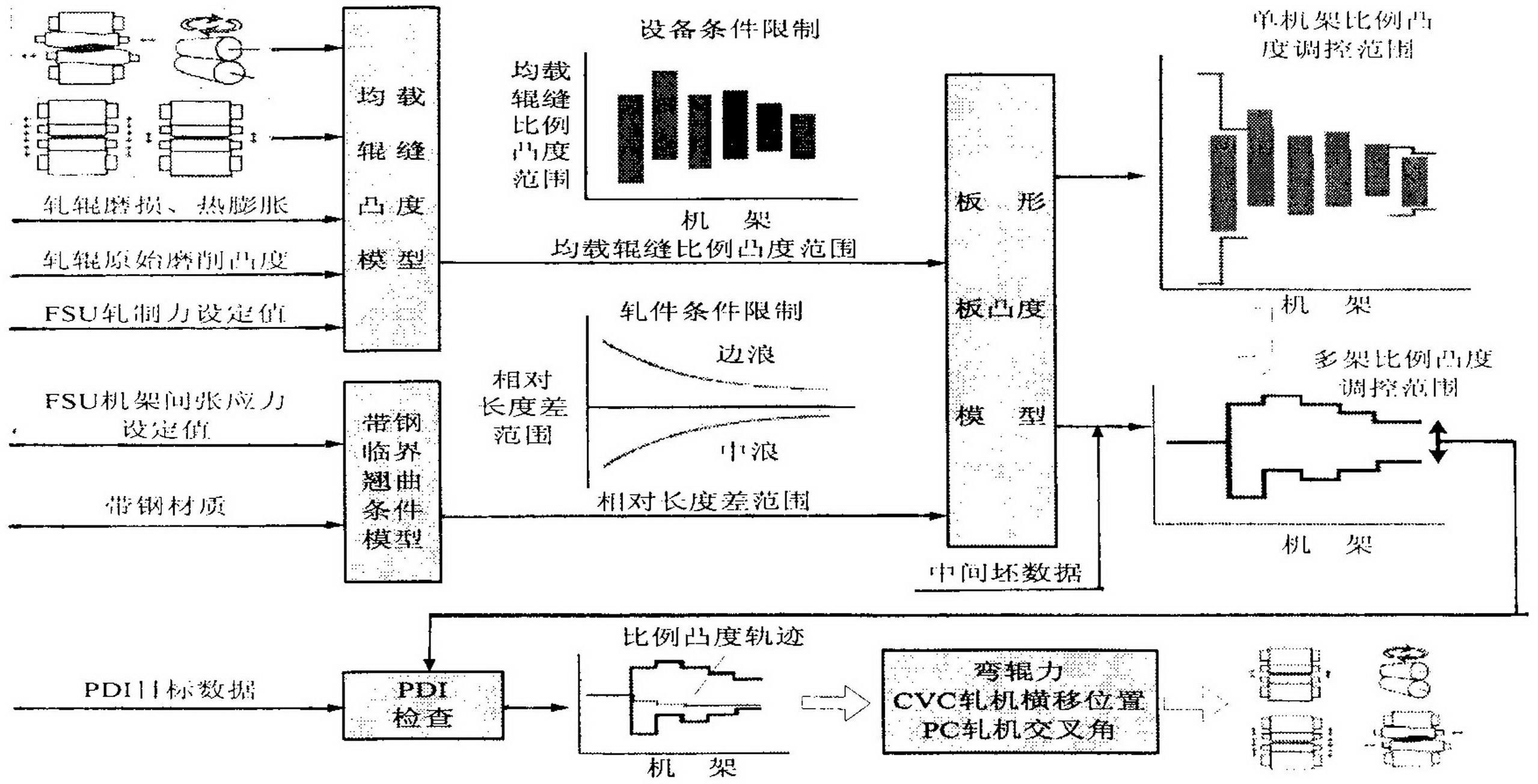

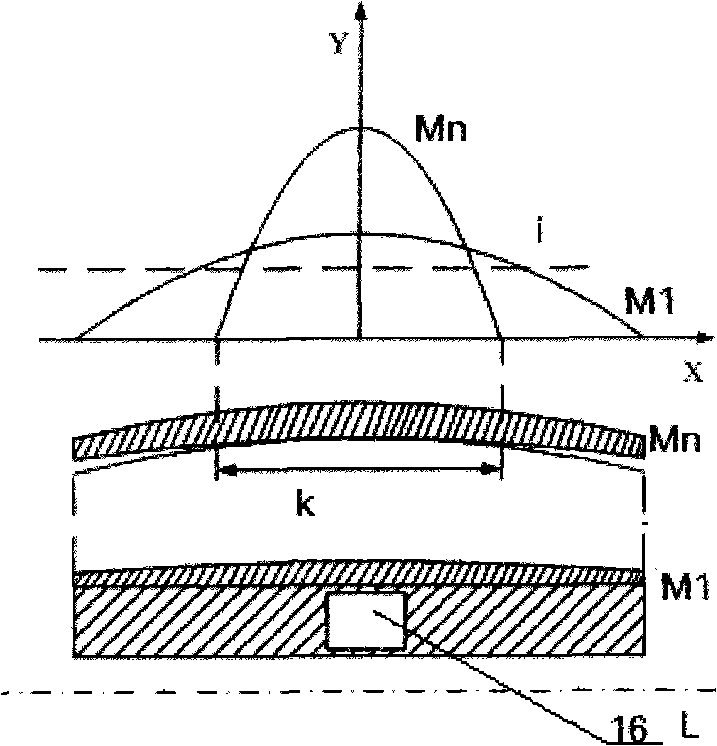

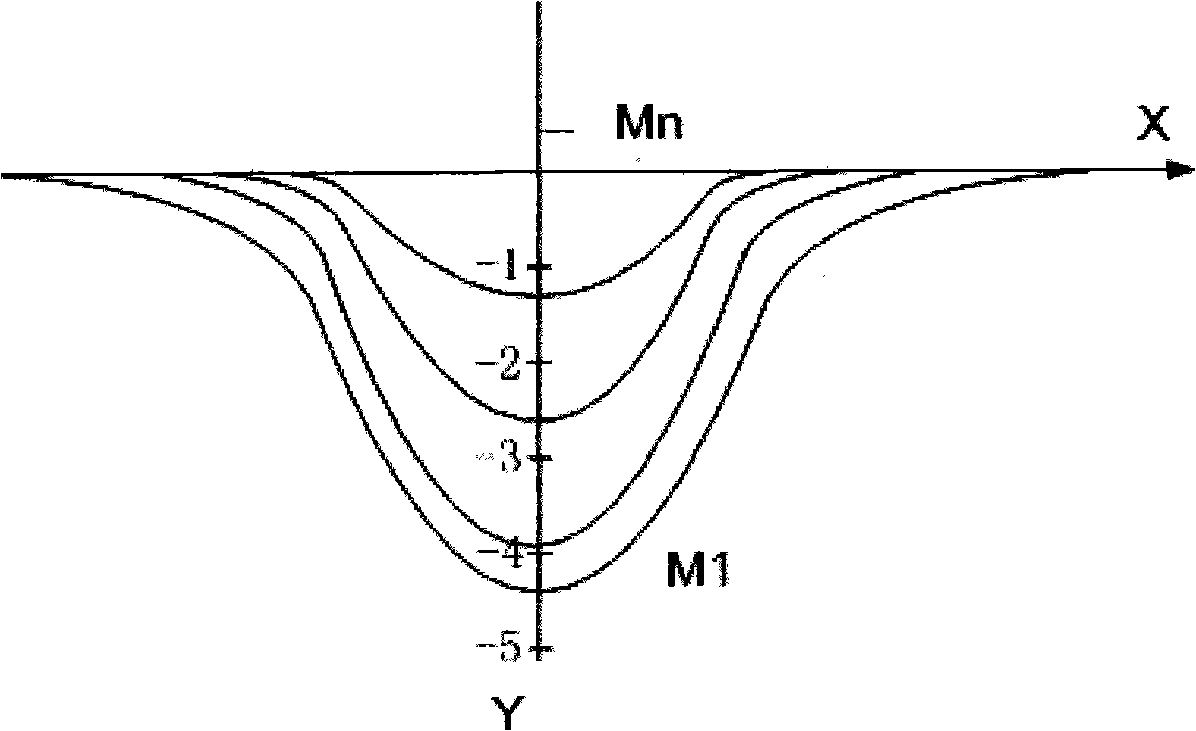

Sheet shape control technology used in hot strip rolling of super-wide sheets

InactiveCN102145348AGood flatness indexGood proportional convexityProfile control deviceThermal dilatationThermodynamics

The invention discloses the technical field of hot strip rolling, in particular to a sheet shape control technology used in hot strip rolling of super-wide sheets. The core technology mainly comprises the steps of AVC (Asia Vital Components) application, AVC roller type curve design, formulation and implementation of a sheet shape control strategy, accurate estimation and calculation of precision of rolling mills, roll wear and thermal expansion, optimization of a model control system, and the like. In the sheet shape control technology, the front four rolling mills of a continuous hot rolling and finishing mill group adopt the AVC rollers, the following three rolling mills adopt the conventional rollers, and the axial drifting mechanism of working rollers and the model control function are optimized, namely, the front three racks are respectively provided with a proportion crown for maintaining good sheet shapes, and meanwhile, the proportion crowns of the racks behind are changed slightly or not changed, and the index of flatness of strip steel at a finishing mill outlet can be kept good.

Owner:ANYANG IRON & STEEL

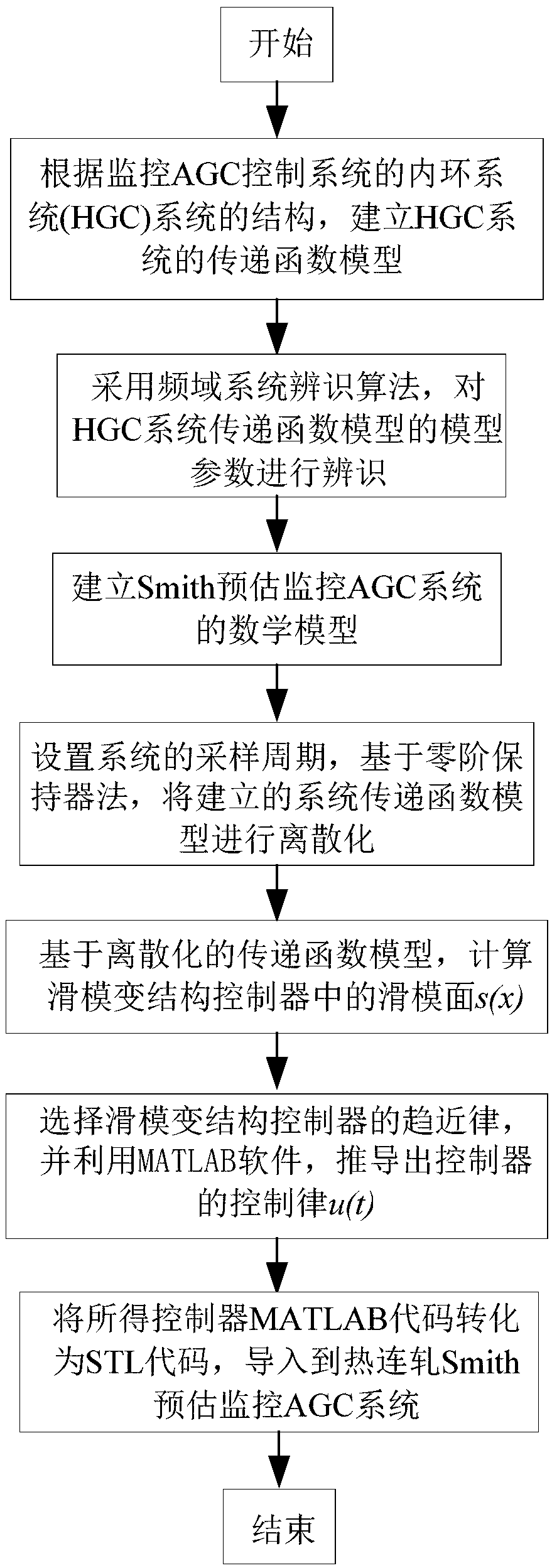

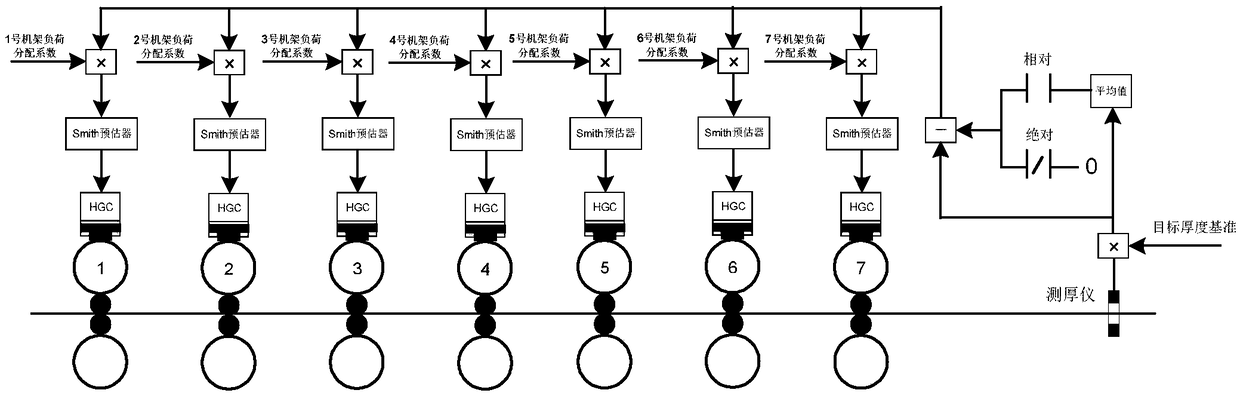

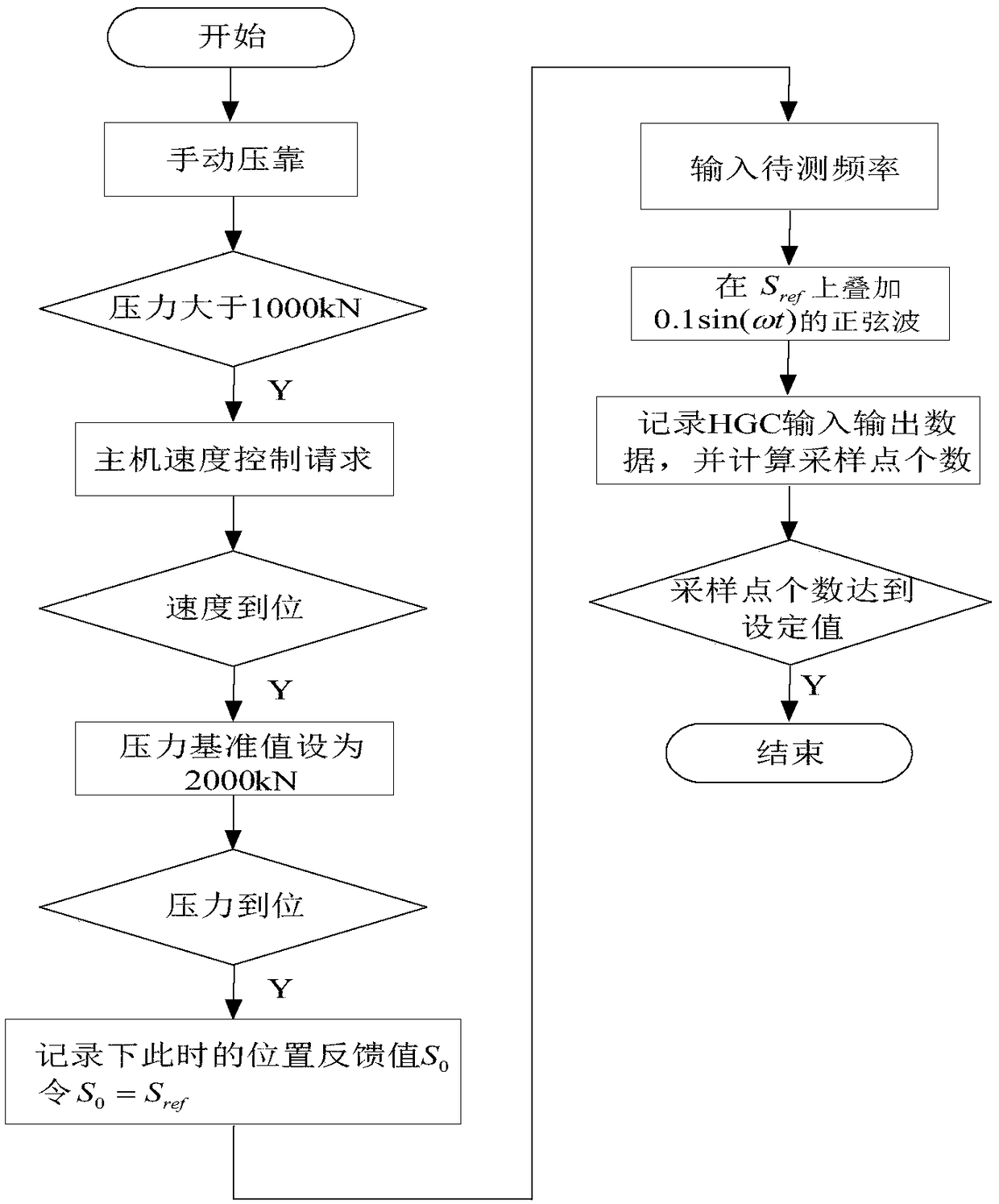

Control method of Smith prediction monitoring AGC system

InactiveCN109298707AImprove robustnessSolving Lag ProblemsProgramme controlElectric testing/monitoringTime lagTransfer function model

The invention relates to a control method of a hot-strip-rolling monitoring AGC system. A transfer function model of an HGC system is established according to a structure of an inner-loop system (HGCsystem) of the Smith prediction monitoring AGC control system; a frequency-domain system identification algorithm is employed for identifying model parameters of the transfer function model of the HGCsystem, and then a mathematical model of the Smith prediction monitoring AGC system is established, and is then discretized; and a sliding-mode variable-structure controller (SMC) of the hot-strip-rolling Smith prediction monitoring AGC system is designed on the basis thereof. Therefore, the problems that according to PID controllers in existing hot-strip-rolling Smith prediction monitoring AGC systems, control accuracy heavily depends on modeling accuracy of control objects, and adaption ability on time lagging, nonlinearity and time-varying of the control objects is poor are solved. Robustness of the hot-strip-rolling Smith prediction monitoring AGC system is improved, and thus control accuracy of hot-strip-rolling strip steel thickness is improved.

Owner:HUAQIAO UNIVERSITY

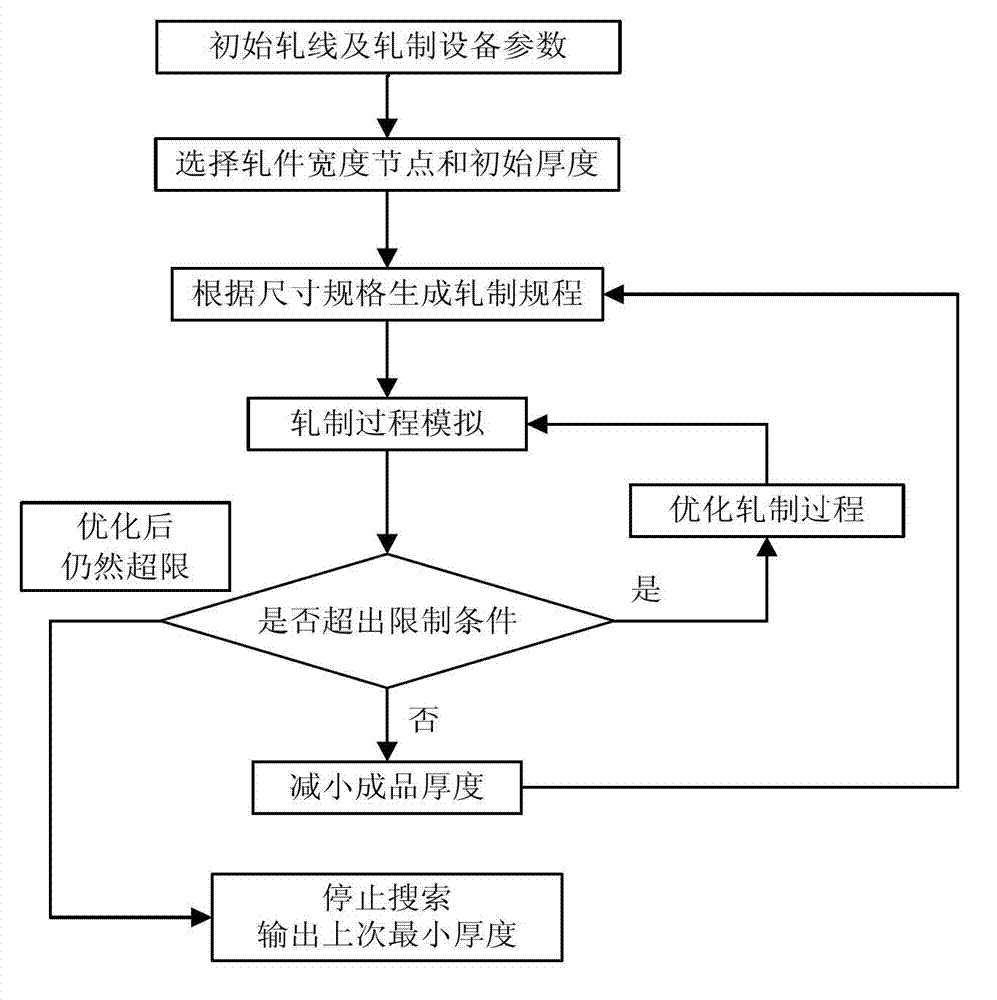

Method for optimizing rolling scope of hot strip rolling

InactiveCN103028603ARealize optimal formulationIncrease productionMetal rolling arrangementsEnergy consumptionMaterials science

The invention discloses a method for optimizing the rolling scope of hot strip rolling. The method comprises the following step: setting initial parameters; selecting the width node value and initial thickness value of a rolled piece; generating an initial rolling schedule of the rolled piece according to the width node value and initial thickness value of the rolled piece; judging whether rolling constraint conditions are satisfied or not; reducing the thickness of the rolled piece according to the thickness variable step size of the rolled piece; recording and outputting the last computed minimum thickness value of the rolled piece, i.e. the corresponding minimum thickness value of the width node; and calculating the next width node value. The method aims at relative equal load and good sheet shape, takes finish rolling temperature, allowable rolling force and allowable power as inequality constraints, utilizes pressing distribution as equality constraint to optimize a pressing schedule, accordingly, the minimum rolling thickness is searched, the optimum formulation of a rolling technology is realized at the same time, the equipment capability can be utilized more effectively, the yield of a rolling machine and the product quality are improved, and the rolling energy consumption and production cost are reduced.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

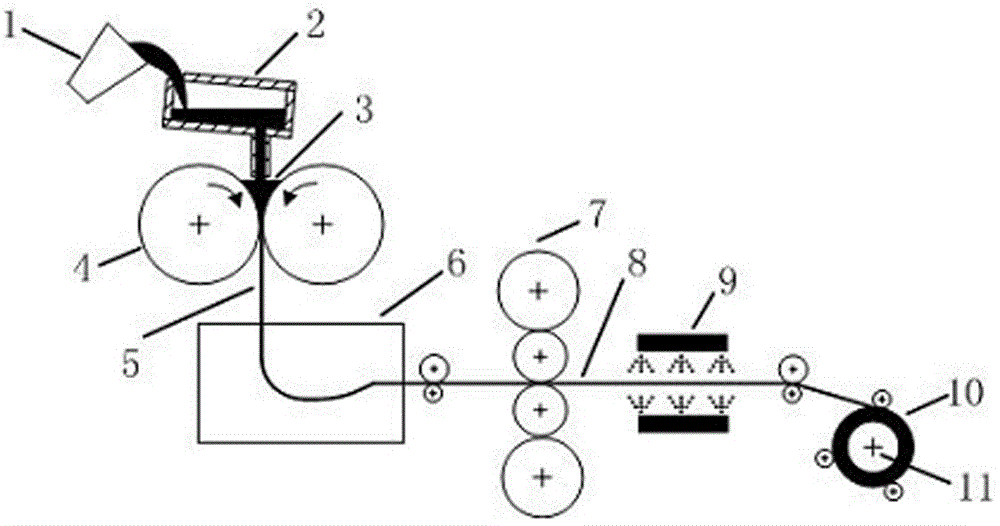

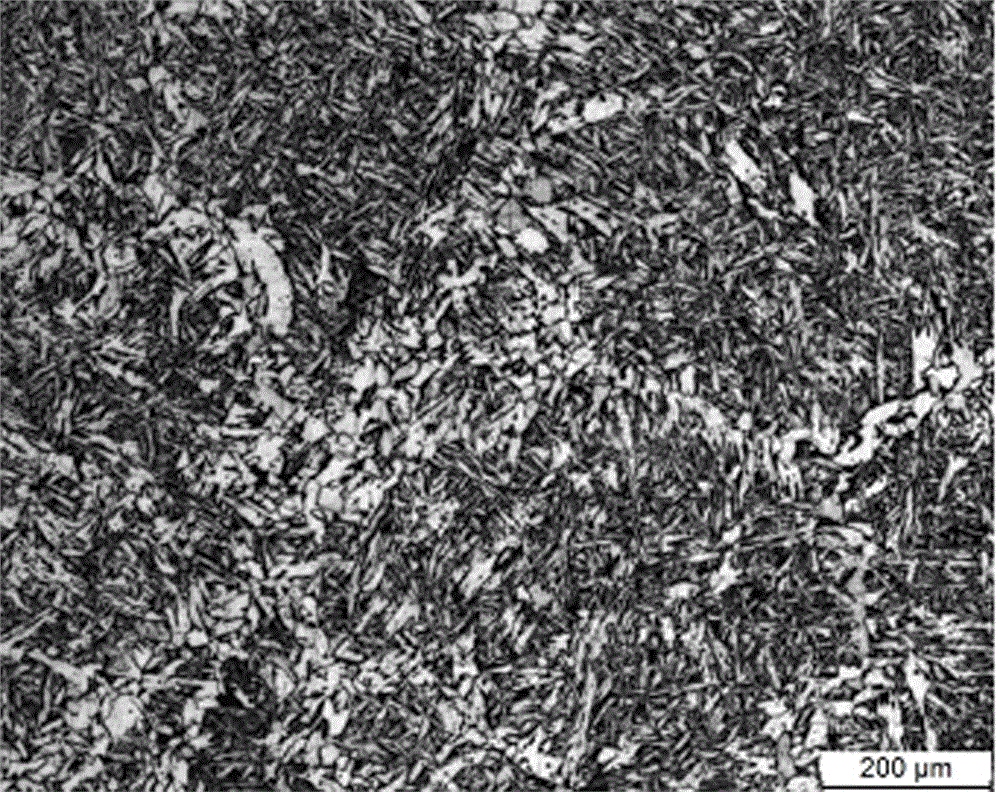

Method for improving volume fraction of acicular ferrite in twin-roll cast low-carbon thin strip steel

A method for improving the volume fraction of acicular ferrite in twin-roll cast low-carbon thin strip steel is carried out according to the following steps that (1) molten steel is smelted, and the chemical components of the molten steel include, by mass, 0.03-0.25% of C, 0.2-0.5% of Si, 1-1.5% of Mn, 0.01% or less of Al, 0.02-0.1% of V, 0.003-0.01% of P, 0.001-0.02% of S, 0.003-0.008% of O, 0.008-0.015% of N, and the balance Fe; (2) a tundish is preheated, the molten steel is poured into twin-roll thin strip casting equipment through the tundish, and the molten steel is solidified and guided out from a roll gap of casting rolls; (3) a cast strip is cooled to 900-1050 DEG C and subjected to hot rolling; and (4) curling is carried out after water cooling. The volume fraction of the acicular ferrite in a low-carbon thin strip steel hot-rolled plate roll is 50-95%, the low-carbon thin strip steel structure is effectively refined, the comprehensive performance of the low-carbon thin strip steel is improved, and the method is short in procedure, saves energy, and is environmentally friendly and low in cost.

Owner:NORTHEASTERN UNIV

Wedge control method for hot rolling strip steel

ActiveCN103203368AReduce the amount of wedgingMeet the wedge volume requirementsProfile control devicePositive pressureSpray nozzle

The invention discloses a wedge control method for hot rolling strip steel. According to the control method, by adopting a plurality modes of raw material preparation, micro-positive pressure control, roller shape design, rolling gap inclination amount control, adjustment on a spraying angle of a high-pressure water spray nozzle, fardage replacement, measuring and adjustment on centering degrees of a vertical roller and guide plates in the front and the rear sides of a rolling machine and the like, the wedge integral control is carried out on hot rolling of strip steel from multiple angles, multiple directions and multiple sections, thus a wedge amount of the strip steel can be effectively reduced, and the requirement on the wedge amount of the strip steel of a high-end product is met.

Owner:BAOSHAN IRON & STEEL CO LTD

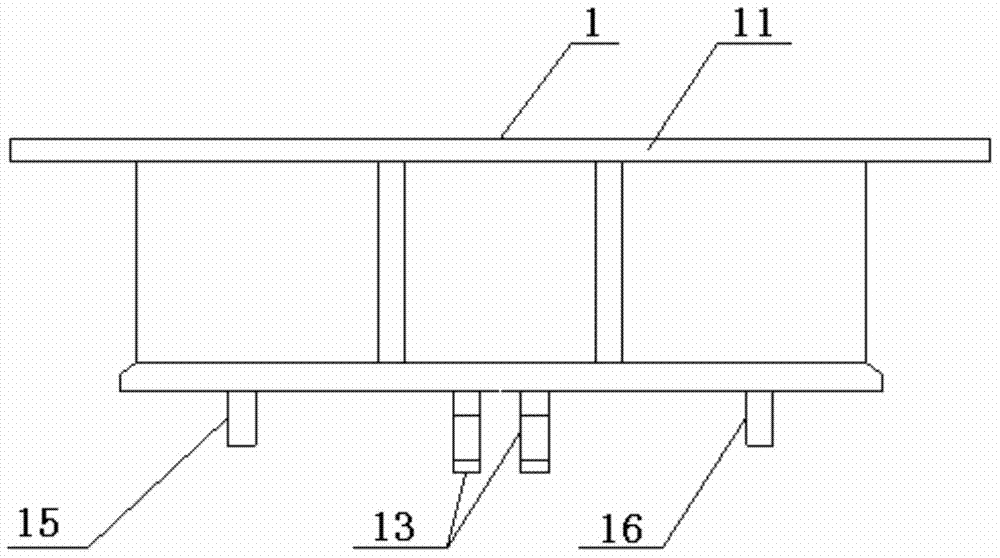

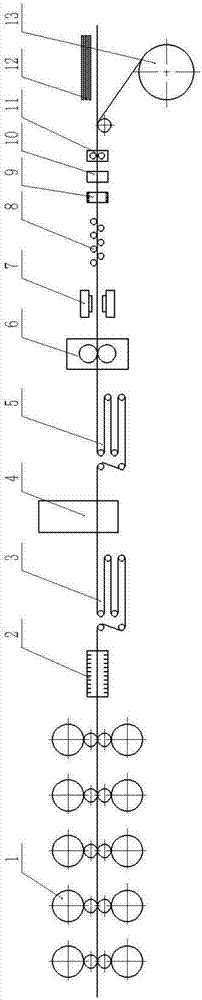

Hot continuous rolling medium-and-heavy plate production method and device without coiling micro-stress

InactiveCN101491812ARemove restrictionsIncreasing the thicknessMetal rolling arrangementsHot strip rollingSteel plates

The invention discloses a method and a device for producing coiling-free microstress hot continuously rolled medium plates. The method comprises the following steps: performing heating, rough rolling, precision rolling and cooling in turn on plate blanks in a hot rolled strip operating line; passing cooled steel plates after the rolling directly through a coiling machine and cutting the steel plates; transferring the steel plates onto a cooling bed for temperature reduction; powerfully straightening the steel plates; and finally, cutting the steel plates crossly to obtain the required medium plates. In the device, the rear of the coiling machine of the conventional hot strip mill is provided with an additional roller table; the starting area of the additional roller table is equipped with a cutting mechanism; one side of the additional roller table is provided with the cooling bed; a shifting out device is arranged between the additional roller table and the cooling bed; the tail area of the cooling bed is provided with a straightening machine; and the rear of the straightening machine is provided with a scale cross shearing mechanism. The method and the device can realize production of the medium plates with the maximum thickness of 60mm in the hot strip rolling line, also can realize alternate production of steel coils and the steel plates at the same time, effectively improve the utilization rate of the device, and increase the productivity.

Owner:WUHAN IRON & STEEL (GROUP) CORP

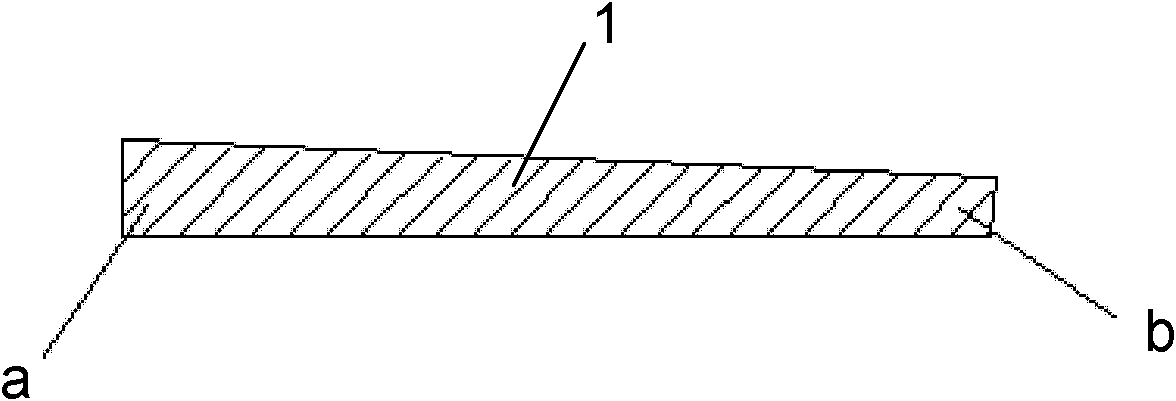

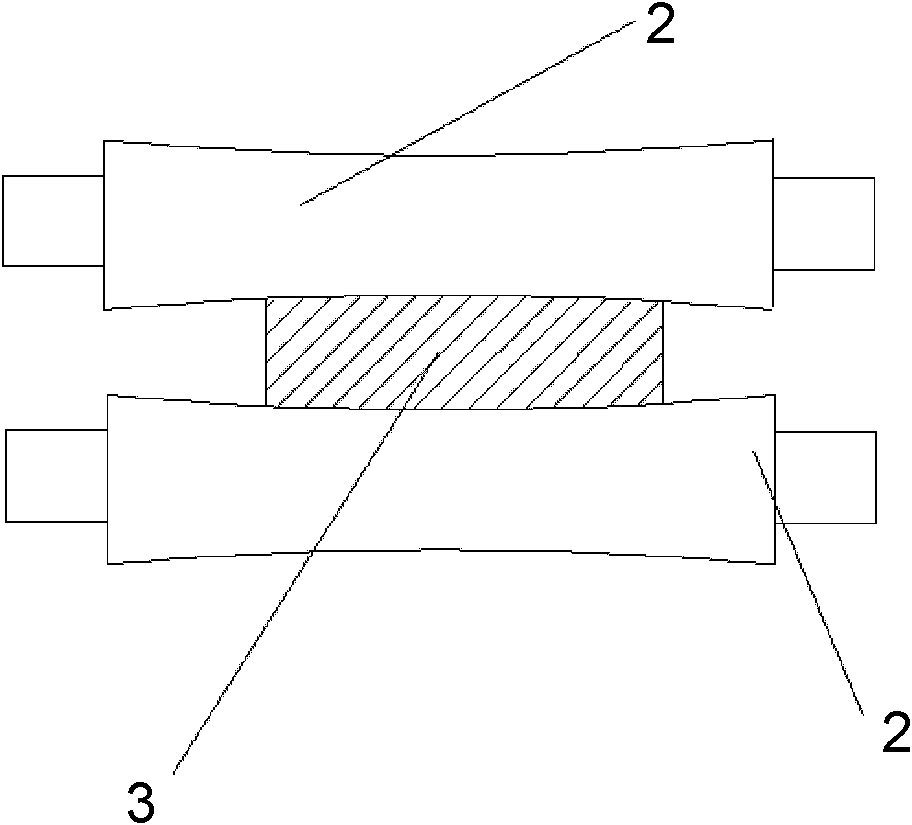

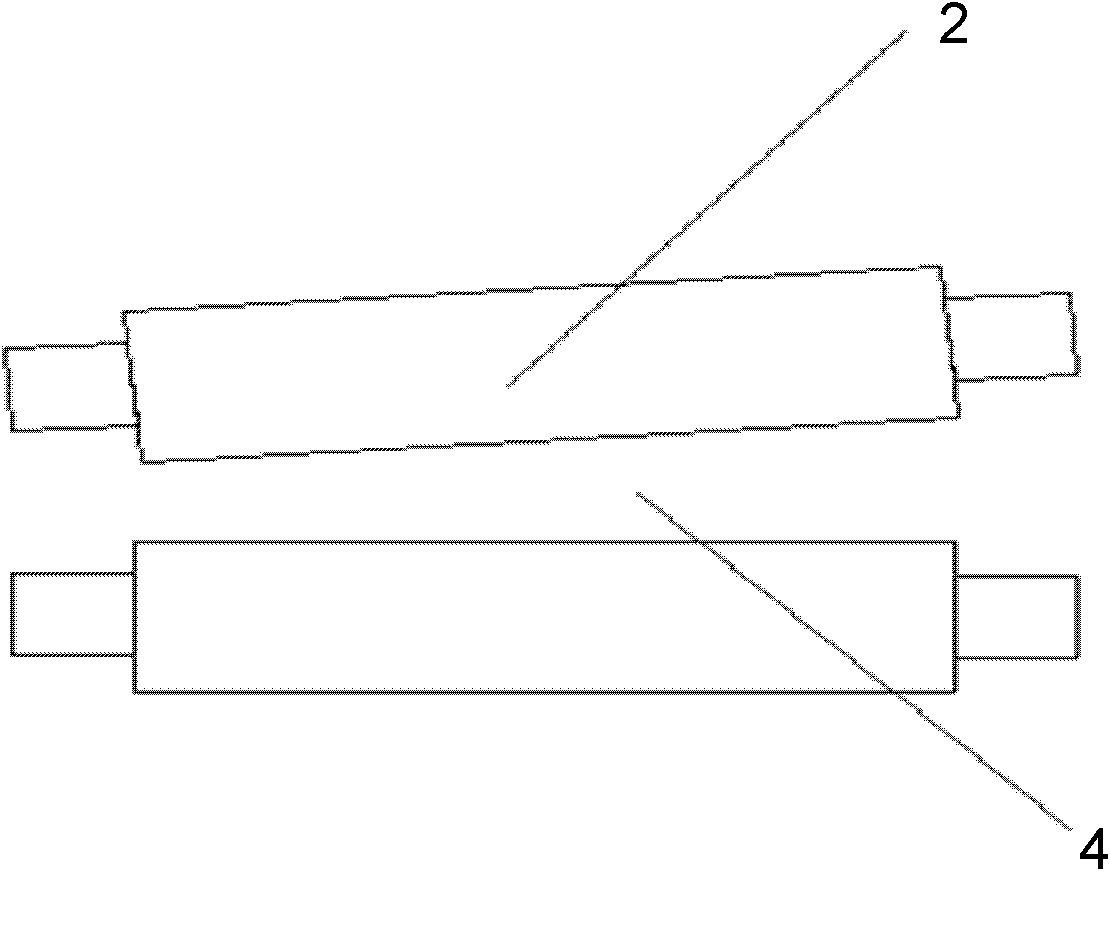

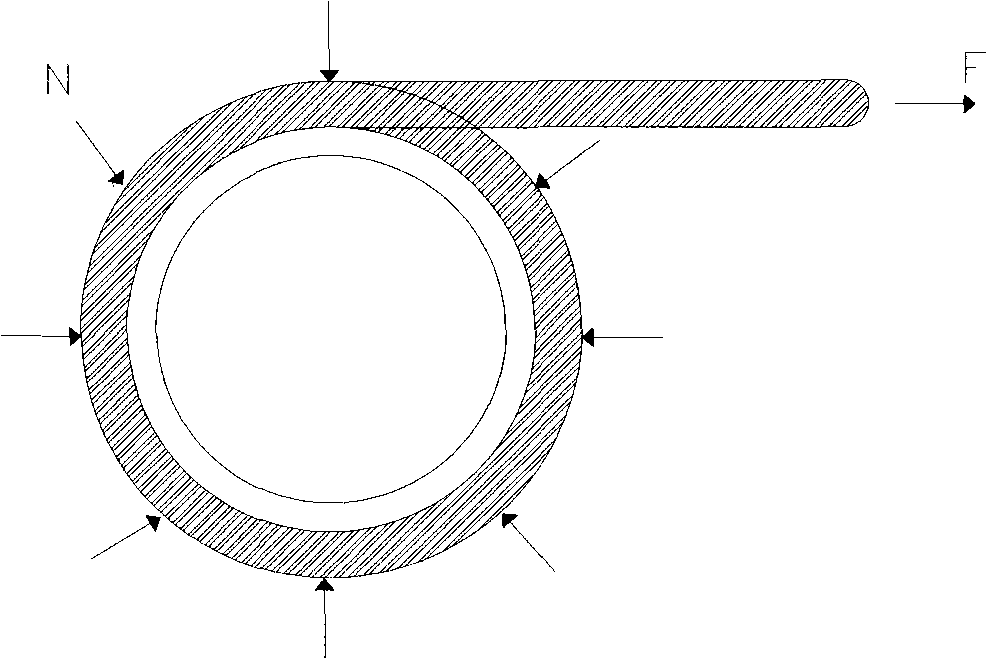

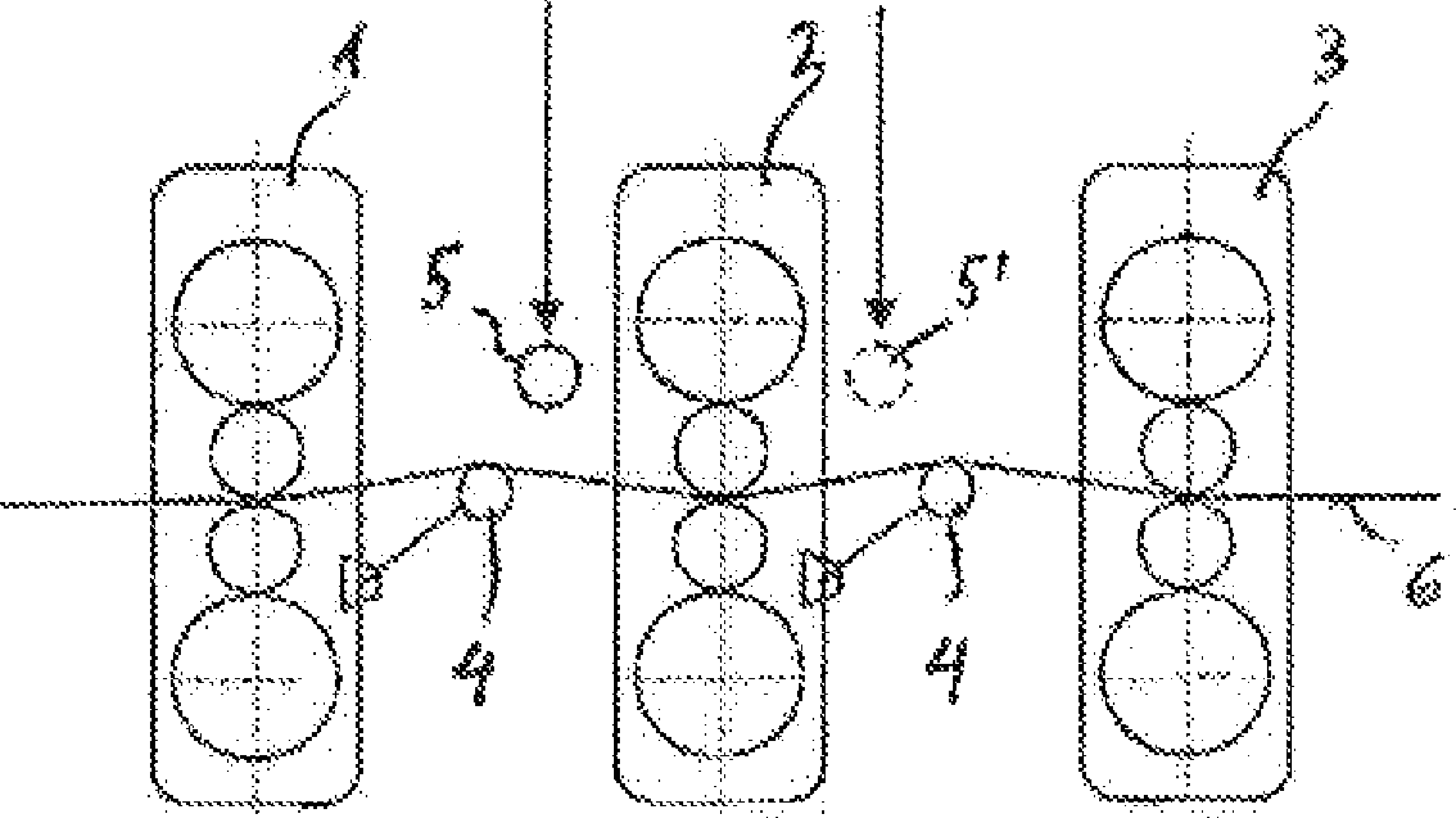

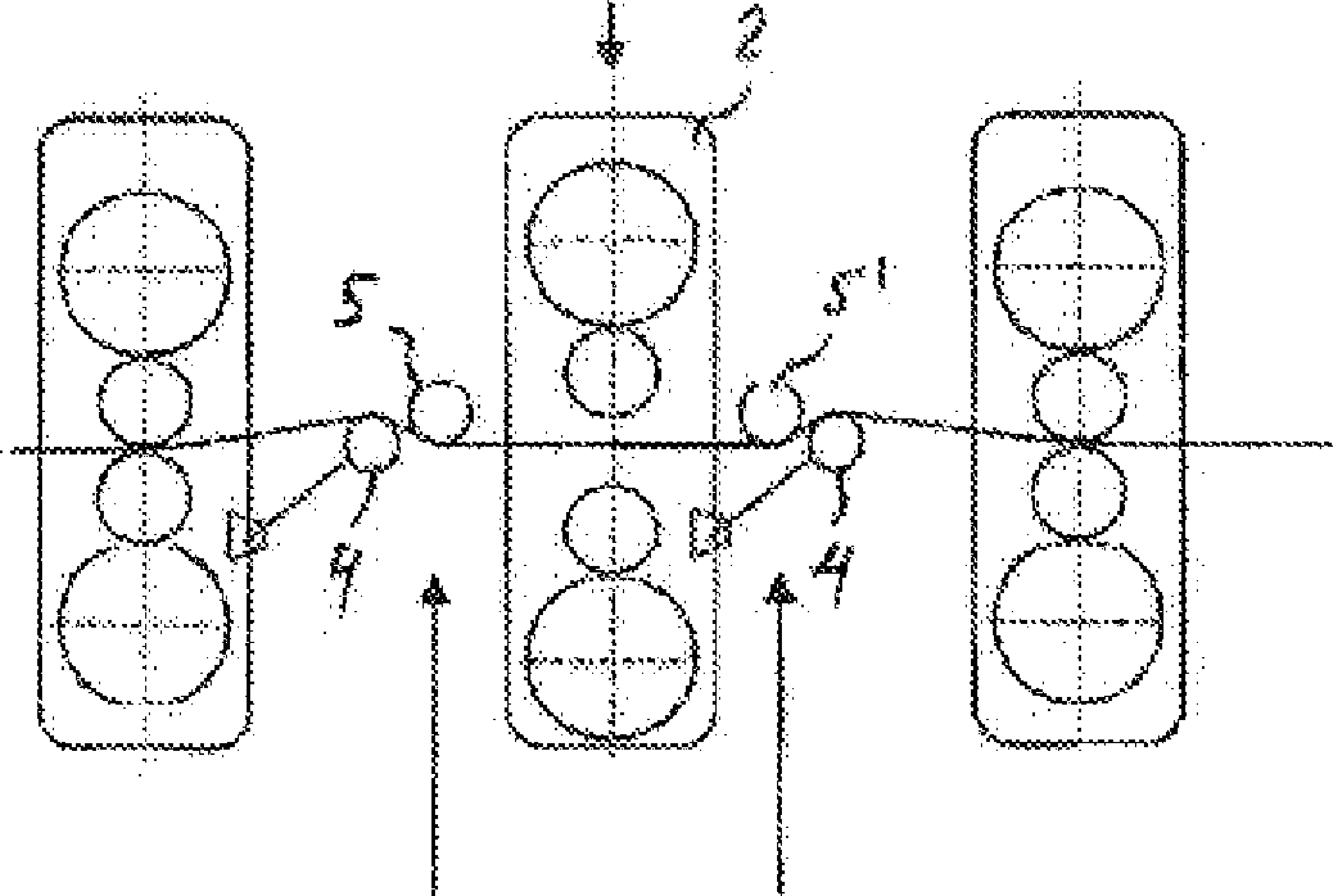

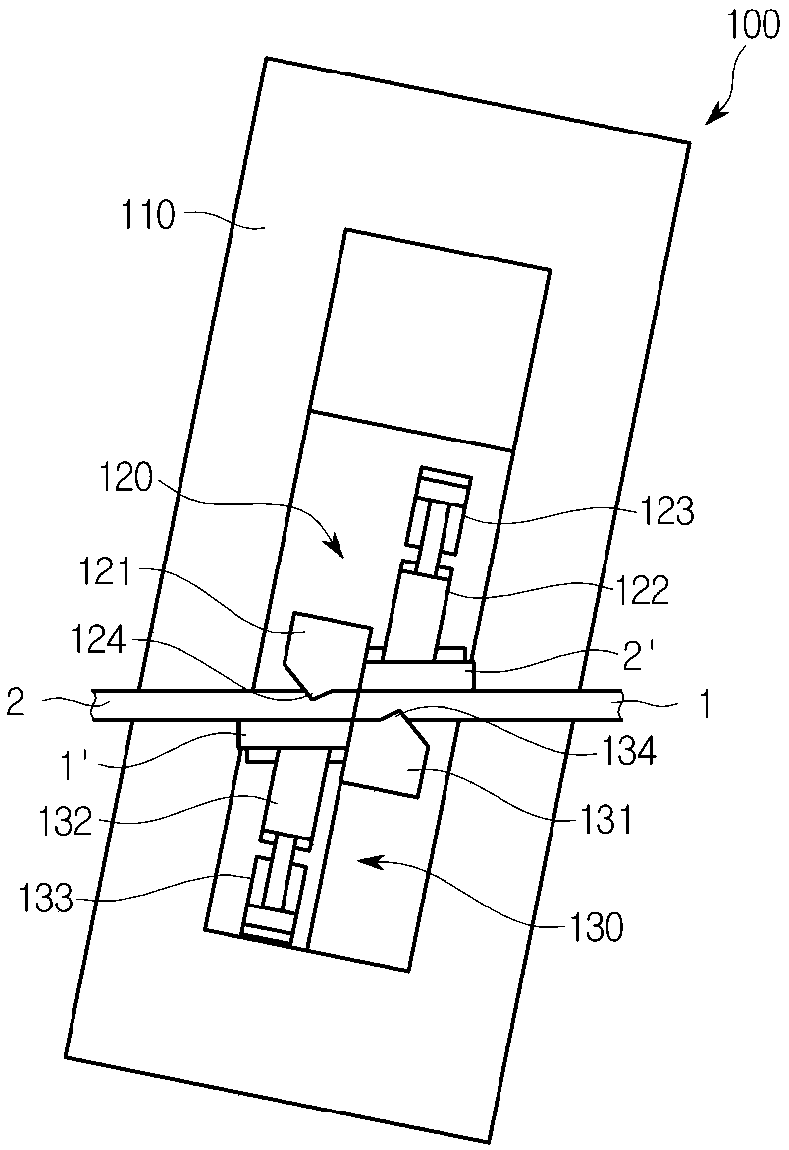

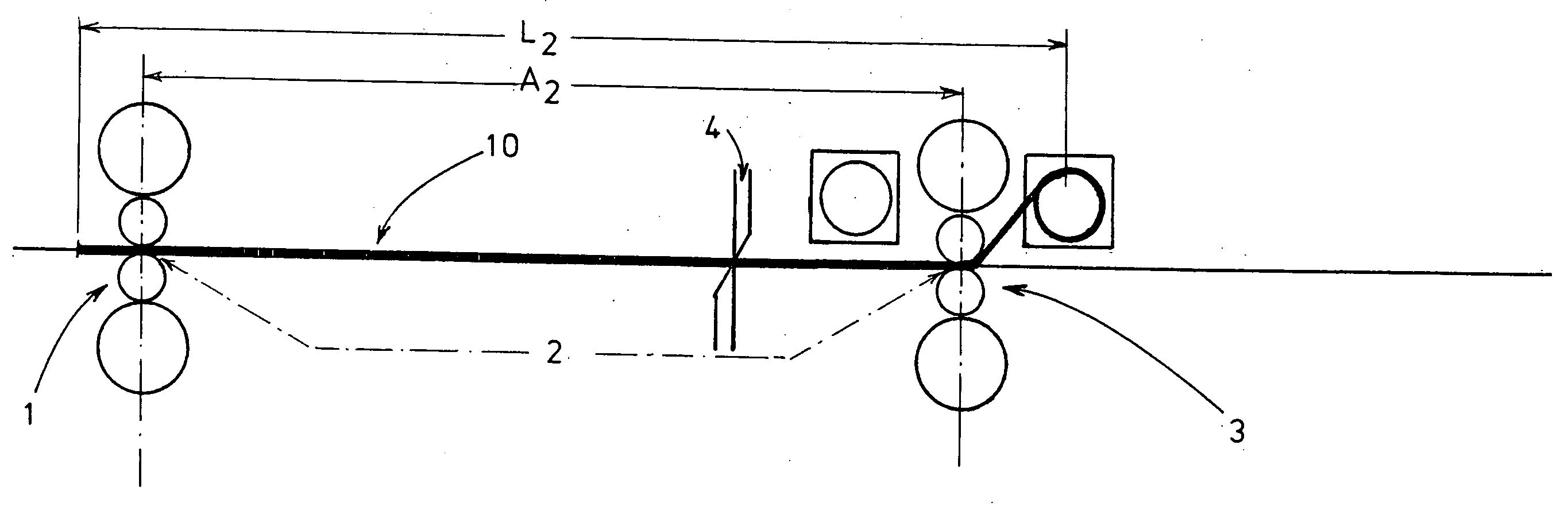

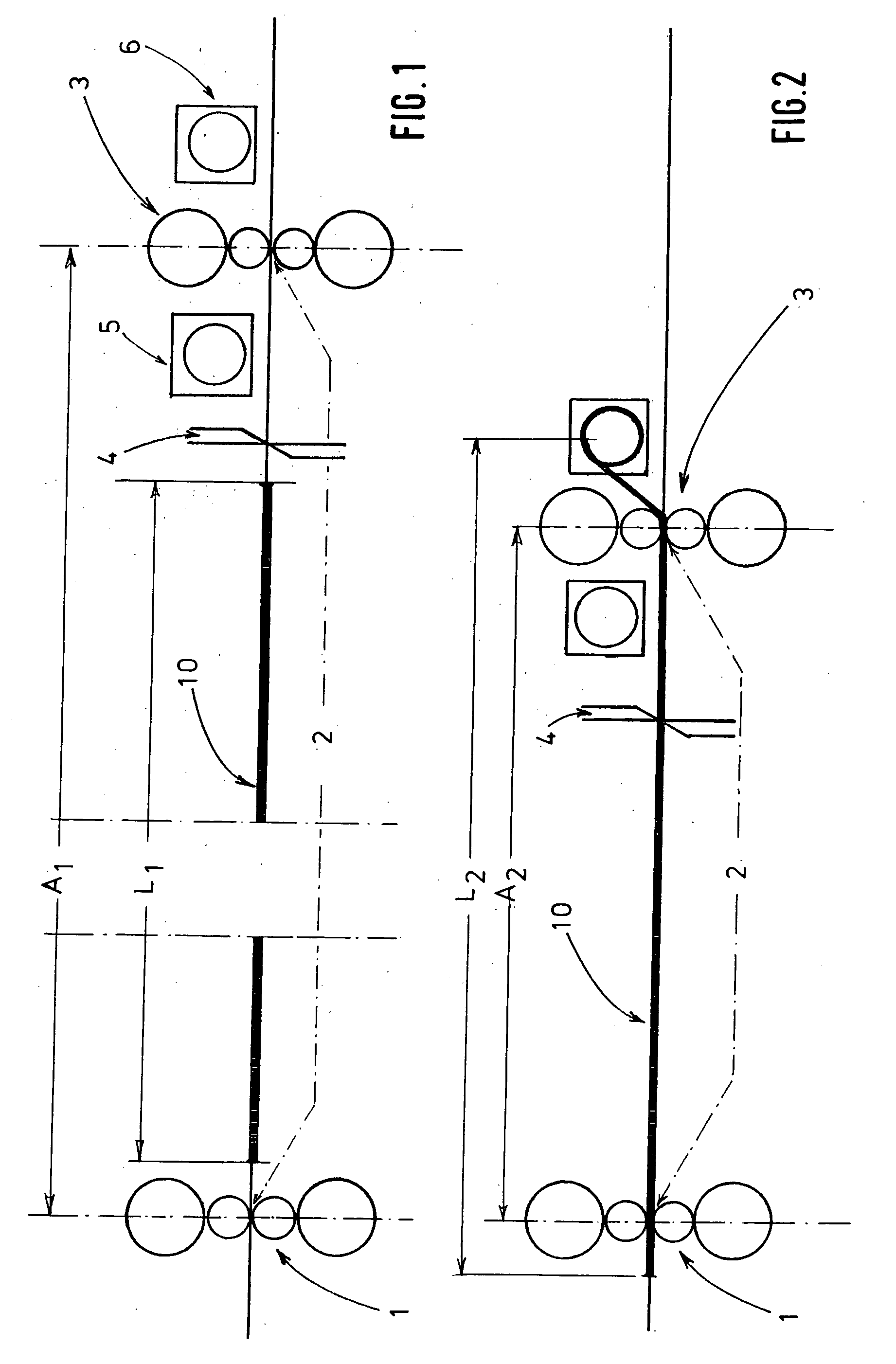

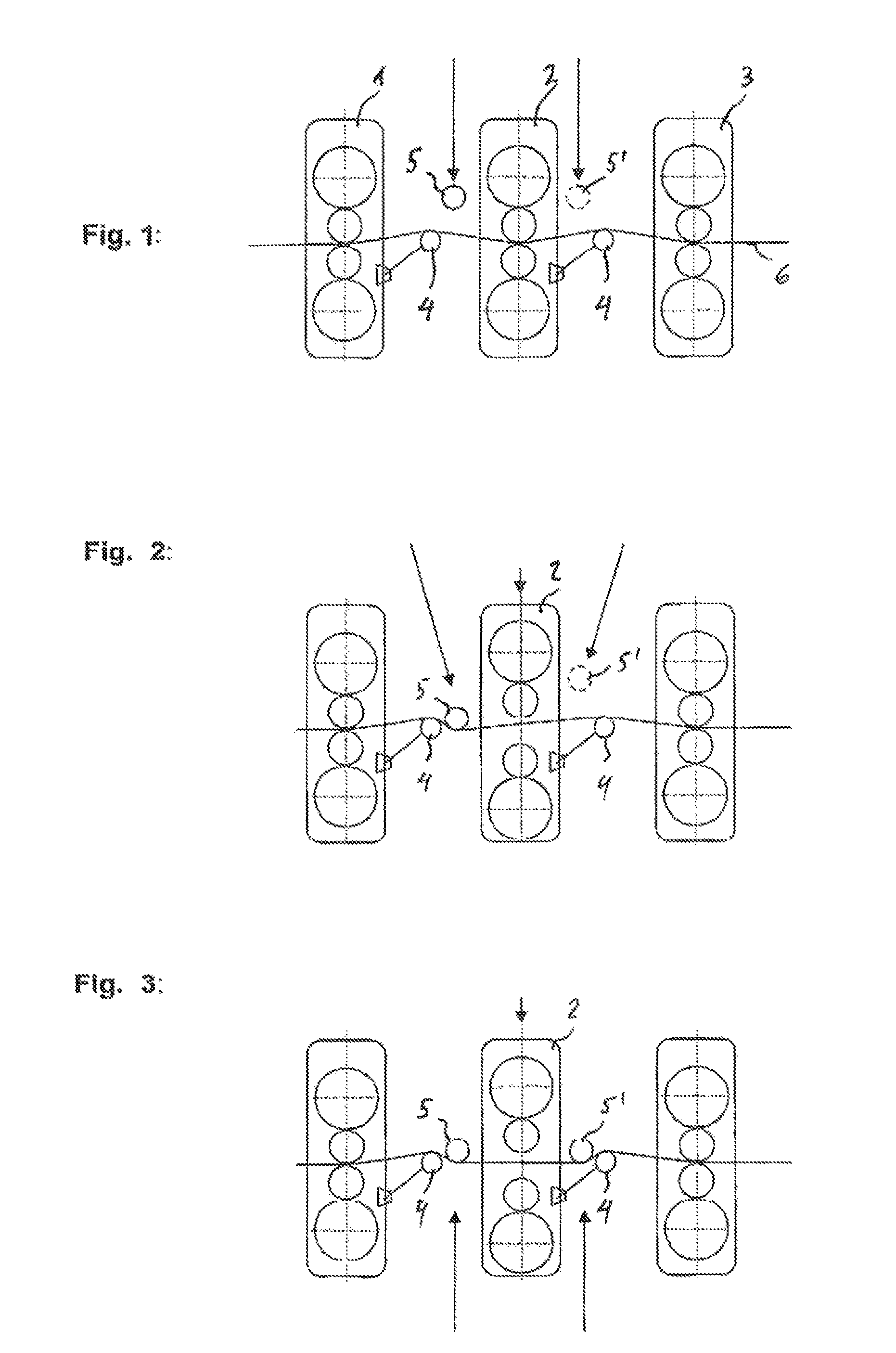

Method for the flying changing of working rolls in continuous casting and rolling installations and hot strip rolling mills using a hold-down roller

ActiveCN102933325AFurnace shorteningReduce buffer timeMetal rolling stand detailsTensioning/braking arrangementsWork rollEngineering

The invention relates to a method for the flying changing of working rolls in continuous casting and rolling installations and hot strip rolling mills, in particular continuous hot strip rolling mills, wherein, to exchange the working rolls by opening the roll stand (2), they can be disengaged from the hot strip to be rolled. According to the invention, a strip tension that can be regulated and substitutes the strip tension of the opened roll stand (2) can be applied to the hot strip (6) to be rolled, before and / or after it enters the opened roll stand (2), by means of at least one hold-down roller (5) that can be introduced into the rolling line.

Owner:SMS DEMAG AG

Hardness compensation method for controlling band steel hot-rolling molding process

ActiveCN102581028AHigh dimensional accuracySolve the problem of inaccurate calculation of rolling pressureRoll force/gap control deviceProfile control deviceHardnessMechanical engineering

The invention relates to a hardness compensation method for controlling the band steel hot-rolling molding process, including the band steel hot-rolling molding process in which band steel is rolled into a predetermined width and thickness via a plurality of rough rolling and fine rolling procedures under the control of a computer program, particularly during the switchover of band steel rough rolling and fine rolling, the hardness compensation formula in the model-controlled band steel hot-rolling molding process is F=NNFKORR'MH'coffMH'EPS, where, F is the rolling pressure, NNFKORR is a pressure self-learning coefficient, MH is a band steel calculation hardness, EPS is a percentage of reduction, and coffMH is a hardness coefficient. In the invention, the band steel hot-rolling molding pressure is controlled precisely and timely, defects of over-pressure and under-pressure in the present band steel hot-rolling process are overcome, the quality of hot-rolled band steel products is greatly improved.

Owner:TAIYUAN UNIV OF TECH

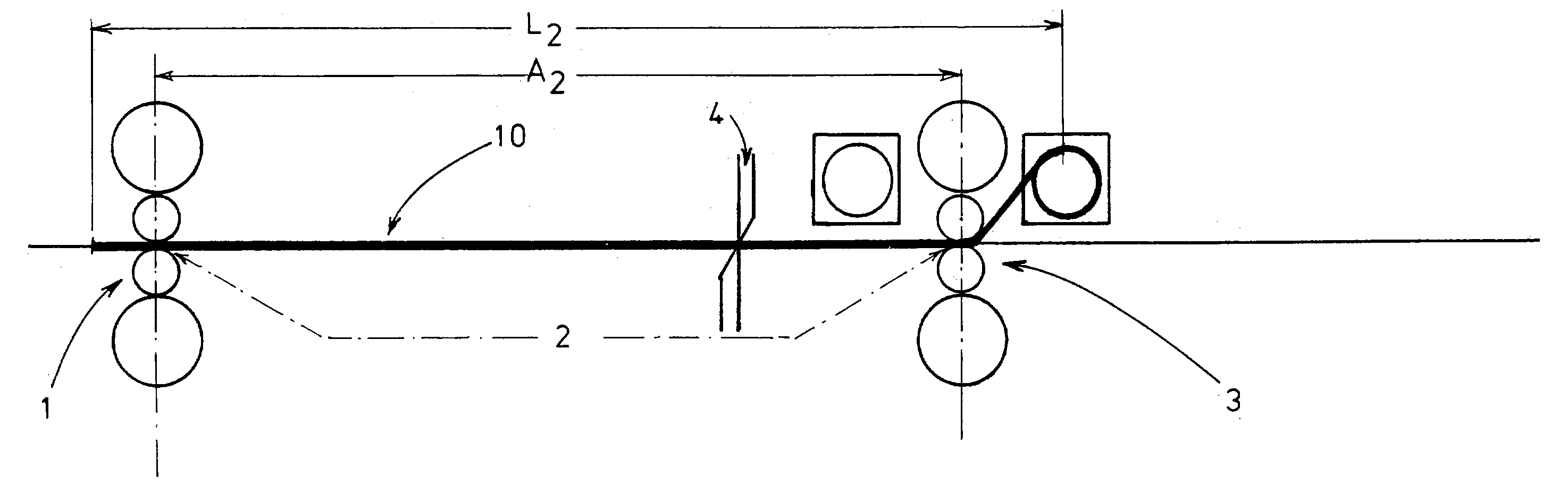

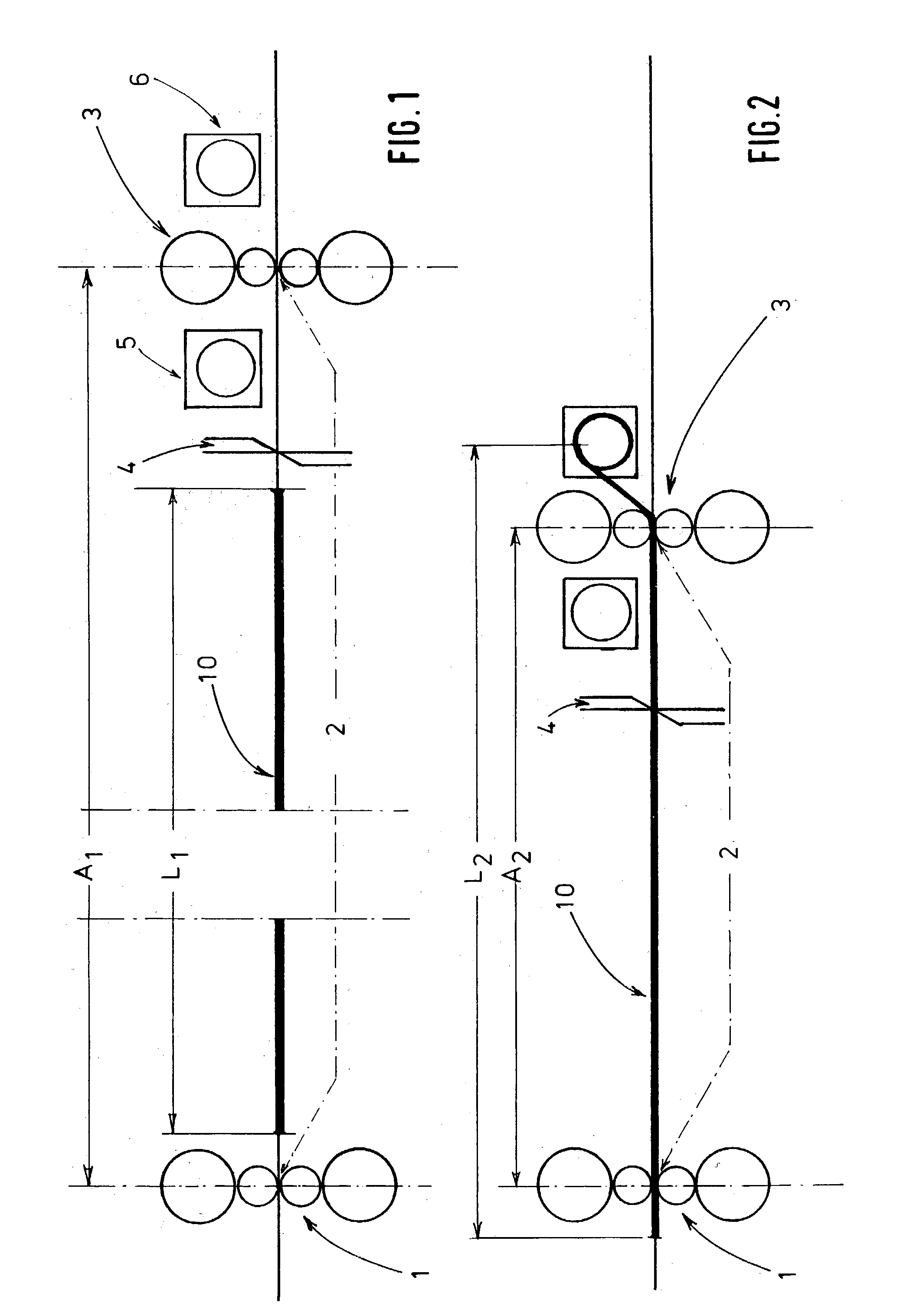

Method and plant for the hot rolling of strip

A method and a plant for the hot rolling of strip, in which the rolling stock is rolled in at least one reversing roughing stand with a number of roughing passes into a broken-down strip, and the broken-down strip is transported over an intermediate roller table into at least one Steckel finishing stand and the strip is finish-rolled in the finishing stand with a number of passes into a finished strip having a predetermined thickness, and the strip is finally wound into a coil. The length of the intermediate roller table determined by the length of the broken-down strip is shortened and tandem rolling is carried out in the roughing stand and the finishing stand at least during the last breaking-down pass of the strip.

Owner:KRAMER STEPHAN

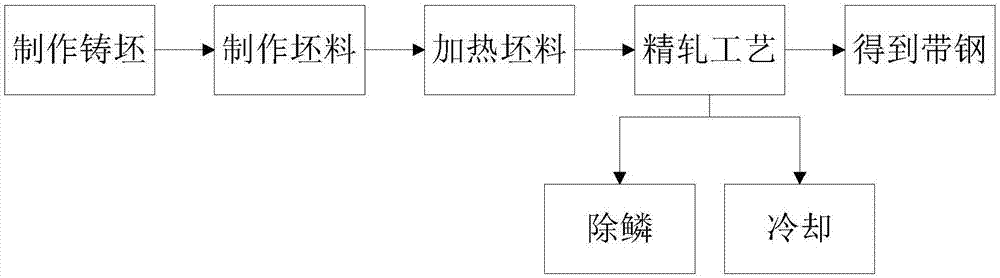

Strip steel hot rolling manufacturing technology

InactiveCN107952795AImprove warped skin defectsImprove qualityRare end control deviceWork cooling devicesManufacturing technologyTemperature difference

The invention discloses a strip steel hot rolling manufacturing technology. The strip steel hot rolling manufacturing technology comprises the steps that firstly, a casting billet with the four arc-shaped edges in the length direction is manufactured, and a billet material is manufactured; secondly, the billet material is heated through a heating furnace; and thirdly, the billet material is subjected to finish rolling through a rolling machine and cooled, and thus strip steel is obtained. According to the technology process, it is known that the four edges of the casting billet for manufacturing the strip steel are each in an arc shape, thus the four edges, in the length direction, of the manufactured strip steel are each in an arc shape, namely, the four edges, in the length direction, ofthe strip steel are omitted to reduce the difference between the edges and the middle part, and therefore the temperature difference between the edge part and the middle part of the strip steel can be reduced, so that the percentage that the strip steel is warped is decreased. Therefore, according to the strip steel hot rolling manufacturing technology provided by the invention, the warping defect of the strip steel can be overcome, the quality of the strip steel is improved, and the problems in the field at the present stage are solved.

Owner:攀钢集团西昌钢钒有限公司

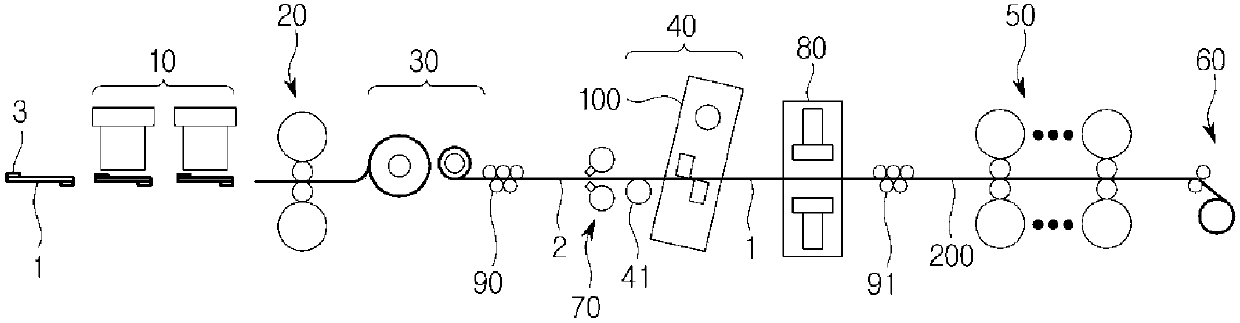

Endless hot rolling method of high grade steel

ActiveCN107716548AHigh strengthImprove rolling rateMetal rolling arrangementsShearing deformationSurface modification

The present invention discloses an endless hot rolling method of high grade steel. The endless hot rolling method of high grade steel hot strip rolling method for producing high grade steel. Accordingto the high-strength steel hot rolling method of embodiments of the present invention, the endless hot rolling method of high grade steel is joined by overlapping two ends of a plurality of joining materials and performing shear deformation includes the following steps: using Si and Cr A modified material having a smaller content than the bonding material forms a surface modification layer on atleast any of two ends overlapping the bonding material; and overlapping both ends of a plurality of bonding materials and performs shearing cut deformation.

Owner:浦项股份有限公司

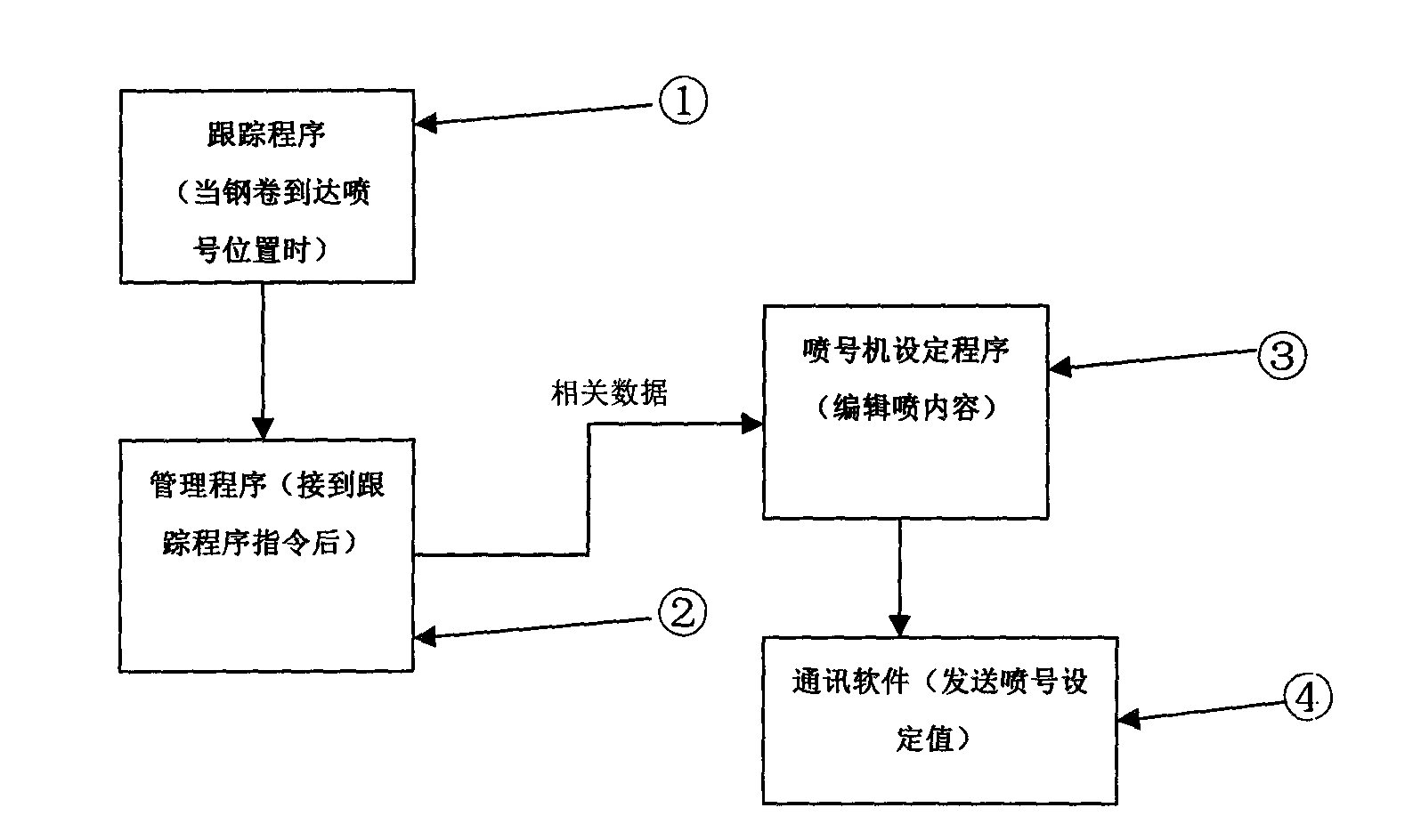

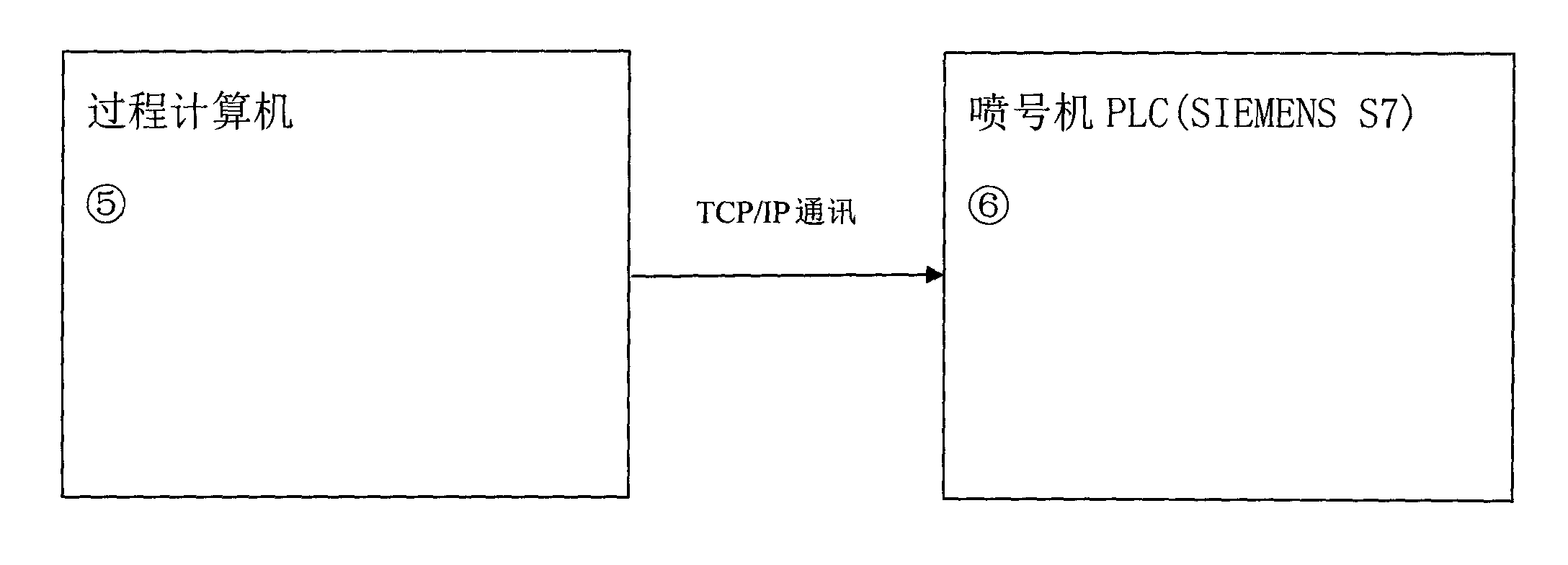

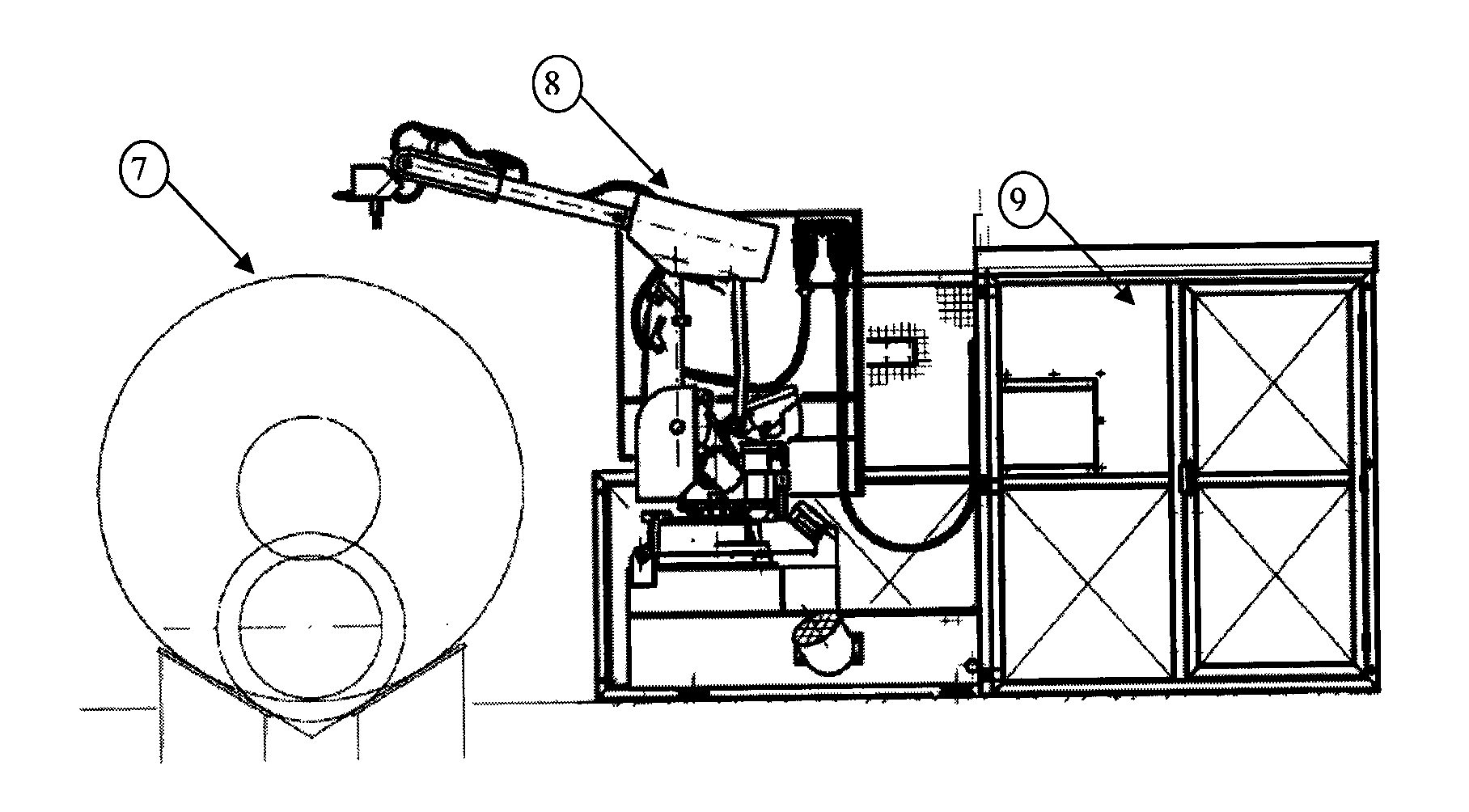

Setting control method of hot continuous rolling steel coil marking machine

InactiveCN102275392ARealize automatic number sprayingHigh degree of printing automationTypewritersOther printing apparatusComputerized systemEngineering

The setting control method of the hot continuous rolling steel coil numbering machine disclosed by the present invention belongs to the technical field of hot continuous rolling equipment control. The setting control method of the hot continuous rolling steel coil numbering machine is managed and controlled by a computer system. Coil numbering software is used to set and control the hot-rolled steel coil numbering machine to spray numbers on hot-rolled steel coils. The advantages of this method are: the hot-rolled steel coil numbering The function of the spraying machine does not need to add any new hardware equipment, and it can realize flexible control of the spraying machine, and use the limited number of printing characters to express rich hot-rolled steel coil information, and realize the hot-rolled steel coil spraying machine. Functional, automatic, modern spraying, rich and varied printing content, high degree of printing automation, reaching the advanced production level of spraying, convenient for steel coil warehouse management, meeting different and special printing requirements of different users and delivery processes Requirements; This method of hot continuous rolling steel coil numbering machine setting control is worth adopting and popularizing.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Short-process production method and device for cold-rolled steel plate punched mesh

A short-process production method for cold-rolled steel plate punching mesh, which mainly includes: after the raw material hot-rolled steel strip is pickled and pre-rolled, it is cold-rolled and continuously annealed, and then enters the stamping process for punching, cleaning and After surface treatment, cut to length, and finally get punched mesh or punched mesh roll. The equipment for the above-mentioned short-process production method of cold-rolled steel plate perforated mesh mainly includes cold continuous rolling unit, cleaning unit, inlet looper, continuous annealing unit, outlet looper, leveling unit, punching machine, straightening machine, cleaning equipment, surface treatment Equipment, shears, coilers or finished pallets. The invention combines the continuous cold rolling and continuous annealing process of the cold-rolled steel plate with the stamping and surface treatment process, so that the rolling deformation, heat treatment and deep processing process of the punching net of the cold-rolled steel plate are recombined, and the production process is shortened compared with the traditional production process. The process reduces the logistics and transportation, reduces the production cost, increases the product price per unit weight, and increases the economic benefits of the steel plant.

Owner:YANSHAN UNIV

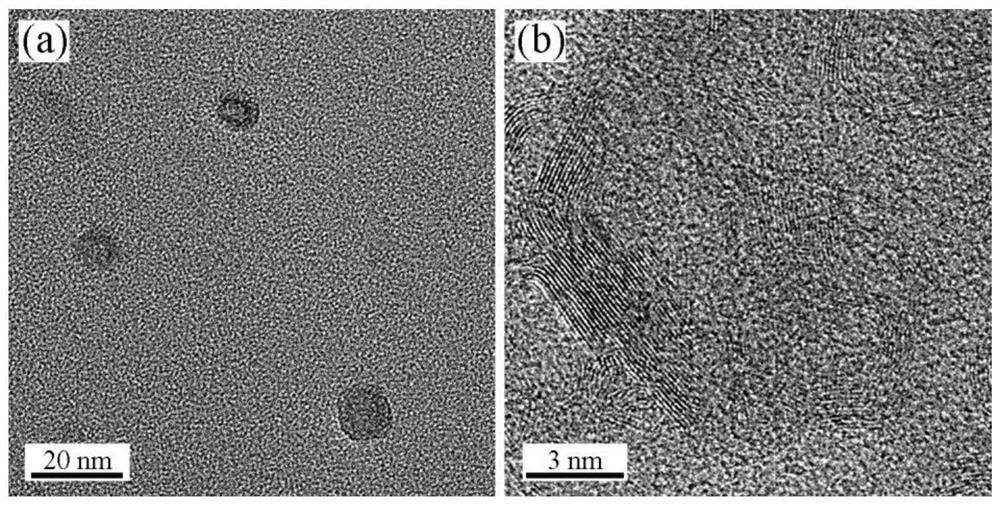

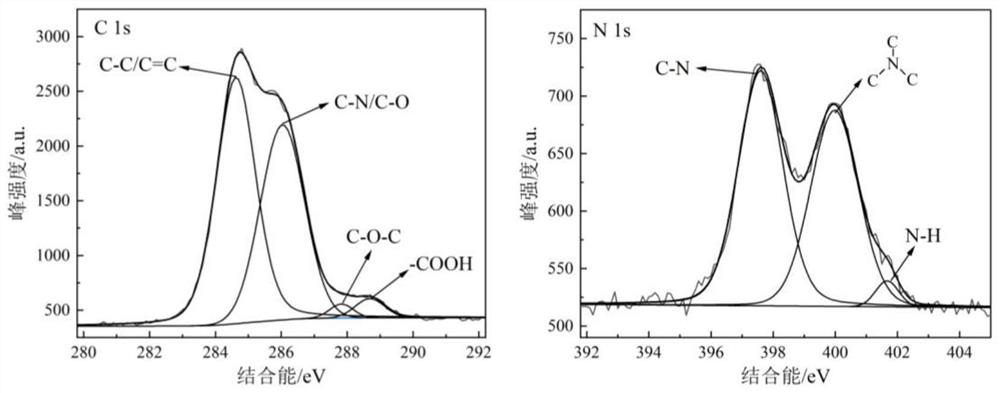

Preparation method of nitrogen-doped carbon quantum dot reinforced hBN nanofluid lubricant

ActiveCN113999710AImprove dispersion stabilityNo reunionAdditivesNano-carbonBetaineHexagonal boron nitride

The invention provides a preparation method of a nitrogen-doped carbon quantum dot reinforced hBN nanofluid lubricant, and belongs to the technical field of lubrication, a dopamine derivative is adopted as a carbon and nitrogen source, an inorganic carbonizer and deionized water are added, and nitrogen-doped carbon quantum dots are synthesized by a solvothermal method; then the prepared nitrogen-doped carbon quantum dots are dispersed into deionized water, and hexagonal boron nitride nanoparticles, a friction modifier composition A, a betaine type surfactant composition B, an ionic dispersant composition C and a defoaming agent are are sequentially and gradually added so as to obtain the required nitrogen-doped carbon quantum dot reinforced hBN nanofluid lubricant. The preparation process is simple, reproducibility is good, cost is low, efficiency is high, and the obtained nanofluid lubricant has good dispersion stability, can effectively reduce friction force and rolling force in the process when being used for plate and strip steel hot rolling process lubrication, improves the surface quality of rolled plate and strip steel, and promotes energy conservation, emission reduction and environment-friendly production in the plate and strip steel rolling process.

Owner:UNIV OF SCI & TECH BEIJING

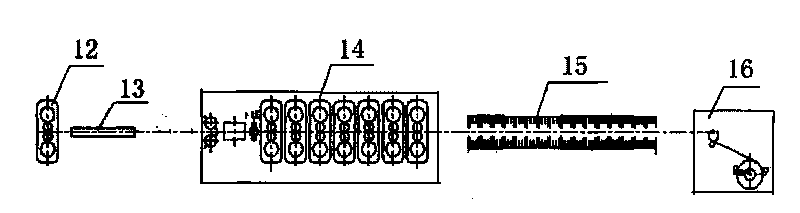

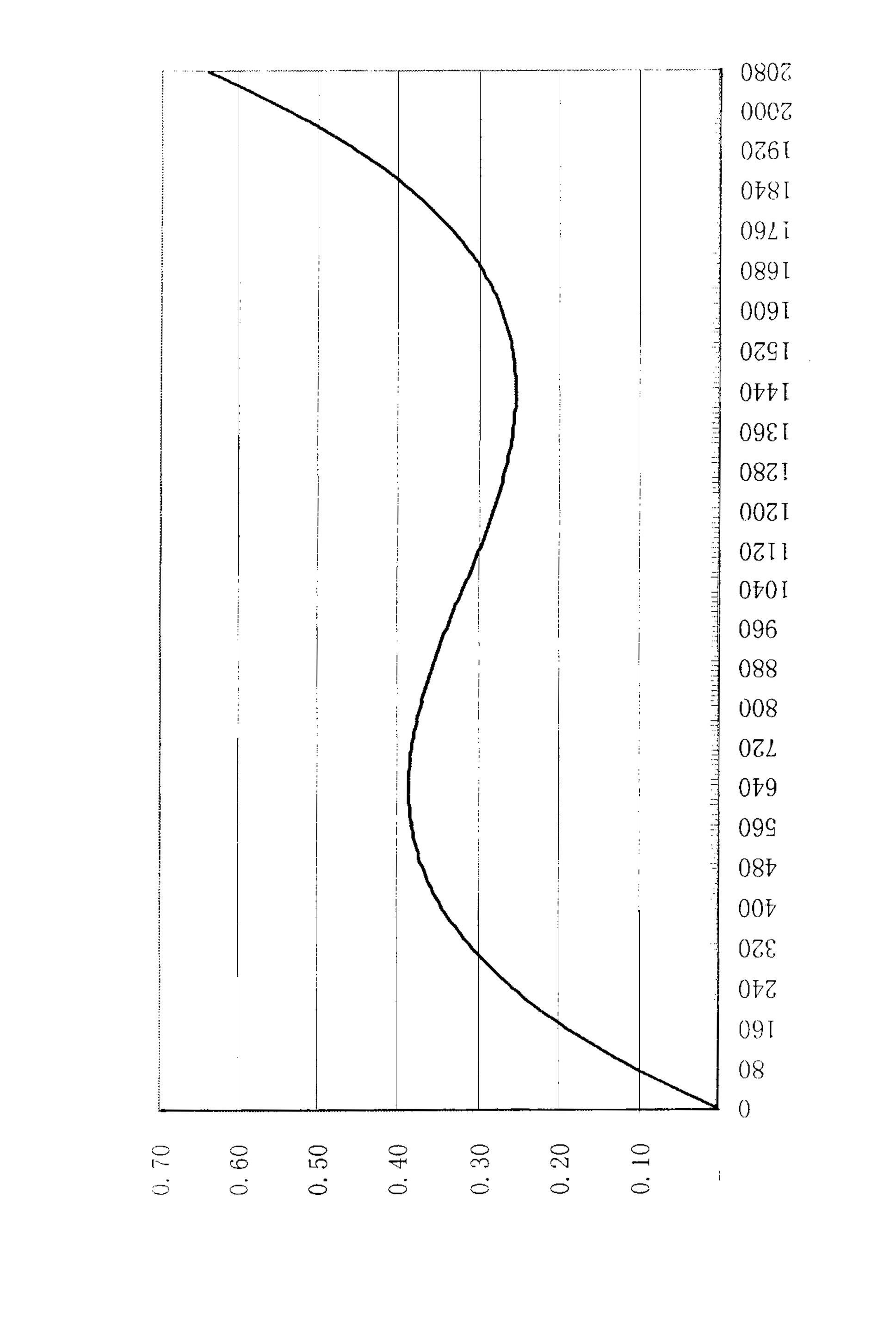

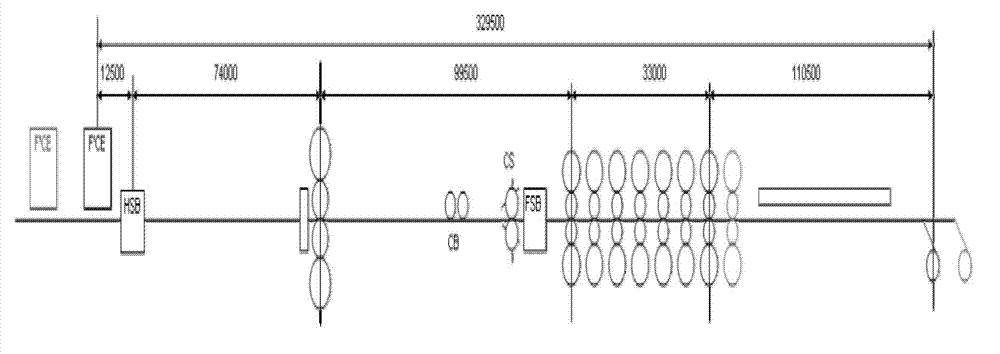

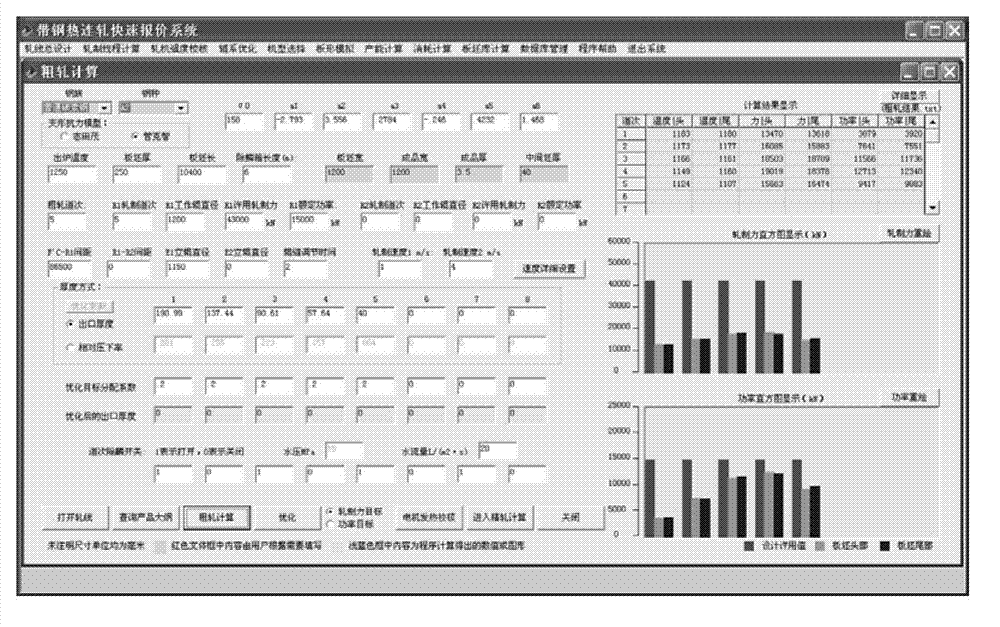

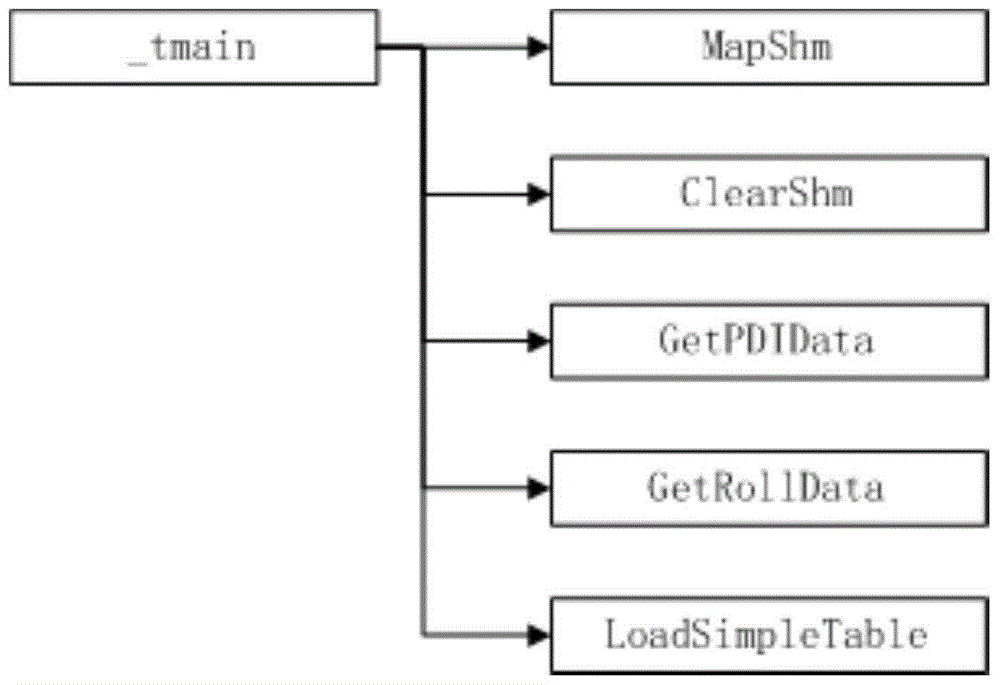

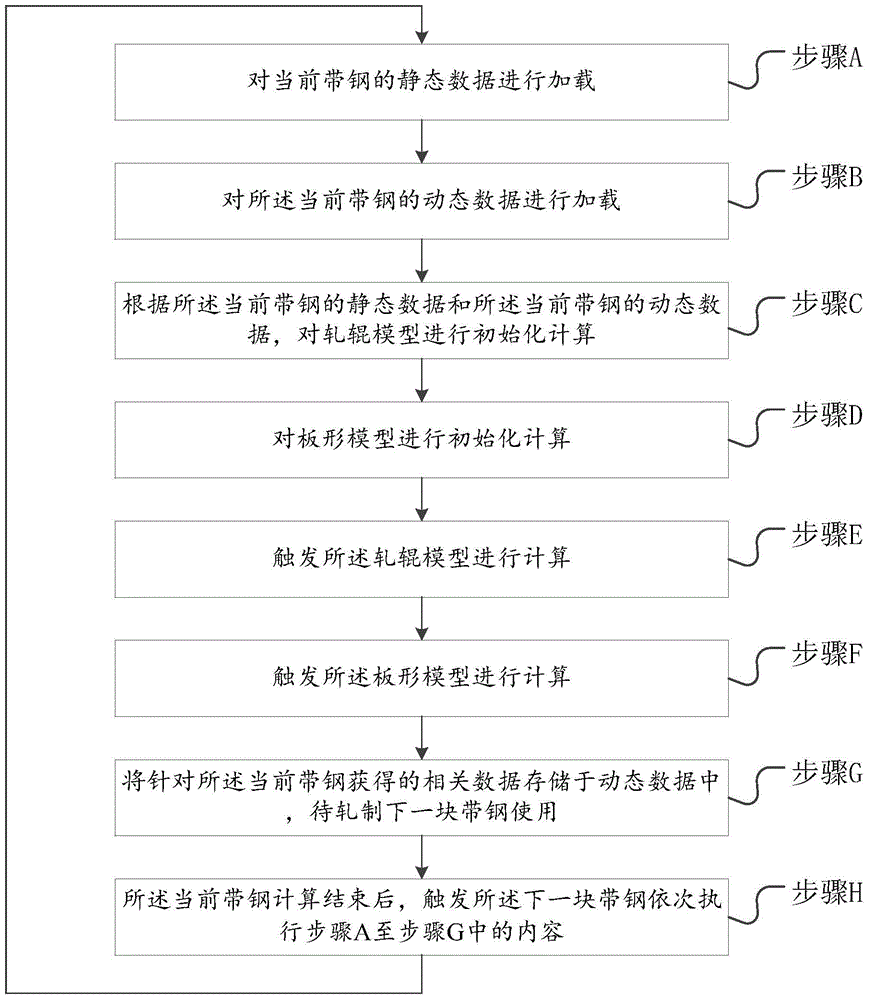

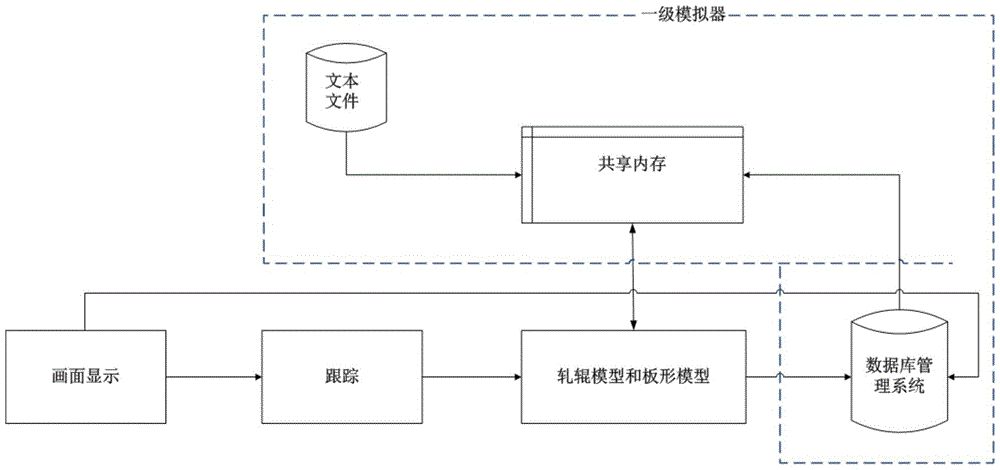

A second-level process simulation method for hot strip rolling

ActiveCN104174655BQuality assuranceAccurate Simulation GuaranteeProfile control deviceEngineeringStrip steel

Owner:SHOUGANG CORPORATION

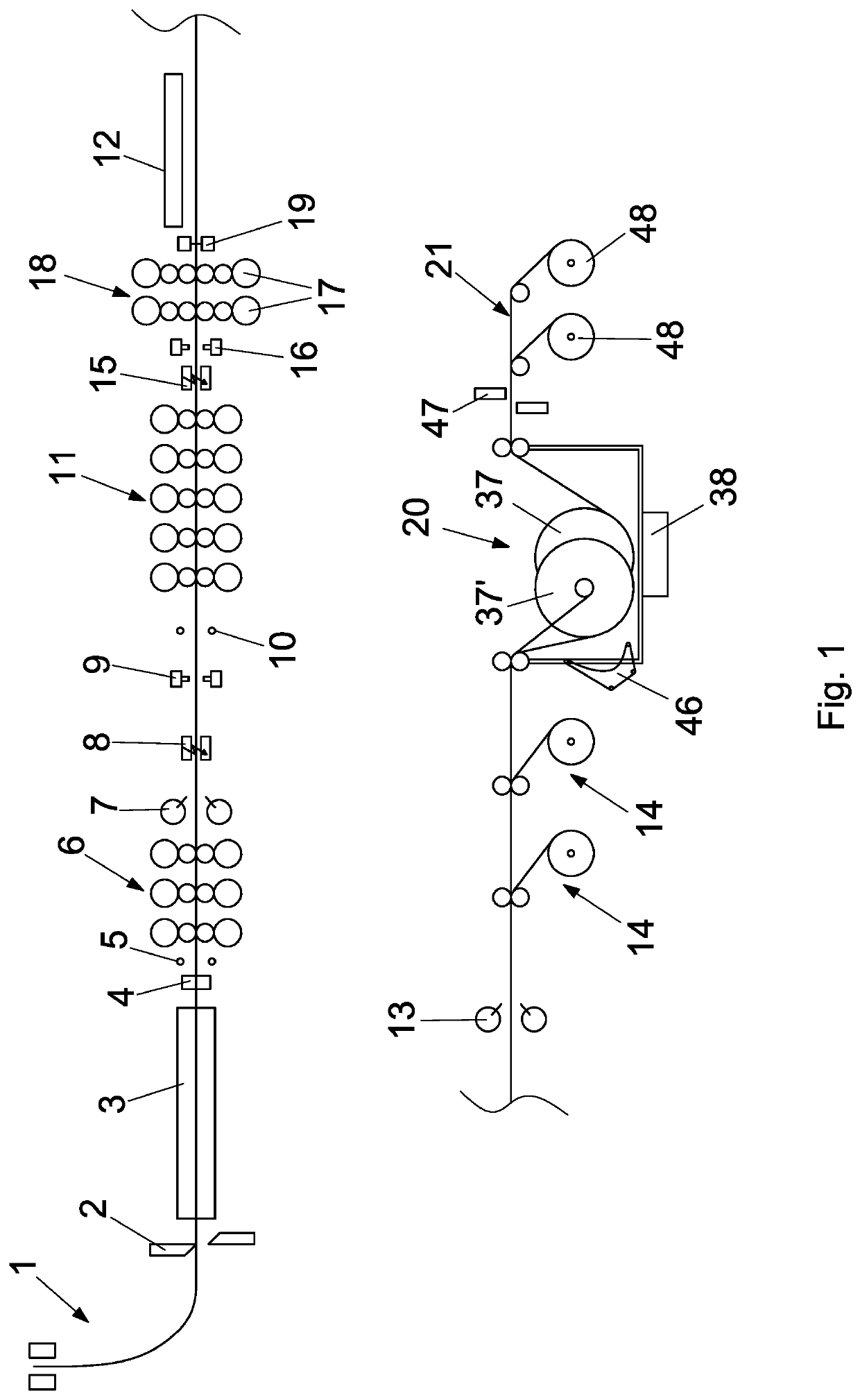

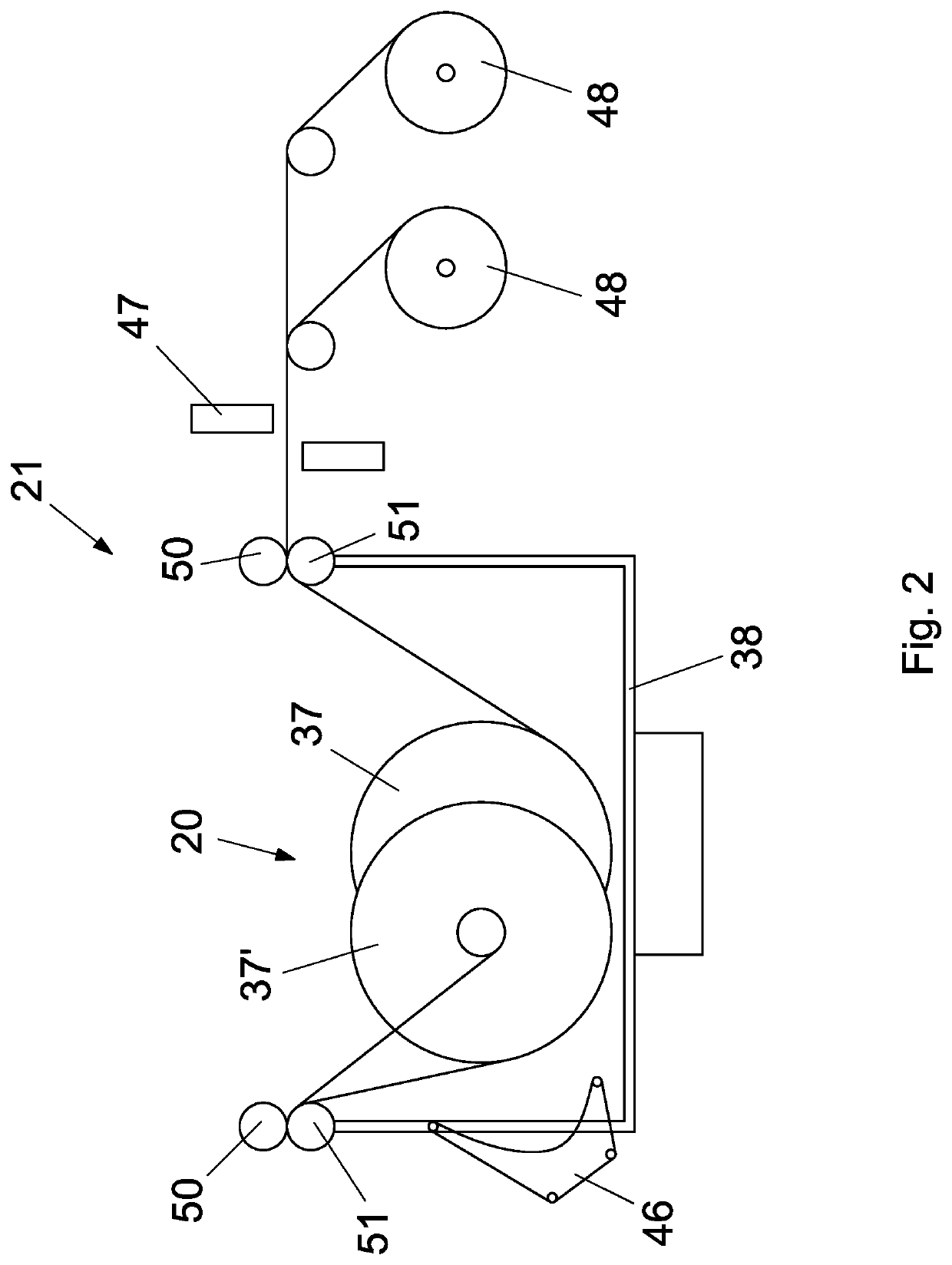

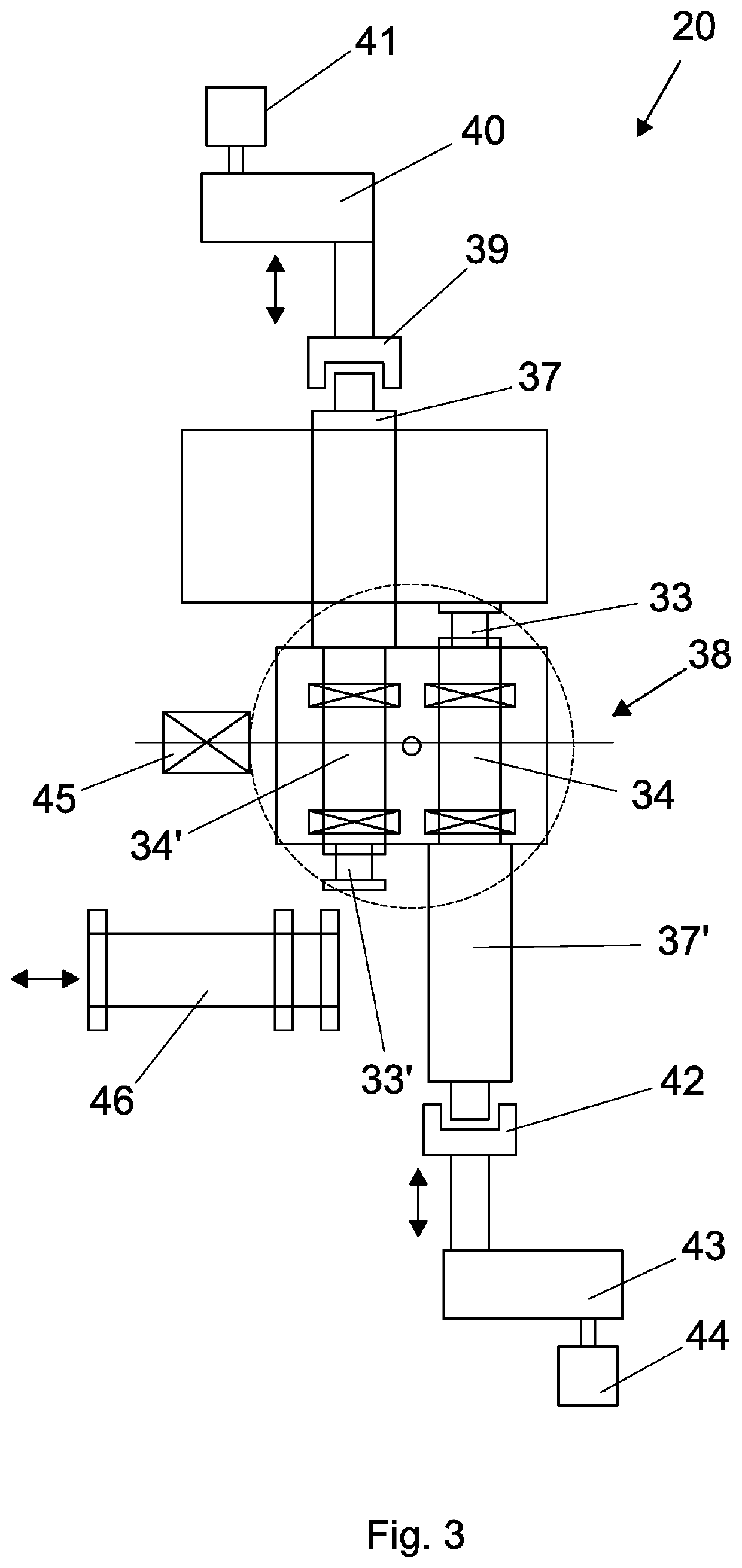

Combined continuous casting and metal strip hot-rolling plant

ActiveUS20200086368A1Avoid difficultyImprove mechanical propertiesWork heating devicesMetal rolling arrangementsEngineeringContinuous casting

A combined continuous casting and endless rolling plant for a metal strip, comprising—a continuous casting line (1) for casting a slab;—a first rolling mill (6) for roughing the slab and for obtaining a transfer bar;—a second rolling mill (11) for finishing the transfer bar and for obtaining a strip;—a third rolling mill (18), comprising at least two rolling stands (17), for further reducing the N thickness of the strip;—accumulation means (20) of the strip comprising at least one first reel (37, 37′) dimensioned to wind and unwind a coil weighing from 80 to 250 metric tons and / or up to 6 meters in diameter, named mega coil;—first cutting means (13), arranged between said third rolling mill (18) and said accumulation means (20), configured to cut the strip after the mega coil has been wound on the at least one first reel (37, 37′);—at least one second reel (48) for winding portions of strip, unwound from said accumulation means (20), up to a predetermined weight limit or coil diameter limit;—second cutting means (47), arranged between said accumulation means (20) and said at least one second reel (48), adapted to cut the strip whenever a portion of strip wound on the at least one second reel (48) reaches said predetermined weight limit or coil diameter limit.

Owner:DANIELI & C OFF MEC SPA

Method and plant for the hot rolling of strip

Owner:KRAMER STEPHAN

A high-strength and high-toughness hot-rolled weather-resistant steel plate and its preparation method

ActiveCN106947913BExcellent cold forming performanceGood welding performanceChemical compositionSheet steel

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

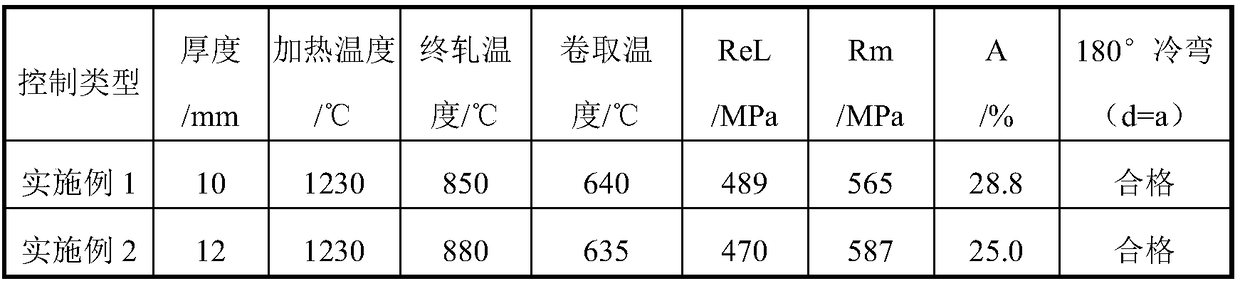

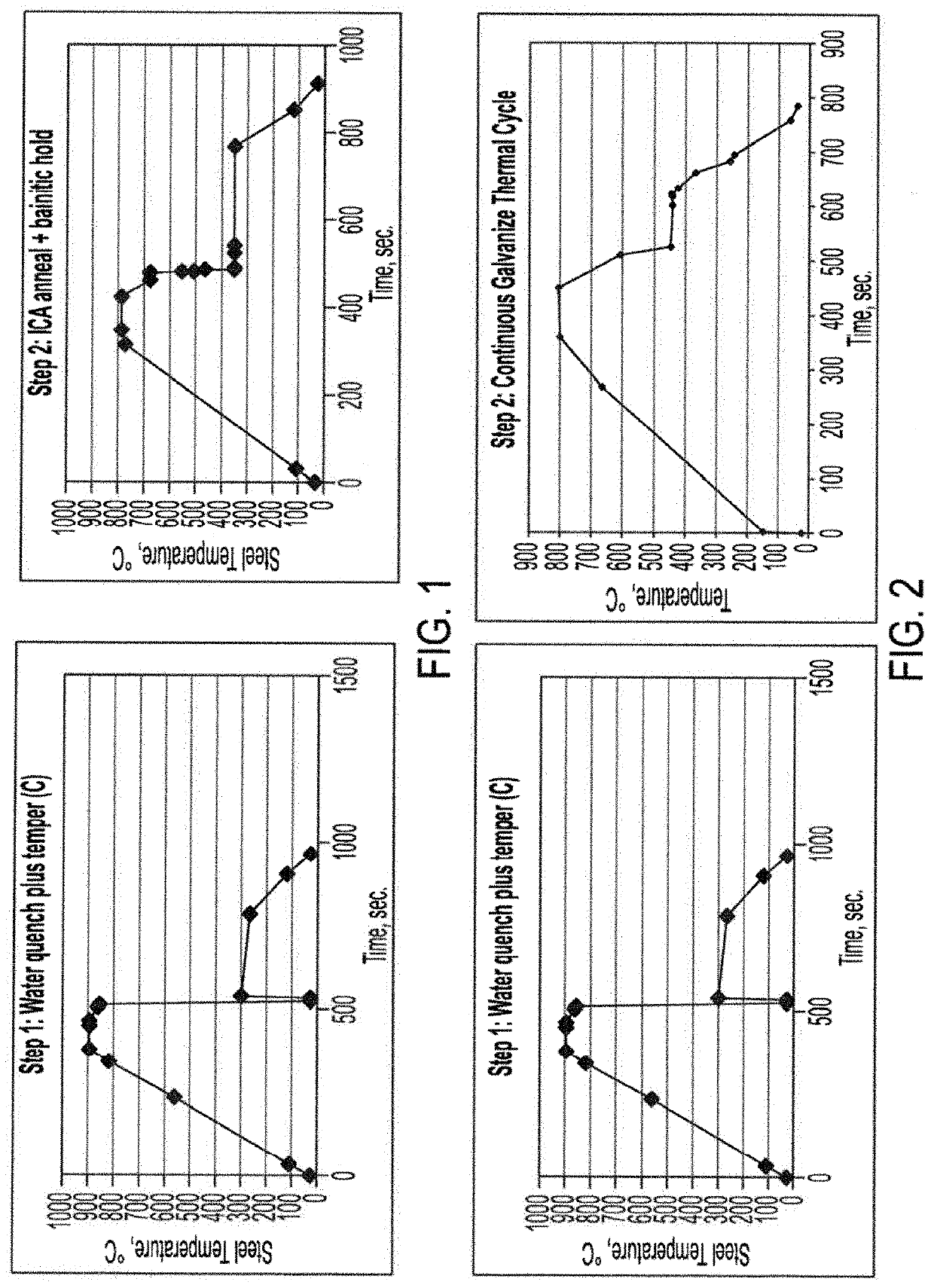

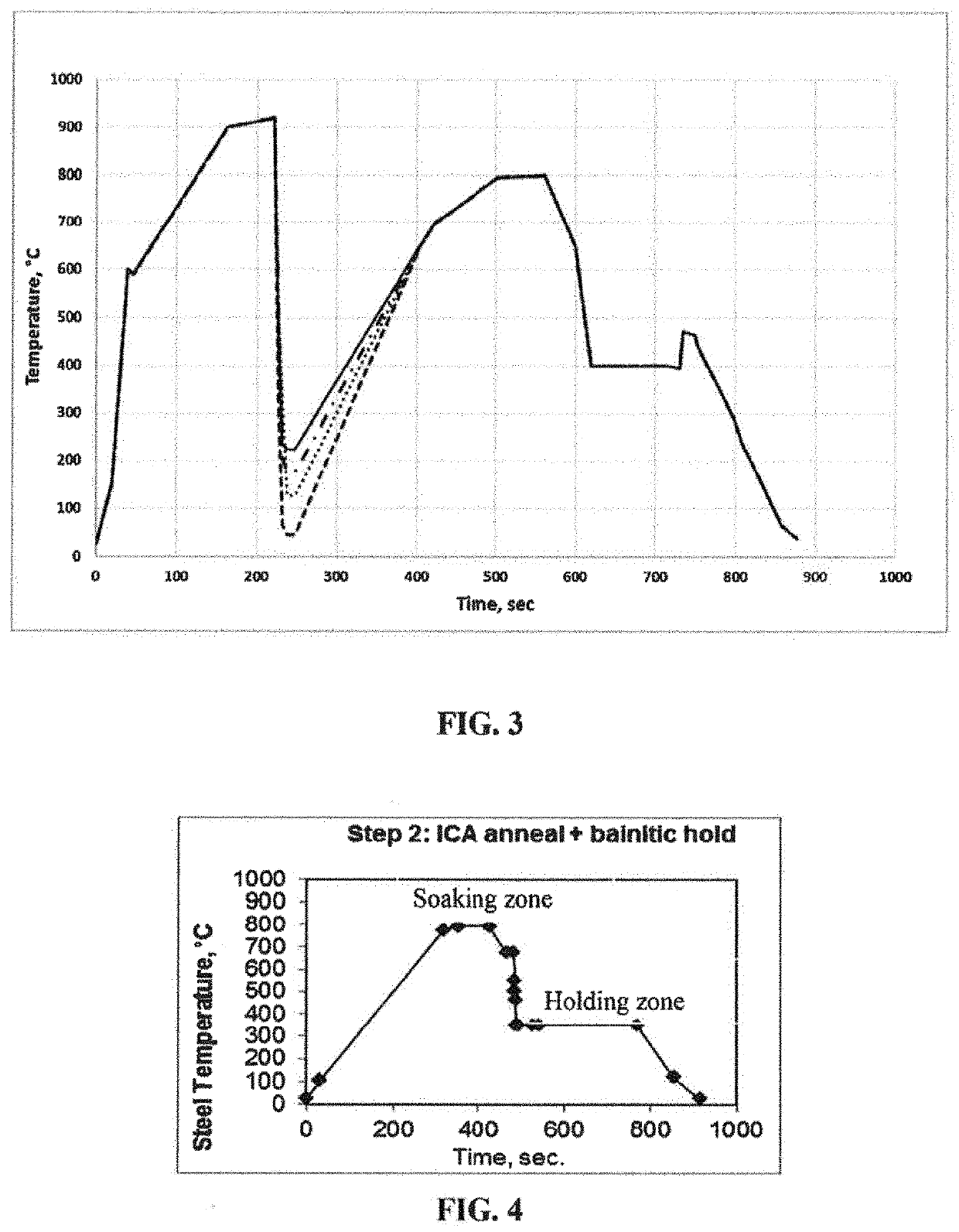

Methods of producing continuously cast hot rolled high strength steel sheet products

ActiveUS20200332385A1High strengthMaintain good propertiesFurnace typesHeat treatment furnacesUltimate tensile strengthAustenite

Methods of producing high strength continuously cast hot rolled steel sheet products are disclosed. The methods include continuously casting a steel slab and then hot rolling with finish rolling on a hot strip mill, quenching on the hot strip mill to form a predominantly matrensitic microstructure, and performing a thermal cycling step including soaking at an intercritical temperature followed by holding at a lower temperature. The resultant hot rolled steel sheet products have a microstructure comprising ferrite and retained austenite. Steels processed in accordance with the present invention exhibit favorable combined ultimate tensile strength and total elongation (UTS·TE) properties, and may fall into the category of Generation 3 advanced high strength steels, desirable in various industries including automobile manufacturers.

Owner:USX CORP

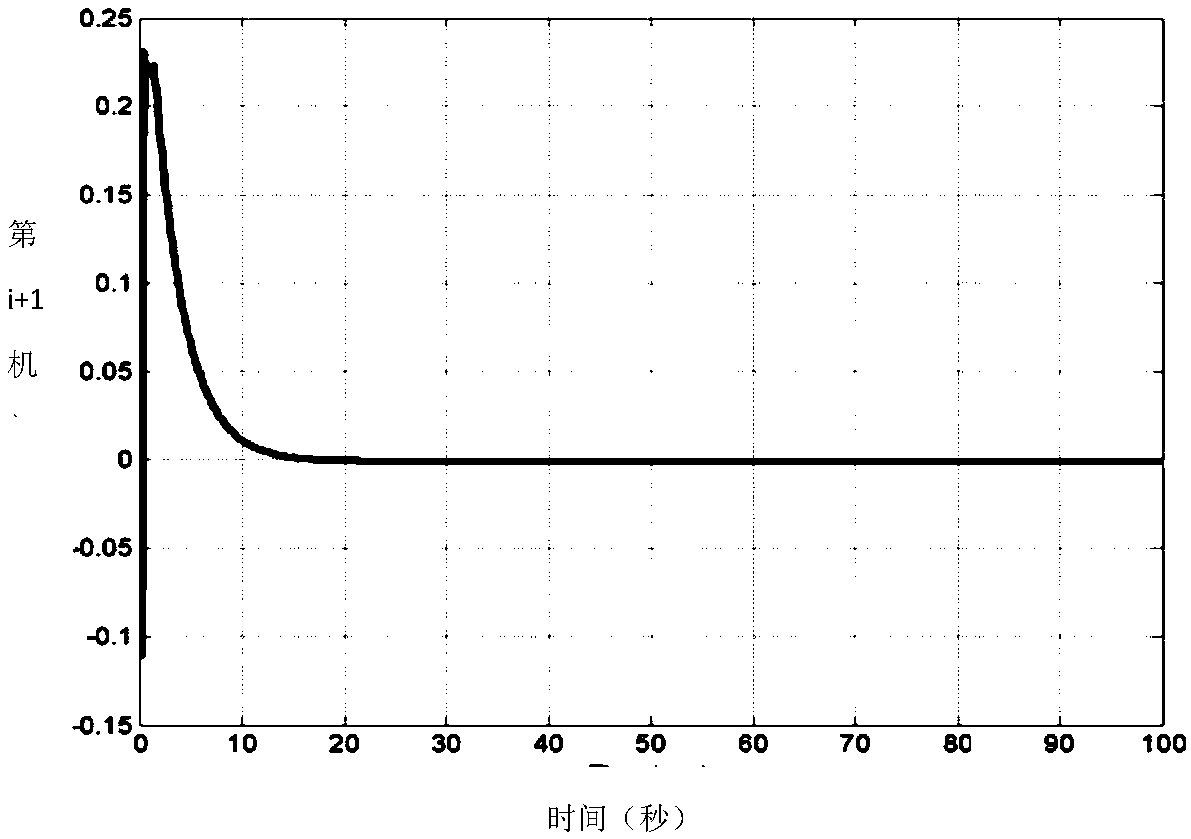

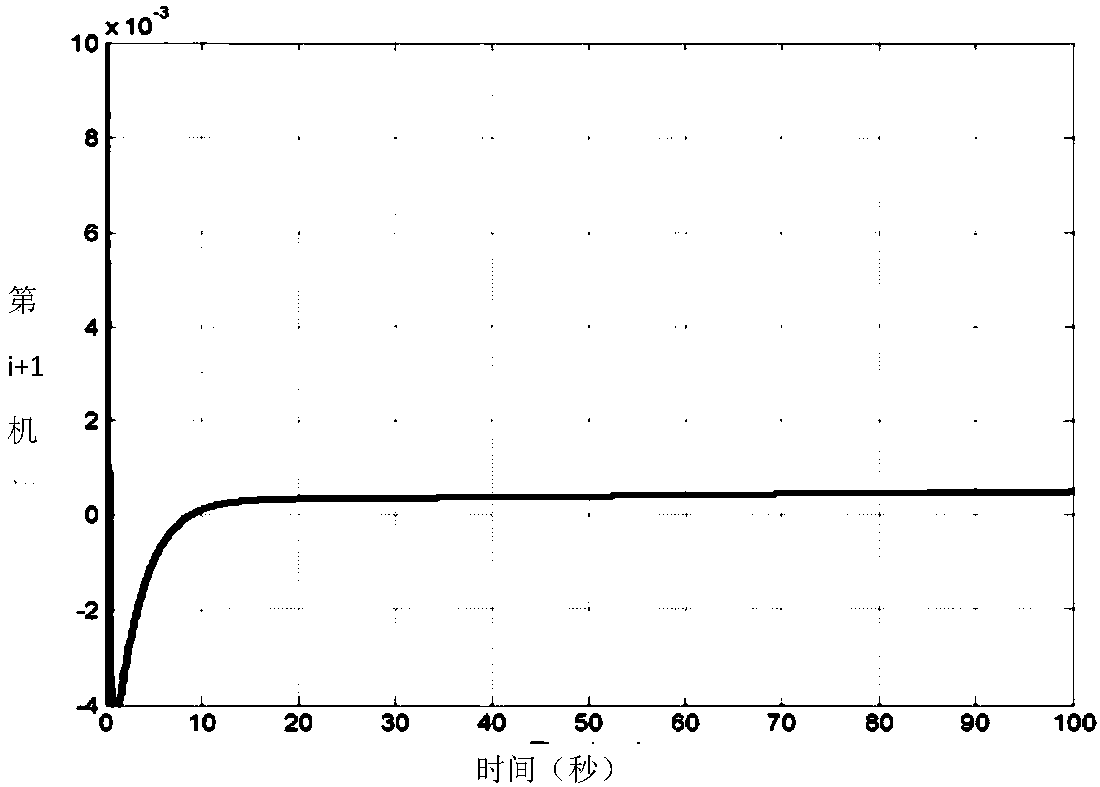

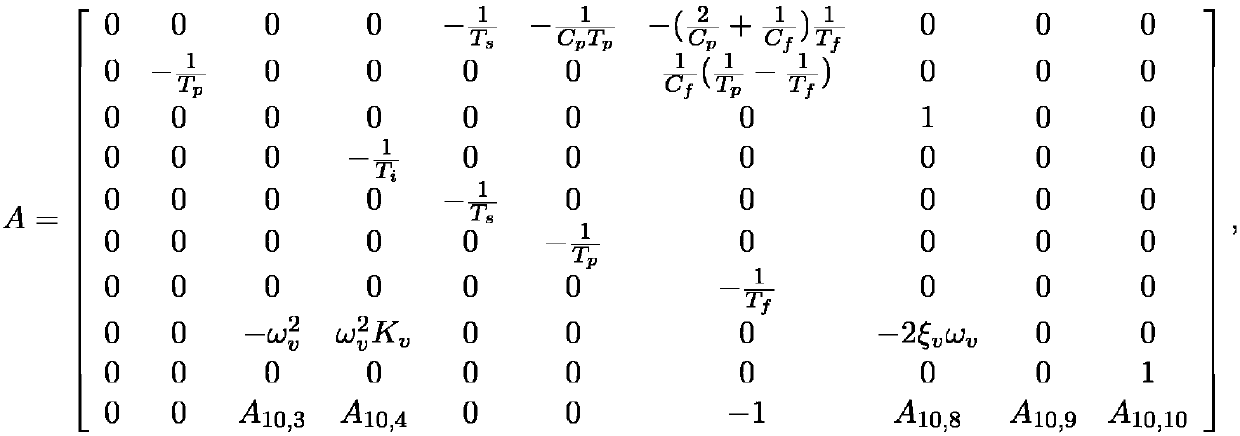

Multi-time-scale model and stability control method for hot strip rolling thin strip flatness and gauge control system

ActiveCN107942657AOvercoming distractionsSmall steady state errorAdaptive controlIntegratorControl system

The invention relates to a multi-time-scale model and stability control method for a hot strip rolling thin strip flatness and gauge control system, and belongs to the field of ferrous metallurgy control technology. For a hot strip rolling thin or ultra-thin strip flatness and gauge integrated control system, a multi-time-scale modeling and stability analysis method is proposed to solve the problem of difficulty in obtaining high control performance by the existing theories and methods. Singular perturbation techniques are adopted for multi-time-scale modeling, system state variables are decomposed into slow and fast categories, and a discrete time linear singular perturbation model for the hot strip rolling thin or ultra-thin strip flatness and gauge control system is established. Based on this model, a slow state feedback and output integrator combined controller is designed, the theorem of solving the controller gain is deduced using a linear matrix inequality method, and the effectiveness of the method is illustrated by simulation and verification. The advantages are that decoupling of the strip flatness and gauge is unnecessary, the dynamics of the controlled system can be accurately characterized, high-precision control performance indexes of the strip flatness and gauge are gained, and the simulation results show the effectiveness of the method.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Method for the flying changing of working rolls in continuous casting and rolling installations and hot strip rolling mills using a hold-down roller

ActiveUS8578749B2Possible to easilyMetal rolling stand detailsTensioning/braking arrangementsWork rollContinuous casting

The invention relates to a method of flying changing of working rolls in continuous casting and rolling installations and hot strip rolling mills, in particular in continuous hot strip rolling mills, wherein for exchange of working rolls by opening a rolling stand, those are disengaged from a to be rolled hot strip. According to the invention a regulated strip tension that can substitute the tension of the open rolling stand, is applied to the to-be-rolled hot strip with at least one hold-down roller that is introduced in a rolling line.

Owner:SMS DEMAG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com