3D printing spray head and 3D printing device comprising same as well as biological ceramic slurry used for 3D printing device

A 3D printing and nozzle technology, which is applied in ceramic forming machines, manufacturing tools, additive processing, etc., can solve the problems of insufficient density and low precision, and achieve the effect of improving printing speed and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0160] [Preparation method of bioceramic slurry for 3D printing]

[0161]The present invention also provides a method for preparing the above-mentioned bioceramic slurry, the method comprising the steps of:

[0162] 1) Under sealed conditions, mix the polymer material, plasticizer and organic solvent, and stir for 1-2 hours. After the polymer material is completely dissolved and the stirring is completed, add hydroxyapatite powder, and continue stirring for 1-2 hours;

[0163] 2) Open the seal, adjust the viscosity to a suitable viscosity after the organic solvent volatilizes, and prepare the bioceramic slurry.

Embodiment 1

[0168] 1. Preparation of bioceramic slurry for 3D printing

[0169] 1) Take 8g of polycaprolactone powder in a beaker and add 2g of dimethyl phthalate.

[0170] 2) Add about 40g of dichloromethane solvent and stir for 1 hour. This process should be sealed to prevent the volatilization of dichloromethane;

[0171] 3) After the polycaprolactone is completely dissolved, it means that the stirring is completed, add 8 g of hydroxyapatite powder, and continue stirring for 1 hour;

[0172] 4) After the mixed solution is uniform and stable, the stirring is completed, and the methylene chloride is volatilized while stirring; after the methylene chloride is volatilized, the sum of hydroxyapatite, dimethyl phthalate and polycaprolactone accounts for the total 40 wt.% of the mass is transferred to the storage tank of the 3D printing nozzle described below for subsequent use.

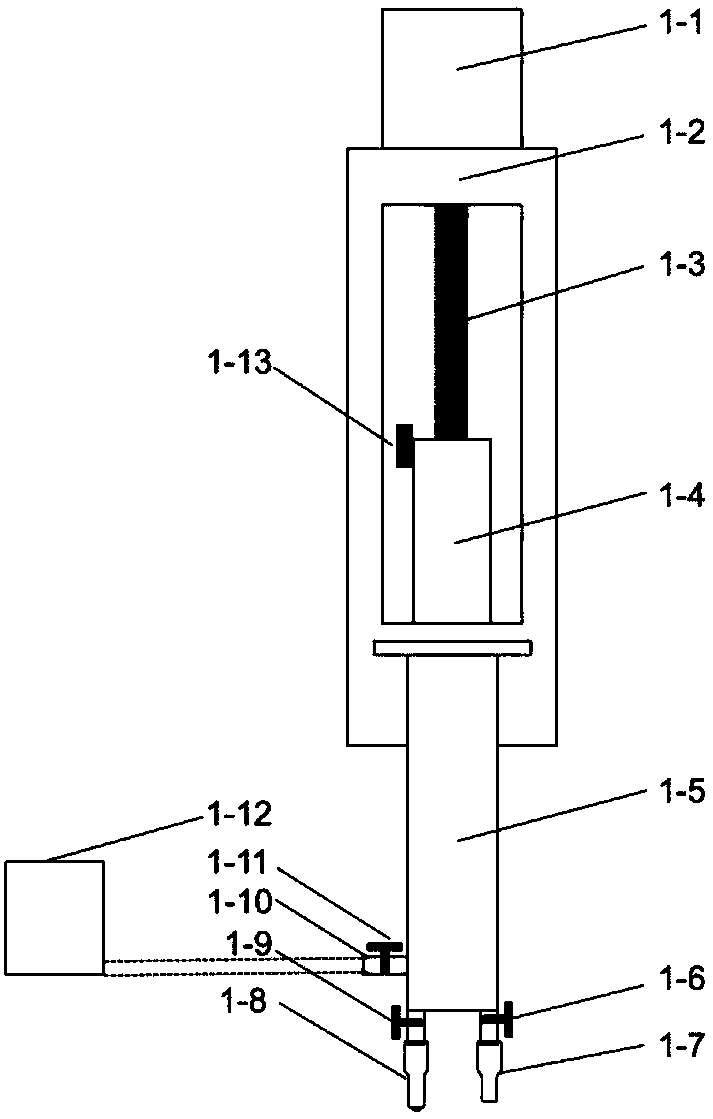

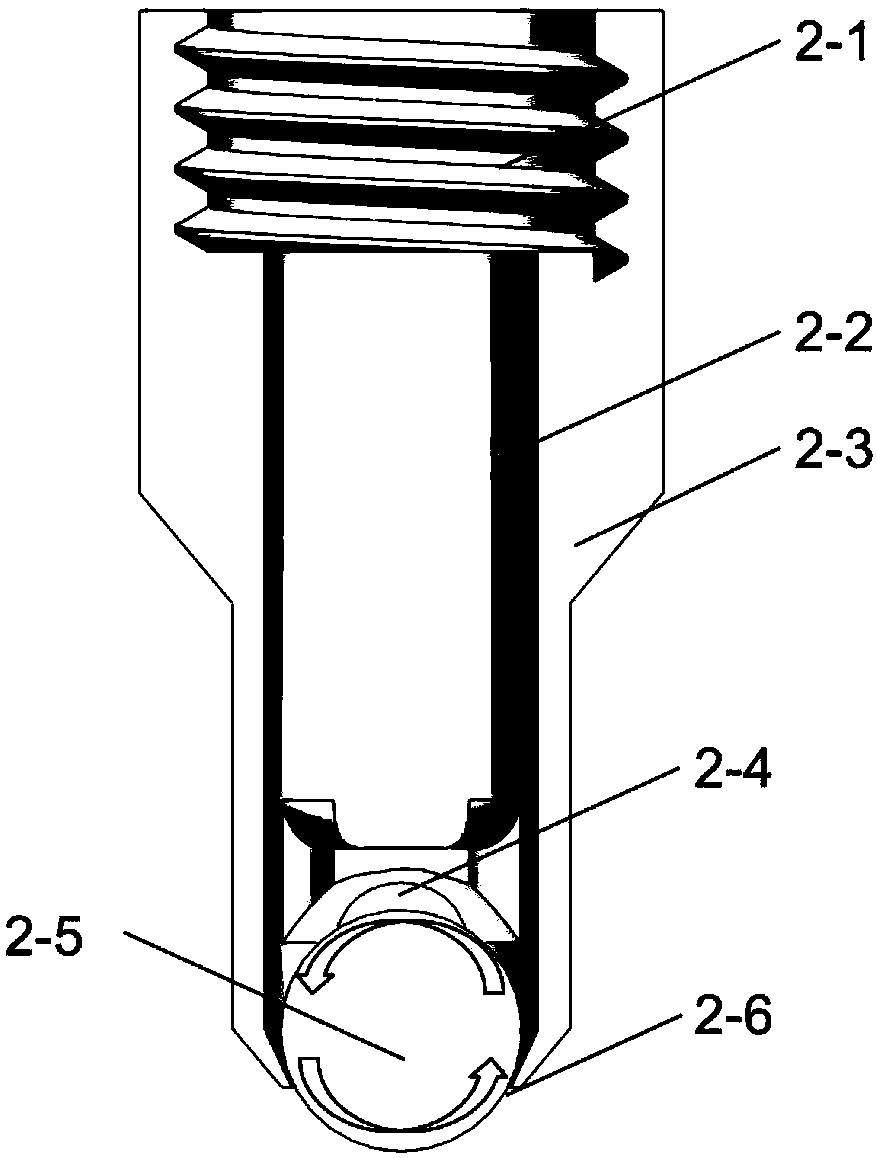

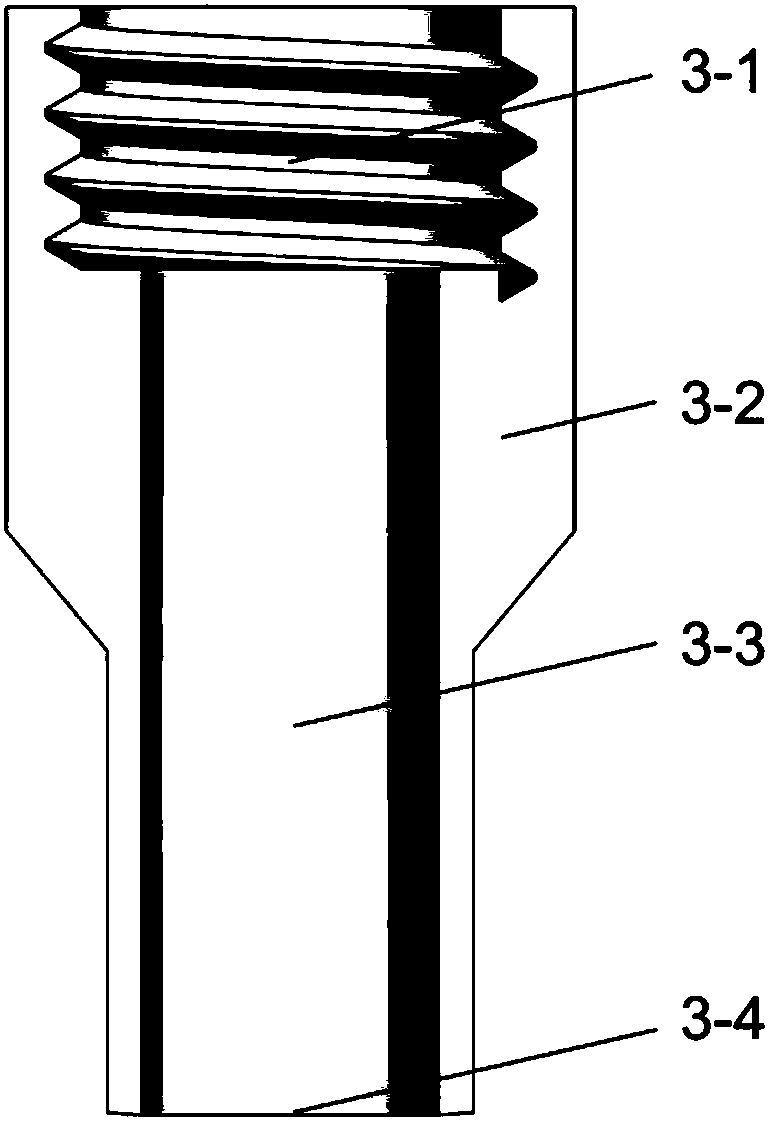

[0173] 2. Contact nozzle structure and non-contact nozzle structure with ball structure

[0174] Such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com