Patents

Literature

333 results about "Parameter error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Error Parameters. Error parameters are provider-specific values that are incorporated into error messages. For example, the provider might associate the error message "Cannot open table <param1>" with a dwMinor value of 10. In the example, the error parameters would be used to supply the name of the table (<param1>) that could not be opened.

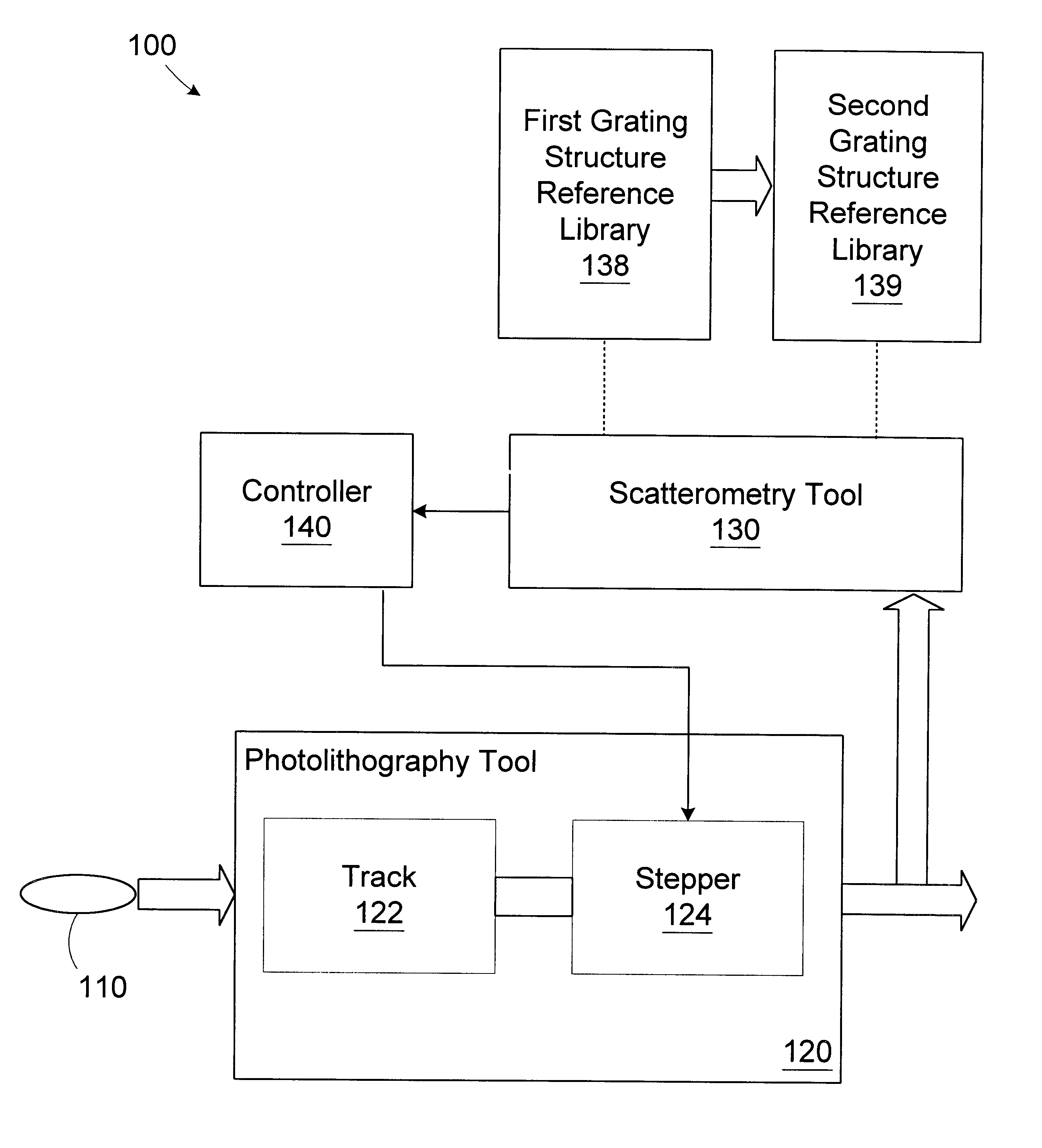

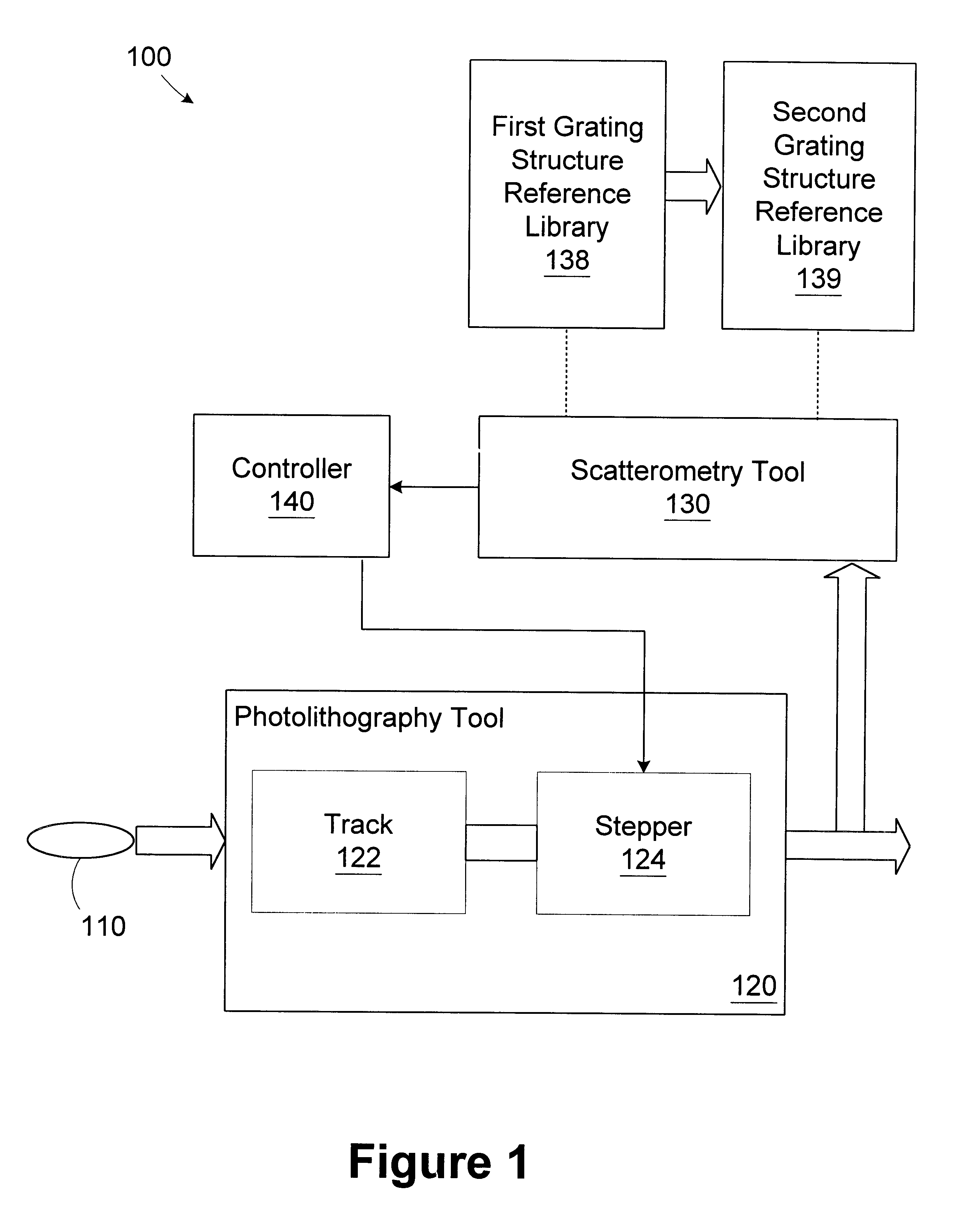

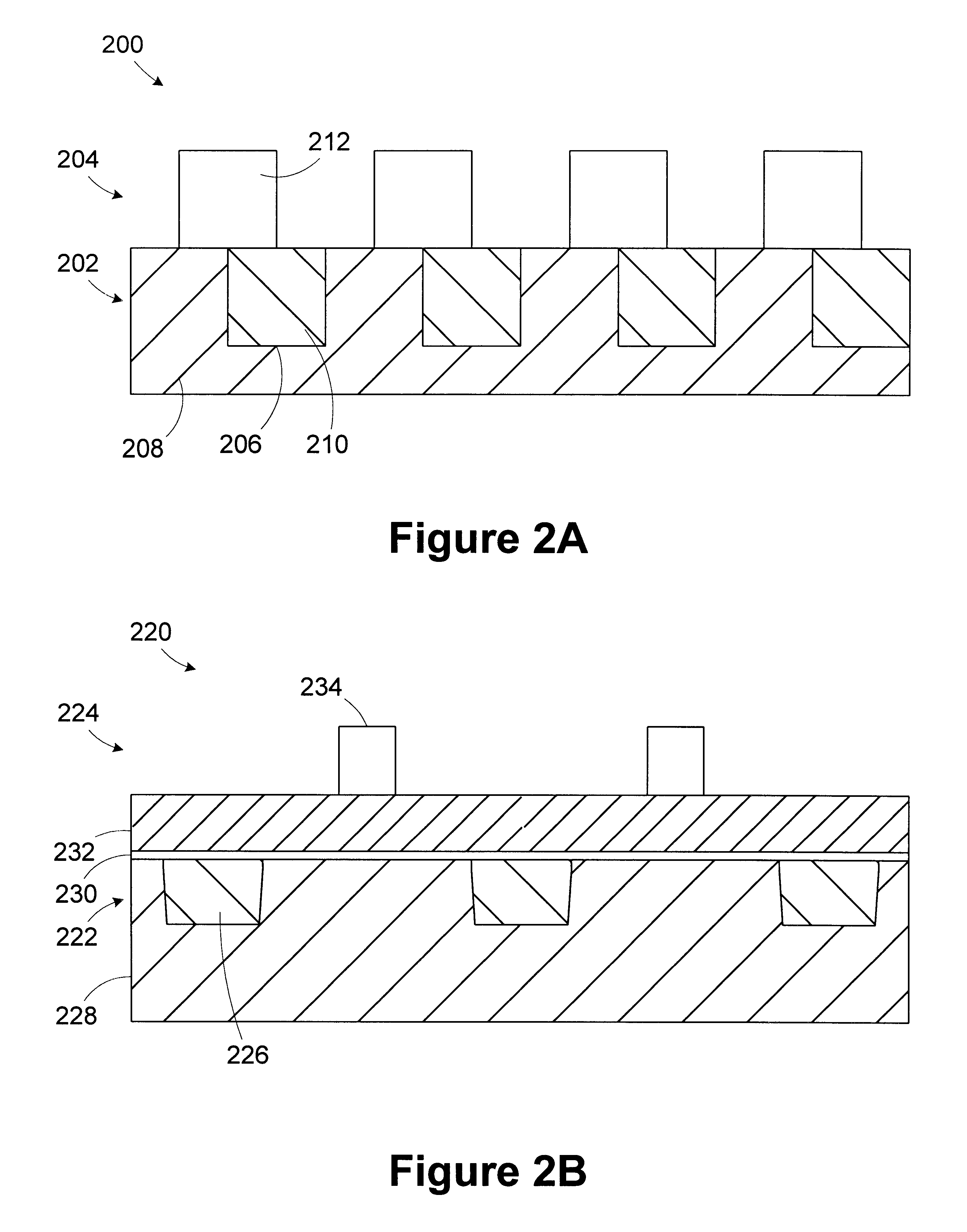

Method and apparatus for controlling photolithography overlay registration

InactiveUS6458605B1Electrolytic capacitorsSemiconductor/solid-state device manufacturingGratingMetrology

A method for controlling a photolithography process includes providing a wafer having a first grating structure and a second grating structure overlying the first grating structure; illuminating at least a portion of the first and second grating structures with a light source; measuring light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile; determining an overlay error between the first and second grating structures based on the reflection profile; and determining at least one parameter of an operating recipe for a photolithography stepper based on the determined overlay error. A processing line includes a photolithography stepper, a first metrology tool, and a controller. The photolithography stepper is adapted to process wafers in accordance with an operating recipe. The first metrology tool is adapted to receive a wafer having a first grating structure and a second grating structure overlying the first grating structure. The metrology tool includes a light source, a detector, and a data processing unit. The light source is adapted to illuminate at least a portion of the first and second grating structures. The detector is adapted to measure light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile. The data processing unit is adapted to determine an overlay error between the first and second grating structures based on the reflection profile. The controller is adapted to determine at least one parameter of the operating recipe of the photolithography stepper based on the determined overlay error.

Owner:FULLBRITE CAPITAL PARTNERS

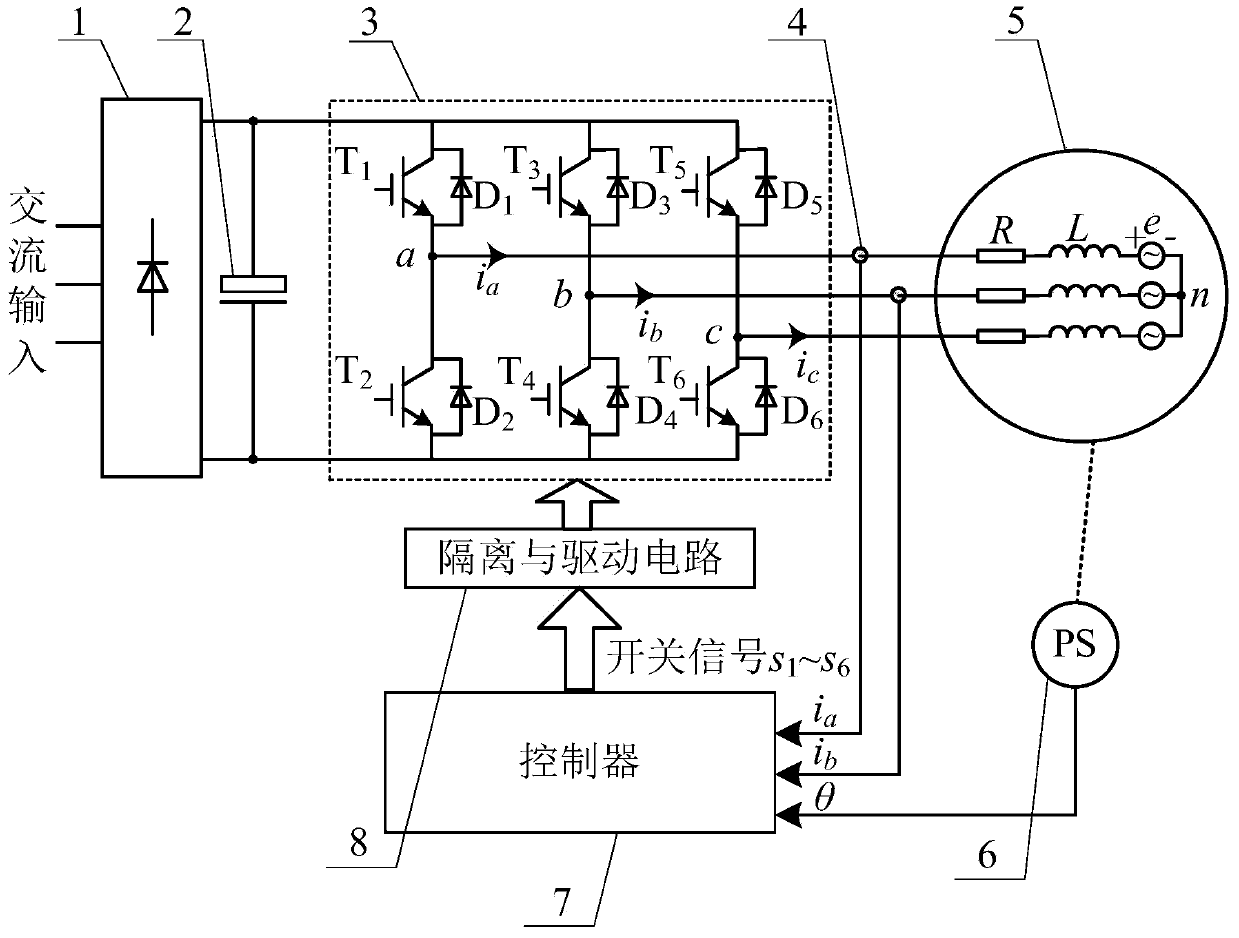

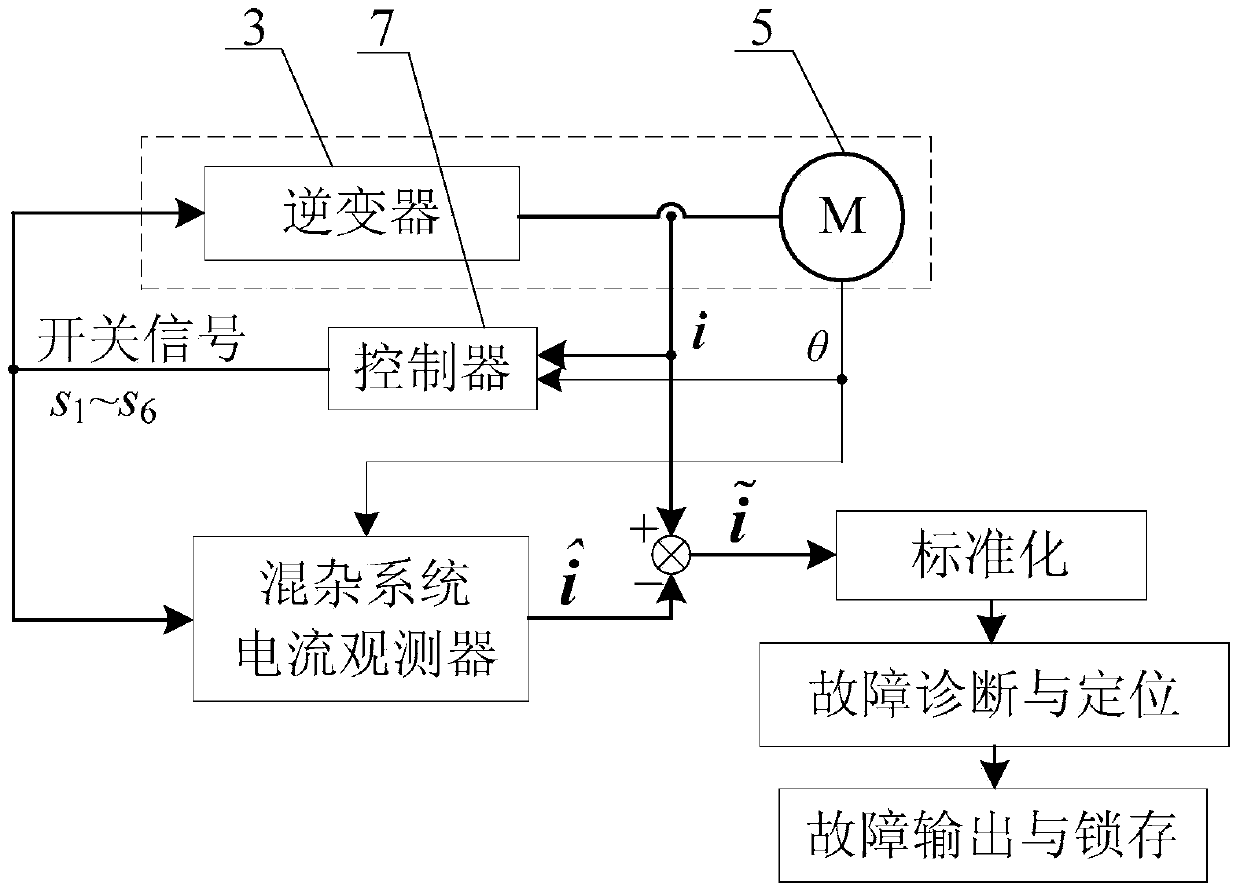

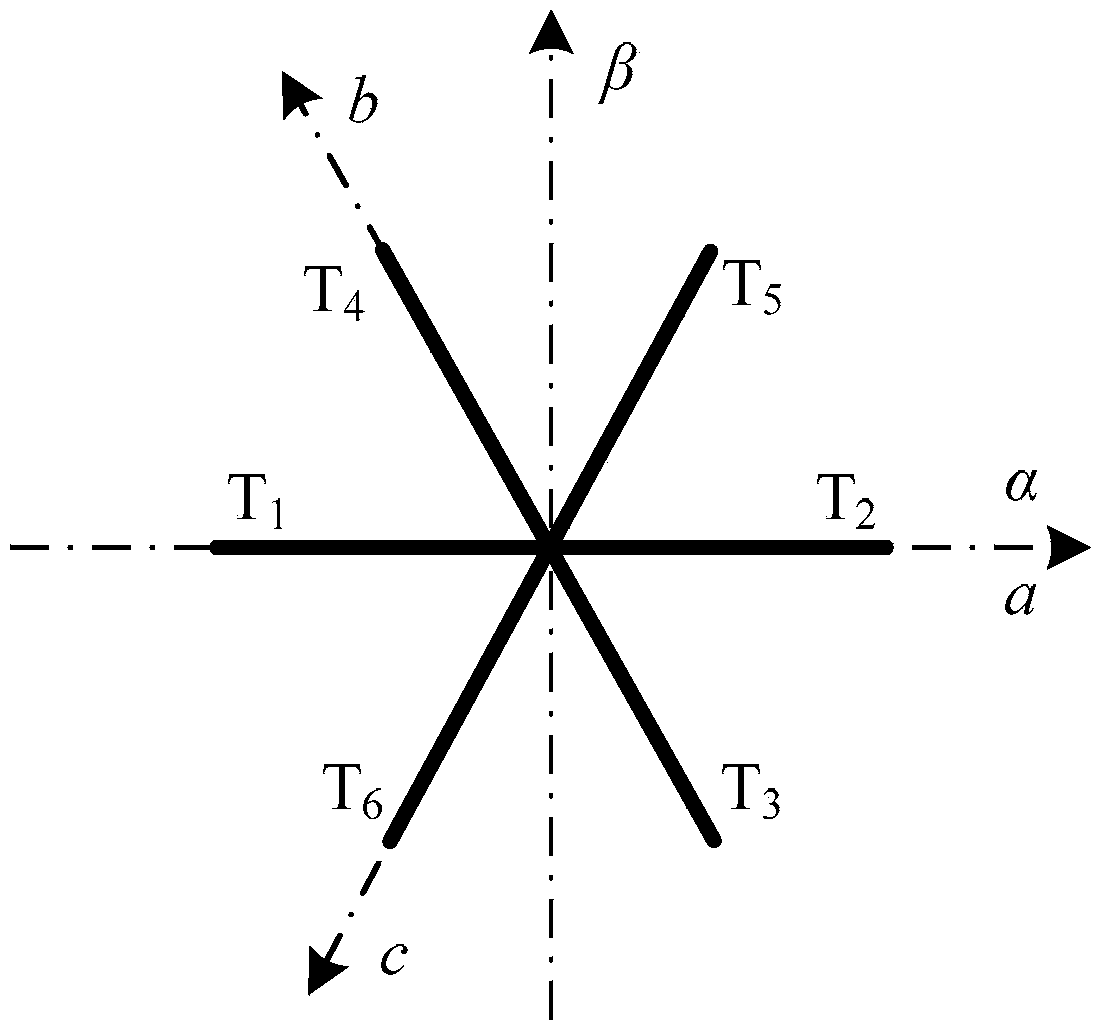

Current-magnitude-based open-circuit failure online-diagnosis method for power tube of inverter

InactiveCN103701394AImprove robustnessElectronic commutation motor controlVector control systemsObservational errorLoop control

The invention discloses a current-magnitude-based open-circuit failure online-diagnosis method for a power tube of an inverter, belongs to the field of motor control, and aims to solve the problem of poor robustness of a current-magnitude-based open-circuit failure diagnosis technology for the power tube of the inverter. The method comprises the following steps of establishing a current observer model of a permanent magnet synchronous motor driving system in a failure-free state, comparing an observed current value with detection current to obtain a three-phase current residual, converting the three-phase current residual to a two-phase coordinate system in a coordinate conversion way to obtain a current residual vector, standardizing the current residual vector, and diagnosing and positioning an open-circuit failure of the power tube of the inverter according to the amplitude and the phase of the standardized current residual vector. The current-magnitude-based open-circuit failure online-diagnosis method for the power tube of the inverter is free of influence of a system closed-loop control algorithm and insensitive to loads, and has higher robustness to parameter errors, measurement errors, system disturbance and the like.

Owner:HARBIN INST OF TECH

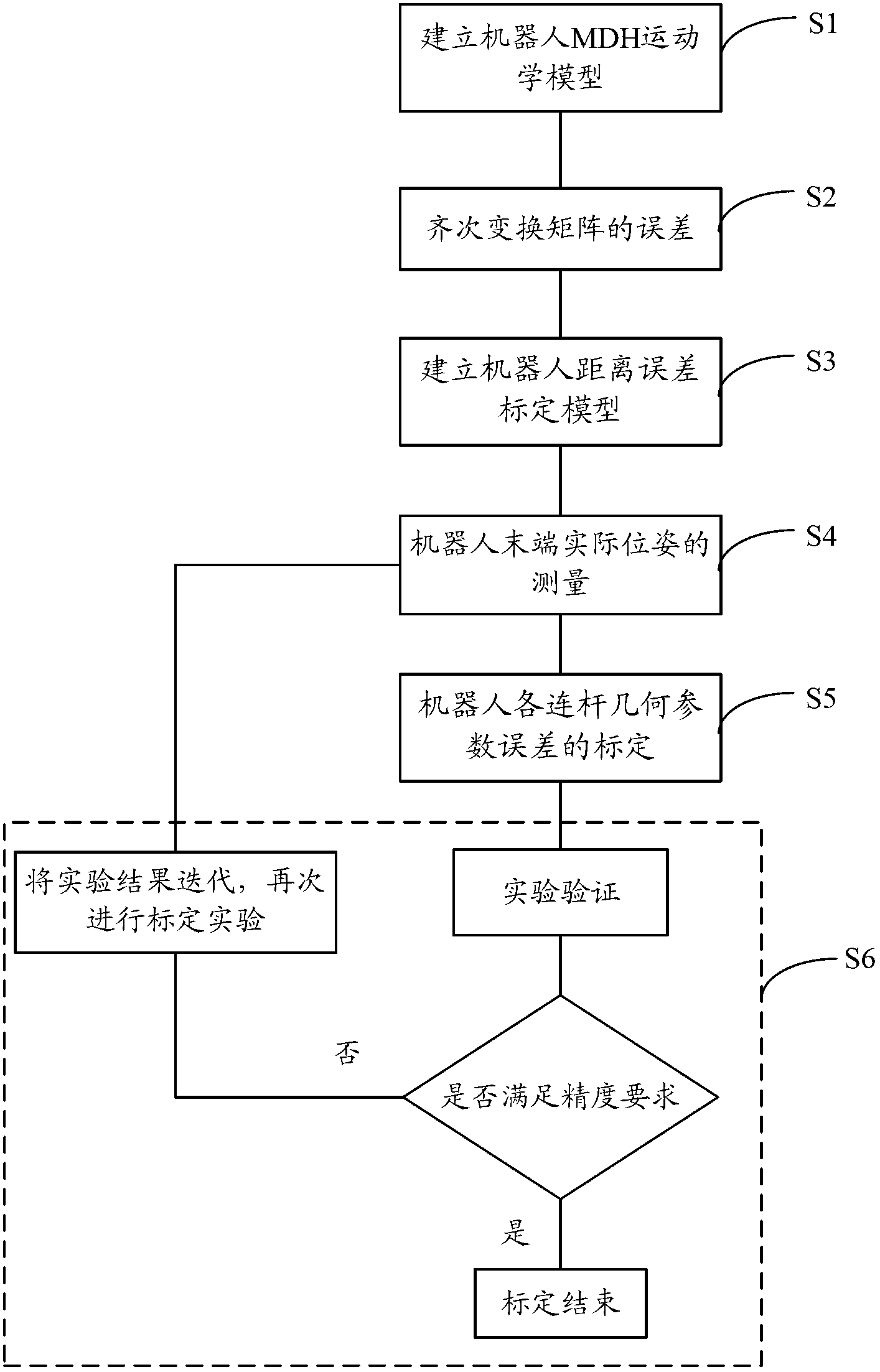

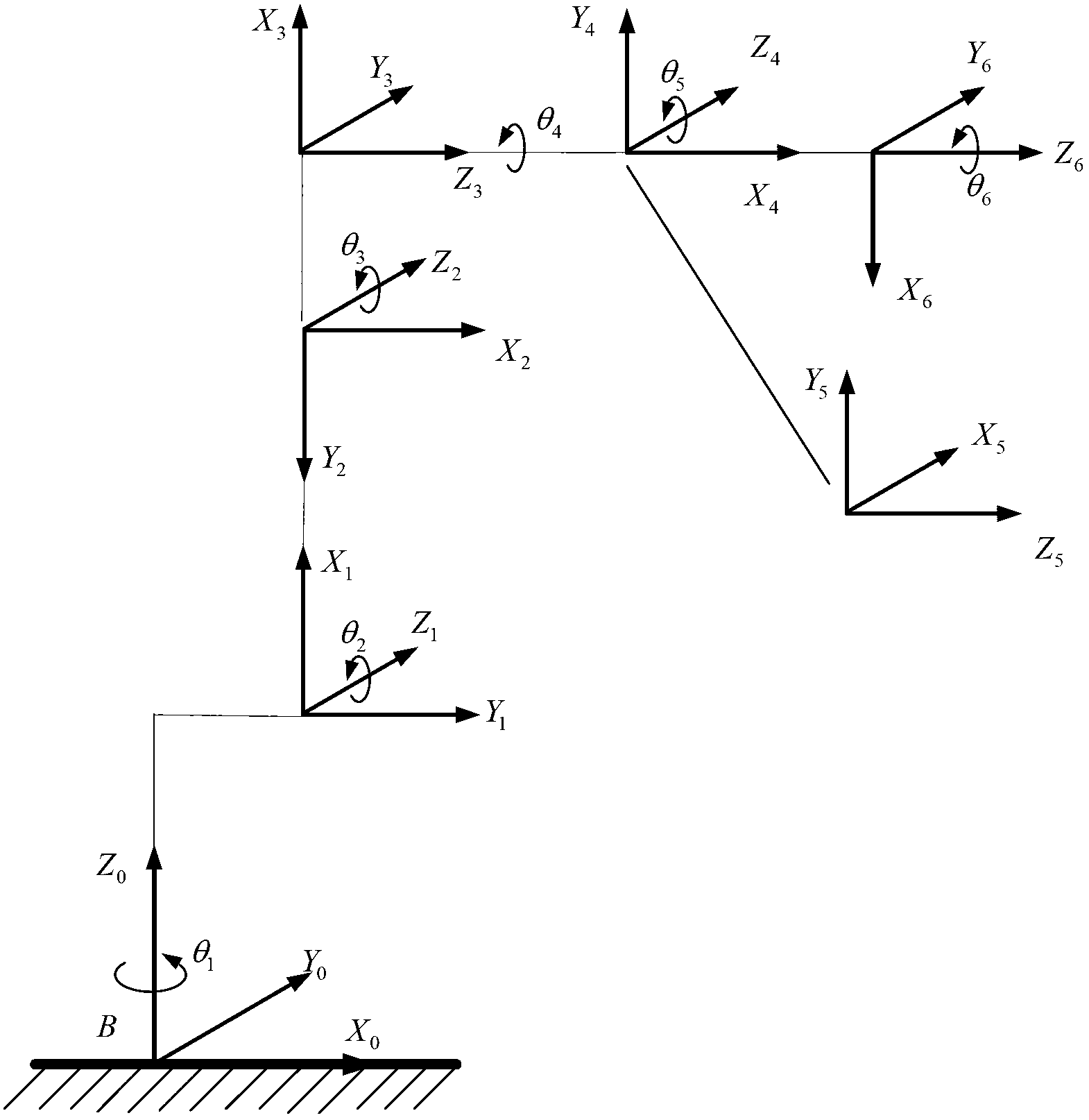

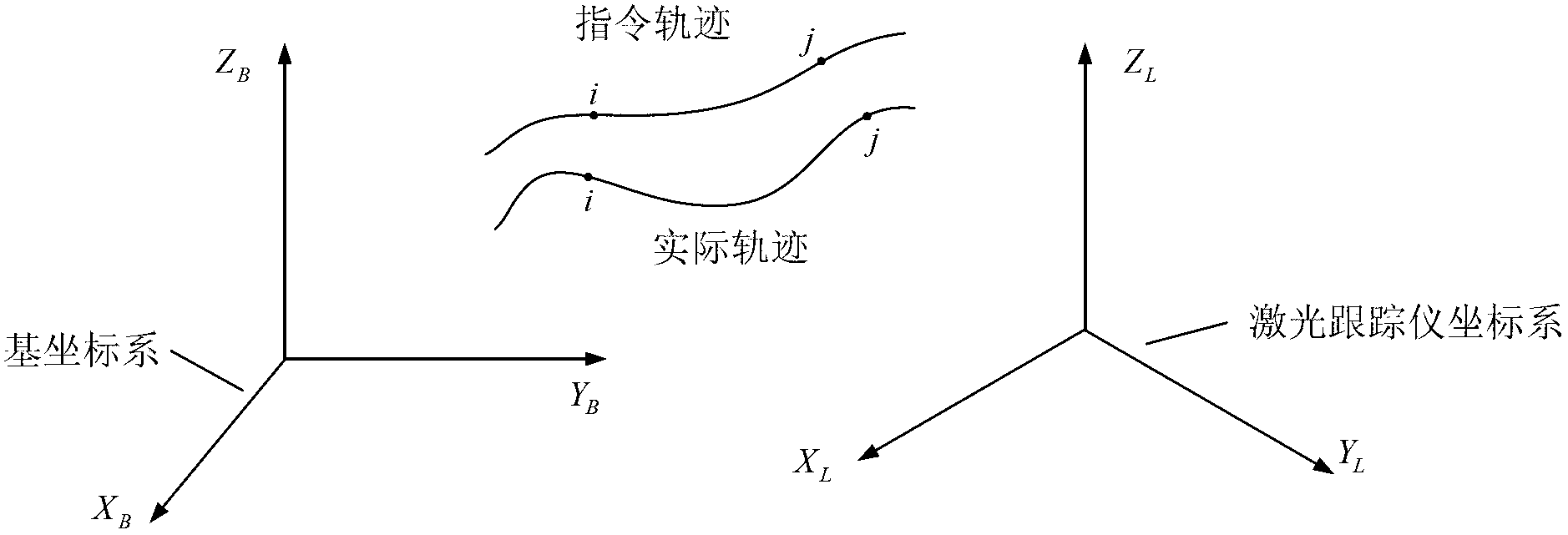

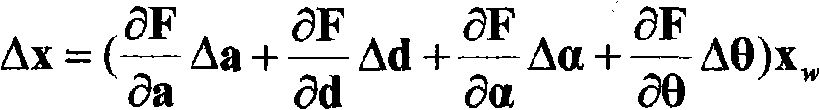

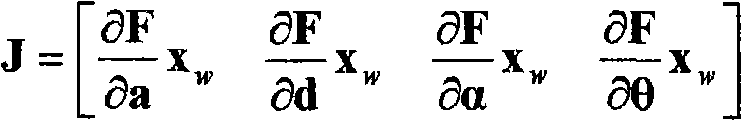

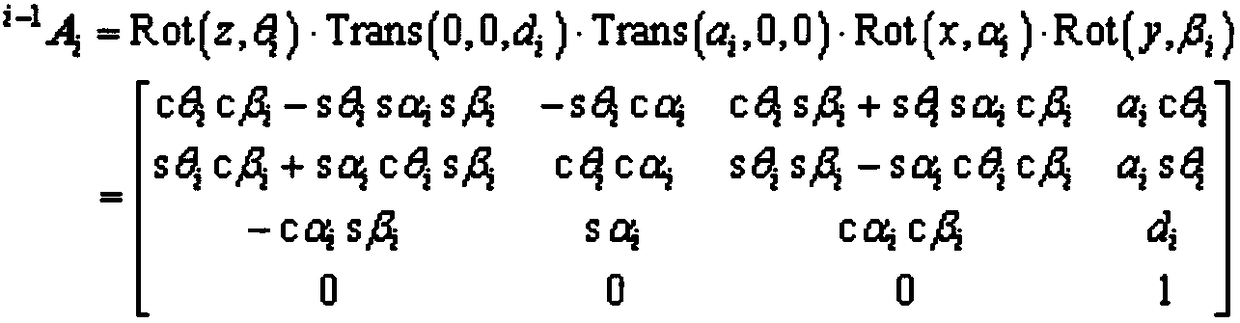

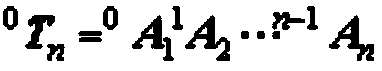

Industrial robot calibration method based on distance error models

InactiveCN103231375ACalibration method is simpleThe calibration method is practicalProgramme-controlled manipulatorSimulationHomogeneous transformation matrix

The invention discloses an industrial robot calibration method based on distance error models. The method comprises: establishing a robot MDH (modified Denavit-Hartenberg) kinematic model; subjecting the errors of a matrix to homogeneous transformation; establishing a robot distance error calibration model; measuring the end actual pose of a robot; calibrating geometrical parameter errors of every connecting rod of the robot; and performing experimental verification. The industrial robot calibration method based on the distance error models has the advantages of being simple, practical, high-efficiency and rapid, is applicable to any series articulated robots, has a strong commonality, and can improve the positioning accuracy and the distance accuracy of an industrial robot simultaneously.

Owner:SUZHOU UNIV

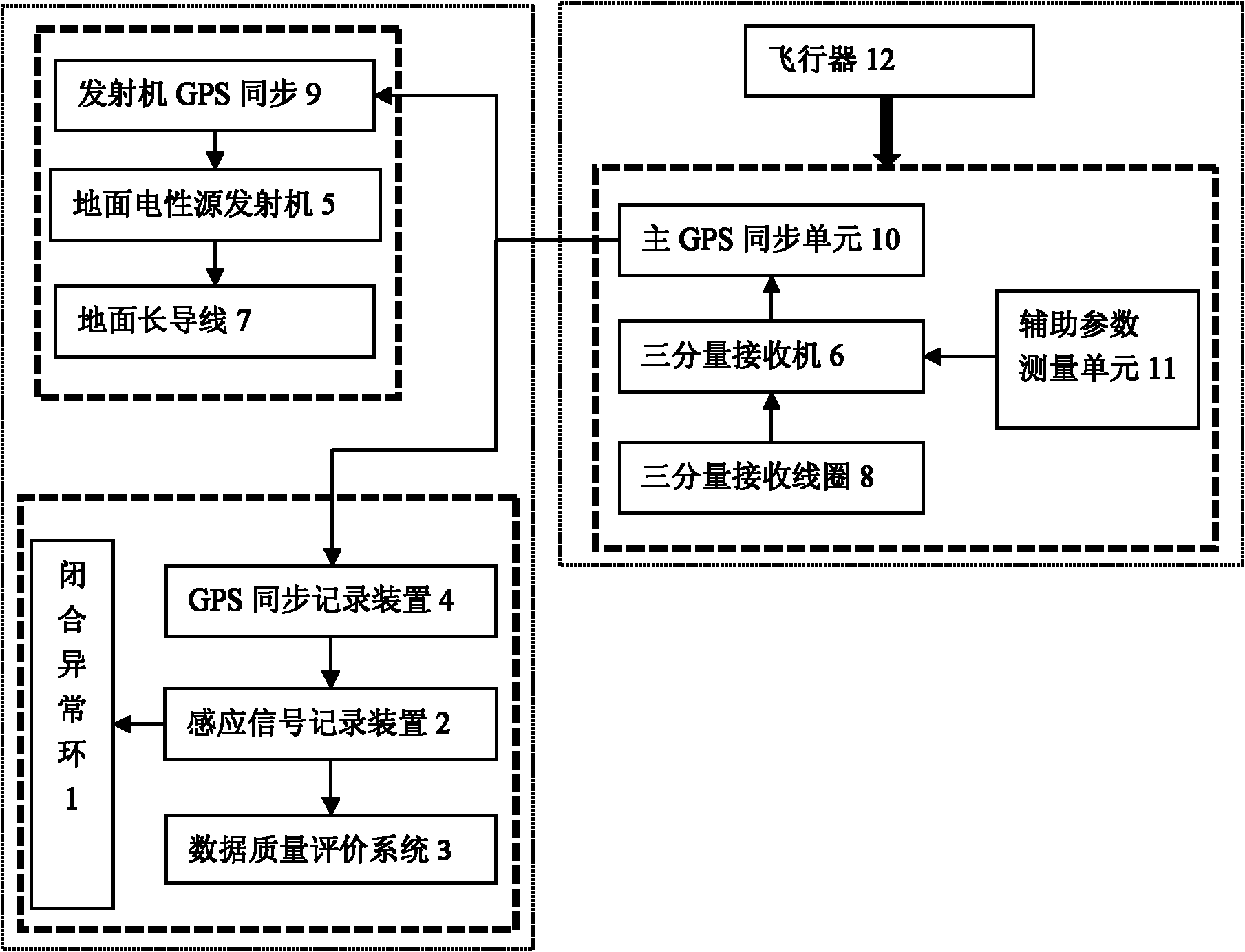

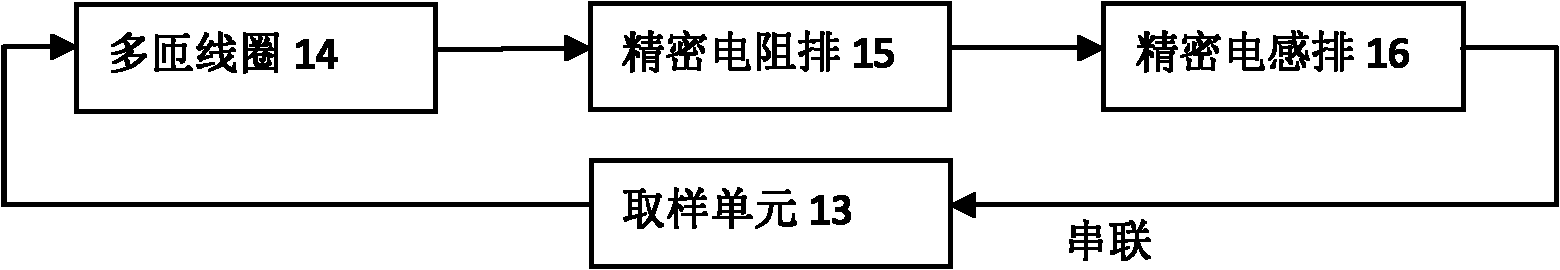

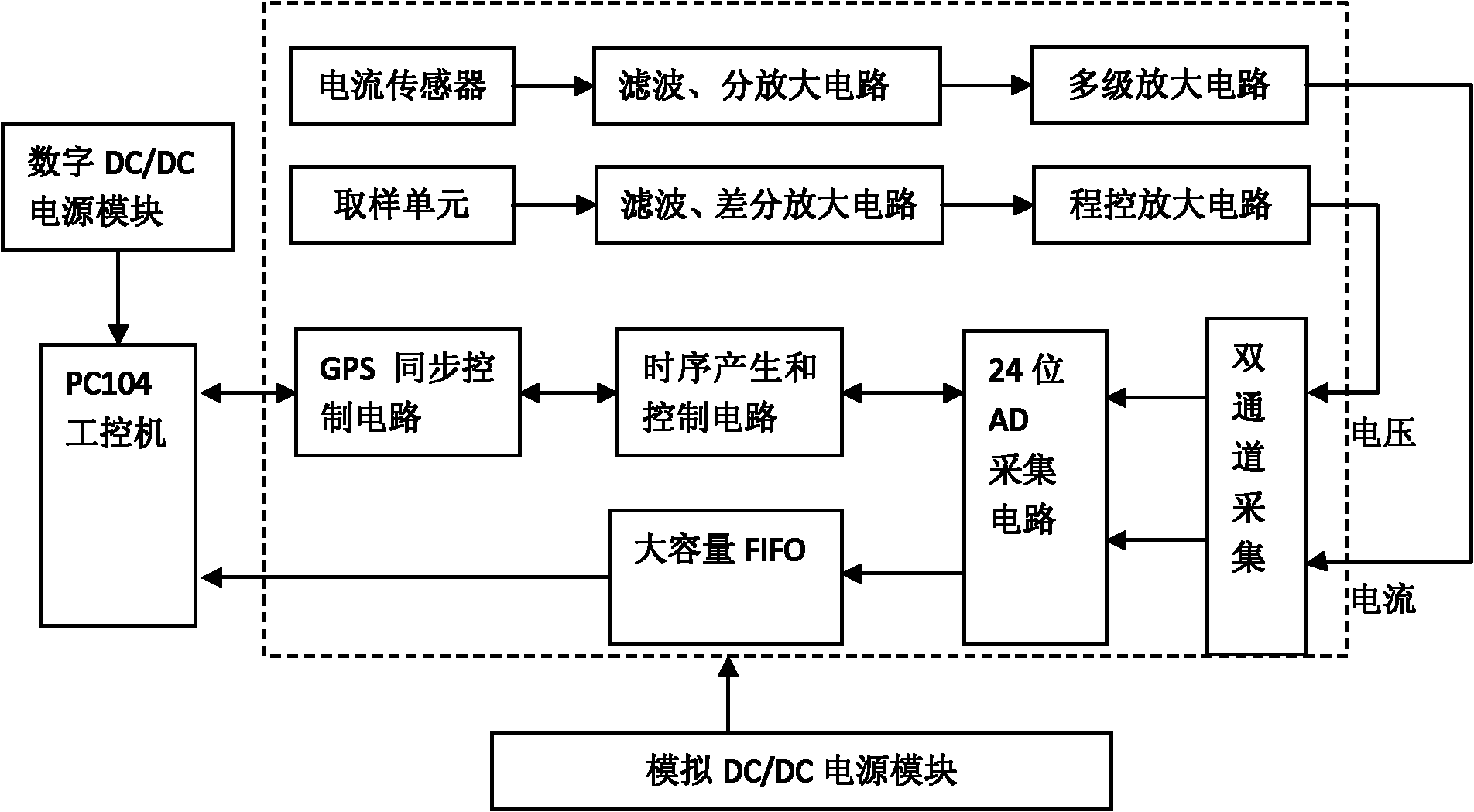

Time-domain ground-air electromagnetic detection system and calibration method

InactiveCN102096113AImplement testRealize CalibrationElectric/magnetic detection for transportGeometric error24-bit

The invention relates to a time-domain ground-air electromagnetic detection system and a calibration method, in particular to a system consisting of an induction signal recording device connected with a ground recording device global position system (GPS) synchronization unit, a closed abnormal ring and a data quality evaluation system, and a calibration method for the time-domain ground-air electromagnetic detection system. The closed abnormal ring and the induction signal recording device are adopted, the induction current and induction voltage are simultaneously recorded, and the 24-bit 200Hz sampling rate, a bandwidth of 0-13KHz and a dynamic range of an amplifier of 160dB are achieved. Moreover, the system is synchronous with a ground transmitter and an air receiver GPS, and during measurement, by removing earth background field data, a pure closed abnormal ring electromagnetic signal containing a geometric error is extracted, is input into the data quality evaluation system, andis compared and fitted with the computed closed abnormal ring theoretical value, the system error, the geometric parameter error and the detection resolution of the time-domain ground-air electromagnetic detection system are determined, and the performance of the electromagnetic detection system is tested and calibrated.

Owner:JILIN UNIV

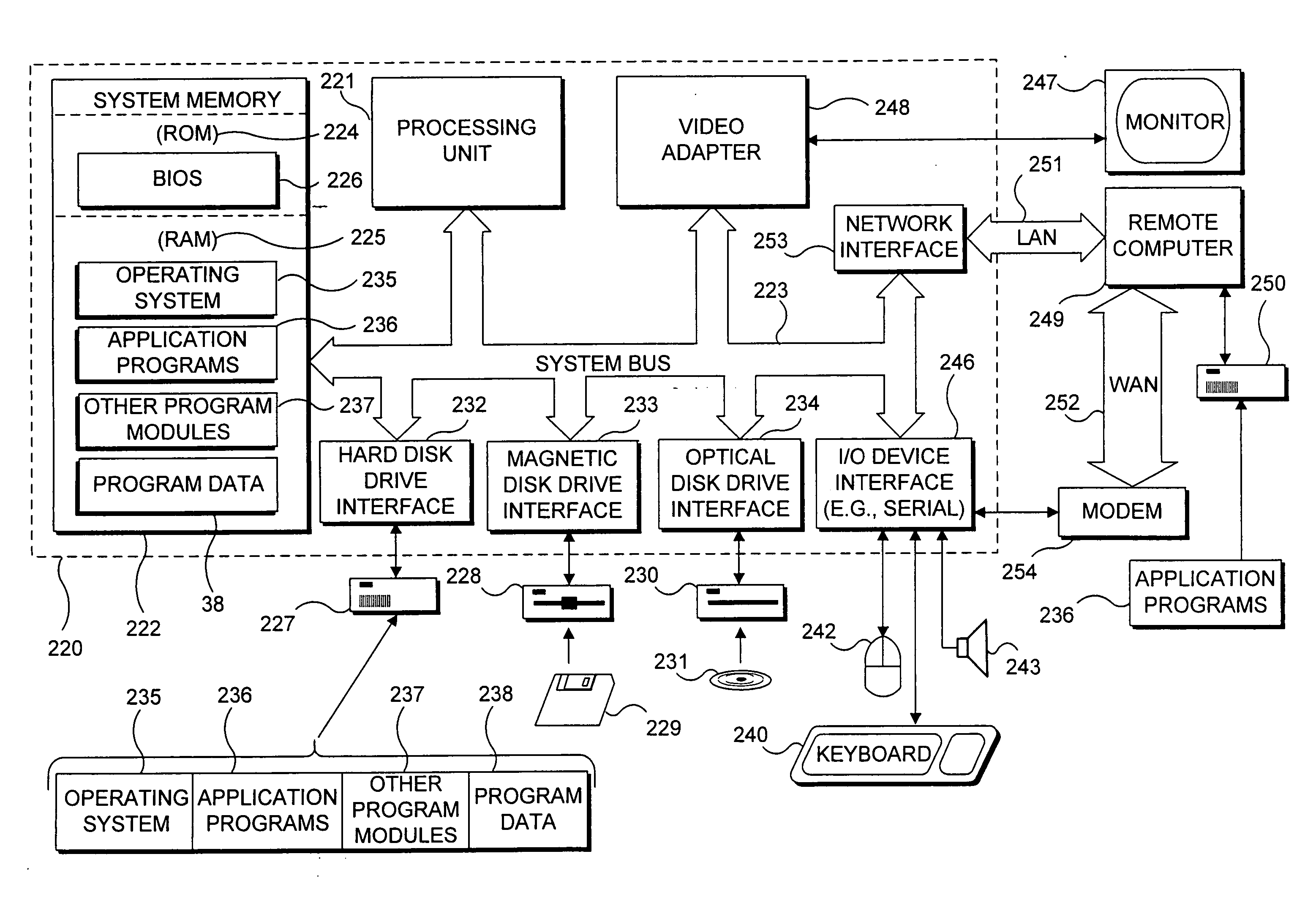

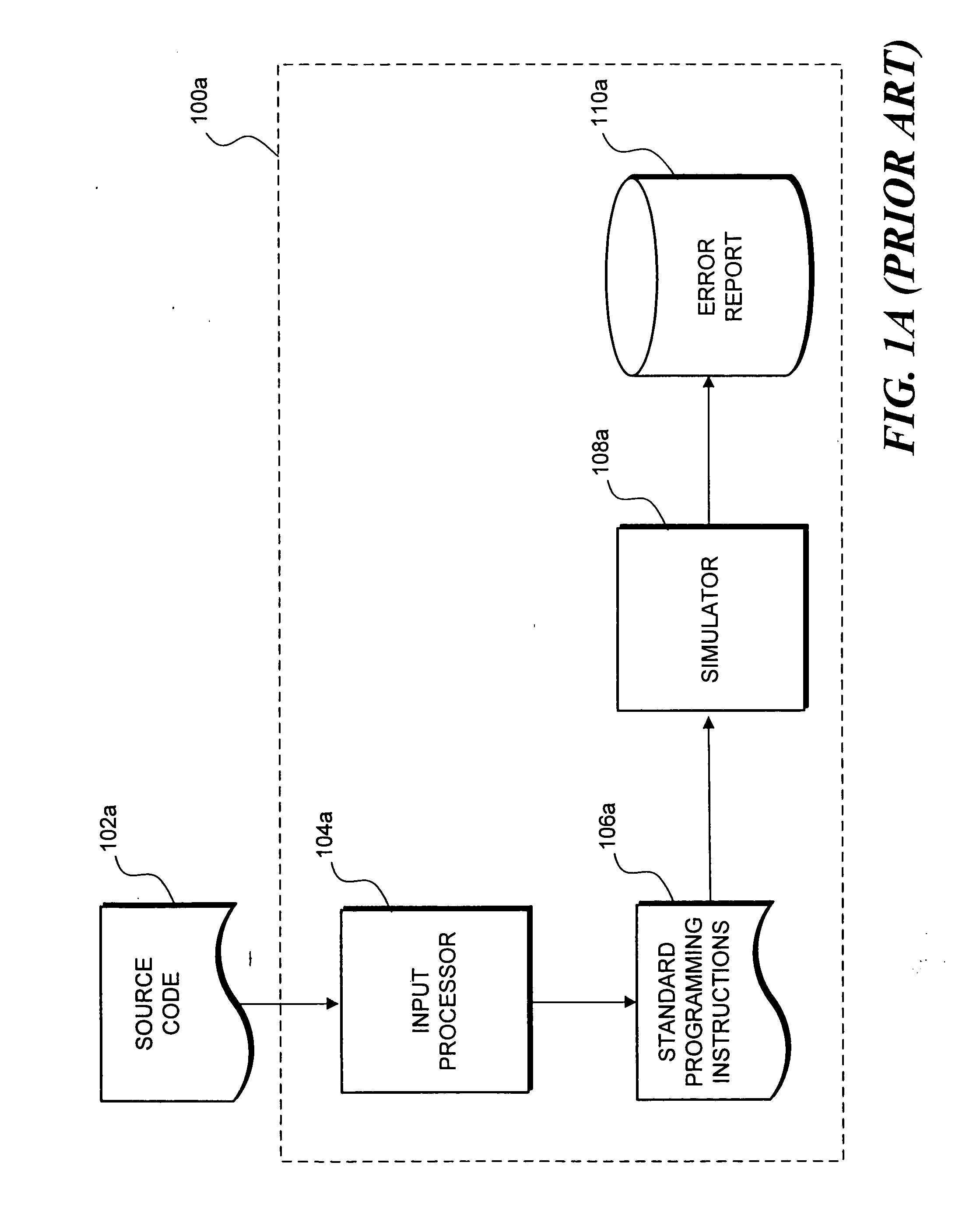

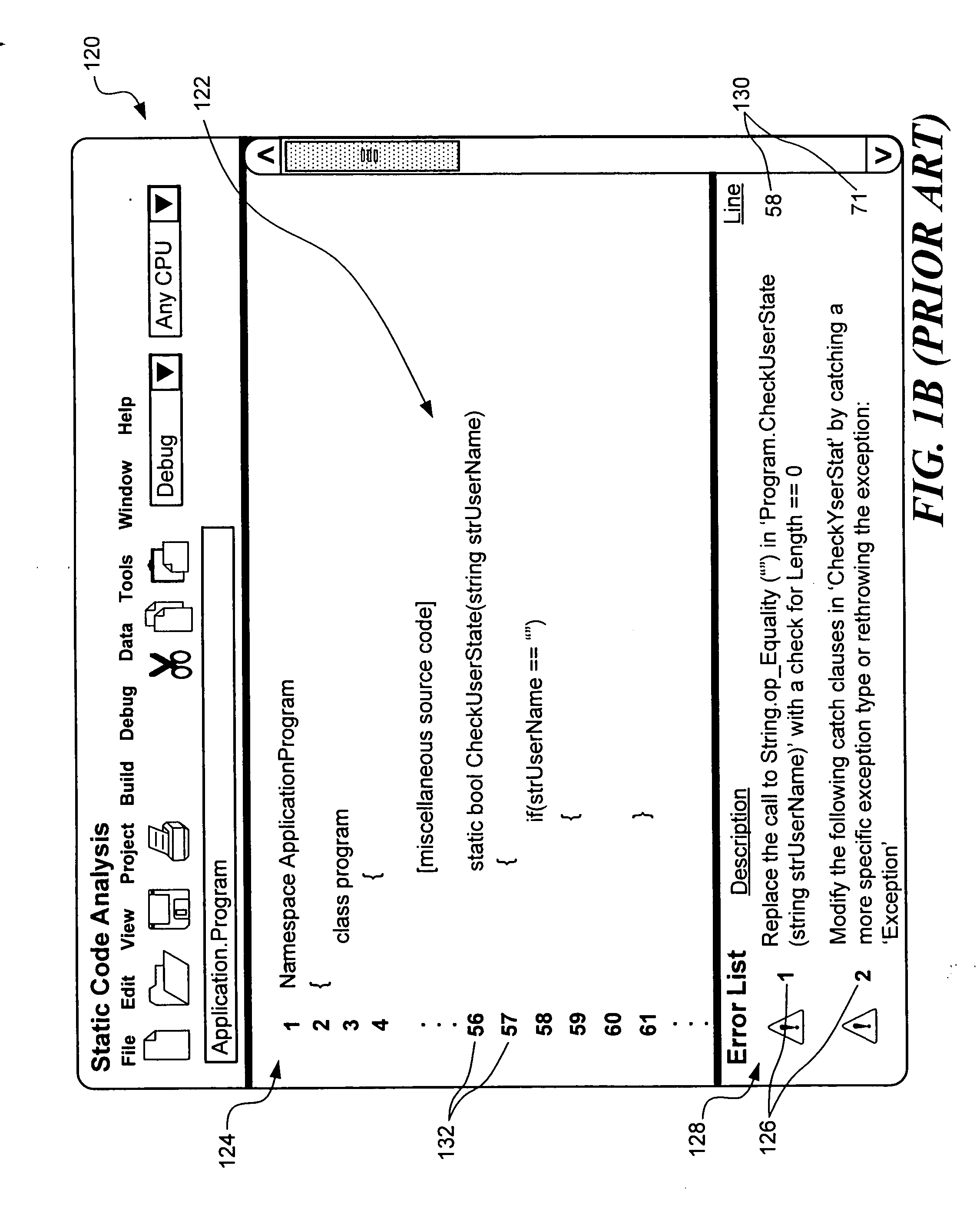

Custom API modeling for source code static analysis simulator

InactiveUS20060190923A1Domestic stoves or rangesLighting and heating apparatusDocumentation procedureSource code

In processing an external function for which source code is not available, such as an application program interface (API), a model is used to evaluate whether the external function is properly invoked. An error potentially resulting from improper invocation of the external function and at least one condition that will result in the potential error are identified. The model is created to test for the condition that will result in the potential error. When the condition is found, generation of an error message is triggered. The model is associated with a source code analyzer such that when the source code is analyzed by the source code analyzer, the model is applied to evaluate invocation of the external function. The potential error and conditions that result in the error, such as input / output parameter errors and dependency errors, may be derived from documentation describing the operation of the external function or API.

Owner:MICROSOFT TECH LICENSING LLC

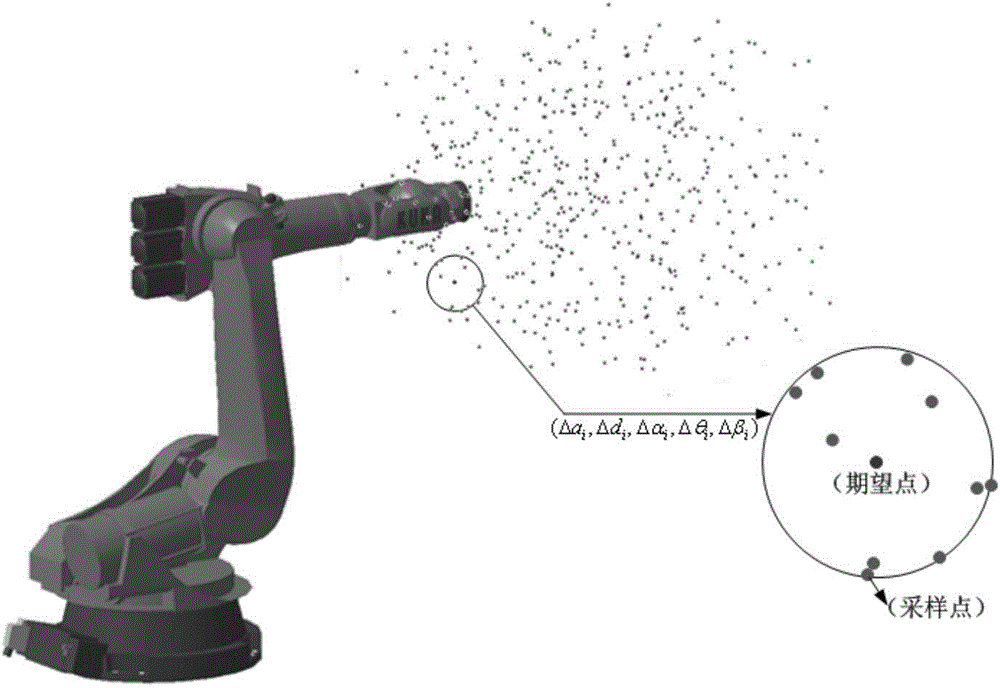

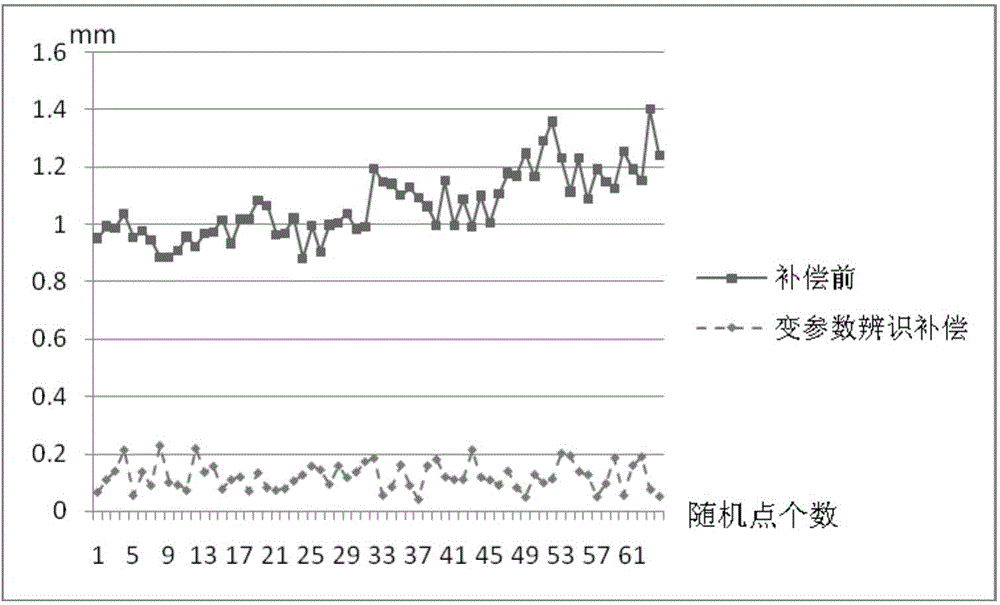

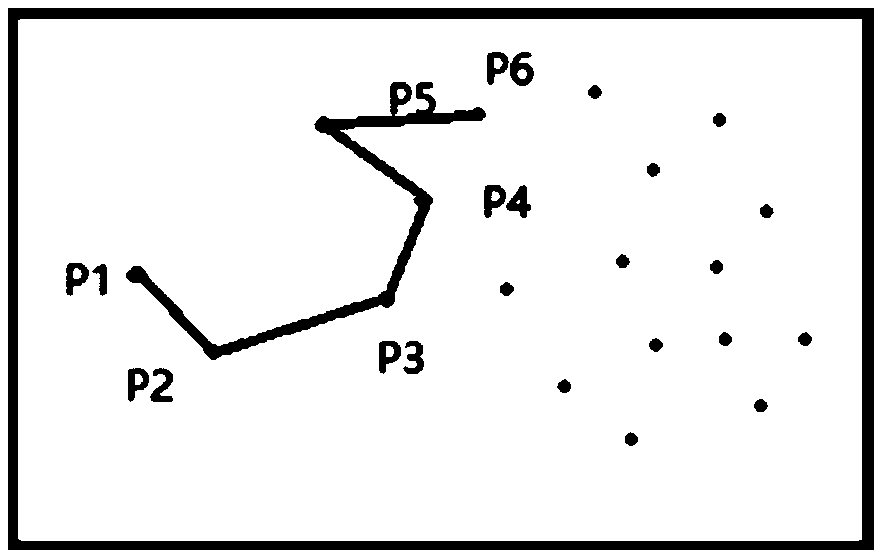

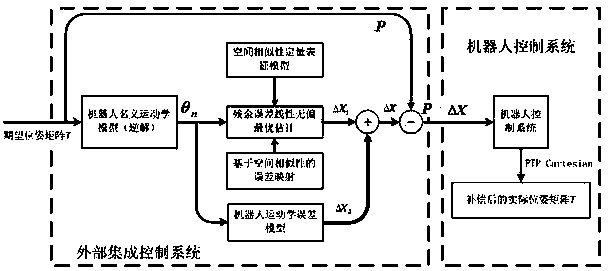

Robot precision compensation method for variable-parameter error recognition

ActiveCN104535027AImprove absolute positioning accuracyFind global convergent solutionNavigational calculation instrumentsLaser trackerInverse kinematics

The invention discloses a robot precision compensation method for variable-parameter error recognition and belongs to the technical field of robot inverse calibration. A variable-parameter error module is provided, errors of pose points of a robot in different spaces are sampled through a laser tracker, a plurality of points which are closest to an expected pose point are sought in the near area range according to the space where the expected pose point is located, and an improved Levenberg-Marquardt damp iterative least square method algorithm is used for solving the global convergent solution of the parameter error corresponding to the expected pose point, and therefore the practical parameter of the expected pose point is solved. The pose point at which the robot should arrive practically is solved through the practical parameter of the expected pose point and through inverse kinematics of the expected pose point, and the absolute positioning precision compensation of the robot at the pose point is achieved. The robot precision compensation method can obviously improve the absolute positioning precision of the robot and can be applied to the field where the requirement for robot precision is high.

Owner:江苏航鼎智能装备有限公司

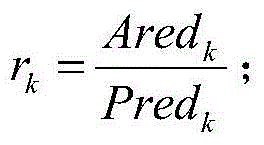

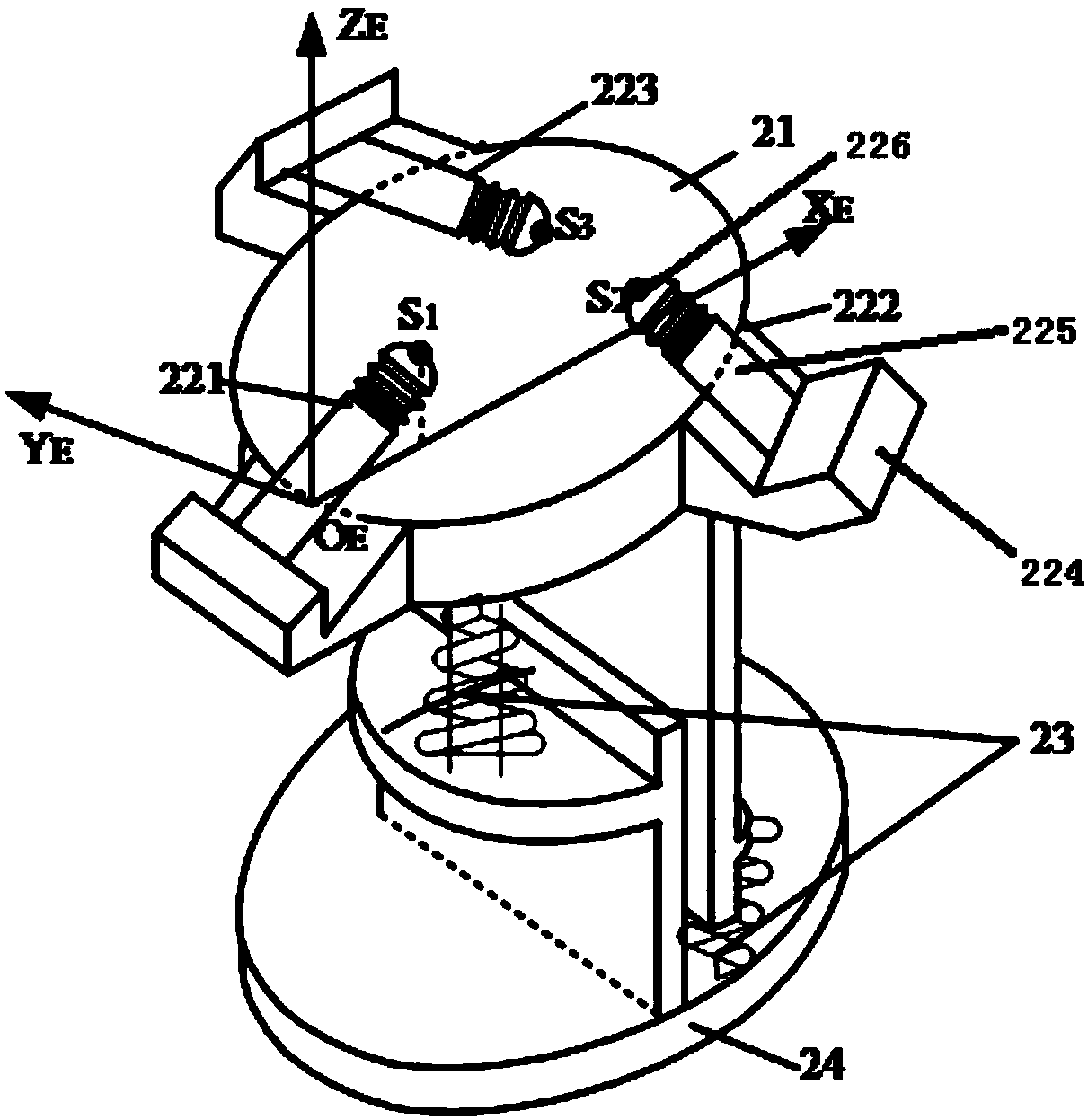

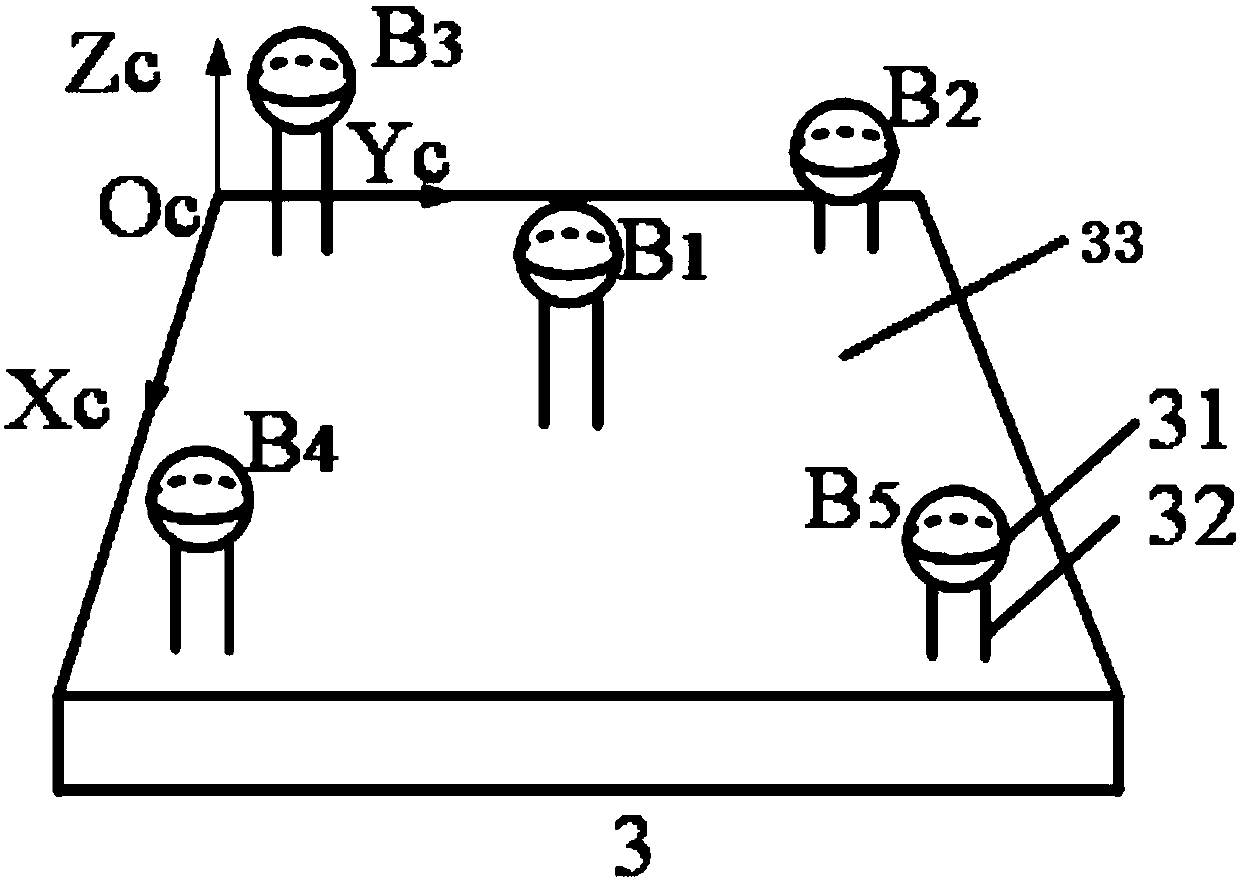

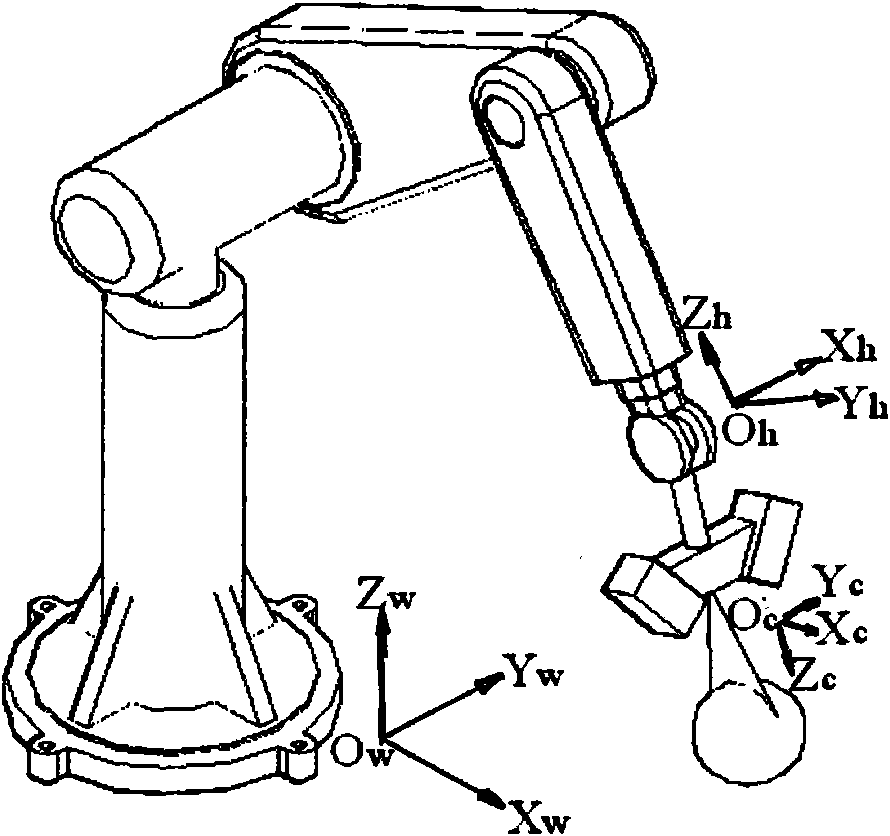

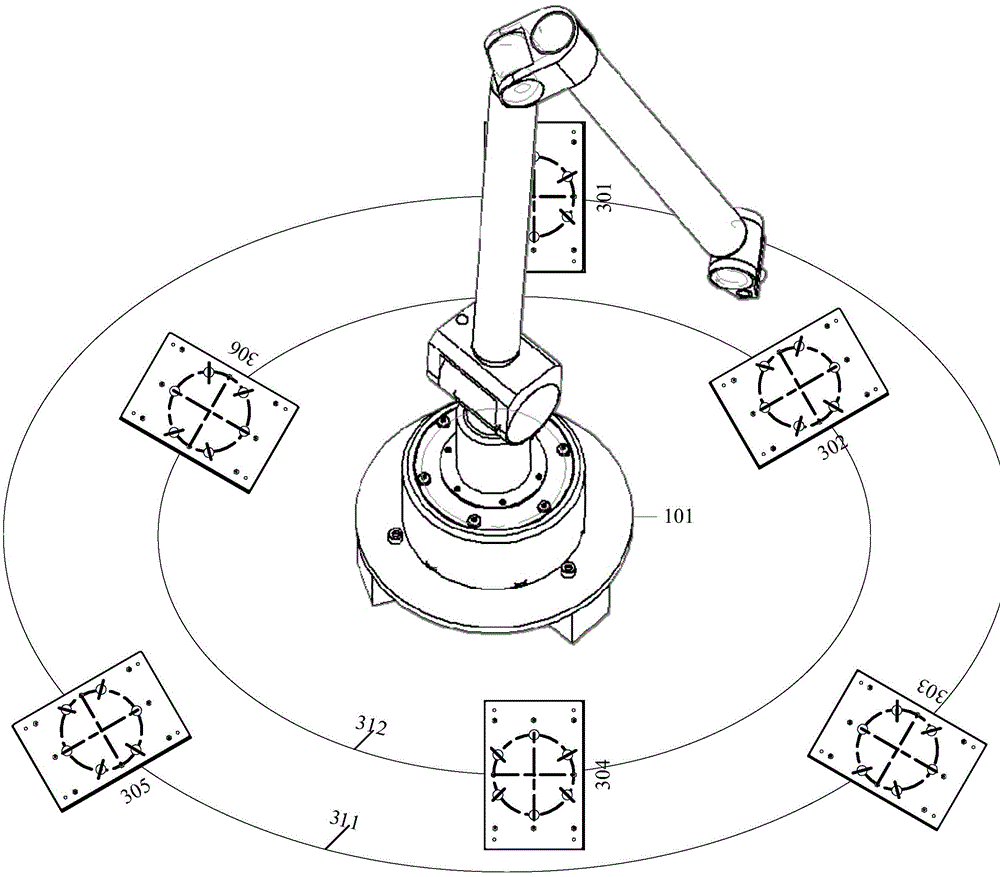

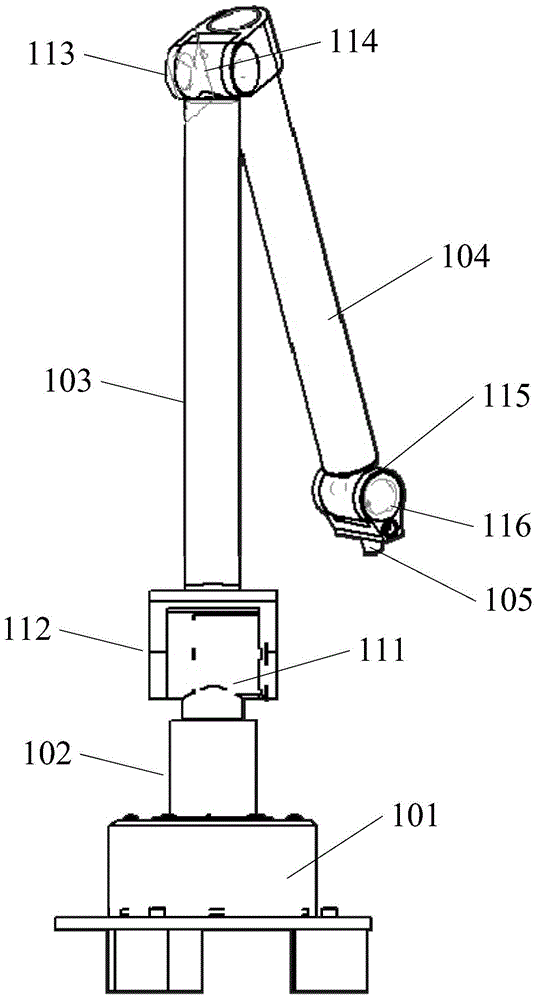

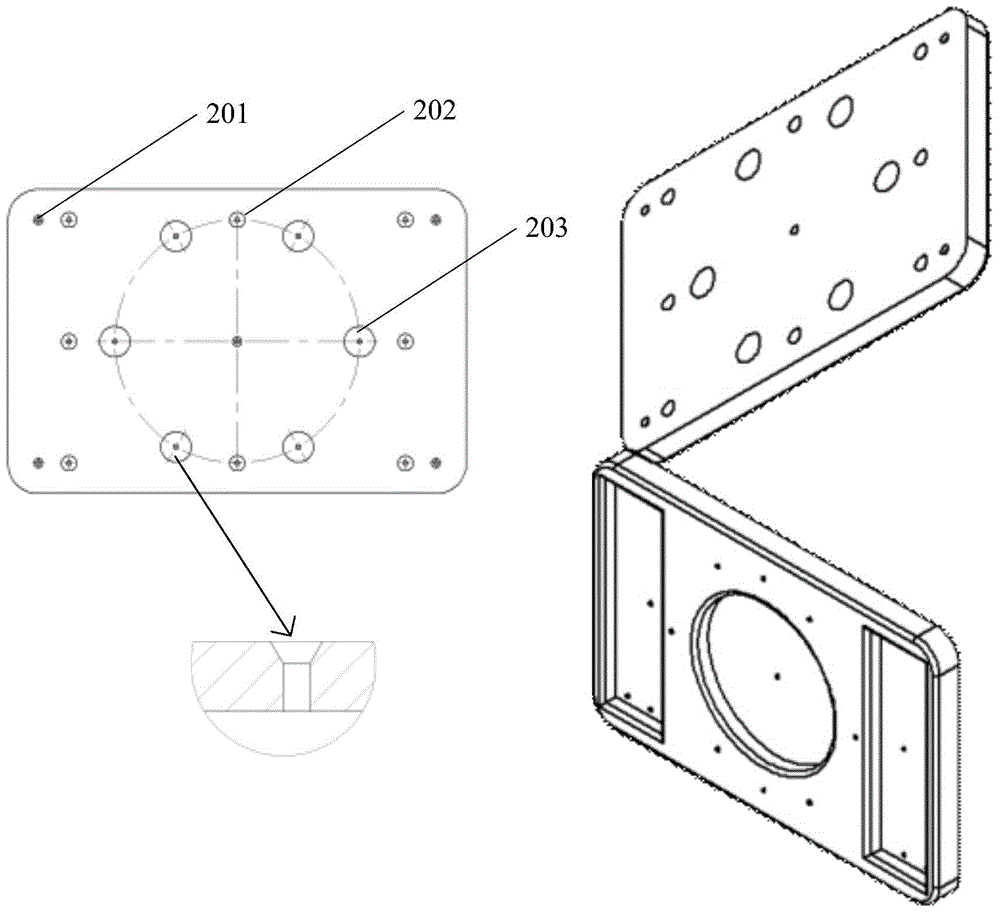

Industrial robot kinematics calibration system and calibration method

The invention relates to an industrial robot kinematics calibration system. The industrial robot kinematics calibration system comprises a measuring device arranged at the tail end of a robot and further comprises a calibration device and a data processing device which are arranged in the robot work space. According to the device, cost is reduced, carrying and using are convenient, and the devicecan be applied to online rapid calibration of a robot on the work site. A measuring coordinate system is established on the measuring device, and the robot is calibrated; and through a method, calibration of robot body geometric parameter errors, and the conversion relation among a robot coordinate system, the measuring coordinate system and a calibration coordinate system can be achieved at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

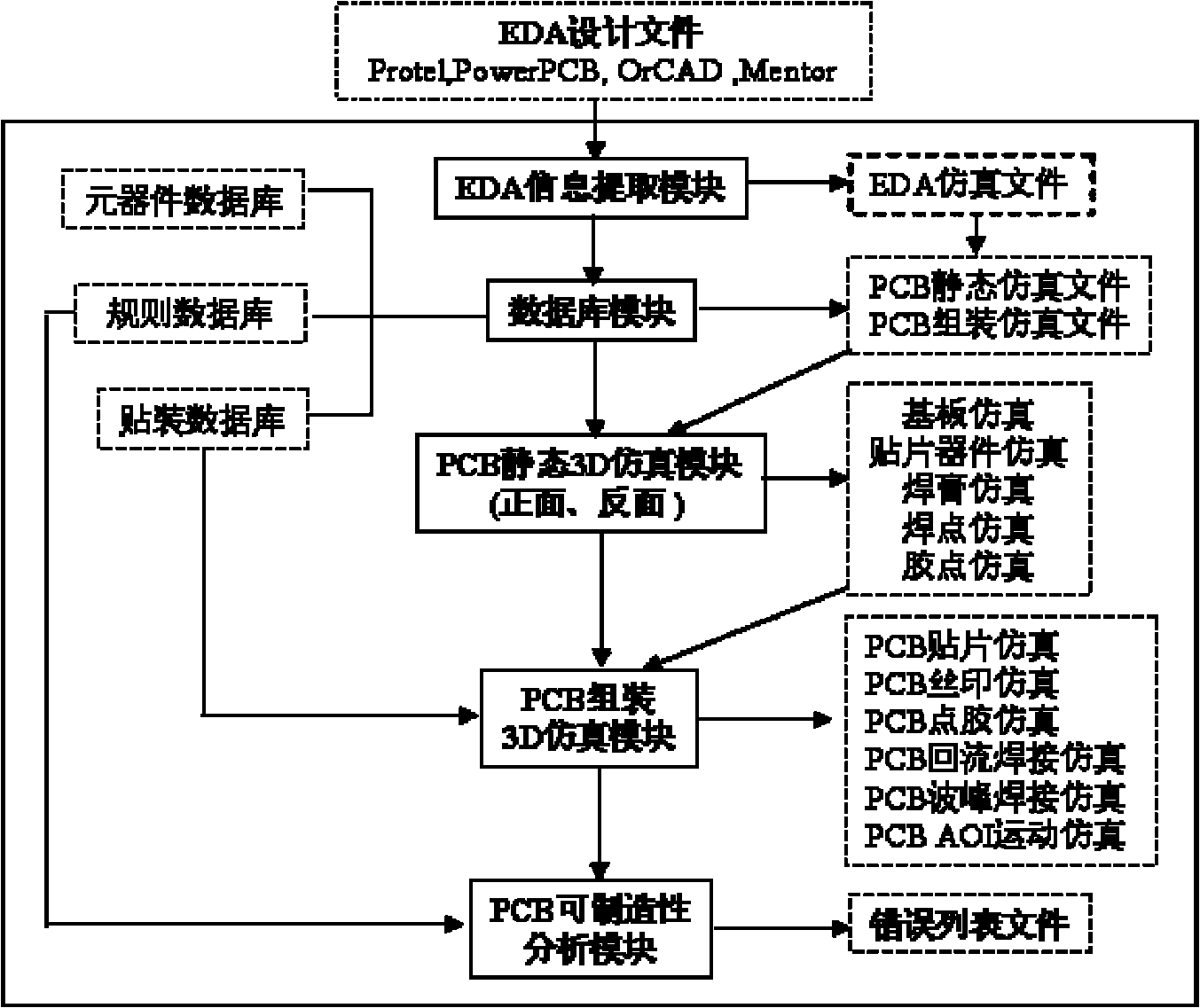

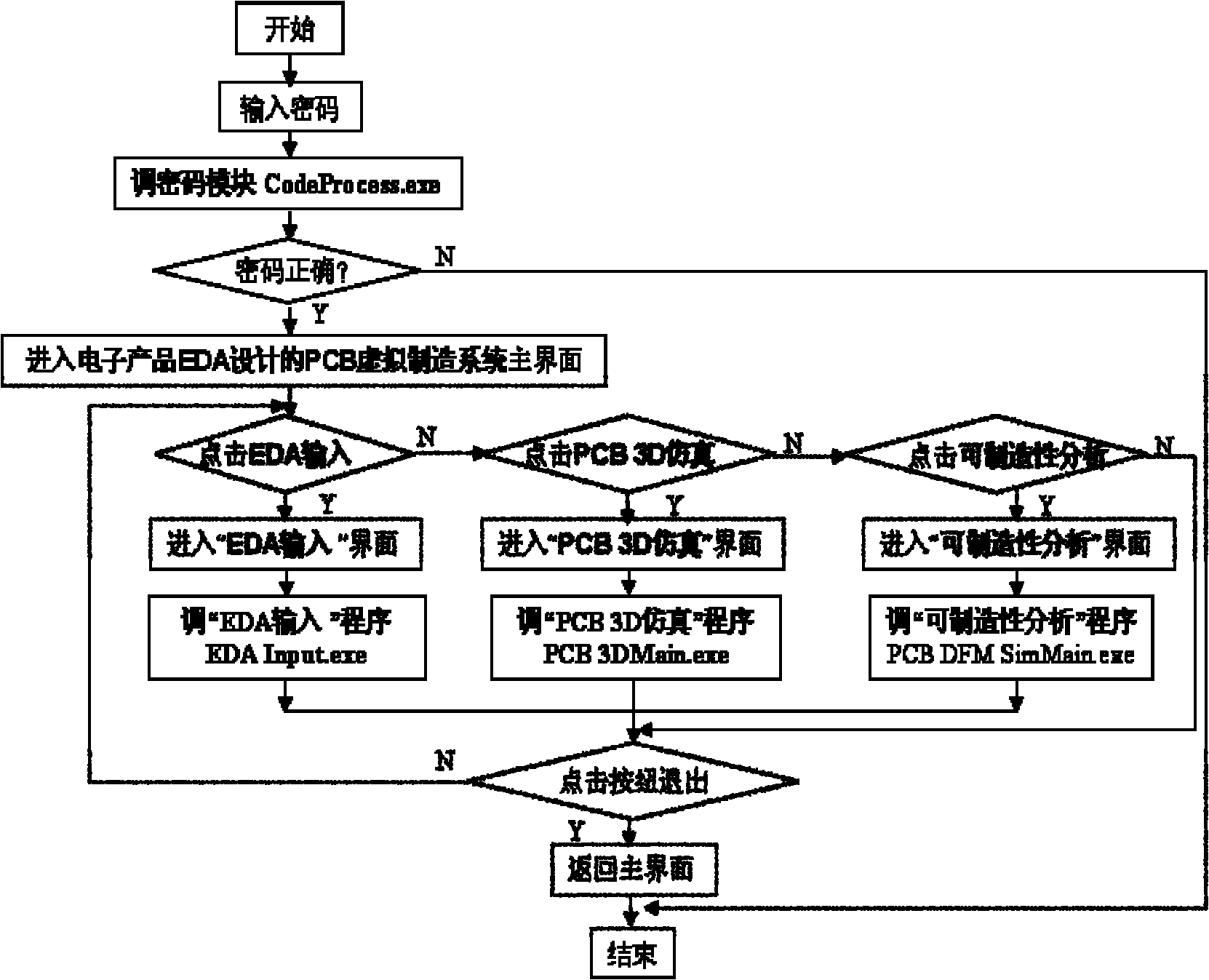

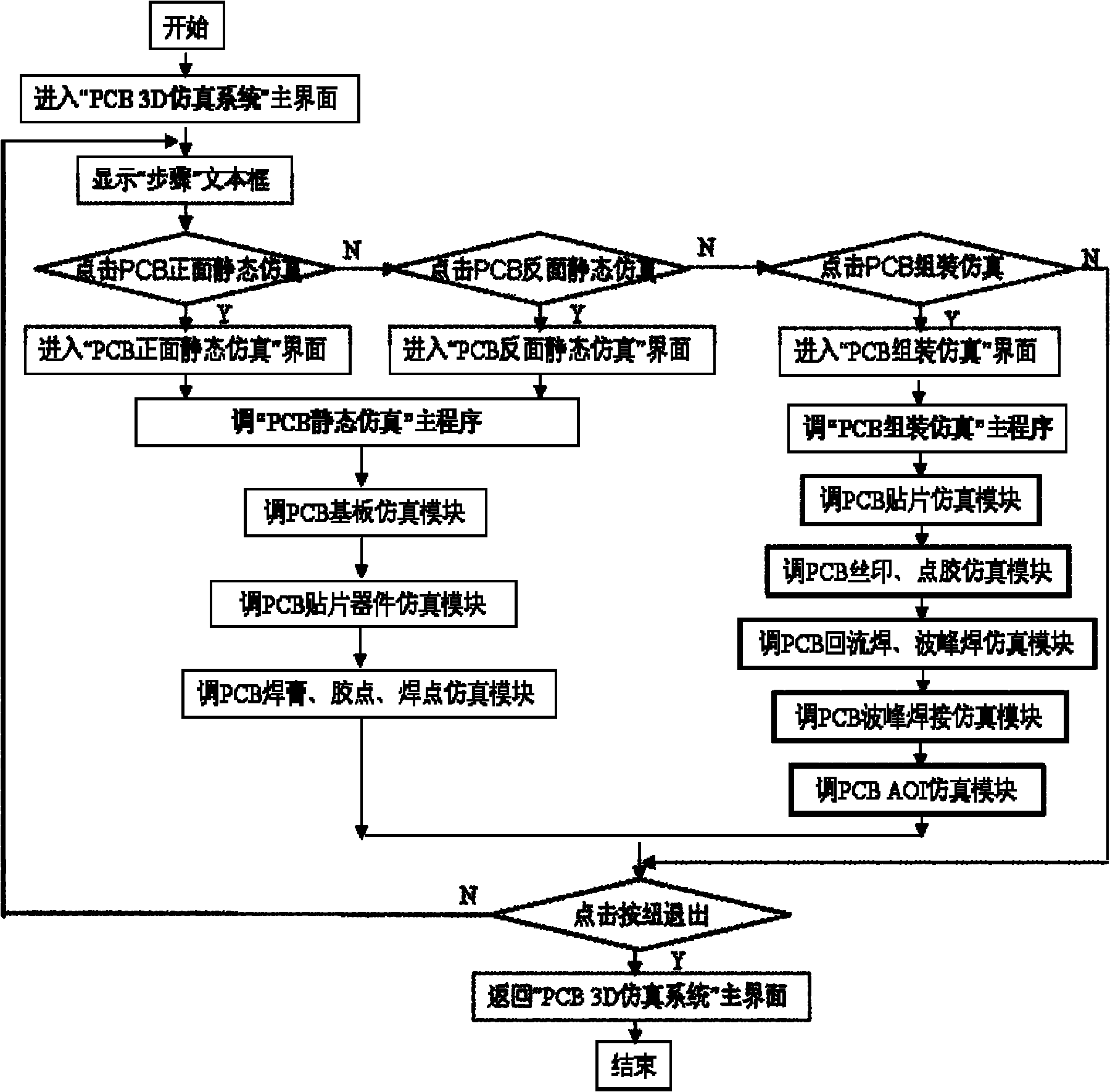

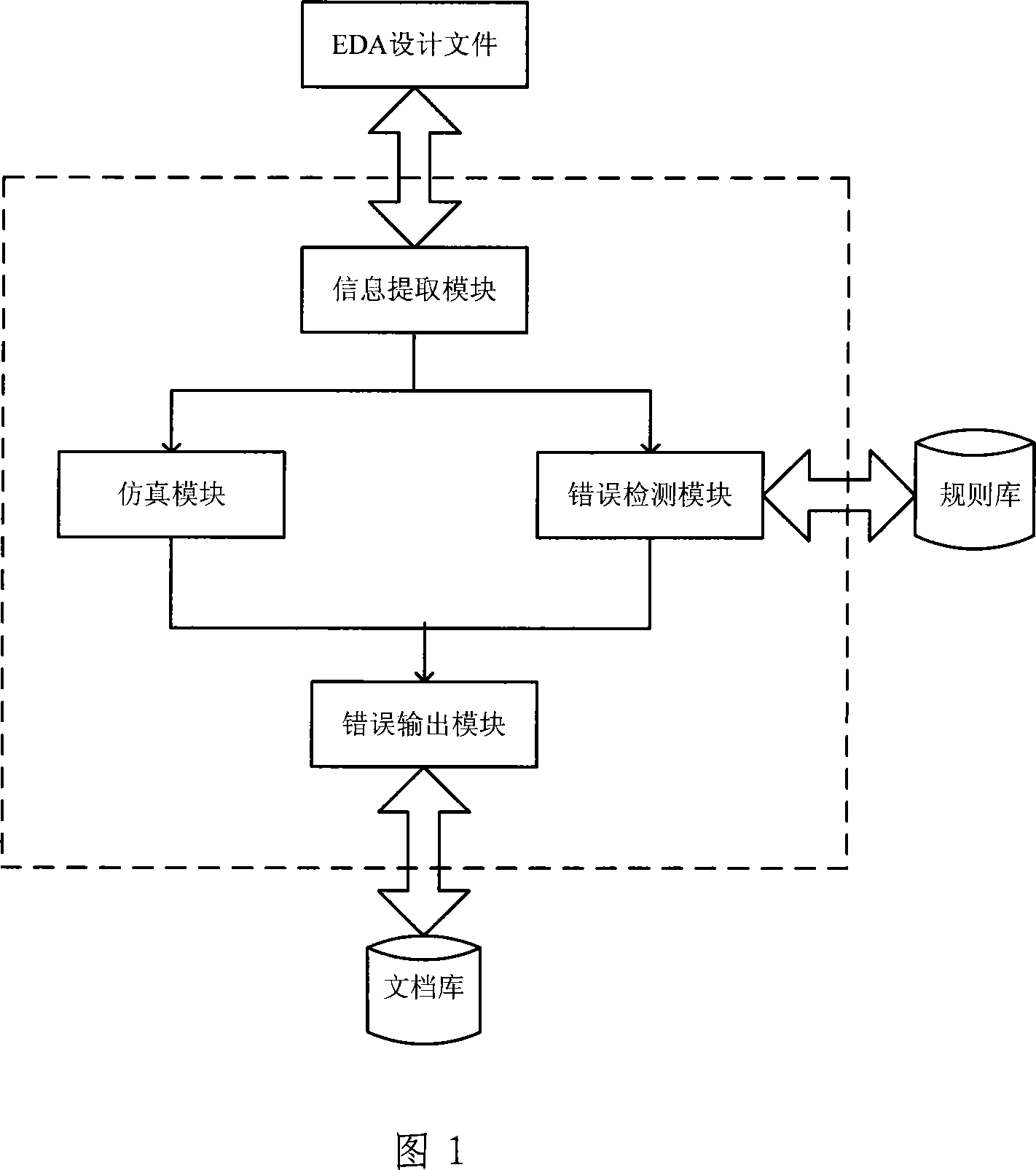

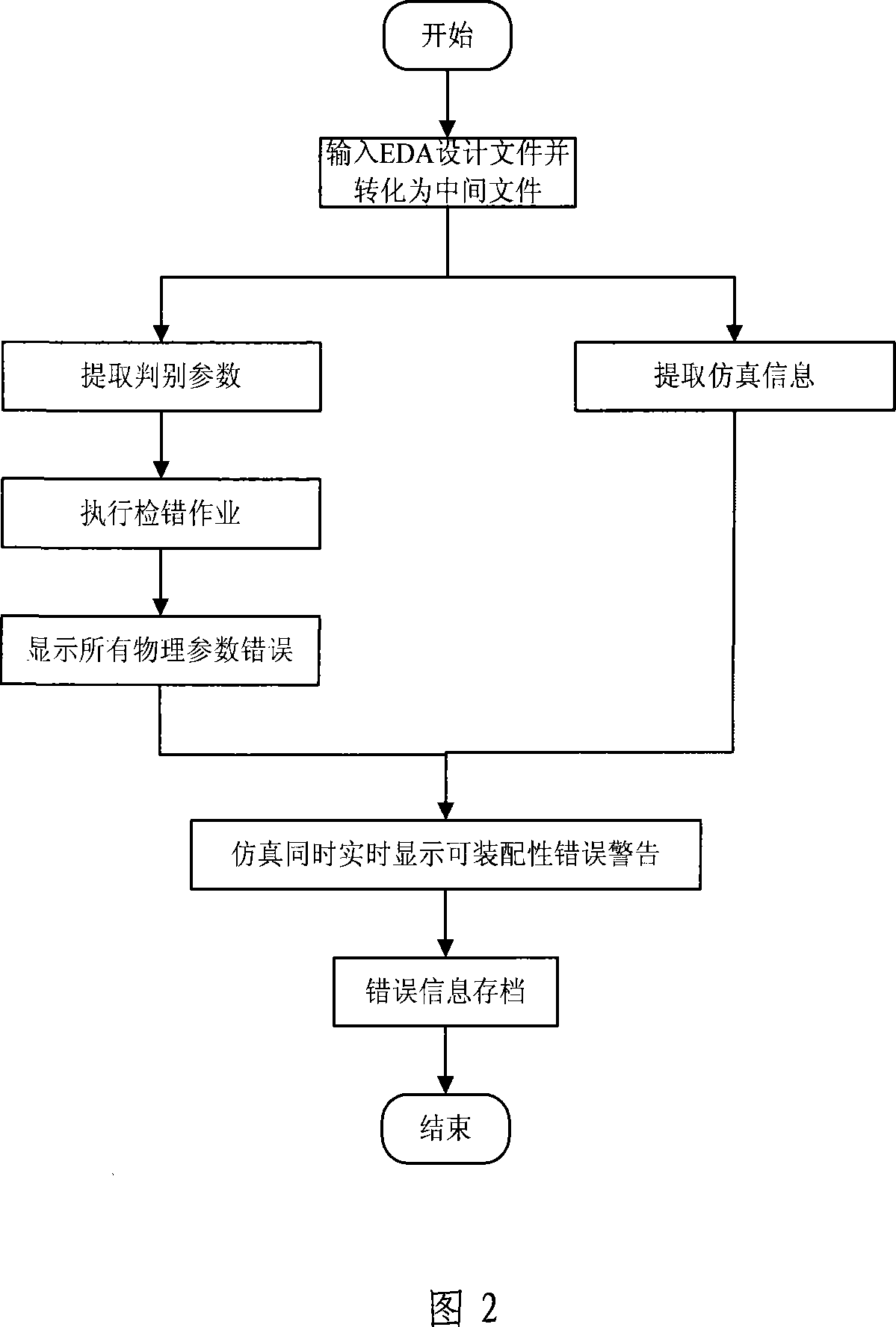

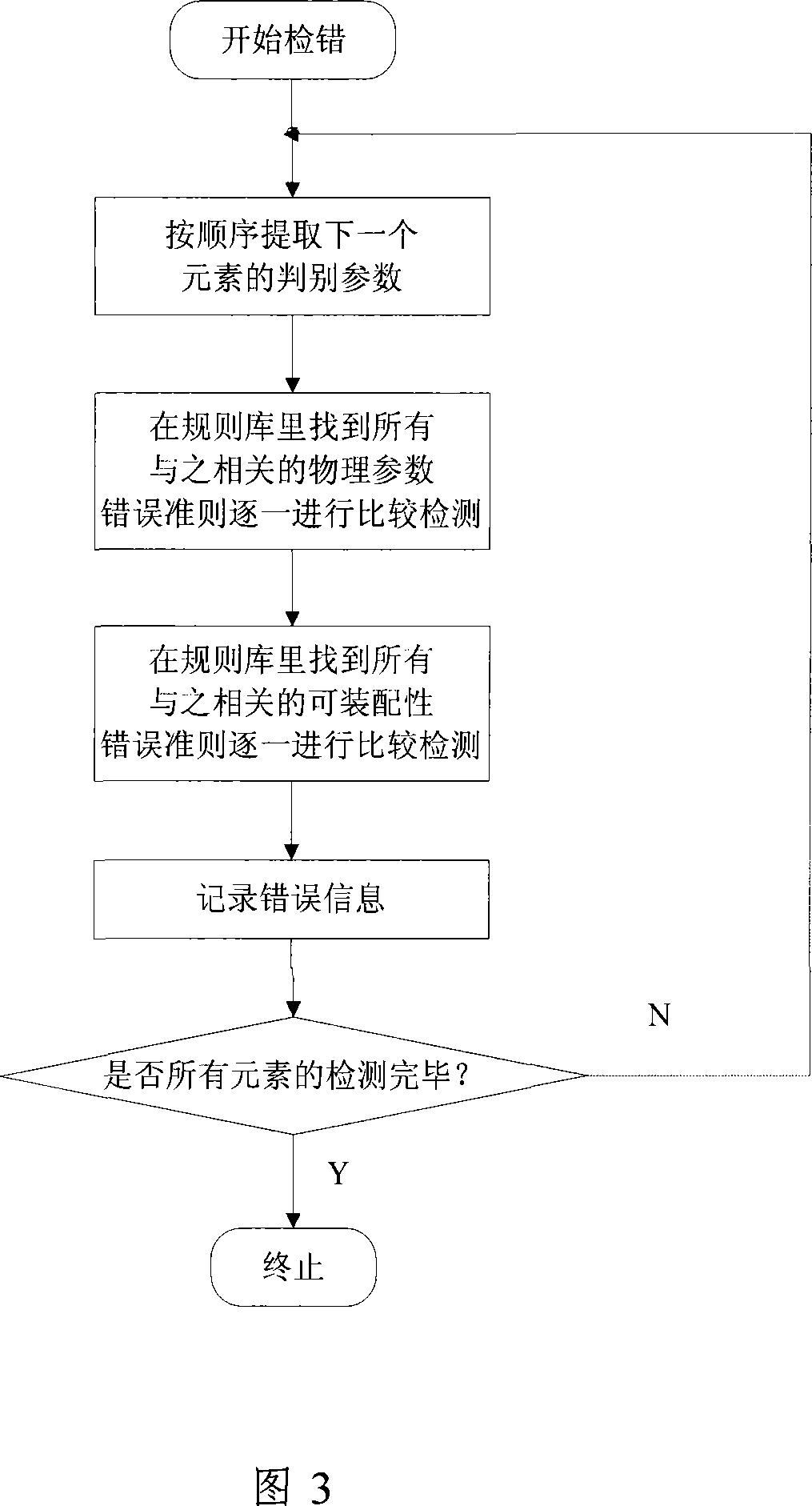

Printed circuit board virtual manufacturing system of electronic design automation of electronic product and realization method thereof

InactiveCN101986316ASave time and costSave production costSpecial data processing applicationsReal time displayPrinted circuit board

The invention relates to a printed circuit board (PCB) virtual manufacturing system of the electronic design automation (EDA) of the electronic product and a realization method thereof. The realization method comprises the following steps: all types of EDA design files can be extracted and converted to an EDA simulation file with the same format and data are input in a database; the PCB static (three-dimensional) 3D simulation and assembly 3D simulation are performed under the VC++ 6.0 environment; and finally PCB manufacturability analysis is performed to extract the simulation information and the judgement parameters of each element, the judgement parameters of each element are detected one by one according to the manufacturability design criteria in a rule database, and the PCB physical parameter error and assembly error of the EDA of the electronic product are displayed and filed instantly. By adopting the method of the invention, the relationship between the PCB design and the manufacture of the isolated island can be built and the visual basis can be provided for the data modification of the EDA optimal deign in the shortest time, thus the aim of optimizing the development cycle and the cost and maximizing the production efficiency can be achieved.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

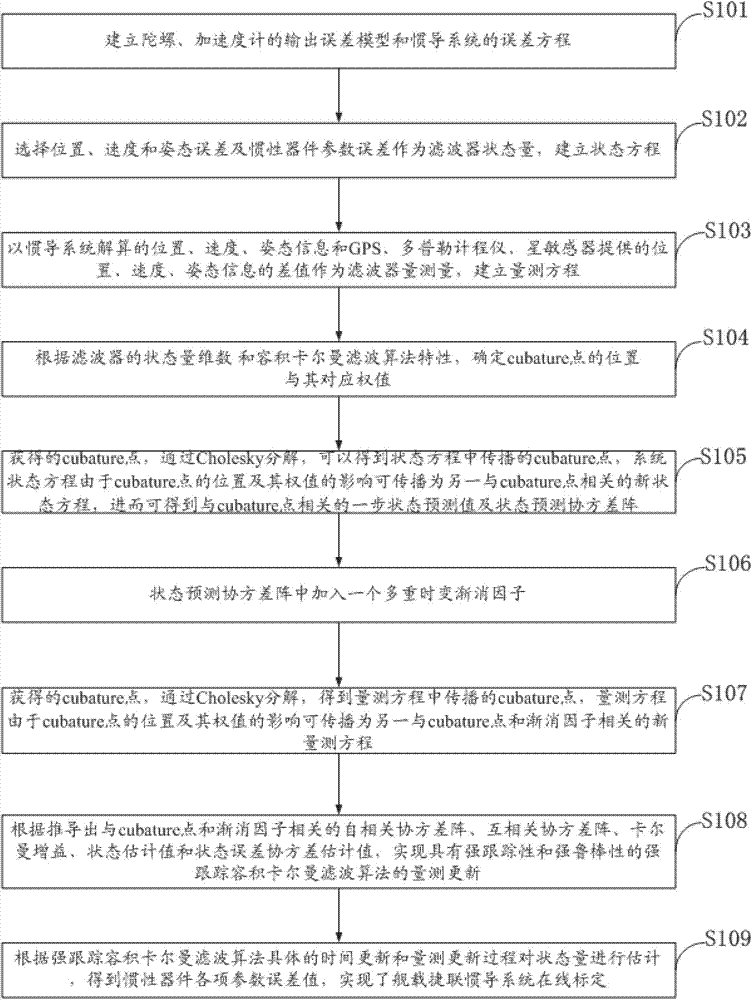

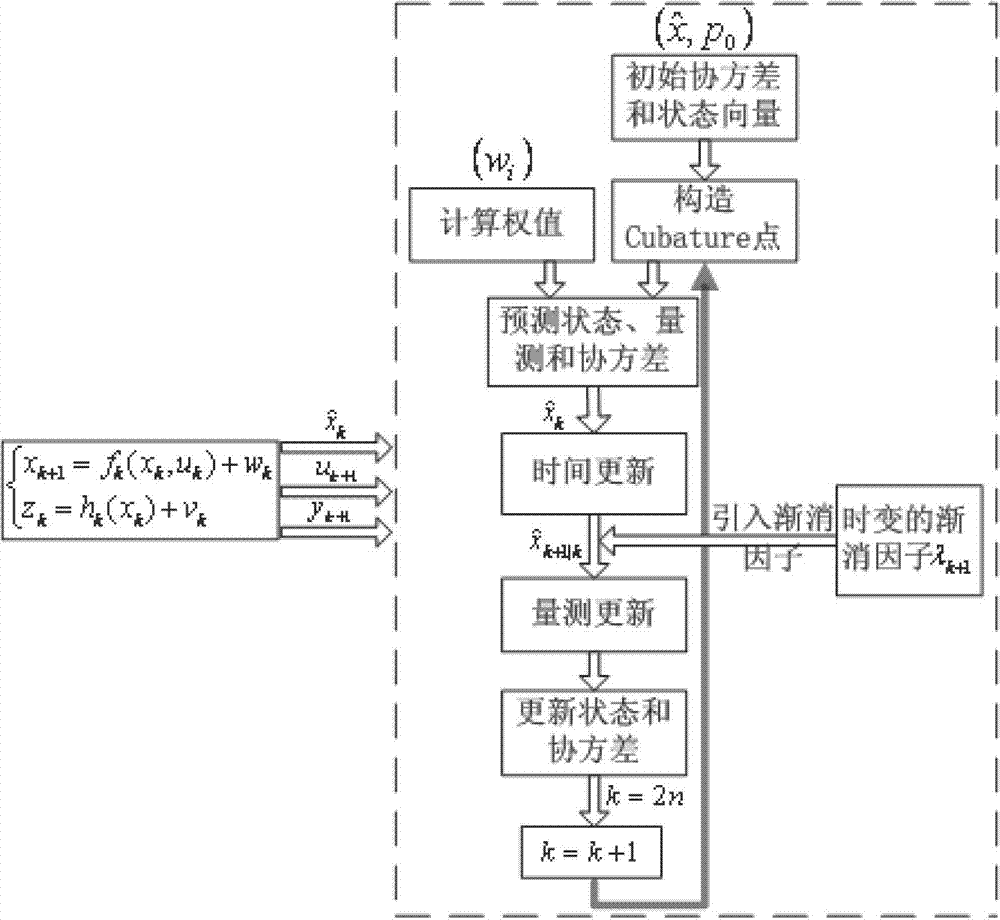

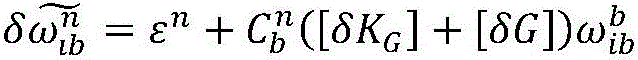

Online calibrating method of ship-based rotary strapdown inertial navigation system

InactiveCN103591965AImprove navigation accuracyEasy to handle calculationsMeasurement devicesState predictionFilter algorithm

The invention discloses an online calibrating method of a ship-based rotary strapdown inertial navigation system. The method comprises the following steps: establishing an inertial component output error model and an inertial navigation system error equation, and researching the calibration of inertial component parameter errors and determining the quantity of state and the quantity of measuration; determining the position and weight of a cubature point according to dimension of the quantity of state, deducing a state equation and a one-step state prediction and state prediction covariance matrix related to the cubature point, and introducing a multiple time-varying fading factor modified state prediction covariance matrix; and deducing a measuring equation related to the cubature point and the fading factors, a self-correlated covariance matrix, a cross-correlated covariance matrix, a gain matrix, a state estimated value and a state error covariance estimated value, and designing a strong tracking volume Kalman filtering method with strong tracking performance and strong robustness. The method disclosed by the invention estimates the inertial component parameter errors by a filtering algorithm and carries out online calibration and compensates the inertial component parameter errors, so that the navigation precision is effectively improved. The method has strong parameter-varying robustness.

Owner:HARBIN ENG UNIV

PCB emulation system have error detection function and realization method thereof

InactiveCN101178750ASave time and costSave production costSpecial data processing applicationsError detection and correctionInformation extraction

Owner:来新泉

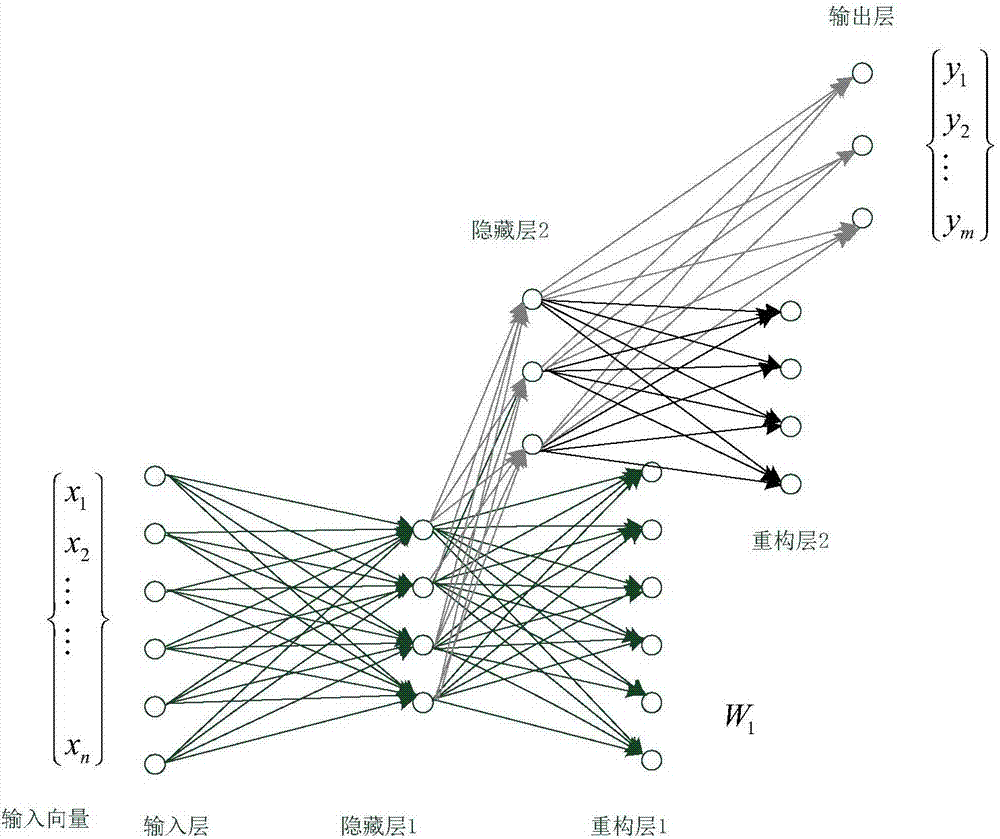

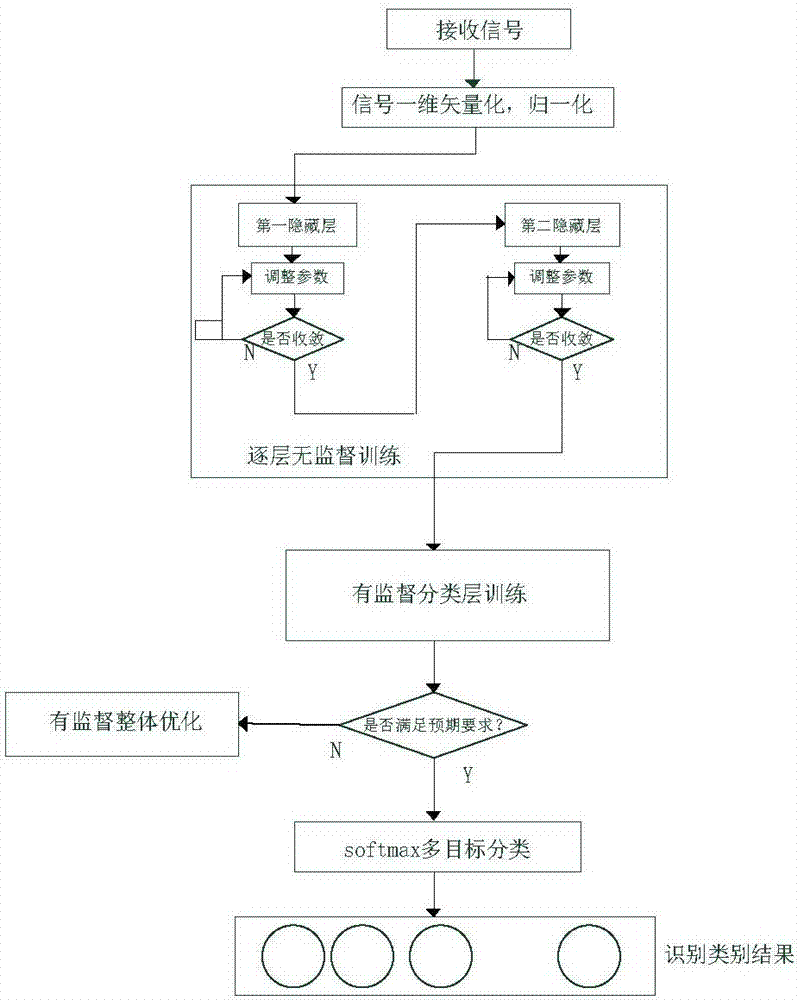

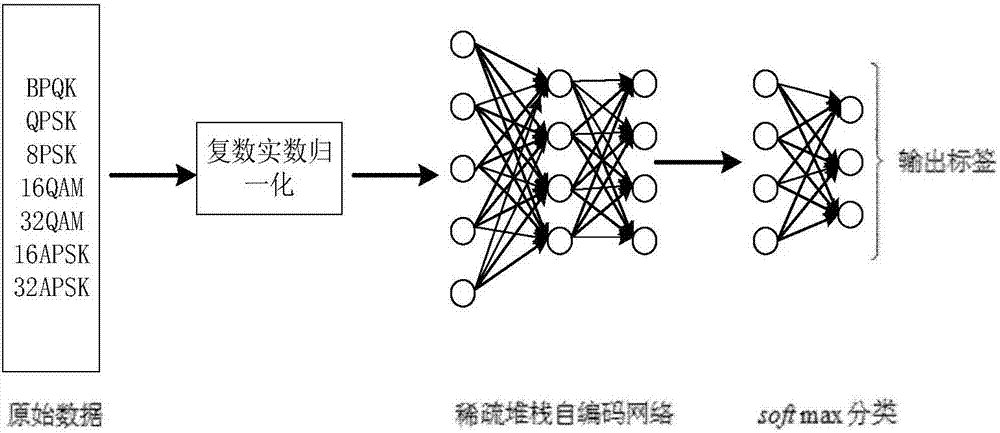

Modulation type identification method based on sparse stack self-coding

InactiveCN107038421AReduce mistakesLow costCharacter and pattern recognitionSignal-to-noise ratio (imaging)Feature parameter

The invention discloses a modulation type identification method based on sparse stack self-coding. The method comprises the following steps: step 1, processing down-converted signals to obtain baseband signals of modulation signals; step 2, performing one-dimensional vectorization and normalization on the baseband signals; step 3, reforming a self-coder to obtain a sparse self-coder, and then constructing a stack sparse self-coder network using the reformed sparse self-coder to extract signal features; introducing a soft max regression model, and taking the signal features extracted by the stack sparse self-coder network as an input; step 4, training the stack sparse self-coder network; and step 5, judging whether the adjustment of network parameters meets the requirement, if so, ending the training, otherwise, repeating step 4 to continuously train the network. The method does not need to artificially extract signal feature parameters, thereby solving the problem of large parameter error in artificial extraction; and the method has good modulation type identification performance in a network having low signal-to-noise ratio and excellent anti-noise performance.

Owner:HANGZHOU DIANZI UNIV

Kinematics calibration method of measurement robot

InactiveCN101660904AEasy to operateHigh precisionUsing optical meansKinematic calibrationEngineering

The invention relates to a kinematics calibration method of a measurement robot; the method mainly aims at computing kinematics parameter error of an industrial robot with a distance-measurement sensor; the method comprises a distance-measurement sensor, an industrial robot and a sphere with known radius, wherein the distance-measurement sensor is arranged at the end of the industrial robot, the sphere with known radius is used as a target and is arranged in a measurable range of a measuring head; the steps of kinematics parameter calibration are: firstly, the robot drives the sensor to measure spherical surface with more than seven poses, measurement data and pose data of the robot are recorded, and then, a centered spherical surface that measurement data is converted to a base coordinatesystem of the robot and spherical radius fixation are taken as a constraint condition, the kinematics parameter error of the robot is computed by nonlinear optimization, so as to realize simultaneouscalibration of a kinematics model and connecting relation of the sensor and the robot.

Owner:DALIAN MARITIME UNIVERSITY

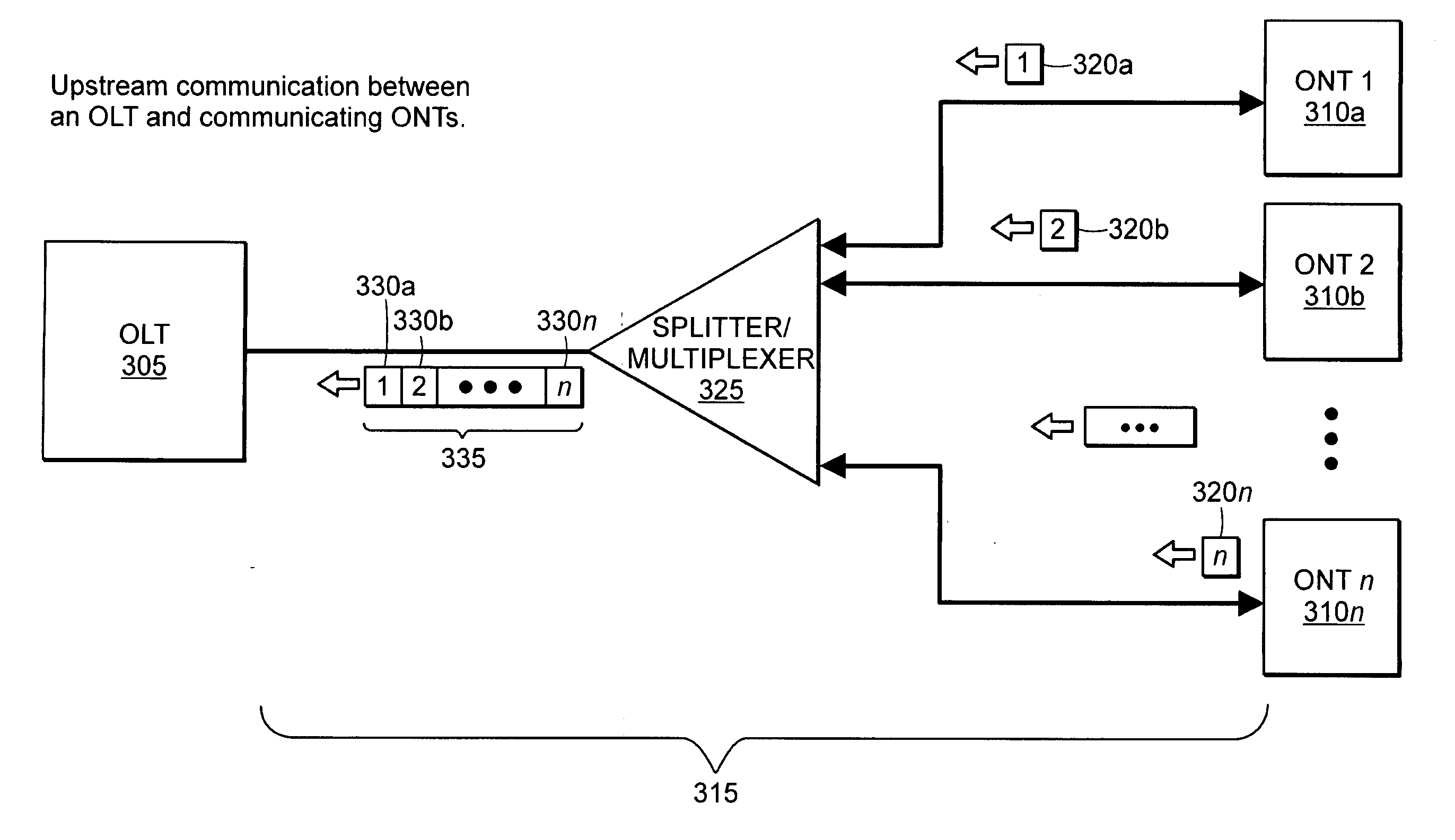

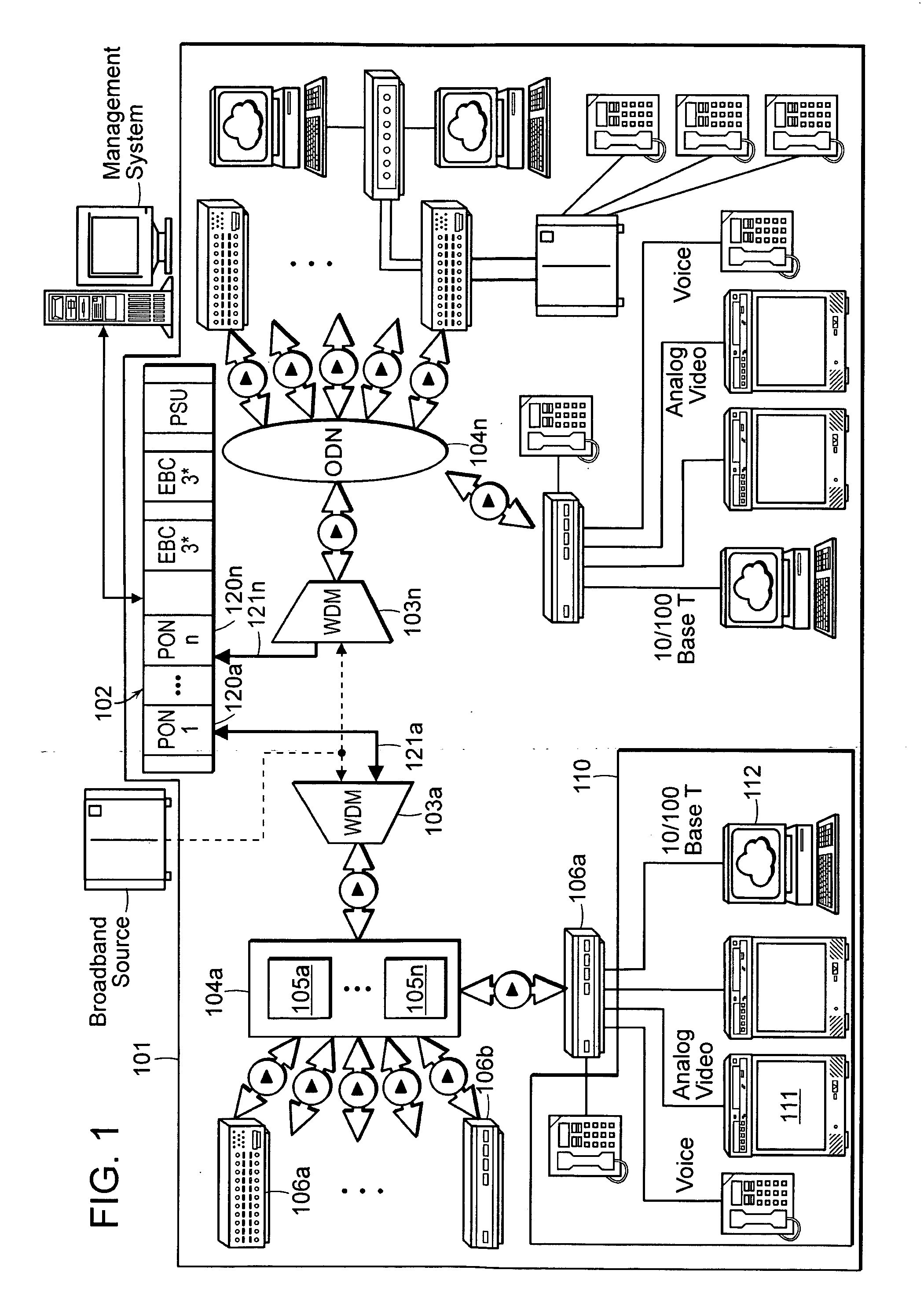

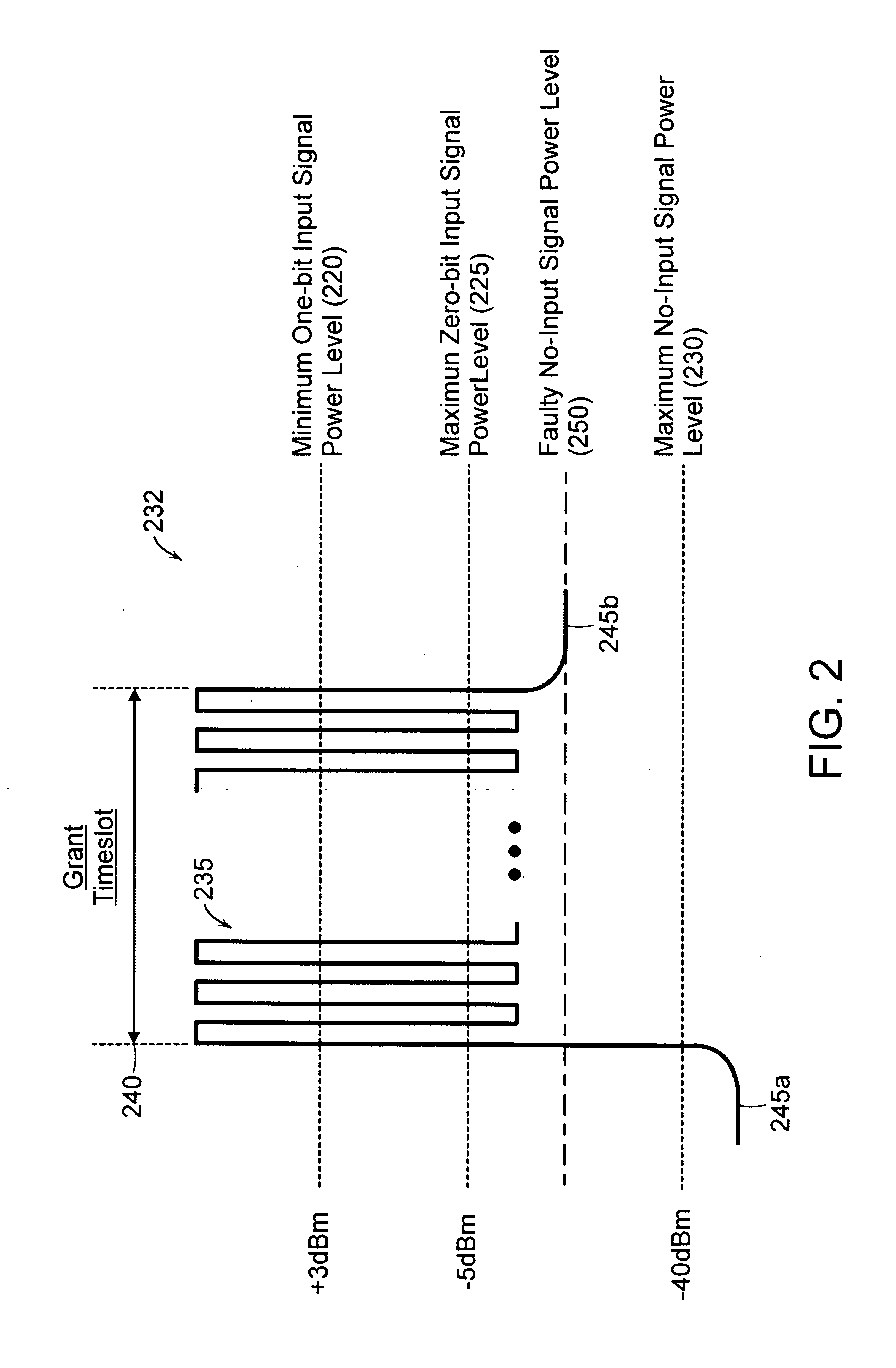

Method and apparatus for diagnosing problems on a time division multiple access (TDMA) optical distribution network (ODN)

ActiveUS20070237523A1Time-division multiplexTransmission monitoringTime division multiple accessCode division multiple access

A method and corresponding apparatus for diagnosing problems on a time division multiple access (TDMA) optical distribution network (ODN) is provided. An example method may include: (i) measuring no-input signal power level on a communications path configured to carry upstream communications between multiple optical network terminals (ONTs) and an optical line terminal (OLT) in a passive optical network (PON) at a time no upstream communications are on the communications path from the ONTs to the OLT; (ii) comparing the measured no-input signal power level to a threshold; and (iii) generating a notification in an event the threshold is exceeded. Through the use of this method, faults in optical transmitters, such as bad solder joints, can be determined. Such faults may cause errors in parameters, such as ranging or normalization parameters, associated with communications. By determining the faults, the time required to resolve communications errors can be reduced.

Owner:TELLABS PETALUMA

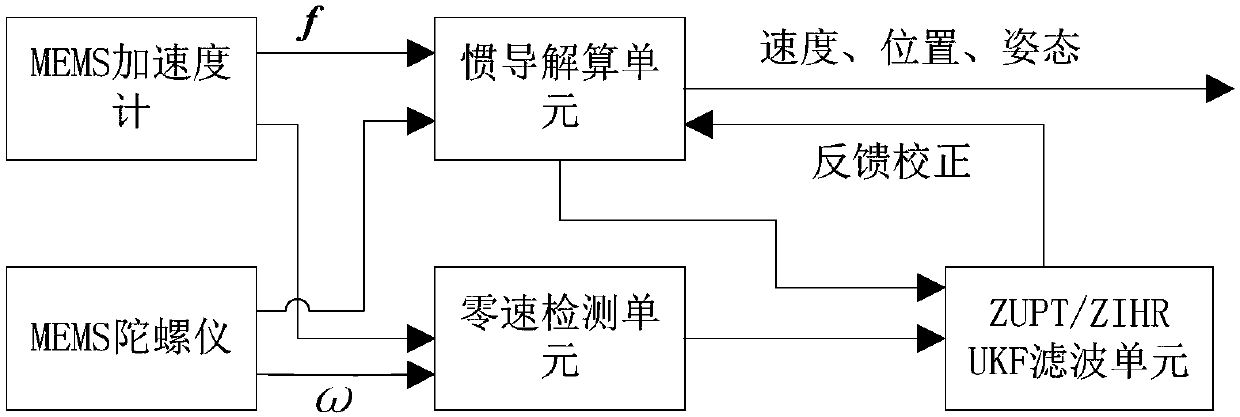

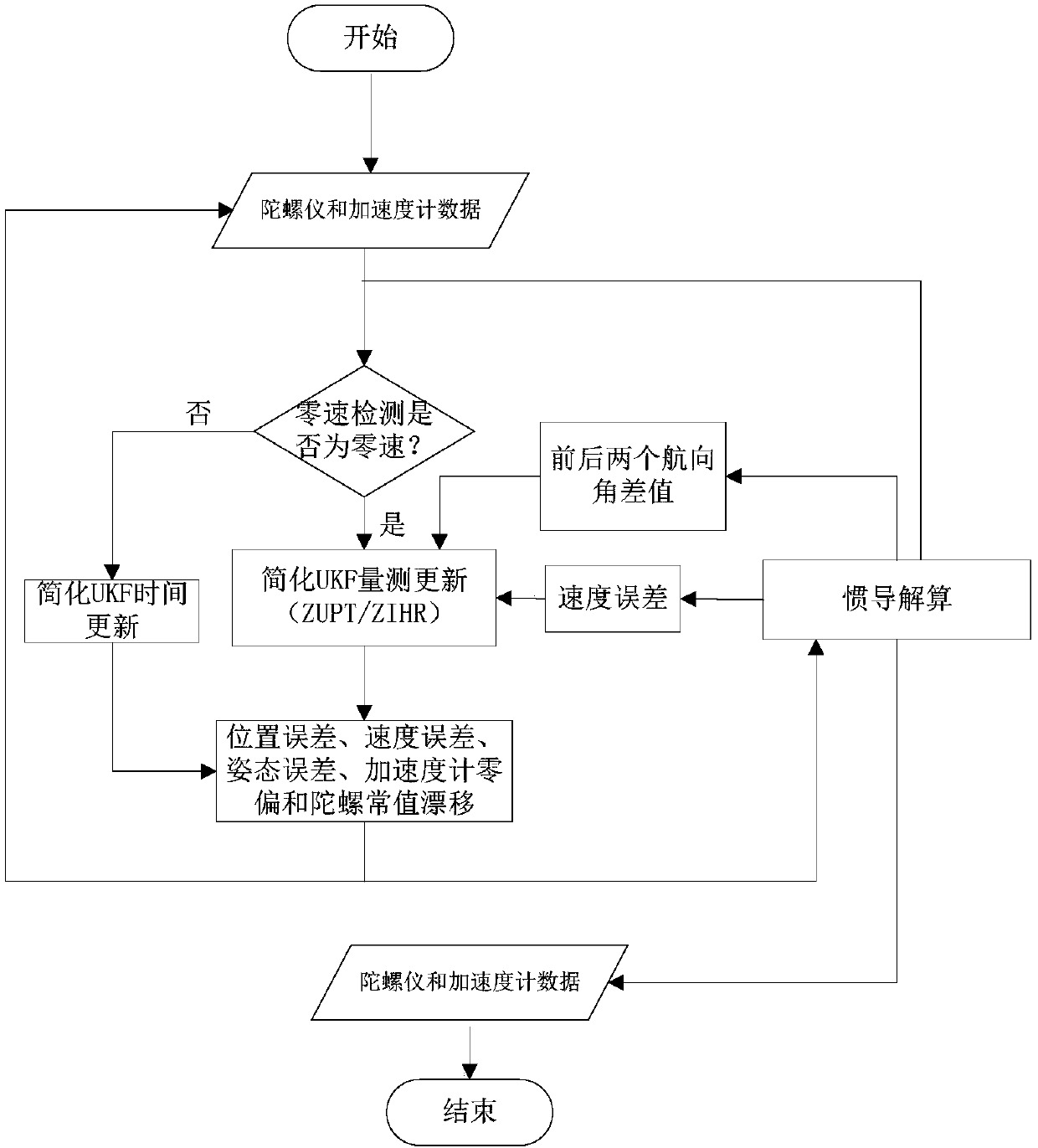

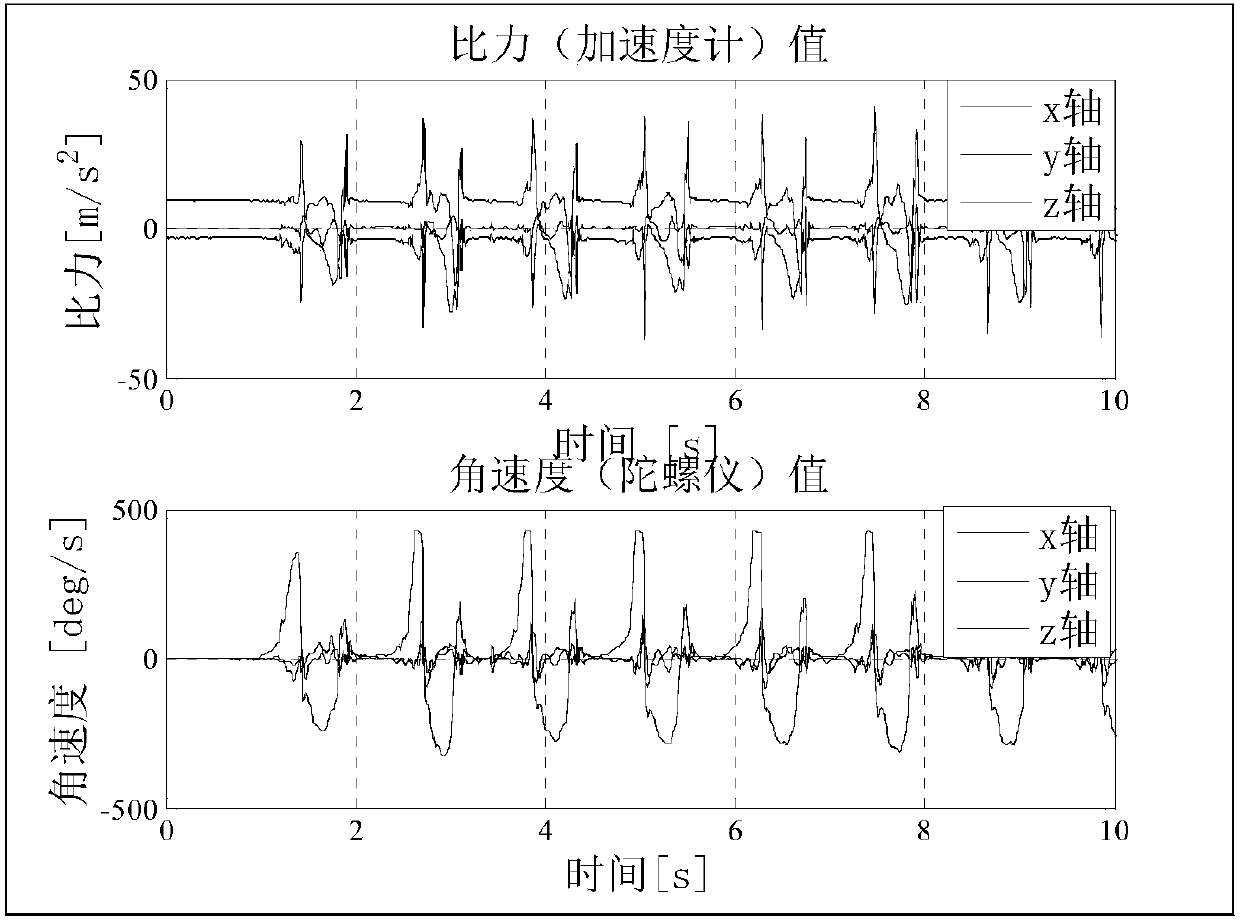

MEMS pedestrian navigation method based on ZIHR heading angle correction algorithm

InactiveCN108426574AAvoid divergenceExtended 1D measurementNavigational calculation instrumentsNavigation by speed/acceleration measurementsCorrection algorithmAccelerometer

The invention provides an MEMS pedestrian navigation method based on ZIHR heading angle correction algorithm. The method includes: 1. conducting initial alignment on an MEMS pedestrian navigation system with an accelerometer and a magnetometer at a static moment; 2. working out an inertial navigation calculation equation and an error equation of the MEMS pedestrian navigation system; 3. conductingzero velocity state detection with the output values of a gyroscope and the accelerometer; 4. working out the relationship between the heading angle difference of adjacent moments under a zero velocity state, gyroscopic drift and a heading error angle in ZIHR (zero integrated heading rate) correction algorithm; and 5. establishing a simplified MEMS pedestrian navigation UKF filter model, and performing UKF filtering. The method provided by the invention maximumly utilizes the information of static moment, has uncomplicated calculation amount, and can well inhibit the divergence of the headingerror angle. Use of the UKF filter for real-time feedback correction at a zero velocity moment can well inhibit the problem of navigation parameter error divergence after long-time operation of a low-precision MEMS sensor, and improve the positioning precision of a pedestrian navigation system.

Owner:HARBIN ENG UNIV

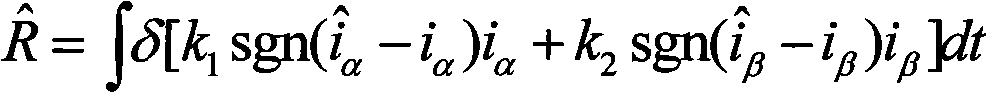

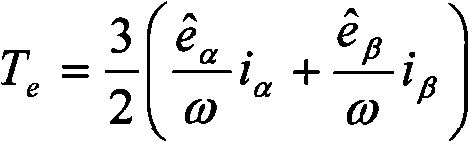

Brushless direct current motor electromagnetic torque observation method based on self-adapting slipform observer

InactiveCN101951211AAccurate torque feedback valueSimple procedureSingle motor speed/torque controlPhase currentsLoop control

The invention discloses a brushless direct current motor electromagnetic torque observation method based on a self-adapting slip-form observer, belonging to the control field of permanent magnet motors. The observation method comprises the following steps of: constructing a state space equation of a brushless direct current motor in an alpha-beta coordinate system based on easily-observing signals, such as motor rotating speed, each phase current of a stator, each ground voltage of the stator, rotor position, and the like; observing a counter emf (Electromotive Force) of the brushless direct current motor in the alpha-beta coordinate system in real time by using the slip-form observer; meanwhile online identifying a stator resistance parameter of the brushless direct current motor to eliminate the influence of a resistance parameter error on counter emf observation; and finally calculating the electromagnetic torque of the brushless direct current motor in real time according to the counter emf, the current and the rotating speed. In the invention, when the stator resistance parameter is unknown or a stator resistance changes due to the influences of temperature and skin effect, the counter emf and the electromagnetic torque of the brushless direct current motor can be accurately observed, the problem of the traditional method influenced by the resistance parameter is solved, and an accurate torque feedback value can be provided for the torque close loop control of the brushless direct current motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

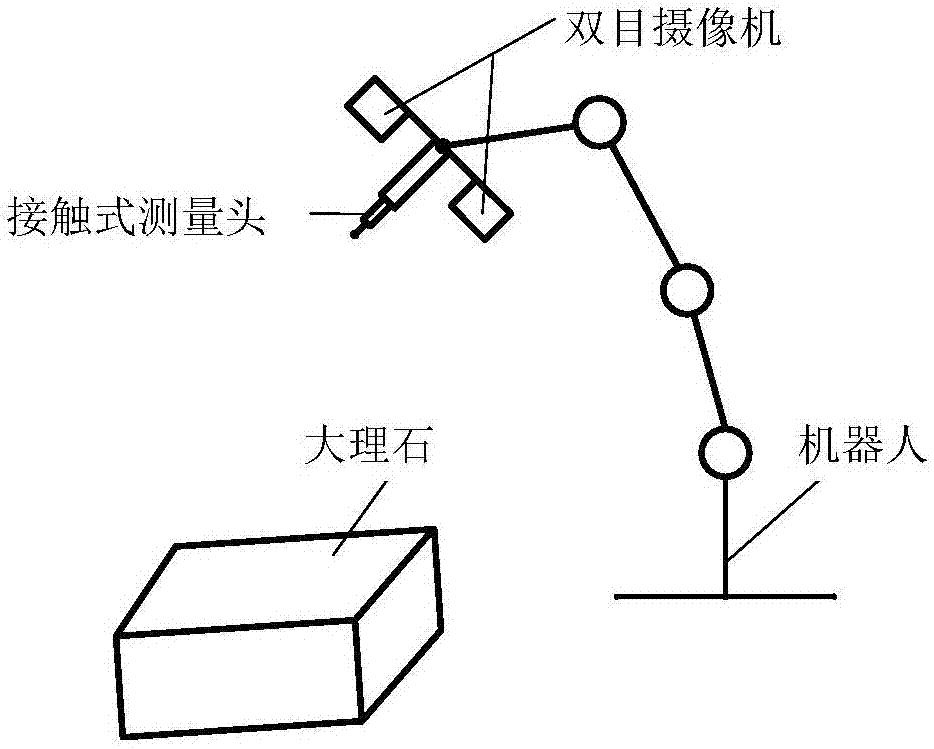

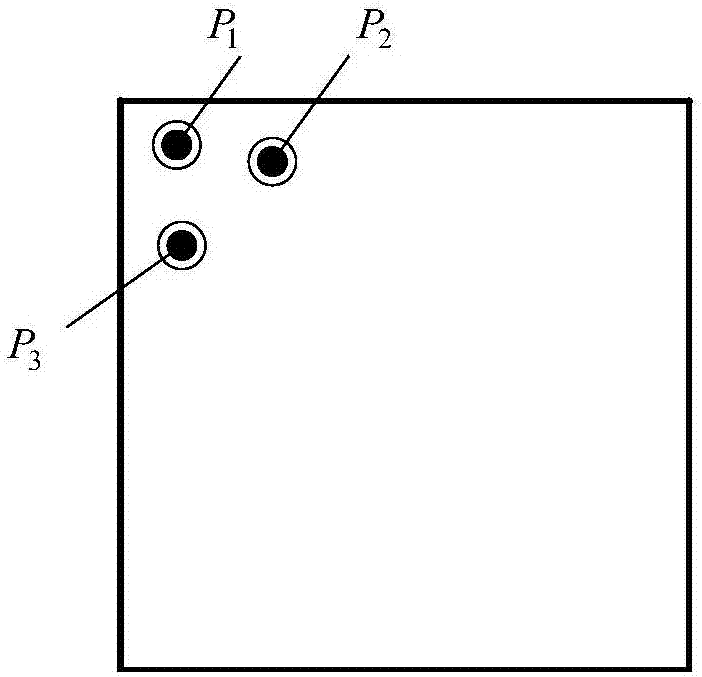

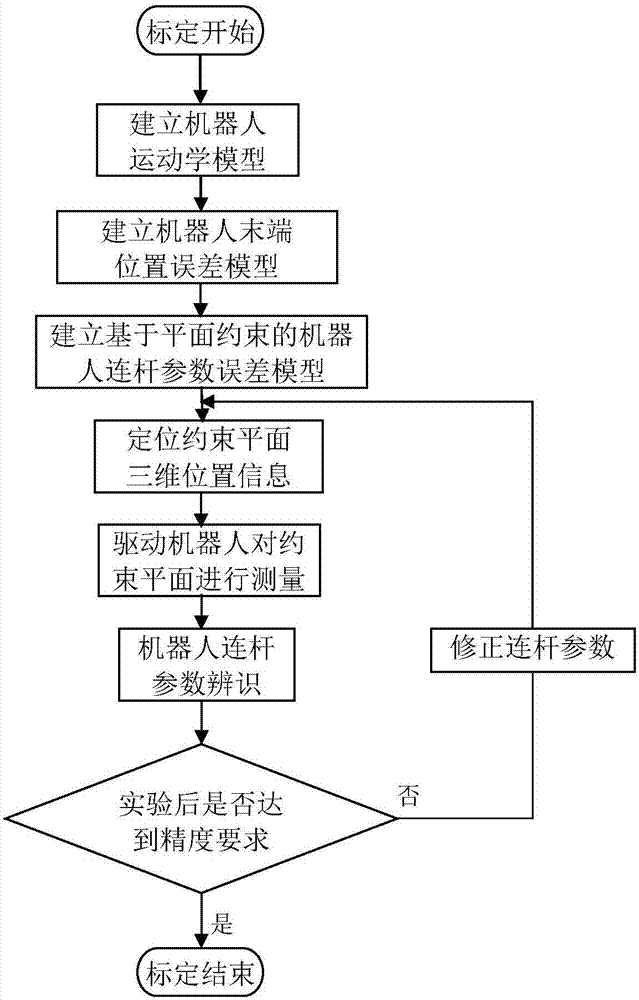

Robot self-calibration method based on vision-assisted positioning

The invention relates to a robot self-calibration method based on plane constraint and vision-assisted positioning. The robot self-calibration method based on plane constraint and vision-assisted positioning is used for obtaining real connection rod parameters of a robot. Firstly, a robot kinematic model combining a D-H method and a MD-H method is established; secondly, a robot terminal position error model is established; thirdly, a robot connection rod parameter error model based on plane constraint is established; fourthly, images, of a constraint plane, in a left camera and a right camera are obtained through binocular vision, target point information in each image is extracted, the three-dimensional position information of the constraint plane under a basic coordinate system of the robot is positioned through three-dimensional matching; the position information is input into a robot control system, and the robot is driven to measure the constraint plane; and finally the measured data are substitute into the plane constraint error model, the real geometric connection rod parameters of the robot are recognized, and after correction, measurement of the constraint plane and recognition are repeatedly conducted until a precision requirement is met. The robot self-calibration method based on plane constraint and vision-assisted positioning has the advantages of being low in cost and high in precision and efficiency.

Owner:JIANGNAN UNIV

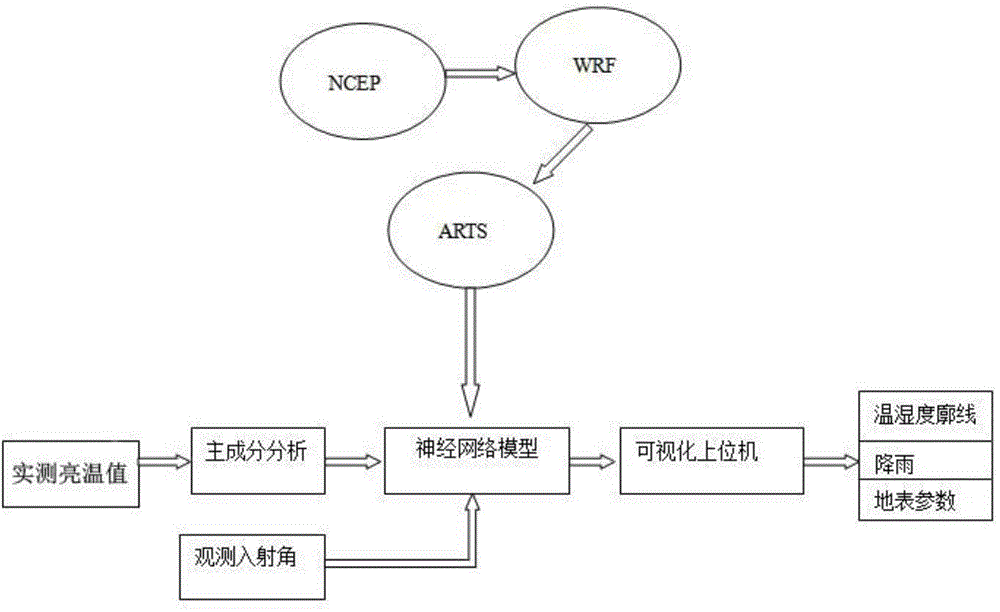

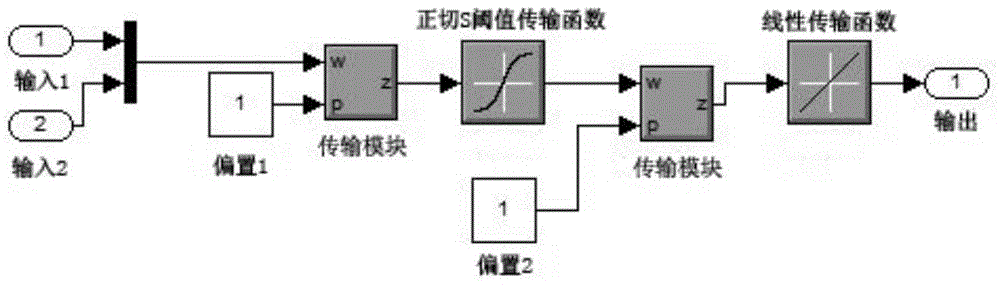

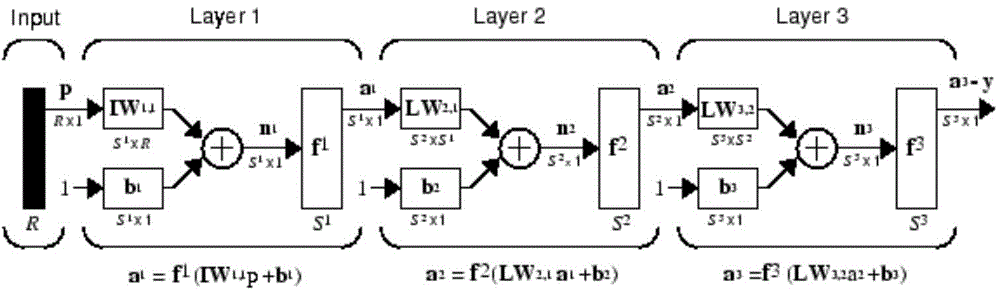

Application data processing method of spaceborne microwave radiometer

ActiveCN105988146AWork to achieve local correctionsIndication of weather conditions using multiple variablesData setBrightness temperature

The present invention provides an application data processing method of a spaceborne microwave radiometer. According to the application processing method, by inputting the global or regional profile data and the radiation brightness-temperature values in a matrix, adopting a wavelet neural network algorithm to train the data, and comparing the outputted atmosphere humiture profile and ground / sea surface parameters with the preset threshold indexes, the back propagation of the atmosphere humiture profile and ground / sea surface parameter errors is implemented; by correcting each layer of weights in an error gradient descent manner, the work of utilizing a data set to correct the inversion parameters locally is realized, the local correction capabilities of the equipment developers and users to the inversion software parameters are improved, and further the detection and inversion precision is improved further.

Owner:NAT SPACE SCI CENT CAS

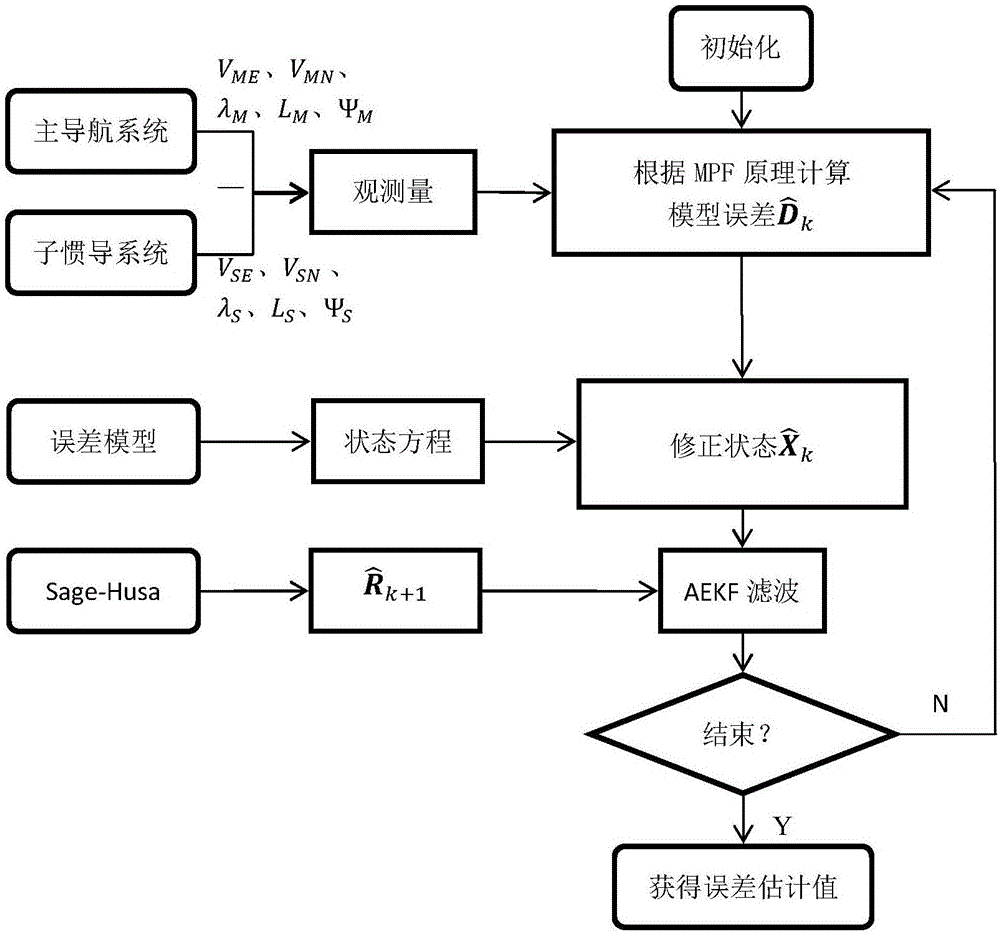

Integrated navigation technology-based online calibration method for marine fiber-optic strapdown inertial navigation system

ActiveCN106767900AHigh precisionSolving Online Calibration ProblemsNavigational calculation instrumentsNavigation by speed/acceleration measurementsNavigation systemSelf adaptive

The invention discloses an integrated navigation technology-based online calibration method for a marine fiber-optic strapdown inertial navigation system. Online calibration is carried out on the fiber-optic strapdown inertial navigation system by adopting a matching mode of ''a position, a speed and a course angle'' according to the position, the speed and course information of a marine primary navigation system. Various parameter error values of an inertial device are estimated by adopting a one-step predicted value of a model predictive filtering correction state, and a measurement noise variance matrix is continuously estimated and corrected by adopting Sage-Huse adaptive extended kalman filtering, so that the filtering accuracy is improved and the online calibration is achieved. Information is output by using the primary navigation system, and various calibration parameters of an inertial measurement assembly are estimated online by using the corresponding filtering method, so that the online calibration problem of the inertial measurement assembly is solved, periodic removal and calibration of the fiber-optic strapdown inertial navigation system are avoided, the accuracy of the fiber-optic strapdown inertial navigation system is effectively improved and the online calibration method has outstanding application value.

Owner:SOUTHEAST UNIV

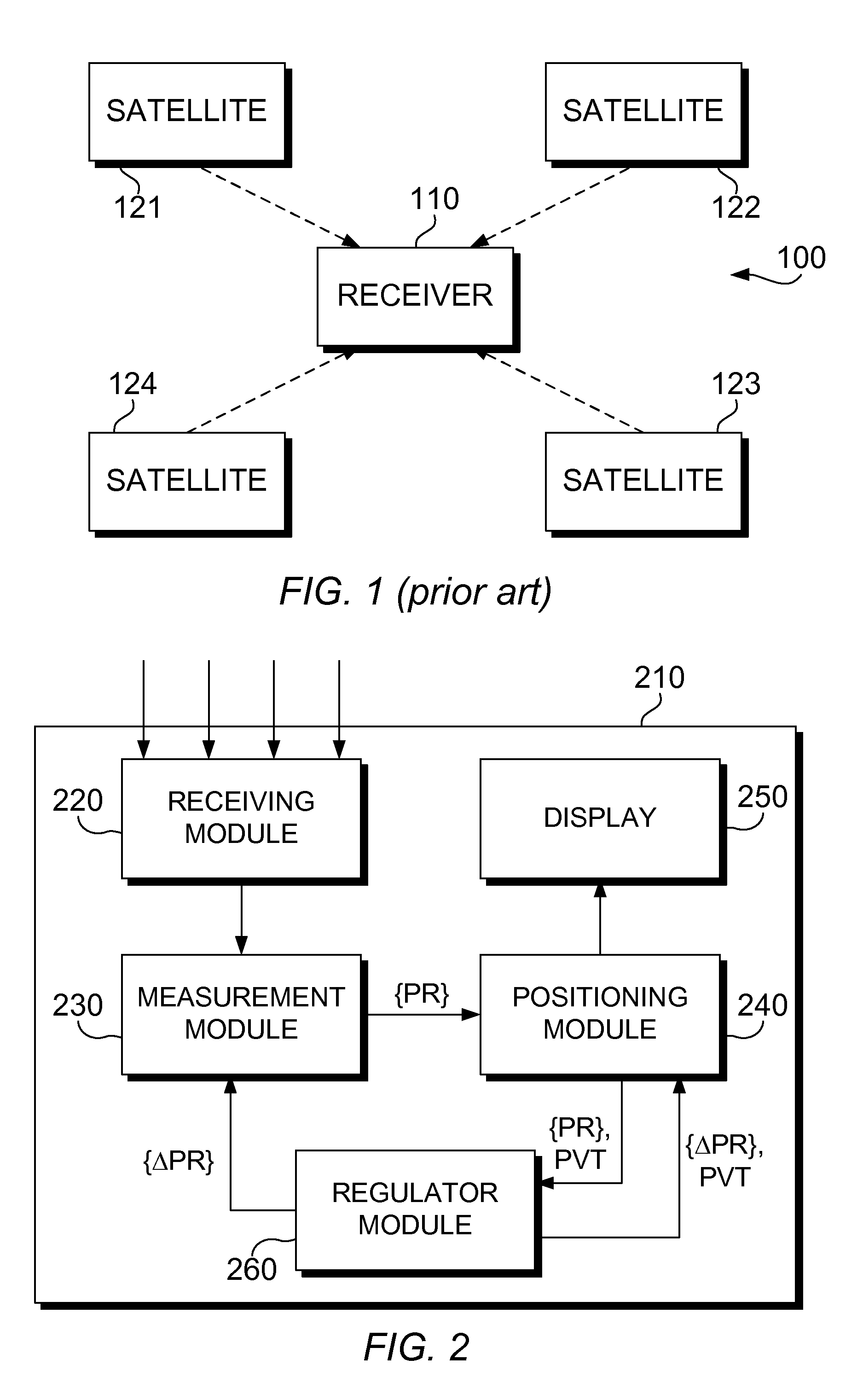

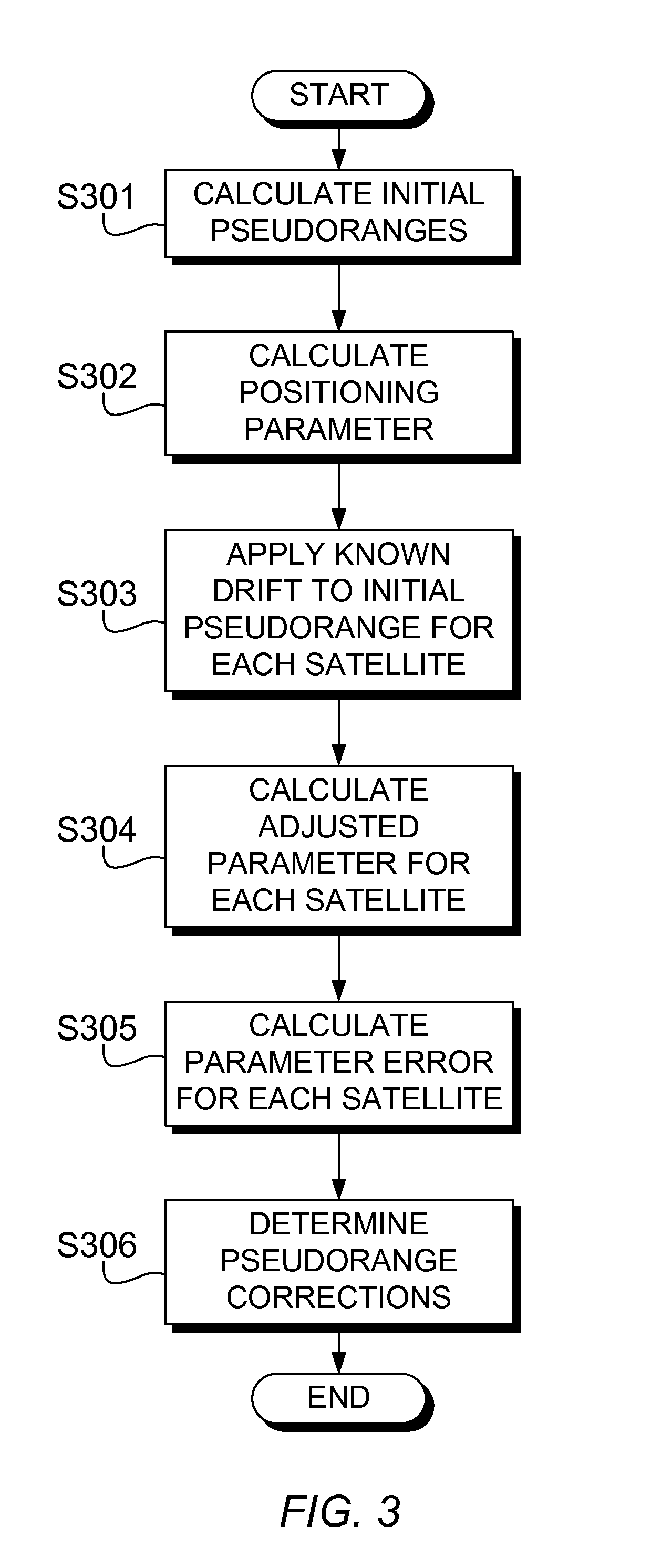

Method and apparatus for receiving positioning signals based on pseudorange corrections

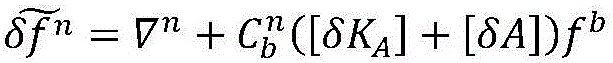

A receiver for receiving positioning signals from a plurality of sources obtains a pseudorange correction for each source by obtaining an initial pseudorange to each source, an initial value of a positioning parameter based on the initial pseudoranges, a difference between the initial value of the positioning parameter and a reference value of the positioning parameter, a parameter error for each one of the sources, and the pseudorange correction for each source based on the difference between the initial and the reference values of the positioning parameter, the parameter error for the source and the value.

Owner:SAMSUNG ELECTRONICS CO LTD

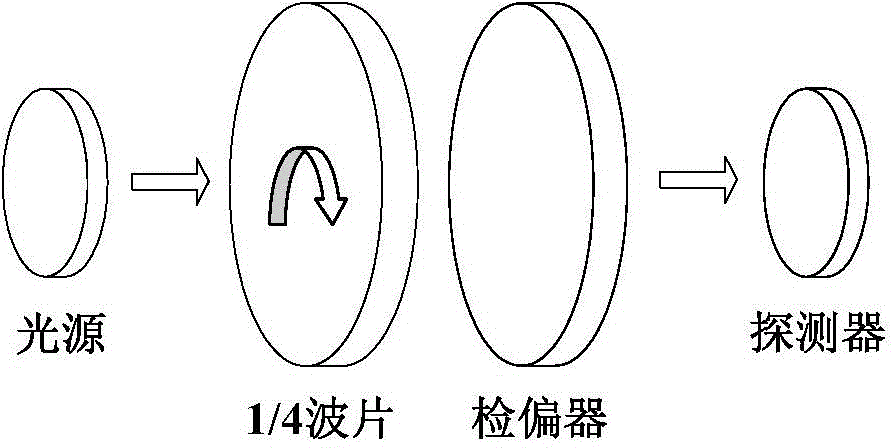

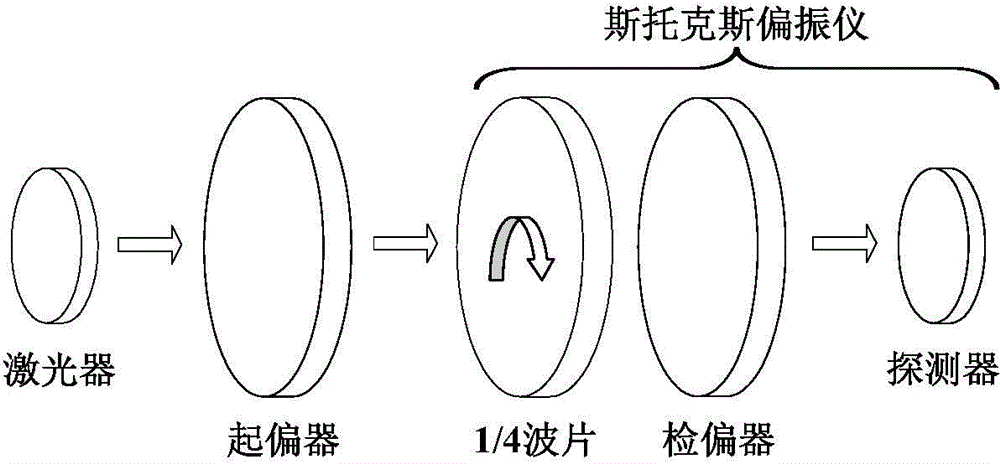

Stokes polarization meter error calibration and compensation method based on wave plate rotating method

ActiveCN104535192APolarisation-affecting propertiesLight polarisation measurementErrors and residualsFourier analysis

The invention provides a Stokes polarization meter error calibration and compensation method based on a wave plate rotating method. The Stokes polarization meter error calibration and compensation method includes the specific steps that horizontal line polarization light generated by a PSG is used as standard reference light; the standard reference light is measured through a to-be-calibrated Stokes polarization meter N times to obtain N light intensity values; Fourier analysis is carried out on the obtained N light intensity values to obtain corresponding Fourier coefficients; the fast axis azimuth angle error and the phase delay amount error of a quarter-wave plate are calculated through the relation between device parameter errors and the Fourier coefficients according to the Fourier coefficients; error compensation is carried out on the Stokes polarization meter through the relation between Stokes parameters and the parameter errors according to the two parameter errors of the quarter-wave plate. The Stokes polarization meter error calibration and compensation method is easy to operate, high in feasibility and high in calibration accuracy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

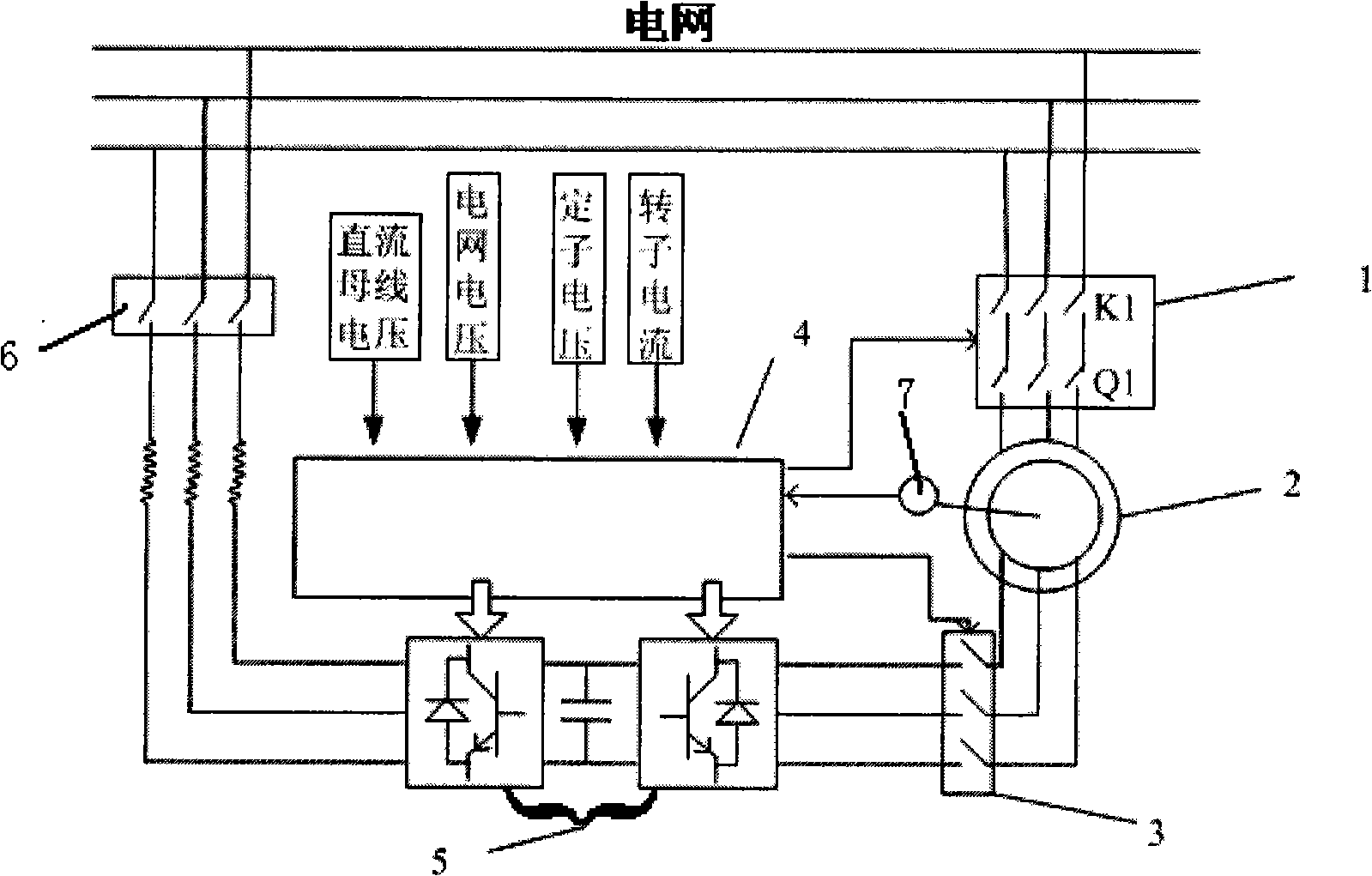

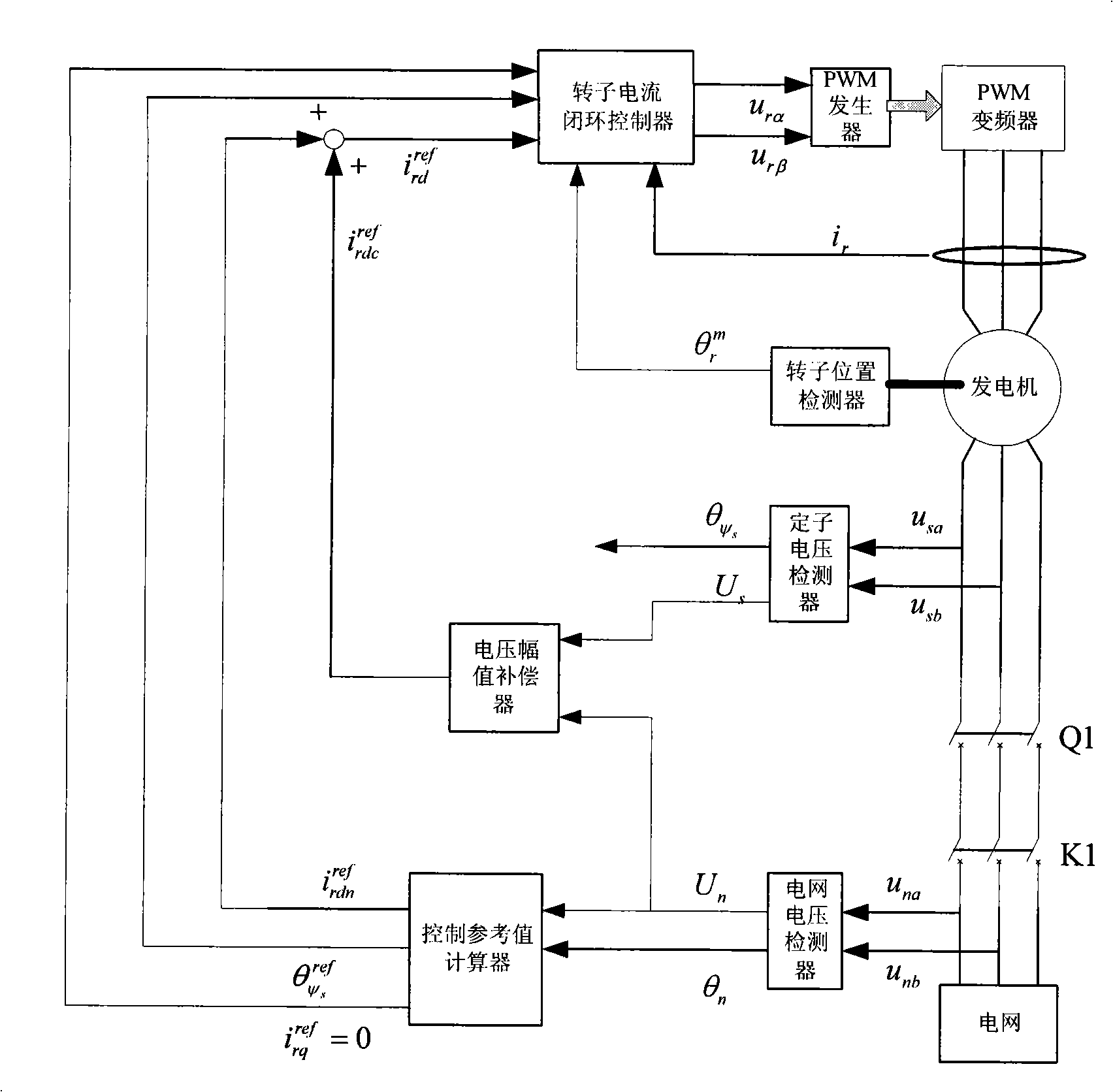

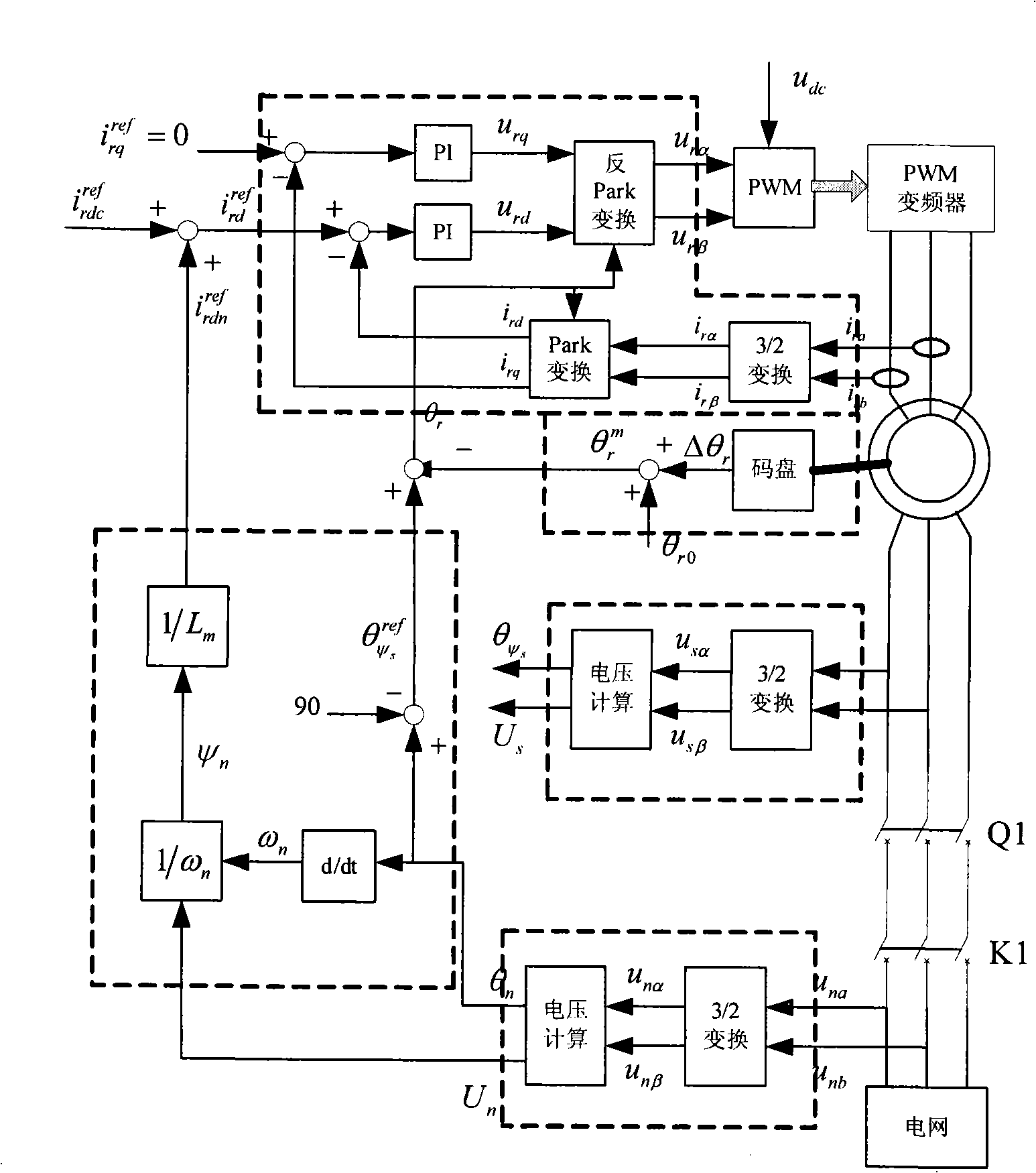

A speed-varying frequency constant dual feedback wind power generation system and its parallel control method

InactiveCN101267117AEliminate the influence caused by the deviation of mutual inductance parametersEliminate the effects ofSingle network parallel feeding arrangementsWind energy generationVoltage amplitudeConstant frequency

The present invention provides a variable speed constant frequency doubly-fed wind power generation system, characterized in that the system includes a stator grid connected device, a motor, a controlling plate, a dual pwm converter, a code disc; the stator of the motor is connected with the power network by the stator grid connected device; the rotor of the motor is connected with the power network by the dual pwm converter; the controlling plate is connected with the power network, the motor, the dual pwm converter and the stator grid connected device; the controlling plate is also connected with the rotor via the code disc. The system eliminates some influence caused by some parameter error of the generating system according to designing a voltage amplitude compensator and a rotor position angle compensator in the controlling plate.

Owner:北京清能华福风电技术有限公司

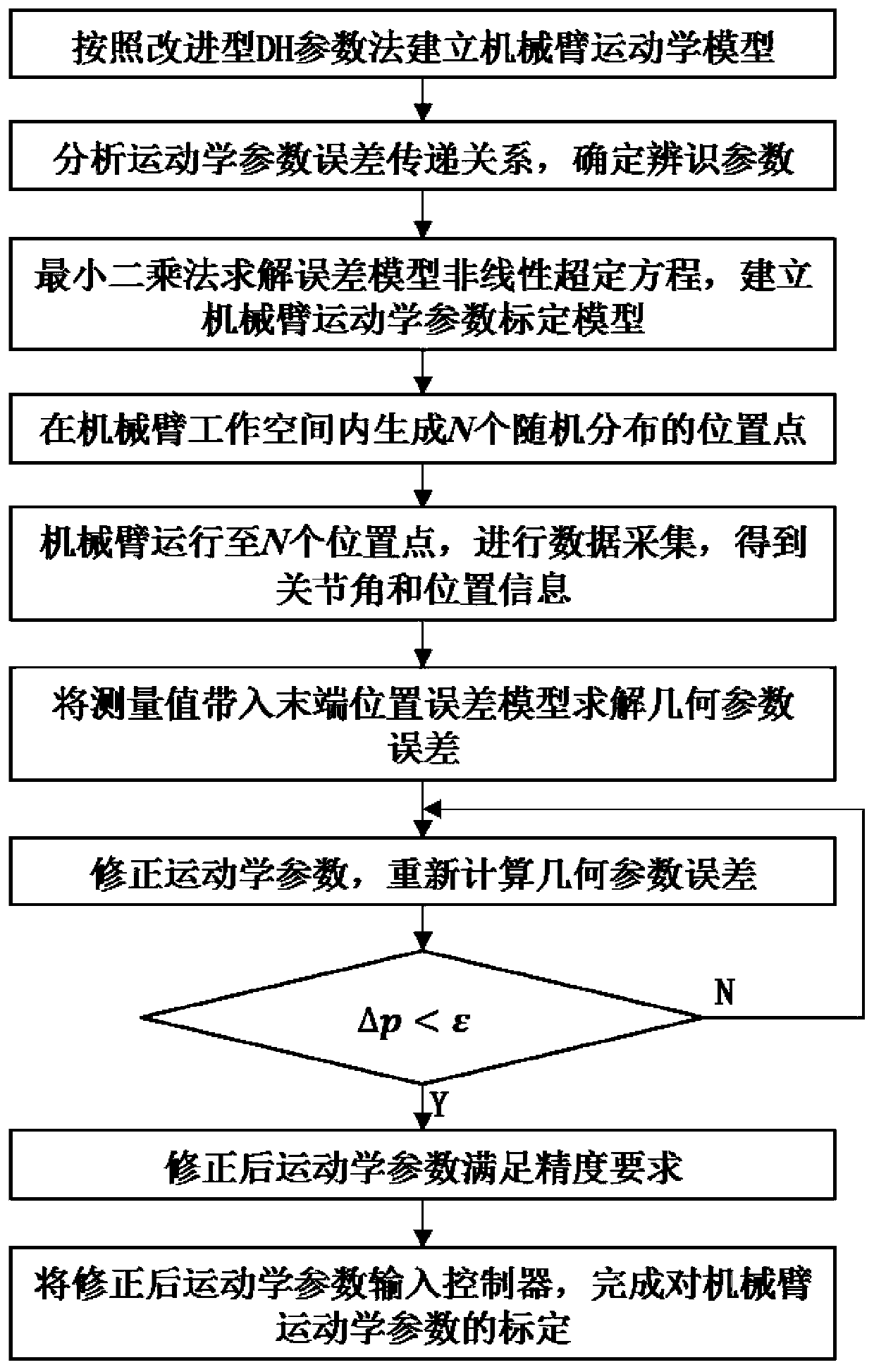

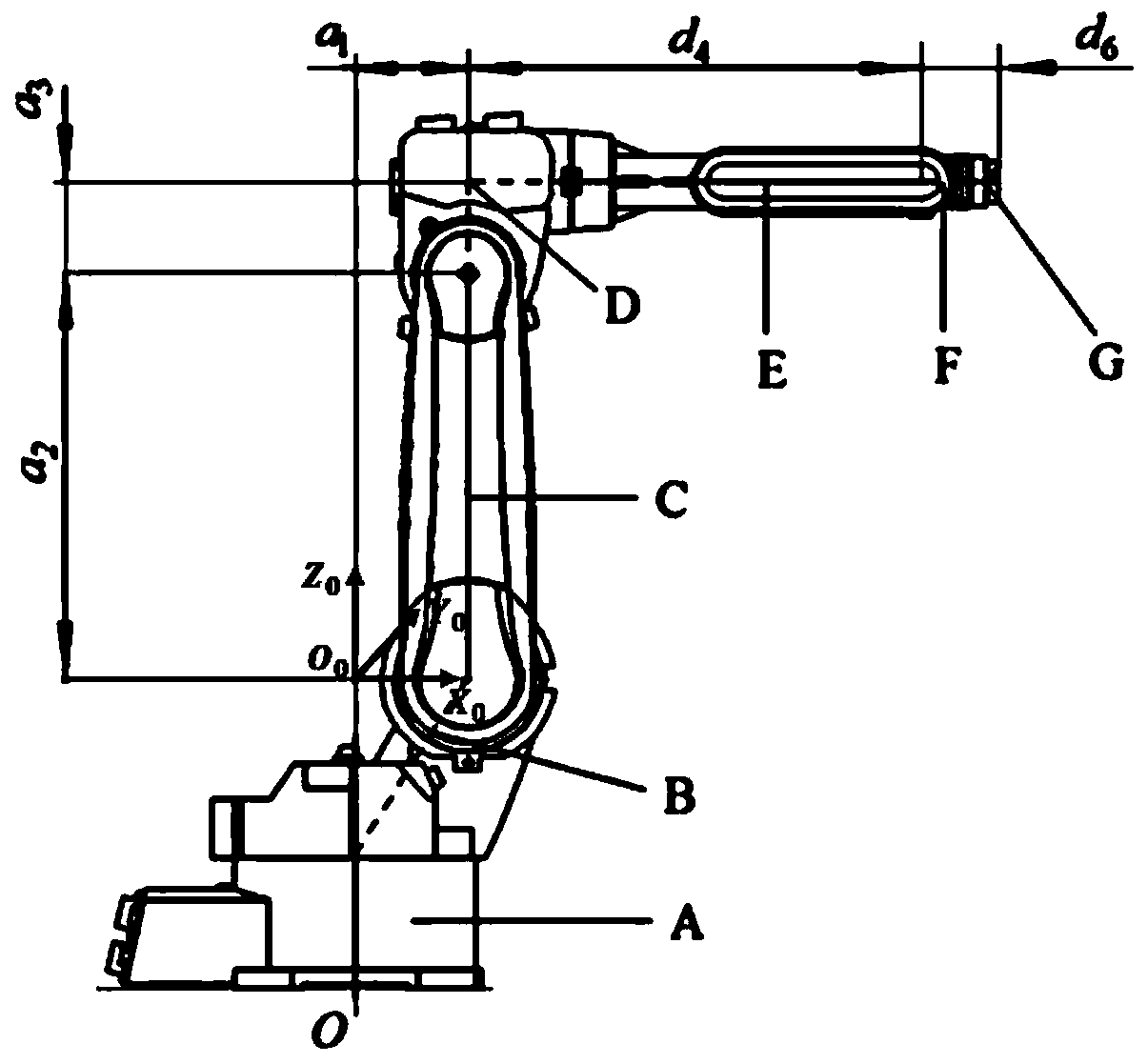

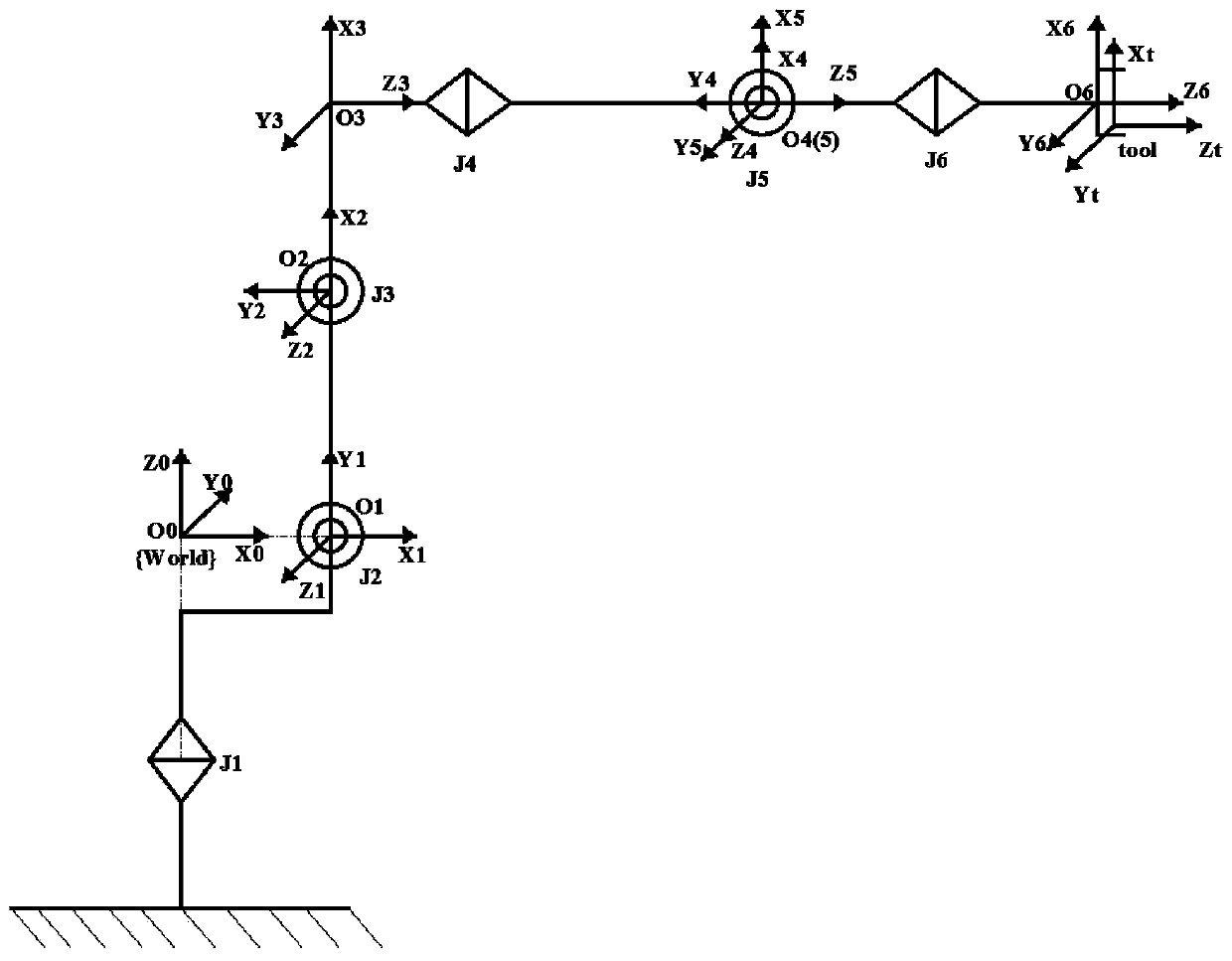

Mechanical arm kinematics parameter calibration method based on measuring of laser tracker

InactiveCN110281241ARealize offline calibrationImprove robustnessProgramme-controlled manipulatorThree-dimensional spaceEngineering

The invention discloses a mechanical arm kinematics parameter calibration method based on measuring of a laser tracker, and belongs to the field of industrial mechanical arm kinematics, and relates to the mechanical arm kinematics parameter calibration method based on measuring of the laser tracker. The method is based on the mechanical arm joint construction. An improved DH parameter method is adopted for building a mechanical arm kinematics model, a kinematics modeling result is used for building a mechanical arm kinematics parameter error calibration model, in consideration with the mechanical arm three-dimensional space work range, the laser tracker is adopted for measuring N absolute position coordinates of the tail end of the mechanical arm, on the basis of the kinematics parameter error calibration model, through repeated iteration, the mechanical arm kinematics parameter error is solved, a corrected kinematics parameter is input into a mechanical arm controller, and offline calibration of the mechanical arm is achieved; the mechanical arm tail end position measuring method is high in robustness, high in speed, and high in process automation degree, the adopted error solving method is high in speed, high in precision and simple in process, and the high-precision rapid calibration of joint type mechanical arm kinematics parameters can be achieved.

Owner:DALIAN UNIV OF TECH

Calibration method of angle encoder eccentricity and structure parameters of joint coordinate measuring machine

The invention discloses a high-accuracy calibration method of a joint coordinate measuring machine. The method comprises the steps that a to-be-calibrated machine is placed in a measuring space of a reference machine by taking the six-freedom-degree joint coordinate measuring machine as the to-be-calibrated machine and a higher-accuracy three-coordinate measuring machine as the reference machine; calibration plates with taper holes are sequentially placed according to six bisectrices of a circle; the measuring machine measures the taper holes in the calibration plates with a plurality of poses in each position; each pose corresponds to a measuring coordinate of one taper hole under a to-be-calibrated coordinate system and a group of joint angle values; the high-accuracy three-coordinate machine measures coordinates of the taper holes in the positions under a reference coordinate system; the joint angle values and reference coordinates corresponding to measuring points serve as sampling data; a multi-target search problem is converted into a single-target nonlinear programming problem based on the sampling data; and a structure parameter error value of the to-be-calibrated machine and an eccentricity parameter of an angle encoder are obtained by identification of a sequential quadratic programming algorithm.

Owner:BEIJING INFORMATION SCI & TECH UNIV

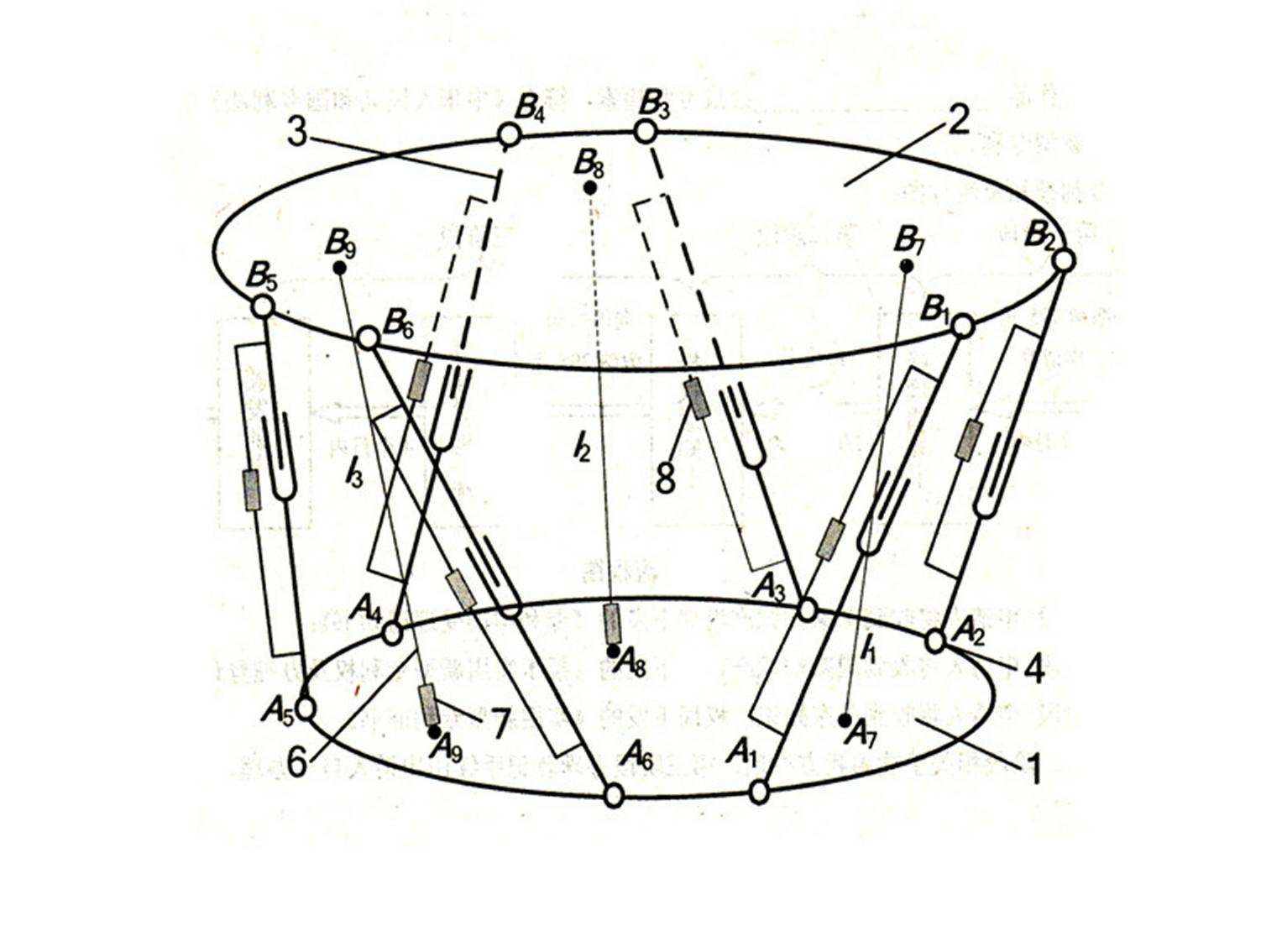

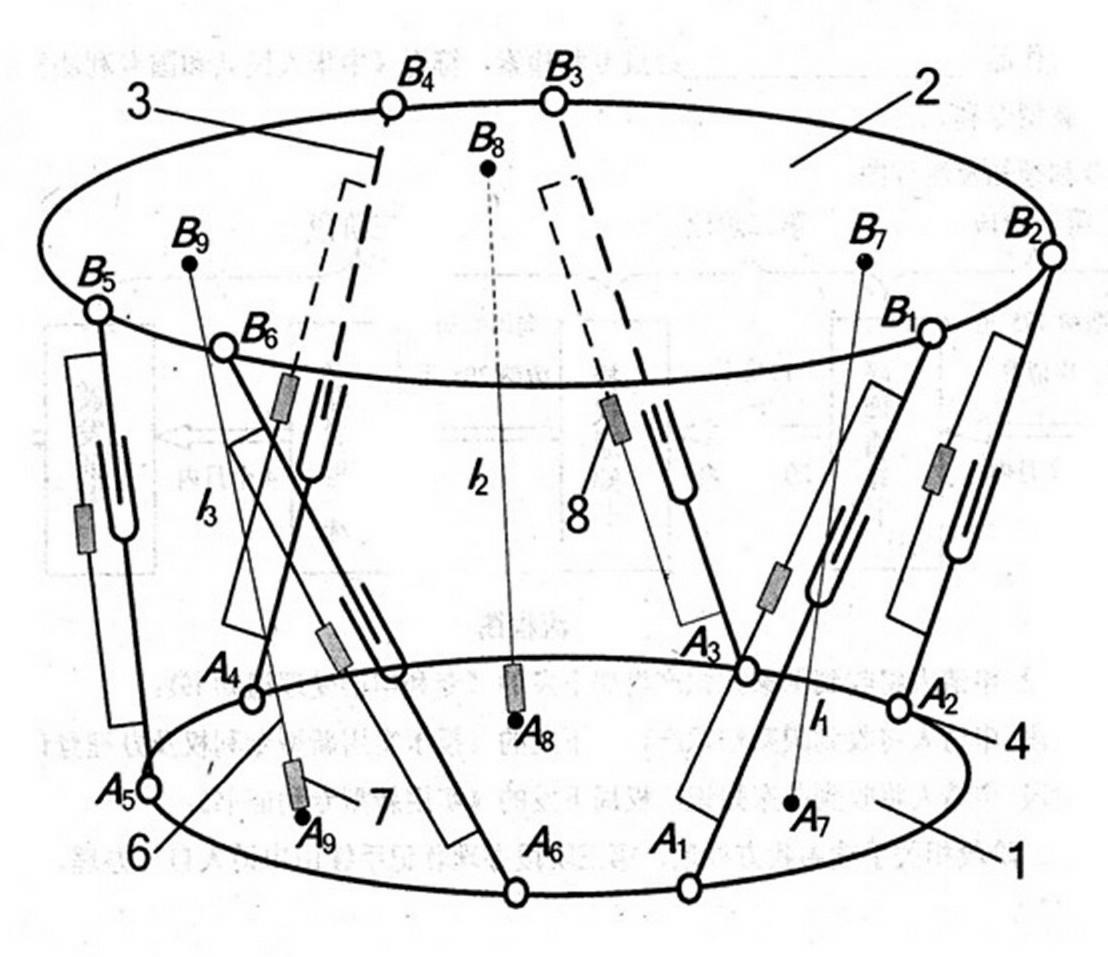

Self-calibration method for parallel robot

InactiveCN102278963ASmall installation sizeCompact structureMeasurement devicesRelative variationEngineering

The invention discloses a self-calibration method of a parallel robot. The method comprises the following steps of: arranging a displacement sensor on each driving branch of the parallel robot, additionally arranging a measuring branch between a fixed platform and a movable platform of the parallel robot, arranging a rope sensor on the measurement branch, establishing a function relation between the relative variation of displacement of the drive branches and the measuring branch and parameters of pose of the movable platform and mechanism parameters of all the branches, driving the parallel robot to carry out pose transformation, enabling the number of established equations to be greater than or more to the number of the mechanism parameters to be identified, and carrying out numerical value solving to obtain poses of the movable platform in any state and mechanism parameter errors and further realize self-calibration. The self-calibration method has the advantage of low cost, convenience for operation and freedom from restriction of distance, hardly has restriction to mechanism design and is a good choice for calibration schemes of the parallel robots.

Owner:YANSHAN UNIV

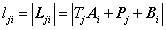

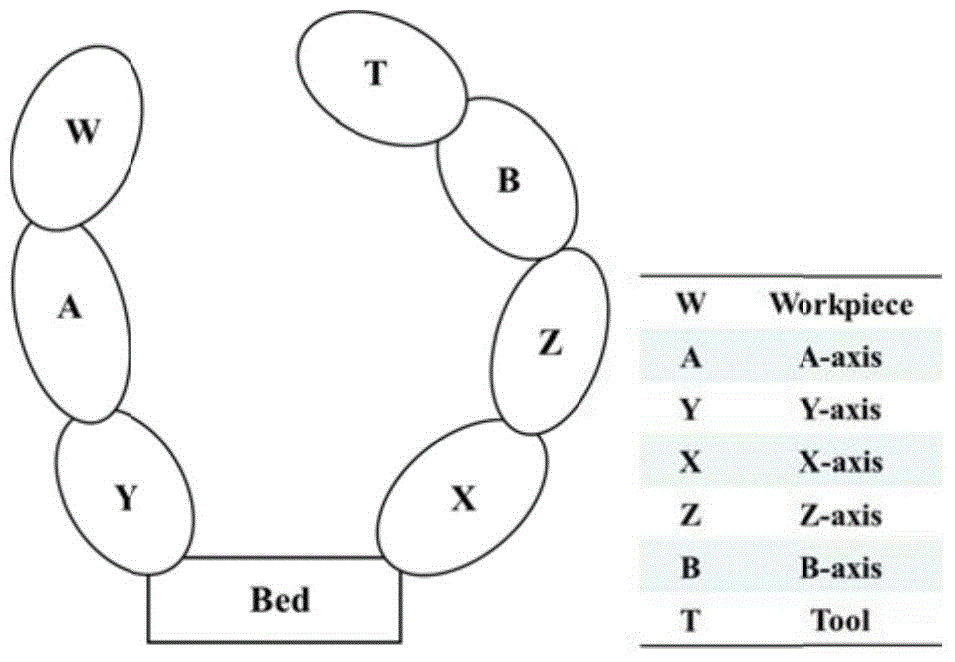

Multi-axis numerical-control machine tool processing precision retaining ability optimization method based on robust design

A multi-axis numerical-control machine tool processing precision retaining ability optimization method based on a robust design belongs to the machine tool precision design field. The invention especially relates to a modeling method of a space error of a multi-axis numerical-control machine tool, a machine tool reliability optimization design method and a robust optimization design method. A space error model of the multi-axis numerical-control machine tool, a reliability model under a multi-failure mode, a sensitive degree model and a machine-tool total cost model are established. A process is characterized in that a minimum sensitivity and lowest cost are taken as an object; the reliability is taken as a constraint; a machine tool geometry parameter error is optimized and a machine tool processing precision retaining ability is increased. By using the method, a multi-axis numerical-control machine tool geometry error acquisition problem and a machine-tool main transmission assembly precision grade determination problem are radically solved.

Owner:BEIJING UNIV OF TECH

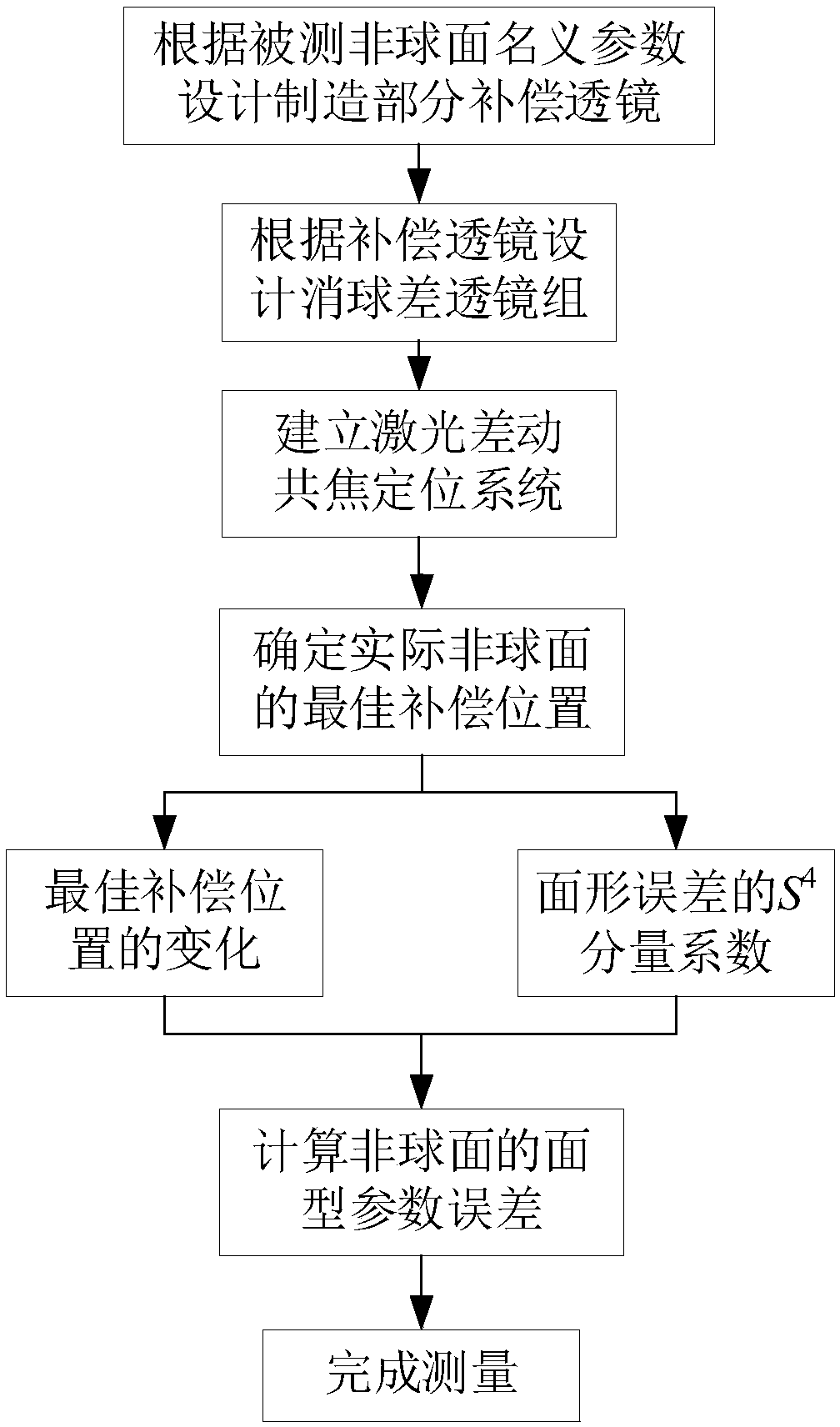

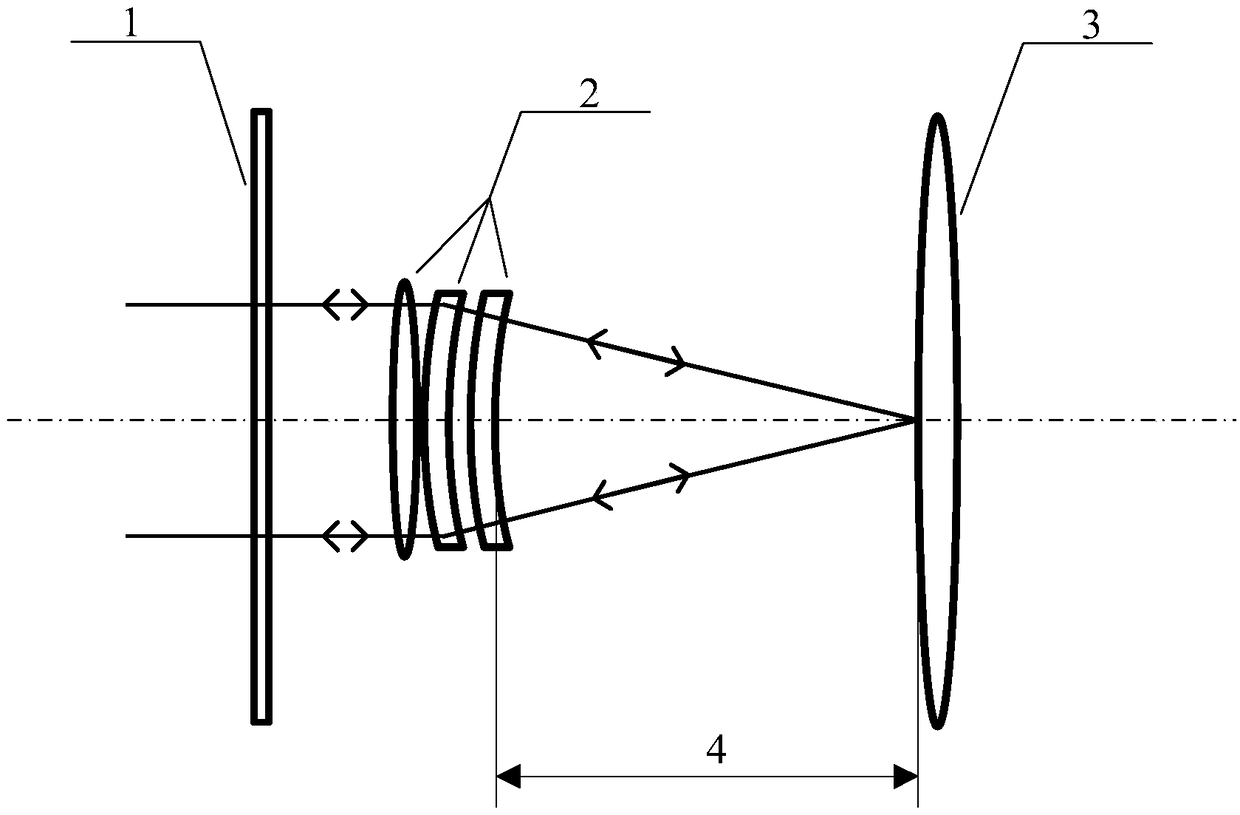

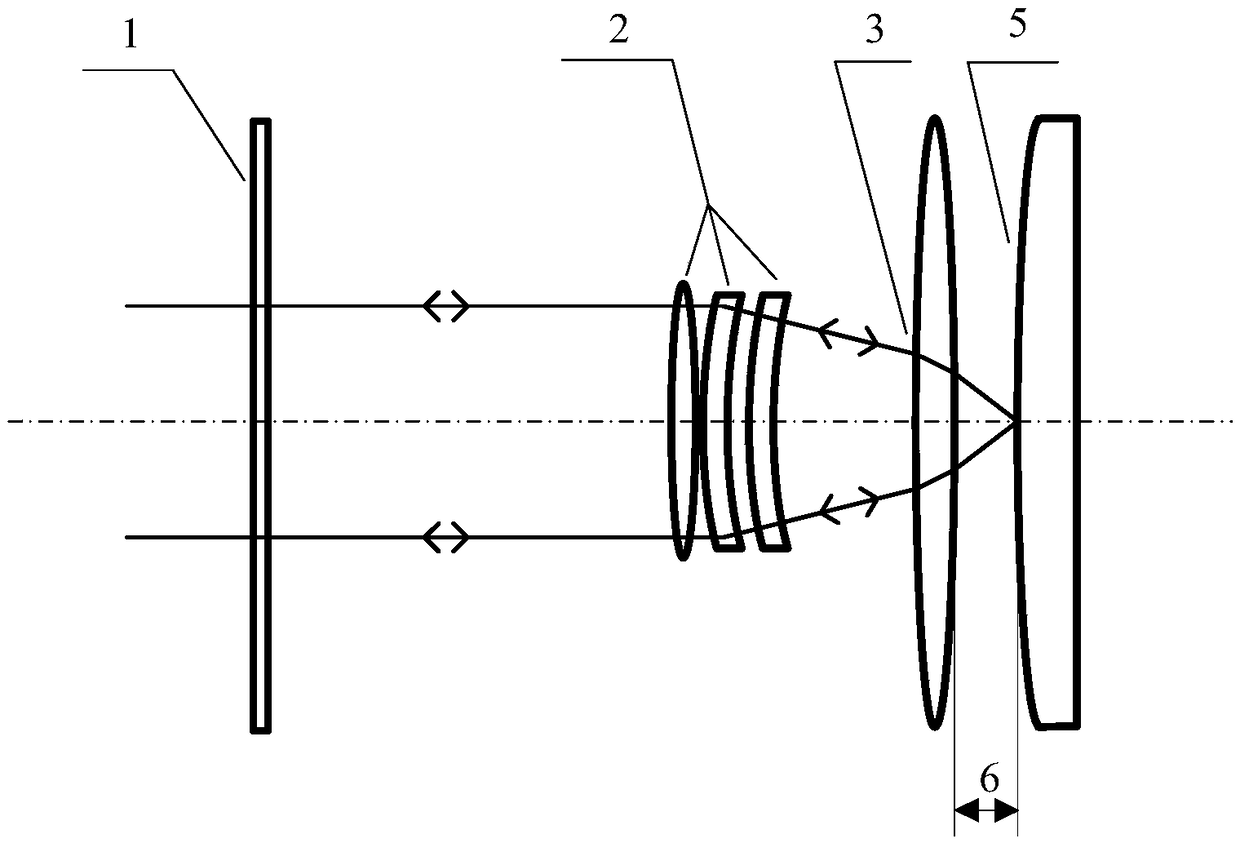

Aspheric surface parameter error interference measuring method combining laser differential confocal positioning

ActiveCN109029291ASolve the problem that it is difficult to determine the relative position of each optical componentHigh measurement accuracyUsing optical meansThermodynamicsSoftware design

The invention discloses an aspheric surface parameter error interference measuring method combining laser differential confocal positioning and belongs to the field of aspheric surface measurement. Animplementation method comprises the following steps: acquiring nominal parameters of a measured aspheric surface, and by utilizing the acquired nominal parameters of the measured aspheric surface andcombining optical design software, designing and processing a part-compensating lens and aplanatic lenses; according to the part-compensating lens and the aplanatic lenses, establishing an aspheric surface parameter error interference measuring system combining the laser differential confocal positioning; obtaining an optimal compensation position change by utilizing the system; measuring a surface figure change between the measured aspheric surface and an ideal aspheric surface, and calculating a coefficient of a quartic component of the surface figure change; and according to a simultaneousequation set, calculating a surface figure parameter error of the aspheric surface, thus measurement on the surface figure parameter error of the aspheric surface is realized. The method disclosed bythe invention can improve accuracy of measurement on the surface figure parameter error of the aspheric surface, realizes non-contact, full-aperture, fast and high-accuracy measurement and has the advantages of no scanning device and simple structure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

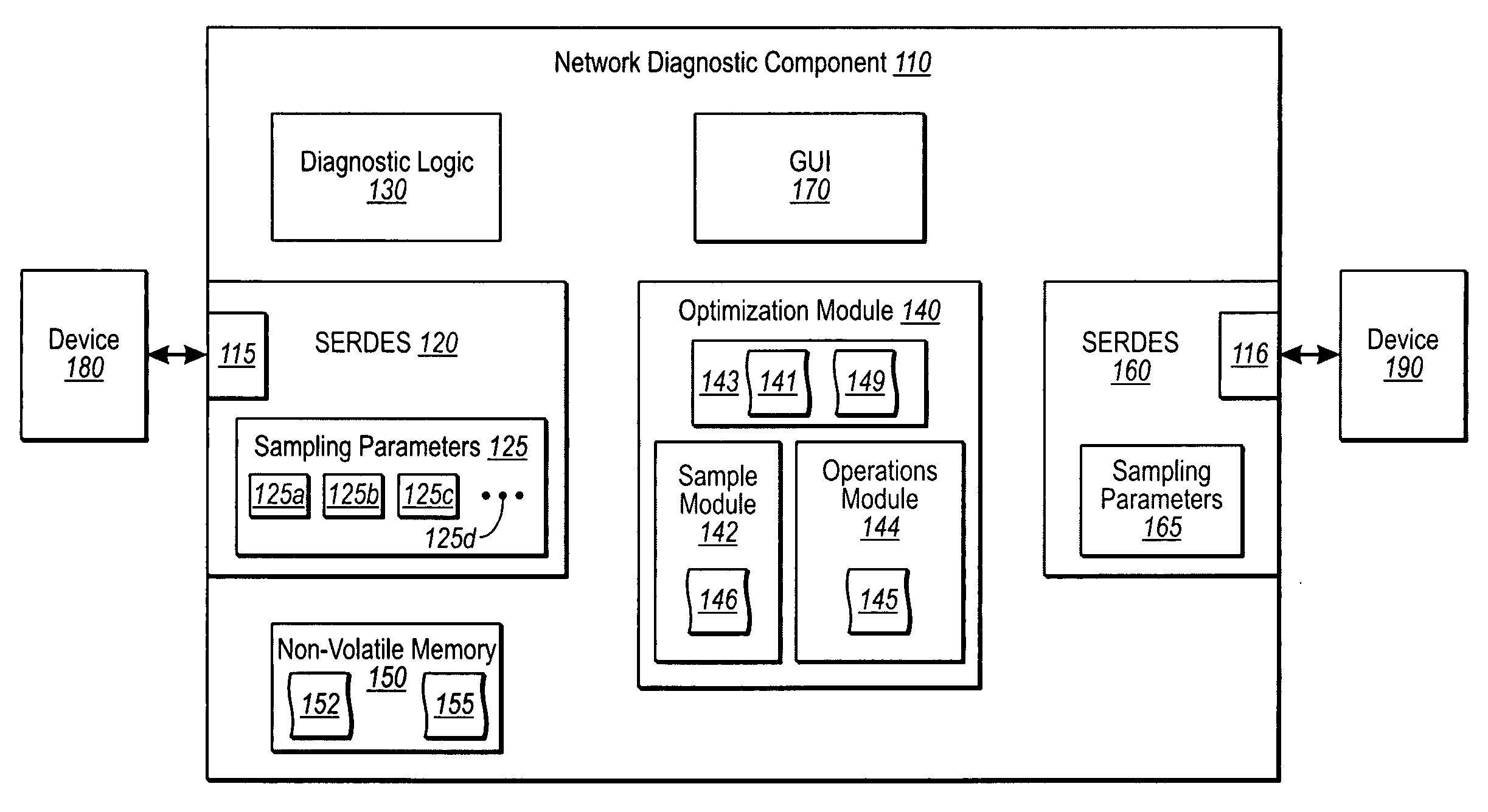

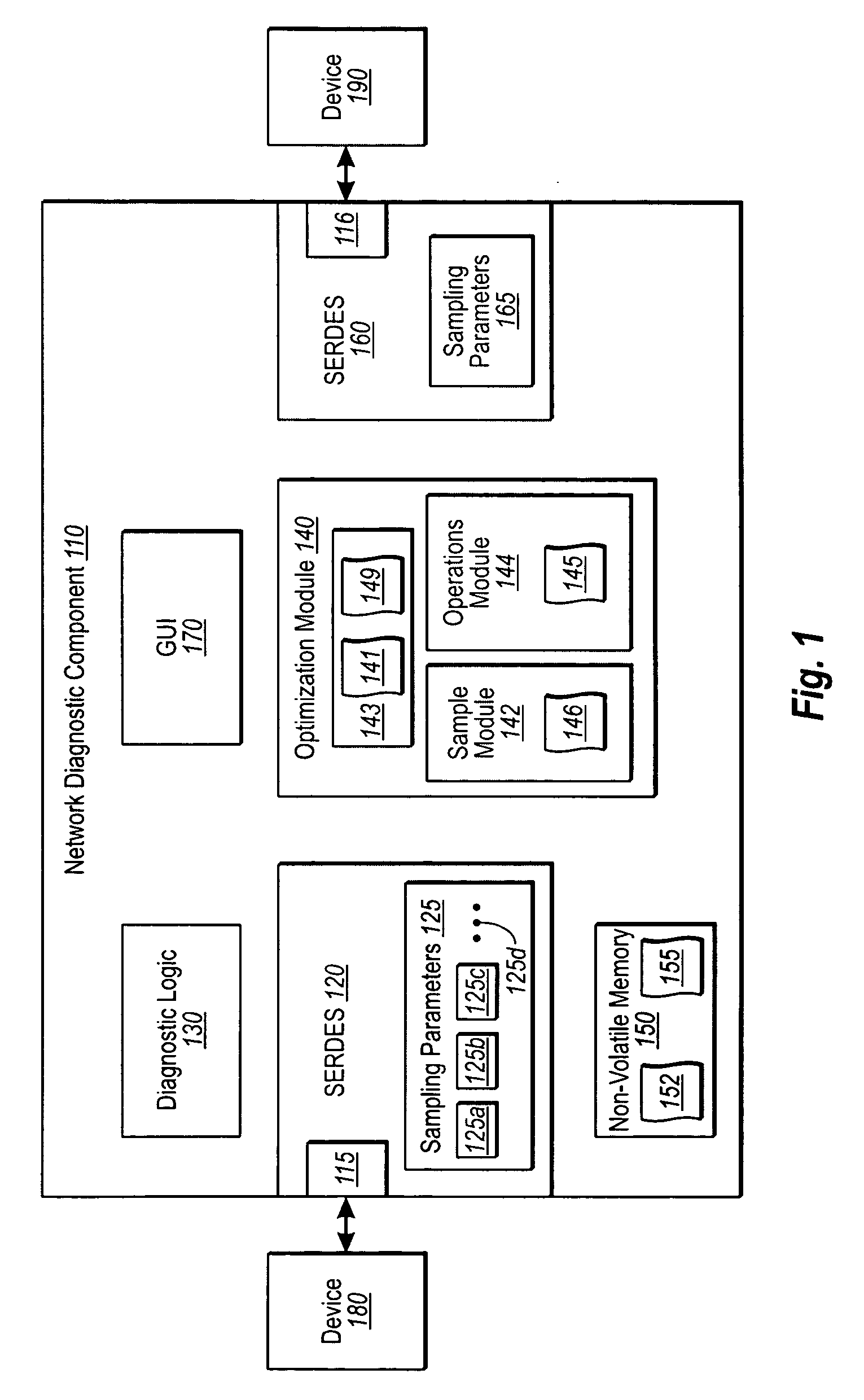

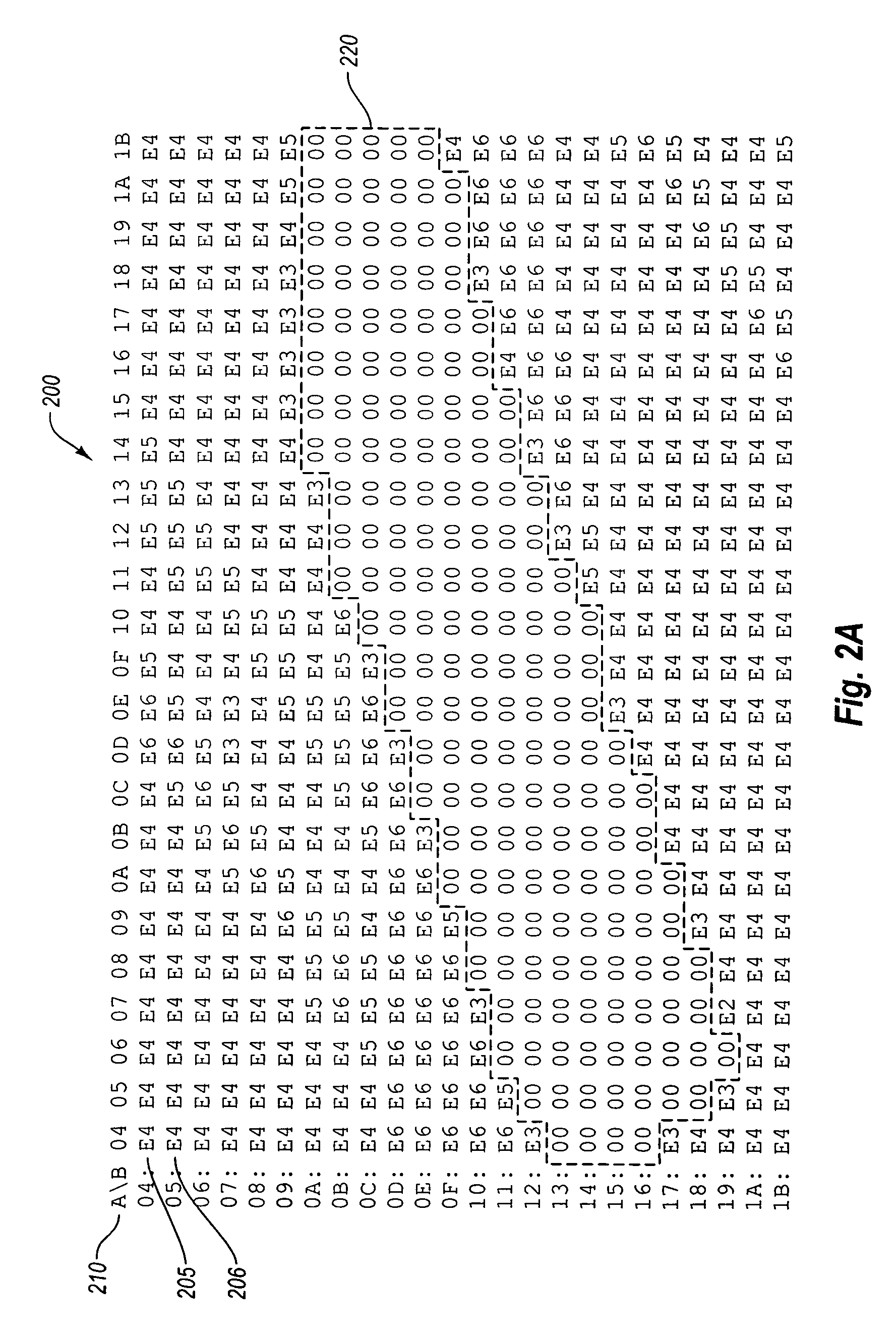

Optimization of serdes sampling parameters

ActiveUS20080253293A1Solution value is not highWell formedError preventionTransmission systemsErrors and residualsComputer science

One or more modules configured to cause a network diagnostic component to perform the following: an act of selecting first specific sampling parameters at which the SERDES is to receive network traffic; an act of determining a number of errors included in a signal output by the SERDES at the selected first specific sampling parameters; an act of repeating for a specified number of the remaining sampling parameters the acts of selecting specific sampling parameters and determining the number of errors in a signal output by the SERDES at the selected specific sampling parameter; an act of recording the number of errors for each selected specific sampling parameter in an output record, and an act of applying an optimization solution on the output record to thereby determine the specific sampling parameters that will cause the SERDES to output a signal with the lowest value of errors.

Owner:II VI DELAWARE INC

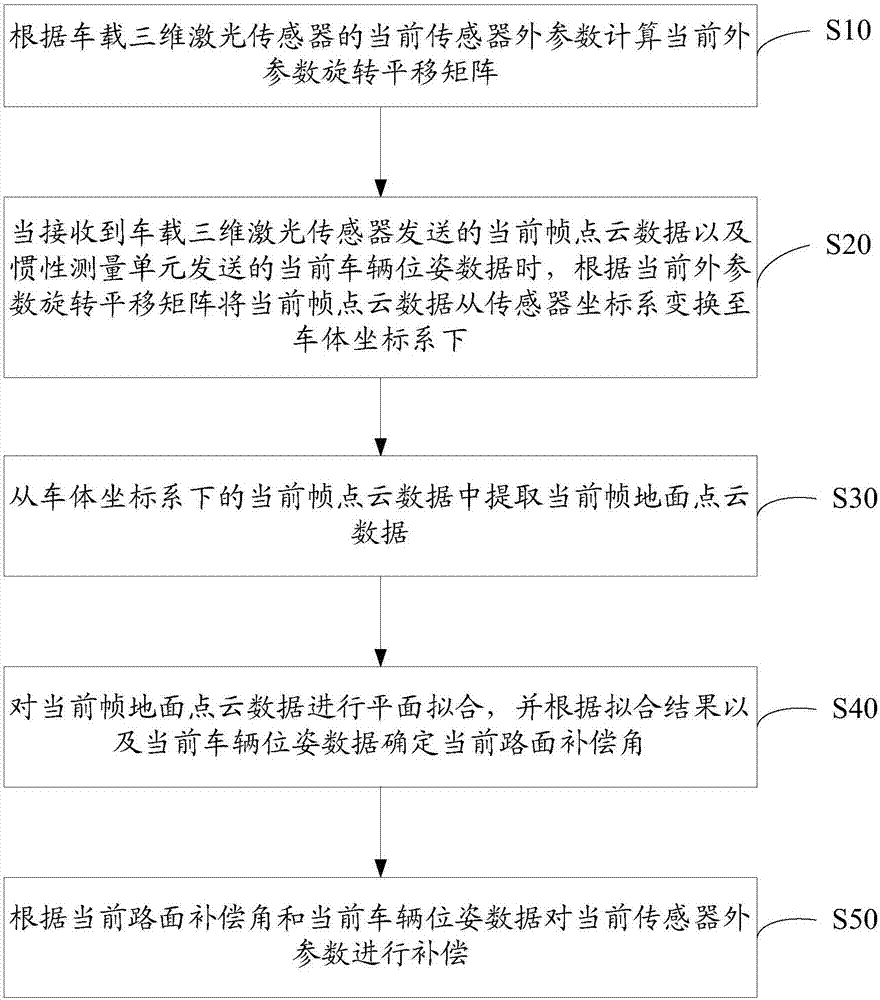

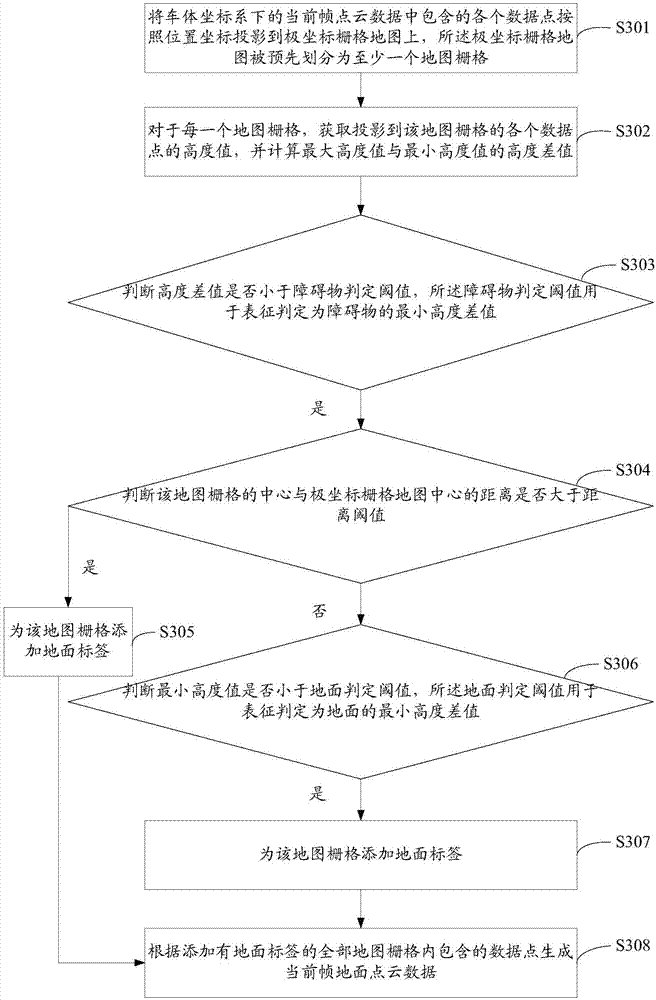

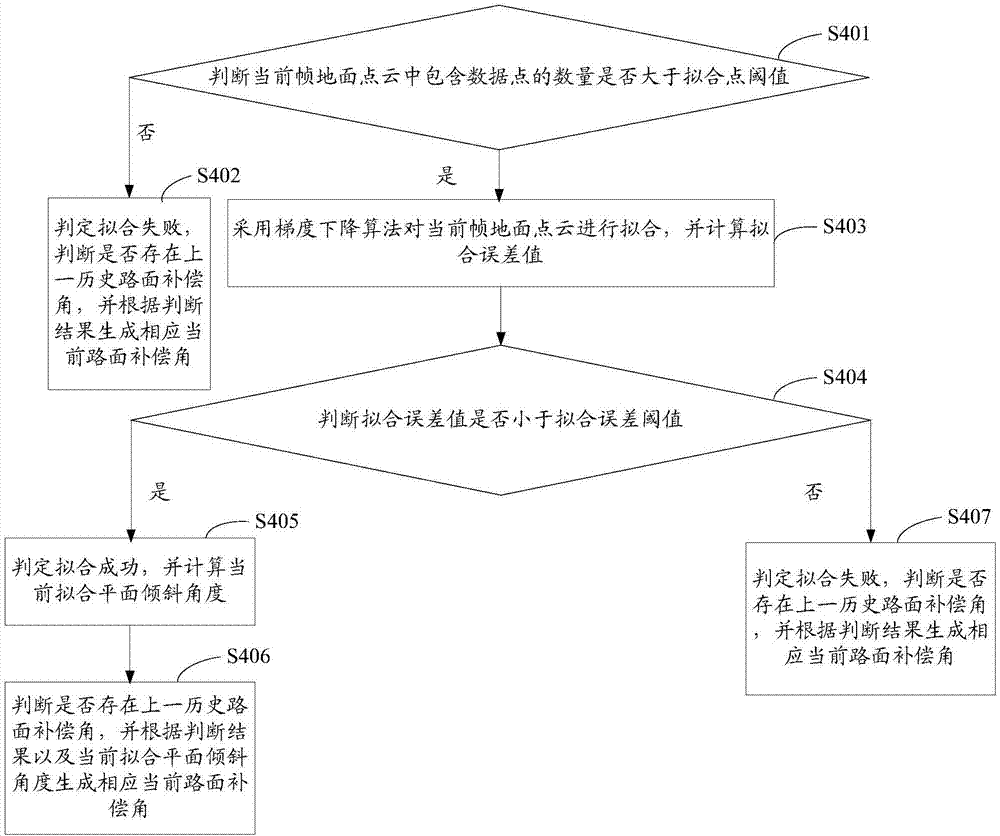

External parameter compensation method and device for vehicle-mounted three-dimensional laser sensor

The invention provides an external parameter compensation method and device for a vehicle-mounted three-dimensional laser sensor. The method comprises the steps that a current external parameter rotation translation matrix is calculated according to current sensor external parameters; when current frame point cloud data sent by the vehicle-mounted three-dimensional laser sensor and current vehicle position and attitude data sent by an inertia measuring unit are received, the current frame point cloud data are transformed from a sensor coordinate system to a vehicle body coordinate system according to the current external parameter rotation translation matrix, and the current frame ground point cloud data are extracted; the current frame ground point cloud data are plane-fitted to determine the current road surface compensation angle; and the current sensor external parameters are compensated according to the current road surface compensation angle and the current vehicle position and attitude data. According to the invention, the single-frame point cloud data and the vehicle position and attitude data are used to compensate the external parameters of the sensor; the external parameter errors of the sensor are reduced, so that the point cloud data transformed into the vehicle body coordinate system are gradually stabilized relative to the ground; and the follow-up environment perception accuracy is improved.

Owner:SAIC MOTOR

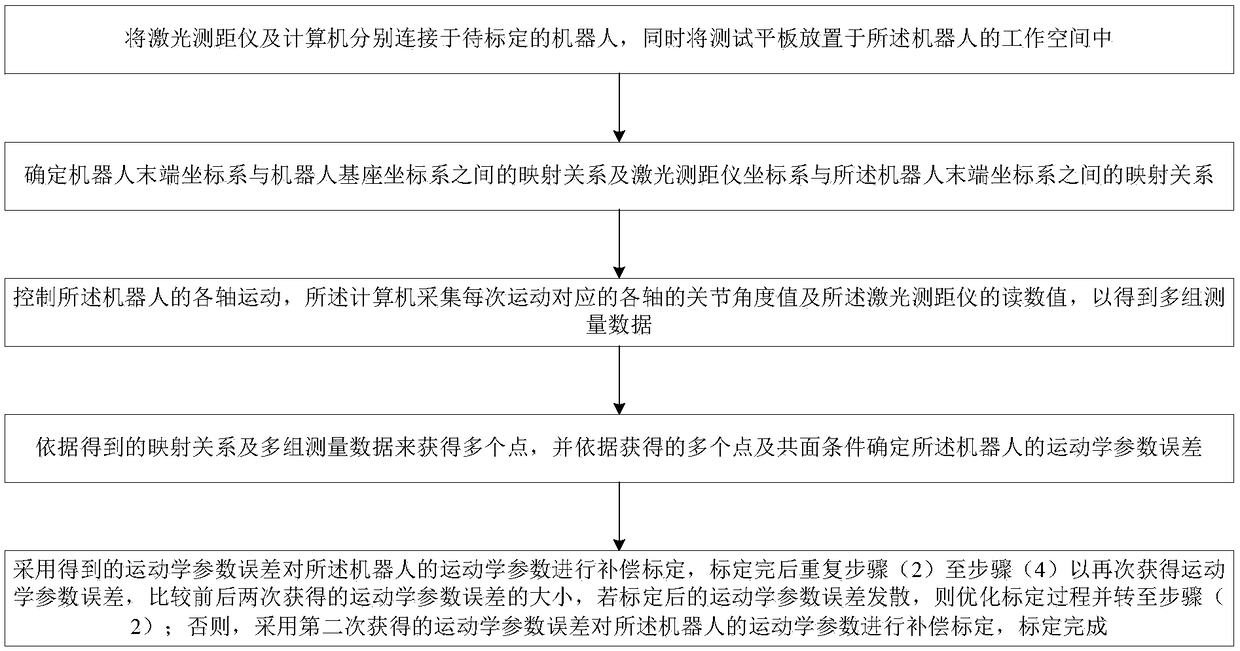

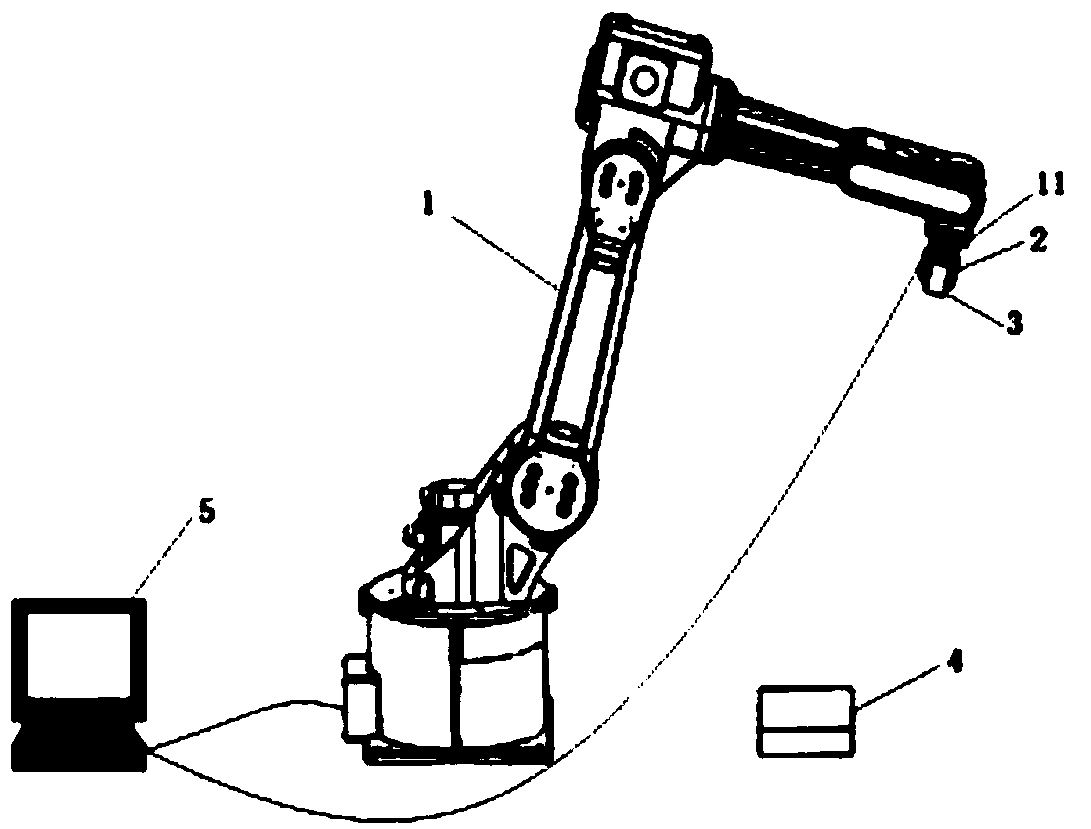

Robot kinematics parameter calibration method based on laser range finder

ActiveCN109304730ASimple structureEasy to installUsing optical meansManipulatorLaser rangingKinematics

The invention belongs to the technical field of information measurement, and discloses a robot kinematics parameter calibration method based on a laser range finder. The method comprises the followingsteps that the laser range finder is connected to a to-be-calibrated robot, and a test flat plate is placed in the working space of the robot; (2) a mapping relation between a robot tail end coordinate system and a base coordinate system of the roboy and the mapping relation between a laser range finder coordinate system and the robot tail end coordinate system of the robot are determined; (3) ajoint angle value corresponding to each time of movement of the robot and a reading value of the laser range finder are gathered; (4) a plurality of points are obtained, and a kinematic parameter error is determined according to a coplane condition; and (5) compensation calibration is carried out on the kinematics parameters of the robot, the kinematics parameter error is acquired again after thecalibration is completed, the kinematics parameter error is compared with the value of the last time, and then calibration completion or re-calibration is determined. According to the method, the measuring efficiency is high, the operation is simple, the implementation is easy, and the accuracy is high.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Robot positioning error graded compensation method

ActiveCN108908327AImprove absolute positioning accuracyCompensate residual errorProgramme-controlled manipulatorPosition errorErrors and residuals

The invention discloses a robot positioning error graded compensation method. The method includes: calculating terminal pose errors before compensation; building a kinematic model and a kinematic error model; calculating the optimal solution of each kinematic parameter error, the corrected kinematic model and the terminal pose under the corrected kinematic model; calculating input compensation quantity after positioning error compensation; calculating actual arrival pose to obtain residual errors after parameter calibration; building a residual error estimation model, and performing expected target point compensation; predicting positioning errors; acquiring predicted target point residual errors; calculating input compensation quantity; calculating terminal actual arrival pose to completethe compensation. By the method, industrial absolute positioning precision can be increased effectively, and the anisotropy of positioning errors in the space can be shown by using the residual errormodel based on space similarity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com