Stage laser positioning calibration device and stage laser positioning calibration method

A laser positioning and calibration device technology, applied in the field of positioning, can solve the problems of expensive camera, affecting positioning, complex processing process, etc., and achieve the effect of simple structure, fast positioning and calibration, and convenient calibration operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

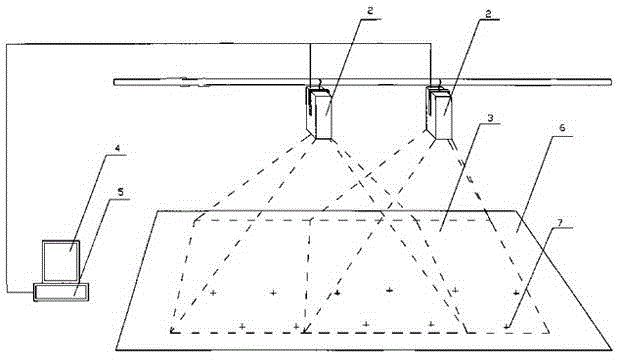

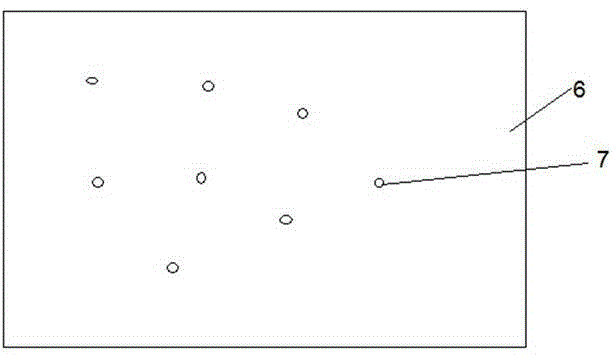

[0032] Such as figure 1 As shown, it is a structural diagram of a specific embodiment of a stage laser positioning and calibration device according to the present invention. see figure 1 In this specific embodiment, a stage laser positioning calibration device specifically includes a main control operator 5, a display 4 and a laser scanning transmitter 2 installed above the stage 6, and the main control operator 5 is connected to the display 4 and the laser scanning transmitter 2 respectively. The connection also includes a locator 7 placed on the positioning object and a positioning data receiver wirelessly connected to the locator 7, and the positioning data receiver is connected to the master operator 5.

[0033] In this specific embodiment, the main control operator 5 controls the laser scanning transmitter 2 to emit laser light onto the stage 6 for position marking, the positioning object stands according to the position marking on the stage 6, and the positioning object...

Embodiment 2

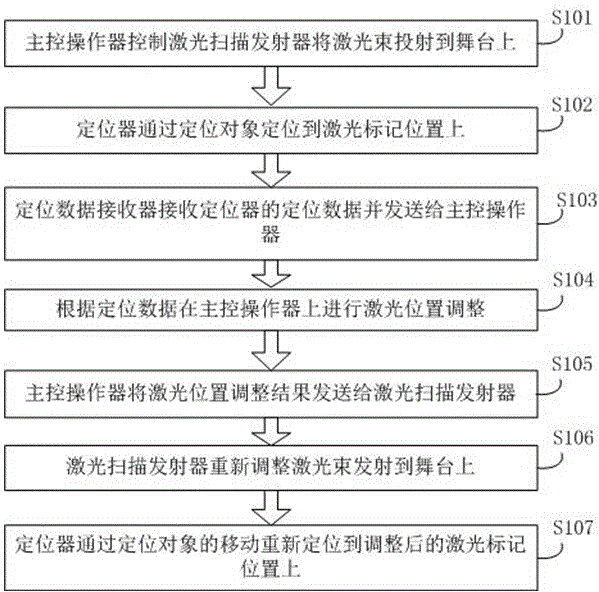

[0039]On the basis of Embodiment 1, the present invention also provides a stage laser positioning calibration method. see figure 2 , is a flowchart of a specific embodiment of a stage laser positioning and calibration method according to the present invention. In this specific embodiment, the stage laser positioning and calibration device described in Embodiment 1 is used to implement.

[0040] Such as figure 2 As shown, a stage laser positioning calibration method in this specific embodiment specifically includes the following steps:

[0041] S101. The main control operator controls the laser scanning transmitter to project the laser beam onto the stage;

[0042] S102. The locator locates the laser marking position through the positioning object;

[0043] S103. The positioning data receiver receives the positioning data of the locator and sends it to the main control operator;

[0044] S104. Perform laser position adjustment on the main control operator according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com