Patents

Literature

151results about How to "Reduce post-processing difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

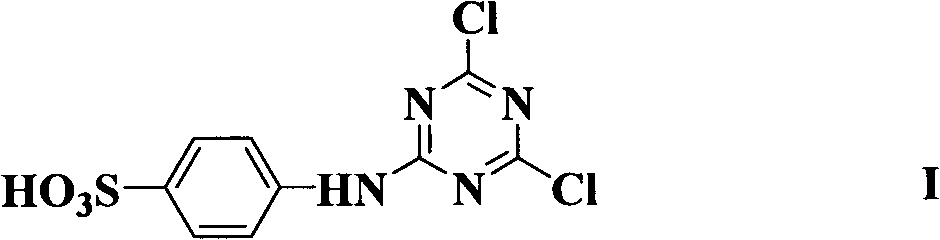

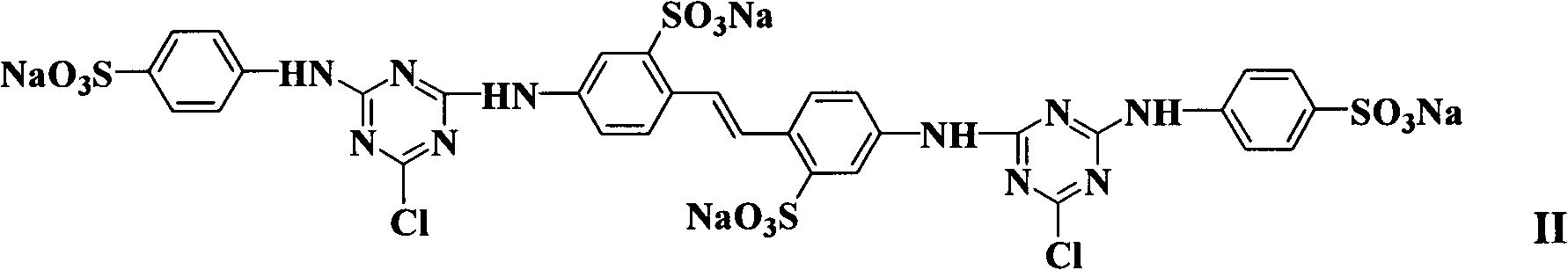

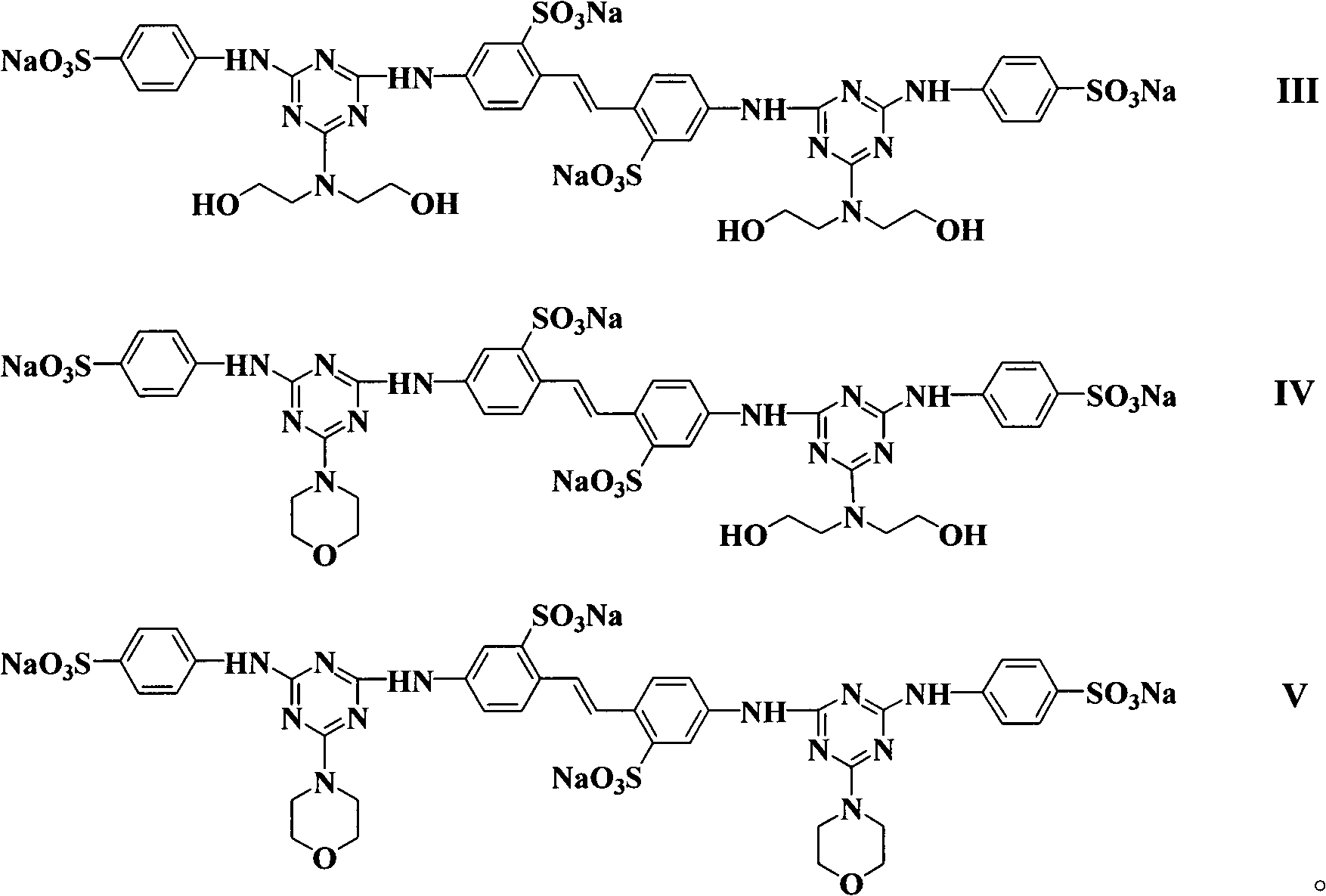

Preparation method of toluylene triazine liquid fluorescent brightener composite

InactiveCN101654894AReduce salt contentGood storage stabilityOrganic chemistryNon-macromolecular organic additionSulfanilic acidMorpholine

The invention provides a preparation method of symmetric and asymmetric toluylene triazine liquid fluorescent brightener composite expressed by the structural formulas (III), (VI) and (V), comprisingthe following steps: taking cyanuric chloride, sulfanilic acid, 4, 4-diaminobenzil-2, 2-disulfonic acid, morpholine and diethanol amine as raw materials; synthesizing by the three steps of reaction; and desalinating and filtering by means of nanofiltration membrane filtration. The liquid fluorescent brightener composite has a built synergistic effect and better brightening effect than a single composite; and the method not only can improve the quality of the fluorescent brightener, but also can reduce the consumption of amounts of raw materials, and greatly elevates product yield and quality.

Owner:山西晋光化工有限公司

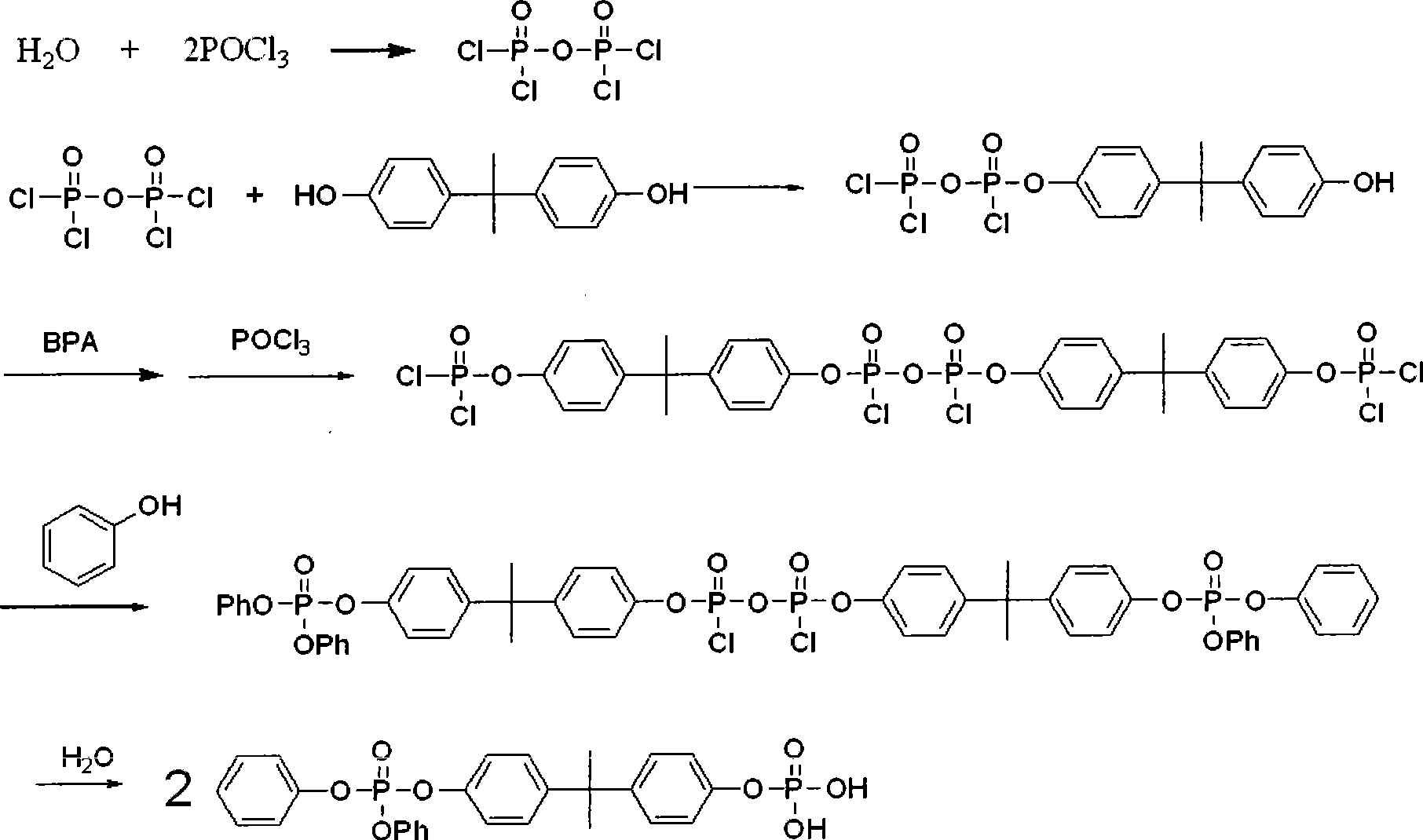

Method for preparing combustion inhibitor bisphenol A bis(diphenyl phosphate)

ActiveCN101456879ASignificant progressSignificant positive effectGroup 5/15 element organic compoundsPhenolBisphenol

The invention relates to a preparation method for flame retardant bisphenol A bi(diphenyl phosphate). The preparation method comprises the following steps: taking phosphorus oxychloride, bisphenol A and phenol as raw materials, adopting anhydrous zinc chloride or anhydrous aluminum chloride as a main catalyst, and adopting anhydrous calcium chloride or calcium phosphate as a promoter; adding the phosphorus oxychloride, the main catalyst and the promoter into a reactor for intensive stirring, when the materials are heated up to 73 to 78 DEG C, continuously adding bisphenol A, after the addition of bisphenol A is completed within 2.5 to 3 hours, heating up to and maintaining the temperature of 110 to 115 DEG C, and continuing the reaction for 1.5 to 2 hours; leaking out excessive phosphorus oxychloride under the normal and reduced pressure; and cooling down the intermediate product to 100 DEG C, continuous dropping phenol into the intermediate product, heating up to 140 DEG C 2 hours later, carrying out the reaction for 3 to 4 hours, monitoring the content of phenol through the liquid chromatography, and complementing phenol till the phenol content in the crude product is less than 0.5 percent. The yield reaches 98 percent; the content of triphenyl phosphate is less than 1.5 percent; and the acid number is 0.03mgKOH / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

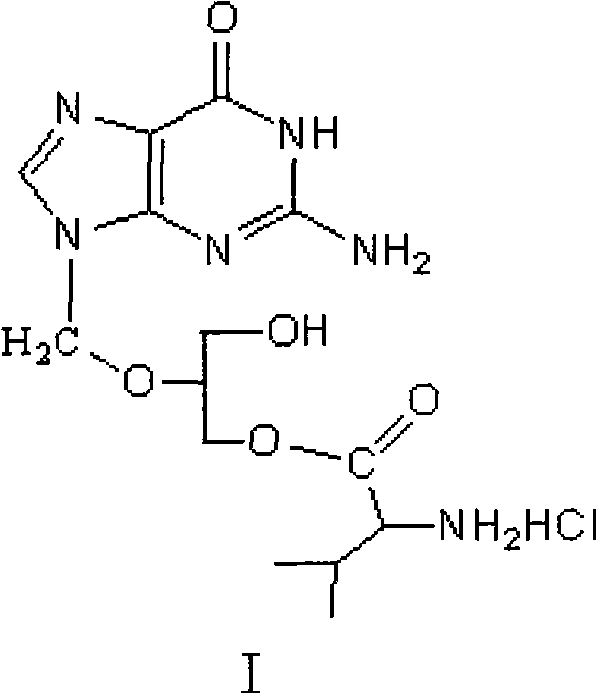

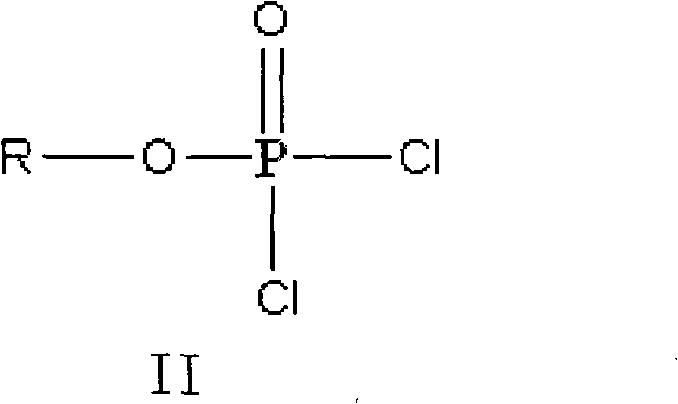

Method for preparing valganciclovir hydrochloride

InactiveCN101955481AEnhanced steric effectHigh yieldOrganic chemistryValganciclovir HydrochlorideHydrogenation reaction

The invention discloses a method for preparing valganciclovir hydrochloride I. The method comprises the following steps of: 1, dissolving phosphorus oxychloride into an inert solvent, and performing a reaction of the mixture and the alcoholic liquor to obtain phosphoryl halide II; 2, performing a reaction of ganciclovir and the phosphoryl halide II obtained in the step to obtain ganciclovir monoester III; 3, esterfying the ganciclovir monoester III in the step 2 and N-carbobenzoxy-L-valine to obtain ganciclovir diester IV; 4, acidizing the ganciclovir diester IV in the step 3 for dephosphorylation to obtain N-carbobenzoxy-L-valine ganciclovir monoester V; and 5, performing a hydrogenation reaction on the product in the step 4 to prepare the valganciclovir hydrochloride I. By the method, the ganciclovir monoester with high purity and yield can be produced, the post-processing is easy, and the post-processing difficulty is reduced.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

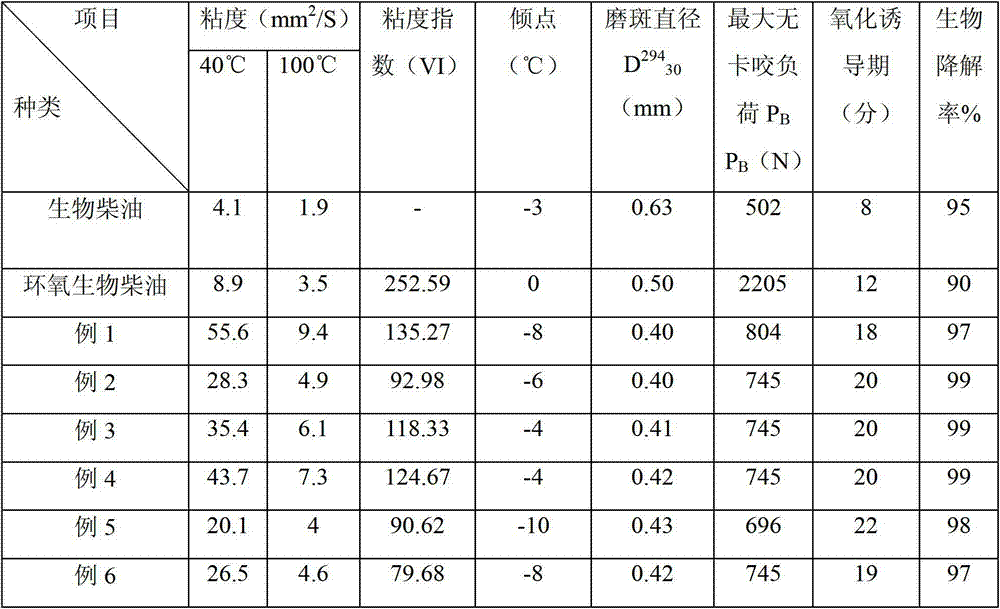

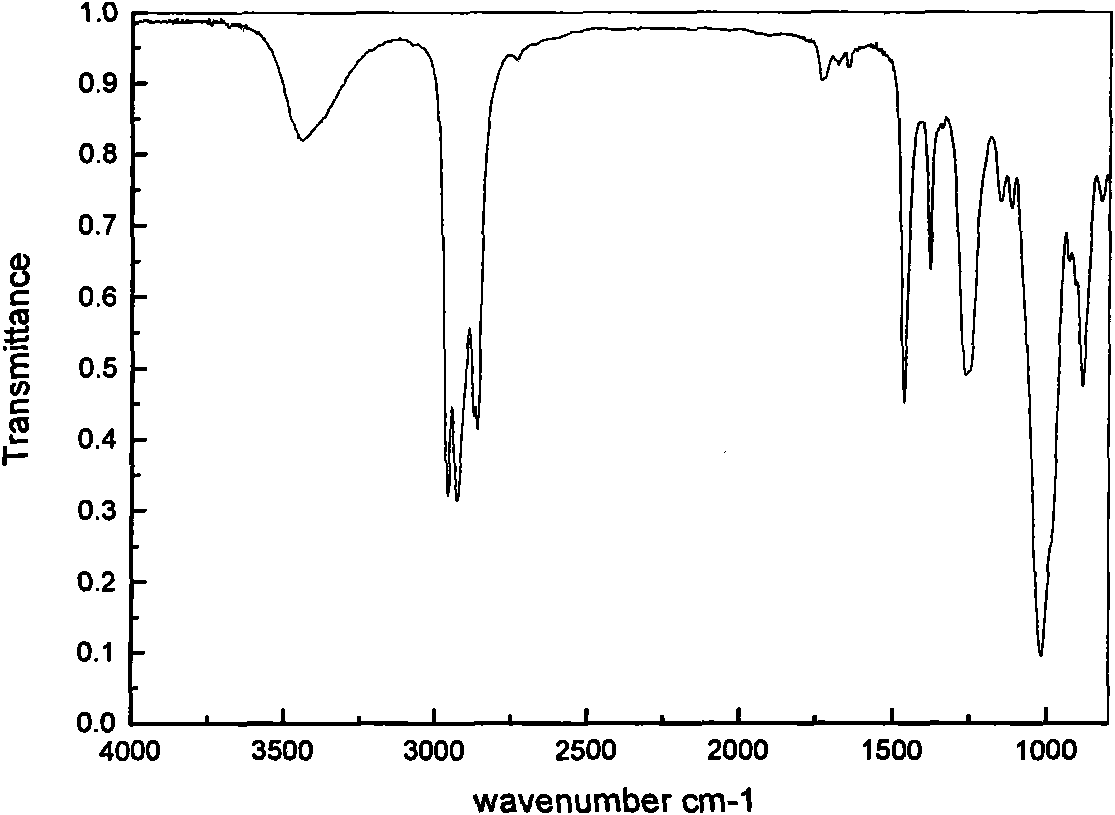

Preparation method of biodegradable lubricating oil

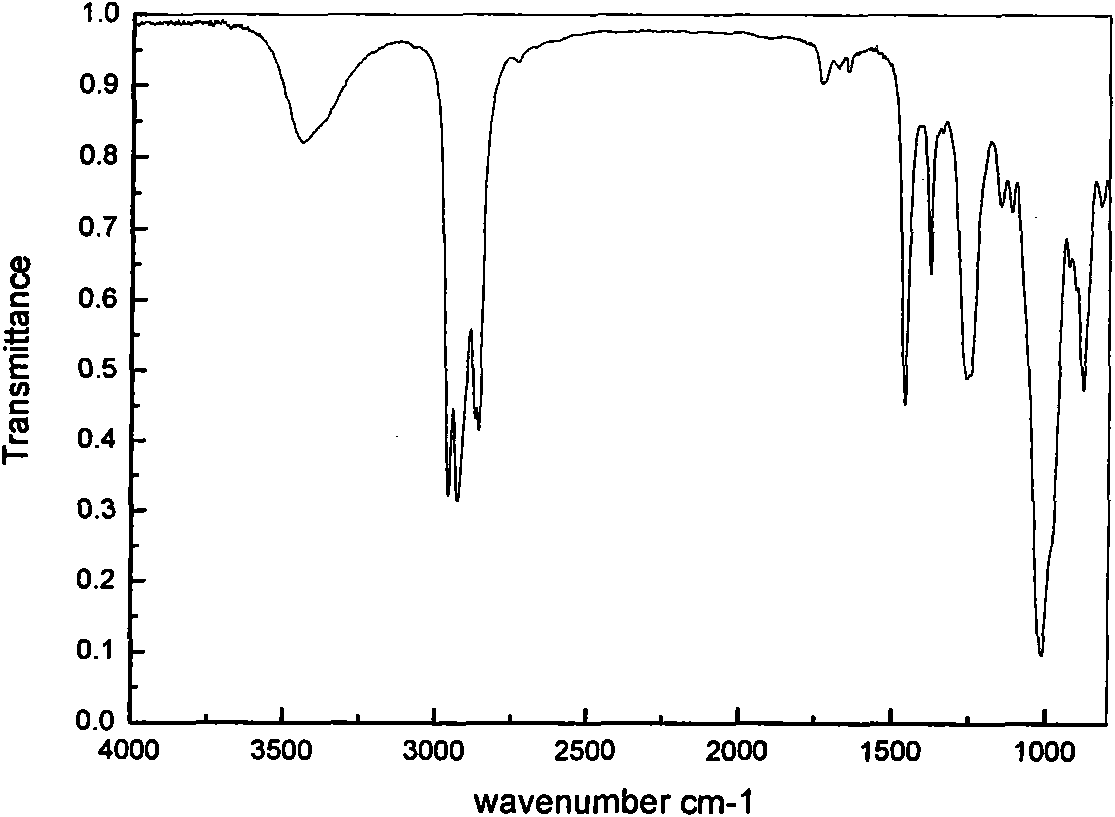

ActiveCN103087797AEmission reductionReduce post-processing difficultyBase-materialsEpoxyIsomerization

The invention belongs to the technical field of a biodiesel modification technology, and particularly relates to a preparation method of alcohol ester type environmentally-friendly lubricant base oil. The method comprises the following steps of: under an ultrasonic-assistedcondition, carrying out chemical modification to epoxy biodiesel (epoxy fatty acid methyl ester) serving as a raw material by solid superacid catalytic isomerization, and opening an unstable epoxy bond in the epoxy biodiesel with fatty acid by adopting an esterification method to form a hydroxy-containing modified biodiesel monoester with a heterogeneous shape. The solid superacid has the characteristics of high catalytic efficiency, good stability, easiness in separation, environment friendliness and the like, and the adoption of ultrasonic reinforcement can greatly shorten the reaction time and reduce the reaction temperature.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

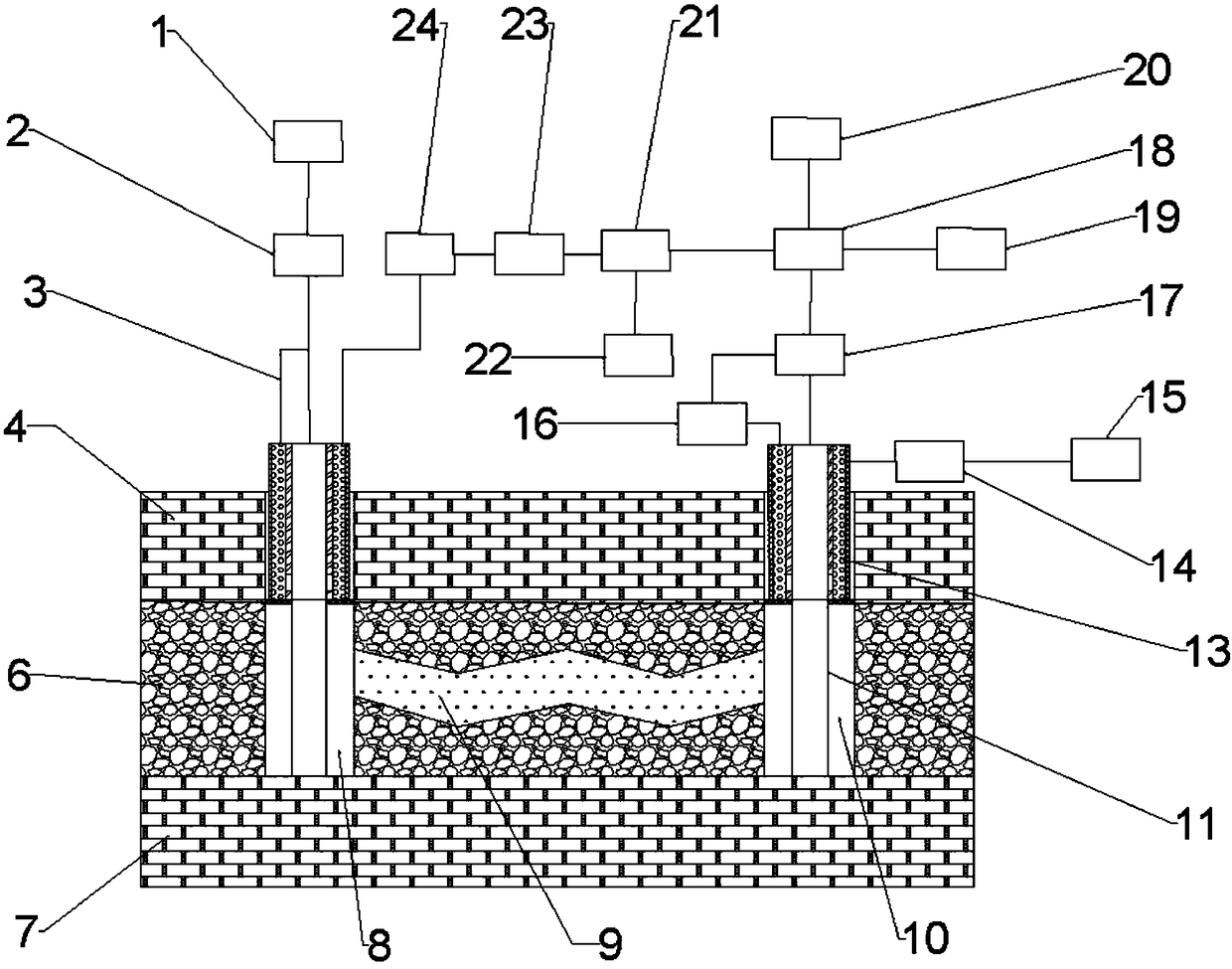

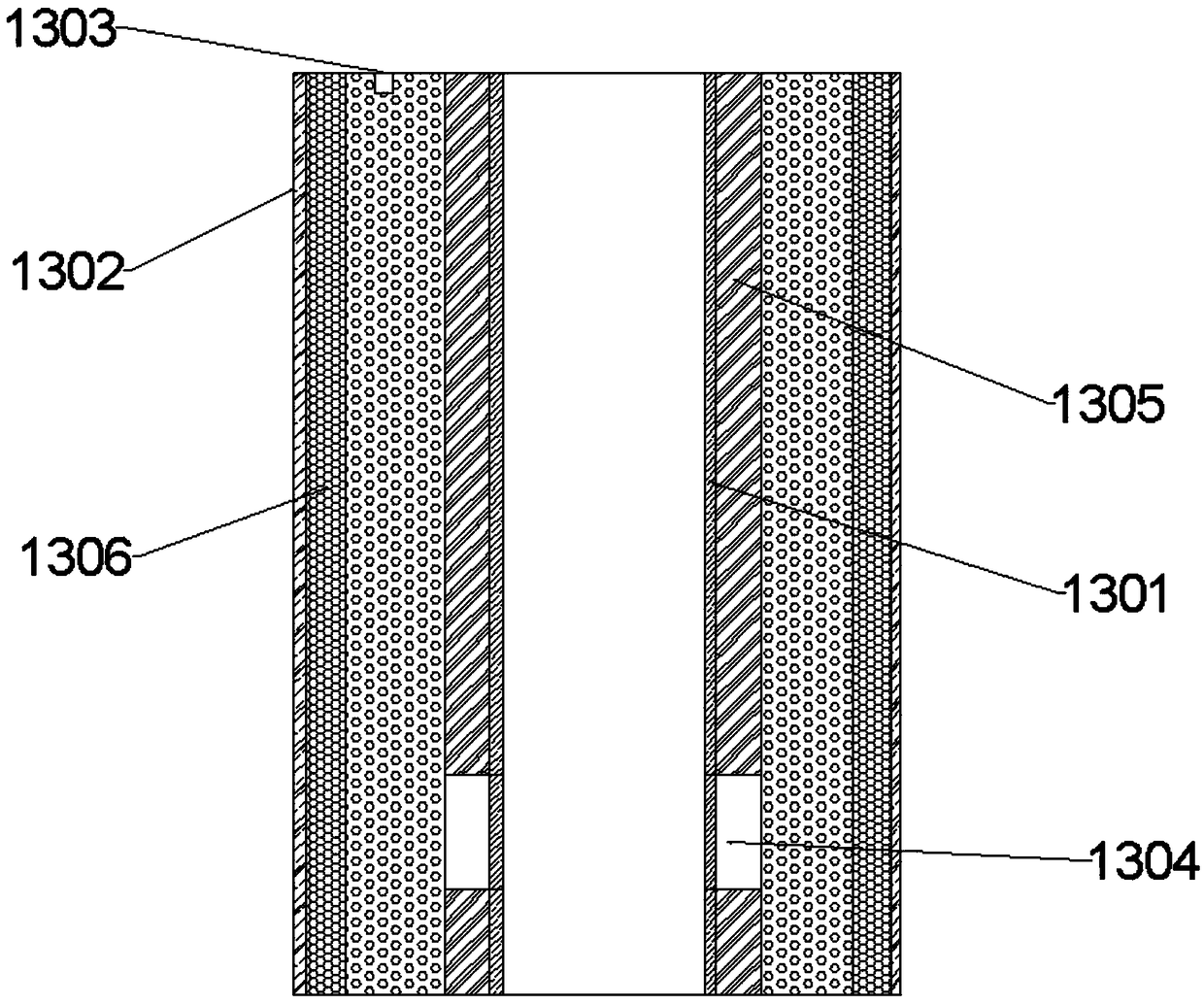

Auxiliary heating device and method for increasing oil-gas recovery rate of oil shale in-situ mining

ActiveCN108487888AAvoid premature condensationEnhanced overall recoveryGeothermal energy generationFluid removalOil shale gasAir compressor

The invention relates to an auxiliary heating device and method for increasing the oil-gas recovery rate of oil shale in-situ mining, and belongs to the field of oil shale in-situ mining. The auxiliary heating device comprises an air compressor, a ground heat exchanger, a heating pipe, a temperature sensor, an automatic temperature control device, a gas pump, a staged condensing device, an oil-water separating device, a three-phase separator, a gas generator set, a combustible gas compressor and the like; and the heating pipe heats a heat injecting well section, the heating pipe and the groundheat exchanger jointly act to provide high-temperature gas for pyrolysis of an oil shale bed. The auxiliary heating method comprises the steps of early-stage preparation, a heating stage and an oil-production and gas-production stage. According to the auxiliary heating device and method, through a heating function of the heating pipe, on the one hand, the temperature of a production well is maintained within a certain range, and in-advance oil and gas condensation is effectively prevented; on the other hand, water in the product and a heating material react to release heat, and thus the watercontent in the product is effectively decreased; and combustible gas in the product is utilized to generate electricity to serve as an auxiliary power supply, and the cost expenditure is reduced.

Owner:JILIN UNIV

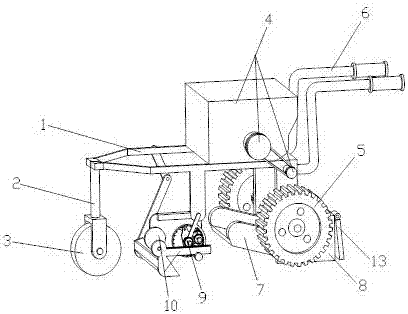

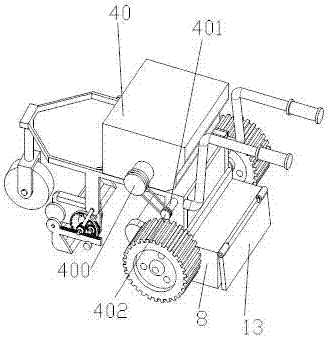

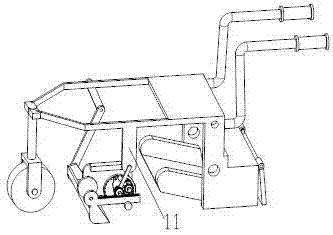

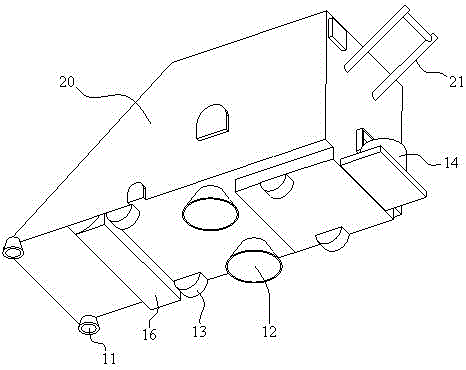

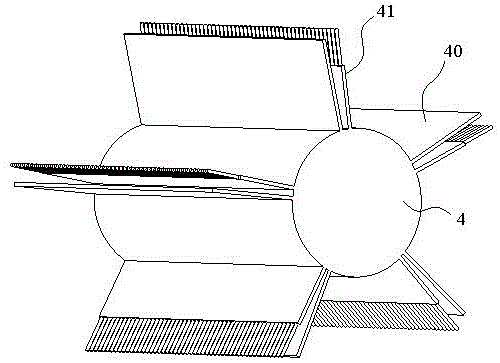

Livestock manure picking and separating device

ActiveCN107439385AAchieve separationReduce post-processing difficultyAnimal housingBird housingsLivestock manureFeces

The invention provides a livestock manure picking and separating device, and belongs to the technical field of livestock manure separation. The livestock manure picking and separating device has the advantages that a power mechanism and a manure picking linkage structure are adopted in combination, and thus manure can be conveniently removed; a picking shovel is adopted to conduct reciprocating work, and thus livestock manure can be fast removed; meanwhile, livestock manure in the same area can be repeatedly treated, sticky manure can be effectively removed, and the ground of a complex working space can be efficiently cleaned.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Lithium battery

InactiveCN103700795AEasy to useAvoid breakingVent arrangementsCell sealing materialsInternal pressureEngineering

A lithium battery lithium battery disclosed in the invention comprises a shell, a stab plate and a pressure limiting plate, the pressure limiting plate is arranged at the middle and upper portion in the shell, the stab plate is arranged in the shell below the pressure limiting plate, and the shell over the pressure limiting plate is provided with a gas vent. A technical problem to be solved in the invention is increasing the safety of the lithium battery. The lithium battery adopting the stab plate and the pressure limiting plate arranged in the shell allows the pressure limiting plate to be stabbed when the internal pressure is too high in order to release a gas, so the safety of the lithium battery is guaranteed, the damage of the shell of the lithium battery is effectively avoided, and the liquid leakage, the environmental corrosion and pollution and the like are prevented.

Owner:叶小平

Process for preparing trioctyl phosphate by sodium alkoxide method

InactiveCN101885737AAvoid pollutionReduce manufacturing costGroup 5/15 element organic compoundsPhosphateOctanol

The invention discloses a process for preparing trioctyl phosphate by a sodium alkoxide method. In the process, octanol and metal sodium react to generate sodium alkoxide, phosphorus oxychloride and the sodium alkoxide undergo esterification, and the separated product is rinsed and neutralized. The environment-friendly trioctyl phosphate synthesizing process by the sodium alkoxide method overcomes the defect that mass acid gas is generated in the conventional decompression production process so as to prevent the acid gas from polluting environment and corroding equipment. The process reduces product post-treatment difficulty, and the reclaimed octanol can be recycled, so that the raw material utilization is improved, and the production cost of the trioctyl phosphate is reduced.

Owner:SHANDONG NORMAL UNIV

Pile casing and water-rich strata shield pile casing receiving method

InactiveCN102797483AEasy to disassembleImprove sealingUnderground chambersTunnel liningWater leakageEngineering

The invention provides a water-rich strata shield receiving pile casing which is characterized by comprising a casing body, an inner flange, an access manhole and an inspection manhole, wherein the inner flange is positioned at one side of the casing body; the access manhole is positioned at the other side of the casing body; the inspection manhole is positioned in the casing body; the casing body is composed of more than one casing plate; the casing plates are connected through high-strength bolts and provided with deep floors and injected holes; and valves are arranged on the injected holes. The water-rich strata shield pile casing receiving method is characterized by comprising the following steps of pile casing base construction, pile casing installation and fixation, packing seal, shield entry and pile casing removing. The pile casing has the beneficial effects of being easy to dismount the casing plates due to the adoption of segmental assembling mode, low in composite cost, short in installation time and high in safety and reliability, being repeatable, and being capable of shortening the construction period obviously and improving work efficiency; and since the pile casing is sheathed outside the soil body of an end well and has extremely good sealing performance, the probability of water leakage, sand leakage and other conditions is reduced greatly.

Owner:TIANJIN URBAN CONSTR TUNNEL

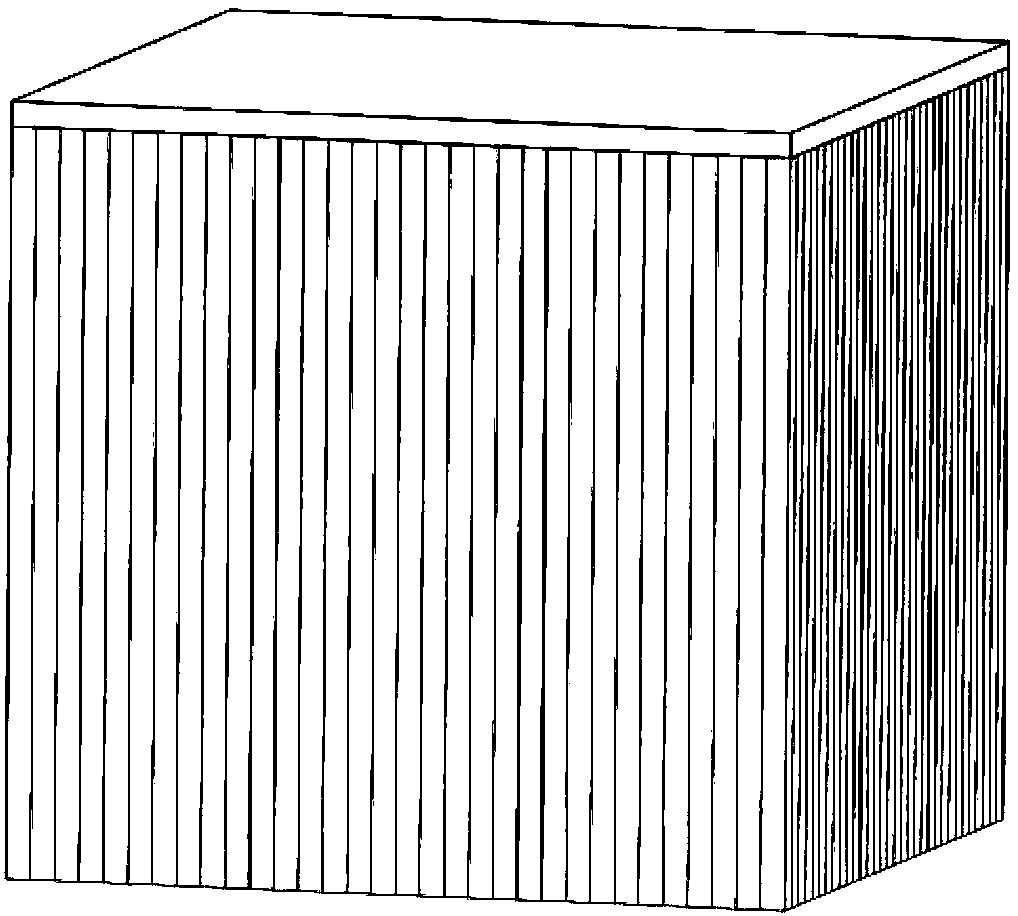

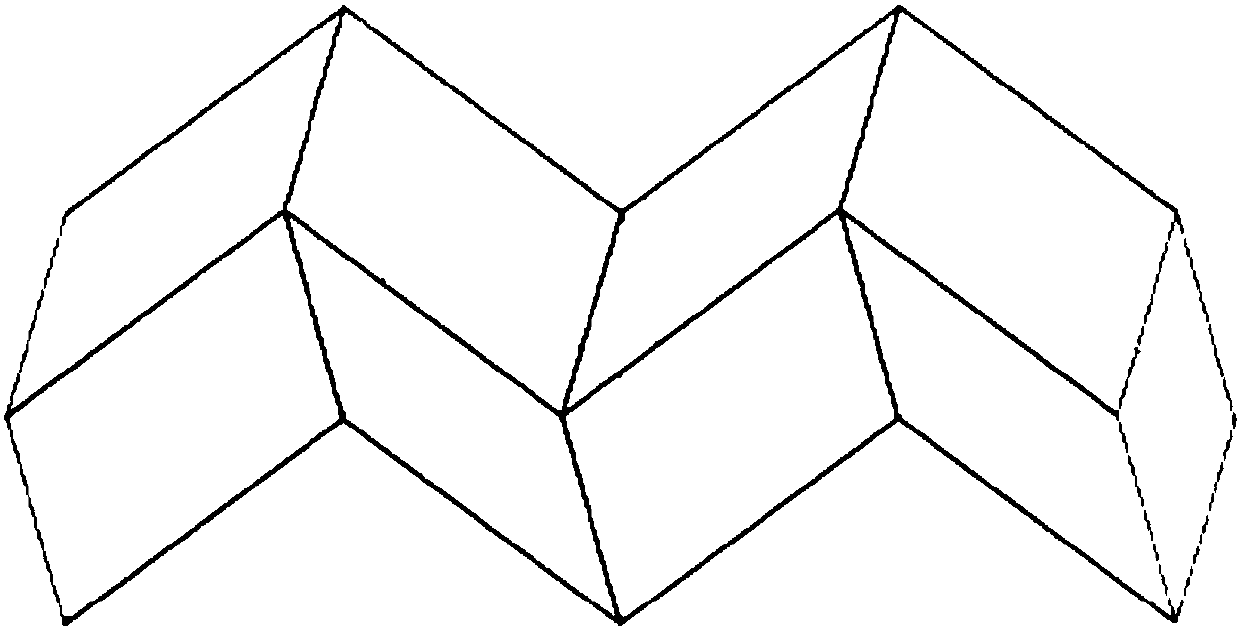

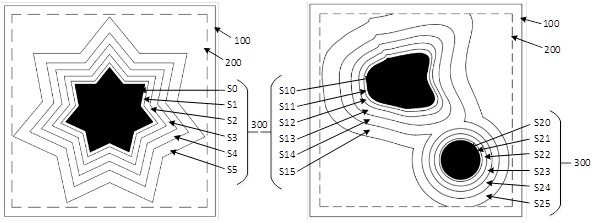

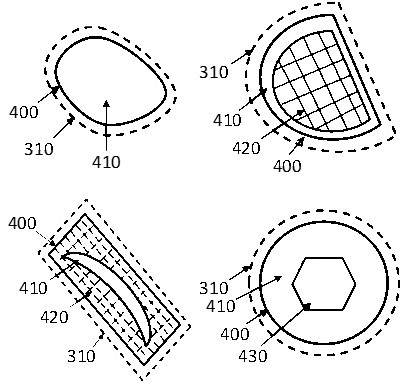

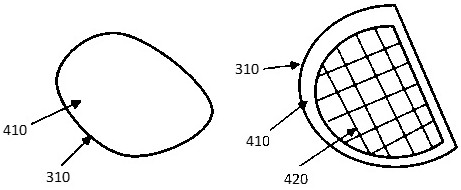

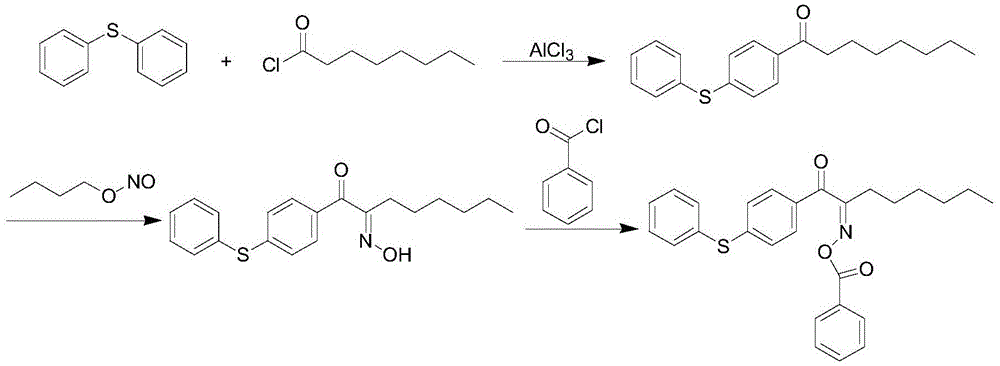

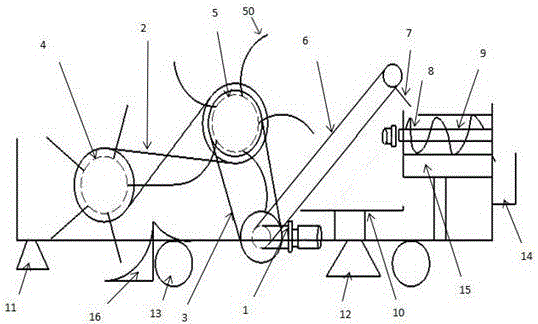

Supporting structure for selective laser melting forming and generating method thereof

ActiveCN107598167AReduce usageIncrease print speedAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingThree dimensional graphics

The invention relates to a supporting structure for selective laser melting forming and a generating method of the supporting structure. The supporting structure is simple in structure, and the loss of raw materials is reduced in the production process, the printing efficiency is improved, and the post-processing difficulty is reduced. The supporting structure comprises a plurality of supporting units which are arranged on the same plane in an array mode; each supporting unit comprises a plurality of supporting single bodies, the supporting single bodies are of hollow tube structures which arearranged in the horizontal direction, the length direction of the hollow tubes is taken an X direction, the plurality of supporting single bodies are arranged in an array mode in a Y direction and aZ direction, every adjacent supporting units are mutually connected through walls of hollow tubes to form the supporting units; and the hollow tubes form lateral powder discharging channels of the supporting units. According to the generating method, a cross section structure is formed by utilizing three-dimensional graphic software, array and arrangement are carried out for the area required to be supported according to requirements, the use requirements are met, and the supporting structure together with the part data can be output and completed to be formed synchronously; and in the settingand forming process, the the supporting units are directly reinforced for guaranteeing of the supporting effect.

Owner:西安国宏天易智能科技有限公司

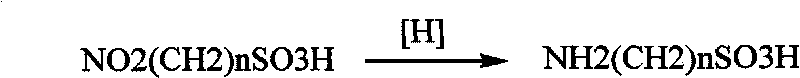

Preparation method of amino-substituted hydrocarbyl sulfonic acid

InactiveCN101759605AReduce decompositionFully transformedSulfonic acid preparationAlcoholDesalination

The invention provides a preparation method of amino-substituted hydrocarbyl sulfonic acid, which is characterized by comprising the following steps of: carrying out substitution reaction by taking esters of amino-substituted hydrocarbyl alcohol as raw materials and sulphite as a nucleophilic substitution reagent at high temperature and high pressure, concentrating and separating for desalination after reaction so that a coarse product of the amino-substituted hydrocarbyl sulfonic acid is obtained, and then purifying and crystallizing the coarse product so that the finished product of the amino-substituted hydrocarbyl sulfonic acid is obtained. The preparation method of the amino-substituted hydrocarbyl sulfonic acid is used for carrying out the substitution reaction at high temperature and high pressure by using the esters of the amino-substituted hydrocarbyl alcohol as raw materials and the sulphite as the nucleophilic substitution reagent so as to have the advantages of short reaction time and energy saving; the preparation method also has the advantage of less side reaction, simple postprocessing operation, high yield and favorable quality of the finished product; and the preparation method has no generation of SO2 gas in the production process so as to greatly improve the production environment and have safety.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

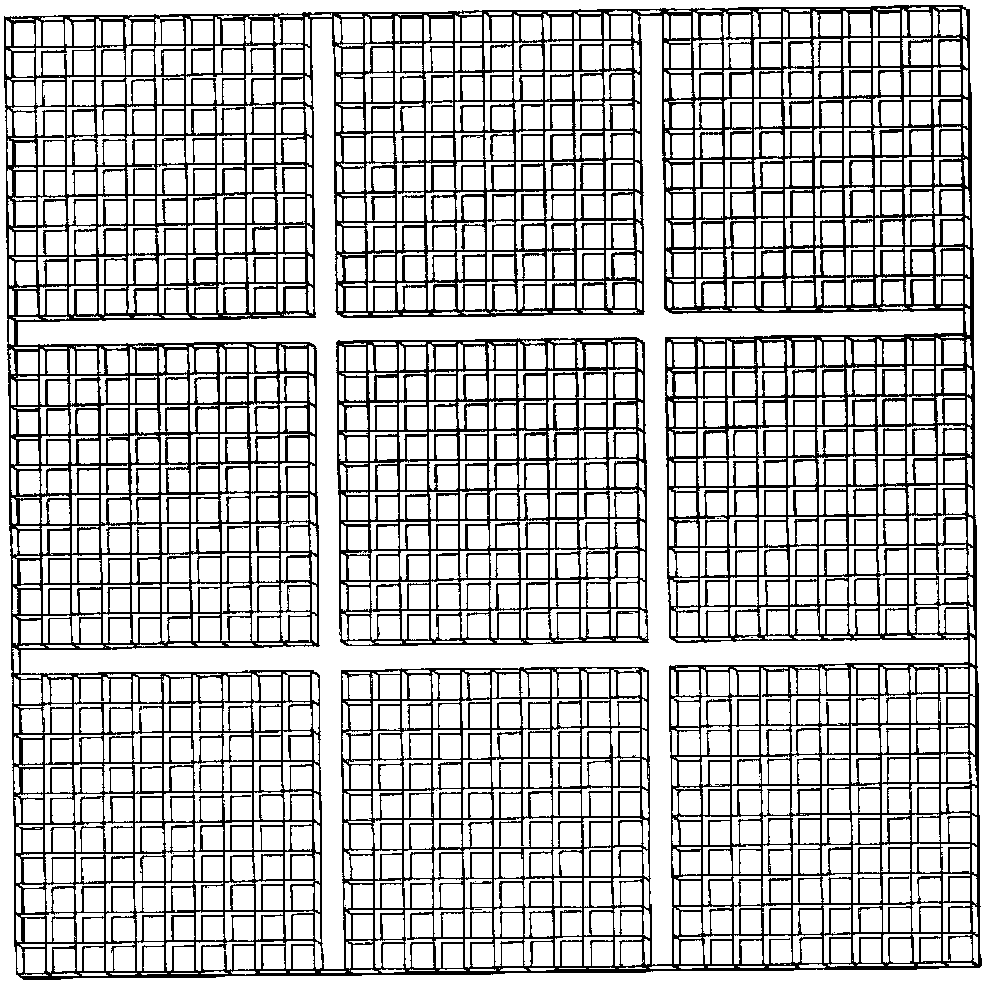

Control method for graded preheating of powder bed and additive manufacturing device

ActiveCN114406288AAvoid temperature gradientsReduce the difficulty of cleaningAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringMechanical engineering

The invention relates to a control method for graded preheating of a powder bed and an additive manufacturing device. The method comprises the steps that a three-dimensional model of a to-be-printed part is sliced, and a scanning path is set to form scanning path data; according to the section shape of the current layer, the preheating range and preheating energy of the 0-th grade to the n-th grade are set; the energy source performs graded preheating on the powder according to the set preheating range and preheating energy of the current layer; scanning and melting the section according to the scanning path to complete printing of the current layer; and powder laying, preheating and scanning melting are repeated till printing of the whole part is completed. The powder bed is preheated in a graded preheating mode with the section shape of each layer of the printed part as the center, so that large temperature grading of a powder bed preheating area and a surrounding non-preheating area is avoided, the risk of curling, peeling or cracking of the powder bed is reduced, the heating influence of powder of the powder bed outside the section is reduced, the powder utilization rate is increased, and the production cost is reduced. Meanwhile, graded preheating can reduce energy input, and the forming efficiency is improved.

Owner:西安赛隆增材技术股份有限公司

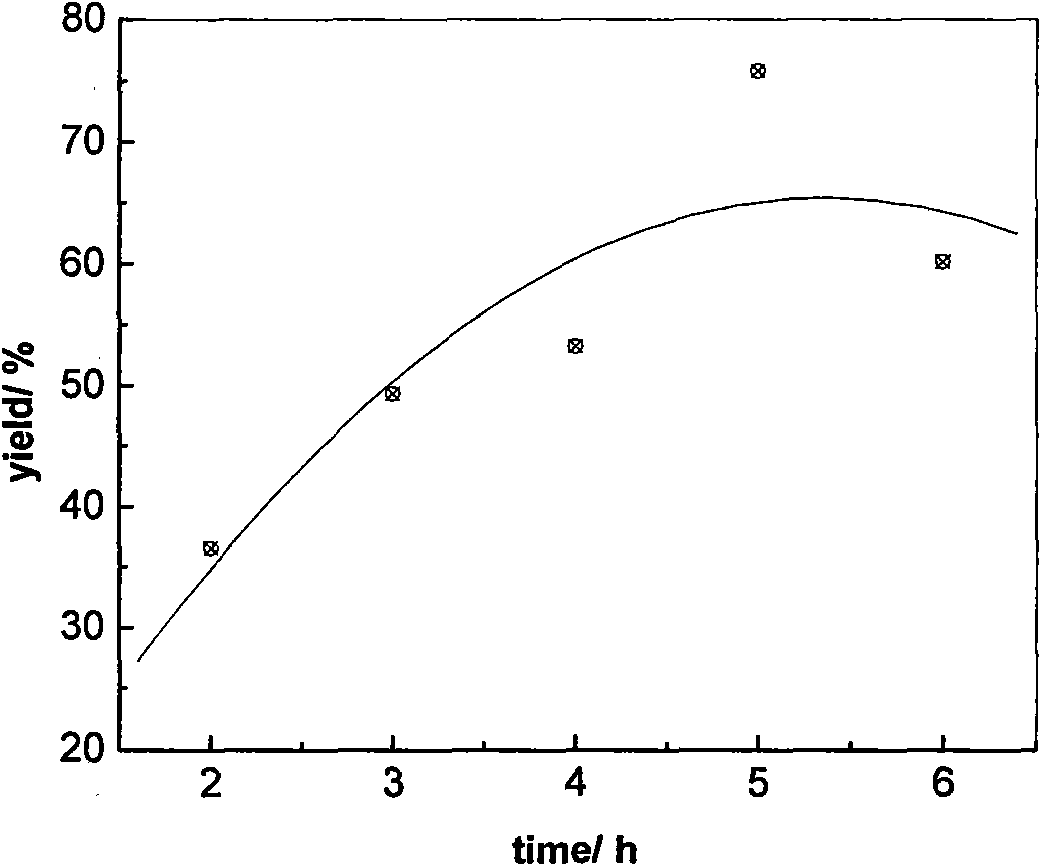

Copper-containing complex catalyst and preparation method and application thereof

InactiveCN104646058AEasy to prepareIncrease processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventDiamine

The invention relates to a copper-containing complex catalyst and a preparation method and application thereof. The preparation method comprises the following steps: adding water into copper carbonate, dripping perchloric acid to generate reaction, evaporating a blue solution after reaction is completed so as to be concentrated to obtain crystals, and finally obtaining copperperchlorate hydrate; adding the copperperchlorate hydrate and organic diamine into a solvent, stirring, performing heating backflow reaction under the temperature of 50-80 DEG C for 5-8 hours, and performing filtering, washing and drying to obtain a product. Compared with the prior art, the preparation method for the catalyst is simpler, and the catalysis activity is relatively high; pollution cannot be generated.

Owner:SHANDONG NORMAL UNIV

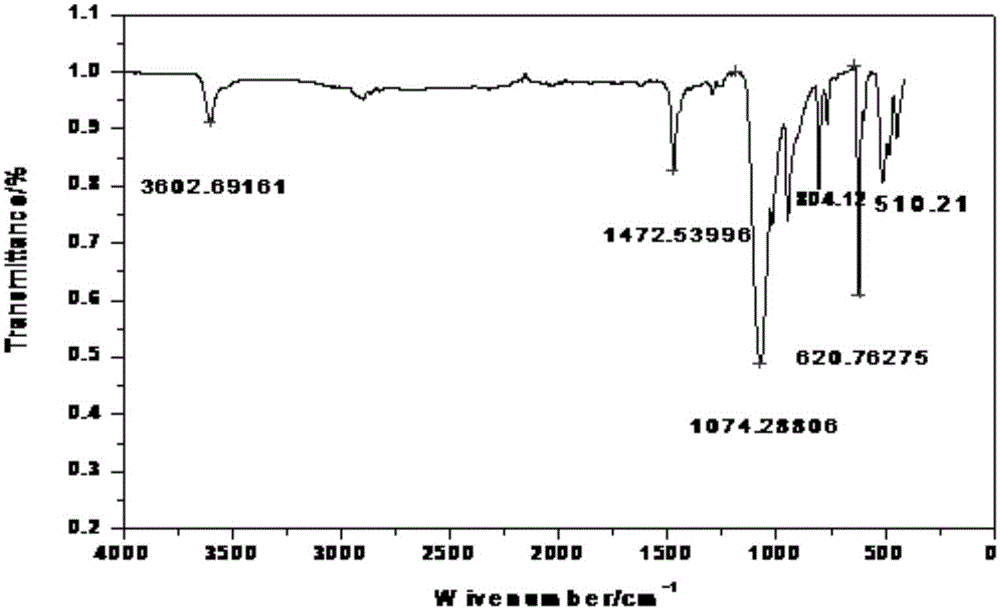

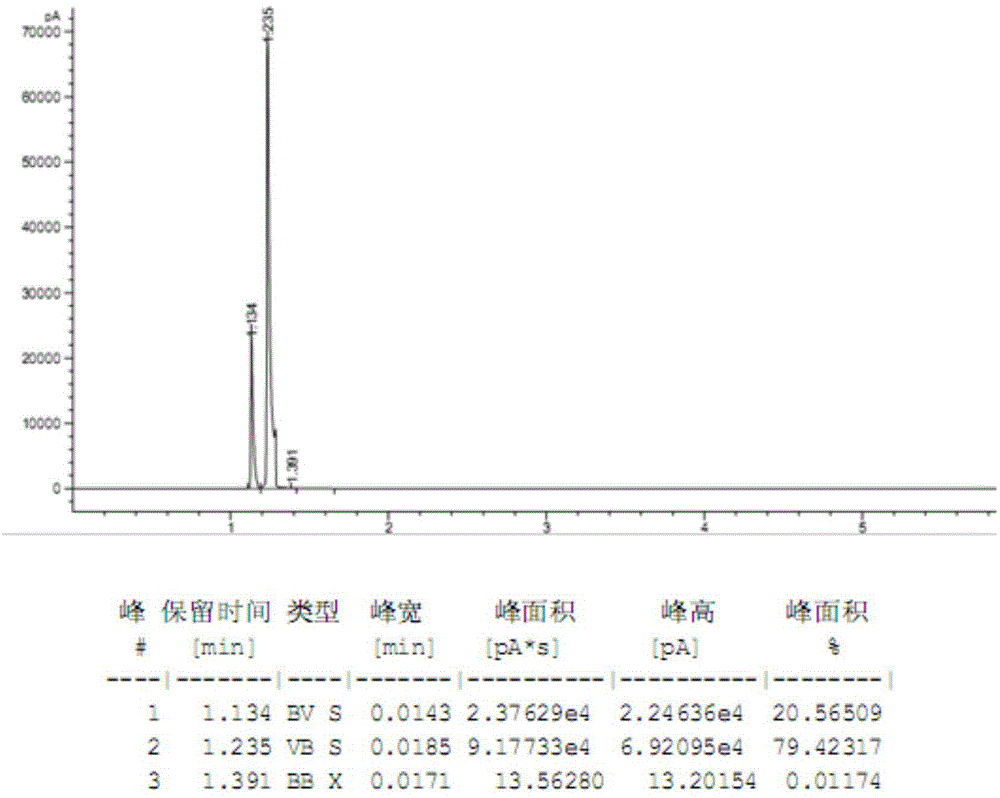

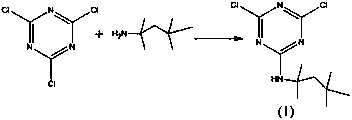

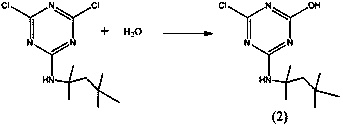

Process for synthesizing hindered amine light stabilizer 944

InactiveCN108623566AReduce generationReduce post-processing difficultyOrganic chemistryHindered amine light stabilizersSolvent

The invention relates to a process for synthesizing a hindered amine light stabilizer 944. The process comprises the following specific steps: adding cyanuric chloride into a solvent to be stirred anddissolved, dropping a tert-octylamine solution and stirring, maintaining the temperature after dropping completion, dropping a sodium hydroxide solution, maintaining the temperature after dropping completion, washing and filtering to obtain an intermediate 1 solution; mixing the intermediate 1 solution and water, maintaining the temperature, cooling, filtering and desolventizing to obtain an intermediate 2; sequentially adding a sodium hydroxide solution and hexamethylendiamine piperidine into the intermediate 1 solution, raising the temperature to 90-120 DEG C, maintaining the temperature for 0.5-2 hours, continuously heating, maintaining the temperature for 0.5-2 hours while raising the temperature by 5-15 DEG C each time, and maintaining the temperature for 5-15 hours after the solution is heated to 130-160 DEG C so as to obtain an intermediate 3 solution; adding the intermediate 2 into the intermediate 3 solution for stirring, maintaining the temperature, washing, filtering and desolventizing the reaction solution, thereby obtaining the hindered amine light stabilizer 944. According to the method disclosed by the invention, production of small-molecule products is reduced, by-products are reduced, and the product quality and yield are improved.

Owner:宿迁联盛科技股份有限公司

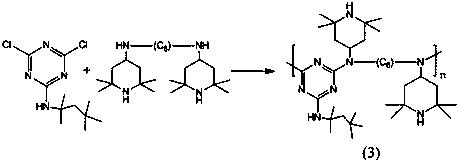

Ketone oxime ester photoinitiator green synthetic method

The present invention discloses a ketone oxime ester photoinitiator green synthetic method. According to the method, diphenyl sulfide as a raw material is condensed with caprylyl chloride under the effect of a zirconium catalyst, and then a ketone oxime ester photoinitiator can be obtained by oximation and esterification. The method does not relate to high temperature and high pressure reaction, and is mild in reaction conditions, and good in security. No aluminum chloride or zinc waste water is produced due to use of the zirconium catalyst during the synthesis process, produced byproducts can be recycled, no environmentally harmful solvent is used, and the ketone oxime ester photoinitiator green synthetic method is environmentally friendly, and therefore suitable for industrial production.

Owner:TIANJIN INGENOCHEM TECH CO LTD

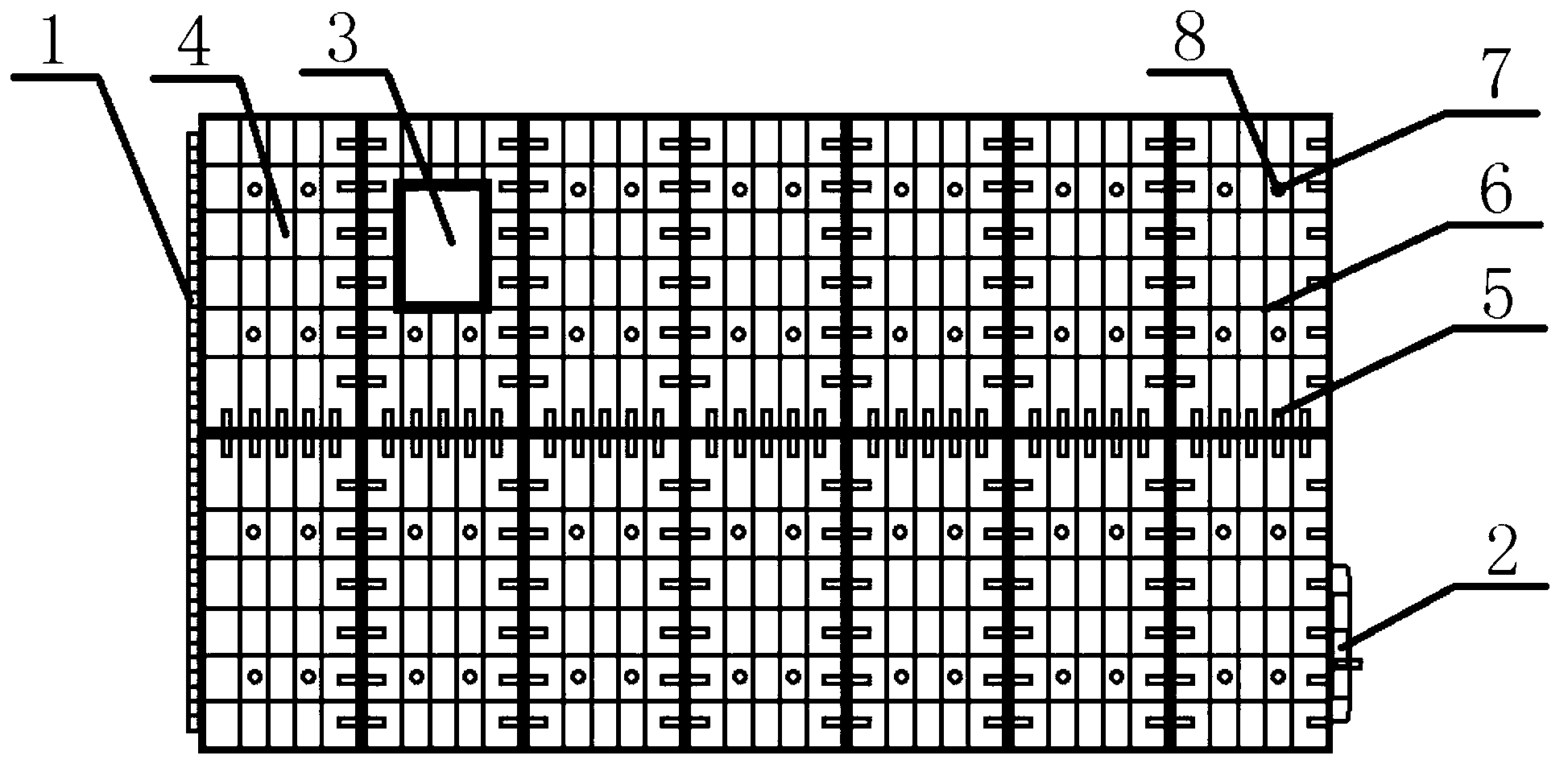

Variable cross-section opening grid supporting structure and generation method thereof

PendingCN109501249AIncrease print speedReduce post-processing difficultyAdditive manufacturing apparatus3D object support structuresSoftwareMechanical engineering

The invention discloses a variable cross-section opening grid supporting structure and a generation method thereof. Opening grid supporting units are formed by arraying a plurality of grid units in different sizes, and a plurality of opening grid supporting units are overlapped so that support units are formed for changing the support form; the side walls of the opening grid supporting units are provided with grid openings penetrating through the opening grid supporting units horizontally so that a lateral powder discharging channel is formed; thus, powder in supports can be cleared completelyafter forming, and recycled before heat treatment after forming of parts; the printing rate is increased, and the post-processing difficulty is reduced; a cross-section structure is formed through three-dimensional drawing software, and the supports are arrayed and arranged according to the requirements; the powder that can not be cleared from the interior of a traditional grid support is clearedcompletely, and the usage amount of the forming powder is reduced; the printing rate is higher through design of the grip supports with lateral powder discharge, and the forming time is shortened; and the efficiency is improved, and the cost is reduced.

Owner:西安国宏天易智能科技有限公司

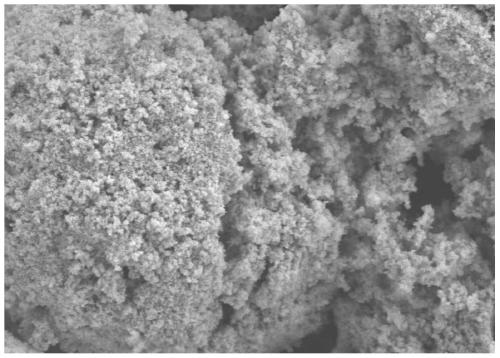

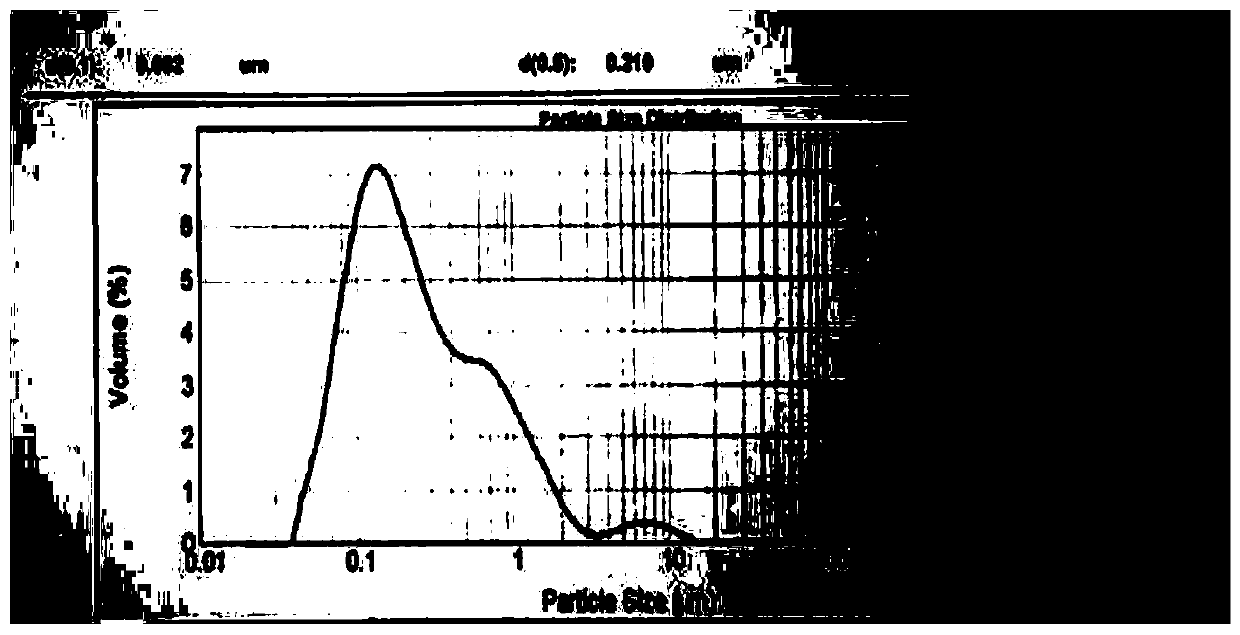

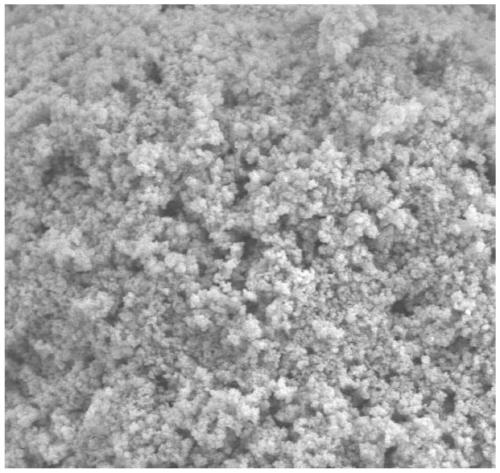

Preparation method of nanometer indium hydroxide

The invention provides a preparation method of nanometer indium hydroxide. The preparation method comprises the following steps: a) introducing ammonia gas into an aqueous indium nitrate solution to obtain a precursor slurry; and b) washing the precursor slurry, and performing spray drying to obtain an indium hydroxide powder. The preparation method provided by the invention can reduce the production of an ammonia nitrate mother liquor, reduce the washing difficulty and the consumption of washing water, reduce the generation of nitrogen-containing wastewater and reduce the wastewater treatmentdifficulty; the preparation method allows the nano-level product to be obtained without a dispersant, so the preparation cost is reduced, the operation steps are simplified, and impurities in the slurry are reduced, thereby the washing difficulty and the consumption of washing water are reduced; and the obtained product has small particle size and a good uniformity, and does not need to be sieved, so the preparation process is simplified.

Owner:先导薄膜材料(安徽)有限公司

Preparation and applications of high-resistivity gas-tightness high-expansion-coefficient aluminum alloy sealing glass powder

ActiveCN108164150AHigh expansion coefficientImprove mechanical propertiesDustproof/splashproof/drip-proof/waterproof/flameproof connectionArgon atmosphereThermal insulation

The invention relates to preparation of high-resistivity gas-tightness high-expansion-coefficient aluminum alloy sealing glass powder, wherein the preparation comprises raw material preparing, mixing,heating, drying, water quenching, drying, ball milling and other steps, and the raw materials comprise, by mole, 35-45% of P205, 15-28% of SnO, 15-27% of Bi2O3, 3-7% of ZnO2, 1-3% of SiO2, 2-4% of Na2O, 1-4% of K2O, 2-5% of BaO, and 2-4% of WO3. The application steps comprise: mixing the prepared alloy sealing glass powder and low temperature paraffin slice, heating, stirring, and screening to obtain the glass powder of desired particles; molding with a molding machine, heating, and carrying out thermal insulation to obtain a dewaxed glass billet; and removing oil stain from an aluminum alloyshell, carrying out dehydration, drying, assembling the sealed aluminum alloy shell and the glass billet, placing in a graphite mold, placing in an argon atmosphere furnace, carrying out thermal insulation, and cooling to a room temperature to obtain the electrical connector with advantages of aging resistance, high resistivity and high gas tightness. According to the present invention, the hightemperature oxidation of the metal during the sealing can be avoided, and the late-stage processing difficulty can be reduced.

Owner:LIAONING SILICATE RES INST

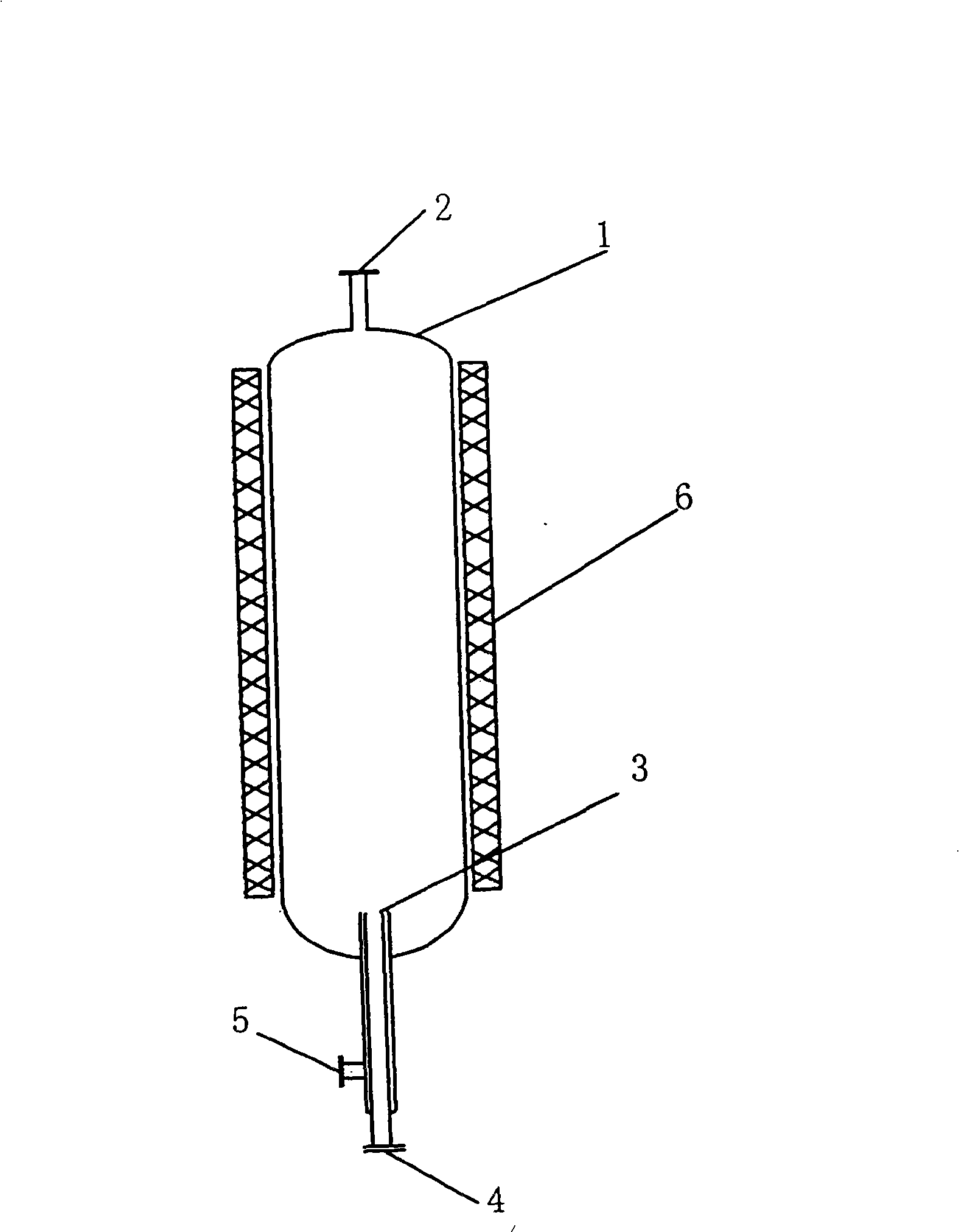

Process for synthesizing hydrogen bromide by vertical combustor

InactiveCN101289167AQuality improvementReduce the amount of entrained bromine gasBromine/hydrogen-bromideCombustion chamberCombustor

The invention relates to a technology for producing nylon-11 engineering plastic by using castor oil, in particular to a method for synthesizing bromine hydride by adopting an upright burner which pertains to the technology. The method solves the problem that the purity of bromine hydride is not high in the bromine hydride synthesizing technology in the prior art of producing nylon-11 engineering plastic by castor oil. Preheated evaporating bromine of 320 DEG C and pure hydrogen, the mole ratio of which is 1 to 1.2, are sent into a combustor from the bottom of the upright burner at the same time, ignited in the combustor that is heated to 800 DEG C to start burning; after the burning is stable, heating is stopped and bromine and hydrogen are supplied constantly to produce qualified bromine hydride in the combustor continuously. The method well solves the problem that the quality of bromine hydride is low, leads to the reduction of byproduct of the bromide 100 times and greatly improves the quality of the product.

Owner:山西宏远科技股份有限公司

Livestock and Poultry Feces Picking-up and Separating Device

InactiveCN106332788AEasy to cleanHigh adaptability to working spaceAnimal housingBird housingsImpellerLivestock

The invention relates to a livestock and poultry feces picking-up and separating device, which comprises a casing, wherein a pickup unit, a transmission unit and a solid-liquid separation unit are arranged. The pick-up unit comprises a shovel-type shaft impeller. Below the casing there is an arc-shaped baffle plate with a gap whose wheel spin shunt is identical with that of shovel-type shaft impeller and the latter has friction with the ground when rotating. The conveying unit comprises a screen-type conveying belt, one end of which is adjacent to the shovel-type shaft impeller; the solid-liquid separating unit comprises no.1 liquid feces collecting tank arranged below the screen-type conveying belt; and on the screen-type conveying belt's end farther from the shovel-type shaft impeller, there designs a screw extruder, whose end is connected to a solid feces collecting tank. This invention pick up feces through a shovel-type shaft impeller, and then separate solid and liquid feces combining the screen-type conveying belt and the screw extruder, showing beneficial technical result and remarkable environmental friendliness.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Novel desulfurization method for calcination tail gas

PendingCN112619372AIncrease concentrationPromote absorptionDispersed particle separationCooling towerProcess engineering

The invention discloses a novel desulfurization method for calcination tail gas, belonging to the technical field of treatment of tail gas produced during titanium dioxide calcination. The novel desulfurization method comprises the following steps: (1) allowing tail gas at the tail of a calcination kiln to enter a spray tower, spraying the tail gas with waste sulfuric acid, directly pumping the waste sulfuric acid which is at the bottom of the tower after spraying to the top of the tower for recycling, and concentrating the waste sulfuric acid; (2) carrying out further spraying operation on the tail gas by using sand filter water, and washing away acid mist carried in the tail gas; and (3) building an alkali liquor cooling tower, subjecting liquid alkali cooled by the alkali liquor cooling tower to circular spraying, reducing the temperature of the tail gas, absorbing SO2 in the tail gas, reducing the temperature of the tail gas to 35 DEG C or below, and discharging the tail gas when the content of SO2 reaches the standard. Due to the adoption of tail gas desulfurization technology, the national policy of energy conservation and emission reduction in China is accorded with, and the survival of enterprises is guaranteed; and SO2 in calcination tail gas is annually saved about 540 t / year, so the surrounding living environment is greatly protected.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

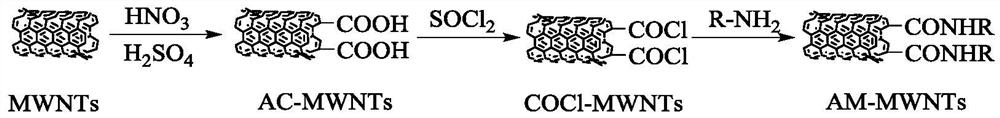

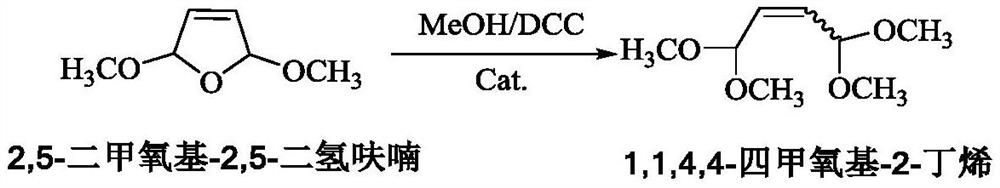

Catalyst and preparation method thereof, and preparation method of 1, 1, 4, 4-tetramethoxy-2-butene

ActiveCN112121859AHigh catalytic activityIncrease the number ofOrganic chemistryOrganic compound preparationRecyclable catalystFuran

The invention provides a catalyst and a preparation method thereof, and a preparation method of 1, 1, 4, 4-tetramethoxy-2-butene. The catalyst is prepared from the following components by mass: 100 parts of carrier aromatic ring primary amine modified multi-walled carbon nanotubes; 10-60 parts of an organic strong acid; and 1-10 parts of a rhodium complex or a palladium complex. The method comprises the following steps: under the action of the catalyst, carrying out acetalation reaction on 2, 5-dimethoxy-2, 5-dihydrofuran and methanol by taking a dehydrating agent as an auxiliary agent to prepare 1, 1, 4, 4-tetramethoxy-2-butene; the process has the advantages of high substrate conversion rate, high product selectivity, low environmental pollution and recyclable catalyst, and can overcomethe defects of low reaction yield, serious equipment corrosion and the like in the existing process.

Owner:WANHUA CHEM GRP CO LTD

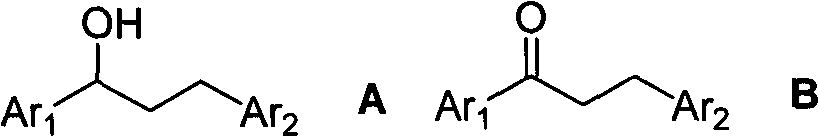

Method for synthesizing 1,3-diphenyl-1-propanol compound

ActiveCN102146020BWidely distributedHigh yieldOrganic compound preparationPreparation by halogen introduction1-PropanolSolvent

The invention relates to a method for synthesizing a 1,3-diphenyl-1-propanol compound, belonging to a method for synthesizing a compound. P-substituted 1-phenyl ethanol and p-substituted benzyl alcohol are used as raw materials, wherein R and R' are hydrogen atoms, halogen atoms Cl, Br, alkyl and alkoxy, and the adding ratio of the substituted 1-phenyl ethanol to the substituted benzyl alcohol is 1: (1-2). The method comprises the following steps of: sequentially adding a dry catalyst, alkali, substituted1-phenyl ethanol and substituted benzyl alcohol into an anhydrous solvent under the condition of nitrogen, placing a reactor into an oil bath of 125 to 135 DEG C, and stirring for 8 to 24 hours; cooling, neutralizing the reaction solution, performing extraction by using ethyl acetate, and concentrating the extract in vacuum till no ethyl acetate smell; and performing chromatographic purification by using a positive silica gel column of 100 to 200 meshes. The invention has the advantages of simple, convenient and feasible method, low production cost, reduced difficulty of purification and post treatment and weakened influence on the environment.

Owner:常州久邦药业有限公司

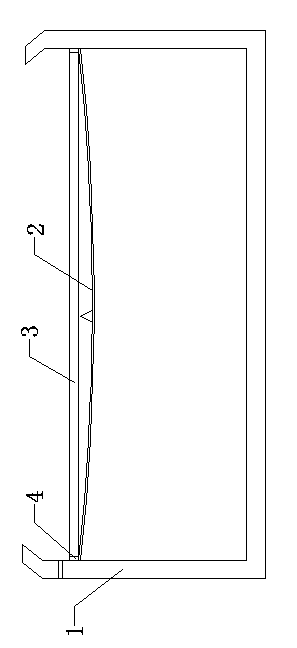

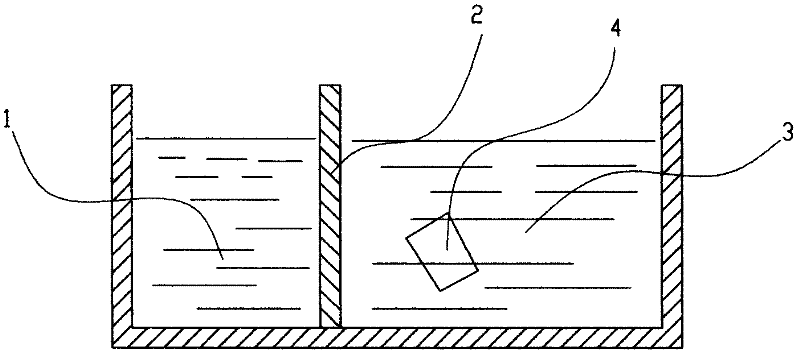

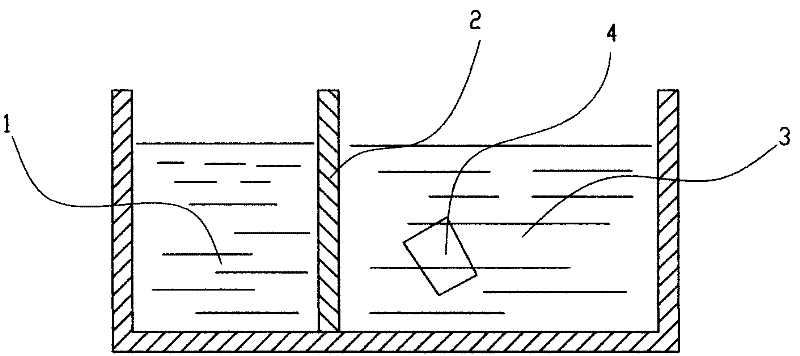

Method for plating metal layer by virtue of ionodialysis chemistry

InactiveCN102210975ASimplify bath preparationSimplify the maintenance processSemi-permeable membranesLiquid/solution decomposition chemical coatingWorking temperatureBiological activation

The invention provides a method for plating a metal layer by ionodialysis chemistry. An ionodialysis plating bath is provided; the plating bath comprises a main salt tank 1 and a traction tank 3; and the main salt tank 1 and the reaction tank 3 are separated by a cation exchange membrane 2. Main salt containing coating metal ions is dissolved in the main slat tank 1; an ionic reducing agent is dissolved in the reaction tank 3; and additive agents such as a coating metal ion complexing agent, a pH value buffer and the like are added in the reaction tank 3. The solution in the reaction tank is heated to the working temperature and the pH value is adjusted; and after being subjected to preplating such as surface washing and surface activation, a substrate to be plated is placed into the reaction tank so as to be plated.

Owner:董季汉

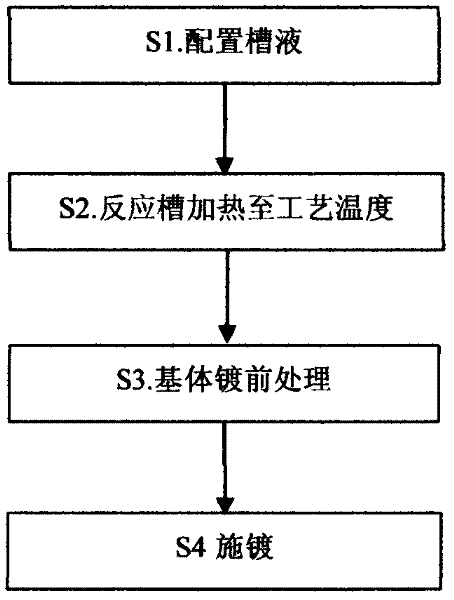

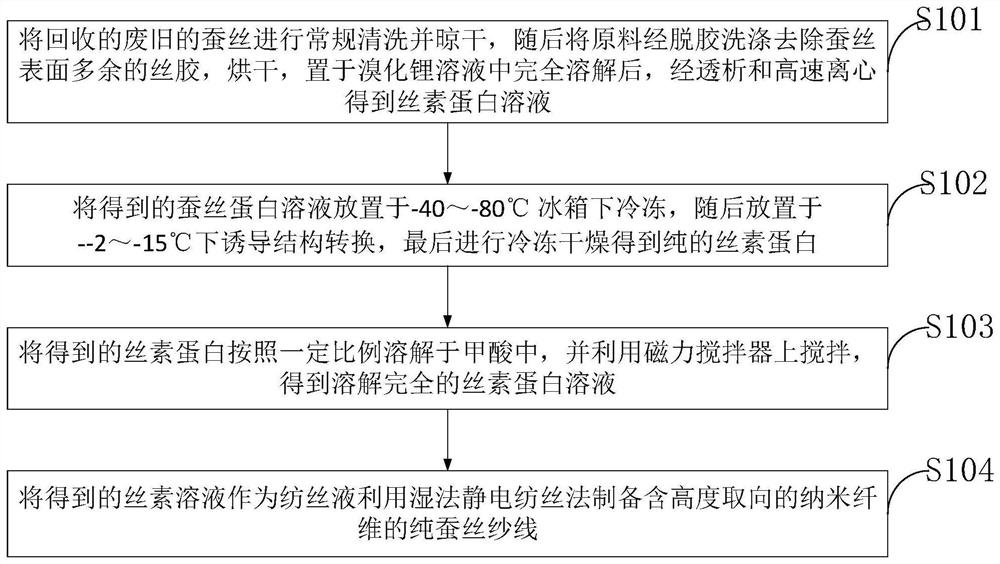

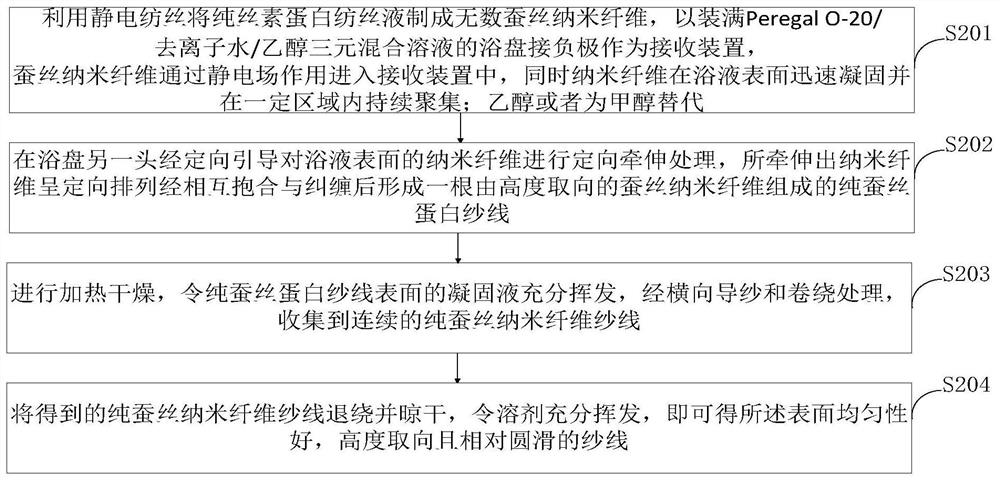

Method for preparing fibroin nanofiber yarn with high degree of orientation by waste silks

InactiveCN111850760AGood biocompatibilityPromote degradationMonocomponent protein artificial filamentFilament/thread formingYarnFiber

The invention belongs to the technical field of nanofiber preparation, and discloses a method for preparing a fibroin nanofiber yarn with high degree of orientation by waste silks. The recycled wastesilks are utilized, regenerated silk fibroin protein is prepared, and then is dissolved in formic acid in a certain proportion to prepare a spinning solution, and a pure silk yarn containing highly oriented nanofibers is prepared. According to the method, the characteristics of wet spinning and electrospinning are combined, a yarn formed by entanglement and cohesion of multiple highly oriented nanofibers is directionally pulled out, and then is collected by heating, guiding and winding; the prepared yarn has excellent biocompatibility and biodegradability, the mechanical properties are good, and a great application prospect in guiding cell oriented production and transportation and transmission of biological factors is achieved; and the preparation method is simple and easy to control, thecost is low, the scientific concept of green sustainable development is conformed, and the value of large-scale industrial promotion is achieved.

Owner:WUHAN TEXTILE UNIV

D-source peptide solid drink

InactiveCN108308488APromote absorptionEnhance physical fitnessFood ingredient functionsProtein food ingredientsDiseaseVitamin C

The present invention relates to D-source peptide solid drink and belongs to the technical field of health-care drink. A technical scheme is as follows: the D-source peptide solid drink contains cardiomyopeptide powder, D-ribose, soybean peptide powder, nattos, enzymes, vitamin C, sea cucumber powder and collagen peptides. The D-source peptide solid drink can effectively nourish myocardium, prevents and cures various heart diseases, myocardial ischemia and thrombosis, also has effects on lifting and tightening skin, promoting intestinal peristalsis, and preventing and relieving constipation and diarrhea, and also has functions on nourishing bones and strengthening body.

Owner:北京昱健健康管理有限公司

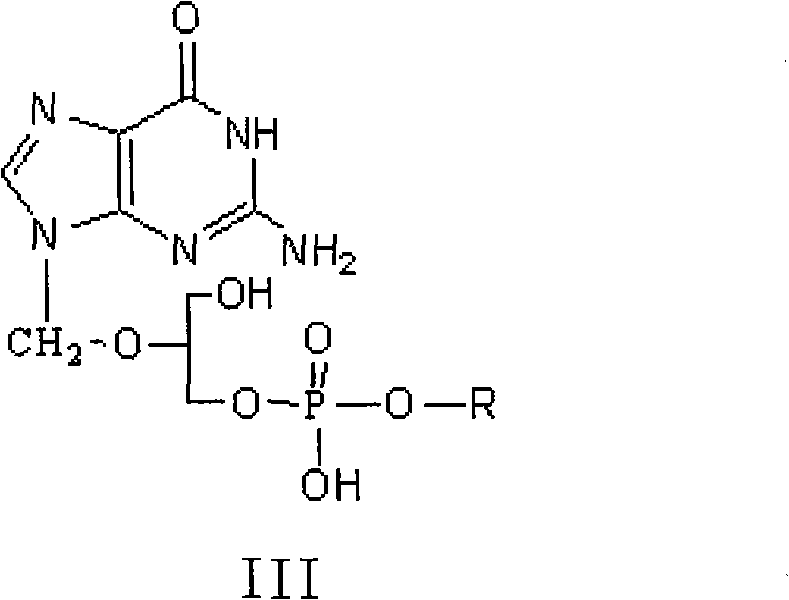

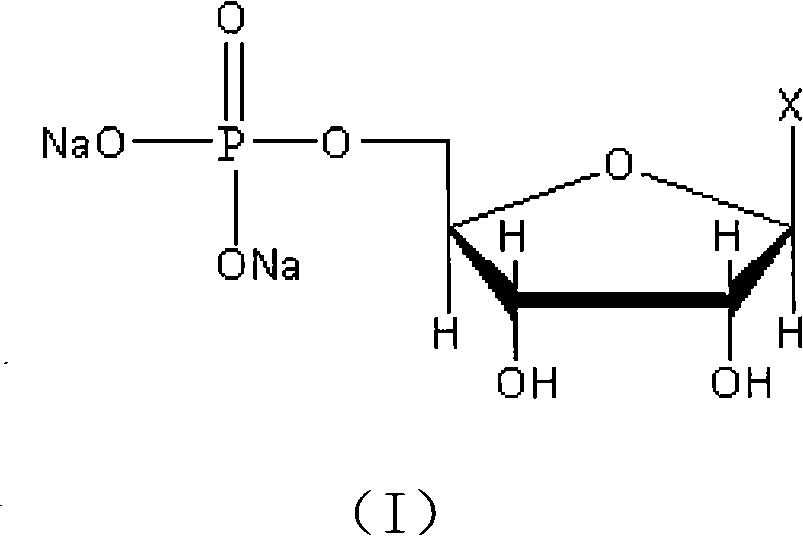

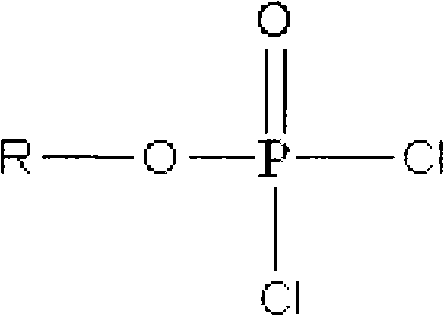

Method for preparing disodium 5'-ribonucleotide

ActiveCN101891772AEasy to purifyGood removal effectSugar derivativesSugar derivatives preparationRadical substitutionRibonucleotide synthesis

The invention provides a method for preparing disodium 5'-ribonucleotide, which comprises the following steps of: preparing phosphoryl dihalide (II), reacting nucleoside with the phosphoryl dihalide (II) to obtain nucleoside phosphodiester (III), and performing R-radical substitution and salifying on the nucleoside phosphodiester (III) to obtain the disodium 5'-ribonucleotide (I). The method has the advantages of high conversion rate, a few byproducts, easy purification, easier impurity removal, reduction in postprocessing difficulty, and capability of preparing the disodium 5'-ribonucleotide with high purity and yield.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

Process method for removing benzopyrene in grease

InactiveCN107057848AAchieve separationReduce lossFatty-oils/fats refiningOil and greaseAqueous solution

The invention relates to a process method for removing benzopyrene in grease. The grease is eluted by adopting DNA (deoxyribonucleic acid) aqueous solution; the benzopyrene in the grease is intercalated with DNA; DNA is dissolved in water, so that the benzopyrene intercalated with the DNA is brought into the water; oil cannot be dissolved in water, so that after standing, separation is carried out to obtain the grease of which the benzopyrene is removed. Currently, removal on the benzopyrene in the grease mainly adopts an adsorption method, such method can also adsorb aroma components in the grease when adsorbing the benzopyrene, and resolving and processing after adsorption are very difficult. According to the process method disclosed by the invention, the adsorption method for removing the benzopyrene is improved; by improvement, grease loss is effectively reduced, a removal effect is improved, and post-processing difficulty is reduced; meanwhile, the process method has the advantages of convenience for use, low cost, low investment and the like, and is suitable for various large and medium-sized grease machining enterprises.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

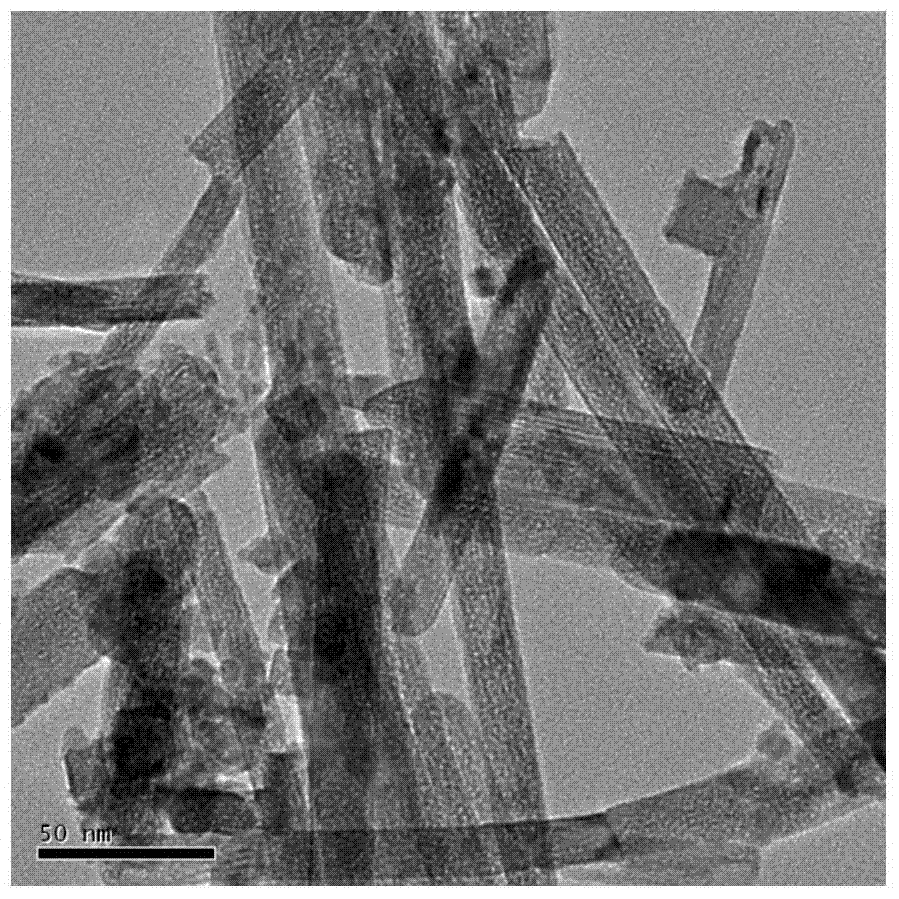

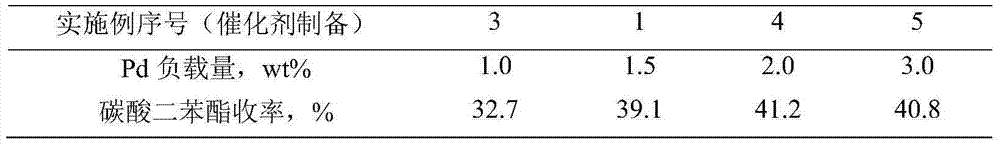

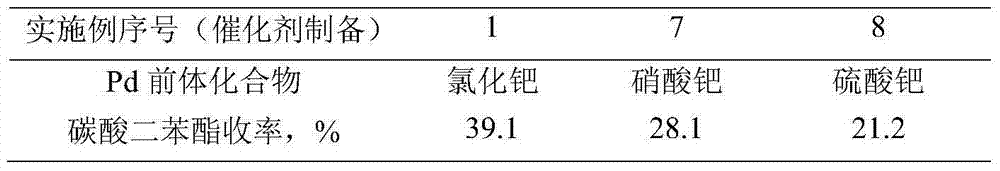

Catalyst for synthesizing diphenyl carbonate in phenol oxidative carbonylation as well as preparation method and application method of catalyst

ActiveCN103611532AEasy to separate and recycleLess amount of PdMaterial nanotechnologyCatalyst carriersHomogeneous catalysisPhenols

The invention relates to a catalyst for synthesizing diphenyl carbonate in phenol oxidative carbonylation as well as a preparation method and an application method of the catalyst. The catalyst comprises carrier rod-shaped nanometer CeO3 and an active component Pd compound, wherein the Pd compound is based on Pd, the weight ratio of the Pd to the CeO2 is 0.1: (10:100). The catalyst is used for synthesizing the diphenyl carbonate in the phenol oxidative carbonylation, solving the separation problem of a homogeneous Pd catalyst and overcoming the shortcomings that a conventional heterogeneous catalyst system is low in reaction rate and long in reaction time, and the like; meanwhile, by using the catalyst, the using amount of additives is reduced in the phenol oxidative carbonylation, only one additive is used, and the defects such as large using amount of the additives, multiple varieties, high difficulty in aftertreatment and high cost of a conventional reaction system are overcome. In addition, according to the method, the catalyst has relatively high activity all the time in the reaction process and can be repeatedly used.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com