Patents

Literature

42results about How to "Increase print speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

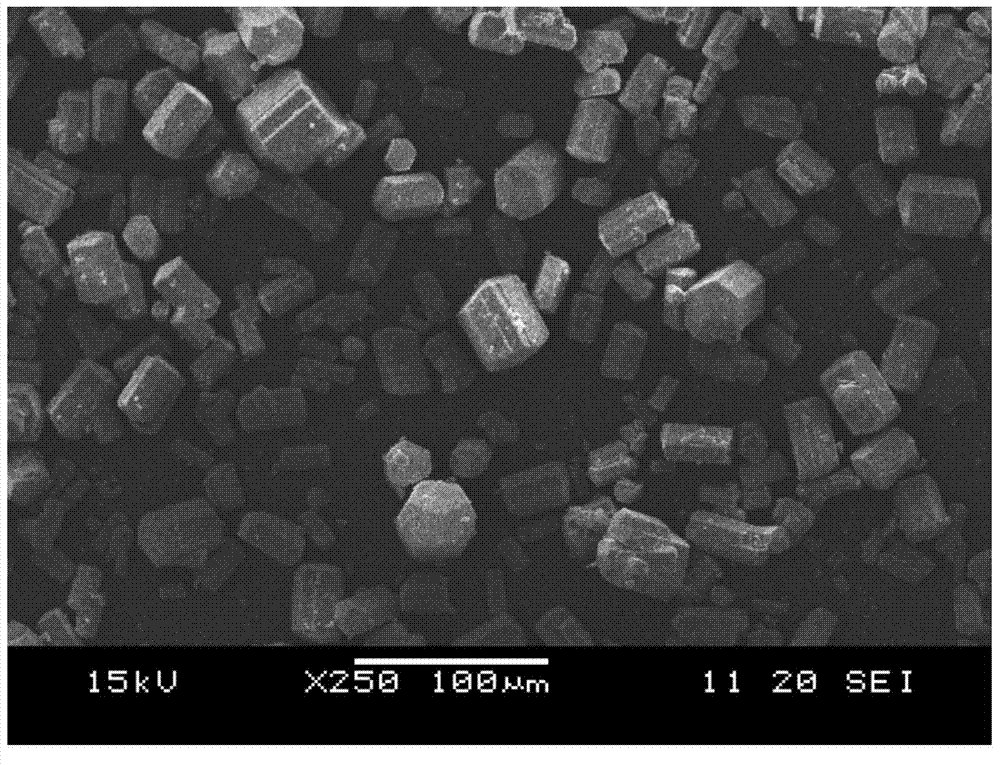

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

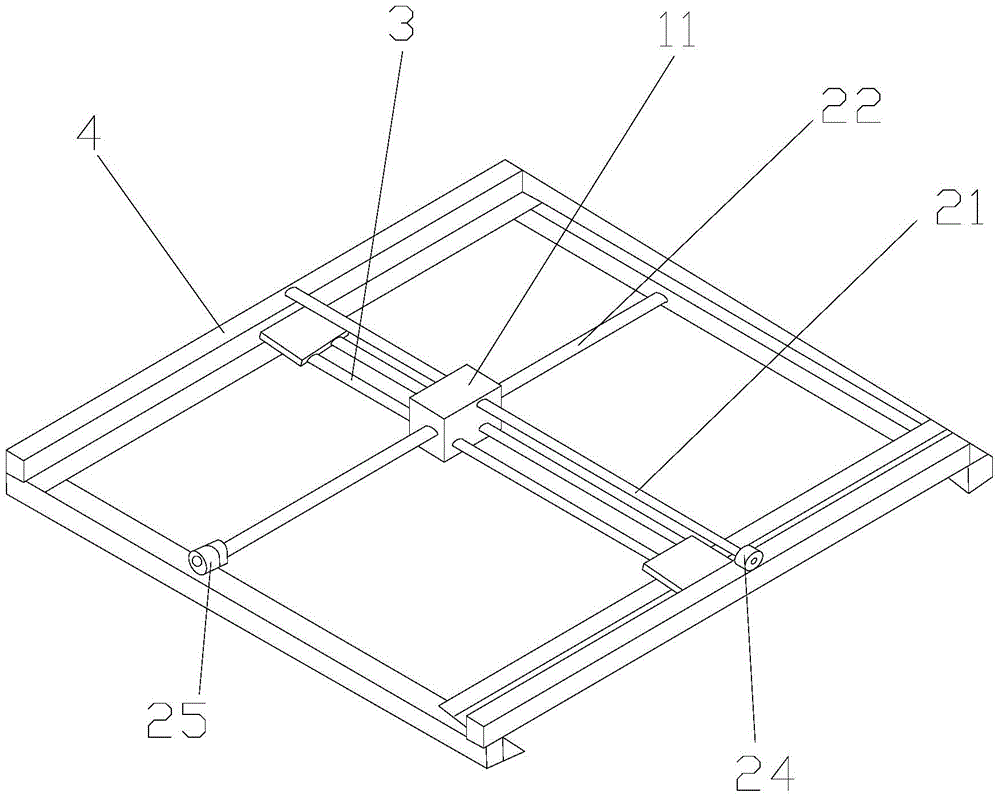

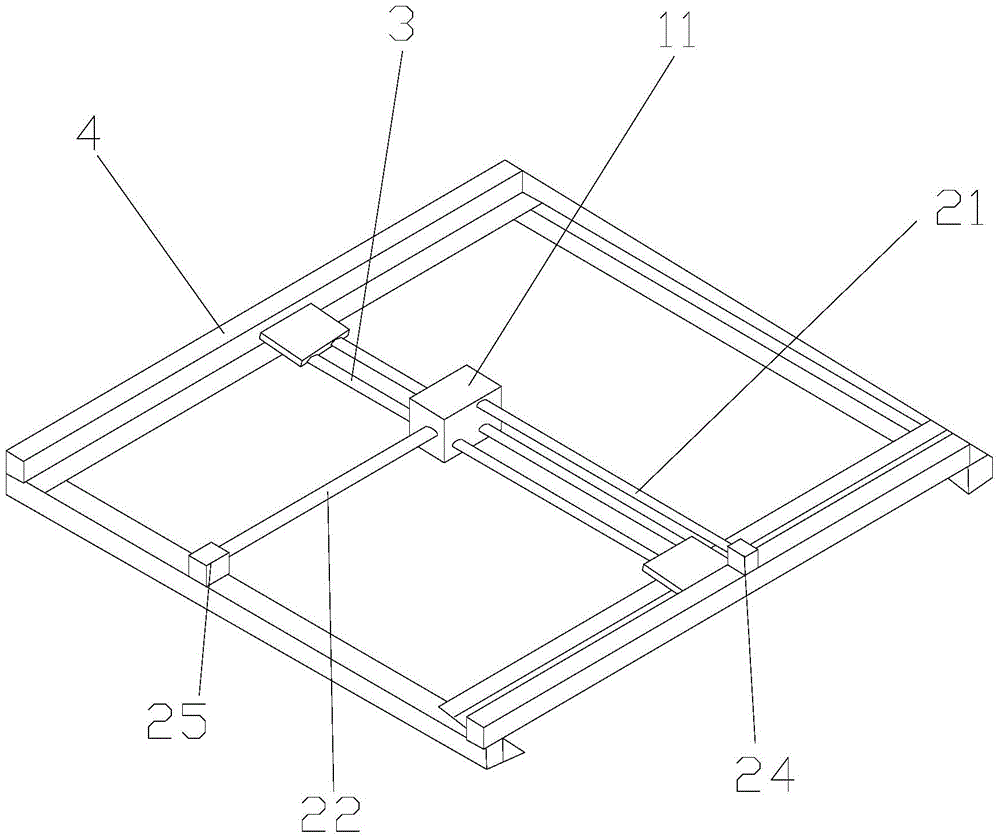

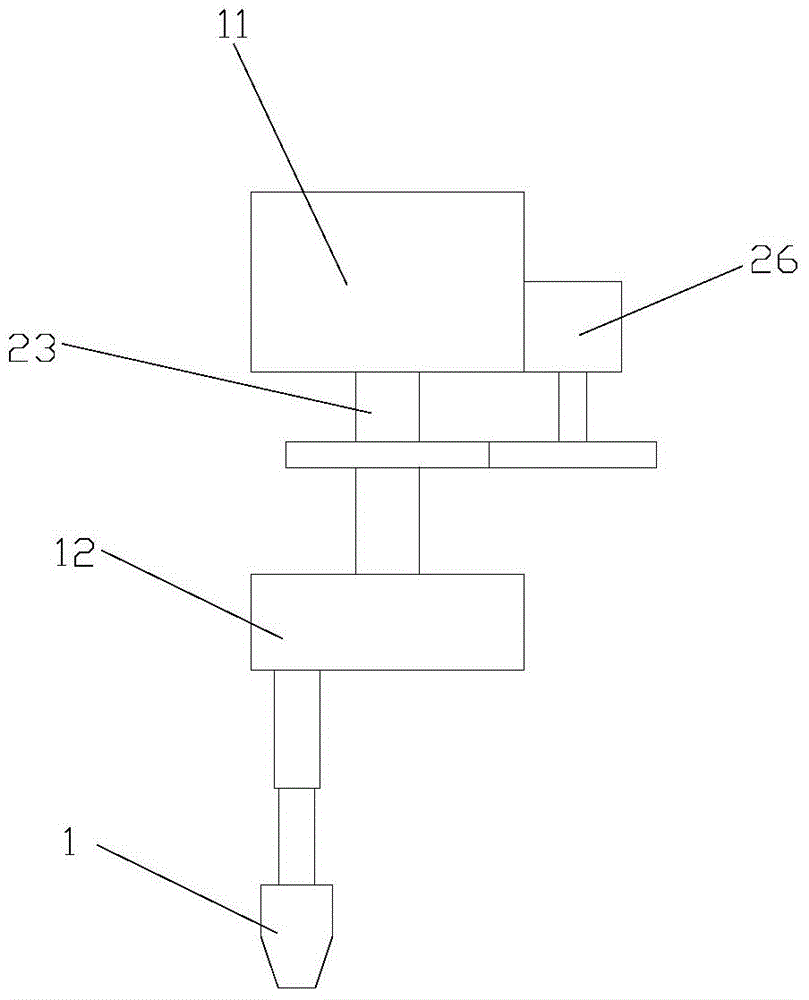

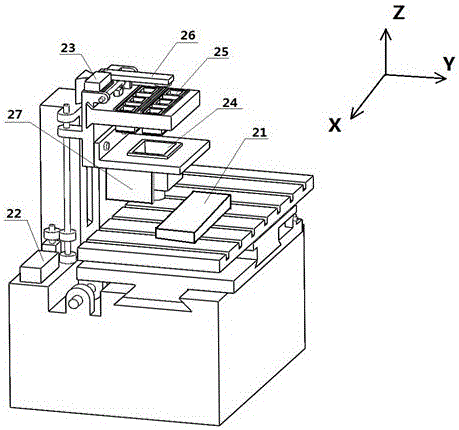

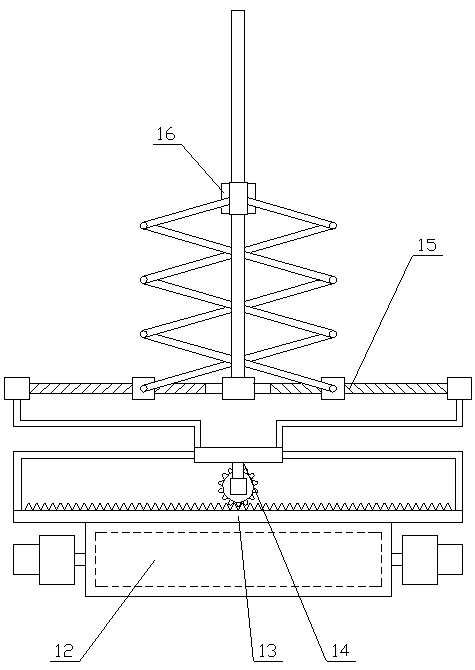

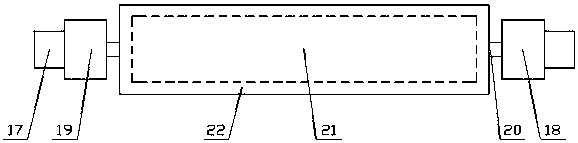

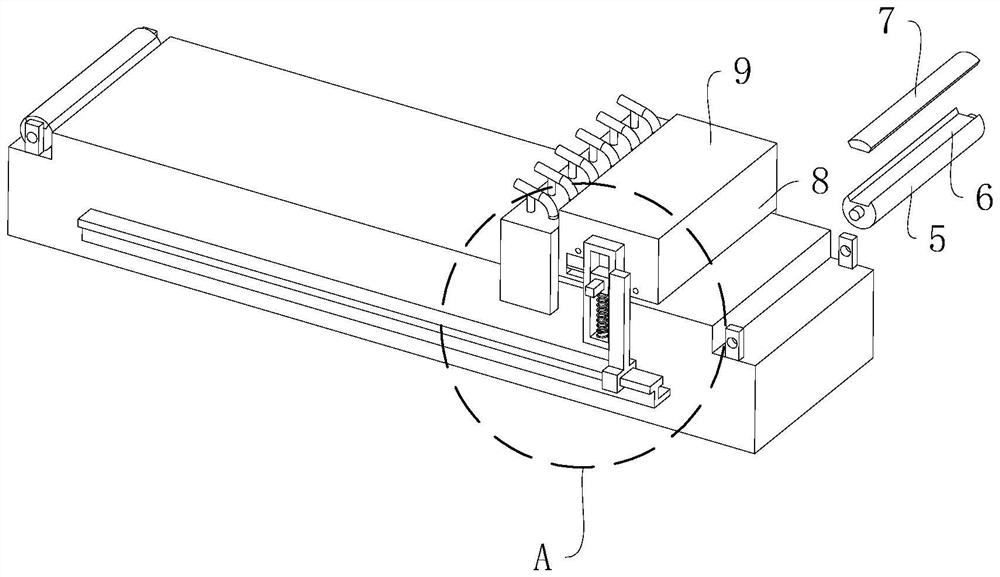

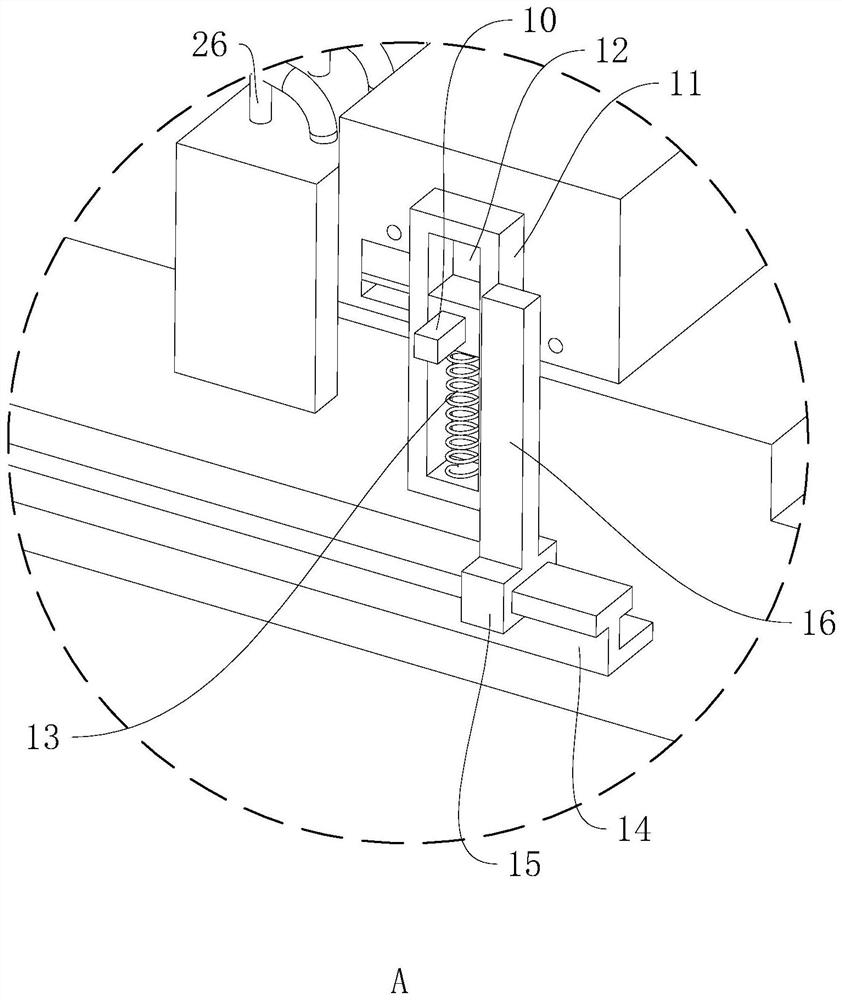

Sprinkling nozzle movement mechanism of 3D printer

ActiveCN104875386ARapid positioningPrecise positioningAdditive manufacturing apparatusEngineering3d printer

The invention provides a sprinkling nozzle movement mechanism of a 3D printer. A first sprinkling nozzle connecting part is arranged on a rack of the 3D printer by a sliding mechanism, the first sprinkling nozzle connecting part is arranged on the sliding mechanism in a sliding manner, a first transmission mechanism is transversely arranged, a second transmission mechanism is longitudinally arranged in a horizontal direction, the first transmission mechanism and the second transmission mechanism are arranged on the rack in a sliding manner, the first transmission mechanism, the second transmission mechanism and the sliding mechanism are sequentially arranged from top to bottom, the first transmission mechanism and the second transmission mechanism penetrate through the first sprinkling nozzle connecting part, the first transmission mechanism is driven by a first driving mechanism on the rack to enable the first sprinkling nozzle connecting part to transversely move, and the second transmission mechanism is driven by a second driving mechanism on the rack to enable the first sprinkling nozzle connecting part to longitudinally move. The sprinkling nozzle movement mechanism of the 3D printer can be used for solving the problem of low forming precision of a printed workpiece due to vibration of the sprinkling nozzle, the printing cost is reduced and the printing quality is improved.

Owner:安徽三维天下科技股份公司

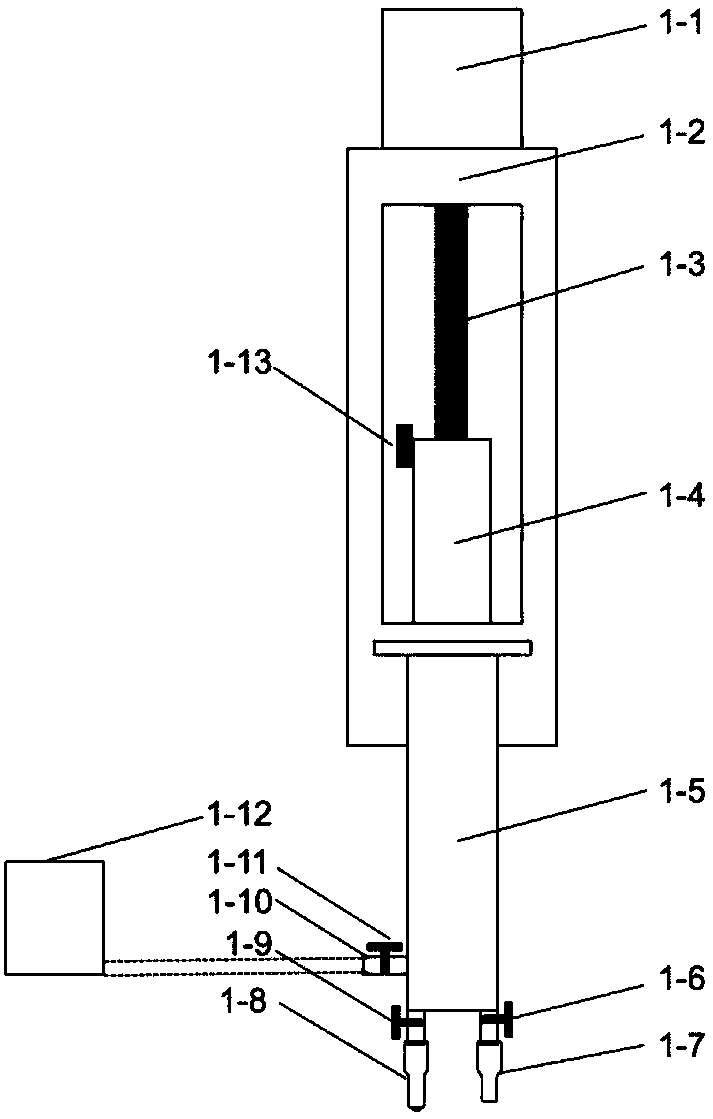

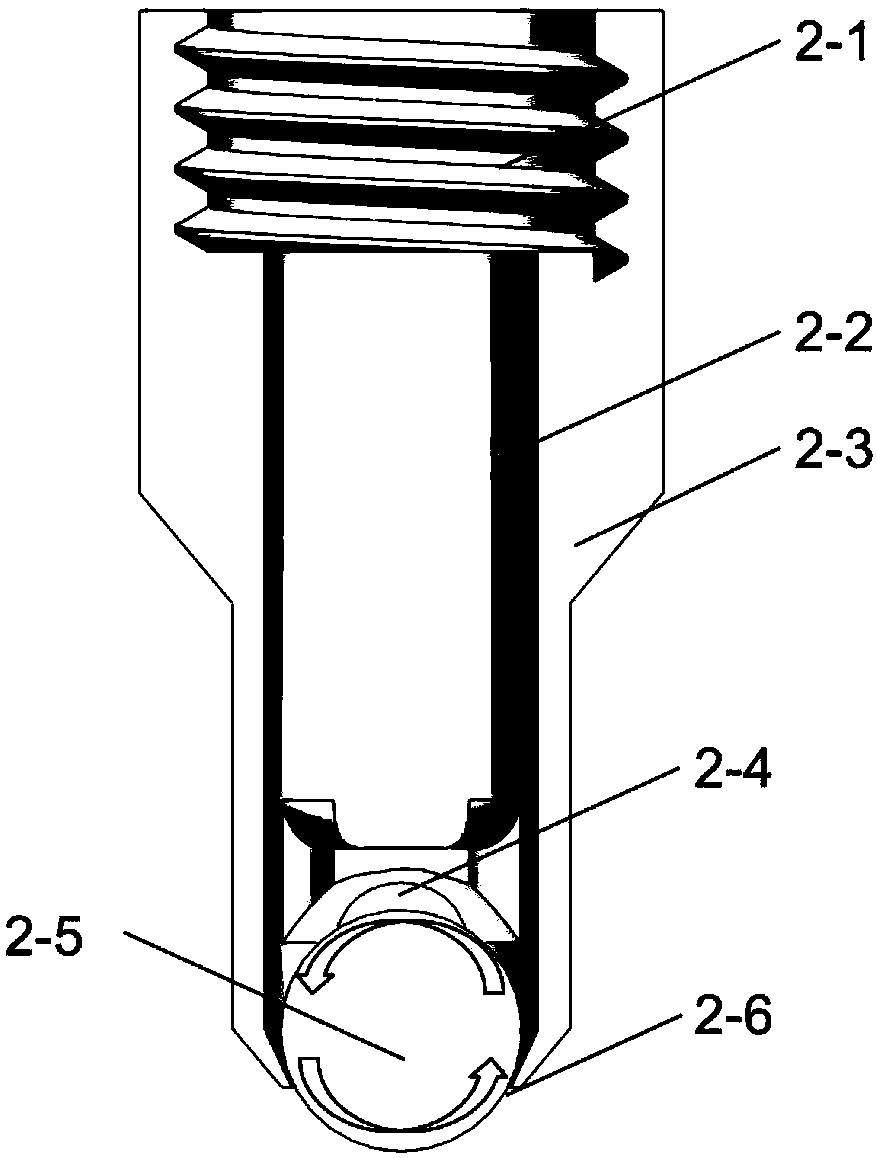

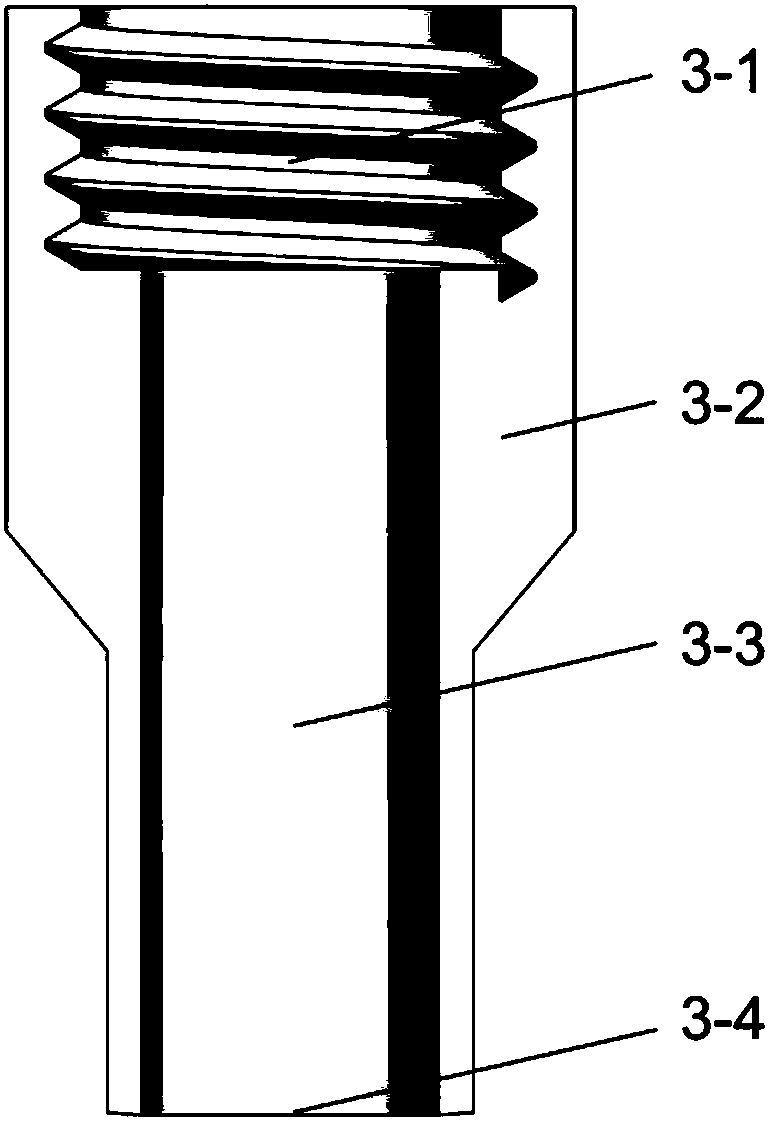

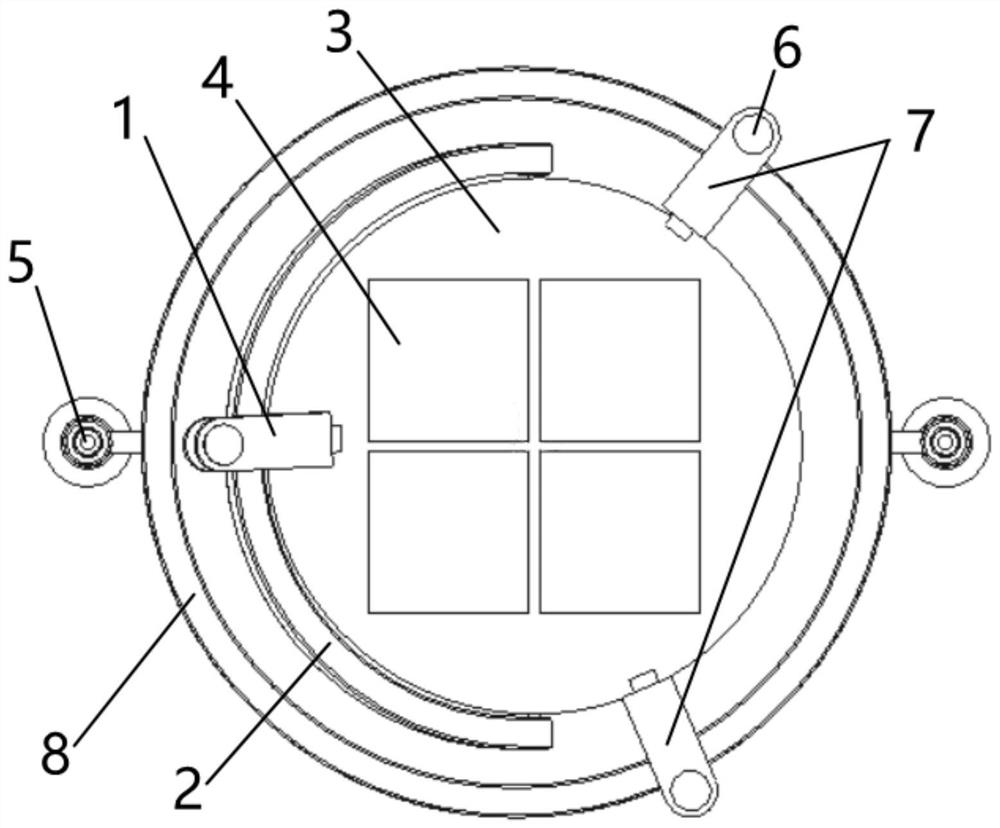

3D printing spray head and 3D printing device comprising same as well as biological ceramic slurry used for 3D printing device

PendingCN108312292ACompact structurePrecise extrusionAdditive manufacturing apparatusCeramic shaping apparatusSpray nozzleContact type

The invention discloses a 3D printing spray head and a 3D printing device comprising same and biological ceramic slurry used for the 3D printing device, and also discloses a 3D printing method. The 3Dprinting spray head can be used for realizing precisely extruding fine materials. The 3D printing spray head comprises a contact type spray nozzle which is of a rolling ball structure, and further comprises a non-contact type spray nozzle, wherein the contact type spray nozzle, which is of the rolling ball structure, is preferably used for printing a solid no-span structure; and the non-contact type spray nozzle is preferably used for printing a structure with span. The 3D printing device can realize precise travelling to print a relatively fine and compact structure. The 3D printing method comprises selecting of the spray head, the 3D printing device comprising the spray head and a 3D printing process. The selection of the 3D printing process comprises theoretical derivation and experimental verification of the spray nozzle.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for machining self-adhesive label

The invention discloses a method for machining a self-adhesive label and relates to the label manufacturing field. The method comprises the seven steps of unreeling, coating, stoving, sand blasting, printing, laminating and calendaring. Continuous unreeling is adopted, backing paper is placed on a rotary label machine, tension applied to the backing paper is manually adjusted and correction and rectifying are conducted at the same time, and then Synchronization of the reeling speed and the unreeling speed is guaranteed, stress is even, the backing paper can be flattened, and coating operation is facilitated; the backing paper is placed on a metal surface heated by an electric heating wire and polished to be pressed and cooled gradually till a glossy film surface is formed on a label, clear dopes used for polishing and coating are made denser and smoother, an ideal high-gloss and high-brightness mirror surface film effect is achieved, and the grade and market competitiveness of a printed product are improved.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

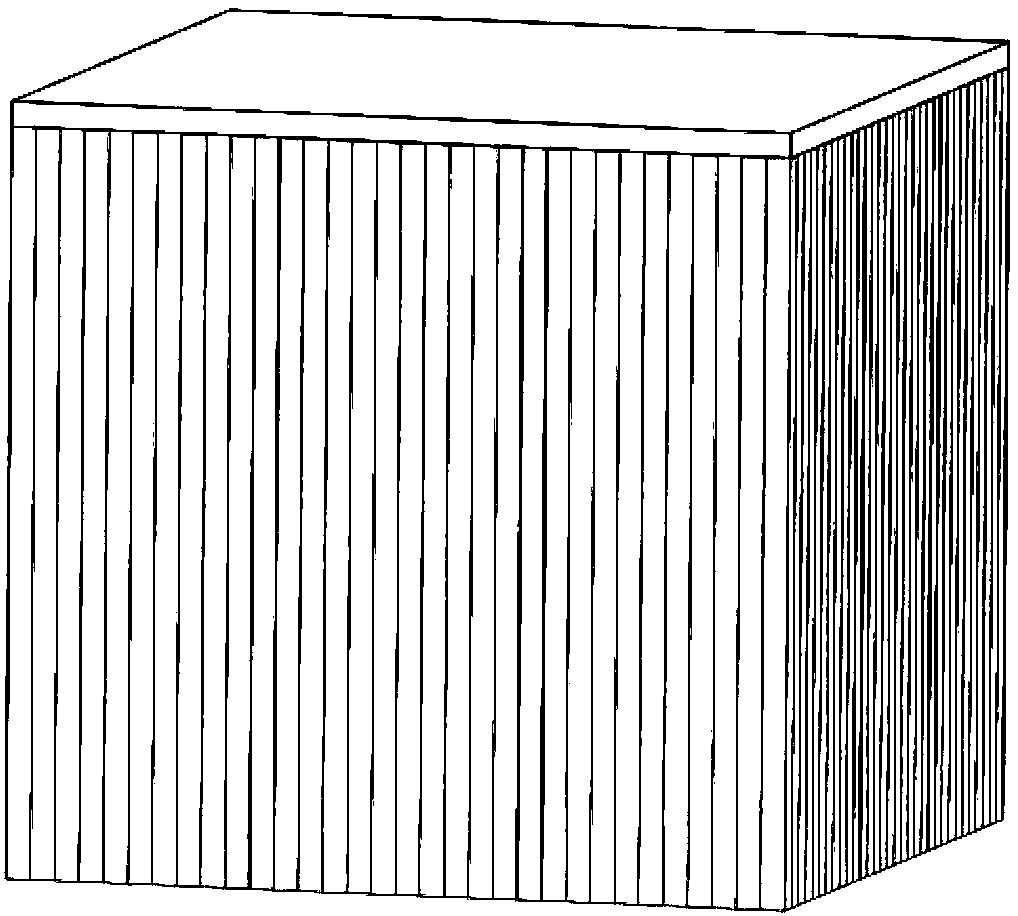

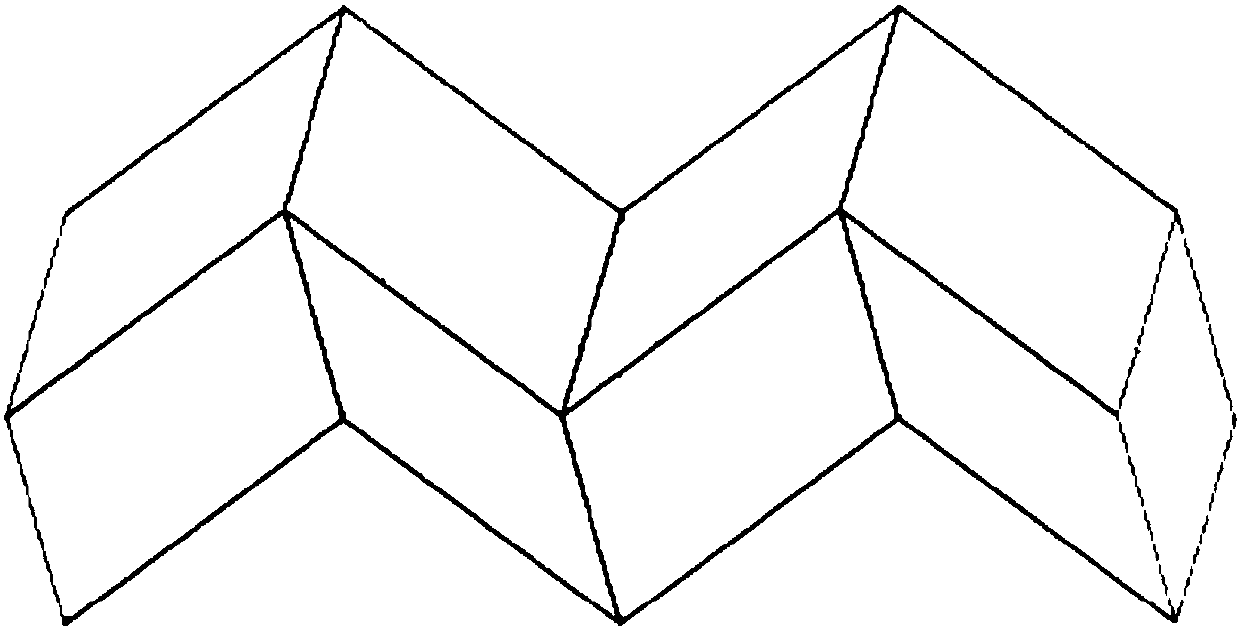

Supporting structure for selective laser melting forming and generating method thereof

ActiveCN107598167AReduce usageIncrease print speedAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingThree dimensional graphics

The invention relates to a supporting structure for selective laser melting forming and a generating method of the supporting structure. The supporting structure is simple in structure, and the loss of raw materials is reduced in the production process, the printing efficiency is improved, and the post-processing difficulty is reduced. The supporting structure comprises a plurality of supporting units which are arranged on the same plane in an array mode; each supporting unit comprises a plurality of supporting single bodies, the supporting single bodies are of hollow tube structures which arearranged in the horizontal direction, the length direction of the hollow tubes is taken an X direction, the plurality of supporting single bodies are arranged in an array mode in a Y direction and aZ direction, every adjacent supporting units are mutually connected through walls of hollow tubes to form the supporting units; and the hollow tubes form lateral powder discharging channels of the supporting units. According to the generating method, a cross section structure is formed by utilizing three-dimensional graphic software, array and arrangement are carried out for the area required to be supported according to requirements, the use requirements are met, and the supporting structure together with the part data can be output and completed to be formed synchronously; and in the settingand forming process, the the supporting units are directly reinforced for guaranteeing of the supporting effect.

Owner:西安国宏天易智能科技有限公司

A 3D printing method based on self-propagating reaction

InactiveCN104923781BIncrease print speedIncrease speedAdditive manufacturing apparatusCombustionChemical reaction

The invention relates to a self-propagating reaction and a 3D printing technology, in particular to a 3D printing method based on a self-propagating reaction. The self-propagating chemical reaction is used in the whole printing process for heat releasing, and an outer heat source is completely or partly not needed. In the printing process, products with needed components and structures are obtained through a self-sustained reaction of fast automatic wave combustion. The printing controllability is good, the speed, the temperature, the conversion rate and the components and the structures of the products in the process are controlled by changing the releasing and transmitting speed of heat. The self-propagating reaction and the traditional 3D printing technology are combined to increase the overall printing speed, the printing period is shortened, a large quality of printed products can be obtained rapidly, and various metal powder materials can be applied. Energy does not need to be supplied continuously once ignition is conducted, compared with laser sintering, cost is lower, efficiency is higher, and equipment is simple and easy to manufacture.

Owner:WUHAN UNIV

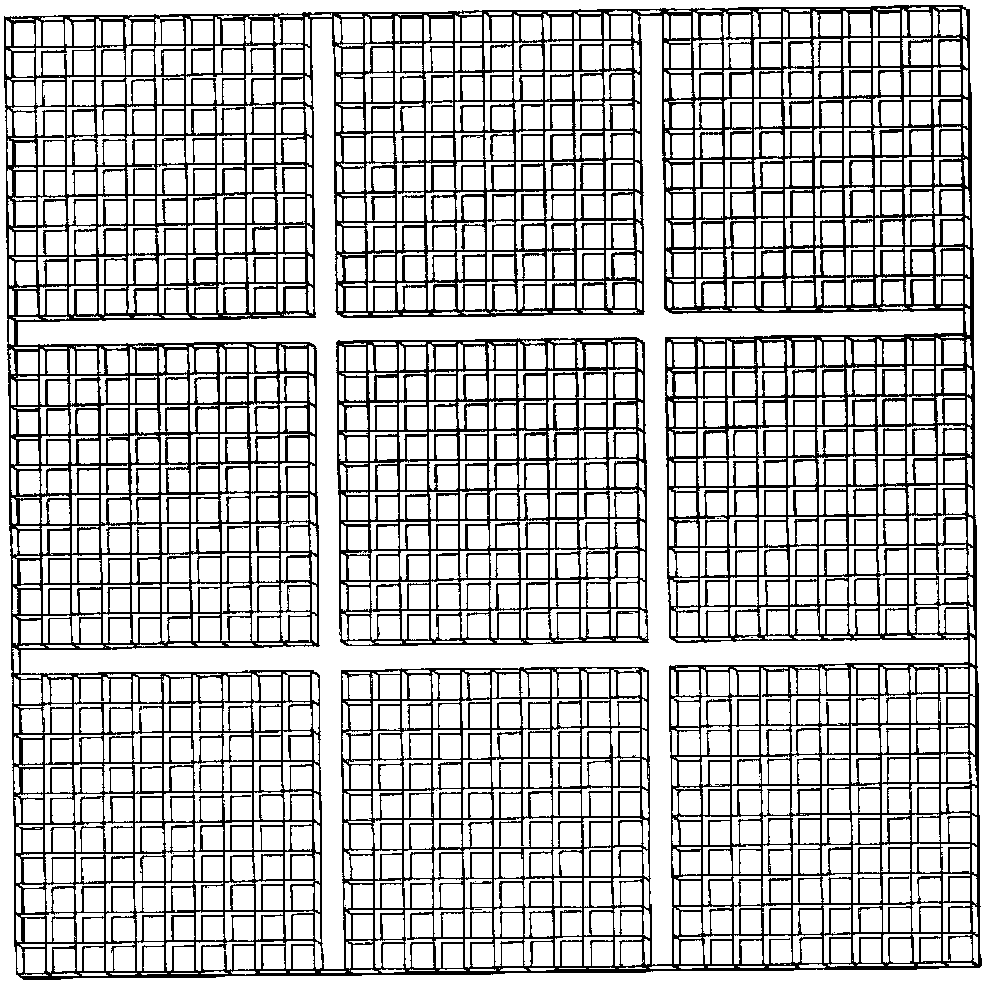

Variable cross-section opening grid supporting structure and generation method thereof

PendingCN109501249AIncrease print speedReduce post-processing difficultyAdditive manufacturing apparatus3D object support structuresSoftwareMechanical engineering

The invention discloses a variable cross-section opening grid supporting structure and a generation method thereof. Opening grid supporting units are formed by arraying a plurality of grid units in different sizes, and a plurality of opening grid supporting units are overlapped so that support units are formed for changing the support form; the side walls of the opening grid supporting units are provided with grid openings penetrating through the opening grid supporting units horizontally so that a lateral powder discharging channel is formed; thus, powder in supports can be cleared completelyafter forming, and recycled before heat treatment after forming of parts; the printing rate is increased, and the post-processing difficulty is reduced; a cross-section structure is formed through three-dimensional drawing software, and the supports are arrayed and arranged according to the requirements; the powder that can not be cleared from the interior of a traditional grid support is clearedcompletely, and the usage amount of the forming powder is reduced; the printing rate is higher through design of the grip supports with lateral powder discharge, and the forming time is shortened; and the efficiency is improved, and the cost is reduced.

Owner:西安国宏天易智能科技有限公司

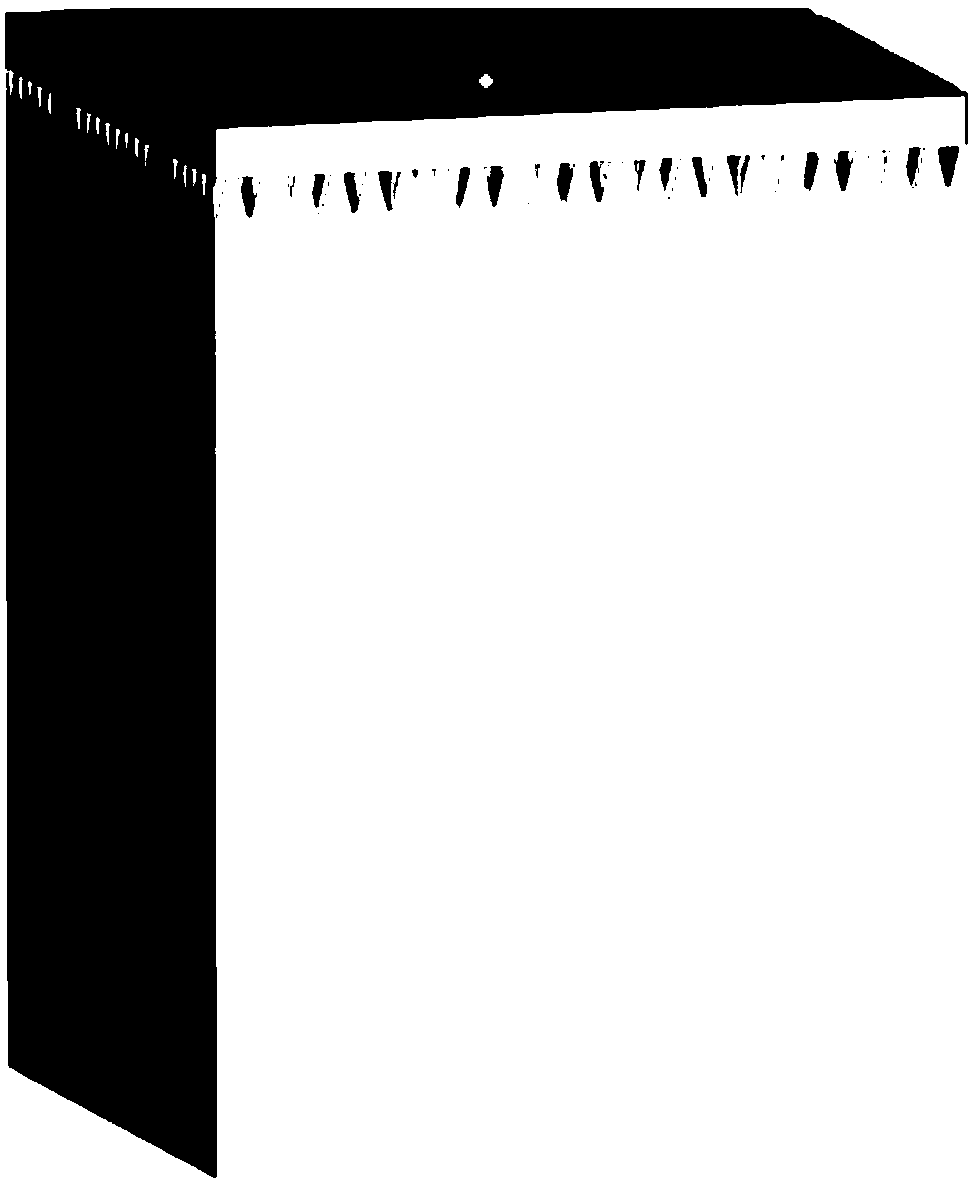

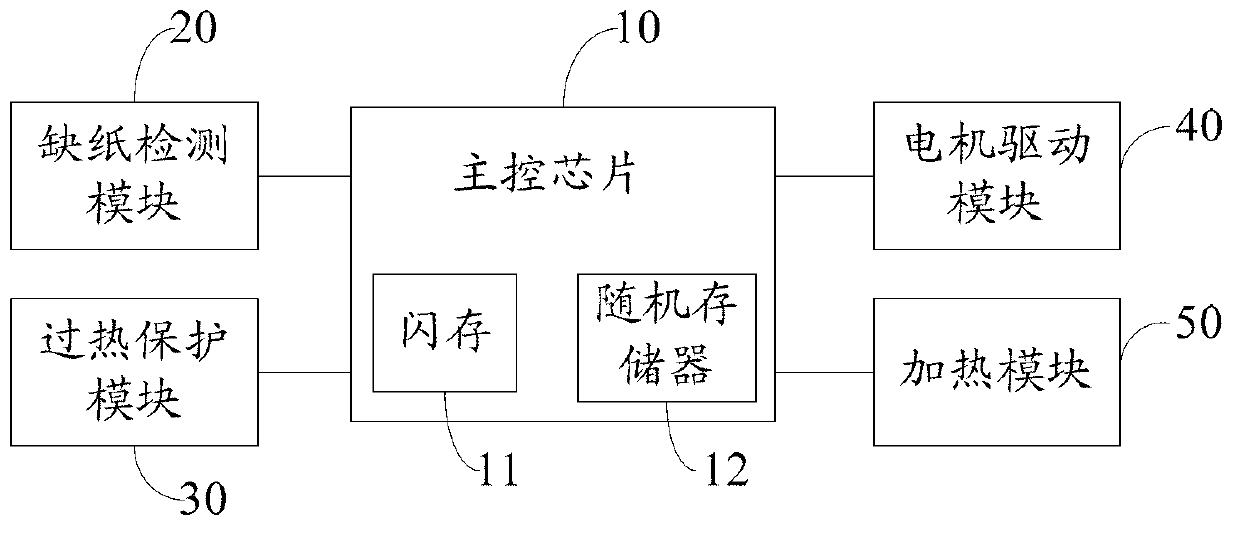

Thermal printer for automotive fault diagnostic apparatus and automotive fault diagnostic apparatus

InactiveCN103342054AIncrease print speedEasy to integrateOther printing apparatusFlash memoryStatic random-access memory

The invention relates to a thermal printer for an automotive fault diagnostic apparatus and an automotive fault diagnostic apparatus. An integrated master control chip is used to control the printer; and a flash memory and a random access memory are integrated at the master control chip. When the master control chip receives data sent by an upper computer of the automotive fault diagnostic apparatus, the data are directly transferred to a printer head by the random access memory to carry out printing. Therefore, received data can be printed rapidly; and a printing rate of the printer can be improved.

Owner:SHENZHEN FCAR TECH CO LTD

Printing machine for biodegradable film

ActiveCN105599435ASimple structureEasy to use and efficientRotary pressesPrinting press partsPrinting pressConductor Coil

The invention discloses a printing machine for biodegradable film. The printing machine comprises a printing machine main shell and a winding shaft to be printed; a film winding driving motor is arranged inside the printing machine main shell, a central control processing device is fixedly installed on the right side of the film winding driving motor, a printing control processing device is arranged on the upper portion of a printing fixing plate, a hydraulic device is arranged in the circle center of the printing fixing plate, a printing head is arranged below the hydraulic device through a hydraulic rod, a printing sensing device is arranged at the bottom of the printing fixing plate, an alarming device is arranged on the upper portion of a printing device outer shell, and the winding shaft to be printed is installed at the bottom of a groove. According to the printing machine for the biodegradable film, the printing precision and the printing quality are improved, emergency stop is achieved when the printing machine is abnormal, and an alarm is given out, so that an operator handles equipment in time, the phenomenon of defective printing is reduced, and the printing speed is increased.

Owner:山西安华生物科技有限公司

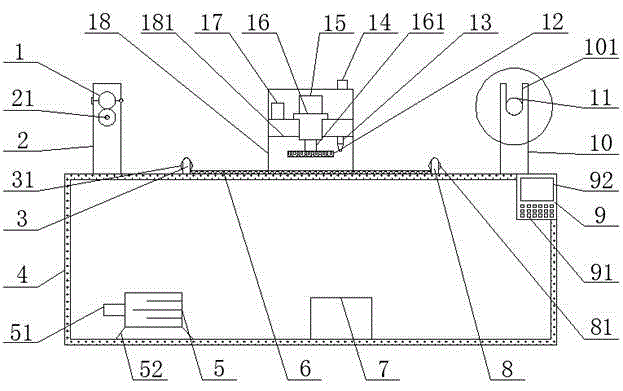

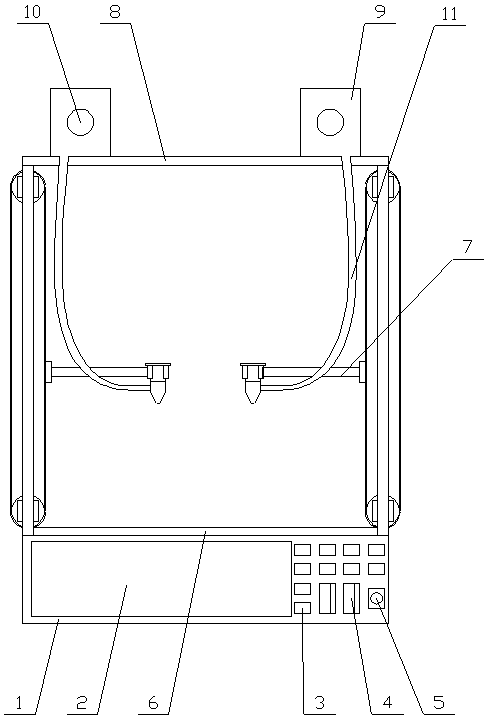

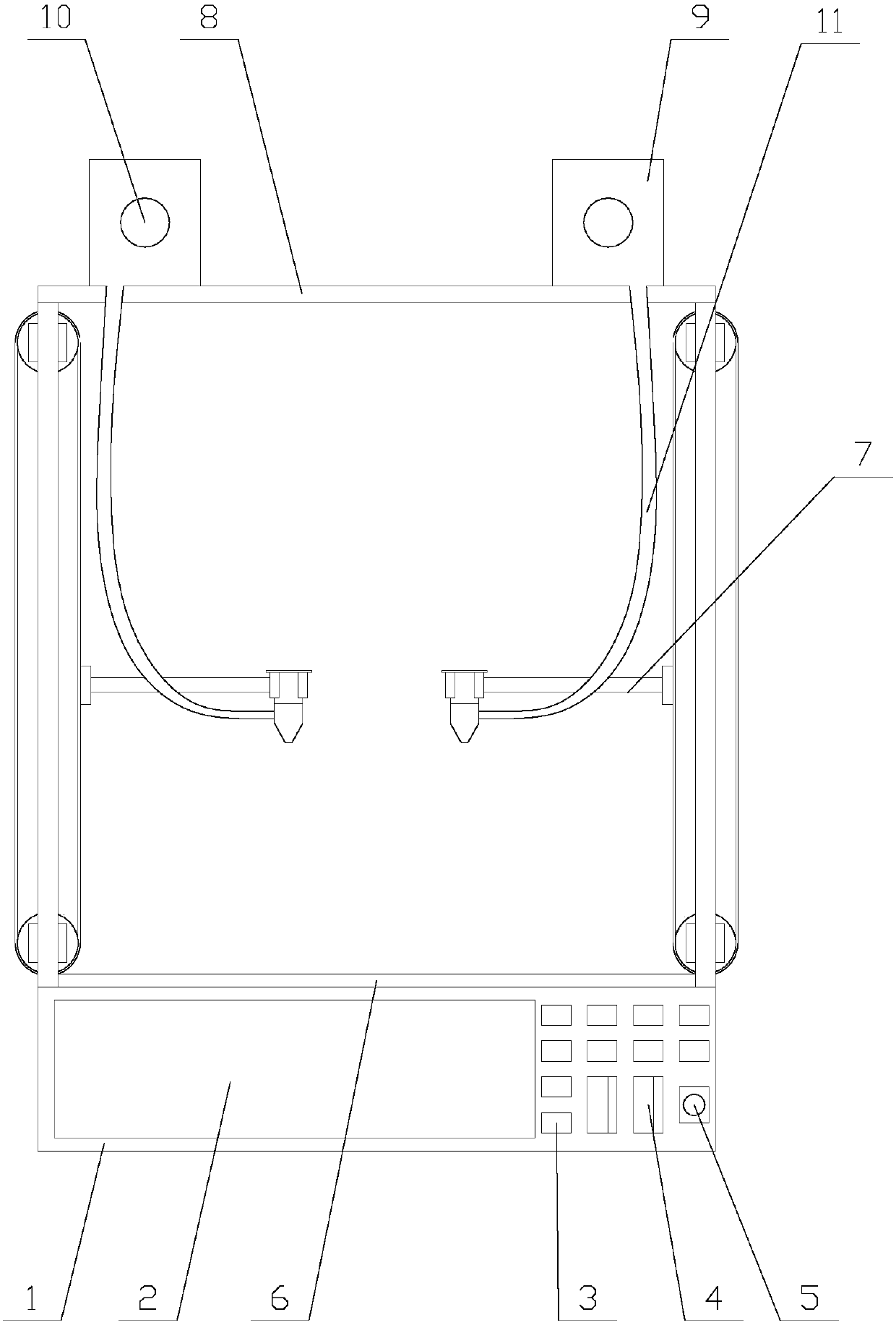

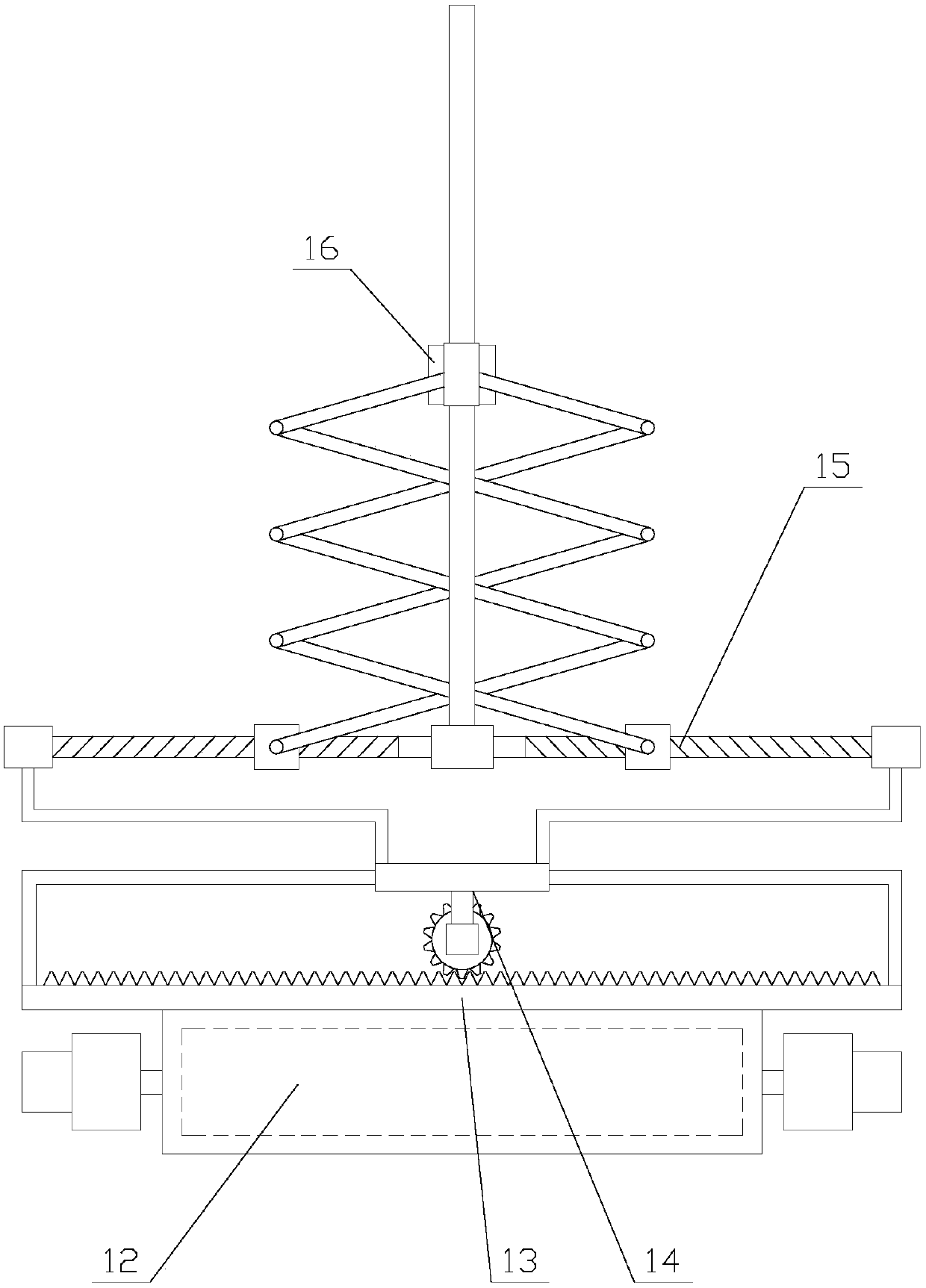

Intelligent 3D printing machine using single-double printing nozzle optional technology

InactiveCN109571934ARealize portable disassembly and maintenanceGuaranteed uptimeManufacturing driving means3D object support structuresOperation mode3d printer

The invention relates to an intelligent 3D printing machine using a single-double printing nozzle optional technology. The intelligent 3D printing machine includes a printing platform, a roof, two feeding mechanisms and two printing mechanisms, each printing mechanism comprises a lifting mechanism, a vertical plate, a first translation mechanism, a second translation mechanism and a printing unit,and each first translation mechanism comprises a frame, a sliding ring, a supporting rod, a second motor, a driving gear and driven teeth; and each second translation mechanism comprises a driving mechanism, a telescopic frame, two moving blocks and two connecting rods, and each printing unit comprises a moving block, a top rod, an inserting plate, a printing nozzle and two guide rail plates. Theintelligent 3D printing machine using the single-double printing nozzle optional technology drives the two printing nozzles to move for printing through the two printing mechanisms, the printing efficiency is speeded up, not only that, the printing nozzles are fixed between the two guide rail plates of the moving blocks through the top rods and the inserting plates, convenient disassembly repairis achieved at failure of the printing nozzles, the single nozzle operation mode is automatically switched, and the continued operation of printing is ensured.

Owner:NANJING LINGYA AUTOMOBILE TECH RES INST

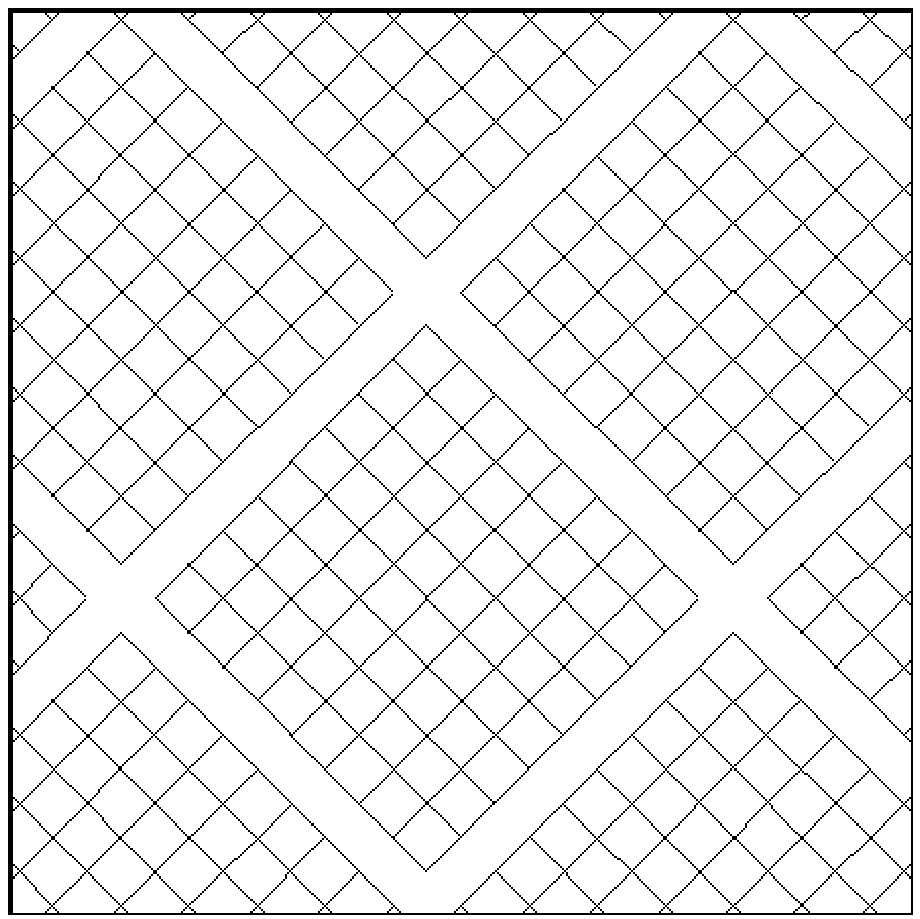

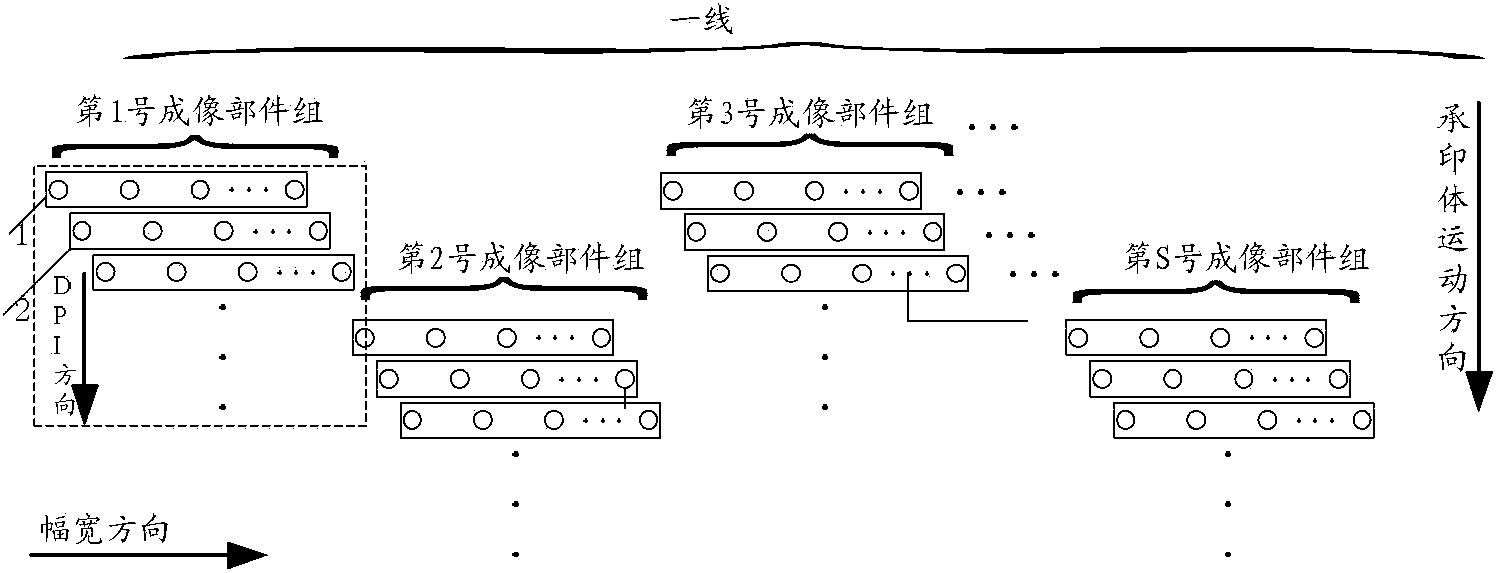

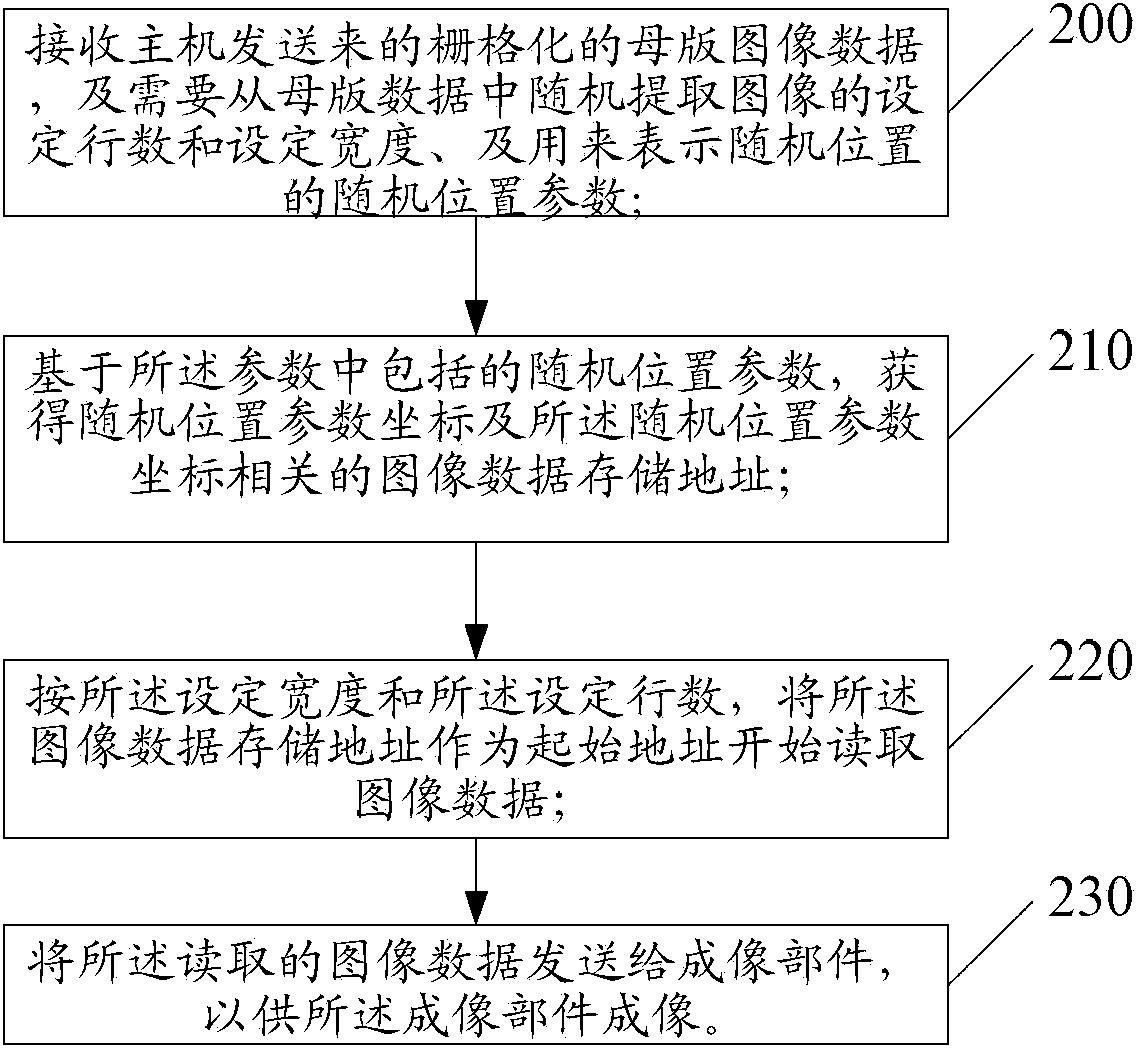

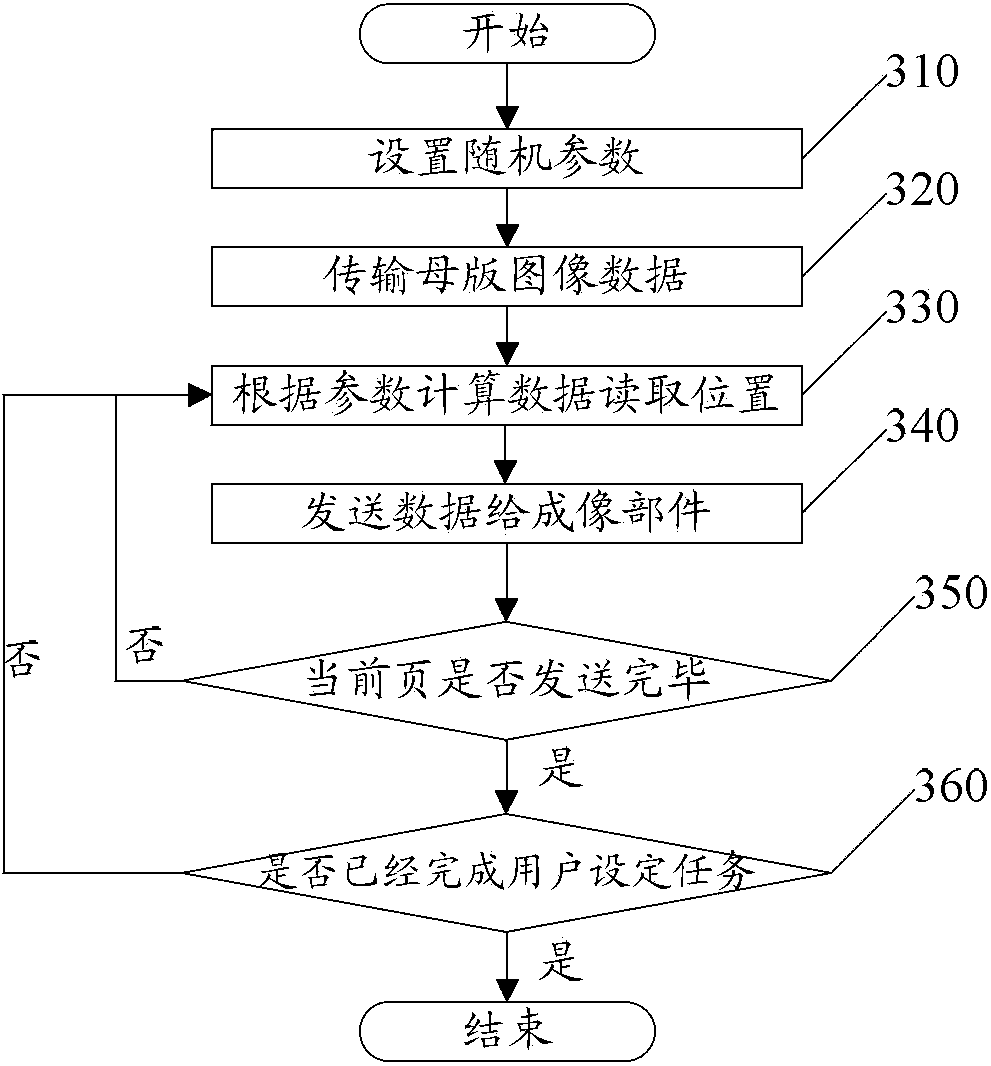

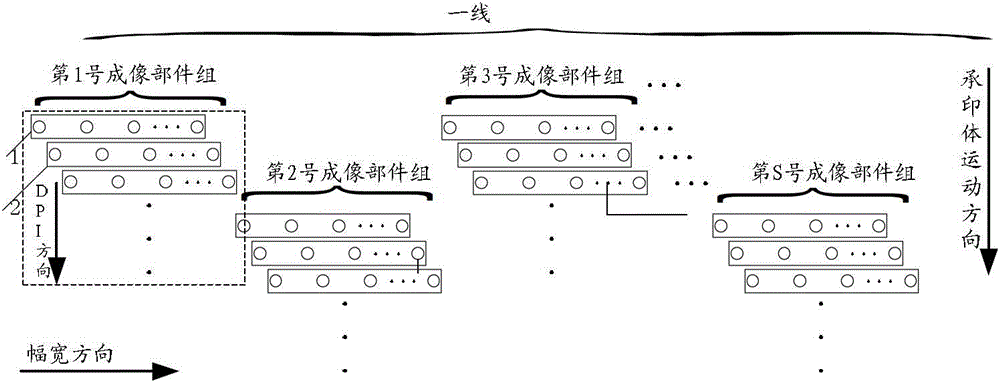

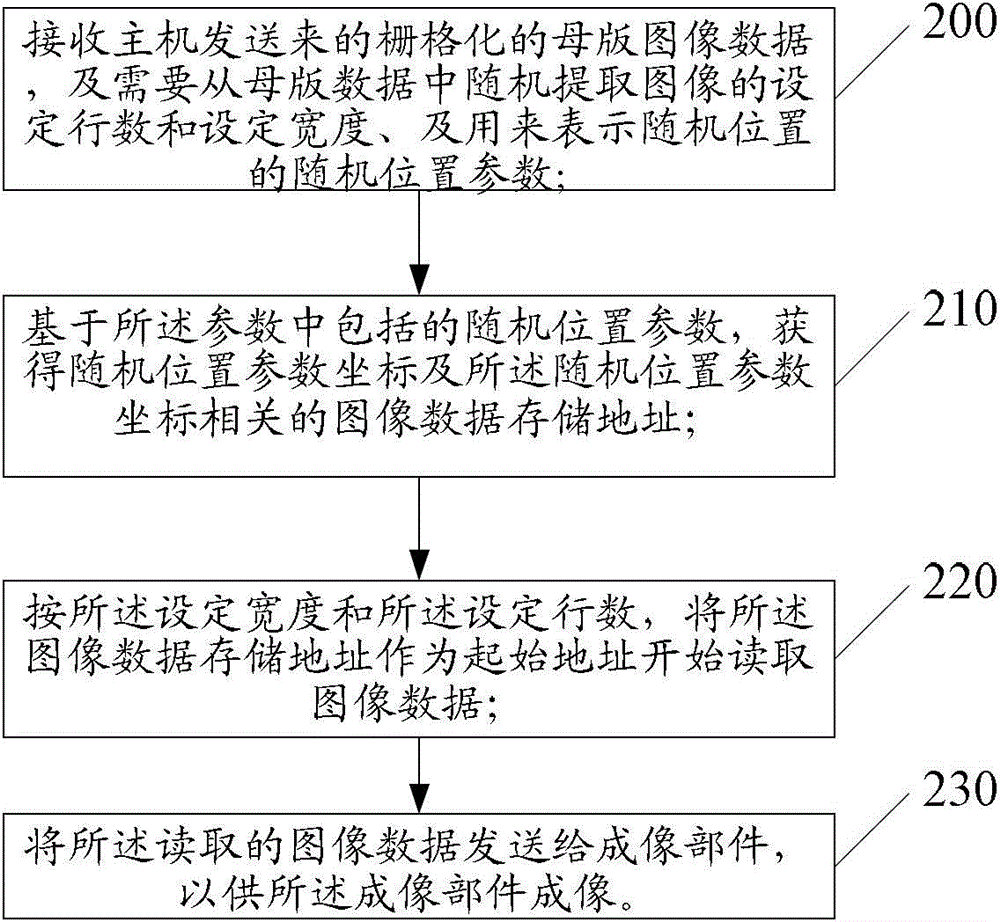

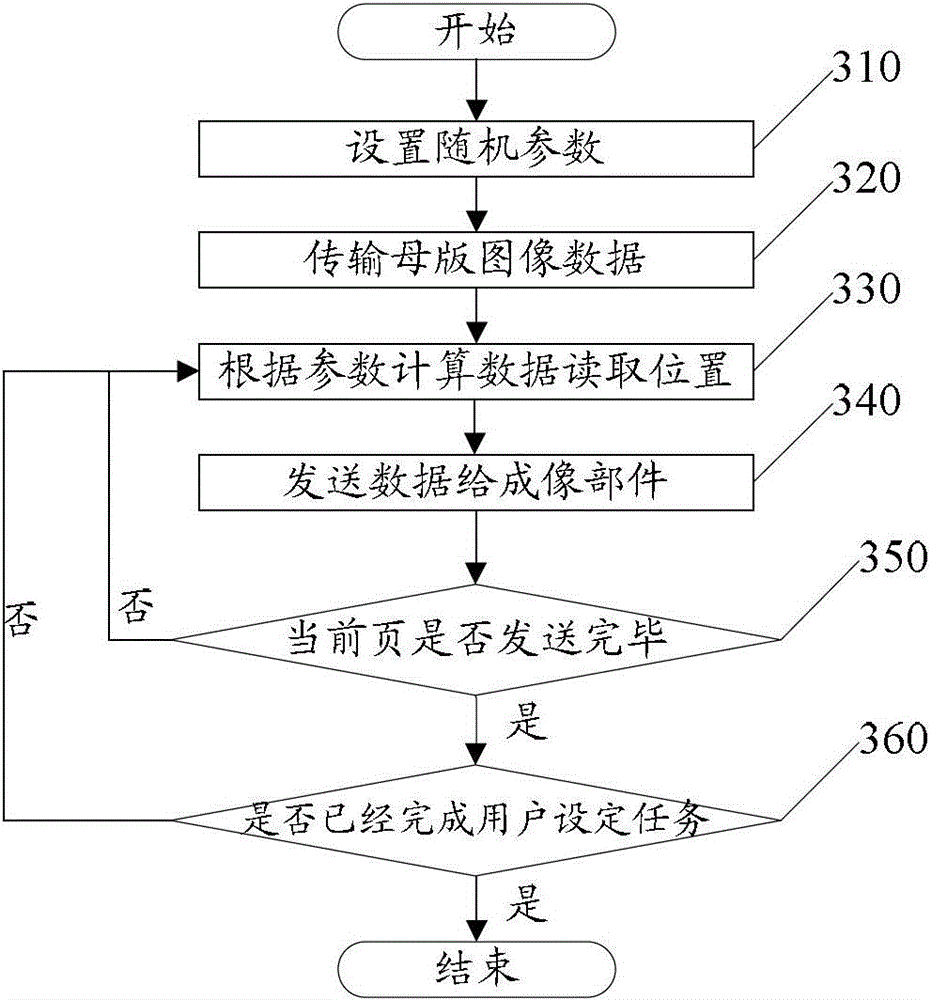

Random image processing method and printing device control system

InactiveCN103419513AReduce storage space wasteReduce redundant stepsOther printing apparatusData memoryRandom number generation

The invention discloses a random image processing method and a printing device control system. The random image processing method is applied in the printing device control system and used for obtaining image data on any one of at least one page and comprises the steps of receiving rasterized mother board image data, set length and set width of images required to be extracted randomly and parameters for representing random number generation modes which are sent by a host computer; obtaining random number coordinates and image data memory addresses relevant with the random number coordinates based on the random number generation modes included in the parameters; using the image data memory addresses as starting addresses to begin to read the image data according to the set width and the set length; sending the read image data to an imaging part for imaging.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

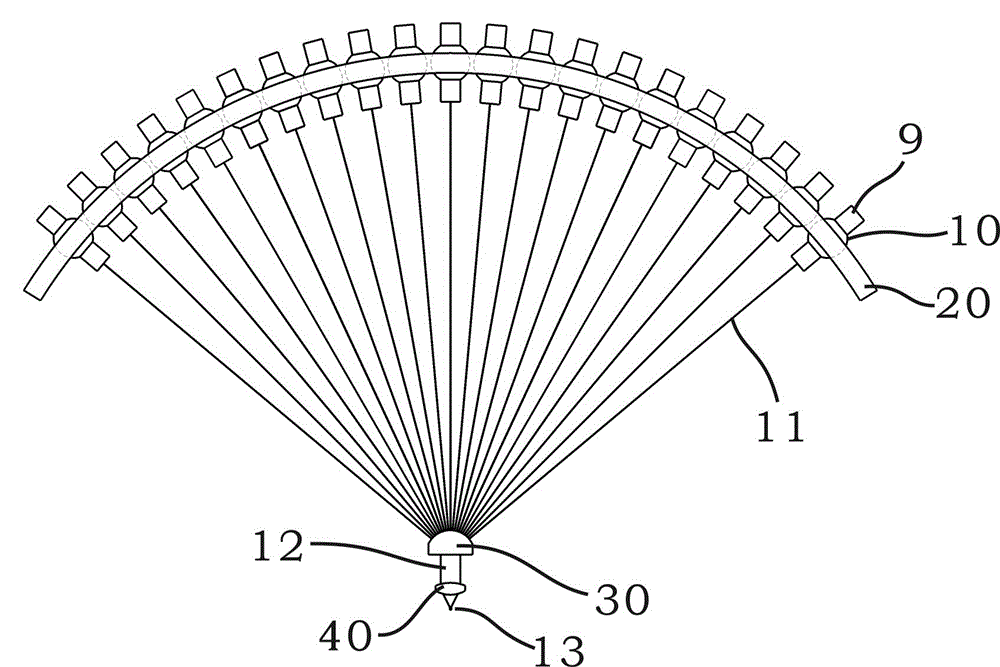

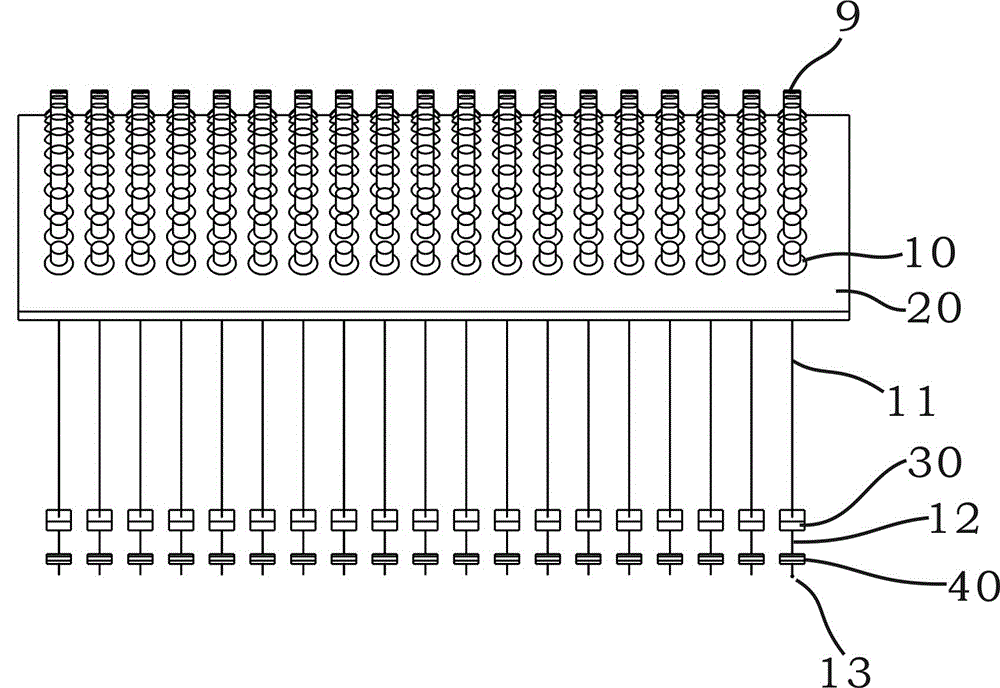

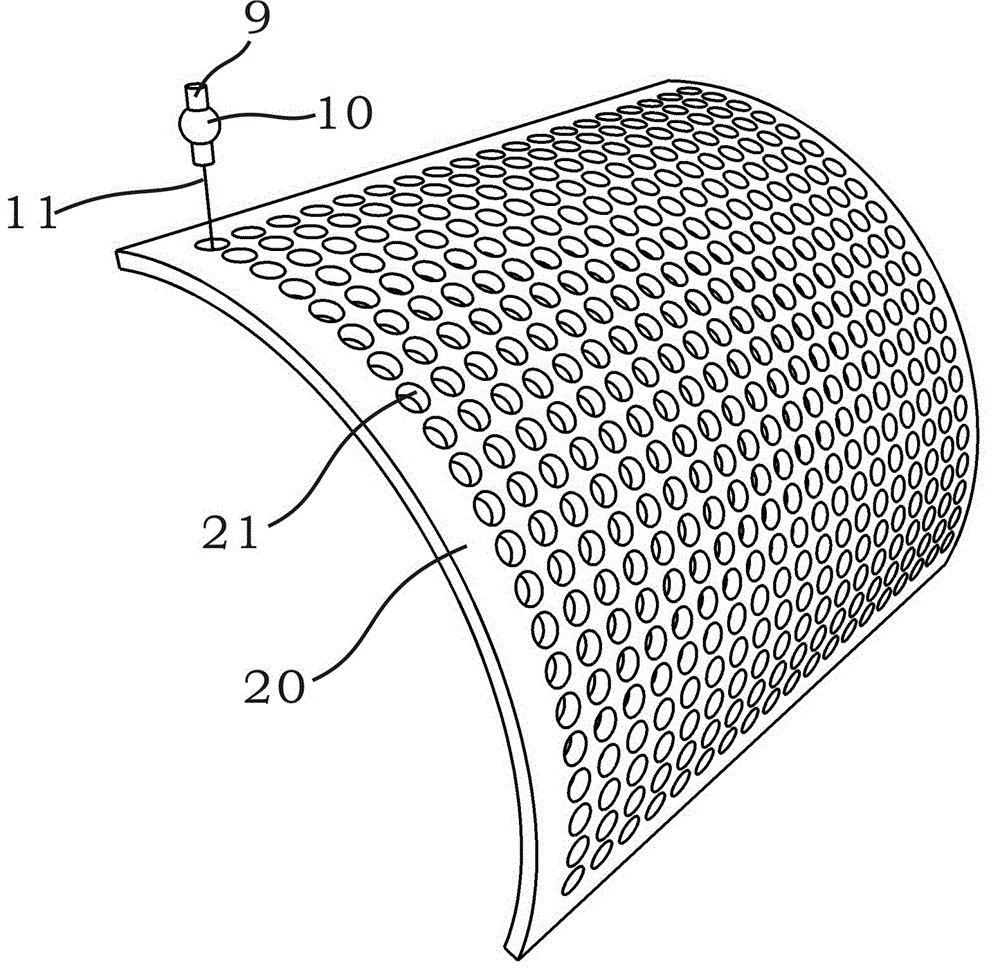

Dot-matrix 3D printing light source utilizing light-emitting diodes

ActiveCN104959602AImprove printing efficiencyHigh Power Switching Control FrequencyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLight-emitting diode

The invention provides a dot-matrix 3D printing light source utilizing light-emitting diodes. The dot-matrix 3D printing light source comprises the light-emitting diodes, a mounting support, first collecting lenses and second collecting lenses. The light-emitting diodes are arranged on the mounting support, and primary light emitted by each light-emitting diode is condensed by the unique corresponding first collecting lens to form secondary light. Then the secondary light is converged by the second collecting lenses to form condensation spots. All the condensation spots are located on a straight line and located on a forming plane of powder materials. Power sources of the light-emitting diodes in the same radial direction are controlled to enable the corresponding condensation spots to melt or sinter the powder materials in specific areas. Due to the fact that the electro-optical conversion efficiency of the adopted light-emitting diodes is more than 90 percent, and no air cooling or water cooling is needed, the electro-optical conversion efficiency of the light source adopted in the 3D printing technology with an SLS method can be improved, the service life is long, good heat radiation is achieved, cost is low, and the 3D printing efficiency is higher.

Owner:SHENZHEN ELEGOO TECH CO LTD

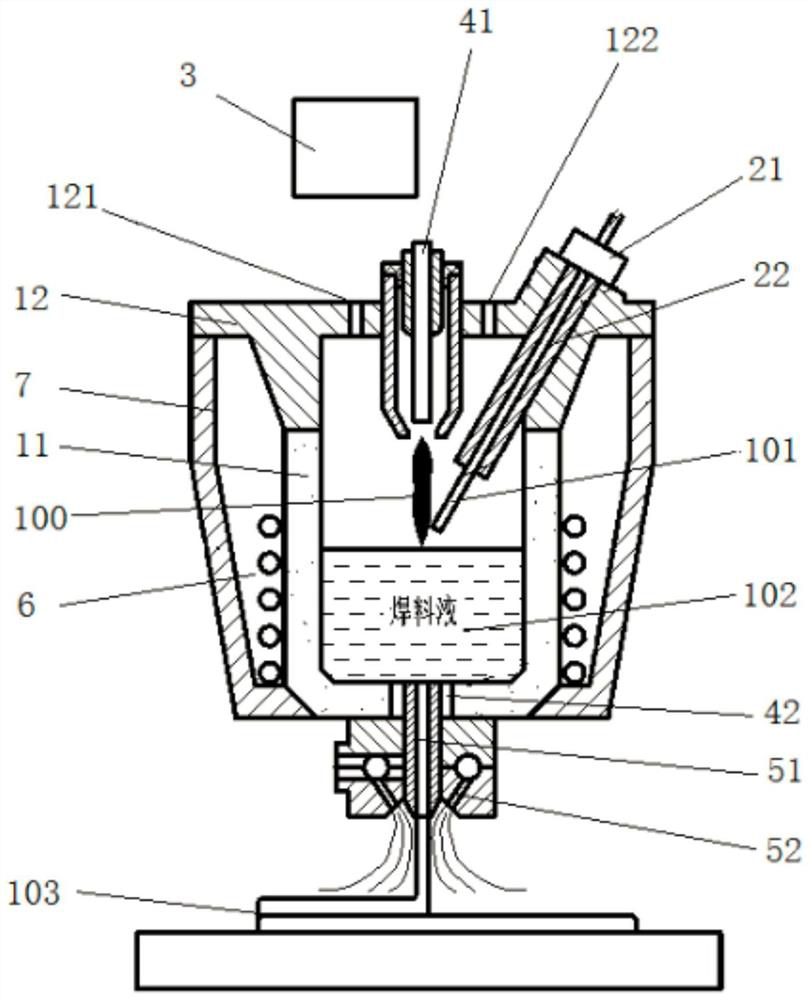

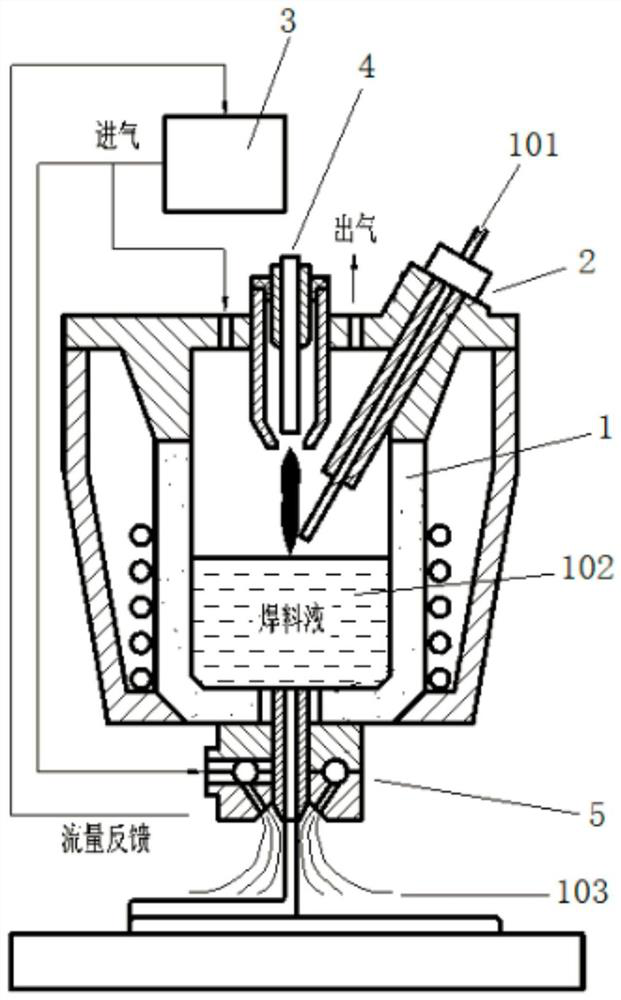

Plasma electric arc additional material device and method

PendingCN111958090AIncrease print speedPrevent splashAdditive manufacturing apparatusArc welding apparatusElectric arcMolten metal

The invention discloses a plasma electric arc additional material device and method. The device comprises a furnace body for containing molten metal, a wire feeding mechanism arranged on the furnace body and used for feeding a metal wire into the furnace body, a gas conveying mechanism for conveying gas into the furnace body, an electric arc generating mechanism comprises a positive electrode anda negative electrode oppositely arranged inside the furnace body, and a discharging mechanism which is arranged at the bottom end of the furnace body and communicates with the furnace body and the gasconveying mechanism to control the molten metal to be discharged, wherein an electric arc region is formed between the positive electrode and the negative electrode to melt the metal wire into moltenmetal. The metal wire inside the furnace body is fused, the molten metal is pressed out of the furnace body through the pressure of gas inside the furnace body, the molten metal is subjected to layer-by-layer additional material printing, the printing speed can be increased, the problem of the stability of a furnace hearth in the printing process is solved, and the problems that slag in the electric arc additional material printing process is splashed and the printing shaft precision is poor are avoided.

Owner:苏州鑫之博科技有限公司

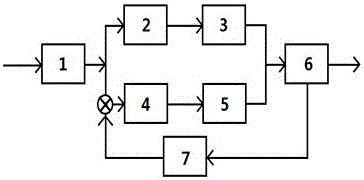

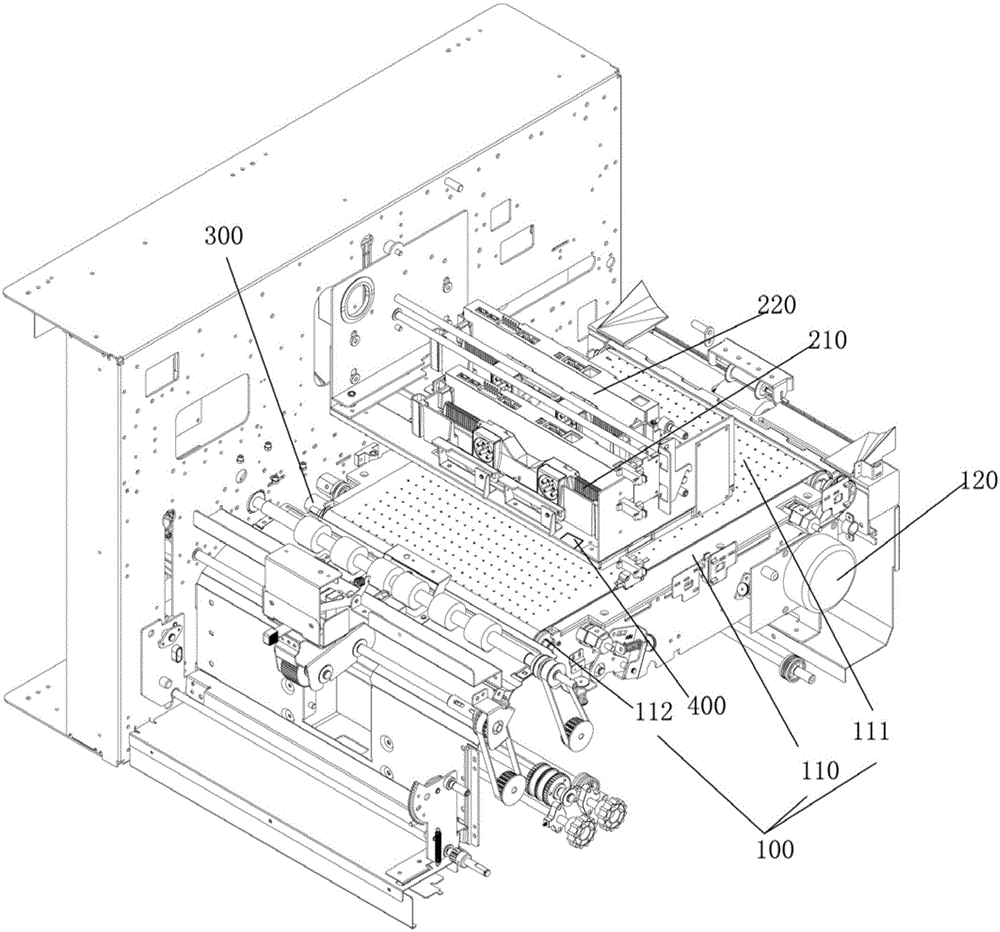

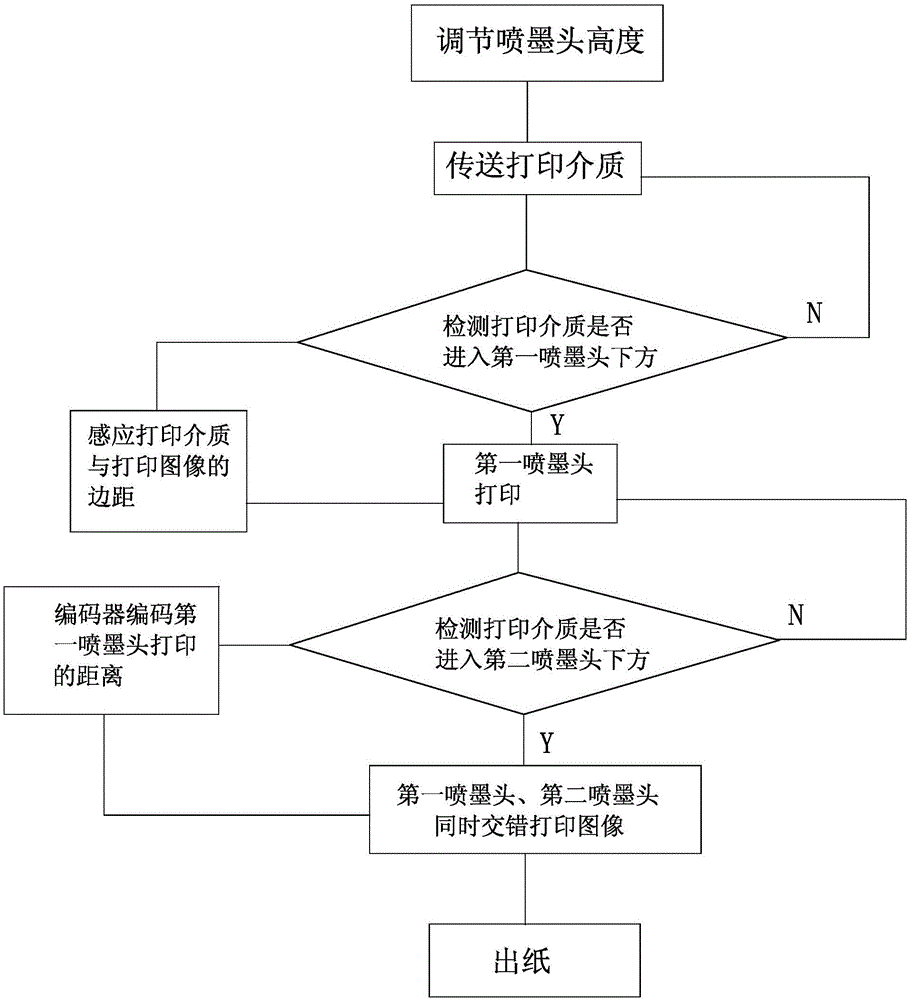

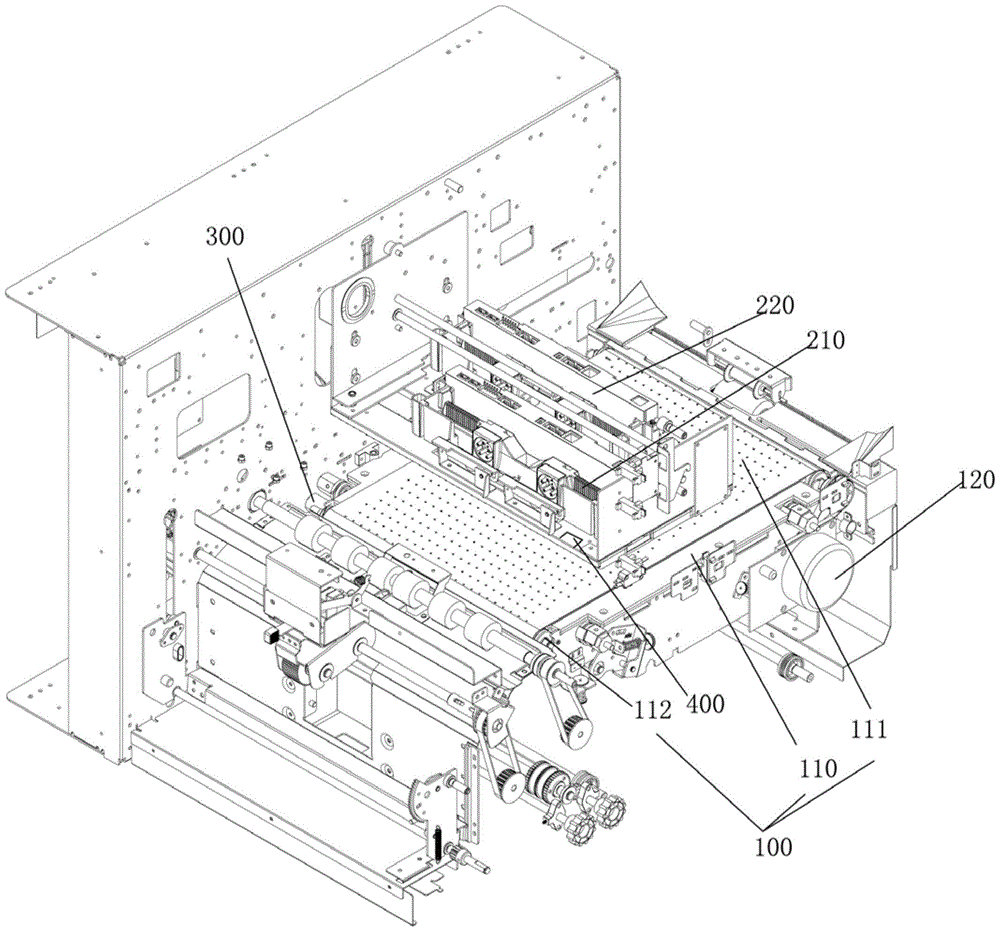

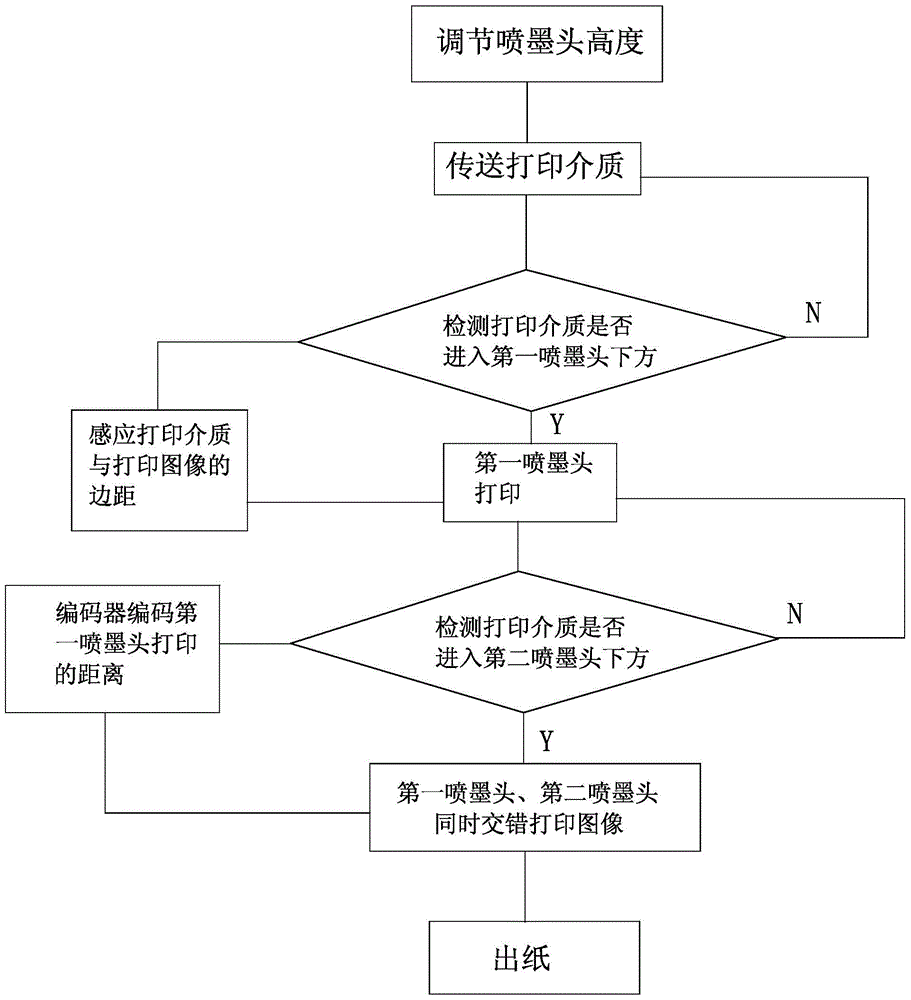

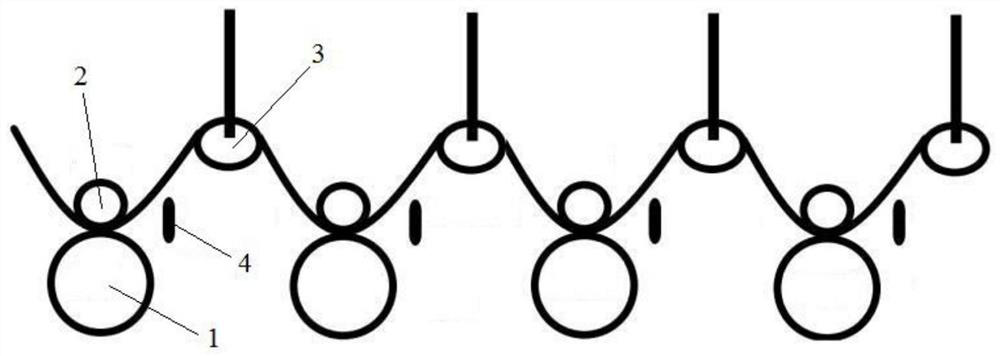

Double-nozzle printing control system and control method

ActiveCN105150684AIncrease print speedHigh speed printingOther printing apparatusControl systemStep number

The invention relates to a double-nozzle printing control system, which comprises a printing medium conveyer that comprises a conveyor belt and a rolling wheel for driving the conveyor belt to convey printing medium; an ink-jet apparatus that comprises a first ink gun and a second ink gun that can be controlled for lifting, wherein the first ink gun and the second ink gun are set on two sides above the conveyor belt crossingly; an encoder that is used to record the step number of a rolling wheel when the first ink gun prints; when the first ink gun prints one side image, the encoder calculates the step number of the rolling wheel at the same time; when the printing medium enters under the second ink gun, the second ink gun is controlled to print the image on the other side at the area corresponding to the area where the first ink gun has printed based on the step number calculated by the encoder. The invention also provides a control method of the double-nozzle printing control system. By using double-nozzle printing, printing rate of the ink jet printer is greatly lifted.

Owner:宁波荣大创想智造科技有限公司

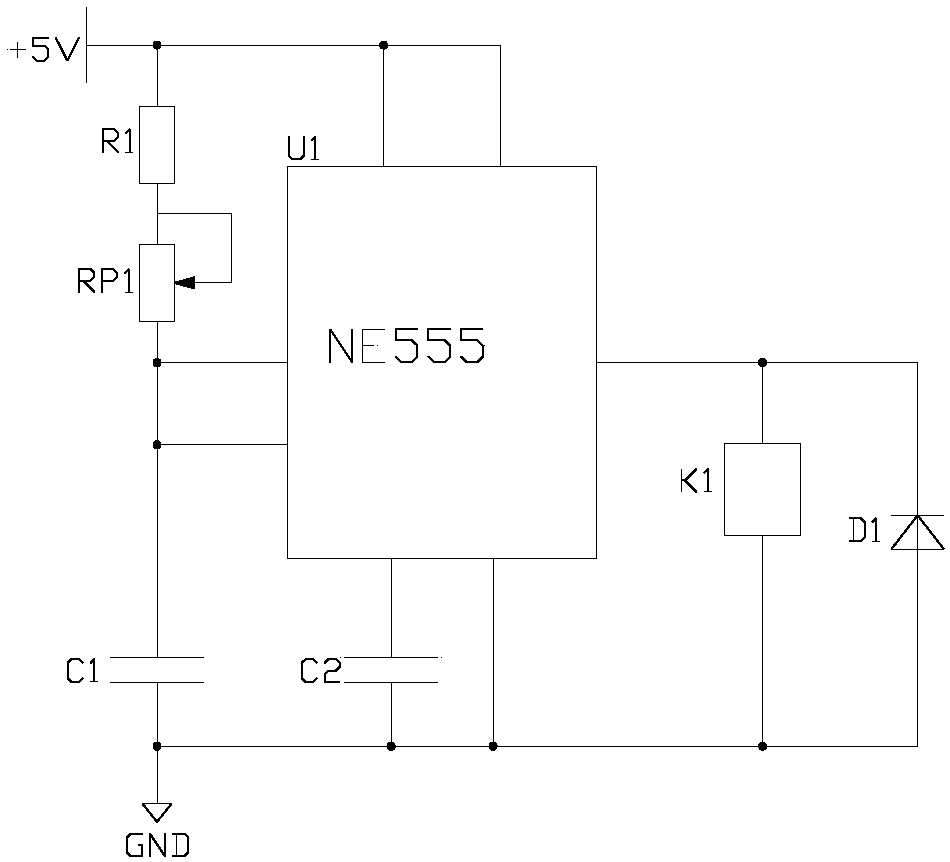

Intelligent 3D (three-dimensional) printer having spray head regulation and switching function

InactiveCN110370619AConvenient Mobile PrintingGuaranteed uptimeManufacturing driving means3D object support structuresEngineering3d printer

The invention relates to an intelligent 3D (three-dimensional) printer having a spray head regulation and switching function. The intelligent 3D printer having the spray head regulation and switchingfunction comprises a printing table, a top plate, two conveying mechanisms and two printing mechanisms, wherein each printing mechanism comprises a lifting mechanism, a vertical plate, a translation mechanism, a displacement mechanism and a printing unit, each translation mechanism comprises a frame, a slip ring, a connection rod, a second motor, a drive gear and a driven gear, each displacement mechanism comprises a drive mechanism, a telescopic frame, two moving blocks and two connection rods, and each printing unit comprises a movable block, a top plate, an insertion plate, a printing sprayhead and two guiderail plates. The intelligent 3D printer having the spray head regulation and switching function drives the two printing spray heads to move for printing respectively through the twoprinting mechanisms, and improves printing efficiency, and furthermore due to the fact that the model number of an integrated circuit in a timed control circuit is NE555, the intelligent 3D printer having the spray head regulation and switching function greatly reduces production cost and improves market competitiveness on the premise of guaranteeing accurate timing.

Owner:葛家顺

A printing machine for biodegradable film

ActiveCN105599435BSimple structureEasy to useRotary pressesPrinting press partsEngineeringPrinting press

The invention discloses a printing machine for biodegradable film. The printing machine comprises a printing machine main shell and a winding shaft to be printed; a film winding driving motor is arranged inside the printing machine main shell, a central control processing device is fixedly installed on the right side of the film winding driving motor, a printing control processing device is arranged on the upper portion of a printing fixing plate, a hydraulic device is arranged in the circle center of the printing fixing plate, a printing head is arranged below the hydraulic device through a hydraulic rod, a printing sensing device is arranged at the bottom of the printing fixing plate, an alarming device is arranged on the upper portion of a printing device outer shell, and the winding shaft to be printed is installed at the bottom of a groove. According to the printing machine for the biodegradable film, the printing precision and the printing quality are improved, emergency stop is achieved when the printing machine is abnormal, and an alarm is given out, so that an operator handles equipment in time, the phenomenon of defective printing is reduced, and the printing speed is increased.

Owner:山西安华生物科技有限公司

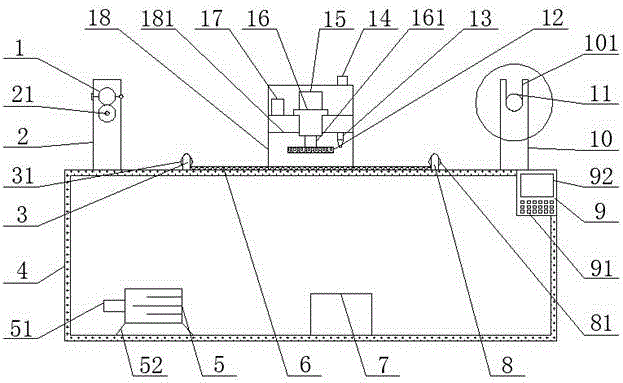

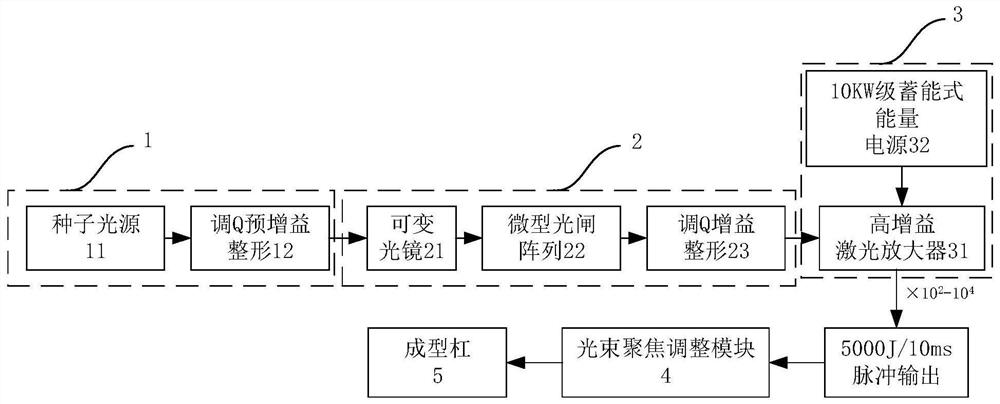

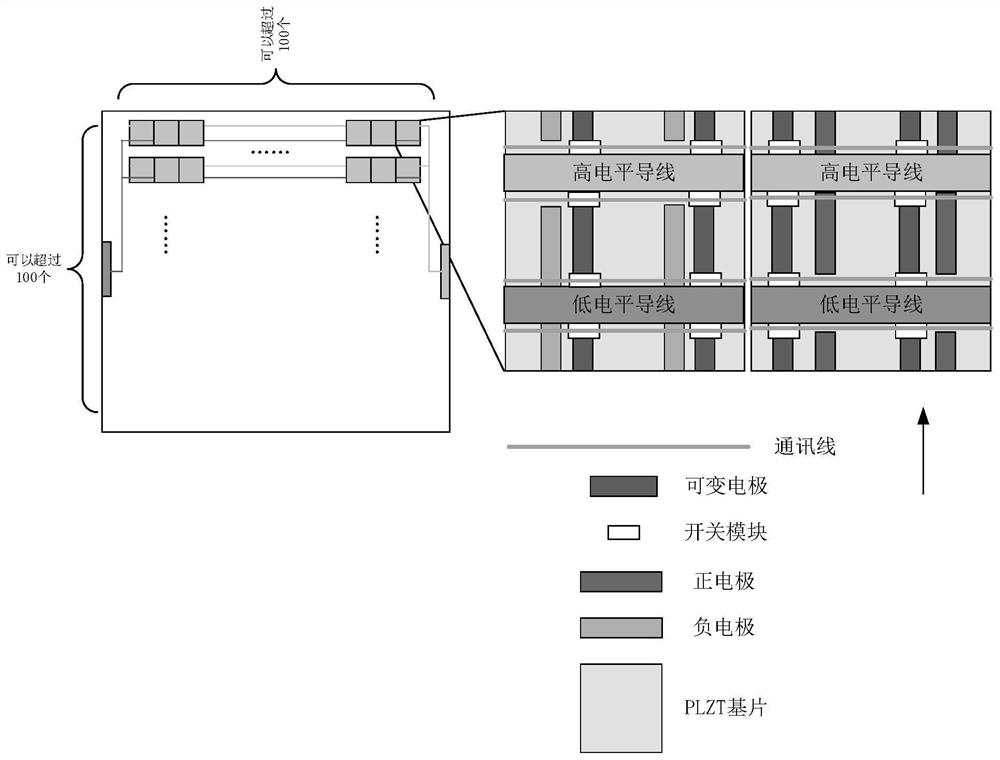

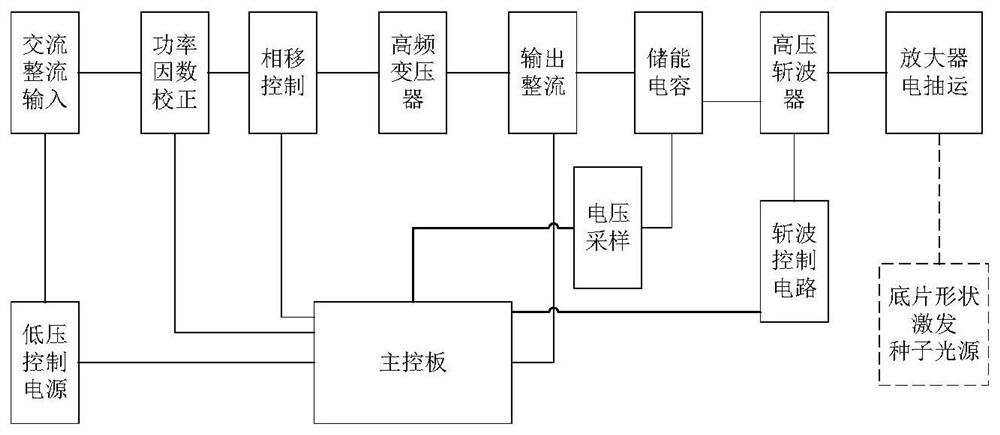

Metal surface exposure type powder bed melting additive manufacturing system

ActiveCN112846238ASolve quality problemsResolving high-energy paradoxesAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedPhysical chemistry

The invention relates to a metal surface exposure type powder bed melting additive manufacturing system. The metal surface exposure type powder bed melting additive manufacturing system comprises a laser light source module, a negative film module, a secondary amplification module, a light beam focusing adjustment module and a forming bar which are connected in sequence, wherein the laser light source module is used for generating laser, and the negative film module is used for cutting the laser to realize high-precision and low-power negative film image acquisition; the secondary amplification module is used for carrying out secondary amplification on acquired negative film light and outputting a high-power pulse; the light beam focusing adjustment module is used for focusing and shaping an input laser beam; and the forming bar is used for forming a required manufacturing shape. Compared with the prior art, the metal surface exposure type powder bed melting additive manufacturing system has the advantages of conveniently realizing selected area surface exposure, improving the printing rate of SLM and the like.

Owner:TONGJI UNIV

UV printing technology

The invention relates to a UV printing technology. The UV printing technology comprises the following steps: (1) winding two ends of a to-be-printed curtain on winding assemblies at two ends of printing equipment so that the curtain can be located at the lower side of a printing assembly; (2) starting the printing assembly and the winding assembly to make the printing assembly abut against the upper end of the curtain, wherein the curtain moves along with rotation of the winding assembly, and the printing assembly completes printing on the surface of the curtain; and (3) starting a drying and fixing assembly at a side end of the printing assembly, wherein a UV printing pattern is fixed to the surface of the curtain through the drying and fixing assembly. The UV printing technology has the advantages that drying and fixing effects are accelerated, various kinds of printing are not affected, and the like.

Owner:浙江德邦印务有限公司

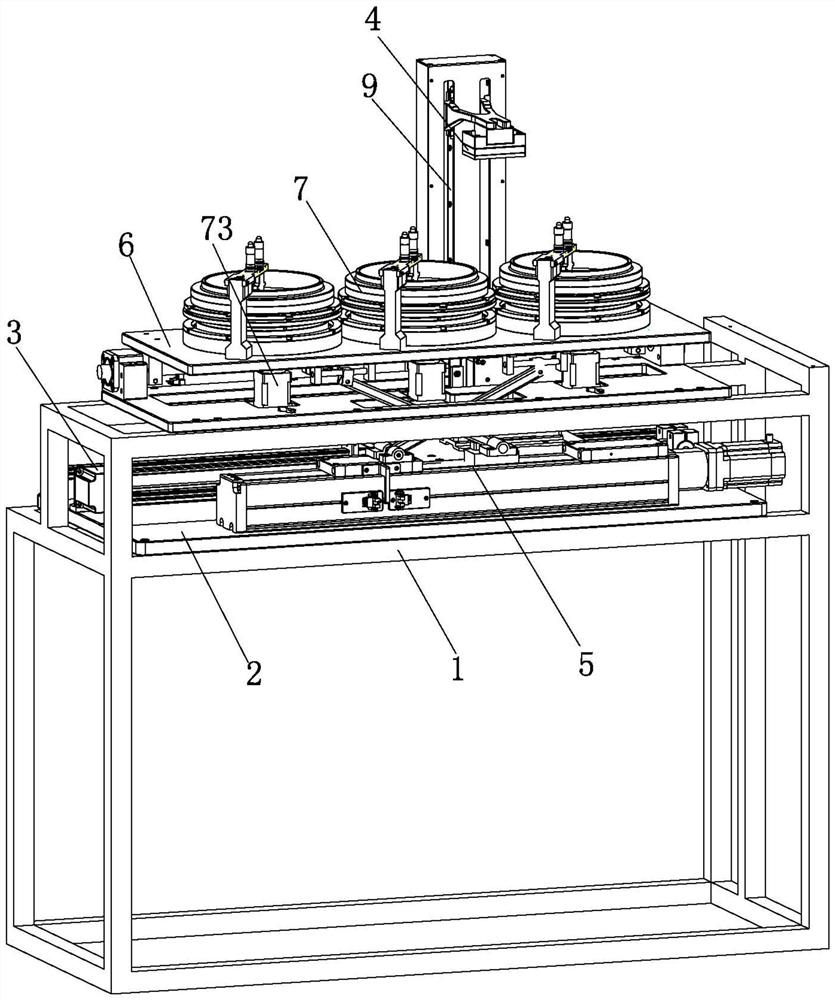

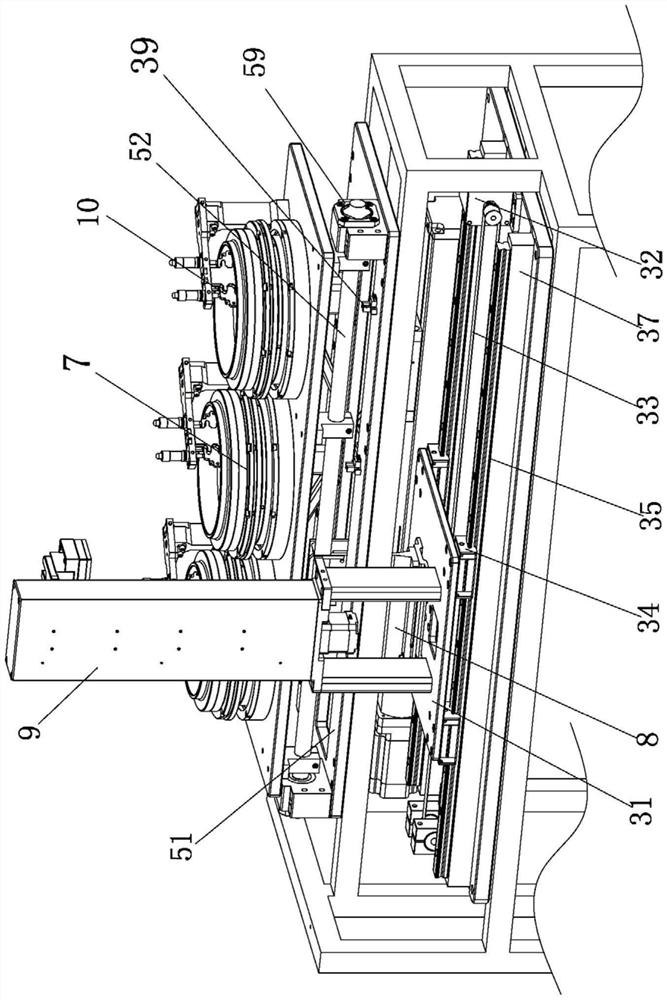

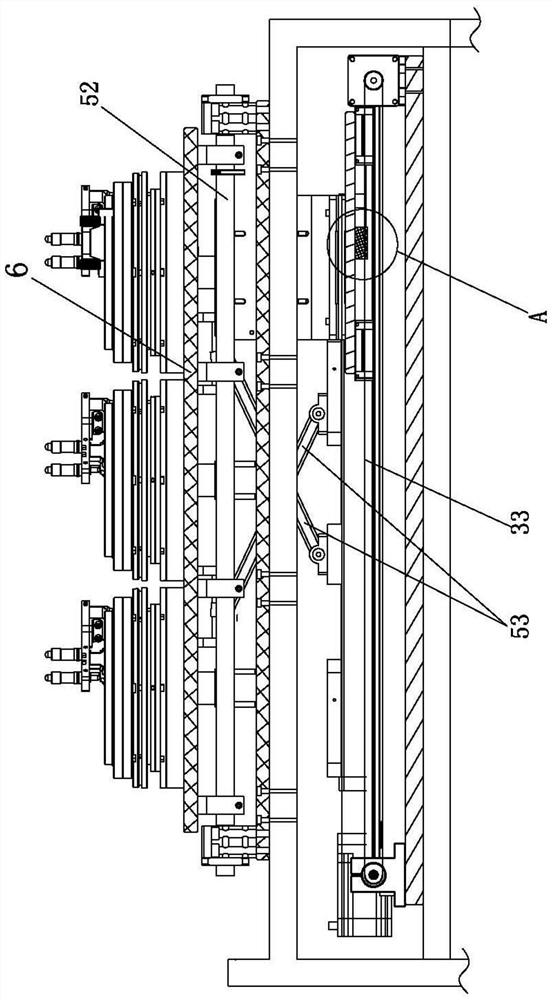

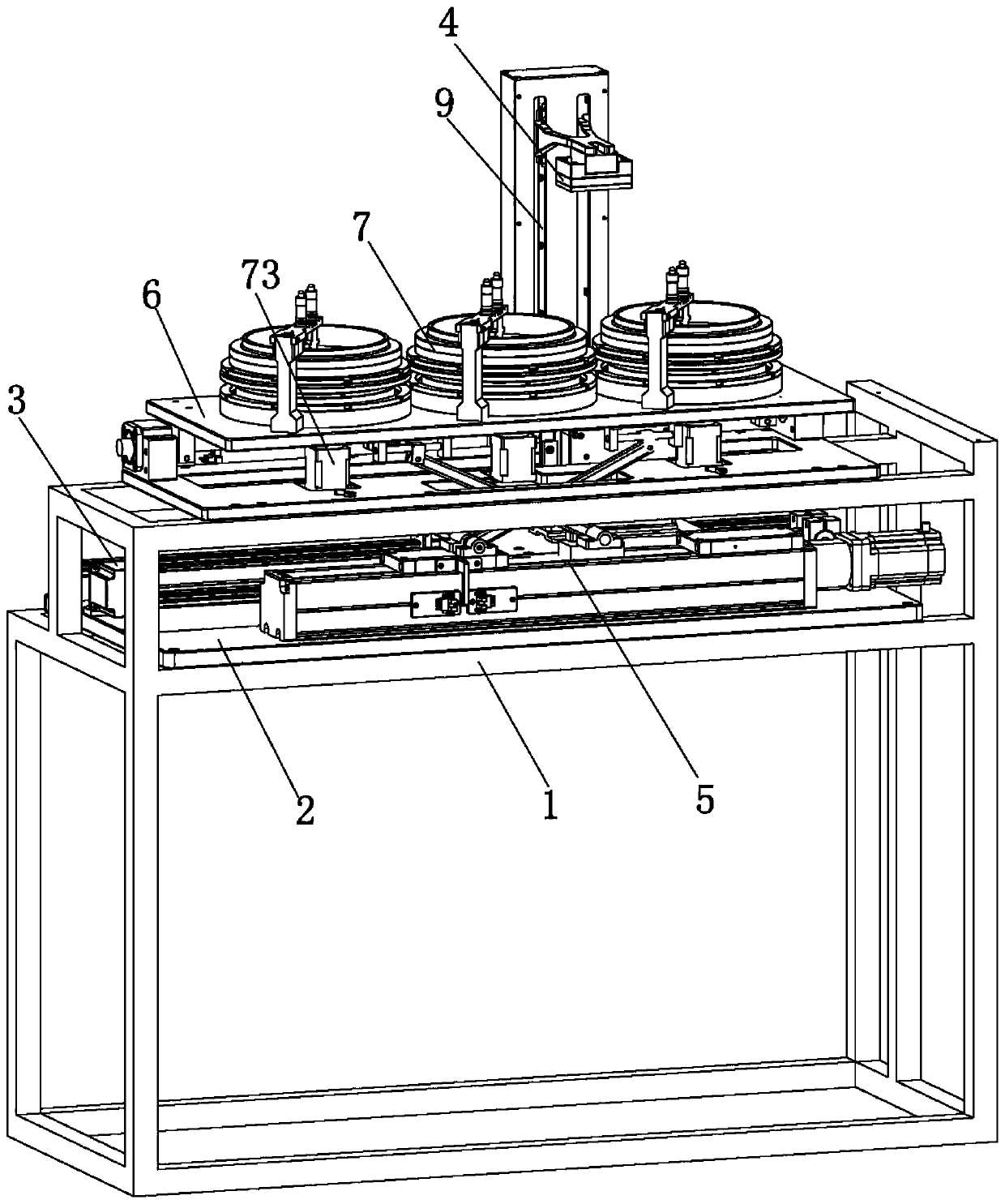

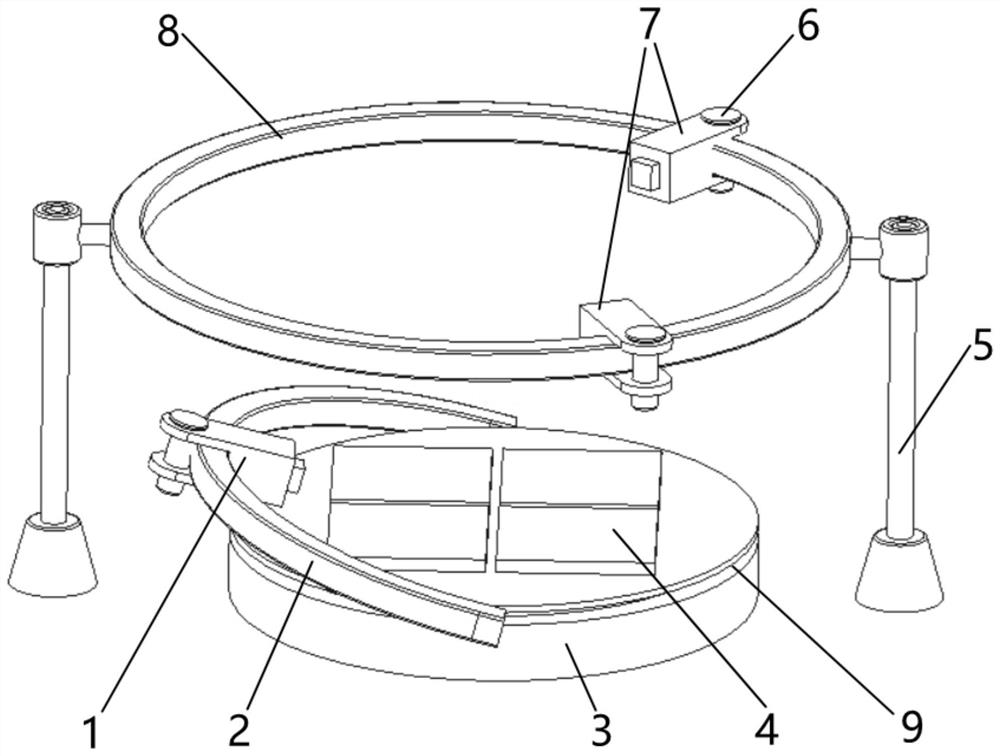

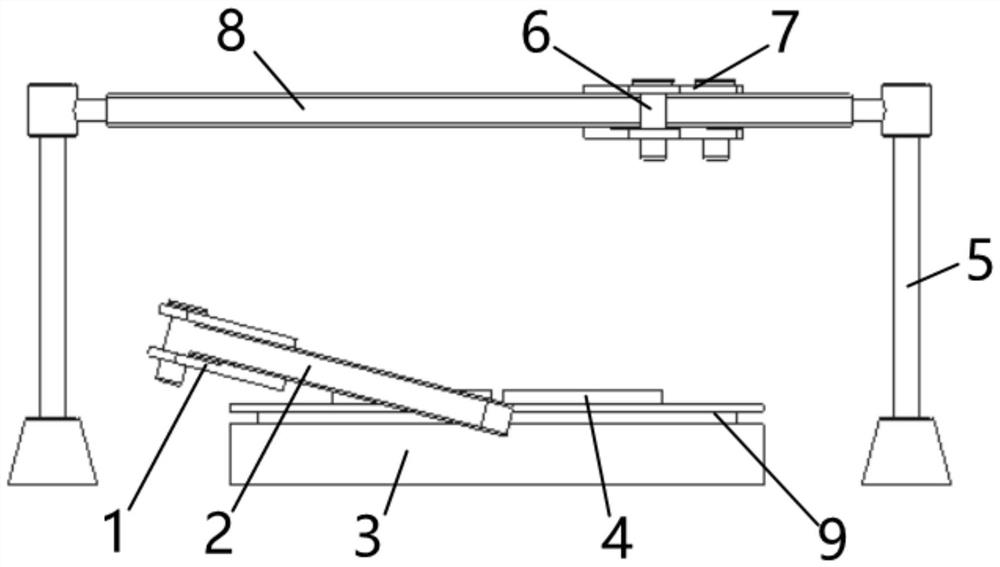

A multi-material 3D printer

ActiveCN110757798BPrecise positioningNo misalignmentManufacturing enclosuresAdditive manufacturing with liquidsComputer printing3d printer

The invention relates to a multi-material 3D printer, comprising a frame, a bottom plate, a Z-axis translation mechanism, a printing platform, an oblique drawing mechanism, a mounting plate and at least two material holding mechanisms; the bottom plate is fixedly mounted on the frame; the The Z-axis translation mechanism is supported on the bottom plate and can move relative to the bottom plate; an optical machine is installed on the Z-axis translation mechanism, and the light machine can move to the bottom of any material holding mechanism along with the Z-axis translation mechanism; the printing platform is installed on On the Z-axis translation mechanism, it can lift up and down and move horizontally; the bottom end of the oblique pulling mechanism is installed on the bottom plate, and the top end is connected to the mounting plate, which can drive the mounting plate to turn over; the material holding mechanism is arranged side by side on the mounting plate ; The printing platform can be translated to the top of each material holding mechanism along the arrangement direction of the material holding mechanism, so as to realize multi-material printing by using different printing materials in each material holding mechanism. The invention can realize the printing of various materials, and the printing demoulding is fast, and can effectively solve the problem that the printing materials cannot be printed.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

Printing method of multi-material 3D printer

InactiveCN110757797ARealize printingPrecise positioningManufacturing enclosuresAdditive manufacturing with liquidsComputer printingProjection image

The invention relates to a printing method of a multi-material 3D printer. The printing method comprises the following steps of: (1) driving a laser machine and a printing platform to horizontally move to corresponding positions by using a Z-axis horizontal moving mechanism; (2) rotating a storage tank, scraping a printing material positioned inside the storage tank by using a scraper blade mechanism so as to form a flat printing layer, and then stopping rotation of the storage tank; (3) moving down the printing platform to make sure that the distance from the lower surface of the printing platform to the bottom of the storage tank is equal to the set printing thickness set by a cutting piece; projecting the image range by using the laser machine to make sure that the printing material inside the projection region is cured on the printing platform; (4) starting an oblique pull mechanism, making a mounting plate be inclined, and separating a curing layer on the printing platform from the storage tank; and (5) still driving the laser machine and the printing platform to horizontally move to the corresponding position of the next to-be-used storage tank, and subsequently repeating thesteps (2) to (4) to print layer by layer until printing is ended. The printing method can realize printing of a plurality of materials, realizes quick demoldinig in printing and can effectively solvethe problem that the printing materials cannot be printed.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

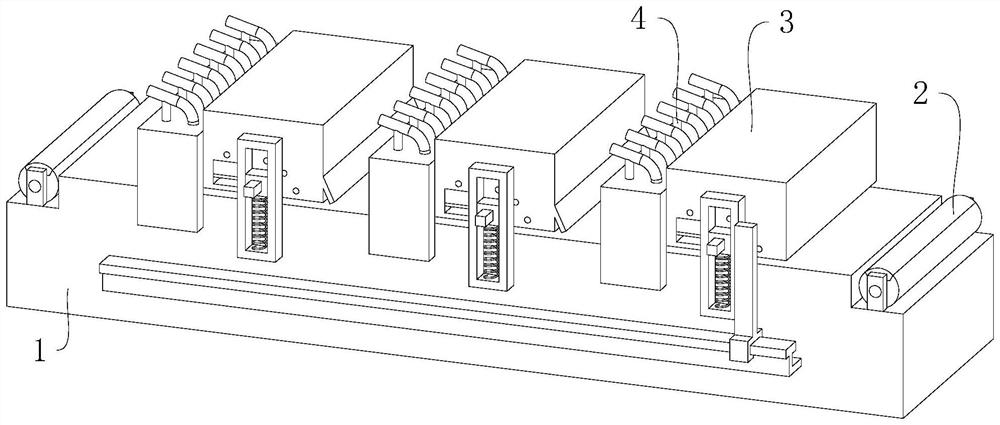

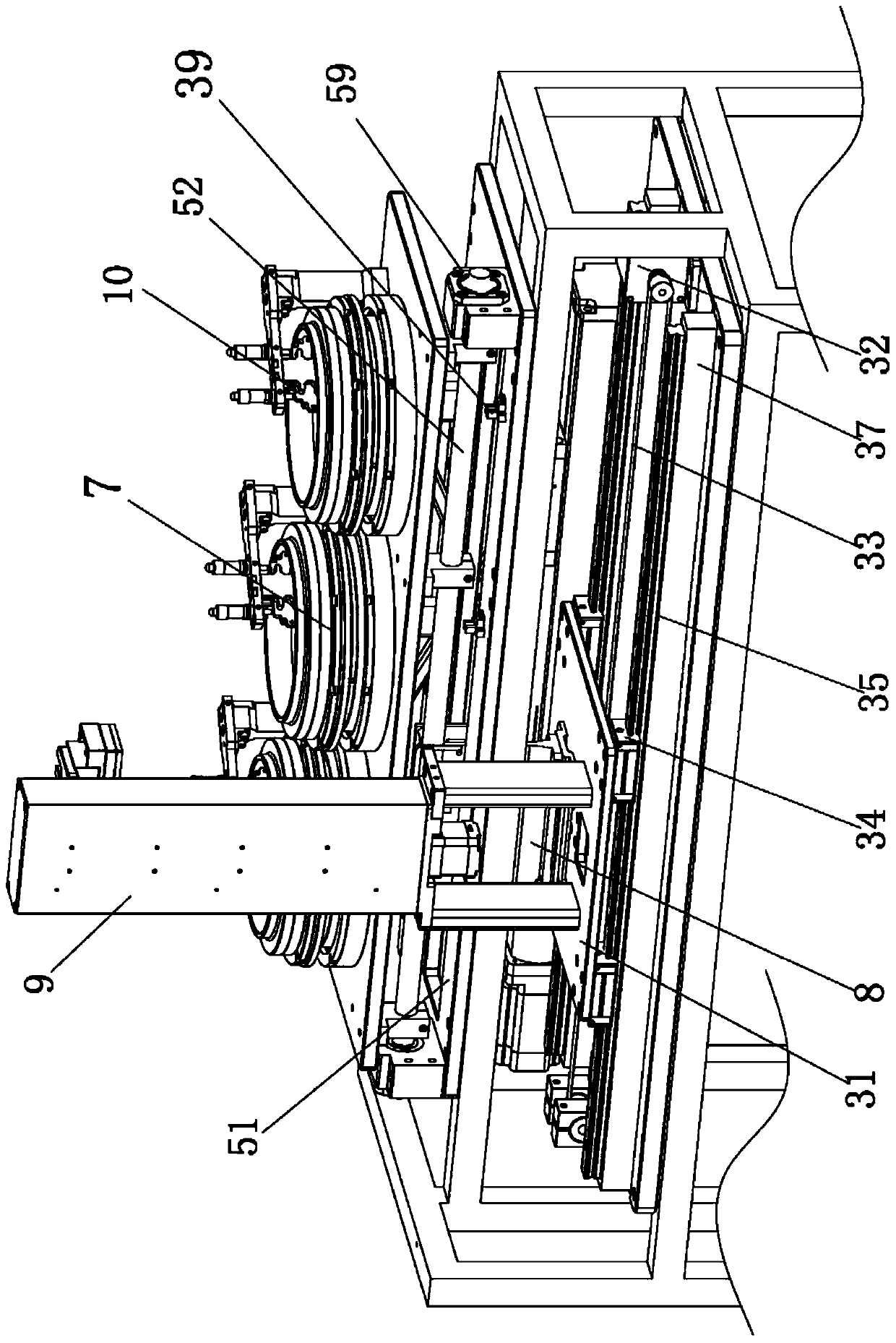

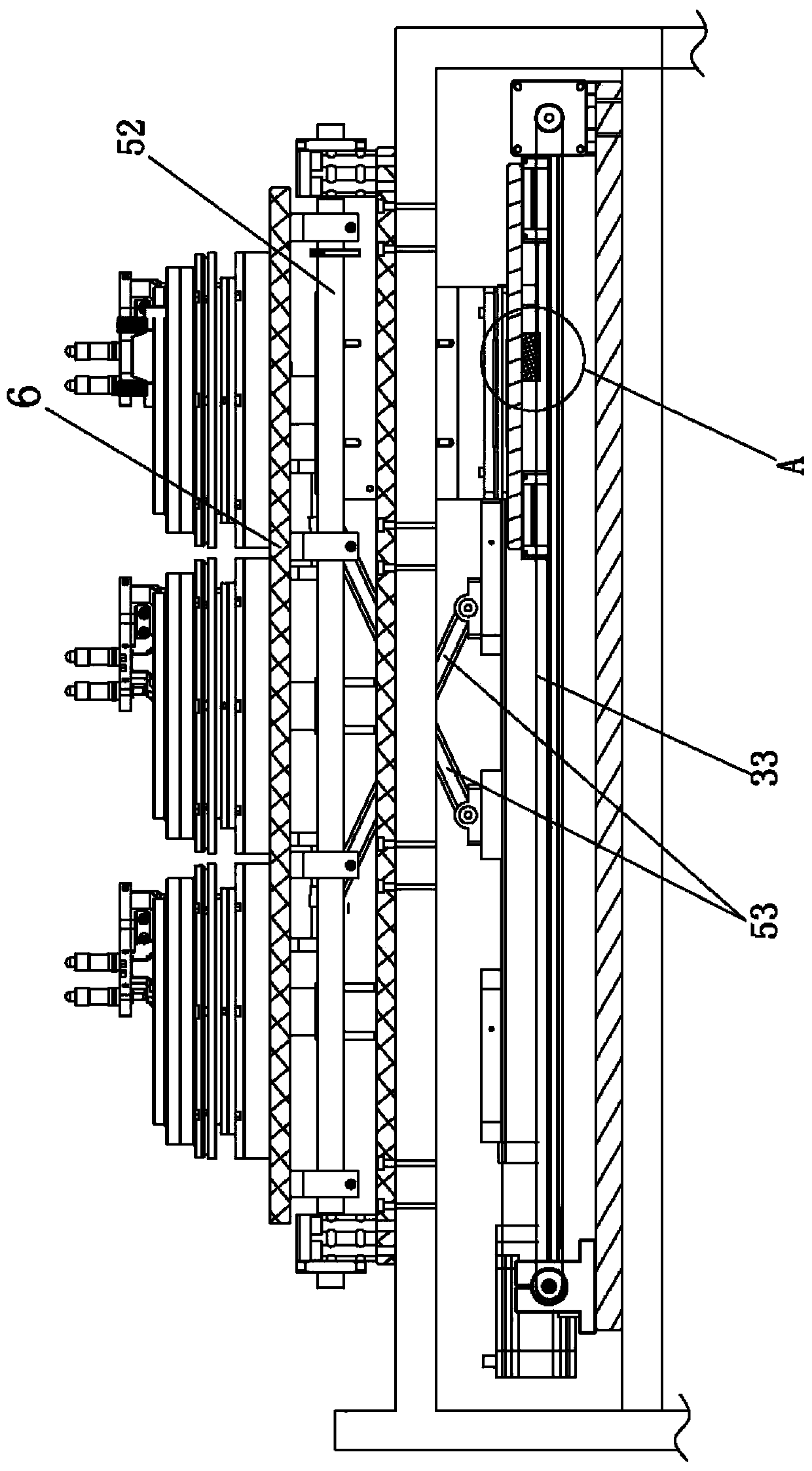

Multi-platform efficient material extrusion additive manufacturing equipment and block printing method

ActiveCN113733559AIncrease speedImprove printing efficiencyManufacturing platforms/substratesIncreasing energy efficiencyErbium lasersMechanical engineering

The invention discloses multi-platform efficient material extrusion additive manufacturing equipment and a block printing method. The equipment comprises a base, four independent printing platforms are arranged on the base, and a guide groove is formed at the side edge of the base and used for being connected with a first support and enabling the first support to rotate around the base along the guide groove. A laser capable of sliding back and forth along the first support is arranged on the first support. A second support is arranged above the base and can move up and down along supporting columns, and a laser capable of sliding along the second support is arranged on the second support. By using the multiple printing platforms, the printing efficiency is greatly improved. According to the block printing method, use of most supports can be avoided, then printing materials can be saved, the printing speed can be increased, the post-processing step of removing the supports is omitted, and the surface quality of a workpiece is improved. In addition, different printing materials and different colors can be applied to different platforms through multi-platform block printing, so that the workpiece can be more attractive and rich in creativity.

Owner:XI AN JIAOTONG UNIV

A dual nozzle printing control system

ActiveCN105150684BIncrease print speedHigh speed printingOther printing apparatusControl systemStep number

The invention relates to a double-nozzle printing control system, which comprises a printing medium conveyer that comprises a conveyor belt and a rolling wheel for driving the conveyor belt to convey printing medium; an ink-jet apparatus that comprises a first ink gun and a second ink gun that can be controlled for lifting, wherein the first ink gun and the second ink gun are set on two sides above the conveyor belt crossingly; an encoder that is used to record the step number of a rolling wheel when the first ink gun prints; when the first ink gun prints one side image, the encoder calculates the step number of the rolling wheel at the same time; when the printing medium enters under the second ink gun, the second ink gun is controlled to print the image on the other side at the area corresponding to the area where the first ink gun has printed based on the step number calculated by the encoder. The invention also provides a control method of the double-nozzle printing control system. By using double-nozzle printing, printing rate of the ink jet printer is greatly lifted.

Owner:宁波荣大创想智造科技有限公司

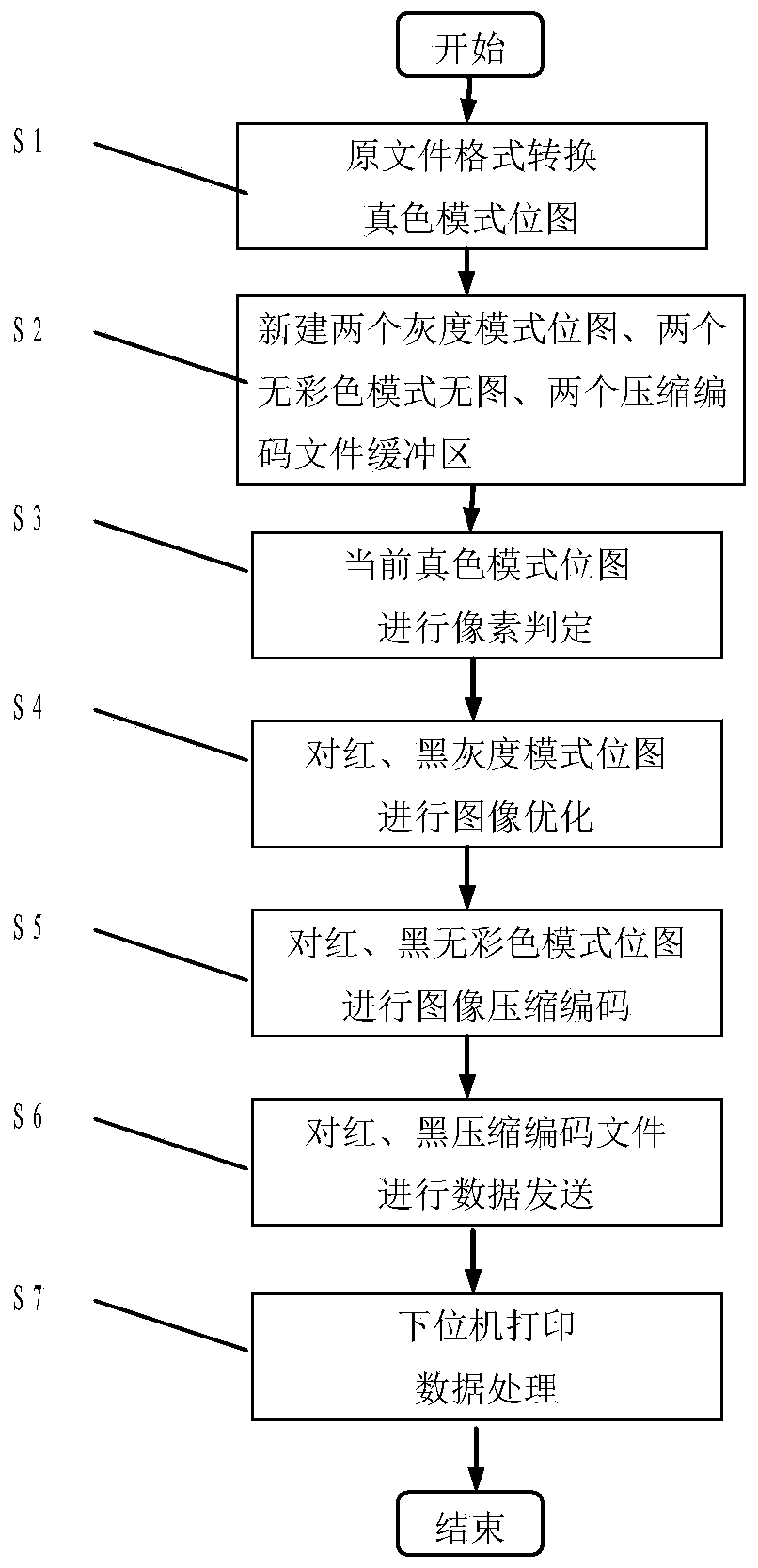

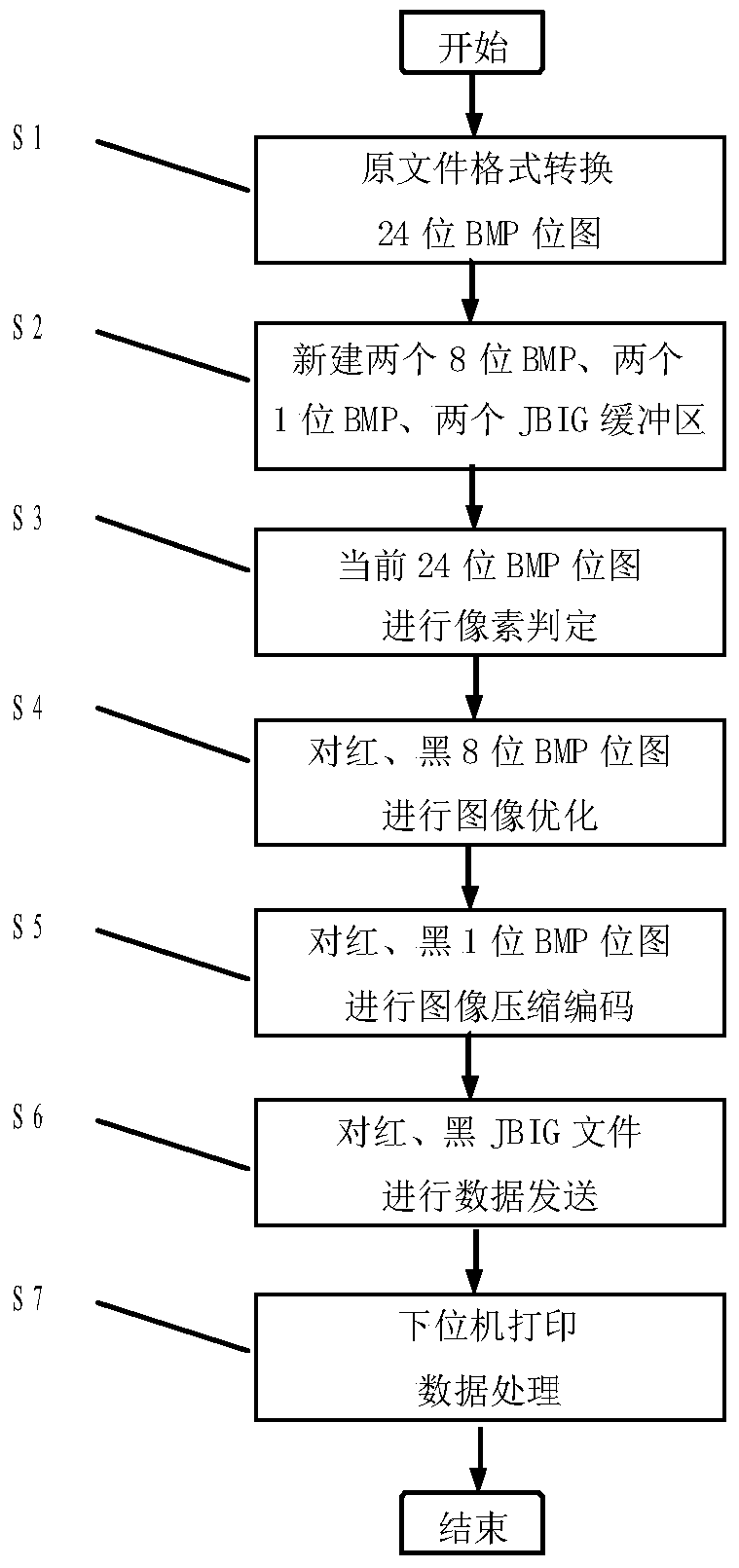

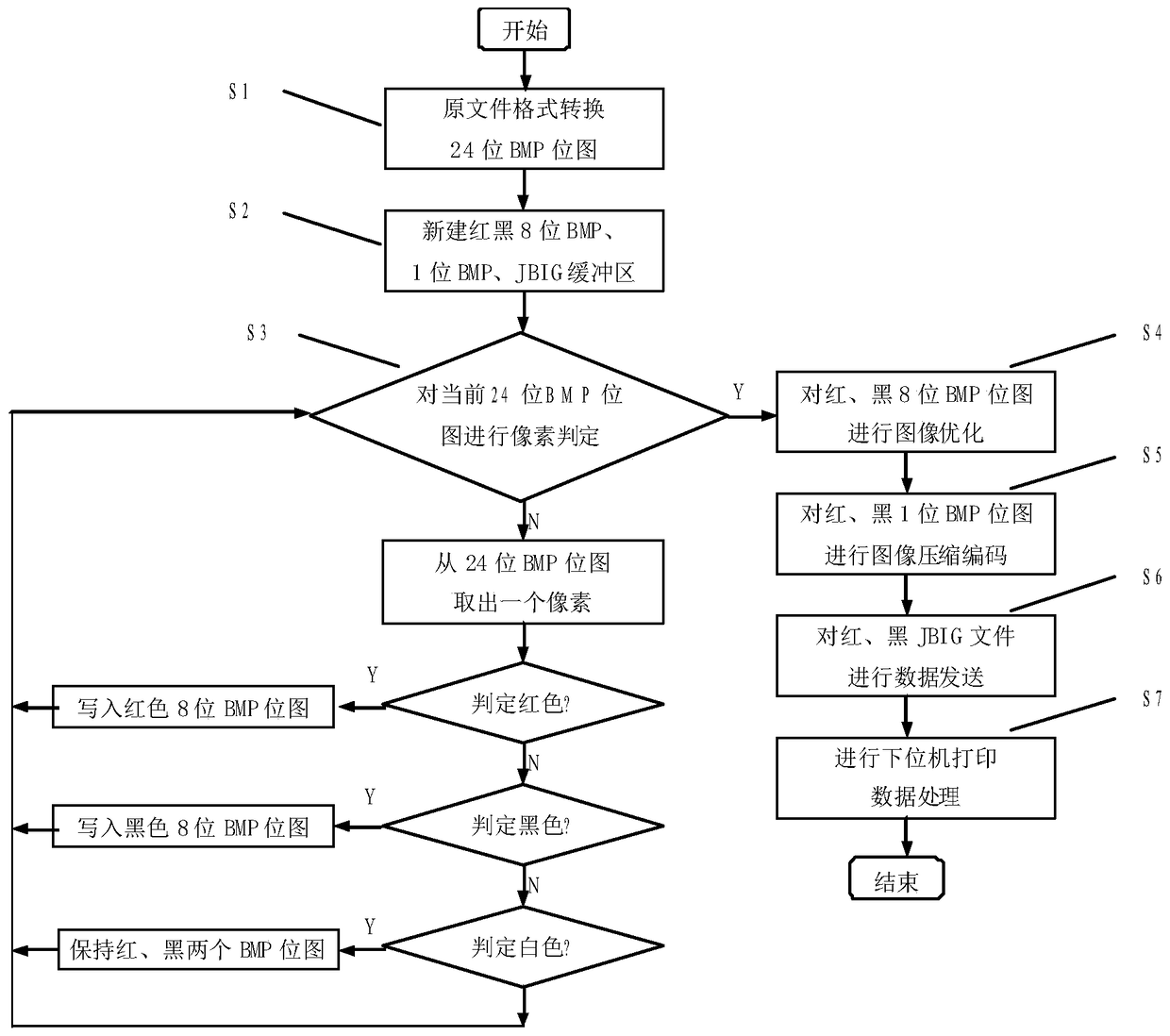

A printing data processing method

ActiveCN105323417BImprove processing efficiencyShort processPictoral communication24-bitDocument format

The invention provides a print data processing method. The print data processing method comprises the following steps: converting an original document format of a page to be printed into a 24-bit BMP bitmap by an upper computer; newly constructing two 8-bit BMP bitmap cache regions, two 1-bit BMP bitmap cache region and two JBIG (Joint Bi Level Image Group) document cache regions by the upper computer; performing pixel judgment on the 24-bit BMP bitmap by the upper computer, and converting the 24-bit BMP bitmap into one red 8-bit BMP bitmap and one black 8-bit BMP bitmap; performing image optimization processing on the red 8-bit BMP bitmap and the black 8-bit BMP bitmap by the upper computer; performing image compression processing on a red 1-bit BMP bitmap and a black 1-bit BMP bitmap by the upper computer; and transmitting red JBIG documents and black JBIG documents to a lower computer by the upper computer, processing print data of the lower computer and finishing the red and black dual-color printing. The print data processing method provided by the invention has the advantages of being high in print data processing efficiency, low in cost of consumable and good in red and black staining degree.

Owner:TOEC TECH

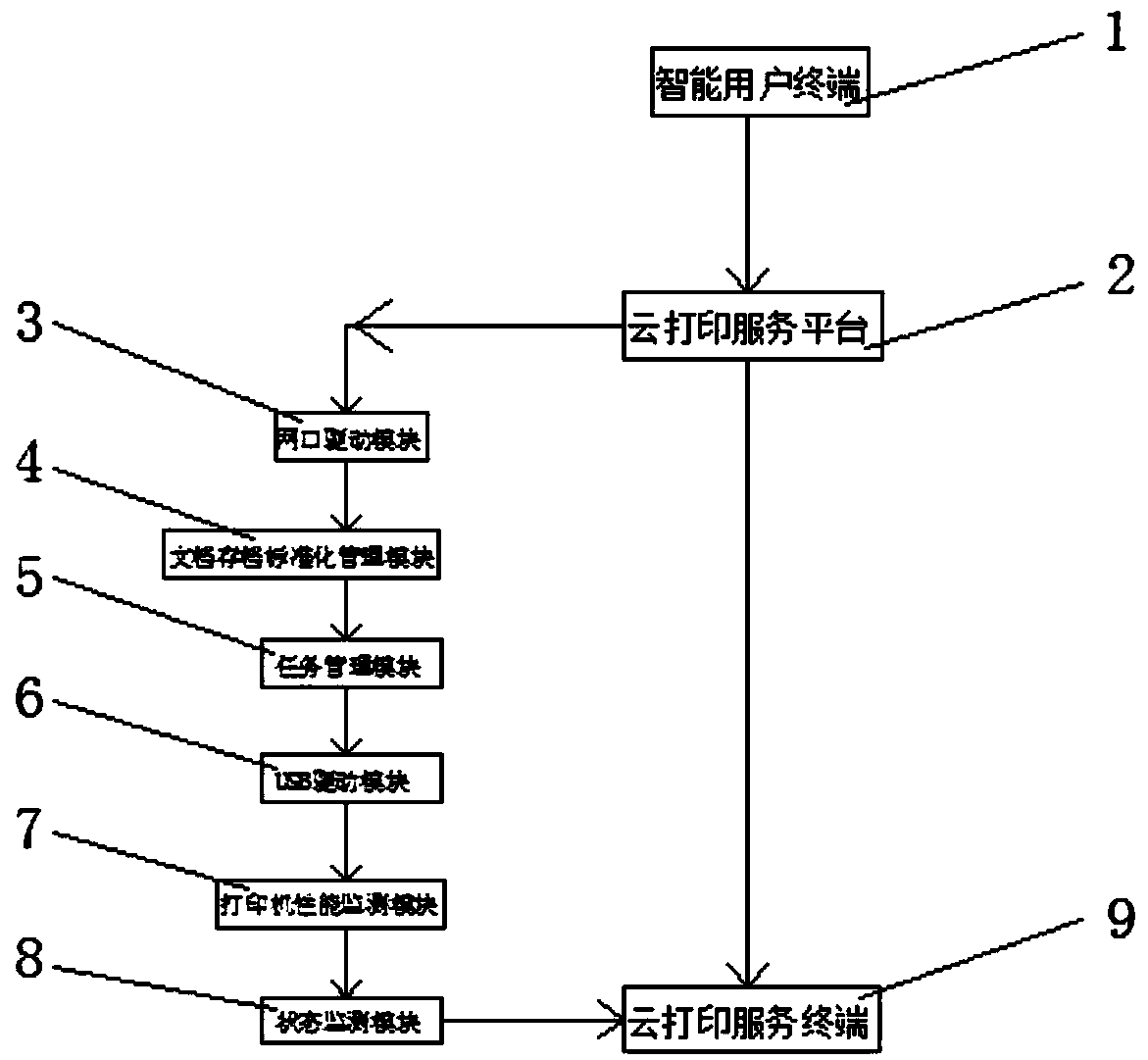

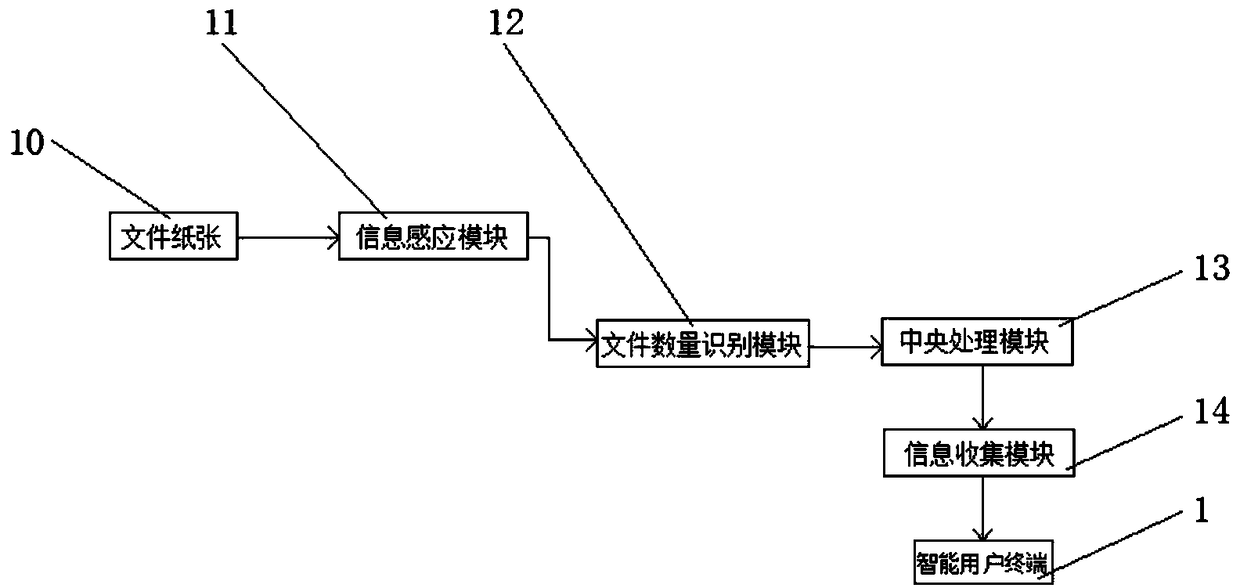

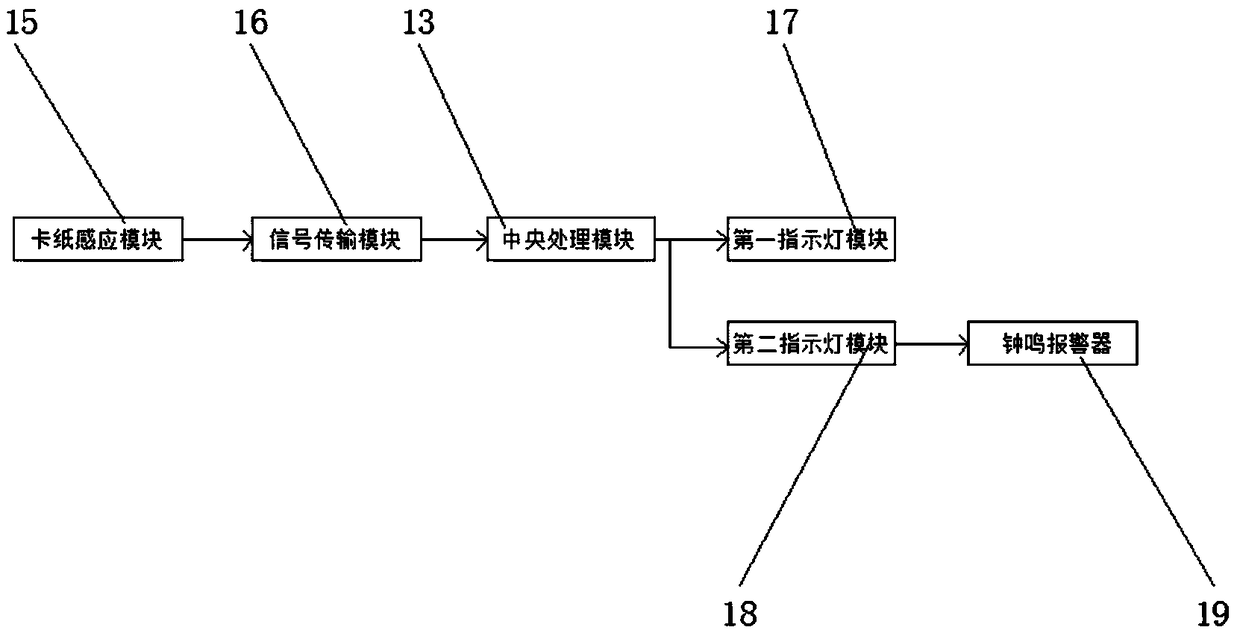

Efficient and convenient cloud printing service terminal

InactiveCN108733330AIncrease print speedAvoid splitting printsOther printing apparatusDigital output to print unitsInformation transmissionComputer module

The invention discloses an efficient and convenient cloud printing service terminal, which comprises an intelligent user terminal, a document archiving standardization management module, a file amountidentification module, an information collection module and an information transmission module, wherein the output end of the intelligent user terminal is connected with a cloud printing service platform; the output end of the cloud printing service platform is connected with an Internet access driving module; the output end of the document archiving standardization management module is connectedwith the cloud printing service platform; and the input end of a second indicator light is connected with a clock buzz alarm. By use of the efficient and convenient cloud printing service terminal, the intelligent user terminal and the cloud printing service plate are connected in series. Since a series connection way can enable information in the intelligent user terminal to be directly transmitted to the cloud printing service platform, transmission efficiency between the intelligent user terminal and the cloud printing service platform can be favorably increased, and in addition, the setting of the file amount identification module enables people to identify a required printing amount after people manually select the amount so as to be favorable for improving a file printing rate.

Owner:ANHUI TIANSINU INFORMATION TECH

A random image processing method and a printing equipment control system

InactiveCN103419513BIncrease flexibilityFlexible Printing JobsOther printing apparatusMemory addressImaging processing

The invention discloses a random image processing method and a printing device control system. The random image processing method is applied in the printing device control system and used for obtaining image data on any one of at least one page and comprises the steps of receiving rasterized mother board image data, set length and set width of images required to be extracted randomly and parameters for representing random number generation modes which are sent by a host computer; obtaining random number coordinates and image data memory addresses relevant with the random number coordinates based on the random number generation modes included in the parameters; using the image data memory addresses as starting addresses to begin to read the image data according to the set width and the set length; sending the read image data to an imaging part for imaging.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Printing process for reducing ink loss

InactiveCN109466197AIncrease profitReduce wasteOther printing apparatusUtilization ratePulp and paper industry

The invention provides a printing process for reducing ink loss, which relates to the technical field of printing. The printing process for reducing ink loss mainly comprises the following steps: preparation of hydrophobic paint, printer setting, ink treatment, substrate treatment, printing preparation, printing treatment and the like. The invention overcomes the shortcomings of the prior art, improves the utilization rate of the traditional ink in printing, reduces the waste of the ink, reduces the generation and discharge of the waste ink, is environmentally friendly and safe, and is suitable for popularization and use.

Owner:安徽同和印刷有限公司

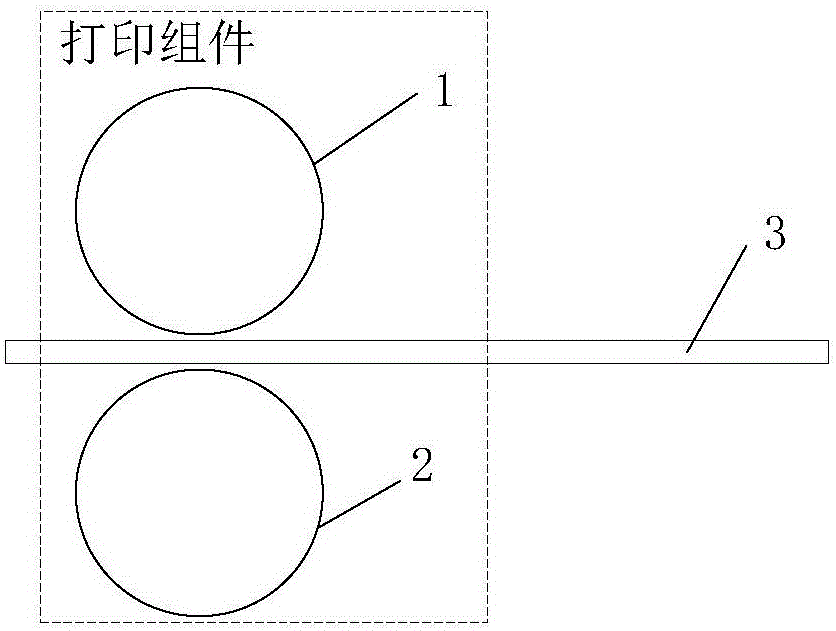

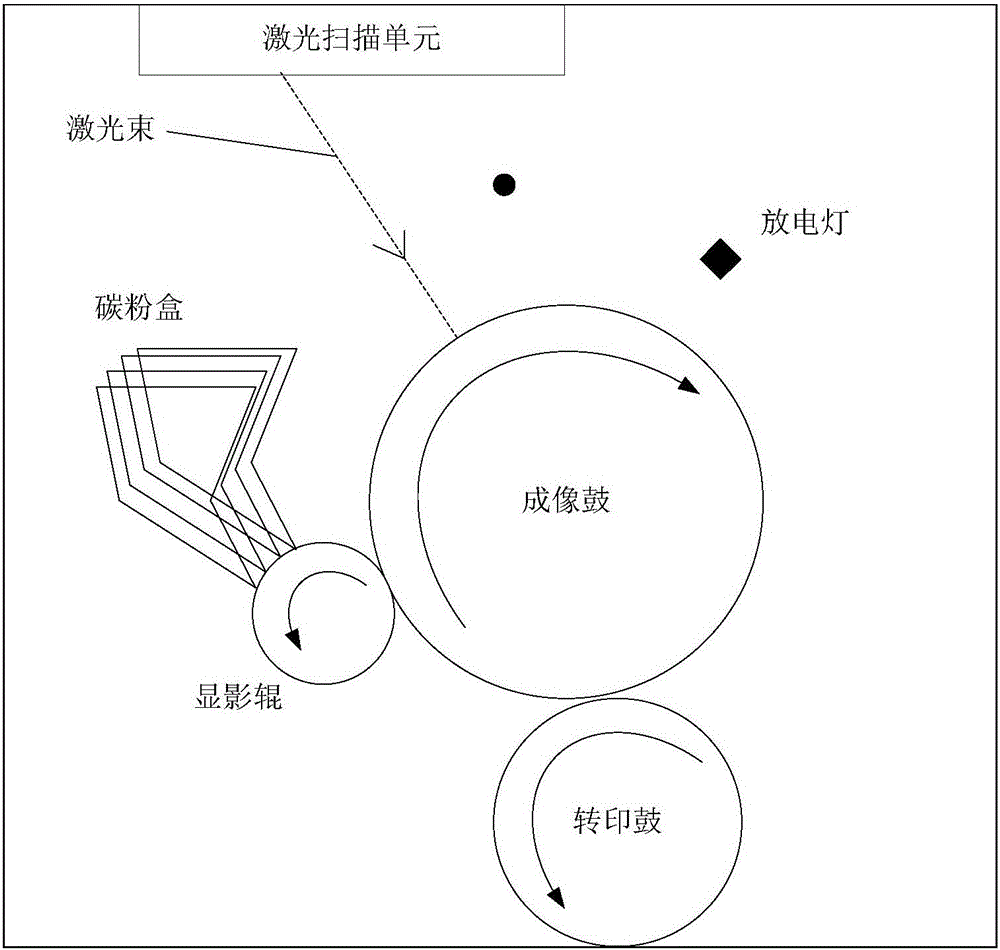

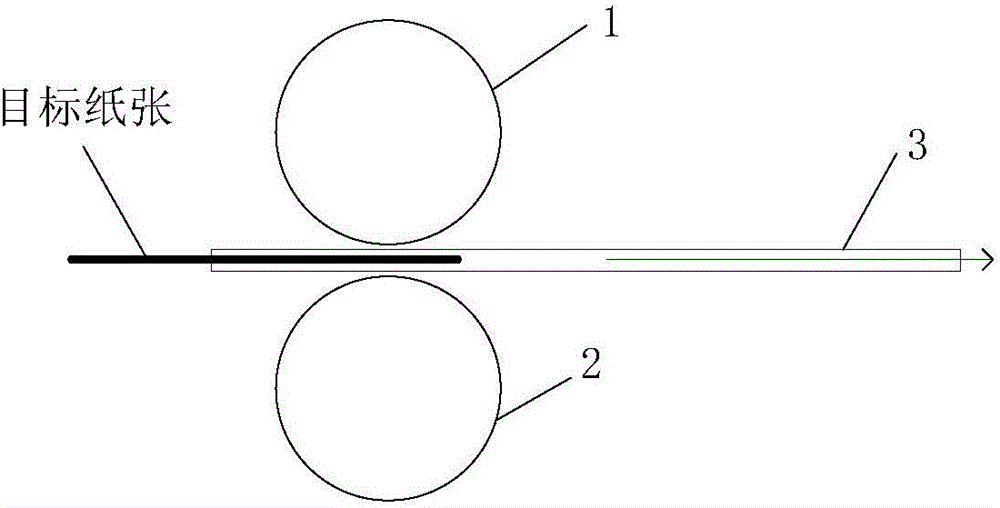

Printing assembly, printer and printing system

The invention discloses a printing assembly, a printer and a printing system. The printing assembly comprises a first toner cartridge unit and a second toner cartridge unit, wherein a paper rail is arranged between the first toner cartridge unit and the second toner cartridge unit, the first toner cartridge unit is used for printing first content on the first surface of target paper in the paper rail, and the second toner cartridge unit is used for printing second content on the second surface of the target paper in the paper rail. The target paper does not need to be turned over or pass the paper rail twice, double-surface printing can be completed as long as the target paper passes through the paper rail once, and therefore the printing speed is increased, and the printing efficiency is improved.

Owner:LENOVO (BEIJING) CO LTD

Functional backboard preparation method and functional backboard

PendingCN113314639ASolve Thickness ProblemsSolve the appearanceFinal product manufactureSynthetic resin layered productsEngineeringHigh reflectivity

The invention relates to a preparation method of a functional backboard. The functional backboard comprises a grid coating, an inner layer film, a base layer film and an outer layer film which are arranged in sequence; a continuous overprinting device is adopted, and the preparation method comprises the following steps: (a) after the inner layer film and the base layer film are compounded, printing the grid coating on the inner layer film in an overprinting mode, and then compounding the inner layer film and the outer layer film; or (b) printing the grid coating on one surface of the inner-layer film in an overprinting manner, compounding the base-layer film with the outer-layer film, and compounding the other surface of the inner-layer film with the base-layer film; or (c) sequentially compounding the inner layer film with the base layer film and the outer layer film, and then printing a grid coating on the inner layer film. According to the invention, multiple times of coating can be realized, the thickness of the coating is increased, the appearance of the grid coating is ensured, the reflectivity is improved, and the power of a component end is greatly improved; the printing rate can be further improved; the loss of a material end can be reduced to the greatest extent through structural diversified design and process; the cost of the whole backboard is reduced, and the product added value is large.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS +1

A kind of processing method of self-adhesive label

ActiveCN103640264BTempo syncImprove protectionPaper/cardboard articlesSand blastingPulp and paper industry

The invention discloses a method for machining a self-adhesive label and relates to the label manufacturing field. The method comprises the seven steps of unreeling, coating, stoving, sand blasting, printing, laminating and calendaring. Continuous unreeling is adopted, backing paper is placed on a rotary label machine, tension applied to the backing paper is manually adjusted and correction and rectifying are conducted at the same time, and then Synchronization of the reeling speed and the unreeling speed is guaranteed, stress is even, the backing paper can be flattened, and coating operation is facilitated; the backing paper is placed on a metal surface heated by an electric heating wire and polished to be pressed and cooled gradually till a glossy film surface is formed on a label, clear dopes used for polishing and coating are made denser and smoother, an ideal high-gloss and high-brightness mirror surface film effect is achieved, and the grade and market competitiveness of a printed product are improved.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com