Control method of Smith prediction monitoring AGC system

A control method and control system technology, applied in the field of automatic control of strip rolling, can solve the problems of control object time lag, poor nonlinear and time-varying processing ability, and system model parameter error sensitivity, so as to improve robustness, The effect of improving control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

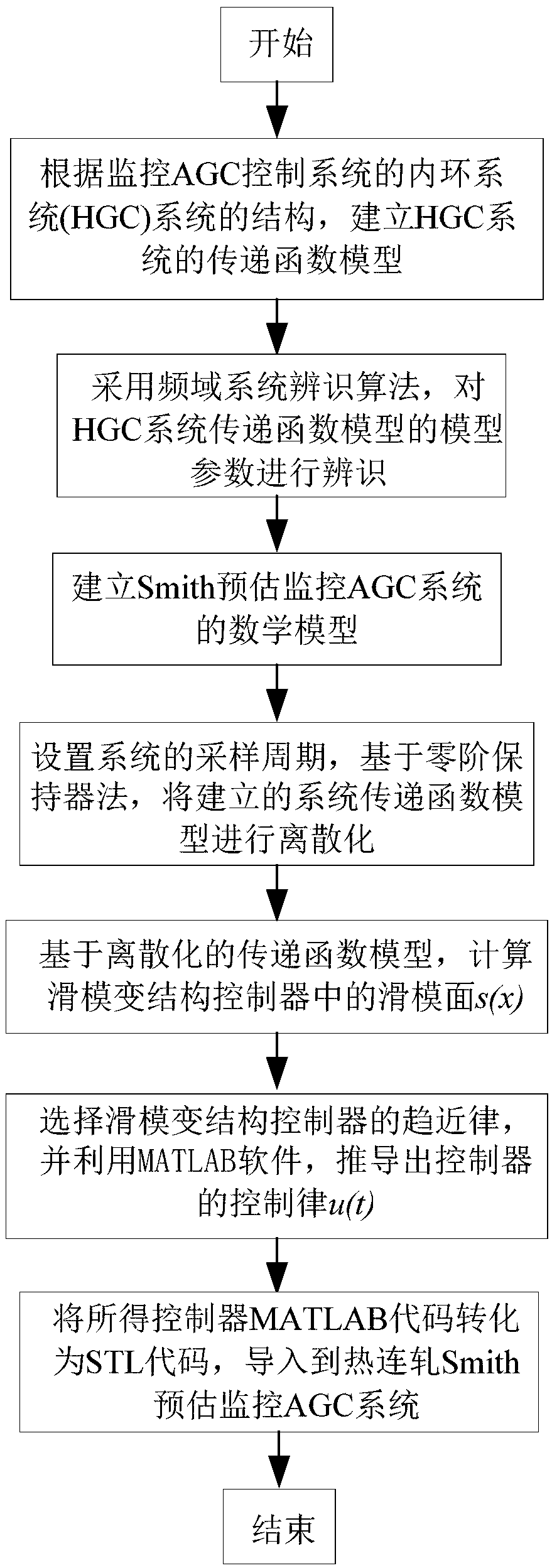

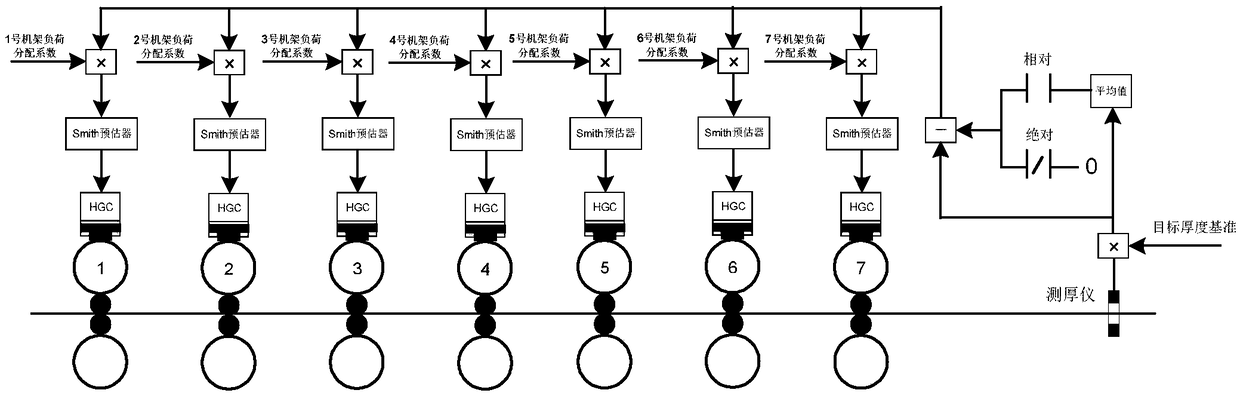

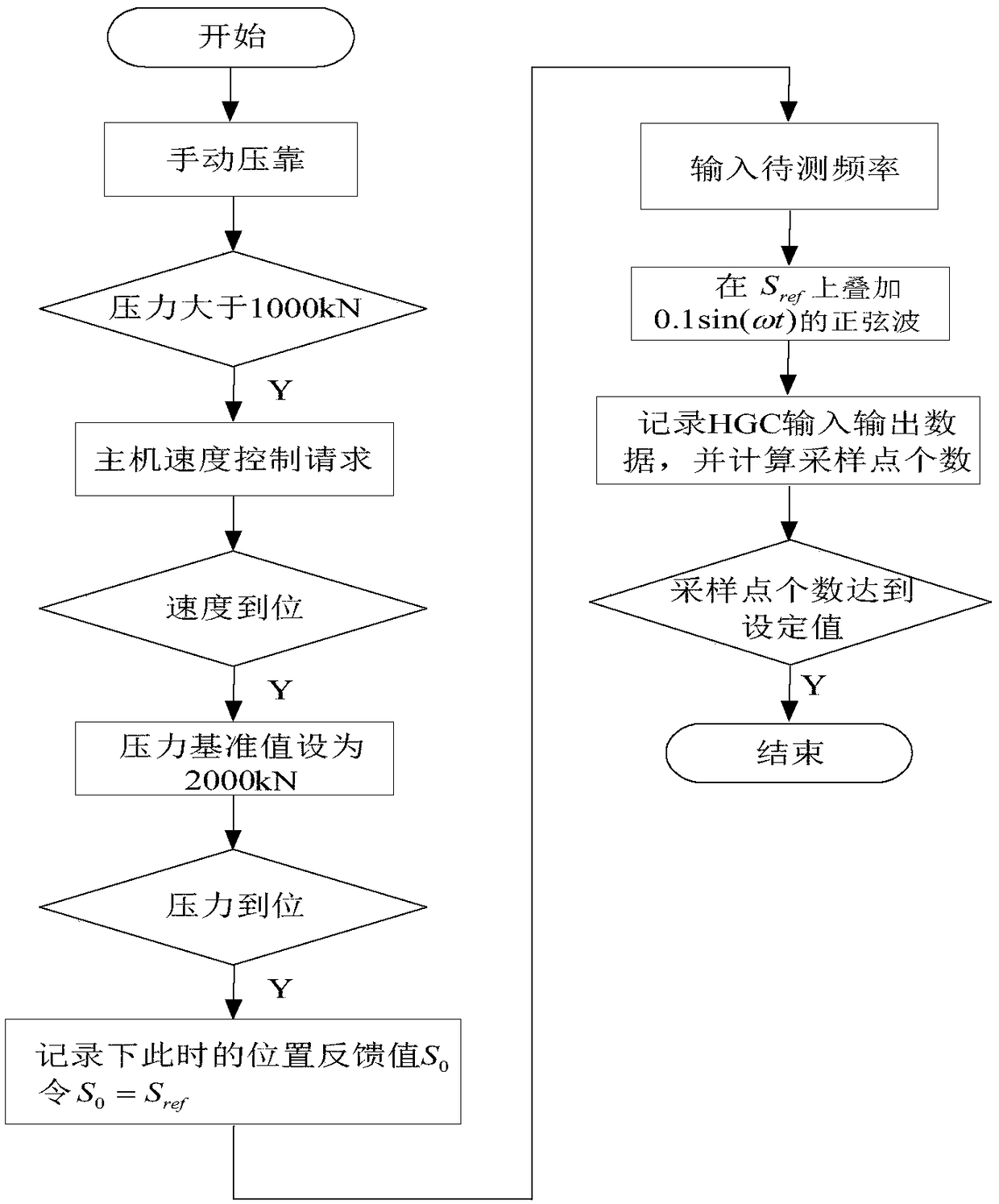

[0046] refer to figure 1 , a control method of Smith estimation monitoring AGC system, according to the structure of the inner loop system (HGC system) of Smith estimation monitoring AGC control system, the transfer function model of the HGC system is established; using the frequency domain system identification algorithm, the HGC system The model parameters of the transfer function model are identified, and then the mathematical model of the Smith predictive monitoring AGC system is established, and then it is discretized; on this basis, the sliding mode variable structure controller (SMC ).

[0047] The specific process includes:

[0048] Step 1: The Smith estimated monitoring AGC system of the last rack takes the HGC system as the actuator, and according to the structure of the HGC system, establishes its traditional function model as follows:

[0049]

[0050] In the formula, K pos is the proportional gain of the PI controller; T pos is the integral gain of the PI c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com