Patents

Literature

244results about How to "Calibration method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

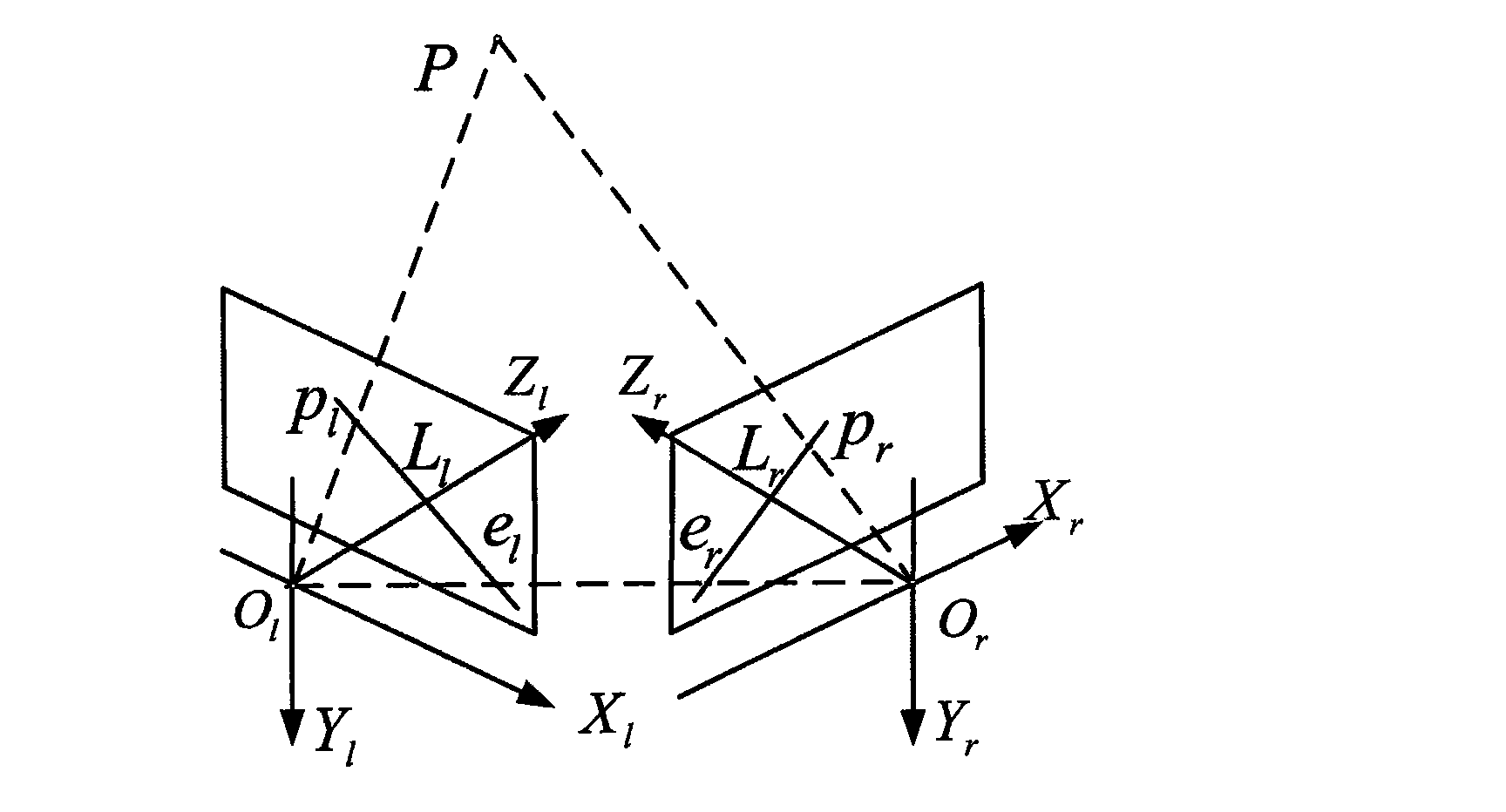

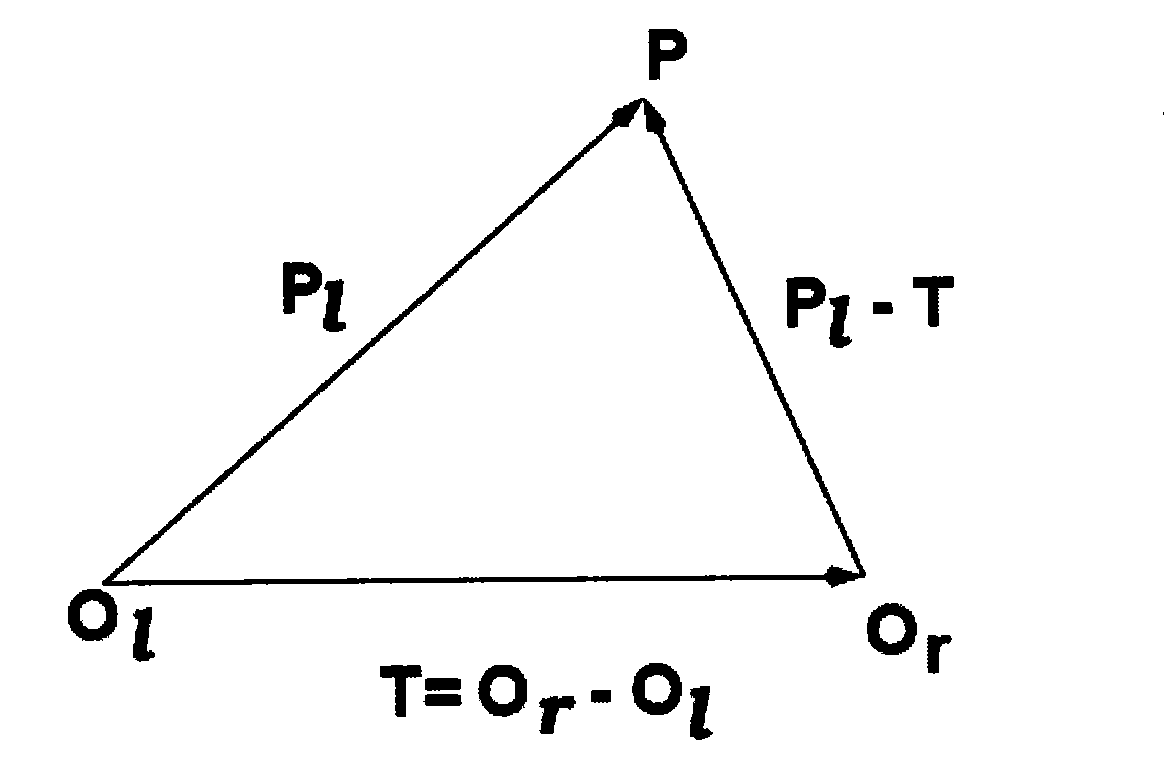

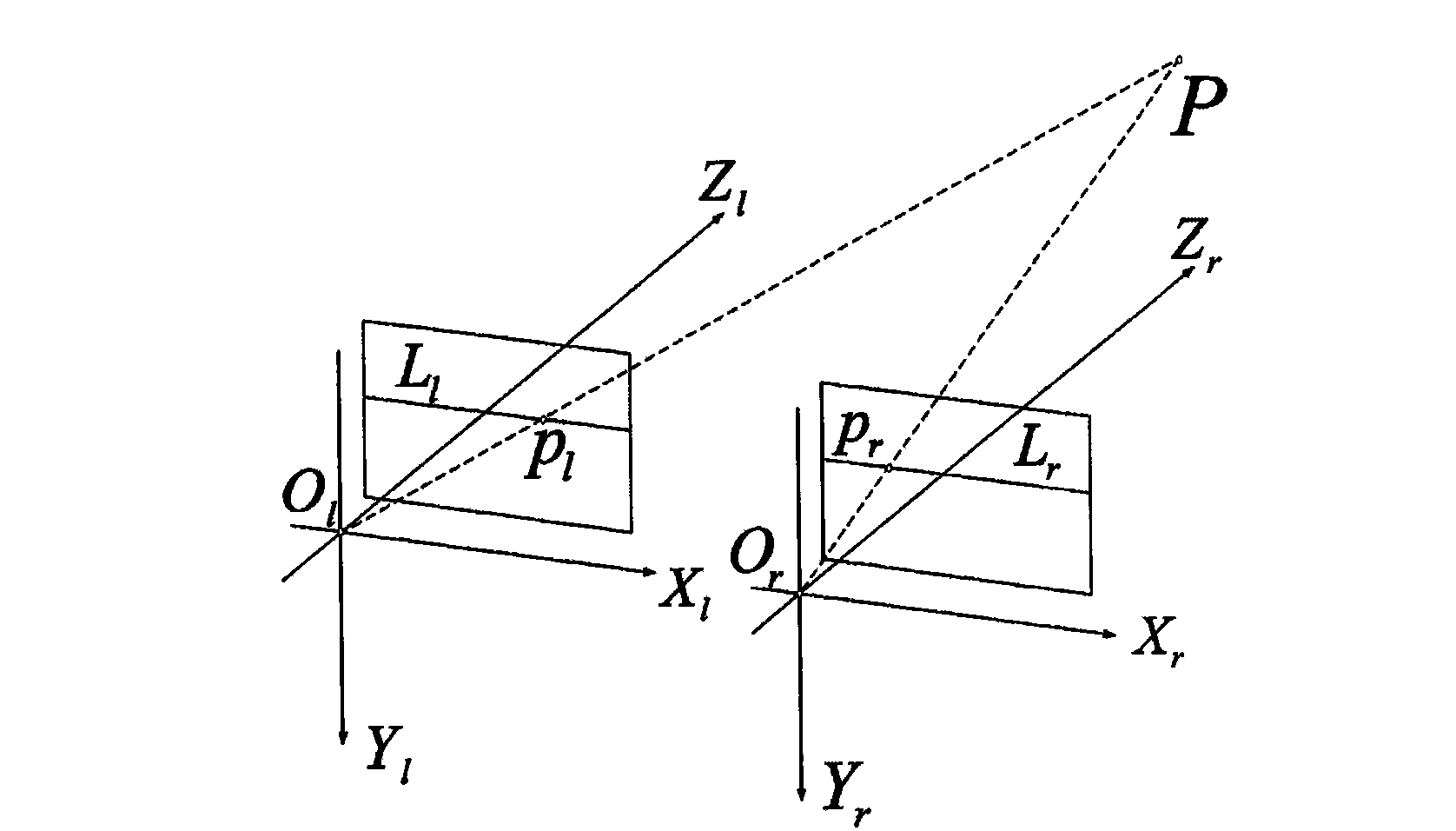

Calibrating method of structural parameters of binocular visual sensing system

InactiveCN101581569ACalibration method is simpleCalibration method is fastUsing optical meansSystem structureOptical axis

The invention provides a calibrating method of structural parameters of a binocular visual sensing system. The calibrating method comprises the steps of: establishing epipolar geometric relationship by utilizing any point of optical centers of a left camera and a right camera, a left image and a right image of the left camera and the right camera, and a target object; utilizing the epipolar geometric relationship to obtain a fundamental matrix which comprises camera internal parameters and structural parameters; obtaining a left pole and a right pole of the left camera and the right camera by decomposing the fundamental matrix; utilizing the information of the left pole and the right pole to calculate a left rotation matrix and a right rotation matrix respectively; rotating and calibrating the left camera and the right camera by virtue of the respective optical centers and the left rotation matrix and the right rotation matrix respectively so as to cause optic axis of the left camera and the right camera to be parallel, and simultaneously rotating the left image of the left camera and the right image of the right camera by virtue of the left rotation matrix and the right rotation matrix respectively so as to cause polar lines on the left image and the right image to be parallel, thus leading to the result that a spatial target point is only different on the X-axis and identical on the Y-axis and the Z-axis in the coordinate of the left image and the right image; and the length of a connecting line between the optical centers of the left camera and the right camera is reversely calculated according to a calibration board in a rotated coordinate system so as to finish the calibration.

Owner:BEIJING INFORMATION SCI & TECH UNIV

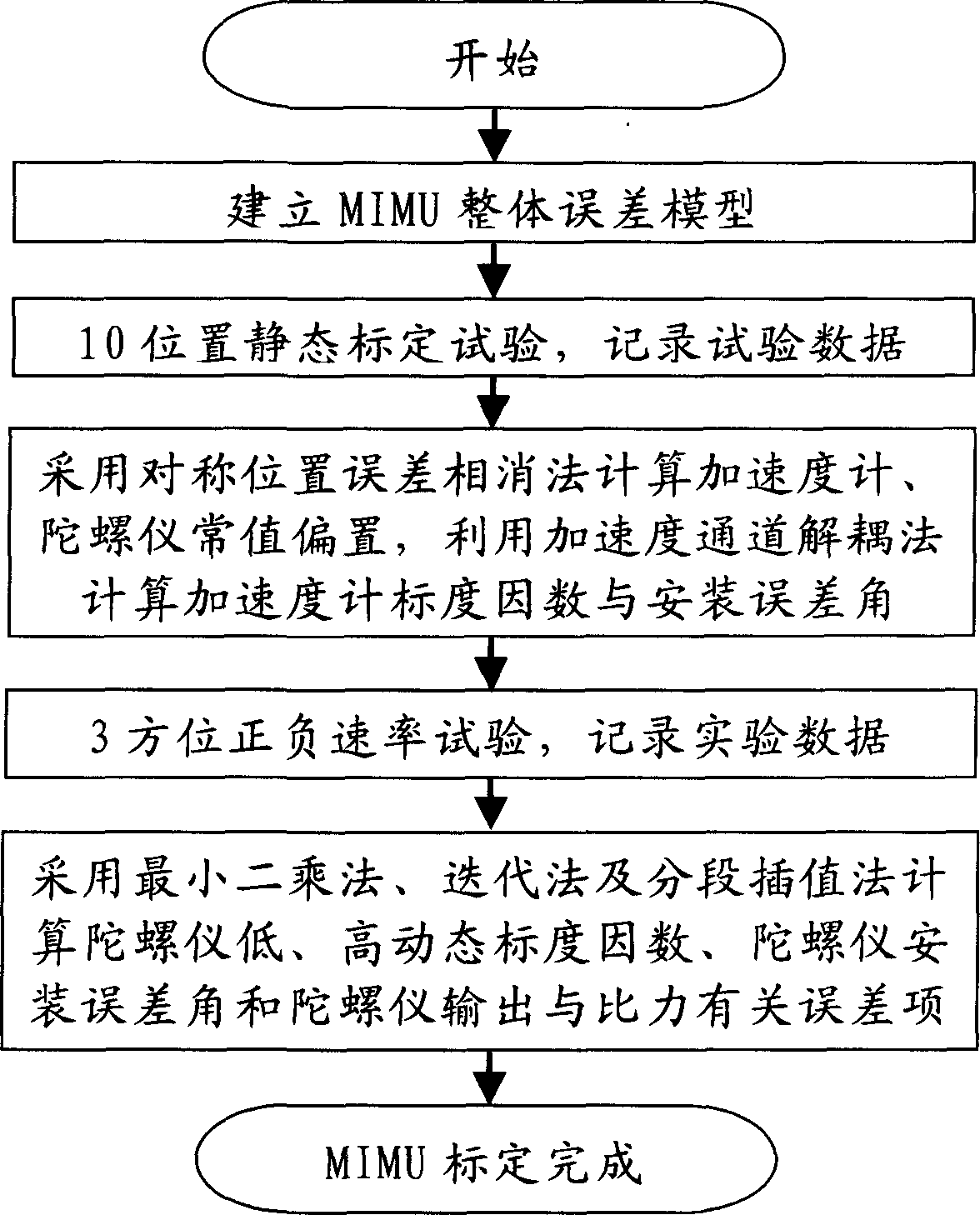

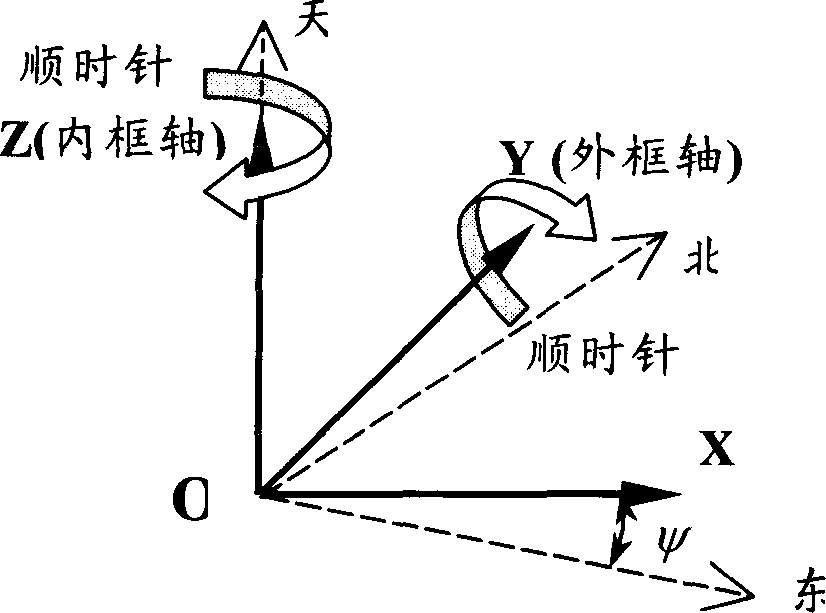

Microinertia measuring unit precisive calibration for installation fault angle and rating factor decoupling

InactiveCN1818555ASolve the errorSolving Scale Factor Coupling IssuesNavigation by speed/acceleration measurementsAccelerometerGyroscope

An accurate calibration method of micro inertia measuring unit by decoupling erection error angle (EEA)with scale factor includes setting up MIMU integral error model and separating couple between EEA of accelerometer and gyroscope and scale factor ,using position error canceling method to calculate out and to separate out scale factor and EEA of accelerometer as well as using least square method and iteration method to calculate out EEA of gyroscope and its relative error items in 10 position static calibration test and in 3 direction positive and negative rate test ,then using interpolation method to calculate out scale factor of gyroscope .

Owner:BEIHANG UNIV

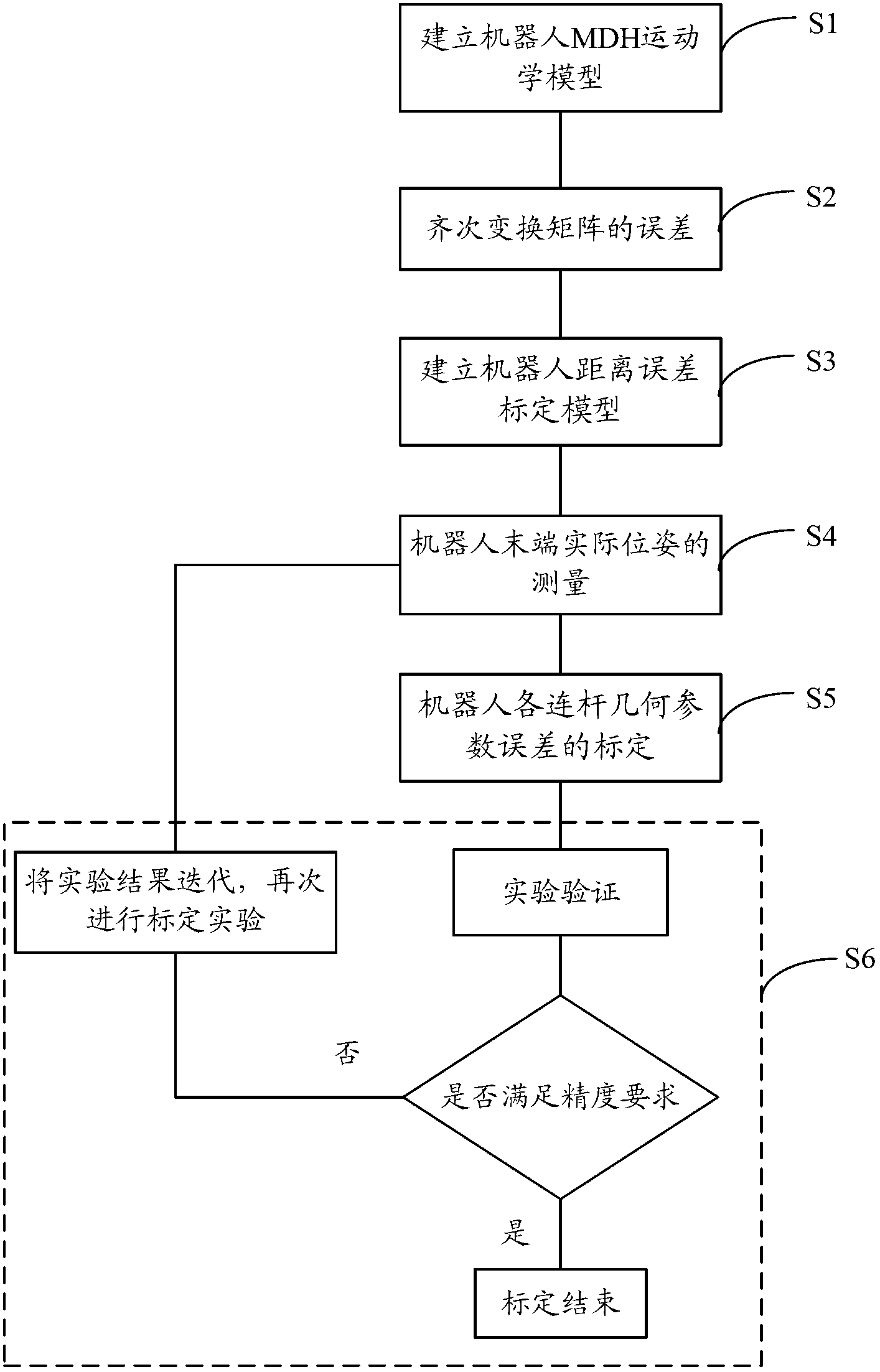

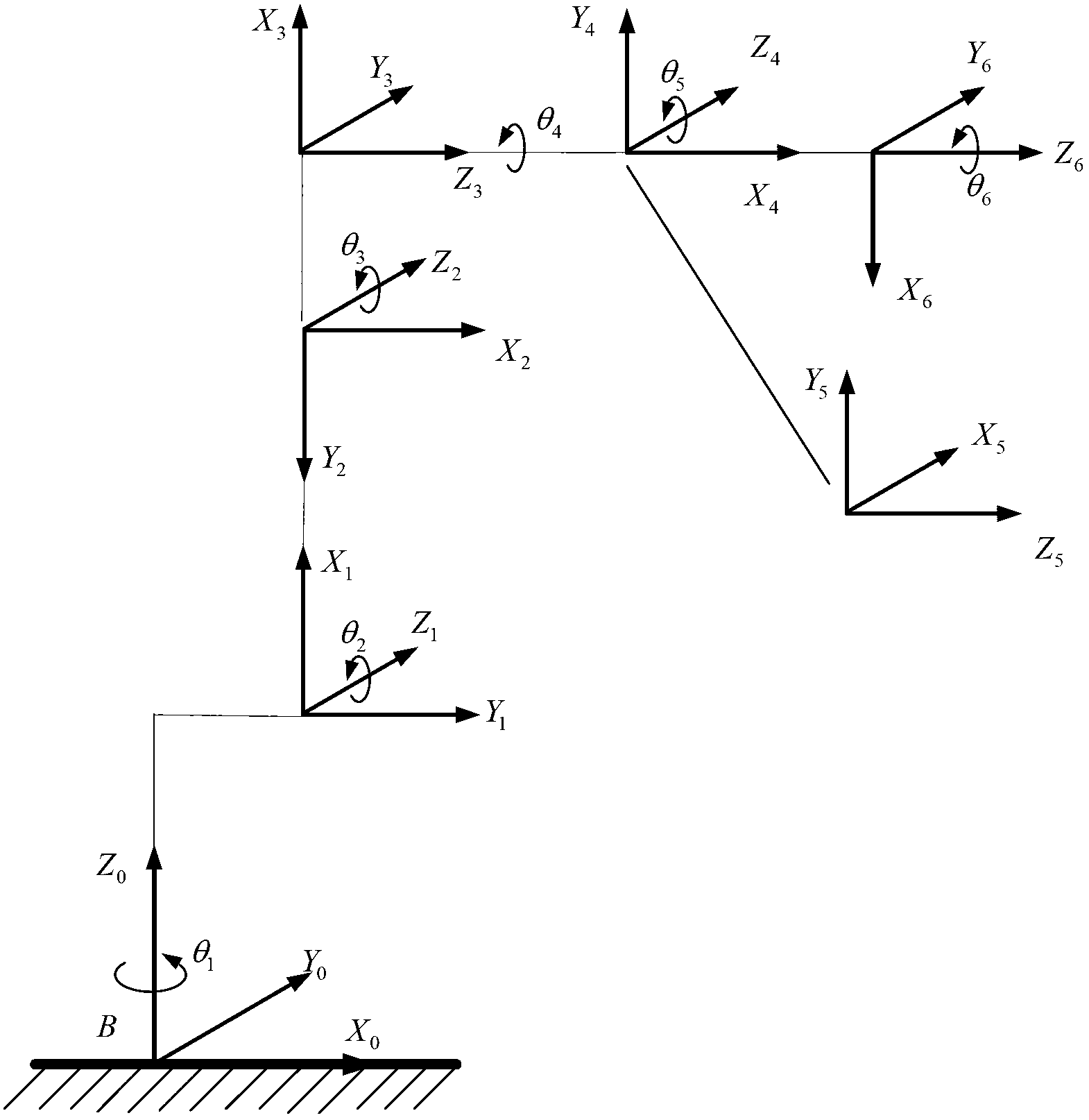

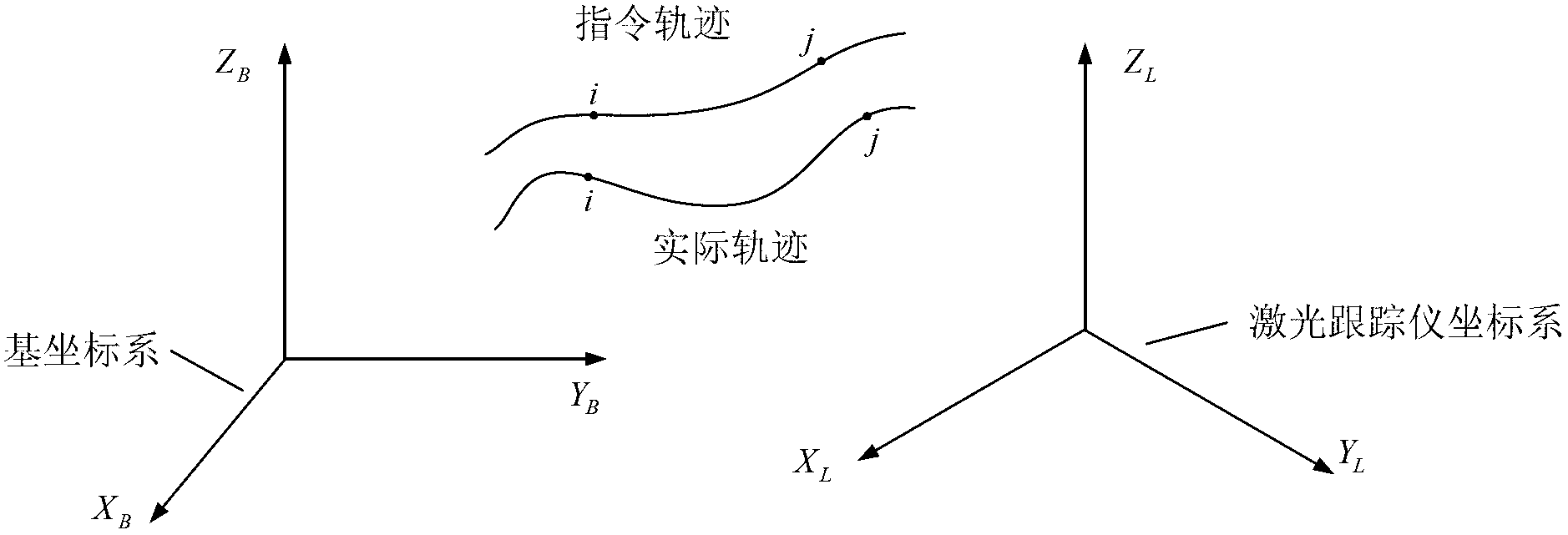

Industrial robot calibration method based on distance error models

InactiveCN103231375ACalibration method is simpleThe calibration method is practicalProgramme-controlled manipulatorSimulationHomogeneous transformation matrix

The invention discloses an industrial robot calibration method based on distance error models. The method comprises: establishing a robot MDH (modified Denavit-Hartenberg) kinematic model; subjecting the errors of a matrix to homogeneous transformation; establishing a robot distance error calibration model; measuring the end actual pose of a robot; calibrating geometrical parameter errors of every connecting rod of the robot; and performing experimental verification. The industrial robot calibration method based on the distance error models has the advantages of being simple, practical, high-efficiency and rapid, is applicable to any series articulated robots, has a strong commonality, and can improve the positioning accuracy and the distance accuracy of an industrial robot simultaneously.

Owner:SUZHOU UNIV

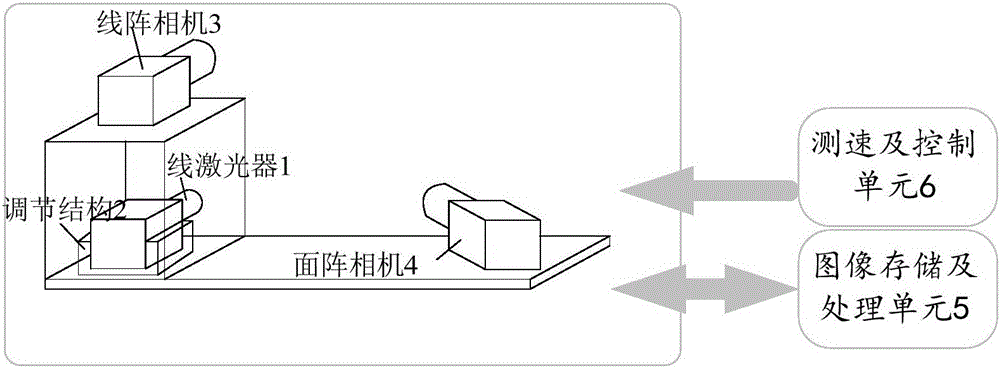

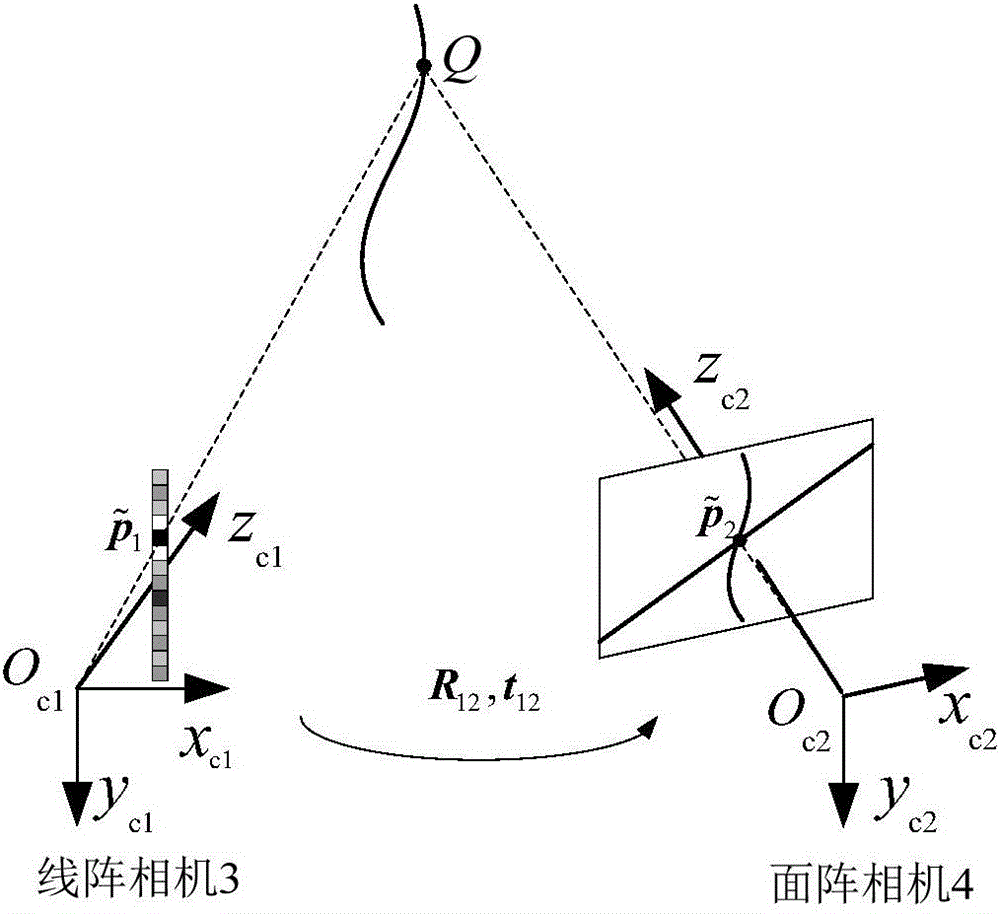

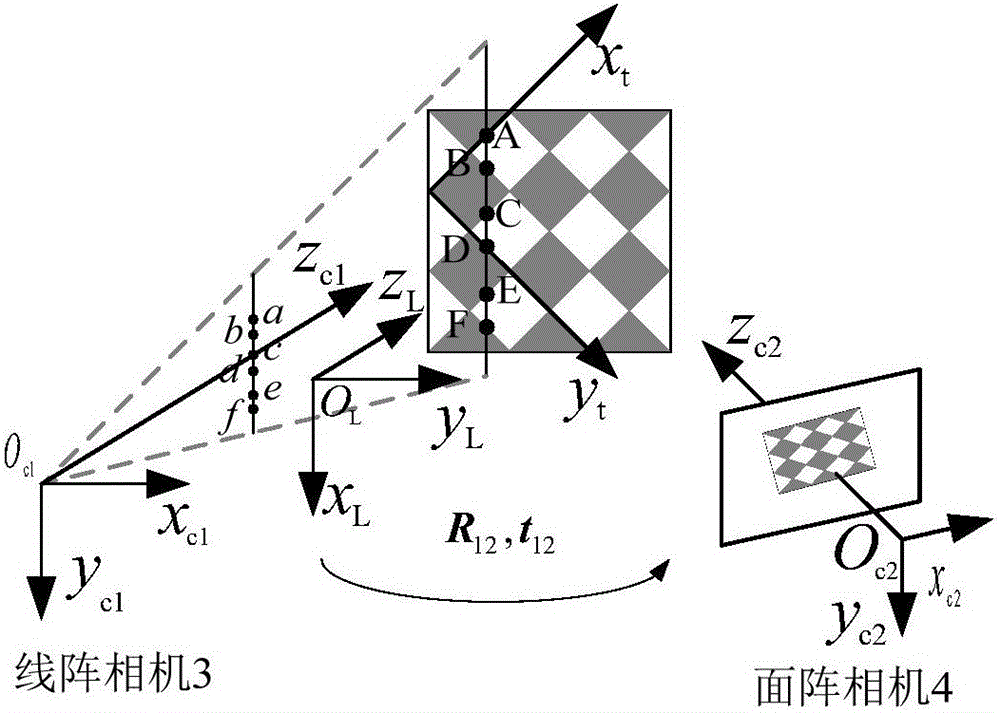

Stereo vision sensor integrates line array camera and area array camera and calibration method

ActiveCN106289106ARealize 3D reconstructionFast frame rateUsing optical meansObject detectionVision sensor

The invention discloses a stereo vision sensor integrates a line array camera and an area array camera and a calibration method. The vision sensor can synchronously acquire gray and depth information of an object image. The sensor mainly comprises the line array camera, the area array camera, a laser and other accessories. The line array camera acquires a clear image through line laser illumination, and forms the stereo vision sensor with the area array camera. The line laser is used as the feature of the area array camera image, matches an epipolar constraint to realize corresponding matching of the line array camera and the area array camera image. Three-dimensional coordinate reconstruction is realized through a stereo vision measurement model. The sensor can simultaneously acquire the image information of the object and the spatial depth information corresponding to each pixel in a push-scan manner. The stereo vision sensor provided by the invention can be widely applied to the fields of object recognition, fault diagnosis and the like.

Owner:BEIHANG UNIV

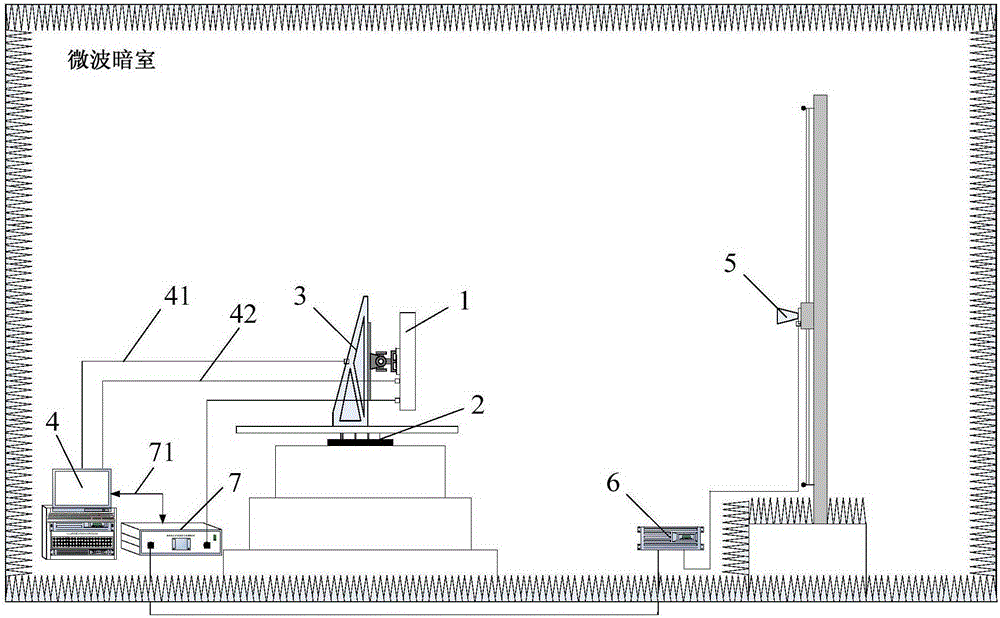

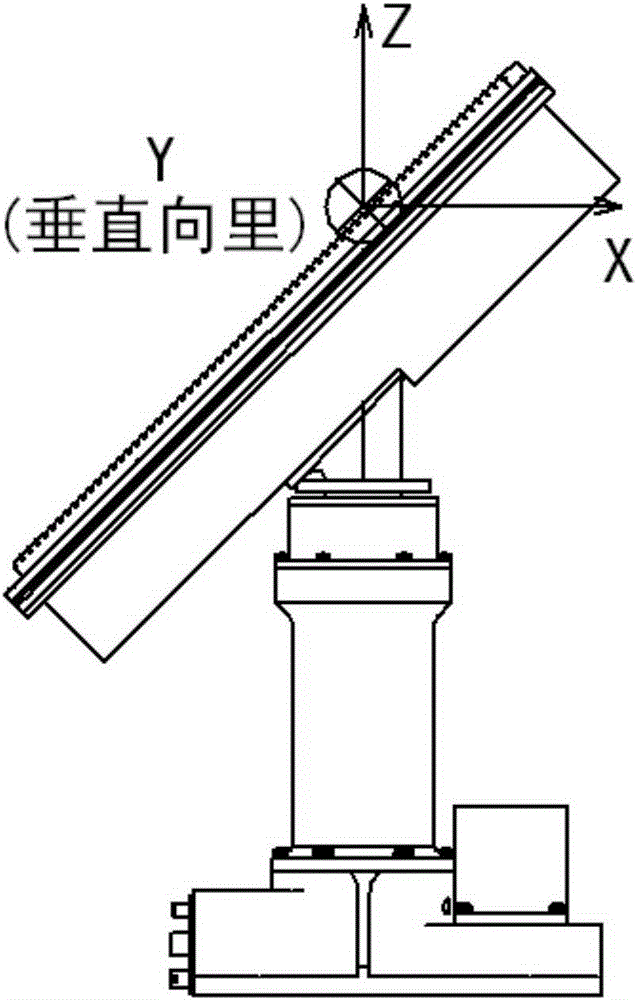

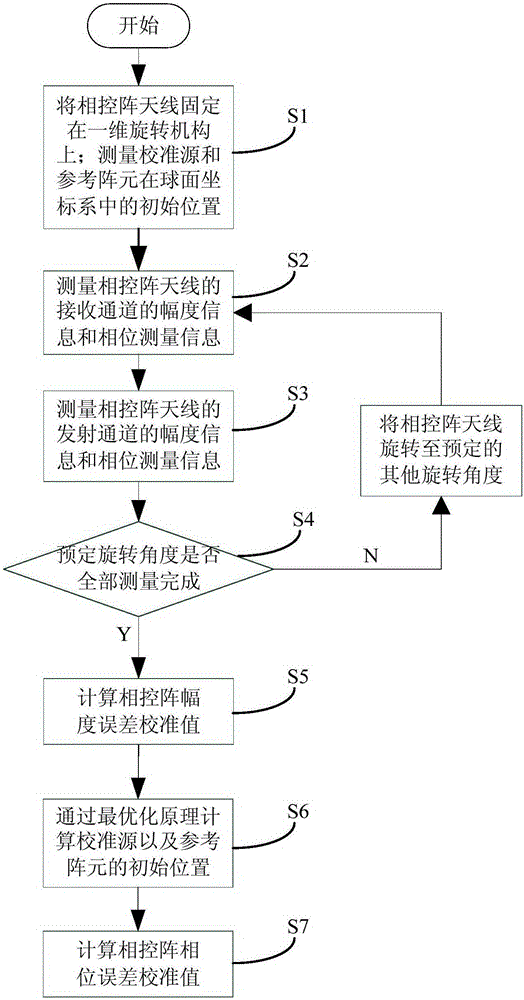

Phased array amplitude-phase error near-field calibration method based on one-dimensional rotation

ActiveCN105353229ACalibration method is simpleEasy to operateWave based measurement systemsAntenna radiation diagramsChannel state informationField conditions

The invention relates to a phased array amplitude-phase error near-field calibration method based on one-dimensional rotation, and the method comprises the steps: S1, building a phased array amplitude-phase error testing system, enabling a phased array antenna to be fixed at an initial rotating angle, and measuring the initial position of a calibration source and the initial position of a reference array element; S2, measuring the receiving channel amplitude information and phase measurement information of the phased array antenna; S3, measuring the transmitting channel amplitude information and phase measurement information of the phased array antenna; S4, judging whether the measurement of all preset rotating angles is carried out or not: executing step S5 if the measurement of all preset rotating angles is carried out, or else enabling the phased array antenna to be rotated to another preset rotating angle, and executing step S2 and step 3; S5, calculating the calibration value of a phased array amplitude-phase error; S6, calculating the initial position of the calibration resource and the initial position of the reference array element through an optimization principle; S7, calculating the calibration value of the phased array amplitude-phase error. The method just needs to meet the far-field condition of a single antenna unit in the phased array antenna, is simple in calibration, is high in operability, is higher in measurement precision, and is easy in engineering realization.

Owner:SHANGHAI RADIO EQUIP RES INST

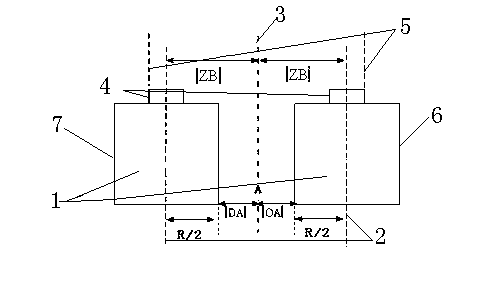

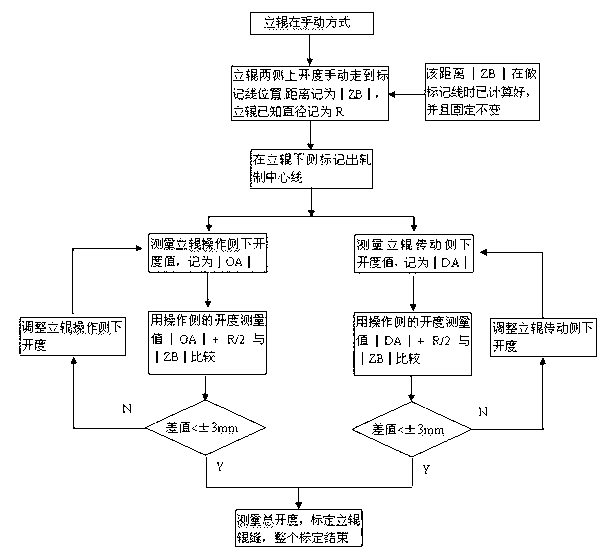

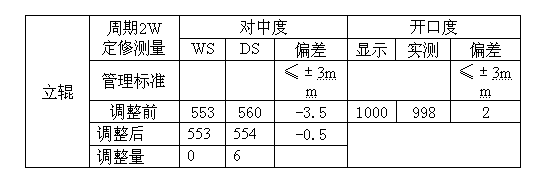

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792AProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelEngineering

The invention relates to a calibration method for clearance between rolls of hot-rolling vertical rolls, which mainly solves the technical problem that strip steel is deficient in quality because verticality and alignment to calibration of vertical rolls are not considered in current methods. The technical scheme is that the calibration method for clearance between rolls of hot-rolling vertical rolls comprises the steps of: 1, finding a rolling center line and marking; 2, additionally arranging two position marks on a transverse slipway of a hot-rolling vertical roll device, and marking the distance from the marks to the rolling center line as |ZB|; 3, hitting apertures on both sides of the vertical rolls to marked positions, wherein a roll block is inside a marking line and aligned with the marking line; 4, measuring the distance from the lower ends on both sides of the vertical rolls to the rolling center line, and marking the measuring point as a point A, the radius of the rolls as R / 2 and the distances from A to a vertical roll operating side and from A to a transmission side as |OA| and |DA|; 5, comparing the measured value |OA|+R / 2 on the operating side with |ZB|, wherein if the difference is in a precision range, the verticality is good, and if the difference is not in the precision range, the clearance between rolls on the operating side is adjusted so that the difference is in the precision control range; 6, adjusting the clearance between rolls on the transmission side by the adjusting method in the step 5; and 7, measuring the total aperture of the vertical rolls, inputting the measured values and calibrating the clearance between rolls of vertical rolls after adjusting the verticality and alignment.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

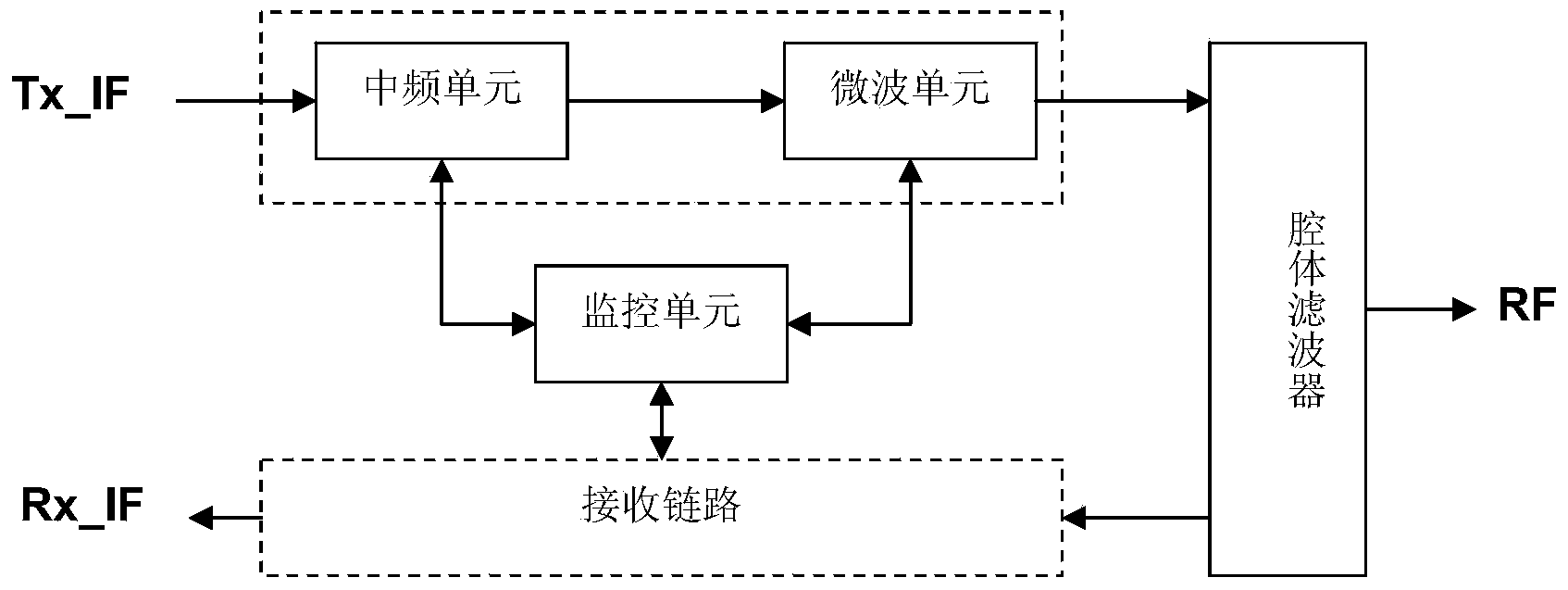

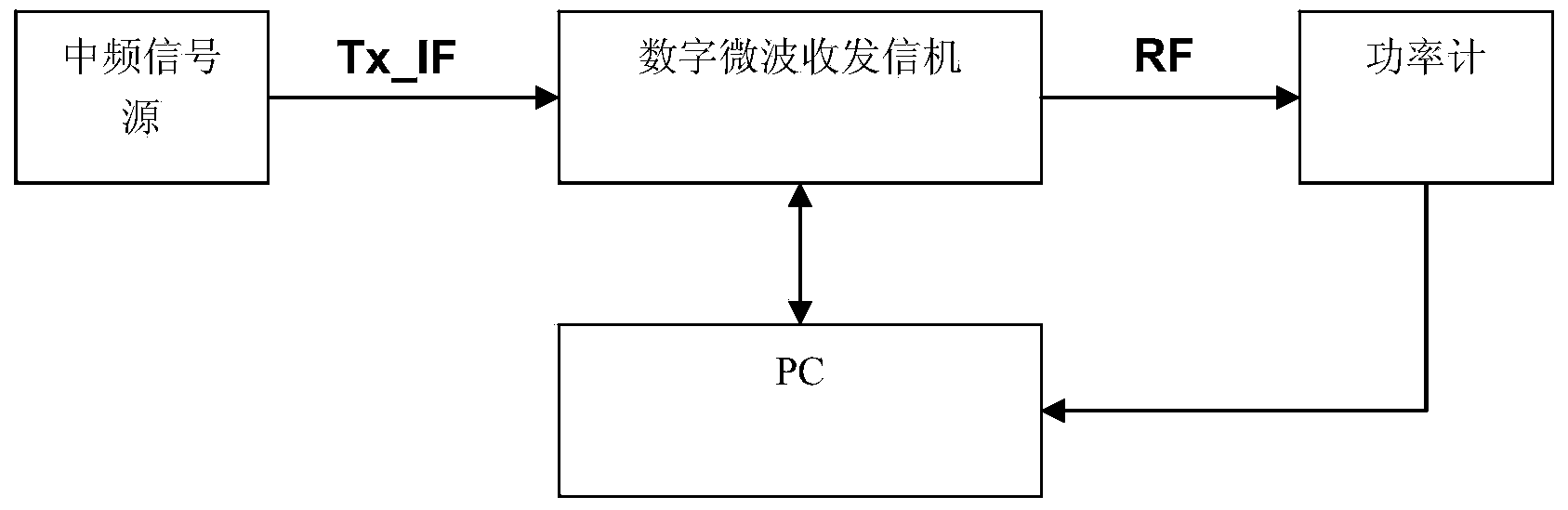

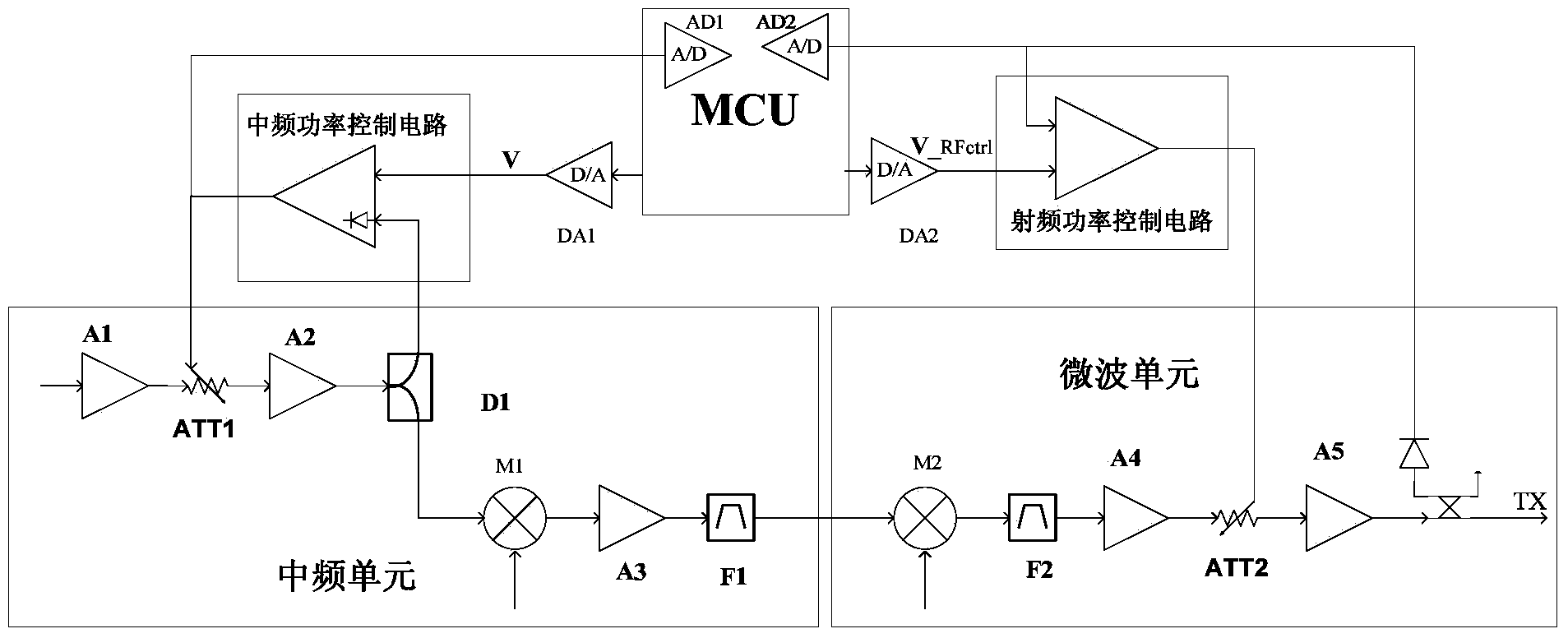

Calibration method and calibration circuit for transmitted power of digital microwave transceiver

ActiveCN103686968ASimple methodImprove mass production efficiencyPower managementTransceiverTransmitted power

The invention discloses a calibration method for the transmitted power of a digital microwave transceiver. The calibration method comprises the following steps of first generating a transmitted power calibration table according to transmitted power control voltages and actual radio frequency transmitted power which corresponds to the transmitted power control voltages and is transmitted by the microwave transceiver, second generating a channel calibration table, and thirdly correcting the transmitted power control voltage value in the transmitted power calibration table by using a channel correcting method. The invention further discloses a calibration circuit for achieving the calibration method for the transmitted power of the digital microwave transceiver. The calibration circuit comprises a microwave unit and a monitoring unit, and the microwave unit comprises a first power detection tube, a second power detection tube, a microwave amplifier and a microwave attenuator. The calibration circuit has the advantages of being high in batch production efficiency, high in calibration rate, high in transmitted power stability, simple in calibration method and the like.

Owner:波达通信设备(广州)有限公司

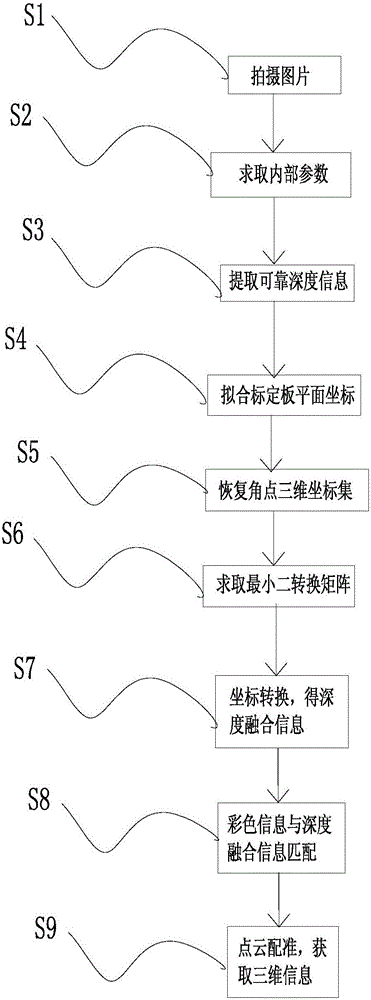

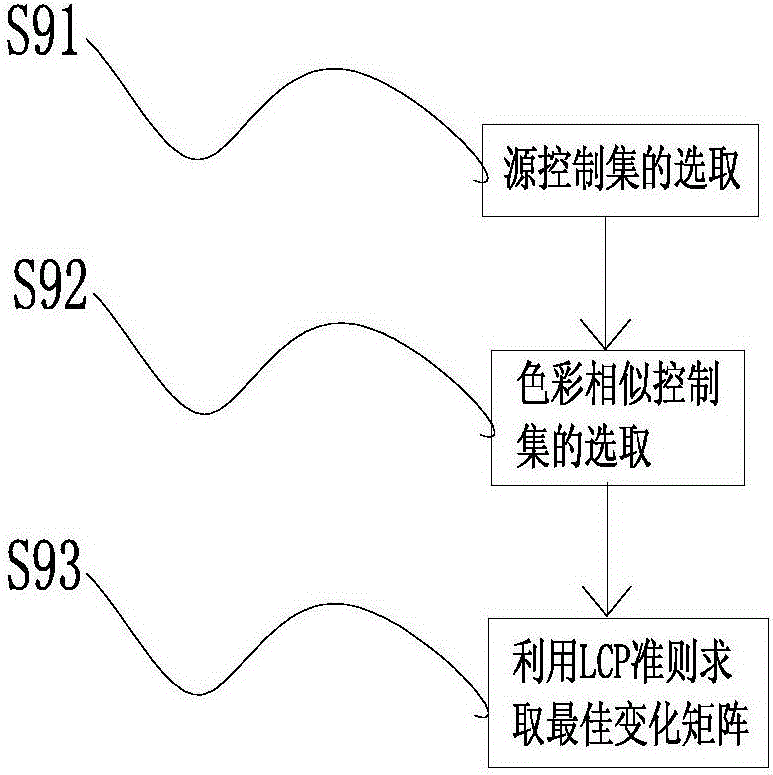

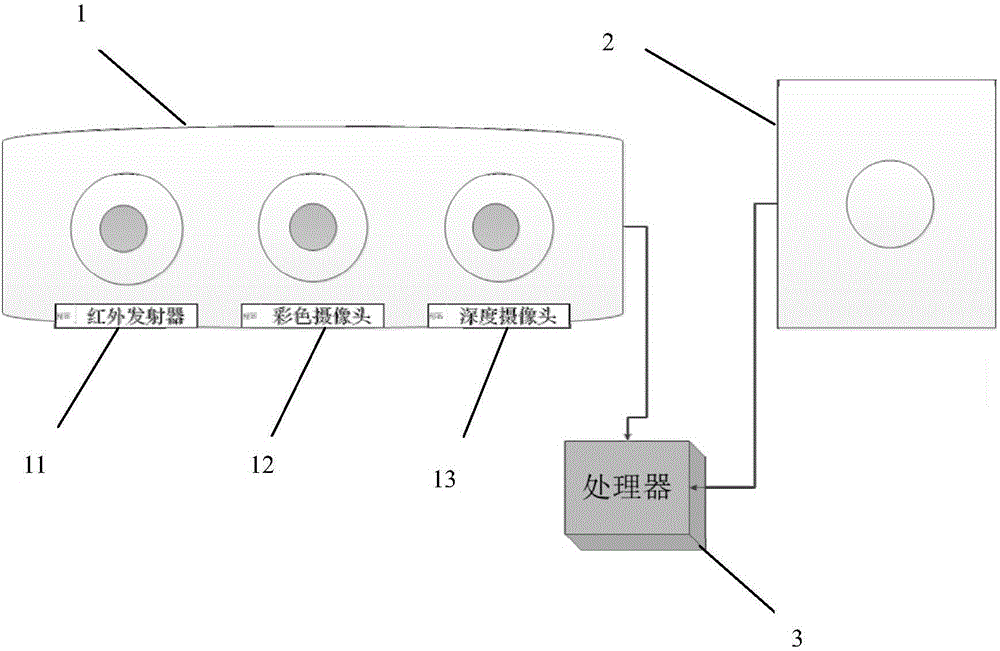

Heterogeneous depth camera-based three-dimensional information obtaining method and apparatus

ActiveCN106780618AHigh resolutionSmall amount of calculationImage enhancementImage analysisLeast squaresDepth map

The invention discloses a heterogeneous depth camera-based three-dimensional information obtaining method. The method comprises the following steps of shooting a picture; calculating internal parameters of a Kinect camera and a TOF camera; extracting reliable depth information according to the shot picture; fitting calibration board plane coordinates of the Kinect camera and the TOF camera according to the reliable depth information; recovering an actual three-dimensional coordinate set of corner points of the Kinect camera and the TOF camera under the fitted calibration board plane coordinates in combination with the internal parameters; calculating a least square conversion matrix between the Kinect camera and the TOF camera; performing coordinate conversion on the reliable depth information according to the least square conversion matrix to obtain depth fusion information; matching color information acquired by the Kinect camera with the depth fusion information; and performing point cloud registration on image information after matching based on a spatial distance between the points to obtain three-dimensional information. By adopting the method, a high-resolution accurate depth map fusing the color information can be quickly obtained, and then accurate three-dimensional information is obtained.

Owner:周超艳

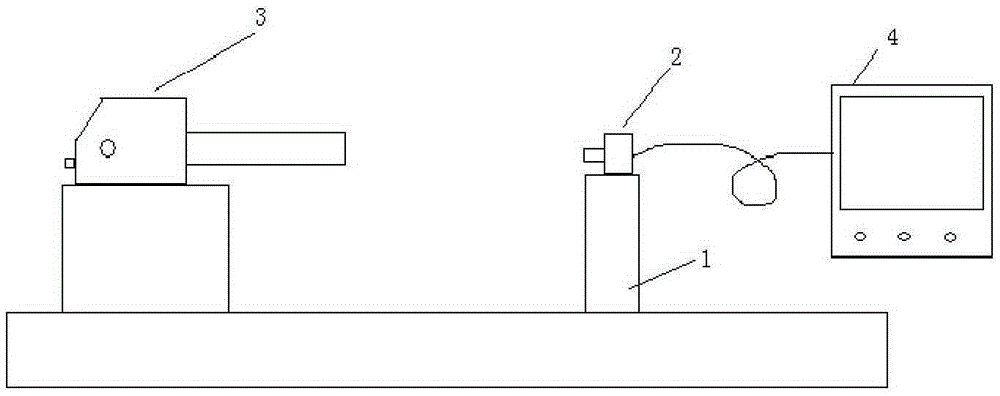

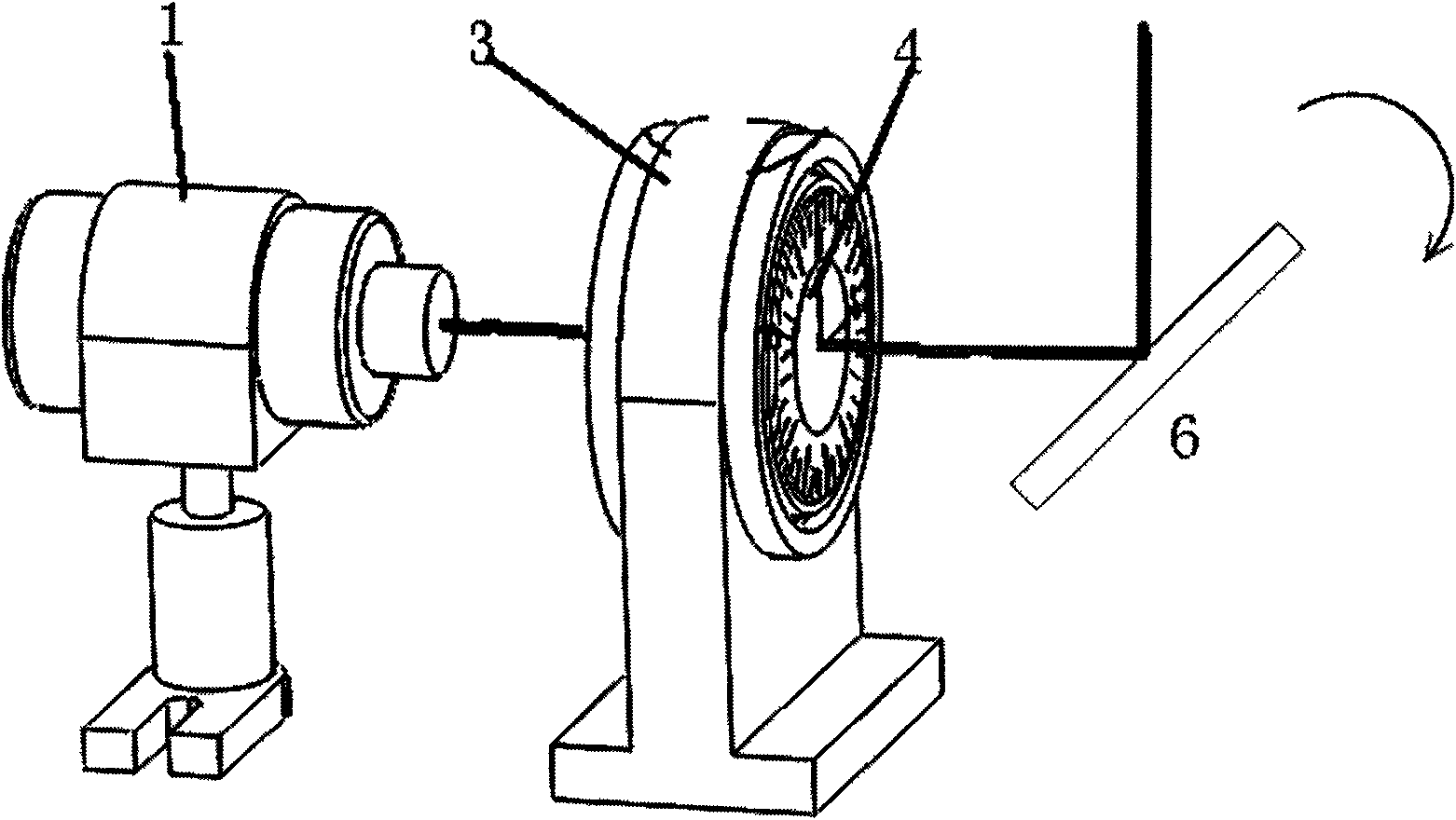

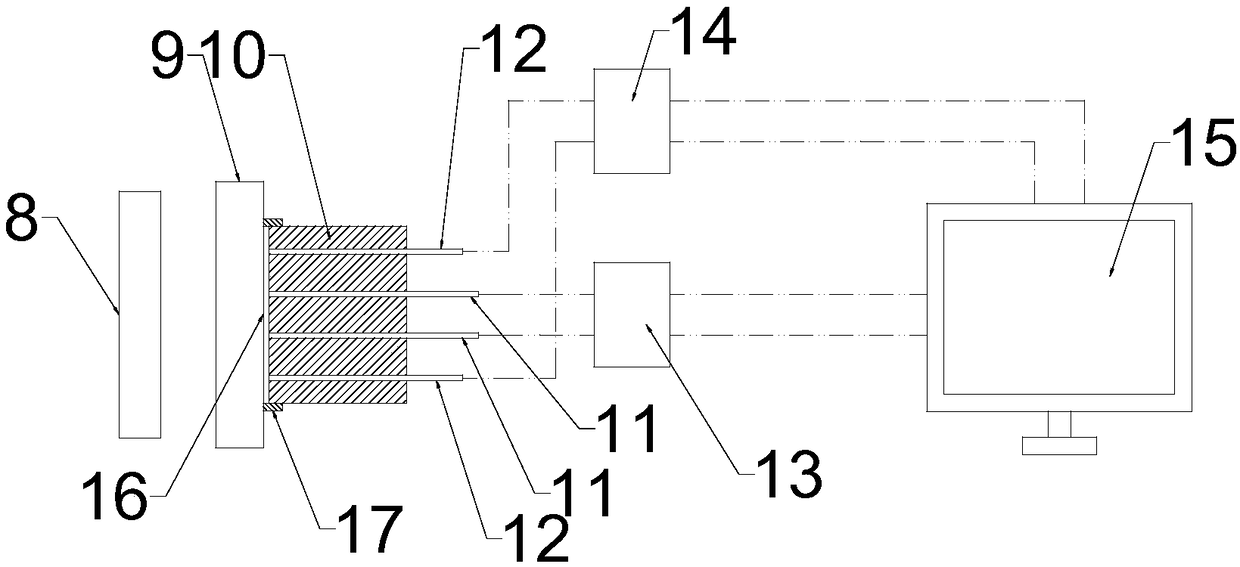

Robot positioning device and method based on novel visual guidance

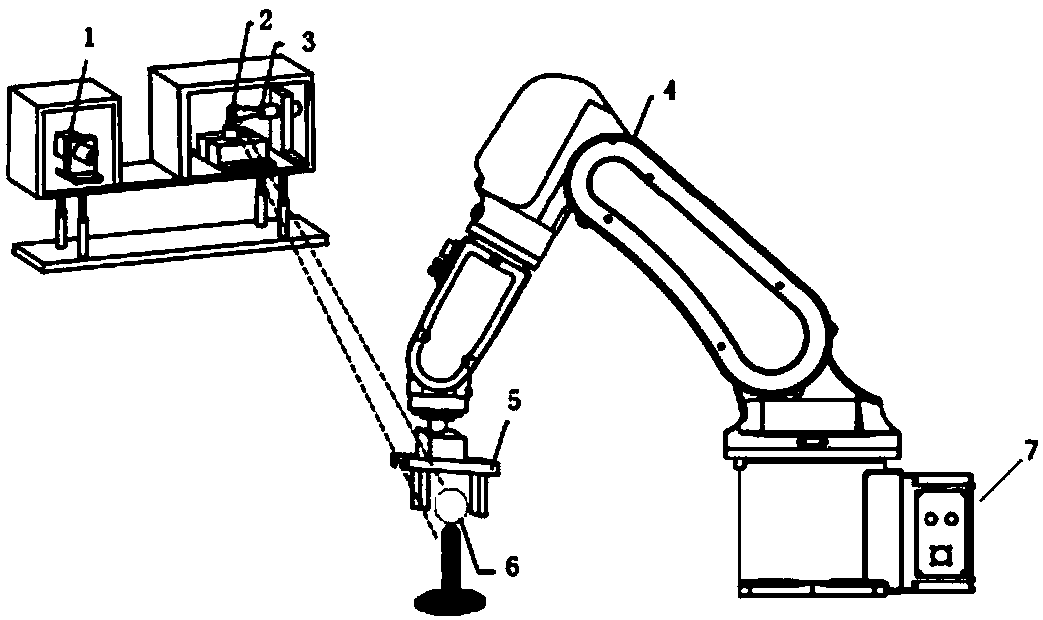

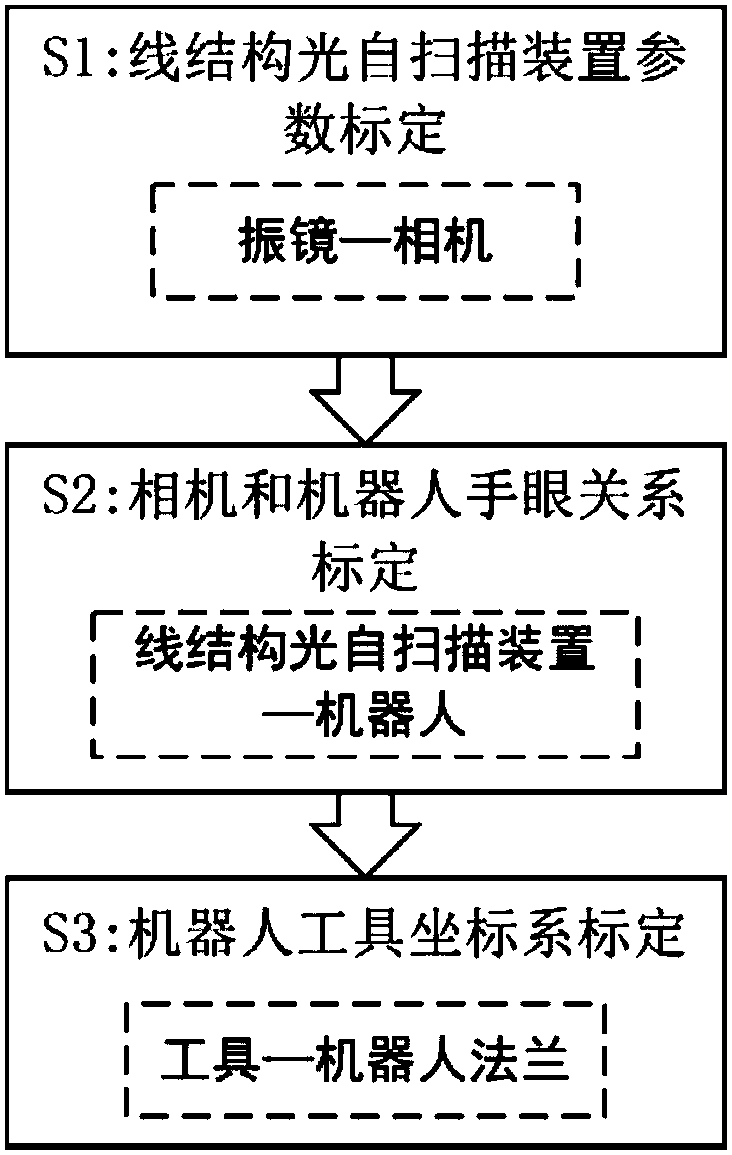

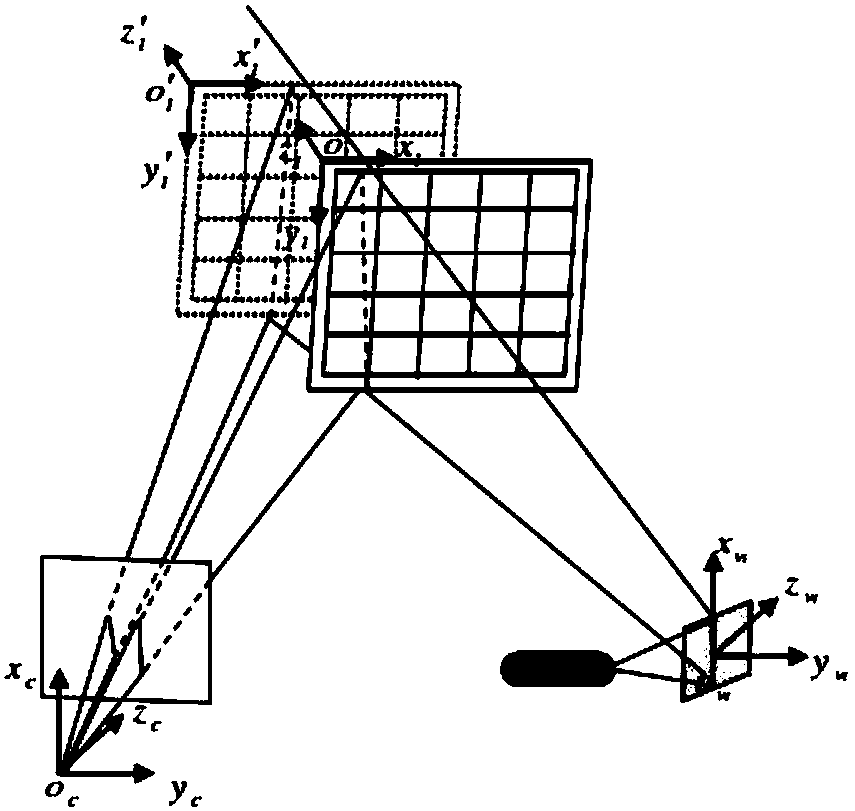

InactiveCN108098762AHigh positioning accuracyCalibration method is simple and easyProgramme-controlled manipulatorLine structureVisual guidance

The invention discloses a robot positioning device and method based on novel visual guidance. A system device comprises a line structured light self-scanning device, a robot module and an upper computer. The line structured light self-scanning device comprises an industrial camera, a laser and a galvanometric scanner. The robot module comprises a robot body and a robot controller. A system methodis a method for joint calibration of a robot hand-eye relationship and a tool coordinate system. By use of the method, a system enables the industrial robot to locate a target object in a random posture. The robot positioning device and method can be applied to the tasks of grabbing and carrying by the robot.

Owner:广州映博智能科技有限公司

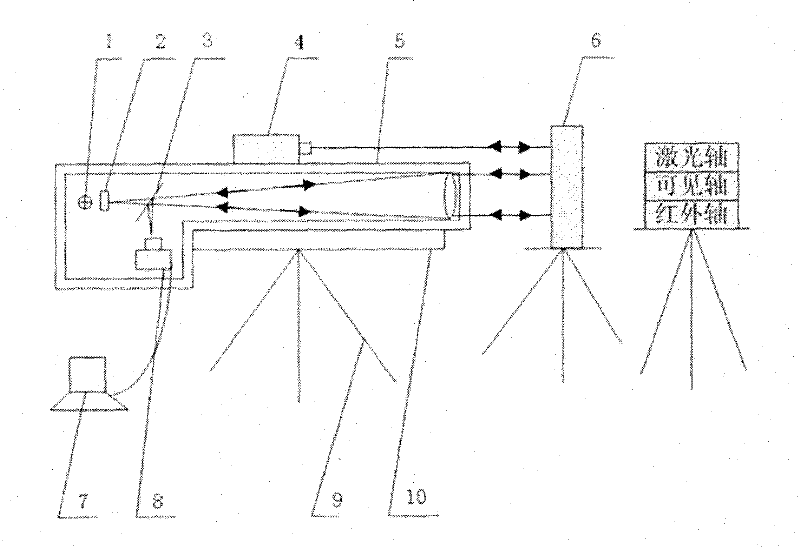

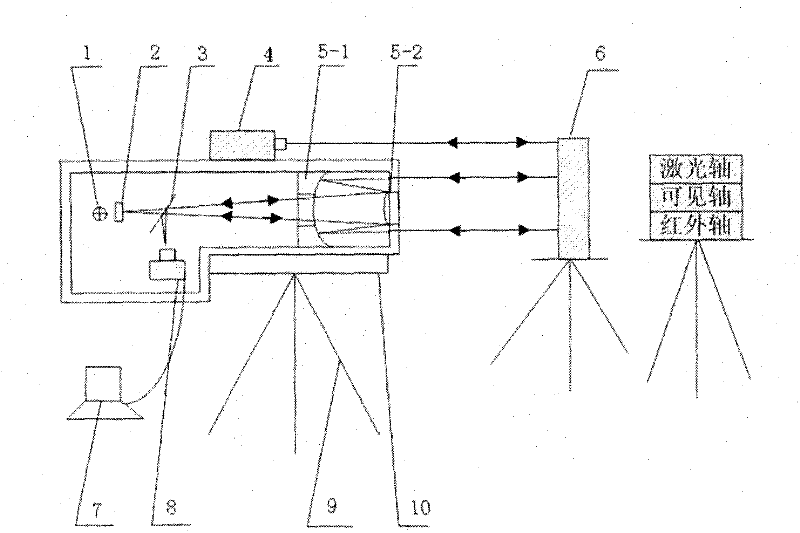

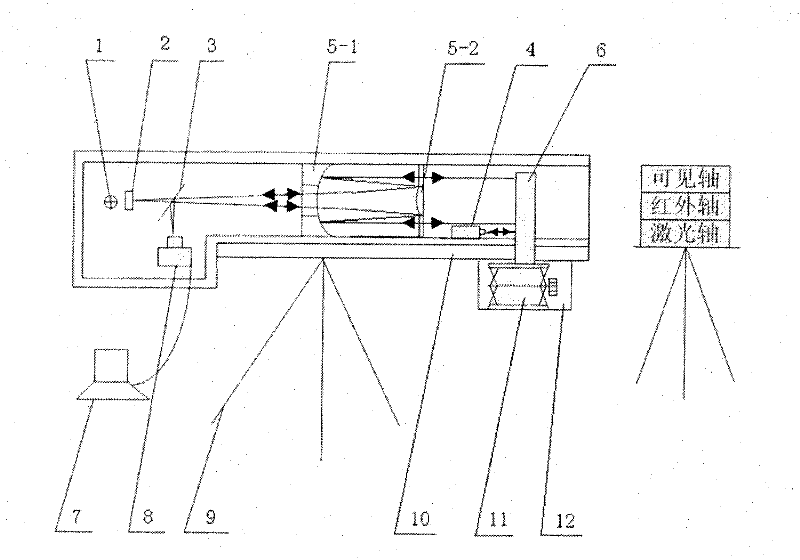

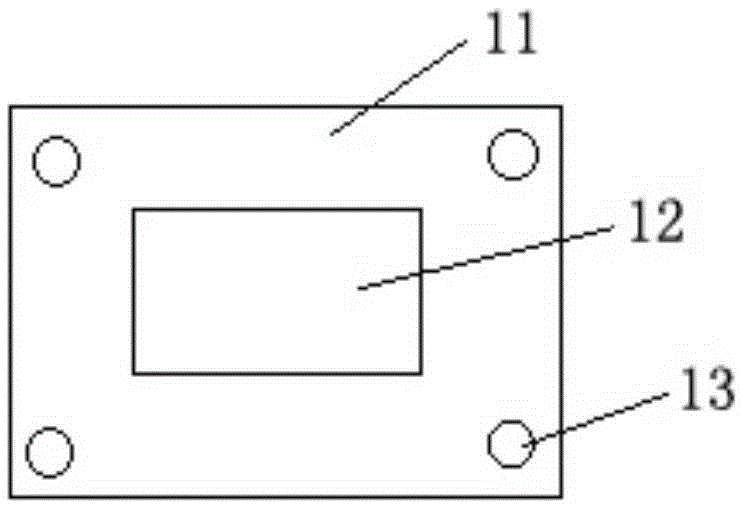

Calibration device for discrete optical axis multispectral alignment instrument

ActiveCN102288137AAchieve calibrationCalibration method is simpleUsing optical meansObject pointDisplay device

The invention relates to a device for calibrating a multi-spectral axis calibrator with a discrete optical axis and belongs to the field of optical measurement. A semi-transmitting and semi-reflecting mirror, a laser and a charge-coupled device (CCD) camera are integrated in a collimator tube; an optical axis of the CCD camera is vertical to that of the collimator tube, and an object point of theCCD camera is positioned at an equivalent focal point of the collimator tube; and an electric cross which is generated by the CCD camera is displayed by a display. During self-calibration, an emergent light beam of the collimator tube is vertically irradiated on a plane reflecting mirror and reflected and then forms a self-calibration image on the display; and during the calibration measurement of the axis calibrator, after an infrared channel or a visible light channel of the measured axis calibrator is aligned with the collimator tube, the laser emits laser to a laser channel of the measured axis calibrator, and the parallel misalignment of the laser and the infrared channel or the parallel misalignment of the laser and the visible light channel is obtained by a data processing system of the laser channel. The device is applicable to calibration of the multi-spectral axis calibrator with the discrete optical axis and has the characteristics of simple calibration method, objective calibration result, reliability and the like.

Owner:中国兵器工业第二0五研究所

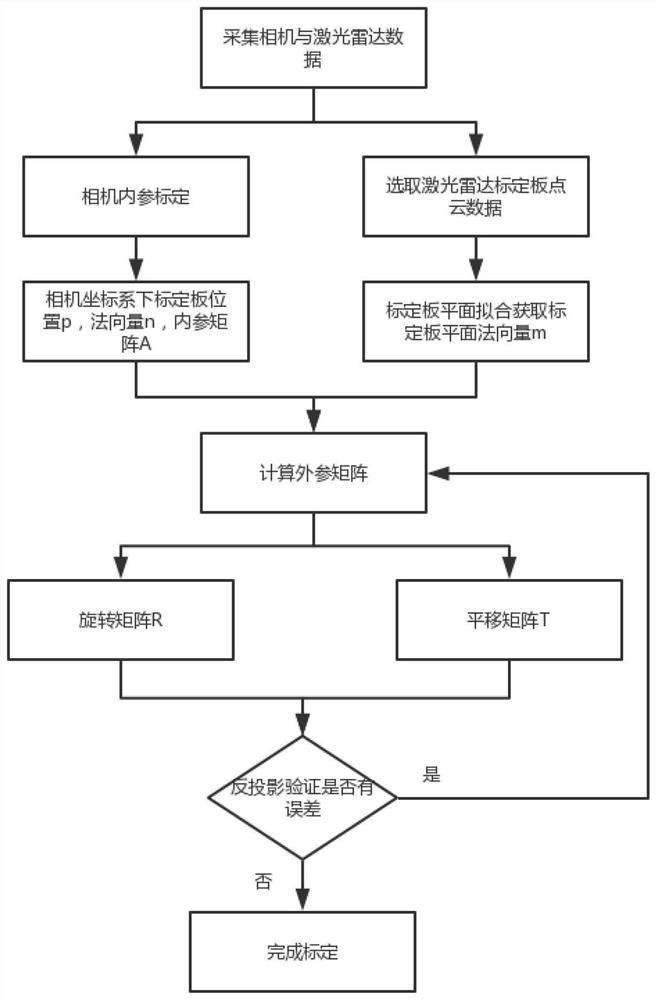

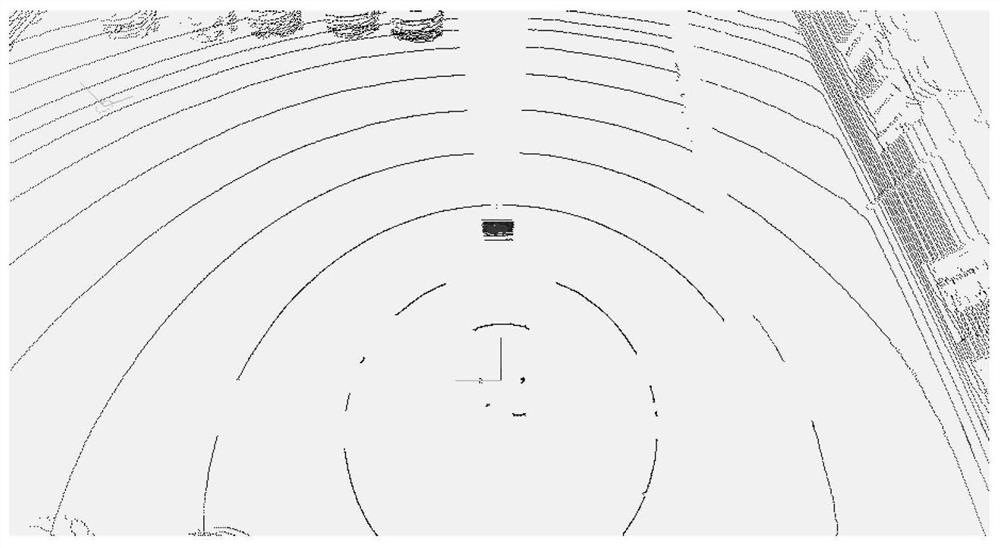

Laser radar and camera combined calibration method based on mobile calibration plate

PendingCN111612845ACalibration method is simpleHigh precisionImage analysisWave based measurement systemsCalibration resultComputer science

The invention discloses a laser radar and camera combined calibration method based on a mobile calibration plate. Firstly, calibration internal parameters are calculated for different poses of a calibration plate; a normal vector of a point cloud data fitting plane of the selected corresponding laser radar calibration plate is acquired, and calibration external parameters are calculated through equation solving to finally complete calibration. The method comprises the following specific steps: step 1, collecting laser radar and camera data of calibration plates at different angles in the viewfield of a camera as calibration data and verification data; 2, acquiring a camera internal reference calibration result of the acquired camera data by using a Zhang Zhengyou calibration method; 3, selecting a calibration plate position point cloud on the corresponding laser radar data; step 4, carrying out plane fitting on the point cloud data obtained in the step 3 and obtaining a correspondingnormal vector; and step 5, substituting the internal reference data obtained in the step 2 into a corresponding calculation formula to obtain a final external reference result. Compared with a single-point selection method, the method for selecting the plane data of the calibration plate is higher in accuracy and simpler to operate.

Owner:JIANGSU UNIV

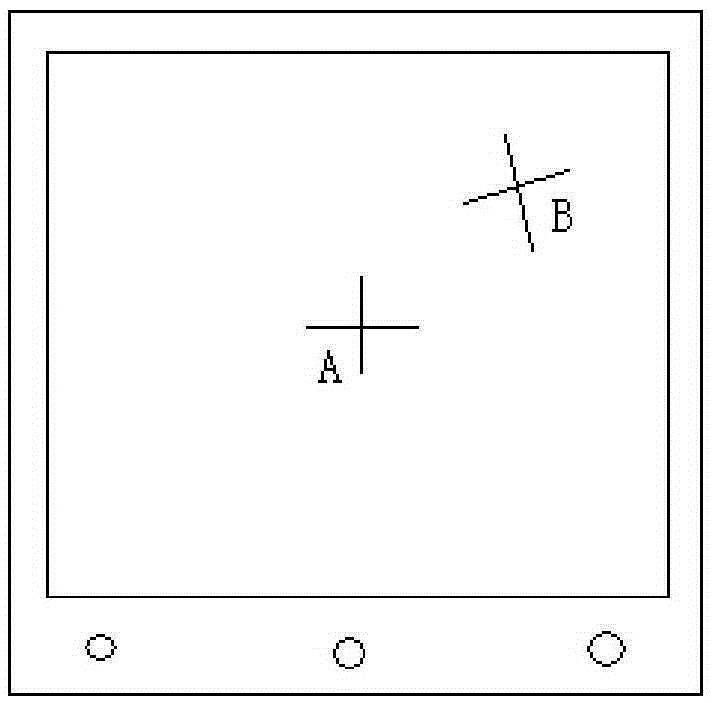

Camera assembling adjusting and calibrating method

InactiveCN105338233AEasy to installCalibration method is simpleTelevision system detailsColor television detailsCamera lensOptical axis

The invention discloses a camera assembling adjusting and calibrating method and belongs to the technical field of bare camera assembling. The method comprises the following steps that firstly, an autocollimator and a camera are arranged in a direct facing mode, the position of the camera is fixed, and the autocollimator is adjusted to make the light axis of the autocollimator to be parallel to the light axis of a lens of the camera; secondly, the camera images a cross target source of the autocollimator, the central cross line of an image and the cross line of the target source are displayed on a displayer, a CCD imaging circuit board is adjusted in an installation plane, and the central cross line of the image is made to coincide with the cross line of the target source; thirdly, the camera is taken down, another camera to be debugged is fixed to the same position, and the same operation in the second step is carried out. The camera assembling adjusting and calibrating method is simple and high in practicability, and the problems that in the prior art, after assembling debugging of cameras, different cameras are not consistent in performance index and low in aiming positioning precision due to errors that the CCD imaging surface is inclined or deflected relative the light axis can be effectively solved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

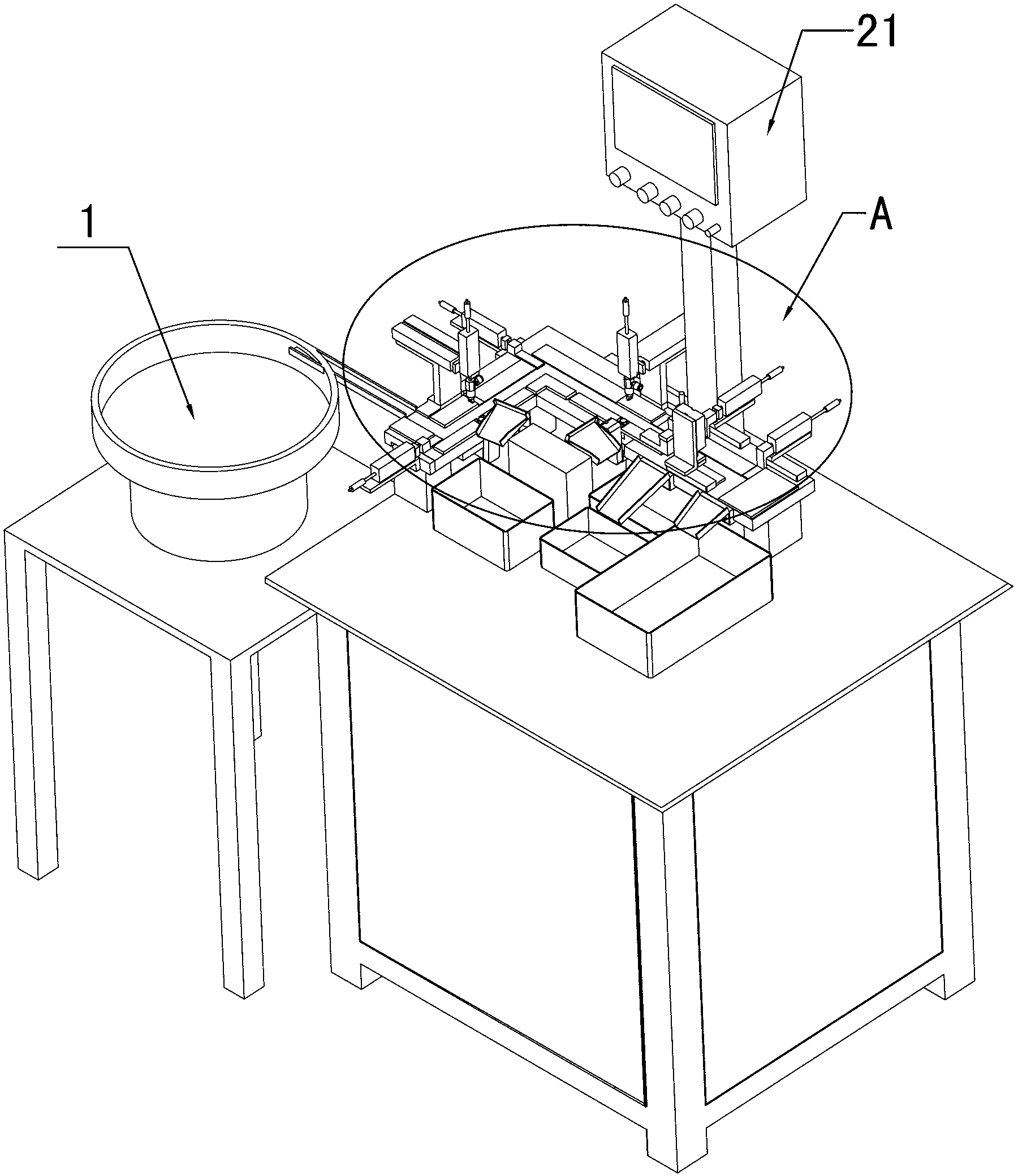

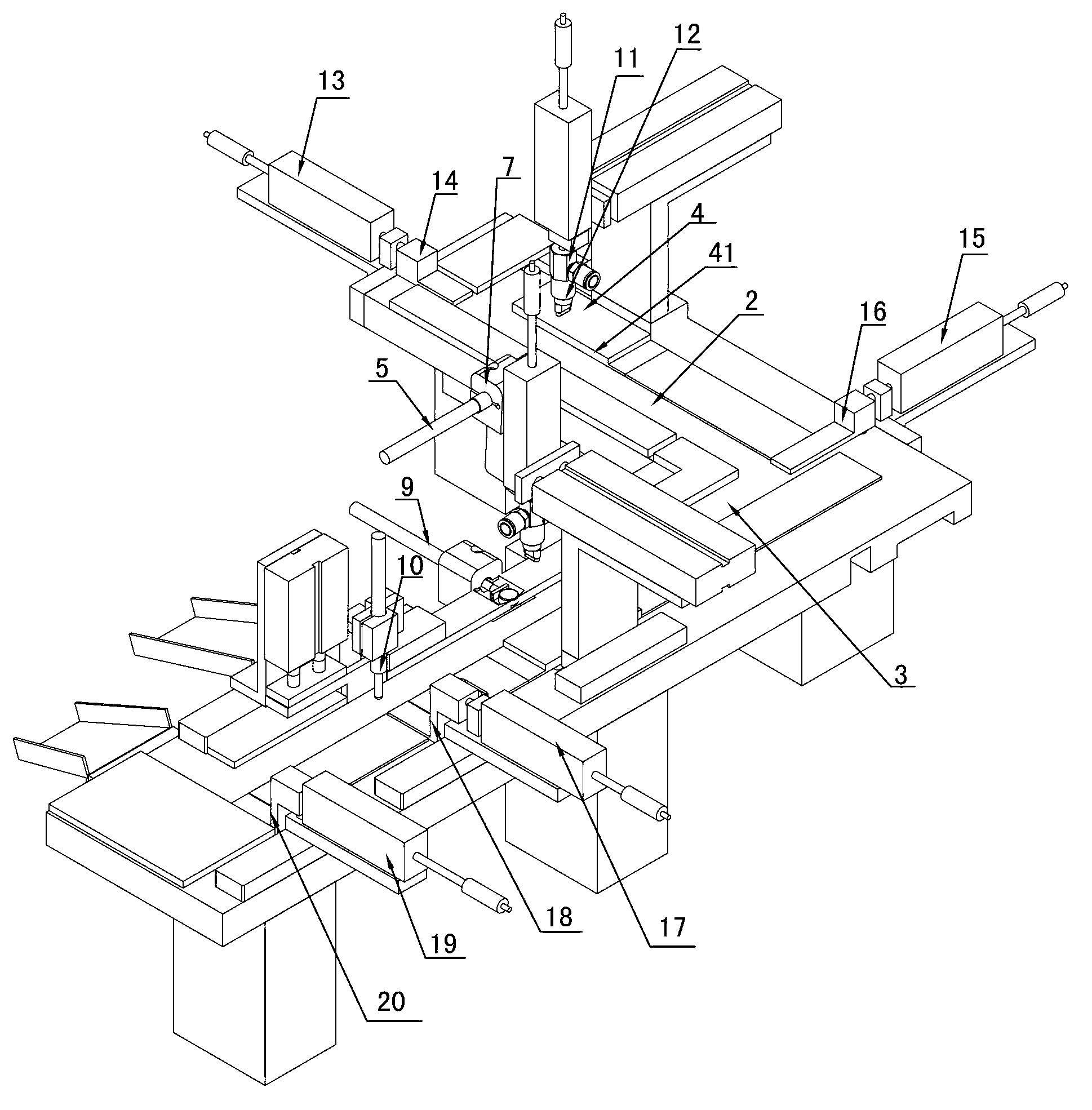

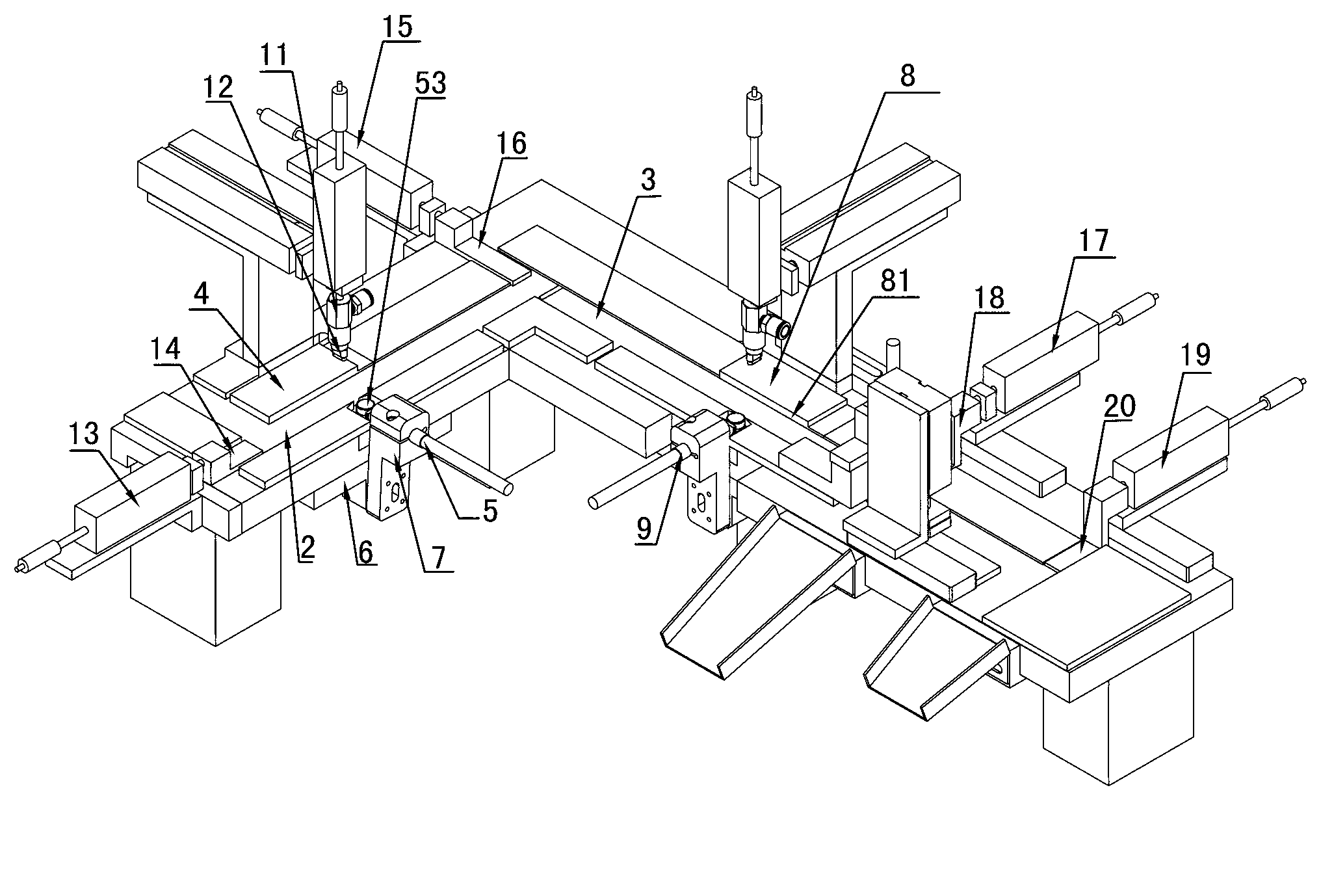

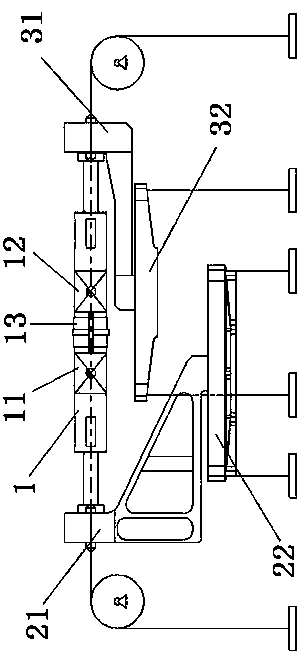

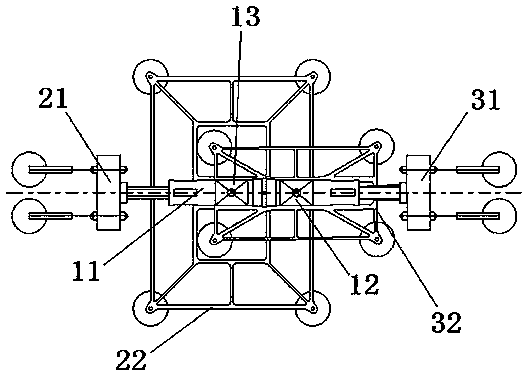

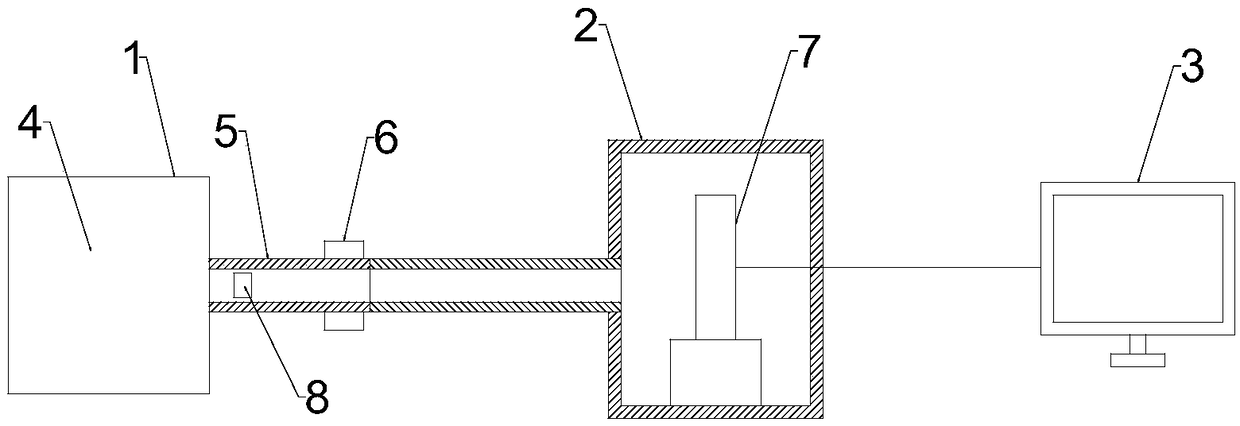

Product three-dimensional dimension automatic selector

ActiveCN103316848AImplement automatic detectionRealize automatic eliminationSortingEngineeringAutomation

The invention discloses a product three-dimensional dimension automatic selector, which comprises a control mechanism, a feeding mechanism, a first transfer passage and a second transfer passage that are horizontal and mutually perpendicular, wherein the inlet of the first transfer passage is provided with a first pneumatic mechanism; the inlet of the second transfer passage is provided with a second pneumatic mechanism; the first transfer passage is provided with a first width sorting mechanism and a first width detection mechanism; the second transfer passage is provided with a second width sorting mechanism and a second width detection mechanism; the first transfer passage or the second transfer passage are provided with a height sorting mechanism and a height detection mechanism; the first width sorting mechanism, the second width sorting mechanism, the height sorting mechanism, the first width detection mechanism, the second width detection mechanism and the height detection mechanism are connected with the control mechanism respectively; the control mechanism is provided with a qualified dimension scope for the first width, the second width and the height of the product. The selector has high automation and work efficiency.

Owner:NINGBO YUNSHENG +5

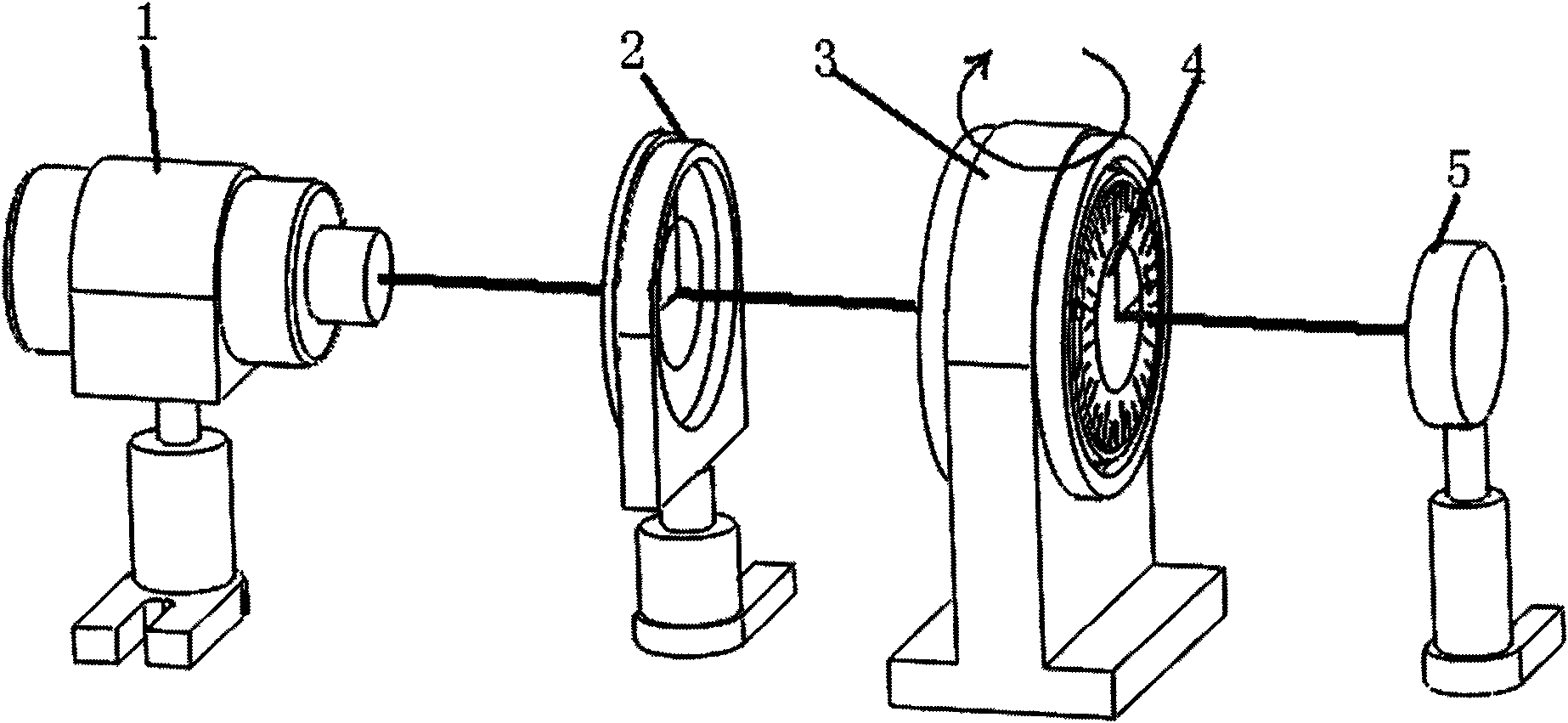

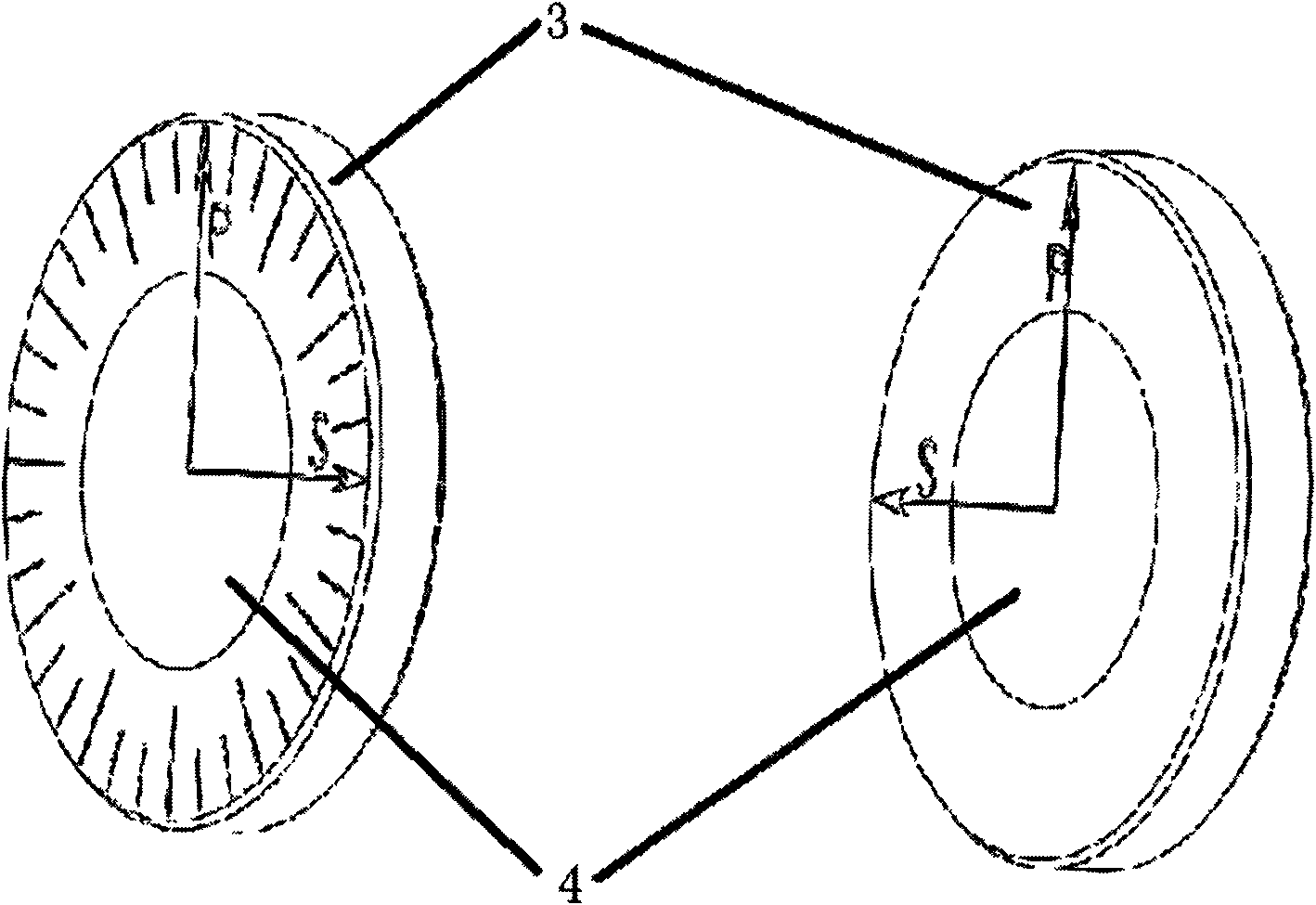

A device and method for calibrating the transmission axis of a polarizer

ActiveCN102279094ALittle outside influenceHigh precisionPhotometryTesting optical propertiesPolarizerEllipse

The invention discloses an apparatus and a method for calibrating a transmission axis of a polaroid. A combination of two to-be-calibrated polaroids and two dielectrics is utilized to realize accurate calibration on a transmission axis of a polaroid; and the apparatus and the method can be applied to measurement and detection fields, wherein the fields are related to polarization and include a polarized optical system, an ellipse polarized measuring field, and a laser technology and the like. According to the method, on the basis of rotationally symmetrical principles of an axis of homology and an absorption axis of a polaroid, two measurements on a polarization angle from the front and back sides are carried out on a linearly polarized beam at any angle; and then axises of homology or absorption axises of measured polaroids can be obtained; and transmission axises of the polaroids can be determined by utilizing different characteristics of linearly polarized lights of a horizontal S and a vertical P when the linearly polarized lights reflect on interfaces of the two dielectrics, so that high precision calibration of the transmission axises of the polaroids can be realized.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

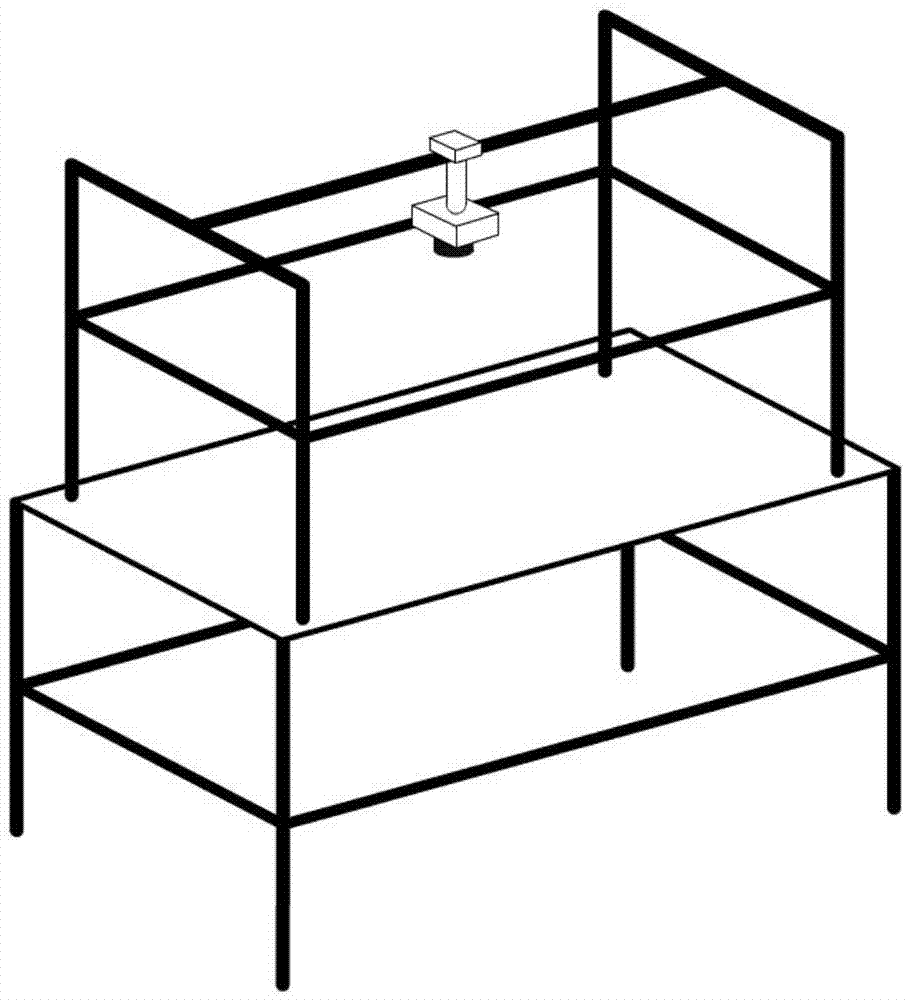

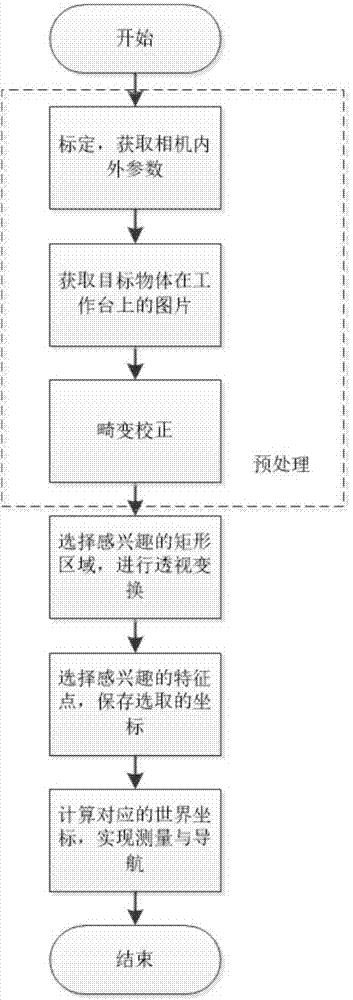

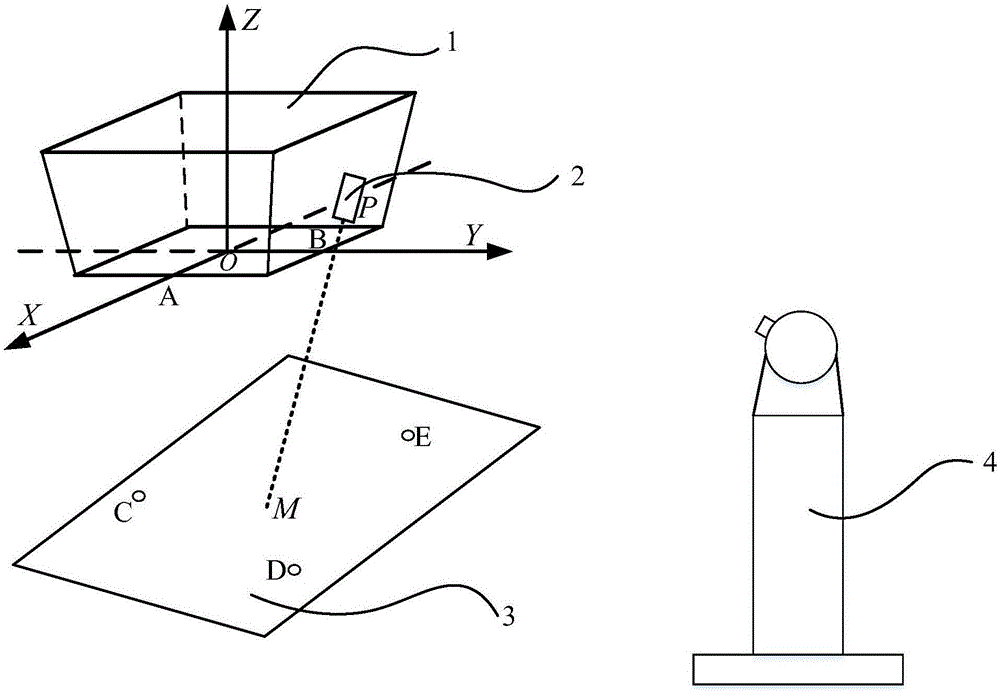

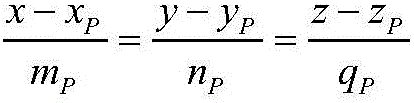

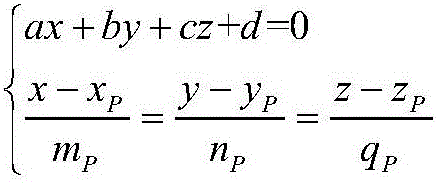

Plane feature point navigation and positioning method and device

InactiveCN104766309AAchieve positioningRealize measurementImage analysisNavigation instrumentsComputer graphics (images)Contact type

The invention discloses a plane feature point navigation and positioning method. The method includes the steps that firstly, a plane target is placed on a working table, a coordinate system is set, and a calibration point is selected from the target to calibrate a camera; distortion correction is conducted on a shot picture, an interesting rectangular area is selected to perform perspective transformation, and a standardized picture is obtained; an interesting feature point is selected, coordinates of the selected point are stored, and a non-contact type visual measurement is completed; next, a transformational matrix between two picture is calculated according to SIFT features of the images, then a matching point of the selected point in the other image is calculated, then the matching point is reprojected to a world coordinate system to obtain real position coordinates, and finally the functions of measurement and navigation and positioning are achieved. The invention further discloses a plane feature point navigation and positioning device. The plane feature point navigation and positioning method and device can achieve navigation and positioning of the plane feature point, and have the advantages of being simple and flexible in operation, accurate in measurement, high in positioning and navigation accuracy and wide in application range.

Owner:JIANGSU GUODIAN AUTHENTICATION OF ARTWORKS TECH CO LTD

Robot kinematic parameter error optimized compensation method and device

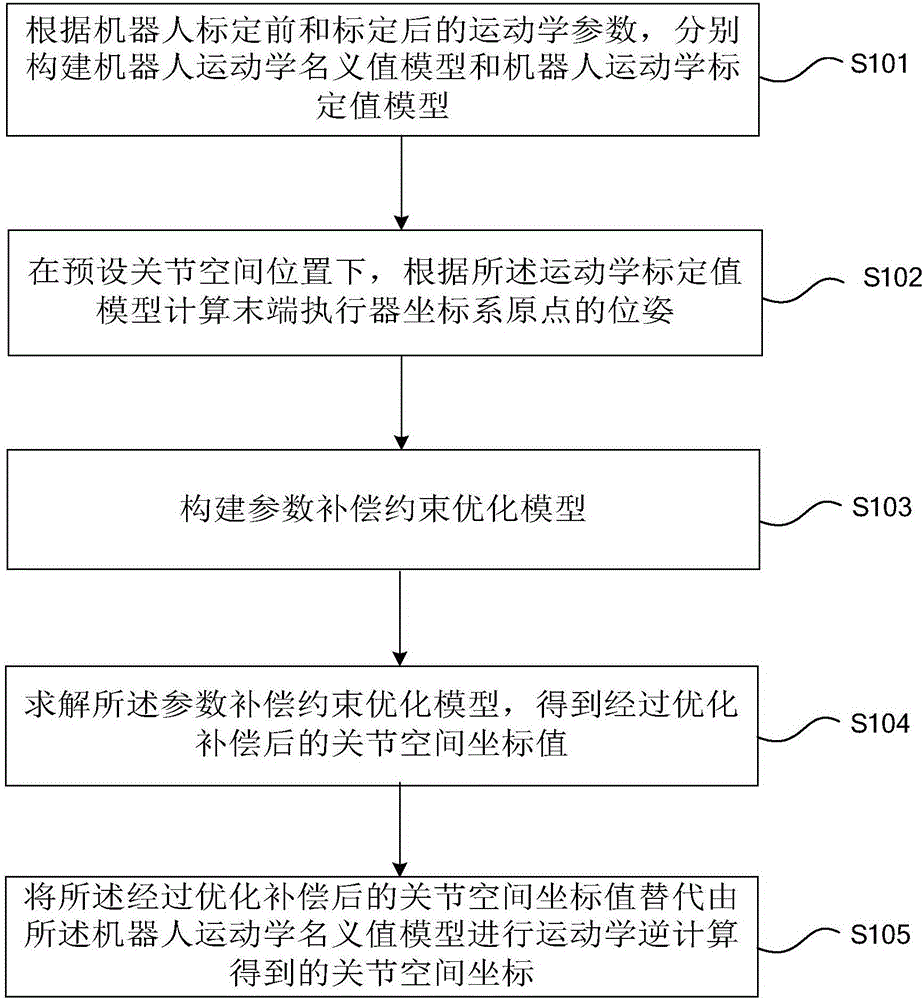

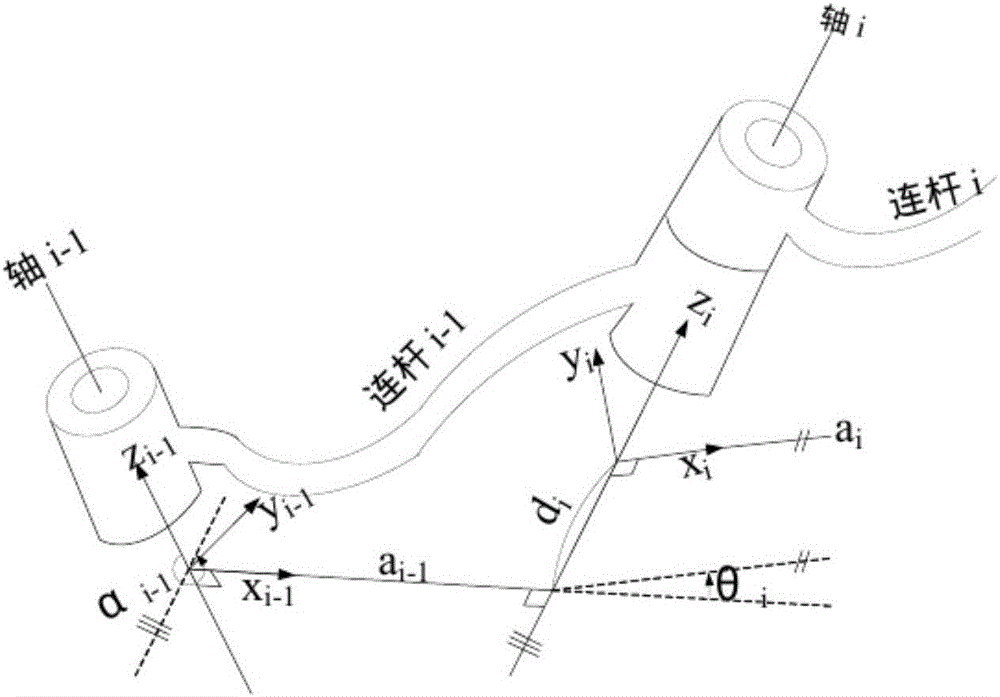

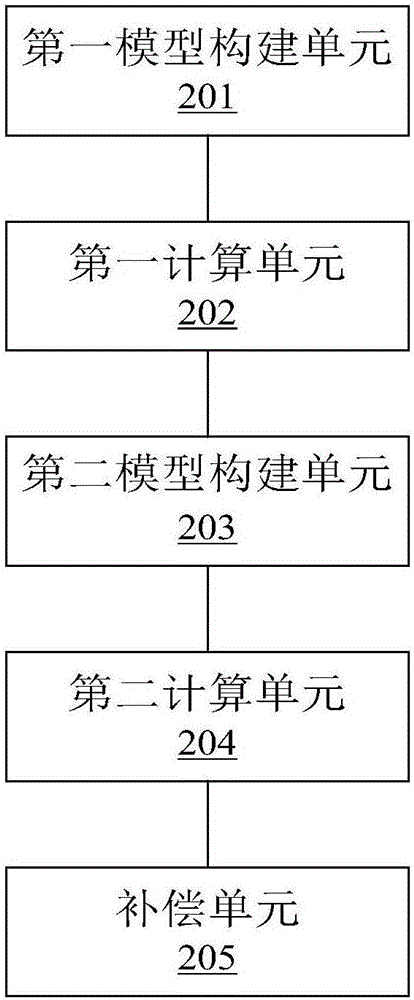

ActiveCN106406277ASolve the problem of kinematics inverse solution analysis failureCalibration method is simpleElectric testing/monitoringSpecial data processing applicationsKinematic calibrationRobot kinematics

The invention relates to the field of robot parameter correction technologies, in particular to a robot kinematic parameter error optimized compensation method and a robot kinematic parameter error optimized compensation device. The robot kinematic parameter error optimized compensation method comprises the steps of: constructing a robot kinematic nominal value model according to robot kinematic parameters before calibration, and constructing a robot kinematic calibration value model according to robot kinematic parameters after calibration; calculating a pose of an end effector coordinate system origin according to the robot kinematic calibration value model at a preset joint spatial position; constructing a parameter compensation constrained optimization model, wherein the parameter compensation constrained optimization model is used for constraining a difference value between the pose of the end effector coordinate system origin and a preset object pose to be minimum; and calculating the parameter compensation constrained optimization model to obtain joint spatial coordinate values after optimized compensation. The robot kinematic parameter error optimized compensation method and the robot kinematic parameter error optimized compensation device can solve the problem of inverse kinematics analysis failure caused after the compensation of the kinematic parameters.

Owner:太仓珞石三盛网络科技有限公司 +2

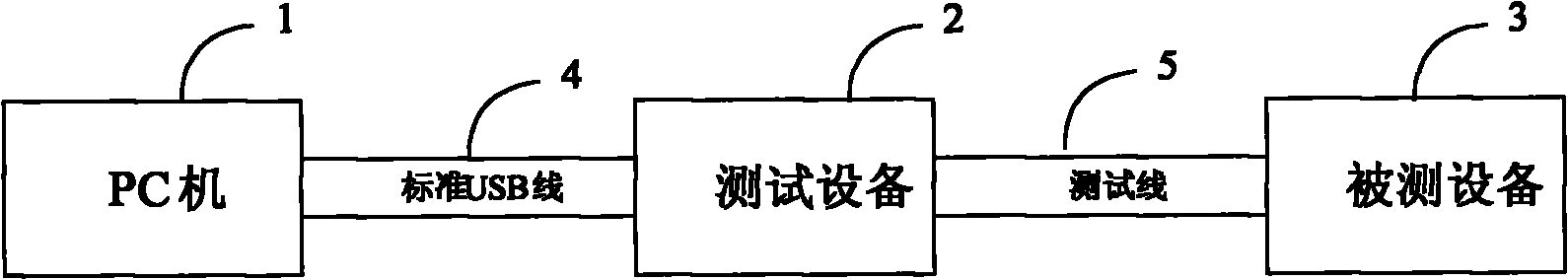

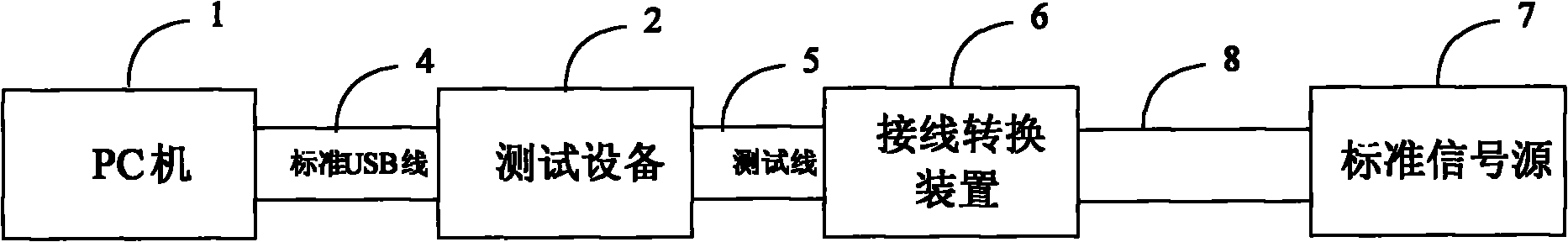

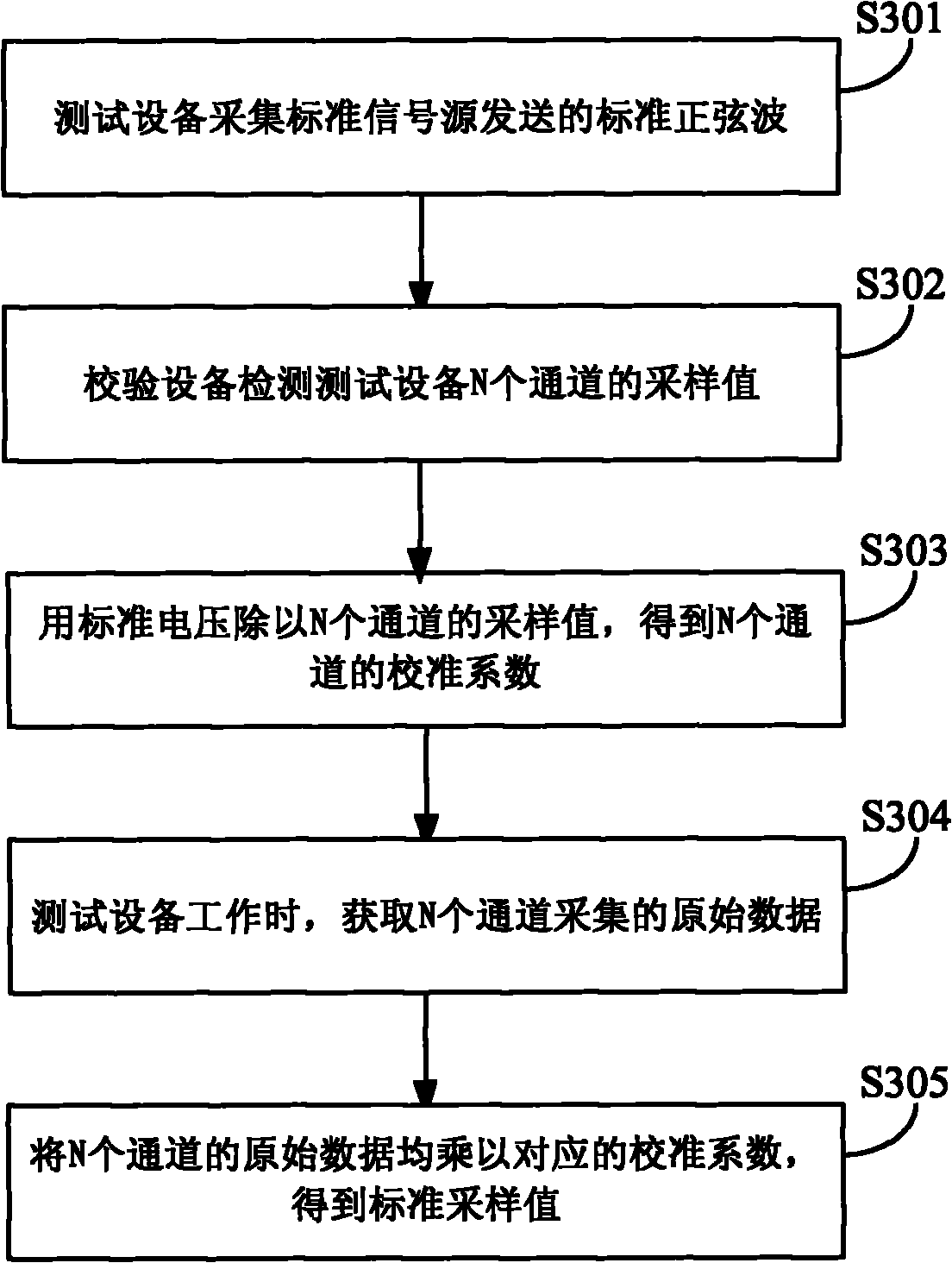

Calibration method and calibration system for field test equipment

ActiveCN101915902AHigh precisionCalibration method is simpleElectrical measurementsField testsSine wave

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

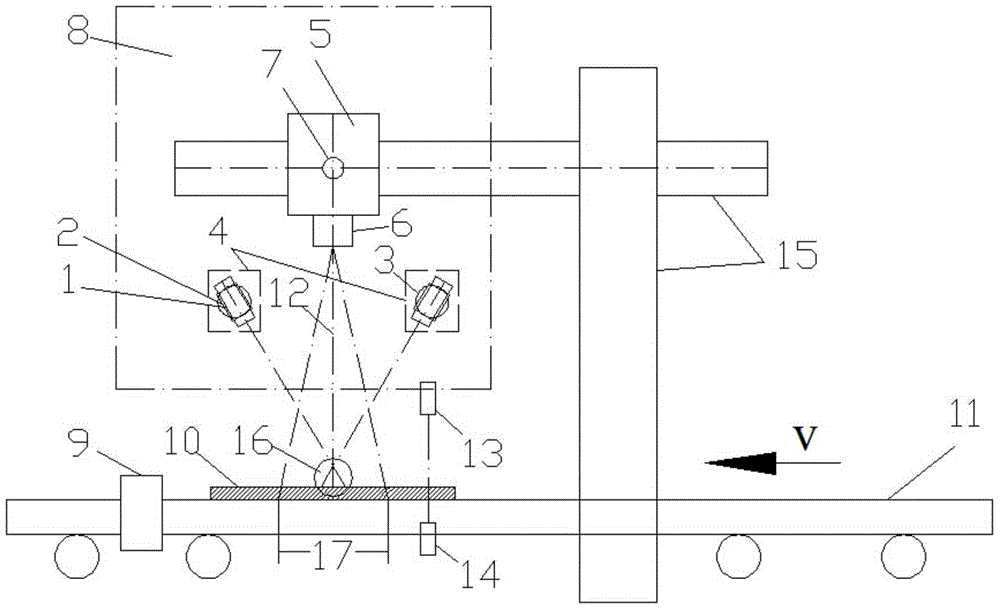

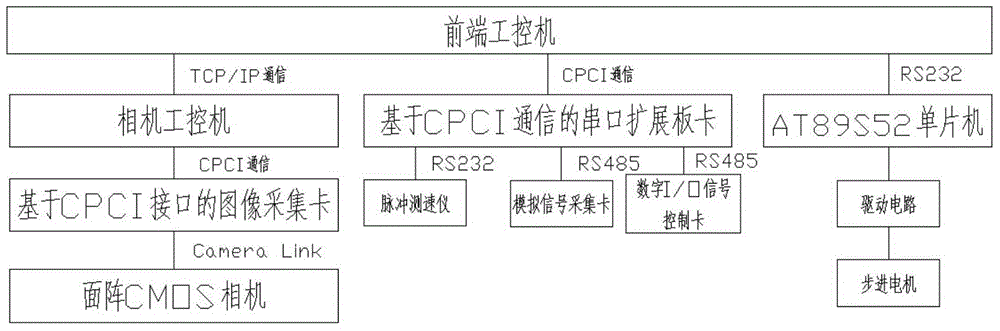

Medium or heavy steel plate morphology detection system based on controllable symmetrical double-line laser angle and method thereof

InactiveCN104833317ACalibration method is simpleImprove detection resolutionUsing optical meansCamera lensCMOS

The invention discloses a medium or heavy steel plate morphology detection system based on a controllable symmetrical double-line laser angle, and a method thereof. A sensor cabinet is internally provided with two planar array CMOS cameras in an equal-height plane. Each planar array CMOS camera is provided with a camera lens and furthermore is fixed on a bracket through a mounting device. Two sides of the planar array CMOS camera are respectively provided with a linear laser source. A pulse speed testing velocimeter is fixed at the side of a conveyor belt. The to-be-measured medium or heavy steel plate is placed on the conveyor belt. The to-be-measured medium or heavy steel plate is provided with the laser ray overlapping area of the symmetrical linear laser sources. Correlation is formed between a photoelectric switch transmitter and a photoelectric switch receiver. The sensor cabinet is placed on a bracket. A detecting device is controlled by a control device. According to the medium or heavy steel plate morphology detection system, simple calibration method is realized in detecting by two symmetrical linear laser sources, and furthermore high detection resolution and high precision are realized. The detecting system with two symmetrical linear laser sources is adopted, thereby realizing large incident angle of the linear laser, preventing detection inflection point failure, reducing drift and ensuring accurate and reliable result.

Owner:ZHEJIANG SCI-TECH UNIV

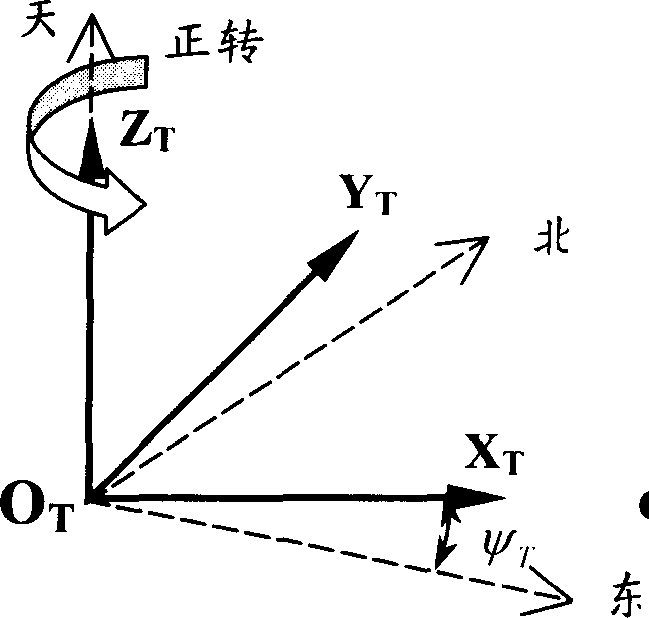

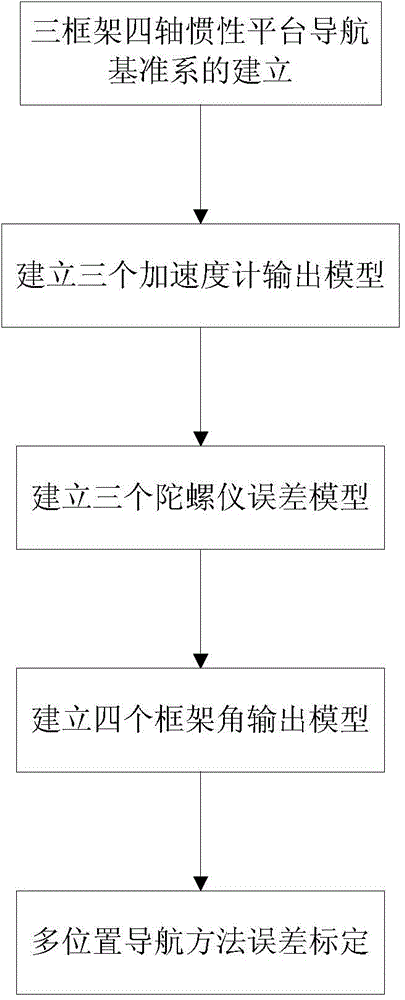

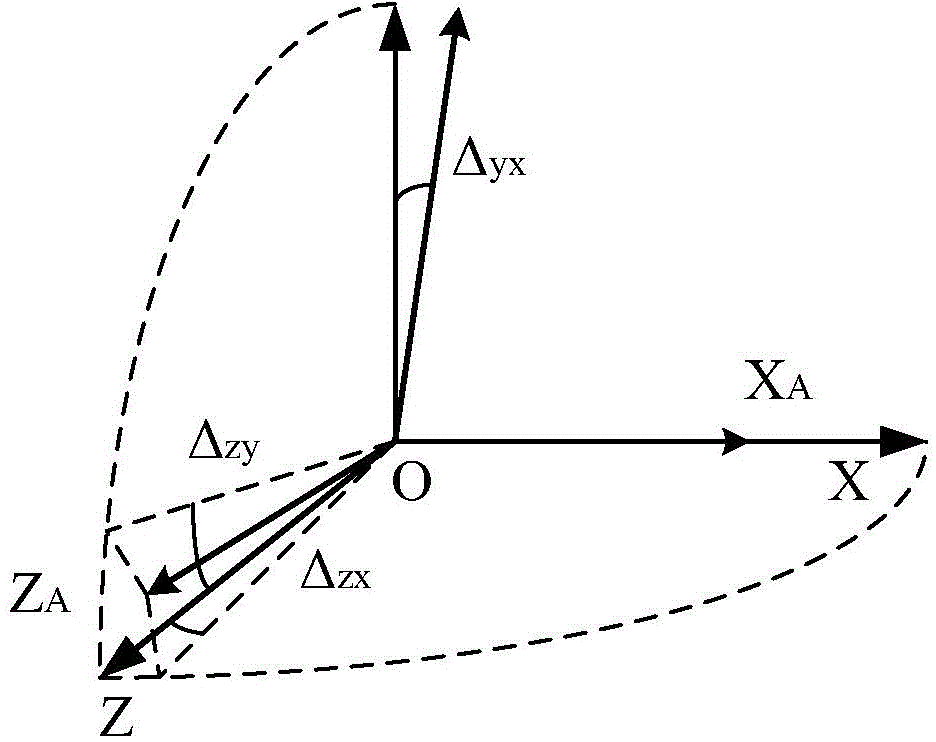

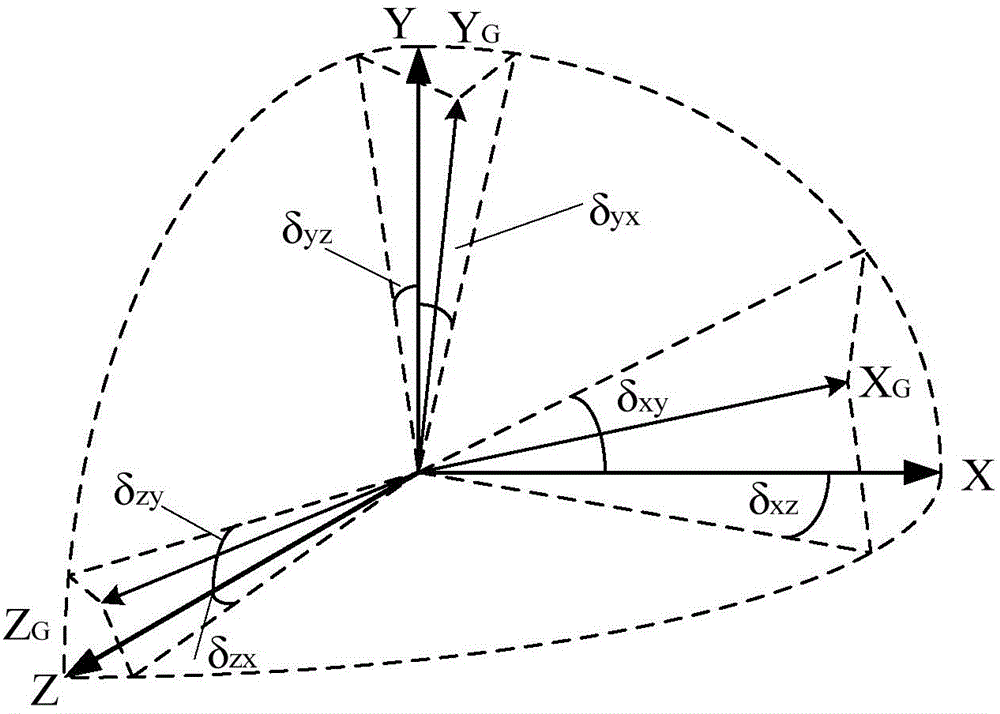

Three-frame four-axis inertial platform error calibration method based on navigation datum system

ActiveCN103983276AImprove the accuracy of useAccurate CalibrationNavigation by speed/acceleration measurementsGyroscopeAccelerometer

A three-frame four-axis inertial platform error calibration method based on a navigation datum system comprises the following steps: with an X accelerometer input shaft as a datum axis, establishing a datum coordinate system OXYZ calibrated by a platform system; based on the datum coordinate system, establishing a platform system accelerometer output error model including an accelerometer installation error, a gyroscope drift error model and a frame angle output error model; and then according to the above three models, completing a calibration work of a three-frame four-axis inertial platform. Relying on a high-precision accelerometer on the platform, the navigation method is adopted to achieve self-calibration, and thus the calibration method is greatly simplified, the calibration cost is reduced, and the calibration accuracy is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

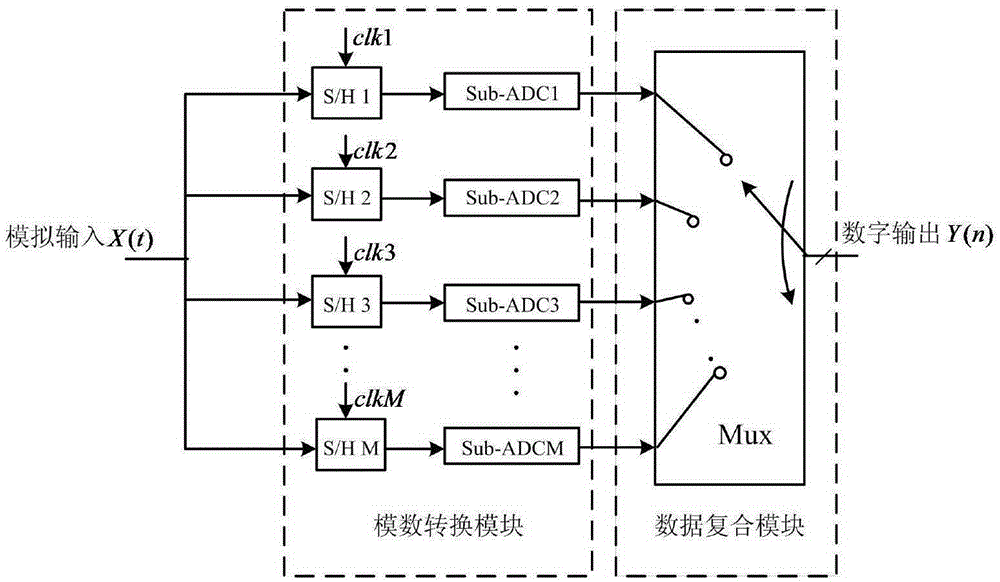

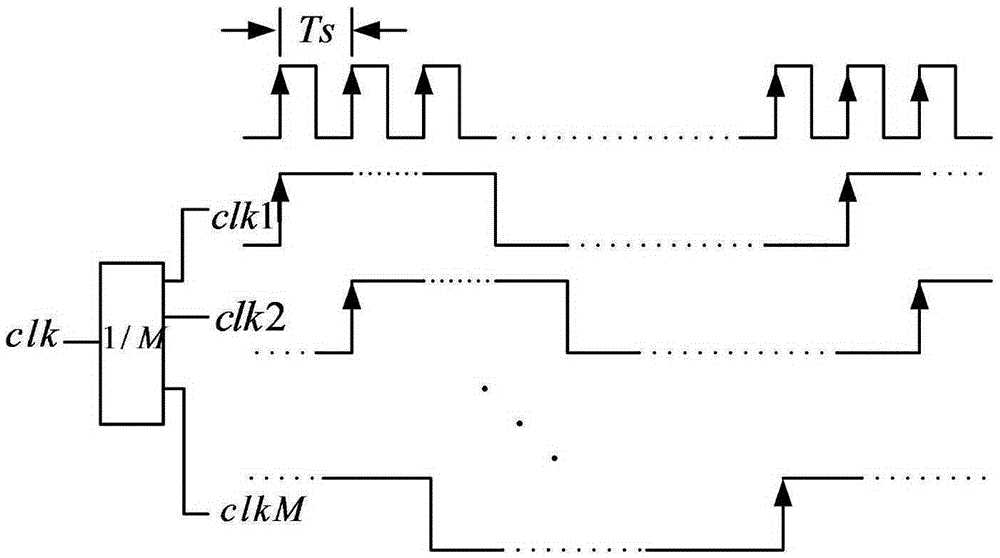

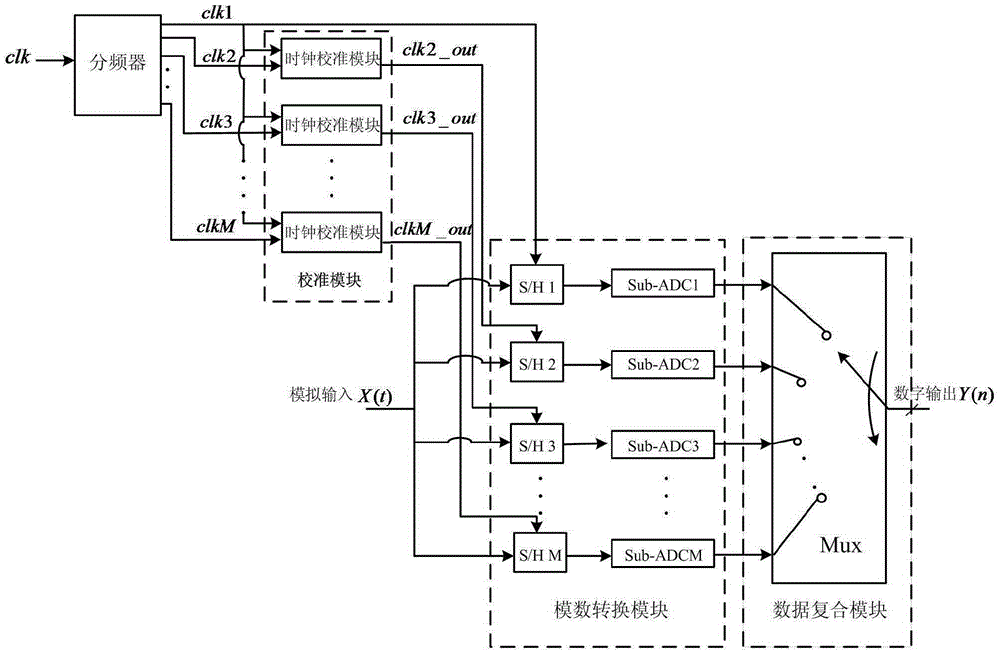

Calibration module for TIADC system clock mismatch errors and calibration method

InactiveCN105262487AEasy to implementReduce resource consumptionAnalogue/digital conversion calibration/testingComputer scienceVIT signals

The invention discloses a calibration module for TIADC system clock mismatch errors and a calibration method. The invention is characterized in that the calibration module comprises a delay module, a subtractor module, a clock sampling module, an error judgment module and a variable delay line module; a sampling clock signal of a first sub channel ADC as a reference clock signal, a clock calibration module is disposed between a sampling clock signal of each of other M-1 sub channel ADC and the corresponding sampling hold circuit of each of the M-1 sub channel ADC; and in this way, the M-1 clock calibration modules constitute the calibration module. The invention is suitable for calibration of a TIADC system of any number of channels and for signals in the entire Nyquist sampling frequency, can be used for easily obtaining the clock mismatch errors of each channel and performing efficient compensation, and therefore achieve the calibration of TIADC clock mismatch errors quickly and accurately with less hardware spending.

Owner:HEFEI UNIV OF TECH

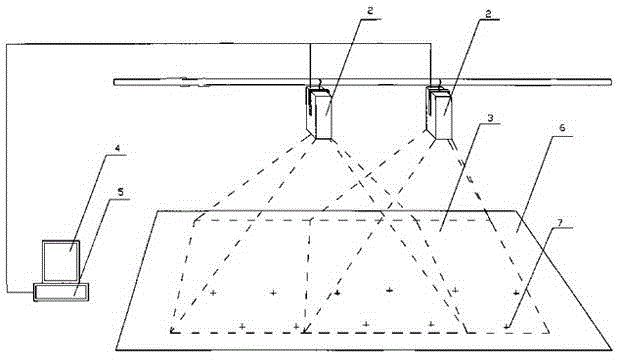

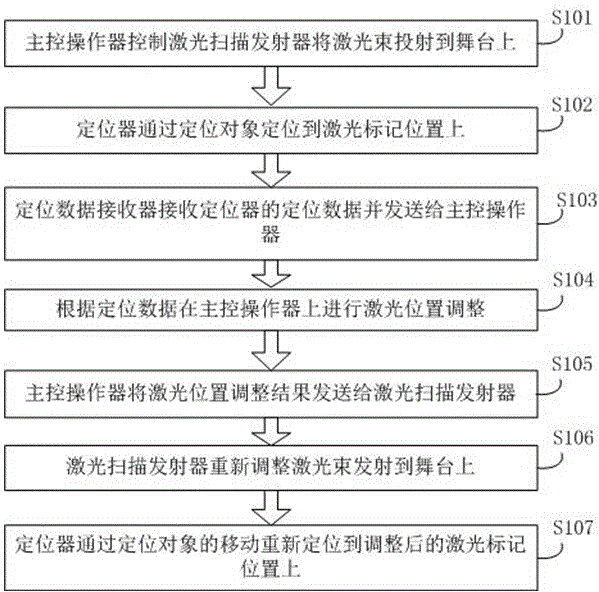

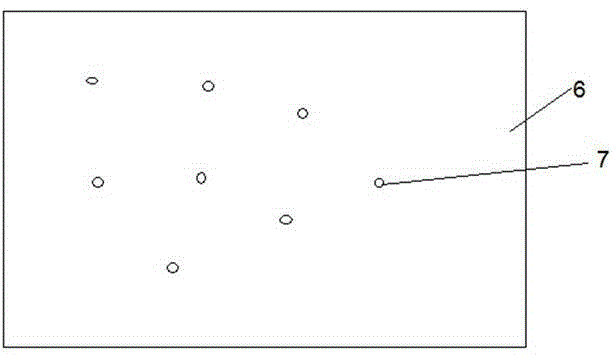

Stage laser positioning calibration device and stage laser positioning calibration method

InactiveCN104613957AImprove positioning accuracyImprove accuracySurveying instrumentsNavigation instrumentsImaging analysisDisplay device

The invention relates to the field of positioning, and particularly relates to a stage laser positioning calibration device and a stage laser positioning calibration method. The device comprises a master control manipulator, a display and a laser scanning transmitter installed above a stage, wherein the master control manipulator is connected with the display and the laser scanning transmitter respectively. The device also comprises a positioner arranged on a positioning object and a positioning data receiver in wireless connection with the positioner, wherein the positioning data receiver is connected with the master control manipulator. According to the stage laser positioning calibration device and the stage laser positioning calibration method provided by the invention, the defect that a laser projection effect is affected by stage light when a camera is adopted for shooting the stage can be overcome, the high cost of the camera is saved and an image analysis step which is needed after the camera is used for shooting images is omitted, and the entire calibration device is simple in structure, convenient for calibration operation, high in positioning and calibration speeds, and low in cost.

Owner:GUANGDONG VTRON TECH CO LTD

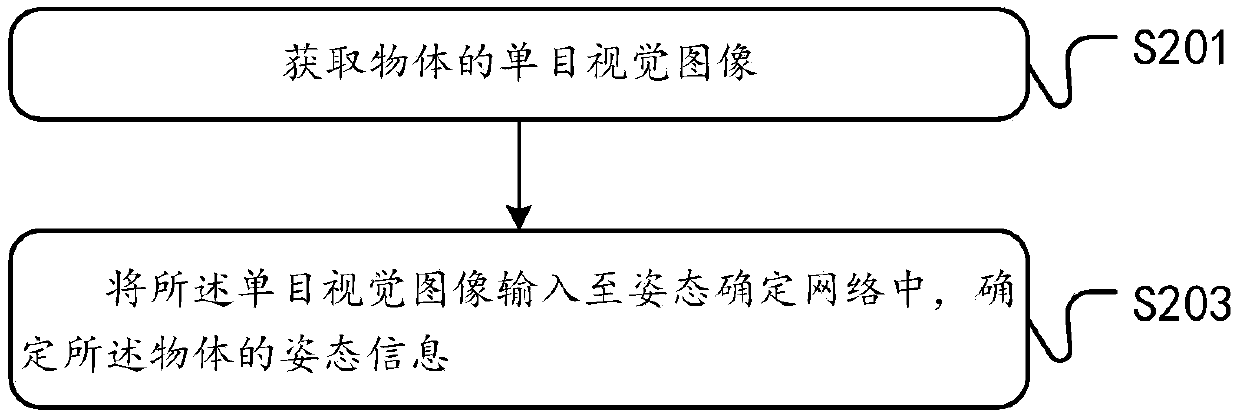

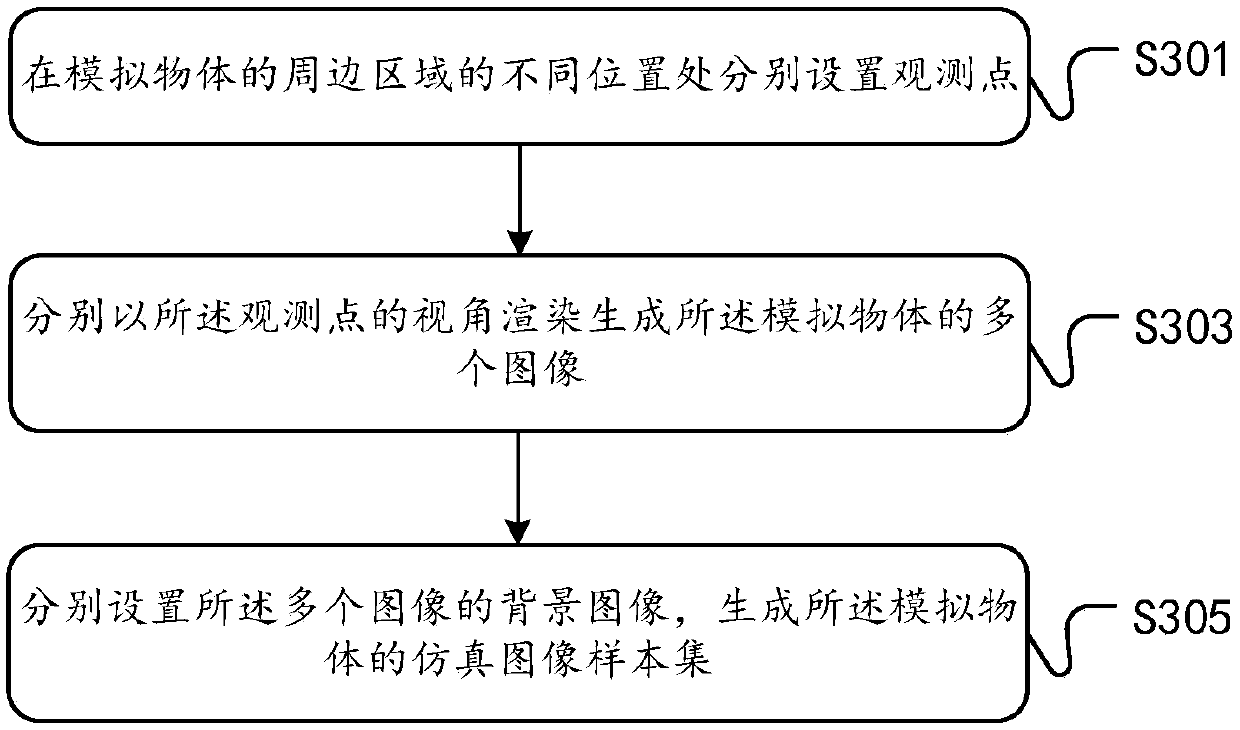

MetObject attitude determination method and devicehod and device for determining object posture, electronic equipment and computer medium

InactiveCN109615655ALower acquisition costsImprove accuracyImage enhancementImage analysisVisual perceptionMonocular vision

The invention relates to an object attitude determination method and device, electronic equipment and a computer medium. The method comprises the steps of obtaining a monocular vision image of an object; inputting the monocular vision image into an attitude determination network, and determining attitude information of the object; W; wherein the attitude determination network is obtained by training a simulation image sample set and a real image sample set. By utilizing the method provided by the embodiment of the invention, the cost of obtaining the sample data can be reduced on the basis ofensuring the high accuracy of the attitude determination network.

Owner:SHENZHEN SENSETIME TECH CO LTD

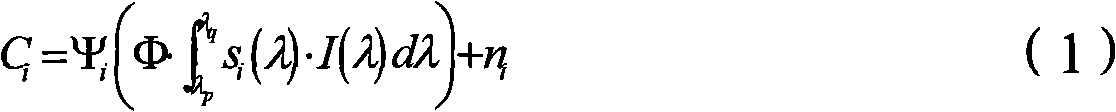

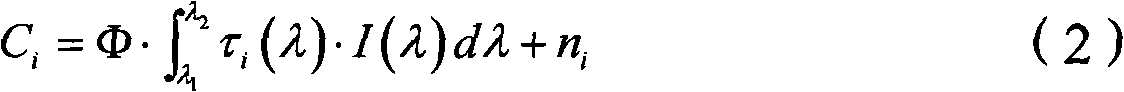

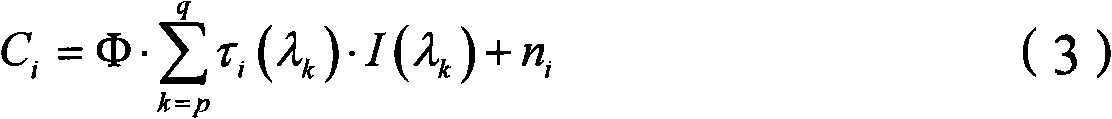

Calibration method and system for relative spectral-response characteristic of CCD imaging device

InactiveCN101294867ACalibration method is simpleThe calibration method is validSpectrum investigationTesting optical propertiesRadiative transferSpectral response

The invention relates to a method for calibrating the relative spectral response characteristic of a CCD imaging device. The method comprises the following steps: A. taking a light source with known spectral radiation distribution as a measurement object, utilizing the CCD imaging device to be calibrated for the imaging of the measurement object, and acquiring and analyzing the image to obtain a measured value; B. changing the spectral radiation flux entering the CCD imaging device through adjusting the thermodynamic temperature of the light source and / or adopting a color filter; C. constructing an equation set of mathematical physics for describing the corresponding relation between the measured value and the relative spectral response characteristic according to the known equation of mathematical physics of radiative transfer of the CCD imaging device; D. taking the measured value of the CCD imaging device under different spectral radiation flux as known quantity and solving the equation of mathematical physics, so as to calibrate the relative spectral response characteristic of the CCD imaging device. The invention further discloses a system for calibrating the relative spectral response characteristic of the CCD imaging device. The method is simple and efficient, and can avoid the introduction of instrument measurement transfer errors.

Owner:TSINGHUA UNIV

Double-end calibration device and calibration method

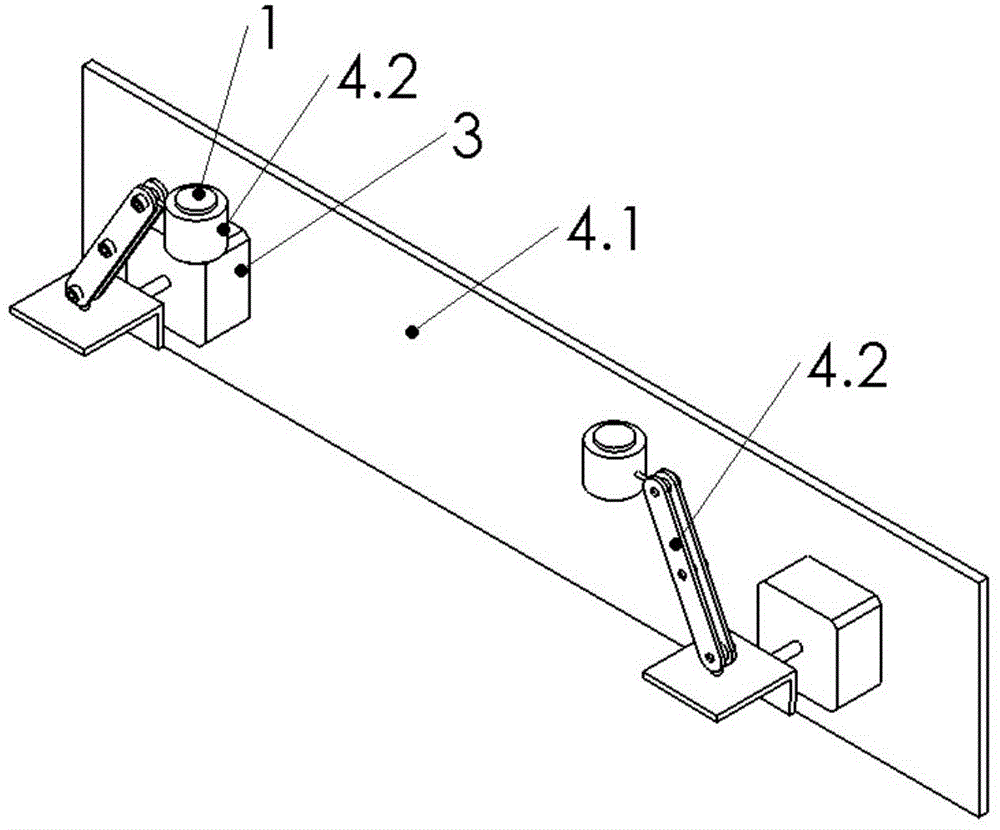

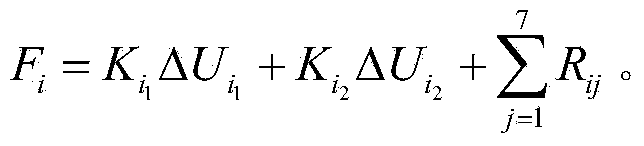

ActiveCN104198113ARealize mock loadingSimple structureForce/torque/work measurement apparatus calibration/testingKinematic couplingMeasurement device

The invention relates to a double-end calibration device and a calibration method and belongs to the technical field of aerodynamic force measurement of aerospace force test. The double-end calibration device with the middle fixed and two ends free is used for calibration during force test of wind tunnel aerodynamic / kinematic coupling research. The double-end calibration device mainly comprises two sets of L-shaped sliders and loading heads which are used cooperatively, one end of the front L-shaped slider is connected with the front loading head while the other end of the same is connected with the front end of a double-end force measurement device, and the rear L-shaped slider is connected with the rear loading head while the other end of the same is connected with the rear end of the double-end force measurement device; the loading heads are four-point type frame loading heads, do not interference with each other in space and are used for applying longitudinal load; the L-shaped sliders are connecting pieces between the force measurement device and the loading heads, do not interference with each other in space, are provided with a pair of longitudinally-symmetrical resistance loading points, and are used for applying axial load. The problem about calibration of the double-end force measurement device in special test is solved, six components can be calibrated at most, and the device and the method are simple and feasible special force measurement device calibration schemes indeed.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

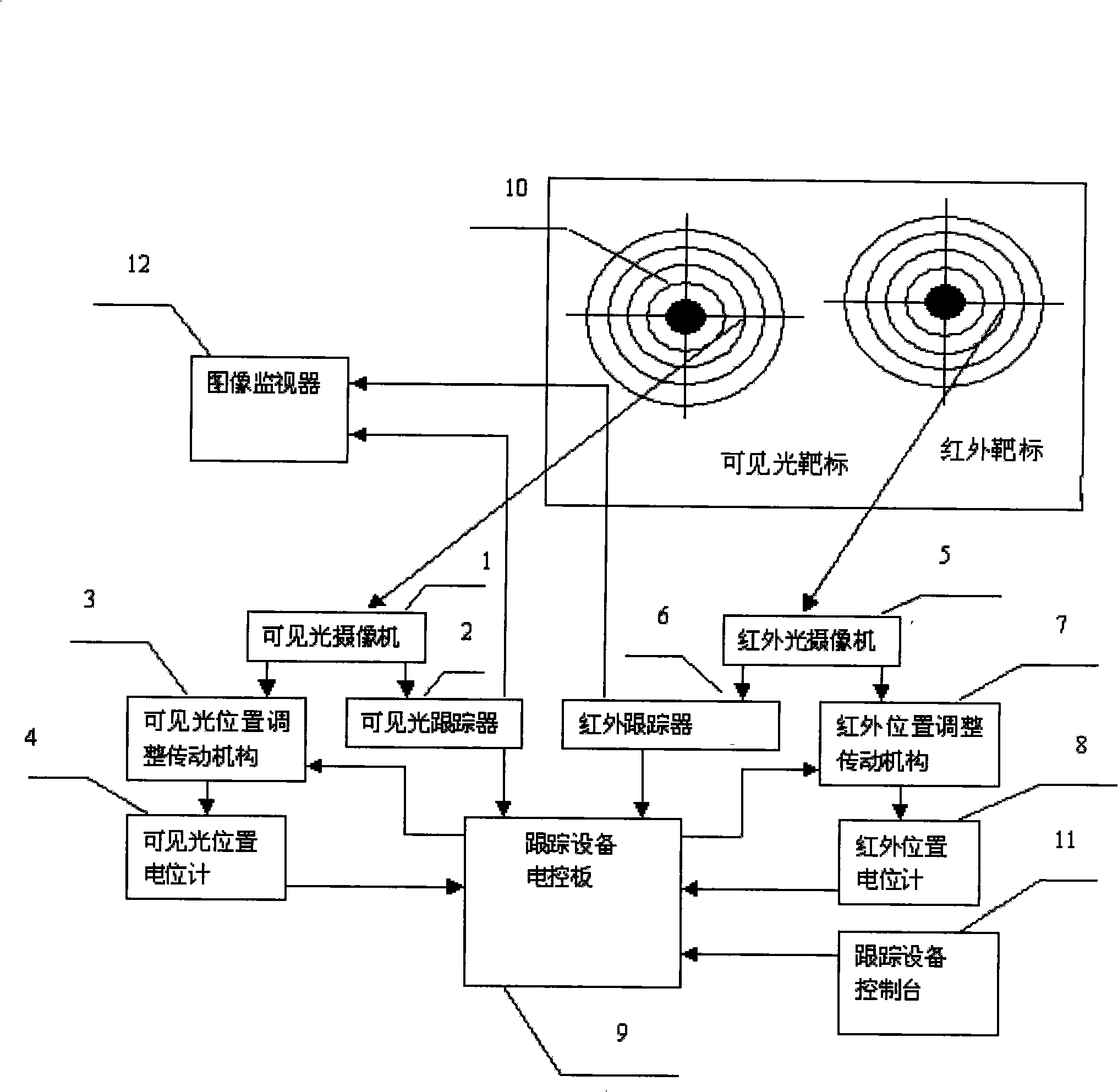

Method for multi-load photoelectric tracking equipment self-adjusting two light axes to be parallel

InactiveCN101294823ACalibration method is simpleSave labor and timeMeasurement devicesPhysicsPotentiometer

A method for realizing automatic self-adjustment of the parallelism of the two optical axes of a multiload photoelectric tracing device belongs to the technology field of photoelectric tracing measurement and relates to a method for adjusting the parallelism of the two optical axes. The technical problem to be solved is to provide a method for realizing automatic self-adjustment of the parallelism of the two optical axes of the multiload photoelectric tracing device. The technical proposal is that the self-subsystem of a device to be adjusted is started; a visible light camera and a noctovisor are respectively connected with a tracing device frame by a transmission gear; the target centers of a drone are traced by a television tracer; the undershooting amount is taken as the position feedback amount of the transmission gear; a potentiometer is taken a position sensor; the transmission gear automatically adjusts the orientation and the pitching direction of the cameras until the two target centers of the drone are aligned with the centers of field coverage of the two cameras; the undershooting amount of the target centers is taken as the position feedback of the optical axes, and the optical axes are automatically adjusted by the transmission gear, which is the key of the method. The method is simple, without the need of additional devices; and the outfield maintenance is easy.

Owner:CHANGCHUN UP OPTOTECH

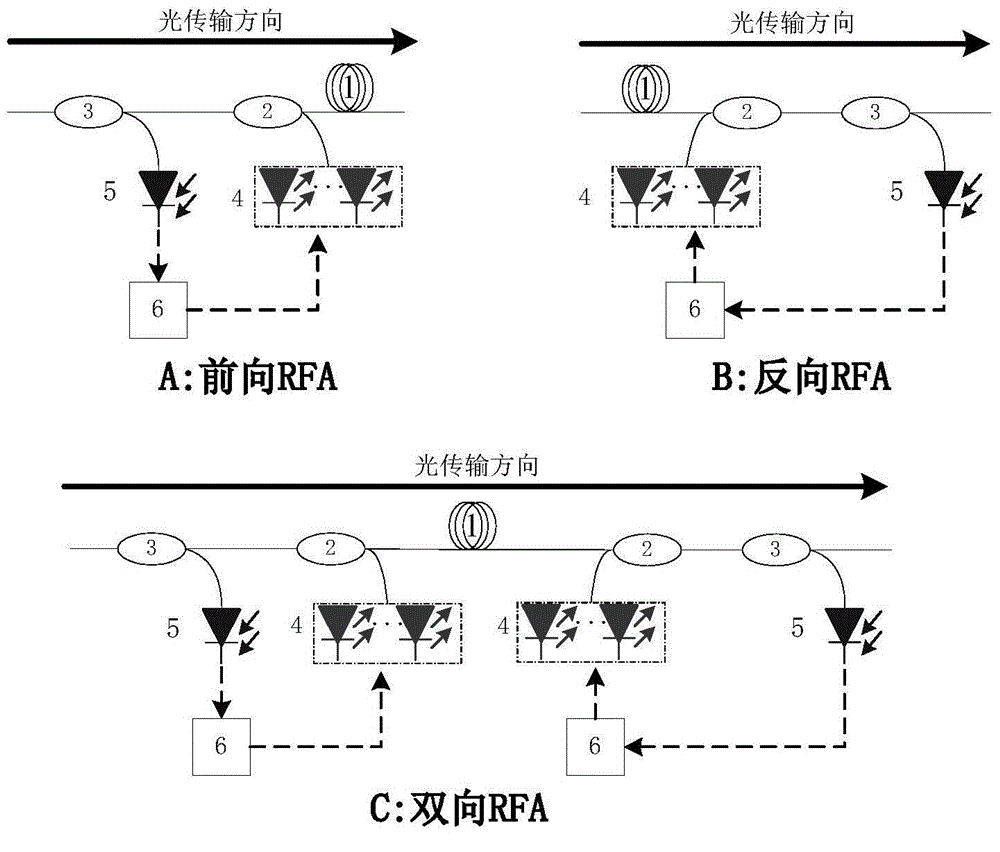

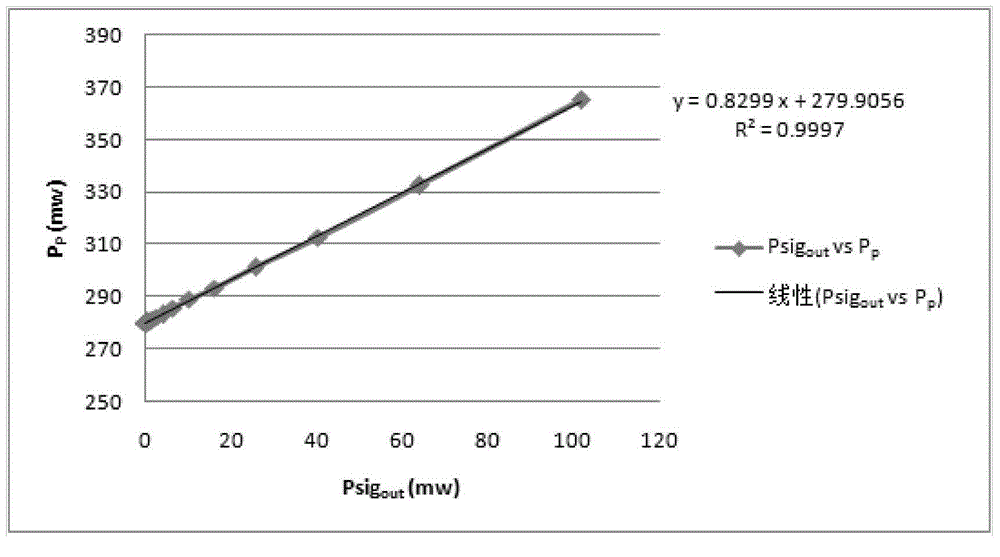

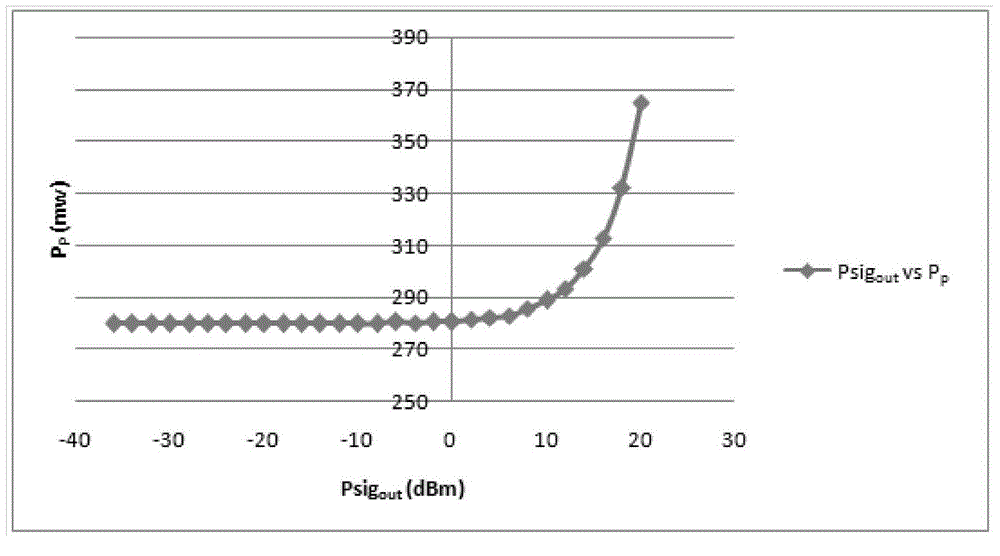

Raman fiber amplifier gain compensation and transient control method

ActiveCN104993872ACalibration method is simpleSimple control methodLaser using scattering effectsElectromagnetic transmissionConstant powerRaman amplifiers

The invention relates to a Raman fiber amplifier gain compensation and transient control method. According to the Raman fiber amplifier gain compensation and transient control method, a pump laser set in a Raman fiber amplifier works in a constant power mode, and when the pump laser set is in a locked output power state, the change in input power or output power of the Raman fiber amplifier is determined, and the power of the pump laser set is adjusted according to the change in input power or output power in order to enable the change in power of the pump laser set and the change in input power or output power to meet the formula deltaPp=k*deltaPtotal, wherein deltaPp is the change in power of the pump laser set and the unit is mw, deltaPtotal is the change in input power or output power and the unit is mw, and k is correction slope. For a Raman fiber amplifier of which the pump laser set works in a constant power mode, when the input optical power changes in a large range, forward, backward and two-way Raman amplifier gain compensation can be realized.

Owner:WUXI TACLINK OPTOELECTRONICS TECH CO LTD

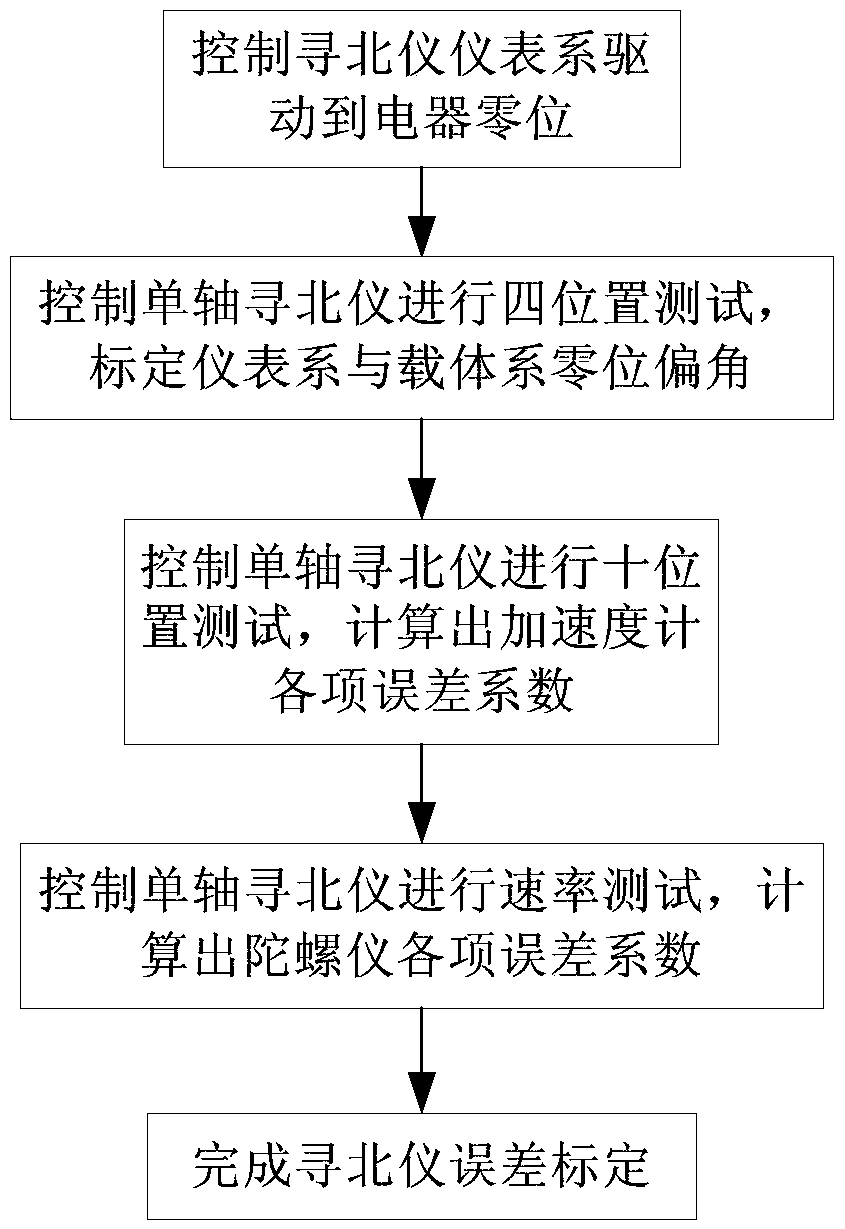

Error calibration method of uniaxial north seeker

ActiveCN105509768ATroubleshooting Uncertain Angle RelationshipsGuaranteed error calibration accuracyMeasurement devicesDrift angleCarrier system

An error calibration method of an uniaxial north seeker comprises the following steps: firstly driving a rotary table to carry out four-position testing, and calibrating control drift angle between an instrument system and a carrier system of the uniaxial north seeker; then using the instrument system of the north seeker as a calibration coordinate system and controlling the rotary table to carry out corresponding position and rate testing; and finally finishing calculation of each error coefficient according to an error model of the uniaxial north seeker. The problem of indeterminate angle relation between the carrier system and the instrument system of the uniaxial north seeker is solved, and by the simple uniaxial north seeker's error compensation model and position and rate calibration method, error calibration of the uniaxial north seeker is realized. The calibration method is less time-consuming, has simple calculation and can be used to rapidly complete calibration test.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

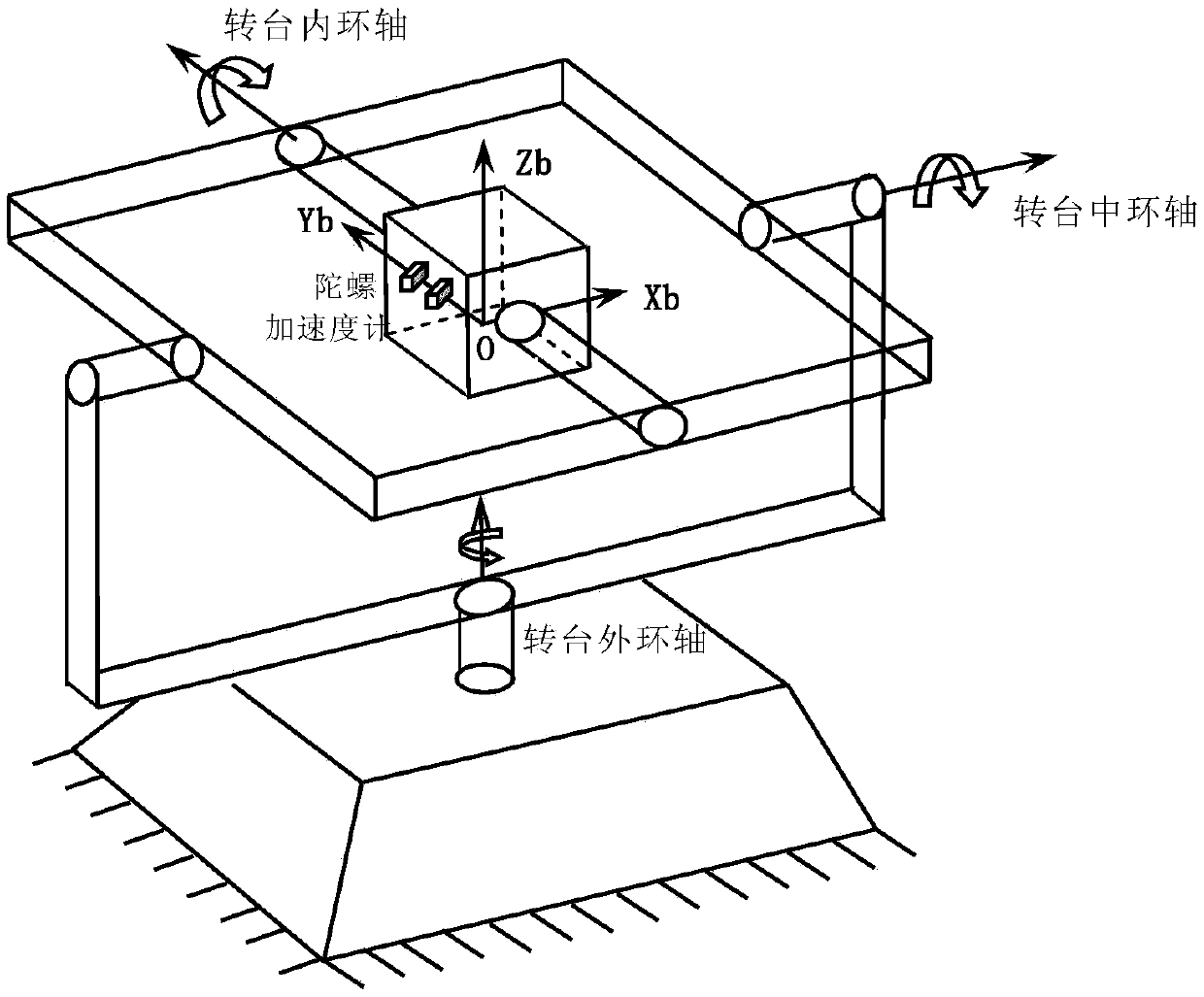

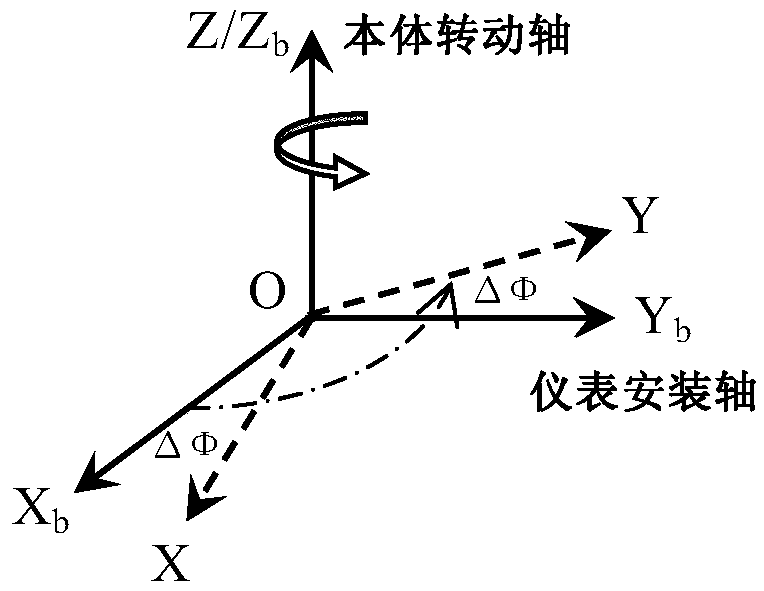

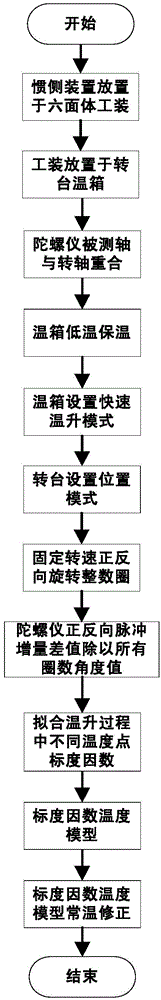

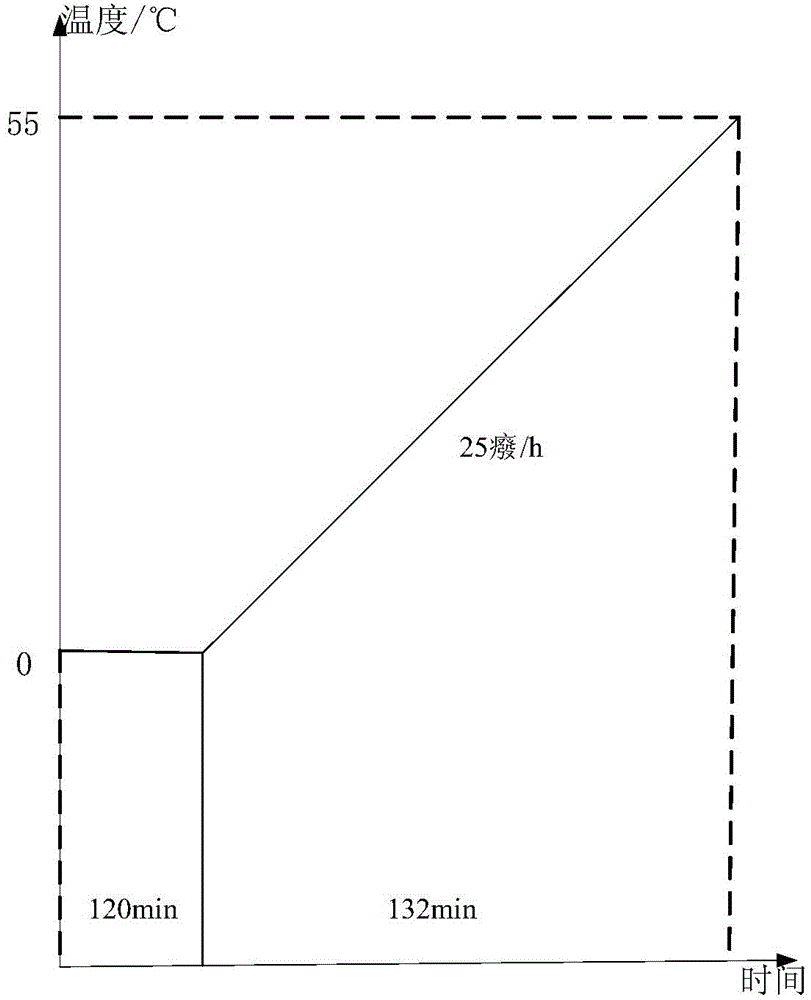

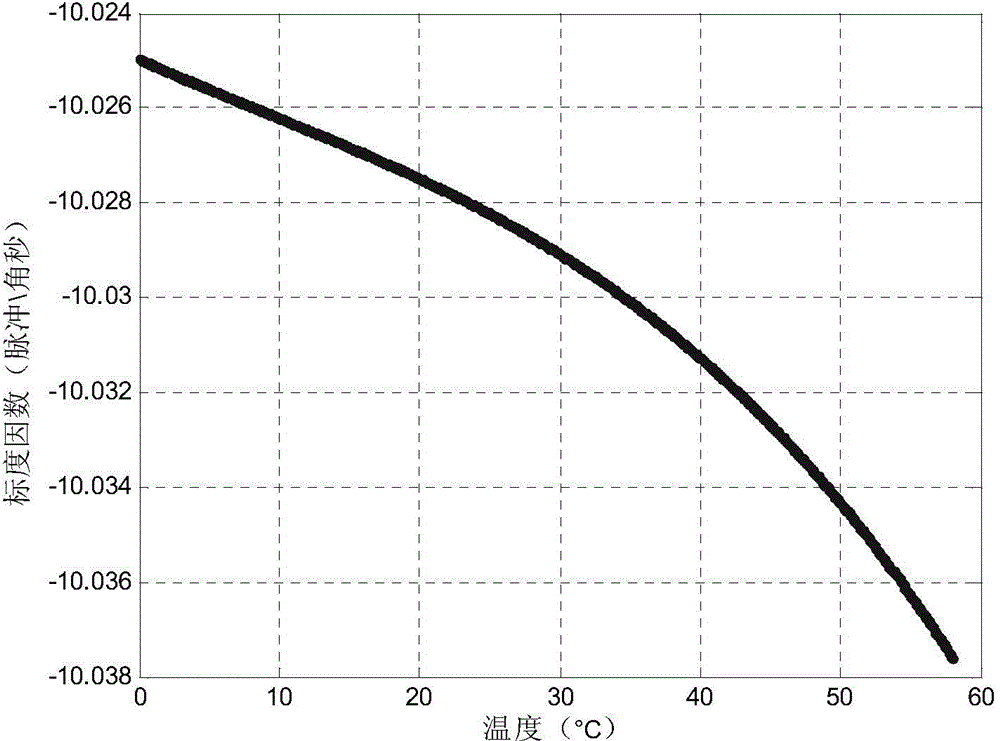

Optical cable gyroscope scale factor temperature modeling method of inertia measurement device

ActiveCN104596545AShort time consumingAccurate modelingMeasurement devicesMeasurement deviceEngineering

The invention provides an optical cable gyroscope scale factor temperature modeling method of an inertia measurement device. A temperature model of an optical cable gyroscope scale factor is obtained by adopting a constant angle calibrating method in a rapid temperature change environment of a temperature box. The method comprises the following steps that firstly, an inertia measurement device is arranged on a rotary platform temperature box by a hexahedron tool so that a tested shaft of a gyroscope is consistent with a rotary platform shaft; low-temperature-point heat preservation is set in the temperature box and the heat preservation time meets a gyroscope optical path temperature to reach heat balance; a rapid temperature rise mode is set by the temperature box from a low temperature point to a high temperature point; the rotary platform is set to a position mode and the rotary platform rotates for integral circles in front and back directions at a constant rotary speed; angle values of all the rotation circles are divided by a pulse increment value output by two times of rotation in the front and back directions of the gyroscope to obtain a scale factor; and a plurality of groups of scale factors under different temperature points are obtained in a rapid temperature rise process of the temperature box, and are subjected to least square fit to obtain a scale factor temperature model. The modeling method has short operation time and an accurate model; and the rapid and accurate modeling of the optical cable gyroscope scale factors in the inertia measurement device can be realized better.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Laser displacement sensor position error calibration method

InactiveCN107525472ACalibration method is simpleSimple methodUsing optical meansData acquisitionModel parameters

The invention discloses a laser displacement sensor position error calibration method, and belongs to the technical field of robots. The used device is composed of an installing base, a laser displacement sensor, a surface plate and a laser tracker. The laser displacement sensor is installed on the installing base. According to the method, a laser displacement sensor installation position error model is established, and the position error model parameters are identified by using the least square method through data acquisition of the laser tracker and other sensors so that accuracy reduction caused by the installation position error of the laser displacement sensor can be eliminated. The method has the advantages of being simple in method and high in calibration accuracy.

Owner:BEIHANG UNIV

Shock wave time calibration device and method for shock test

The invention relates to the technical field of impact compression loading, in particular to a shock wave time calibration device and method for a shock test. The calibration device comprises a controllable high-speed emitting device, a target chamber and a signal collecting device, wherein the target chamber is a vacuum target chamber; an experiment target is arranged in the target chamber; the experiment target comprises a substrate, a fixed column, an optical probe and an electric probe; a light-emitting gap is formed between the substrate and the fixed column; the optical probe and the electric probe are connected with the signal collecting device; and the controllable high-speed emitting device is used for driving a flyer to impact the left side wall of the substrate. According to thecalibration device and method, two waveforms generated according to signals detected by the electric probe and the optical probe are comparatively analyzed, and a more accurate waveform data graph isselected to finally judge a time point when a shock wave enters a sample, so that an important parameter, namely, the time point when the shock wave enters the sample can be more accurately calibrated, and follow-up experiment data is more reliable and effective.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com