Precision vibration damping and locating device

A positioning device and precise technology, applied in non-rotational vibration suppression, electrical components, semiconductor/solid-state device manufacturing, etc., to achieve precise position positioning, high repeat positioning accuracy, and small device deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment is given below in conjunction with the accompanying drawings to further describe the present invention.

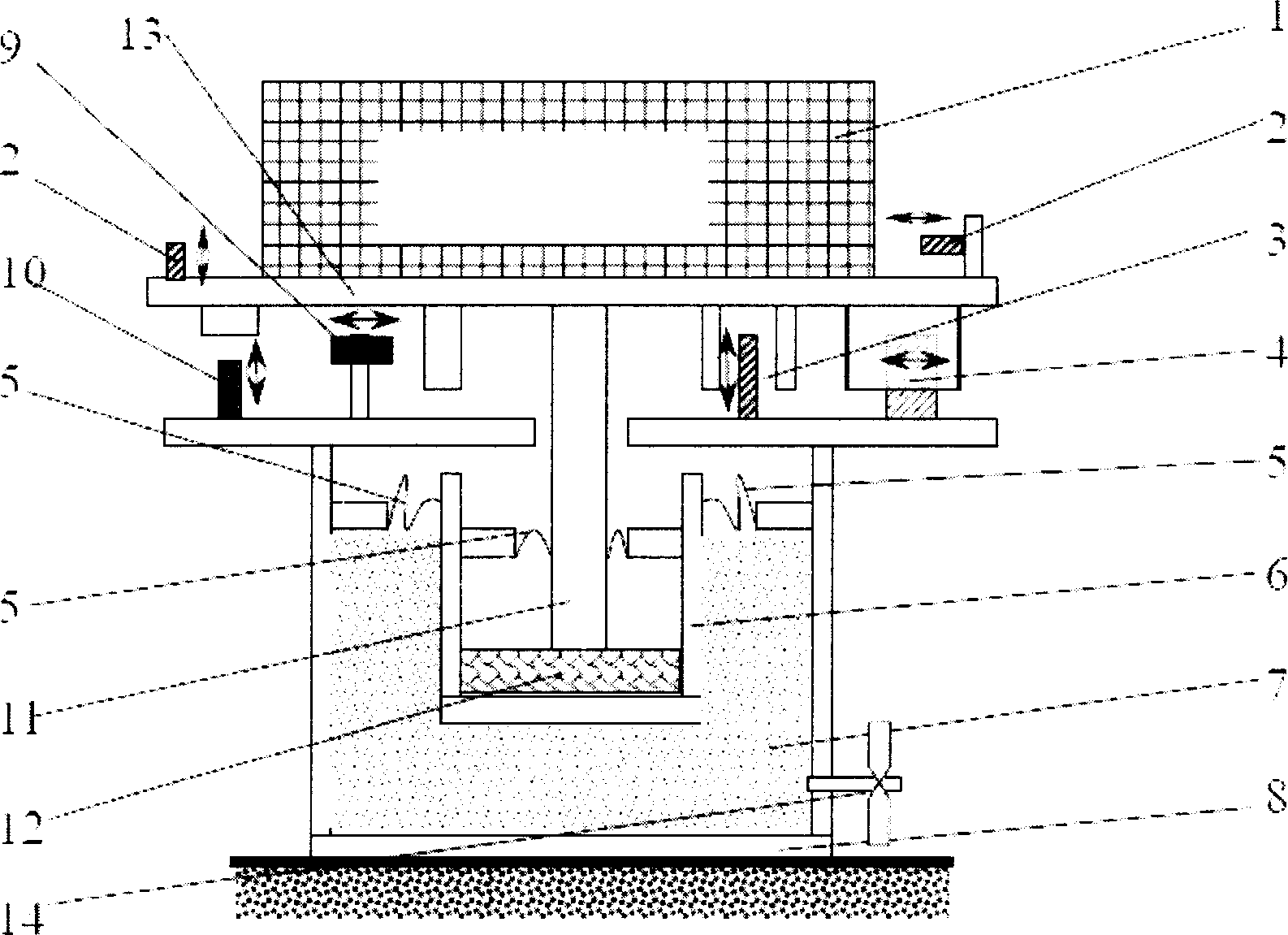

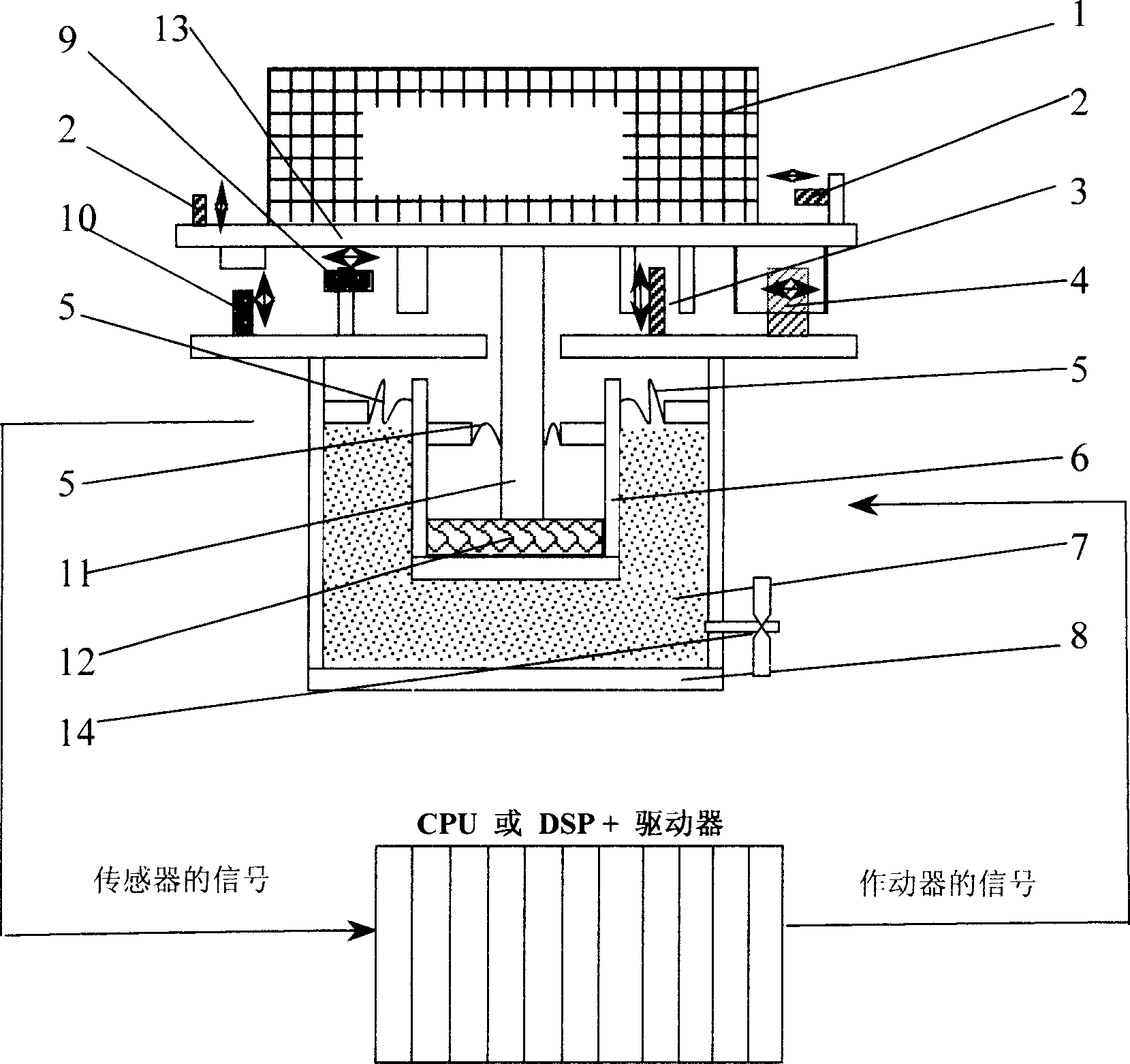

[0028] Such as figure 1 As shown: the entire damping device consists of passive damping components and active damping actuators. The passive damping component is mainly a cavity structure, which can have a certain range of motion in the horizontal and vertical directions. The cavity 8 can be composed of gas, Rubber, metal rubber or liquid filled7. If the filling medium is liquid or gas, the cavity 8 needs to be sealed, and the low-frequency resonance frequency of the system is controlled by the solenoid valve 14 to realize active control. Connected to the vibration damping platform 13 through the piston mechanism supported by these filling carriers, the vibration source is firstly isolated or attenuated to a greater extent in a wider frequency band; there is an active vibration damping component and a passive vibration damping component The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com