Patents

Literature

244results about How to "Accurate positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Force control traction and swinging multi-degree-of-freedom mechanical arm control device and method

ActiveCN105583824AEasy to handle and solveGuaranteed synchronous samplingProgramme-controlled manipulatorManual tractionEngineering

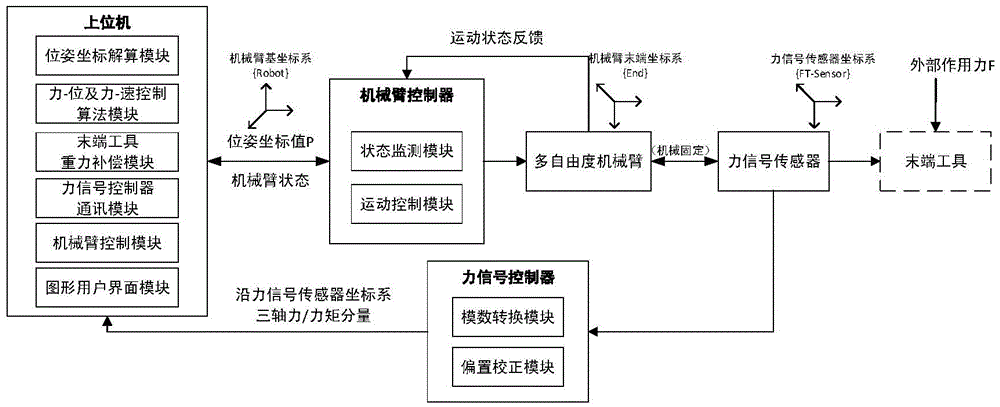

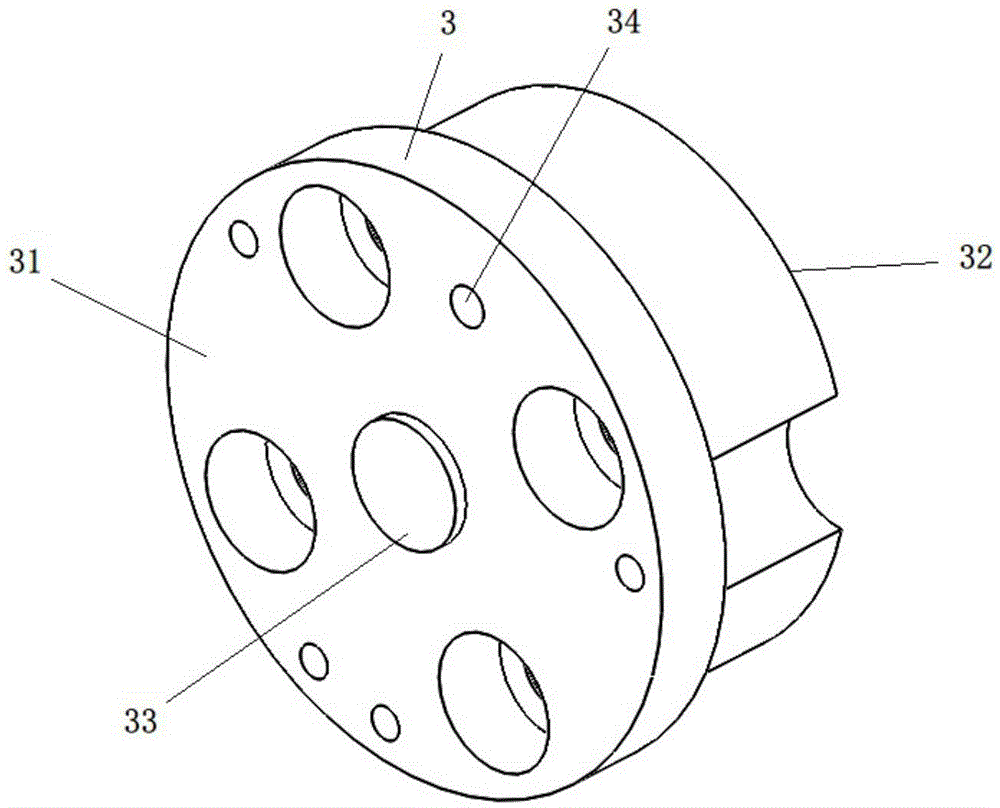

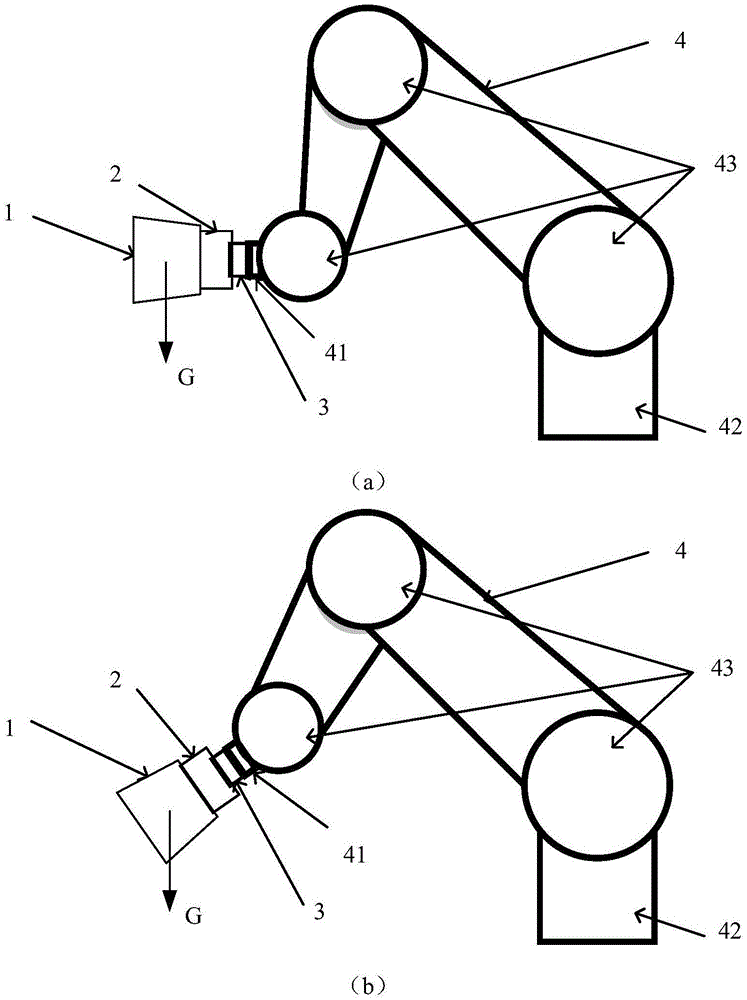

The invention discloses a force control traction and swinging multi-degree-of-freedom mechanical arm control device and method. A force signal sensor is mounted on a flange plate at the tail end of a mechanical arm in a specific mode by a mounting connector, and the pose information and force / moment information of the tail end of the mechanical arm are sampled synchronously. Based on feedback control of external action force, force feedback information is converted into pose offset information of the tail end of the mechanical arm. The pose and speed of the tail end of the mechanical arm are changed along with the external action force through a force-pose offset control algorithm and a force-speed control algorithm, and accurate swinging can be achieved when manual traction is stopped. According to the force control traction and swinging multi-degree-of-freedom mechanical arm control device and method, a tail end tool can achieve traction operation conveniently in real time according to the will of an operator, the current pose can be kept without external force action, and accurate positioning is achieved; meanwhile, the operator can change the motion trail of the tail end of the mechanical arm by exerting external force in the process that the mechanical arm moves to a target spot, and the mechanical arm can achieve emergent obstacle avoidance in the movement process.

Owner:TSINGHUA UNIV

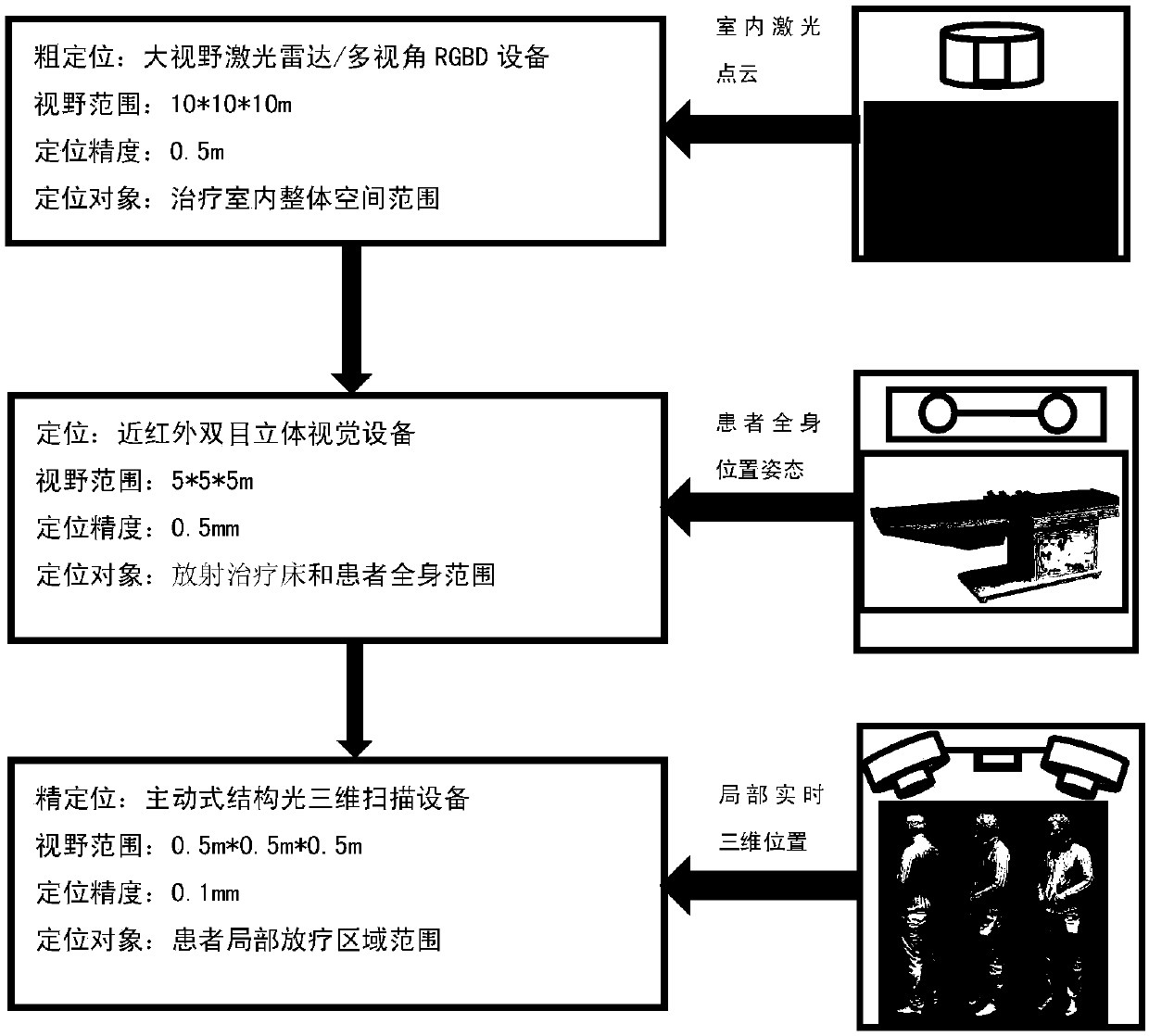

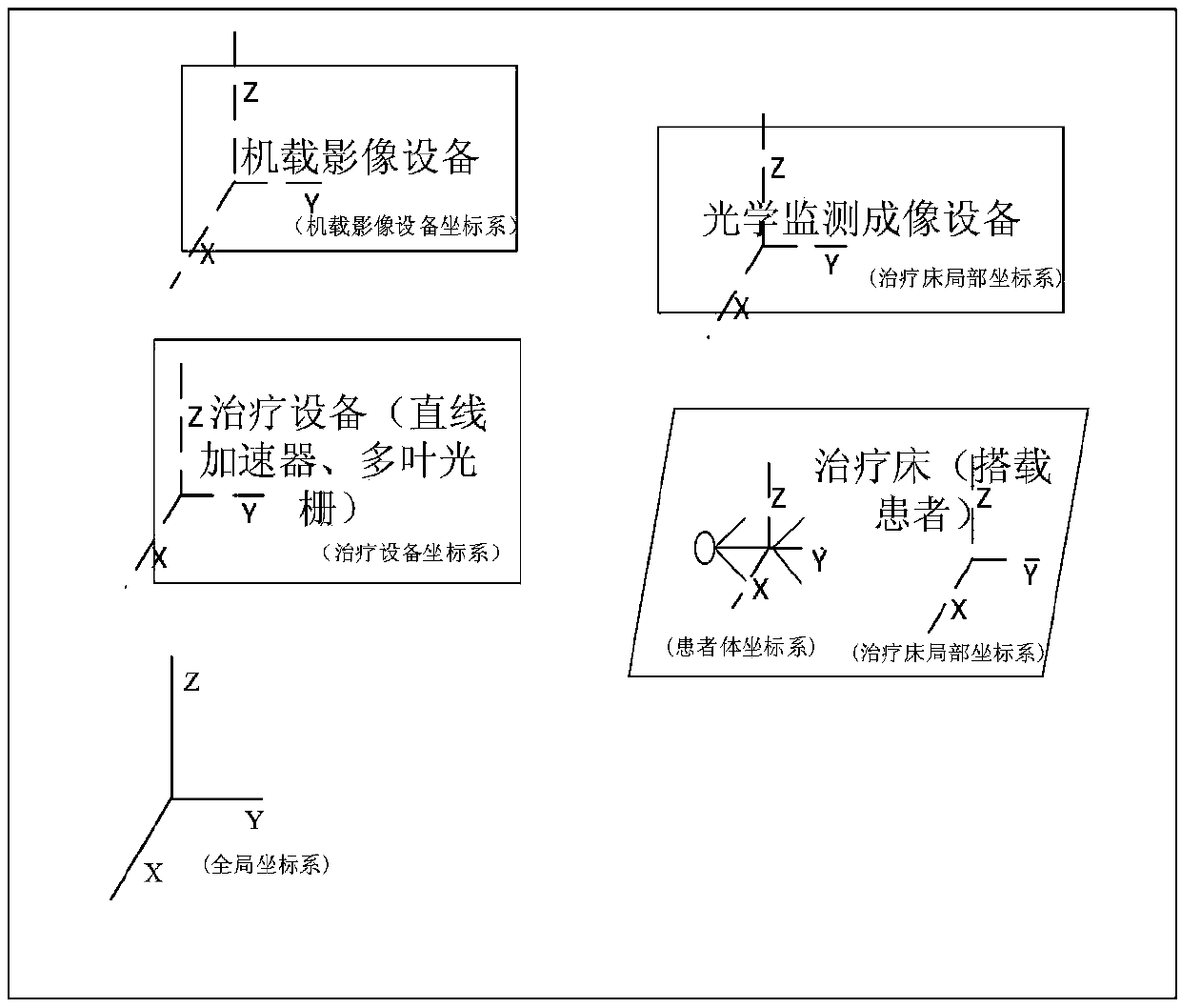

Intelligent control method of visual monitoring and visual servo of tumor radiation therapy

InactiveCN107358607AQuality assuranceAccurate positioningImage enhancementImage analysisDiagnostic Radiology ModalityTherapeutic Devices

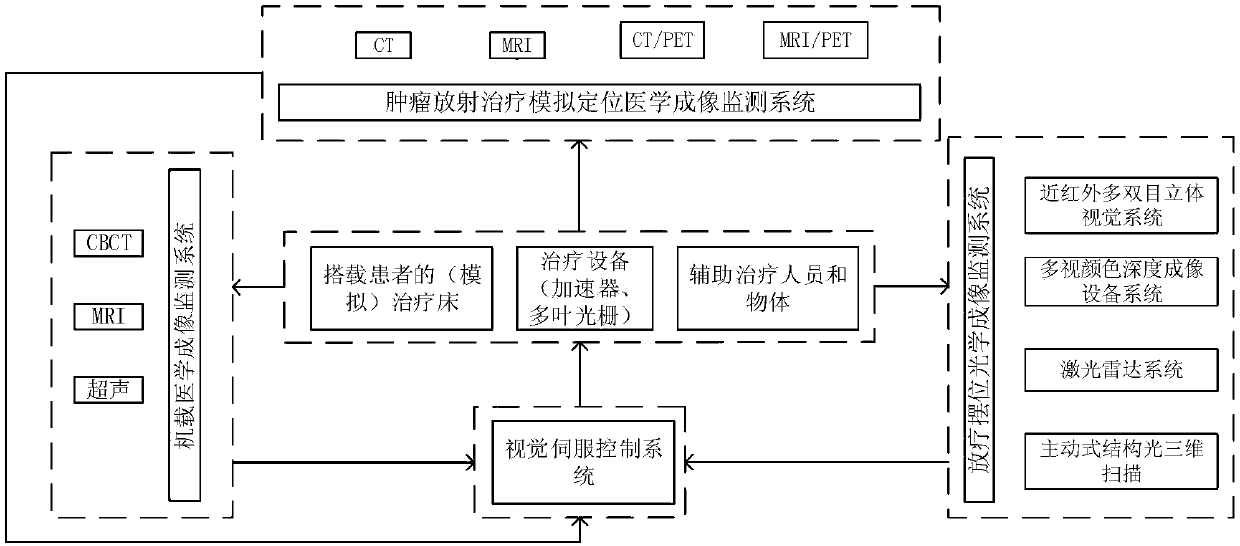

The invention relates to an intelligent control method of visual monitoring and visual servo of tumor radiation therapy. The method comprises: (1) according to multi-mode medical images and multi-vision optical images collected by a radiation-oncology-plan-stage simulation and positioning medical imaging system, a radiation-oncology-positioning-stage treatment room internal optical imaging system, and a radiation-oncology-plan-execution-stage onboard medical imaging system and the like, intelligent analysis processing is carried out to monitor, identify and localize a tumor radiotherapy target and an organ at risk, radiotherapy beds with patients, radiotherapy equipment, and the auxiliary treatment staff and objects in a treatment room during the whole radiotherapy process; and (2), on the basis of optical images and / or medical images collected at different stages of the tumor radiotherapy process as well as the quality guaranteeing requirement of the clinical radiotherapy process, a multi-stage multi-vision servo intelligent control system (algorithm) is used for carrying out intelligent, automatic, high-precision, high-robust visual servo control on the radiotherapy beds, radiotherapy equipment, the onboard medical image system, and the optical imaging system in the treatment room during the tumor radiotherapy process.

Owner:强深智能医疗科技(昆山)有限公司

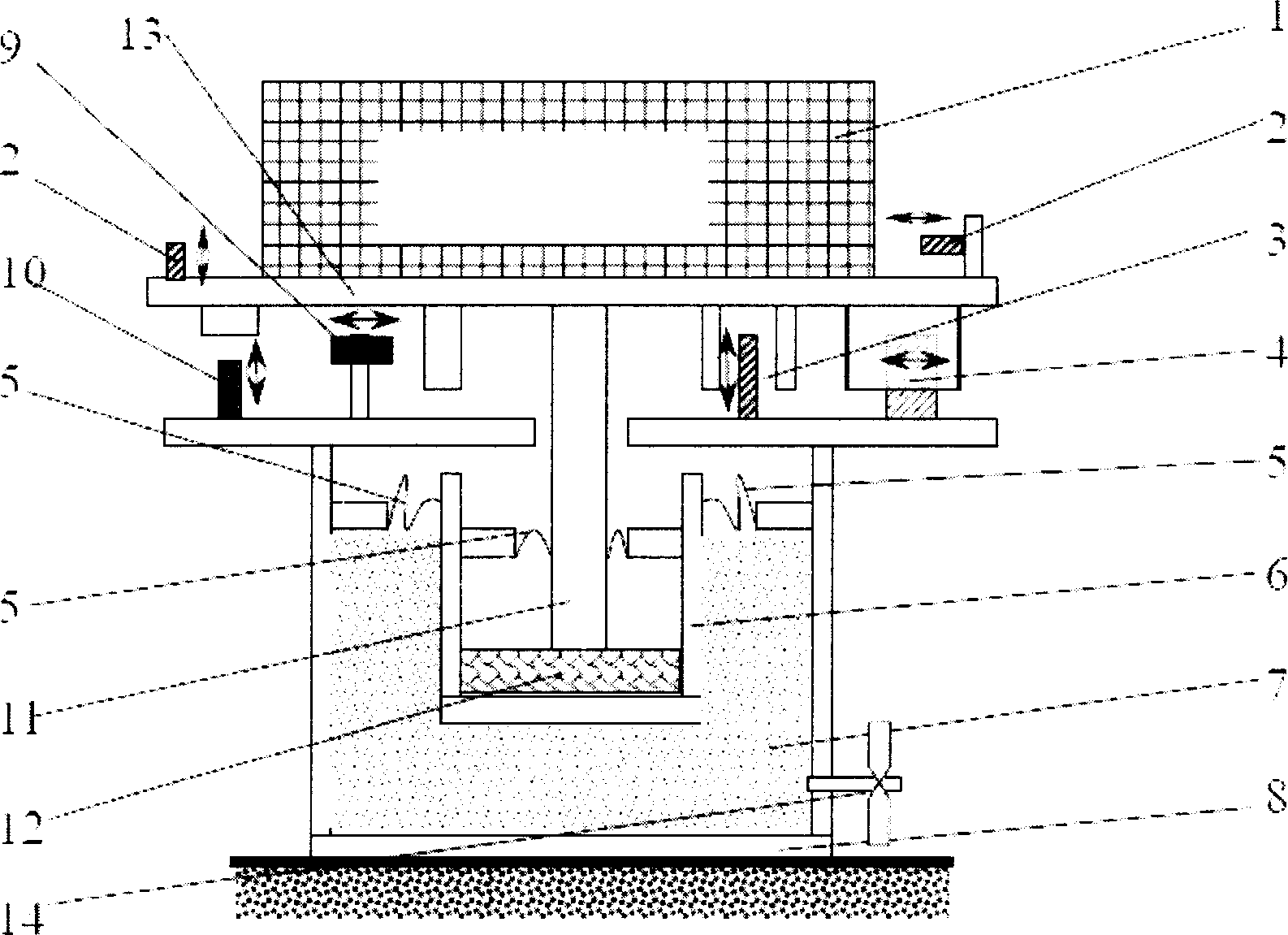

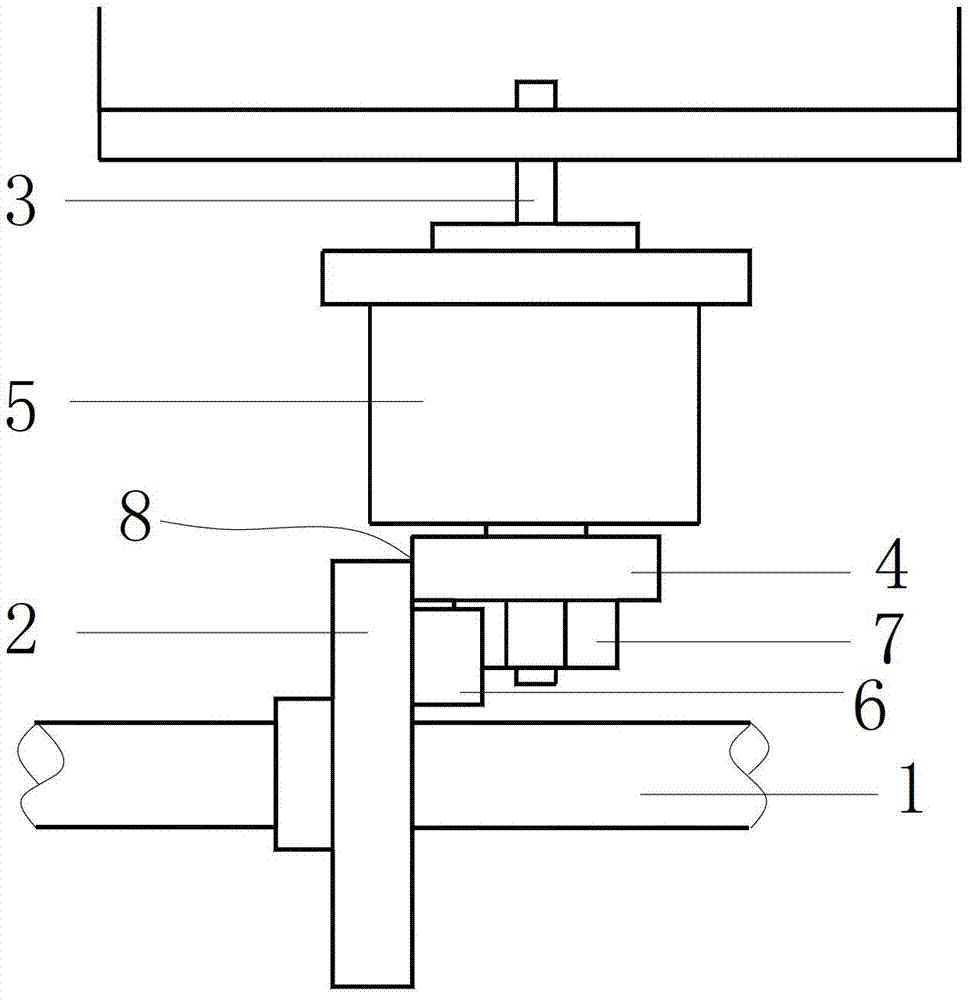

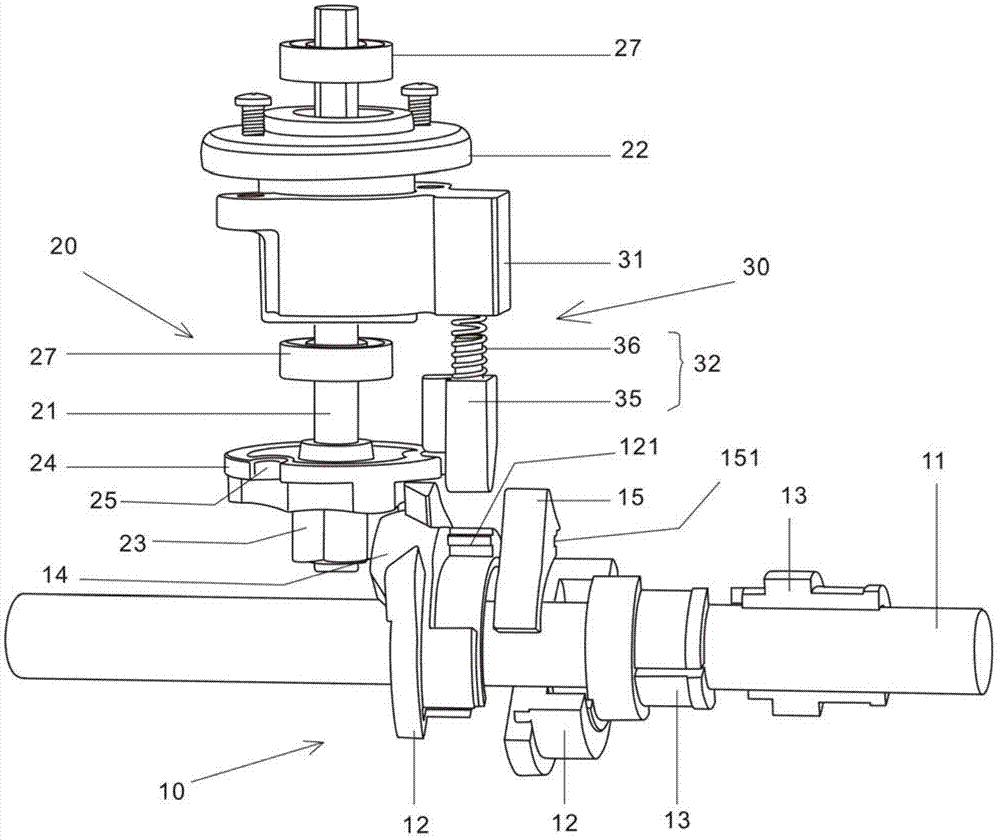

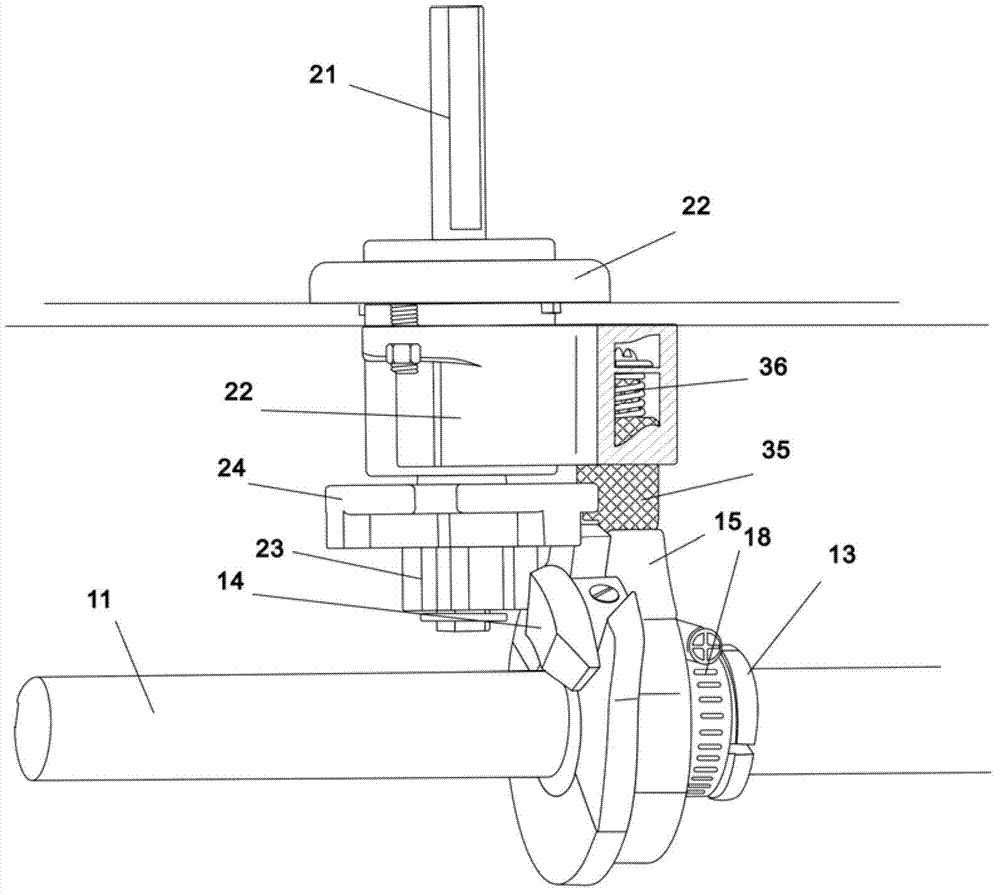

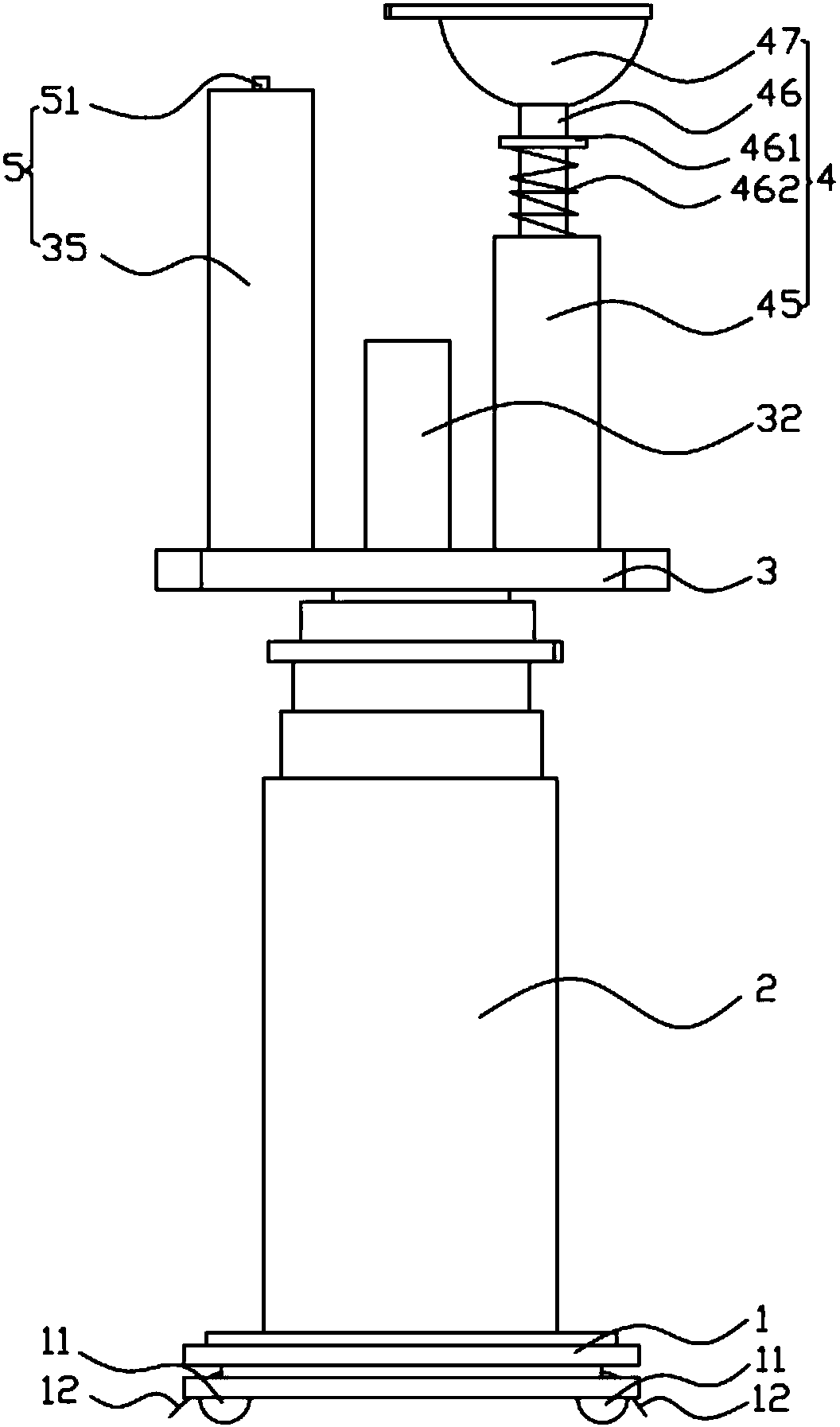

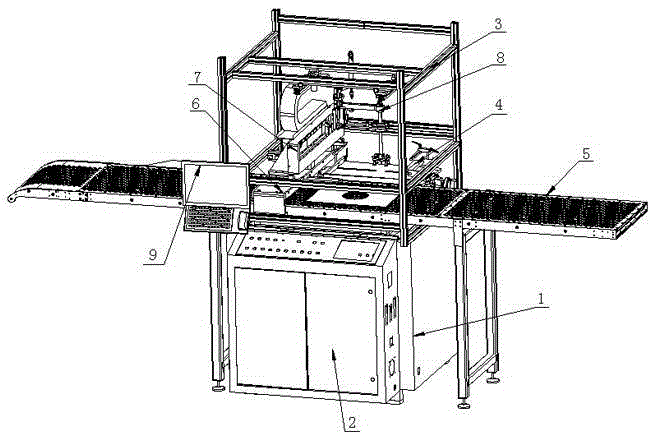

Precision vibration damping and locating device

InactiveCN1724892AAccurate positioningCompact structureNon-rotating vibration suppressionSemiconductor/solid-state device manufacturingPolicy makerRoom temperature

The invention relates to an effectively damping multi-freedom locating device with the passive control as the principal and the active control as the auxiliary, used to realize accurate horizontal and height location, and comprising passive damping component and active damping component, where the passive damping component is of a cavity structure able to have a certain horizontal and vertical moving range and is connected through the cavity-supported piston mechanism to a damped platform for isolating or attenuating the vibrating source in a wider frequency band by a large margin; an active control component joins the damped vibrating components, and is composed of vibration sensor, signal processor, data collector, operation policy maker, electric machine driver, and two linear electric machines in the vertical and horizontal directions, so as to make accuracy location. The invention has compact structure, high reliability, high repeated locating accuracy, strong adaptability, small device deformation, moving stability and meets the strict requirements of the precision devices, such as photo-etcher, etc. at normal temperature.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

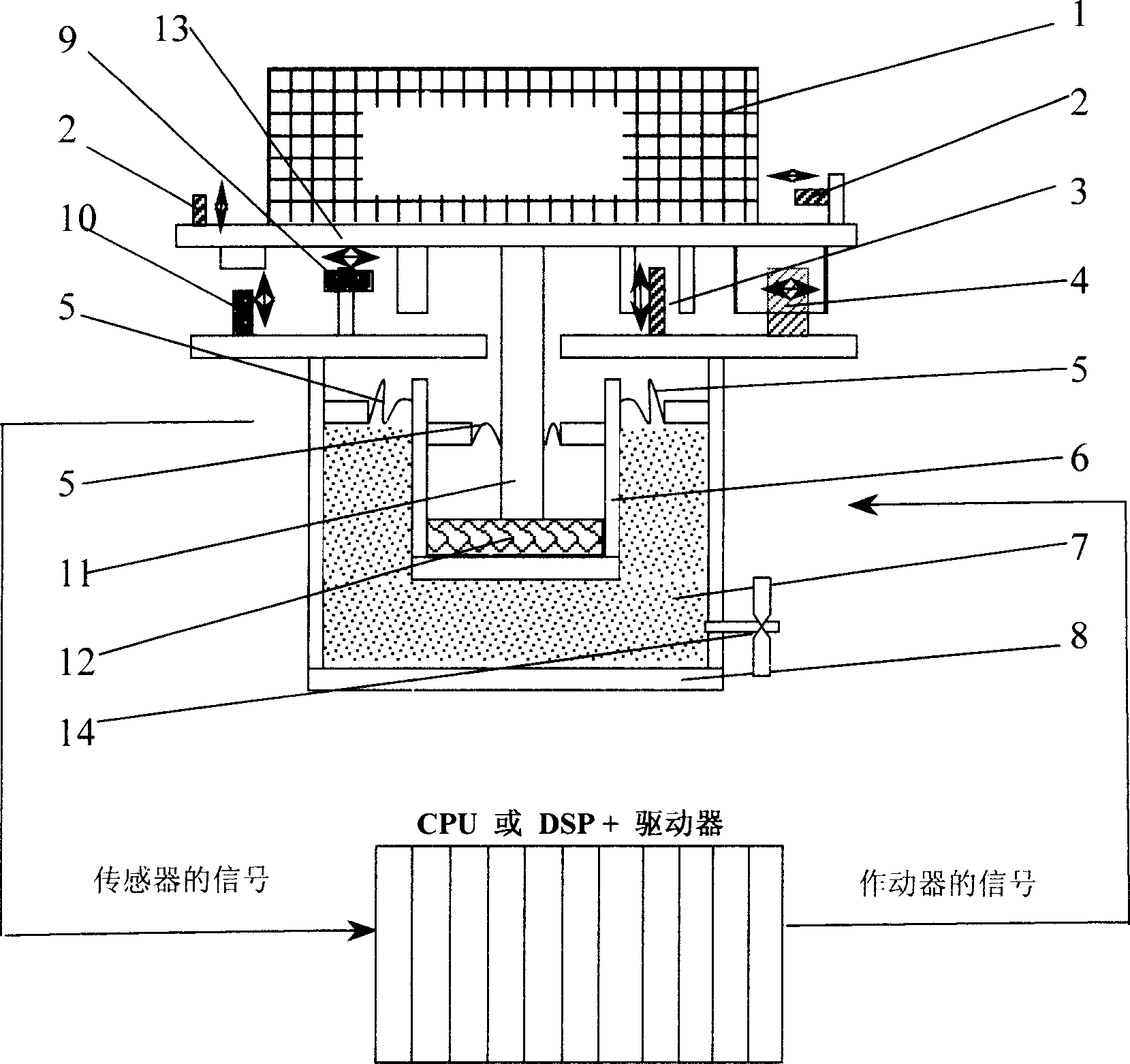

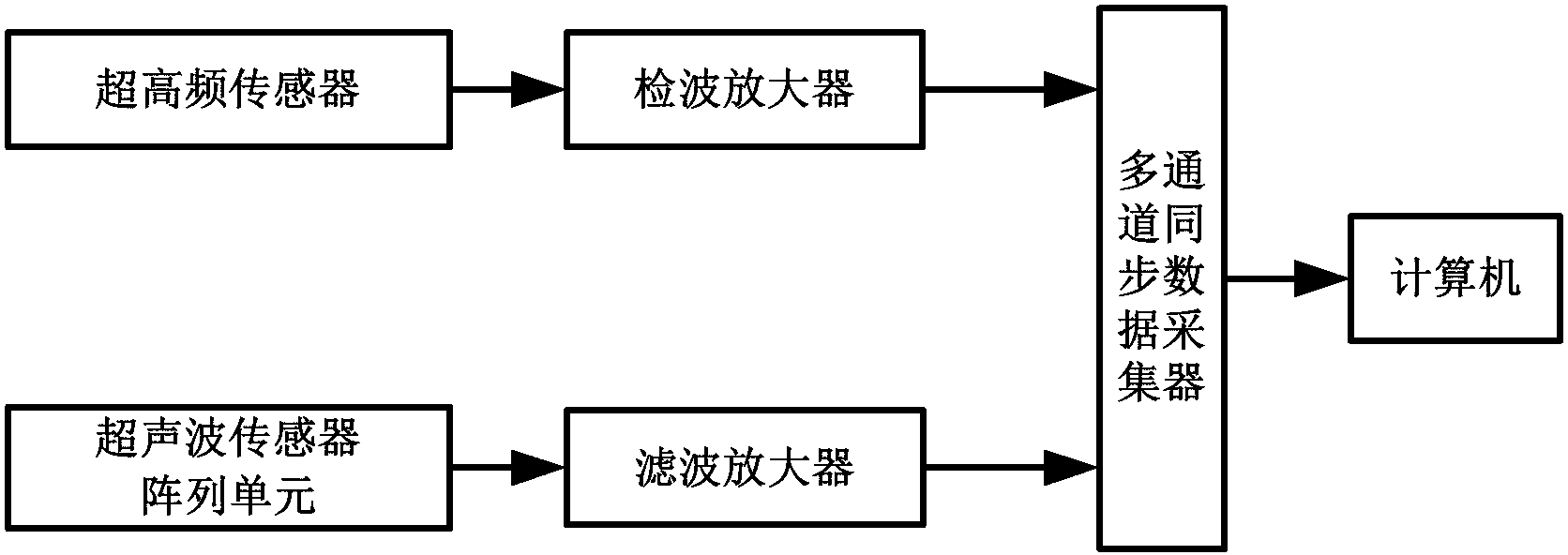

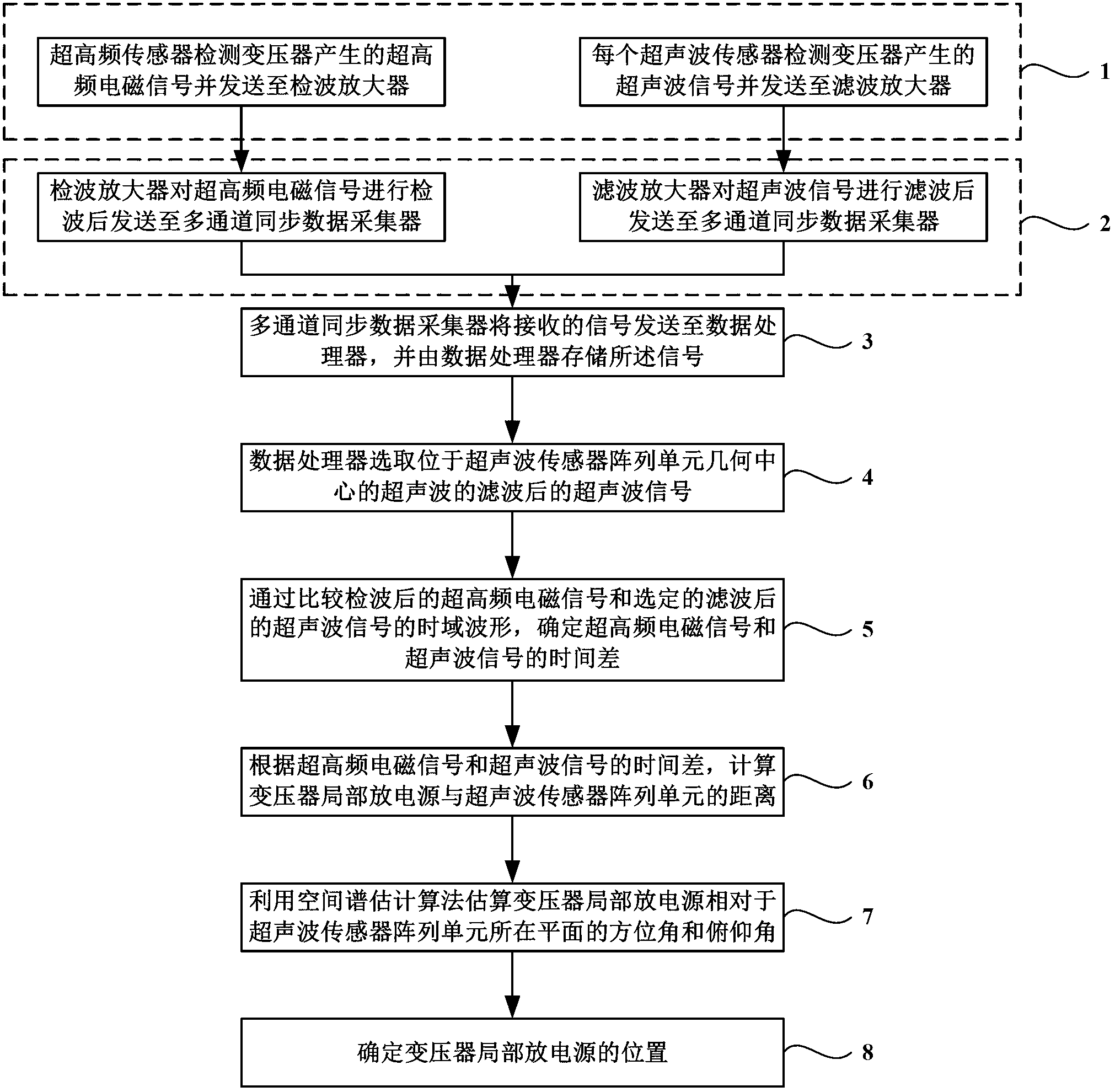

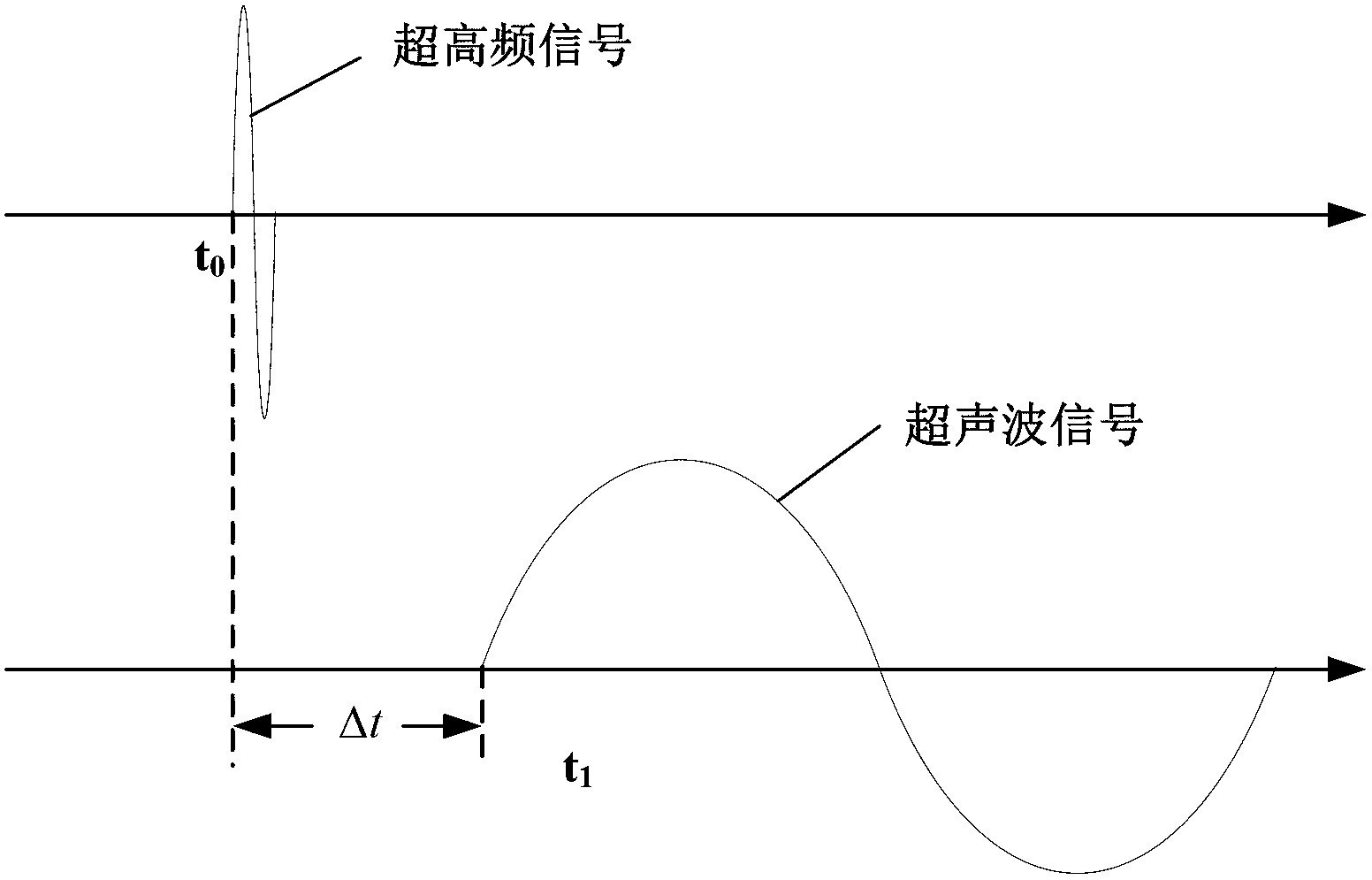

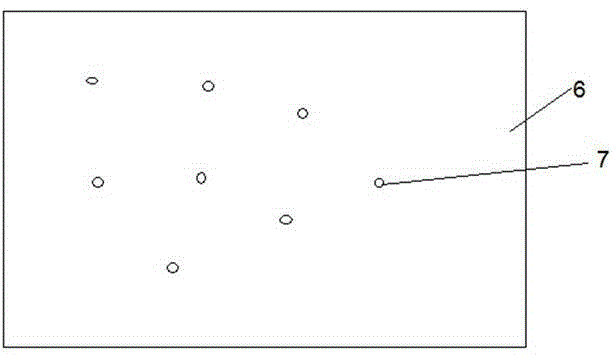

Positioning system and method of local discharge of transformer

InactiveCN102707208AFast positioningAccurate positioningTesting dielectric strengthUltrahigh frequencyPartial discharge

The invention discloses positioning system and method of the local discharge of a transformer, belonging to the technical field of discharge monitoring of the transformer. The positioning system comprises an ultrahigh-frequency sensor, a detector amplifier, an ultrasonic sensor array unit, a filter amplifier, a multi-channel synchronous data acquisition unit and a data processor. The positioning method comprises the following steps of: acquiring an ultrahigh-frequency electromagnetic signal and an ultrasonic signal, comparing the ultrahigh-frequency electromagnetic signal with the ultrasonic signal, determining the time-domain relation of the ultrahigh-frequency electromagnetic signal and the ultrasonic signal, and calculating the distance between a local discharge source and the geometric center of the ultrasonic sensor array unit according to the time-domain relation; then determining an azimuth angle and a pitching angle of the local discharge source relative to a plane with the ultrasonic sensor array unit positioned by utilizing the ultrasonic signal; and finally determining the specific position of the local discharge source according to the calculated distance, azimuth angle and pitching angle. The invention has high positioning speed and high positioning accuracy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Advertising equipment capable of turning over on three sides

The invention discloses advertising equipment capable of turning over on three sides, comprising a driving shaft assembly and a driven shaft assembly, wherein the driving shaft assembly drives the driven shaft assembly to realize the triangular prism rotation. The advertising equipment is characterized by having the positioning function and comprising a locating assembly, wherein the locating assembly which movably coordinates with the driving shaft assembly makes a periodic movement when the driving shaft assembly rotates, the other end of the periodically-moving locating assembly coordinates with a locating structure arranged on the driven shaft assembly to realize the location of the triangular prism. The locking and the unlocking of the triangular prism is completed by a group of independent locating assemblies, the problem of big friction is overcome when the driven wheel rotates, therefore, the transmission mechanism and the triangular prism rotate freely and locate accurately, the locking and the unlocking of the locating assembly is realized synchronously with the driving mechanism and the driven mechanism without deflection, at the same time, the problem that the large power is needed supplying instantly when the motor starts can be avoided, the motor load can be greatly reduced, the failure rate can be reduced, the damage of the motor and the driving shaft can be reduced, and the maintenance cost and the failure rate can be decreased.

Owner:SHENZHEN QIANTING TECH DEV

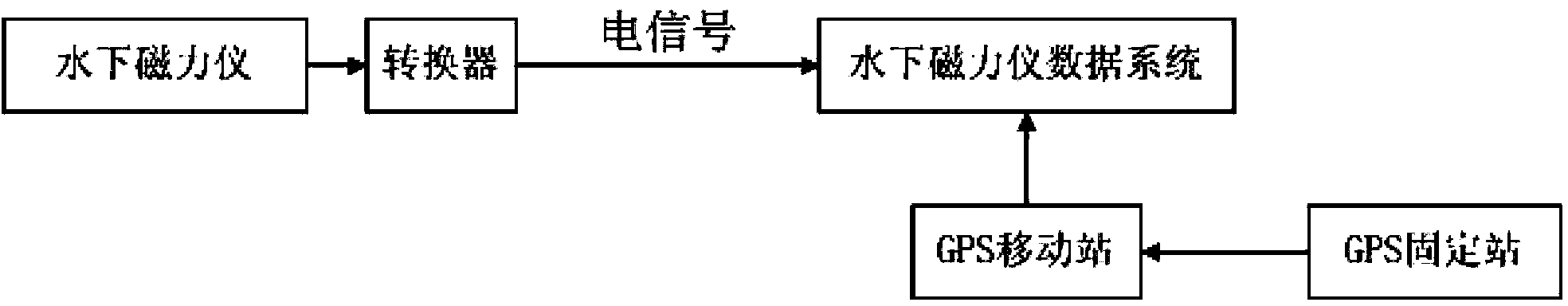

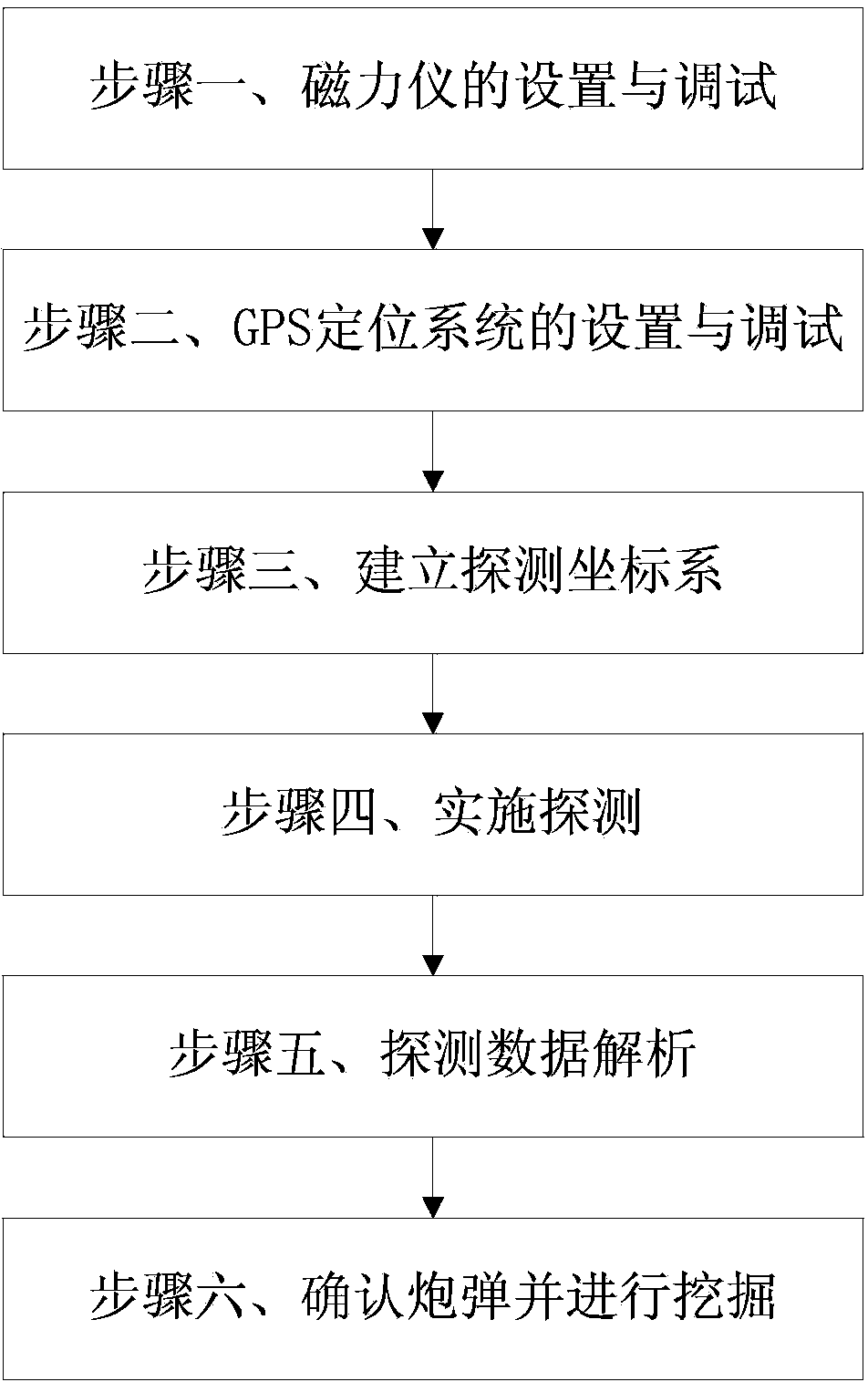

Method for detecting Japan abandoned chemical weapons in water areas

InactiveCN103645515ASolve the detection problemHigh sensitivityWater resource assessmentSatellite radio beaconingGas cylinderChemical weapon

The invention pertains to the technical field of underwater exploration, and specifically relates to a method for detecting Japan abandoned chemical weapons in water areas, wherein the method is suitable for detecting Japan abandoned chemical weapons, such as single or multiple chemical bombs, poison gas cylinders, chemical aerial bombs, bulk toxic agent barrels, etc., in various water area environments. The method of the invention is completed through six steps, the advantage of high magnetic method detection sensitivity can be realized, and the method plays an irreplaceable role in the detection of deeply-buried ammunition. In terms of technology safety, the magnetic method detection is use to passively measure the magnetic field strength generated by a target body, pulse currents and electromagnetic waves do not need to be transmitted to the underground, and no risk factor exists even for Japan abandoned chemical bombs and aerial bombs provided with fuzes. In terms of detection operation efficiency, a magnetometer has advantages over other instruments. The Japan abandoned chemical weapons comprise chemical bombs, poison gas cylinders, chemical aerial bombs and barreled toxic agent, the common characteristic of the chemical weapons is that all of the chemical weapons is provided with a ferromagnetism metal housing, so typical conditions of the magnetic method detection can be satisfied.

Owner:中国人民解放军防化学院

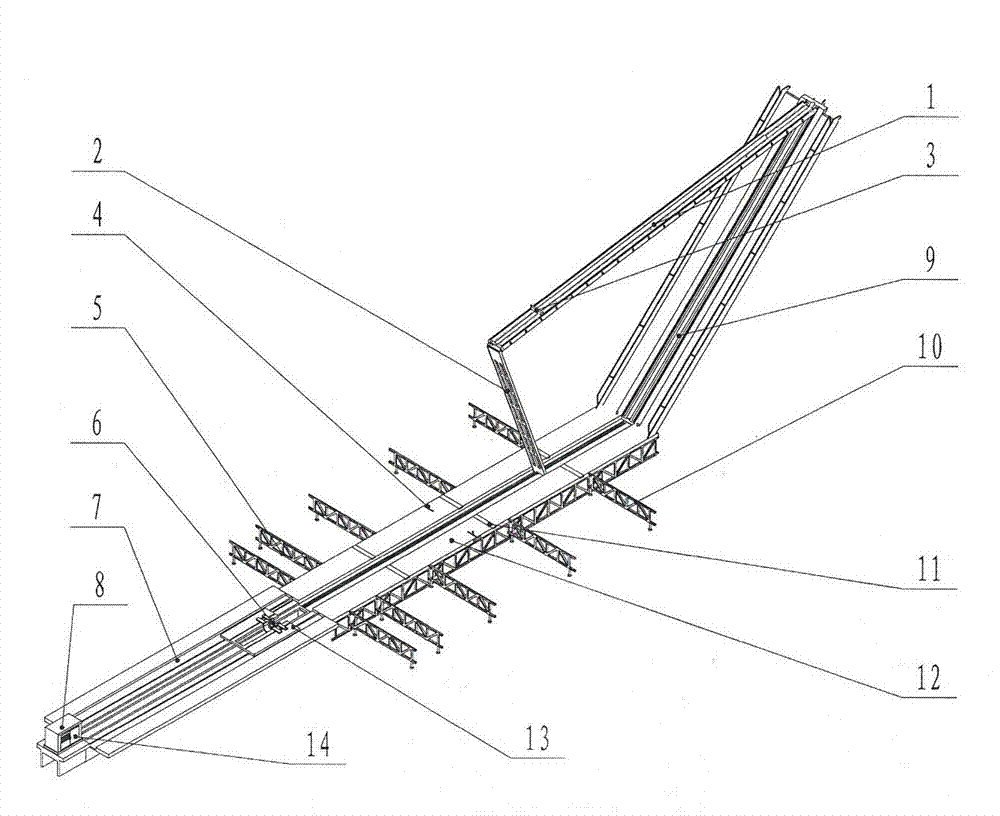

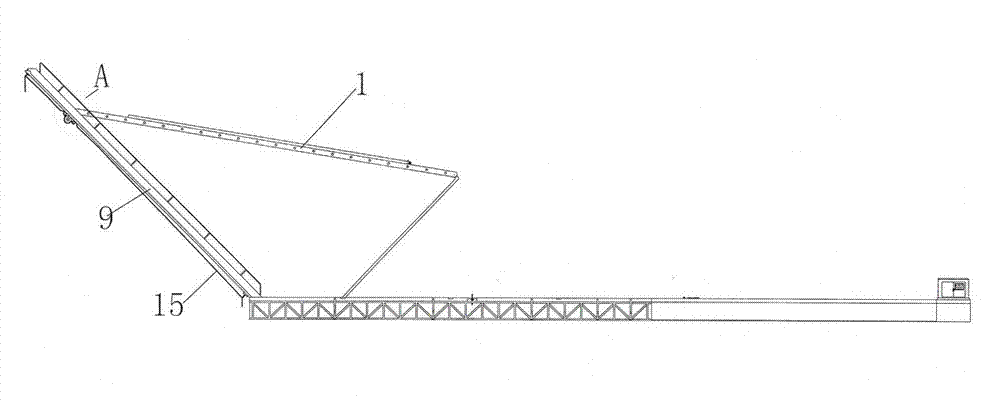

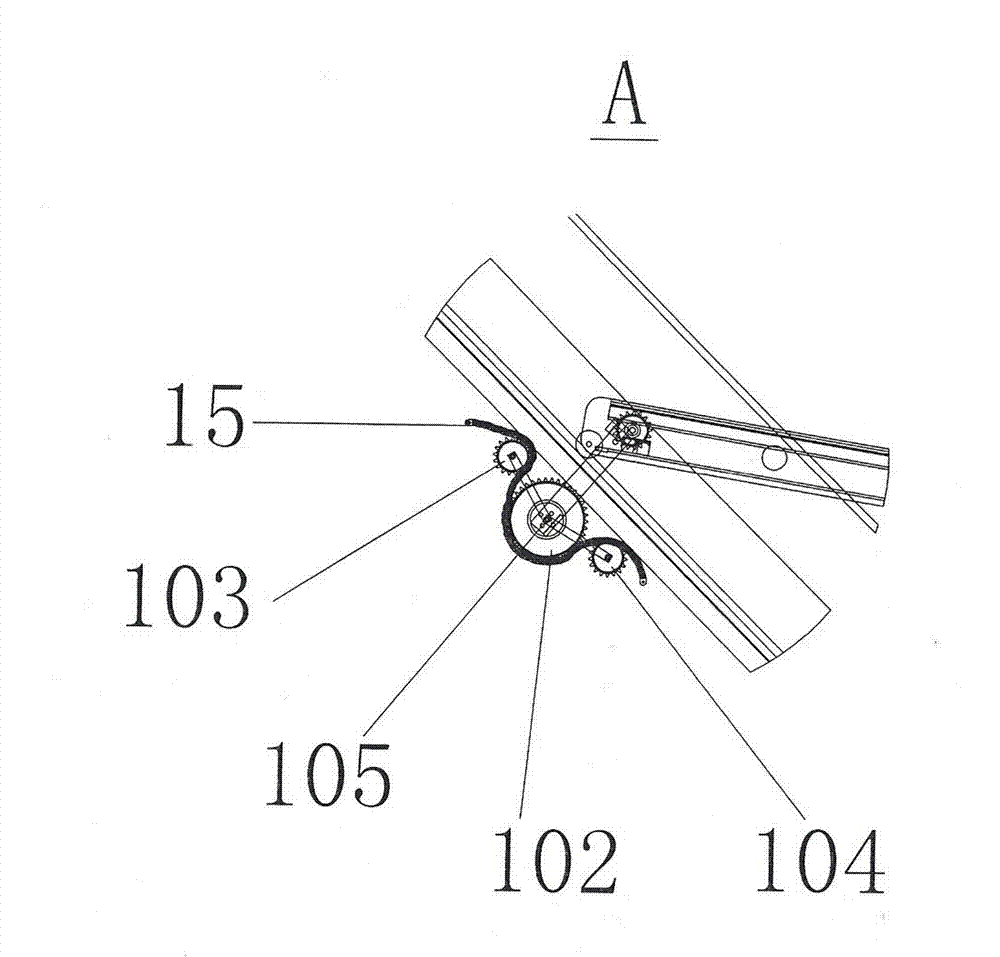

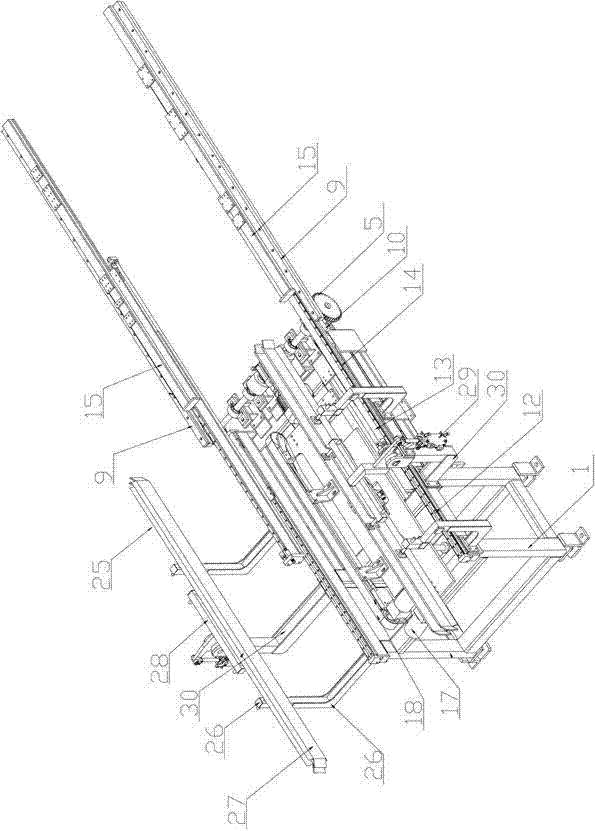

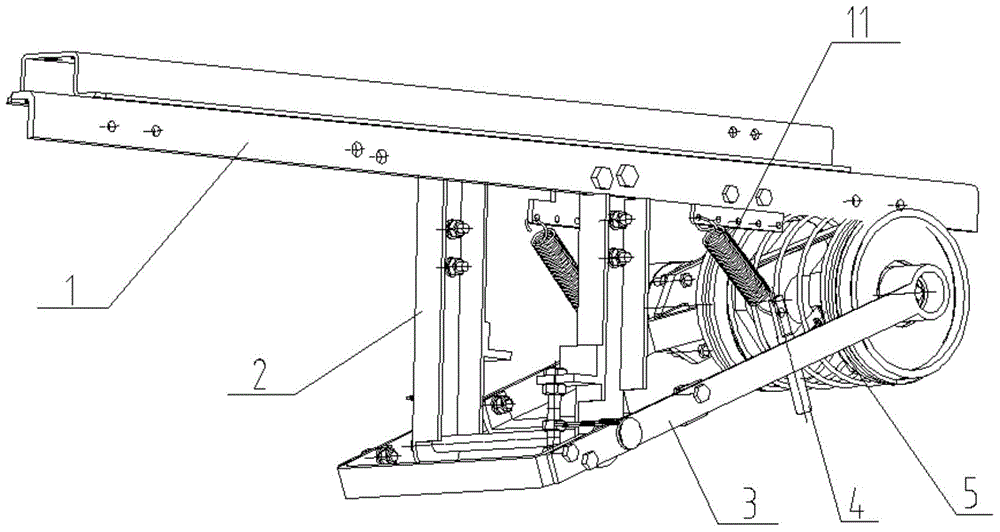

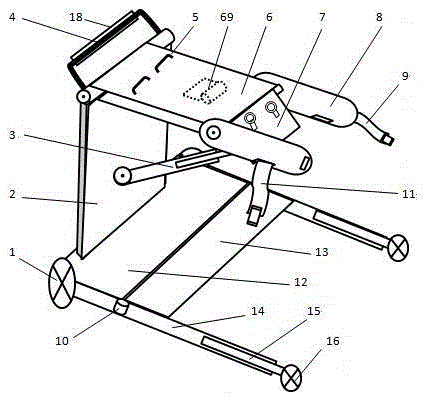

Intelligent full-hydraulic power catwalk

InactiveCN102787813AReduce labor intensityThe average gear ratio is accurateDrilling rodsDrilling casingsEngineeringDrilling system

The invention discloses an intelligent full-hydraulic power catwalk which comprises a supporting arm, a lifting leg, a pulley, a drill rod positioning mechanism, a plurality of active outriggers, a twisting machine, a twisting machine sliding rail, a control box, a ramp, outriggers, an overturning plate, a foundation support, a waterpower decoring device and a hydraulic station. The ramp is connected with the foundation support via a bolt, the twisting machine and the twisting machine sliding rail are mounted on one side of the foundation support, the waterpower decoring device is mounted on the twisting machine, the drill rod positioning mechanism and the overturning plate are arranged on the foundation support, the pulley is arranged on the supporting arm, the active outriggers are arranged on two sides of the foundation support, the hydraulic station supplies power to a system, and operation of the system is control by the control box. By the aid of the intelligent full-hydraulic power catwalk, processes including joint and throw rod connecting, hole bottom power connecting and disconnecting and water power rock coring can be integrated, twisting and water power decoring can be automatically finished without removal of a drill rod, technical requirements for drilling deep well coring are met, construction fields are greatly reduced, labor intensity is lowered, and working efficiency of a drilling system is improved. Since the power catwalk is fully hydraulically controlled, stepless speed change can be realized, transmission mechanism is simplified, and adaptability and reliability of the power catwalk are improved.

Owner:JILIN UNIV

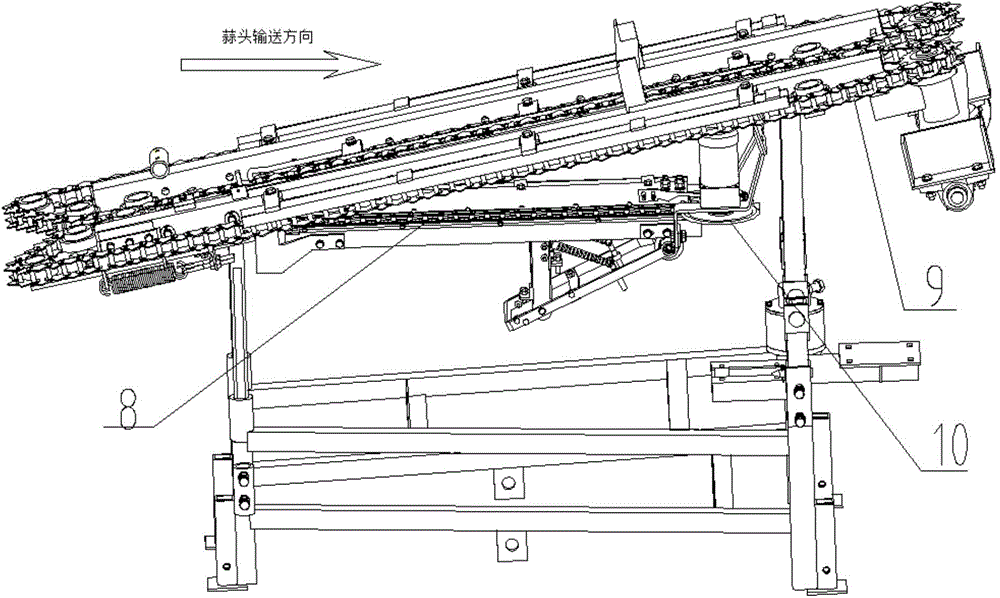

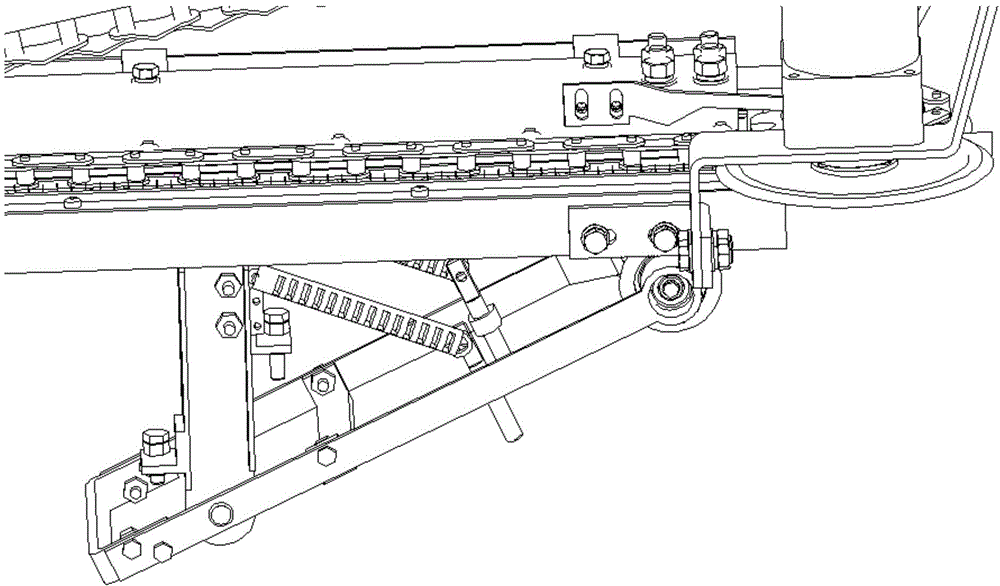

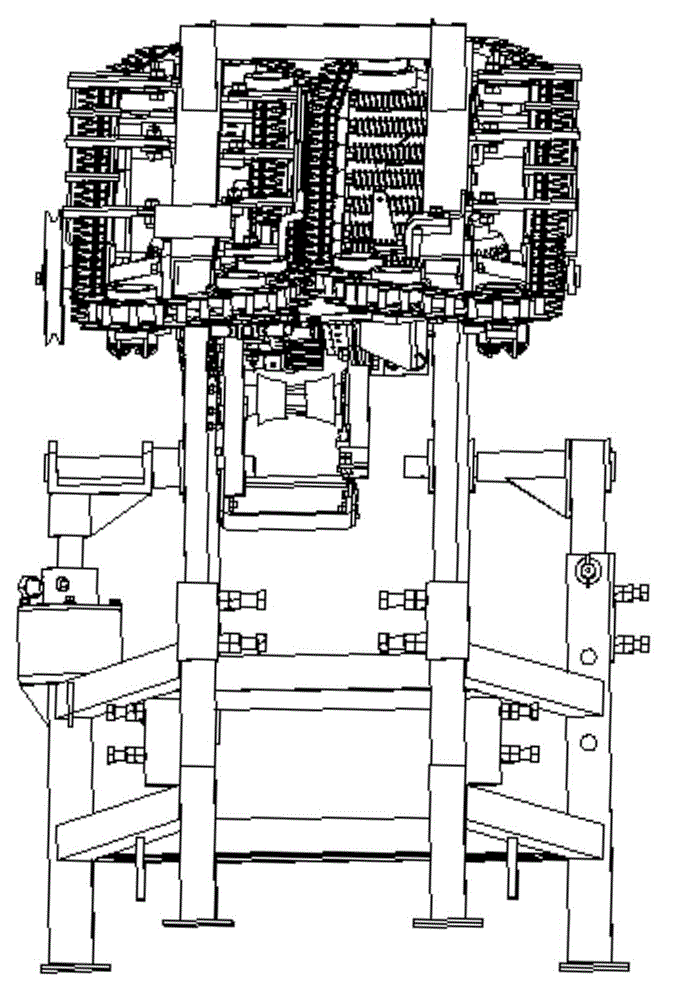

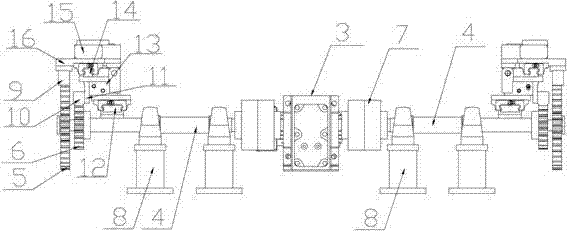

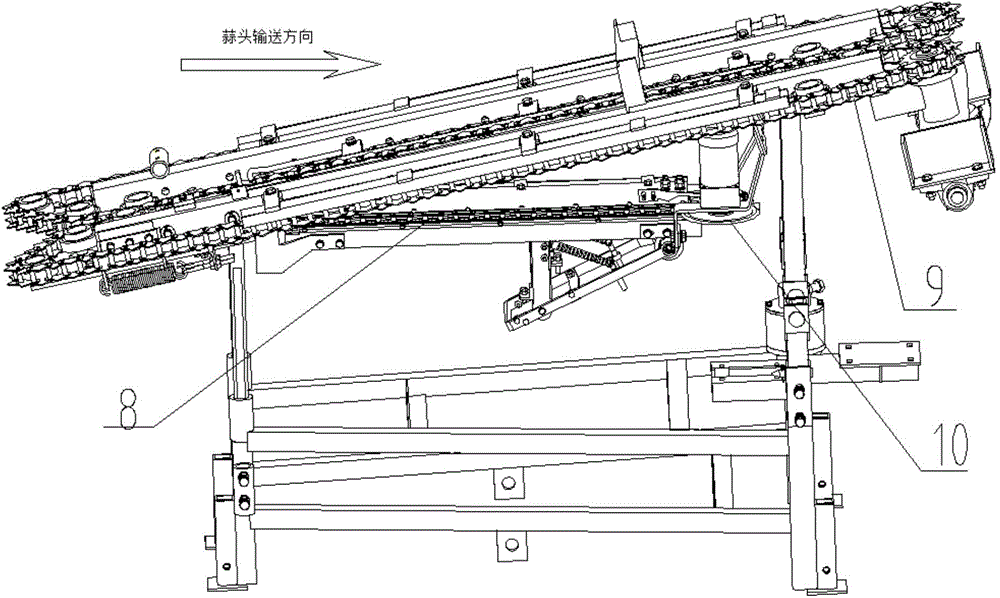

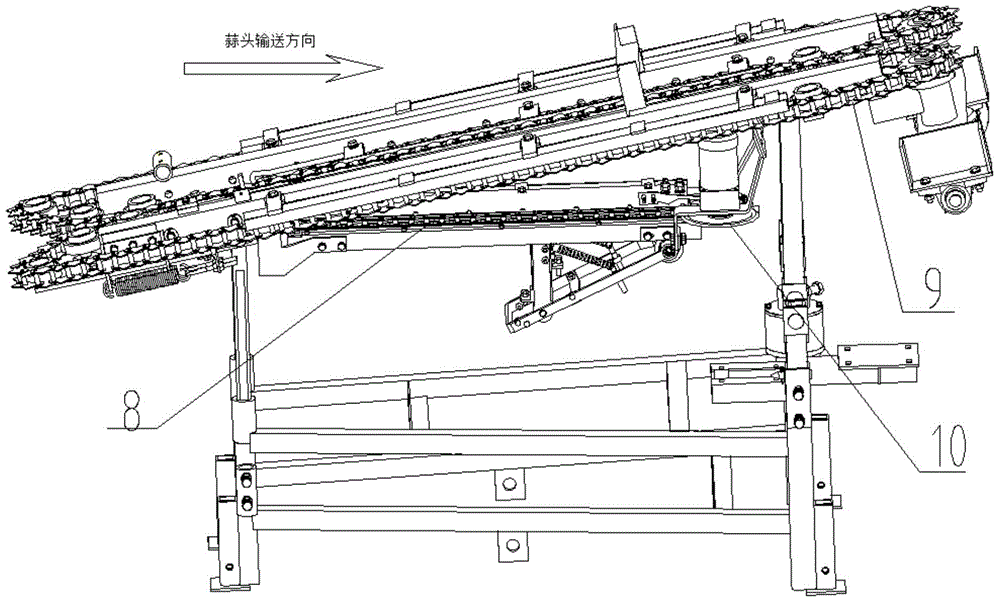

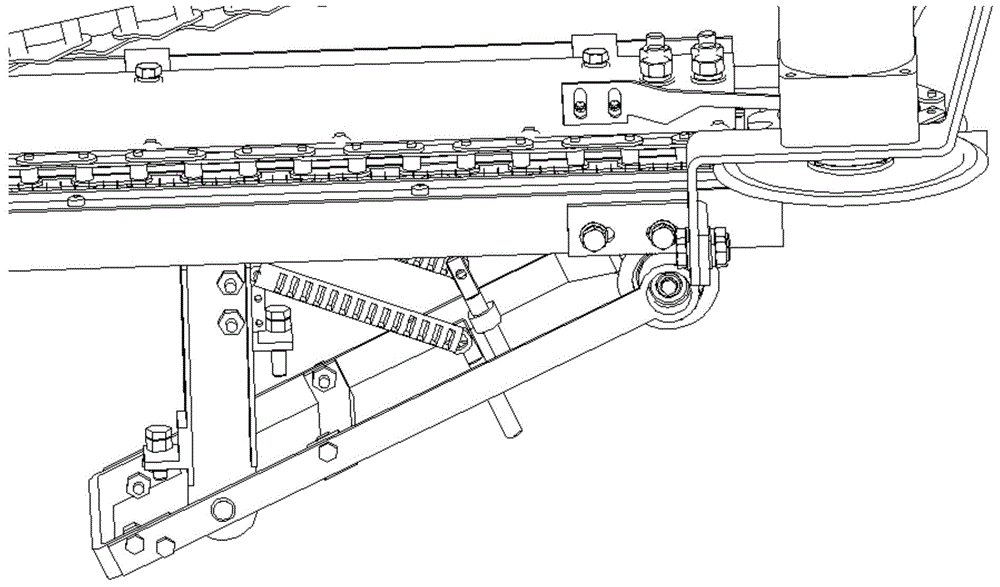

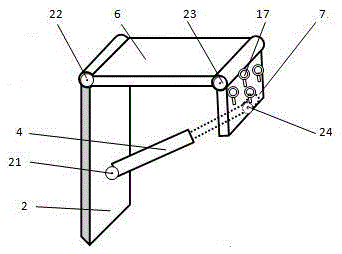

Garlic root cutting device

ActiveCN104126854ARealize automatic root cuttingEffective protectionFood treatmentElectric machineryEngineering

The present invention relates to a garlic root cutting device, and the device is characterized by comprising a couple of beams (1), wherein the beams (1) are used for supporting an align chain (8); vertical rods (2) are fixed on the beams (1) and extend downward, and the lower end of each vertical rod forms a hinge connection with a support beam (3), wherein the ends of the support beams (3) are fixedly provided with a root cutting assembly ; the supporting beams (3) are connected to the beams(1) or the vertical rods (2) through springs; the root cutting assembly includes a contour wheel, wherein the contour wheel is a pair of curved surface wheel bodies (5) and the surface wheel bodies are opposite and have a certain gap; the big ends of the surface wheel bodies (5) face outside, the small ends of the surface body face inside, and the circumferential surface is concave and profiles the lower part of a garlic body; the contour wheel is coaxially provided with a root cutting wheel (7), and the root cutting wheel (7) is driven by a motor (6); the outer diameter of the root cutting wheel (7) is less than the outer diameter of the contour wheel, a root cutting knife (7a) on the root cutting wheel cut off the root extending in a gap between the surface wheel bodies (5).

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

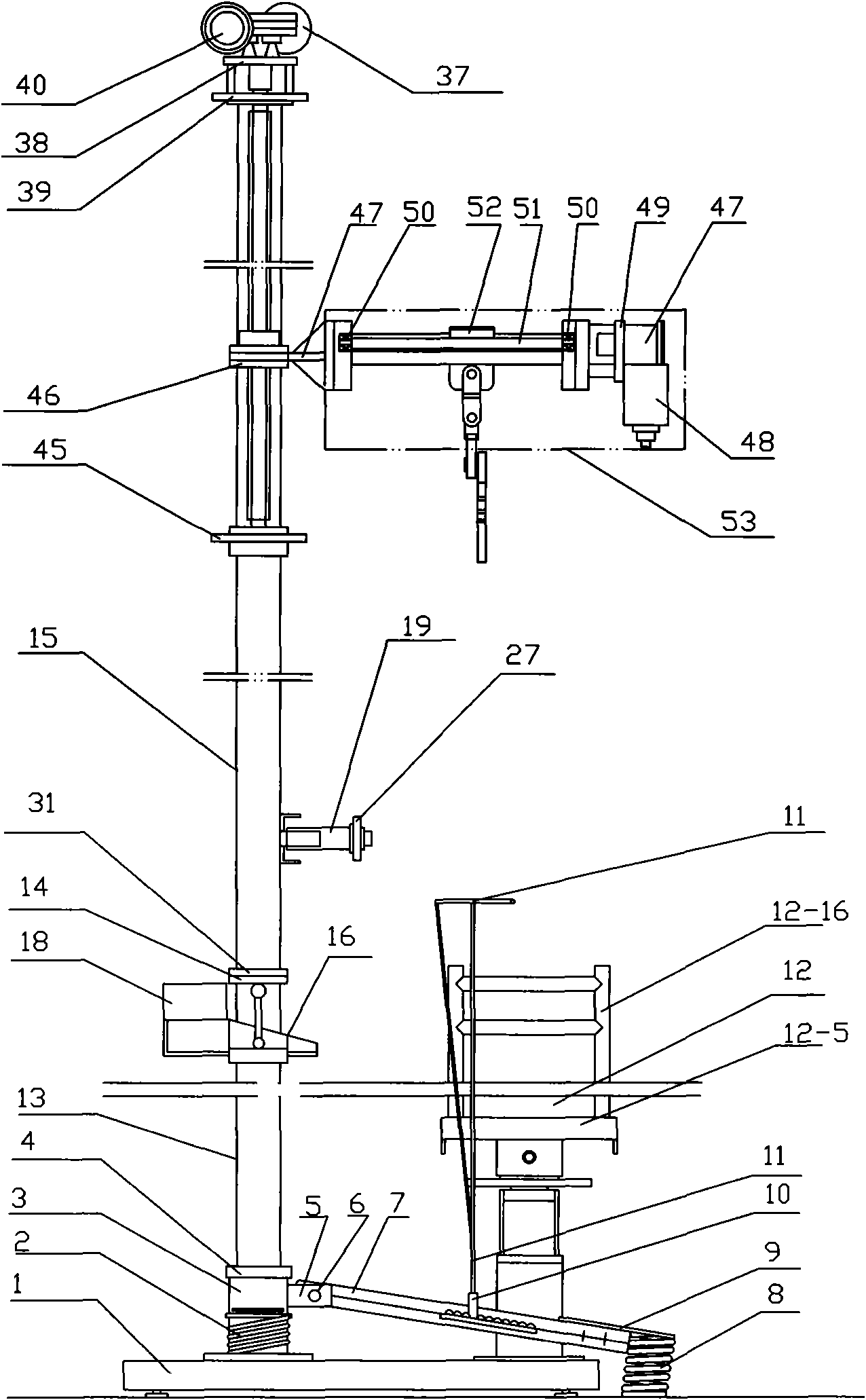

Equipment capable of punching ceiling and mounting expansion bolt conveniently

PendingCN107932052AImprove installation efficiencyFrequent disassemblyMetal working apparatusStone-like material working toolsEngineeringExpansion joint

Equipment capable of punching a ceiling and mounting an expansion bolt conveniently comprises a pedestal; a lifting device is fixedly arranged on the pedestal; the top of the lifting device is rotatably connected with a rotating platform; a drilling device and an expansion bolt mounting device are fixedly arranged on the two sides of the upper part of the rotating platform correspondingly; a cliptype feeding device is inserted into the expansion bolt mounting device; the pedestal is placed on the ground; the lifting device is used for driving the rotating platform to move up and down; the rotating platform is driven by a first driving device to rotate; the drilling device comprises a drill bit; the expansion bolt mounting device comprises a guide pipe; the upper end of the guide pipe is lower than the upper end of the drill bit; an inner hole of the guide pipe only allows a combined piece formed by combining a countersunk bolt and an expansion pipe to pass through; the guide pipe andthe drill bit are arranged on the two sides of the rotating platform symmetrically; an ejection device is fixedly arranged below the guide pipe; the clip type feeding device is internally provided with a plurality of combined pieces; the clip type feeding device is used for conveying the plurality of combined pieces to be between the guide pipe and the ejection pipe sequentially; and the equipmentsimplifies operation, has high efficiency and is safe.

Owner:SHENZHEN STYLE DECORATION

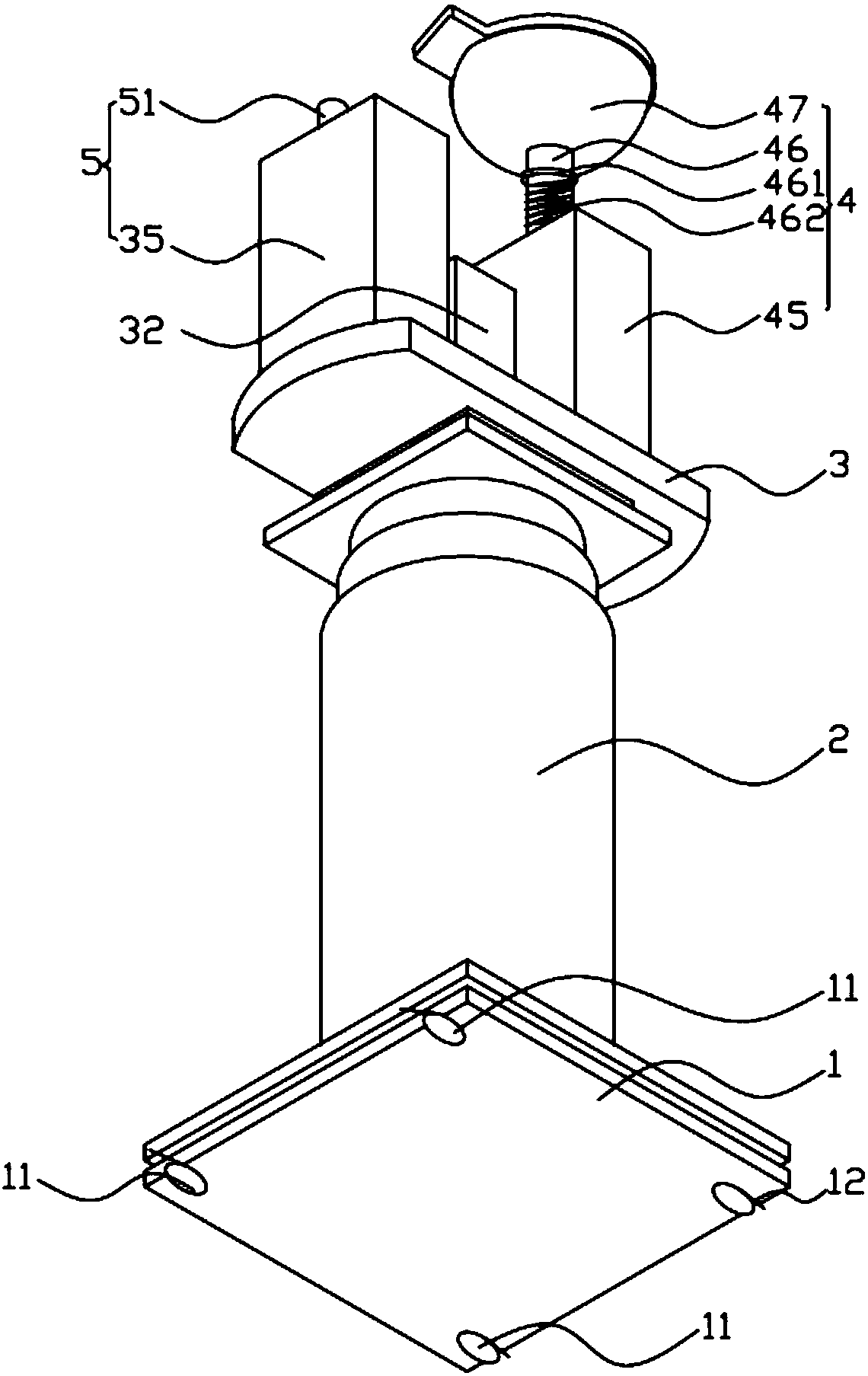

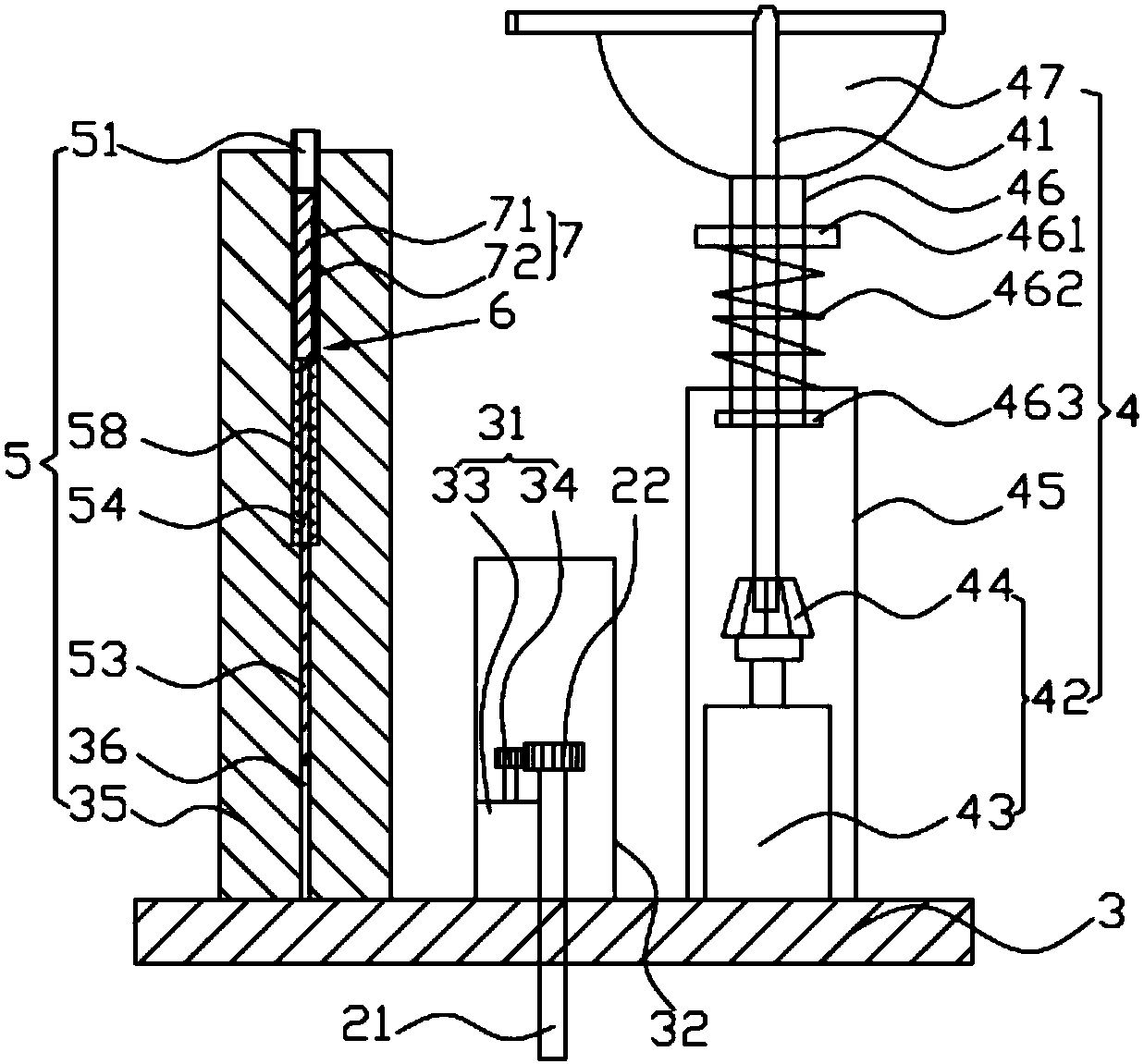

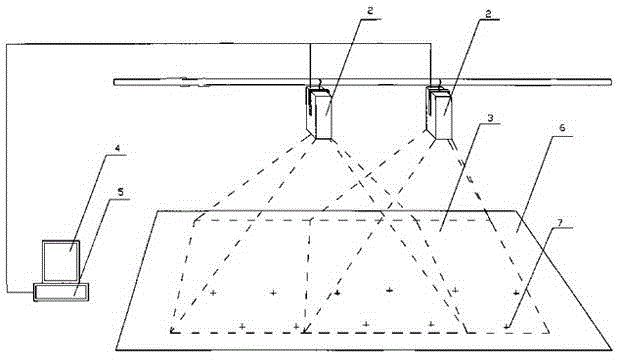

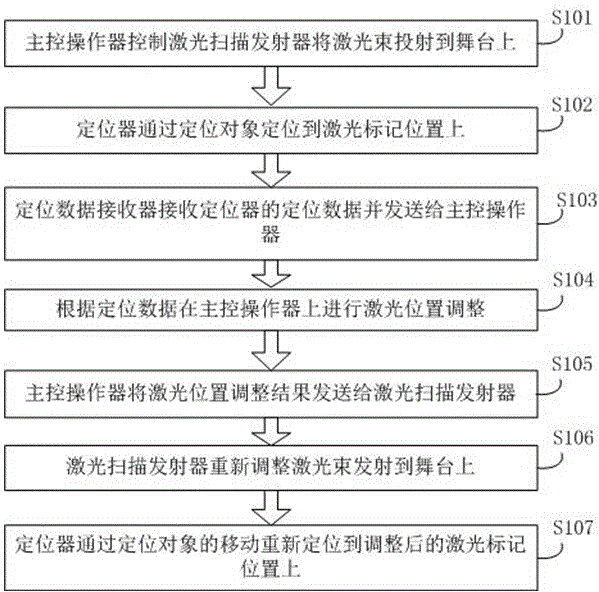

Stage laser positioning calibration device and stage laser positioning calibration method

InactiveCN104613957AImprove positioning accuracyImprove accuracySurveying instrumentsNavigation instrumentsImaging analysisDisplay device

The invention relates to the field of positioning, and particularly relates to a stage laser positioning calibration device and a stage laser positioning calibration method. The device comprises a master control manipulator, a display and a laser scanning transmitter installed above a stage, wherein the master control manipulator is connected with the display and the laser scanning transmitter respectively. The device also comprises a positioner arranged on a positioning object and a positioning data receiver in wireless connection with the positioner, wherein the positioning data receiver is connected with the master control manipulator. According to the stage laser positioning calibration device and the stage laser positioning calibration method provided by the invention, the defect that a laser projection effect is affected by stage light when a camera is adopted for shooting the stage can be overcome, the high cost of the camera is saved and an image analysis step which is needed after the camera is used for shooting images is omitted, and the entire calibration device is simple in structure, convenient for calibration operation, high in positioning and calibration speeds, and low in cost.

Owner:GUANGDONG VTRON TECH CO LTD

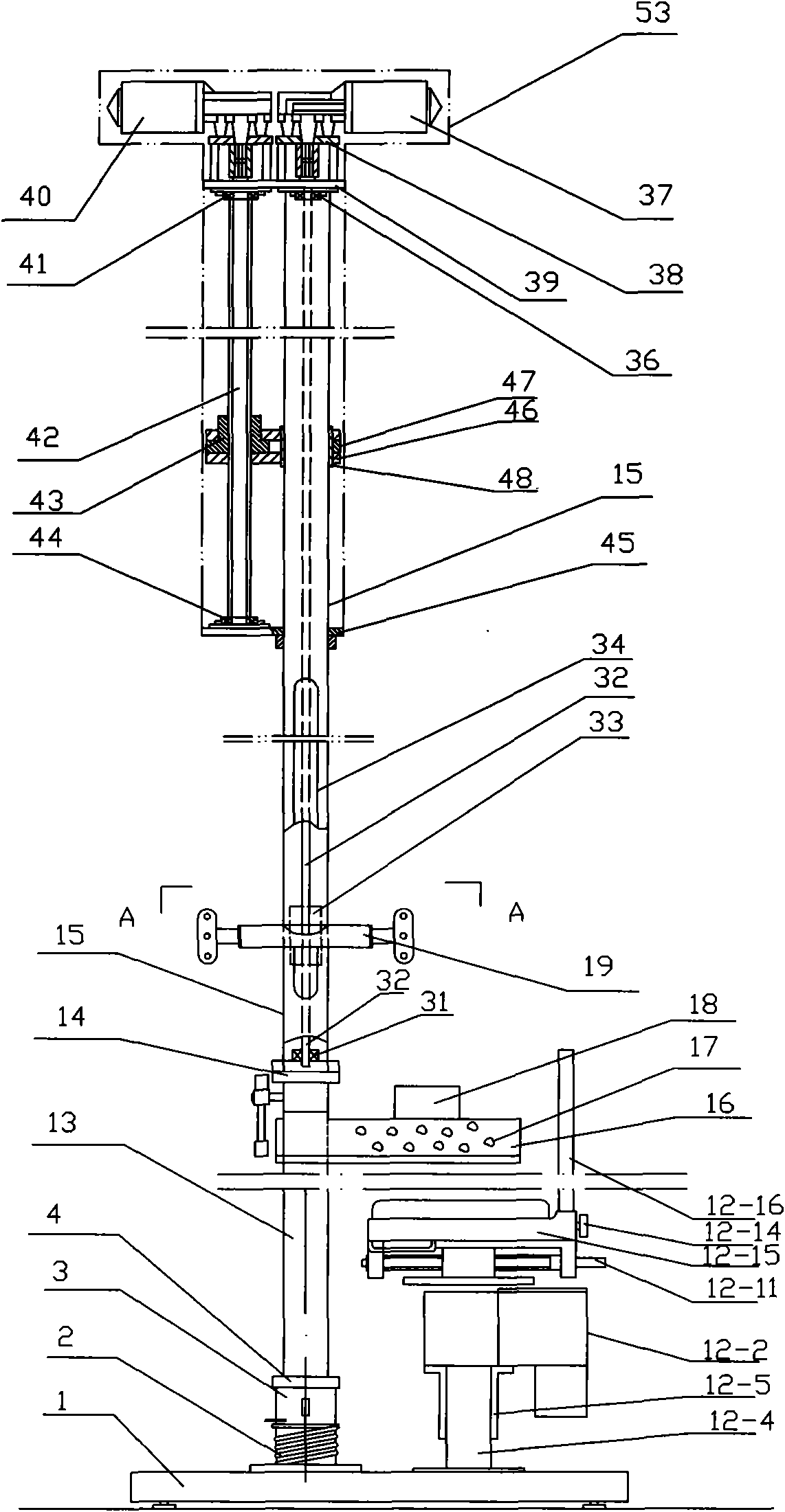

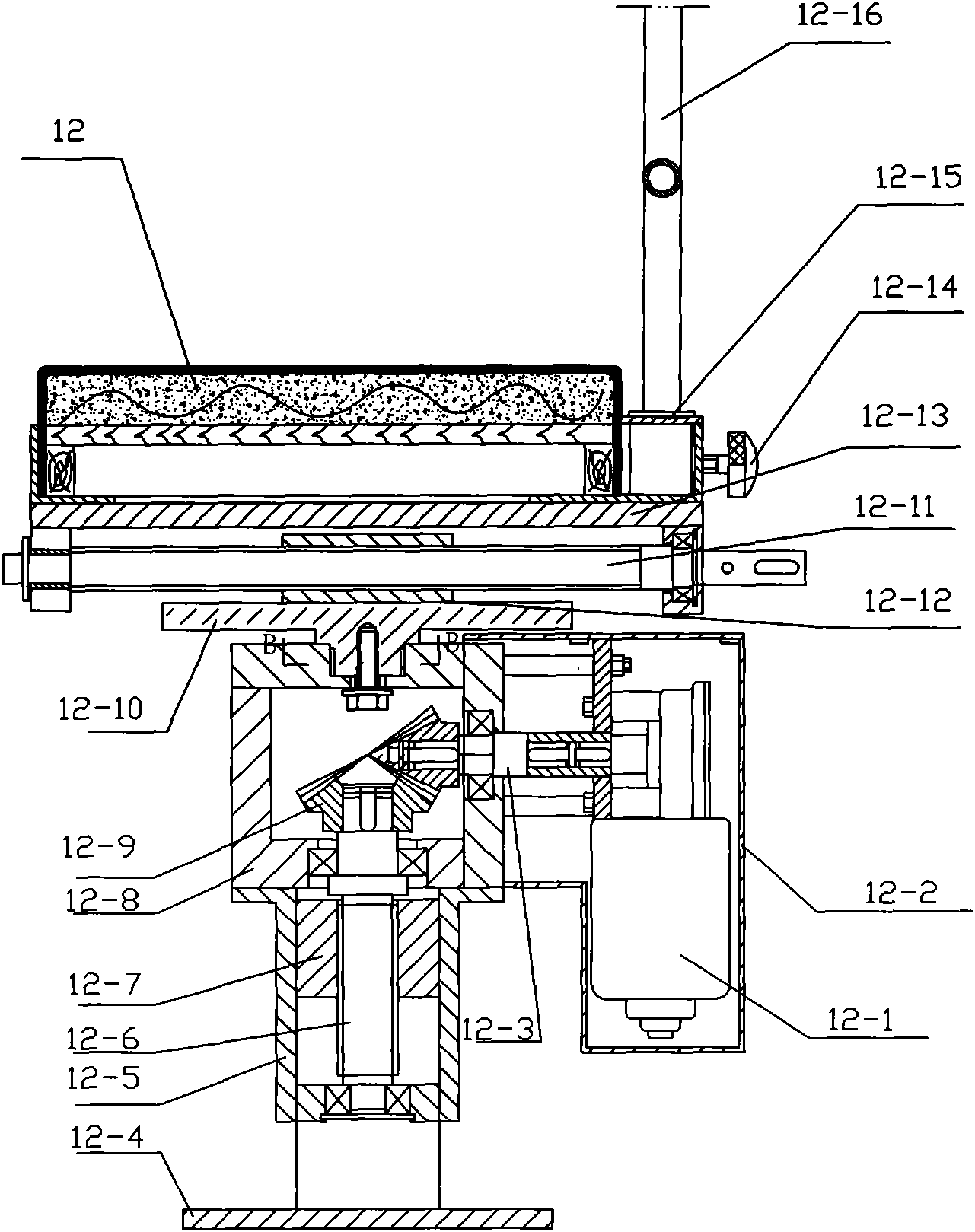

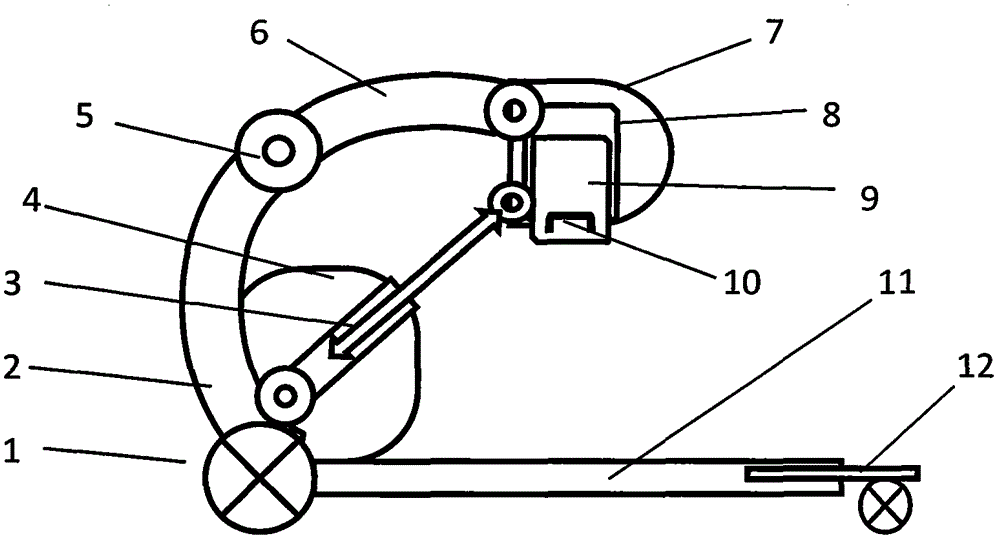

Electric vertically-pulled spinal correction machine

InactiveCN101653390AIncrease intervertebral spaceFlexible operationChiropractic devicesFractureEngineeringChassis

The invention relates to an electric vertically-pulled spinal correction machine, which is characterized in that an electric rotary lifting seat is arranged at one side of a chassis; a hollow stand column consisting of an upper support and a lower support is arranged at the other side of the chassis; the top end of the upper support is connected with an upper supporting board provided with a motorframe; an electric chest positioning bracket device is arranged at one side surface of the motor frame which is arranged at the same side with the upper support; an electric transverse arm longitudinal positioning device is arranged at the other side surface of the motor frame and is provided with an electric transverse arm traverse positioning mechanism; a lever-type pedal plate is arranged at the heel part of the stand column; a belt loop of the pedal plate is connected with a soft belt ring; and the top section of the lower support is provided with a switchboard. The invention not only hasreasonable design and compact structure, realizes mechanical operation by mechanical adjustment on all traction directions and parts instead of manual adjustment, but also is added with a chest, lever-type pedal plate and a correction counterweight display screen, thus having the advantages of good traction effect, wide treating range, flexible operation, convenient use and the like.

Owner:BEIJING ZHANG DEHONG SPINE BENDING DISEASE INST

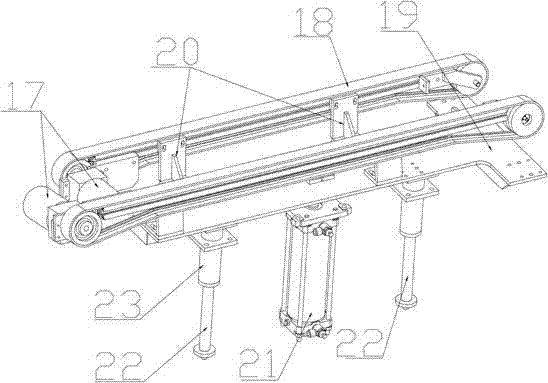

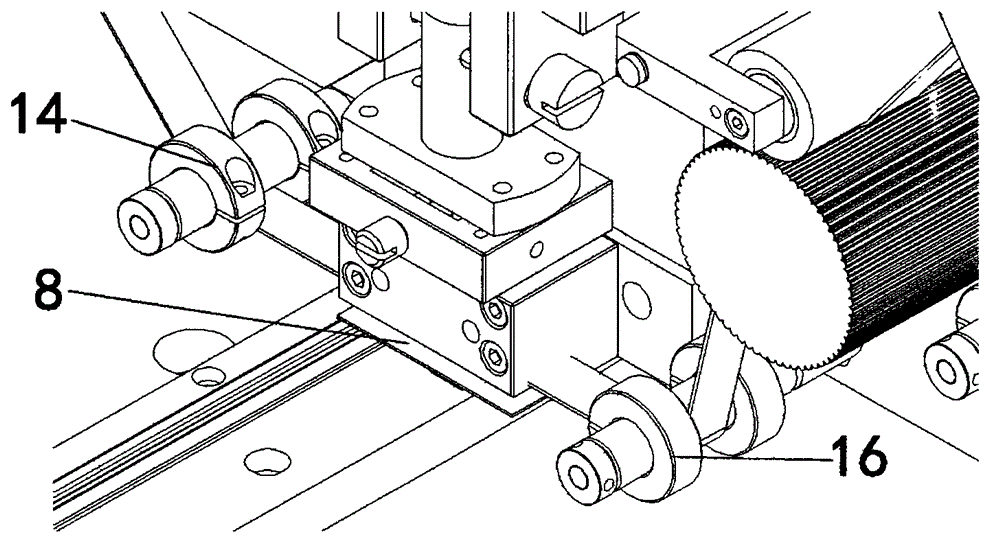

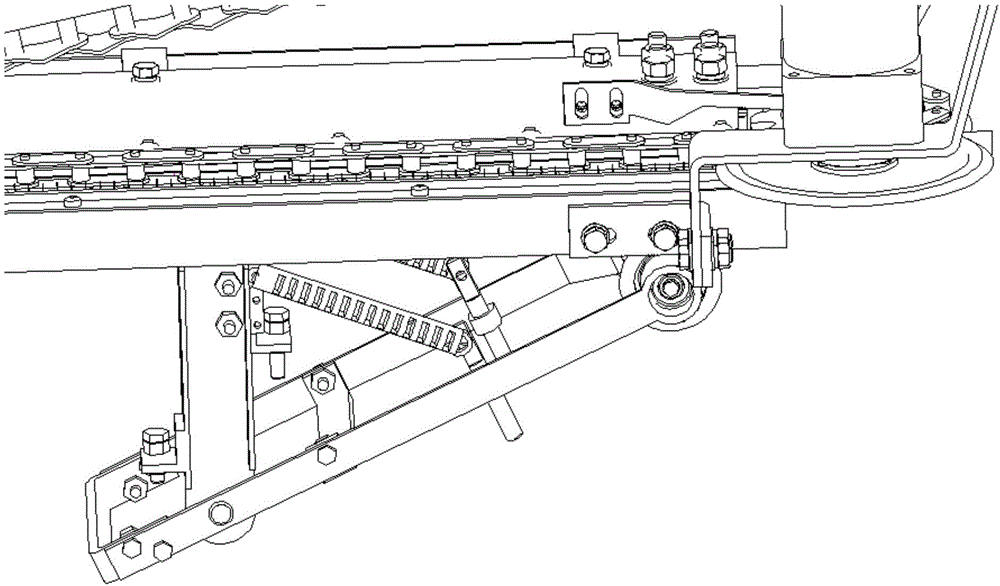

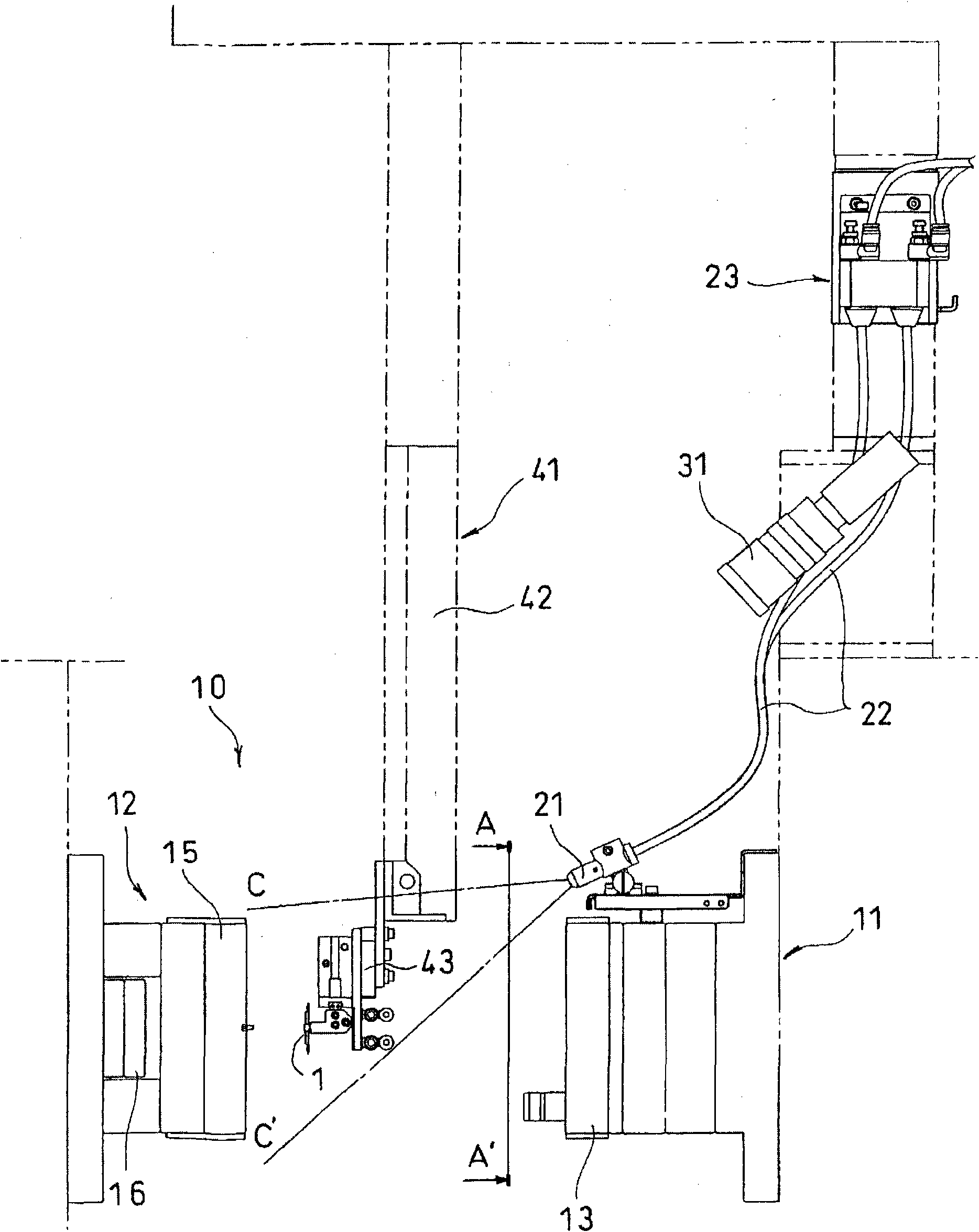

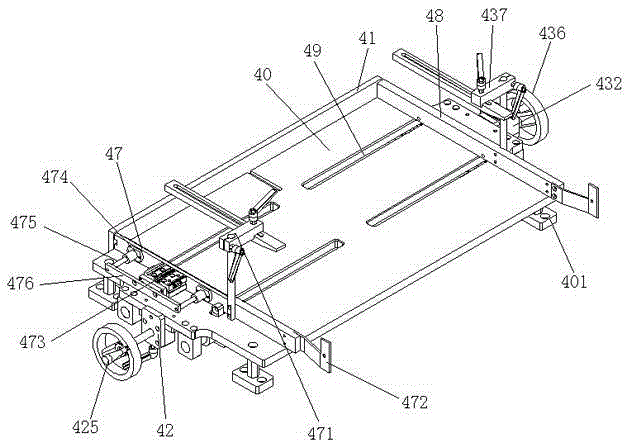

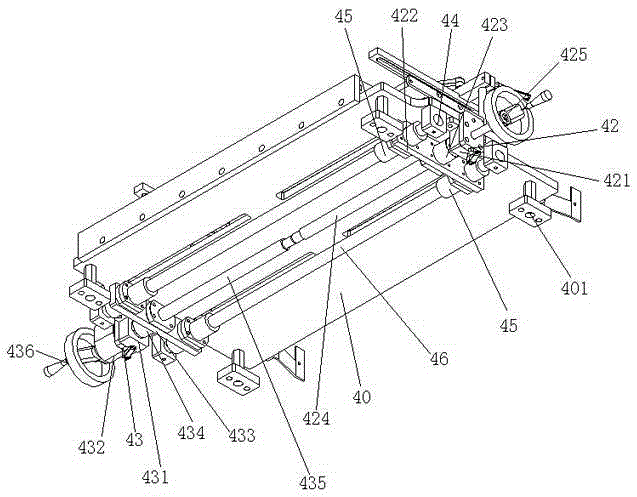

Conveying mechanism of automobile door

ActiveCN103482319AImprove delivery efficiencyKeep shapeConveyor partsMechanical conveyorsDrive shaftCar manufacturing

The invention relates to a conveying mechanism of an automobile door and belongs to the technical field of automobile manufacturing. The conveying mechanism of the automobile door comprises an underframe, a delivering mechanism, a transferring mechanism and guiding mechanisms, wherein the delivering mechanism, the transferring mechanism and the guiding mechanisms are arranged on the underframe, a climbing mechanism is arranged on the bottom of the delivering mechanism, the guiding mechanisms are symmetrically arranged on the two sides of the delivering mechanism and are fixed on the underframe, the transfering mechanism comprises a double-layered sliding rail, a motor, transmission shafts, main gears and pinions, the transmission shafts, the main gears and the pinions are arranged on the two ends of the motor respectively, the double-layered sliding rail comprises a lower sliding rail assembly and an upper sliding rail assembly, a first rack is correspondingly arranged above each main gear, a second rack is correspondingly arranged above each pinion, the first racks are meshed with the main gears, the second racks are meshed with the pinions, and the first racks and the second racks are fixedly connected to the upper sliding rail assembly and the lower sliding rail assembly respectively. The conveying mechanism of the automobile door has the advantages that the automation degree is high, the whole conveying process can be achieved stably, safety and reliability are guaranteed, quality of products is guaranteed, labor intensity of workers is relieved, and workpiece conveying efficiency is improved.

Owner:烟台宇信科技有限公司

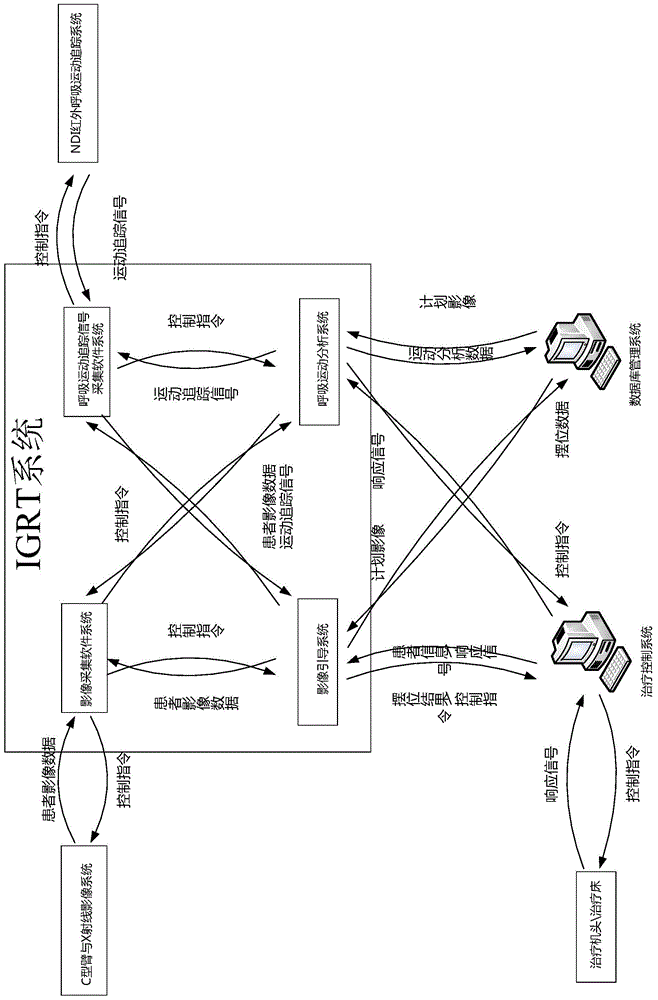

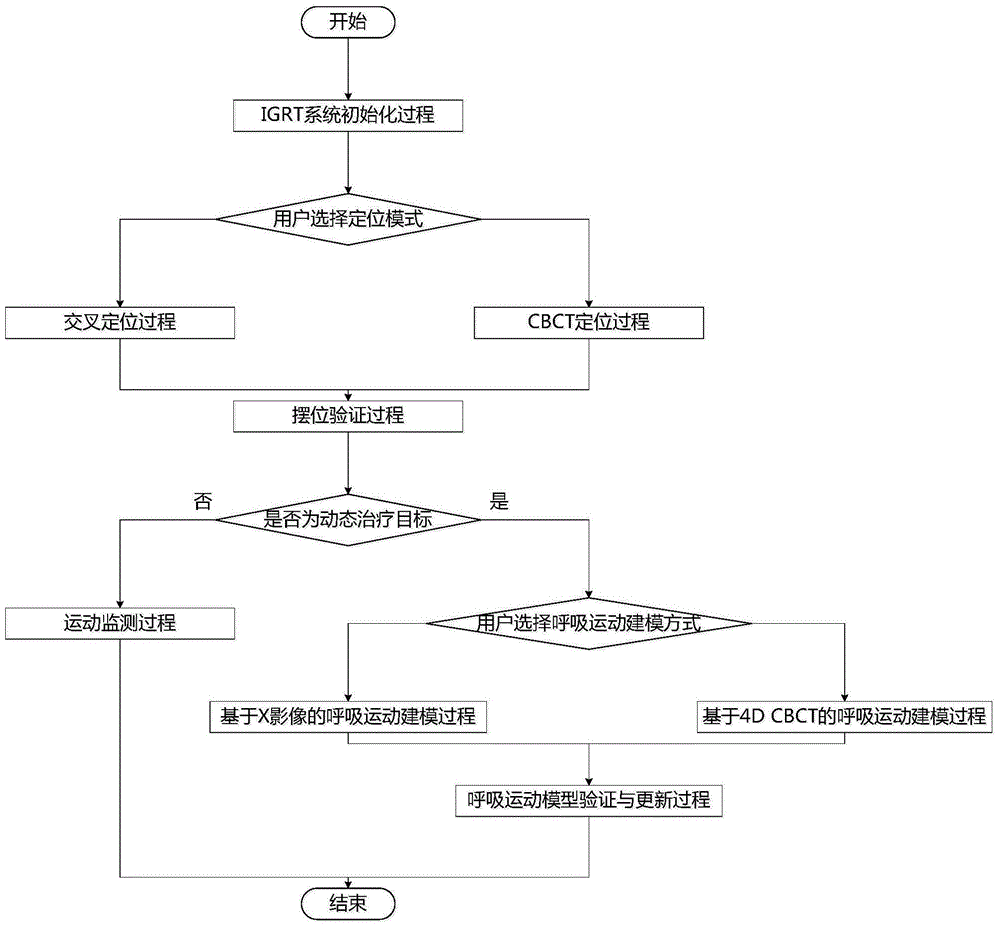

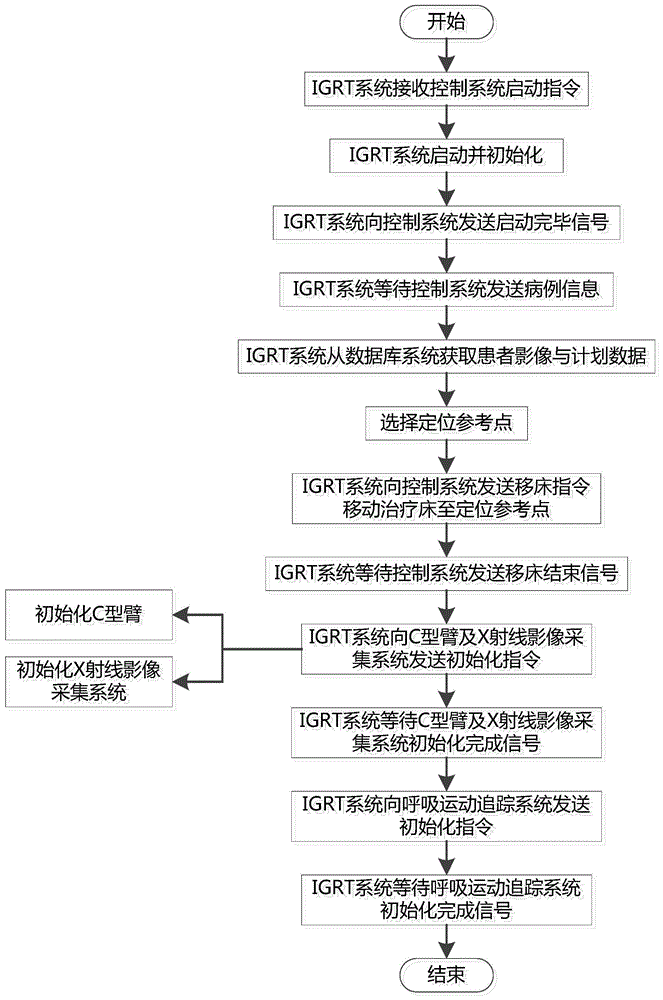

Image guide and breathing exercise analysis method

ActiveCN104888356ARapid positioningAccurate positioningComputerised tomographsTomographyCbct imagingAdaptive radiotherapy

The invention discloses an image guide and breathing exercise analysis method. According to the image guide and breathing exercise analysis method, on the basis of two patient positioning ways of a cross positioning two-dimensional X-ray image and a three-dimensional CBCT (Cone Beam Computed Tomography) image, patient positioning and adaptive radiotherapy analysis can be quickly and precisely performed before treatment by utilizing the three-dimensional CBCT image, and online monitoring of the patient posture change and real-time tracing of moving tissues can be performed under treatment by utilizing the cross positioning two-dimensional X-ray image. In addition, an individualized positioning method can be established aiming at different patients and different treatment positions.

Owner:RADIATION THERAPY MEDICAL SCI & TECH CO LTD

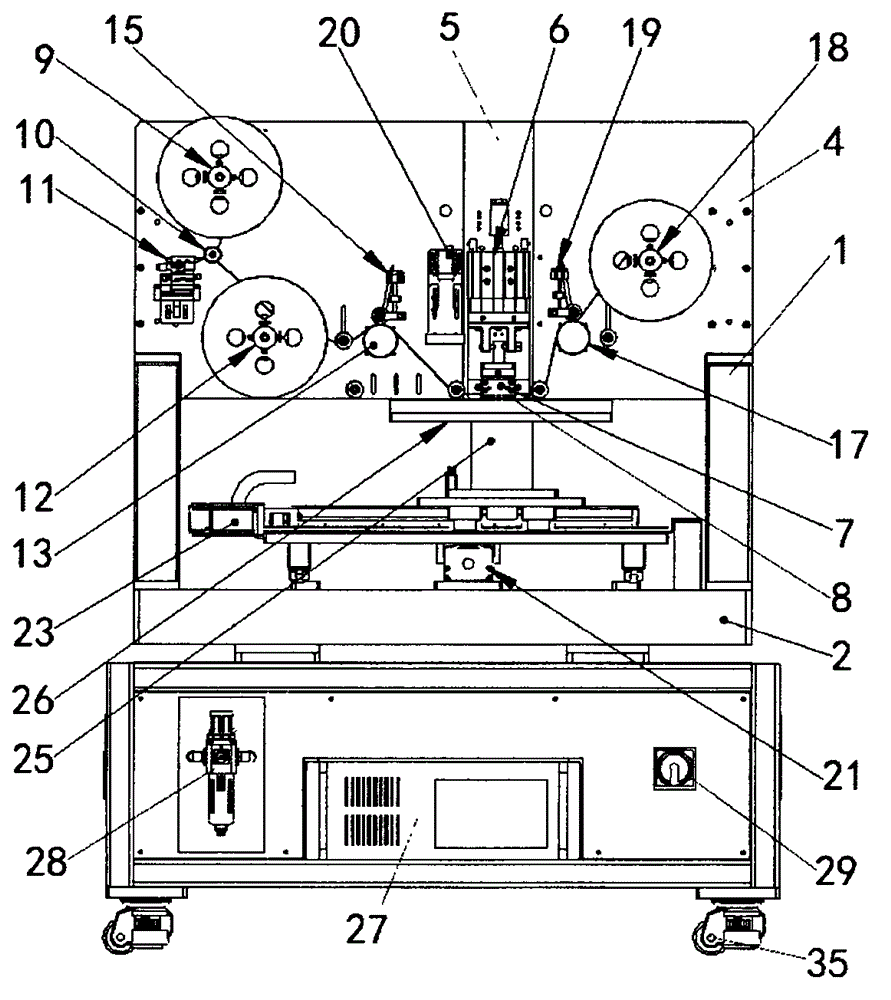

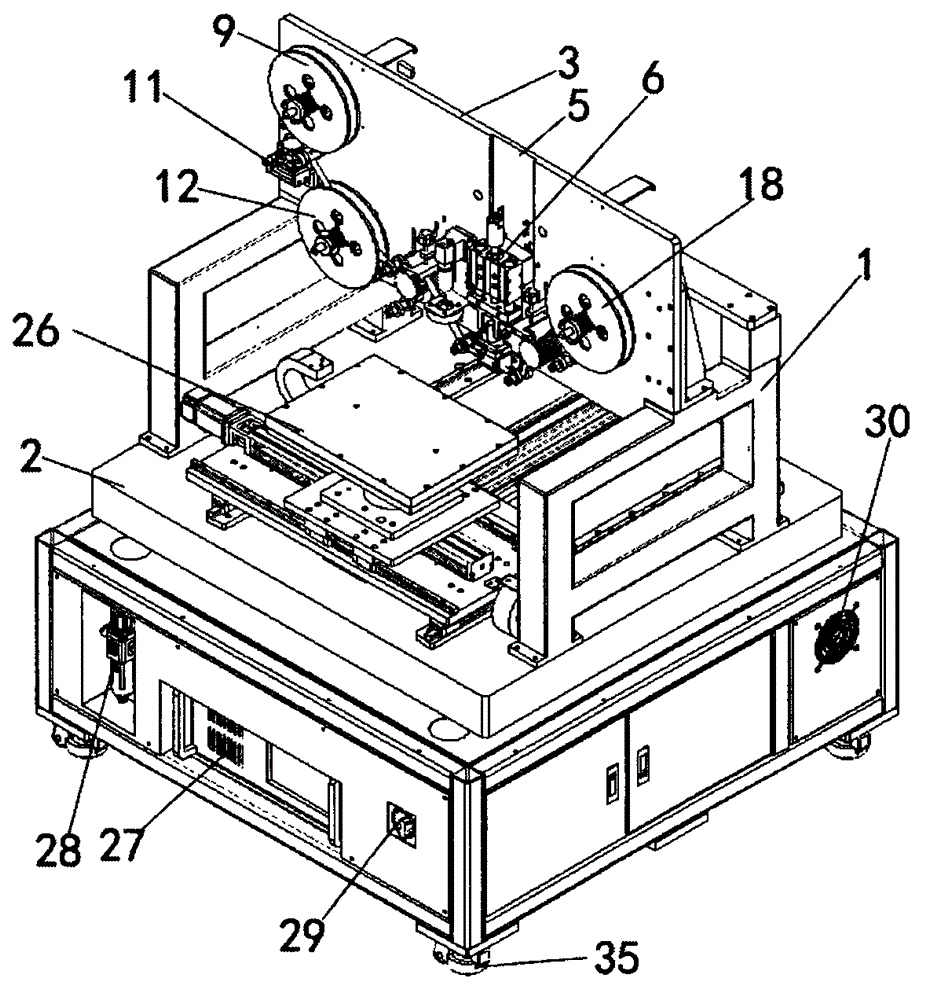

Automatic adhesive paper pasting equipment

InactiveCN106142214ARealize automated productionAccurate positioningPrinted circuit manufactureMetal working apparatusPulp and paper industrySteel frame

The invention discloses automatic adhesive paper pasting equipment which comprises a lower control mechanism and an upper operating mechanism. The upper operating mechanism comprises a steel frame, an operating platform, an upper hood and an image visual module, wherein a vertical template is fixed to the steel frame, a groove in the vertical direction is formed in the template, and a blanking module is mounted in the groove. A cutting die is horizontally fixed below the blanking module, and a flat channel layer is arranged in the cutting die. A conveying mechanism is arranged on one side of the flat channel layer, and a recovery mechanism is arranged on the other side of the flat channel layer. The conveying mechanism comprises an adhesive paper separator. A moving mechanism used for horizontally placing a circuit board is arranged in the steel frame and comprises a horizontally arranged jig. By means of the automatic adhesive paper pasting equipment, automatic production in an adhesive paper pasting procedure can be achieved, the cleanliness of adhesive paper pasting materials is guaranteed, separation of the adhesive paper pasting materials from release paper on the adhesive paper pasting materials is guaranteed, a winding phenomenon is avoided, and production efficiency is greatly improved.

Owner:LENSEND AUTOMATION TECH SUZHOU

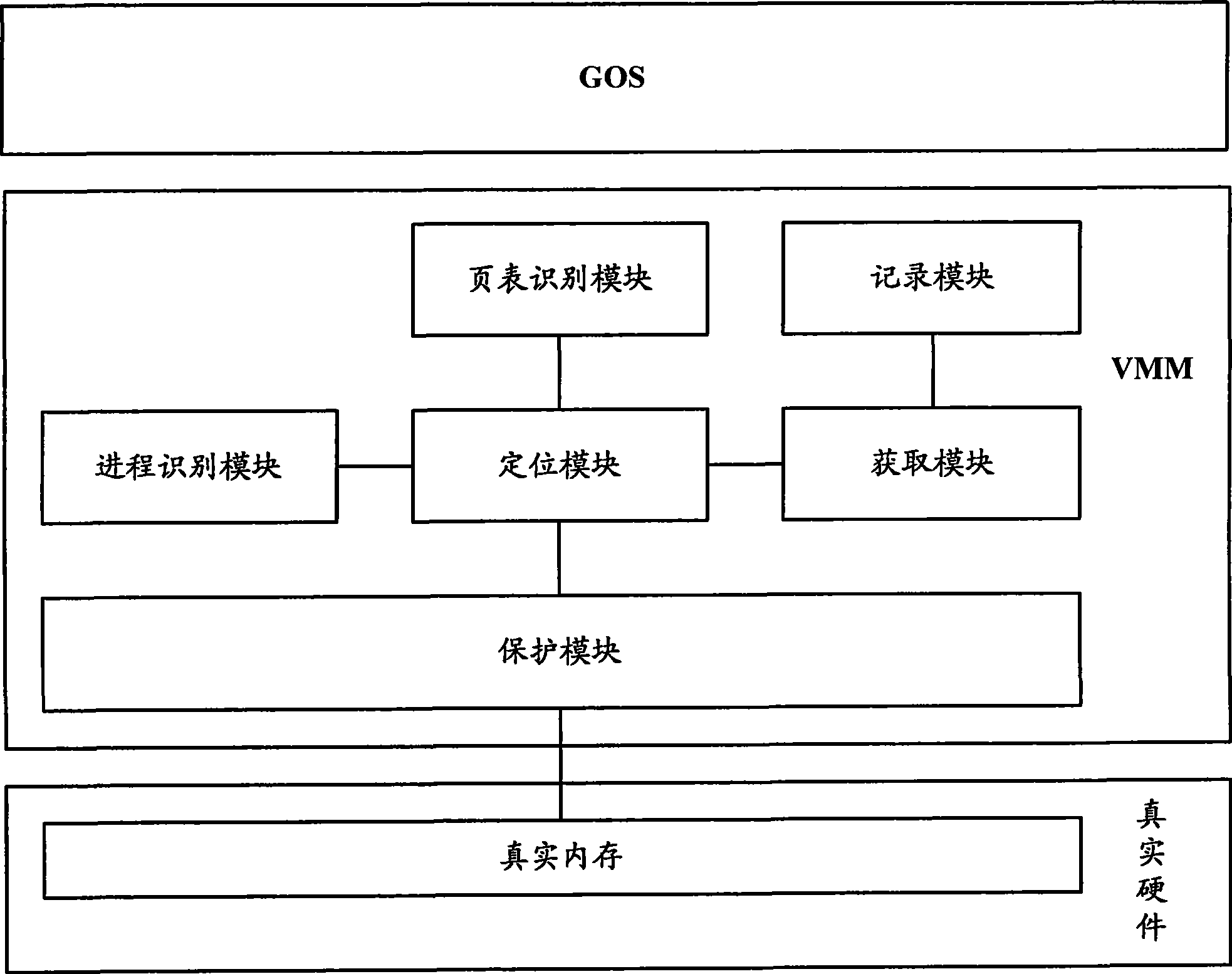

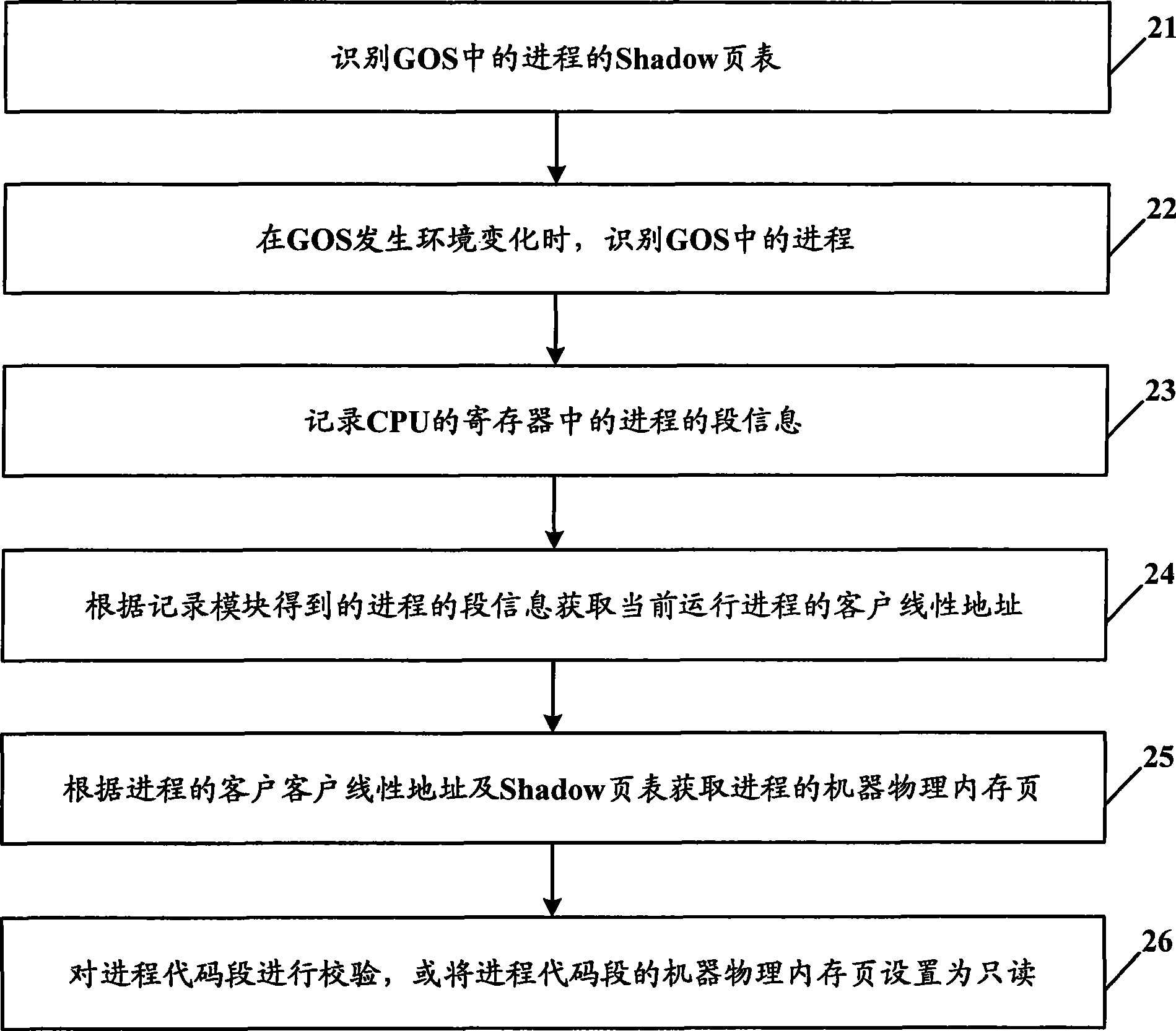

Virtual machine monitor, virtual machine system and process handling method of client operating system

ActiveCN101499016AEffective protectionProtection securityMultiprogramming arrangementsPlatform integrity maintainanceMemory addressOperational system

The invention provides a virtual machine monitor, a virtual machine operating system and a method of handling customers. The virtual machine monitor comprises an obtaining module used for obtaining process segmental information while the operating system is changing by the environment. According to the information referred to in paragraph referred to the process of acquiring customers linear address; the process of identification modules, described the process used to identify; Page Table Identity Module, used to identify the process of identification modules described in the process of identification of the corresponding shadow page table, shadow page table above are described in Records of customer and machine linear physical memory address page Address correspondence; positioning module for customers under the above mentioned linear address and the shadow page table location described in the process of physical machines memory page. The invention has an accurate realization of the machine process the positioning of physical memory pages; at the same time, protecting the process the security of that system.

Owner:LENOVO (BEIJING) LTD

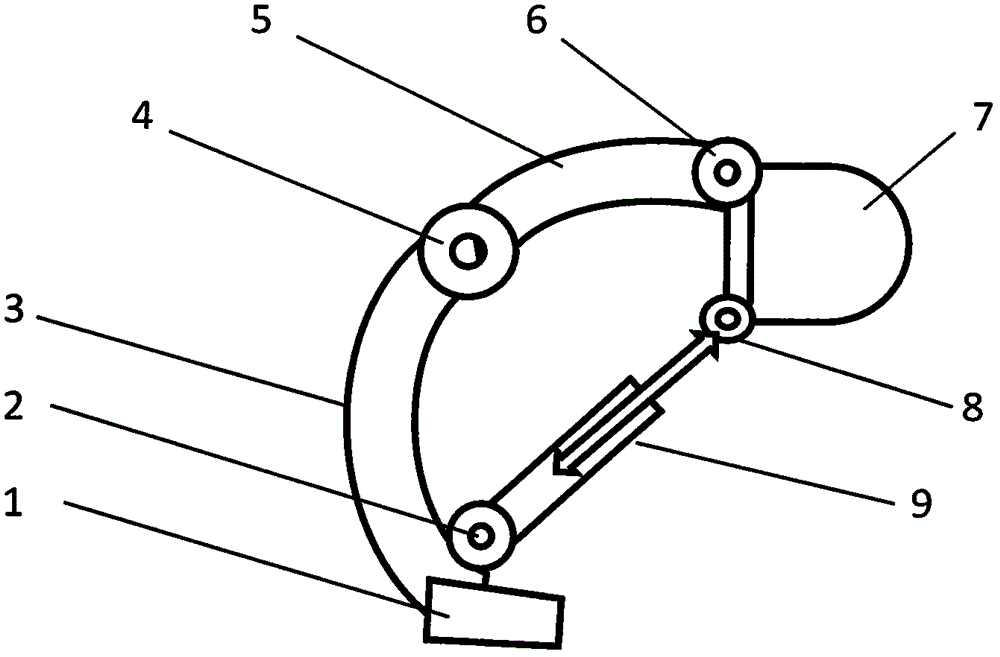

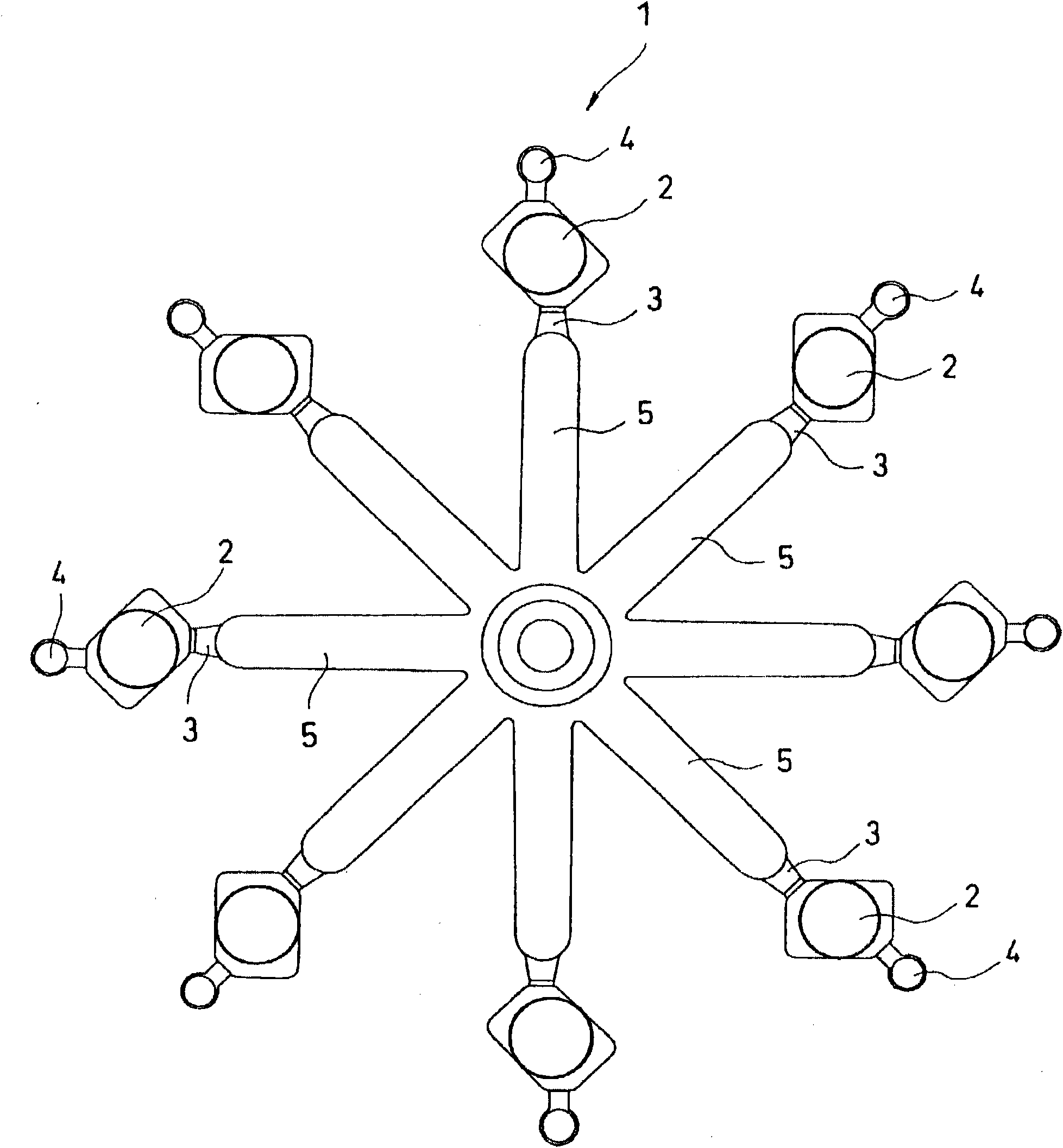

Revolving garlic cirrus cutter with arc-like orbit and cutting assembly

The invention relates to a revolving garlic cirrus cutter with an arc-like orbit. The revolving garlic cirrus cutter is characterized by comprising a revolving shaft (7c), wherein a pair of support plates (7b) is symmetrically fixed at the two ends of the revolving shaft (7c); the support plates (7b) are regular polygons; cirrus cutting blades (7a) are obliquely fixed on each side edge of the pair of support plates (7b); the cutting edge of each cirrus cutting blade (7a) is the same in the installing direction and the inclination angle; and when the garlic cirrus cutter rotates by taking the revolving shaft (7c) as an axle center, cutting orbits formed by the plurality of cirrus cutting blades (7a) are of arc-like shapes. The bottom side face of garlic is convex, so that the probability of damages to the garlic can be lowered if the middle part of a cirrus cutting arc is concave downwards; since garlic cirrus is scattered radially, the cirrus cutting arc contributes to the orderliness of the remaining garlic cirrus left after cutting as well as the expansion of a cirrus cutting range; and a slide cutting effect is achieved, the separation of the garlic cirrus is facilitated, and meanwhile impact during cirrus cutting is reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

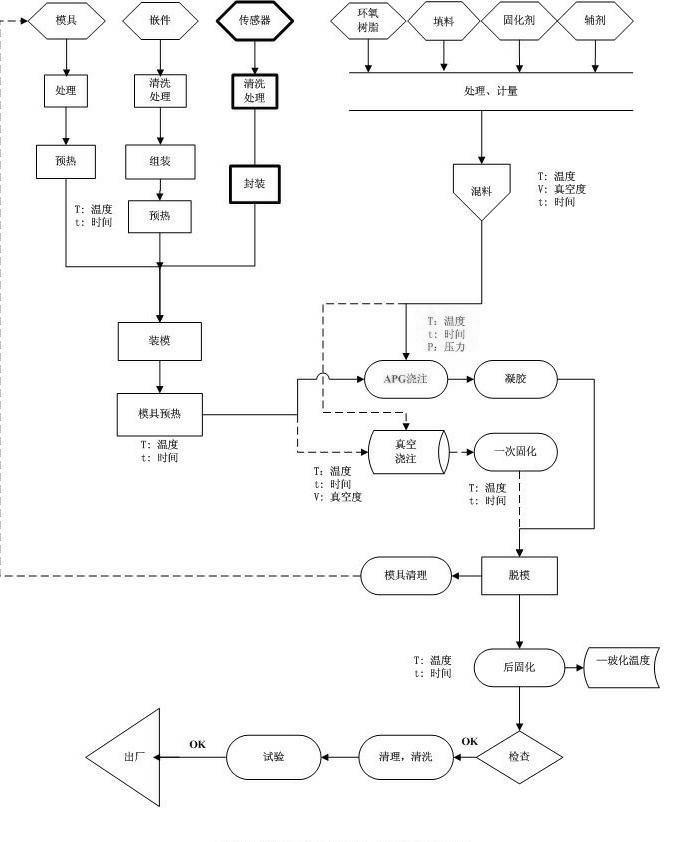

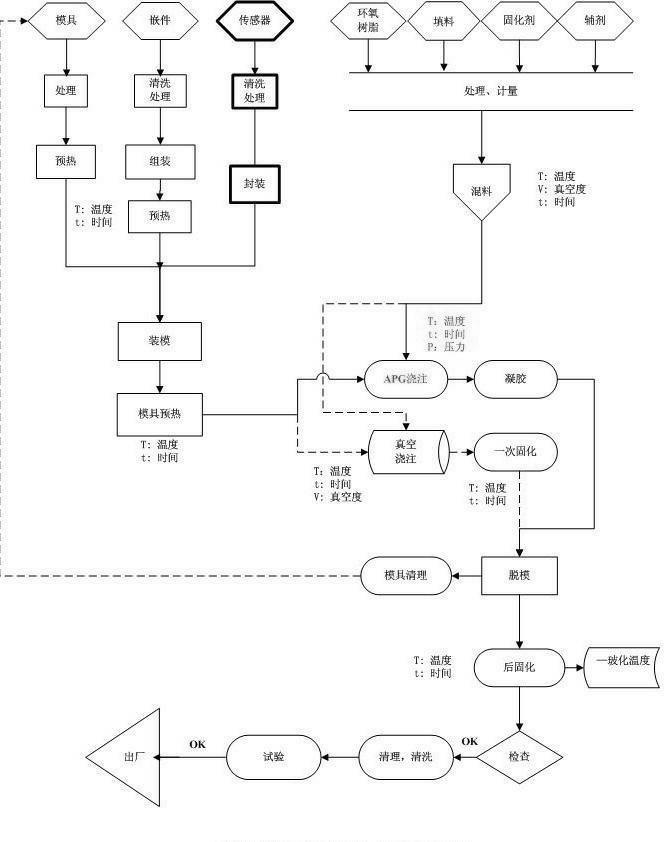

Method for producing insulator or contact box with temperature and/or voltage sensor

ActiveCN102211375AAccurate measurementAccurate measurement positionInsulatorsState of artCommunications system

The invention discloses a method for producing an insulator or a contact box with a temperature and / or voltage sensor. The method comprises the following steps of: a) loading an insert and the sensor into a mold, and preheating; b) mixing materials; c) pouring; d) demoulding; and e) post-curing. Compared with the prior art, the invention has the advantages that: 1) the voltage or / and temperature sensor is sealed inside the contact box or the insulator, so that the interference of outside dirty, light, heat, mechanical deformation and the like to signals is prevented; through an optical fiber transmission signal, the problem of high-voltage insulation is solved and the hidden danger that high voltage enters a low-voltage control system and a communication system is eliminated; 2) the temperature sensor is used to be directly contacted with a detected position, so that the method is accurate in measurement positions and measurement temperatures and high in reliability and safety, and has the characteristics of accurate detection temperature, low discreteness, no temperature upper limit and no temperature compensation simultaneously; and 3) an optical temperature sensor is not subjected to outside electromagnetic interference, so that the stability of a temperature signal is ensured.

Owner:麦克奥迪(厦门)智能电气有限公司

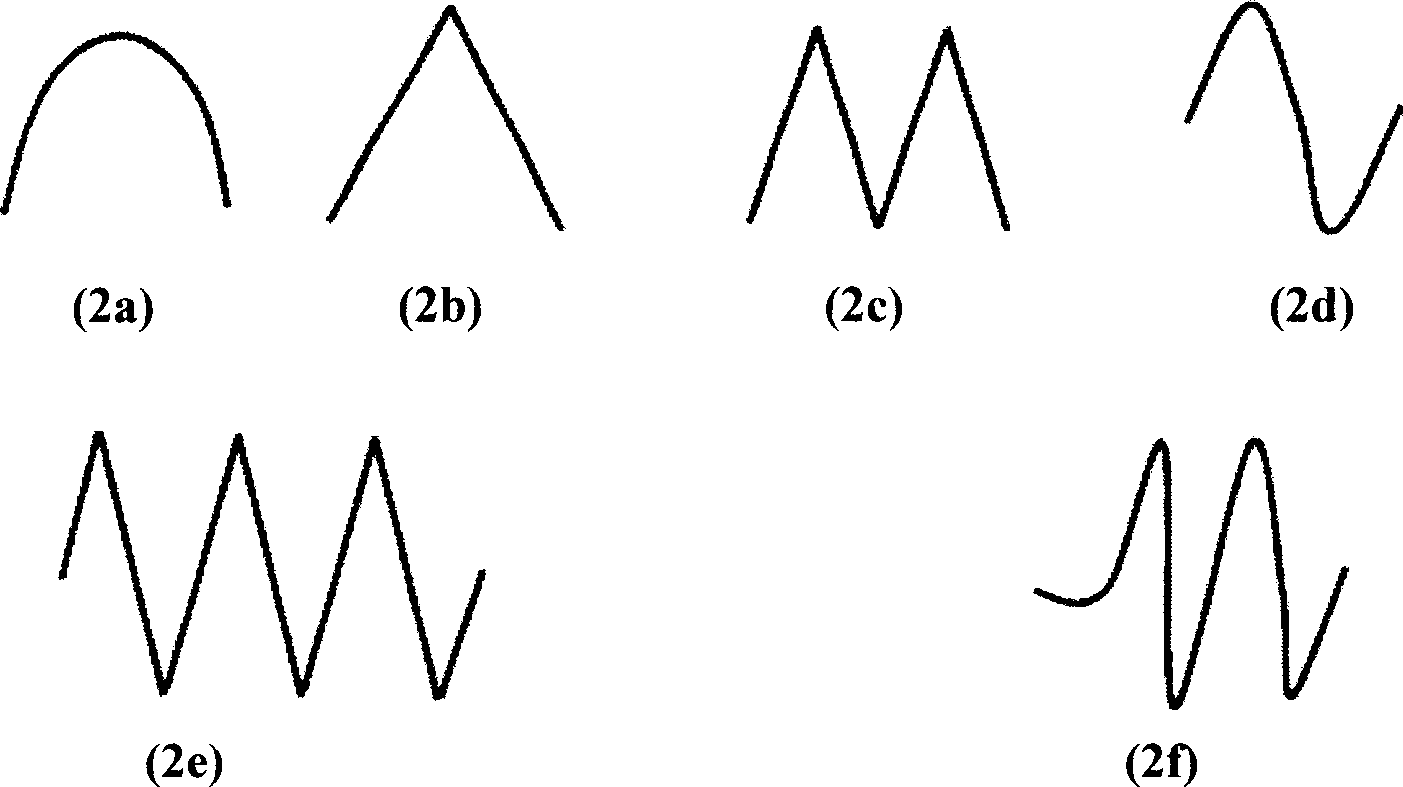

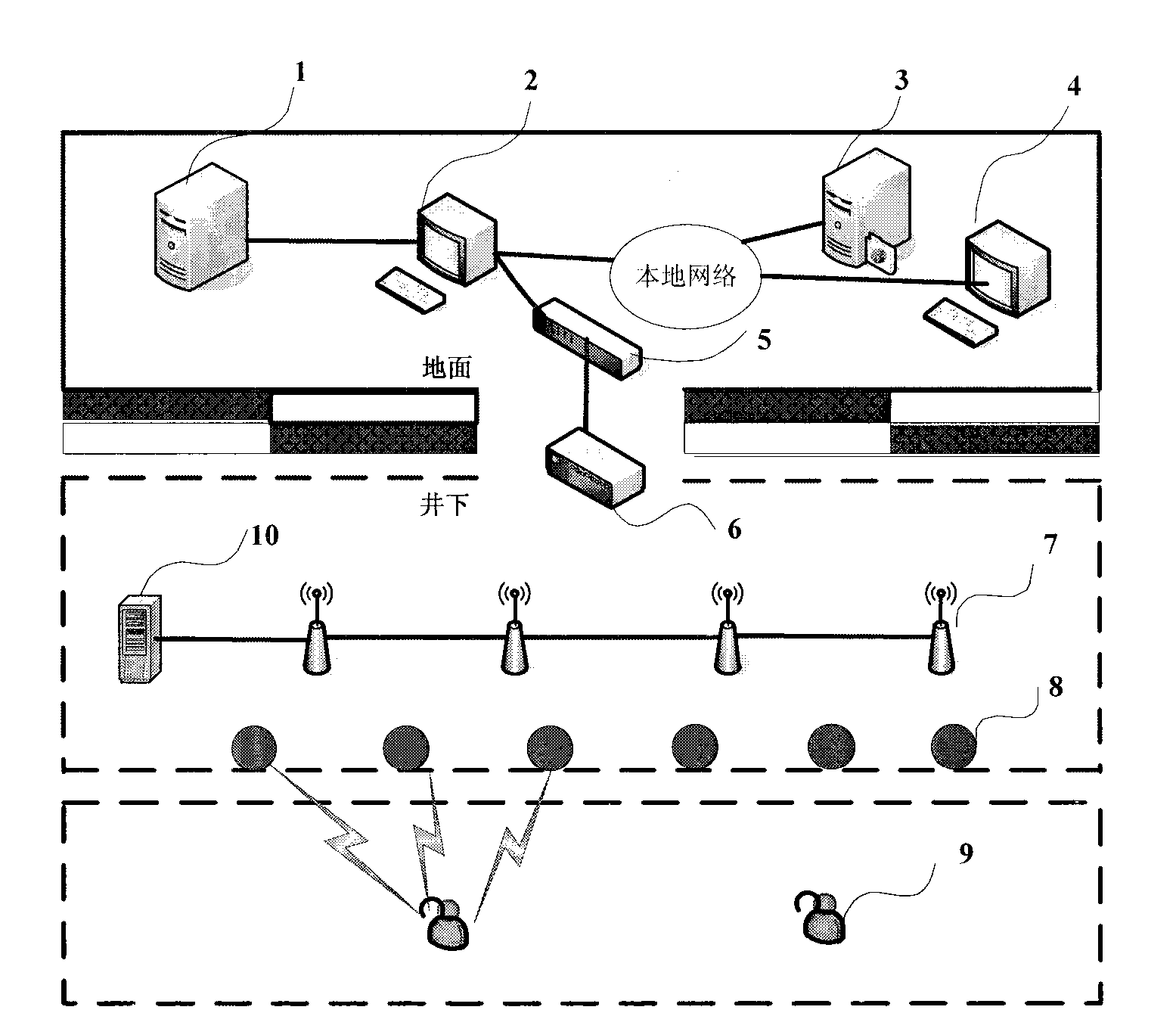

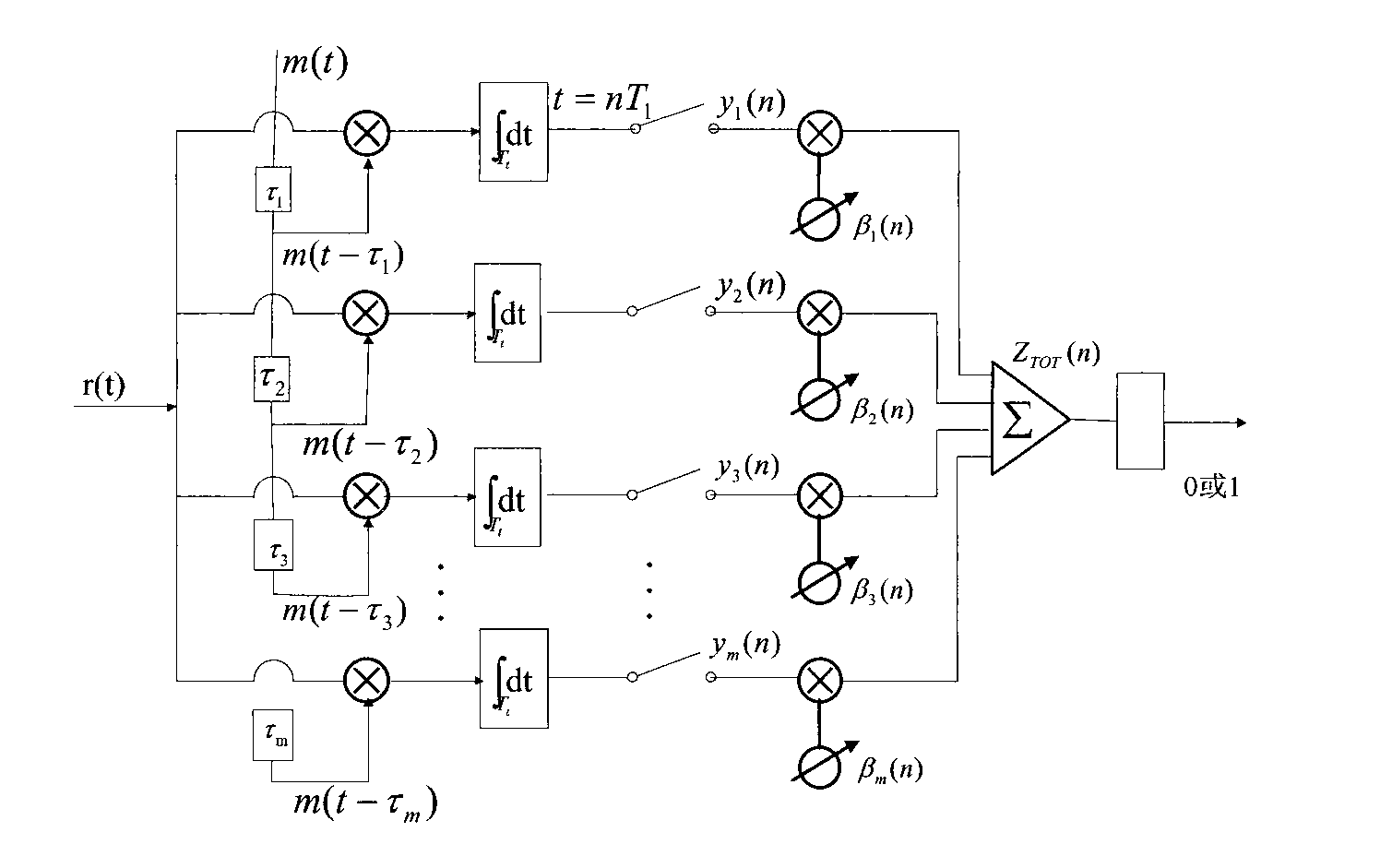

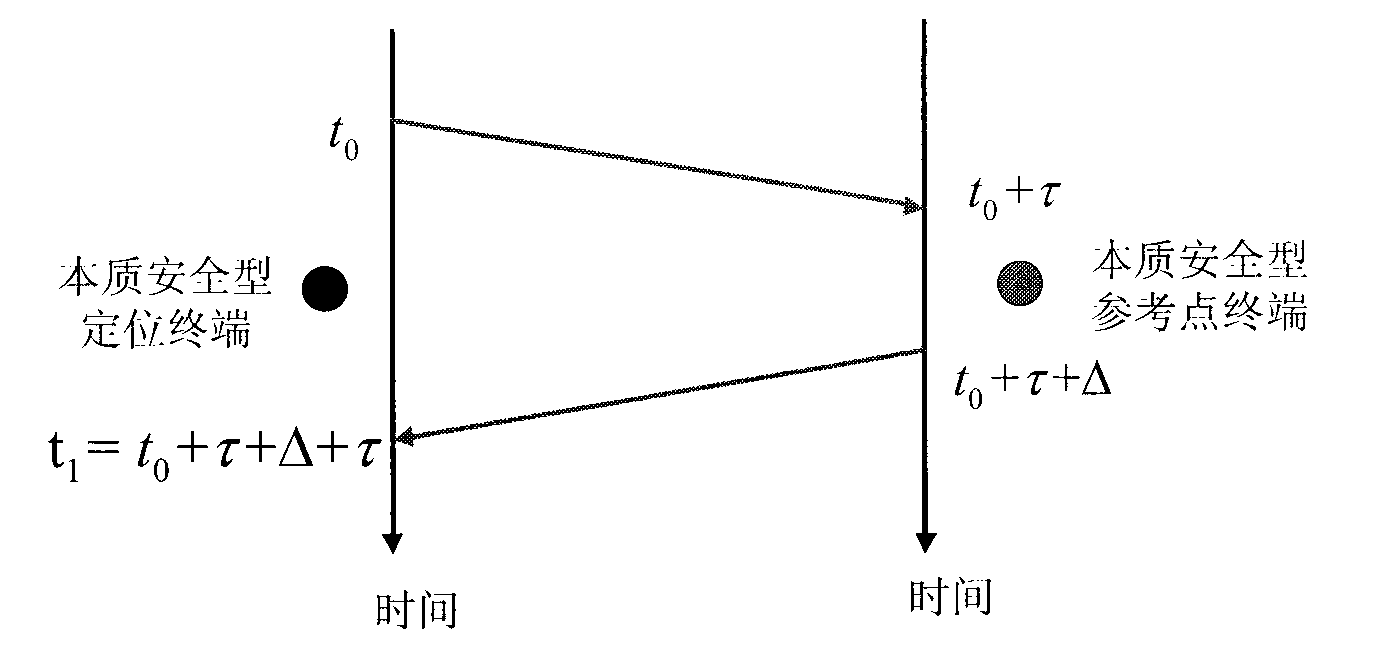

Mine ultra-wide band locating method and system based on non-line-of-sight inhibition

InactiveCN102832966AShort durationImprove spatial resolutionSpatial transmit diversityTransmission monitoringIntrinsic safetyAnti jamming

The invention discloses a coal mine under-well ultra-wide band locating method and a coal mine under-well ultra-wide band locating system. The method comprises the following steps: by adopting a RAKE receiver technology, collecting multipath components in signals, and weighing the multipath components; performing non-line-of-sight identification on the signals by utilizing the constructed identification parameters, performing data reconstruction on the non-line-of-sight signals, and performing location calculation by adopting a Taylor sequence expansion method and utilizing the reconstructed data and line-of-sight signals. The system comprises a well-surface part and an under-well part. The well-surface part comprises a ground monitor terminal, a locating server, a central switch, a dynamic host configuration protocol server, and an upper layer terminal; the under-well part comprises an intrinsically safe gateway, an intrinsically safe direct current power supply, an intrinsically safe wireless relay station, an intrinsically safe reference point terminal and an intrinsically safe locating terminal. The ultra-wide band locating method and the ultra-wide band locating system are simple in structure, accurate in positioning and strong in anti-jamming ability, can effectively inhibit multipath effect and non-line-of-sight effect, and meet use requirements of the mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Full-automatic shifting machine

InactiveCN104814841ARealize self-controlled movementRealize automatic comfort fixationWheelchairs/patient conveyanceWheelchairRemote control

Owner:许征文

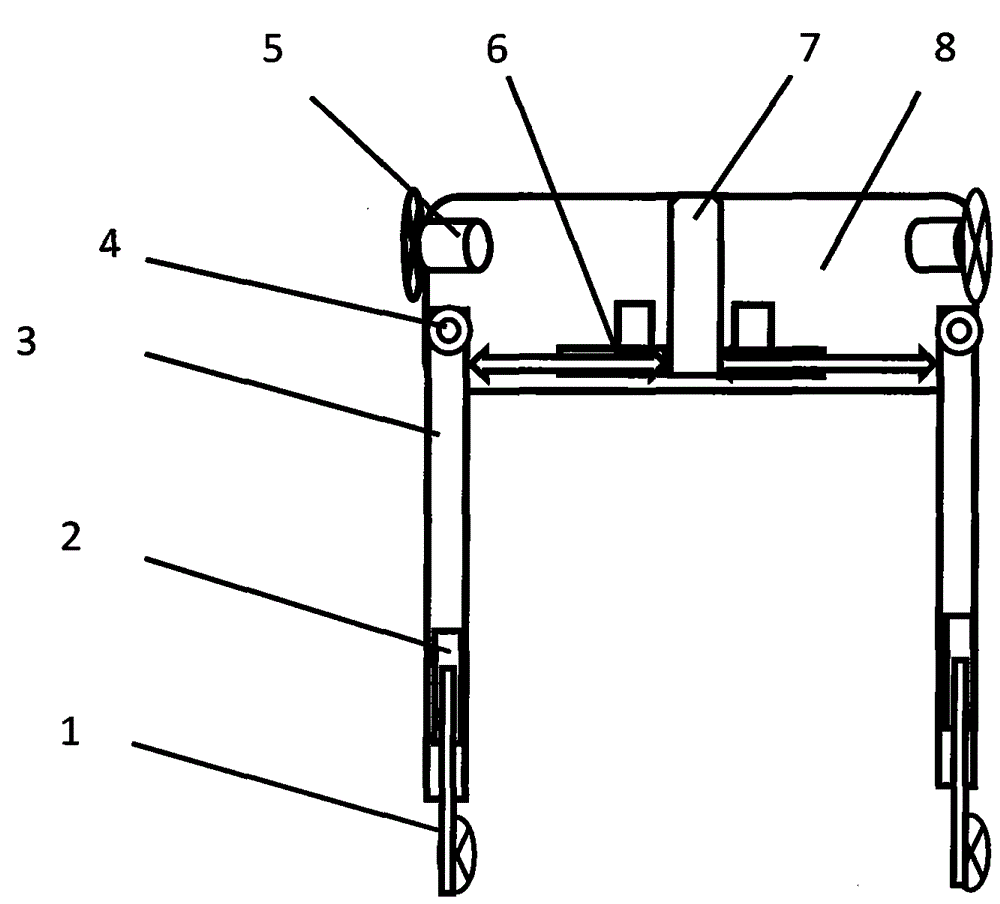

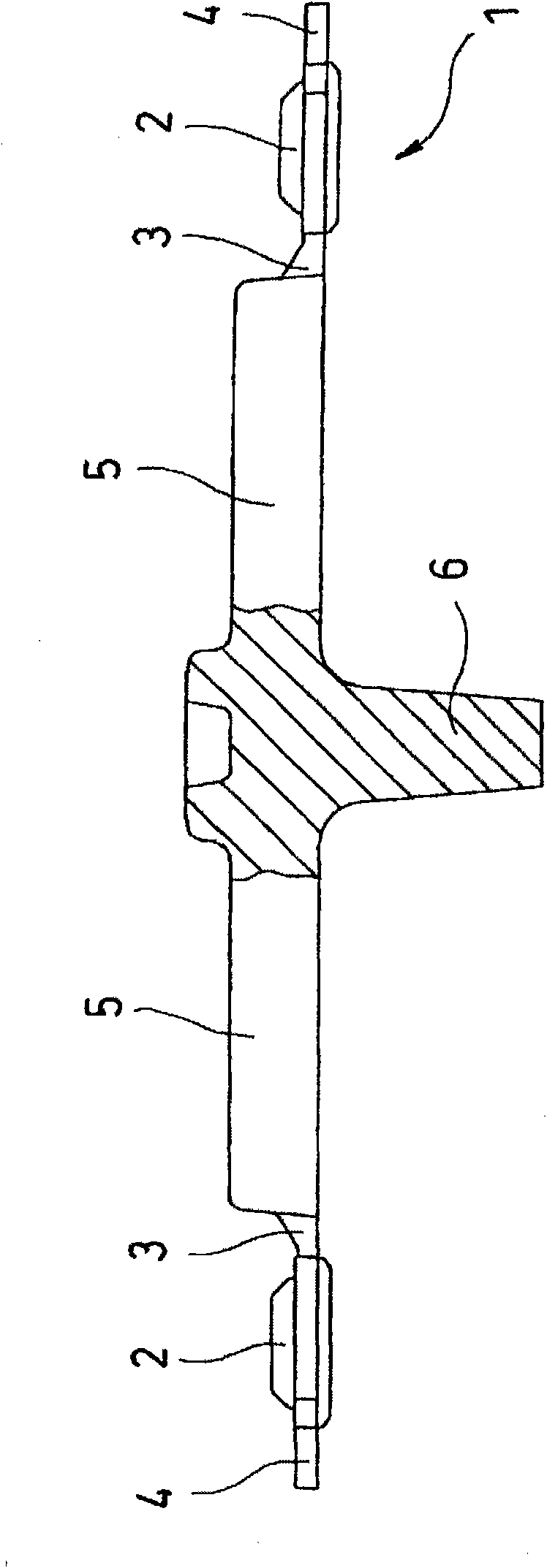

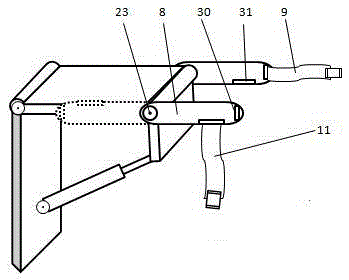

Device for cutting off root hairs of garlic using copying of spring protecting knife

ActiveCN104126855ARealize automatic root cuttingEffective protectionFood treatmentVertical barCopying

The invention relates to a device for cutting-off root hairs of garlic using the copying of a spring protecting knife. The device is characterized by comprising a pair of cross beams (1), wherein the cross beams (1) are used for supporting an alignment chain (8), vertical bars (2) are fixed on the cross beams (1) and extend downwards, the lower ends of the vertical bars (2) are hinged to supporting beams (3), a root hair cutting component is fixedly arranged at the tail ends of the supporting beams (3), and the supporting beams (3) are connected with the cross beams (1) or the vertical bars (2) through regulating springs (11); the root hair cutting component comprises a copying spring (5) which is horizontally arranged, a hair cutting knife wheel (7) is arranged in a coaxial manner with the copying spring (5) and is driven by a motor (6), the outer diameter of the hair cutting knife wheel (7) is smaller than that of the copying spring (5), and hair cutting knives (7a) on the hair cutting knife wheel cut off root hairs extending in gaps of the copying spring (5).

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Process for producing molded item of thermosetting resin and injection molding machine therefor

InactiveCN101557916AImprove cooling effectEasy to demouldOptical articlesInjection molding machineLiquid resin

A process for producing a molded item of thermosetting resin, and injection molding machine therefor, capable of preventing burring and bubble inclusion at molding operation. There is provided a process for producing a molded item of thermosetting resin with the use of a mold having a cavity for forming a product part, a gate forming a gate part, a runner forming a runner part and an overflow catcher communicating with the cavity and forming an overflow part, which process comprises the injection step of injecting a liquid resin until filling the region from the runner through the gate to the cavity and further the region from the cavity to the overflow catcher; the hardening step of heating the liquid resin within the mold so as to effect hardening; the demolding step of detaching a resin molded item having the runner part, gate part, product part and overflow part from the mold; and the cutting step of cutting the gate part and overflow part off the product part of the demolded resin molded item.

Owner:TOSHIN SEIKO CO LTD +1

Object space positioning method and device in three-dimensional virtual reality scene

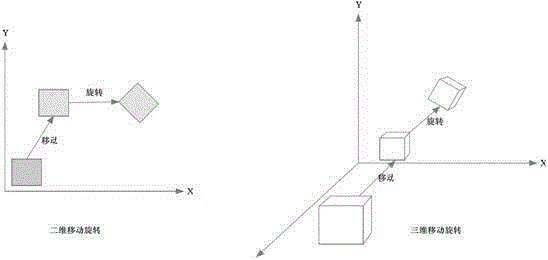

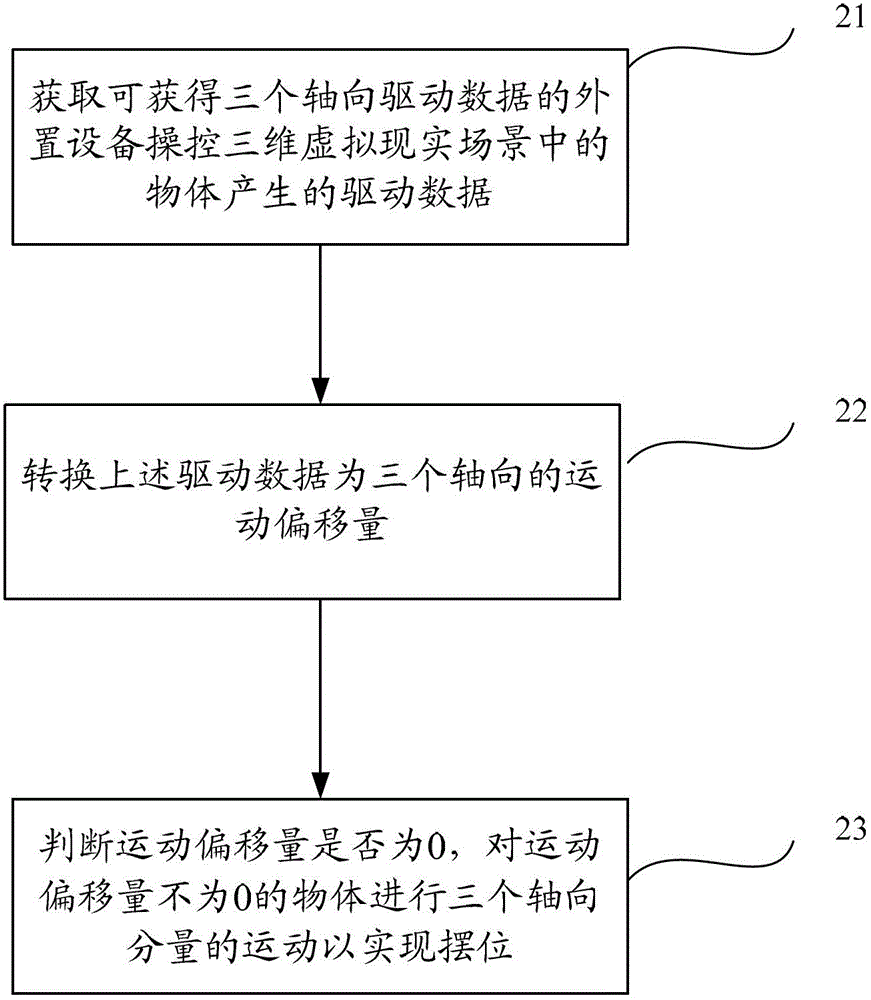

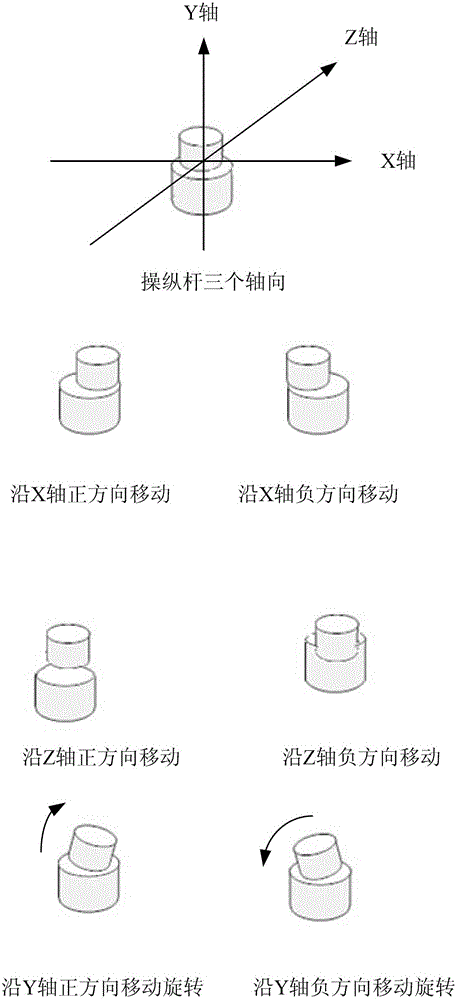

ActiveCN102722908AAccurate positioningShorten design timeInput/output processes for data processing3D modellingComputer visionVirtual reality

The invention discloses an object space positioning method and device in a three-dimensional virtual reality scene. According to the object space positioning method, an external device capable of obtaining three pieces of axial drive data can be used for moving objects in the three-dimensional virtual reality scene to obtain motion offset (including movement offset and rotation offset) of the objects, and thus the exact space placing position of the objects in the three-dimensional virtual reality scene can be finished only in a three-dimensional view, and other views only taken as visual reference objects are placed on operation positions; and therefore, the design time of designers of the three-dimensional virtual reality scene is shortened, and the work load is reduced.

Owner:北京三维直点科技有限公司

Vision positioning mechanism

ActiveCN105300359AAccurate positioningPrecise positioningPicture taking arrangementsControl systemVisual positioning

The invention relates to a vision positioning mechanism which comprises an underframe, an electric cabinet, a camera fixing frame, a feeding platform, a camera fixing mechanism, a conveyer belt, a back-and-forth nudge mechanism, a feeding transmission mechanism, a rotational positioning mechanism and a control system. The vision positioning mechanism has a vision positioning function. Facial tissue is conveyed through the conveyer belt to beneath the camera fixing mechanism. The camera fixing mechanism takes a picture and feeds back three-dimensional spatial position information of the facial tissue to the control system. A paper box is conveyed through the feeding platform. After the rotational positioning mechanism absorbs the paper box, the feeding transmission mechanism is controlled according to positioning information sent by the control system to move to the right to a positioning point at the right side of the paper box. Meanwhile, the control system controls the back-and-forth nudge mechanism to move forwards to a positioning point at the front side of the paper box. The rotational positioning mechanism moves downwards to accurately position the absorbed paper box onto the facial tissue so as to make the facial tissue and the paper box to be accurately positioned and fit each other. The vision positioning mechanism has advantages of high automation degree and intelligent operation degree, good effect, high efficiency and low cost, and is simple to use.

Owner:广东力顺源智能自动化有限公司

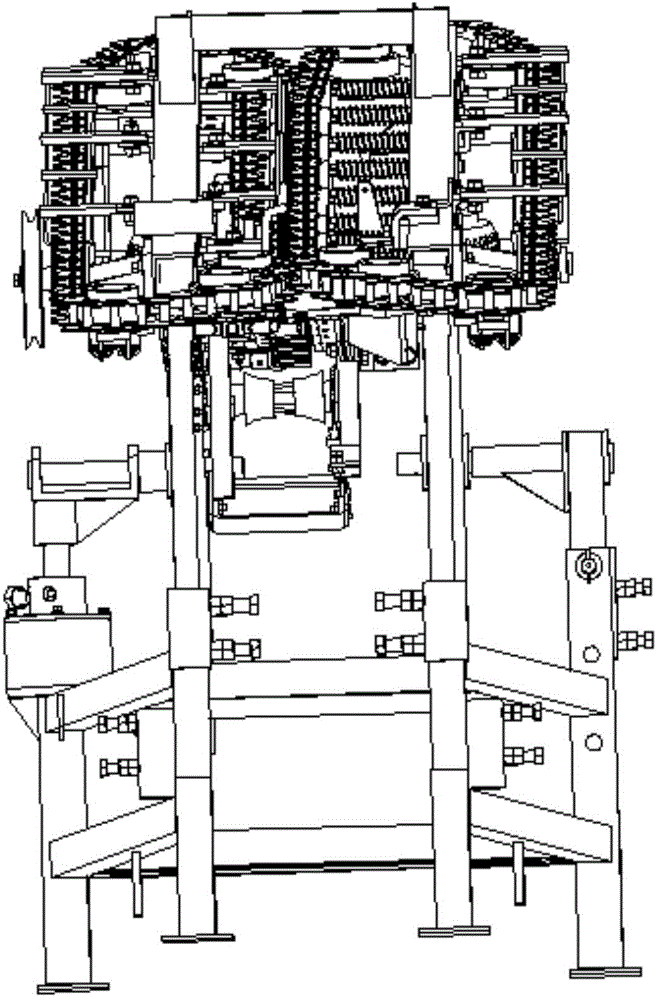

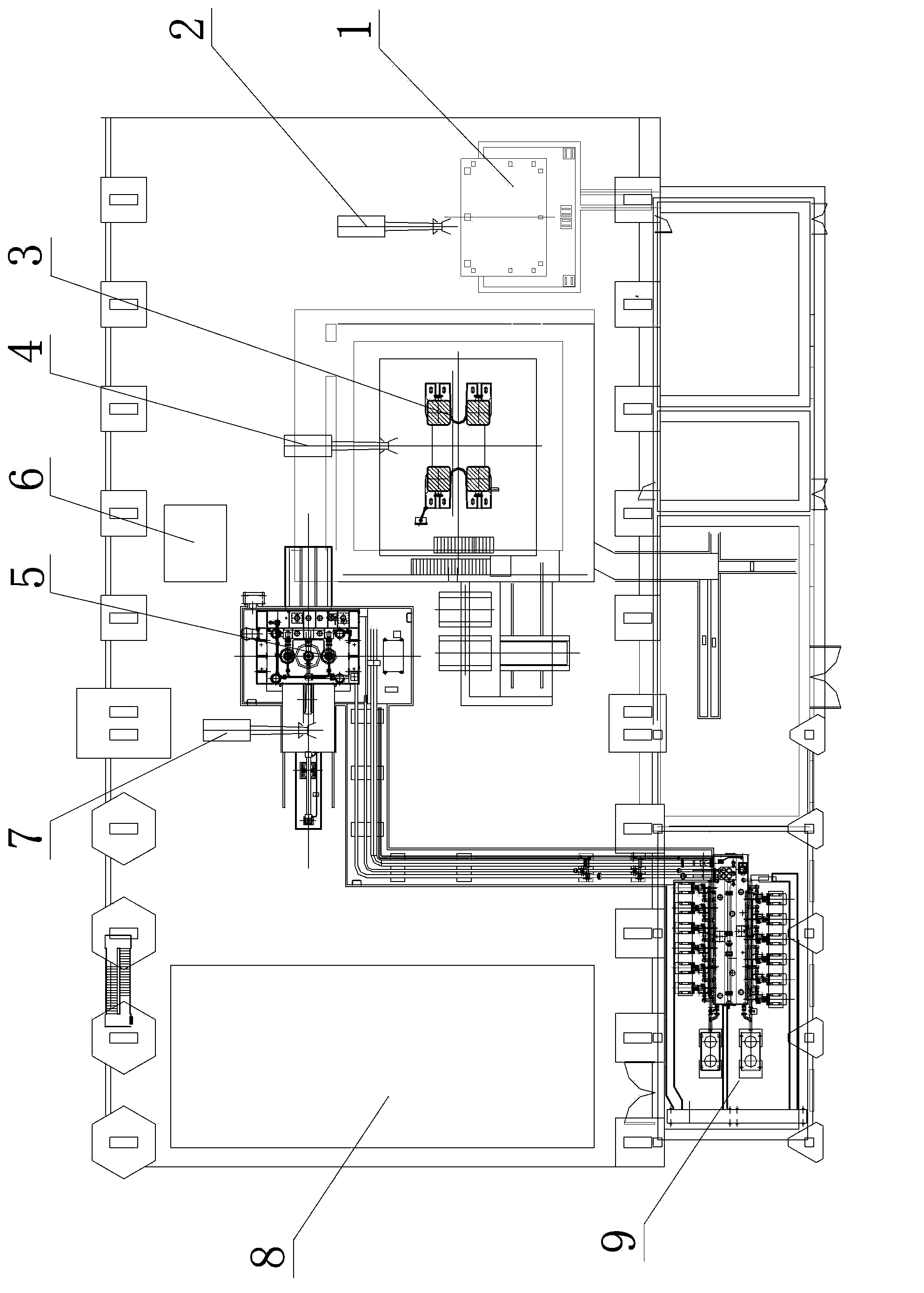

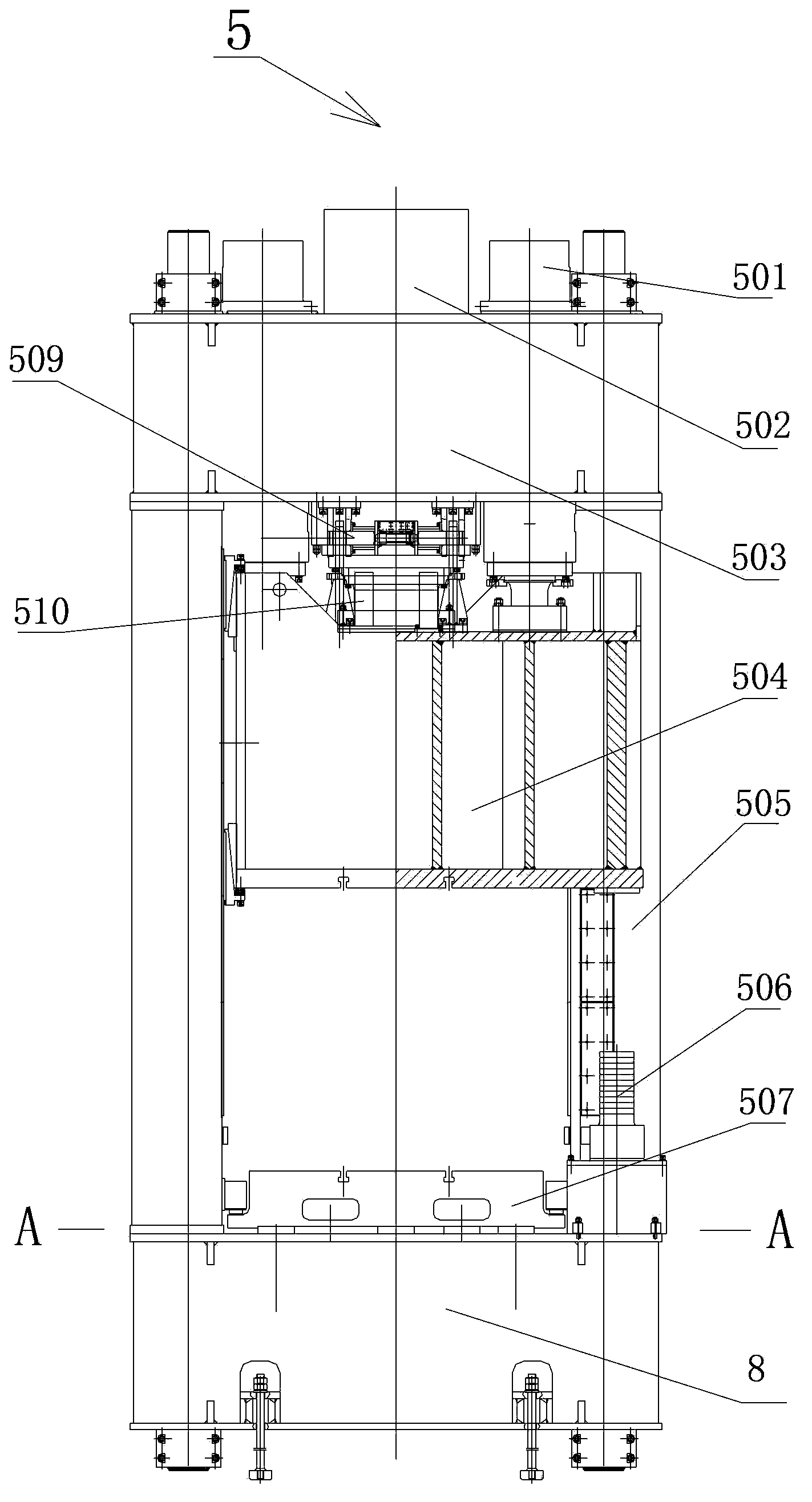

Full-automatic pressing production line for large turbine blade

ActiveCN104338887ASimple structureQuick and easy die changeEngine componentsHandling devicesManipulatorTurbine blade

The invention relates to a full-automatic pressing production line for a large turbine blade. The full-automatic pressing production line for the large turbine blade is characterized by comprising a gas heating furnace, a plurality of operation manipulators, a blade pre-profiling hydraulic machine, a blade shaping and trimming hydraulic machine, a workpiece flash waste material collecting device and a finished product storage device, wherein the gas heating furnace is positioned on one side of the pre-profiling hydraulic machine; the first operation manipulator is arranged on the other side of the gas heating furnace; the second operation manipulator is arranged on the other side of the pre-profiling hydraulic machine; the blade shaping and trimming hydraulic machine is arranged on the other side of the second operation manipulator; the flash waste material collecting device and the third manipulator are respectively arranged on the side which is close to the blade shaping and trimming hydraulic machine; and the finished product storage device is arranged on the other side of the blade shaping and trimming hydraulic machine. The full-automatic pressing production line has the advantages that workers do not need to operate in high-temperature and severe environments, the labor intensity is reduced, die changing operation is safe and reliable, flash waste materials can be quickly separated from one another conveniently, materials are discharged automatically, the movable worktable can be positioned accurately, and the product quality and the production efficiency can be greatly improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

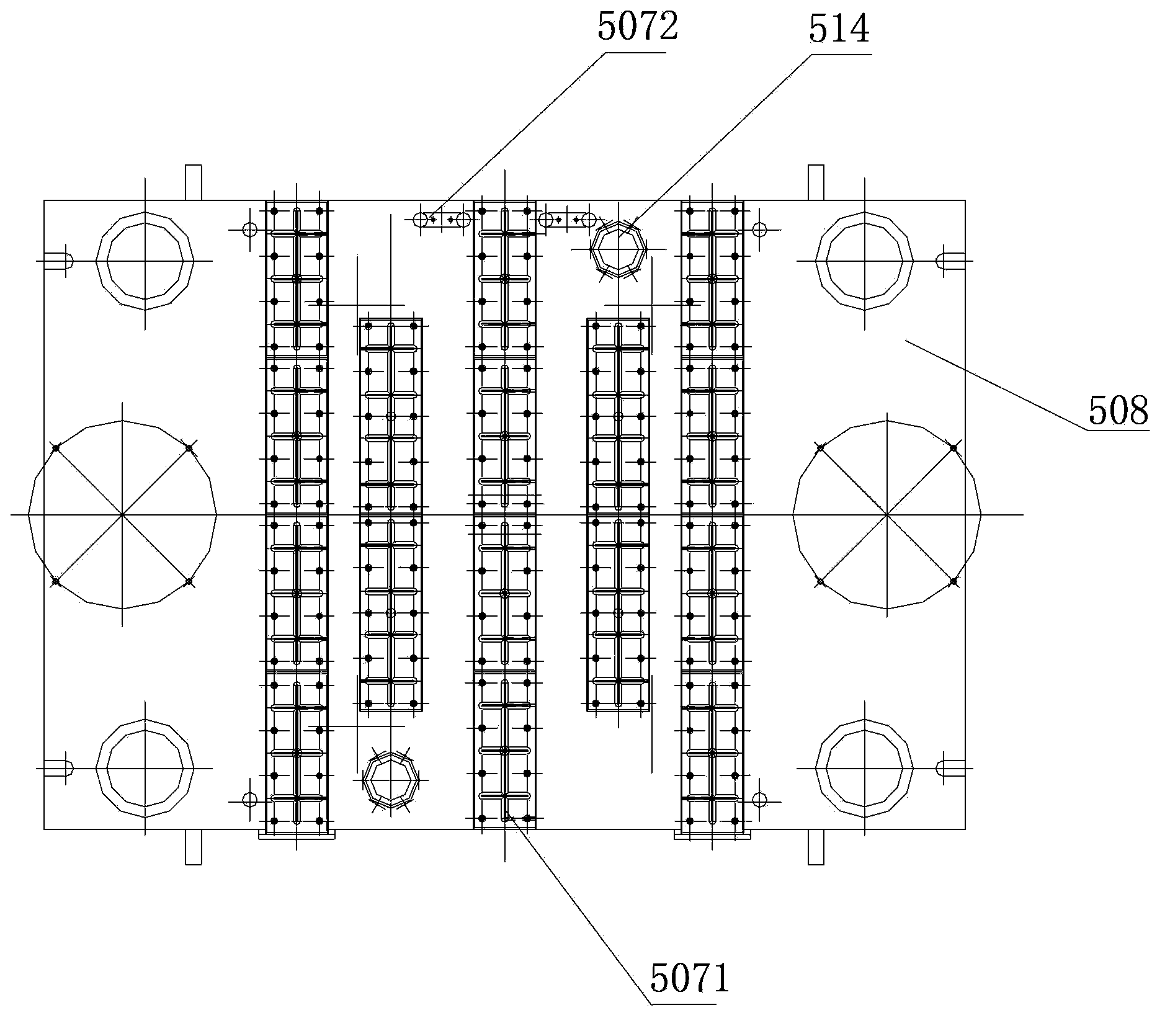

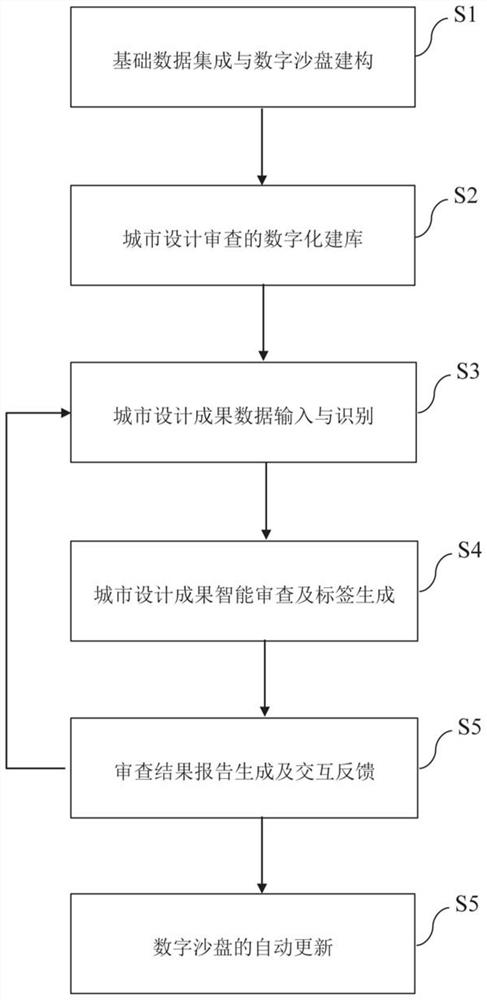

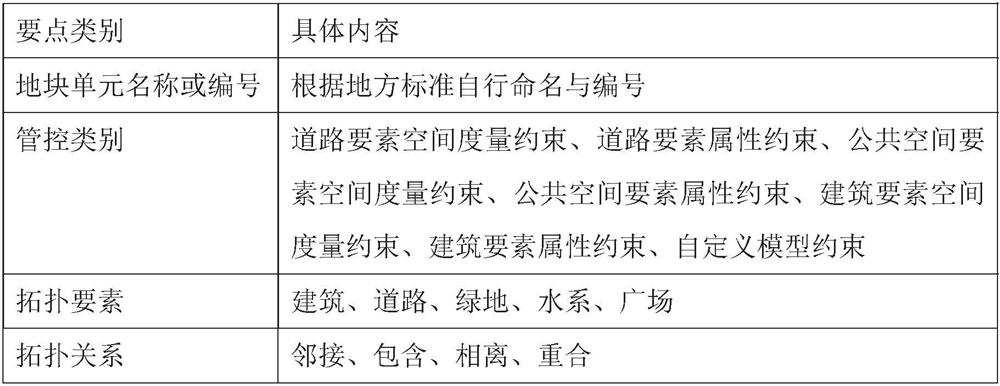

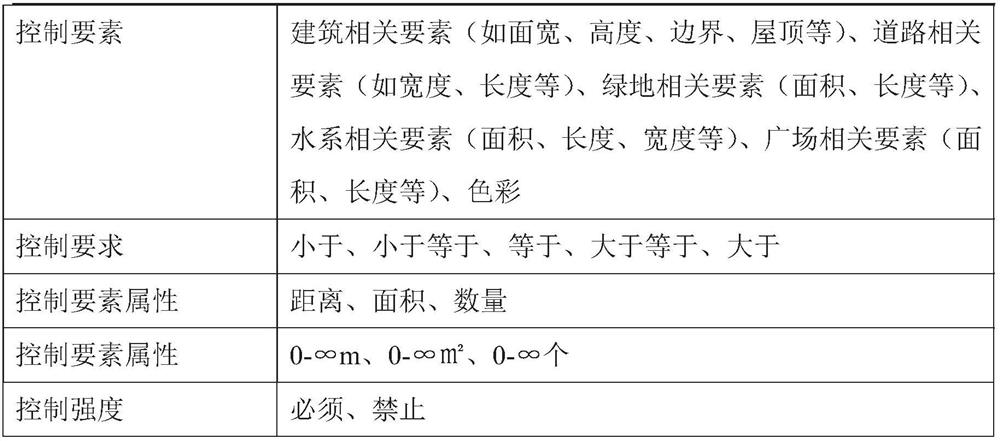

City design paperless intelligent interaction review method based on solid model

ActiveCN112270027AMeet computing requirementsMeet control requirementsGeometric CADOffice automationUrban designThree-dimensional space

The invention discloses a city design paperless intelligent interaction review method based on a solid model. The method comprises the steps of basic data integration and digital sand table construction, digital library construction of urban design review, urban design result data input and identification, urban design result intelligent review and label generation, review result report generationand interactive feedback, and automatic updating of the digital sand table. On the basis of actual measurement of the status quo and model correction, digital library building is performed on urban design review key points according to a digital sand table so that intelligent interactive review of urban design results can be realized. According to the invention, all management and control key points in legal planning and specification standards can be extracted, intelligent interactive examination covering all key points is carried out on urban design results through intelligent embedding ofintelligent codes and a three-dimensional digital sand table, and paperless generation of examination results and omnibearing display in a real three-dimensional space scene are realized.

Owner:SOUTHEAST UNIV

Frame type multifunctional free ascending and descending shifting machine

The invention relates to a rehabilitation auxiliary instrument and provides a frame type multifunctional free ascending and descending shifting machine. Specifically, the frame type multifunctional free ascending and descending shifting machine is a shifting instrument, a multi-angle ascending and descending device body formed by connecting four parts in series in a hinged mode is installed on a base with trundles. An electric lifter or a hydraulic lifter provides power for the ascending and descending device body and drives four body fixing and protecting devices connected with the ascending or descending device body to ascend or descend, and the body is held up or put down in different modes to achieve safe transfer of the body, wherein the four body fixing and protecting devices are of different structures and different functions. The frame type multifunctional free ascending and descending shifting machine has the advantages of being small in size, flexible in moving, high in stability, easy to control, convenient to use, capable of achieving the function of a wheelchair and the like.

Owner:许征文

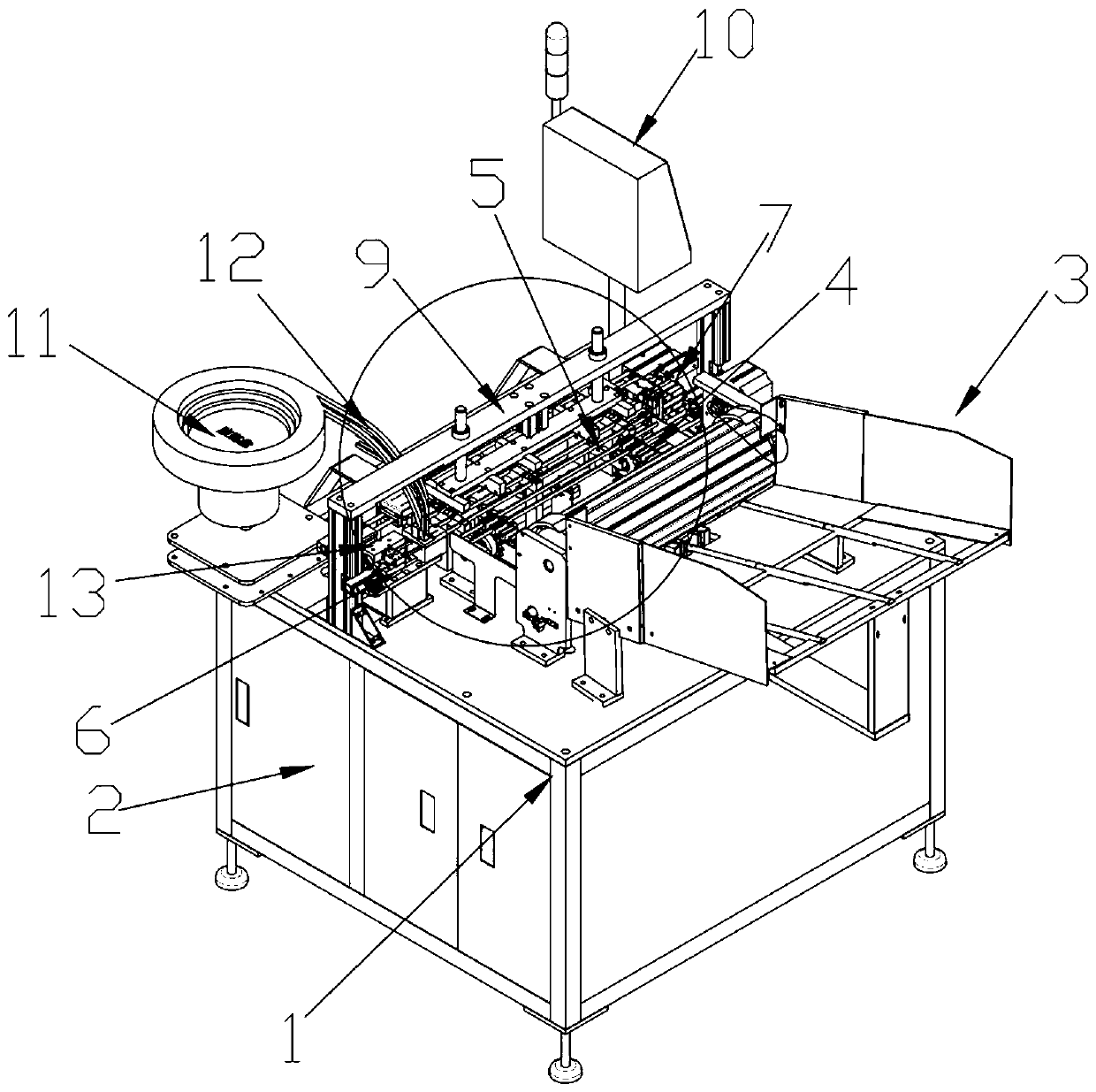

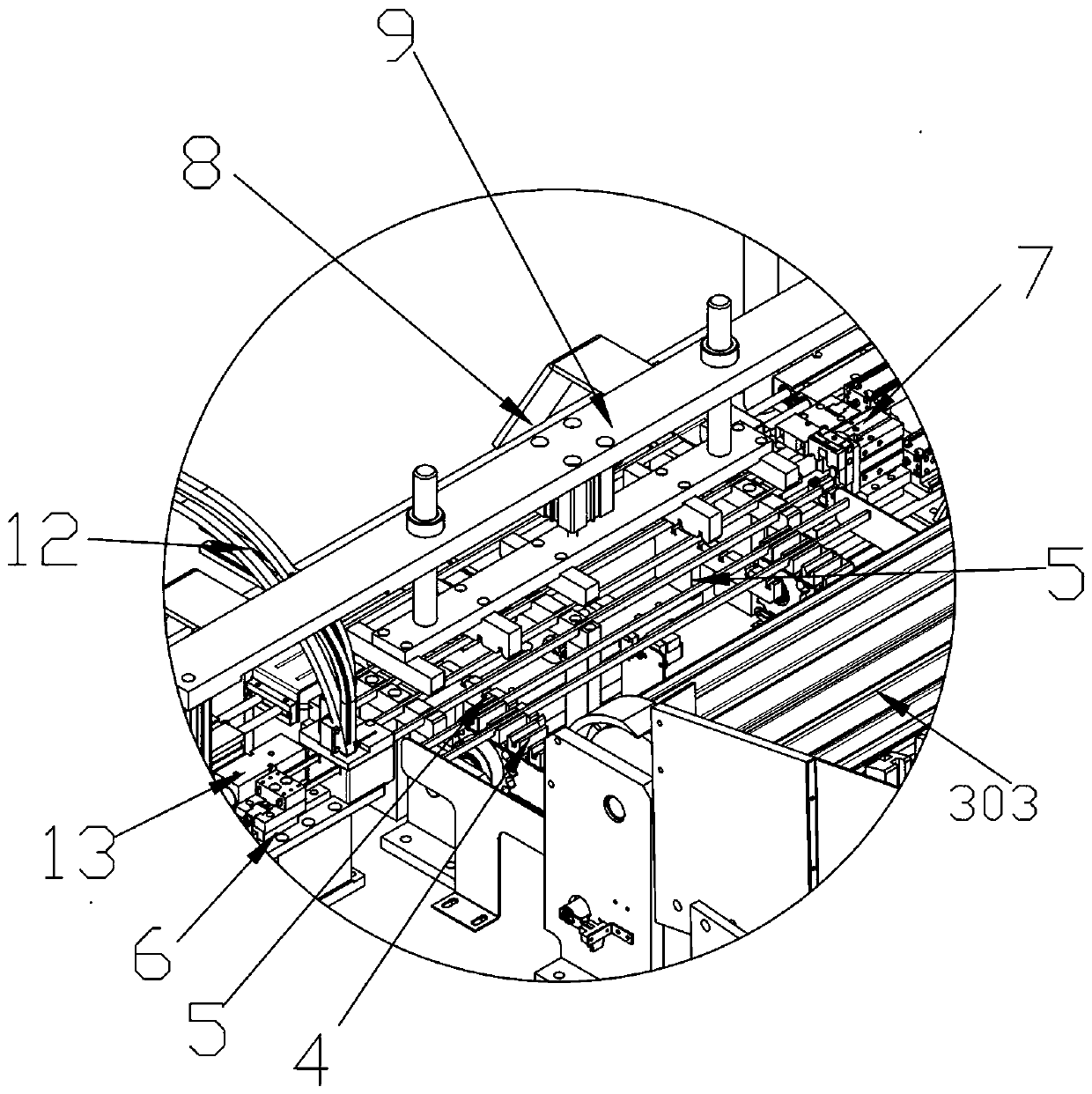

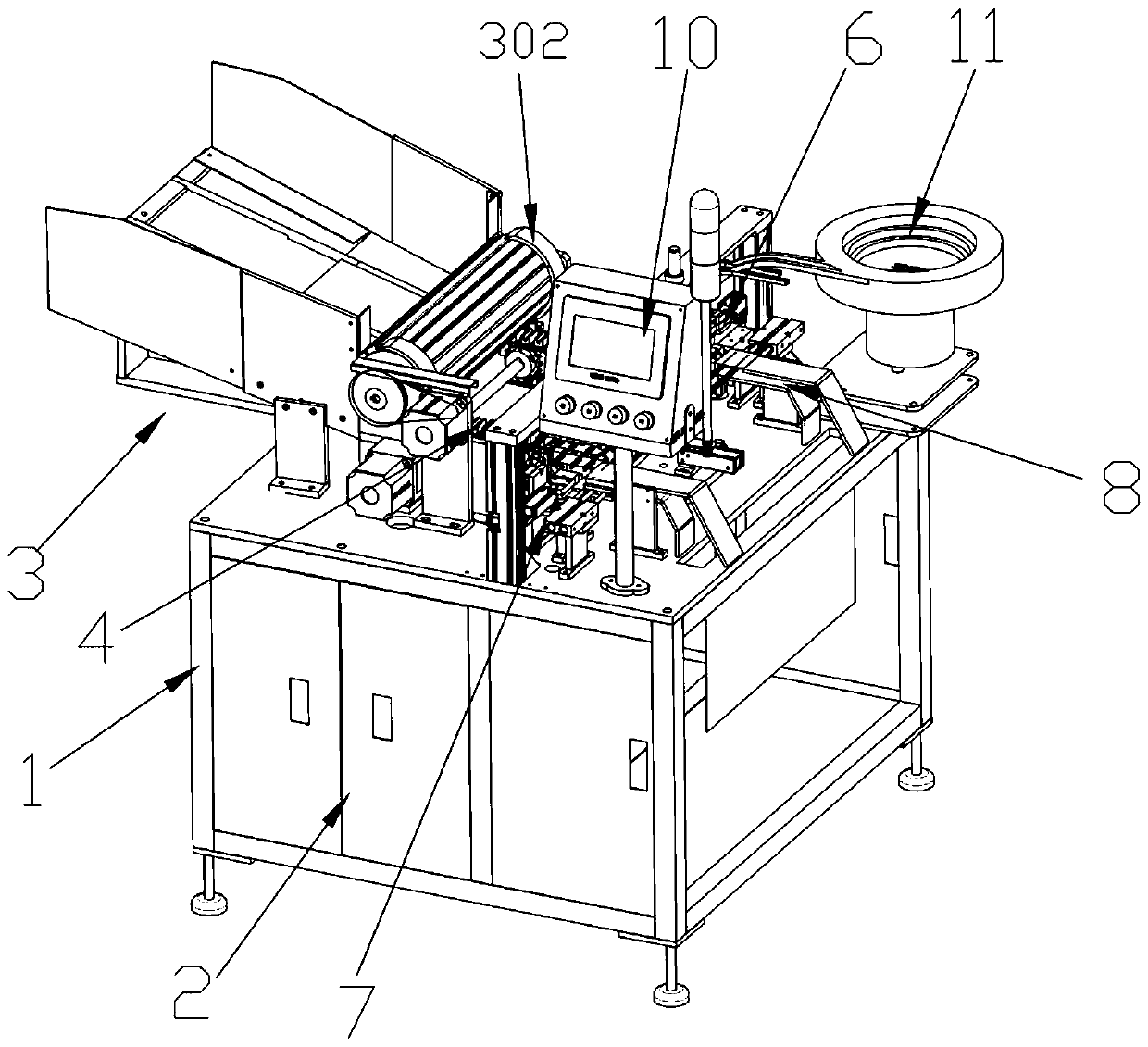

Automatic assembling machine for IC packaging pipe rubber plug

ActiveCN108673132AAccurate positioningRealize automatic feedingAssembly machinesMetal working apparatusEngineeringAssembly line

The invention relates to an automatic assembling machine for an IC packaging pipe rubber plug in the field of automation equipment. The automatic assembling machine comprises a rack and an automatic assembling platform. A plane installing plate is arranged on the top of the rack. The automatic assembling platform comprises a rubber plug blanking mechanism, a packaging pipe rear end locating mechanism, a prepressing mechanism and a material receiving mechanism. A material transferring mechanism is further arranged between the rubber plug blanking mechanism and the packaging pipe rear end locating mechanism. An automatic feeding system is arranged at the front end of the automatic assembling platform. An automatic discharging mechanism is arranged at the rear end of the automatic assemblingplatform. The automatic feeding system comprises a packaging pipe blanking mechanism, a packaging pipe conveying mechanism and a material moving mechanism which are sequentially arranged from front toback. Compared with traditional manual assembling, the whole process is completed through automatic assembly line operation, automatic feeding, automatic assembling and automatic discharging can be achieved, the working efficiency is high, the defect rate is extremely low, a great deal of labor cost can be saved, and precise assembling and precise detecting can be achieved by means of the automation machine.

Owner:泰州炬昕微电子有限公司

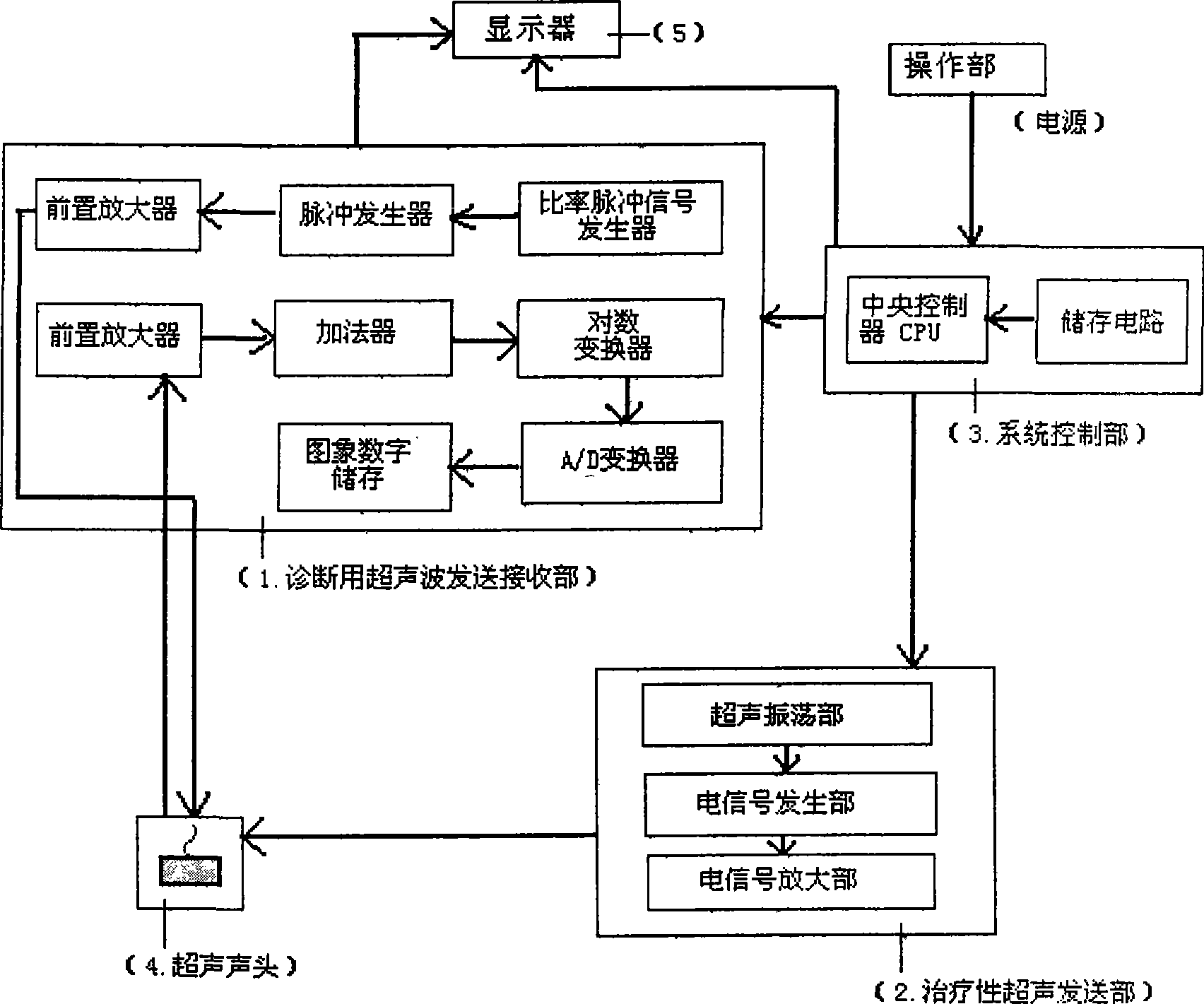

Therapeutic equipment for ultrasound localization of blood vessel and control technique

InactiveCN101485579AAccurate positioningGood treatment effectUltrasound therapyBlood flow measurement devicesTherapeutic DevicesDisplay device

The invention relates to an ultrasonic positioning blood vessel therapeutic device and control technology. The therapeutic device consists of a diagnostic ultrasonic transmitting and receiving part, a therapeutic ultrasonic transmitting part, a system control part, an ultrasonic sound head, a display and a power supply operating part, wherein the operating part turns on a power supply to connect the system control part; and the system control part consists of a storage circuit and a central control CPU, and sends instructions to turn on the diagnostic ultrasonic transmitting and receiving part, the therapeutic ultrasonic transmitting part, the ultrasonic sound head and the display. The control technology mainly makes use of ultrasonic Doppler Effect to detect blood vessel stenosis or obstruction, and transmits ultrasonic with therapeutic function after determining a lesion part of a blood vessel; moreover, the control technology can detect therapeutic effect in time and displays the detection result on a display screen.

Owner:郎鸿志

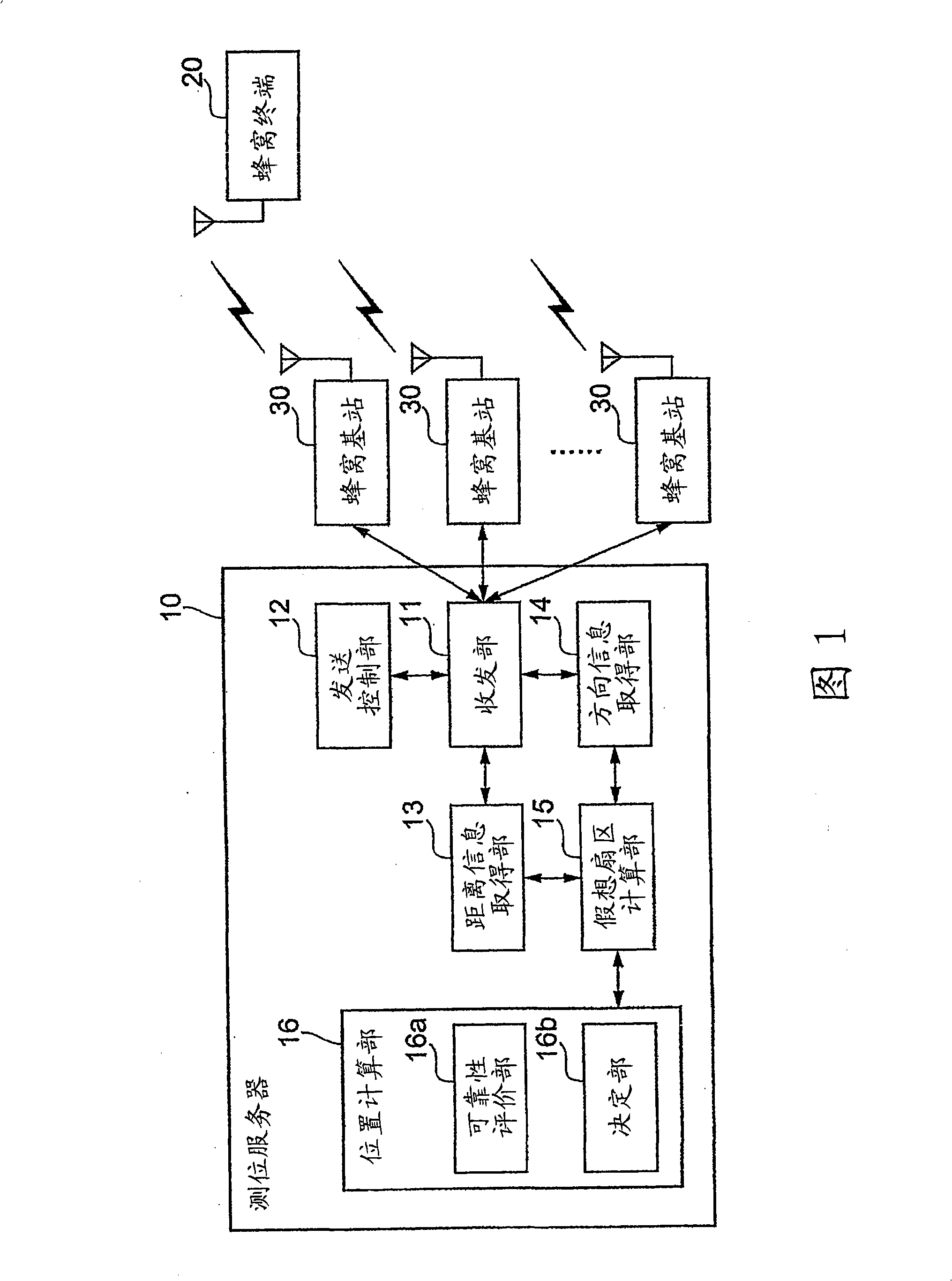

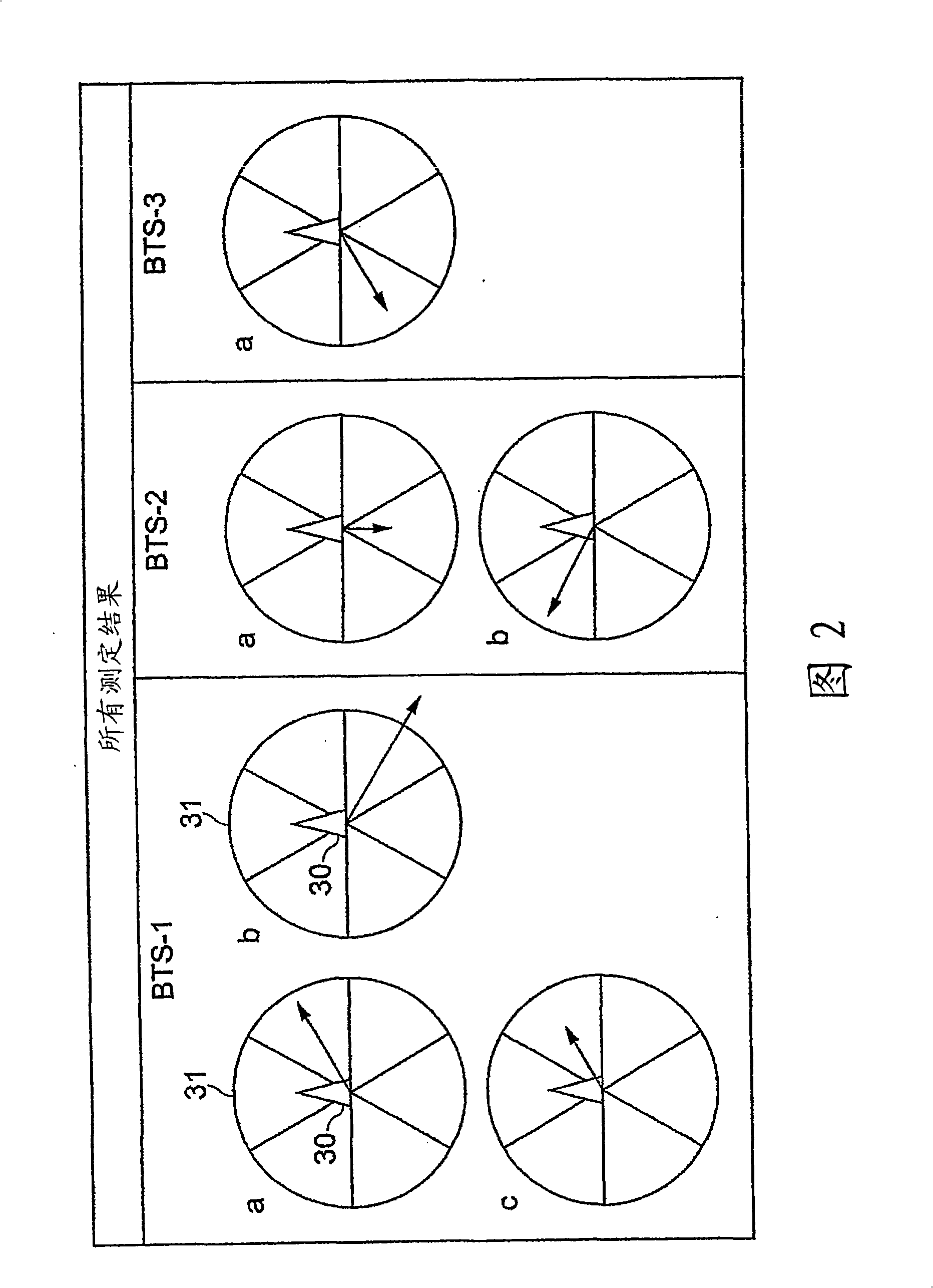

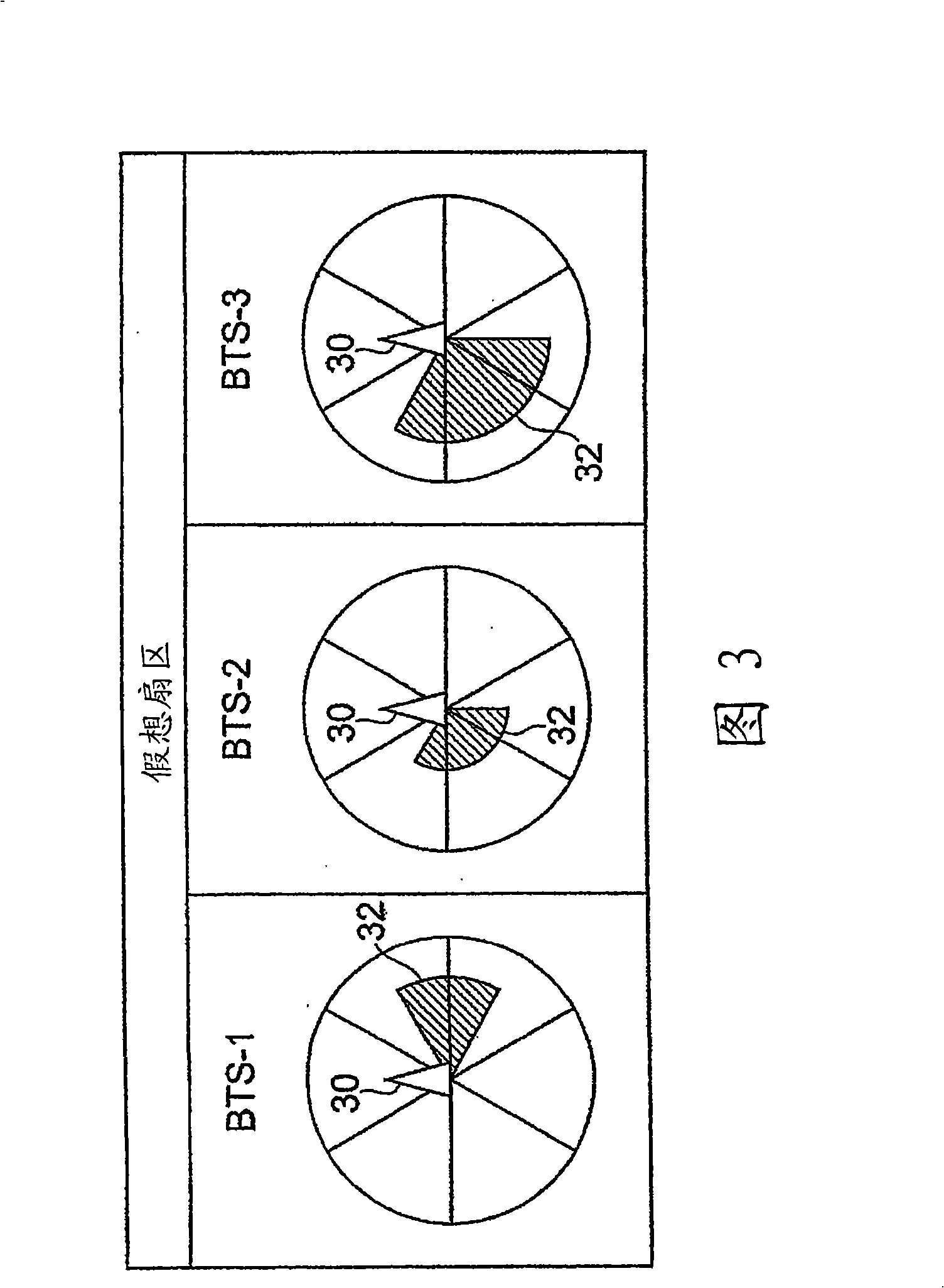

Positioning system, positioning method and positioning program

InactiveCN101334467AAccurate positioningPosition fixationWireless communicationComputer terminalDirection information

An object of the present invention is to implement accurate positioning of a mobile communication terminal even in an environment in which delay waves are included in radio waves arriving at the mobile communication terminal from radio wave sources. A positioning server 10 forming a positioning system for estimating a location of a cellular terminal 20 has a distance information acquisition unit 13 for acquiring information indicating distances calculated based on radio waves transmitted and received between a plurality of cellular base stations 30 and the cellular terminal 20; a direction information acquisition unit 14 for acquiring a plurality of pieces of information indicating directions of radio waves received by the cellular terminal 20; a virtual sector calculation unit 15 for calculating for each of the cellular base stations, a range of directions from the cellular base station 30 to the cellular terminal 20 from the information indicating the directions of the radio waves, based on a range calculation rule stored in advance; and a location calculation unit 16 for calculating the location of the cellular terminal 20, based on the distances and the range of directions.

Owner:NTT DOCOMO INC

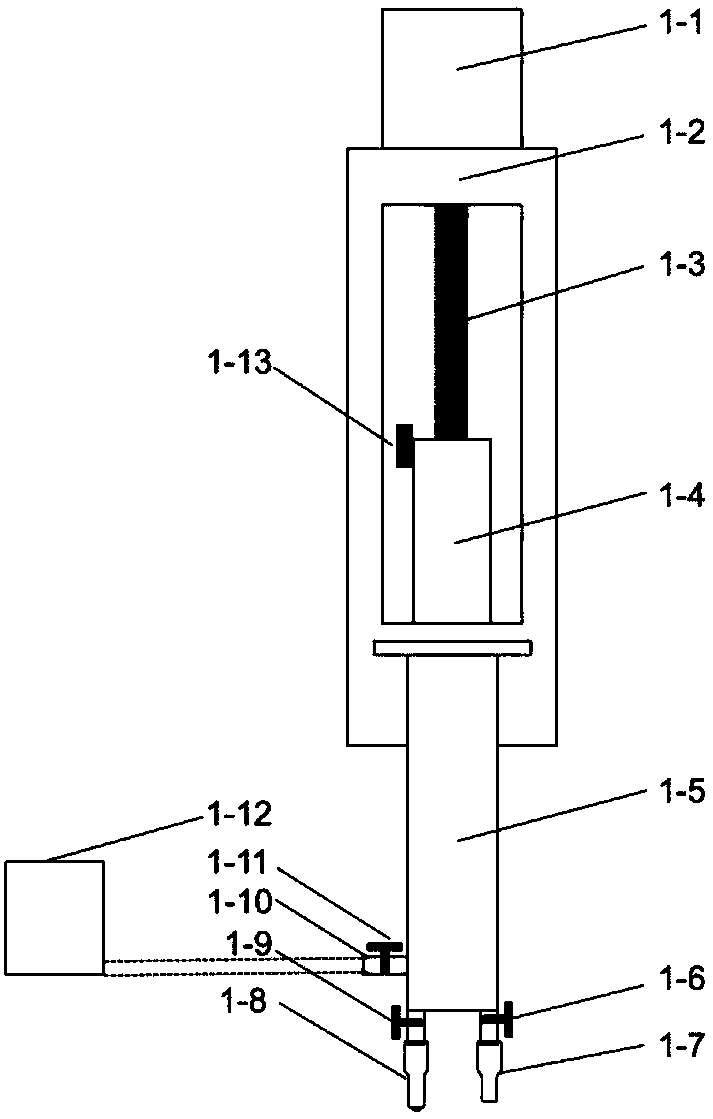

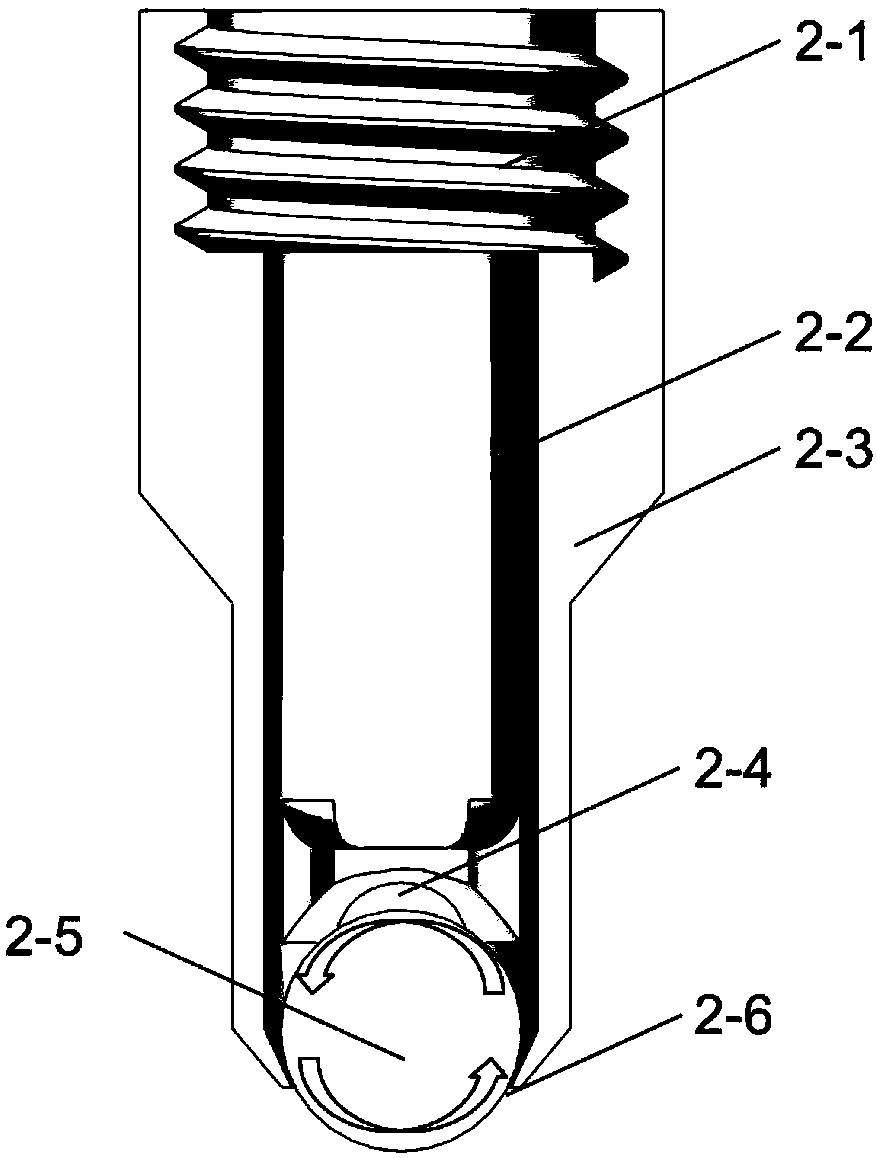

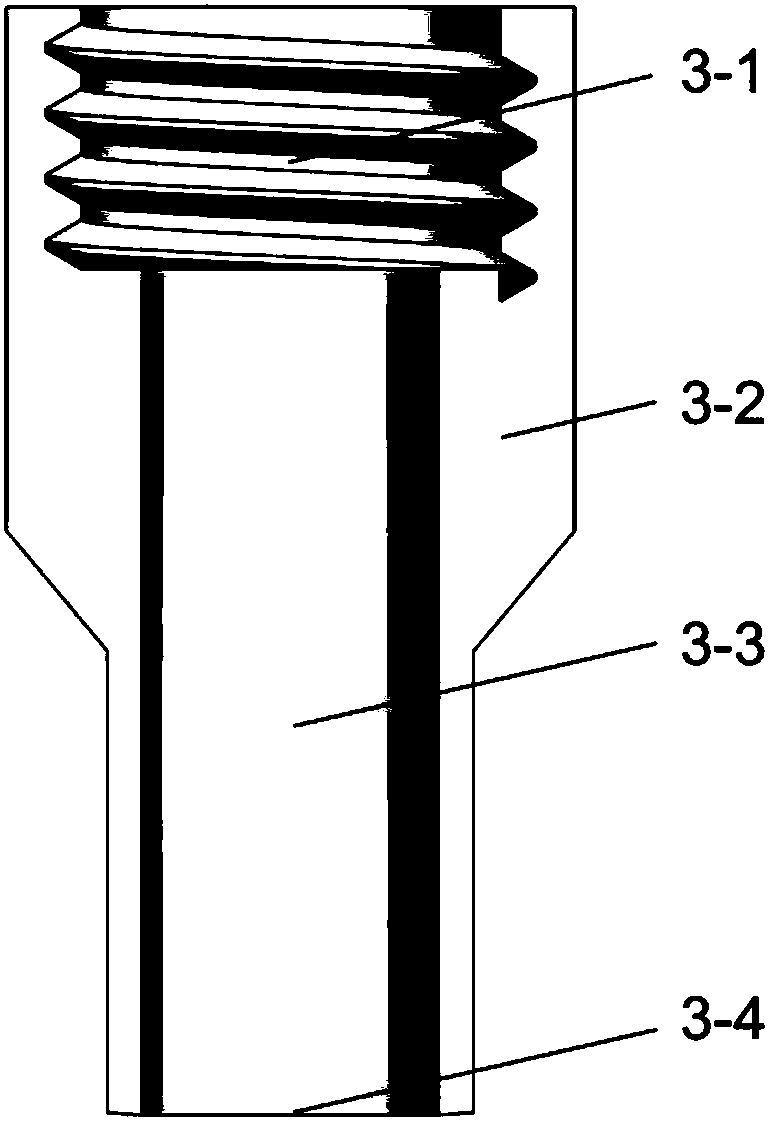

3D printing spray head and 3D printing device comprising same as well as biological ceramic slurry used for 3D printing device

PendingCN108312292ACompact structurePrecise extrusionAdditive manufacturing apparatusCeramic shaping apparatusSpray nozzleContact type

The invention discloses a 3D printing spray head and a 3D printing device comprising same and biological ceramic slurry used for the 3D printing device, and also discloses a 3D printing method. The 3Dprinting spray head can be used for realizing precisely extruding fine materials. The 3D printing spray head comprises a contact type spray nozzle which is of a rolling ball structure, and further comprises a non-contact type spray nozzle, wherein the contact type spray nozzle, which is of the rolling ball structure, is preferably used for printing a solid no-span structure; and the non-contact type spray nozzle is preferably used for printing a structure with span. The 3D printing device can realize precise travelling to print a relatively fine and compact structure. The 3D printing method comprises selecting of the spray head, the 3D printing device comprising the spray head and a 3D printing process. The selection of the 3D printing process comprises theoretical derivation and experimental verification of the spray nozzle.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com