Variable cross-section opening grid supporting structure and generation method thereof

A support structure and variable cross-section technology, applied in 3D object support structure, additive manufacturing, processing and manufacturing, etc., can solve the problems of increased post-processing difficulty, powder cannot be removed, material waste, etc., to shorten the forming time and reduce post-processing difficulty , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

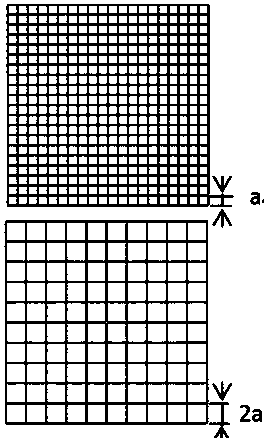

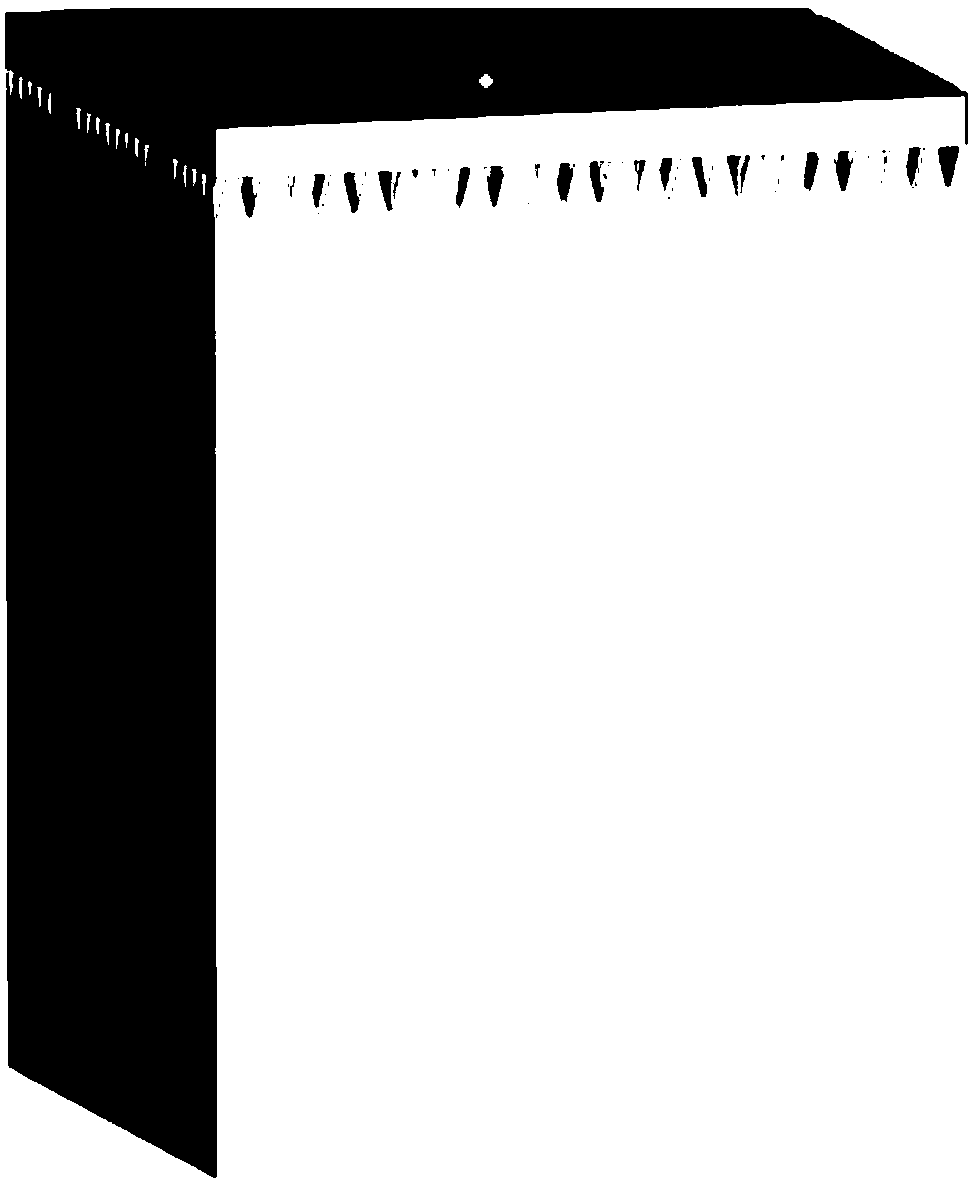

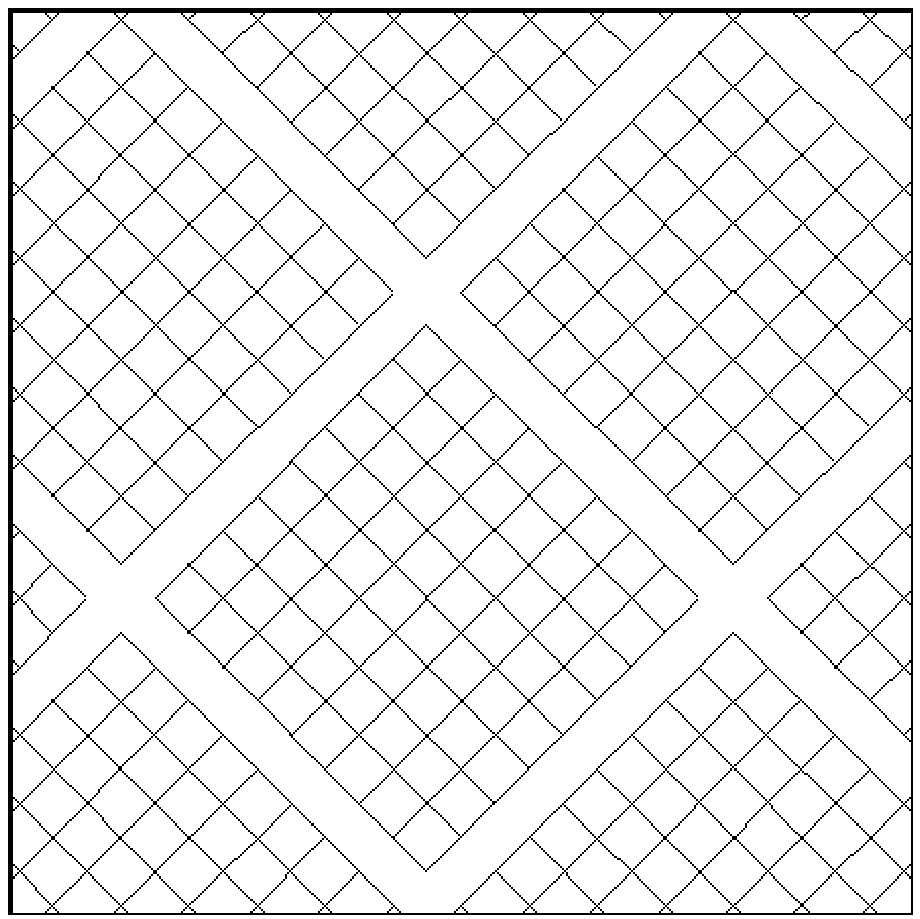

[0033] Such as image 3 , Figure 5 As shown, a variable cross-section open-hole grid support structure according to the present invention includes a plurality of open-hole grid support units 1 stacked in sequence along the vertical direction, and each open-hole grid support unit 1 is composed of multiple The grid unit body 2 is arrayed along the horizontal direction. The grid unit body 2 is an empty pipe structure arranged along the vertical direction. The grid openings 3 form a powder outlet channel. The size of the grid unit body 2 of a plurality of opening grid support units 1 along the vertical direction increases sequentially. The lower layer of two adjacent opening grid support units 1 The size of the grid unit body 2 of the perforated grid support unit 1 is twice that of the grid un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com